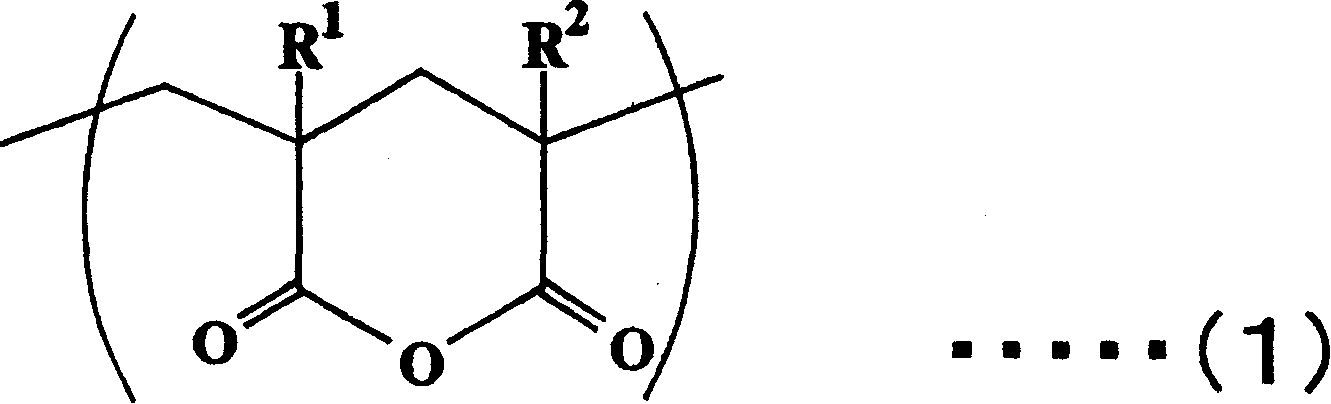

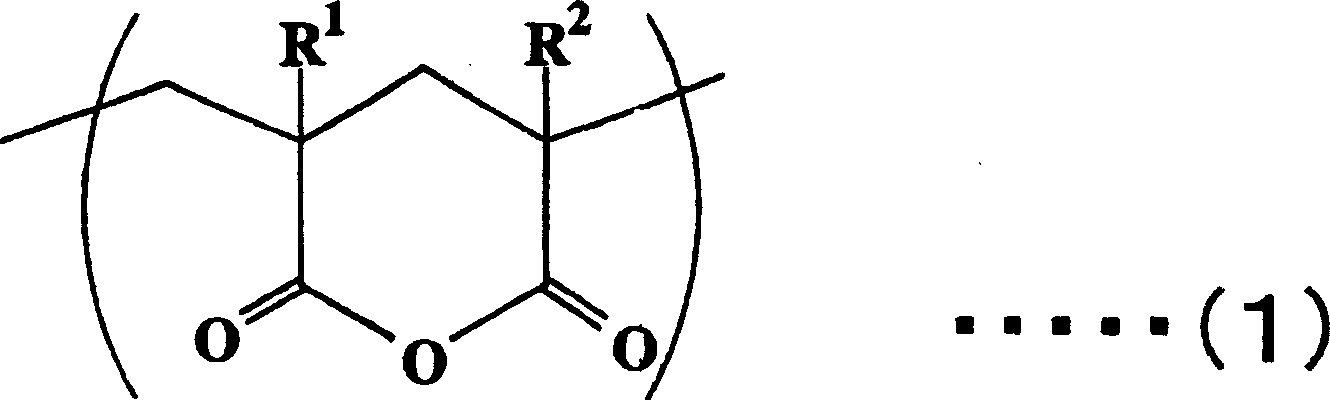

Acrylic resin films and process for producing the same

An acrylic, resin film technology, applied in instruments, optics, optical components, etc., can solve the problems of dimensional instability, lack of heat resistance, etc., and achieve excellent transparency, good surface adhesion, and heat resistance. The effect of sexual height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0200] [Measuring method of physical properties]

[0201] Hereinafter, the constitution and effects of the present invention will be described in more detail through examples. However, the present invention is not limited to the following examples. Before describing each example, methods for measuring various physical properties used in the examples will be described.

[0202] (1) Composition of each component

[0203] The acrylic resin film was dissolved in acetone, and the solution was centrifuged at 9000 rpm for 30 minutes to separate acetone-soluble components and acetone-insoluble components. The acetone-soluble component was dried under reduced pressure at 60° C. for 5 hours, and each component unit was quantified to specify the component composition of the acrylic resin.

[0204] By proton nuclear magnetic resonance ( 1 H-NMR) method to quantify each component unit. exist 1 In the H-NMR method, the copolymer composition can be determined from the integral ratio of...

reference example

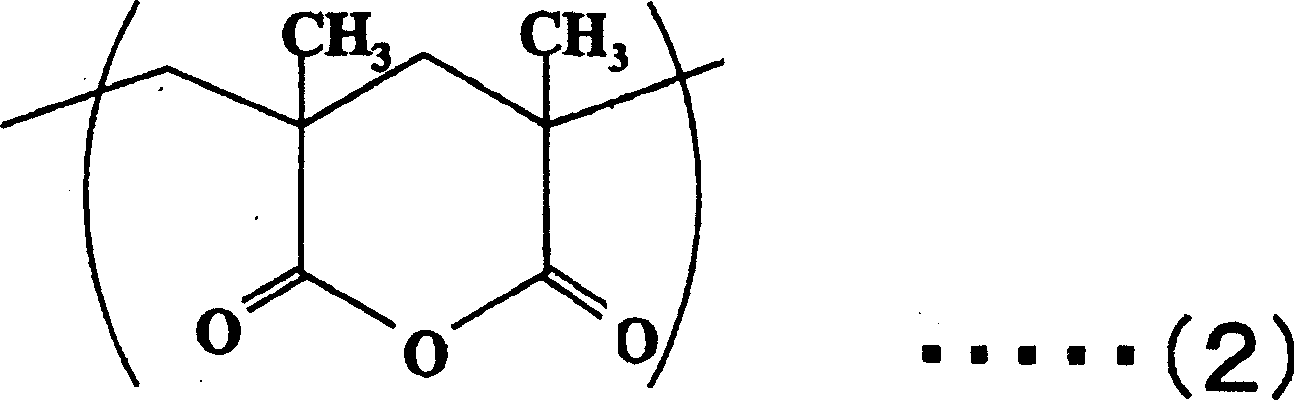

[0259] The additive (NaOCH 3 ) was mixed therein, using a twin-screw extruder (TEX30 (manufactured by Nippon Steel Works, L / D=44.5)), nitrogen was purged from the hopper at an amount of 10 L / min, while the screw rotation speed was 100 rpm, the raw material The intramolecular cyclization reaction was carried out at a supply rate of 5 kg / h and a cylinder temperature of 290° C. to obtain a granular acrylate resin (A1). The compositional ratio of the glutaric anhydride unit in 100 mass parts of this acrylate resin (A1) was 31 mass parts. Reference example (2) Acrylic resin (A2)

[0260] Except that the polymethyl methacrylate-polymethacrylic acid copolymer (MMA / MAA=72 / 28) obtained by the suspension polymerization method was used as the acrylate resin, the same operation was performed as in Reference Example 1 to obtain the acrylate resin (A2 ). The composition ratio of the glutaric anhydride unit of this acrylate resin was 23 mol%.

[0261] Reference Example (3) Acrylic Elasto...

Embodiment 1

[0265] The 75 parts by mass acrylic resin (A1) obtained in the above-mentioned reference example (1) and the acrylic elastomer particle (B1) obtained in the reference example (3) were mixed in a composition ratio of 25 parts by mass, and a double-screw was used to An extruder (TEX30 (manufactured by Nippon Steel Works, L / D=44.5)) was kneaded at a screw speed of 150 rpm and a cylinder temperature of 280° C. to obtain a granular acrylate resin.

[0266] Subsequently, using a 65mmφ single-screw extruder with a vent hole, the particles dried at 100°C for 3 hours were extruded through a T die (set temperature 250°C), so that both sides were completely attached to the polishing roller Cooling was carried out to obtain an unstretched acrylic resin film. Using a linear simultaneous biaxial tenter, the acrylic resin film was stretched 1.5 times in the longitudinal direction and 1.5 times in the transverse direction at a preheating temperature of 130°C and a stretching temperature of 14...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com