Acrylic resin/organosilicon hybrid composite electronic potting adhesive and preparation method thereof

An acrylic resin, hybrid composite technology, applied in the direction of adhesive, adhesive type, graft polymer adhesive, etc., can solve the lack of corrosion resistance, the comprehensive performance of organic-inorganic hybrid electronic potting glue is not good enough and other problems, to achieve the effect of not easy phase separation, good impact resistance, and good hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

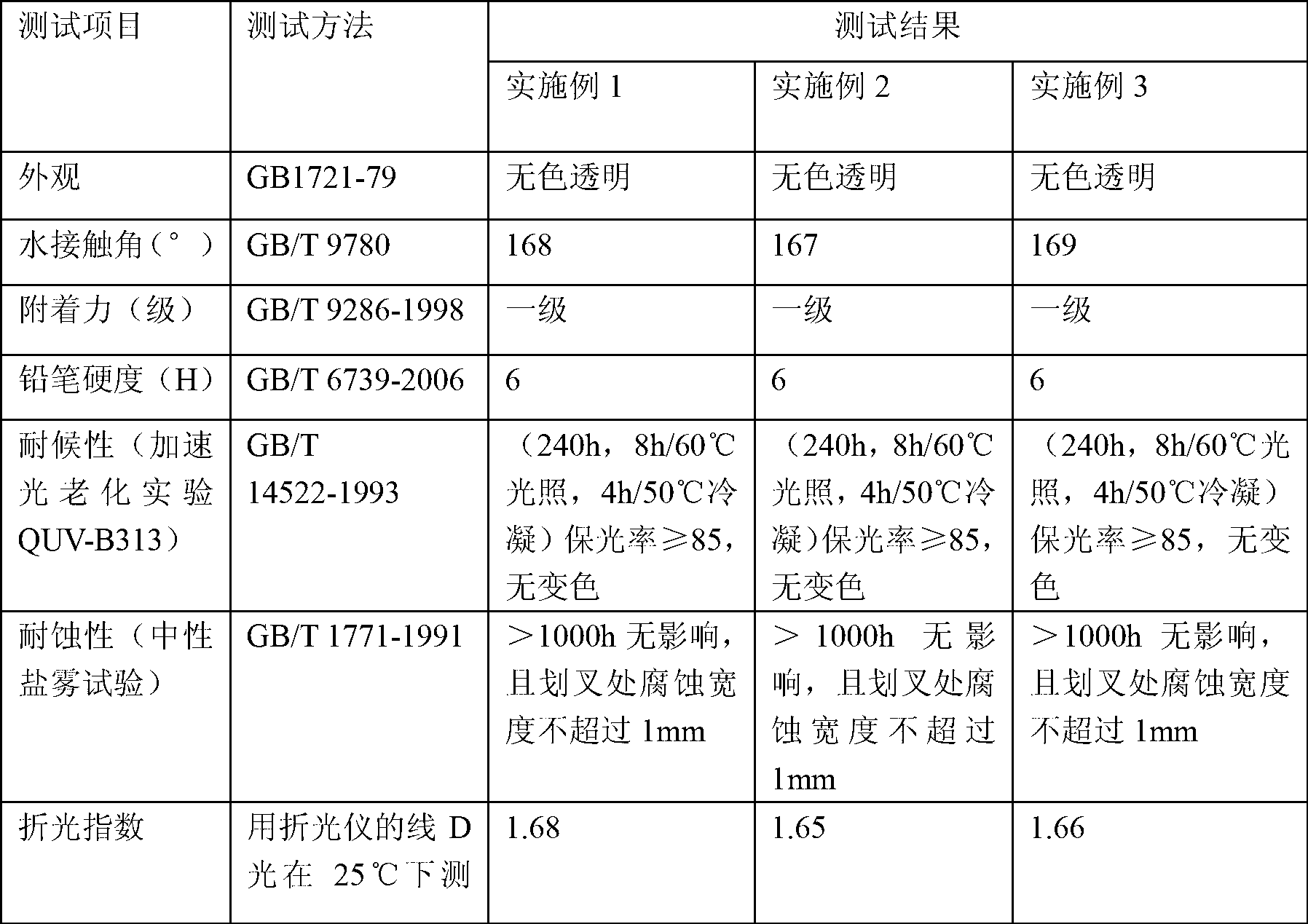

Examples

Embodiment 1

[0025] An acrylic resin / organic silicon hybrid composite electronic potting glue, which is prepared by the following preparation steps:

[0026] (1) Add 60 parts by weight of isopropanol and 5 parts by weight of distilled water into a clean reaction device, stir and raise the temperature. When the temperature rises to 45°C, slowly add 20 parts by weight of tetramethoxysilane dropwise to it (TMOS), then dropwise add an acid catalyst that is composed of hydrochloric acid and hydrofluoric acid in a mass ratio of 8:0.5, until the pH value is 4, after the dropwise addition is completed, it is incubated for 0.5h;

[0027] (2) After that, the temperature was raised to 65°C, and after continuing to react for 2 hours, 2 parts by weight of dodecafluoroheptyltrimethoxysilane was added dropwise under stirring, kept warm, stirred and refluxed for 2 hours, and hybrid silica sol A was obtained;

[0028] (3) 2 parts by weight of deionized water, 70 parts by weight of hybrid silica sol A and 0...

Embodiment 2

[0031] An acrylic resin / organic silicon hybrid composite electronic potting glue, which is prepared by the following preparation steps:

[0032] (1) Add 90 parts by weight of isopropanol and 20 parts by weight of distilled water into a clean reaction device, stir and raise the temperature. When the temperature rises to 55°C, slowly add 40 parts by weight of tetramethoxysilane dropwise to it (TMOS), then dropwise add an acid catalyst that is composed of hydrochloric acid and hydrofluoric acid in a mass ratio of 8:2, until the pH value is 5, after the dropwise addition is completed, it is incubated for 2h;

[0033] (2) After that, the temperature was raised to 80°C, and after continuing to react for 3 hours, 10 parts by weight of dodecafluoroheptyltrimethoxysilane was added dropwise under stirring, kept warm, stirred and refluxed for 4 hours, and hybrid silica sol A was obtained;

[0034](3) 10 parts by weight of deionized water, 95 parts by weight of hybrid silica sol A and 1 p...

Embodiment 3

[0037] An acrylic resin / organic silicon hybrid composite electronic potting glue, which is prepared by the following preparation steps:

[0038] (1) Add 80 parts by weight of isopropanol and 15 parts by weight of distilled water into a clean reaction device, stir and raise the temperature. When the temperature rises to 50°C, slowly add 30 parts by weight of tetramethoxysilane dropwise to it (TMOS), then dropwise add an acid catalyst that is composed of hydrochloric acid and hydrofluoric acid in a mass ratio of 8:1.5, until the pH value is 4.5, after the dropwise addition is completed, it is incubated for 1h;

[0039] (2) After that, the temperature was raised to 70°C, and after continuing to react for 2.5 hours, 7 parts by weight of dodecafluoroheptyltrimethoxysilane was added dropwise under stirring, kept warm, stirred and refluxed for 3 hours, and hybrid silica sol A was obtained;

[0040] (3) 7 parts by weight of deionized water, 85 parts by weight of hybrid silica sol A an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com