Patents

Literature

664 results about "Inorganic polymer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Inorganic polymers are polymers with a skeletal structure that does not include carbon atoms in the backbone. Polymers containing inorganic and organic components are sometimes called hybrid polymers, and most so-called inorganic polymers are hybrid polymers. One of the best known examples is polydimethylsiloxane, otherwise known commonly as silicone rubber. Inorganic polymers offer some properties not found in organic materials including low temperature flexibility, electrical conductivity, and nonflammability. The term inorganic polymer refers generally to one-dimensional polymers, rather than to heavily crosslinked materials such as silicate minerals. Inorganic polymers with tunable or responsive properties are sometimes called smart inorganic polymers. A special class of inorganic polymers are geopolymers, which may be anthropogenic or naturally occurring.

Composition exhibiting enhanced formulation stability and delivery of topical active ingredients

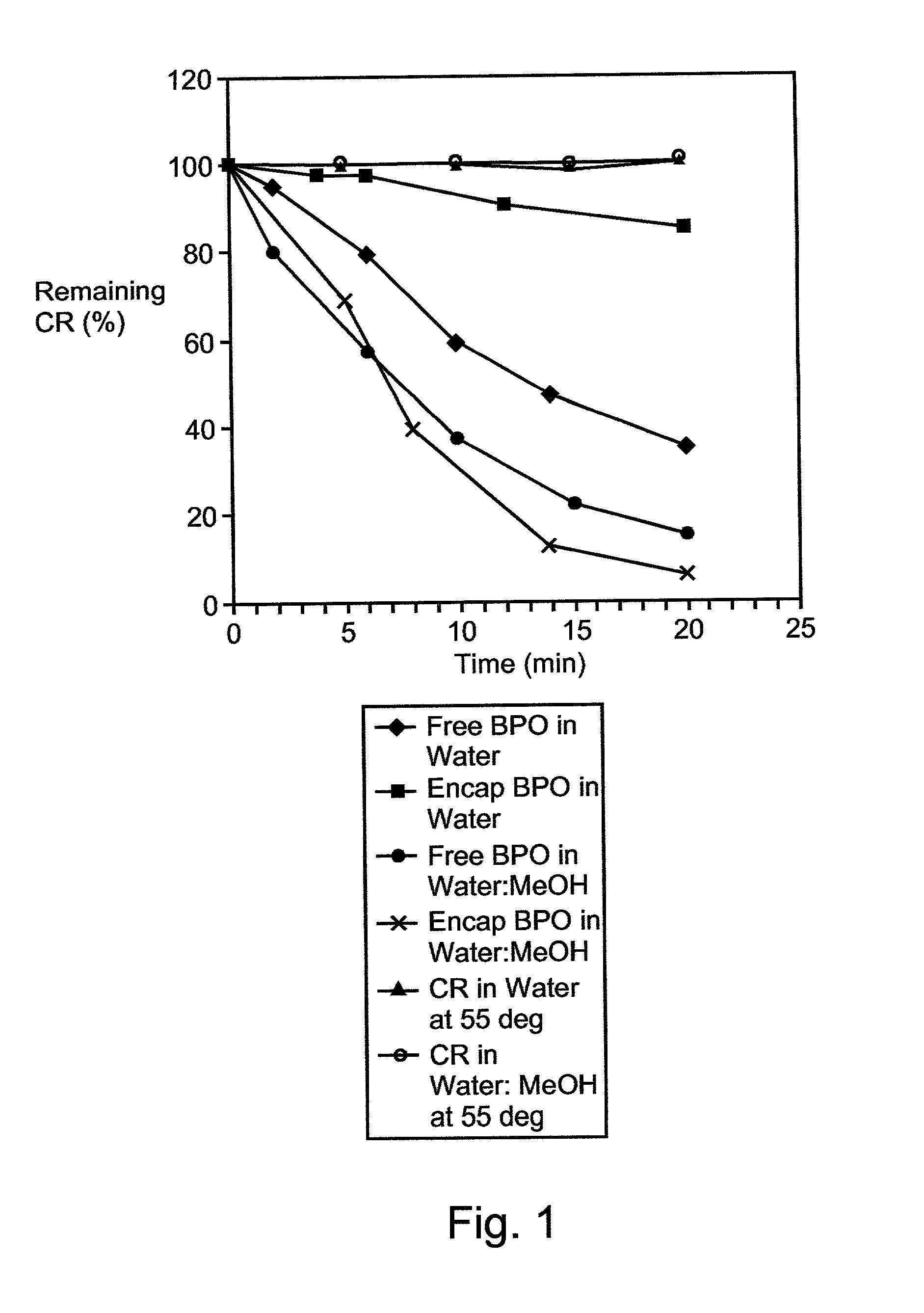

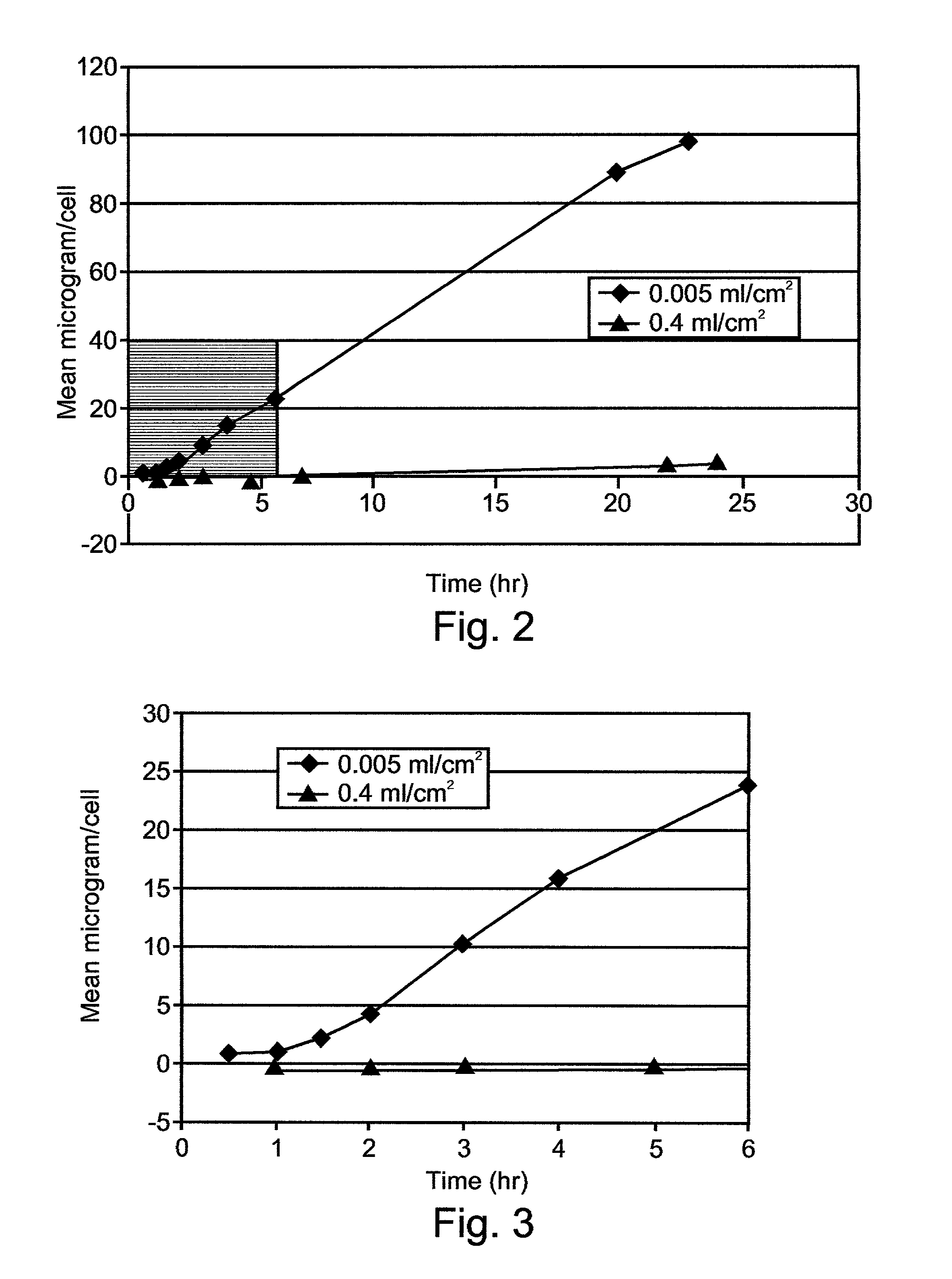

InactiveUS7758888B2Improve stabilityExtended shelf lifeAntibacterial agentsCosmetic preparationsBenzoyl peroxideMedicine

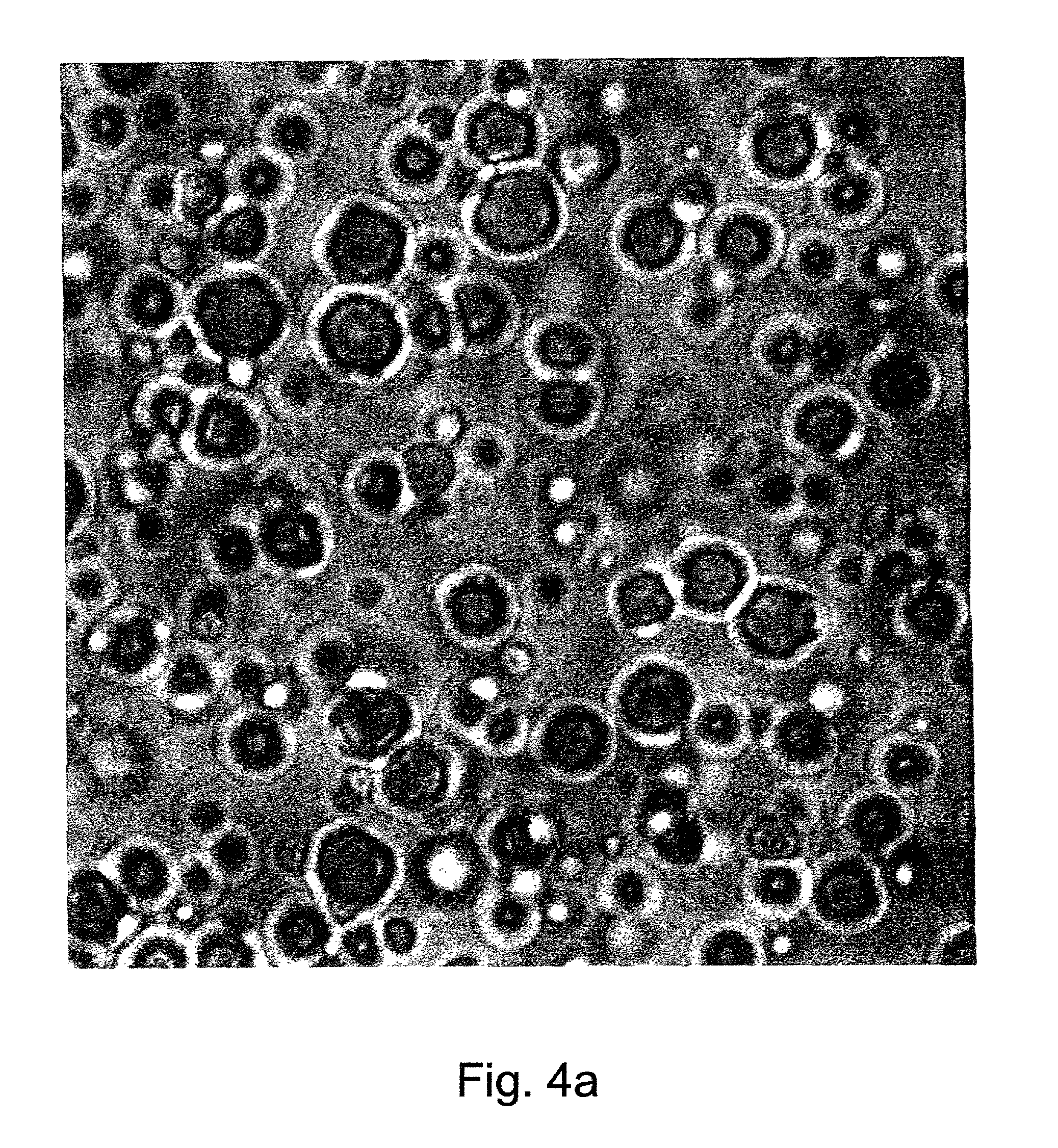

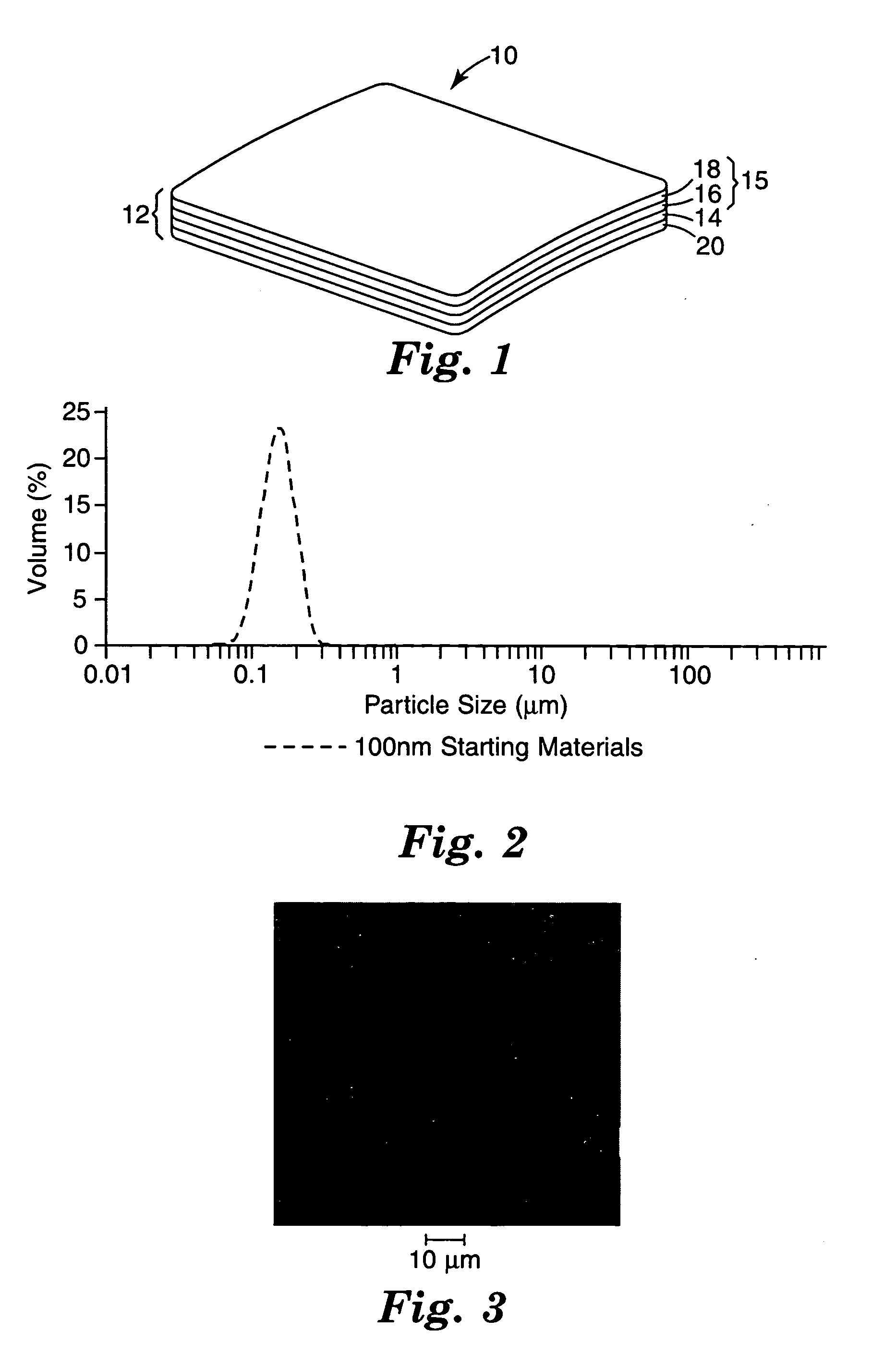

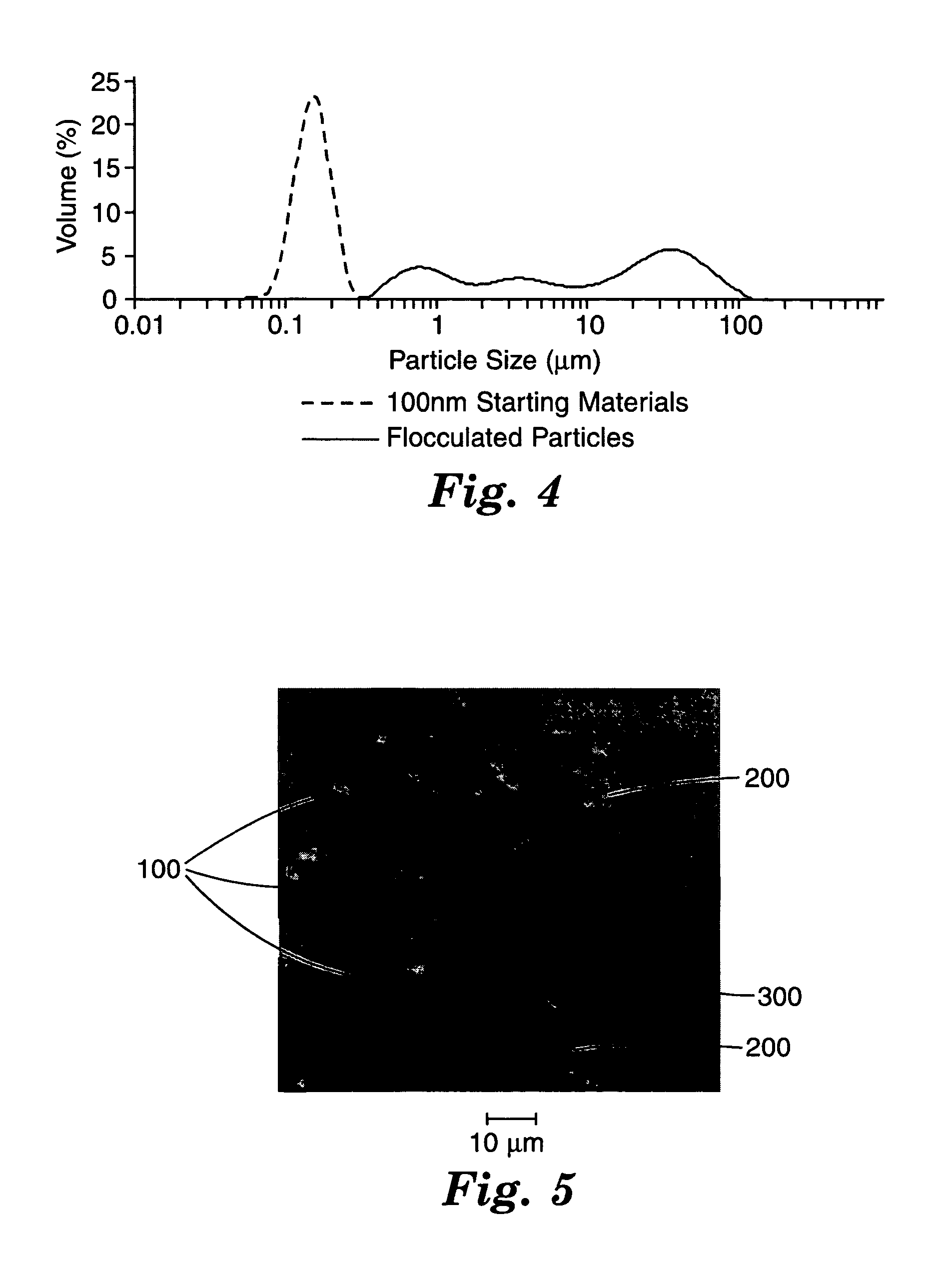

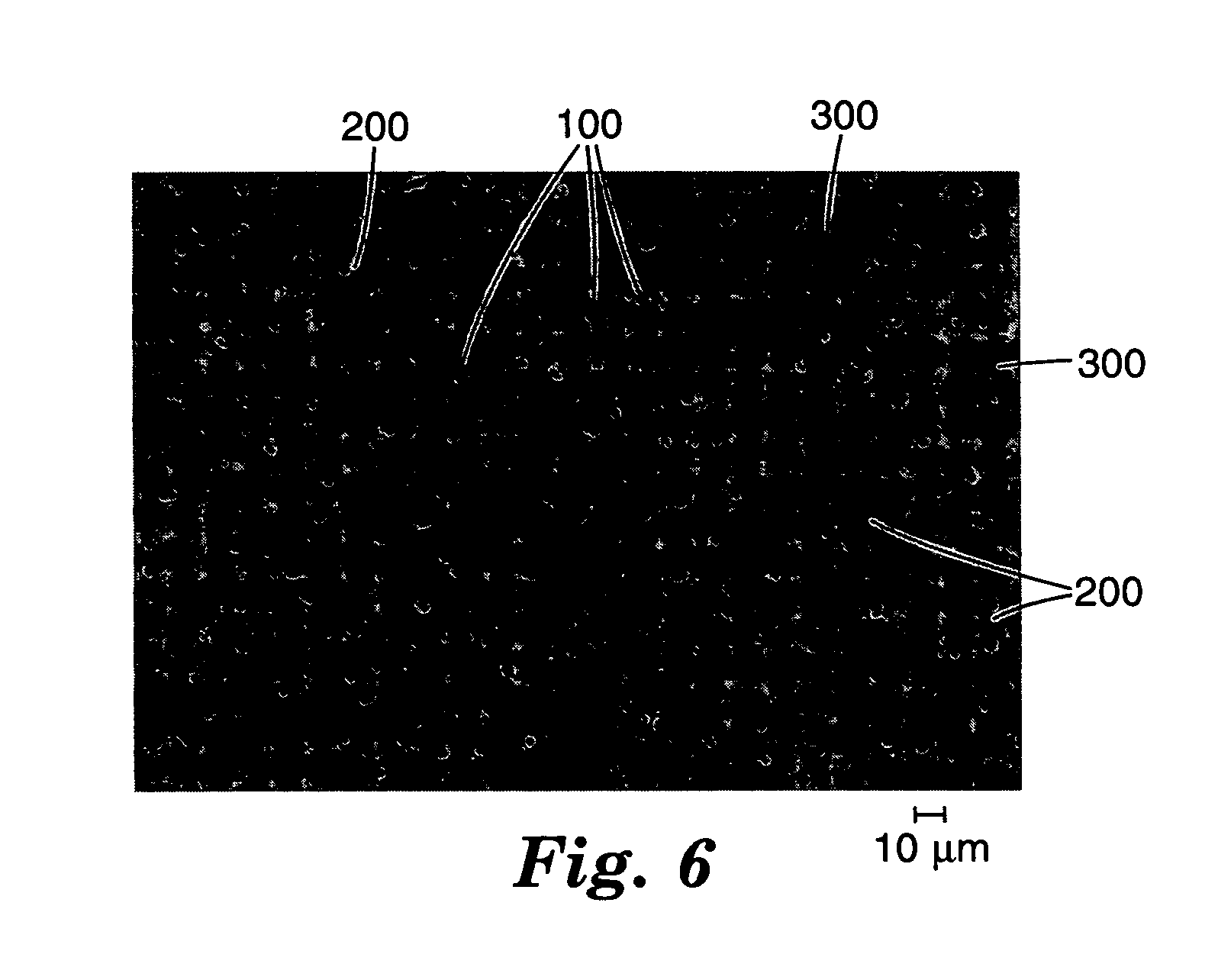

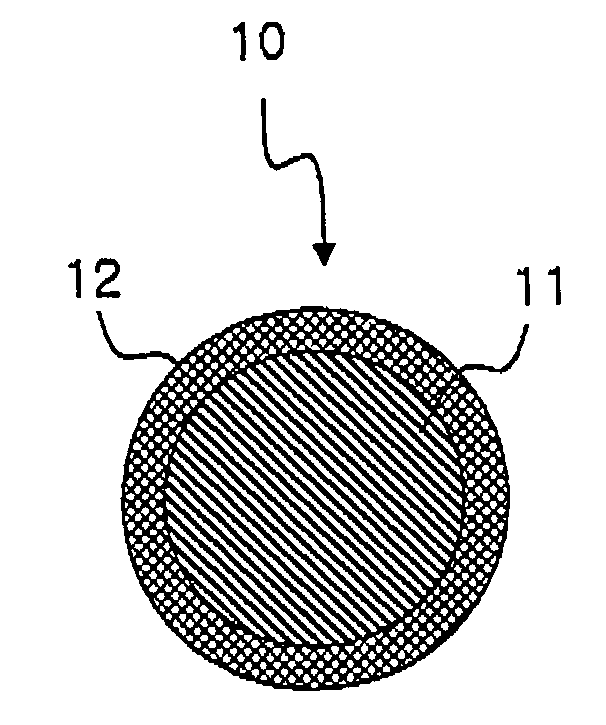

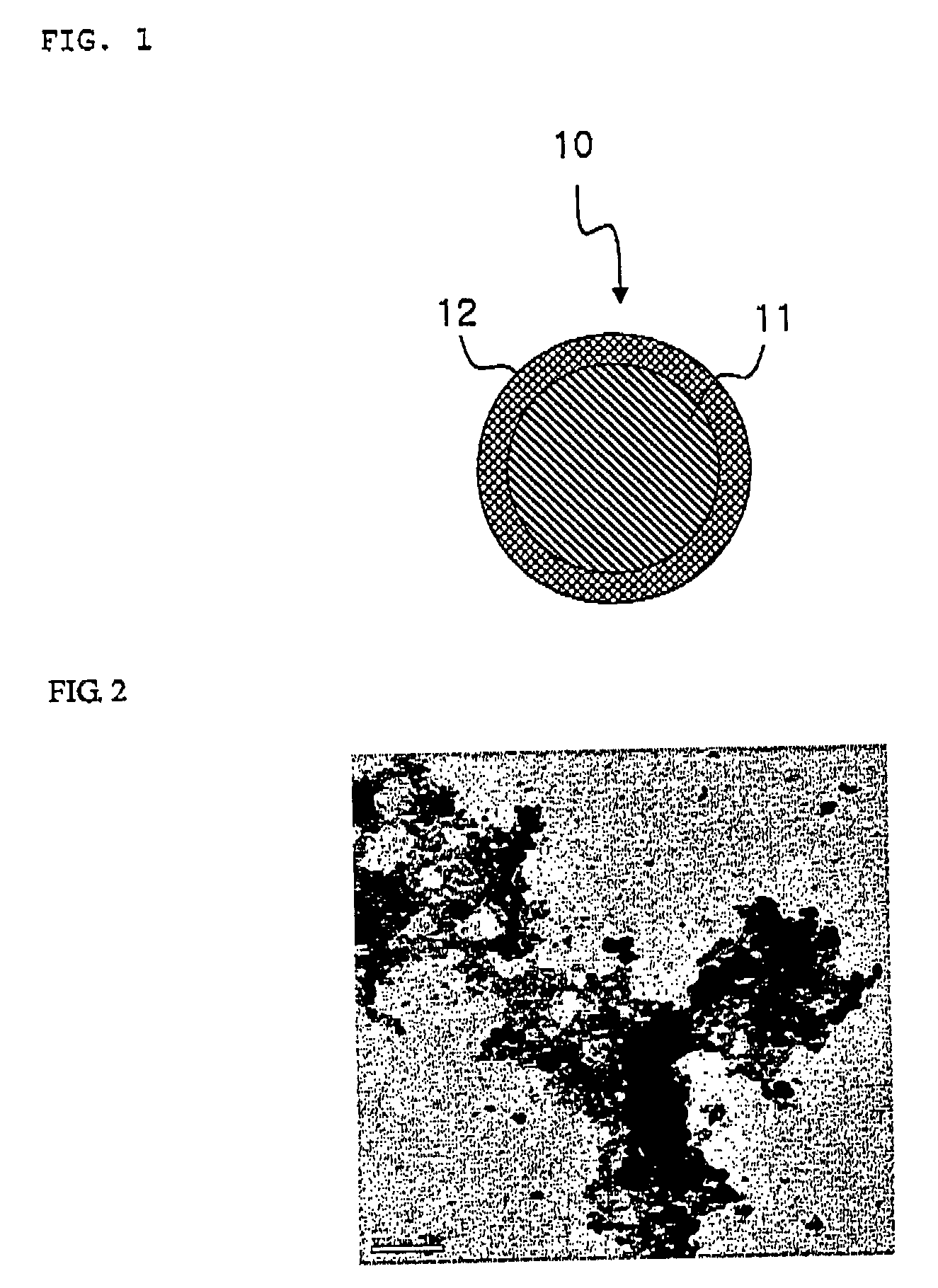

A therapeutic, cosmetic or cosmeceutic composition for topical application, capable of stabilizing an active ingredient and delivering the active ingredient, comprising a plurality of microcapsules having a core-shell structure. The microcapsules have a diameter of approximately 0.1 to 100 micron. The core of each microcapsule includes at least one active ingredient and is encapsulated within a microcapsular shell. The shell is comprised of at least one inorganic polymer obtained by a sol-gel process, and the shell protects the active ingredient before topical application and is designed to release the active ingredient from the microcapsules following application. The composition is useful in encapsulating active ingredients, such as benzoyl peroxide, that are unstable in other formulation, or are irritating to the skin.

Owner:SOL GEL TECH

Curing binder material for carbon nanotube electron emission cathodes

InactiveUS20070262687A1Improve adhesionReduce exhaustMaterial nanotechnologyCathode ray/electron stream lampsField emission deviceBiological activation

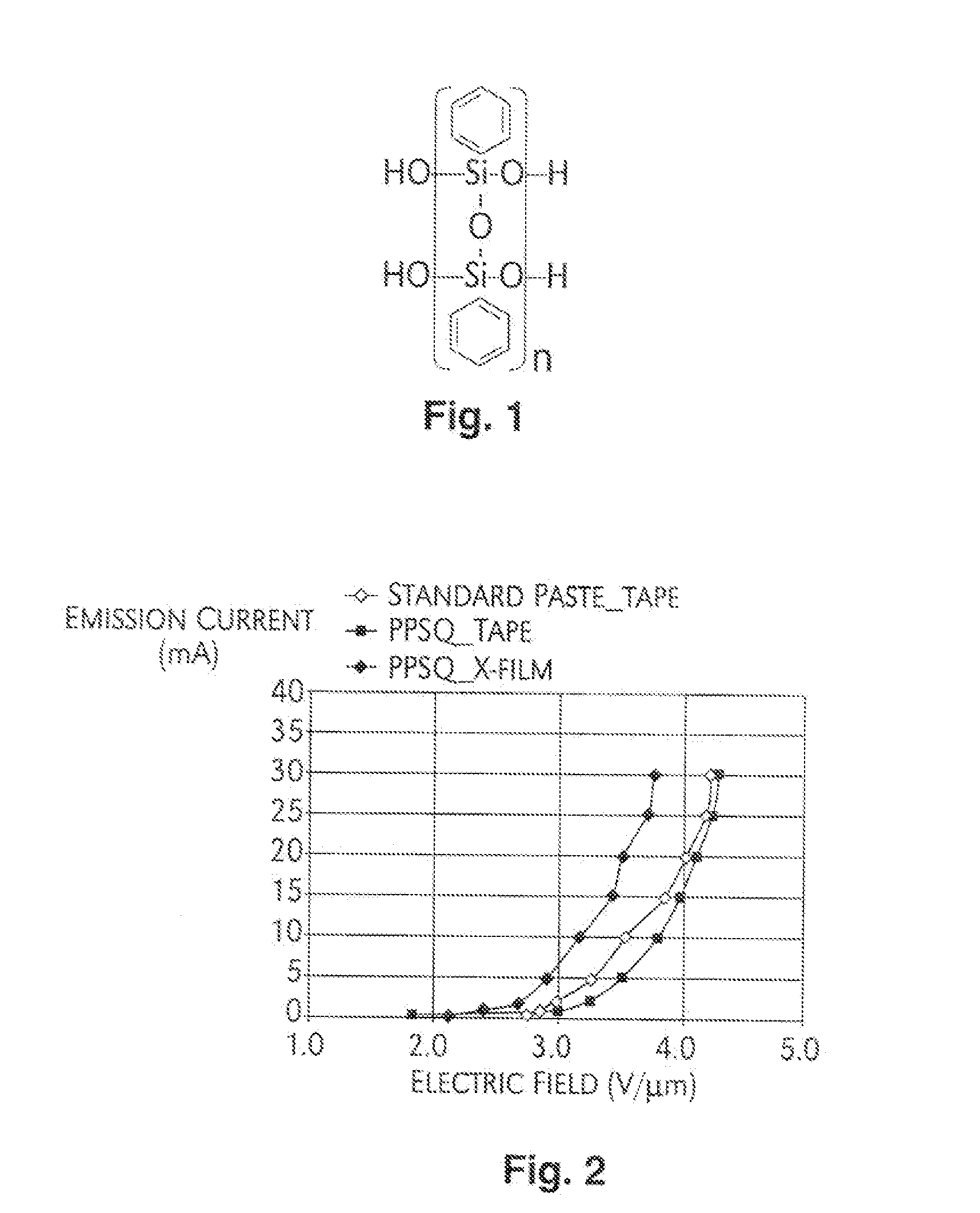

A binder material, inorganic polymer, is used to formulate carbon nanotube pastes. This material can be cured at 200° C. and has a thermal-stability up to 500° C. Low-out gassing of this binder material makes it a good candidate for long life field emission devices. Due to better adhesion with this binder material, a strong adhesive peelable polymer from liquid form can be applied on the CNT cathode to achieve a uniform activation with even contact and pressure on the surface. The peelable polymer films may be used both as an activation layer and a mask layer to fabricate high-resolution patterned carbon nanotube cathodes for field emission devices using lithographic processes.

Owner:SAMSUNG ELECTRONICS CO LTD

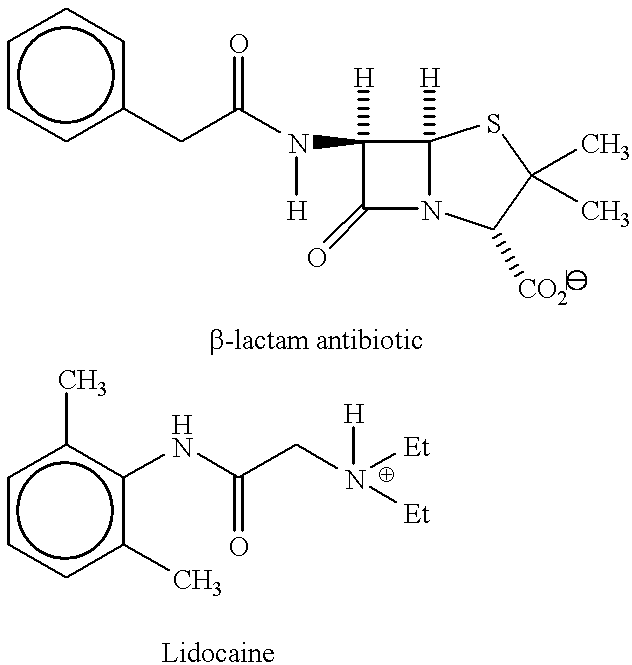

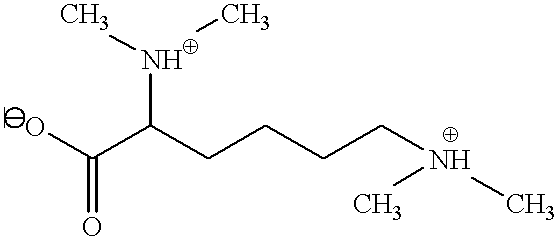

Inorganic-polymer complexes for the controlled release of compounds including medicinals

InactiveUS6391336B1Control releasePowder deliveryPeptide/protein ingredientsControlled releaseActive agent

This invention relates generally to the production and use of inorganic-polymer complexes for the controlled release of compounds including medicinals. The inorganic compound used is advantageously calcium sulfate-hemihydrate. The invention includes a composition for the controlled release of an active agent comprising: a) a hydrated or crystallized inorganic compound, and b) a matrix polymer which slows the release of the active agent, wherein the composition is a solid matrix due to the hydration or crystallization of the inorganic compound. Further included is a composition for the controlled release of an active agent comprising: a) a hydrated or crystallized inorganic compound, and b) a complexing agent which forms a salt or conjugate with the active agent, wherein the composition is a solid matrix due to the hydration or crystallization of the inorganic compound.

Owner:ROYER BIOMEDICAL INC

Ordered vertically oriented porous inorganic films produced through solution processing

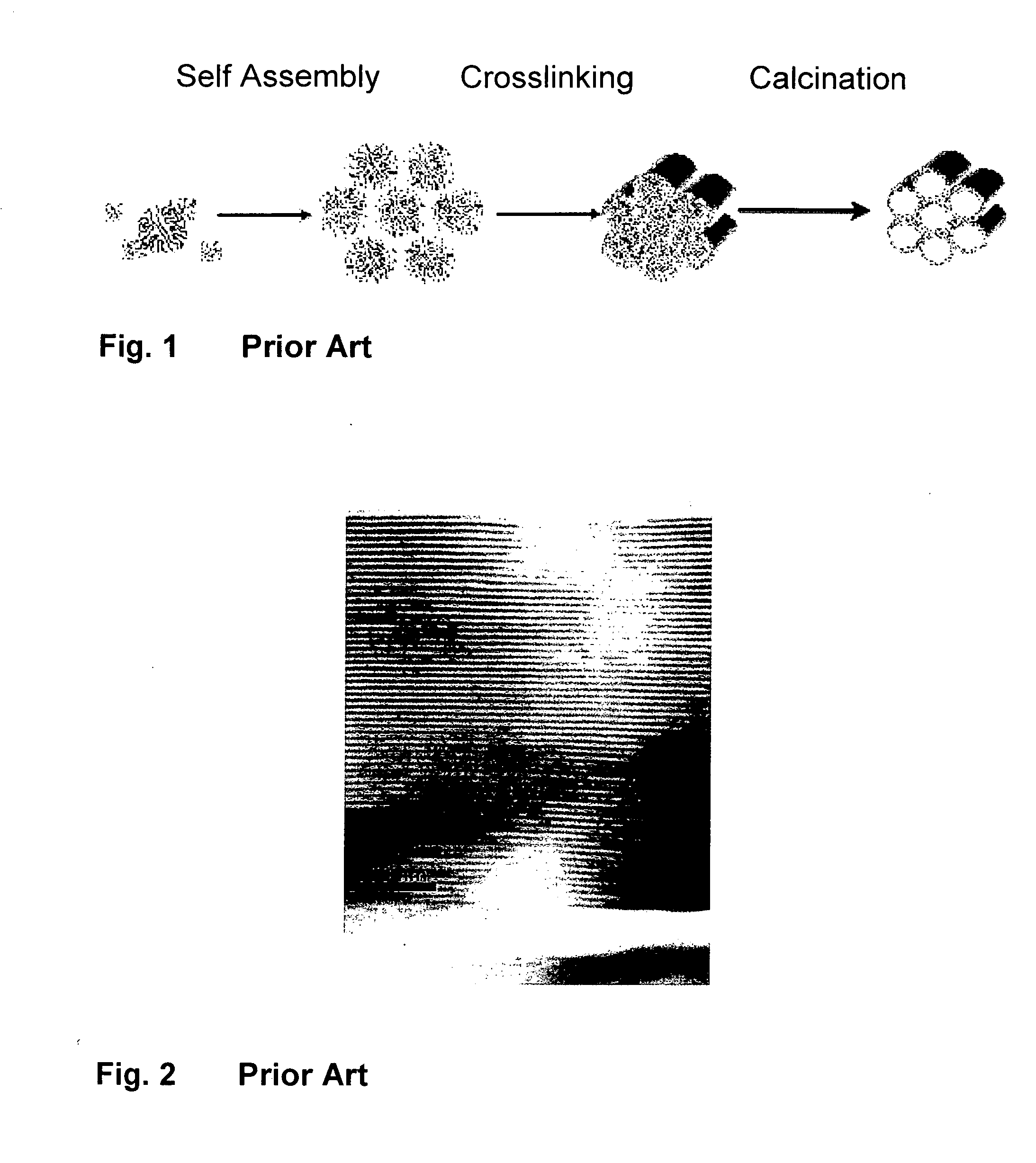

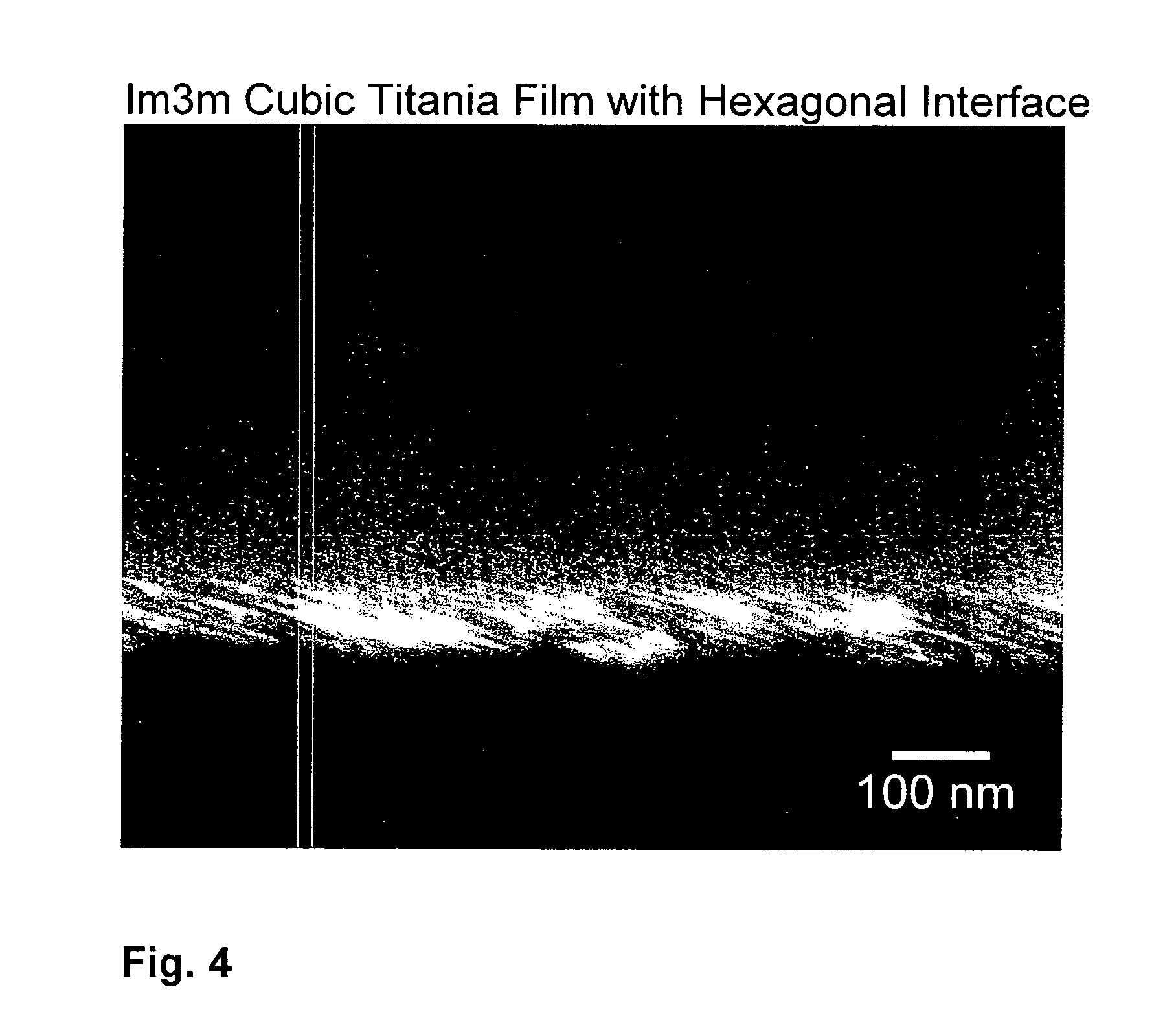

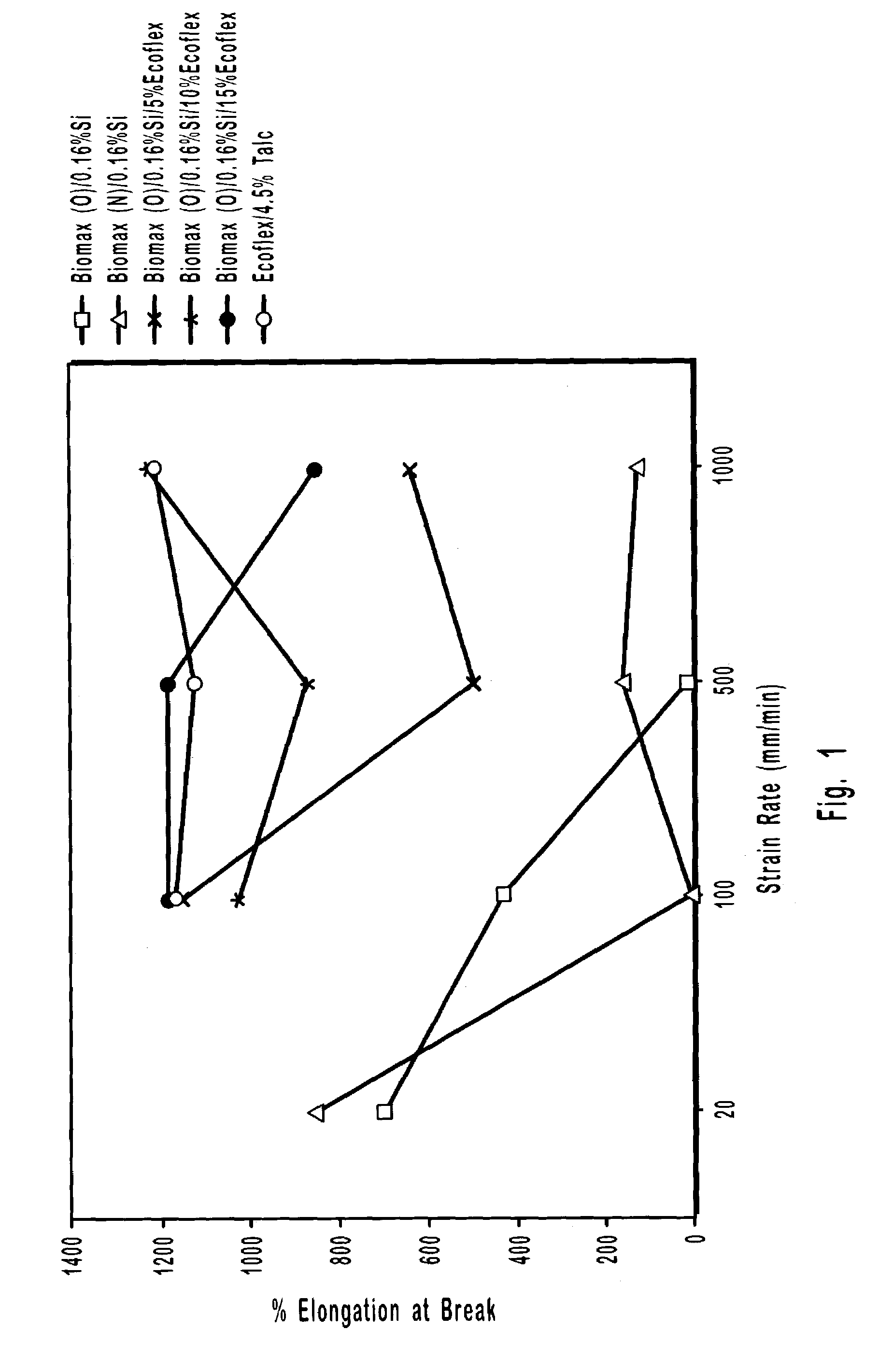

InactiveUS20060278158A1Easy to produceFrom gel statePhotosensitive materialsPatterned substrateSelf-assembly

Porous films with straight pores oriented normal to the plane of the films are produced through solution processing techniques. The production takes advantage of inorganic-surfactant or inorganic-polymer co-assembly and a patterned substrate. The patterned substrate, which is also produced via solution phase self-assembly, forces vertical orientation in a hexagonal cylinder system with no practical limits in substrate size or type. This provides a route to vertically oriented inorganic pores with a pitch ranging from 3 nm to over 15 nm and pore sizes ranging from 2 nm to over 12 nm. The size is tuned by choice the choice of organic templating agents and the deposition conditions. The pores can be produced with or without a capping layer which can be used to seal the nanopores.

Owner:RGT UNIV OF CALIFORNIA

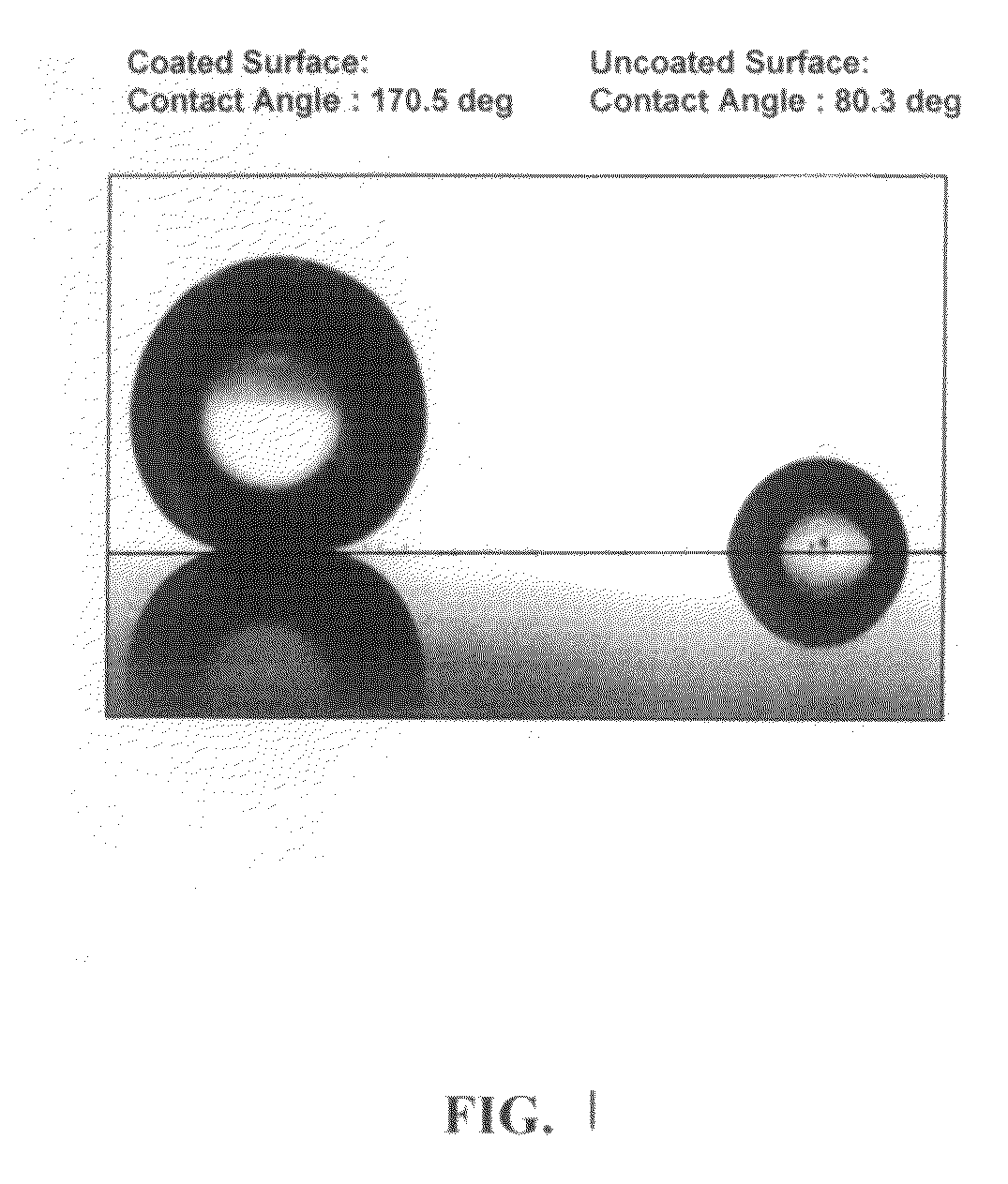

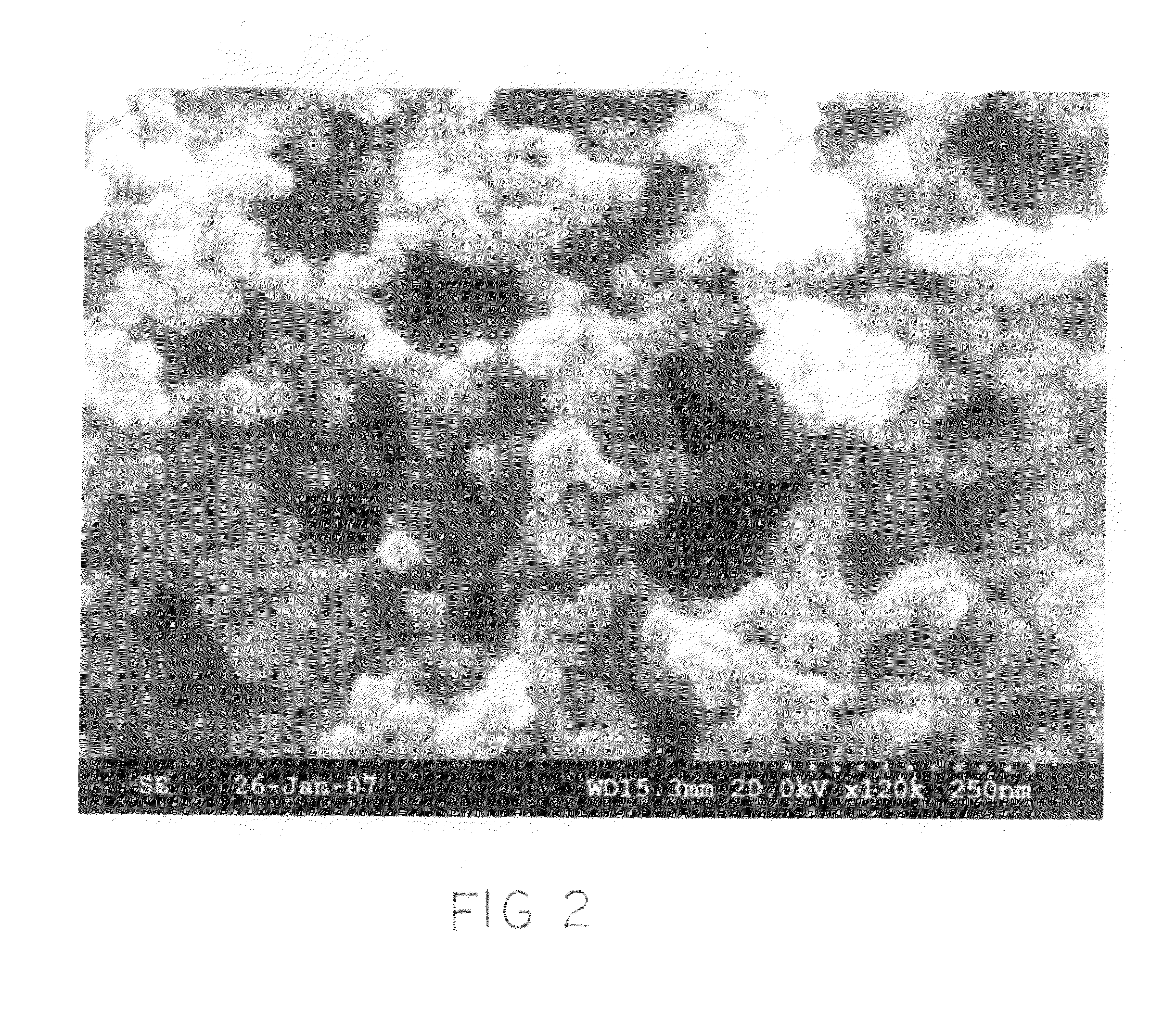

Hydrophobic self-cleaning coating compositions

InactiveUS20080221009A1Not to damageEfficient use ofNon-ionic surface-active compoundsNon-surface-active detergent compositionsEvaporationEngineering

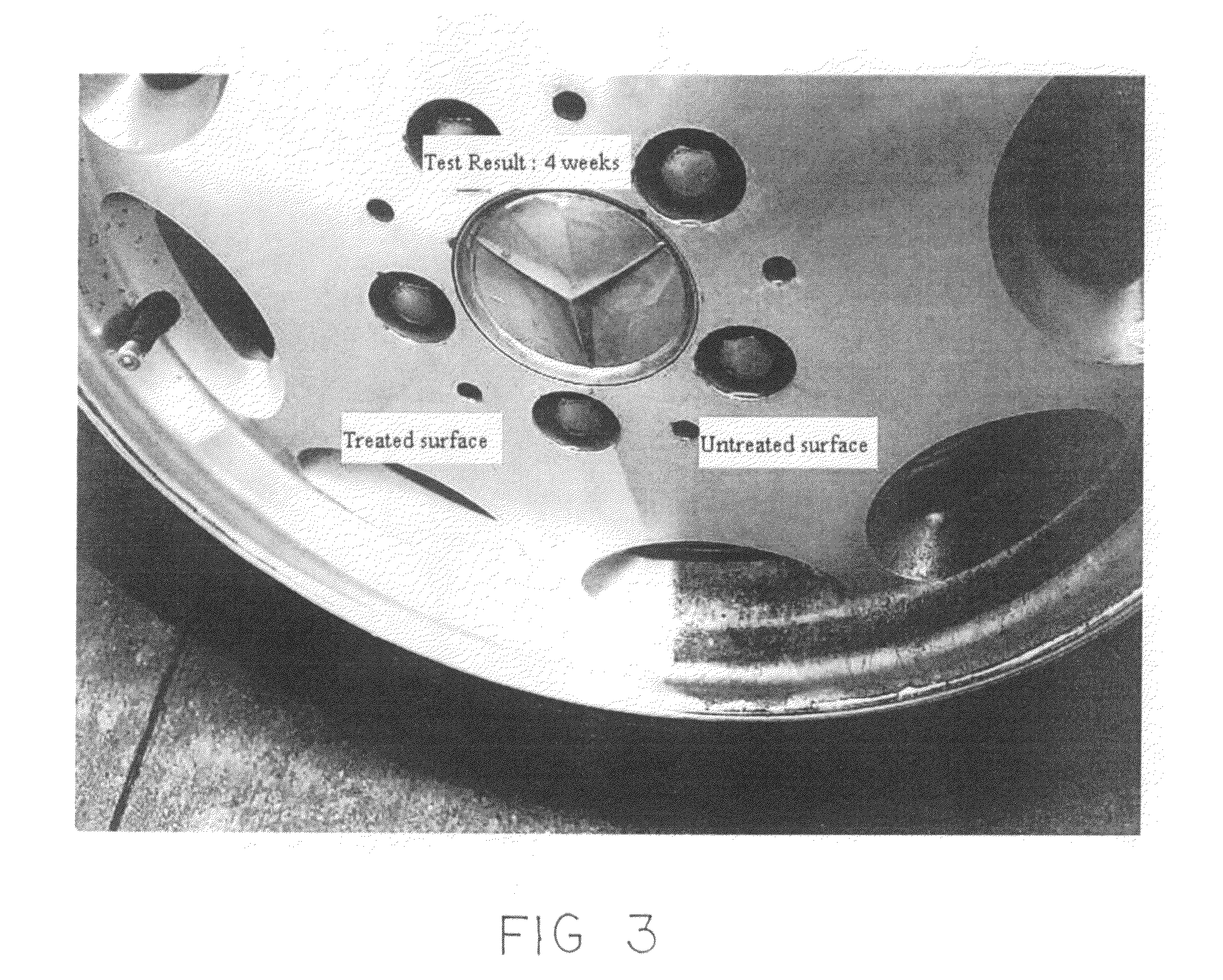

A super hydrophobic self cleaning coating composition that can be applied by conventional methods such as by spraying the composition onto a surface creating a wet and dry dirt repellent coating on the surface. The super hydrophobic self cleaning coatings are used on exterior automotive and boat surfaces, and in many other applications, to produce a self cleaning surface, reduce adherence of dirt and contaminants to a treated surface, and reduce drag in some applications providing an energy savings. The coating utilizes a blend of organic and / or inorganic polymers with hydrophobic nanoparticles of fumed silica and / or titania in a volatile solvent which evaporates at ambient temperature. The coating solves the problem of poor resistance to UV light, opaque appearance, and / or some abrasion resistance not found in previous coatings of similar nature. A preferred coating has good resistance to UV light and some resistance to abrasion. Clear, nearly transparent and translucent coatings are produced as compared to conventional coatings of comparable hydrophobicity which are typically white or opaque. The coating can be applied by a single and easy spraying method and the super hydrophobic property can be achieved by drying the film by evaporation of the solvent at ambient temperature for 5 to 10 minutes. Embodiments of the super hydrophobic self-cleaning coating composition result in a clear coating or in some cases a translucent dirt repellant film for coating on painted material, plastic, metal, glass, ceramic, fiberglass or a polymer substrate. The coating utilizes a blend of organic and / or inorganic polymers with hydrophobic nanoparticles of fumed silica and / or titania in a volatile solvent. At least one preferred coating composition comprising an effective amount of a treated fumed silica in a solvent resulting in a coated surface providing a contact angle of at least 165 degrees as compared to water having a contact angle of from 10 to 15 degrees on a noncoated surface. The composition imparts a degree of hydrophobicity to a surface so that the surface will have a tilt angle of sliding of less than 2 degrees as compared to water on a noncoated surface having a tilt angle of sliding of 90 degrees or higher. The coating composition is removed by washing with a detergent or applying pressure to the coating wiping same from the treated surface. Exposure to water in the form of rain or snow does not remove the coating composition.

Owner:ASHLAND LICENSING & INTPROP LLC

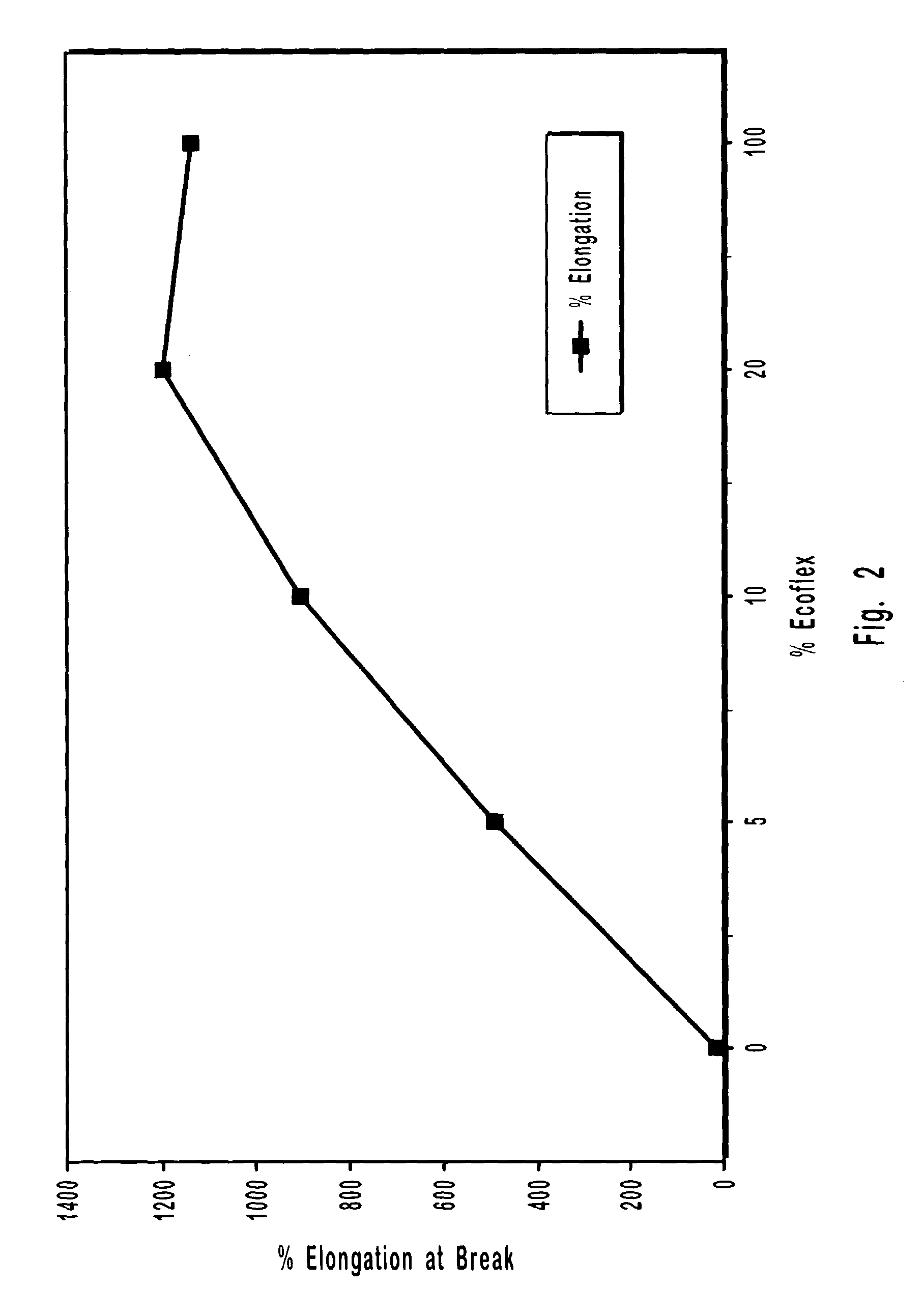

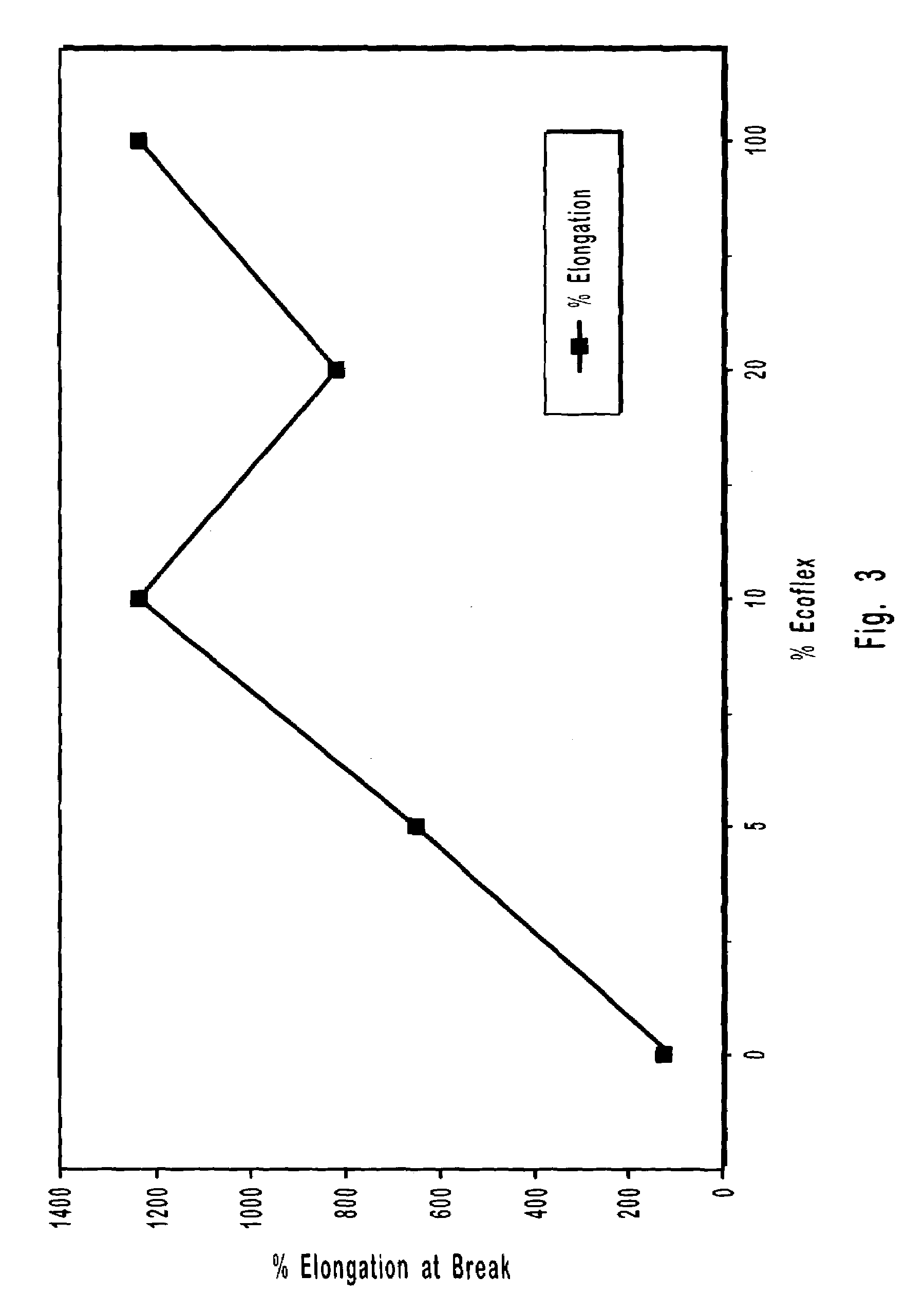

Fibrous sheets coated or impregnated with biodegradable polymers or polymers blends

ActiveUS7172814B2High glass transition temperatureImprove the crystallization processBio-packagingPaper coatingPolymer scienceBiopolymer

Fibrous sheets are coated or impregnated with a biodegradable composition to render the sheets more resistant to penetration by liquids. Biodegradable polymer blends suitable for use in coating or impregnating a fibrous sheet can be manufactured from at least one “hard” biodegradable polymer and at least one “soft” biodegradable polymer. “Hard” biopolymers typically have a glass transition temperature of at least about 10° C. “Soft” biodegradable polymers typically have a glass transition temperature less than about 0° C. Another useful biodegradable polymer composition includes one or more biodegradable polymers and sufficient inorganic filler so as to render the treated sheet microwaveable. The biodegradable polymer compositions are especially well-suited for coating or impregnating paper sheets, e.g., 12–15 lb / 3000 ft2 tissue paper to yield food wraps. Food wraps will typically be manufactured to have good “dead-fold” properties so as to remain in a wrapped position and not spring back to an “unwrapped” form.

Owner:BIO TEC BIOLOGISCHE NATURVERPACKUNGEN

Hydrophobic coating compositions for drag reduction

Owner:VGP IPCO LLC

Microcapsules Loaded with Active Ingredients and a Method for Their Preparation

ActiveUS20070292676A1Exemption stepsBiocideCosmetic preparationsIn situ polymerizationBULK ACTIVE INGREDIENT

The invention relates to microcapsules having a core material encapsulated within a microcapsular shell, the core material comprises at least one active ingredient, wherein the microcapsular shell comprises at least one inorganic polymer comprising polymerized precursors obtained by in-situ polymerization of the precursors; wherein the concentration of the core material based total weight of the microcapsules is above 95% w / w. The invention further relates to a composition and to a suspension comprising the microcapsules. The invention additionally relates to a process for preparing the microcapsules.

Owner:SOL GEL TECH

Antiglare coating and articles

The present invention relates to articles comprising an antiglare layer, coating compositions suitable for making antiglare layers, methods of making an antiglare article, and methods of making antiglare coating compositions. In some embodiments the article is a (e.g. illuminated) display article such as a touch screen. The antiglare layer comprises aggregate inorganic oxide particles in a cured inorganic polymer matrix.

Owner:3M INNOVATIVE PROPERTIES CO

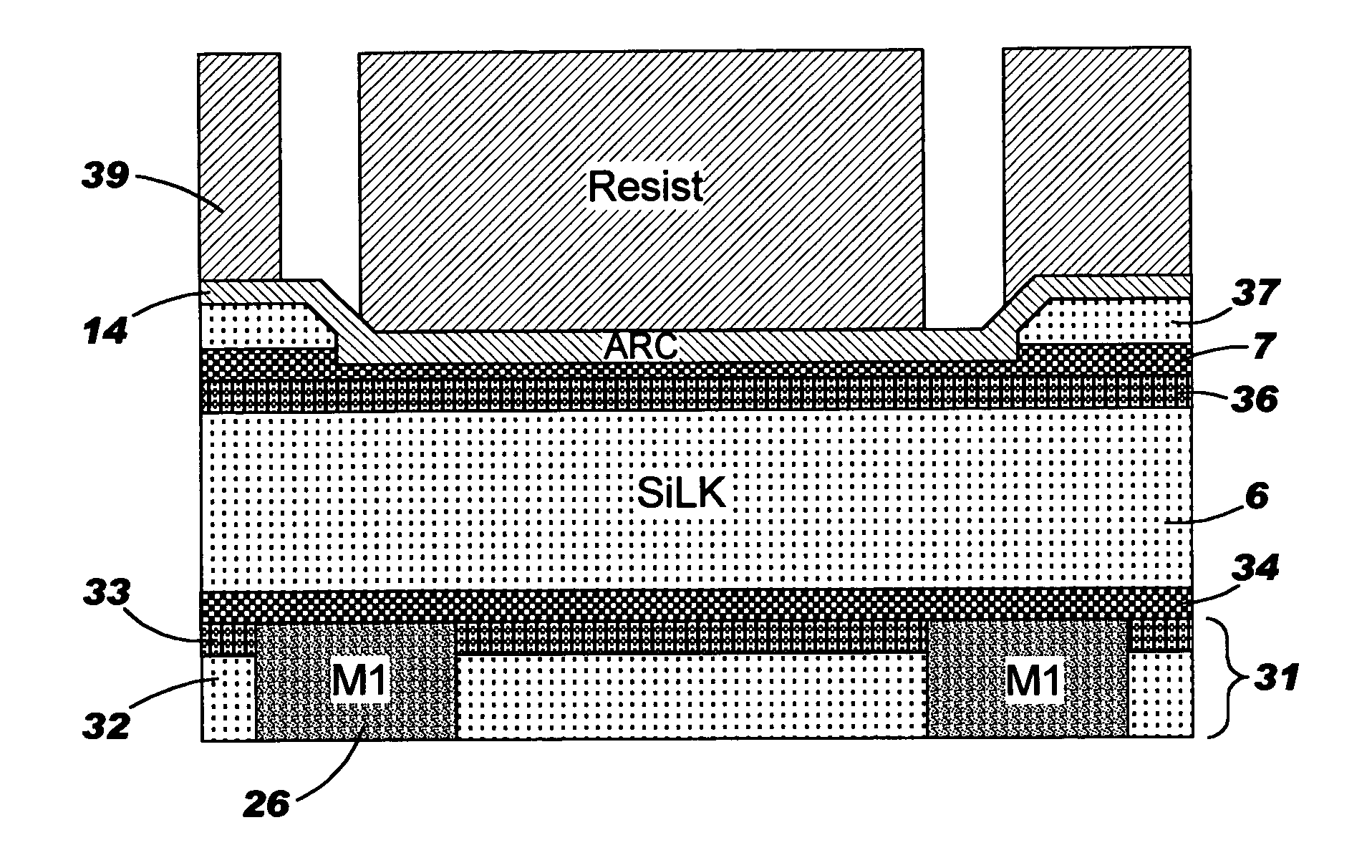

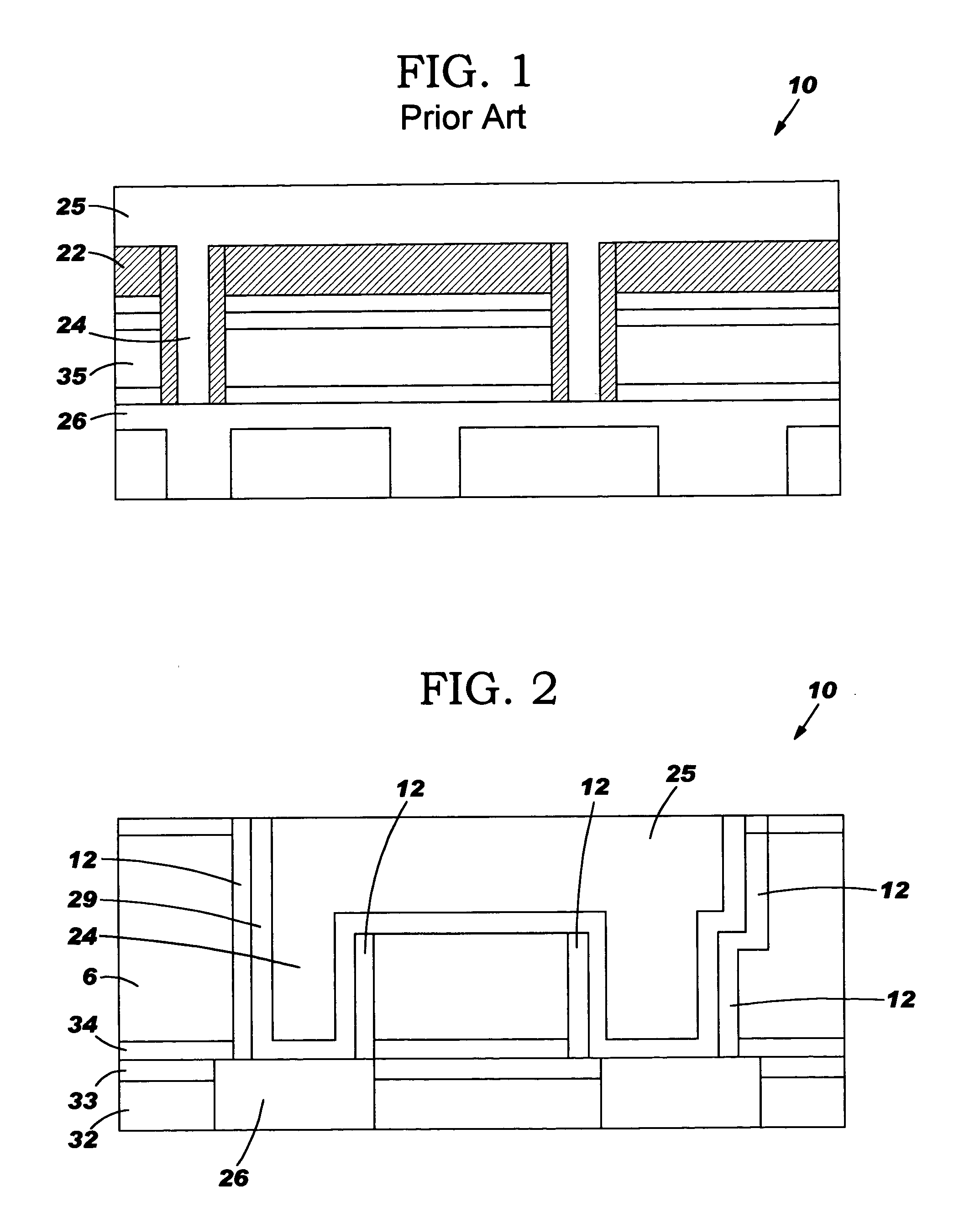

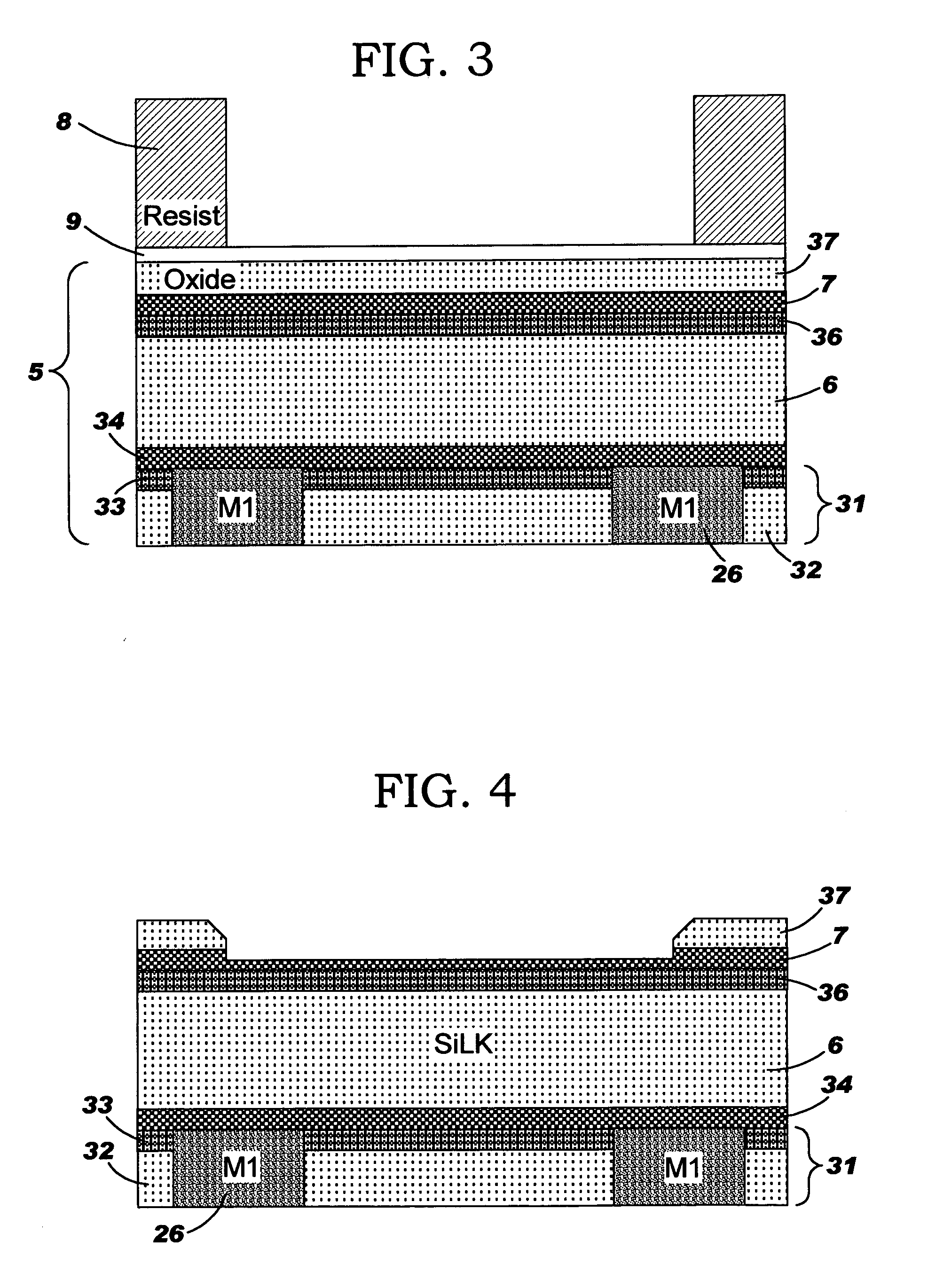

Sacrificial inorganic polymer intermetal dielectric damascene wire and via liner

ActiveUS20050153505A1Thermal mechanical stressSemiconductor/solid-state device detailsSolid-state devicesSilicate glassInorganic polymer

The present invention provides a method of forming a rigid interconnect structure, and the device therefrom, including the steps of providing a lower metal wiring layer having first metal lines positioned within a lower low-k dielectric; depositing an upper low-k dielectric atop the lower metal wiring layer; etching at least one portion of the upper low-k dielectric to provide at least one via to the first metal lines; forming rigid dielectric sidewall spacers in at least one via of the upper low-k dielectric; and forming second metal lines in at least one portion of the upper low-k dielectric. The rigid dielectric sidewall spacers may comprise of SiCH, SiC, SiNH, SiN, or SiO2. Alternatively, the via region of the interconnect structure may be strengthened with a mechanically rigid dielectric comprising SiO2, SiCOH, or doped silicate glass.

Owner:AURIGA INNOVATIONS INC

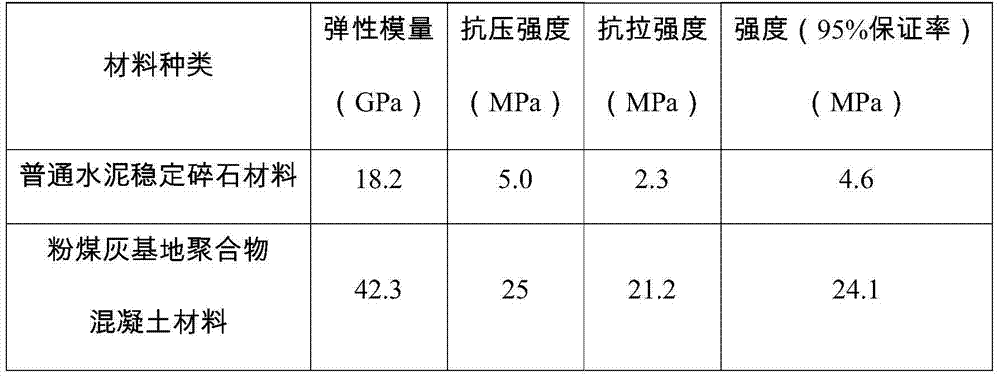

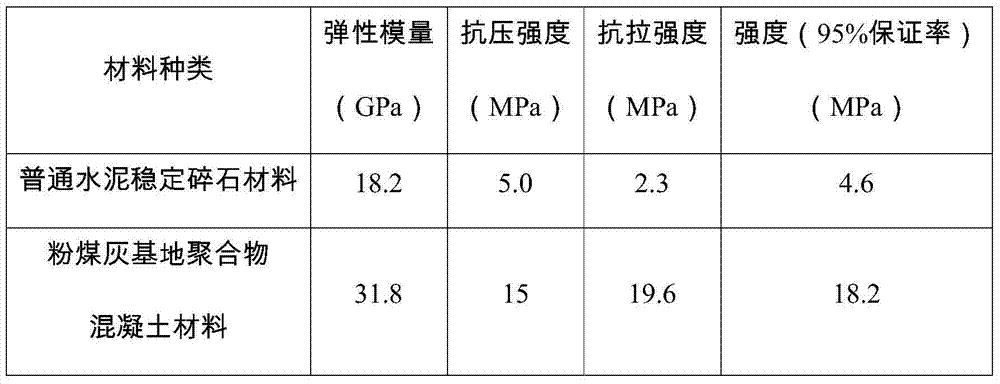

Flyash-based polymer concrete material and preparation method thereof

ActiveCN104496333APromote environmental protectionImprove mechanical propertiesPolymer sciencePolymer concrete

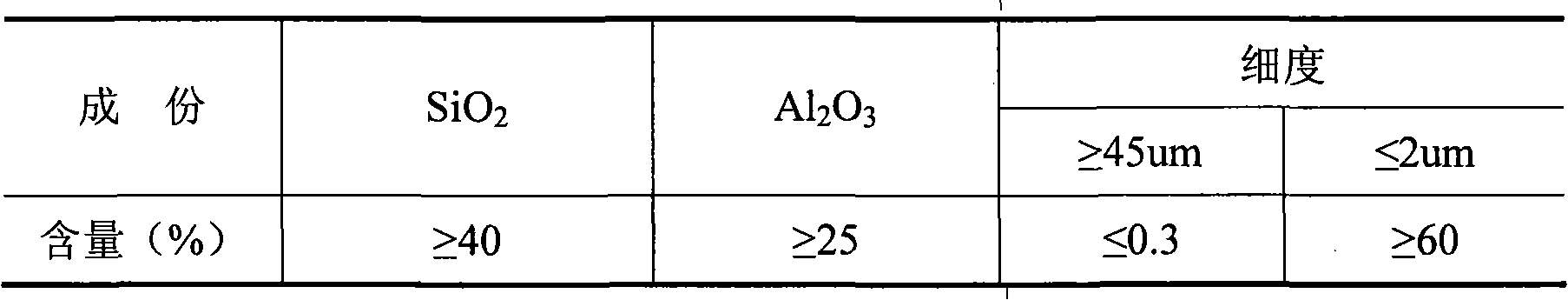

The invention discloses a flyash-based polymer concrete material and a preparation method and an application thereof. The flyash-based polymer concrete material comprises the following components in percentage by mass: 25%-45% of flyash, 0-15% of metakaolin, 10%-15% of cement, 0-5% of coal gangue and slag, 25%-35% of an alkali activator, 0.5%-1% of a retarder and 1%-5% of deionized water. An alkali-activated flyash-based polymer is adopted as a main gel material, so as to prepare an inorganic polymer concrete material; the polymer concrete material has the characteristics of high environmental protection property, good mechanical property and high early strength.

Owner:SHANGHAI PUDONG NEW AREA CONSTR GRP CO LTD

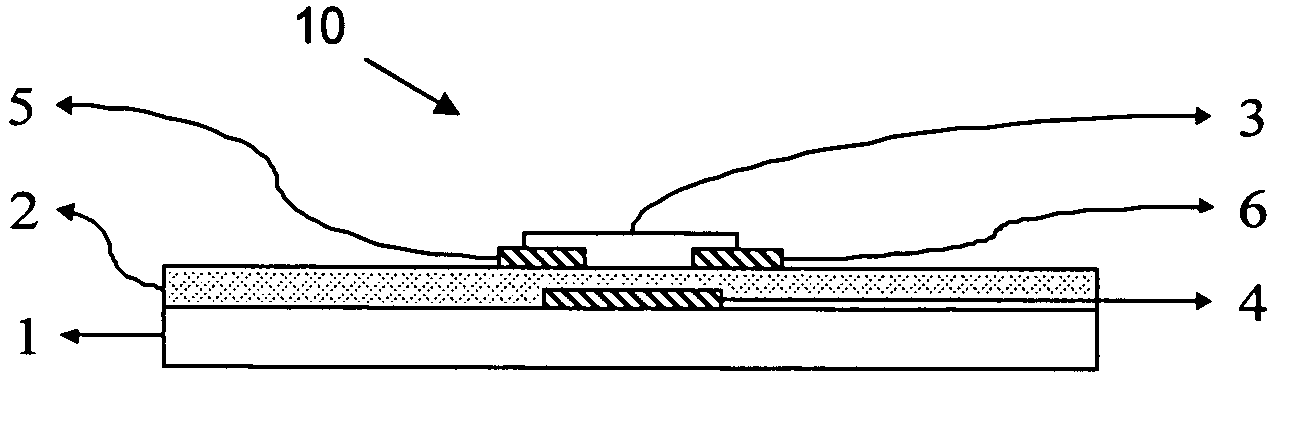

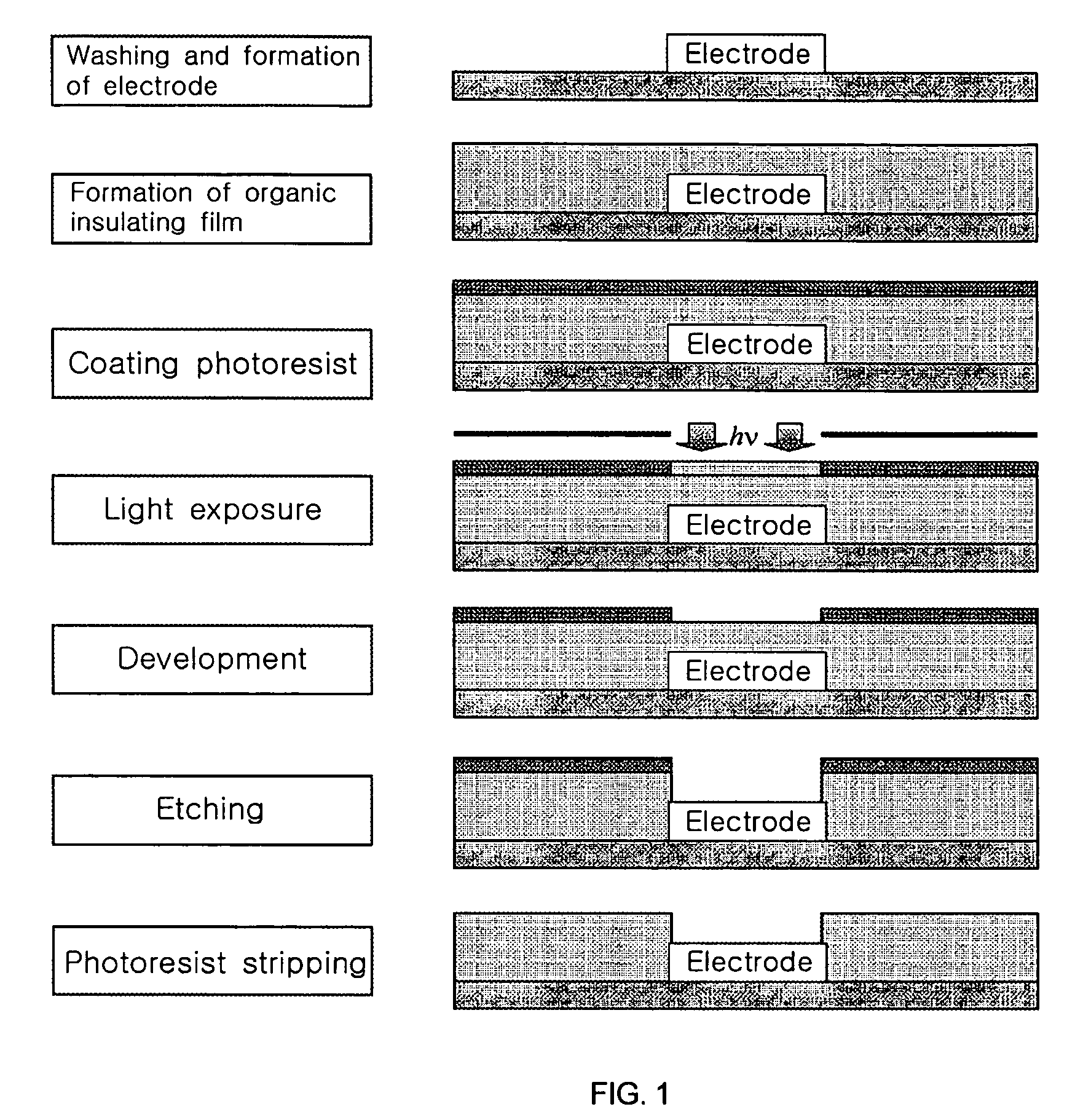

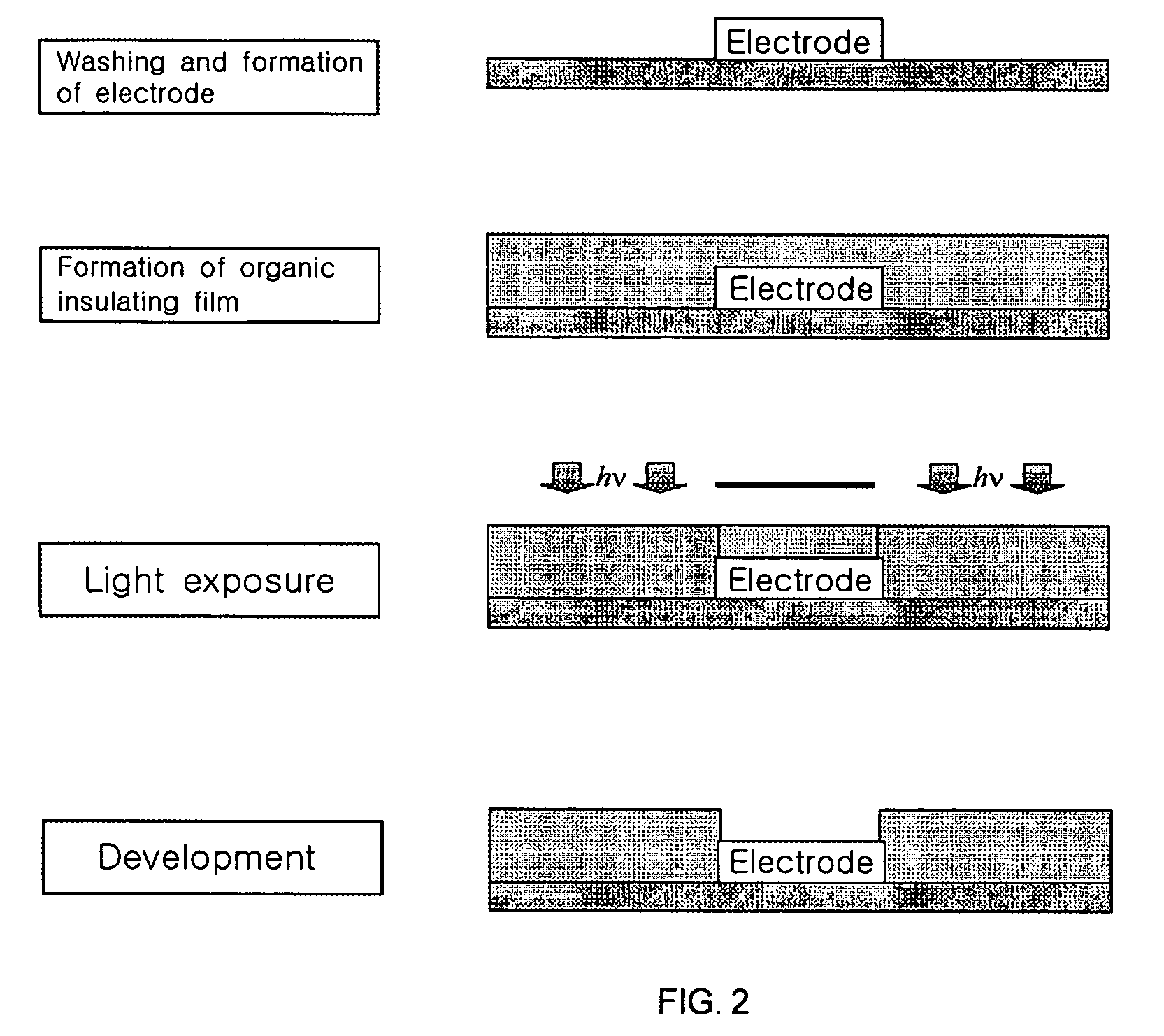

Composition for forming organic insulating film and method for forming pattern of organic insulating film using the same

InactiveUS20060006380A1Simple procedureHigh carrier mobilitySolid-state devicesSemiconductor/solid-state device manufacturingOrganic filmLight irradiation

A photo-patternable composition for forming an organic insulating film which includes (i) a functional group-containing monomer, (ii) an initiator generating an acid or a radical upon light irradiation, and (iii) an organic or inorganic polymer. Further disclosed is a method for forming a pattern of an organic insulating film using the composition. Since an organic insulating film can be simply patterned without involving any photoresist process, the overall procedure is simplified and eventually an organic thin film transistor with high charge carrier mobility can be fabricated by all wet processes.

Owner:SAMSUNG ELECTRONICS CO LTD

Organic-inorganic hybrid material, optical thin layer of this material, optical material comprising same, and process for producing same

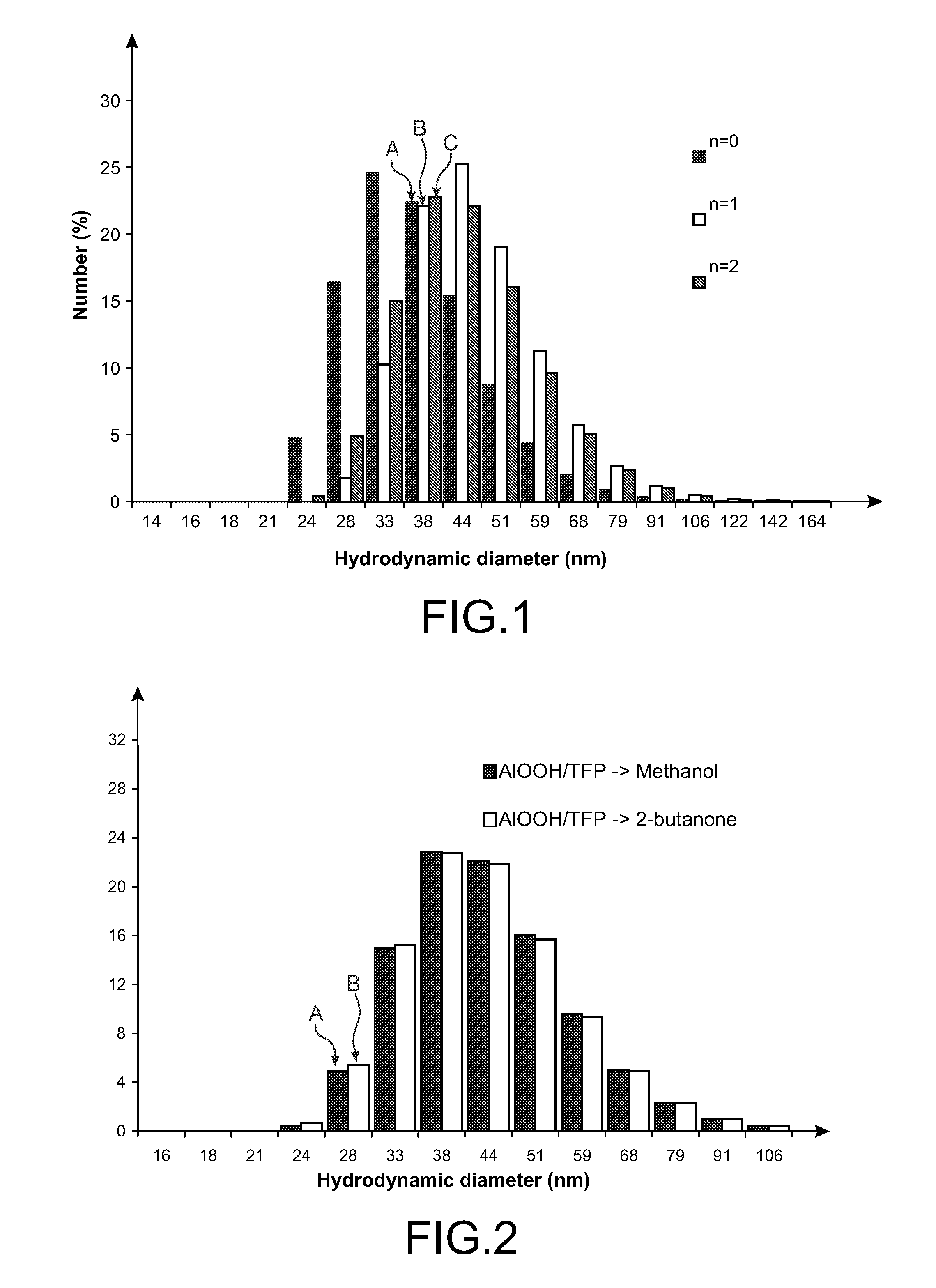

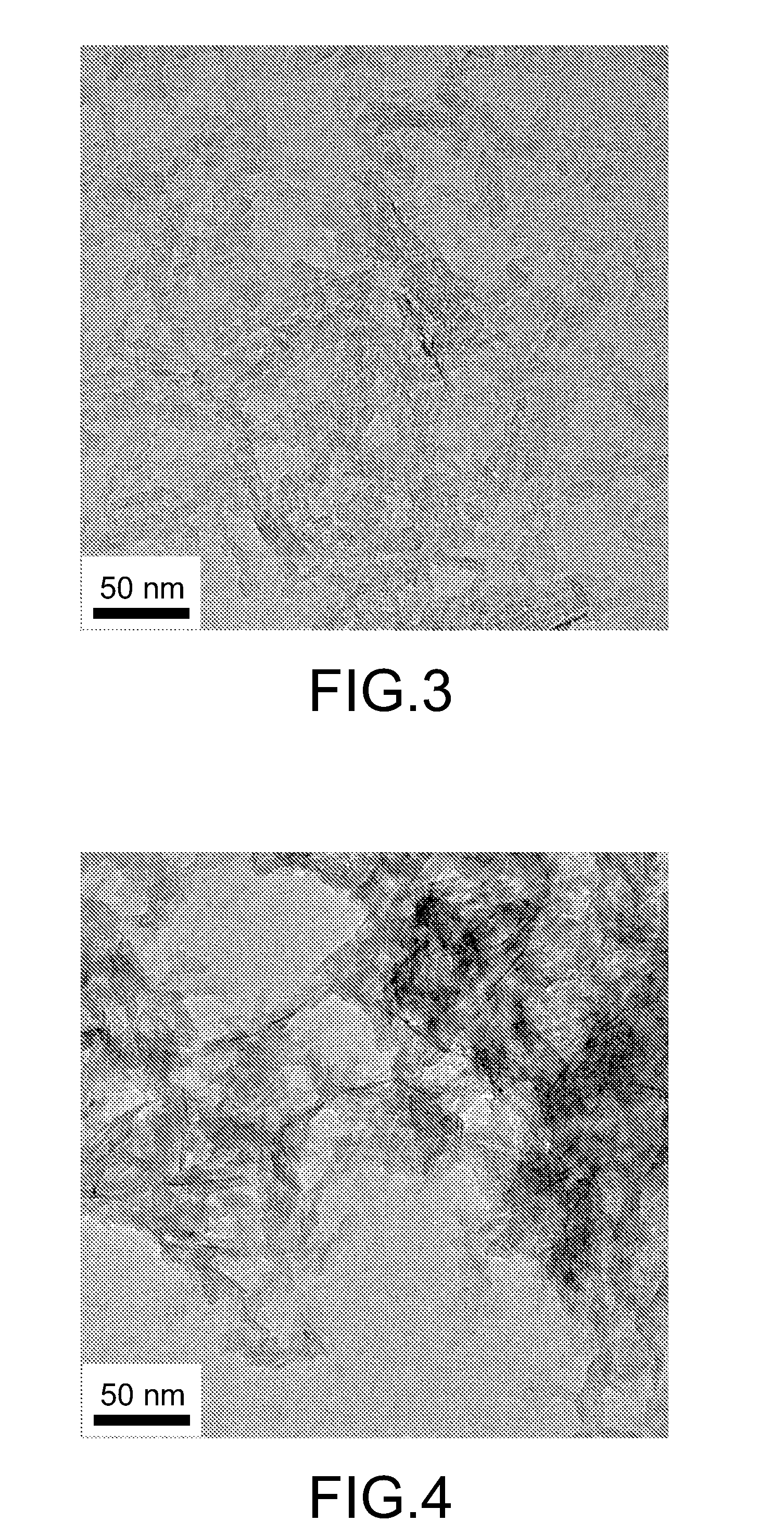

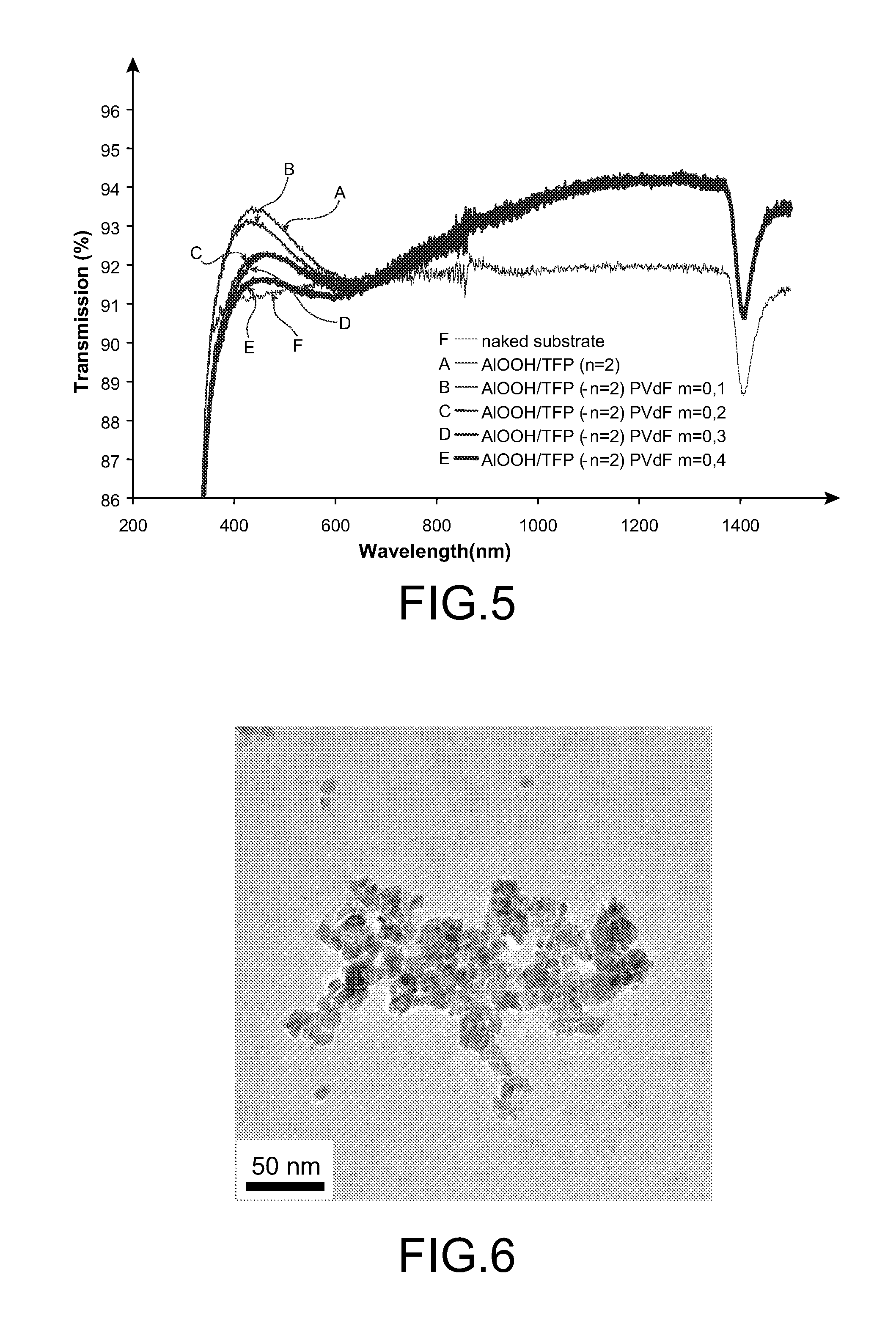

InactiveUS20110003130A1Easy to useMaterial nanotechnologyAnti-reflective coatingsInorganic compoundOptical thin film

Organic-inorganic composite material comprising:colloidal particles of at least one inorganic compound chosen from metal or metalloid oxides and oxyhydroxides, prepared by means of a process of hydrolysis-condensation in a protic or polar solvent, said particles having been surface-functionalised by reaction with an organic compound;and an organic or inorganic polymer.Process for preparing this composite material and optical material comprising a layer of this composite material.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

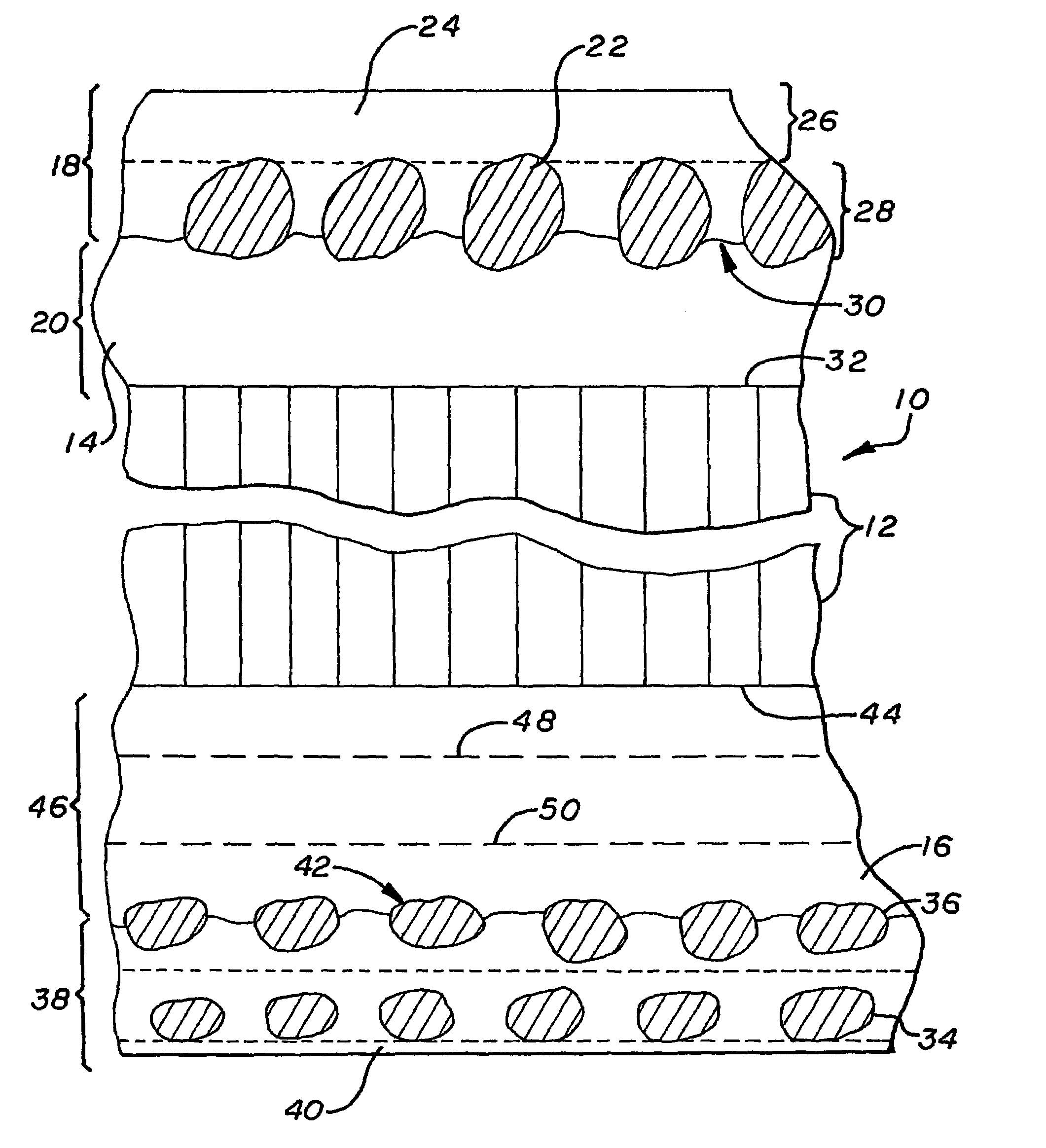

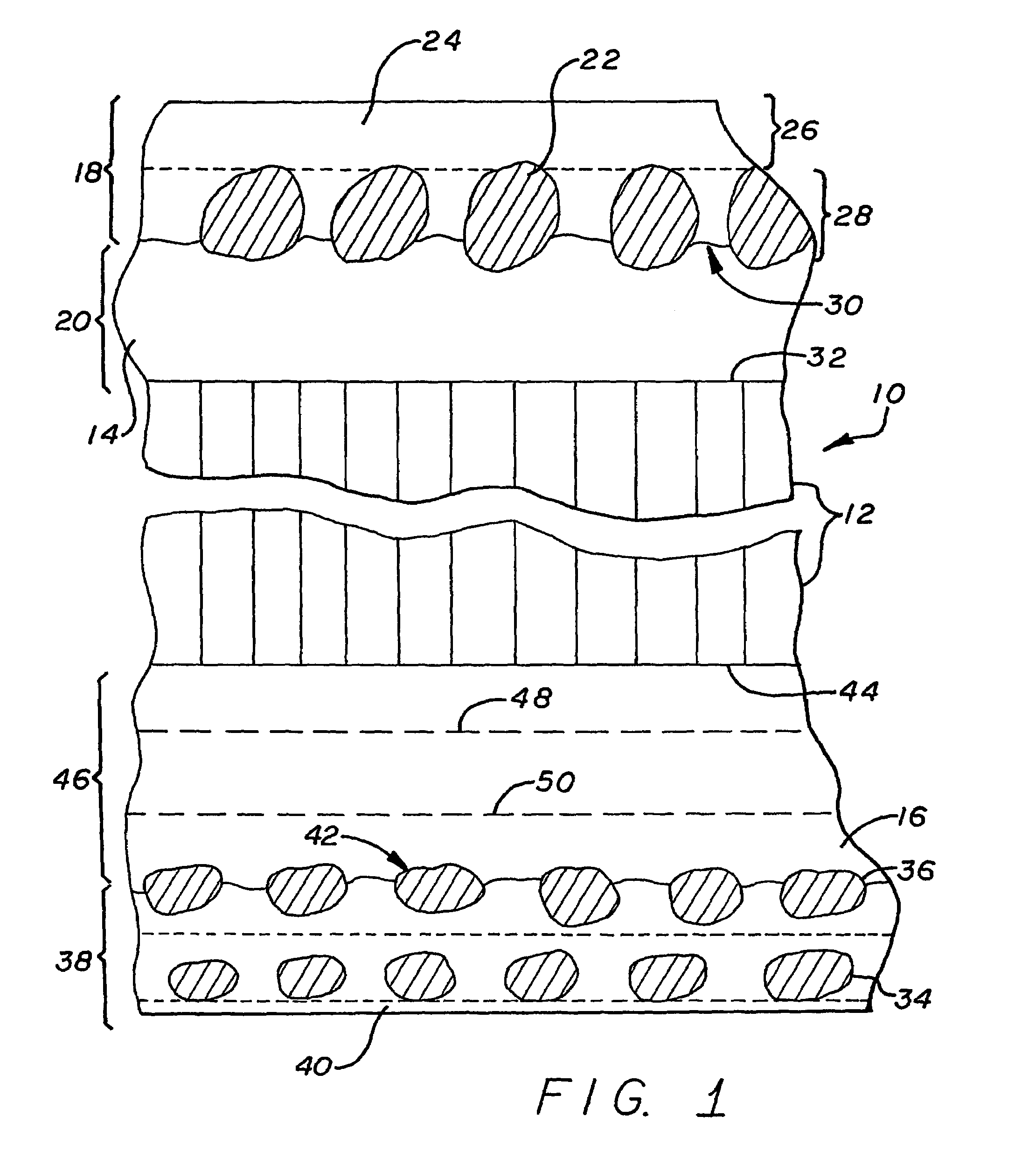

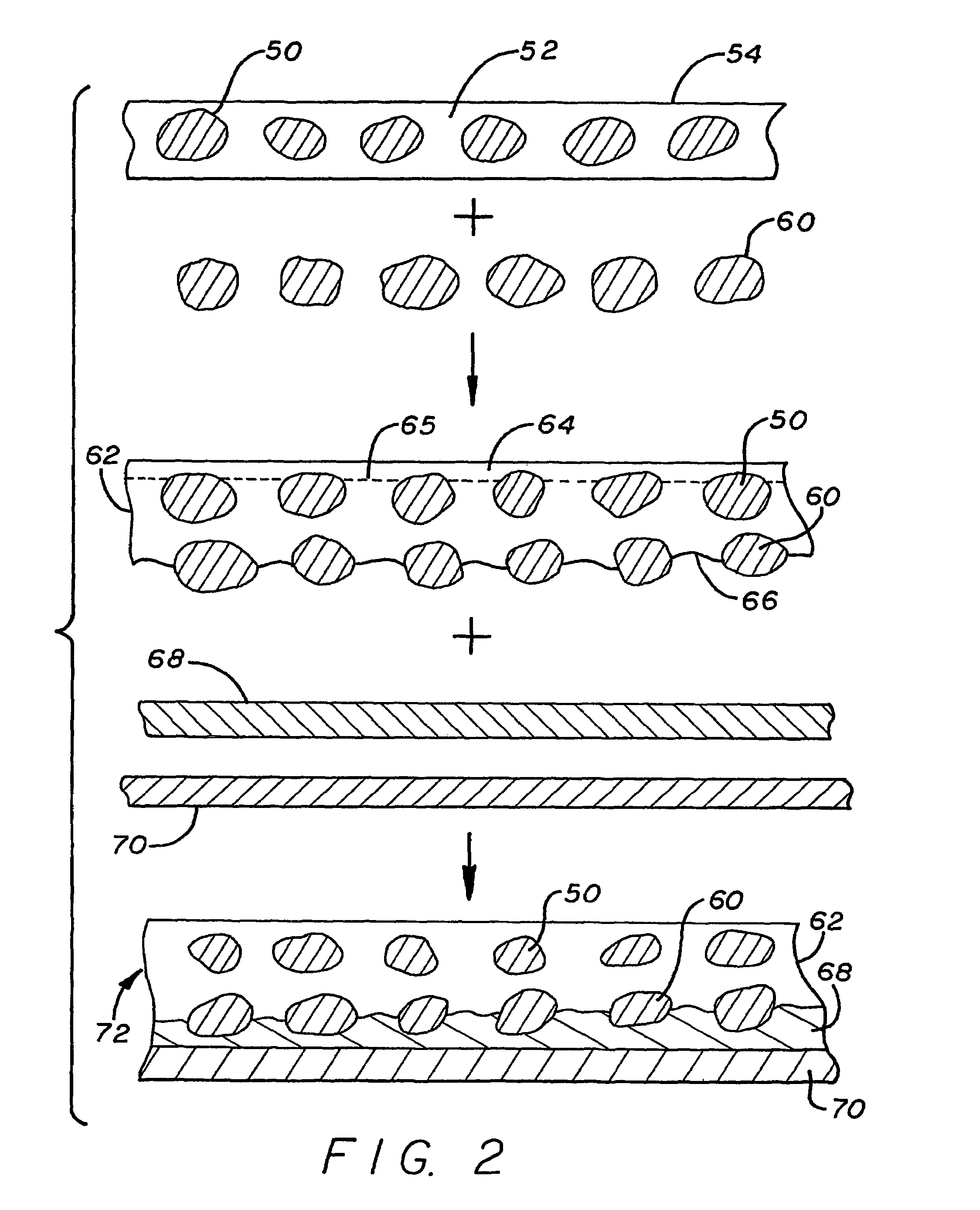

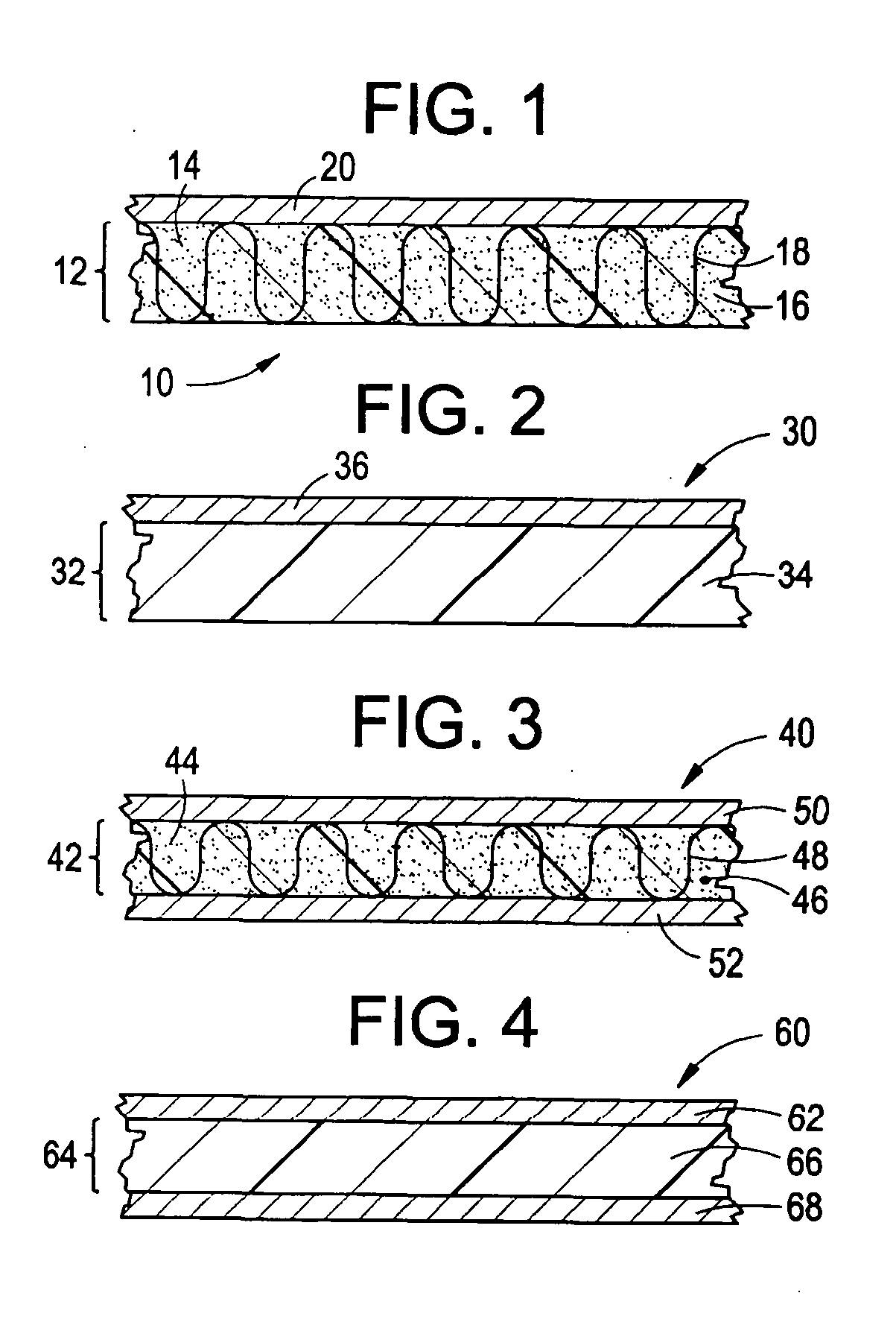

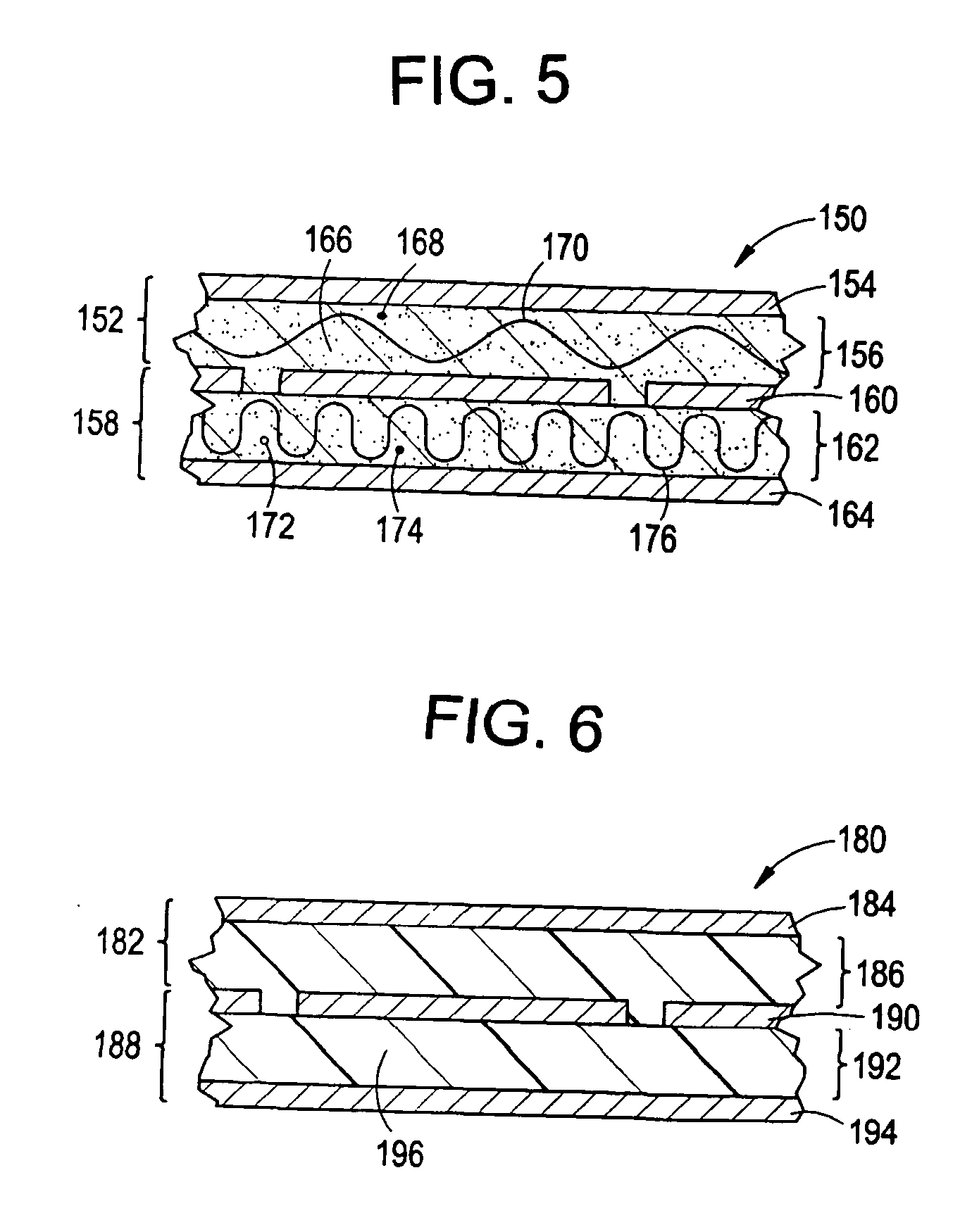

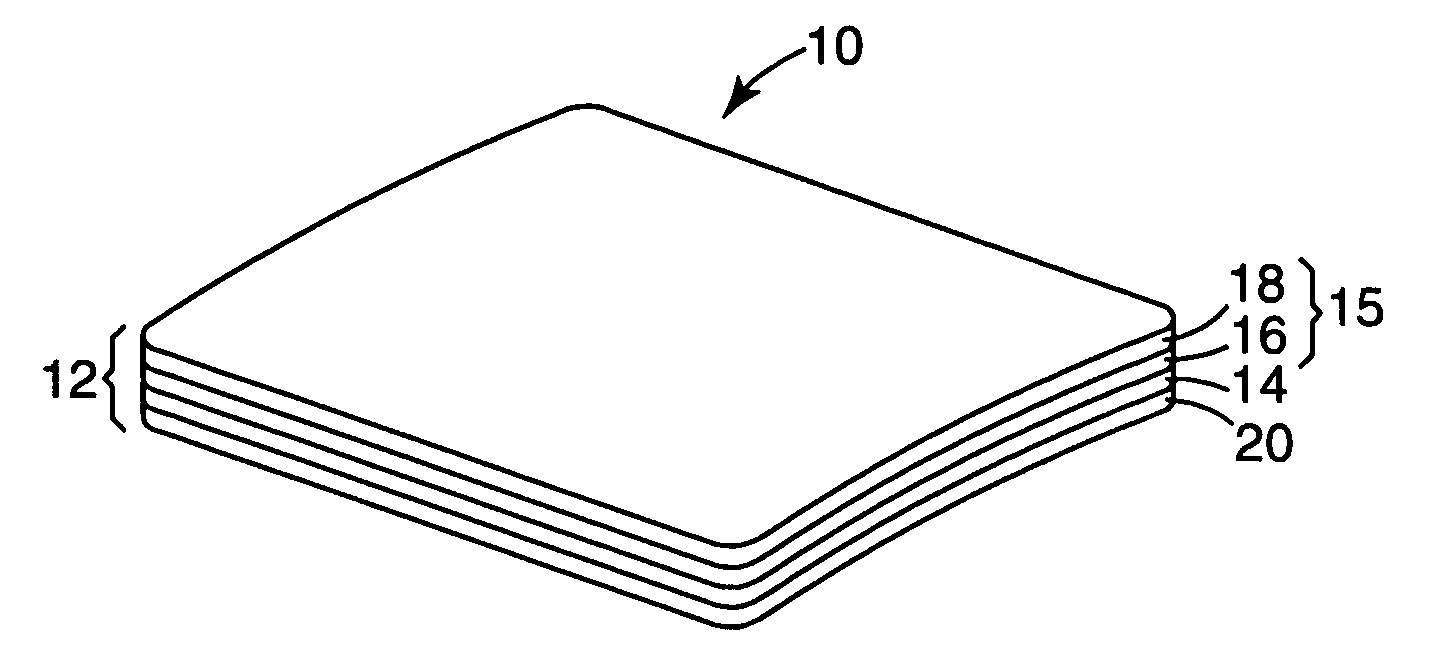

Composite panel with fire resistant face sheets

InactiveUS6992027B1Poor adhesionReduce adhesionSynthetic resin layered productsGlass/slag layered productsFiberFire protection

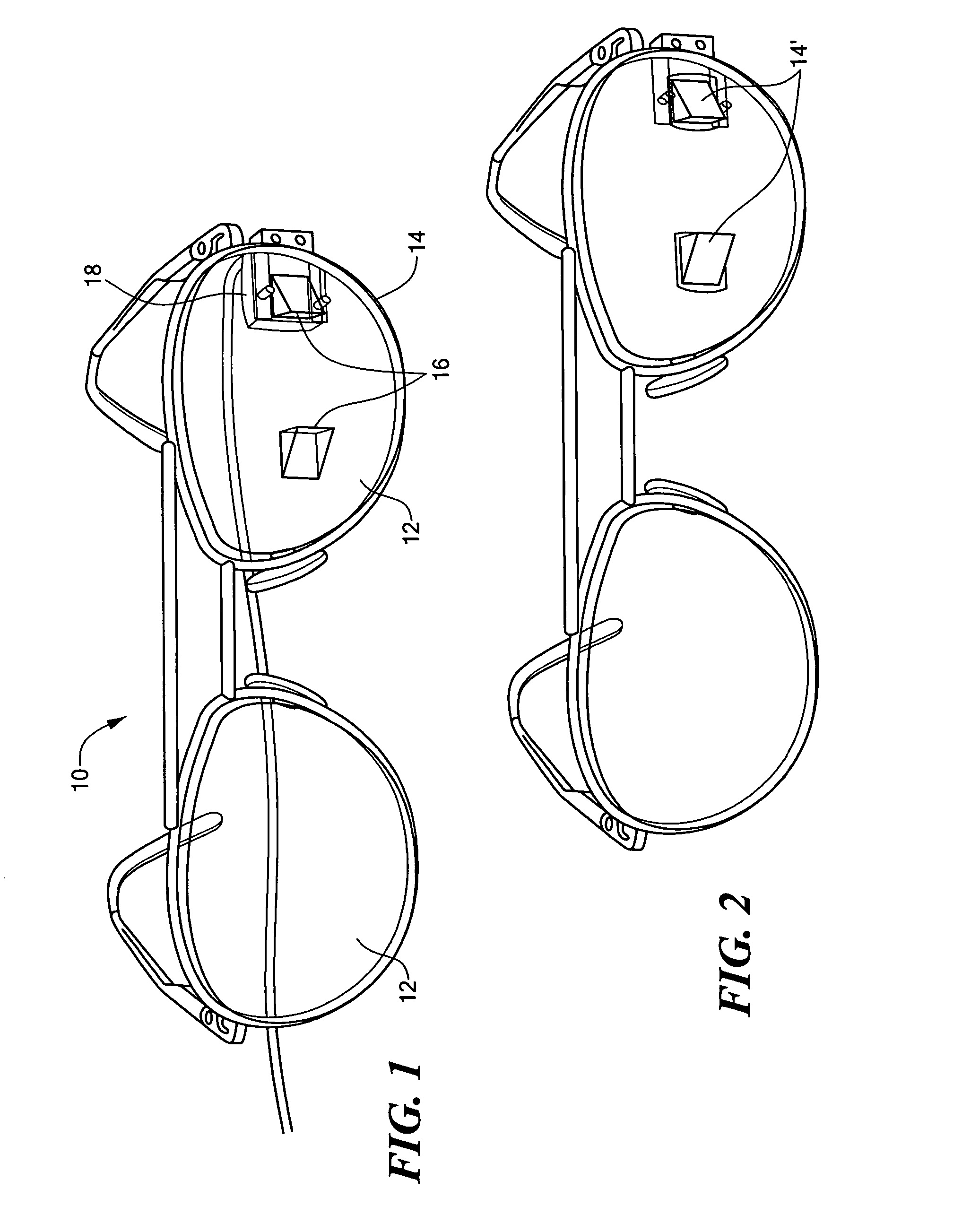

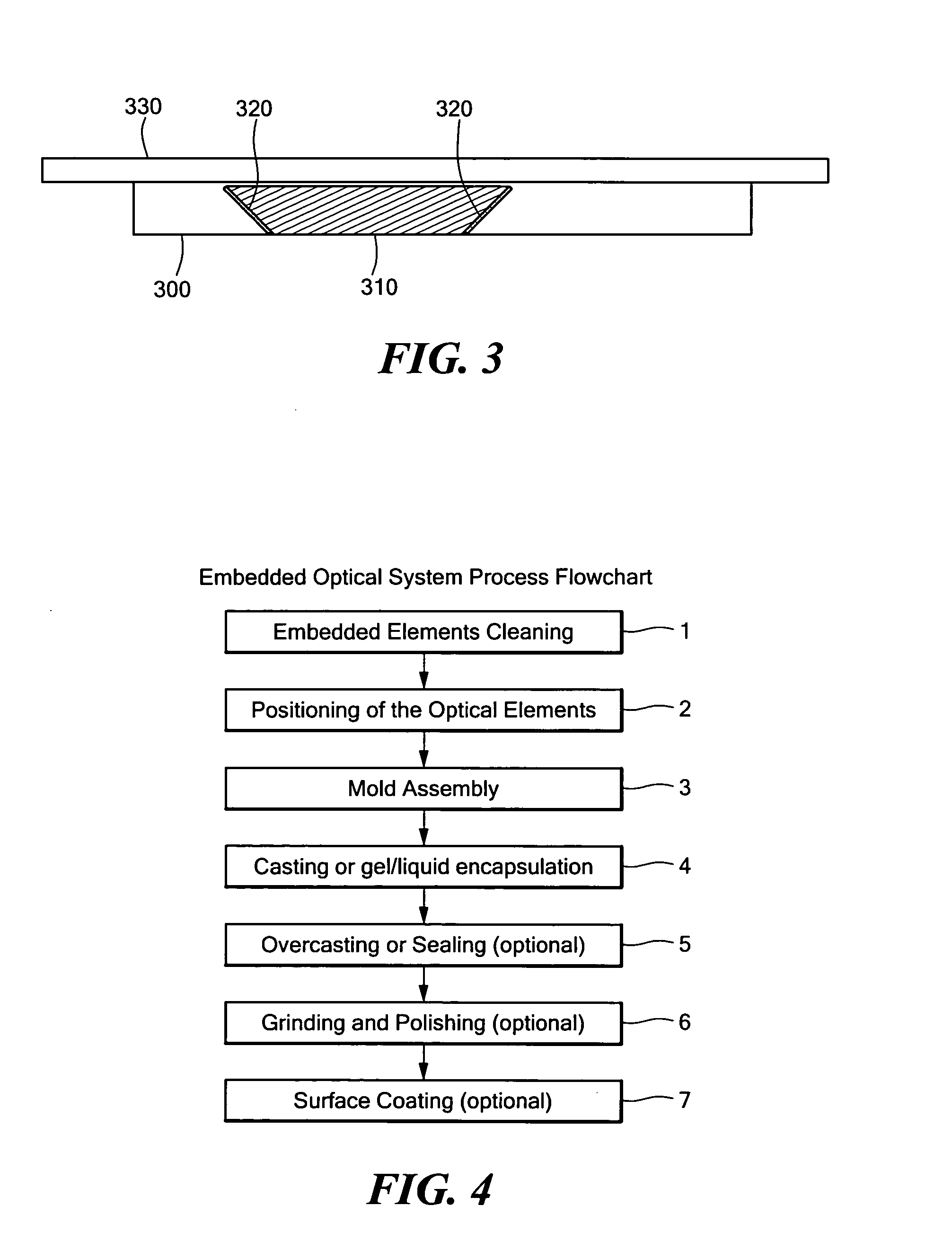

A fire resistant laminate for application to a core structure (12) to form a sandwich panel (10) having fire resistant face sheets (14&16). The laminate includes a fire protection (18) in which at least one layer of fibers (22) is embedded within a cured inorganic polymer matrix (24). The laminate further includes an adhesive layer (20) for bonding to the core structure.

Owner:HEXCEL COMPOSITES LTD (GB)

Method for preparing Nano SiO2 fire retardant viscose fiber, and film

ActiveCN101050559ASimple processEasy to operateFlame-proof filament manufactureArtificial filaments from viscoseFire retardantSodium sulfate

The present invention relates to a preparation method of nano SiO2 fire-retardant viscose fiber and film, specially, it relates to a preparation method of fire-retardant viscose fiber formed from cellulose and SiO2 and organic-inorganic polymer nano composite membrane made of cellulose and SiO2. Said method includes the following steps: adding silicone sol with a certain mass into a viscose solution whose composition contains alpha-cellulose whose mass percentage content is 6-9% and sodium hydroxide whose mass percentage content is 5-6%; fully stirring and mixing them at 10-50 deg.C, deforming so as to obtain viscose-silicone sol solution, then adding said viscose-silicone sol into a coagulation acid bath prepared by using sulfuric acid, sodium sulfate, zinc sulfate and water, coagulating at 10-100 deg.C, spinning so as to obtain nano SiO2 fiber-retardant viscose fiber, utilizing coating process so as to obtain organic-inorganic polymer nano composite membrane of cellulose / SiO2.

Owner:QINGDAO UNIV

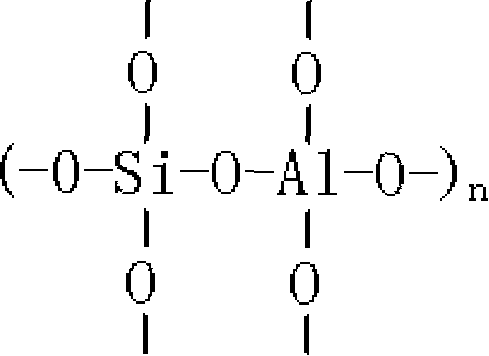

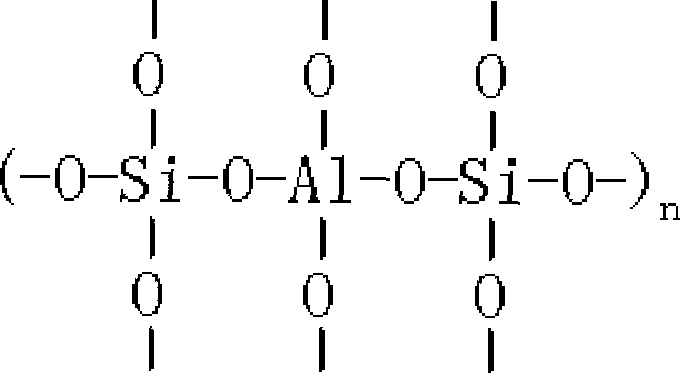

Polymer coating composite and preparation method thereof

InactiveCN101045832ALow costEasy to use on siteSolid waste managementCement productionPolymer scienceOxygen

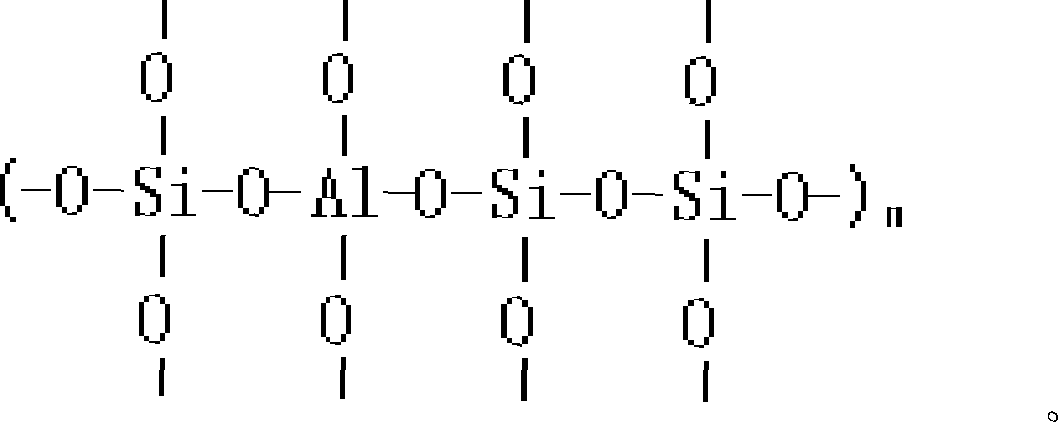

This invention relates to a dope combination. The film coating it formed is amorphous gelatinous substance, base unit is three-dimensional network formed by connection of silicon - oxygen tetrahedron and aluminium - oxygen tetrahedron. end product takes electrovalent bond and covalent bond as main, vander waas bond as complement, possess linkage structure of organic heavy polymer, and double property of inorganic polymer and organic polymer. The unique performance supple the insufficiency of organic high molecular polymer. It possesses favorable performance of acid-proof, alkali-proof, impervious, antifreeze, seawater resistance and high temperature resistance.

Owner:袁景华 +1

Luminescent metallic cluster particles and uses thereof

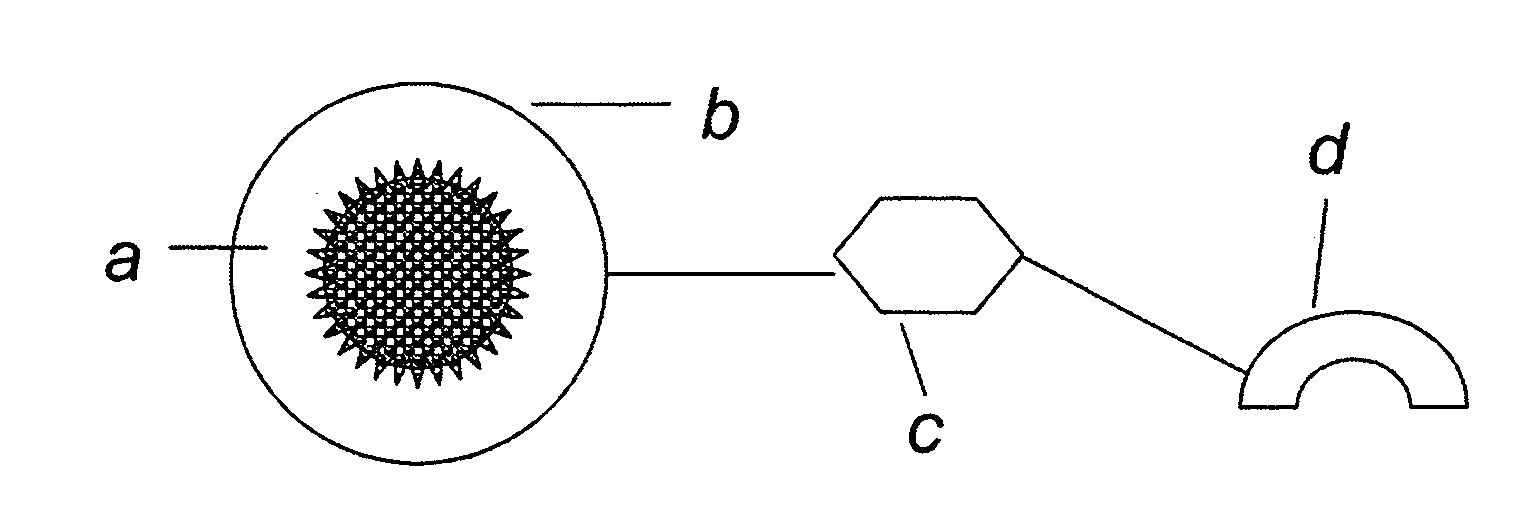

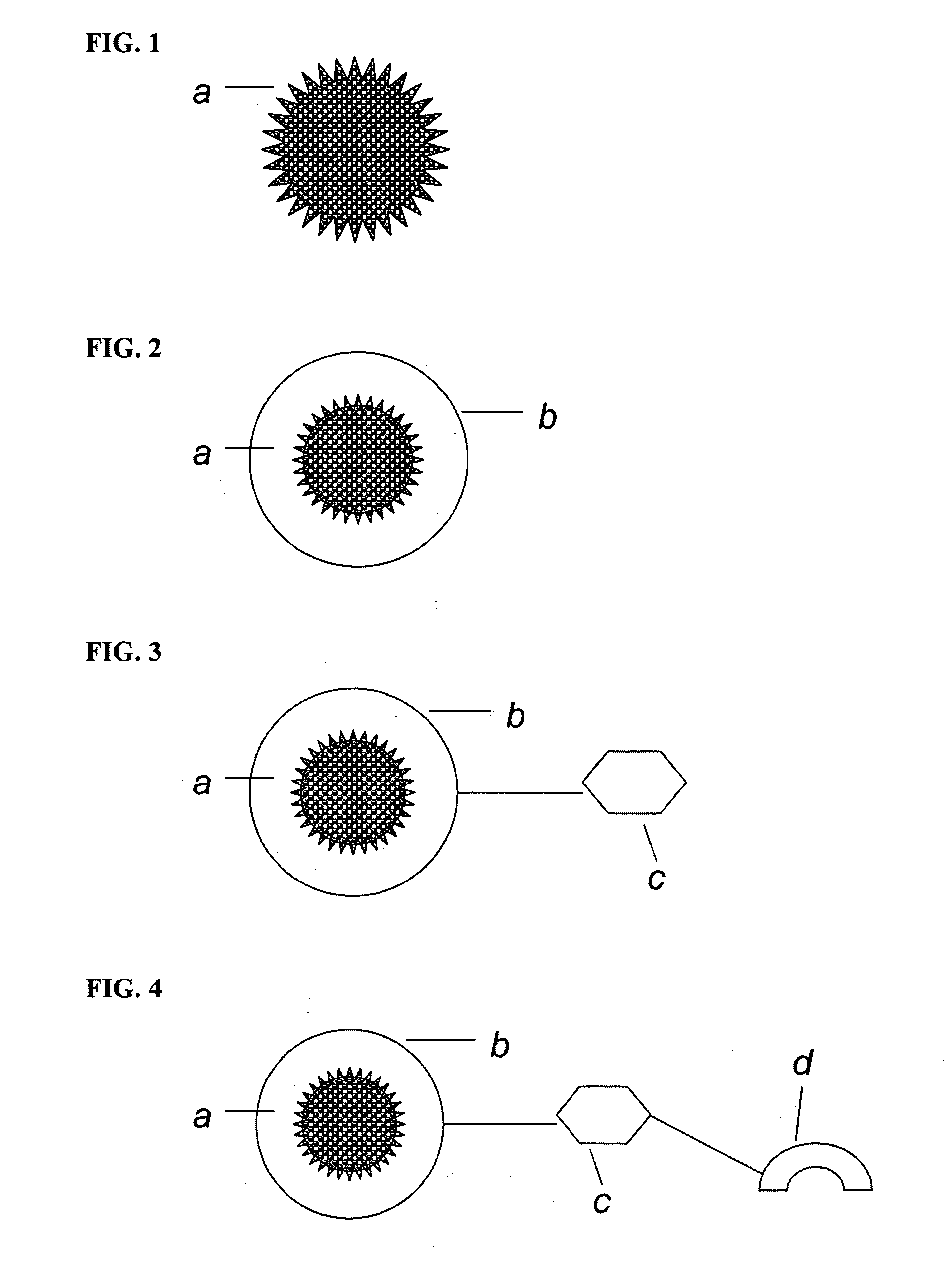

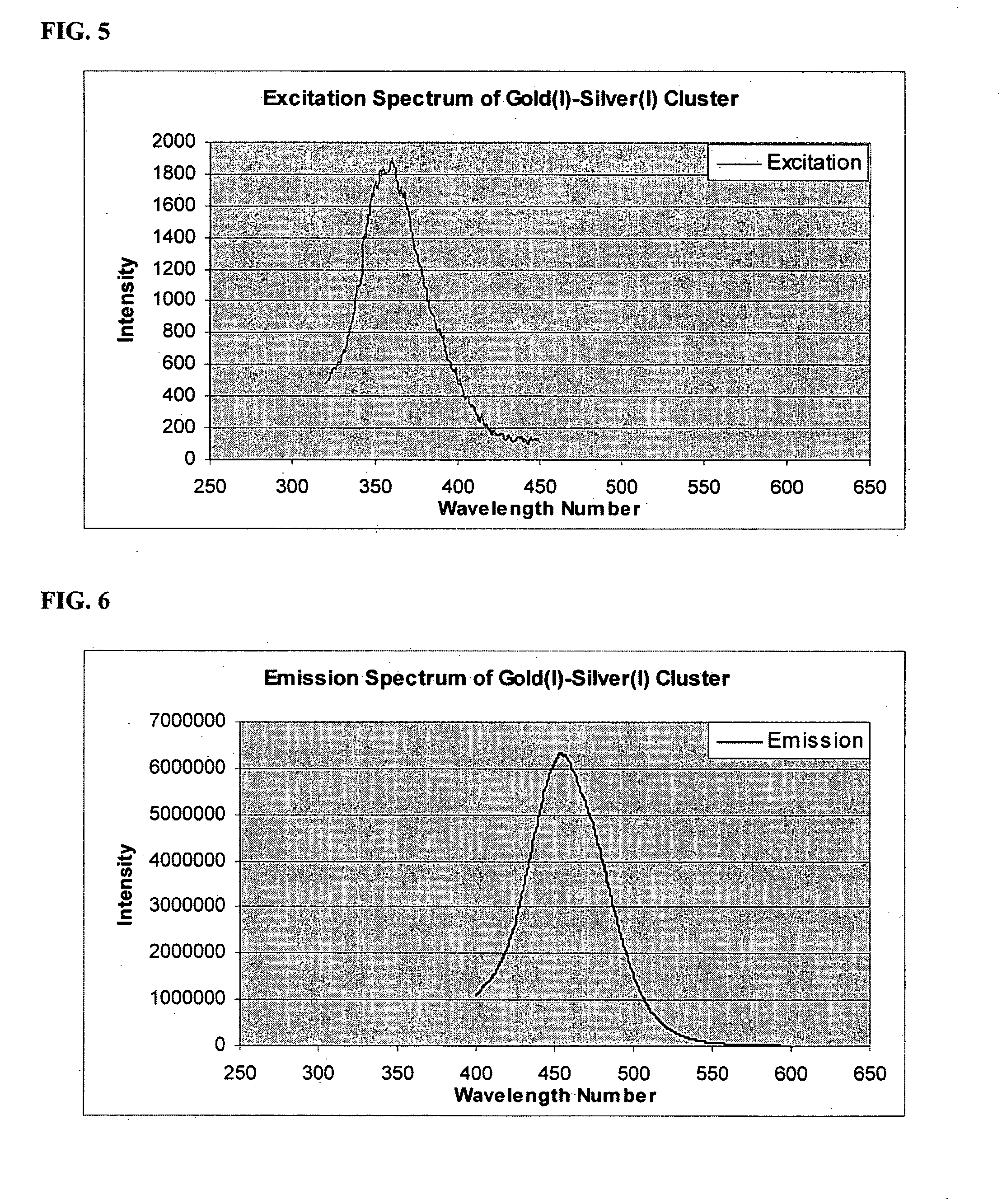

A luminescent particle having a luminescent core structure formed from at least one type of luminescent metallic cluster complex and a shell that covers said core structure is described. The luminescent core structure includes one or more aggregates of metal cluster complexes. The shell has one or more layers of thin films formed predominately of organic or inorganic polymers, hydrid polymers, or combinations thereof. The luminescent particles can be adapted for optical detection or imaging applications. Methods of fabricating the various iterations of the luminescent particles are also provided.

Owner:KIMBERLY-CLARK WORLDWIDE INC

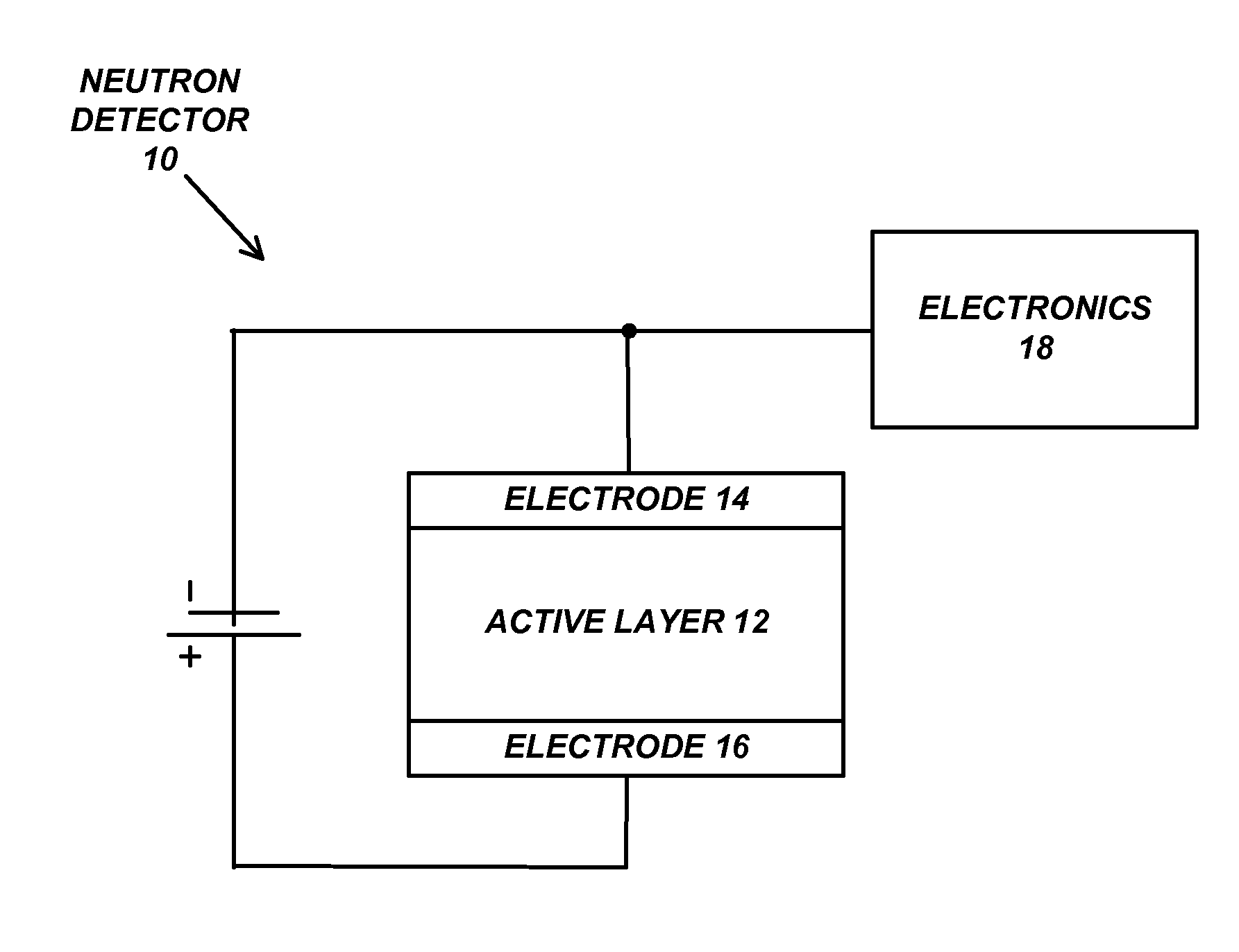

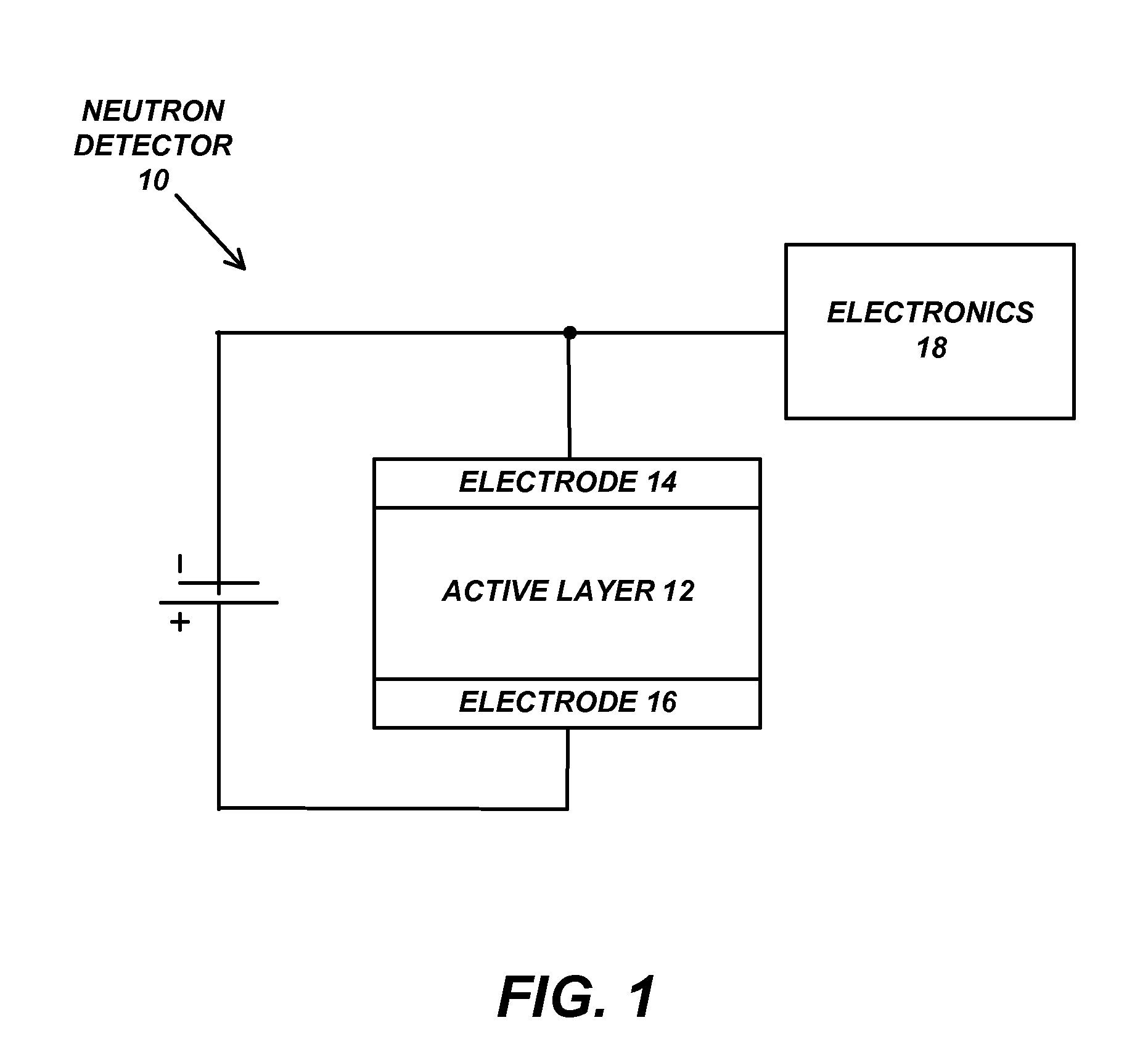

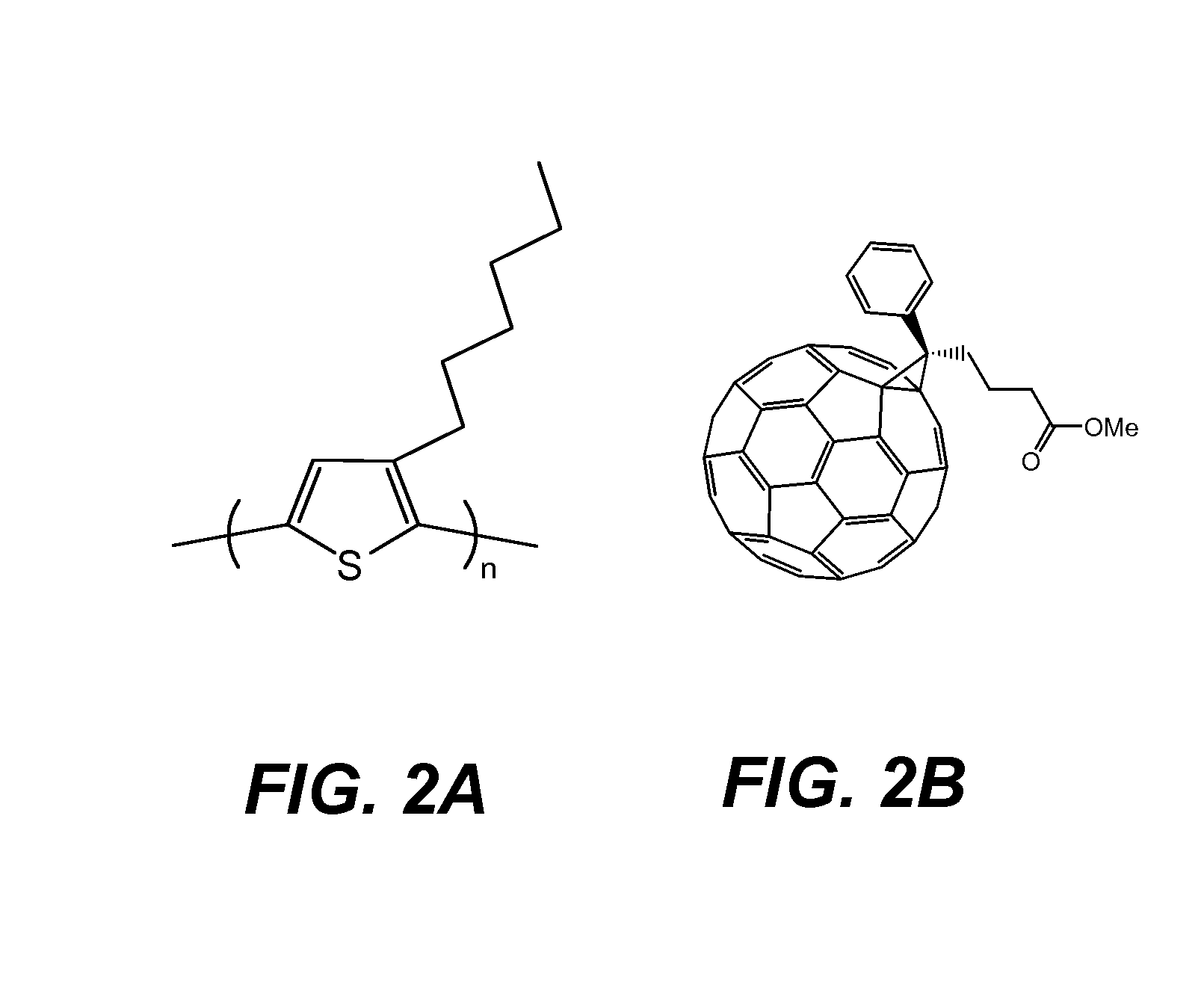

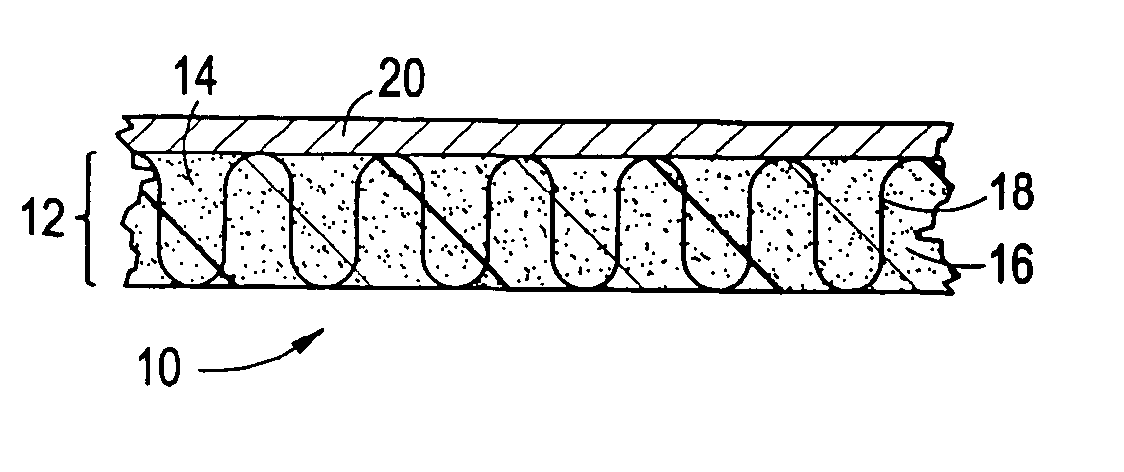

Neutron detectors based on organic and inorganic polymers, small molecules and particles, and their method of fabrication

InactiveUS20080128628A1Measurement with semiconductor devicesMaterial analysis by optical meansSemiconductor materialsEvaporation

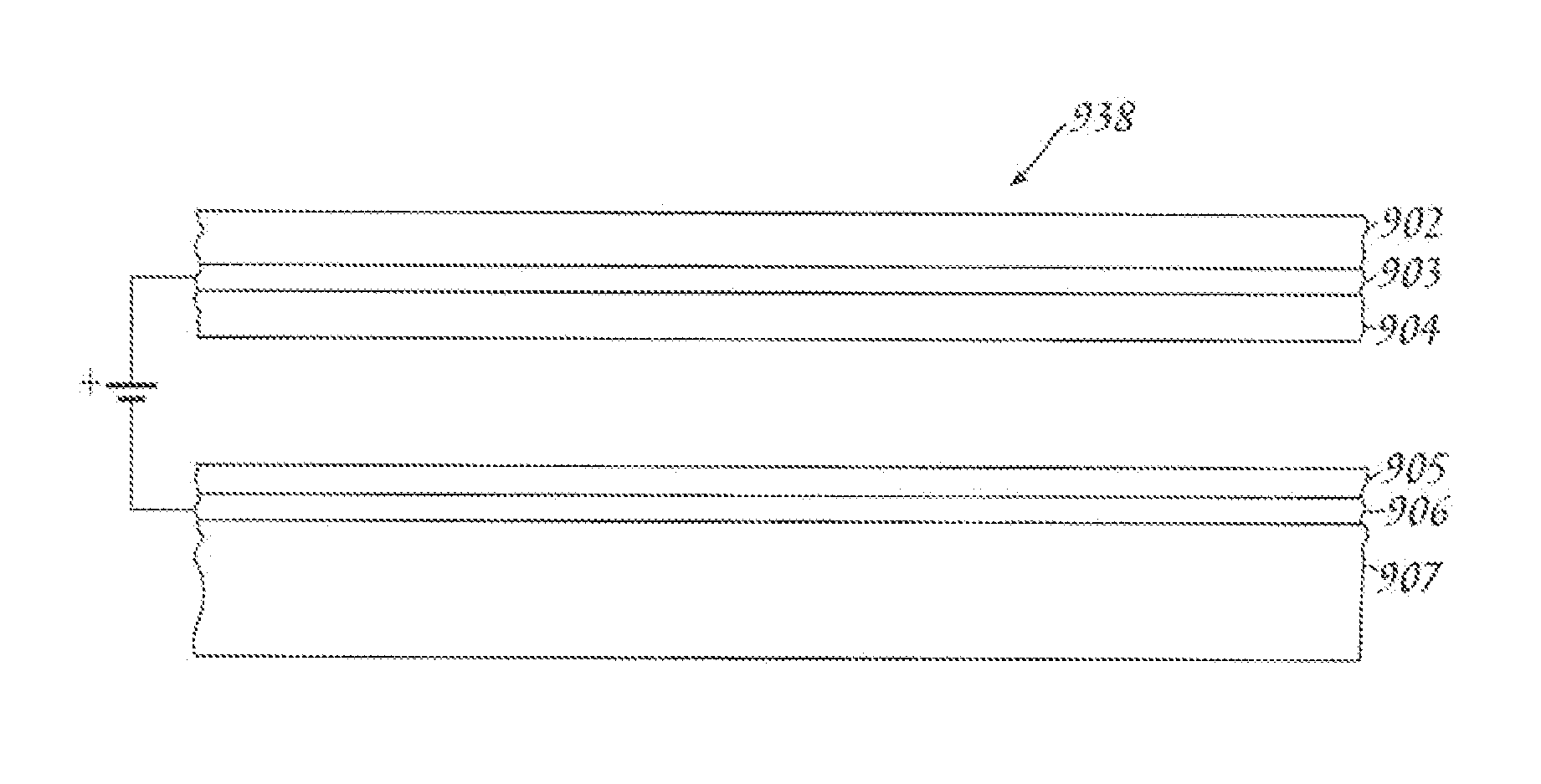

A neutron detector, and method for fabricating same, having an active layer comprised of organic and inorganic materials such as polymers and / or small molecules. These materials function as a semiconductor host matrix that transports carriers excited by neutron absorption. The active layer is comprised of host semiconductor materials, composites of the host semiconductor materials with other polymers molecules, and particles, or multi-layer structures of the host semiconductor materials with other materials. The host semiconductor materials include in their molecular structure neutron capturing atoms such as 10B, 6Li, 157Gd, 235U, 239Pu, 51V, and 103Rh, or alternatively are blended with molecules or particles that contain the above atoms in addition to electron accepting molecules or particles. Using these materials allows for the simplified fabrication of inexpensive, large area, relatively lightweight, and flexible neutron detectors via film casting from solution, thermal evaporation, inkjet printing, and film laminate, or film extrusion.

Owner:RGT UNIV OF CALIFORNIA

Circuit materials, circuits, multi-layer circuits, and methods of manufacture thereof

ActiveUS20050173780A1Excellent ElectricalGood physical propertiesSemiconductor/solid-state device detailsPrinted circuit aspectsOptoelectronicsSilsesquioxane

An electrical circuit material having a conductive layer disposed a substrate, wherein the substrate comprises an organic or inorganic polymer comprising a covalently bound polyhedral silsesquioxane (POSS). The substrate may further comprise an additional dispersed POSS, any other fillers including fibrous webs. Use of covalently bound POSS allows for flame retardancy in compositions having acceptable dielectric constants and dissipation factors.

Owner:WORLD PROPERTIES

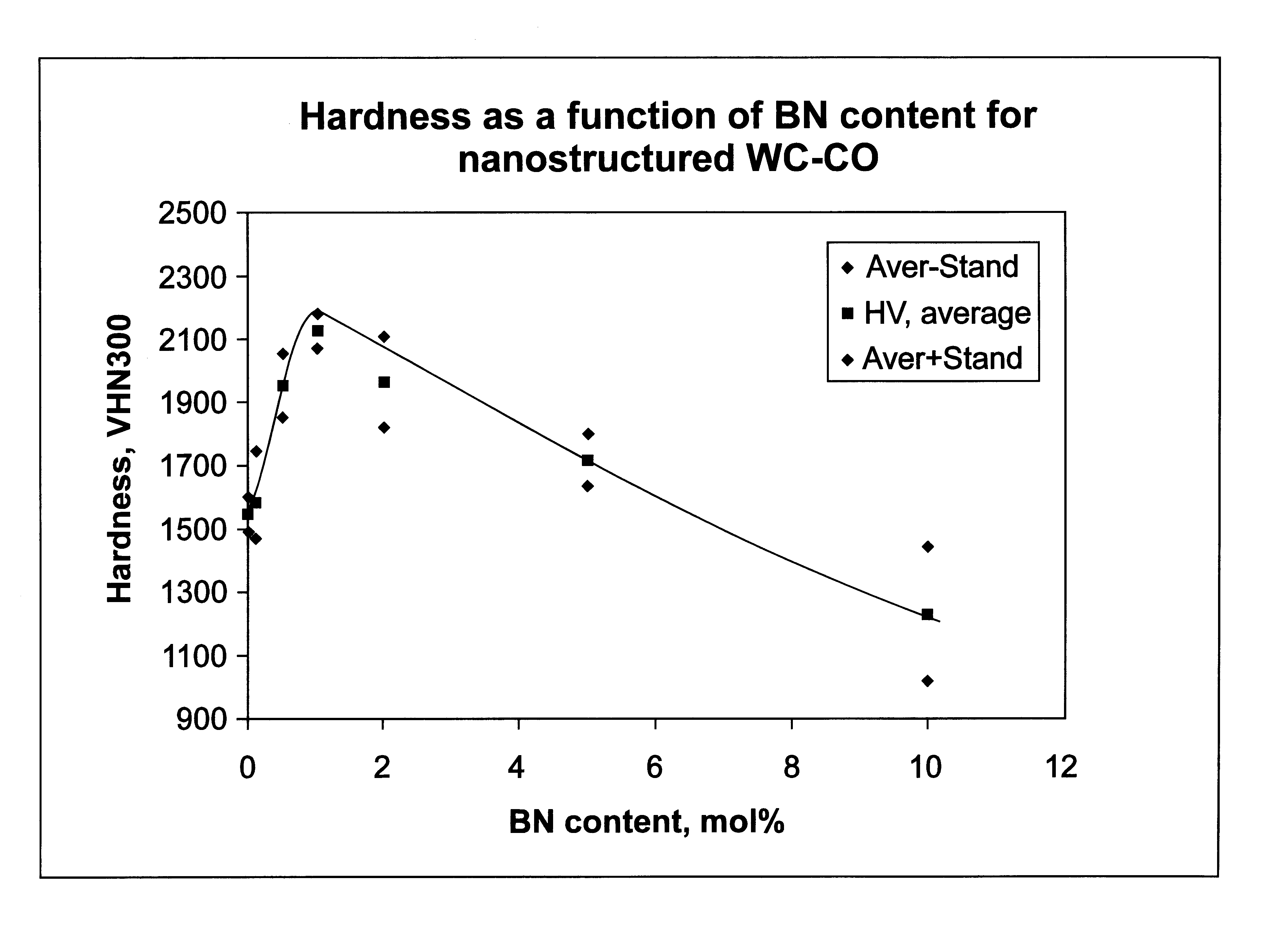

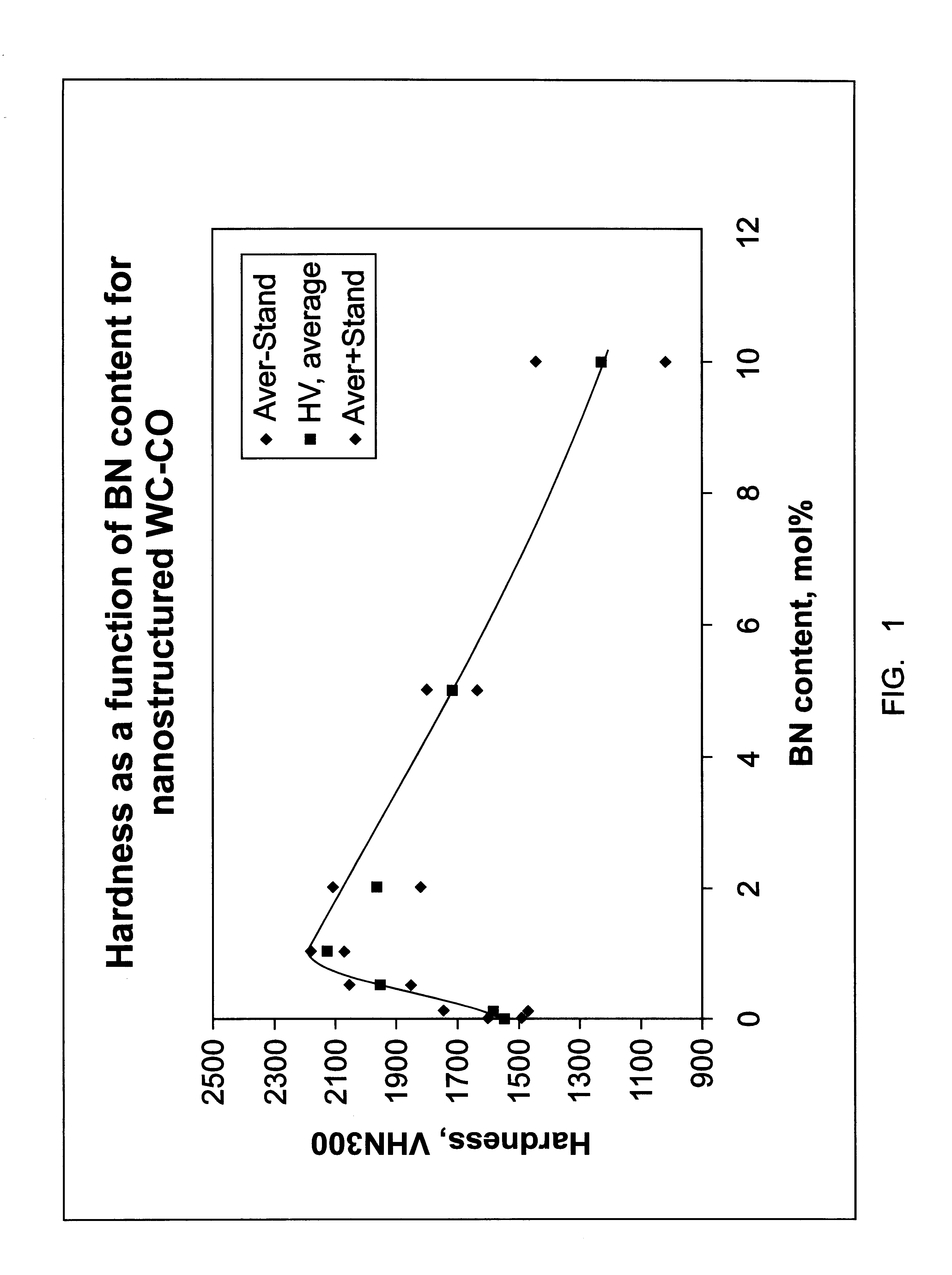

Grain growth inhibitor for nanostructured materials

InactiveUS6287714B1Material nanotechnologyNitrogen compoundsGrowth retardantNanostructured materials

A method comprising incorporation of an inorganic polymer precursor of a grain growth inhibitor into nanostructured materials or intermediates useful for the production of nanostructured materials. The precursor / nanostructured material composite is optionally heat treated at a temperature below the grain growth temperature of the nanostructured material in order to more effectively disperse the precursor. The composites are then heat treated at a temperature effective to decompose the precursor and to form nanostructured materials having grain growth inhibitors uniformly distributed at the grain boundaries. Synthesis of the inorganic polymer solution comprises forming an inorganic polymer from a solution of metal salts, filtering the polymer, and drying. Alloying additives as well as grain growth inhibitors may be incorporated into the nanostructured materials.

Owner:INFRAMAT CORPORATION

Concrete maintenance and reinforcement treatment method

InactiveCN102220813AGood sealingIncreasing the thicknessBuilding repairsBridge erection/assemblyFiberAdhesive

The invention relates to a concrete maintenance and reinforcement treatment method. The method comprises the following steps: (1) carrying out nondestructive treatment on the concrete base surface defects; (2) carrying out rust-proof treatment on reinforcing bars; (3) carrying out concrete alkalinity recovery treatment; (4) carrying out concrete crack repairing treatment; (5) daubing new and old concrete adhesives; (6) daubing inorganic polymer mortar and carrying out curing; (7) sticking carbon fiber cloth; (8) brushing an inorganic water and salt injury resistant concrete protective agent; and (9) brushing a surface self-cleaning material, thus completing construction. The method has the following beneficial effects: rust can be removed or prevented from the reinforcing bars to protect the reinforcing bars and prevent further corrosion; by adopting the carbon fiber cloth for reinforcement, the concrete structure has the characteristics of high strength, light weight, simpleness and convenience in construction and corrosion resistance; the bearing capability of the beam body is improved; the deflection of the structure is reduced; the construction efficiency is greatly improved by adopting the airless spraying and coating operations; the coating is saved by 30%; and by brushing the self-cleaning material, the structure has the self-cleaning capability, thus avoiding cleaning or reducing the cleaning frequency.

Owner:SHANGHAI FAHE BRIDGE & TUNNEL MAINTENANCE ENG TECH

Antiglare coating and articles

ActiveUS20060046071A1Material nanotechnologyGroup 4/14 element organic compoundsSilica particlePolymer science

The present invention relates to articles comprising an antiglare layer, coating compositions suitable for making antiglare layers, methods of making an antiglare article, and methods of making antiglare coating compositions. In some embodiments the article is a (e.g. illuminated) display article such as a touch screen. The antiglare layer comprises aggregate silica particle in a cured inorganic polymer matrix.

Owner:3M INNOVATIVE PROPERTIES CO

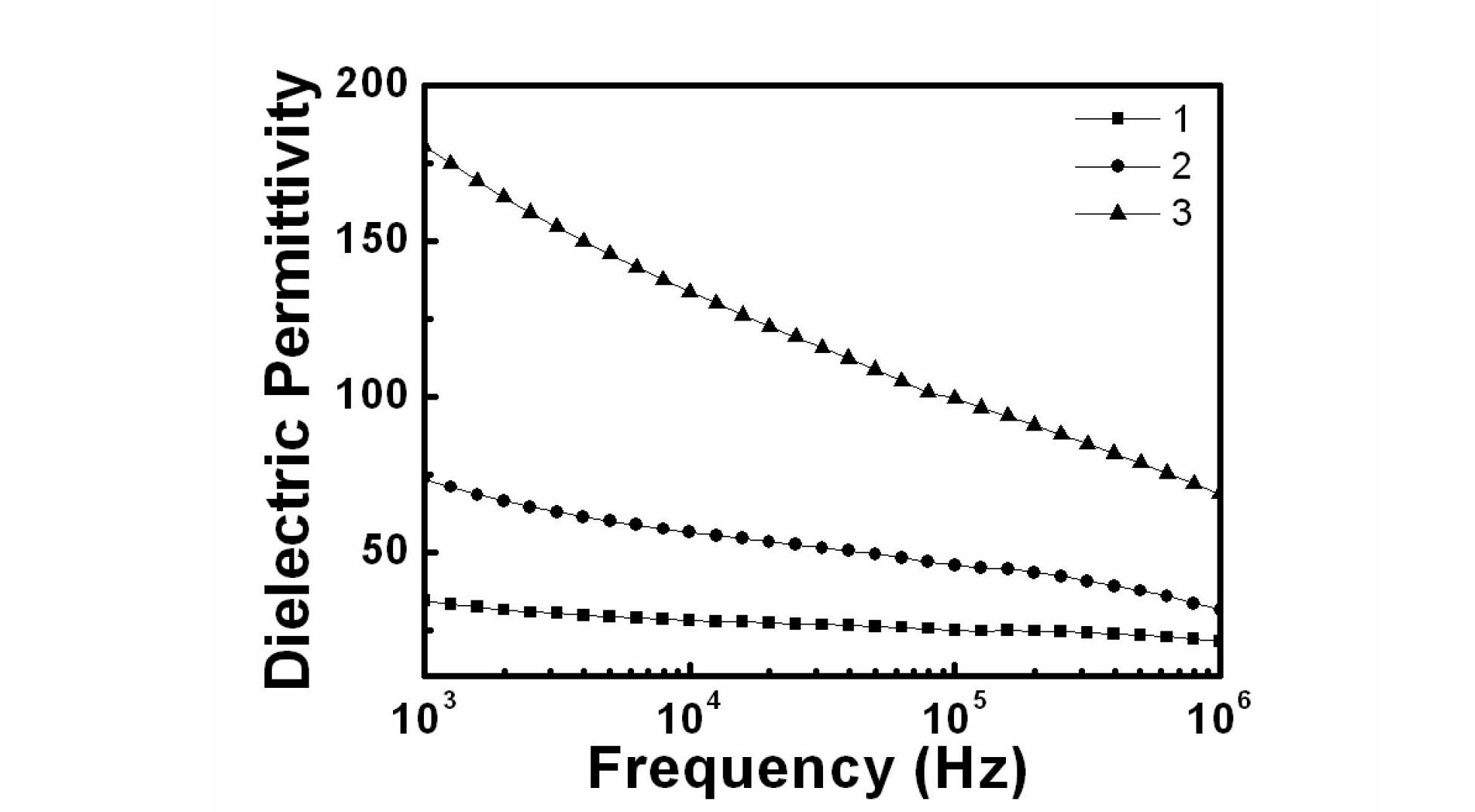

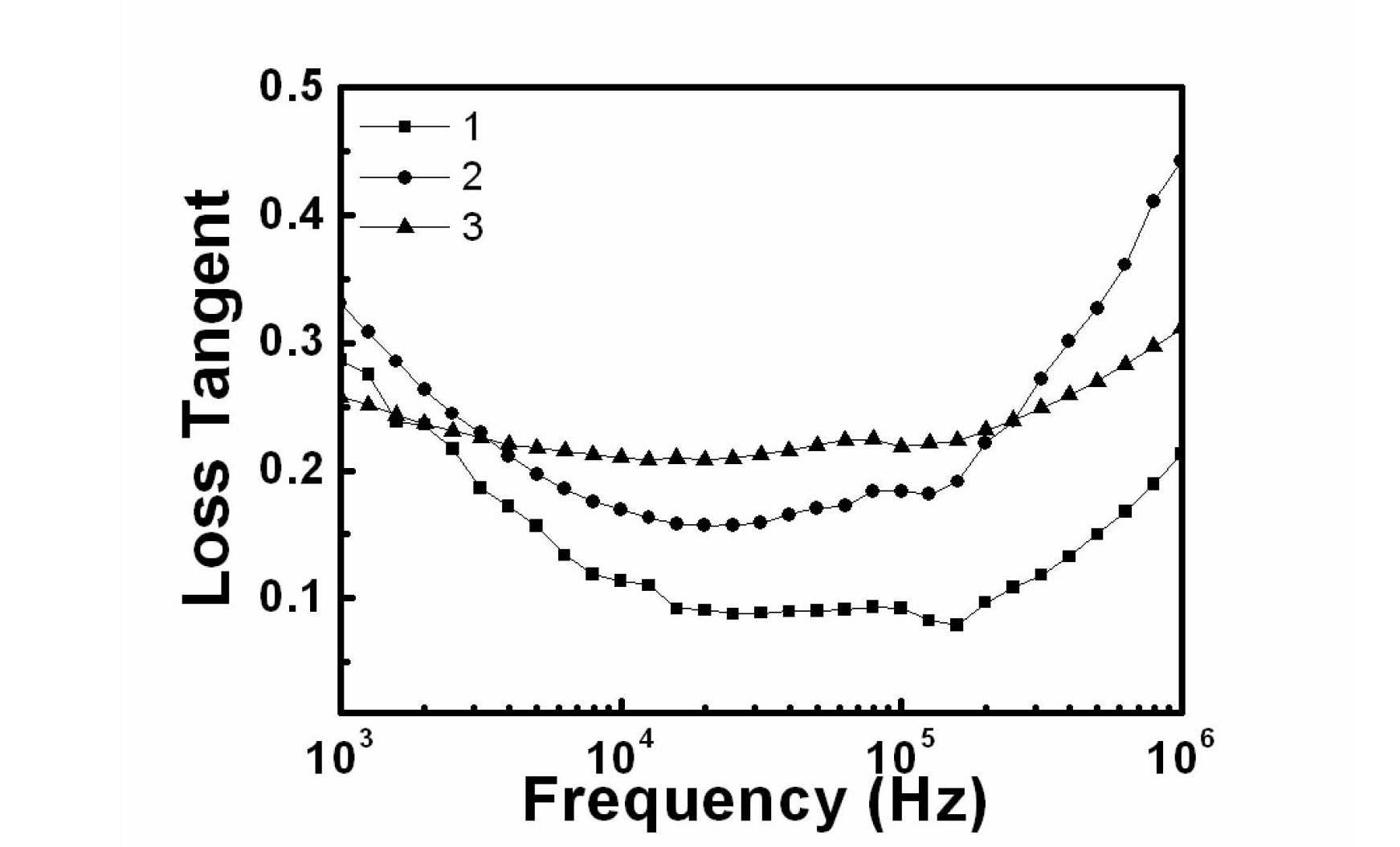

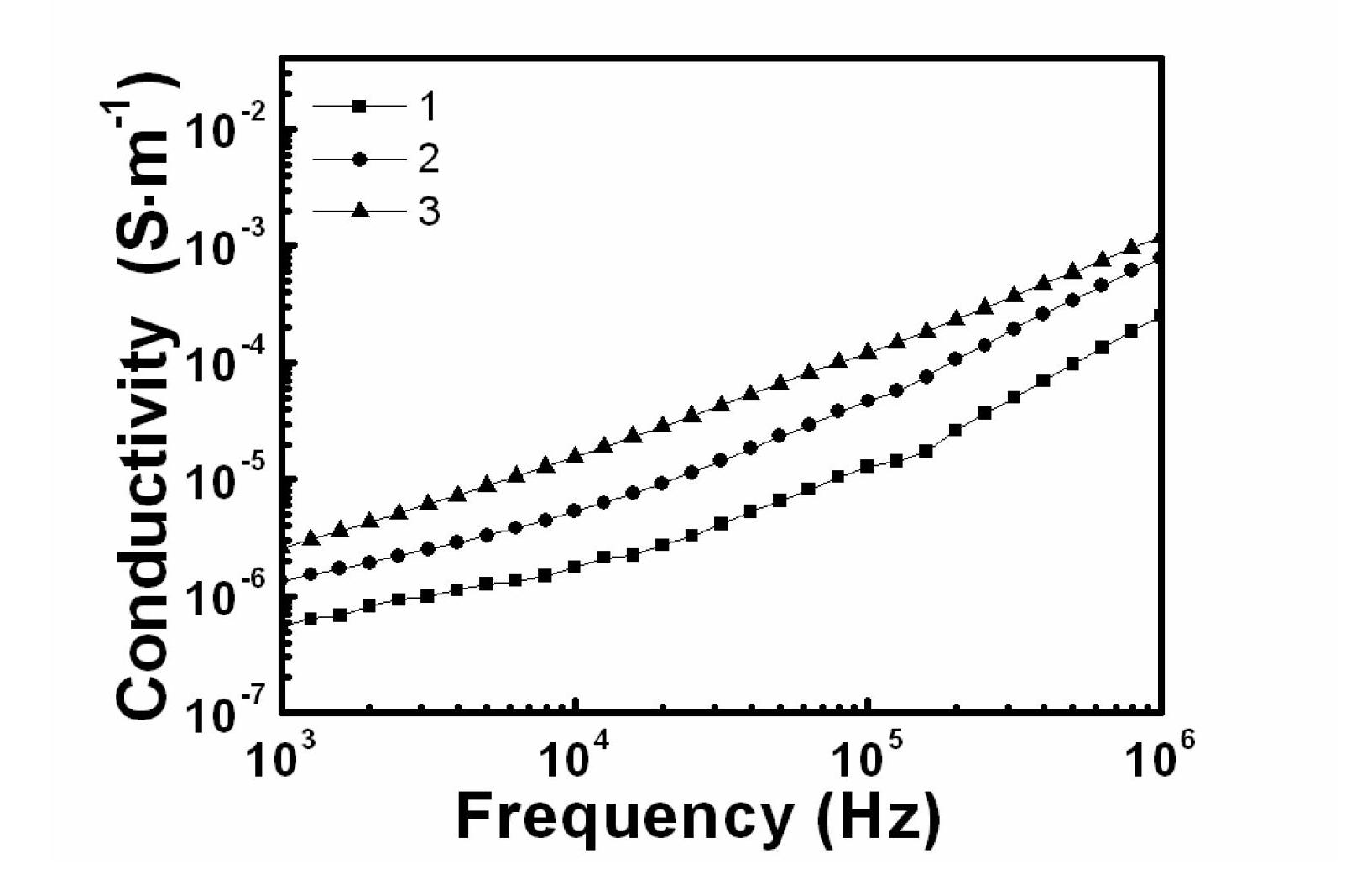

High-dielectric-constant three-phase composite material containing modified graphene and preparation method thereof

Owner:UNIV OF SCI & TECH BEIJING

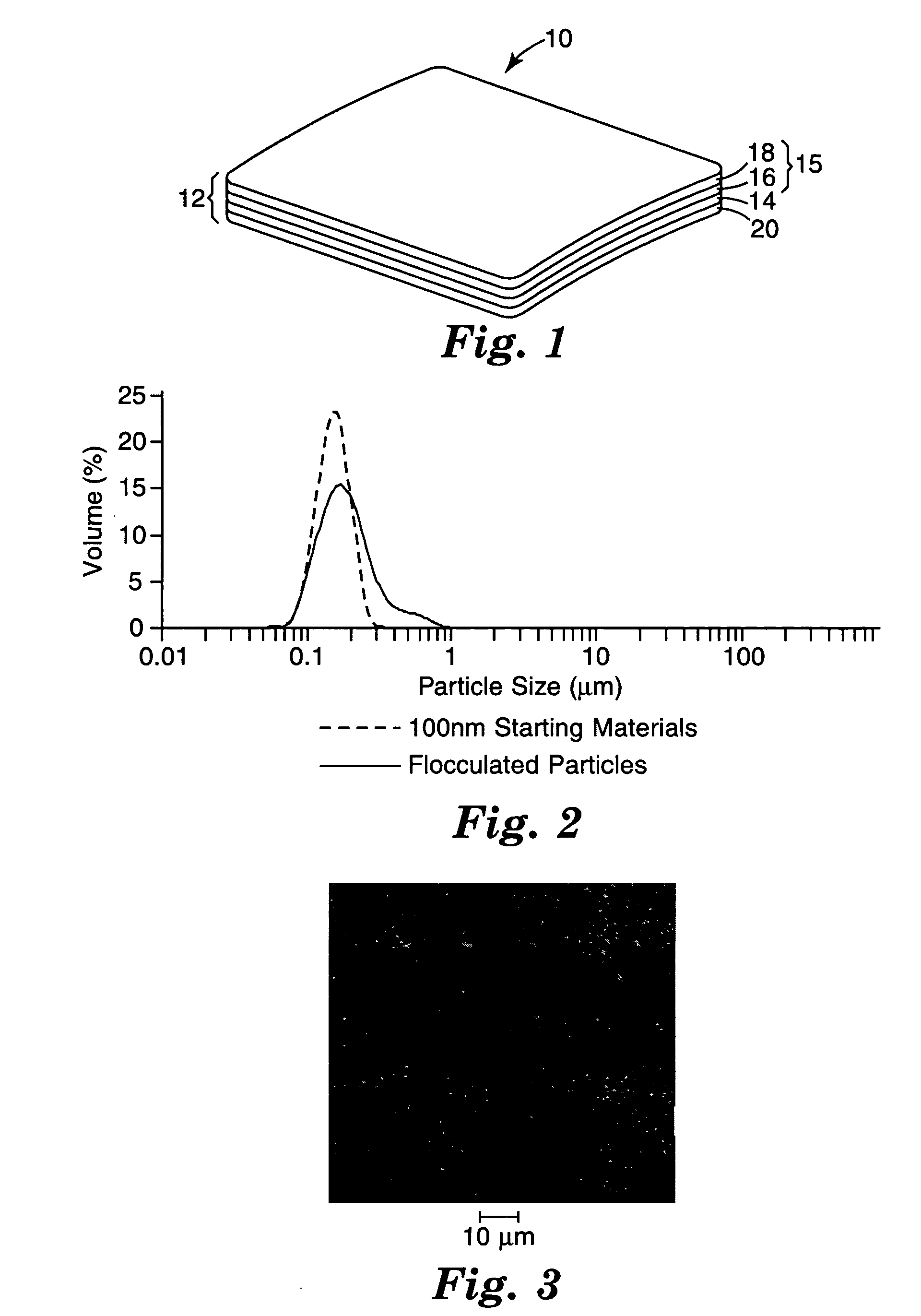

Method for preparing a photochromic nanoparticle and nanoparticle prepared therefrom

InactiveUS20080026217A1Maintain transparencyEasy production processMaterial nanotechnologyLiquid surface applicatorsMean diameterCore shell

The present invention provides a photochromic nanoparticle having a core-shell structure comprising (a) a polymer nano particle having a mean diameter controlled in a range of 10˜150 nm and containing a photochromic dye; and (b) a silicate inorganic polymer layer enveloping the polymer nanoparticle, and a method for preparing the same. The photochromic nanoparticle according to the present invention has structural and physical stability continuously in a long term and has transparency because of low light scattering, so that it can be applied to optical products.

Owner:LG CHEM LTD

Production of polymerized ferric-aluminum chloride composite coagulating agent

InactiveCN101074128AReduce manufacturing costLow costWater/sewage treatment by flocculation/precipitationPhosphateChlorate salt

Production of inorganic polymer coagulating agent is carried out by controlling Fe2+ concentration between 75-90g / L in hydrochloric acid pickling effluent, taking it as ferric source, taking calcium aluminate powder as aluminum source with Al2O3 content 47-56 wt%, putting two kinds of raw material into reactor in proportion of calcium aluminate powder: hydrochloric acid pickling effluent=0.05-0.10, reacting while agitating at 50-80 degree for 1-3 hrs, adding into minor chlorate oxidant and phosphate stabilizer, heating, reacting while agitating, and cooling to room temperature to obtain final product. It's simple and can be used for domestic sewage and industrial effluent treatment.

Owner:SHANGHAI UNIV

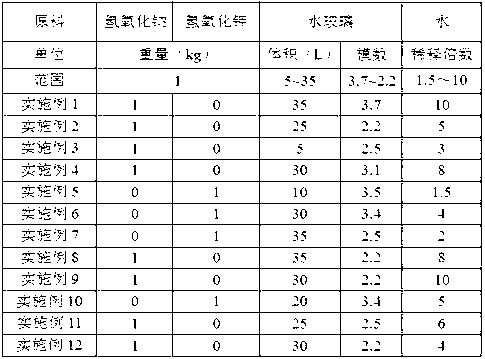

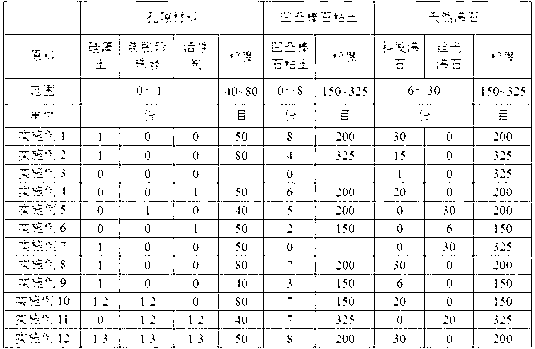

Covering material for immobilized in-situ remediation of nitrogen in bottom sediment and preparation method thereof

ActiveCN102701552AMeet industrial requirementsReduce ammonia nitrogen contentSludge treatmentWater/sewage treatment by ion-exchangeIon exchangeAmmonium adsorption

The invention discloses a covering material for immobilized in-situ remediation of nitrogen in bottom sediment and a preparation method of the covering material, belonging to the technical field of bottom sediment covering of surface water body. The covering material is the mixture of a powdery raw material and a binding agent, wherein relative to 1L of the binding agent constituting the covering material, the content of the powdery raw material is 1-2kg; the powdery raw material comprises the following components in parts by weight: 0-1 part of porous material, 0-8 parts of attapulgite clay and 6-30 parts of natural zeolite; the binding agent consists of an active material and an excitant; and relative to 1kg of the active material constituting the binding agent, the content of the excitant is 1-3L. According to the preparation method, the powdery raw material consists of natural materials such as zeolite, the binding agent consists of inorganic polymers, and the covering material is granulated and formed by an extruder and cured at room temperature. The covering material is a medium material with strong ion exchange capability and excellent biological load property and does not need to be sintered; and moreover, the covering material provided by the invention has the advantages of higher ammonium adsorption capability and lower cost as compared with the traditional materials.

Owner:NANJING UNIV

Inkjet printer and printer head

InactiveUS20030197758A1Reduce surface tensionReduce moisturePrintingColloidal silicaVena contracta diameter

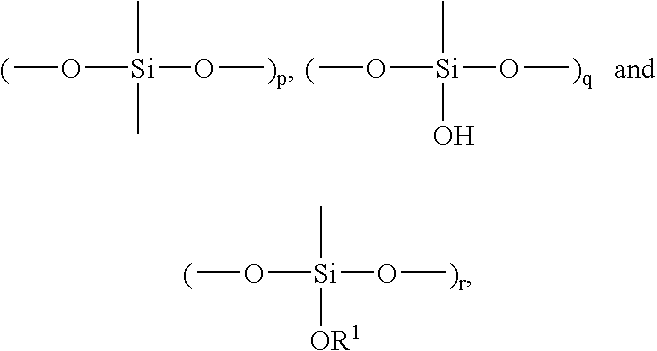

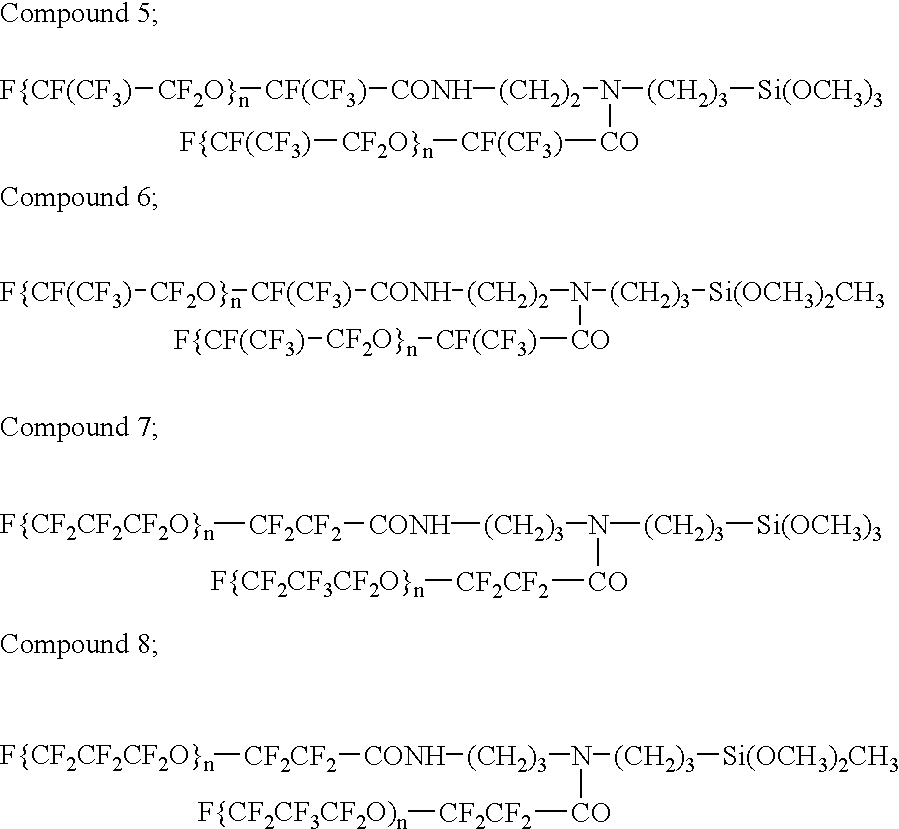

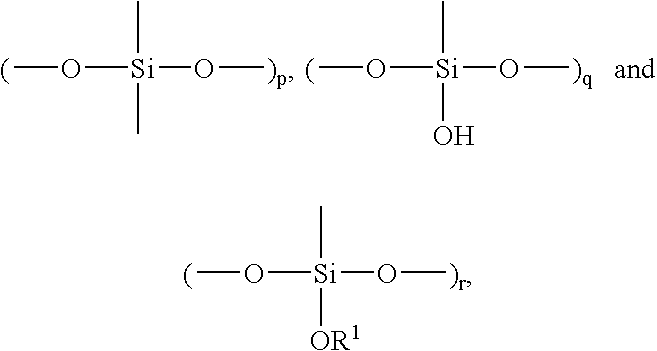

An inkjet head having an ink flow path communicated with an ink chamber to an inkjet nozzle and having an orifice plate to which the nozzle is formed. An ink-philic layer is formed on the surface of the ink flow path, and an ink repellent layer is formed on the surface of the orifice plate where the nozzle is formed. The ink-philic layer is made of amorphous silica or inorganic polymer of colloidal silica bonded with a polymer of (SiOR), and the ink repellent layer contains a compound having perfluoropolyether chain and alkoxysilane residue as a terminal.

Owner:RICOH KK +2

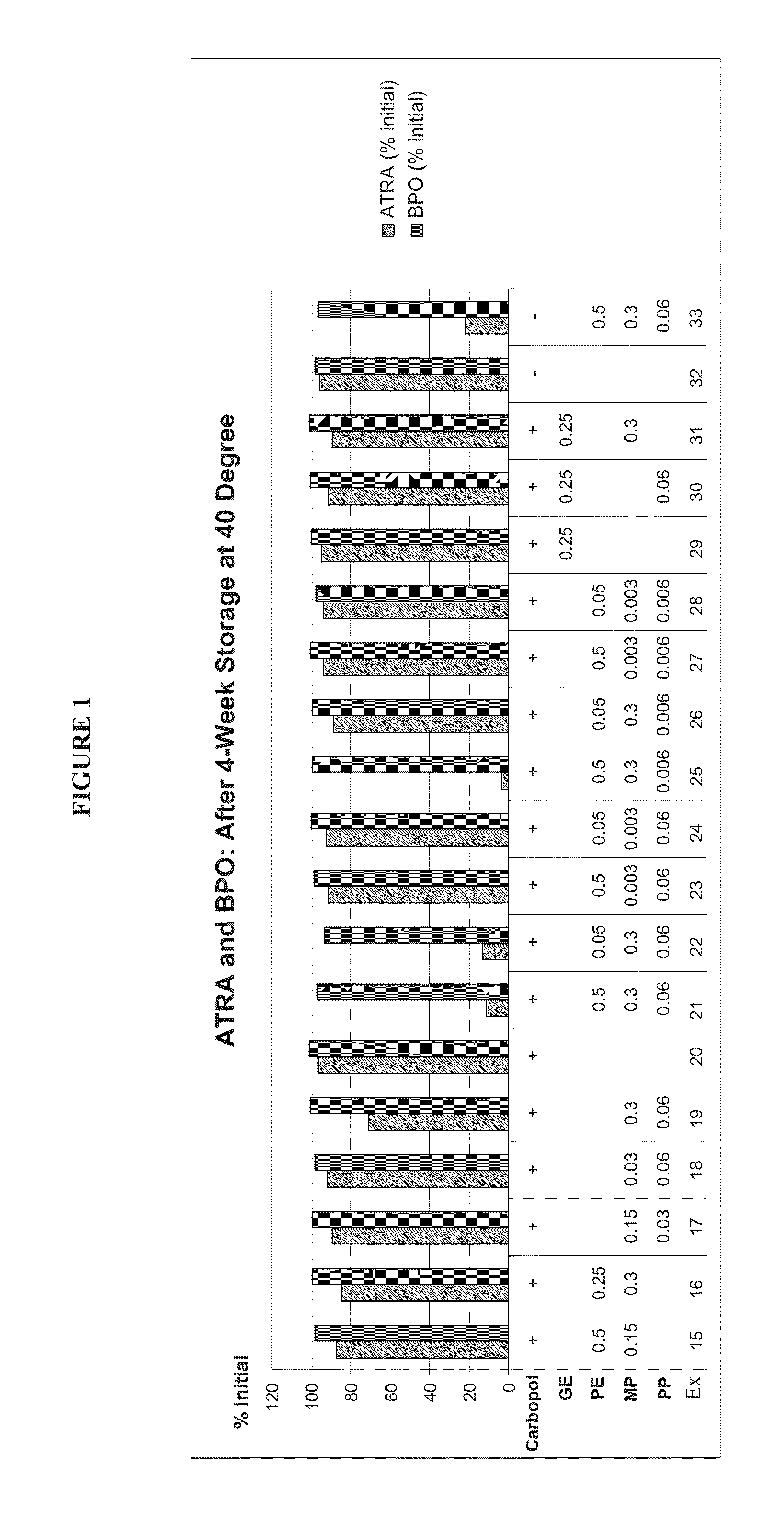

Stabilized topical formulations containing core-shell microcapsules

The present disclosure relates to compositions for topical application, where the compositions comprise microcapsules having a core that comprises benzoyl peroxide and a shell that comprises an inorganic polymer, microcapsules having a core that comprises a retinoid and a shell that comprises an inorganic polymer, and a stabilizing agent. The composition can be in a variety of forms, such as emulsion and gel.

Owner:SOL GEL TECH

Inorganic polymer material for sealing heavy metal castoff

InactiveCN101318788AImprove physicsImprove mechanical propertiesSolid waste managementCement productionSlagMetakaolin

The invention provides an inorganic polymeric material used to fixedly seal heavy metal wastes, which is an inorganic silicon-aluminum polymeric material used in the environmental protection field. The material comprises the following compositions in weight percentage: 9.9 to 35.1 percent of metakaolin, 3.94 to 27.6 percent of ore slag, 0.1 to 9.9 percent of active low calcium silicon-aluminum material, 9.6 to 10.6 percent of alkali excitant and 50.0 to 54.7 percent of sand. The material has the advantages of high doped quantity of the heavy metal wastes, high fixing seal efficiency, wide source of raw materials, convenient preparation and processing, high mechanical strength, excellent durability and low cost.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com