Patents

Literature

172 results about "Zeotropic mixture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

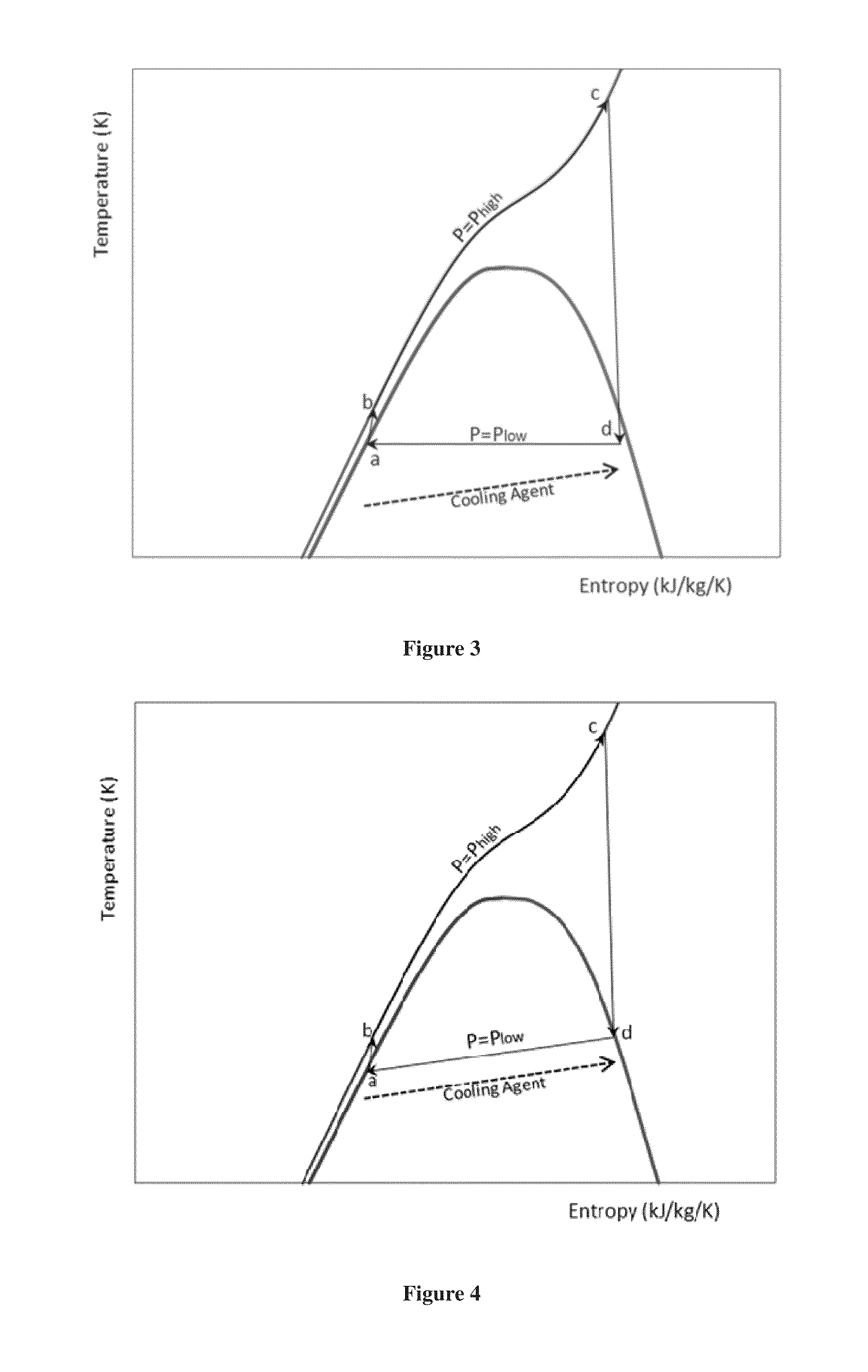

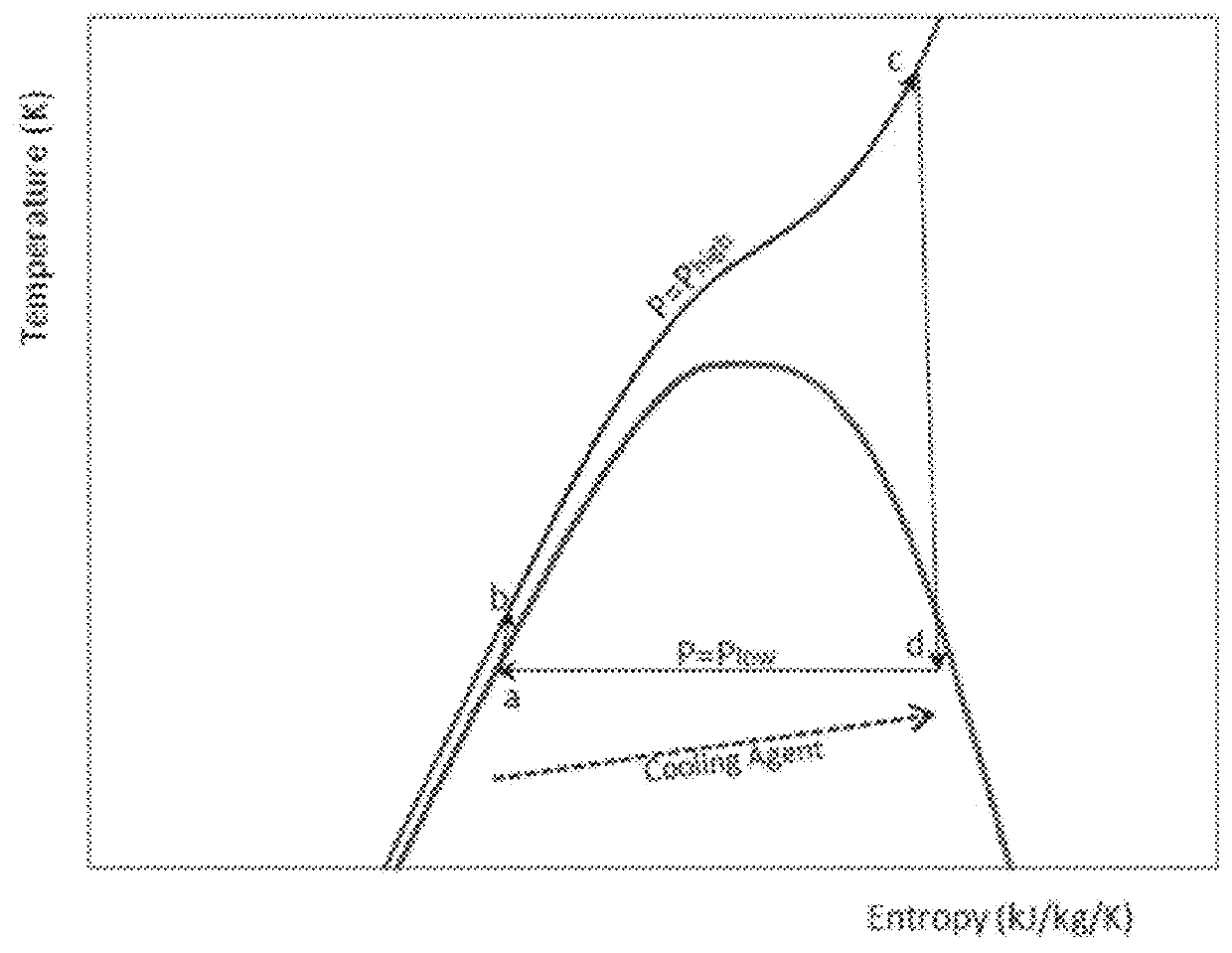

A zeotropic mixture, or non-azeotropic mixture, is a mixture with components that have different boiling points. For example, nitrogen, methane, ethane, propane, and isobutane constitute a zeotropic mixture. Individual substances within the mixture do not evaporate or condense at the same temperature as one substance. In other words, the mixture has a temperature glide, as the phase change occurs in a temperature range of about four to seven degrees Celsius, rather than at a constant temperature. On temperature-composition graphs, this temperature glide can be seen as the temperature difference between the bubble point and dew point. For zeotropic mixtures, the temperatures on the bubble (boiling) curve are between the individual component's boiling temperatures. When a zeotropic mixture is boiled or condensed, the composition of the liquid and the vapor changes according to the mixtures's temperature-composition diagram.

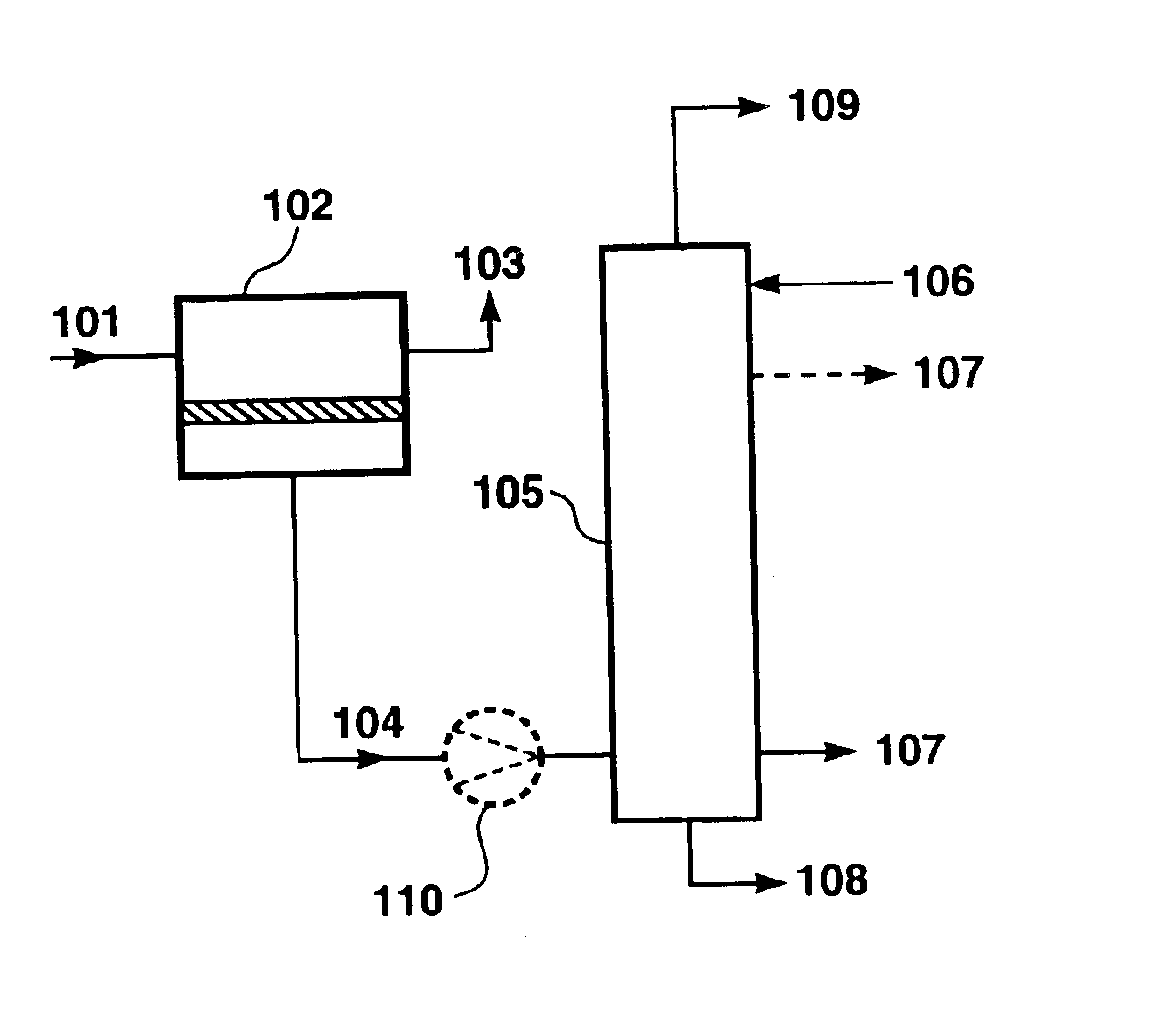

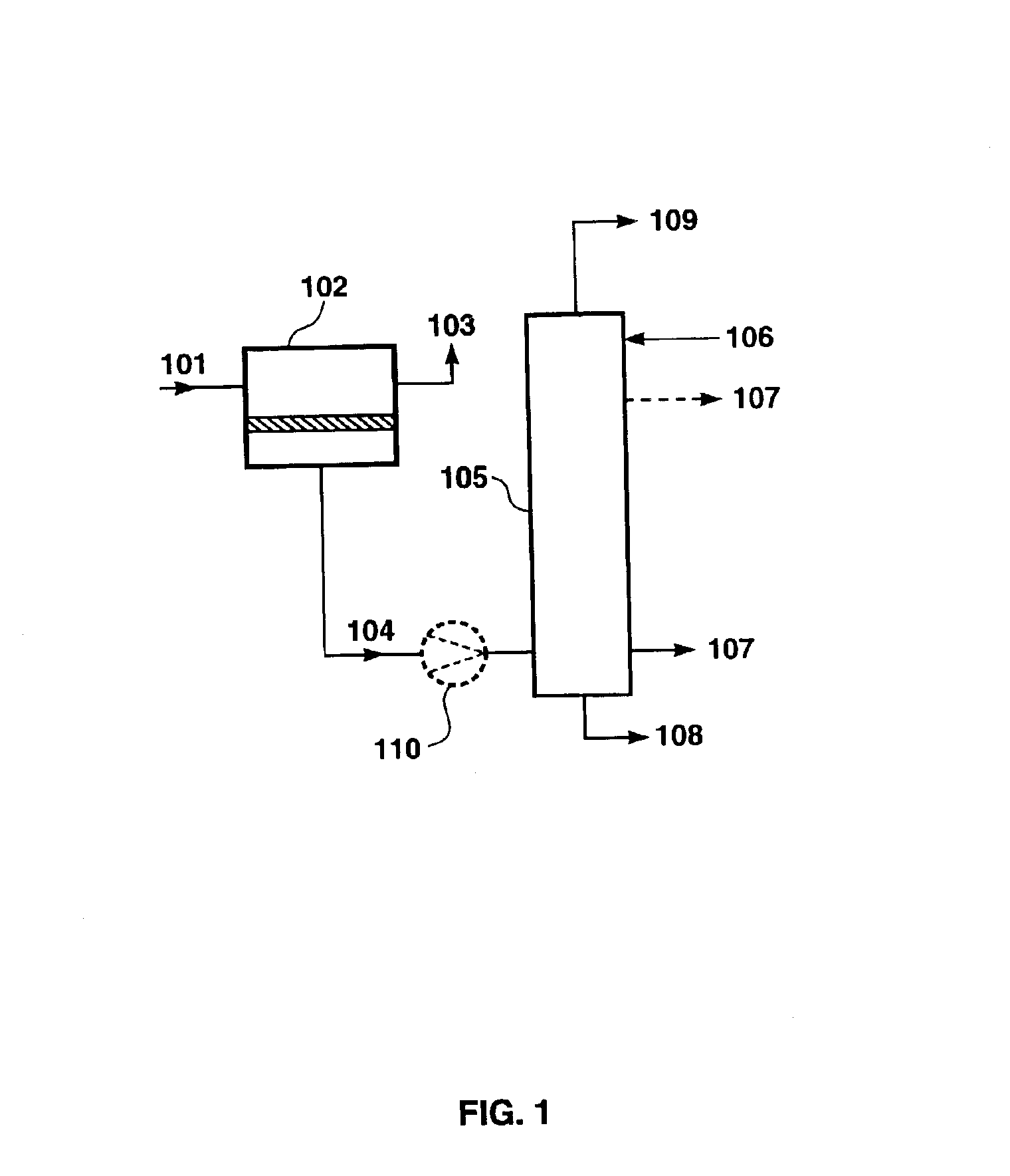

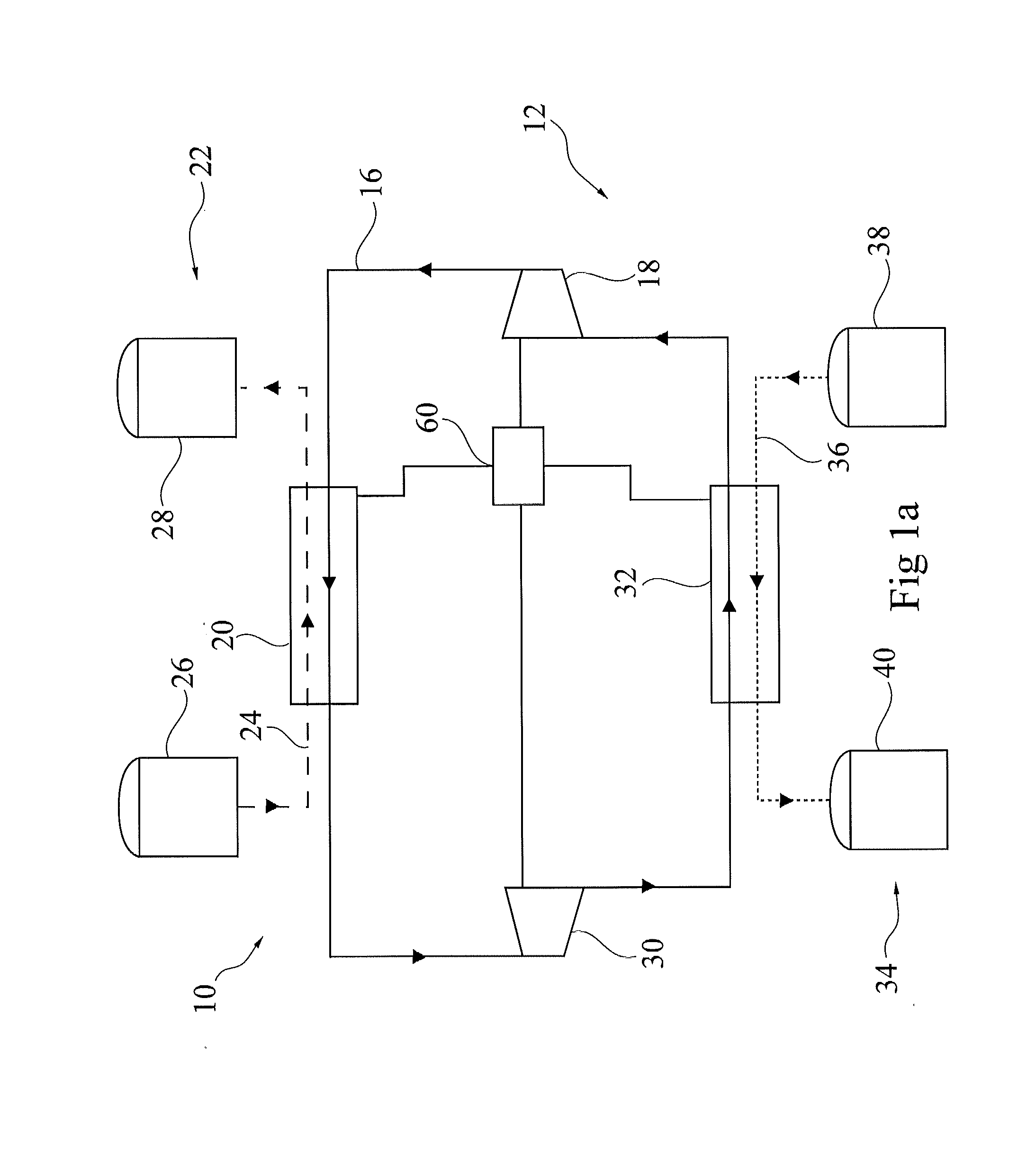

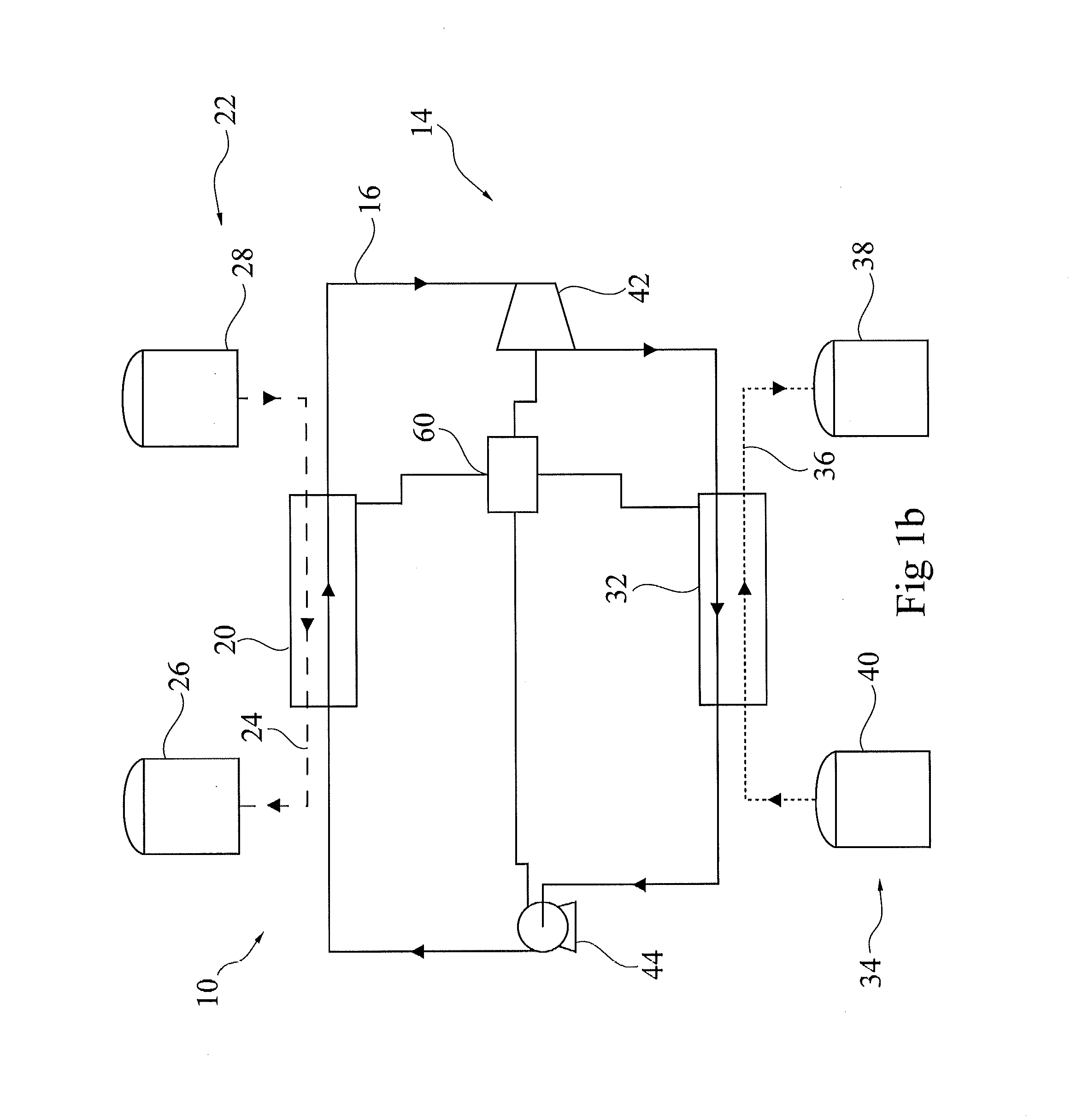

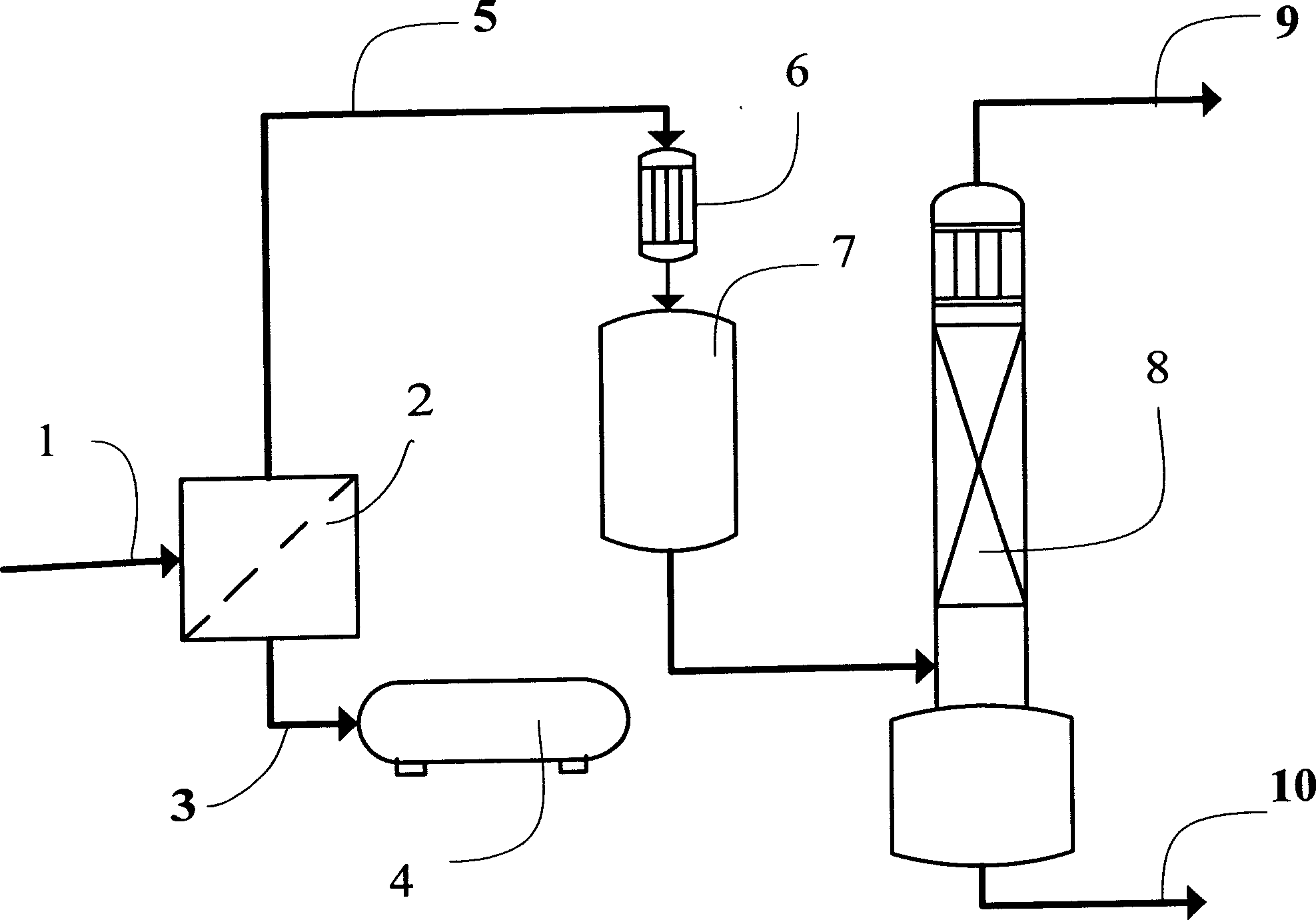

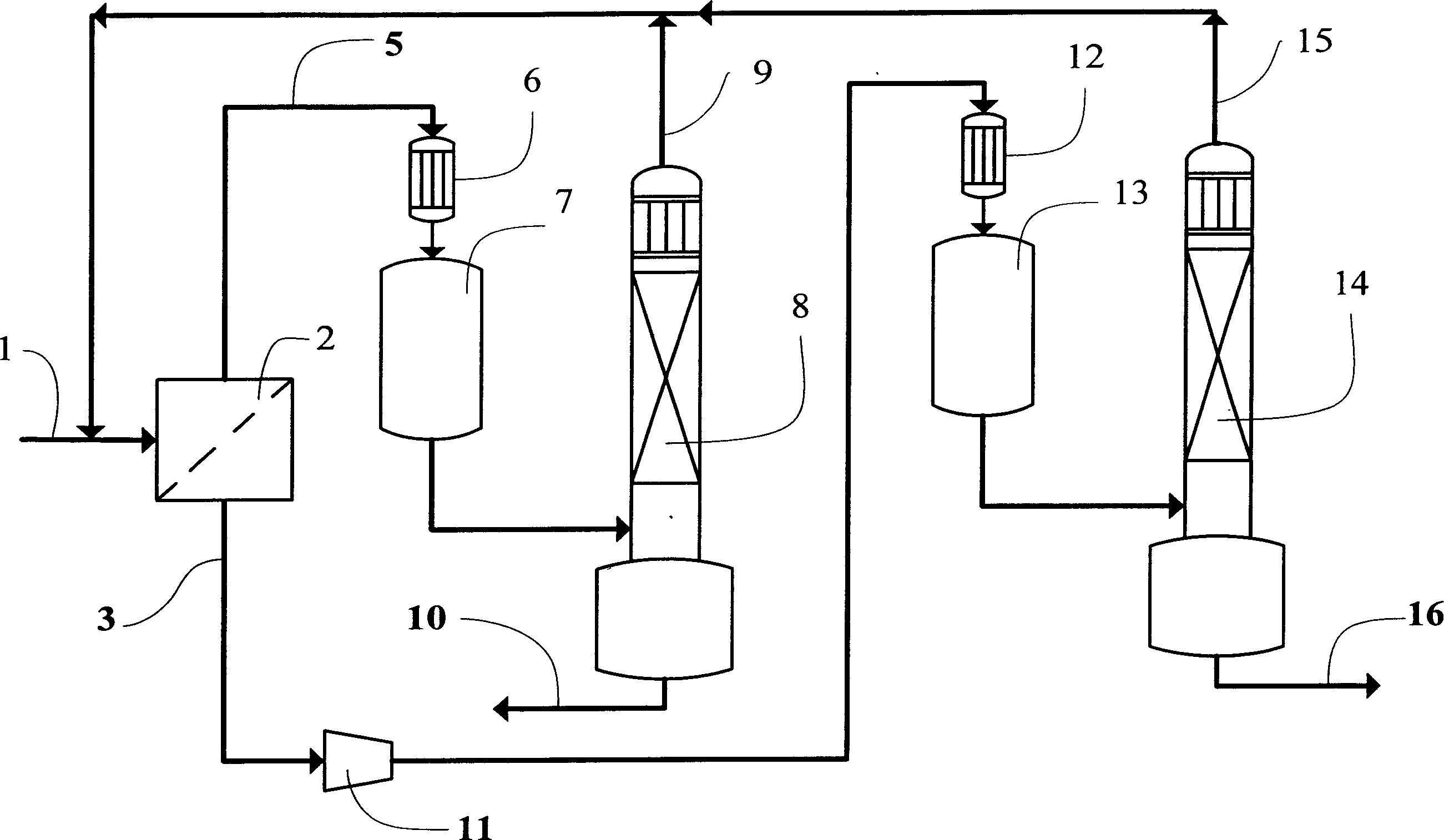

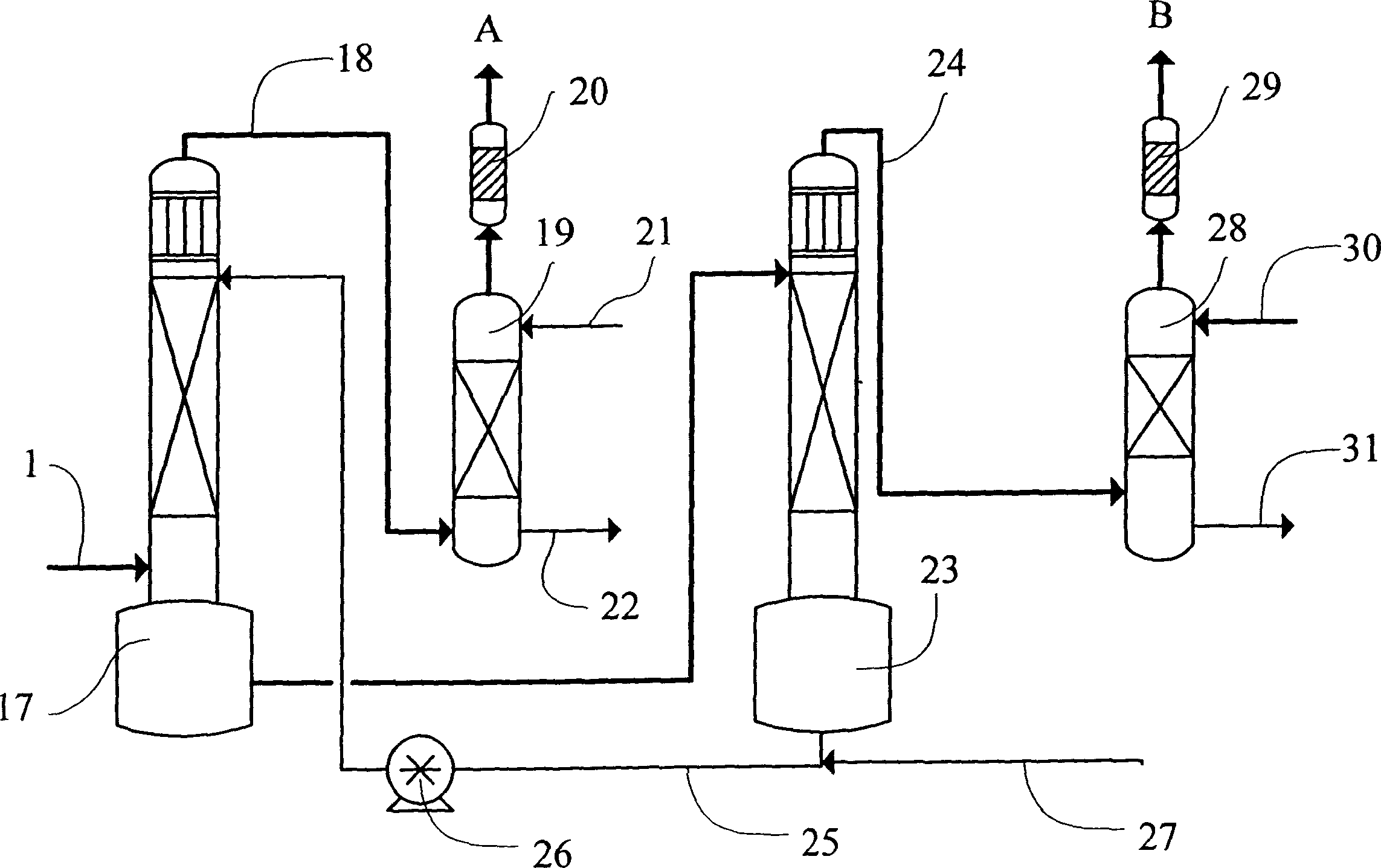

Separation of organic mixtures using gas separation or pervaporation and dephlegmation

InactiveUS6899743B2Easy to separateLow costSemi-permeable membranesSolid sorbent liquid separationZeotropic mixtureGas phase

A process for treating mixtures of organic components, including azeotropic mixtures. The process includes a gas- or liquid-phase membrane separation step in conjunction with a dephlegmation step to treat at least a portion of the permeate vapor from the pervaporation step. The process yields a membrane residue stream, a stream enriched in the more volatile component as the overhead stream from the dephlegmator and a condensate stream enriched in the less volatile component as a bottoms stream from the dephlegmator. Any of these may be the principal product of the process.

Owner:MEMBRANE TECH & RES

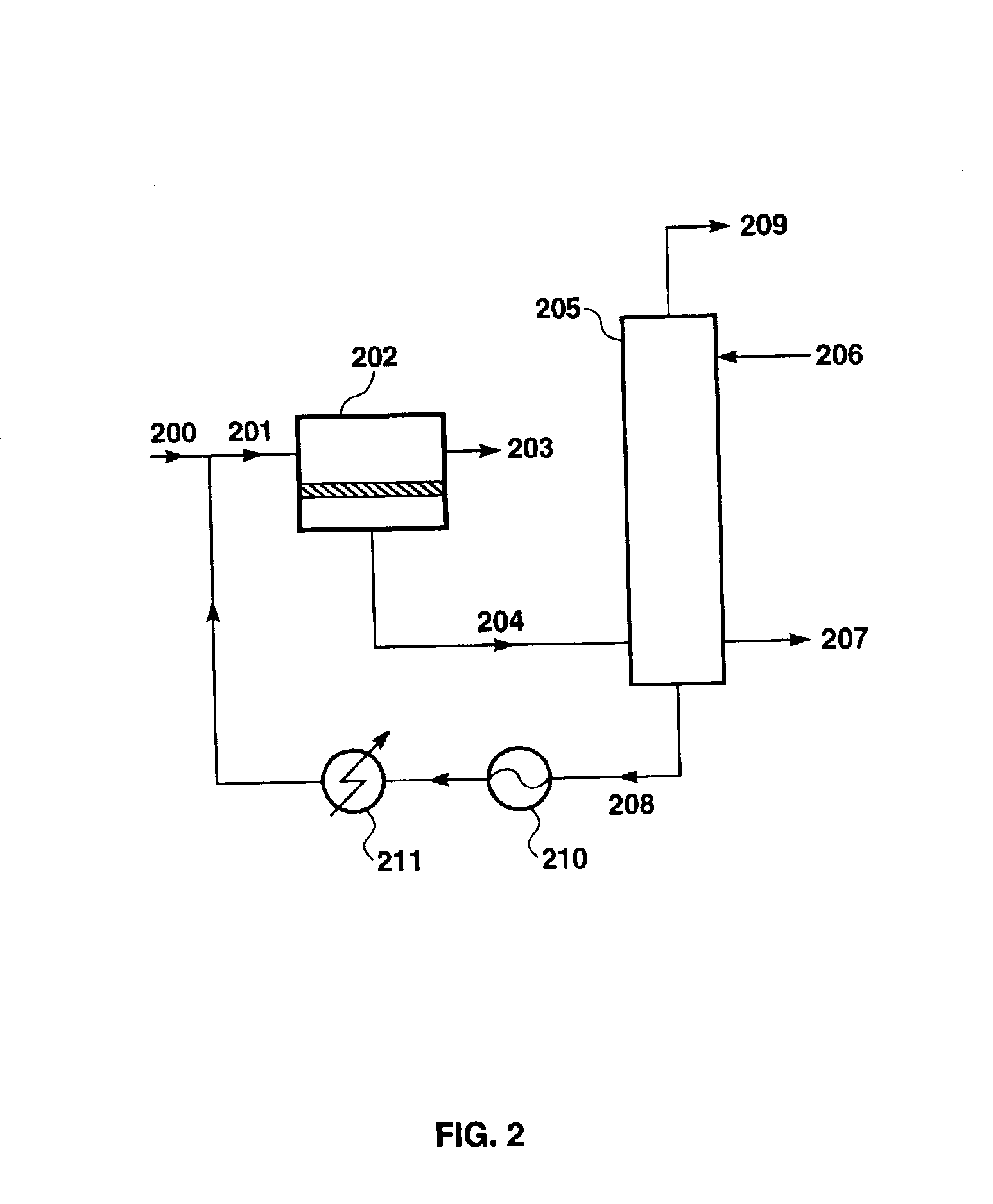

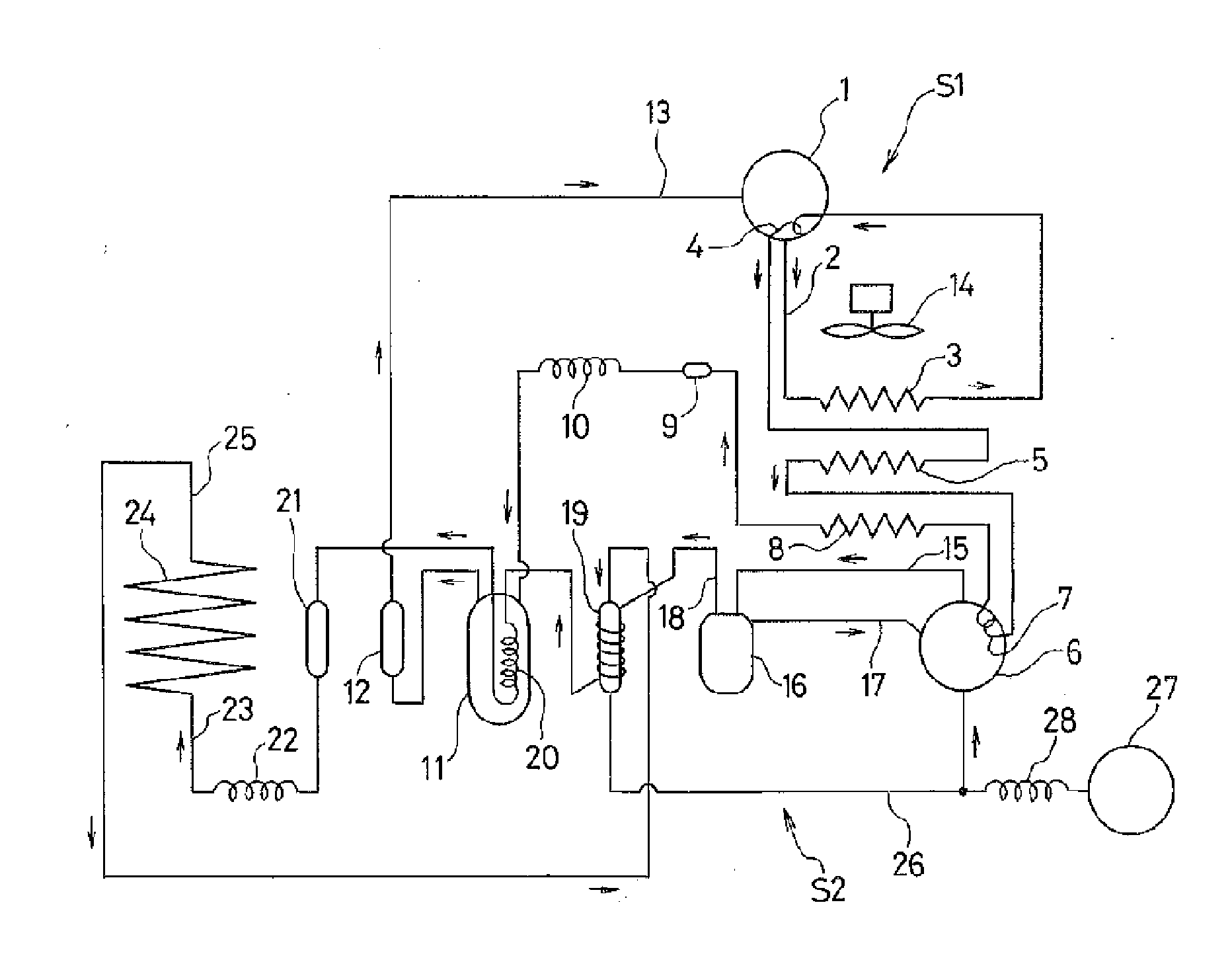

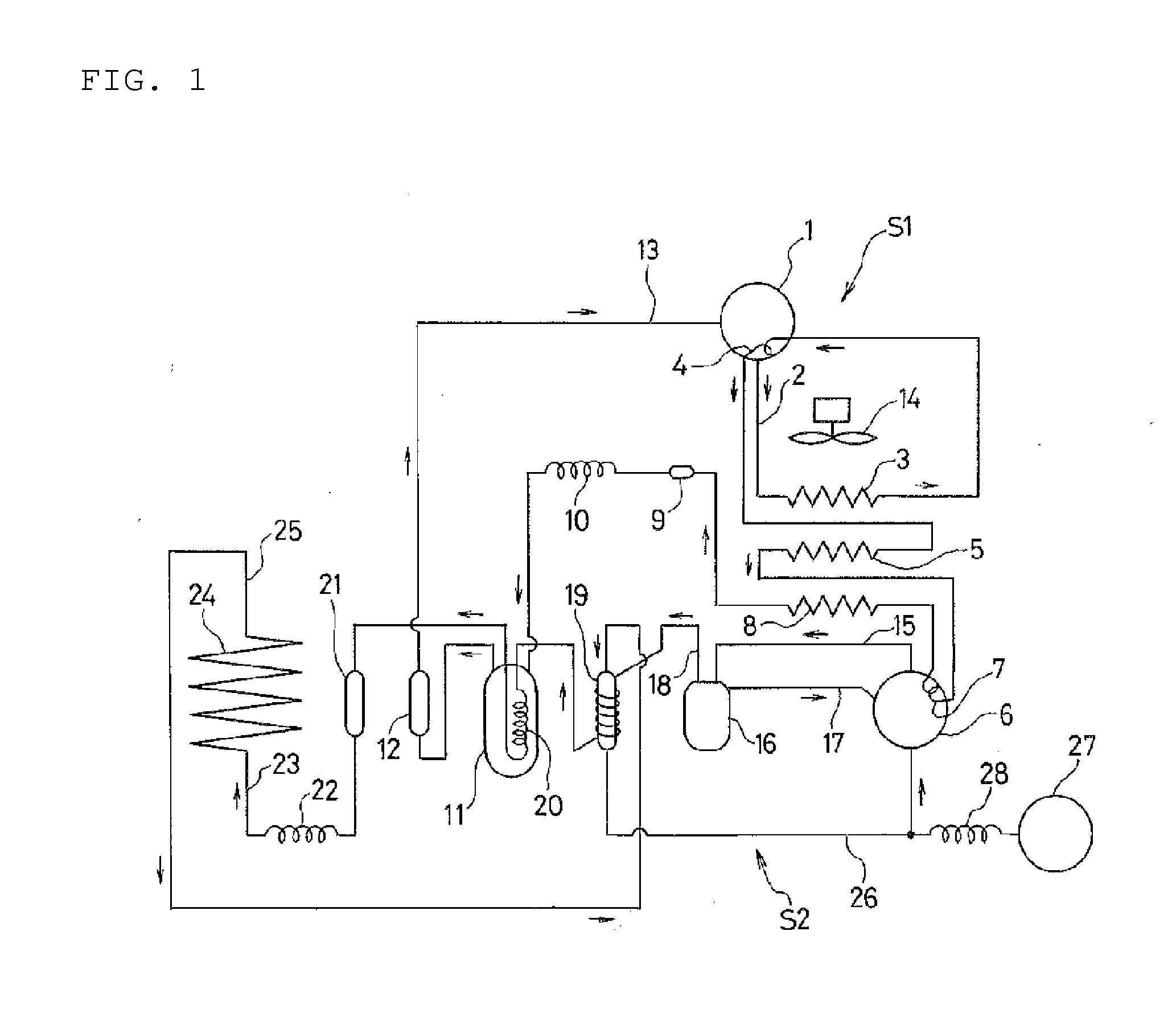

Thermoelectric energy storage system

A thermoelectric energy storage system and method are provided for storing electrical energy by transferring thermal energy to a thermal storage in a charging cycle, and for generating electricity by retrieving the thermal energy from the thermal storage in a discharging cycle. The thermoelectric energy storage includes a working fluid circuit configured to circulate a working fluid through a heat exchanger, and a thermal storage conduit configured to transfer a thermal storage medium from a thermal storage tank through the heat exchanger. The working fluid includes a zeotropic mixture. The working fluid is in a mixed vapor and liquid phase and has continuously rising or continuously falling temperature during heat transfer due to the working fluid including the zeotropic mixture.

Owner:ABB RES LTD

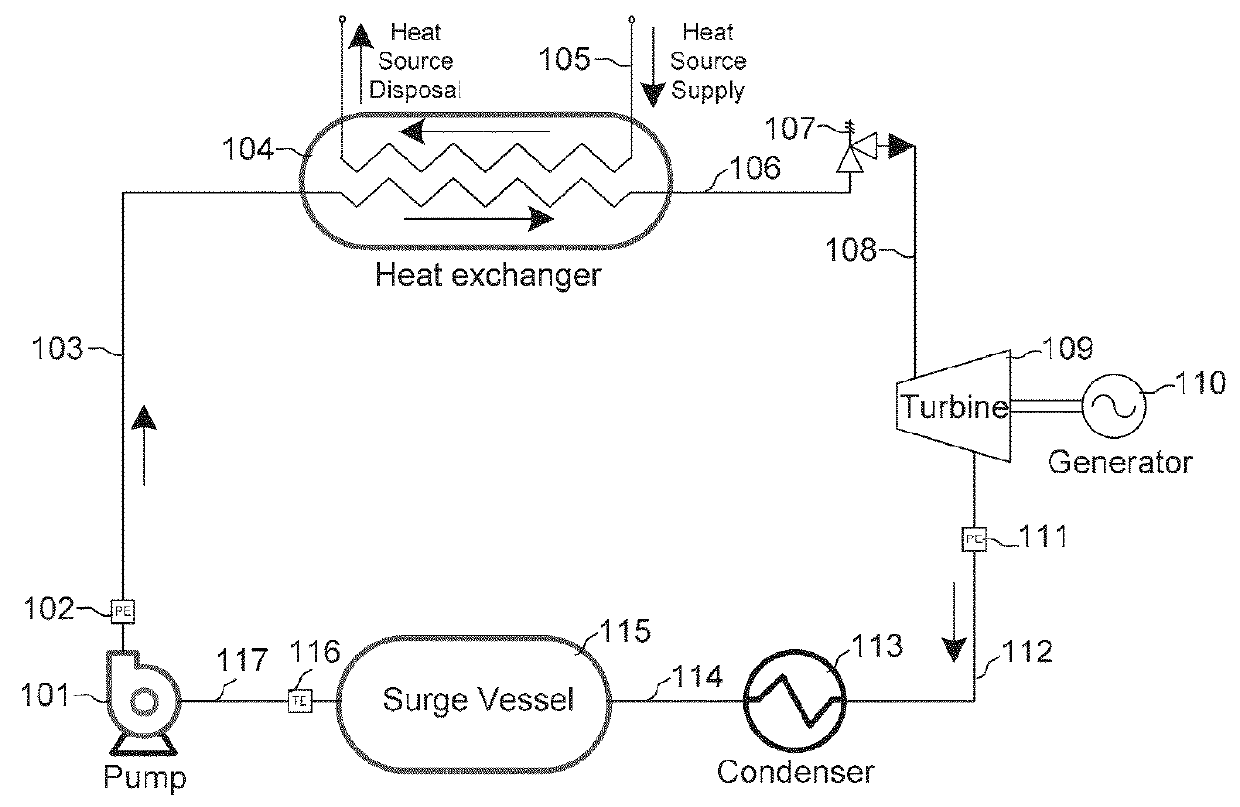

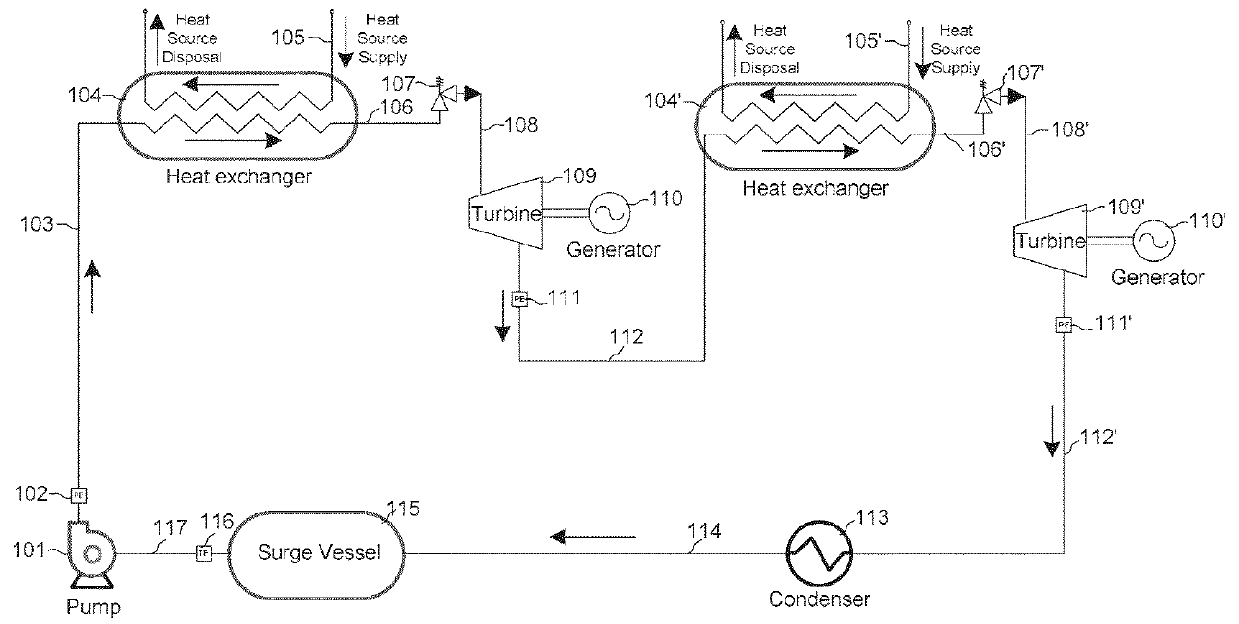

Method and system for generating power from low- and mid- temperature heat sources

ActiveUS20130213040A1Minimal human interventionValid conversionReciprocating combination enginesCombination enginesWorking fluidZeotropic mixture

A method and system for generating power from low- and mid-temperature heat sources using a zeotropic mixture as a working fluid. The zeotropic mixture working fluid is compressed to pressures above critical and heated to a supercritical state. The zeotropic mixture working fluid is then expanded to extract power. The zeotropic mixture working fluid is then condensed, subcooled, and collected for recirculation and recompression.

Owner:UNIV OF SOUTH FLORIDA

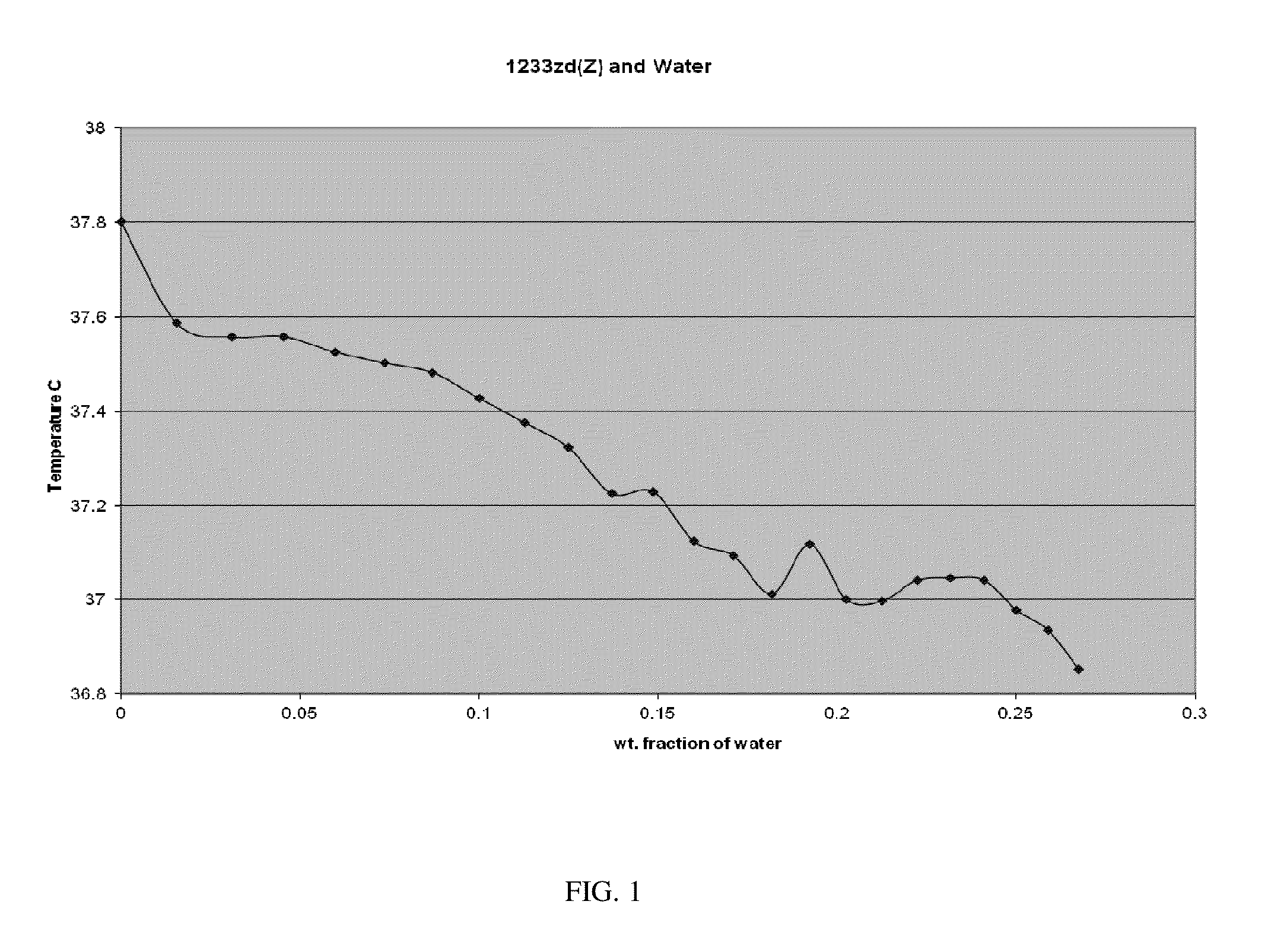

Azeotrope-like compositions comprising 1-chloro-3,3,3-trifluoropropene

An azeotrope-like mixture consisting essentially of chlorotrifluoropropene and at least one component selected from the group consisting of a C1-C3 alcohol, a C5-C6 hydrocarbon, a halogenated hydrocarbon, methylal, methyl acetone, water, nitromethane, and combinations thereof.

Owner:HONEYWELL INT INC

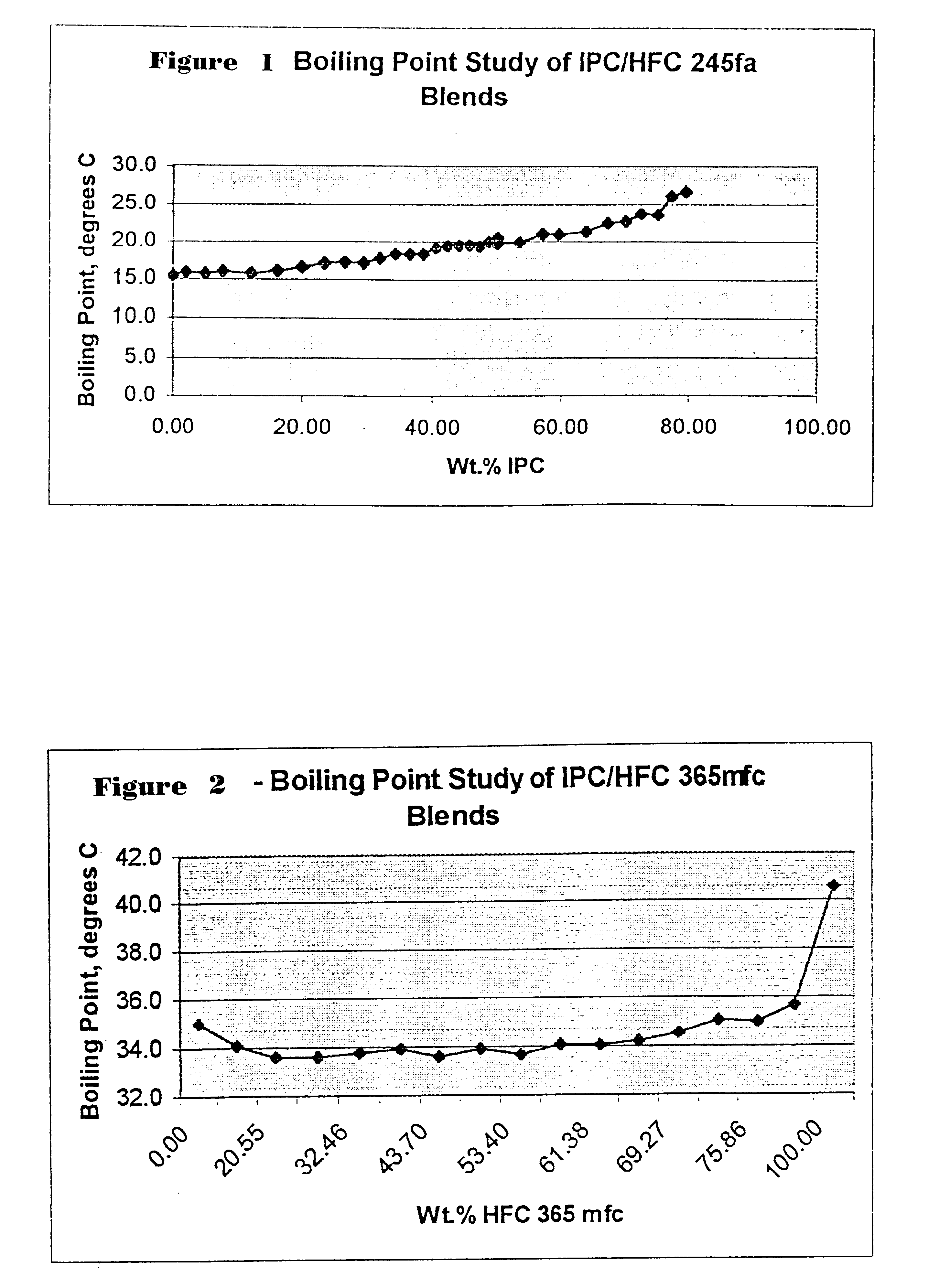

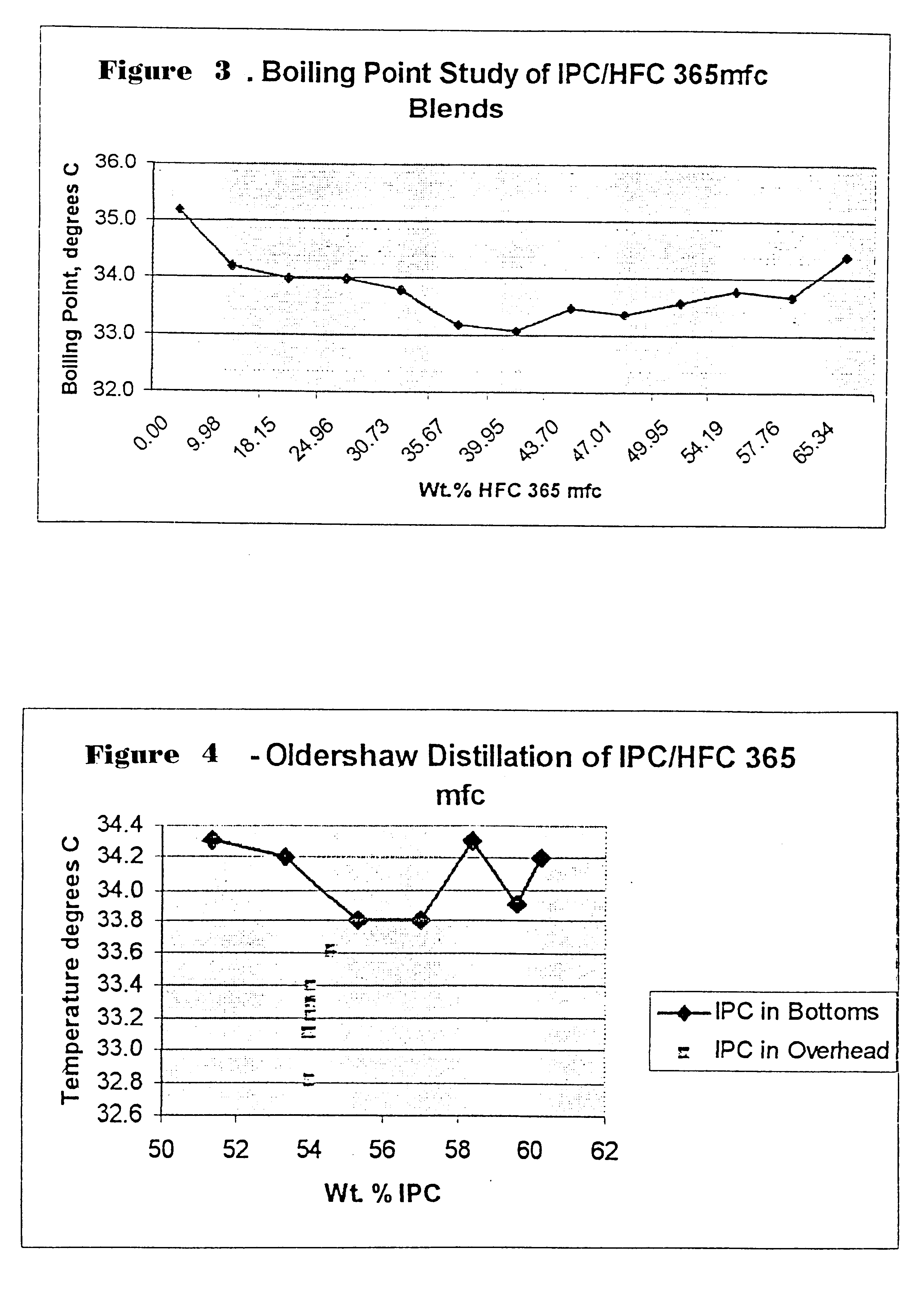

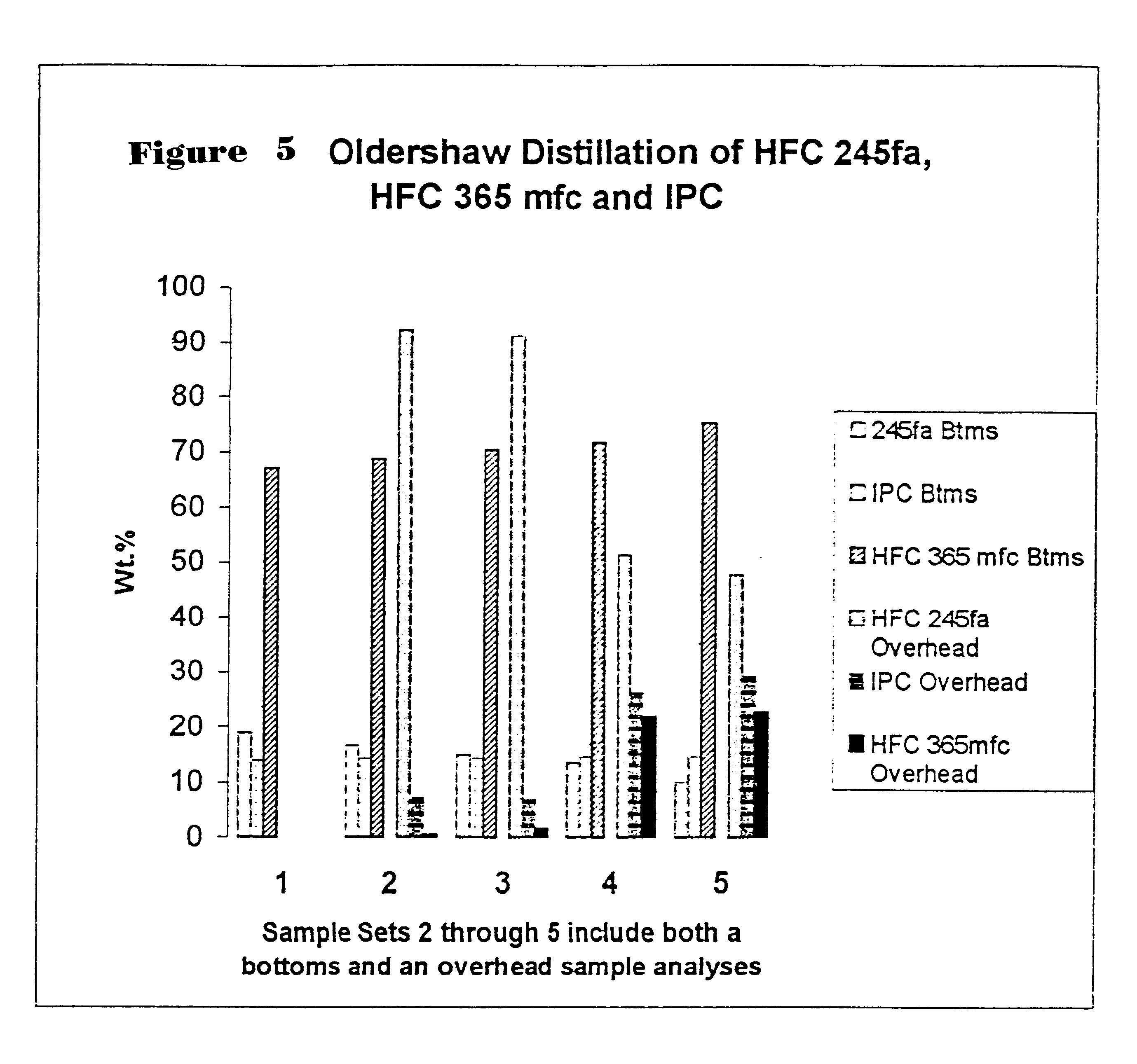

Isopropyl chloride with hydrofluorocarbon or hydrofluoroether as foam blowing agents

InactiveUS6646020B2Combustibility is reduced and eliminatedReduce flammabilityHeat-exchange elementsLiquid soapsPolyisocyanurateHydrofluoroether

A composition useful as a blowing agent having no flash point or reduced combustibility comprising 2-chloropropane and a gas selected from the group consisting of a fluorohydrocarbon, perfluorocarbons, fluoroethers, hydrofluoropolyethers and mixtures thereof is disclosed. A polyisocyanurate foam or a polyurethane modified polyisocyanurate foam having a mainly closed cell structure and also a method for preparing this foam, the latter comprising closed cells wherein a foam blowing agent consisting of a mixture of 2-chloropropane and one or more HFC compounds including pentafluoropropane, pentafluorobutane, heptafluoropropane, hexafluoropropane or pentafluoroethane are disclosed. Pentanes can be added if desired. Azeotropic mixtures in which 2-chloropropane is an ingredient are disclosed.

Owner:OCCIDENTAL CHEM CORP

Azeotrope-like compositions comprising 1-chloro-3,3,3-trifluoropropene

ActiveUS20120128964A1Cosmetic preparationsOrganic active ingredientsZeotropic mixture1,3,3,3-Tetrafluoropropene

An azeotrope-like mixture consisting essentially of a binary azeotrope-like mixture consisting essentially of trans-1-chloro-3,3,3-trifluoropropene (trans-HFO-1233zd) and a second component selected from the group consisting of 2,3,3,3-tetrafluoropropene (HFO-1234yf) and trans-1,3,3,3-tetrafluoropropene (trans-HFO-1234ze), and combinations of these and various uses thereof.

Owner:HONEYWELL INT INC

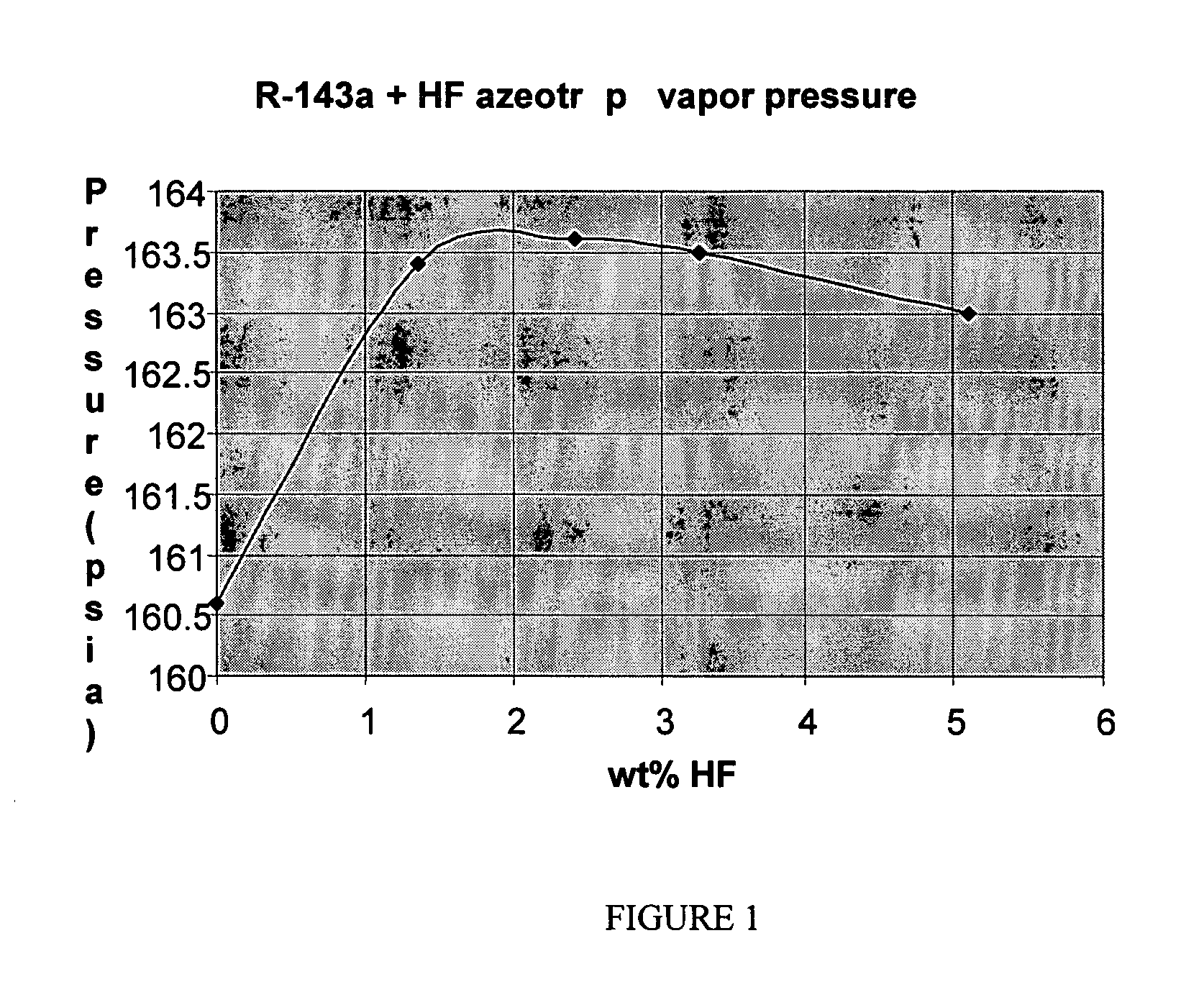

Azeotrope-like compositions of trifluoroethane and hydrogen fluoride

The invention relates to azeotropic and azeotrope-like mixtures of 1,1,1-trifluoroethane (HFC-143a) and hydrogen fluoride and a process for separating the azeotrope-like mixtures. The compositions of the invention are useful as an intermediate in the production of HFC-143a. The latter is useful as a nontoxic, zero ozone depleting fluorocarbon useful as a solvent, blowing agent, refrigerant, cleaning agent and aerosol propellant.

Owner:HONEYWELL INT INC

Azeotrope-like compositions comprising trans-1-chloro-3,3,3-trifluoropropene

ActiveUS20100102273A1Other chemical processesNon-surface-active detergent compositionsZeotropic mixtureMedicinal chemistry

An azeotrope-like mixture consisting essentially of chlorotrifluoropropene and at least one component selected from the group consisting of pentane, hexane, methanol, and trans-1,2-dichloroethene.

Owner:HONEYWELL INT INC

Binary refrigerating apparatus

InactiveUS20160018135A1Low GWP valueIncrease volumeCompression machines with cascade operationHeat-exchange elementsZeotropic mixtureEngineering

A binary refrigerating apparatus employs a refrigerant composition that has a small global-warming potential (GWP) to be earth friendly, can be used as a refrigerant capable of achieving a low temperature of −80° C., and is excellent in refrigerating capacity and other performance. A refrigerant composition used as a low-temperature-side refrigerant is a refrigerant mixture including a non-azeotropic mixture in which 20% by mass or less of carbon dioxide (R744) is mixed to difluoroethylene (R1132a). A refrigerant composition used as a high-temperature-side refrigerant is a combination of: a non-azeotropic mixture comprising the refrigerant group of difluoromethane (R32), pentafluoroethane (R125), 1,1,1,2-tetrafluoroethane (R134a) and 1,1,3-trifluoro ethane (R143a); and 1,1,1,2,3-pentafluoropentene (HFO-1234ze), having a global-warming potential (GWP) of 1500 or less.

Owner:PANASONIC HEALTHCARE HLDG CO LTD

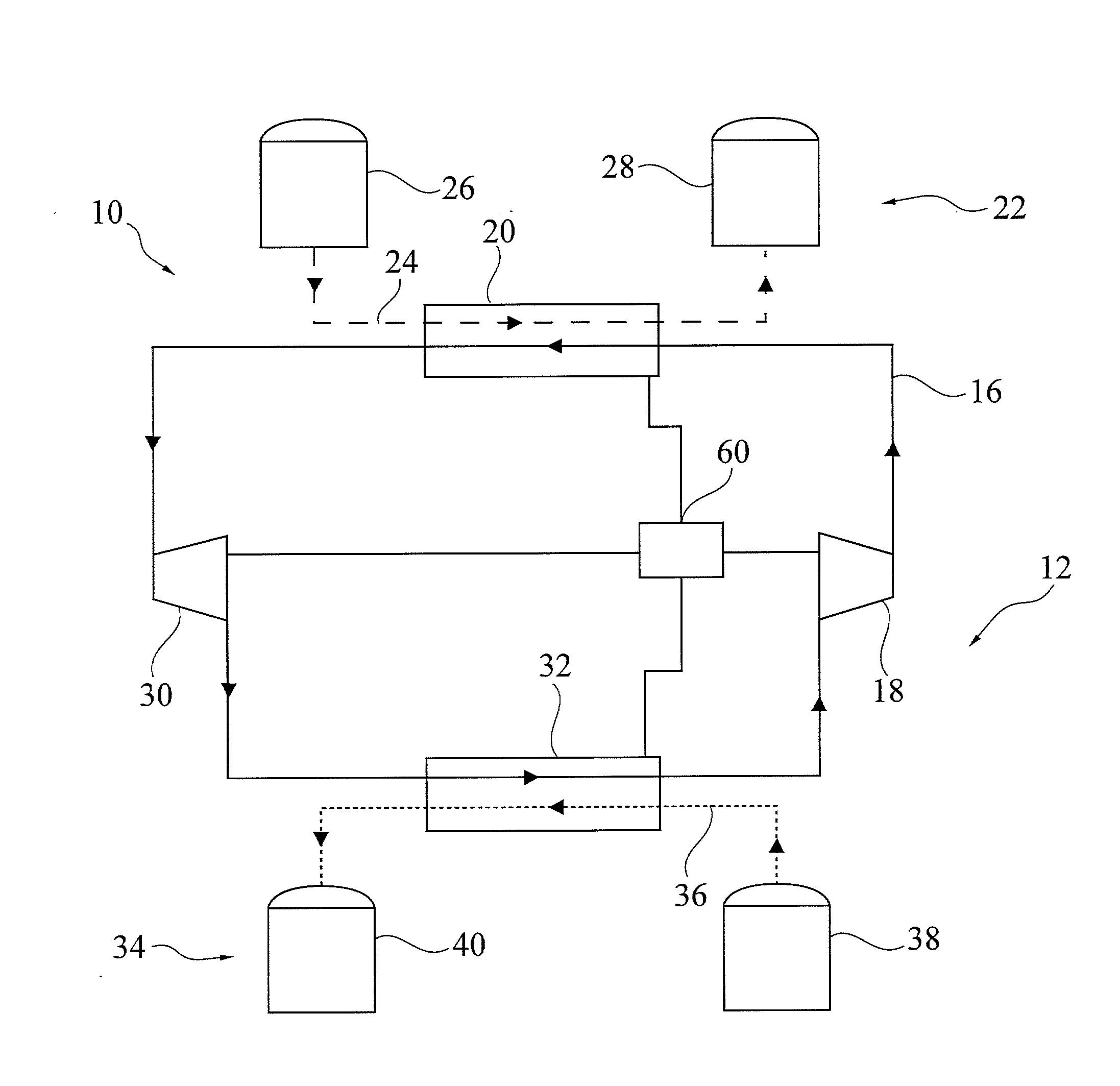

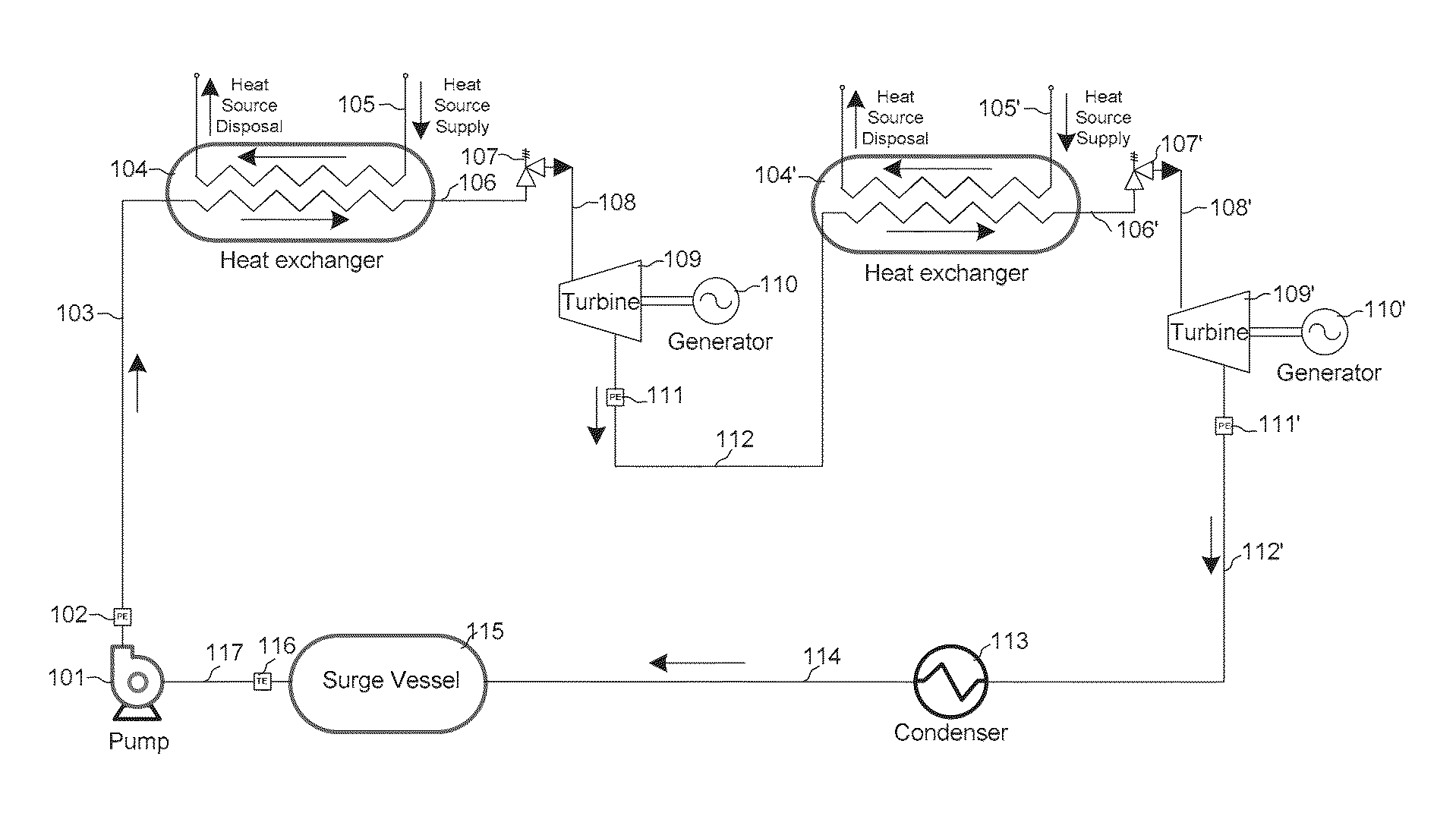

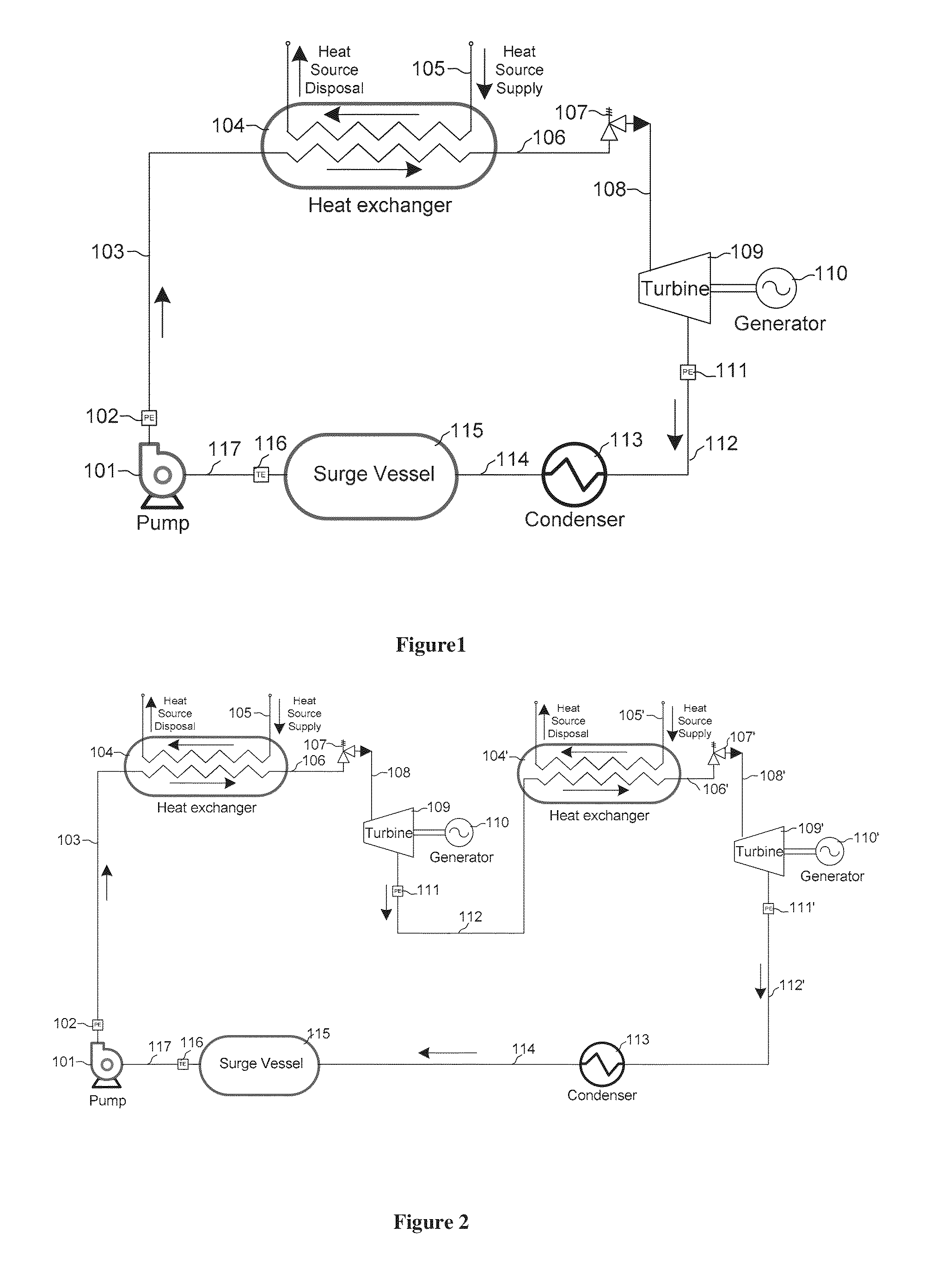

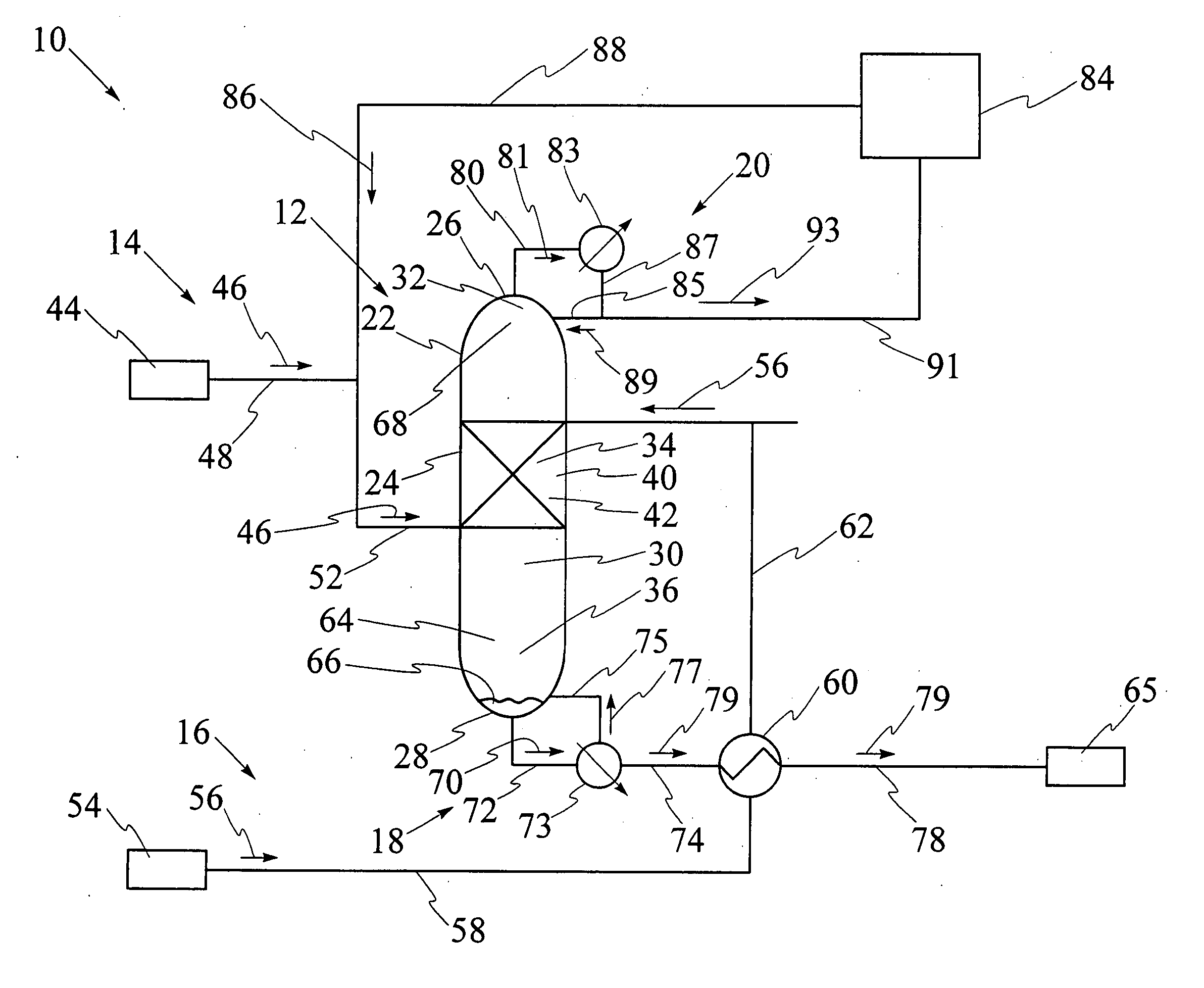

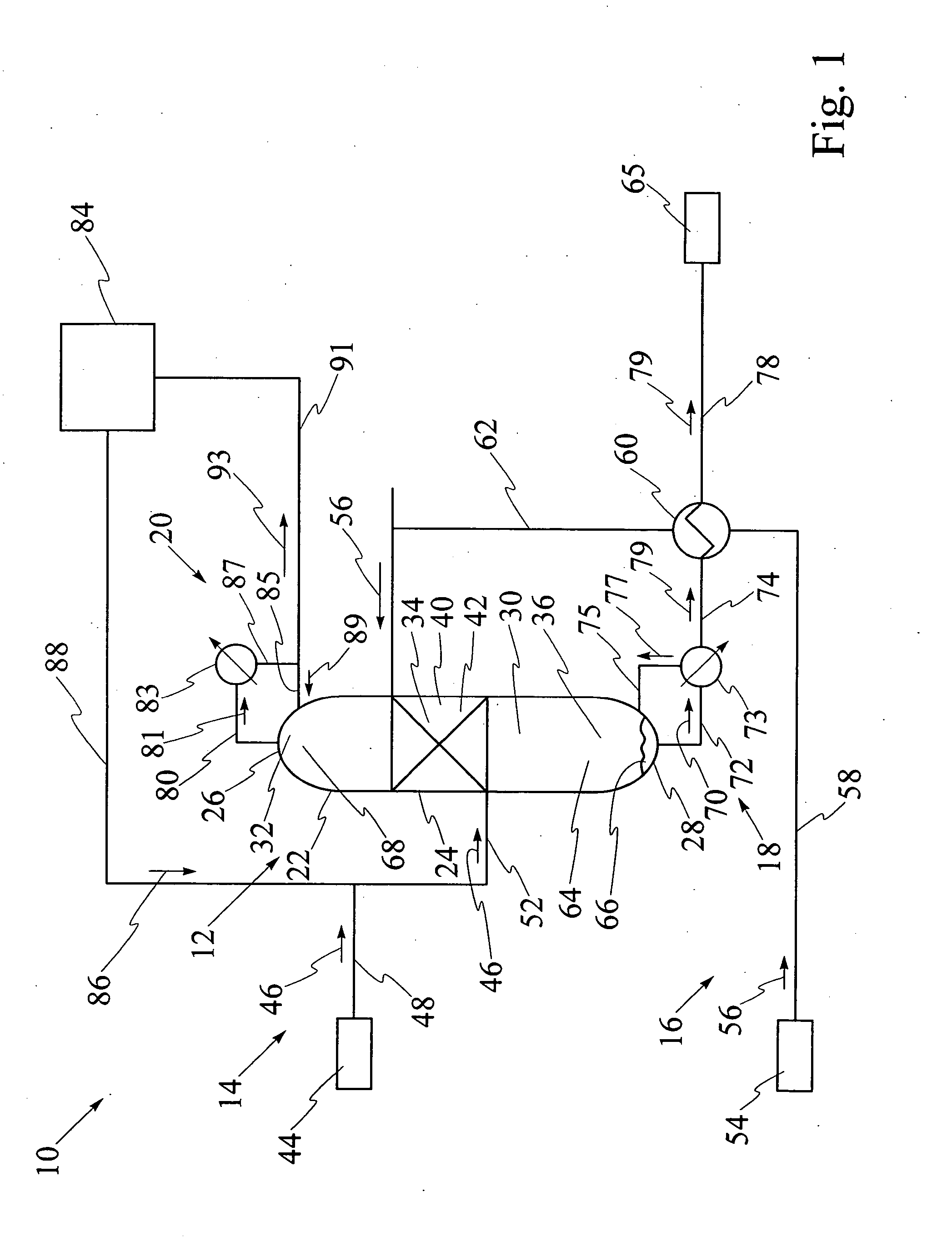

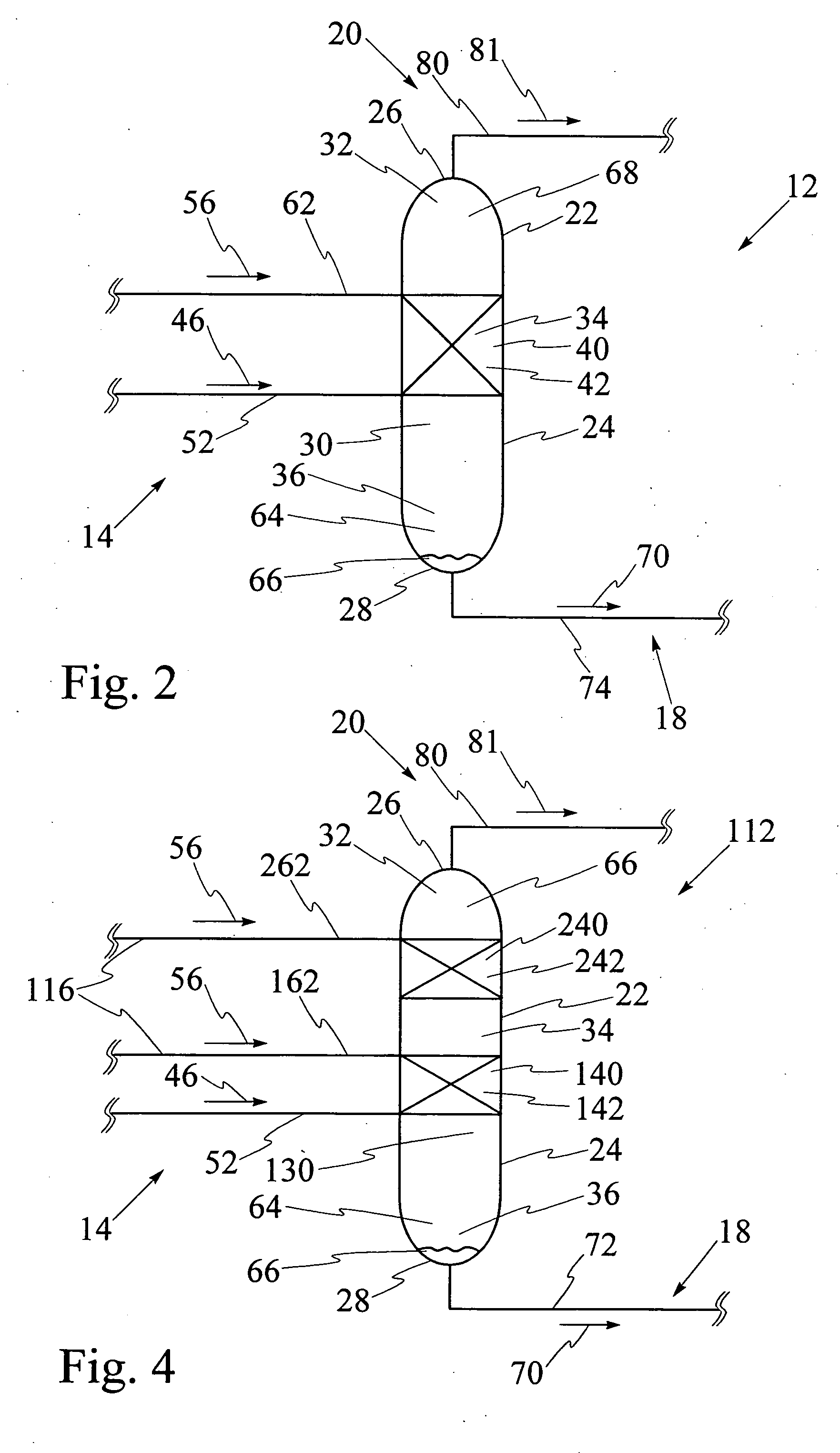

Method and system for generating power from low- and mid- temperature heat sources using supercritical rankine cycles with zeotropic mixtures

ActiveUS9376937B2Thermally matched wellSimple configurationReciprocating combination enginesCombination enginesWorking fluidZeotropic mixture

A method and system for generating power from low- and mid-temperature heat sources using a zeotropic mixture as a working fluid. The zeotropic mixture working fluid is compressed to pressures above critical and heated to a supercritical state. The zeotropic mixture working fluid is then expanded to extract power. The zeotropic mixture working fluid is then condensed, subcooled, and collected for recirculation and recompression.

Owner:UNIV OF SOUTH FLORIDA

Azeotrope-like compositions comprising trans-1-chloro-3,3,3-trifluoropropene

ActiveUS7935268B2Other chemical processesNon-surface-active detergent compositionsZeotropic mixture1,2-Dichloroethene

An azeotrope-like mixture consisting essentially of chlorotrifluoropropene and at least one component selected from the group consisting of pentane, hexane, methanol, and trans-1,2-dichloroethene.

Owner:HONEYWELL INT INC

Foam-forming compositions containing azeotropic or azeotrope-like mixtures containing z-1,1,1,4,4,4-hexafluoro-2-butene and their uses in the preparation of polyisocyanate-based foams

Foam-forming compositions containing azeotropic or azeotrope-like mixtures containing cis-1,1,1,4,4,4-hexafluoro-2-butene are disclosed. The foam-forming composition contains (a) an azeotropic or azeotrope-like mixture of cis-1,1,1,4,4,4-hexafluoro-2-butene with methyl formate, 1,1,1,3,3-pentafluorobutane, trans-1,2-dichloroethylene, pentane, isopentane, cyclopentane, HFC-245fa, or dimethoxymethane; and (b) an active hydrogen-containing compound having two or more active hydrogens. Also disclosed is a closed-cell polyurethane or polyisocyanurate polymer foam prepared from reaction of an effective amount of the foam-forming composition with a suitable polyisocyanate. Also disclosed is a process for producing a closed-cell polyurethane or polyisocyanurate polymer foam by reacting an effective amount of the foam-forming composition with a suitable polyisocyanate.

Owner:THE CHEMOURS CO FC LLC

Method for charging refrigerant blend

InactiveUS6018952AFluid circulation arrangementHeat-exchange elementsZeotropic mixtureElectrical and Electronics engineering

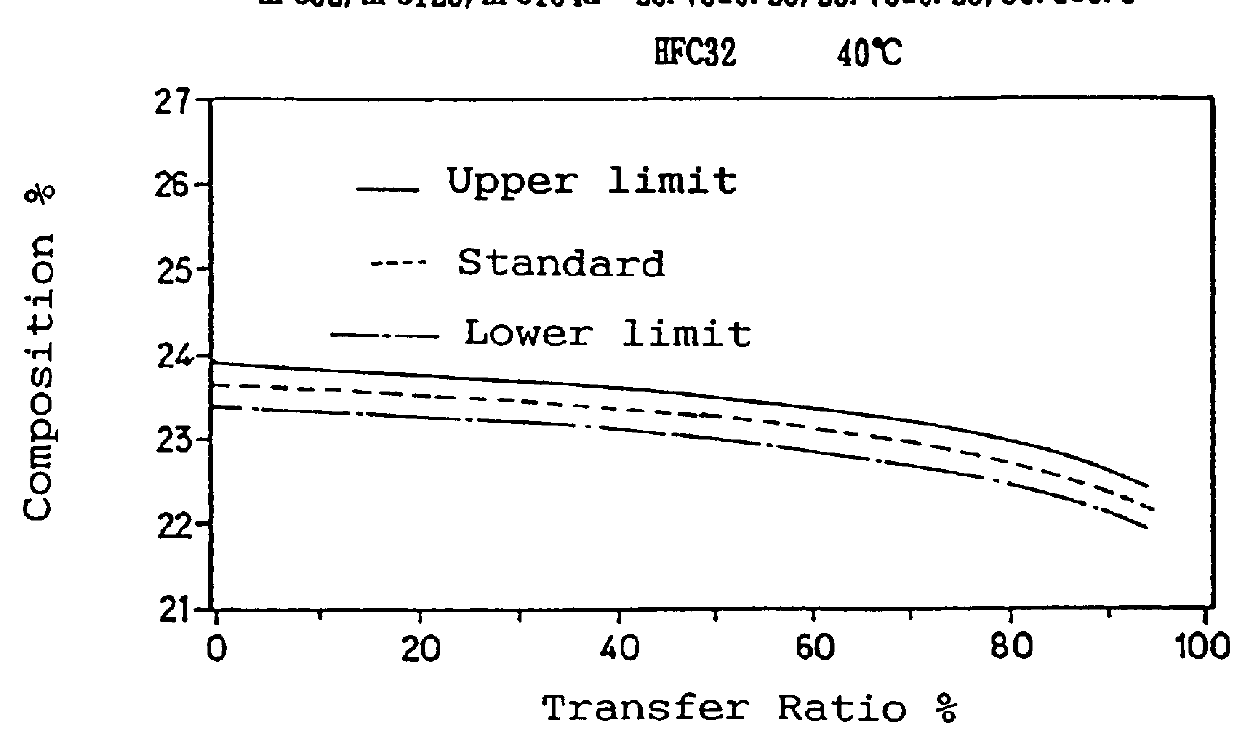

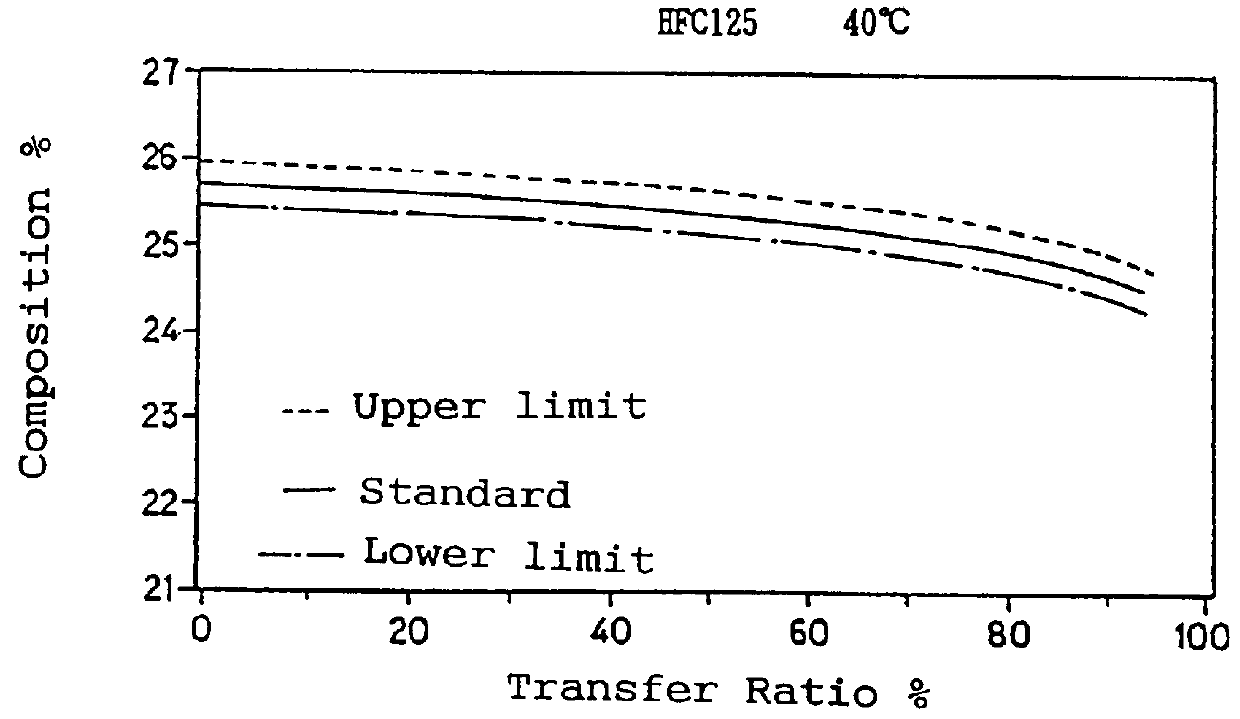

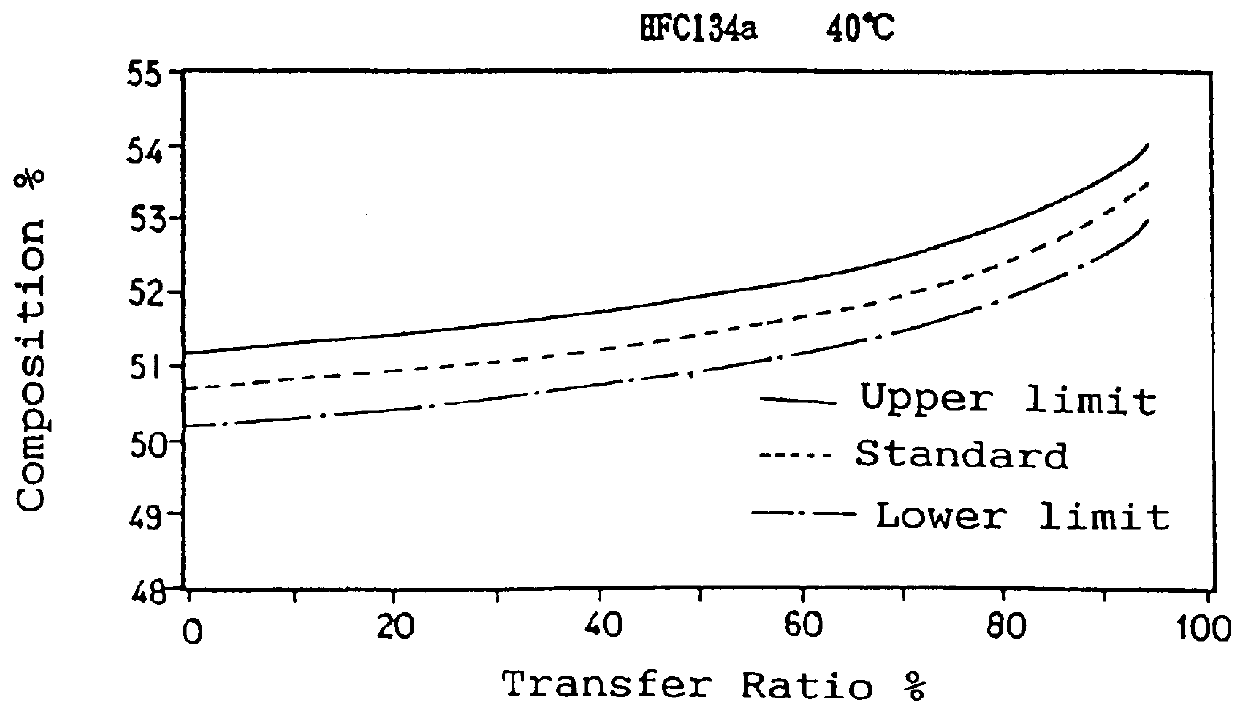

The present invention provides A method for charging a refrigerant blend, when using as a refrigerant a non-azeotropic blend whose permissible range falls within 22 to 24% of difluoromethane, 23 to 27% of pentafluoroethane and 50 to 54% of 1,1,1,2-tetrafluoroethane, comprising adjusting a composition of non-azeotropic blend in a feeding container to the level of 23.5 to 24.0% of difluoromethane, 25.5 to 26.0% of pentafluoroethane and 50.0 to 51.0% of 1,1,1,2-tetrafluoroethane, discharging and transferring the non-azeotropic blend from the feeding container in liquid phase into another container in which a refrigerant is used so as to allow the composition change associated with the transfer to fall within the permissible range; and a method for producing a vapor compression refrigerating equipment.

Owner:DAIKIN IND LTD

Azeotrope-Like Compositions Of 2,3,3,3-Tetrafluoropropene And 3,3,3-Trifluoropropene

InactiveUS20100119460A1Cosmetic preparationsNon-macromolecular adhesive additivesZeotropic mixture2,3,3,3-Tetrafluoropropene

Provided are azeotropic or azeotrope-like mixtures of 2,3,3,3-tetrafluoropropene (1234yf) and 3,3,3-trifluoropropene (1243zf), as well as methods for producing and using the same.

Owner:HONEYWELL INT INC

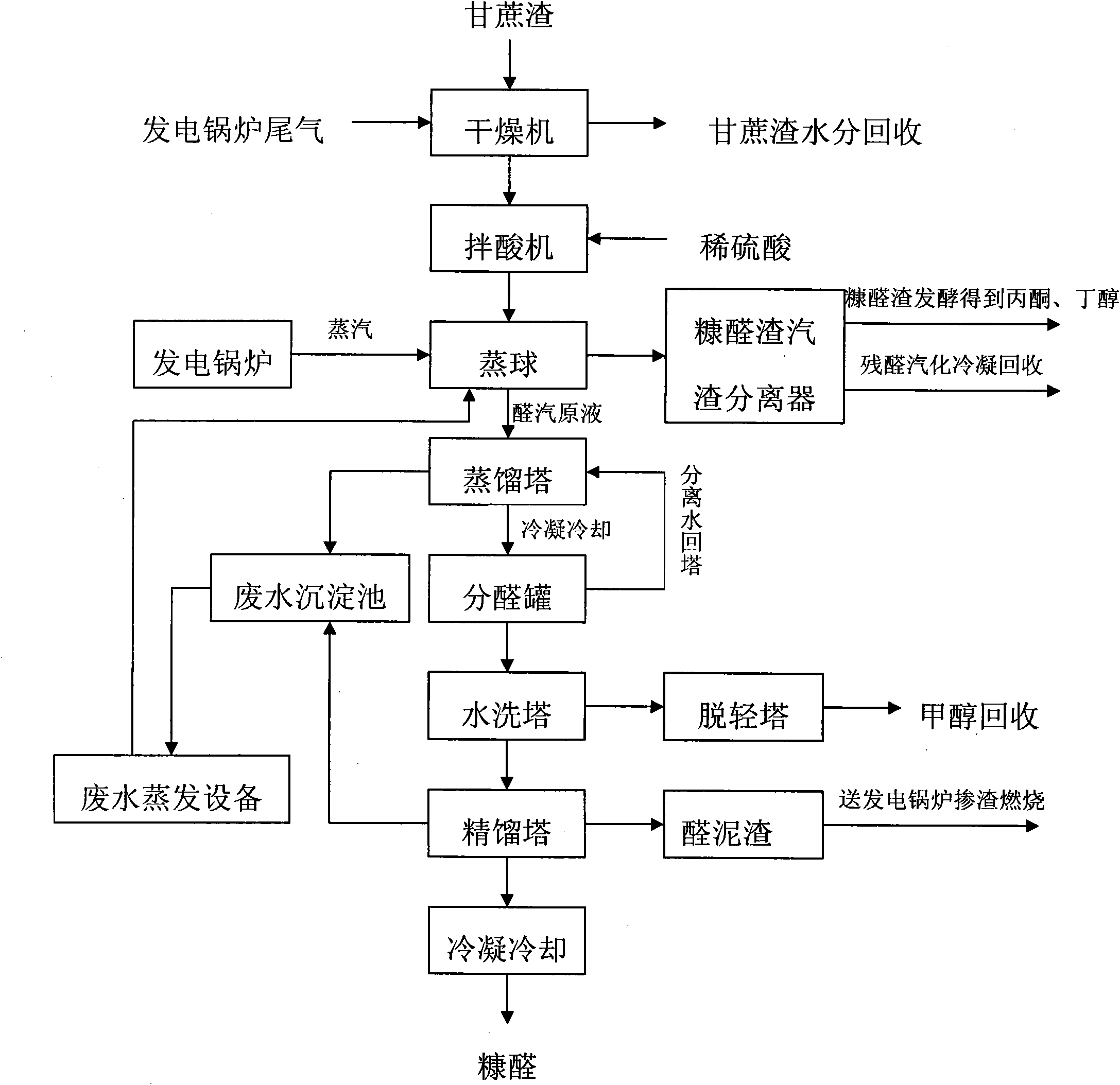

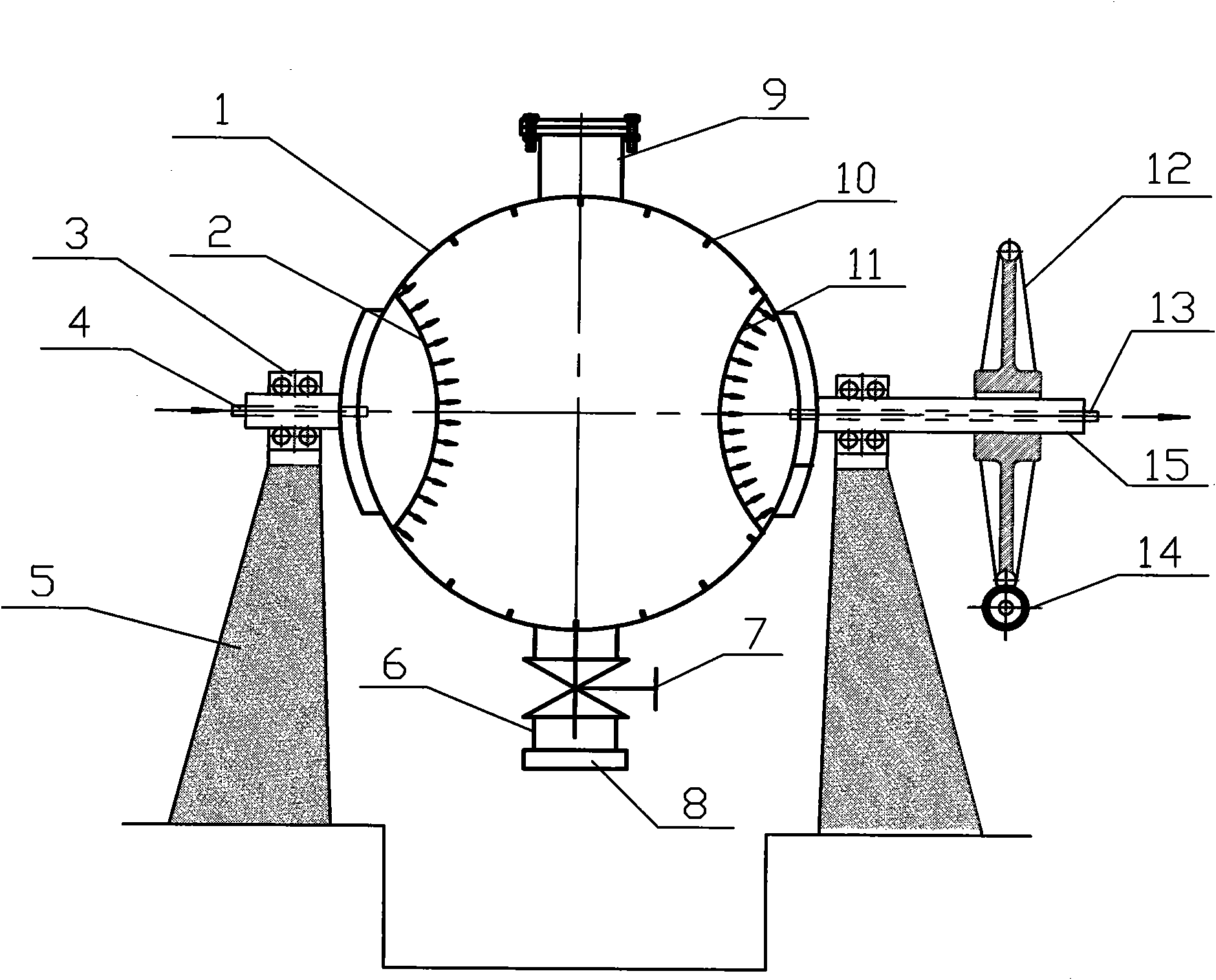

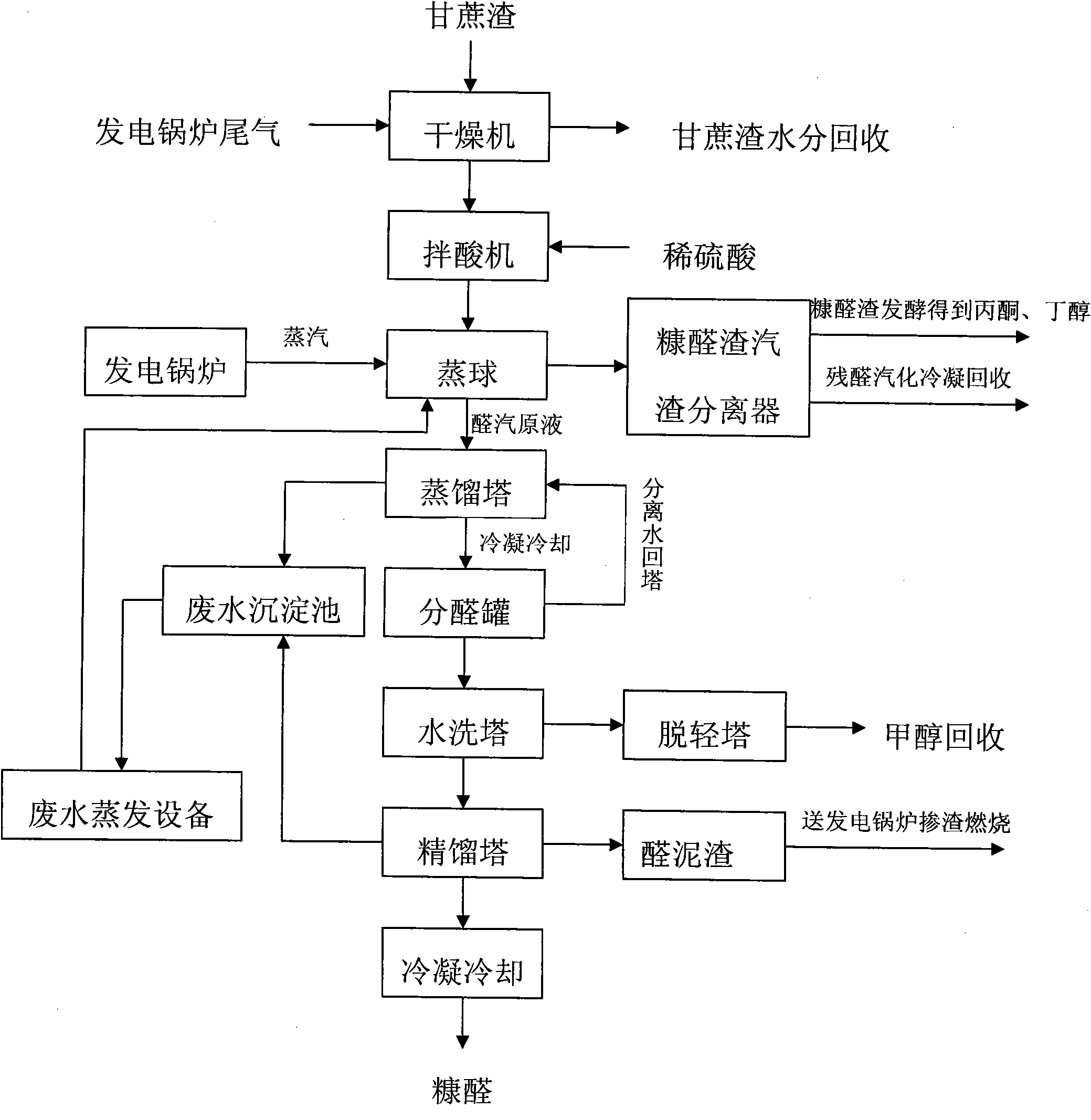

Process for producing furfural by bagasse

InactiveCN101914078AEasy dischargeSmooth slag dischargeOrganic chemistryDrying gas arrangementsDistillationFurfural

The invention discloses a process for producing furfural by bagasse, which comprises the following steps of: after drying and stirring acid into bagasse used as a raw material, delivering the bagasse into a spherical boiler for hydrolyzing for two hours so as to form an aldehyde steam stock solution; then delivering the obtained aldehyde steam stock solution into a primary distillation tower for distilling over most of water; after condensing an aldehyde water azeotropy mixture, delivering the aldehyde water azeotropy mixture into an aldehyde separating tank for delaminating; delivering rough furfural into a water scrubber for washing most acetic acid and methanol out of the rough furfural; and then refining in a rectifying tower to obtain finished product furfural; processing wastewater separated by the water scrubber by using a light component removing tower for recycling methanol; and after separating aldehyde steam in the furfural residues separated by the spherical boiler through a furfural residue steam-residue separator, adding cellulase into the furfural residues for fermenting to obtain acetone and butanol. The furfural is extracted from bagasse left after sugar production, and the cellulose left after furfural production is added into the furfural residues for fermenting to obtain the acetone and the butanol, thereby achieving the aims of clean co-production and comprehensive utilization. By adopting the self-made spherical boiler instead of the traditional hydrolysis kettle, the invention solves the problem of difficult residue discharge.

Owner:山东瑞德生物科技有限公司

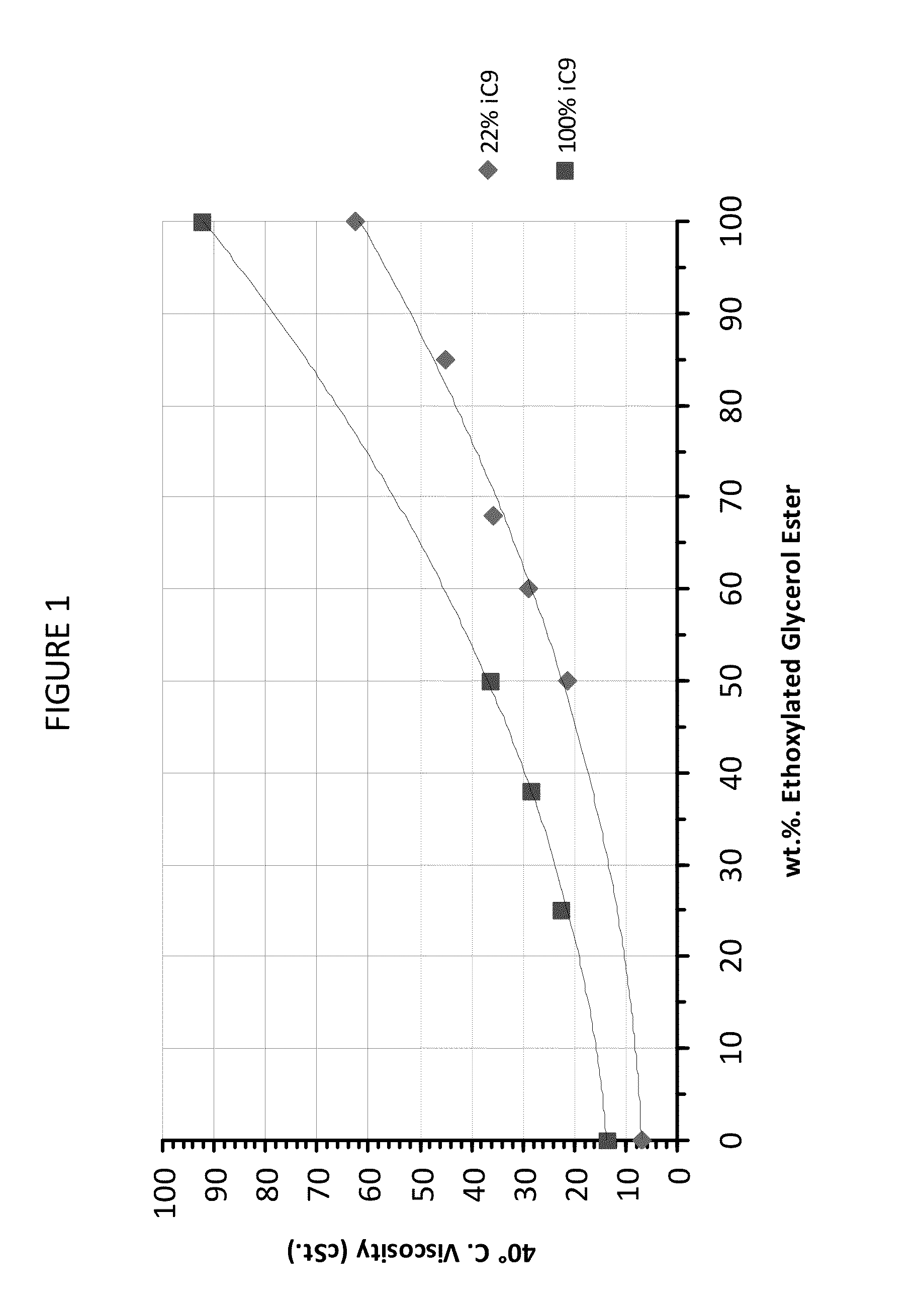

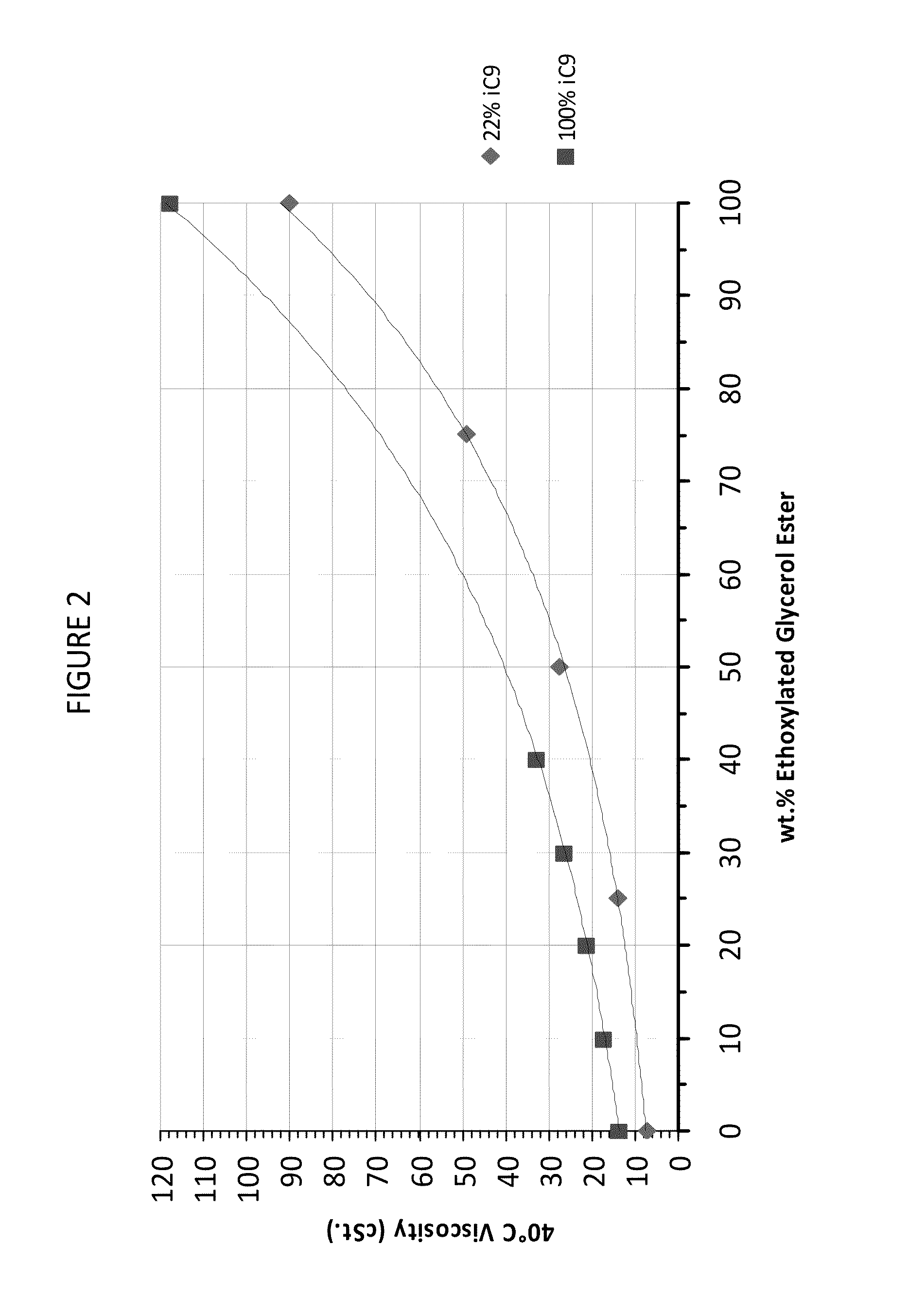

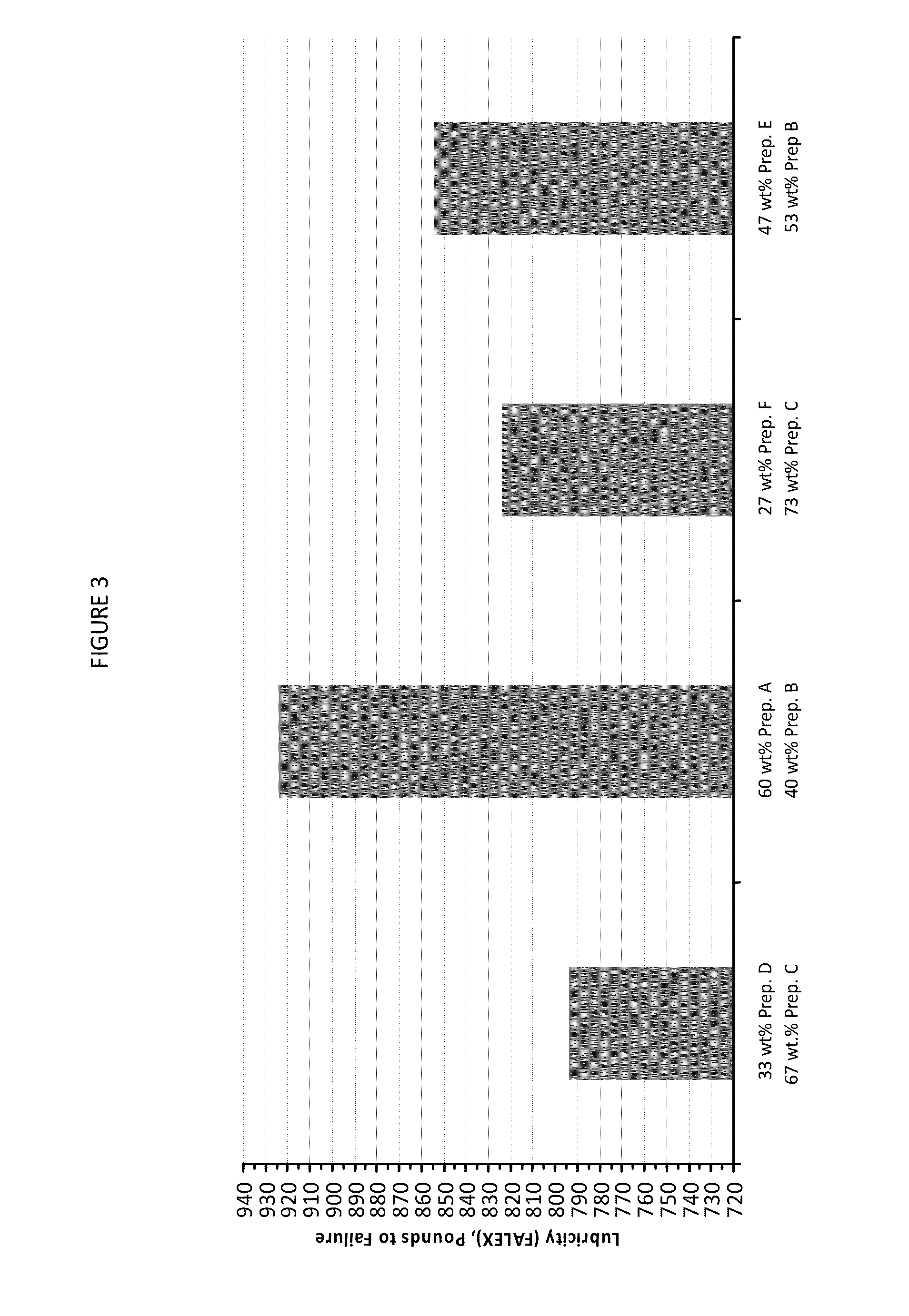

Refrigeration compressor lubricant

ActiveUS20130200295A1Good compatibilityExcellent indexHeat-exchange elementsAdditivesRefrigeration compressorDichlorodifluoromethane

Owner:COPELAND LP

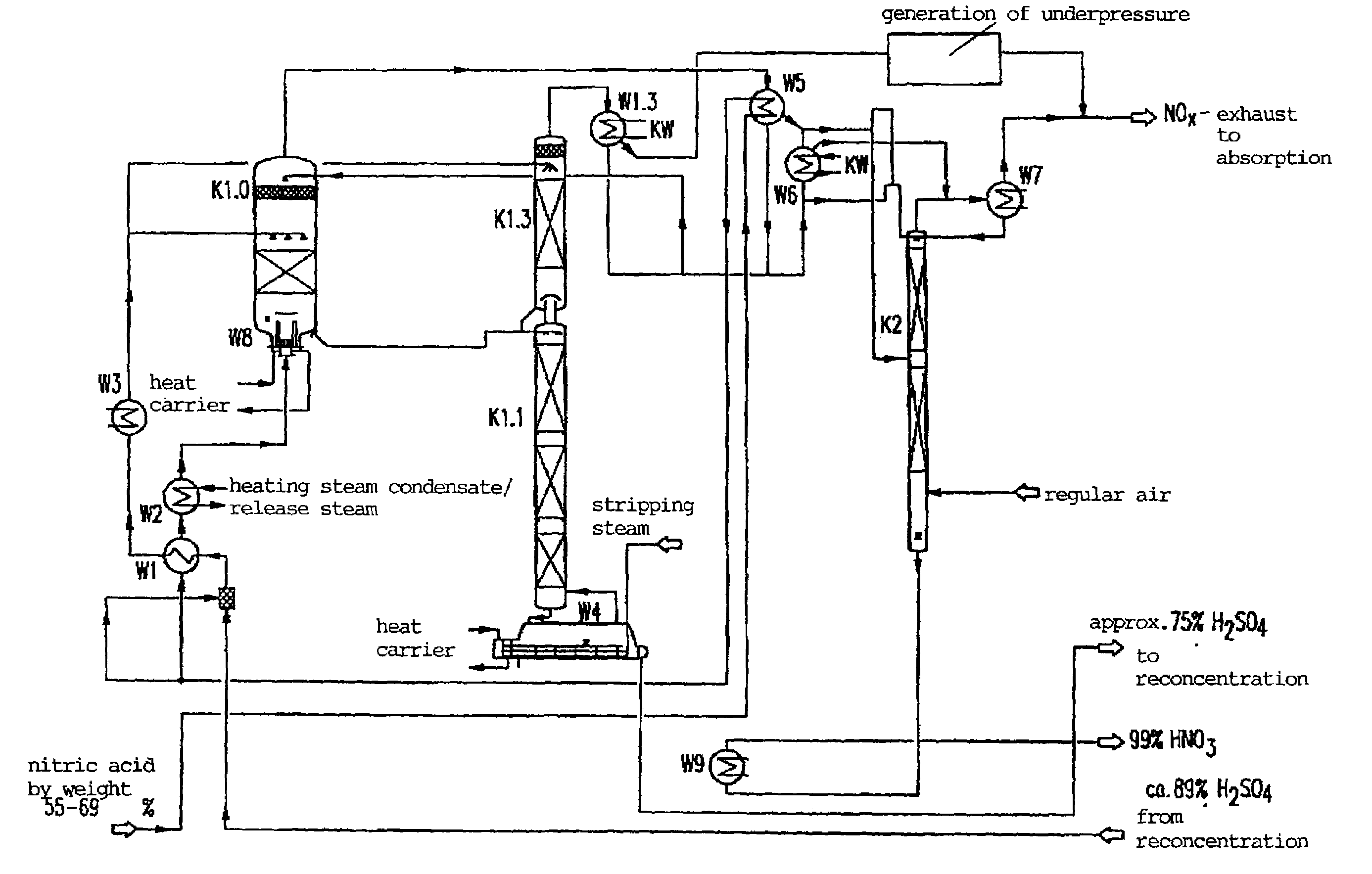

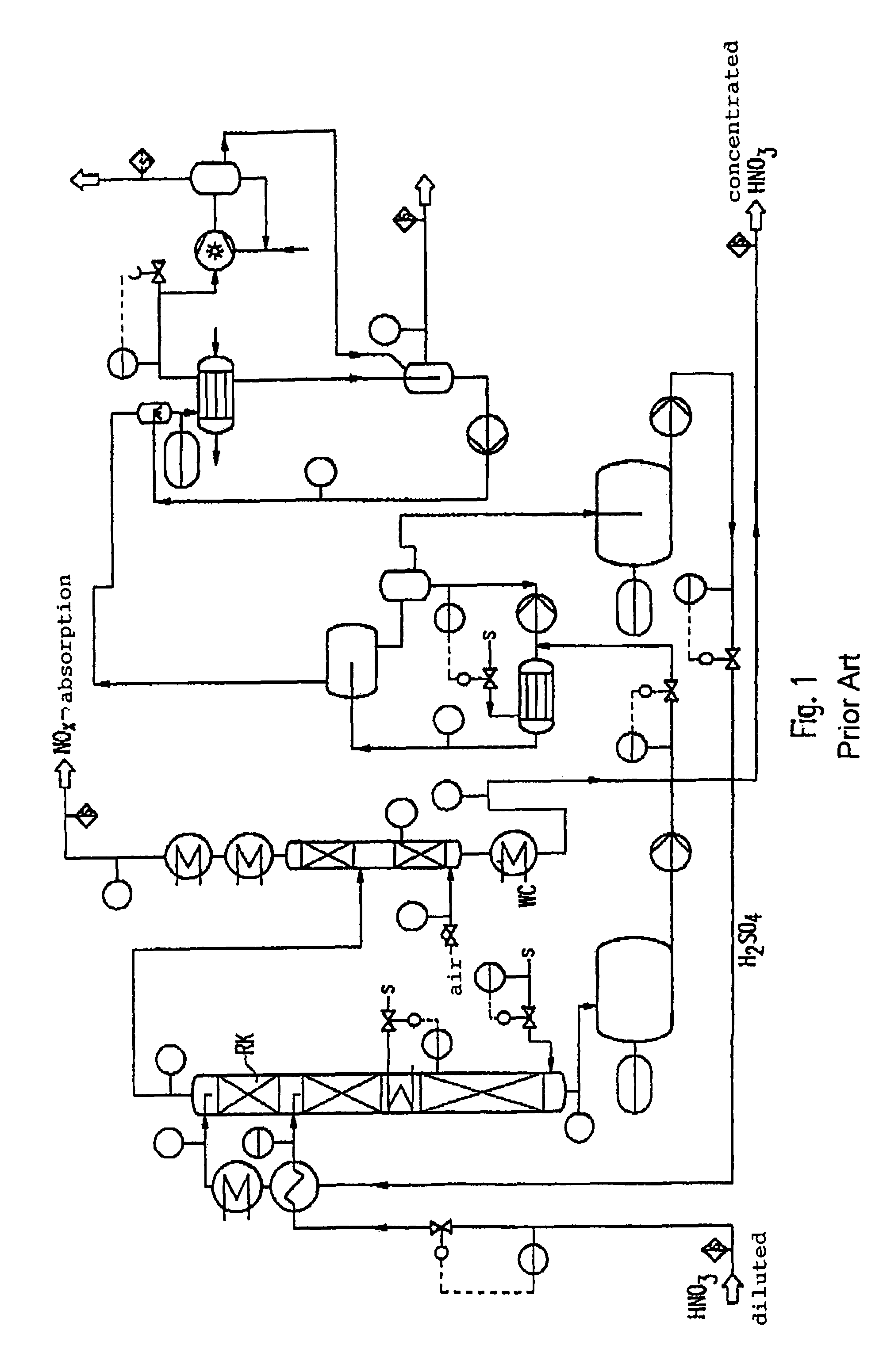

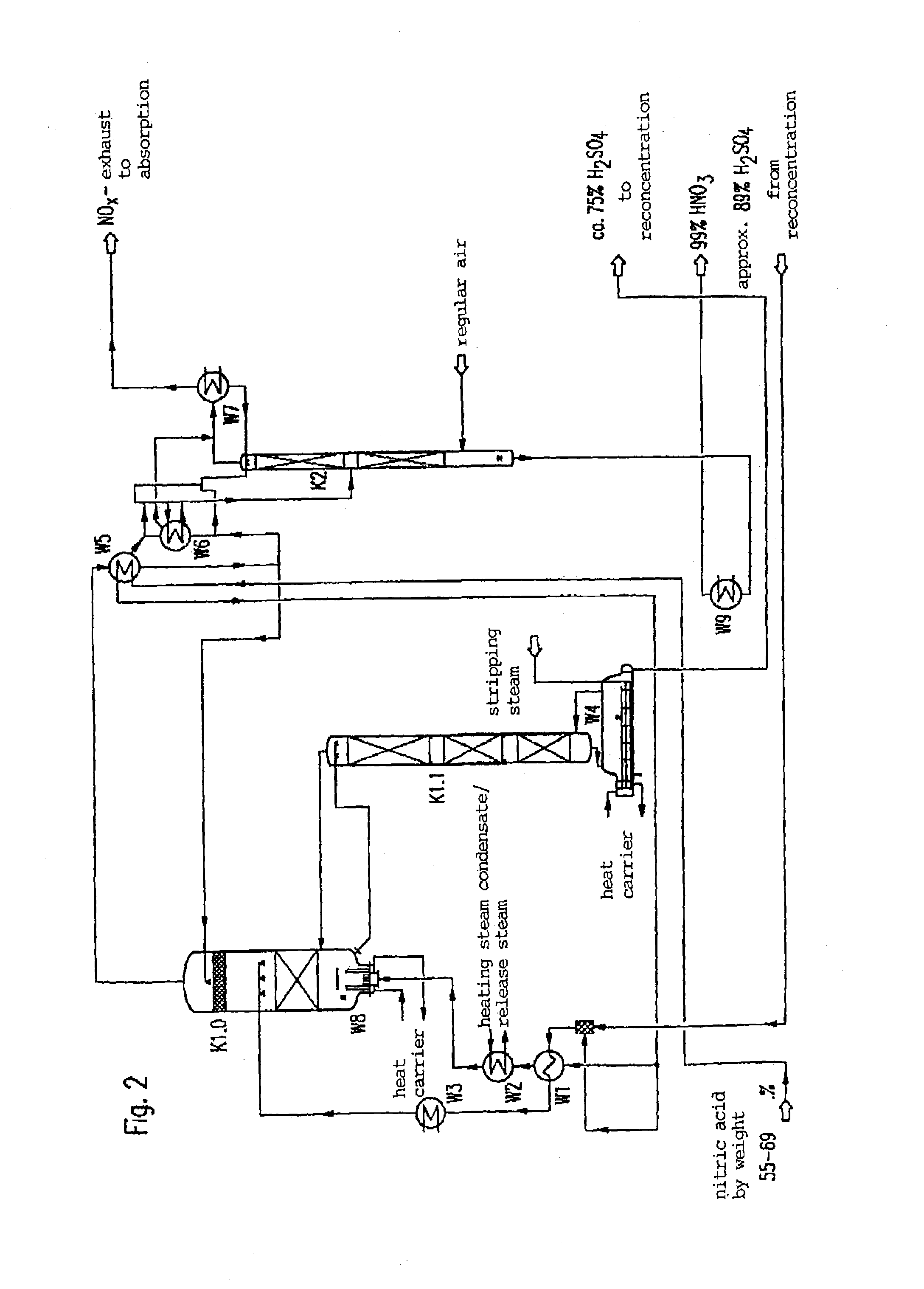

Method for producing concentrated nitric acid and installation for carrying out a method of this type

InactiveUS6969446B1Inhibition formationLow costDrying using combination processesEvaporation with vapour compressionZeotropic mixtureNitric acid

Process for producing a nitric acid of a concentration from 75 to 99.9% from a more diluted nitric acid, wherein a nitric acid of a concentration of about 45 to 70% is rectified in contact with a liquid extraction medium to prevent the formation of a nitric acid-water-azeotropic mixture, and the vapors of the concentrated nitric acid are condensed and a concentrated nitric acid is obtained and wherein additionally the extraction medium is reconstituted through reconcentration and returned into the extractive rectification, wherein the nitric acid to be concentrated is fed as a boiling liquid or partially vaporized to the extractive rectification preferably carried out in two columns (K 1.0, K 1.1), by utilizing the amounts of heat available to the entire process (W1, W2, W5), wherein, before feeding into the extractive rectification nitric acid is added to the extraction medium, and the energy required for the extractive rectification is supplied through indirect heating (W4, W8) and the extraction medium supplied in most concentrated form to the extractive rectification, so that simultaneously at the greatest possible dilution of the extraction medium flowing from the extractive rectification, the circulation amount of extraction medium is minimized and the utilization of energy maximized.

Owner:QVF ENG GMBH

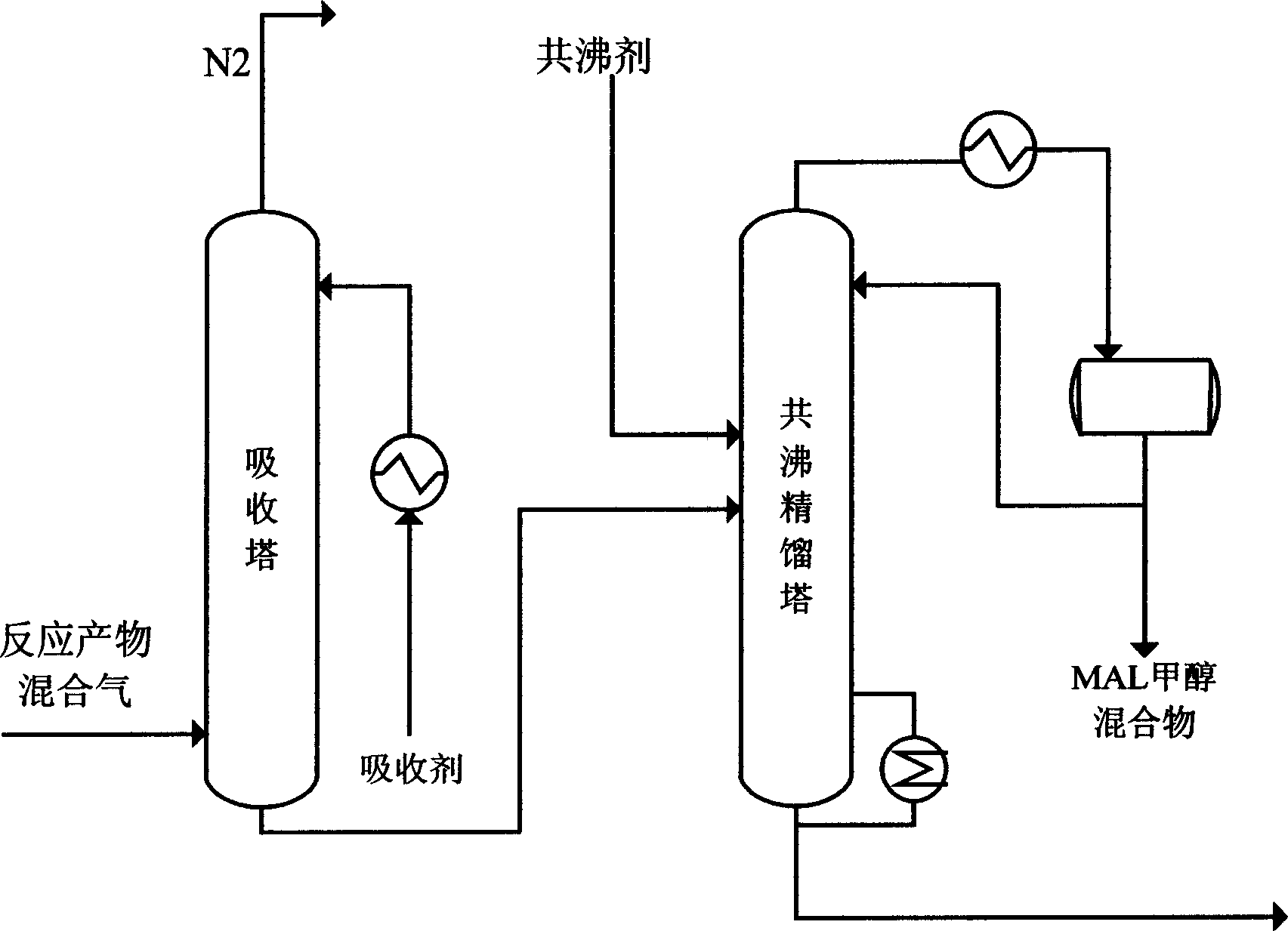

Method for separating methyl-acrolein in methyl-methyl acrylate

ActiveCN1817844AEasy to removeReduce water contentOrganic compound preparationCarboxylic acid esters preparationZeotropic mixtureAcrolein

Separation of methylacrolein in methyl methacrylate production is carried out by reacting to obtain mixed gas containing MAL, cooling and absorbing for MAL by 0~60 degrees C water, azeotropic rectifying with methanol as azeotropic agent, and separating MAL from mixed gas to obtain azeotropic mixture of MAL and methanol with water content lower 500pp. It is simple.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Azeotrope-like compositions comprising 1-chloro-3,3,3-trifluoropropene

An azeotrope-like mixture consisting essentially of chlorotrifluoropropene and at least one component selected from the group consisting of a C1-C3 alcohol, a C5-C6 hydrocarbon, a halogenated hydrocarbon, methylal, methyl acetone, water, nitromethane, and combinations thereof.

Owner:HONEYWELL INT INC

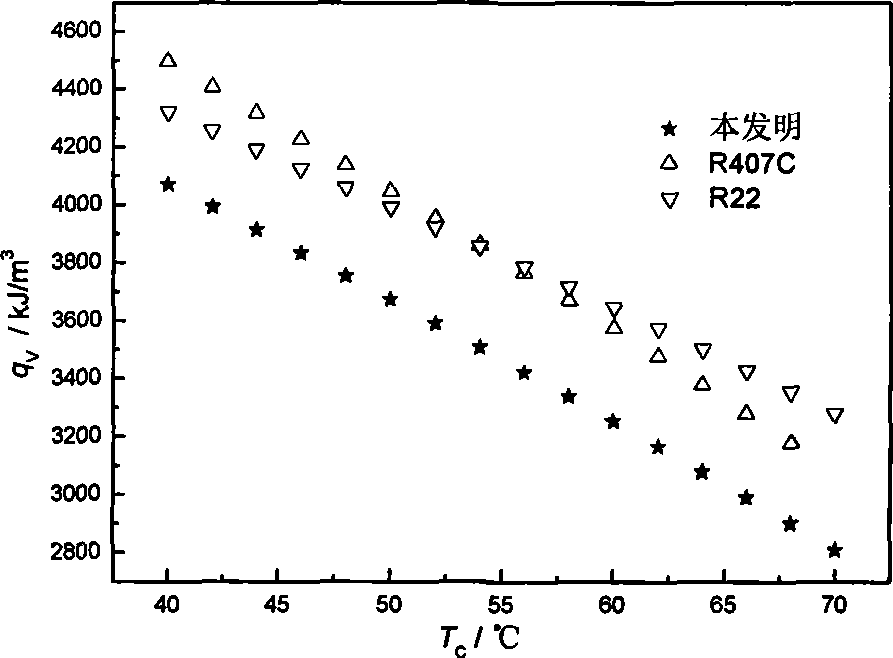

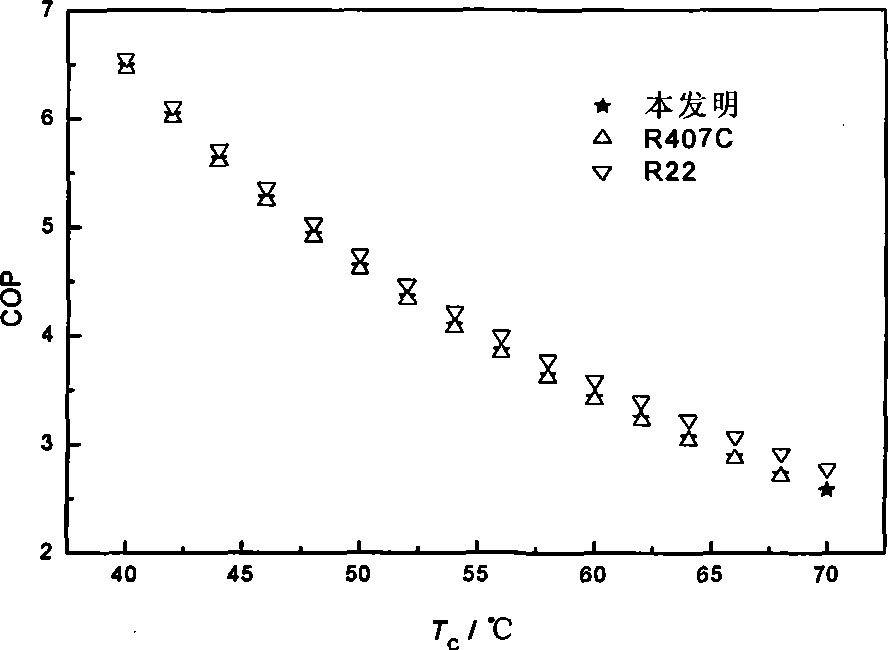

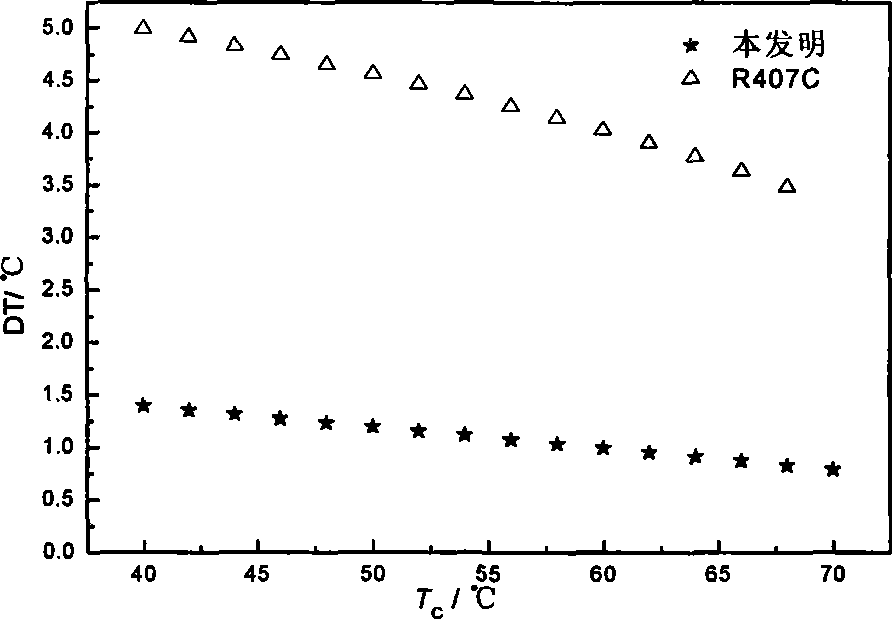

Environment friendly mixing refrigerant for air conditioner

InactiveCN101381595AImprove cooling efficiencyHeat-exchange elementsRefrigeration compressorZeotropic mixture

The invention relates to an environment-friendly mixed refrigerant for an air conditioner. The refrigerant comprises the following compositions according to mass percentage: 10 to 40 percent of dimethyl ether, 55 to 85 percent of propylene and 5 to 35 percent of 1, 1, 1, 2, 3, 3, 3-heptafluoropropane. The refrigerant has superior environmental performance; the value of ODP is zero; the value of GWP is far less than R22 and R407C; under the conditions of standard working condition and variable working condition; the refrigerating capacity of the refrigerant in unit volume is equal to the COP value and R22, which is quite suitable for direct charging and filling by a compressor; the slipping temperature of the refrigerant is only 0.42 DEG C which is far less than R407C and is close to the temperature of an approximate azeotrope, thereby removing the adverse influence caused by the large slipping temperature; and the air exhaust temperature of the refrigerant is the lowest and is favorable for protecting the refrigeration compressor. The environment-friendly mixed refrigerant can be used as a perfect refrigerant for substituting R22 in the domestic air conditioner.

Owner:XI AN JIAOTONG UNIV

Azeotrope-like compositions comprising 1-chloro-3,3,3-trifluoropropene

ActiveUS8734671B2Cosmetic preparationsOrganic active ingredientsZeotropic mixture1,3,3,3-Tetrafluoropropene

An azeotrope-like mixture consisting essentially of a binary azeotrope-like mixture consisting essentially of trans-1-chloro-3,3,3-trifluoropropene (trans-HFO-1233zd) and a second component selected from the group consisting of 2,3,3,3-tetrafluoropropene (HFO-1234yf) and trans-1,3,3,3-tetrafluoropropene (trans-HFO-1234ze), and combinations of these and various uses thereof.

Owner:HONEYWELL INT INC

Azeotrope-like compositions of trans-1,1,1,4,4,4-hexafluoro-2-butene and water

Provided are azeotropic and azeotrope-like compositions of trans-1,1,1,4,4,4-hexafluoro-2-butene (HFO-1336mzz(E)) and water. Such azeotropic and azeotrope-like compositions are useful in isolating HFO-1336mzz(E) from impurities during production. Azeotropes of the instant invention are similarly useful in final compositions, such as blowing agent, propellants, refrigerants, diluents for gaseous sterilization and the like.

Owner:HONEYWELL INT INC

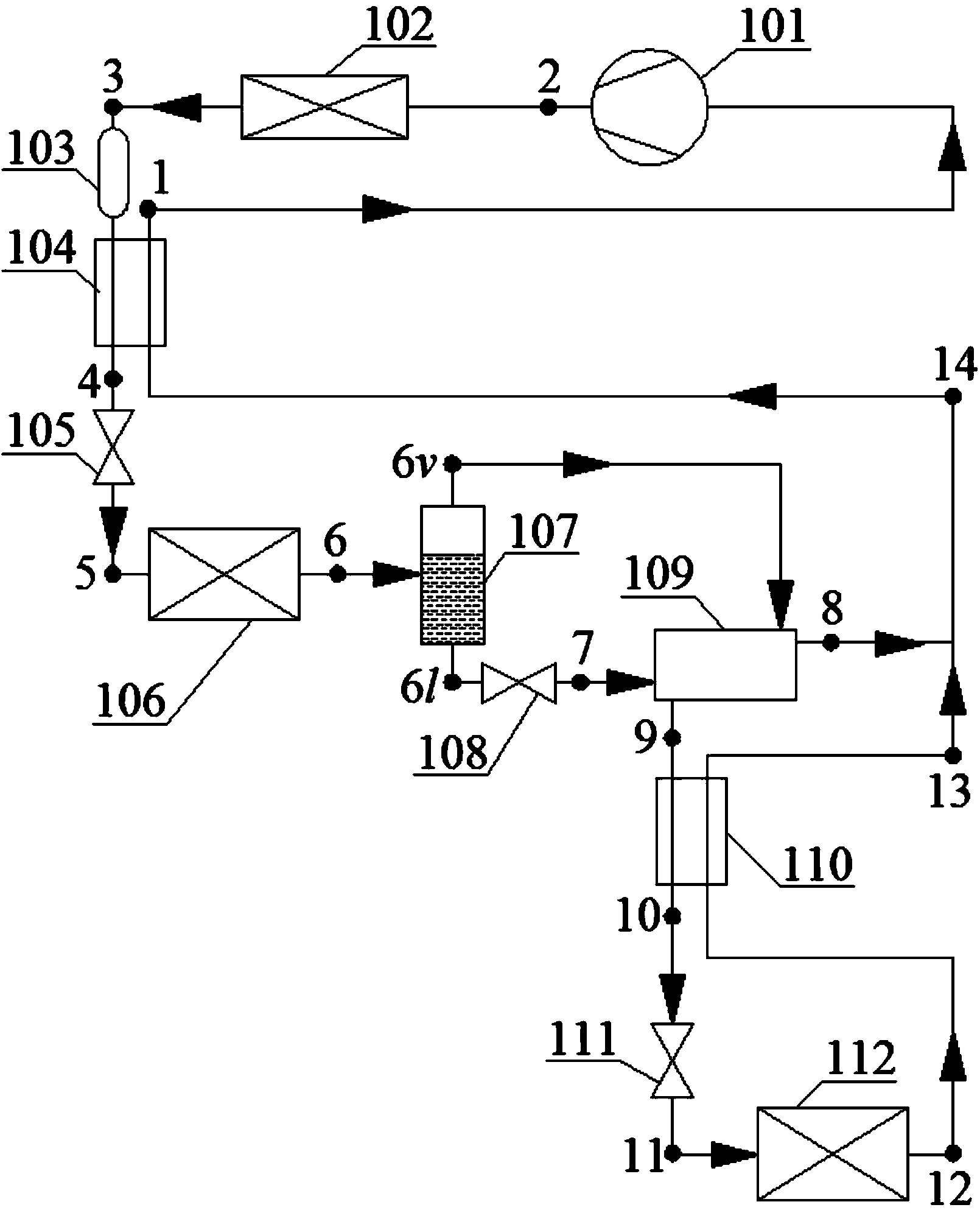

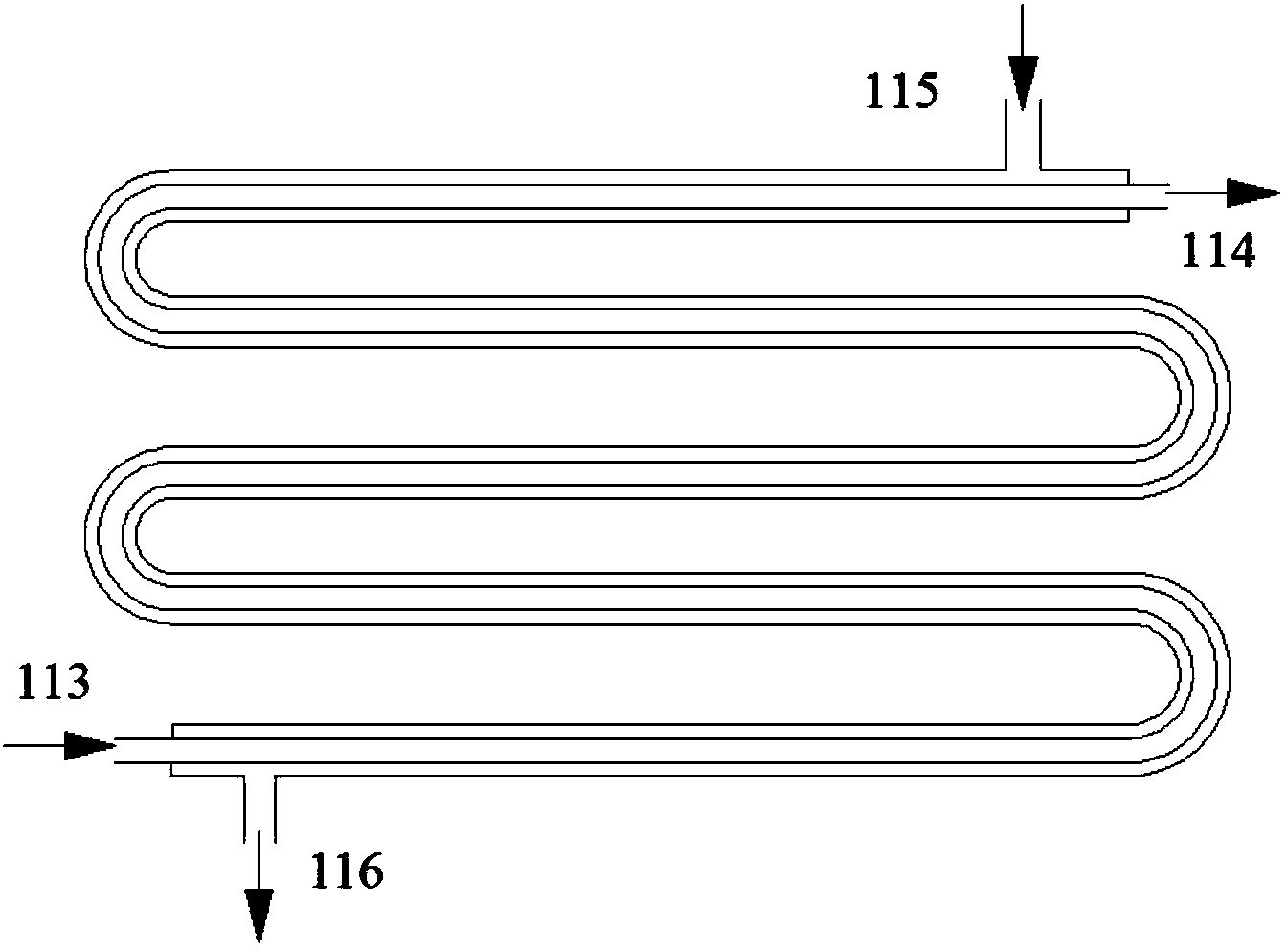

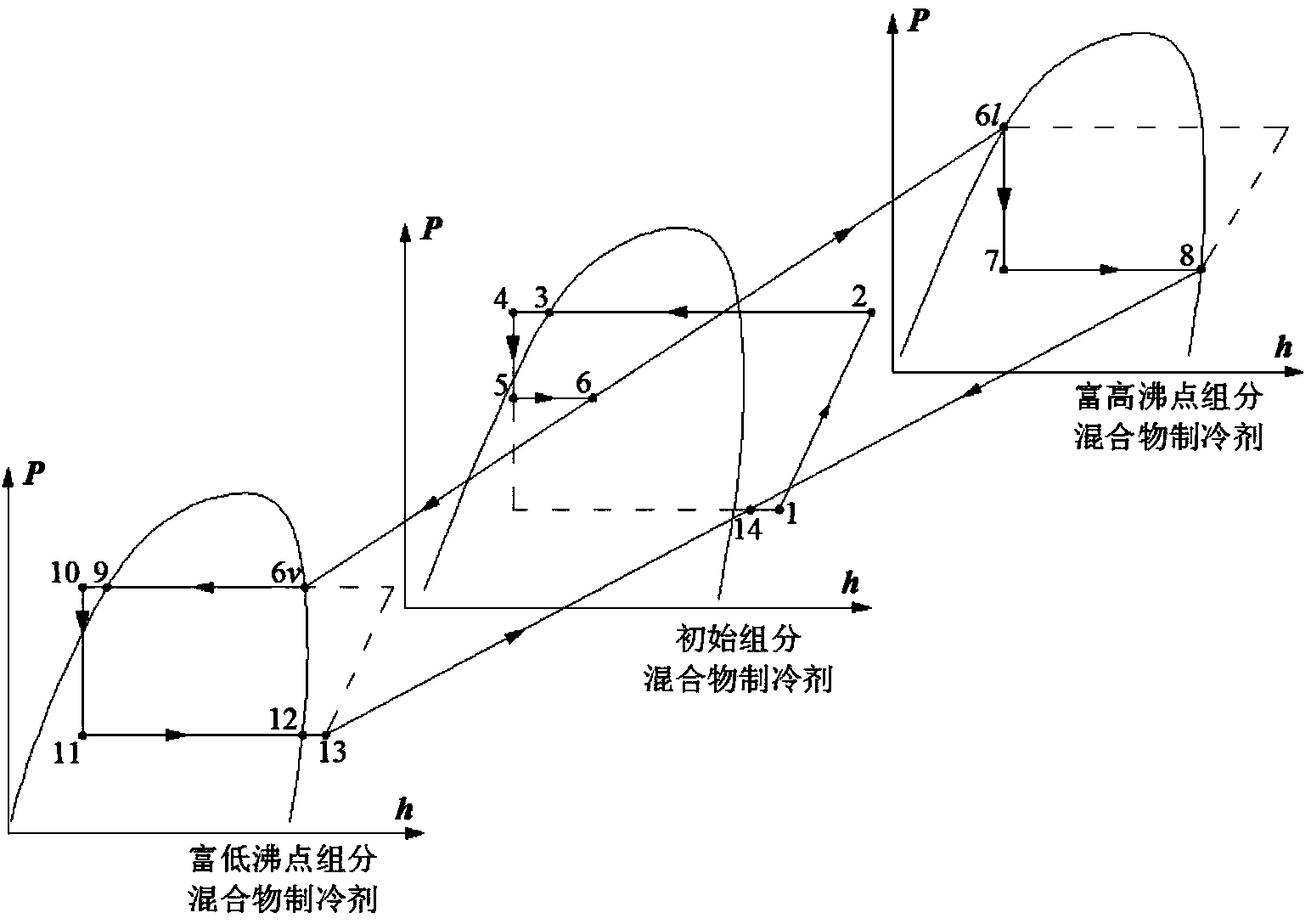

Non-azeotropic hydrocarbon mixture automatic overlapping refrigerating cycle system for double-temperature refrigerator

ActiveCN103512257AReduce heat transfer irreversible lossImprove cooling efficiencyMechanical apparatusCompression machines with several evaporatorsHydrocarbon mixturesVapor–liquid separator

A non-azeotropic hydrocarbon mixture automatic overlapping refrigerating cycle system for a double-temperature refrigerator comprises a compressor, the compressor, a condenser, a dry filter, a first heat returning device, a first capillary tube and a refrigerating chamber evaporator are sequentially connected, an outlet of the refrigerating chamber evaporator is connected with an inlet of a gas-liquid separator, an outlet of the gas-liquid separator is divided into two paths, a saturation liquid state cooling agent in one path passes a second capillary tube to be connected with a cooling fluid inlet of a condensation evaporator, a saturation liquid state cooling agent in the other path is connected to a hot fluid inlet of the condensation evaporator, a hot liquid outlet of the condensation evaporator passes a second heat returning device and a third capillary tube to be connected with an inlet of a freezing chamber evaporator, and an outlet of the freezing chamber evaporator passes the second heat returning device to be connected with a cold fluid outlet of the condensation evaporator and then passes the first heat returning device to be connected with an inlet of the compressor. The performance of the refrigerating cycle system of the double-temperature refrigerator is effectively improved by utilizing the temperature glide and the achievable automatic overlapping cycle characteristic of the non-azeotropic mixture cooling agent, and the development of the energy-saving technology of household refrigerator products is promoted.

Owner:XI AN JIAOTONG UNIV

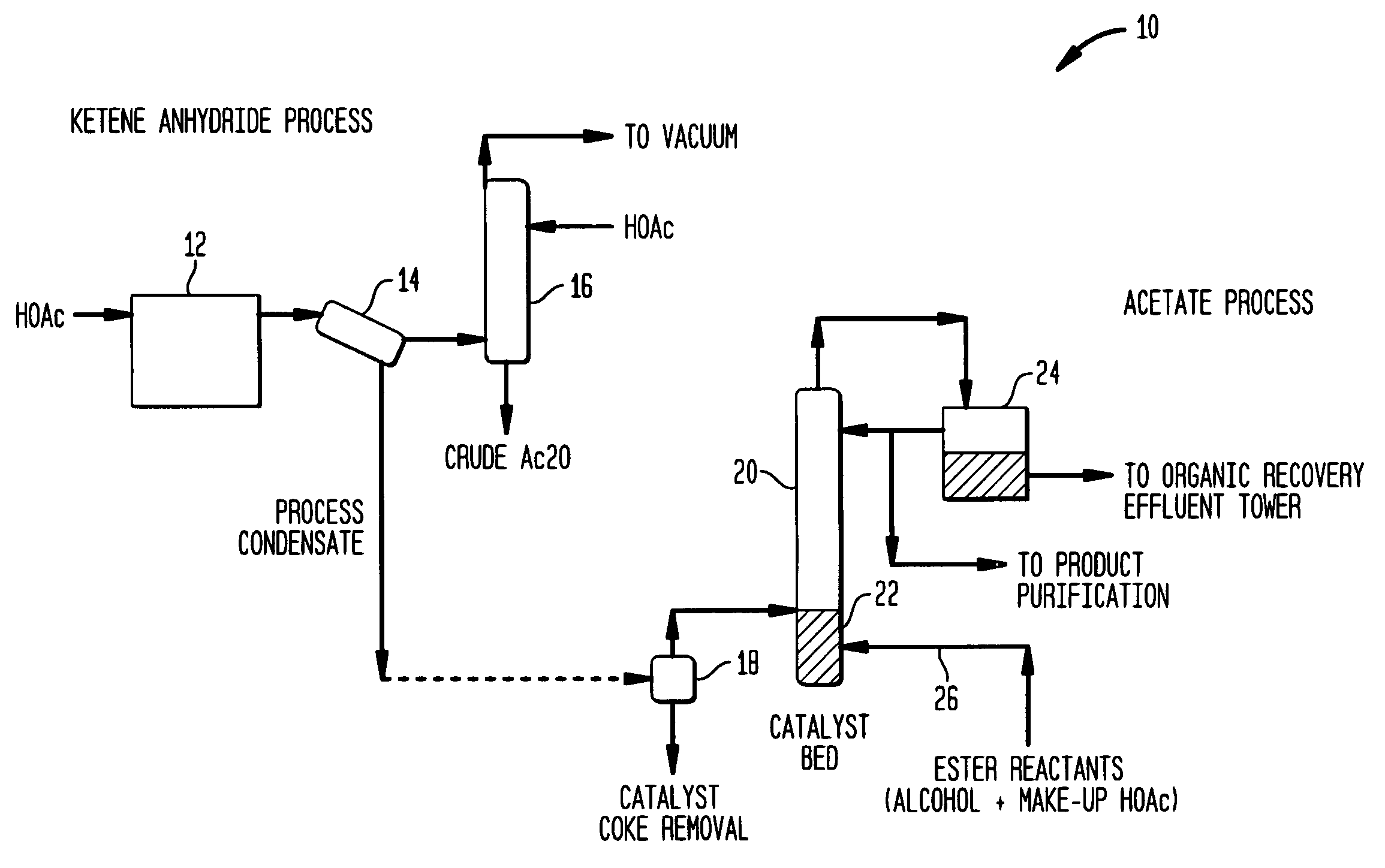

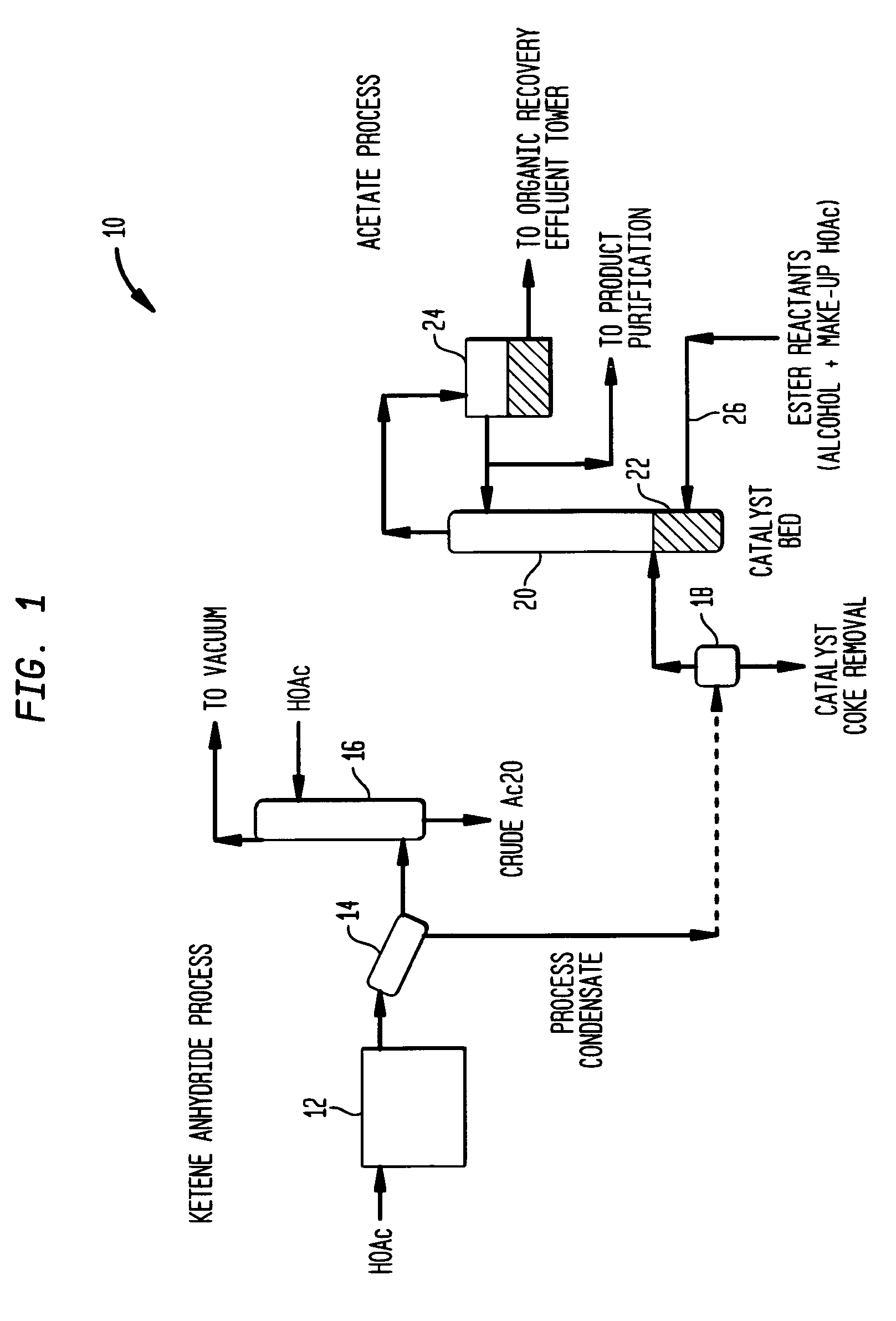

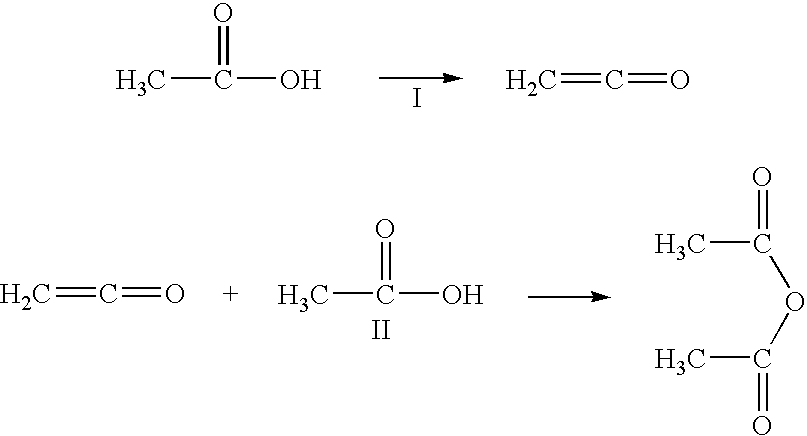

Acetic anhydride and acetate ester co-production

ActiveUS7199263B2Minimizes decompositionOrganic compound preparationCarboxylic acid esters preparationAcetic acidAcetic anhydride

A method of co-producing acetic anhydride and an acetate ester includes pyrolizing acetic acid at elevated temperature to produce a first ketene stream, the first ketene stream being a vapor phase stream comprising ketene, acetic acid and water; cooling the first ketene stream to condense acetic acid and water therefrom, thereby generating (i) a weak acid aqueous stream and (ii) a ketene feed stream; feeding the ketene feed stream to an acetic anhydride reactor where the ketene is reacted with acetic acid to produce acetic anhydride; concurrently with step (c), feeding the weak acid aqueous stream to an esterification reactor wherein acetic acid in the weak acid stream is reacted with an organic alcohol to produce an acetate ester. Preferably, the organic alcohol is selected from organic alcohols which (i) form acetate esters which esters and optionally alcohols provide azeotropic mixtures with water and (ii) wherein the azeotropic mixtures have a water content greater than the amount of water generated by reaction of the alcohol with acetic acid to facilitate azeotropically separating the acetate ester from the reaction mixture.

Owner:CELANESE INT CORP

Method for purifying by-product methyl acetate generated during production of PVA (polyvinyl acetate)

InactiveCN102757342ASimple processAdd lessCarboxylic acid esters separation/purificationPolyvinyl acetateZeotropic mixture

The invention discloses a method for purifying by-product methyl acetate generated during production of PVA (polyvinyl acetate). The method comprises the three unit processes: extractive distillation, purification and drying. The extractive distillation process is that an azeotropic mixture of by-product crude methyl acetate, methanol and water is added from the middle lower part of an extractive distillation column, an extracting agent is added from the upper part of the extractive distillation column, the temperature at the top of the extractive distillation column is controlled to 55 to 65 DEG C; and the azeotropic mixture of methyl acetate and methanol as well as the extracting agent is discharged from the top of the extractive distillation column; and the purification process is that the azeotropic mixture of methyl acetate and methanol as well as the extracting agent, which is discharged from the top of the extractive distillation column, is sent to a purification column for purification, and pure methyl acetate is obtained in a column bottom, and dried to obtain finished methyl acetate. The extracting agent is acetic acid or acetic acid aqueous solution, does not bring new substances to a system, and can be recycled; and methyl acetate with the purity of more than 99.5% and the yield of more than 90% can be obtained under the condition of smaller additive amount of azeotropic mixture of by-product crude methyl acetate, methanol and water as well as the extracting agent.

Owner:ANHUI WANWEI UPDATED HIGH TECH MATERIAL CO LTD

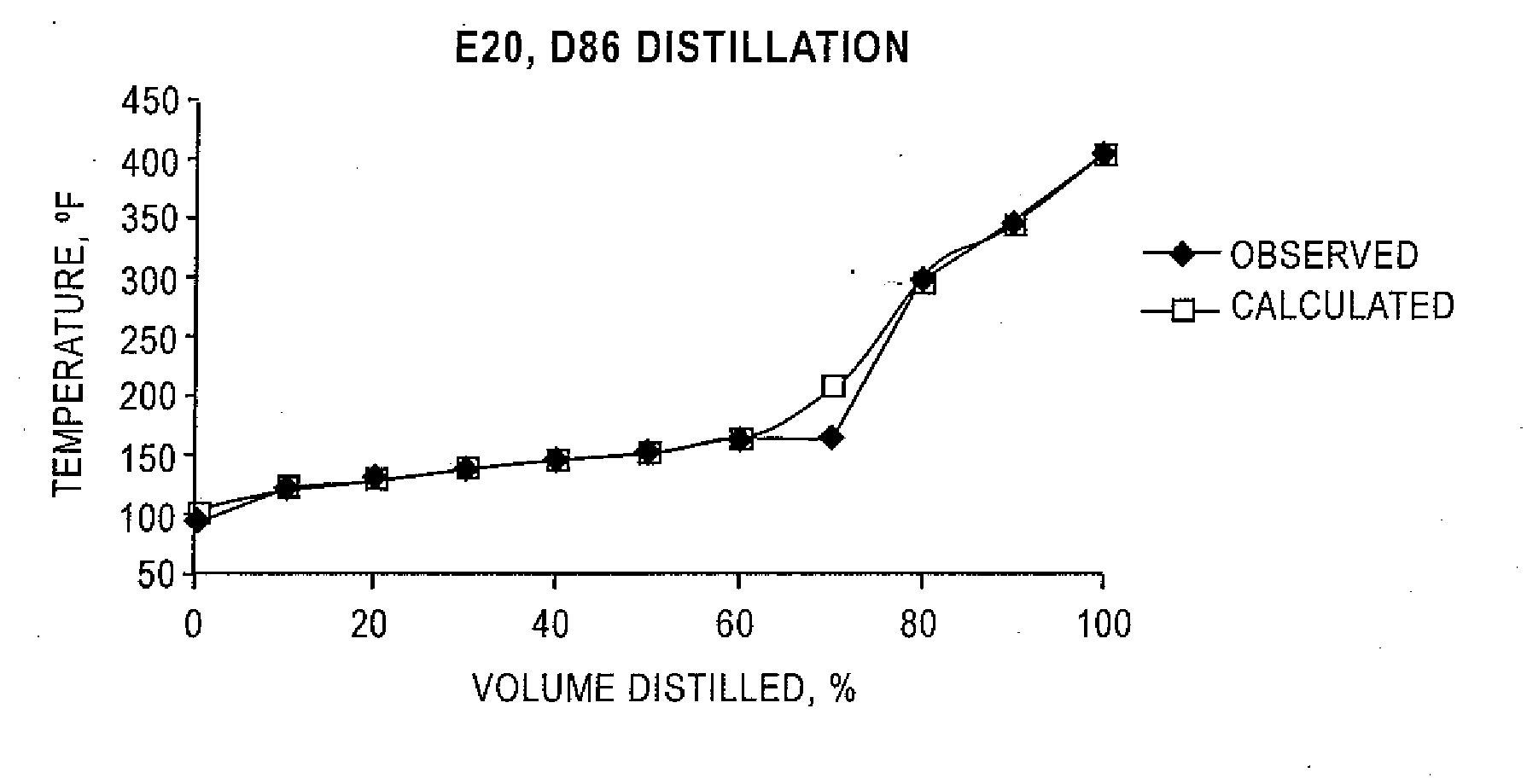

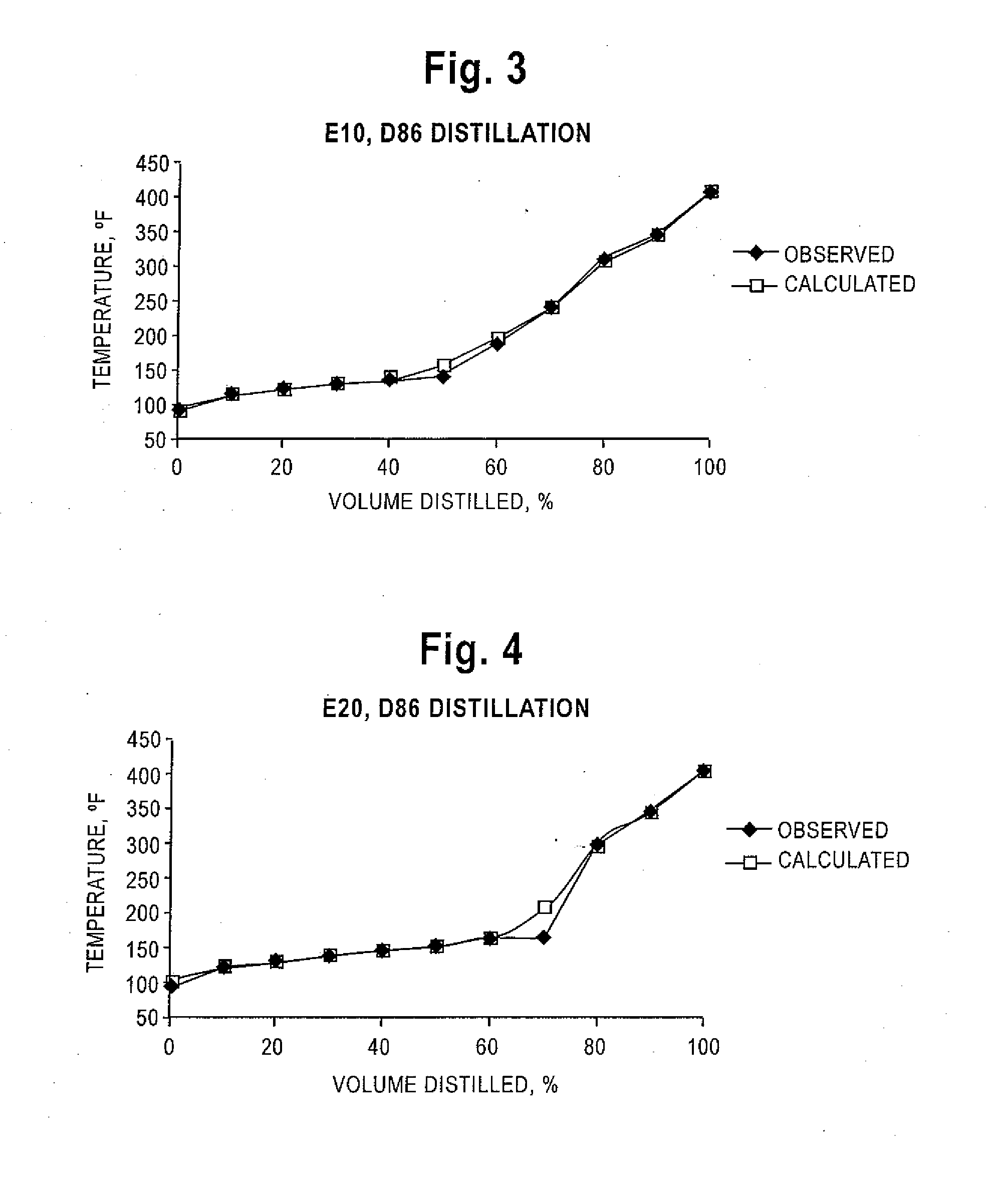

Process for determining the distillation characteristics of a liquid petroleum product containing an azeotropic mixture

InactiveUS20090292512A1Computation using non-denominational number representationMaterial resistanceZeotropic mixturePetroleum product

A process for determining the distillation characteristics of a liquid petroleum product that contains an azeotropic mixture of an oxygenated or nitrogen-containing component and at least one petroleum blending component.

Owner:BP CORP NORTH AMERICA INC

Method for separating and recovery difluorochloromethane azeotropic hexafluoropropene

ActiveCN1830929AHigh purityNo pollution in the processDispersed particle separationHalogenated hydrocarbon separation/purificationTetrafluoroethyleneZeotropic mixture

A process for separating and recovering bifluoro-chloromethane-hexafluoropropene azeotrope includes such steps as passing said gas-state mixed azeotrope through gas separating membrane to obtain penetrated bifluoro-chloromethane gas and residual hexafluoropropene gas, condensing the residual gas, rectifying to obtain pure hexafluoropropene, recovering the mixed azeotrope from tower top, returning it along with said penetrated gas back to rectifying system in tetrafluoro ethene production apparatus, and rectifying separation to recover bifluoro-chloromethane.

Owner:CHANGSHU 3F ZHONGHAO NEW CHEM MATERIALS +1

Process for production of alcohols

InactiveUS20040171890A1Maintain temperatureOrganic compound preparationChemical industryHydration reactionAlcohol

The invention disclosed relates to the production of alcohols. A first aspect of the invention relates to a process for production of alcohols, and in particular to a process for the catalytic hydration of an olefin to the corresponding alcohol in substantially anhydrous form, under selected mild reaction conditions, and using a selected catalyst. A second aspect of the invention relates to a process for dehydration of an azeotropic mixture, including a first alcohol and water. A hydration reaction between the water in the azeotropic mixture and an added olefin, under selected mild conditions, and using a selected catalyst, produces a product including a second alcohol corresponding to the olefin, and the first alcohol, in substantially anhydrous form.

Owner:THE GOVERNORS OF THE UNIV OF ALBERTA

Hemocompatible polymers on hydrophobic porous polymers

InactiveUS7807210B1Improve solubilityReduce accumulationSurgeryPharmaceutical containersSolubilityHydrophobic polymer

The present invention relates to providing a porous, hydrophobic polymer with a hemocompatible substance and to the materials produced thereby. One embodiment of the present invention relates to the providing of expanded poly(tetrafluoroethylene) with one or more complexes of heparin, typically containing heparin in combination with a hydrophobic counter ion. The hemocompatible substance is dissolved in a mixture of solvents in which a first solvent wets the polymer to be coated and the second solvent enhances the solubility of the hemocompatible substance material in the solvent mixture. Typical first solvents wetting hydrophobic polymers include non-polar such as hydrochlorofluorocarbons. Typical second solvents include polar solvents such as organic alcohols and ketones. Azeotropic mixtures of the second solvent in the first solvent are used in some embodiments of the present invention although second solvents may be employed in a range of concentration ranges from less than 0.1% up to saturation. A typical example providing a heparin complex to an endoluminal stent, consisting of coating DURAFLO onto an ePTFE stent-covering material.

Owner:ABBOTT CARDIOVASCULAR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com