Recovering method and device for lithium ion battery pole piece

A lithium-ion battery and recovery method technology, which is applied in the field of lithium-ion battery pole piece recovery, can solve problems such as environmental pollution, difficult waste liquid treatment, and inability to recover collected fluid well, so as to reduce the treatment process and reduce environmental impact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

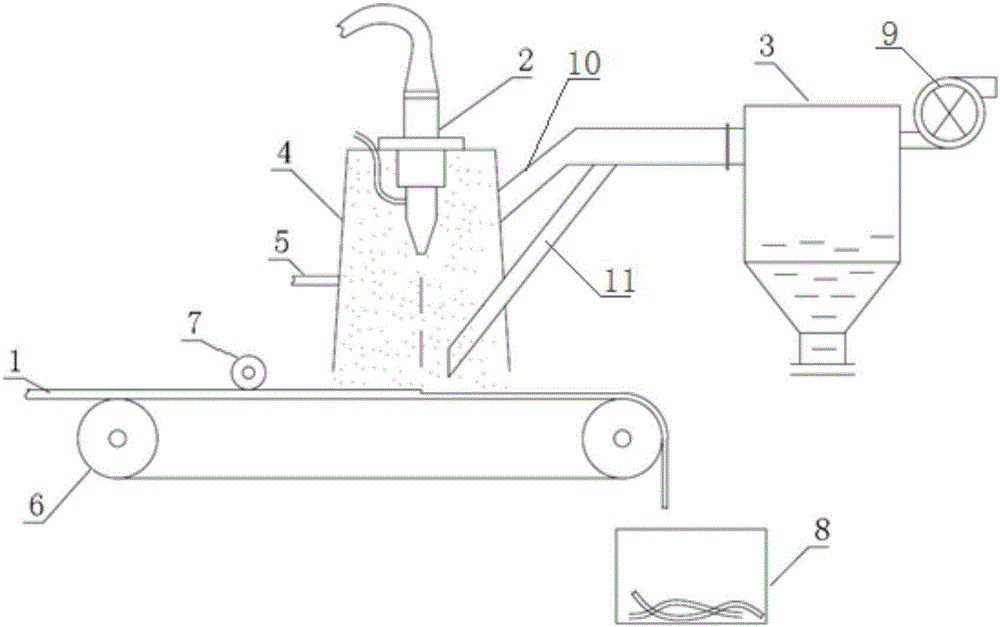

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and examples, in order to facilitate the understanding of the present invention, but the present invention is not limited to the listed embodiments.

[0024] A method for recycling lithium-ion battery pole pieces, comprising the following steps:

[0025] (1) The disassembled pole piece of the lithium-ion battery is flattened with a pressure roller under vacuum conditions;

[0026] (2) Pass the flattened pole piece through the laser recovery cavity equipped with a laser at an even speed, and at the same time, the laser recovery cavity is led to the protective gas nitrogen or argon, and the active material powder on the surface of the pole piece is removed by the laser. scrape down;

[0027] (3) The powder in the laser recovery cavity is sucked out and collected by the air pump, and the current collector after removing the active material enters the receiving box...

PUM

| Property | Measurement | Unit |

|---|---|---|

| laser power | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com