Water-based expansive type nano fireproof coating for cable and preparation method thereof

A fire retardant coating, intumescent technology, applied in fire retardant coatings, epoxy resin coatings, coatings, etc., can solve problems such as poor flame retardant performance and poor compatibility, and achieve good compatibility, good water resistance, and wide application. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Preparation of nano flame retardant:

[0028] Add each flame retardant component to water that is 5 times the total weight of each flame retardant component, then add surface modifier, heat to 60 o After C, adjust the pH value of the system to 7.0 with dilute sulfuric acid, react for 3 hours and cool to obtain a nano-flame retardant sol containing aluminum hydroxide, that is, a nano-flame retardant. The selection and dosage of each flame retardant component and surface modifier are shown in Table 1.

[0029] (2) Preparation of fire retardant coating:

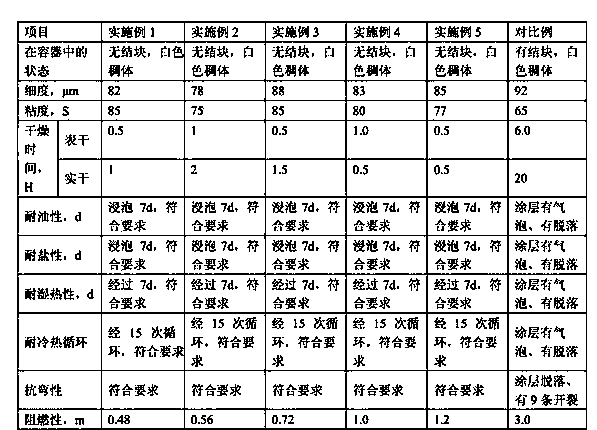

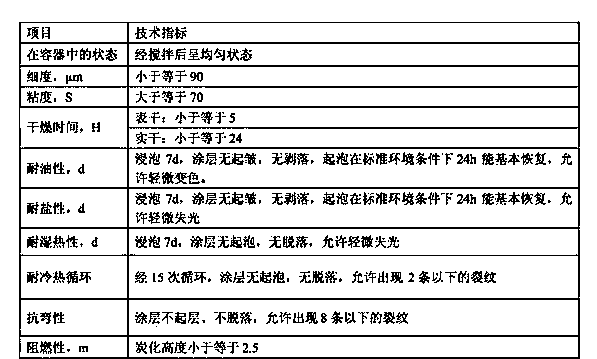

[0030] According to the filler and additive components selected in Table 2-3, and according to the dosage of each component in the formula in Table 4, first add the paint base to the mixing tank, stir evenly, and then add nano flame retardant and flame retardant synergist , fillers, additives and water, after stirring for 20 minutes, add them to the ball mill and grind them. After mixing evenly, use a scraper finene...

Embodiment 2

[0033] (1) Preparation of nano flame retardant:

[0034] Add each flame retardant component to water that is 6 times the total weight of each flame retardant component, then add surface modifier, heat to 50 o After C, adjust the pH value of the system to 6.0 with dilute sulfuric acid, react for 5 hours and cool to obtain a nano-flame retardant sol containing aluminum hydroxide, that is, a nano-flame retardant. The selection and dosage of each flame retardant component and surface modifier are shown in Table 1.

[0035] (2) Preparation of fire retardant coating:

[0036] According to the filler and additive components selected in Table 2-3, and according to the dosage of each component in the formula in Table 4, first add the coating matrix to the mixing tank, after stirring evenly, add nano-flame retardant and flame retardant synergist , fillers, additives and water, after stirring for 20 minutes, add them to the ball mill and grind them. After mixing evenly, use a scraper f...

Embodiment 3

[0039] (1) Preparation of nano flame retardant:

[0040] Add each flame retardant component to water that is 10 times the total weight of each flame retardant component, then add surface modifier, heat to 30 o After C, adjust the pH value of the system to 5.5 with dilute sulfuric acid, react for 0.5 hours and cool to obtain a nano-flame retardant sol containing aluminum hydroxide, that is, a nano-flame retardant. The selection and dosage of each flame retardant component and surface modifier are shown in Table 1.

[0041] (2) Preparation of fire retardant coating:

[0042] According to the filler and additive components selected in Table 2-3, and according to the dosage of each component in the formula in Table 4, first add the coating matrix to the mixing tank, after stirring evenly, add nano-flame retardant and flame retardant synergist , fillers, additives and water, after stirring for 20 minutes, add them to the ball mill and grind them. After mixing evenly, use a scrape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com