Production equipment for continuous fiber reinforced thermoplastic structural panel

A technology that enhances thermoplasticity and production equipment. It is applied in the direction of layered products, lamination devices, and lamination auxiliary operations. It can solve the problems of low heating efficiency and low production efficiency, and achieve high heating efficiency, labor saving, and rolling surface. smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

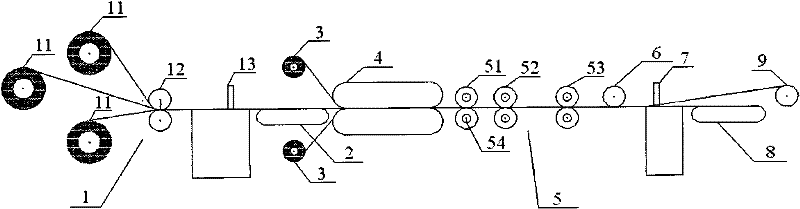

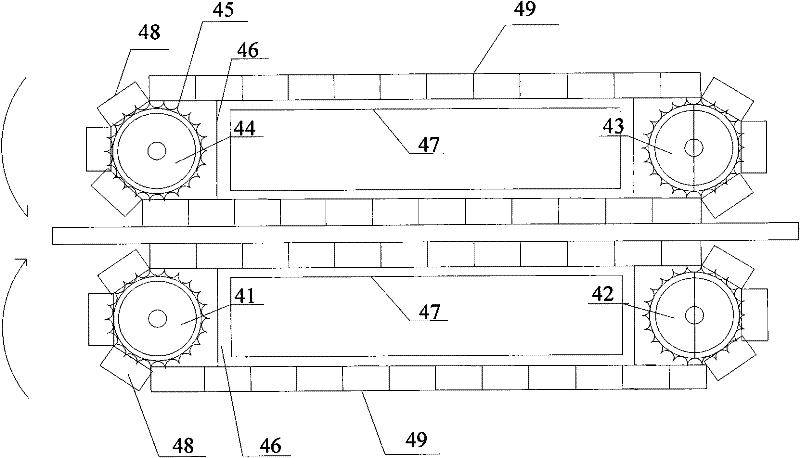

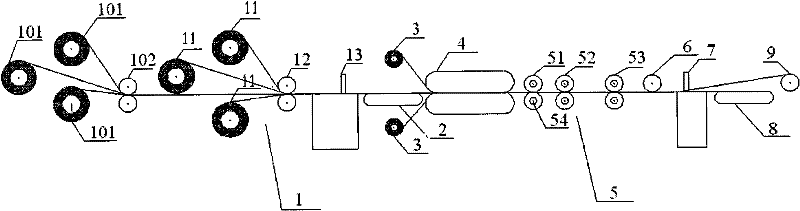

[0023] Continuous fiber reinforced thermoplastic structural sheet and coil production. Continuous fiber reinforced thermoplastic prepreg tape (continuous glass fiber reinforced polypropylene, nylon, PBT, PET, continuous carbon fiber reinforced PP, PET, PBT, nylon, etc.) is actively unwound on the automatic unwinding device 11, and the speed of the traction roller is adjusted. The ratio of its line speed to the line speed of the unwinding roller shaft 11 is greater than 1. Under the action of traction roller shaft 12, the continuous prepreg tape is conveyed into crawler hot rolling unit 4 through front conveying unit 2 for melting and compounding, and the heating device coil is adjusted to adjust the heating temperature of each section. The composited sheet is sent into the first cooling roller 51, the second cooling roller 52, and the third cooling roller 53 for cooling and shaping, the flow rate of the cooling medium is adjusted to control the cooling speed of the sheet, and ...

Embodiment 2

[0025] Production of sandwich panels formed from continuous fiber reinforced thermoplastics and honeycomb materials. Continuous fiber reinforced thermoplastic prepreg tape (continuous glass fiber reinforced polypropylene, nylon, PBT, PET, continuous carbon fiber reinforced PP, PET, PBT, nylon, etc.) is actively unwound on the unwinding roller 3, and the honeycomb materials are laid in sequence On the front conveying unit 2, under the traction force of the conveyor belt and the roller press, the continuous fiber-reinforced thermoplastic prepreg tape is sent into the crawler hot roller press 4 for fusion compounding, and the heating device coil is adjusted to adjust the heating temperature of each section. The composited sheet is sent into the first cooling roller 51, the second cooling roller 52, and the third cooling roller 53 for cooling and shaping, the flow rate of the cooling medium is adjusted to control the cooling speed of the sheet, and the rolling pressure is adjusted ...

Embodiment 3

[0027] Production of cut-to-length continuous fiber reinforced thermoplastic structural panels. Continuous fiber reinforced thermoplastic prepreg tape (continuous glass fiber reinforced polypropylene, nylon, PBT, PET, continuous carbon fiber reinforced PP, PET, PBT, nylon, etc.) is actively unwound on the unwinding roller 11, and the speed of the pulling roller 12 is adjusted , so that the ratio of its line speed to the line speed of the unwinding roller shaft 11 is greater than 1. According to the length requirement of the plate, the timing cutting time is set, and the timing cutting device 13 cuts the multi-layer prepreg tape into a predetermined length. The outer packaging film is actively unwound on the unwinding roller 3, and its linear speed is adjusted to be consistent with the linear speed of the traction roller 12. The cut prepreg tape is sent to the crawler hot roller through the front conveying unit 2 together with the outer packaging film The pressing unit 4 perfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com