Method for modifying lithium-rich manganese-based cathode material

A cathode material, lithium-rich manganese-based technology, applied in battery electrodes, electrical components, circuits, etc., can solve problems such as large-scale production that is not suitable for industrialization, and achieve the stability of material crystal structure, improve electrochemical performance, The effect of strong bond energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for modifying the lithium-rich manganese-based cathode material of the present invention, comprising the following steps:

[0027] (1) Weigh aluminum fluoride (AlF 3 )0.2793g, weigh the precursor (Mn 0.675 Ni 0.1625 co 0.1625 )(OH) 2 10.0000g, weigh lithium carbonate (Li 2 CO 3 ) 6.4502g, the three are fully mixed uniformly; wherein the aluminum element content in the doped modified metal fluoride salt is 3mol% of the metal element content contained in the precursor;

[0028] (2) Sinter the above mixed material at a sintering temperature of 970°C for 15h at a heating rate of 10°C / min, and then cool to room temperature with the furnace to obtain AlF 3 Modified lithium-rich manganese-based cathode materials (Li 1.2 mn 0.54 Ni 0.13 co 0.13 o2 ).

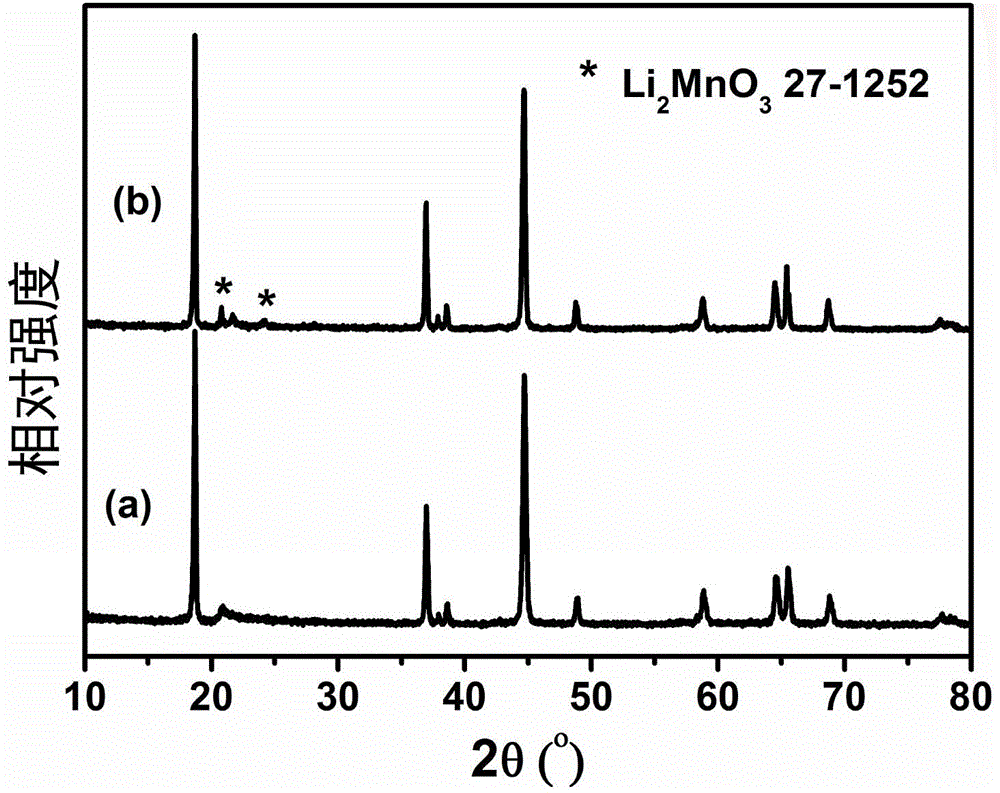

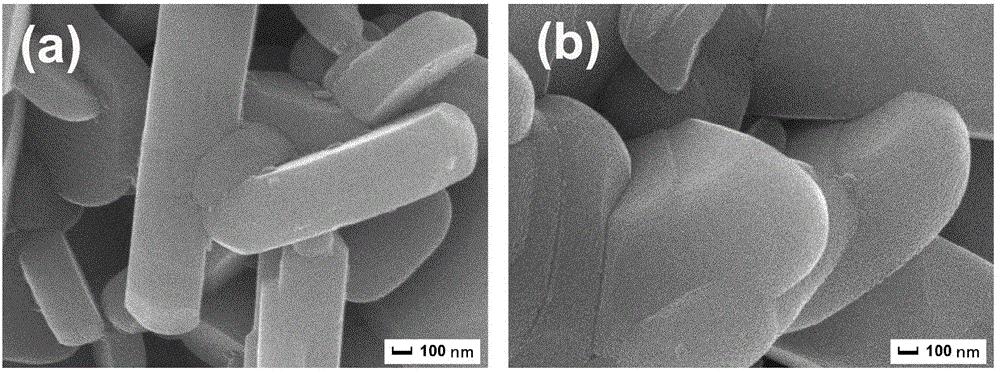

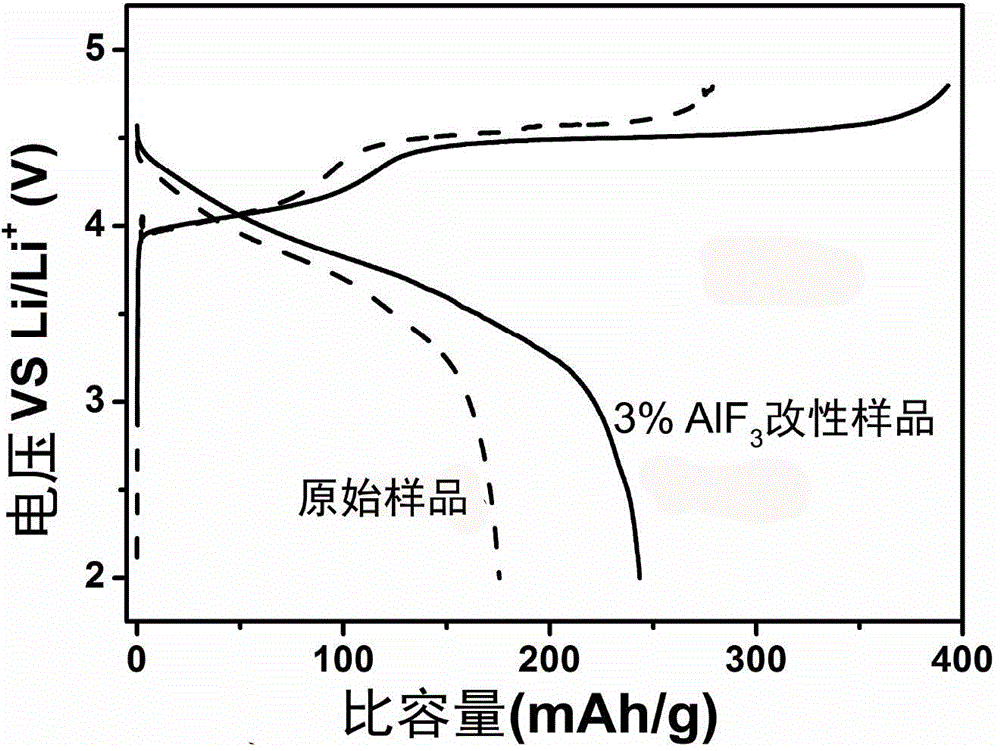

[0029] From the above-mentioned AlF of this embodiment 3 XRD patterns of modified lithium-rich manganese-based cathode materials ( figure 1 ) shows that AlF 3 The addition of makes the lithium-rich phase di...

Embodiment 2

[0032] A method for modifying the lithium-rich manganese-based cathode material of the present invention, comprising the following steps:

[0033] (1) Weigh zirconium fluoride (ZrF 4 )0.9268g, weigh the precursor (Mn 0.675 Ni 0.1625 co 0.1625 )(OH) 2 10.0000g, weigh lithium carbonate (Li 2 CO 3 ) 6.4502g, the three are fully mixed uniformly; wherein the zirconium element content in the doped modified metal fluoride salt is 5mol% of the metal element content contained in the precursor;

[0034] (2) Sinter the above mixed material at a sintering temperature of 850°C for 48h at a heating rate of 10°C / min, and then cool to room temperature with the furnace to obtain ZrF 4 Modified lithium-rich manganese-based cathode materials (Li 1.2 mn 0.54 Ni 0.13 co 0.13 o 2 ).

[0035] The ZrF that is made by this embodiment 4 The TEM spectrum of modified lithium-rich manganese-based cathode material (see Figure 5 ) It can be seen that the above-mentioned modification process c...

Embodiment 3

[0037] A method for modifying the lithium-rich manganese-based cathode material of the present invention, comprising the following steps:

[0038] (1) Weigh ammonium fluorotitanate (N 2 h 8 TiF 6 ) 1.7081g, weigh the precursor (Mn 0.75 Ni 0.25 )CO 3 10.0000g, weigh lithium carbonate (Li 2 CO 3 ) 5.0212g, the three are fully mixed uniformly; wherein the content of titanium element in the doped modified metal fluoride salt is 10mol% of the content of the metal element contained in the precursor;

[0039] (2) Sinter the above-mentioned uniformly mixed mixture at a sintering temperature of 1000°C for 24 hours, with a heating rate of 10°C / min, and then cool to room temperature with the furnace to obtain ammonium fluorotitanate-modified lithium-rich manganese-based positive electrode material (Li 1.2 mn 0.6 Ni 0.2 o 2 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com