Patents

Literature

2173 results about "Chlorogenic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

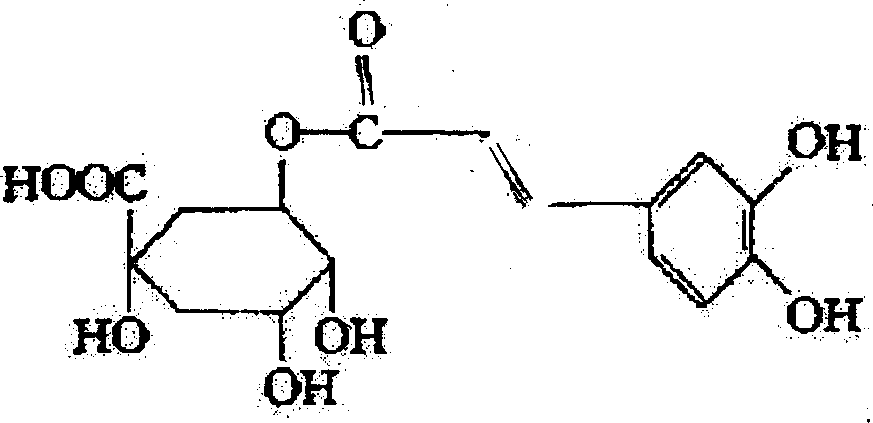

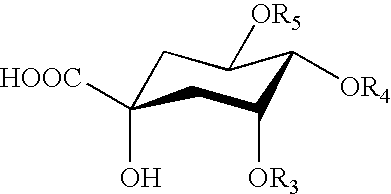

Chlorogenic acid (CGA) is the ester of caffeic acid and (−)-quinic acid, functioning as an intermediate in lignin biosynthesis. The term "chlorogenic acids" refers to a related polyphenol family of esters, including hydroxycinnamic acids (caffeic acid, ferulic acid and p-coumaric acid) with quinic acid.

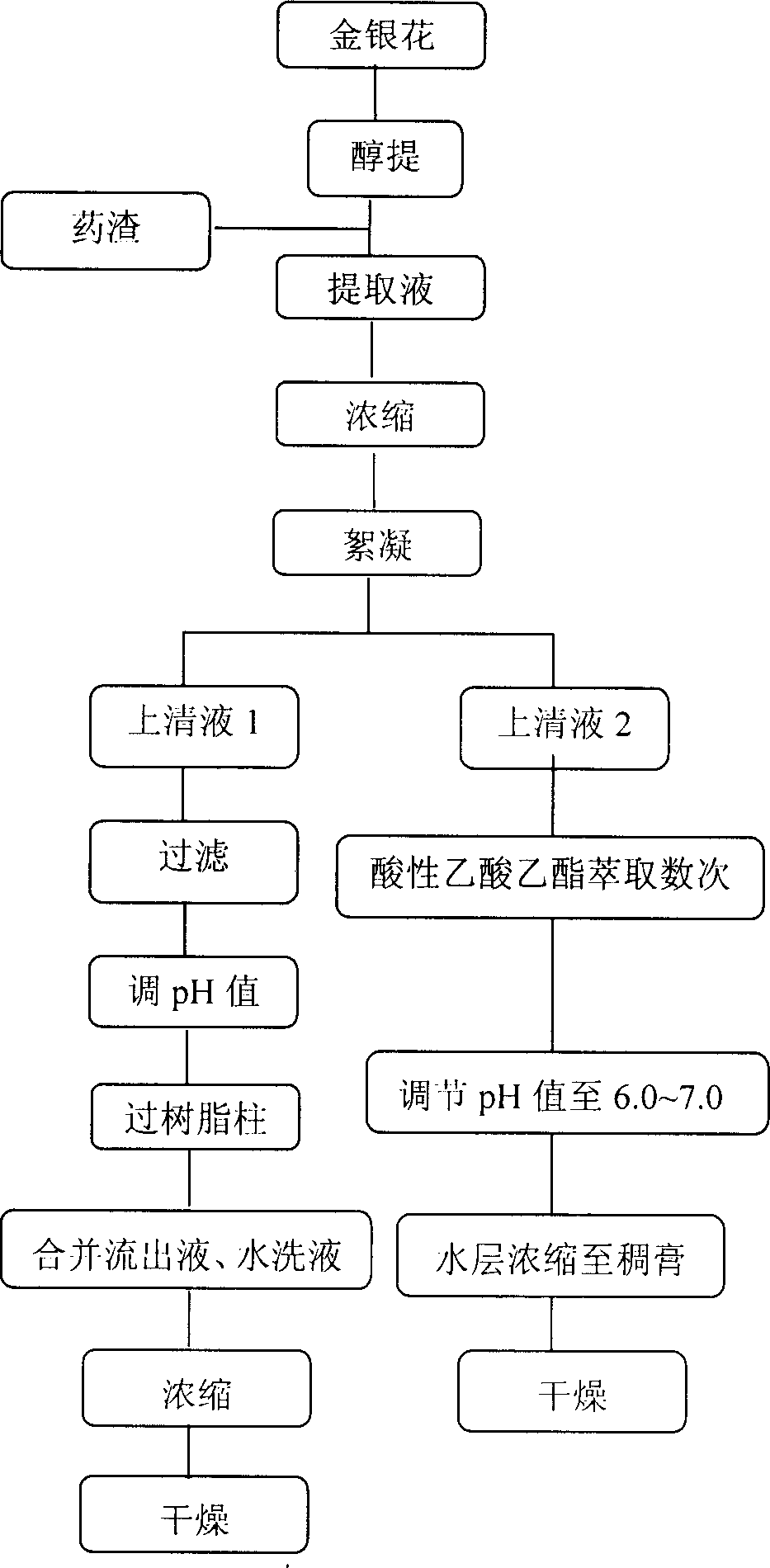

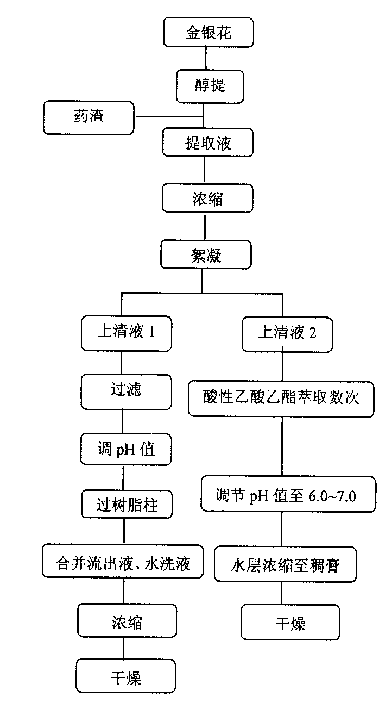

Extracting and purifying method for chlorogenic acid in honeysuckle

InactiveCN1425643AAddressing Purity IssuesOrganic compound preparationCarboxylic acid esters preparationReflux extractionChlorogenic acid

The present invention relates to extraction and purification of functional components in Chinese herbal medicine and aims at provindg extraction and purification process of chlorogenic acid in honeysuckle in relatively high yield and purity. The techonlogical scheme includes twice reflux extraction of honeysuckle cut into sections with dilute alcohol, concentrating the extractive, flocculating for initial purification and final purification through macroporous resin or ethyl acetate extraction. The said process is simple and practical and has less loss of chlorogenic acid and high product yield and purity.

Owner:CHINA AGRI UNIV

Process for preparing chlorogenic acid from honeysuckle

The present invention relates to process of extracting chlorogenic acid from honeysuckle and belongs to the field of medicinal chemical technology. The process includes the steps of: reflux extraction of honeysuckle with water or ethanol, filtering to collect filtrate, recovering solvent, ethanol deposition to eliminating impurity, letting stand overnight, filtering, decompression recovering solvent, adding water and letting stand overnight, filtering, eluting the filtrate in macroporous resin column, concentrating eluent, collecting chlorogenic acid component, eluting on polyamide column with eluent, collecting chlorogenic acid component, concentration, rectification to obtain chlorogenic acid product with content over 95 %. The present invention is suitable for industrial application.

Owner:济南永曜医药科技有限公司

Slowly-released compound acidifier for poultry and livestock feed, preparation method thereof and feed

ActiveCN102578387AMatching scienceDefinitelyClimate change adaptationAnimal feeding stuffDiseaseFeed conversion ratio

The invention discloses a slowly-released compound acidifier for poultry and livestock feed, a preparation method thereof and feed containing the same. The compound acidifier comprises the following compositions in part by weight: 30 to 80 parts of complex organic acid, 15 to 50 parts of supplementary materials and 5 to 20 parts of coating agents. The complex organic acid is citric acid, fumaric acid, malic acid, lactic acid, linoleic acid, crataegolic acid, ursolic acid, chlorogenic acid, glycyrrhizic acid and oleanolic acid, and the supplementary materials are silicon dioxide, hydroxypropyl methylcellulose and ethyl cellulose. The acidifier is scientifically proportioned, has strong efficiency and is long-acting and slow-releasing, nutrients in the feed are free from being damaged, the acidifier has good fluidity and is easy to be uniformly mixed with the feed, the digestive absorption of nutrients can be promoted, the conversion rate of the feed can be improved, the productivity of poultry and livestock can be improved, the time for domestic animals for sale can be effectively shortened, the health of gastrointestinal mucosa of the animals can be protected, the immunologic function of the animals can be strengthened, and diseases can be prevented.

Owner:BEIJING DABEINONG ANIMAL HEALTH TECH +1

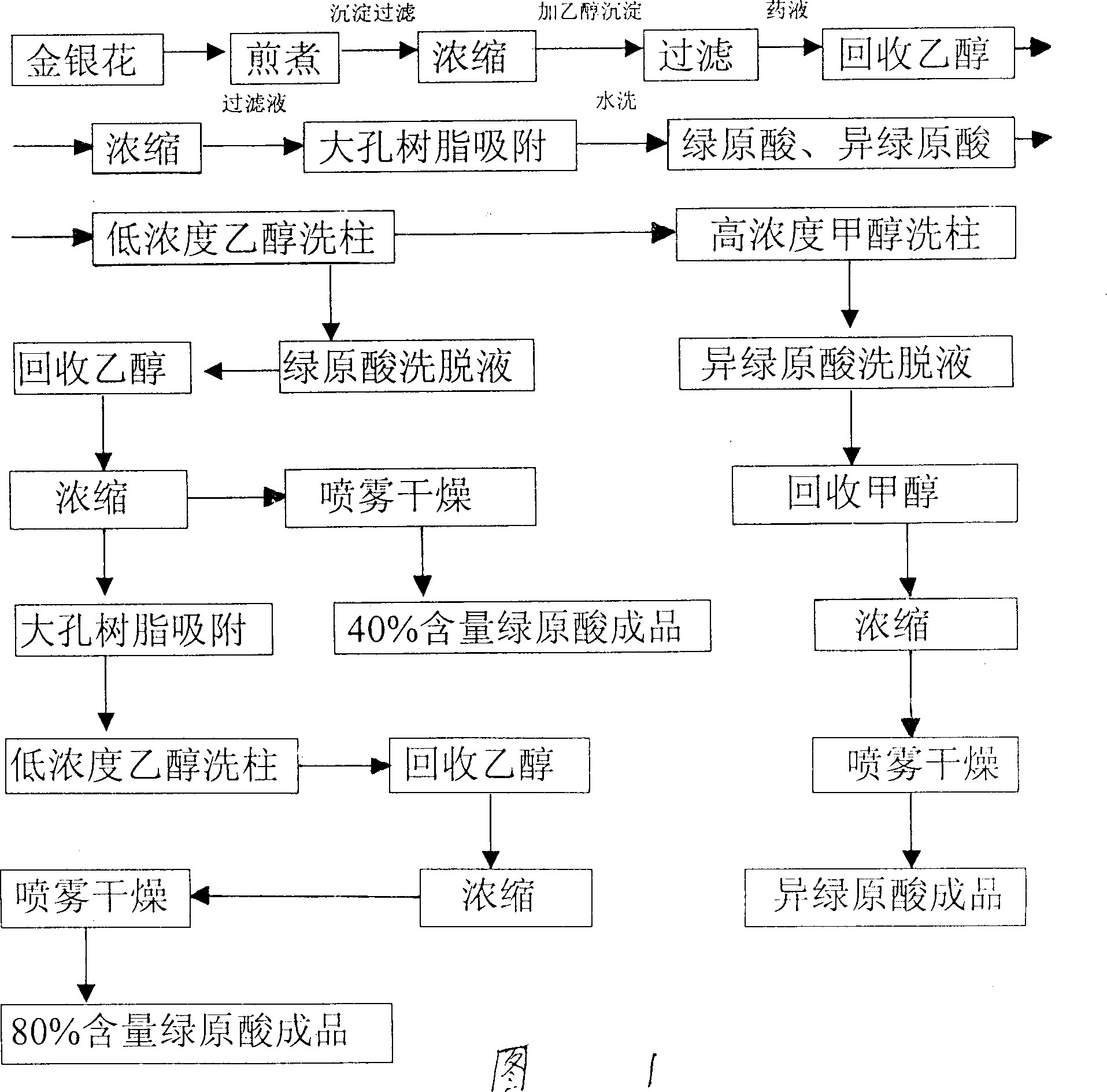

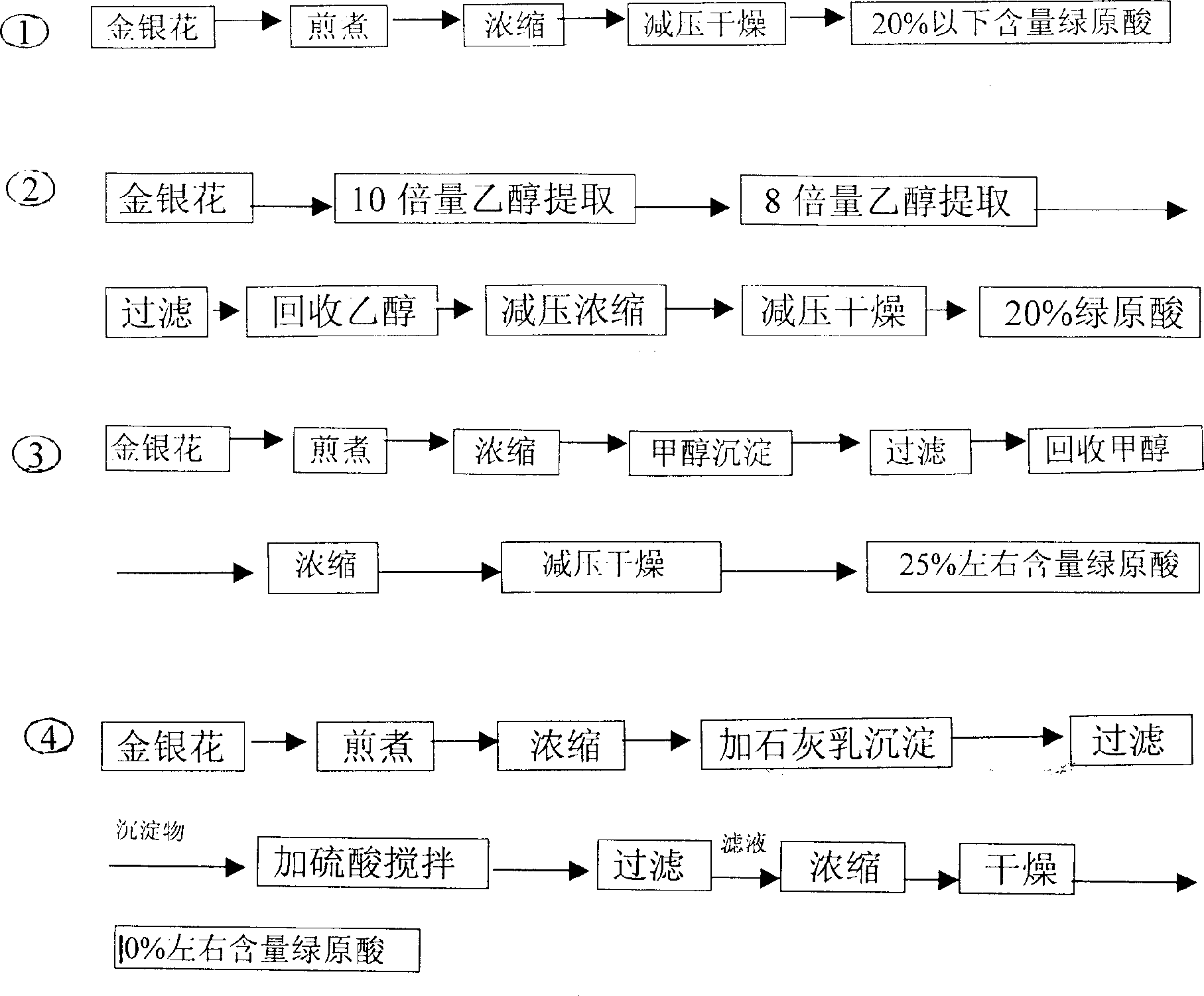

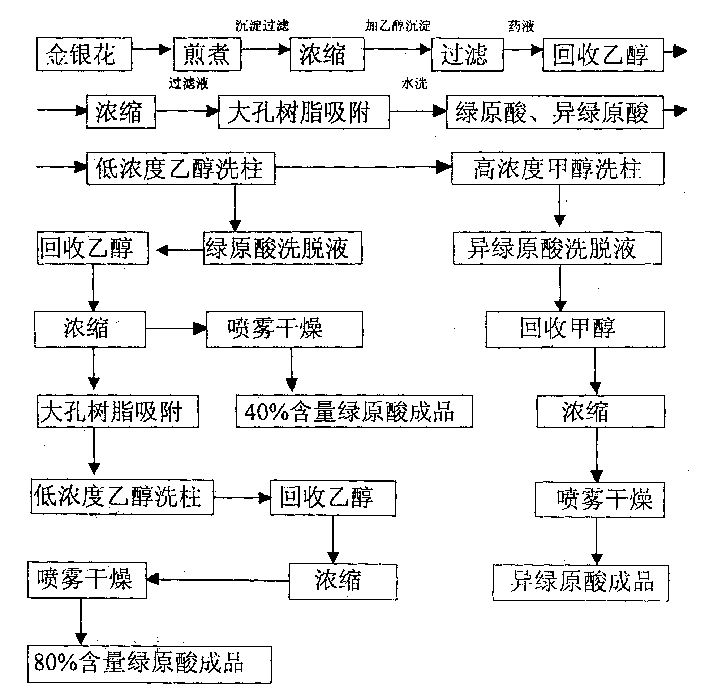

Macroporous resin adsorption process of extracting chlorogenic acid in high content

InactiveCN1398845AExact purposeIncrease useOrganic compound preparationCarboxylic acid esters preparationChlorogenic acidAlcohol

A chlorogenic acid extraction process of the present invention includes crushing honeysuckle, water extraction of chlorogenic acid and macroporous resin adsorption to separate high content chlorogenic acid. It features that in the last technological step, the chlorogenic acid extracting liquid is saturated and adsorbed with macroporous resin, the chlorogenic acid in resin is washed and dissolved with low concentration alcohol to obtain chlorogenic acid eluting liquid, the eluting liquid is concentrated while recovering alcohol and the concentrated chlorogenic acid condensate is spray-dried to obtain chlorogenic acid powder product with chlorogenic acid content over 40%. The isochlorogenic acid in the resin column is produced into powder product through methanol washing and dissolving, concentrating and spray drying, after recovering method.

Owner:刘斌

Coffee drink composition

Owner:KAO CORP

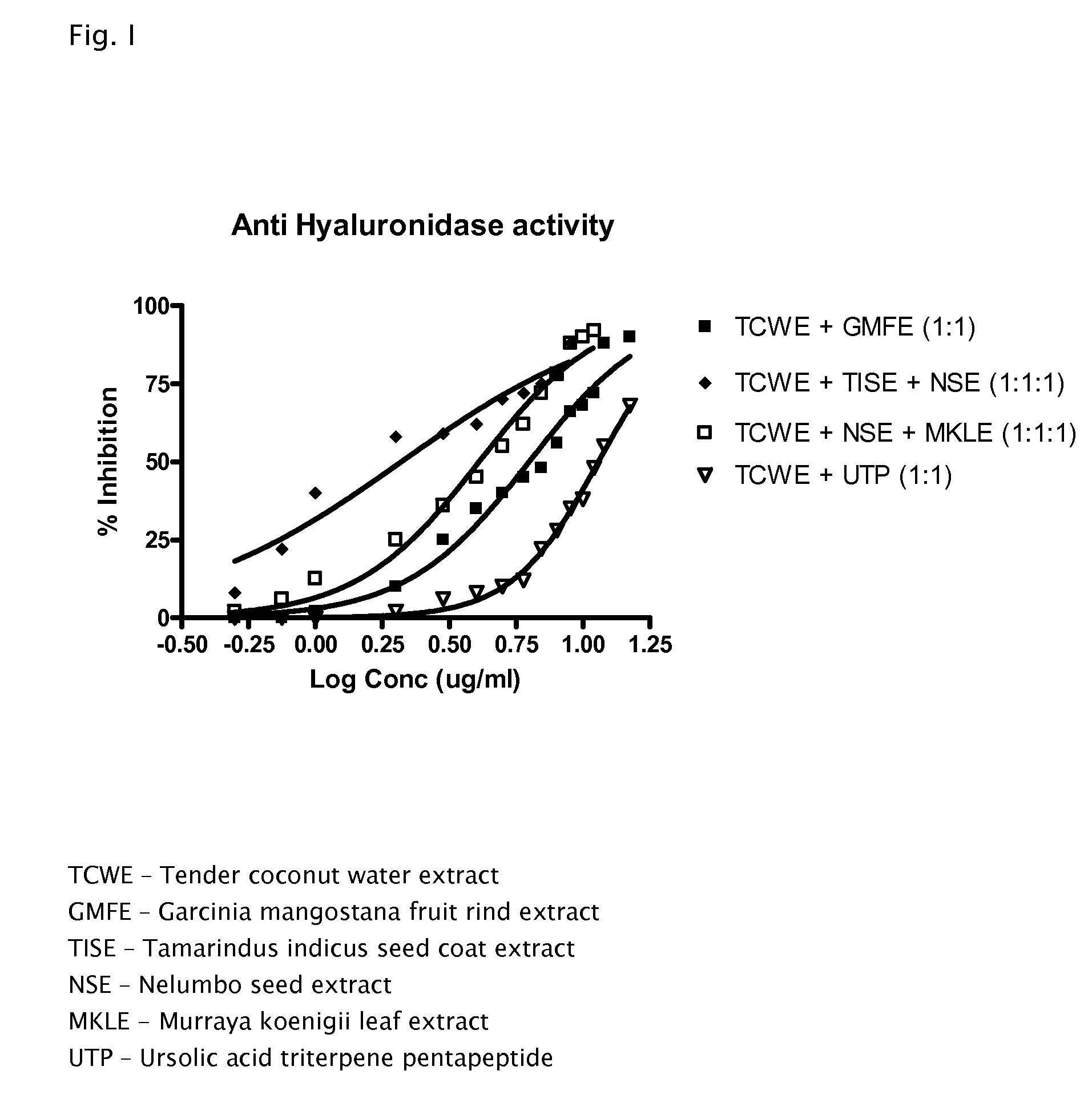

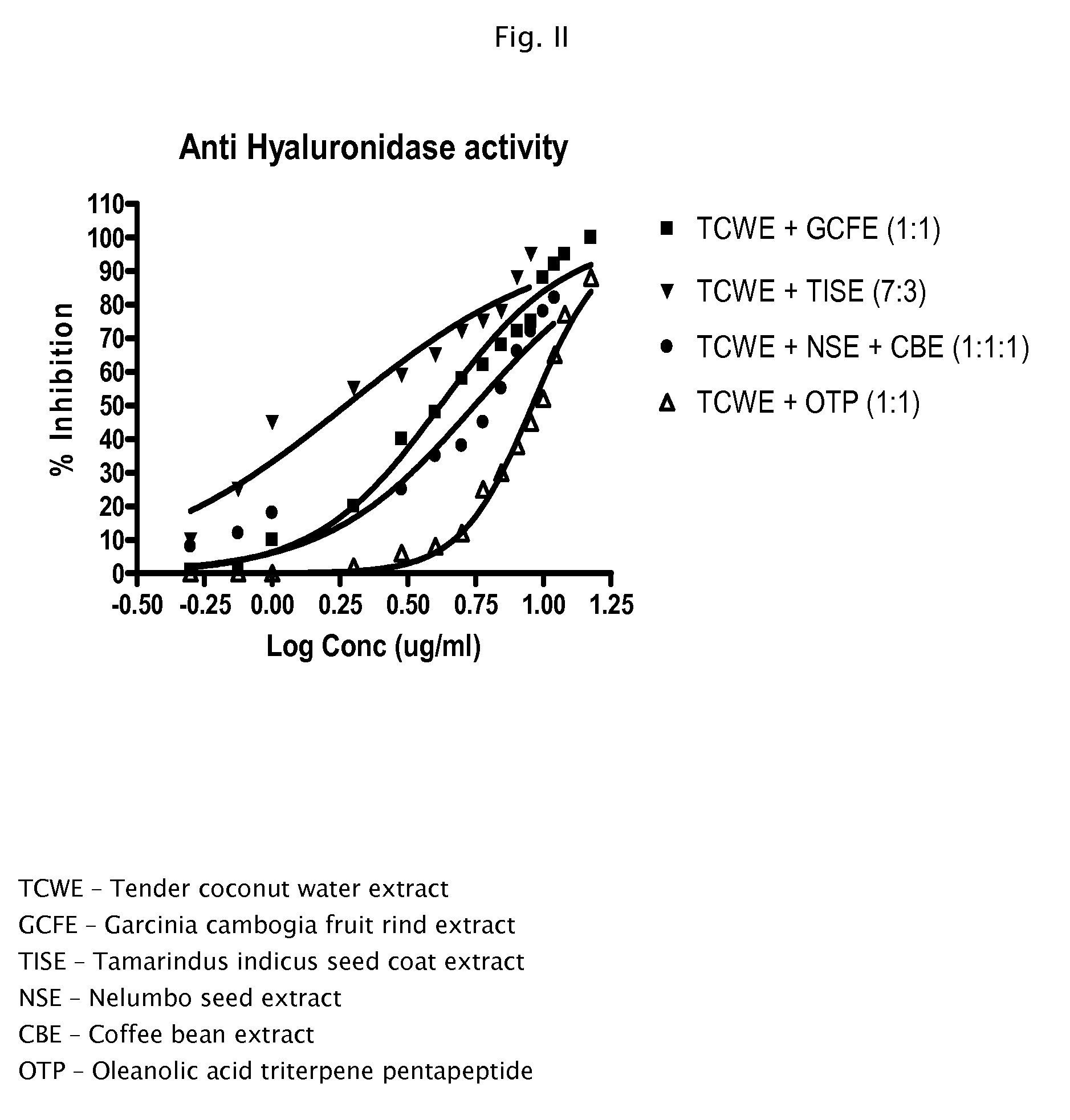

Anti-skin damage compositions with complimentary dual mode of action

InactiveUS20090169651A1ConstantMaintenanceBiocideCosmetic preparationsChlorogenic acidAdditive ingredient

Disclosed are skin care compositions exerting a novel complementary dual mode of action in protecting the skin from day-to-day insults. The skin care compositions of the present invention comprise the extract from the liquid endosperm of Cocos nucifera as the principle ingredient along with one or more actives including the fruit rind extracts of Garcinia cambogia, Garcinia indica and Garcinia mangostana, seed coat extract of Tamarindus indicus, Chlorogenic acid extract from the beans of Coffea arabica, seed extracts of Nelumbo species, the leaf extracts of Murraya koenigii and the triterpene pentapeptides of oleanolic acid and ursolic acid. While the extract of Cocos nucifera has been included as a nutritional supplement (a natural cell culture medium) to ensure the maintenance of the viability and constant renewal of the cells of the skin, the other actives have been carefully chosen based on one or more of their effective skin care properties. The compositions of the present invention offer a safe prophylactic / therapeutic management solution to the wide range of pathological states associated with skin insults and the associated psycho-social issues.

Owner:SAMI LABS LTD

Industrialized production method for synchronously producing stevioside, flavone and chlorogenic acid

ActiveCN105001281ASimple processShort processSugar derivativesCarboxylic acid esters separation/purificationHigh concentrationOrganic solvent

The invention provides an industrialized production method for synchronously producing stevioside, flavone and chlorogenic acid. The method includes the following steps that step1, stevia rebaudiana leaves are weighed, extracted by adding water and filtered to obtain an extracting solution, flocculating agents are added under the condition of heat preservation, the pH is adjusted to 7-12, standing is performed for 0-120 minutes at the temperature of 30 DEG C-75 DEG C, then filtering is performed to obtain filter mud and filter liquid, and resin purification is performed on the filter liquid so as to obtain the stevioside product; step2, the filter mud is extracted through acid solvent, and extracting solutions are merged and concentrated; step3, solvent is added into a concentrated solution for dilution, and macroporous adsorption resin is added for adsorption; step4, gradient resolution is performed on the macroporous adsorption resin in the step3, a low-concentration resolution liquid is concentrated and dried to obtain the chlorogenic acid product, and high-concentration resolution liquid is concentrated to be standby; step5, after water is added into the high-concentration resolution liquid for dilution, organic solvent the same as the high-concentration resolution liquid in volume is used for extraction, and organic phases are merged, concentrated and dried to obtain the flavone product. By the adoption of the method, the stevioside, flavone and chlorogenic acid are extracted at the same time, the production cost is lowered, and the comprehensive utilization value of the stevioside is increased.

Owner:CHENGUANG BIOTECH GRP CO LTD

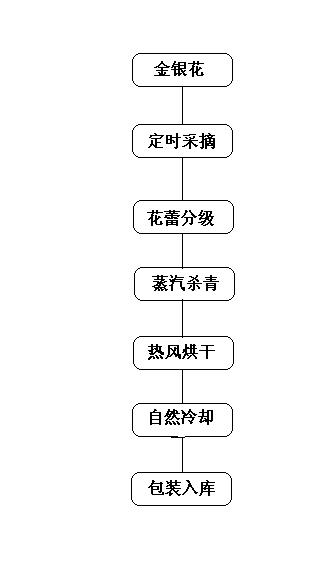

Processing method of honeysuckle tea

InactiveCN102356794ARapid inhibitory activityAvoid decompositionTea substituesCold airChlorogenic acid

A processing method of honeysuckle tea has a technical scheme that the method comprises the following steps of picking at regular time, bud grading, enzyme deactivation by steam, hot air drying, natural cooling, packaging and warehousing; the beneficial effect is that: honeysuckle buds are picked at 8:30-11:00 in the morning everyday, which can ensure that fresh flowers contain the most beneficial components and dew is prevented; grading of the buds can ensure uniform processing; enzyme deactivation by steam can rapidly inhibit the activity of polyphenol oxidase, and effectively prevent the decomposition of honeysuckle chlorogenic acid; direct hot air drying is performed after enzyme deactivation without cooling or cold air dehumidification, which can rapidly remove residual water contained in fresh flowers, destroys the activity of polyphenol oxidase, and allows the honeysuckle tea to be maintained to be undeteriorated for a long time; the honeysuckle tea processed by the method has a jade green color, and a lifelike shape; nutrient components can be maintained to be less lost; the infused tea has a bright and clear soup color, and a complete flower shape; the invention can greatly increase the drinking value and appearance quality of honeysuckle tea.

Owner:重庆市秀山红星中药材开发有限公司

Preparation method of high pure crocin and geniposide

InactiveCN103387489ARealize comprehensive utilizationEfficient use ofSugar derivativesNatural dyesChlorogenic acidGradient elution

The invention discloses a preparation method of high pure crocin and geniposide. The preparation method comprises following main steps: selecting raw materials of gardenia ellis plants, extracting with water or an alcohol-water mixed solution, merging the extracting solutions, condensing, filtering, subjecting the obtained extracting solution to an adsorption treatment by macroporous resin, then performing gradient elution with a ethanol-water mixed solution, obtaining geniposide and gardenia yellow refined extracts; subjecting the geniposide refined extract to a recrystallization treatment with ethyl acetate so as to obtain the geniposide product; subjecting the gardenia yellow refined extract to go through column chromatography, which has been pressurized and stuffed with modified silica gel, to separate, and obtaining the high pure crocin product (color value larger than 600) and a chlorogenic acid component. The products have the advantages of high purity, simple technology, strong operability and convenience for automation, comprehensive utilization of the plant resources is achieved, the solvent is convenient to recycle and reuse, and the preparation method is easy to apply to the industrial amplification.

Owner:SUZHOU QIUSHI HERBAL HEALTH TECH CO LTD

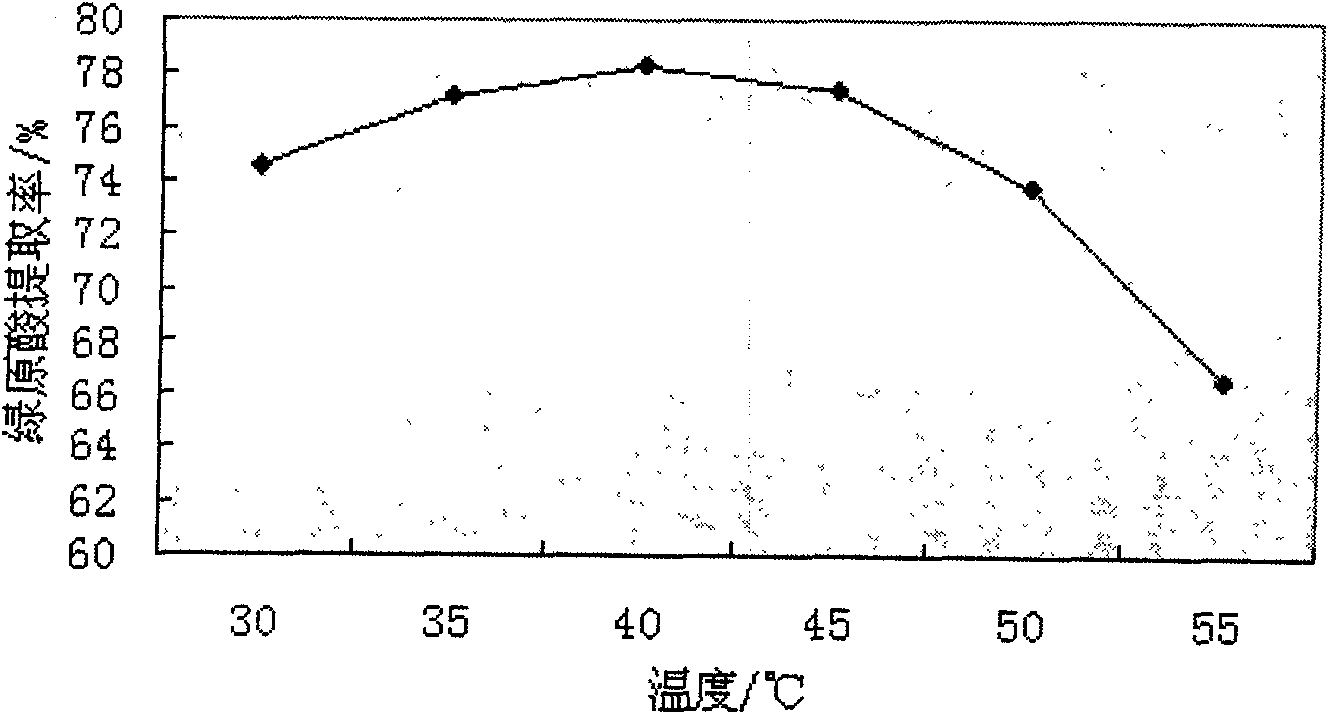

Method for extracting chlorogenic acid from honeysuckle by using compound enzyme method

InactiveCN101830804AGood process repeatabilityThe result is stableCarboxylic acid esters separation/purificationPectinaseChlorogenic acid

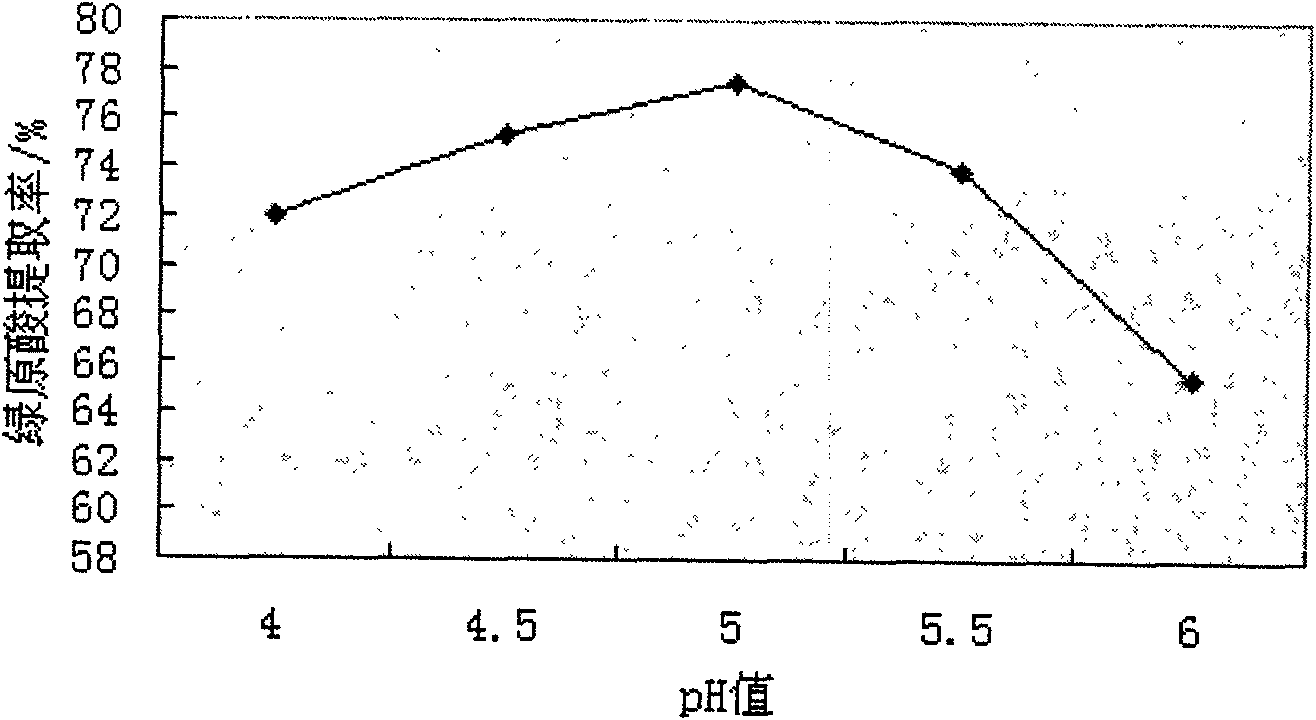

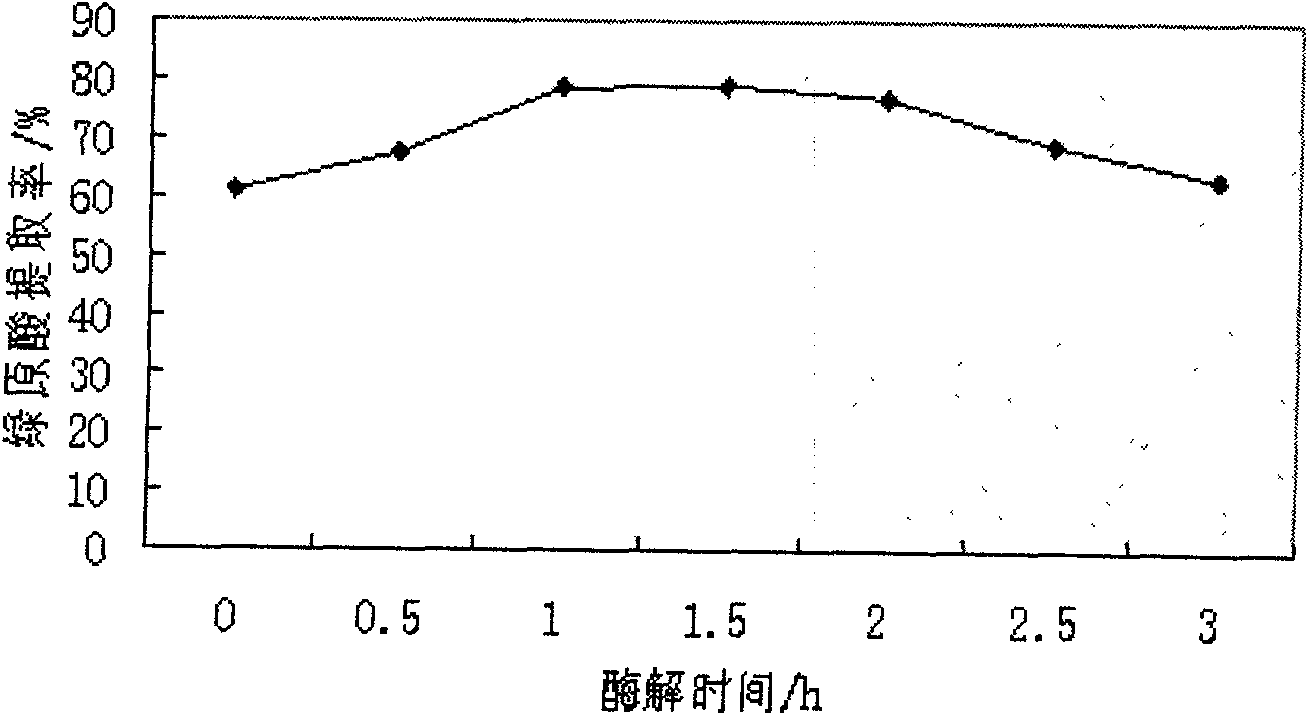

The invention relates to a method for extracting chlorogenic acid from honeysuckle by using a compound enzyme method and researches a novel process for extracting a main medicinal effective component of the chlorogenic acid from the honeysuckle by a cellulose and pectinase compounding enzyme method. Through a single factor experiment and an orthogonal test, optimal process conditions for extracting the chlorogenic acid from the honeysuckle by using the compound enzyme method can be optimized: the enzymolysis temperature is 45DEG C, the pH is 4.5, the compound ratio of the cellulose to the pectinase is 1.0:0.3 and the enzymolysis time is 1.5 hours. The test result shows that the process repeatability is favorable and the result is stable. The extraction rate of the chlorogenic acid extracted from the honeysuckle by using the compound enzyme method can reach 83.06 percent which is improved by 16.93 percent in comparison with the extraction rate of the chlorogenic acid extracted by using a water extraction process.

Owner:ZHONGXIN PHARMA FACTORY OF TIANJIN ZHONGXIN PHARMA GROUP

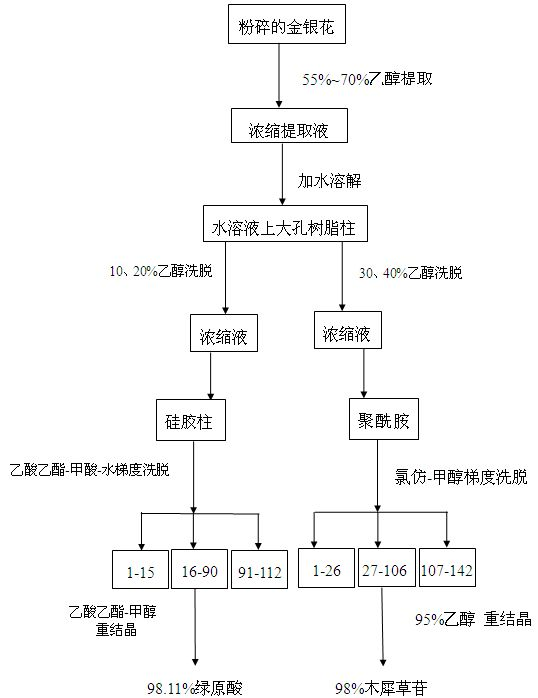

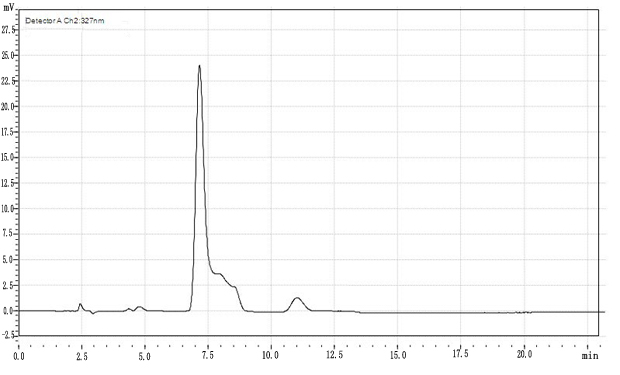

Method for simultaneously preparing chlorogenic acid and luteoloside from honeysuckle flower

InactiveCN101985421AHigh puritySimple processSugar derivativesOrganic compound preparationChlorogenic acidPolyamide

The invention discloses a method for simultaneously preparing chlorogenic acid and luteoloside from honeysuckle flower, which comprises the following steps of: extracting by using ethanol, enriching by using D101 macroporous resin, separating and purifying by using a silicagel column and a polyamide column, recrystallizing and the like. In the method, the chlorogenic acid and the luteoloside are extracted from the honeysuckle flower by a hot ethanol solvent extraction method; the aims of enriching the chlorogenic acid and the luteoloside and separating the chlorogenic acid from the luteoloside are fulfilled by regulating the concentration and pH value of eluent used by the macroporous resin; and the chlorogenic acid and the luteoloside are subjected to silicagel column chromatography, polyamide column chromatography and recrystallization respectively to form the chlorogenic acid and the luteoloside with the purity of over 95 percent.

Owner:NORTHWEST A & F UNIV

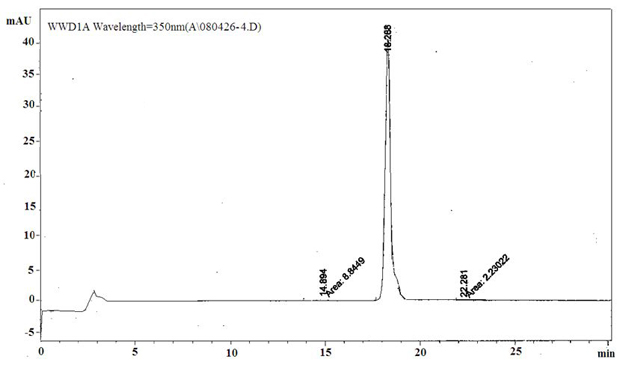

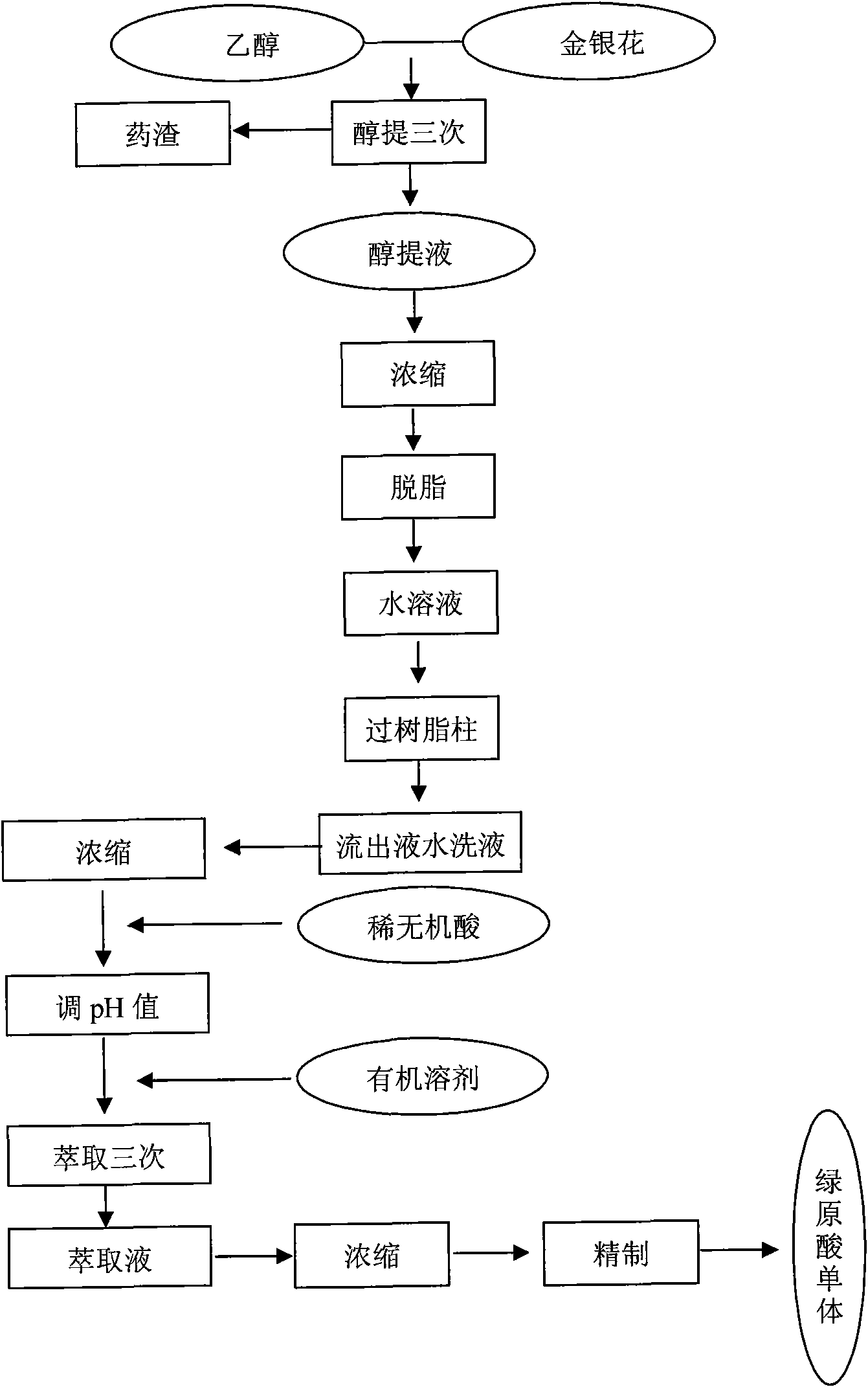

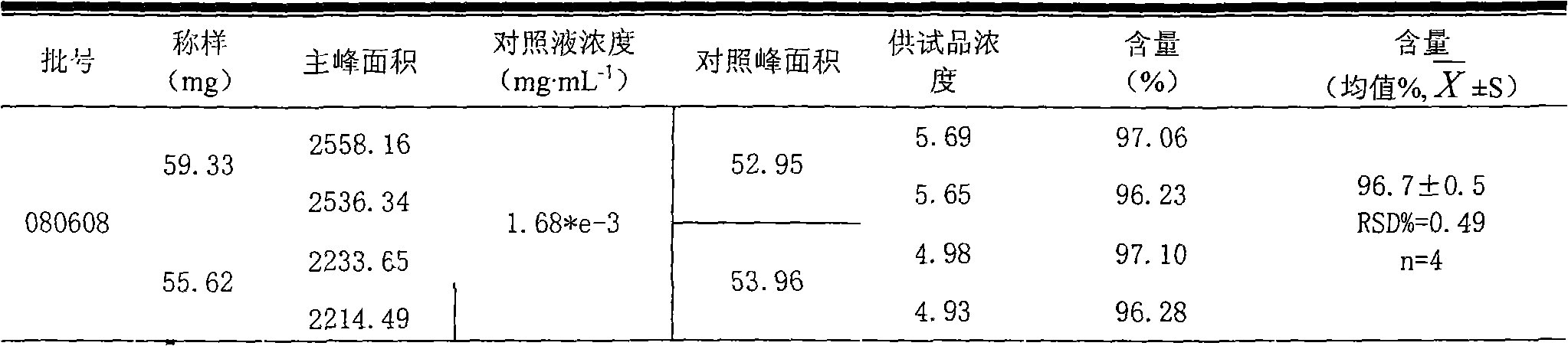

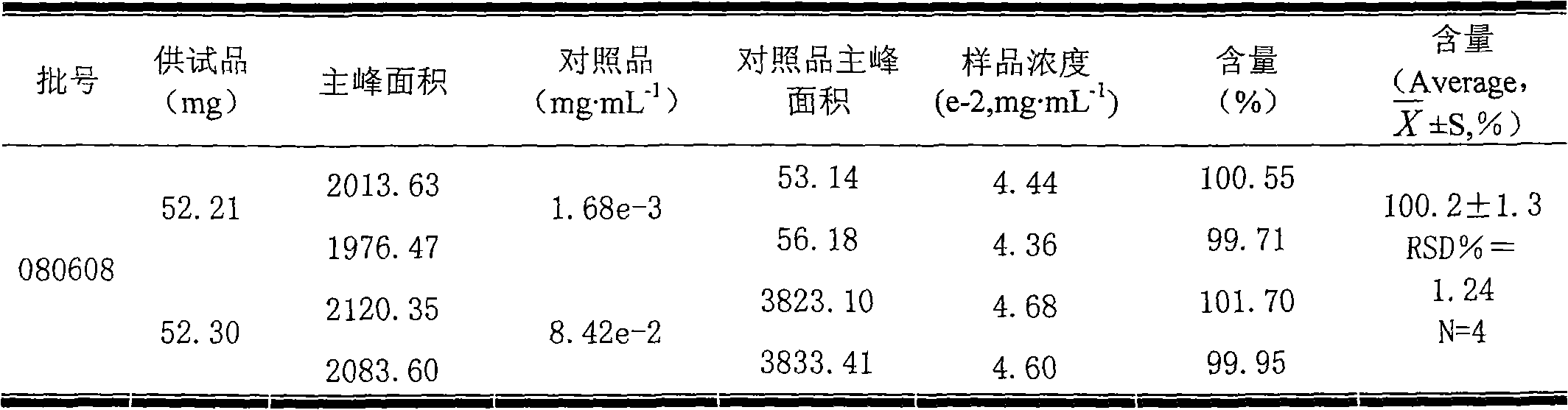

Method for extracting and separating chlorogenic acid from honeysuckle

ActiveCN101838200AHigh extraction rateImprove transfer rateOrganic compound preparationCarboxylic acid esters separation/purificationAlcoholChlorogenic acid

The invention relates to the field of the medicine, in particular to a method for extracting and separating a chlorogenic acid monomer from honeysuckle. The prior art is lack of a method for the mass preparation of the chlorogenic acid monomer from the honeysuckle. In the invention, the technology is realized by the following preparation steps of: (1) soaking by alcohol: putting the honeysuckle into an alcohol solution for soaking, heating, refluxing, filtering and concentrating; (2) degreasing: degreasing the obtained filtrate thrice by adopting a weak-polarity solvent, and taking a water layer; (3) enriching by macroporous resin: enabling a water layer solution obtained in the step (2) to pass through the macroporous resin, washing by water, collecting effluent liquid and water washing liquid, concentrating and regulating the pH value; (4) extracting: extracting a solution obtained in the step (3) by adopting a moderate-polarity solvent, taking an organic layer, concentrating and recovering the solvent to obtain a faint yellow puffy solid substance; and (5) recrystallizing. The invention adopts an alcohol extraction method to enhance the extraction rate and the transfer rate of the chlorogenic acid, the final transfer rate of the chlorogenic acid is as high as 84 percent, and the purity of the obtained product can reach more than 98 percent.

Owner:SHANGHAI INOHERB COSMETIC

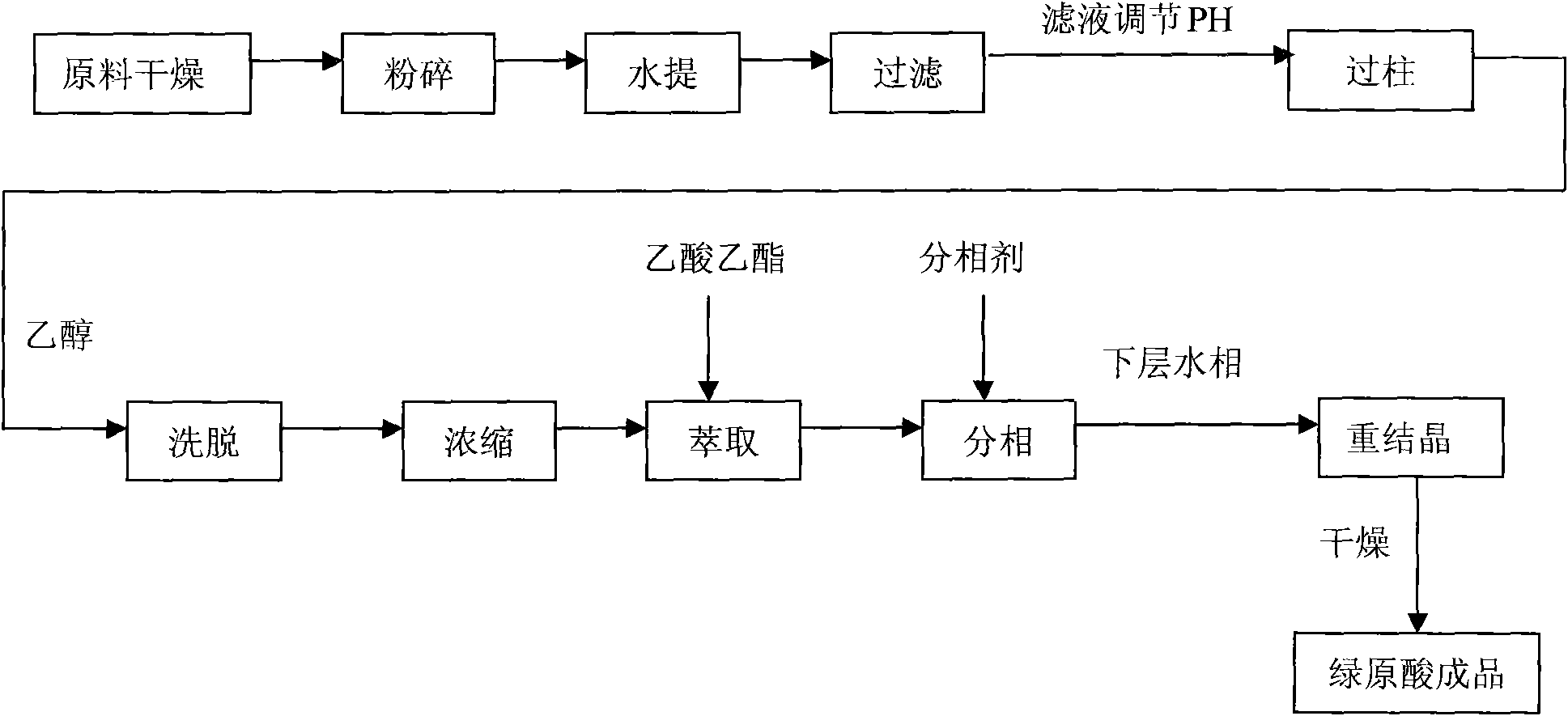

Method for extracting chlorogenic acid

InactiveCN101602668AEnables step-by-step gradient purificationHigh purityOrganic compound preparationCarboxylic acid esters separation/purificationChlorogenic acidSolvent

The invention relates to a method for extracting chlorogenic acid, which belongs to the technical field of pharmaceutical chemicals. The method combines macroporous resin enrichment, ethyl acetate extraction and a mixed solvent split-phase method to achieve multi-step gradient purification of the chlorogenic acid so as to obtain a chlorogenic acid product with high purity. The method comprises the processes of water extraction, column passing, extraction, phase splitting and recrystallization. The macroporous resin adopted by the column passing process is 306 type or XAD series resin; and the split-phase agent adopted by the split-phase method is petroleum ether, chloroform or the mixture of the petroleum ether and the chloroform. The method is applicable to the process of extracting and preparing the chlorogenic acid from honeysuckles, cortex eucommiae leaves and cortex eucommiae barks.

Owner:INST OF APPLIED CHEM JIANGXI ACAD OF SCI

Method for extracting chlorogenic acid from Eucommia leaves and use thereof

InactiveCN101486651AEasy to operateLow costAntibacterial agentsOrganic active ingredientsDiseaseChlorogenic acid

The invention discloses a method for extracting chlorogenic acid from folium cortex eucommiae. The invention also discloses an application of the chlorogenic acid in prevention substances of fish diseases. The method comprises the steps of grinding, enzyme treatment, ultrasonication, filtering, extraction, concentration, purification, and the like; the method has the advantages of simple and convenient technique operation, low cost, no hazardous solvent, high yield, being applicable to industrialized production, and the like; in addition, the chlorogenic acid has good bacteriostasis effect on pathogenic bacteria commonly seen in aquiculture, with a bacteriostasis effect on aeromonas hydrophila equal to that of antibacterials like antibiotics, can strengthen the immunity of the organism and has relatively strong prevention effect on bacterial diseases.

Owner:江苏省苏微微生物研究有限公司

Process of preparing high purity chlorogenic acid and flavonid with eucommia leaf

ActiveCN1974527AImprove product qualityHigh content of target ingredientsOrganic compounds purification/separation/stabilisationCarboxylic acid esters separation/purificationChlorogenic acidEthyl acetate

The process of preparing high purity chlorogenic acid and flavonid with eucommia leaf includes the following steps: crushing eucommia leaf and extracting with pH 3-6 alcohol solution of 45 %-55 % concentration; saturation adsorbing the extracted solution with medium polarity JD-1 macroporous resin, and eluting successively with water, 20 %-45 % concentration alcohol solution and 60 %-75 % concentration alcohol solution to obtain crude chlorogenic acid product and flavonid-containing powder separately; eluting the crude chlorogenic acid product in silica gel column with ethyl acetate, acetone, methanol or ethanol, collecting the eluted solution, decompression concentrating, and re-crystallizing the concentrate in acetone or water to obtain refined chlorogenic acid product. The present invention has simple technological process, convenient operation, reuse of the macroporous resin, low comprehensive cost and excellent industrial application foreground.

Owner:GUANGZHOU HANFANG PHARMA

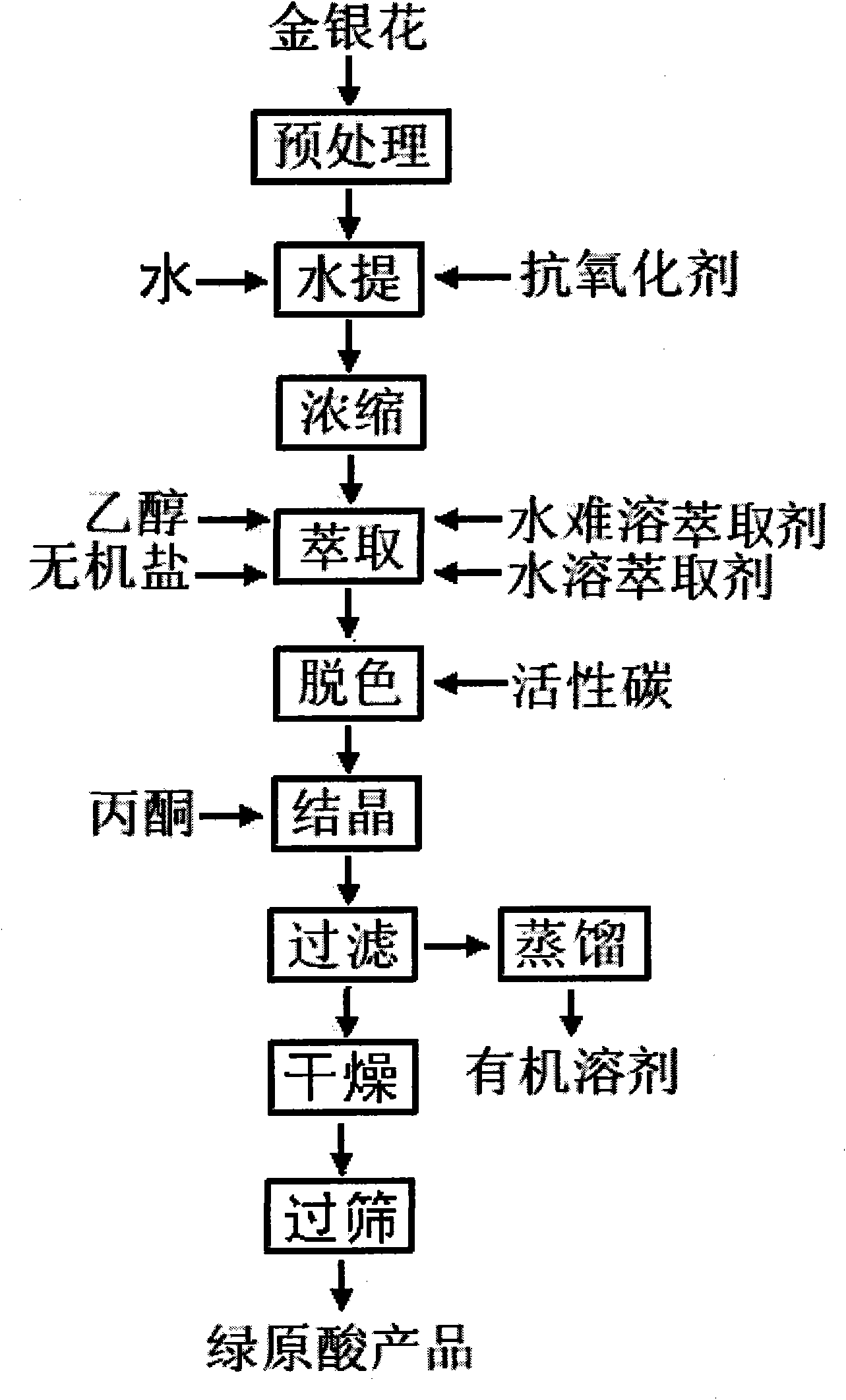

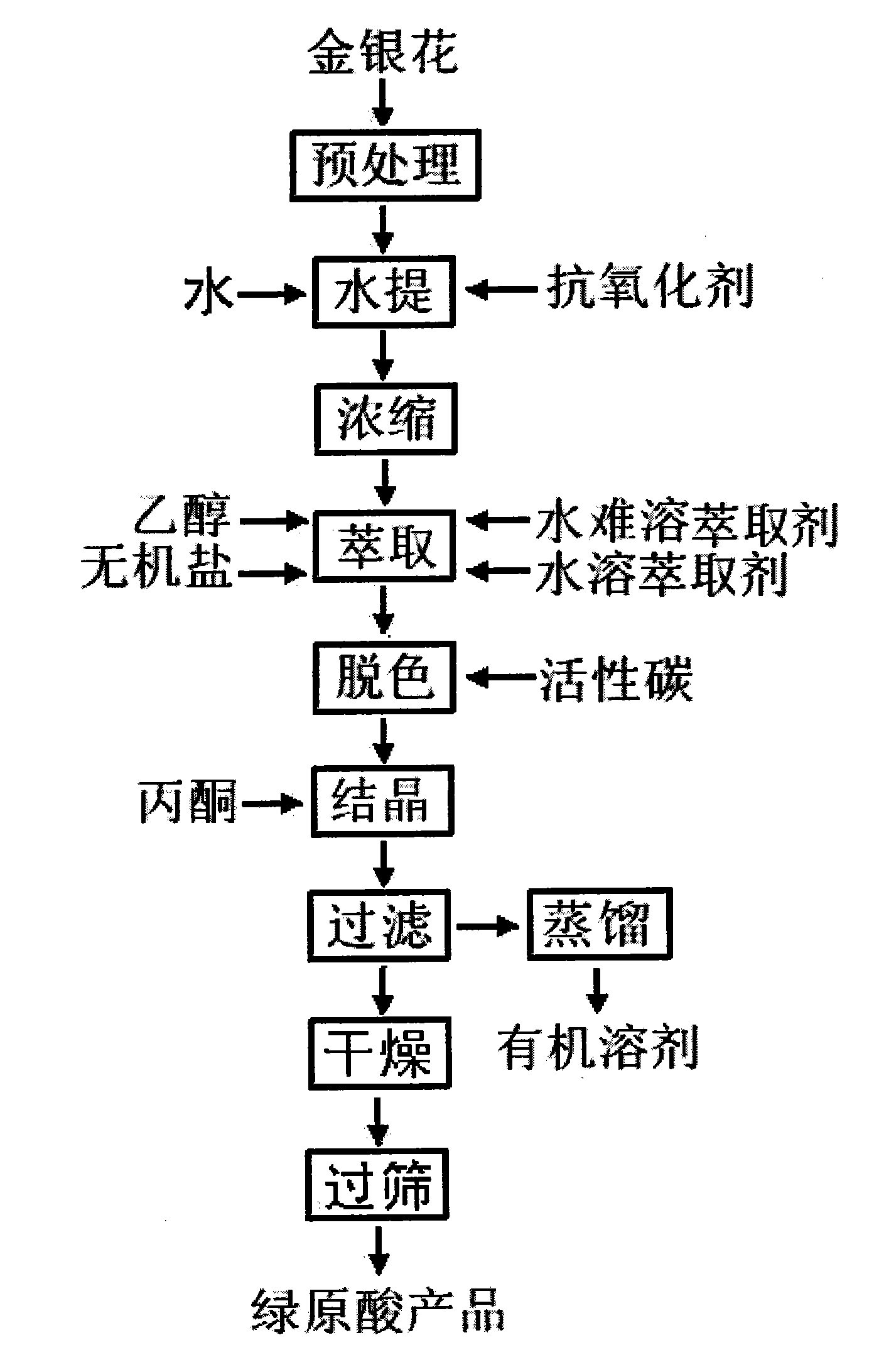

Method for preparing honeysuckle chlorogenic acid

InactiveCN102001947AImprove separation efficiencyLarge amount of processingCarboxylic acid esters separation/purificationChlorogenic acidOrganic solvent

The invention discloses a method for preparing honeysuckle chlorogenic acid, comprising the following steps of: carrying out water extraction on honeysuckle and branches and leaves of honeysuckle, which are used as raw materials, and then forming a dual-aqueous phase system by mixing a water soluble organic solvent together with a saline solution and a water soluble compound in proportion; then dissolving total extract into the dual-aqueous phase system for distribution so that the average concentration of the extract in two phases is 30-50 percent to achieve distribution balance; then extracting with an extracting agent which is not solvable with the two aqueous phases to separate out extract liquor; firstly removing impurities the polarity of which is lower than that of the chlorogenic acid; performing a three-phase extracting method, i.e. extracting the rest dual-aqueous phase with another extracting agent; carrying out selective direct enrichment and separating purification to obtain a chlorogenic acid initial product; and then decolorizing, crystallizing and drying to obtain the chlorogenic acid product with the mass fraction of 95 percent. The method simplifies production process, has better repeatability and no pollutant emission, and is suitable for industrial production; and the chlorogenic acid produced by using the method has high mass fraction.

Owner:GUANGXI JINHONGXIN BIOTECH

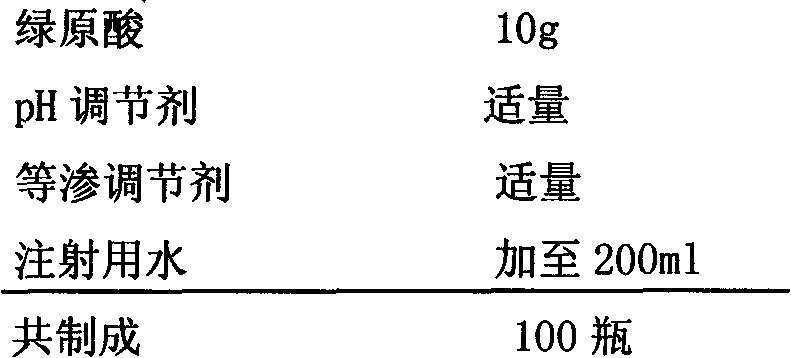

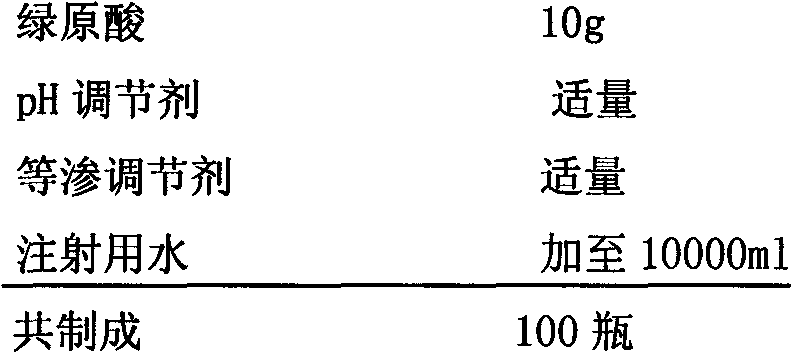

Preparation of high purity chlorogenic acid preparation and clinical application thereof

InactiveCN102391119AAntibacterialSuppressor mutationAntibacterial agentsOrganic active ingredientsDiseaseChlorogenic acid

Chlorogenic acid, i.e. 1, 3, 4, 5-tetrahydroxycyclohexanecarboxylic acid-(3, 4-dihydroxycinnamic acid ester), exists in a plurality of plants, and also, high purity chlorogenic acid can be prepared through synthesis. Chlorogenic acid has a lot of biological activity, such as antibacterium, antivirus, antioxidation, antitumor and the like. However, there exists no report and research on oral preparations prepared by high purity chlorogenic acid and application of the preparations in clinics. In the invention, high purity chlorogenic acid is extracted from plants or obtained through synthesis, and is then added with a proper amount of accessories, thus obtaining oral preparations like tablets, capsules, granules, oral solutions, etc. The preparations provided in the invention can be applied in clinics for treating cardio-cerebrovascular diseases, infections, hepatitis B, tumors and other diseases, and also can be used in health care medicines for heat clearing and detoxifying, face nursing and skin moistening, as well as hangover relieving, etc.

Owner:肖文辉 +1

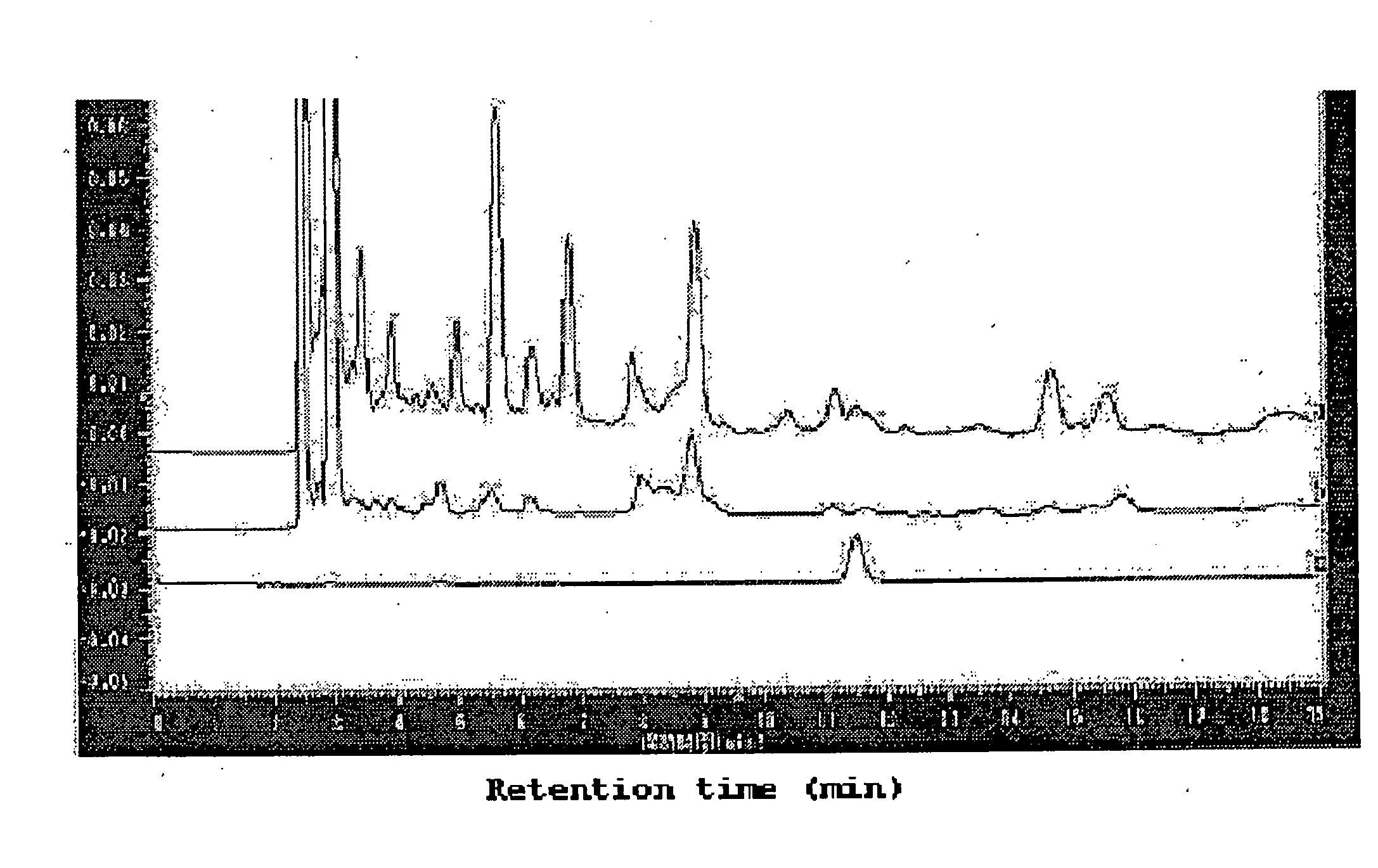

Method of producing chlorogenic acid composition

InactiveUS20090053381A1Organic active ingredientsOrganic compound preparationHigh concentrationChlorogenic acid

The present invention provides a method for obtaining a chlorogenic acid composition which contains high concentration of chlorogenic acids and a reduced amount of caffeine at a high yield.A method of producing a chlorogenic acid composition, which comprises allowing a water-soluble composition extracted from raw coffee beans or roasted coffee beans to be adsorbed to a column filled with an adsorbent and then eluting a chlorogenic acid composition by passing a 0.5 to 20 vol % ethanol aqueous solution.

Owner:KAO CORP

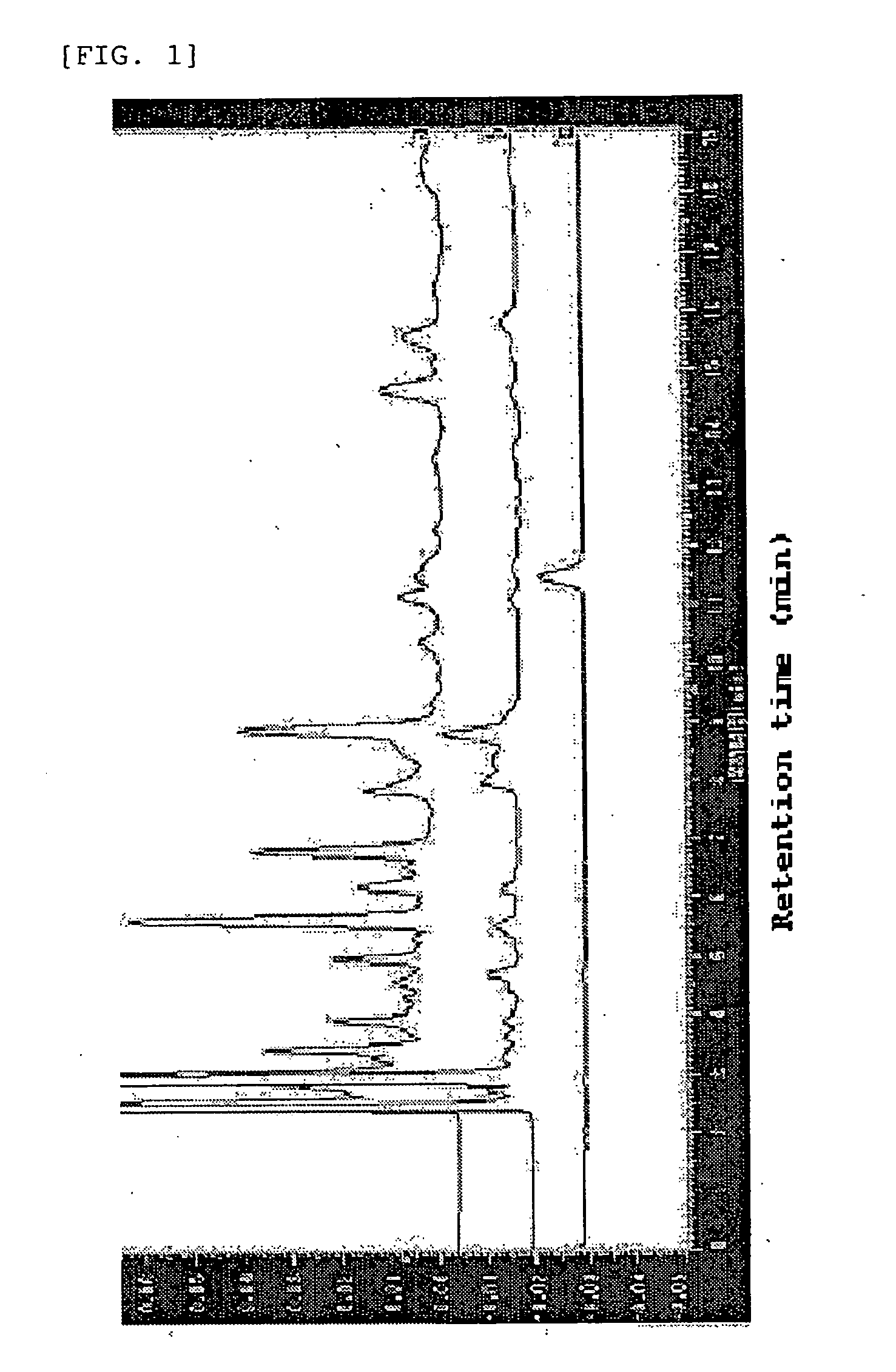

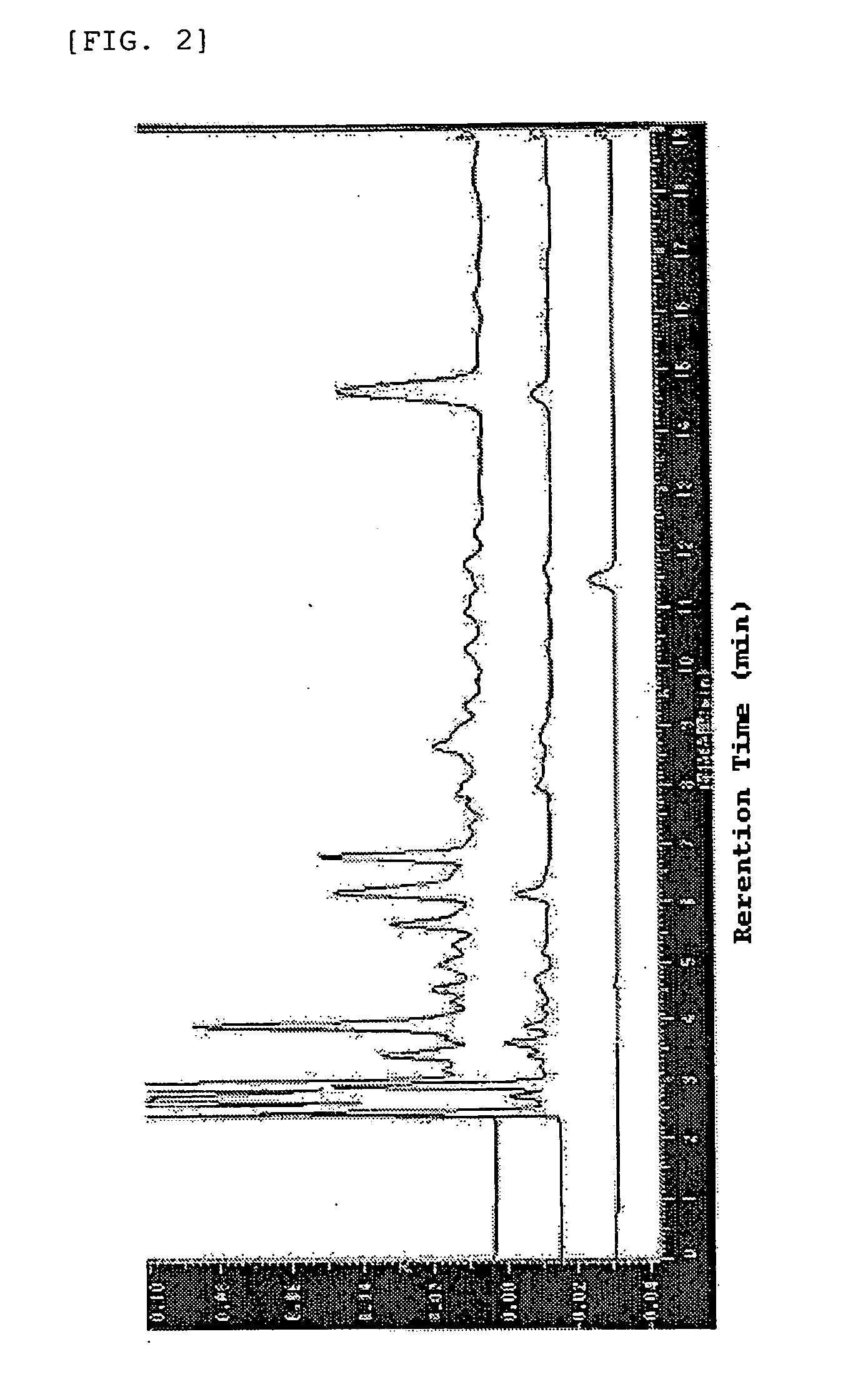

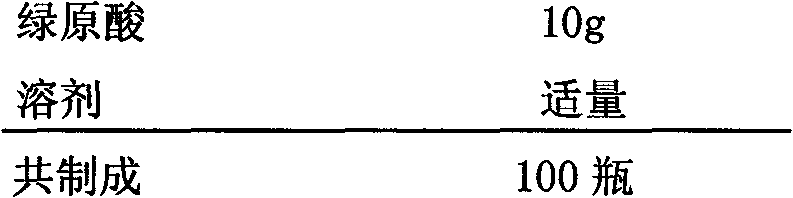

Novel method for adsorption separation of high purity chlorogenic acid

InactiveCN101314568AWide choiceLow costOrganic compound preparationCarboxylic acid esters preparationChlorogenic acidAbsorption column

The invention provides a novel method for absorption and separation of high-purity chlorogenic acid, comprising an absorption process, an impurity cleaning process and an elution process. The method is characterized in that: after chlorogenic acid stock solution is dynamically absorbed by at least dual tandem absorption column which is filled with macroporous resins until penetration, impurity removal solution is added for impurity removal; and finally eluent is used for elution until no chlorogenic acid flows out, and effluent is collected. The purity of the pure chlorogenic acid solution obtained by the method can reach over 92 percent as shown by HPLC detection, and the concentration can reach between 0.1 and 0.8 milligram per milliliter; and the pure chlorogenic acid solution can be widely applied in the fields such as foodstuff, medicines, cosmetics and so on. Solid, namely dried chlorogenic acid powder, obtained after direct drying of the pure chlorogenic acid solution prepared by the method, does not require reprocessing, can be directly applied, and is convenient for conveying.

Owner:NANJING UNIV OF TECH

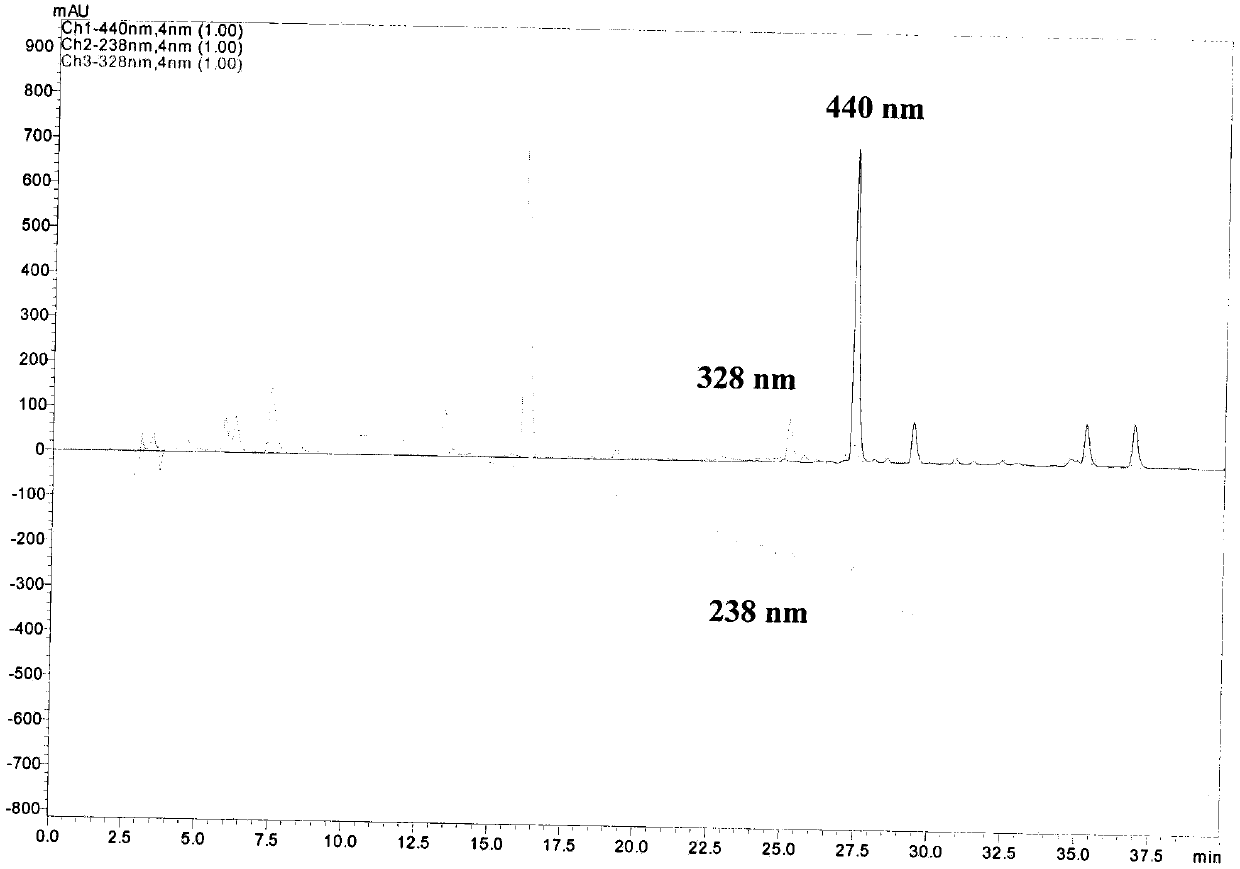

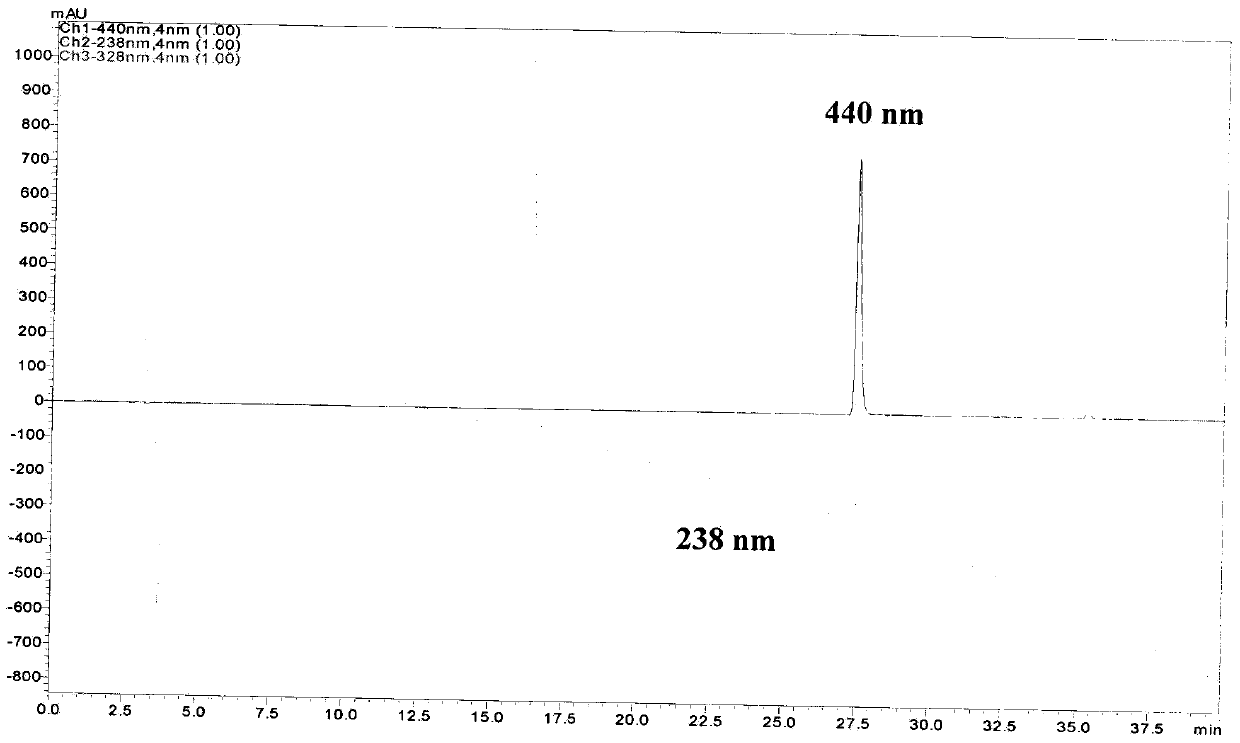

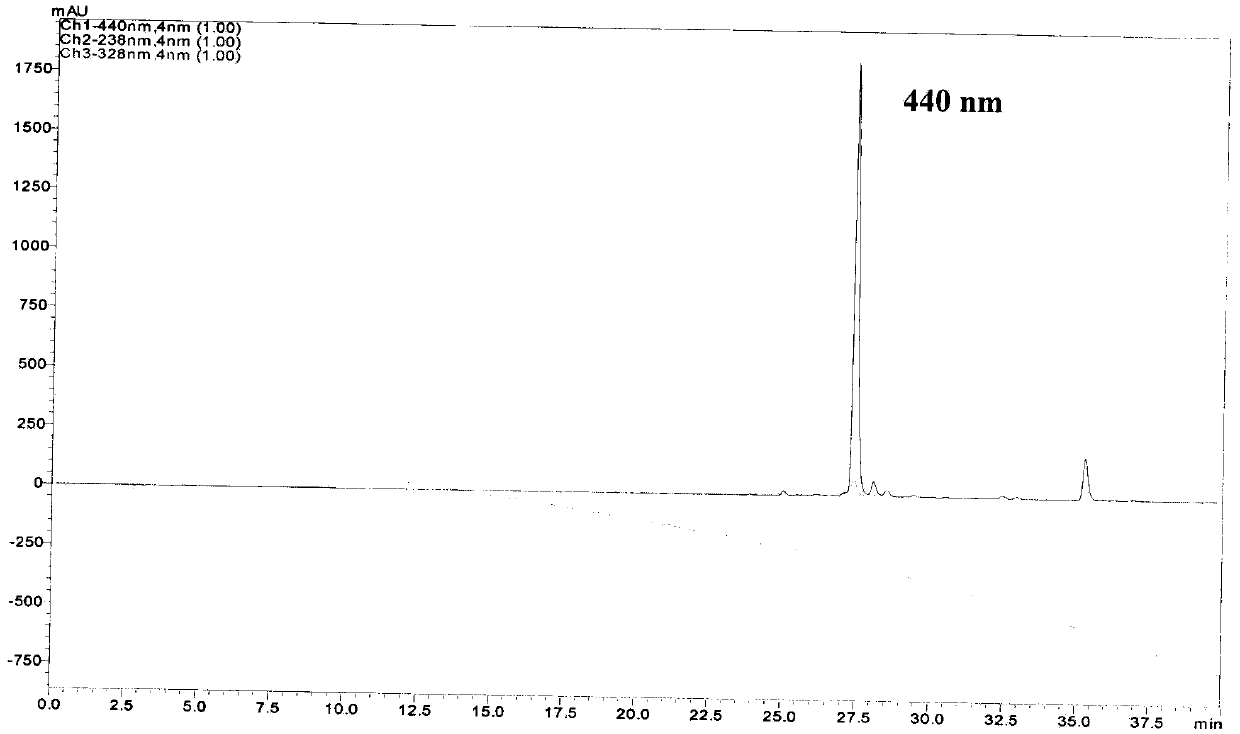

Technique for preparing gardenia yellow pigment

The process of preparing gardenia yellow pigment includes the following steps: 1. simultaneous water extracting and enzymolysis to obtain extracted solution; 2. adding calcium salt into the extracted solution to clarify, centrifuging and ultrafiltering to obtain filtrate; and 3. macroporous resin adsorption of the filtrate, three-section eluting chromatography, concentrating, and drying to obtain gardenia yellow pigment with high color number and low jasminodin content. The process is simple and suitable for use in industrial production and can eliminate jasminodin chlorogenic acid effectively, and the gardenia yellow pigment product has A238 / A440 not higher than 0.4, A325 / A440 not higher than 0.35, color number of about 400 and stable quality.

Owner:DAMIN FOODSTUFF ZHANGZHOU CO LTD

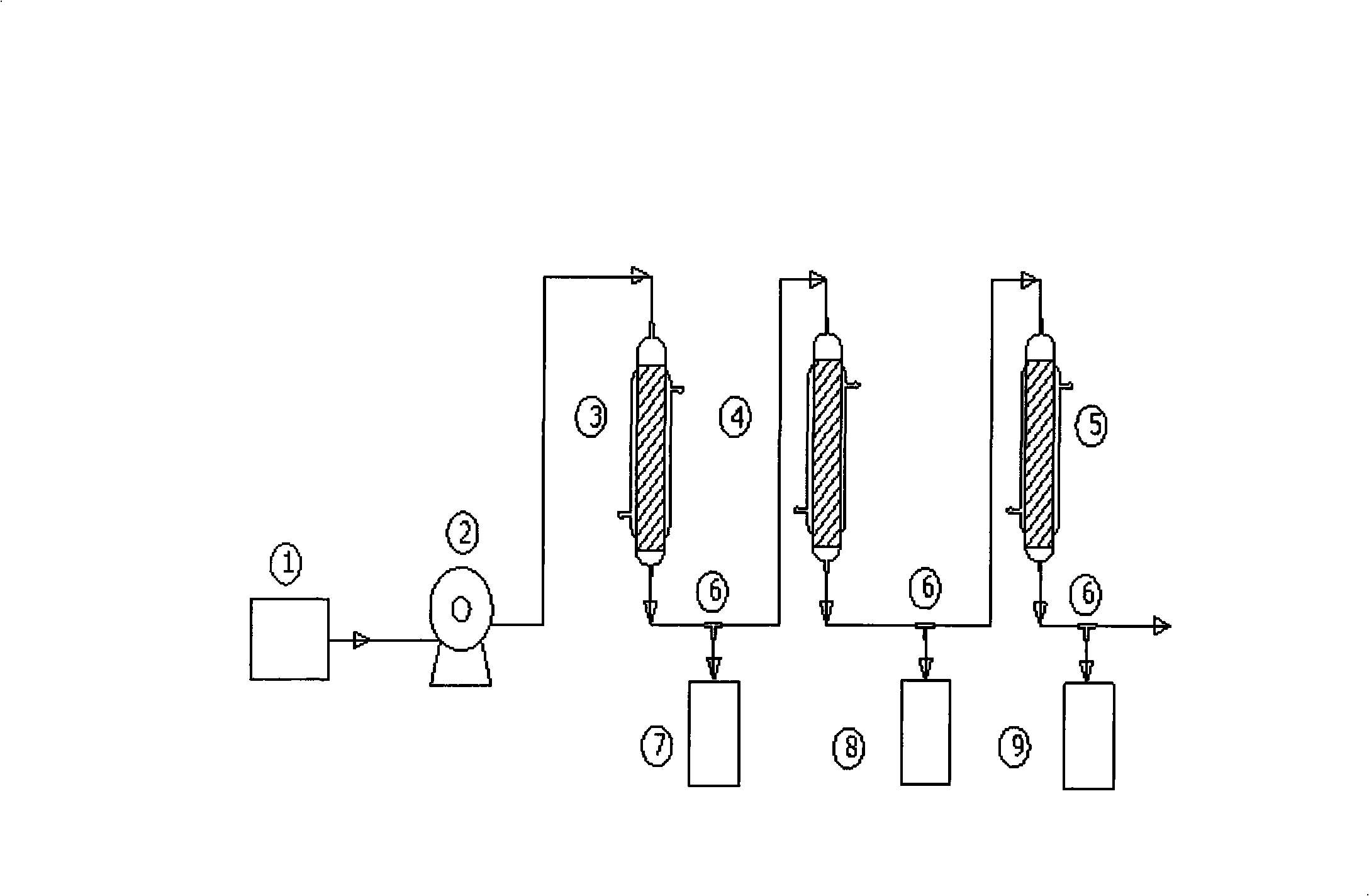

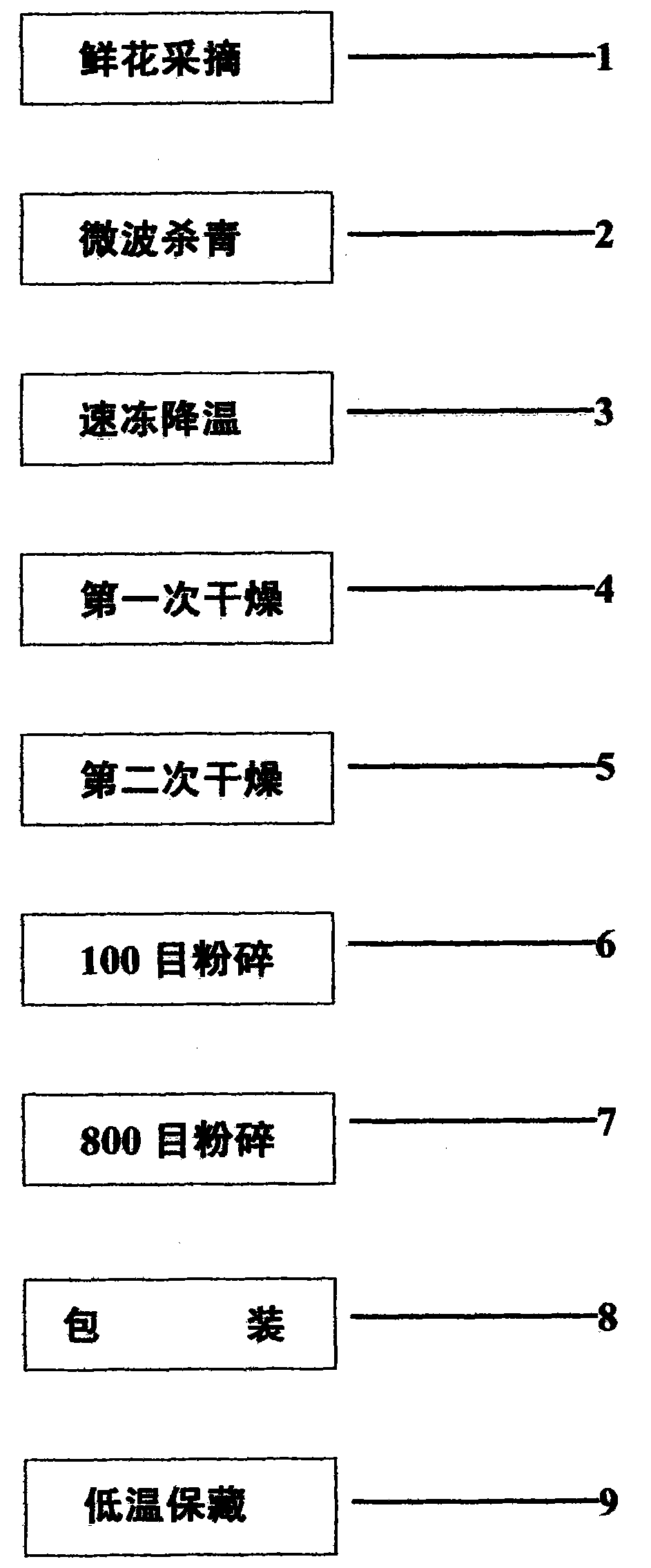

Honeysuckle micro powder tea

InactiveCN102113594ANo industrial pollutionNo pesticide residueTea substituesChlorogenic acidMicrometer

The invention relates to honeysuckle tea, in particular to honeysuckle micro powder tea, and provides honeysuckle micro powder tea with a particle size of 18 micrometers. The honeysuckle micro powder tea is characterized in that the tea contains as high as more than or equal to 5 percent of chlorogenic acid, has pale green color and faint scent smell, and avoids precipitates and granular sensation after being infused. A production method comprises the following steps of: picking fresh flowers, green-removing by using microwaves, quick freezing and cooling, performing secondary drying, crushing twice and refrigerating at low temperature. Due to the function of clearing heat and detoxicating and resisting bacteria in broad spectra, the honeysuckle micro powder tea has excellent inherent quality and shape characteristic.

Owner:李全才 +2

Method for extracting high-purity chlorogenic acid from honey suckle flower

InactiveCN101851163ANo lossRetain bioactive ingredientsCarboxylic acid esters separation/purificationChlorogenic acidHigh volume manufacturing

The invention discloses a method for extracting high-purity chlorogenic acid from honey suckle flower. The technical scheme of the invention comprises the following steps of: firstly, smashing the honey suckle flower material by the low-temperature supersonic air stream to obtain the cell-level honey suckle flower micro powder; secondly, carrying out the enzyme treatment, ultrasonic treatment, water extraction and filtering on the cell-level honey suckle flower micro powder to obtain the initial solution of the chlorogenic acid; and finally, flocculating, decolouring, purifying, condensing and drying the initial solution to obtain the high-purity chlorogenic acid. The invention solves the problems that the chlorogenic acid extract of the prior art is difficult to filter due to the large quantity of the precipitate in the impurity-removal and purification process; the invention has the advantages of advanced technique, simple and convenient operation, low cost, no harmful solvent, highpurity, high yielding rate, suitability for industrial large-mass production and the like.

Owner:湖南济草堂金银花科技开发有限公司

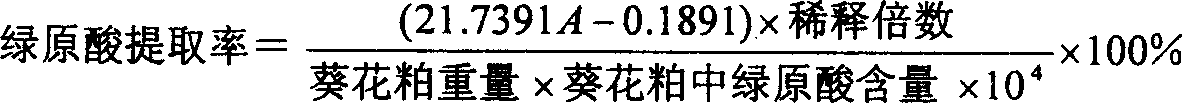

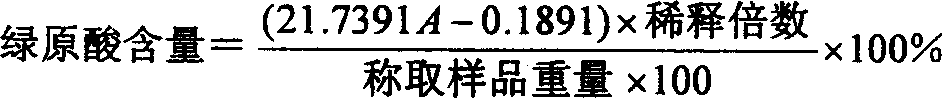

Chlorogenic acid extracting and purifying process from sunflower seed dregs

InactiveCN1740137AHigh extraction rateHigh purityOrganic compound preparationCarboxylic acid esters preparationSolubilityChlorogenic acid

The present invention belongs to the field of plant functional product extracting and purifying technology. The chlorogenic acid extracting and purifying process includes the steps of: extracting sunflower seed dregs with alcohol aqua to obtain alcohol aqua of chlorogenic acid, concentration to eliminate alcohol, acid precipitation to eliminate sunflower protein, extracting with ethyl acetate, separation, concentration to eliminate ethyl acetate and obtain coarse chlorogenic acid product in the content of about 70 %, and final purification with D101 macroporous resin to obtain chlorogenic acid product in the purity over 92 %. The present invention has the advantages of greatly raised chlorogenic acid extracting rate and high chlorogenic acid product purity.

Owner:JIANGNAN UNIV

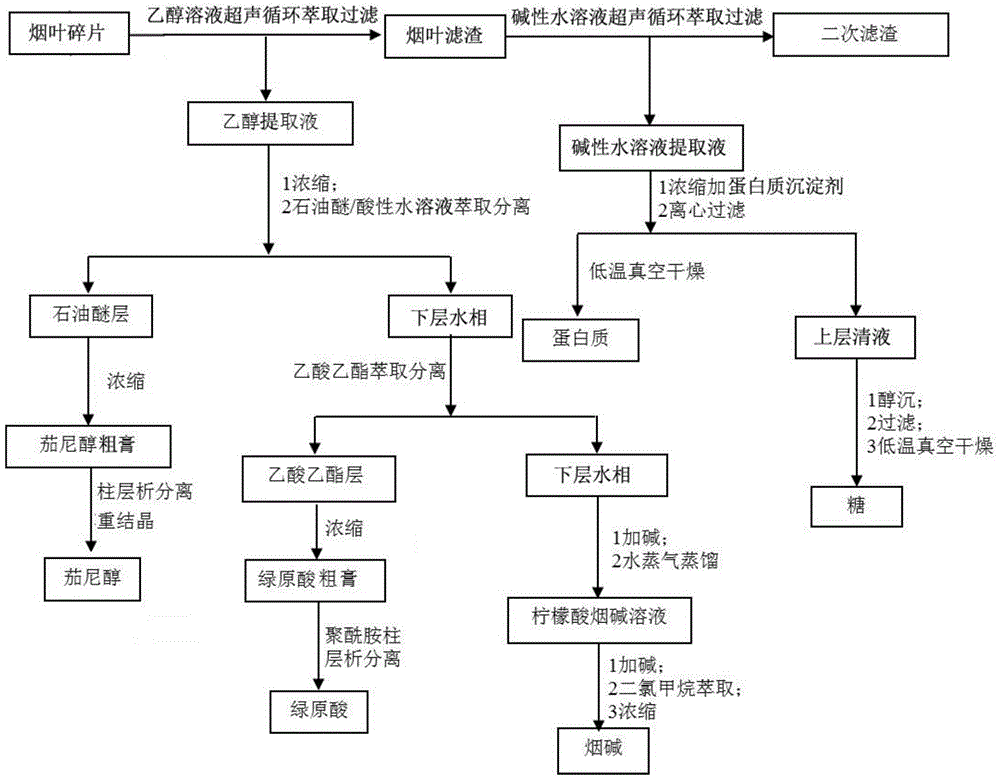

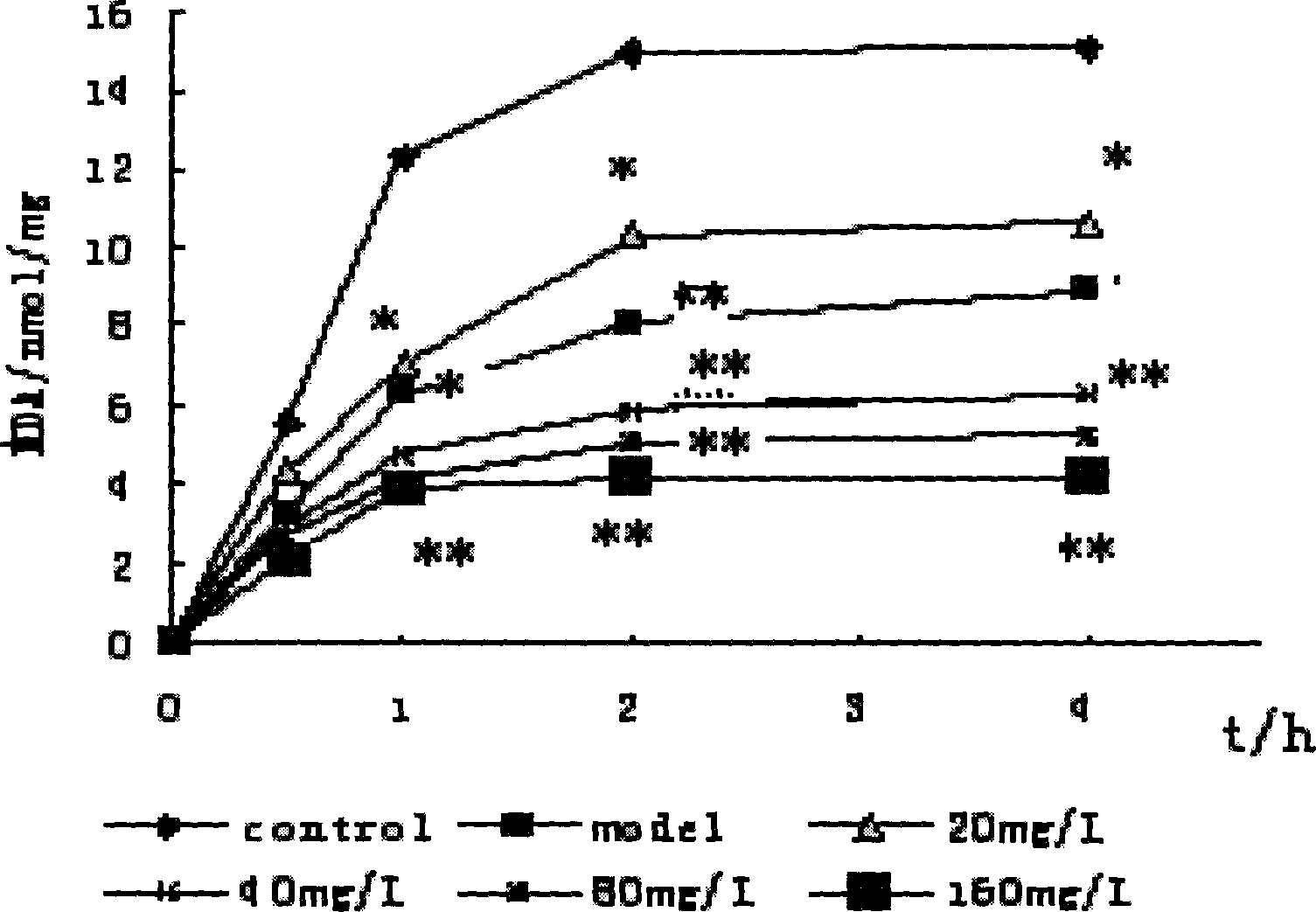

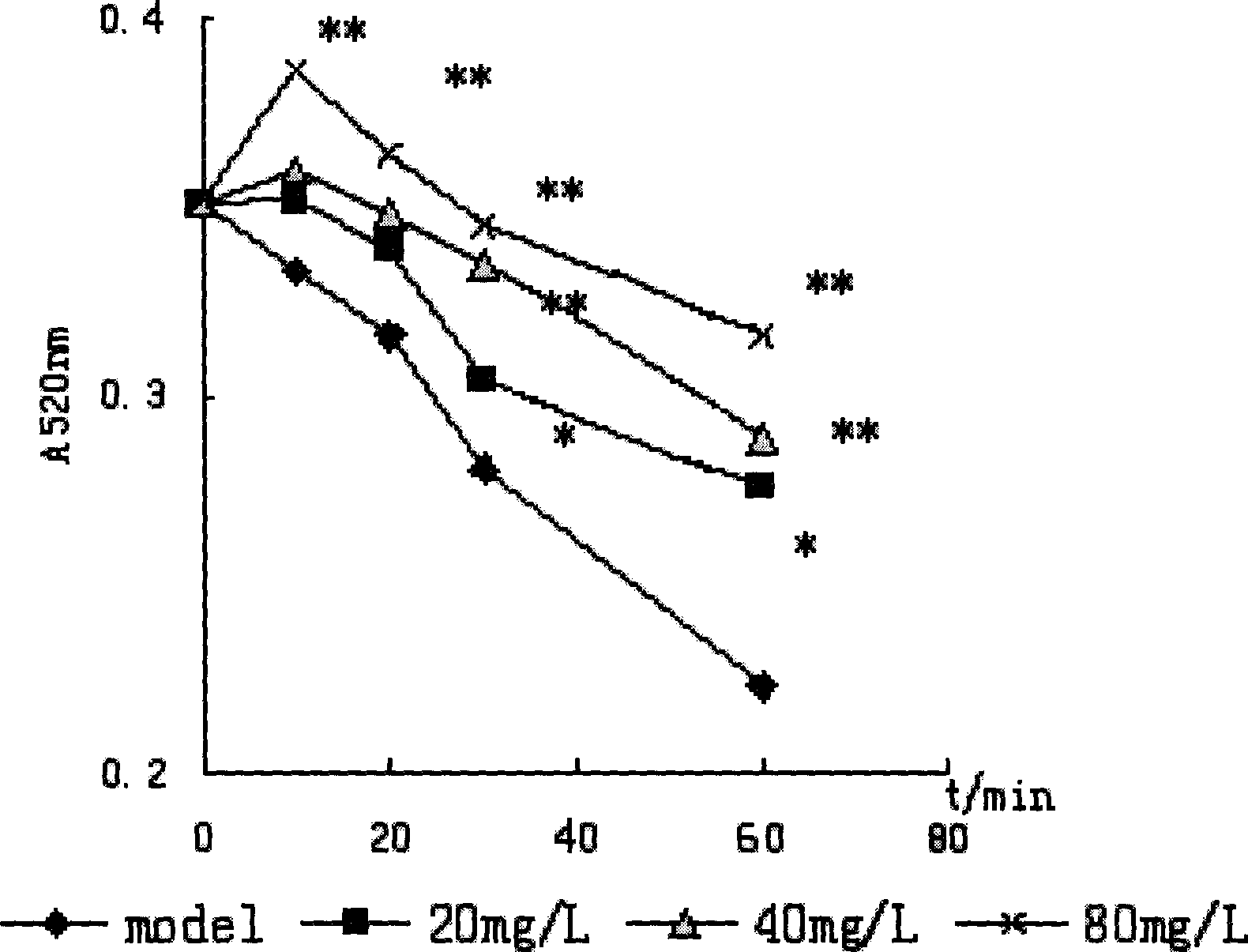

Method for comprehensively extracting multiple effective components from tobacco leaves

InactiveCN104151140AIncrease profitEmission reductionSugar derivativesPeptide preparation methodsChlorogenic acidPurification methods

The invention discloses a method for comprehensively extracting multiple effective components from tobacco leaves. The method comprises the following steps: performing twice ultrasonic circulation extraction on the tobacco leaves to respectively obtain crude ointment containing solanesol, nicotine and chlorogenic acid and an extract containing protein and sugar, and with the combination of separation and purification methods such as liquid-liquid two-phase extraction, column chromatography, recrystallization, steam distillation and precipitation, separating five effective components, namely, solanesol, nicotine, chlorogenic acid, protein and sugar from the tobacco leaves one by one. The method can continuously extract and separate the multiple effective components form the tobacco leaves, can greatly improve the utilization rate of a tobacco leaf raw material, has the advantages that the extraction efficiency is high, a great number of separation products are obtained and a small amount of wastes are discharged, and is an efficient and environment-friendly comprehensive tobacco leaf multi-component extraction technique.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

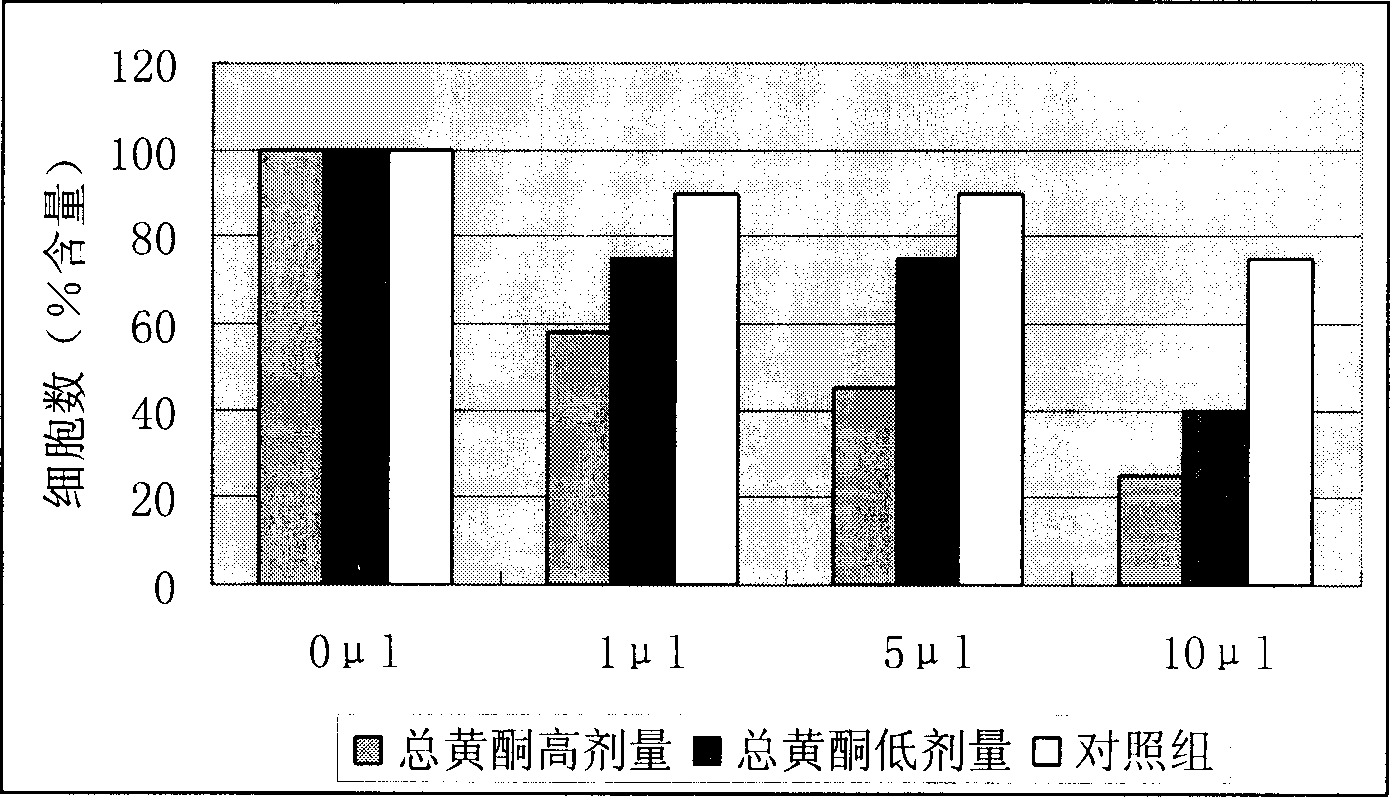

American goldenrod herb total flavone extract and its preparing method and use

InactiveCN1899341AEfficient enrichmentHigh in flavonoidsSugar derivativesSugar derivatives preparationDiseaseChlorogenic acid

The present invention relates to American goldenrod herb total flavone extract and its preparation process and use. The American goldenrod herb total flavone extract contains quercetin, quercetin-3-O-beta-D-heteroside, kaempferol-3-O-alpha-L-rhamnoside, chlorogenic acid, etc. capable of preventing and treating senile dementia, various inflammatory respiratory diseases, esophagus cancer, etc. The preparation process is simple, high extracting rate, and the extract has high pharmacological effect, stable property, low toxicity and controllable quality.

Owner:LINSAIJIAO BIOLOGICAL SCI & TECH DEV SHANGHAI

Coffee Product

InactiveUS20080113077A1Improve the level ofIncrease aromaGreen coffee treatmentMeat/fish preservation by freezing/coolingChlorogenic acidCoffee processing

A coffee product comprises (i) a first portion consisting of unroasted coffee, in an amount of from 1 to 90% by weight based on the total weight of the ground coffee composition, and (ii) a second portion consisting of ground coffee which has been roasted to a higher degree of roast than said first portion, in an amount of from 99 to 10% by weight based on the total weight of the ground coffee composition in a weight ratio of (i) to (ii) is from 10:90 to 80:20 wherein the coffee product comprises at least 4 g of chlorogenic acids per 100 g of product.

Owner:NESTEC SA

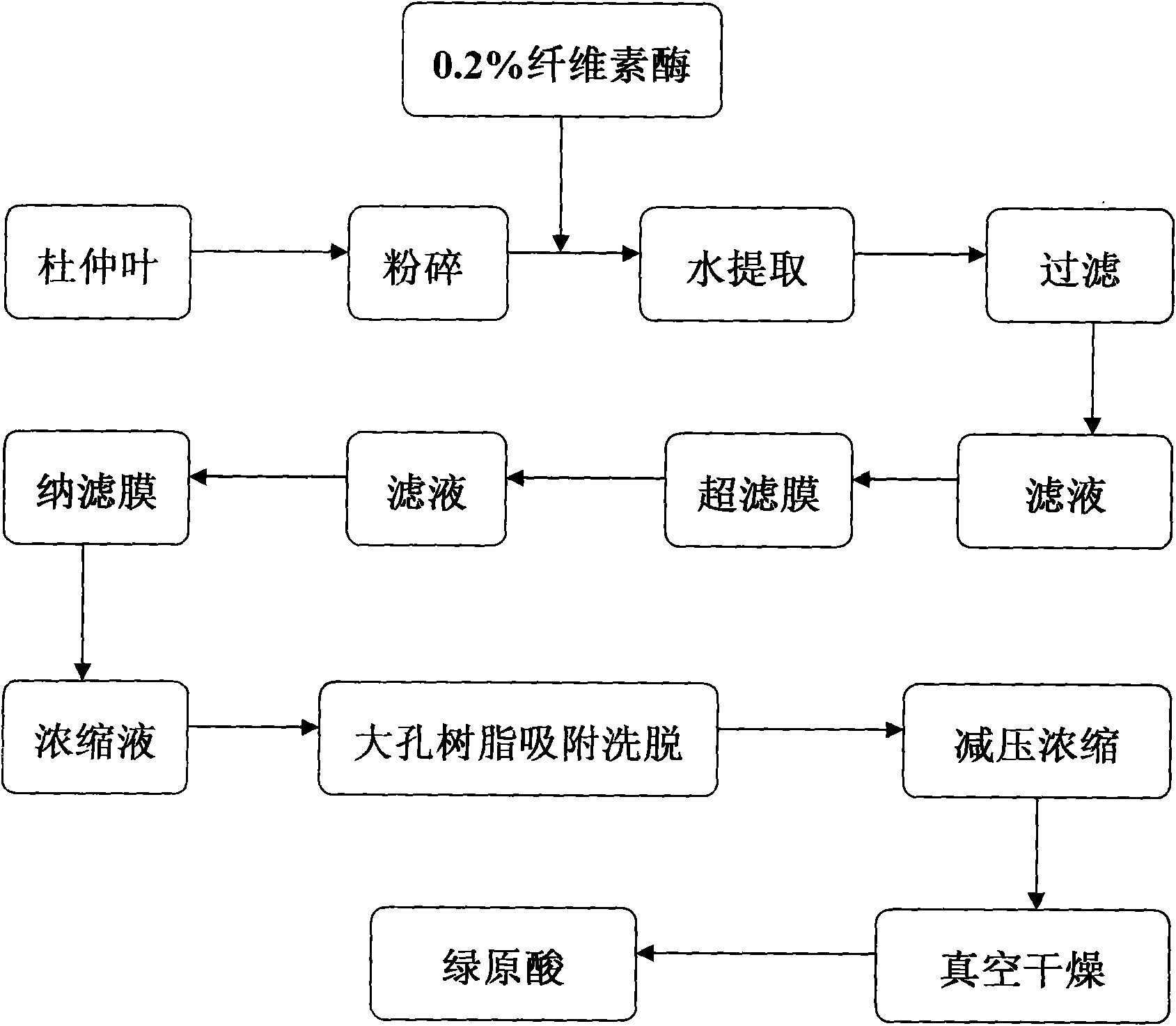

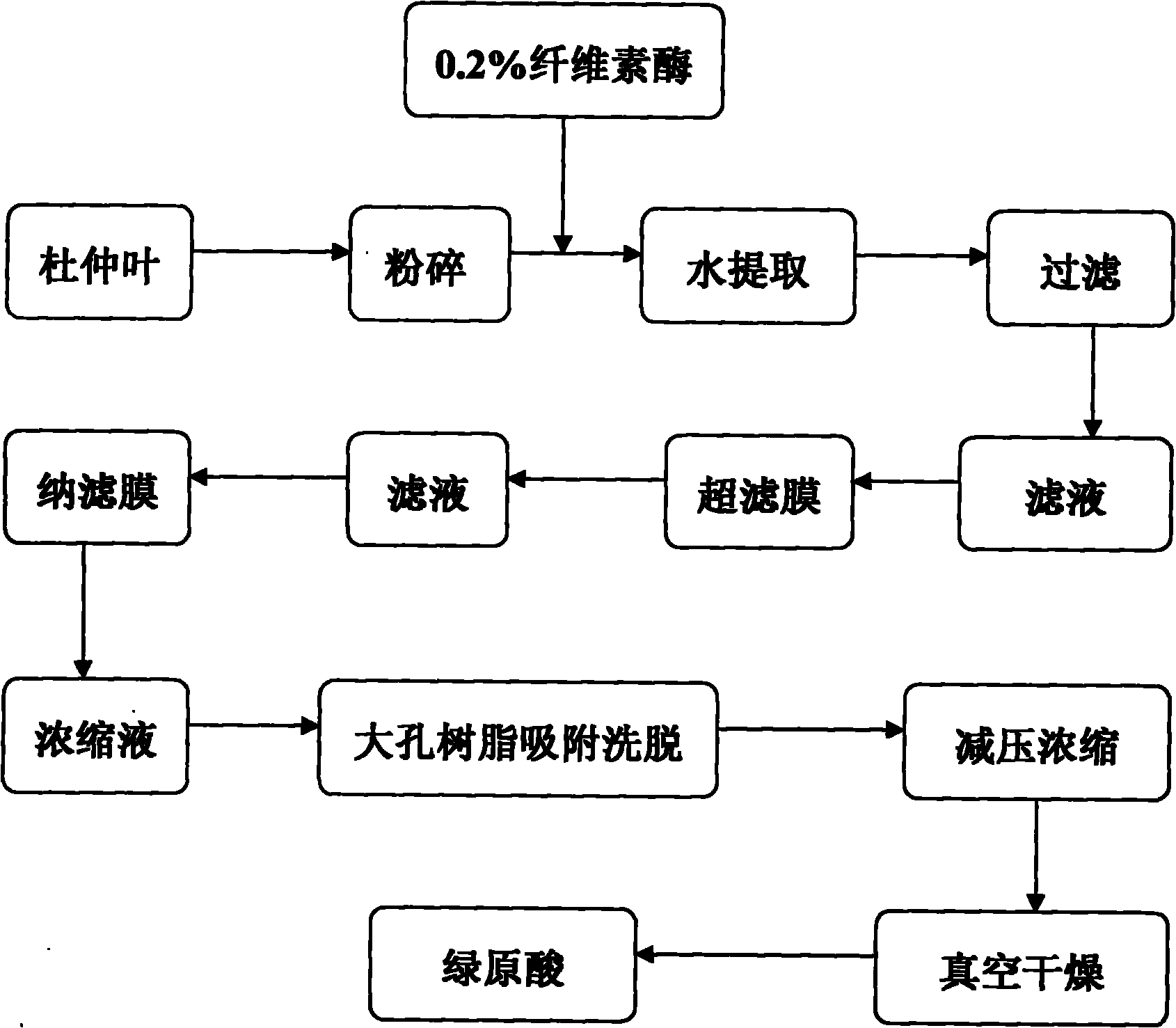

Method for preparing chlorogenic acid in Eucommia ulmoides leaves

InactiveCN102040519ALow water extraction temperatureReduce extraction timeIon-exchange process apparatusOrganic compound preparationChlorogenic acidChemical oxygen demand

The invention discloses a method for preparing chlorogenic acid in Eucommia ulmoides leaves, which comprises the following steps of: crushing the Eucommia ulmoides leaves, performing warm water extraction assisted by cellulose, performing conventional filtration, removing impurities by using an ultrafiltration membrane, performing nanofiltration and concentration, separating and purifying by using macroporous resin, and concentrating and drying to obtain chlorogenic acid powder. The chlorogenic acid in the Eucommia ulmoides leaves is subjected to warm water extraction assisted by cellulose, the extraction rate can reach 95 percent, the water extraction temperature is lower, and the extraction time is shortened; the ultrafiltration membrane is adopted to remove the impurities from the extracting solution and separate other byproducts, the membrane operating process is simple, the membrane flux can be stable for a long time, and the membrane is easy to clean, has long service life and is suitable for industrialization; a nanofiltration membrane is adopted to concentrate the extracting solution from which the impurities are removed, the load of the subsequent process is lightened, and the service life of the resin can be prolonged; the filtrate obtained through nanofiltration has the chemical oxygen demand (COD) value of less than or equal to 100 and can be returned to the production process, and wastewater is not generated basically; and the macroporous adsorbent resin can effectively purify the chlorogenic acid, the purity of the chlorogenic acid in the prepared powder is more than 60 percent and the extraction ratio is more than 1.4 percent.

Owner:HUBEI LAOLONGDONG DUZHONG DEV

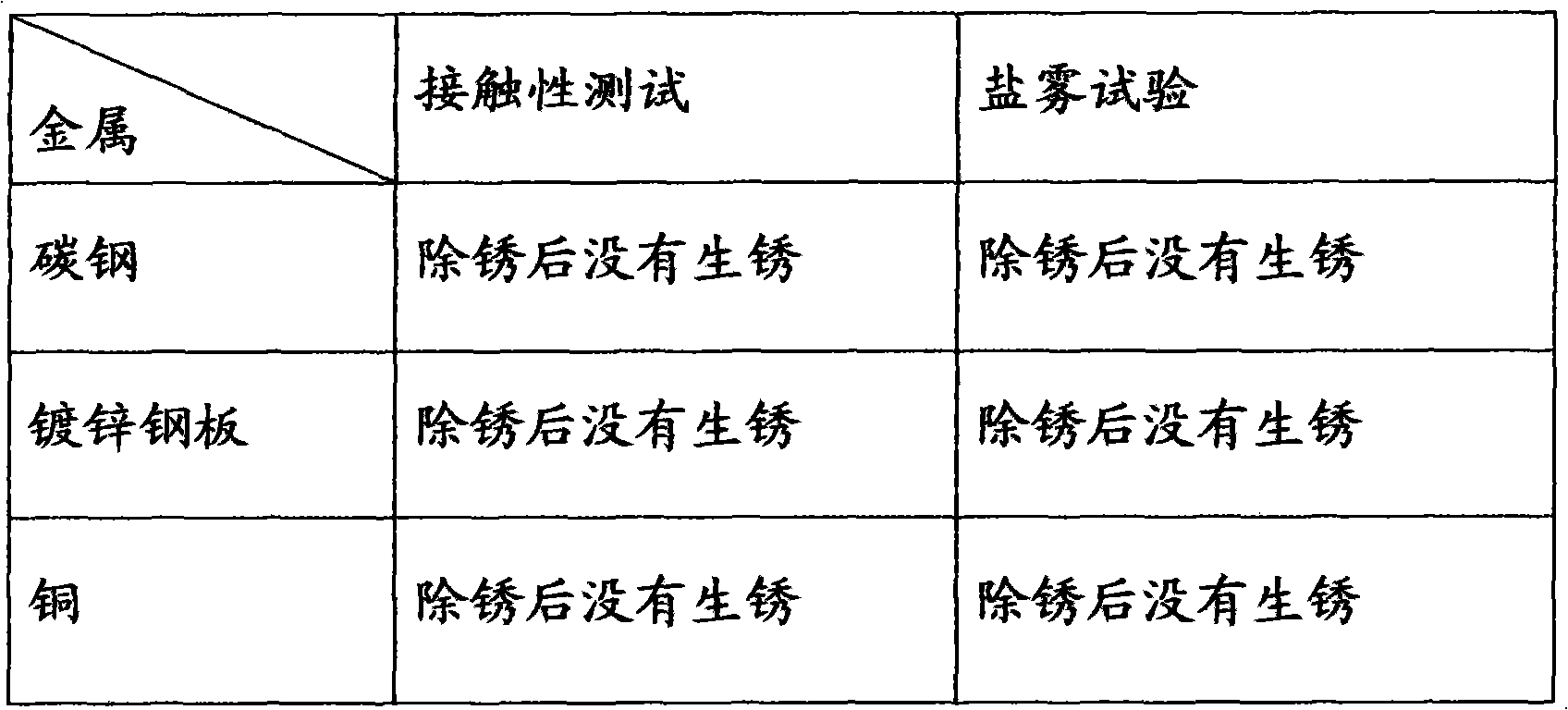

Environment-friendly rust remover and production method thereof

The invention discloses an environment-friendly rust remover, comprising the following raw materials in parts by weight: 15-30 parts of organic acid, 5-15% of glycerin, 0.1-2 parts of dextrin, 0.5-10 parts of sodium molybdate, 0.5-2 parts of phosphoric acid, 45-70 parts of water and 0.05-0.1 part of SI-1 additive. The organic acid used in the invention is any one of citric acid, tartaric acid, malic acid, chlorogenic acid, oxalic acid, benzoic acid, salicylic acid and caffeic acid. The invention improves the traditional formula, the manufacturing process is advanced and the manufacturing method is simple, rapid and efficient. The invention overcomes the shortcoming that the existing rust removers pollute the environment, and the rust remover not only has good rust removing function, but also has excellent rust prevention function.

Owner:金福东

Agent for preventing, improving or treating hypertension

InactiveUS20020054923A1Increase pressureSuitable for useBiocideOrganic chemistryChlorogenic acidAlcohol sugars

The invention relates to an agent for preventing, improving or treating hypertension, which exhibits a hypotensive effect, inhibits the rise of blood pressure and improves hypertension, and food for preventing or improving hypertension, which does not become a burden in daily intake, has a higher antihypertensive effect and is useful as a diet during treatment for patients of hypertension. The agent for preventing, improving or treating hypertension contains the following components (A) and (B): (A) a compound selected from the group consisting of caffeic acid, chlorogenic acid and ferulic acid, and esters and pharmaceutically acceptable salts thereof; and (B) a component selected from the group consisting of central nervous system stimulating components, food fibers, extracts of perennial evergreen leaves of the genus Camellia, Theaceae, or Eucommia ulmoides Oliver, Eucommiae, organic acids having a molecular weight of 60 to 300 (excluding citric acid) and pharmaceutically acceptable salts thereof, and sugar alcohols.

Owner:KAO CORP

Extraction method for antibiosis antiviral active placement from honeysuckle

A process for extracting the antibacterial and antivirus components from honeysuckle flower includes such steps as extracting in alcohol solution, adsorbing by macroreticular resin adsorbent, eluting, adsorbing by polyamide column, and eluting. Its quality standard based on the chlorogenic acid or isochlorogenic acid as reference is defined. Its advantages are high content (25-80%) and low cost.

Owner:RUNTONG BIOLOGICAL MEDICINE HEILONGJIANG PROV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com