Patents

Literature

2178results about "Carboxylic acid esters separation/purification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Noble metal support

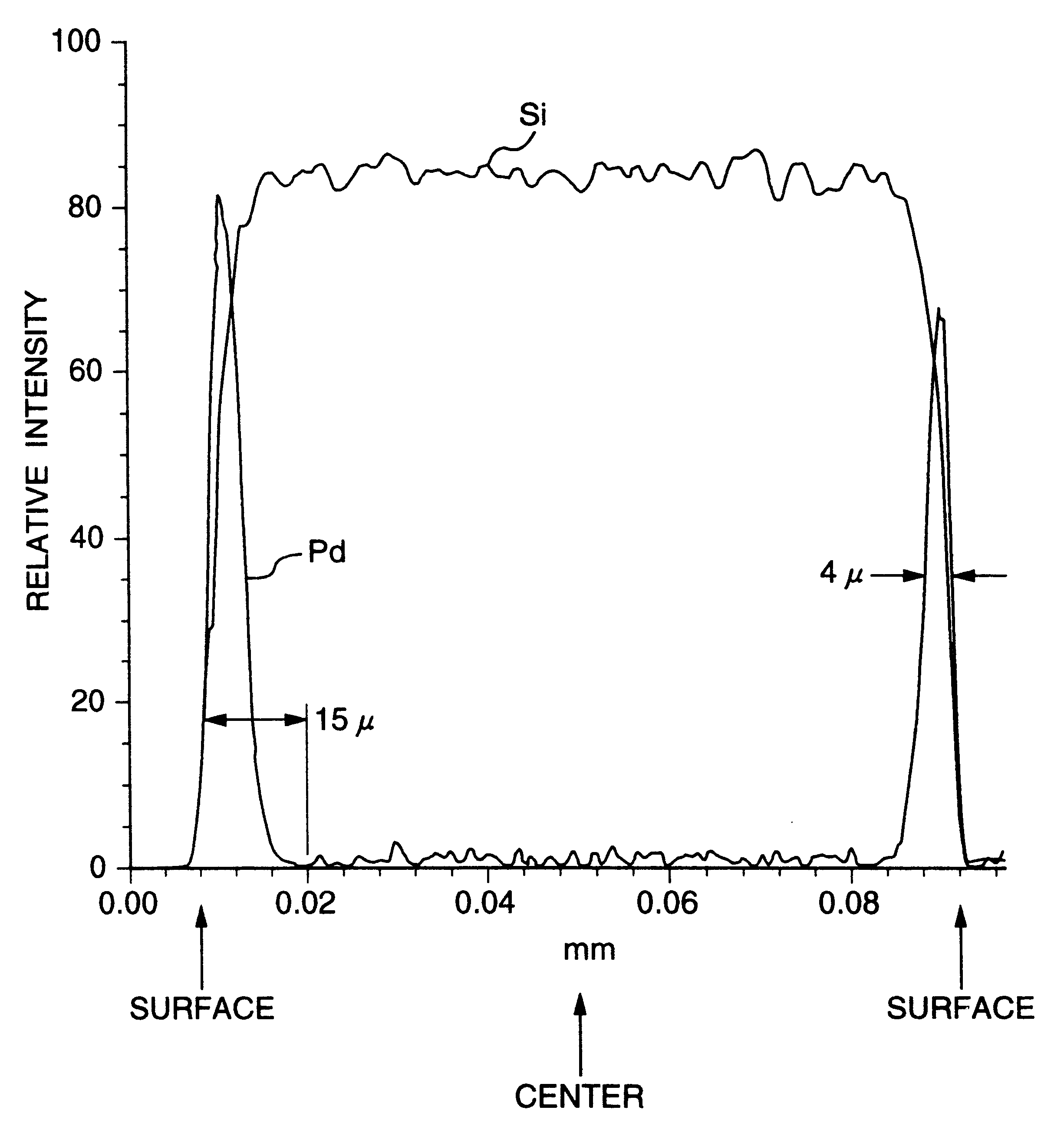

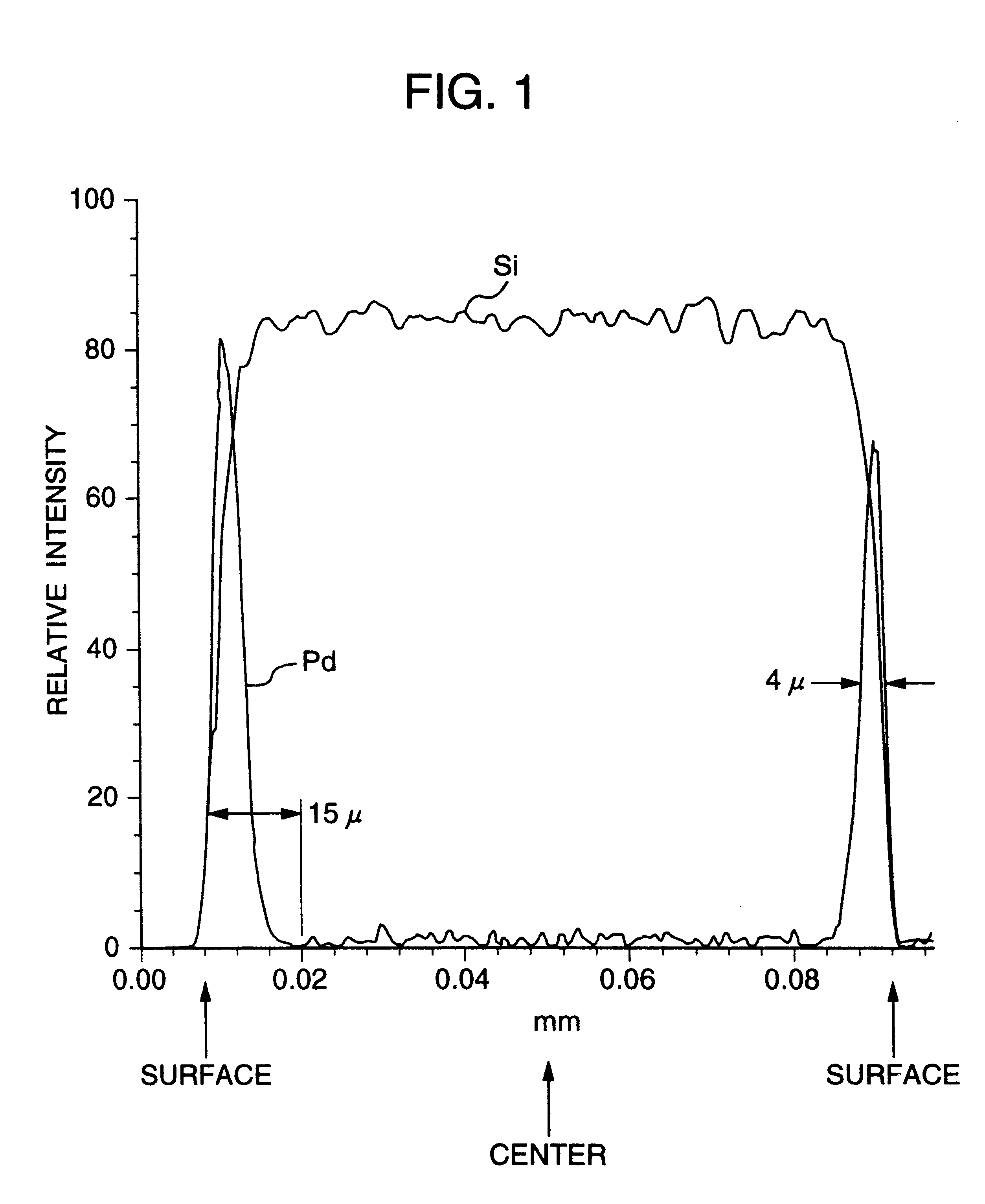

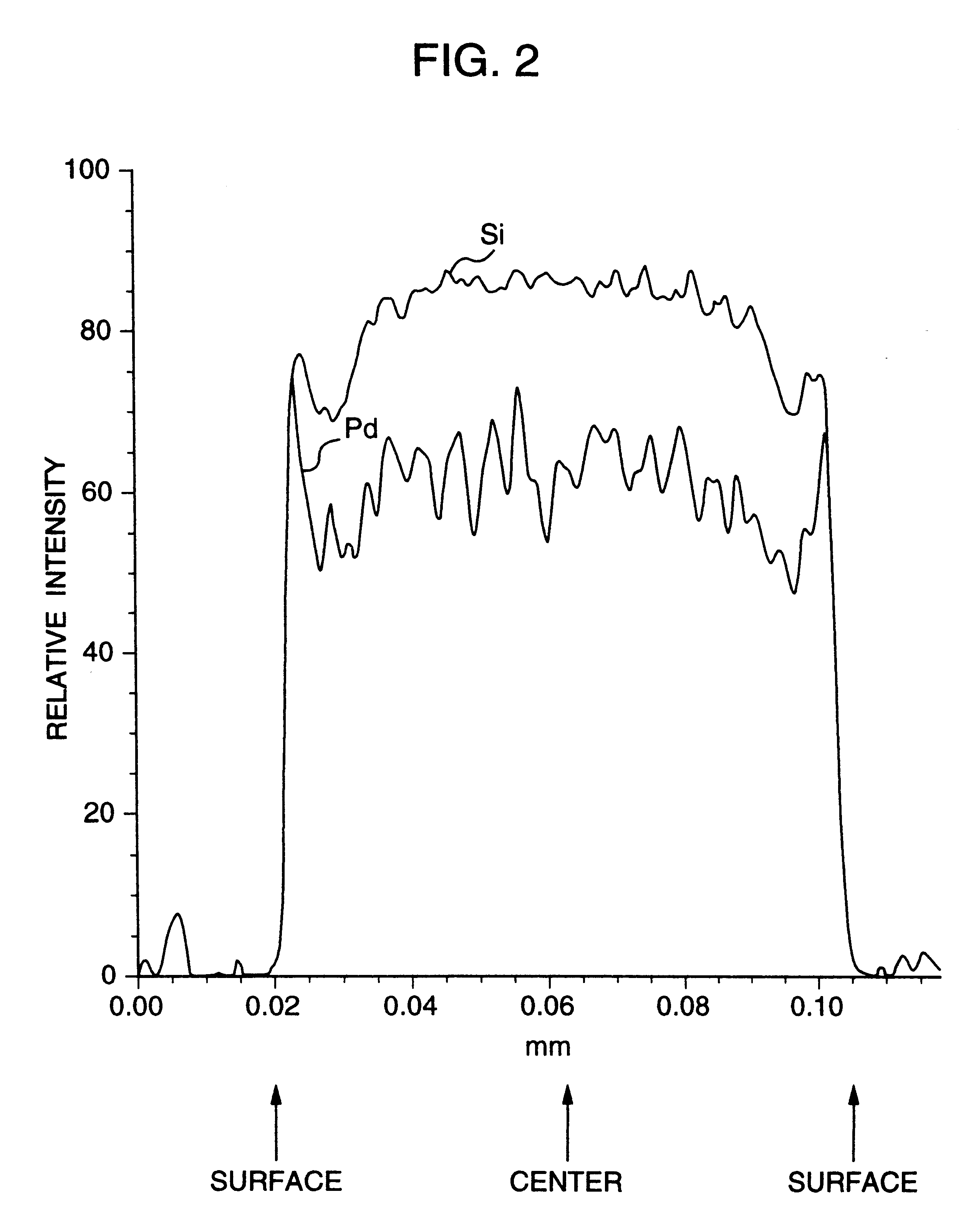

InactiveUS6228800B1Efficient use ofLong catalyst lifeOrganic compound preparationCatalyst activation/preparationPalladiumChemistry

A noble metal-supported article which comprises a carrier and a palladium-containing metal component supported on the carrier, which article has (A) a layer in which substantially no palladium is supported in the interior of the carrier and (B) a layer in which palladium is supported in the region from the outer surface to a depth of less than 100 mum of the carrier.

Owner:ASAHI KASEI KK

Methylidene malonate process

ActiveUS20100286438A1High purityImprove stabilityOrganic compound preparationPreparation by carbon monoxide or formate reactionMalonatePolymerization

An improvement in the production of methylidene malonates is attained by use of specific reaction phase and / or separation phase polymerization inhibitors and combinations thereof.

Owner:HB FULLER CO

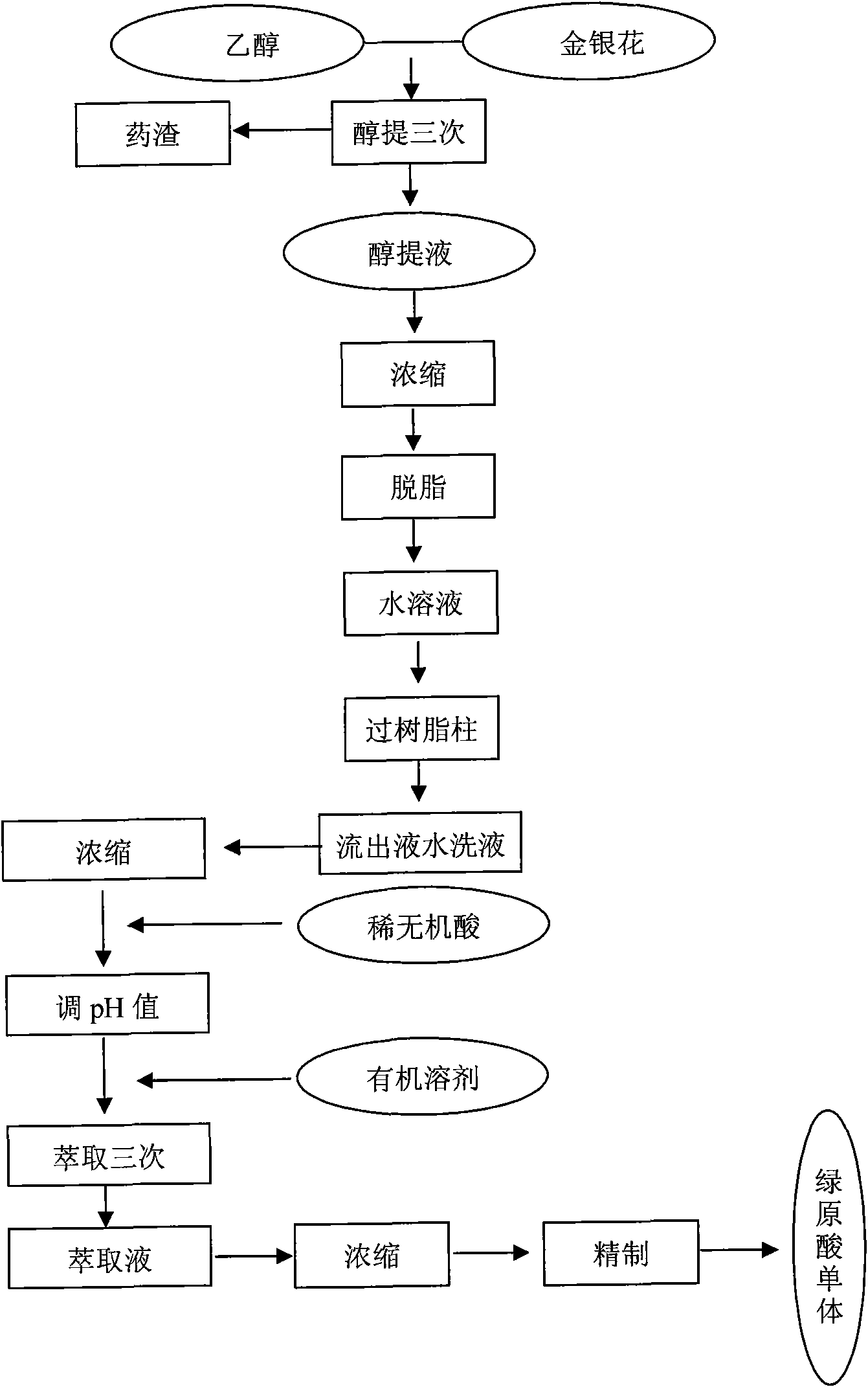

Process for preparing chlorogenic acid from honeysuckle

The present invention relates to process of extracting chlorogenic acid from honeysuckle and belongs to the field of medicinal chemical technology. The process includes the steps of: reflux extraction of honeysuckle with water or ethanol, filtering to collect filtrate, recovering solvent, ethanol deposition to eliminating impurity, letting stand overnight, filtering, decompression recovering solvent, adding water and letting stand overnight, filtering, eluting the filtrate in macroporous resin column, concentrating eluent, collecting chlorogenic acid component, eluting on polyamide column with eluent, collecting chlorogenic acid component, concentration, rectification to obtain chlorogenic acid product with content over 95 %. The present invention is suitable for industrial application.

Owner:济南永曜医药科技有限公司

Method for extracting 'Danfen' phenolic acid-A

InactiveCN1830947AHigh yieldHigh purityCarboxylic acid esters separation/purificationAlcoholOrganic solvent

A process for preparing danshinolic acid A from red sage root includes such steps as extracting in water or alcohol, concentrating, high-temp and -pressure reaction, purifying by chromatographic column, regulating pH value, extracting in organic solvent, concentrating and drying.

Owner:PHARMA RES INST OF BENCAO TIANYUAN OF BEIJING

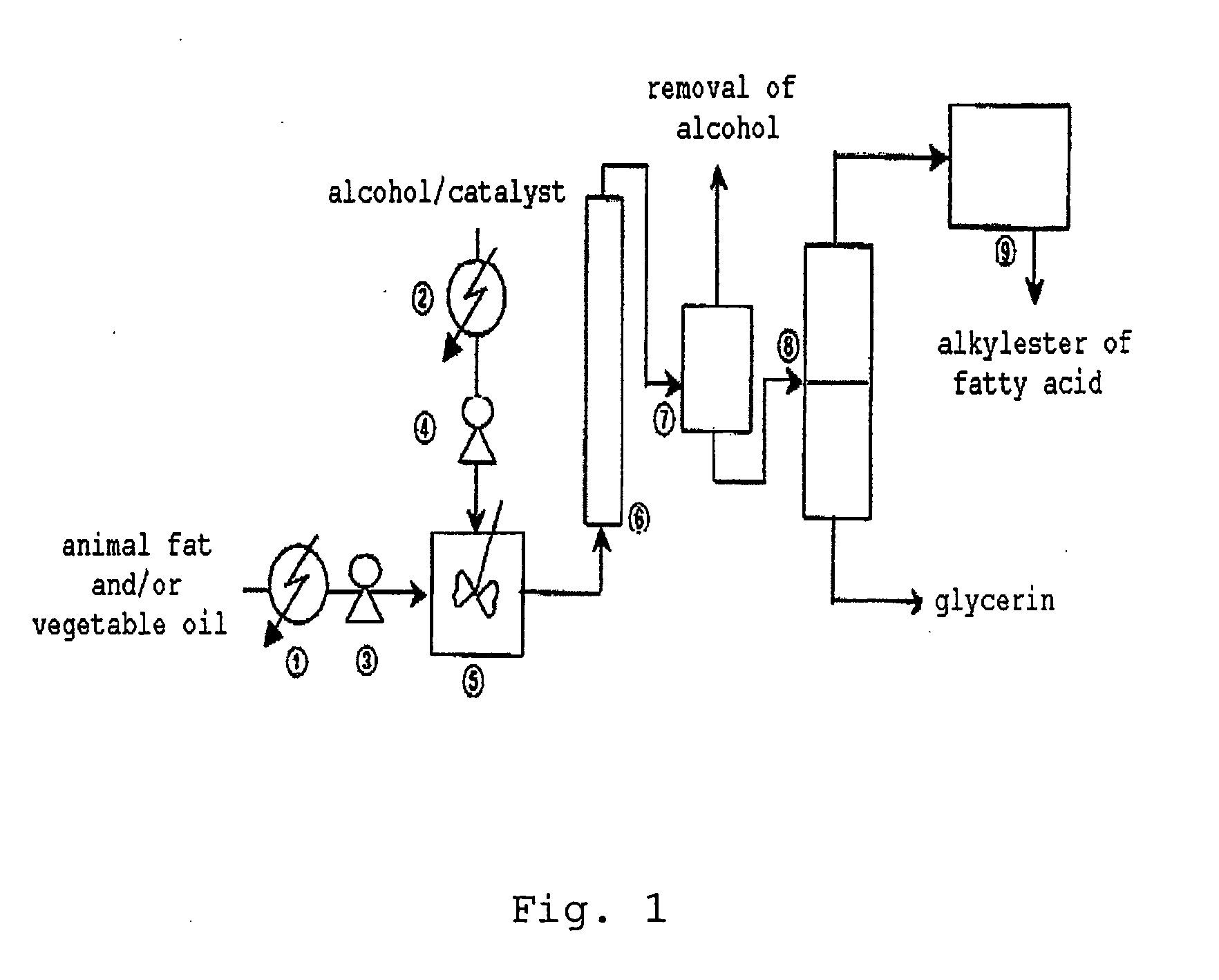

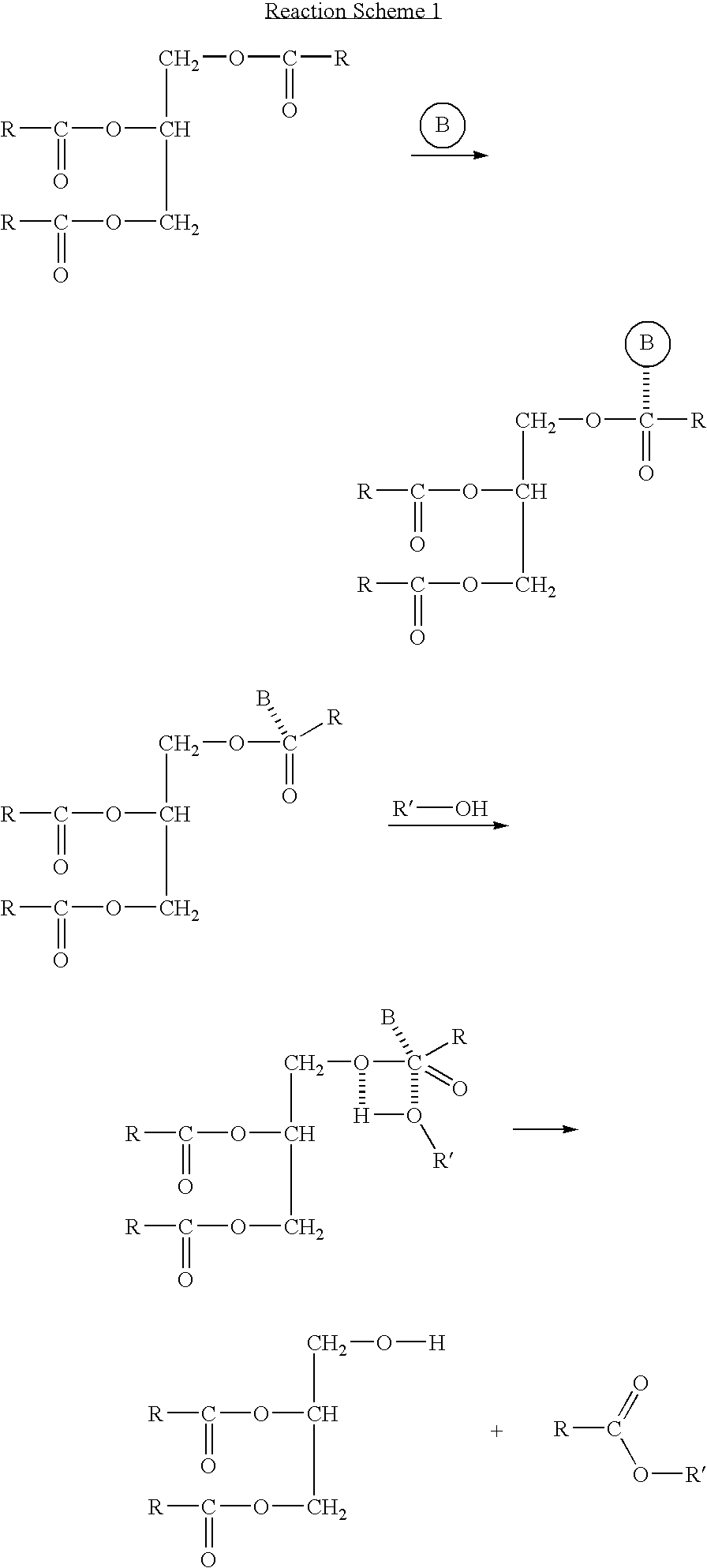

Process for producing alkylester of fatty acid in a single-phase continuous process

InactiveUS20050080280A1Phase separationFatty oils/acids recovery from wasteFatty acid esterificationAlcoholVegetable oil

The present invention relates to a process for preparing an alkylester of fatty acid with high purity via one-step continuous process by reacting an animal fat and / or vegetable oil with a lower alcohol in the presence of alkali catalyst by passing through a continuous tubular reactor while maintaining a single-phase, removing residual lower alcohol from the reaction mixture and removing residual glycerin, catalyst, etc. by phase separation. In accordance with the present invention, an alkylester of fatty acid can be produced with a high yield of 97% or more via one-step continuous process in a continuous tubular reactor without any limitation in flow types by reacting an animal fat and / or vegetable oil with a lower alcohol in the presence of alkali catalyst and carrying out a simple separating process.

Owner:M ENERGY

Methylidene malonate process

ActiveUS20100286433A1Speed up the processOrganic compound preparationCarboxylic acid esters separation/purificationMalonateChemistry

Novel improved processes for the production and isolation of methylidene malonates via direct and indirect adduct processes.

Owner:HB FULLER CO

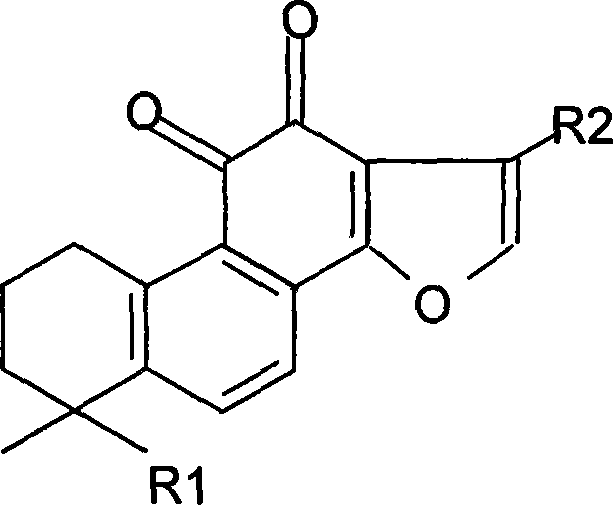

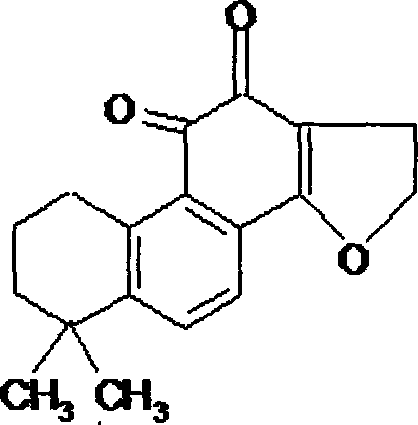

Total tanshinone and total phenolic acid extract in red-rooted salvia root and its production

The invention is concerned with a kind of extract of total ketone of salviae miltiorrhizae and total phenolic acid and its produce method form radix Salviae Miltiorrhizae. The extract of total ketone of salviae miltiorrhizae has cryptotanshinone, tanshinone I, tanshinone IIA, methyl Tanshinon, dihydrotanshinon I and ramification. The extract of total phenolic acid has salvianolic acid A, salvianolic acid B, protocatechuic aldehyde and ramification. The extract can be got form one or arbitrary compound of extraction with solvent method, macroporous resin method, column chromatography and liquid-liquid counter-current chromatography. The summation of the content to each total ketone of salviae miltiorrhizae is 20 to 100 percnte (w / w) of the extract of total ketone of salviae miltiorrhizae, the contene of cryptotanshinone, tanshinone I and tanshinone IIA is 5 to 100 percent (w / w) of whole content of total ketone of salviae miltiorrhizae. The summation of the content to each total phenolic acid is 5 to 100 percent (w / w) of the extract of the radix salviae miltiorrhizae total phenolic acid. The content of salvianolic acid B is the 5 to 100 percent (w / w) of the whole salvianolic acid.

Owner:石任兵 +1

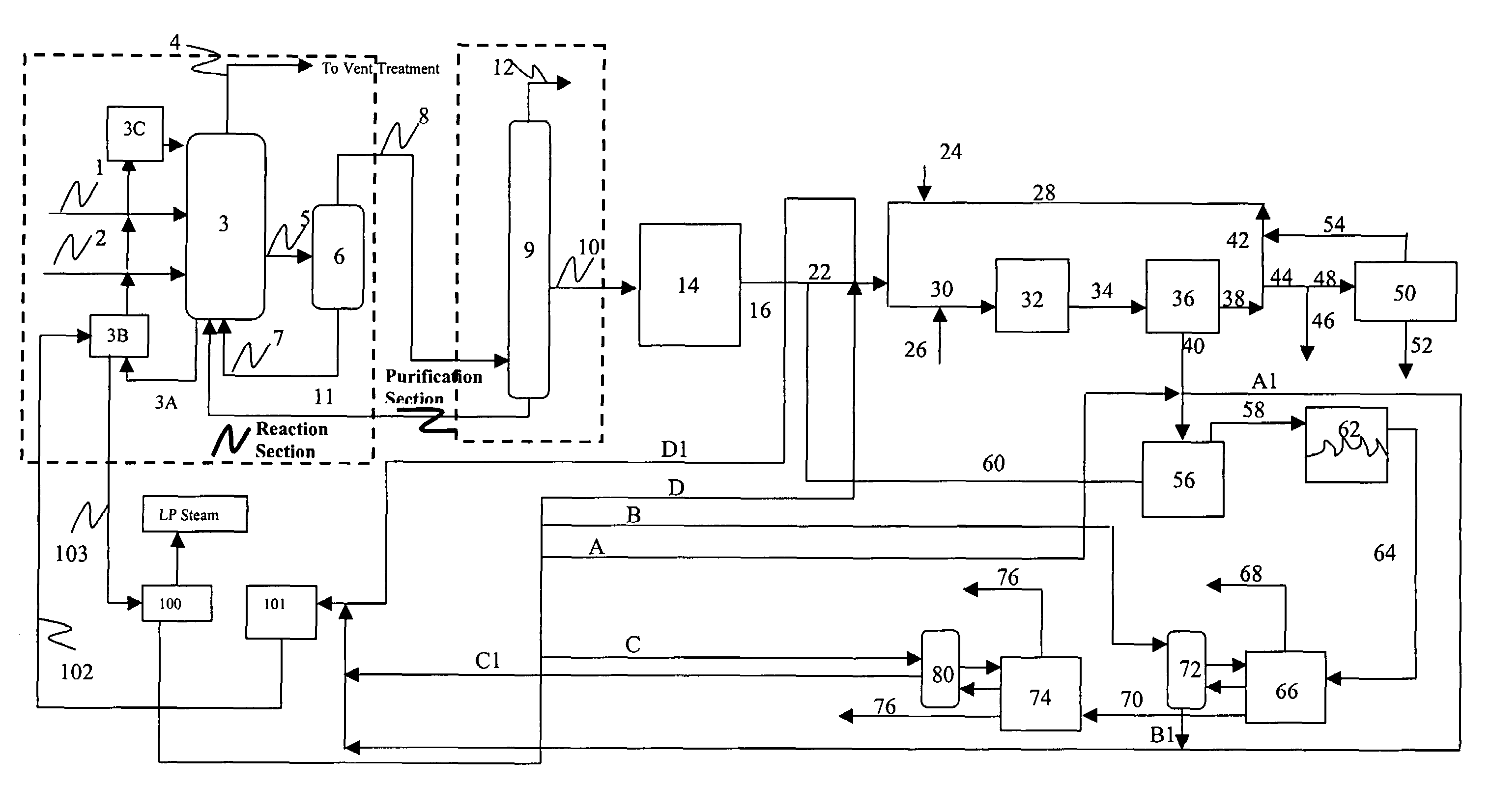

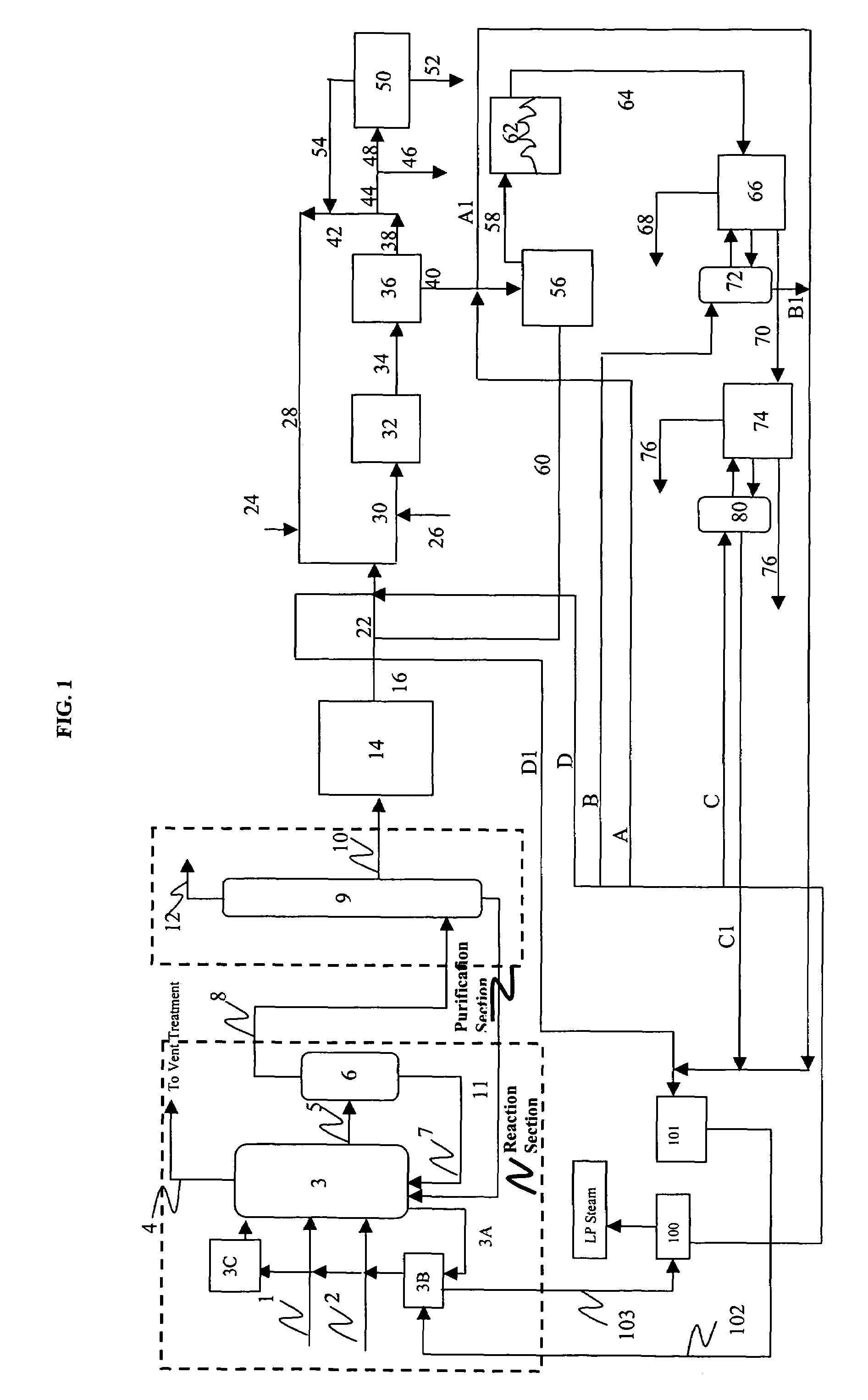

Utilization of acetic acid reaction heat in other process plants

InactiveUS7465823B2Save energy and costOrganic compound preparationChemical industryAcetic acidProcess plant

Owner:CELANESE INT CORP

Industrialized production method for synchronously producing stevioside, flavone and chlorogenic acid

ActiveCN105001281ASimple processShort processSugar derivativesCarboxylic acid esters separation/purificationHigh concentrationOrganic solvent

The invention provides an industrialized production method for synchronously producing stevioside, flavone and chlorogenic acid. The method includes the following steps that step1, stevia rebaudiana leaves are weighed, extracted by adding water and filtered to obtain an extracting solution, flocculating agents are added under the condition of heat preservation, the pH is adjusted to 7-12, standing is performed for 0-120 minutes at the temperature of 30 DEG C-75 DEG C, then filtering is performed to obtain filter mud and filter liquid, and resin purification is performed on the filter liquid so as to obtain the stevioside product; step2, the filter mud is extracted through acid solvent, and extracting solutions are merged and concentrated; step3, solvent is added into a concentrated solution for dilution, and macroporous adsorption resin is added for adsorption; step4, gradient resolution is performed on the macroporous adsorption resin in the step3, a low-concentration resolution liquid is concentrated and dried to obtain the chlorogenic acid product, and high-concentration resolution liquid is concentrated to be standby; step5, after water is added into the high-concentration resolution liquid for dilution, organic solvent the same as the high-concentration resolution liquid in volume is used for extraction, and organic phases are merged, concentrated and dried to obtain the flavone product. By the adoption of the method, the stevioside, flavone and chlorogenic acid are extracted at the same time, the production cost is lowered, and the comprehensive utilization value of the stevioside is increased.

Owner:CHENGUANG BIOTECH GRP CO LTD

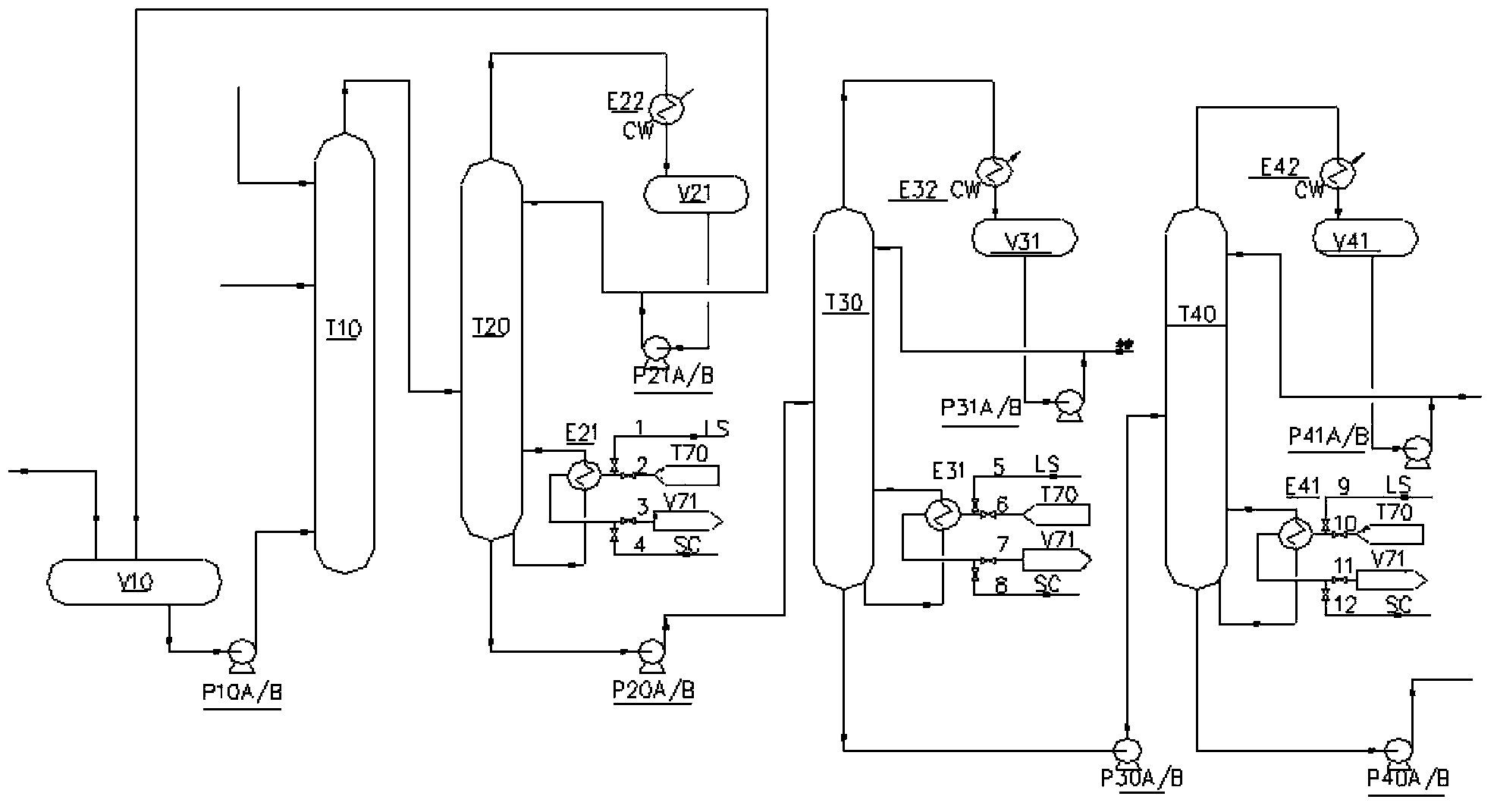

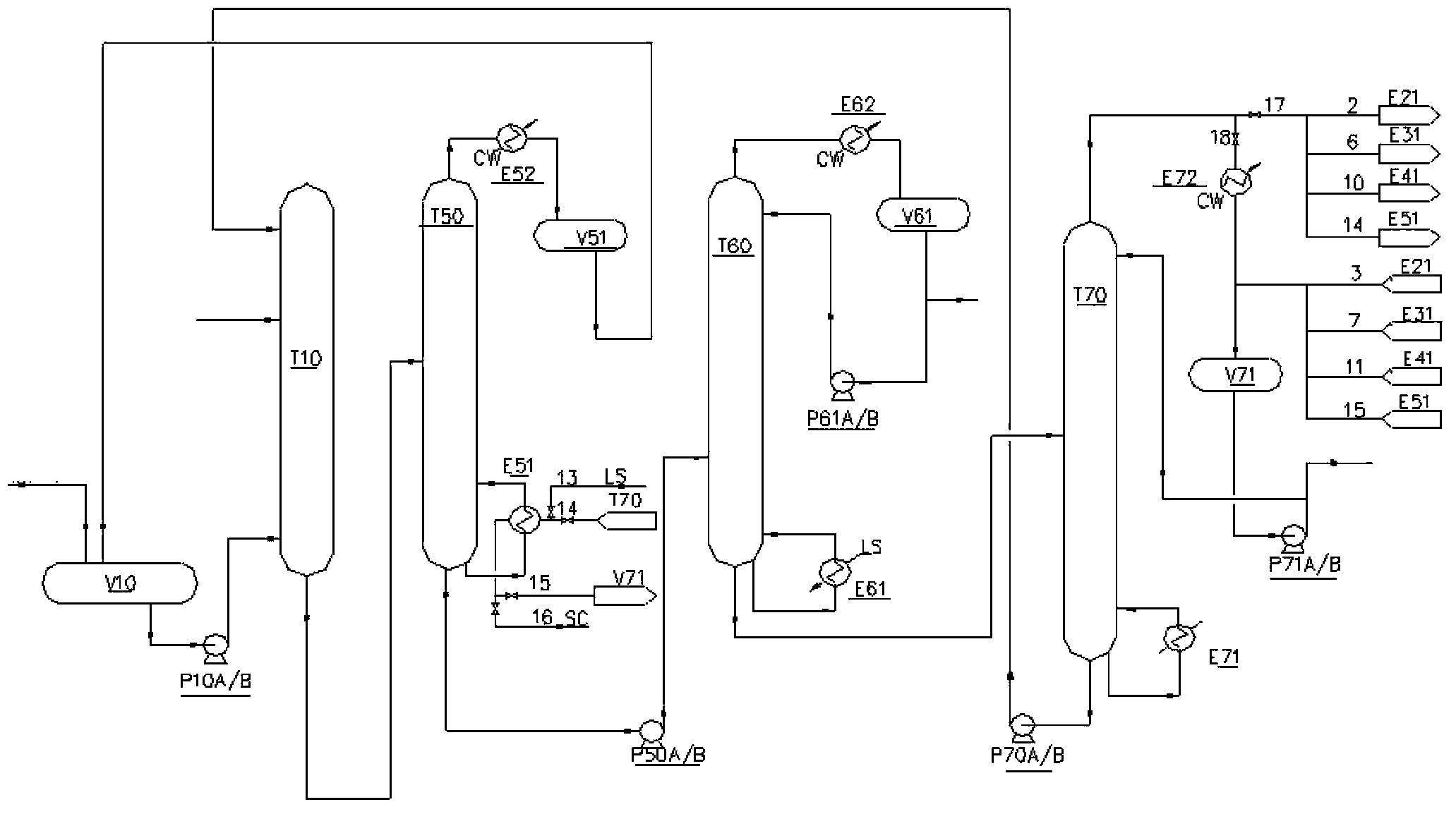

Separation equipment and separation method of methyl methacrylate (MMA)

InactiveCN103833551AReduce energy consumptionLess investmentOrganic compound preparationCarboxylic acid esters separation/purificationSolventTower

The invention relates to the field of chemical technology, and particularly relates to separation equipment and separation method of methyl methacrylate (MMA). The separation equipment of MMA comprises a separation device, and the separation device comprises a solvent tank, an extraction tower, a solvent recovery tower, an impurity ester removal tower and an MMA refining tower. The separation method of MMA comprises a separation process and is operated by the separation equipment by the following steps: 1) extracting the MMA reaction liquid with washing water and n-hexane in the extraction tower to obtain an extract phase from the tower top; 2) heating and refining the extract phase through the solvent recovery tower to obtain coarse MMA from the tower kettle and n-hexane from the tower top; 3) recycling the n-hexane obtained from the tower top in the solvent tank. After the coarse MMA is subjected to impurity ester removal in the impurity ester removal tower and then is processed by the MMA refining tower to obtain the purified MMA product. According to the separation equipment and separation method provided by the invention, the common easily-available n-hexane with a wide source is used as an MMA extraction agent, and the n-hexane is recycled through an MMA refining process.

Owner:华东理工大学工程设计研究院有限公司

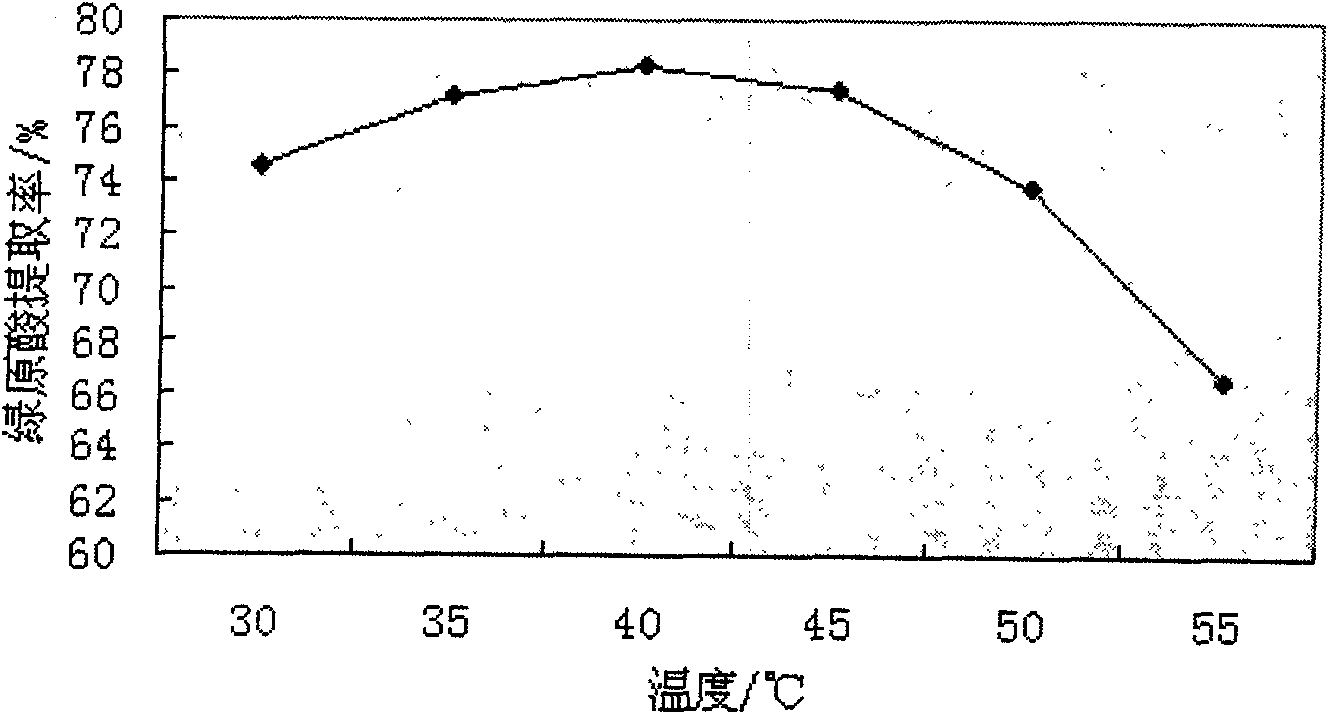

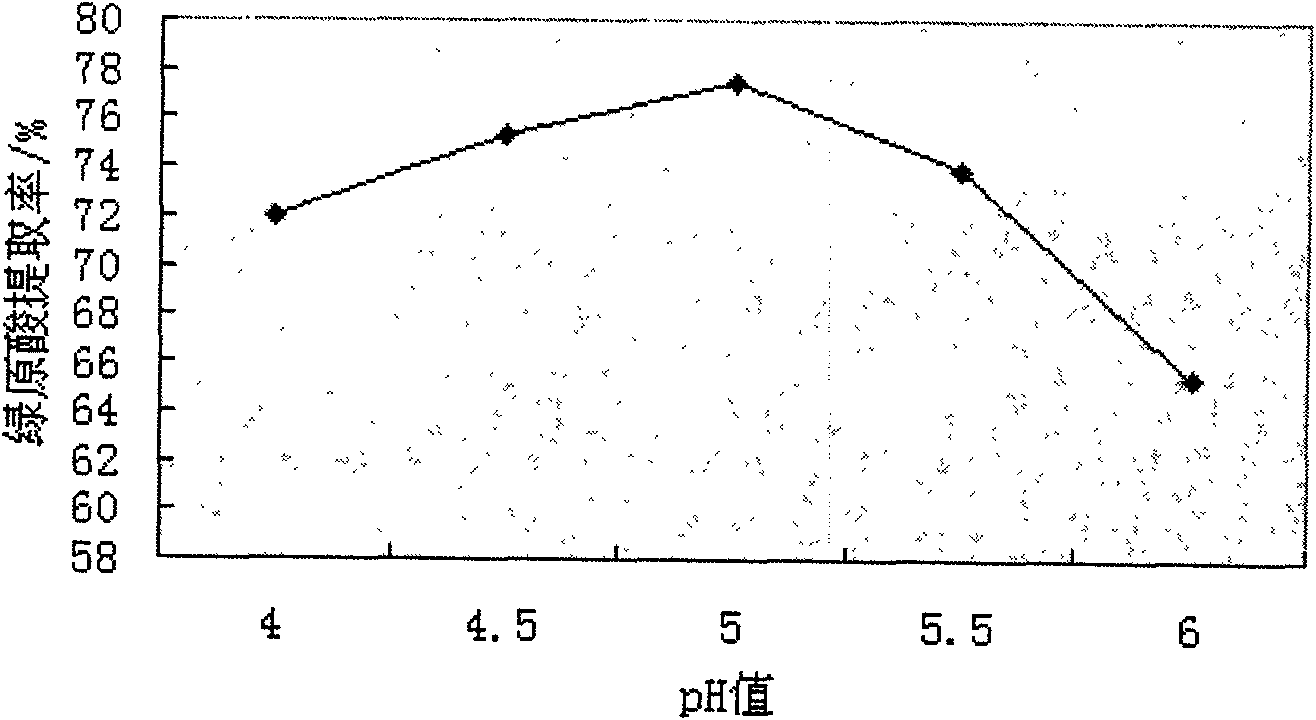

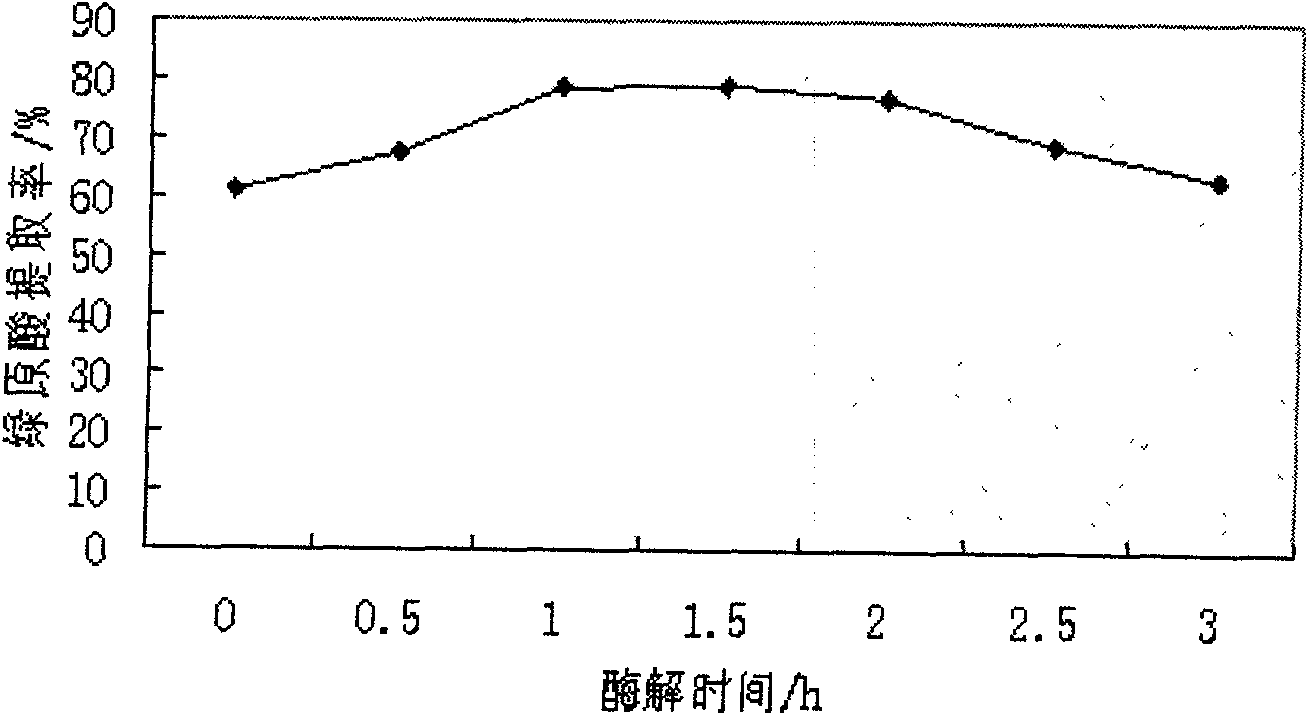

Method for extracting chlorogenic acid from honeysuckle by using compound enzyme method

InactiveCN101830804AGood process repeatabilityThe result is stableCarboxylic acid esters separation/purificationPectinaseChlorogenic acid

The invention relates to a method for extracting chlorogenic acid from honeysuckle by using a compound enzyme method and researches a novel process for extracting a main medicinal effective component of the chlorogenic acid from the honeysuckle by a cellulose and pectinase compounding enzyme method. Through a single factor experiment and an orthogonal test, optimal process conditions for extracting the chlorogenic acid from the honeysuckle by using the compound enzyme method can be optimized: the enzymolysis temperature is 45DEG C, the pH is 4.5, the compound ratio of the cellulose to the pectinase is 1.0:0.3 and the enzymolysis time is 1.5 hours. The test result shows that the process repeatability is favorable and the result is stable. The extraction rate of the chlorogenic acid extracted from the honeysuckle by using the compound enzyme method can reach 83.06 percent which is improved by 16.93 percent in comparison with the extraction rate of the chlorogenic acid extracted by using a water extraction process.

Owner:ZHONGXIN PHARMA FACTORY OF TIANJIN ZHONGXIN PHARMA GROUP

Method of producing a carboxylic alkyl ester

ActiveUS20090137825A1Increase productionHigh purityOrganic compound preparationChemical industryCarboxylic saltReactive distillation

The present invention relates to a novel process for preparing alkyl polycarboxylates from an aqueous solution of an ammonium salt of the polycarboxylic acid by reactive distillation, and to a process for hydrogenating the alkyl carboxylates prepared in this way.

Owner:BASF AG

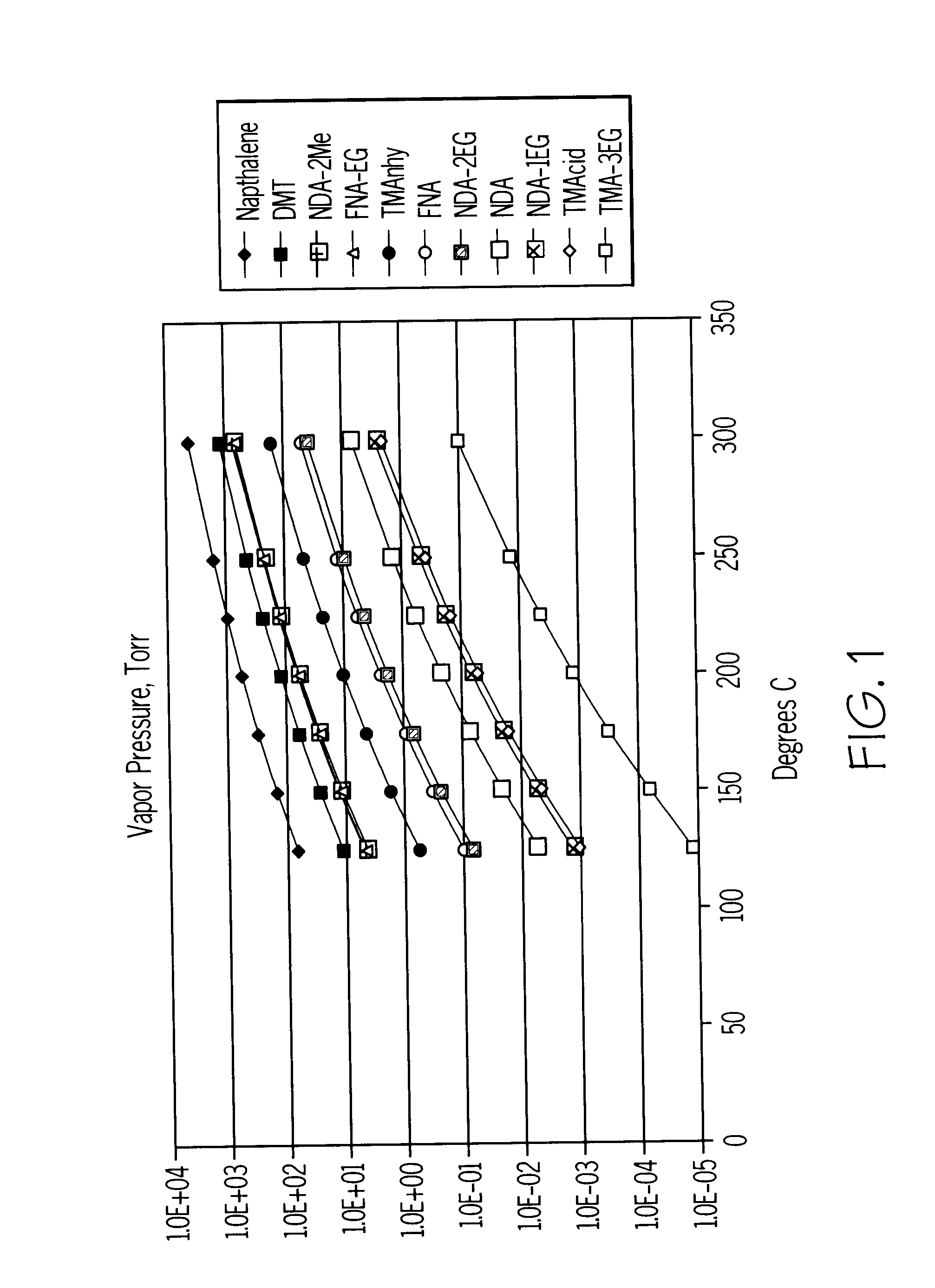

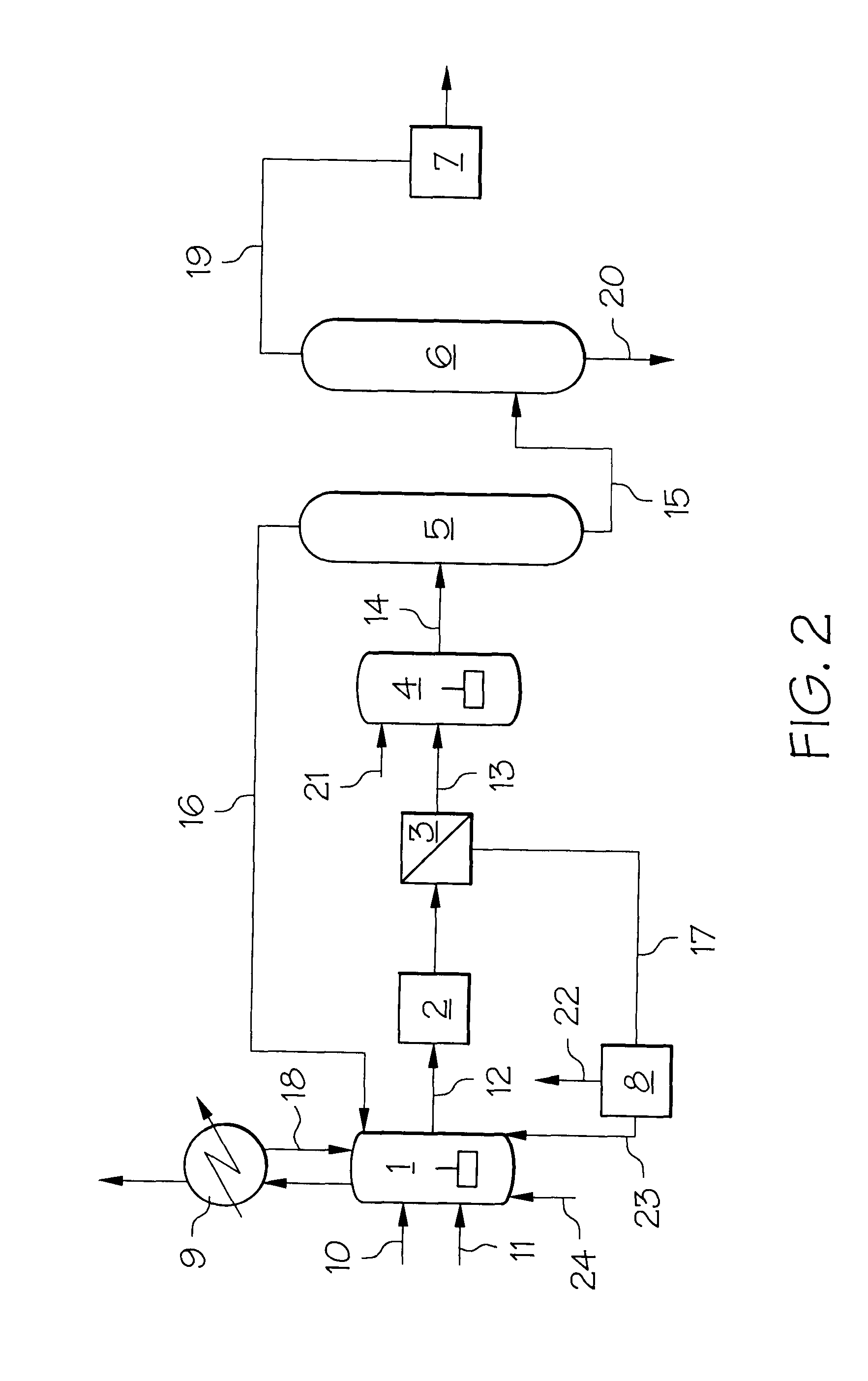

Production, purification and polymerization of aromatic dicarboxylic acids

InactiveUS6642407B2Reduce pressureOrganic compound preparationCarboxylic acid esters separation/purificationPolyesterPartial oxidation

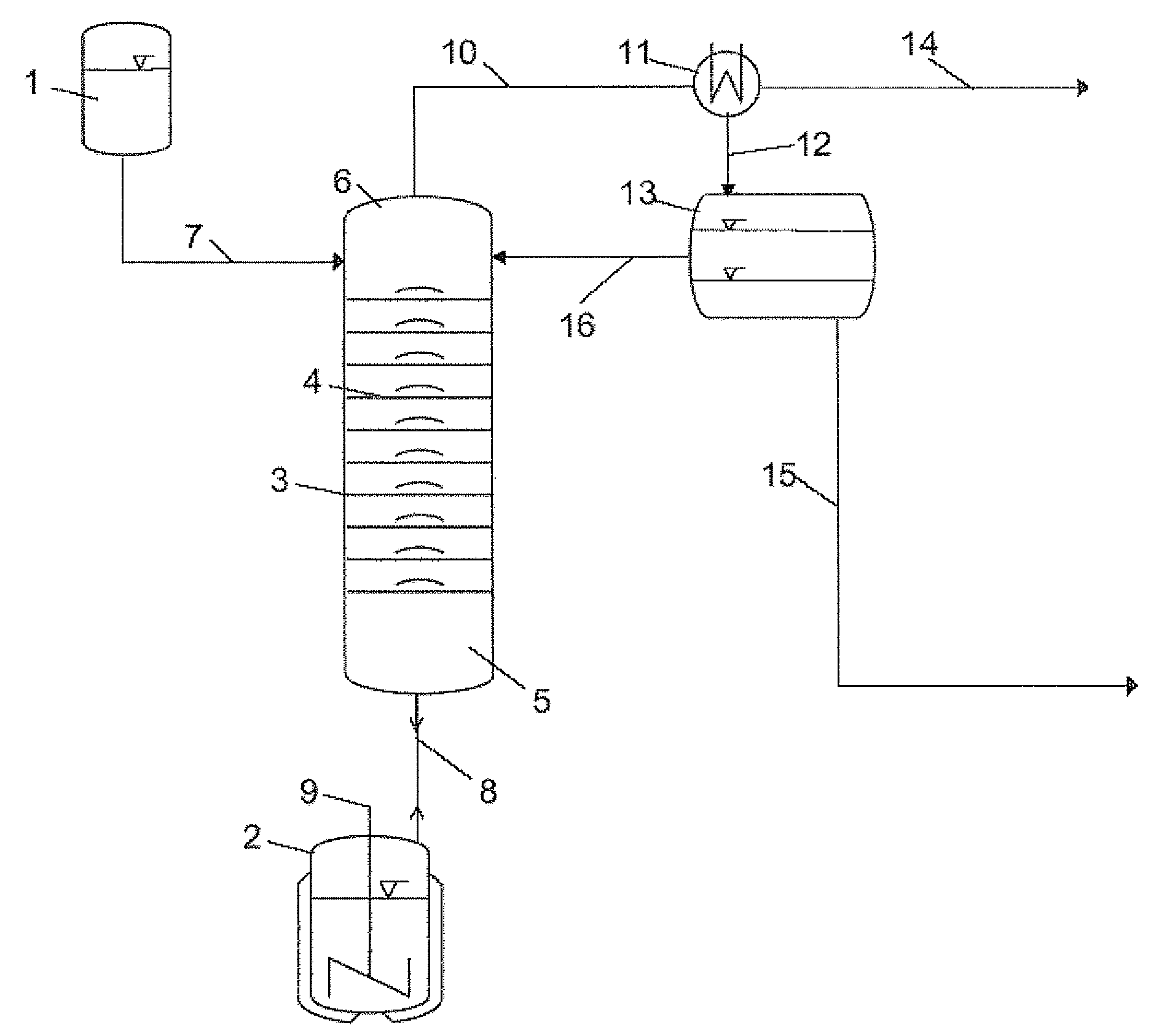

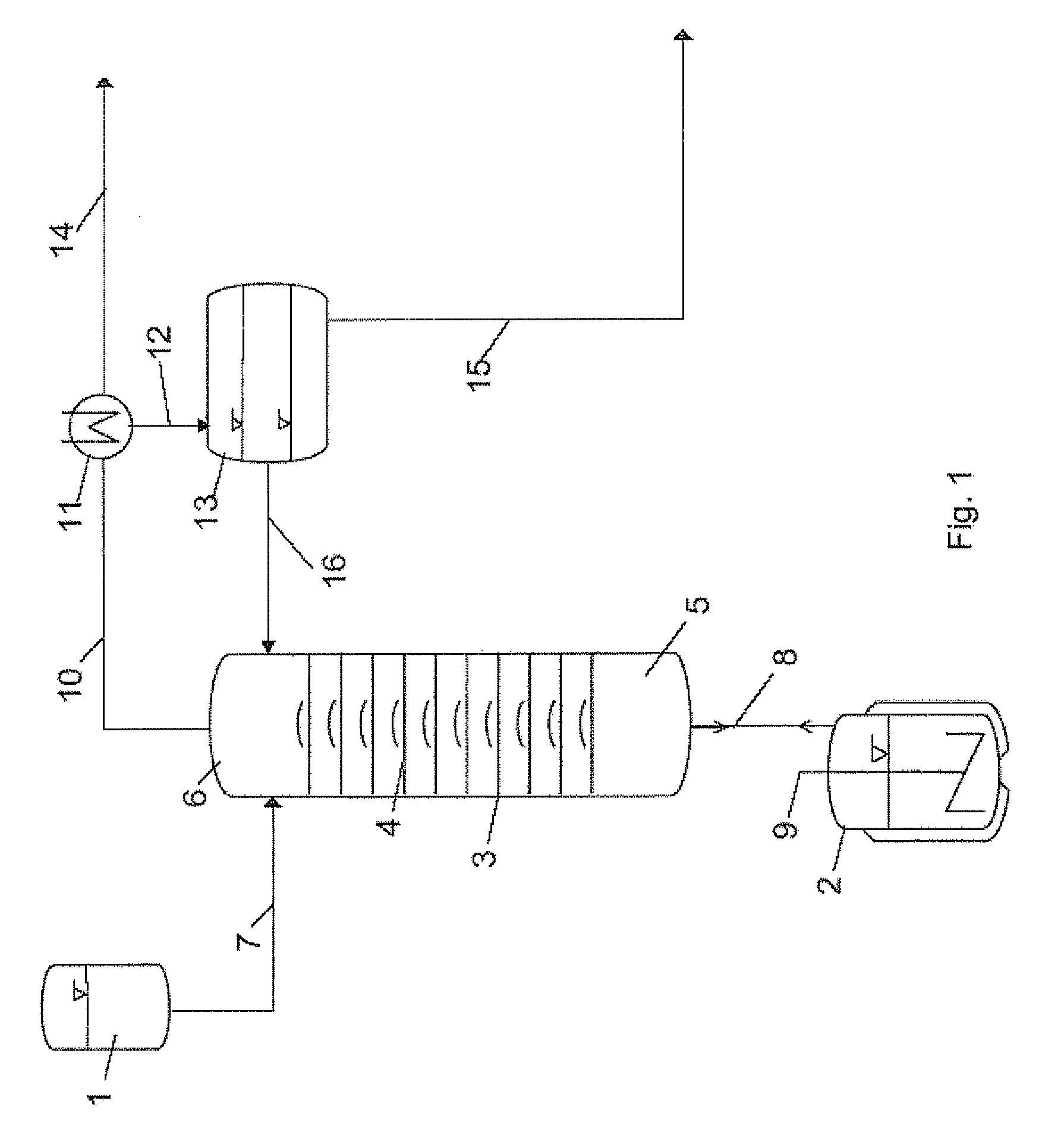

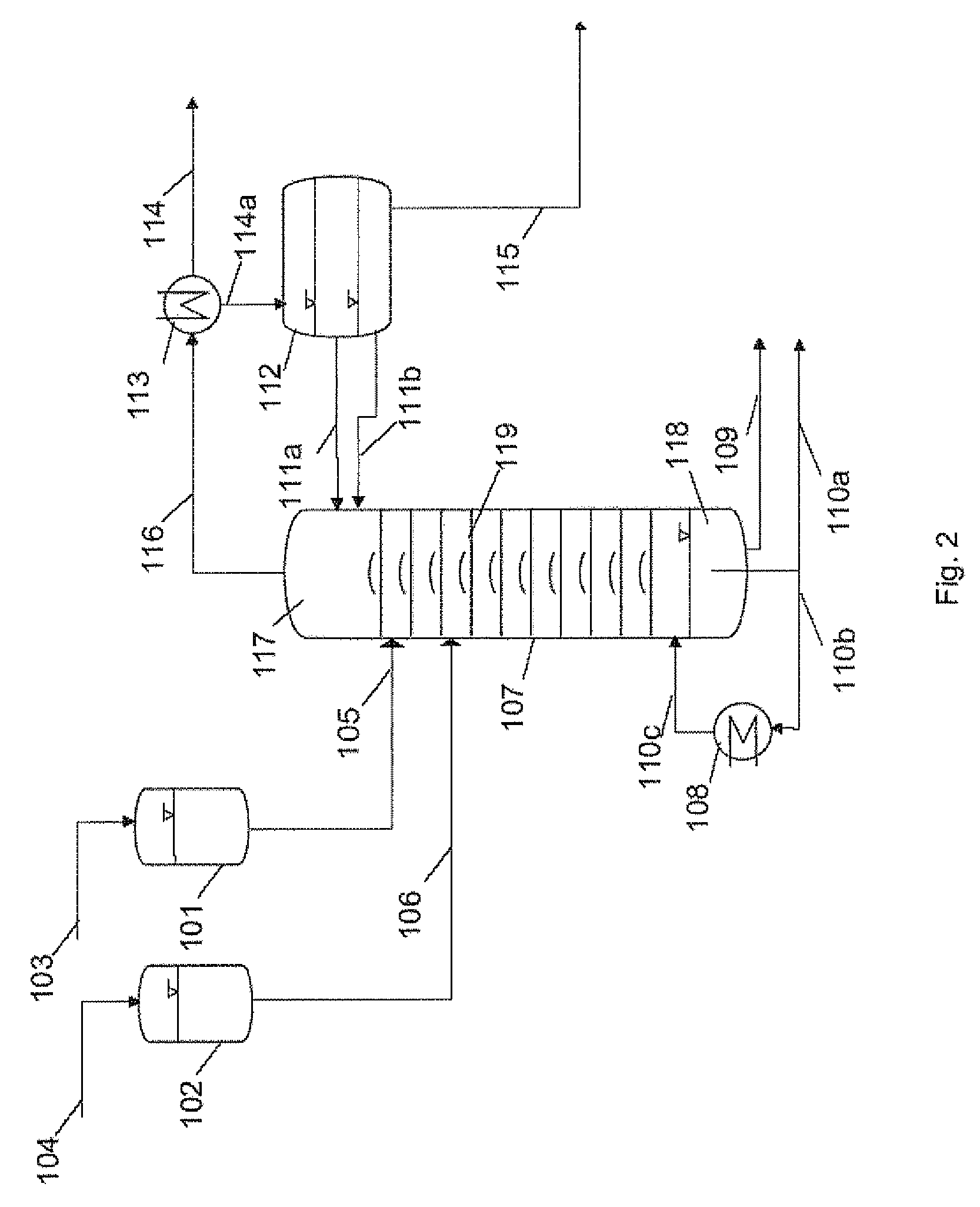

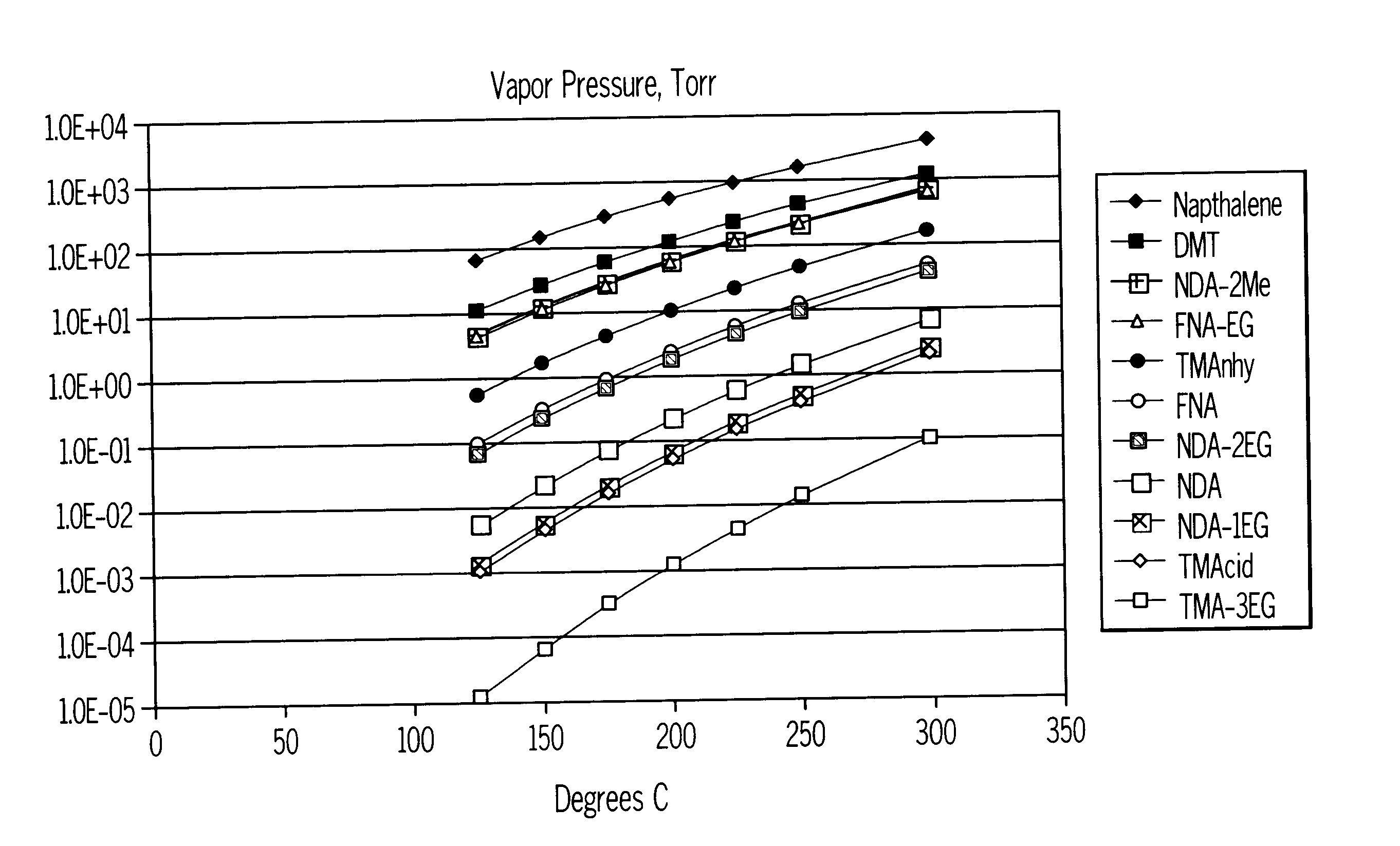

This invention provides a process for purifying the crude aromatic dicarboxylic acids produced by oxidation of dialkyl aromatic hydrocarbons and for using the purified acids in the preparation of polyethylene terephthalate, polyethylene naphthalate and other polyesters. The invention simplifies the manufacturing process by converting the crude aromatic acids into bis-glycol esters in an esterification reactor 4, from which the esterified partial oxidation impurities present in the oxidation product are removed by distillation in distillation tower 5. After removal of the volatile impurities, the dicarboxylic acid esters can separated by distillation in distillation tower 6 or by crystallization and converted to polyesters by polycondensation. The volatile impurities removed as overhead from tower 5 can be recycled as stream 16 to the oxidation reactor where they act as oxidation promoters thereby optionally allowing for a bromine-free oxidation process for dialkyl aromatic hydrocarbons.

Owner:EXXONMOBIL CHEM PAT INC

Efficient methods for making tetrahalophthalate esters having excellent purity

InactiveUS6150552AReduce acidityImprove economyOrganic compound preparationCarboxylic acid esters separation/purificationAlcoholCatalytic metal

Provided are methods for the preparation and purification of alkyl tetrahalophthalate esters by the reaction of a tetrahalophthalic compound with an alkanol in the presence of a titanate catalyst. More particularly, improved methods are provided for making and recovering an ester with little contamination by catalytic metal components and color bodies, and with little acidity, in a high yield from the esterification reaction by pretreating the starting materials to reduce the acidity thereof, reacting the starting materials in the presence of a titanate catalyst, stripping excess alcohol, hydrolyzing the catalyst, and filtering out solids to yield a high purity tetrahalophthalate ester product.

Owner:PABU SERVICES

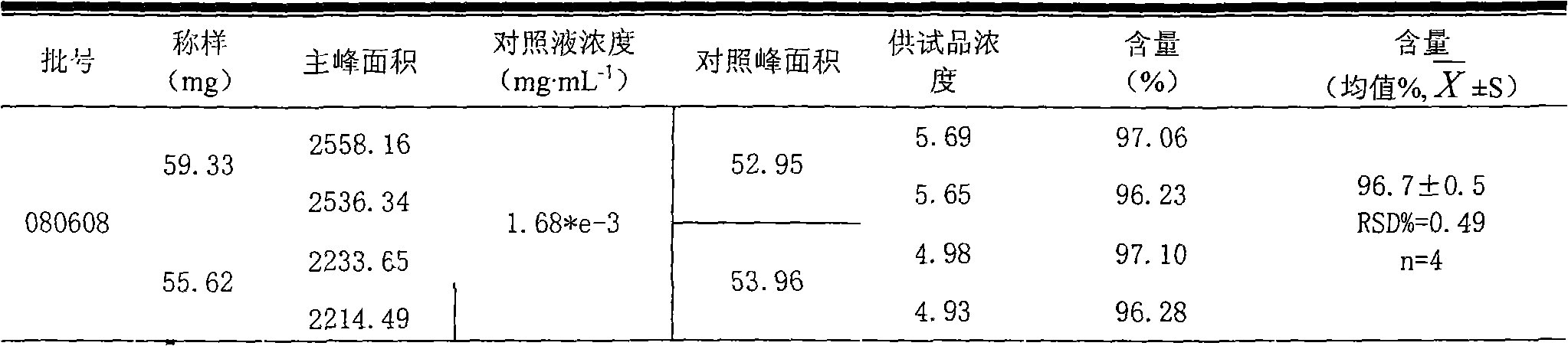

Method for extracting and separating chlorogenic acid from honeysuckle

ActiveCN101838200AHigh extraction rateImprove transfer rateOrganic compound preparationCarboxylic acid esters separation/purificationAlcoholChlorogenic acid

The invention relates to the field of the medicine, in particular to a method for extracting and separating a chlorogenic acid monomer from honeysuckle. The prior art is lack of a method for the mass preparation of the chlorogenic acid monomer from the honeysuckle. In the invention, the technology is realized by the following preparation steps of: (1) soaking by alcohol: putting the honeysuckle into an alcohol solution for soaking, heating, refluxing, filtering and concentrating; (2) degreasing: degreasing the obtained filtrate thrice by adopting a weak-polarity solvent, and taking a water layer; (3) enriching by macroporous resin: enabling a water layer solution obtained in the step (2) to pass through the macroporous resin, washing by water, collecting effluent liquid and water washing liquid, concentrating and regulating the pH value; (4) extracting: extracting a solution obtained in the step (3) by adopting a moderate-polarity solvent, taking an organic layer, concentrating and recovering the solvent to obtain a faint yellow puffy solid substance; and (5) recrystallizing. The invention adopts an alcohol extraction method to enhance the extraction rate and the transfer rate of the chlorogenic acid, the final transfer rate of the chlorogenic acid is as high as 84 percent, and the purity of the obtained product can reach more than 98 percent.

Owner:SHANGHAI INOHERB COSMETIC

Method for extracting chlorogenic acid

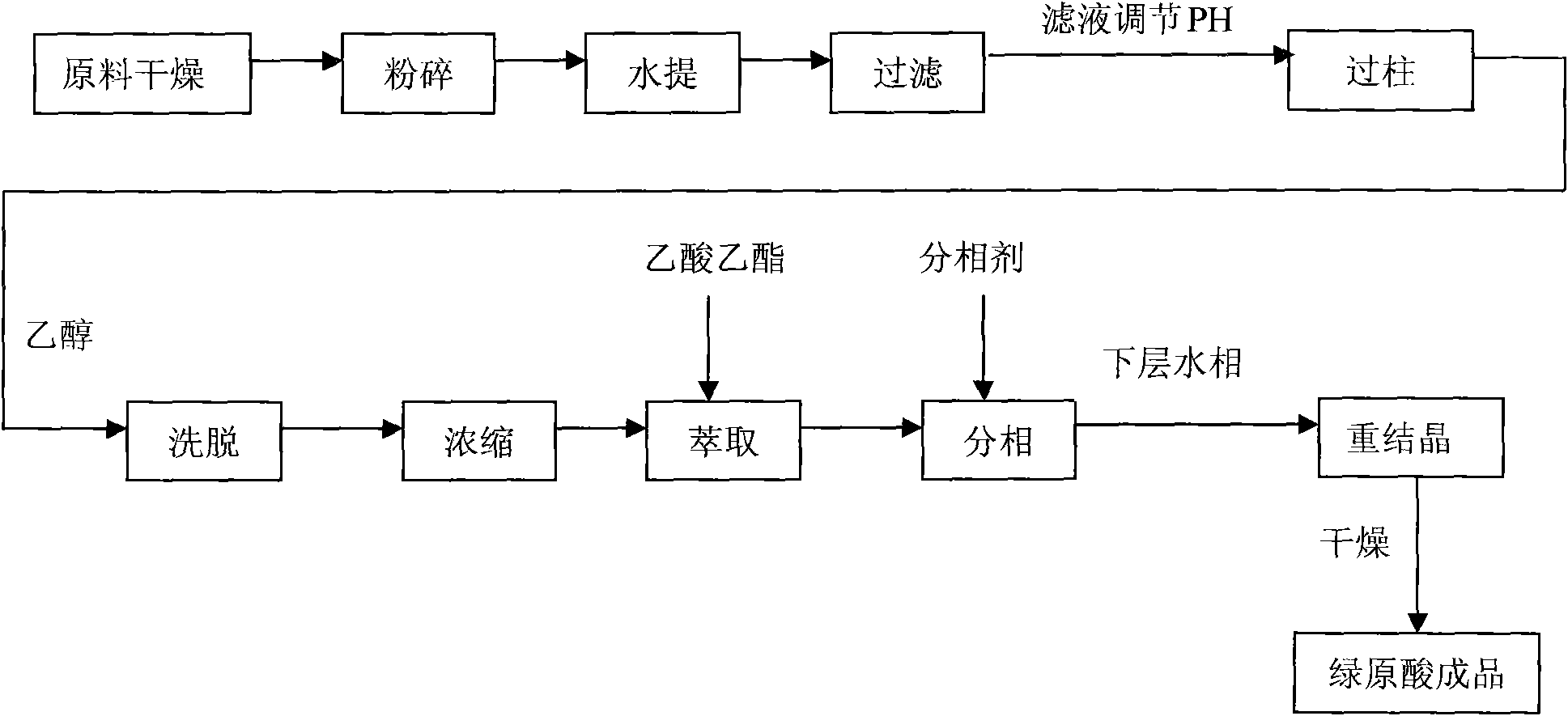

InactiveCN101602668AEnables step-by-step gradient purificationHigh purityOrganic compound preparationCarboxylic acid esters separation/purificationChlorogenic acidSolvent

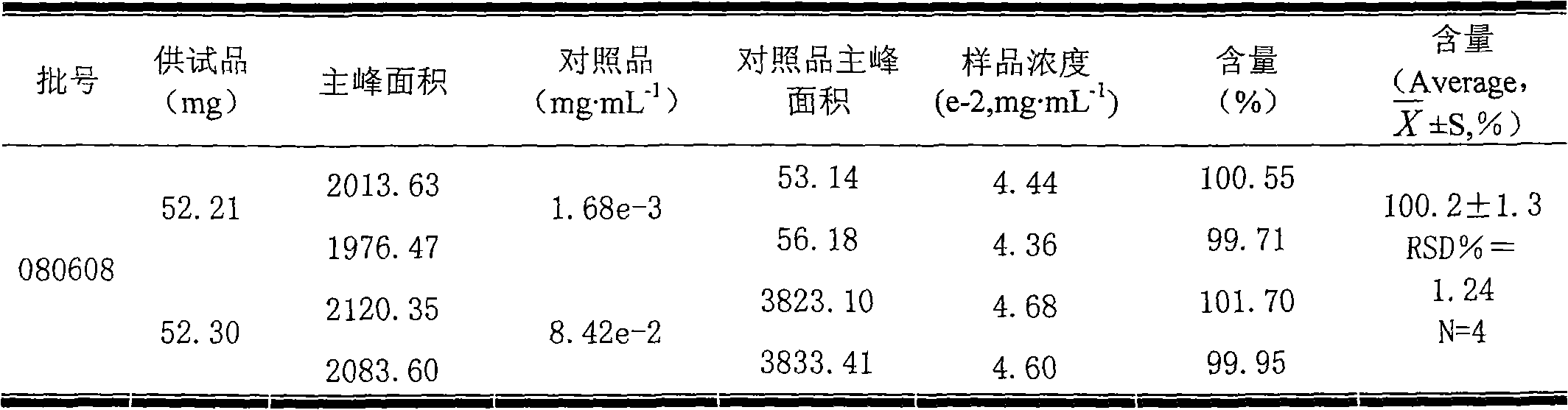

The invention relates to a method for extracting chlorogenic acid, which belongs to the technical field of pharmaceutical chemicals. The method combines macroporous resin enrichment, ethyl acetate extraction and a mixed solvent split-phase method to achieve multi-step gradient purification of the chlorogenic acid so as to obtain a chlorogenic acid product with high purity. The method comprises the processes of water extraction, column passing, extraction, phase splitting and recrystallization. The macroporous resin adopted by the column passing process is 306 type or XAD series resin; and the split-phase agent adopted by the split-phase method is petroleum ether, chloroform or the mixture of the petroleum ether and the chloroform. The method is applicable to the process of extracting and preparing the chlorogenic acid from honeysuckles, cortex eucommiae leaves and cortex eucommiae barks.

Owner:INST OF APPLIED CHEM JIANGXI ACAD OF SCI

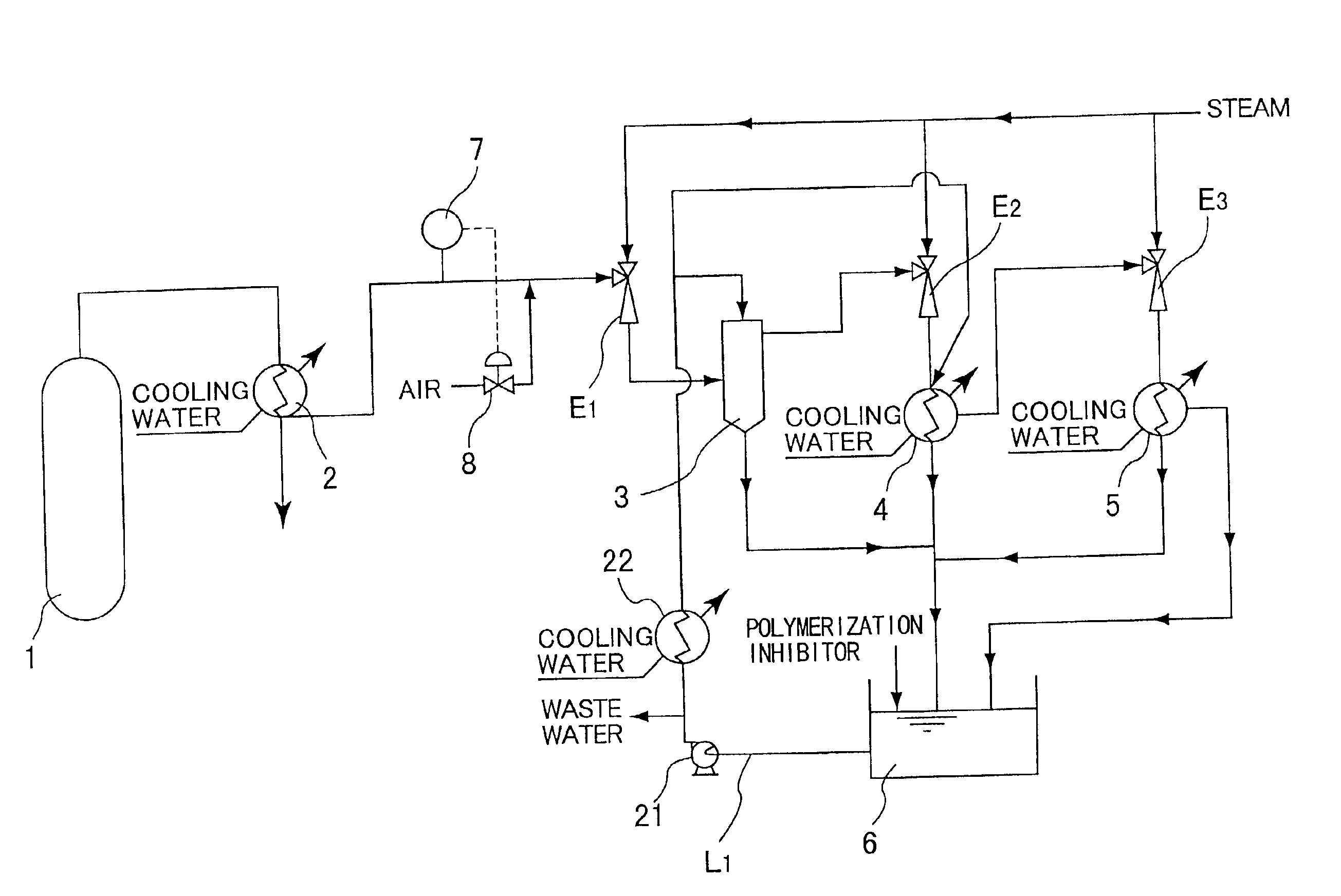

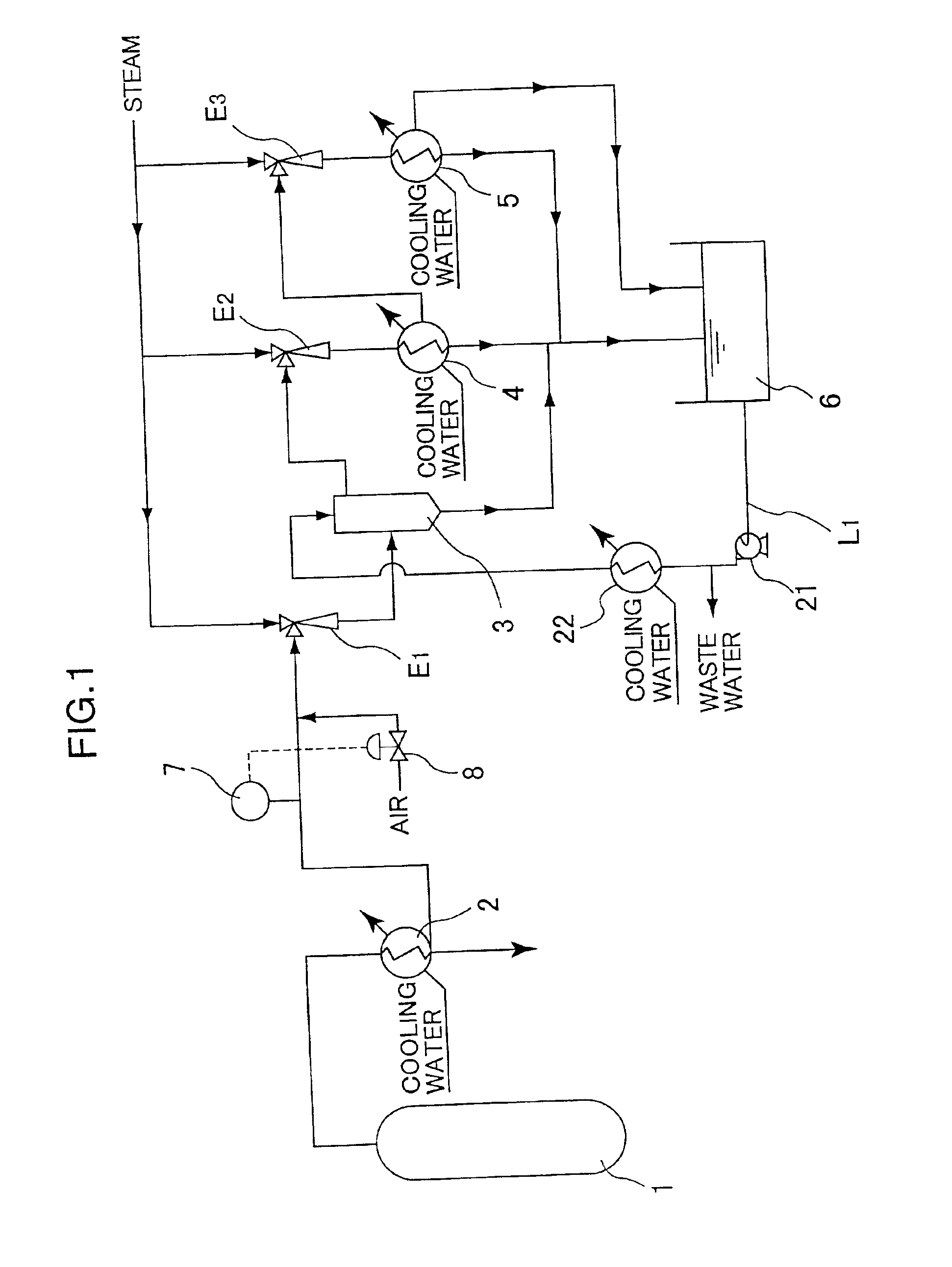

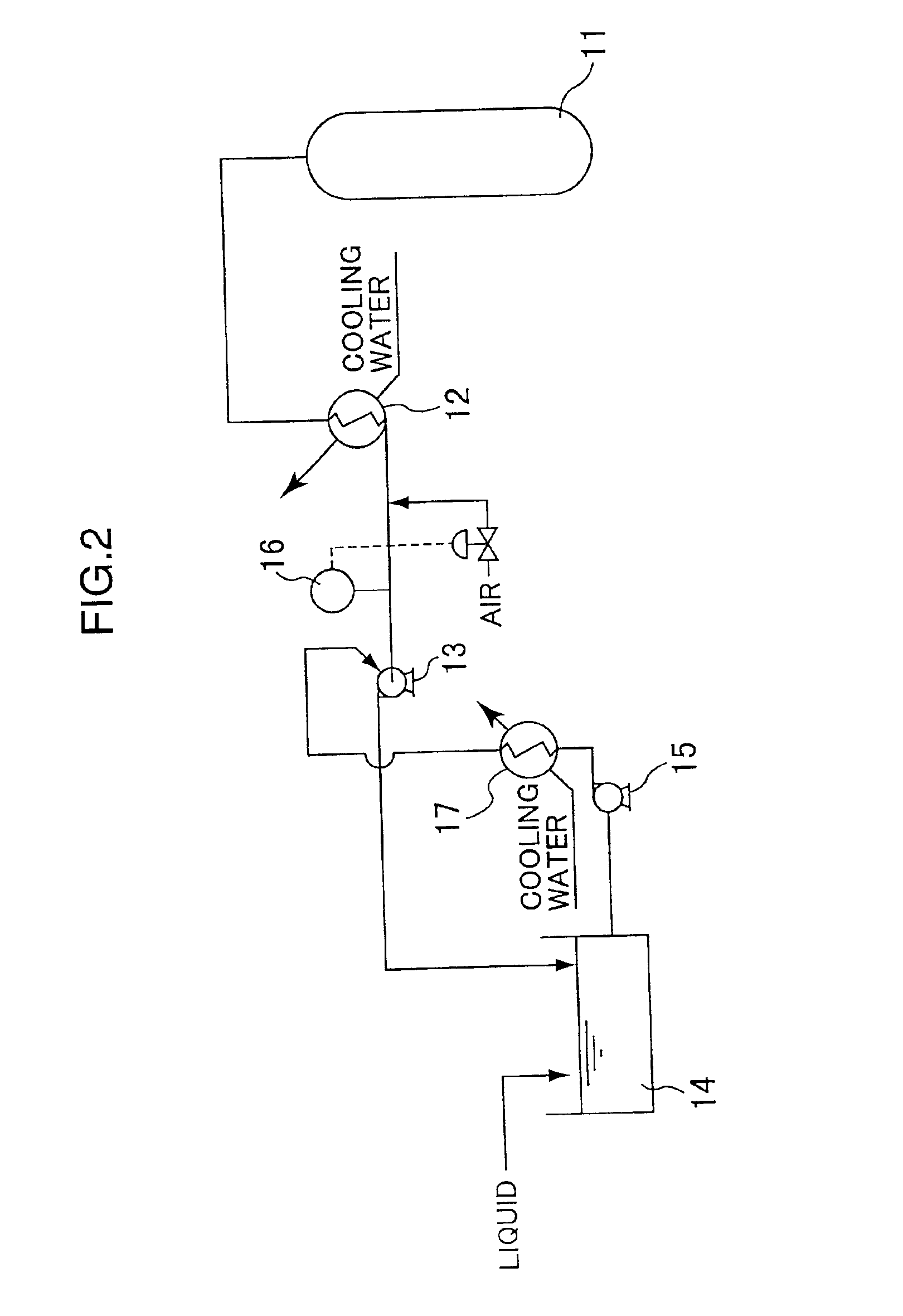

Process for inhibiting a polymerization in a vacuum section of an easily polymerizable compound purification system

InactiveUS6878239B1Inhibition of polymerizationImprove purification effectOrganic compounds purification/separation/stabilisationOrganic compound preparationMeth-Product gas

A process for inhibiting a polymerization of an easily polymerizable compound purification system is disclosed.According to the present invention, the polymerization of the easily polymerizable compound such as (meth)acrylic acid and (meth)acrylate flowed into a vacuum section can be inhibited by contacting a liquid containing a polymerization inhibitor with the compound directly in the vacuum section.When the vacuum section includes a gas and liquid contact chamber (usually a condenser), the liquid containing a polymerization inhibitor may be supplied to the chamber. When the vacuum section includes a liquid ejector and / or a nash pump as a vacuuming device, the liquid containing a polymerization inhibitor may be circulated by the liquid ejector and / or the nash pump for reducing a pressure of a purifying section. Examples of easily polymerizable compounds are (meth)acrylic acid and (meth)acrylates. The process of the invention is capable of inhibiting the polymerization of the easily polymerizable compound such as (meth)acrylic acid and (meth)acrylate in a vacuum section of a purifying system. The system of the invention is suitable for purifying the easily polymerizable compound.

Owner:NIPPON SHOKUBAI CO LTD

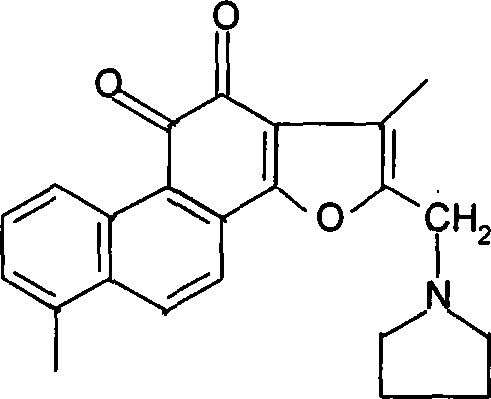

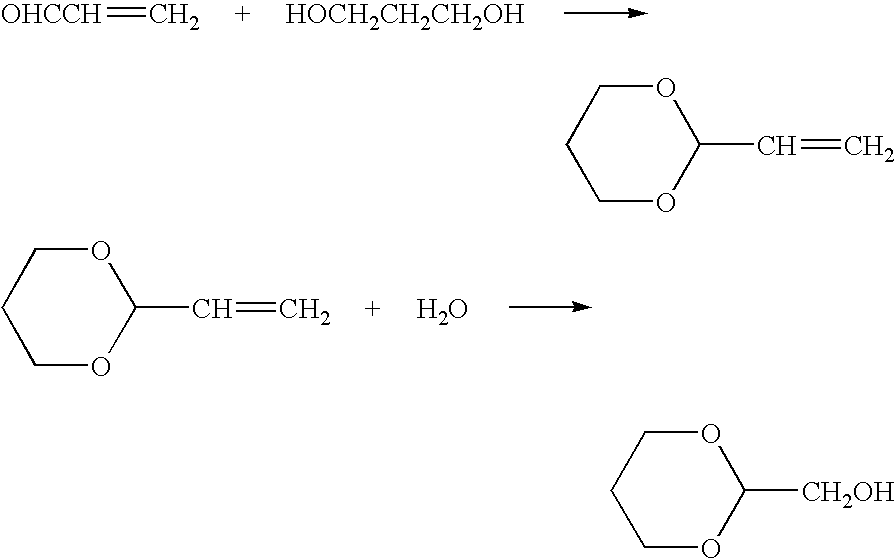

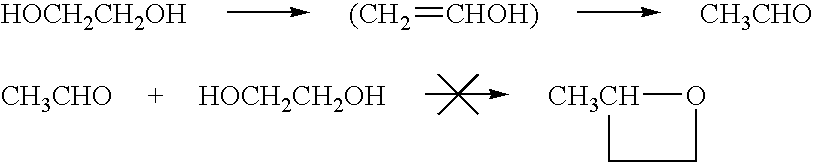

Ester-forming monomer

InactiveUS6867322B1High recovery rateEasy to separateOxygen-containing compound preparationOrganic compound preparationDepolymerizationPolymer science

An ester-forming monomer obtained by depolymerization of polytrimethylene terephthalate and having an acrolein content of no greater than 0.5 wt %. Polymers obtained using the monomer and fibers, films and molded articles comprising the polymers. The ester-forming monomer is obtained by reacting polytrimethylene terephthalate with at least one compound selected from among monoalcohols, 1,3-propanediol and water in the presence of a basic substance. When the recovered ester-forming monomer is used as the starting material for production of a polymer, it is possible to produce a molding polymer for fibers, films and the like with quality equivalent to or higher than that obtained using virgin monomer.

Owner:ASAHI KASEI KK

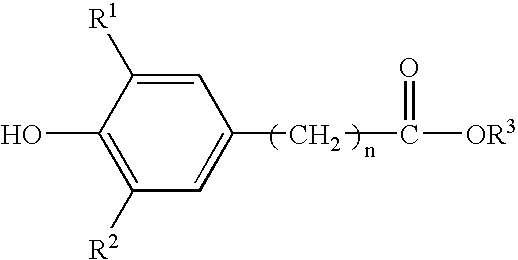

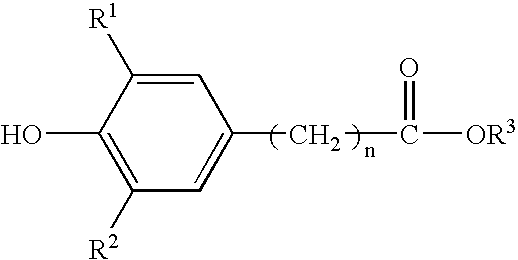

Method for the preparation of a hydroxyalkyl hindered phenolic antioxidant

ActiveUS20050242328A1Substantial process cost savingImprove solubilityFatty substance preservation using additivesHydrocarbon purification/separationAlcoholStrong acids

A method of making a hindered phenolic antioxidant is disclosed wherein the method comprises: reacting an ester of the formula: wherein R1, R2, and R3 are independently selected alkyl groups and n is 0, 1, or 2, with an aliphatic polyhydroxyl alcohol of the general formula R(OH)n wherein R is an aliphatic group of from 2 to about 12 carbon atoms and n is an integer of from 2 to 7, provided that one hydroxyl is primary and the others are secondary or tertiary, in the presence of a strong acid catalyst; then, neutralizing the strong acid catalyst with an overbased detergent; and isolating the hindered phenolic antioxidant after the neutralization step.

Owner:CROMPTON CORP

Process of preparing high purity chlorogenic acid and flavonid with eucommia leaf

ActiveCN1974527AImprove product qualityHigh content of target ingredientsOrganic compounds purification/separation/stabilisationCarboxylic acid esters separation/purificationChlorogenic acidEthyl acetate

The process of preparing high purity chlorogenic acid and flavonid with eucommia leaf includes the following steps: crushing eucommia leaf and extracting with pH 3-6 alcohol solution of 45 %-55 % concentration; saturation adsorbing the extracted solution with medium polarity JD-1 macroporous resin, and eluting successively with water, 20 %-45 % concentration alcohol solution and 60 %-75 % concentration alcohol solution to obtain crude chlorogenic acid product and flavonid-containing powder separately; eluting the crude chlorogenic acid product in silica gel column with ethyl acetate, acetone, methanol or ethanol, collecting the eluted solution, decompression concentrating, and re-crystallizing the concentrate in acetone or water to obtain refined chlorogenic acid product. The present invention has simple technological process, convenient operation, reuse of the macroporous resin, low comprehensive cost and excellent industrial application foreground.

Owner:GUANGZHOU HANFANG PHARMA

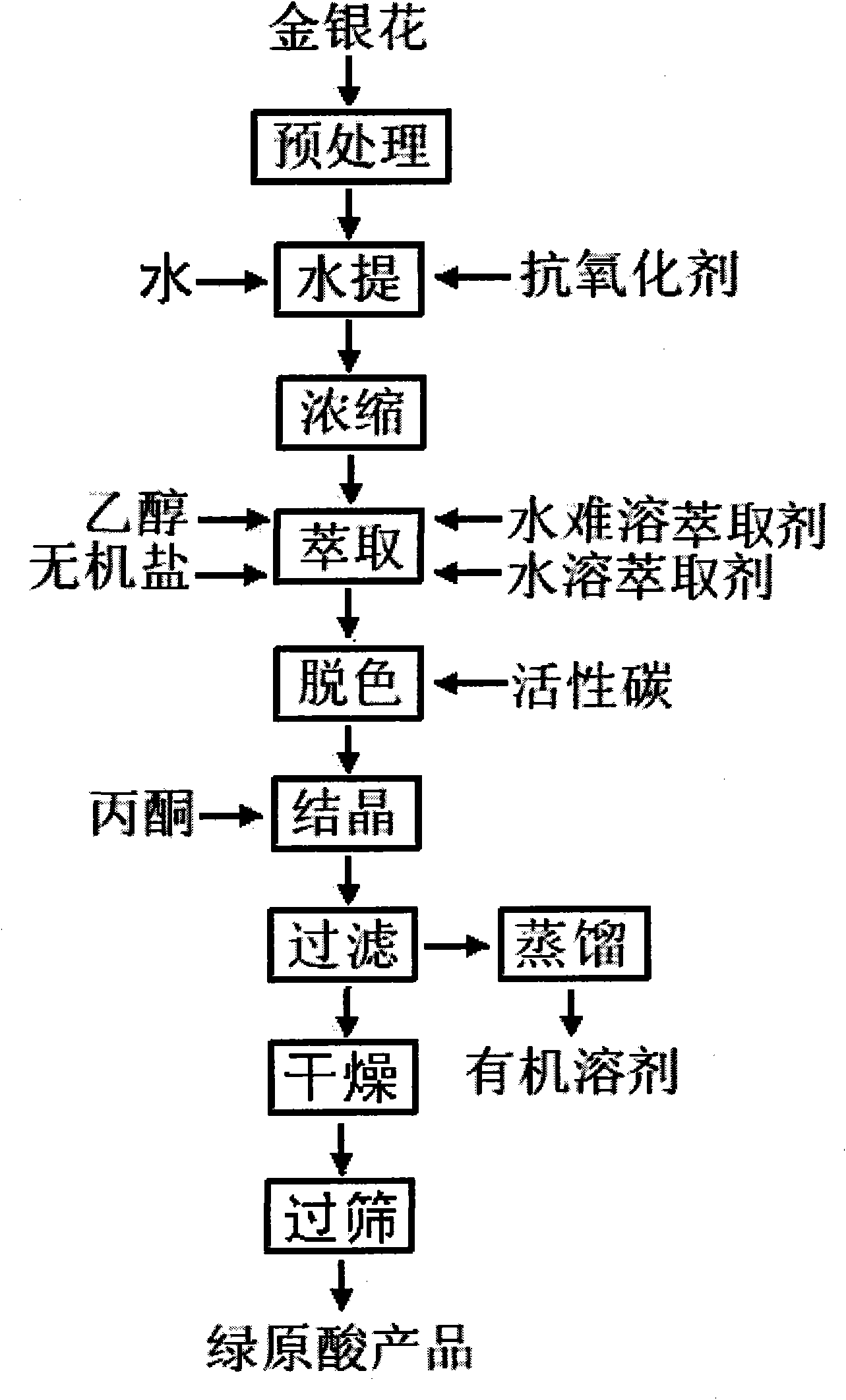

Method for preparing honeysuckle chlorogenic acid

InactiveCN102001947AImprove separation efficiencyLarge amount of processingCarboxylic acid esters separation/purificationChlorogenic acidOrganic solvent

The invention discloses a method for preparing honeysuckle chlorogenic acid, comprising the following steps of: carrying out water extraction on honeysuckle and branches and leaves of honeysuckle, which are used as raw materials, and then forming a dual-aqueous phase system by mixing a water soluble organic solvent together with a saline solution and a water soluble compound in proportion; then dissolving total extract into the dual-aqueous phase system for distribution so that the average concentration of the extract in two phases is 30-50 percent to achieve distribution balance; then extracting with an extracting agent which is not solvable with the two aqueous phases to separate out extract liquor; firstly removing impurities the polarity of which is lower than that of the chlorogenic acid; performing a three-phase extracting method, i.e. extracting the rest dual-aqueous phase with another extracting agent; carrying out selective direct enrichment and separating purification to obtain a chlorogenic acid initial product; and then decolorizing, crystallizing and drying to obtain the chlorogenic acid product with the mass fraction of 95 percent. The method simplifies production process, has better repeatability and no pollutant emission, and is suitable for industrial production; and the chlorogenic acid produced by using the method has high mass fraction.

Owner:GUANGXI JINHONGXIN BIOTECH

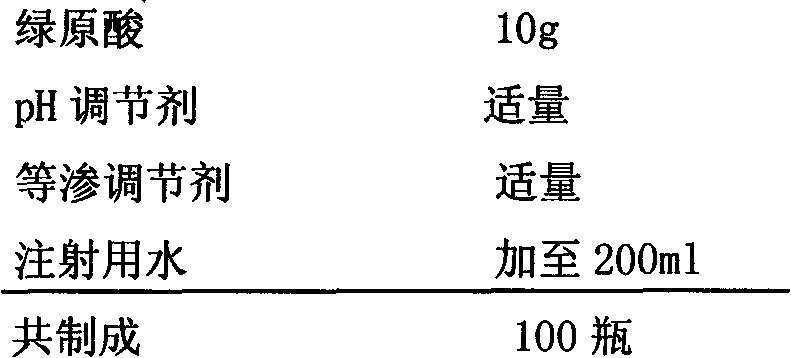

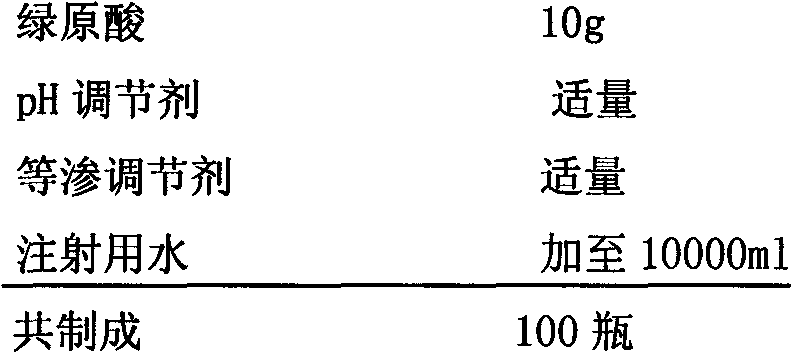

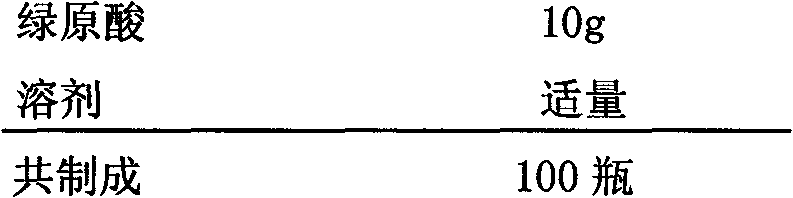

Preparation of high purity chlorogenic acid preparation and clinical application thereof

InactiveCN102391119AAntibacterialSuppressor mutationAntibacterial agentsOrganic active ingredientsDiseaseChlorogenic acid

Chlorogenic acid, i.e. 1, 3, 4, 5-tetrahydroxycyclohexanecarboxylic acid-(3, 4-dihydroxycinnamic acid ester), exists in a plurality of plants, and also, high purity chlorogenic acid can be prepared through synthesis. Chlorogenic acid has a lot of biological activity, such as antibacterium, antivirus, antioxidation, antitumor and the like. However, there exists no report and research on oral preparations prepared by high purity chlorogenic acid and application of the preparations in clinics. In the invention, high purity chlorogenic acid is extracted from plants or obtained through synthesis, and is then added with a proper amount of accessories, thus obtaining oral preparations like tablets, capsules, granules, oral solutions, etc. The preparations provided in the invention can be applied in clinics for treating cardio-cerebrovascular diseases, infections, hepatitis B, tumors and other diseases, and also can be used in health care medicines for heat clearing and detoxifying, face nursing and skin moistening, as well as hangover relieving, etc.

Owner:肖文辉 +1

Method for separating sec-butyl acetate from reaction mixture of acetic acid and hybrid C4

ActiveCN101007761AThe mass content of acetic acid is smallOrganic compound preparationCarboxylic acid esters separation/purificationSec-Butyl acetateChemistry

The invention discloses a separating method of butyl para-acetate from the reacted compound of acetic acid and C4, which comprises the following steps: flashing to remove non-reacted C4 and light component; flowing production from the bottom of flashing tower into coboiling rectifying tower; adding coboiler A to separate butyl para-acetate and acetic acid; transmitting mass from coboiler into acid condensing tower; adding coboiler B to coboil and rectify again; condensing acetic acid; obtaining the product with purity over 99% and acetic acid content less than 0.01% and water less than 0.05%; recycling acetic acid.

Owner:HUNAN ZHONGCHUANG CHEM

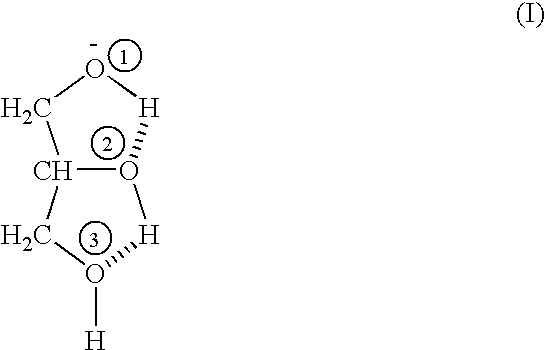

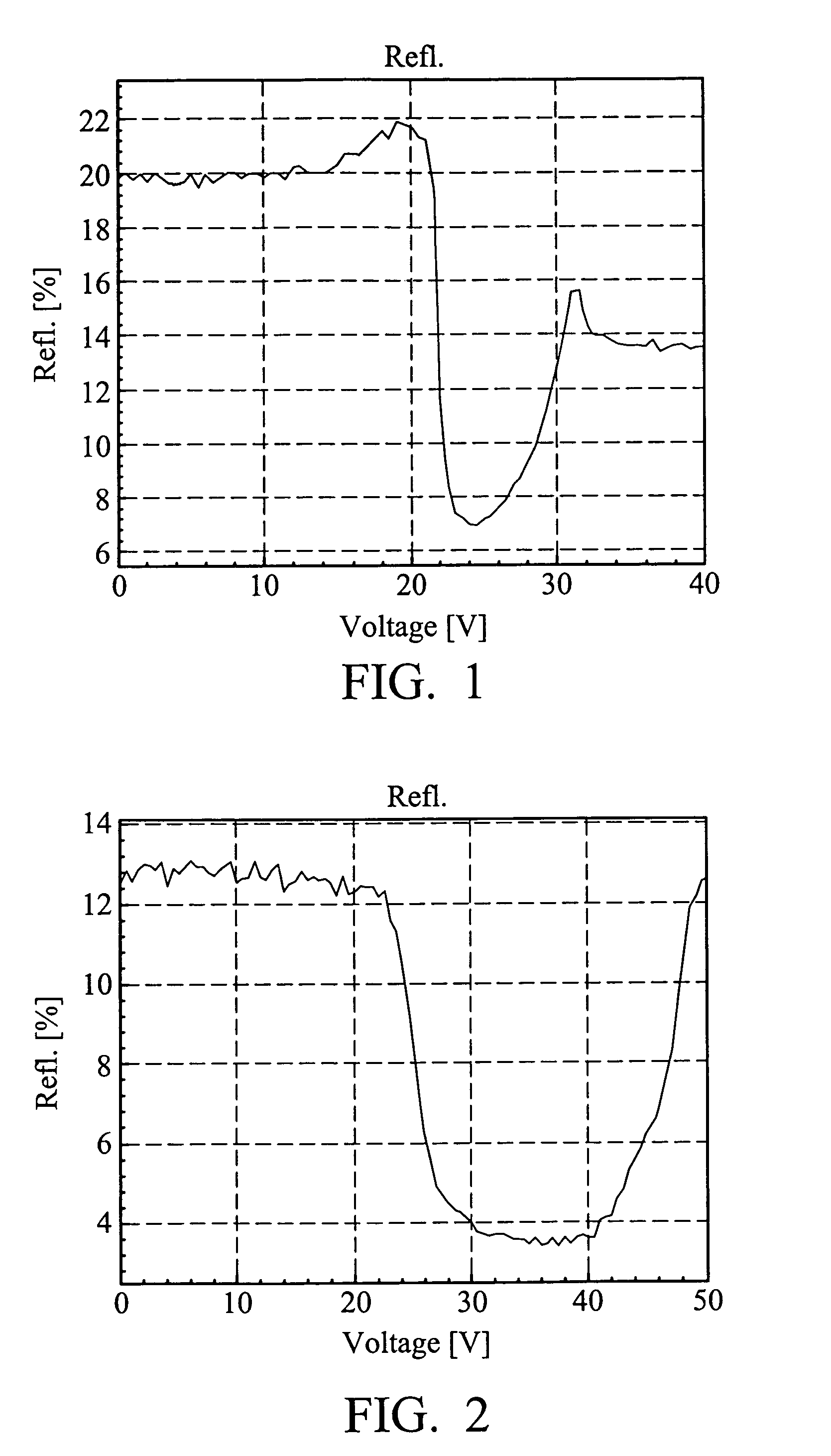

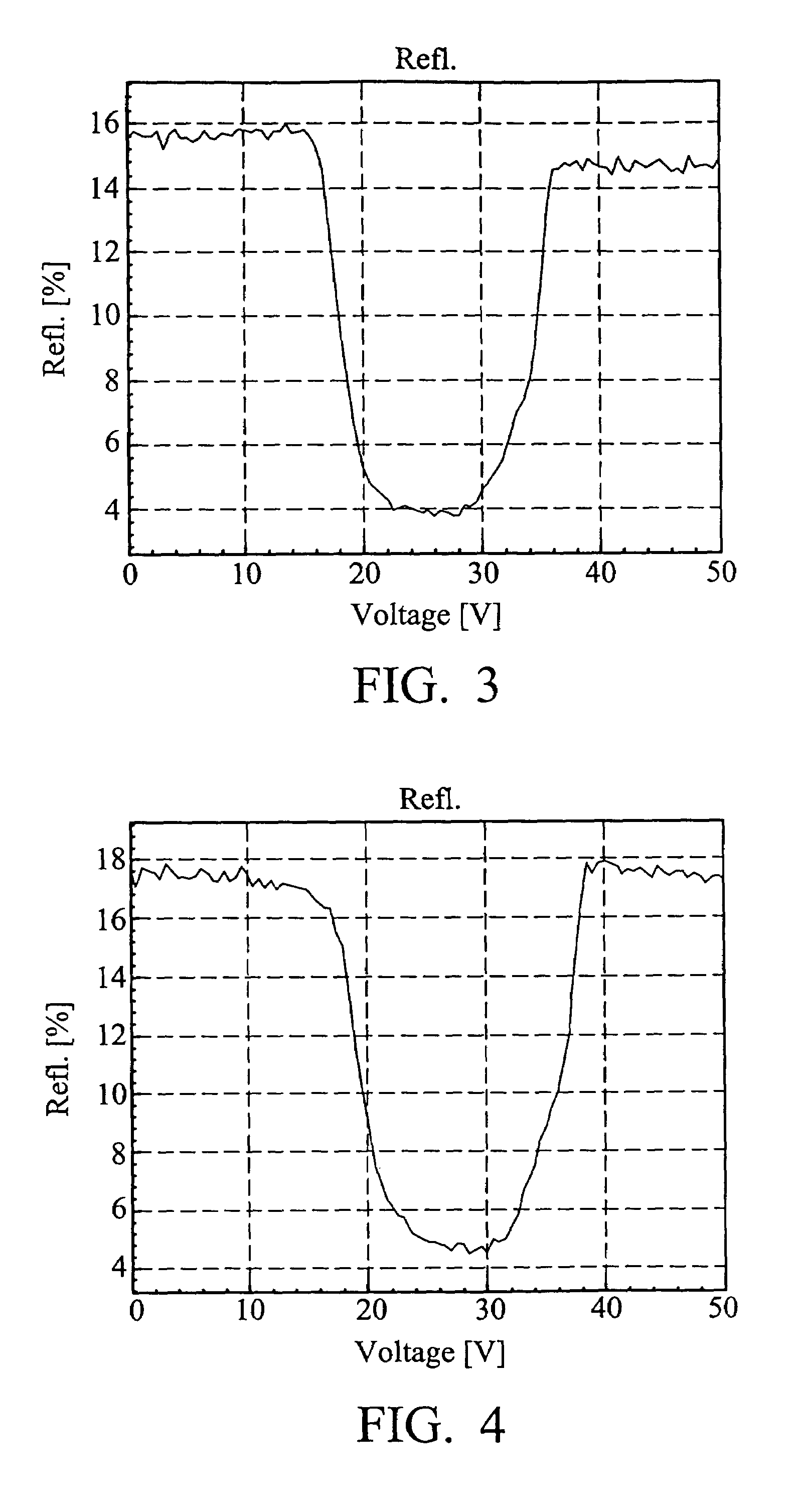

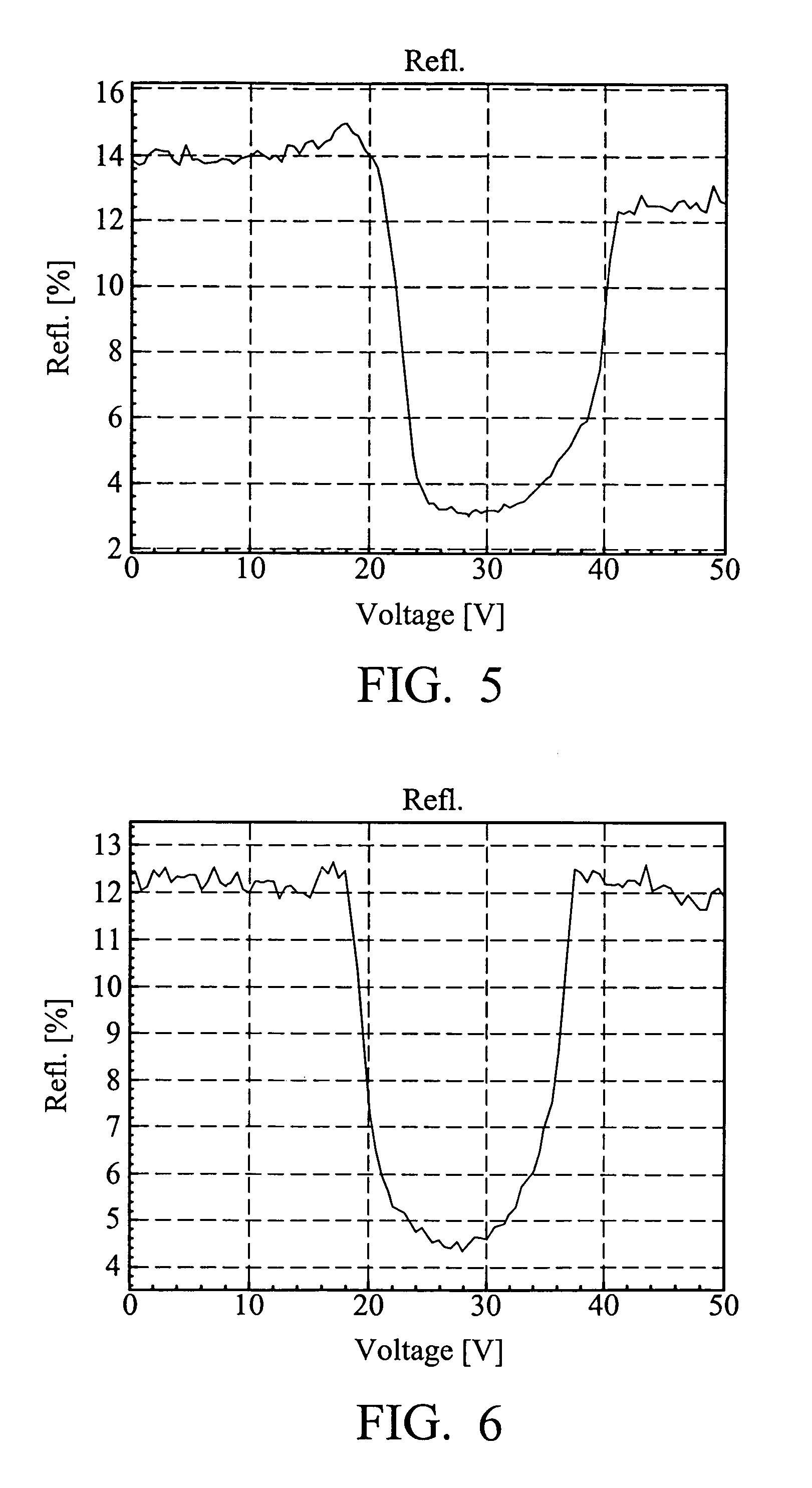

Liquid crystal compounds, preparation thereof, and composition containing the same

ActiveUS7022259B2Increase powerShorten the timeLiquid crystal compositionsOrganic compound preparationAlcoholChain structure

A liquid crystal compound with high helical twisting power, a method for preparing the same, and a liquid crystal composition containing the same. The liquid crystal compounds include cyclic group chain structures similar to the liquid crystal to serve as the core structure, and multi-ring structures of natural alcohol with optical activity, such as alcoholates of terpenol, borneol, cinchonidine, quinine, or derivatives thereof. As a result, the liquid crystal composition containing the liquid crystal compounds can filter out light of specific wavelengths from incident light due to optical activity and high helical twisting power thereof.

Owner:IND TECH RES INST

Method for extracting high-purity chlorogenic acid from honey suckle flower

InactiveCN101851163ANo lossRetain bioactive ingredientsCarboxylic acid esters separation/purificationChlorogenic acidHigh volume manufacturing

The invention discloses a method for extracting high-purity chlorogenic acid from honey suckle flower. The technical scheme of the invention comprises the following steps of: firstly, smashing the honey suckle flower material by the low-temperature supersonic air stream to obtain the cell-level honey suckle flower micro powder; secondly, carrying out the enzyme treatment, ultrasonic treatment, water extraction and filtering on the cell-level honey suckle flower micro powder to obtain the initial solution of the chlorogenic acid; and finally, flocculating, decolouring, purifying, condensing and drying the initial solution to obtain the high-purity chlorogenic acid. The invention solves the problems that the chlorogenic acid extract of the prior art is difficult to filter due to the large quantity of the precipitate in the impurity-removal and purification process; the invention has the advantages of advanced technique, simple and convenient operation, low cost, no harmful solvent, highpurity, high yielding rate, suitability for industrial large-mass production and the like.

Owner:湖南济草堂金银花科技开发有限公司

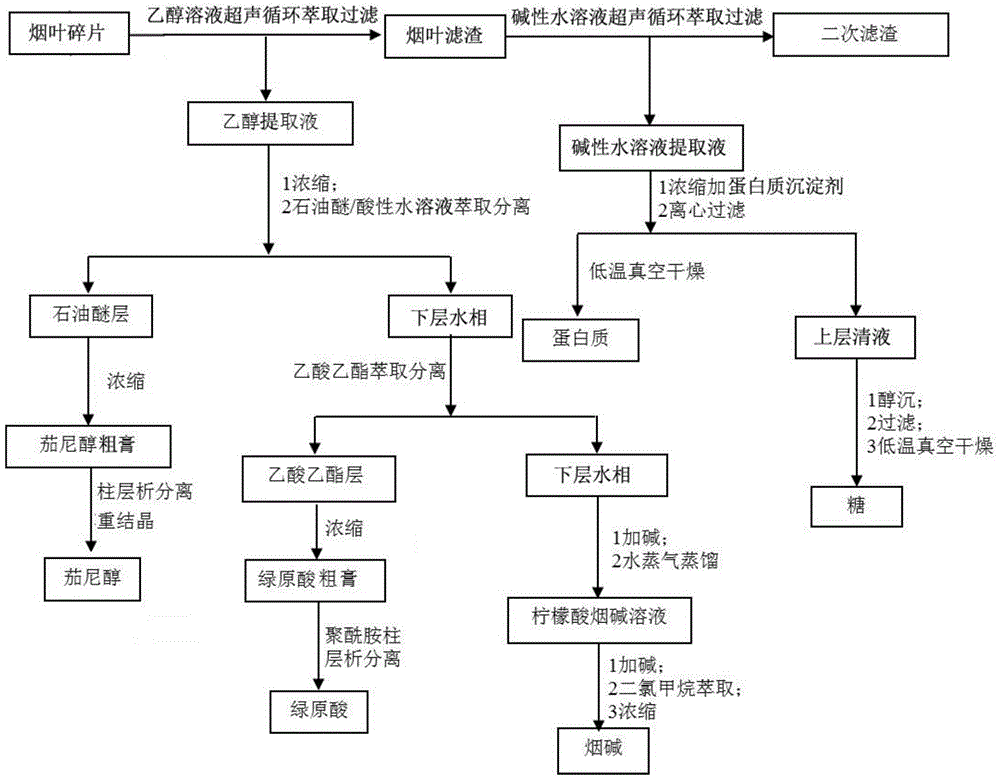

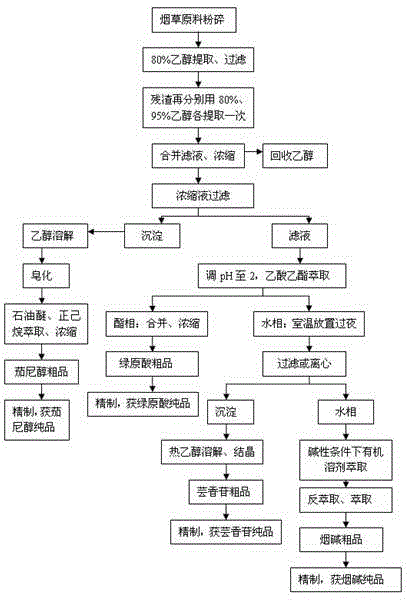

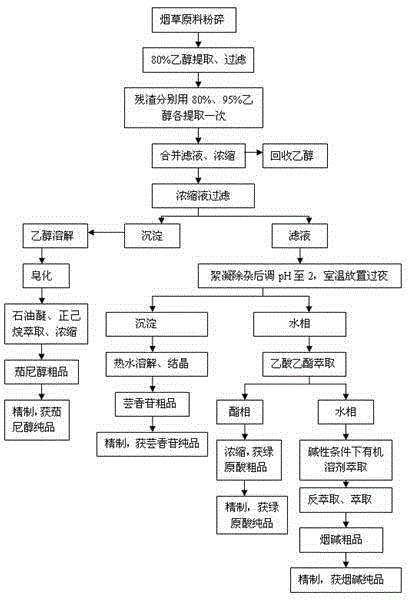

Method for comprehensively extracting multiple effective components from tobacco leaves

InactiveCN104151140AIncrease profitEmission reductionSugar derivativesPeptide preparation methodsChlorogenic acidPurification methods

The invention discloses a method for comprehensively extracting multiple effective components from tobacco leaves. The method comprises the following steps: performing twice ultrasonic circulation extraction on the tobacco leaves to respectively obtain crude ointment containing solanesol, nicotine and chlorogenic acid and an extract containing protein and sugar, and with the combination of separation and purification methods such as liquid-liquid two-phase extraction, column chromatography, recrystallization, steam distillation and precipitation, separating five effective components, namely, solanesol, nicotine, chlorogenic acid, protein and sugar from the tobacco leaves one by one. The method can continuously extract and separate the multiple effective components form the tobacco leaves, can greatly improve the utilization rate of a tobacco leaf raw material, has the advantages that the extraction efficiency is high, a great number of separation products are obtained and a small amount of wastes are discharged, and is an efficient and environment-friendly comprehensive tobacco leaf multi-component extraction technique.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

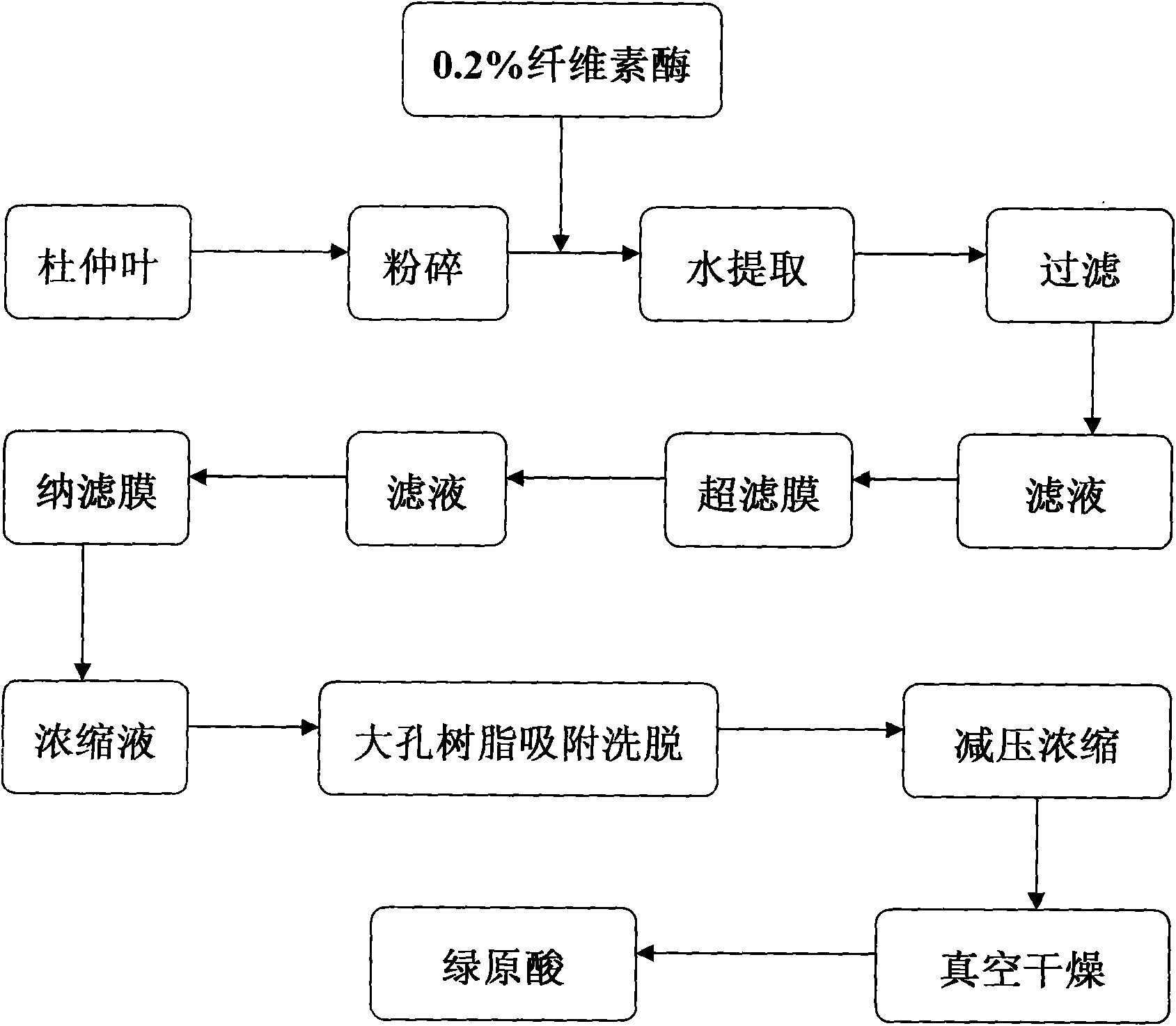

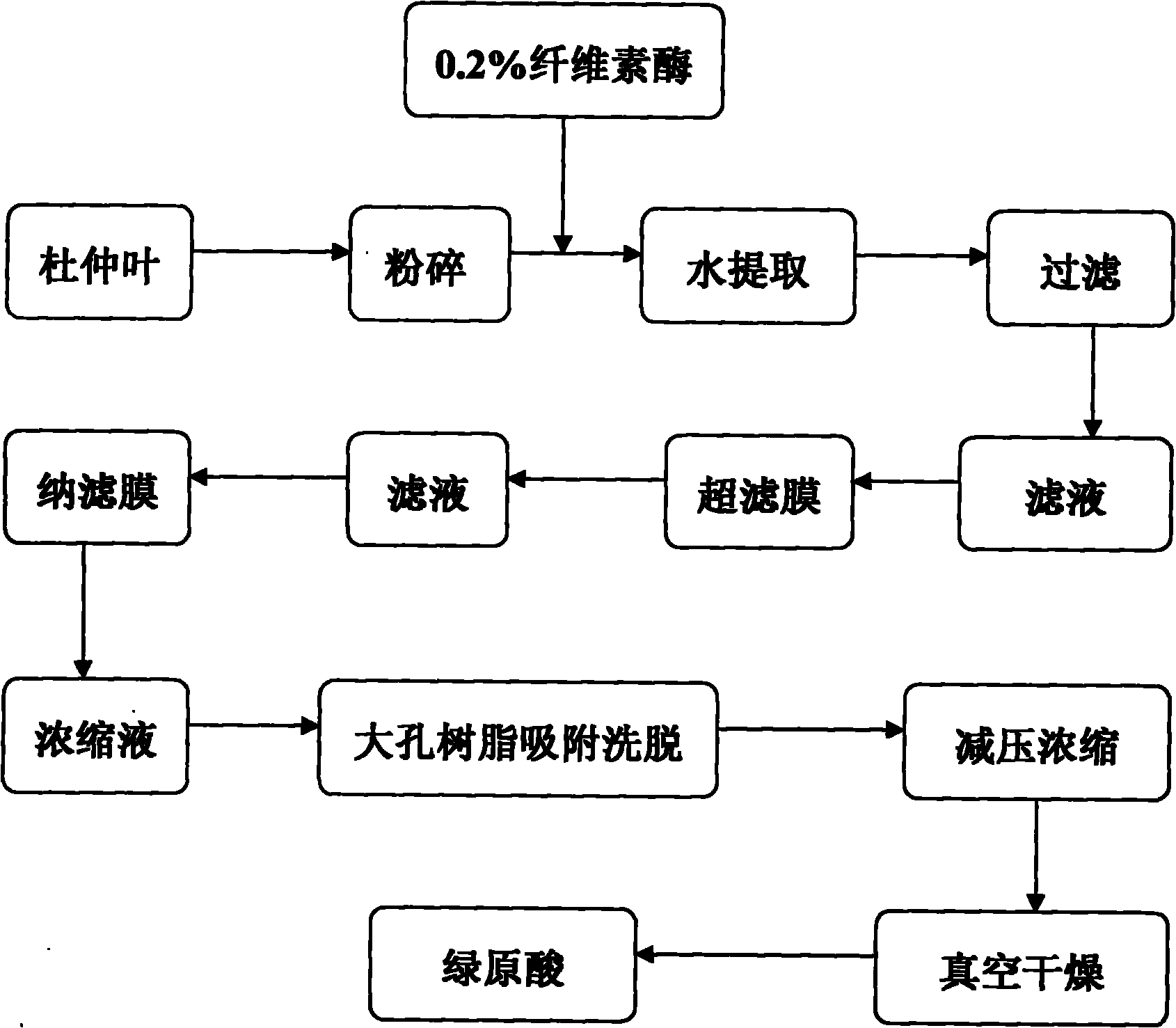

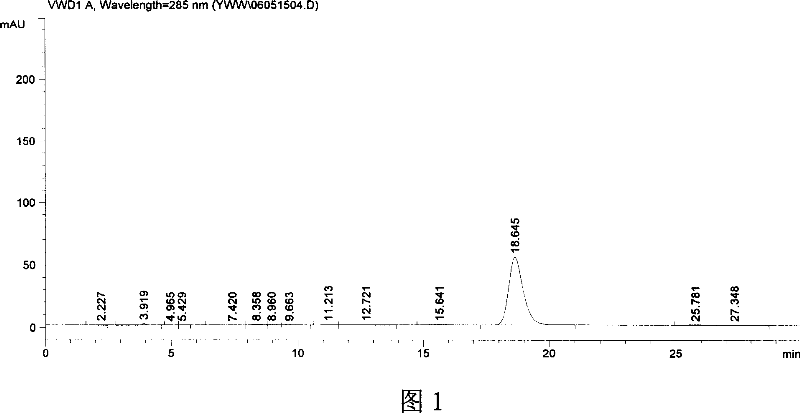

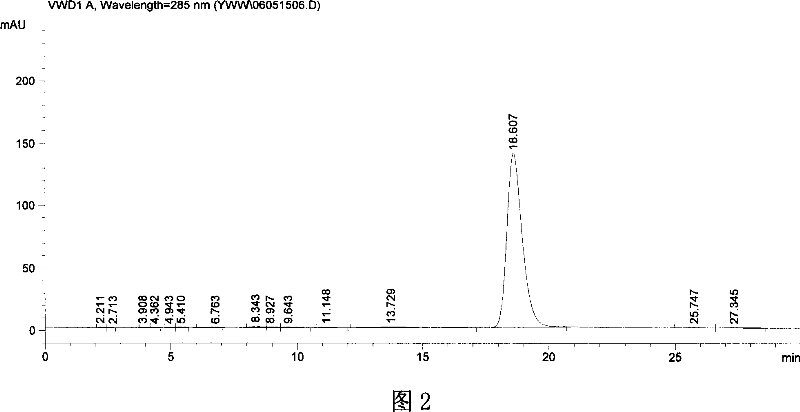

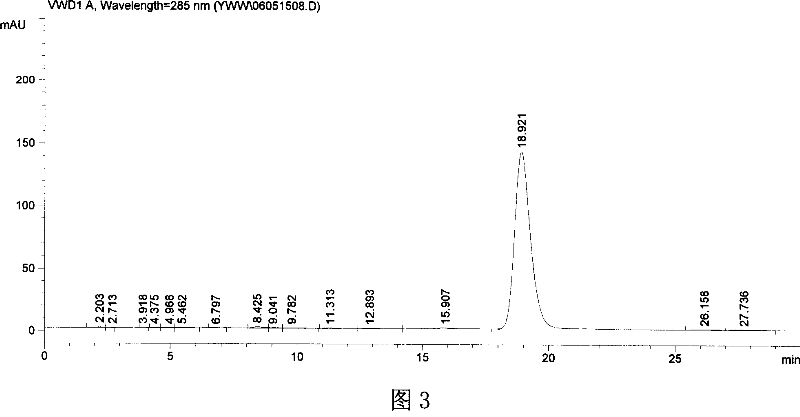

Method for preparing chlorogenic acid in Eucommia ulmoides leaves

InactiveCN102040519ALow water extraction temperatureReduce extraction timeIon-exchange process apparatusOrganic compound preparationChlorogenic acidChemical oxygen demand

The invention discloses a method for preparing chlorogenic acid in Eucommia ulmoides leaves, which comprises the following steps of: crushing the Eucommia ulmoides leaves, performing warm water extraction assisted by cellulose, performing conventional filtration, removing impurities by using an ultrafiltration membrane, performing nanofiltration and concentration, separating and purifying by using macroporous resin, and concentrating and drying to obtain chlorogenic acid powder. The chlorogenic acid in the Eucommia ulmoides leaves is subjected to warm water extraction assisted by cellulose, the extraction rate can reach 95 percent, the water extraction temperature is lower, and the extraction time is shortened; the ultrafiltration membrane is adopted to remove the impurities from the extracting solution and separate other byproducts, the membrane operating process is simple, the membrane flux can be stable for a long time, and the membrane is easy to clean, has long service life and is suitable for industrialization; a nanofiltration membrane is adopted to concentrate the extracting solution from which the impurities are removed, the load of the subsequent process is lightened, and the service life of the resin can be prolonged; the filtrate obtained through nanofiltration has the chemical oxygen demand (COD) value of less than or equal to 100 and can be returned to the production process, and wastewater is not generated basically; and the macroporous adsorbent resin can effectively purify the chlorogenic acid, the purity of the chlorogenic acid in the prepared powder is more than 60 percent and the extraction ratio is more than 1.4 percent.

Owner:HUBEI LAOLONGDONG DUZHONG DEV

Preparation method of salvia miltiorrhiza tanshinoate A

ActiveCN101041620AGood curative effectHigh yieldCarboxylic acid esters separation/purificationPlant ingredientsSalvia miltiorrhizaOrganic solvent

The invention discloses a making method of salviol acid A, which comprises the following steps: extracting salvia miltiorrhizae through water or alcohol; removing solid impurity; purifying salviol acid A through column chromatogram; condensing eluent; adjusting pH value of organic solvent; extracting; condensing; drying; obtaining the product with high-extracting rate; fitting for large-scale of manufacturing.

Owner:CHIATAI QINGCHUNBAO PHARMA

Method for simultaneously extracting and separating chlorogenic acid, solanesol, alkaloid and rutin in tobacco

ActiveCN104086425AEfficient extractionEfficient separationSugar derivativesCarboxylic acid esters separation/purificationChlorogenic acidMedicinal chemistry

The invention relates to a method for simultaneously extracting and separating chlorogenic acid, solanesol, alkaloid and rutin in tobacco. The method comprises the following steps: 1, extracting simultaneously, namely, crushing a tobacco raw material, extracting by using 80% ethanol once under the conditions that the temperature is 40-50 DEG C, the ultrasonic frequency is 45KHz and the ratio of material to liquid is 10:1, and performing suction filtration or centrifugation, respectively extracting the residue by using 80% and 95% ethanol once; combining the extract solutions of three times, thereby obtaining crude extract of chlorogenic acid, solanesol, alkaloid and rutin in tobacco, wherein the extraction rates of chlorogenic acid, solanesol, alkaloid and rutin in tobacco are 100%; and 2, separating, namely, separating solanesol, separating chlorogenic acid and rutin, and separating alkaloid. By adopting the method, simultaneous and efficient extraction on chlorogenic acid, solanesol, alkaloid and rutin in tobacco is achieved, the extraction rates are all 100%, the four components are effectively separated through simple steps, the utilization rate of the tobacco resource is improved, at the same time the operation is simple, the organic solvent is saved, and the energy consumption is reduced.

Owner:TOBACCO RES INST CHIN AGRI SCI ACAD

Method for preparing BDO or succinic diester with by-product from maleic anhydride

InactiveCN101343211AEmission reductionThe process is easy to controlCarboxylic acid esters separation/purificationHydroxy compound separation/purificationDistillationWastewater

The invention discloses a method for using by-products of maleic anhydride to prepare BDO or succinic acid diester, wherein, the by-products comprise at least one of wastewater, waste residues and maleic anhydride residues, a preparation method thereof includes the major steps of esterification, distillation, reduction, etc., thereby obtaining a BDO or succinic acid diester product. The method can fully recycle maleic anhydride, fumaric acid, maleic acid, succinic acid, etc. in the by-products such as wastewater, waste residues and maleic anhydride residues in the production process of maleic anhydride, thereby obtaining products such as chemical intermediate BDO or succinic acid diester with great market demands, and maximally reducing the discharge of wastes; and the preparation method has advantages of simple and controllable technical process and rather low cost.

Owner:隆鑫

Popular searches

Metal/metal-oxides/metal-hydroxide catalysts Preparation by transesterification Preparation by ester-hydroxy reaction Organic chemistry methods Fatty-oils/fats refining Fatty-oils/fats separation Carboxylic compound separation/purification Pharmaceutical delivery mechanism Antineoplastic agents Cardiovascular disorder

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com