Patents

Literature

12061 results about "Aluminum foil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite roofing members having improved dimensional stability and related methods

InactiveUS6044604AGood baseRoof covering using slabs/sheetsConstruction materialGlass fiberPolymer science

A composite recovery board (10) containing a foam core (11) of polyisocyanurate, polyurethane materials or mixtures thereof; a facer (15), applied to one major surface (13) of the foam core, where the facer includes polymer materials, reinforced polymer materials, cellulosic materials, paper, aluminum foil or trilaminates thereof, wherein the reinforced polymer material and the cellulosic material are reinforced with glass strands, glass fibers, or mixtures thereof; and, gypsum board (14), applied to the opposite major surface (12) of the foam core. A method of reroofing a roof by applying composite recovery boards of the present invention to a roof deck; and, applying a weather protective layer over the recovery boards. A continuous method of making a composite recovery board by feeding gypsum board (14) into a laminator assembly (21); depositing a foamable polymer liquid (36) onto the gypsum board; feeding a facer material (15) into the laminator assembly above the foamable polymer liquid; allowing the polymer liquid to rise between the gypsum board and facer material forming polymer foam of a pre-determined thickness; curing the polymer foam under heat (44) to create the composite board; and cutting the composite board to desired lengths.

Owner:FIRESTONE BUILDING PRODS

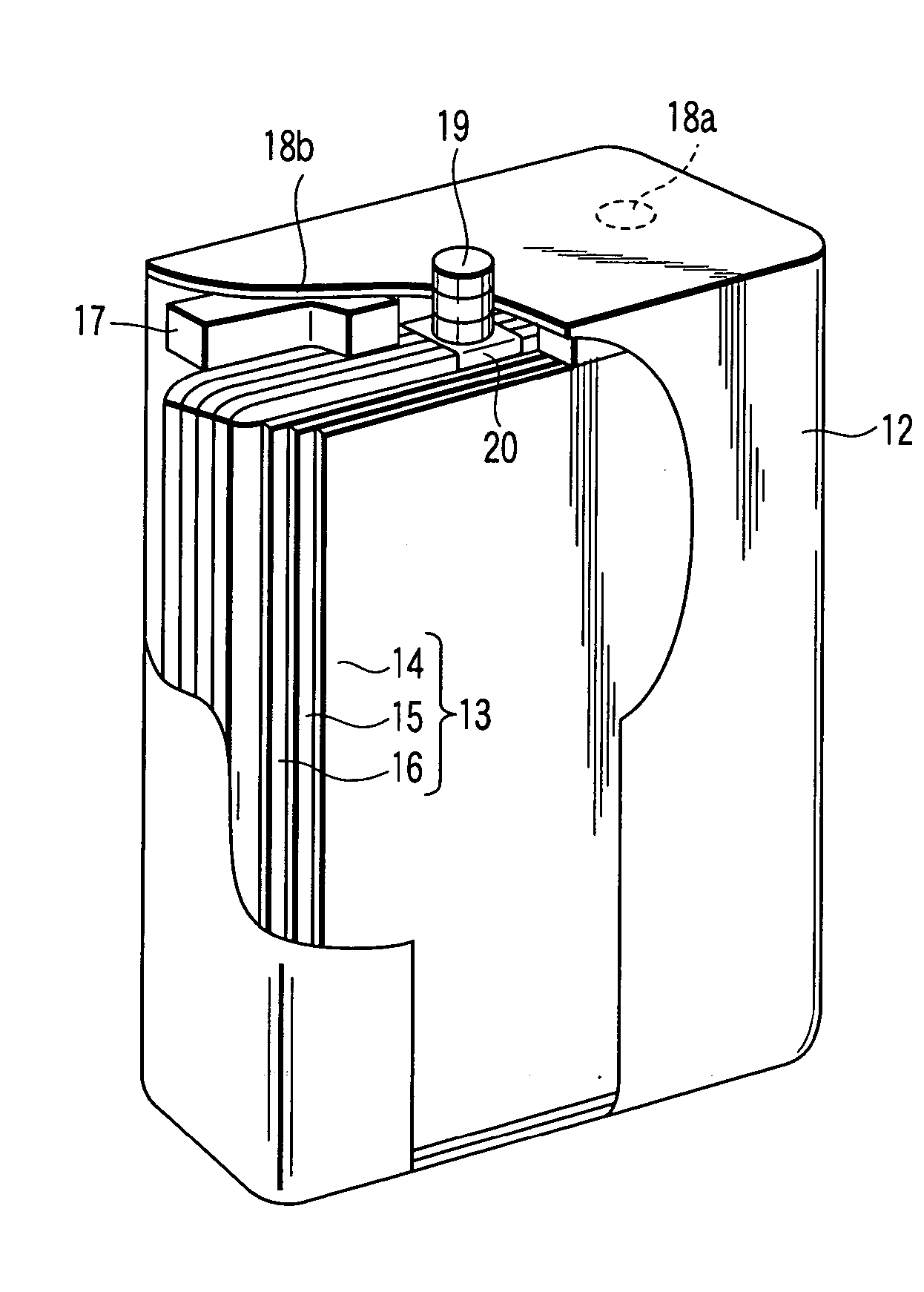

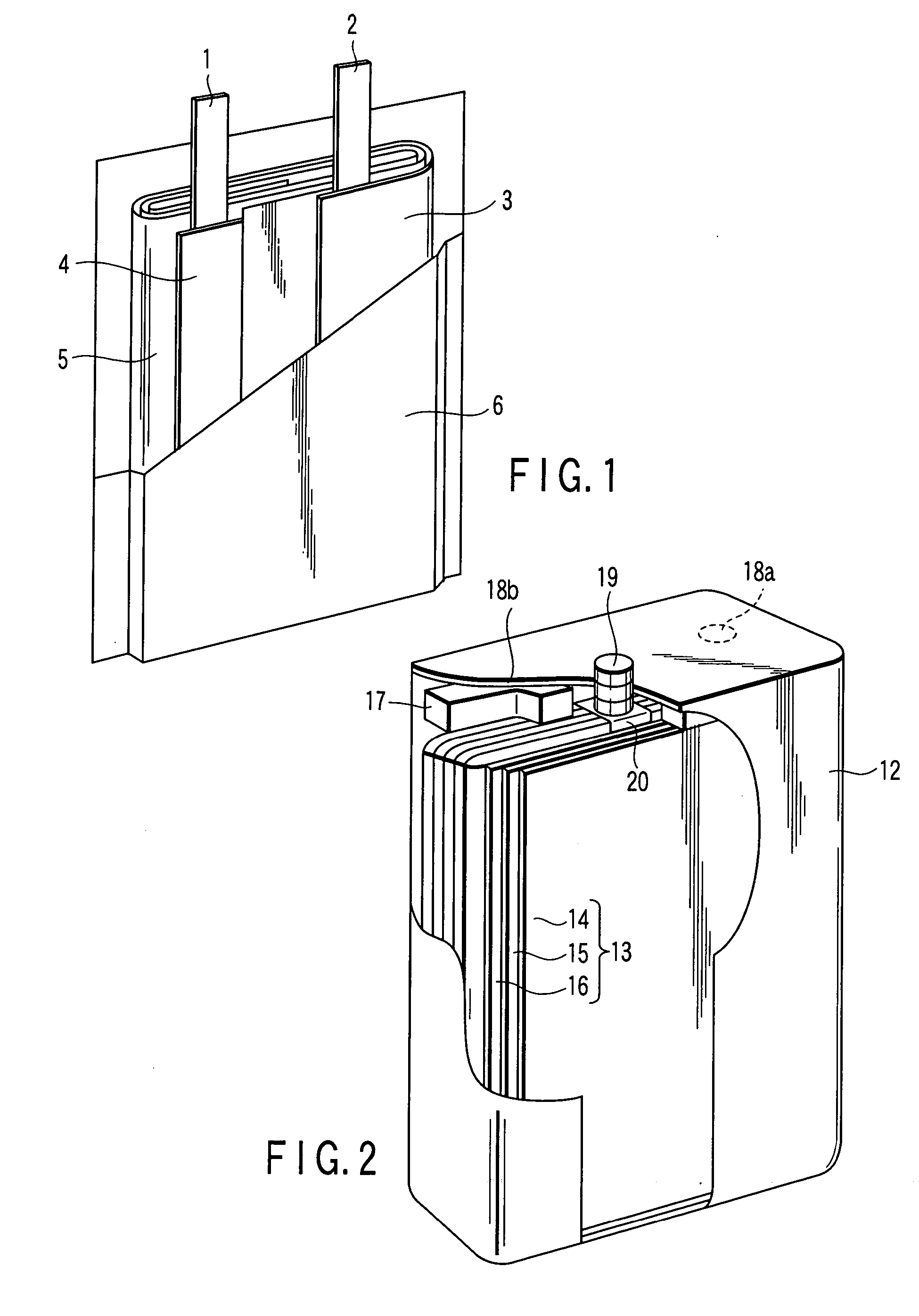

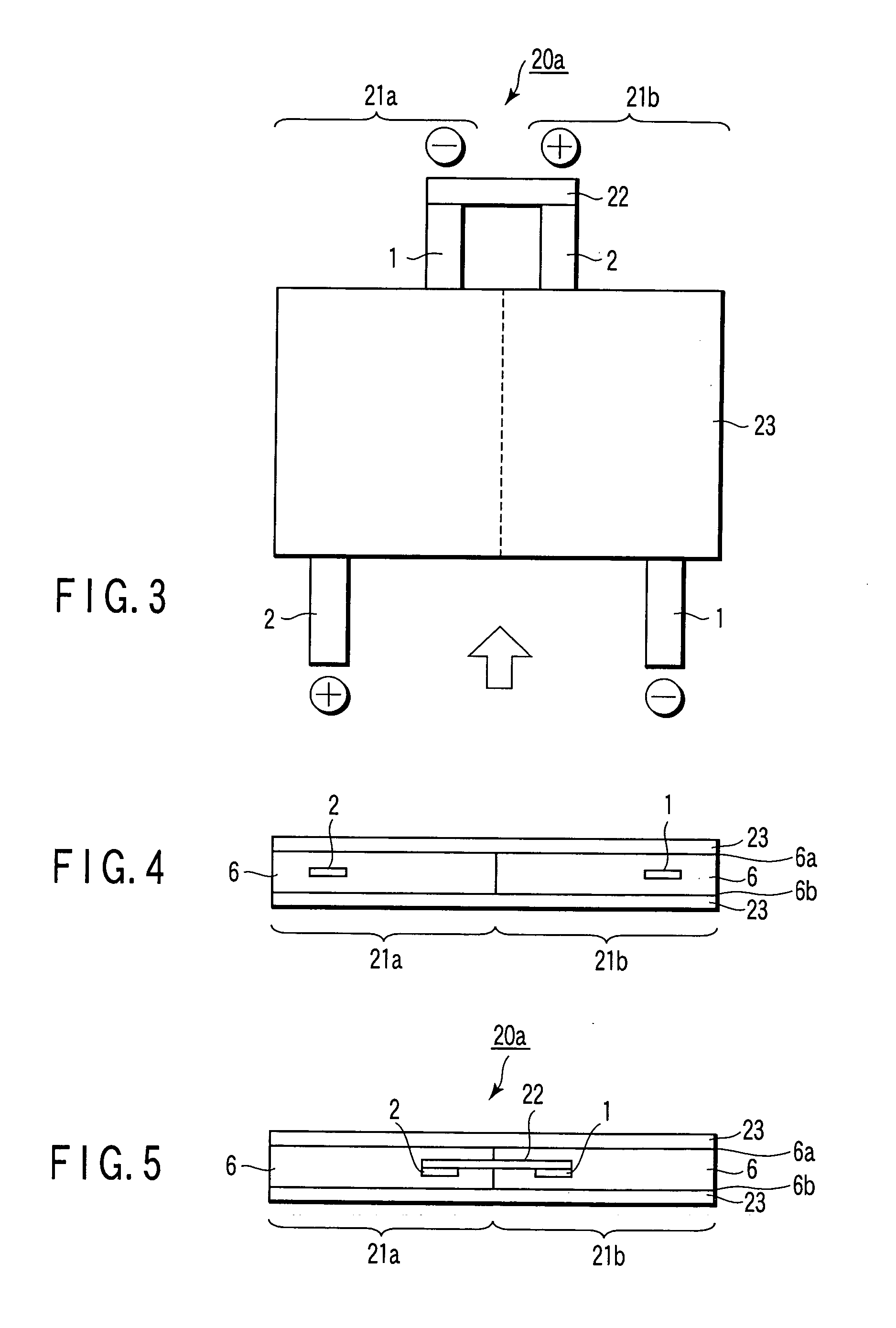

Nonaqueous electrolyte secondary battery and battery module

ActiveUS20050069777A1Excellent in battery capacity characteristic and cycle performanceEasy dischargeFinal product manufactureElectrode carriers/collectorsAlloyAluminum foil

A nonaqueous electrolyte secondary battery includes a case, a nonaqueous electrolyte provided in the case, a positive electrode provided in the case, and a negative electrode provided in the case, the negative electrode comprising a negative electrode current collector and a negative electrode layer that is carried on the negative electrode current collector and contains negative electrode active material particles, and the negative electrode current collector comprising an aluminum foil having an average crystal grain size of 50 μm or less or an aluminum alloy foil having an average crystal grain size of 50 μm or less.

Owner:KK TOSHIBA

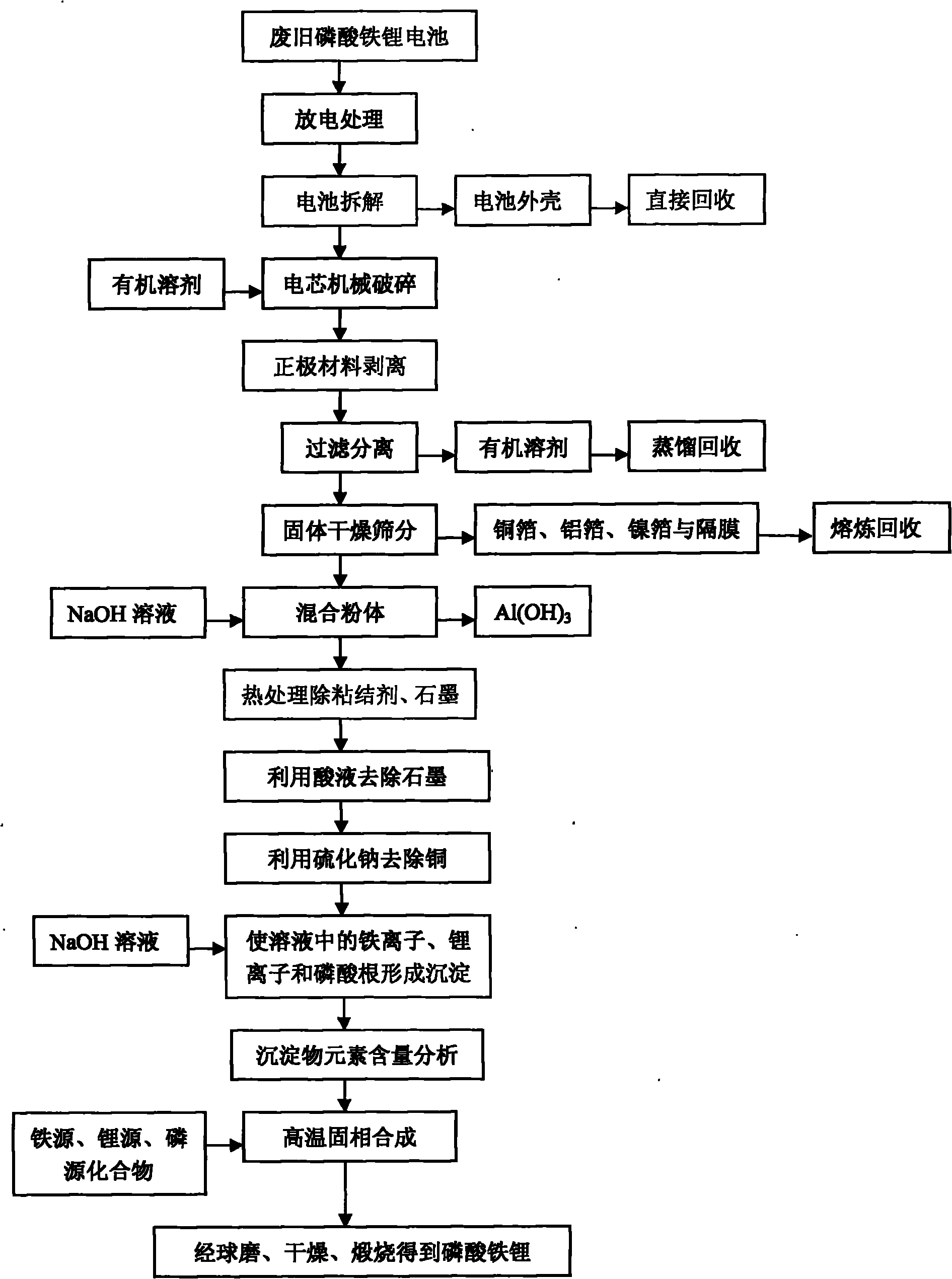

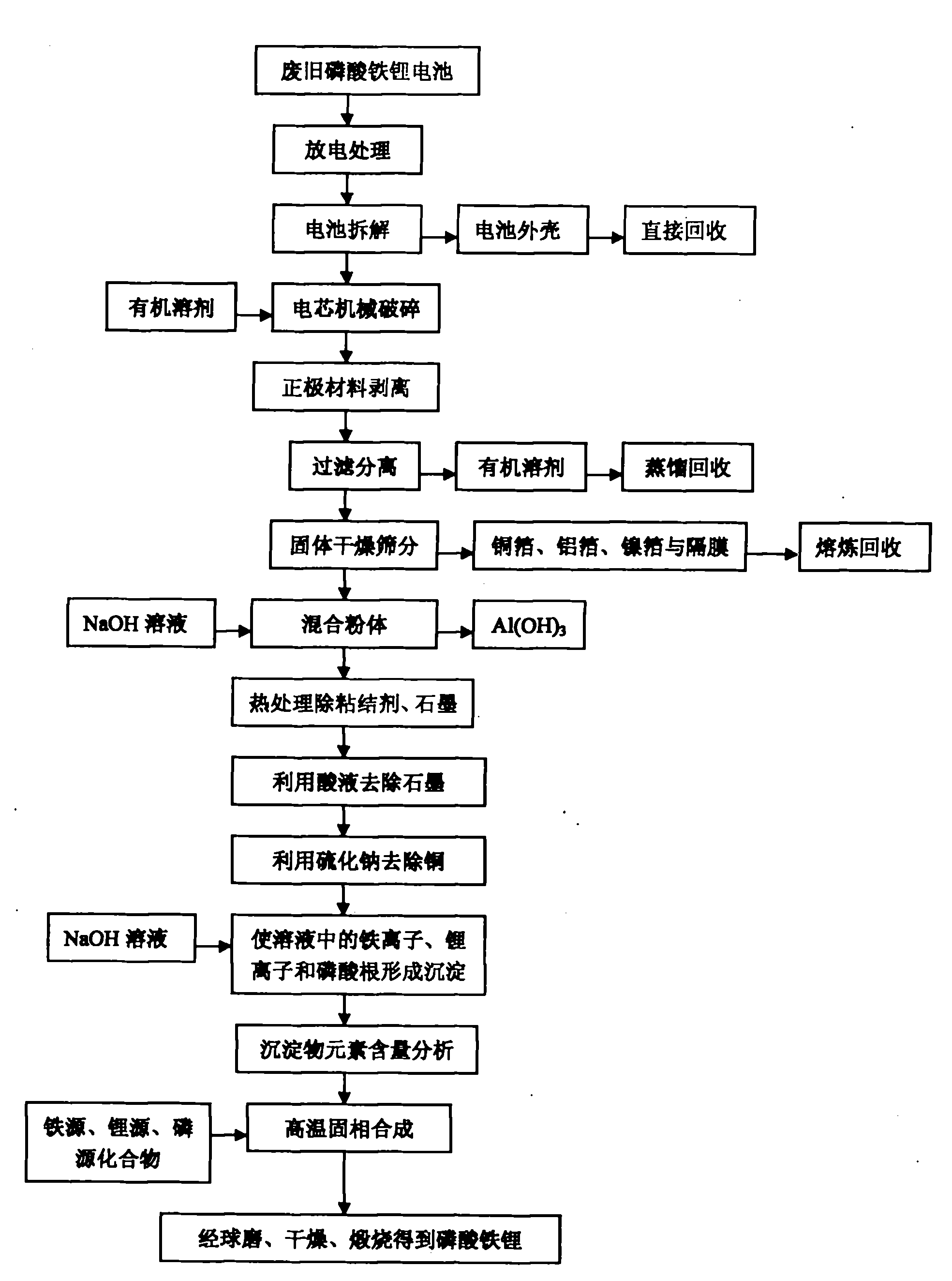

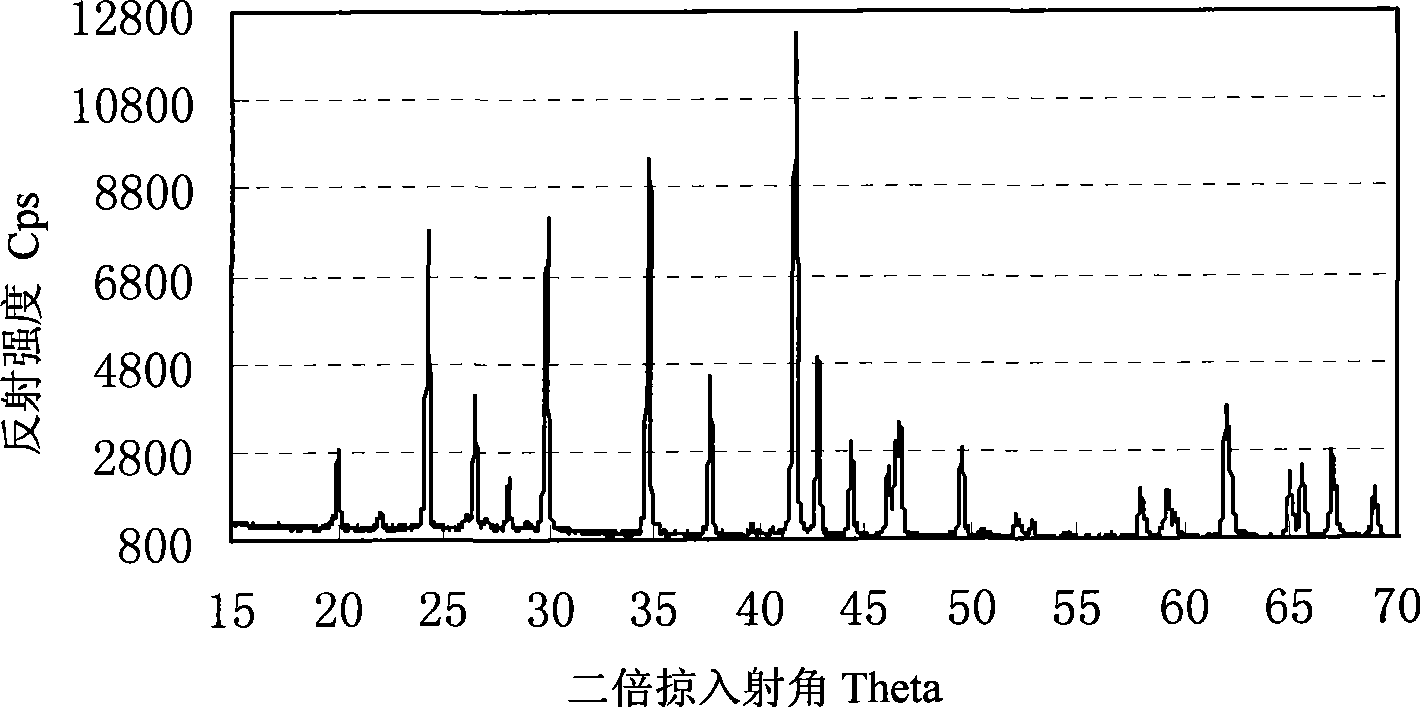

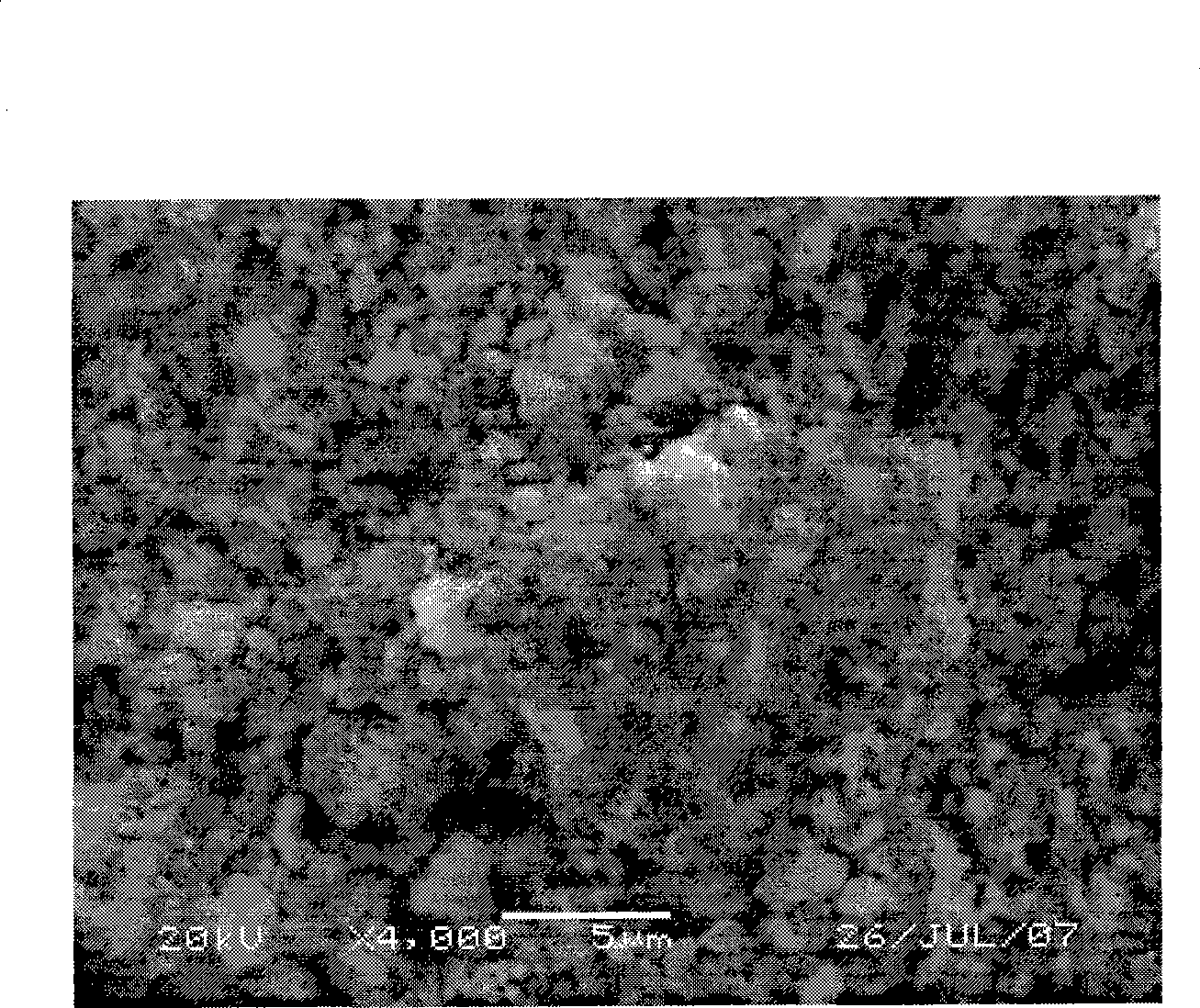

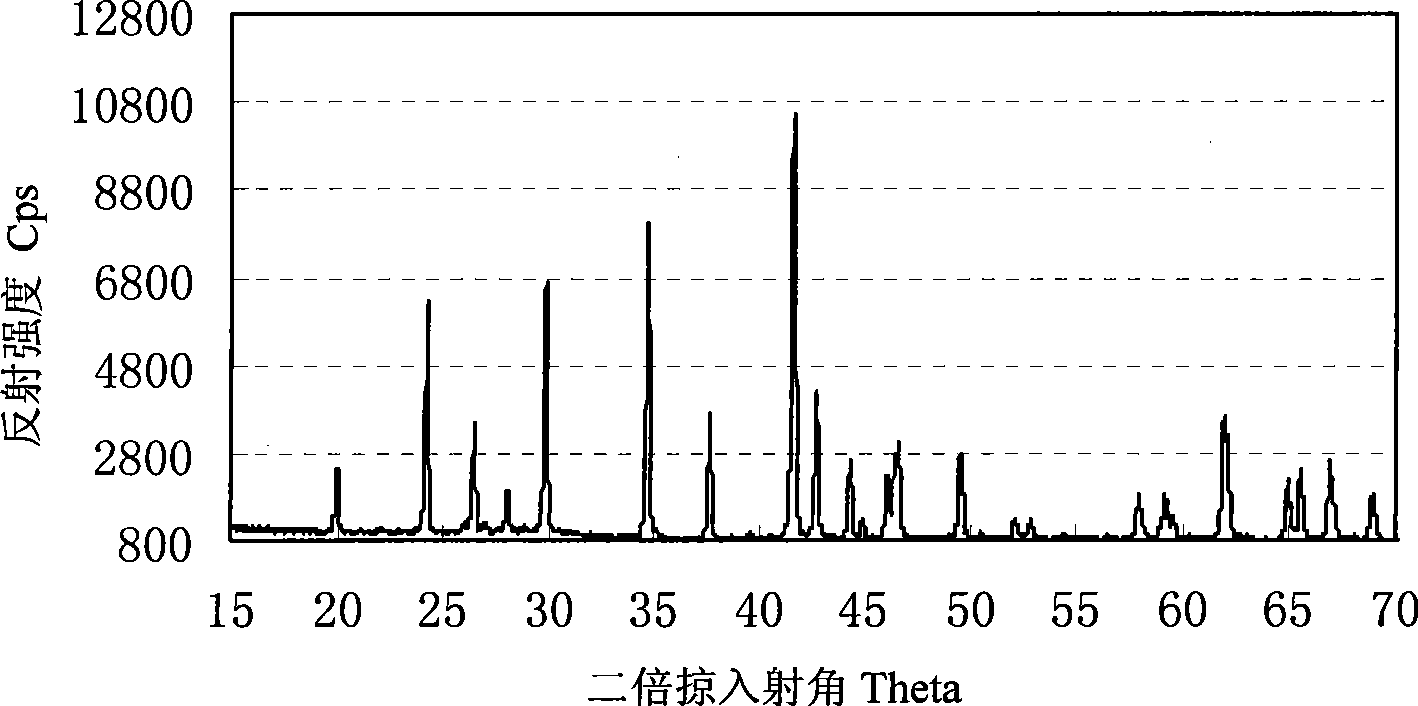

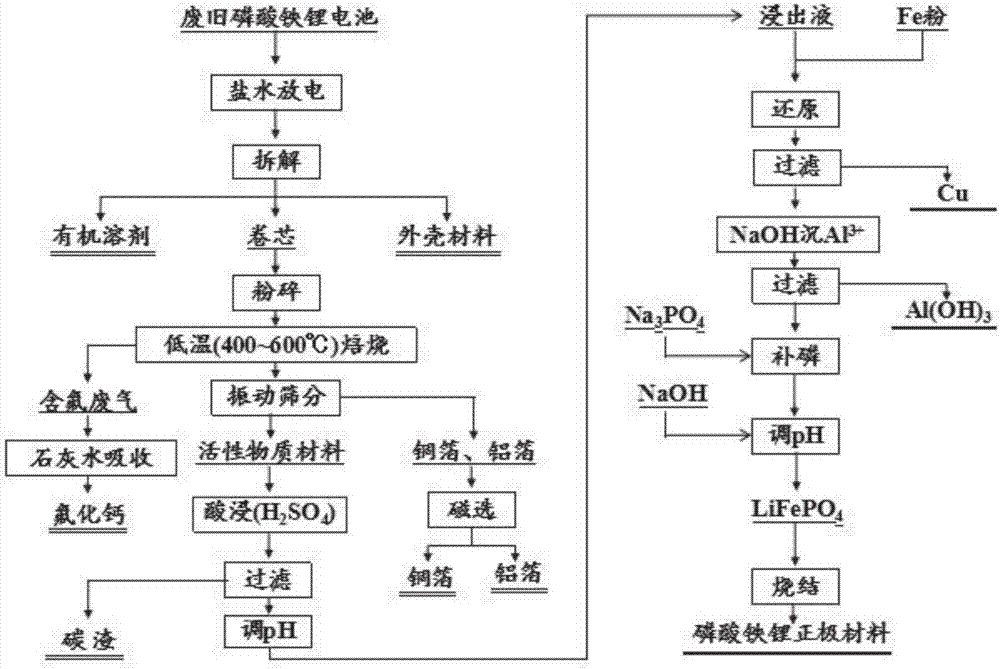

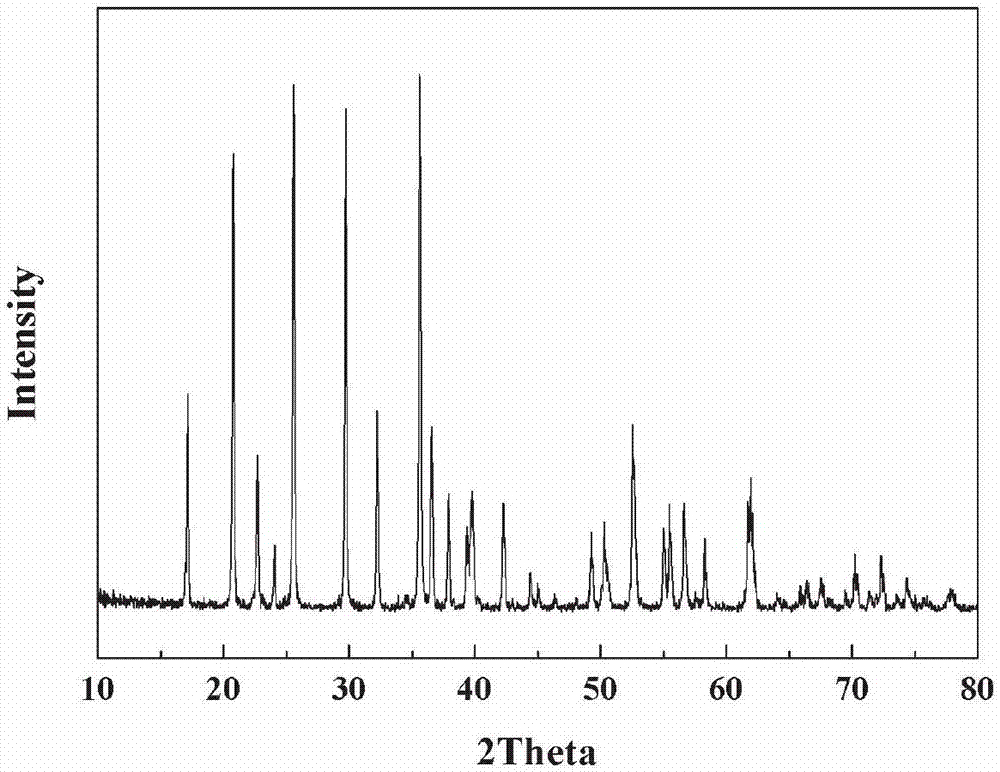

Comprehensive recovering method of waste lithium iron phosphate battery

InactiveCN101847763AImprove performanceLow priceWaste accumulators reclaimingProcess efficiency improvementAdhesiveCalcination

The invention provides a comprehensive recovering method of waste lithium iron phosphate batteries, which has simple and reasonable process, low recovering cost and high added value. The method comprises the following steps: utilizing an organic solvent to dissolve an adhesive on battery cell fragments, and realizing the separation of lithium iron phosphate material and clean aluminum and copper foils through screening, wherein the aluminum and copper foils are recovered by smelting; utilizing a NaOH solution to remove residual aluminum foil scraps in the lithium iron phosphate material, and removing graphite and remaining adhesive by heat treatment; after dissolving the lithium iron phosphate with acid, utilizing sodium sulphide to remove copper ions, and utilizing the NaOH solution or ammonia solution to allow iron, lithium and phosphorus ions in the solution to generate sediments; adding iron source, lithium source or phosphorus source compounds to adjust the molar ratio of iron, lithium and phosphorus; and finally adding a carbon source, and obtaining a lithium iron phosphate cathode material through ball milling and calcination in inert atmosphere. After the treatment of the steps, the recovery rate of valuable metals in the batteries is more than 95%, and the comprehensive recovery rate of the lithium iron phosphate cathode material is more than 90%.

Owner:CHERY AUTOMOBILE CO LTD

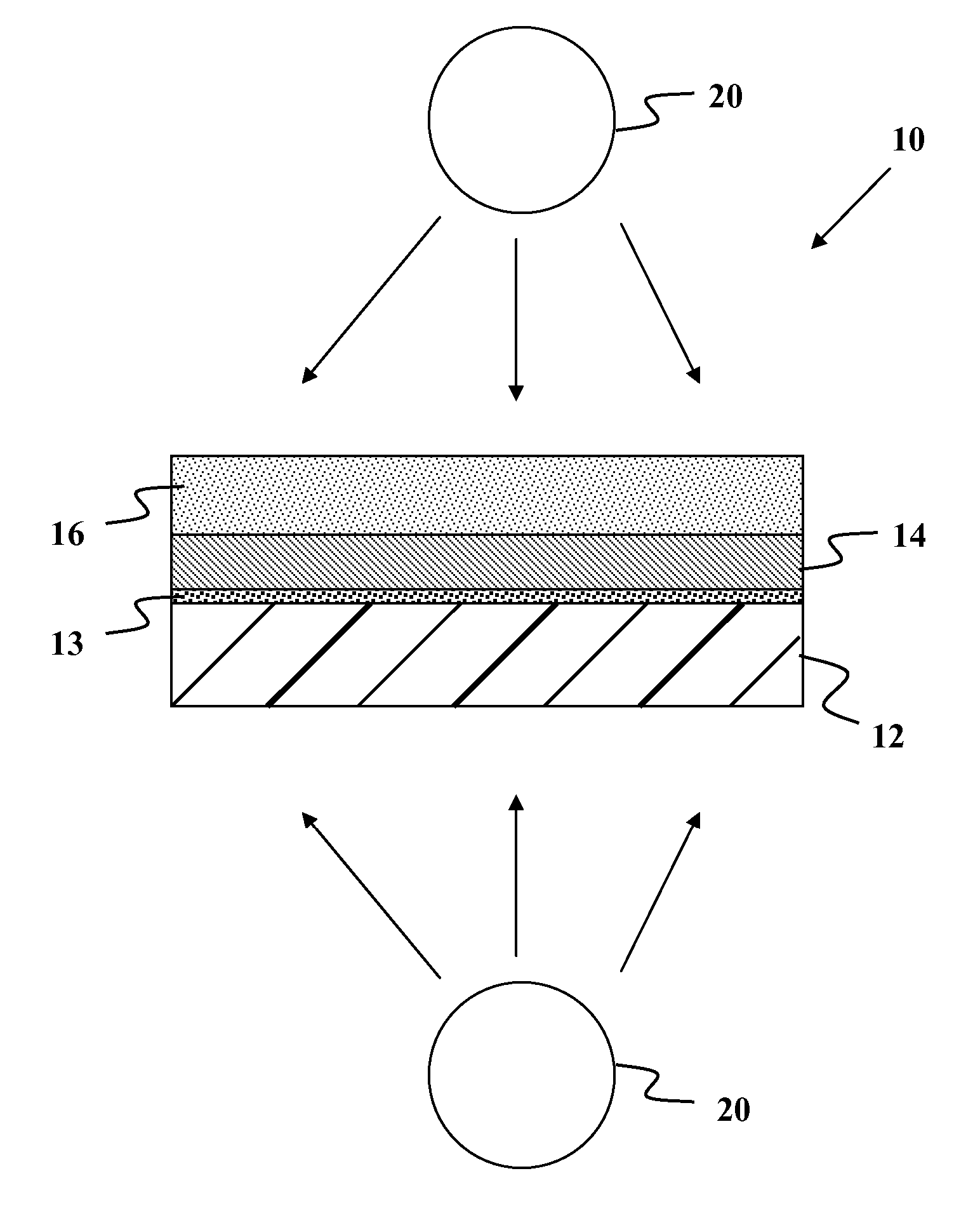

Formation of solar cells with conductive barrier layers and foil substrates

InactiveUS20070000537A1Streamlined fabricationReduce the amount requiredPhotovoltaic supportsFinal product manufactureAmorphous siliconSolar cell

Methods and devices are provided for absorber layers formed on foil substrate. In one embodiment, a method of manufacturing photovoltaic devices may be comprised of providing a substrate comprising of at least one electrically conductive aluminum foil substrate, at least one electrically conductive diffusion barrier layer, and at least one electrically conductive electrode layer above the diffusion barrier layer. The diffusion barrier layer may prevent chemical interaction between the aluminum foil substrate and the electrode layer. An absorber layer may be formed on the substrate. In one embodiment, the absorber layer may be a non-silicon absorber layer. In another embodiment, the absorber layer may be an amorphous silicon (doped or undoped) absorber layer. Optionally, the absorber layer may be based on organic and / or inorganic materials.

Owner:AERIS CAPITAL SUSTAINABLE IP

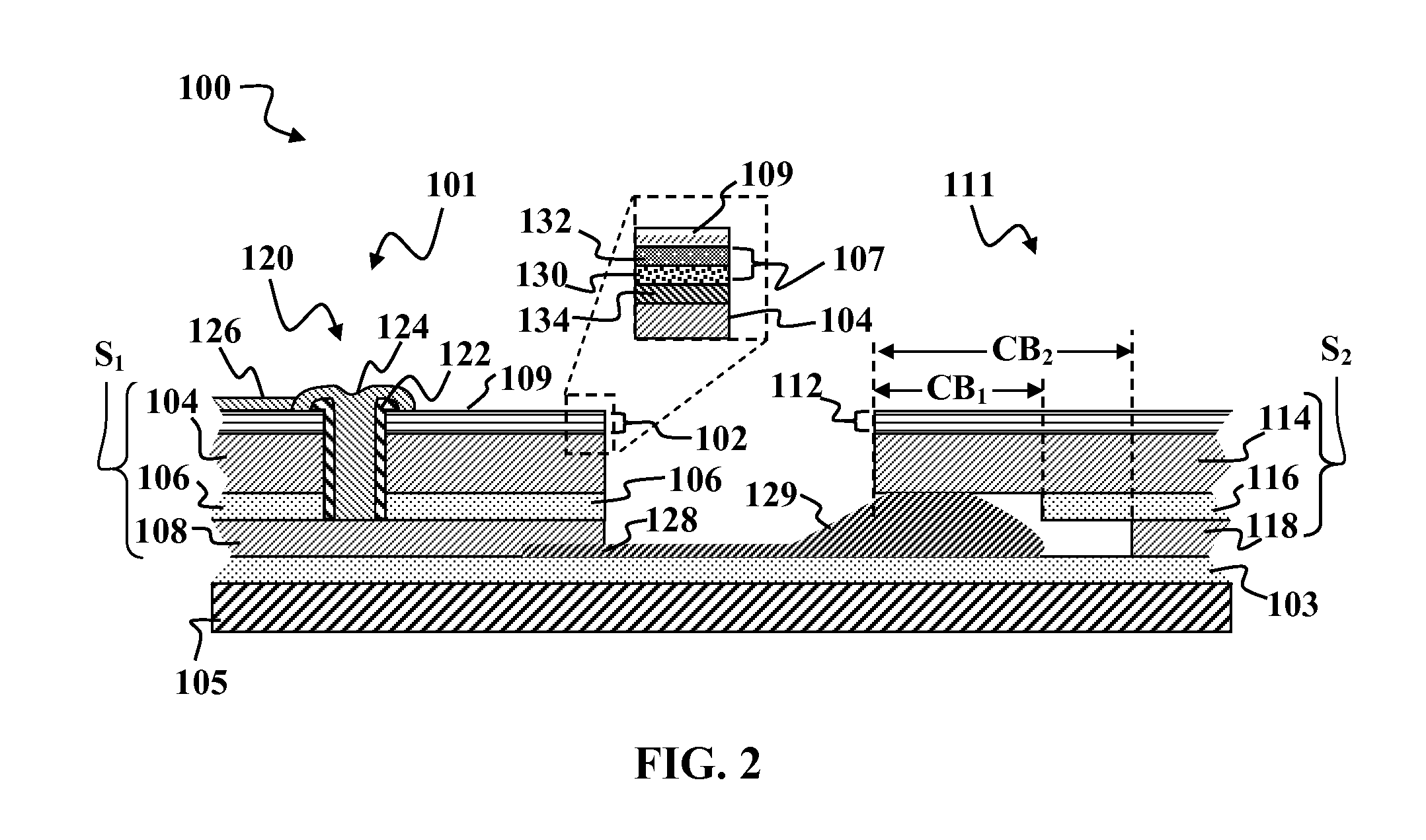

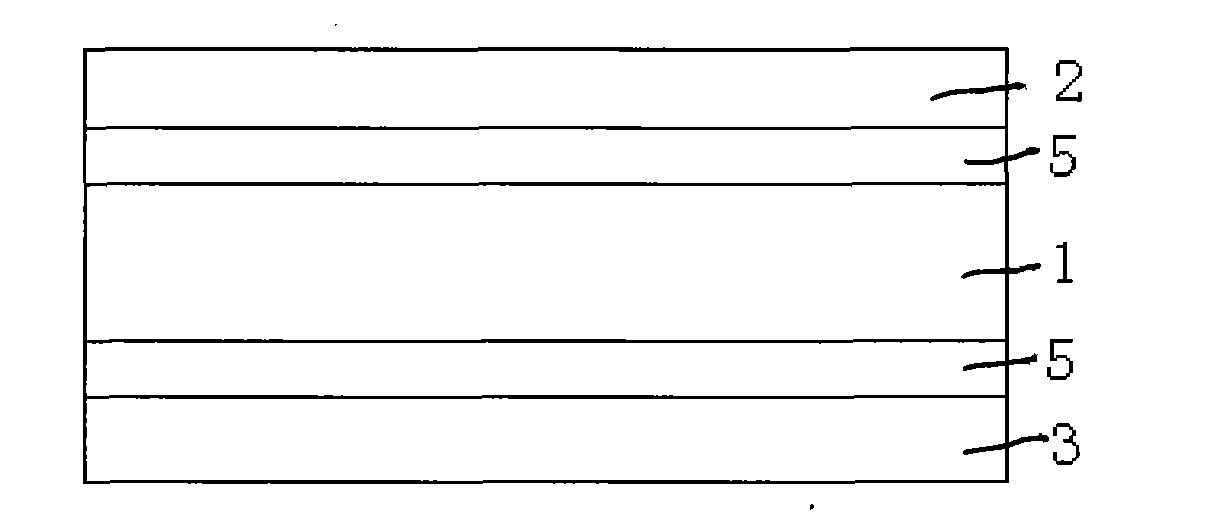

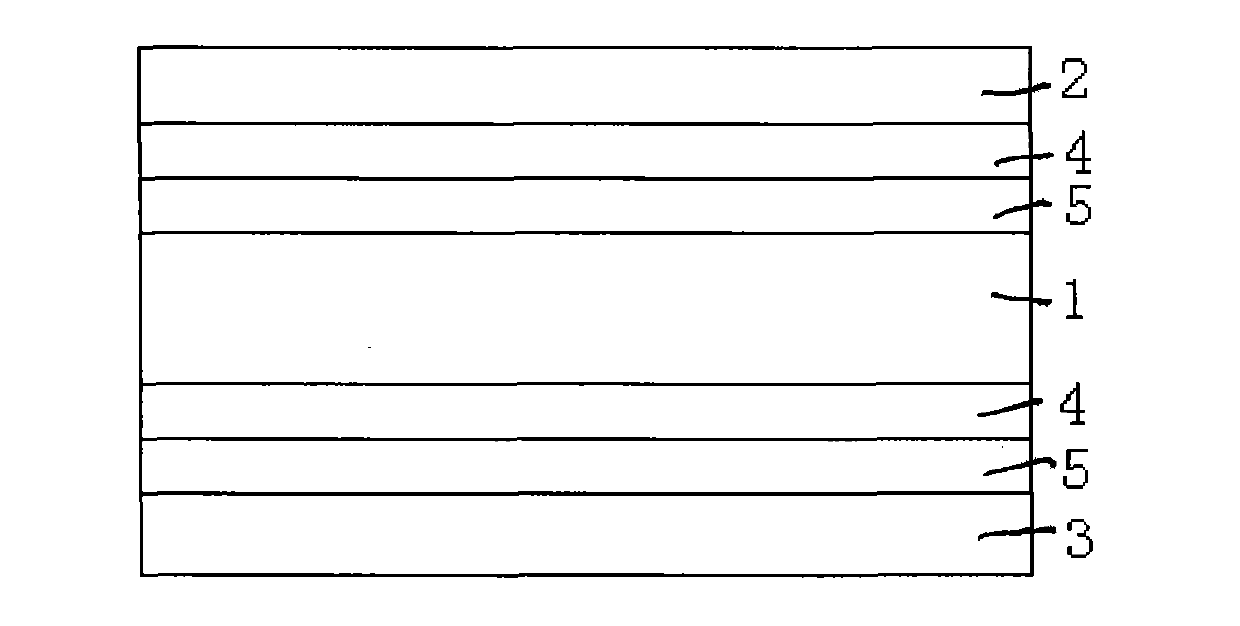

Anode or cathode pole piece of lithium ion battery and coating method thereof

InactiveCN101174685ALower surface energyLow densityElectrode manufacturing processesActive material electrodesCyclic processPole piece

The present invention relates to a lithium-ion battery anode or cathode pole piece and a spreading method of the anode pole piece or the cathode pole piece, wherein, the anode pole piece and the cathode pole piece consists of a foil, a conducting adhesive thin layer and an electrode active material layer in turn; the thickness of the conducting adhesive thin layer is five to ten microns. The electrode pole piece is made in the procedures that a layer of conducting adhesive thin layer in the thickness of five to ten microns are pre-coated on the surface of the foil before the sizing agent is spread, so that a conducting adhesive thin layer having good adhesive force, good conductivity and compact structure is formed on the surface of the foil. Then the electrode active material sizing agent is spread on the conducting adhesive thin layer, and is dried under an appropriate temperature to produce a required pole piece. The present invention can reduce the surface of the foil, and can improve the wetting quality of the sizing agent, thereby improving the adhesion performance of the anode material and the collecting body (aluminum foil) so as to reduce the powder-dropping of the battery during the cycling process, and to prolong the cycling service life of the battery; moreover, the present invention can reduce the content of the adhesive agent in the sizing agent, and improve the utilization rate of the active substance, and the method of the present invention does not produce negative influence on the performance of the battery.

Owner:CENT SOUTH UNIV

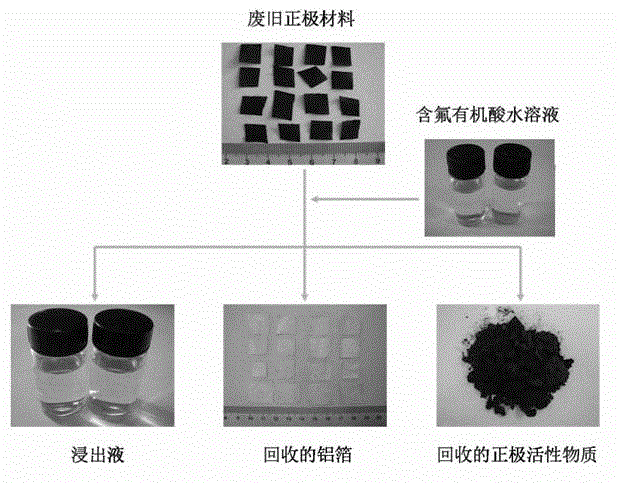

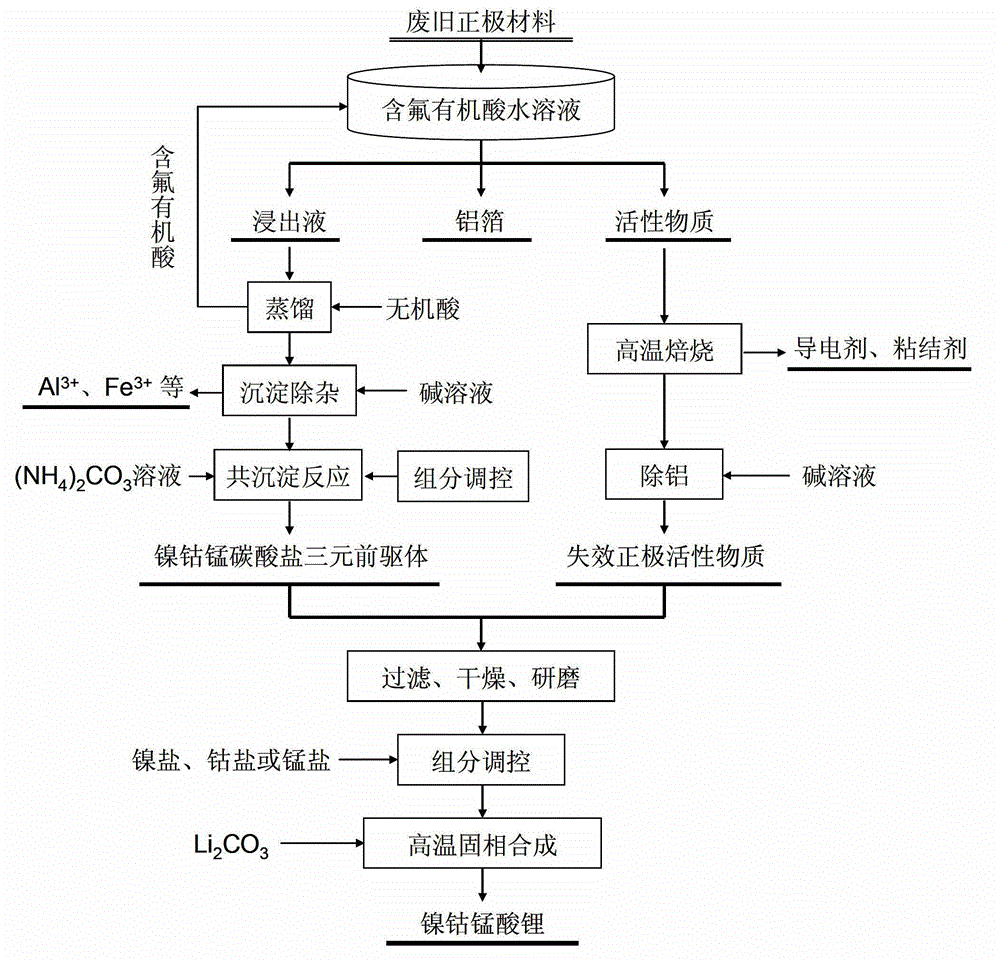

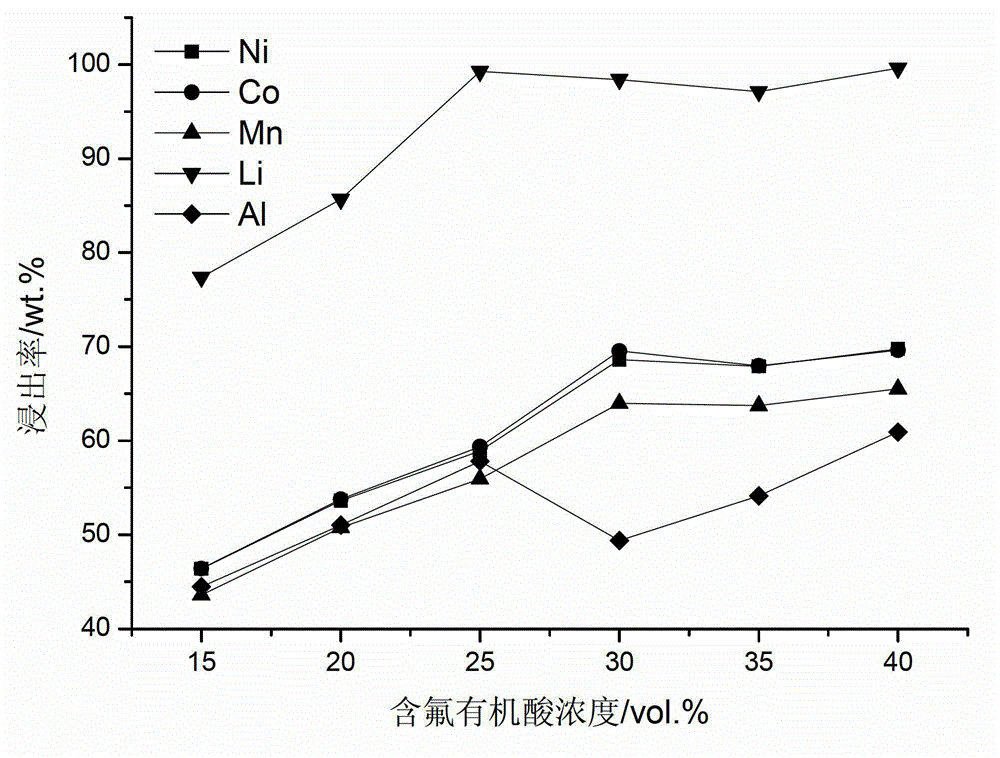

Full-component resource reclamation method for waste positive electrode materials of lithium ion batteries

ActiveCN102751549AAvoid secondary pollutionImprove separation efficiencyWaste accumulators reclaimingBattery recyclingRecovery methodDistillation

The invention provides a full-component resource reclamation method for waste positive electrode materials of lithium ion batteries. The method comprises the following steps: 1) separating active substances and aluminum foils in waste positive electrode materials of lithium ion batteries by using an aqueous solution of fluorine-containing organic acid and carrying out liquid-solid-solid separation so as to obtain leachate, the lithium-containing active substances and the aluminum foils; 2) respectively carrying out high temperature roasting and impurity removal with alkali liquor on the lithium-containing active substances; 3) respectively carrying out recovery of the fluorine-containing organic acid through addition of acid and distillation, deposition of impurity ions through addition of alkali and ammonium carbonate coprecipitation on the leachate so as to prepare nickel-cobalt-manganese carbonate ternary precursor; and 4) carrying out component regulation on a mixture of the treated active substances and the nickel-cobalt-manganese carbonate ternary precursor, adding lithium carbonate in a certain proportion and carrying out high temperature solid phase sintering so as to prepare a lithium nickel cobalt manganese oxide ternary positive electrode material. The method provided in the invention has the following advantages: the application scope of the method is wide; separation efficiency of the lithium-containing active substances and the aluminum foils is high; short-flow direct re-preparation of positive electrode materials in waste lithium ion batteries is realized; and the method is applicable to large-scale resource reclamation of waste lithium ion batteries.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Synthetic recovering method for positive pole waste tablet from ferric phosphate lithium cell

ActiveCN101383441AReduce manufacturing costAchieve recyclingElectrode manufacturing processesSolid waste disposalRecovery methodPhosphate

The invention relates to a synthesized recovery method for waste positive plates of iron phosphate lithium batteries. The method comprises the following steps: collected waste positive plate material is mechanically crashed into fragments; the fragments are positioned in a welding furnace which is protected by vacuum atmosphere, inert gases and / or reducing gases and / or nitrogen and are heat processed in the temperature of 150-750 DEG C; aluminum foil basal bodies are separated from the fragments after heat process by adopting mechanical separation or ultrasonic concussion to obtain a mixture of iron phosphate lithium positive material, conduction agent and caking agent giblets; the mixture of iron phosphate lithium anode material, conduction agent and caking agent giblets is roasted for 8-24 hrs in 80-150 DRG C; the mixture after roasting is classified to control the grain diameter of the powder material to be not more than 20 microns, and the D50 is controlled to be 3-10 microns so as to obtain iron phosphate lithium positive recovery material. The method has simple technique, takes effect fast and reduces the material consumption and production cost of a manufacturer.

Owner:ZHENGZHOU BAK BATTERY CO LTD

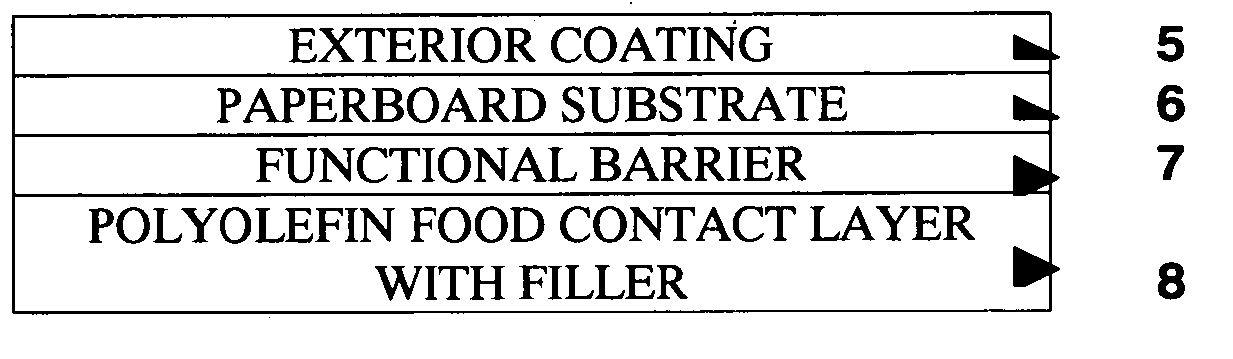

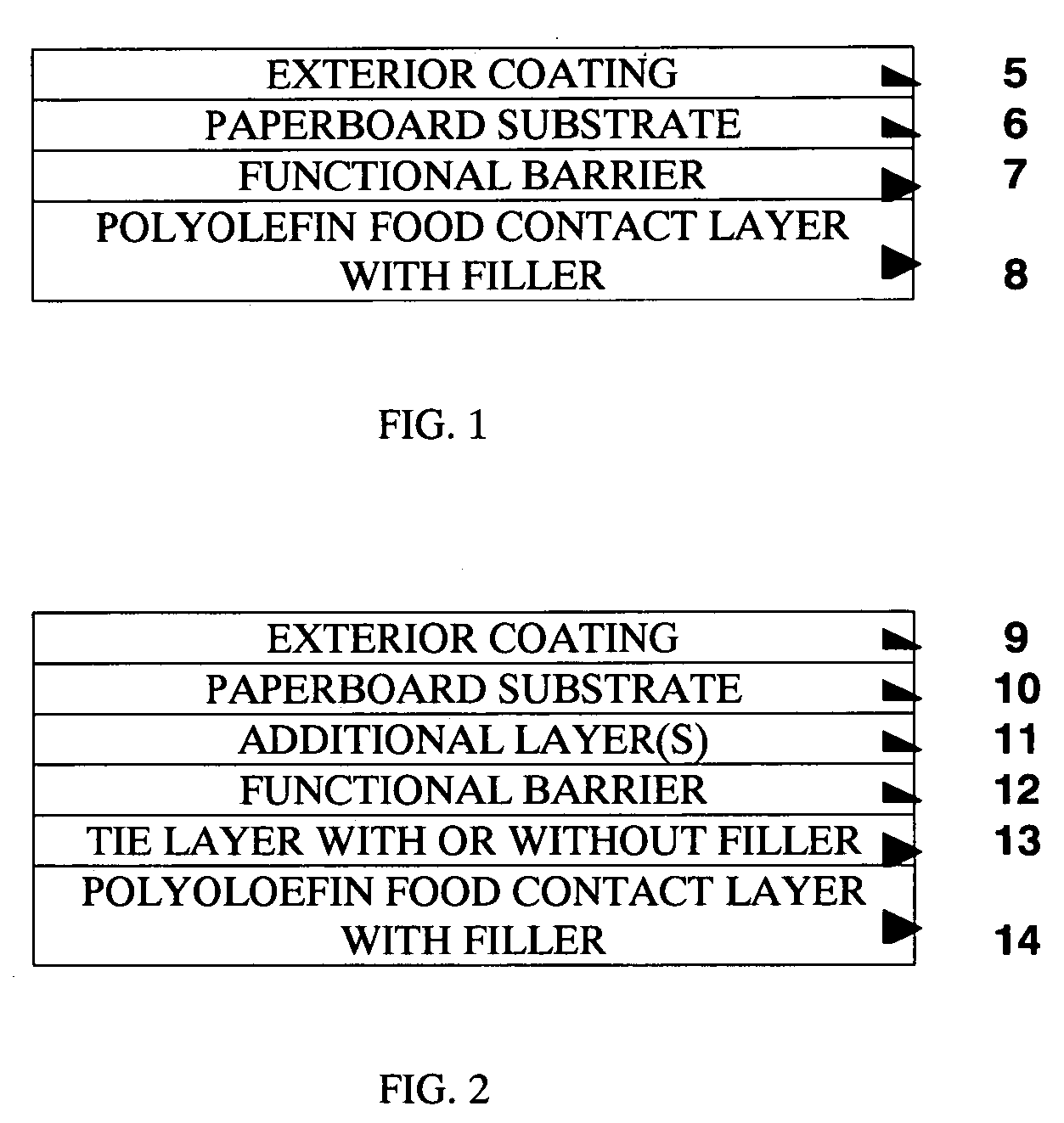

Paperboard laminate for food packaging applications

A laminate structure having improved resistance to the migration of essential oils, aromas and flavors and improved oxygen barrier characteristics for beverage packaging comprising an exterior coating of polyethylene applied onto the outer surface of paperboard substrate, a barrier layer of aluminum foil, EVOH, polyamide or PET applied directly or indirectly onto the paperboard and tie and other sublayers which may or may not contain inorganic filler applied intermediate the barrier layer and the innermost food contact layer which may or may not contain filler. The containers or cartons prepared from the laminate structures are characterized by minimized scalping and preserved product quality.

Owner:INT PAPER CO

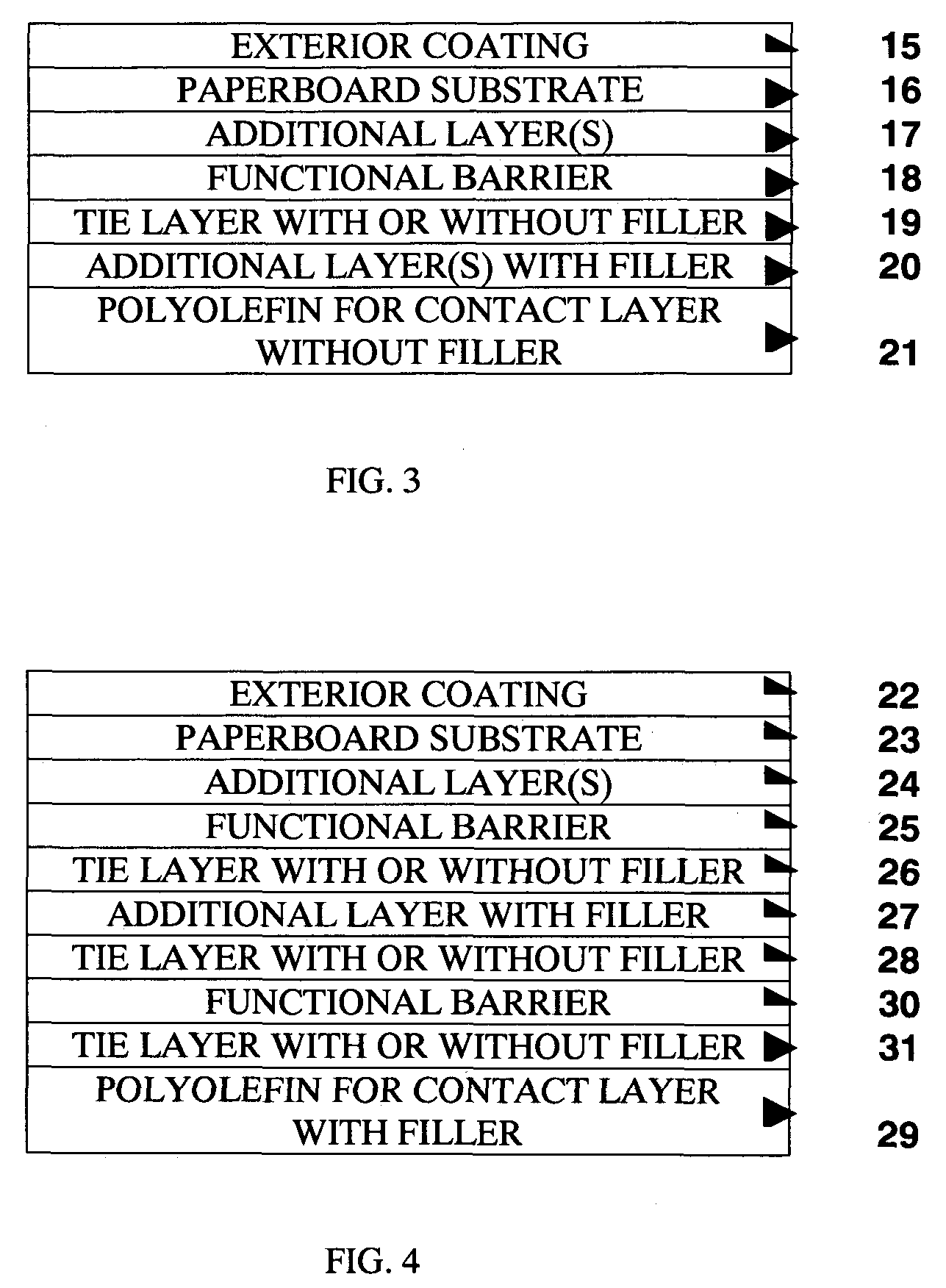

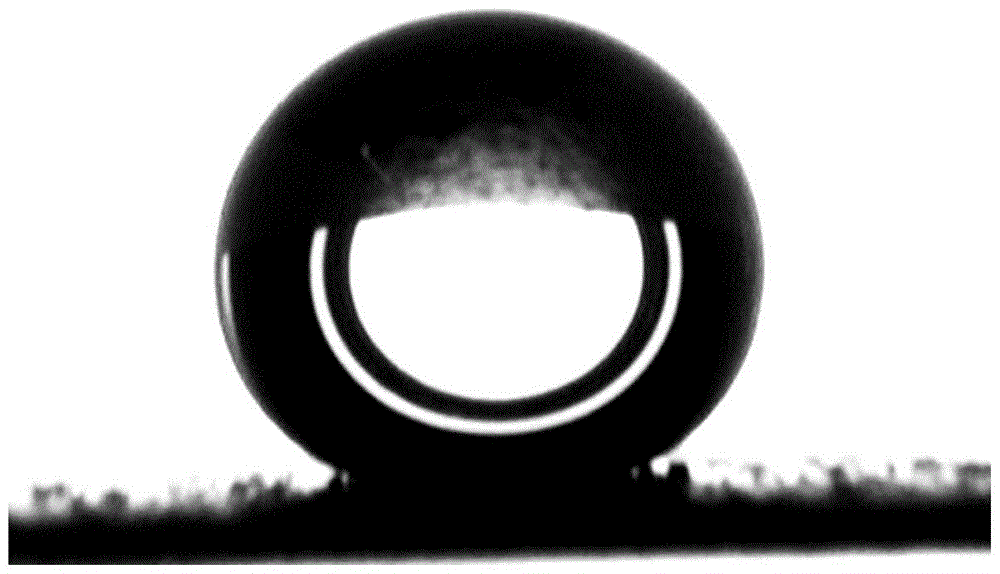

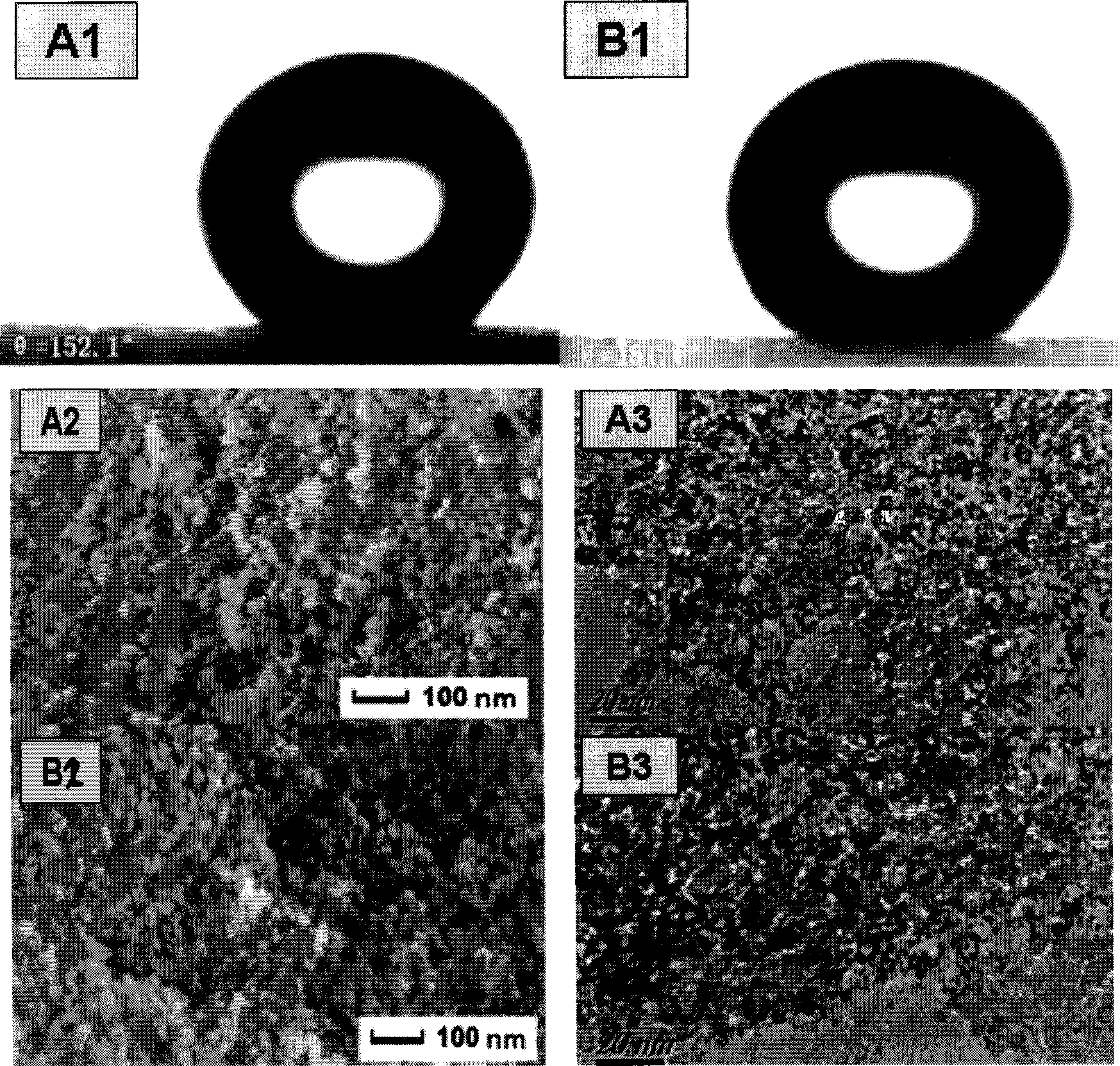

Preparation method for energy-saving anti-icing/deicing coating combining super-hydrophobic coating and heating coating

ActiveCN105032731ASimple processSuitable for large area applicationsChemical industryPretreated surfacesSilanesGas phase

The invention discloses a preparation method for an energy-saving anti-icing / deicing coating combining a super-hydrophobic coating and a heating coating. The preparation method includes seven steps. The novel heating coating is added based on the super-hydrophobic coating, the super-hydrophobic coating anti-icing technology and the heating anti-icing technology are combined, and a novel anti-icing technology is provided. The super-hydrophobic coating is obtained by modifying commercial gas-phase silicon dioxide with fluoroalkyl silane, mixing the modified commercial gas-phase silicon dioxide with resin according to a proper proportion and meanwhile adding heat-conductive particles. The heating coating is obtained by evenly spraying high-temperature-resistant conductive resin into a fixed shape and then attaching aluminum foil to two ends as electrodes. The preparation method for the energy-saving anti-icing / deicing coating combining the super-hydrophobic coating and the heating coating has the advantages of coating anti-icing and electric heating anti-icing, improves the heat efficiency by changing the heating mode, and realizes efficient and energy-saving deicing.

Owner:BEIHANG UNIV

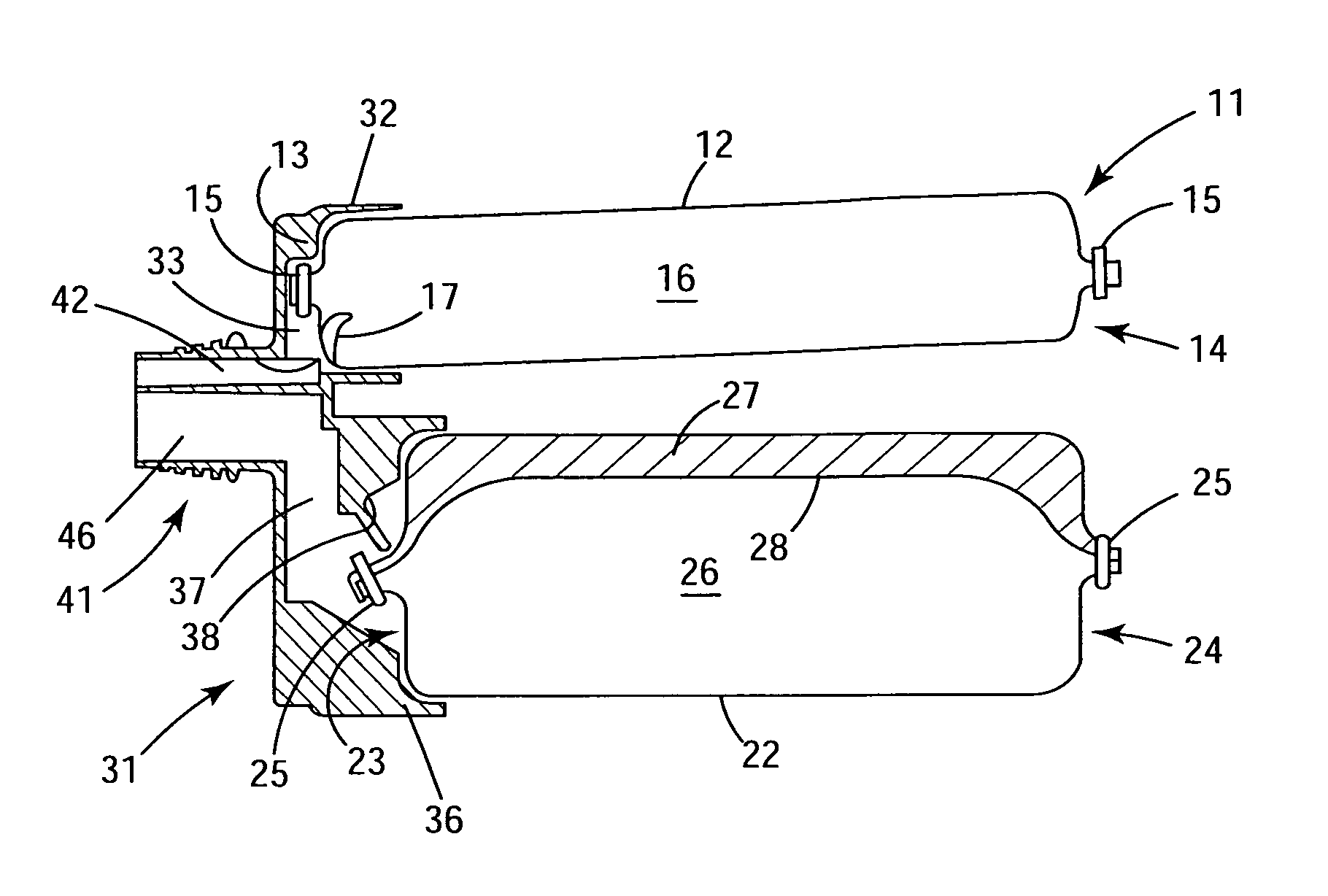

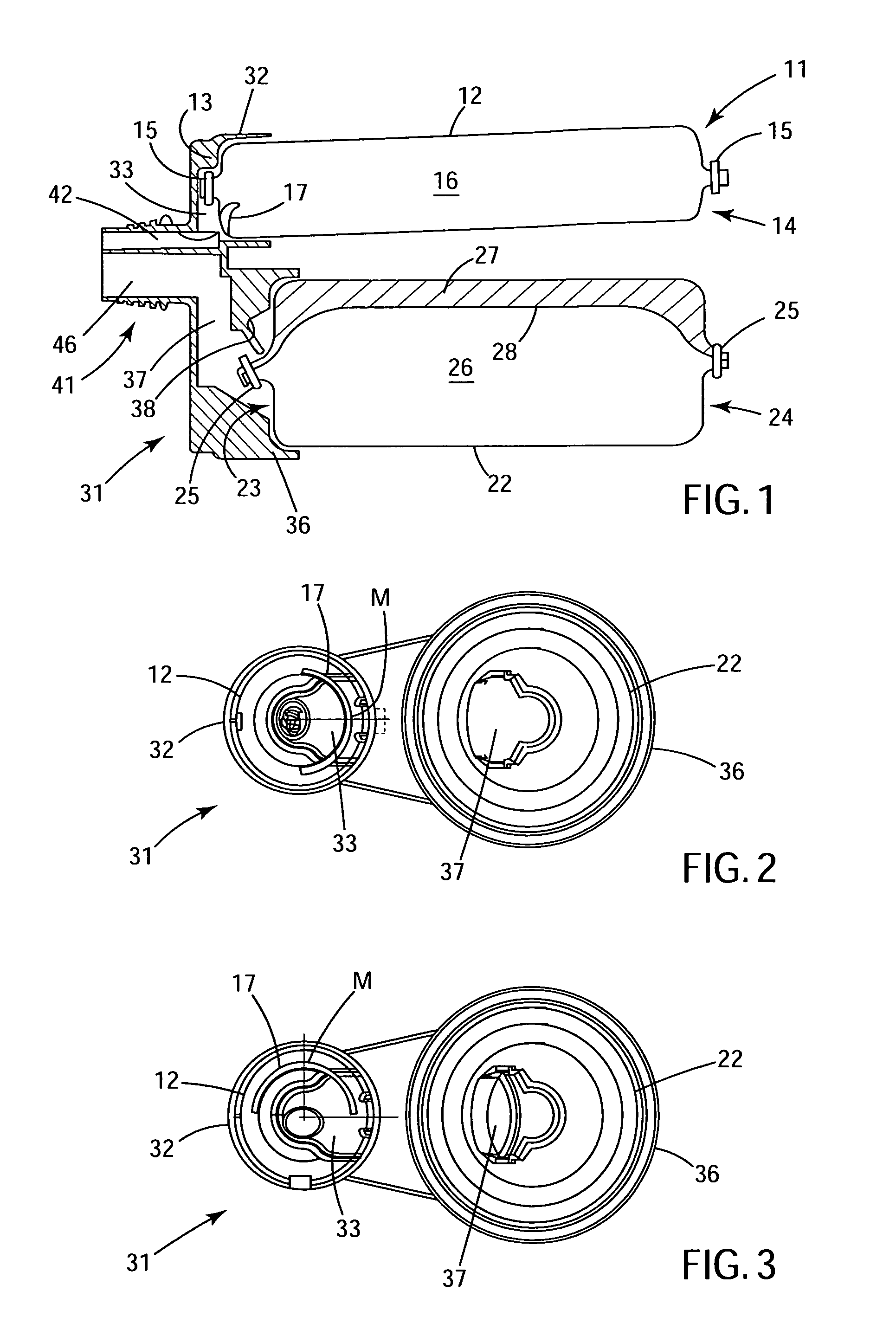

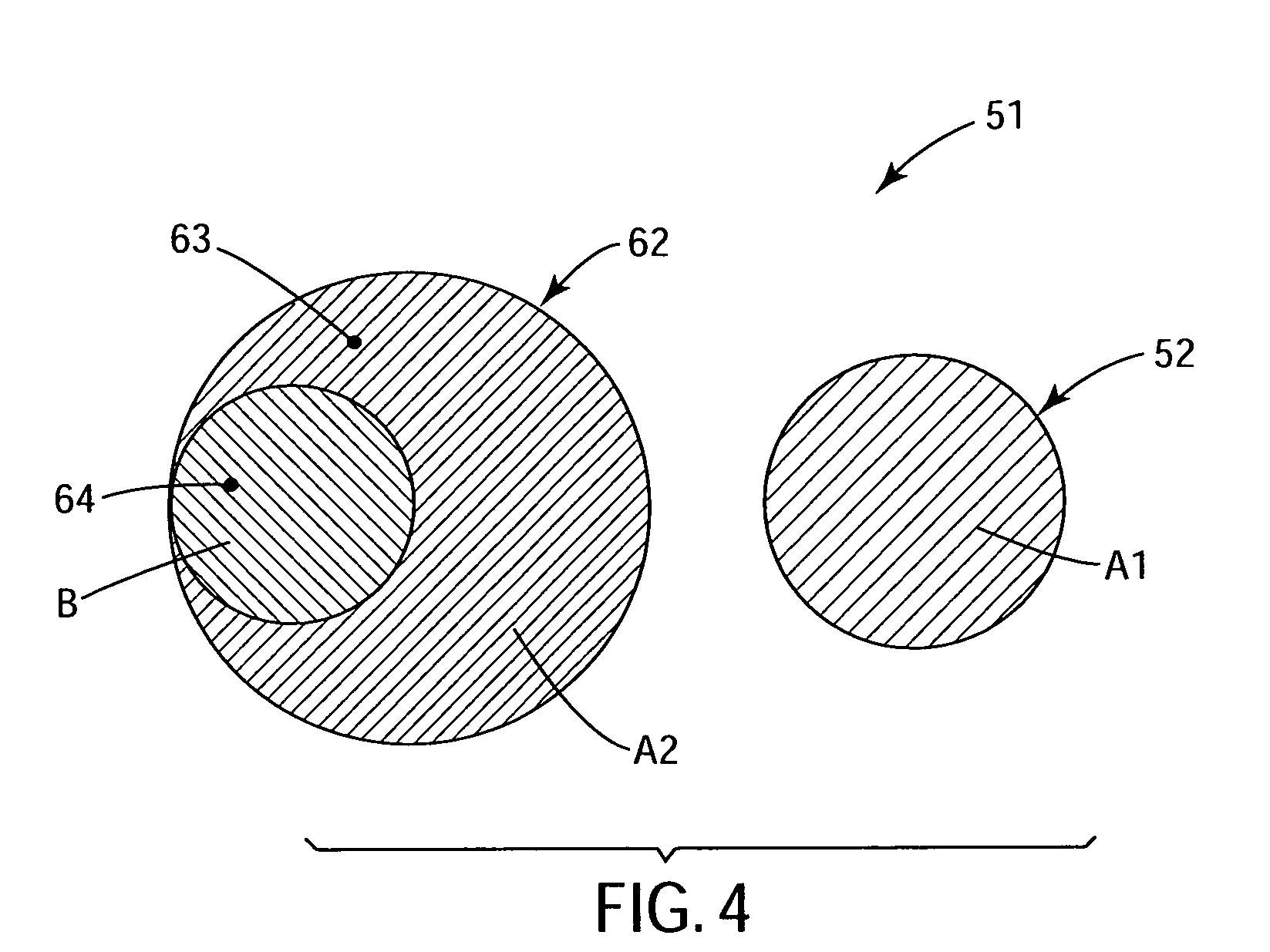

Foil container

InactiveUS8313006B2Avoid componentsAvoid reactionLiquid surface applicatorsClosuresEngineeringAluminum foil

A foil container for storing components of a multi-component mass and for being inserted in a receptacle of an ejection device, includes a first foil bag (12) that stores at least one component (16) of the multi-component mass, a second foil bag (22) arranged next to the first foil bag (12) and that stores at least two components (26, 27) of the multi-component mass separately from each other, and a head portion (31) having at least two receiving sections (32, 36) for receiving respective ends (13, 23) of the first and second foil bags (12, 22).

Owner:HILTI AG

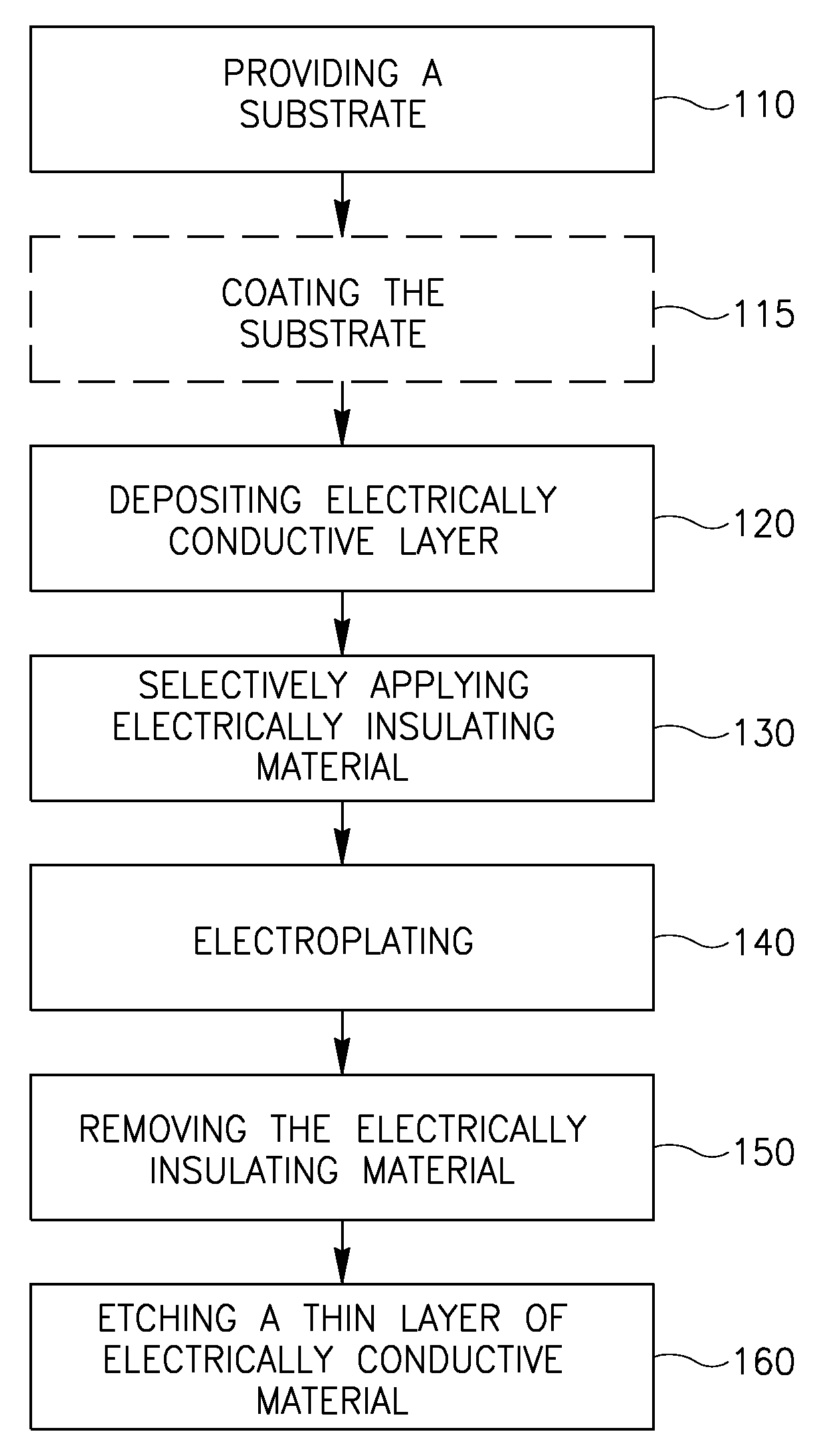

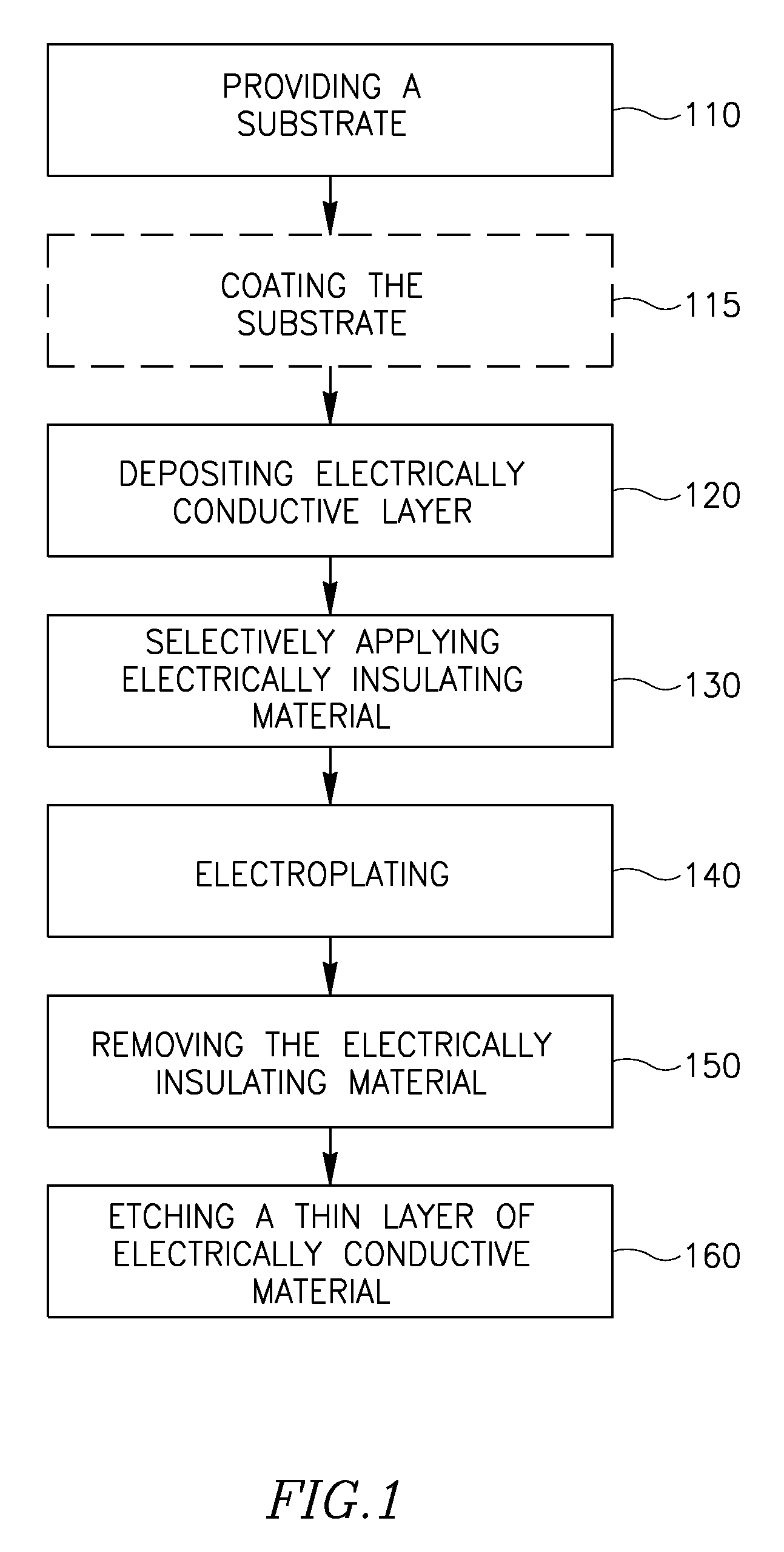

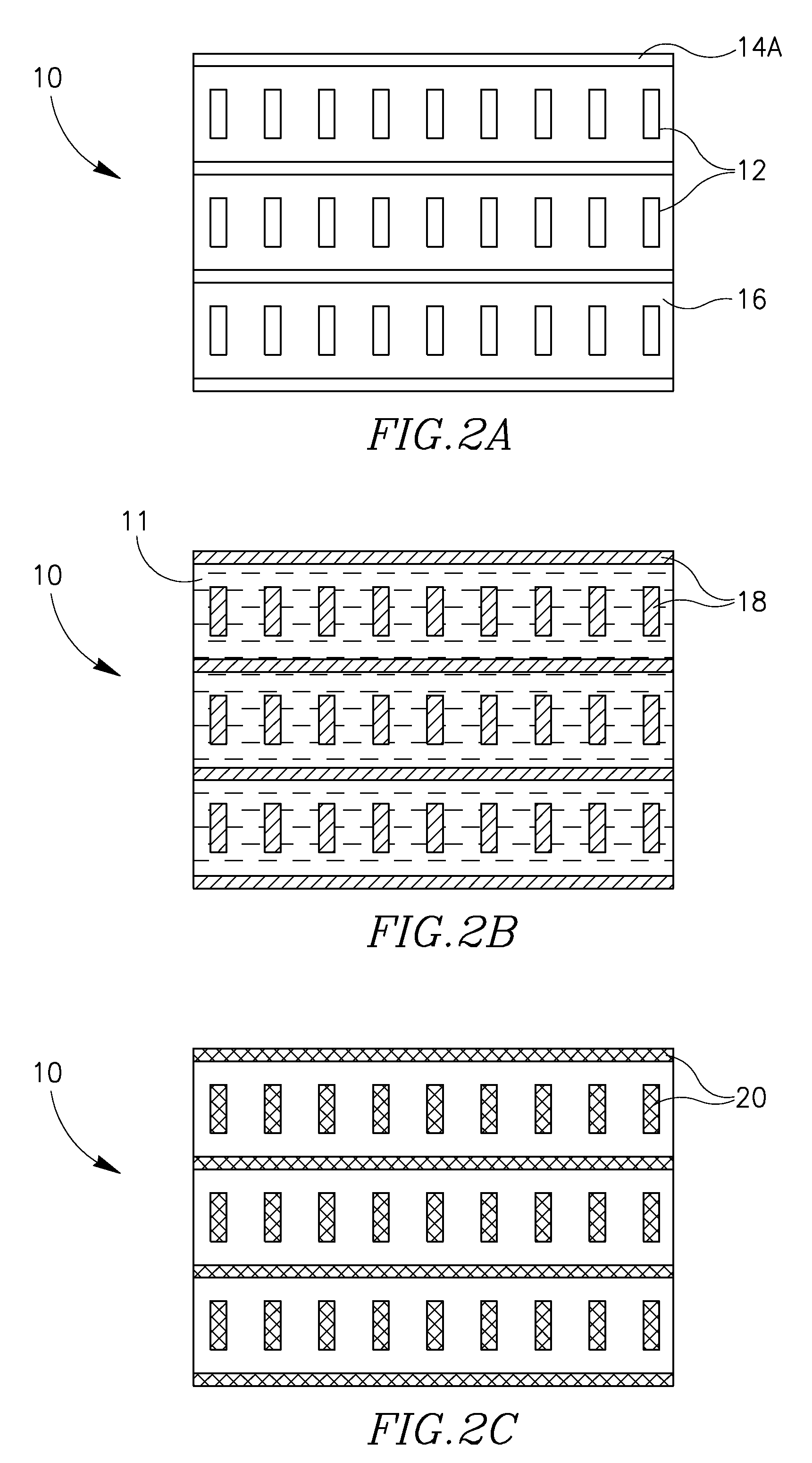

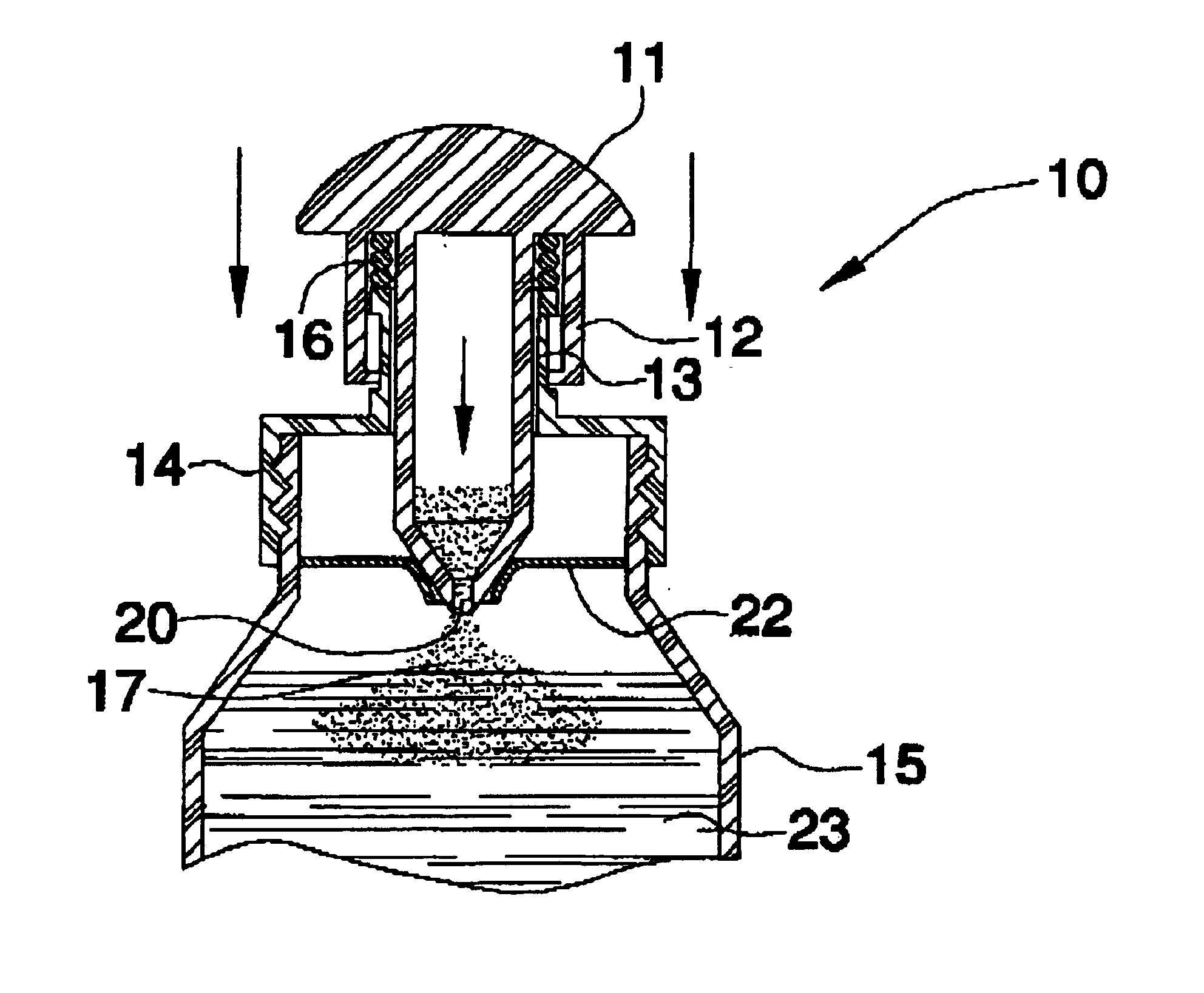

Patterns of conductive objects on a substrate and method of producing thereof

InactiveUS20090165296A1Magnetic/electric field screeningPrinted circuit aspectsResistConductive materials

According to embodiments of the present invention, a method for manufacturing a pattern of conductive elements on a substrate is provided. The method includes coating an aluminum foil laminated onto the substrate with an electrically conductive material, applying an etch-resist material on selective areas pre-designed to carry the conductive objects, chemically etching to remove the aluminum and the electrically conductive material from areas not covered by the etch-resist material that are complementary to the selective areas and removing the etch-resist material.

Owner:HANITA COATINGS R C A

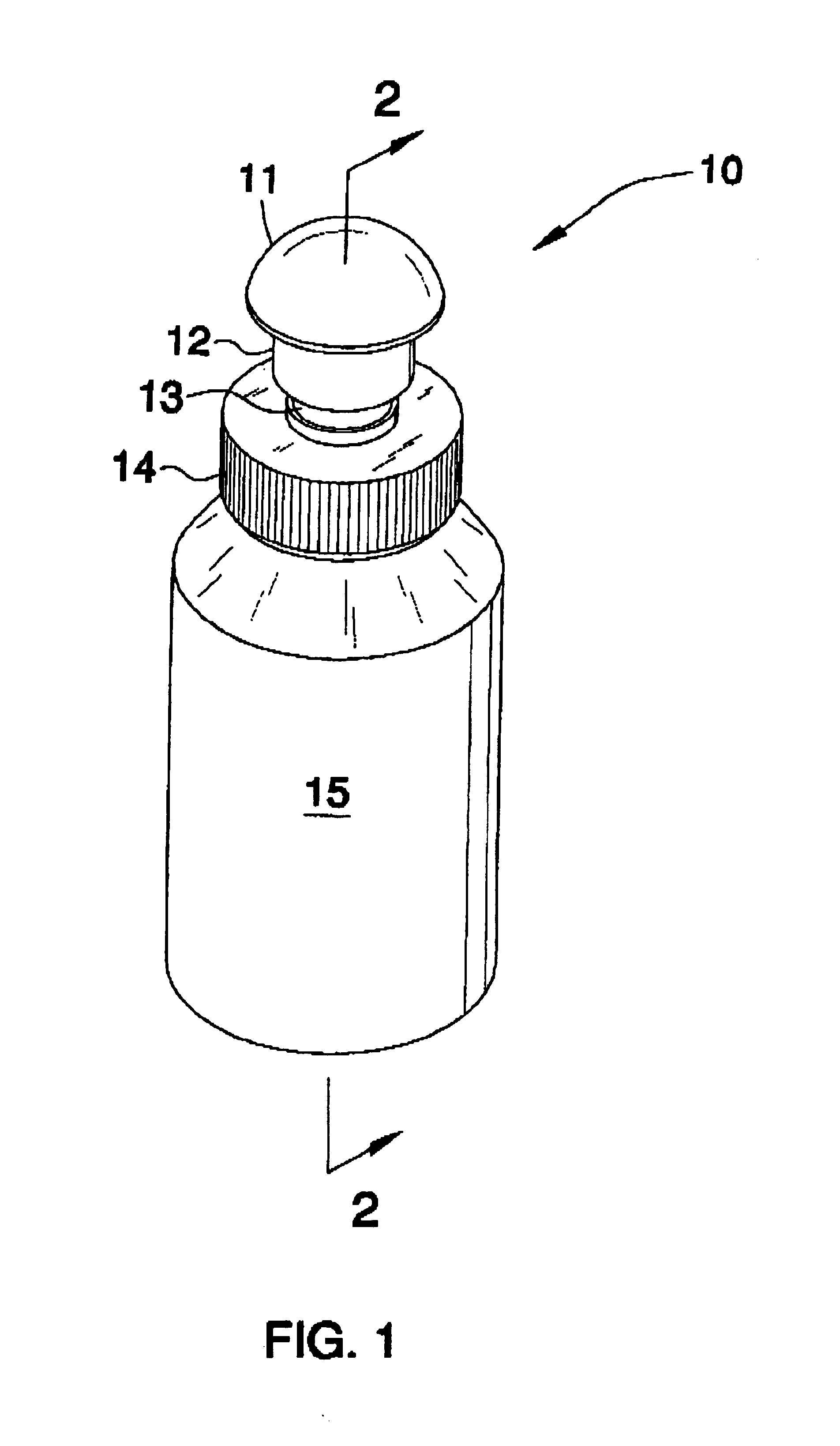

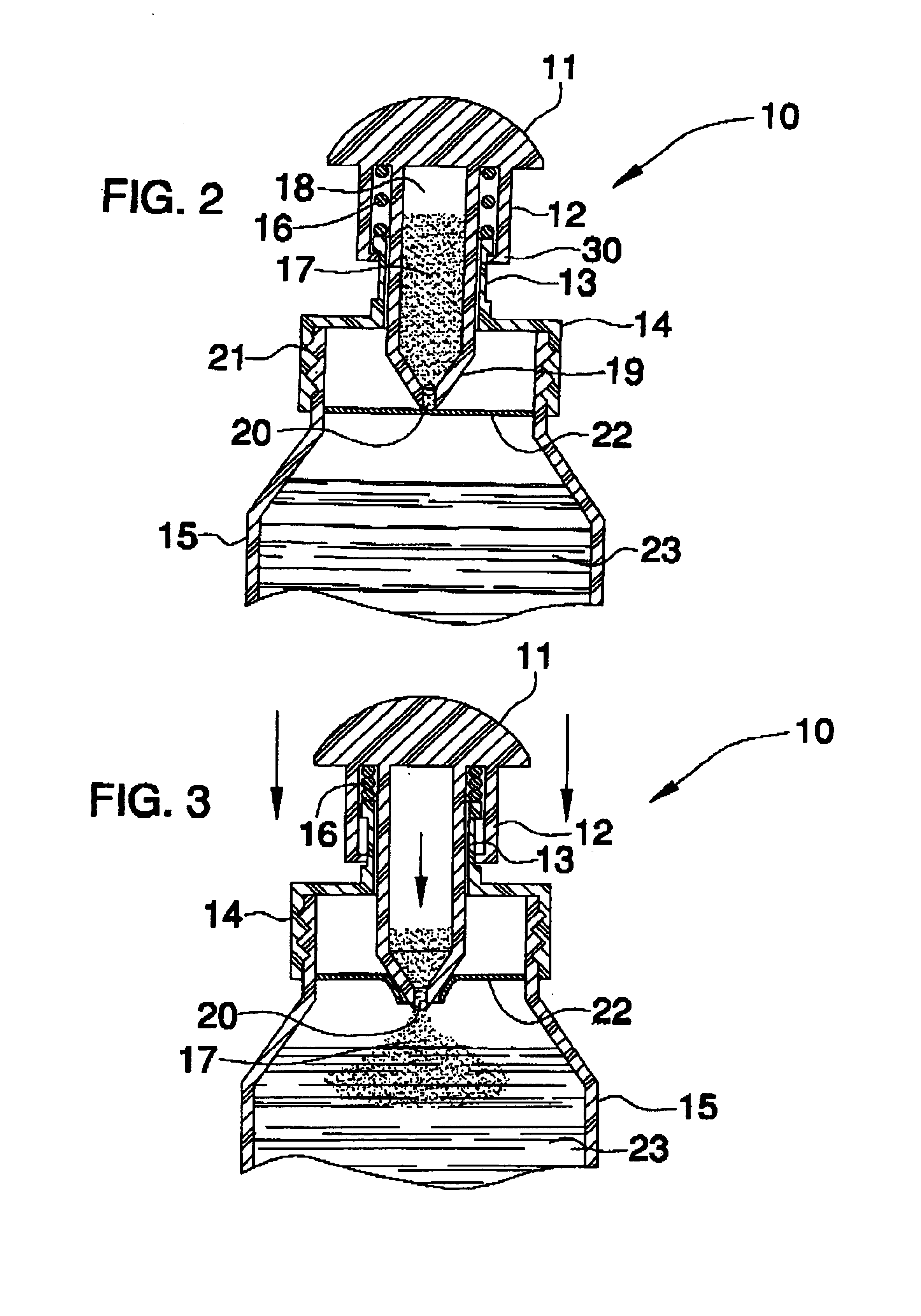

Bottle cap including an additive dispenser

A cap includes a plunger member including a cavity portion integral therewith and extending downwardly therefrom. The cavity portion is capable of containing additive therein and includes a lower portion having an opening for dispensing the additive into the container. A receiving member receives the plunger member and includes a threaded portion for engaging a container. A spring member is preferably disposed between the cavity portion and a neck portion and becomes compressed when the plunger member is moved towards a down position. A membrane preferably extends across an opening of a container and engages the opening of the cavity portion when the plunger member is at an up position. The membrane may be formed from aluminum foil so that it can be penetrated when the plunger member is moved to a down position and to thereby allow the opening of the cavity to pass therebelow so that the additive can be introduced into a container.

Owner:BASHAM MARK FLOYD +1

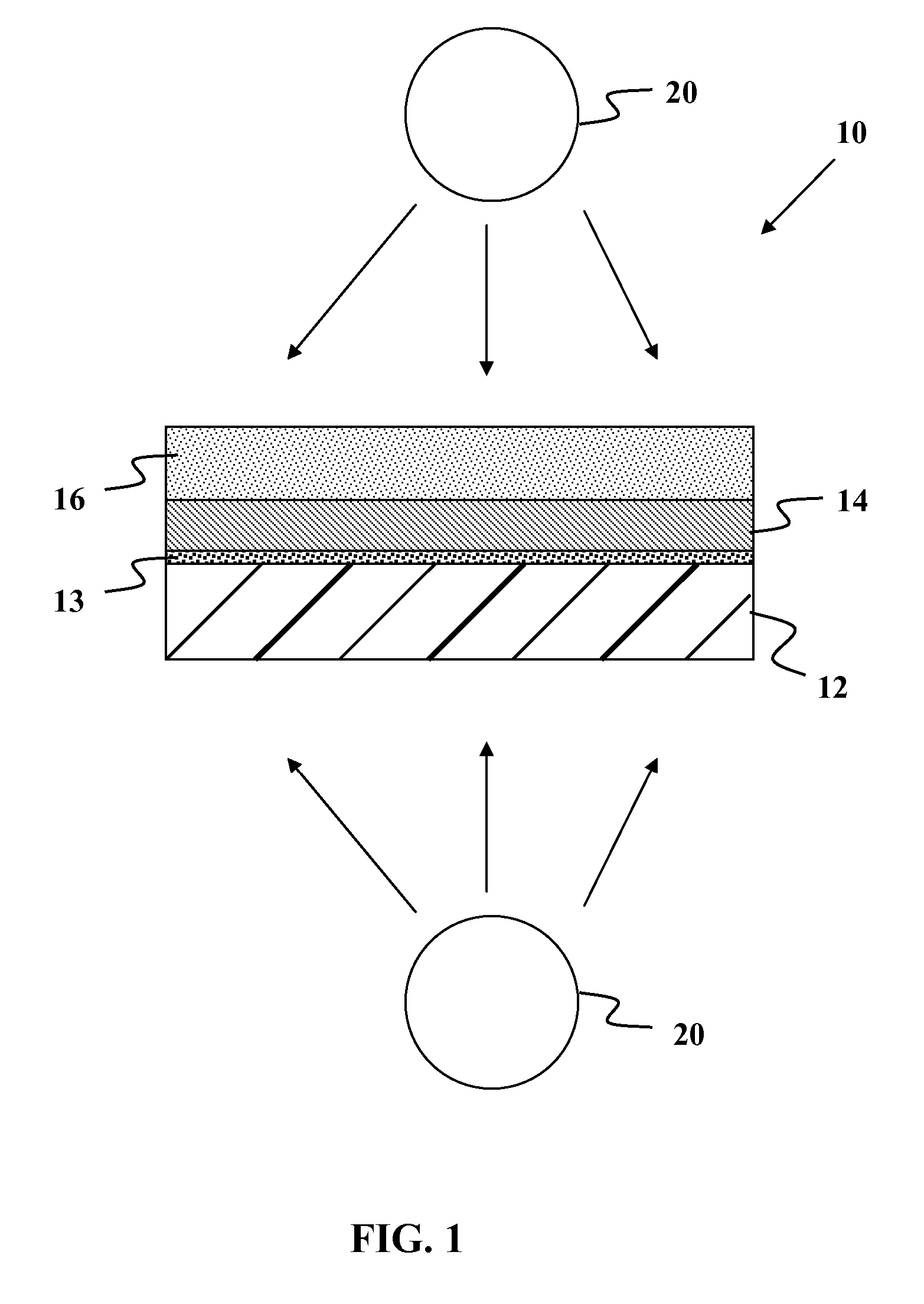

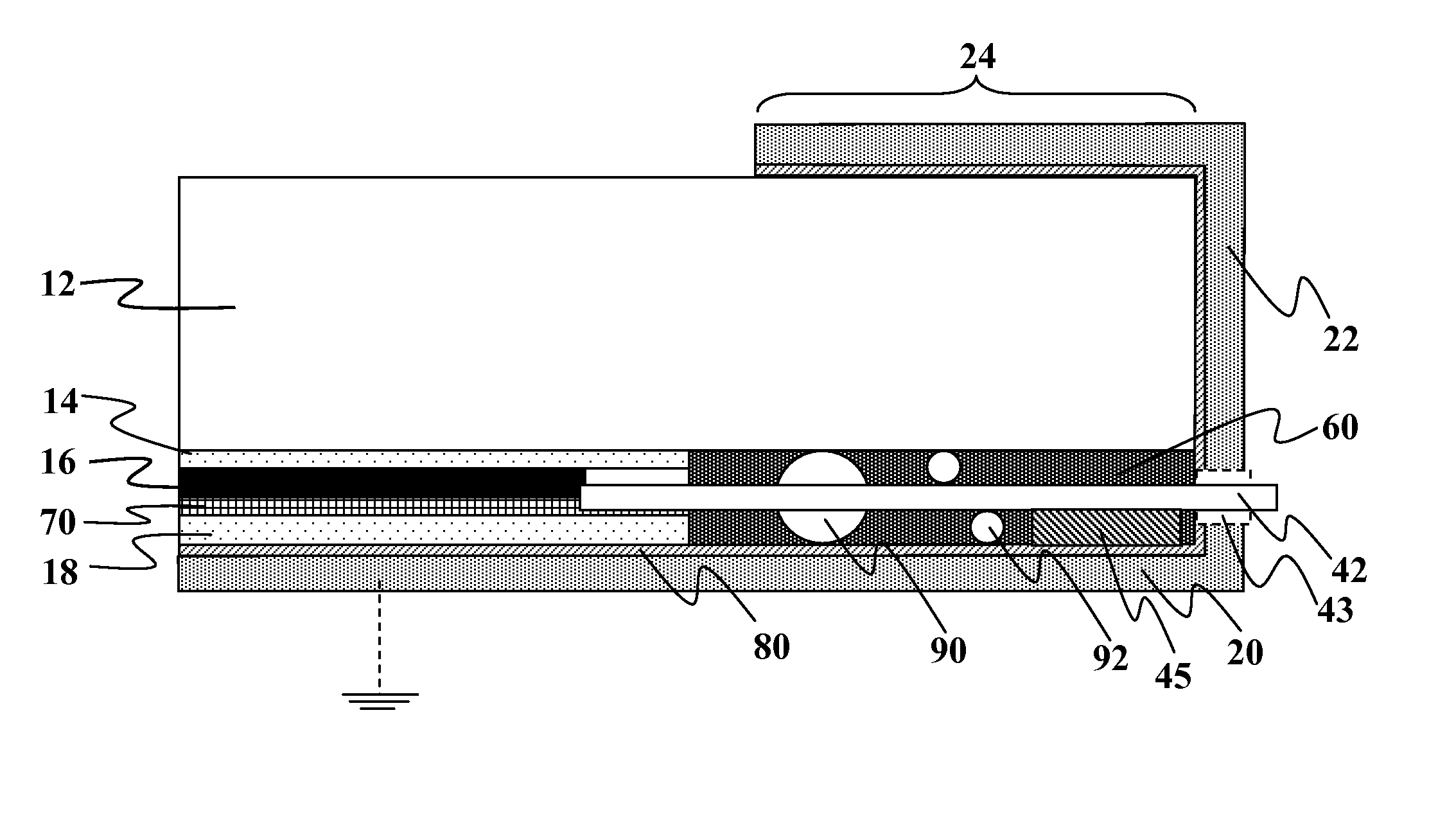

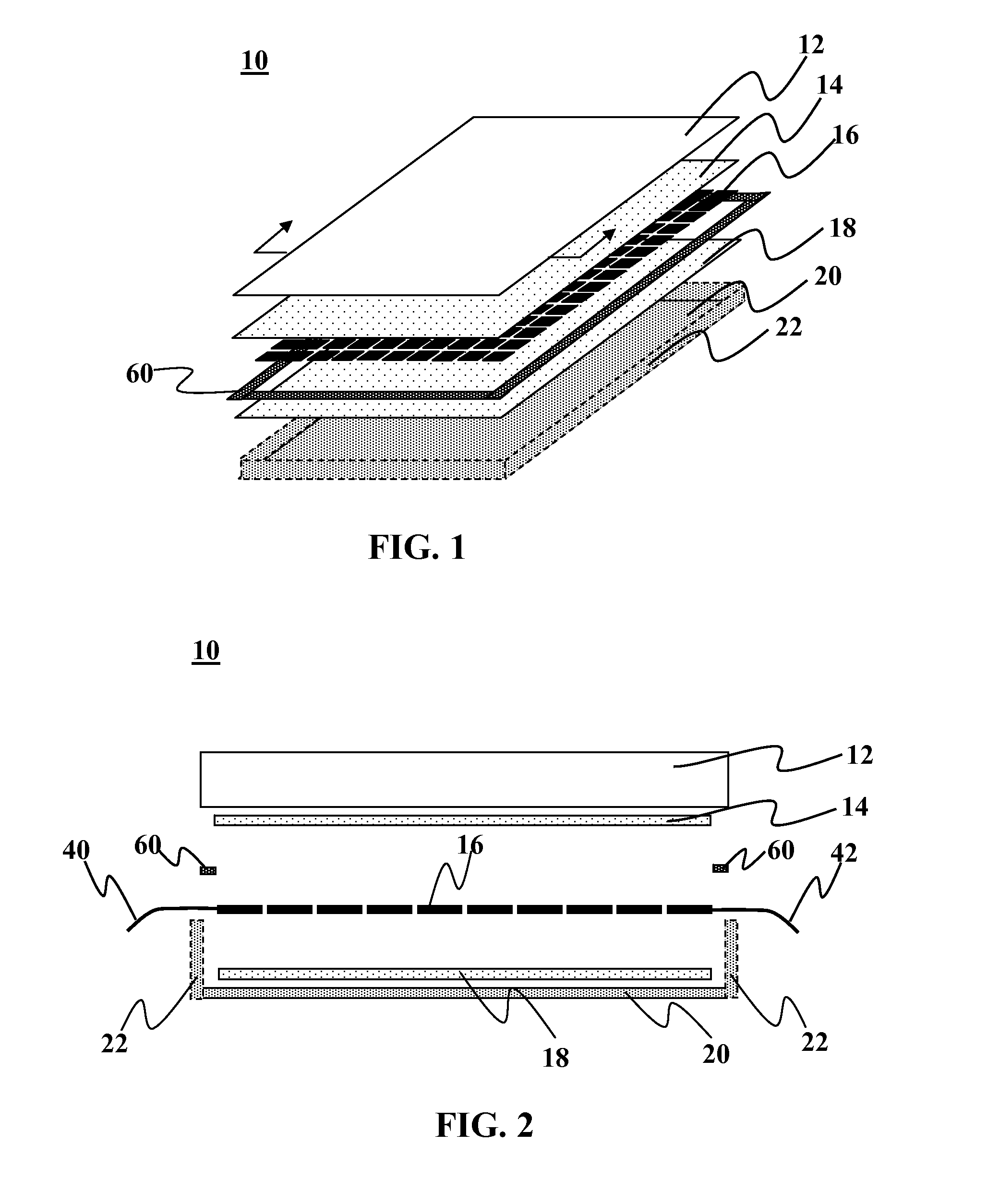

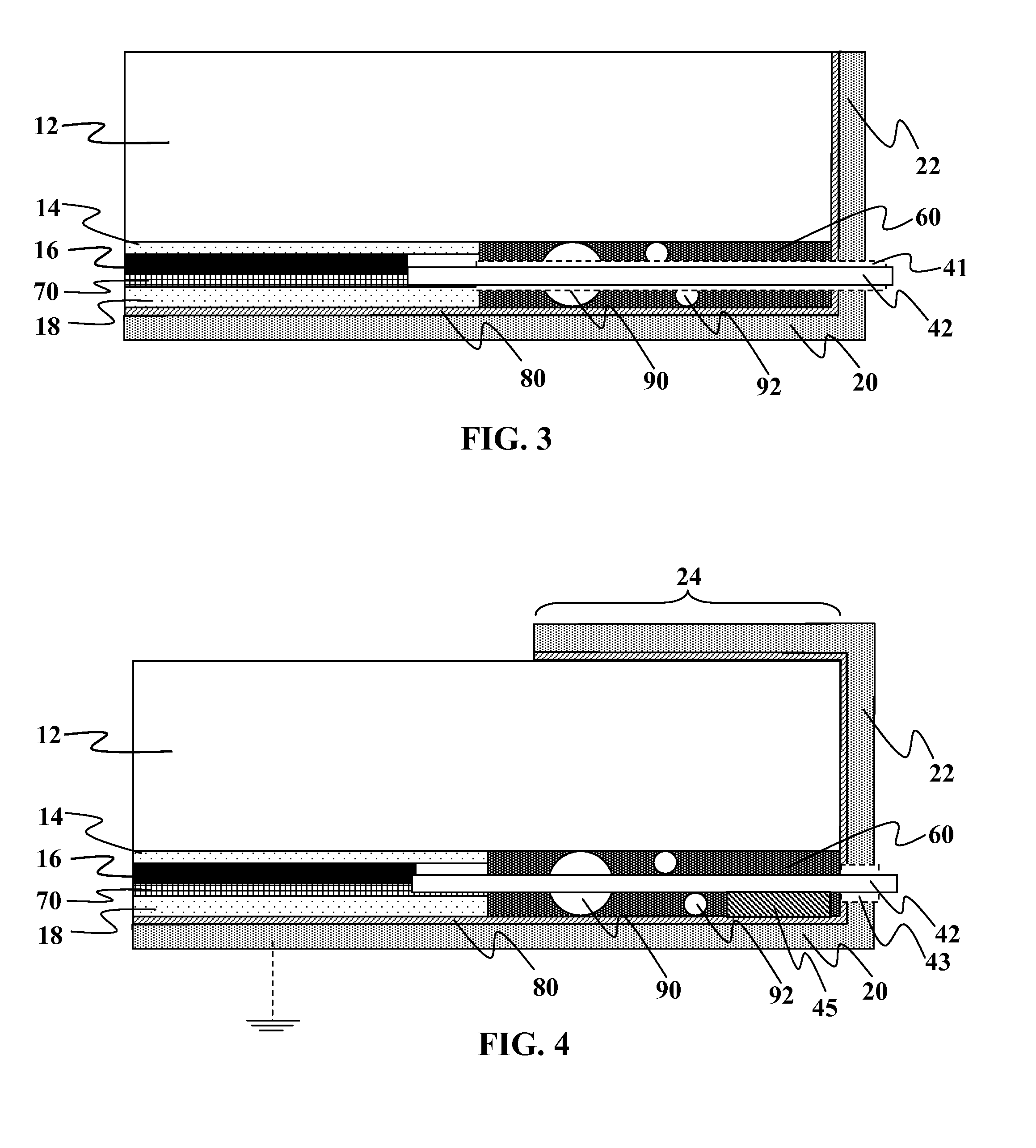

Structures for low cost, reliable solar modules

InactiveUS20080289681A1Simplifies solar module designReduce material costsPhotovoltaic supportsPV power plantsEngineeringAluminum foil

Methods and devices are provided for improved large-scale solar installations. In one embodiment, a photovoltaic module is provided comprising a module front layer comprising a glass plate, a module back layer comprising an electrically conductive foil, and a plurality of solar cells arranged to be protected by the front layer and the back layer. In some embodiments, the module back layer is aluminum foil. The module back layer may have an externally exposed surface. The module back layer may be electrically grounded. An electrically insulating pottant material may be used with the solar cells to separate them from the module back layer. This allows for a high voltage withstand between the cells and the outer surface of the back layer.

Owner:ADRIANI PAUL M +2

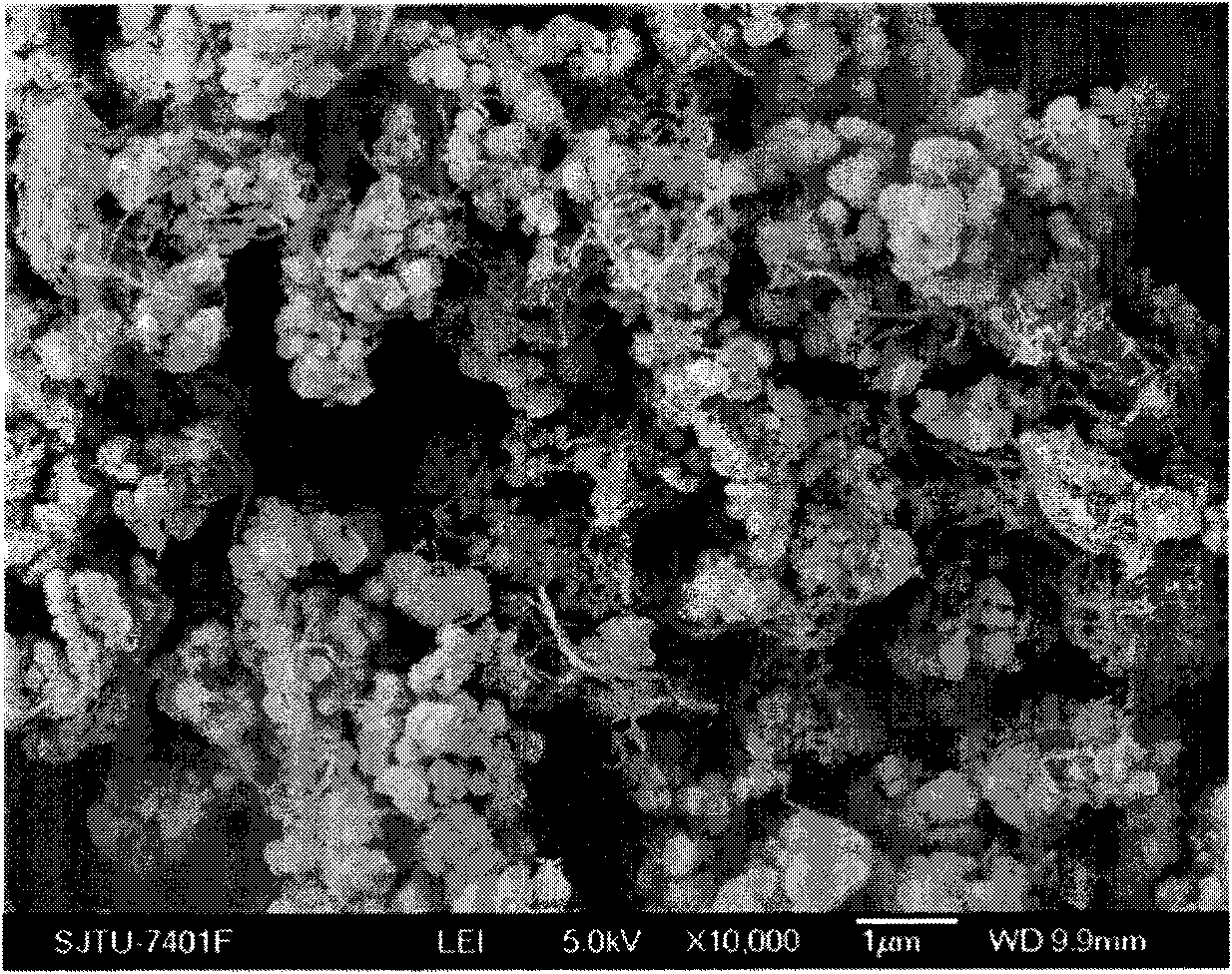

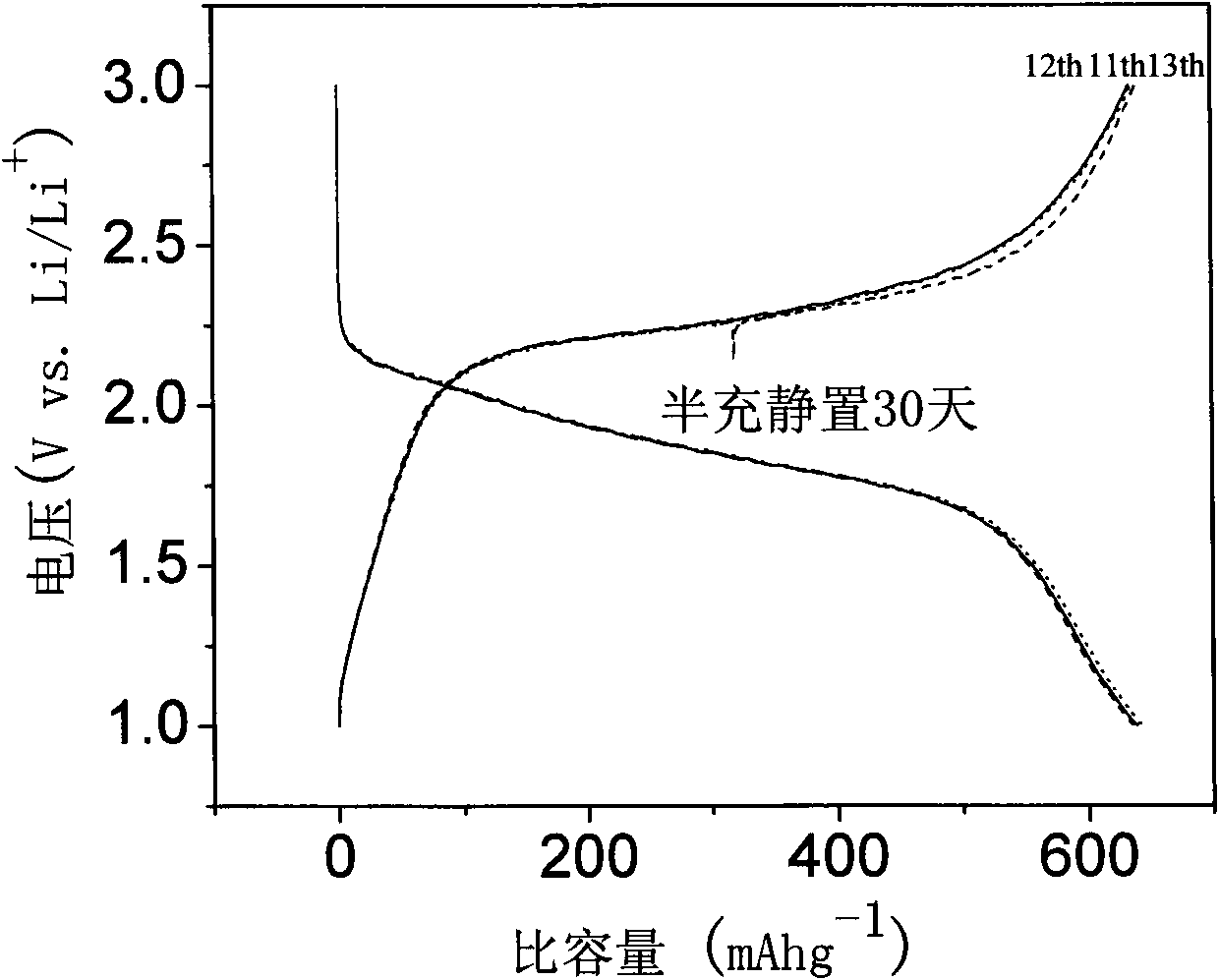

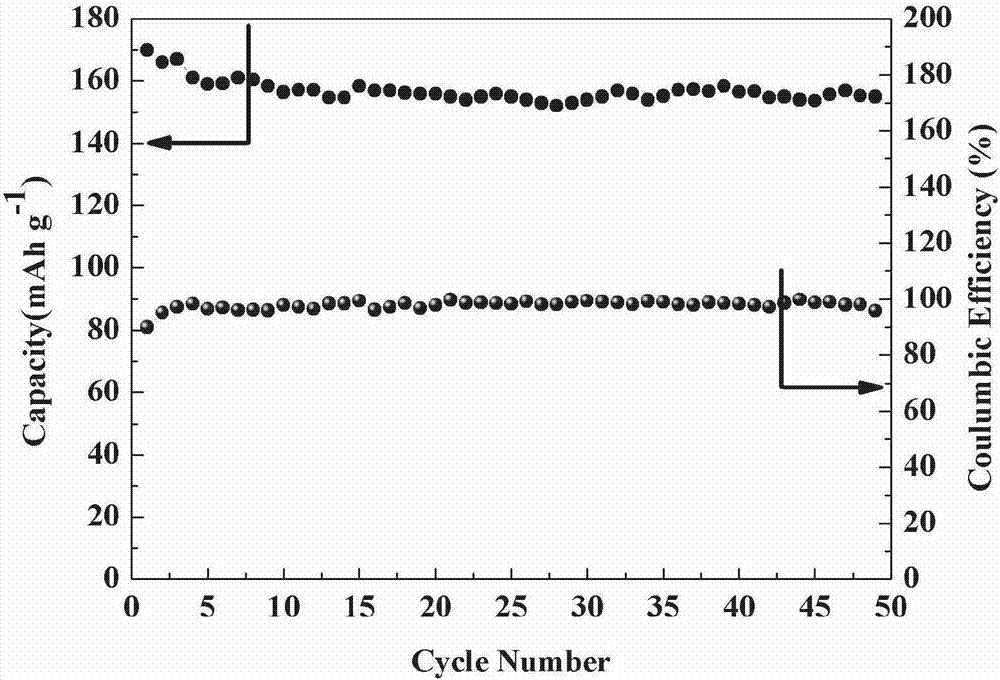

Sulfenyl anode of lithium-sulfur rechargeable battery and preparation method thereof

InactiveCN101577323APrevent self-dischargeImprove conductivityElectrode manufacturing processesActive material electrodesLithium metalMass ratio

The invention discloses sulfenyl anode of a lithium-sulfur rechargeable battery and a preparation method thereof. The sulfenyl anode is prepared by the steps of: equally mixing sulfenyl compound active material, cyclodextrin binder and carbon conductivity agent, coating the mixture on an aluminum foil current collector and obtaining the sulfenyl anode after drying and pressing. The coating thickness is 50 to 100 microns and the aluminum foil thickness is 20 to 30 microns; the mass ratio of the sulfenyl compound active material, the cyclodextrin binder and the carbon conductivity agent is 7 to 8:0.6 to 1:0.6 to 1.5, wherein the sulfenyl compound active material is formed by the steps of: equally mixing carbon nano tube, sulfur and polyacrylonitrile according to the mass ratio of 0.1 to 0.2:6 to 8:1 and sintering the mixture in protection of inert gas at the temperature of 300 to 320 DEG C for insulation for 6 to 8 hours. By using the lithium-sulfur rechargeable battery with the sulfenyl anode and lithium metal cathode, the reversible capacity of the sulfenyl compound active material reaches 680mAh.g under 0.1C multiplying power charge-discharge condition; and compared with the discharge capacity of second circulation, the discharge capacity after 100 times of circulation decreases less than 10 percent.

Owner:SHANGHAI JIAO TONG UNIV

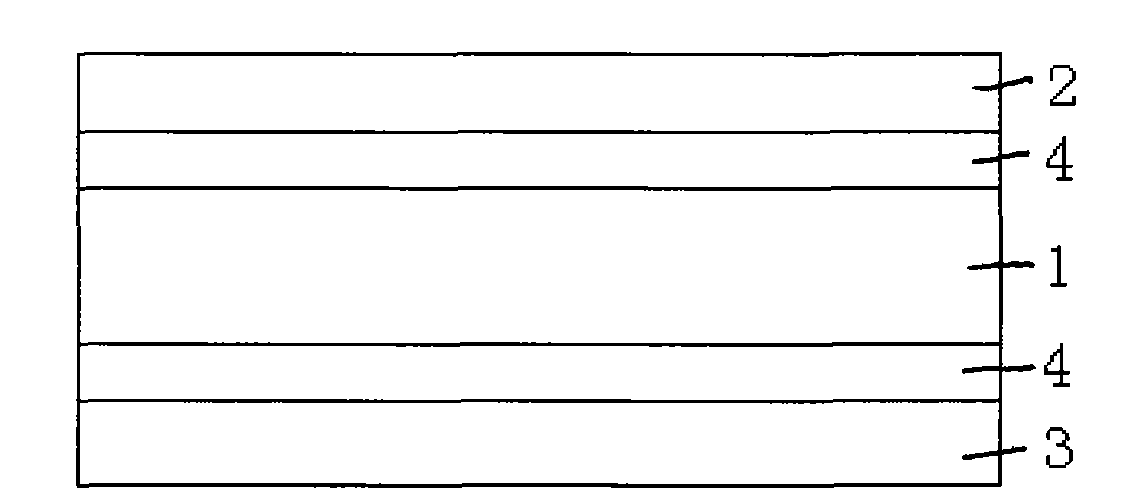

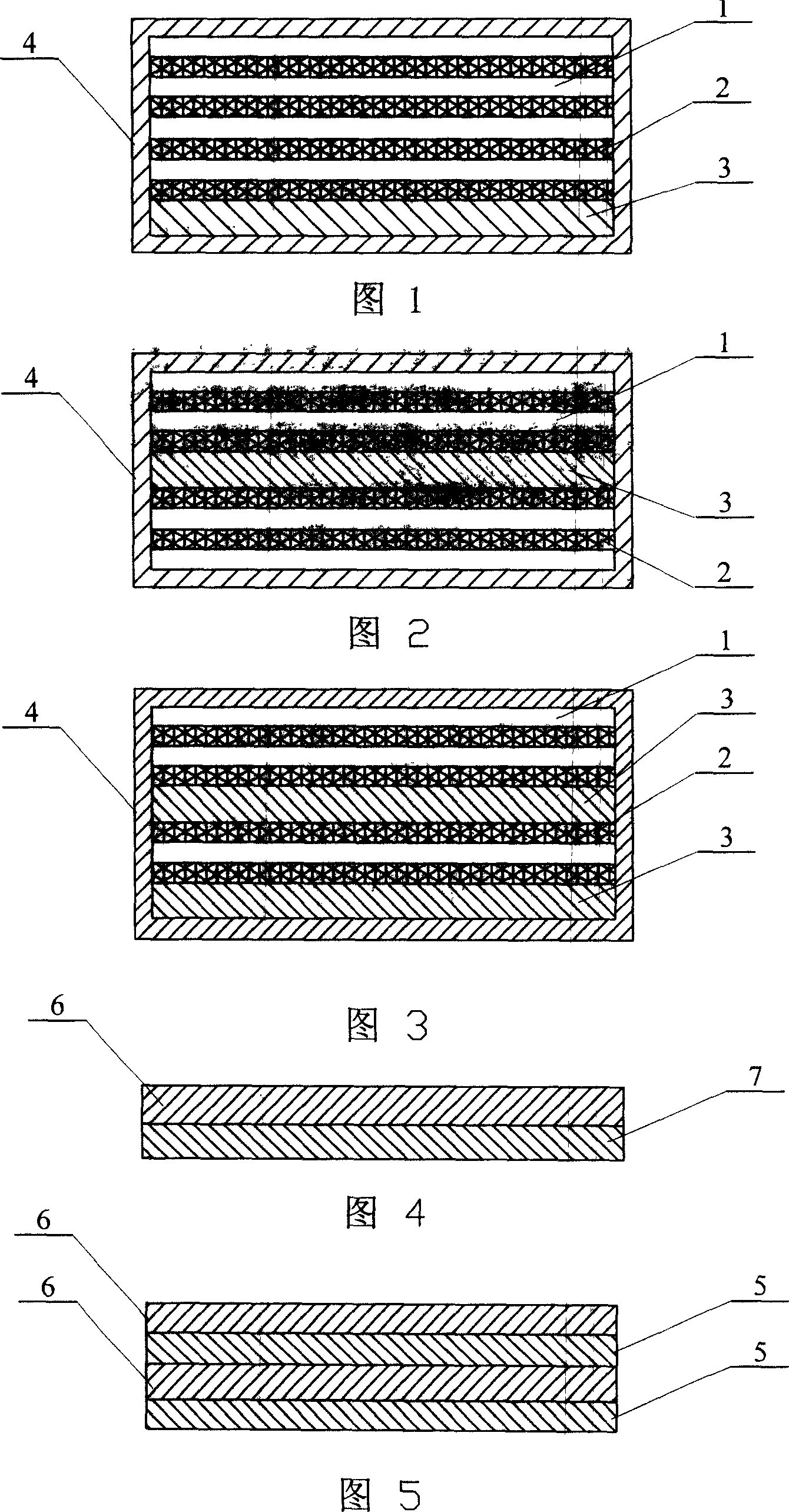

Aluminum-plastic membrane used for packaging lithium battery

ActiveCN101992570AImprove heat resistanceImprove wear resistanceCell component detailsMetal layered productsPlasma technologyAluminum foil

The invention discloses an aluminum-plastic membrane used for packaging the lithium battery. The aluminum-plastic membrane mainly comprises a protective layer, an aluminum foil layer and a heat sealing layer, wherein the protective layer is bound and combined with the aluminum foil layer through a glue layer, the heat sealing layer is bound and combined with the aluminum foil layer through a glue layer; before the binding and combining, the plasma technology is adopted to perform surface grafting treatment to the surfaces of the protective layer, the aluminum foil layer and the heat sealing layer; and then the protective layer and the aluminum foil layer are separately combined with the both sides of one glue layer through hot-pressing, and the aluminum foil layer and the heat sealing layer are are separately combined with the both sides of one glue layer through hot-pressing. The aluminum-plastic membrane has higher chemical resistance, moisture-proof property, oxygen-isolating property and packaging-binding property, also has explosion-proof property and is suitable for the soft package lithium battery.

Owner:MING CROWN ADVANCED MATERIAL CO LTD

Method for preparing hydrophobic SiO2 aerogel

The invention relates to a method for preparing lyophobic SiO2 aerogel, belonging to the technical field of new material preparation. The method comprises the steps: tetraethyl orthosilicate, absolute ethyl alcohol and oxalic acid solution are firstly mixed in a container for sealing, and then the mixed solution is put into water bath, hydrolyzed under agitation and added with ammonia dropwise; when gel is formed, the absolute ethyl alcohol is added into the gel for exchanging the water in the gel; n-hexane is used for exchanging ethanol in the gel; wet gel which is processed by solvent exchange and aging is dipped into the mixed solution of modifying agent and n-hexane for surface modification, then the n-hexane is added for exchanging the unreacted modifying agent; finally, a test tube is sealed by a aluminum foil provided with a needle hole and is placed into an oven for classified drying under normal pressure, so that the modified SiO2 aerogel is obtained. The SiO2 aerogel prepared by the method has the advantages of high porosity, large specific surface area, good hydrophobic property, etc. The method has the advantages of mild reaction condition, easy control of the reaction as well as simple and convenient process flow.

Owner:YANGZHOU TIANCHEN FINE CHEM +1

Method for regenerating positive active material from waste lithium iron phosphate batteries

ActiveCN106910889ARealize combination generationQuality assuranceCell electrodesWaste accumulators reclaimingFiltrationCopper foil

The invention discloses a method for regenerating a positive active material from waste lithium iron phosphate batteries. The method comprises the steps as follows: 1) waste lithium iron phosphate batteries are discharged in saline water, and organic solvents, roll cores and casing materials are disassembled; 2) the roll cores are subjected to crushing, calcination and other steps, and active materials, copper foil and aluminum foil are separated through vibrating screening. Fluorine-containing waste gas is absorbed with lime water, the copper foil and the aluminum foil are separated with a magnetic separation method, the active materials are leached out with sulfuric acid, and a leachate and carbon residues are obtained through separation; 3) Cu<2+> in the leachate is reduced to elementary copper by adding iron powder, meanwhile, Fe<3+> is reduced to Fe<2+>, copper and excessive iron residues are filtered out, aluminum is removed through precipitation with an alkaline liquid, the filtrate is supplemented with a phosphorus source after filtration, the pH value is adjusted by adding the alkaline liquid, coarse lithium iron phosphate precipitates are produced, and finally, battery-grade lithium iron phosphate is obtained through sintering. Comprehensive utilization of the waste lithium iron phosphate batteries and regeneration of the active materials are realized with a simple, practical, economical and feasible method, no secondary pollution is produced, and the method is suitable for industrial production.

Owner:CENT SOUTH UNIV

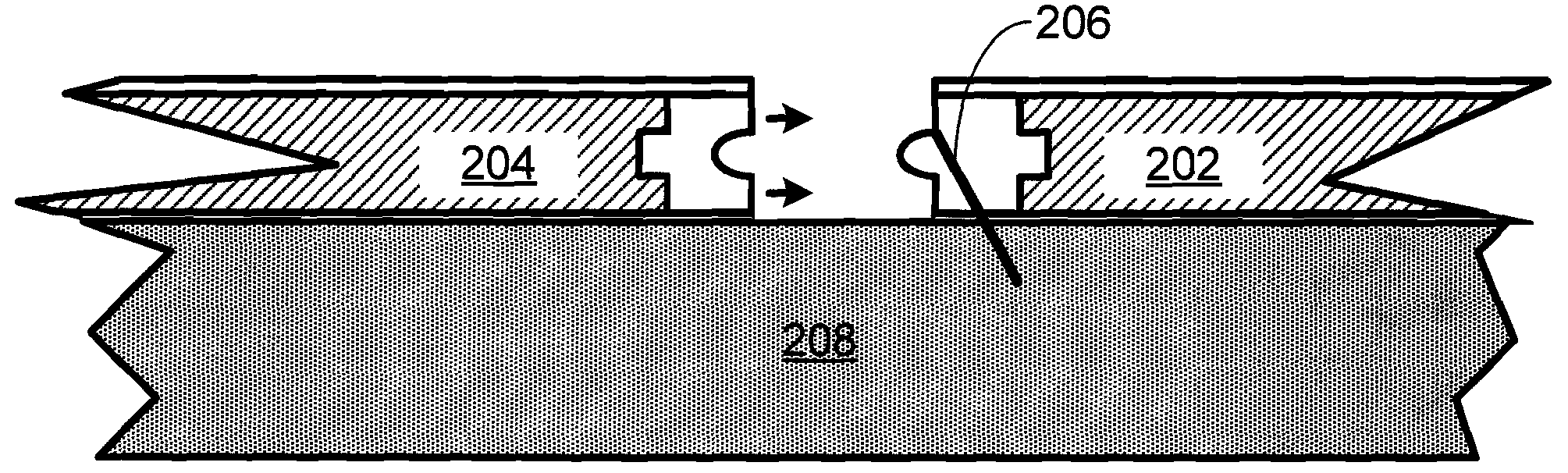

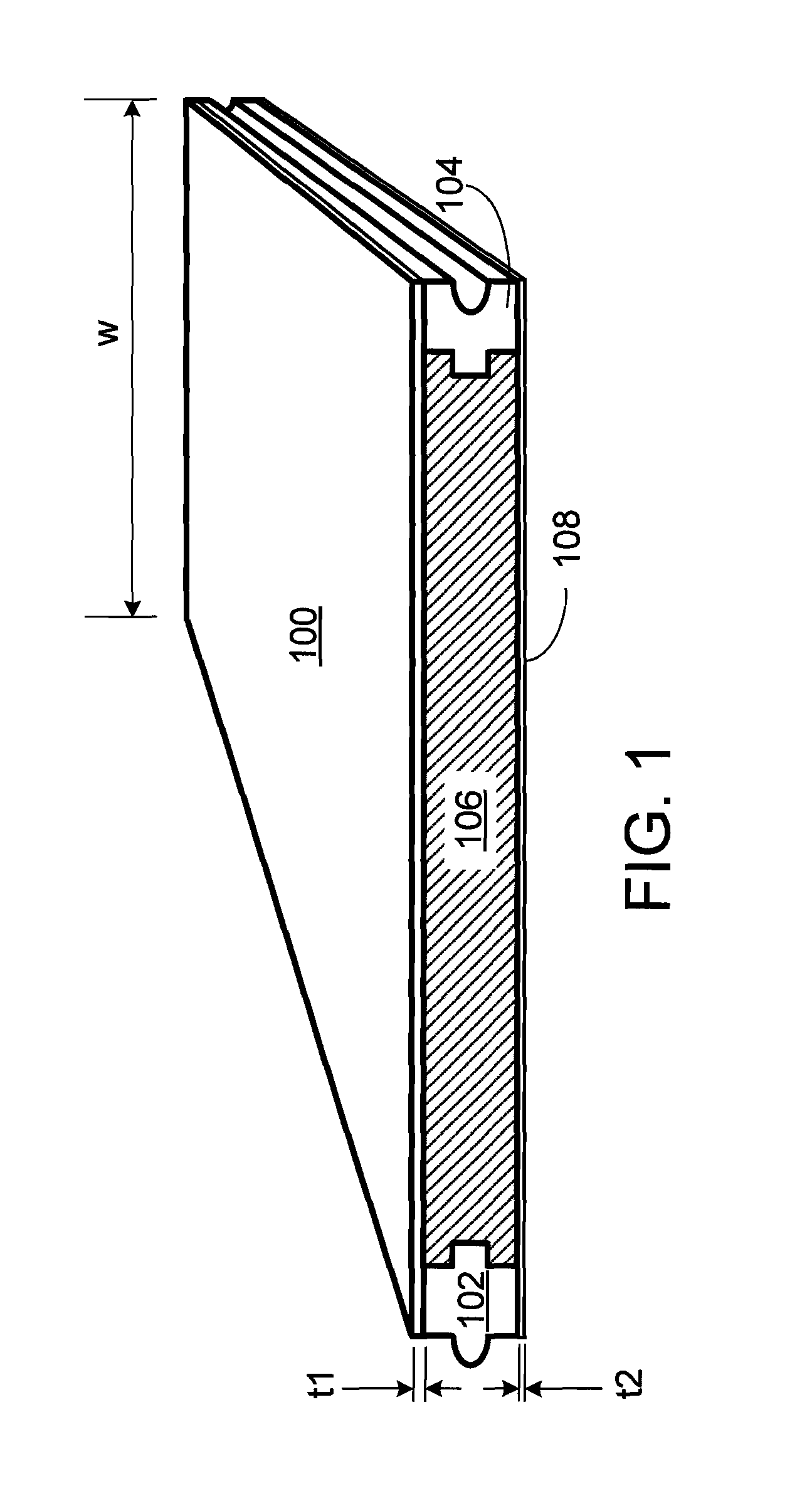

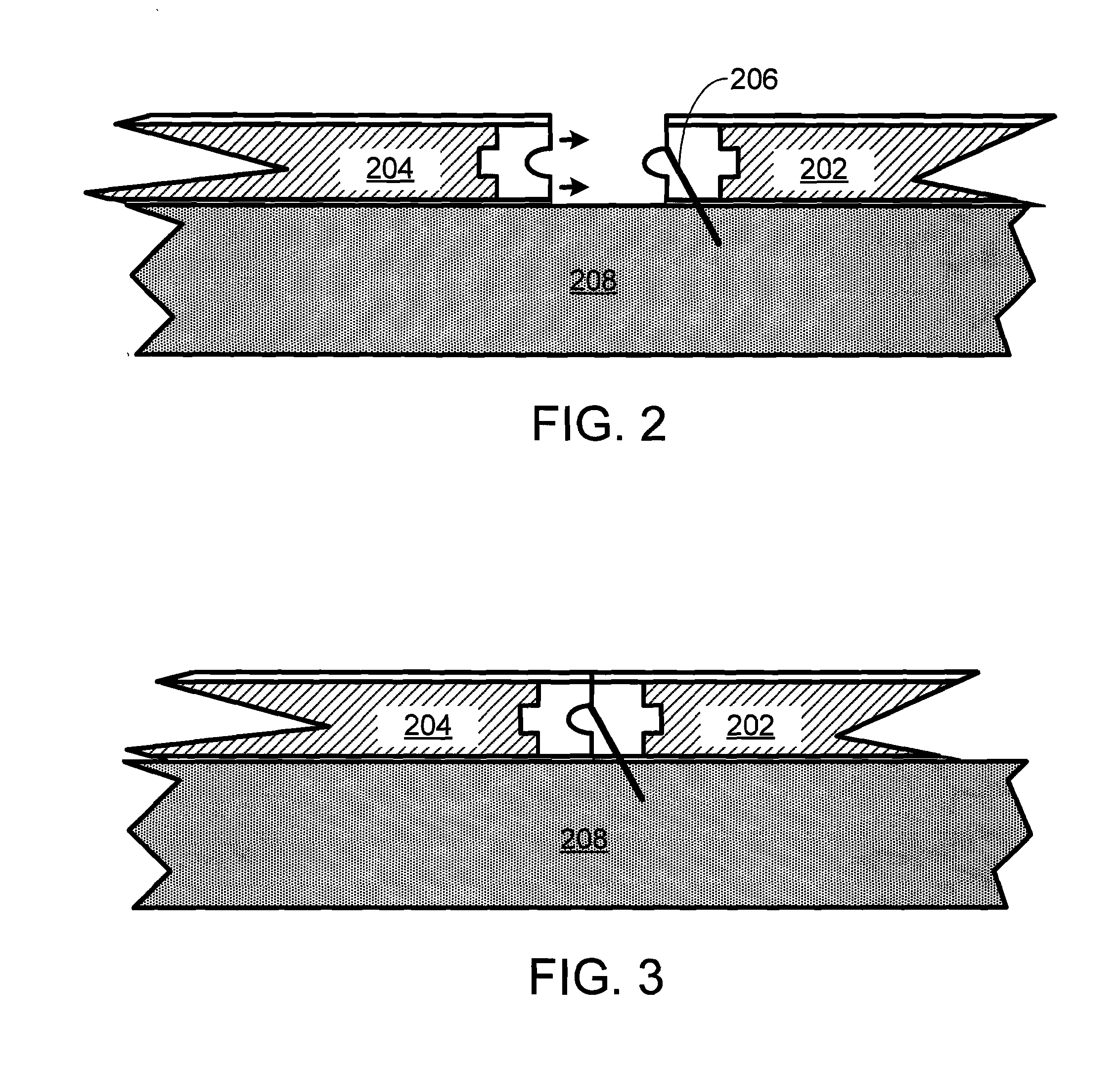

Water Resistant Wide Flooring Boards

A water resistant floor board comprises a top layer, a tongue connector, a groove connector, a body, and a bottom layer. The body is made from a man-made material and placed between the tongue connector and the groove connector, and the top layer is placed above the body, the tongue connector, and the groove connector. The bottom layer is a moisture resistant aluminum foil covering the body, the tongue connector, and the groove connector. The tongue and groove connectors are made from moisture resistant solid wood, and the body is made from man-made material. The top layer has a moisture resistant coating.

Owner:LIU DAVID C

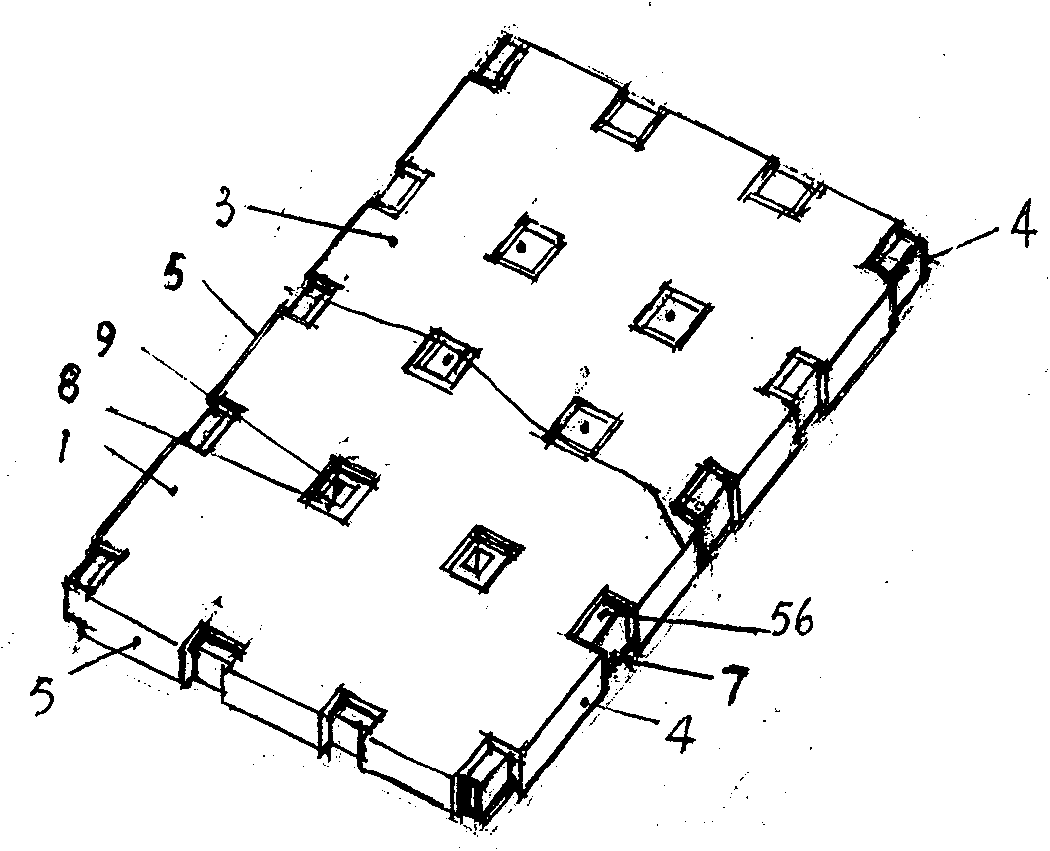

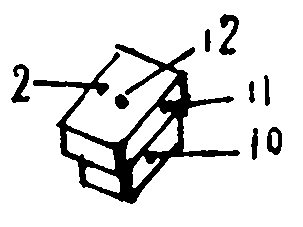

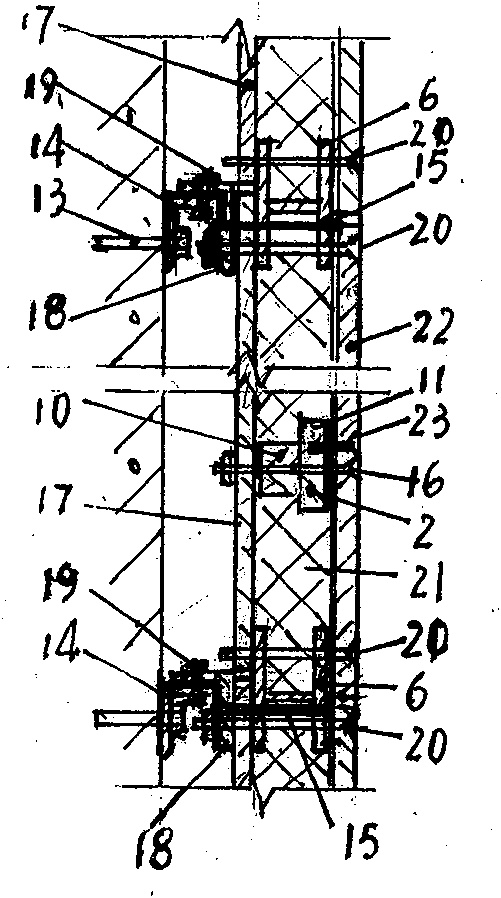

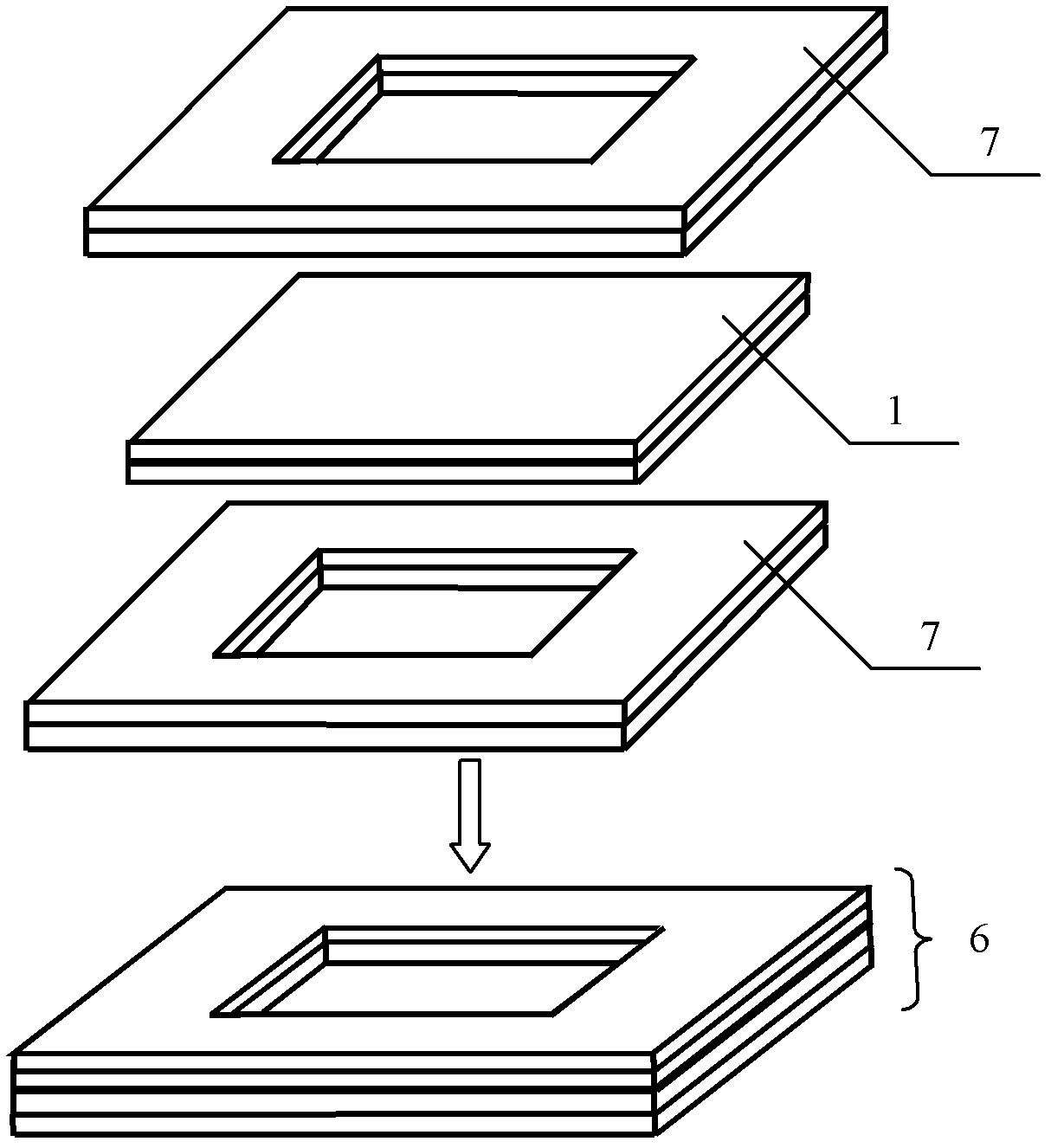

Novel multipurpose composite insulation board and construction method and processing device thereof

InactiveCN101831963AEasy to processSimple installation and constructionConstruction materialCovering/liningsBrickEngineering

The invention relates to a novel multipurpose composite insulation board and a construction method and a processing device thereof. The novel multipurpose composite insulation board is manufactured by forming notches 7 with countersunk head openings 56 and through holes 9 with countersunk head openings 8 on the four sides and in the middle of an XPS insulation board and reserving connection intensifying anchoring supporting seats 2 in the through holes 9 or the notches of the board or reserving supporting seats 95 and 96 on the four sides of the board or sticking an aluminum foil reflecting layer 3 on the upper surface of the insulation board after forming a square or round-bottom groove on the insulation board. A conventional square supporting seat is improved into a supporting seat with a countersunk head of which the four sides are 5 to 50 millimeters wider than those of a supporting block and the upper part is embedded into the countersunk head opening, so support stressed area can be enlarged, and more importantly, a broken bridge insulating function is realized. The insulation board is easy to manufacture and simple and convenient to install and realizes production site assembly in a factory, so on-site wall plastering operation, facing tile wetting operation and paint spraying operation are eliminated; a nail framework does not needing paving; and the insulation board is widely applicable for insulation of warming ground surfaces, wall faces and roofs.

Owner:冯刚克

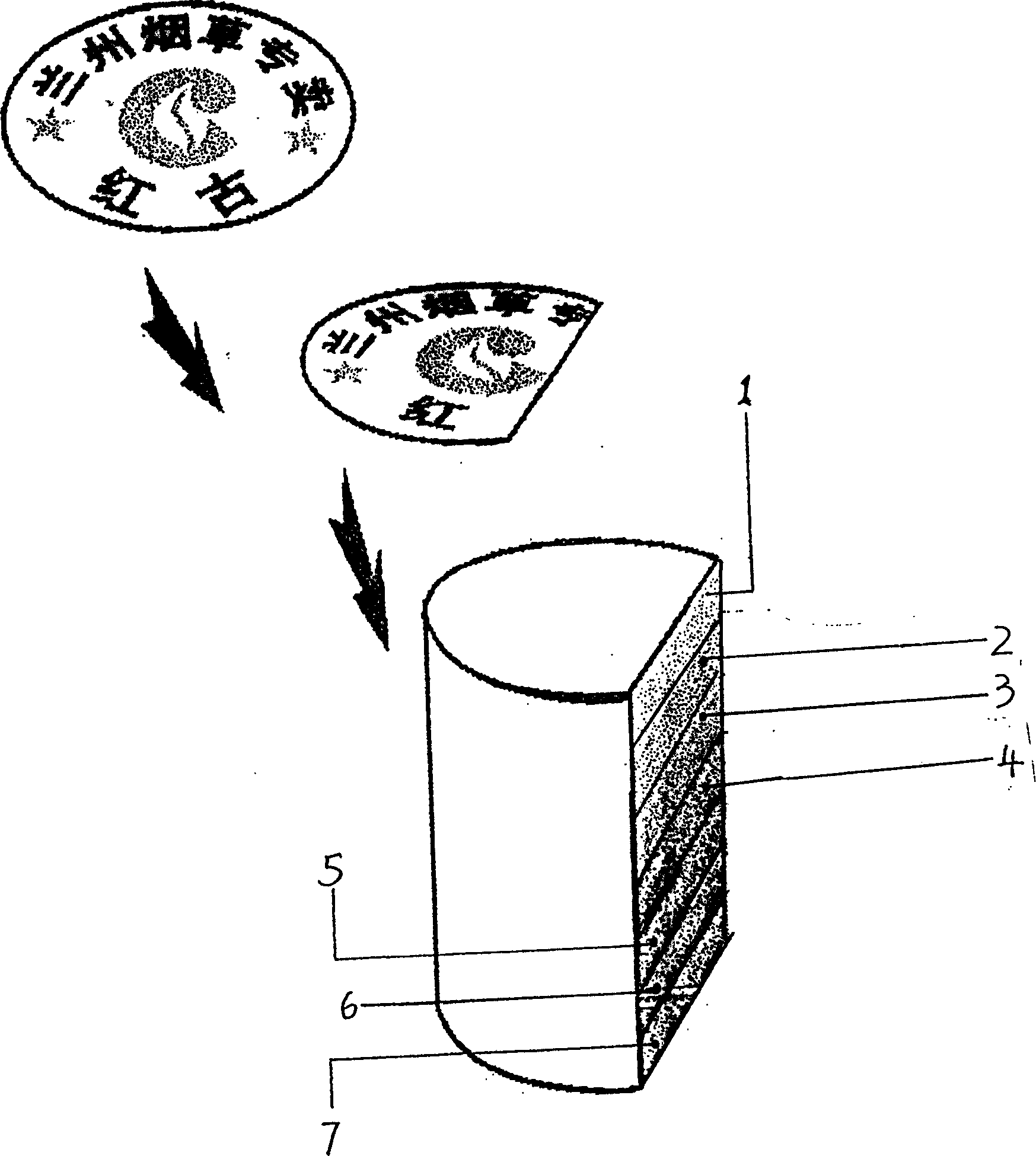

Cigarette perfuming agent and its preparation method and application

InactiveCN101215805AImprove qualityMellow tasteNon-fibrous pulp additionNon-macromolecular adhesive additivesAluminum foilInternal quality

The invention discloses a cigarette flavor enhancer and a process for preparation and the application, the flavor enhancer agent is mixed by flavor materials with stronger volatility and outstanding characteristic and plant extraction which has promoting effect to the smoking of cigarette, the improvement of the internal quality is firstly achieved by cigarette packing material through the invention, and the process comprises coating flavor enhancer agent on the surface of aluminum foil inner lining paper according to the proposition which is 0.01%-5%, or adding into the existing adhesive agent for aluminum foil liner paper according to the proposition which is 0.01%-5%, making full use of the characters that aluminum foil liner paper directly contacts with cigarettes, continuously decorating and improving the smoking of cigarette, and covering imperfect breath of the existing aluminum foil liner paper itself. The invention can have a good connection with the existing cigarette technique and equipment, and production can be achieved by the invention without adjusting the existing equipment. The invention has the advantages of reasonable process, convenient operation and low production cost, which has an excellent application prospect.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

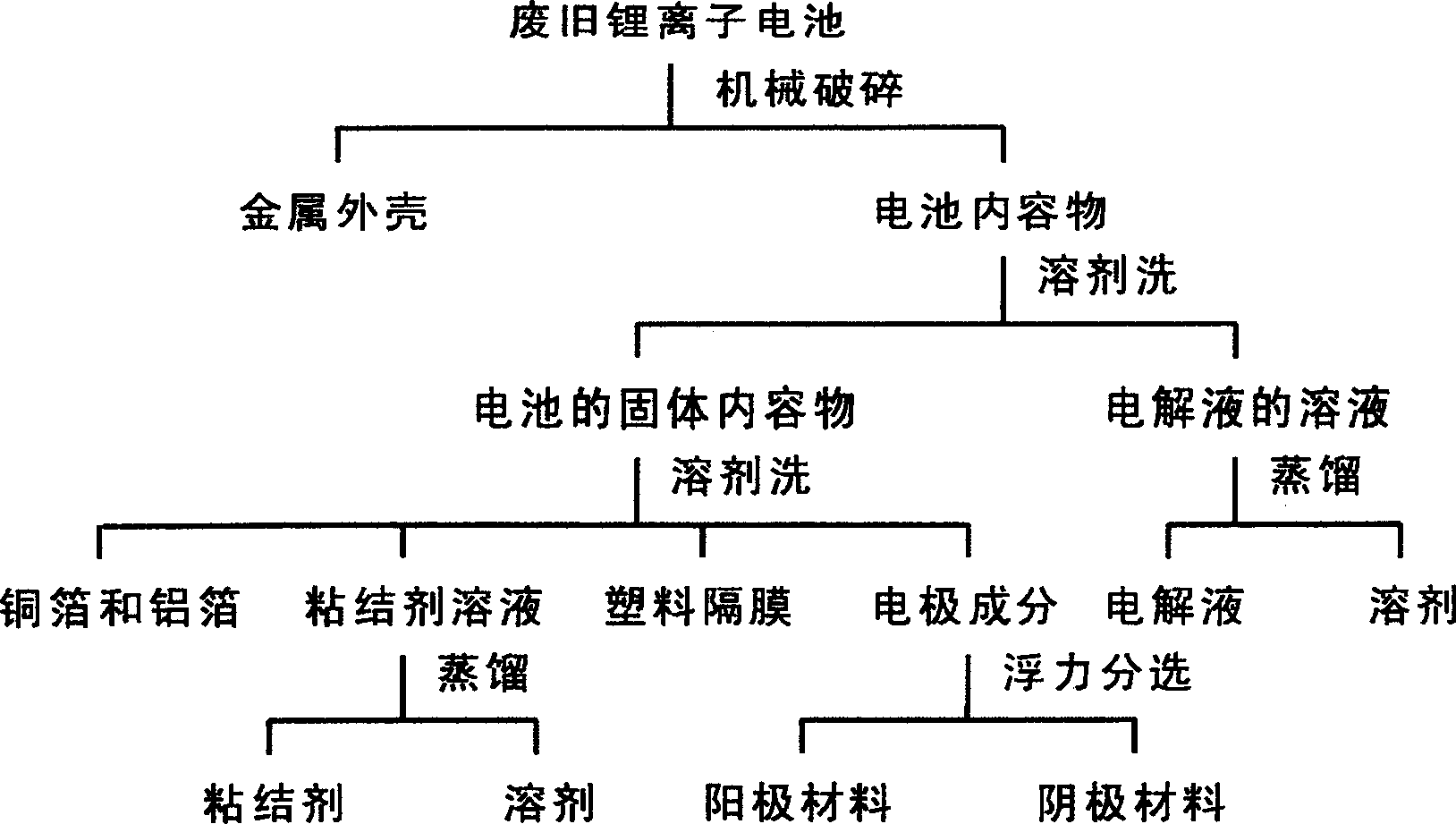

Resource separation of waste lithium ion battery

InactiveCN1819326AReserve availabilityLow added valueReclaiming serviceable partsWaste accumulators reclaimingAdhesiveCopper foil

The invention can make separation for all kinds of components in wasted Li-ion battery such as: case, electrolyte, anode material, cathode material, adhesive, copper foil, and aluminum foil. The process includes: breaking wasted batteries by mechanical process; separating metal case from others; washing out electrolyte using organic solvent, and filtering it from remaining solid; processing the remaining component where the electrolytes are removed using organic solvent to make all electrode active component eluted from current collector, and separated from diaphragm, copper foil, and aluminum foil. The solvent and adhesive can be reused.

Owner:SOUTHEAST UNIV

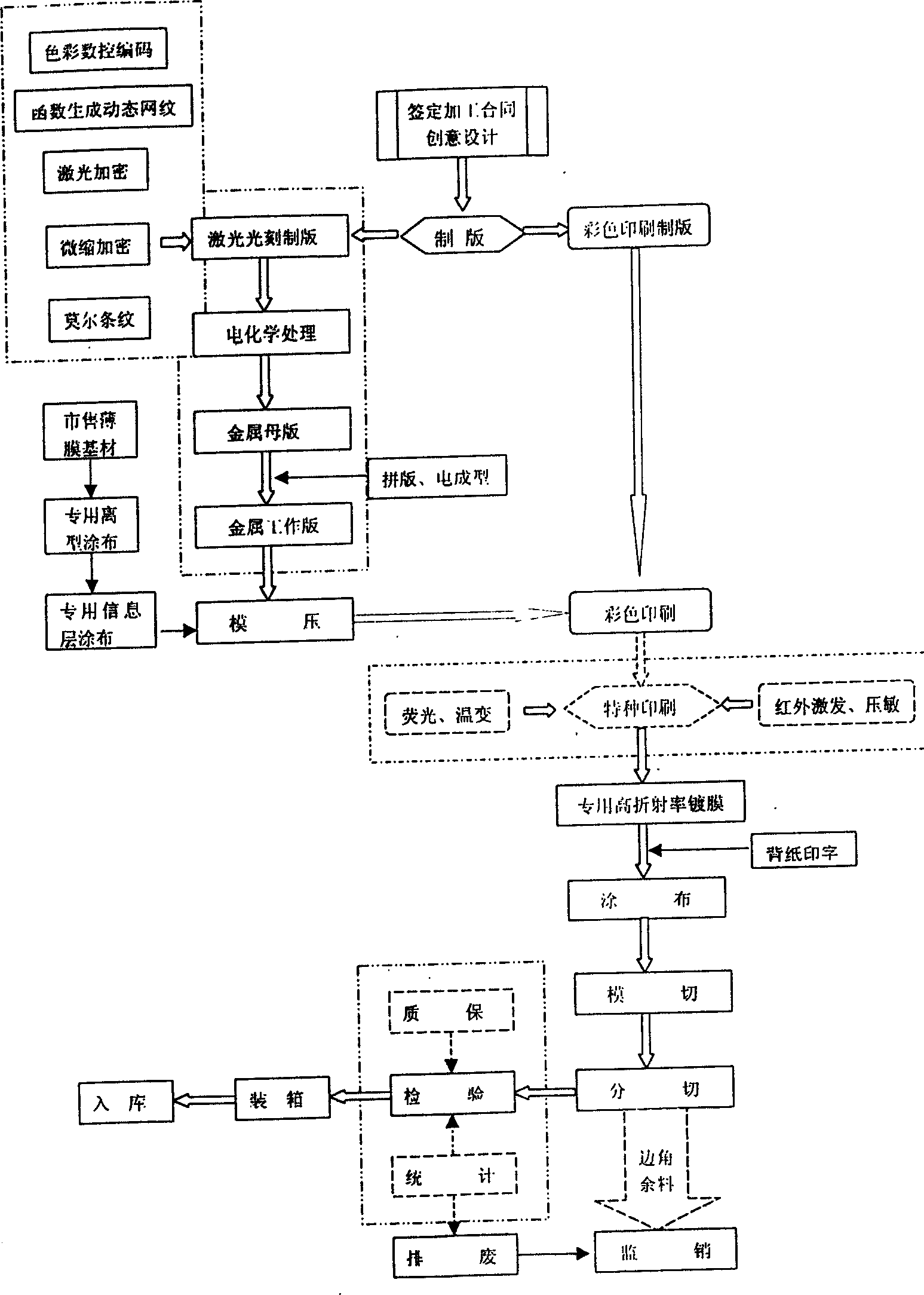

Holographic colour print antiforge mark and its production technology

InactiveCN1514423AIncrease investmentHigh anti-counterfeiting strengthStatic indicating devicesInformation layerColor printing

The invented antifalse mark is different from general color printing label and traditional holographic mark on aluminum foil. The mark includes basal lamina, information layer, isolation layer, color printing layer, special type printing layer and not dried glue layer etc. Technical flow includes following procedures: designing, plate making, raw materials preparing, die pressing, color printing, special type printing, glue spreading, die cutting, parting cut and checking up pack. The invention possesses advantages of integrating multiple antifalse techniques, easy of recognition and convenient use.

Owner:河南天畅防伪包装有限公司

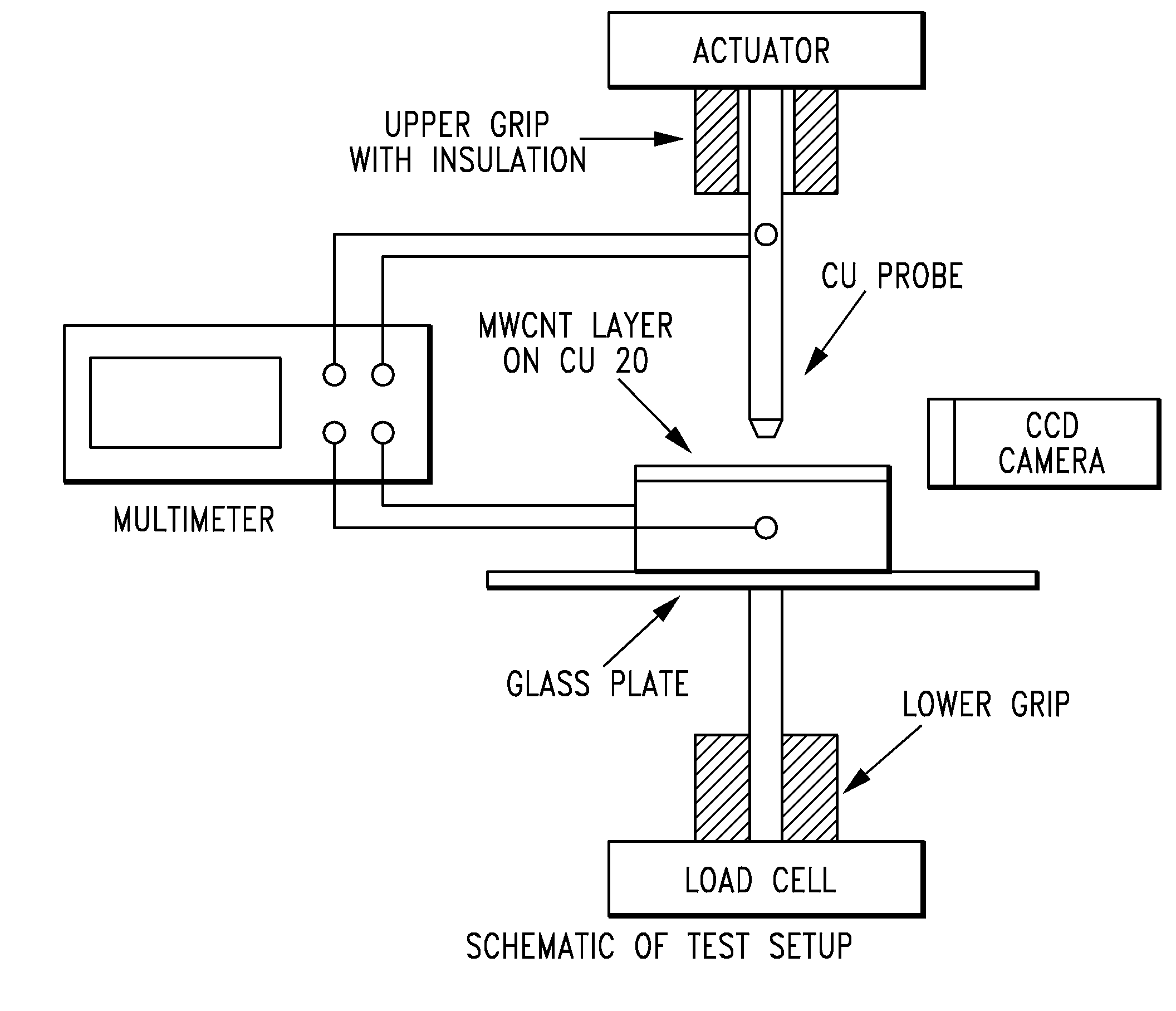

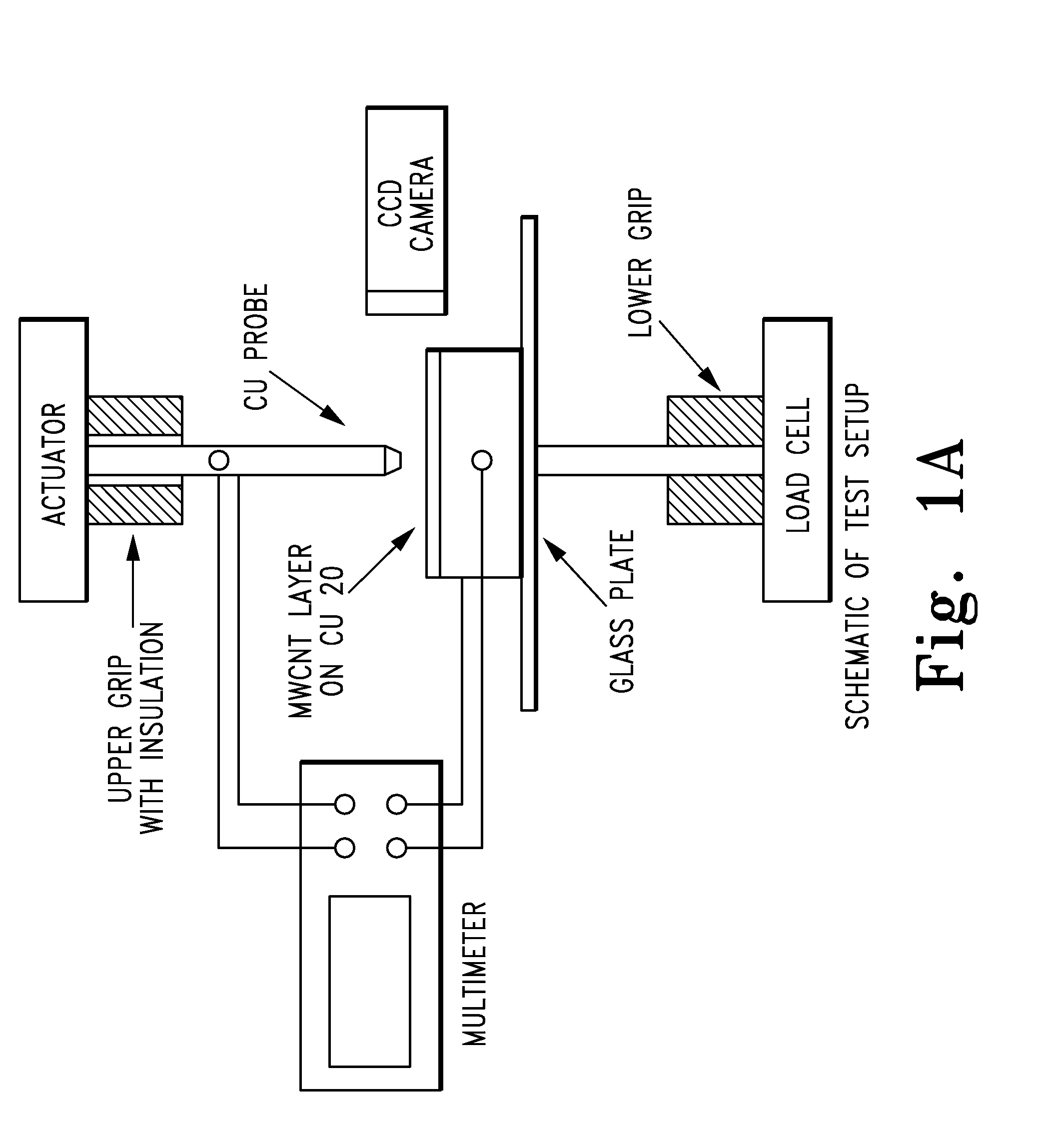

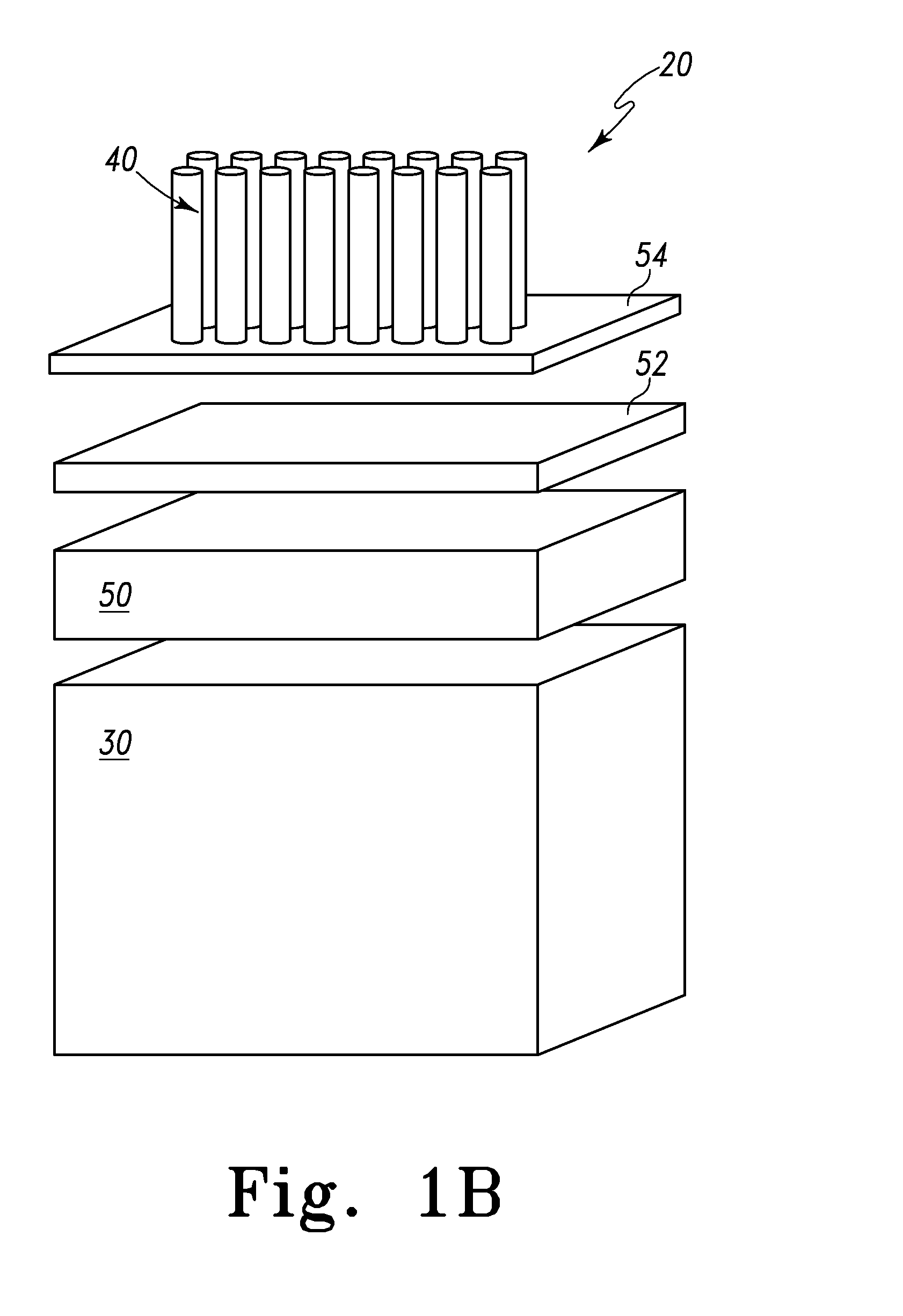

Electrothermal interface material enhancer

InactiveUS20080236804A1Envelopes/bags making machineryMaterial nanotechnologyMetallic foilCarbon nanotube

Vertically oriented carbon nanotubes (CNT) arrays have been simultaneously synthesized at relatively low growth temperatures (i.e., <700° C.) on both sides of aluminum foil via plasma enhanced chemical vapor deposition. The resulting CNT arrays were highly dense, and the average CNT diameter in the arrays was approximately 10 nm, A CNT TIM that consist of CNT arrays directly and simultaneously synthesized on both sides of aluminum foil has been fabricated. The TIM is insertable and allows temperature sensitive and / or rough substrates to be interfaced by highly conductive and conformable CNT arrays. The use of metallic foil is economical and may prove favorable in manufacturing due to its wide use.

Owner:PURDUE RES FOUND INC

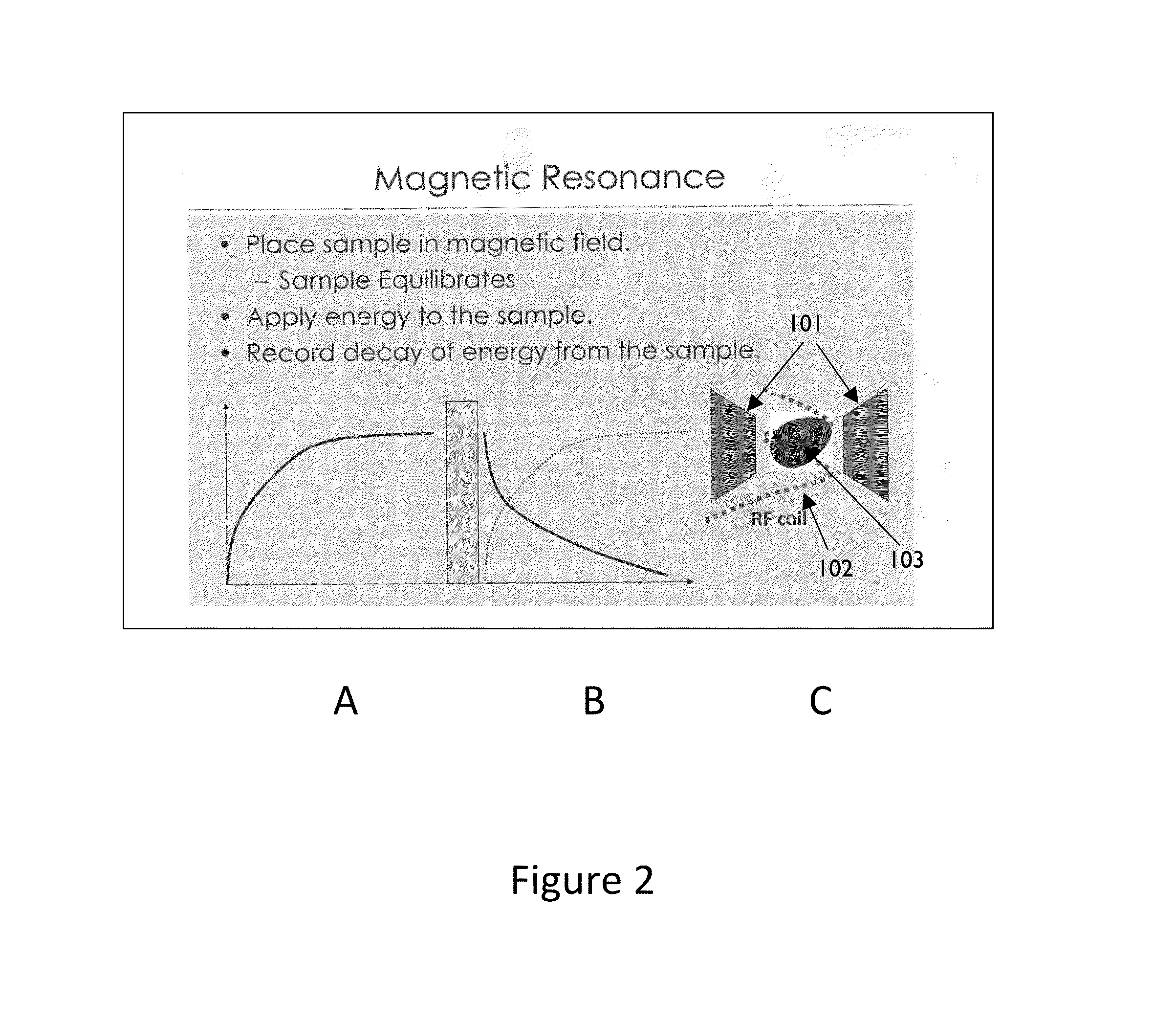

Non-invasive MRI system for analyzing quality of solid food products enveloped by flexible aluminum foil wrapper and methods thereof

InactiveUS20140050827A1Magnetic measurementsAnalysis using nuclear magnetic resonanceControl systemQuality control system

The present invention provides a quality control system characterized by:a. a line of substantially-solid food-products, said products at least partially enclosed in a flexible aluminum foil wrapper and randomly-orientated on said line;b. an MRI device adapted to image each of said products on said line; said MRI is in communication with a computer readable medium adapted to (i) store at least one computer-retrievable standardized parameter related with a standard product; (ii) analyze said MRI thereby providing an online parameter; (iii) compare said online parameter with said predefined standardized parameter; and thereby (iv), detect defects in said products.

Owner:ASPECT IMAGING

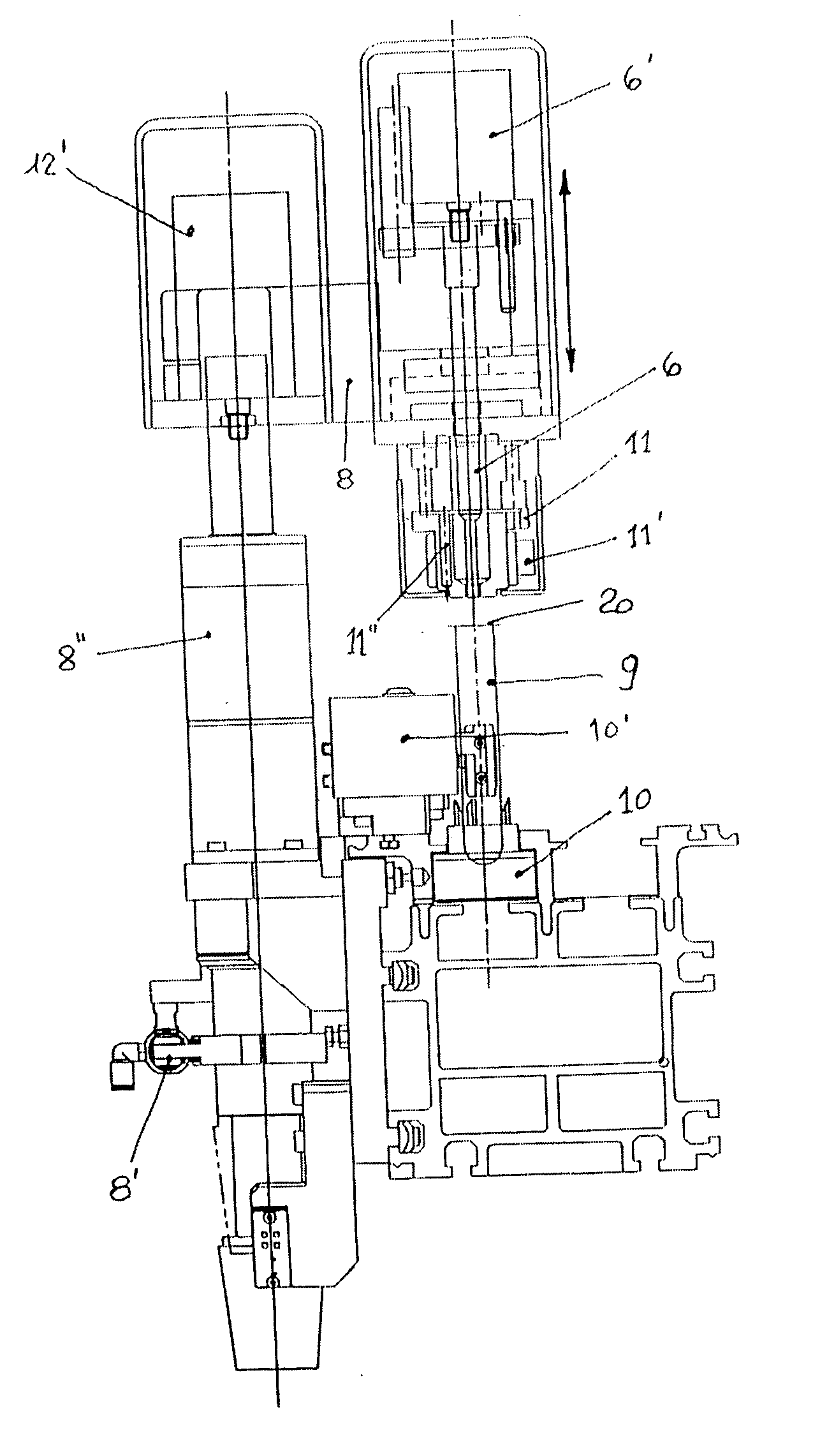

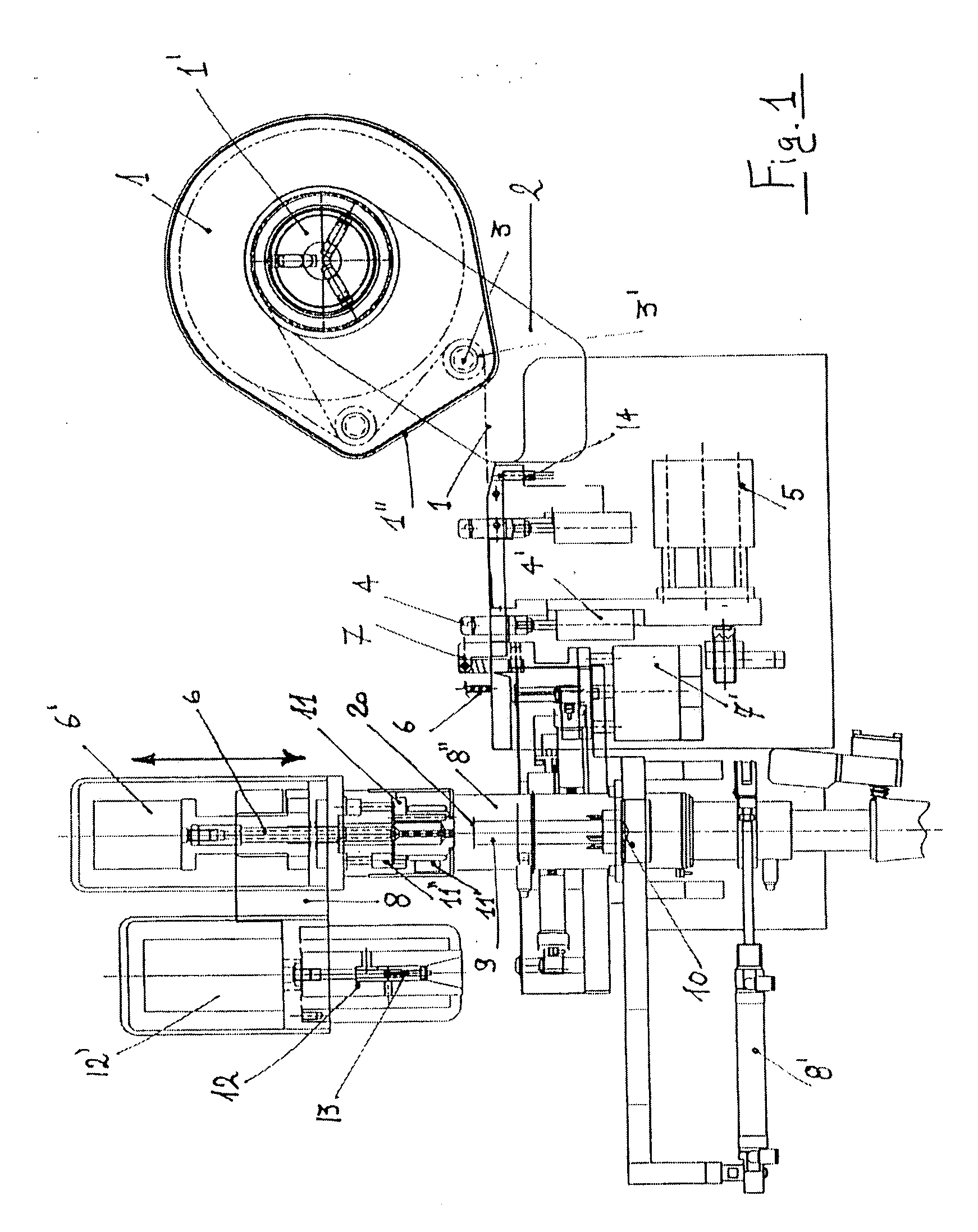

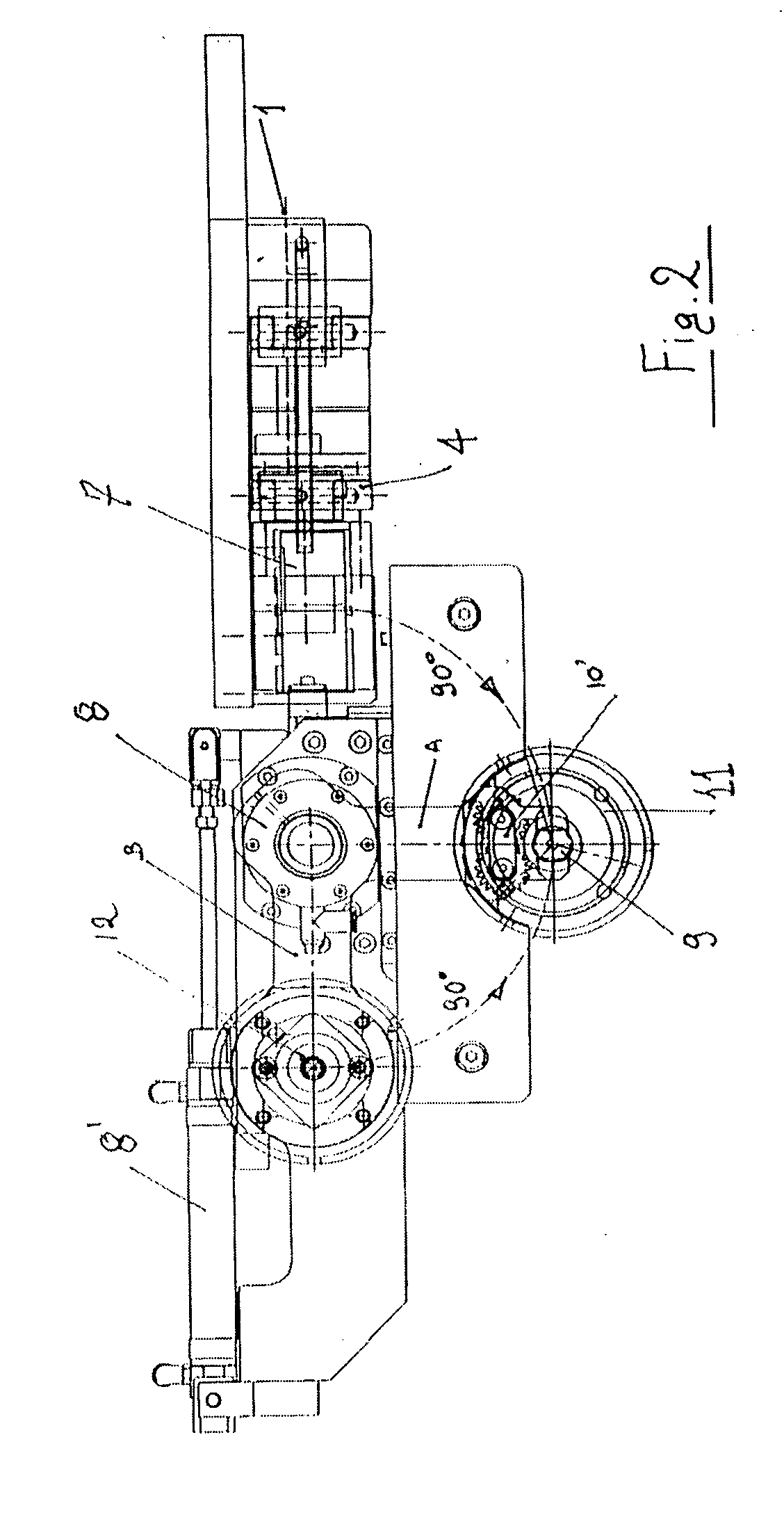

Resealer of test tubes for clinical analyses fed from ready-to-use containers of sealing tape

ActiveUS20070248496A1Fast feedingAvoid wastingAnalysis using chemical indicatorsLaboratory glasswaresAnalysis feedEngineering

The invention relates to an automatic machine designed to reseal test tubes for clinical analyses with aluminum sealing tape housed in ready-to-use, cassette-type containers. The machine uses a heat-sealing process to apply a piece of aluminum foil, which will form the cap, over the mouth of the test tube, causing it to adhere to the edge of the test tube itself to achieve perfect resealing.

Owner:ECOCAPS SRL

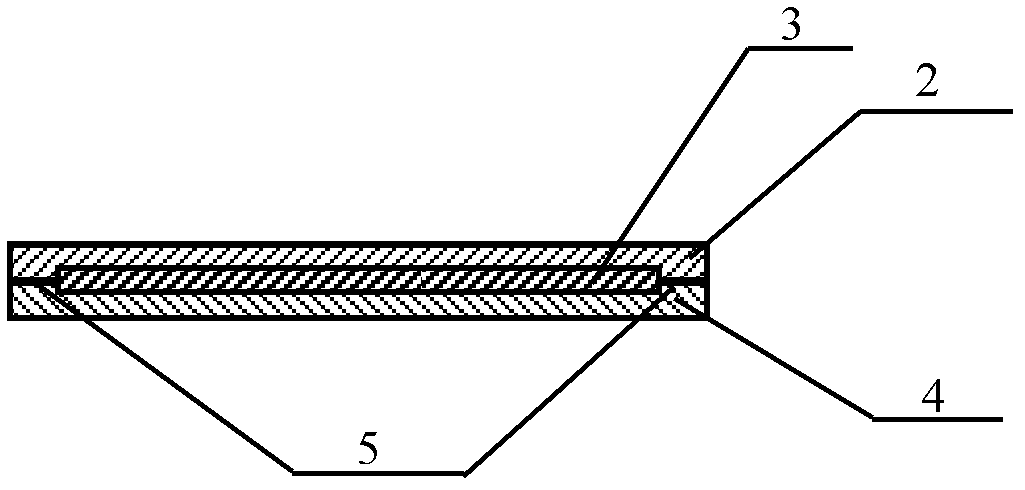

Bipolarity current collector and preparation method

ActiveCN103219521AEasy to packImprove securityFinal product manufactureElectrode carriers/collectorsHigh voltage batteryCopper

The invention discloses a bipolarity current collector and a preparation method, which belongs to the chemical energy storage battery technical field. The provided bipolarity current collector comprises aluminum foil, a non-aluminum conducting layer and a polymer barrier layer positioned between aluminum foil and non-aluminum conducting layer; the edges of the aluminum foil and the non-aluminum conducting layer are partially or wholly conductively contacted, the width of a conductive contact area of the edges are 0.1-1.5 centimeters. The bipolarity current collector can avoid the occurrence of internal short circuit and cathode oxidation of the current copper aluminum laminated foils under the condition that a hole is existed; composite insulation frames are hot-pressed on the bipolarity current collector, and can avoid the occurrence of short circuit of the marginal part of the composite current collector, and the security of high voltage battery can be increased.

Owner:BEIJING HAWAGA POWER STORAGE TECH +1

Environment-friendly type aqueous aluminum foil protecting agent and preparation thereof

InactiveCN101407655ALow VOC contentReduce manufacturing costPolyurea/polyurethane coatingsPolyamide coatingsGeneral purposeOrganosolv

The invention relates to an environmental-friendly waterborne aluminum foil protective agent and a prepration method thereof, wherein, the protective agent comprises the following components according to the formula by weight: 45 percent to 70 percent main resin; 0 percent to 20 percent assisted resin; 10 percent to 50 percent water; 0 percent to 35 percent cosolvent; 0 percent to 0.5 percent film-forming auxiliary agent; 0 percent to 0.5 percent leveling agent; 0 percent to 0.5 percent defoamer; 0 percent to 2 percent anti-abrasion agent; and 0 percent to 0.5 percent pH regulator. Compared with the prior art, the environmental-friendly waterborne aluminum foil protective agent and the prepration method have the advantages: (1) the aluminum foil protective agent contains no organic solvent which is harmful to human body and has very low content of VOC, and water and ethanol are used for dilution during the using process, thereby being non-toxic and low in production cost; (2) the aluminum foil protective agent has good adhesion, good transparency, high smoothness and high thermal resistance performance; (3) the aluminum foil protective agent belongs to the general purpose products, and the range of application is broad; and (4) the production process is reasonable, the operation is simple and the production efficiency is high.

Owner:SHANGHAI WEIKAI CHEM

Method for composite preparation of Ti alloy/TiAl alloy composite plate material by using laminated rolling-diffusion method

InactiveCN101011706AReduce manufacturing costThe preparation method is simpleTemperature control deviceFurnace typesDiffusion methodsAlloy composite

The invention discloses a making method of titanium alloy / TiAl composite board, which is characterized by the following: overlapping A (titanium foil) and C (aluminium foil); placing at least one layer B (titanium or titanium alloy foil, titanium or titanium alloy board) on the upper and lower surfaces of overlapped layer or among overlapping layer; setting adjacent layer C to B; adopting three layers or more of A or B as the most outer layer; jacketing; rolling under 20-750 deg.c and 750-1300 deg.c.

Owner:HARBIN INST OF TECH

Current collector carbon coated aluminum foil and its preparation method

InactiveCN102832392AGood adhesionImprove conductivityElectrode manufacturing processesElectrolytic capacitorsInterface impedanceInternal resistance

The invention discloses a current collector carbon coated aluminum foil and its preparation method. A carbon-containing composite layer is arranged on the substrate of the current collector carbon coated aluminum foil, and is combined with the substrate through a binder, wherein the thickness of the carbon-containing composite layer is 1-100mum; the carbon-containing composite layer comprises granular conductive carbon black pre-dispersed by a dispersant, and fibrous conductive carbon; the granular conductive carbon black and the fibrous conductive carbon filled between the layers of the granular conductive carbon black form a netted node form conductive network. The composite layer is tightly combined with the substrate of the aluminum foil, so the conductivity and the corrosion resistance of the aluminum foil are improved, and the aluminum foil is protected from oxidation or chemical corrosion. The preparation method of the aluminum foil comprises the following operations: mixing the conductive carbon black with the dispersant in an organic solvent to pre-disperse, adding the fibrous conductive carbon, uniformly mixing, adding the binder to prepare a slurry, coating on the aluminum foil, and carrying out vacuum drying. The current collector carbon coated aluminum foil enables the interface impedances of the current collector and an active layer to be reduced, the internal resistance of a battery to be reduced, and the cycle life and the ratio performances of the battery to be improved when the aluminum foil is used as a lithium ion battery anode current collector. The aluminum foil has the advantages of simple technology, low cost and wide application prospect.

Owner:HUNAN CMAX NEW ENERGY TECH

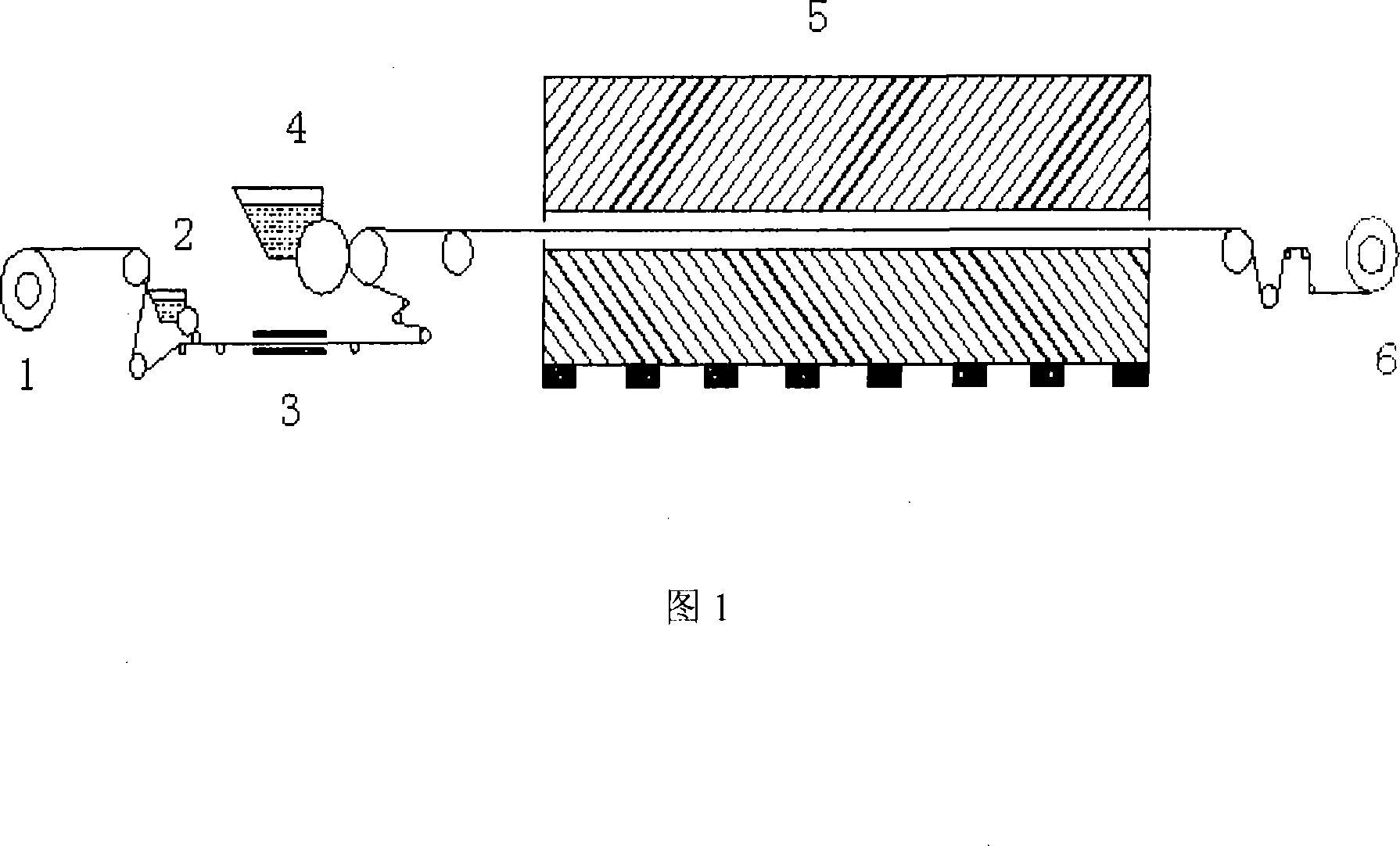

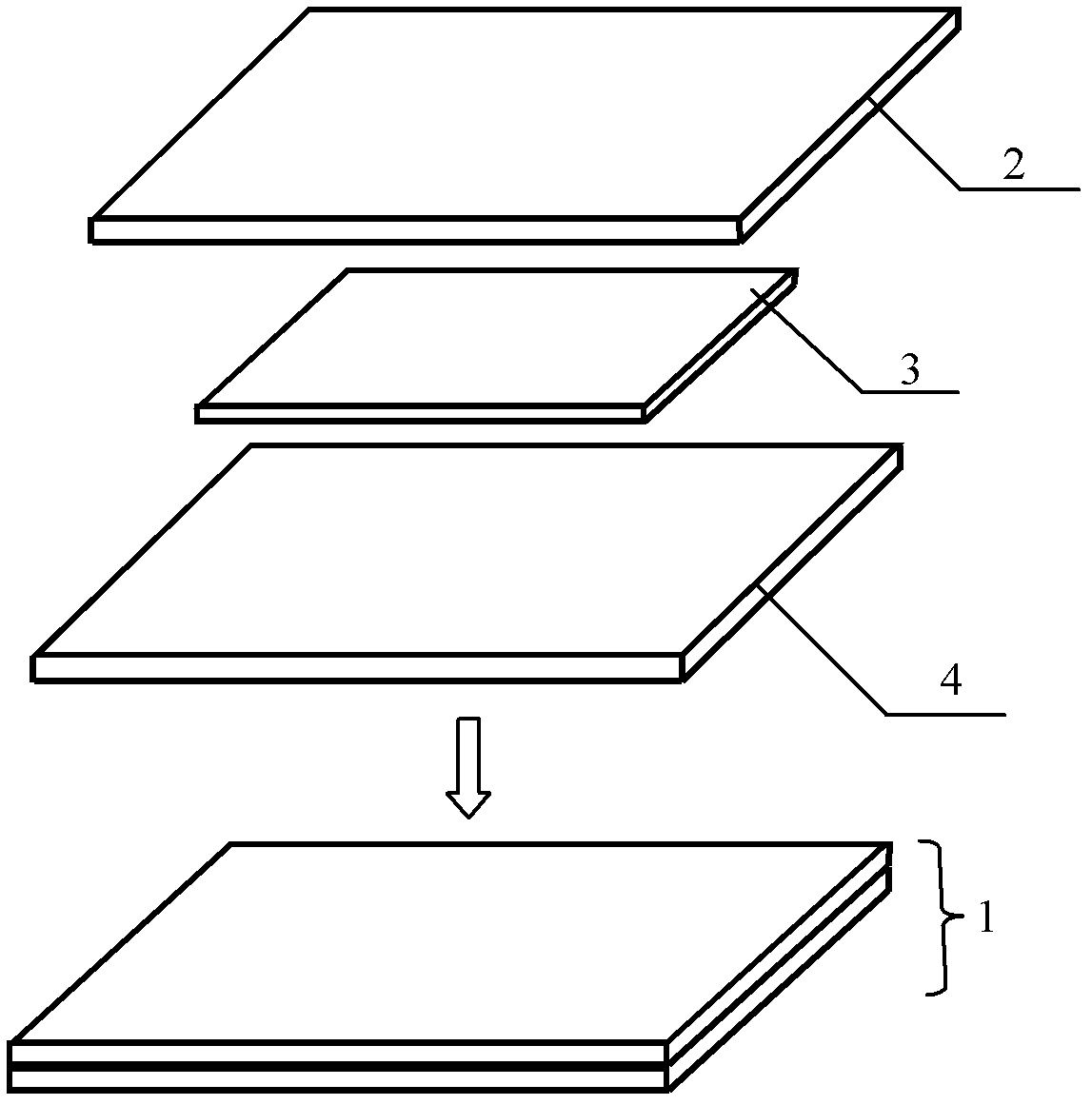

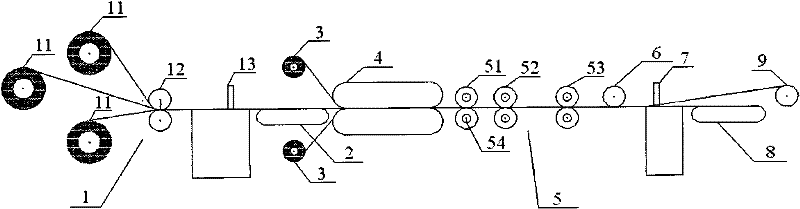

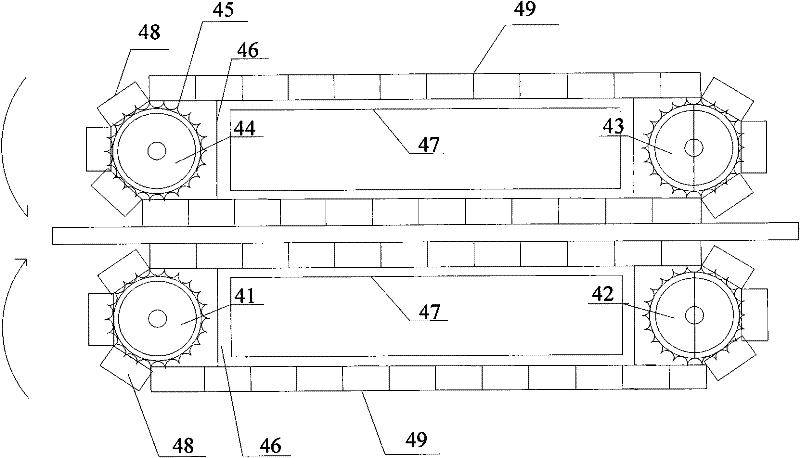

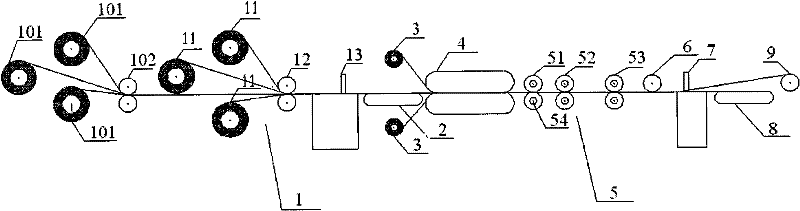

Production equipment for continuous fiber reinforced thermoplastic structural panel

ActiveCN102452209AEasy dischargeHigh degree of production automationLamination ancillary operationsLaminationThermoplasticCompression molding

The invention relates to production equipment for a continuous fiber reinforced thermoplastic structural panel. In the molding process of the panel, a continuous fiber reinforced thermoplastic prepreg tape and a sandwich material are conveyed to a panel compositing place by an automatic conveyer and performed with compression molding by crawler-type hot pressing compositing, and cold pressing molding by a roll shaft. The mode of heating is electromagnetic heating. Compared with prior art, the invention has simple process and high production efficiency and is able to produce continuous panels and large area composite panels. The equipment is suitable for use in sandwich panels formed by the continuous fiber reinforced thermoplastic structural panel and continuous fiber reinforced thermoplastic plastic and composite panels formed by continuous fiber reinforced thermoplastic plastic and metals such as aluminum foil and the like.

Owner:LIAONING LIAOJIE SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com