Method for preparing epoxy resin super-hydrophobic coat

A technology of super-hydrophobic coating and epoxy resin, applied in the direction of epoxy resin coating, coating, liquid spraying equipment, etc., can solve the problems of poor applicability, high production cost of super-hydrophobic surface, complicated preparation process, etc., and achieve low cost , easy to obtain raw materials, good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Preparation of coating sol:

[0044] Dissolve 0.35g of nano-sized silica balls and 0.21g of micron-sized silica particles in 25ml of absolute ethanol, add silane coupling agent KH-5500.18g, stir and react at room temperature for a period of time, then add epoxy resin coating 6.2 g and octadecyltrichlorosilane 0.21g, continue stirring reaction, make coating sol; Epoxy resin selects epoxy resin water-based paint for use;

[0045] (2) Coating film on the surface of the base material:

[0046] Immerse the glass sheet in the sol prepared in step (1), slowly and uniformly extract it from the sol with a pulling machine, the pulling speed is 50 mm / s, and leave it standing at room temperature after being proposed;

[0047] (3) Heating and curing process:

[0048] Put the base material of the coating film in step (2) into an oven, heat it up to 180°C to cure and crosslink the epoxy resin, and take it out to obtain a superhydrophobic epoxy resin coating.

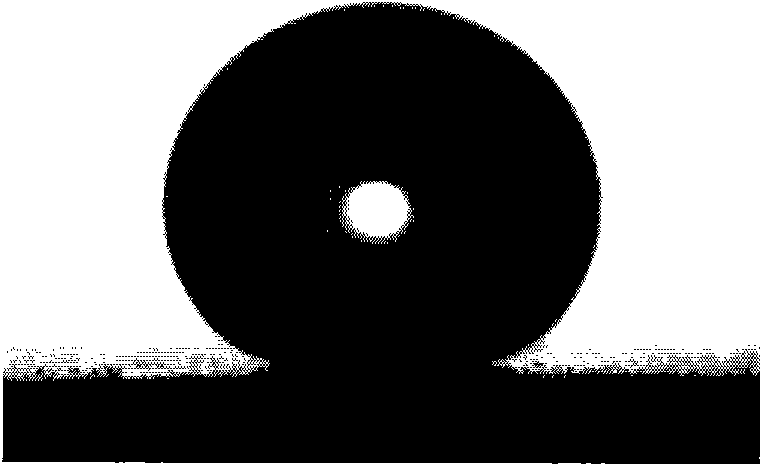

[0049] as attache...

Embodiment 2

[0051] (1) Preparation of coating sol:

[0052]Dissolve 0.85g of nano-sized silica balls and 0.53g of micron-sized silica particles in 25ml of absolute ethanol, add 0.19g of silane coupling agent KH-5500, stir and react at room temperature for a period of time, and then add 6.2g of epoxy resin coating With octadecyl trichlorosilane 0.21g, continue stirring reaction, make coating sol; Epoxy resin is selected epoxy resin water-based paint;

[0053] (2) Coating film on the surface of the base material:

[0054] Immerse the glass sheet in the sol prepared in step (1), slowly and uniformly extract it from the sol with a pulling machine, the pulling speed is 5 mm / s, and leave it standing at room temperature after being proposed;

[0055] (3) Heating and curing process:

[0056] Put the base material of the coating film in step (2) into an oven, heat at 180°C to cure and crosslink the epoxy resin, and take it out to obtain the superhydrophobic epoxy resin coating.

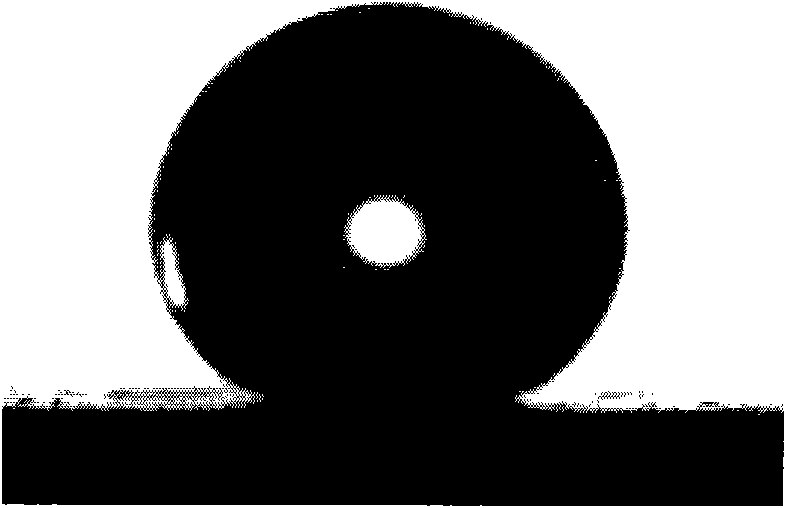

[0057] as atta...

Embodiment 3

[0059] (1) Preparation of coating sol:

[0060] Dissolve 0.31g of nano-sized silica balls and 0.33g of micron-sized silica particles in 25ml of absolute ethanol, add silane coupling agent KH-5500.44g, stir and react at 60°C for a period of time, then add epoxy resin coating 6.1 g and octadecyl trichlorosilane 0.20g, continue stirring reaction, make coating sol; Epoxy resin chooses waterborne epoxy resin coating;

[0061] (2) Coating film on the surface of the base material:

[0062] Immerse the glass sheet in the sol prepared in step (1), slowly and uniformly extract it from the sol with a pulling machine, the pulling speed is 50 mm / s, and leave it standing at room temperature after being proposed;

[0063] (3) Heating and curing process:

[0064] Put the base material of the coating film in step (2) into an oven, heat at a temperature of 200°C to cure and crosslink the epoxy resin, and take it out to obtain an epoxy resin superhydrophobic coating.

[0065] as attached im...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water contact angle | aaaaa | aaaaa |

| Roll angle | aaaaa | aaaaa |

| Water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com