Patents

Literature

635results about How to "Excellent surface hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

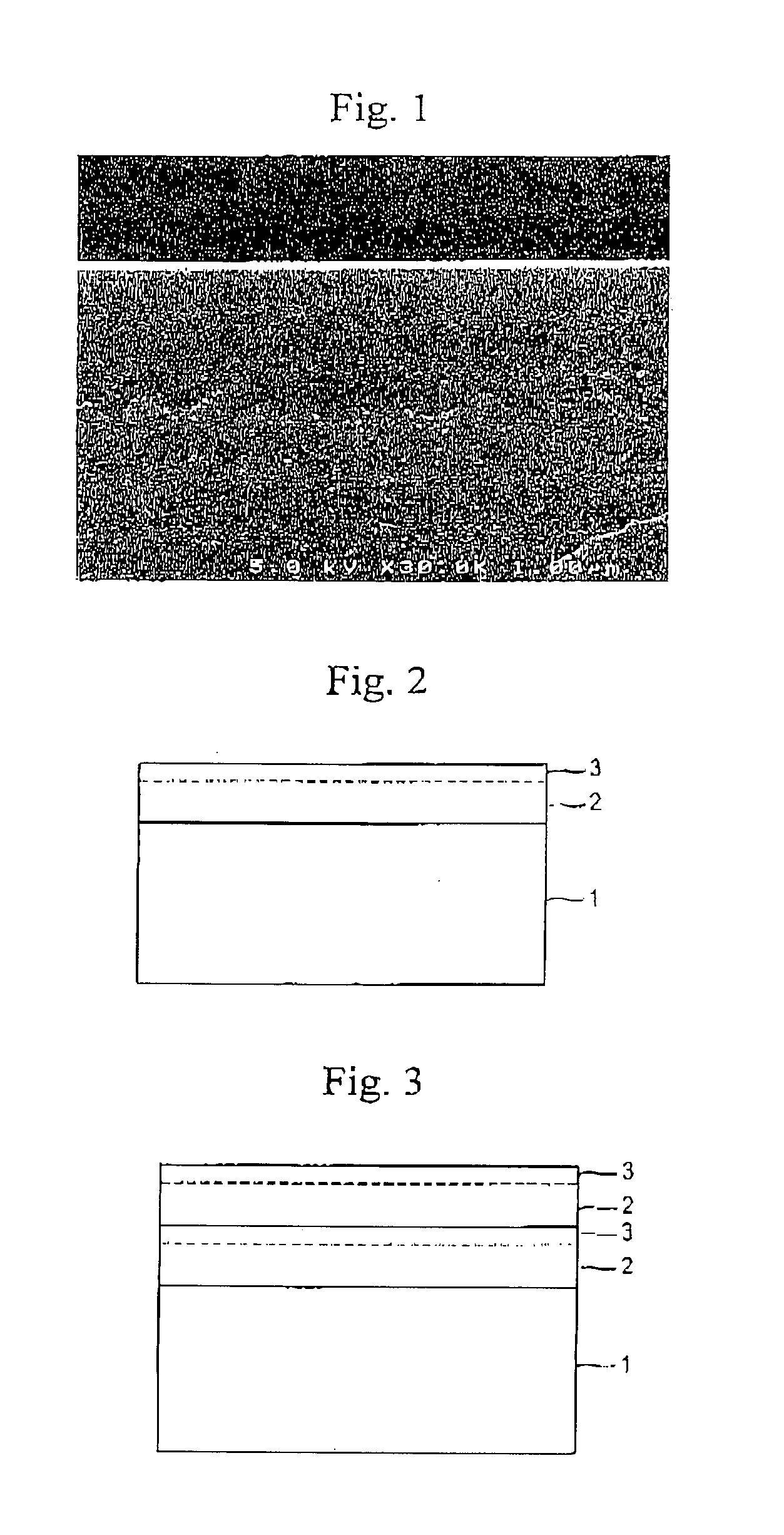

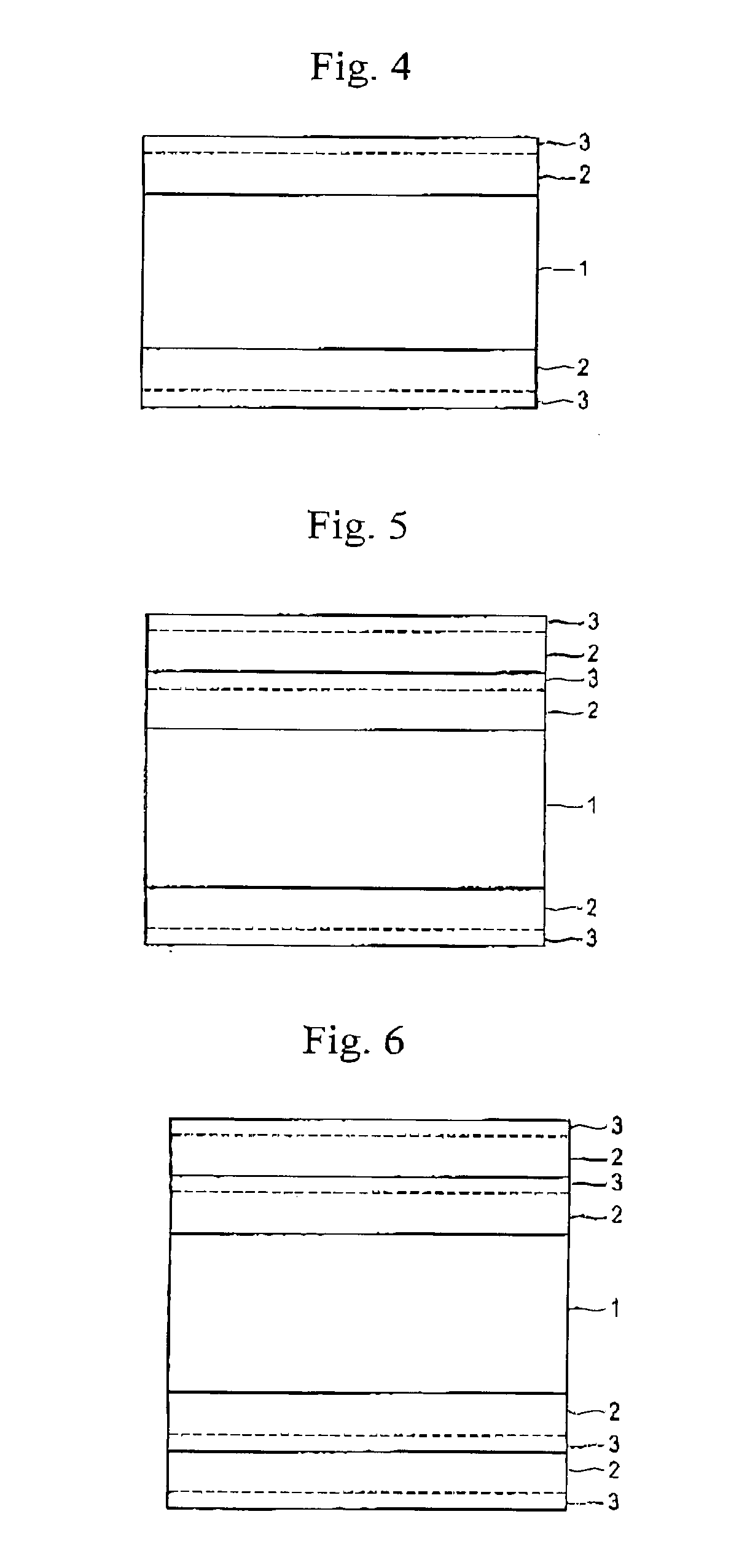

Method for fabrication of transparent gas barrier film using plasma surface treatment and transparent gas barrier film fabricated thereby

InactiveUS20100285319A1Excellent gas barrier performanceEconomical and simple methodSynthetic resin layered productsPretreated surfacesOptoelectronicsInorganic layer

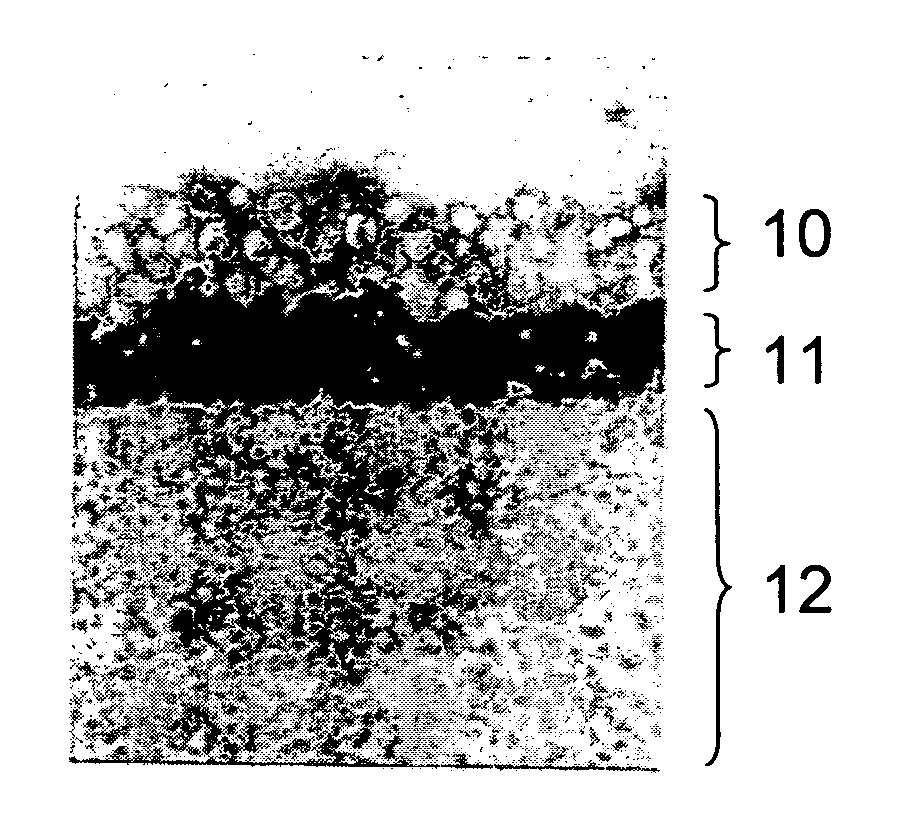

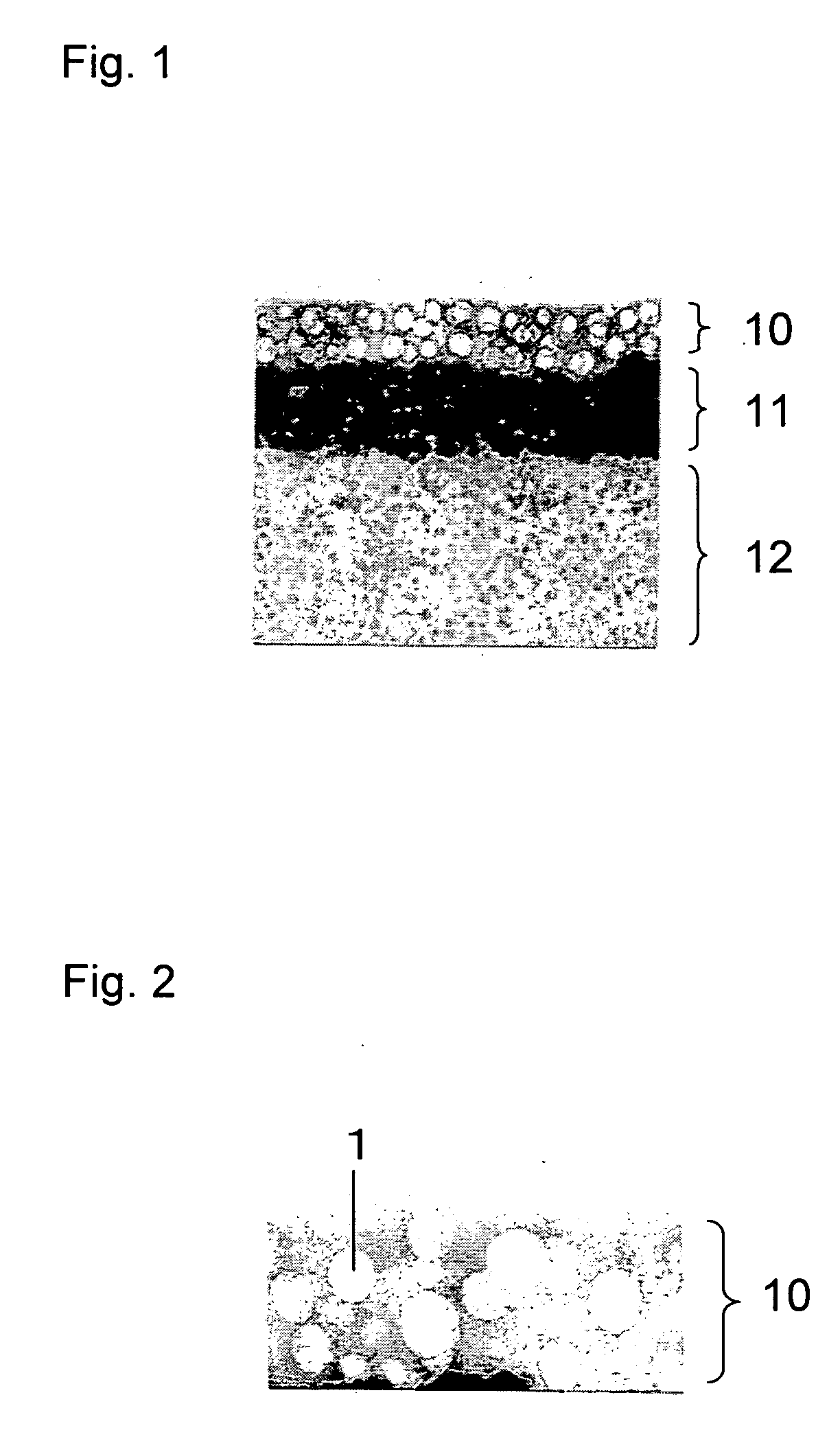

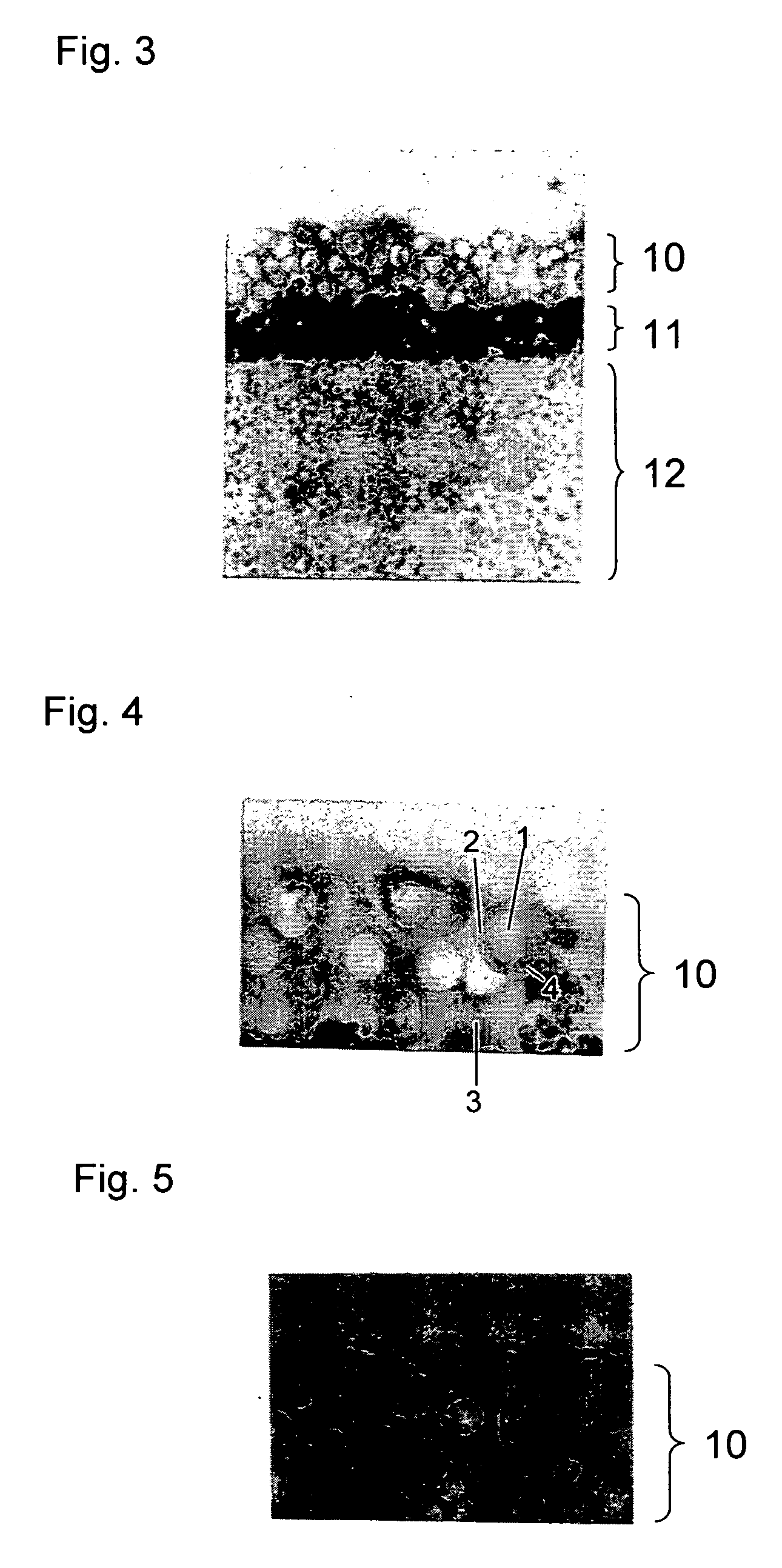

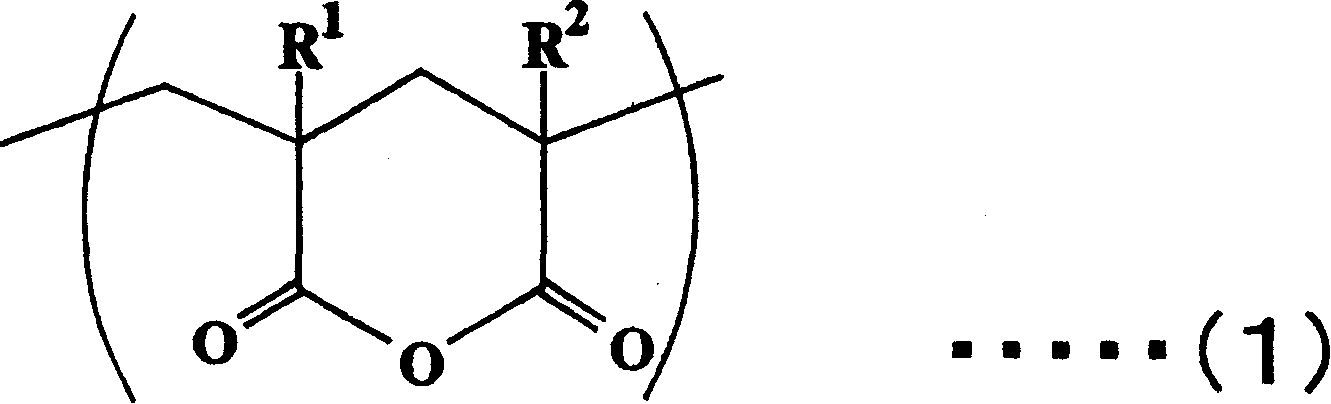

The present invention relates to a method of fabricating a transparent gas barrier film by using plasma surface treatment and a transparent gas barrier film fabricated according to such method which has an organic / inorganic gradient interface structure at the interface between an organic / inorganic hybrid layer and an inorganic layer. Since the method of the present invention is capable of fabricating a gas barrier film by plasma surface treatment instead of deposition under high vacuum, it can mass-produce a transparent gas barrier film with excellent gas barrier properties in an economical and simple manner. Further, since the transparent gas barrier film fabricated according to the method of the present invention shows excellent gas barrier properties and is free of crack formation and layer-peeling phenomenon, it can be effectively used in the manufacture of a variety of display panels.

Owner:KOREA INST OF SCI & TECH

Special plastic/acrylonitrile butadiene styrene (PC/ABS) alloy for notebook computer shell

ActiveCN101974218AExcellent surface hardnessImprove scratch resistanceGlass fiberPolymethyl methacrylate

The invention discloses a special plastic / acrylonitrile butadiene styrene (PC / ABS) alloy for a notebook computer shell. The formula comprises the following materials in parts by weight: 30-80 parts of polycarbonate, 5-65 parts of acrylonitrile-butadiene-styrene copolymer, 5-15 parts of compatilizer, 1-15 parts of flame retardant agent, 3-20 parts of filler, 1-10 parts of hardness modifier, 0.5-5 parts of anti-falling agent and 0-1 part of auxiliary agent. By adopting specific high-molecular polymers of polymethyl methacrylate (PMMA), ultrahigh-molecular polysiloxane and the like, the special PC / ABS alloy selects mineral fillers of specific-size mica, glass fiber and the like to carry out rematching therewith and generates synergistic effect, thus obviously improving the surface hardness and scraping resistance of the material and simultaneously having no influence on the other performances of the material. The PC / ABS alloy material has excellent impact resistance, surface scraping resistance and flame retardance, can meet the requirements of plastic for the notebook computer shell and has considerable promotion and application values.

Owner:大河宝利材料科技(苏州)有限公司

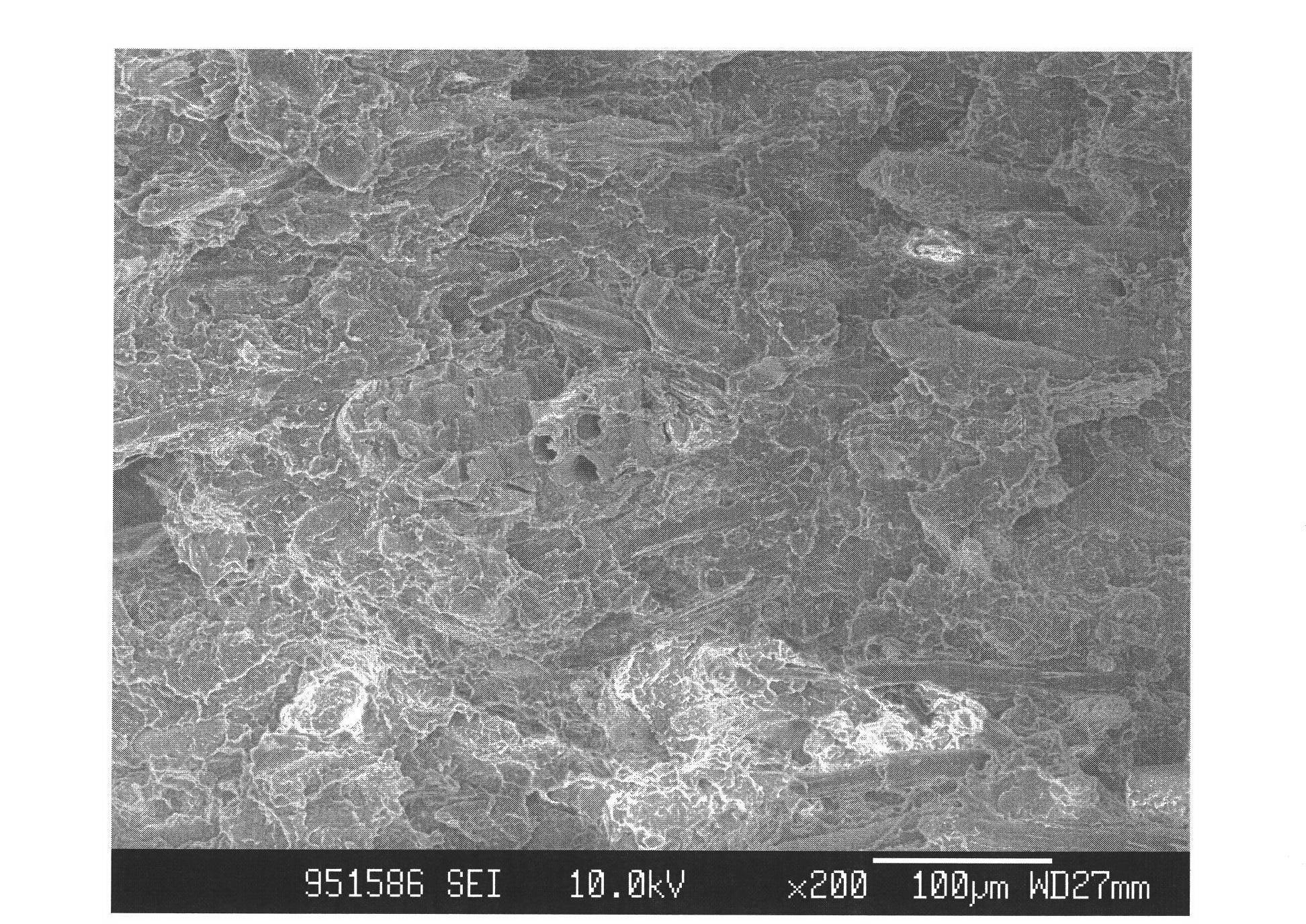

High wear-resistant wood-plastic composite and preparation method thereof

The invention provides a high wear-resistant wood-plastic composite and a preparation method thereof, and relates to a composite obtained by mixing modified plant fiber powder, modified nano ceramics particles and plastic powder. The high wear-resistant wood-plastic composite comprises the modified plant fiber powder, the modified nano ceramics particles, the recycled plastic powder and the like, wherein the modified nano ceramics particles comprises modified nano Al2O3, modified nano Si3N4, modified nano SiC or the mixture thereof, which can obviously improve the microhardness of the wood-plastic composite, reduce the wear rate and improve the mechanical property. The high wear-resistant wood-plastic composite is prepared from the components by the common melt-mixing method in the plastic processing. The surface hardness and the wearability of the wood-plastic composite are greatly increased, and the strength and the toughness are also greatly improved, so that the overall performance of the wood-plastic composite is greatly enhanced. The wood-plastic composite can be used in the fields of construction material, furniture, package and the like.

Owner:GUANGDONG XINXIU NEW MATERIAL CO LTD

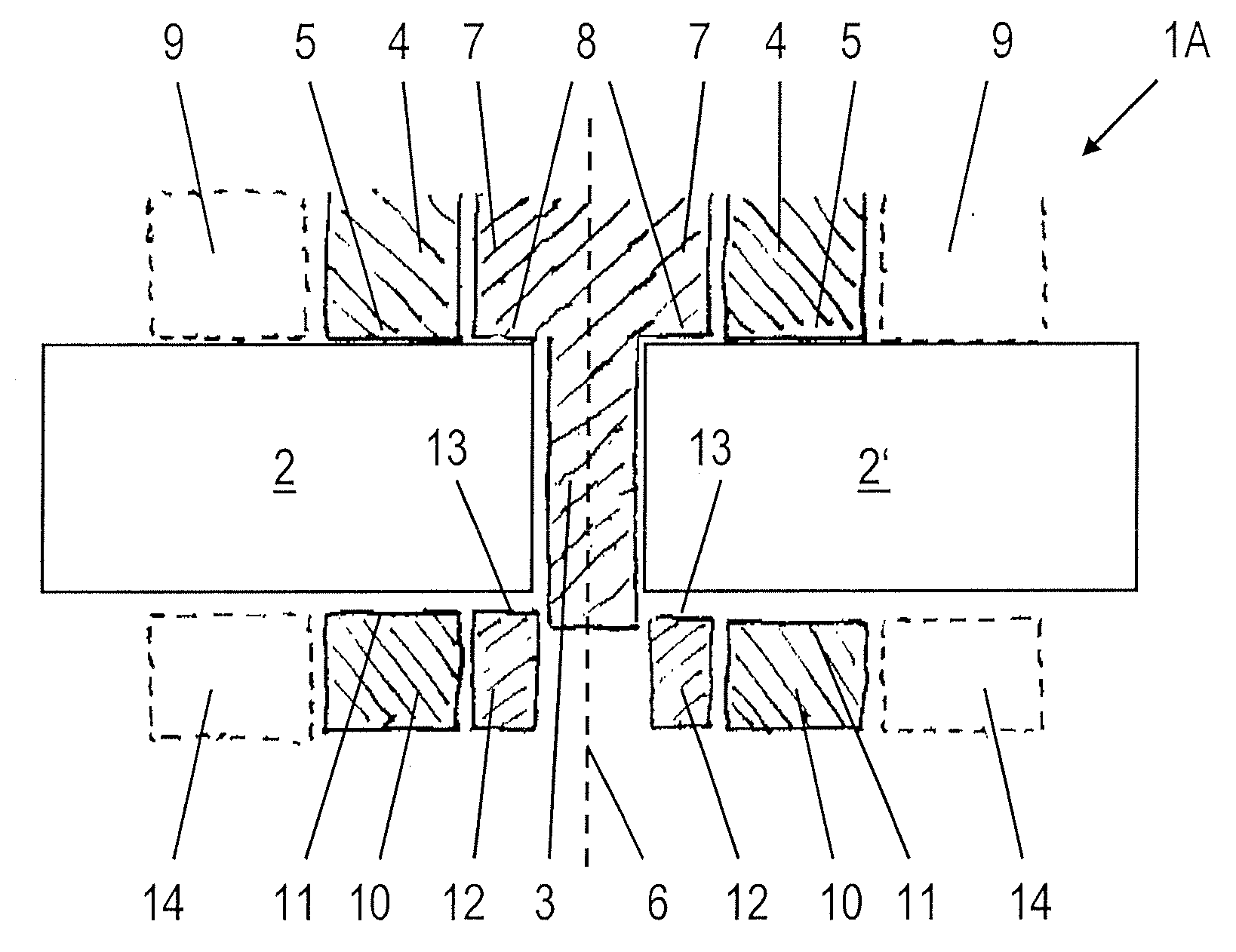

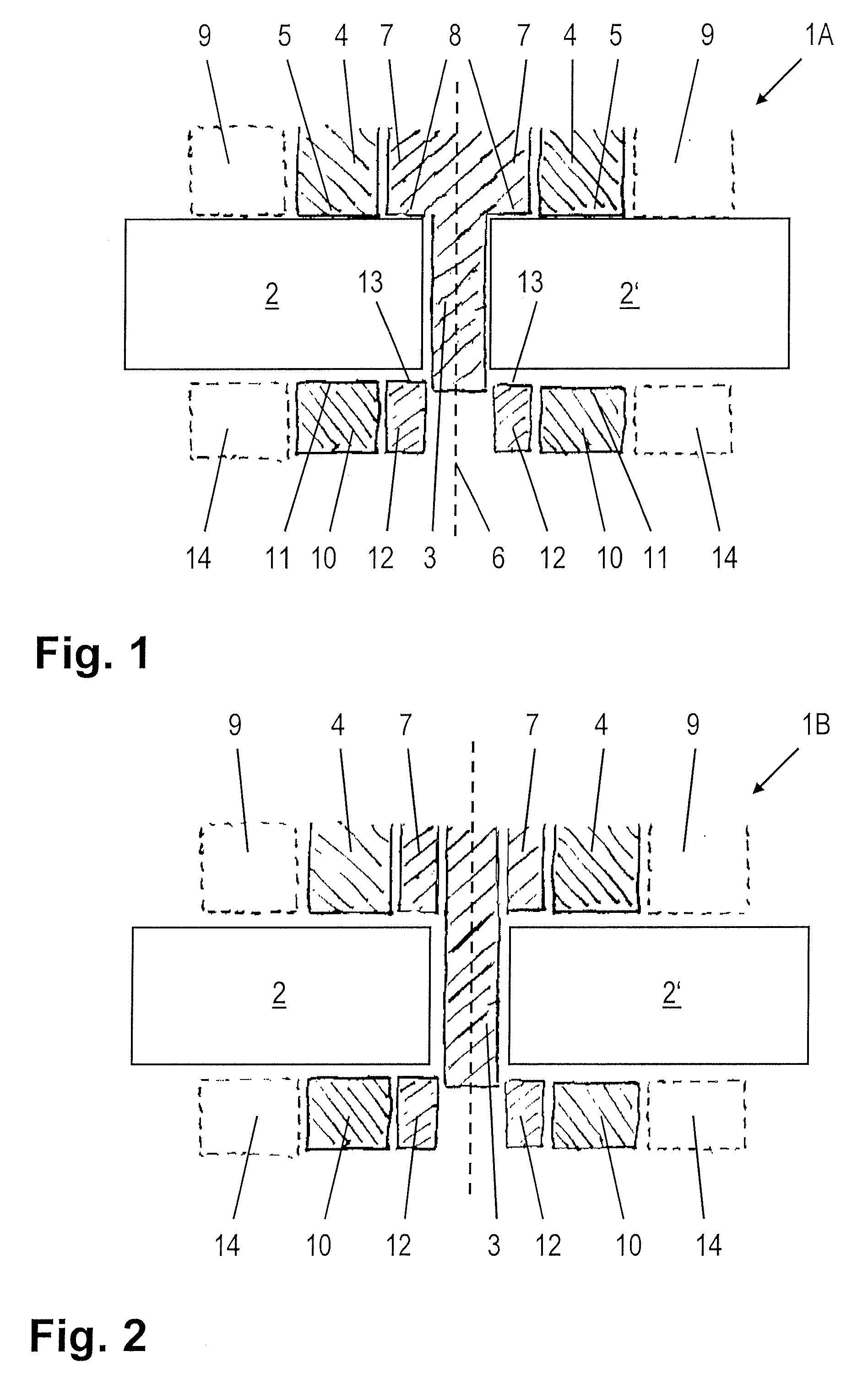

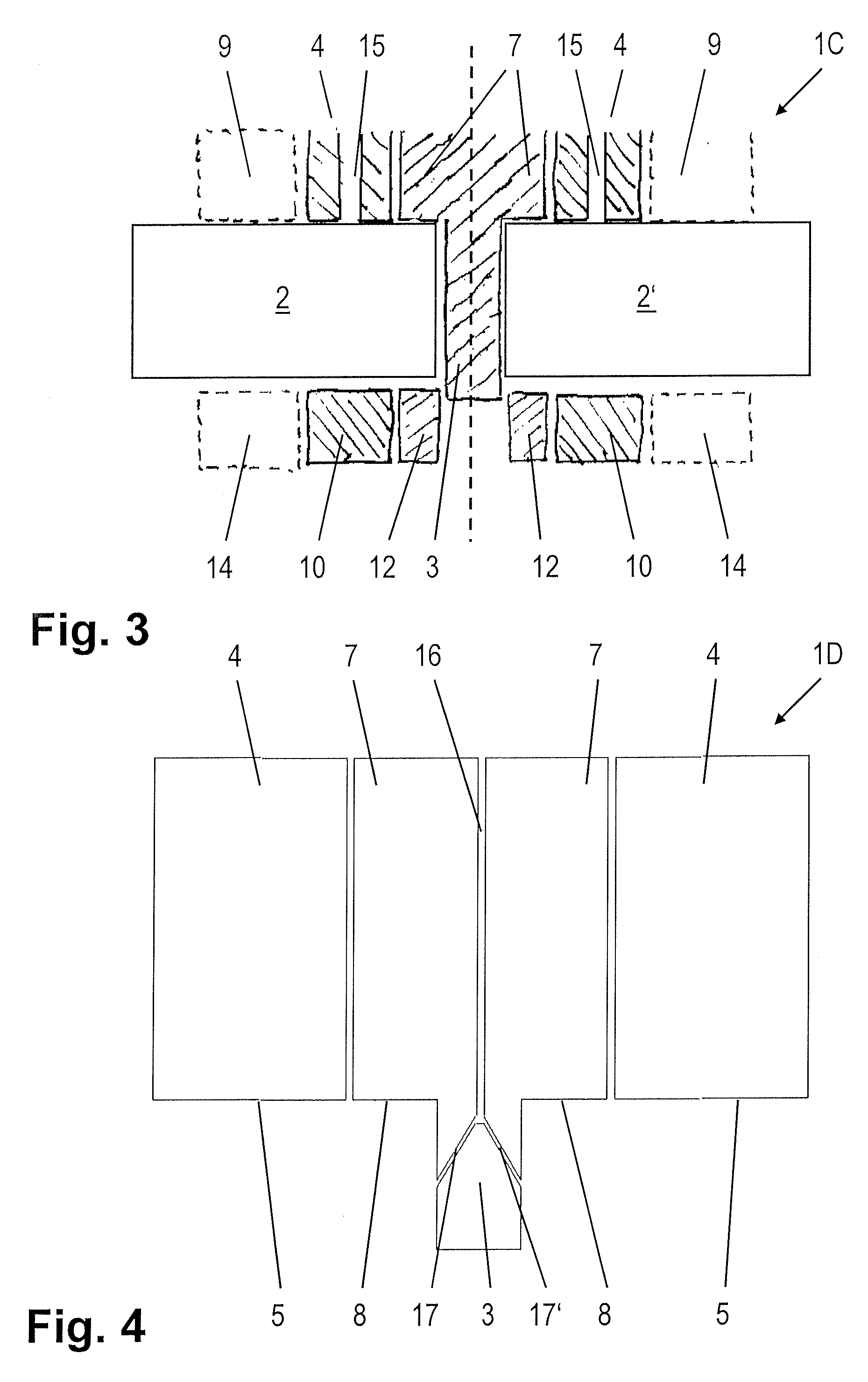

Friction stir welding appparatus

InactiveUS20060289604A1Small sizeMuch successWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention illustrates and describes an apparatus for friction stir welding, having a pin (3) and a first friction surface segment (4), the pin (3) and the first friction surface segment (4) being rotationally driven about an axis of rotation (6), and the first friction surface segment (4) having a first friction surface (5) for resting on a workpiece (2). The object of providing a friction stir welding apparatus which can be used to better set the energy which is introduced into the workpiece by way of the friction between pin and friction surface, on the one hand, and workpiece, on the other hand, is achieved by virtue of the fact that a first inner segment (7) is provided, having a first inner friction surface (8) for resting on a workpiece (2, 2′), that the first inner segment (7) surrounds the pin (3), that the first friction surface segment (4) surrounds the first inner segment (7), and that the first friction surface segment (4) is rotationally driven independently of the first inner segment (7).

Owner:GKSS FORSCHUNGSZENTRUM GEESTHACHT GMBH

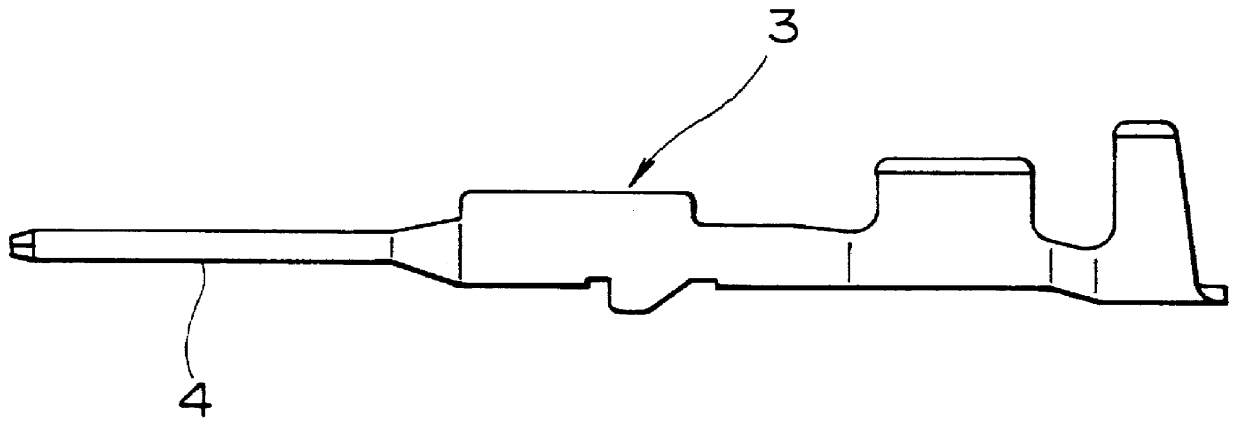

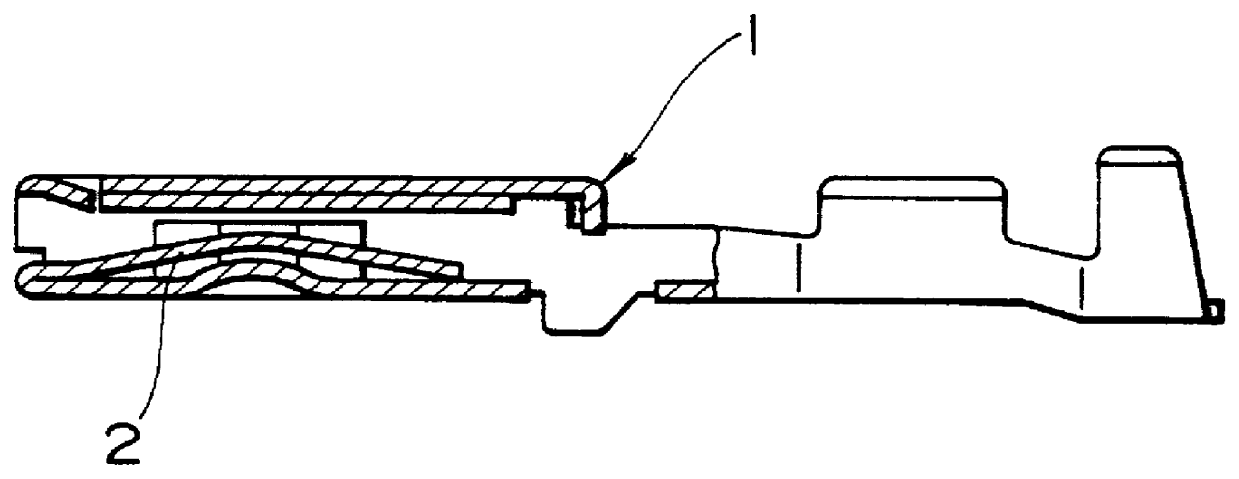

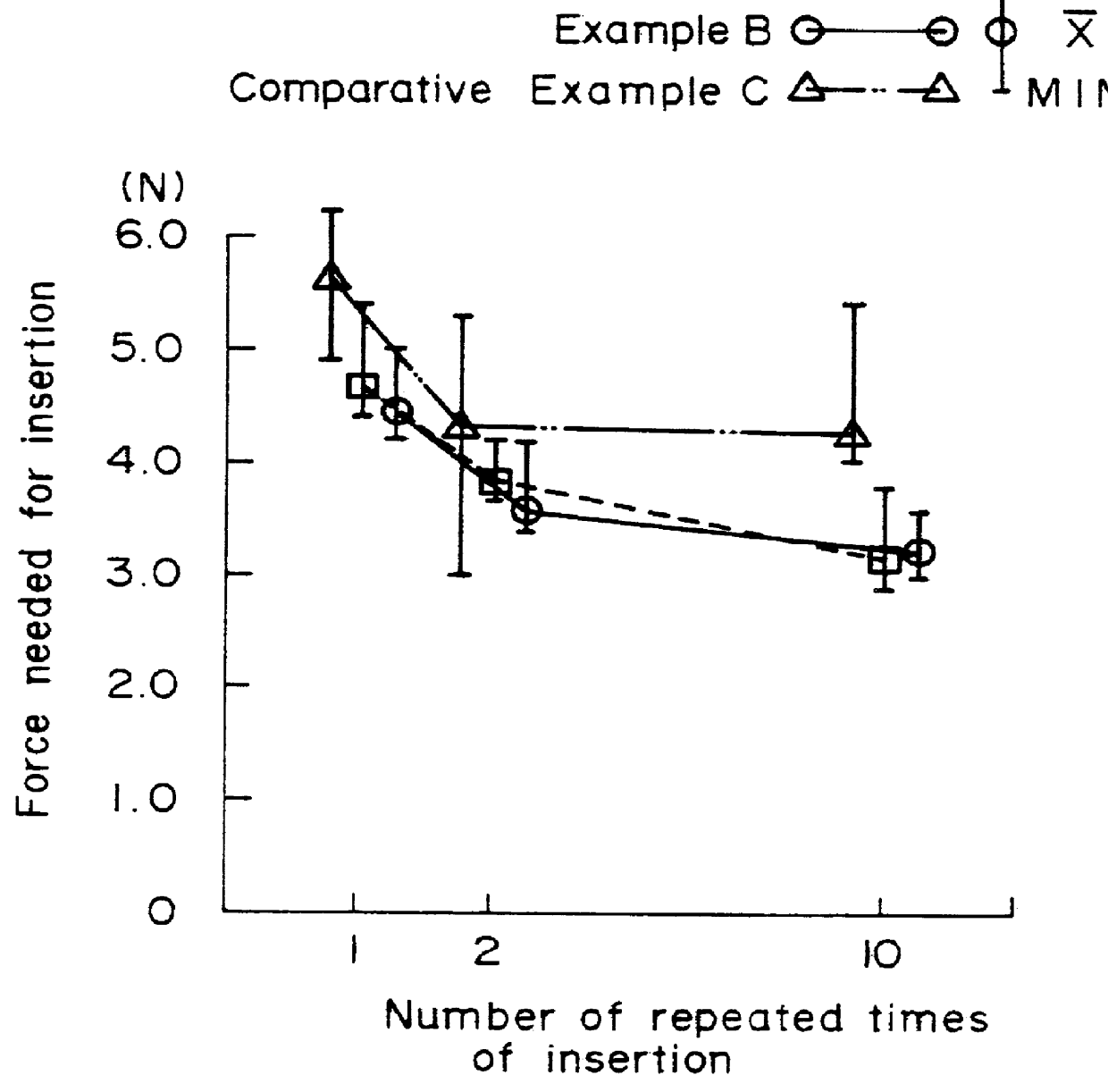

Hard coated copper alloys

InactiveUS6040067AHigh strengthImprove workabilityRecord information storageSolid state diffusion coatingCorrosionHigh resistance

The invention provides a coated Cu alloy and a process for producing the coated Cu alloy having a surface which has a low coefficient of friction and a high resistance to abrasion and is suitable for fabricating connectors, charging-sockets of electric automobiles etc. The coated Cu alloy is produced by coating the surface of a copper alloy with Sn and heat treating the coated Cu alloy at a temperature in the range of 100-450 DEG C. for 0.5-24 hours. The Cu alloy which is coated with Sn consists of 1-41 wt % Zn with the balance being Cu and incidental impurities. By using the coated Cu alloy, the force of insertion, resistance to abrasion and resistance to corrosion of connectors can be significantly improved.

Owner:DOWA METALS & MINING CO LTD +1

Thermosetting acrylic resin for powder coating as well as synthesis method and applications of thermosetting acrylic resin

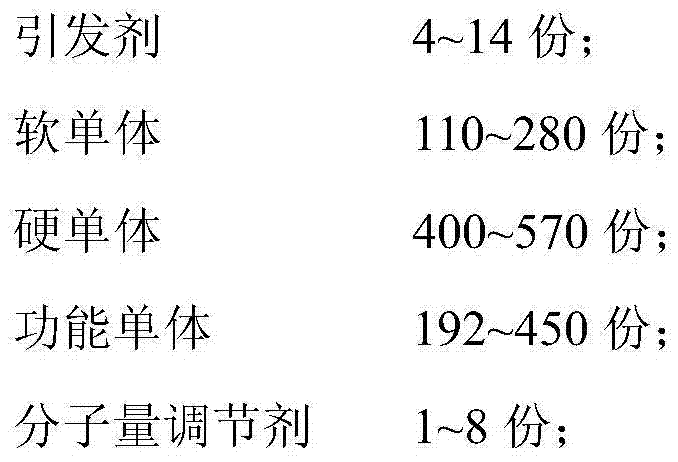

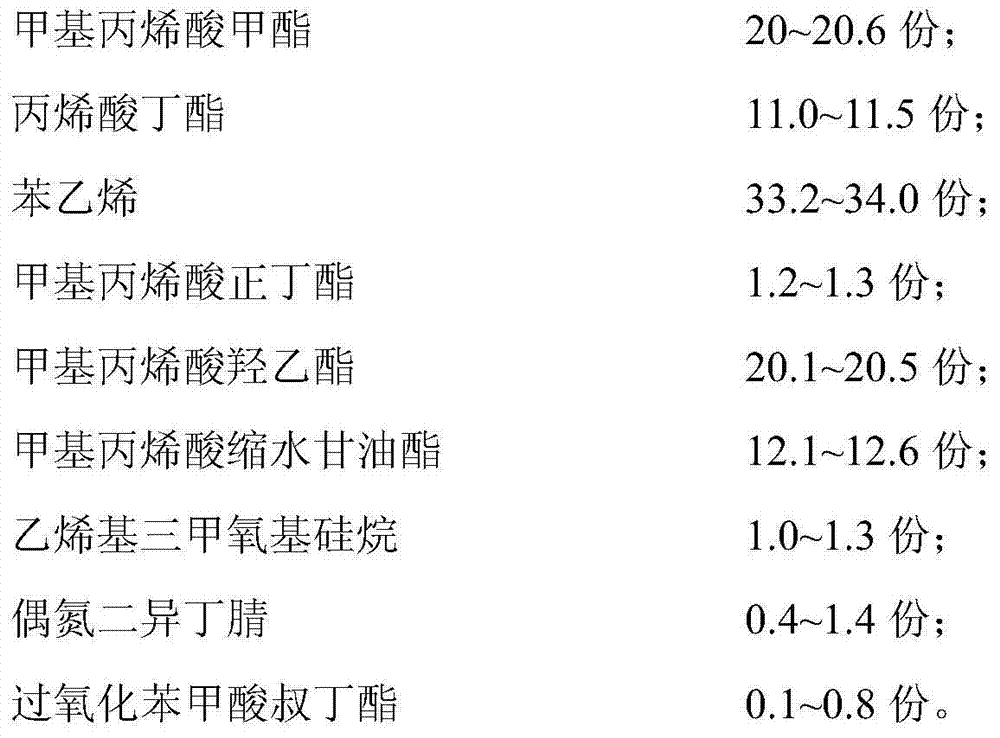

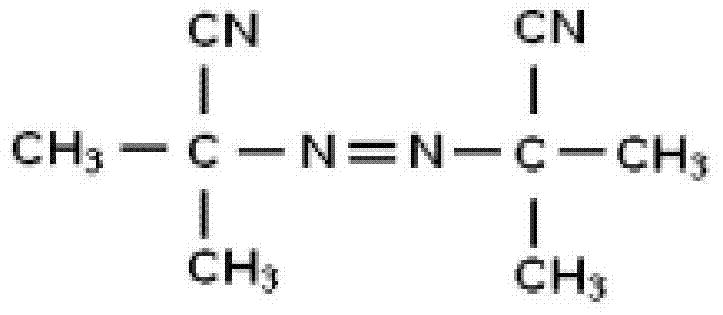

The invention relates to thermosetting acrylic resin for a powder coating. The thermosetting acrylic resin is prepared from the following raw materials in parts by mass: 4-14 parts of an initiator, 110-280 parts of soft monomers, 400-570 parts of hard monomers, 192-450 parts of functional monomers, and 1-8 parts of a molecular weight regulator, wherein the soft monomers refer to acrylic acid alkyl ester compounds, and the hard monomers refer to methacrylate, styrene, or compounds of derivatives of methacrylate and styrene. The acrylic resin contains epoxy functional groups and hydroxyl functional groups simultaneously, wherein the epoxy equivalent is 570-630g / mol and the hydroxyl value is 40-50mgKOH / g; the acrylic resin can react with various substances such as carboxyl, amidogen and isocyanate and can be used for powder coating. A coating film, which is formed after the thermosetting powder coating prepared from the acrylic resin in combination with other materials is sprayed, has excellent weather resistance, good leveling performance, outstanding surface hardness, and high glossiness, durability and decorating performance; the powder coating can be used for indoor or outdoor metal sectional materials or building materials. The thermosetting acrylic resin can substitute for TGIC (triglycidyl isocyanurate) to a certain extent so as to avoid the use of the toxic substances.

Owner:阜阳市诗雅涤新材料科技有限公司

Siloxane-Based Coating Material, Optical Article, and Production Method of Siloxane-Based Coating Material

InactiveUS20070266896A1Excellent surface hardnessGood storage stabilityAntifouling/underwater paintsSynthetic resin layered productsSiloxaneScratching

The invention provides a coating material containing silica fine particles, a siloxane compound, and a curing agent and giving an even coating film in the case it is used for forming a coating film. The invention gives a siloxane-based coating material excellent in storage stability and giving high surface hardness of a coating film when the coating material is used for forming the coating film. The invention also provides an optical article excellent in anti-reflection property and scratching resistance.

Owner:TORAY IND INC

Acrylic resin films and process for producing the same

InactiveCN1946794AHigh transparencyGood weather resistanceOptical elementsGlutaric anhydrideElastomer

[PROBLEMS] To provide: a novel, industrially useful acrylic resin film excellent in all of transparency, weatherability, heat resistance, and toughness, in view of the fact that there has been no acrylic resin film having such properties; an acrylic resin film which comprises the acrylic resin film having, e.g., a hard coating layer formed on at least one side of the film and further having an antireflection film formed on at least one side of the film; and an optical filter comprising this film. [MEANS FOR SOLVING PROBLEMS] The former acrylic resin film comprises an acrylic resin having units of glutaric anhydride and acrylic elastomer particles incorporated in the resin, and has a total light transmittance of 91% or higher, a haze of 1.5% or lower, a value of the number of folding operations of 20 or larger, and a degree of thermal shrinkage less than 5% in at least one of the machine direction and the transverse direction in a thermal shrinkage test.

Owner:TORAY IND INC

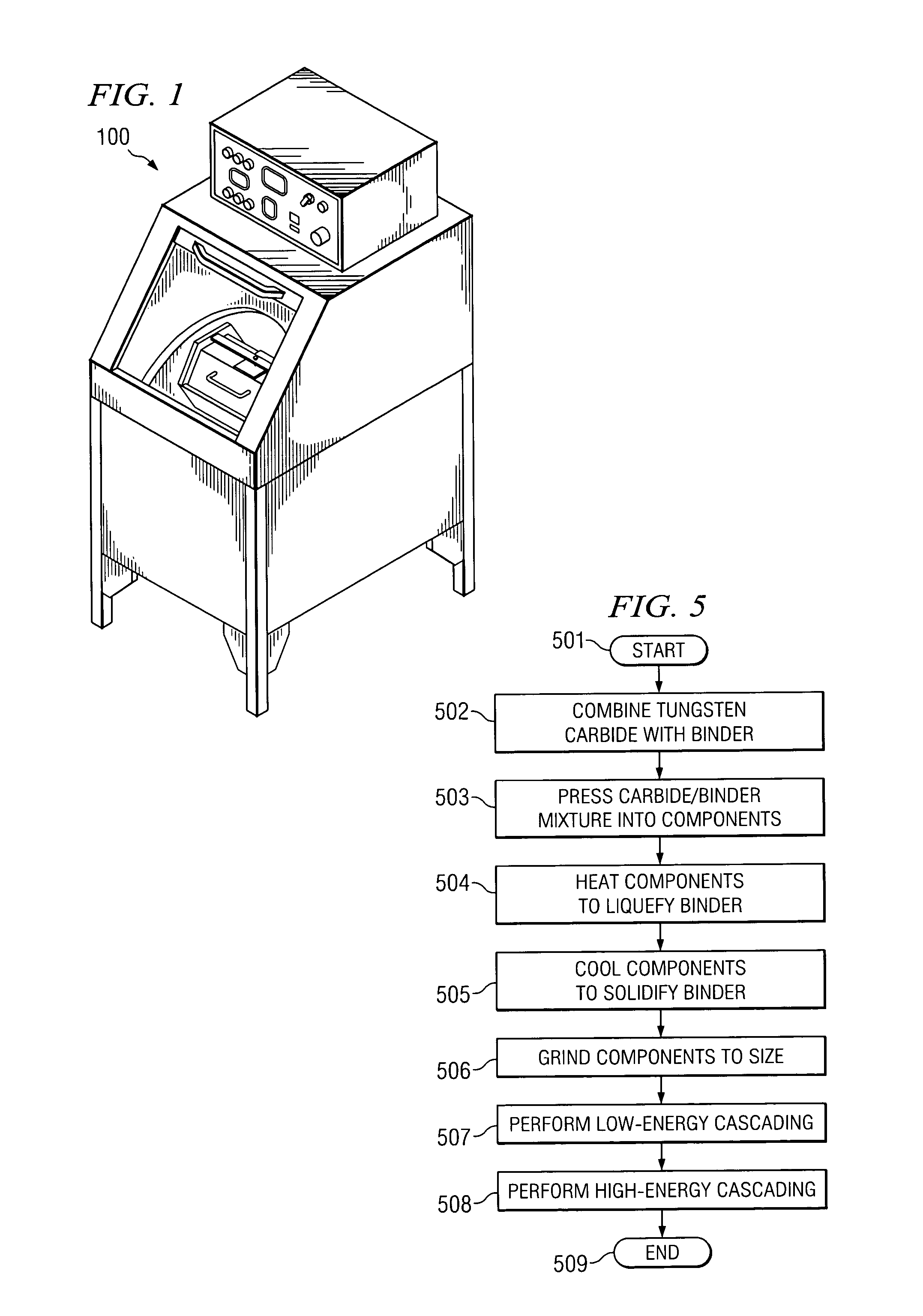

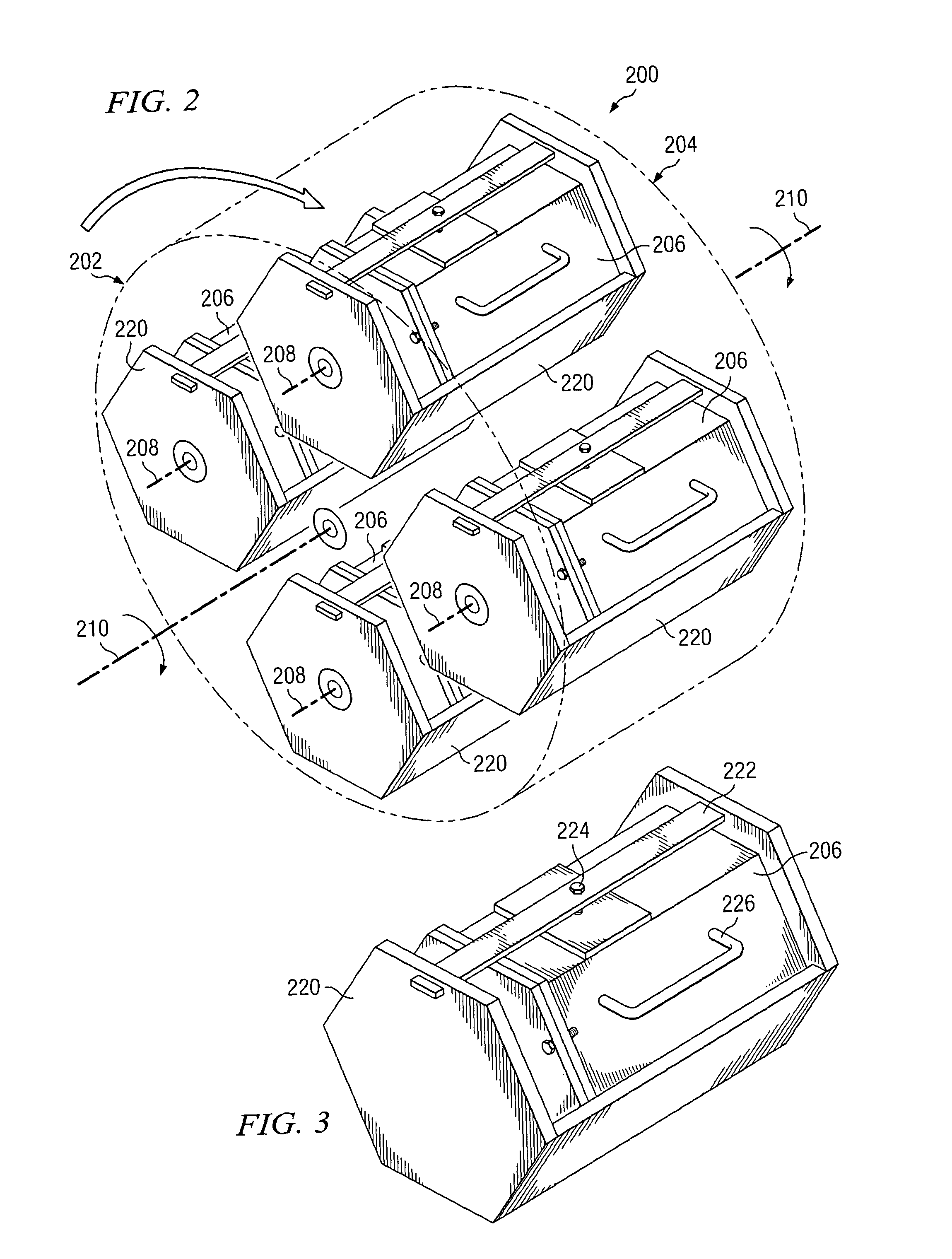

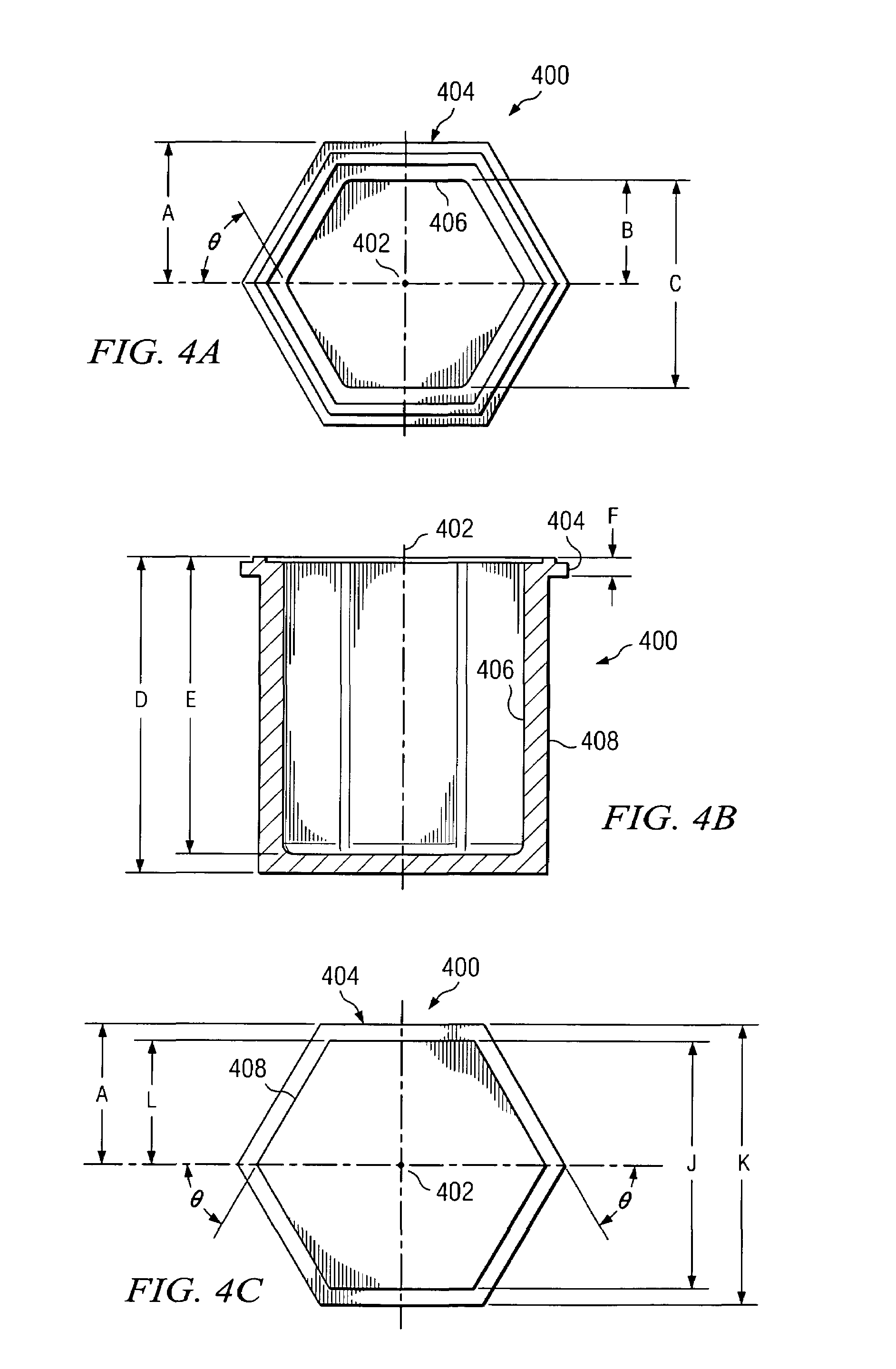

High-energy cascading of abrasive wear components

ActiveUS7258833B2Increases near surface hardness and toughnessPrevents and reduces chipping and cracking and fractureEdge grinding machinesPolishing machinesHigh energyTungsten carbide

In accordance with the present invention, a method for manufacturing tungsten carbide components is provided. The method includes forming a composite material out of tungsten carbide powder and binder powder, pressing the composite material into a plurality of components, heating the plurality of components, optionally under pressure, to liquefy the binder, cooling the plurality of components until the binder solidifies, optionally grinding each of the plurality of components to a desired size, and cascading the plurality of components in a cascading machine under high energy conditions.

Owner:CREDIT SUISSE AG CAYMAN ISLANDS BRANCH

Biaxially oriented layered polyester film and film with hard coat layer

InactiveUS6926945B2Excellent adhesion to functionalEasy to slipSynthetic resin layered productsRecord information storageWaxAcrylic resin

There is provided an easily adhesive, biaxially oriented laminated polyester film for optical use which has excellent adhesion, transparency and easy slipperiness. The biaxially oriented laminated film has a coating layer formed on at least one surface of an aromatic polyester film, the coating layer containing either a polyester resin, an acrylic resin and wax or a polyester resin and an acrylic resin having an oxazoline group and an alkylene oxide chain.

Owner:TEIJIN DUPONT FILMS JAPAN

Surface modified nano silicon dioxide and acrylic resin coating containing the same

InactiveCN101497749AGood water and oil resistanceImprove stain resistanceCoatingsPigment treatment with non-polymer organic compoundsPolymer scienceWeather resistance

The invention discloses a nano-silicon dioxide which is functionalized by acrylic ester and modified on surface by perfluoro alkoxy, a method for preparing the nano-silicon dioxide, and an acrylic resin coating containing the nano-silicon dioxide. The acrylic resin coating containing the nano-silicon dioxide also contains single-functional acrylic ester, acrylic ester containing at least two acrylic ester groups, alcoholic solvent and evocating agent. The acrylic resin coating containing fluorine and silicon can be quickly solidified, and the coating film hereby formed has excellent oil resistance, water resistance, weather resistance, pollution resistance, surface hardness and surface gloss.

Owner:浙江池河科技有限公司

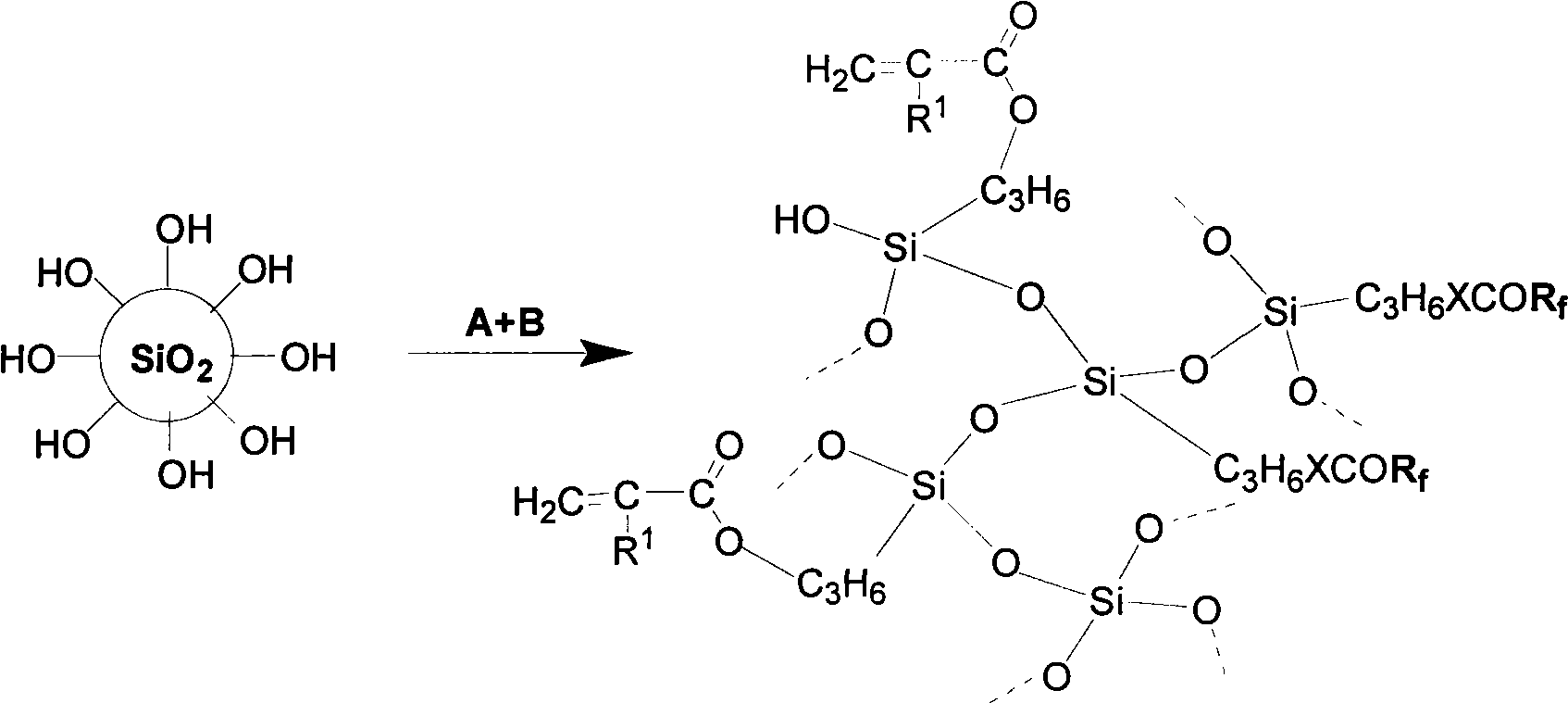

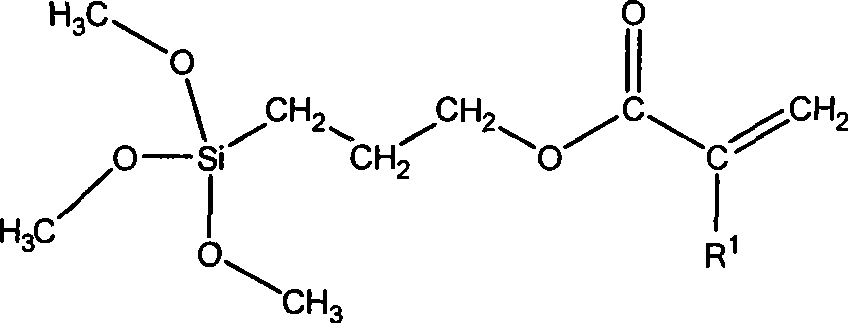

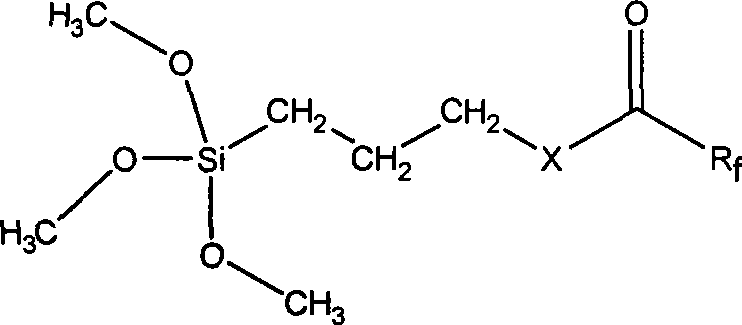

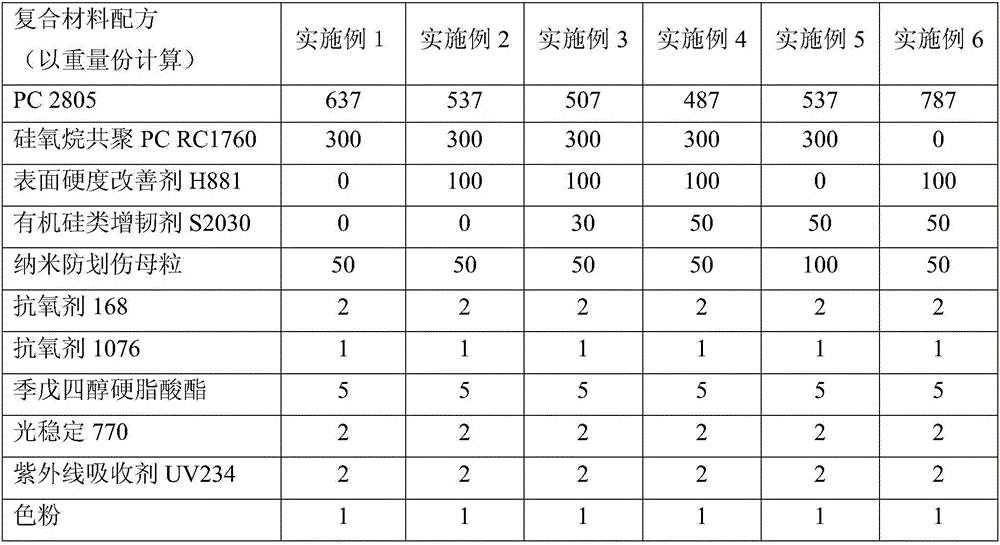

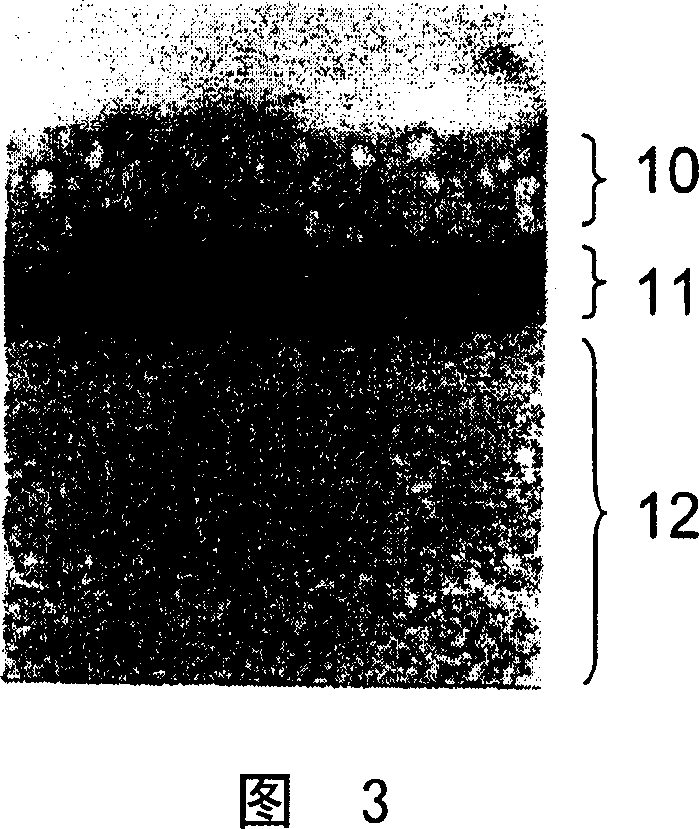

Transparent low-temperature-resistant scuffing-resistant polycarbonate composite material

The invention relates to the field of polymer composite materials, in particular to a transparent low-temperature-resistant scuffing-resistant polycarbonate composite material. The polycarbonate composite material is prepared from, by weight, 300-800 parts of bisphenol A polycarbonate resin, 100-500 parts of siloxane copolymerized PC resin, 10-50 parts of organosilicone flexibilizer, 50-200 parts of surface hardness improving agent, 10-100 parts of nanometer scuffing-resistant master batch and 5-15 parts of additive. The siloxane copolymerized PC, the surface hardness improving agent and the nanometer scuffing-resistant master batch are composited for use, on the basis that the luminousness and the basic mechanical properties of PC are uninfluenced, the surface hardness and the low-temperature properties of the material are improved, the surface hardness can be increased to 2 H, the abrasion resistance of the surface of a product is obviously improved, and the surface glossiness and the weather resistance are also improved. Moreover, the surface tension of the product can be increased, and the product is easier to clean; the composite material is good in mechanical property, high temperature impact property and low temperature impact property.

Owner:SHANGHAI CHANGWEI JINCI ENG PLASTIC

Siloxane coating material, optical articles and process for the production of siloxane coating materials

ActiveCN1969023AGood storage stabilityInhibit secondary aggregationAntifouling/underwater paintsSynthetic resin layered productsHigh surfaceHardness

The invention provides a coating material containing silica fine particles, a siloxane compound, and a curing agent and giving an even coating film in the case it is used for forming a coating film. The invention gives a siloxane-based coating material excellent in storage stability and giving high surface hardness of a coating film when the coating material is used for forming the coating film. The invention also provides an optical article excellent in anti-reflection property and scratching resistance.

Owner:TORAY IND INC

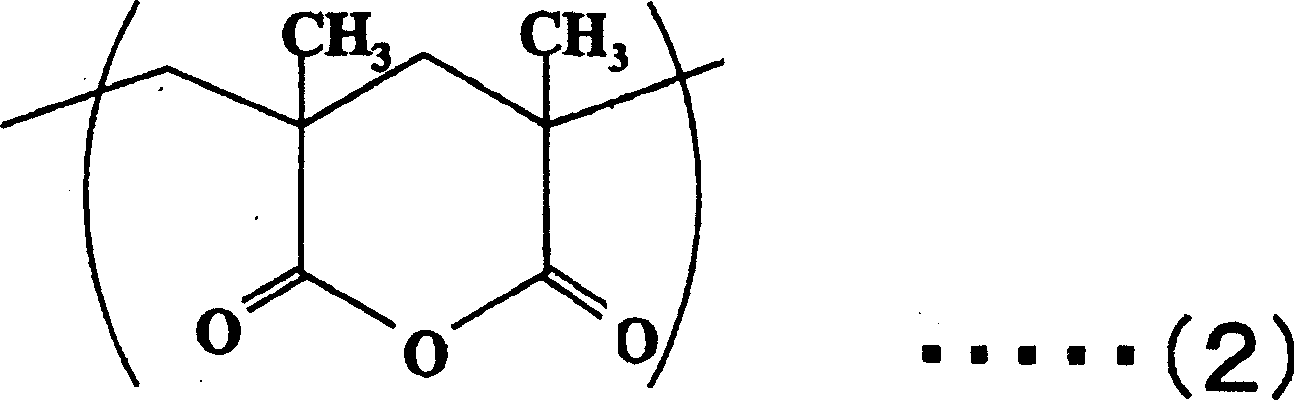

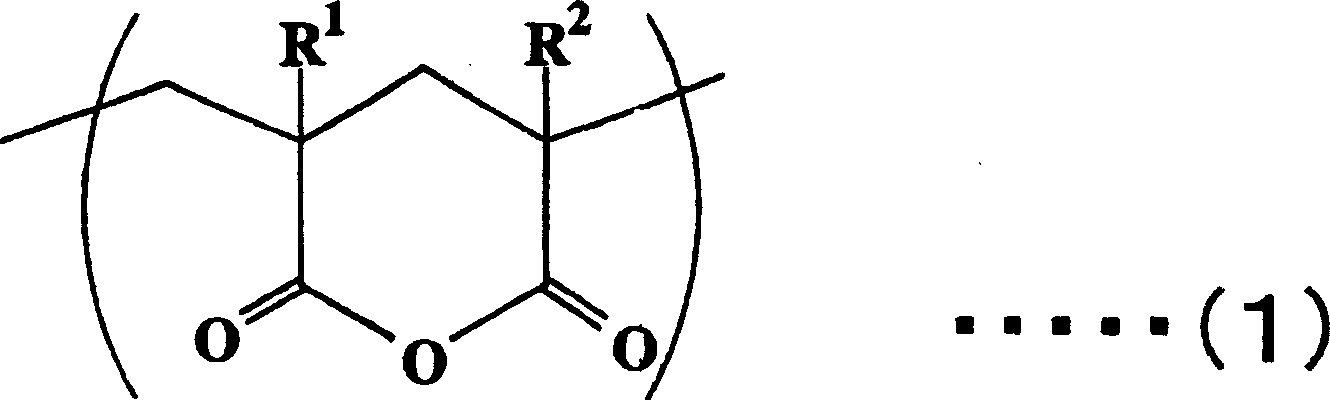

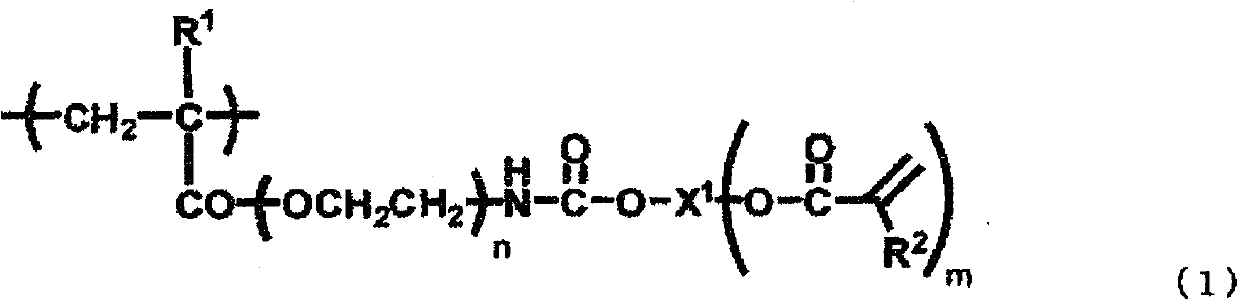

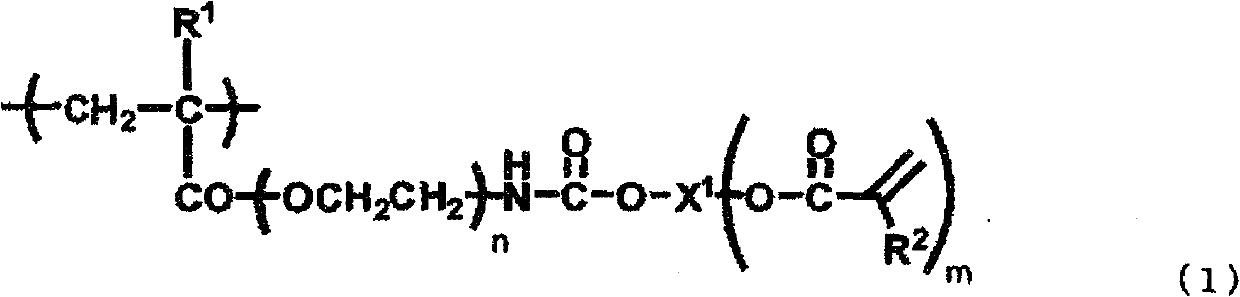

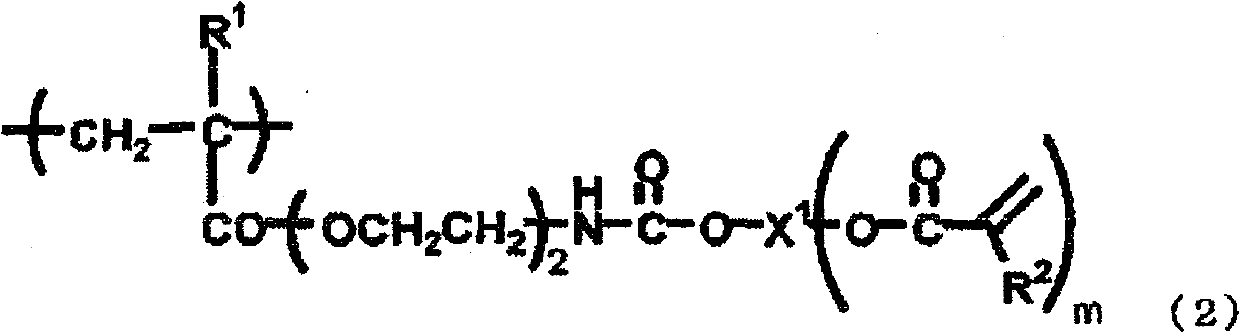

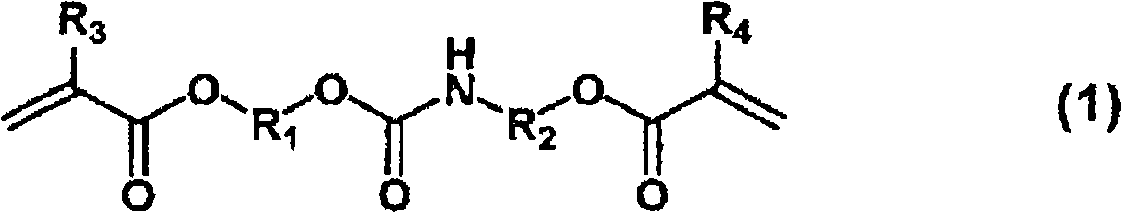

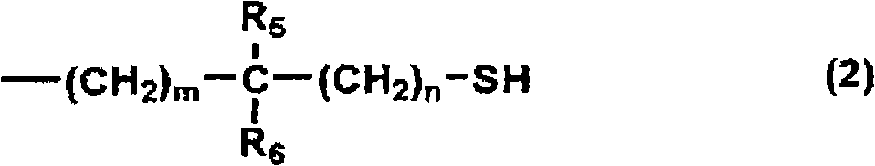

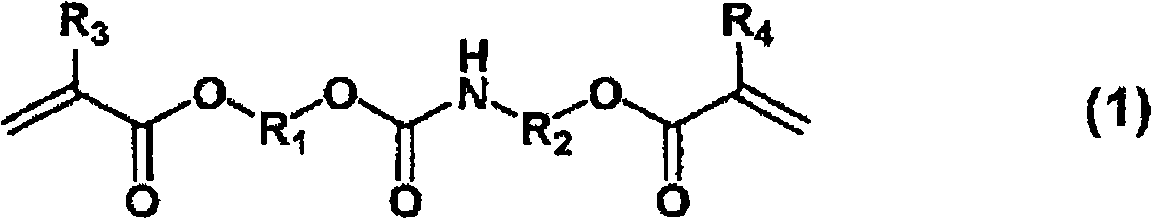

Curable composition containing a reactive (meth)acrylate polymer and a cured product thereof

InactiveCN102037035AExcellent surface hardnessGood flexibilityPolyureas/polyurethane adhesivesEster polymer adhesivesEthyl groupAcrylate polymer

Provided is a curable composition which has superior surface hardness, excellent flexibility and bending properties, and makes it possible to form a heat-resistant cured film having both strength and flexibility, and a cured product (film) thereof. The curable composition includes a reactive (meth)acrylate polymer (A) having the monomer unit indicated by general formula (1), a polymerization initiator (B), and a reactive monomer (C). In formula (1), R1 represents a hydrogen atom, a methyl group, or an ethyl group; R2 represents a hydrogen atom or a methyl group; X1 represents a straight chain or branched hydrocarbon group of 2 - 6 carbon atoms, or polyethylene glycol, polypropylene glycol, or an alcohol residue of a caprolactone-modified terminal diol on both ends; and n represents an integer from 2 to 4, and m represents an integer from 1 to 5.

Owner:RESONAC HOLDINGS CORPORATION

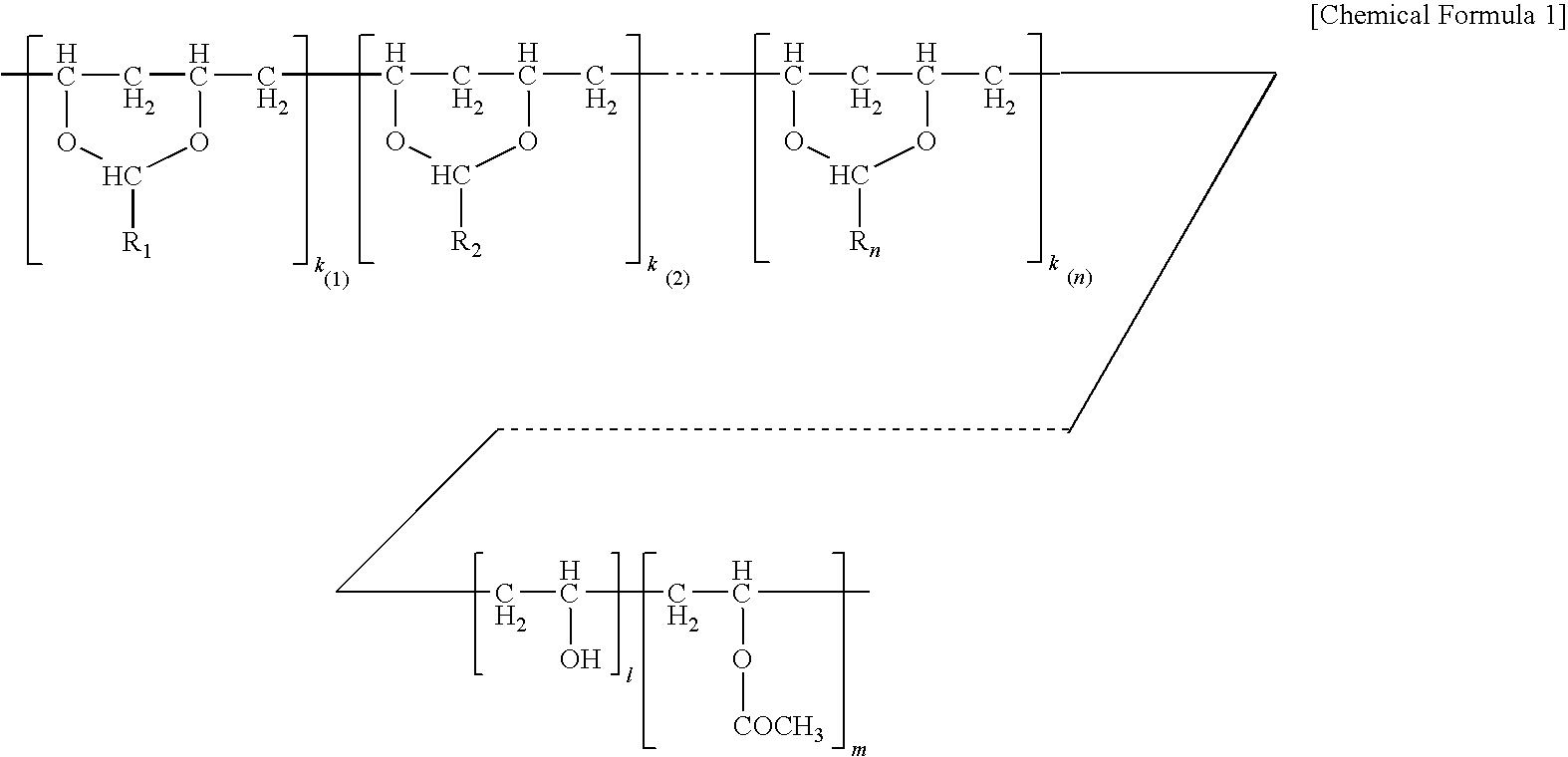

Acrylic thermoplastic resin composition, acrylic resin film and acrylic resin composite

InactiveUS20100015400A1Improve toughnessMaintain transparencySynthetic resin layered productsLaminationVitrificationAcrylic resin

An acrylic thermoplastic resin composition is obtained by melt-kneading a methacrylic resin (A) and a polyvinyl acetal resin (B) at a resin temperature of not less than 140° C. while applying shear at a shear rate of 100 sec−1 or more, and then cooling the kneaded product to not more than 120° C. In the acrylic thermoplastic resin composition, at least the methacrylic resin (A) forms a continuous phase, and among glass transition temperatures of the acrylic thermoplastic resin composition, a glass transition temperature TgA P ascribed to the methacrylic resin (A) indicates a value between a glass transition temperature (TgA) of the methacrylic resin (A) alone and a glass transition temperature (TgB) of the polyvinyl acetal resin (B) alone. A film- or sheet-like molded article is obtained by molding the resin composition. An acrylic resin composite is obtained by laying a layer of metal and / or metal oxide on at least one side of the acrylic resin molded article.

Owner:KURARAY CO LTD

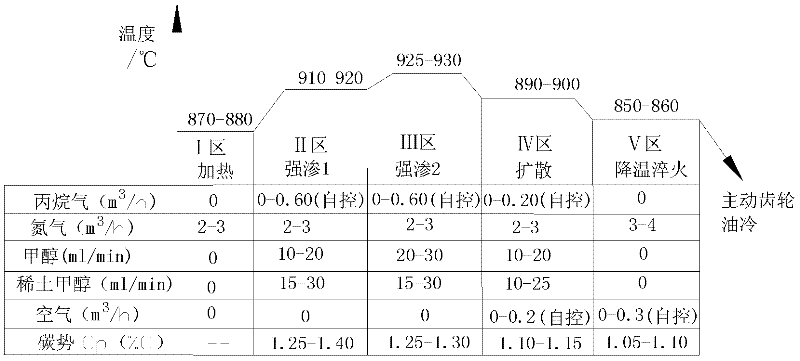

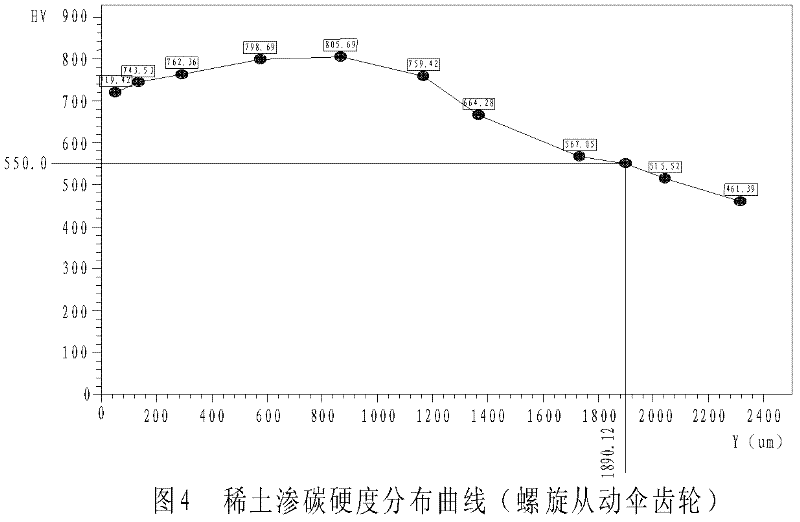

Heat treatment method of spiral bevel gear of cargo truck on double-row rare earth carburization equipment

ActiveCN102373400AEmission reductionIncrease carburizing speedSolid state diffusion coatingCarbon potentialRare earth

The invention provides a heat treatment method of a spiral bevel gear of a cargo truck on double-row rare earth carburization equipment, and relates to a carburization heat treatment technological process of the spiral bevel gear of the cargo truck. The invention solves the problems that energy consumption of carburization heat treatment is high, production cost of a product is high and carburization quenching and gear thermal distortion still exist in a carburization process. The method provided by the invention comprises the following steps of: taking a preheating zone as a strong leakage region 1 and taking a carburizing region as a strong leakage region 2, namely taking a region II and a region III as a carburizing speed main control region and taking a region IV and a region V as a metallographic structure main control region, carrying out temperature control in the regions I, II, III, IV and V, carrying out carbon potential control in the regions II, III, IV and V, and inputtingcarburizing medium propane gas, rare earth methanol penetrating agent, nitrogen, methanol and air into a furnace, thus the heat treatment method is realized. The metallographic structure and surface hardness of the spiral bevel gear subjected to the heat treatment method provided by the invention are all optimized, and heat treatment quality of the spiral bevel gear is improved; meanwhile, capacity is improved by 23%, heat treatment production cost is reduced by 18.9%, and pollution of exhaust emission to the environment is reduced.

Owner:哈尔滨汇隆汽车箱桥有限公司 +3

Method for preparing ZnAlNi multi-component alloy anticorrosive coating on workpiece surface

InactiveCN101665898AImprove corrosion resistanceExcellent surface hardnessSolid state diffusion coatingAluminium powderAlloy

The invention provides a method for preparing an anticorrosive coating on a workpiece surface. The method comprises the following steps: providing the following co-doping agent powder by weight percent: 15wt%-30wt% of zinc powder, 10wt%-20wt% of aluminium powder, 10wt%-20wt% of nickel powder, 0.1wt%-2.0wt% of activating agent powder and the balance filling agent; and embedding a workpiece in the co-doping agent powder, heating the workpiece to 400-600 DEG C, and performing heat preservation for 3-10h for co-doping treatment. Compared with the prior art, one part of nickel is added into the co-doping agent powder to change the content of other components in the co-doping agent; and the experimental result proves that the nickel element is added into the anticorrosive coating to obviously improve corrosion resistance and surface hardness of the anticorrosive coating.

Owner:BEIJING ZHONGLUDACHENG SCI & TECH DEV

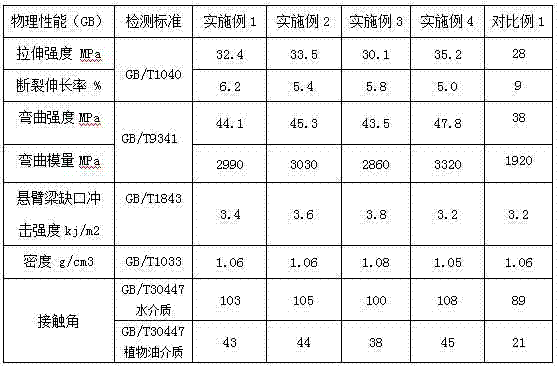

Reinforced greasy-dirt-resistant high-gloss polypropylene composite material and preparation method thereof

ActiveCN104744818ALower surface free energyGood oil resistancePolypropylene compositesPolymer science

The invention provides a reinforced greasy-dirt-resistant high-gloss polypropylene composite material and a preparation method thereof. The reinforced greasy-dirt-resistant high-gloss polypropylene composite material is prepared form the following components in parts by weight: 60-80 parts of PP resin, 10-15 parts of superfine precipitated barium sulfate, 6-10 parts of reinforced magnesium sulfate whiskers, 2-5 parts of fluoride, 0.2-0.4 part of an antioxidant, 0.1-0.3 part of a nucleating agent, 0.5-1 part of a lubricating agent and 0-3 parts of other auxiliaries. According to the reinforced greasy-dirt-resistant high-gloss polypropylene composite material prepared by the method disclosed by the invention, the surface polarity of the material is changed and the greasy dirt resistance of the material is improved; meanwhile, the composite material meets the European Union Regulation (EC) No.1935 / 2004 of related food contact materials, and has the characteristics of being high in gloss, low in after shrinkage, high in rigidity, and the like. The material is applied to a housing of a kitchen appliance, so that the surface of the kitchen appliance has capacity of resisting greasy dirt and self-cleaning capacity, and the self-cleaning anti-greasy-dirt environmental requirements of modern kitchen appliance are met.

Owner:ORINKO NEW MATERIAL CO LTD

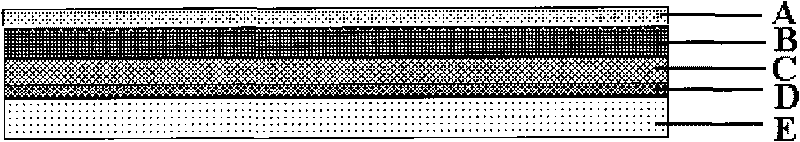

Back film for solar module

ActiveCN101764163AHigh gas barrierGood mechanical strengthSynthetic resin layered productsPhotovoltaic energy generationChemistryWater vapor

The invention discloses a back film for a solar module; the back film comprises an outer surface fluoride containing layer, a middle layer and an inner surface ethylene- vinyl acetate copolymer layer; the middle layer comprises a polyester layer, an ethylene-vinyl alcohol copolymer layer and a bonding layer; the middle layer is prepared by co-extruding the polyester material layer, the ethylene-vinyl alcohol copolymer layer and the bonding layer; the outer surface fluoride containing layer is a fluoride containing film compounded on the polyester layer of the middle layer or the fluoride containing coating coated on the polyester layer of the middle layer; and the inner surface ethylene- vinyl acetate copolymer layer is applied on the bonding layer of the middle layer by curtain coating. The back film of the solar module provided by the invention has the advantages of low water vapor transmission rate and high insulation performance, not only has excellent barrier and insulation performance, but also has the packaging performance.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

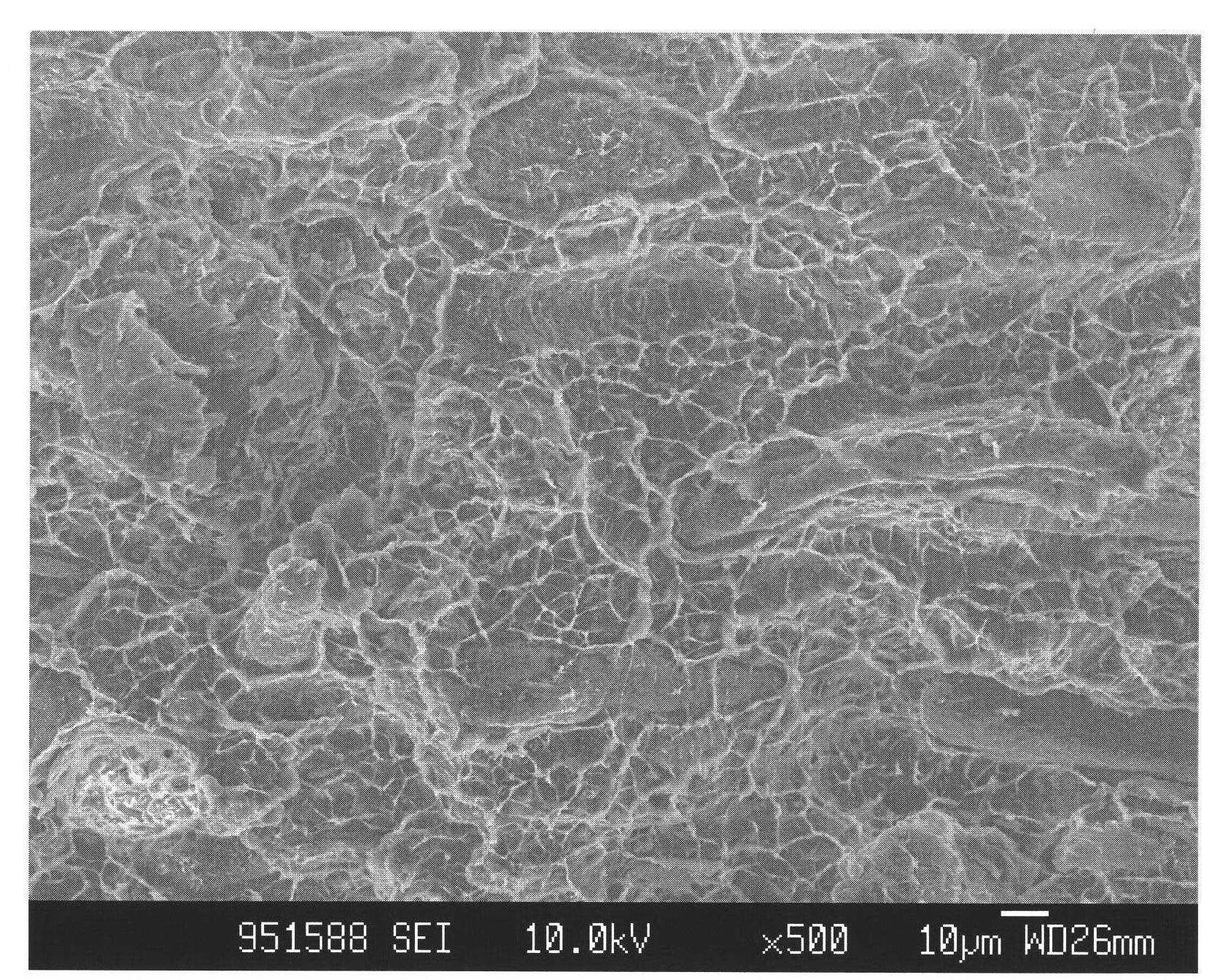

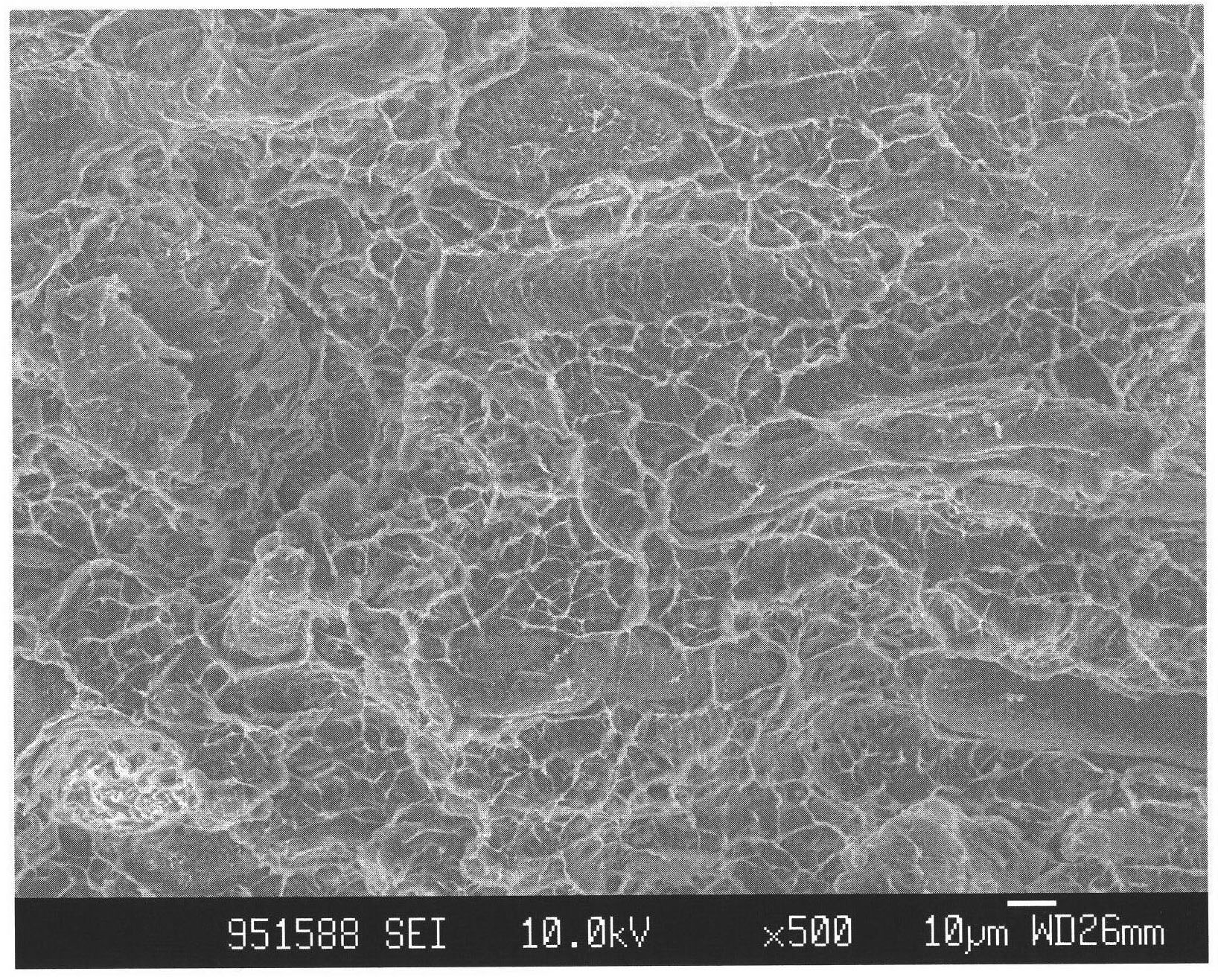

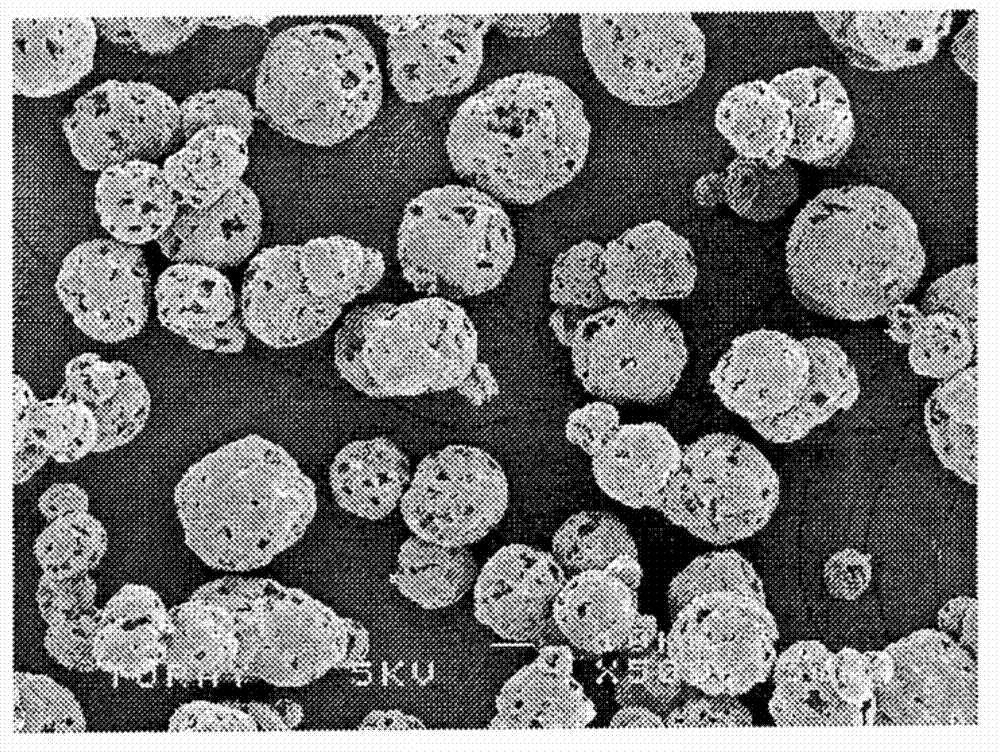

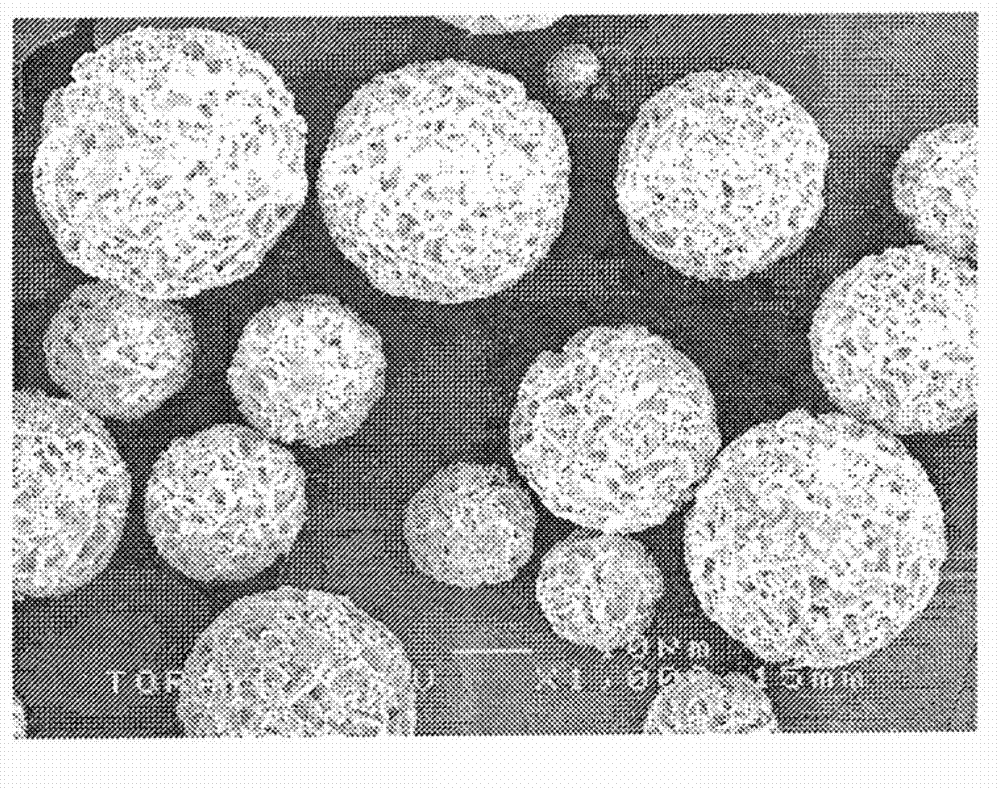

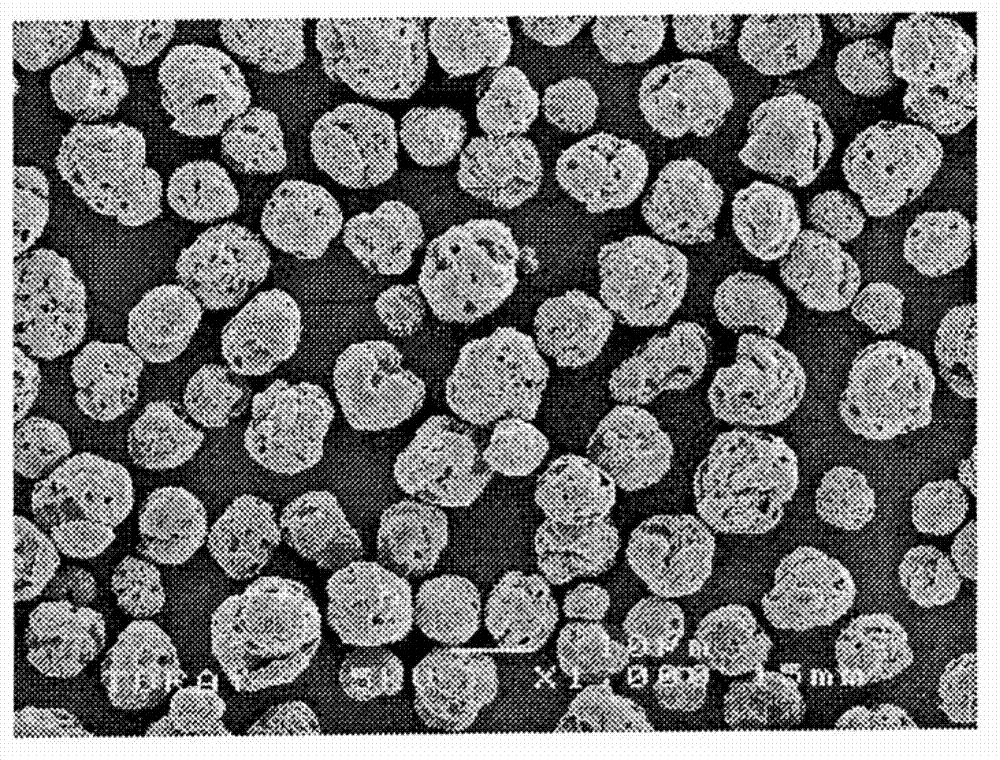

Method for producing microparticles of polylactic acid-based resin, microparticles of polylactic acid-based resin and cosmetic using same

ActiveCN103201319AEasy to manufactureHigh oil absorptionCosmetic preparationsMake-upMicroparticleSolvent

Provided are: a method for producing microparticles of a polylactic acid-based resin; porous microparticles of a polylactic acid-based resin, said microparticles having a small particle diameter, showing a high oil absorption ability and being appropriately usable for cosmetics; smooth-surfaced microparticles of a polylactic acid-based resin, said microparticles having a spherical form, showing a narrow particle diameter distribution and being appropriately usable for toners; and a cosmetic using the aforesaid microparticles of a polylactic acid-based resin. The method for producing microparticles of a polylactic acid-based resin comprises: dissolving a polylactic acid-based resin (A) and a polymer (B), which is different from polylactic acid-based resins, in an ether-type organic solvent (C); applying a shear force thereto to form an emulsion; and then contacting the emulsion with a poor solvent of the polylactic acid-based resin (A). According to this production method, porous microparticles of the polylactic acid-based resin, said microparticles having a fusion enthalpy of the polylactic acid-based resin (A) of 5 J / g or greater, having a small particle diameter and showing a high oil absorption ability, and smooth-surfaced microparticles of the polylactic acid-based resin, said microparticles having a fusion enthalpy less than 5 J / g, having a spherical form and showing a narrow particle diameter distribution, can be provided.

Owner:TORAY IND INC

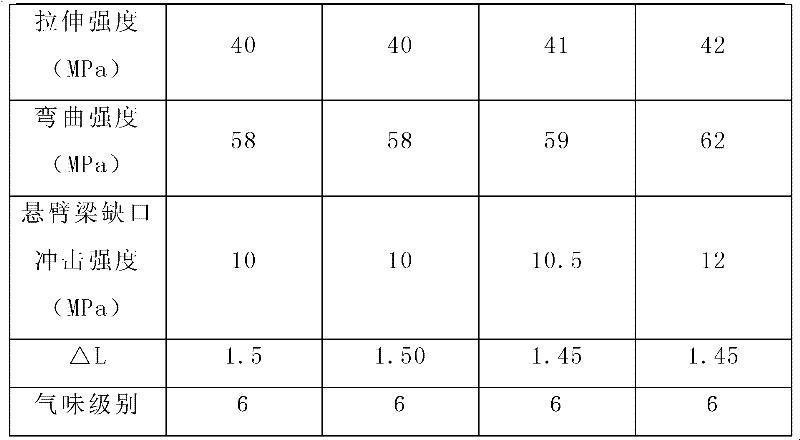

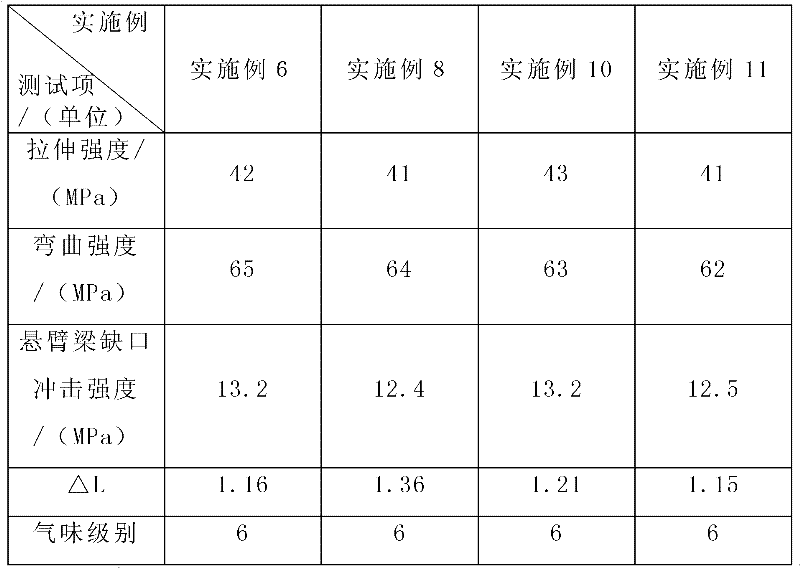

Low-odor scraping-resistant polypropylene material and preparation method thereof

The invention relates to a low-odor scraping-resistant polypropylene material and a preparation method of the low-odor scraping-resistant polypropylene material and belongs to the technical field of polypropylene materials. In order to solve the technical problems that the odor of the polypropylene material in the prior art is difficult to eliminate, the odor can be eliminated only through aiming at a certain single ingredient, the scraping resistance is poor, and the production cost is high when fluorine-containing polymers are adopted for production. The invention provides the low-odor scraping-resistant polypropylene material and also provides the preparation method of the polypropylene material, wherein the polypropylene material comprises acrylic resin, nanometer silicon dioxide, ultra-fine talcum powder, odor eliminating agents, disperse lubricating agents, antioxidants and hindered amine light stabilizers, the method comprises material mixing and squeezing granulation steps, and the low-odor scraping-resistant polypropylene material is obtained. The polypropylene material provided by the invention has the advantages of low odor and scraping resistance. The product obtained from the material has the advantage that the performance such as tensile strength, bending strength, cantilever beam notch impact strength and delta L is high. The method has the advantages that the process is simple, the operation is easy, raw materials are easy to obtain, and the industrial production is favorably realized.

Owner:浙江明江新材料科技股份有限公司

All-solid low-energy-curing matte UV coating for PVC plastic and preparation method for UV coating

The invention discloses an all-solid low-energy-curing matte UV (ultraviolet) coating for a PVC (polyvinyl chloride) plastic and a preparation method for the UV coating. The coating contains the following components: 25-30% of special modified acrylic resin, 5-10% of urethane acrylate, 20-25% of high-functionality active monomers, 20-25% of a reactive diluent, 2-5% of a photoinitiator 1, 1-4% of a photoinitiator 2, 3-6% of a photoinitiator 3, 0.3-1.0% of a dispersant, 5-10% of extinction powder, 0.5-1.0% of wax powder, 0.1-0.5% of a defoamer and 0.1-0.5% of a leveling agent. The UV coating does not contain a solvent and can be cured to form a low-luster, high-scratch-resistant and pollution-resistant paint film only by 150-200 mj / m<2> of UV energy; and the UV coating is applied to soft PVC and can enable a base material not to be thermally damaged in a curing process, so that the application range of the UV coating is greatly expanded.

Owner:HUNAN JINHAI SCI & TECH

Method for preparing ZnAlMg multi-component alloy anticorrosive coating on workpiece surface

InactiveCN101665900AImprove corrosion resistanceExcellent surface hardnessSolid state diffusion coatingAluminium powderAlloy

The invention provides a method for preparing an anticorrosive coating on a workpiece surface. The method comprises the following steps: providing the following co-doping agent powder by weight percent: 15wt%-30wt% of zinc powder, 10wt%-20wt% of aluminium powder, 10wt%-20wt% of magnesium powder, 0.1wt%-2.0wt% of activating agent powder and the balance filling agent; and embedding and heating a workpiece in the co-doping agent powder to 400-600 DEG C, and performing heat preservation for 3-10h for co-doping treatment. Compared with the prior art, one part of magnesium is added into the co-doping agent powder to change the content of other components in the co-doping agent; and the experimental result proves that the magnesium element is added into the anticorrosive coating to obviously improve corrosion resistance and surface hardness of the anticorrosive coating.

Owner:BEIJING ZHONGLUDACHENG SCI & TECH DEV

LED lampshade material and preparation method thereof

ActiveCN104788869AImprove toughnessImprove heat resistancePoint-like light sourceGlobesPolyethylene glycolThermal expansion

The invention relates to a lampshade material. The lampshade material comprises the following raw materials in parts by mass: 100 parts of PMMA, 4-6 parts of an organic silicon material, 1-2 parts of methylacryloyl methoxyl silane, 0.5-1 part of polyethylene glycol, 0.4-0.8 part of an organic silicon photodiffusion agent, 1-1.5 parts of carboxymethylcellulose, 1-2 parts of nano negative ion powder, 0.5-1.5 parts of nano yttrium oxide, 2-5 parts of polytetrafluoroethylene ultrafine powder, 0.5-1.5 parts of an antioxidant and 0.5-1.5 parts of a light stabilizing agent. The invention further relates to a preparation method of the lampshade material. The lampshade material is good in light permeability and gentle in light, the thermal expansion coefficient of the lampshade material is matched with an LED chip, and the wafer of an LED lamp is not bent because of temperature change in normal operation, so that the LED lamp is solid and stable in overall structure in the use process, the service life can be prolonged, the lampshade material has an air purification function, the preparation method of the lampshade material is simple, the dispersing property of the lampshade material can be remarkably improved, the light transmittance rate and the haze degree are remarkably increased, and the mechanical property and the surface hardness are remarkably improved.

Owner:NINGBO LAIHE CHRISTMAS GIFTS

Anti-glare material and optical layered product

InactiveUS20090233048A1Highly visible and quality displayReduce in quantityLayered productsRecord information storageSlope angleComposite material

Owner:TOMOEGAWA CO LTD

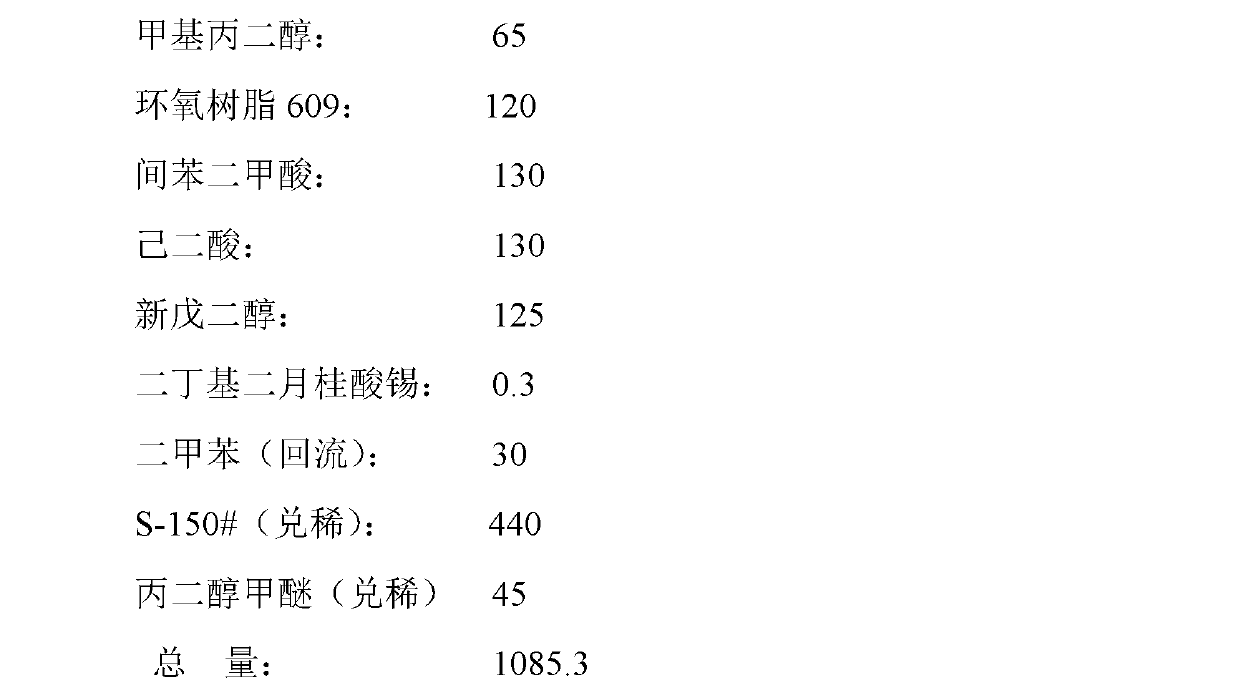

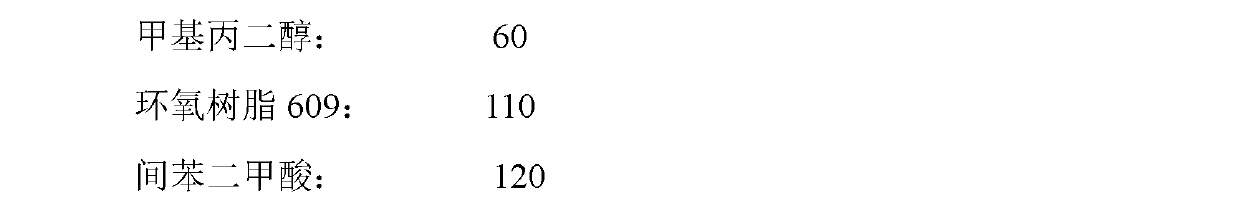

Epoxy modified saturated polyester resin for undercoat of coil coating and undercoat of coil coating

ActiveCN102993422AStrong adhesion and corrosion resistanceImprove processabilityAnti-corrosive paintsPolyester coatingsSolventCorrosion resistant

The invention discloses an epoxy modified saturated polyester resin for an undercoat of a coil coating and the undercoat of the coil coating. The epoxy modified saturated polyester resin comprises the following components in parts by weight: 50-80 parts of methylpropanediol, 100-140 parts of epoxy resin 609, 110-150 parts of isophthalic acid, 110-150 parts of hexanedioic acid, 105-145 parts of neopentyl glycol, 0.1-0.6 part of organic tin, 20-40 parts of dimethylbenzene, 380-500 parts of S-150# solvent oil and 30-60 parts of propylene glycol monomethyl ether. The prepared epoxy modified saturated polyester resin is applied to the undercoat of the coil coating, so that the undercoat of the coil coating is high in adhesion and corrosion resistant performance to metals, high in machinability, high in deformation property under high surface hardness and weather ability and low in cost, and the comprehensive performance is obviously improved.

Owner:WUXI HUHUANG PAINT

PC/ABS modified alloy metal

The invention provides a PC / ABS modified alloy which essentially comprises the raw material components of mass fraction compounding ratio: 60 to 75 for PC / ABS, 12 to 21 for polymethyl methacrylate, 1 to 4 for compatilizer, 4 to 8 for plasticizer, 4 to 8 for bromide fire retardant, 1 to 3 for stibium fire retardant, 2 to 5 for acrylic impact modifiers, and 0.2 to 0.5 for oxidation inhibitor. The PC / ABS modified alloy of the invention makes use of adding harden stiffening agent, compatible plasticizer in the mixing process to improve the surface hardness of the PC / ABS alloy as well as to further achieve the surface hardness and fire resistance on the basis of PC / ABS alloy mechanical properties without change, and meets the technological requirement. As a result, the PC / ABS alloy has the larger utilization scale with more economic benefits. Besides, the PC / ABS modified alloy avoids employing paint spray to provide surface hardness, which is beneficial for environment protective.

Owner:MITAC PRECISION TECH CO LTD SHUNDE DISTRICT FOSHAN CITY

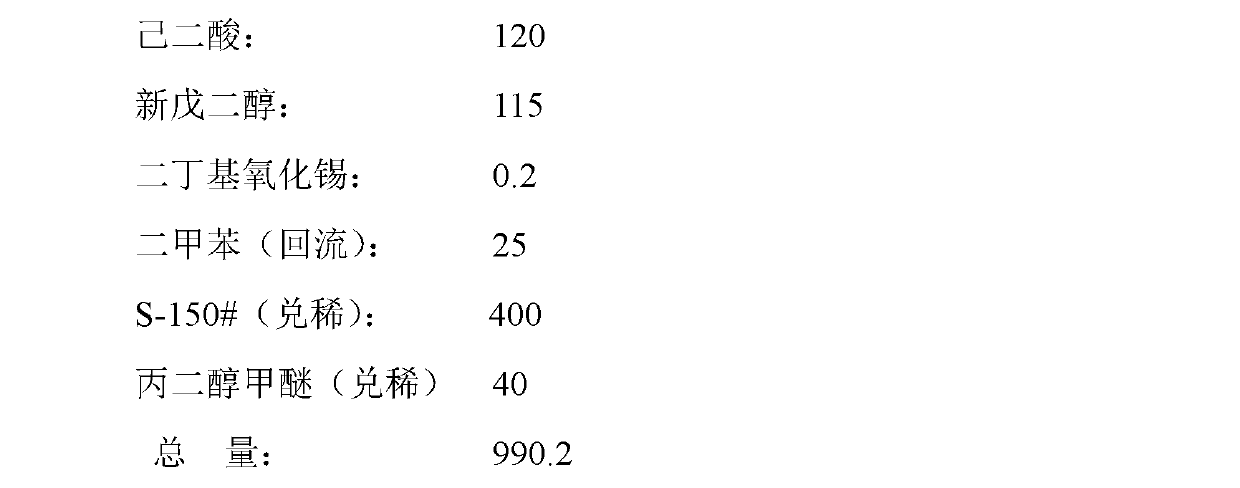

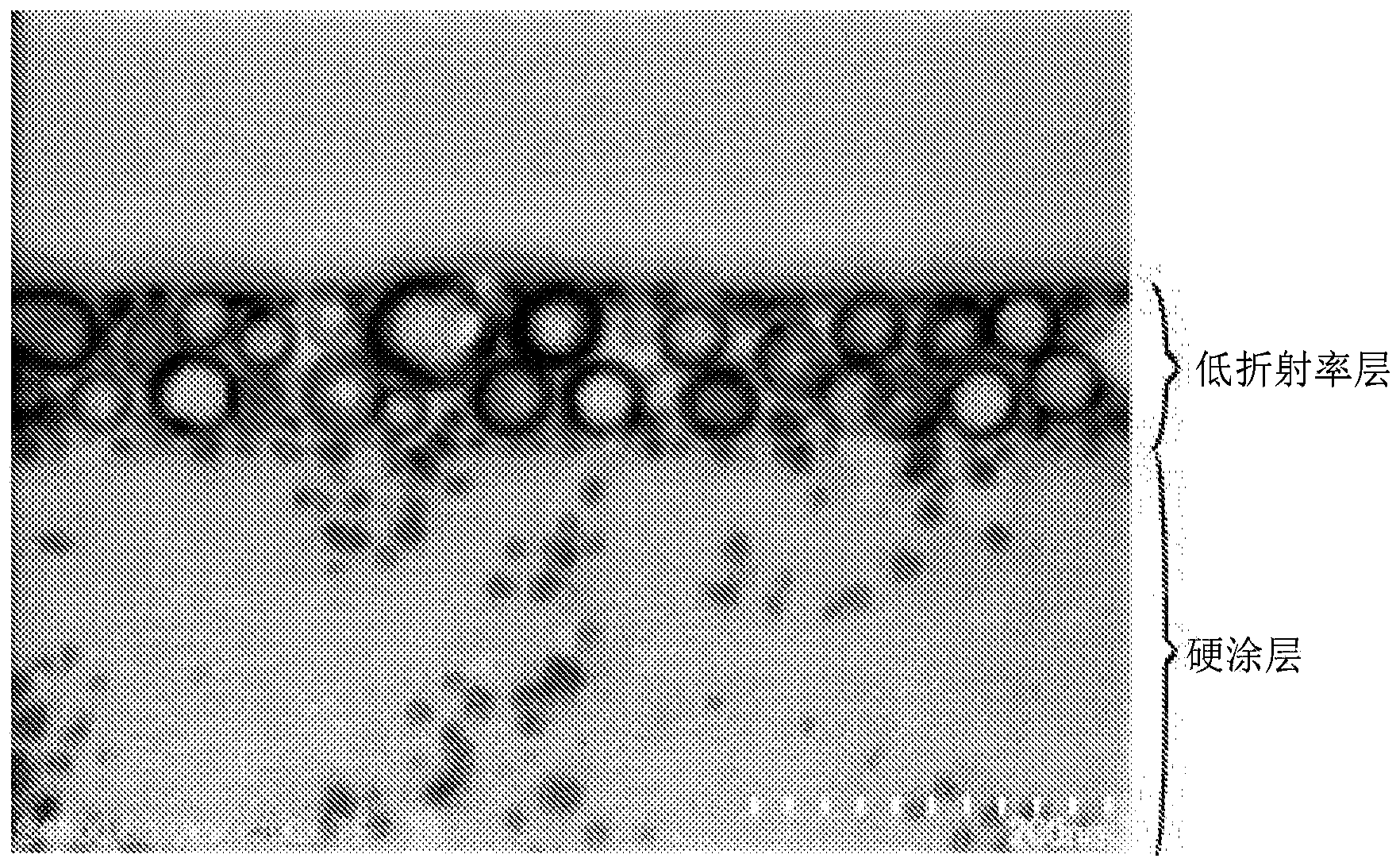

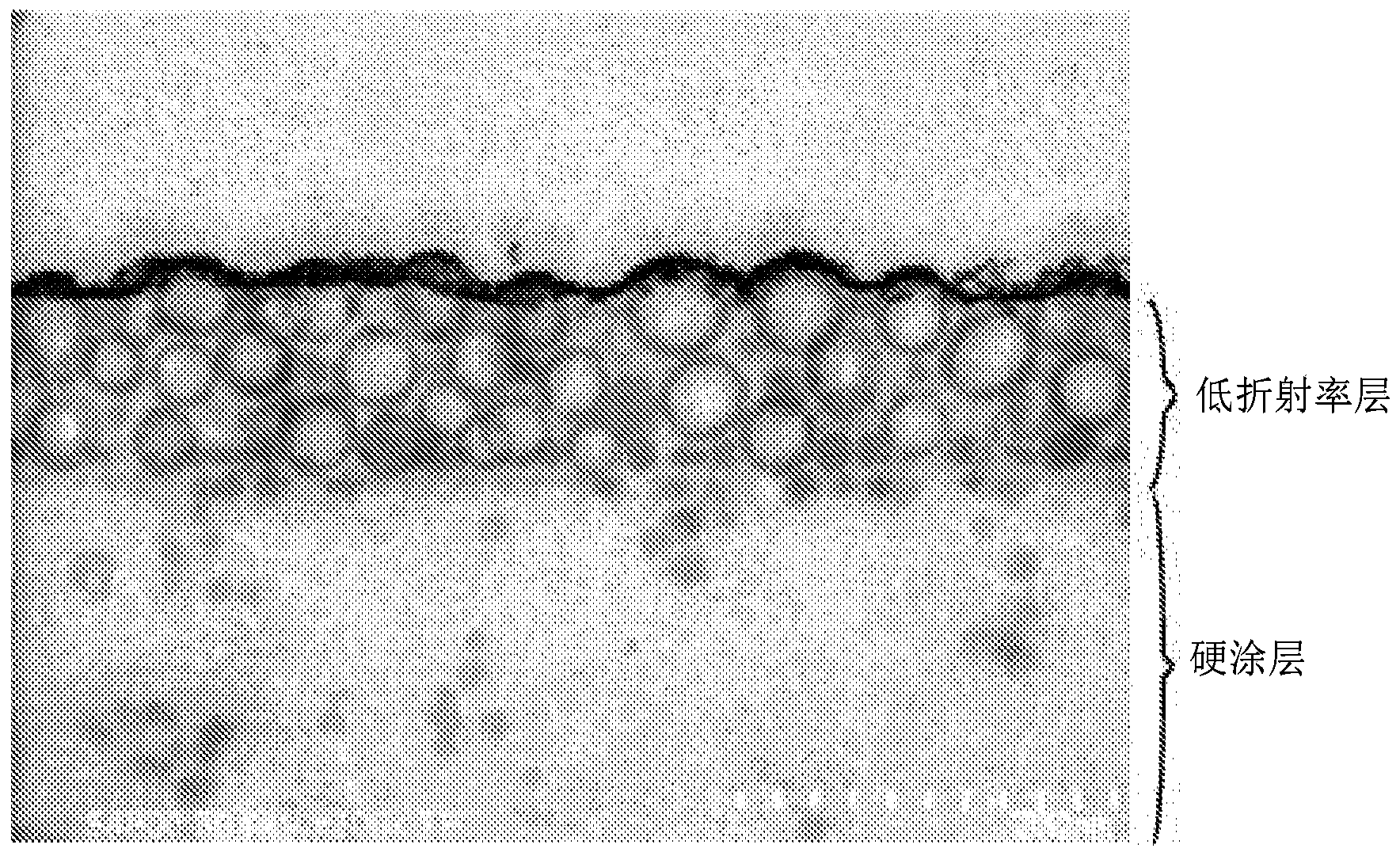

Antireflection film, polarizing plate, and image display device

ActiveCN103460079AExcellent surface hardnessGood anti-reflection performanceSynthetic resin layered productsPolarising elementsMeth-Acrylic resin

The purpose of the present invention is to provide an antireflection film that has a sufficient surface hardness and a uniform surface, comprises a low-refractive-index layer having a sufficiently low refractive index, and has excellent antireflection performance. An antireflection film wherein a hard coating layer is formed on a light-permeable substrate and a low-refractive-index layer is formed on the hard coating layer is characterized in that the low-refractive-index layer of the antireflection film comprises (meth)acrylic resin, hollow silica microparticles, reactive silica microparticles and an antifouling agent and the reactive silica microparticles in the low-refractive-index layer are unevenly distributed near the interface on the hard coating layer side and / or near the interface of the side opposite the hard coating layer.

Owner:DAI NIPPON PRINTING CO LTD

Curable composition and cured product thereof

InactiveCN101679635AExcellent surface hardnessImprove scratch resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer scienceCarbamate

Owner:SHOWA DENKO KK

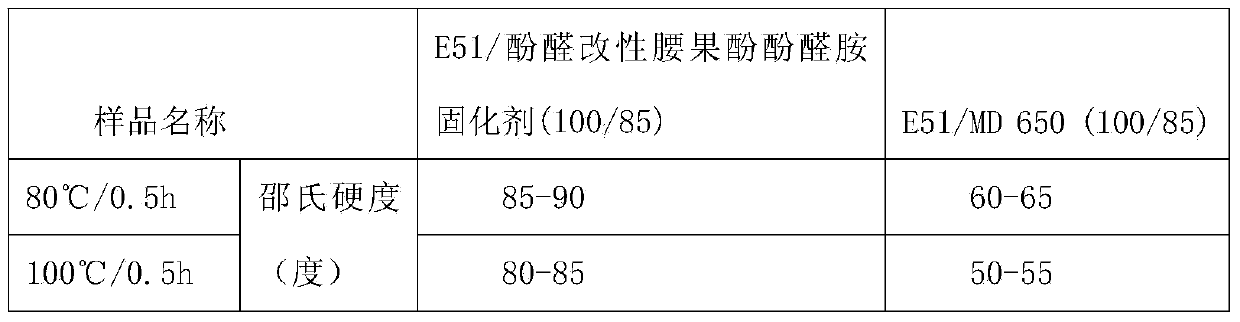

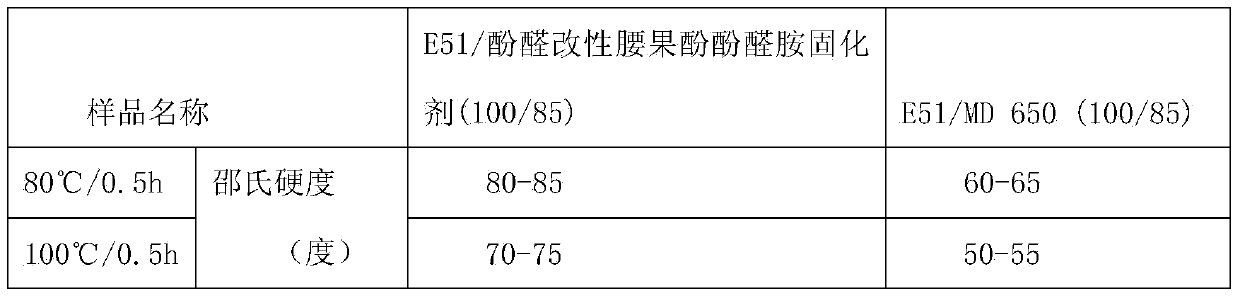

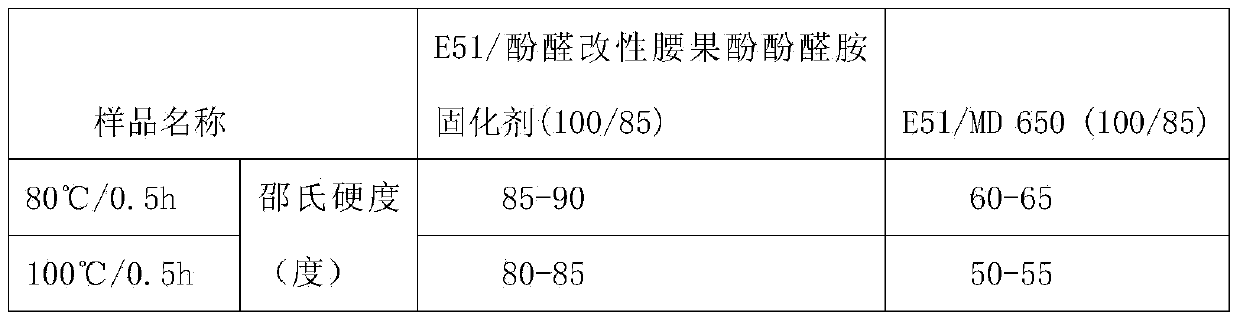

Preparation method of cardanol-based high temperature-resistant epoxy resin curing agent

The invention relates to a preparation method of a cardanol-based high temperature-resistant epoxy resin curing agent. The preparation method comprises the steps of firstly weighing cardanol, a phenolic compound, paraformaldehyde and diamine or polyamine according to weight, adding the cardanol, the phenolic compound and the paraformaldehyde into a reaction container, adding a catalyst, heating at the temperature of 75-100 DEG C for 2-6h to obtain an intermediate, then cooling the intermediate to 60-68 DEG C, adding the diamine or the polyamine, adding the remaining paraformaldehyde at the temperature in a stirring state, then heating till the temperature achieves 65-95 DEG C, reacting for 4-8h, and dehydrating in a vacuum state to obtain the cardanol-based high temperature-resistant epoxy resin curing agent provided by the invention. The synthesized curing agent has the advantages of great surface hardness and Shore hardness, excellent gloss, good high temperature resistance and low-temperature fast curing. According to the preparation method disclosed by the invention, the epoxy resin curing agent with a wide range of curing temperature, high temperature resistance and excellent surface performance is obtained and is suitable for requirements of primer paint and finish paint.

Owner:上海美东生物材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com