Patents

Literature

24699 results about "Acetone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acetone, or propanone, is the organic compound with the formula (CH₃)₂CO. It is a colorless, volatile, flammable liquid and is the simplest and smallest ketone. Acetone is miscible with water and serves as an important solvent in its own right, typically for cleaning purposes in laboratories. About 6.7 million tonnes were produced worldwide in 2010, mainly for use as a solvent and production of methyl methacrylate and bisphenol A. It is a common building block in organic chemistry. Familiar household uses of acetone are as the active ingredient in nail polish remover and as paint thinner. It has VOC exempt status in the USA.

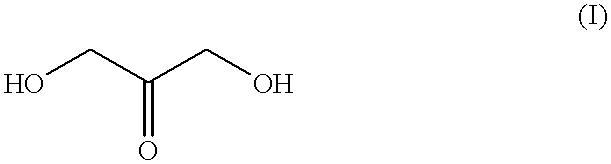

Self-tanning dihydroxyacetone formulations having improved stability and providing enhanced delivery

A composition is provided which is useful for self-tanning skin coloring and is characterized by improved stability, which comprises from about 0.5% to about 20.0% by weight, based on total weight of said composition, of a self-tanning skin coloring agent subject to chemical instability, which is preferably dihydroxyacetone; from about 2.0% to about 40.0% by weight of a polyethoxyglycol, which is preferably ethoxydiglycol; and from about 0.1% to about 15.0% by weight of a polyol comprising a polyhydric compound having at least three hydroxyl groups and at least three carbon atoms, which is preferably D-sorbitol. The self-tanning composition may further optionally contain from about 0.1% to about 8.0% by weight of a water soluble dihydroxyl compound having at least two, and up to eight carbon atoms, which is preferably ethylene glycol; and the self-tanning composition may still further optionally contain an acidifying agent in amount sufficient to maintain the pH of said total composition at from about 3.5 to about 4.5, which is preferably sorbic acid. Cosmetologic products and methods of tanning are also provided.

Owner:SCHERING PLOUGH HEALTHCARE PRODUCTS INC

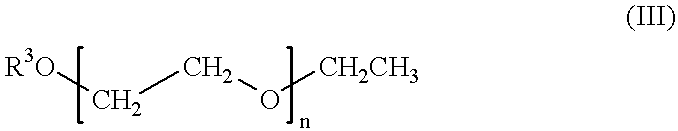

Ethanol recovery process

ActiveUS20070031954A1Permeate pressureSimple equipmentMembranesFermented solutions distillation/rectificationAlcoholFractionation

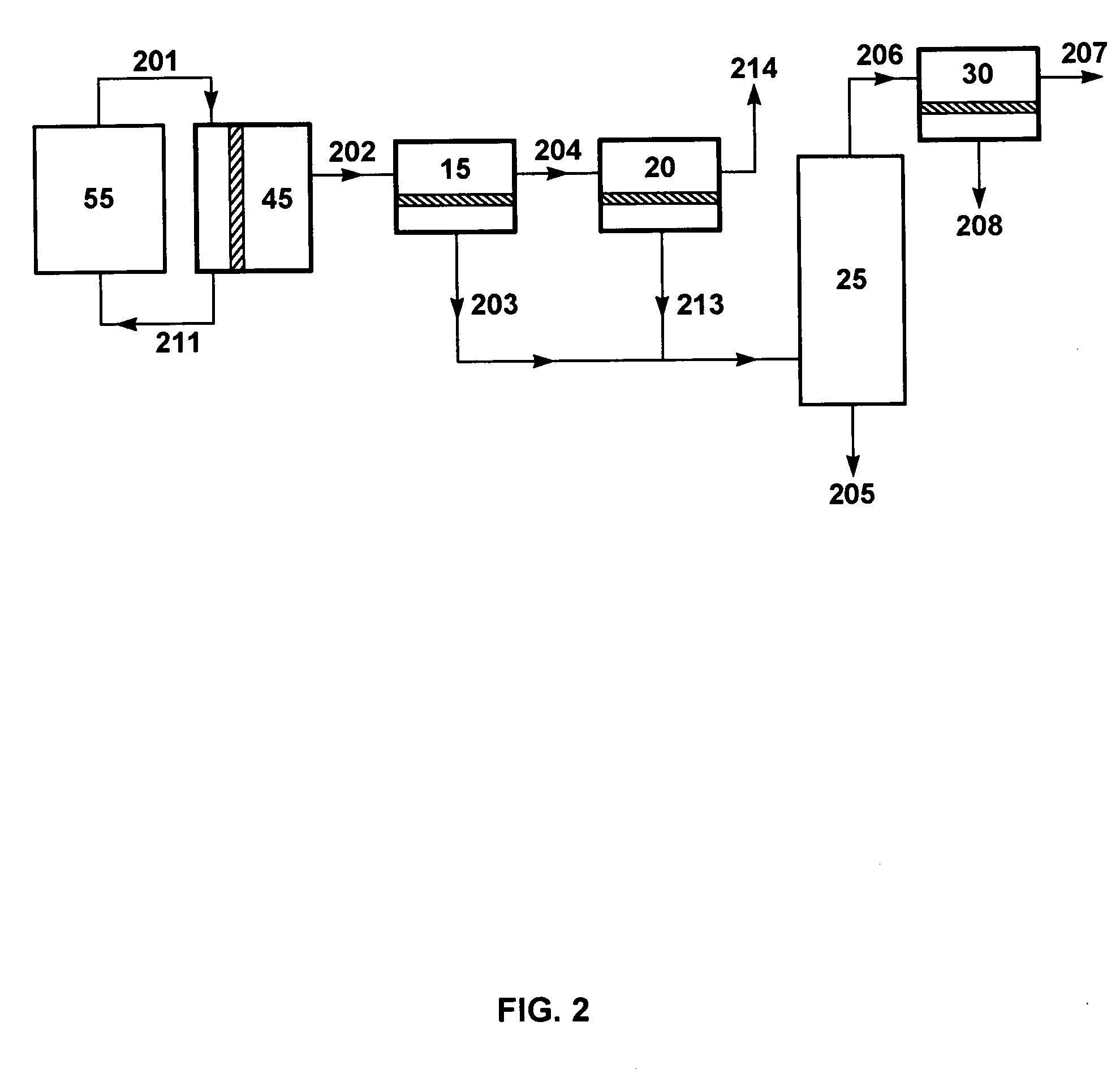

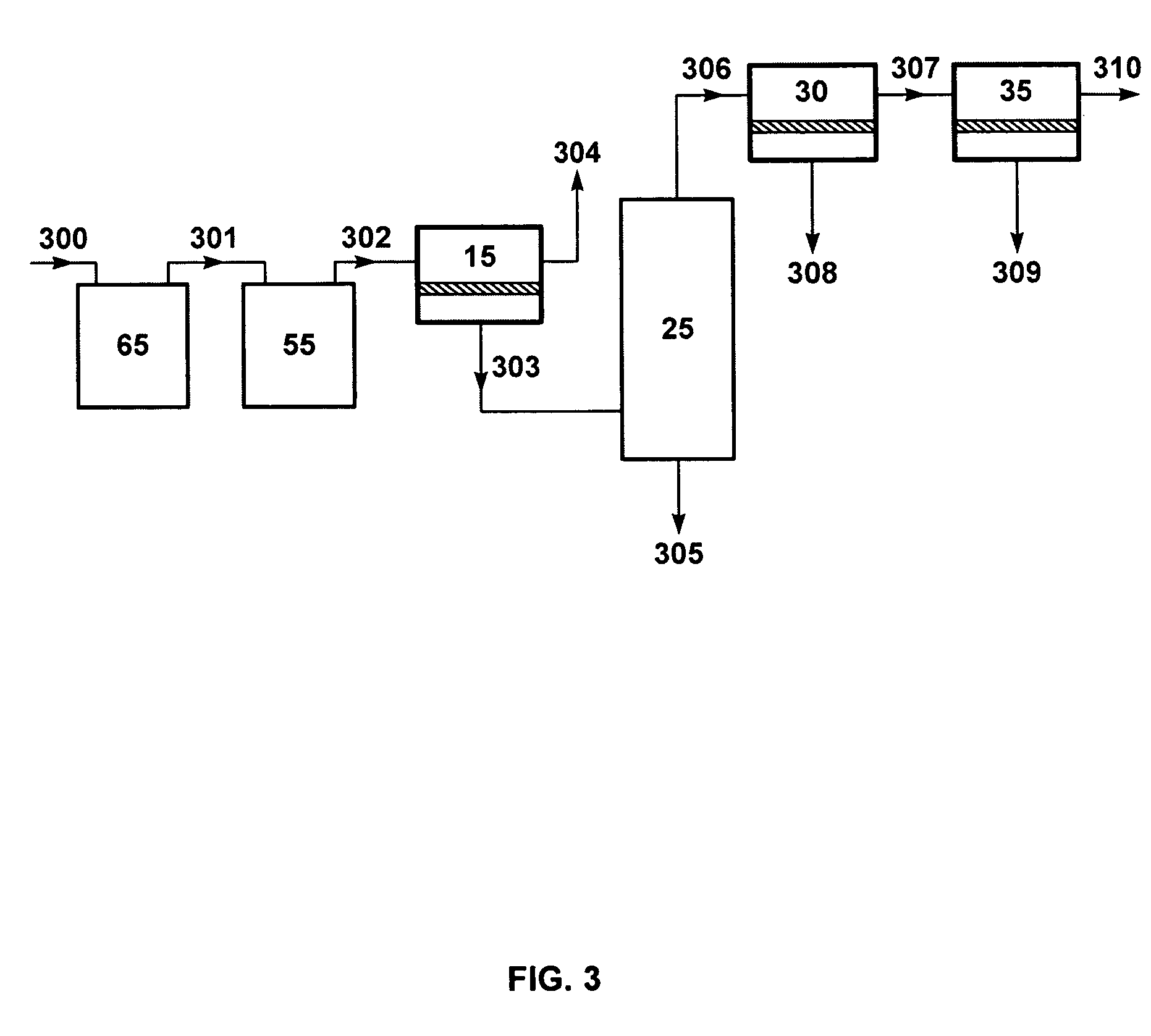

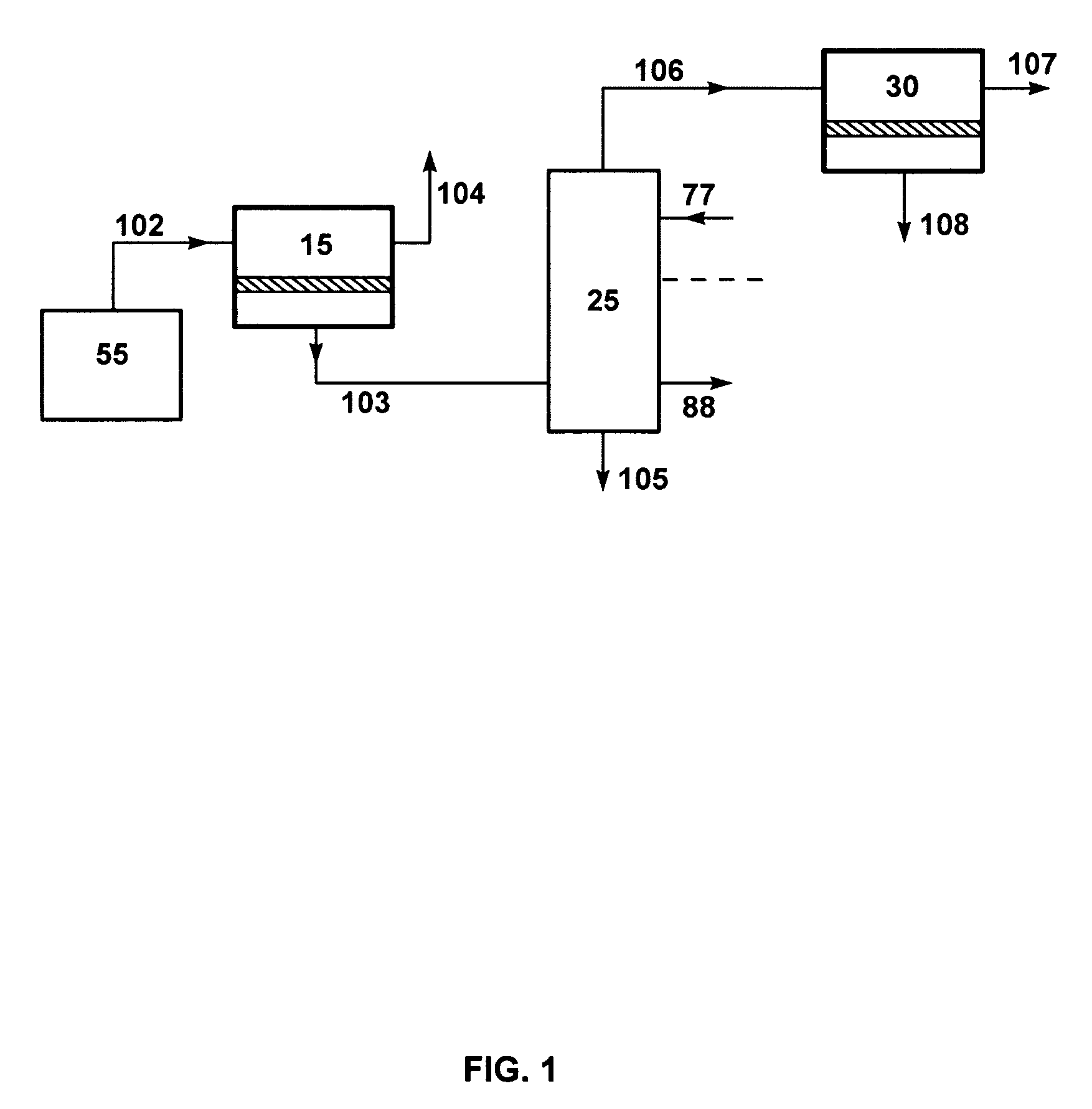

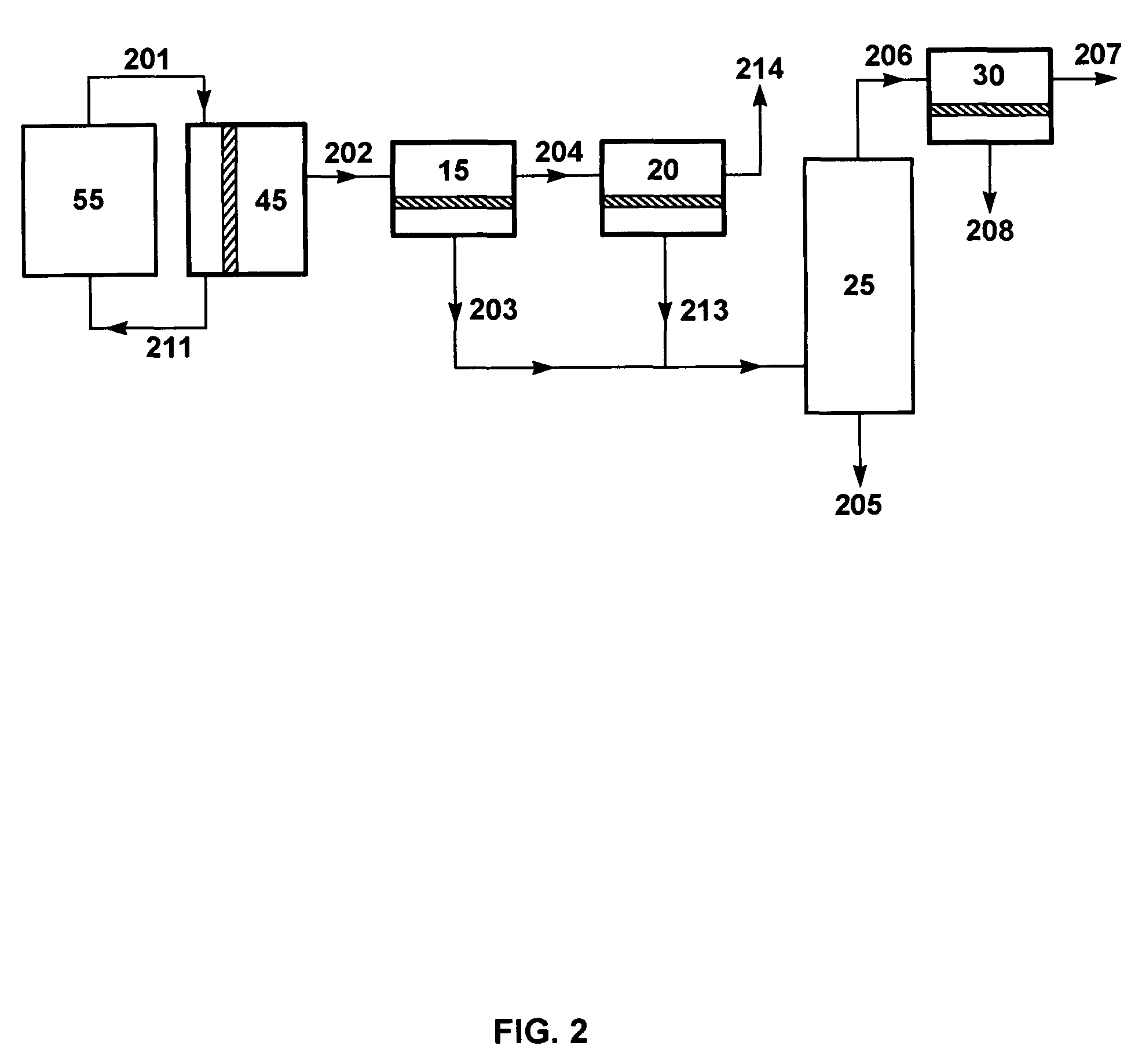

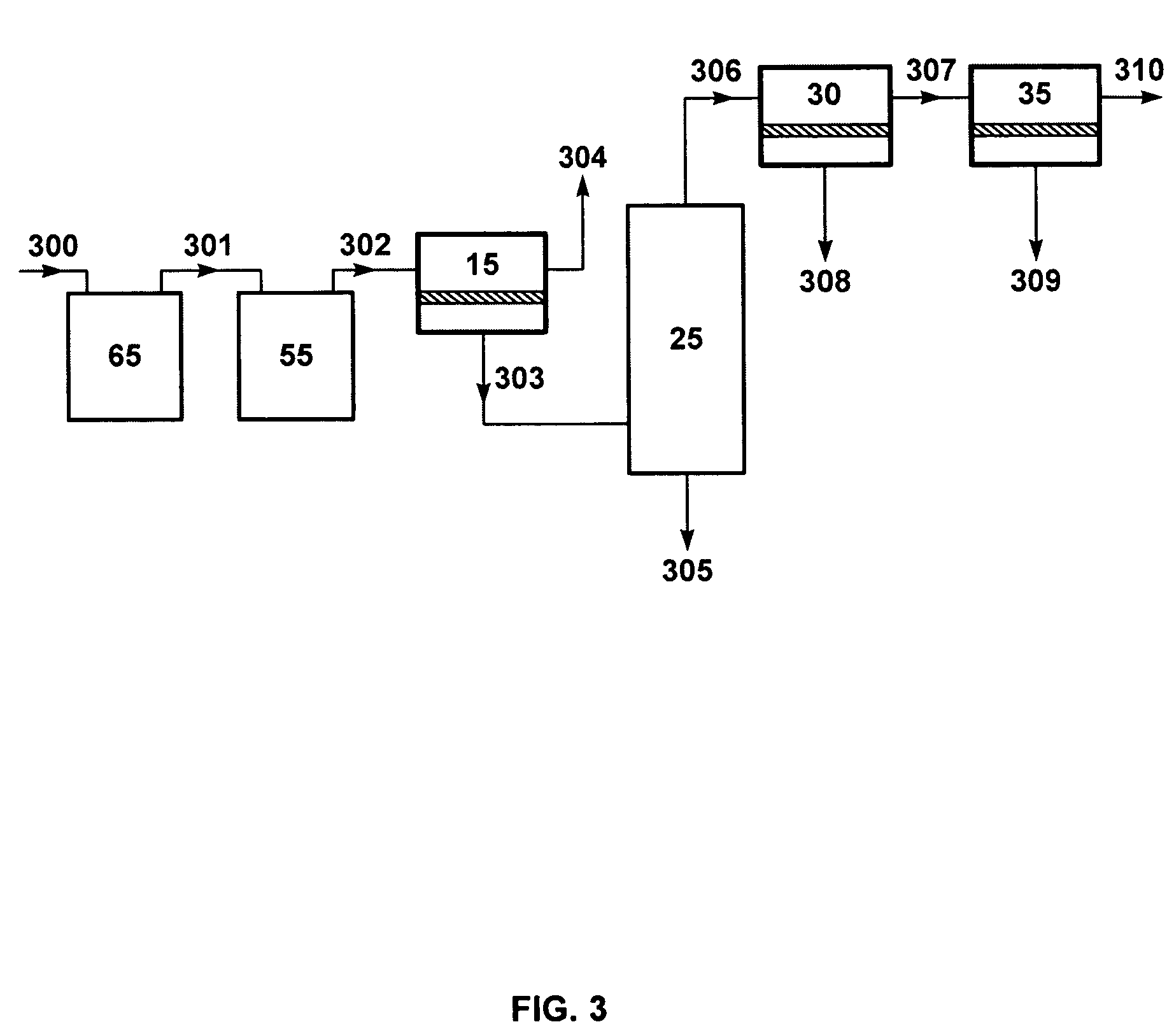

A process for producing and recovering light alcohols, particularly ethanol, alcohol mixtures containing ethanol, and ABE mixtures (alcohol mixtures containing acetone, butanol and ethanol), using a combination of steps including fermentation, first membrane separation, dephlegmation and dehydration by second membrane separation.

Owner:MEMBRANE TECH & RES

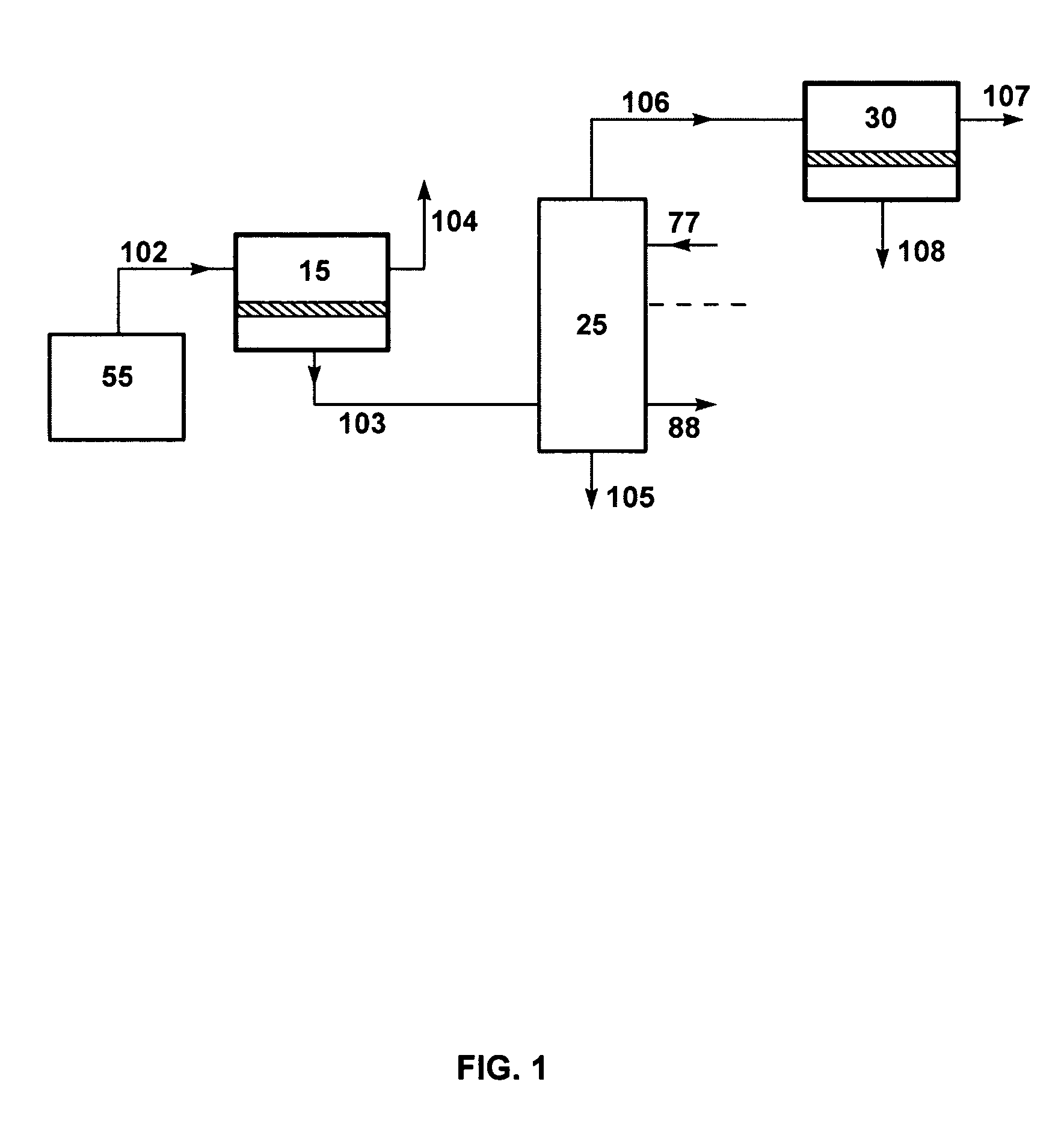

Process for continuous solvent production

InactiveUS20050089979A1High solventProducing strainBioreactor/fermenter combinationsBiological substance pretreatmentsMicrobial inoculationSolvent

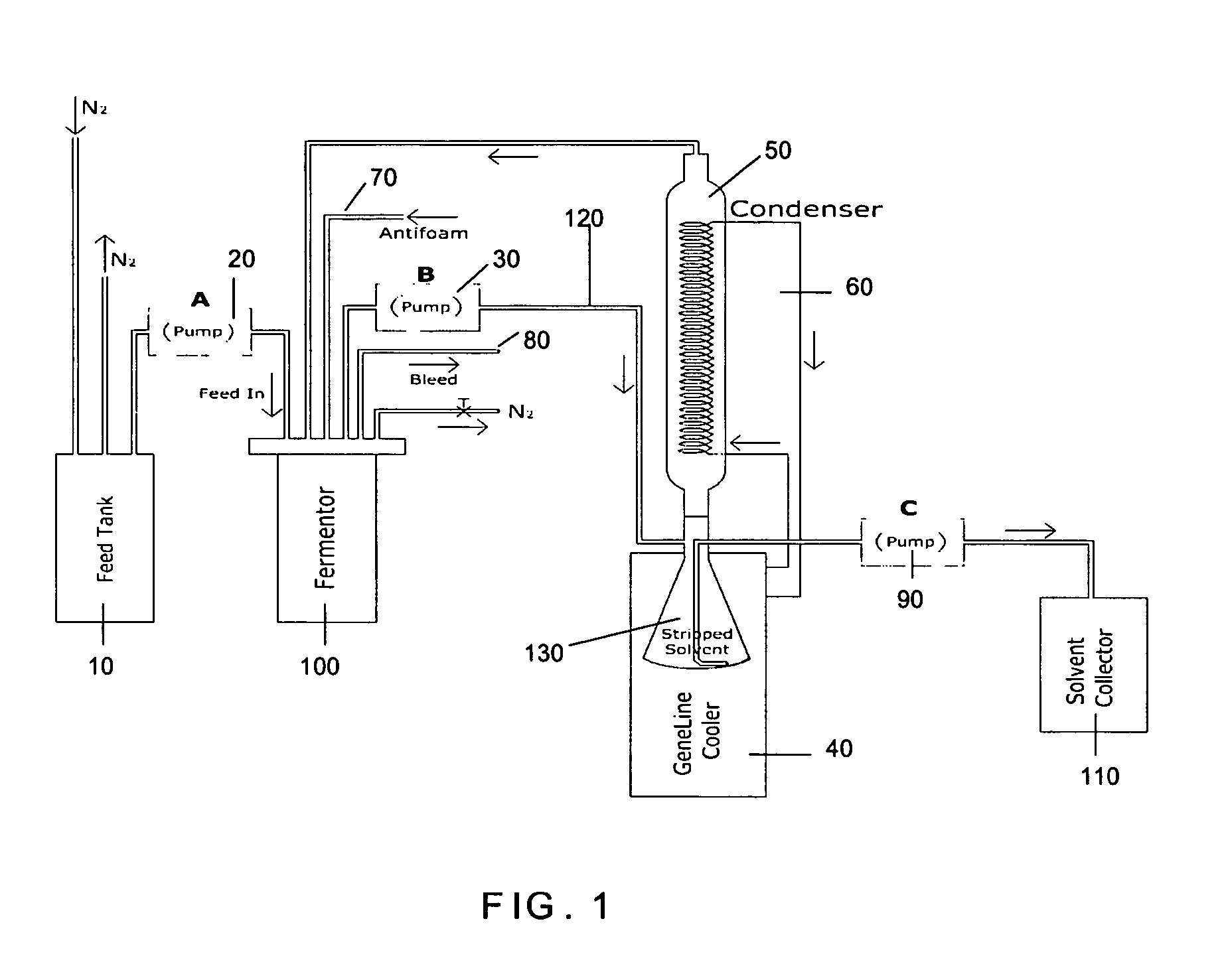

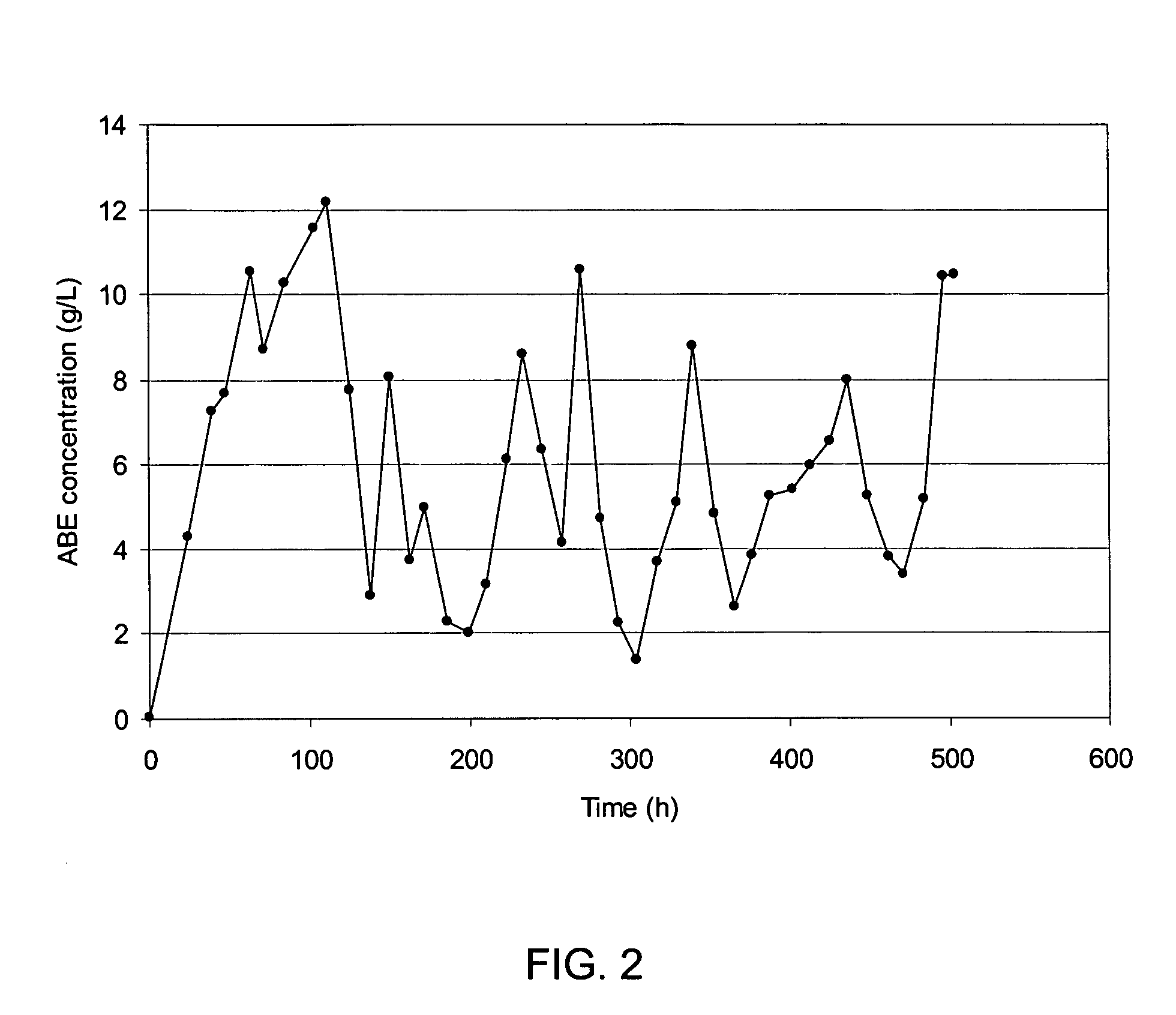

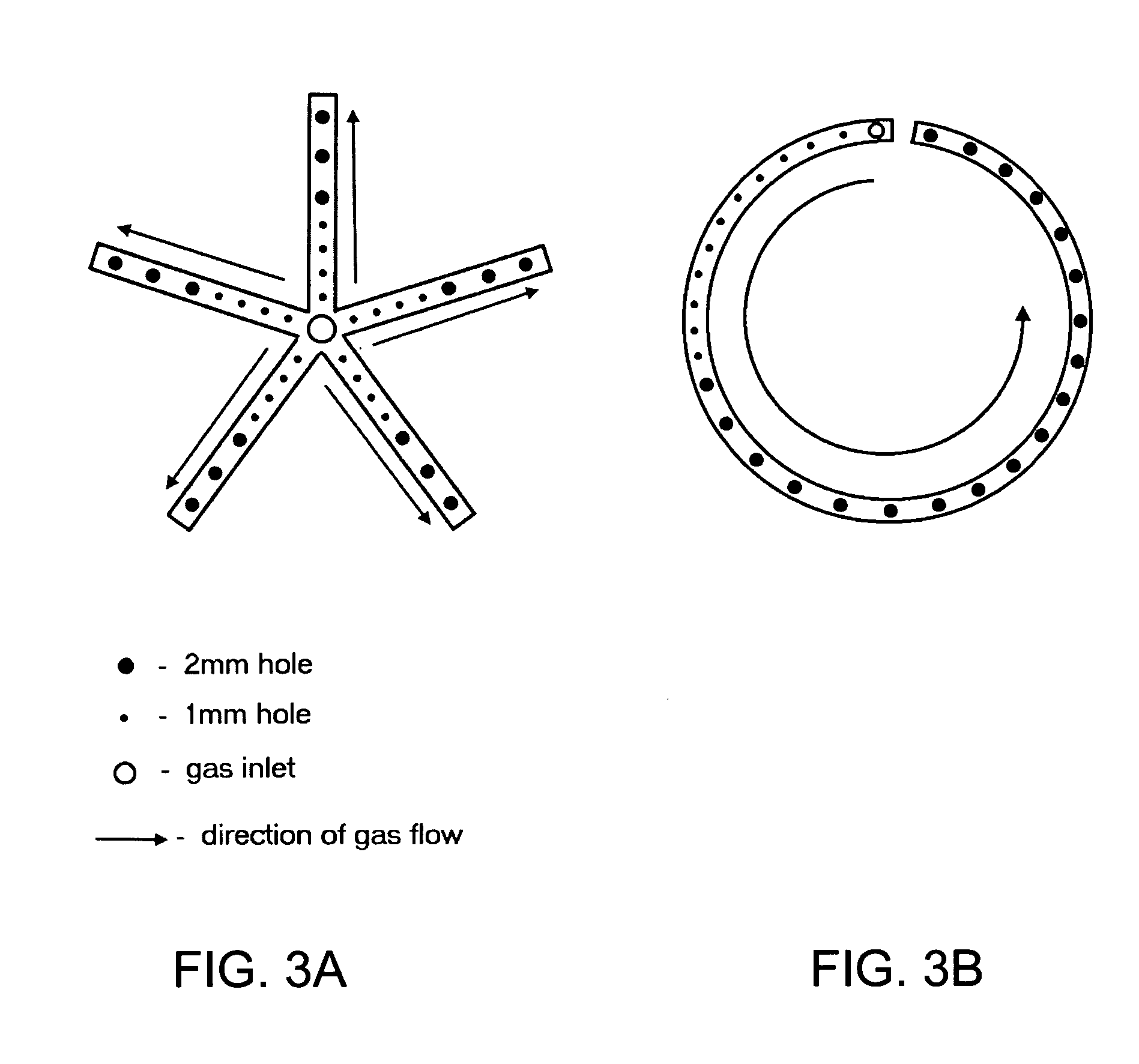

A continuous process for production of solvents, particularly acetone-butanol-ethanol (ABE) using fermentation of solventogenic microorganisms and gas stripping is provided. The solventogenic microorganisms are inoculated in a nutrient medium containing assimilable carbohydrates (substrate) and optional other additives. Control of the solventogenic microorganism concentration in the fermentor (cell concentration) and the assimilable carbohydrate concentration in the fermentor, along with removal of solvents formed results in a continuous process for production of solvents.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

Ethanol recovery process

ActiveUS7732173B2Reduce stressSimple equipmentMembranesFermented solutions distillation/rectificationAlcoholMedicinal chemistry

A process for producing and recovering light alcohols, particularly ethanol, alcohol mixtures containing ethanol, and ABE mixtures (alcohol mixtures containing acetone, butanol and ethanol), using a combination of steps including fermentation, first membrane separation, dephlegmation and dehydration by second membrane separation.

Owner:MEMBRANE TECH & RES

Film coating composition for whitening teeth

PCT No. PCT / CN97 / 00004 Sec. 371 Date Sep. 17, 1998 Sec. 102(e) Date Sep. 17, 1998 PCT Filed Jan. 20, 1997 PCT Pub. No. WO97 / 25968 PCT Pub. Date Jul. 24, 1997The invention relates to a tooth-whitening varnish composition, comprising 6-20% of carbamide peroxide, 2-9% of film forming agent and 77-88% of volatile organic solvent, based on the total weight of the composition. The volatile organic solvent is selected from ether, ethylacetate, ethyl alcohol, or acetone. The film forming agent is artificial or natural material selected from cellulose, polyvinyl, butyral, coumarone resin or shellac. The composition can rapidly form films on dry tooth surfaces, and a remarkable tooth-whitening effect can be obtained.

Owner:IVOCLAR VIVADENT INC

2-(3-cyano-4-isobuoxy phenyl)4-methyl-5-thiazole aminic acid crystal and preparation method thereof

The present invention discloses two crystal models and the preparation method of the anti-hyperuricemia drug 2-(3-ayano-4-isobuoxy phenyl)-4-methyl-5- thiazole acid. The preparation method of the crystal models commonly uses the low-toxicity ethanol, ethyl acetate or acetone as the solvent; the safety is relatively high. In addition, the hygroscopicity of the two crystal models is low in the high-humidity environment and the two crystal models are suitable for the steady pharmaceutical preparation.

Owner:SHANGHAI INST OF PHARMA IND CO LTD +1

Hydrophobic self-cleaning coating composition

InactiveUS20080250978A1Efficient use ofSolve the lack of resistanceSemiconductor/solid-state device manufacturingMixingWater basedMineral spirit

The present invention provides a water based, low VOC super hydrophobic coating composition that can be used to make wet and dry dirt repellent surfaces to keep the surfaces clean for a reasonable period of time. The coating utilizes hydrophobic nanoparticles dispersed in water. This treatment produces a virtually transparent coating releasing very little or no VOC compounds whereas previous coatings of comparable hydrophobicity release up to 99 percent VOC compounds. The coating can be applied by a simple, single application method and the super hydrophobic property can be achieved by drying at room temperature for 5 to 10 minutes. A preferred coating can be easily removed and renewed when desired. The aqueous hydrophobic self cleaning coating composition that can be applied by conventional methods such as by spraying the composition onto a surface creating a wet and dry dirt repellent coating on the surface. The hydrophobic self cleaning coatings are used on exterior automotive and boat surfaces, and in many other applications, to produce a self cleaning surface, reduce adherence of dirt and contaminants to a treated surface, and reduce drag in some applications providing an energy savings. The coating solves the problem of poor resistance to UV light, opaque appearance, and / or abrasion found in previous coatings of similar nature. A preferred coating has good resistance to UV light and some resistance to abrasion. Clear, nearly transparent and translucent coatings are produced as compared to conventional coatings of comparable hydrophobicity which are typically white or opaque. The coating can be applied by a single and easy spraying method and the super hydrophobic property can be achieved by drying the film by evaporation of the solvent wetting solution and water based carrier at ambient temperature for 5 to 10 minutes. Embodiments of the hydrophobic self-cleaning coating composition can be produced resulting in a clear coating or in some cases a translucent dirt repellant film or coating on painted material, plastic, metal, glass, ceramic, fiberglass or a polymer substrate. The coating typically utilizes hydrophobic nanoparticles of fumed silica and / or titania wetted by a hydrophilic solvent such as acetone for no VOC applications, or with mineral spirits, alcohol or a light distillate if VOC are not a consideration, together with a selected surfactant typically having an HLB value in a range of from 9 to 13.At least one preferred coating composition comprising an effective amount of a treated fumed silica wetted with a solvent and dispersed in water, upon drying, resulted in a coated surface providing a contact angle of at least 165 degrees and a surface energy below 12 dynes / centimeter as compared to water having a contact angle of from 65 to 80 degrees on a noncoated surface. The composition imparts a degree of hydrophobicity to a surface so that the surface will have a tilt angle of sliding of less than 2 degrees as compared to water on a noncoated surface having a tilt angle of sliding of 90 degrees or higher. The coating composition is removed by washing with a detergent or applying pressure to the coating wiping same from the treated surface. Exposure to water in the form of rain or snow does not remove the coating composition.

Owner:ASHLAND LICENSING & INTPROP LLC

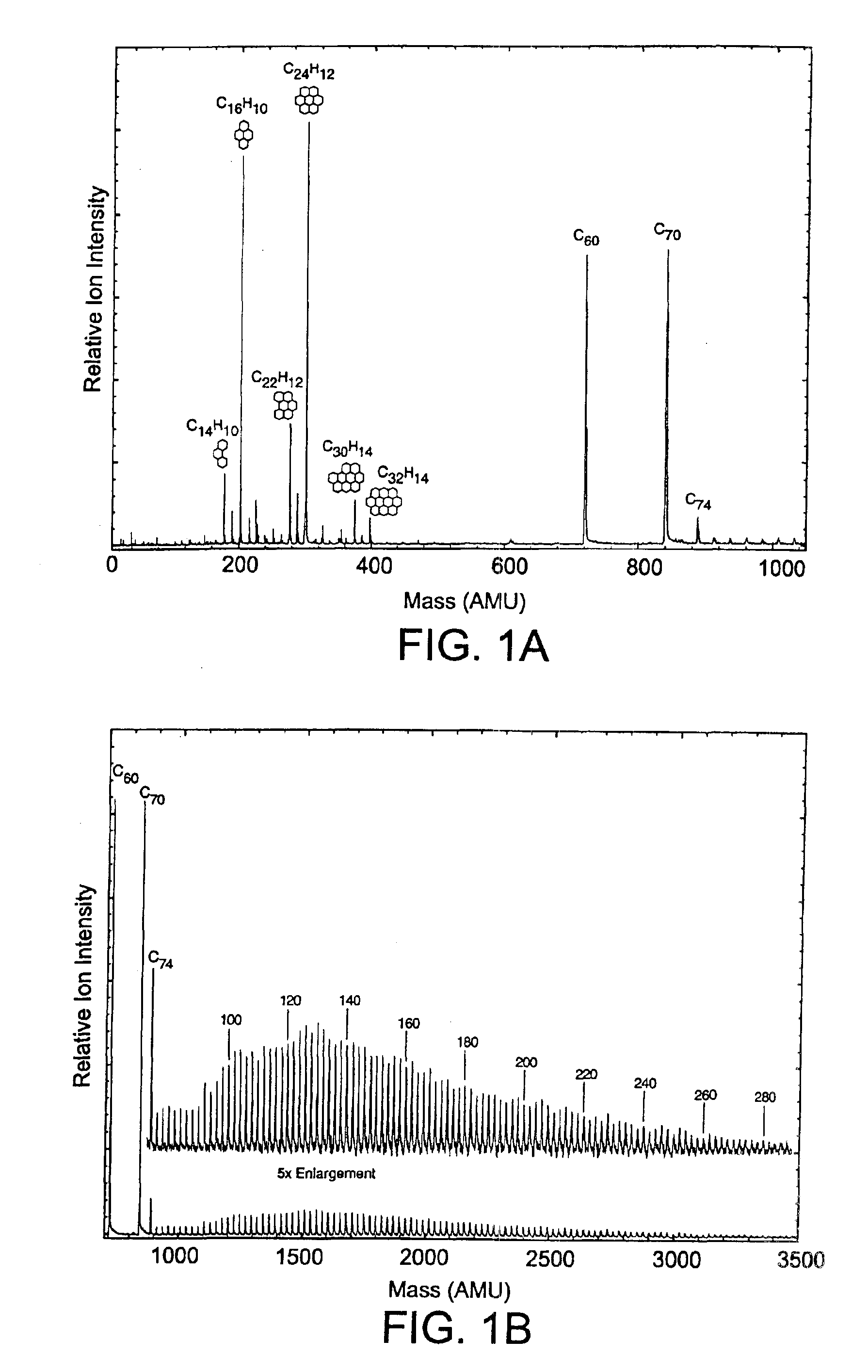

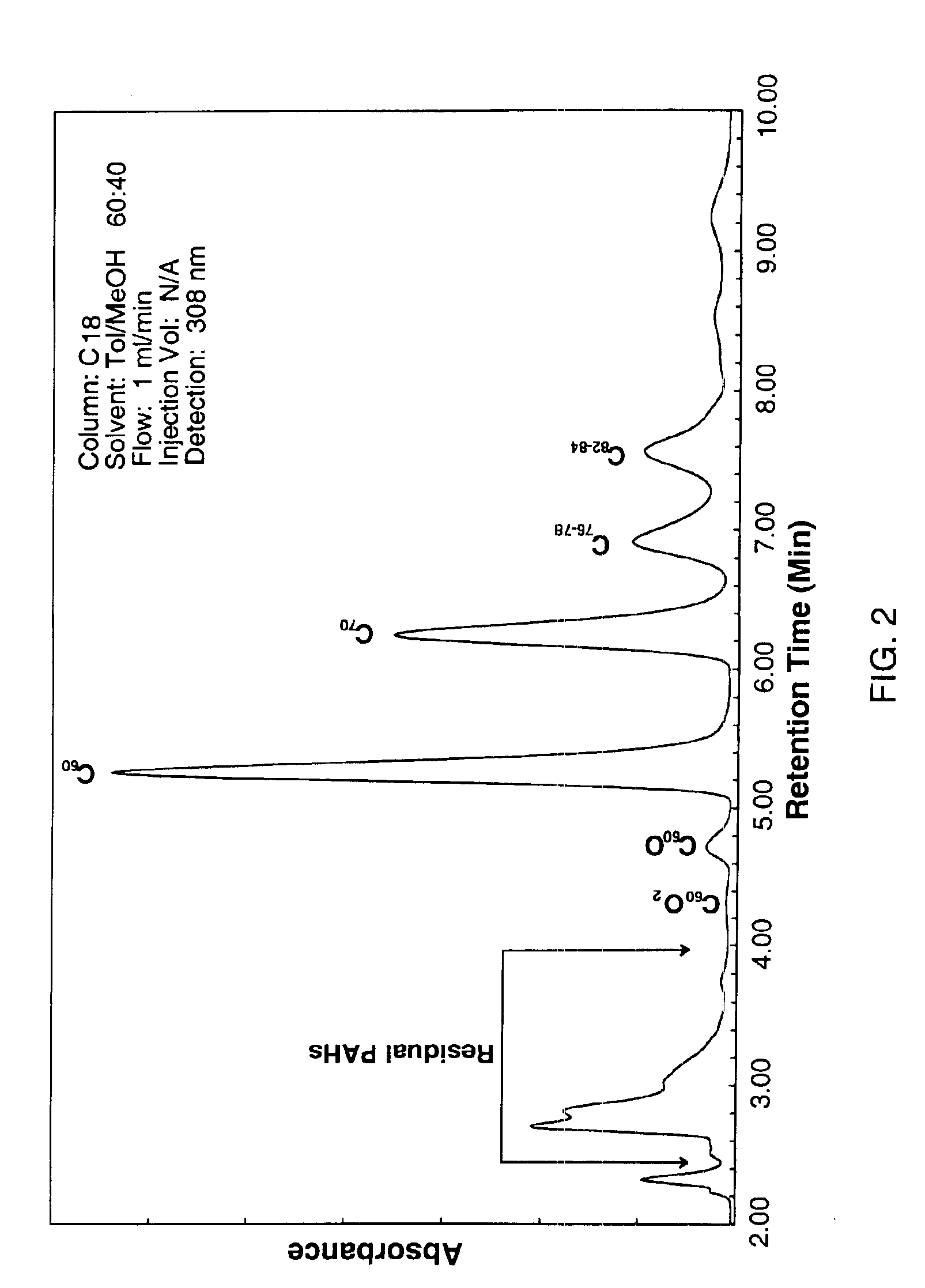

Process for the removal of impurities from combustion fullerenes

InactiveUS6923915B2Without incurring undo costEfficient removalMaterial nanotechnologyFullerenesO-XylenePurification methods

The invention generally relates to purification of carbon nanomaterials, particularly fullerenes, by removal of PAHs and other hydrocarbon impurities. The inventive process involves extracting a sample containing carbon nanomaterials with a solvent in which the PAHs are substantially soluble but in which the carbon nanomaterials are not substantially soluble. The sample can be repeatedly or continuously extracted with one or more solvents to remove a greater amount of impurities. Preferred solvents include ethanol, diethyl ether, and acetone. The invention also provides a process for efficiently separating solvent extractable fullerenes from samples containing fullerenes and PAHs wherein the sample is extracted with a solvent in which both fullerenes and PAHs are substantially soluble and the sample extract then undergoes selective extraction to remove PAHs. Suitable solvents in which both fullerenes and PAHs are soluble include o-xylene, toluene, and o-dichlorobenzene. The purification process is capable of treating quantities of combustion soot in excess of one kilogram and can produce fullerenes or fullerenic soot of suitable purity for many applications.

Owner:FRONTIER CARBON CORP

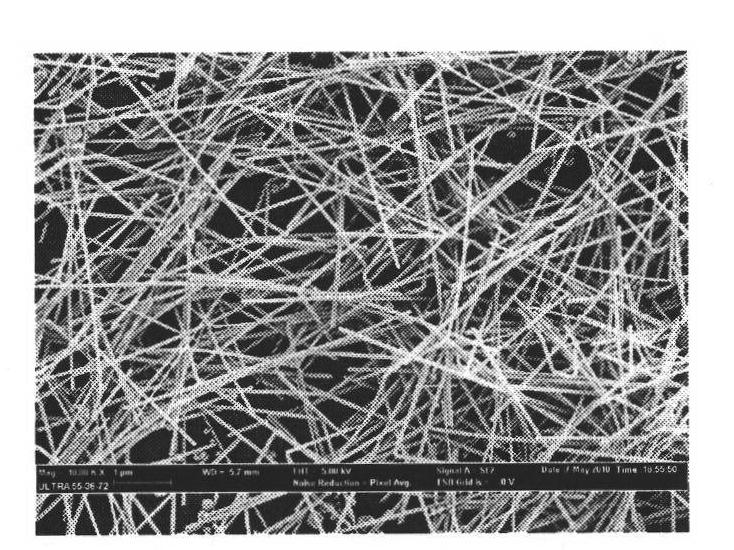

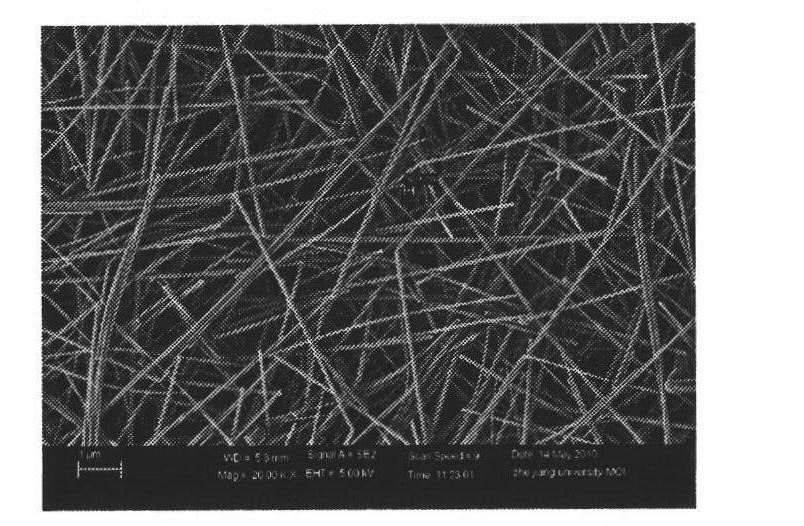

Quick and efficient synthesis method for silver nanowires

InactiveCN101934377AImprove production efficiencyReduce reaction preparation timeHigh concentrationSynthesis methods

The invention discloses a quick and efficient synthesis method for silver nanowires. The method comprises the following steps of: 1) introducing inert gas into a reactor, adding 2 volume parts of glycol into the reactor, and stirring, heating, condensing and refluxing the glycol; quickly adding 1 volume part of glycol solution of silver nitrate at molar concentration of between 0.1 and 0.5m into the reactor; slowly dropwise adding 1 to 2 volume parts of PVP at molar concentration of between 0.15 and 0.75m and 4 to 32 mu m of glycol solution of MnCl2 at the same time; and reacting and cooling the mixture to the room temperature to obtain reaction mother liquor of the silver nanowires; and 2) transferring the reaction mother liquor of the silver nanowires into a centrifugal tube; adding acetone into the centrifugal tube and performing centrifugal separation to remove supernatant and retain precipitate; adding de-ionized water or ethanol into the centrifugal tube and performing centrifugal separation to remove the supernatant and retain precipitate, and repeating the operation for 1 to 3 times; and extracting and dispersing the precipitate with ethanol to obtain the silver nanowires. The method shortens the reaction time and also has high selectivity for the synthesis of the silver nanowires under conditions of high concentration.

Owner:ZHEJIANG UNIV

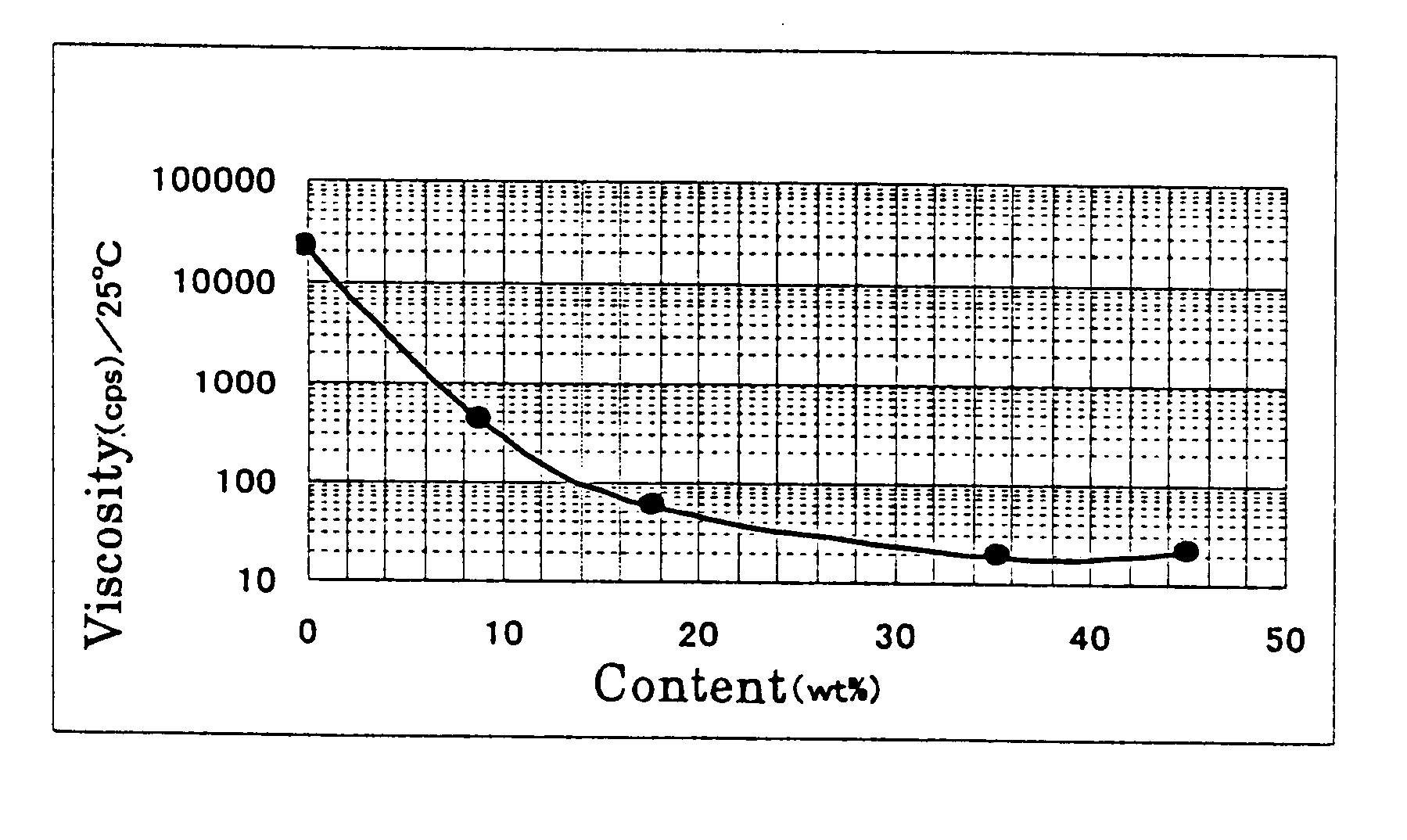

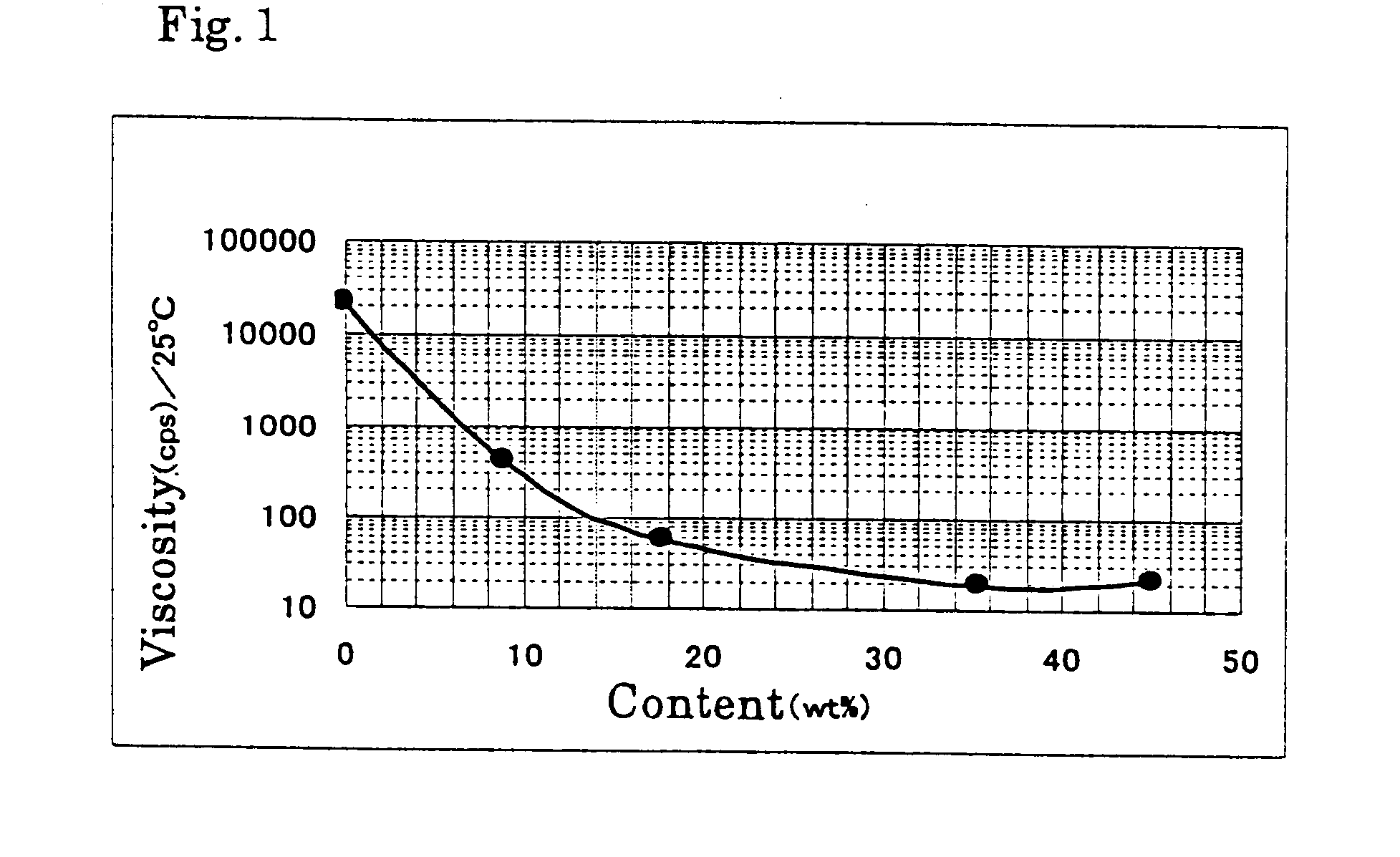

Method for preparing N-long chain acyl neutral amino acid

InactiveUS6703517B2Efficient conductionLow viscosityCosmetic preparationsHair cosmeticsNeutral Amino AcidsAlanine

A method for preparing a highly purified N-long chain acyl neutral amino acid for use of a detergent and the like in a simple and convenient manner and in a high yield by reacting a neutral amino acid such as glycine, gamma-aminobutyric acid, and alanine, with a saturated or unsaturated fatty acid halide having 8 to 22 carbon atoms, wherein the reaction is performed in a mixture of water and one or more kinds of hydrophilic organic solvents selected from the group consisting of acetone, acetonitrile, a secondary alcohol having 3 or 4 carbon atoms, and a tertiary alcohol having 4 carbon atoms such as isopropanol, sec-butanol, and tert-butanol in the presence of a base.

Owner:AJINOMOTO CO INC

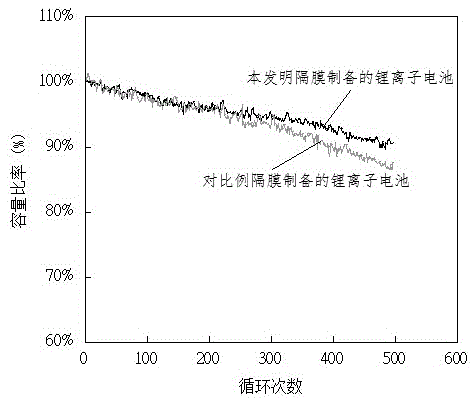

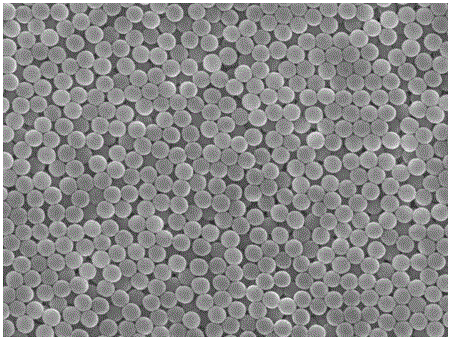

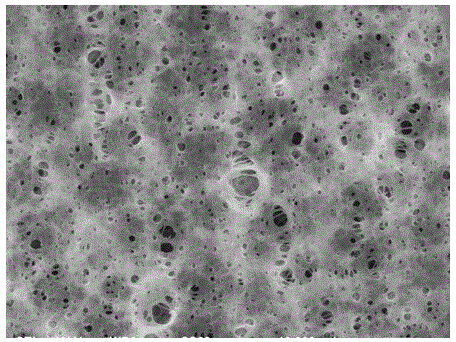

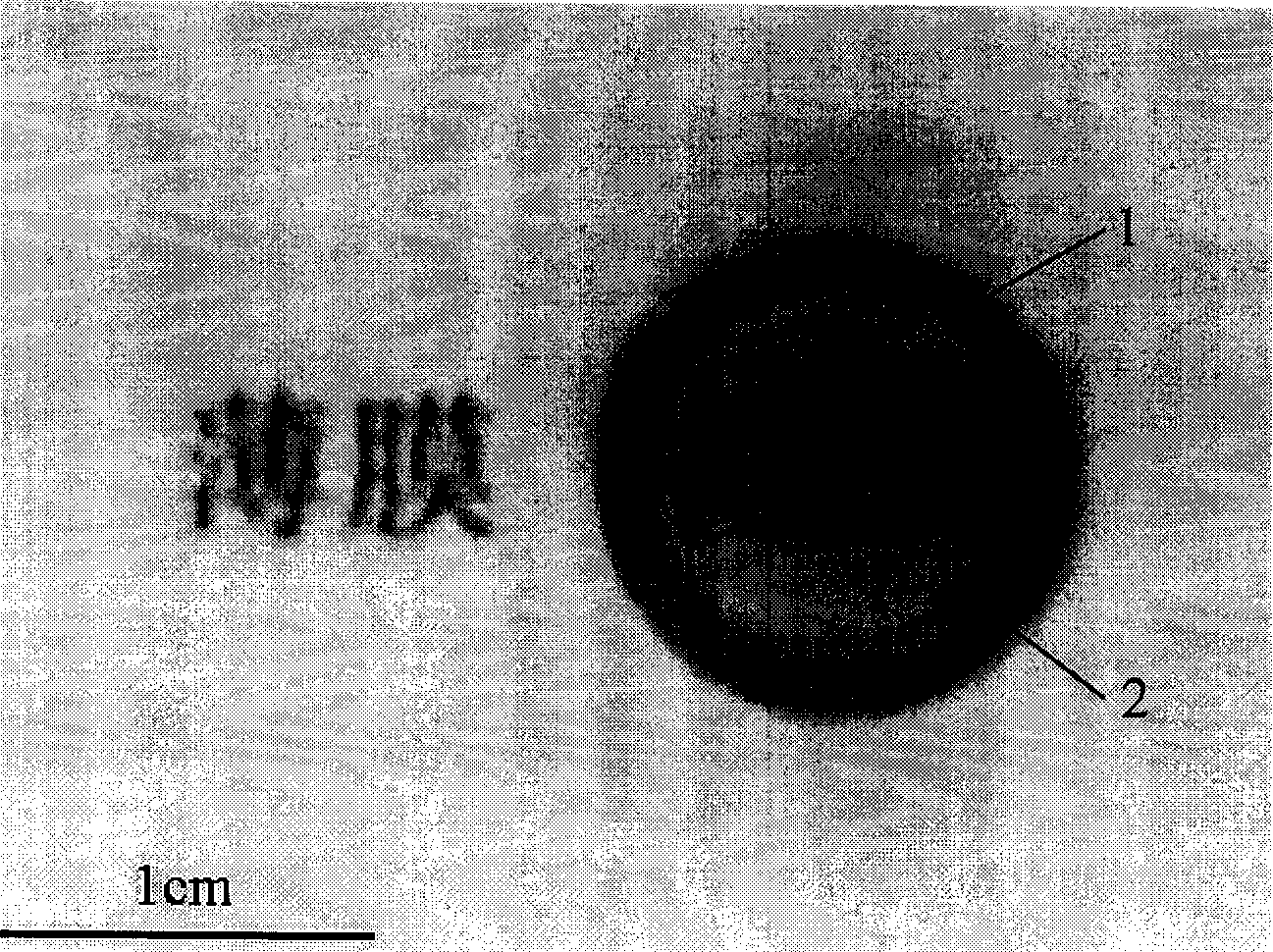

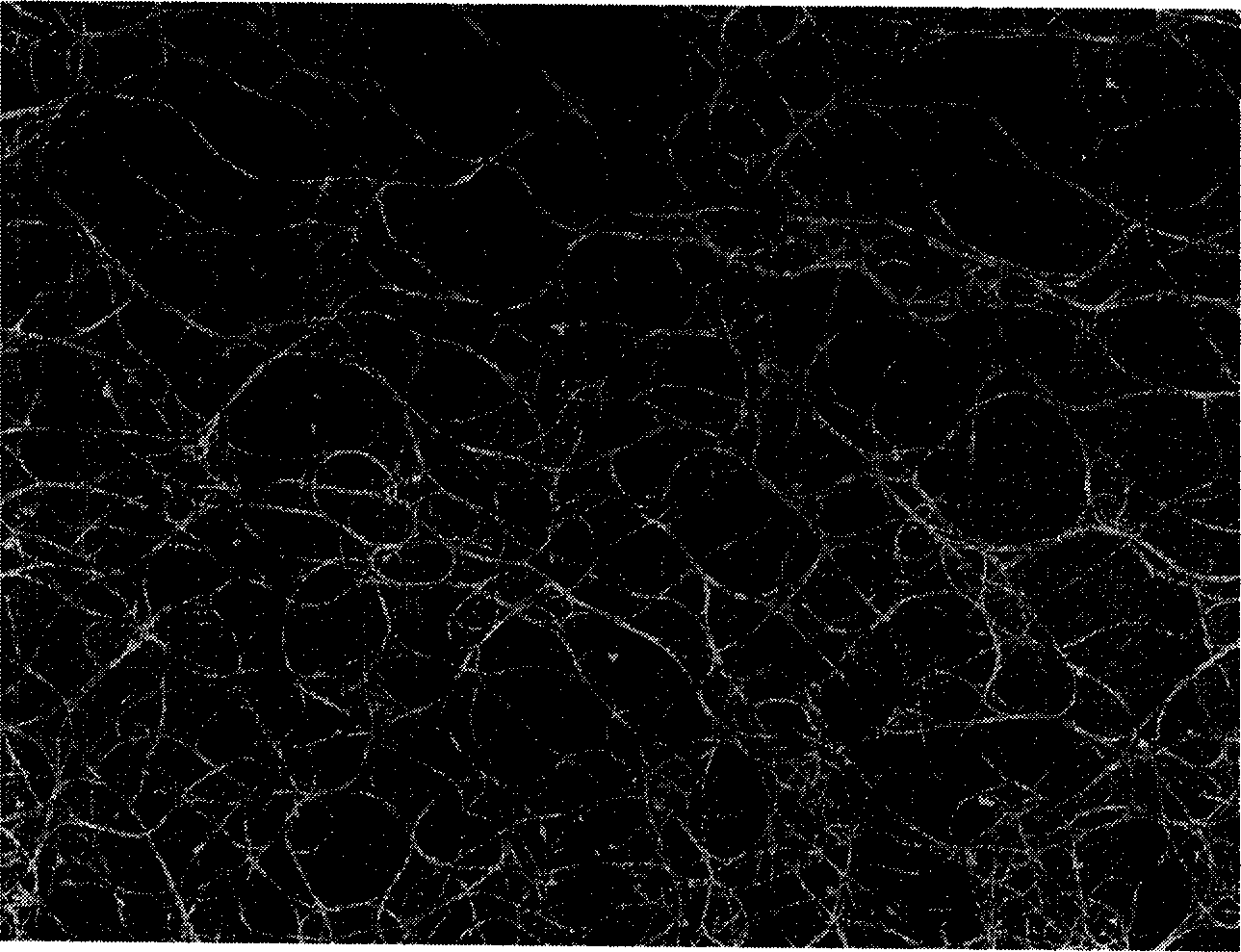

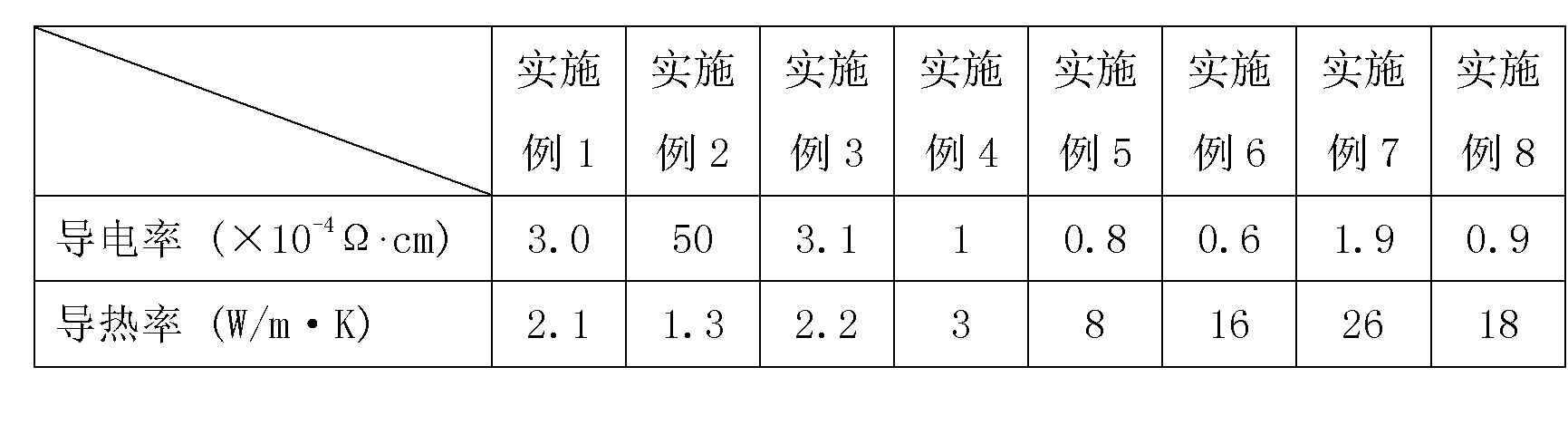

PVDF-coated lithium-ion battery separator and preparation method thereof

The invention provides a PVDF-coated lithium-ion battery separator and a preparation method thereof. The PVDF-coated lithium-ion battery separator comprises a base film and a coating, wherein the coating coats a single side or double sides of the base film; the coating is obtained by coating and drying slurry; and the coating is 0.1-0.5 micron in thickness and contains evenly arranged PVDF spherical particles. According to the PVDF-coated lithium-ion battery separator, a traditional technology that an existing PVDF-coated lithium-ion battery separator takes oil substances of acetone and the like as solvents is abandoned. Water is adopted as the solvent of a PVDF material; and no a thickening agent is added, so that the low-viscosity water-based PVDF coating slurry is obtained; an ultra-thin coating of which the PVDF particles are regularly arranged and which is relatively loose is obtained after the slurry is coated; the ultra-thin coating improves the hardness of a pole piece and the effective utilization space of the battery when effectively bonded to the lithium-ion battery separator and the pole piece; and the ventilation loss caused by the thickness of the coating is reduced.

Owner:CANGZHOU MINGZHU SEPARATOR TECH CO LTD

Large-area ultra-thin carbon nanotube film and its preparation process

The large-area untrathin nano carbon tube film with well feature in microcosmic level comprises nano carbon tubes with centimeter-level length and more then 90wt% purity. Wherein, the least thickness of single-layer film can achieve 20nm with near transparent color and more then 10cm2 film area; there are multiple functional groups on tube surface. It also discloses the opposite preparation technique: with the macroscopic body of nano carbon tube, oxidating the macroscopic body in air; then, dipping into hydroperoxide; adding strong acid to poach till the liquid shows neutrality; finally, adding alcohol or acetone into the liquid to float the tube and form the film.

Owner:TSINGHUA UNIV +1

Asymmetric Gas Separation Membranes with Superior Capabilities for Gas Separation

InactiveUS20080143014A1Excellent permeation fluxHigh selectivityMembranesSemi-permeable membranesCellulose diacetatePolymer science

This invention relates to a method of making flat sheet asymmetric membranes, including cellulose diacetate / cellulose triacetate blended membranes, polyimide membranes, and polyimide / polyethersulfone blended membranes by formulating the polymer or the blended polymers dopes in a dual solvent mixture containing 1,3 dioxolane and a second solvent, such as N,N′-methylpyrrolidinone (NMP). The dopes are tailored to be closed to the point of phase separation with or without suitable non-solvent additives such as methanol, acetone, decane or a mixture of these non-solvents. The flat sheet asymmetric membranes are cast by the phase inversion processes using water as the coagulation bath and annealing bath. The dried membranes are coated with UV curable silicone rubber. The resulting asymmetric membranes exhibit excellent permeability and selectivity compared to the intrinsic dense film performances.

Owner:UOP LLC

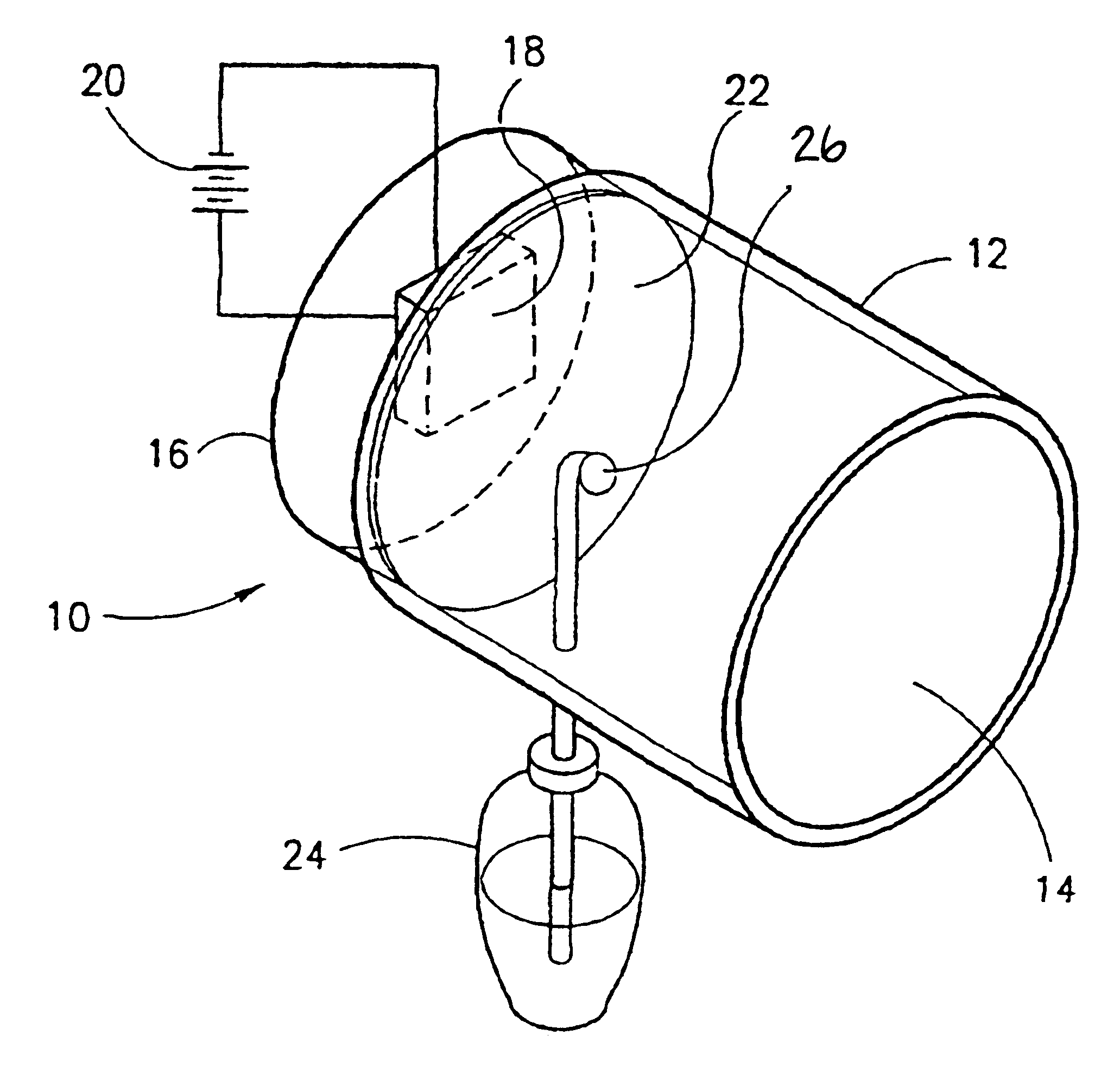

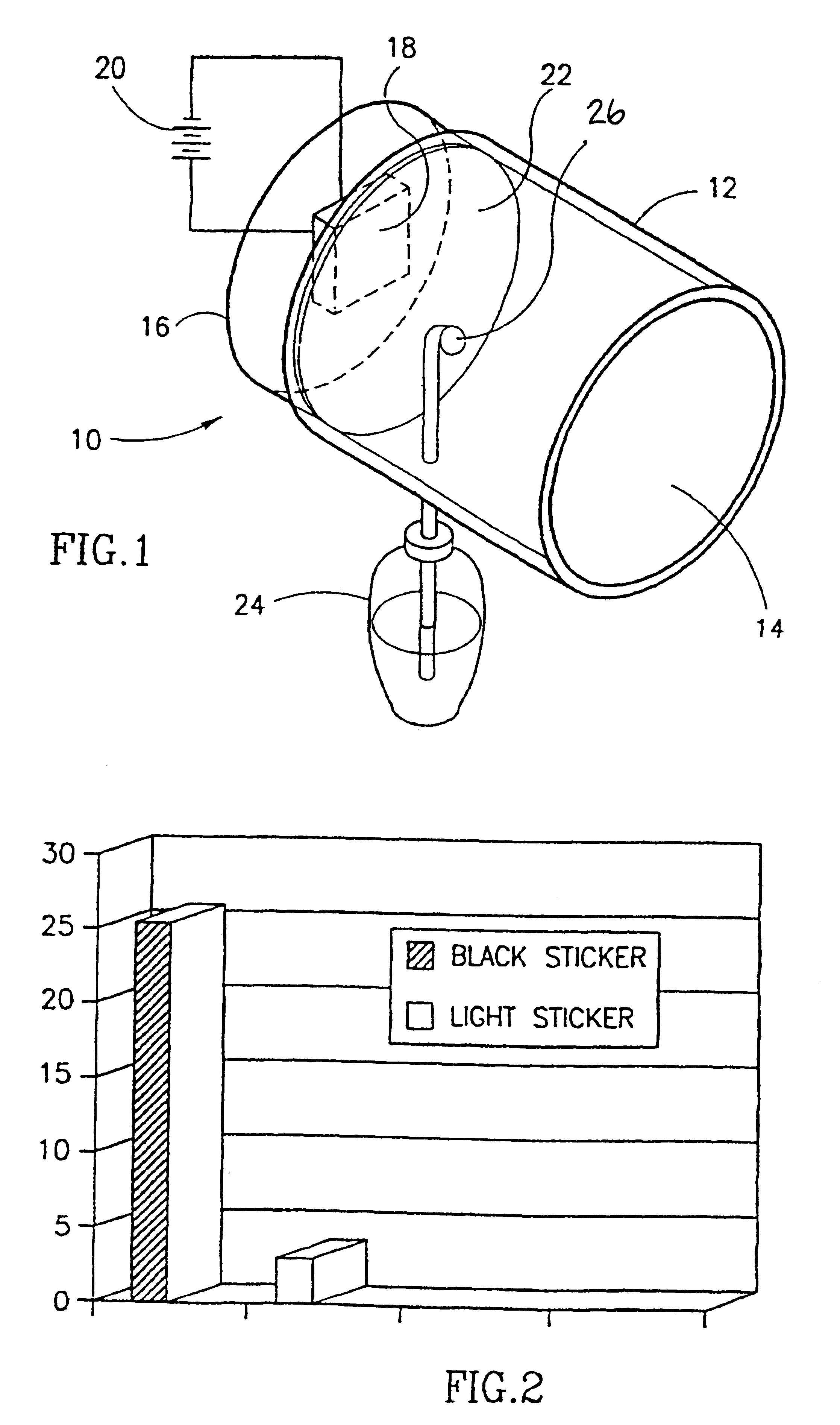

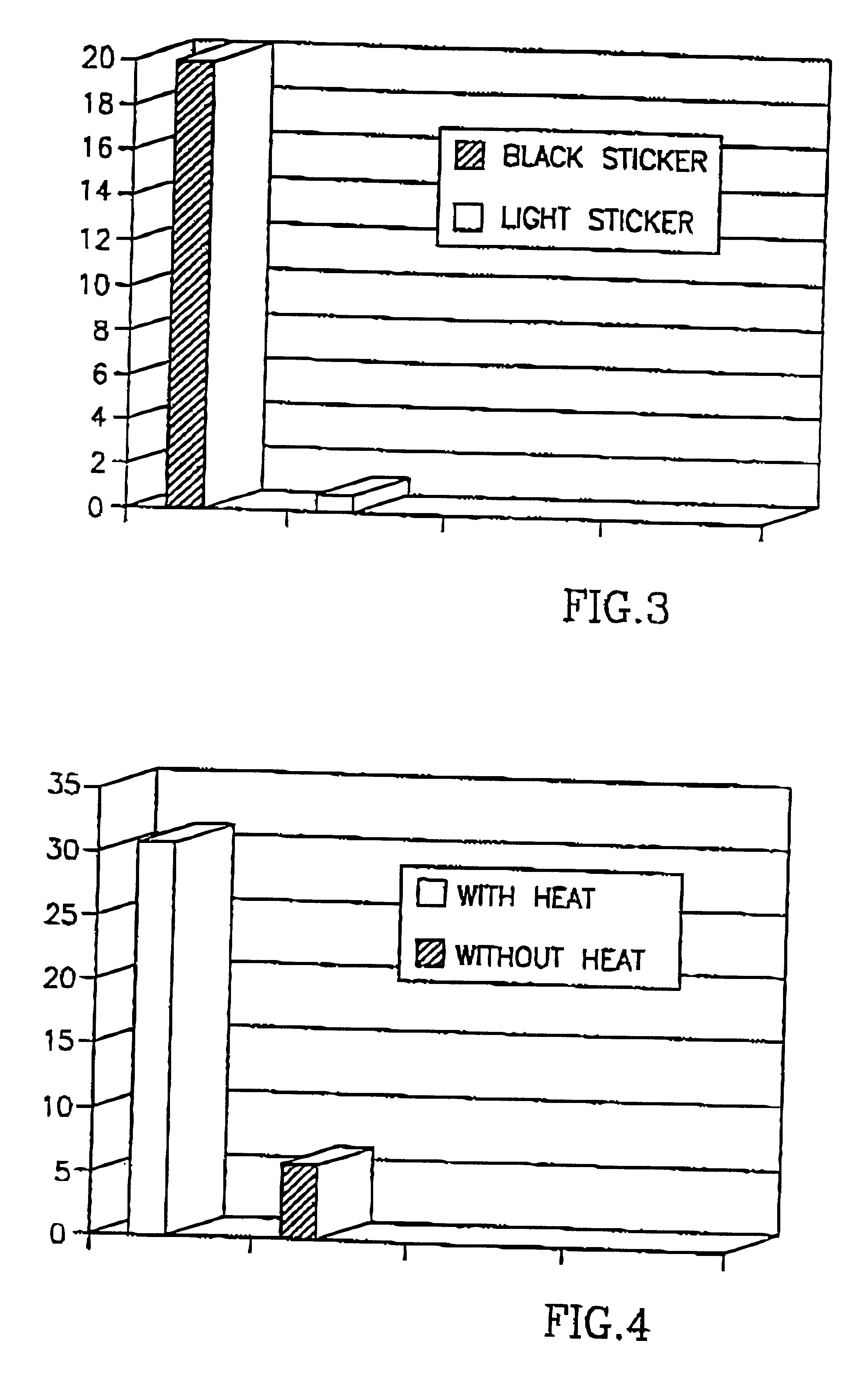

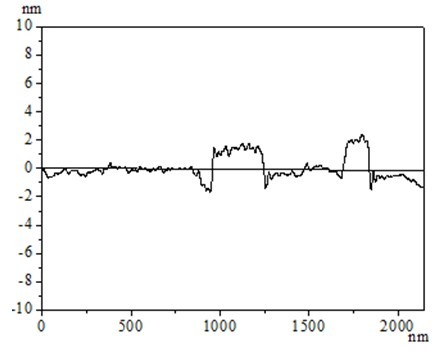

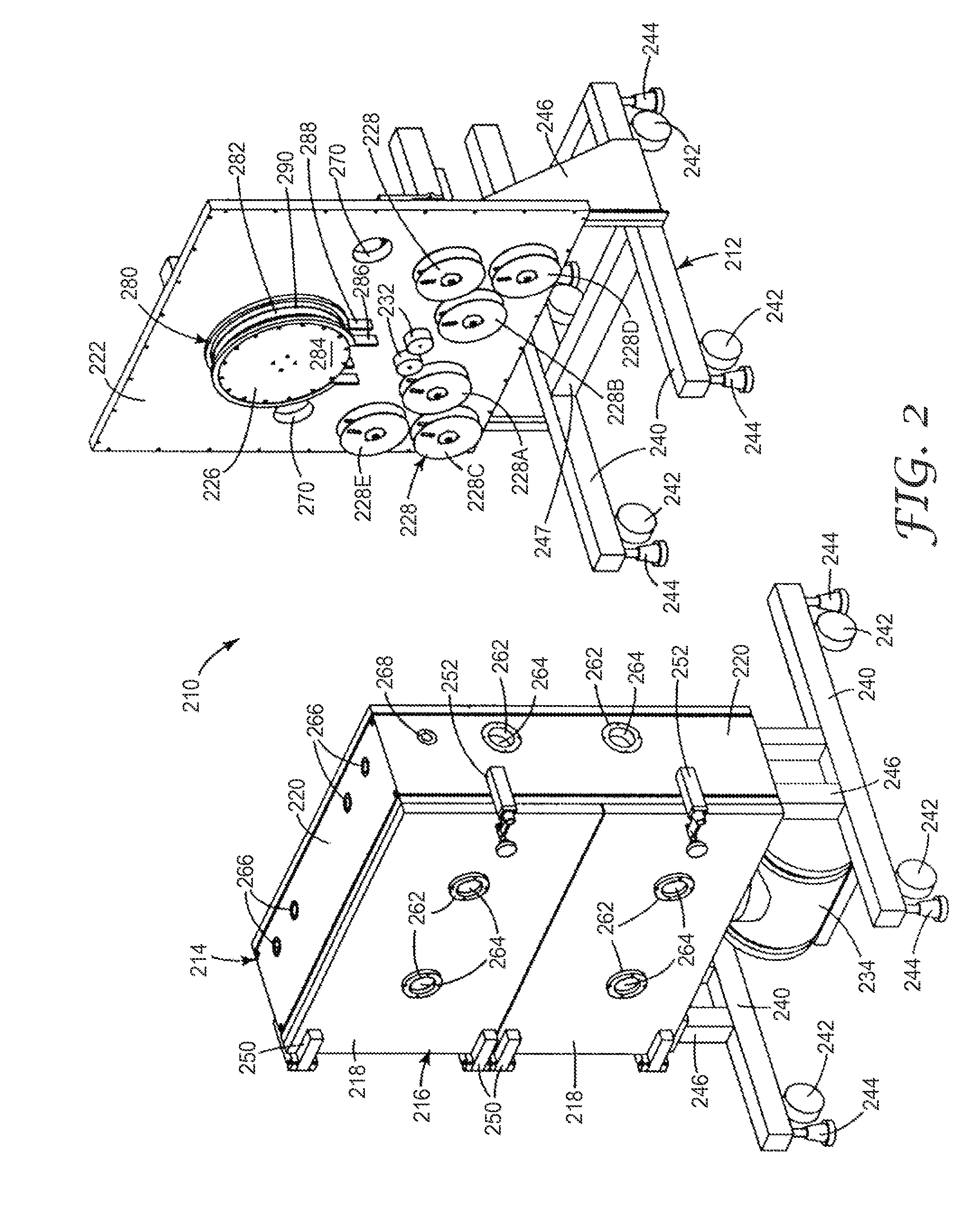

Insect trap

InactiveUS6516559B1Insect catchers and killersAgainst vector-borne diseasesMicroorganismCelsius Degree

A method and a device (10) for trapping insects which feed on mammalian blood, such as mosquitoes, utilize in combination a chemical attractant (24) and a physical attractant consisting of a dark panel (22), heated to e.g., 30 to 45 degrees Celsius. The chemical attractant may include carbon dioxide, generated for example by action of microorganisms on a fermentable substrate in aqueous medium, or it may be selected from fermenting yeast, yeast extract, peptone, acetone, lactic acid and carbon dioxide. The insects may be killed by adhesive applied onto the panel (22).

Owner:A TRAP

Preparation method of dispersible silane functionalized graphene

The invention provides a preparation method of dispersible silane functionalized graphene. The method comprises the steps of: conducting ultrasonic dispersion to graphene oxide in absolute ethyl alcohol so as to form a uniform graphene oxide dispersion solution, then adjusting the pH value to 3-4, or under the protection of an inert atmosphere, adding silane into the dispersing solution for modification, with silane and graphene oxide in a mass ratio of 0.1:1-5:1, continuing the reaction for 12h-48h at a temperature ranging from normal temperature to 78DEG C, carrying out centrifugation, then adding hydrazine hydrate to the obtained solid, performing heating reduction, and filtering the reaction solution, then washing and drying the filter cake, thus obtaining dispersible silane functionalized grapheme. The method of the invention is simple and practicable, and the obtained silane functionalized grapheme has good dispersibility in solvents like absolute ethyl alcohol, acetone, toluene, ethyl acetate, butyl acetate, and tetrahydrofuran (THF), etc.

Owner:SOUTH CHINA UNIV OF TECH

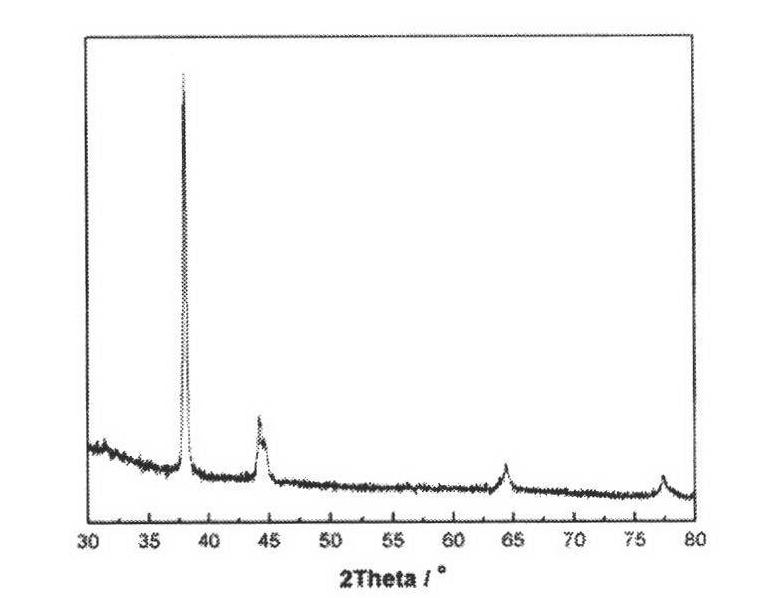

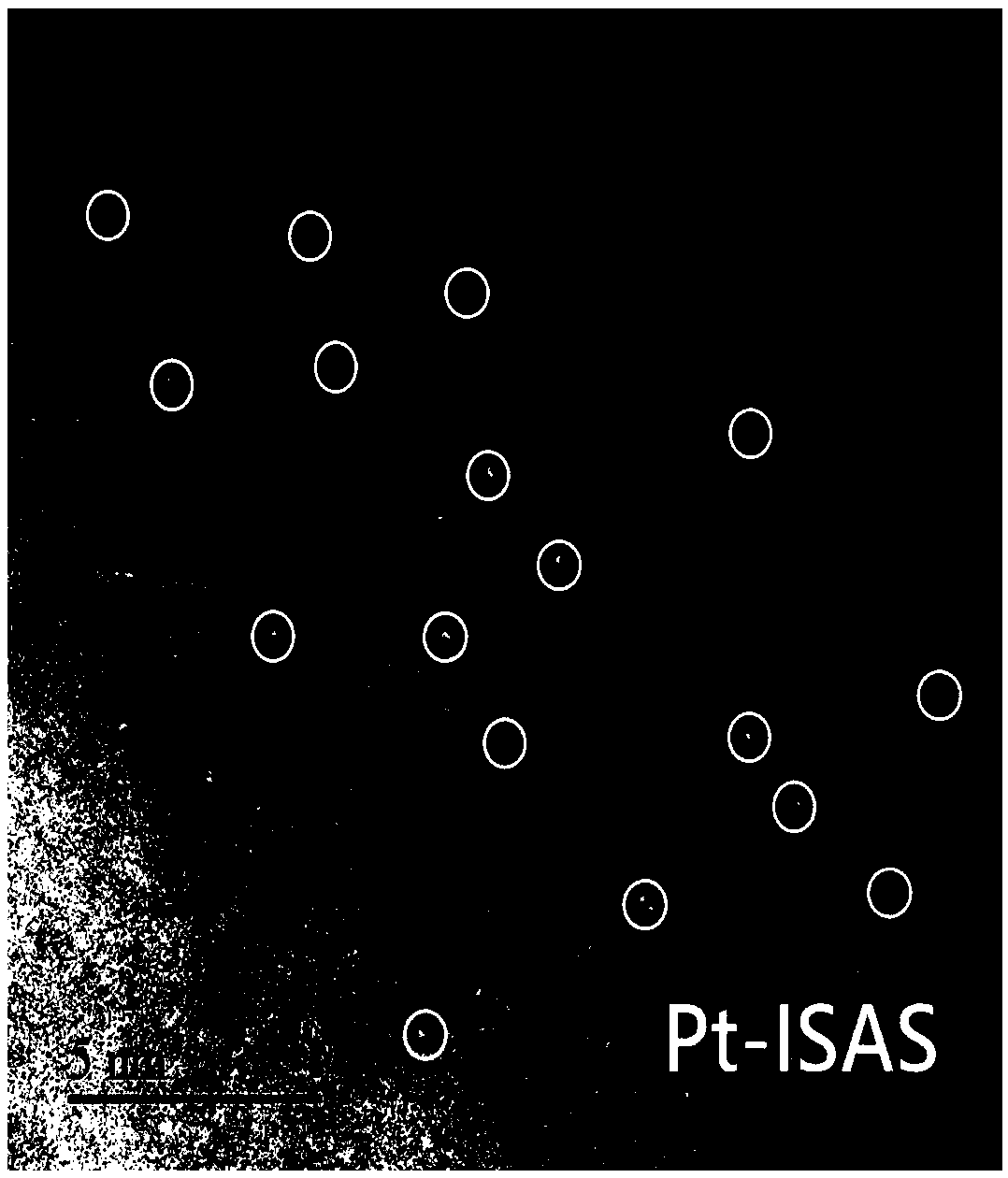

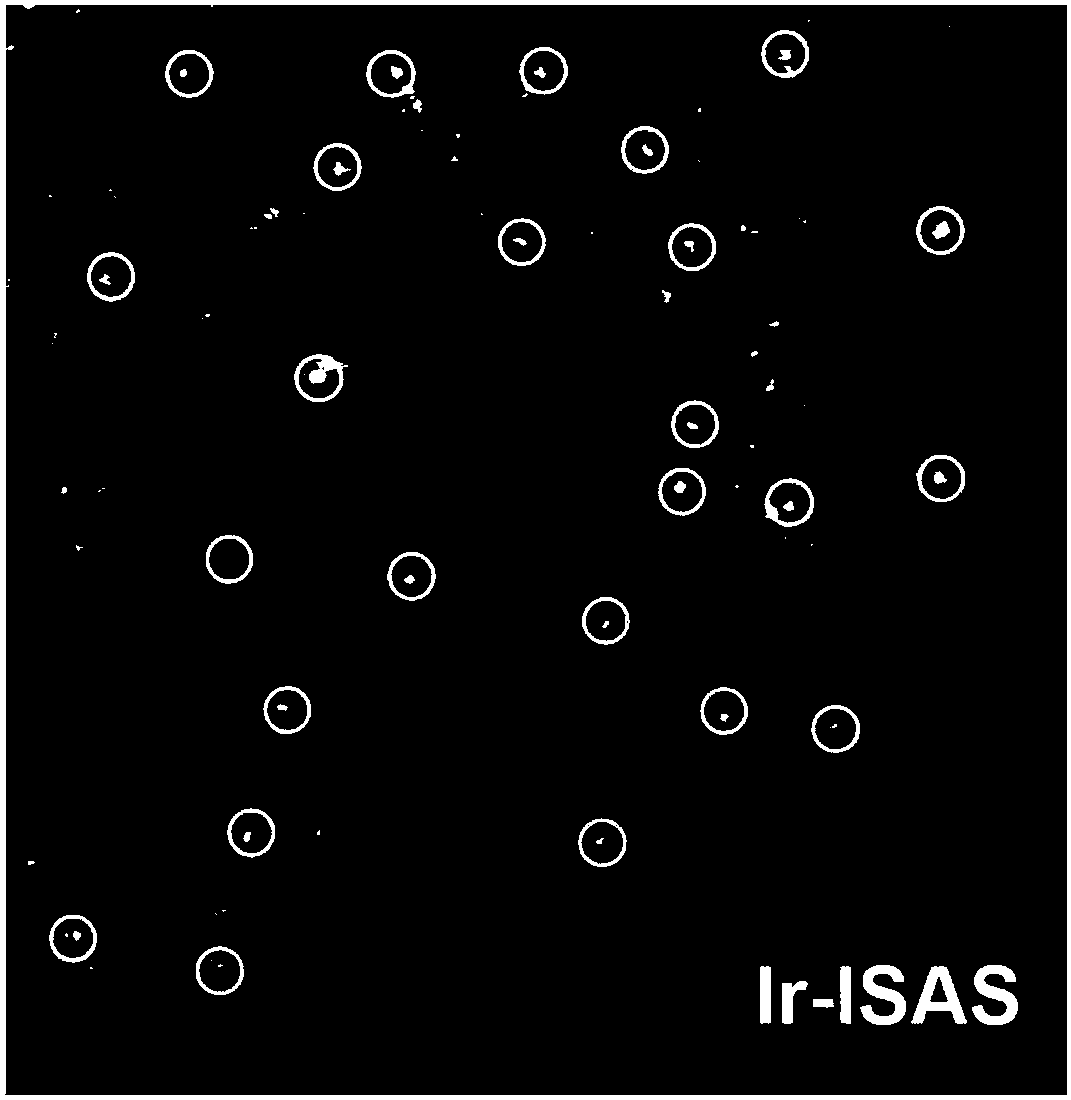

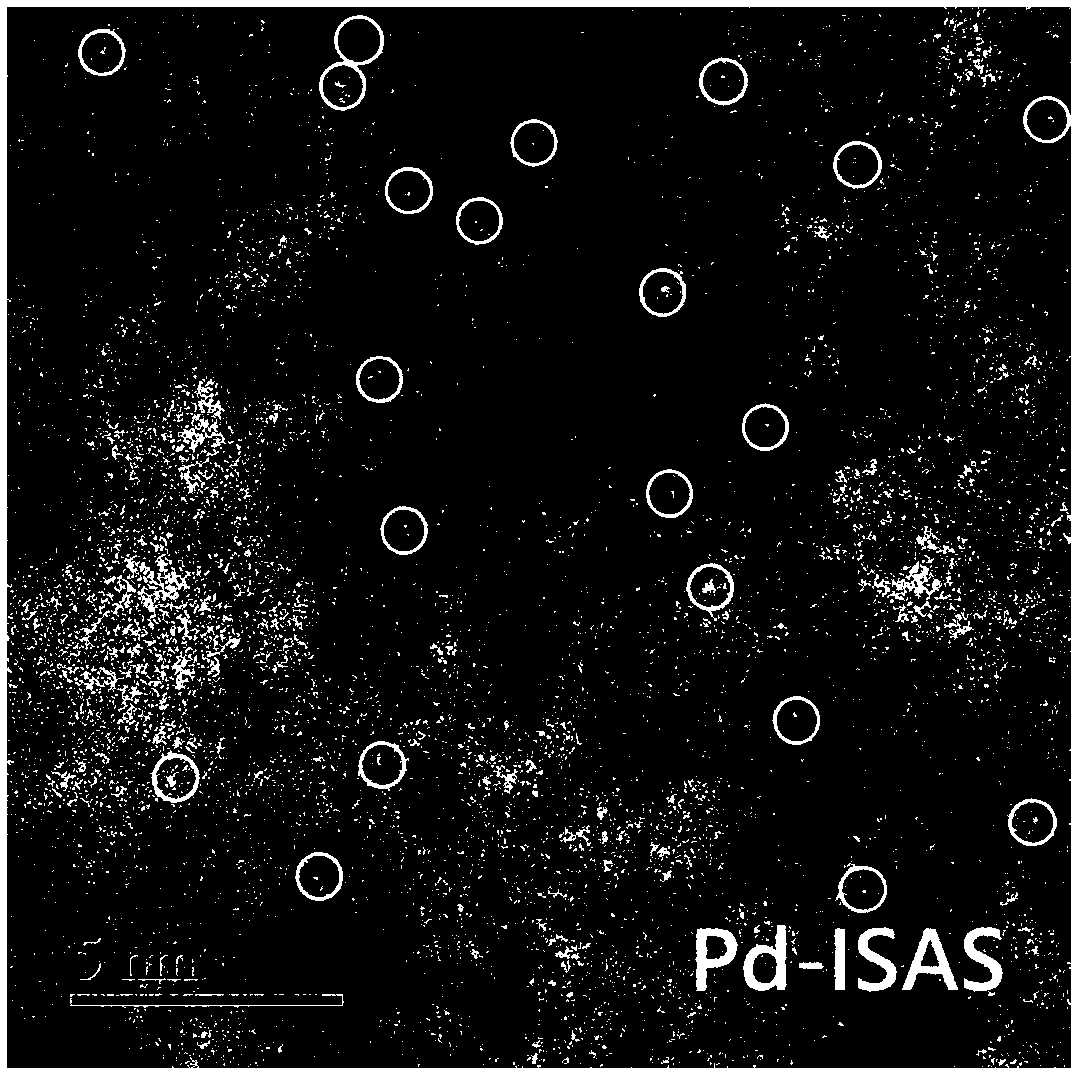

Preparation method of metal monatomic site catalyst

ActiveCN107626294ASmall particlesUniform particle size distributionCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsZinc compoundsPorous carbon

The invention provides a preparation method of a metal monatomic site catalyst. According to the synthetic strategy, a porous complex composite material coated with an acetylacetone metal salt is formed from a zinc compound and an imidazole organic ligand through coordination in a methanol solution of the acetylacetone metal salt, and then a porous carbon support doped with nonmetal heteroatomic nitrogen is formed from the imidazole organic ligand through a high-temperature pyrolytic reaction in an inert gas atmosphere, wherein metal atoms interact with surrounding nonmetal heteroatomic nitrogen and exist in the form of single atoms. The method is simple, safe, low in cost and applicable to synthesis of various noble metal and non-noble metal monatomic site catalysts, and the obtained metal monatomic site catalyst is high in metal concentration and good in heat stability, can be applied to the fields of energy, catalysis, medicine, biology and the like and has quite broad market prospect.

Owner:TSINGHUA UNIV

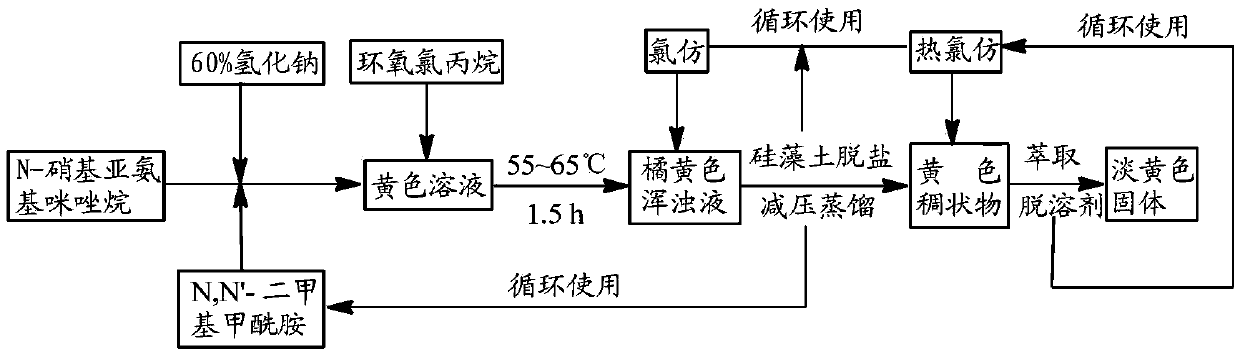

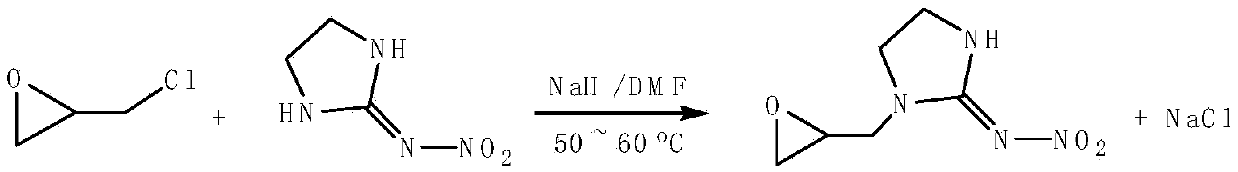

Method for preparing cycloxylidin

The invention discloses a method for preparing cycloxylidin, which belongs to the technical field of pesticides preparation. The method comprises the following steps: under nitrogen protection, N-nitroiminoimidazolidine and an organic solvent are added in a reactor, then sodium hydride is added in batches, and the material is heated to the temperature of 50-60 DEG C, chloropropylene oxide is added drop by drop in the reactor, after the reaction product is cooled, chloroform is added, and the product is filtered by diatomite, then evaporative crystallization is carried out, and the crystals can be precipitated, vacuum distillation is carried out on a processed filtrate to obtain a light yellow dense solid, then heat chloroform is used for extraction, and finally heat ethanol or acetone is used for recrystallization to obtain cycloxylidin: 1-(2,3-glycidyl)-N-nitroimidazoline-2-ylamine, wherein the yield is about 83%. The method has the advantages of short reaction time, high yield and green environmental protection, and is more suitable for large-scale industrial production.

Owner:山东聚强绿洲生物科技有限公司

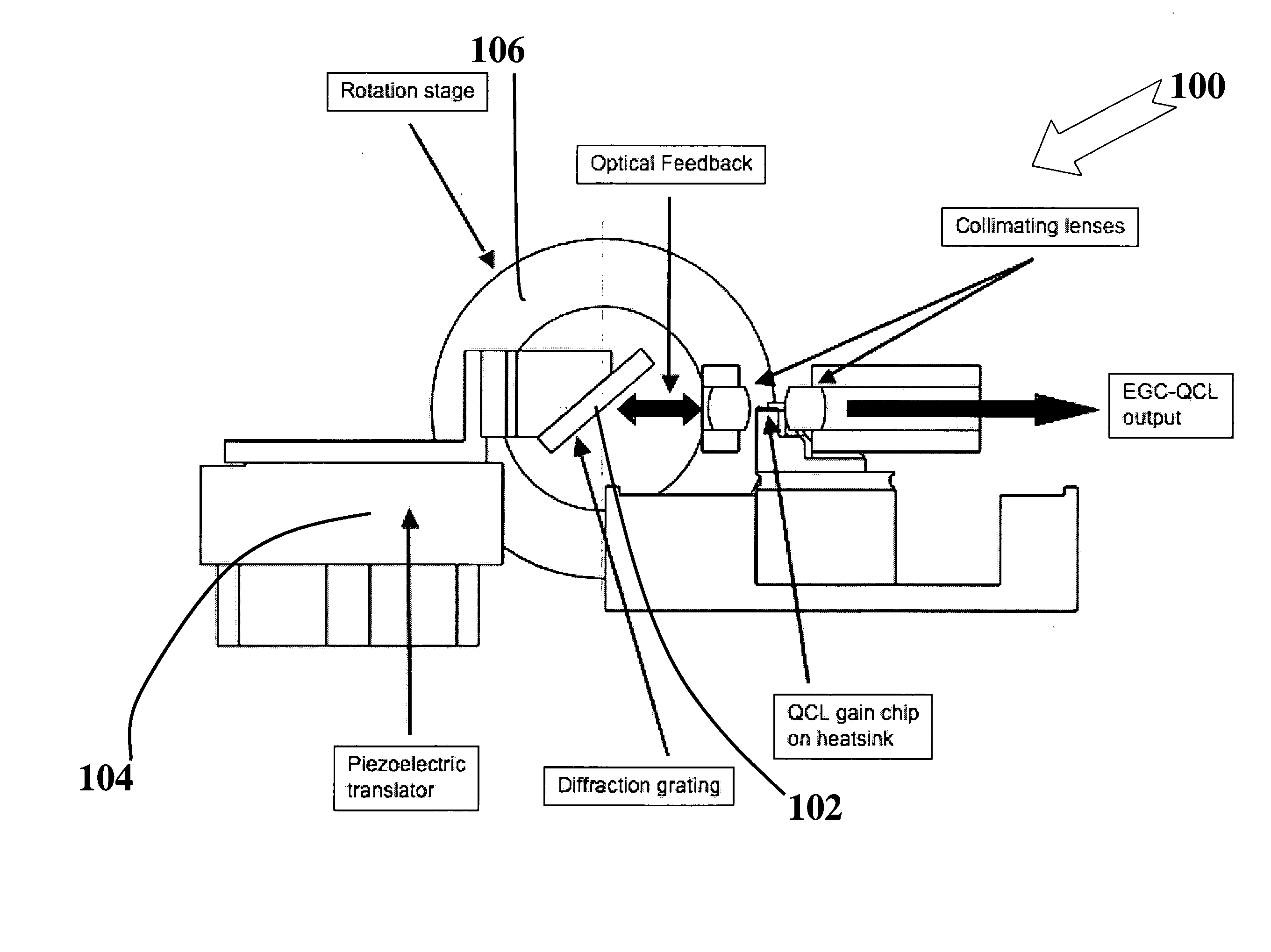

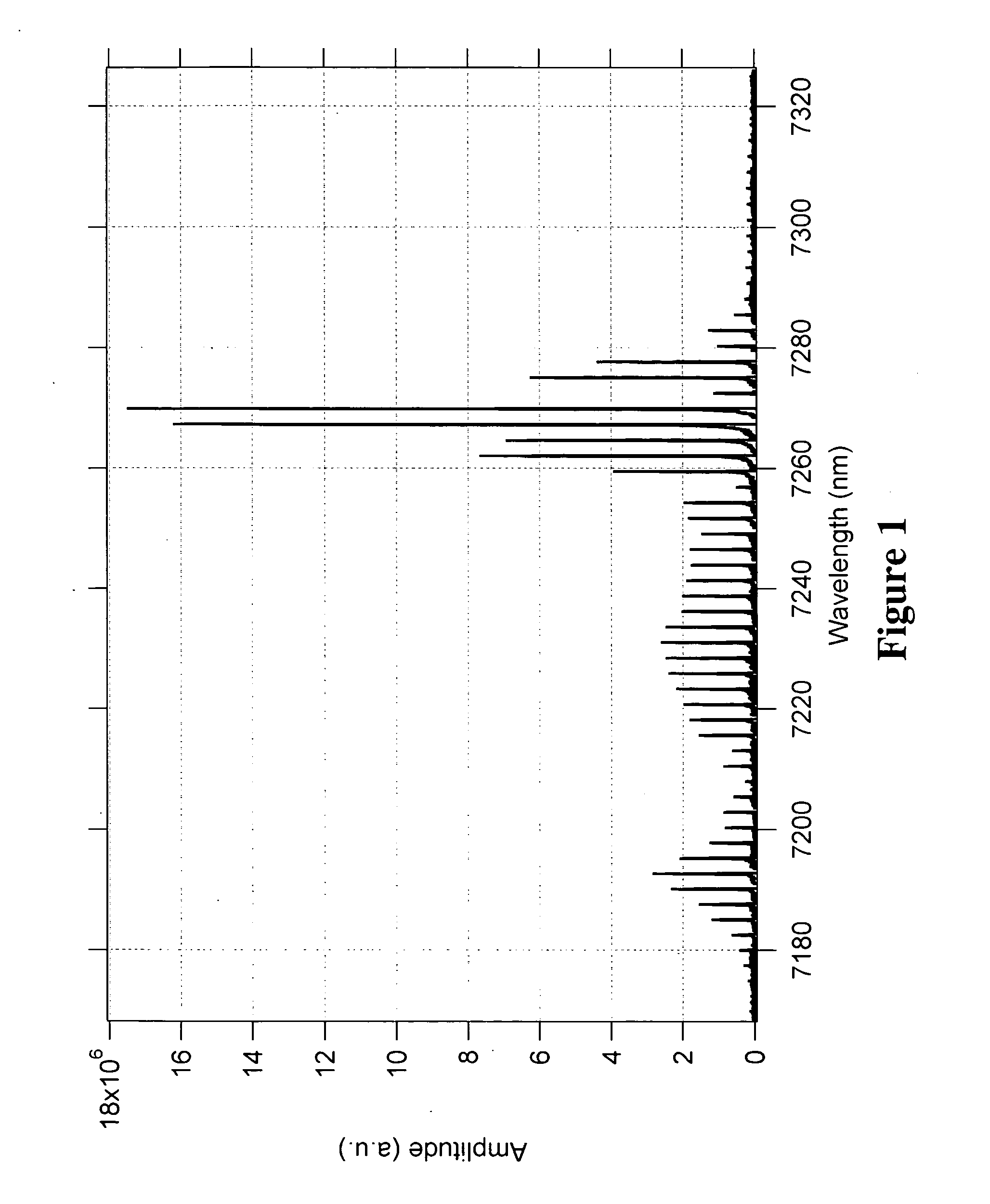

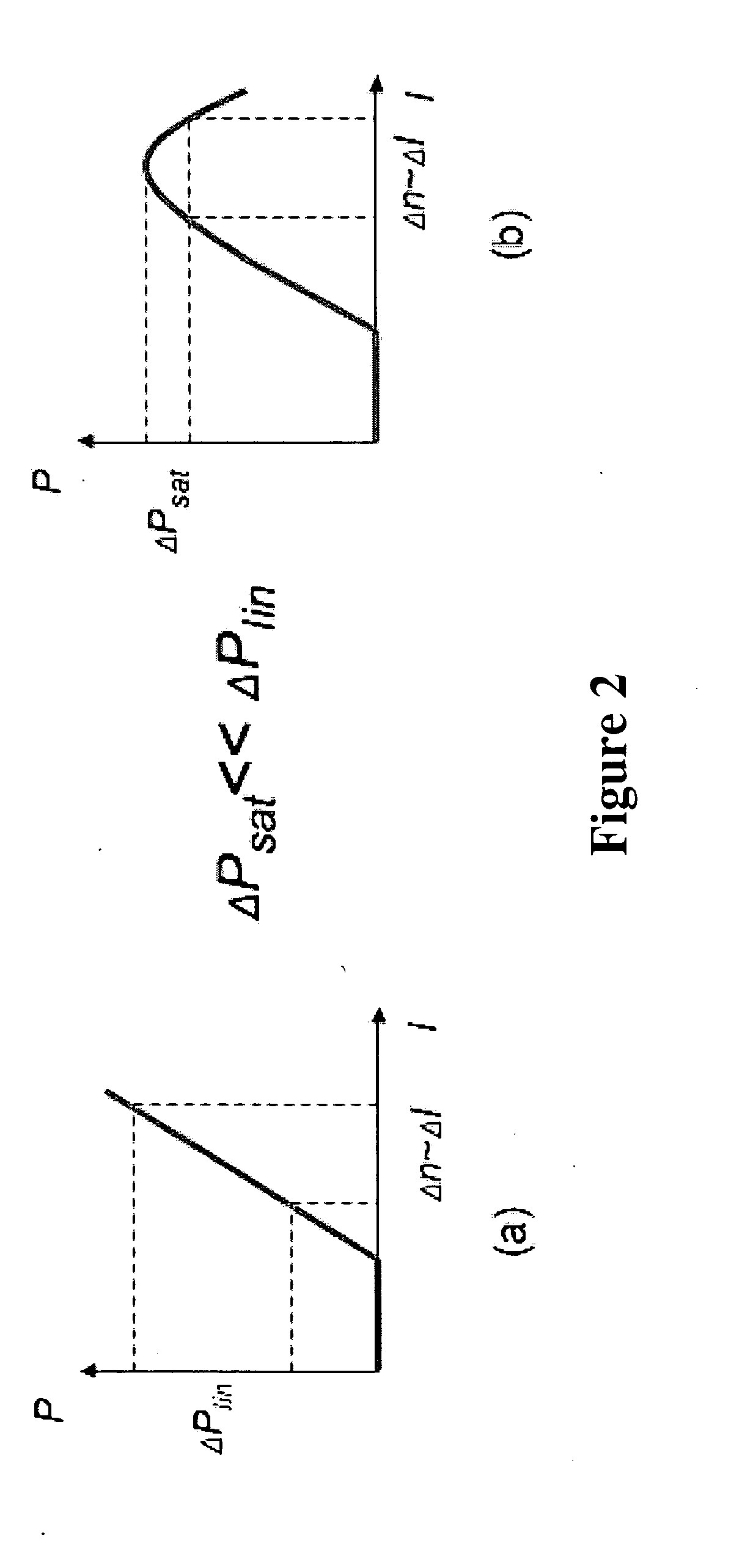

Tunable quantum cascade lasers and photoacoustic detection of trace gases, TNT, TATP and precursors acetone and hydrogen peroxide

ActiveUS20080159341A1High rejectionShorten the timeMaterial analysis by optical meansOptical resonator shape and constructionQuantum cascade laserPeroxide

Methods and apparatus for broad tuning of single wavelength quantum cascade lasers and the use of light output from such lasers for highly sensitive detection of trace gases such as nitrogen dioxide, acetylene, and vapors of explosives such as trinitrotoluene (TNT) and triacetone triperoxide (TATP) and TATP's precursors including acetone and hydrogen peroxide. These methods and apparatus are also suitable for high sensitivity, high selectivity detection of other chemical compounds including chemical warfare agents and toxic industrial chemicals. A quantum cascade laser (QCL) system that better achieves single mode, continuous, mode-hop free tuning for use in L-PAS (laser photoacoustic spectroscopy) by independently coordinating gain chip current, diffraction grating angle and external cavity length is described. An all mechanical method that achieves similar performance is also described. Additionally, methods for improving the sensor performance by critical selection of wavelengths are presented.

Owner:DAYLIGHT SOLUTIONS

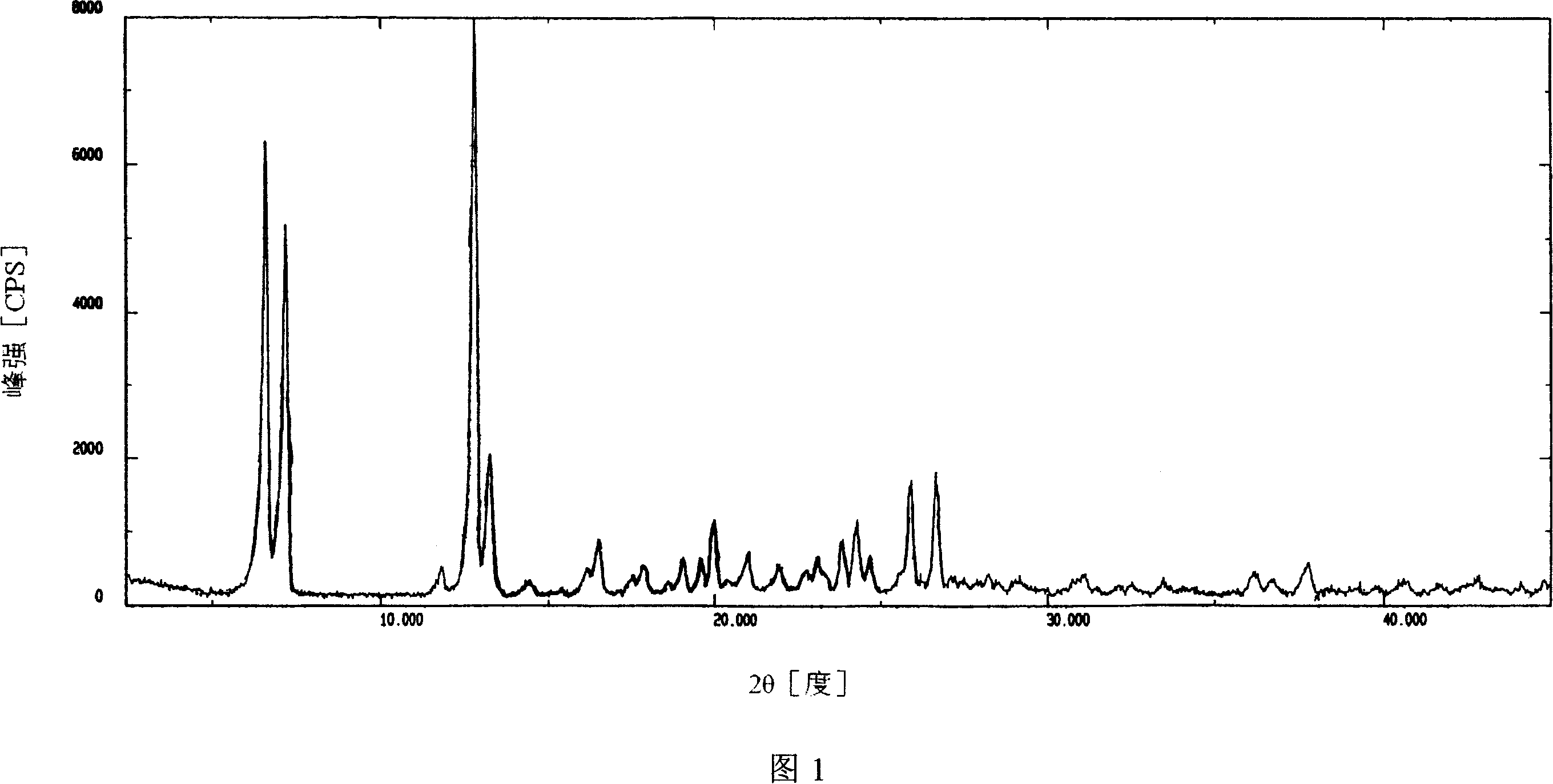

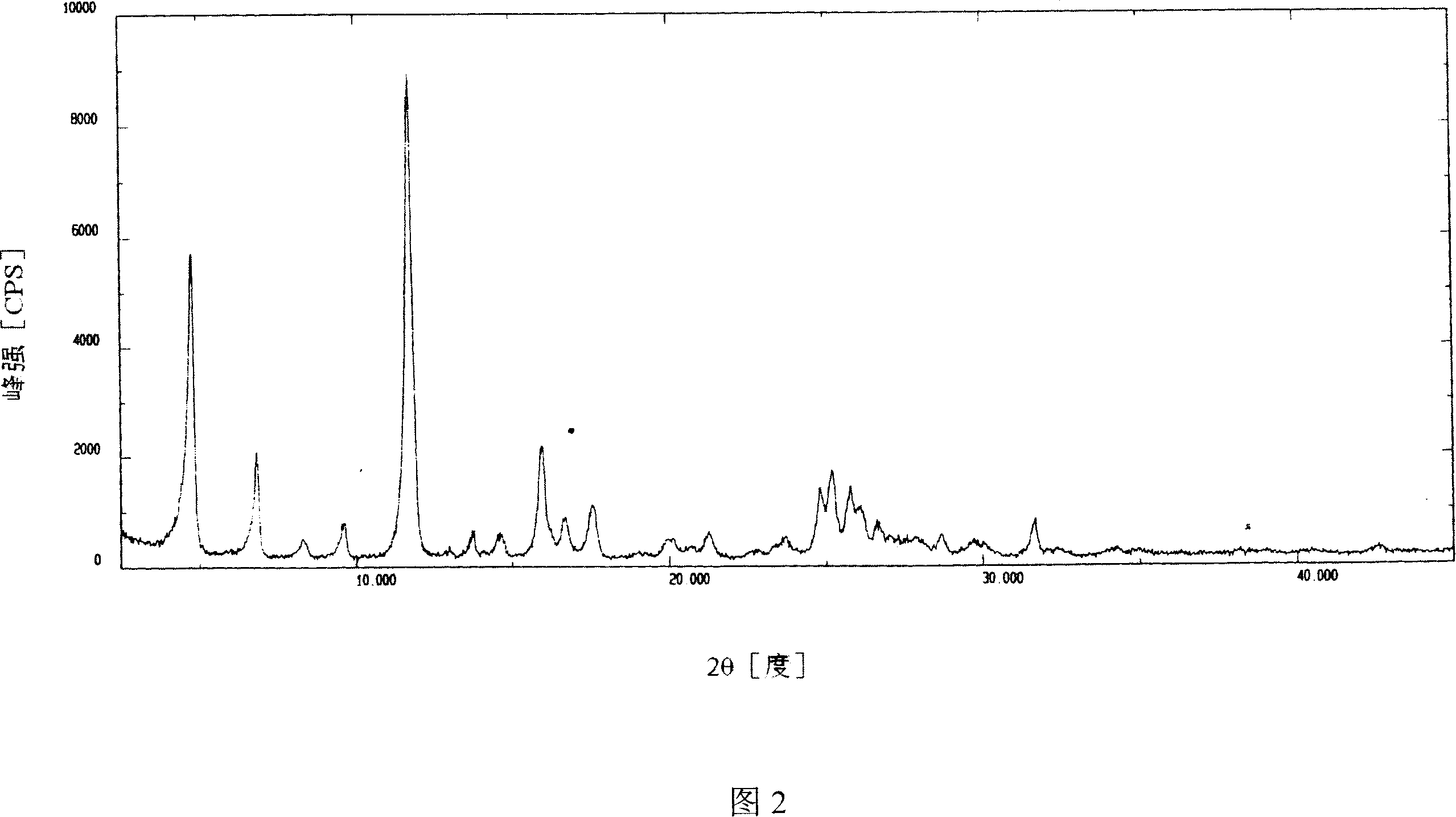

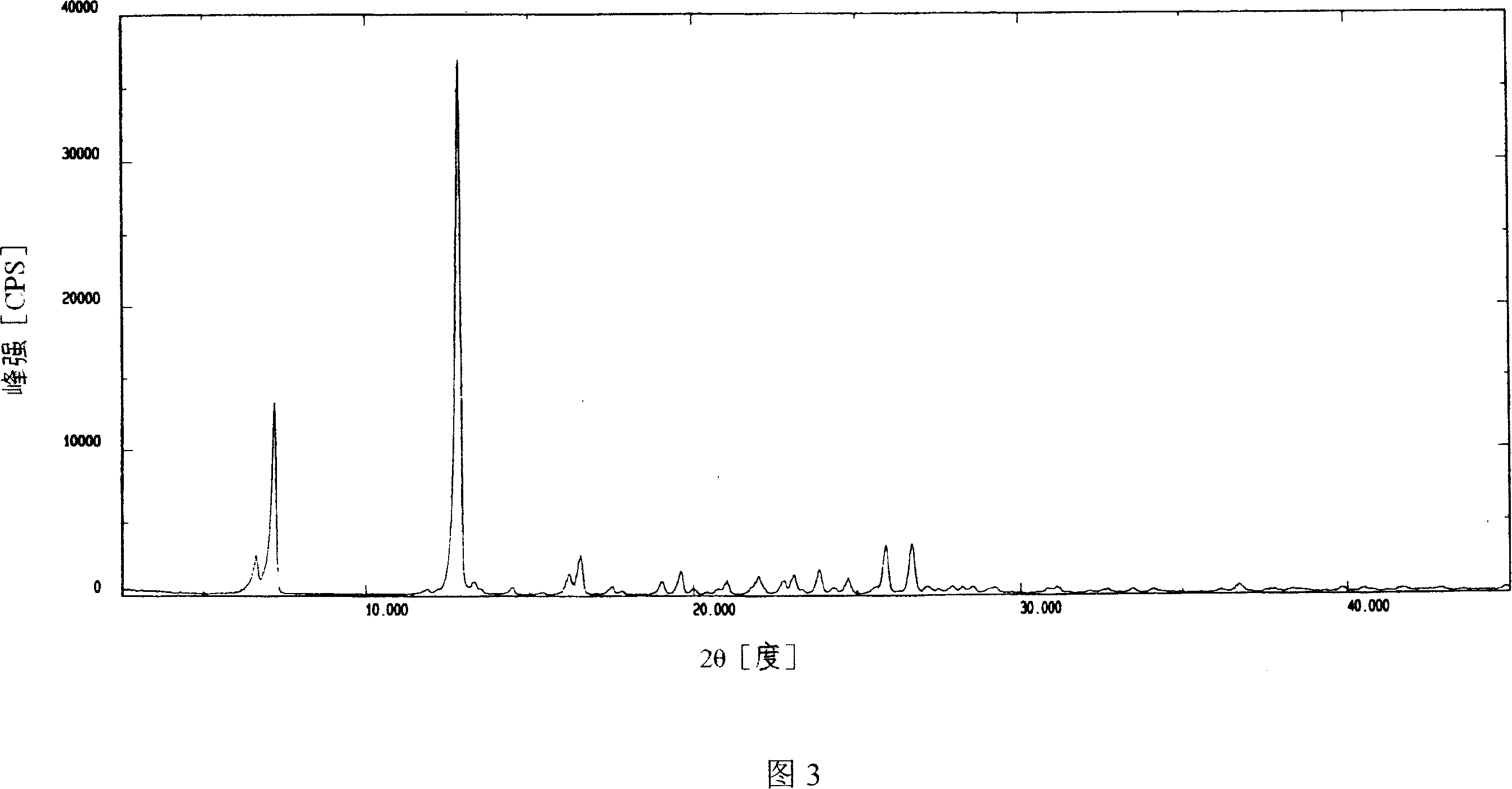

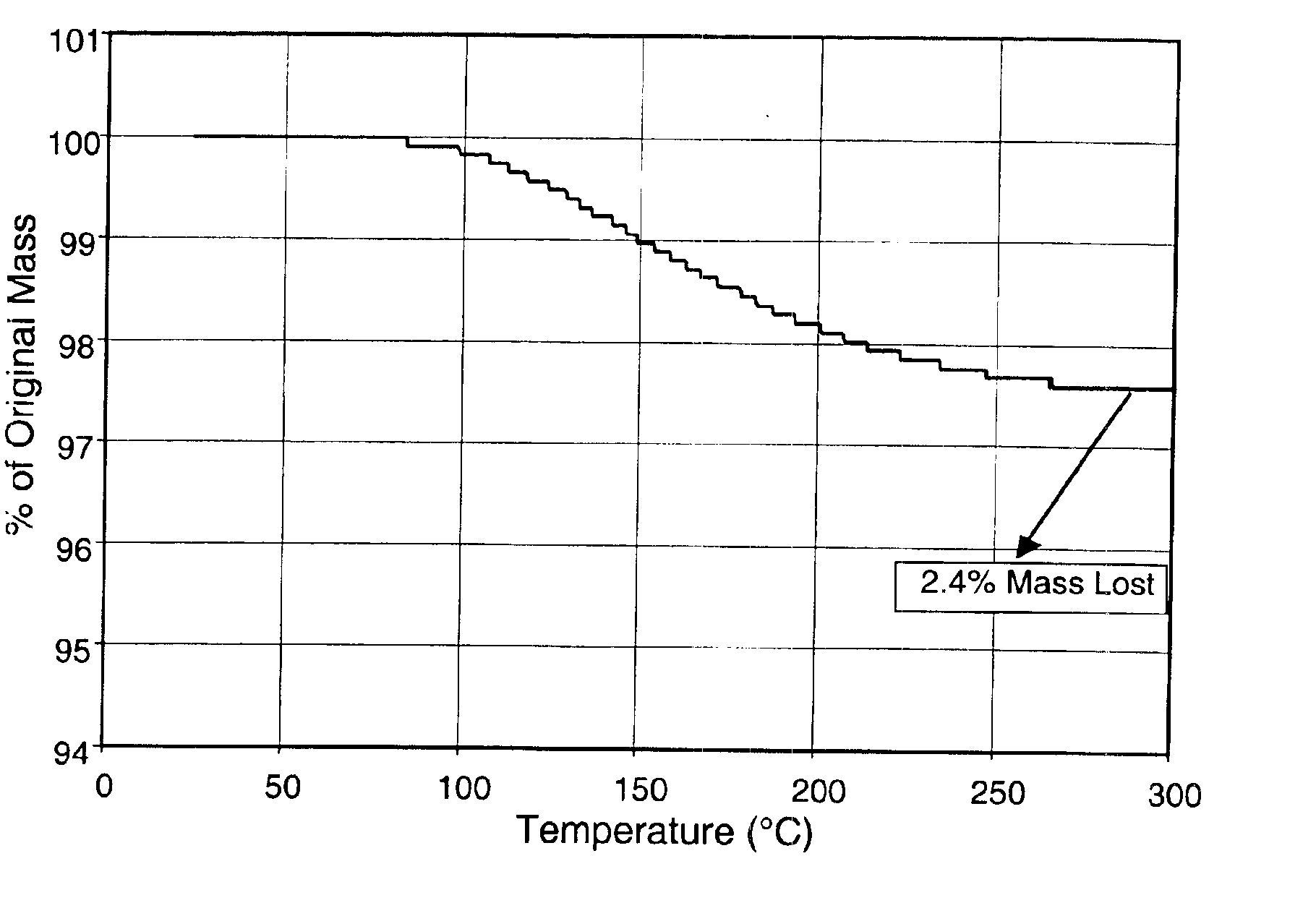

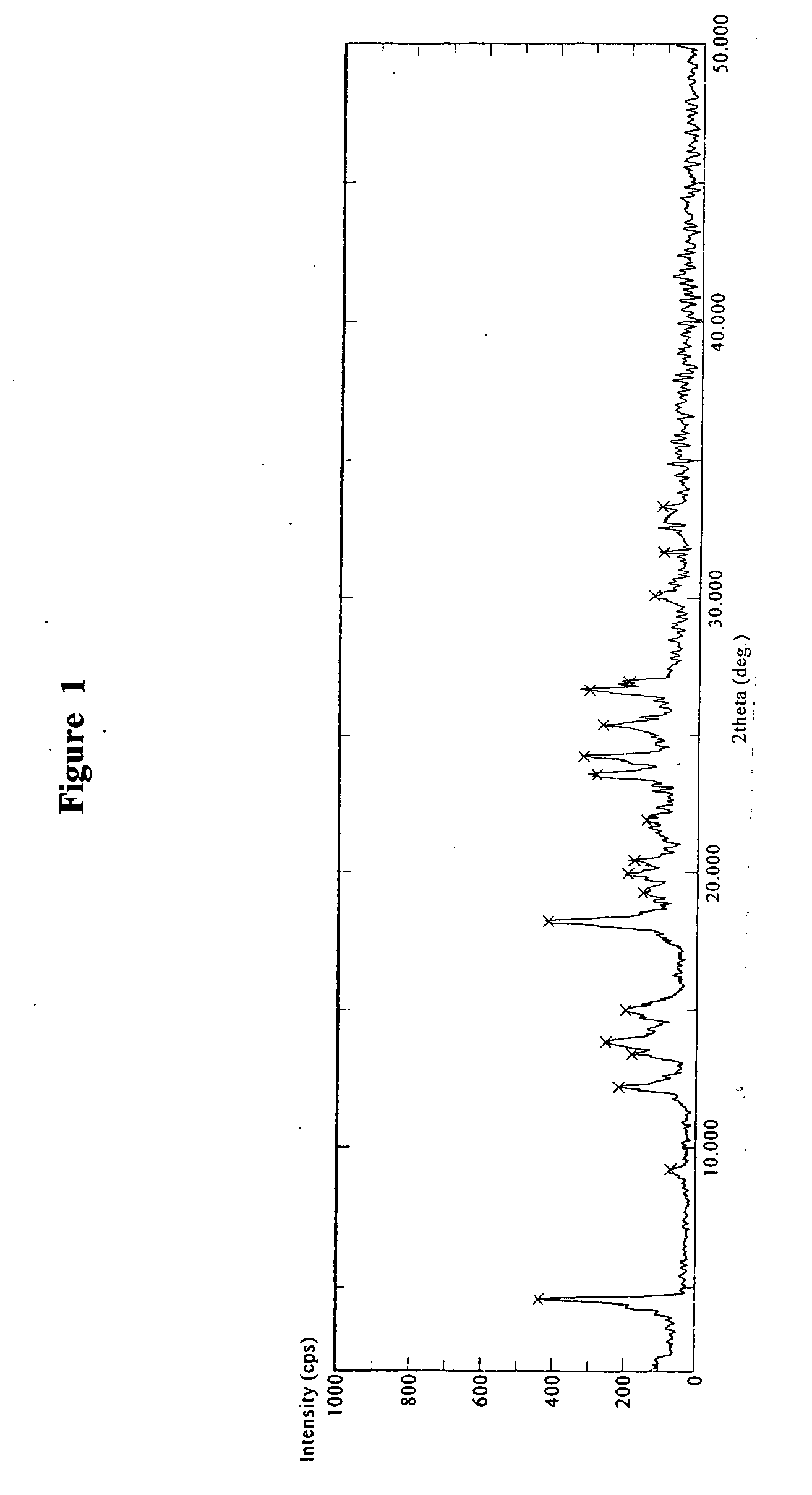

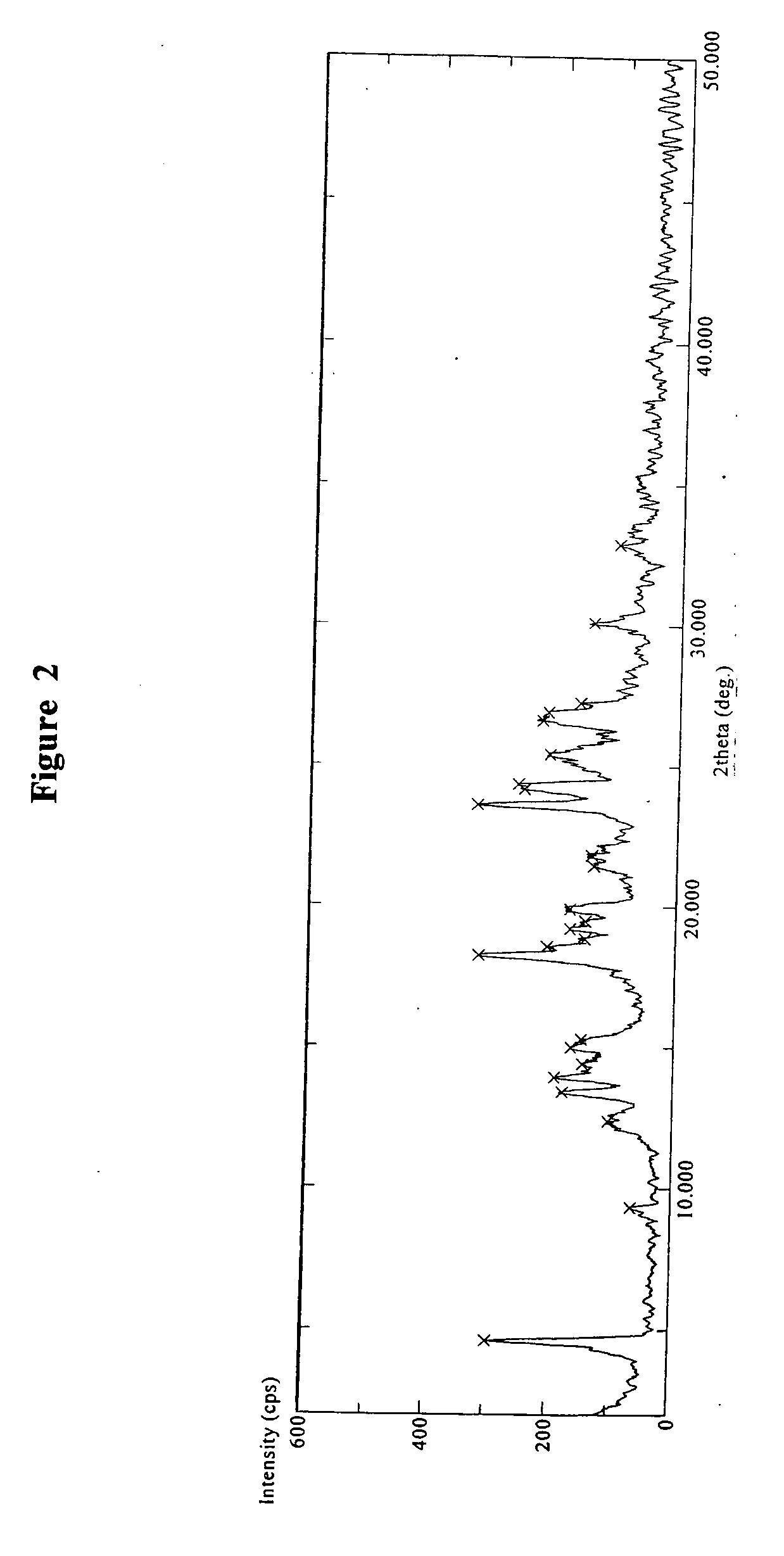

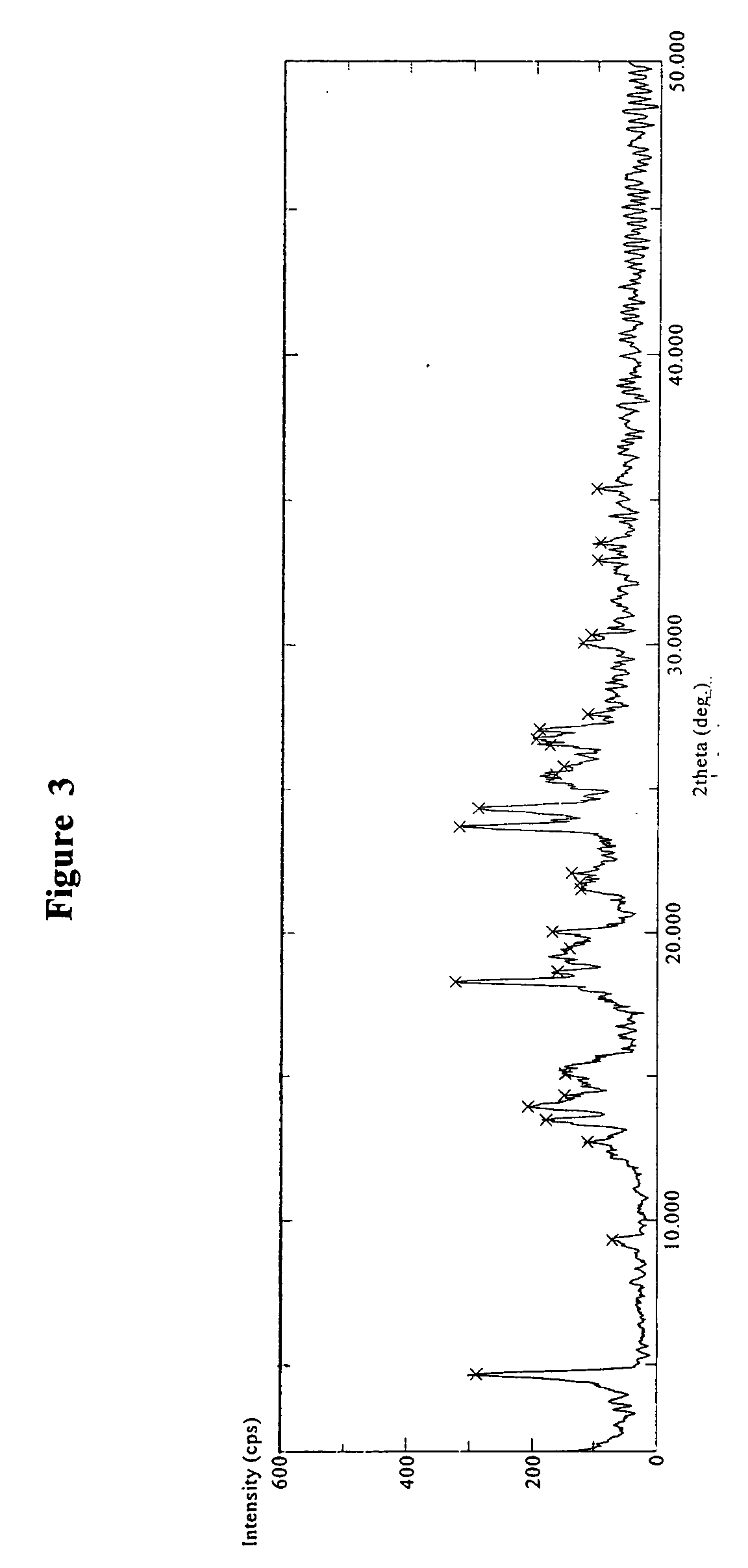

Crystalline polymorph of sitagliptin phosphate and its preparation

InactiveUS20090247532A1Big advantageBulk handlingBiocideOrganic chemistryOrganic solventDistillation

The present invention is directed to a novel polymorph form of crystalline sitagliptin phosphate, named as Form V herein. The present invention further provides processes for preparations of Form V, pharmaceutical composition comprising Form V and its use in therapy. Form V can be prepared from recrystallizing sitagliptin phosphate in a mixture of methanol and water, a mixture of acetone and water, or from distillation of a mixture of organic solvents and water followed by recrystallization in the remaining aqueous solution.

Owner:MAI DE

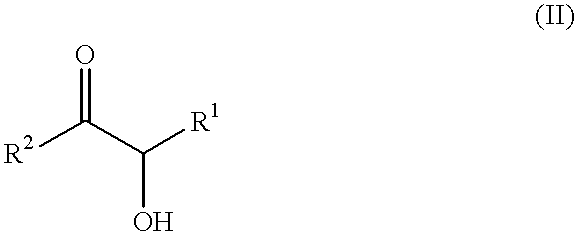

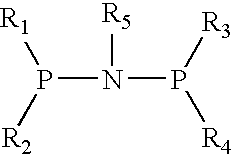

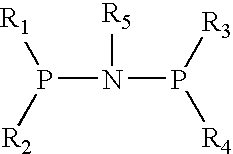

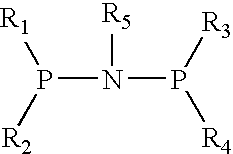

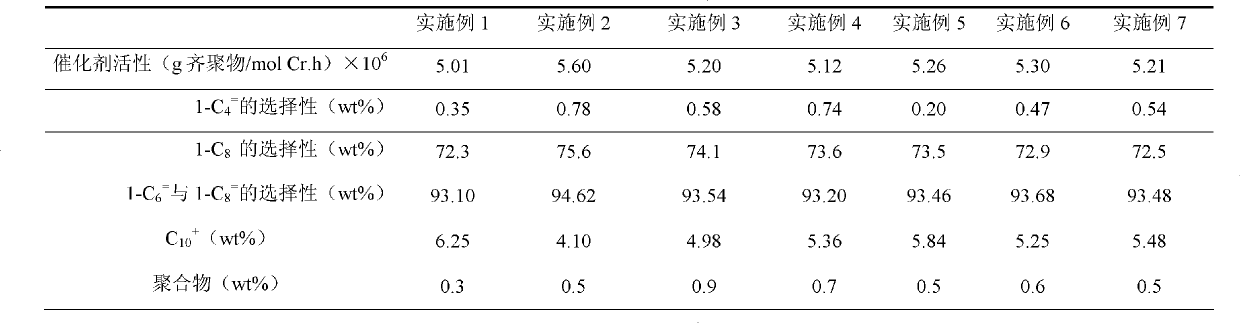

Catalyst composition for ethylene oligomerization and the use thereof

ActiveUS20070232481A1High activityGood choiceOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbons from unsaturated hydrocarbon additionChromium Compounds1-Octene

The present invention relates to a catalyst composition for ethylene oligomerization and the use thereof. Such catalyst composition includes chromium compound, ligand containing P and N, activator and accelerator; wherein the chromium compound is selected from the group consisting of acetyl acetone chromium, THF-chromium chloride and / or Cr(2-ethylhecanoate)3; general formula of the ligand containing P and N is shown as: in which R1, R2, R3 and R4 are phenyl, benzyl, or naphthyl. R5 is isopropyl, butyl, cyclopropyl, cyclopentyl, cyclohexyl or fluorenyl; the activatior is methyl aluminoxane, ethyl aluminoxane, propyl aluminoxane and / or butyl aluminoxane; general formula of the accelerator is X1R6X2, in which X1 and X2 are F, Cl, Br, I or alkoxyl, R6 is alkyl or aryl; the molar ratio of a, b, c and d is 1:0.5˜10:50˜3000:0.5˜10. After mixing the four components mentioned previously under nitrogen atmosphere for 10 minutes, they are incorporated to the reactor, or these four components are incorporated directly into the reactor. Then ethylene is introduced for oligomerization. Such catalyst can be used in producing 1-octene through ethylene oligomerization. It is advantageous in high catalysing activity, high 1-octene selectivity, etc. The catalytic activity is more than 1.0×106 g product·mol−1 Cr ·h−1, the fraction of C8 linear α-olefin is more than 70% by mass.

Owner:PETROCHINA CO LTD

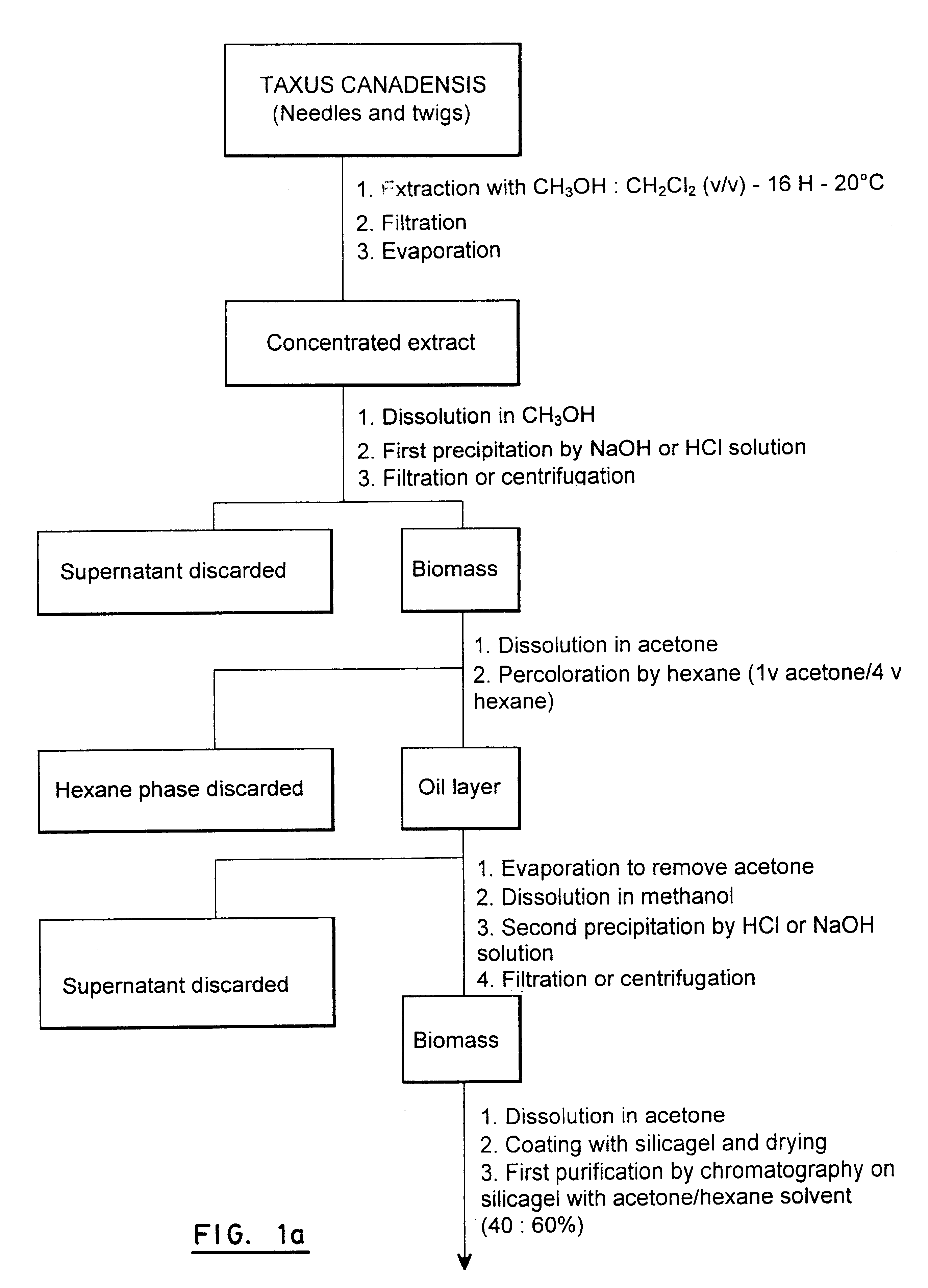

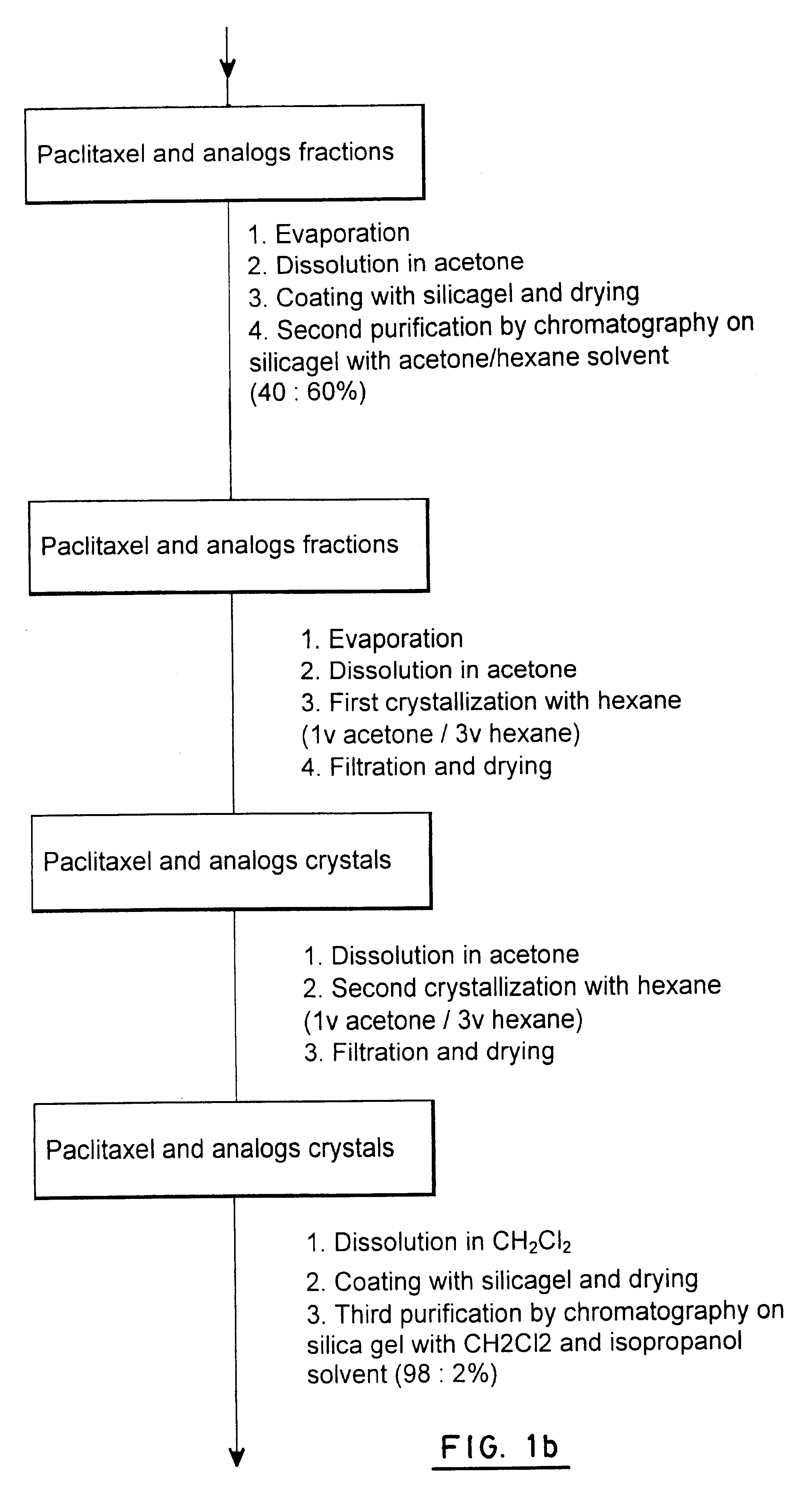

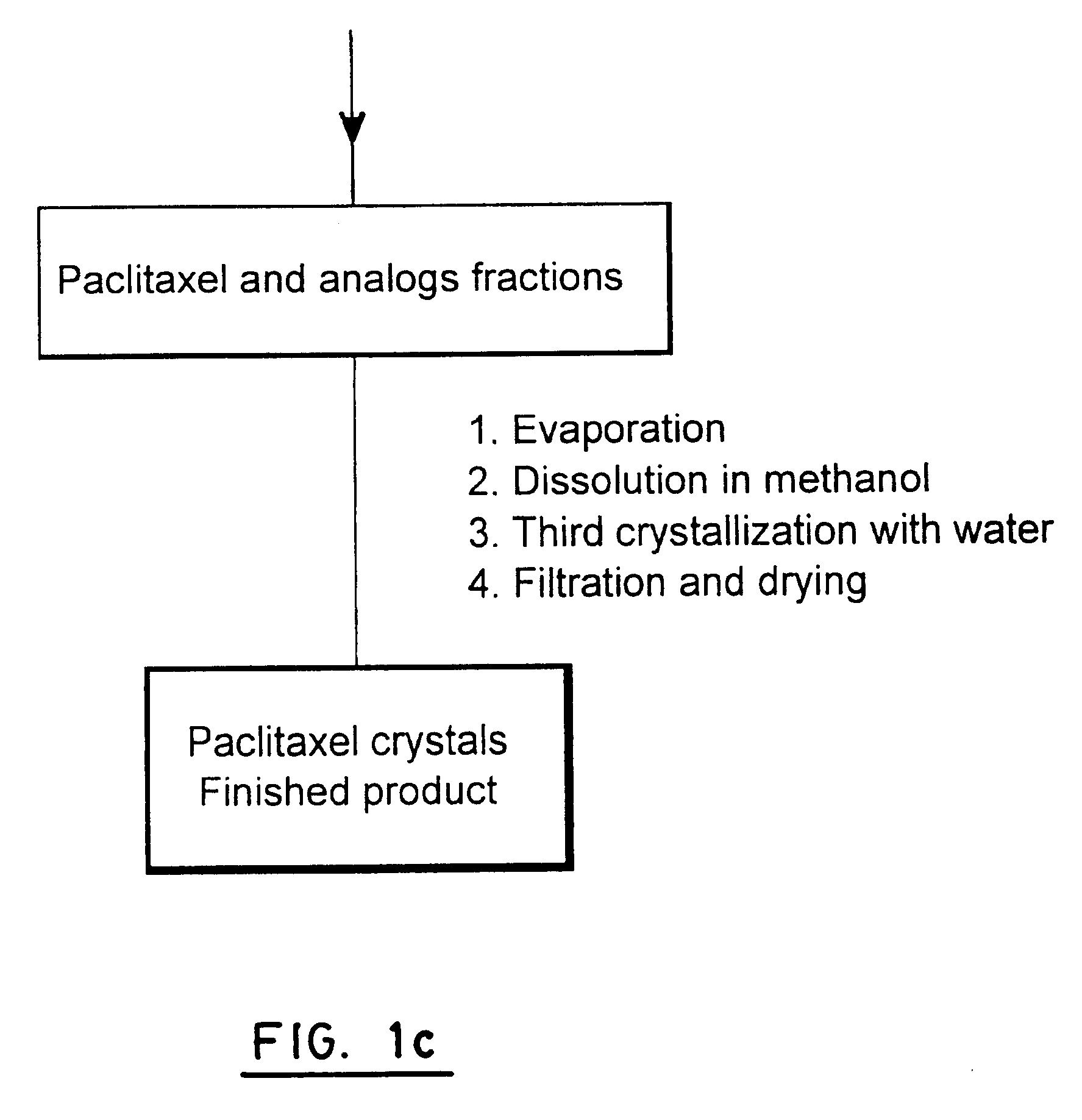

Process for extraction and purification of paclitaxel from natural sources

A process for the extraction and purification of Paclitaxel from a natural source of taxanes, comprising extracting Paclitaxel with an organic solvent from a natural source of taxanes, and treating the raw material with a base or an acid to obtain a biomass by precipitation. The biomass is isolated and dried, and resin and natural pigments are removed. The biomass is then dissolved in acetone and at least one non-polar solvent is added, until a Paclitaxel-enriched oily phase is obtained. The Paclitaxel-enriched oily phase is then treated with a base or an acid to obtain a second biomass, which is recovered by precipitation and dried. A solution of the second biomass in a volatile solvent is chromatographically purified at least once and crystallized.

Owner:CHAICHEM PHARMA INT

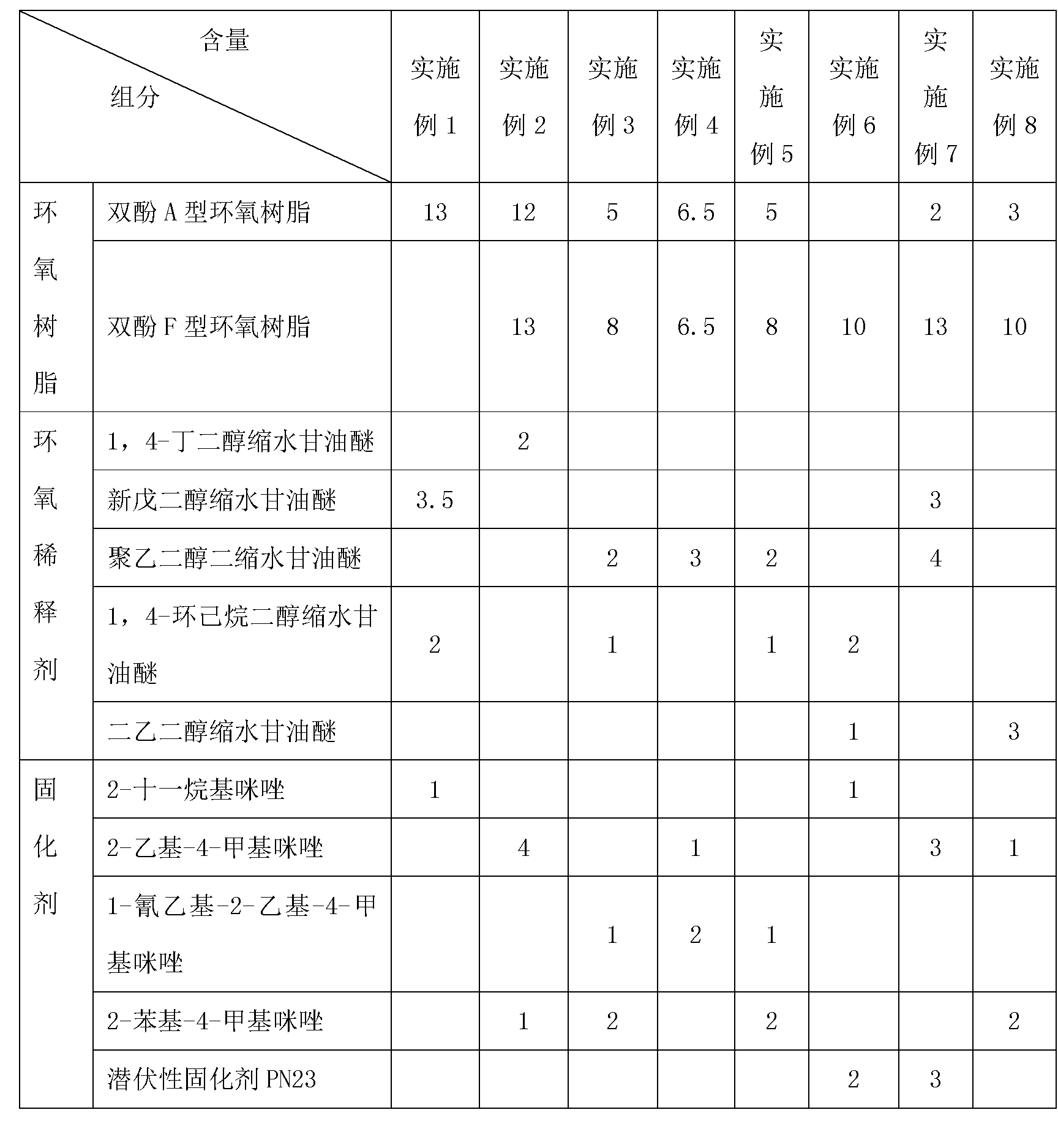

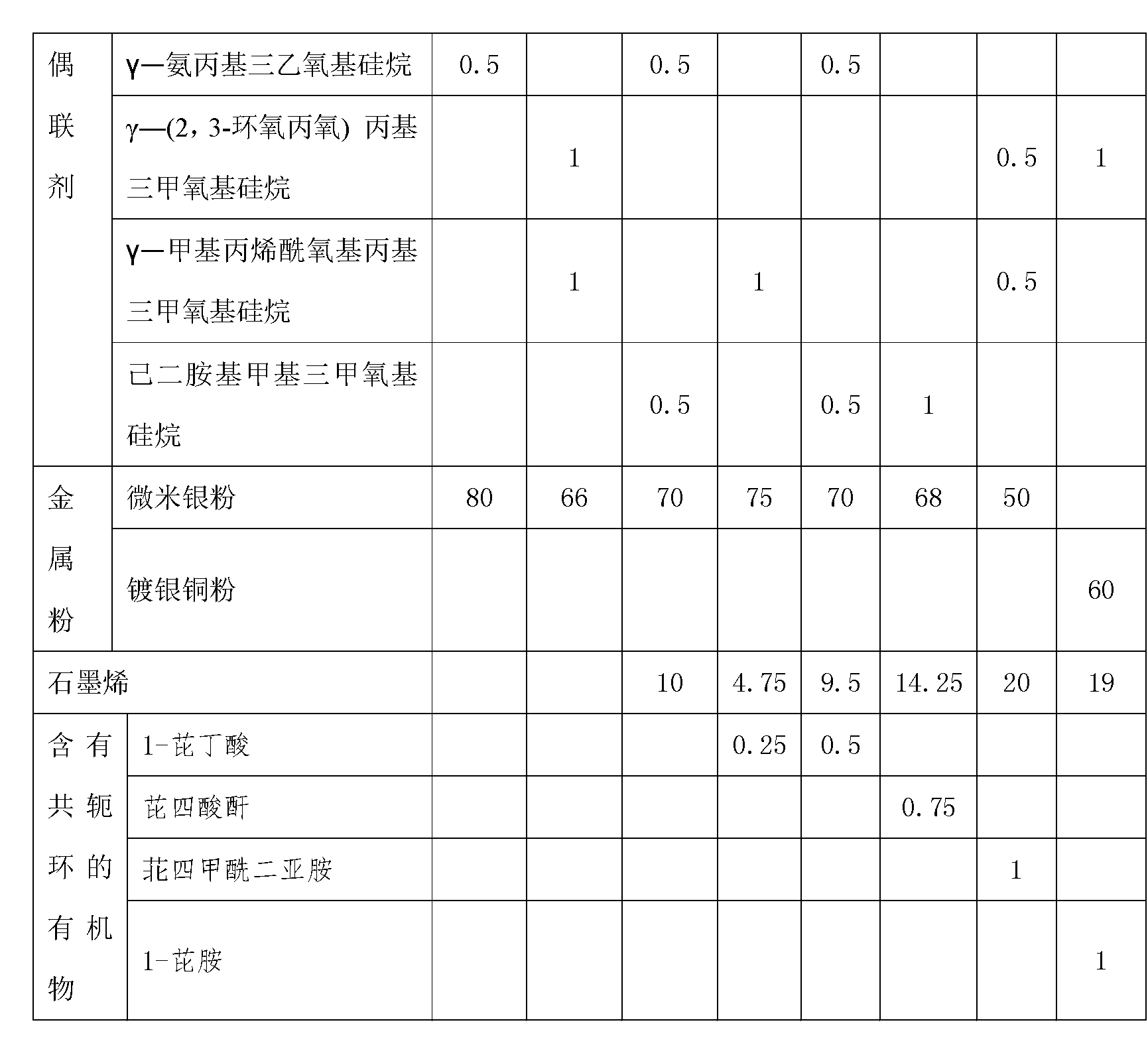

Method for preparing high-heat-conductivity conductive adhesive containing graphene

ActiveCN103194165AGood dispersionScatter to reachEpoxy resin adhesivesPigment treatment with non-polymer organic compoundsEpoxyAdhesive

The invention provides a method for preparing high-heat-conductivity conductive adhesive containing graphene. The method comprises the steps of (1) functionalizing surface of graphene, namely adding graphene to acetone solution of an organic matter containing a conjugate ring, and strongly ultrasonically shaking for 6-48 hours at 40-100 DEG C to form non-covalent modified graphene; (2) mixing epoxy resin with an epoxy diluent for 3-30 minutes at room temperature to obtain a mixture of epoxy resin and the epoxy diluent, and sequentially adding metal powder and a coupling agent to the mixture; (3) adding the non-covalent modified graphene prepared in the step (1) to the mixture in the step (2); and (4) adding a curing agent to the mixture in the step (3) to prepare the even conductive adhesive. The method has the advantages that dispersing and enhancing interface joint in an epoxy system are facilitated by functionalizing the surface of graphene by a non-covalent bond; and then graphene is mixed with metal powder to obtain the high-heat-conductivity conductive adhesive. The high-heat-conductivity conductive adhesive has the application prospect in a high-power apparatus.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

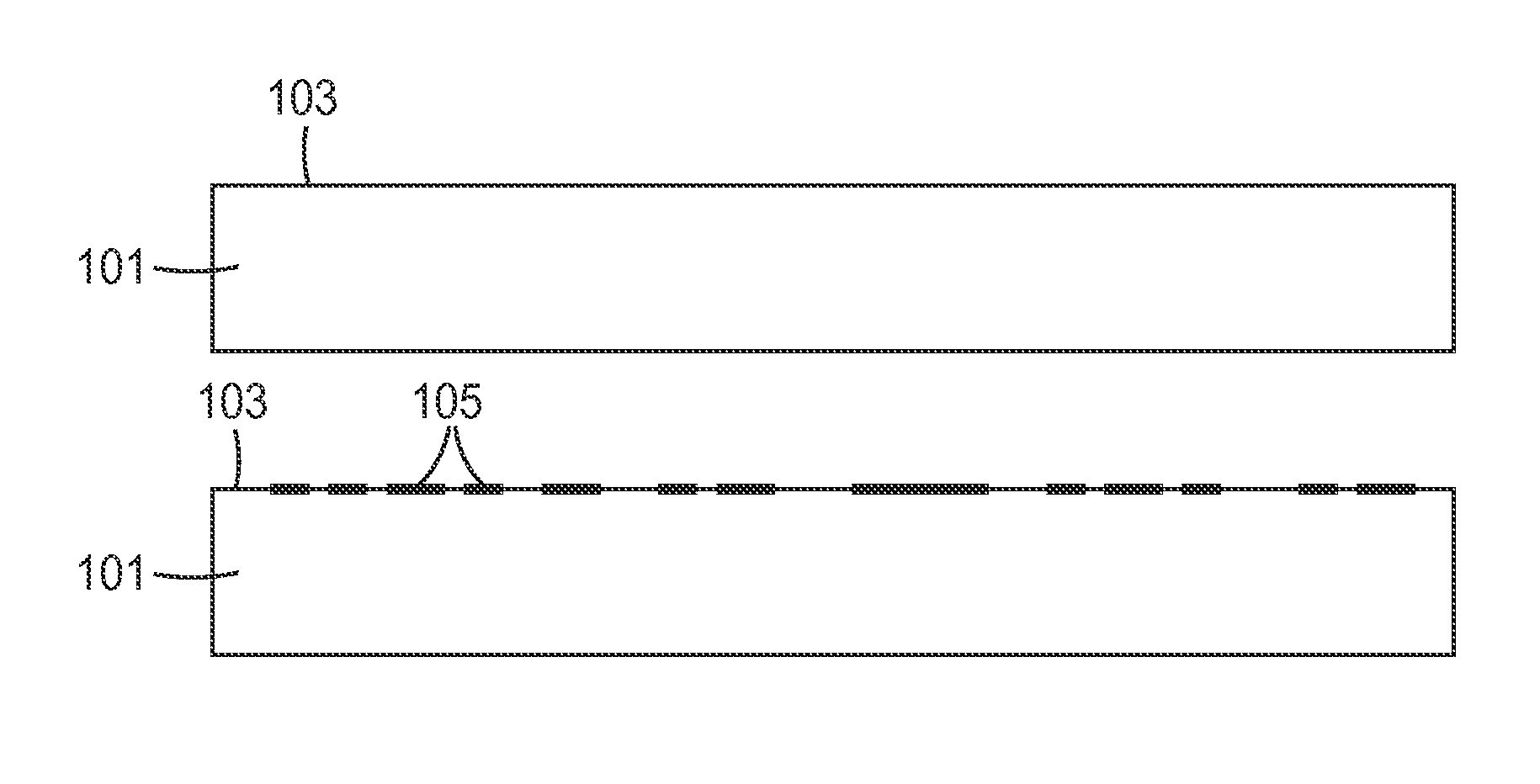

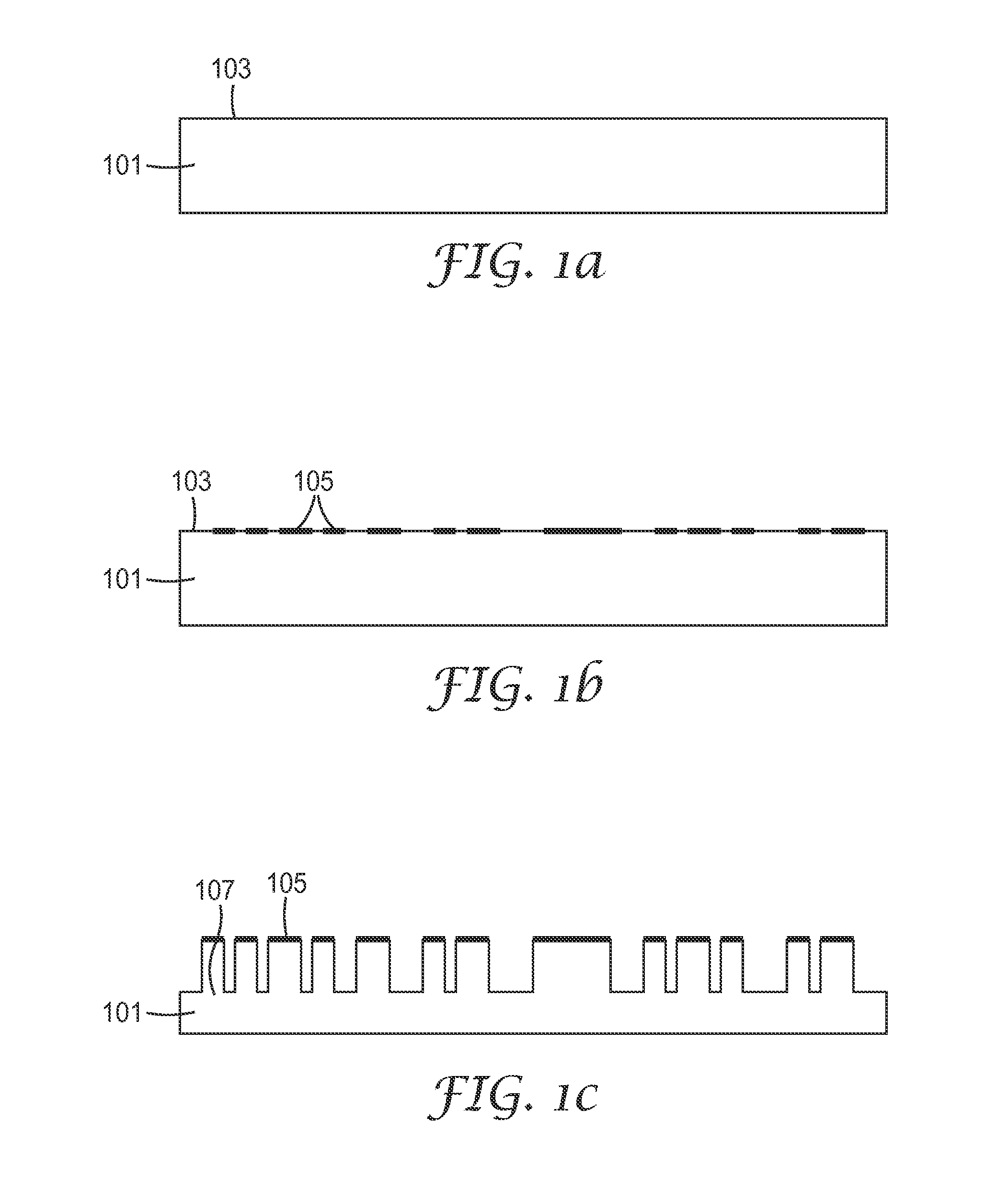

Method of making a nanostructure

ActiveUS8634146B2Reduce reflectivityScratch resistantMaterial nanotechnologyLayered productsMetal acetylacetonatesAlloy

A method of making a nanostructure is provided that includes applying a thin, random discontinuous masking layer (105) to a major surface (103) of a substrate (101) by plasma chemical vapor deposition. The substrate (101) can be a polymer, an inorganic material, an alloy, or a solid solution. The masking layer (105) can include the reaction product of plasma chemical vapor deposition using a reactant gas comprising a compound selected from the group consisting of organosilicon compounds, metal alkyls, metal isopropoxides, metal acetylacetonates, and metal halides. Portions (107) of the substrate (101) not protected by the masking layer (105) are then etched away by reactive ion etching to make the nanostructures.

Owner:3M INNOVATIVE PROPERTIES CO

Method for recovering carbon-fiber enhanced epoxy resin composite material

The invention relates to a method for recovering a carbon-fiber enhanced epoxy resin composite material. In the existing method, the requirement for equipment is high and the recovery cost is large. The method comprises the following steps of: cutting materials needing to be decomposed into blocks with the volume being 5cm<3>, putting the blocks in a backflow device containing acid liquor, heating for 5-20 minutes at the temperature of boiling point, cleaning and carrying out vacuum drying; then putting the obtained mixture into a reaction kettle, adding an organic solvent and an oxidizing agent, firstly heating, then cooling to normal temperature, and obtaining a primary product; and after cleaning, putting a solid product in the primary product into industrial acetone solution for dipping, obtaining recovered carbon fiber and carrying out pressure-reduced distillation on a liquid product to obtain phenol and derivatives thereof. In the method, reaction under low temperature and low pressure is realized and has the advantages of moderate reaction condition, easy control of reaction, fewer side products, no pollution basically and no corrosion to equipment and the like, so that the method is a green recovering method.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Ethylene oligomerization catalyst composition and application thereof

InactiveCN103285926AHigh activityOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsArylAluminoxane

The invention relates to an ethylene oligomerization catalyst composition and an application thereof. The composition comprises the following components: a component a contains chromium acetylacetonate, tetrahydrofuran chromium chloride and / or chromium 2-ethylhexanoate; in the formula of a component b, R1, R2, R3 and R4 are phenyl, benzyl or naphthyl; and R5 is isopropyl, butyl, cyclopropyl, cyclopentyl, cyclohexyl or fluorenyl; a component c contains methyl aluminoxane, ethyl aluminoxane, propyl aluminoxane and / or butyl aluminoxane; a component d has a formula X1R6X2, wherein X1 and X2 are F, Cl, Br, I or alkoxy, and R6 is alkyl or aryl; in the formula of a component e, R is a linking group and selected from alkyl and derivatives thereof as well as aryl and derivatives thereof; and the molar ratio is 1: (0.5-10): (50-3000): (0.5-10): (0.5-10). The catalyst has the catalytic activity being more than 5.0*10<6>g mol<-1>Cr.h<-1>, and the mass of 1-hexene and 1-octylene is more than 93%.

Owner:PETROCHINA CO LTD

Processing method of aluminum and aluminum alloy super hydrophobic surface

InactiveCN101007304ASuperhydrophobicEasy to rollAntifouling/underwater paintsPretreated surfacesNickel saltCopper

The invention involves an aluminum or aluminum alloy super-hydrophobic surface preparation method. The method is: polishing the surface of aluminum or aluminum alloy using metallographic sandpaper or polishing paste, pure water washing, acetone ultrasonic cleaning, pure water washing and other clean treatment, handing it with chemical etching solution containing nitric acid and metal salts (copper or nickel salt) 30s-20min under 90 ~ 100 degree C, then coating low surface energy material on its surface to get super-hydrophobic property. The aluminum or aluminum alloy surface treated by the invention has excellent hydrophobicity, the contact angle of water and surface can be as high as 150-165 degree, droplets are easy to roll on the surface. The method of the invention need not complex equipment, cost is low, technology is simple and repeatability is good.

Owner:SOUTH CHINA UNIV OF TECH

Azeotrope-like compositions comprising 1-chloro-3,3,3-trifluoropropene

An azeotrope-like mixture consisting essentially of chlorotrifluoropropene and at least one component selected from the group consisting of a C1-C3 alcohol, a C5-C6 hydrocarbon, a halogenated hydrocarbon, methylal, methyl acetone, water, nitromethane, and combinations thereof.

Owner:HONEYWELL INT INC

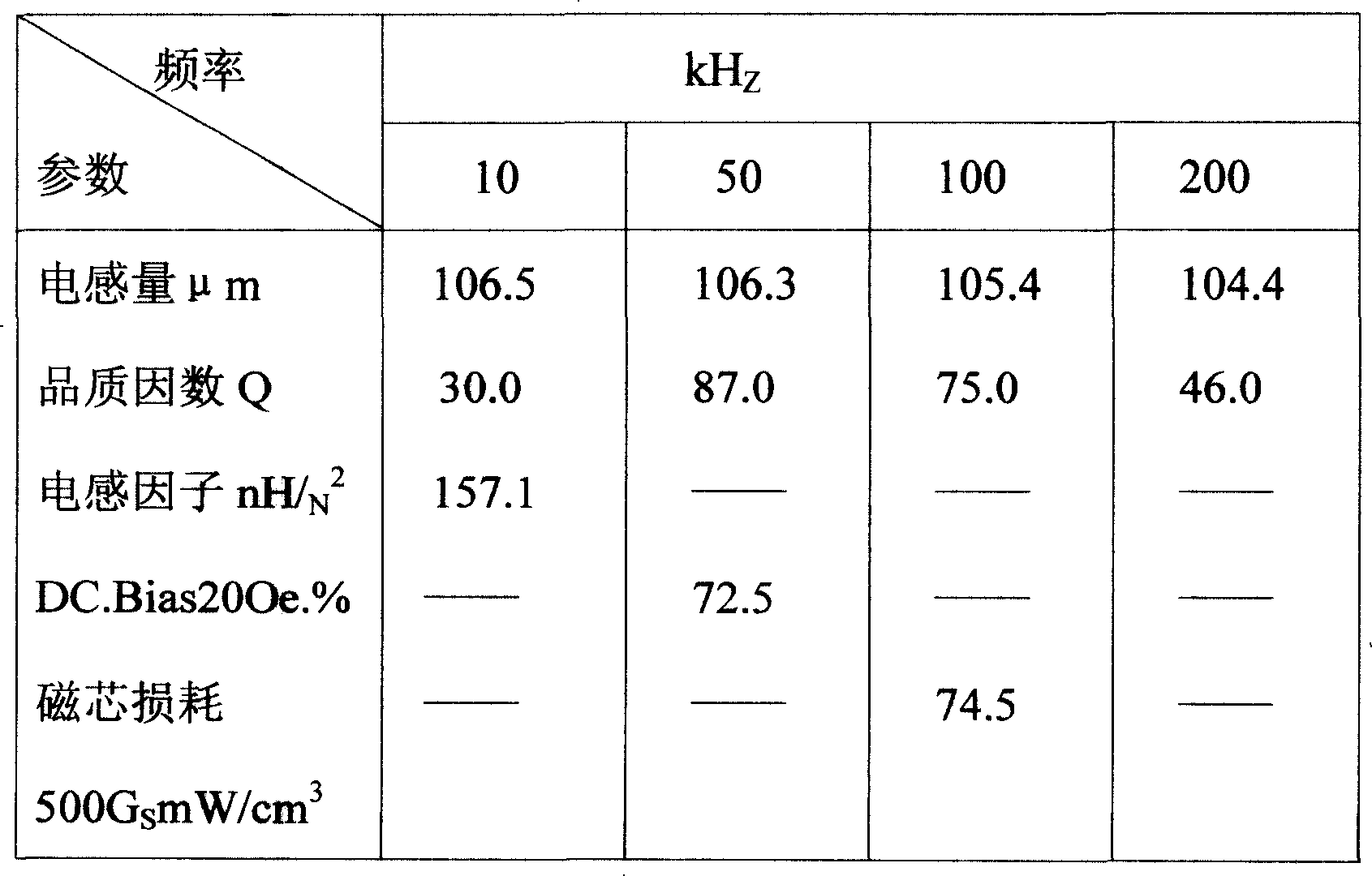

Manufacturing method of Fe-6.5Si alloy powder and manufacturing method of magnetic powder core

The making of Fe-6.5Si alloy magnetic powder core comprises grain proportion, alloy powder inactivating, adding insulation agent to the metal powder, binder, lubricant and stripping agent, compression, heat treatment, solidification, surface coating, with the inactivating treatment getting phosphopyruvic acid with 5-15% phosphate chrome, the rest being acetone, adding alloy powder with 2-6% of mass percentage. Adding small quantity Ti nor Ni, it can reach the saturated alloy magnetic sensing strength BS value of 16000- 18000 Gaussian, coercitive force <=80A / m. It has better forming and compression feature. It reduces broken stress. The made magnetic powder core having magnetic conductivity of 125, with low metal core consumption.

Owner:武汉欣达磁性材料有限公司

Method for purifying poly ether-ether-ketone

InactiveCN1640911AEasy to buyEase of industrial mass productionChemical recyclingVitrificationPoly ether ether ketone

The normal pressure poly(ether-ether-ketone) purifying process includes the technological steps of purification, suction filtering and washing, and drying. During purification, metered poly(ether-ether-ketone) and metered organic solvent and surfactant used as purifying treating agent and purifying assistant separately inside reactor are heated at normal pressure to the temperature between the vitrification point of poly(ether-ether-ketone) and the boiling point of the purifying treating agent for purification for at least 1 hr. Then, the temperature is lowered to below 100 deg.c, and the product is suction filtered, washed with boiling acetone, absolute alcohol and deionized water, and dried to obtain high purity poly(ether-ether-ketone) product. The said process can lower the content of inorganic ion in poly(ether-ether-ketone) product.

Owner:SICHUAN UNIV

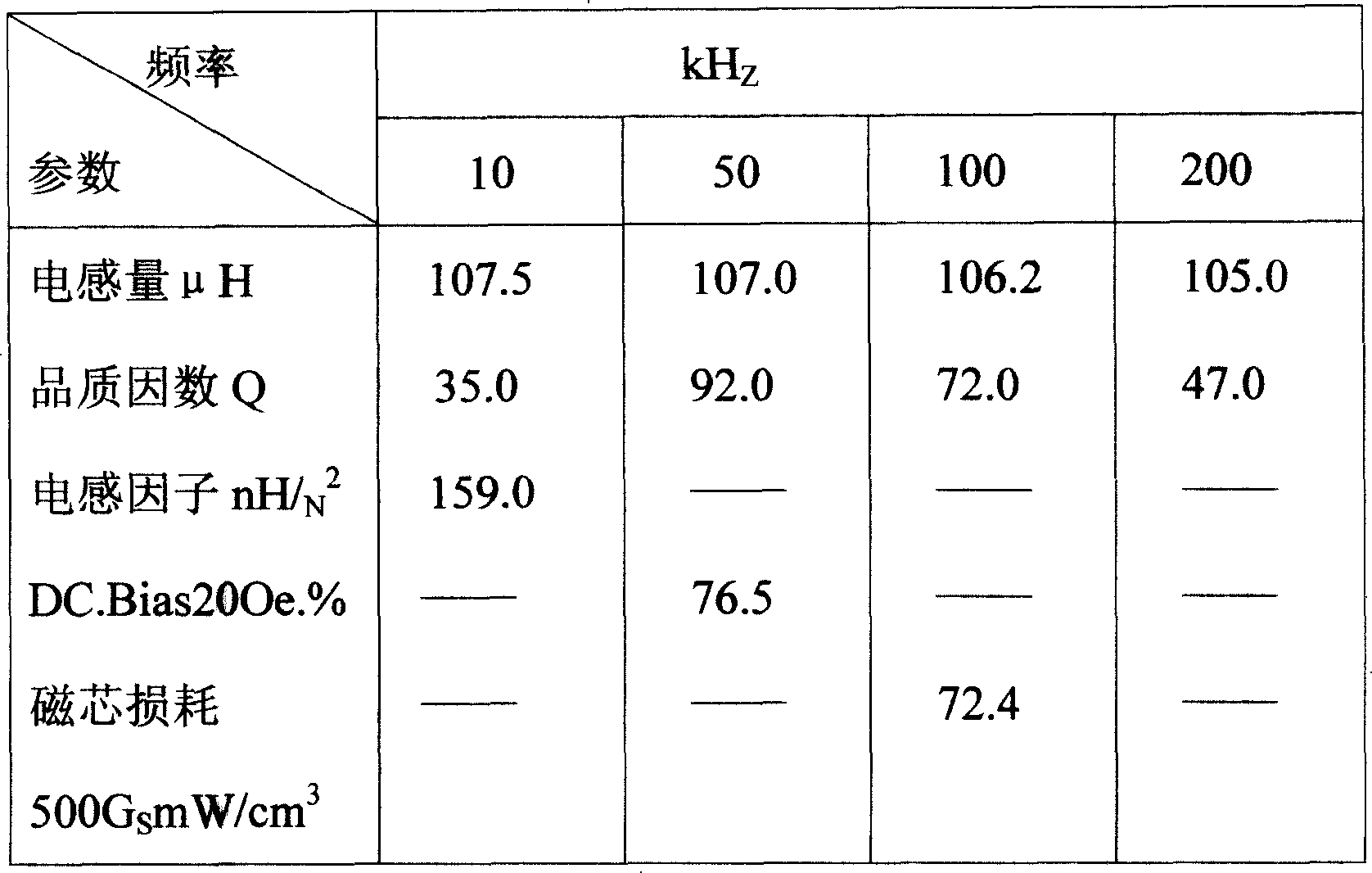

AlxCrFeNiCuVTi high-entropy alloy material and preparation method thereof

The invention relates to an AlxCrFeNiCuVTi high-entropy alloy material and a preparation method thereof. The high-entropy alloy comprises a component of AlxCrFeNiCuVTi, wherein x is a molar ratio, and the value range of x is 0.5-1.5. The preparation method of the alloy material comprises the following steps of: putting raw materials into a solution including acetone and ethanol, cleaning for 23-30 minutes by using an ultrasonic oscillator, and then drying in a 50DEG C drying oven for 6 hours; weighing alloys according to a molar ratio, and putting the alloys into a water-cooling copper crucible; when the air pressure in a furnace body reaches 3*10<-3>Pa, introducing high-purity argon to clean for 3-5 times; introducing high-purity argon to ensure that the air pressure in a furnace chamber is kept to be 0.8-0.9 atmospheric pressure, and then electrifying, wherein the smelting striking current is 30-40A, the current after stabilization is 90A, the time for smelting the alloys once is 10 seconds, and a sample needs to be smelted for 5 times repeatedly; and when the components of a smelted sample are uniformly cooled, taking the alloy out of the furnace. Compared with a conventional crystal alloy, the AlxCrFeNiCuVTi high-entropy alloy material has higher hardness, strength, high temperature stability, corrosion resistance and work hardening capacity.

Owner:梧州漓佳铜棒有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com