Patents

Literature

100results about How to "Reduce post-processing steps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

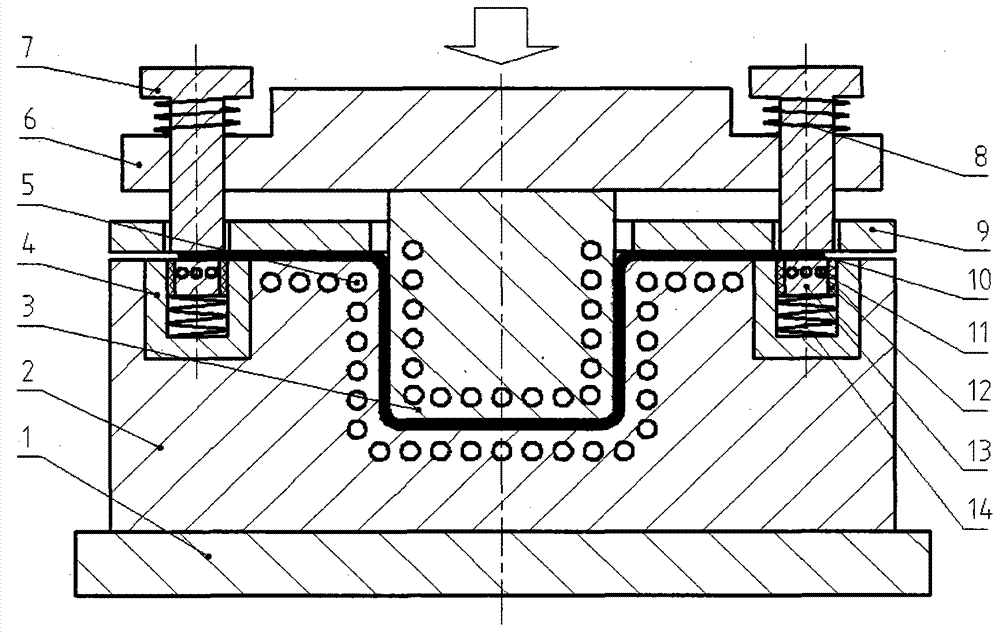

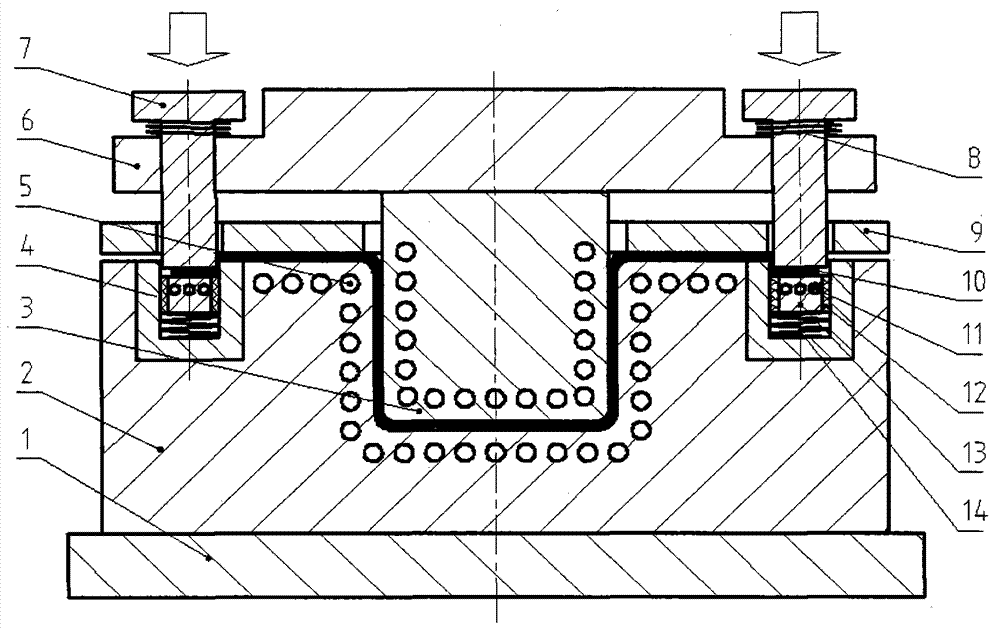

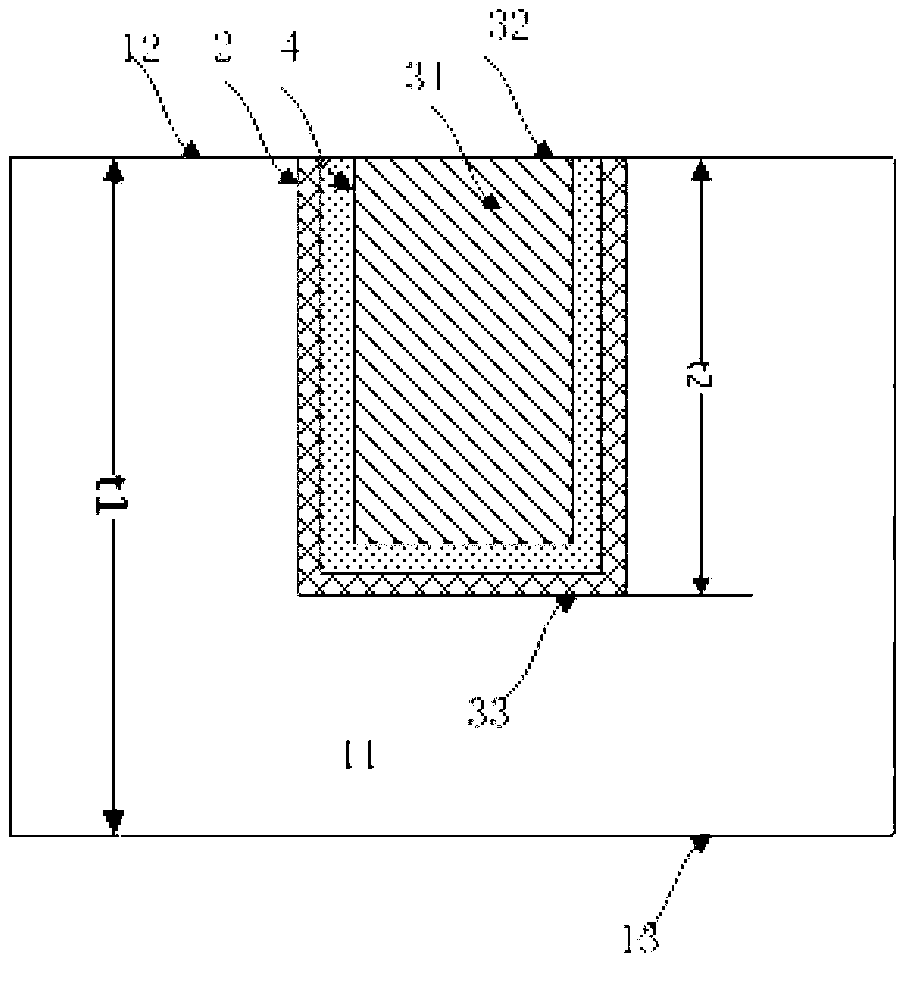

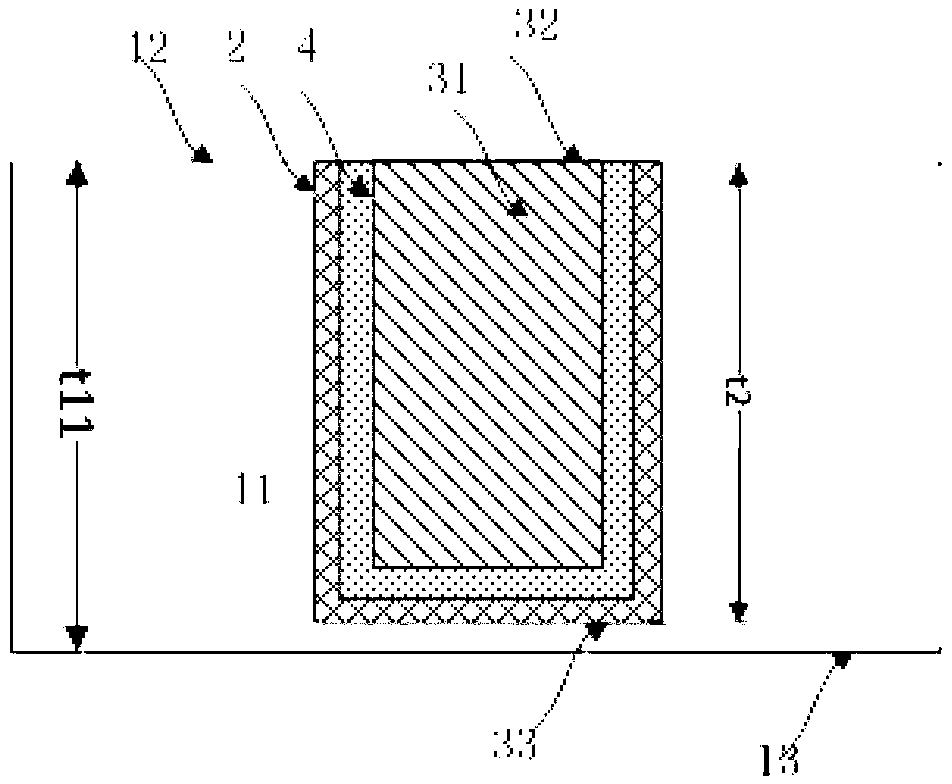

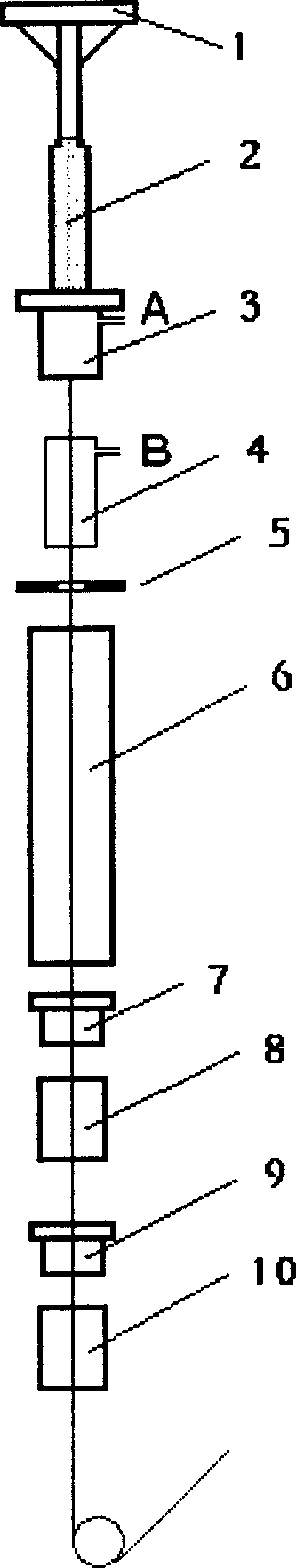

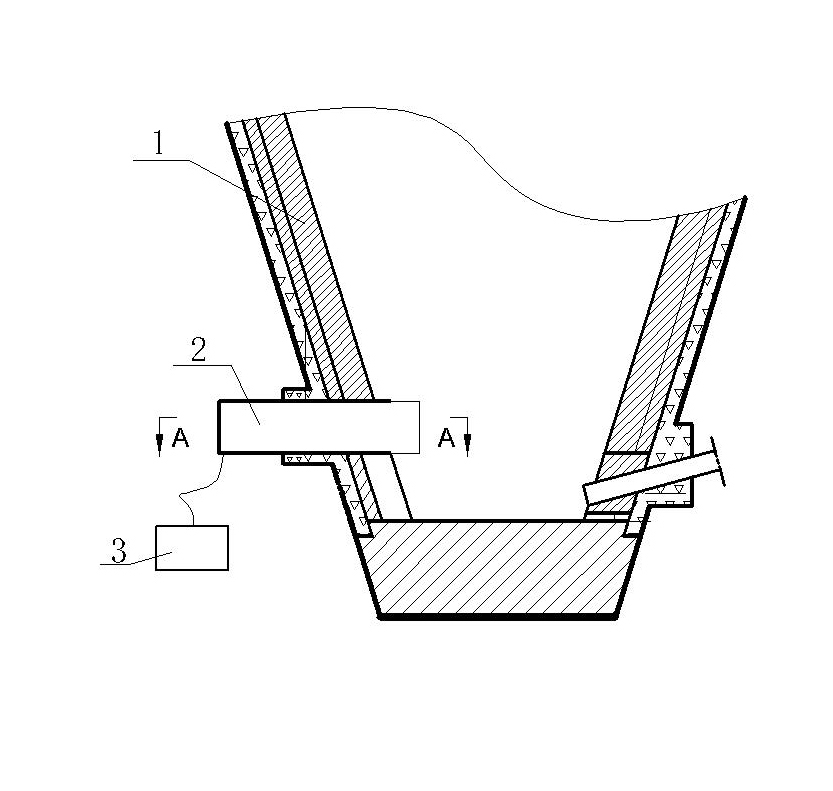

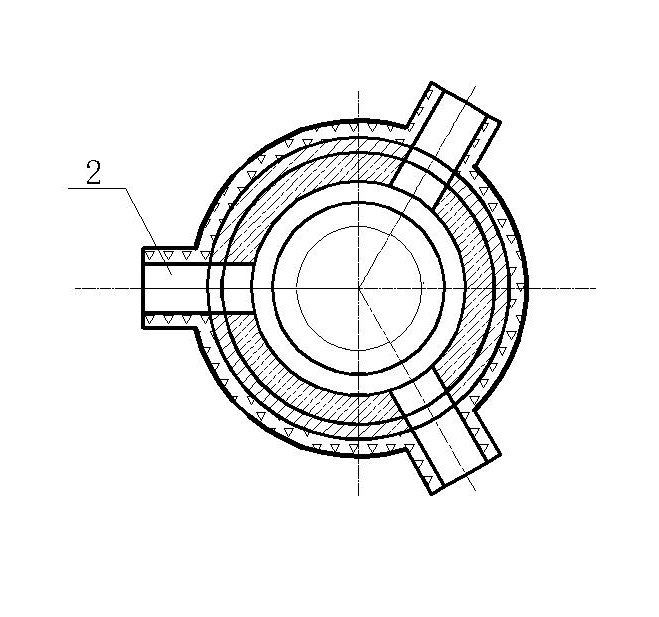

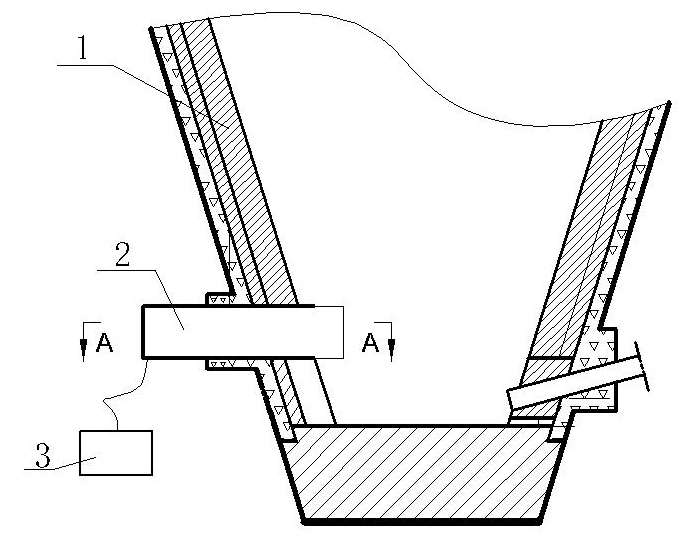

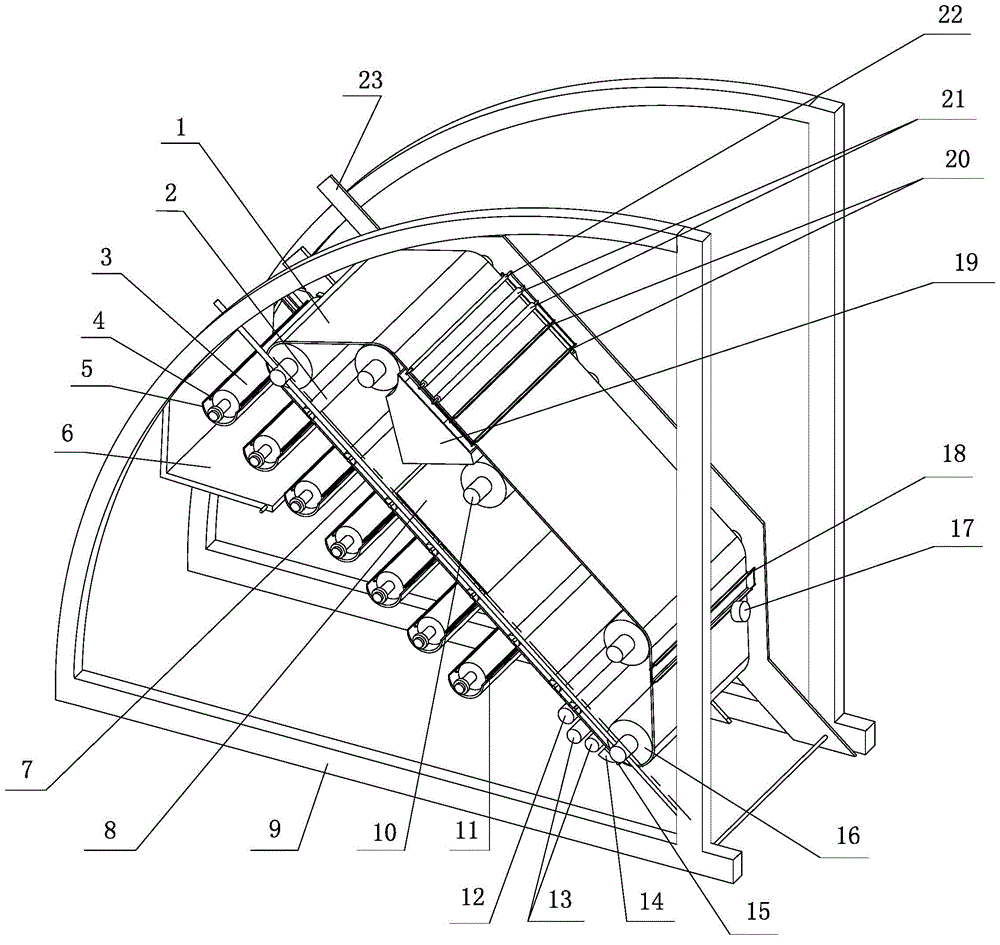

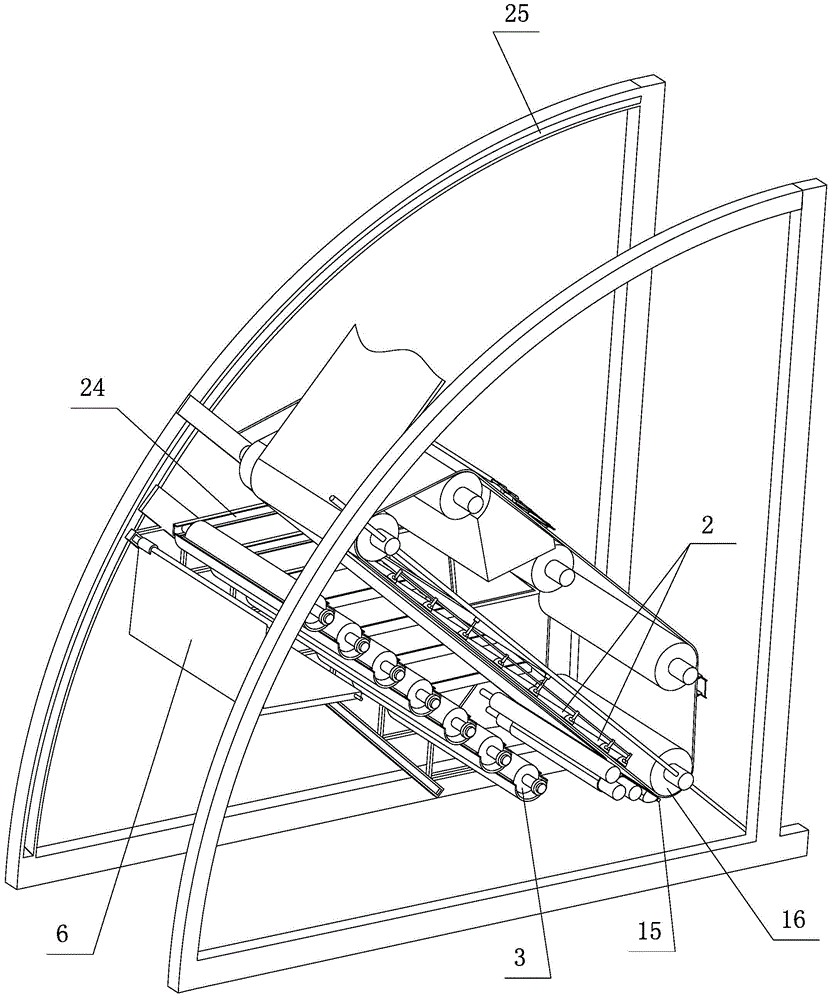

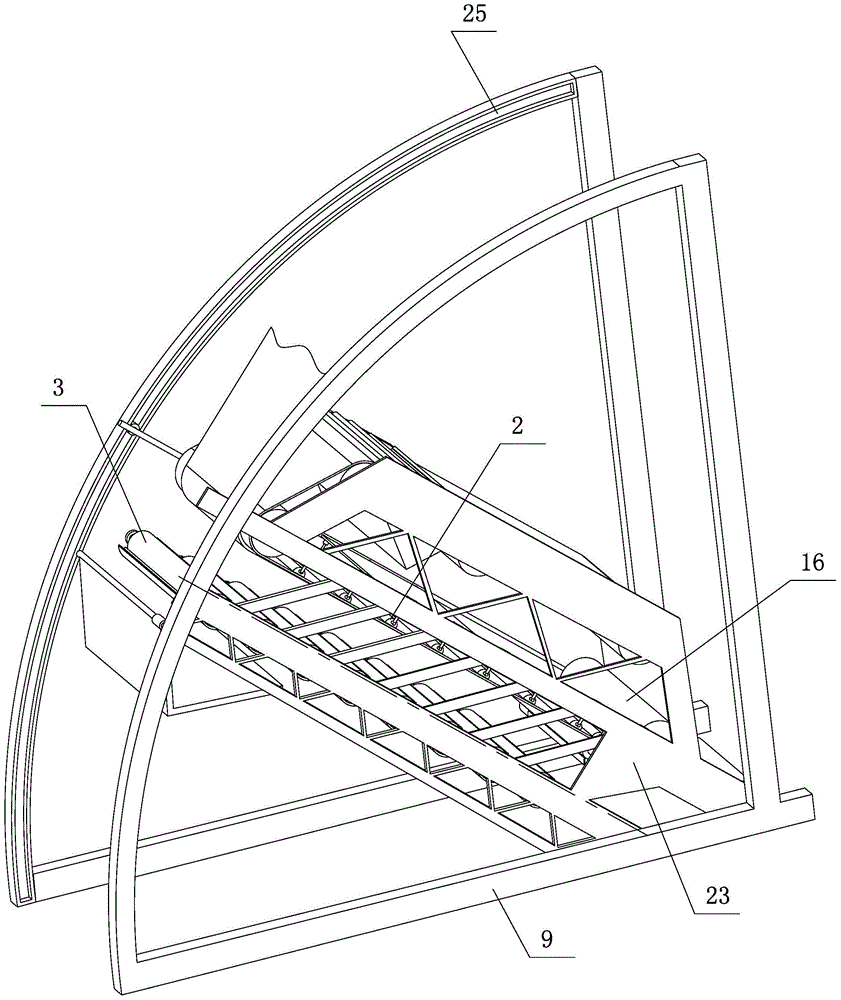

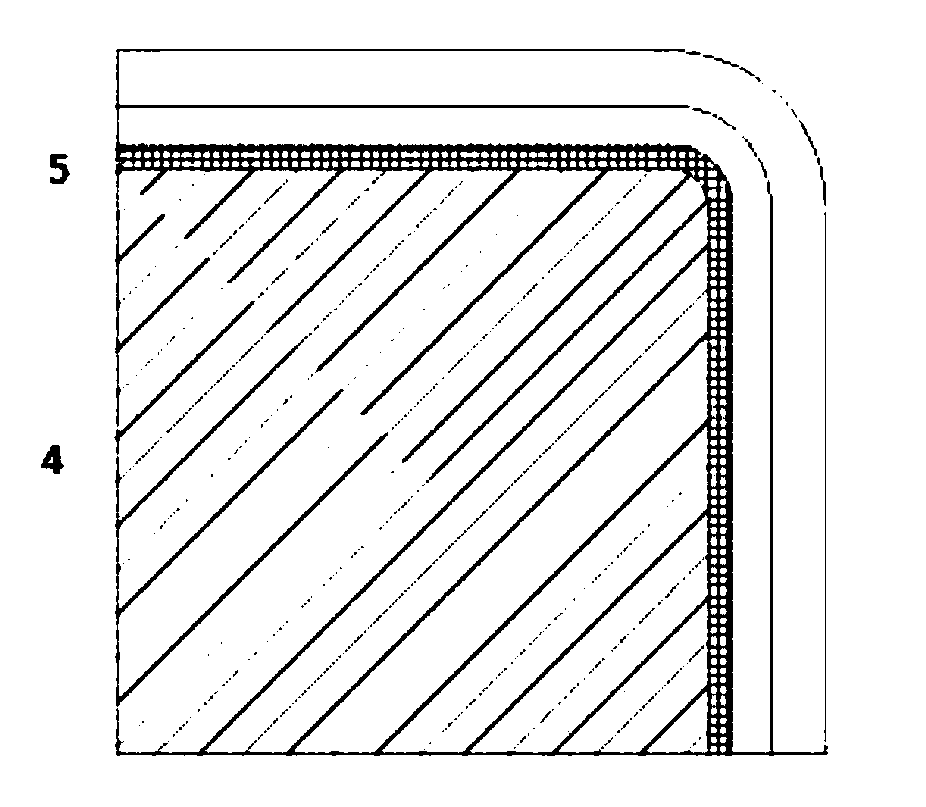

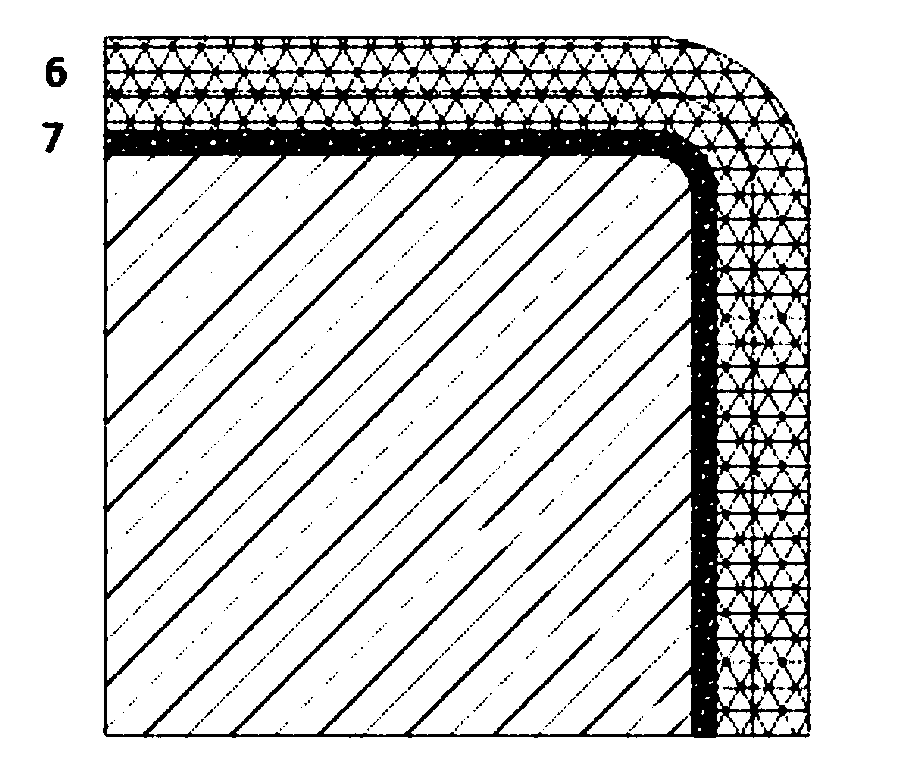

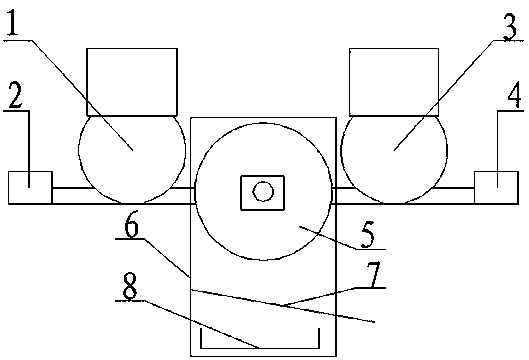

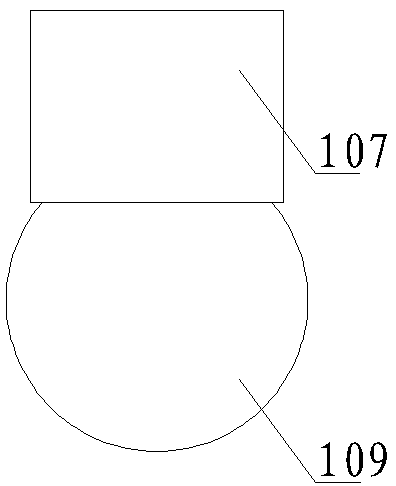

Hot stamping and warm blanking composite forming technology and mould for ultrahigh-strength steel

The invention provides a hot stamping and warm blanking composite forming technology and mould for ultrahigh-strength steel. By means of the composite mould, blanking is composited in a hot stamping process, and trimming and punching are performed on sheet metal at a temperature higher than a martensite formation temperature. The hot stamping and warm blanking composite forming technology comprises the following processes of putting the sheet metal of the ultrahigh-strength steel heated to achieve complete austenitizing into the composite mould, performing stamping forming and then performing cooling and quenching; heating sheet metal needing blanking locally, keeping a warm state, performing warm blanking after completion of forming, and performing cooling further in a pressure maintaining mode. The hot stamping and warm blanking composite forming technology and mould for ultrahigh-strength steel effectively solves the problems of poor quality, low precision, high cost and long period of holes trimmed and punched in the later period of the ultrahigh-strength steel and has great practical significance in production practice.

Owner:JILIN UNIV

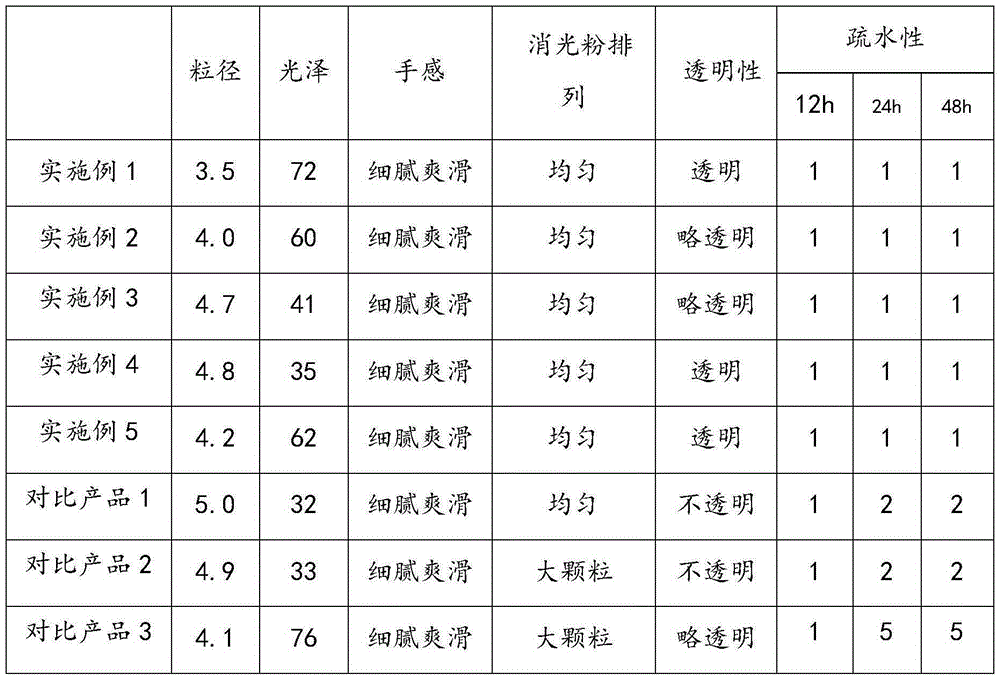

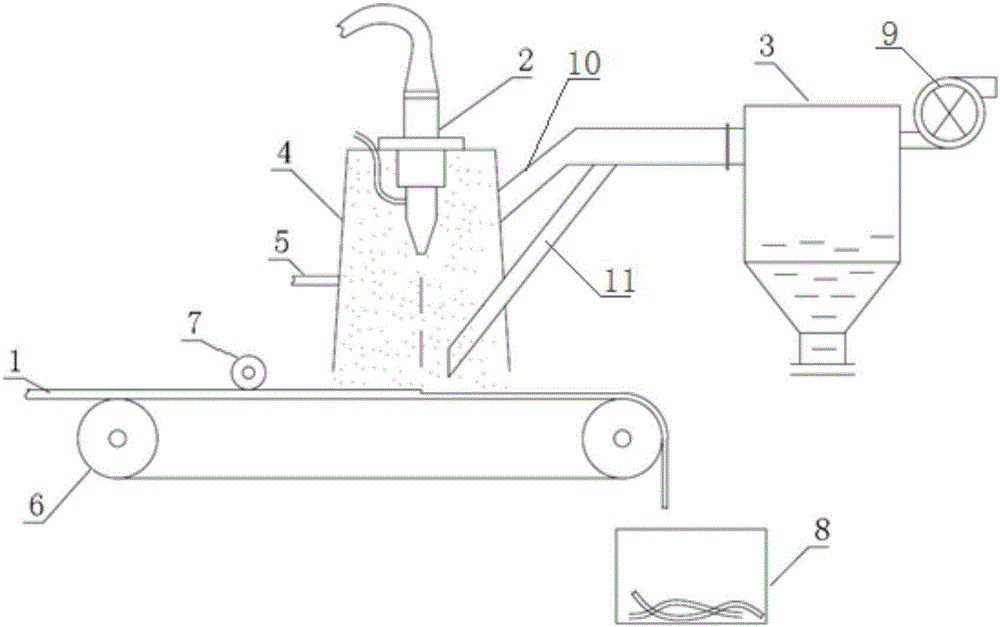

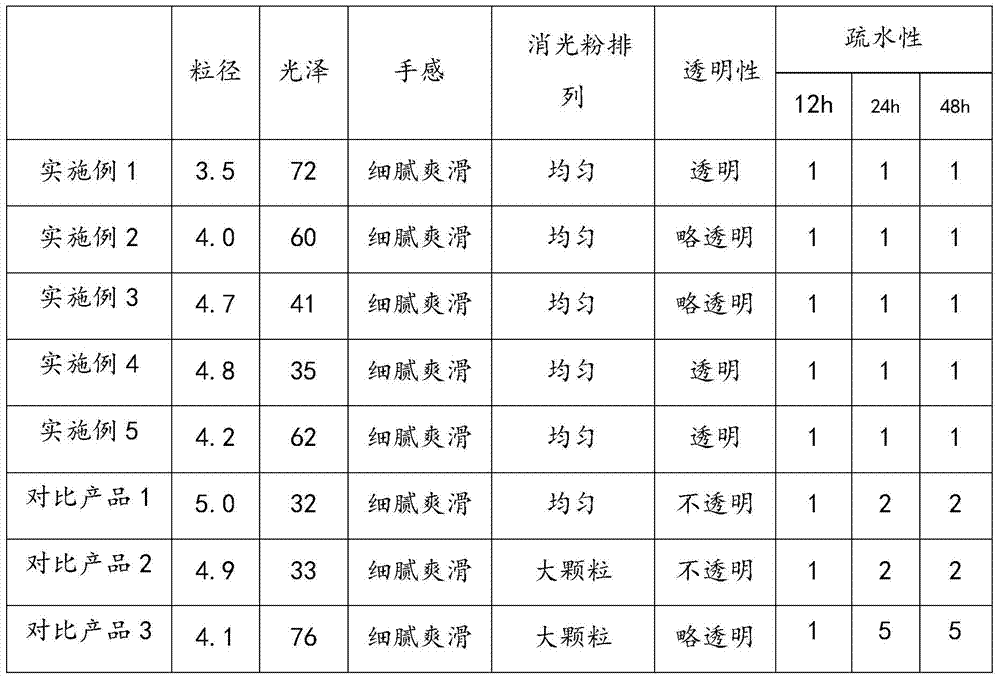

Preparation method of modified silicon dioxide obtained via super-hydrophobic modification

ActiveCN105400239AReduce post-processing stepsReduce energy consumptionCoatingsPigment treatment with macromolecular organic compoundsAcetic acidMixed states

The invention discloses a preparation method of modified silicon dioxide obtained via super-hydrophobic modification. The preparation method comprises following steps: 1) a raw material A (a silicon dioxide base material, dry powder) is delivered into a mixer, a mixed state is maintained, a raw material C (a super-hydrophobic modification accessory ingredient prepared via mixing of 1.5% acetic acid aqueous solution and isopropanol at a mass ratio of 1-3:4-10) is atomized, and is sprayed into the mixed uniformly, and stirring is kept; 2) a raw material B (a hydrophobic modification agent organic silane coupling agent) is atomized, and is sprayed into the mixer uniformly, and stirring is kept; 3) aging is carried out; and 4) ultrafine grinding is carried out so as to obtain a finished product. Fewer processing steps are needed; energy consumption is low; requirements of industrialized large-scale production can be satisfied; particle size distribution of the modified silicon dioxide obtained via super-hydrophobic modification is uniform; pore structures are stable; and hydrophobic performance is stable. The prepared super-hydrophobic silicon dioxide prepared via the preparation method is taken as a flatting agent, and can be used for providing paint with super hydrophobic performance; film forming coating particle arrangement is uniform; and luster is soft.

Owner:北京航天赛德科技发展有限公司

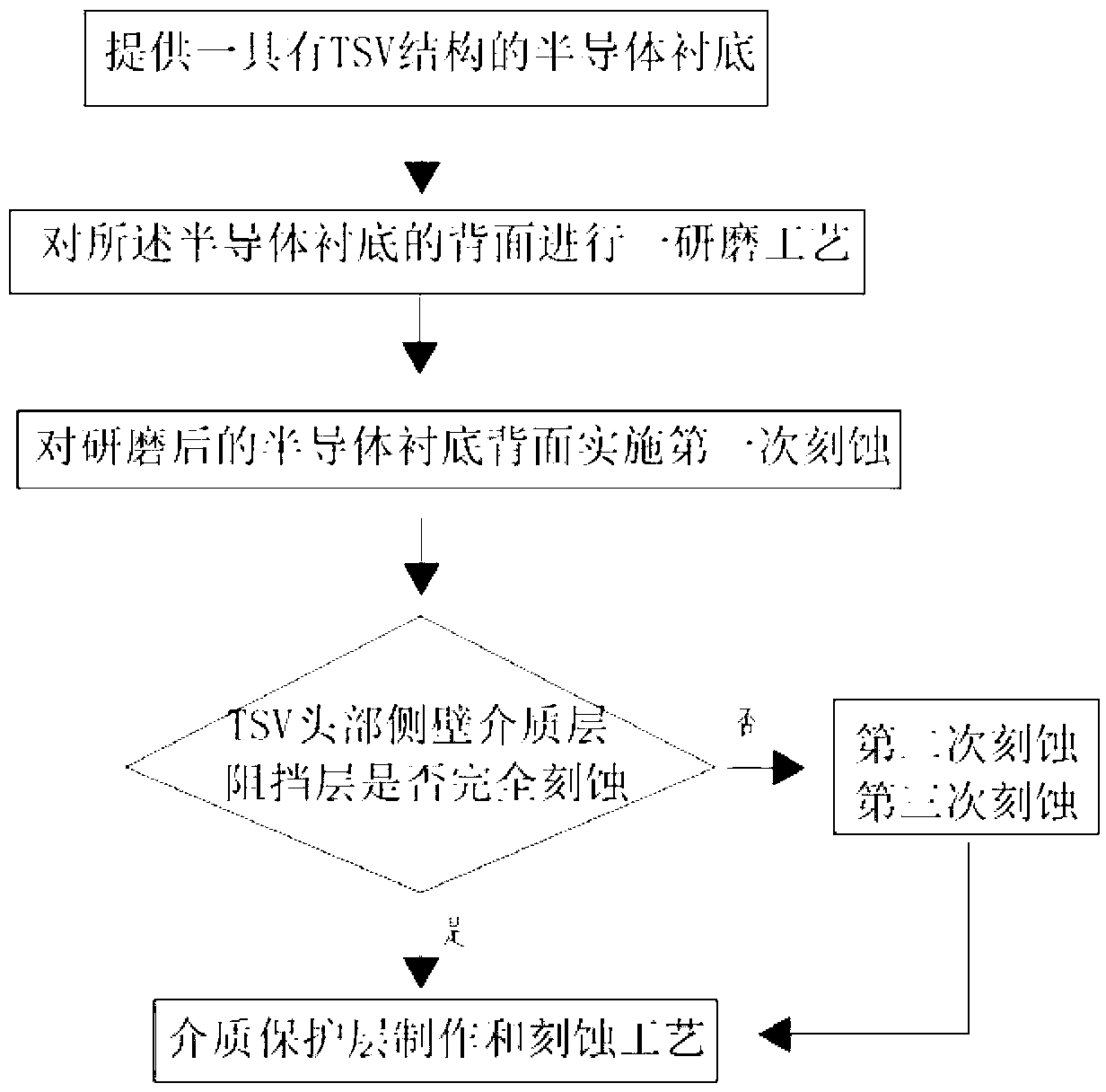

Through silicon via (TSV) back surface exposure process

ActiveCN103219281AAvoid damagePrevent oxidation and corrosionSemiconductor/solid-state device manufacturingHigh surfaceCopper

The invention discloses a through silicon via (TSV) back surface exposure process. By retaining a substrate above a TSV during the grinding of the back surface of the substrate, the damage to an exposed part of the TSV and the substrate caused by a physical thinning process is avoided, and the ground surface of the substrate with high total thickness variation (TTV) has high surface smoothness, so that the consistency in the subsequent etching process is high. The substrate is etched by an etching solution with high selection ratio of the substrate to a medium layer through a first wet method, the situation of etching of the medium layer and a barrier layer on the TSV for the first time decides whether or not the substrate is etched for the second time and the third time, the exposed part of the TSV has an enough height, and a conductive column of the exposed part is protected from being damaged by the etching solution. A photosensitive material serves as a medium protection layer, and a final TSV exposure structure is etched in an exposure and development manner, so that the corrosion and oxidization of conductive column copper in the conventional process are avoided, and the subsequent processing steps are simplified.

Owner:NAT CENT FOR ADVANCED PACKAGING

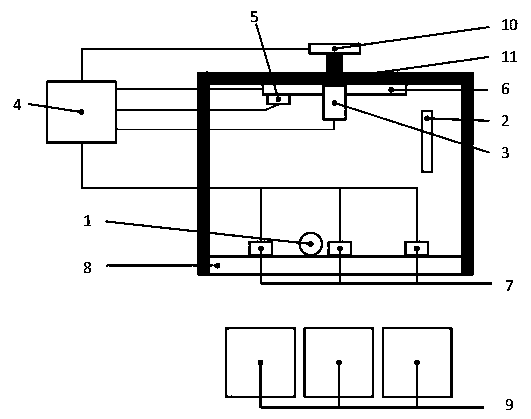

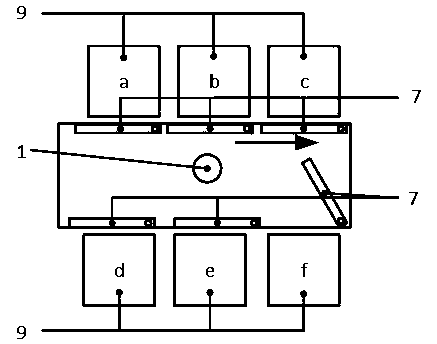

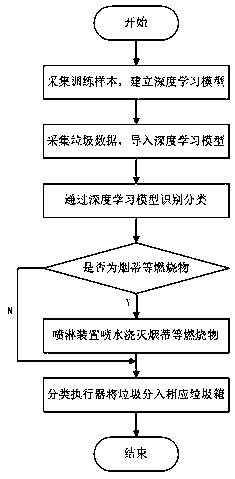

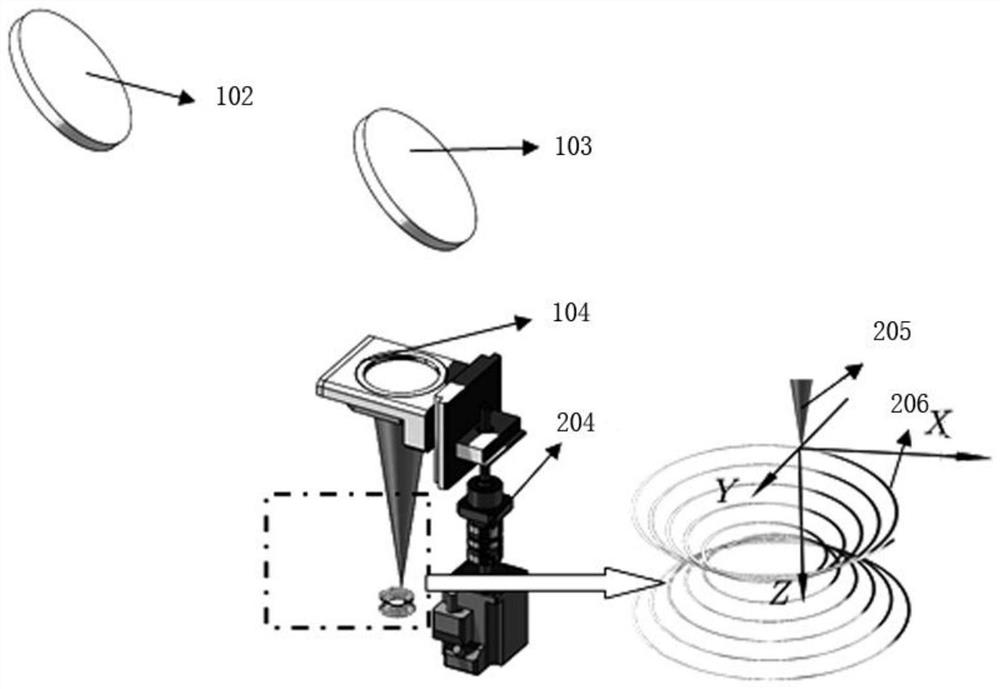

Automatic garbage classifying system and method

PendingCN109368079AReduce post-processing stepsAvoid enteringWaste collection and transferRefuse receptaclesLaser scanningEngineering

The invention discloses an automatic garbage classifying system and method and belongs to the technical field of garbage classification. The system comprises a rack, a garbage can, a trigger, a camera, a central processing unit, a sliding track, a classifying executor, a garbage receiving platform and a laser scanner, wherein the trigger, the camera, the central processing unit, the sliding track,the classifying executor and the garbage receiving platform are installed on the rack, and the laser scanner is installed on the sliding track. The laser scanner is connected with the sliding track in a sliding manner. The central processing unit is connected with the trigger, the camera, the classifying executor, the garbage receiving platform and the laser scanner and controls the trigger, thecamera, the classifying executor, the garbage receiving platform and the laser scanner to operate. According to the system and the method, the manner of combining an image and three-dimensional pointcloud is used for scanning garbage to obtain the colorful outline, and high-accuracy automatic classification is carried out. The garbage can be classified into multiple types according to the situation, and only the classifying executor and the garbage can need to be increased. The system can recognize substances with sparks and carry out spraying directly, and the situation that a fire source enters the garbage can is eradicated.

Owner:浙江梧斯源通信科技股份有限公司

Water-based coating for lost foam cast steel

InactiveCN101569919AAvoid crackingSolve the problem of surface microporosityFoundry mouldsFoundry coresWater basedSodium Bentonite

The invention belongs to the technical field of coating compositions for lost foam, is applicable to forming EPS foam pattern coatings of lost foam steel castings, and particularly discloses a water-based coating for lost foam cast steel. The water-based coating for the lost foam cast steel comprises the following components (calculated as the weight): 100 portions of quartz powder, 2 to 3 portions of lithium bentonite, 1 to 2 portions of white latex, 1 to 1.2 portions of sodium carboxymethyl cellulose, 2 to 3 portions of water soluble phenolic resin, 0.1 to 0.15 portion of aluminum powder, 0.08 portion of glass fiber, 0.02 to 0.03 portion of active agent, and 0.02 to 0.03 portion of defoaming agent. The coating ensures that the surface quality of castings is improved, meets the technical requirement of the castings, saves subsequent treatment procedures, improves production efficiency, improves the working environment of laborers, more importantly, eliminates the potential safety hazard during the subsequent use, and also improves the economic benefit of enterprises.

Owner:山东醴泉机械科技有限公司

Industrial method of culturing housefly larva

The industrial method of culturing housefly larva includes the following steps: 1. setting adsorptive matter to the container for culturing housefly larva; 2. injecting to the adsorptive matter the liquid culture medium comprising bran 5-10 wt%, whole milk powder 5-10 wt%, brown sugar 5-8 wt%, carrot juice 5- 15 wt% and water for the rest and with probiotics; 3. spreading housefly egg to the surface of adsorptive matter and incubating the egg into housefly larva; 4. cultivating for 4-10 days; and 5. separating housefly larva with screen. The said housefly larva culturing process has high bran utilizing rate and lowered cost, and is suitable for automation of housefly larva culturing.

Owner:GUANGDONG INST OF APPLIED BIOLOGICAL RESOURCES

Method for disassembling and recycling waste refrigerators

InactiveCN101658856AImprove product added valueIncrease added valueWaste processingSolid waste disposalRefrigerantRefrigerated temperature

The invention relates to a method for disassembling and recycling waste refrigerators. The method comprises the following steps: recycling refrigerant CFC-12 from compressors by a secondary refrigerant recovery device, then disassembling the waste refrigerators to realize integral recovery of side plates and back plates of the waste refrigerators and steel plate of refrigerator doors, treating rigid polyurethane foam respectively to reduce energy consumption of breaking and heating the rigid polyurethane foam to recover the CFC-11 so as to decrease discharge of the CFC-11 and further realize purposes of energy conservation and environmental protection.

Owner:刘景洋

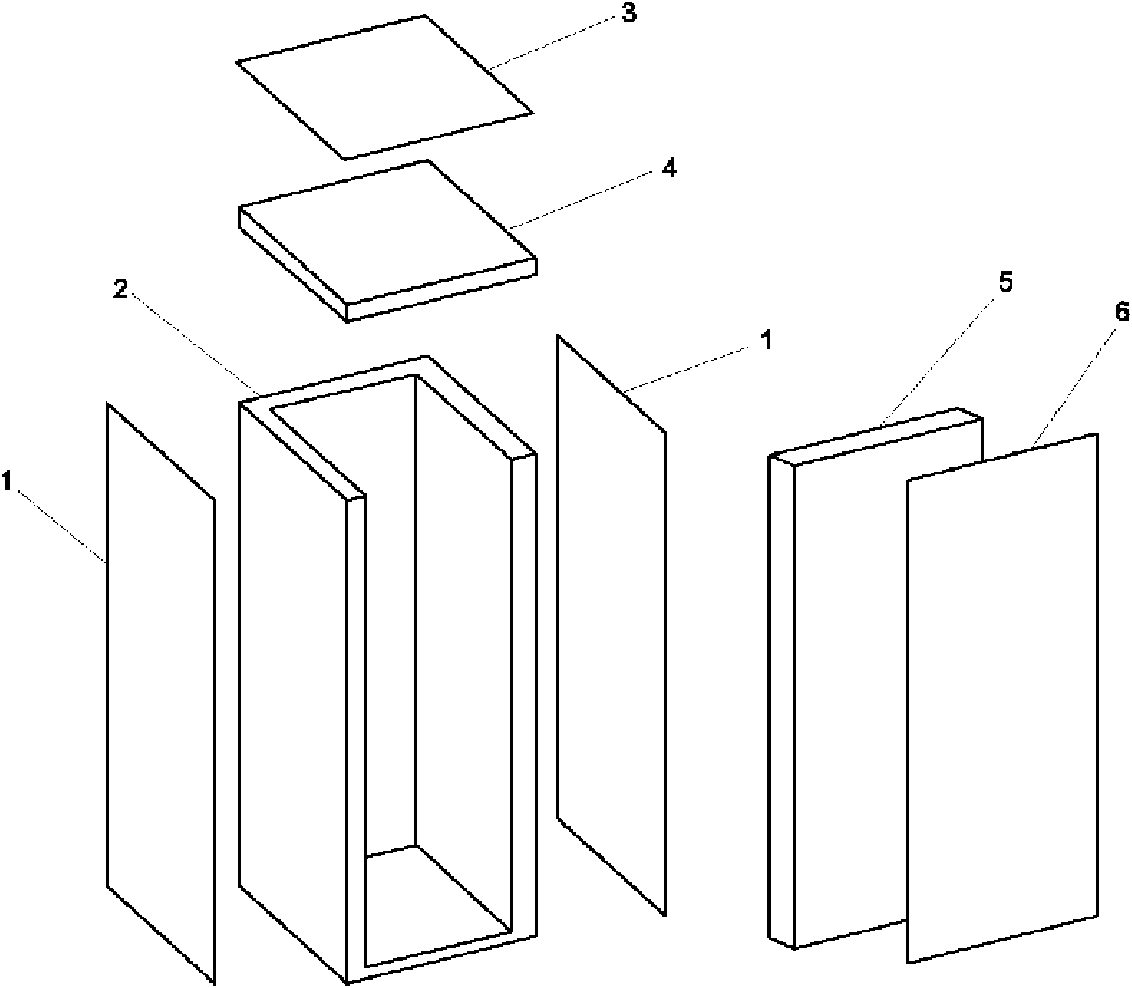

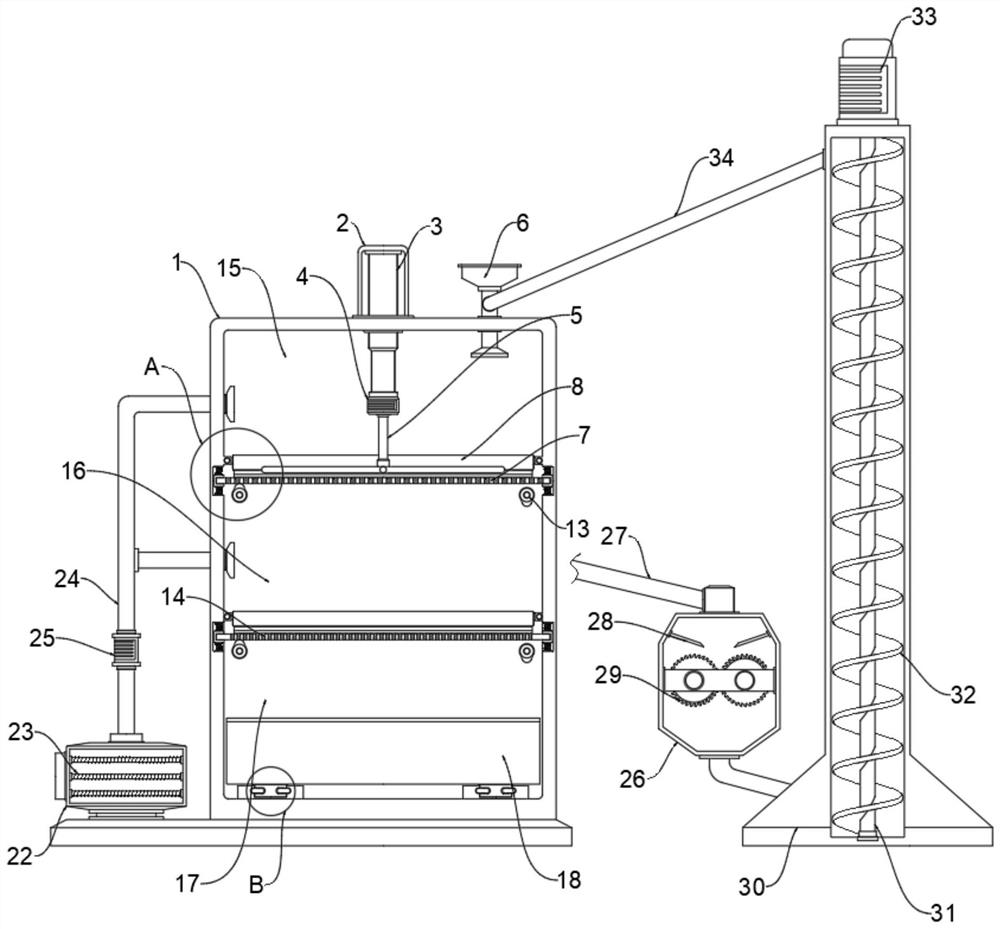

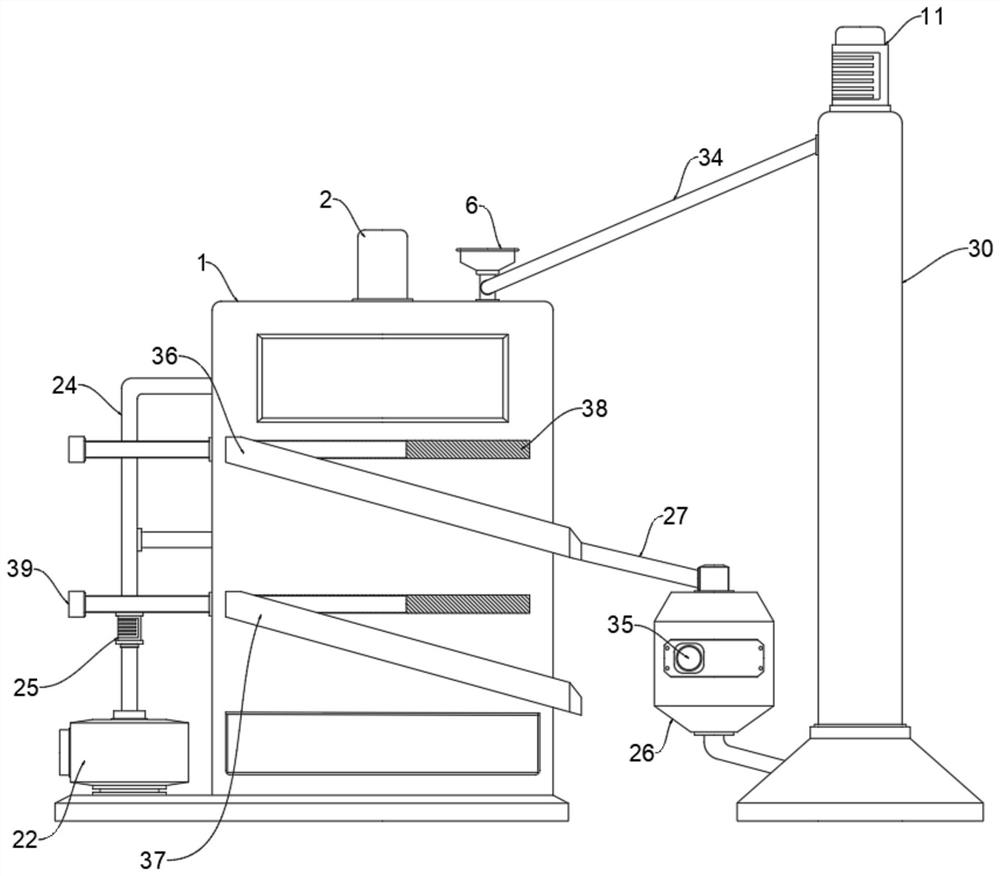

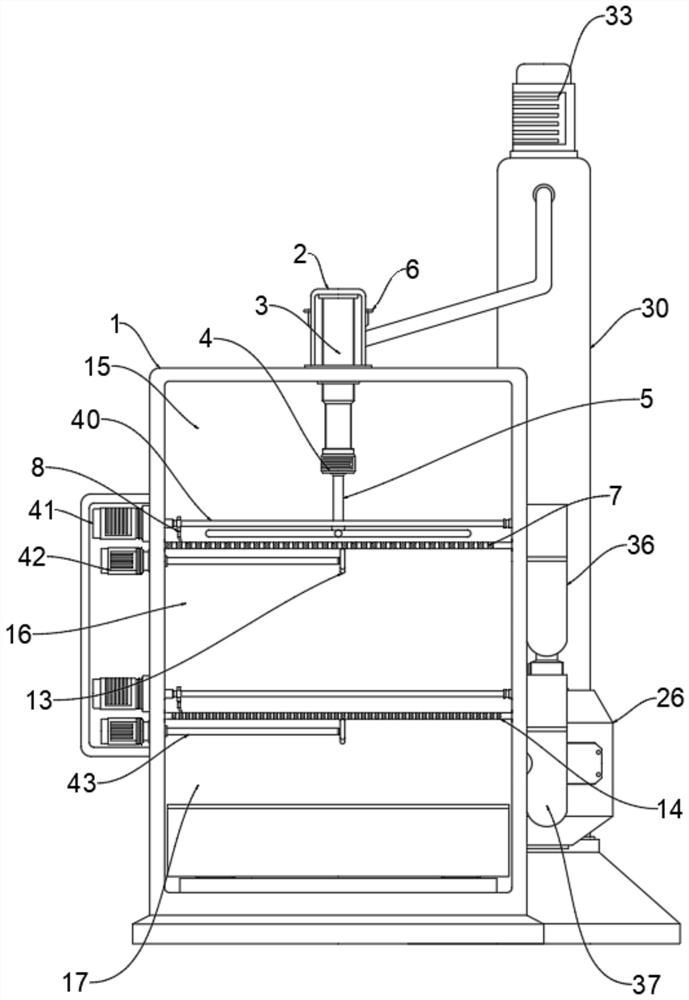

Particle screening device for pig feed production and working method thereof

PendingCN111774290AEasy to filterAvoid blockingSievingFeeding-stuffElectric machineryProcess engineering

The invention discloses a particle screening device for pig feed production and a working method thereof, and relates to the technical field of pig feed production. The purpose is to solve the existing problem of how to improve overall sieving efficiency on the premise of ensuring the screening effect of pig feed. A feeding pipe is fixedly arranged on one side of the upper end of a sieving device,a dispersing rod is installed on an output shaft of a first motor, the inner part of the sieving device is composed of a first sieving cavity, a second sieving cavity and a second sieving cavity, sliding blocks are arranged at the back ends above a first sieve plate and a second sieve plate, a first discharging groove is fixedly arranged at the front end of the first sieve plate, a second discharging groove is fixedly arranged at the front end of the second sieve plate, a crushing device is installed on one side of the front end of the sieving device, a feeding device is installed on one sideof the crushing device, a heating device is installed on the other side of the sieving device, and the improvement of the overall sieving efficiency is achieved on the premise of ensuring the screening effect of the pig feed.

Owner:红安正邦养殖有限公司

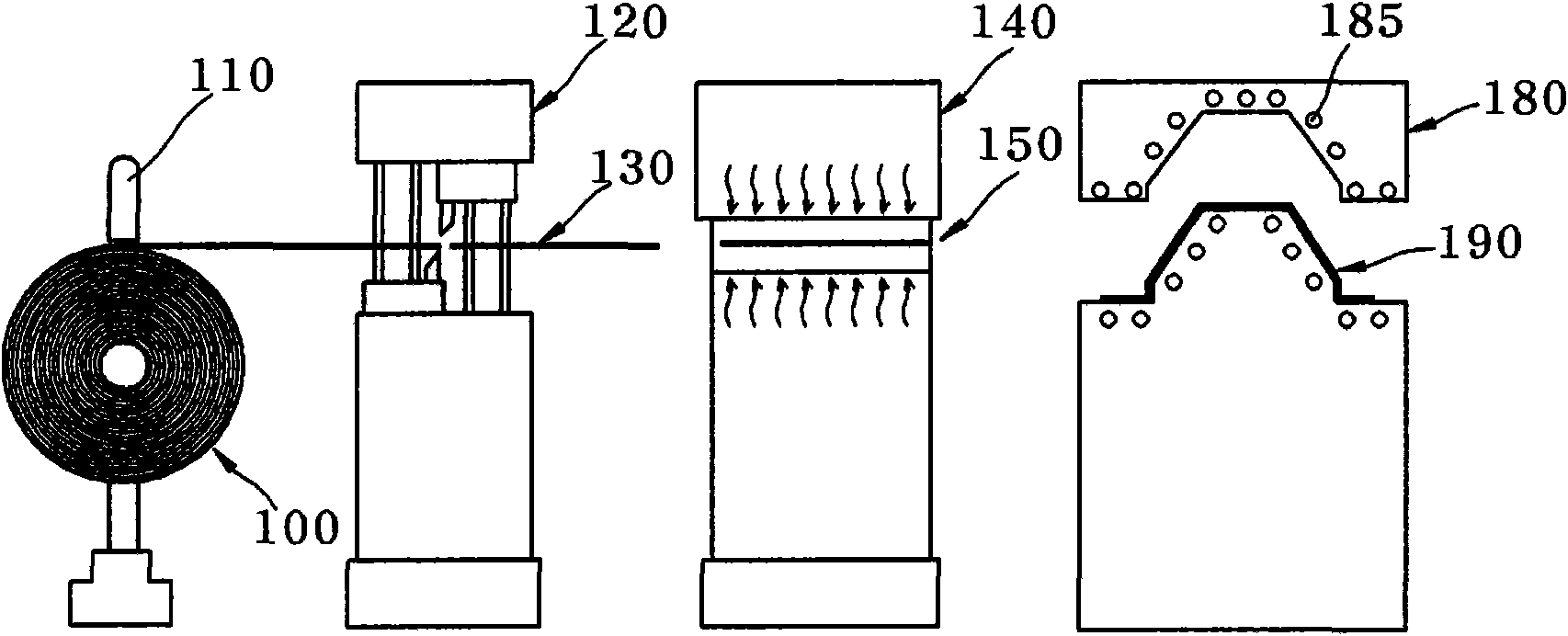

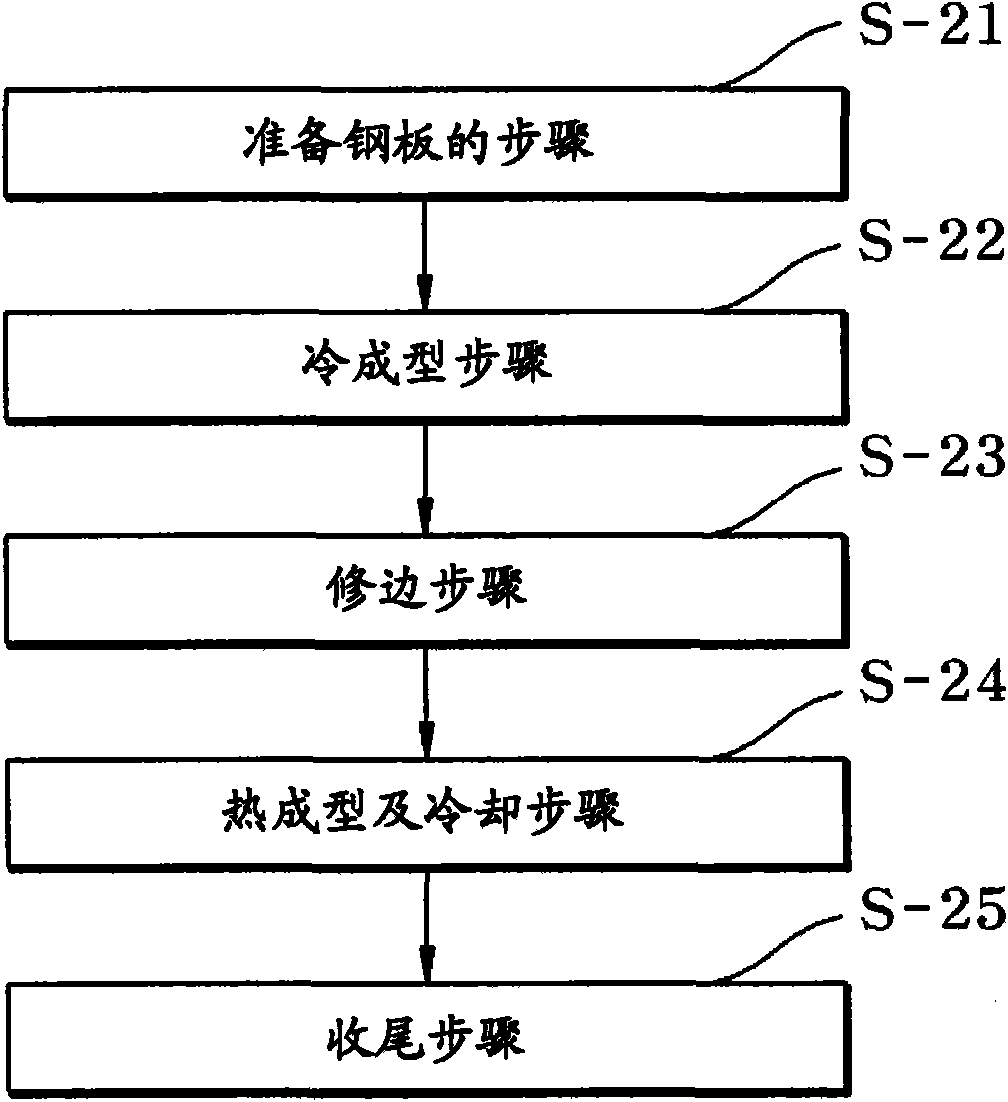

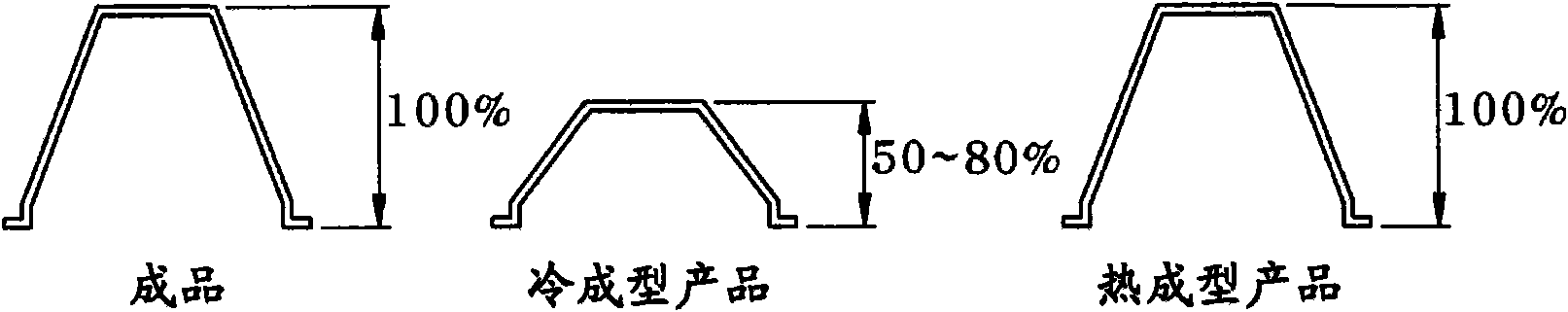

Method for manufacturing super strong steel body

ActiveCN101896293ASolve the errorReduce post-processing stepsLaser beam welding apparatusQuenching devicesSheet steelCold formed

The present invention relates to a method for manufacturing a super strong steel body, more specifically, to the method for manufacturing a super strong steel body suitable for the processing of products with complicated shapes and deep casting depths. The present invention comprises: a sheet preparation step for blanking a steel sheet with curing ability in a certain shape and cutting the steel sheet; a cold forming step for cold pressing the steel sheet and forming the steel sheet with 50-80% the thickness of the height of the end product; a trimming step for precisely cutting the cold formed product along the outline of the finished goods; and a hot forming and cooling step for simultaneously hot press forming the trimmed goods with 20-50% the thickness of the height of the end product and cooling the trimmed goods from the heated state after heating the trimmed goods over 700 DEG C for austenitization.

Owner:HYUNDAE STEEL CO LTD

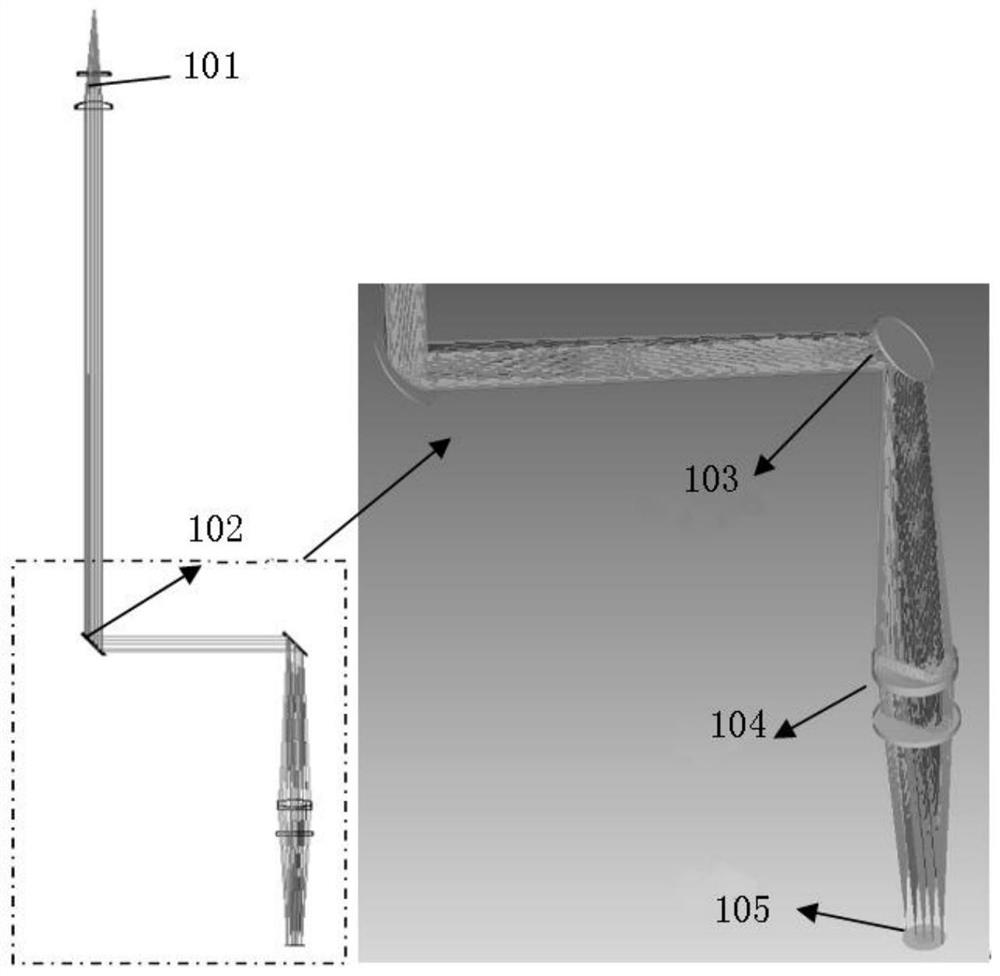

Method for manufacturing optical fiber unsensitive to hydrogen

ActiveCN1631825AFacilitated DiffusionEasy to handleGlass making apparatusGlass productionFiberHydrogen

The invention relates to a method for making optical fiber, concretely for a fiber without sensitivity to hydrogen, its characteristic is: blow into mixed air containing deuterium to process with optical fiber and optical fiber stick in the technical course of drawing the optical fiber and optical fiber stick, blowing into mixed air containing deuterium, there fore help deuterium diffusion by using the high temperature in the furnace and of optical fiber, which makes deuterium atom react with diadvantage and increase the processing effect of deuterium; it blows the mixed air directly into the jacket pipe of optical fiber stick through pipe, so that deuterium can penetrate into the core layer of optical fiber to react more completely, increasing the processing effect of deuterium compared with the present technology, the production efficiency, suitable for large-scale production.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

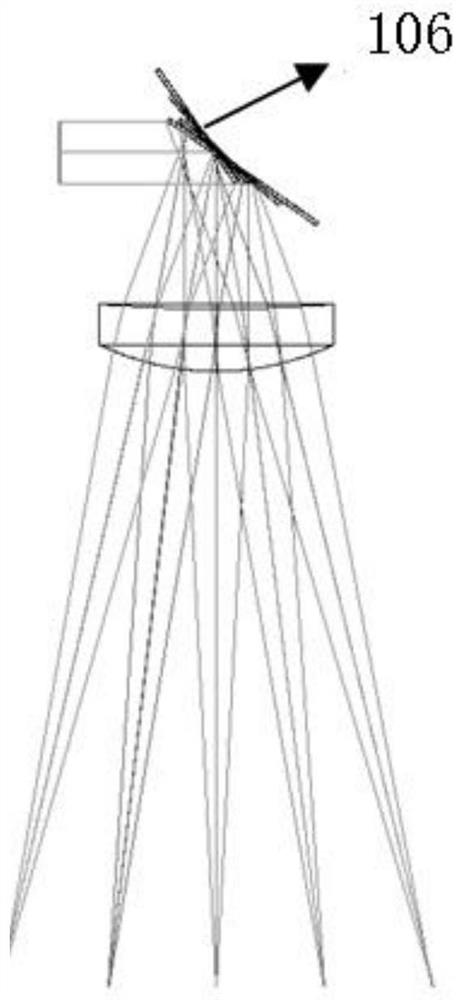

Thick material cutting method for dynamically controlling three-dimensional track of laser spot and system of method

ActiveCN113182672AImprove processing qualityAvoid dross problemsLaser beam welding apparatusLaser processingLight spot

The invention discloses a thick material cutting method for dynamically controlling a three-dimensional track of a laser spot and a system of the method, and belongs to the field of laser processing. The system comprises a laser device for emitting lasers. A collimating lens is used for collimating and distributing laser beams, a reflector is used for changing the light path of the collimated laser beams, a focusing lens assembly is used for focusing the collimated laser beams, the focused lasers are emitted to a to-be-cut thick material, a focus light spot of the lasers is controlled to fall into the to-be-cut thick material, the focus light spot of laser cutting is moved along a preset cutting track, and cutting of the thick material is completed; in the cutting process, the focus light spot is controlled to conduct high-frequency vibration on the cutting track, and the high frequency ranges from 1.5 kHz to 4 kHz; and through dynamic control over the three-dimensional track of the laser spot, high-frequency movement of the spot focus in all directions of the optical axis is achieved, and therefore energy distribution of a section heat affected zone of a thick material workpiece is adjusted, the phenomena of slag adhering, thick stripes and the like generated by laser cutting of the section are avoided, and the section processing quality is improved.

Owner:FOSHAN HONGSHI LASER TECH CO LTD

Urban domestic sewage treatment technique

InactiveCN108751598AImprove processing qualityReduce pollutionTreatment using aerobic processesWater/sewage treatment by irradiationTherapeutic effectTreated water

The invention discloses an urban domestic sewage treatment technique. Two groups of grilles having different pore diameters are used to filter sewage first; precipitating and anaerobic reaction are carried out to release phosphorus for ammoniating, so that it is convenient for a reaction tank to remove nitrogen and phosphorus of the sewage; a Carrousel oxidation ditch reaction tank removes nitrogen and phosphorus of the sewage, and the sewage is disinfected by ultraviolet lamps before discharging; waste gas generated by the Carrousel oxidation ditch reaction tank is subjected to air purification so that air pollution can be decreased; an MBR (membrane bioreactor) disinfects the treated water in two different groups of manners after nitrogen and phosphorus removal, and the treated water canbe used as tap water or be directly used; sewage treatment effect and quality are improved. In addition, sludge from sewage treatment is applied to agriculture after metal extraction and dewatering.The urban domestic sewage treatment technique has the advantages that resource waste can be decreased, secondary pollution can be avoided, energy is saved, environment is protected, the technical pathis short, the cost is low, and the technique is convenient to perform, has multiple functions, is widely applicable and good in safety and stability, and is easy to popularize.

Owner:即墨市污水处理有限公司

Method for controlling content of silicon tetrachloride in fused salt chlorination process of high titanium slag

ActiveCN102040243AReduce post-processing stepsReduce consumptionTitanium halidesGraphite electrodeMolten salt

The invention provides a method for controlling content of silicon tetrachloride in fused salt chlorination process of high titanium slag, comprising the following steps of: introducing a graphite electrode into a fused salt chlorination furnace, connecting the graphite electrode with an electric furnace transformer, filling multi-component fused salt in the fused salt chlorination furnace, then adding high titanium slag, petroleum coke and chlorine, controlling the secondary voltage of the electric furnace transformer to be 20-50v and the output current to be 500-3500A, measuring the fused salt current for every 1-2h, obtaining the relation among the operating time of the fused salt chlorination furnace, and the fused salt current and the mass content of the high titanium slag in the fused salt; sampling the fused salt in the furnace during the production process, analyzing data and obtaining the mass content of SigmaTi and C, and controlling the mass content of SigmaTi at 1-3% and the mass content of the C at 2-7% by regulating the addition quantity of the high titanium slag and the petroleum coke and observing the current change of the fused salt. The method can ensure the stability of silicon tetrachloride content in titanium tetrachloride products during fused salt chlorination production, ensure that the silicon tetrachloride content in the titanium tetrachloride is below 0.18%, and also ensure the long-term and stable production of the fused salt chlorination furnace.

Owner:中信钛业股份有限公司

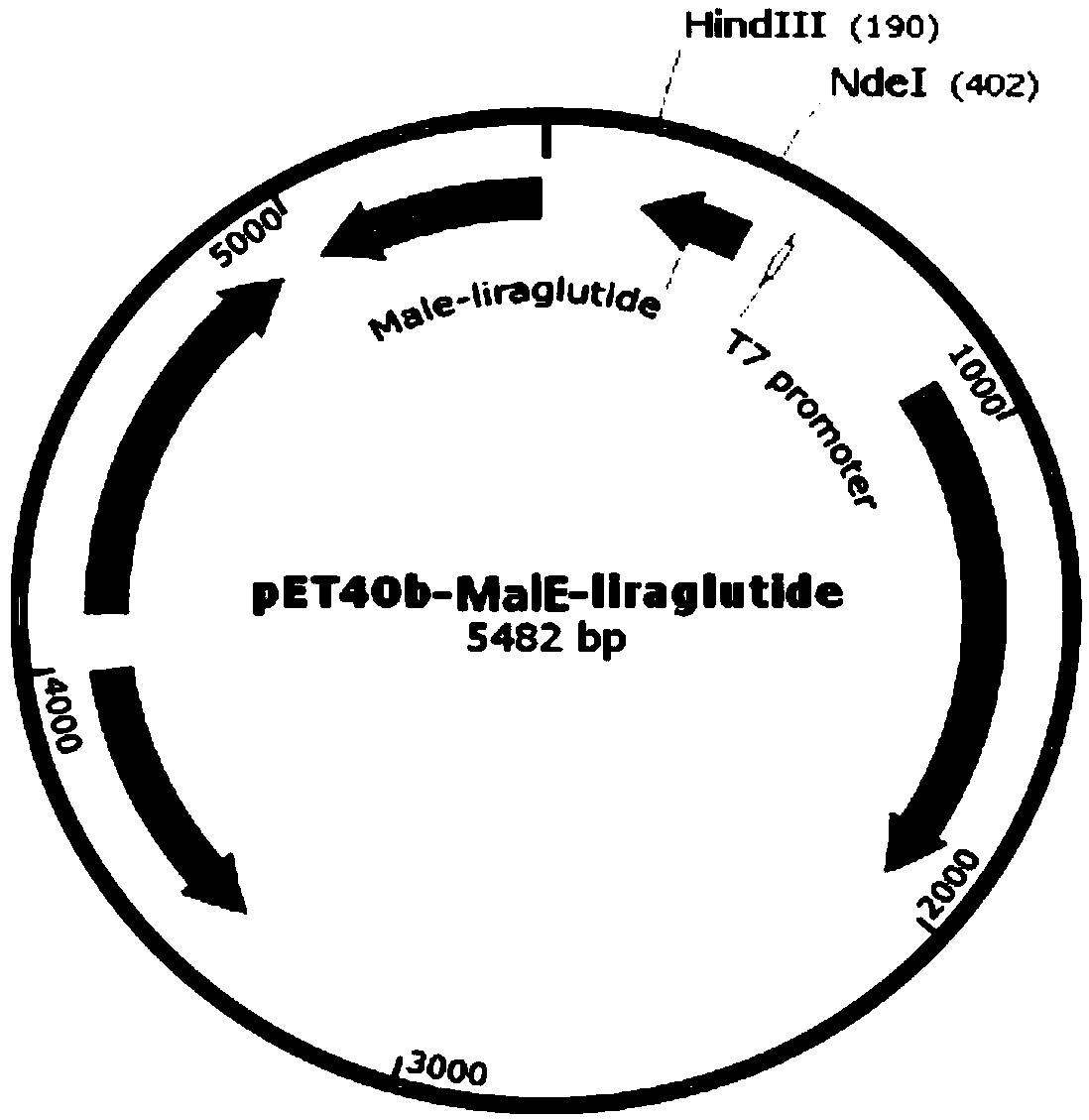

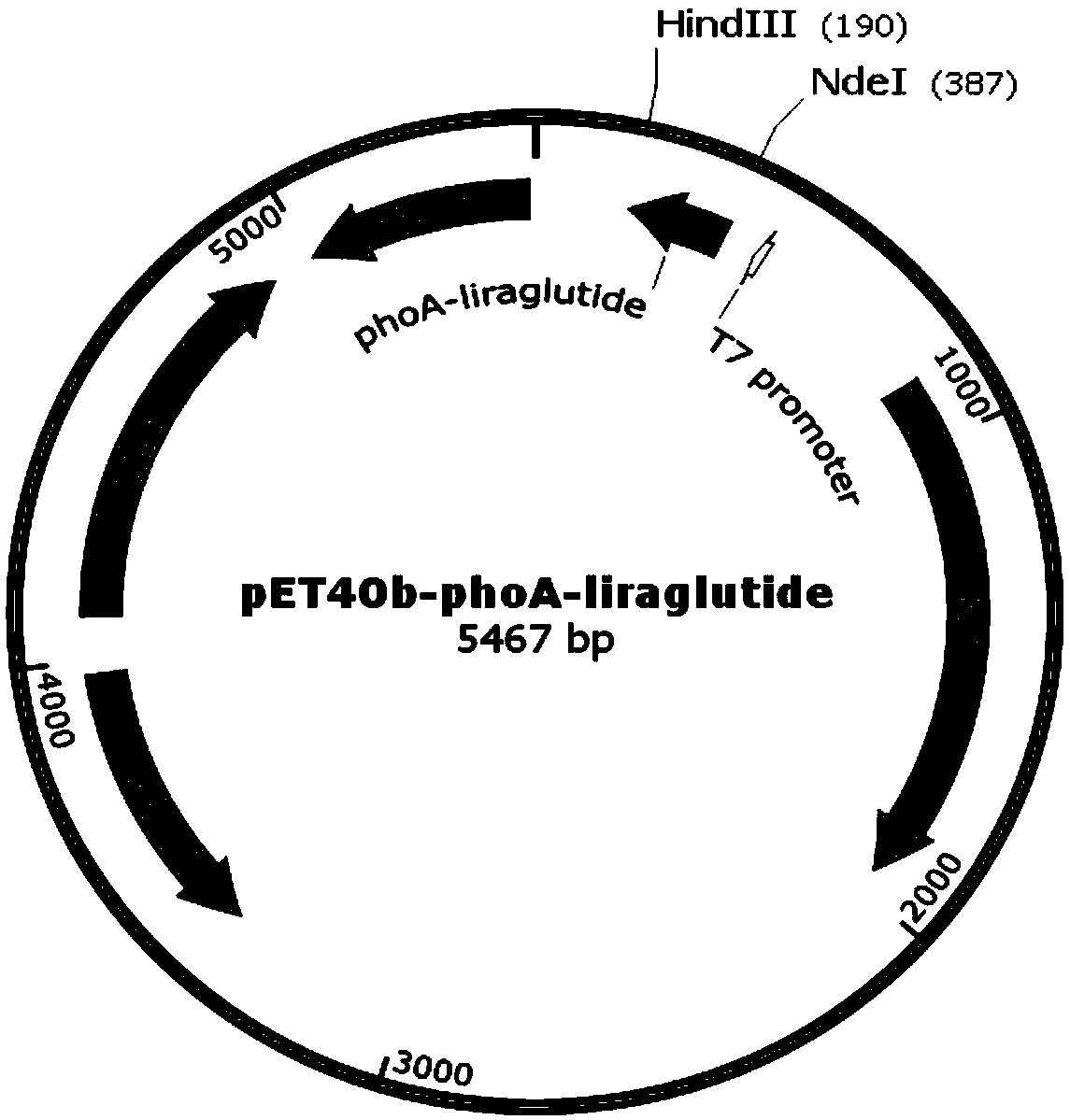

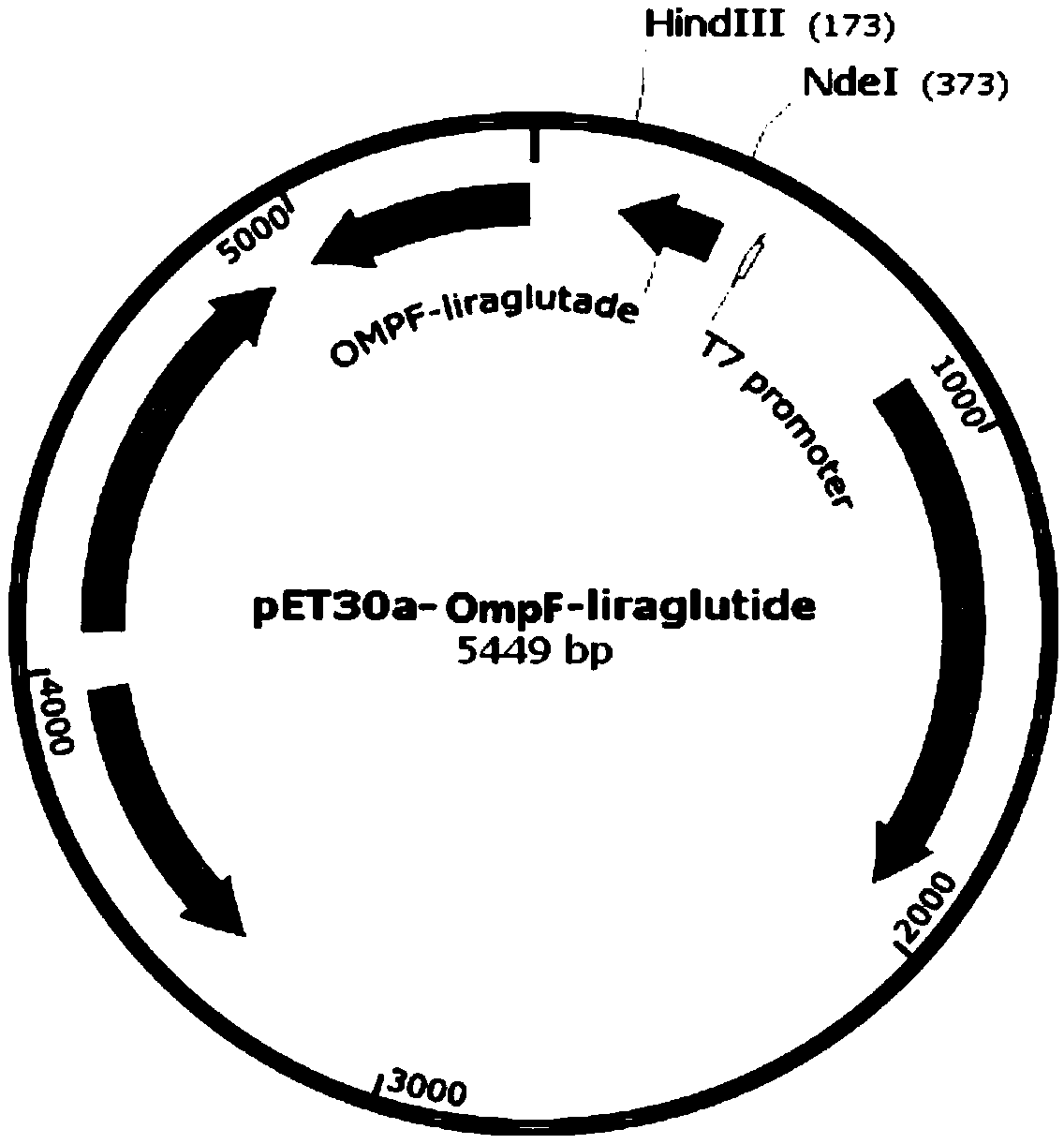

Recombinant engineering bacterium capable of efficiently expressing liraglutide precursor and application of recombinant engineering bacterium

ActiveCN110724187AHigh purityImprove stabilityBacteriaMicroorganism based processesDiabetes TherapyFusion Protein Expression

The invention provides a recombinant engineering bacterium for efficiently expressing a liraglutide precursor and an application of the recombinant engineering bacterium. According to the invention, asignal peptide and an enterokinase restriction enzyme cutting site are designed at the N end of a liraglutide precursor molecule Arg34G LP-1 (7-37), the C end is connected with termination codon, a target gene is formed, then, the target gene is inserted between two restriction enzyme cutting sites of an expression vector; the recombinant engineering bacterium for expressing the liraglutide precursor is constructed, the engineering bacterium is subjected to high-density fermentation culture and is expressed in the form of an inclusion body of a fusion protein, the expression quantity of the recombinant fusion protein is high, the recombinant fusion protein accounts for about 25%-35% of the total protein of the bacterium, and the expression quantity of the inclusion body of a target protein reaches 15-20g / L. The inclusion body is low in impurity protein content, beneficial to separation and purification, and high in purification efficiency and good in stability, the production cost isgreatly reduced, the production efficiency is improved, and the inclusion body has the good application prospect in the field of diabetes treatment medicine preparation.

Owner:GAN&LEE PHARMA

High-precision digital template guide belt type direct embossing machine

InactiveCN104354462AHigh coloring rateReduce the chance of contaminating the printed surfaceRotary pressesPrinting press partsEngineeringSlurry

The invention relates to a high-precision digital template guide belt type direct embossing machine, and belongs to the technical field of an embossing machine. The high-precision digital template guide belt type direct embossing machine comprises an embossing guide belt and a plurality of high-precision digital template pattern rollers, wherein the high-precision digital template pattern rollers are in mutually parallel arrangement and are arranged on the same plane A, an include angle B between the embossing support surface of the embossing guide belt and the horizontal plane is adjustable between 0 degrees and 90 degrees, the plane A is parallel to the embossing support surface, meanwhile, when the included angle B is smaller than 90 degrees, the plane A is positioned under the embossing support surface, a slurry groove is respectively formed right under each high-precision digital template pattern roller in a matched way, each high-precision digital template pattern roller is respectively matched with a scraper, and each group of high-precision digital template pattern rollers, slurry grooves and scrapers can move and can be positioned between the original position and the embossing position through being driven by a driving mechanism. The high-precision digital template guide belt type direct embossing machine has the advantages that the slurry feeding quantity is low, the embossing defective rate is low, and the coloring rate is high.

Owner:SHAOXING YANGTING TEXTILE PROD

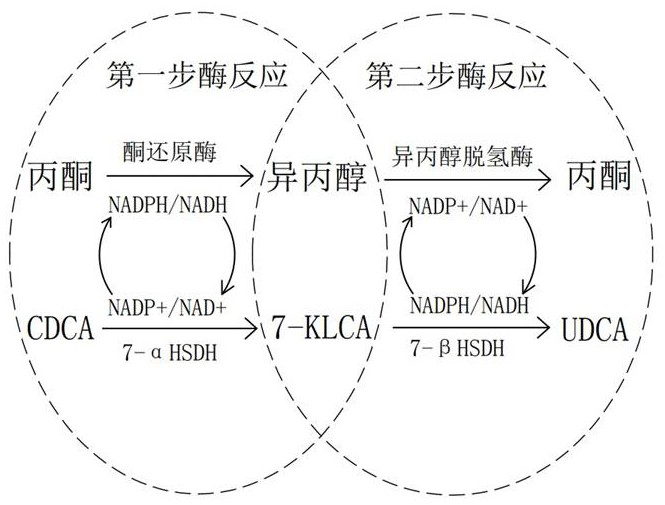

Method for preparing ursodeoxycholic acid through cyclic enzyme catalysis

PendingCN112280818AEasy distillation recoverySimple processFermentationCholic acidChenodeoxycholic acid

The invention discloses an application of acetone / isopropanol circulation in preparation of ursodeoxycholic acid (UDCA) by an enzyme method, and provides an environment-friendly, economic and efficient new idea for preparation of UDCA by a two-step enzyme method. The method comprises the following steps of 1, reducing acetone into isopropanol by using ketoreductase, and converting NADPH / NADH intoNADP+ / NAD+ to provide NADP+ / NAD+ for catalyzing chenodeoxycholic acid (CDCA) to generate 7KLCA by using 7alpha steroid dehydrogenase (7alpha HSDH); in the second step, isopropanol being oxidized intoacetone through isopropanol dehydrogenase, NADP+ / NAD+ being converted into NADPH / NADH, and NADPH / NADH being provided for catalyzing 7KLCA to generate UDCA through 7beta steroid dehydrogenase (7beta HSDH). According to the two-step enzyme method, immobilized enzyme is utilized, the process is simple, second-step reaction can be carried out through simple treatment after first-step reaction is finished, and intermediate purification is not needed; the addition amount of NADP+ / NAD+ in the reaction is small, and acetone and isopropanol can be recycled, so production cost and the environmental protection pressure are greatly reduced.

Owner:UNIV OF JINAN

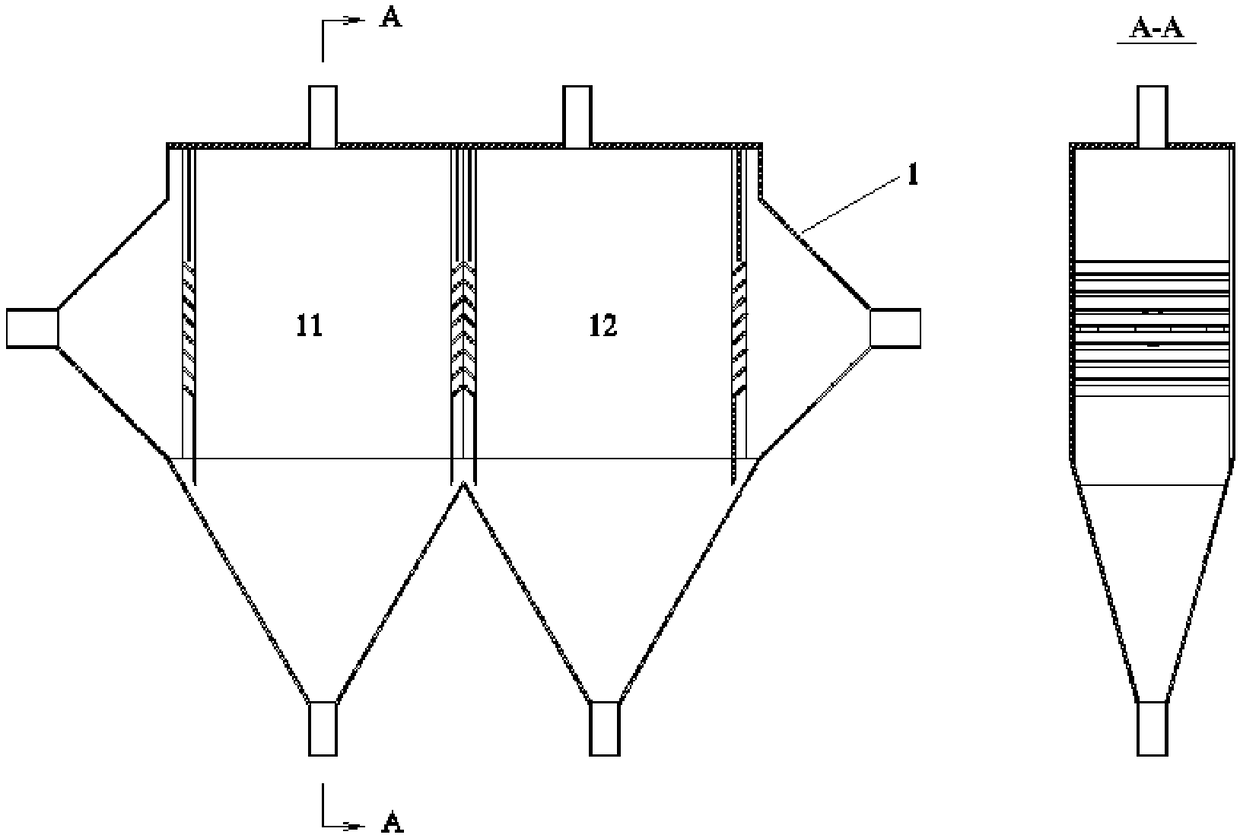

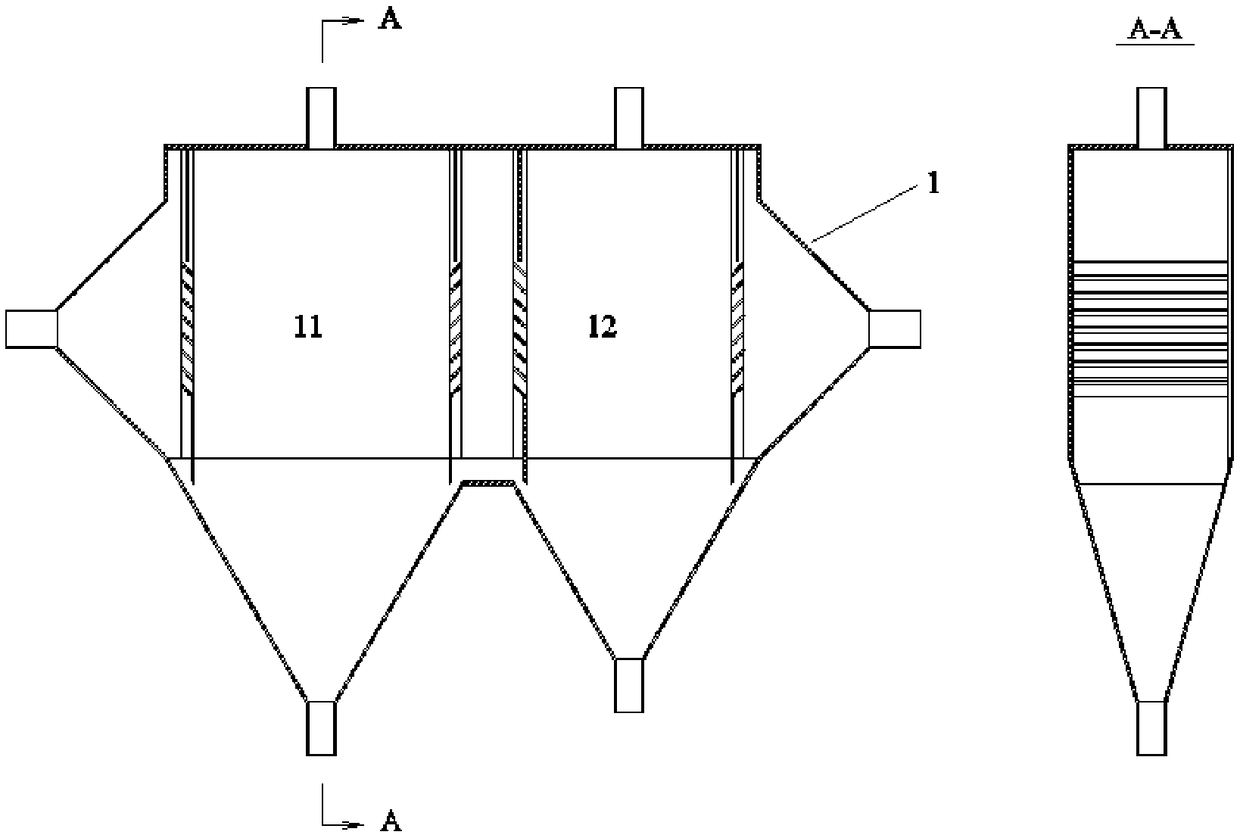

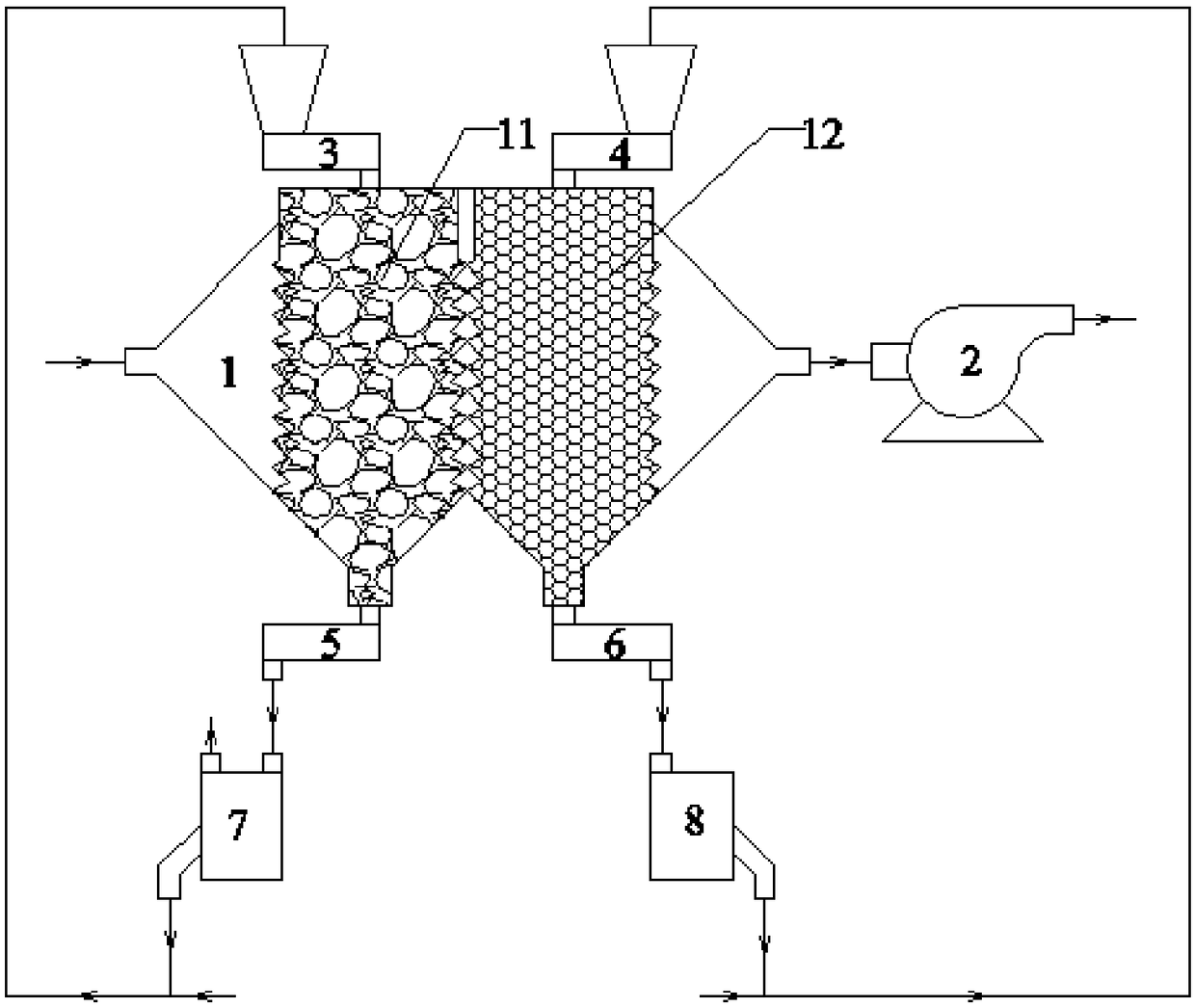

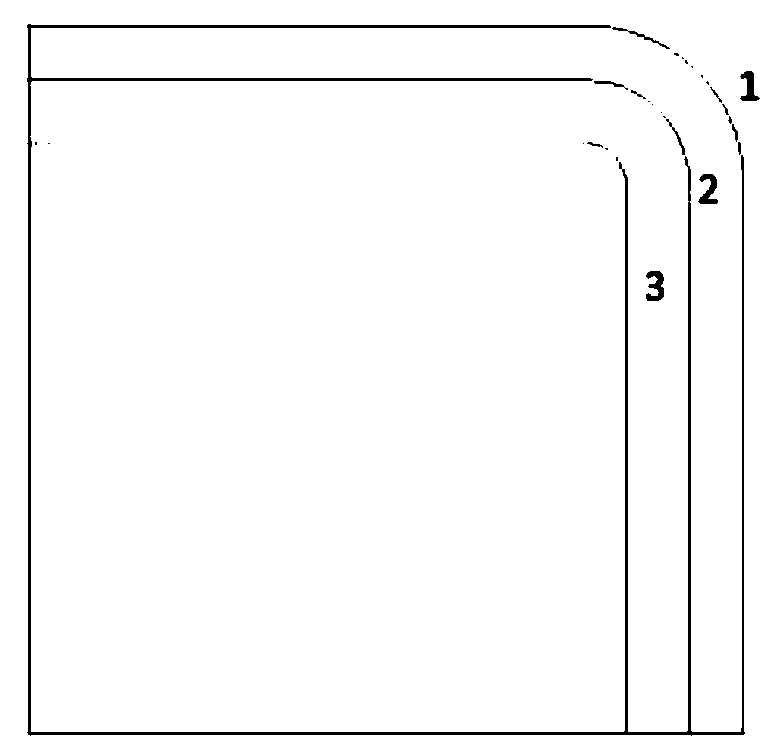

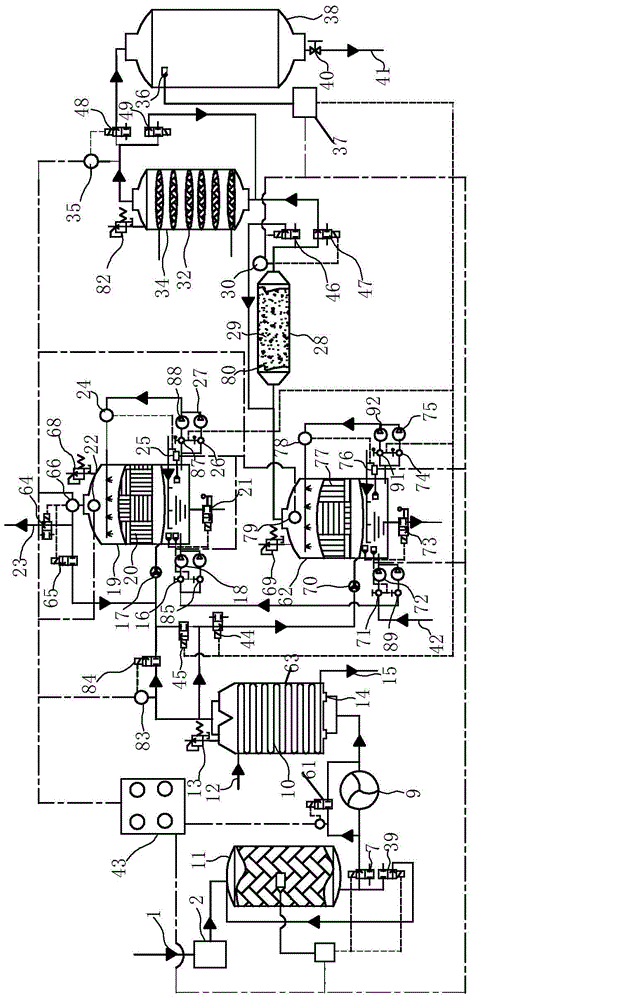

Double-moving-bed reactor, application thereof to flue gas dedusting and denitrating integration device and treatment method

ActiveCN108079785ALow costReduce post-processing stepsGas treatmentDispersed particle filtrationProcess engineeringFlue gas

The invention provides a double-moving-bed reactor, an application thereof to flue gas dedusting and denitrating integration device and a treatment method. The double-moving-bed reactor comprises a gas inlet cavity, a filter material bed, a catalyst bed and a gas outlet cavity which are adjacent in sequence, and the gas inlet cavity, the filter material bed, the catalyst bed and the gas outlet cavity are separated through a first partition board, a second partition board and a third partition board respectively. According to the device, integrated dedusting and denitrating can be realized, flue gas firstly enters the filter material bed for dedusting, most ultrafine dust in the flue gas is removed, influence of the dust on a catalyst is eliminated, then the flue gas enters the catalyst bedfor removing nitrogen oxides, the two processes are integratedly performed in one reactor, the dedusting and denitrating effects are good, dust removal rate almost reaches 100%, and content of the nitrogen oxides also meets the first level discharge standard. Meanwhile, by means of recycling of a filter material and the catalyst, continuous and stable operation of the dedusting and denitrating process is realized.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Surface quality improving method for DLP photocureable additive manufacturing

InactiveCN109719954ACuring width is smallImprove surface qualityAdditive manufacturing apparatusManufacturing data aquisition/processingGalvanometerLight beam

The invention belongs to the technical field of additive manufacturing, and particularly relates to a surface quality improving method for DLP photocureable additive manufacturing. The surface qualityimproving method is characterized by comprising the following steps: performing slicing treatment on a three-dimensional digital model, thereby obtaining an inner area and an edge outline of the three-dimensional digital model; separately performing data processing on the inner area and the edge outline of the three-dimensional digital model to obtain a light beam curing scanning path and a DLP curing inner boundary; and performing DLP curing on the inner part of the DLP curing inner boundary to obtain a cured area, utilizing a scanning galvanometer to control a light beam to scan along the light beam curing scanning path, thereby obtaining an outer outline area of the three-dimensional digital model, wherein part of the area in the outer outline area is superposed with the DLP curing boundary, and the curing area is connected to the outer outline area. The surface quality improving method is scientific and reasonable in principle, is simple in curing process, can effectively improvesurface quality of current DLP light source photocureable additive manufacturing, and reduces follow-up processing processes.

Owner:UNIV OF SCI & TECH BEIJING

System for peeling non-peeled walnuts

The invention discloses a system for peeling non-peeled walnuts. The system comprises a peeling system, a cleaning system, a drying system and a picking system. According to the system for peeling thenon-peeled walnuts disclosed by the invention, through the arrangement of the peeling system, the cleaning system, the drying system and the picking system, the non-peeled walnuts are processed, so that the efficiency is specially high; the outer surfaces of the processed walnuts are clean without dirty matters; and meanwhile, the walnuts are picked, so that post-processing steps of the walnuts are reduced.

Owner:山东仲雅信息技术有限公司

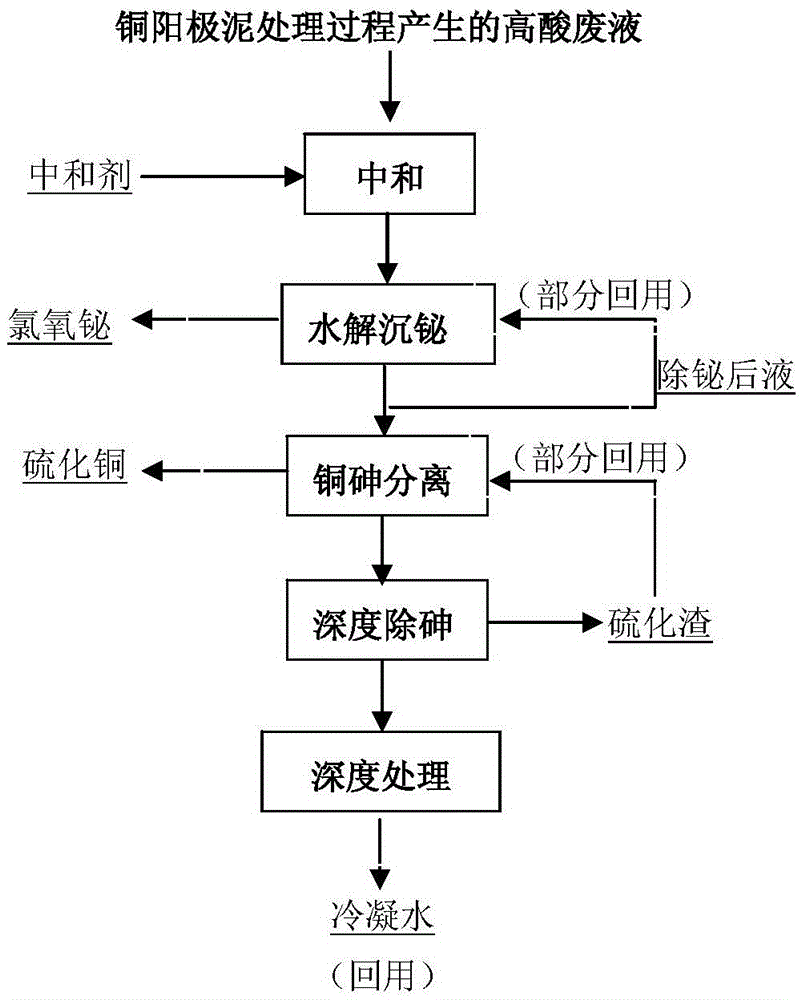

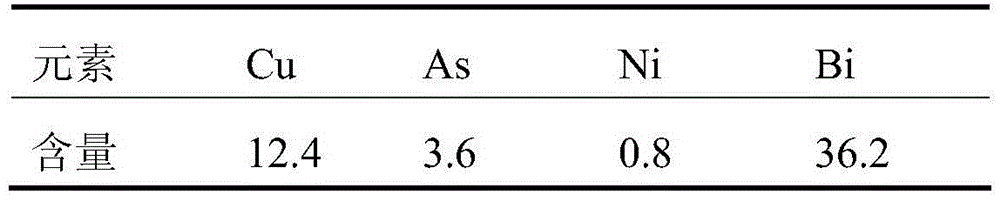

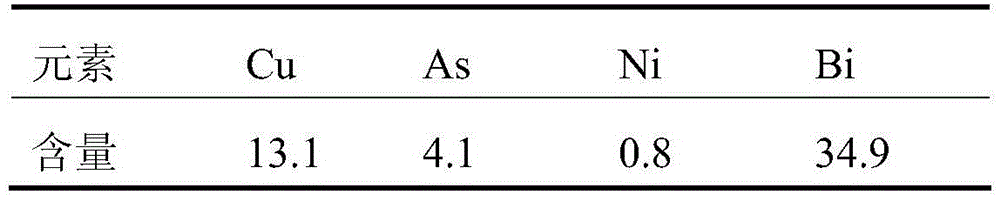

Method for separating copper, bismuth and arsenic in high-acid waste liquor generated by copper anode slime treatment

The invention discloses a method for separating copper, bismuth and arsenic in high-acid waste liquor generated by copper anode slime treatment. The method mainly includes the following steps of (1) recycling bismuth chloro oxide through neutralizing hydrolysis, (2) carrying out copper-arsenic separation after sulfide slag flows back so as to recycle copper, (3) carrying out efficient sulfuration to deeply remove the arsenic and obtain arsenic slag, and (4) carrying out deep treatment. By means of the method, efficient separation and deep recycling of the copper, the bismuth and the arsenic in the high-acid waste liquor are achieved, resource recovery of valuable elements and removal of the harmful element arsenic are achieved, operation cost is reduced, and environmental risks are lowered.

Owner:CHANGSHA SCI ENVIRONMENTAL TECH +1

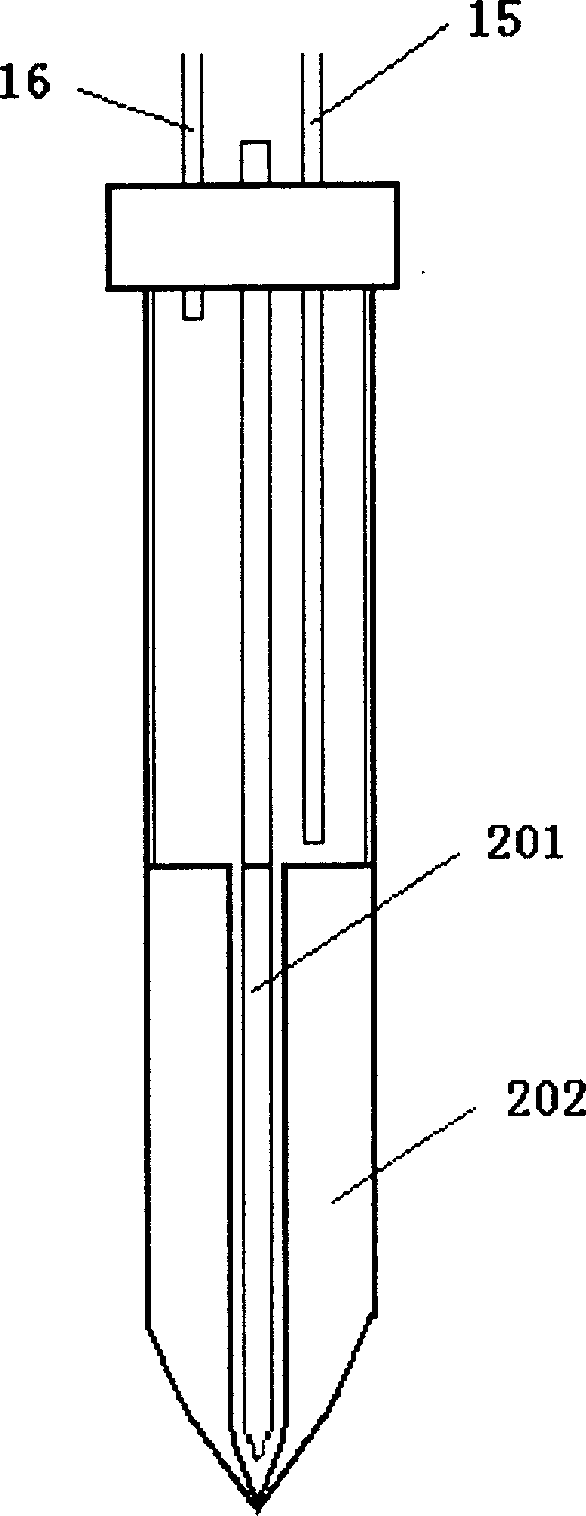

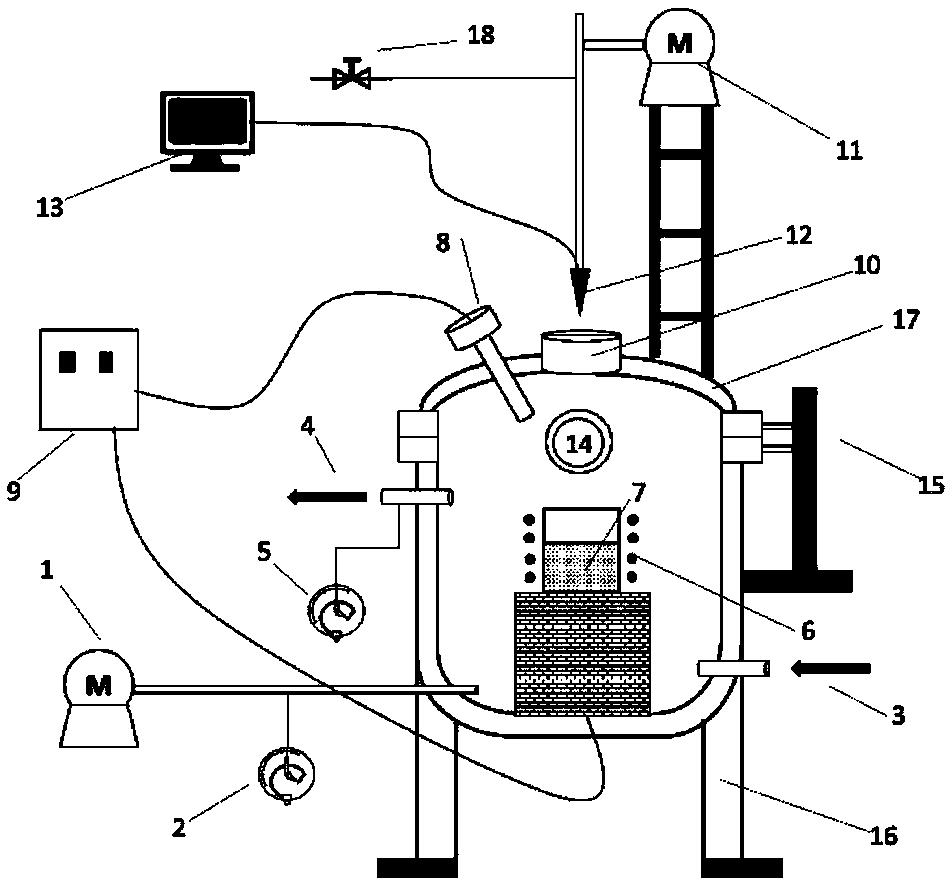

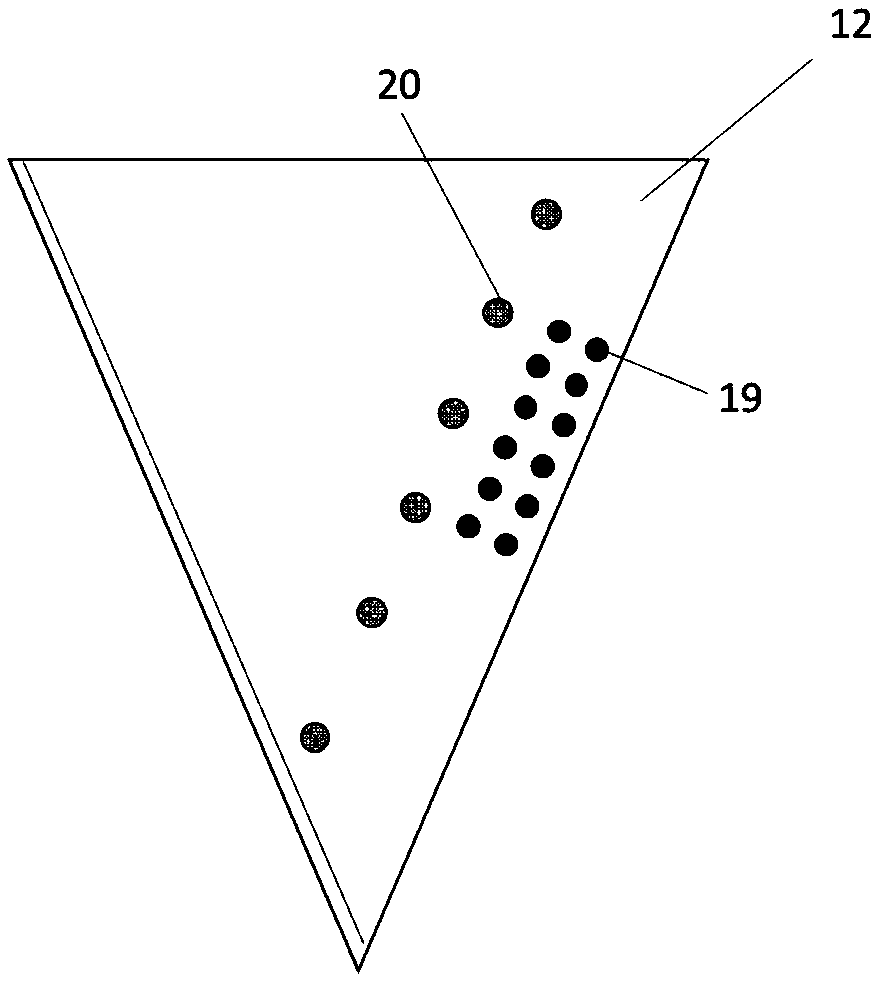

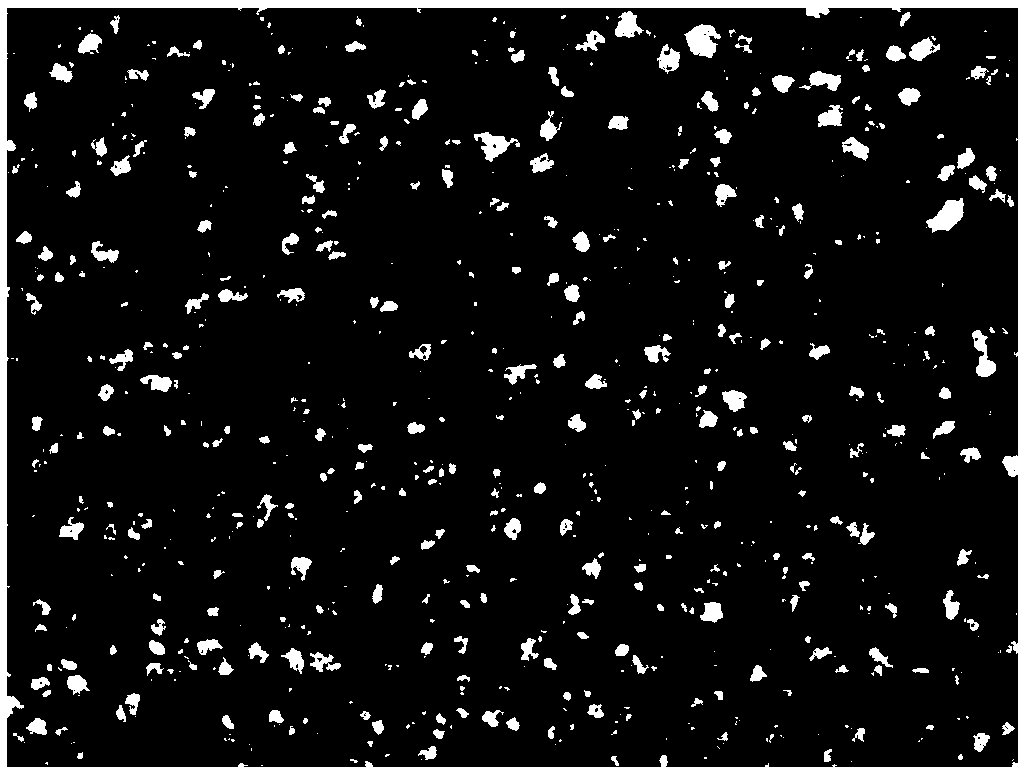

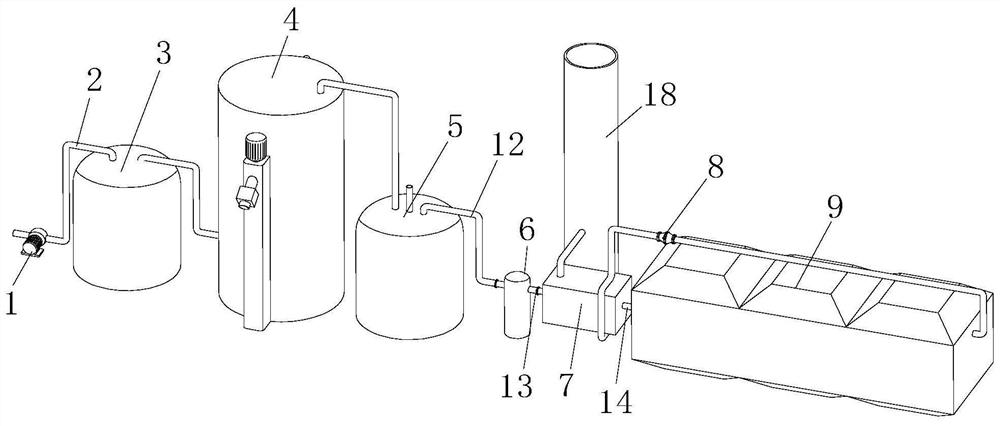

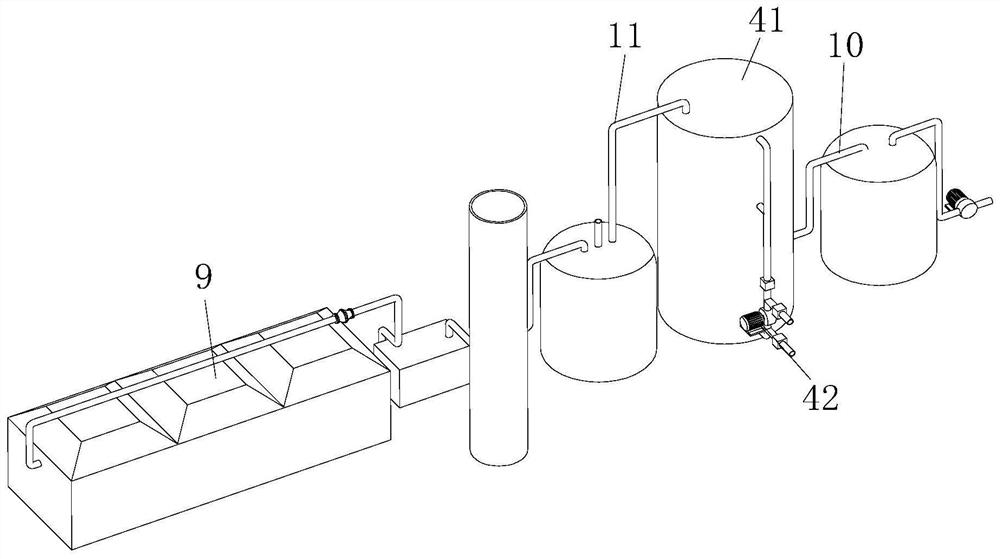

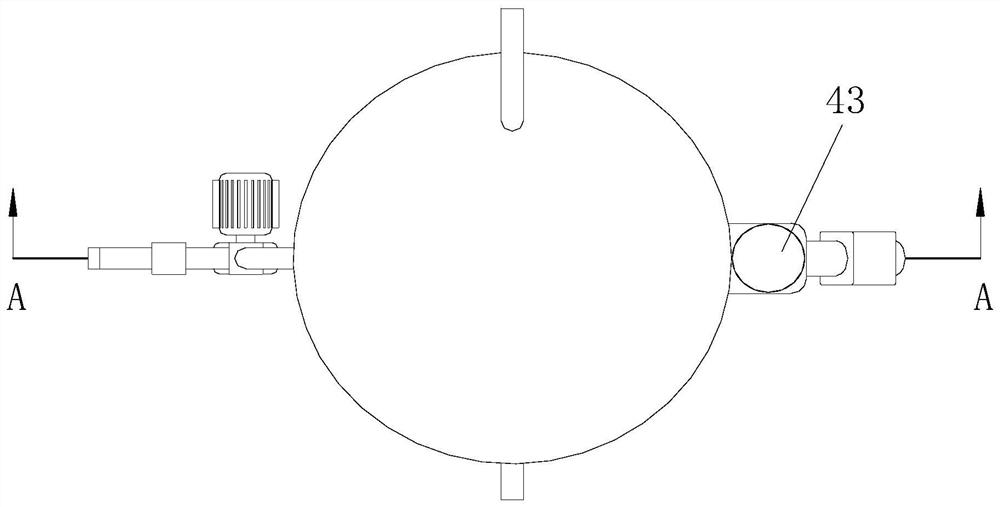

Device for simulating oxide film generation on thin-strip continuous casting crystallization roll and method thereof

ActiveCN109036073AEasy to controlReduce experiment costEducational modelsSurface oxidationMeasuring instrument

The invention discloses a device for simulating oxide film generation on a thin-strip continuous casting crystallization roll and a method thereof. The device comprises a melting system, an atmospherecontrol system, a film collecting system, an oxygen partial pressure measuring instrument which is used for measuring the oxygen partial pressure in an induction furnace, and a temperature acquiringsystem which is connected with a thermocouple that is embedded into a substrate. The wall surface of the furnace body which corresponds with the upper part of a crucible is provided with an air curtain cover. The inside wall of the air curtain curve is provided with a plurality of gas holes which can eject protective gas for preventing contact between the protective atmosphere and outer air. The film collecting film comprises the substrate above a crucible, and a lifting mechanism which controls the substrate to lift. The substrate is internally provided with a cooling liquid pipe with a cooling medium. The device and the method can be used for simulating an oxide film generating process on the surface of a crystallization roll in actual double-roll thin-strip continuous casting and has high simulating performance and high economic performance. Furthermore the oxide deposited film formed on the substrate can be easily collected, thereby facilitating research of an oxide film forming mechanism and influence of the oxide film to heat transferring in a sub-quick solidification process.

Owner:CENT SOUTH UNIV

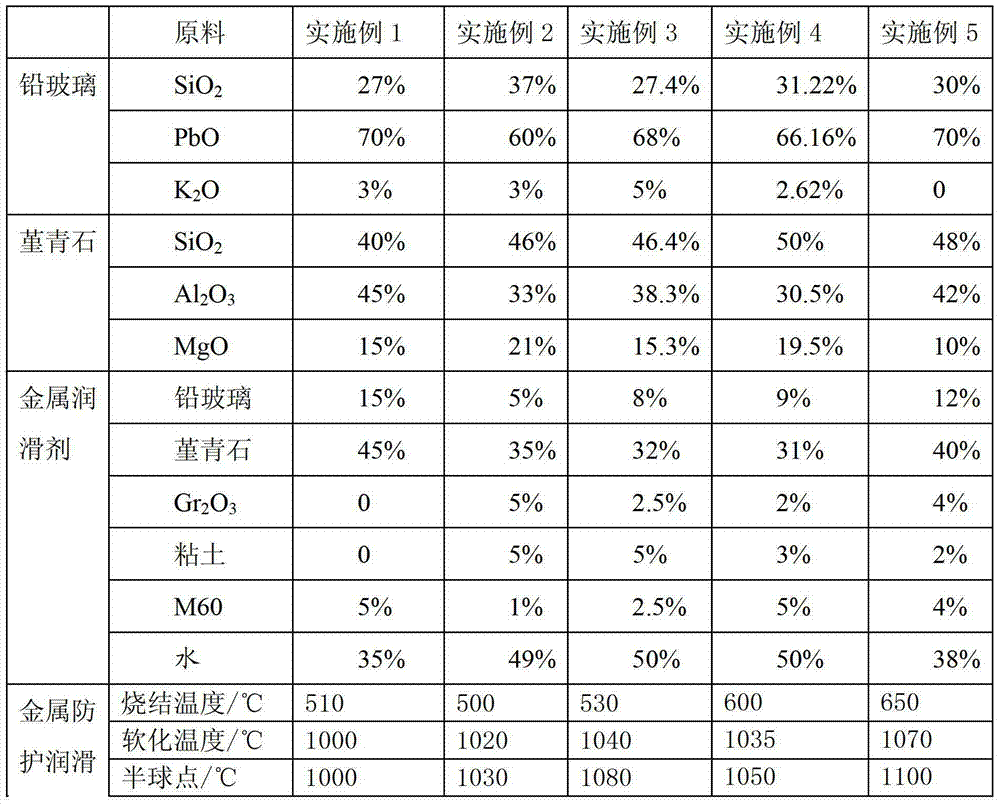

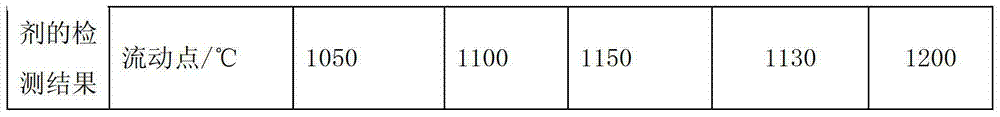

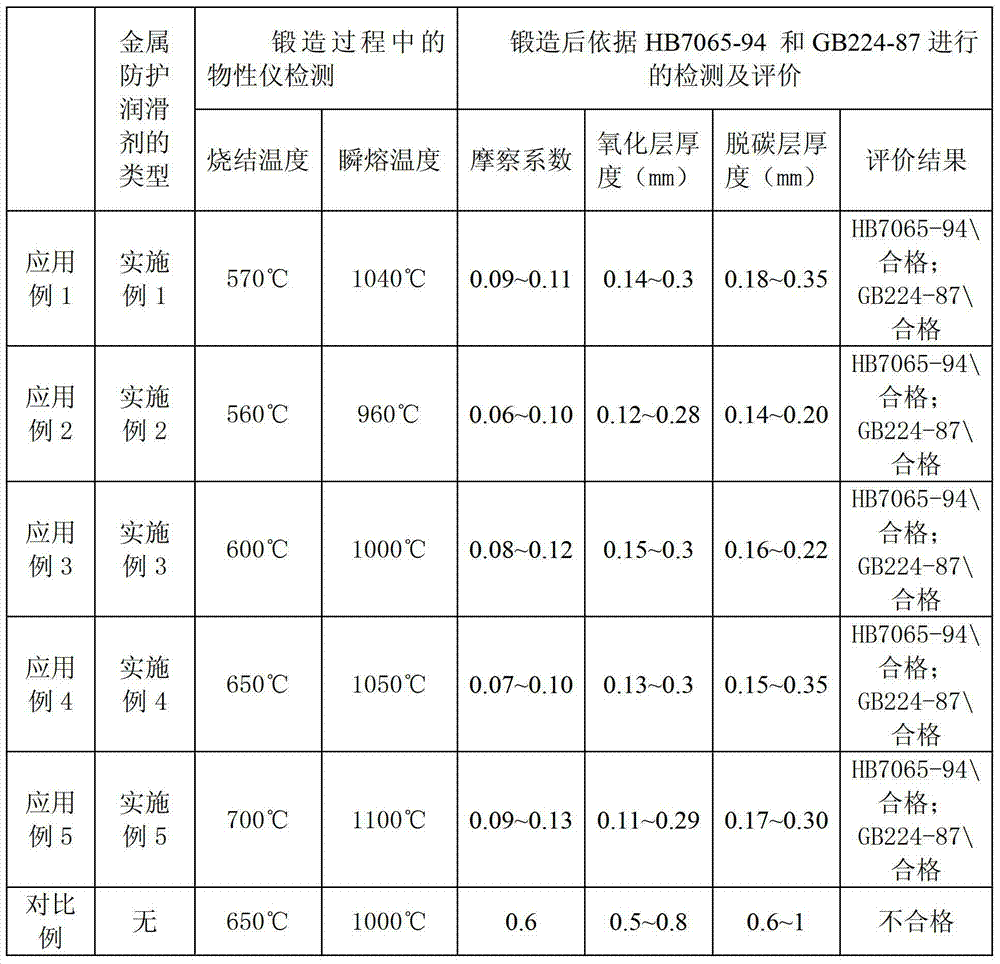

Metal protection lubricant as well as preparation method and application thereof

ActiveCN103242943AAnti-friction effectImprove uniformityLubricant compositionMetal formingThermal deformation

The invention relates to a metal protection lubricant for preventing metals from being damaged when being machined and forged as well as a preparation method and an application of the metal protection lubricant. The metal protection lubricant comprises the following raw material components: lead glass, cordierite, Gr2O3, clay, methylcellulose and water. The metal protection lubricant not only isolates the external atmosphere to protect metal profile matrixes, but also functions as a good lubricant which has the abrasion reduction function in thermal deformation machining, the metal protection time is greatly prolonged, metal erosion is prevented, and moreover the metal protection lubricant can automatically drop off after being forged, so that later treatment procedures caused by coating are canceled, the protection of the properties of metals is sufficiently achieved, the forging quality is effectively improved, the surface effect in metal forming is optimized, and the quality of a product is improved, and the service life of a product, such as a die, which is forged in such a mode is prolonged, and therefore, the metal protection lubricant is applicable to popularization and application in relevant fields.

Owner:北京玻璃研究院有限公司 +1

Coking VOCS tail gas treatment device

ActiveCN111773921ASeparation in timeReduce consumptionGas treatmentRecuperative heat exchangersFlame arresterVapor–liquid separator

The invention discloses a coking VOCS tail gas treatment device. The invention relates to the field of coking VOCS tail gas treatment. The device comprises a gas conveying pump, a gas inlet pipe, a buffer tank, a washing mechanism, a water seal tank, a gas-liquid separator, a preheating mechanism, a flame arrester and a catalytic oxidation furnace, a washing air inlet pipe is arranged between thebuffer tank and the washing mechanism, the washing mechanism comprises a washing tower, a washing assembly and a filtering assembly, a washing gas outlet pipe is arranged on the upper portion of the washing tower, a separation pipe is arranged between the water seal tank and the gas-liquid separator, a preheating gas inlet pipe is arranged between a gas-liquid separation tank and the preheating mechanism, and a preheating gas outlet pipe is arranged between the preheating gas inlet pipe and the catalytic oxidation furnace. Washing waste gas washing oil is filtered in time through the filteringassembly, impurities in the washing oil are reduced, the washing oil recycling frequency is increased, then washing oil consumption is reduced, the cost is reduced, secondary pollution caused by thewashing oil to the environment is avoided, energy of substances in waste gas is fully utilized, and the purposes of energy conservation and environmental protection are achieved.

Owner:山东康源环保科技有限公司

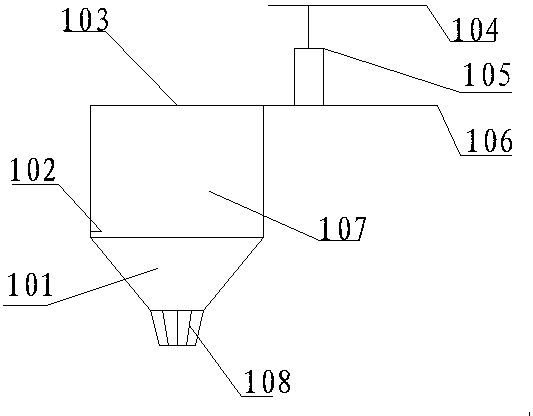

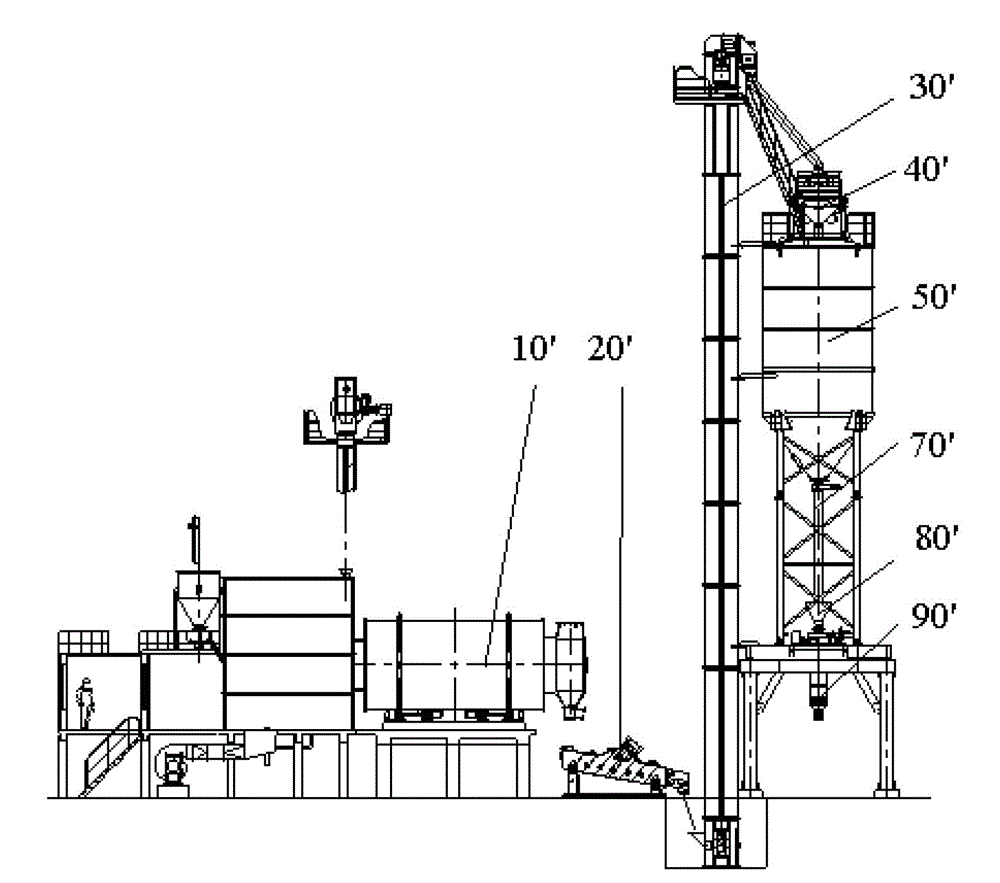

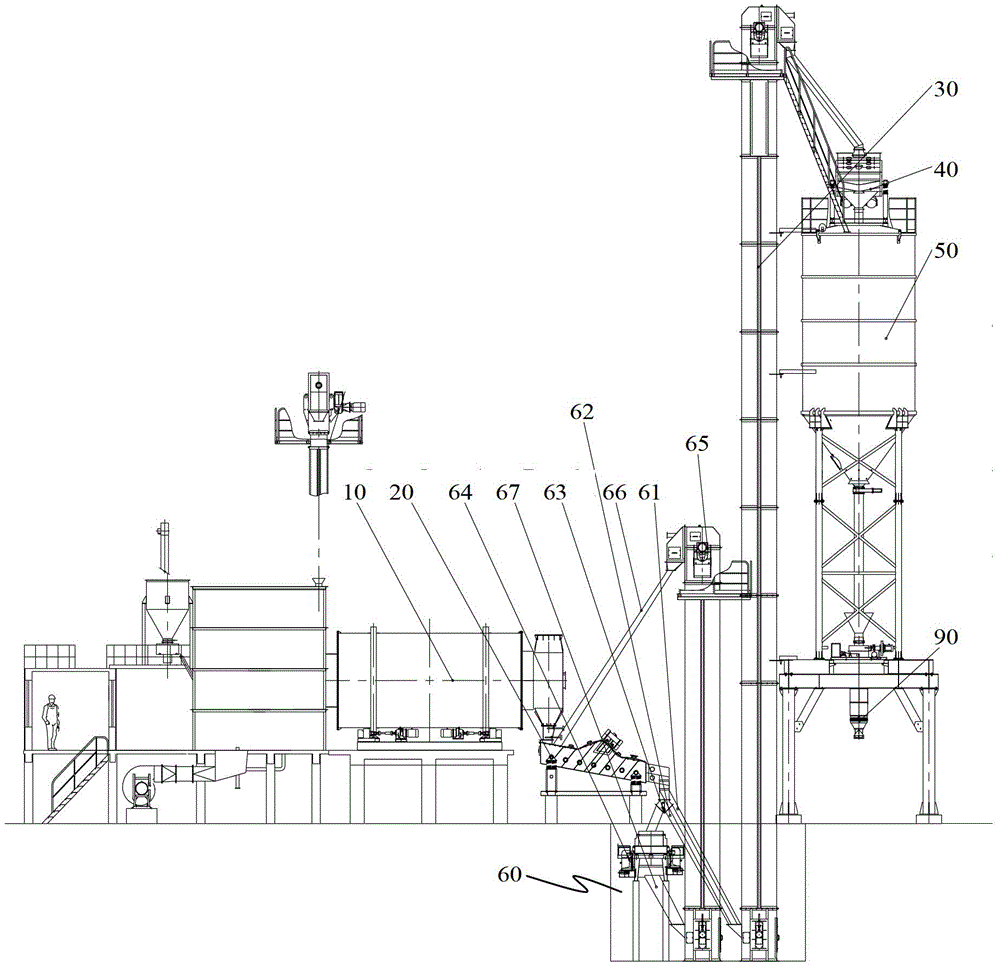

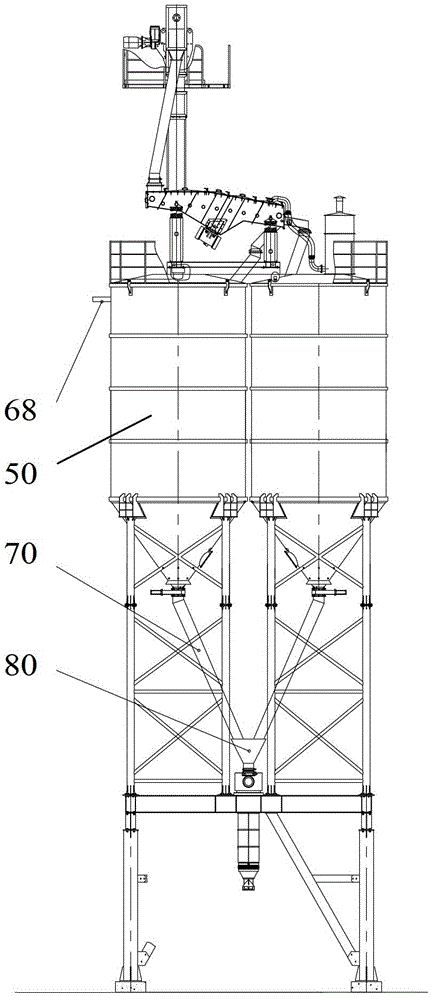

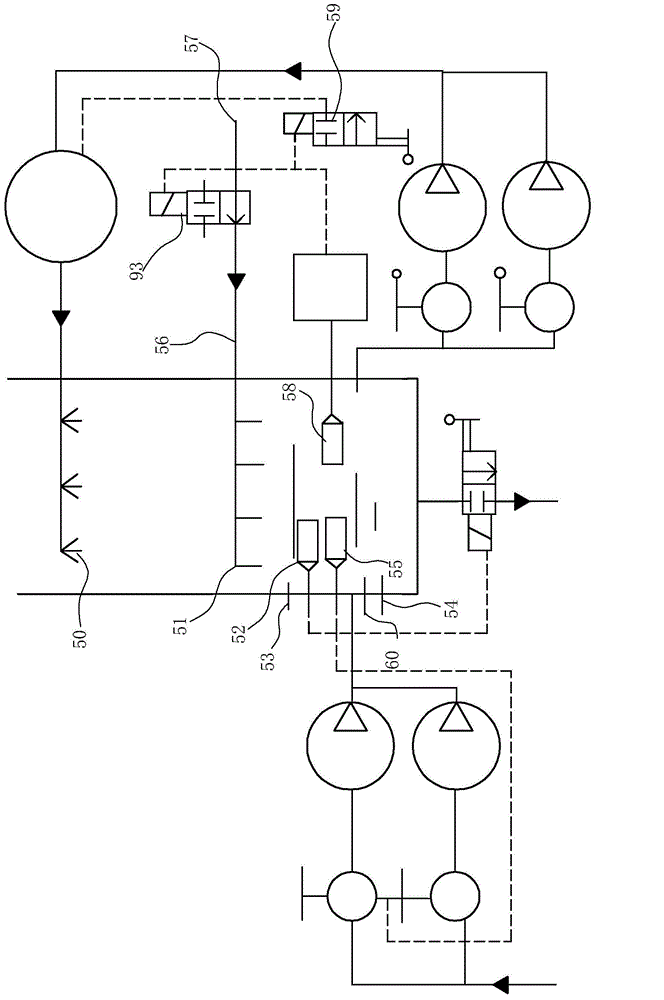

Sand drying storage system, operation method thereof and dry and mixed mortar batching plant

The invention provides a sand drying storage system, an operation method thereof and a dry and mixed mortar batching plant. The sand drying storage system comprises a drying device (10), a first screening plant (20), a first hoisting plant (30), a second screening plant (40), a storage bin (50) and a secondary sand making system (60), the first screening plant (20) is arranged at a discharge end of the drying device (10), the first hoisting plant (30) is arranged at a discharge end of the first screening plant (20), the second screening plant (40) is disposed at a discharge end of the first hoisting plant (30), the storage bin (50) is arranged at a discharge end of the second screening plant (40), and the secondary sand making system (60) is connected to the discharge end of the first screening plant (20) and can secondarily process dry sand outputted by the first screening plant (20). By the aid of the sand drying storage system, a sand silo can be effectively prevented from being excessively filled with sand, production cost is lowered, production efficiency is improved, and resources are more reasonably utilized.

Owner:ZOOMLION HEAVY IND CO LTD

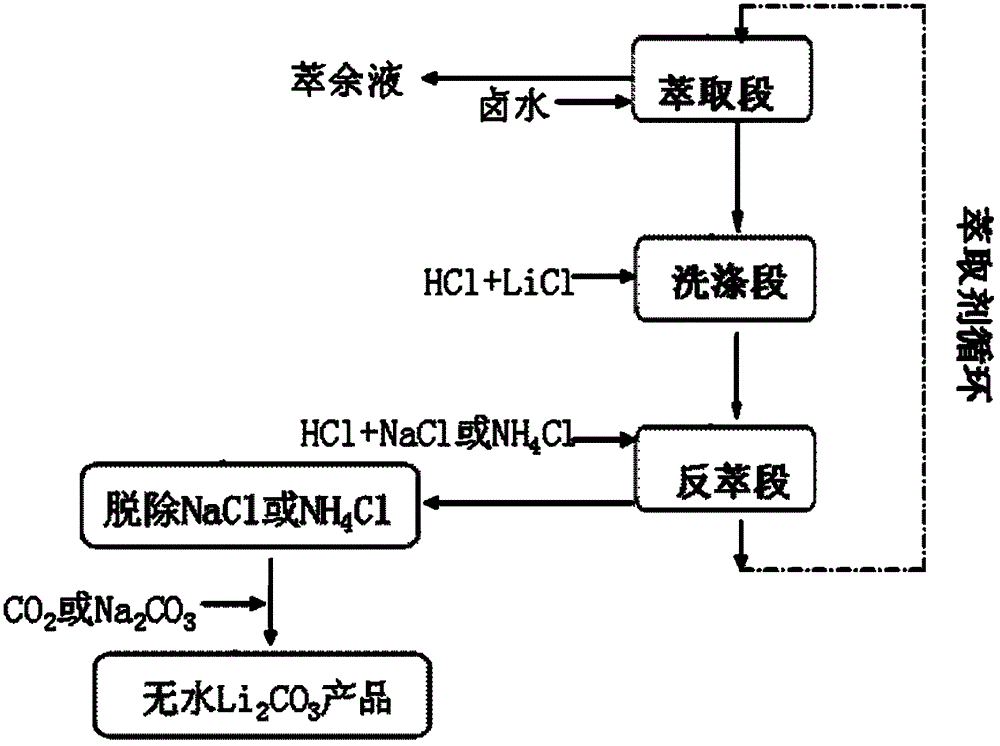

Method for extracting lithium carbonate from salt lake brine with high magnesium/lithium ratio

InactiveCN102275956BReduce lossesNo decrease in recycling efficiencyNanotechnologyLithium carbonates/bicarbonatesInorganic saltsHigh magnesium

The invention discloses a method for extracting lithium carbonate from salt lake brine with high magnesium / lithium ratio, belonging to the technical filed of inorganic salt extraction. The method comprises the following steps of: carrying out extraction, washing and stripping steps to obtain a stripping solution composed of NaCl and LiCl or NH4Cl and LiCl, then introducing CO2 or adding Na2CO3, and controlling the pH value and dynamic conditions to obtain a nanoscale or microscale Li2CO3 product. The method disclosed by the invention has the advantages of simple steps, low equipment requirement and wide sources of raw materials, and is suitable for industrial production.

Owner:TSINGHUA UNIV

Recovering method and device for lithium ion battery pole piece

ActiveCN106299527AReduce the impactReduce post-processing stepsSolid waste disposalWaste accumulators reclaimingElectrical batteryPole piece

The invention provides a recovering method and device for a lithium ion battery pole piece. The recovering method includes the steps that the pole piece disassembled from a lithium ion battery is flattened; the flattened pole piece passes through a laser recovering cavity provided with a laser device at constant speed, and active substance powder on the surface of the pole piece is scrapped by laser; the powder in the laser recovering cavity is sucked and collected through a sucking pump, and a current collector with the active substance removed enters a material receiving box. The current collector and the active substance are separated through a pure physical method, a chemical agent does not need to be added, and the negative effect on the environment is avoided.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

A kind of preparation method of superhydrophobic modified silicon dioxide

ActiveCN105400239BReduce post-processing stepsReduce energy consumptionCoatingsPigment treatment with macromolecular organic compoundsAcetic acidMixed states

The invention discloses a preparation method of modified silicon dioxide obtained via super-hydrophobic modification. The preparation method comprises following steps: 1) a raw material A (a silicon dioxide base material, dry powder) is delivered into a mixer, a mixed state is maintained, a raw material C (a super-hydrophobic modification accessory ingredient prepared via mixing of 1.5% acetic acid aqueous solution and isopropanol at a mass ratio of 1-3:4-10) is atomized, and is sprayed into the mixed uniformly, and stirring is kept; 2) a raw material B (a hydrophobic modification agent organic silane coupling agent) is atomized, and is sprayed into the mixer uniformly, and stirring is kept; 3) aging is carried out; and 4) ultrafine grinding is carried out so as to obtain a finished product. Fewer processing steps are needed; energy consumption is low; requirements of industrialized large-scale production can be satisfied; particle size distribution of the modified silicon dioxide obtained via super-hydrophobic modification is uniform; pore structures are stable; and hydrophobic performance is stable. The prepared super-hydrophobic silicon dioxide prepared via the preparation method is taken as a flatting agent, and can be used for providing paint with super hydrophobic performance; film forming coating particle arrangement is uniform; and luster is soft.

Owner:北京航天赛德科技发展有限公司

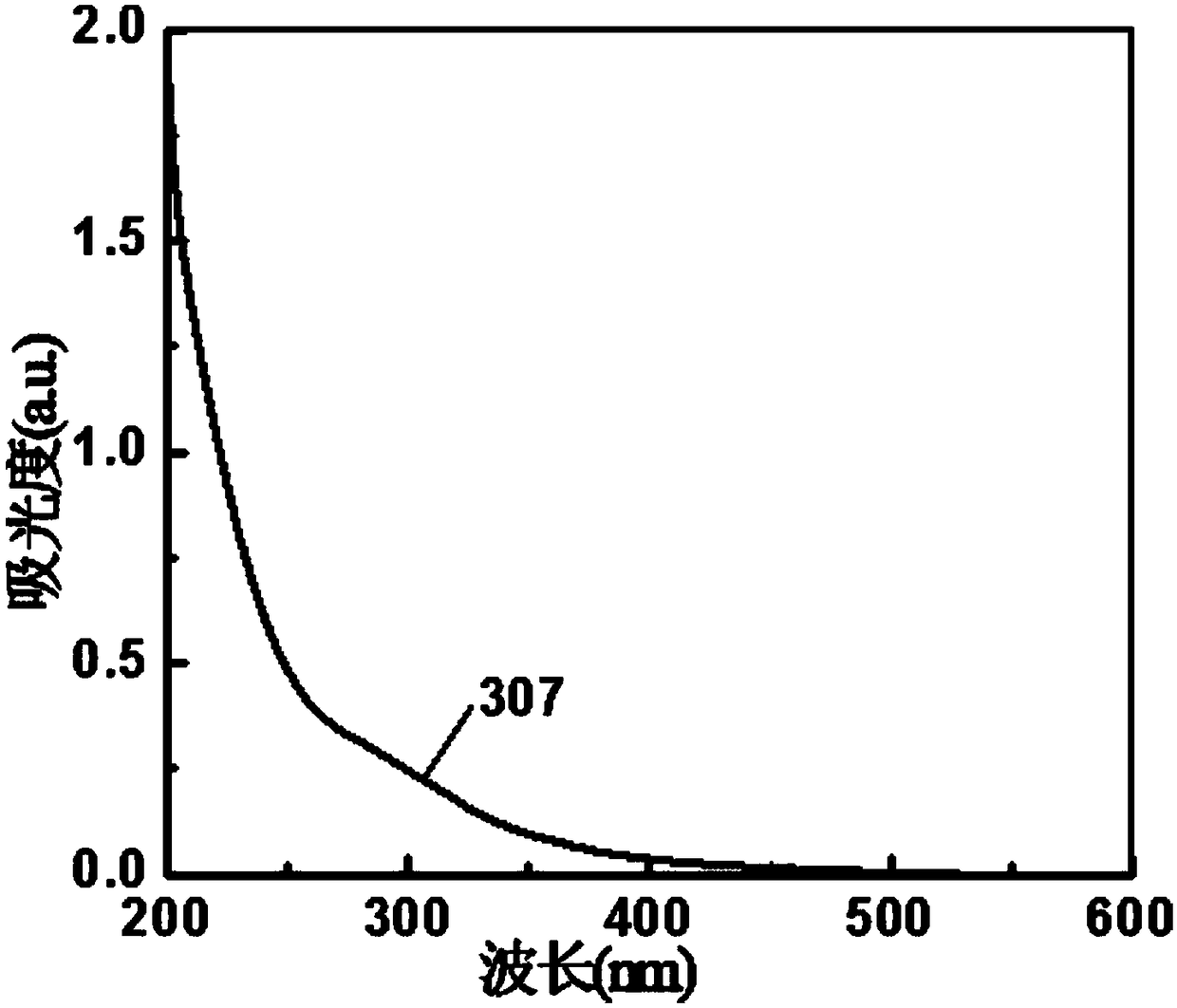

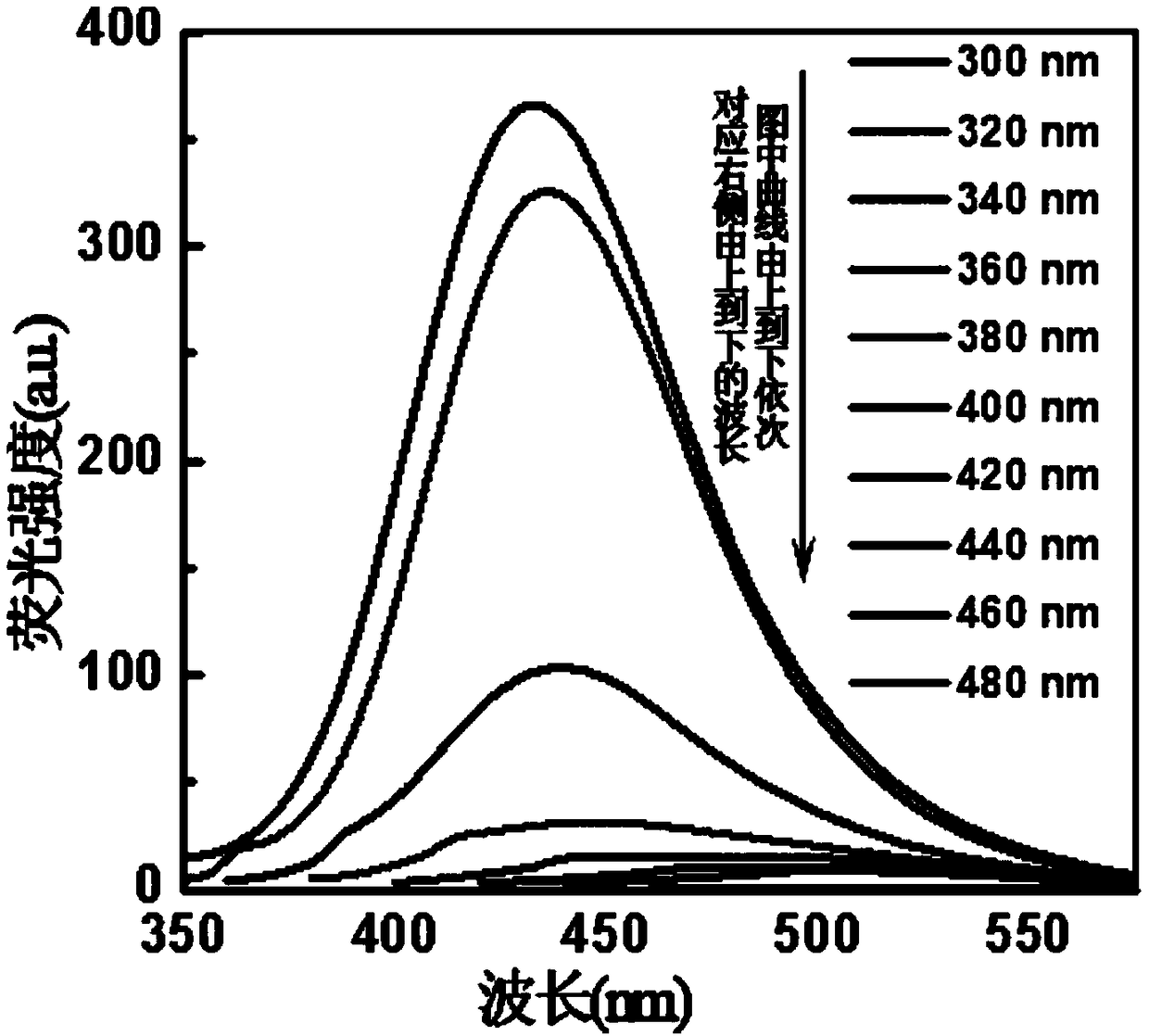

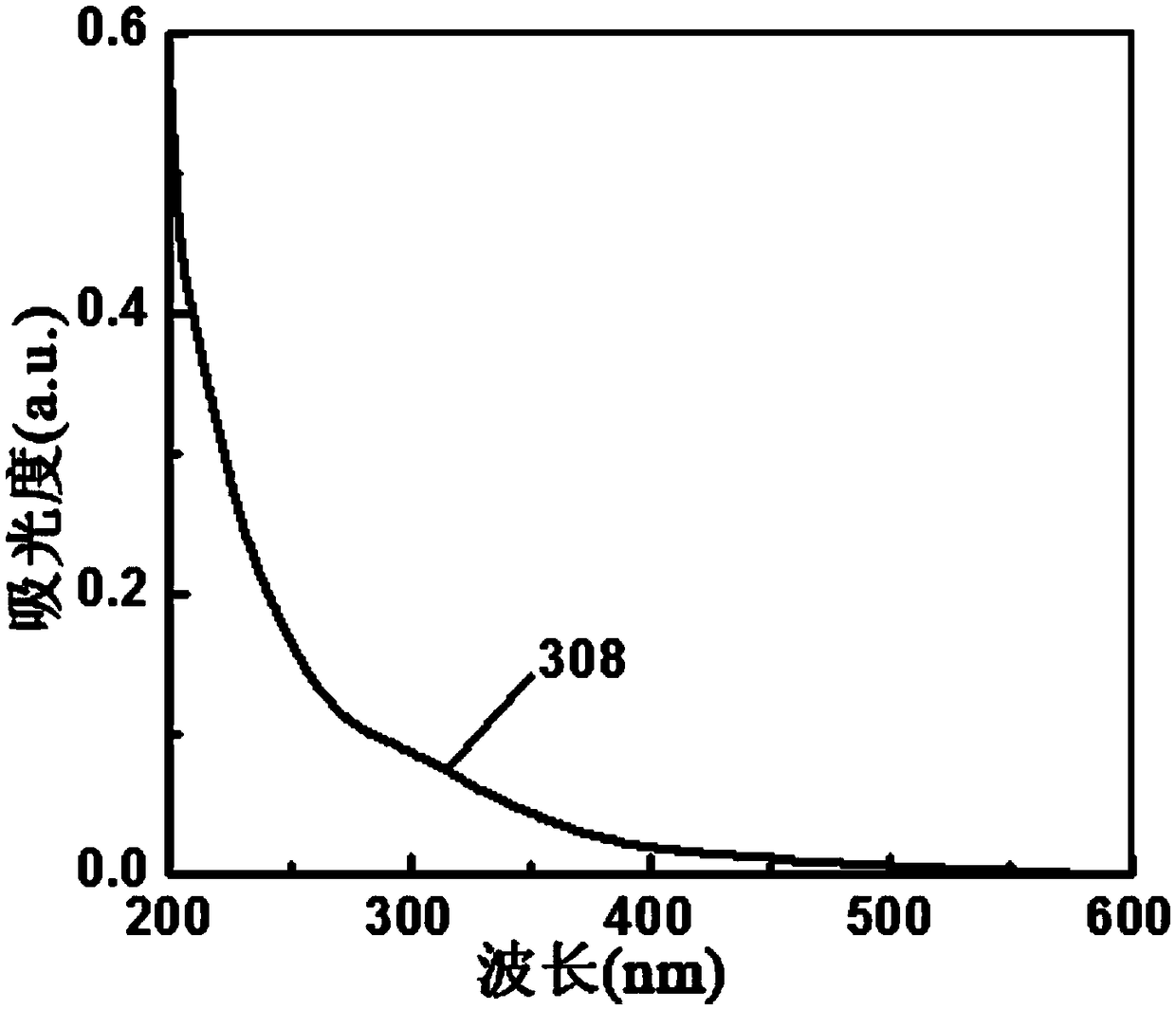

Petroleum liquid product-based graphene quantum dot, and preparation method and application thereof

ActiveCN108996492ASynthetic operation method is simpleReduce tedious and redundant stepsGrapheneFluorescence/phosphorescenceIonChemistry

The invention provides a petroleum liquid product-based graphene quantum dot, and a preparation method and an application thereof. The method comprises the steps: adding concentrated sulfuric acid andconcentrated nitric acid to a petroleum liquid product, and carrying out ultrasonic treatment to obtain a petroleum liquid product-based dispersion liquid; stirring the petroleum liquid product-baseddispersion liquid in a reactor, carrying out oxidation reaction, then cooling to room temperature, adjusting to neutral with an alkali, and thus obtaining a petroleum liquid product-based crude product; and centrifuging the obtained petroleum liquid product-based crude product, taking a supernatant, allowing to pass through a microporous filter membrane, carrying out dialysis interception to obtain the petroleum liquid product-based graphene quantum dot. The preparation method is simple, is low in cost, and reduces tedious and redundant steps. The prepared petroleum liquid product-based graphene quantum dot has the advantages of small size, uniform particle size, good water solubility and dispersibility and excellent performance, and can be widely applied in the field of ion detection, and especially is used for detection of copper ions in water bodies and living bodies.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

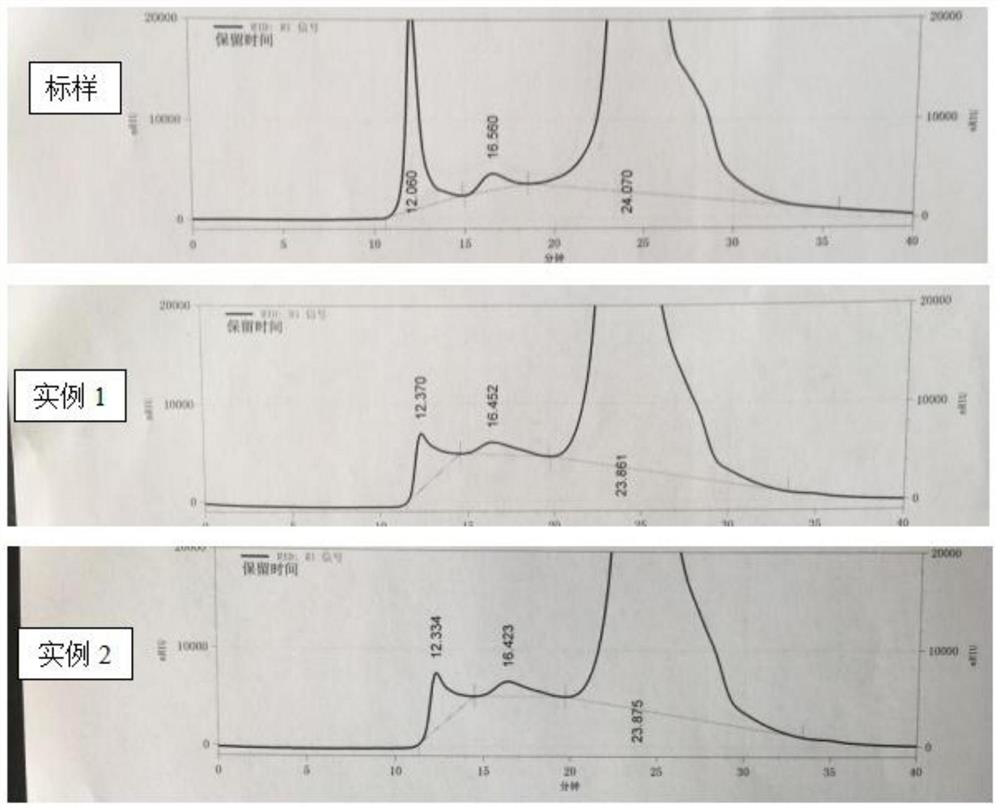

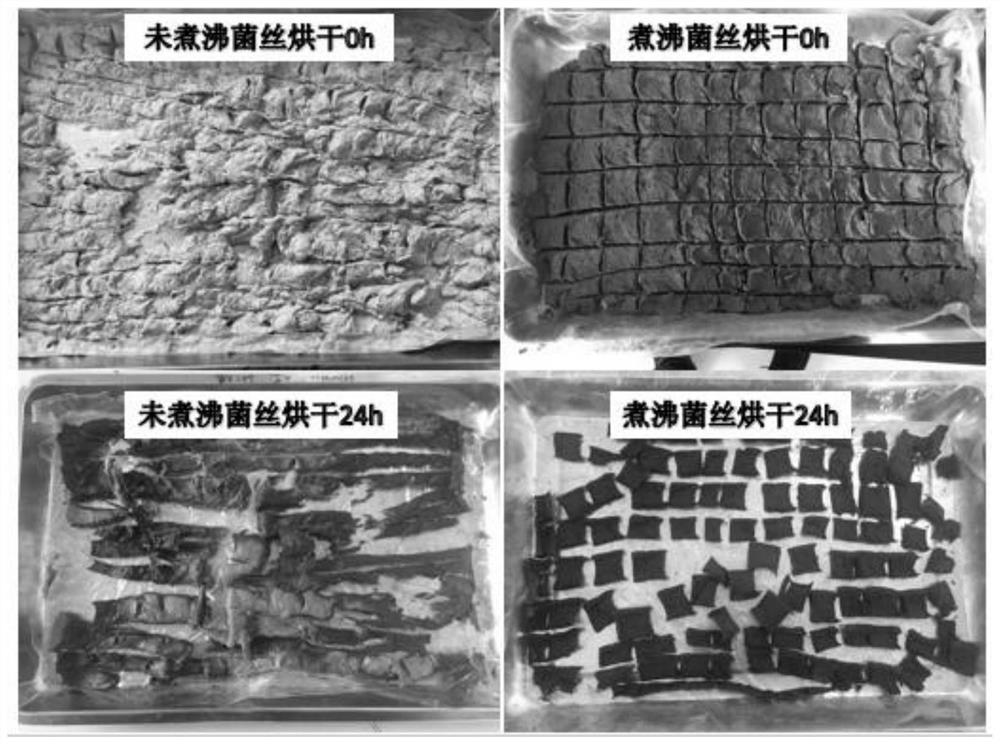

Novel preparation method of coriolus versicolor polysaccharopeptide

PendingCN113150063ANo lossFree from lossMicroorganism based processesPeptide preparation methodsBiotechnologyHypha

The invention discloses a novel preparation method of coriolus versicolor polysaccharopeptide, which comprises the following steps of: directly heating and boiling coriolus versicolor fermentation broth in a fermentation tank, and directly extracting hyphae in the fermentation broth by using filtrate in the fermentation broth, so that the problem of loss of effective components in the hyphae possibly generated after the hyphae are separated and dried in the original process is avoided, a mixture of intracellular polysaccharide and extracellular polysaccharide of the coriolus versicolor can be obtained at the same time, and the yield and the utilization rate are improved. In addition, the method is simple in technological process and easy to operate.

Owner:JIANGSU SHENHUA PHARMA

Device and technology for treating exhaust gas of tank ship and preparing inert gas from exhaust gas

InactiveCN104645797AReduce purification costsReduce maintenanceDispersed particle separationIncinerator apparatusCombustorProcess engineering

The invention relates to a device for treating an exhaust gas of a tank ship and preparing an inert gas from the exhaust gas. The device comprises a pipeline combustor, a catalytic conversion device, a cooler and a CO2 washing tower, which are sequentially connected with one another through a pipeline to form an exhaust gas treatment device, wherein the cooler is also connected with an O2 washing tower, a dryer, a copper net deaerating device and an inert gas storage cabinet to form a device for preparing the inert gas from the exhaust gas. The invention further relates to a technology for treating the exhaust gas of the tank ship and preparing the inert gas from the exhaust gas. Compared with the prior art, the device and the technology have the advantages that the exhaust gas treatment device is combined with the device for preparing the inert gas from the exhaust gas through the pipeline combustor, the catalytic conversion device and the cooler; the discharged gas can be relatively clean by the CO2 washing tower and the O2 washing tower in the exhaust gas treatment device; meanwhile, the exhaust gas of the ship can be effectively treated by the device for preparing the inert gas from the exhaust gas; the components in the exhaust gas reach the requirements of the inert protective gas in an oil tank; and the treatment cost of the exhaust gas is greatly reduced.

Owner:ZHEJIANG OCEAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com