Patents

Literature

26317results about How to "Raw materials are easy to get" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

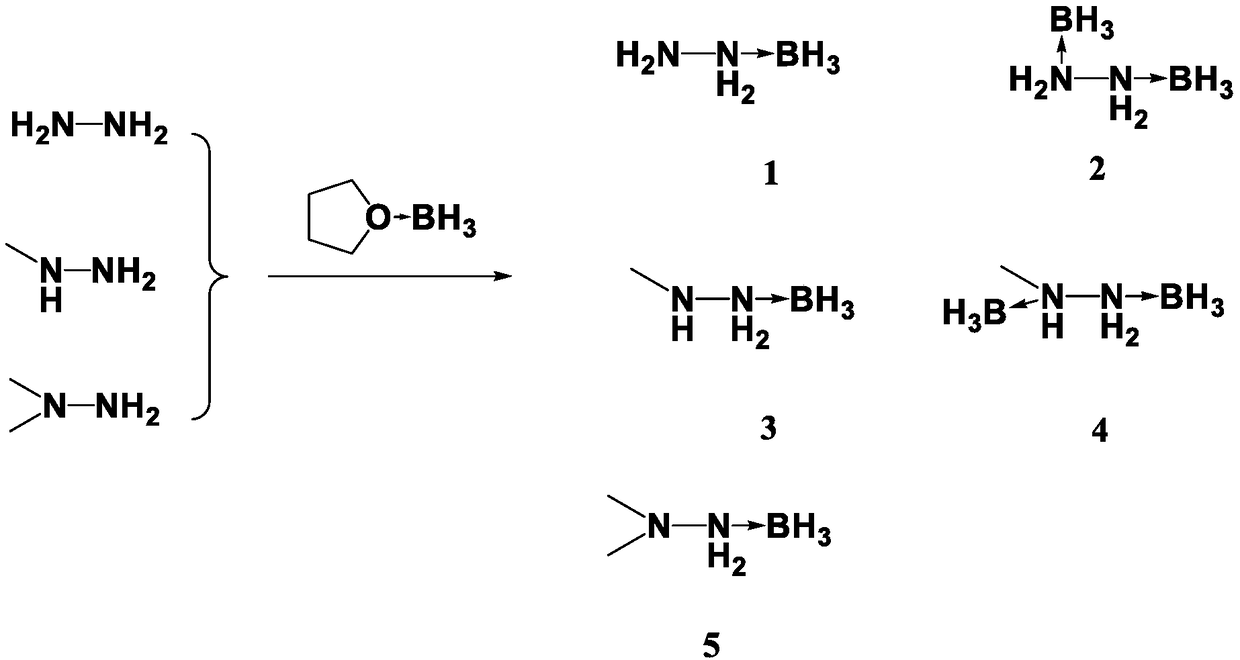

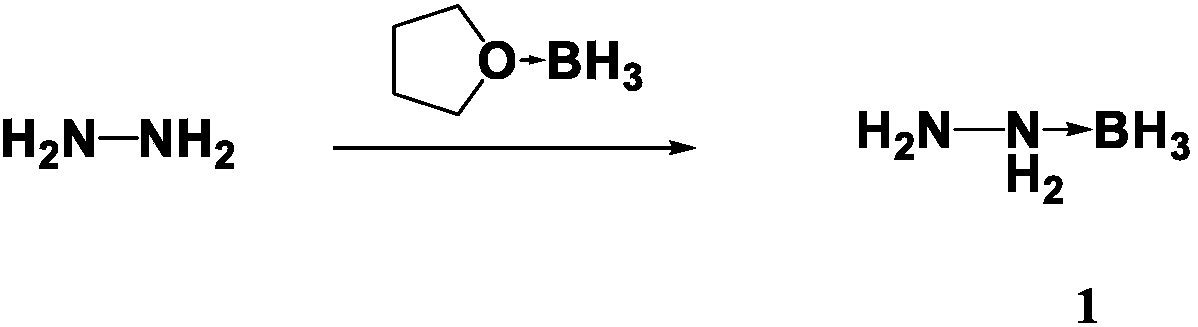

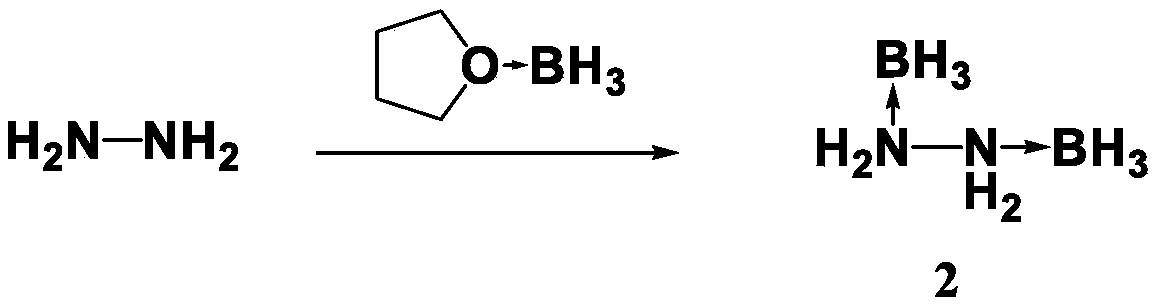

Preparation method for propellant fuel

InactiveCN108910843AShorter ignition delay timeHazard reductionOrganic chemistryHydrazineEvaporationIgnition delay

The invention discloses a preparation method for propellant fuel. The preparation method comprises the following steps: uniformly mixing hydrazine or a methyl derivative thereof with a tetrahydrofuransolution of borane to perform a reaction, and after the reaction, performing rotary evaporation on the tetrahydrofuran solution to obtain a first product; adding a first solvent into the first product, then performing washing, and then performing rotary evaporation to remove the first solvent, so as to obtain a hydrazinoborane derivative. According to the method, hydroboration is carried out on ahighly-volatile hydrazine fuel and a methylated derivative of hydrazine, the obtained borohydride of the hydrazine is a colorless non-volatile liquid or a white solid, has no volatility and greatly reduces hazard of the hydrazine fuel, and is a novel aerospace propellant fuel since the ignition delay time of the hydrazine borofluoride is extremely short.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Process for supercritical preparation of biologic diesel oil

InactiveCN1594504AReduce pollutionRaw materials are easy to getBiofuelsLiquid hydrocarbon mixture productionBiodieselPhase splitting

The invention discloses a process for supercritical preparation of biologic diesel oil by using animal or plant oil, waste edible oil, oiling crop seeds as raw material through the steps of filtering, dewatering, esterification, ester interchange, filtering, steaming methanol and phase-splitting.

Owner:WUHAN CHEM COLLEGE

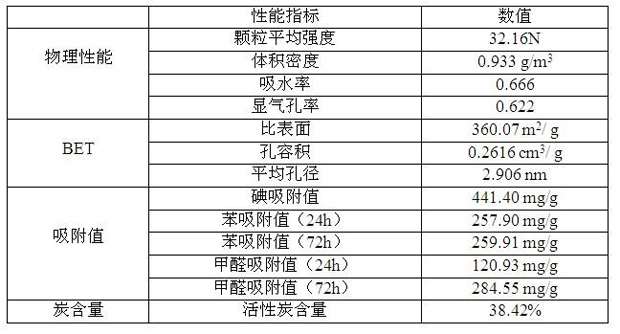

Activated alumina and activated carbon compounded material and preparation method thereof

InactiveCN101890336AAchieve the perfect combinationEasy to useCatalyst carriersOther chemical processesActivated carbonAir purification

The invention provides an activated alumina and activated carbon compounded material and a preparation method thereof. According to a formula, the material comprises the following raw materials in percentage by mass: 40 to 99 percent of aluminum hydroxide, 1 to 60 percent of activated carbon, and 15 to 35 percent of binder. The material is prepared by uniformly mixing, pelleting, ageing, molding, airing, sintering, rinsing, drying and the like. The invention aims to compound the activated carbon with the activated alumina; on the one hand, the material with a certain shape can be processed, the defects of loose shape, low strength, difficult recovery and the like of the activated carbon are overcome, and the material is easy to recycle; and on the other hand, the adsorption property of the activated alumina material is greatly improved. The method has the advantages of simpleness, practicality, readily available raw materials, low cost and suitability for industrial mass production, and can be widely applied to various fields such as industry, agriculture, environmental protection, air purification, water treatment and the like.

Owner:FUZHOU UNIV

Method for producing biological diesel oil by using high-acidity waste animal and vegetable oil

InactiveCN1412278ASolve pollutionReduce pollutionLiquid hydrocarbon mixture productionBio-feedstockVegetable oilPtru catalyst

The present invention relates to a method for producing biological diesel oil-fatty acid methyl ester by using waste animal and vegetable oil with high acid value. It is characterized by that it adopts acidic catalysis method, under the action of acidic catalyst is makes the waste animal and vegetable oil react with low carbon alcohol, and adopts the following four steps: (1) dewatering; (2) esterification and ester exchange; (3) phase separation; and (4) decolouring so as to produce the invented biological diesel fatty acid methyl ester.

Owner:宋庭礼 +1

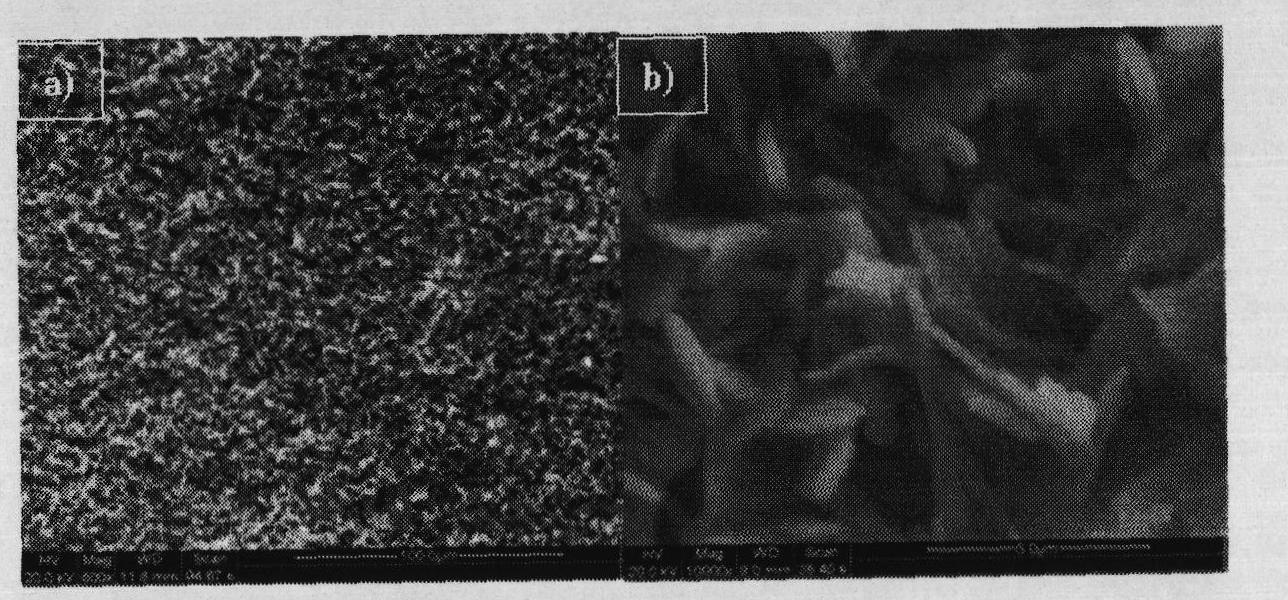

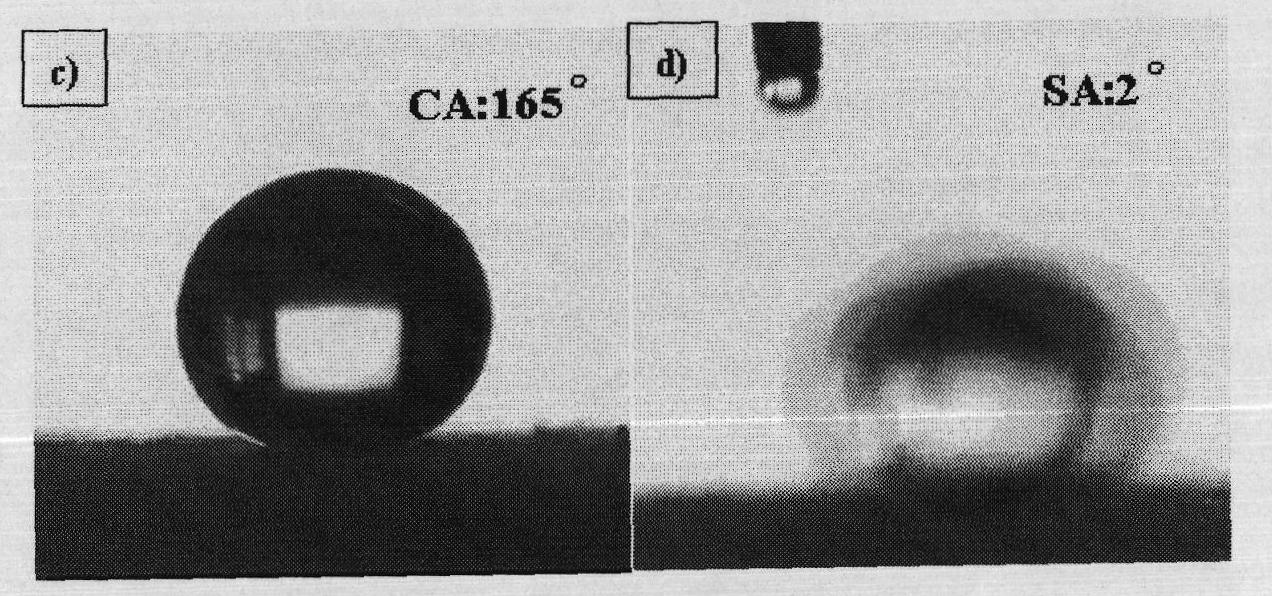

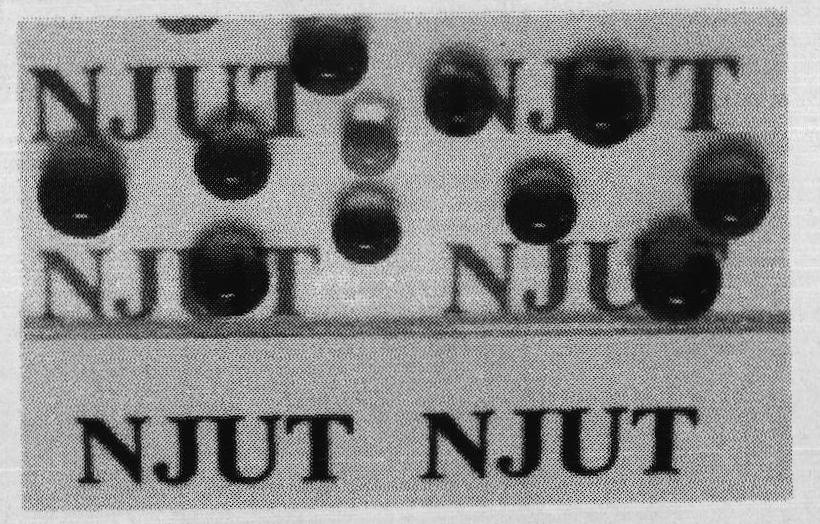

Super-hydrophobic polyurethane/ oxide nano particle hybrid coating material and preparation method thereof

ActiveCN101838496ALow costSimple equipment and preparation processPolyurea/polyurethane coatingsSurface energySelf-assembly

The invention relates to a super-hydrophobic polyurethane / oxide nano particle hybrid coating and a preparation method thereof. The super-hydrophobic coating is prepared by oxide nano particles, silane coupling agent and polyurethane which have wide material source and are easily obtained through a self-assembly method, and has the contact angle of 140-168 degrees and the rolling angle of 1-20 degrees as well as good visible light permeability. The invention solves the problems that the currently prepared transparent super-hydrophobic coating needs extremely low surface energy perfluorinated silane modification, has high production cost and complicated technique, and can not realize large-scale production. The method has simple technique, easily obtained raw material and low cost; and theprepared super-hydrophobic coating can be taken as a dustproof and antifogging protective coating of the surface of solids such as glass and the like, and a waterproof insulating layer used in a micro-electronic device, a sensor and the like.

Owner:JIANGSU FENGMANG COMPOUND MATERIAL SCI&TECH GRP CO LTD

Oil-displacing agent for enhancing crude oil recovery efficiency in tertiary recovery

InactiveCN101665685AOvercome elasticityOvercome structureDrilling compositionSalt resistanceActive agent

The invention relates to an oil-displacing agent for enhancing crude oil recovery efficiency in tertiary recovery and a preparation method thereof, belonging to the technical field of intensified oilproduction in oil fields. The surface active agent used in the invention comprises following components in percentage by weight: 0.01-0.3 percent of water soluble high molecular polymer, 0-20 percentof non-ionic surface active agent, 5-65 percent of anion active agent, 0-5 percent of ampholytic active agent, 0.01-1.5 percent of additive and the balance of water. The oil-displacing agent and the polymer are based on a novel intensified oil displacing system which has complementary structure and good compatibility and is obtained by various associations and the interaction among molecules. Thesystem has the performances of high temperature resistance, salt resistance, higher viscosity, ultralow interfacial tension, and the like, is in accordance with the environmental requirement and can obviously enhance the oil recovery efficiency of oil fields after being used for oil-displacing.

Owner:TIANJIN NORMAL UNIVERSITY

Chemical/ionic/physical compounding cross linking hydrogel and preparation method thereof

The invention relates to chemical / ionic / physical compounding cross linking hydrogel and a preparation method thereof. The hydrogel is polymerized in a way that olefin monomer M1, a chemical cross-linking agent M2, multivalent ion biomacromolecule M3, an ionic cross-linking agent M4 and a physical cross-linking agent M5 are dissolved in water. The method comprises the following steps: preparing chemical / physical cross linked gel prepolymerization liquid, preparing chemical / ionic / physical cross linked gel prepolymerization liquid and preparing and purifying chemical / ionic / physical compounding cross linked gel. According to the invention, the characteristics and properties of the chemical cross-linking agent, the physical cross-linking agent and the ionic cross-linking agents are taken into consideration comprehensively, the compounding cross linking of molecular chains is realized; the prepared hydrogel is optically transparent and has higher mechanical ductility and rebound elasticity; the mechanic, optical and thermal performances and other performances can be regulated conveniently by controlling technology parameters and conditions; and the prepared hydrogel can be used in the fields such as tissue engineering, food industry, agricultural irrigation, daily chemical engineering, oil production, dye adsorption and biological medicine.

Owner:TIANJIN POLYTECHNIC UNIV

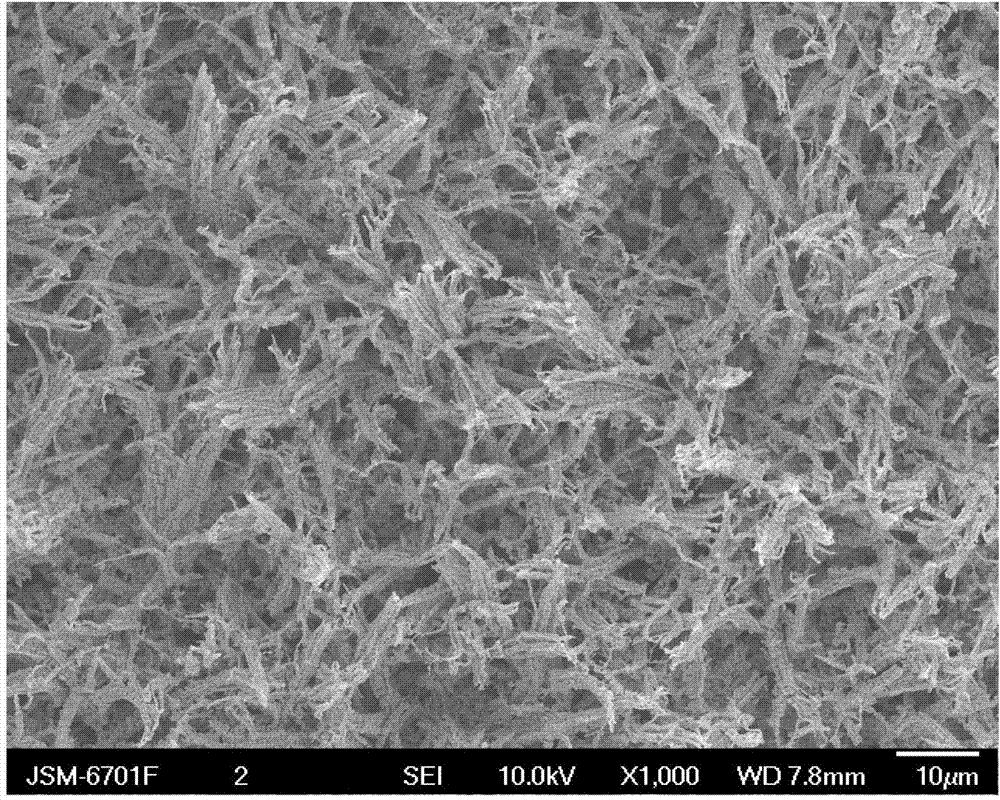

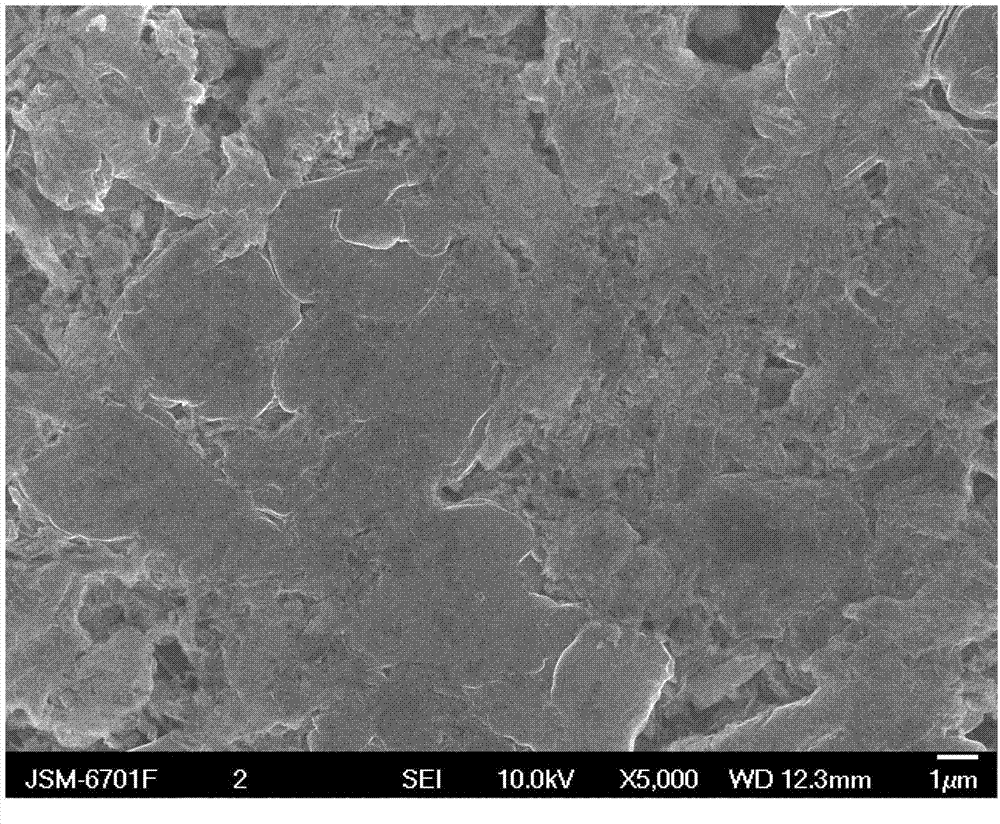

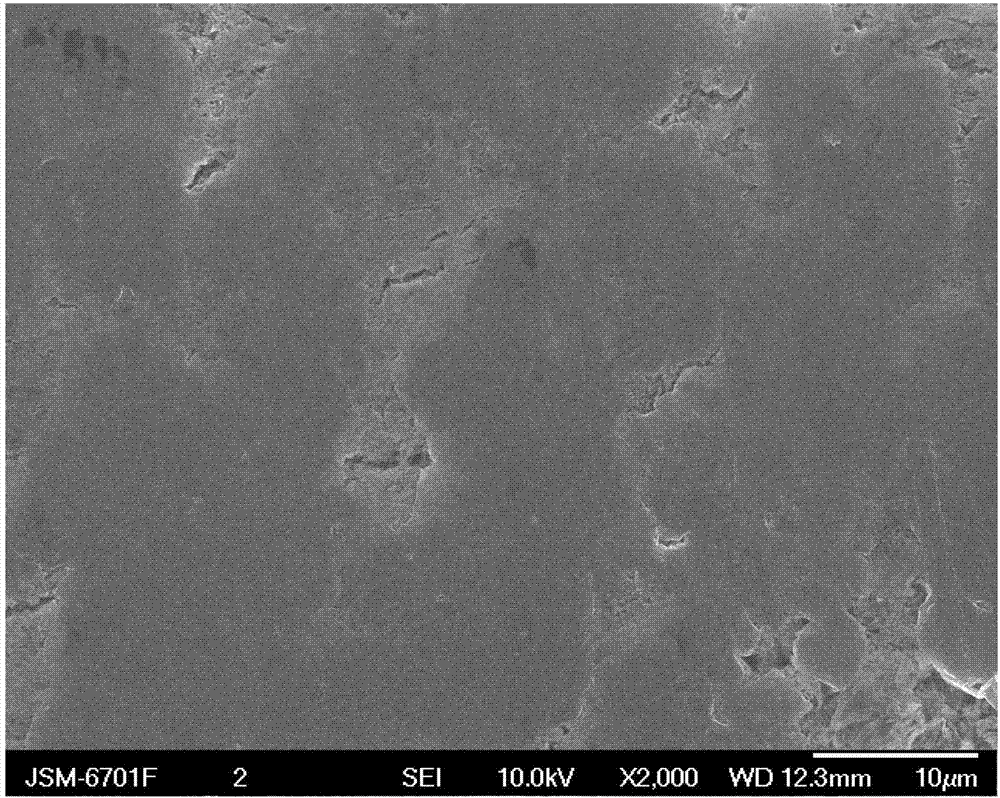

Three-dimensional porous current collector as well as preparation method and use thereof

ActiveCN104716330AFull pore volumeImprove cycle lifeElectrode manufacturing processesElectrode carriers/collectorsCopper foilMetal

The invention discloses a three-dimensional porous current collector which is used as a negative current collector of a metal secondary battery. At least one surface of the three-dimensional porous current collector is provided with a porous structure, sufficient in pore volume and moderate in thickness. Compared with a flat current collector, a metal negative electrode loaded on the three-dimensional porous current collector can be used for effectively restraining the formation of dendritic crystals, so that the safety of the metal negative electrode is improved, the cycle life of the metal negative electrode is long, and the voltage polarization of the metal negative electrode is small. The three-dimensional porous current collector can be prepared from a flat copper foil, and can be prepared through simple steps. The method for preparing the three-dimensional porous current collector is simple, suitable for large-scale production and very high in practicability, and the raw materials are easily available.

Owner:INST OF CHEM CHINESE ACAD OF SCI

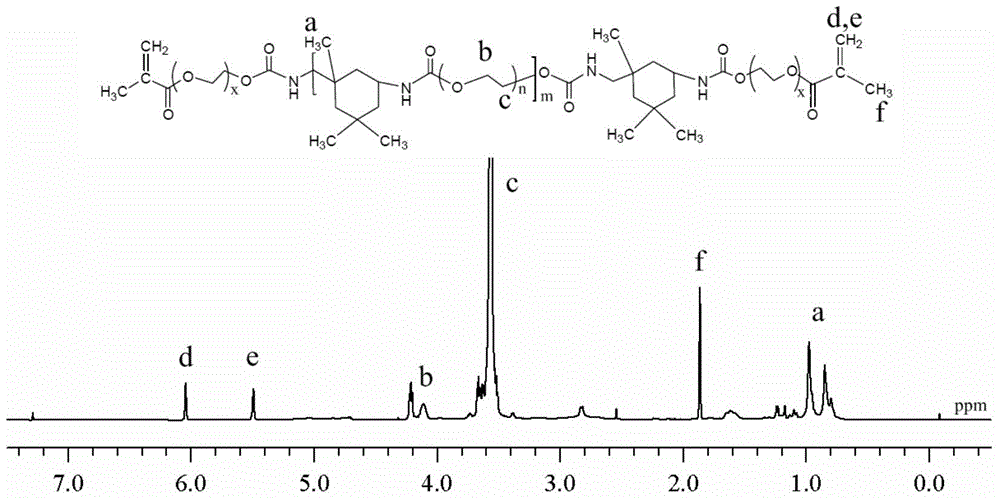

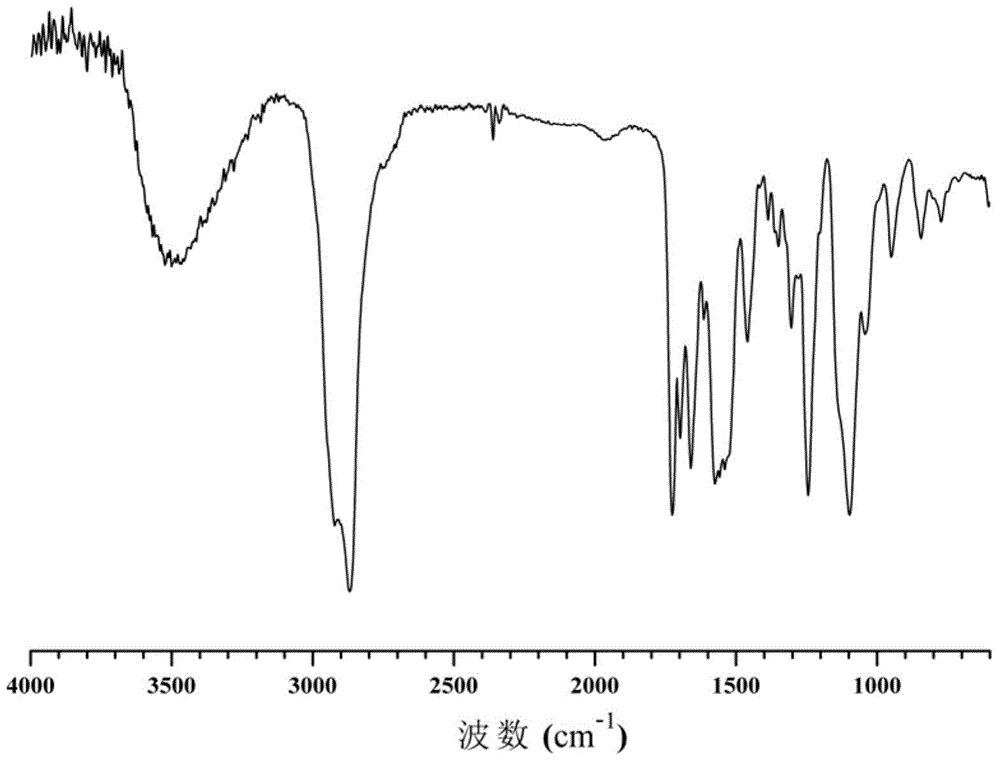

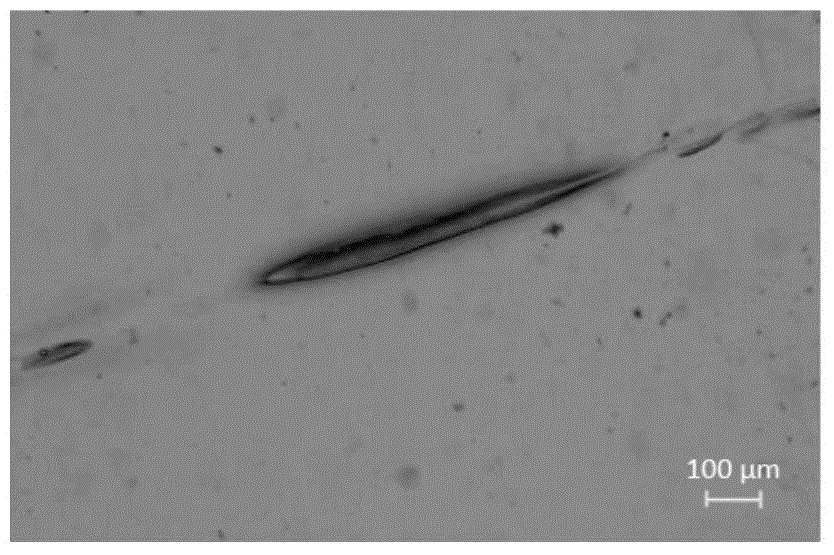

Self-healing polyurethane resin containing disulfide bond and preparation method thereof

The invention relates to self-healing polyurethane resin containing disulfide bond and a preparation method thereof. The polyurethane resin comprises, by weight parts, 10-30 parts of polyether or polyester polyol, 3-20 parts of polyisocyanates, 1-10 parts of chain extender containing the disulfide bond, 0.001-1 part of organic tin or tertiary amine catalyst and 50-80 parts of organic solvent. The method for preparing the self-healing polyurethane resin containing the disulfide bond comprises the steps of weighing raw materials, stirring, heating and performing dehydration for the polyether or polyester polyol under vacuum conditions, lowering the temperature to 85 DEG C or below, adding the polyisocyanates and the organic tin or tertiary amine catalyst, reacting, lowering the temperature to 50 DEG C or below, adding the organic solvent and the chain extender containing the disulfide bond, reacting and performing vacuum defoamation to obtain the self-healing polyurethane resin. The self-healing polyurethane resin heals by itself under the heating or ultraviolet (UV) light conditions, the required conditions are mild, the healing speed is high, the effect is good, the preparation method is simple and easy to control, and raw materials are goods of commercialized production and are cheap and easy to obtain.

Owner:DONGHUA UNIV

Method for preparing environment-friendly type organosilicon modified acrylic ester binding agent

InactiveCN101423735APromote environmental protectionImprove stabilityFibre treatmentEster polymer adhesivesPolymer scienceAdhesive

The invention relates to a method for preparing an environment-friendly silicone-modified acrylate adhesive. Raw materials of the preparation method comprise a basic monomer, a modified monomer and an auxiliary agent, wherein the basic monomer comprises a hard monomer, a soft monomer and a crosslinking monomer; the modified monomer comprises a silane monomer, a coupling agent and inorganic nano-powder; the crosslinking monomer is glycidyl acrylate or glycidyl methacrylate; and the grain diameter of the inorganic nano-powder is less than 80 nanometers. In the preparation method, the crosslinking monomer adopts the glycidyl acrylate or the glycidyl methacrylate so as to be environment-friendly. The product prepared by the method is a nanometer / silicone double-modified molecular composite polymer material. The molecular composite material is combined with the advantages of two polymer materials, namely silicone and polyacrylic ester and an inorganic nanometer material, and has better performance and broad application.

Owner:WUHAN TEXTILE UNIV

Energy-saving temperature-control phase-change material

InactiveCN102827588ARaw materials are easy to getLarge latent heatScarvesHead-scarvesMaterials scienceWater of crystallization

The invention relates to an energy-saving temperature-control phase-change material. The energy-saving temperature-control phase-change material is characterized by comprising compositions in percentage by weight: 50-90% of phase-change host, 1-40% melting point control agent, 0.1-10% nucleating agent, 5-15% of crystal modifier and the balance of water. Crystallized hydrated salt phase-change material has the advantages that raw materials are easily available, the price is low, the energy density is large and the like, and the defects of being supercooling, carrying out phase separating, blocking and the like also seriously hinders the popularization and application. The phase-change host is of crystallized hydrated salt, has fixed melting point, the phase-change temperature is regulated through adding the melting point control agent so as to be capable of completing meeting the requirement of normal application. The phase-change crystal particles are fine through adding the crystal modifier, phase separation can also be prevented, attenuation is slowed down, the stability of the phase-change materials is improved, and the service life of the product is prolonged.

Owner:杨宁

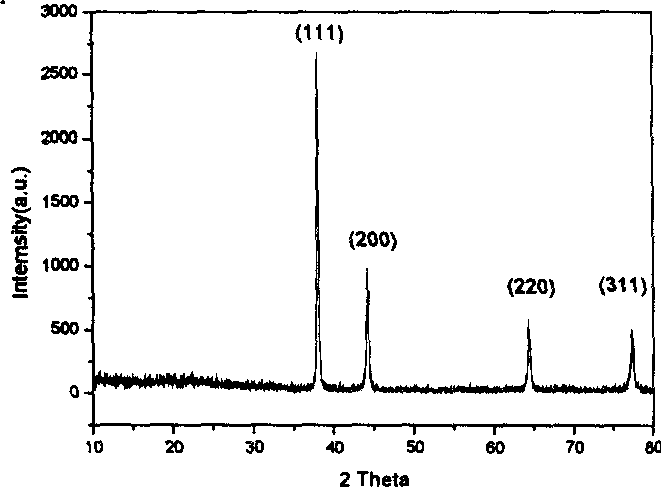

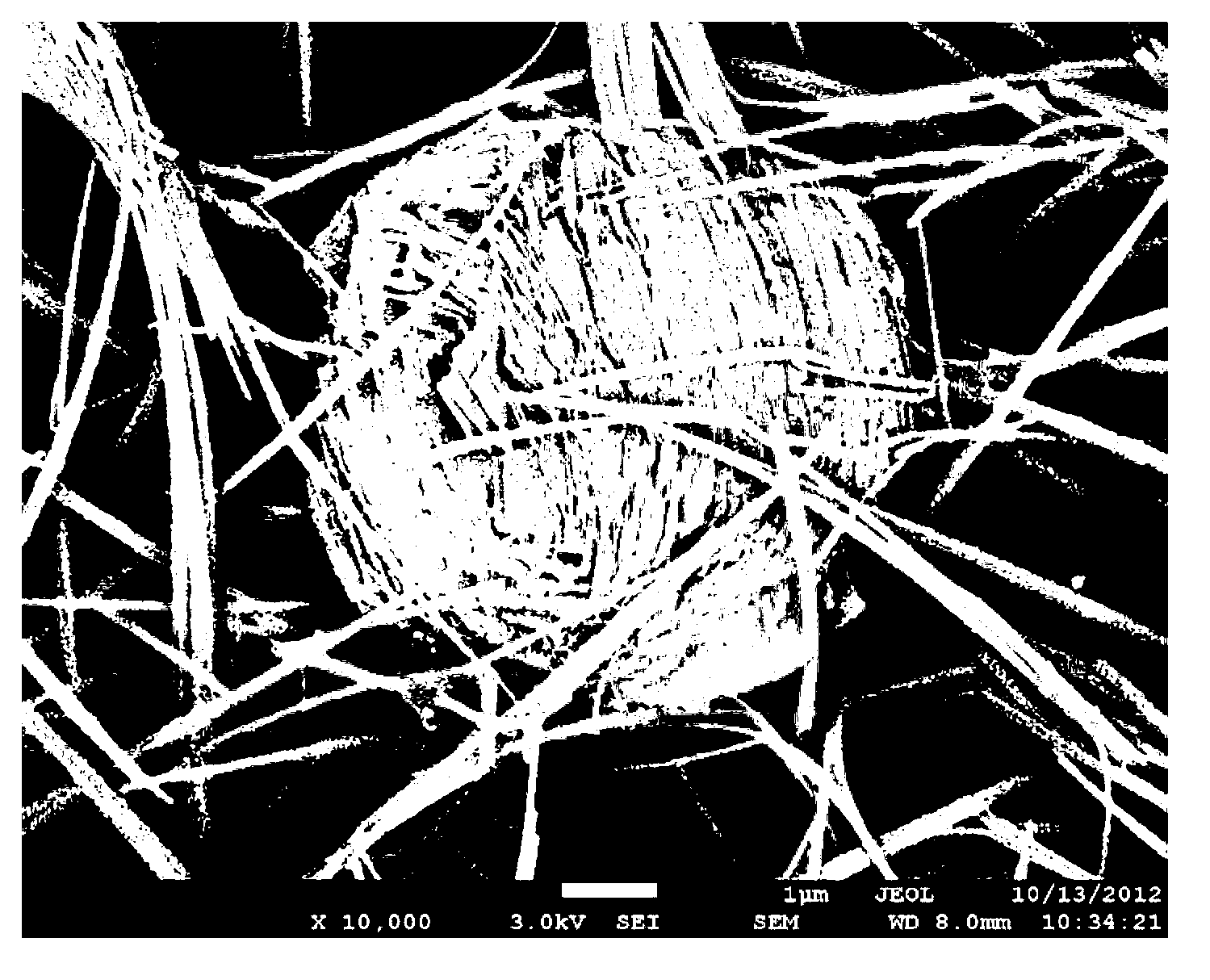

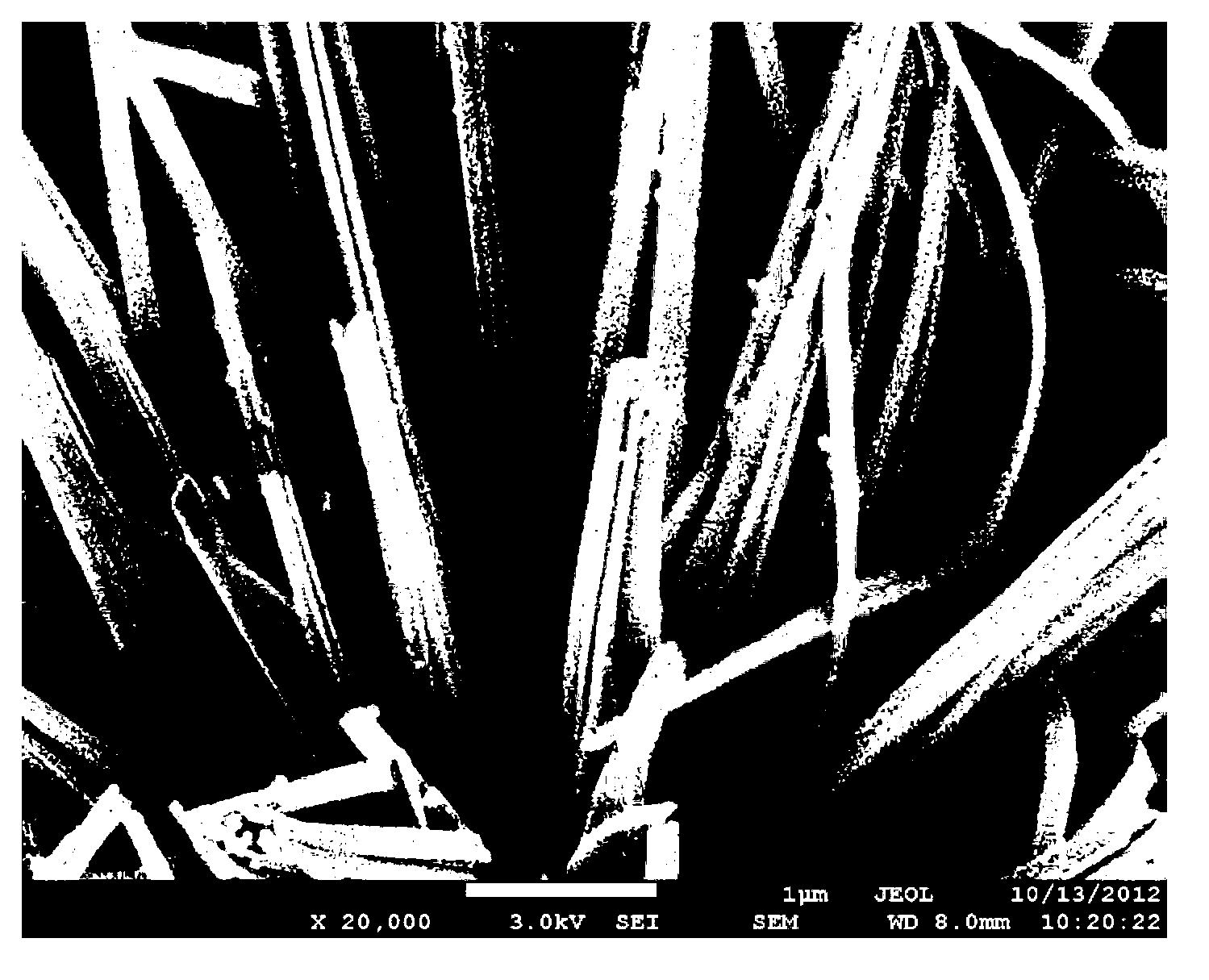

Silver nanometer wire synthesizing process

InactiveCN1740405ARaw materials are easy to getSimple processFrom melt solutionsHigh concentrationPolymer solution

The present invention belongs to the field of nanometer material preparing technology, and provides a two-step silver nanometer wire synthesizing process with high form selectivity and high efficiency. Under the protection of inert gas, very dilute ethylene glycol solution of silver nitrate is first added into ethylene glycol to prepare silver crystal seed; ethylene glycol solution of silver nitrate in relatively high concentration and ethylene glycol polymer solution in the corresponding concentration and volume are then added into the reaction system with crystal seed; and through crystal growth, silver nanometer wire is obtained. By means of regulating reaction condition, the size and form of the silver nanometer wire may be controlled. The present invention has low reaction cost and high silver nanometer wire yield, and the obtained silver nanometer wire has high purity, good structure and high mechanical performance.

Owner:ZHEJIANG UNIV

Temperature-resistant salt-resistant composite foam oil displacement agent for tertiary oil recovery and preparation method thereof

InactiveCN102086389ARaw materials are easy to getReduce manufacturing costDrilling compositionSulfonateActive agent

The invention relates to a temperature-resistant salt-resistant composite foam oil displacement agent for tertiary oil recovery and a preparation method thereof, belonging to the field of chemical oil displacement for increasing the crude oil recovery ratio of the oil field. The oil displacement agent is compounded by 0.5-1% of alpha-alkene sulfonate as a main surfactant and other auxiliary agents and comprises the following components in percentage by mass:0.1-1.5% of anionic surfactant, 0.2-0.8% of zwitterionic surfactant, 2-10% of organic solvent, 5-12% of stabilizing agent and the balance of a salt solution added to be 100%. Compounds related to the oil displacement agent are industrially produced fine chemical products, the raw materials are easy to obtain, the production cost is low, and the preparation is simple; the oil displacement agent has performances of temperature resistance, salt resistance, ultralow interfacial tension and the like; the persistence of the foam is strong, and the half-life period can be more than 120min at 85 DEG C; the oil displacement age has excellent compatibility with other surfactants, and the comprehensive recovery ratio of the crude oil can be increased by about 10-15%.

Owner:SHANGHAI UNIV

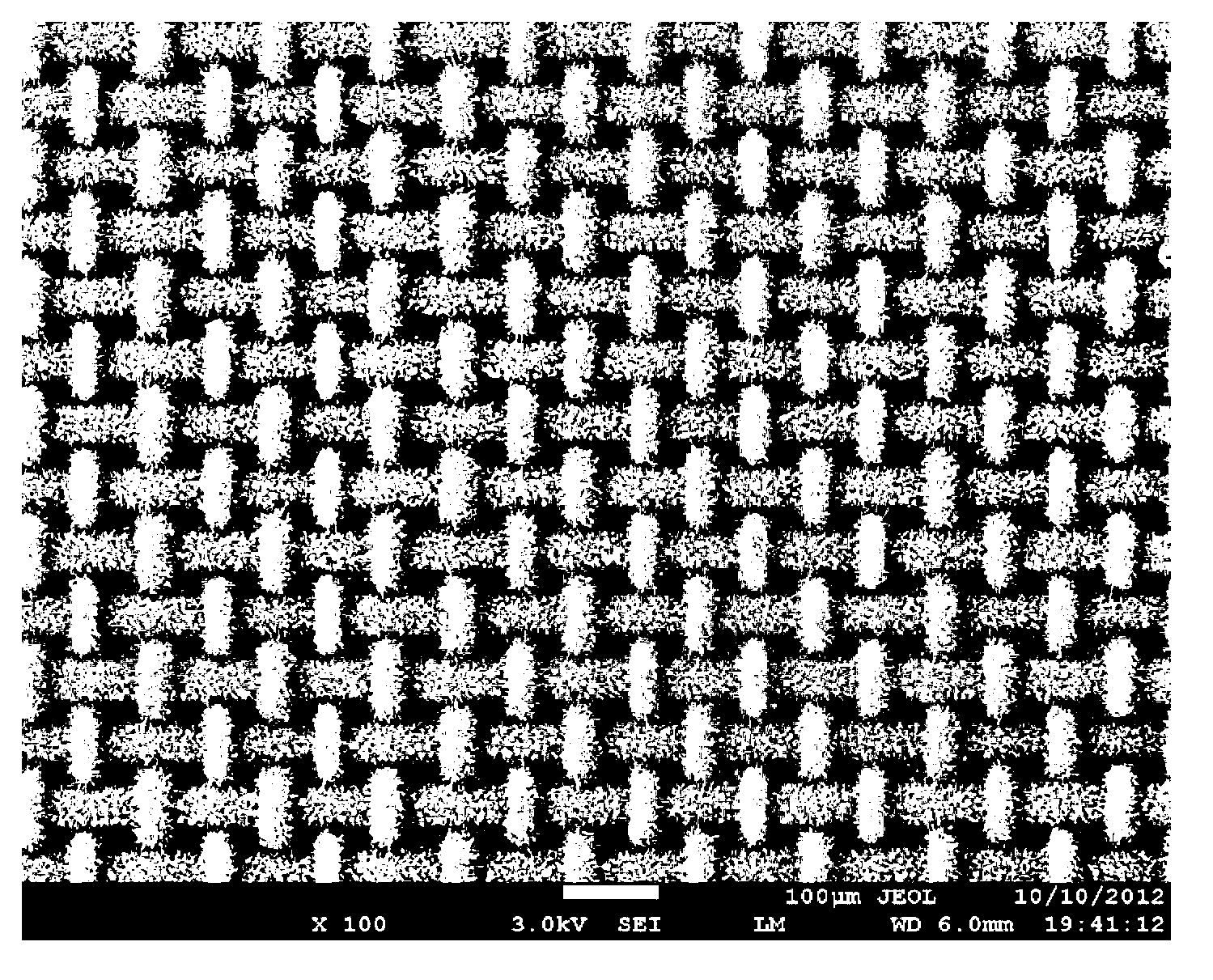

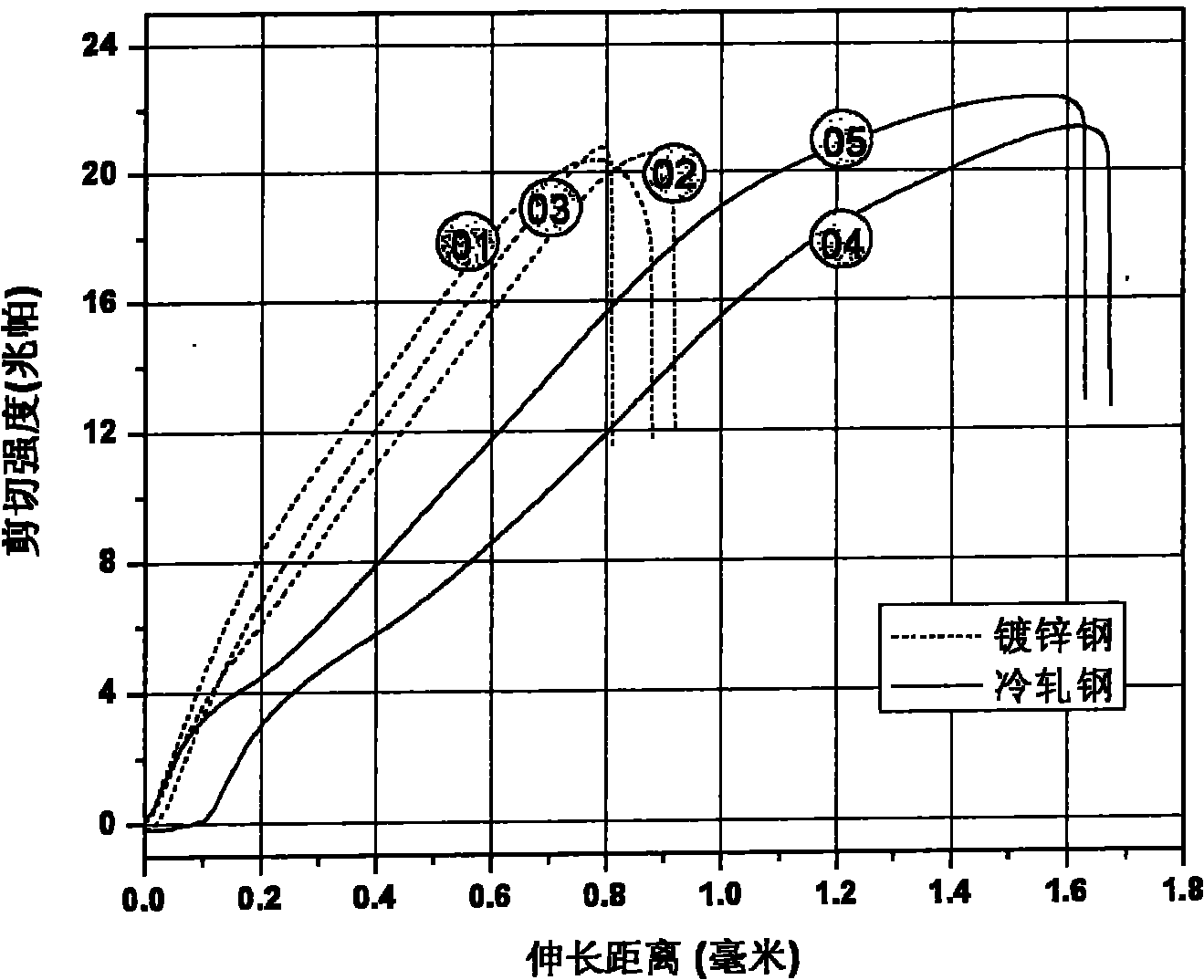

Super-hydrophilic and underwater super-oleophobic oil-water separation mesh membrane having, and its preparation method

The invention discloses a super-hydrophilic and underwater super-oleophobic oil-water separation mesh membrane, and its preparation method. The method comprises the following steps: 1, cleaning a copper mesh, and airing; 2, dissolving an alkaline medium and an oxidant in water, and uniformly stirring to obtain a mixed solution; and 3, dipping the aired copper mesh in the mixed solution, and carrying out an oxidation reaction to obtain the oil-water separation mesh membrane. The oil-water separation mesh membrane has the advantages of easily available raw material, low cost, simple equipment and making technology, realization of large-scale preparation, large water flux, fast water-water separation speed, good oil-water separation effect, suitableness for the treatment of sewage containing a large amount of water, very good separation effect on n-hexane, petroleum ether, dichloroethane, benzene, gasoline, diesel oil, kerosene, machine oil, crude oil, animal and plant oil, and the like, easy cleaning, repeatable use, and good stability.

Owner:TSINGHUA UNIV

Room-temperature curing epoxy structural adhesive composition and preparation method thereof

InactiveCN101818037AIncreased shear strengthHigh T-peel strengthEpoxy resin adhesivesNitrile rubberAdhesive

The invention relates to a room-temperature curing epoxy structural adhesive composition, which comprises a component A and a component B, wherein the component A comprises bisphenol A epoxy resin, toughness modified bisphenol A epoxy resin, silane coupling agent, thixotropic agent and colorant; and the component B comprises polyamide, polyether amine, a filler and a curing accelerator; the toughness modified bisphenol A epoxy resin is liquid nitrile rubber-modified bisphenol A epoxy resin and / or polymer-toughened bisphenol A epoxy resin with a nuclear shell structure; meanwhile, the invention also provides a method for preparing the room-temperature curing epoxy structural adhesive compositiion. The structural adhesive of the invention has the advantages of good toughness, strong high-temperature strength, short curing time, simple preparation method, and the like.

Owner:HENKELCHINAINVESTMENT

Elastic polyester fibre and preparation method thereof

InactiveCN101126180AIncrease elasticityConvenient careFilament/thread formingMonocomponent polyesters artificial filamentFiberPolymer science

The invention relates to a springy polyester fiber and the preparing method. The technical problem of the invention to be solved is that the invention provides a springy fiber and the preparing method to make up the disadvantages of the capability of the spandex and the applying arrange. The springy fiber of the invention adopts the method of the compound filature and uses two screw extrusion machines to respectively melt the two components, and the product is obtained through the extrusion of the compound filature component. The invention is characterized in that the components of the springy fiber comprise two of the following high polymers which have heat shrinking capability difference: the high fasculation PETP, the PET, the PBT, the PTT with the weight proportion of 30-70:50.

Owner:ZHEJIANG HENGYI GRP CO LTD

Preparation method of carbon quantum dots with adjustable fluorescence colors

InactiveCN103663412AHigh yieldImprove quantum efficiencyNano-carbonFluorescence/phosphorescenceUltraviolet lightsTumor cells

The present invention relates to a preparation method of carbon quantum dots with adjustable fluorescence colors, and belongs to the technical field of nanometer materials. According to method, citric acid or a citrate is adopted as a carbon source, a nitrogen-containing compound is adopted as a nitridation agent, hydrogen peroxide is adopted as an oxidant, a hydrothermal synthesis method is adopted to obtain an aqueous solution of carbon quantum dots emitting blue or green fluorescence under ultraviolet light excitation, reaction conditions are easily controlled, and the method is suitable for scale production. The prepared carbon quantum dots have advantages of adjustable fluorescence color, high yield, high quantum efficiency, good result reproducibility and the like, wherein the product can be directly used for tumor cell labeling and live cell imaging labeling. According to the present invention, only the one reactant is required, the raw materials are easily-available and non-toxic, the production process does not require special protection, the reaction condition is easily controlled, and the obtained carbon quantum dots have advantages of high yield, high quantum efficiency, good result reproducibility and the like; and the method has characteristics of high yield, simple preparation process, low cost, easy scale production and the like.

Owner:UNIVERSITY OF CHINESE ACADEMY OF SCIENCES

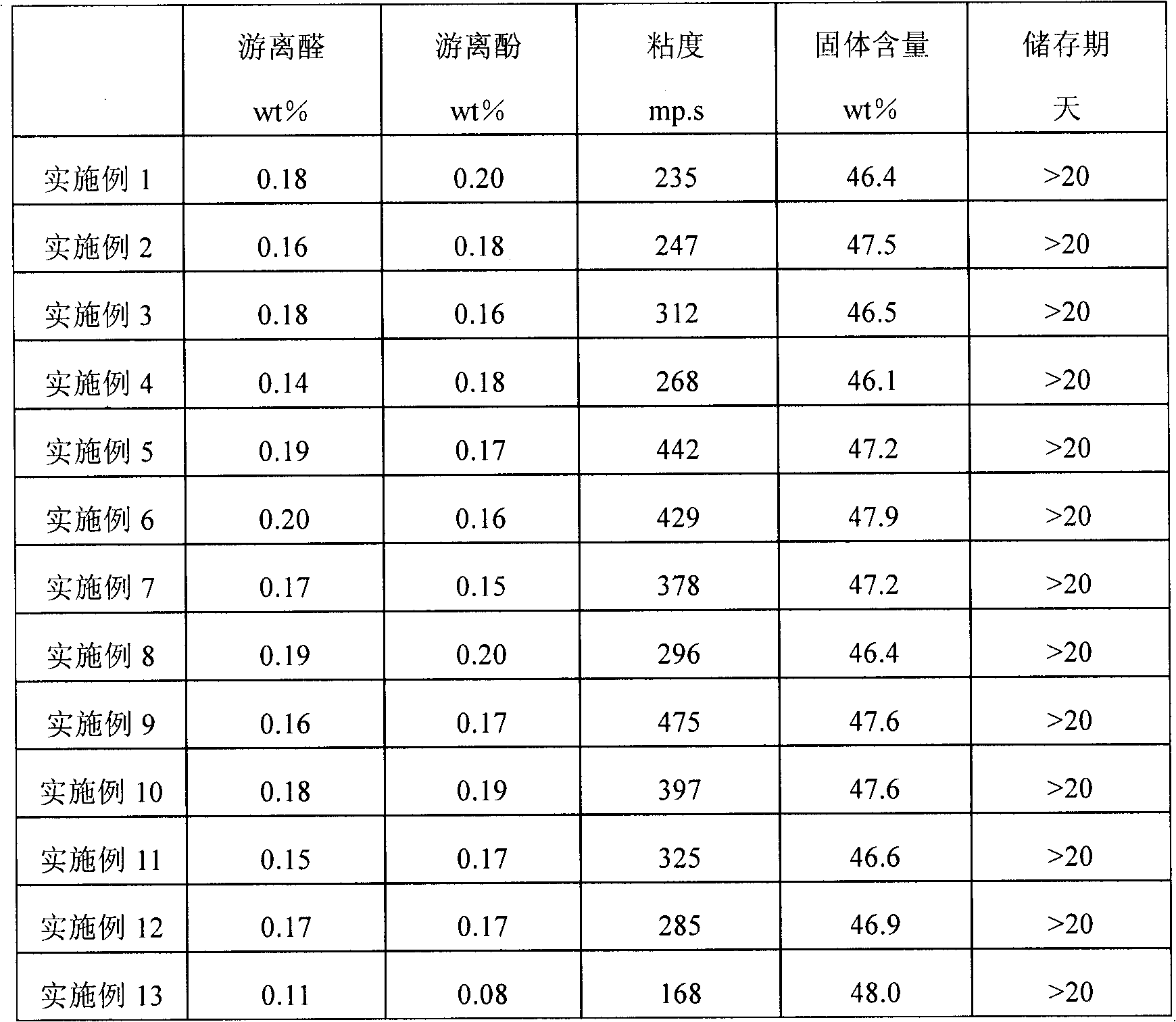

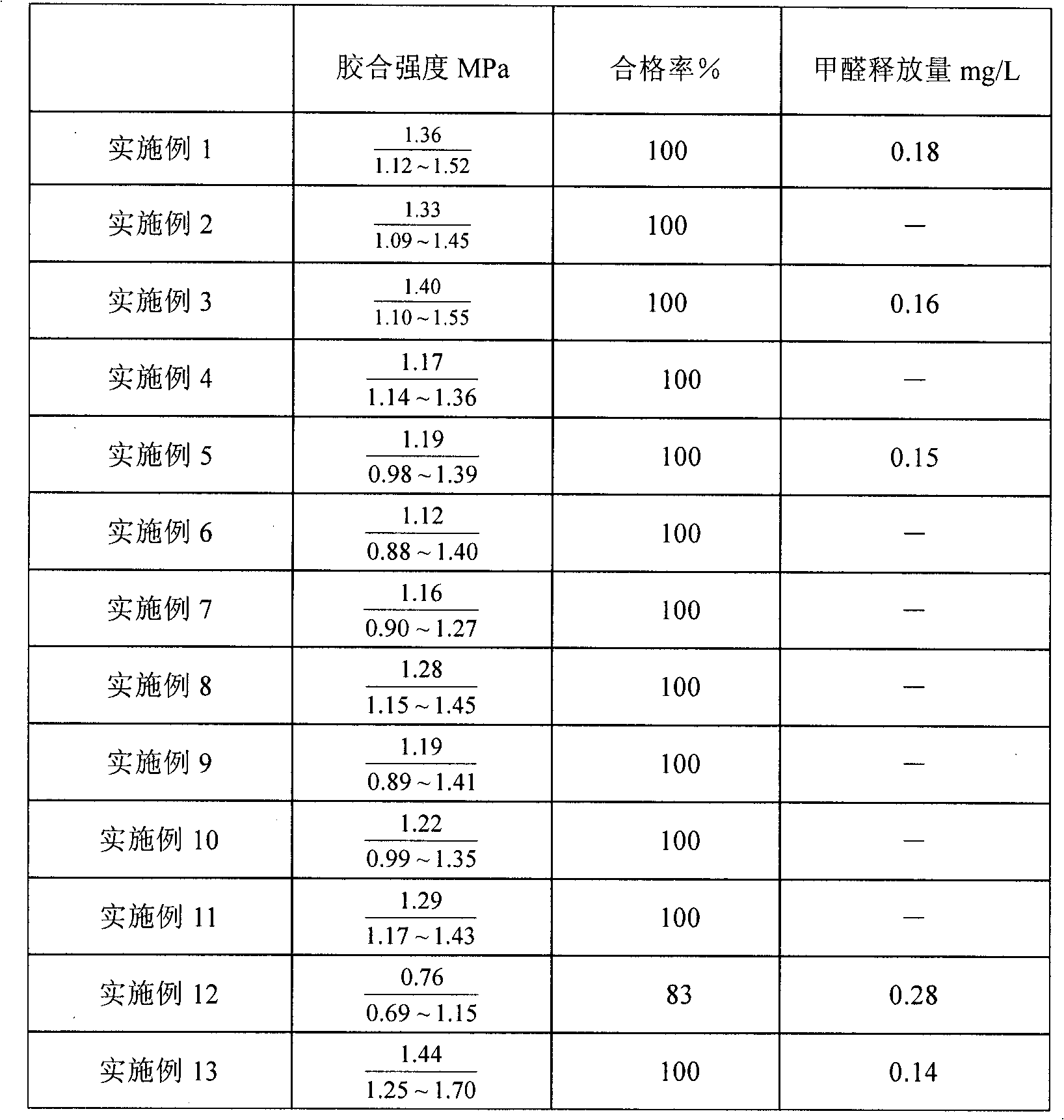

Method for preparing environmentally-friendly adhesive for lignin-based timber

ActiveCN102061141AAdequate responseLow in free phenolsAldehyde/ketone condensation polymer adhesivesAdhesiveTime ratio

The invention discloses a method for preparing an environmentally-friendly adhesive for a lignin-based timber. The method comprises the following steps of: 1) adding phenol, formaldehyde solution, lignin, first alkali liquor and diluting water into a reactor, heating to the temperature of between 75 and 85 DEG C and reacting for 2.5 to 3.5 hours, wherein the molar ratio of formaldehyde to the phenol is 2.20:1-2.40:1; the formaldehyde solution is added for three times in a mass ratio of 1.5 to 1.0 to 1.0; and the reaction time ratio of the added formaldehyde solution is 1.2 to 1.0 to 1.0; 2) cooling to 70 DEG C, adding a formaldehyde collector and second alkali liquor, and reacting at the temperature of between 65 and 70 DEG C for 20 to 50 minutes; and 3) cooling to the temperature of between 30 and 40 DEG C, adding an intensifier, stirring for 10 to 30 minutes, cooling and discharging. In the method, a 50 to 60 percent petroleum-based phenol raw material can be substituted; the methodis stable in reaction, easy to control and easy for industrial production; formaldehyde emission of a plywood reaches E0 level; adhesive strength meets the requirements of national class I plates; and a new approach is provided for the development of an environmentally-friendly biomass-based timber adhesive and recycling of wastes.

Owner:青岛生物能源与过程研究所

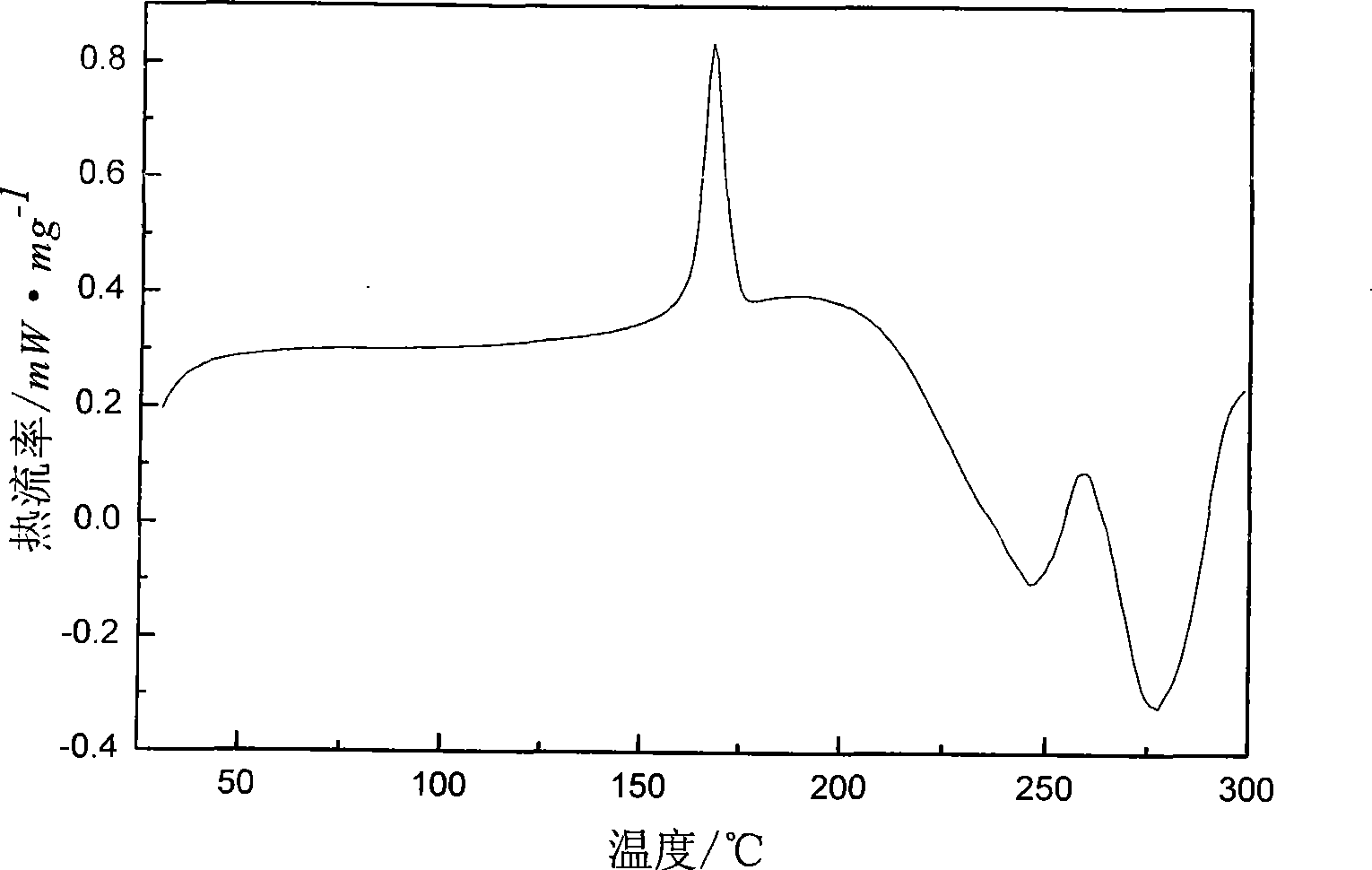

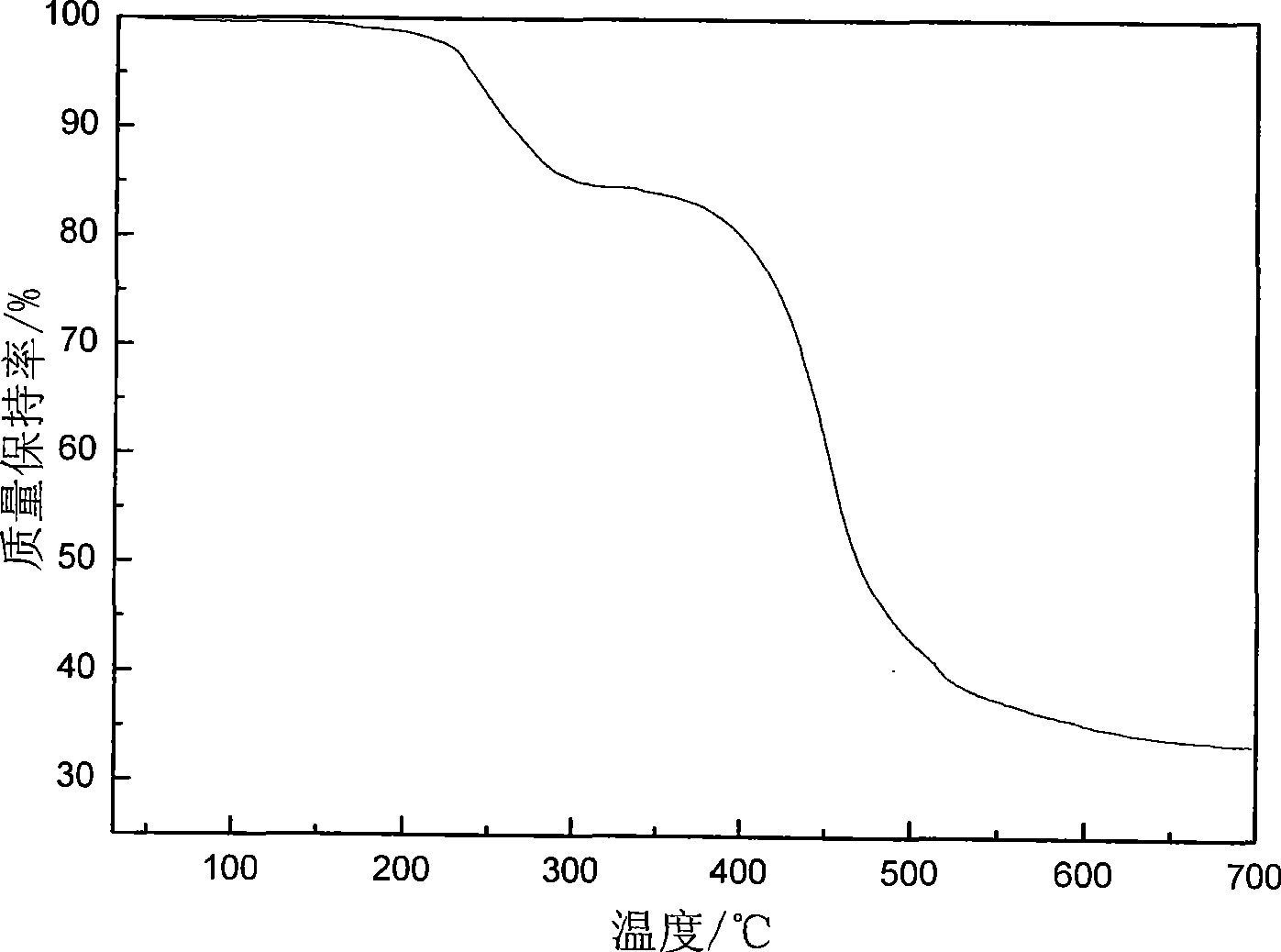

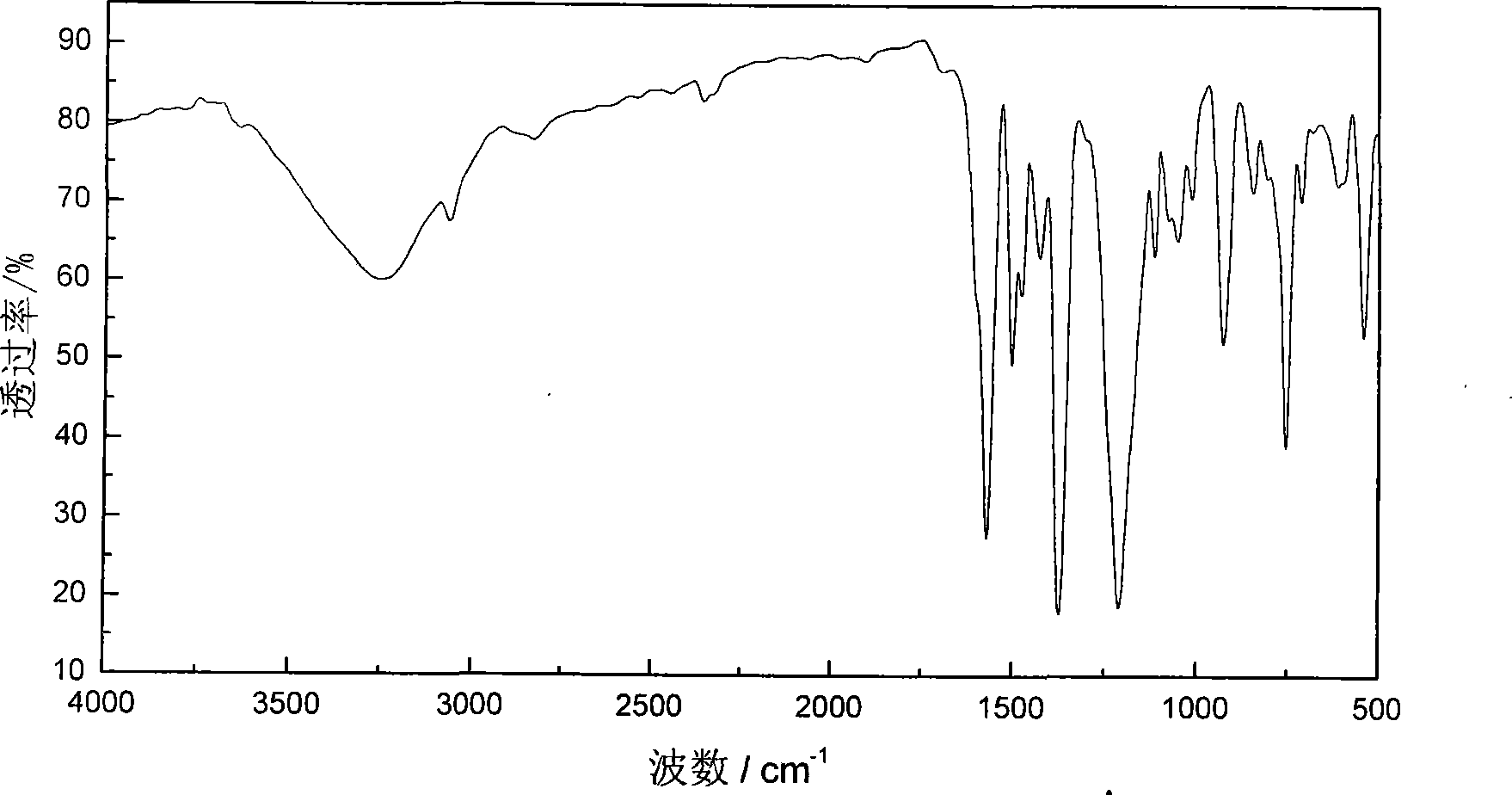

Phosphaphenanthrene flame-retardant compound containing s-triazine structure, and preparation and use thereof

ActiveCN101376665AReduce energy consumptionEasy to operateGroup 5/15 element organic compoundsEpoxyPolymer science

The invention discloses an oxa-phosphaphenanthrene flame retardant compound containing the sym-triazine structure and a preparation method thereof. The method is characterized in that an intermediate is synthesized from 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide(DOPO) and p-hydroxybenzaldehyde as raw material by the solution method, and then reacts with cyanuric chloride in the presence of phase transfer catalyst to obtain a 2,4,6-tri(4-(10-methenyl hydroxy-9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide)phenoxy)-1,3,5-triazine product. The compound is white crystal, and has a melting point of 166 to 169 DEG C, good thermal stability and high flame retardation efficiency, and can be adopted as a reactive flame retardant for the flame retardation of thermosetting resins such as epoxy resin, polyurethane and the like, and also as an additive flame retardant for the flame retardation of engineering plastics such as ABS, nylon and the like.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

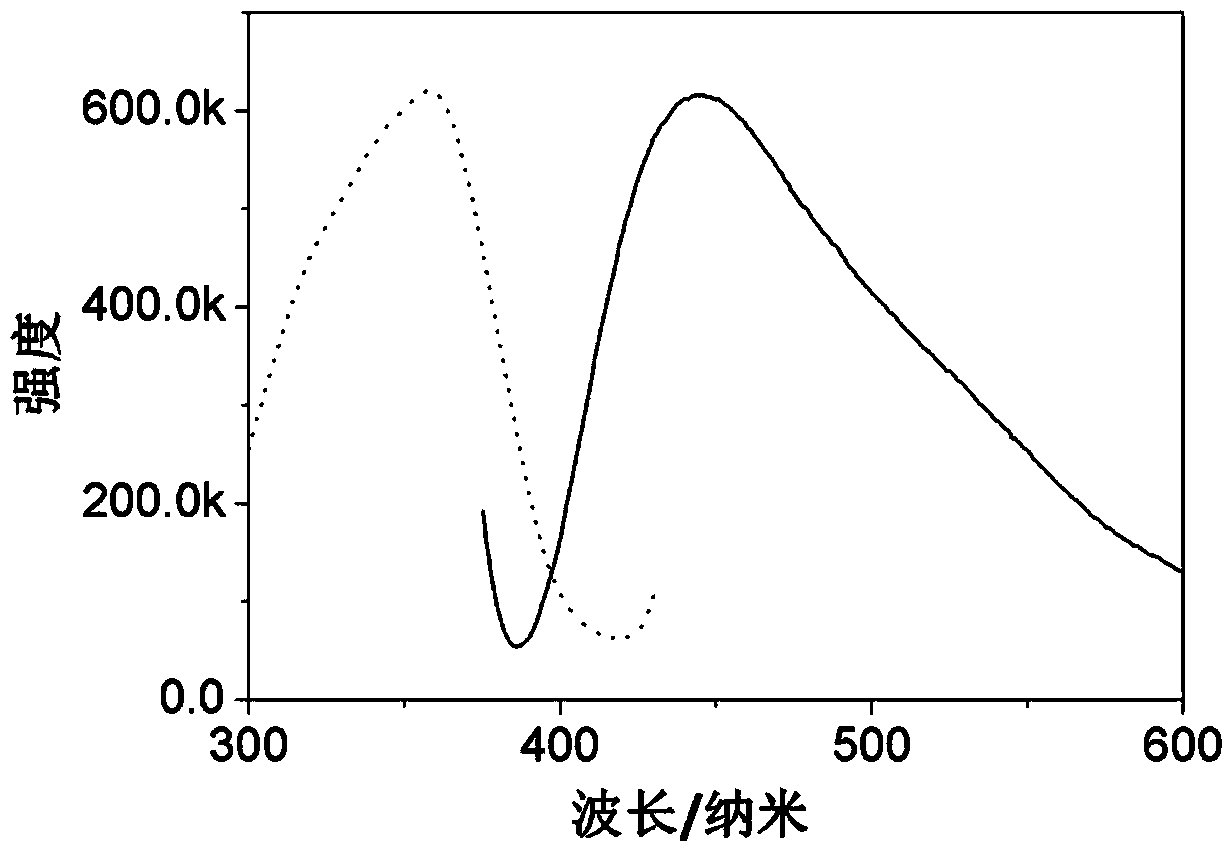

Magnetic fluorescent double functional microballoon with core-shell structure and preparation method thereof

InactiveCN1523076ASimple methodRaw materials are easy to getMicroballoon preparationLuminescent compositionsCitrate sodiumChemistry

The present invention relates to a magnetic fluorescent double-functional microsphere with core-shell structure and its preparation method. Firstly, said invention uses strong acid and sodium citrate to modify surface of inorganic magnetic nano granules, then uses alkyl orthosilicate as precursor body, and adopts gel-sol process to prepare silicon dioxide magnetic microsphere with core-shell structure, finally utilizes the copolycondensation method of alkyl orthosilicate and silane coupling agent of bonded fluorescein to prepare silicon dixide fluorescent microsphere with magnetism. Said microsphere has magnetic response characteristic, and can send out fluorescence under the excitation of UV-light and visible light.

Owner:FUDAN UNIV

Biological degradation liquid film and preparation method

InactiveCN101161718AHigh strengthImprove water resistanceOrganic fertilisersSoil conditioning compositionsCarboxymethyl cellulosePlasticizer

The invention belongs to a biodegradation liquid mulching film and the preparation method thereof. The invention prepares polyvinyl alcohol into an aqueous solution with mass fraction of 5-10 percent; carboxymethyl cellulose is also prepared into an aqueous solution with mass fraction of 5-10 percent; starch with mass fraction of 5-10 percent is added into a reactor having an agitator, a condenser and a thermometer and is gelatinized for 30 minutes under 75-85 DEG C and then becomes transparent and slabby starch paste, the prepared polyvinyl alcohol solution and carboxymethyl cellulose solution are then added into the reactor, and surfactant and plasticizer are also added into the solution. The PH value is set as 2-4, cross-linking agent is then added, and the biodegradation liquid mulching film is obtained after 1-2-hour reaction under 85-90 DEG C. The film can be sprayed to the land surface through spray method after being thinned up.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

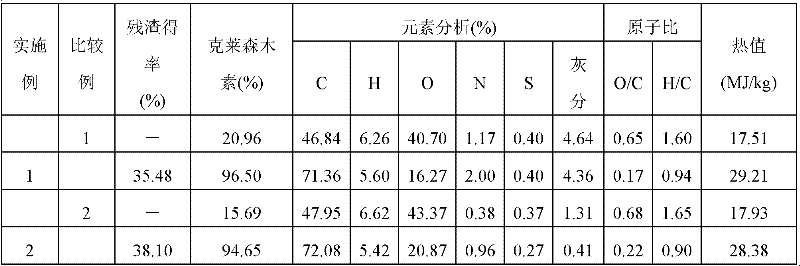

Method for preparing biomass carbon by utilizing agricultural and forestry waste

InactiveCN102583311AImprove protectionRaw materials are easy to getSolid waste disposalCarbon preparation/purificationBiomass carbonSorbent

The invention relates to a method for preparing biomass carbon by utilizing agricultural and forestry waste, belonging to the technical fields of preparation of carbon materials and utilization of biomass resources. The method comprises the following steps of: adopting agricultural and forestry waste as raw materials; under the condition of subcritical water, fully mixing dried biomass materials and deionized water according to the proportion of 1:(10-30); under the protection of inert atmosphere, carbonizing for 2-6 hours at the temperature of 220-250 DEG C; and then carrying out vacuum filtration and hot-water cleaning, and drying to obtain the biomass carbon. The biomass carbon prepared by the invention is coaly carbon material with an aromatic-ring structure, is high in carbon content and calorific value and large in specific surface area, and can be used as a soil conditioner or an absorbent. The method has the advantages that the materials are low in cost and easy to obtain, the process is simple, the operation is convenient, the manufacturing cost is low, the industrial promotion is convenient, and the application range and the application value of biomass resources are further expanded in the aspect of carbon materials.

Owner:BEIJING FORESTRY UNIVERSITY

Method for preparing formaldehyde room temperature oxidation catalyst

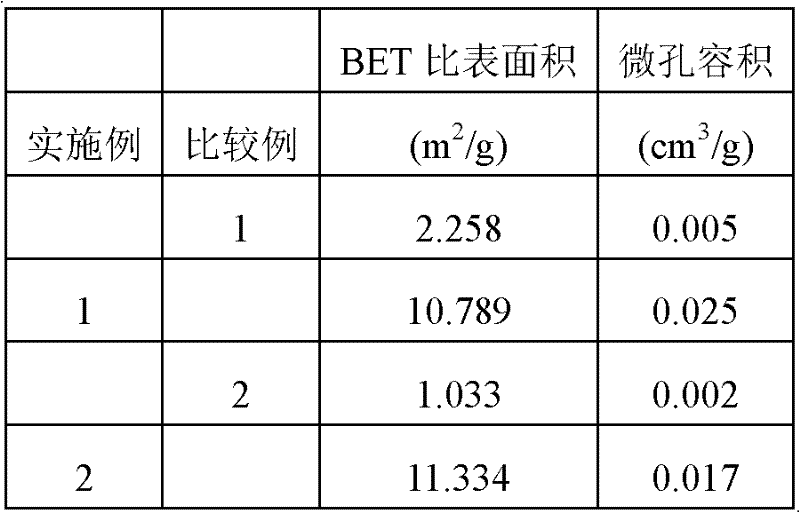

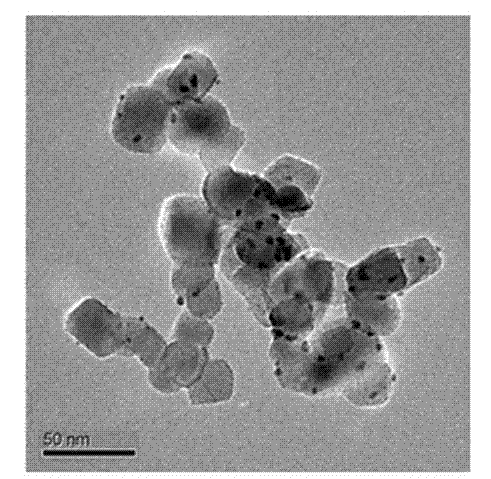

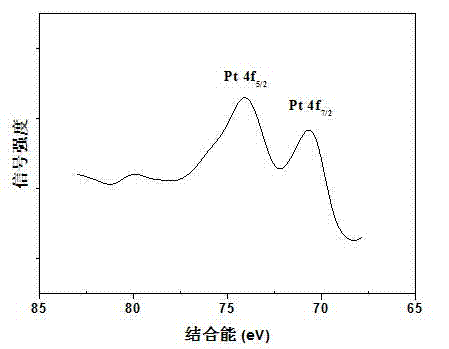

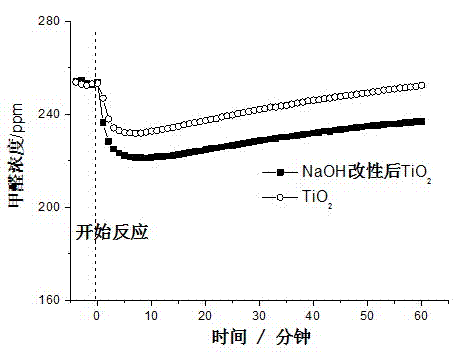

InactiveCN102895969AEasy to operateReduce manufacturing costMolecular sieve catalystsMetal/metal-oxides/metal-hydroxide catalystsPtru catalystInorganic oxide

The invention relates to a method for preparing formaldehyde room temperature oxidation catalyst. The method comprises the following steps: making porous inorganic oxide as a carrier; making sodium borohydride as reducing agent; making soluble hydroxide as additive; and drying the carrier including noble metal processed by carrier impregnation noble metal precursor-room temperature reduction-deposition so as to prepare catalyst. According to the invention, sodium borohydride reducing agent is added for one time at the room temperature, thus, the aperture of generated noble metal nano particle is smaller than that of particle prepared in a high-temperature burning / hydrogen reducing method; crystal particle is within 0.1-5nm; and dispersibility is good; the loading quantity of the noble metal is within 0.05-10wt%, preferably within 0.5-2%; corresponding aperture is within 0.5-3nm; prepared loading-type noble metal catalyst has very high oxidative activity to formaldehyde in air on a room temperature condition without illumination or heat; activity is not changed basically in repeated using procedures; and the method disclosed by the invention is characterized by simple compound line, easily-acquired raw material and is suitable for industrial production.

Owner:WUHAN UNIV OF TECH

Continuous casting slab high-temperature oxidation resistant coatings and preparation process thereof

InactiveCN101693791AGood anti-oxidation effect at high temperatureRaw materials are easy to getCoatingsOxidation resistantSuspending Agents

The invention relates to a preparation process of continuous casting slab high-temperature oxidation resistant coatings, which is characterized in that less than 120 meshes of powder, reductant containing carbon, inorganic binders, surfactants, suspending agents and the like with the compositions such as 25-55 wt% SiO2, 10-20 wt% Al203, 11-23 wt% MgO and the like are respectively grinded and mixed evenly, then water is used to be mixed and stirred sufficiently evenly, and finally the density of the coatings are adjusted within 1200-1500 kg / m3. The coatings can not only be sprayed onto continuous casting slabs at normal temperature, but also be sprayed onto high-temperature casting slabs, form continuous whole protective coating layers under the action of high temperature, effectively reduce temperature drop of the casting slabs and oxidation burning loss in even heating process of a heating furnace without changing original performance of matrixes, and effectively decrease dilution of alloying elements on the surfaces of the casting slabs. After the casting slabs are out of the heating furnace, natural spalling capability of the coating layers is strong, and oxidation matrixes of the casting slabs are smooth. Raw materials of the oxidation resistant coatings are easy to be obtained, and the coatings have low cost and simple preparation process and are adaptable to oxidation resistance for various steels when being heated at 700-1300 DEG C / 2-8 hours.

Owner:UNIV OF SCI & TECH BEIJING

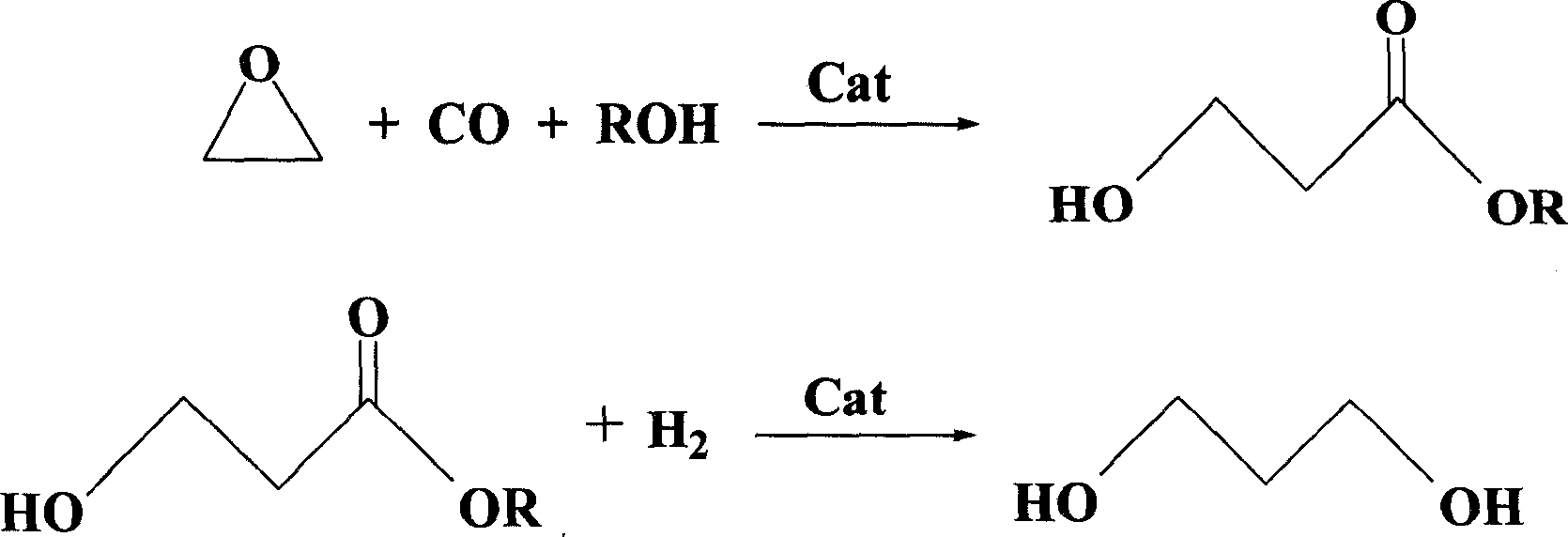

Prepn process of 3-hydroxy propionate and propylene glycol

InactiveCN101020635AHigh activityImprove stabilityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAccelerantCobalt catalyst

The present invention is process of preparing 3-hydroxy propionate and 1, 3-propylene glycol with epoxide as material. The present invention prepares 3-hydroxy propionate with epoxide, CO and alcohol under the action of cobalt catalyst and co-catalyst, and prepares 1, 3-propylene glycol under the action of 3-hydroxy propionate hydrogenating catalyst. The present invention has the advantages of simple reaction apparatus, simple operation, mild reaction condition, high catalyst activity, no environmental pollution, low production cost, etc.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

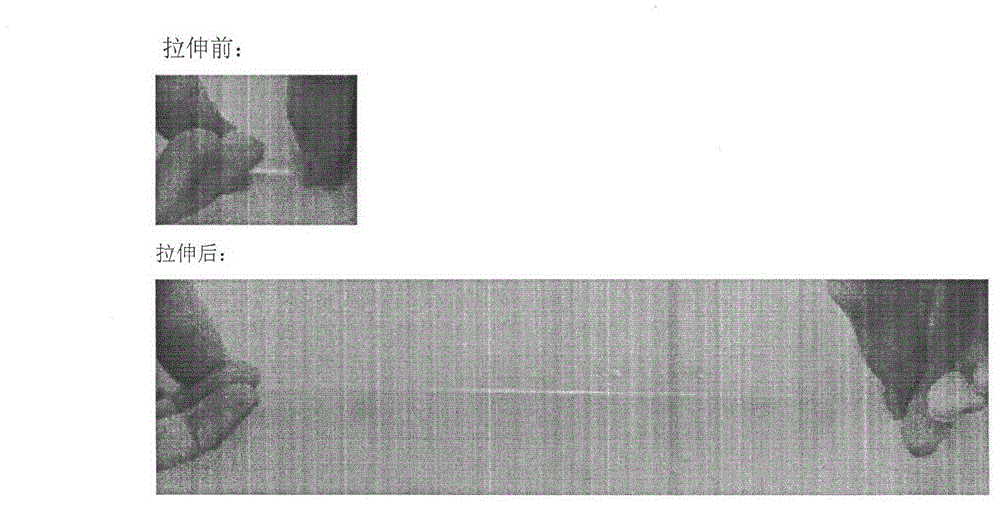

Self-repairing polyurethane hydrogel and preparation method thereof

The invention relates to a self-repairing polyurethane hydrogel and a preparation method thereof. The polyurethane hydrogel comprises the following components in parts by mass: 10-30 parts of polyisocyanate, 30-50 parts of hydrophilic polyester polyol or hydrophilic polyether polyol, 10-50 parts of acrylamide monomer, 0.5-3 parts of chain extender, 3-10 parts of methacrylic acid functional monomer containing an UPy unit, 0.5-2 parts of catalyst and 0.5-3 parts of photoinitiator. The preparation method comprises the following steps of firstly preparing a hydrophilic polyurethane macromonomer terminated with an acrylic acid monomer and carrying out radical polymerization with the methacrylic acid functional monomer containing the UPy unit under the action of photo-initiation. According to the self-repairing polyurethane hydrogel, the self-repairing of the damage of the polyurethane hydrogel can be completed without need of any repairing agent or specific environmental requirements, the polyurethane hydrogel has the advantages of high repairing efficiency, high mechanical strength and low cost and the repeatedly repairing function can be achieved on the same site.

Owner:SOUTH CHINA UNIV OF TECH

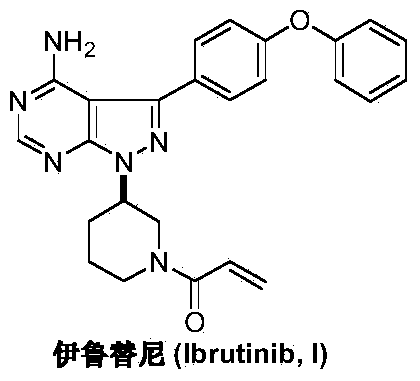

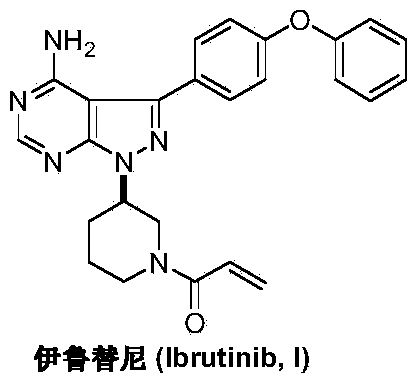

Preparation method of Ibrutinib

ActiveCN103626774AEase of industrial productionRaw materials are easy to getOrganic chemistryCyanideBenzoyl chloride

The invention discloses a preparation method of Ibrutinib (I). The preparation method comprises the following steps: performing condensation and methyl oxidization reaction on 4-phenoxyl benzoyl chloride (II) serving as a raw material and methylene cyanide and dimethyl sulfate to generate 4-phenoxyl phenyl (methoxyl) ethenylidene dicyan methane (III); performing pyrazol cyclization reaction between the intermediate (III) and 1-(3R-diazanyl-1-piperidyl)-2-propylene-1-ketone(IV) to obtain 1-[(3R)-[3-(4-phenoxyl phenyl)-4-nitrile-5-amino-1H-pyrazolyl]-1-piperidyl]-2-propylene-1-ketone(V). The pyrimidine cyclization reaction between the intermediate (V) and a cyclization agent is performed to prepare the Ibrutinib (I). The preparation method has easily-available raw materials, and is simple in process, economical and environment-friendly, and suitable for industrial production.

Owner:TONGLING WANGYANTANG BIOTECHNOLOGY CO LTD

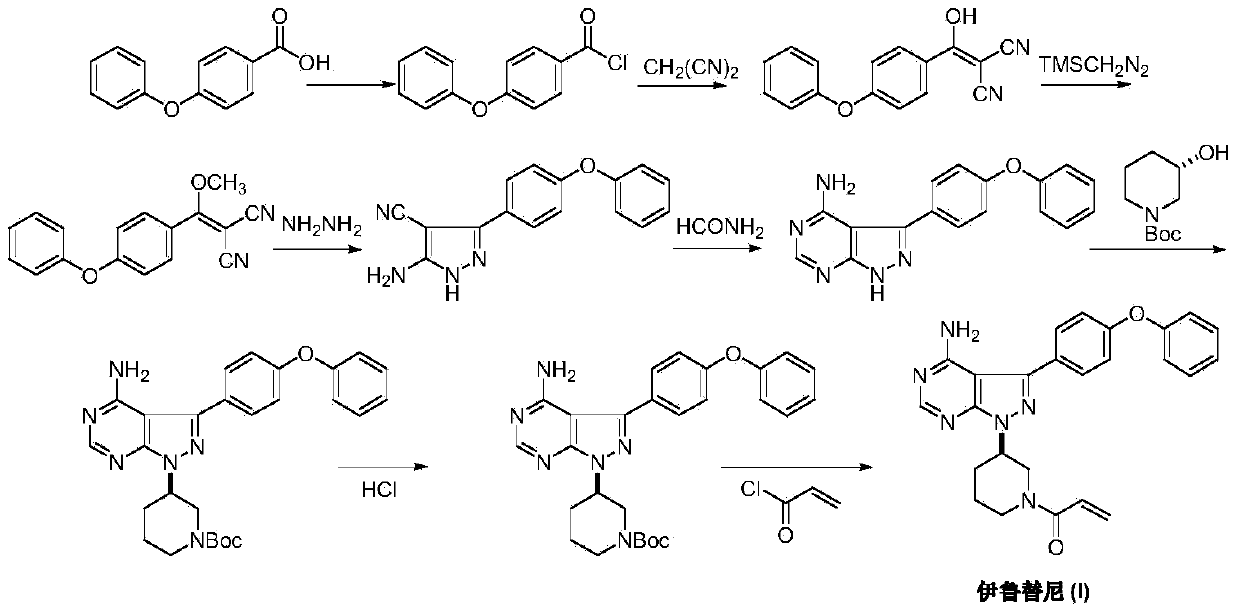

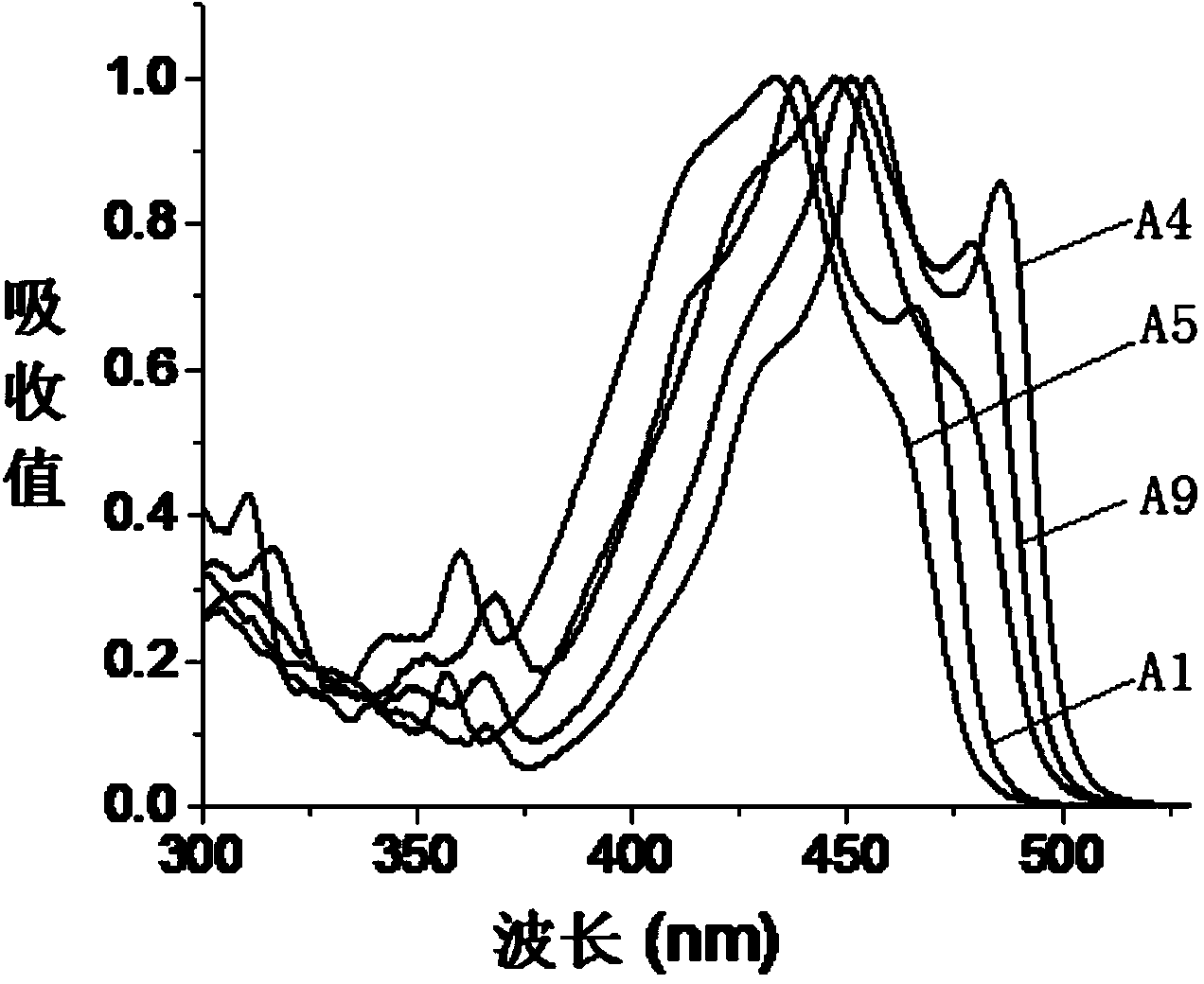

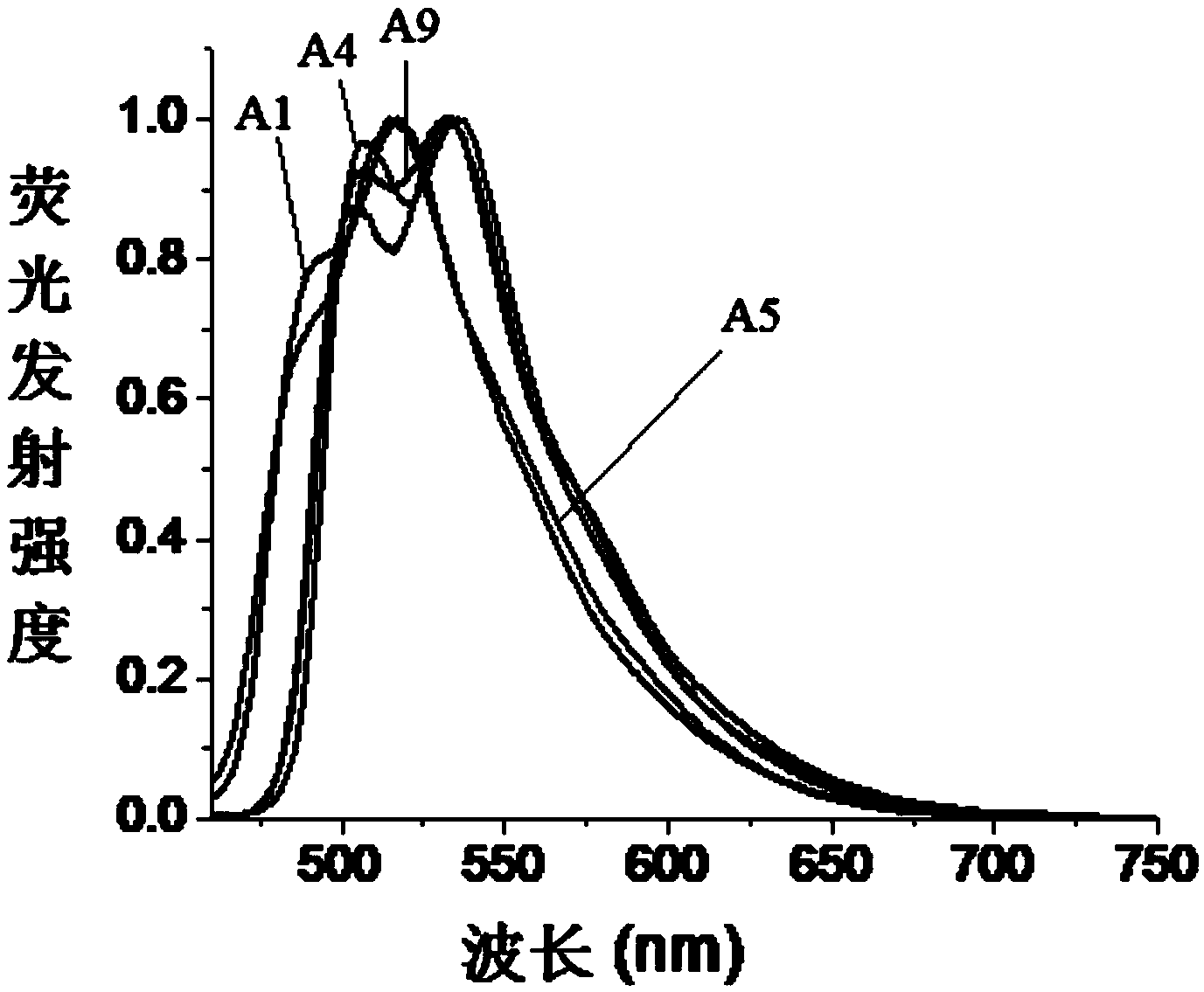

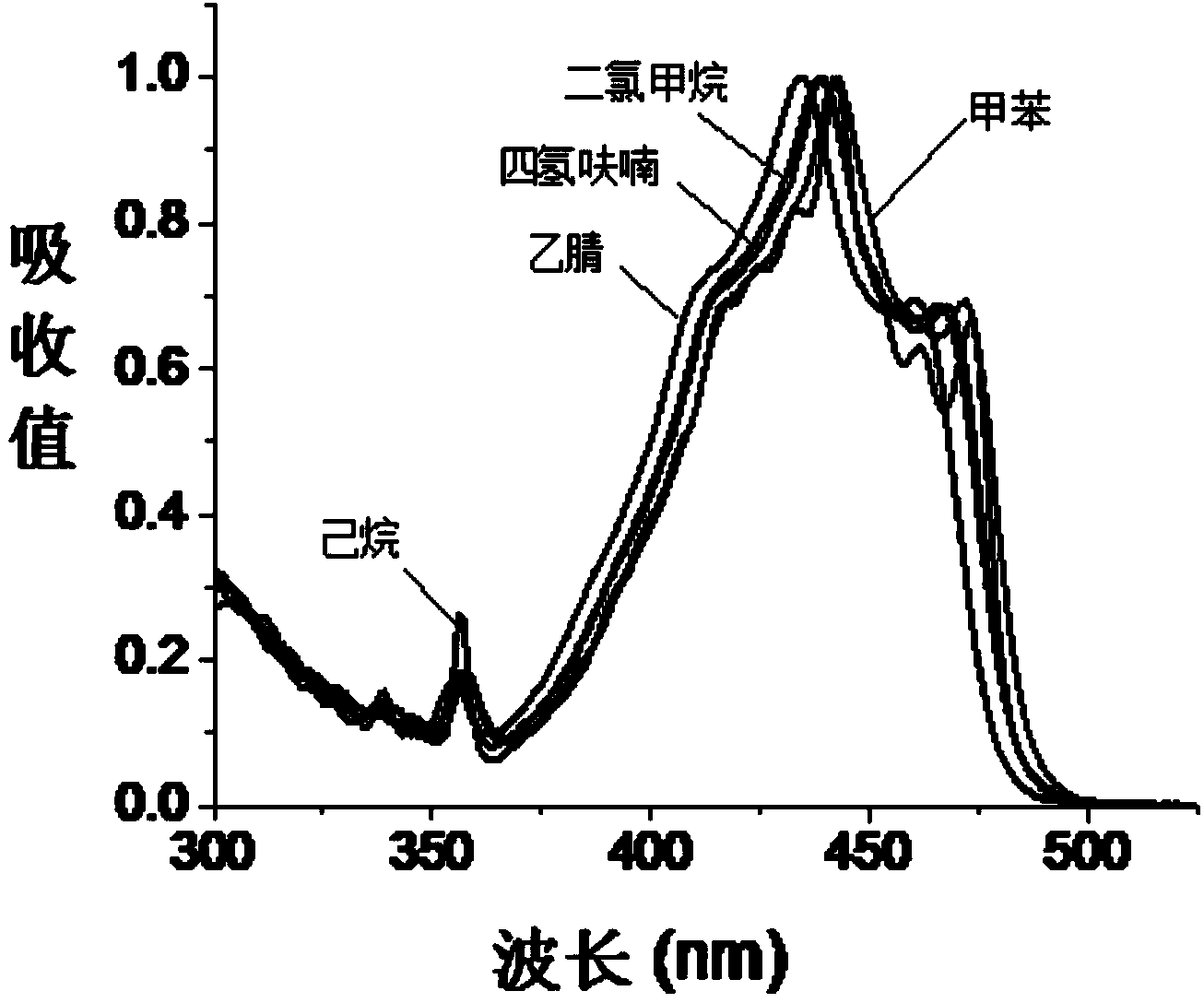

Fluorine-boron fluorescent dye as well as preparation method and application thereof

InactiveCN103865290ANarrow absorbencyNarrow emission peakAzo dyesGroup 3/13 element organic compoundsQuantum yieldHalogen

The invention discloses a fluorine-boron fluorescent dye as well as a preparation method and application thereof, wherein the structure of the fluorine-boron fluorescent dye is shown as a formula (I) or a formula (II), in the formula (I) and the formula (II), R1 is H or halogen; R2 is CN; R3, R4, R5 and R6 are independently selected from H, halogen, C1-C6 alkyl or C1-C6 alkoxy; V, W, X, Y and Z are independently CH or N, and when V, W, X, Y or Z is N, N has no substituent group. According to the fluorine-boron fluorescent dye and the preparation method thereof, the maximal fluorescence emission wavelength of the fluorine-boron fluorescent dye is 518-600nm, and the fluorine-boron fluorescent dye also has excellent fluorescence quantum yield and Stokes shift, which shows that the fluorine-boron fluorescent dye has good application prospect in the bioanalysis fields of fluorescence labeling, bioimaging and so on; meanwhile, the preparation method is simple in steps, and raw materials can be obtained easily.

Owner:ANHUI NORMAL UNIV

Microcapsule essence perfume for cigarettes as well as preparation method of microcapsule essence perfume

InactiveCN103451019AChemically stableNo pollution in the processTobacco treatmentEssential-oils/perfumesFlavorGlycerol

The invention discloses a microcapsule essence perfume for cigarettes as well as a preparation method of the microcapsule essence perfume. The microcapsule essence perfume contains the following raw materials in parts by weight: 1-3 parts of essence, 0.05-0.2 part of glycerinum or / and propylene glycol, 1-5 parts of wall materials and 0.01-0.03 part of emulsifier. The preparation method comprises the steps of: mixing essence, glycerinum or / and propylene glycol to obtain a mixture, evenly stirring the mixture, adding 95% ethanol with 1-10 times weight of the mixture, and mixing and evenly mixing to obtain a mixed solution; adding wall materials and emulsifier in the mixed solution and stirring for homogenization; and sealing, standing for 1-2 hours at normal temperature, refrigerating for 15-60 minutes at the temperature of minus 20 DEG C to minus 80 DEG C, drying for 8-24 hours at the vacuum degree of 30-80MPa and the temperature of 40-80 DEG C, grinding dried products, sieving the ground products to prepare microcapsule particles, thereby obtaining the microcapsule essence perfume for cigarettes. The perfume for cigarettes is made to microcapsules, so that perfume is free from being affected by external factors, and loss and fragrance distortion caused by volatile components in the perfume for cigarettes are effectively reduced.

Owner:HUBEI CHINA TOBACCO IND +1

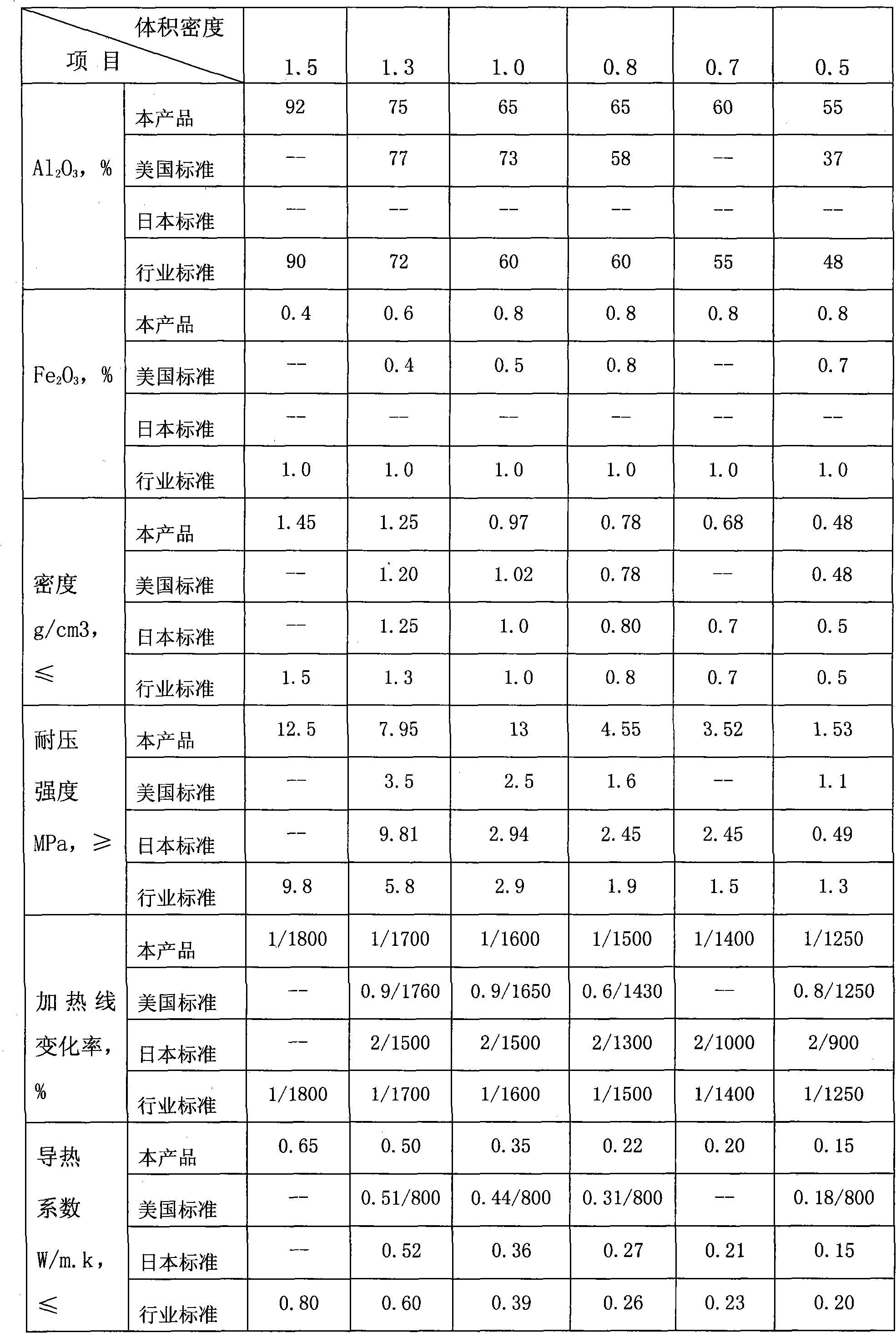

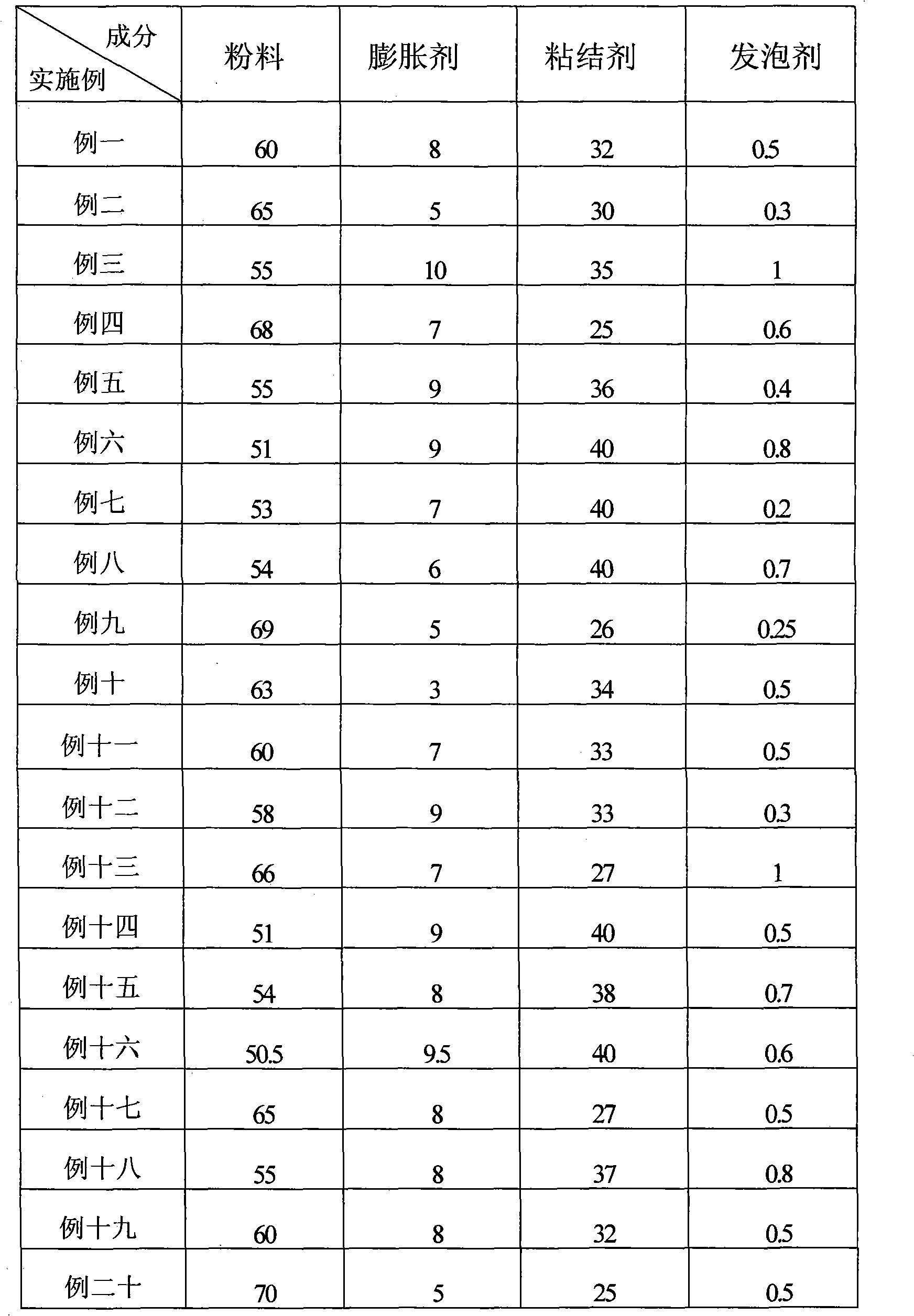

Ultra-microporous lightweight insulated firebrick and manufacture method thereof

The invention discloses an ultra-microporous lightweight insulated firebrick and a manufacture method thereof. The ultra-microporous lightweight insulated firebrick is prepared by the following raw materials in percentage by weight: powder mainly comprising 50-70 Al2O3 and SiO2, 5-10 expanding agent, 25-40 caking agent and 0.2-1.0 external foaming agent. The manufacture method comprises the following steps: uniformly mixing and stirring the raw materials into pasty material; mixing the foaming agent and water according to a ratio of 1: (15-20); adding the mixture to the pasty material to mix uniformly; then, casting into brick blanks; and drying and keeping the brick blanks at a temperature of 1200-1600 DEG C for 6-8 hours. The firebrick has the advantages of high compressive strength, low coefficient of heat conductivity and low linear change ratio and can be directly used for a fireproof coating of thermal equipment so that the product has the lightweight insulation and fireproofness functions and good insulation effect and is beneficial to energy saving and environmental protection. Compared with the prior art, the invention has obvious economic benefits.

Owner:郑州东方炉衬材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com