Automatic garbage classifying system and method

An automatic classification and garbage technology, applied in the direction of garbage bins, garbage collection, waste collection and transfer, etc., can solve the problems of inaccurate classification and garbage, achieve a wide range of applications, and reduce the effect of subsequent processing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings of the description.

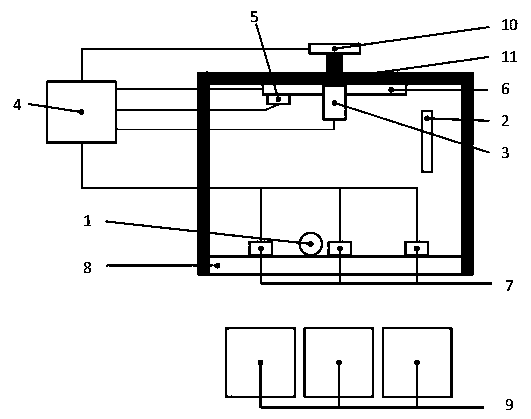

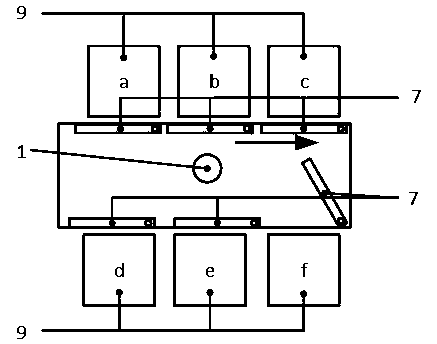

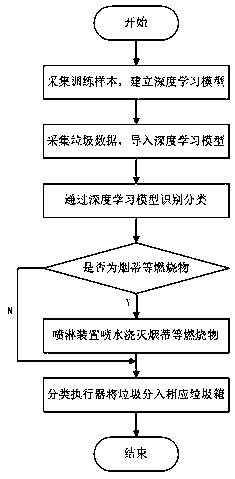

[0026] An automatic garbage sorting system, such as figure 1 and figure 2 As shown, it includes a frame 11 , a trigger 2 , a camera 3 , a central processing unit 4 , a laser scanner 5 , a sliding track 6 , several sorting actuators 7 , a garbage receiving platform 8 , several garbage cans 9 and a sprinkler 10 . The frame 11 is provided with a garbage input port, and a trigger 2 is installed above the garbage input port. The trigger 2 adopts an infrared grating trigger, and the trigger 2 can sense that an object passes through the input port. The sliding track 6 and the camera 3 are all fixedly installed on the top of the frame 11, the laser scanner 5 is installed on the sliding track 6, and can slide along the sliding track 6, and the plane scanned by the laser scanner 5 is perpendicular to the moving direction of the lase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com