Patents

Literature

774 results about "Aluminum salts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminium salts have been used for over half a century as the active ingredient in antiperspirants to control sweat and associated body odour.

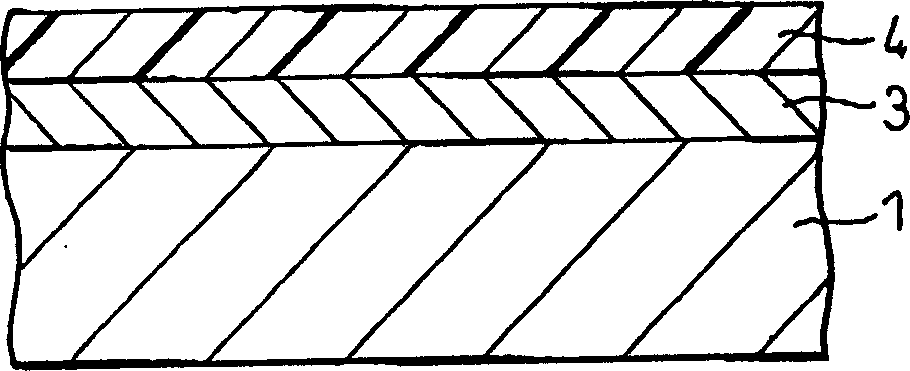

Alumina-coated granules, as well as preparation method and application thereof

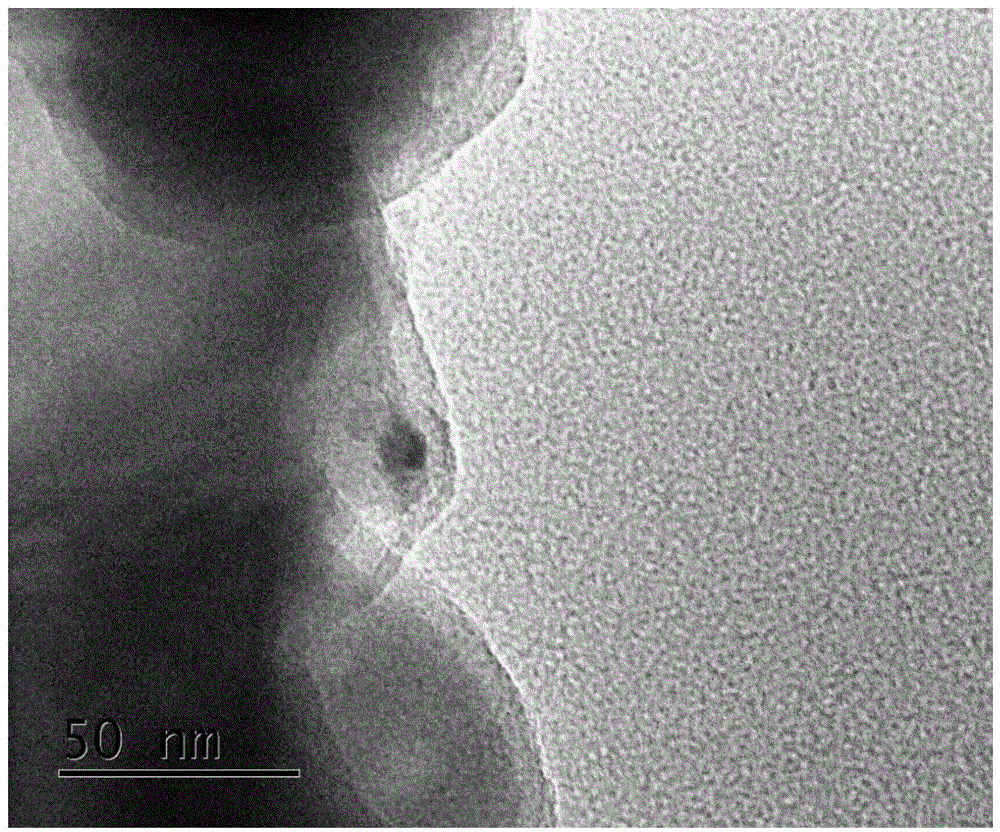

InactiveCN103606660AThickness adjustment and controlUniform thicknessCell electrodesLithium-ion batteryLithium electrode

The invention discloses alumina-coated granules, as well as a preparation method and application thereof. The alumina-coated granules consist of cores and shells which coat the cores. The cores are made of at least one of materials of metals, oxides, metal hydroxides, metal inorganic salts, non-metals, carbides, nitrides, lithium salts, semiconductors and organic compounds; the shell is made of Al2O3. By adopting a liquid phase method, the cores to be coated are mixed with aluminum salts, metal aluminum is precipitated by producing an alkaline environment in situ or externally adding alkaline, so that uniform, continuous and controllable coating can be formed on the surfaces of the cores. The coating method provided by the invention is simple, and has mild conditions and high universality; the coating layer has controllable thickness, completeness and uniformity; the alumina-coated granules has high practicability and a great application prospect in the field of catalysis, lithium ion batteries, surface-enhanced Raman, biomedicine and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Hydrocracking catalyst for moderate oil and preparation thereof

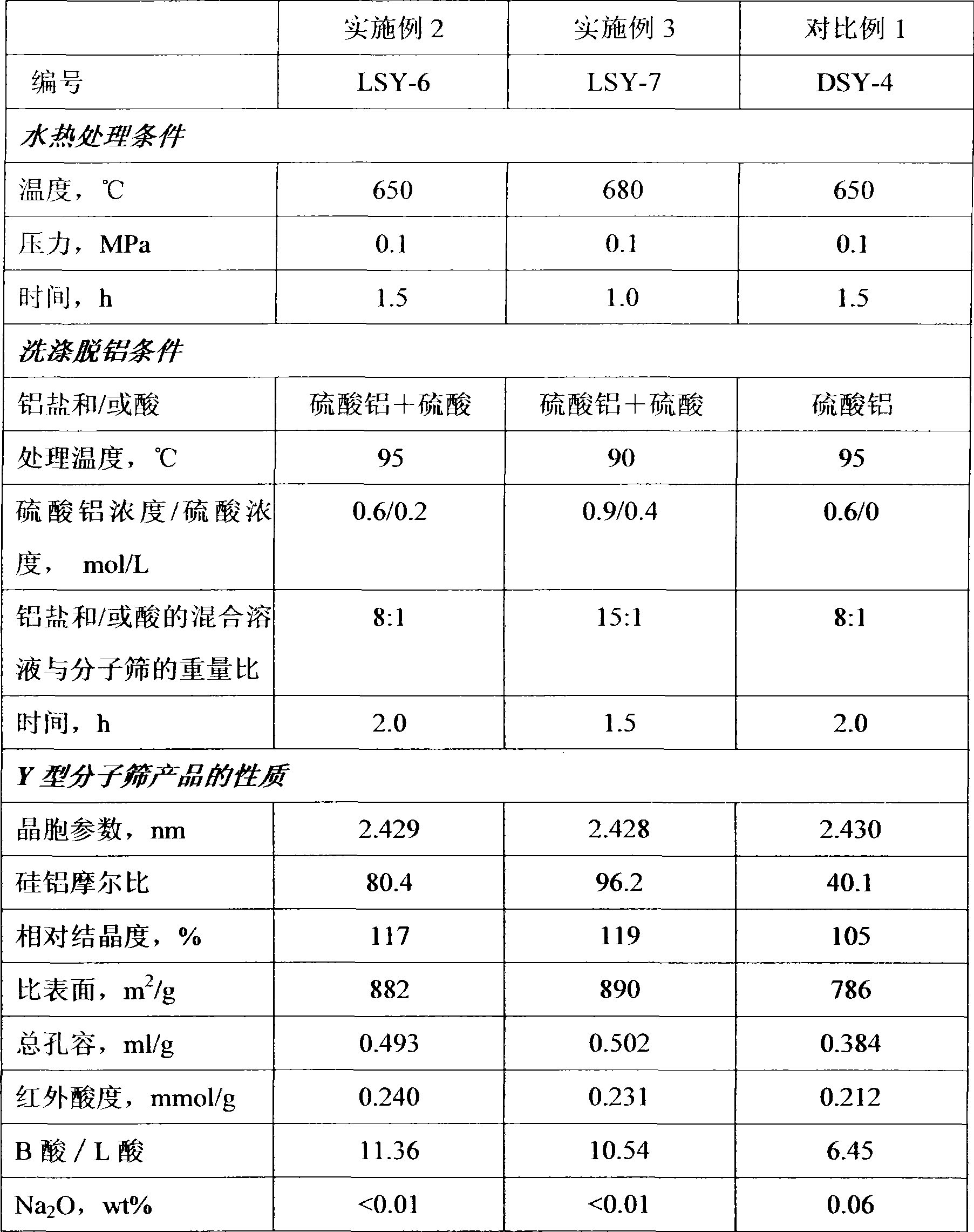

ActiveCN101450319AHigh ratio of silicon to aluminumLarger than surfaceMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveAmorphous silicon

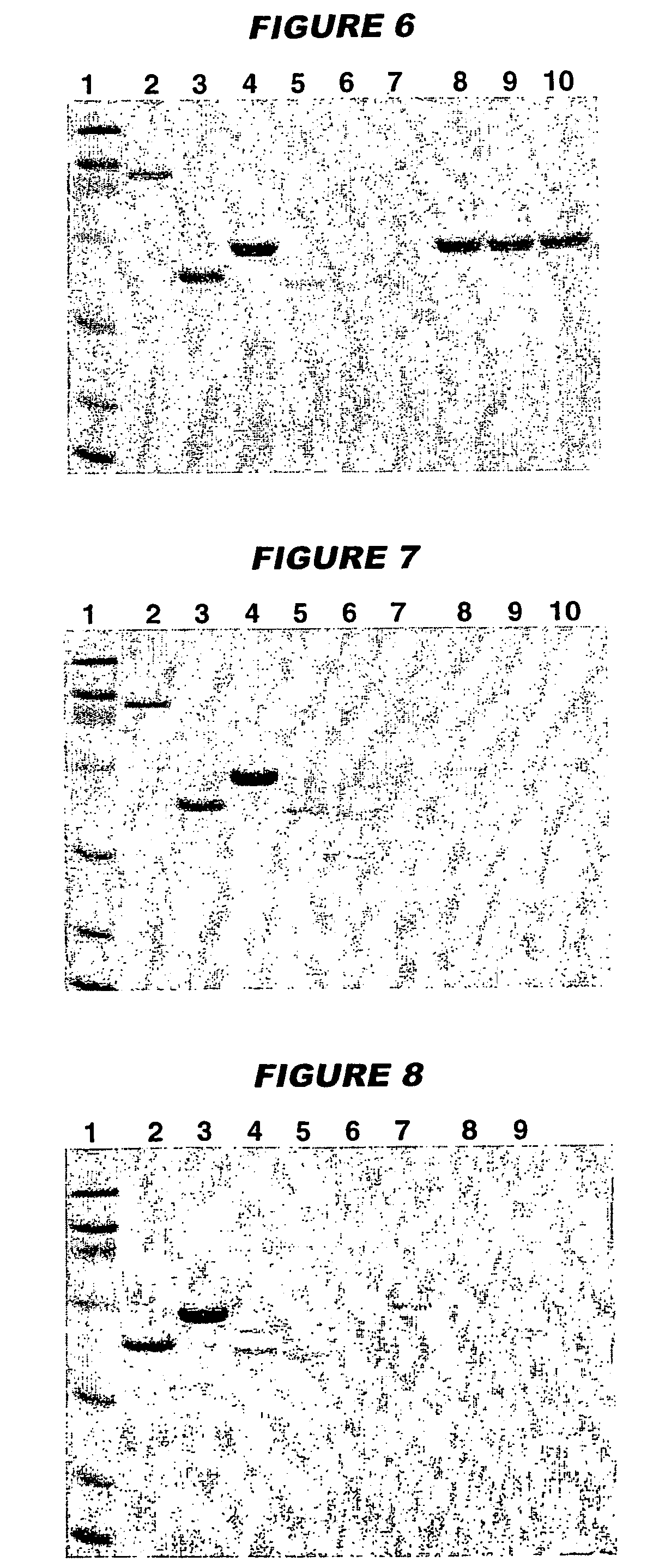

The invention discloses a high-activity and high and medium oil type hydrocracking catalyst and a preparation method thereof. The catalyst comprises hydrogenation active metals and a carrier containing modified Y molecular sieves, amorphous silicon aluminum and alumina, wherein the modified Y molecular sieves have high crystallinity, large silicon aluminum ratio and proper total acid amount and acid distribution, and are obtained by treating Y molecular sieves after hydro-thermal treatment by a mixed aqueous solution of aluminum salts and an acid. The hydrocracking catalyst has high activity and good intermediate distillate oil selectivity and product quality, and is particularly suitable for hydrocracking technology for producing intermediate distillate oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Vaccines comprising aluminium adjuvants and histidine

To improve the stability of vaccines comprising aluminum salt(s), the invention uses the amino acid histidine. This can improve pH stability and adjuvant adsorption and can be reduce antigen hydrolysis. Histidine is preferably presen during adsorption to the aluminium salt(s). The antigen in the vaccine may be a protein or a saccharide and is preferably from N. meningitidis.

Owner:GLAXOSMITHKLINE BIOLOGICALS SA

Hydrocracking catalyst containing Y molecular sieve and preparation method thereof

ActiveCN101450320AHigh ratio of silicon to aluminumLarger than surfaceMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveNaphtha

The invention discloses a hydrocracking catalyst for producing heavy naphtha in great abundance and a preparation method thereof. The catalyst contains hydrogenation active metals and a carrier which consists of modified Y molecular sieves and alumina, wherein the Y molecular sieves are obtained by using a mixed aqueous solution of aluminum salts and an acid to perform hydro-thermal treatment. The properties of the modified Y molecular sieves are as follows: the specific surface area is between 750 m<2> / g and 850 m<2> / g; the total pore volume is between 0.35 and 0.48 ml / g; the relative crystallinity is between 90 and 130 percent; the cell parameter is between 2.437 and 2.445 nanometers; the silicon-aluminum mol ratio is between 15 and 70; the infrared acid amount is between 0.5 and 1.0 mmol / g; the B acid / L acid is more than 7.0; and the content of sodium oxide is less than or equal to 0.05 weight percent. The hydrocracking catalyst has the characteristics of good catalytic activity, high heavy naphtha selectivity, high yield, high latent content of heavy naphtha arene, and so on.

Owner:FUSHUN RES INST OF PETROLEUM & PETROCHEMICALS SINOPEC CORP

Adjuvant and Vaccine Compositions

InactiveUS20100226932A1Small sizeSnake antigen ingredientsInorganic non-active ingredientsSterolEmulsion

Abstract Compositions comprising an emulsion and aluminum salt nano- / micro-particles surface stabilized with at least one surfactant are useful as immunological adjuvants. The emulsion of these compositions comprises at least one oil; at least one surfactant; a plurality of surfactant vesicles; optionally at least one sterol; and an aqueous phase. The present invention also provides vaccines comprising one or more antigens combined with the emulsion and surface stabilized aluminum salt particles of the present invention, or one or more antigens combined with non-ionic surfactant vesicles.

Owner:NOVAVAX

Method for preparing aluminum oxide coated modified lithium nickel cobalt manganese oxygen cathode material

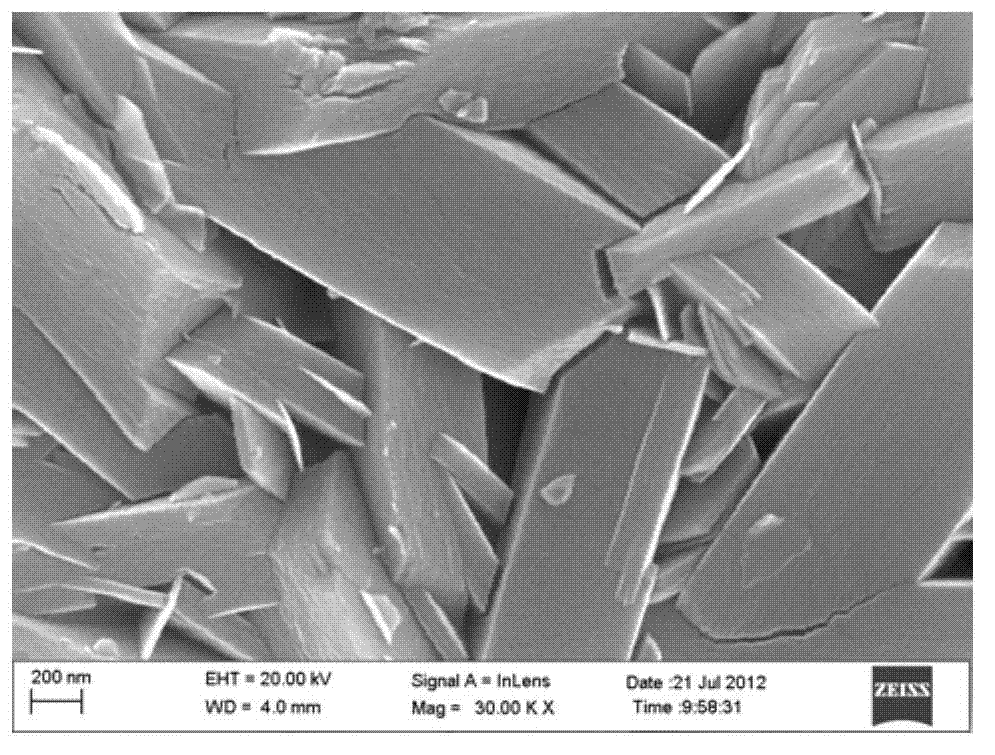

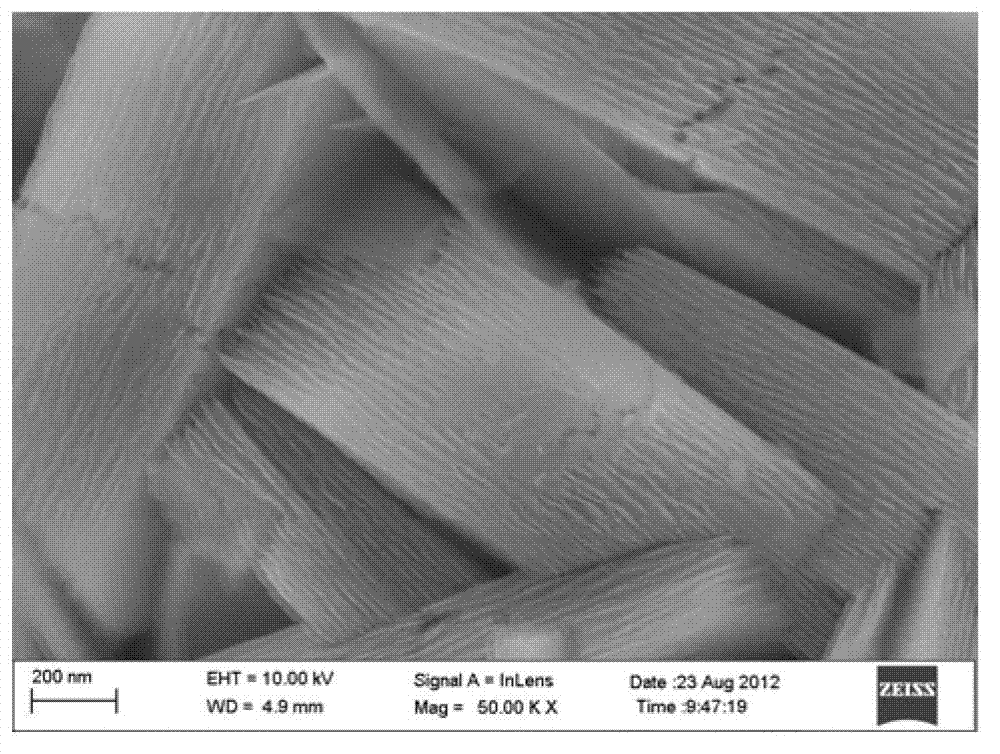

ActiveCN103178258AAdvantages of preparation methodInhibition of agglomerationCell electrodesManganates/permanganatesLamellar crystalsReaction temperature

The invention discloses a method for preparing an aluminum oxide coated modified lithium nickel cobalt manganese oxygen cathode material. The method comprises the following steps of: (1) preparation of a precursor: mixing water-soluble metallic nickel salt, cobalt salt and manganese salt into a mixed solution, dripping the mixed solution, a precipitator and a morphological control agent into a reaction container, controlling the pH value and reaction temperature of a system, and performing filtering, washing and vacuum drying after reaction to obtain a (NixCoyMn1-x-y)(OH)2 precursor, wherein x, y and x+y are more than 0 and less than 1; (2) preparation of an aluminum oxide coated precursor: dispersing the (NixCoyMn1-x-y)(OH)2 precursor, water-soluble aluminum salt and a disperser into deionized water, stirring while heating until the disperser is hydrolyzed, filtering to obtain an Al(OH)3-coated (NixCoyMn1-x-y)(OH)2 precursor, roasting the precursor in a sintering furnace to obtain Al2O3-coated (NixCoyMn1-x-y)(OH)2 precursor powder; and (3) uniformly mixing the Al2O3-coated (NixCoyMn1-x-y)(OH)2 precursor powder with lithium salt powder, and calcinating at high temperature to obtain an aluminum oxide coated modified Li(NixCoyMn1-x-y)O2 cathode material with a lamellar crystal structure.

Owner:NINGDE AMPEREX TECH

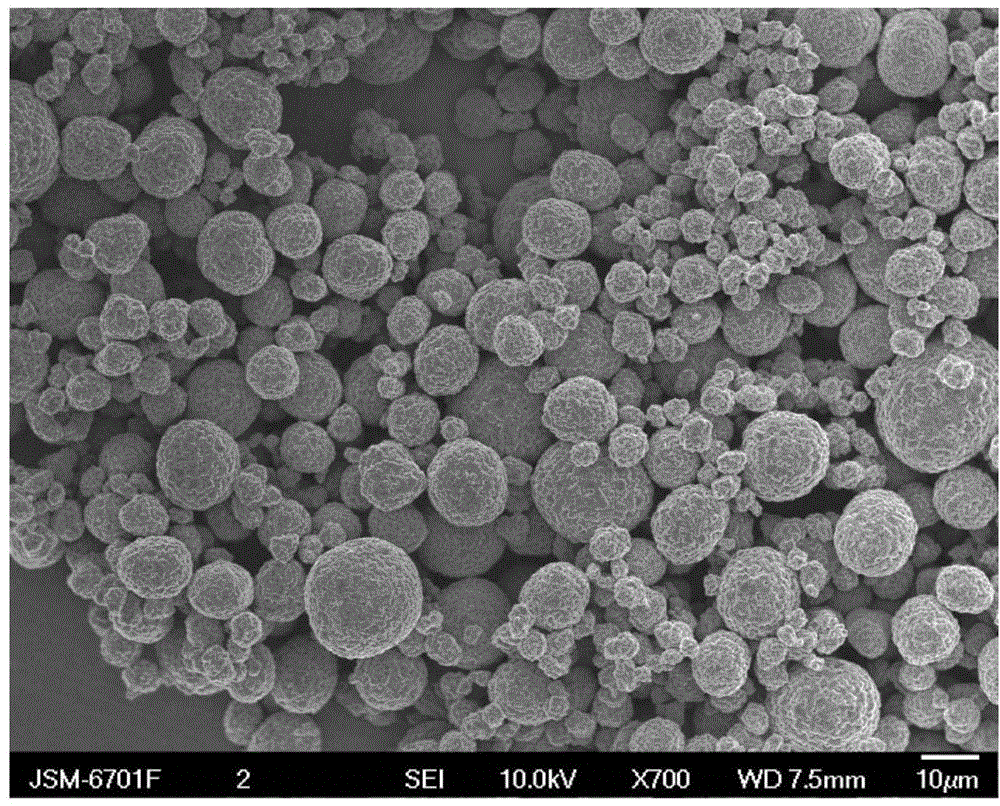

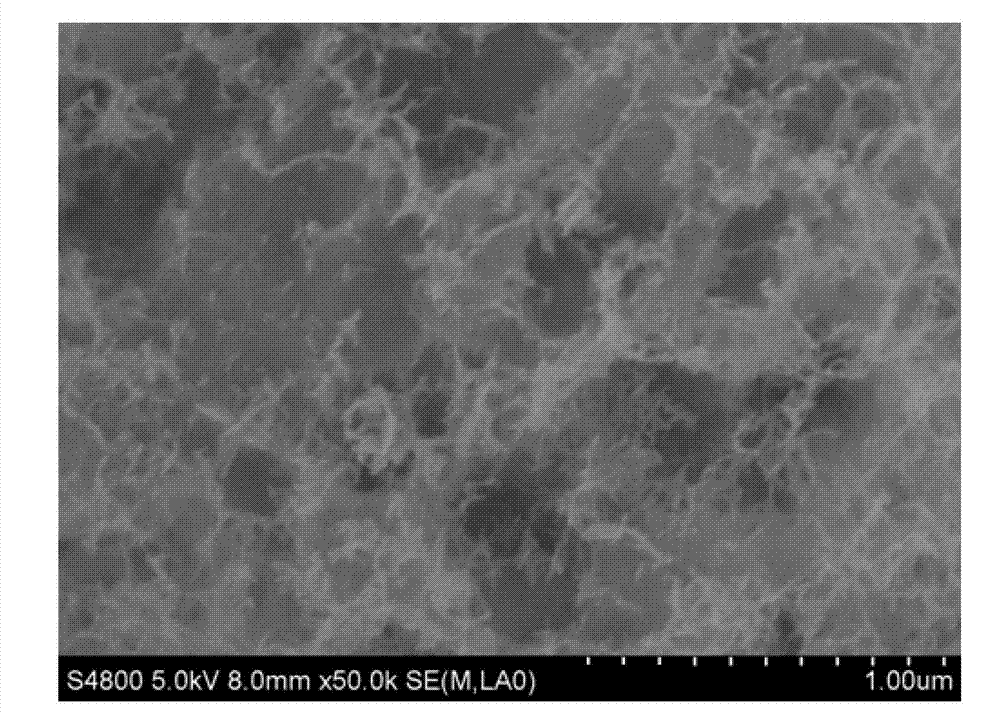

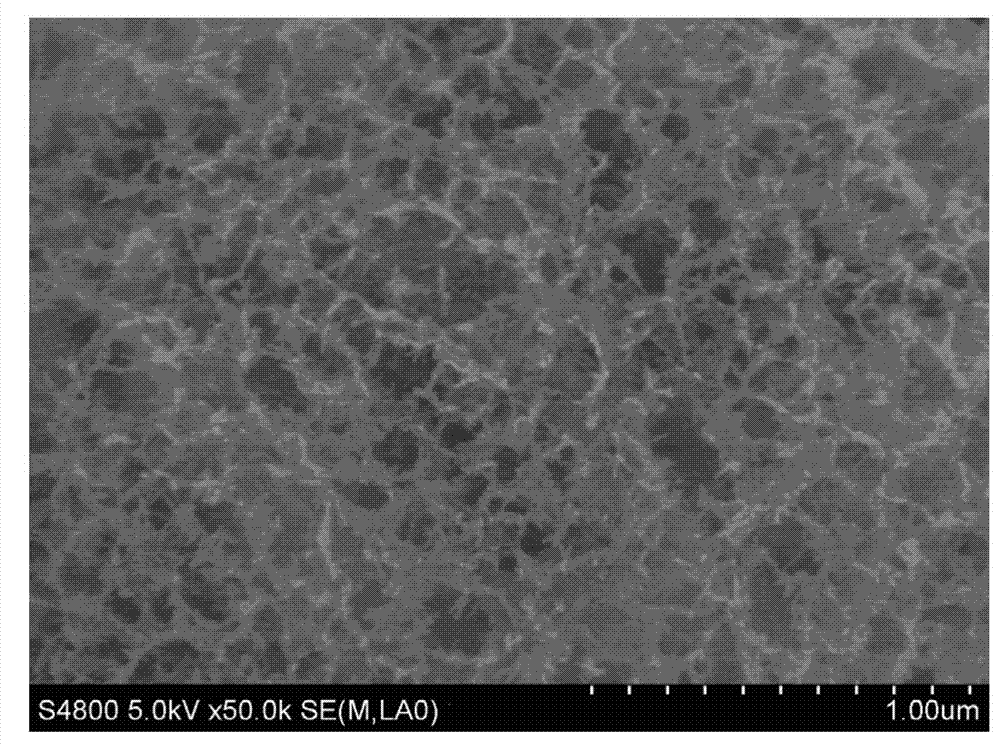

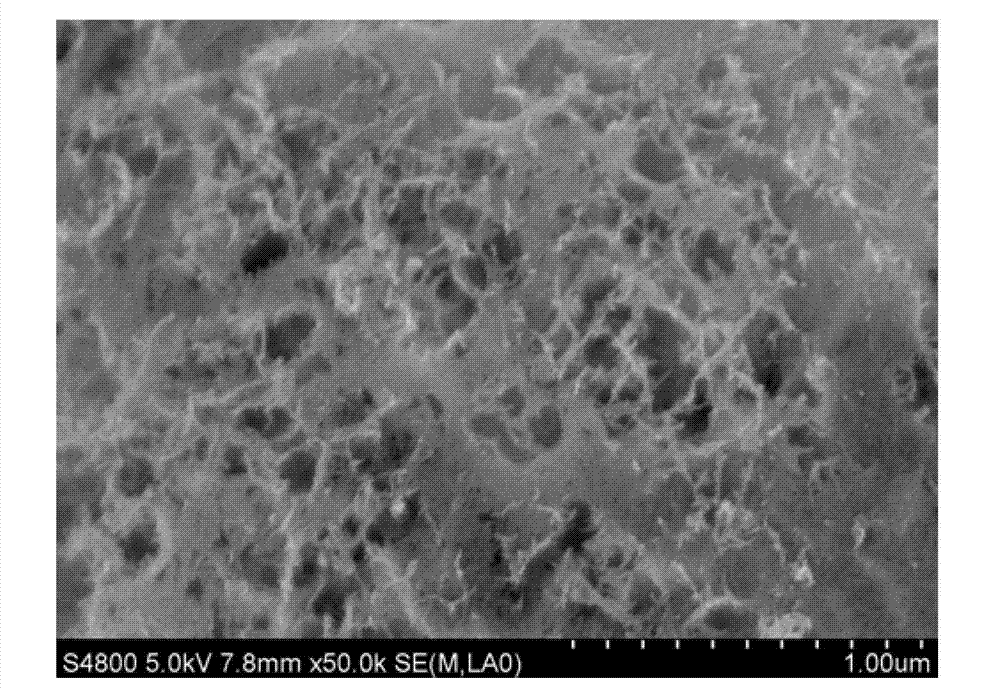

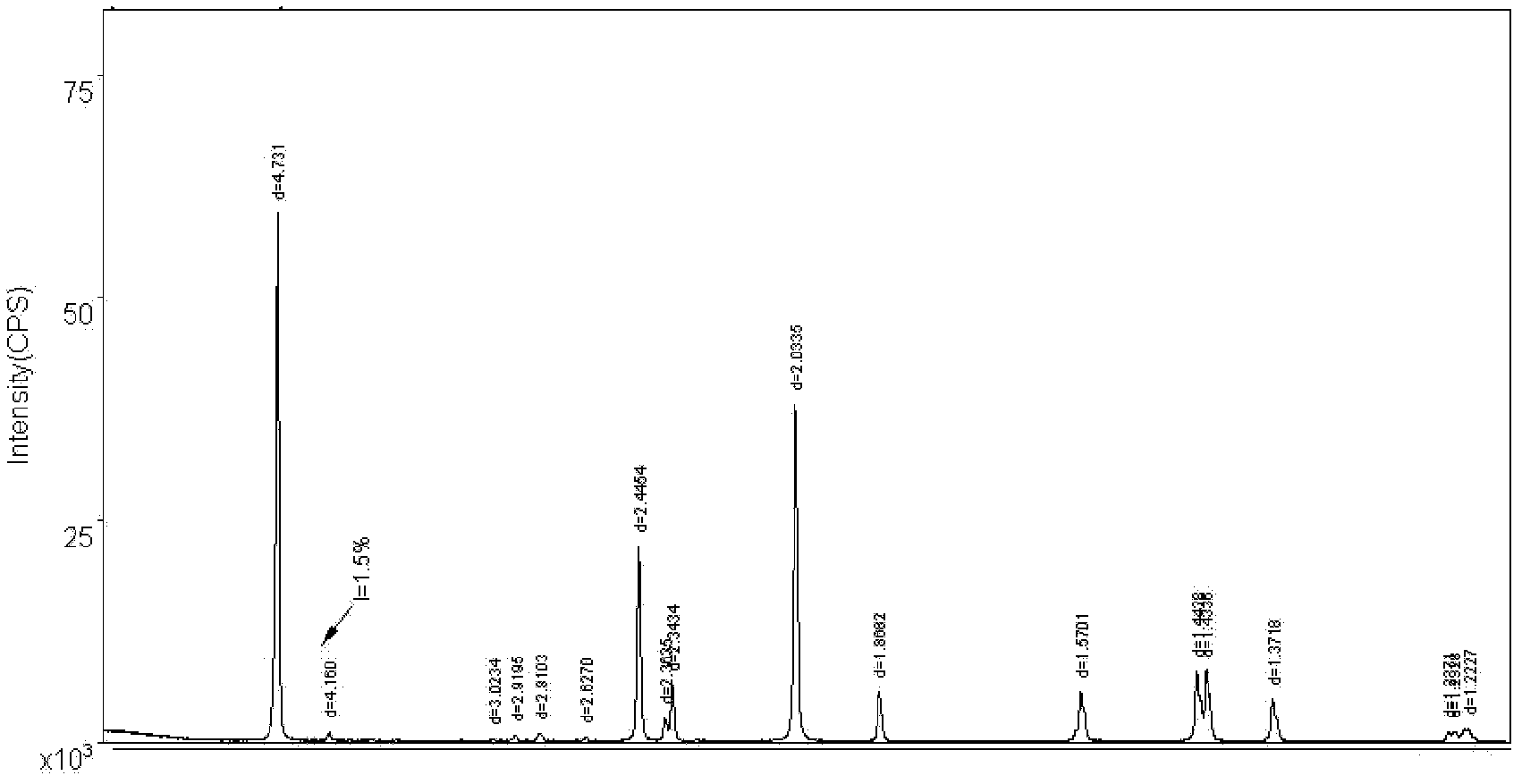

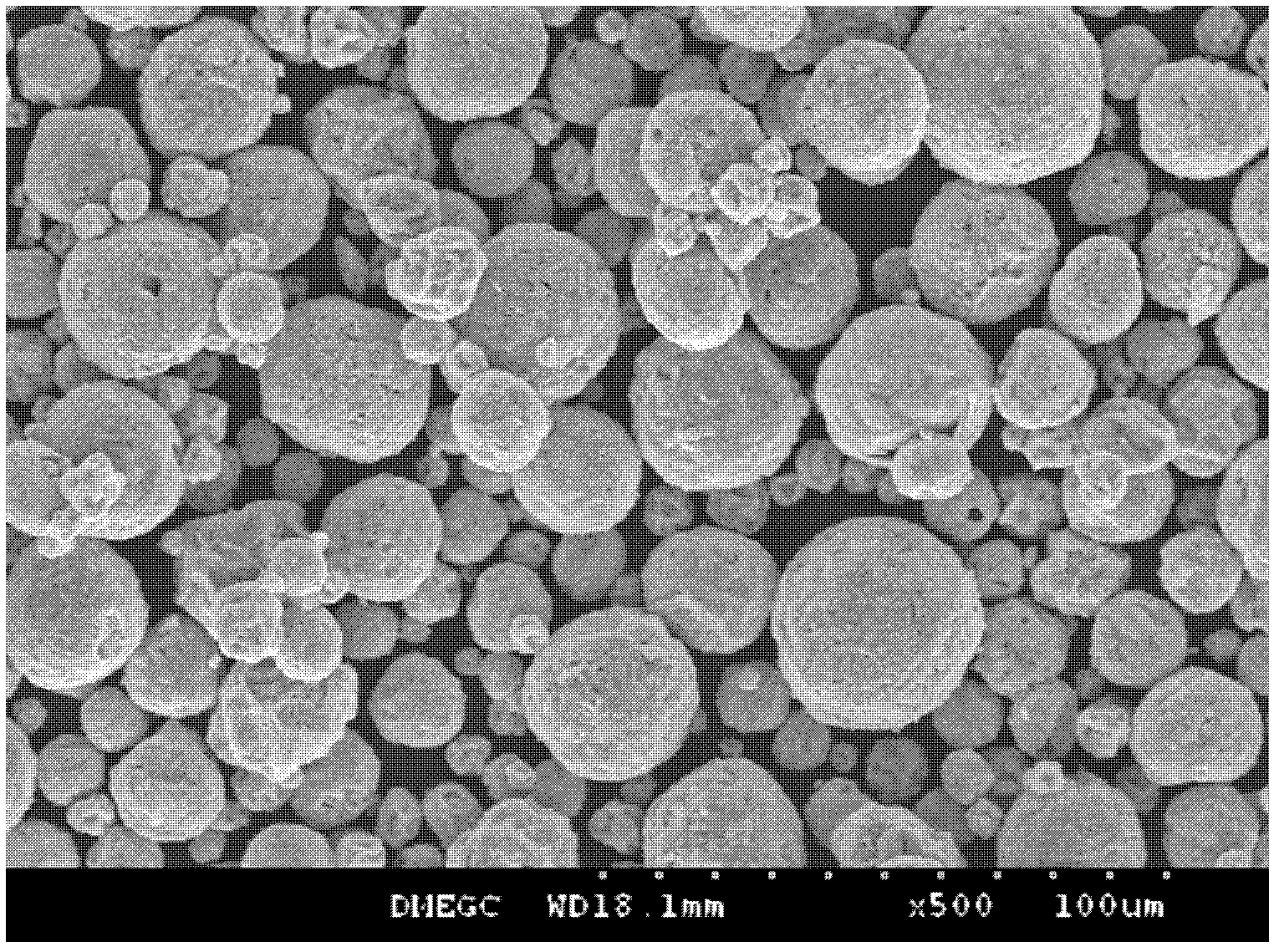

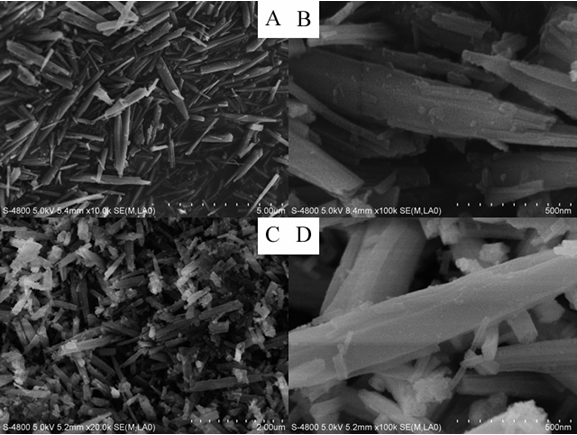

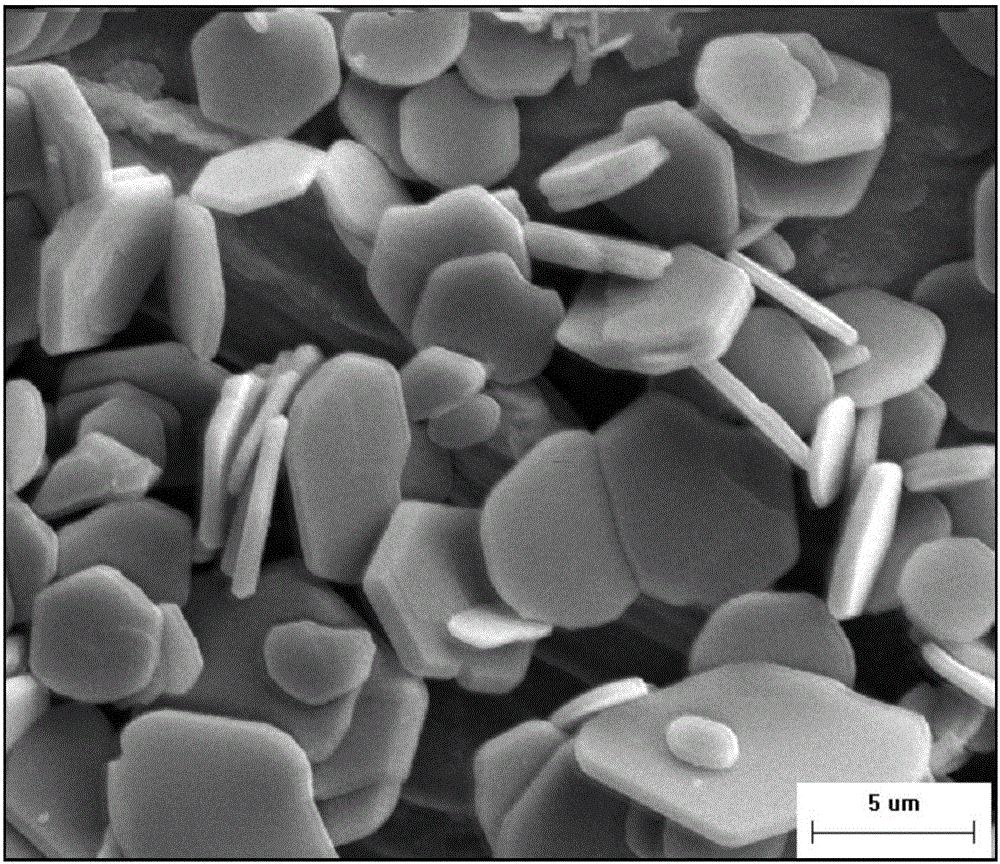

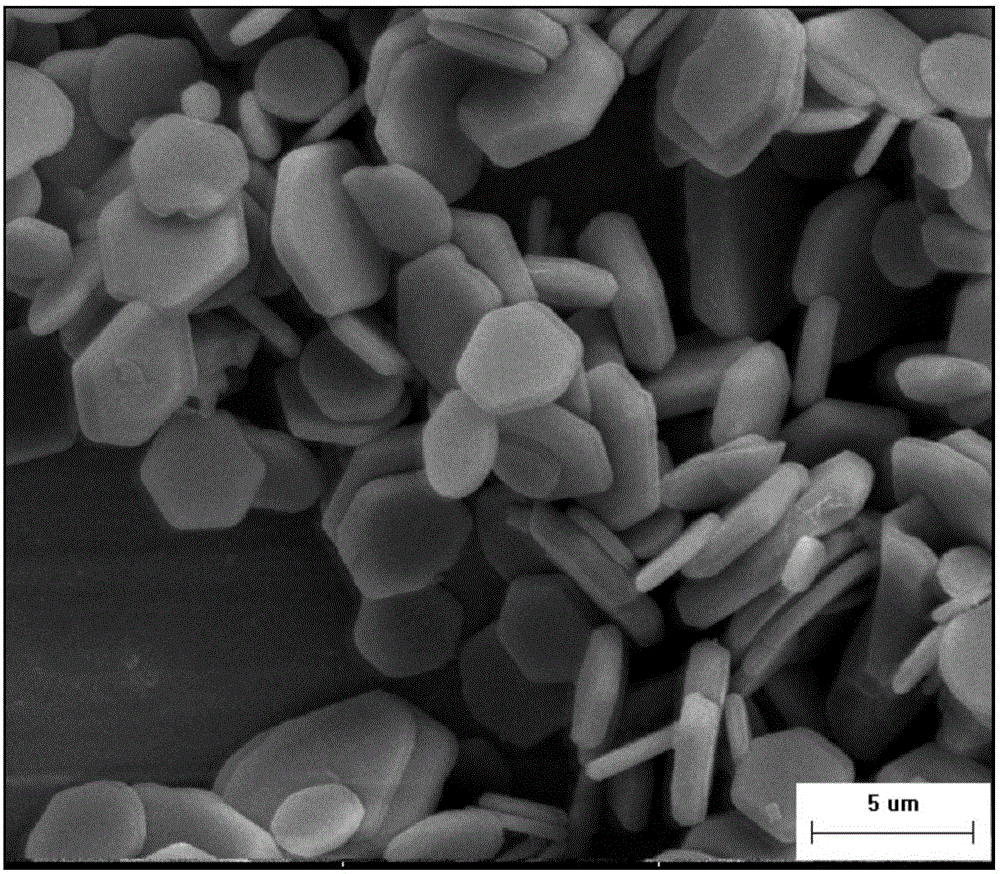

Gamma-alumina particles and method for manufacturing same

InactiveCN103204527AReduce dosageEffective dispersionAluminium oxides/hydroxidesReaction rateScanning electron microscope

The invention discloses gamma-alumina particles and a method for manufacturing the same. The method includes co-precipitation procedures implemented in a step 1) and a step 2), a hydrothermal ageing procedure implemented in a step 3), a spray-drying procedure implemented in a step 4) and a heating procedure implemented in a step 5) so that the gamma-alumina particles are manufactured. The gamma-alumina particles and the method have the advantages that the procedures for manufacturing the gamma-alumina particles are simple, and follow-up treatment procedures required by a common hydrothermal method are omitted; cheap soluble aluminum salt is used as a raw material during manufacture, and accordingly the cost is low; as verified and tested by experiments, the manufactured gamma-alumina particles are high in specific surface area which ranges from 180m<2> / g to 260m<2> / g; the manufactured gamma-alumina particles have hollow foam-shaped morphological structures when observed under a scanning electron microscope and are of micropore-mesopore-macropore composite aperture structures, so that active components in catalysts can be effectively dispersed by the hollow foam-shaped morphological structures of the gamma-alumina particles when gamma-alumina is used as a carrier of the catalysts; and material transmission in a catalytic procedure is facilitated by the hollow foam-shaped morphological structures and the composite aperture structures, and accordingly the catalytic reaction rate is increased.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

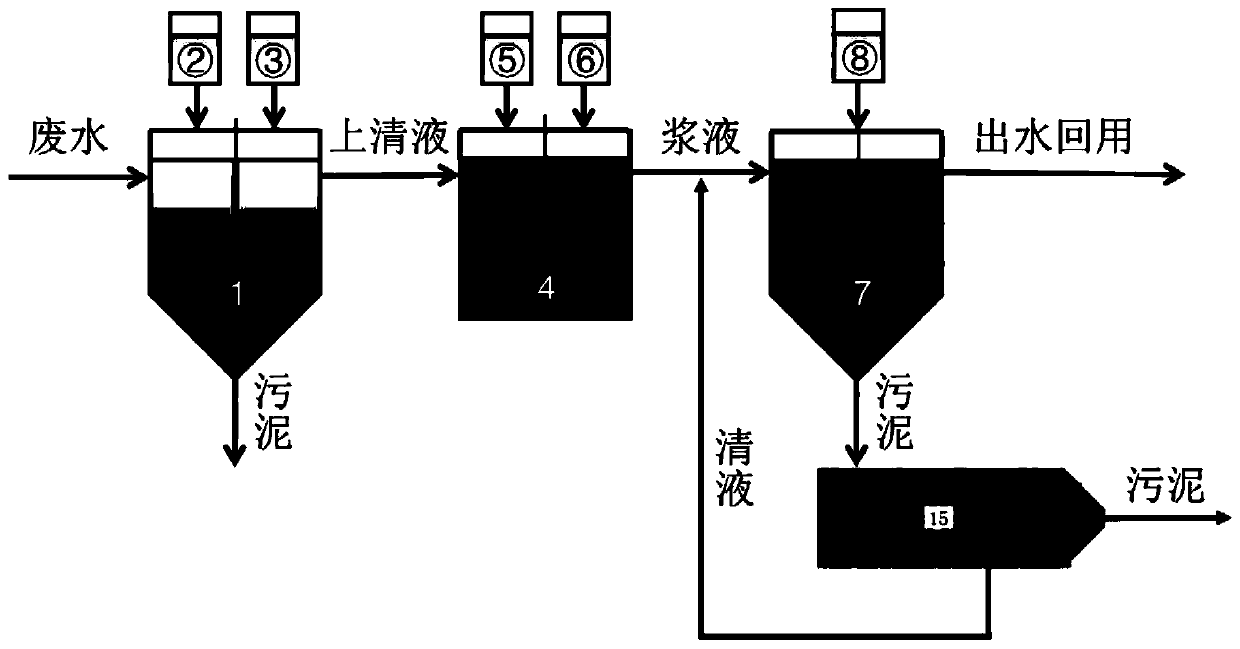

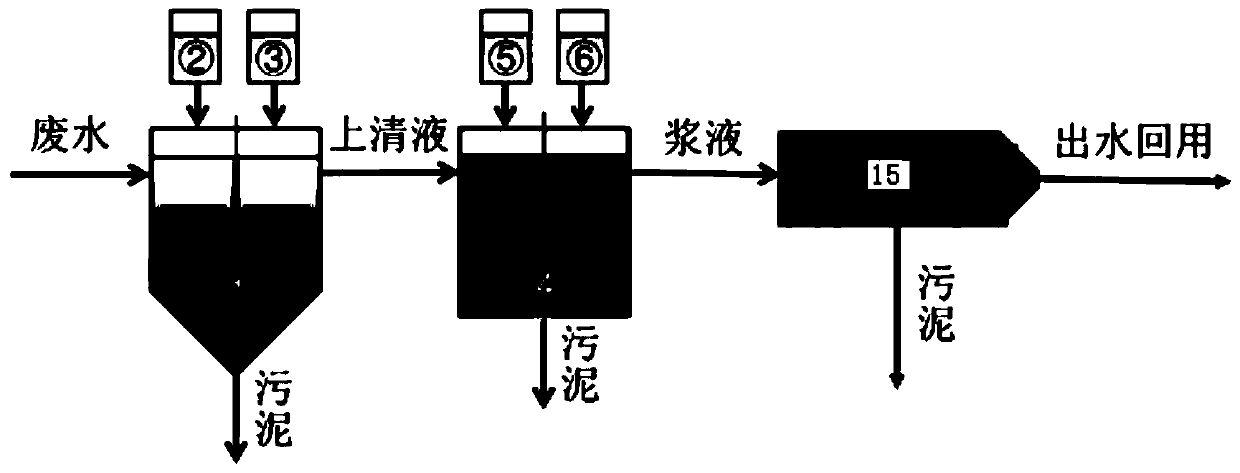

Composite reagent for treating recycled water of printing and dyeing wastewater and application method of composite reagent

InactiveCN104108775AAchieve efficiencyAchieve economyWaste water treatment from textile industryWater/sewage treatment by flocculation/precipitationSolubilityFlocculation

The invention discloses a composite reagent for treating recycled water of printing and dyeing wastewater and an application method of the composite reagent. The composite reagent comprises the following components by weight percent: 20% to 70% of aluminum salt coagulant, 5% to 30% of iron salt coagulant, 5% to 40% of mineral material and 5% to 45% of activated carbon. The method comprises the following steps: preparing the composite reagent for treating the recycled water of the printing and dyeing wastewater into powder or an aqueous liquid in which the content of effective components accounts for 5% to 30%; regulating a pH value of effluent in a printing and dyeing wastewater biochemical system to be within 3 to 9; adding the powder or the aqueous liquid of the composite reagent into the effluent in the printing and dyeing wastewater biochemical system under the condition that the adding quantity of the effective components is between 20mg / L and 1000mg / L after the pH value of the effluent is regulated; and stirring for 0.2 to 2 hours and then standing so as to obtain the recycled water conforming to the water quality standard in textile industry. According to the method, macromolecular colloidal pollutants in the biochemical effluent of the printing and dyeing wastewater, which are difficult to degrade, can be removed by utilizing the coagulation / flocculation performance of aluminum salts and iron salts in the composite reagent; and meanwhile, soluble inert pollutants in the wastewater are removed by utilizing the adsorbability of the activated carbon and the mineral material in the composite reagent.

Owner:HANGZHOU DIANZI UNIV

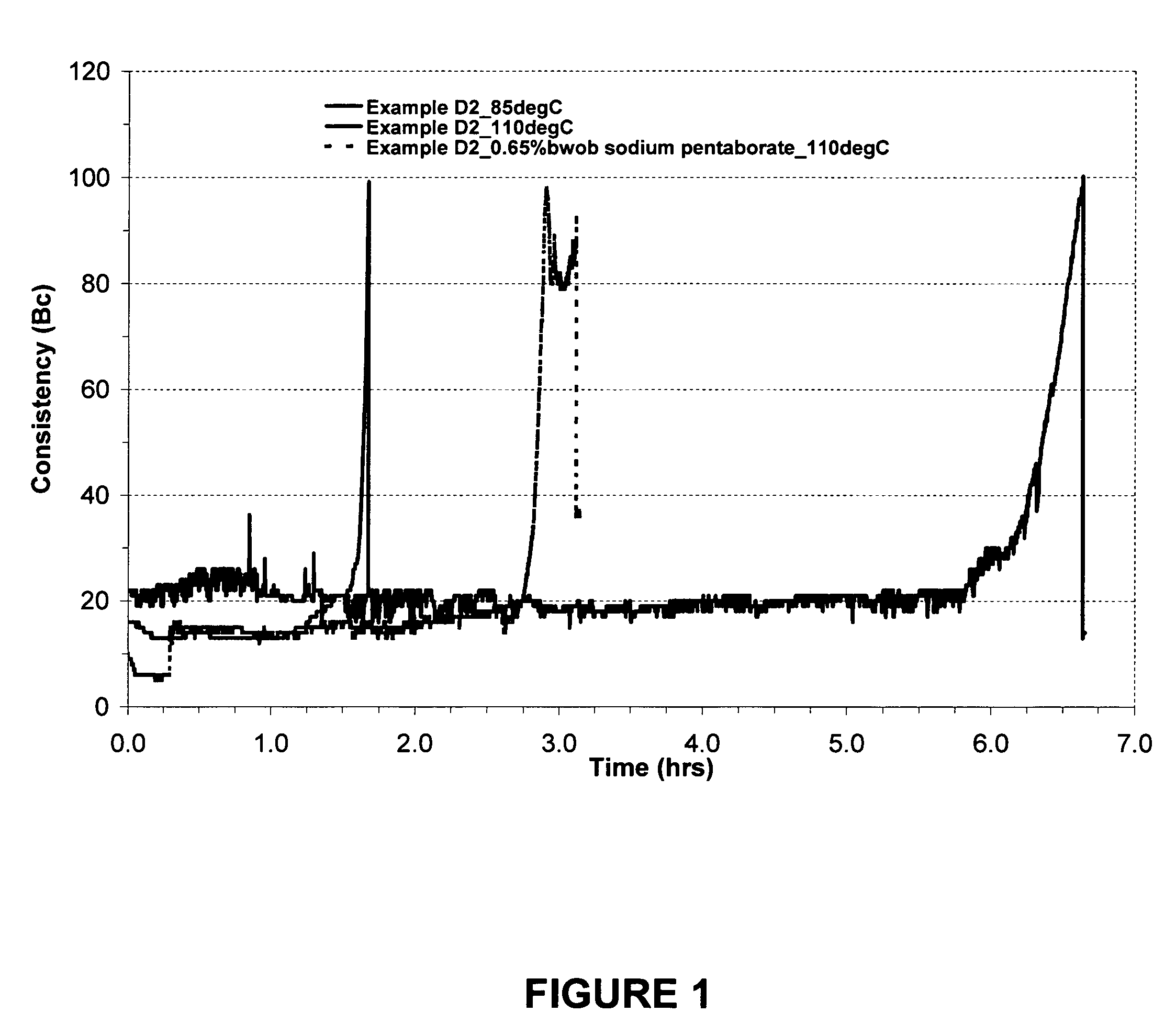

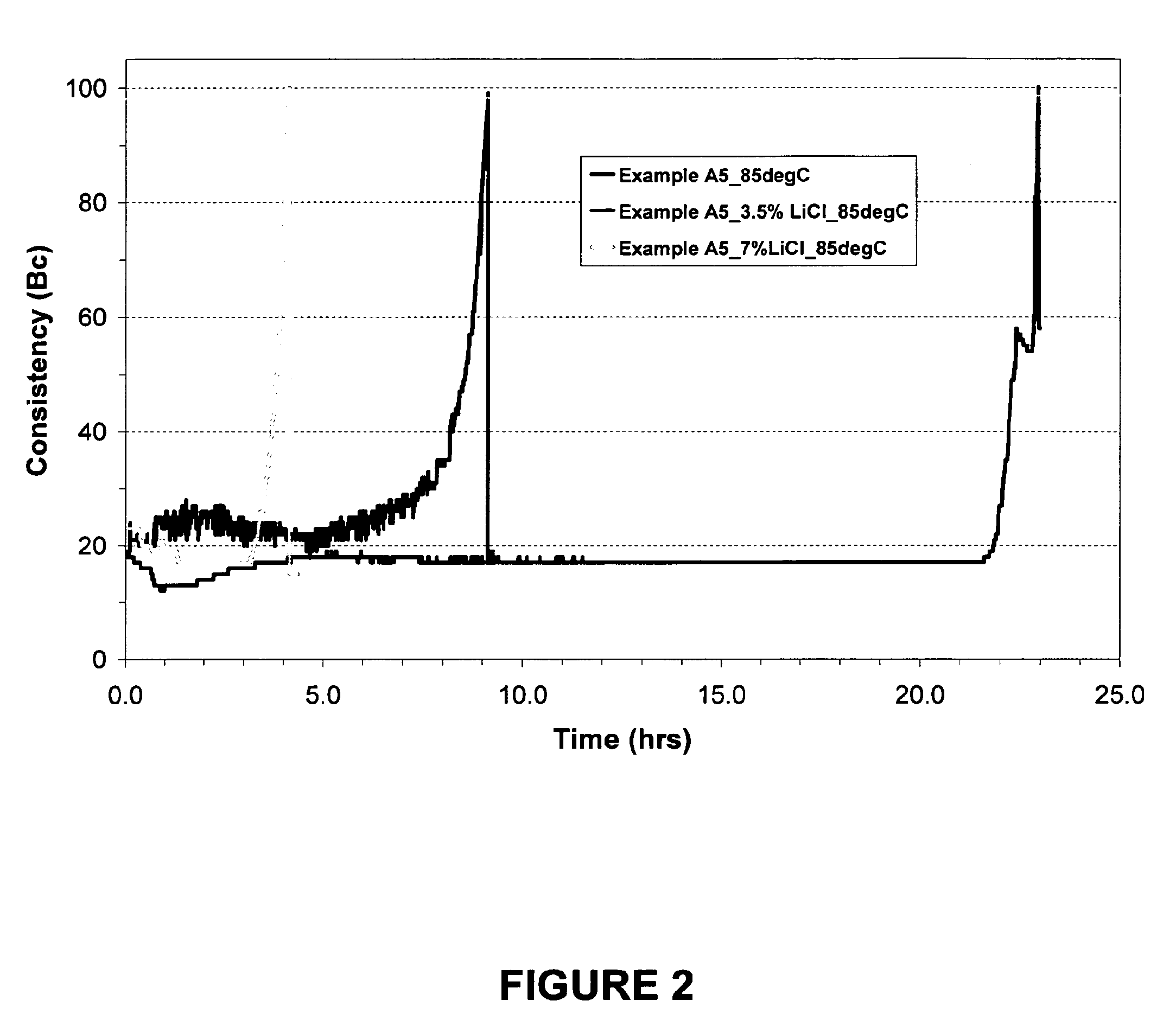

Pumpable geopolymer formulation for oilfield application

InactiveUS20110073311A1Enhanced pumpabilityImprove stabilityFluid removalCement productionAluminateCarrier fluid

The invention provides geopolymeric compositions, which have controllable thickening and setting times for a wide range of temperatures and a large range of geopolymer slurry densities. The geopolymer slurry compositions have good mixability and pumpability, whilst the set materials develop good compressive strength and permeability. The invention discloses a method for preparing geopolymer for oilfield cementing applications. The geopolymeric compositions according to the invention comprises a suspension made of an aluminosilicate source, a carrier fluid, an activator taken from the list constituted by: a metal silicate, a metal aluminate, an alkali activator, or a combination thereof, and an aluminum containing compound taken in the list constituted of bauxite, aluminum oxide and aluminum salt and the suspension is a pumpable composition in oilfield industry and the suspension is able to set under well downhole conditions.

Owner:SCHLUMBERGER TECH CORP

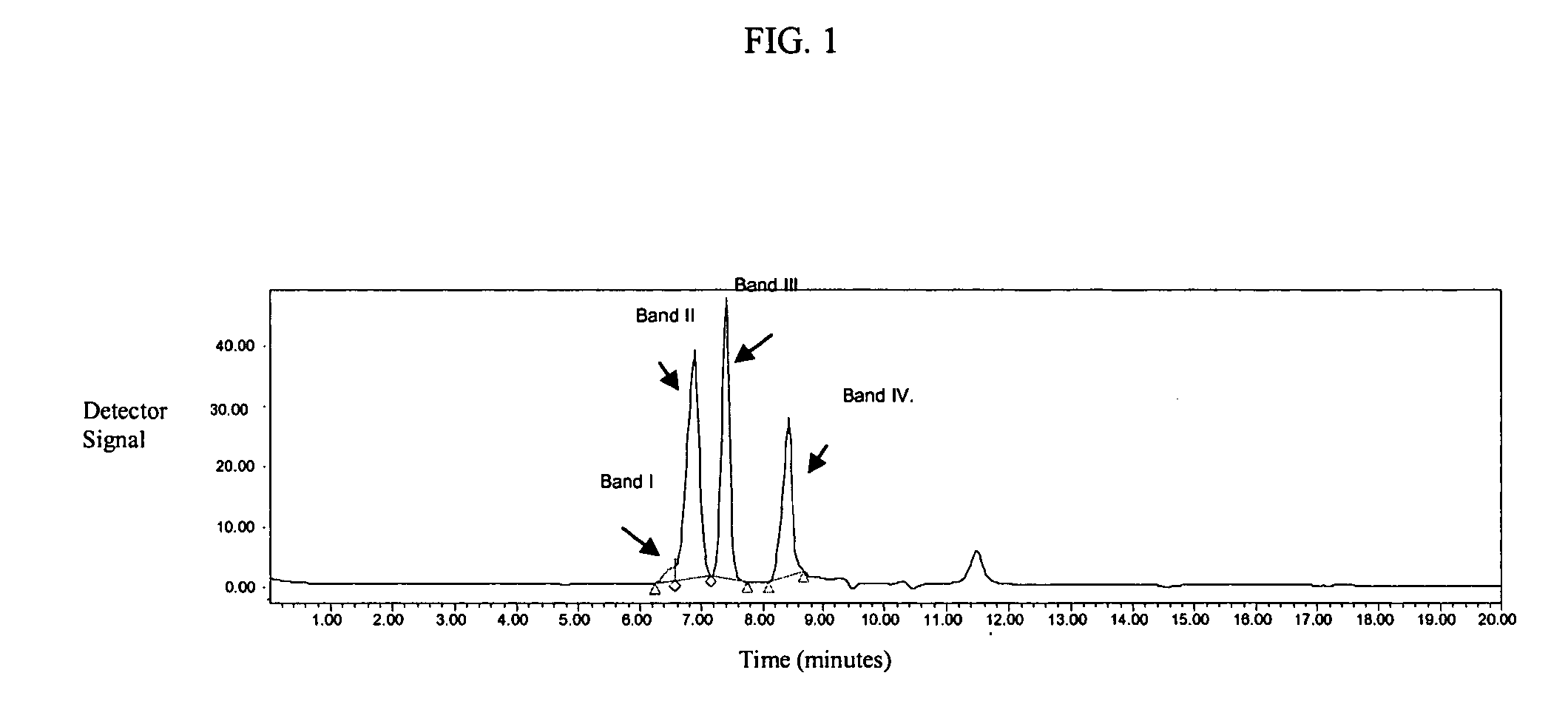

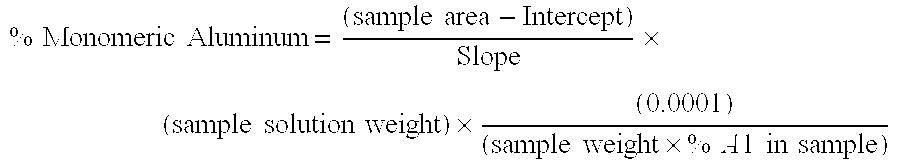

Enhanced efficacy basic aluminum halides, antiperspirant active compositions and methods for making

InactiveUS6902724B1Good curative effectImprove skinCosmetic preparationsToilet preparationsAluminium chloridePharmacology

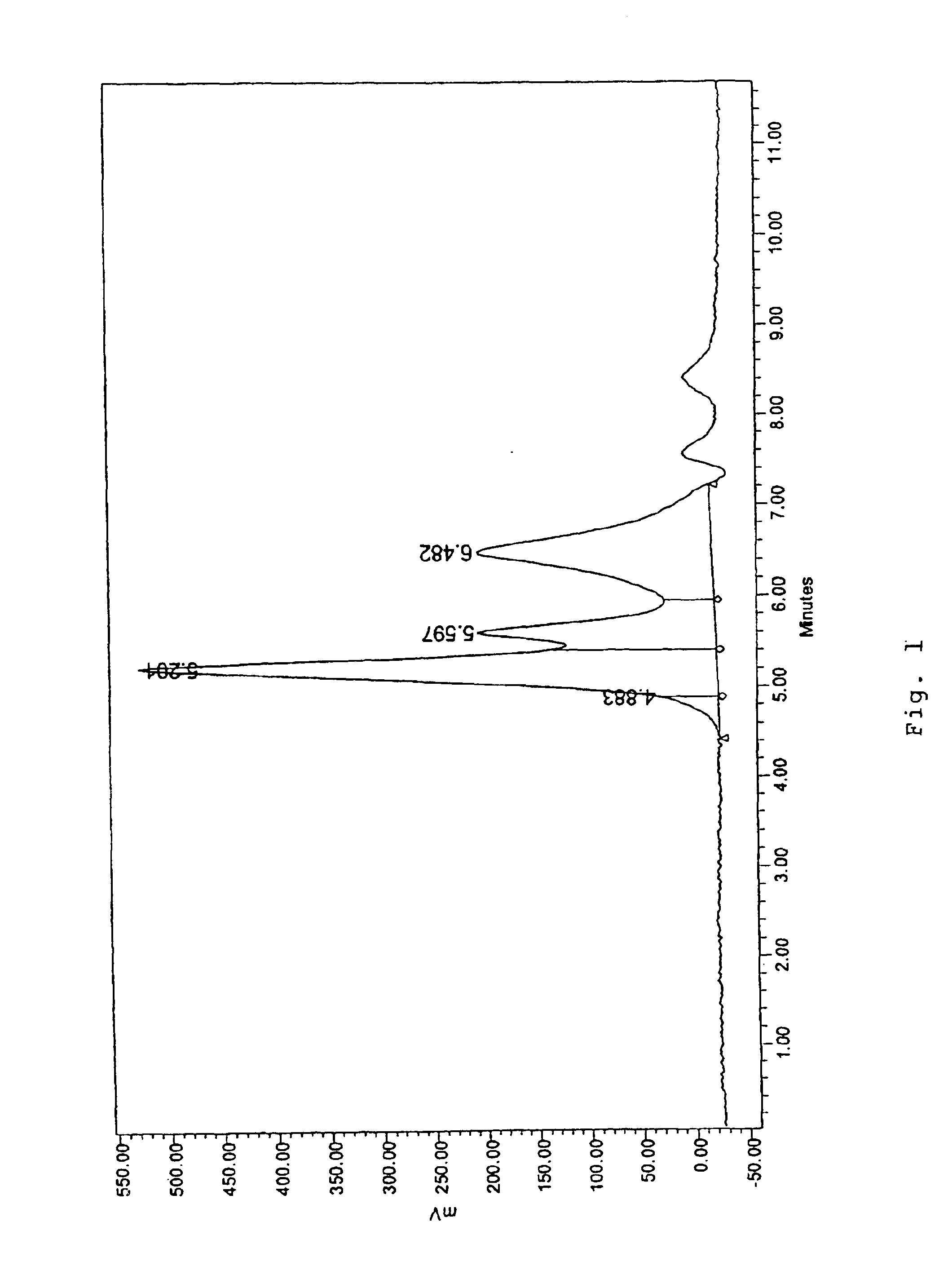

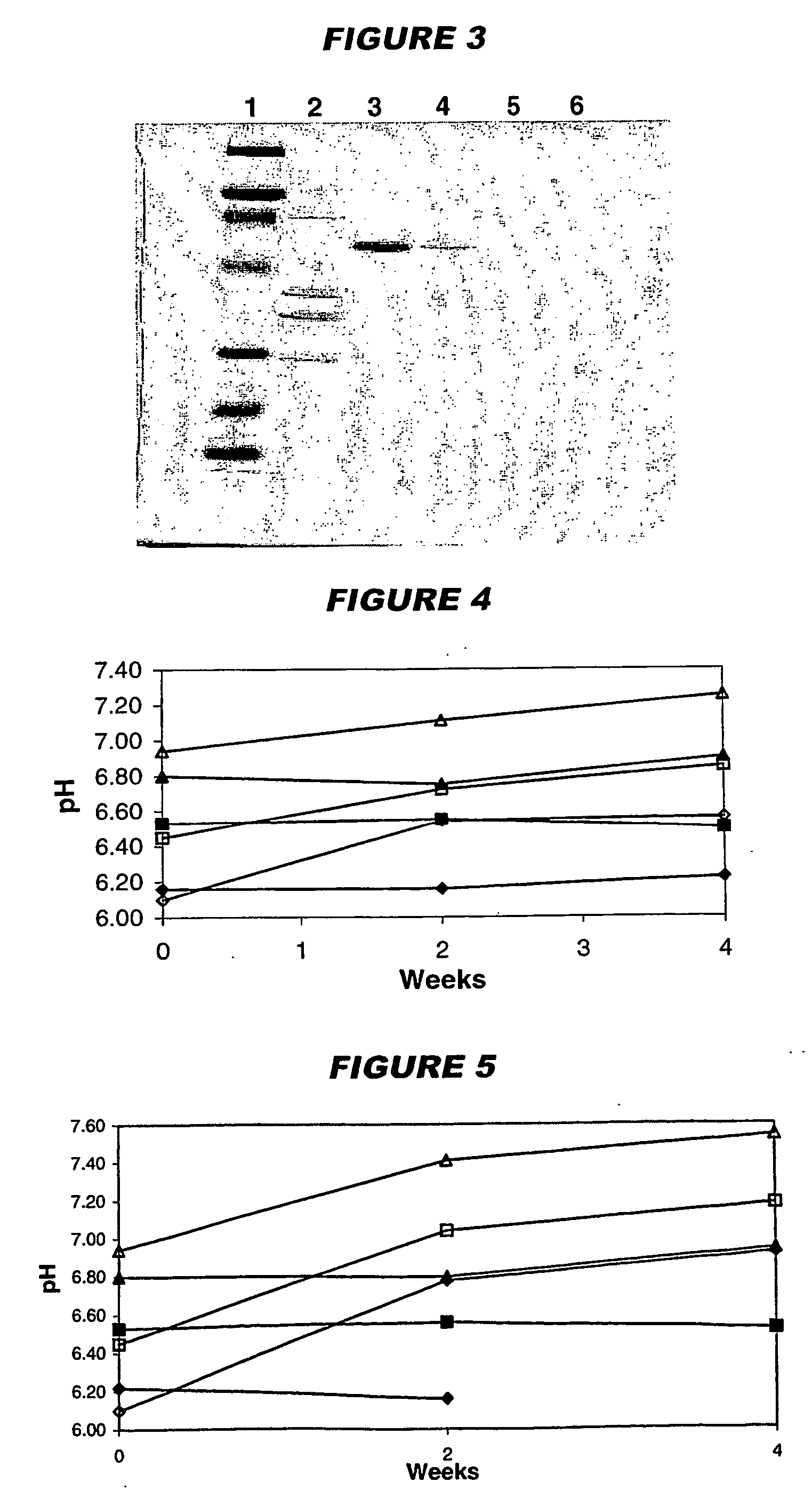

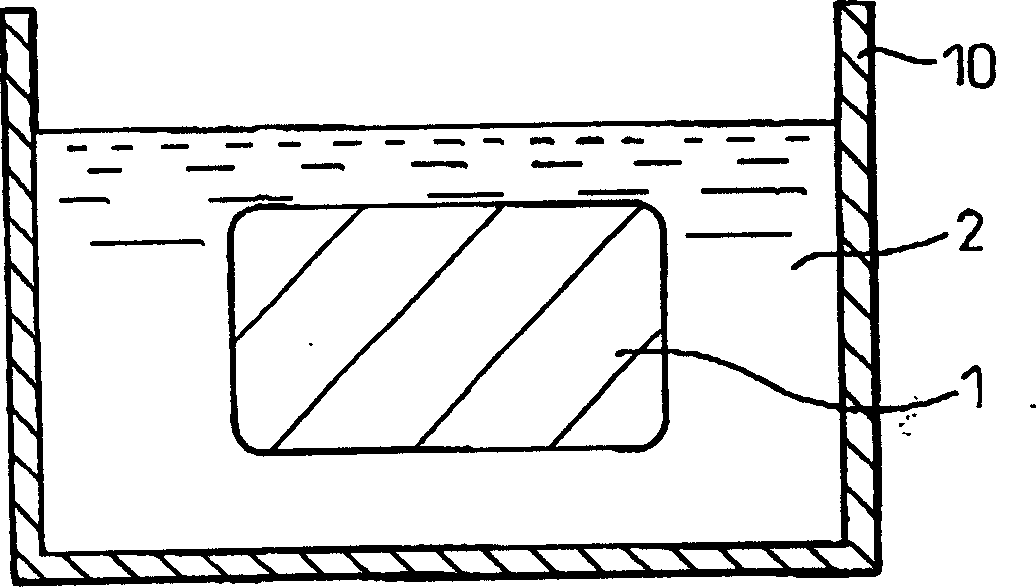

Disclosed are basic aluminum halides having enhanced antiperspirant efficacy; methods of making such materials and antiperspirant compositions containing such basic aluminum halides, and optionally an amino acid, salts of amino acids, antimicrobial agents, or an organic solvent having at least two carbon atoms and at least one hydroxy group and mixture thereof and methods of making such mixtures. Basic aluminum halides having enhanced antiperspirant efficacy are produced by reacting (a) aluminum powder; (b) an aluminum halide; and (c) water at a temperature greater than about 85° C. This reaction is maintained until reaction products having an Al:halide ratio of about 1.2:1 to 1.5:1 and preferably 1.3 to 1.4:1; and a solution solids concentration of about 30-40 weight percent on an anhydrous basis are obtained. The products are characterized as having a Size Exclusion Chromatography (HPLC) Test Band I of less than 5%, preferably less than 1%, Band II percent aluminum value of 20-60% preferably about 35 to 55%, Band III percent aluminum value of 10 to 35% preferably 15-30% and Band IV value of 15 to 50% and preferably 25 to 35% and sum of peak 3 and 4 areas of at least 45% and no more than 70% and preferably 65%. The enhanced efficacy basic aluminum chloride salts of this invention are more economical to produce, show enhanced efficacy and are more stable compared to the conventional enhanced efficacy aluminum salts which show rapid degradation of Band III to Band II peak areas ratio are less irritant and more skin friendly.

Owner:SUMMIT RES LAB

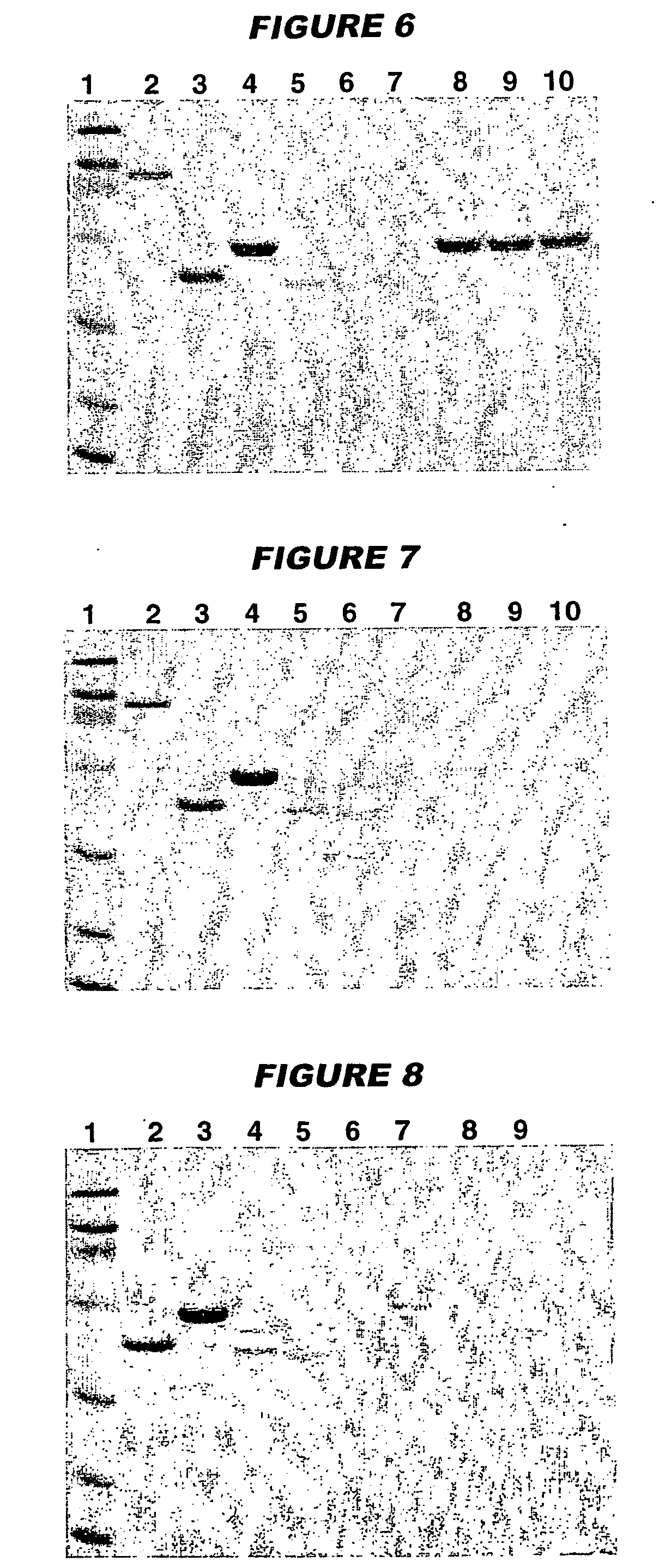

Vaccines comprising aluminium adjuvants and histidine

InactiveUS20050158334A1Easy to controlMinimise adsorptionAntibacterial agentsOrganic active ingredientsAntigenAdjuvant

To improve the stability of vaccines comprising aluminum salt(s), the invention uses the amino acid histidine. This can improve pH stability and adjuvant adsorption and can be reduce antigen hydrolysis. Histidine is preferably presen during adsorption to the aluminium salt(s). The antigen in the vaccine may be a protein or a saccharide and is preferably from N. meningitidis.

Owner:GLAXOSMITHKLINE BIOLOGICALS SA

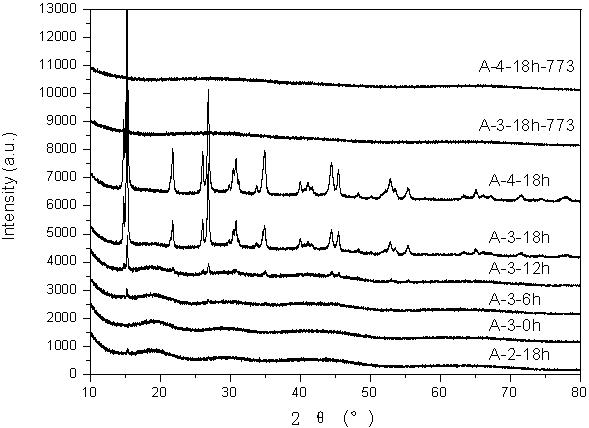

Magnesium-aluminum-iron hydrotalcite, preparation method and application thereof as coadsorbent

InactiveCN101962208ARaw materials are easy to getMild preparation conditionsOther chemical processesWater contaminantsIron saltsSorbent

The invention provides magnesium-aluminum-iron hydrotalcite, a preparation method and application thereof as a coadsorbent. The preparation method comprises the following steps of: adding a mixed salt solution to an alkali solution to carry out a coprecipitation reaction by controlling the pH of the reaction ending point to 8.0-12; and then aging, filtering, washing and drying to obtain the magnesium-aluminum-iron hydrotalcite, wherein the mixed salt solution comprises magnesium salts, aluminum salts and iron salts, and after the magnesium-aluminum-iron hydrotalcite is roasted at 300-800 DEG C for 1-10 hours, an adsorbent for coadsorbing phenol and chromium (VI) in water is obtained. The invention has the advantages of moderate reaction condition, easy raw material obtaining, low production cost and reusability, and the adsorption rates of the phenol and the chromium (VI) can both reach higher 70 percent, thus the magnesium-aluminum-iron hydrotalcite has good application prospect. The chemical structural general formula of the magnesium-aluminum-iron hydrotalcite is as follows: [M2<+1>-xM3+x(OH)2]x+(CO3<2->)x / 2.yH2O.

Owner:SHANGHAI UNIV OF ENG SCI

Method for preparing sludge-based formed magnetic active carbon

ActiveCN103521180AUniform sizeHigh compressive strengthOther chemical processesAlkali metal oxides/hydroxidesMagnetic stabilitySludge

The invention provides a method for preparing sludge-based formed magnetic active carbon. The method comprises the steps as follows: sludge is used as a raw material, an activating agent is added for carbonizing and activating the sludge; nano-sized Fe3O4 is used as a magnetic source for magnetizing the sludge active carbon; and sodium carboxymethylcellulose and aluminum salt are composited to an organic-inorganic binding agent, the binding agent and a p-toluenesulfonhydrazide foaming agent are used for uniformly binding powdery magnetic active carbon into a formed magnetic active carbon precursor with abundant pore structures, and finally, the formed magnetic active carbon precursor is heated to obtain the sludge-based formed magnetic active carbon. According to the method, the sludge is used as a main raw material, the resource utilization of the sludge is achieved, the recycling is convenient, and reutilization can be achieved; and further, the sludge-based formed magnetic active carbon has a stable structure and good magnetic stability, and can be widely used in the fields such as sewage treatment, soil pollution treatment and the like.

Owner:FUJIAN UNIV OF TECH

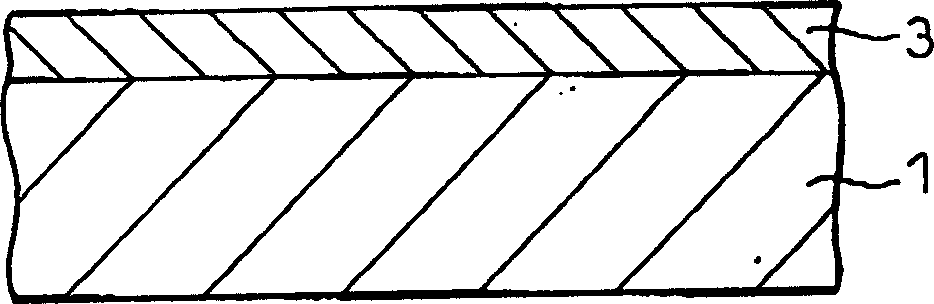

Shaped metal article and method of producing shaped metal article having oxide coating

The present invention discloses a shaped metal product with an oxide coating layer and a preparation method thereof. The shaped metal product has a metal body with an oxide coating layer applied on its surface. The metal body is composed of magnesium, aluminum and zinc. It is composed of a single metal selected from the group consisting of magnesium, aluminum and zinc, or is made of a metal alloy containing at least one metal selected from the group consisting of magnesium, aluminum and zinc as a main component, and the oxide coating layer is made of an aluminum salt as a main component. The oxide coating layer is formed by surface treatment or anodizing treatment of the metal body in a separate treatment solution.

Owner:FUJITSU LTD

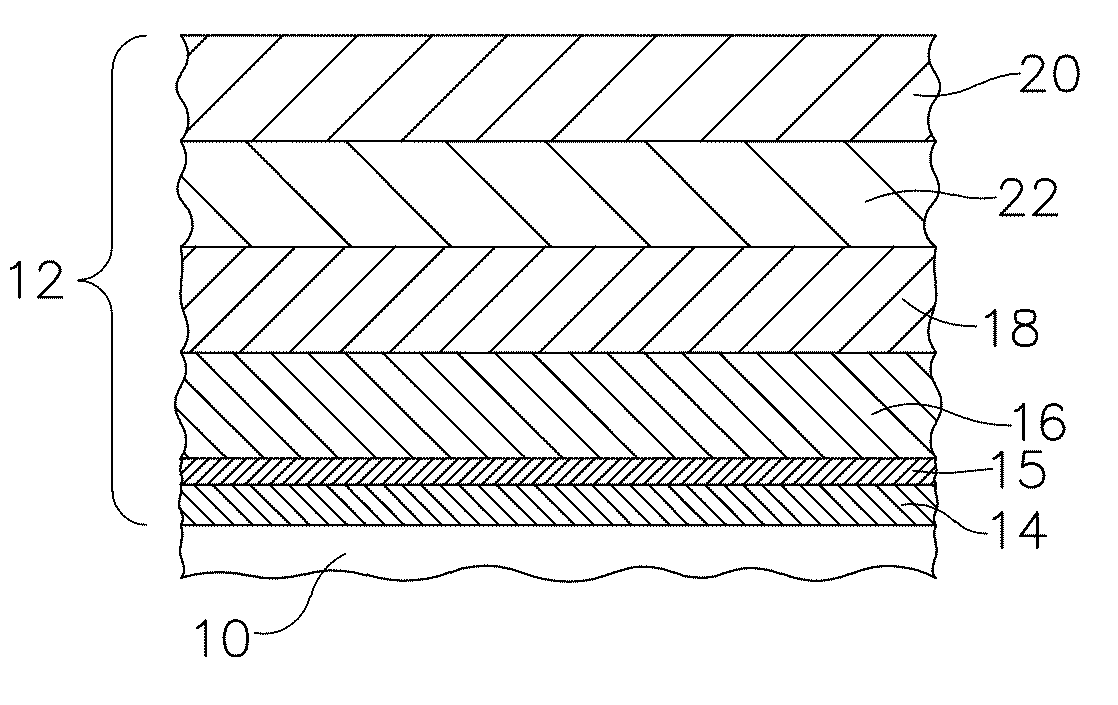

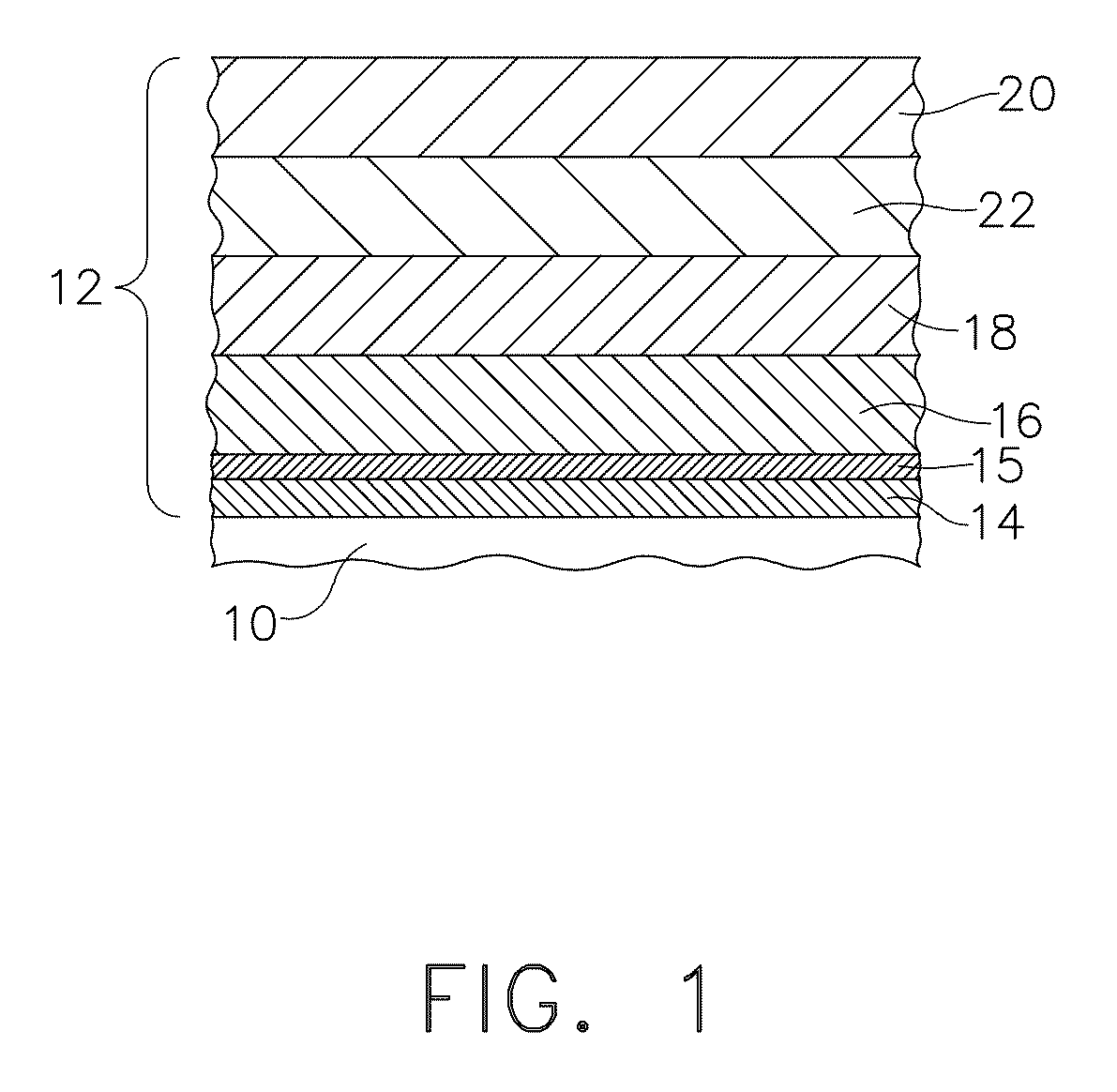

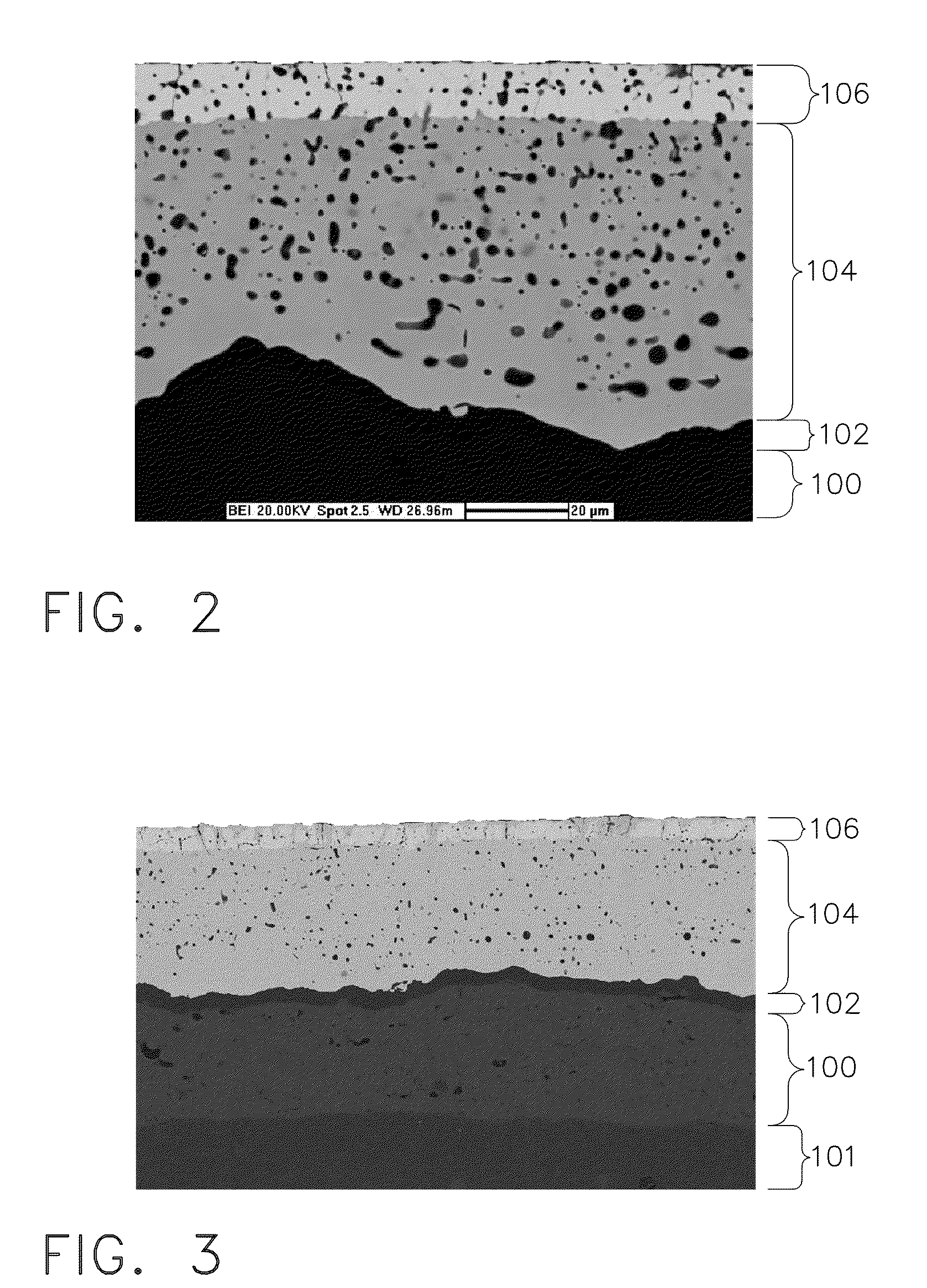

Methods of improving surface roughness of an environmental barrier coating and components comprising environmental barrier coatings having improved surface roughness

Methods for improving surface roughness of an environmental barrier coating including providing a component having a plasma sprayed environmental barrier coating; applying a slurry to the environmental barrier coating of the component, the slurry being a transition layer slurry or an outer layer slurry; drying the environmental barrier coating having the applied slurry; and sintering the component to produce a component having an improved surface roughness where the slurry includes a solvent; a primary transition material, or a primary outer material; and a slurry sintering aid selected from iron oxide, gallium oxide, aluminum oxide, nickel oxide, titanium oxide, boron oxide, alkaline earth oxides, carbonyl iron, iron metal, aluminum metal, boron, nickel metal, iron hydroxide, gallium hydroxide, aluminum hydroxide, nickel hydroxide, titanium hydroxide, alkaline earth hydroxides, iron carbonate, gallium carbonate, aluminum carbonate, nickel carbonate, boron carbonate, alkaline earth carbonates, iron oxalate, gallium oxalate, aluminum oxalate, nickel oxalate, titanium oxalate, solvent soluble iron salts, solvent soluble gallium salts, solvent soluble aluminum salts, solvent soluble nickel salts, solvent titanium salts, solvent soluble boron salts, and solvent soluble alkaline earth salts.

Owner:GENERAL ELECTRIC CO

Fluorination catalysts, method for their preparation, and method for producing fluorinated compounds using the catalysts

InactiveUS20070027348A1High rateHigh selectivityOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by halogen replacementIron saltsNickel salt

The present invention provides a novel fluorination catalyst that has high stability at high temperatures, is easily regenerated and is superior in catalytic activity and selectivity and a method for the preparation of the fluorination catalyst. The present invention also provides a method for the preparation of a novel fluorinated compound, and particularly, 1,1,1,3,3-pentafluoropropane (HFC-245fa), by using the catalyst. The fluorination catalyst of the present invention is obtained by treating a metal salt containing a chromium salt such as chromium oxide with chlorine gas and / or oxygen gas. Examples of the metal salt may include, besides a chromium salt, one or more catalytically active metal salts selected from magnesium salts, aluminum salts, zinc salts, sodium salts, nickel salts, iron salts, cobalt salts, vanadium salts, manganese salts and copper salts.

Owner:NAT INST OF ADVANCED IND SCI & TECH

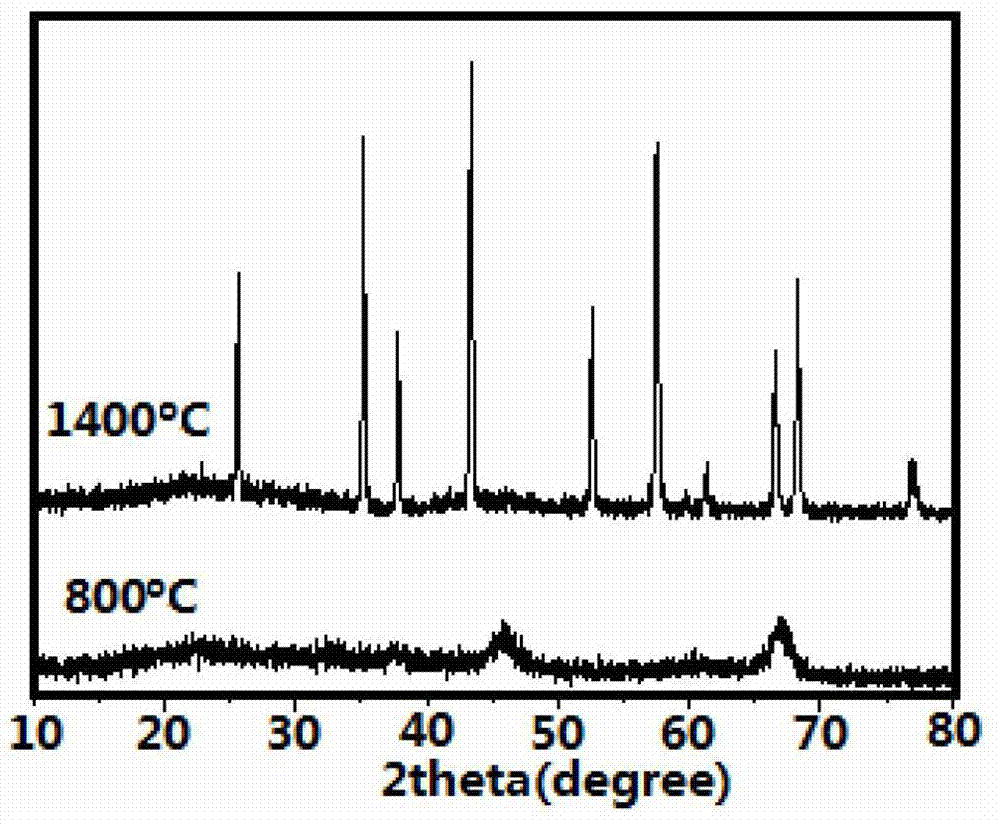

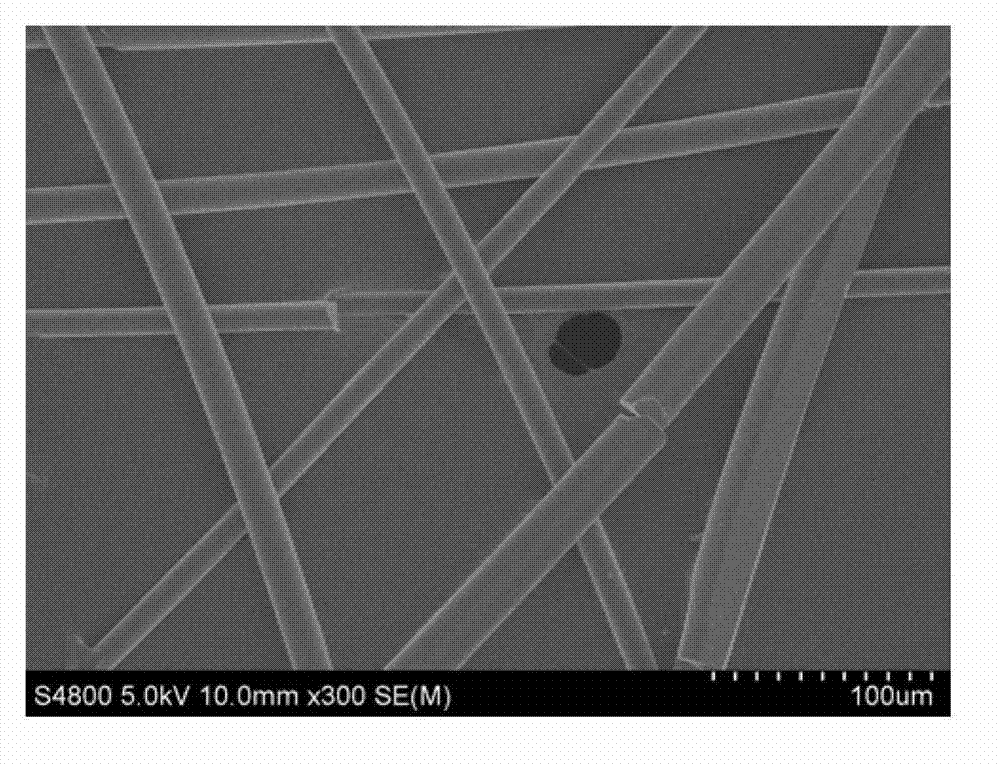

Preparation method of aluminum oxide ceramic continuous fiber

The invention relates to a preparation method of aluminum oxide ceramic continuous fiber, which comprises the following steps of: preparing a sol spinnable precursor by use of inorganic aluminum salt, aluminum powder, aluminum isopropoxide, nitric acid and crystal grain inhibitor; spinning gel fiber by a dry spinning technology; and performing drying and high-temperature calcination to obtain the aluminum oxide ceramic continuous fiber with diameter of 10-60 microns. According to the invention, the prepared sol system is particularly stable, the cost of the raw materials is low, and the preparation process is simple; and the filament can be obtained without adding auxiliaries such as macromolecules and the like. The filamentation environment is mild in the dry spinning. The calcined ceramic continuous fiber has flexibility and can be used as reinforcement in a composite material to improve strength and heat resistance of the material.

Owner:SHANDONG UNIV

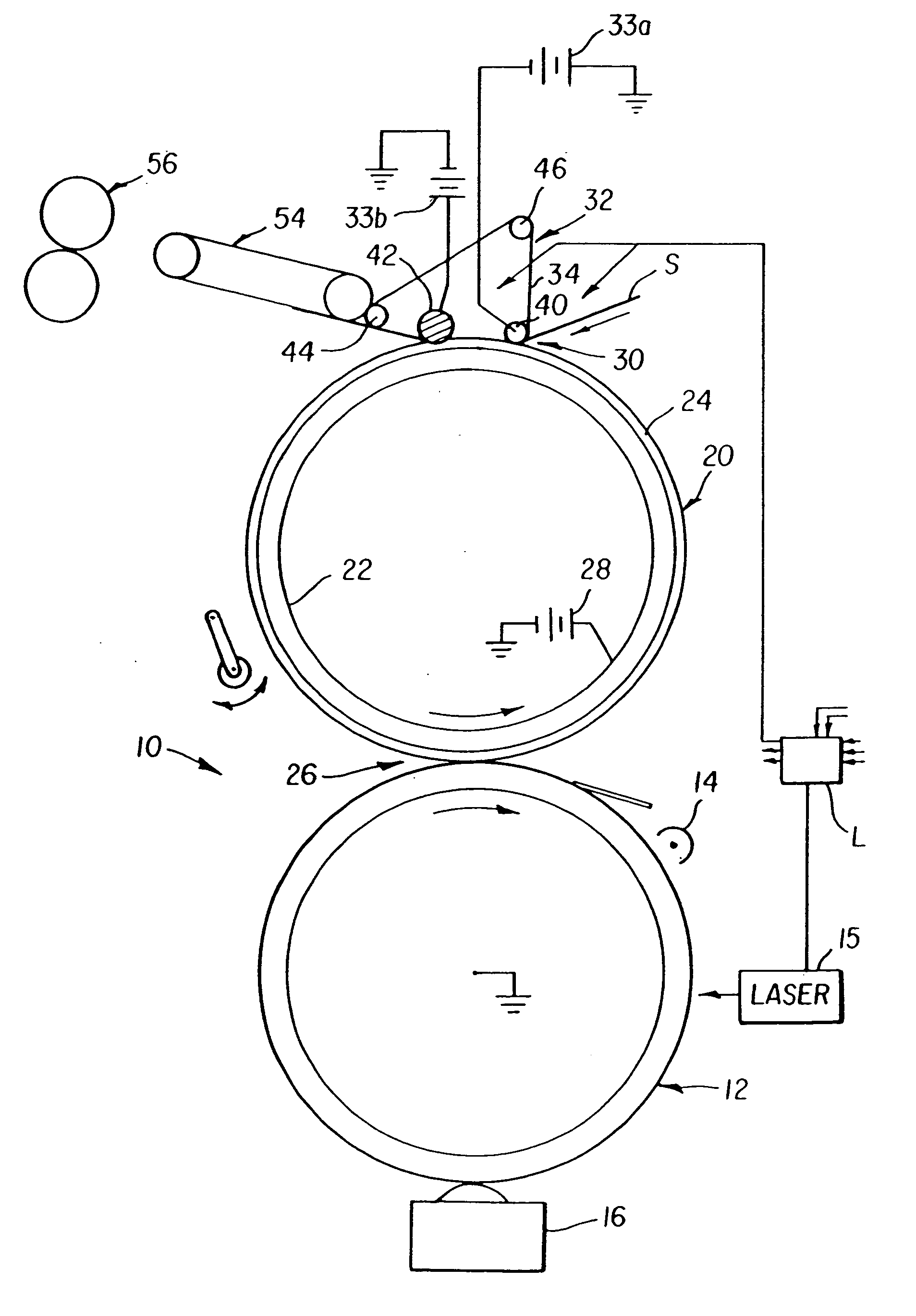

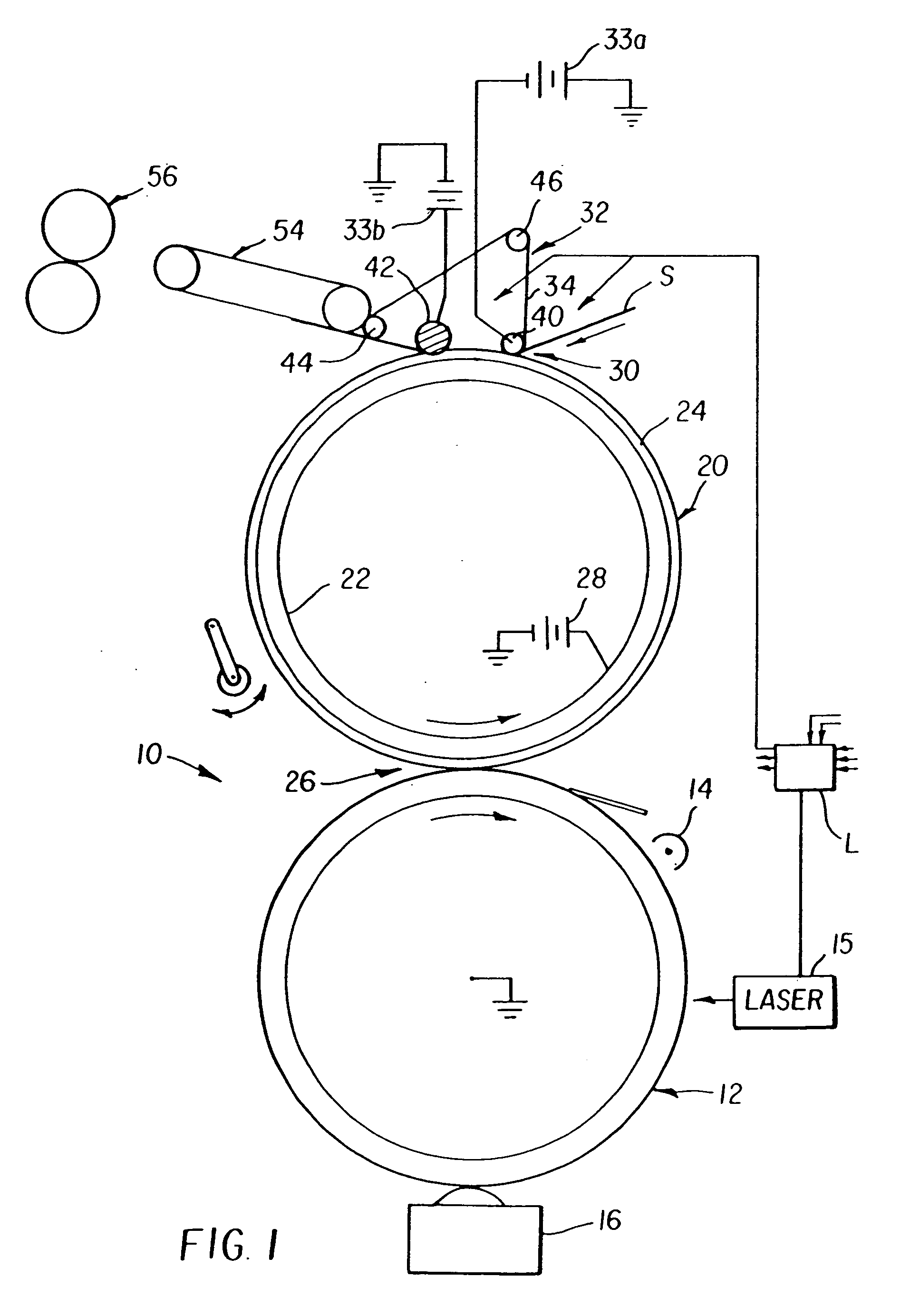

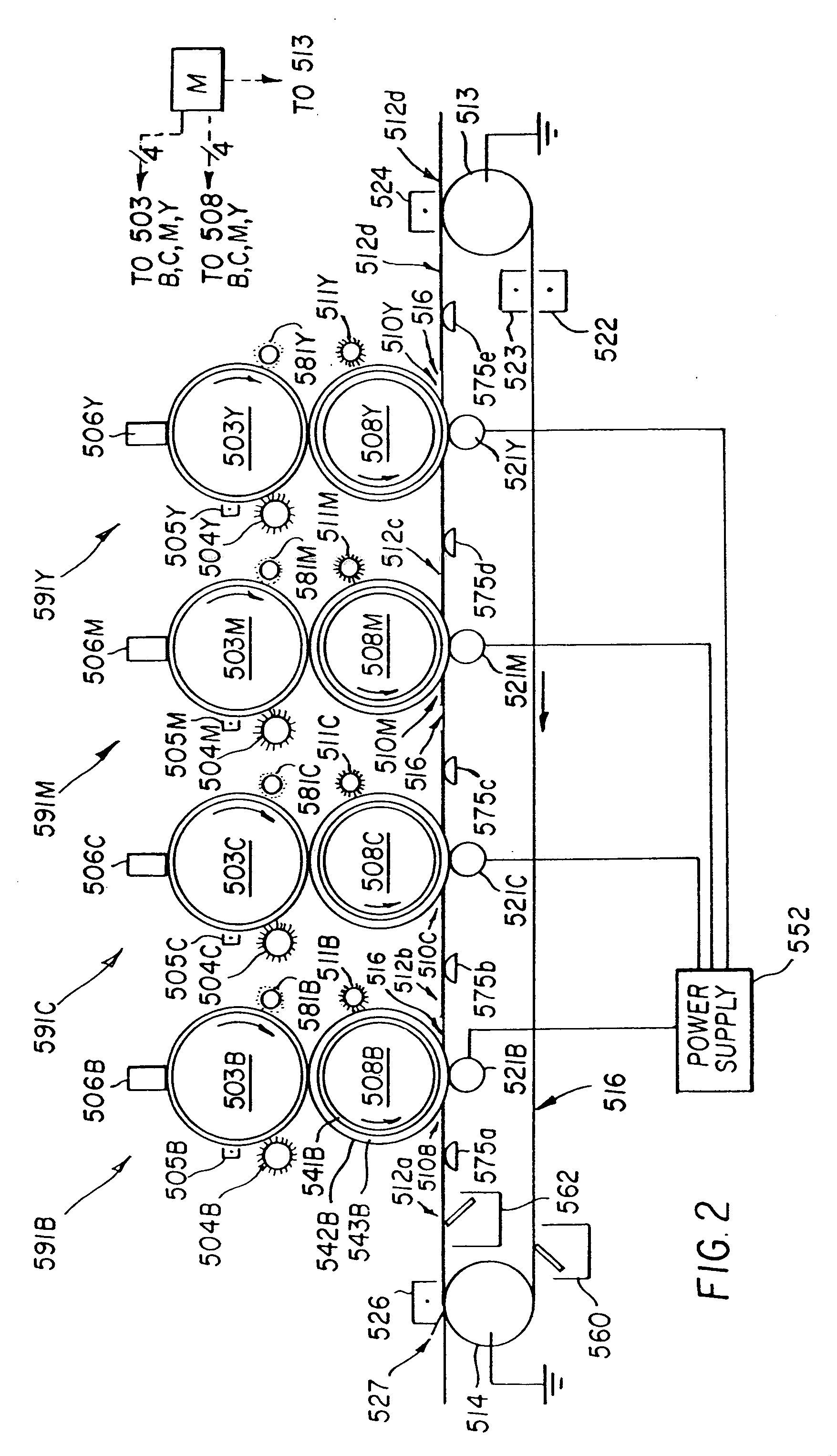

Electrostatographic apparatus having transport member with high friction layer

ActiveUS20060165974A1Eliminate slippageConvenient registrationSynthetic resin layered productsRecord information storageInorganic particleAlumina hydrate

A method for forming a receiver transport member for an electrostatographic reproduction apparatus. The transport member transports receiver members with respect to a fuser assembly and is frictional coupled to a transfer member for driving the transfer member. The method for forming the transport member provides a substrate bearing a high friction layer that includes inorganic particles, with a compound of aluminum selected from the group consisting of aluminum hydroxide, alumina hydrate, aluminum oxide, pseudo-boehmite, boehmite alumina, aluminum salts, and mixtures thereof, dispersed in an organic binder so that the high friction layer is capable of preventing a loss of frictional coupling due to release oil applied to a receiver member bearing a fused toner image.

Owner:EASTMAN KODAK CO

Enhanced efficacy antiperspirant active

An enhanced efficacy aluminum only salt active. The method for making such active comprises the steps of (a) providing an aqueous solution of an aluminum salt having a Band III polymer concentration of at least about 20%; (b) adding to the aqueous solution of step (a) an aqueous solution of a monomeric aluminum salt to form a mixture; and (c) rapidly drying the mixture to form a product powder. The active comprises an aluminum only salt having a Band III polymer concentration of at least about 20%, an aluminum to anion ratio of from about 1.1:1 to about 1.8:1 and a level of monomeric aluminum of from about 2% to about 20% of the total aluminum.

Owner:THE PROCTER & GAMBLE COMPANY

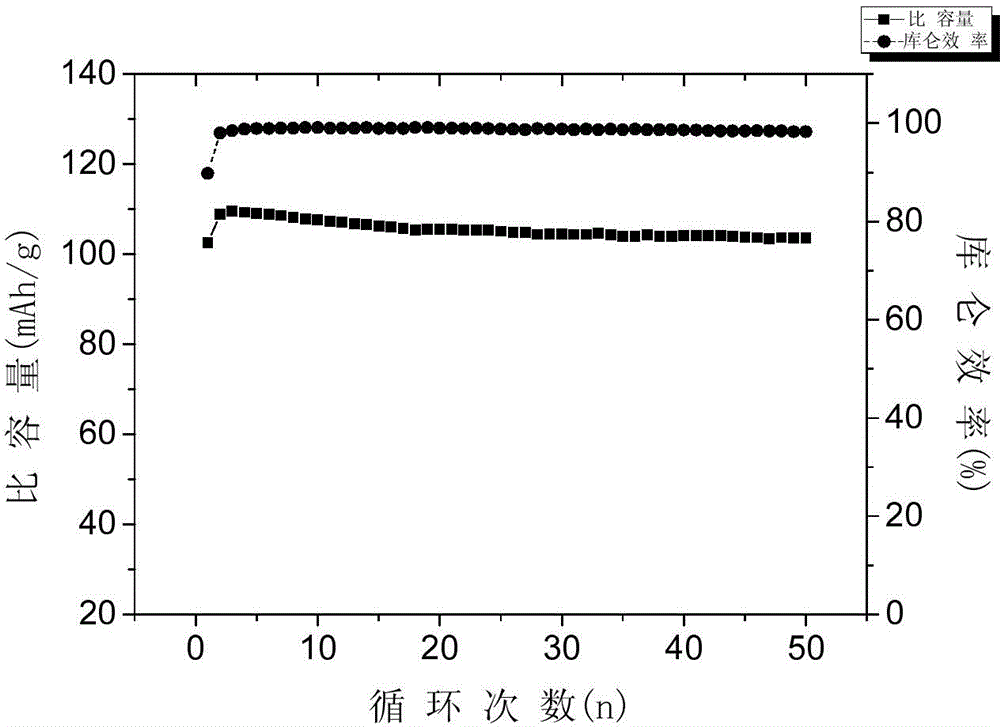

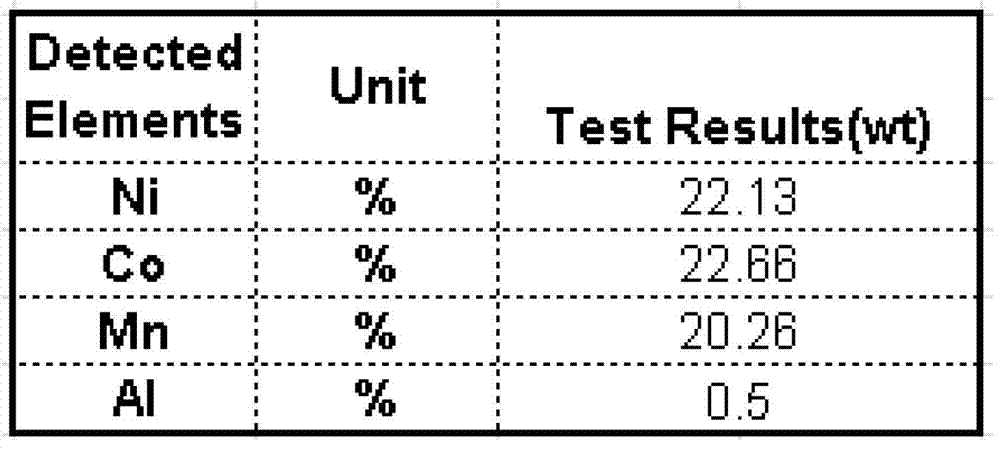

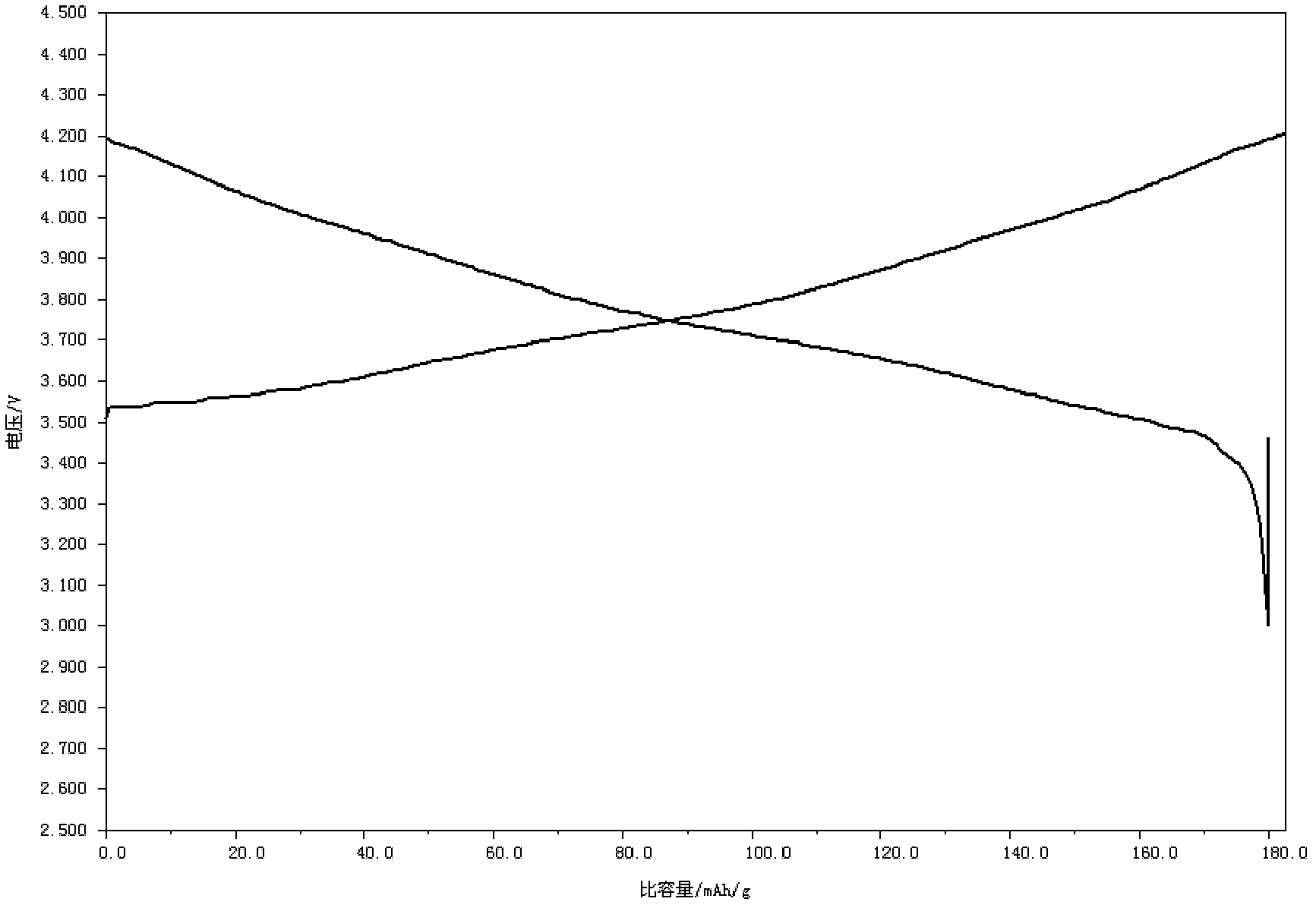

Preparation method of lithium-nickel-cobalt-aluminum composite metal oxide

ActiveCN102694166AReduce pollutionReduced corrosion protection equipment requirementsCell electrodesPhysical chemistryAluminum composites

The invention belongs to the field of a secondary battery, and particularly relates to a preparation method of a lithium-nickel-cobalt-aluminum composite metal oxide, which comprises the following steps: using a pollution-free carbonate complexing agent to firstly precipitate nickel and cobalt salts to form a spherical precursor, then precipitating aluminum salts through a secondary precipitation method to obtain a nickel-cobalt-aluminum precipitate, cleaning, drying, mixing with lithium salts, and sintering to obtain the lithium-nickel-cobalt-aluminum composite metal oxide having mixed and doped metal ions and anions. The invention solves the problems that the industrial preparation of the lithium-nickel-cobalt-aluminum composite metal oxide (a lithium ion positive pole material) is difficult in the prior art, ammonia gas is polluted in the preparation process, the obtained material has low tap density and poor cycle performance and the like. Besides, the prepared product has the characteristics of high tap density and high cycle performance.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

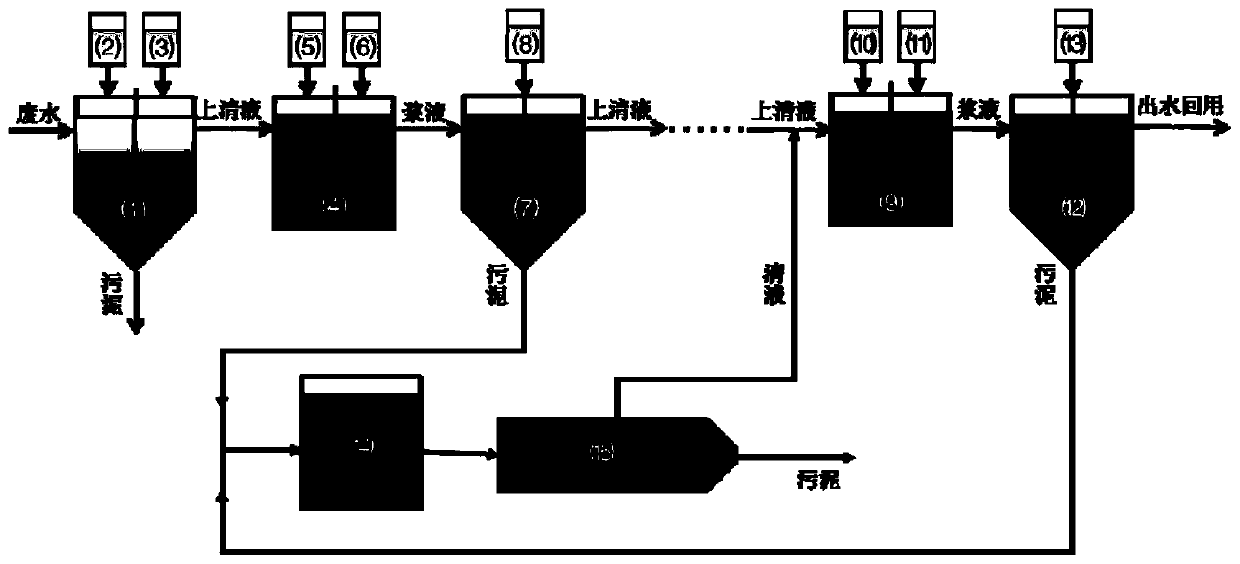

Precipitating and desalting high-salt wastewater recycling process

PendingCN110668540AAchieving zero emissionsEfficient removalWater contaminantsWater/sewage treatment by flocculation/precipitationSulfate radicalsDivalent metal

The invention relates to a high-salt wastewater precipitation desalting recycling process, which is a two-stage process and comprises the following steps: a first stage: removing sulfur by a calcium sulfate method, to be more specific, synchronously removing sulfate radicals and divalent metal salts by adding lime to a calcium sulfate method sulfur removal unit; and a second stage: performing deepsulfur removal and chlorine removal, to be more specific, simultaneously deeply removing the sulfate radicals and chloride ions by adding lime and aluminum salt in a deep sulfur removal and chlorineremoval unit. Compared with the prior art, the multi-stage precipitation desalting process provided by the invention considers the problem of efficient sludge dewatering while treating sewage, improves the removal efficiency and reduces the treatment cost.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

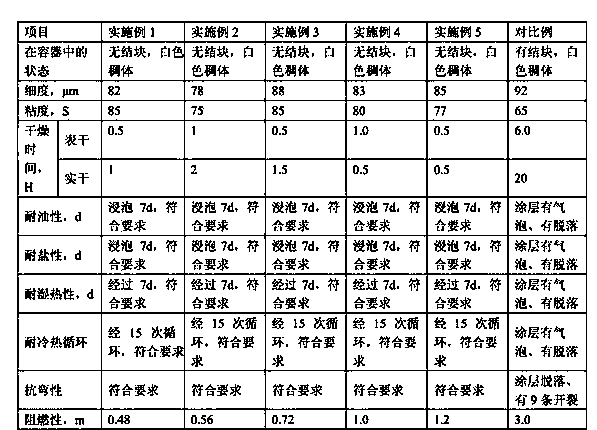

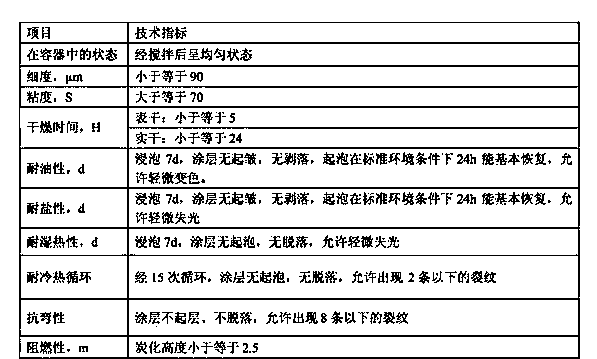

Water-based expansive type nano fireproof coating for cable and preparation method thereof

ActiveCN103740231AGood component compatibilityImprove bending resistanceFireproof paintsEpoxy resin coatingsPtru catalystFoaming agent

The invention relates to a water-based expansive type nano fireproof coating for a cable and a preparation method of the water-based expansive type nano fireproof coating. The water-based expansive type nano fireproof coating for the cable is characterized by comprising the following components in parts by weight: 20-40 parts of a coating base body, 15-45 parts of a nano flame retardant, 2-10 parts of a flame retardant synergist, 5-10 parts of a filler, 1-5 parts of an assistant and 10-30 parts of water, wherein the nano flame retardant is obtained by nano-crystallizing the flame retardant which comprises soluble aluminum salt, a charring catalyst, a charring agent and a foamer, and the flame retardant synergist is biomass ash of a power plant. As the components of the water-based expansive type nano fireproof coating are good in compatibility, the water-based expansive type nano fireproof coating is good in buckling resistance, humidity resistance, oil resistance and water resistance, excellent in flame retardance and low in charring height.

Owner:ZHONGYING CHANGJIANG INTERNATIONAL NEW ENERGY INVESTMENT CO LTD

Heavy metal ion stabilizer for ecological environment and environment restoration method

ActiveCN103555337AEnhanced flocculation adsorption collection capacityStrengthening non-transferable exchange capabilitiesContaminated soil reclamationOrganic fertilisersPlant rootsEcological environment

The invention relates to a heavy metal ion stabilizer for an ecological environment and an environment restoration method. Bentonite is modified in a conventional mode by taking water soluble aluminum salts as a bentonite modifier, thereby preparing aluminum salt modified bentonite taken as the low-concentration heavy metal ion stabilizer for the ecological environment, wherein the adding amount of the modifier accounts for 2% to 30% of the mass of the bentonite. The invention further provides the method for environment restoration by using the heavy metal ion stabilizer. The heavy metal ion stabilizer is wide in source and low in cost, and cannot generate biotoxicity, thereby preventing additional environmental burdens as well as soil solidification and ridging. In addition, the heavy metal ion stabilizer can be used for actively corroding and sucking metal ions while avoiding plant root systems.

Owner:长沙紫宸科技开发有限公司

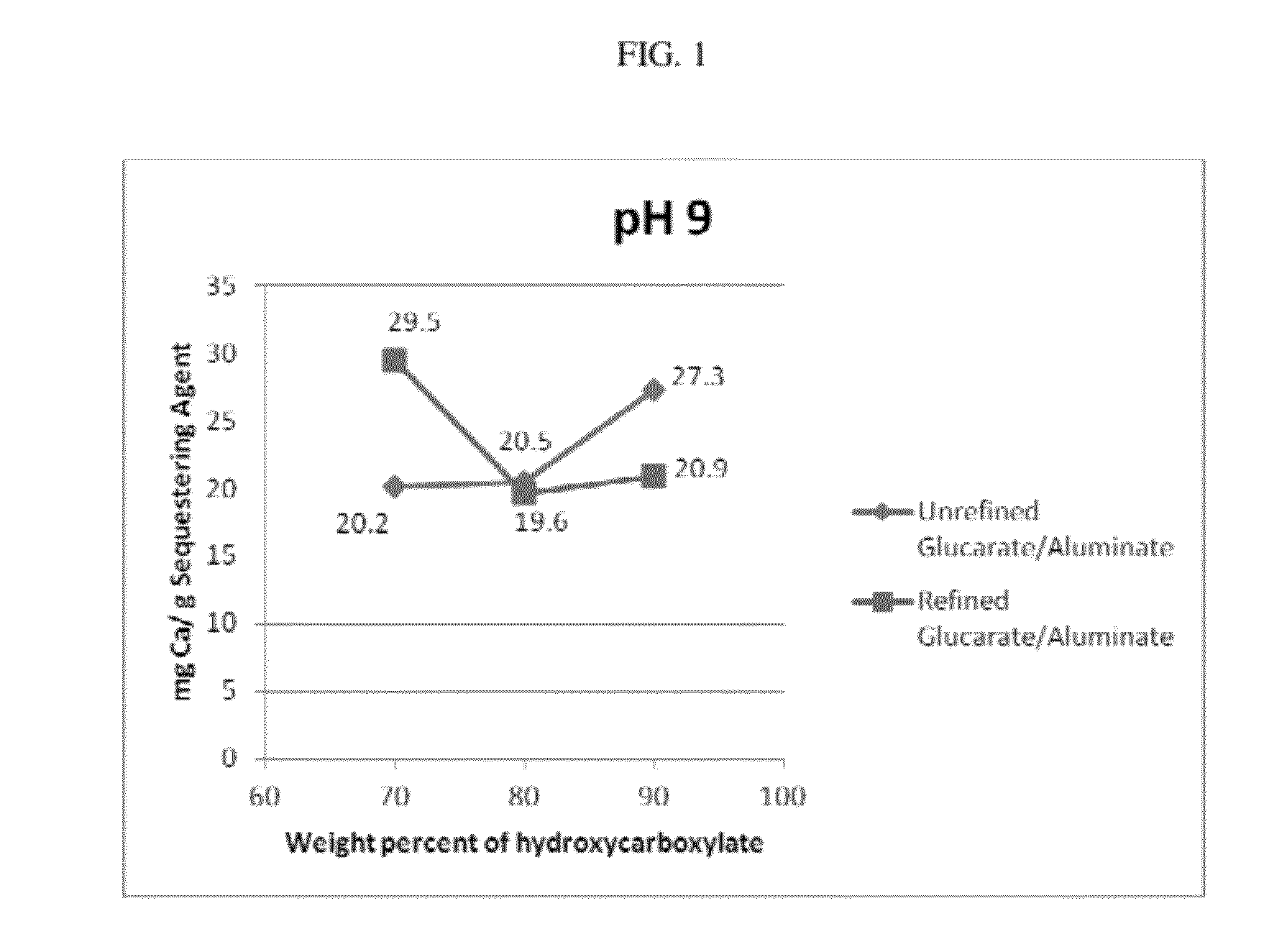

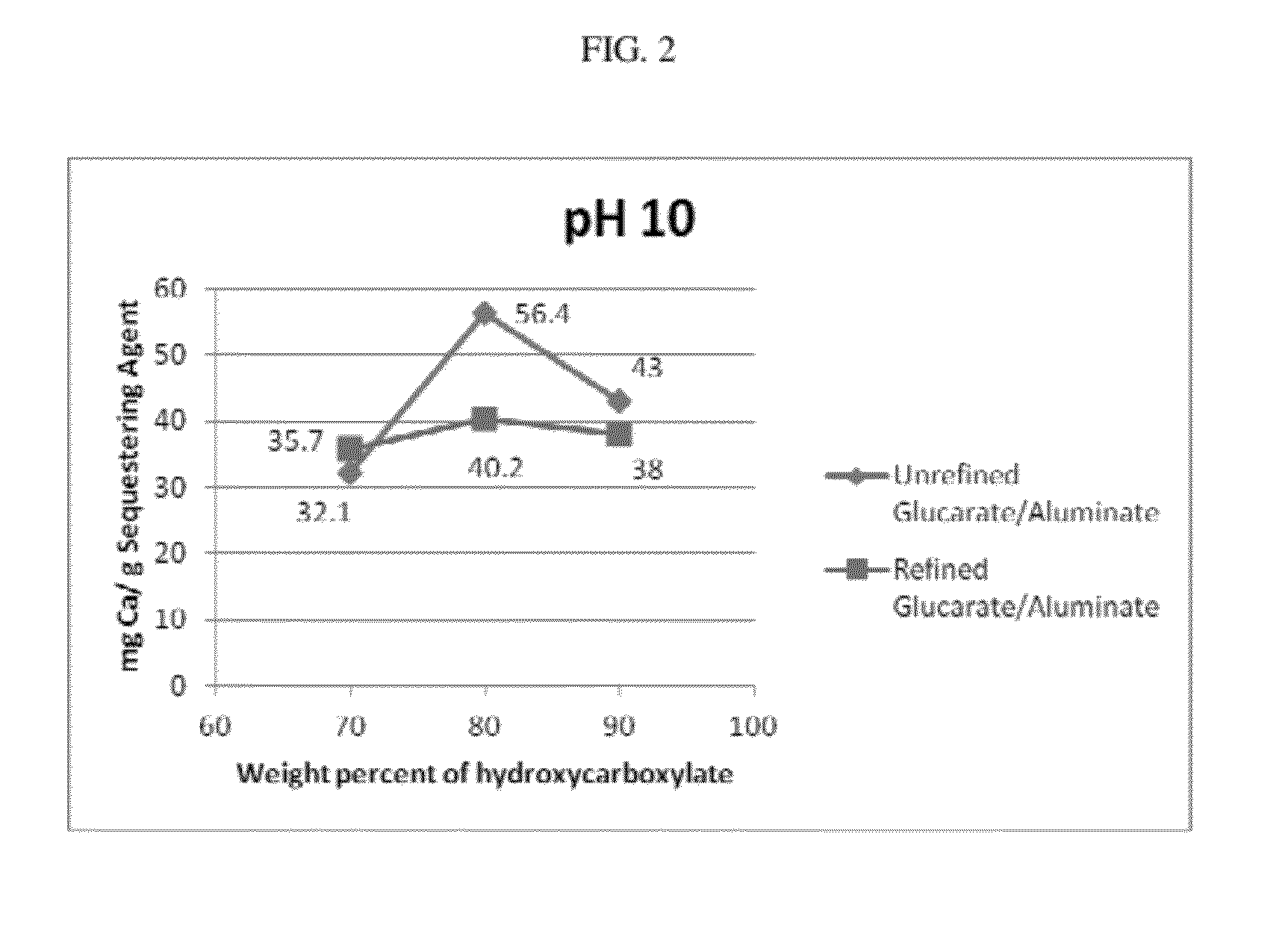

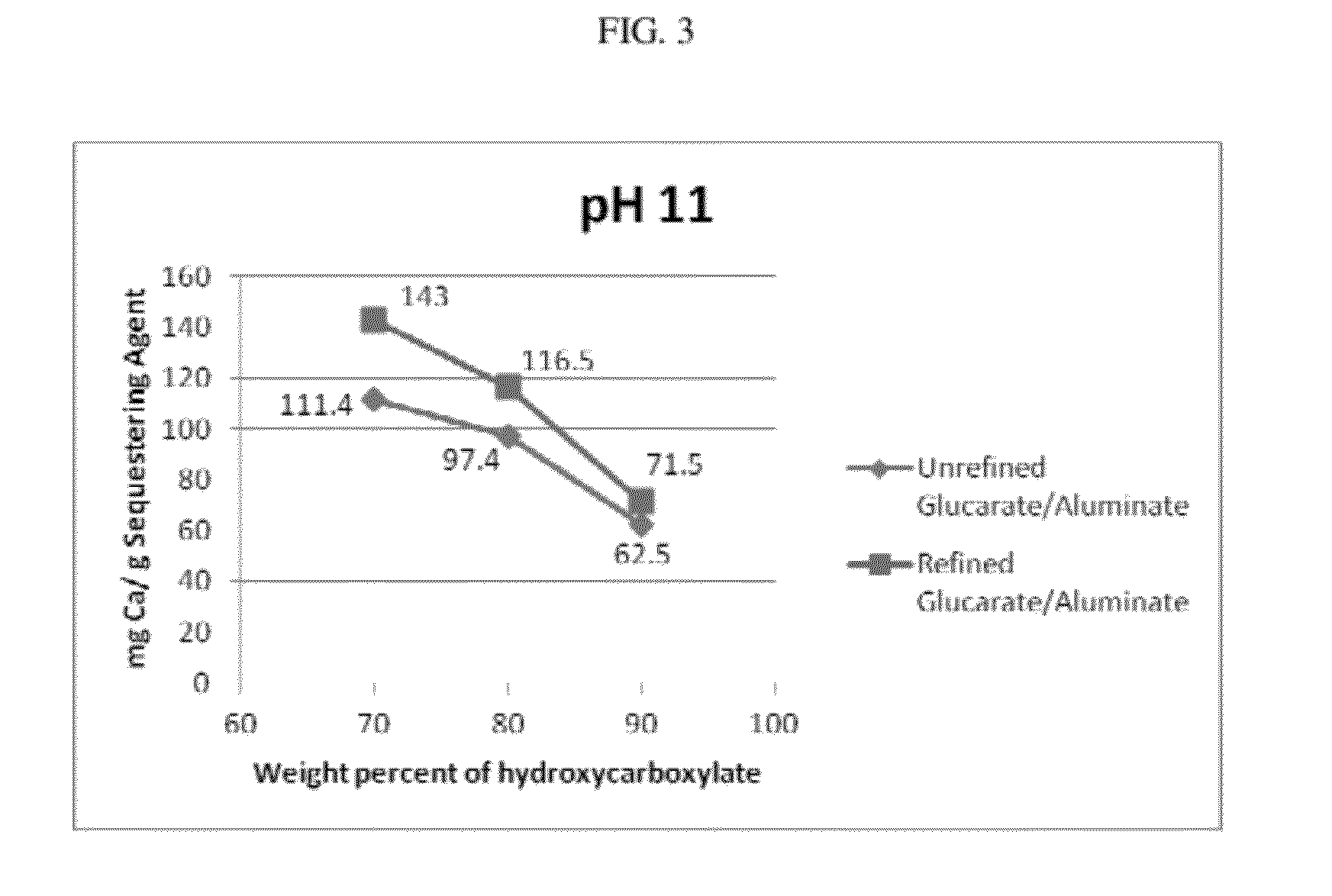

Calcium sequestering composition

InactiveUS20120295986A1Inorganic/elemental detergent compounding agentsBiocideNuclear chemistryAluminum salts

This invention relates to compositions which are capable of sequestering calcium ions and are derived in part from renewable carbohydrate feedstocks. The calcium sequestering compositions are mixtures containing one or more hydroxycarboxylic acid salts and one or more aluminum salts.

Owner:RIVERTOP RENEWABLES

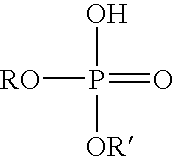

Fibrous mesoporous alumina and preparation method thereof

InactiveCN102153119ASimple processOperational securityAluminium oxides/hydroxidesAluminium nitrateAmmonium carbonate

The invention discloses fibrous mesoporous alumina and a preparation method thereof. At a medium / low temperature, inorganic aluminum salt is used as aluminum source and ammonium salt is used as precipitant to prepare fibrous mesoporous alumina through the precipitation method, wherein inorganic aluminum salt is aluminum nitrate and ammonium salt is ammonium carbonate; the traditional precipitation method is adopted to drop ammonium carbonate solution in aluminum nitrate solution and obtain precipitate; and the precipitate is aged, washed, filtered and dried to obtain fibrous precursor powder, and the obtained fibrous precursor powder is calcined to obtain fibrous mesoporous alumina. The preparation method has simple technology and safe operations and is suitable for large-scale mass production. By using inorganic aluminum salt as aluminum source and ammonium carbonate as precipitant, the production cost is low. The prepared mesoporous alumina is fibrous, the diameter is 70-500nm and the length is 2-3mu m. The fibrous mesoporous alumina has larger specific surface area and bore diameter which are separately 290-380m<2> / g and 3.8-6.5nm and can be widely used in the fields such as adsorption and catalysis, thus the fibrous mesoporous alumina has important and practical application value.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Method for preparing porous ceramic from active alumina precursor

The invention relates to a method for preparing high-strength and high-porosity ceramic by preparing an active alumina precursor from inorganic aluminum salt, adding ceramic fibers and ceramic powder into the active alumina precursor, and carrying out filtering, washing, molding and sintering. Concretely, the method comprises the following steps of adding a dispersant and short ceramic fibers into an inorganic aluminum salt solution, carrying out uniform dispersion, adding the dispersion liquid into a precipitating agent solution to obtain precipitates, adding ceramic powder into the precipitates, carrying out filtering and washing to obtain the precursor, mixing the precursor and a binder to obtain a uniform mixture, carrying out molding and drying to obtain a high-strength green blank, carrying out machining such as turning according to demand, and carrying out two-step sintering in atmosphere, wherein in the two-step sintering, the first sintering process comprises that activated aluminum oxide in the ceramic blank is transformed into alpha-alumina in reduction atmosphere or inert gas atmosphere and simultaneously, the organic matter is transformed into carbon, and the second sintering process comprises that the carbon is oxidized and volatilized in oxidation atmosphere so that the porous ceramic is obtained. Compared with the foamed ceramic which is prepared by the prior art and has a similar cost, the foamed ceramic prepared by the method has high ceramic strength and high porosity.

Owner:SHANDONG UNIV OF TECH

Preparation method of alumina support

ActiveCN103055947ALittle influence on mechanical strengthReduce intensityCatalyst carriersAluminium oxides/hydroxidesFiberActivated carbon

The invention discloses a preparation method of an alumina support. The method comprises the steps of enabling activated carbon fibers with developed pore structures to adsorb inorganic aluminium salts through dipping and then using the activated carbon fibers as pore-enlarging agents, kneading and forming the activated carbon fibers with an alumina precursor, and then drying and roasting the product, thus obtaining the alumina support. The alumina support prepared by the method is higher in specific surface area, more concentrated in pore size distribution and high in mechanical strength, also contains part of macropores with sizes more than 100nm, is suitable for preparing heavy / residual oil hydrogenation catalysts, and is favorable for removing macromolecular impurities in heavy / residual oil and delaying the increase of diffusion resistance in heavy / residual oil hydrogenation, thus being favorable for maintaining the activities of the hydrogenation catalysts and lengthening the running period.

Owner:CHINA PETROLEUM & CHEM CORP +1

Ink-jet recording material suitable for pigment ink

An ink-jet recording material having on a support at least one ink-receiving layer comprising pigment and binder, which further contains in the uppermost layer of the ink-receiving layers at least one water-soluble acidic or neutral salt selected from the group consisting of aluminum salts, magnesium salts, sodium salts, potassium salts and zinc salts, and thereby acquires suitability for an ink-jet recording process using pigment ink.

Owner:NIPPON PAPER IND CO LTD

Hydrocarbon fluids and methods of using same

A new hydrocarbon fluid composition and methods of using the fluid are disclosed. The fluid is comprised of a liquid hydrocarbon, a phosphate ester, an iron or aluminum salt crosslinker, a hydrocarbon foaming agent and a gas. The fluid can be used in many applications.

Owner:ONEIL BRIAN W +2

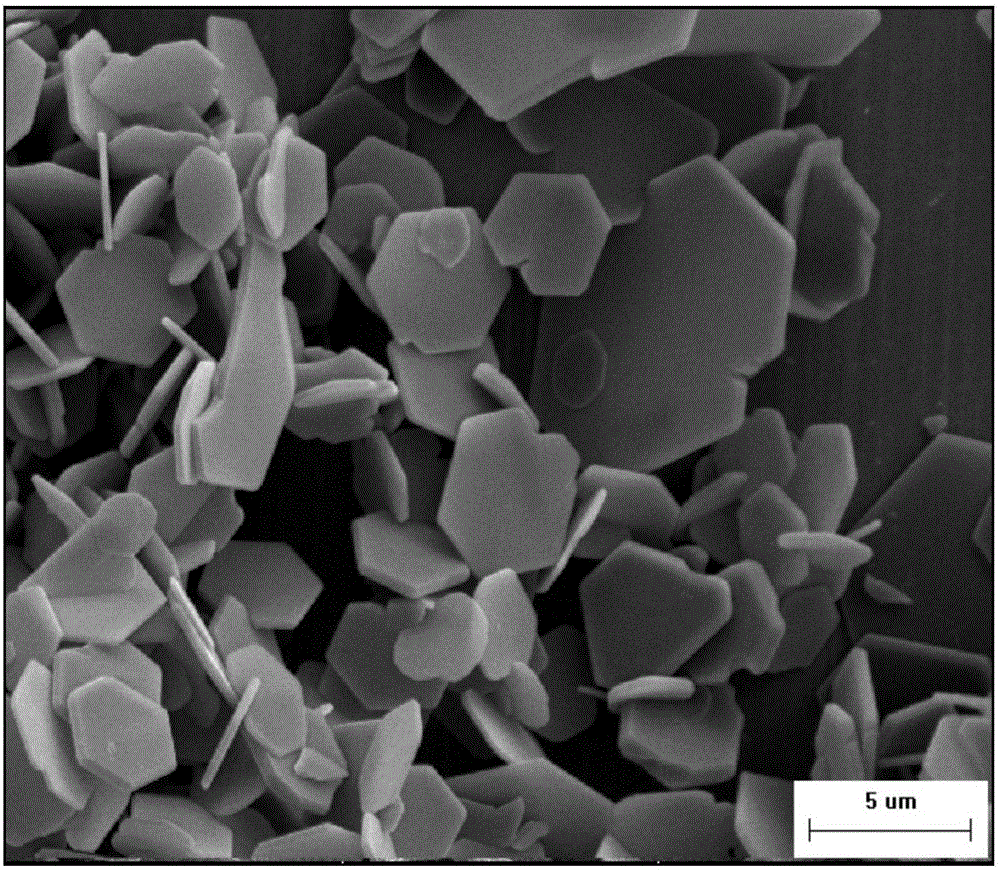

Sheet alpha-Al2O3 powder body with controllable particle diameter size and preparation method of sheet alpha-Al2O3 powder body

InactiveCN104986786ASmall particle sizeEvenly dispersedMaterial nanotechnologyAluminium oxides/hydroxidesMolten saltNano al2o3

The invention discloses a sheet alpha-Al2O3 powder body with a controllable particle diameter size and a preparation method of the sheet alpha-Al2O3 powder body. The preparation method comprises the following steps of: (1) preparing a mixed precursor solution which is obtained by uniformly mixing water-soluble aluminum salt, soluble salt, nanometer aluminum oxide crystal seeds and / or sheet alpha-Al2O3 crystal seeds, wherein the water-soluble aluminum salt contains unstable aluminum oxide; (2) adding an alkaline aqueous solution to the mixed precursor solution obtained in the step (1), and when a hydrolysis reaction is ended, and controlling the final pH to be 5.0-9.0 so as to obtain mixed gel containing hydrolysis products; (3) drying the mixed gel, and then calcining the dried mixed gel so as to obtain a mixture of the sheet alpha-Al2O3 powder body and fused salt; and (4) cleaning the fused salt with ionized water, sucking and filtering the cleaned fused salt, and drying the filtered fused salt so as to obtain the pure sheet alpha-Al2O3 powder body. The particle diameter size of the prepared sheet aluminum oxide powder body is controllable. The sheet aluminum oxide is uniform to disperse and is smooth and level, and twin crystals do not appear.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com