Patents

Literature

60results about How to "Strong bond energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

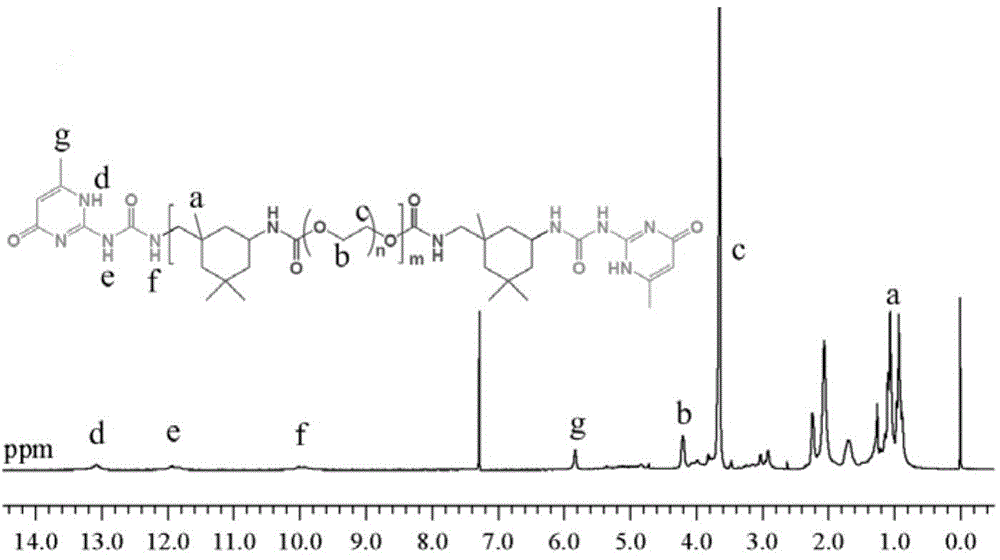

Self-repairing polyurethane hydrogel and preparation method thereof

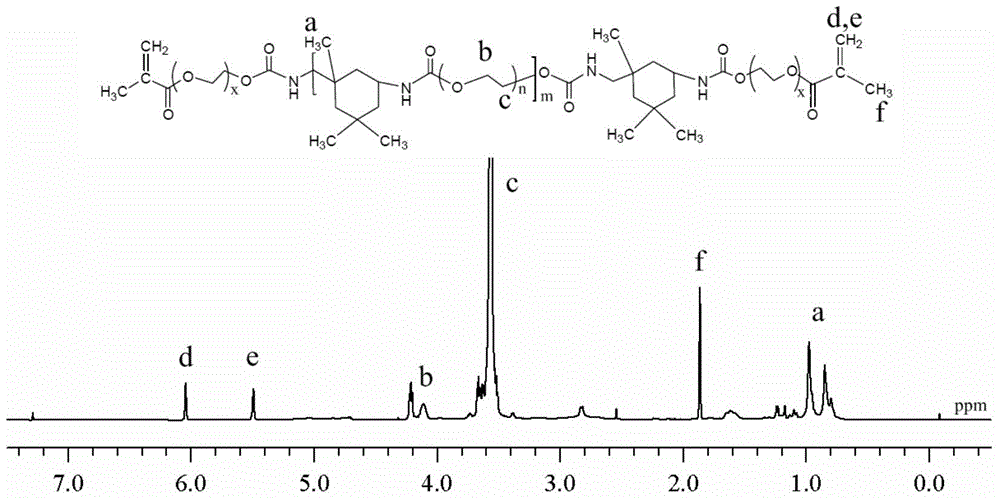

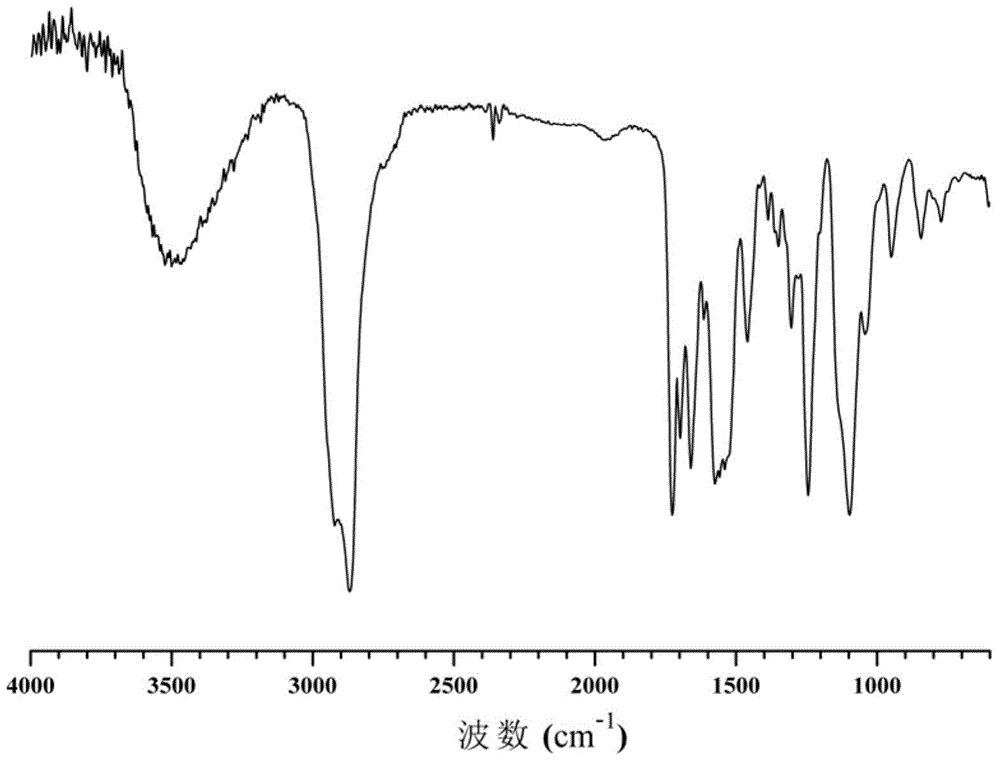

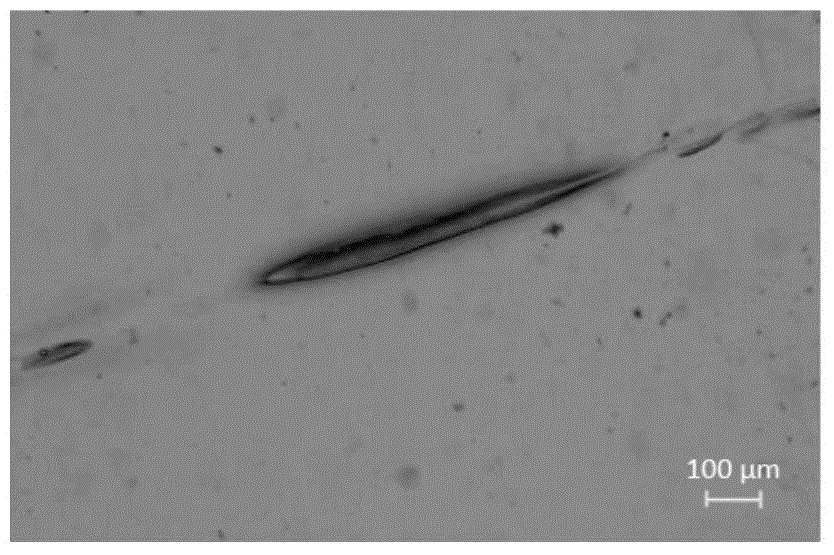

The invention relates to a self-repairing polyurethane hydrogel and a preparation method thereof. The polyurethane hydrogel comprises the following components in parts by mass: 10-30 parts of polyisocyanate, 30-50 parts of hydrophilic polyester polyol or hydrophilic polyether polyol, 10-50 parts of acrylamide monomer, 0.5-3 parts of chain extender, 3-10 parts of methacrylic acid functional monomer containing an UPy unit, 0.5-2 parts of catalyst and 0.5-3 parts of photoinitiator. The preparation method comprises the following steps of firstly preparing a hydrophilic polyurethane macromonomer terminated with an acrylic acid monomer and carrying out radical polymerization with the methacrylic acid functional monomer containing the UPy unit under the action of photo-initiation. According to the self-repairing polyurethane hydrogel, the self-repairing of the damage of the polyurethane hydrogel can be completed without need of any repairing agent or specific environmental requirements, the polyurethane hydrogel has the advantages of high repairing efficiency, high mechanical strength and low cost and the repeatedly repairing function can be achieved on the same site.

Owner:SOUTH CHINA UNIV OF TECH

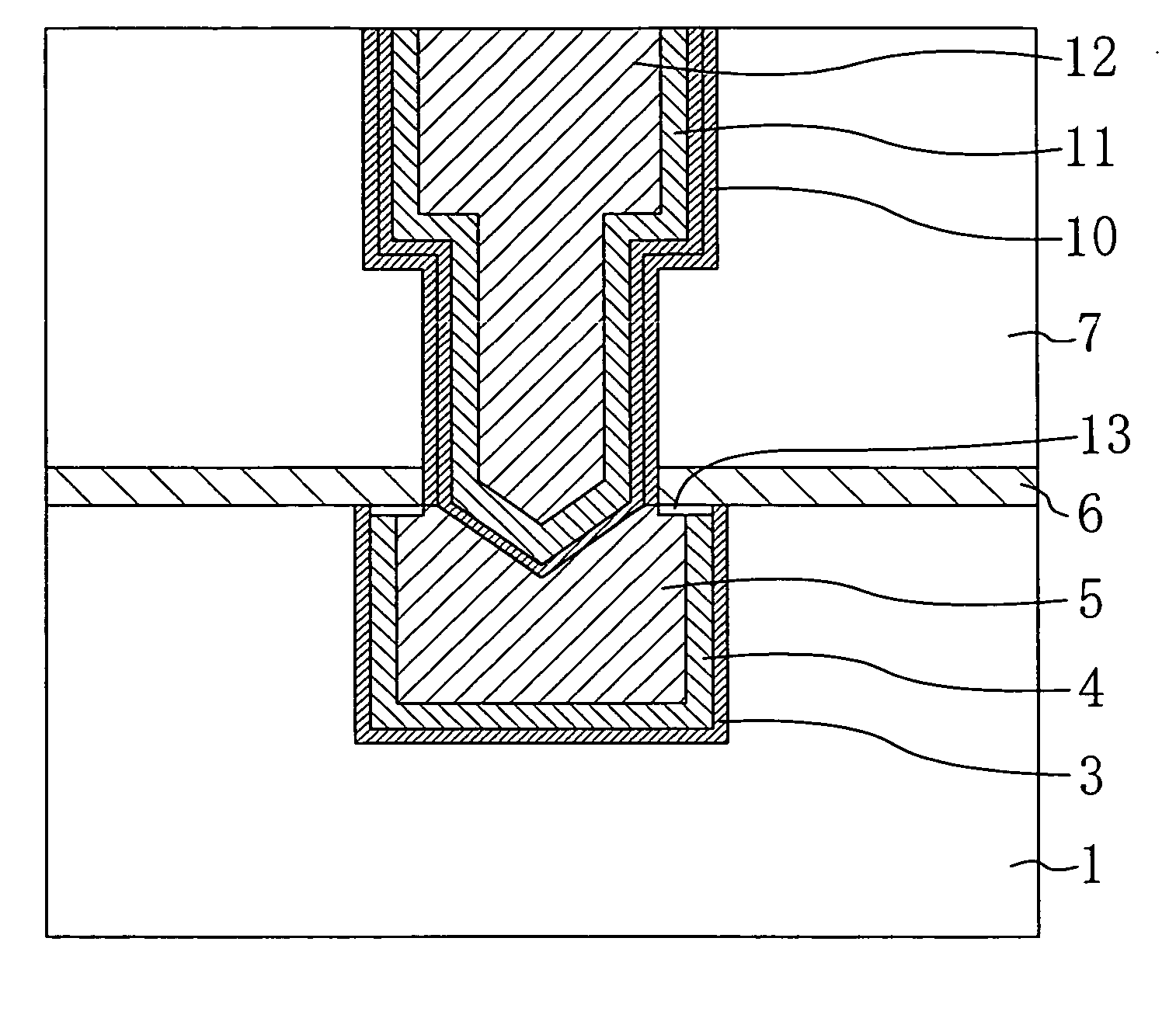

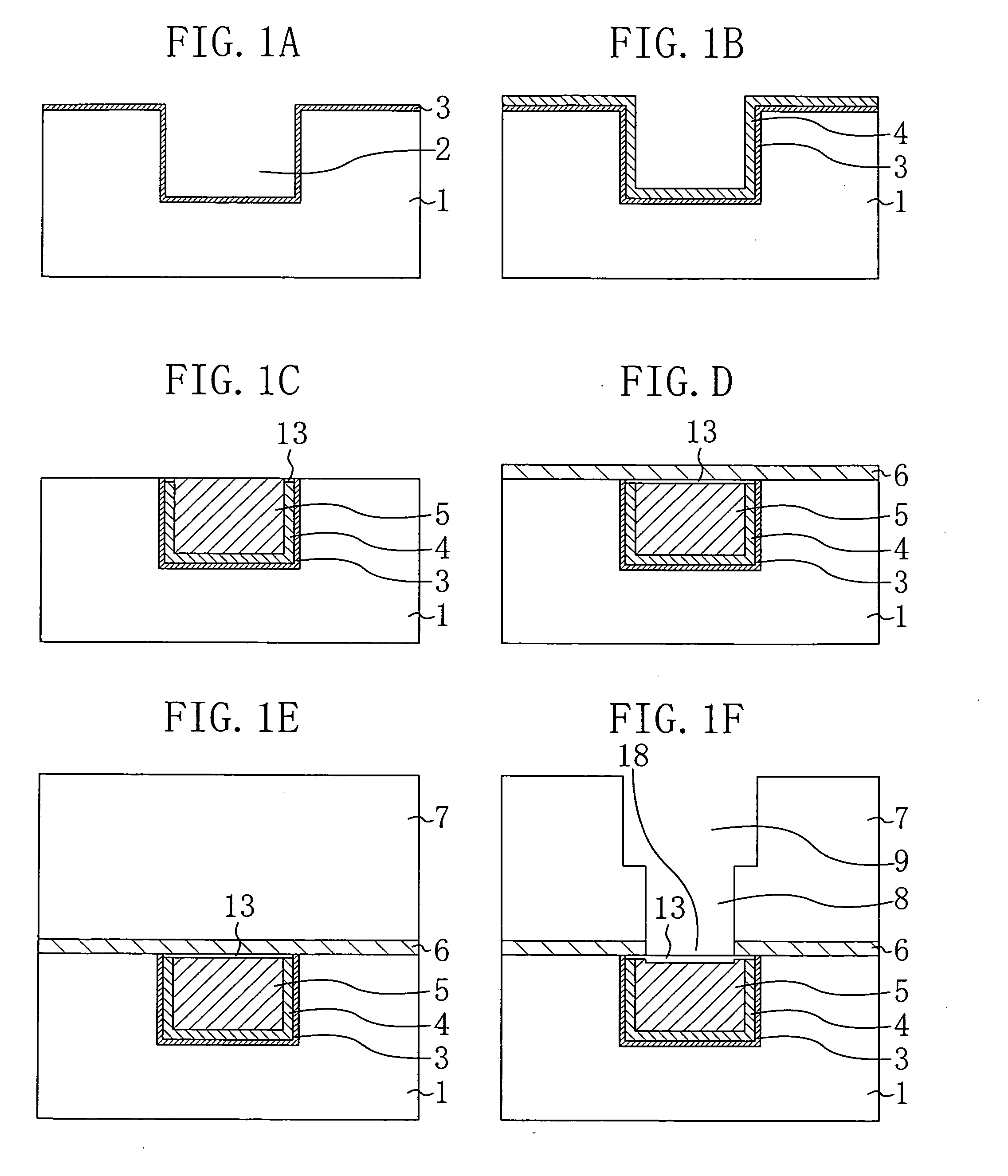

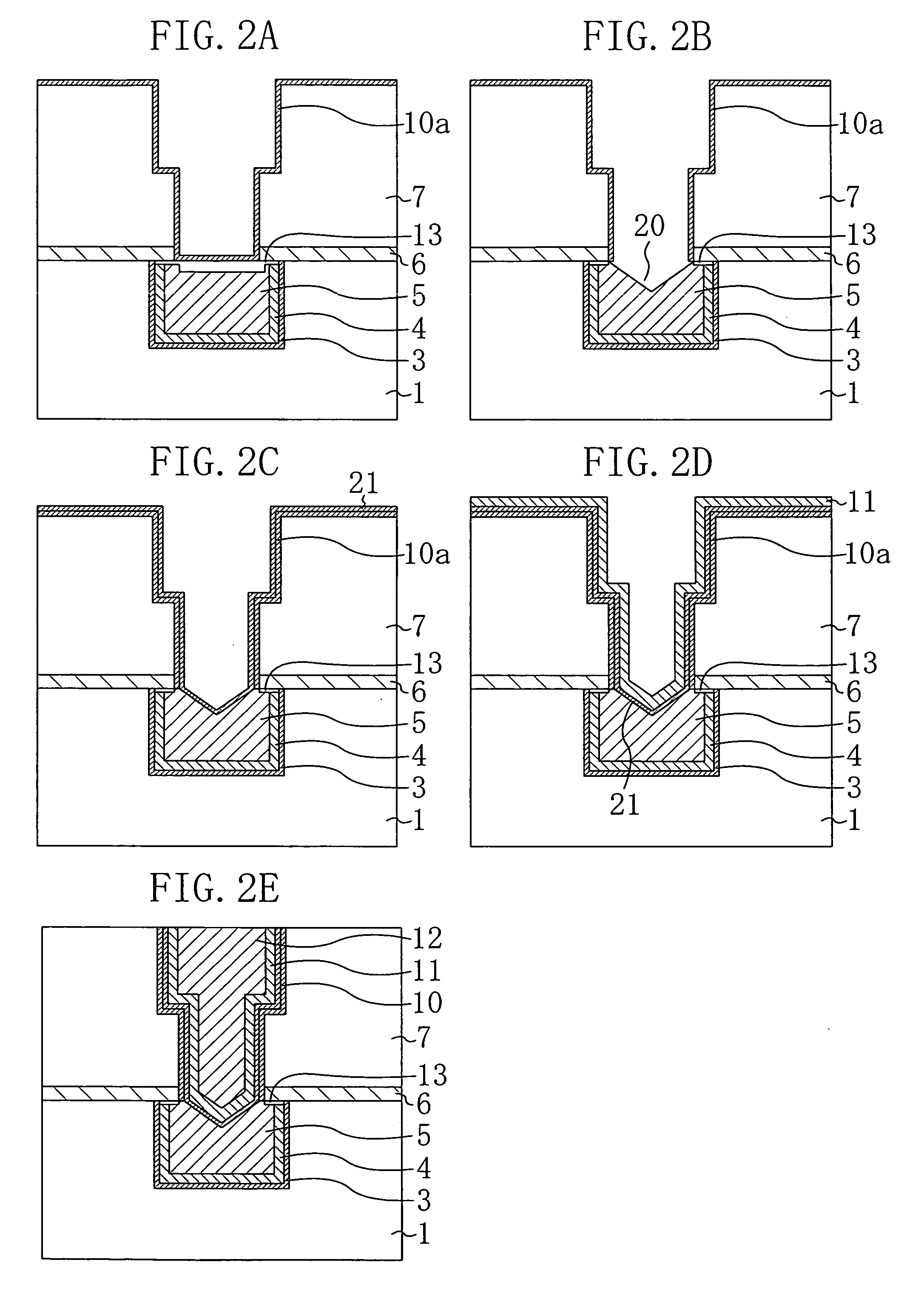

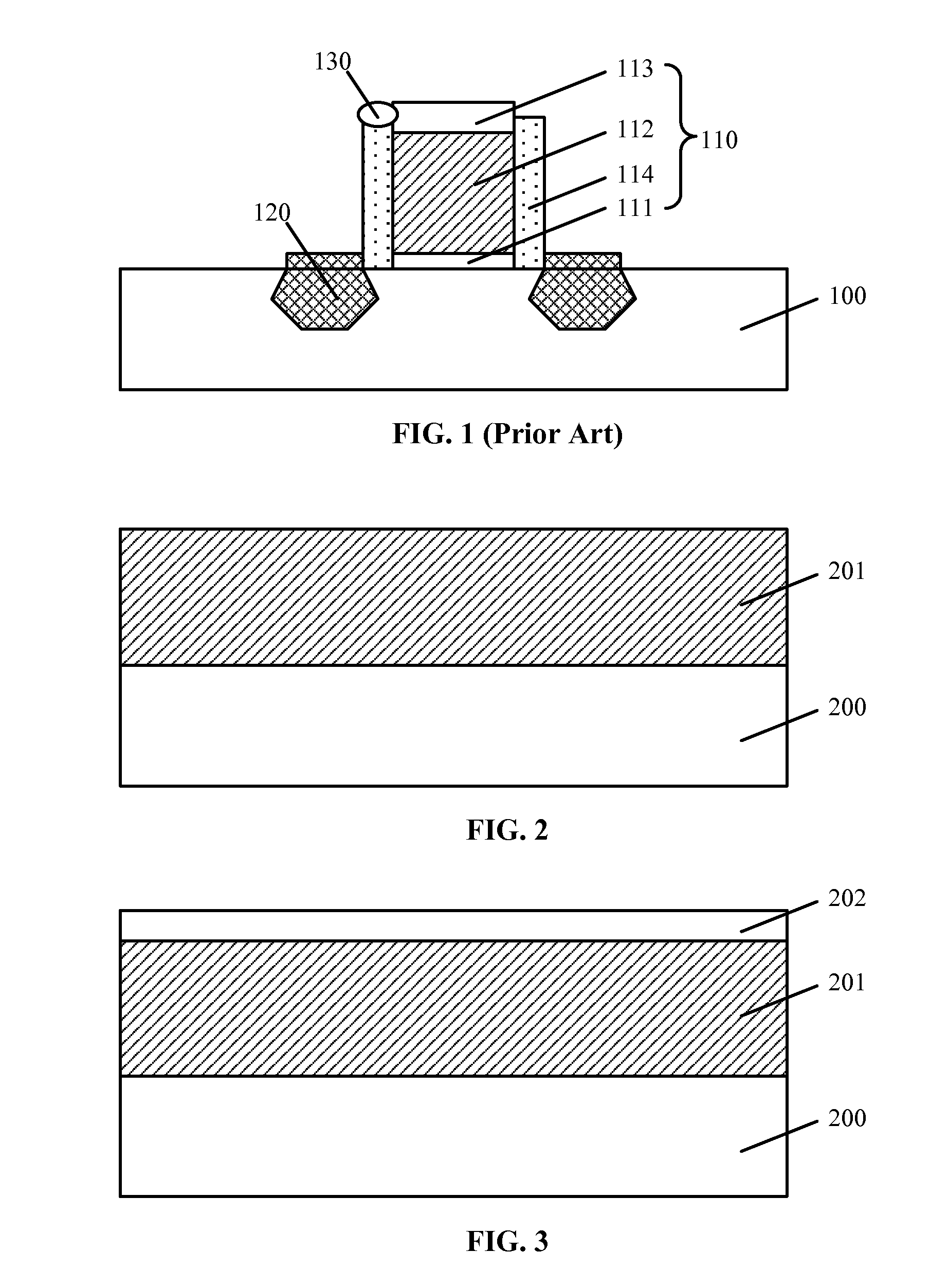

Semiconductor device and manufacturing method therof

InactiveUS20070145591A1Lower the resistance valueImprove the immunitySemiconductor/solid-state device detailsSolid-state devicesDielectricDevice material

The semiconductor device manufacturing method includes the steps of: applying a first wire including a barrier metal film, a seed film, and a wiring material film in a first wire trench formed in a first interlayer dielectric film; after a second interlayer dielectric film is formed on the first interlayer dielectric film, forming a via hole and a second wire trench in the second interlayer dielectric film so as to expose the wiring material film; applying a barrier metal film on the semiconductor device; and after the barrier metal film on the wiring material film is removed by using, for example, a re-sputtering process, applying a barrier metal film on the wiring material film. The re-sputtering process can remove an oxide film of impurity metal in the seed film applied on the wiring material film.

Owner:PANASONIC CORP +1

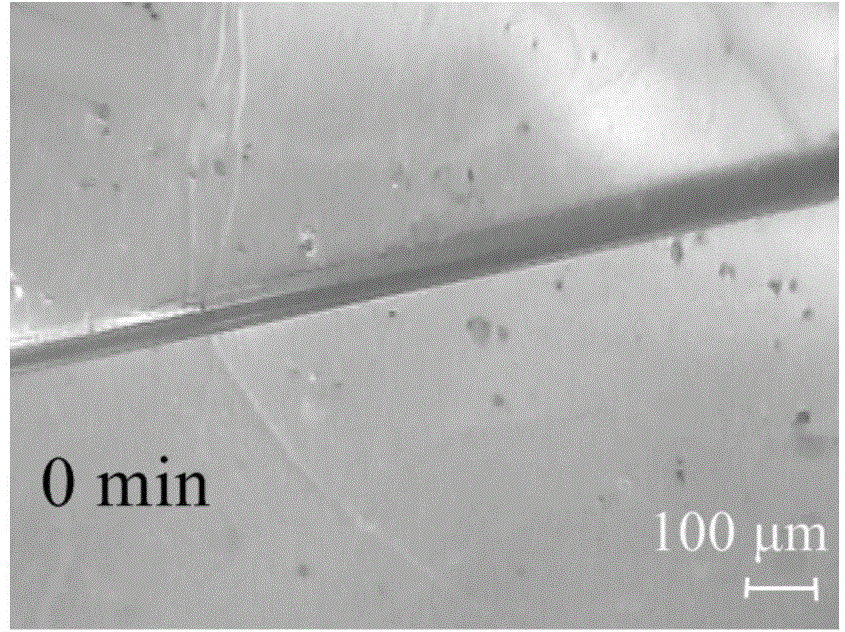

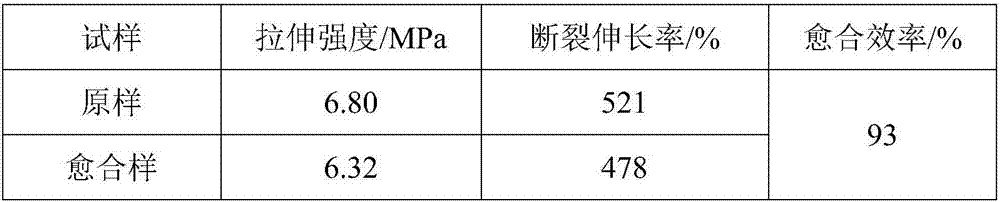

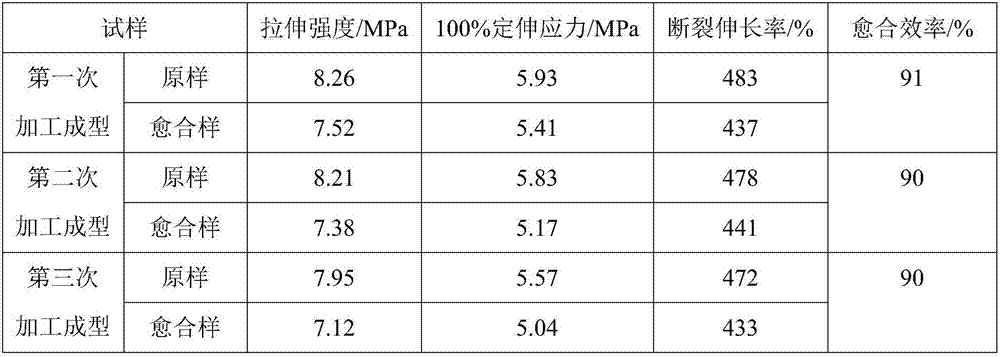

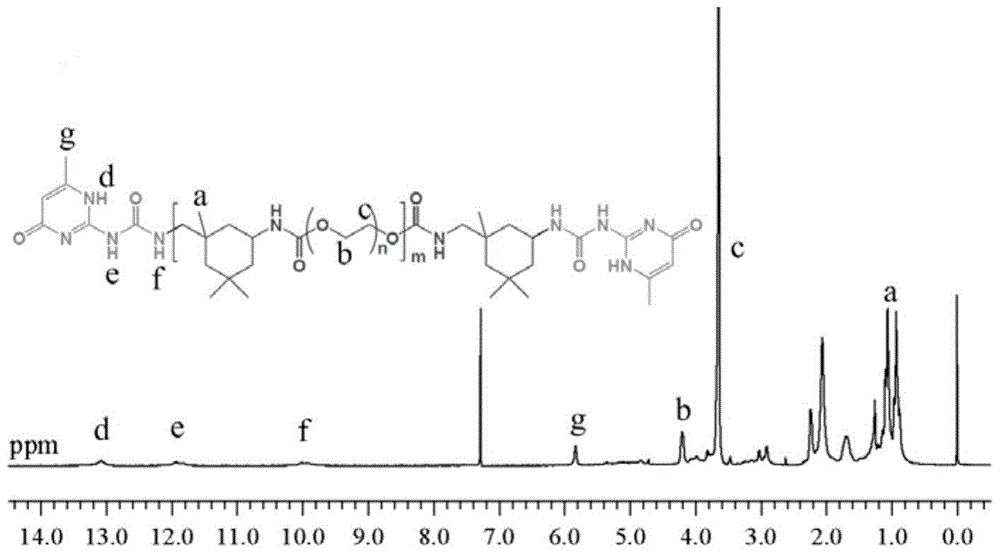

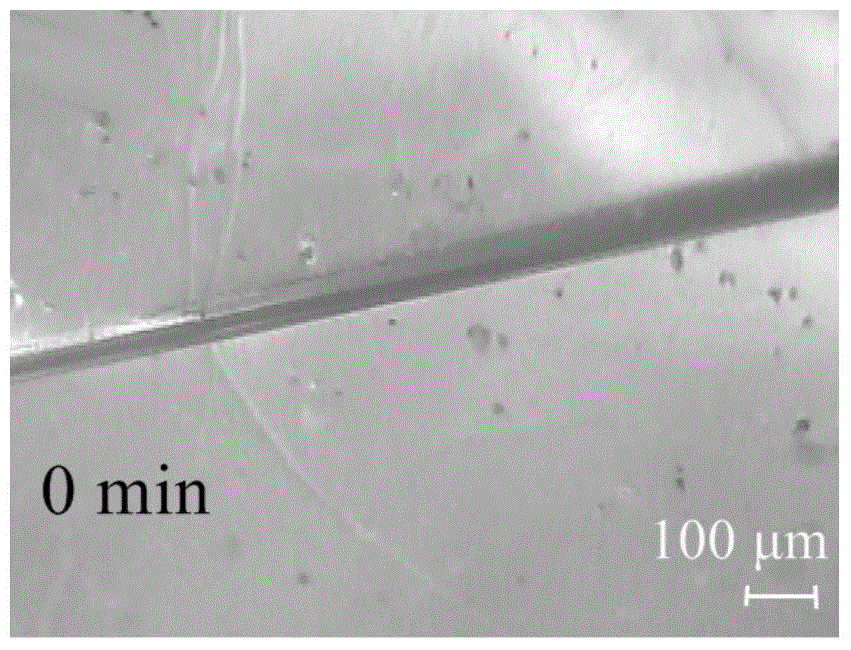

Self-repairing polyurethane coating and preparation method thereof

ActiveCN104356338ARepair damageGood physical and mechanical propertiesPolyurea/polyurethane coatingsPolyesterPolyol

The invention discloses a self-repairing polyurethane coating and a preparation method thereof. The polyurethane coating comprises the following raw materials in parts by mass: 15-20 parts of polyisocyanates, 40-60 parts of hydrophilic polyester polyol or polyether polyol, 2-3 parts of a chain extender and 7-15 parts of methylcystein. The preparation method comprises the following steps: preparing a hydrophilic polyurethane prepolymer from hydrophilic polyester polyol or polyether polyol and the chain extender, and reacting the isocyanate group in the hydrophilic polyurethane prepolymer with methylcystein, so as to obtain a polyurethane material of which the tail end or the main chain contains 2-urea-4-pyrimidone units; spraying or coating the polyurethane material on the surface of a substrate, thereby obtaining the self-repairing polyurethane coating. The self-repairing of the self-repairing polyurethane coating disclosed by the invention can be completed without external repairing agent or requirements of special environment, the coating is good in transparency, high in strength, good in filming property, simple in process and low in cost, and the function of repeated repairing in same positions can be achieved.

Owner:SOUTH CHINA UNIV OF TECH

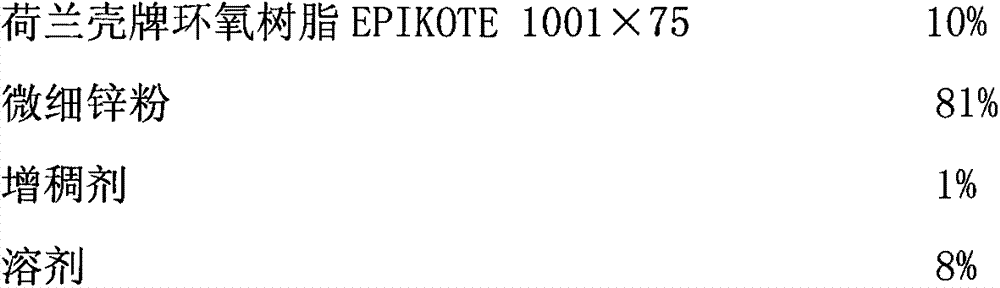

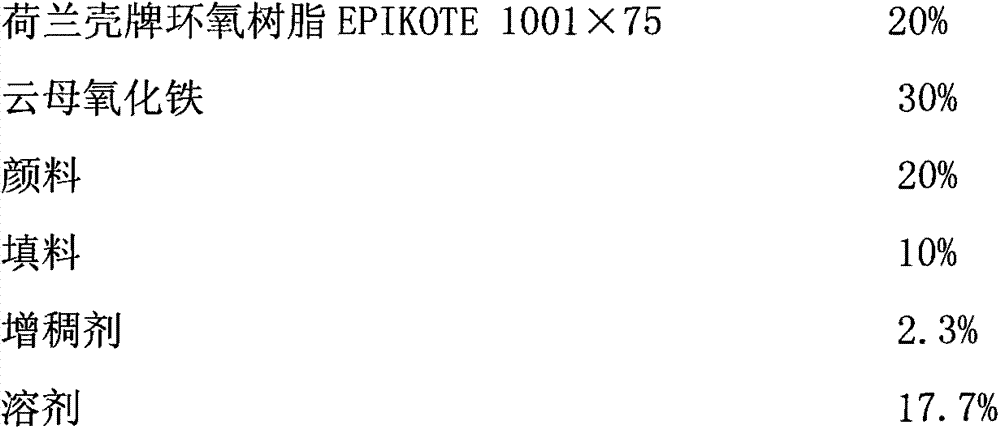

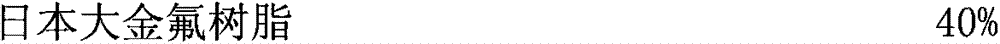

Super-weatherproof heavy-duty high-solid thermal insulating electrostatic conducting coating system

InactiveCN103497643AHigh content of zinc dustImprove anti-corrosion performanceAnti-corrosive paintsEpoxy resin coatingsHeat conductingCoating system

The invention discloses a super-weatherproof heavy-duty high-solid thermal insulating electrostatic conducting coating system and belongs to the technical field of chemical coatings. The super-weatherproof heavy-duty high-solid heat conductance barrier electrostatic coating system comprises a bottom coat, an intermediate coat and a surface coat, wherein the bottom coat is formed by coating an epoxy zinc rich primer, the intermediate coat is formed by coating an epoxy mica iron oxide paint and the surface coat is formed by coating a fluoro-carbon finish; the fluoro-carbon finish is added with hollow glass micro beads and a heat conducting powder. The electrostatic coating system provided by the invention is excellent in heavy duty, heat insulation and weather-proofing properties, high in electrostatic conductivity, high in solid content, low in volatilization, healthy and has environment-friendly effect, is long in system service life, and suitable for various steel structure facilities such as a gasoline can, a container, a steel pipe, a bridge, petrochemical equipment, a ship and a harbor facility.

Owner:浙江绿色德环保科技股份有限公司

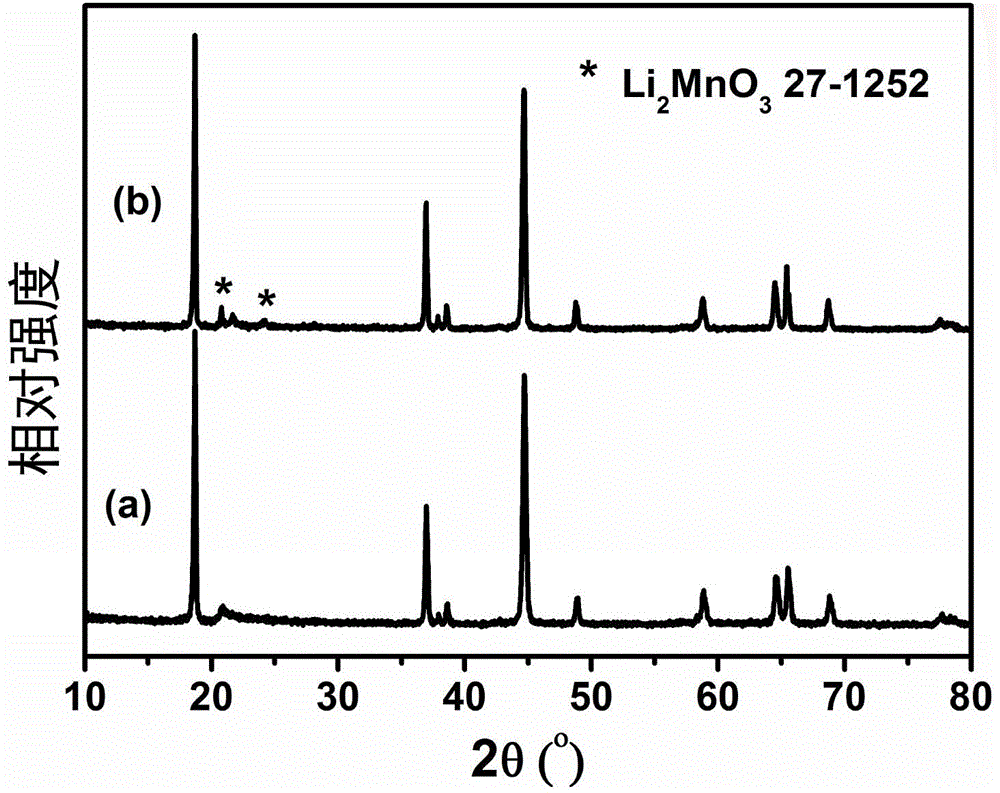

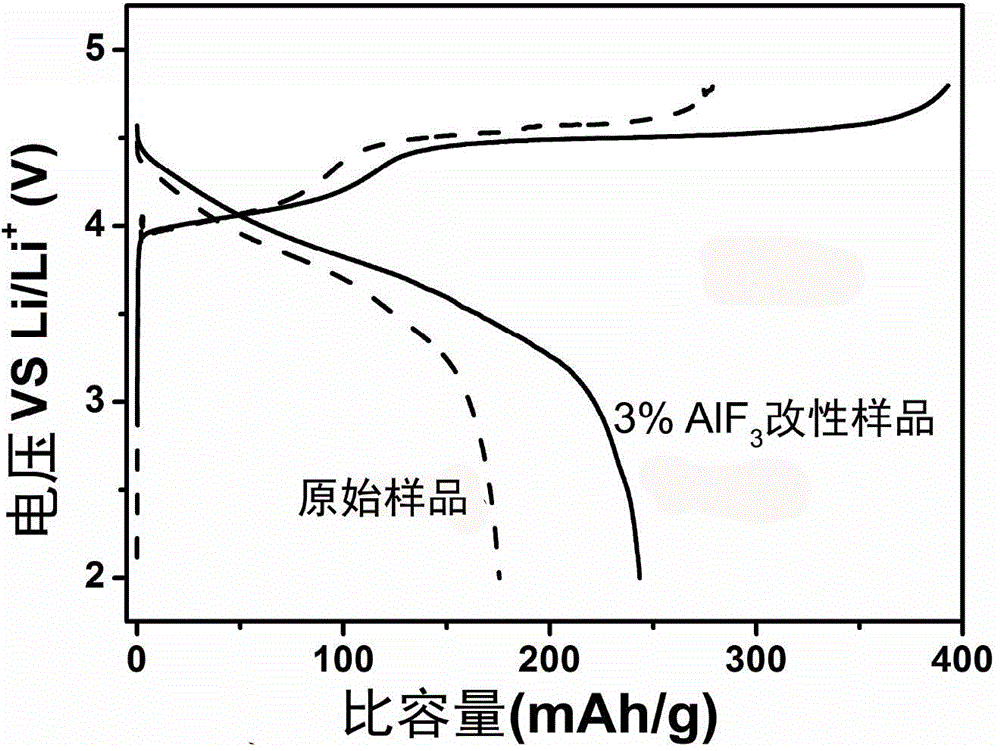

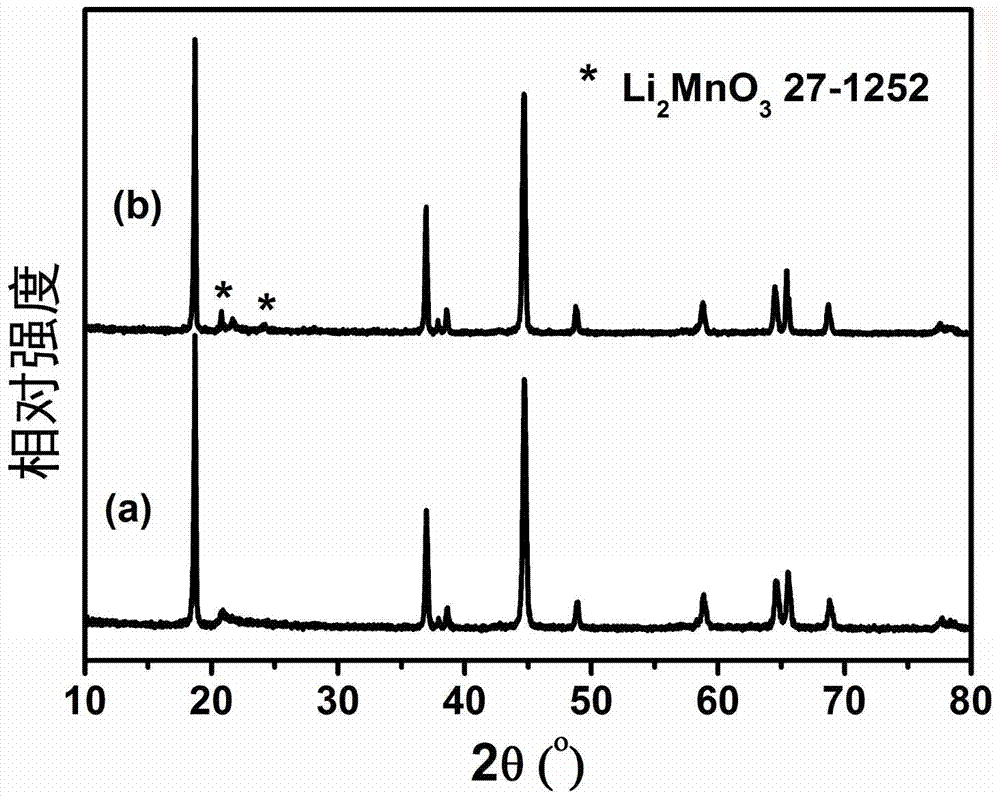

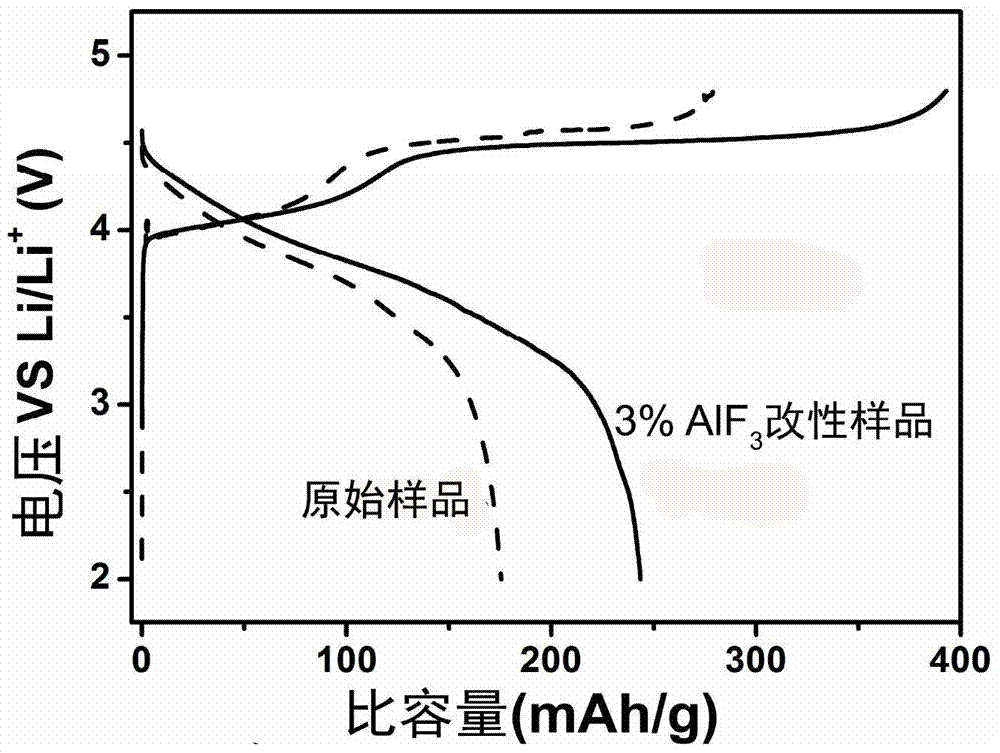

Method for modifying lithium-rich manganese-based cathode material

ActiveCN104681809ARealize regulationReduce manufacturing process stepsCell electrodesLithium carbonateManganese

The invention discloses a method for modifying a lithium-rich manganese-based cathode material. The method comprises the following steps: preparing a precursor of the lithium-rich manganese-based cathode material, uniformly mixing the precursor with lithium carbonate and doping and modifying metal villiaumite, sintering the uniformly mixed mixture at a high temperature to obtain a modified lithium-rich manganese-based cathode material. The modification process of the method disclosed by the invention is simple and easy to control, the steps of the existing preparation process are not added, and the electrochemical performance of the product is excellent.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

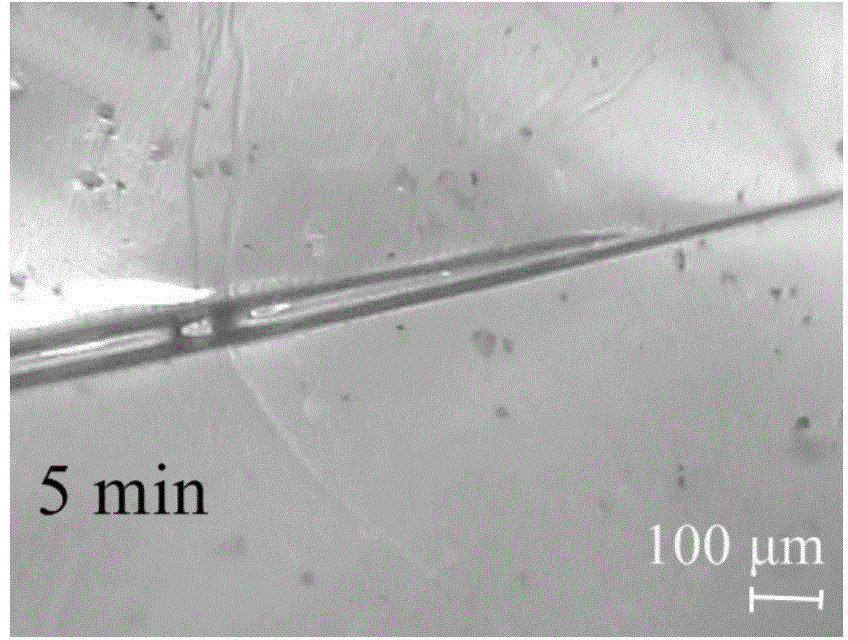

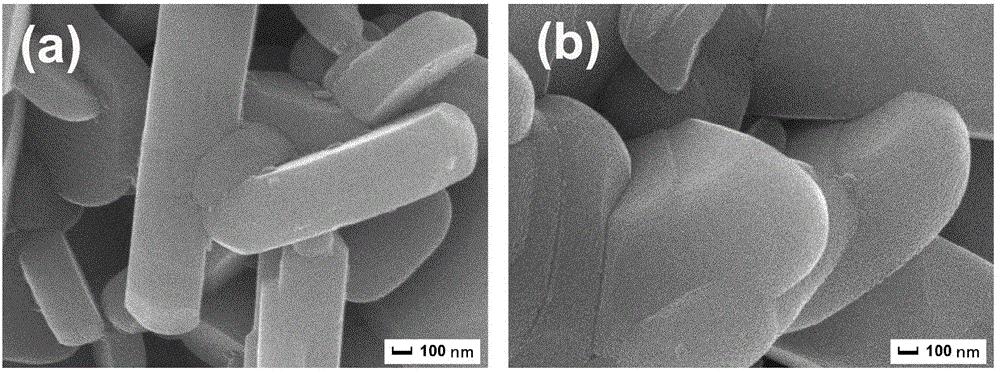

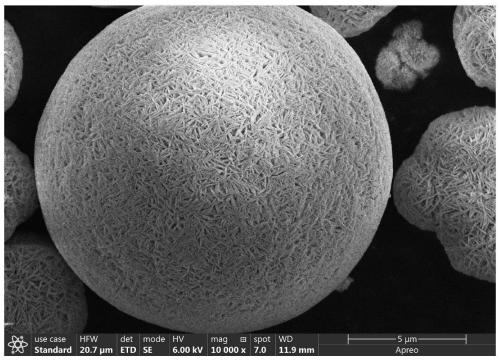

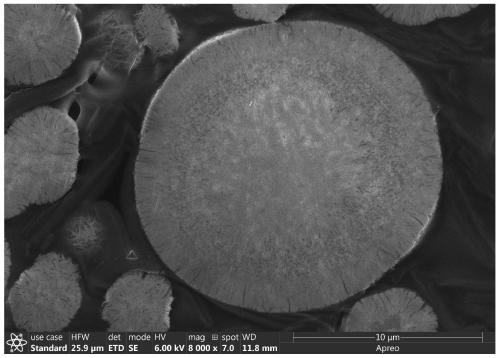

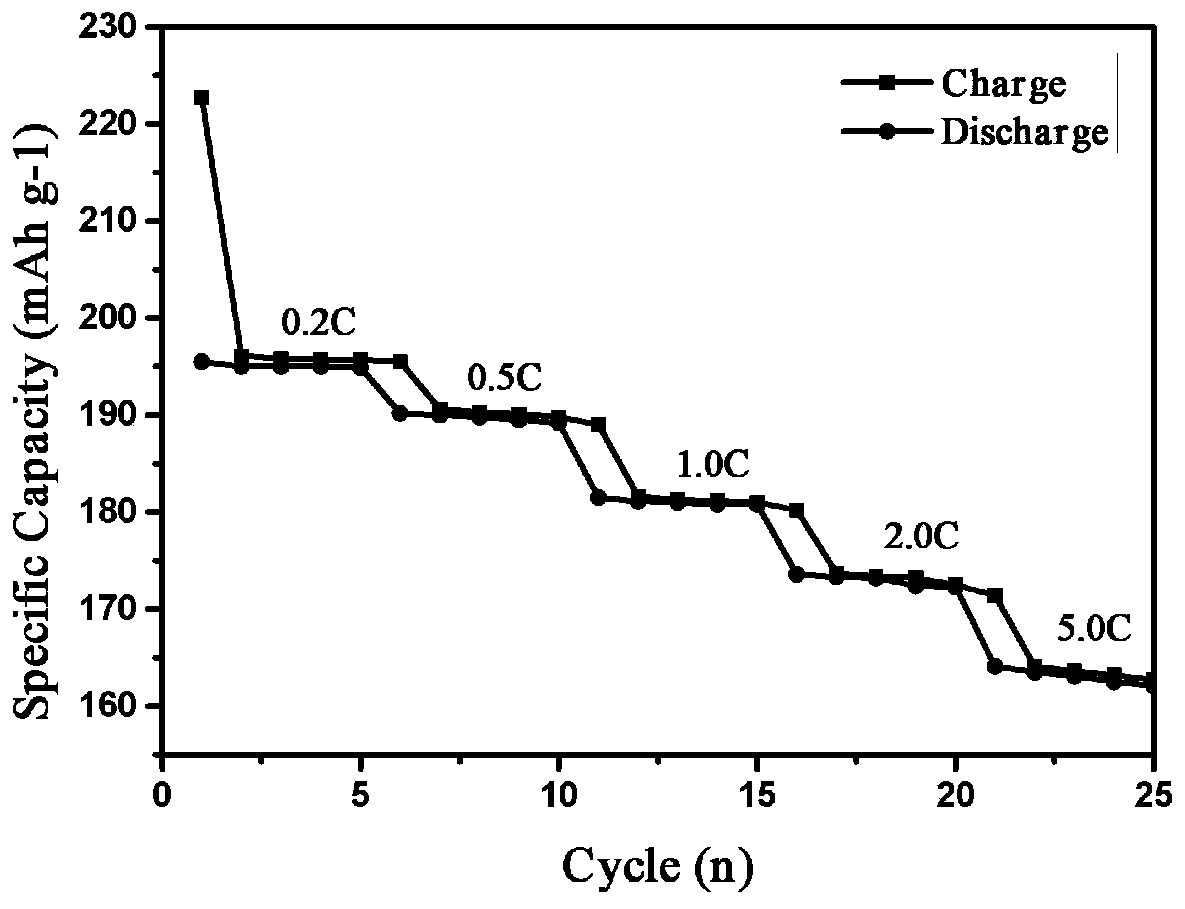

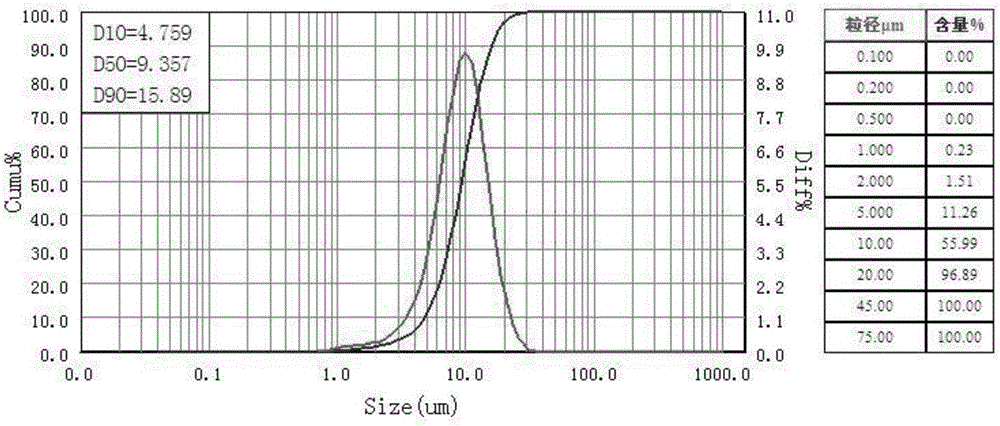

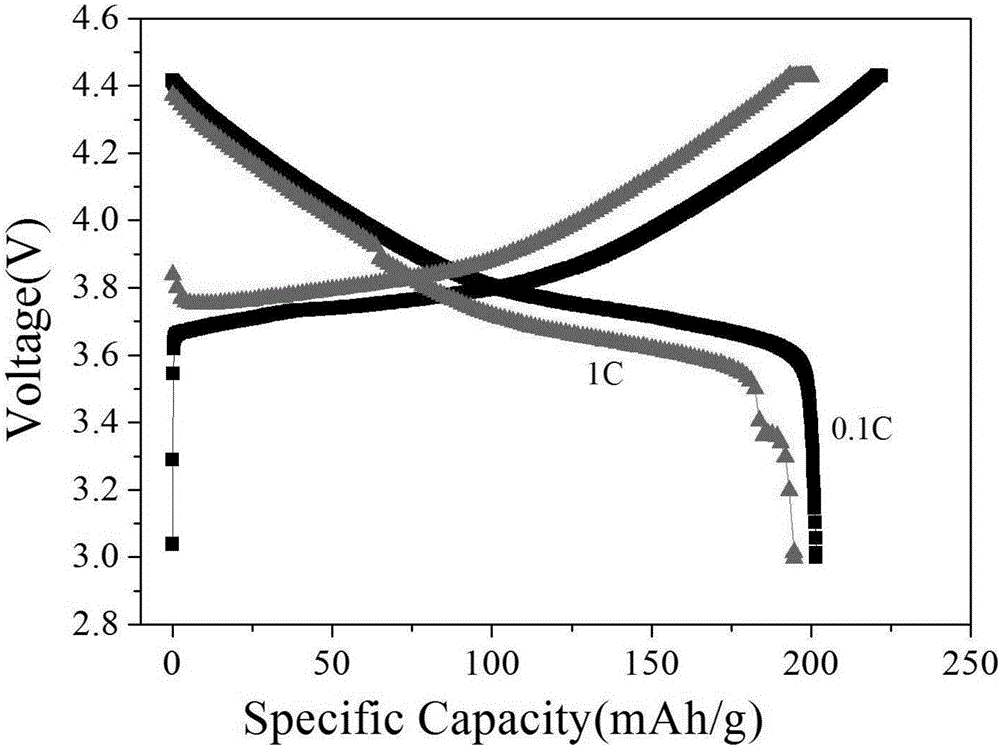

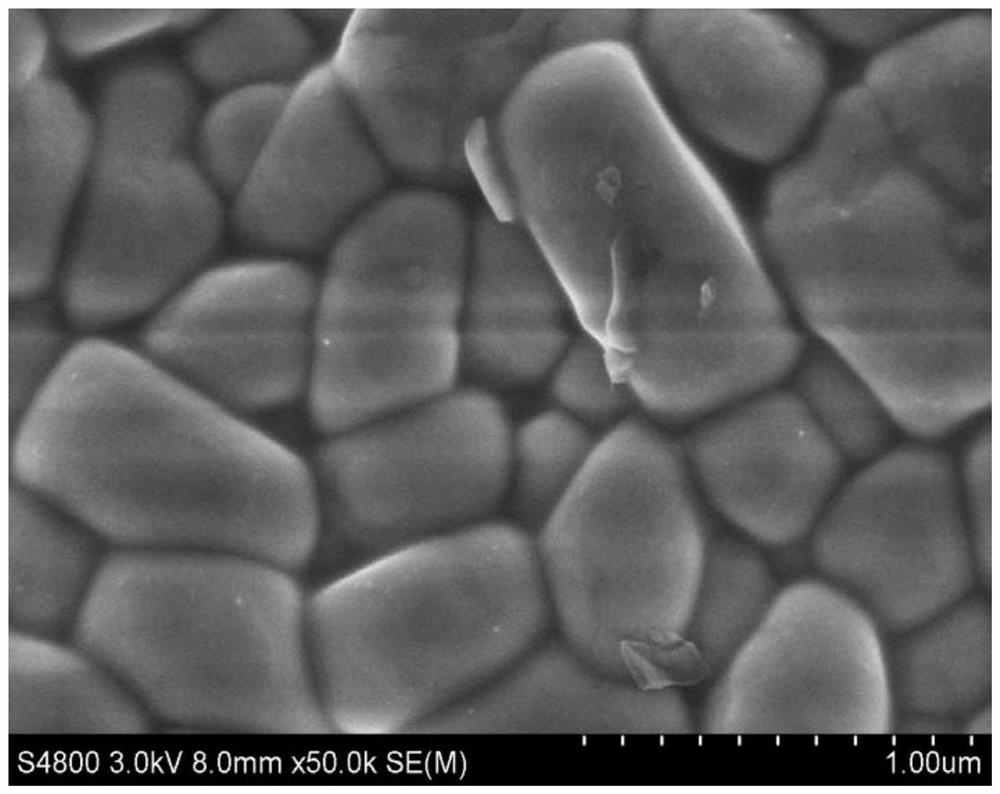

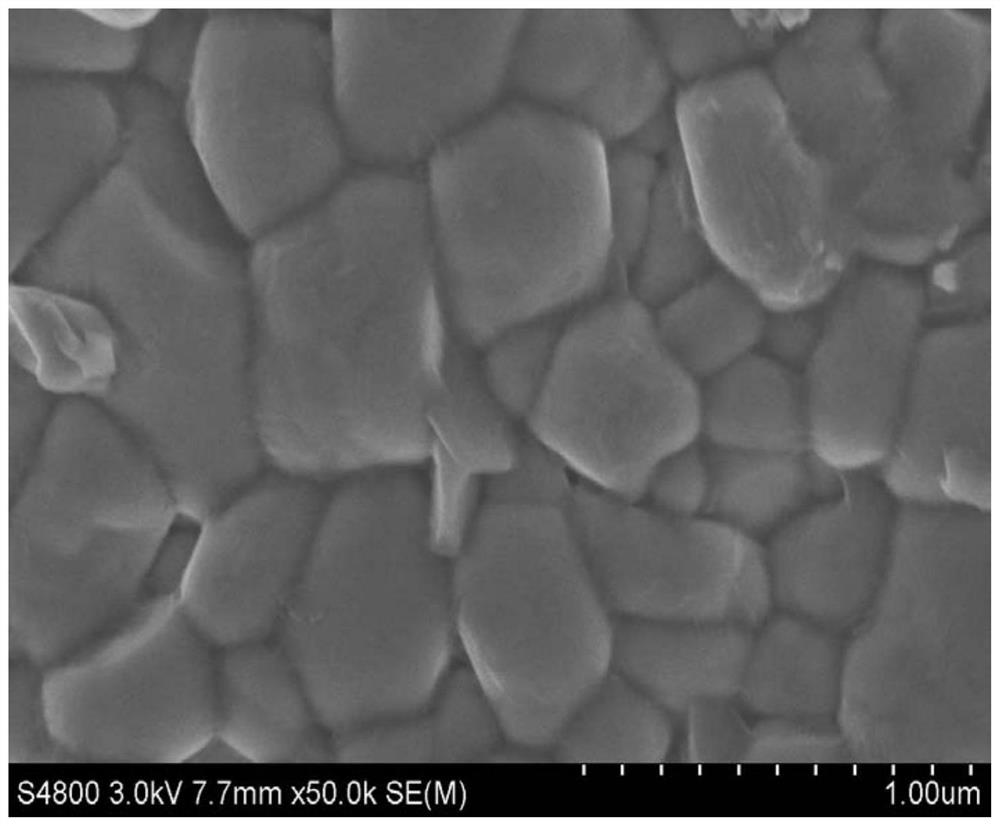

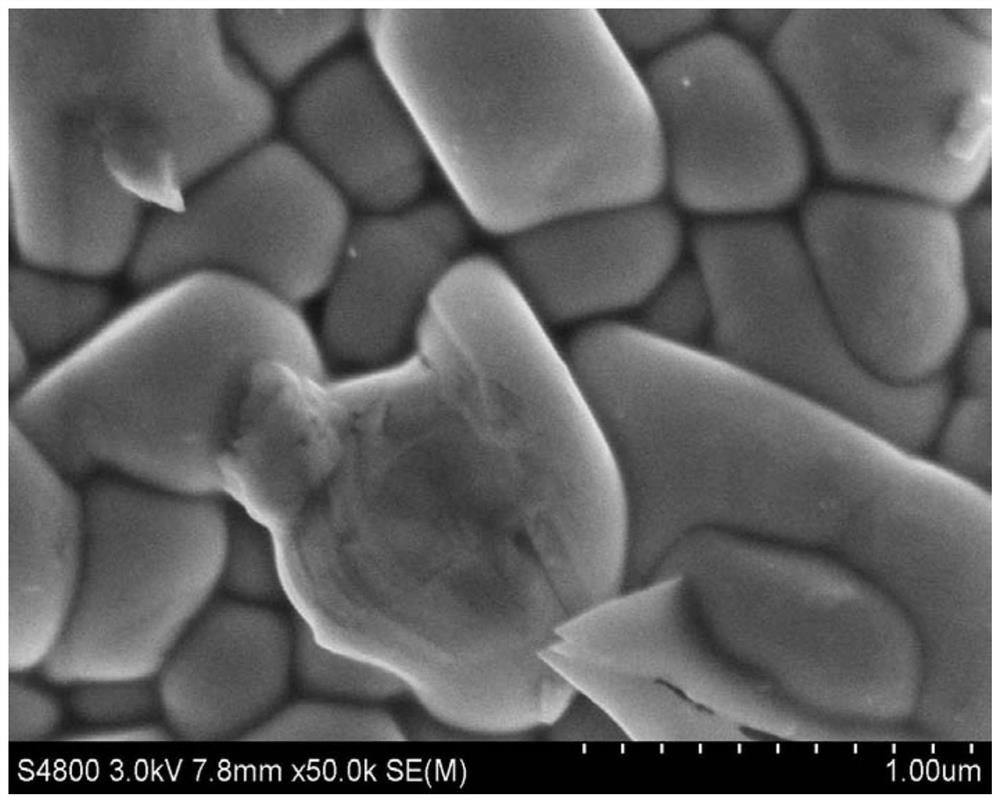

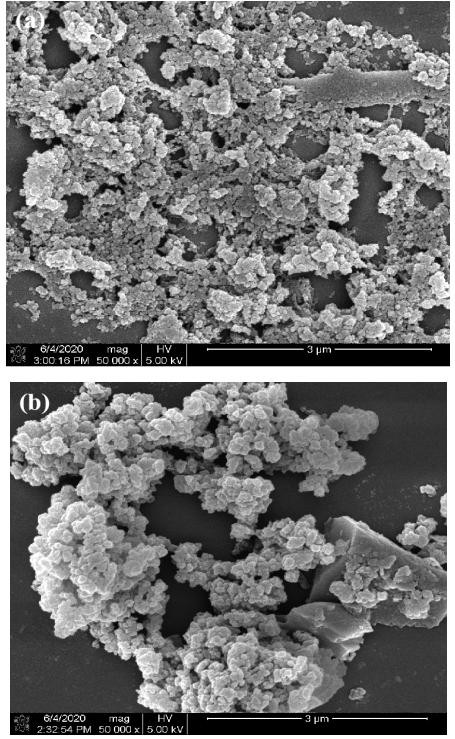

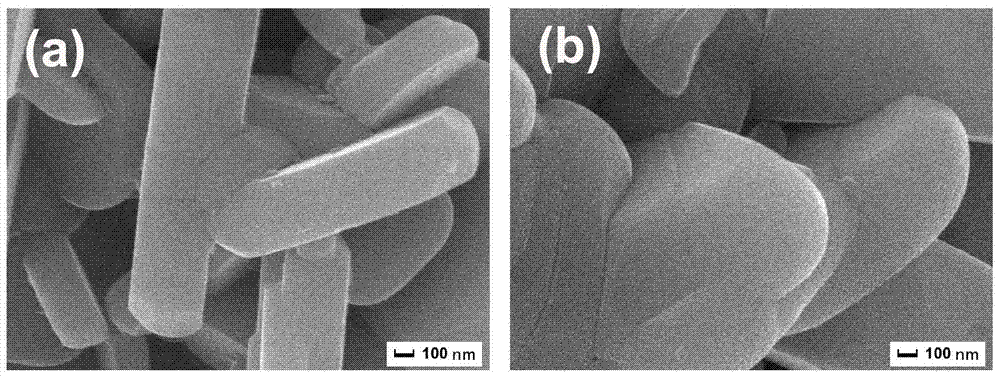

Al/La co-doped high-nickel ternary precursor with core-shell structure and preparation method thereof, and positive electrode material

ActiveCN111422926AImprove cycle performanceSmall sizeCell electrodesSecondary cellsManganeseLithium-ion battery

The invention relates to the field of lithium ion battery materials, and provides an Al / La co-doped high-nickel ternary precursor with a core-shell structure and a preparation method thereof, and a positive electrode material prepared from the precursor. The preparation method mainly comprises the following three steps: step 1, synthesizing an Al-doped high-nickel ternary precursor with rod-like primary particles under the condition of a low pH value; 2, increasing the pH value on the basis of the step 1, growing a La-doped high-nickel ternary precursor shell with needle-shaped primary particles by taking the Al-doped high-nickel ternary precursor as an inner core so as to synthesize an Al / La co-doped high-nickel ternary precursor with a core-shell structure; and 3, mixing the Al / La co-doped high-nickel ternary precursor with the core-shell structure and a lithium salt, and carrying out high-temperature calcination in an oxygen atmosphere to obtain the Al / La co-doped ternary positive electrode material with the core-shell structure. Due to the unique co-doped core-shell structure, the stability of an internal structure is effectively enhanced, the generation of mixed phases such ascation mixing and rock salt structures is inhibited, the breakage of grain boundaries is reduced, the average oxidation state of manganese ions is improved, the Jahn-Teller effect is effectively inhibited, the rapid attenuation of the capacity in a cycle process is reduced, the cycle stability of the material is remarkably improved, and the cycle life of the material is remarkably prolonged. Theproduct synthesized by adopting a coprecipitation method is uniform in component, good in sphericity, good in reproducibility, easy in condition control, low in preparation cost, high in economic value and wide in application prospect.

Owner:ZHUJI PAWA NEW ENERGY

Lithium NCM (nickel cobalt manganese) material and preparation method thereof

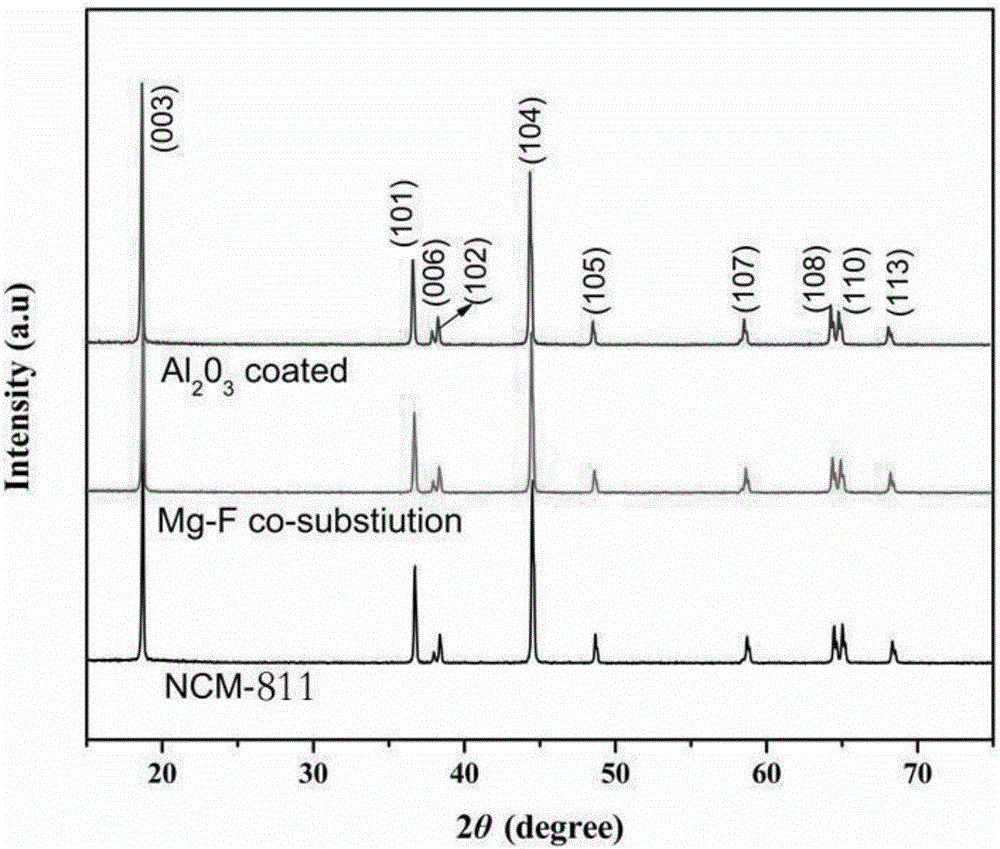

InactiveCN107180963AReduce solubilityChange the band structureCell electrodesSecondary cellsManganeseCobalt

The invention discloses a lithium NCM (nickel cobalt manganese) material. The lithium NCM material is prepared by doping Mg (magnesium), Al (aluminum) or Ti (titanium) and F (fluorine) into a 811 type lithium NCM cathode material. The lithium nickel manganese cobalt material has the advantages that by simultaneously doping Mg, Al or Ti and F into the 811 type NCM electrode material, the rate discharge property and specific capacity of the material are effectively improved; the corrosion of HF (hydrogen fluoride) to the material is effectively inhibited, the dissolving of Co is reduced, and the structure stability and thermal stability of the material are greatly improved.

Owner:四川新锂想能源科技有限责任公司

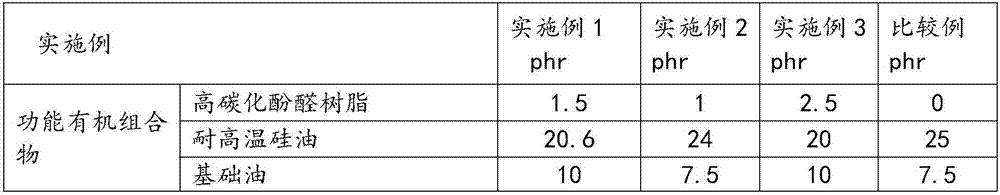

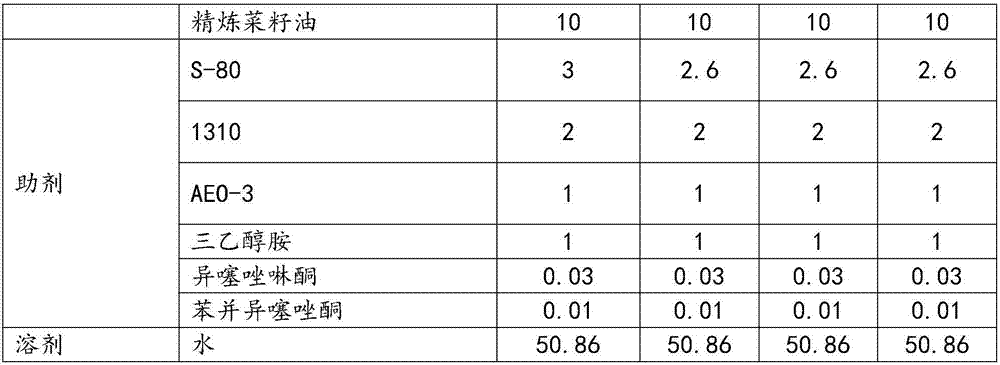

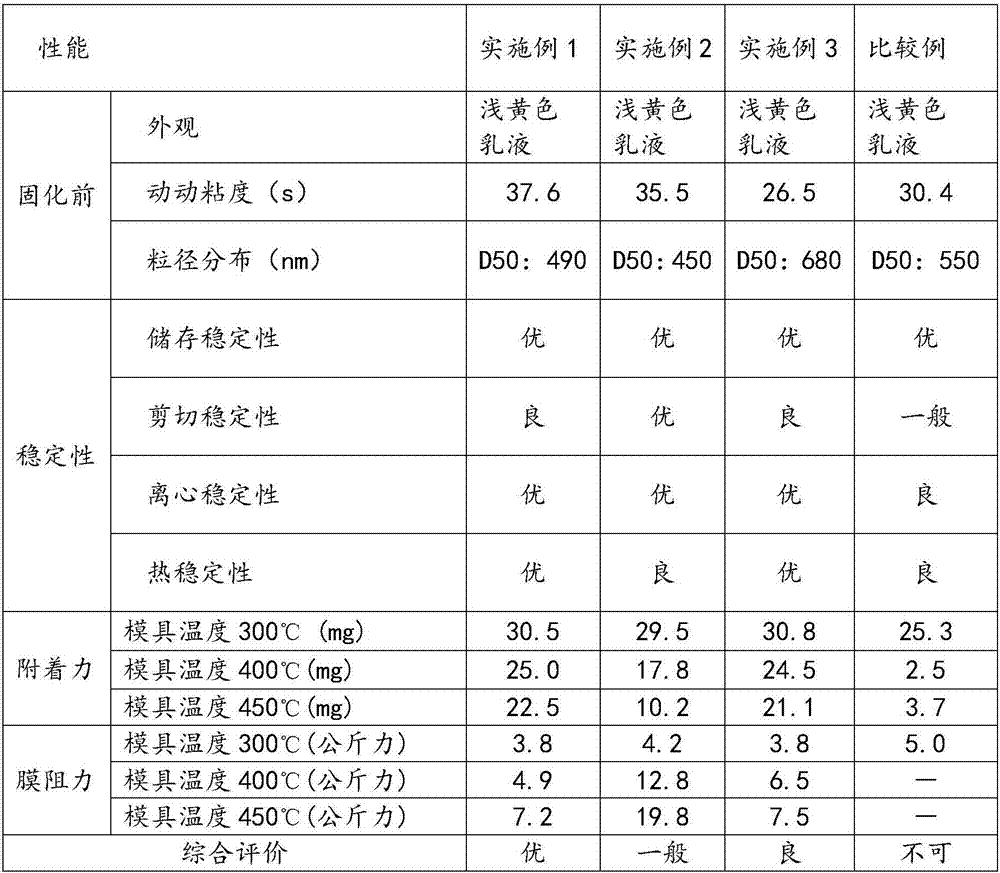

High-property water-based metal die-casting releasing agent, preparation method and application of high-property water-based metal die-casting releasing agent

The invention provides a high-property water-based metal die-casting releasing agent and further discloses a preparation method and application of the metal die-casting releasing agent. The high-property water-based metal die-casting releasing agent comprises the components of a functional organic composition, an assistant and a solvent. The functional organic composition comprises high-temperature-resisting resin, high-temperature-resisting silicone oil, mineral oil, animal and vegetable grease and the like, the assistant comprises a non-ionic surface active agent, a defoaming agent, a preservative, a sterilizing agent and the like, and the solvent is specifically deionized water. The high-property water-based aluminum alloy die-casting releasing agent is light yellow grey emulsion, the kinematic viscosity is 5-38 mm2 / s, the particle size is 200-500 nm, and the emulsion is stable; and in the aluminum die-casting technological process, the good lubricating and die releasing propertiesare achieved, the good cooling and heat-insulating properties are achieved, the good high-temperature wetting and lubricating properties are achieved, die sticking and destruction under pulling are prevented, carbon deposit and coking are avoided, thus a casting is purely white and bright, smoke and pollution are avoided, the clean environment is kept, and use is convenient and fast.

Owner:上海力太化学有限公司

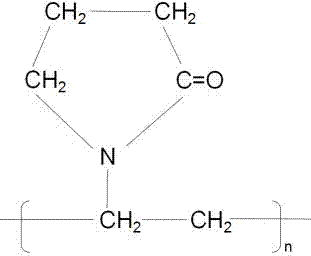

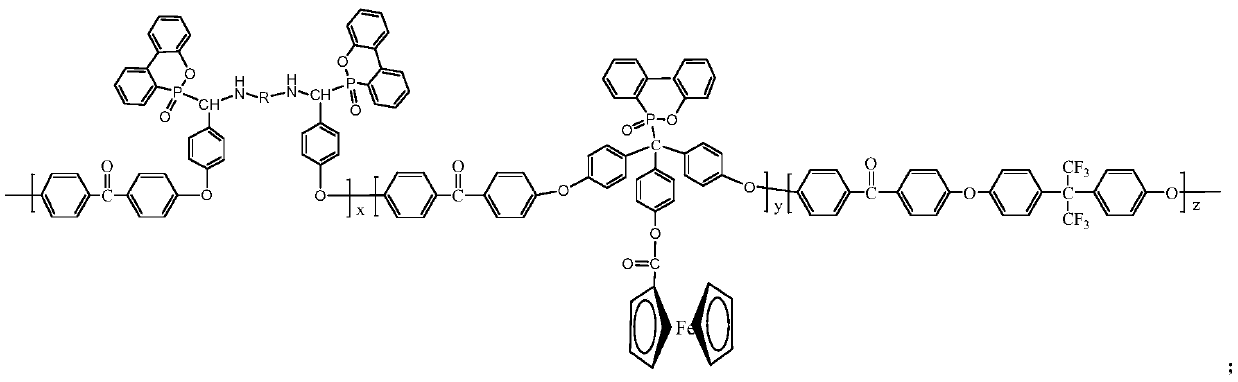

Method for preparing lithium battery polymer electrolyte having high conductivity

ActiveCN106910939AAvoid pollutionStrong bond energySolid electrolytesFinal product manufactureSolventLithium electrode

The invention relates to a method for preparing a lithium battery polymer electrolyte having high conductivity, which relates to a preparation method for increasing the conductivity of a polymer dielectric film in a lithium ion battery. The problem of low conductivity of the solid polymer dielectric film under normal temperature can be solved, so that the usage requirement cannot be satisfied. The preparation method comprises the following steps: dissolving 0.5 g of PVDF in 3.5 mL of a N, N-methyl methanamide (DMF) solvent, stirring the materials for 12 hours, weighing 0.85 g of EDTA and dispersing the material in 1 mL of the DMF solvent, stirring the materials for 12 hours, mixing the materials and stirring a mixture for 12 hours, weighing 0.01 g of PVP and dispersing the material in 1 mL of the DMF solvent for 3 hours, continuously mixing the material with a solution of PVDF and EDTA, adding 0.25 g of lithium bis(trifluoromethanesulfonyl) imide in the mixture, and continuously stirring the mixture for 6 hours until a polymer is stable and uniform, casting the stirred polymer electrolyte on a clean glass plate , placing the glass plate in a vacuum drying box, heating the material at the temperature of 110 DEG C for 1 hour to obtain a film. The method is used in the field of the lithium battery.

Owner:HARBIN UNIV OF SCI & TECH

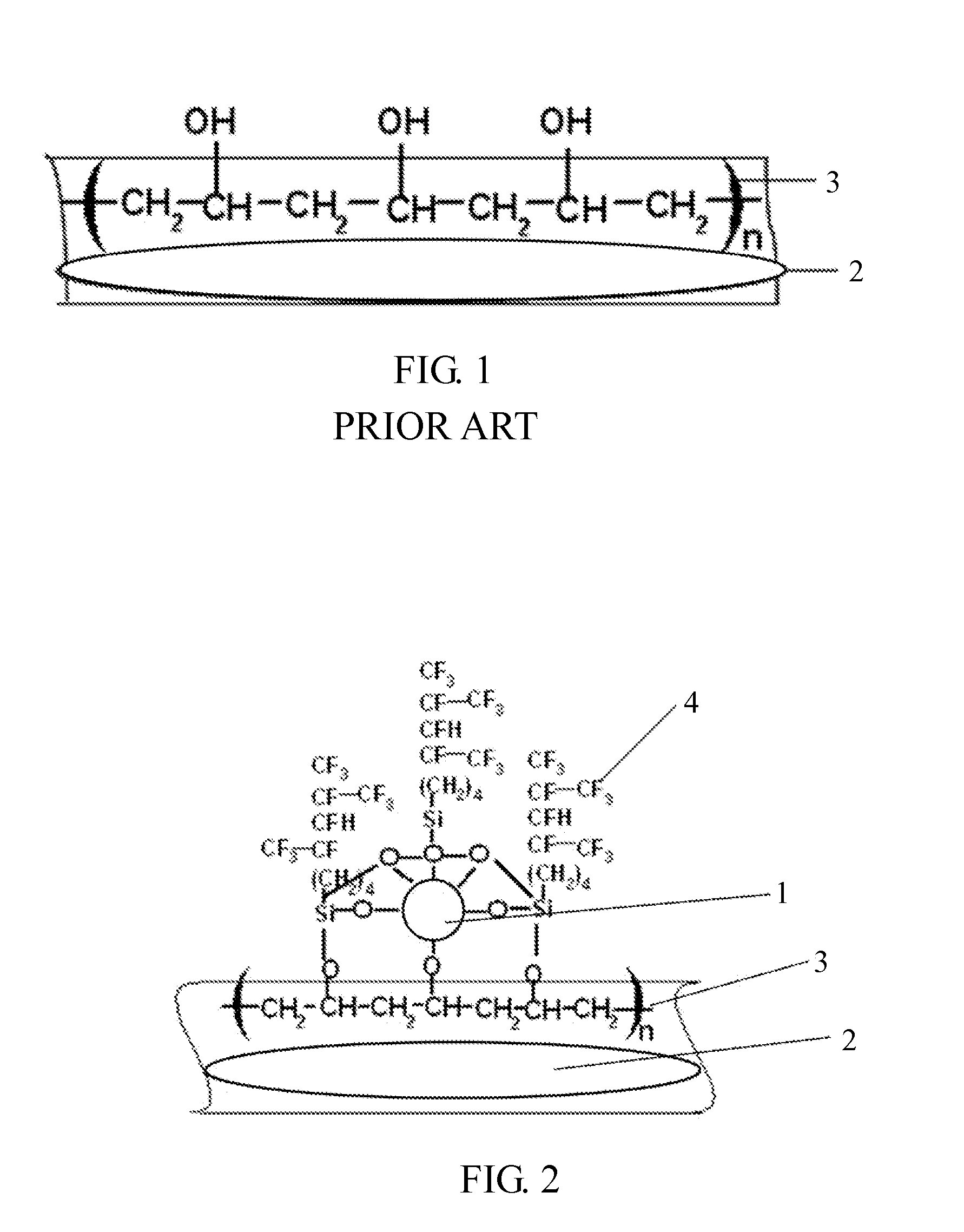

Base Film of Modified Polyvinyl Alcohol and Its Preparation Method and Polarizer

InactiveUS20130045390A1Improve heat resistanceEnhance humidity resistanceMaterial nanotechnologyPigmenting treatmentNano siliconPolymer science

The present invention provides a base film of modified polyvinyl alcohol as well as a method for preparing the base film of modified polyvinyl alcohol and a polarizer made from the base film. The method includes steps of: (1) executing surface graft modification of nano-silicon dioxides with fluorinated silane to obtain modified nano-silicon dioxide powders; (2) adding the modified nano-silicon dioxide powders obtained from the step (1) to an aqueous solution of polyvinyl alcohol polymers, in order to prepare a composite solution of polyvinyl alcohol polymers; and (3) pouring the composite solution of polyvinyl alcohol polymers prepared from the step (2) onto a surface of a casting substrate to obtain a base film of modified polyvinyl alcohol (PVA). The present invention enhances the heat and humidity resistances and the stability of the PVA base film, and improves its mechanical performance and sticking-resistance.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Ternary positive electrode material, preparation method thereof and lithium ion battery

PendingCN112864385AReduce the amount of residual alkaliImprove cycle performanceSecondary cellsPositive electrodesPhysical chemistryLithium-ion battery

The invention provides a ternary positive electrode material, a preparation method thereof and a lithium ion battery. The ternary positive electrode material comprises a core and a composite coating layer coating the core, the core is a high-nickel ternary material, and the composite coating layer comprises a boron-containing compound and a phosphorus-containing compound. The method comprises the following steps: mixing a boron source, a phosphorus source and a high-nickel ternary material, and sintering in an oxidizing atmosphere to obtain the ternary positive electrode material. According to the ternary positive electrode material provided by the invention, through the high-nickel ternary material core and the composite coating layer including the boron-containing compound and the phosphorus-containing compound, the residual alkali amount is low, and the rate discharge capacity and the cycle performance are good.

Owner:SHENZHEN CITY BATTERY NANOMETER TECH

A biodegradable polyurethane releasing agent and a preparing method thereof

A biodegradable polyurethane releasing agent is disclosed. The releasing agent comprises following components by weight: 10-20 parts of natural liquid wax, 20-30 parts of amino silicone oil emulsion, 5-10 parts of polydimethylsiloxane emulsion, 1-8 parts of silica aerogel, 2-5 parts of other auxiliary agents and 20-30 parts of deionized water. A preparing method of the releasing agent is also disclosed. The releasing agent is good in biodegradability, safe, nontoxic, good in releasing effects, and free of influence on product quality and molds after releasing. The preparing method is simple and low in cost.

Owner:SUZHOU JINGRO TECH

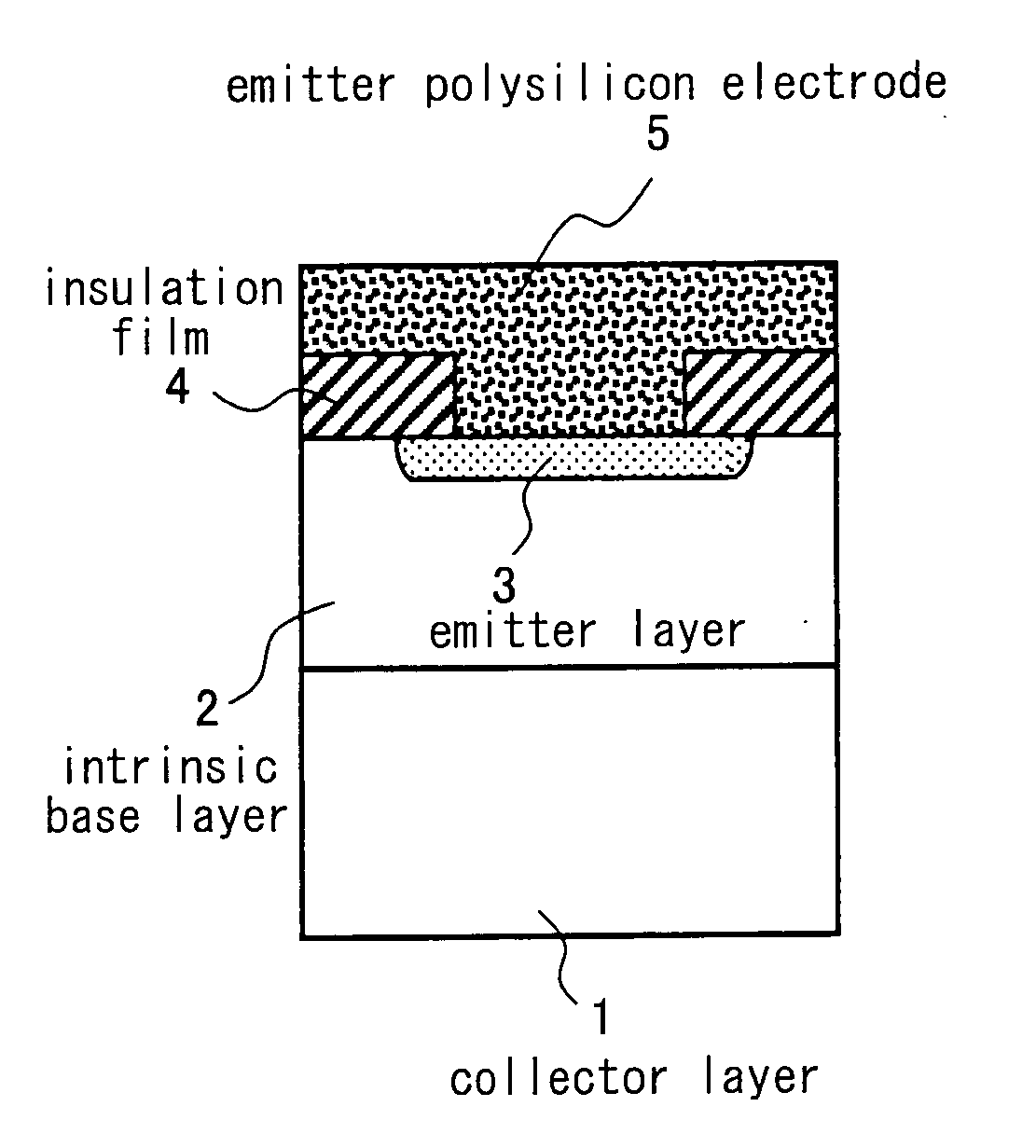

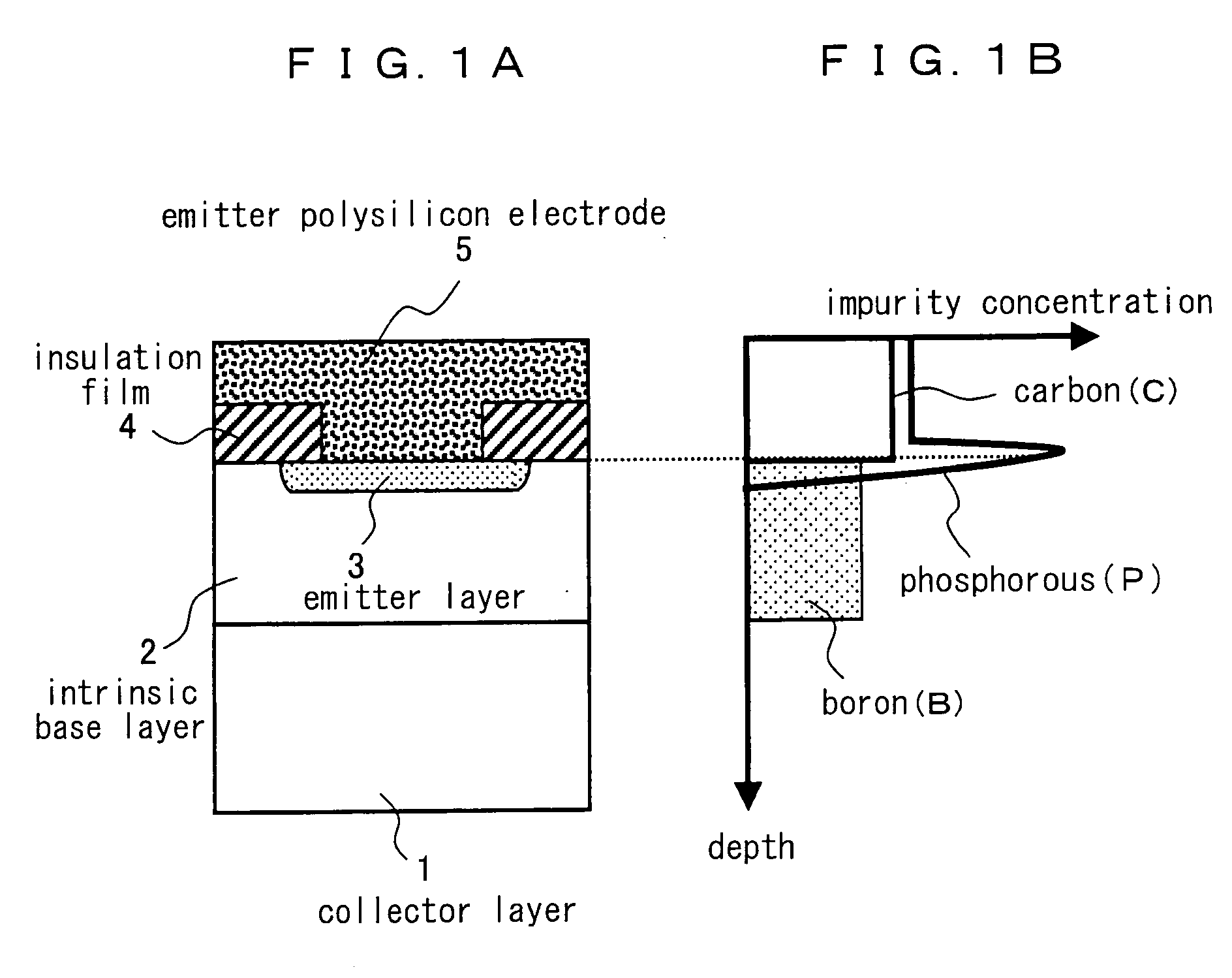

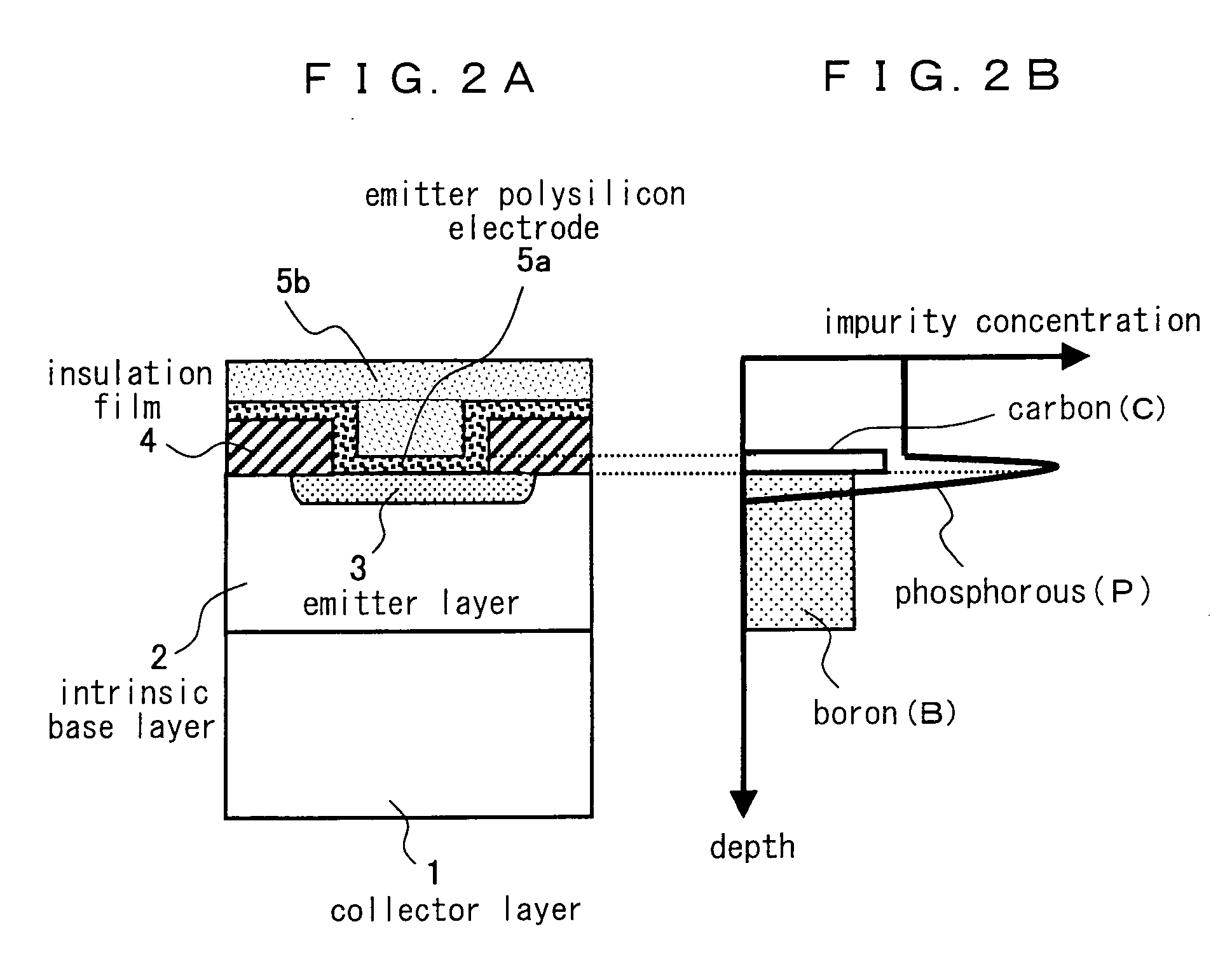

Bipolar transistor

InactiveUS20060186437A1Strong bond energyReduce parasitic resistanceSemiconductor devicesMaterials sciencePolycrystalline silicon

A bipolar transistor, wherein a outgoing electrode is made of a polycrystalline Si film, and C atom, or Ge atom together with C atom are added in the polycrystalline Si film.

Owner:PANASONIC CORP

Method for preparing flaky calcium-zinc stabilizer

InactiveCN109942984AImprove stabilityImprove the lubrication effectBulk chemical productionBond energyPolymer science

The invention discloses a method for preparing flaky calcium-zinc stabilizer. The method comprises the following raw material components in parts by weight: 31.25 parts of stearic acid, 1.5 parts of calcium hydroxide, 3.5 parts of zinc oxide, 6.97 parts of auxiliary stabilizer, 53.97 parts of filler, 13.25 parts of catalyst and 0.7 part of water. According to the flaky calcium-zinc stabilizer, calcium and zinc are adopted as main elements to replace lead salt stabilizers, the acute nodes of a polar group and PVC resin have relatively strong affinity due to relatively large electronegativity inthe plasticizing process to form a compound with relatively strong bond energy, so that the attraction of the ionic bond in each layer of PVC can be weakened or eliminated, mutually winding chain segments of PVC can be easily scattered, the boundary among molecular groups can easily disappear, PVC resin plasticization can be promoted, the PVC product performance can be improved, mechanical abrasion can be reduced, and the service life of downstream equipment can be prolonged; and the stabilizer has the advantages of no toxicity, harmlessness and no dust pollution, has relatively high stability and lubrication, and can be used for preparing PVC products with relatively good dispersion, compatibility and relatively high smoothness.

Owner:浙江东阳君邦科技有限公司

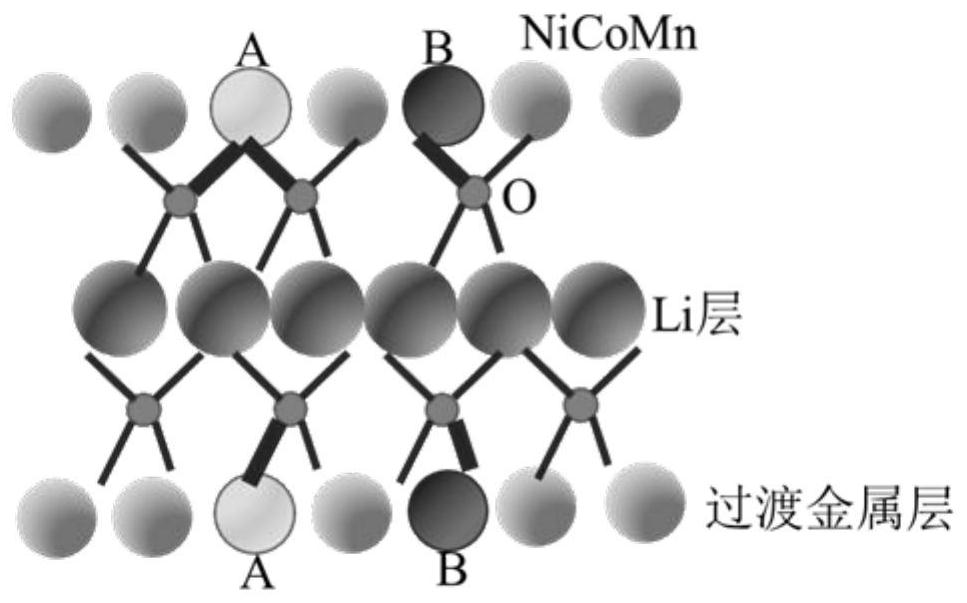

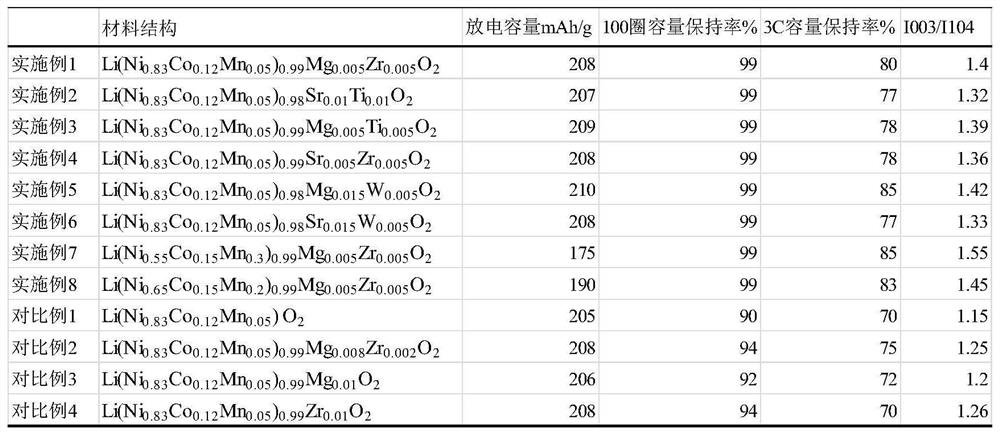

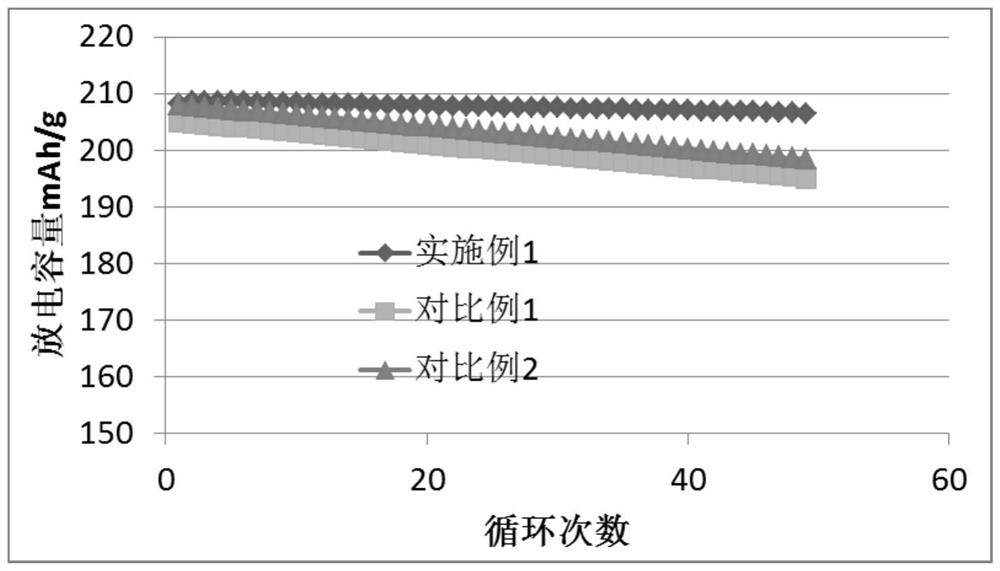

Five-element lithium ion battery positive electrode material, preparation method and lithium battery prepared from five-element lithium ion battery positive electrode material

ActiveCN111668475AStrong structural stabilityImproved magnification performanceCell electrodesSecondary cellsChemical physicsPhysical chemistry

The invention discloses a five-element lithium ion battery positive electrode material with an equivalent valence ratio, high stability and long cycle, a preparation method and a lithium battery prepared from the five-element lithium ion battery positive electrode material. The five-element positive electrode material has the following structure: Li(NiCoMn)xAyBzO2, wherein x is greater than or equal to 0.98, the element A comprises one of Mg and Sr, the element B is one of Zr, Ti and W, and the ratio of the element A to the element B needs to meet the following equation: (3-A valence)*y=(B valence-3)*z, and x+y+z=1. Compared with traditional ternary and other non-equal-proportion system materials, the five-element lithium ion battery positive electrode material has higher structural stability, and the cycle performance is obviously improved; and material defects are few, Li / Ni mixed arrangement is low, and the rate capability is more excellent.

Owner:WANHUA CHEM GRP CO LTD

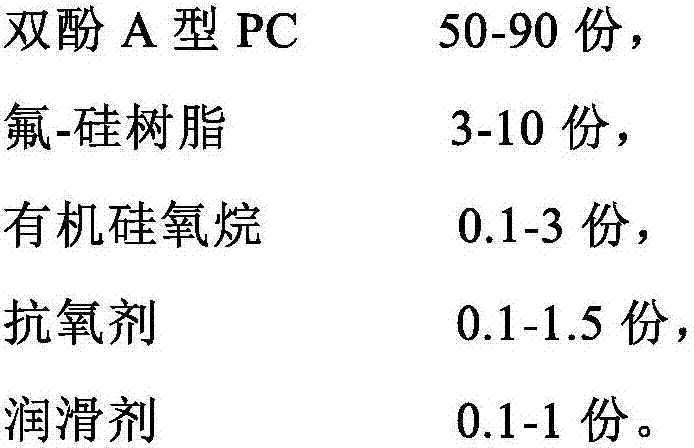

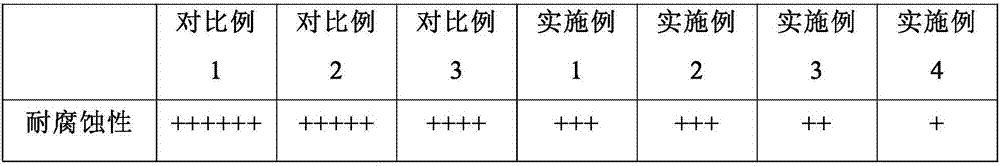

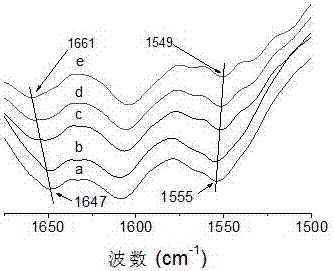

PC (Polycarbonate) composition resistant to chemical corrosion and preparation method thereof

The invention discloses a PC (Polycarbonate) composition resistant to chemical corrosion and a preparation method thereof. The PC composition is prepared from the following ingredients in parts by weight: 50-90 parts of bisphenol A type PC, 30-50 parts of fluoro-silicon resin, 0.1-3 parts of organosiloxane (PDMS), 0.1-1.5 parts of antioxidant and 0.1-1 part of lubricant. Compared with the prior art, the PC composition provided by the invention has the advantages that by using excellent corrosion resistance of fluorine and synergistic corrosion prevention and compatibility effects of organosilicone, the resistance to chemical corrosion of PC compounds are improved, and the effect of having efficient corrosion prevention without spraying anticorrosive paint is achieved.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

A self-healing elastomer material and a preparing method thereof

ActiveCN107099137AImprove mechanical propertiesLower glass transition temperaturePrepolymerDouble bond

A self-healing elastomer material and a preparing method thereof are disclosed. The method includes (1) reacting a first component containing a double bond and an ester group or carboxyl and a second component containing two or more amino groups at a temperature ranging from -15 DEG C to 50 DEG C for 1-72 h to obtain a prepolymer, removing an organic solvent, and then reacting the mixture at 25-200 DEG C for 1-12 h to obtain hyperbranched polyamidoamine (HPAMAM) having an amino molecular chain tail end; and (2) reacting the HPAMAM, polybasic acid and an alkaline metal compound which are metered at 100-200 DEG C for 1-24 h to obtain the self-healing elastomer material. The functional material synthesized based on the hyperbranched polyamidoamine is a hyperbranched material formed by self-assembling of hydrogen bonds and ionic bonds. The material has elasticity at room temperature. As reversible hydrogen bonds and ionic bonds exist, the material has a property that the material is self-healing at room temperature, is thermoplastic and can be repeatedly processed.

Owner:SOUTH CHINA UNIV OF TECH

A kind of self-healing polyurethane coating and preparation method thereof

ActiveCN104356338BAchieve self-healingImplement multiple repeat repairsPolyurea/polyurethane coatingsPolyesterPolyol

Owner:SOUTH CHINA UNIV OF TECH

Tablet calcium-zinc stabilizing agent

PendingCN109897308AImprove stabilityImprove the lubrication effectBulk chemical productionDispersityHigh energy

The invention discloses a tablet calcium-zinc stabilizing agent. The tablet calcium-zinc stabilizing agent is prepared from, by weight, 31.25 parts of stearic acid, 1.5 parts of calcium hydroxide, 3.5parts of zinc oxide, 6.97 parts of an auxiliary stabilizing agent, 53.97 parts of a filling agent, 13.25 parts of a catalyst and 0.7 part of water. The tablet calcium-zinc stabilizing agent with calcium and zinc as main elements replace a lead salt stabilizing agent; in a plasticizing process, due to high electronegativity, a conjugate with high bond energy is formed under strong affinity of a polar group and an acute node of PVC resin, and accordingly attractive force of each layer of ionic bonds of PVC is weakened or eliminated, intertwined PVC segments can be easily diffused, boundary of molecular groups is easy to disappear, PVC resin plasticizing is promoted, performances of PVC products are improved, mechanical wear is reduced, and the service life of downstream equipment is prolonged. The stabilizing agent has advantages of nontoxicity, harmlessness and no dust pollution and is high in stability and lubricating property, and the PVC products with high dispersity, compatibilityand smoothness can be prepared.

Owner:浙江东阳君邦科技有限公司

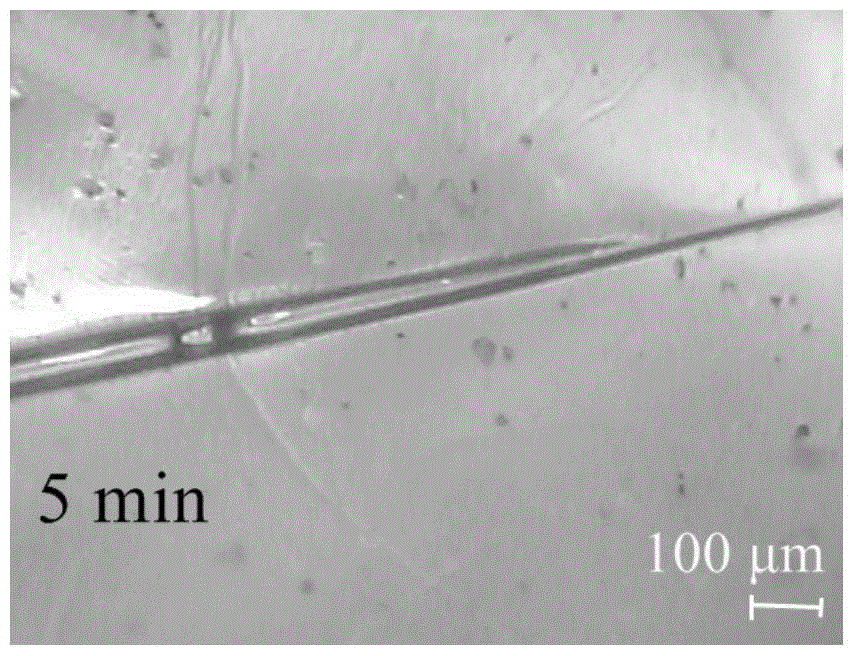

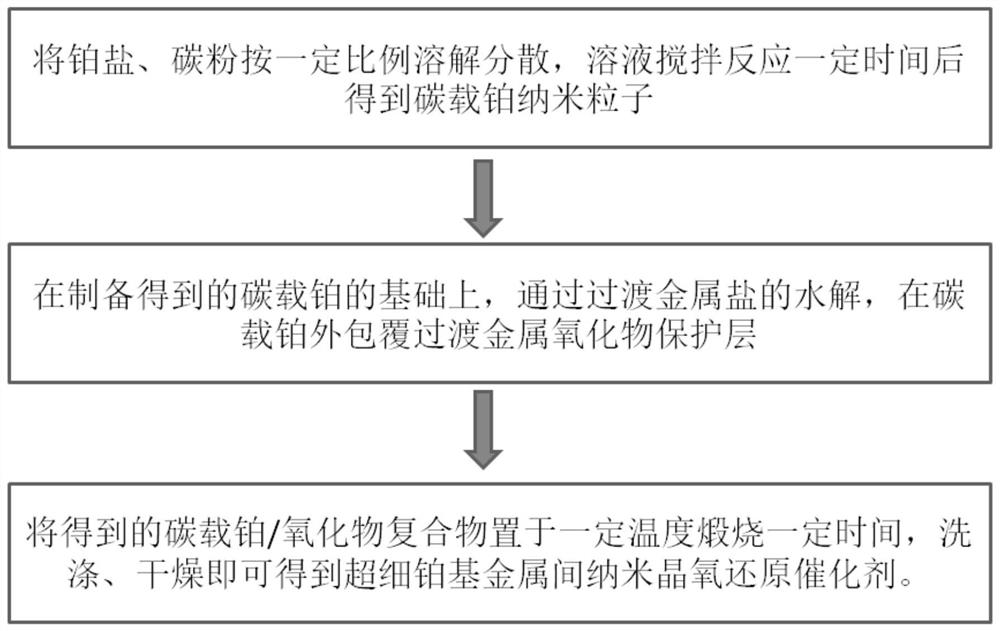

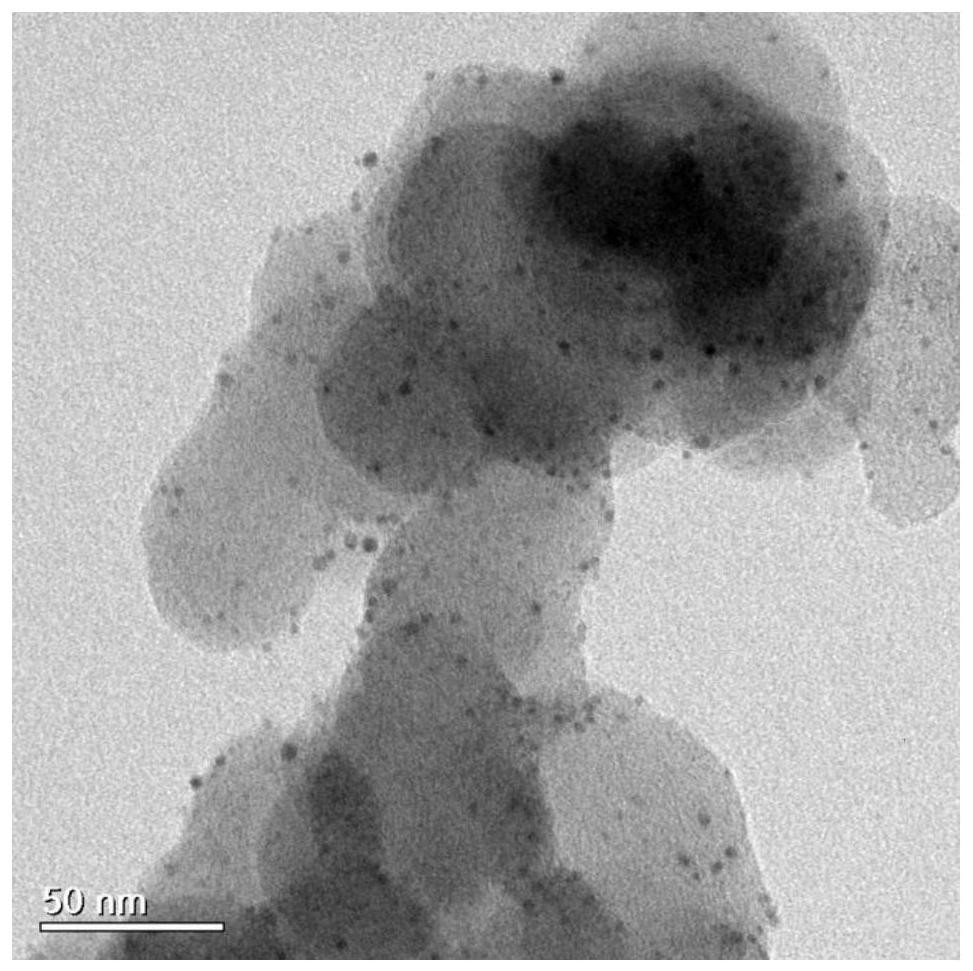

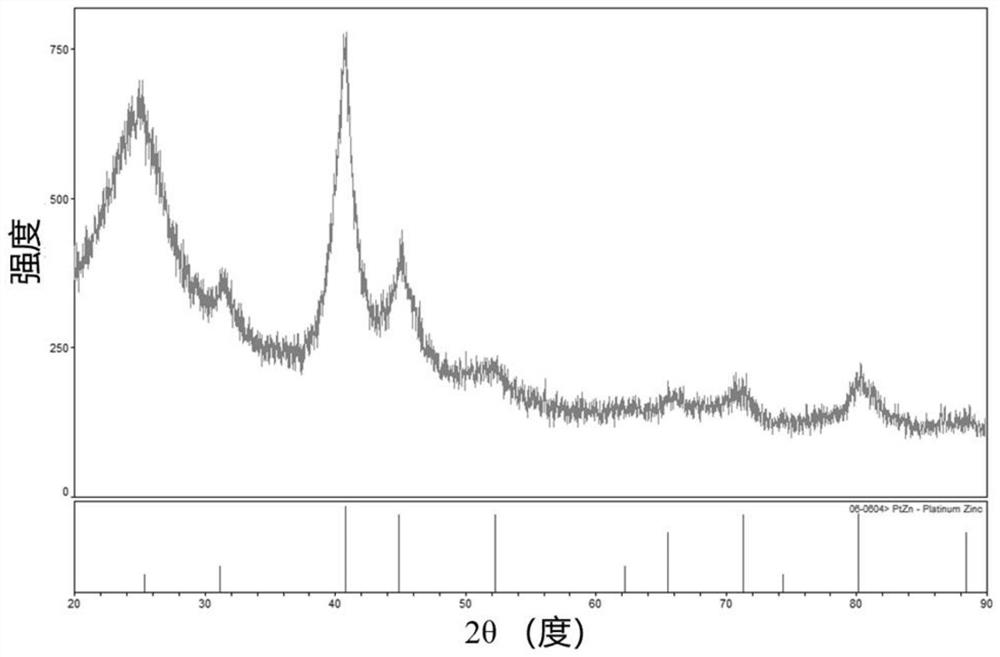

Platinum-based intermetallic nanocrystal with ordered structure and preparation and application thereof

ActiveCN113206259ARaise the chemical potentialEasy to driveCell electrodesPlatinum saltsPtru catalyst

Owner:HUAZHONG UNIV OF SCI & TECH

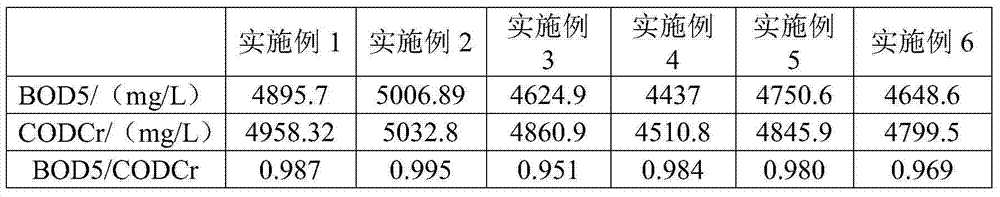

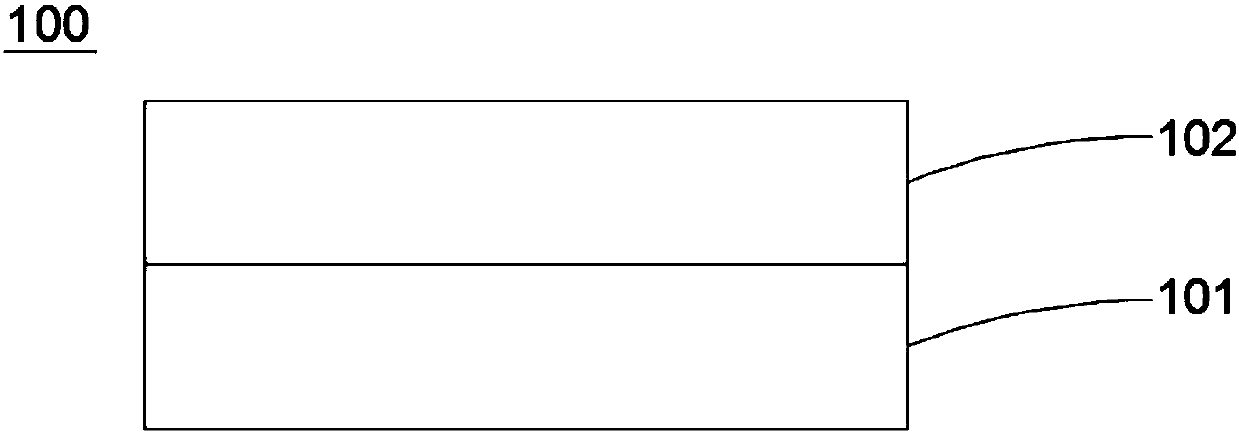

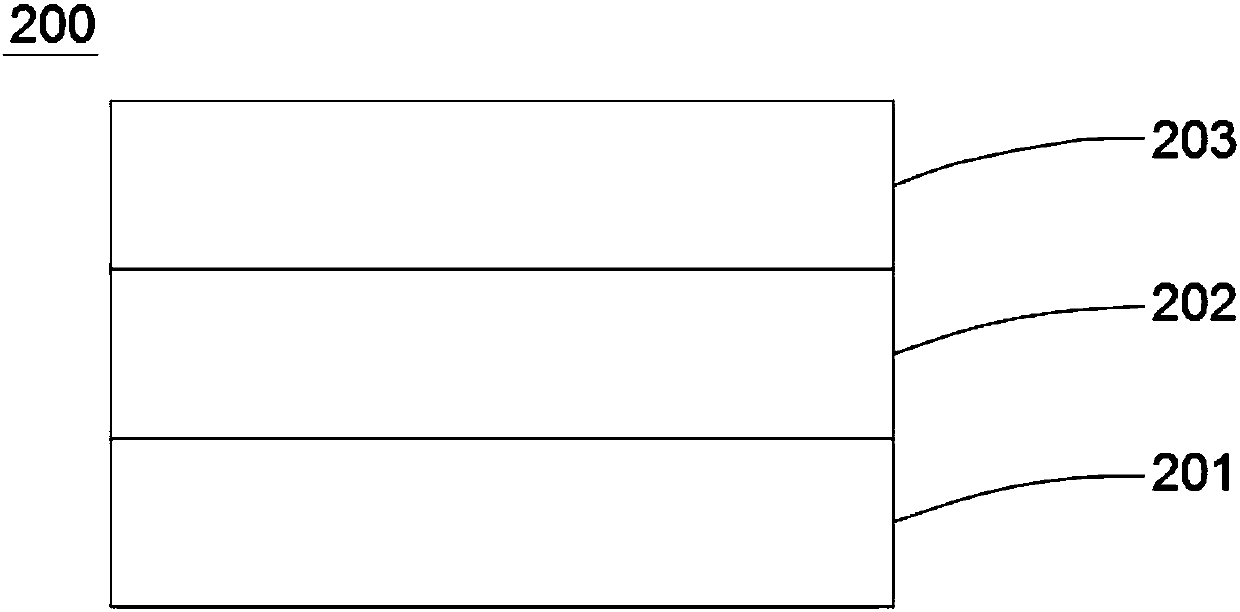

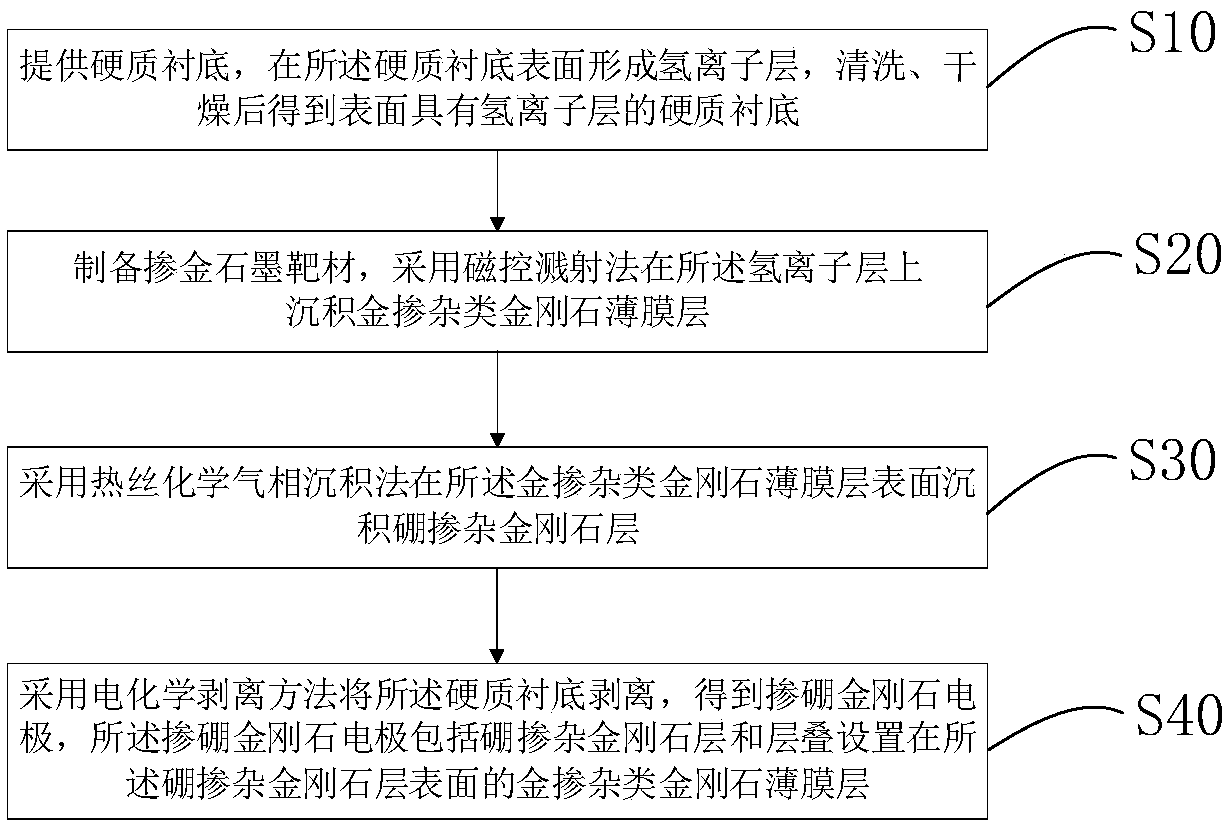

Boron-doped diamond electrode and preparation method and application thereof

PendingCN110241386AStrong bond energyCompact structureWater contaminantsVacuum evaporation coatingBoronDiamond thin film

The invention provides a boron-doped diamond electrode. The boron-doped diamond electrode comprises a boron-doped diamond layer and a gold-doped diamond-like film layer laminated on the boron-doped diamond layer. The boron-doped diamond electrode has stable structure, high electrocatalytic activity and low resistance energy consumption. The invention further provides a preparation method and application of the boron-doped diamond electrode.

Owner:SHENZHEN INST OF ADVANCED TECH

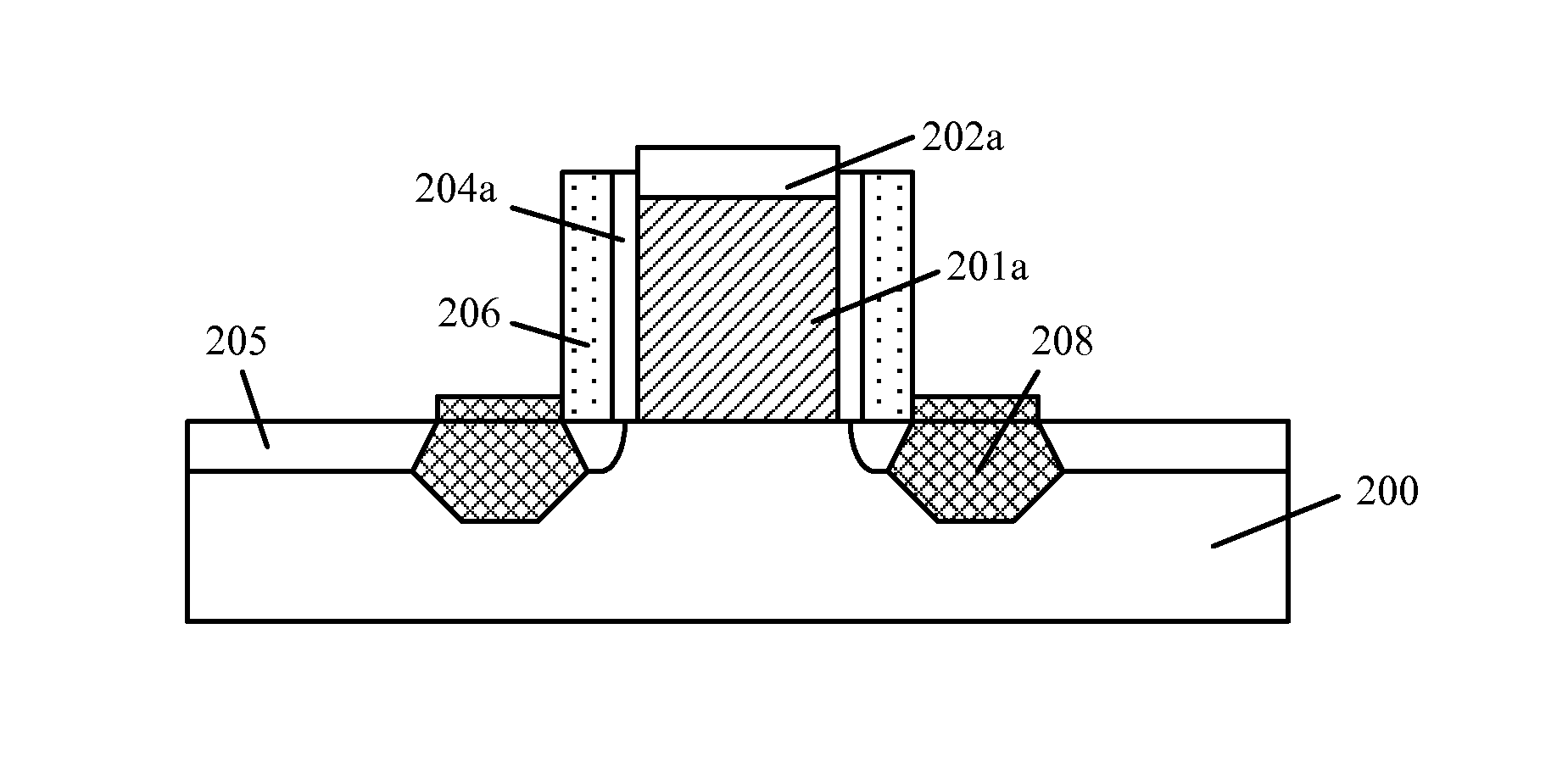

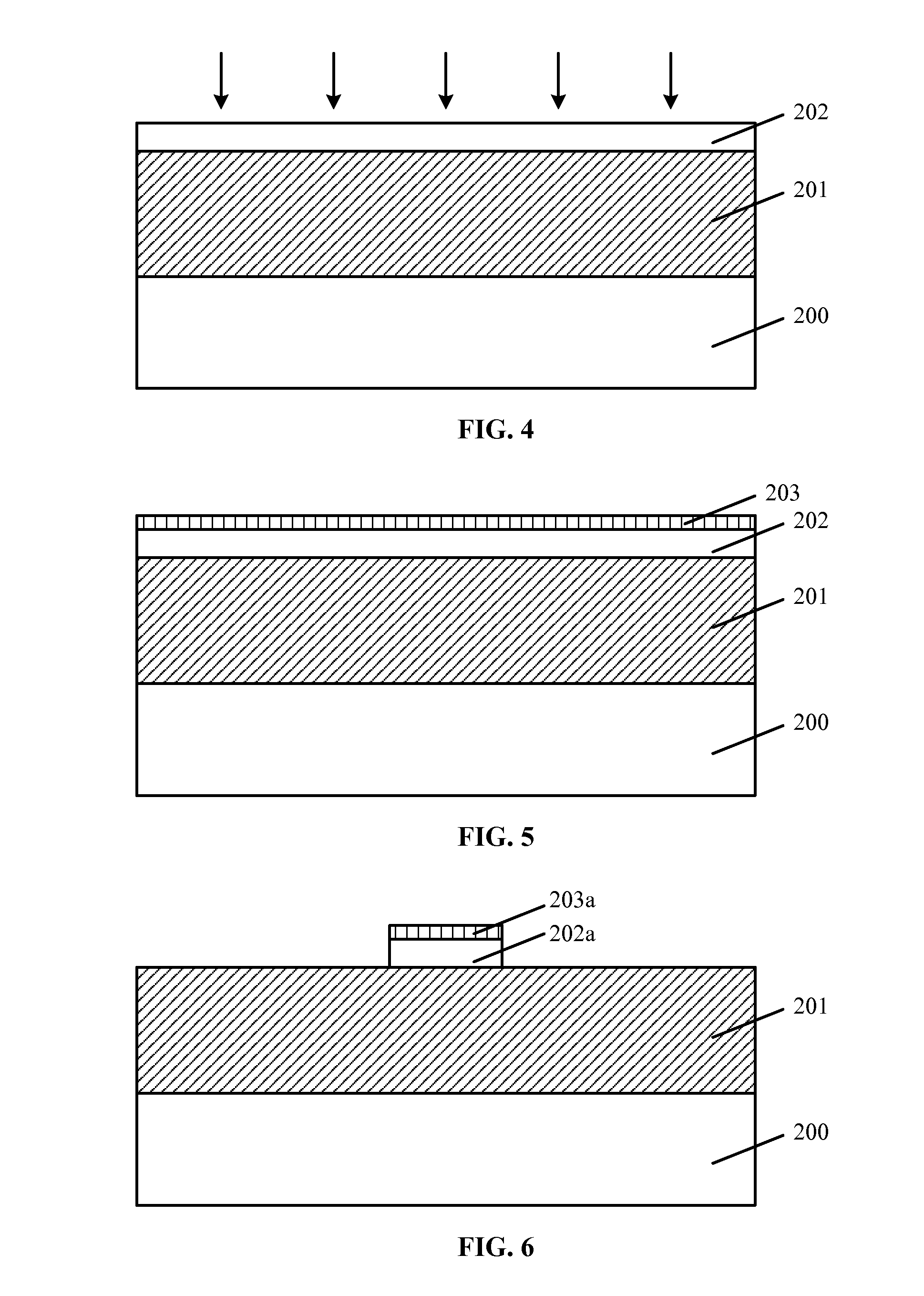

Semiconductor structures and fabrication method thereof

ActiveUS20160093718A1Improve reliabilityBonding energyTransistorSemiconductor/solid-state device manufacturingSemiconductor structureTransistor

A method is provided for fabricating transistors. The method includes providing a semiconductor substrate. The substrate has a gate film and a mask film formed on a top surface. The mask film contains implanted carbon ions. The method further includes forming a mask layer by etching the mask film and then forming a gate layer by etching through the gate film using the mask layer as a mask until the substrate is exposed. The method also includes forming a first sidewall containing implanted carbon ions on the side surface of the gate layer and the mask layer; forming a stress layer in the substrate on both sides of the gate layer and the first side-wall; and forming a source region on one side of the gate layer and the first sidewall and a drain region on the other side of the gate layer and the first side wall.

Owner:SEMICON MFG INT (SHANGHAI) CORP

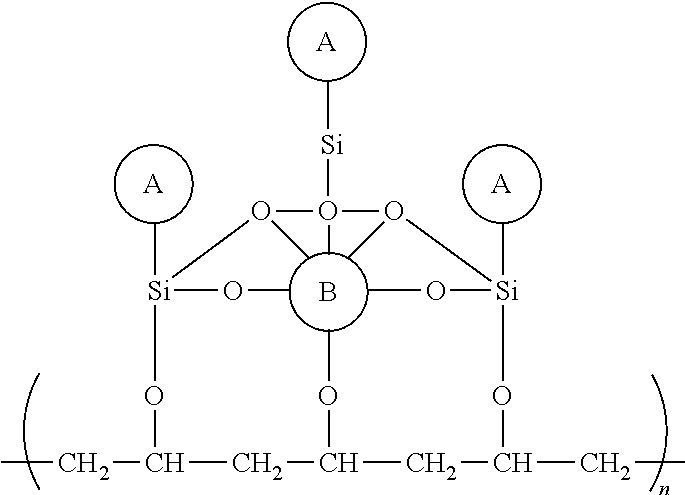

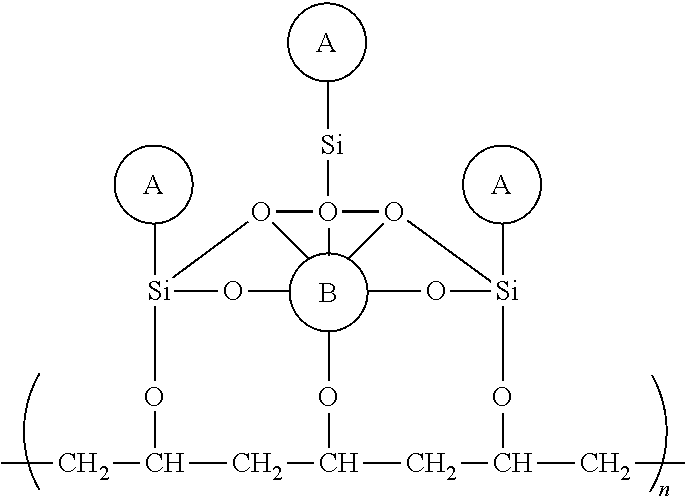

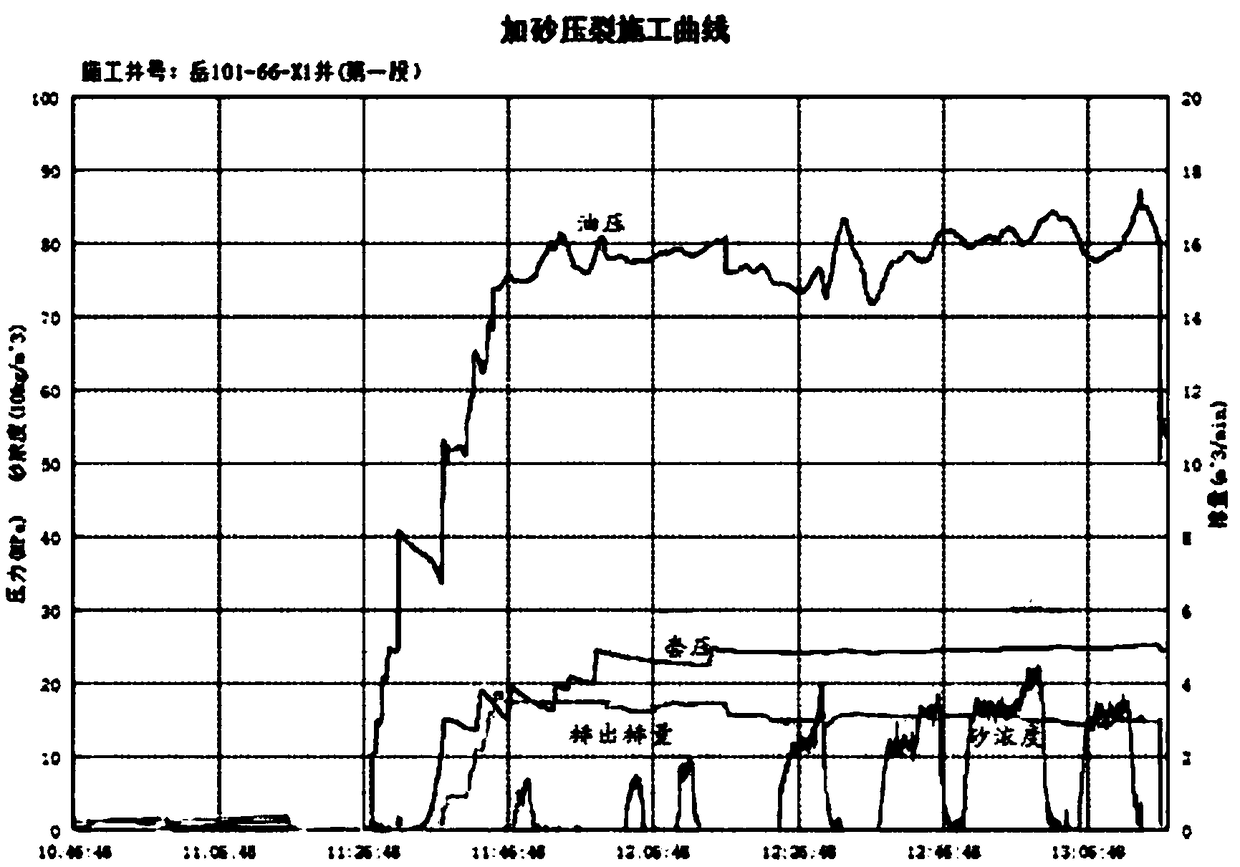

Preparation method of normal temperature crosslinking aluminum crosslinker for shale gas fracturing fluid

ActiveCN108690064AReduce corrosionGlue in good conditionGroup 3/13 element organic compoundsDrilling compositionFracturing fluidTemperature resistance

The invention relates to a preparation method of a normal temperature crosslinking aluminum crosslinker for a shale gas fracturing fluid. The preparation method includes the steps: firstly, dissolvingaluminum ion auxiliaries in water to prepare first mixed solution; heating the first mixed solution to reach the temperature of 50-80 DEG C, stirring the first mixed solution and adding an organic matter serving as a complex ligand to obtain second mixed solution; secondly, performing thermostatic reaction on the second mixed solution for 2-4 hours and keeping the second mixed solution clear andtransparent; adding pH (potential of hydrogen) regulators into the second mixed solution and adjusting the pH value of the second mixed solution to be 6.0-8.0 to obtain faint yellow homogeneous transparent liquid. The pH of the crosslinker prepared by the preparation method is 6-8, and corrosion of oil pipe equipment and the like is reduced. Effective crosslinking components are released at normaltemperature and can be crosslinked with low-concentration hydrolytic polyacrylamide in fracturing construction to form a stable gel system, the crosslinker has performances such as strong viscous elasticity, high temperature resistance and high salinity resistance, a most permeable zone can be limitedly plugged, water injection effects are improved, and gas well recovery ratio is increased.

Owner:SICHUAN WELDON CHEM

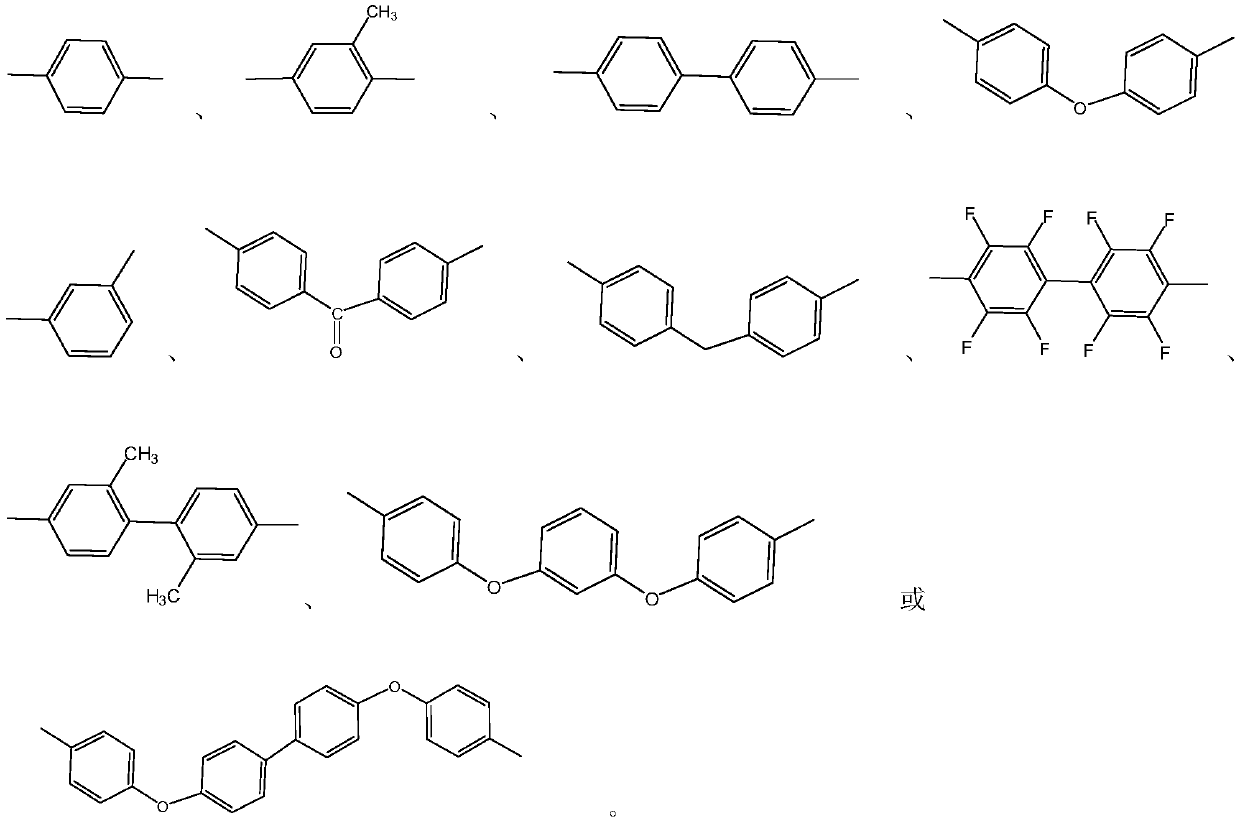

Thin-wall high-temperature-resistant radiation-resistant flame-retardant cable material polyether-ether-ketone and preparation method thereof

InactiveCN109880078AGood stabilityLong-lasting flame retardant performancePlastic/resin/waxes insulatorsPoly ether ether ketoneSmoke

The invention discloses a preparation method of a thin-wall high-temperature-resistant radiation-resistant flame-retardant cable material, namely, polyether-ether-ketone. The method comprises the following steps: placing a three-component bisphenol monomer, difluorobenzophenone, and K2CO3 or Na2CO3 into an organic solvent according to a molar ratio of 1:1:(1.2-2.0), conducting reacting at 130-150DEG C for 1-5 hours under the action of N2 flow, and the conducting reacting at 150-170 DEG C for 3-20 hours to prepare the thin-wall high-temperature-resistant radiation-resistant flame-retardant cable material polyether-ether-ketone. The method is simple and easy to implement, and the thin-wall high-temperature-resistant radiation-resistant flame-retardant cable material polyether-ether-ketone is prepared by adopting a stepwise polymerization method. The cable material prepared by the invention has the characteristics of high strength, high wear resistance, high oil resistance, high-temperature resistance, radiation resistance, good electrical insulation property, low smoke, no halogen, flame retardancy and the like, is very suitable for extrusion of ultrathin-wall cables, can meet the processing technology of ultrathin-walled insulated cables and the technical requirements of products, is convenient to produce, and has good economic benefits and popularization values.

Owner:QUANGANG PETROCHEM RES INST OF FUJIAN NORMAL UNIV

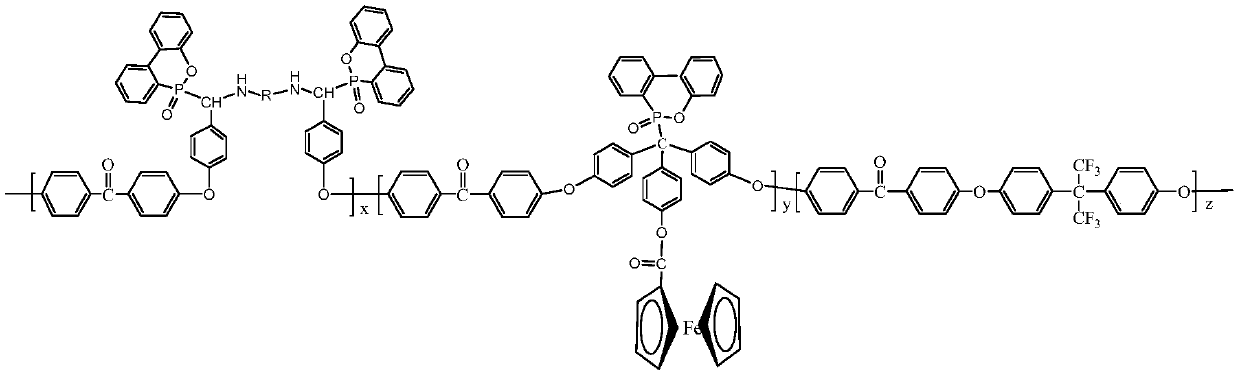

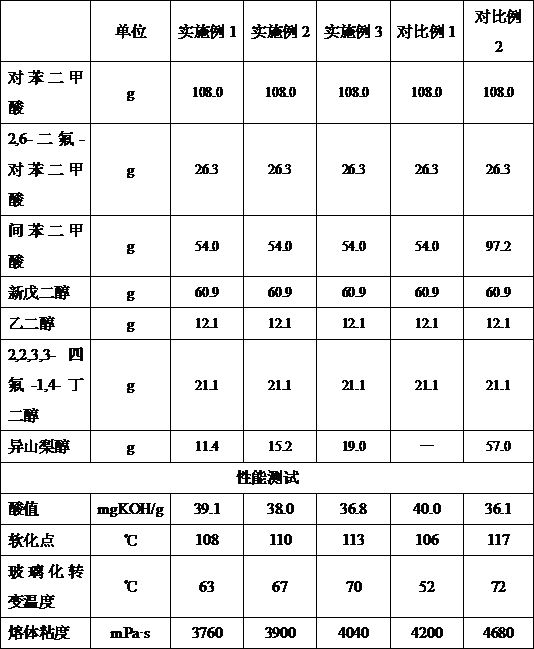

Corrosion-resistant weather-resistant high-storage-performance polyester resin for powder coating

ActiveCN112961334AKey can be strongGood corrosion resistanceGeneral water supply conservationAnti-corrosive paintsComposite materialWeather resistance

The invention relates to the technical field of powder coatings, in particular to polyester resin for a powder coating with corrosion resistance, weather resistance and high storage performance, the powder coating and a coating. The polyester resin is prepared from, by weight, 90-125 parts of terephthalic acid, 22-30 parts of fluorine-containing dicarboxylic acid, 46-60 parts of isophthalic acid, 50-70 parts of neopentyl glycol, 10-14 parts of ethylene glycol, 18-24 parts of fluorine-containing dihydric alcohol; through reasonable matching of the components, the glass transition temperature of the polyester resin is improved, and the polyester resin has excellent corrosion resistance and weather resistance.

Owner:SHANDONG SHANGHE POWER TECH

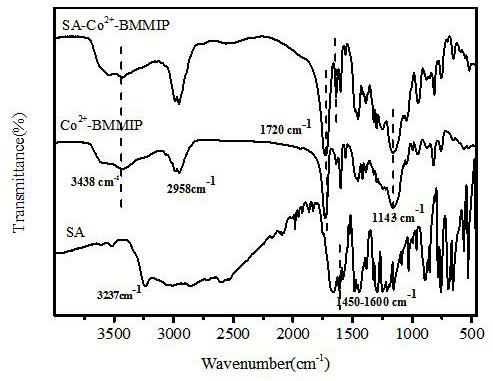

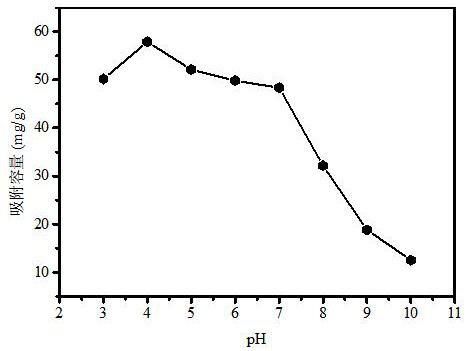

Metal ion coordination bifunctional monomer molecularly imprinted polymer as well as preparation method and application thereof

InactiveCN111777713AGood adsorption and selectivityImprove performanceOther chemical processesWater contaminantsSpecific adsorptionMolecularly imprinted polymer

The invention discloses a metal ion coordination bifunctional monomer molecularly imprinted polymer as well as a preparation method and application thereof as a solid-phase extraction agent, and belongs to the field of adsorption material preparation processes. The preparation method comprises the following steps: providing a specific adsorption site for a molecularly imprinted polymer by using abifunctional monomer, introducing a metal ion Co<2+>, forming a bifunctional monomer-metal ion-template complex with stronger bond energy with the bifunctional monomer and a template, polymerizing, eluting and drying to obtain the metal ion coordination bifunctional monomer molecularly imprinted polymer. Compared with a molecularly imprinted polymer without metal ion mediation, the adsorption capacity (Q=51.13 mg / g) and the selectivity (IF=3.66) of the molecularly imprinted polymer for organic pollutants with intra-molecular hydrogen bonds are increased. Therefore, the material can be used forspecific extraction of organic pollutants in an aqueous solution.

Owner:FUZHOU UNIVERSITY

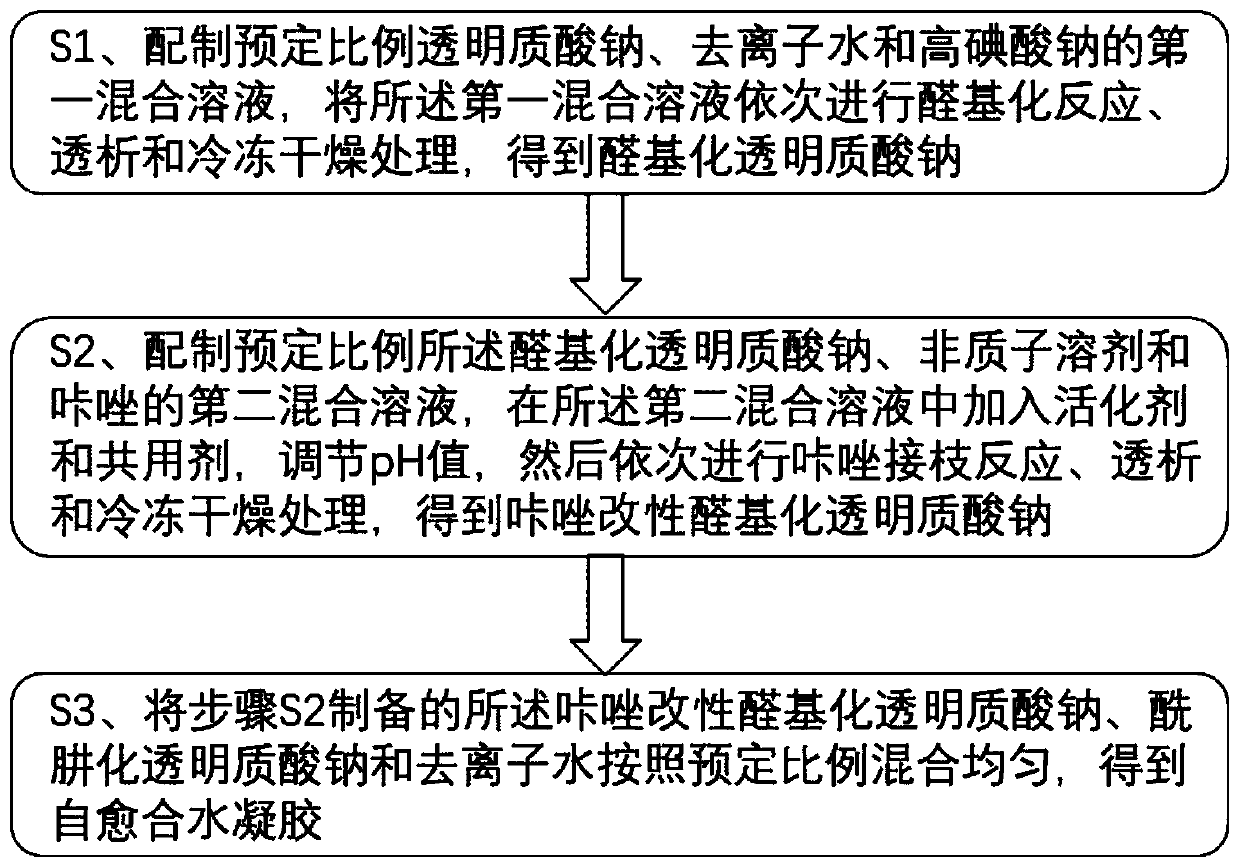

Self-healing hydrogel and preparation method thereof

ActiveCN111019195AHave self-healing abilityImprove self-healing abilityPhotodynamic therapyPharmaceutical non-active ingredientsCarbazoleGraft reaction

The invention provides a self-healing hydrogel and a preparation method thereof. The self-healing hydrogel is composed of carbazole modified aldehyde sodium hyaluronate, hydrazide sodium hyaluronate and deionized water, and the strength of the self-healing hydrogel ranges from 1000 cps to 100000 cps. The preparation method of the self-healing hydrogel provided by the invention comprises the following steps: preparing a first mixed solution of sodium hyaluronate, deionized water and sodium periodate, and carrying out aldehyde reaction to obtain aldehyde sodium hyaluronate; then, preparing a second mixed solution of aldehyde sodium hyaluronate, an aprotic solvent and carbazole, adding an activating agent and a sharing agent, adjusting the pH value, and carrying out carbazole grafting reaction to obtain carbazole modified grafted aldehyde sodium hyaluronate; and finally, uniformly mixing the prepared carbazole modified grafted aldehyde sodium hyaluronate, hydrazide sodium hyaluronate anddeionized water according to a preset proportion to obtain the self-healing hydrogel. The self-healing hydrogel prepared by the invention has excellent self-healing performance and biocompatibility, and also has special photoelectric characteristics.

Owner:武汉华卫科技有限公司

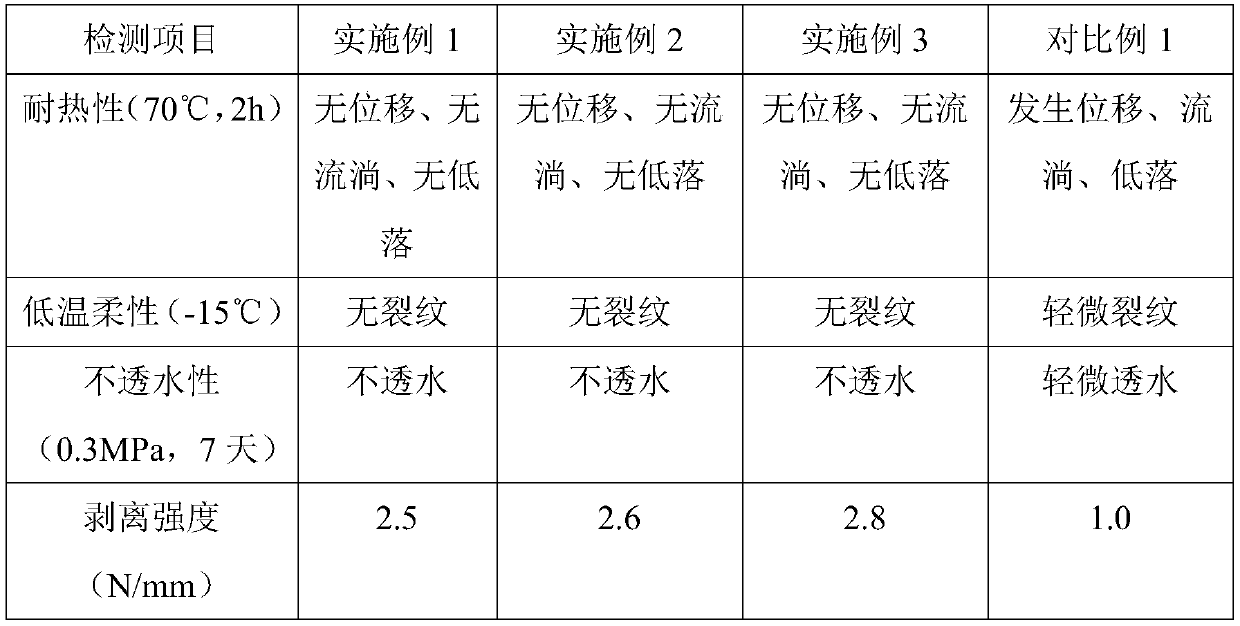

Preparation method of building composite waterproof material

The invention relates to a preparation method of a building composite waterproof material, and belongs to the technical field of building materials. According to the method, a styrene-acrylic emulsionis added to form the building composite waterproof material. The styrene-acrylic emulsion is an acrylate copolymer emulsion modified by styrene. The styrene is adopted to completely or partially replace methyl methacrylate in the emulsion, and styrene chain segments are introduced, so that the water resistance, the alkali resistance, the pollution resistance and the pulverization resistance of acoating film are improved, the durability of the material can be improved when the styrene is applied to the building waterproof material, and the bonding strength of the styrene to a building base material is high.

Owner:浙江合塑实业集团有限公司

Modification method of lithium-rich manganese-based cathode materials

ActiveCN104681809BRealize regulationReduce manufacturing process stepsCell electrodesLithium carbonateManganese

The invention discloses a method for modifying a lithium-rich manganese-based cathode material. The method comprises the following steps: preparing a precursor of the lithium-rich manganese-based cathode material, uniformly mixing the precursor with lithium carbonate and doping and modifying metal villiaumite, sintering the uniformly mixed mixture at a high temperature to obtain a modified lithium-rich manganese-based cathode material. The modification process of the method disclosed by the invention is simple and easy to control, the steps of the existing preparation process are not added, and the electrochemical performance of the product is excellent.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

Deuterium used as nutrient ingredient to prepare deuterized functional foods, deuterized functional beverages, vitamin preparations, pet foods, pet beverages and animal feeds

InactiveCN102038192AEasily damagedReduce mitosisAnimal feeding stuffAccessory food factorsNutrientVitamin Preparations

The isotope of hydrogen, namely deuterium (2H), is a nutrient element. After being ingested into bodies, deuterium can stabilize a cell molecule structure by replacing hydrogen atoms of carbon-hydrogen (C-H) in the cell molecule structure to form a carbon-deuterium (C-2H) structure, can reduce the breakage of carbon-hydrogen covalent bonds of the cell molecule due to the oxidation of free radicals and cell apoptosis and can fight against the harm of the free radicals on organisms. In the invention, the deuterium is used as a nutrient element to be added into various beverage products, various foods and various vitamin products, and after being ingested into bodies, the deuterium has the functions of reducing the occurrence of diseases, preventing cancer, strengthening bodies and prolonging life. The Deuterium can be also used as a nutrient element to be added into various pet feeds and beverages and various animal feeds; after being ingested into animal bodies, the deuterium can strengthen the animals, reduce the occurrence of diseases and prolong the life of pets.

Owner:陈松源

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com