Self-repairing polyurethane hydrogel and preparation method thereof

A technology of polyurethane and hydrogel, applied in the field of preparation of polyurethane hydrogel, can solve the problems of inability to achieve multiple repairs, complex preparation process, affecting transparency, etc., and achieves improved physical and mechanical strength, simple synthesis route, and improved the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

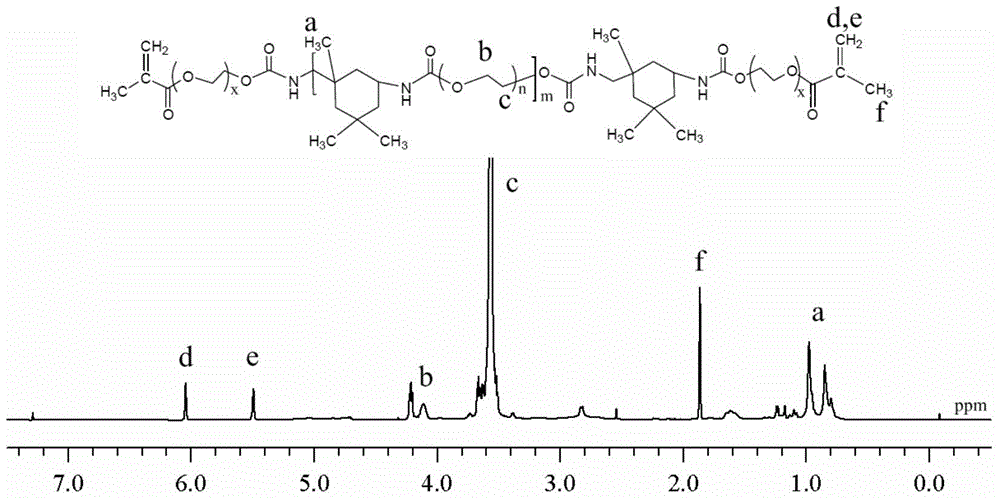

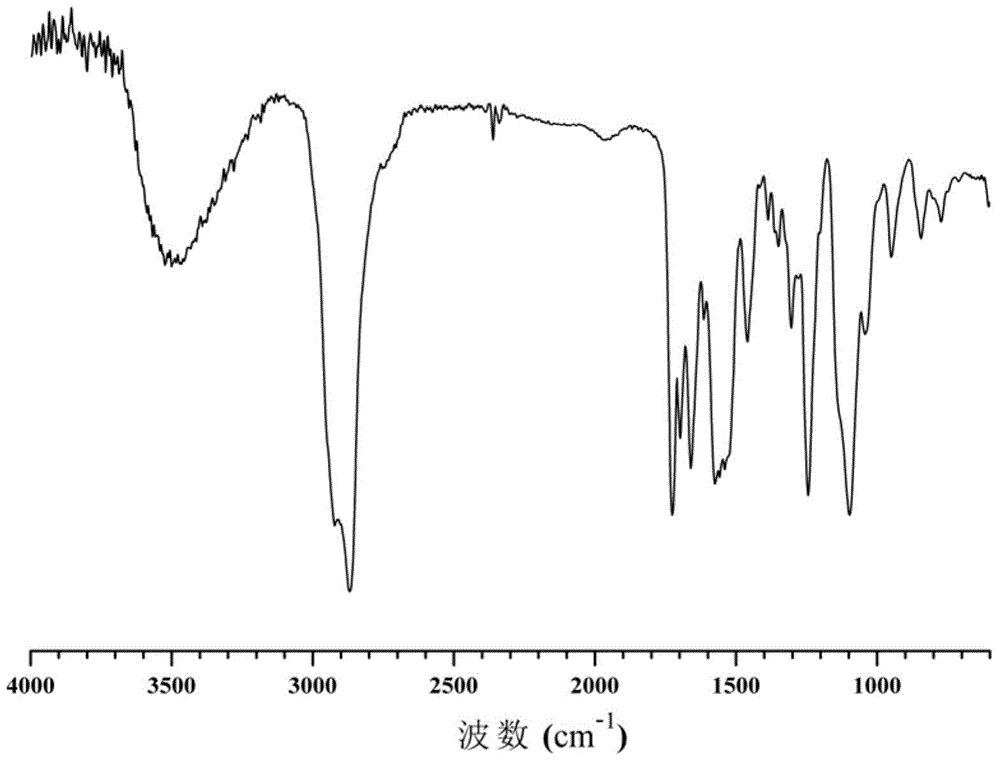

[0045] Synthesis of polyethylene glycol acrylate-terminated hydrophilic polyurethane macromers: in terms of mass fraction, first add 50 parts of polyethylene glycol, 0.5 parts of 1,4-butanediol and 1 part of trimethylolpropane to 250 mL In the Erlenmeyer flask, stir evenly, heat up to 120-130°C, keep the vacuum degree above 0.08MPa and dehydrate for 2.5 hours, place it to lower the temperature to 60°C; then, add 14.5 parts of isophorone diisocyanate dropwise After the addition, the temperature was controlled to react at 70-85°C for 3 hours, and the mass content of -N=C=O in the prepolymer was measured by di-n-butylamine titration. When the actual measured value is close to the theoretical value, add 23.5 parts of polyethylene glycol acrylate and 2 parts of dibutyltin dilaurate drop by drop, and react for 24 hours; use infrared to track the consumption of isocyanate groups, and wait until the infrared characteristic peaks basically disappear So far, the polyethylene glycol acry...

Embodiment 2

[0053] Preparation of self-healing polyurethane hydrogel: In terms of mass fraction, 89.5 parts of polyethylene glycol acrylate-terminated hydrophilic polyurethane macromers prepared in Example 1 and 5 parts of HEMA‐UPy monomers were dissolved in In dimethyl sulfoxide, under the condition of avoiding light, add 2 parts of photoinitiator 2959, stir until completely dissolved; The free radical polymerization reaction was carried out in a UV oven for 1 hour under photoinitiation; then, the product was taken out and placed in deionized water, and the water was changed every 12 hours for 6 consecutive days, and the prepared polyurethane hydrogel could be taken out.

[0054] The mechanical properties and self-healing properties of the obtained polyurethane hydrogel are equivalent to those of the polyurethane hydrogel obtained in Example 1.

Embodiment 3

[0056] Preparation of self-healing polyurethane hydrogel: in terms of mass fraction, 89.5 parts of polyethylene glycol acrylate-terminated hydrophilic polyurethane macromers prepared in Example 1 and 10 parts of PEGMA-UPy monomers were dissolved in In dimethyl sulfoxide, under the condition of avoiding light, add 2 parts of photoinitiator 2959, stir until completely dissolved; The free radical polymerization reaction was carried out in a UV oven for 1 hour under photoinitiation; then, the product was taken out and placed in deionized water, and the water was changed every 12 hours for 6 consecutive days, and the prepared polyurethane hydrogel could be taken out.

[0057] The mechanical properties and self-healing properties of the obtained polyurethane hydrogel are equivalent to those of the polyurethane hydrogel obtained in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com