Patents

Literature

3473 results about "Silica particle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

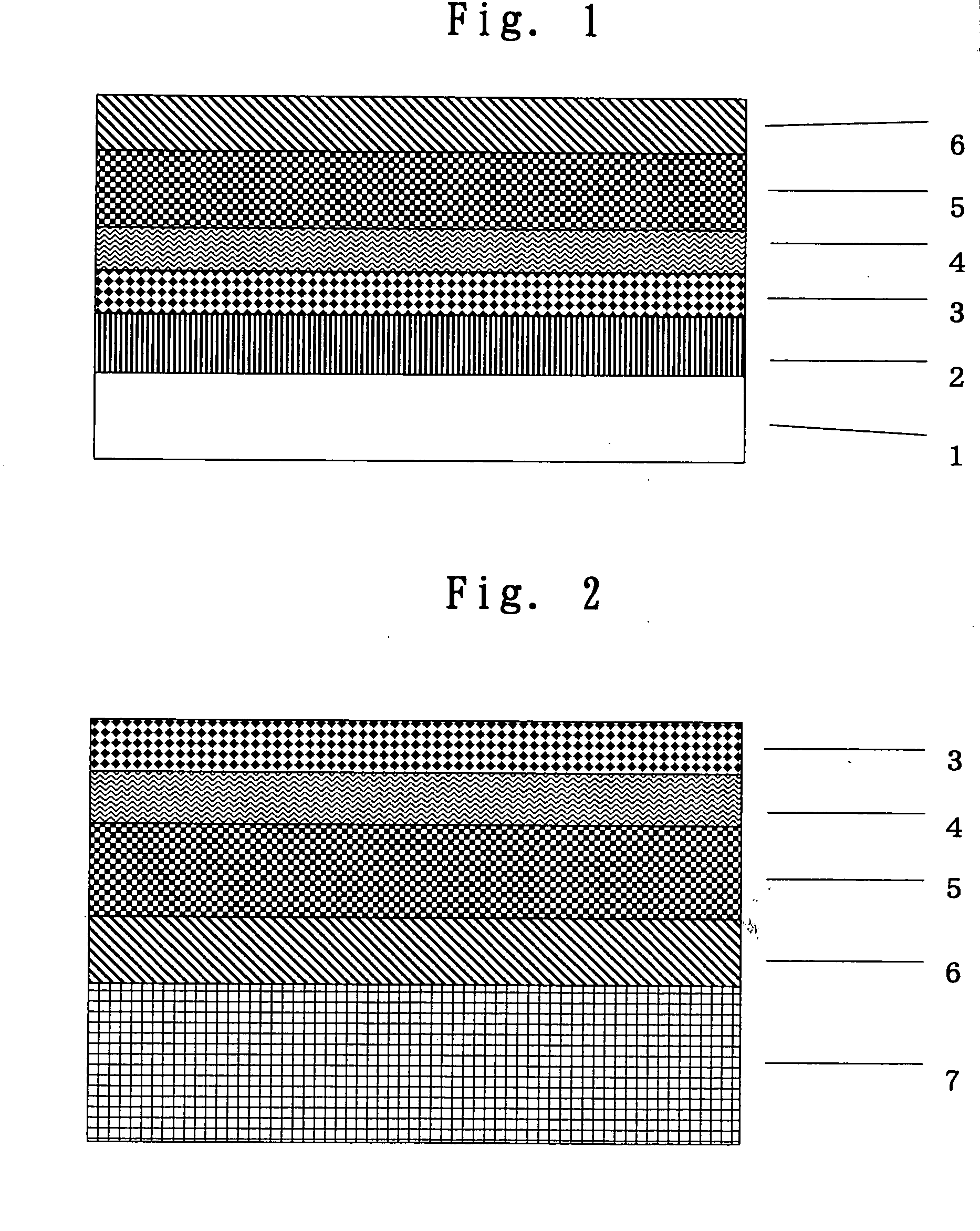

Antireflection film, polarizing plate, method for producing them, liquid cryatal display element, liquid crystal display device, and image display device

ActiveUS20070146887A1Reduce weightLow costLiquid crystal compositionsSynthetic resin layered productsSilica particleLiquid-crystal display

To provide an antireflection film which is easily and inexpensively producible and which has an antireflection property, a scratch resistance and a stain resistance in a sufficient level, and a polarizing plate and a liquid crystal display device utilizing the antireflection film of such excellent ability, the antireflection film includs a transparent support and a low-refractive index layer having a lower refractive index than the transparent support, wherein the low-refractive index layer is an outermost layer, and the low-refractive index layer contains a hollow silica particle and a compound that reduces a surface free energy of the outermost layer.

Owner:FUJIFILM CORP

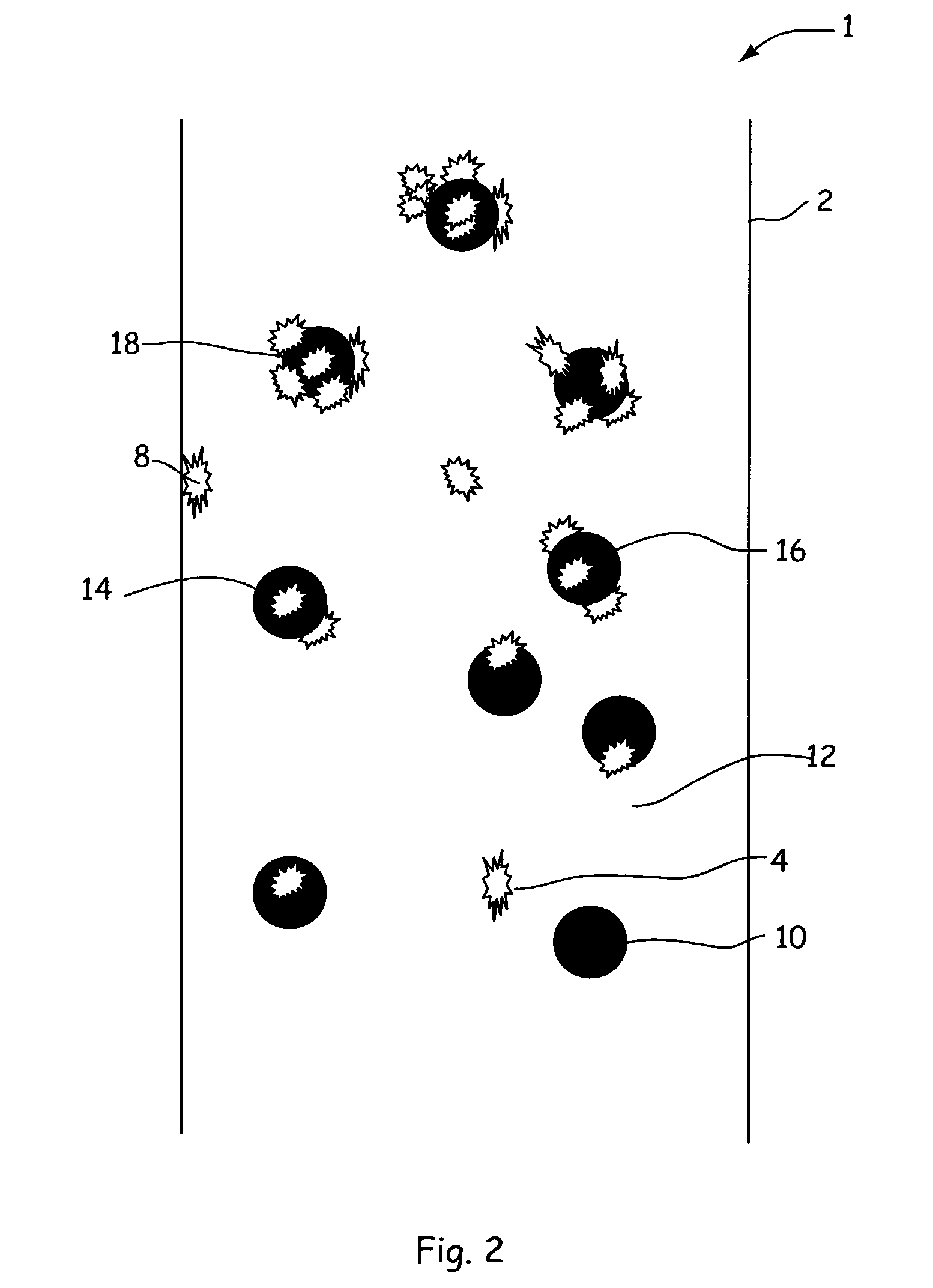

Processing compositions and method of forming the same

ActiveUS20060110542A1Increased durabilityImprove conditionsPigmenting treatmentFouling preventionSilica particleAdditive ingredient

A method for processing compositions, compositions obtained by such a process and methods of use are disclosed for forming a detachable and renewable protective coating which is substantially transparent. The inventive process compositions are produced by making a highly concentrated dispersion of hydrophobically modified silica particles in the presence of an optional, yet preferable, disilazane derivative under high shear conditions. These process compositions are intended to be further diluted to final treatment compositions, optionally while adding other functional ingredients.

Owner:EVONIK OPERATIONS GMBH

Method for reducing odor using metal-modified silica particles

ActiveUS20050084438A1Stability can be compromisedAmeliorate pH-lowering affectMaterial nanotechnologyNon-fibrous pulp additionSilica particleCompound (substance)

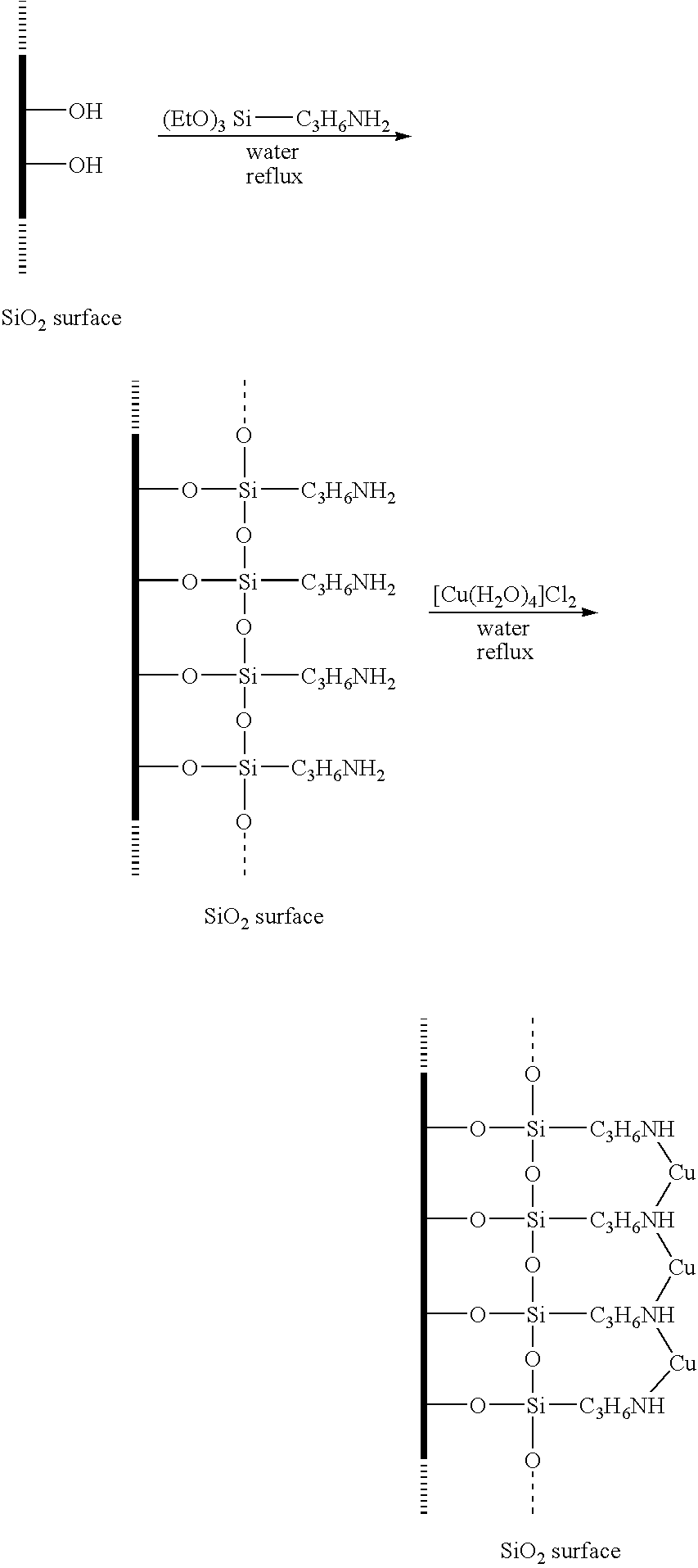

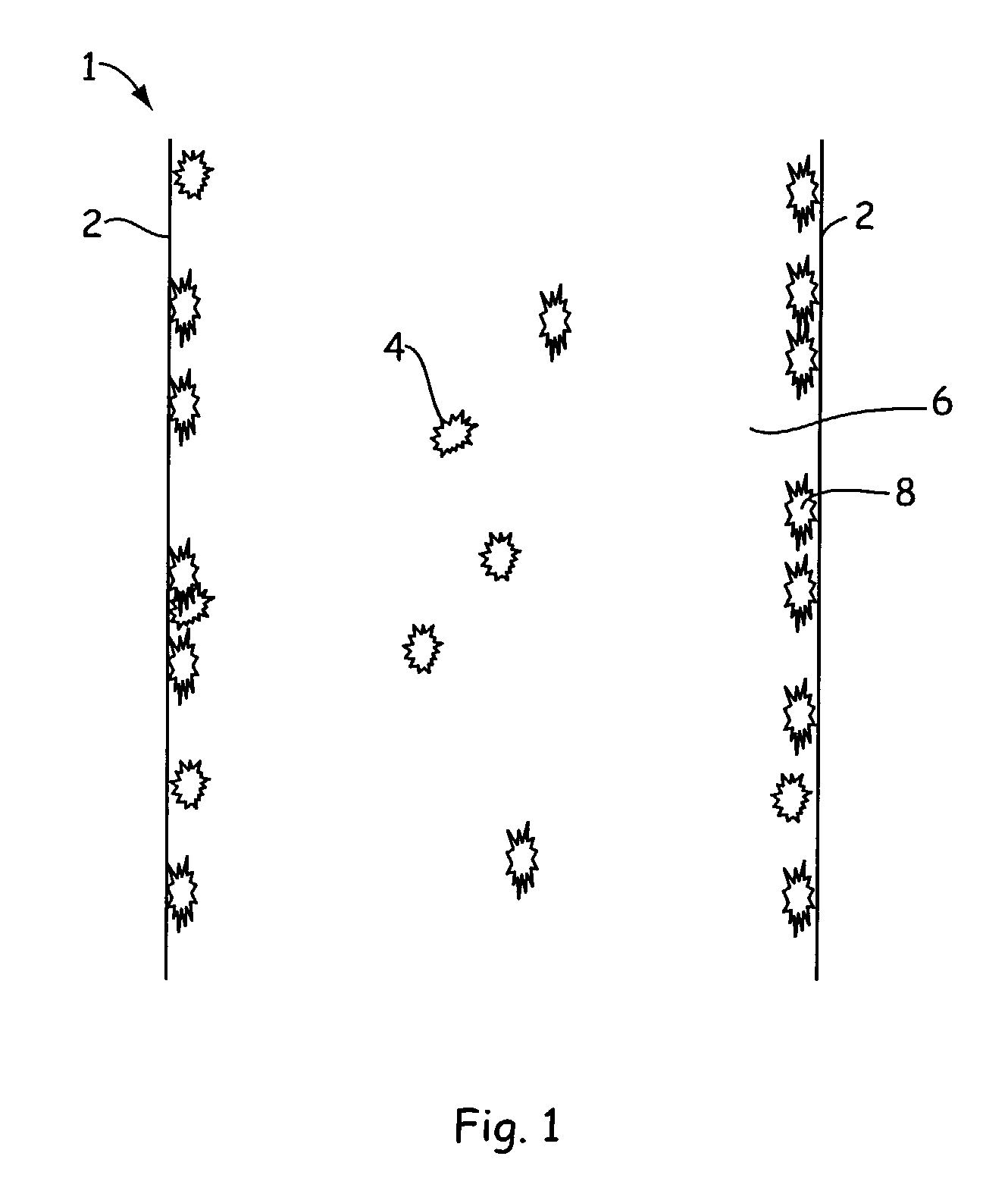

A method for reducing odor is provided. In one embodiment, the method comprises modifying the surface of silica particles with a transition metal so that the silica particles are bonded to the transition metal through a covalent or coordinate bond. The method further comprises contacting the modified silica particles with an odorous compound, the transition metal facilitating the capture of the odorous compound.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Methods for prevention of surface adsorption of biological materials to capillary walls in microchannels

InactiveUS7252928B1Inhibit bindingPrevent and reduce adsorptionNanotechElectrolysis componentsSilica particleLipid formation

Methods for reducing surface adsorption of biological materials to the walls of microfluidic conduits in microscale devices are provided. In an example of the methods, one or more colloidal-size particles, such as colloidal silica particles, are flowed in a fluid within the microfluidic conduit in the presence of one or more adherent biological materials (such as one or more proteins, cells, carbohydrates, nucleic acids, lipids and the like) to adsorb to the materials and prevent them from binding to the capillary walls of the microfluidic conduit. Other adsorption inhibition agents such as detergents and nonaqueous solvents can be used alone or in combination with colloidal particles to reduce surface adsorption in microfluidic conduits.

Owner:CAPLIPER LIFE SCI INC

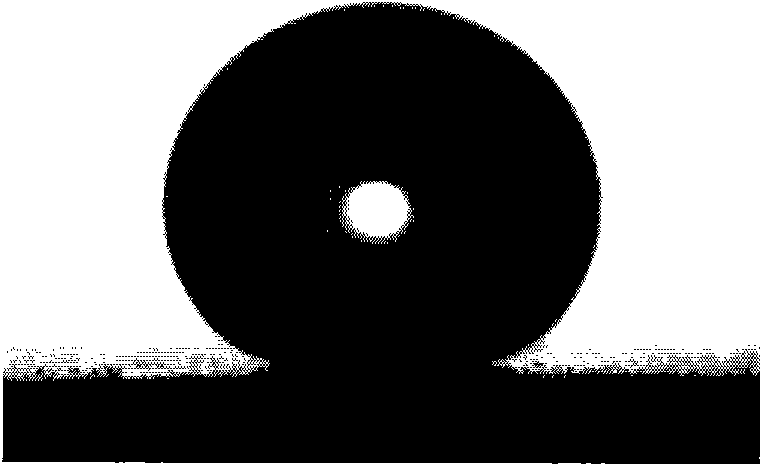

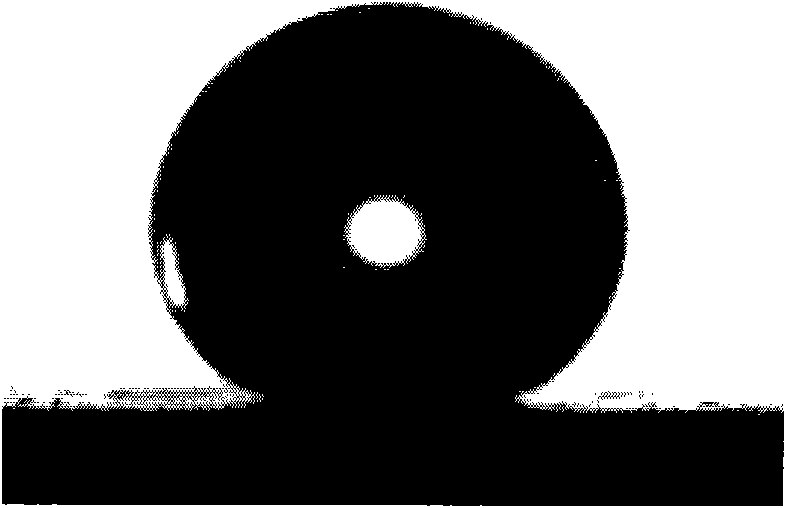

Method for preparing epoxy resin super-hydrophobic coat

InactiveCN101575478ASimple processGood repeatabilityLiquid spraying plantsMovable spraying apparatusEpoxySilica particle

The invention discloses a method for preparing an epoxy resin super-hydrophobic coat, comprising the following steps: (1), preparing collosol of the coat: dissolving silicon dioxide particles in a solvent, adding a silane coupling agent, heating and stirring for reaction, adding an epoxy resin paint and a hydrophobing agent, stirring for reaction, and obtaining the collosol of the coating layer; (2) coating film on the surface of a substrate material: coating the collosol obtained in the step (1) on the surface of the substrate through the way of lifting-pulling coating film, rotationally coating, curtain coating or spraying, after lifting, placing statically at the room temperature for using; and (3) heating and curing: putting the substrate material coated by the film in the step (2) in an oven, raising temperature to heat to make the epoxy resin cure and cross, taking out to obtain the epoxy resin super-hydrophobic coat. The invention has the advantages of easy technique, easily obtained raw materials, low cost and good repeatability; and the obtained coat has good super-hydrophobicity and self-cleaning performance for the industrial production of the super-hydrophobic paint properly.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

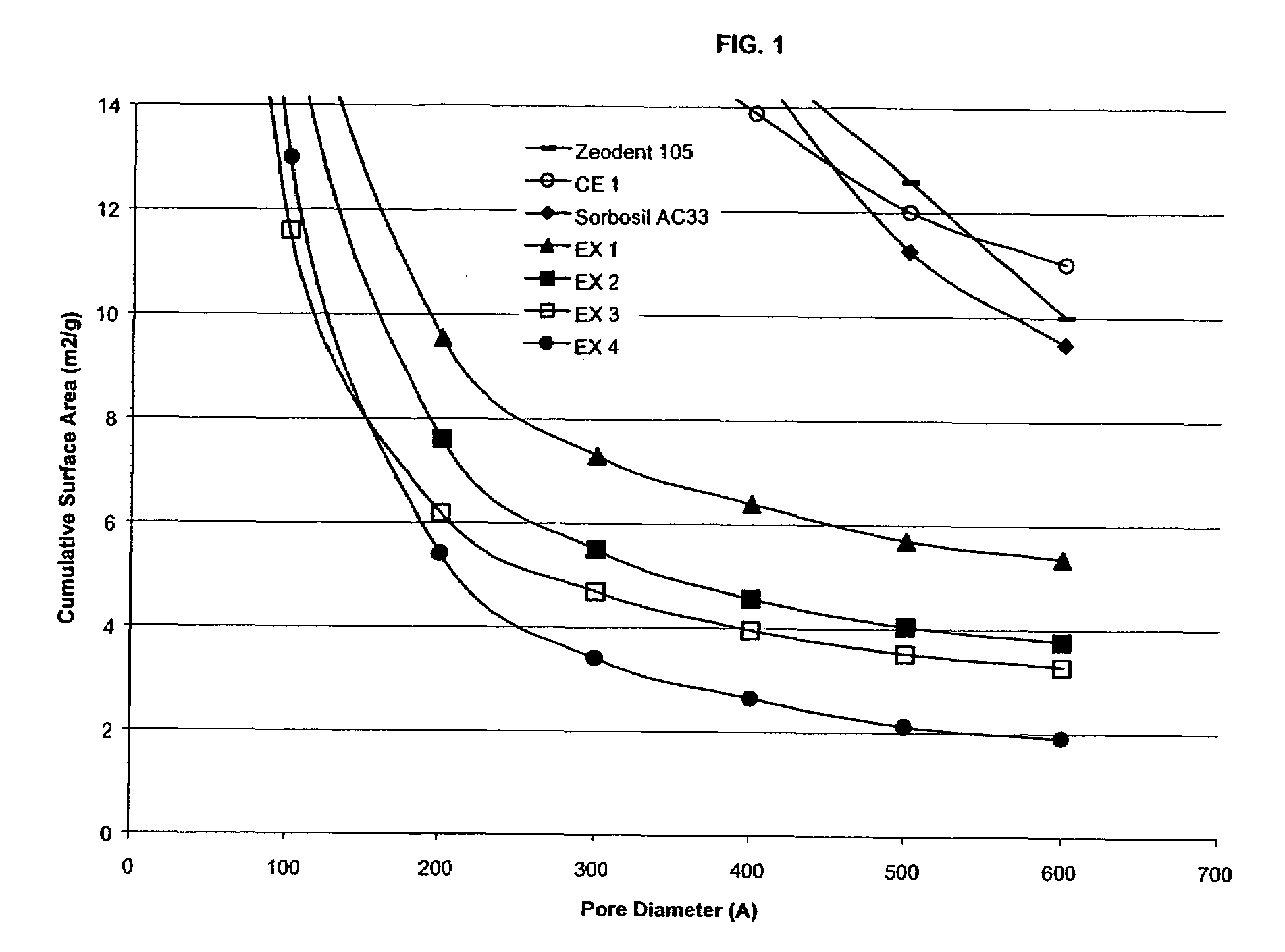

Precipitated silica product, dentifrices containing same, and processes

InactiveUS7255852B2Reduce the possibilityIncrease volumeCosmetic preparationsPigmenting treatmentSilica particleAntimicrobial action

Owner:EVONIK OPERATIONS GMBH

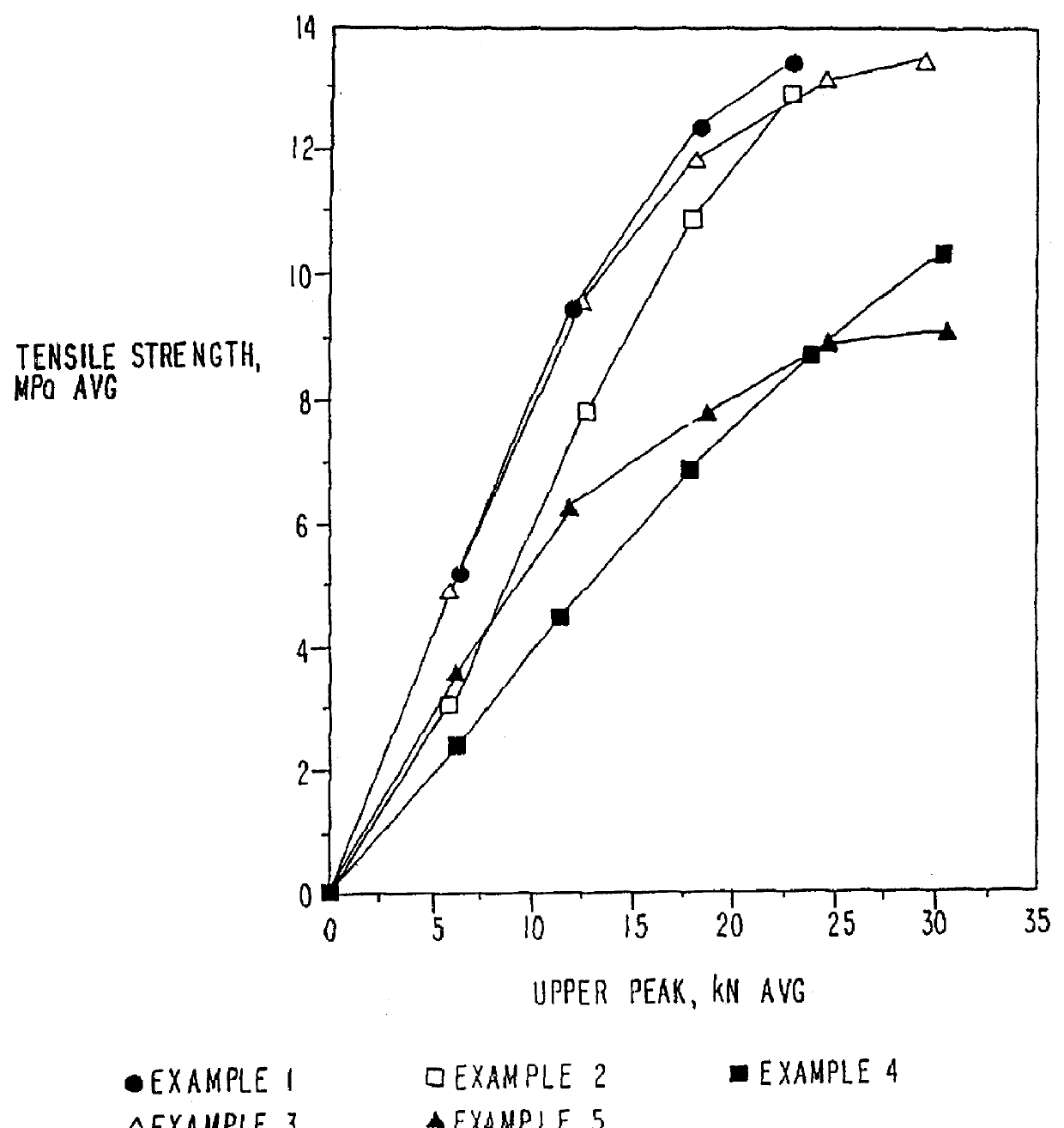

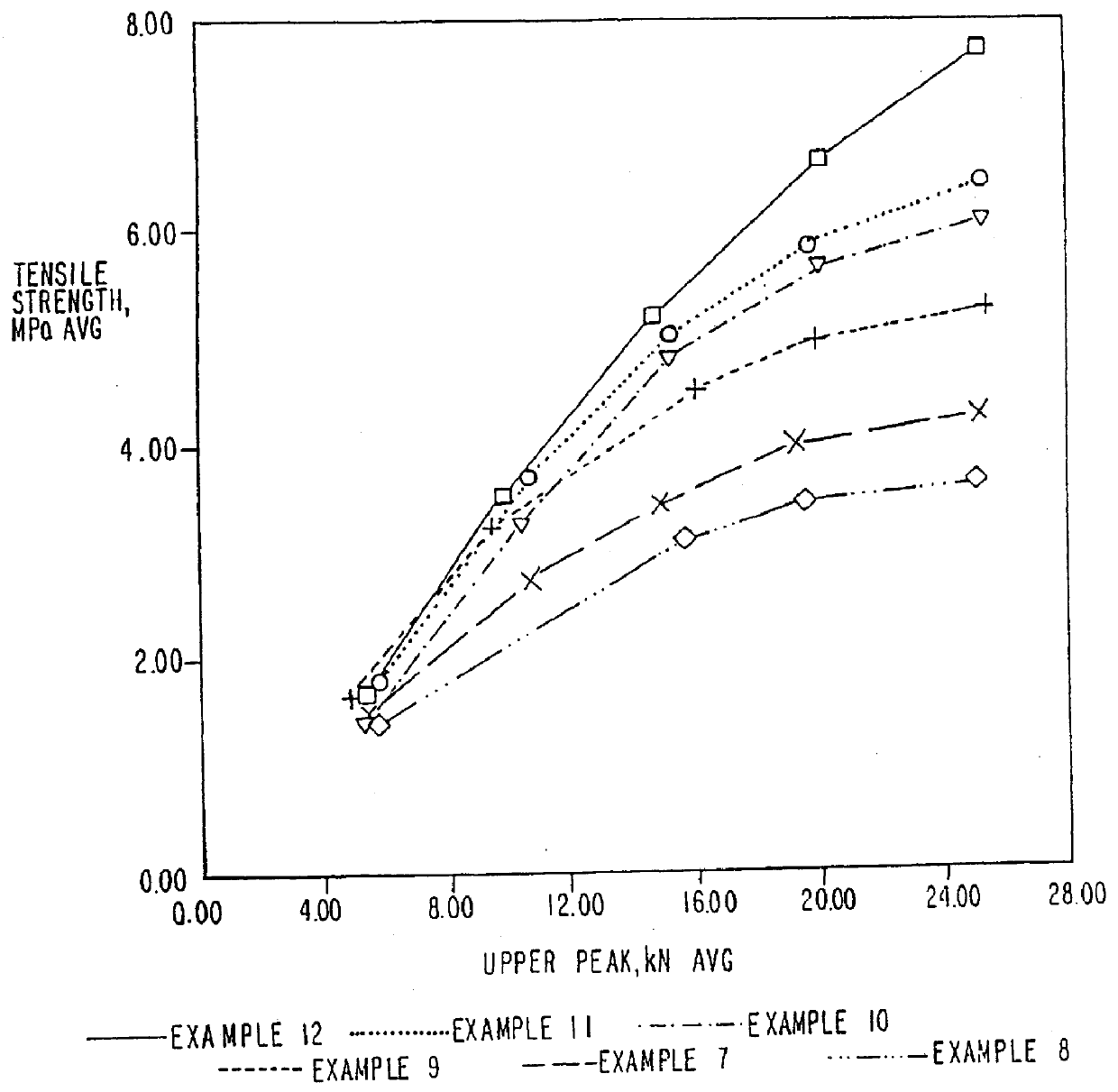

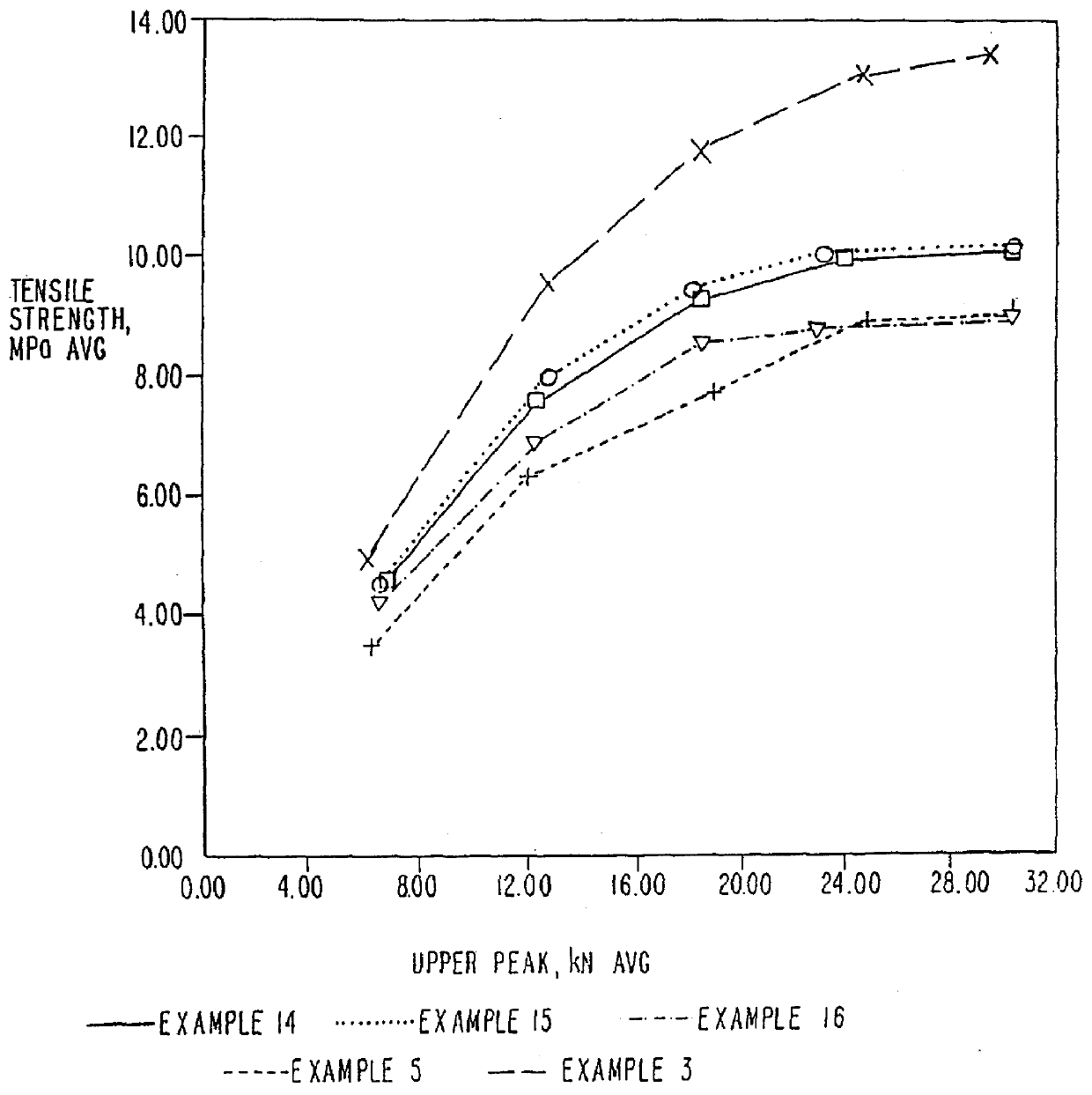

Pharmaceutical excipient having improved compressibility

InactiveUS6103219AImprove compression performanceReduce the amount requiredCosmetic preparationsPowder deliverySilica particleColloid

A microcrystalline cellulose-based excipient having improved compressibility, whether utilized in direct compression, dry granulation or wet granulation formulations, is disclosed. The excipient is an agglomerate of microcrystalline cellulose particles and from about 0.1% to about 20% silicon dioxide particles, by weight of the microcrystalline cellulose, wherein the microcrystalline cellulose and silicon dioxide are in intimate association with each other. The silicon dioxide utilized in the novel excipient has a particle size from about 1 nanometer to about 100 microns. Most preferably, the silicon dioxide is a grade of colloidal silicon dioxide.

Owner:J RETTENMAIER & SOEHNE GMBH CO KG ROSENBERG

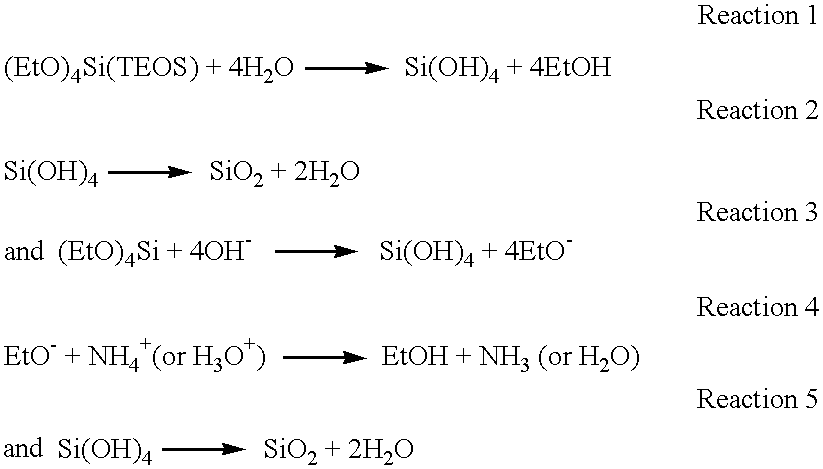

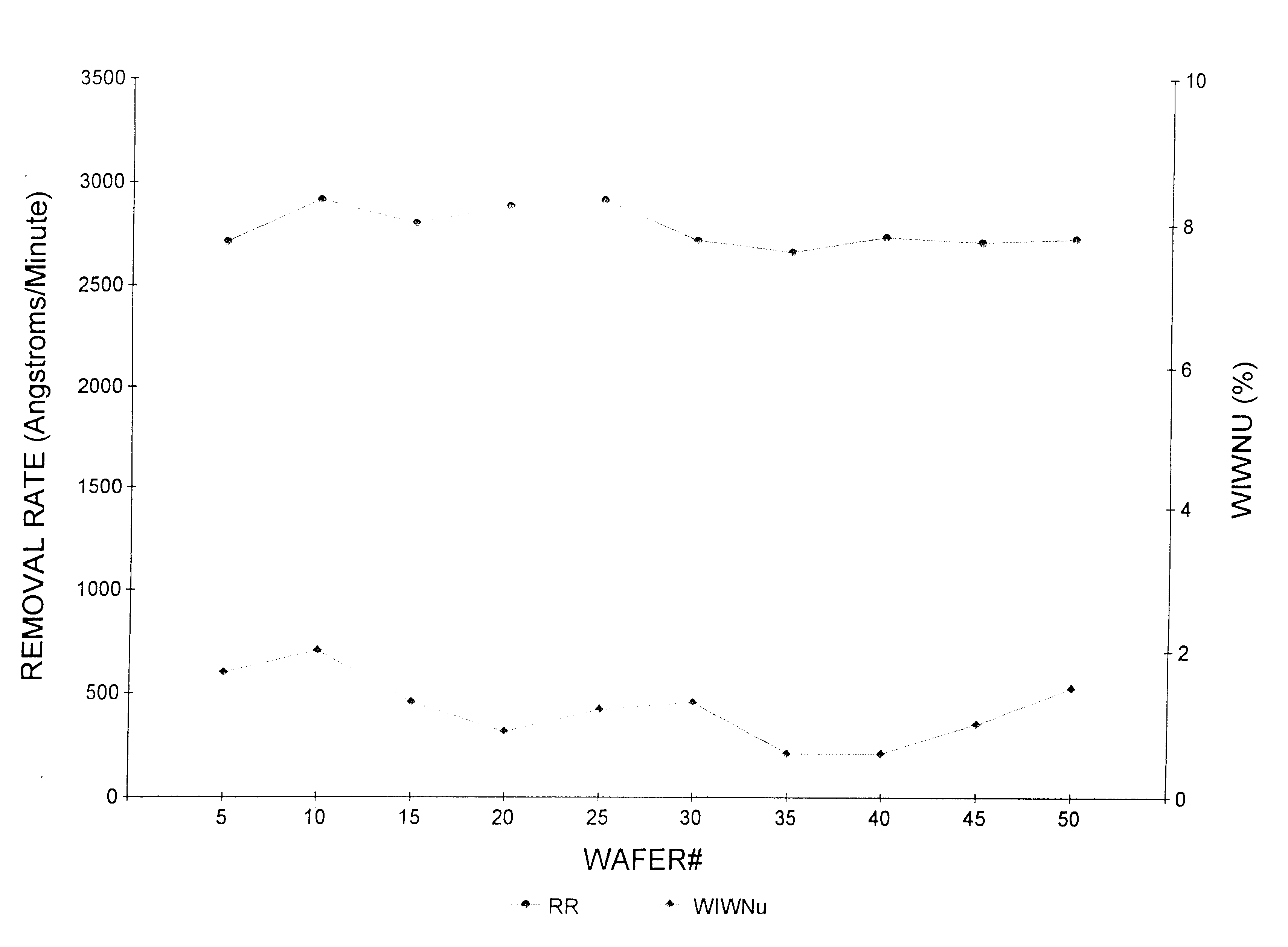

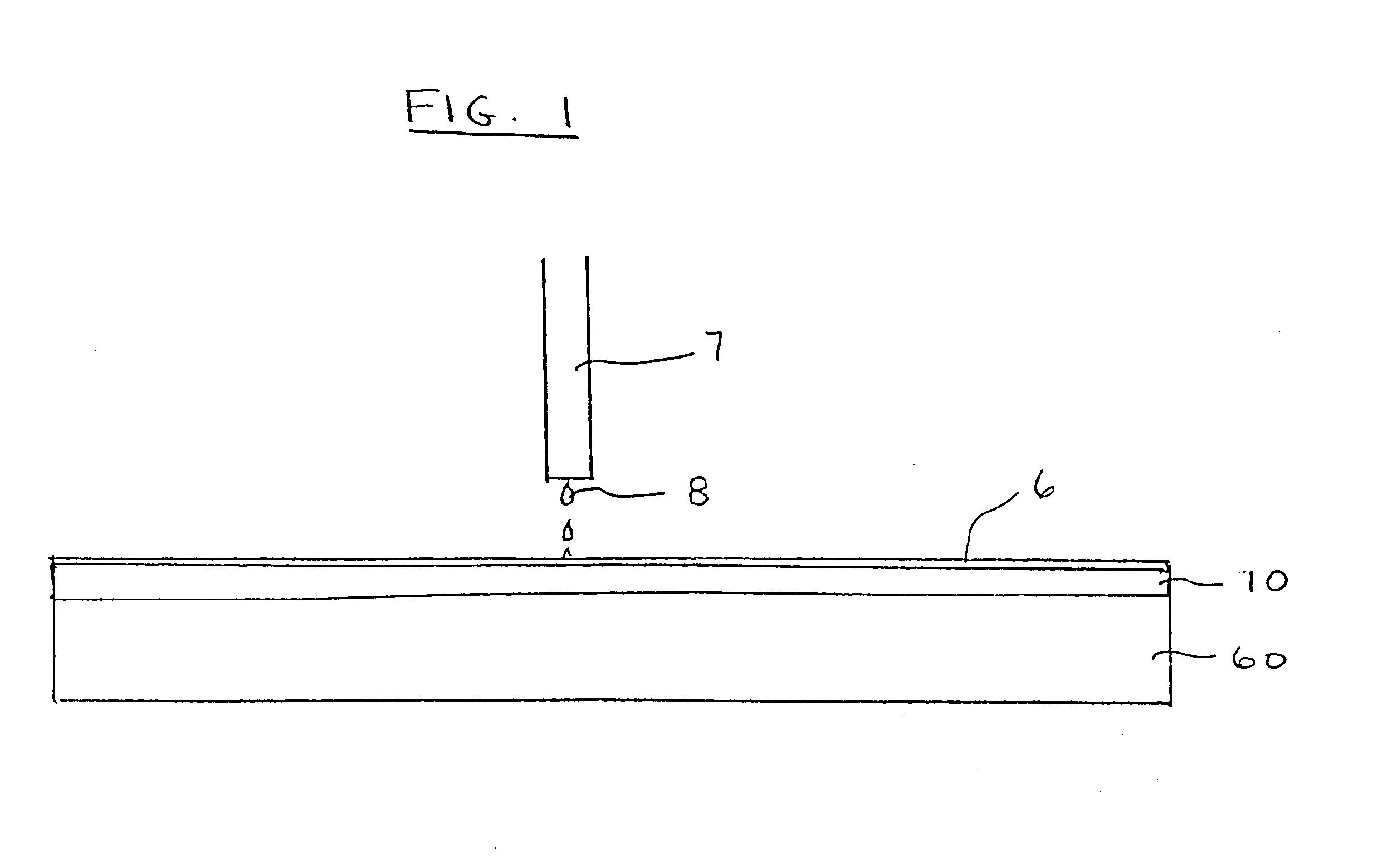

Planarization compositions and methods for removing interlayer dielectric films

InactiveUS6322600B1Improve planarization qualityQuality improvementPigmenting treatmentOther chemical processesThinningDielectric thin films

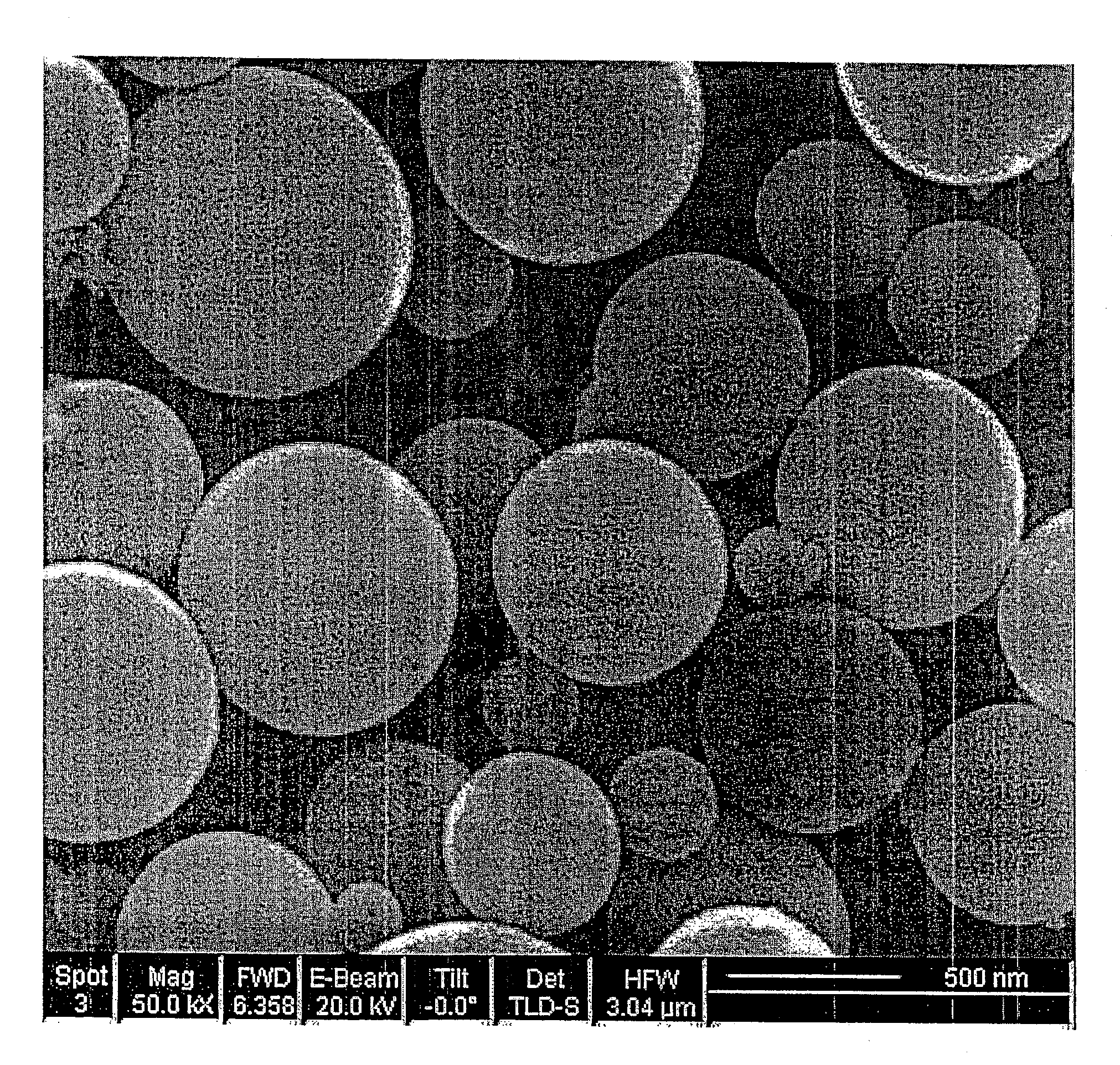

A planarization composition is set forth for chemical mechanical planarization of dielectric layers for semiconductor manufacture. The composition comprises spherical silica particles having an average diameter of from 30 nm to about 400 nm, and a narrow range of particle sizes, wherein about 90% of the particles is within 20% of the average particle diameter. The composition includes a liquid carrier comprising up to about 9% alcohol and an amine hydroxide in the amount of about 0.2 to about 9% by weight. The pH of the composition is in the range of about 9 to about 11.5, and the remainder of the solution is water. The composition has low amounts of metal ions, and the composition is used for thinning, polishing and planarizing interlayer dielectric thin films, shallow trench isolation structures, and isolation of gate structures. The invention also comprises methods for using the planarization composition in the manufacture of semiconductor devices.

Owner:ADVANCED TECH MATERIALS INC

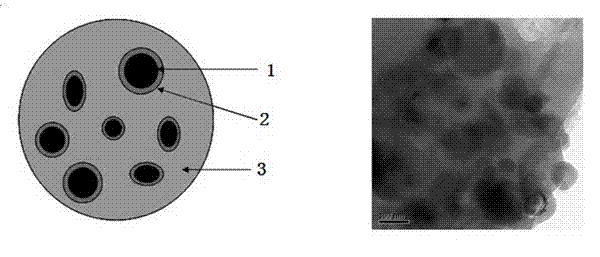

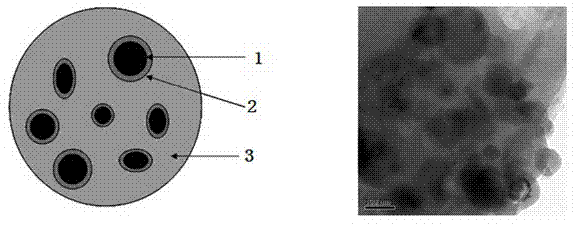

Profile control oil-displacement agent for core-shell type inorganic/organic polymer composite microballoon

InactiveCN102485830AGood expansion performanceGood temperature and salt resistanceDrilling compositionCross-linkMicrosphere

The invention discloses a profile control oil-displacement agent for a core-shell type inorganic / organic polymer composite microballoon. A preparation method of the core-shell type inorganic / organic polymer composite microballoon comprises the following steps of carrying out surface modification of inorganic cores of inorganic nano-particles such as silica particles and magnetic particles, and carrying out graft polymerisation by a dispersion polymerization method or an inverse emulsion polymerization method to form polymer shells (such as polyacrylamide cross-linked copolymers) on the surfaces of the inorganic cores. The inorganic components and the organic components bind by chemical bonds so that the core-shell type inorganic / organic polymer composite microballoon has very stale structure. The core-shell type inorganic / organic polymer composite microballoon retains the advantages of polymer microballoons and inorganic particles, and has strong heat-resistant and mineralization-resistant capabilities, high plugging strength and good dilatancy. The core-shell type inorganic / organic polymer composite microballoon can move in rock pores and can plug the rock pores. When a plugging pressure difference is improved to a certain degree, elastic deformation of the core-shell type inorganic / organic polymer composite microballoon can be produced and the deformed core-shell type inorganic / organic polymer composite microballoon sequentially moves to a deep rock stratum part so that a liquid flow direction is changed gradually and a crude oil yield is improved. The profile control oil-displacement agent provided by the invention has a large potential.

Owner:BEIJING UNIV OF CHEM TECH

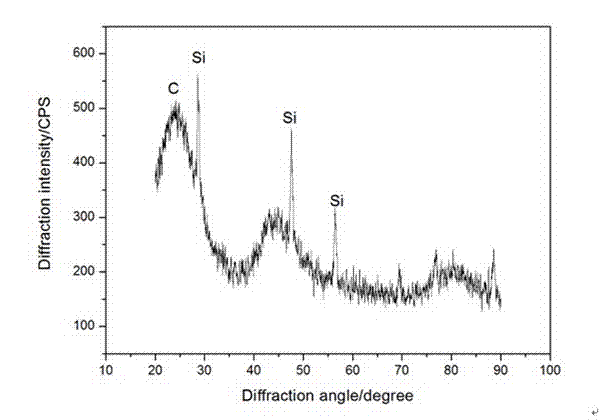

Silicon-carbon composite anode material and preparing method thereof

ActiveCN102509781AHigh specific capacityImprove cycle performanceCell electrodesCarbon compositesPorous carbon

The invention provides a silicon-carbon composite anode material, which comprises a nuclear shell structure and a support substrate, wherein particle size of the silicon-carbon composite anode material is 1-200 micrometers, and porous carbon serving as the support substrate is obtained through decomposition of biomass materials. The invention further provides a preparing method of the silicon-carbon composite anode material, which includes the following steps: 1 reaming the biomass materials in physical activation or chemical activation mode to prepare the porous carbon, or preparing small molecular organics serving as a precursor of the porous carbon in hydrolyzing mode; 2 mixing silica particles and the obtained porous carbon or the precursor of the porous carbon in solution and performing ultrasonic treatment; 3 evaporating the solution mixture to dry so as to obtain solid-state powder; and 4 drying the solid-state powder, and performing thermal treatment, crushing and sieving on the solid-state powder to obtain the silicon-carbon composite anode material. The silicon-carbon composite anode material and the preparing method thereof are simple in process, short in flow path, easy to operate and low in cost, and lithium ion batteries manufactured by the silicon-carbon composite anode material are suitable for various mobile electronic equipment or devices driven by mobile energy.

Owner:SHANGHAI JIAO TONG UNIV

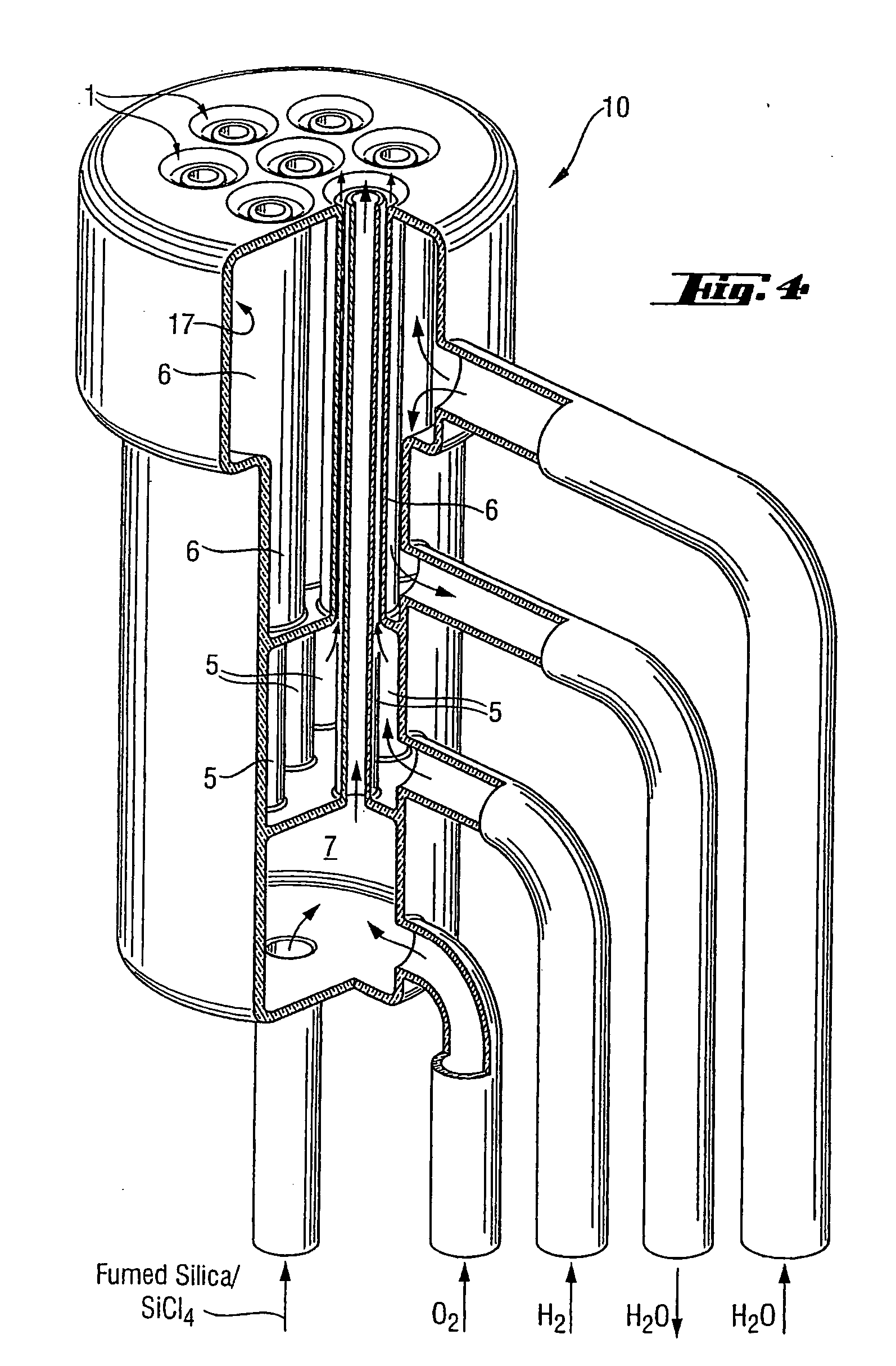

Method for forming mesoporous silica layer, its porous coating, Anti-reflection coating, and optical member

InactiveUS20100136319A1Low refractive indexLayered productsPretreated surfacesPtru catalystActive agent

A method for forming a mesoporous silica layer composed of nanometer-sized, mesoporous silica particles on an optical substrate or a dense layer formed thereon, comprising the steps of (1) hydrolyzing and polycondensing alkoxysilane in a solvent containing a catalyst, a cationic surfactant and a nonionic surfactant to prepare composites comprising nanometer-sized, mesoporous silica particles and these surfactants, (2) applying a solution containing the composites to the substrate or the dense layer, (3) drying the solution to remove the solvent, and (4) removing both surfactants by baking the resultant coating at 120-250° C. in an oxygen-containing gas atmosphere, or plasma-treating it using an oxygen-containing gas.

Owner:RICOH IMAGING COMPANY +1

Pharmaceutical excipient having improved compressibility

InactiveUS6217909B1Improve compression performanceReduce the amount requiredInorganic/elemental detergent compounding agentsPowder deliverySilica particleSilicon dioxide

Owner:J RETTENMAIER & SOEHNE GMBH CO KG ROSENBERG

Precipitated silica materials exhibiting high compatibility with cetylpyridinium chloride

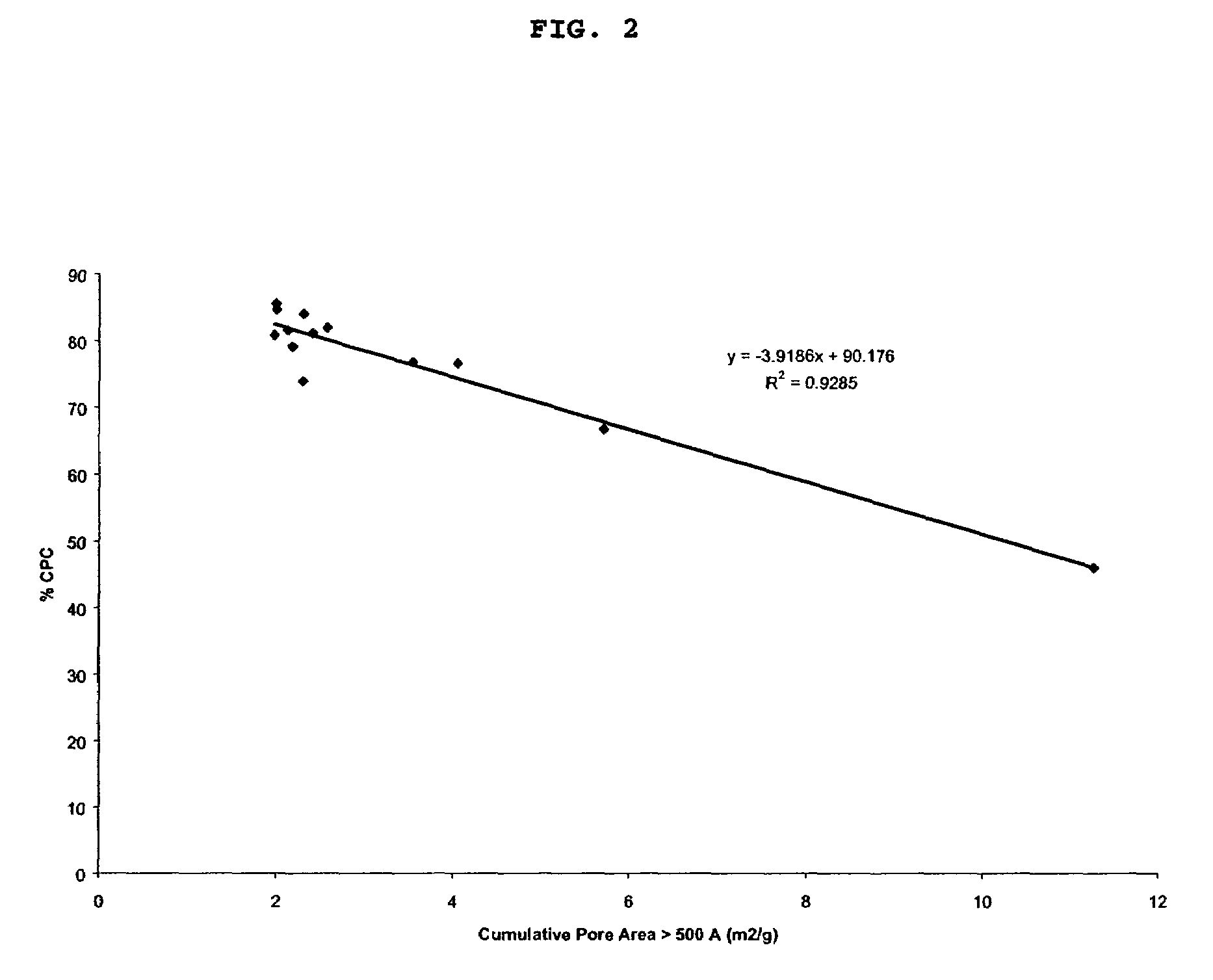

ActiveUS7438895B2Increase volumeImprove compatibilityCosmetic preparationsBiocideAntimicrobial actionSilica particle

Precipitated silica comprising porous silica particles having a cumulative surface area for all pores having diameters greater than 500 Å of less than 6 m2 / g, as measured by mercury intrusion, and a percentage cetylpyridinium chloride (% CPC) Compatibility of greater than about 85%. The precipitated silica product is especially well-adapted for use in dentifrices containing cetylpyridinium chloride, which do not attach to the low surface area silica product in a meaningful level and thus remain available for antimicrobial action. Processes for making the silica product including the introduction of sodium sulfate powder during different process steps in order to enhance such a compatibility with CPC are provided.

Owner:EVONIK OPERATIONS GMBH

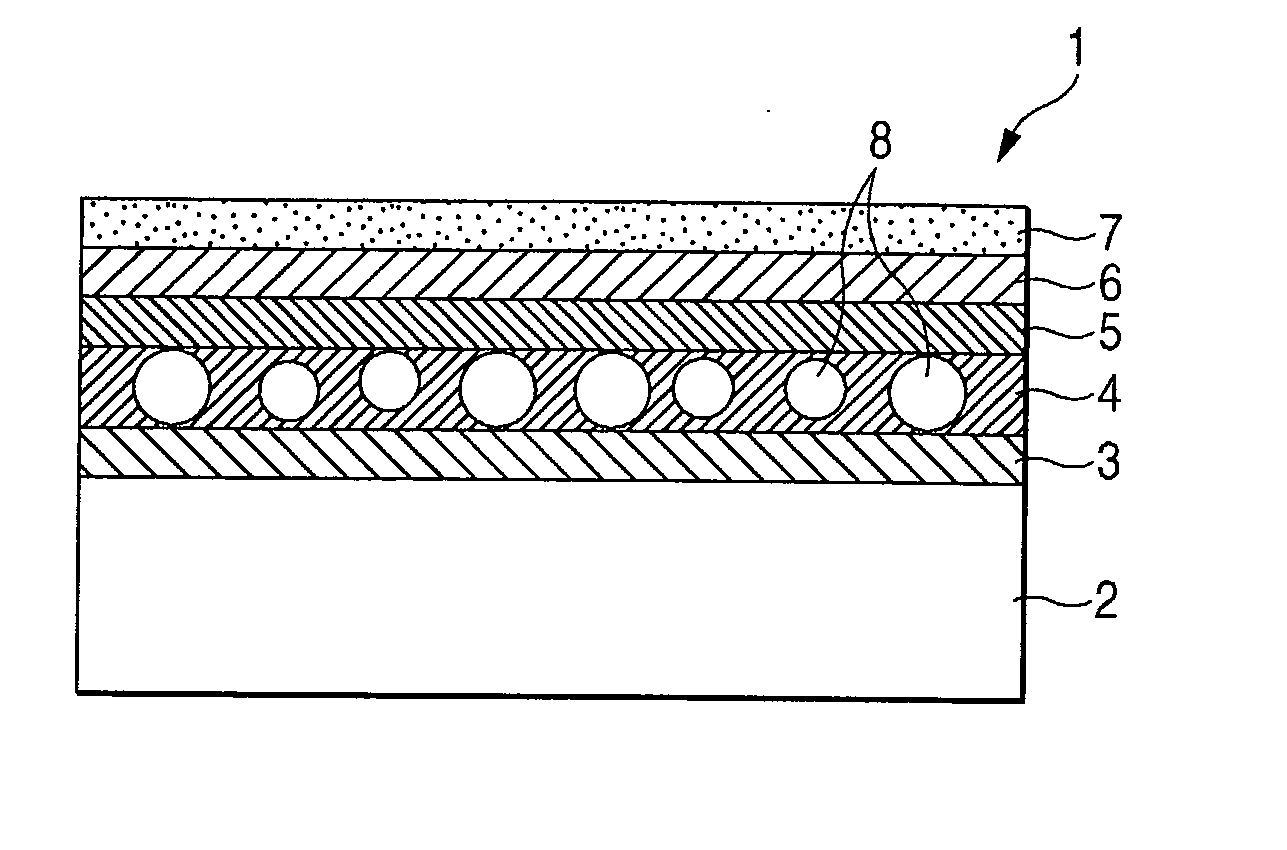

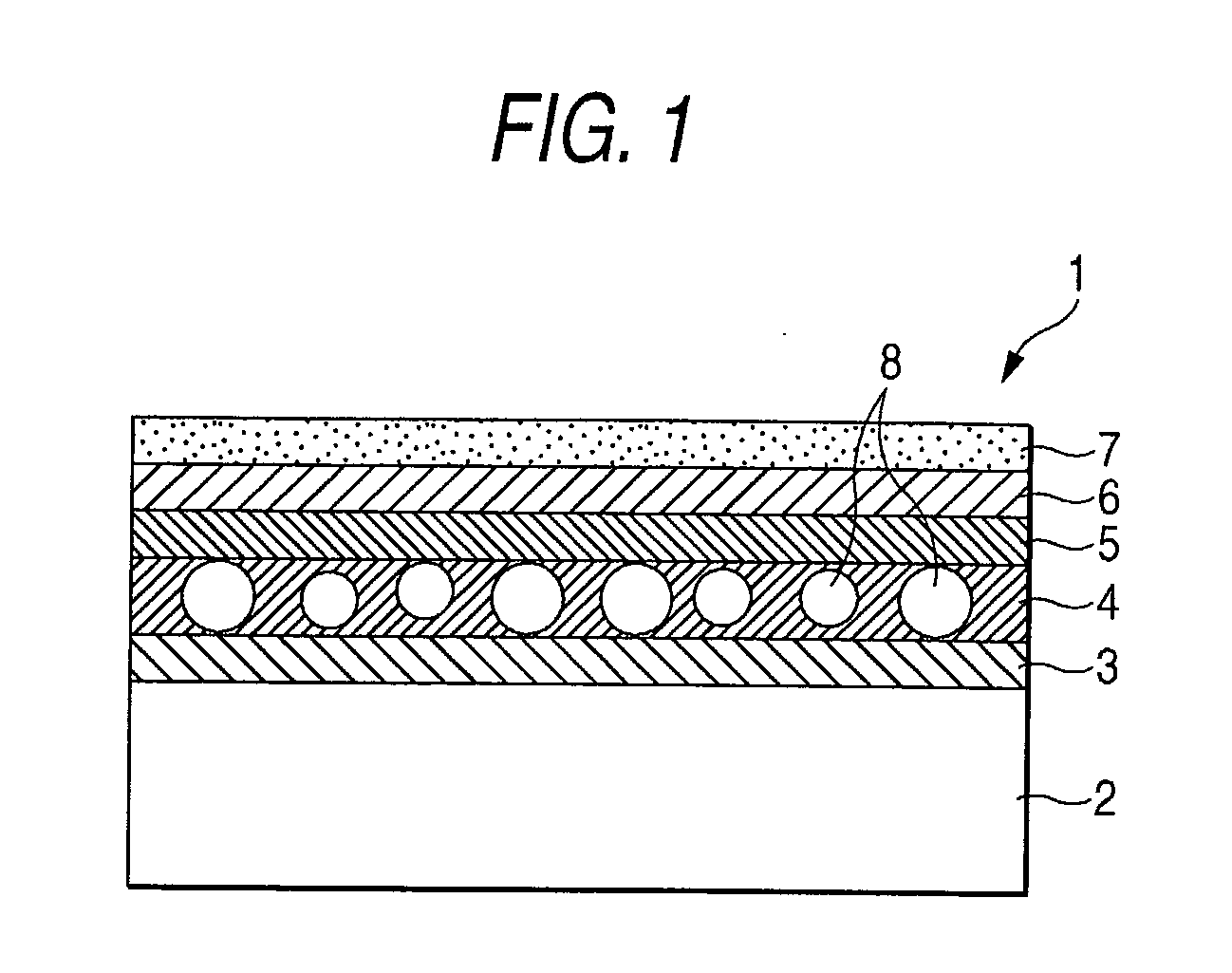

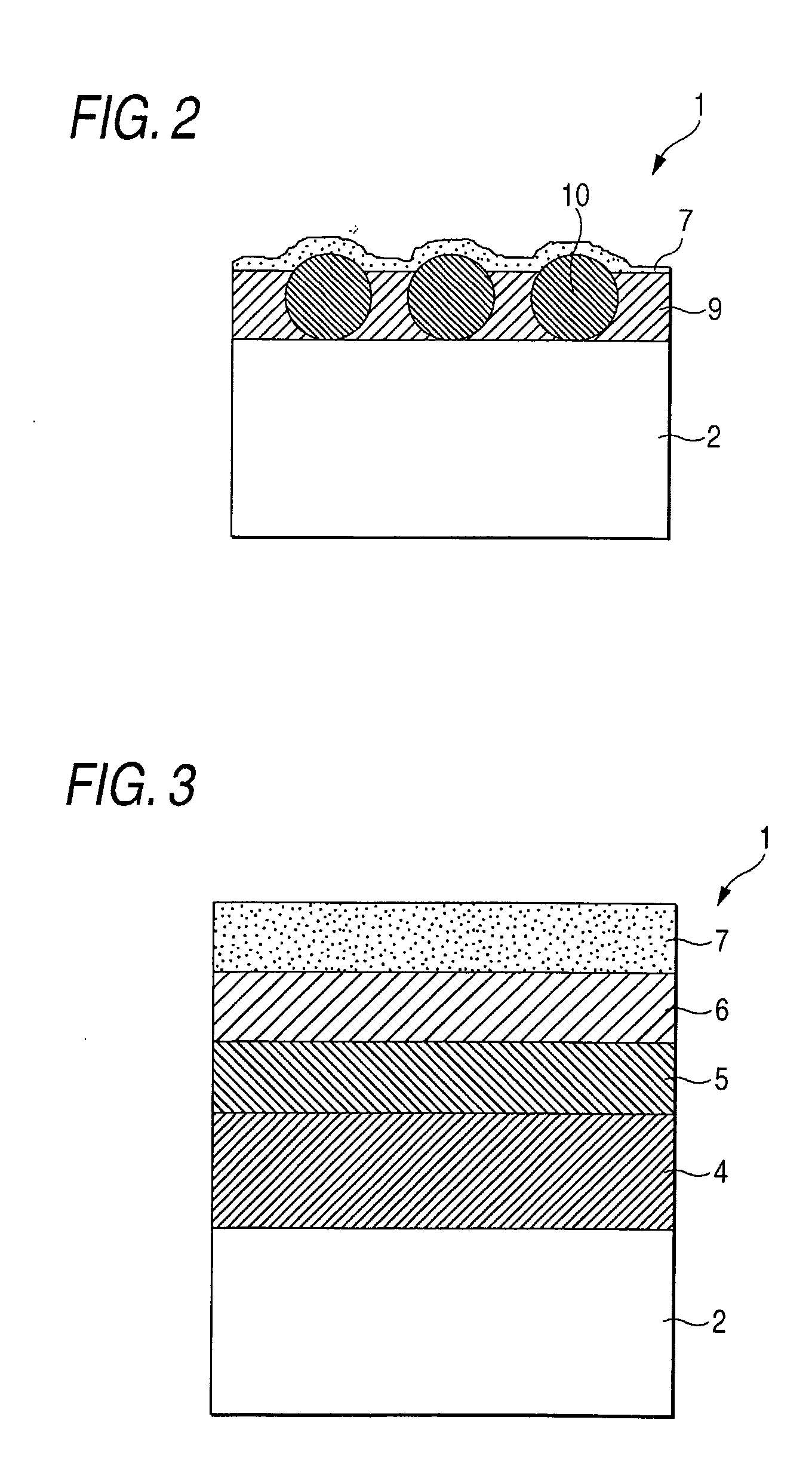

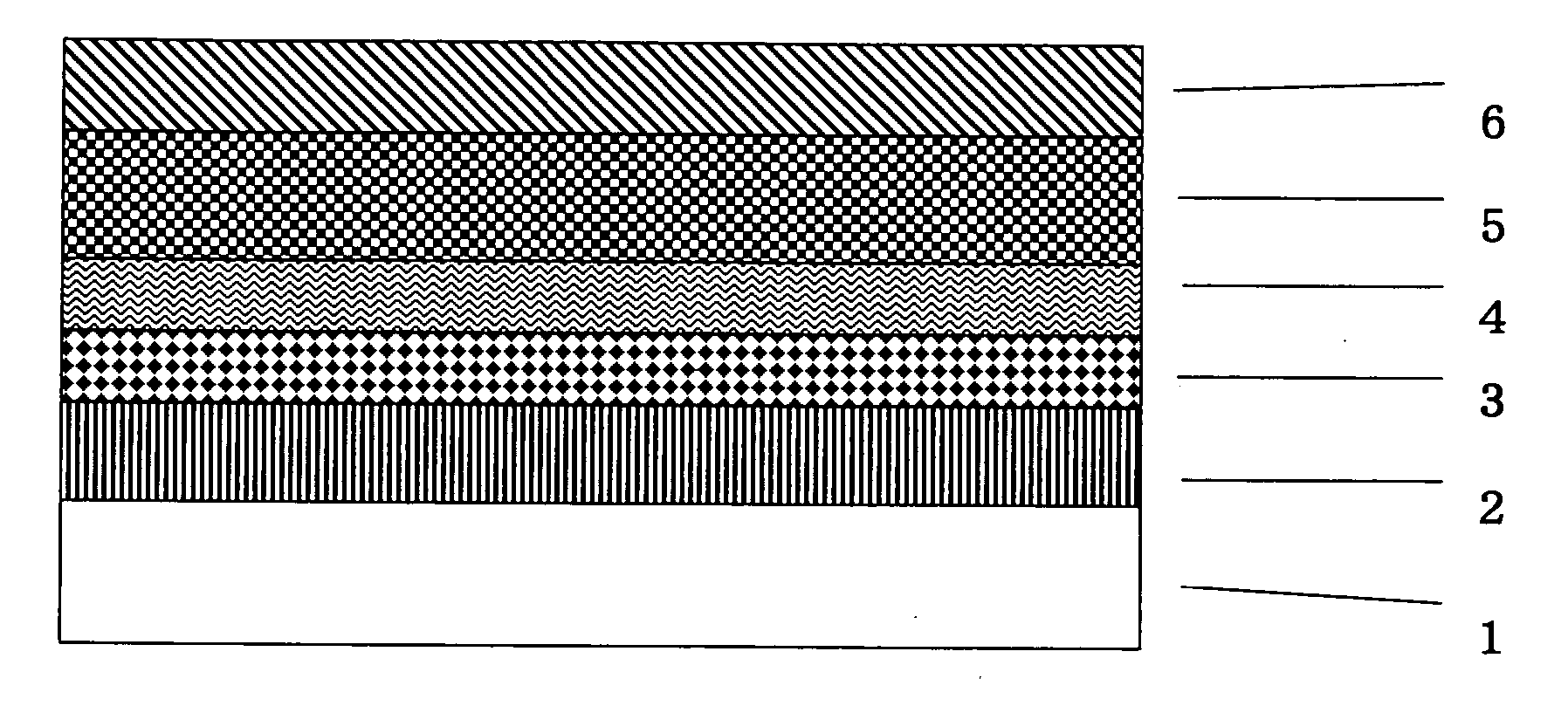

Antireflection film, production method of the same, polarizing plate and display

InactiveUS20060181774A1Improve visibilityImproved scratch resistance and pencil hardness and crack resistanceWash-standsHolders and dispensersRefractive indexDisplay device

An antireflection film comprising a transparent substrate film having thereon a hard coat, a high refractive index layer and a low refractive index layer, wherein: (i) the high refractive index layer is formed by applying a coating solution containing the following (a) to (c); (ii) the low refractive index layer is formed by applying a coating solution containing the following (d) and (e); (iii) the antireflection film is heat treated, wherein (a) metal oxide particles having an average primary particle diameter of 10 to 200 nm; (b) a metal compound; (c) an ionizing radiation curable resin; (d) an organosilicon compound having a prescribed structure, a hydrolyzed compound of the organosilicon compound, a decomposed compound of the organosilicon compound or a polycondensed compound of the organosilicon compound; and (e) hollow silica particles each having an outer shell, and a void or a porous portion in the inside.

Owner:KONICA MINOLTA OPTO

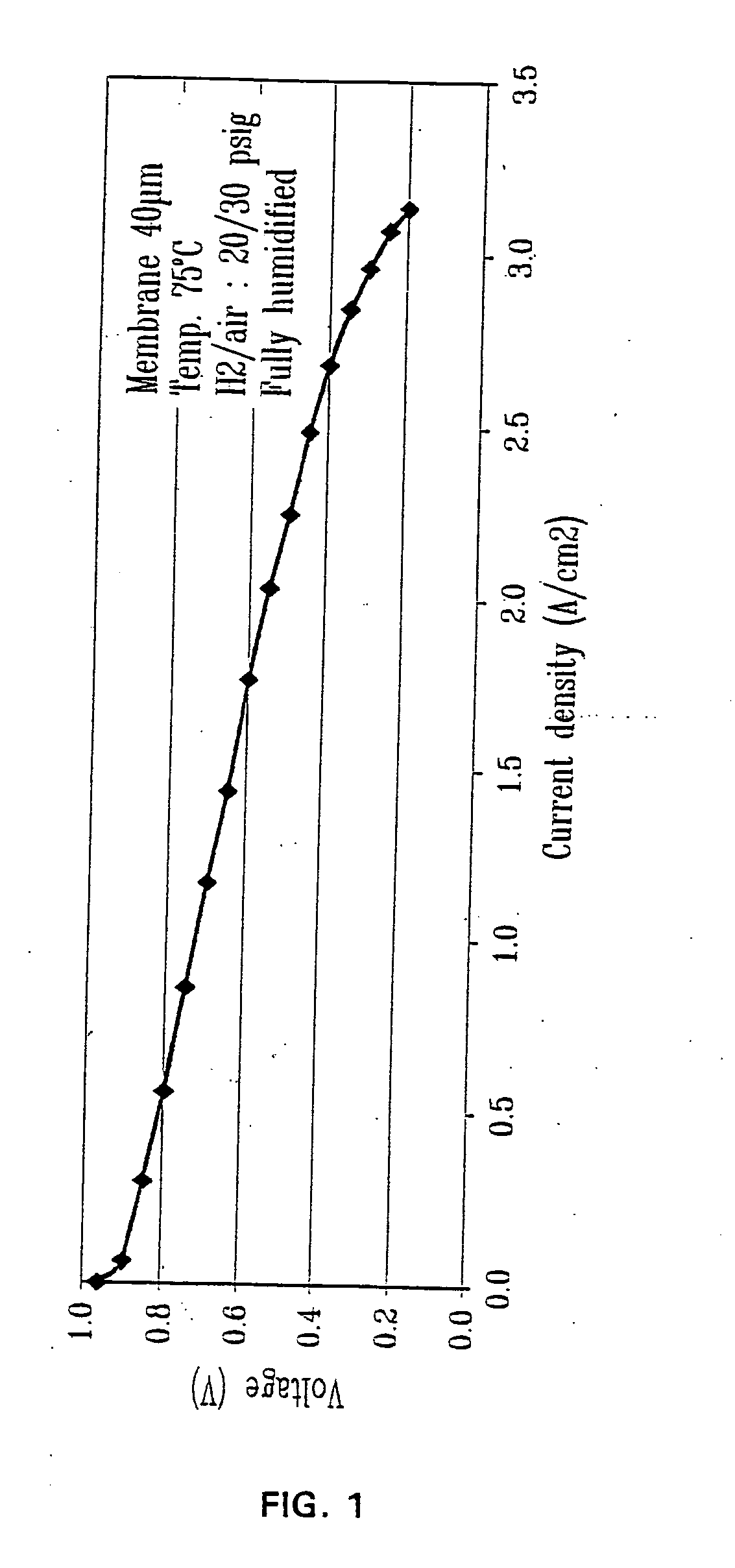

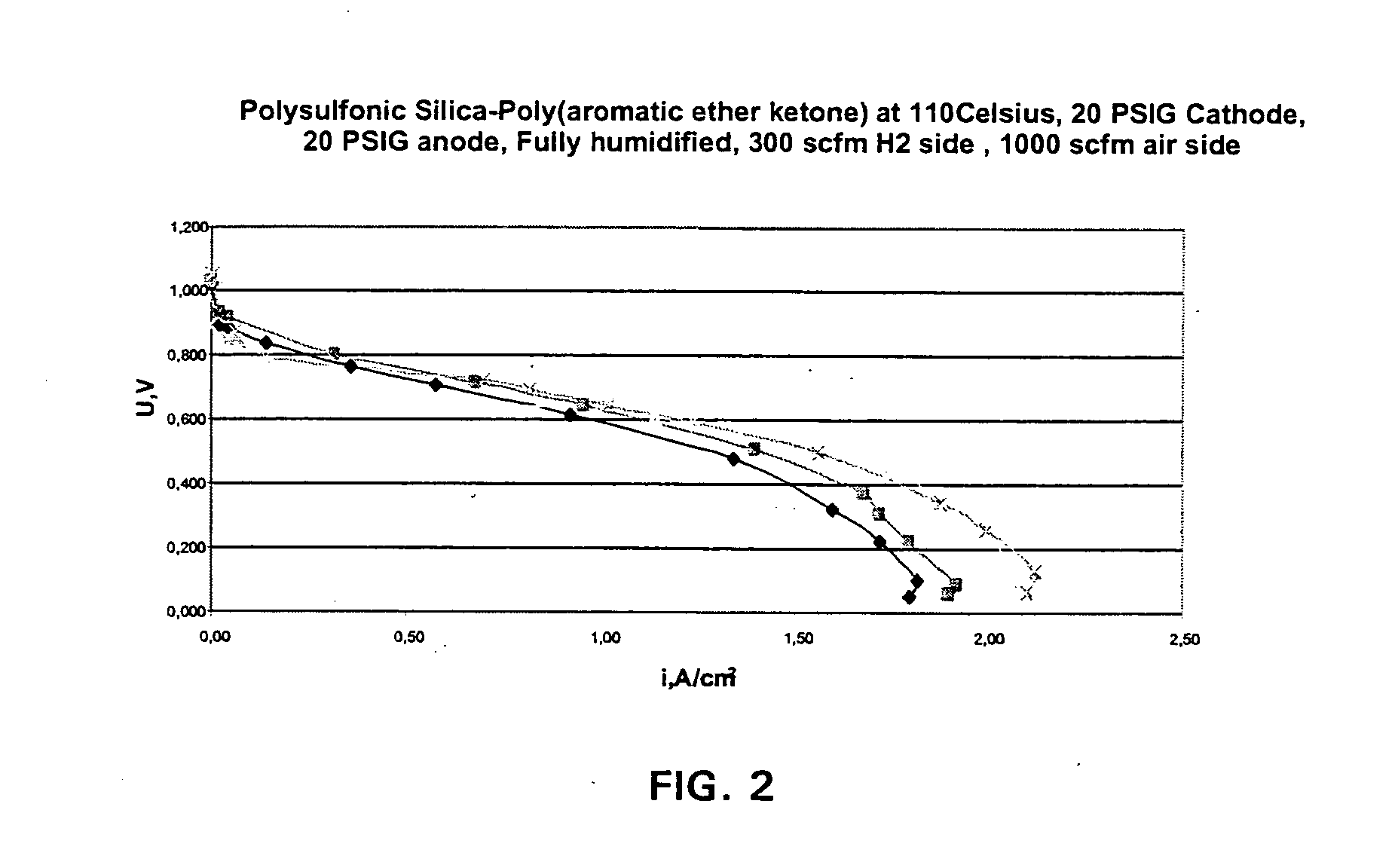

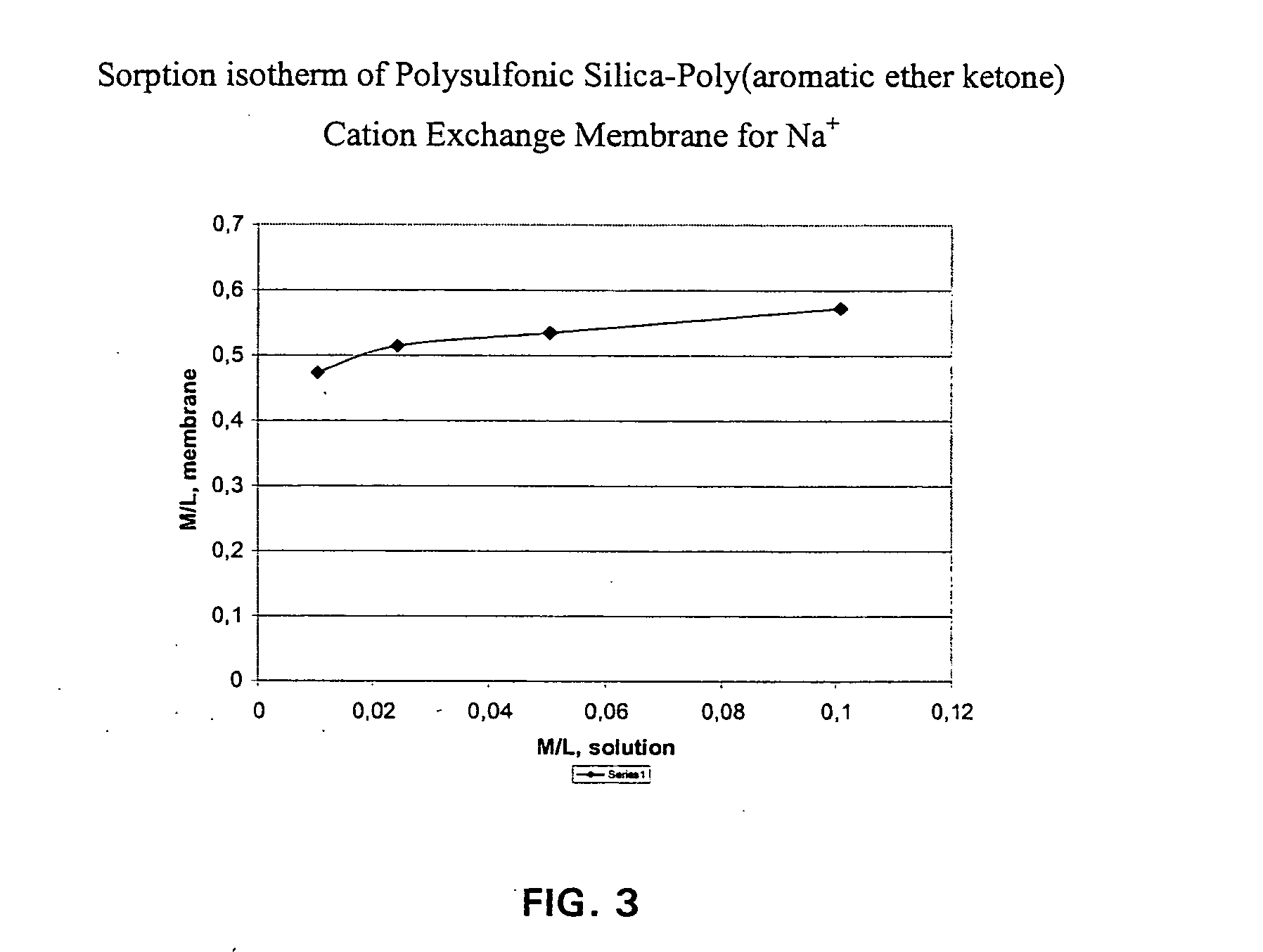

Ion exchange composite material based on proton conductive functionalized inorganic support compounds in a polymer matrix

InactiveUS20050053818A1Improve mechanical propertiesImprove impermeabilitySemi-permeable membranesSolid electrolytesIon exchangeLiquid fuel

The composite material comprise acid functionalized inorganic supports such as silica dispersed in a functionalized and / or non-functionalized polymer matrix that is based on numerous polymers such as poly(aromatic ether ketones), or poly(benzoyl phenylene), or derivatives thereof. The composite material is characterized by good water retention capabilities due to the acidic functions and the hydrophilicity of the silica particles. Moreover, a good impermeability to gas and liquid fuels commonly used in fuel cell technology, like hydrogen gas or methanol solution, is also obtained due to the presence of silica particles. Good mechanical properties of the composite material let the material to be formed easily in thin film or membrane form. In that form, the composite material is usable for proton exchange membrane for fuel cells, for drying or humidifying membrane for gas or solvent conditioning, or as acid catalytic membrane.

Owner:SIM COMPOSITES INC

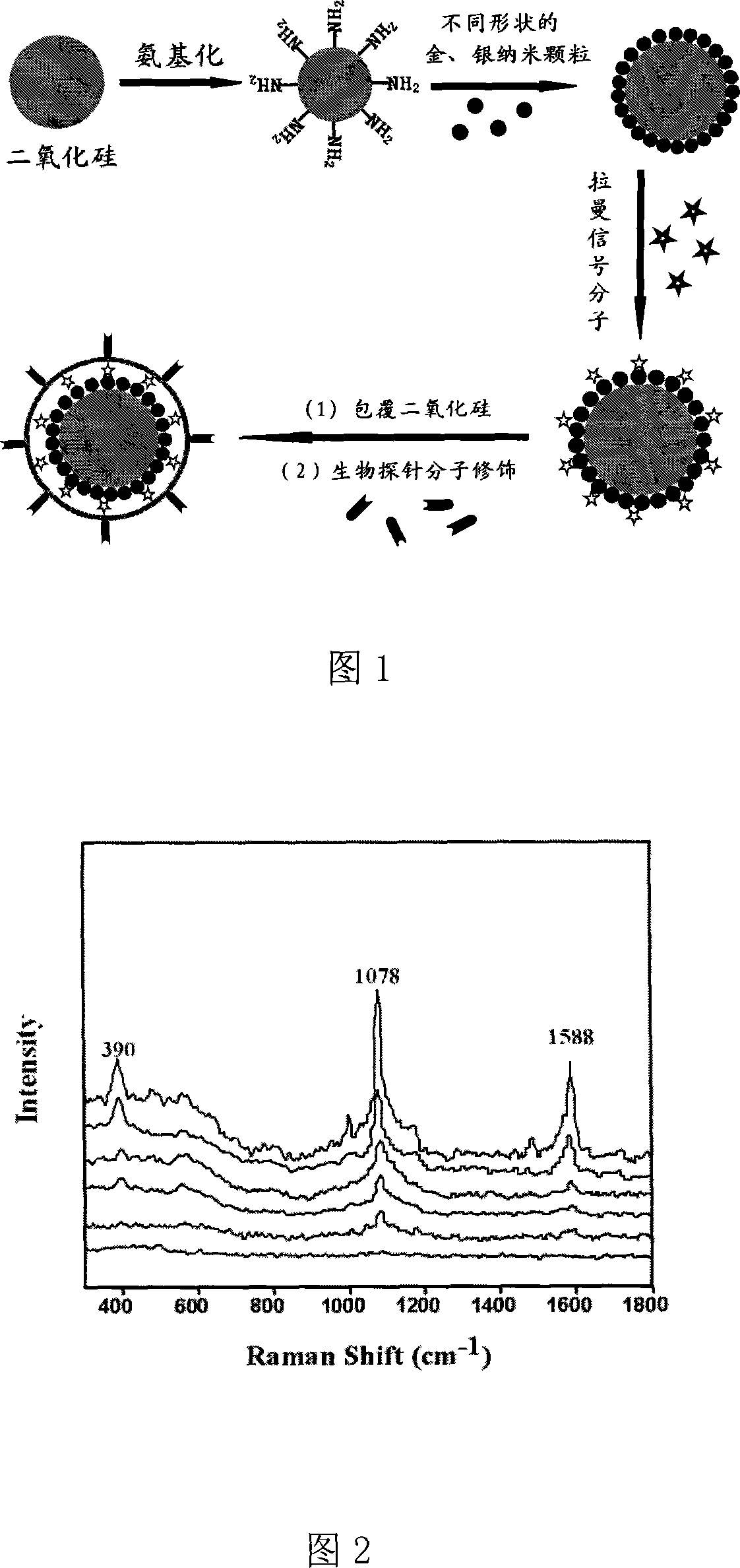

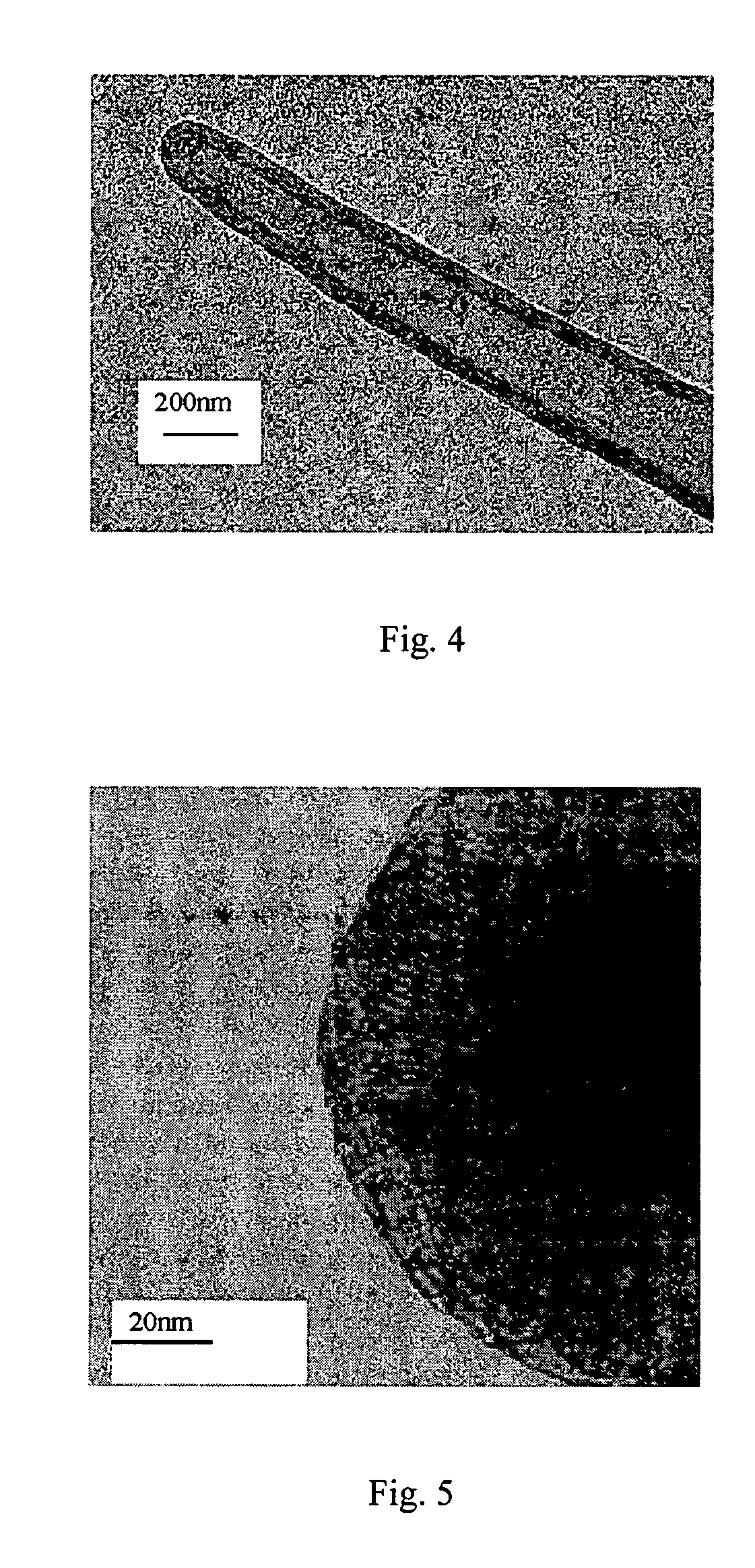

SERS biological probe and method for making same

InactiveCN101216429AStrong SERS effectSignificant SERS effectRaman scatteringBiological testingProtein moleculesSignalling molecules

The invention discloses a SERS biological probe and a preparation method thereof. The SERS biological probe provided by the invention comprises a SiO2 core and a metal nanoparticle layer on the surface of the SiO2 core, wherein a plurality of Raman signal molecules connected with the metal nanoparticle layer; a SiO2 layer is also provided outside the metal nanoparticle layer; the Raman signal molecules are positioned between the metal nanoparticle layer and the SiO2 layer; the SiO2 layer surface is modified with biological probe molecules; and the metal nanoparticle layer is Au nanoparticle layer or Ag nanoparticle layer. The SERS biological probe provided by the invention has wide generality, and has wide application prospect in identification and detection of biological molecules (DNA molecules and protein molecules), rapid disease diagnosis, biomedical imaging technology as well as in the fields of serious disease treatment, food hygiene, environmental monitoring, etc.

Owner:CAPITAL NORMAL UNIVERSITY

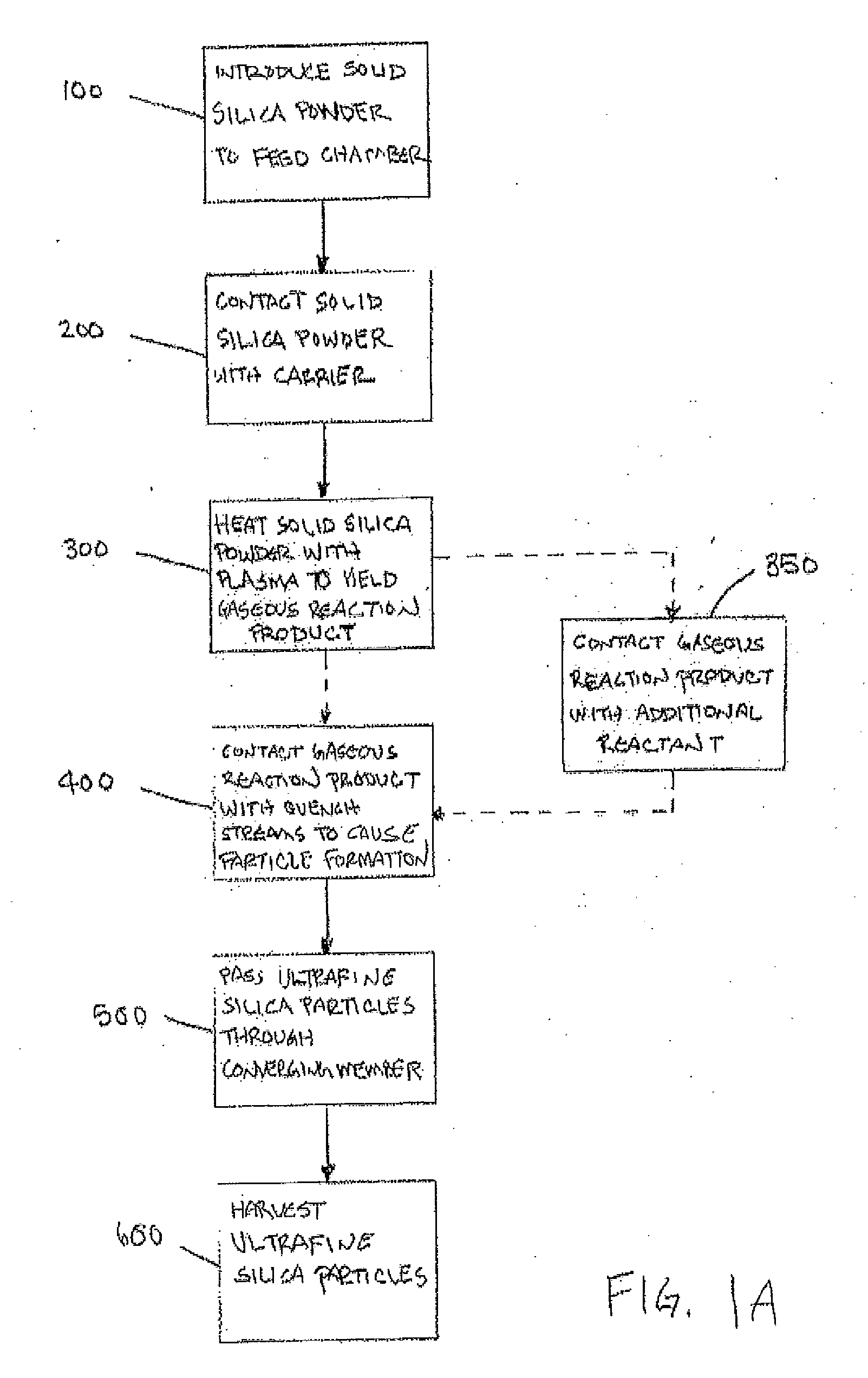

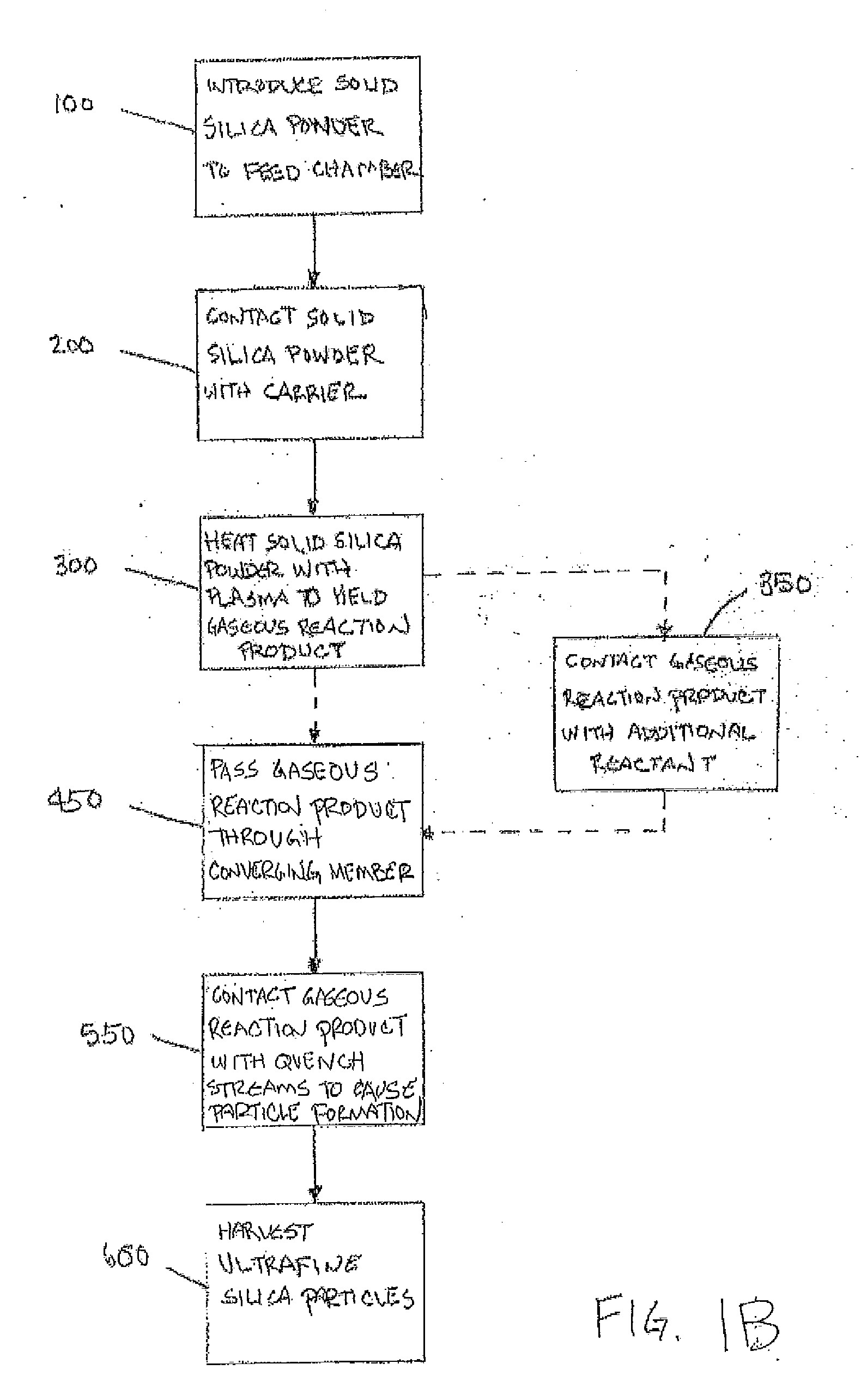

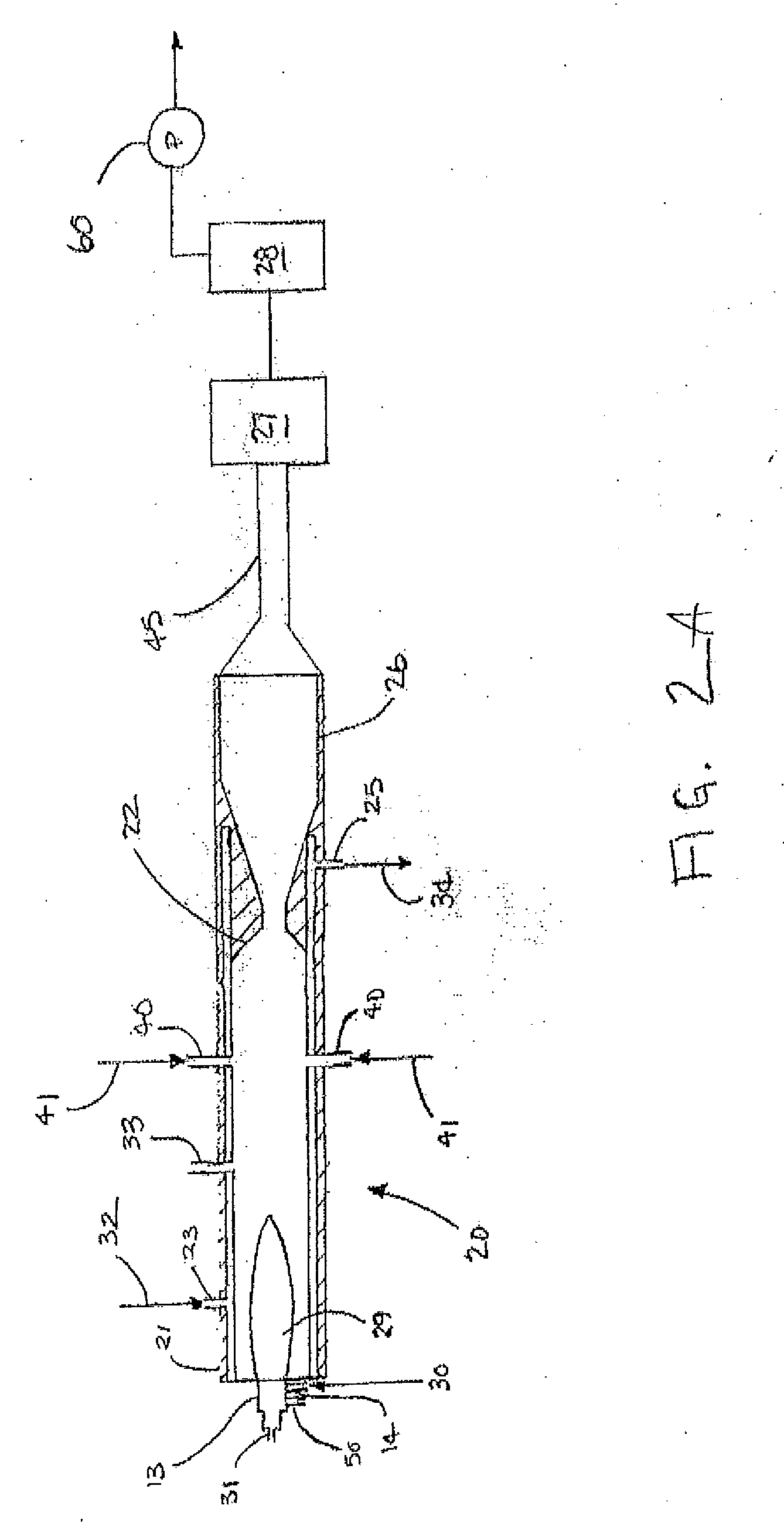

Method and apparatus for the production of ultrafine silica particles from solid silica powder and related coating compositions

Owner:PPG IND OHIO INC

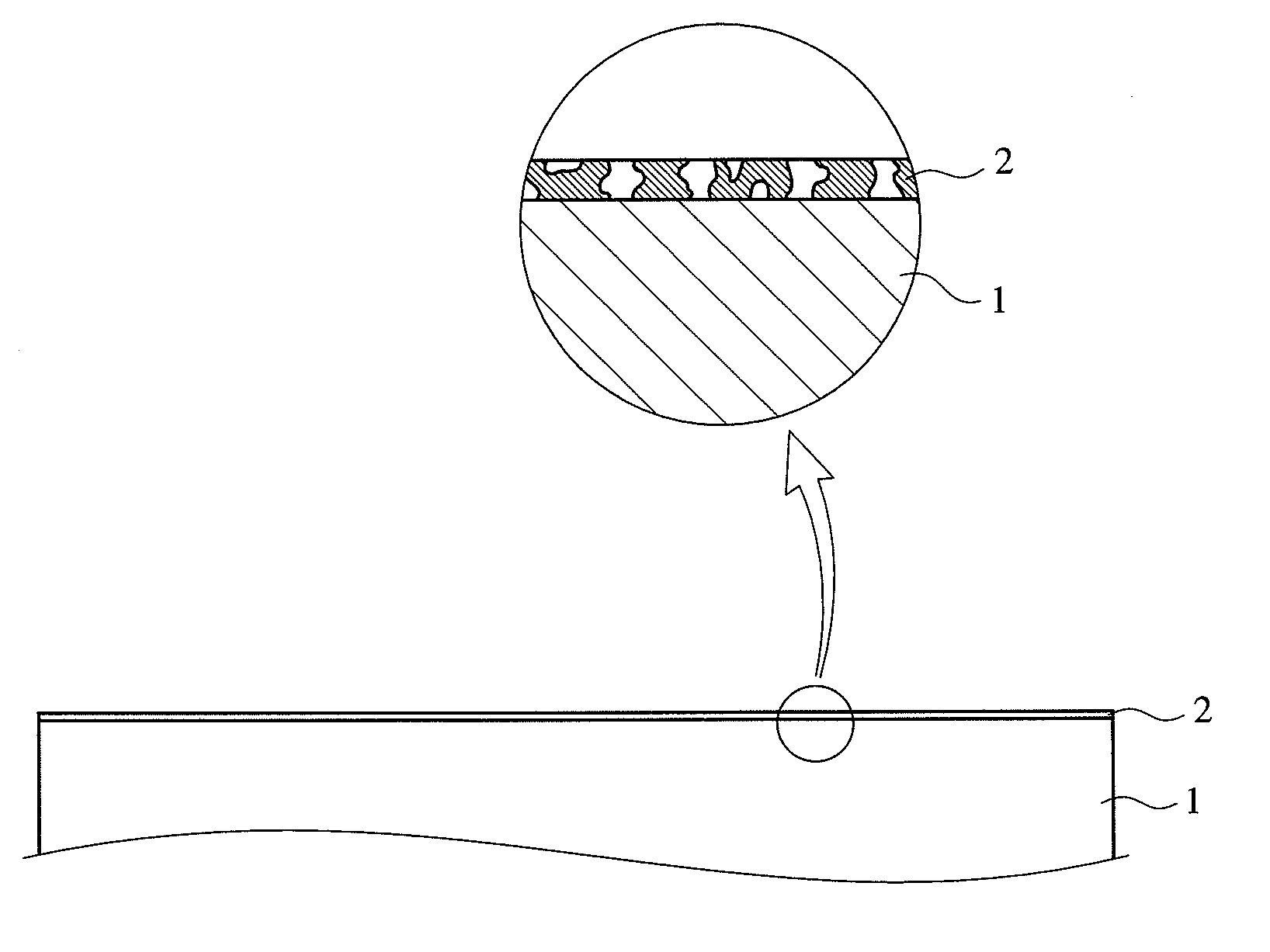

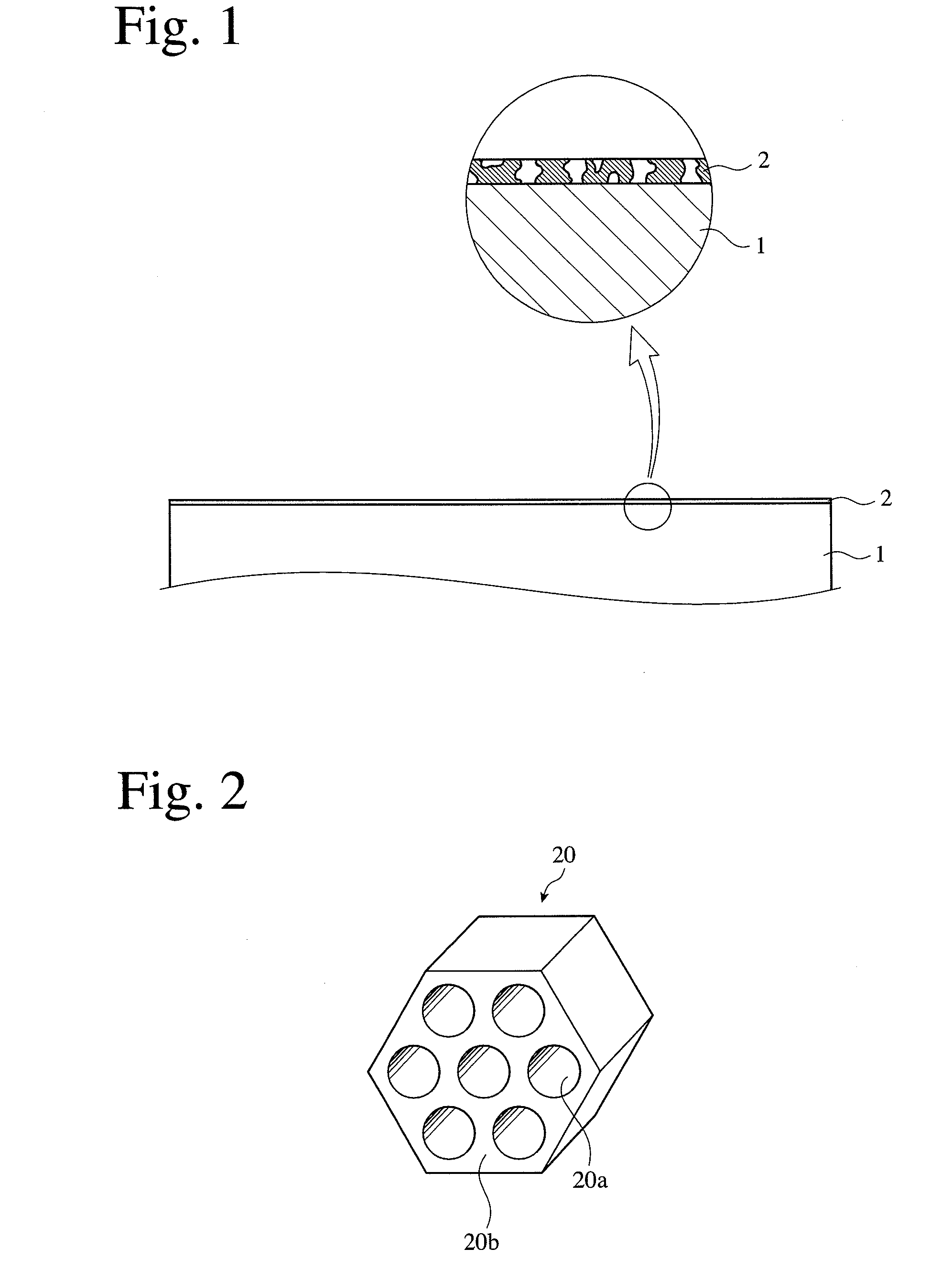

Organ model

ActiveUS20120045743A1Suitable for operationSuitable for useSynthetic resin layered productsPretreated surfacesSilica particleSurface layer

A material for forming an organ model containing an aqueous gel, which comprises polyvinyl alcohol having an average degree of polymerization of 300 to 3500 and a degree of saponification of not less than 90% by mole, and silica particles; a method for producing a material for forming an organ model, comprising cooling an aqueous polyvinyl alcohol solution which contains polyvinyl alcohol having an average degree of polymerization of 300 to 3500 and a degree of saponification of not less than 90% by mole and silica particles, to a temperature of −10° C. or lower, and thawing the resulting formed aqueous gel; and an organ model at least provided with a surface layer comprising the material for forming an organ model. Thus, it is possible to provide: an organ model which has a hydrophilic property similar to an organ of a human body, gives such an incision feel that an incised portion spreads just similar to a living human organ and, therefore can be appropriately used in, for example, exercising surgical procedures; a material for forming an organ model appropriately usable for the organ model; and a method for producing the same.

Owner:YUUGENGAISHA SEIWADENTAL

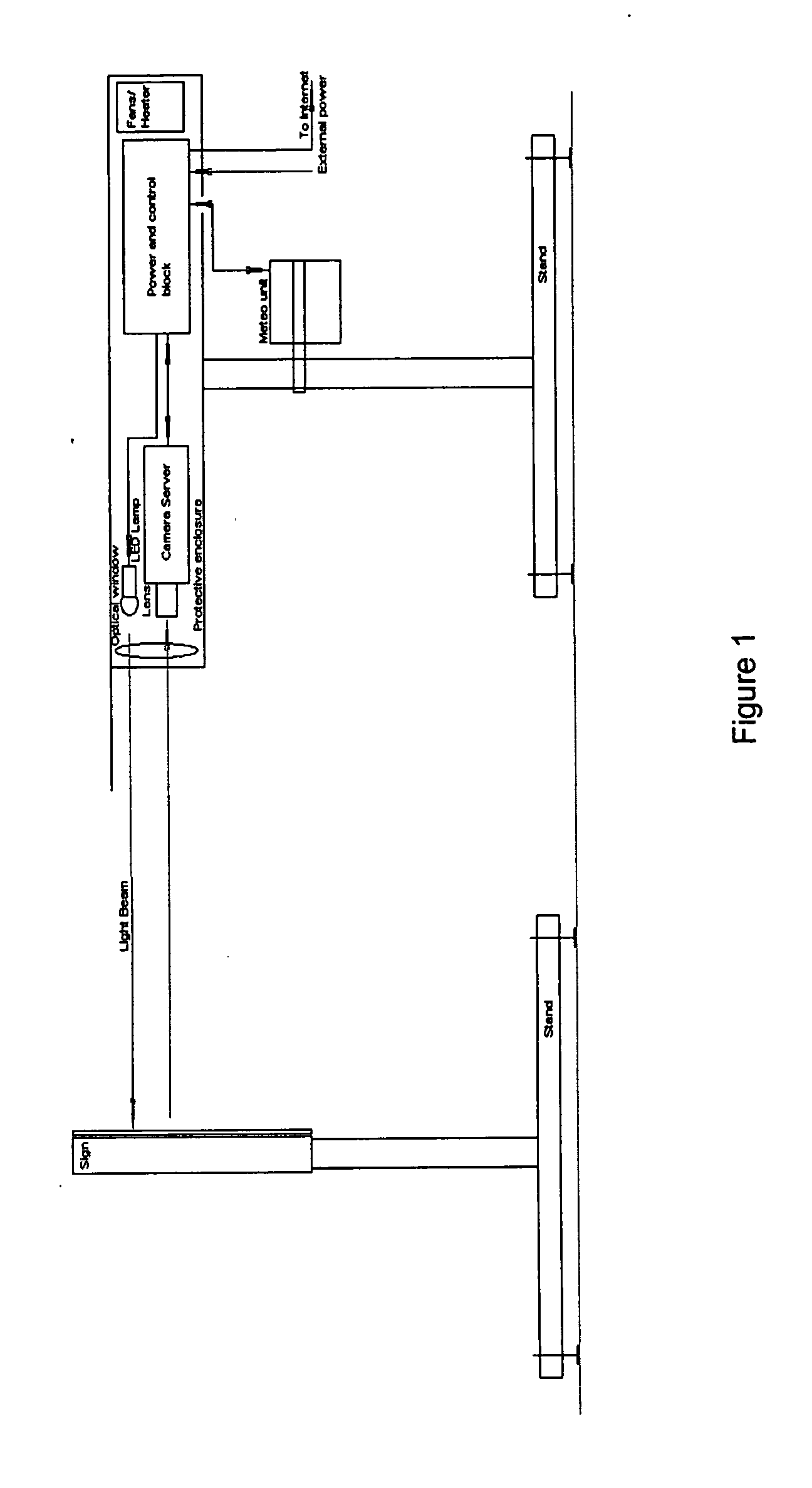

Coating compositions incorporating nanotechnology and methods for making same

InactiveUS20070027232A1Resisting deteriorationSpecial tyresPolyester coatingsWater basedSilica particle

The present invention relates to coating compositions, particularly water-based coating compositions, which incorporate nanotechnology. More specifically, the water-based coating compositions may include: a binder; a plurality of hydrophobic silica particles; and a solvent. The coating compositions may be applied to a variety of different surfaces, such as, for example, metals, plastics and signs, among others to impart resistance to corrosion and / or deterioration over time, as well as good adhesion thereto.

Owner:CHEMCOAT

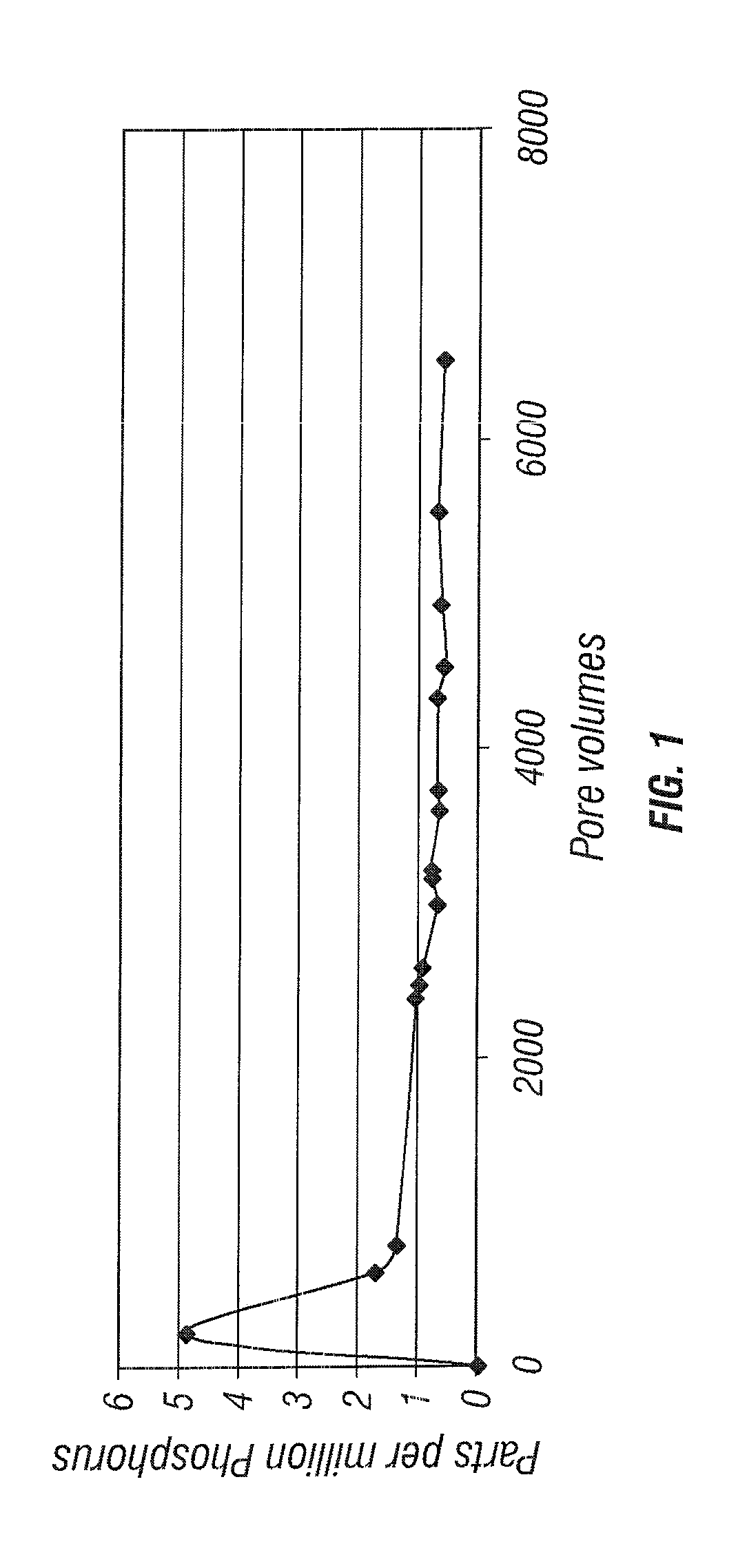

Method of inhibiting or controlling formation of inorganic scales

A well treating composition of a composite containing a scale inhibitor adsorbed onto a water-insoluble adsorbent is useful in the control, formation and treatment of inorganic scales in a subterranean formation or wellbore. In addition, the well treating composition is useful in controlling the rate of release of scale inhibitor in the wellbore. The water-insoluble adsorbent may be activated carbon, silica particulate, precipitated silica, zeolite, diatomaceous earth, ground walnut shells, fuller's earth and organic synthetic high molecular weight water-insoluble adsorbents. The composite may be introduced into an oil or gas well with a carrier fluid.

Owner:BAKER HUGHES INC

Antireflection film

InactiveUS20060269724A1Improve performanceExcellent to abrasionSynthetic resin layered productsTraffic signalsSilica particleSurface roughness

An antireflection film comprising silica particles and at least one binder compound, which has a silica particle content of 30% by weight or more, an arithmetic mean surface roughness (Ra) of not more than 2 nm, and a surface silicon atom content of 10 atom % or more.

Owner:ASAHI KASEI KK

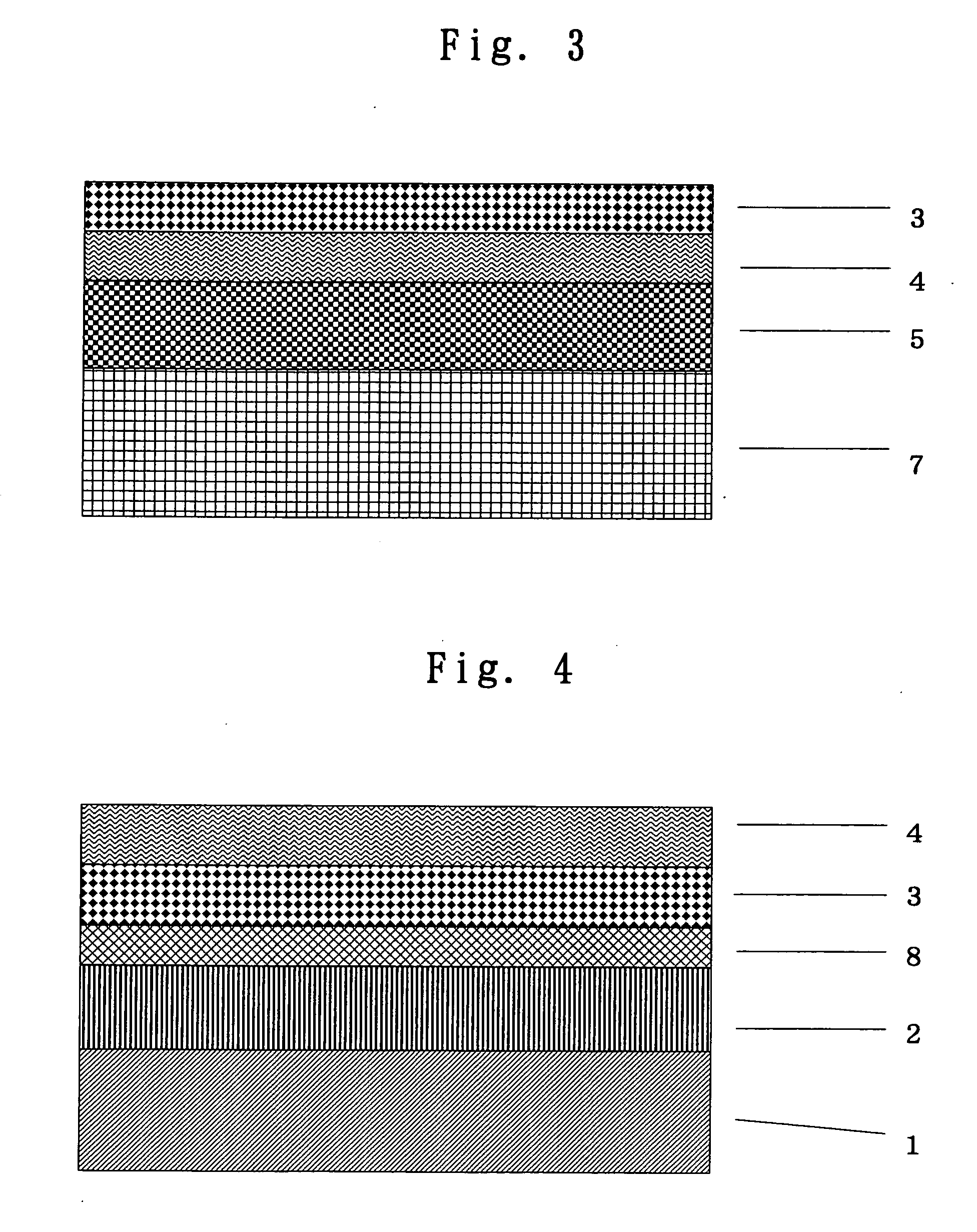

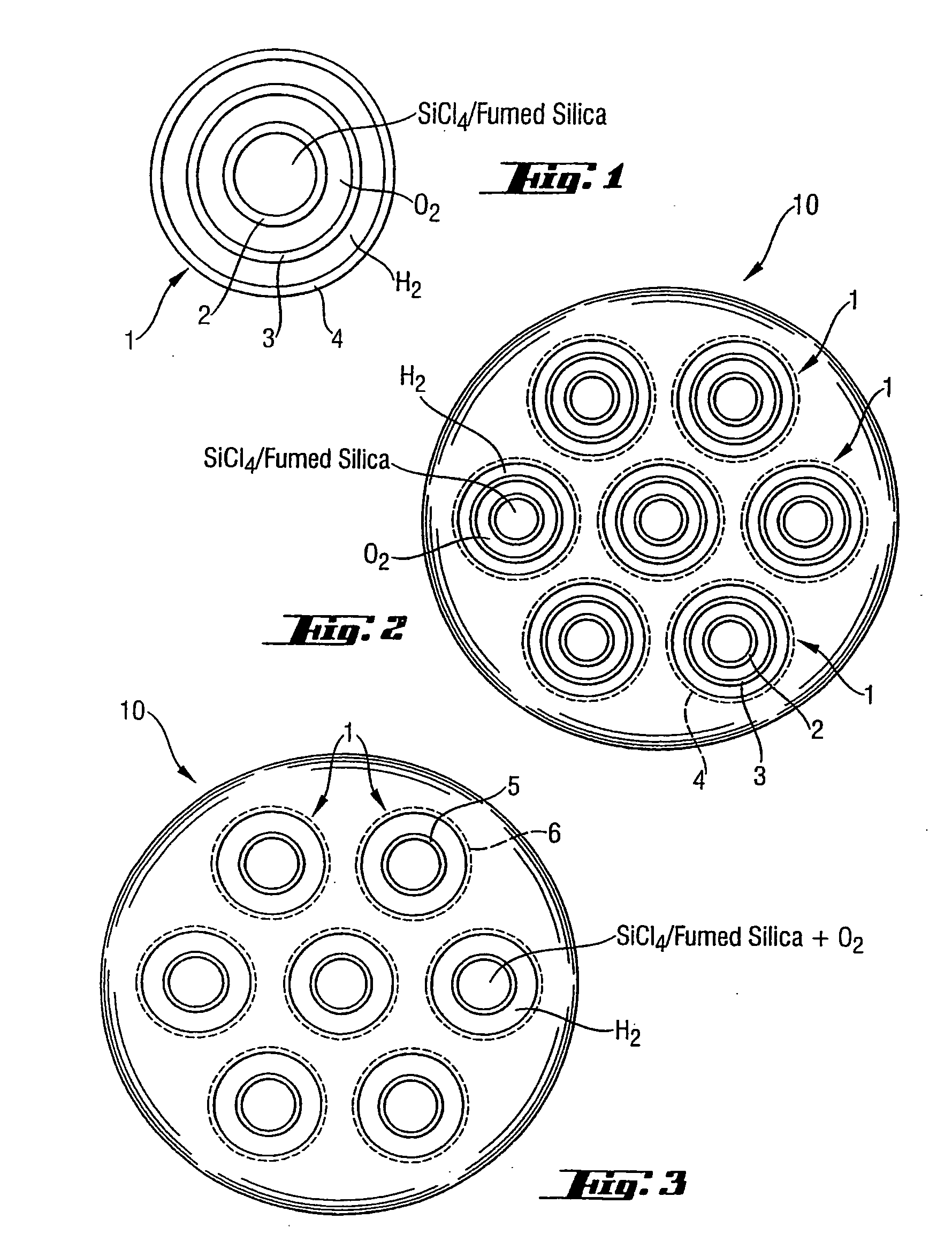

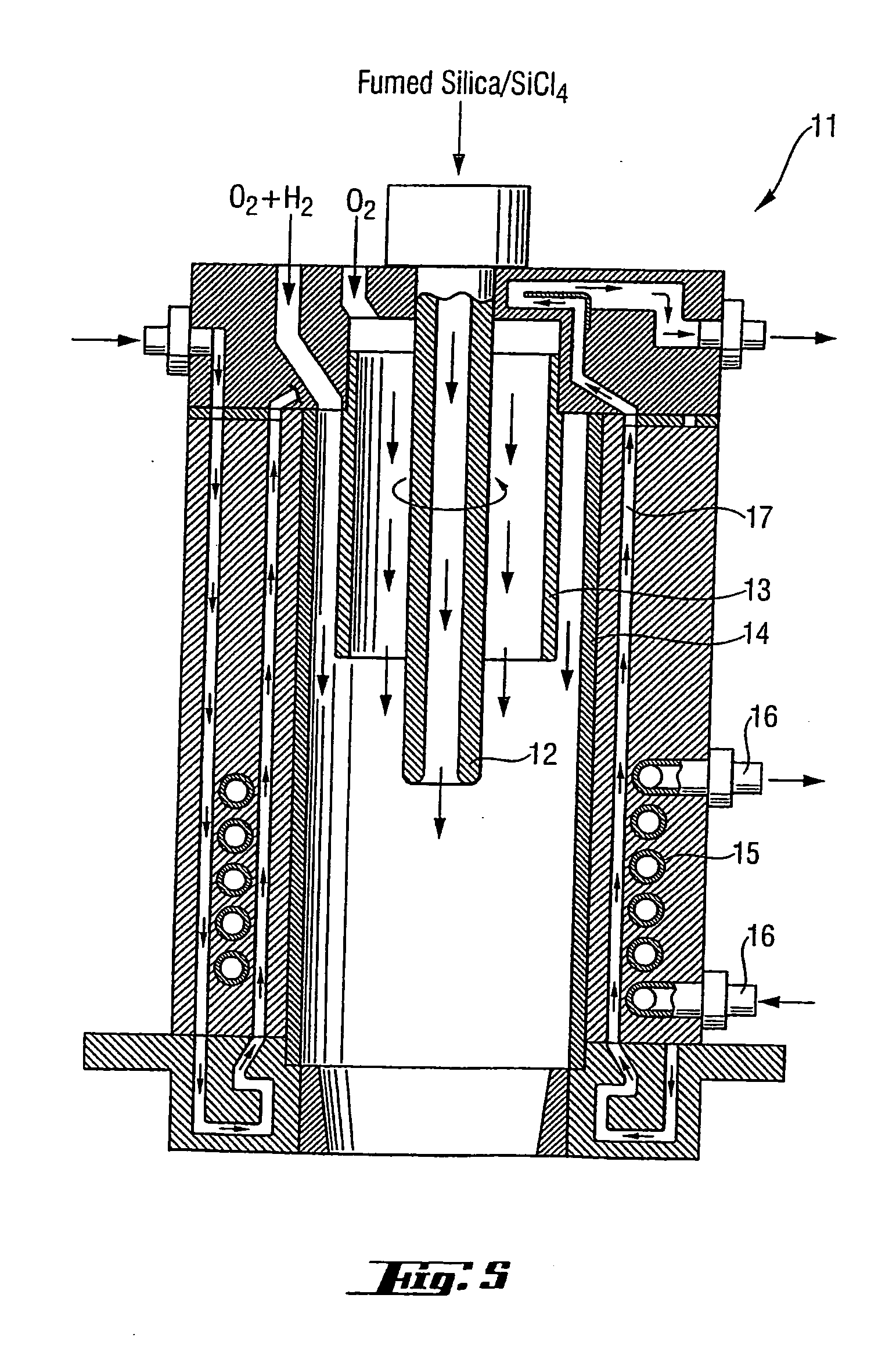

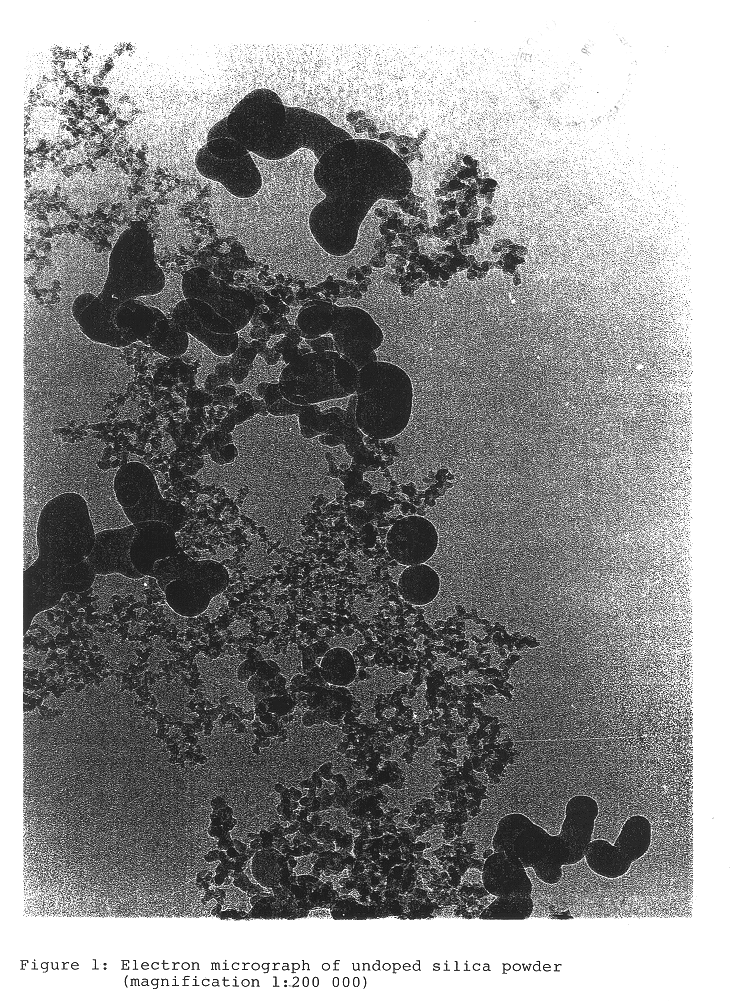

High-purity silica powder, and process and apparatus for producing it

Use of a flame hydrolysis apparatus for preparing fumed silica particles or a plasma torch apparatus for sintering fumed silica particles to fused silica particles is capable of producing highly pure silica with non-silicon metal impurities less than 500 pb, when at least an inner nozzle is constructed of a silicon-containing material having a low level of non-silicon metal impurities. Preferably, all surfaces in the respective apparatus which contact silica are of similar construction. The silica contains a low level of impurities as produced, without requiring further purification.

Owner:WACKER CHEM GMBH

Aqueous dispersion

ActiveUS20040097600A1Effective and stableShorten drying timeMaterial nanotechnologyPigmenting treatmentSilica particleSilane compounds

The invention relates to a method of producing an aqueous dispersion comprising mixing at least one silane compound and colloidal silica particles to form silanized colloidal silica particles, mixing said silanized colloidal silica particles with an organic binder to form the dispersion. The invention also relates to a dispersion obtainable by the method, and the use thereof.

Owner:AKZO NOBEL CHEM INT BV

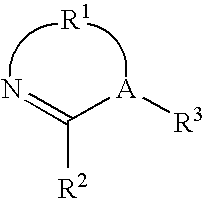

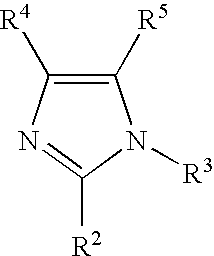

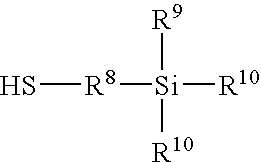

Method of producing a tire composition having improved silica reinforcement

Vulcanizable elastomeric compositions and vulcanizates are prepared by employing a nitrogen-containing heterocycle. The nitrogen-containing heterocycle is believed to enhance interaction between a silica particle and a silica-interactive compound.

Owner:BRIDGESTONE CORP

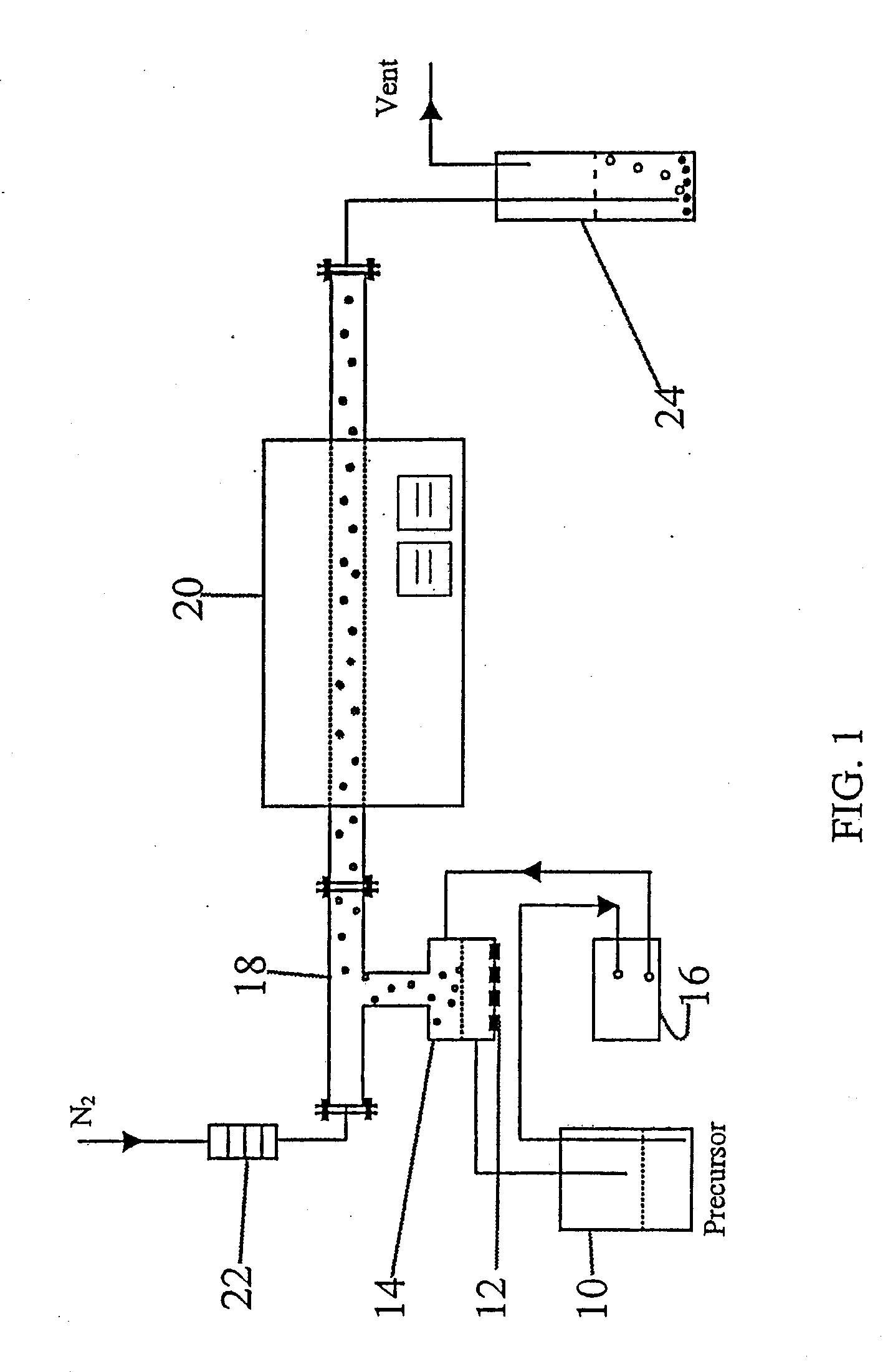

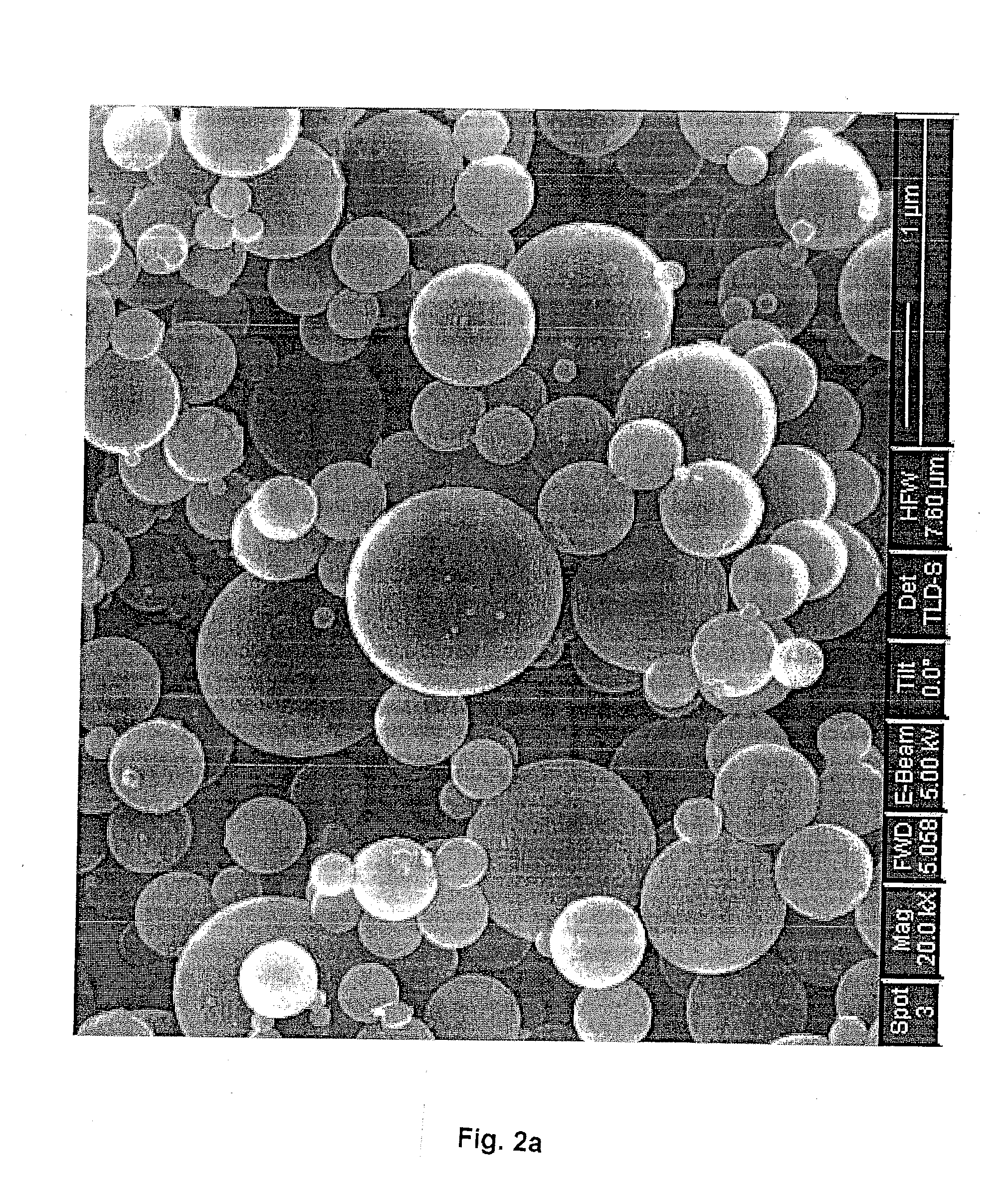

Controllable Synthesis of Porous Carbon Spheres, and Electrochemical Applications Thereof

InactiveUS20110082024A1Good dispersionExcellent ORR activityMaterial nanotechnologyReactant parameters controlColloidal silicaSmall droplet

The invention disclosed relates to porous carbon of spherical morphology having tuned porosity and to a method of making same, comprising: (a) providing a precursor solution, by combining in an aqueous solution a colloidal silica template material and a water-soluble pyrolyzable carbon source, wherein the particle size of the colloidal silica template and the colloidal silica / carbon source weight ratio are controlled, (b) atomizing the precursor solution into small droplets by ultrasonic spray pyrolysis (c) directing the droplets into a high temperature furnace operating at a temperature of 700-1200° C., under an inert gas atmosphere, where the droplets are transformed into solid spherical composite carbon / silica particles, (d) collecting the resulting composite carbon / silica particles exiting from the furnace, and (e) removing the silica from the particles, to provide substantially pure porous carbon of spherical morphology having tuned porosity defined by surface area and pore size. The porous carbon according to the invention is used as catalyst supports in PEM fuel cells, as electrodes in supercapacitors and lithium in batteries, for hydrogen storage and as earners for drug delivering.

Owner:NAT RES COUNCIL OF CANADA

Preparation method of super-hydrophobic cellulose material with micro-nano structure

The invention relates to a preparation method of a super-hydrophobic cellulose material with a micro-nano structure. The method comprises the following steps: (1) adding ethyl orthosilicate and functionalized siloxane into an ethanol system containing deionized water to obtain a dispersion liquid of functionalized silica particles A in the presence of ammonium hydroxide serving as a catalyst; with the dispersion liquid of functionalized silica particles A as seeds, sequentially adding the ethyl orthosilicate, the functionalized siloxane, the deionized water, the ammonium hydroxide and the ethanol so as to obtain a dispersion liquid of functionalized silica particles B; (2) performing ultrasonic dispersion on the two types of functionalized silica particles in dimethylformamide, then adding a hydrophobic polymer and a low surface energy additive into the system and evenly stirring so as to form white dispersion liquid; and (3) coating the white dispersion liquid obtained in the step (2) on a natural cellulose material in a direct spraying manner or a spin coating manner so as to obtain the super-hydrophobic cellulose material with the micro-nano structure. The coating material has strong scouring resistance and acid-alkali resistance besides the excellent hydrophobic property.

Owner:山东天洋新材料有限公司

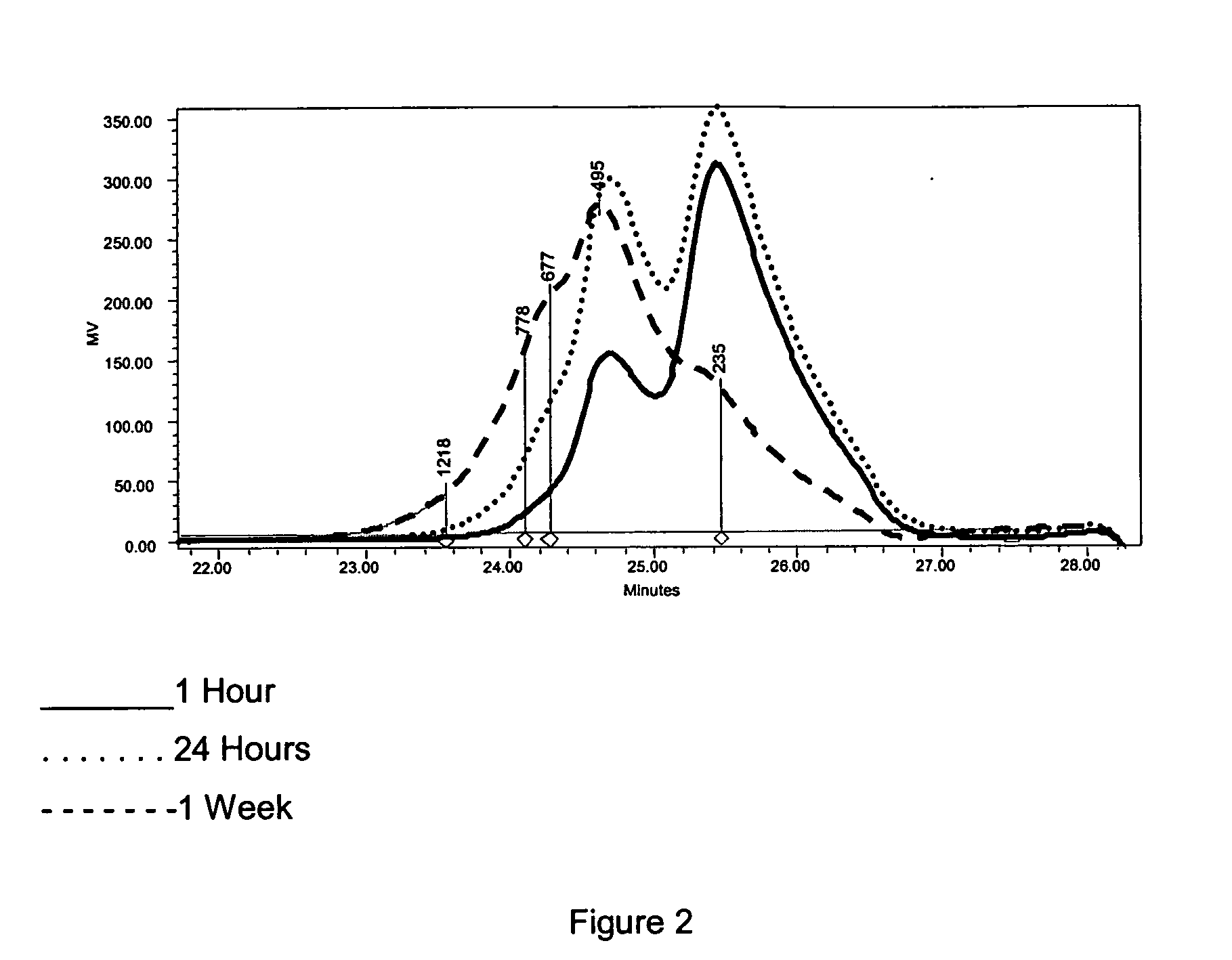

Aqueous dispersion, a process for the preparation and the use thereof

InactiveUS6676719B2Improve stabilityTrend downCosmetic preparationsNon-fibrous pulp additionSilica particleSilicon dioxide

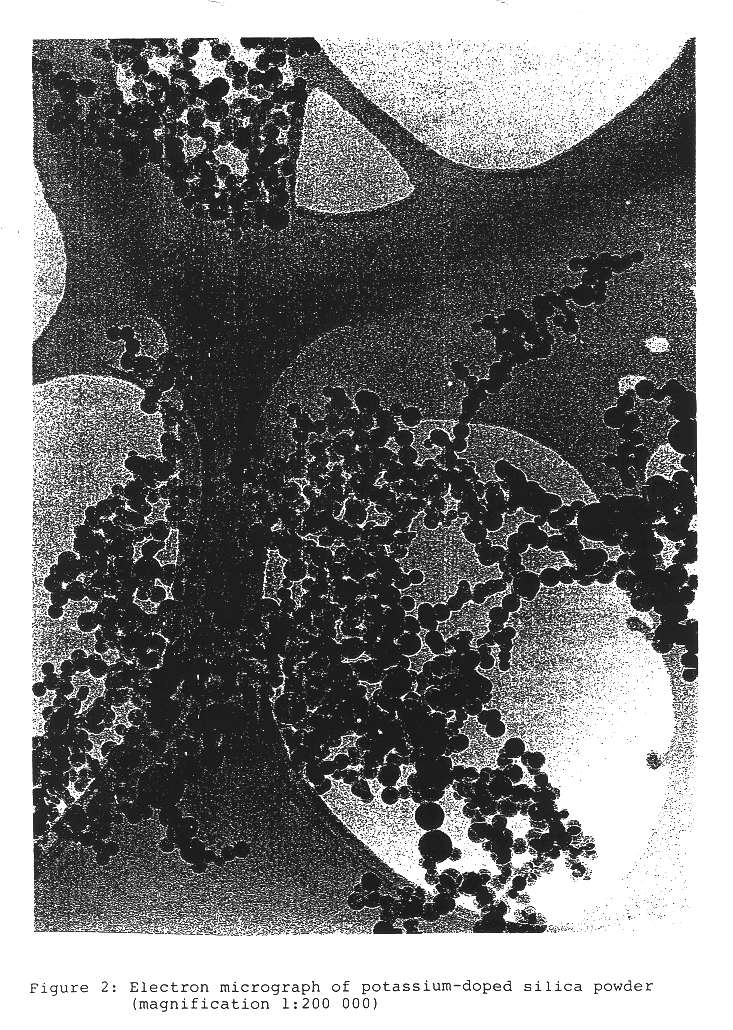

A pyrogenic process is used to prepare alkali-doped silica particles. Particles produced by this process exhibit homogeneous doping, reduced agglomeration, greater stability and higher removal rates. Aqueous dispersions containing alkali-doped pyrogenic silica with average particle size less than 100 nm are used for polishing surfaces (CMP).

Owner:EVONIK DEGUSSA GMBH

Sintered quartz glass products and methods for making same

InactiveUS6012304AReduce sinteringLonger sintering timeGlass shaping apparatusCeramic shaping apparatusSilica particleDevitrification

A number of unique processes are disclosed for manufacture of sintered high-purity quartz glass products in which a shaped silica body or preform is made from an aqueous slurry of micronized silica particles by gel casting, slip casting or electrophoretic deposition. The silica particles may comprise a major portion by weight of crystalline silica. In one embodiment of the invention the sintered quartz glass is transparent, substantially bubble-free and suitable for scientific or optical uses. In another embodiment the porous silica preform is fired in steam to increase the hydroxyl content and then nitrided in a nitrogen-hydrogen reducing atmosphere. A minute amount of chemically-combined nitrogen in the high-purity quartz glass is sufficient to provide a tremendous improvement in physical properties and an incredible increase in the resistance to devitrification.

Owner:LOXLEY TED A +2

Dew resistant coatings

The present invention relates to dew resistant coatings and articles having the dew resistant coating adhered thereto. The dew resistant coatings comprise elongate silica particles. These coating are useful on articles or surfaces used in outdoor applications and articles and surfaces used in moist indoor environments.

Owner:AVERY DENNISON CORP

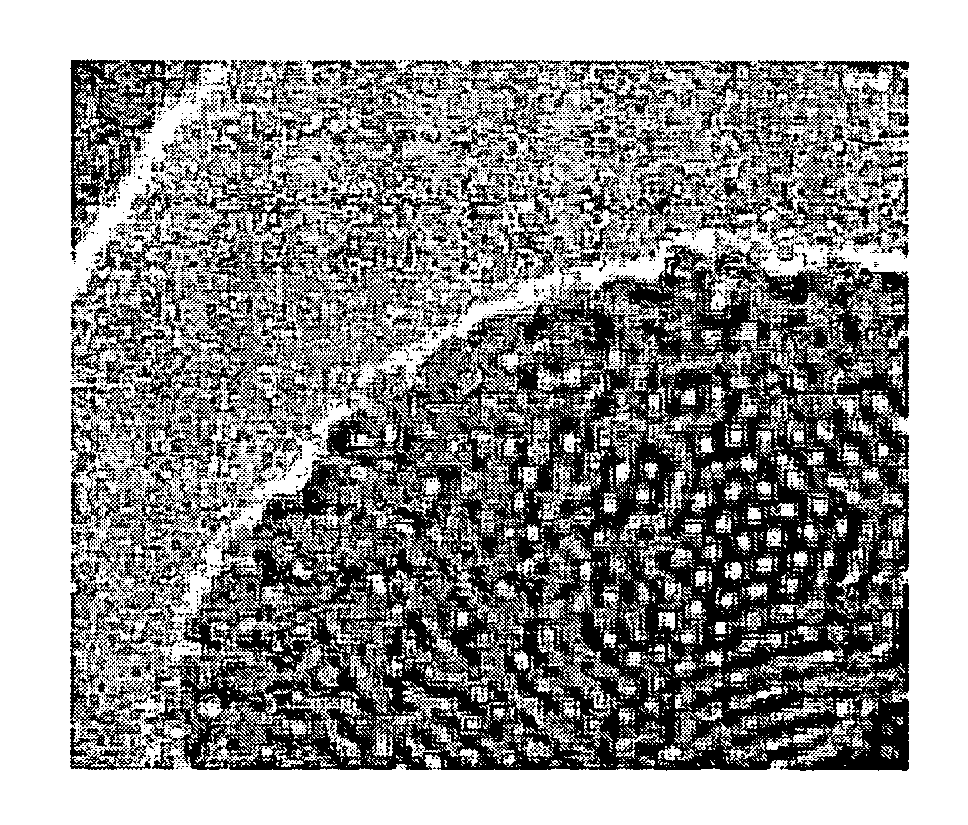

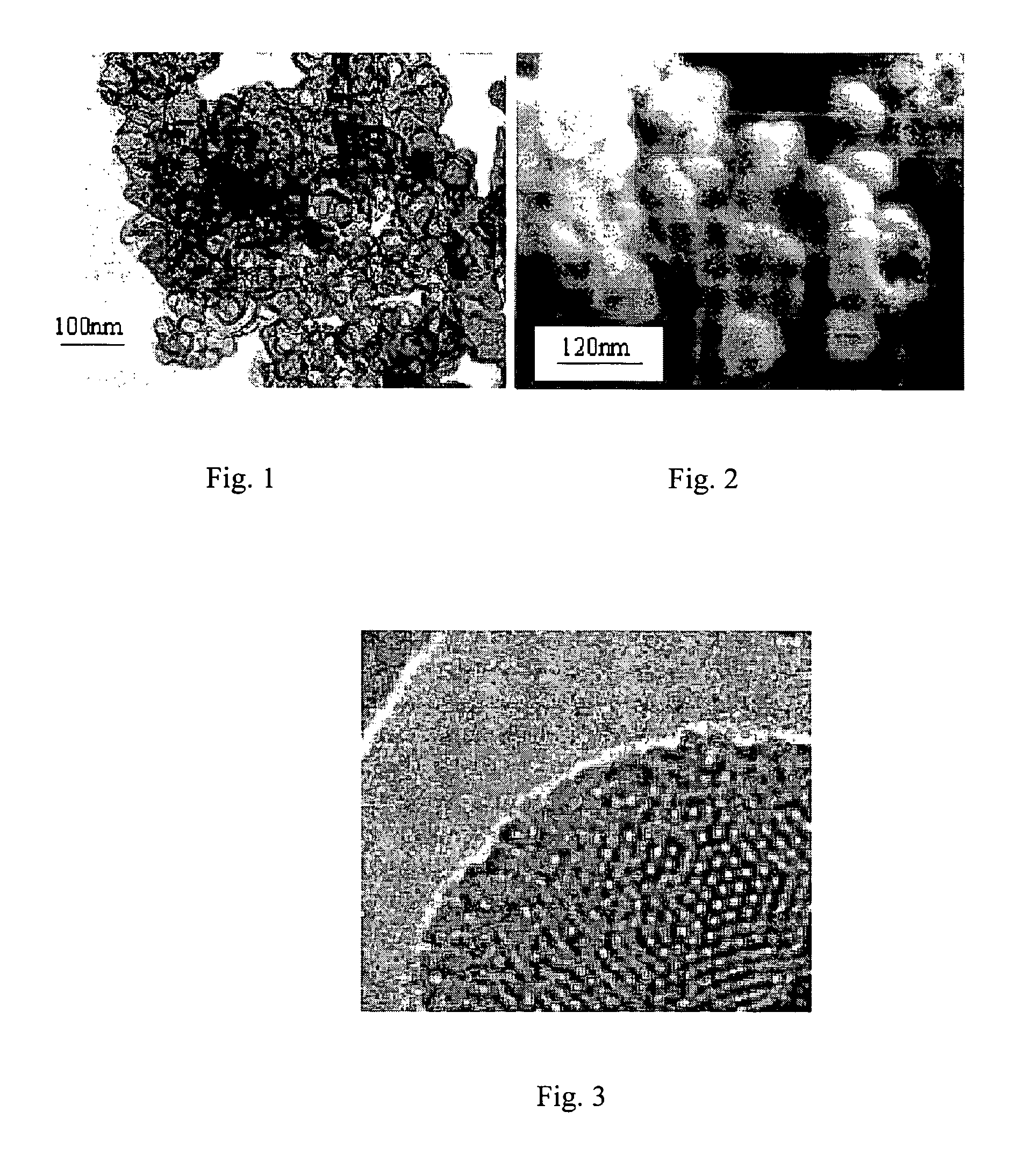

Hollow-structured mesoporous silica material and preparation process

A hollow-structured mesoporous silica material composed of hollow silica particles that have a shell having radial-arrayed channels, and a process for its preparation. The thin-shell type of mesoporous materials with different morphologies are prepared by growing and synthesizing mesoporous silica on the surface of calcium carbonate nanoparticles with different shapes as inorganic templates, and then removing the inorganic templates. The hollow-structure mesoporous silica material can be used in many fields such as the preparation of catalyst, pesticide and optical fiber.

Owner:BEIJING UNIV OF CHEM TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com