Patents

Literature

10234results about How to "Improve heating efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

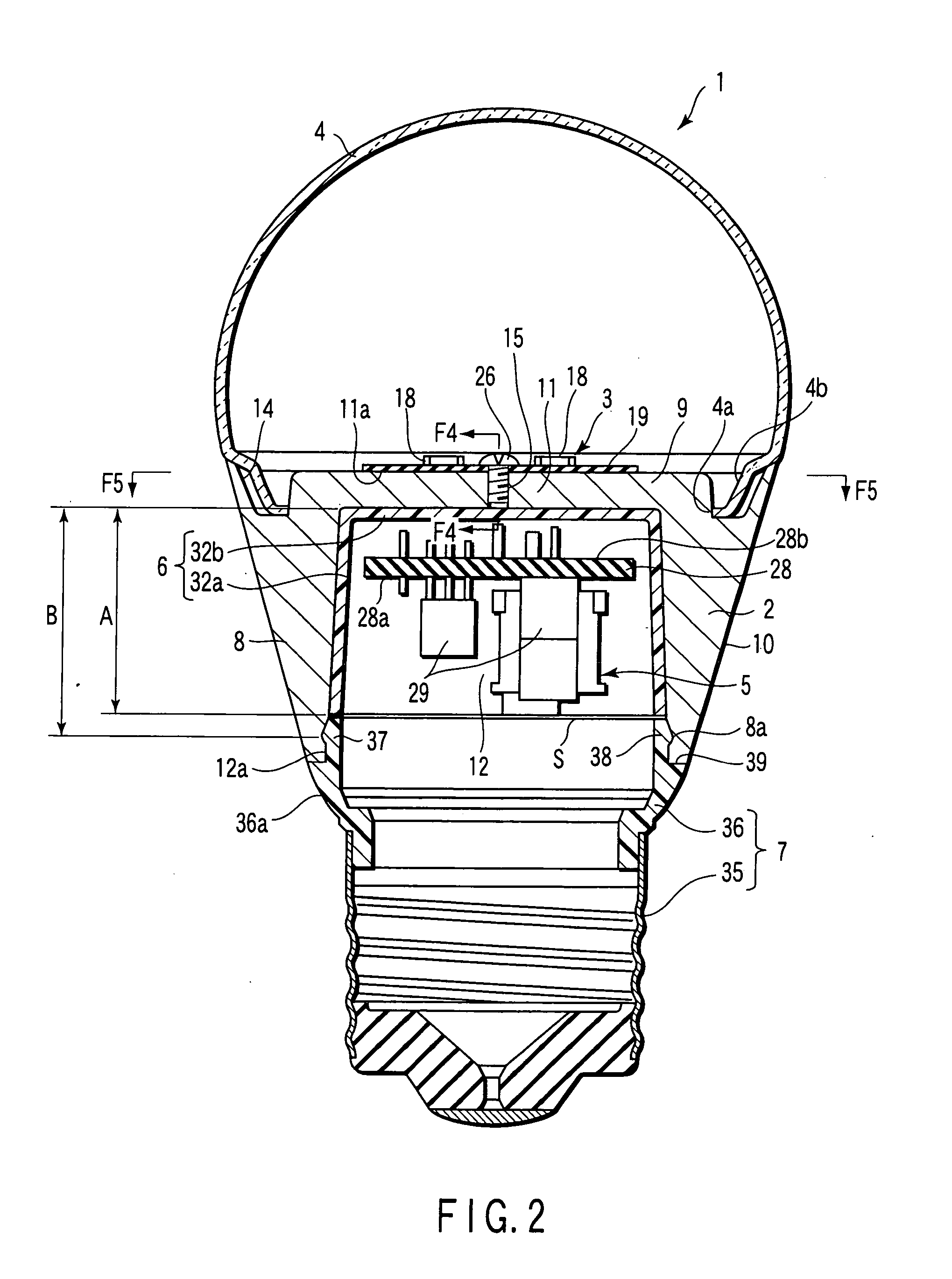

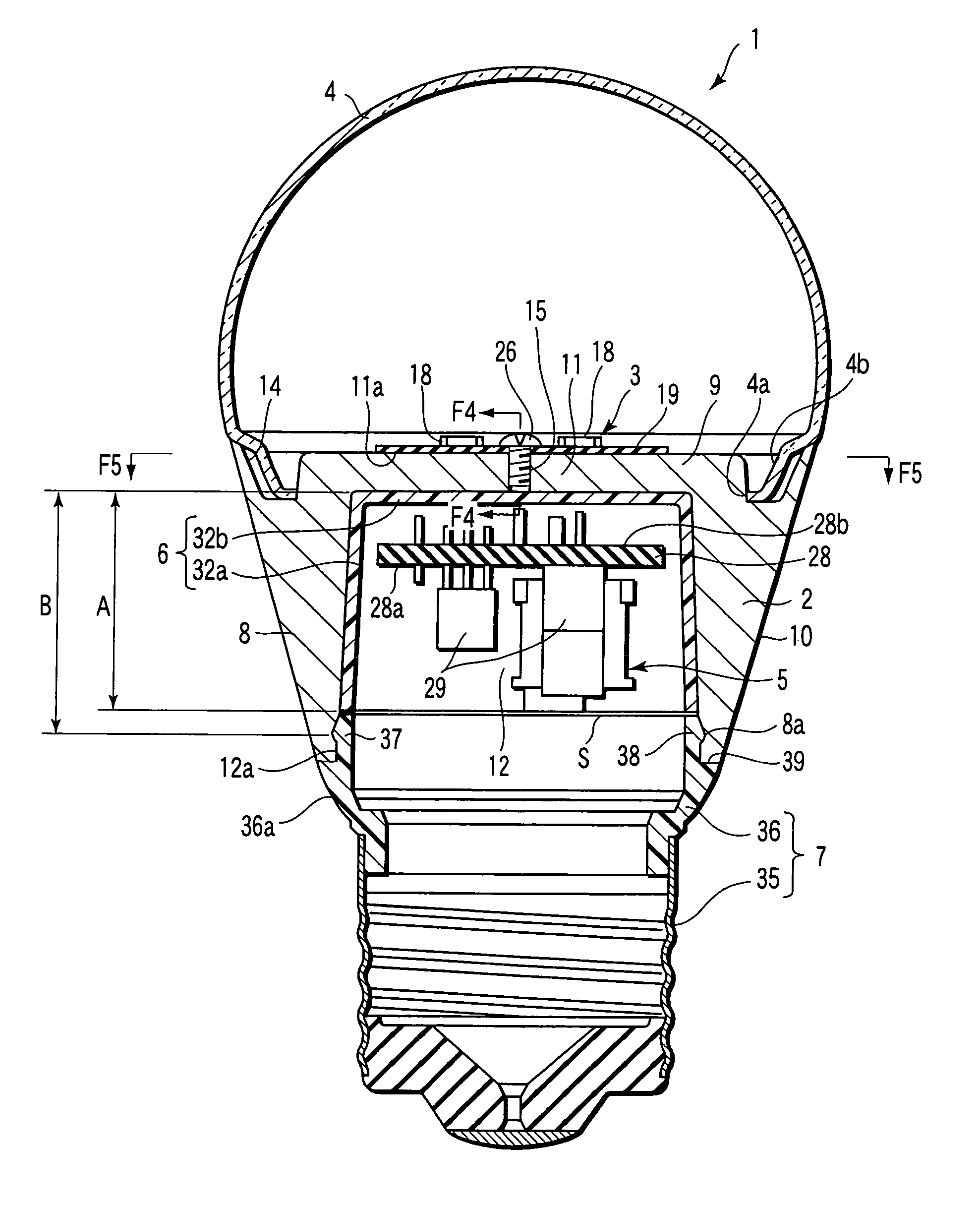

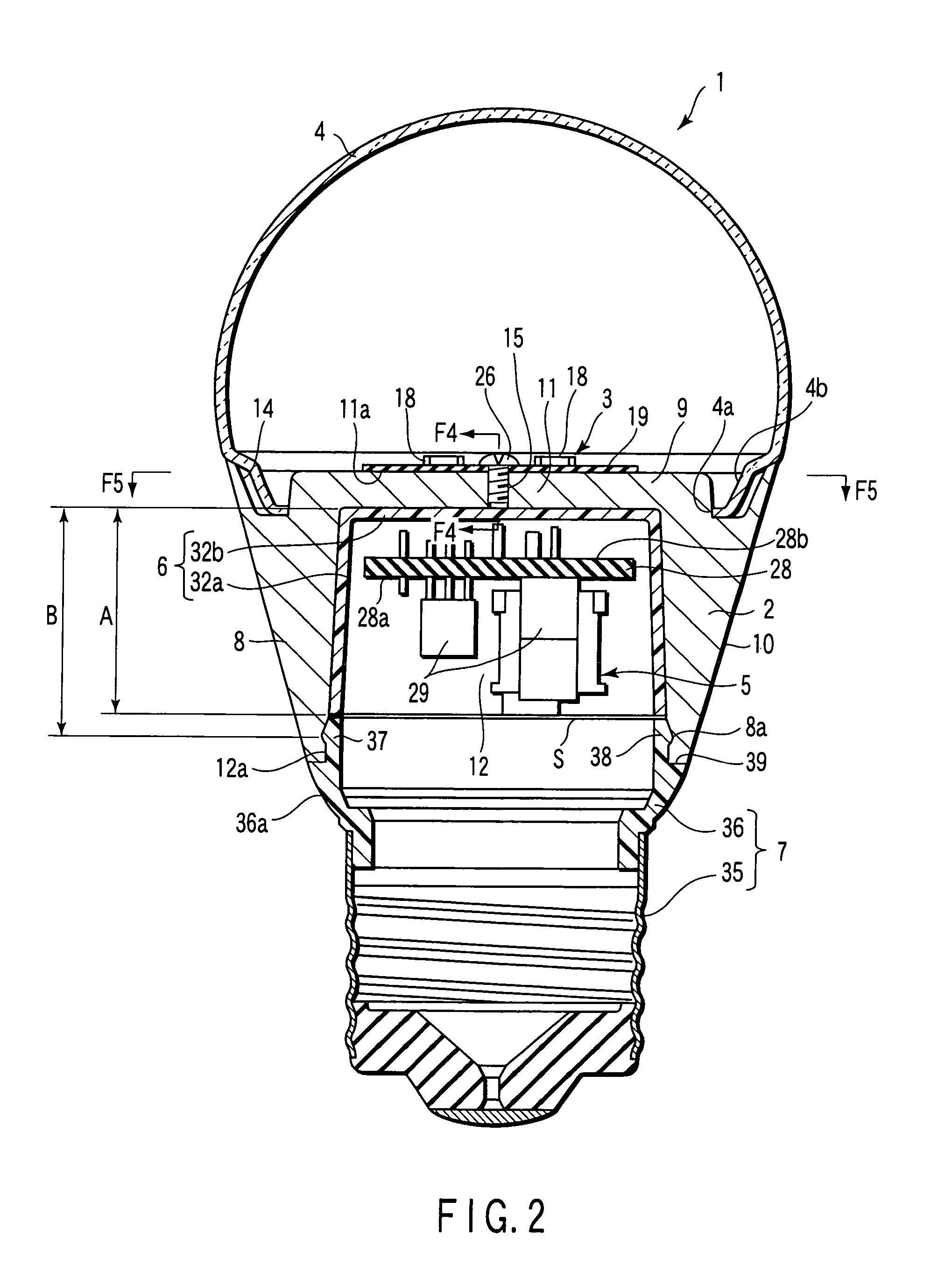

Lamp having outer shell to radiate heat of light source

InactiveUS20060227558A1Efficient transferImprove thermal conductivityCoupling device connectionsPoint-like light sourceEffect lightThermal radiation

Owner:TOSHIBA LIGHTING & TECH CORP

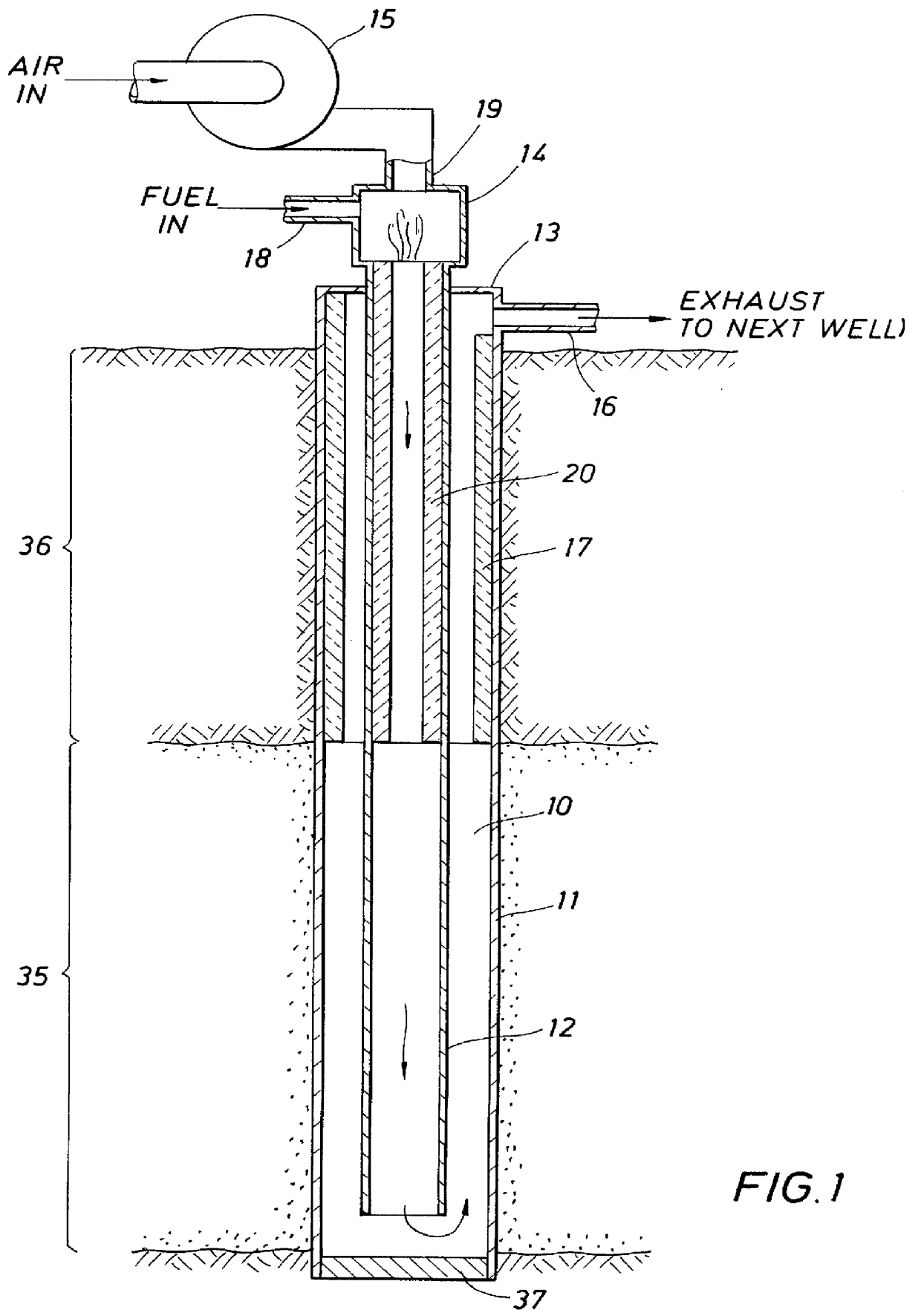

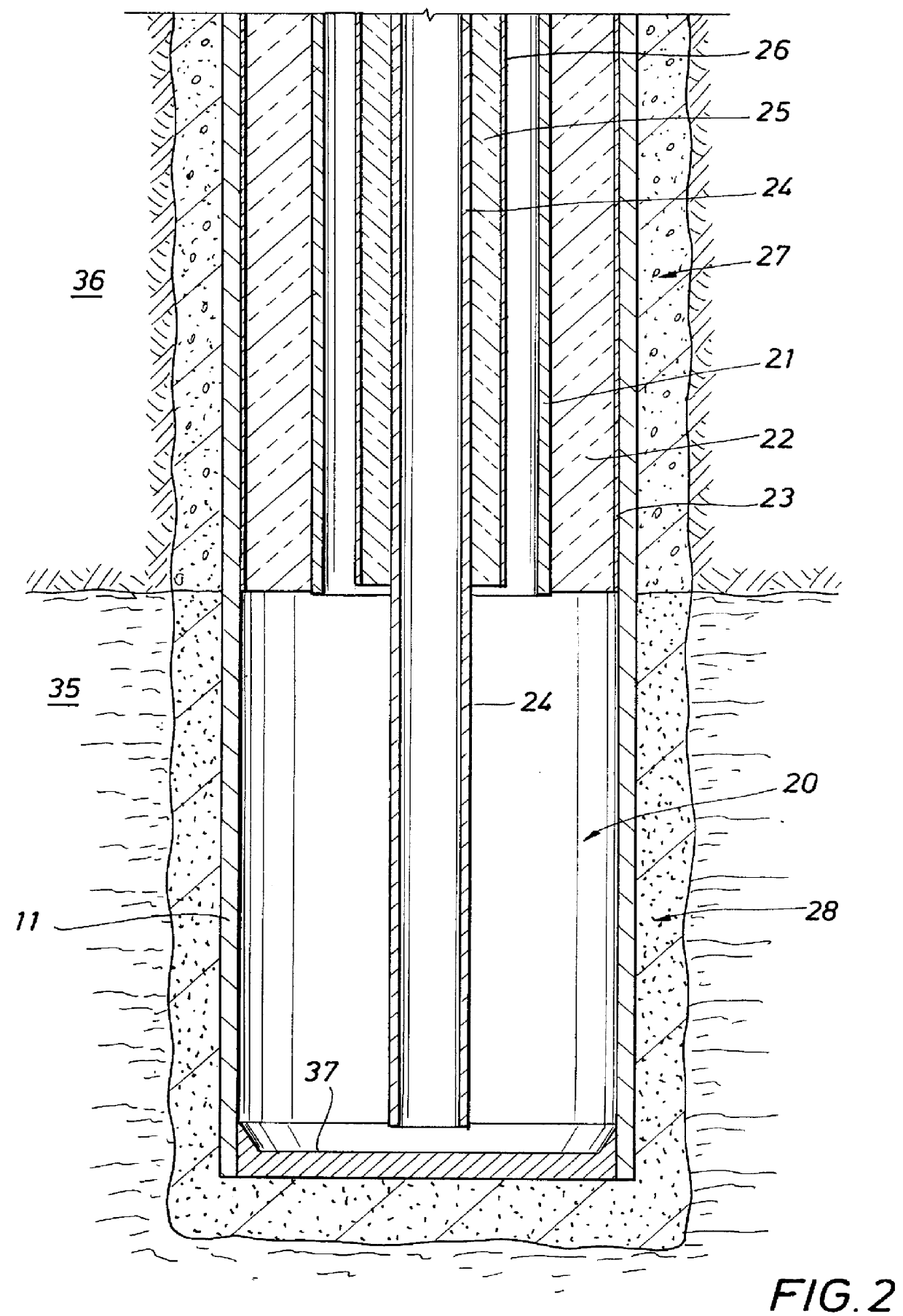

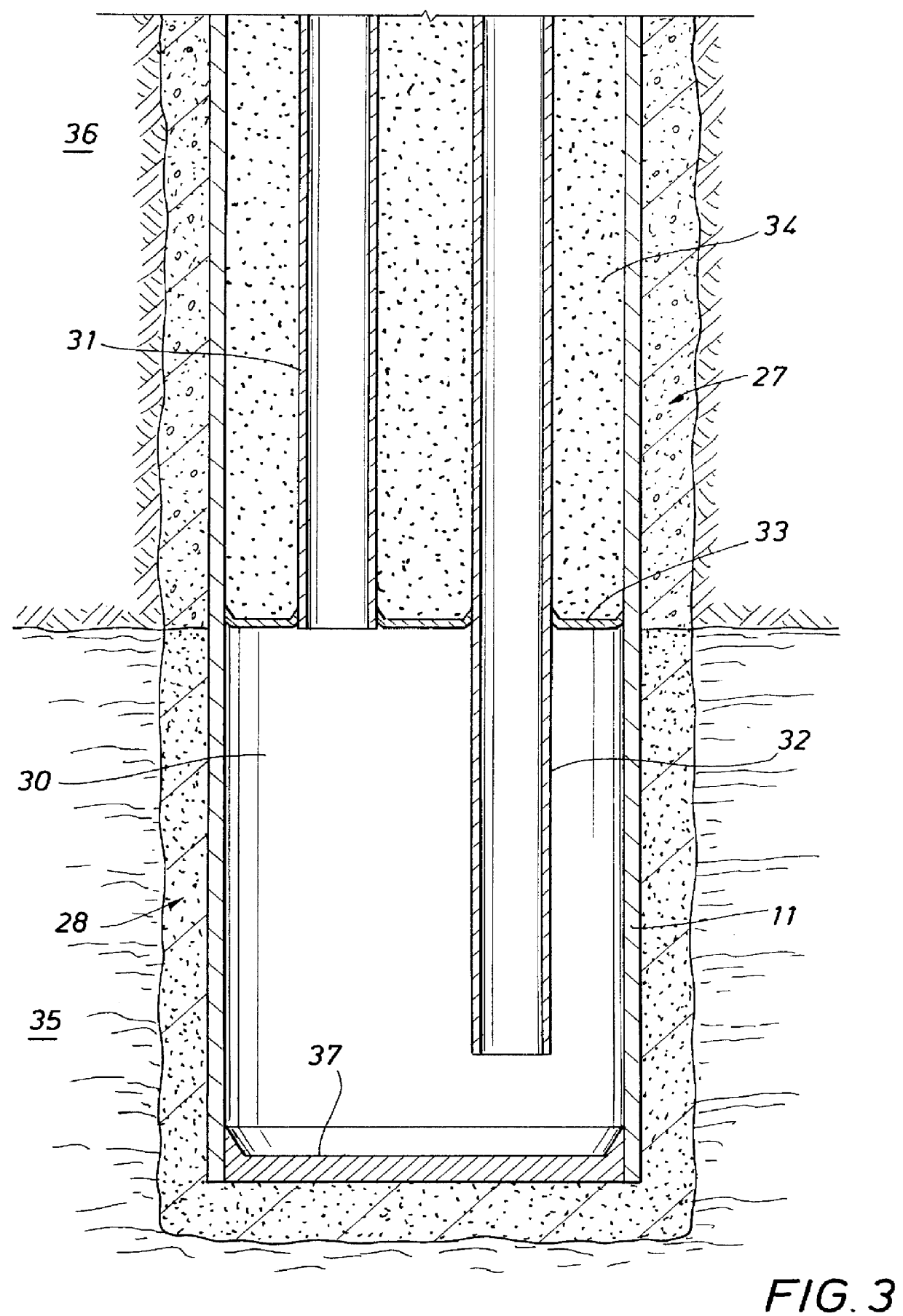

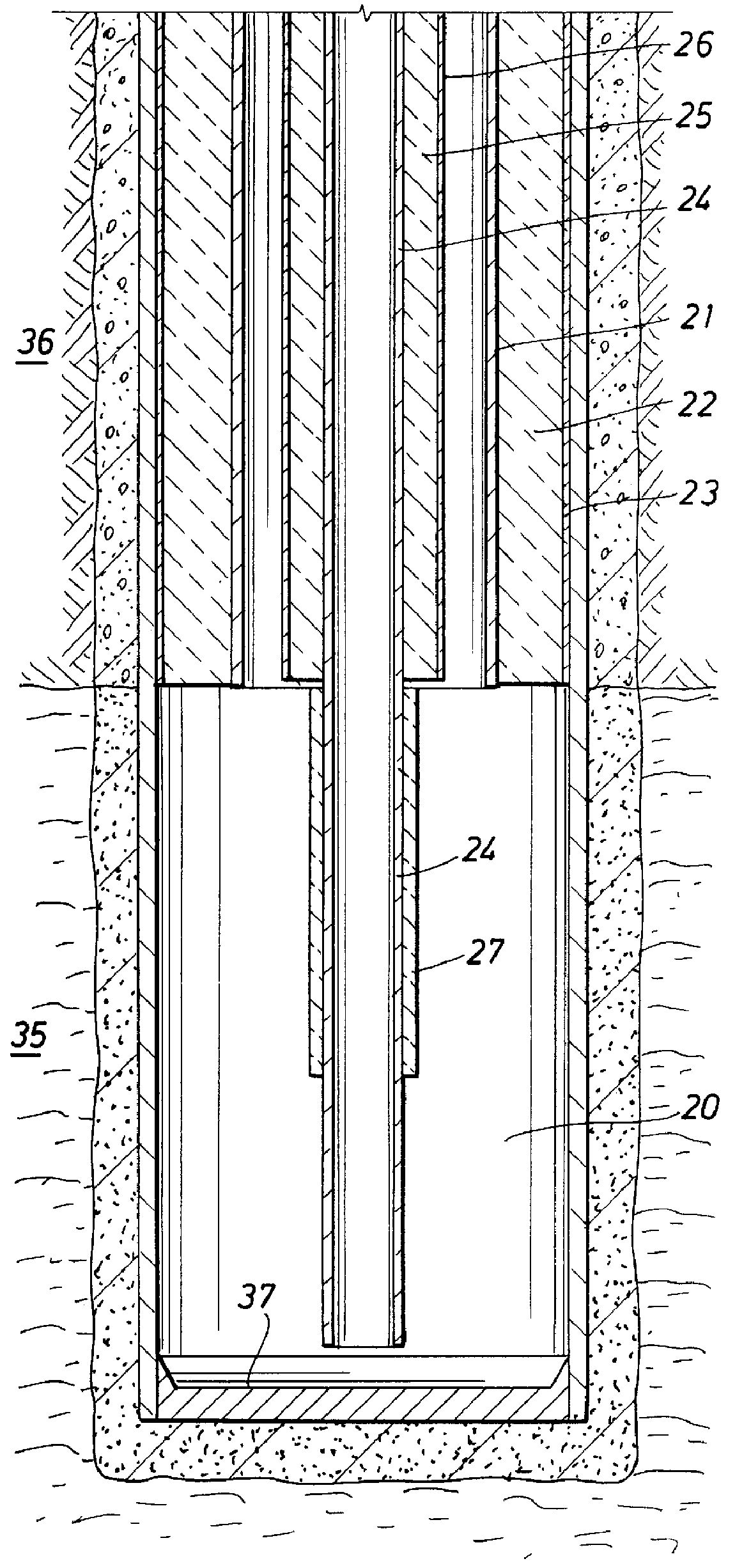

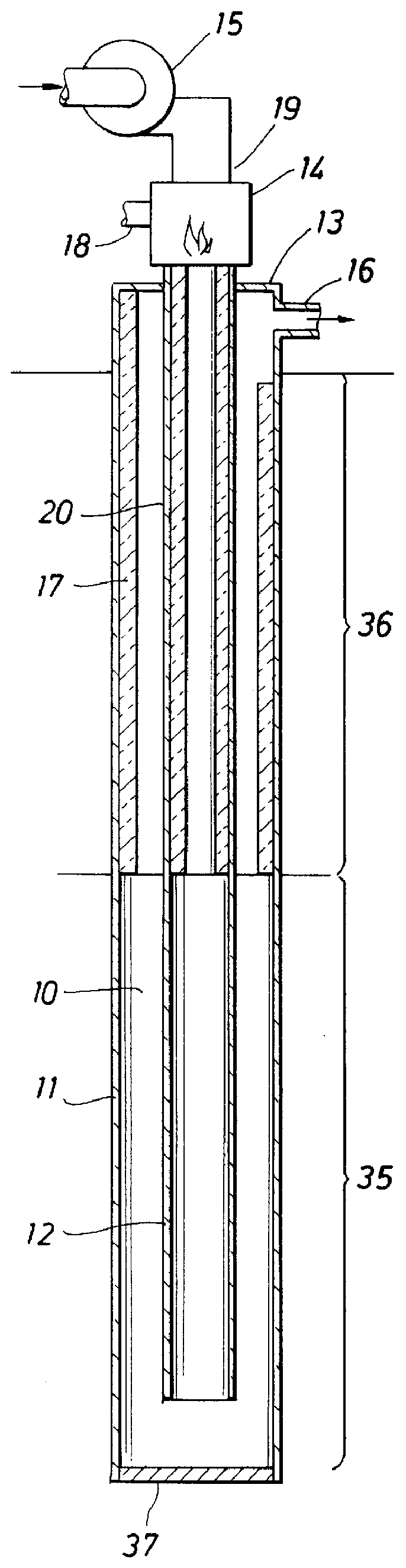

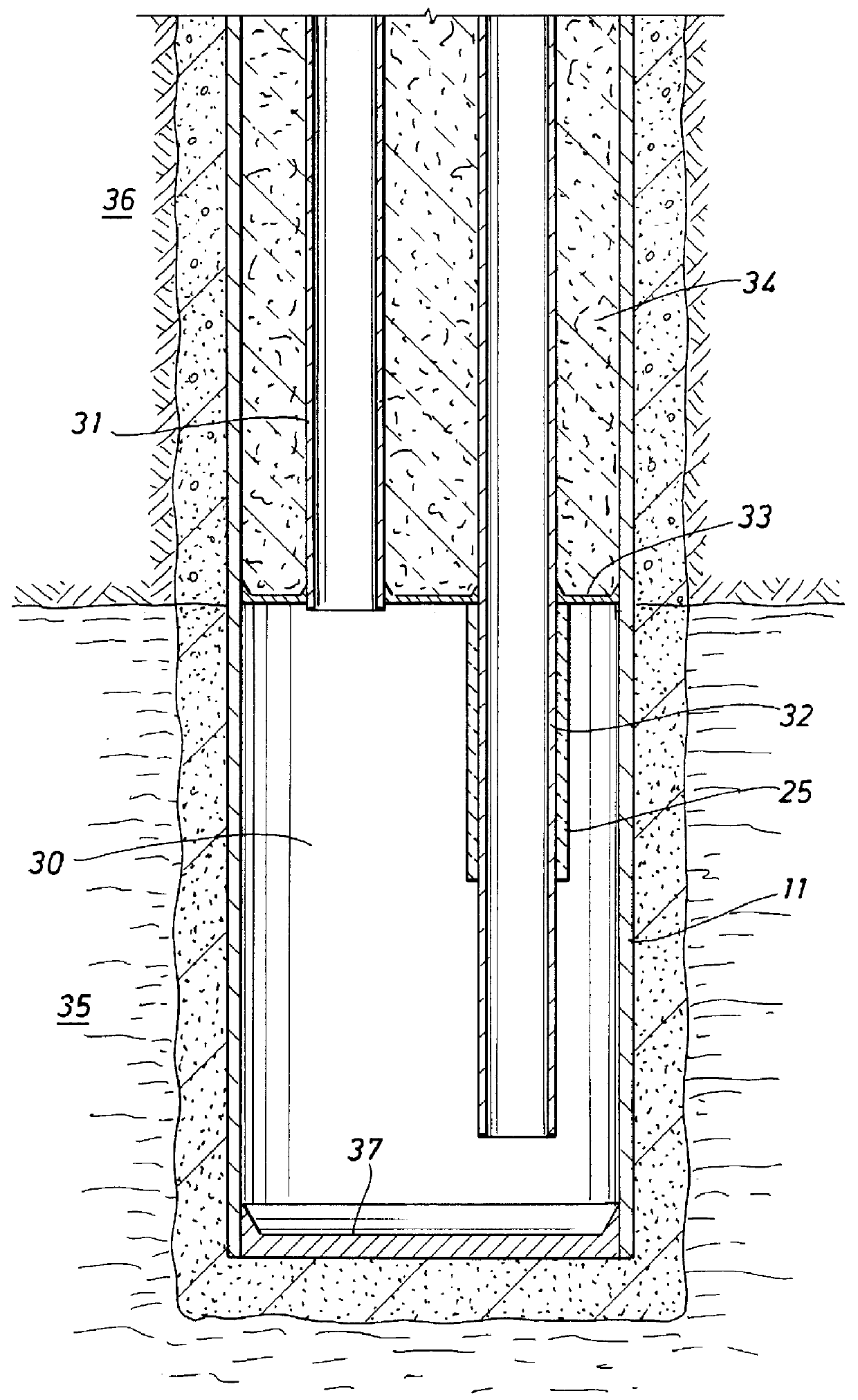

Heater well method and apparatus

A method and apparatus is disclosed for heating of formations using fired heaters. Each fired heater may consist of two concentric tubulars emplaced in the formation, connected via a wellhead to a burner at the surface. Combustion gases from the burner go down to the bottom of the inner tubular and return to the surface in the annular space between the two tubulars. The two tubulars may be insulated in an overburden zone where heating is not desired. A plurality of fired heaters can be connected together such that the combustion gases from a first fired heater well are piped through insulated interconnect piping to become the air inlet for a second fired heater well, which also has a burner at its wellhead. This can be repeated for other heater wells, until the oxygen content of the combustion gas is reduced near zero. The combustion gas from the last fired heater well may be routed through a heat exchanger in which the fresh inlet air for the first heater well is preheated. A substantially uniform temperature is maintained in each heater well by using a high mass flow into the heater well.

Owner:SHELL OIL CO

Heater well method and apparatus

InactiveUS6079499AImprove efficiencyImprove completenessInsulationFluid removalGeomorphologyWellbore

A method and apparatus is disclosed for heating of formations using fired heaters. The method includes the steps of: providing a wellbore within the formation to be heated, the wellbore comprising a casing within the formation to be heated, a tubular defining, in the inside of the tubular, a flowpath for hot gases from the surface to a point in the wellbore near the bottom of the formation to be heated, and a volume between the tubular and the casing providing a flowpath for hot gases from near the bottom of the formation to be heated to the top of the formation to be heated, wherein the flowpaths are in communication with each other near the bottom of the formation to be heated and the volume between the casing and the tubular at the top of the formation to be heated is in communication with a point above the surface, and insulation for a portion of the length of the wellbore within the formation to be heated between the flowpath for hot gases from the surface to the point in the wellbore near the bottom of the formation to be heated and the flowpath for hot gases from near the bottom of the formation to be heated to the surface; and supplying a flow of hot gases to the flowpath for hot gases from the surface to a point in the wellbore near the bottom of the formation to be heated.

Owner:SHELL OIL CO

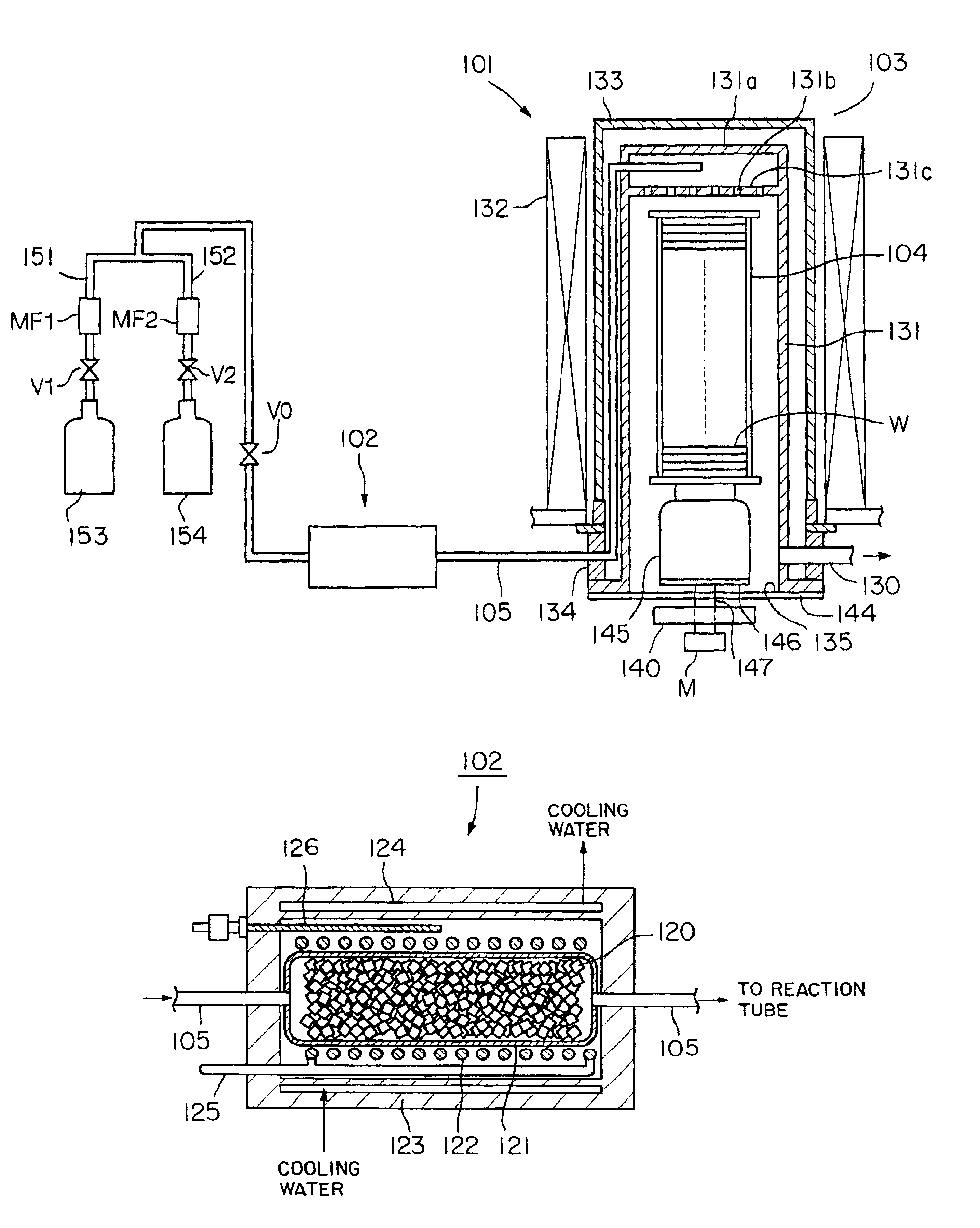

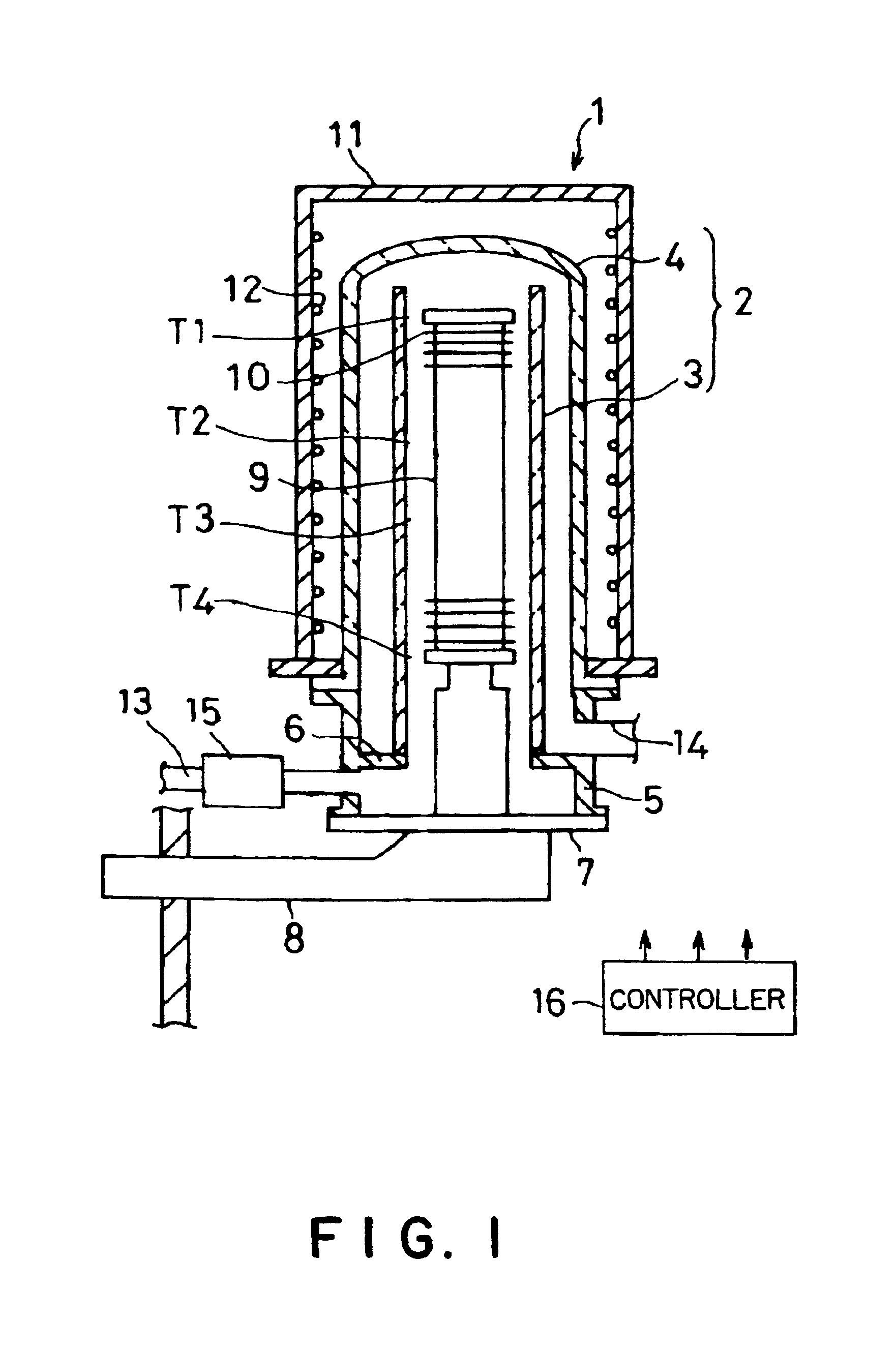

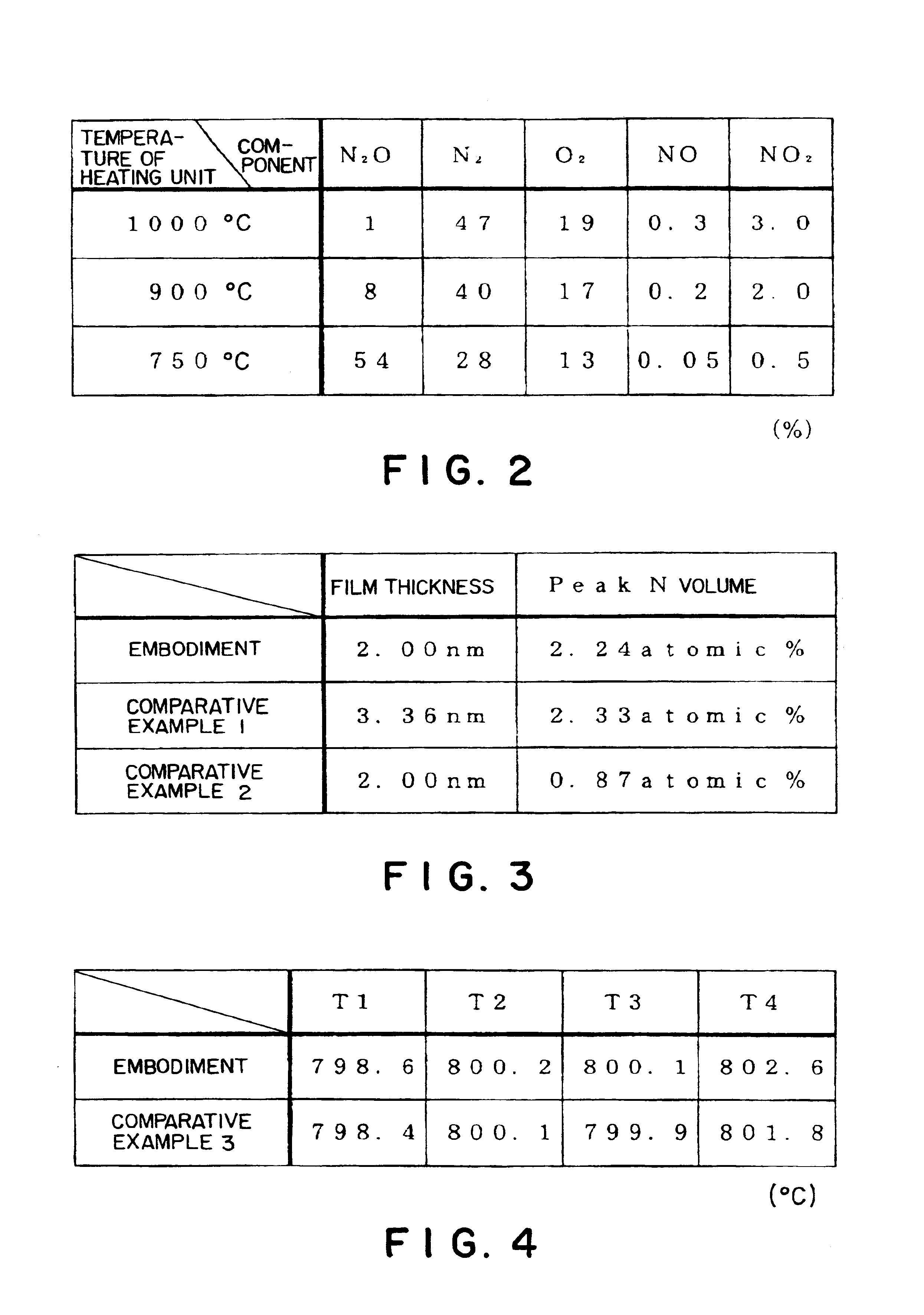

Method of forming oxynitride film or the like and system for carrying out the same

InactiveUS6884295B2High film forming ratePromote oxidationSemiconductor/solid-state device manufacturingWater heatersReaction temperatureProduct gas

This invention is an oxynitride film forming method including: a reaction chamber heating step of heating a reaction chamber to a predetermined temperature, the reaction chamber containing an object to be processed; a gas heating step of heating a process gas to a temperature not lower than a reaction temperature at which an oxynitride film can be formed, the process gas consisting of dinitrogen oxide gas; and a film forming step of forming an oxynitride film on the object to be processed by supplying the heated process gas into the heated processing chamber. The temperature to which the reaction chamber is heated in the reaction chamber heating step is set at a temperature below a temperature at which the process gas undergoes a reaction.

Owner:TOKYO ELECTRON LTD

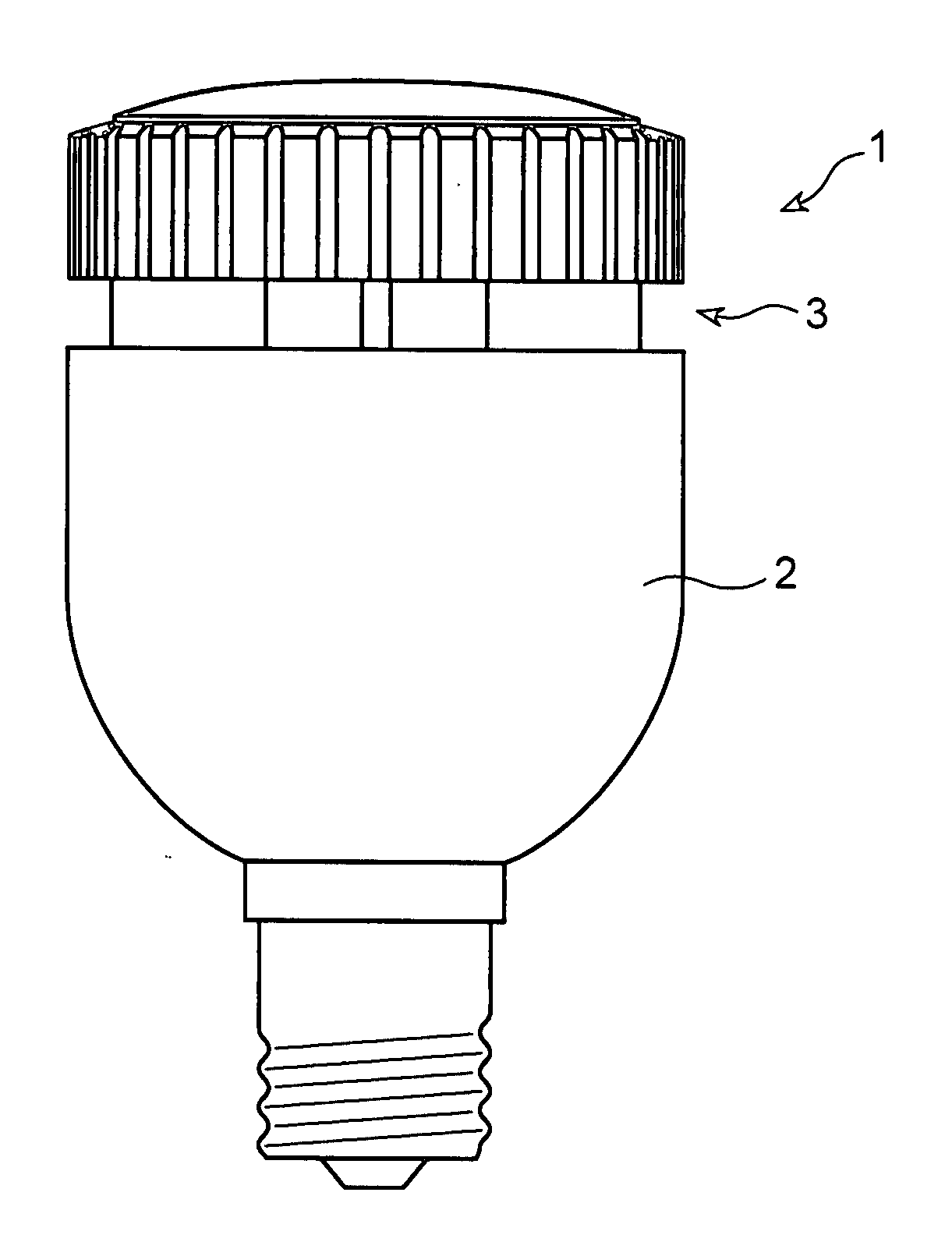

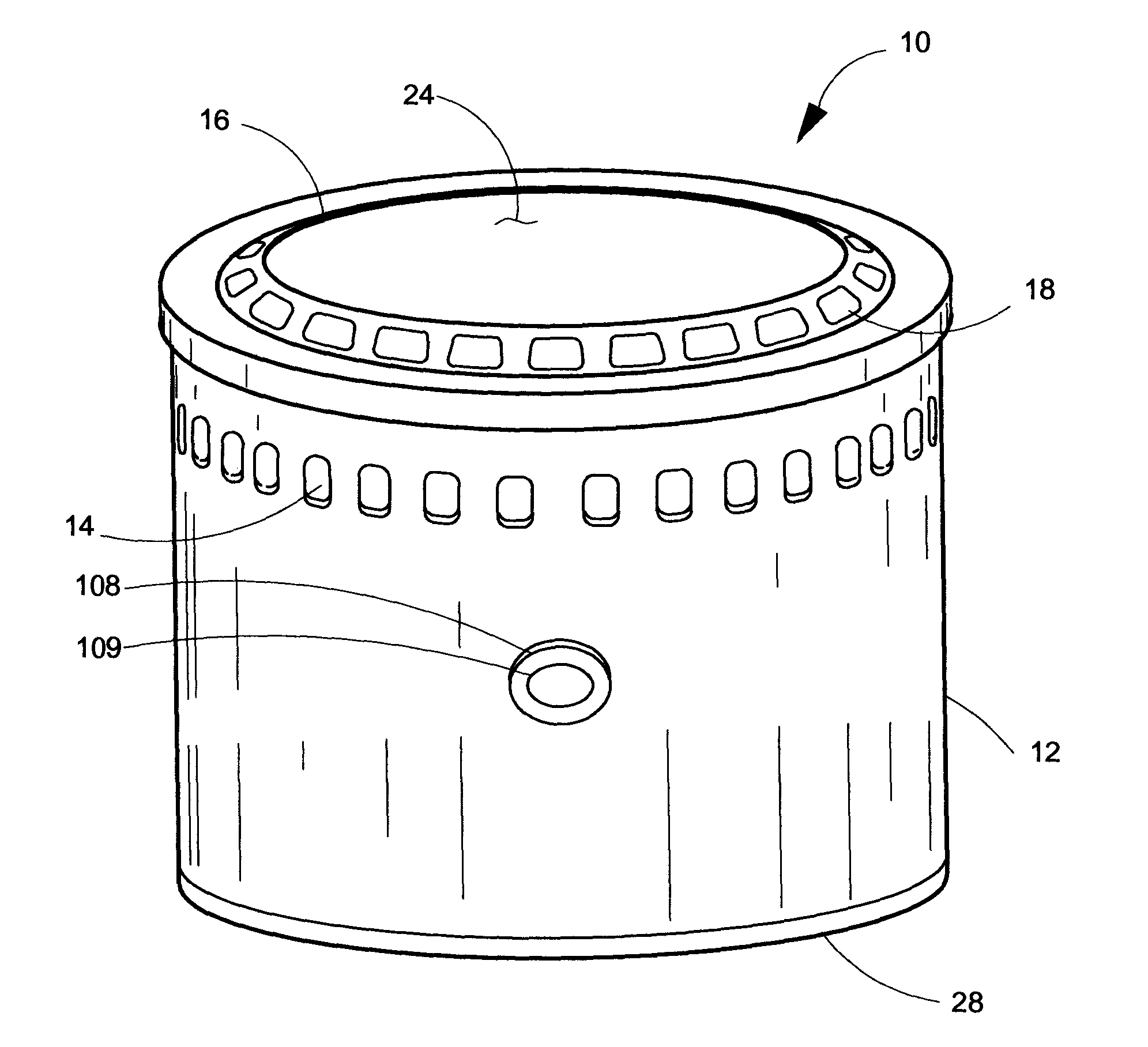

Lamp having outer shell to radiate heat of light source

InactiveUS7758223B2Increase the areaPrevent rustCoupling device connectionsLighting support devicesEngineeringMechanical engineering

A lamp includes an outer shell having heat conductivity, a base provided in the outer shell, and a cover provided in the outer shell. The outer shell has a light source support, and a heat radiating surface exposed to the outside of the outer shell. The light source support is formed integral with the heat radiating surface. A light source is supported on the light source support. The light source is heated during lighting, and thermally connected to the light source support. The light source is covered with the cover.

Owner:TOSHIBA LIGHTING & TECH CORP

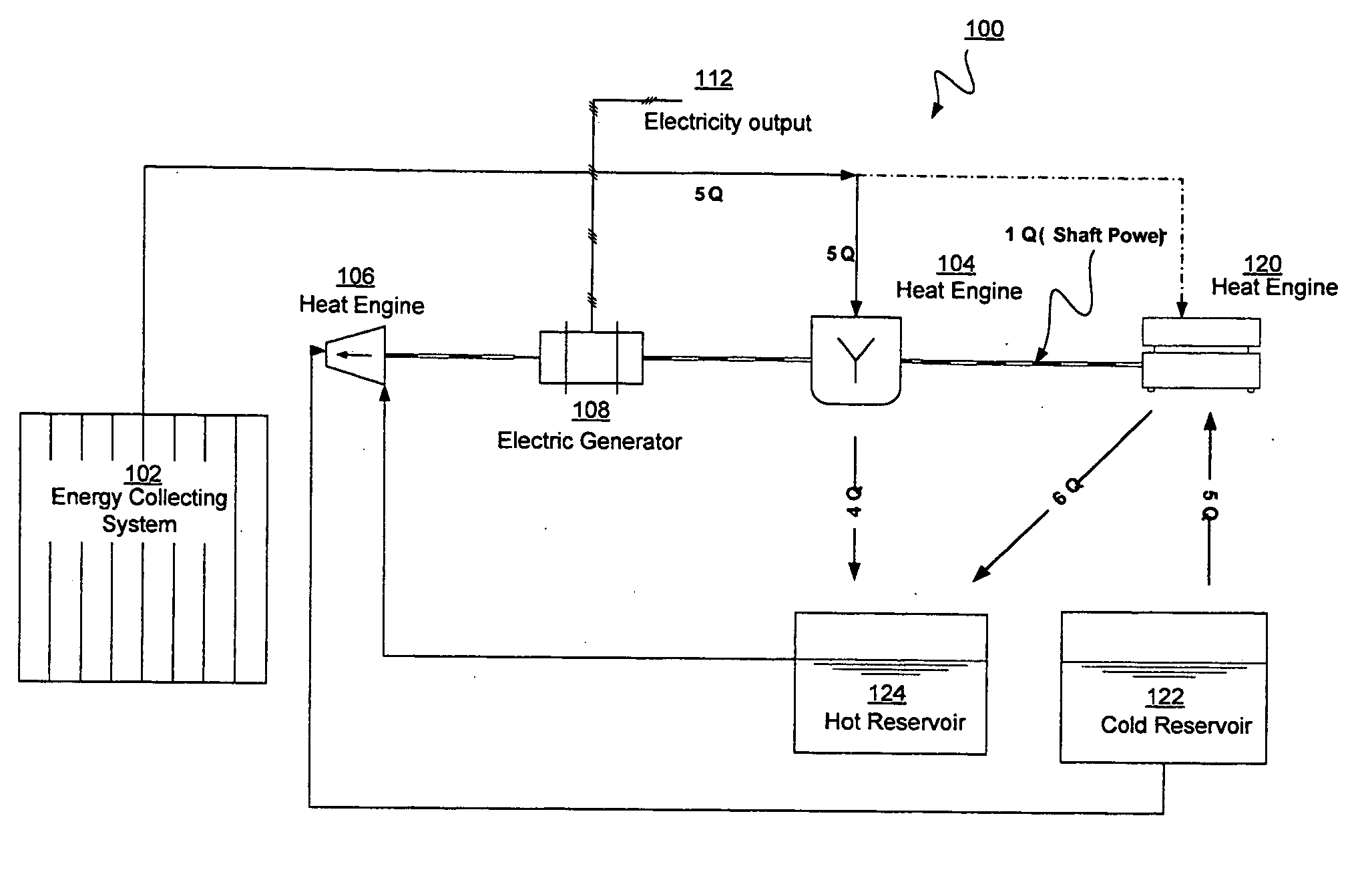

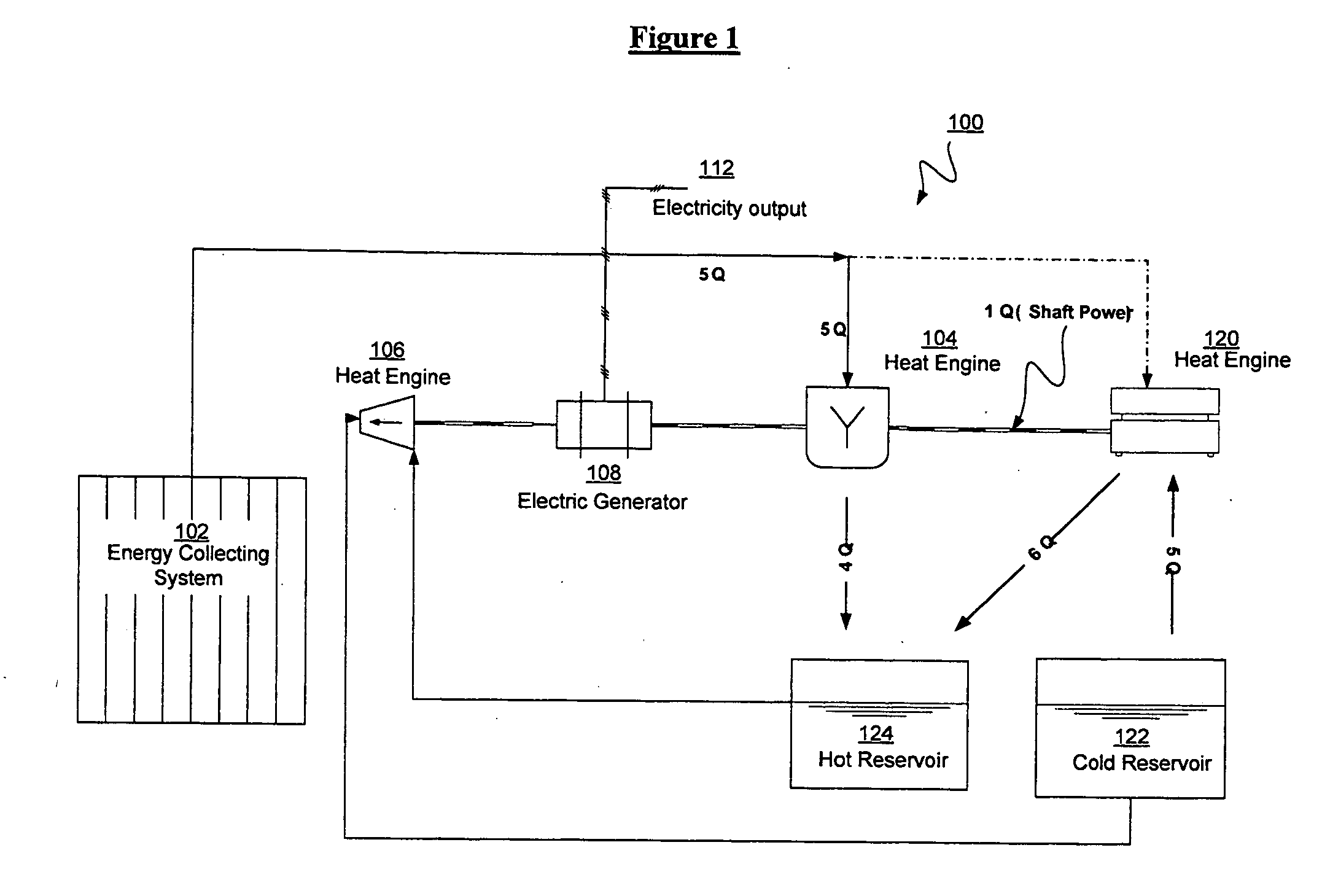

Efficient low temperature thermal energy storage

InactiveUS20090179429A1Improve heating efficiencyInternal combustion piston enginesFrom solar energyThermal energyWorking fluid

Thermal energy derived from a low temperature heat source is stored in one reservoir above ambient temperature and in another reservoir below ambient temperature for use in driving an organic Rankine cycle engine to produce electricity. The organic Rankine cycle engine may utilize an organic working fluid that boils below or near ambient temperature. Solar energy may be used to power a heat pump or chiller that provides the hot and cold storage fluids stored in hot and cold reservoirs for use in the organic Rankine cycle engine.

Owner:AREVA SOLAR

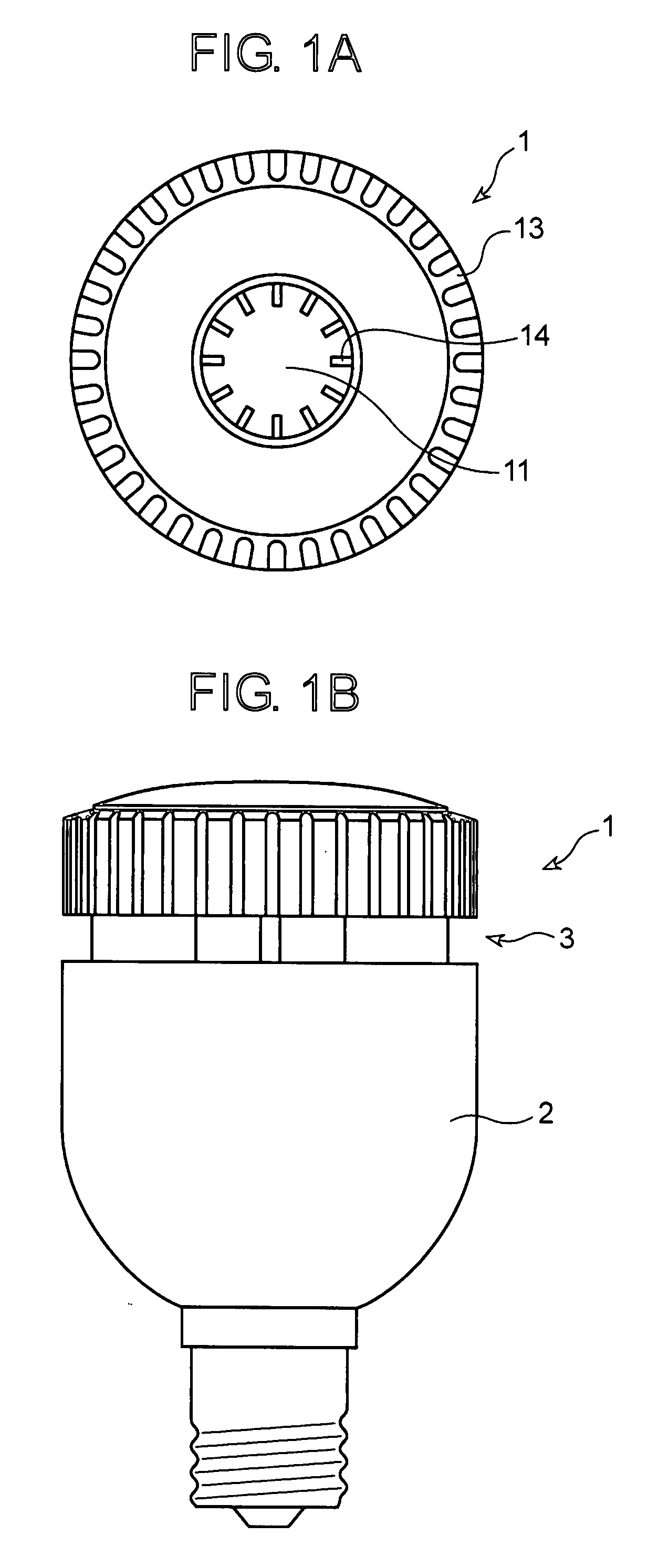

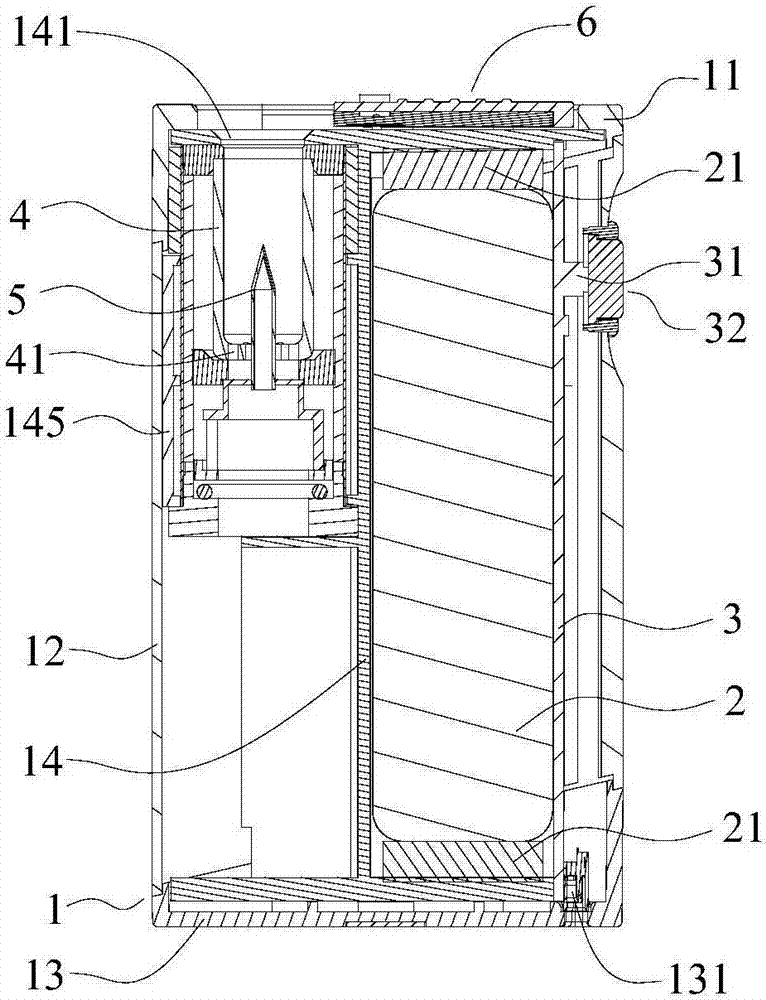

LED lighting device

InactiveUS20080024067A1Improve heating efficiencyLimit temperature risePoint-like light sourceElectric circuit arrangementsAir cycleEffect light

An LED lighting device has high cooling efficiency and long life with a plurality of high-intensity LEDs mounted thereto. The LED lighting device is composed of a light emission part provided with a plurality of LEDs and a heat radiator for the LEDs, a power source part generating a current to be supplied to the LEDs from a commercial power source, and an air circulation part for circulating ambient air. The light emission part and the power source part are thermally separated by the air circulation part. The light emission part is provided with an annular heat radiation base having a hole formed at a central portion thereof and a substrate attaching face formed around the hole, and an LED substrate which is attached to the substrate attaching face and on which a plurality of LED chips are mounted. The heat radiation base has heat radiation fins as the heat radiator which are formed on an outer periphery of the heat radiation base and on an inner periphery of the hole. By the presence of the air circulating part, little heat generated from the power source part is transmitted to the light emission part. Therefore, it is possible to accomplish desired designing of heat radiation of the light emission part concerned with intensity and life of an LED, which is critical to performance of an LED lighting device.

Owner:ATEX CO LTD

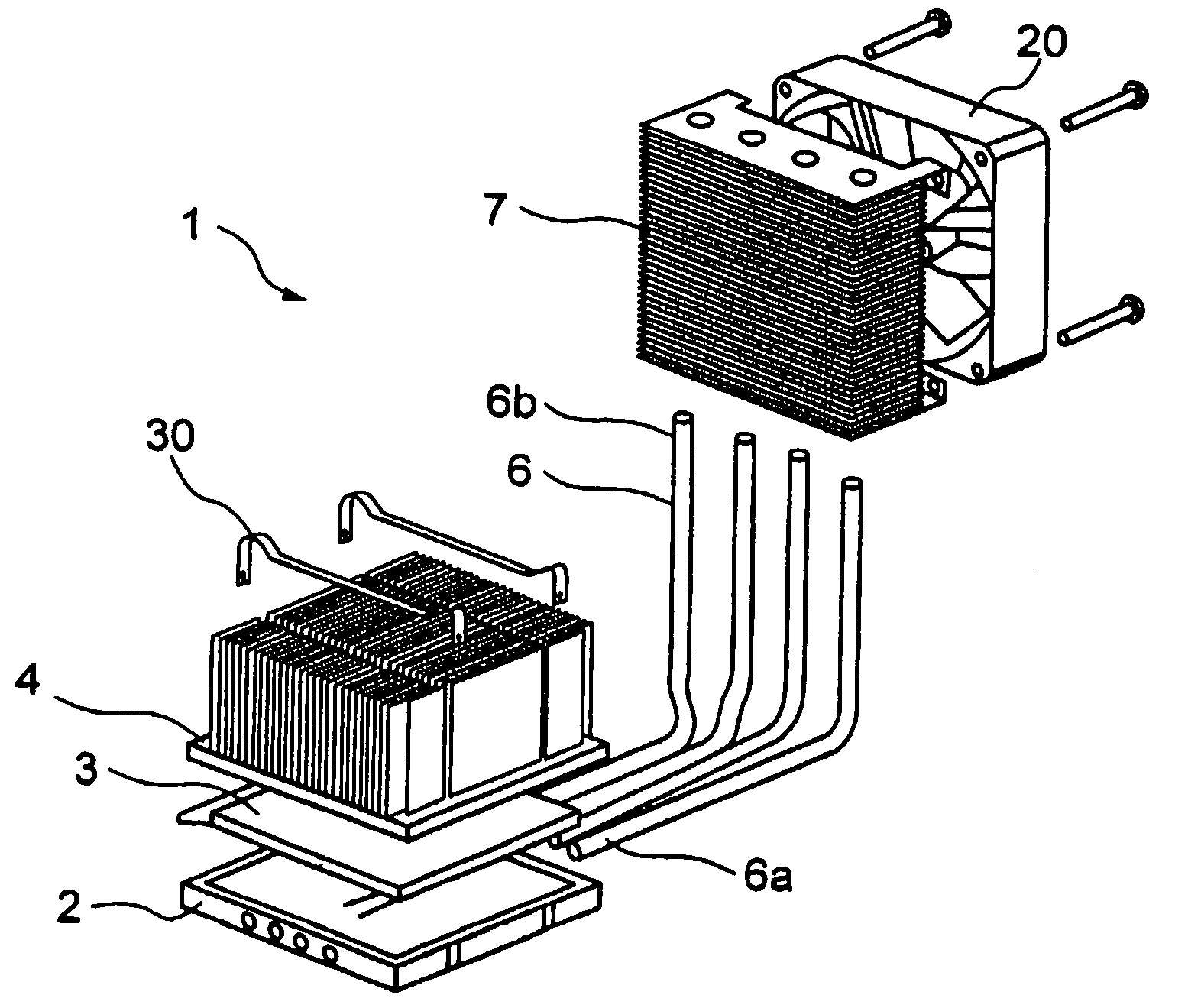

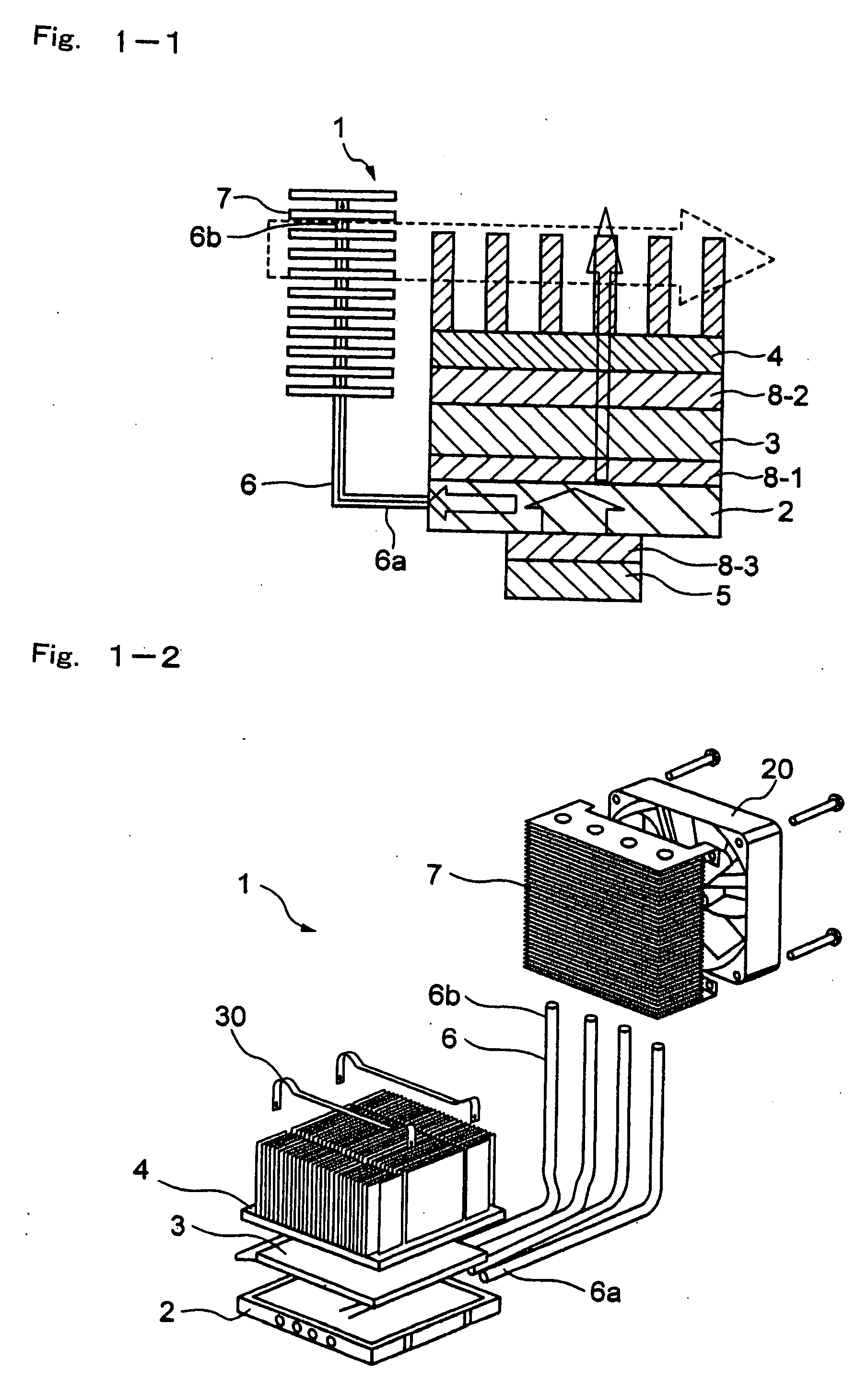

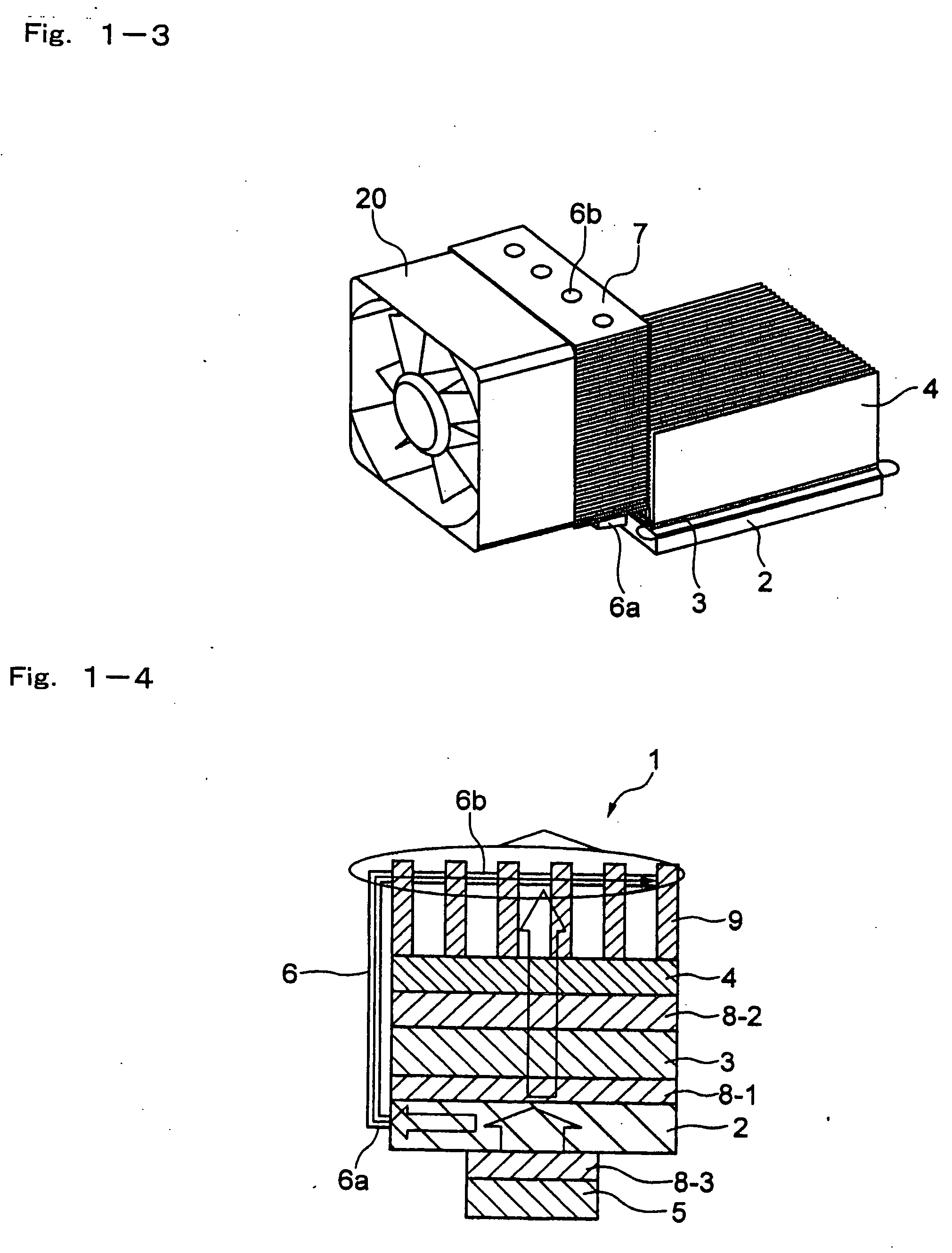

Module for cooling semiconductor device

InactiveUS20050257532A1Improve cooling efficiencyReduce heat gainDomestic cooling apparatusIndirect heat exchangersThermoelectric coolingDevice material

A module for cooling a heat generating element comprising a heat receiving plate thermally connected to at least one heat generating element; a heat transfer device one end portion of which is thermally connected to the heat receiving plate and other end portion of which is thermally connected to a heat dissipating plate; a thermoelectric cooler one face of which is thermally connected to one face of the heat dissipating plate; a first heat sink thermally connected to other face of the heat dissipating plate; and a second heat sink thermally connected to other face of said thermoelectric cooler.

Owner:FURUKAWA ELECTRIC CO LTD

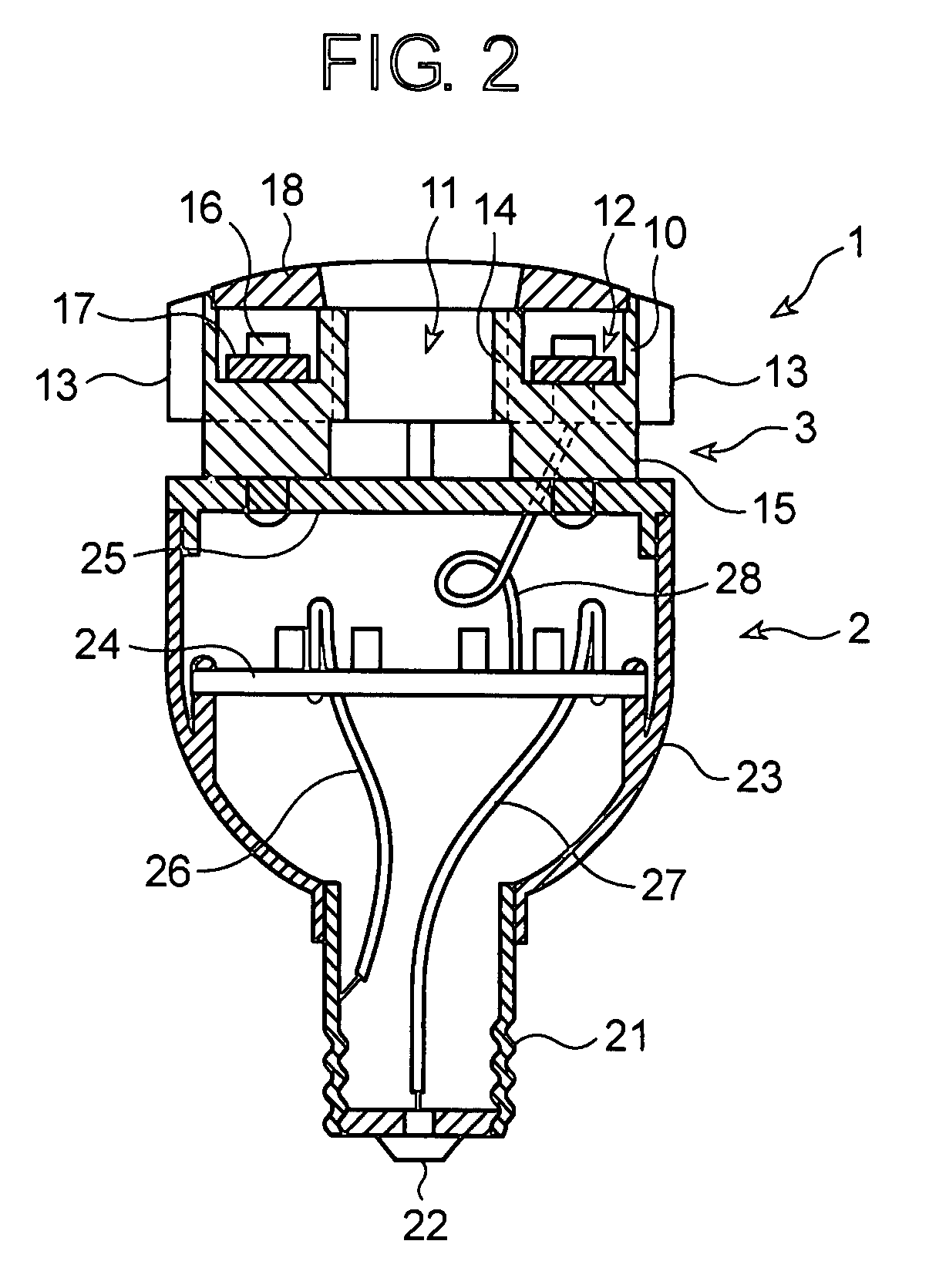

Electronic cigarette

ActiveCN101390659AWon't ageNot transgenderCoil arrangementsTobacco devicesElectronic cigaretteEngineering

The invention discloses an electronic cigarette which comprises a cigarette-like shell with a hollow cavity, an electrical source, a cigarette pellet and cigarette rod fittings. The electrical source, a pneumatic switch, a magnetostrictive vibrator and an electromagnetic induction heater are arranged in sequence inside the shell from the front end to the back end; wherein, a high frequency generator is respectively connected with the magnetostrictive vibrator, the electromagnetic induction heater and the pneumatic switch through leads. A light-emitting diode is arranged at the front end of the shell and is respectively connected with the pneumatic switch and the electric source through leads. The back end of the shell is connected with the cigarette pellet in which a tobacco solution chamber is arranged.

Owner:BEIJING SHUIWUTANG TECH & TRADE CO LTD

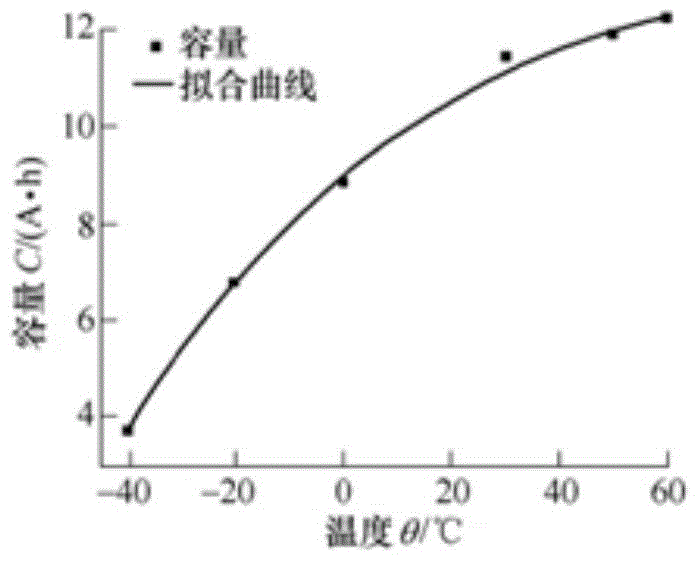

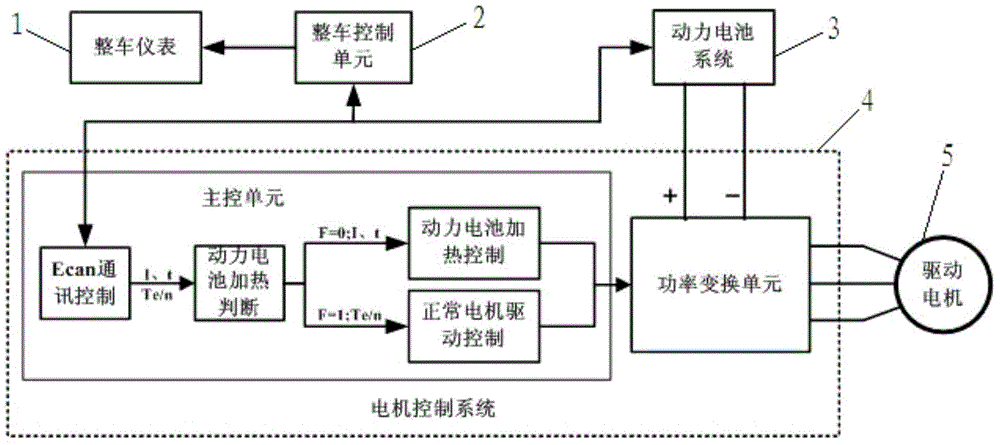

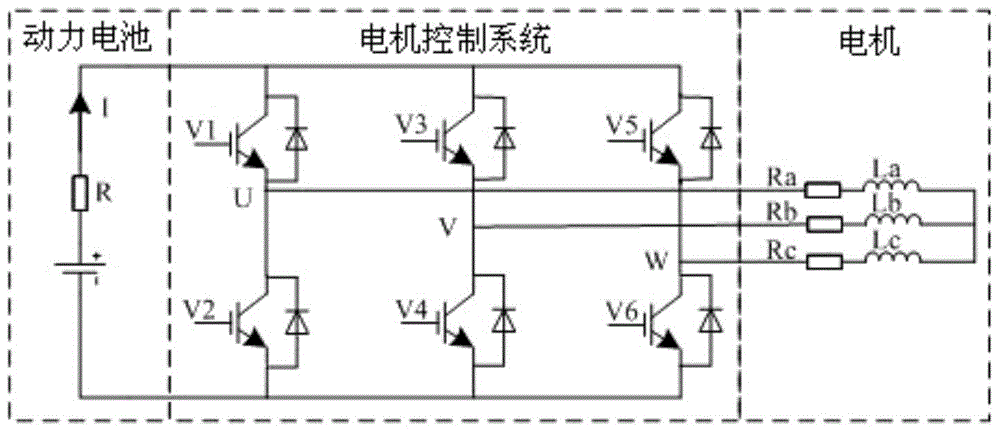

Heating control method of power battery pack of electric vehicle

ActiveCN103560304AIncrease temperatureControl heating rateCell temperature controlElectrical batteryEngineering

The invention belongs to the technical field of power batteries of vehicles, and particularly relates to a heating control method of a power battery pack of an electric vehicle. The heating control method is implemented by a whole vehicle instrument, a whole vehicle control unit, a power battery system, a motor control system and a driving motor, wherein the whole vehicle instrument is connected with the whole vehicle control unit, the whole vehicle control unit is connected with the power battery system and the motor control system respectively, and the motor control system is connected with the power battery system and the driving motor respectively. According to the method, power batteries are heated by virtue of an original electric drive system of the electric vehicle, the energy of the power batteries is mainly used for the self heating of the power batteries, so that the temperature of the power batteries can be rapidly raised without extra cost, and the heating efficiency is high.

Owner:DONGFENG MOTOR CORP HUBEI

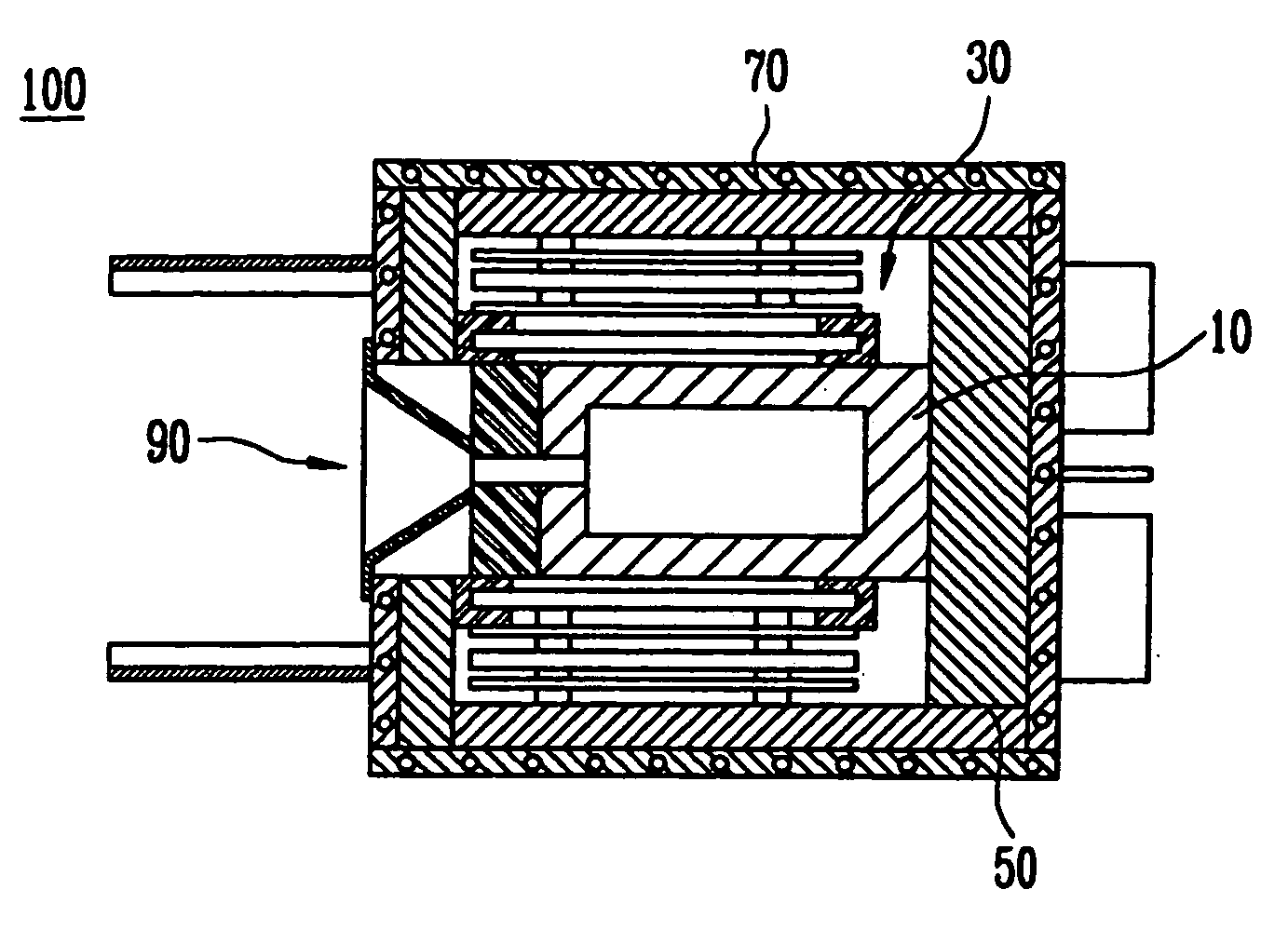

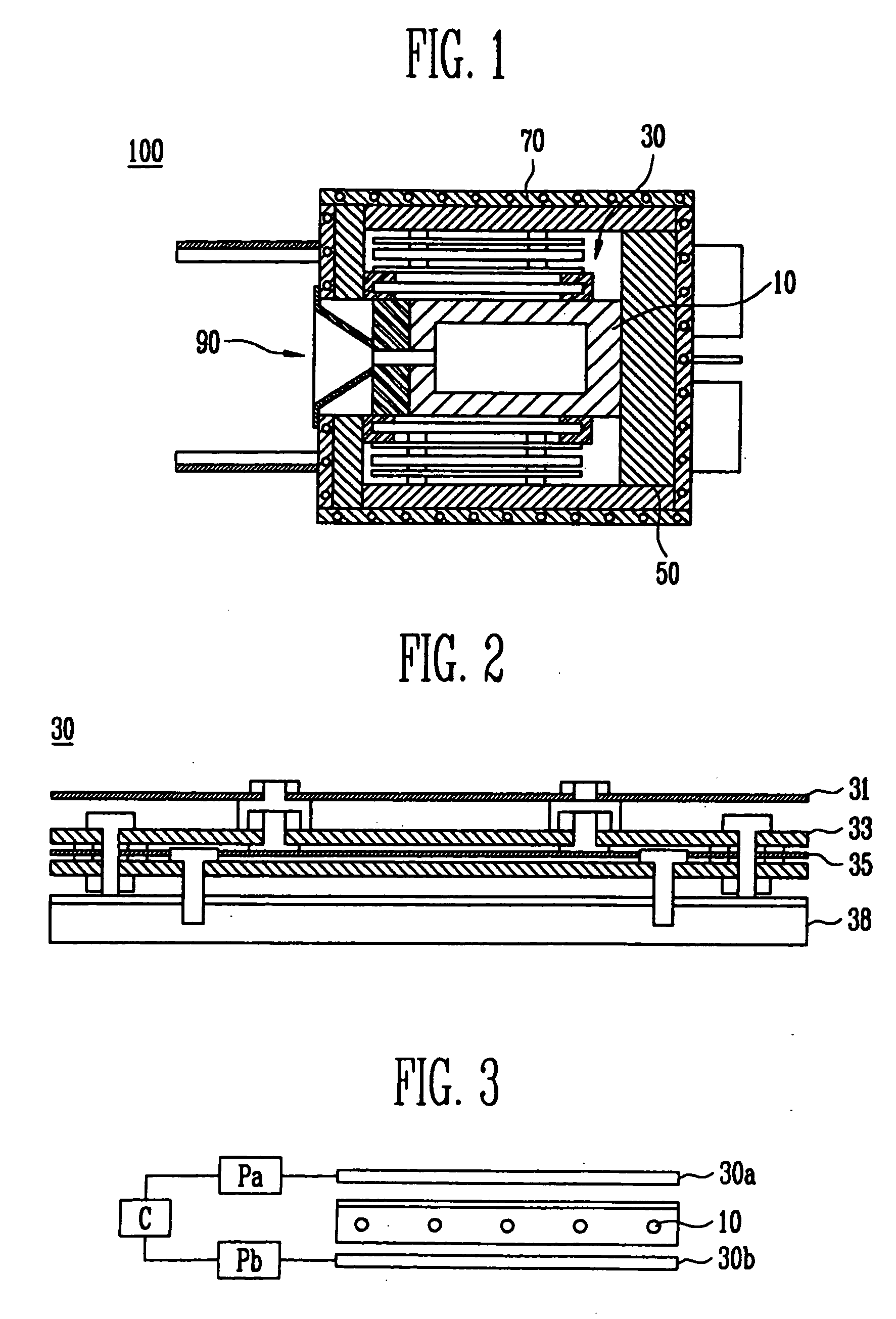

Apparatus for depositing an organic layer and method for controlling a heating unit thereof

InactiveUS20070077358A1Improve heating efficiencyMinimize timeVacuum evaporation coatingSputtering coatingCrucibleEvaporation

An apparatus for depositing an organic layer and a method for controlling the heating unit thereof are provided. The apparatus includes a crucible positioned in a deposition chamber and containing materials for evaporation. The apparatus also includes a heating unit having first and second heat sources for heating the crucible. A housing isolates the heat emitted from the heating unit and an outer wall anchors the crucible. A nozzle sprays the materials evaporated from the crucible. The first and second heat sources are positioned on first and second sides of the crucible, respectively, and are independently controlled to minimize the time required to stabilize the deposition rate.

Owner:SAMSUNG DISPLAY CO LTD

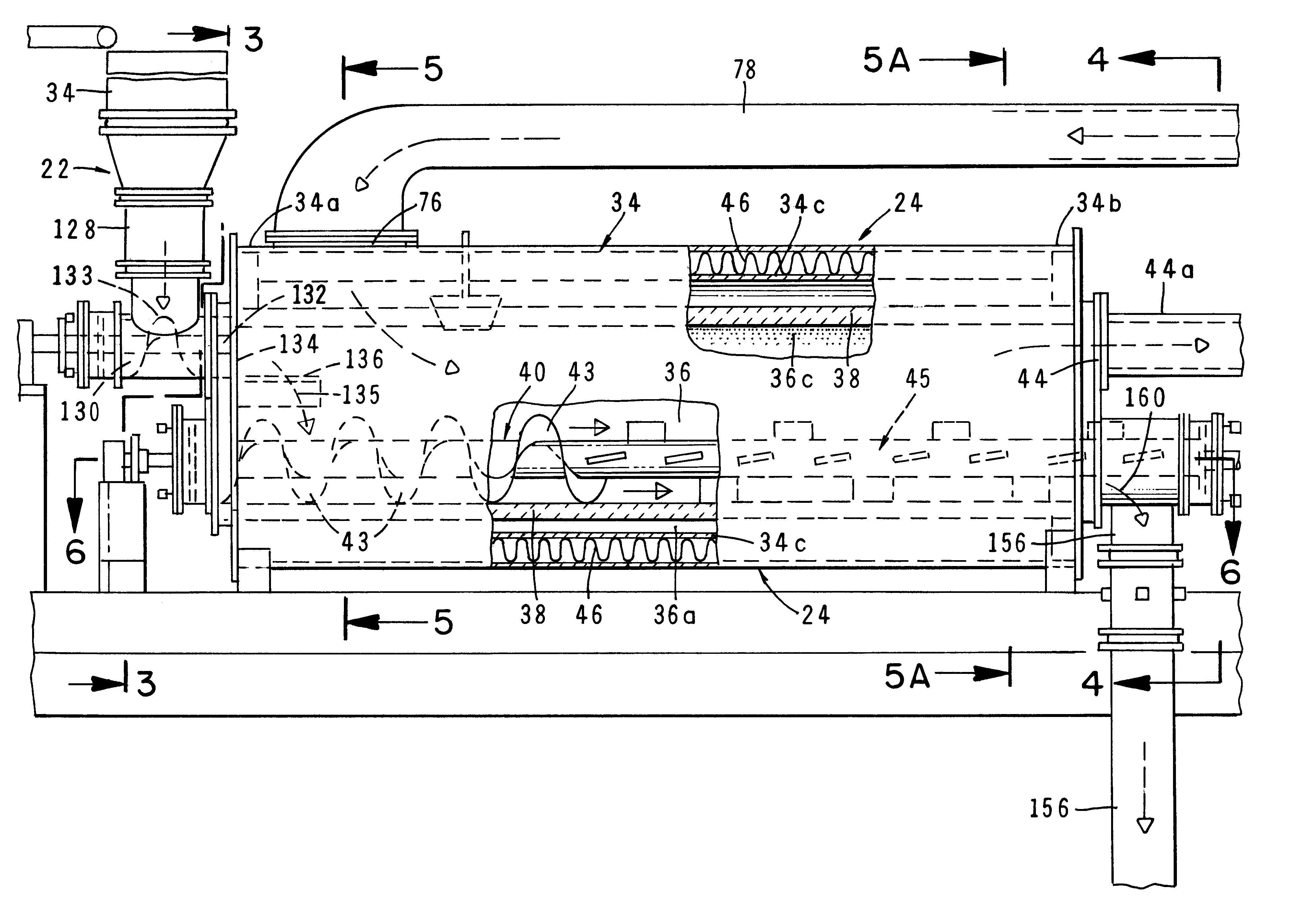

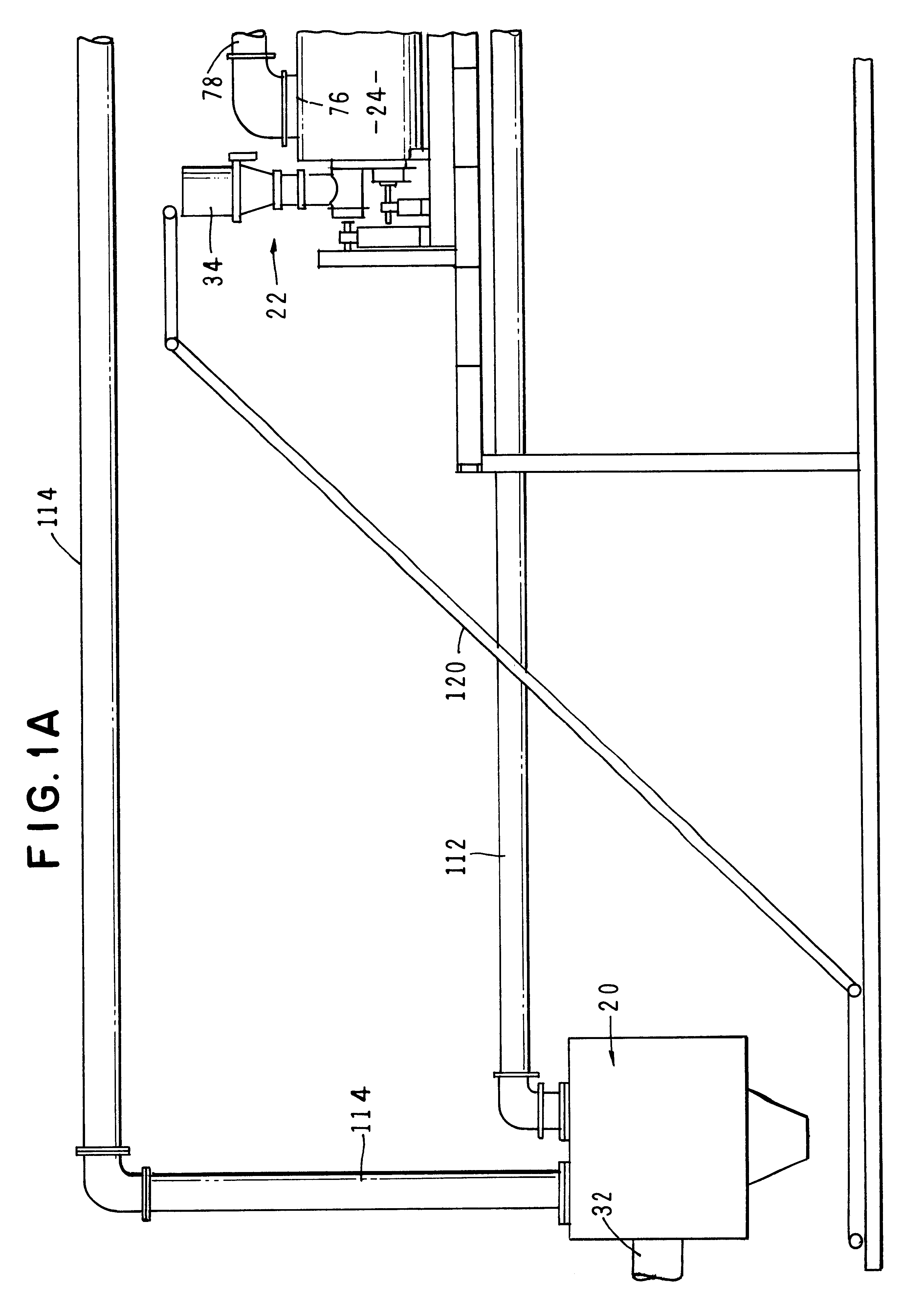

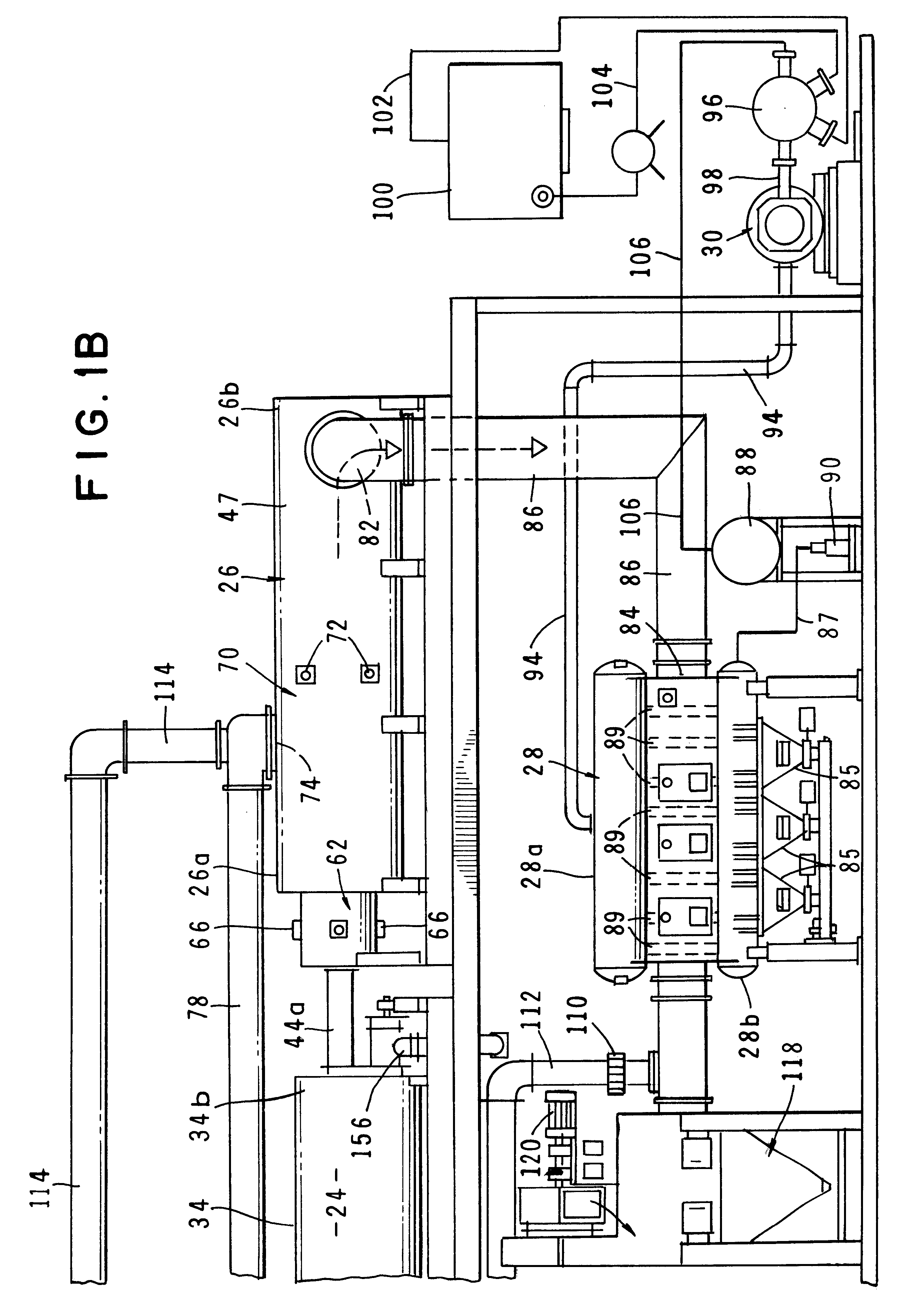

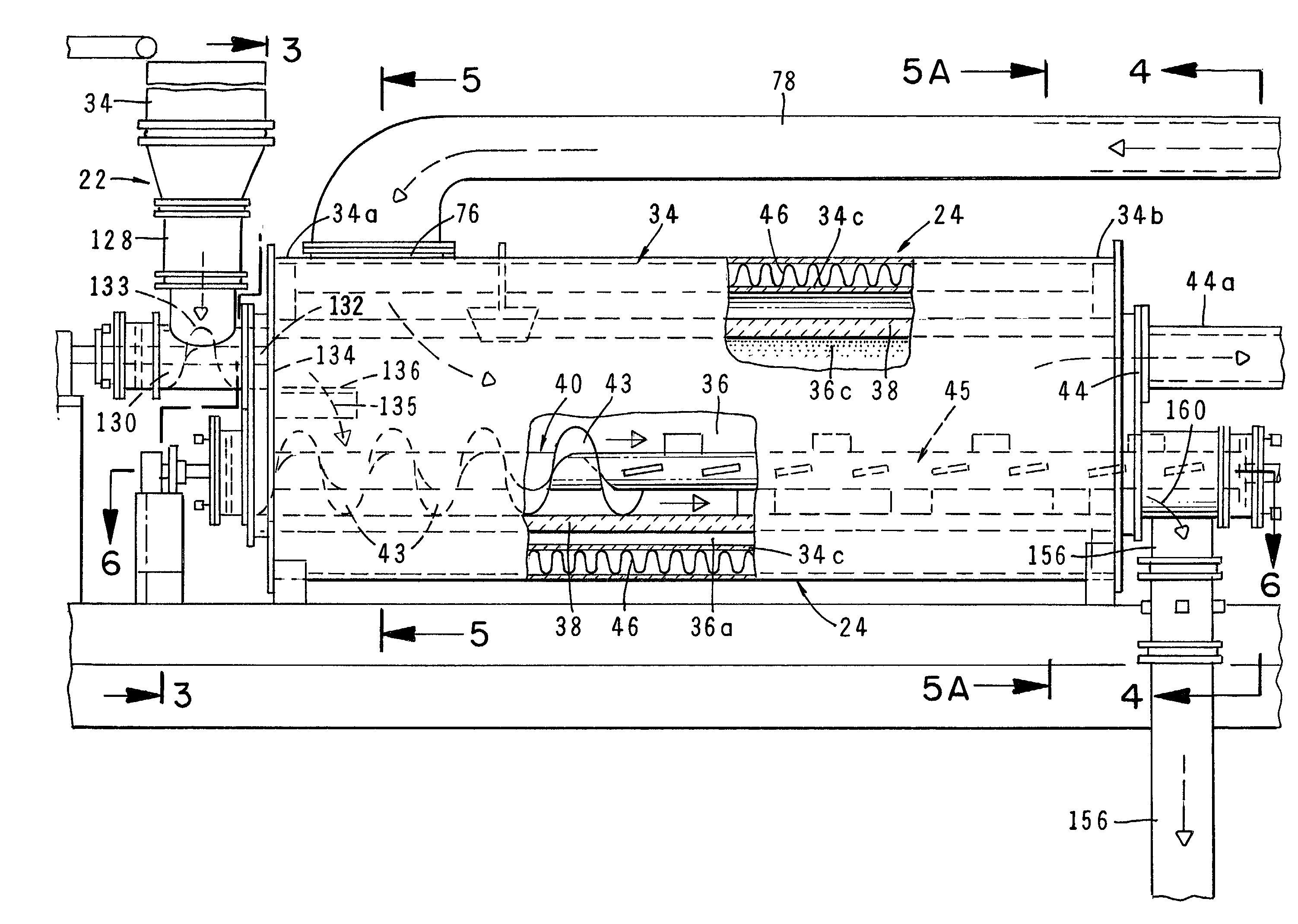

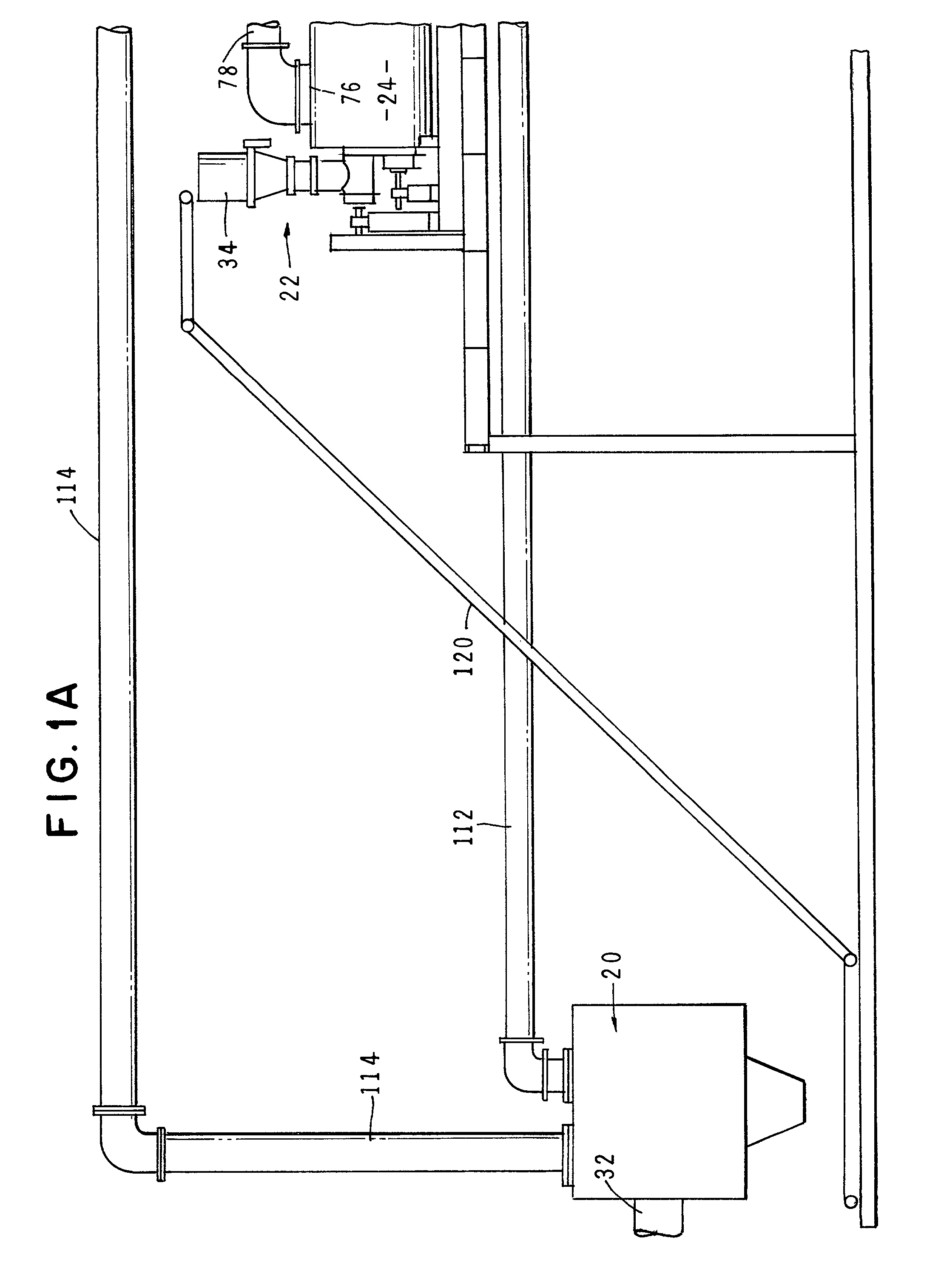

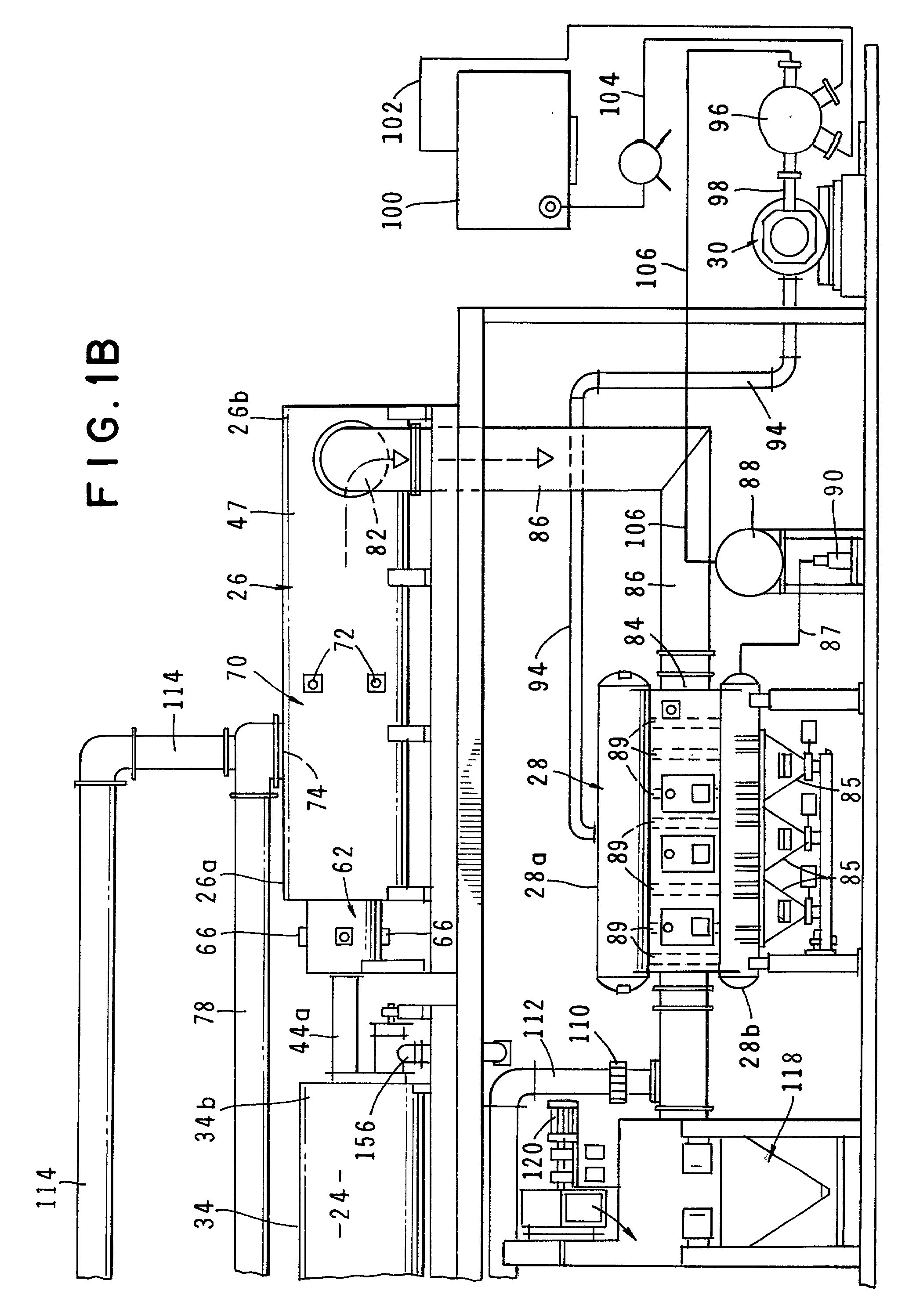

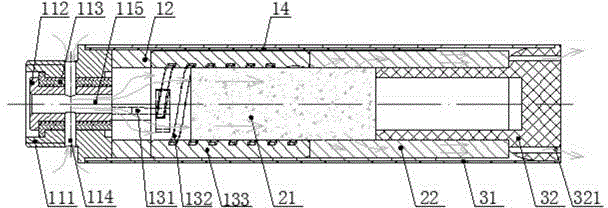

Method and apparatus for treatment of waste

InactiveUS6619214B2Efficient and reliable in operationEasy maintenanceSolid fuel combustionIncinerator apparatusEngineeringTransfer mechanism

An apparatus for treating waste material that comprises four major cooperating subsystems, namely a pyrolytic converter, a two-stage thermal oxidizer, a steam generator and a steam turbine driven by steam generated by the steam generator. In operation, the pyrolytic converter is uniquely heated without any flame impinging on the reactor component and the waste material to be pyrolyzed is transported through the reaction chamber of the pyrolytic converter by a pair of longitudinally extending, side-by-side material transfer mechanisms. Each of the transfer mechanisms includes a first screw conveyor section made up of a plurality of helical flights for conveying the heavier waste and a second paddle conveyor section interconnected with the first section for conveying the partially pyrolyzed waste, the second section comprising a plurality of paddle flights. Once operating, the apparatus is substantially self-sustaining and requires a minimum use of outside energy sources for pyrolyzing the waste materials.

Owner:APS IP HLDG

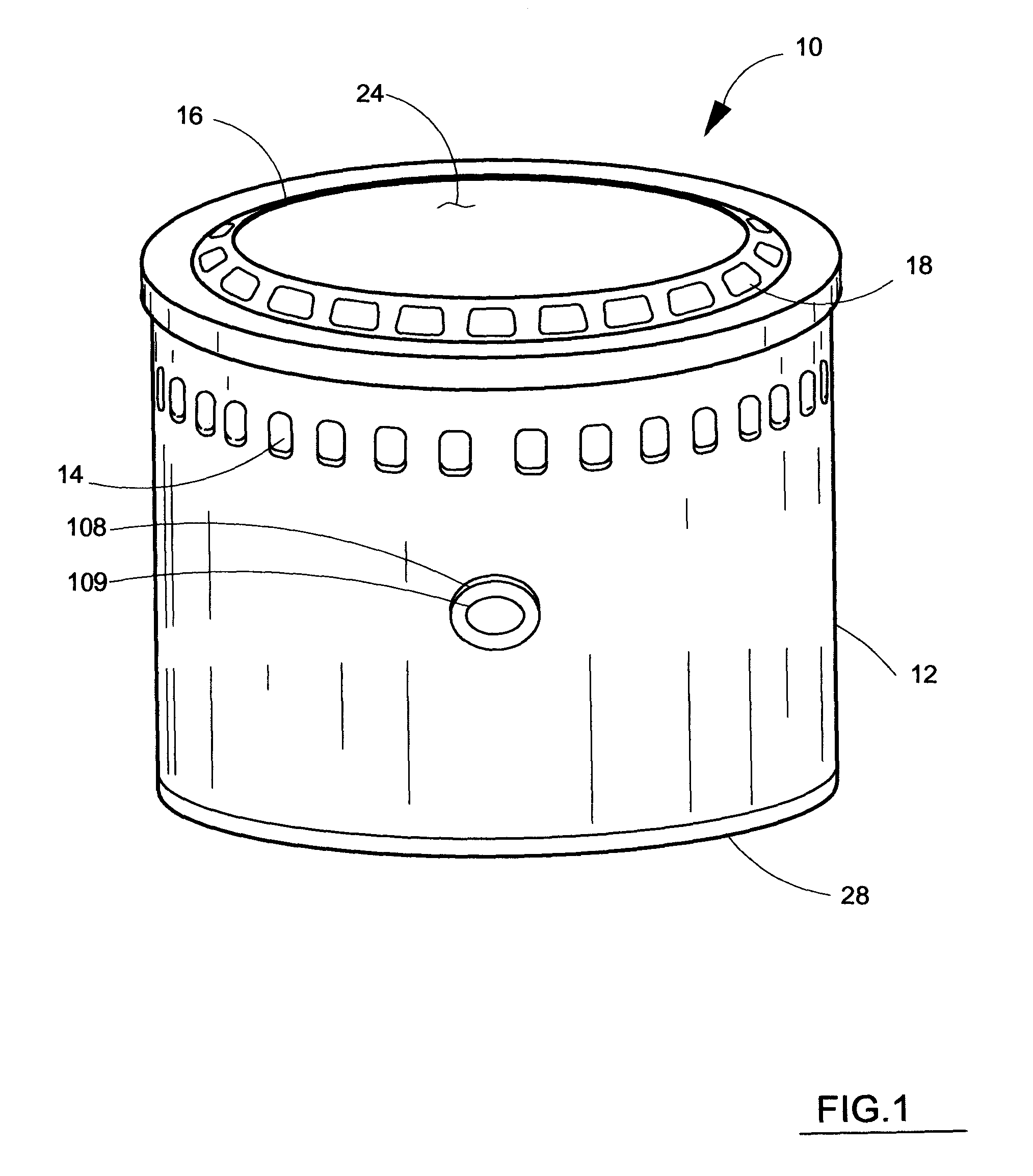

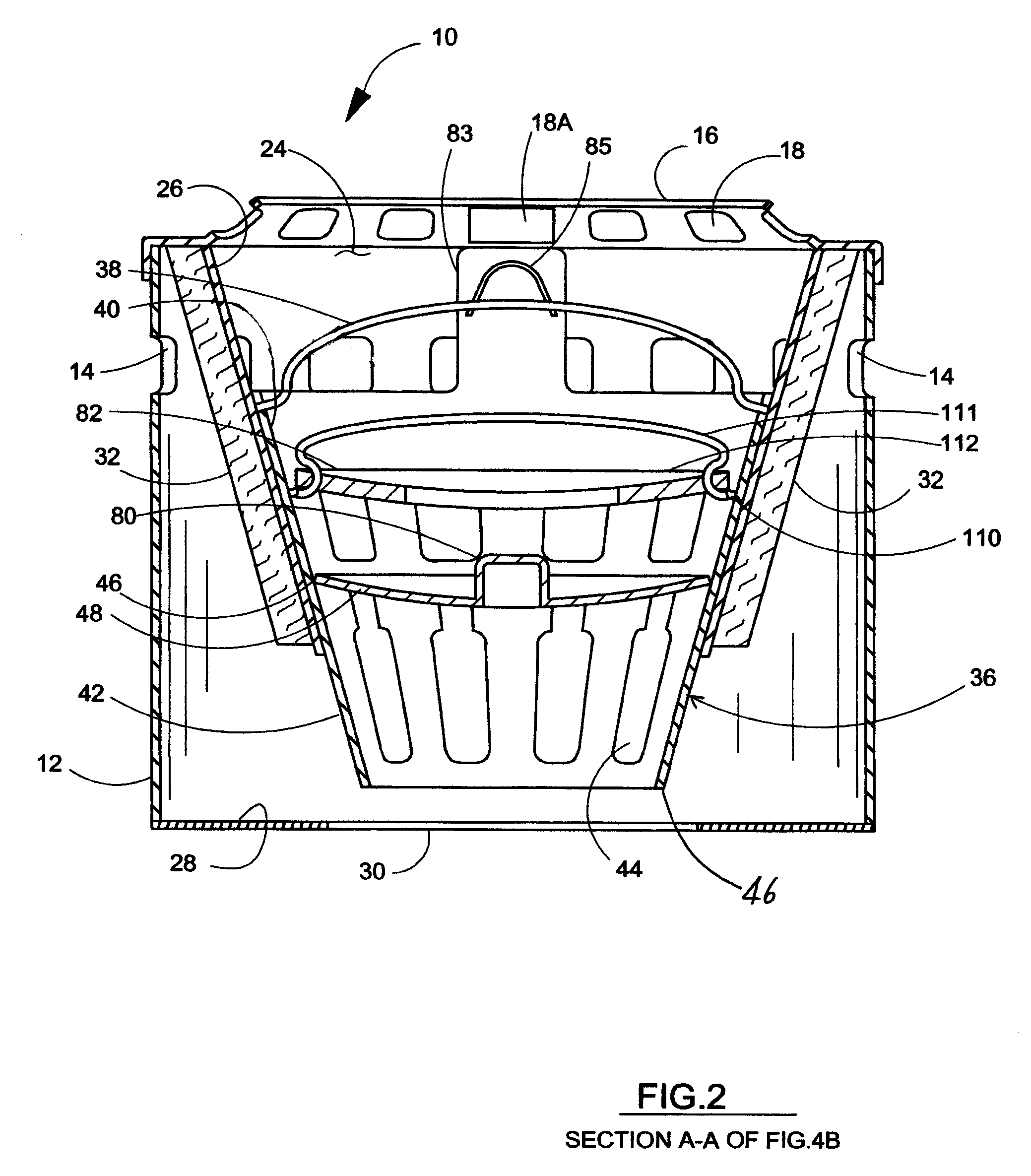

High Efficiency Combustion Stove

InactiveUS20120060819A1Provide such operationImprove safety factorStoves/ranges foundationsLighting and heating apparatusCombustion chamberCoal fired

The invention is a stove system that is portable, has a double walled external structure for the passage of air used in combustion of the fuel, which air also maintains the external surface at a cool enough temperature that it can be touched, and which air flow prevents the waste of heat laterally to the ambient air from a hot outer surface. This increases cooking efficiency, because almost all heat that reaches the air flow between the two walls is drawn right into the combustion chamber in the form of preheated air by reason of the chimney effect. Thus almost no heat can escape the outside wall except by reaching the cooking pot bottom and pot sides after passing out the cover vents as exhaust. An internal heat concentrator ring improves the overall efficiency of the burner. The stove is preferably powered with coal, and uses about half as much coal as a conventional coal fired stove resulting from cooking efficiency. Provision is made for generation of electrical energy from the excess stove heat. Additionally, special thermally designed cook pots add to the stove system to decrease food cooking time while reducing the fuel required.

Owner:HUNT LARRY +1

Method and apparatus for treatment of waste

InactiveUS20020195031A1Efficient and reliable in operationEasy maintenanceSolid fuel combustionIncinerator apparatusEngineeringTransfer mechanism

An apparatus for treating waste material that comprises four major cooperating subsystems, namely a pyrolytic converter, a two-stage thermal oxidizer, a steam generator and a steam turbine driven by steam generated by the steam generator. In operation, the pyrolytic converter is uniquely heated without any flame impinging on the reactor component and the waste material to be pyrolyzed is transported through the reaction chamber of the pyrolytic converter by a pair of longitudinally extending, side-by-side material transfer mechanisms. Each of the transfer mechanisms includes a first screw conveyor section made up of a plurality of helical flights for conveying the heavier waste and a second paddle conveyor section interconnected with the first section for conveying the partially pyrolyzed waste, the second section comprising a plurality of paddle flights. Once operating, the apparatus is substantially self-sustaining and requires a minimum use of outside energy sources for pyrolyzing the waste materials.

Owner:APS IP HLDG

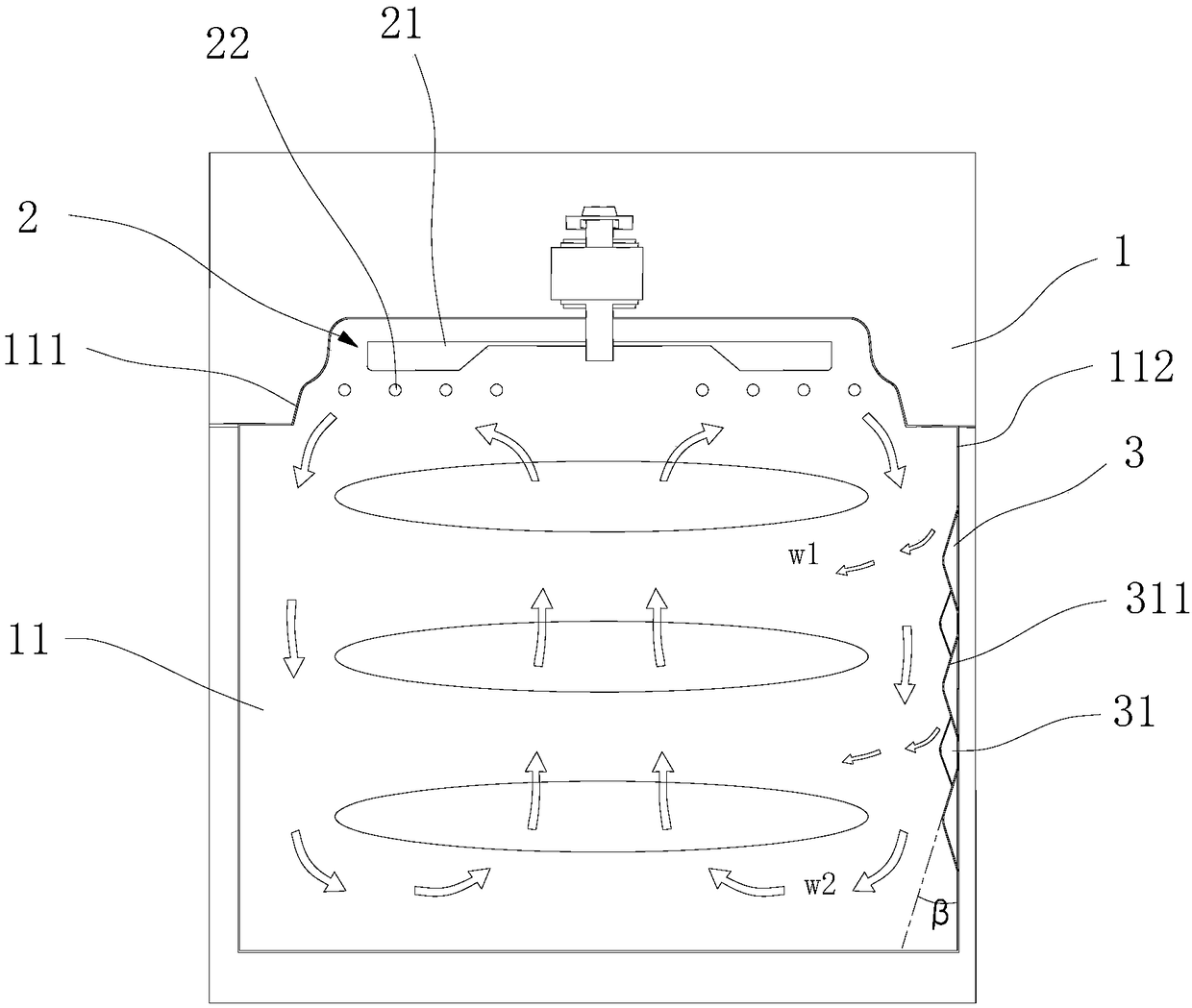

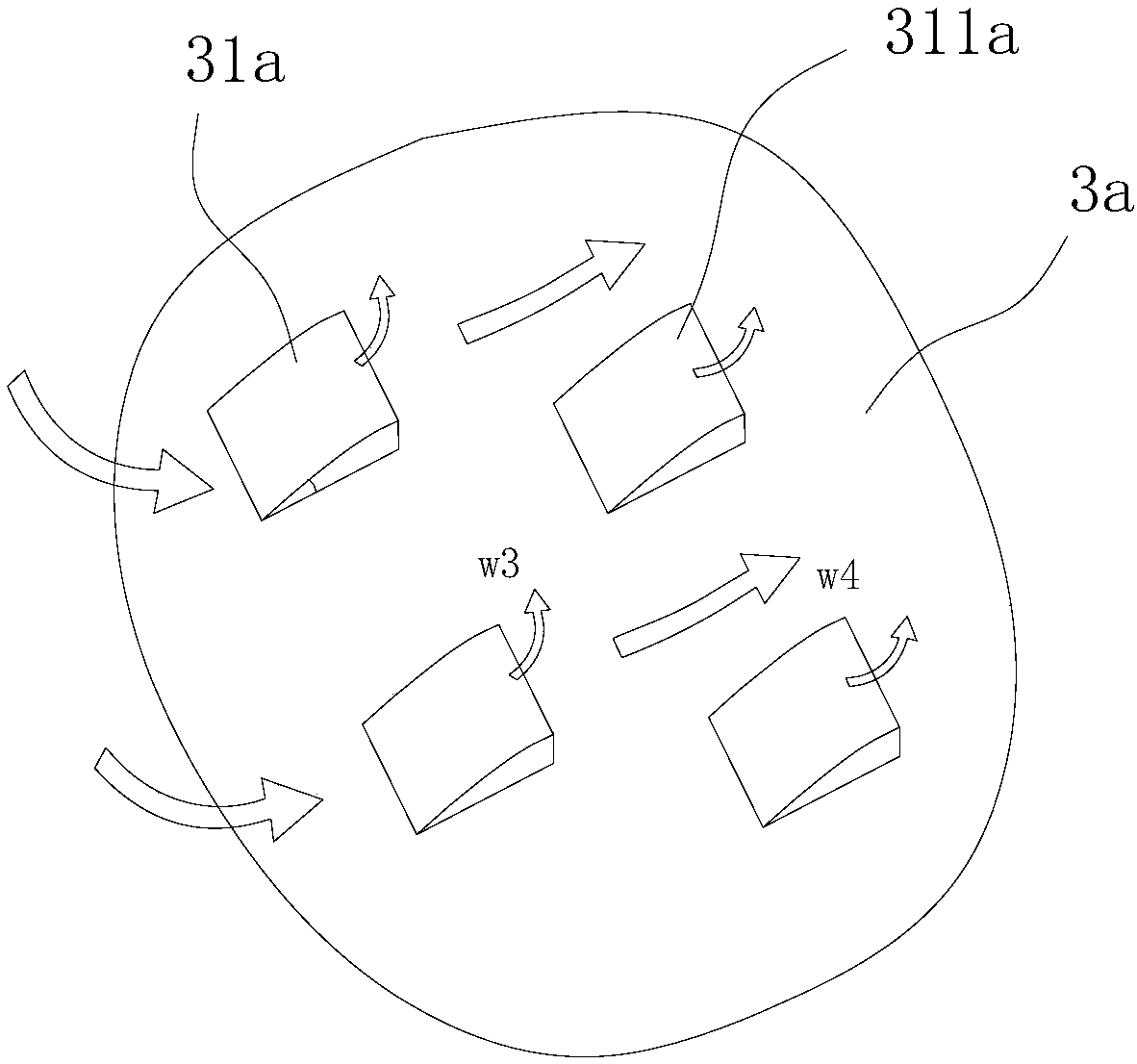

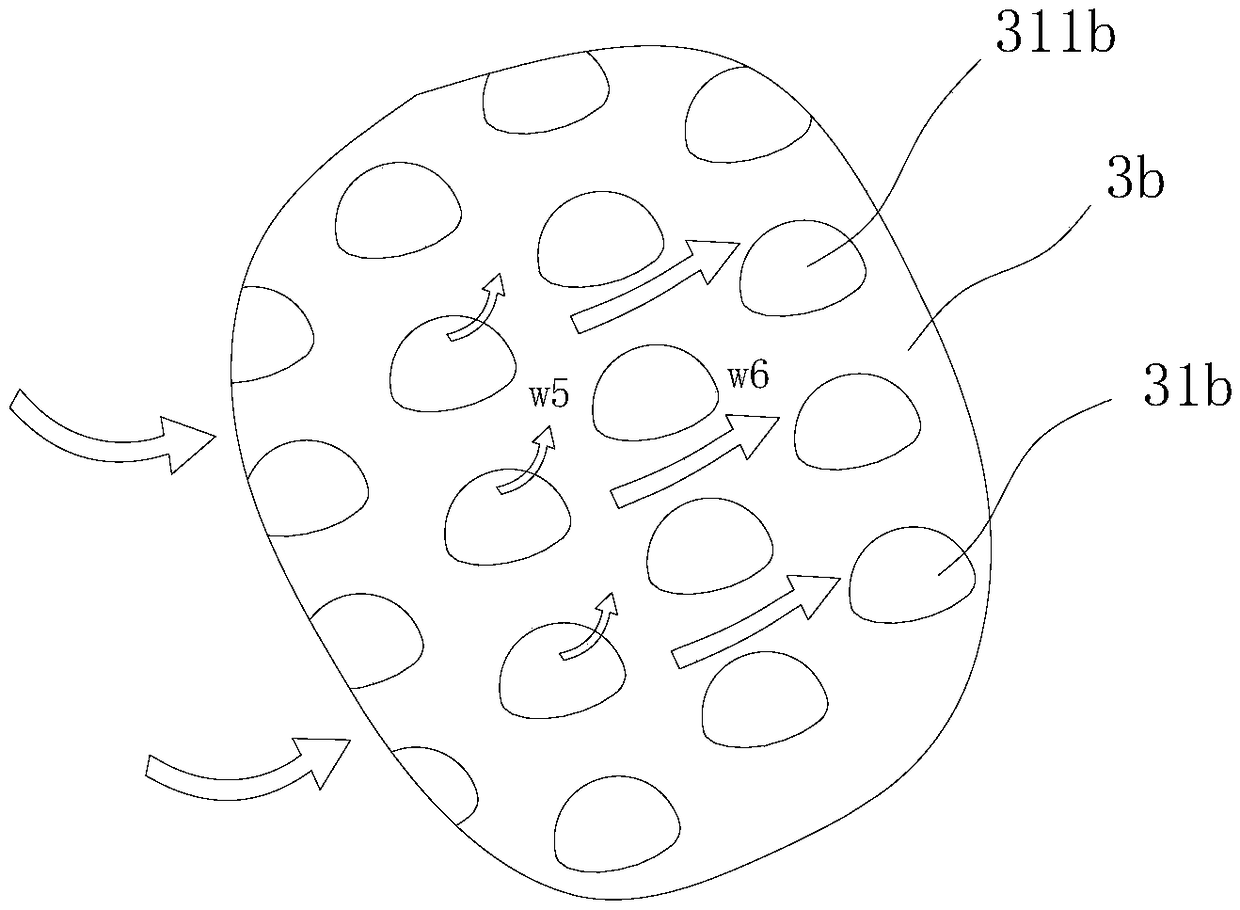

Cooking device

PendingCN108703675AFully heatedImprove cooking resultsRoasting apparatusRoasters/grillsProcess engineeringAirflow

Owner:FOSHAN SHUNDE KUFU ELECTRIC APPLIANCES CO LTD

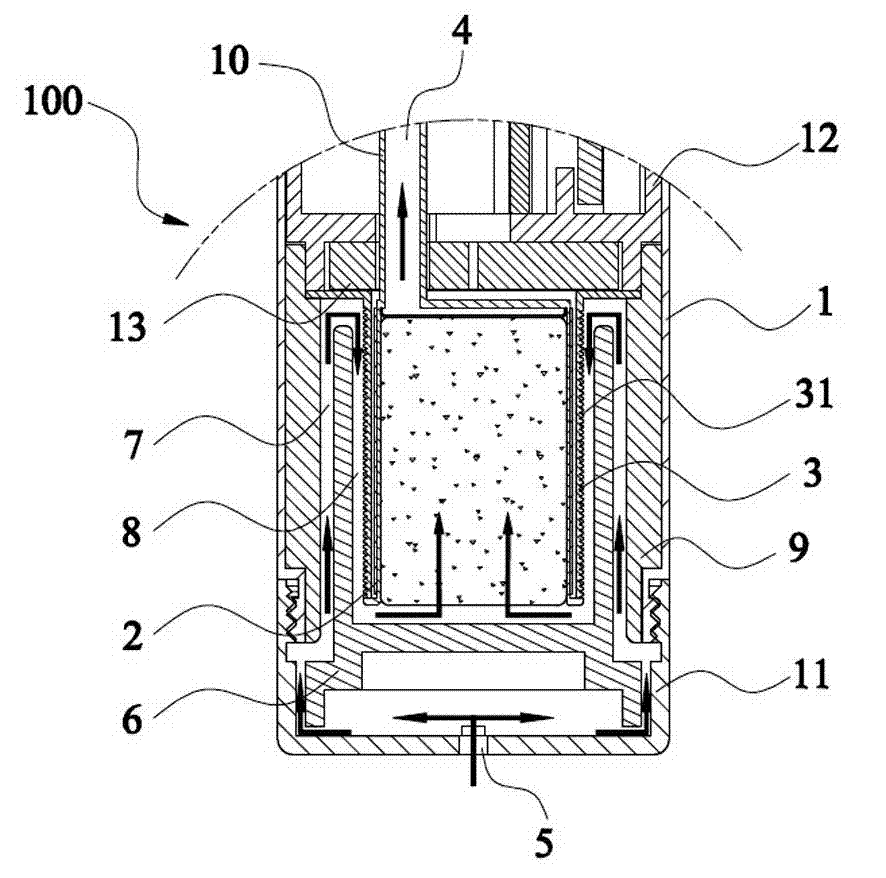

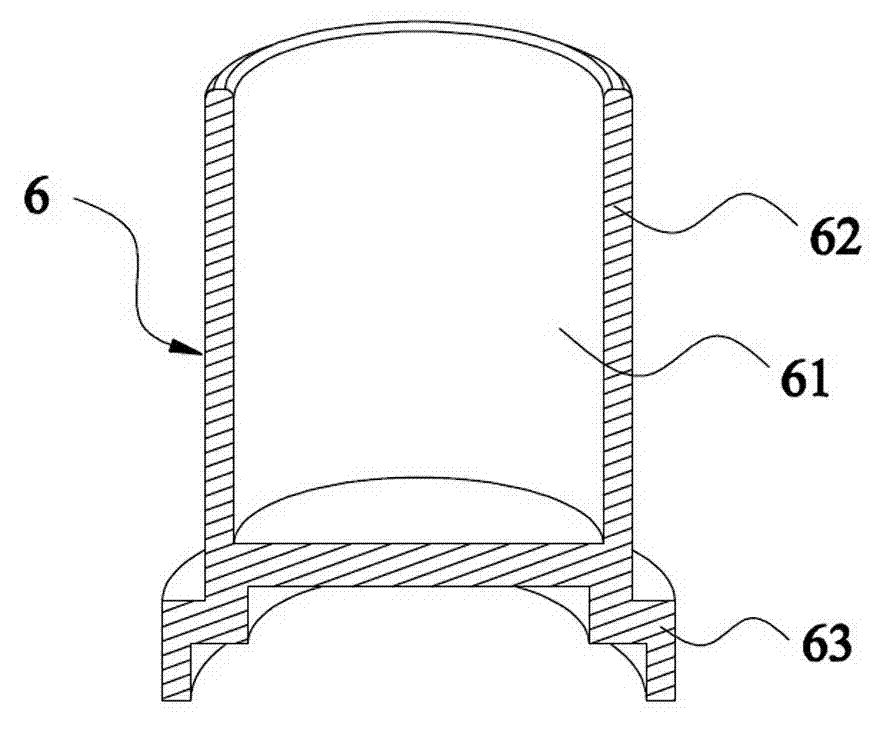

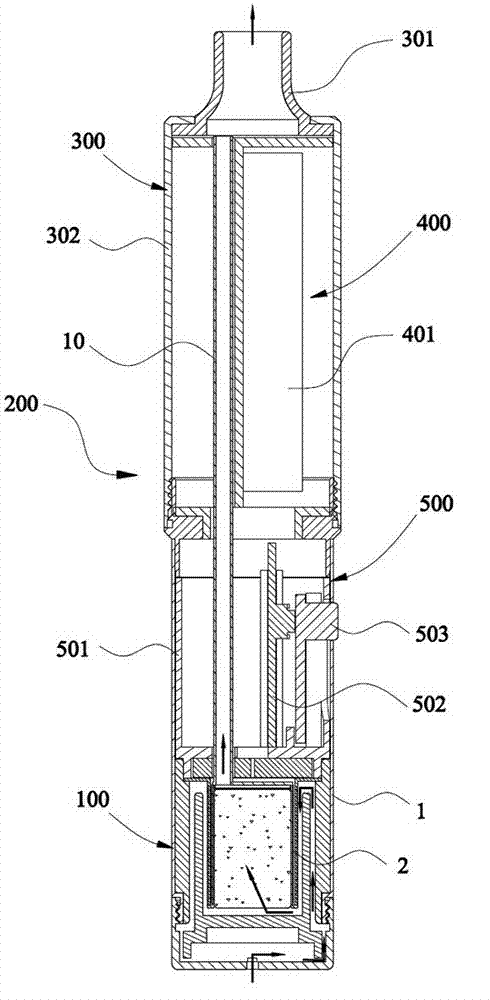

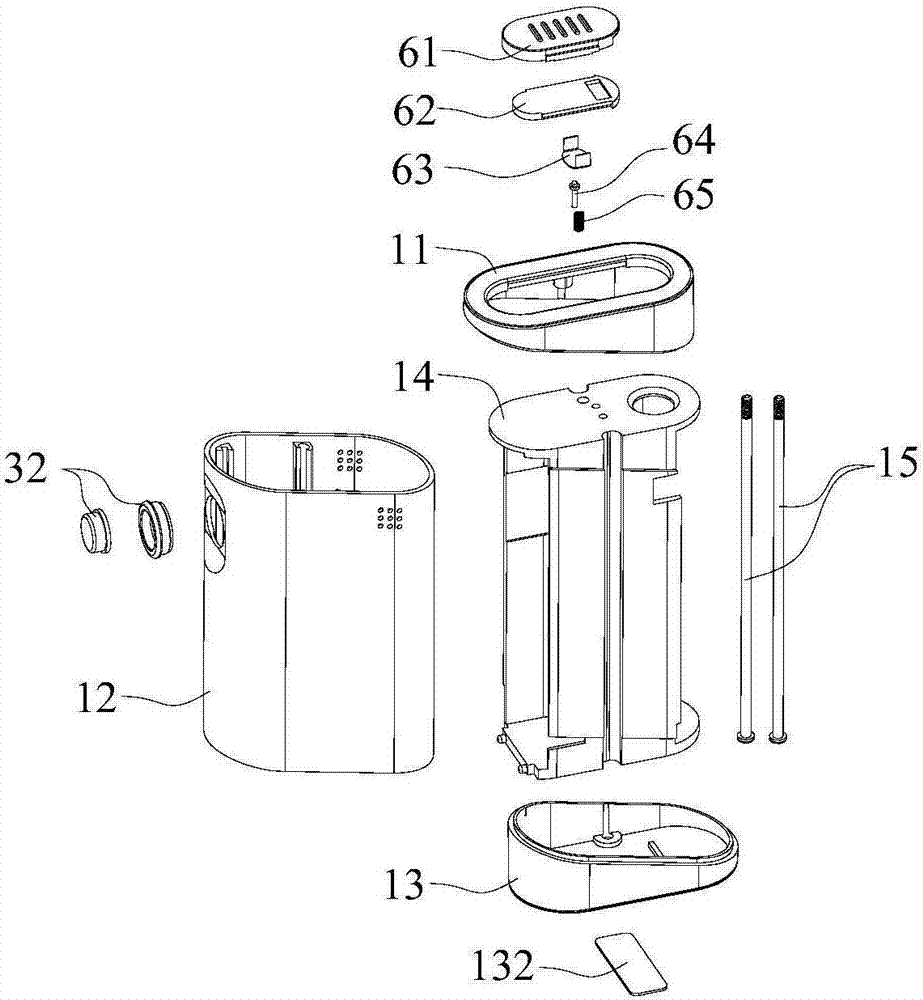

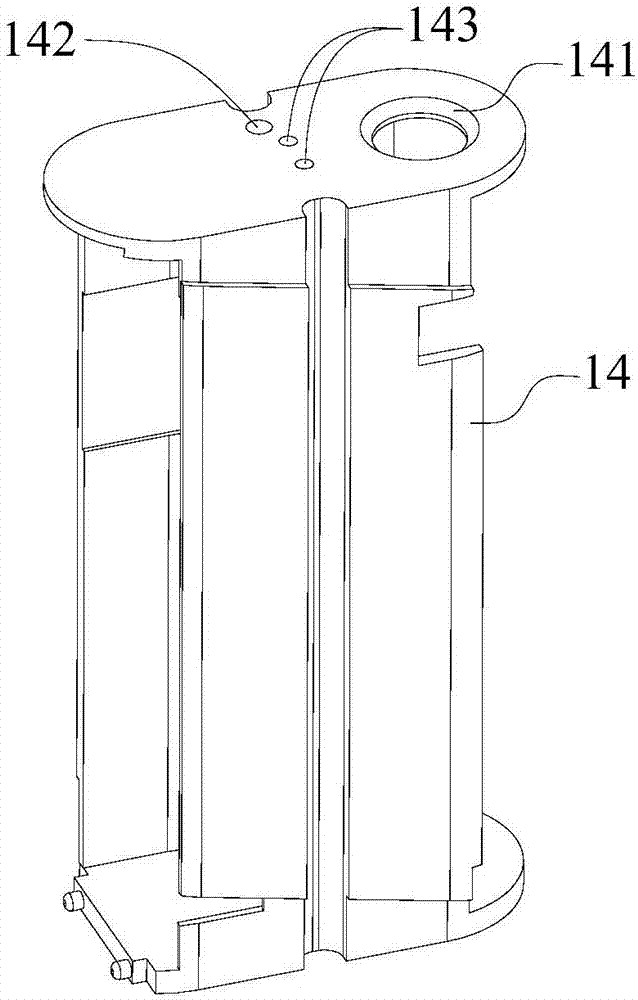

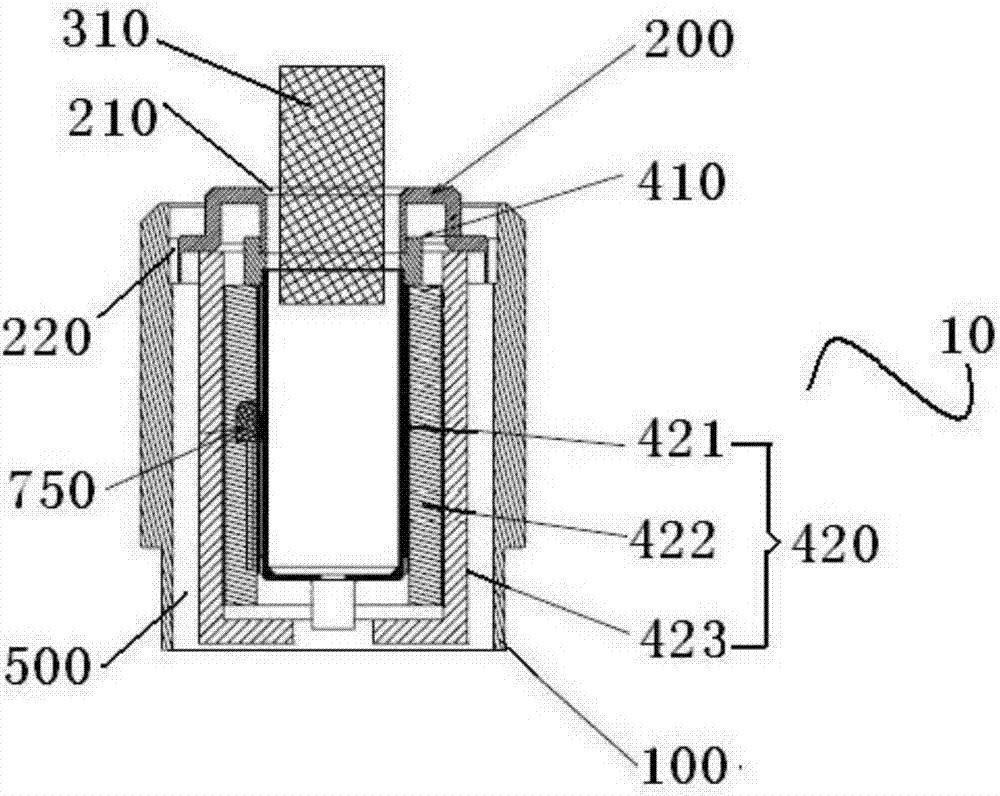

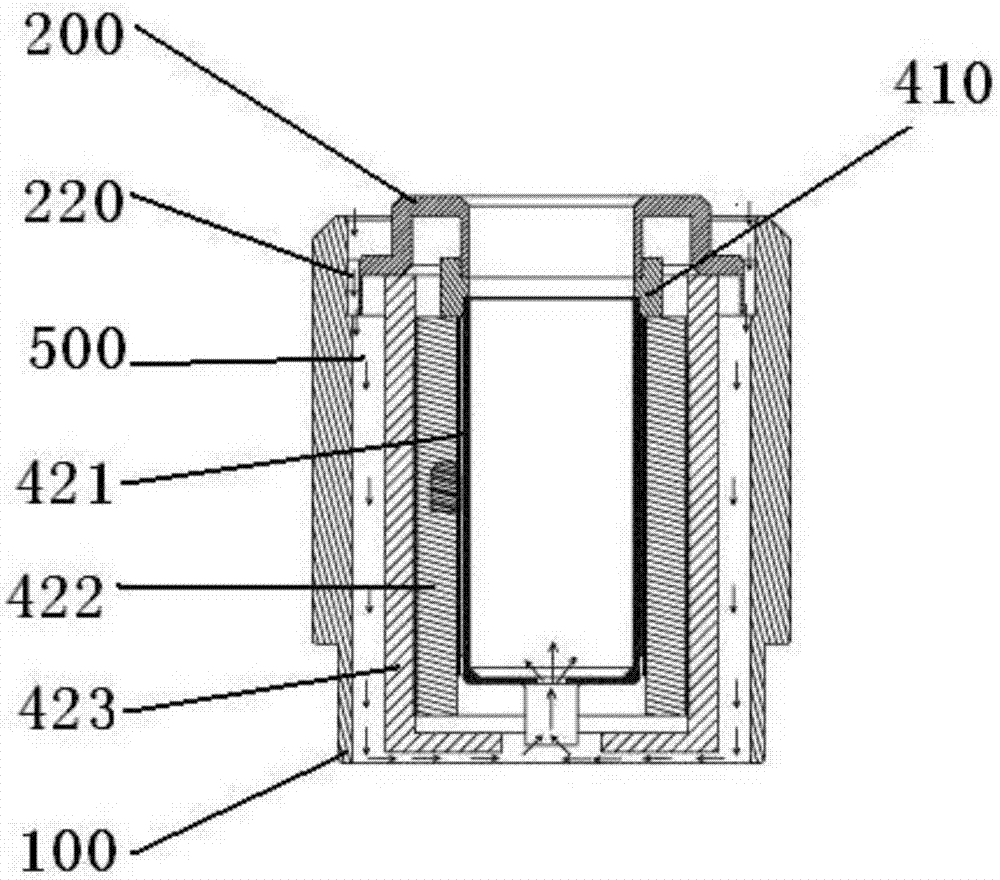

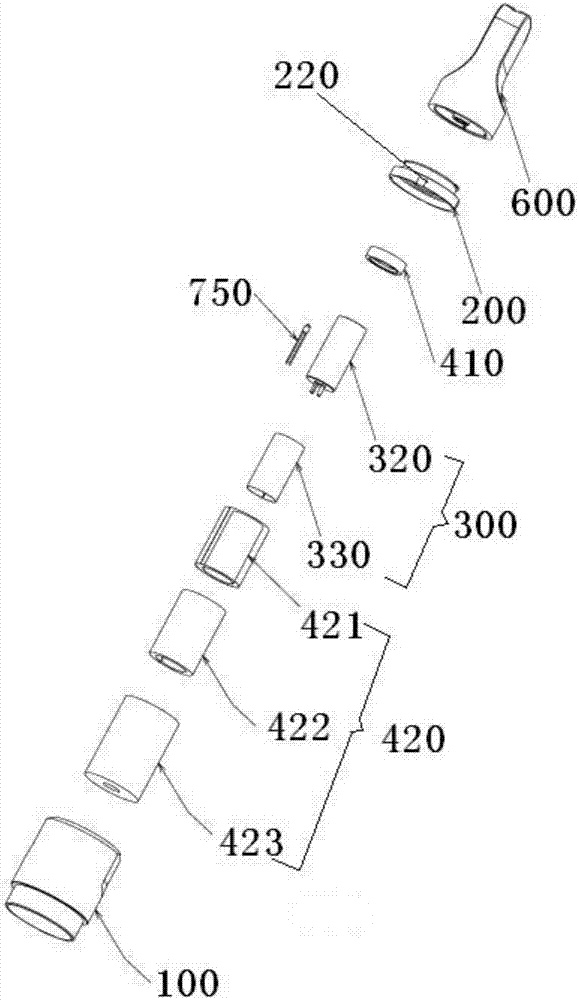

Baking type atomization device and aerosol inhalation device

The invention discloses a baking type atomization device which comprises a shell, a baking chamber arranged in the shell, a heating unit, an air inlet and an air outlet. The baking chamber is sleeved with the heating unit. The baking type atomization device further comprises an air guide ring, the air guide ring is provided with a cavity suitable for containing the baking chamber, a first gap communicated with the air inlet is arranged between the outer wall of the air guide ring and the inner wall of the shell, and a second gap for being communicating the first gap and the baking chamber is arranged between the heating unit and the inner wall of the air guide ring. According to the baking type atomization device and an aerosol inhalation device, the double-heating mode of circumferential type heating and thermal current heating is used for heating the baking chamber and preheating air in the second gap, so that the temperature in the baking chamber rises rapidly, the baking time is shortened greatly, therefore, rapid heating is achieved, electric energy is saved effectively, and the heating efficiency is improved. The invention further provides the aerosol inhalation device with the baking type atomization device.

Owner:SHENZHEN FIRST UNION TECH CO LTD

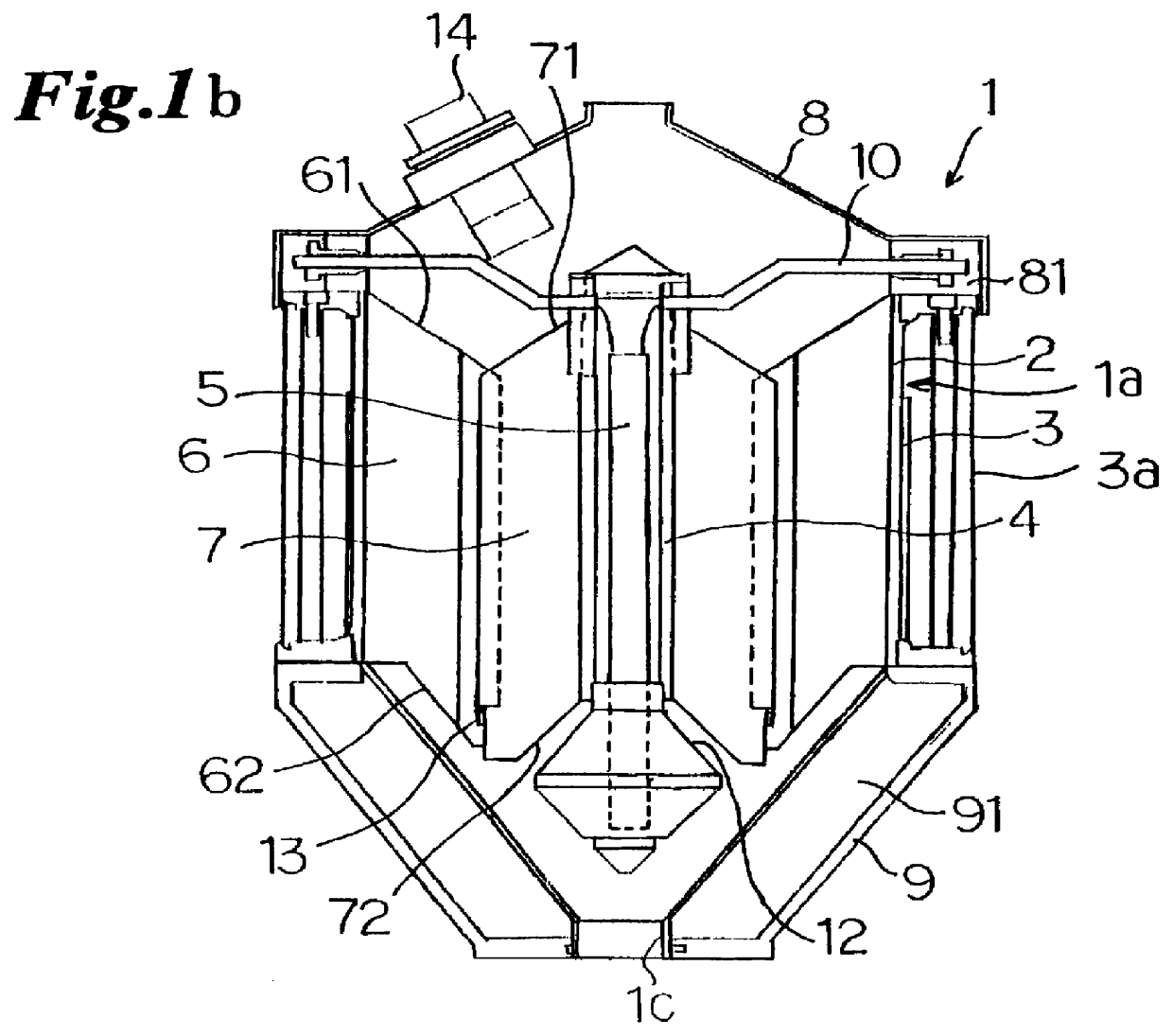

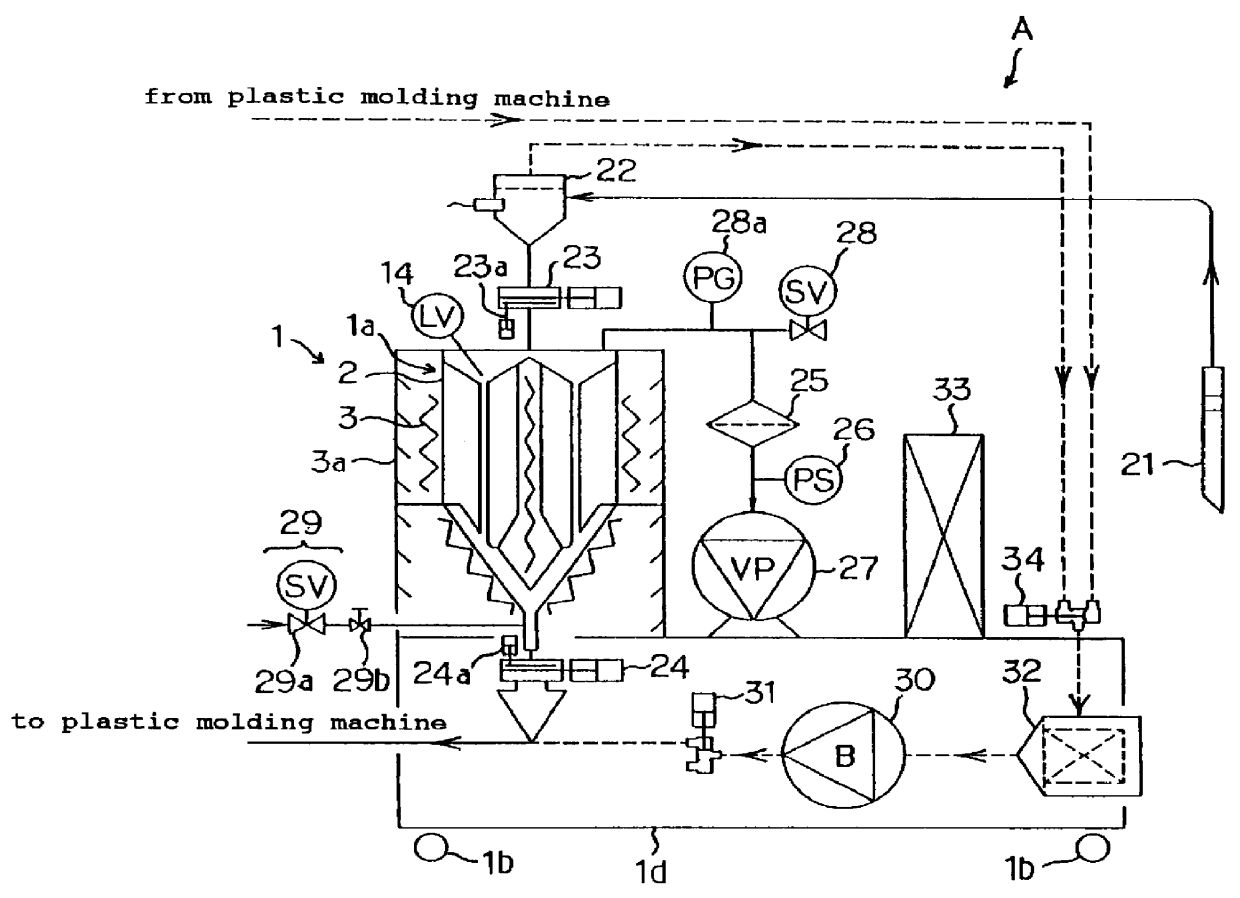

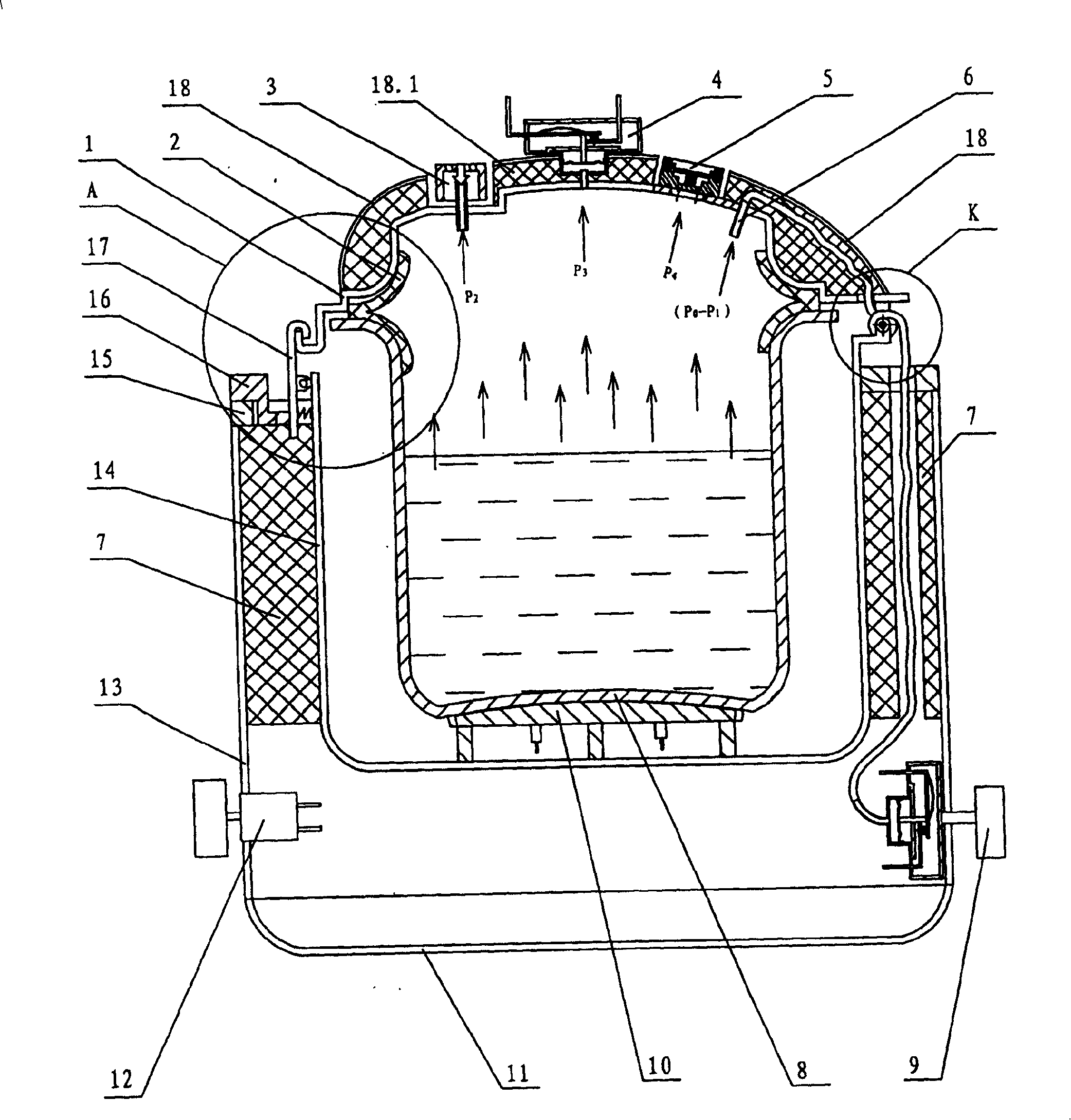

Vacuum-type automatic dehumidifying and drying apparatus for powdered or granular material

InactiveUS6163976AEfficient conductionImprove heating efficiencyDrying solid materials with heatDrying solid materials without heatEngineeringMechanical engineering

A vacuum-type automatic dehumidifying and drying apparatus for powdered or granular material such as a pelletized or powdered resin or the like, provided with a drying hopper connected to an evacuating means having at its bottom a material discharge valve, and provided with a material collector communicating with the drying hopper via a material feeding valve above the drying hopper for collecting the powdered material therein. The apparatus comprises a double constructed drying hopper having a cylindrical main body made of a high heat conductivity material provided on its inner peripheral surface with plural fins, which define compartment walls, projecting inwardly and provided on its outer peripheral surface with a heating means surrounding the cylindrical main body. The main body is outwardly enclosed with a heat insulation wall, and comprises an outer air inlet for introducing outer air thereinto, a material sensor for detecting amount of the material stored in the hopper, and an evacuating means connected to the main body.

Owner:MATSUI MFG

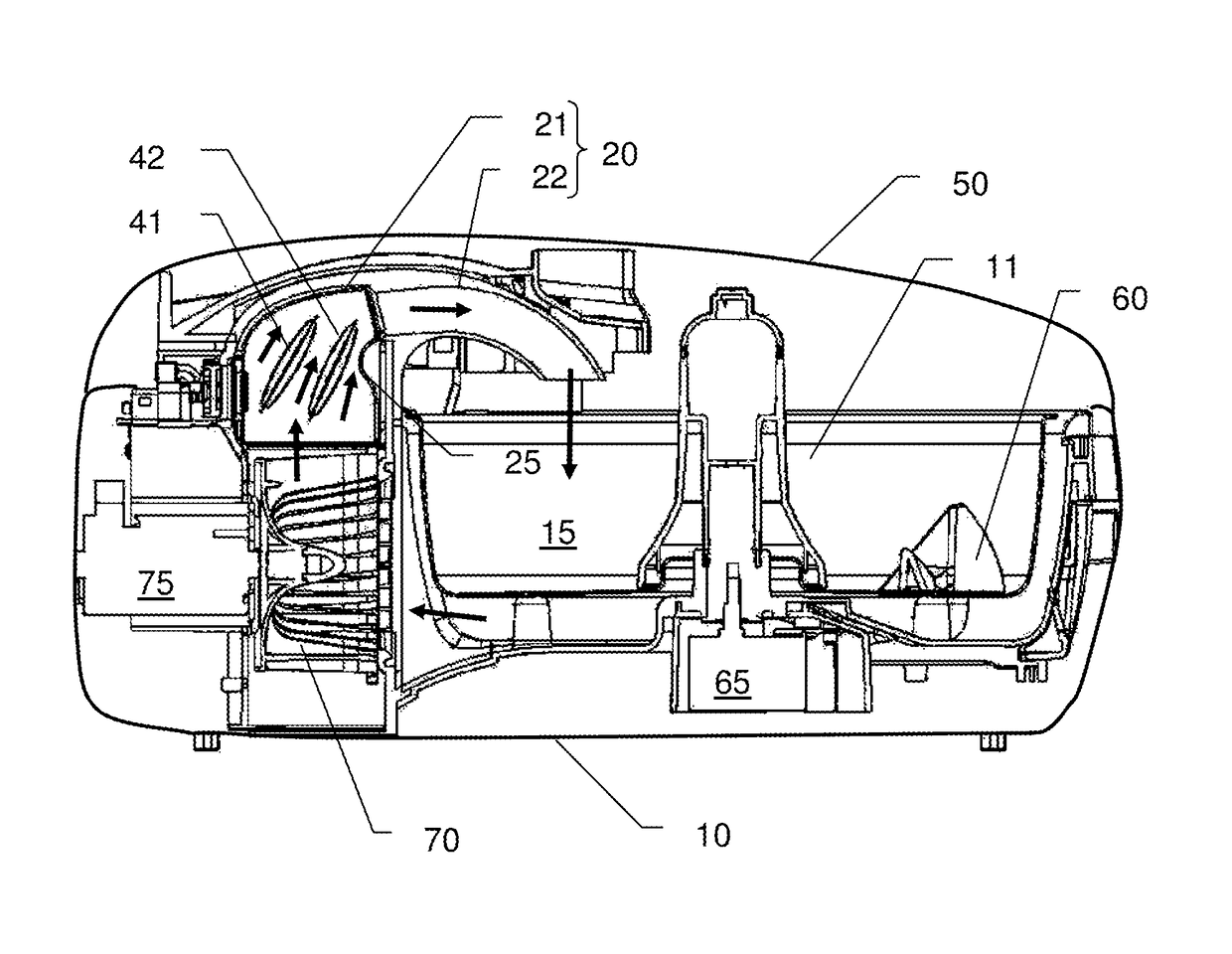

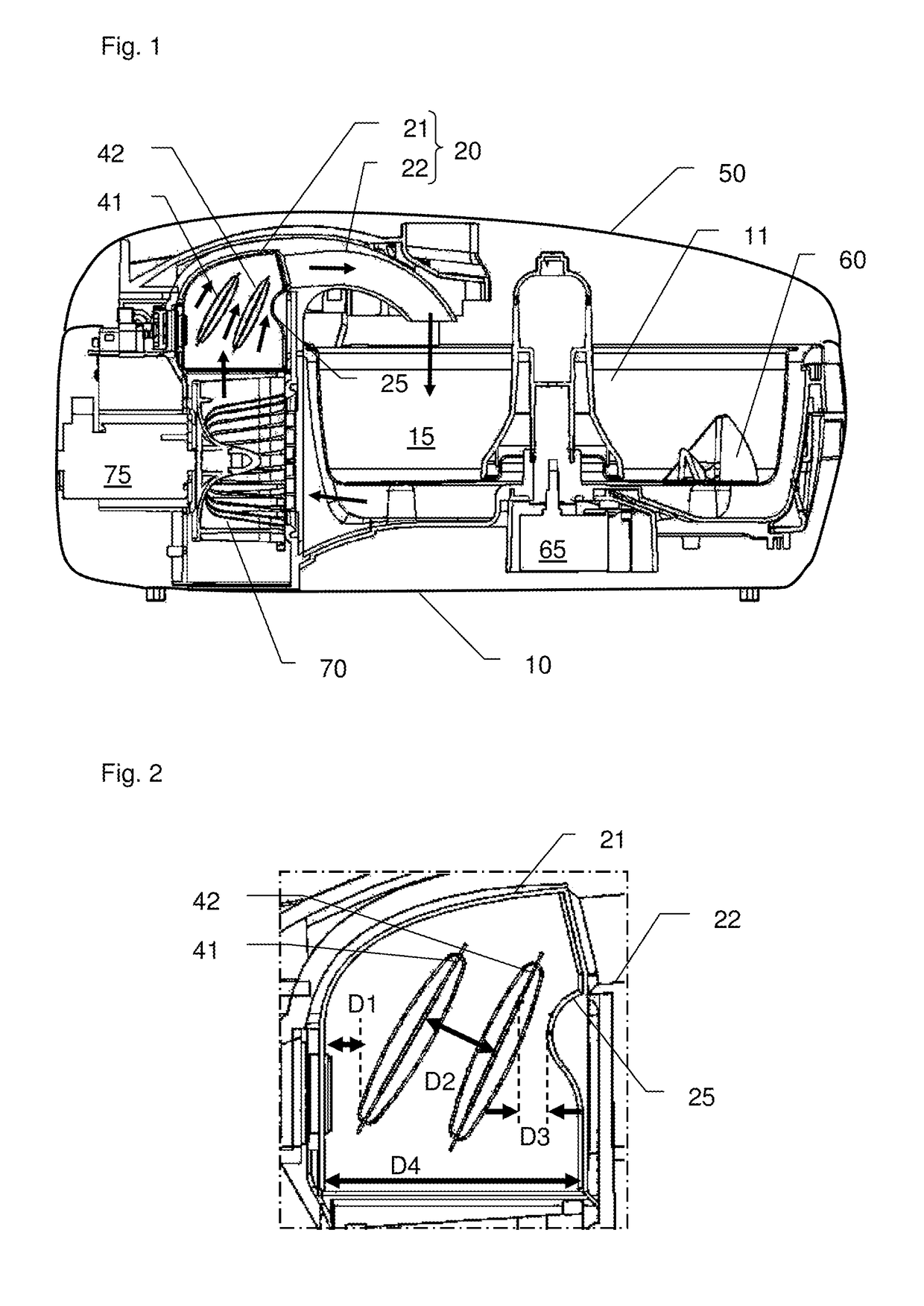

Appliance for cooking by air flow

ActiveUS10117546B2Creates turbulenceAvoid creating dead zoneRoasters/grillsFrying pansEngineeringBreathing

Owner:SEB SA

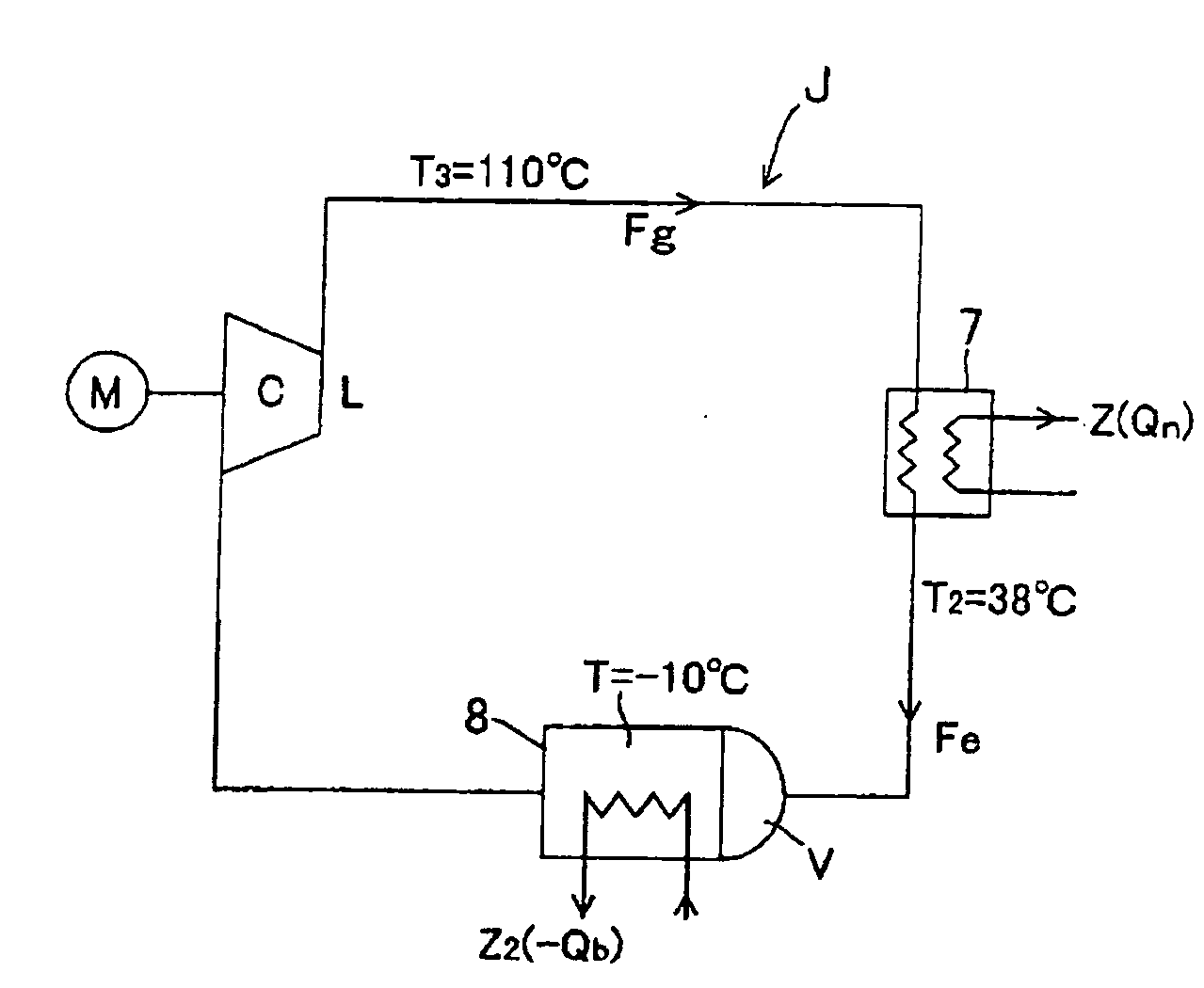

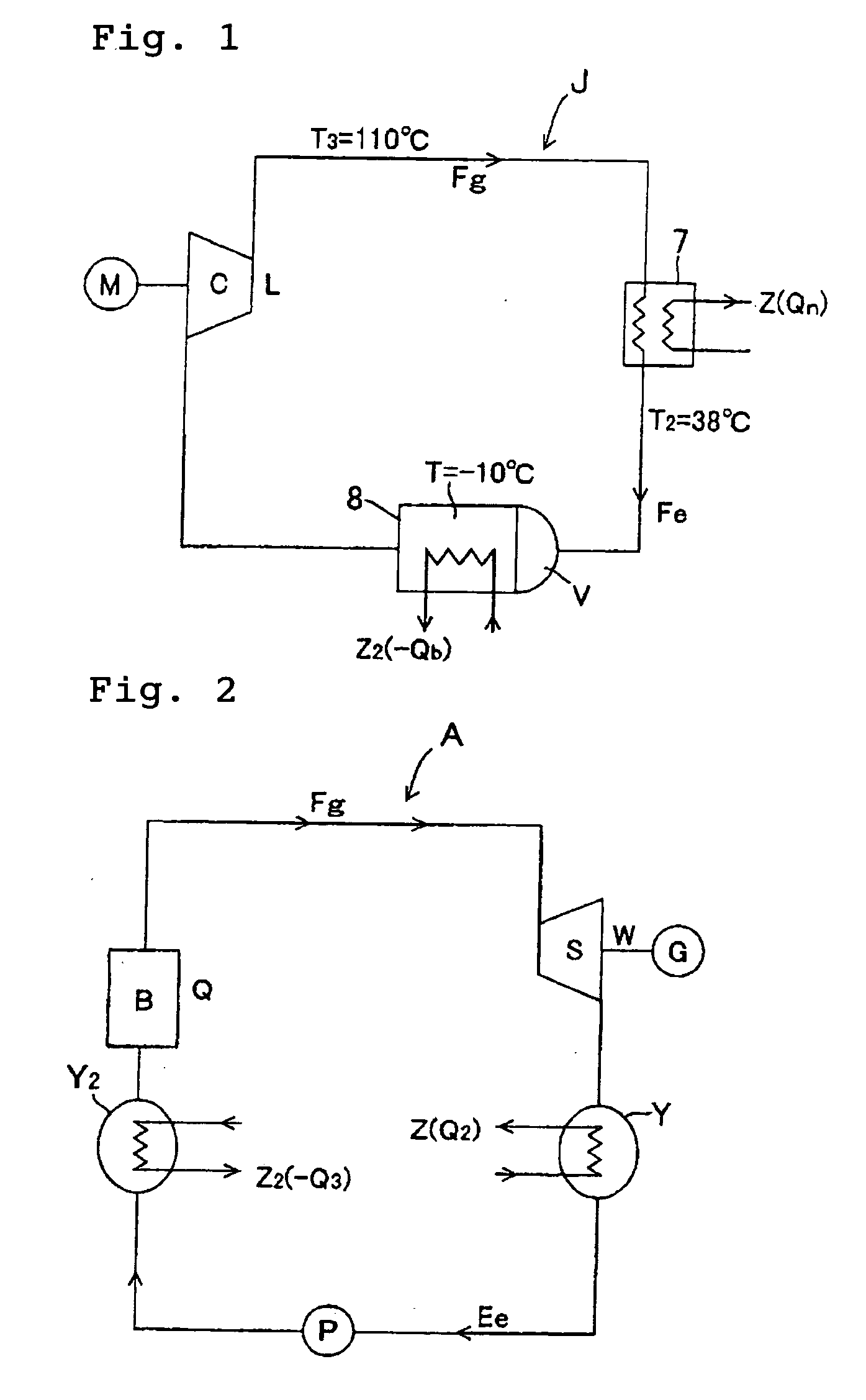

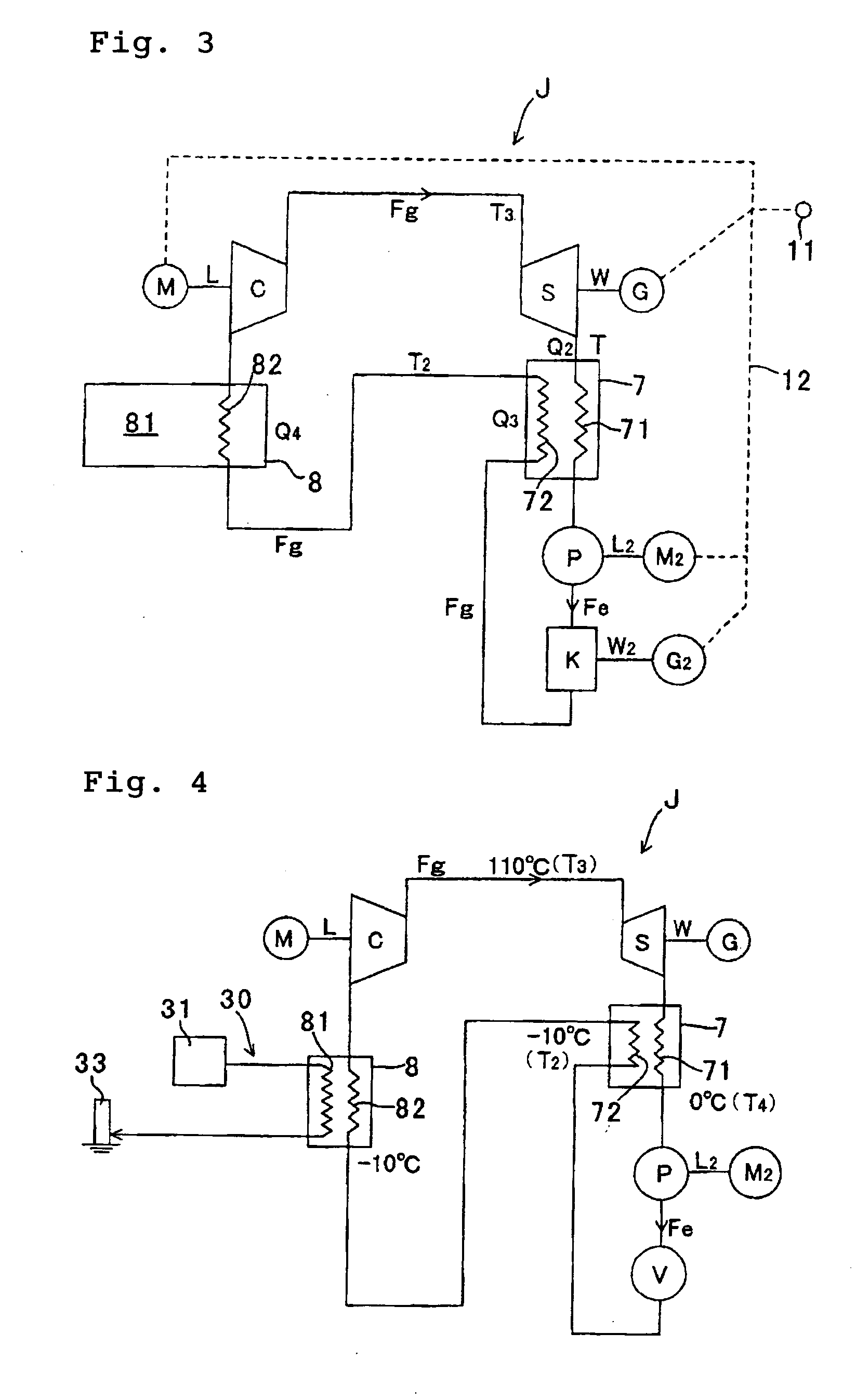

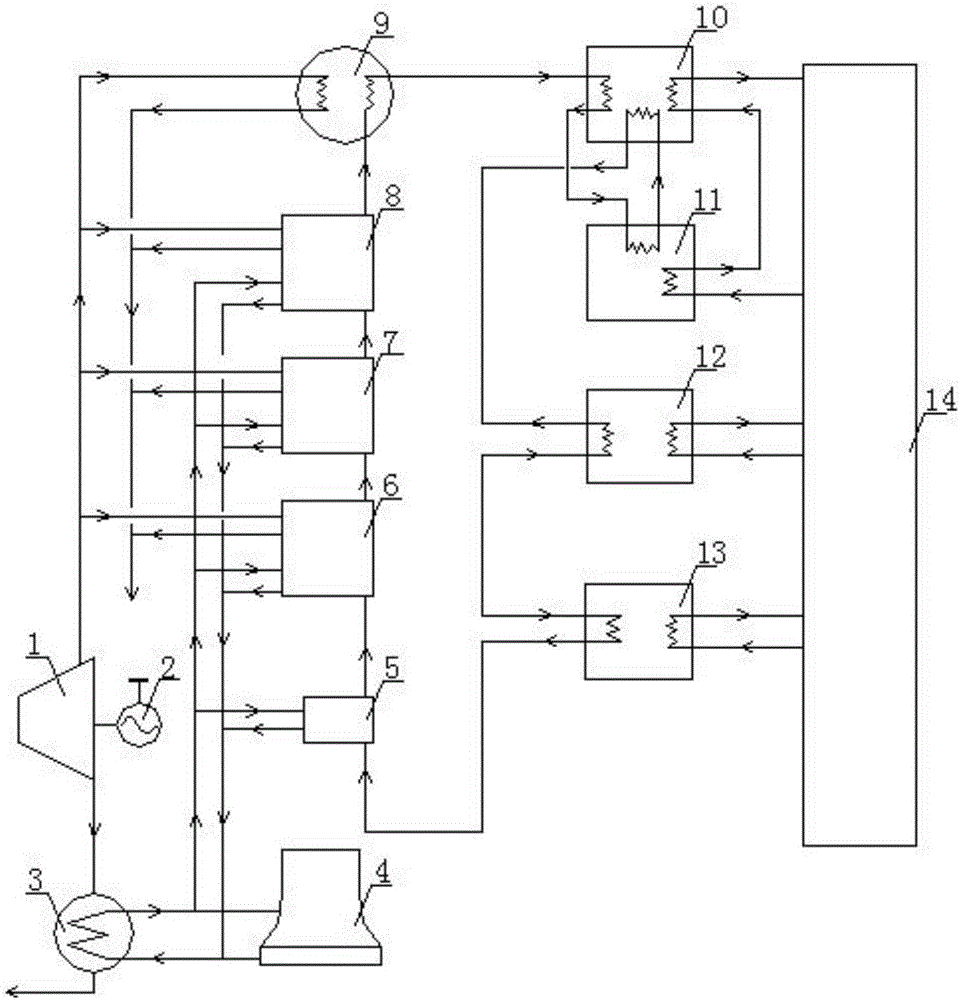

Heat Cycle System and Composite Heat Cycle Electric Power Generation System

InactiveUS20090165456A1Improve thermal efficiencyImprove heating efficiencyWorking fluid for enginesSteam useEngineeringHeat recirculation

A high-efficiency heat cycle system including a compressor, a first turbine, first and second heat exchangers 7 and 8, a first pump, and an expander, and a composite heat cycle power generator using the high-efficiency heat cycle system. Working gas Fg compressed in the compressor (C) drives a first turbine (S) and is thereafter cooled by passing through a heat dissipating side of a first heat exchanger (7) and then raised in pressure by a first pump (P) to form high-pressure working liquid Fe, the high-pressure working liquid is expanded and evaporated in a expander (K) to form working gas Fg, said working gas Fg is heated by passing through a heat receiving side 82 of the second heat exchanger before being introduced into the compressor C. A heat dissipating side 81 of the second heat exchanger comprises a heat dissipating portion of a refrigerating machine or a heat dissipating portion for waste heat from a heating machine.

Owner:MASADA NOBORU

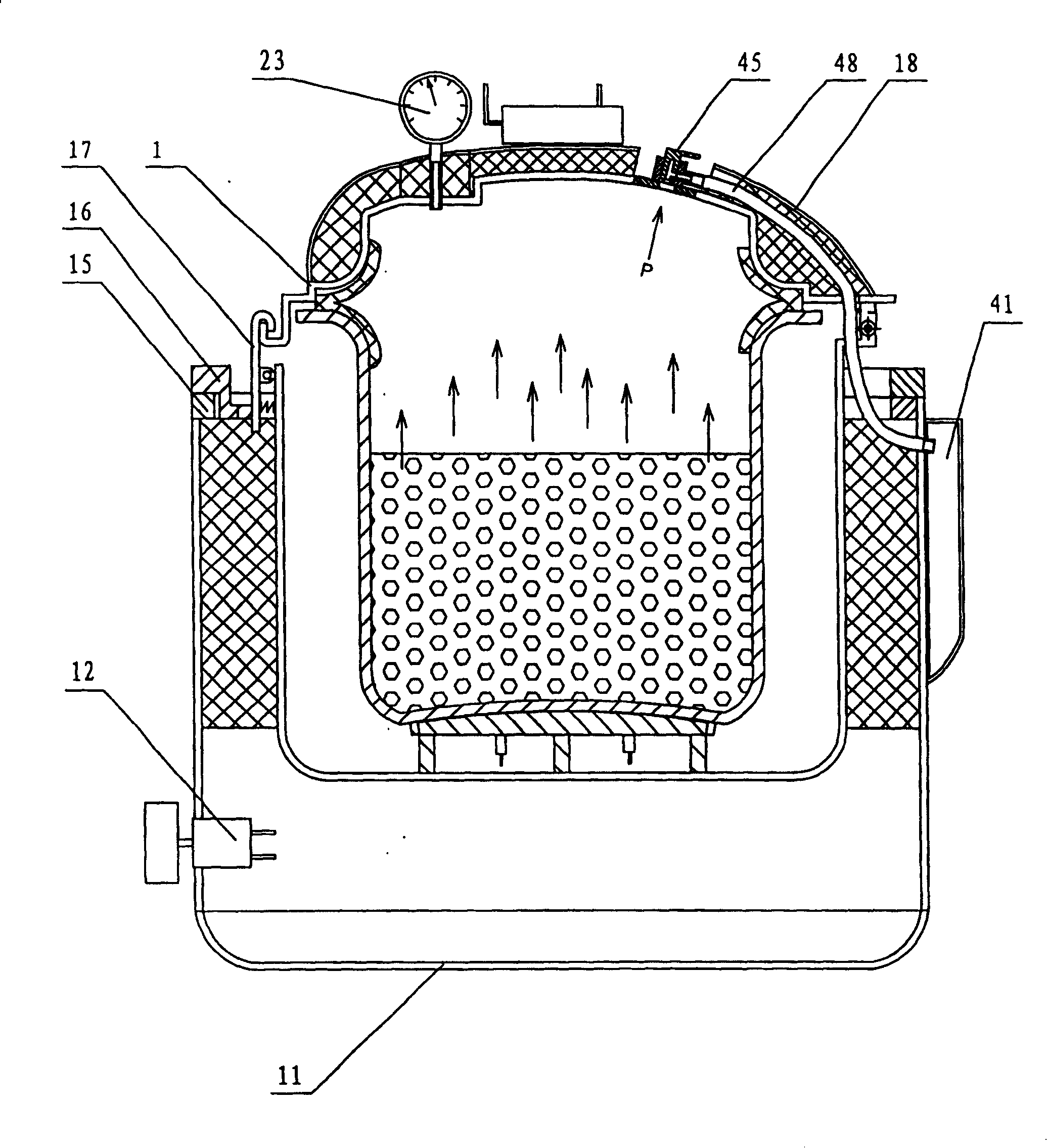

Electric pressure cooker capable of controlling pressure precisely

InactiveCN100401957CReduce lossImprove heating efficiencyPressure-cookersEngineeringAtmospheric pressure

There is an accurate pressure-controlling electric rice cooker, which contains an inner pot inside pot body crust, and the inner pot is connected with electric plate, and there is a resilient seal ring between the inner pot and pot cover. Between the crust and the inner pot there is a middle pot; between the crust and the middle pot there is a heat-insulating layer. The electric rice cooker has a pressure switch, which contains an air duct or air channel connected with inner pot chamber. The other end of the air duct or air channel is communicated with a pressure membrane case, in which there are movable membranes that are joined with push rod. On the other side of the push rod there is a movable contact spring, which connects with an unmovable contact spring, and both the two contact springs couple with main controlling electric of electric rice cooker separately. This invention has simple and reasonable structure, its pressure controlling is accurate, safety degree is high, and after cooking it can exhaust quickly and safely, discharge pressure in blocked style, and its heat insulation effect is good, heat conductivity is high and is energy saving.

Owner:李剑锋

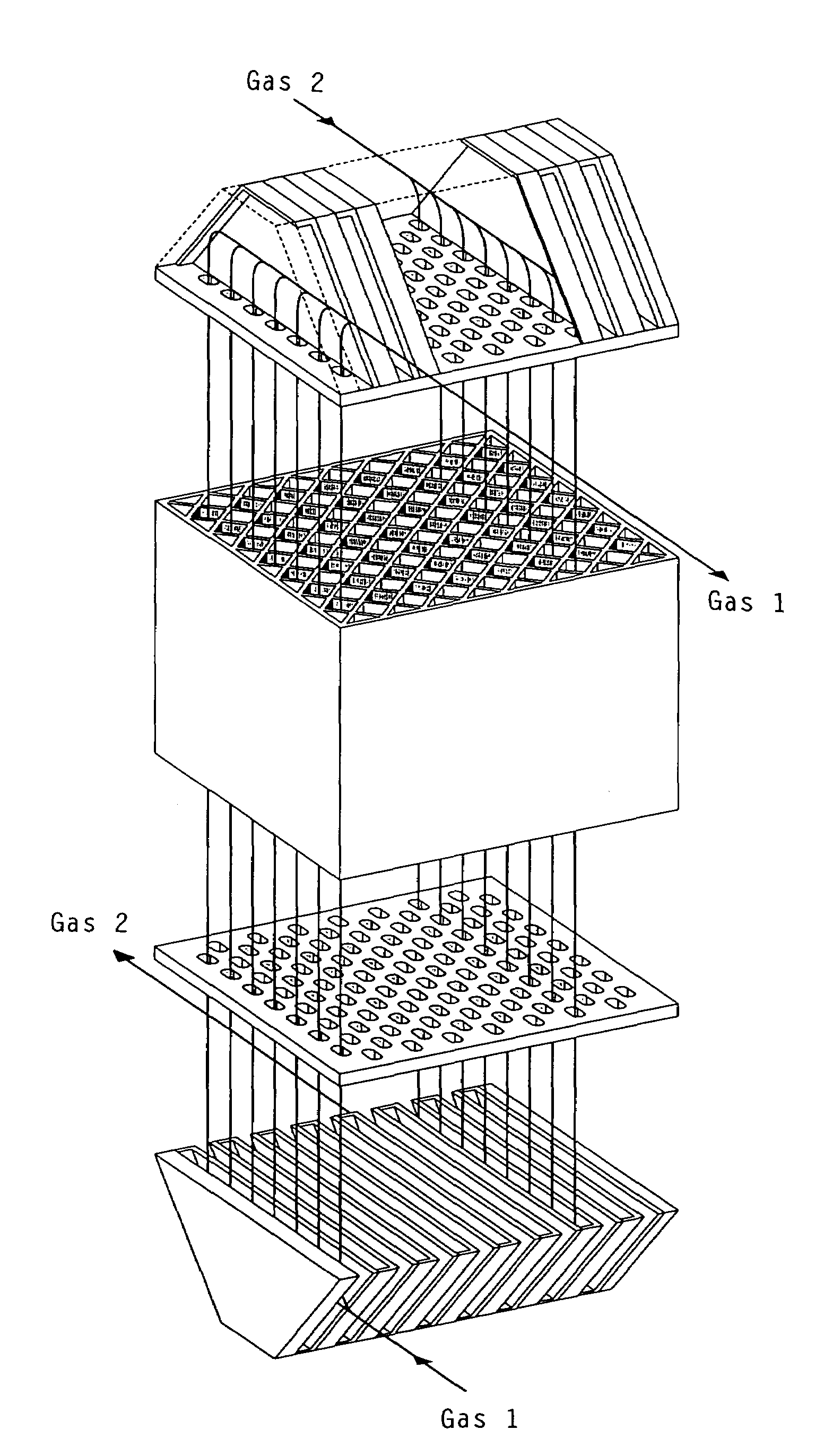

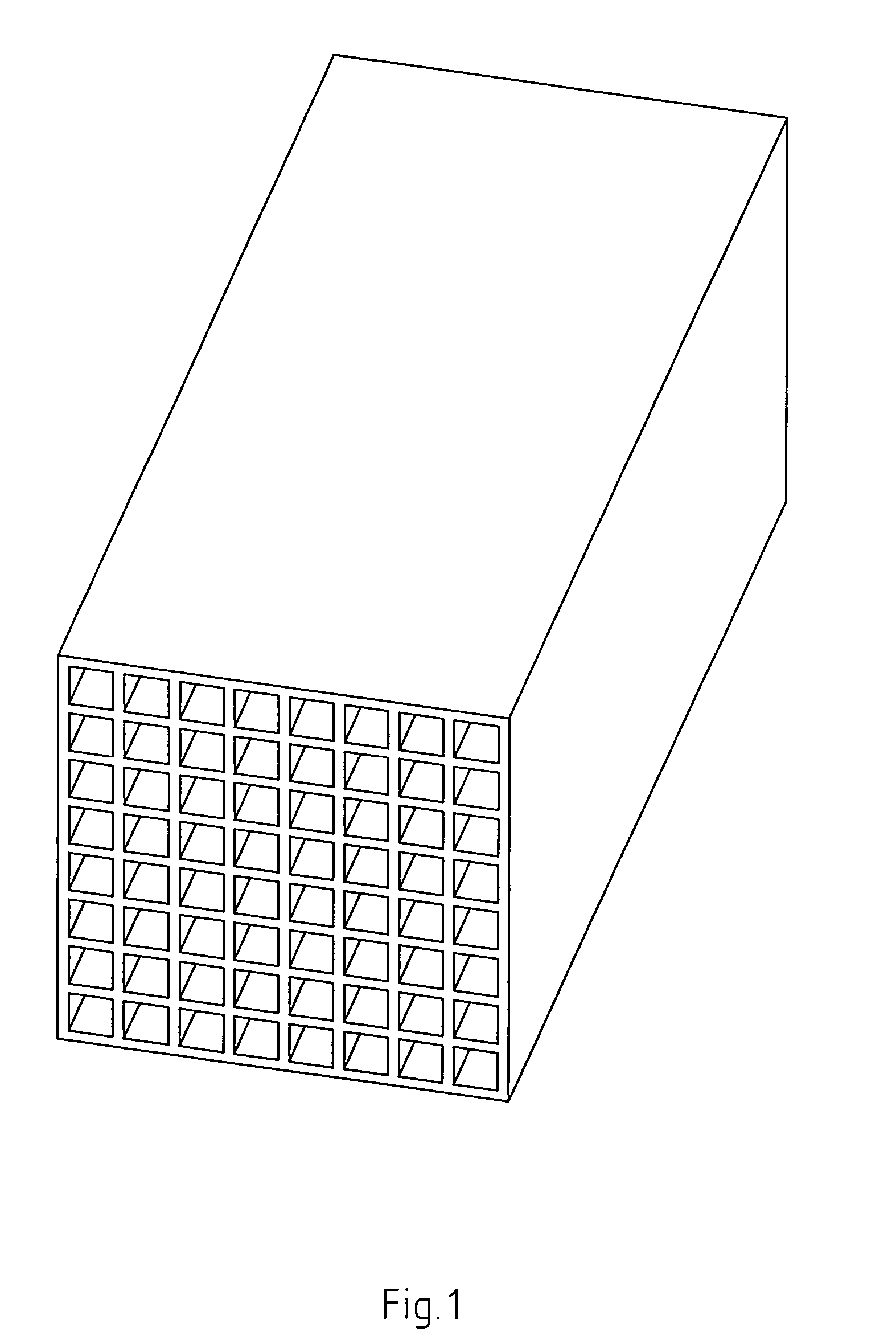

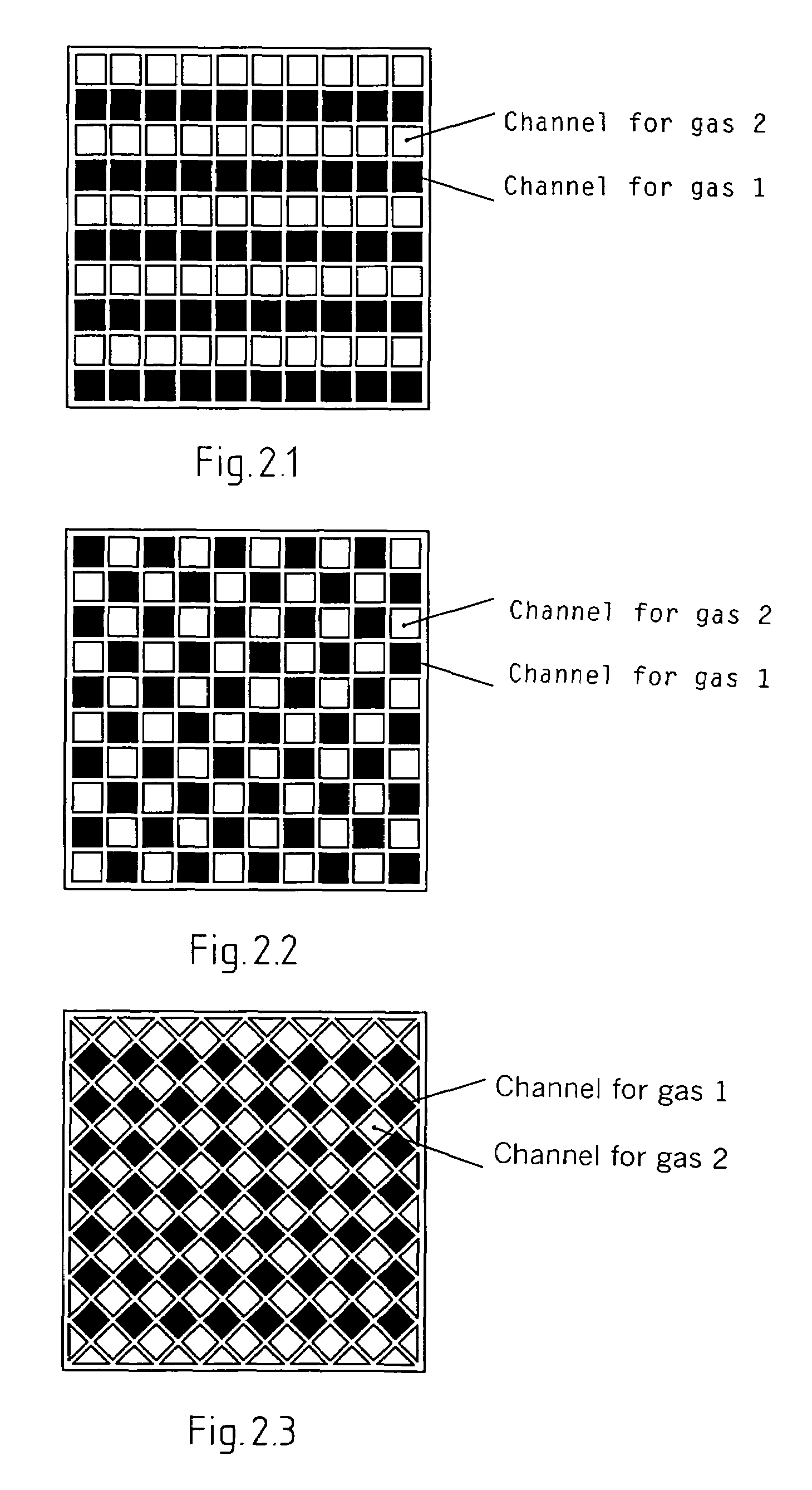

Method and equipment for feeding two gases into and out of a multi-channel monolithic structure

InactiveUS7285153B2Improve heating efficiencyEfficient heatingAuxillary pretreatmentIsotope separationProduct gasMass transfer

A method with associated equipment for feeding two gases into and out of a multi-channel monolithic structure. The two gases will normally be gases with different chemical and / or physical properties. The first gas and the second gas are fed by means of a manifold head into channels for the first and second gases, respectively. The gases are distributed in the monolith in such a way that at least one of the channel walls is a shared or joint wall for both gases. The walls that are joint walls for the two gases will then constitute a contact area between the two gases that is available for mass and / or heat exchange. This means that the gases must be fed into channels that are spread over the entire cross-sectional area of the monolith. The entire contact area or all of the monolith's channel walls are directly used for heat and / or mass transfer between the gases. This means that the channel for one gas will always have the other gas on the other side of its channel walls.

Owner:STATOIL ASA PETRO SA (NO)

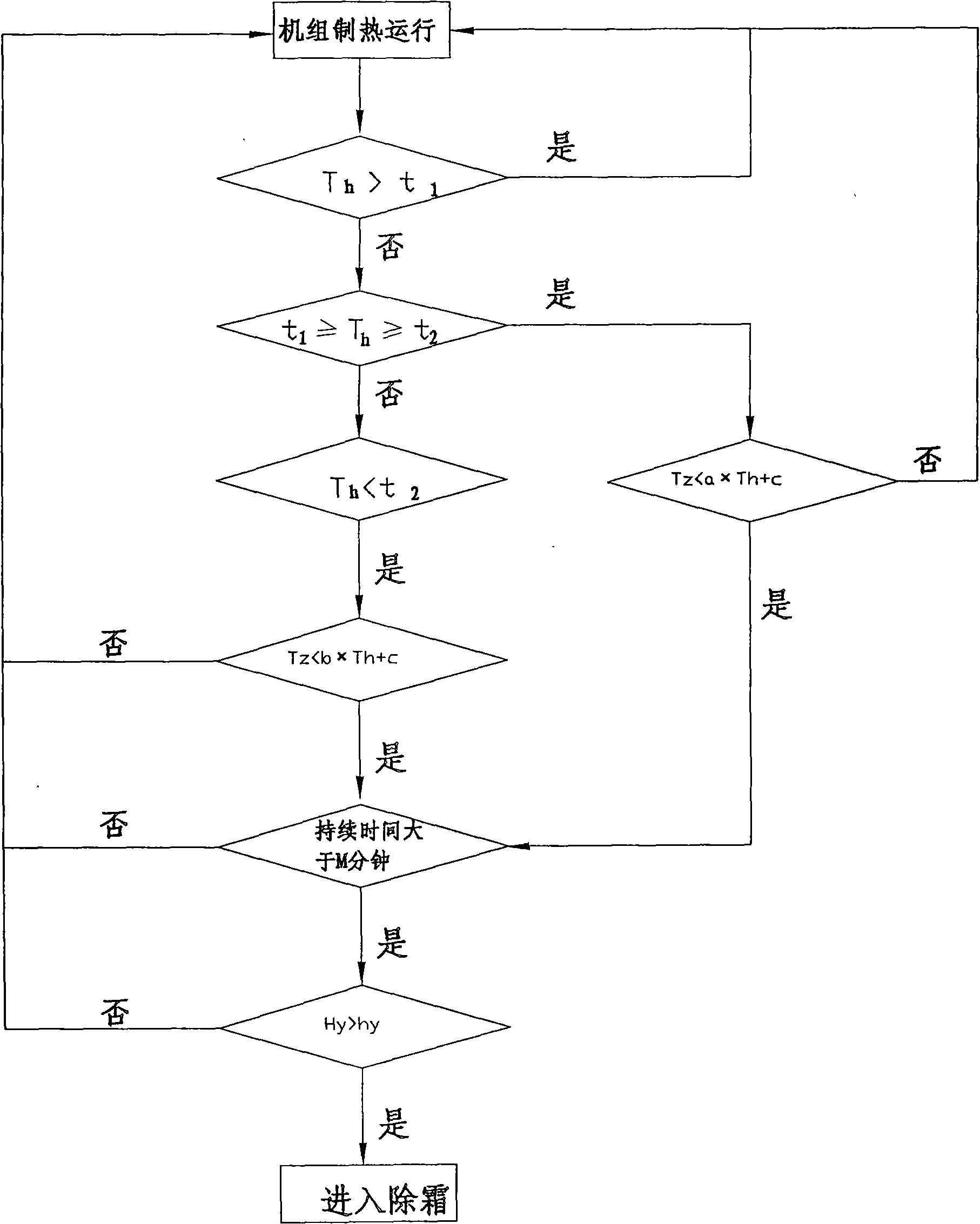

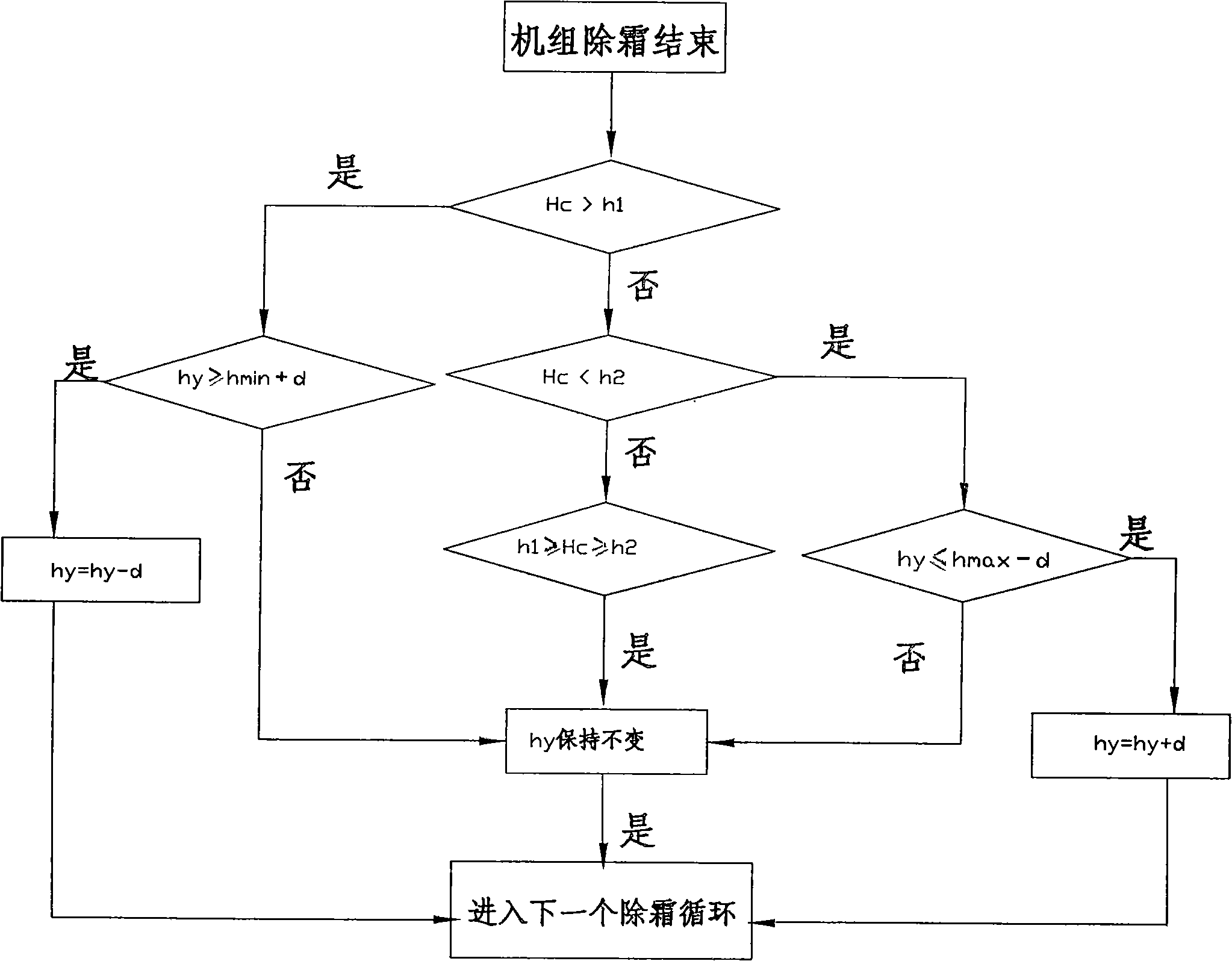

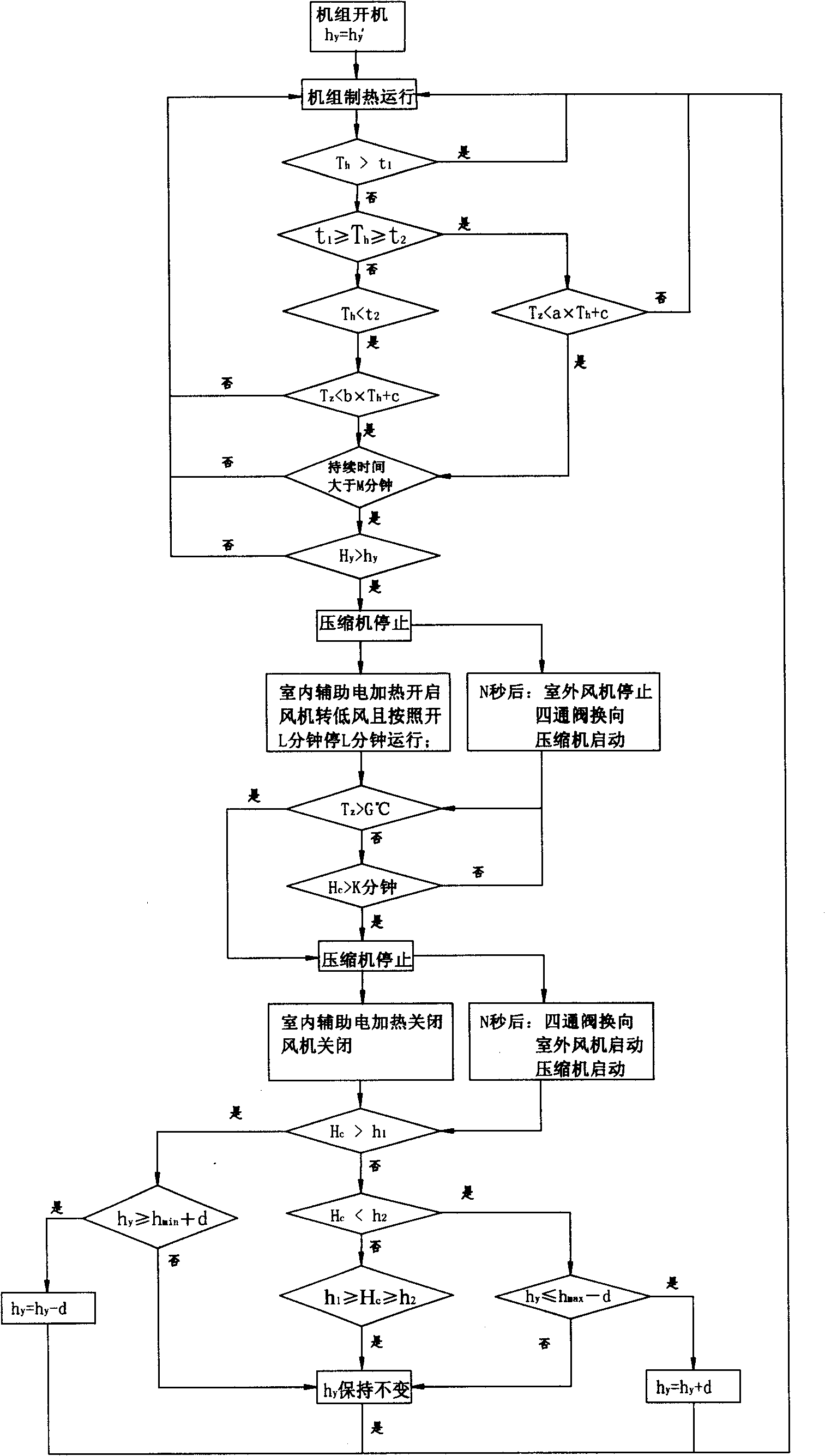

Defrosting method for heat pump type air conditioner

InactiveCN101303185AImprove heating efficiencyShorten defrost timeCorrosion preventionRefrigeration componentsHeating timeOutdoor temperature

The invention discloses a defrosting method for a heat-pump type air conditioner, which decides whether the defrosting operation mode, namely setting environment determination temperature t<1> and t<2> and three constants a, b and c, is carried out by combination of coil tube temperature T of an outdoor heat exchanger, outdoor temperature T, actual heating time H and set heating time h; under the following conditions, the unit starts the defrosting operation mode: 1. when T is less than or equal to t<1> and more than or equal to t<2>, if the coil tube temperature T of the outdoor heat exchanger meets the condition of T less than a, T plus c and H larger than h in a continuous M minutes, the unit starts to defrost; 2. when T is less than t<2>, if the coil tube temperature T of the outdoor heat exchanger meets the conditions of T less than b, T plus c and H larger than h in a continuous M minutes, the unit starts to defrost. The defrosting method has the advantages of shortening defrosting time, improving defrosting efficiency, leading to thorough defrosting and greatly improving heating efficiency.

Owner:NINGBO AUX ELECTRIC

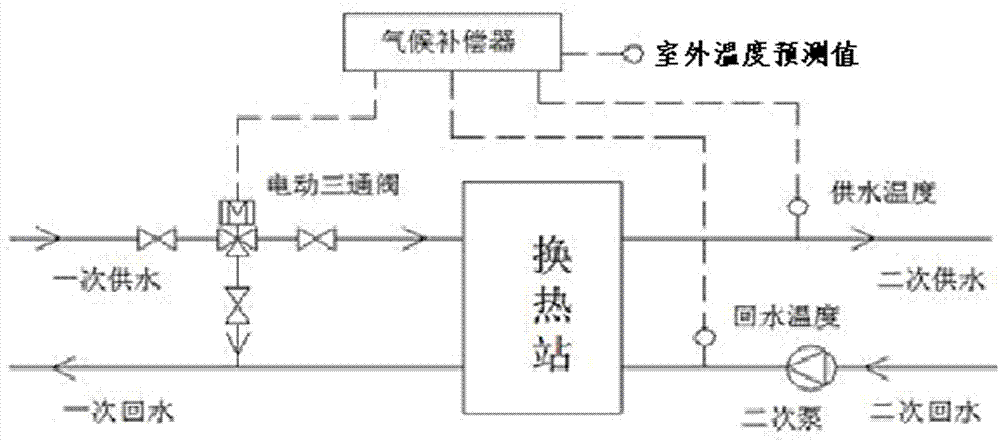

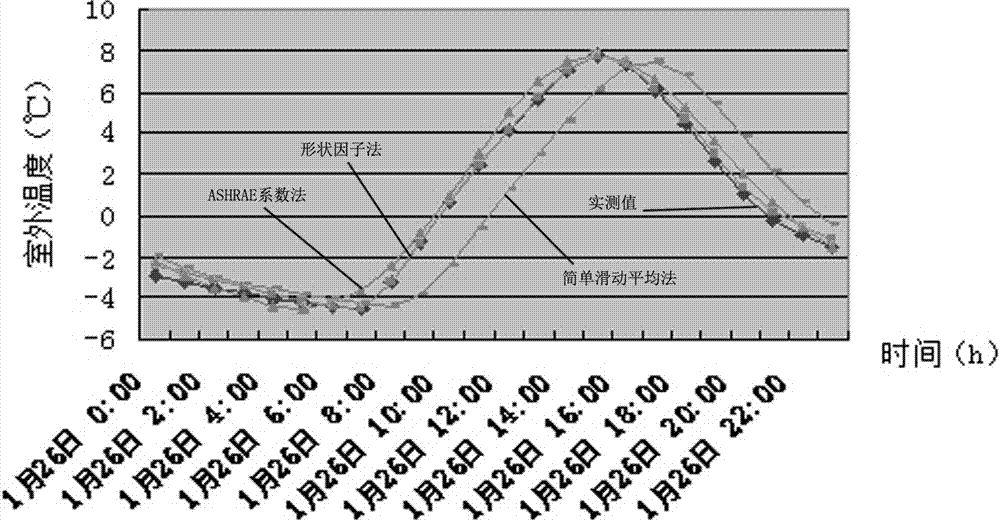

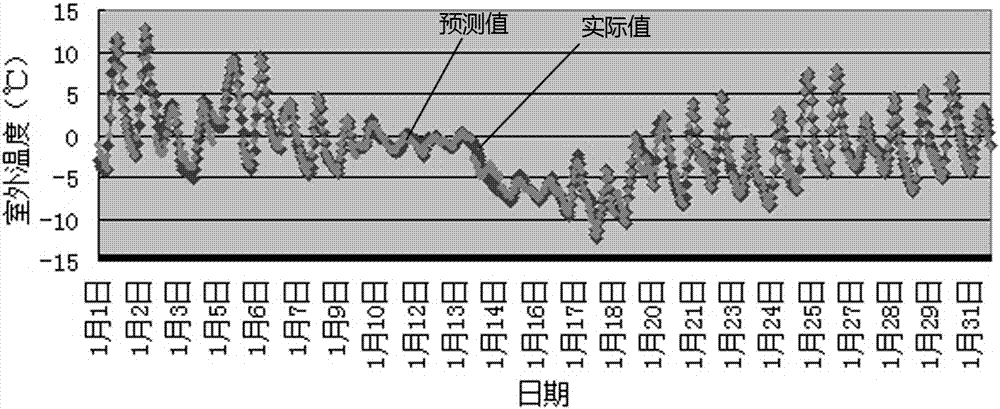

Dynamic climate compensation method for centralized heating

ActiveCN107120721AStable indoor temperatureEnsure heating qualityLighting and heating apparatusSpace heating and ventilation detailsHysteresisValue set

The invention discloses a dynamic climate compensation method for centralized heating. Firstly, the outdoor temperature is predicted, water supply and return temperatures are adjusted some time ahead according to the predicted value of the outdoor temperature, and the hysteresis of pipe network adjustment in the manner that adjustment is performed while sampling is overcome. The outdoor temperature of the next day is predicted according to local historical meteorological data and weather forecast of the meteorological department, and the value is used as basic data for prediction of a thermal load; and then the thermal load is predicted, that is, the thermal load curve of the next day is calculated according to the outdoor temperature. With the method, the outdoor temperature is reasonably predicted so as to realize advanced dynamic adjustment of a climate compensator; heating medium parameters of a heating system are adjusted by the aid of an adjusting model according to the thermal load value set in advance, a heat source is changed from original wide passive heating into active heating, on the premise that the indoor temperature for the user is stable, the operation adjusting indictor of the heating system within the specified time are given in advance, the heating efficiency is improved, and the heating energy consumption is reduced.

Owner:石家庄华浩能源科技有限公司

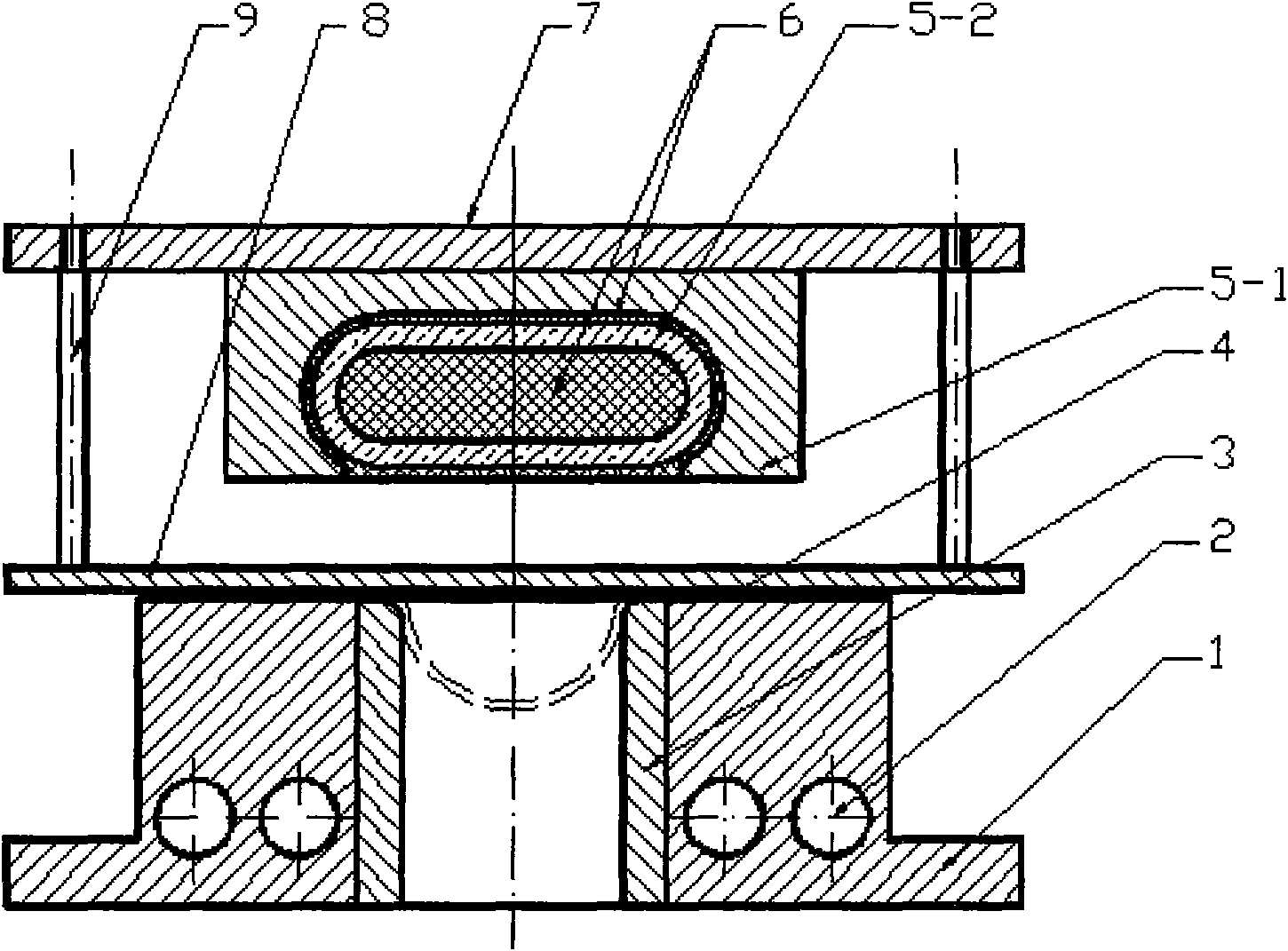

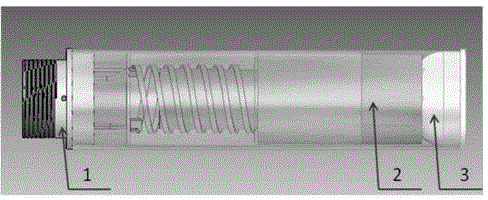

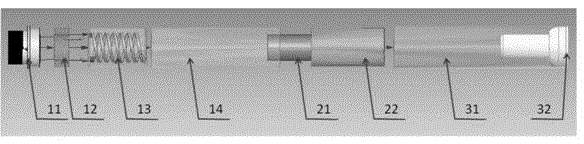

Thermo electromagnetic forming method of magnesium alloy sheet material

The invention provides a plastic working method capable of improving the forming property of a magnesium alloy sheet material, namely a thermo electromagnetic forming method. The method comprises the following steps: putting the magnesium alloy sheet material on a cavity die; heating the magnesium alloy sheet material through a heating rod in the cavity die so that the temperature of the magnesium alloy sheet material is raised to be between 100 and 300 DEG C; compacting the magnesium alloy sheet material by an electromagnetic forming coil under the action of a pressing machine; and discharging the electromagnetic forming coil by an electromagnetic forming device so that the magnesium alloy sheet material is adhered to the die and formed. The method uses an energy storage capacitor to perform instantaneous discharge on the electromagnetic forming coil to generate a hard pulse magnetic field so that a heated blank is formed at a high speed under the action of an impacting electromagnetic force, and the method combines the advantages of thermo-forming and electromagnetic forming so the forming property of the magnesium alloy sheet material is effectively improved, and the limitations of lubrication in single thermo-forming and material and environmental pollutions caused by the single thermo-forming, limited forming speed, die strength, rigorous forming process conditions, small parameter adjustable range and the like are overcome.

Owner:WUHAN UNIV OF TECH

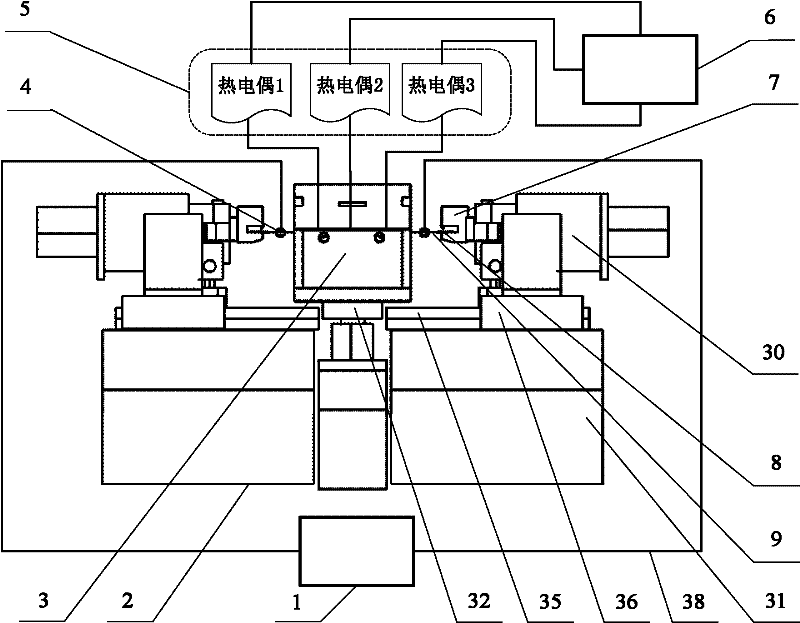

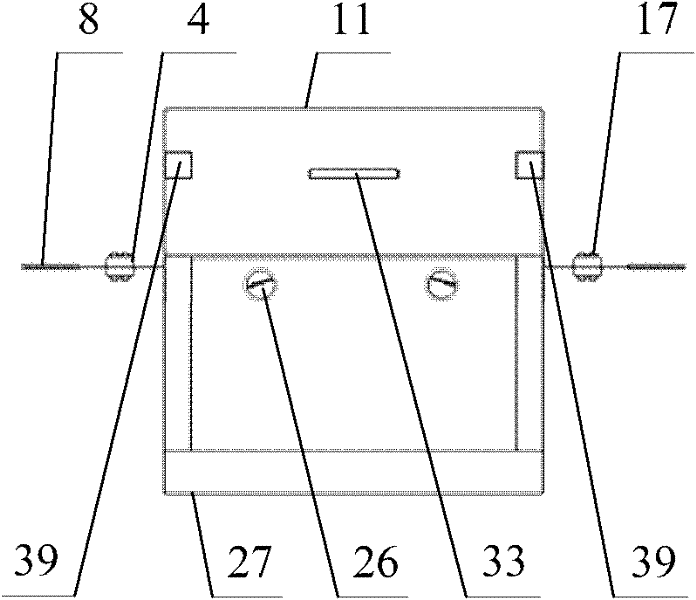

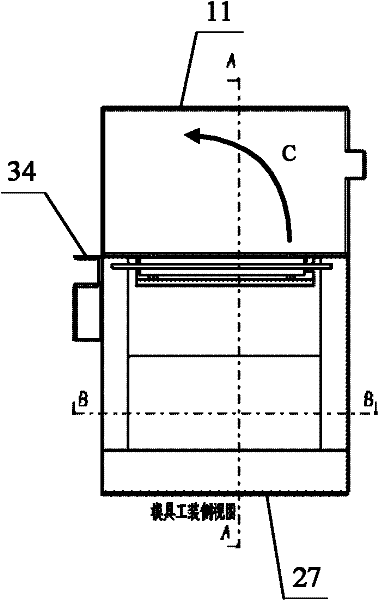

Hot forming tool of titanium alloy thin-wall part and machining method of hot forming tool

ActiveCN102500675AViscoplastic deformation facilitatesAvoid lostShaping toolsTemperature controlProcess integration

The invention provides a hot forming tool of a titanium alloy thin-wall part, comprising five parts, namely stretching equipment, a mould device, a blank, a power supply system and a temperature control system, wherein the mould device is arranged on a central worktable of the stretching equipment; the blank passes through a side wall crack of the mould device; an insulating and heat-insulation cushion layer is used for insulating the blank, a clamp of the stretching equipment, the surface of a mould and a tool of the mould; the power supply system is switched on to electrify an electrode clamping plate and generate a current in the blank; the blank is heated and the temperature of the blank is measured and controlled by the temperature control system; and after the temperature of the blank reaches a target temperature, the part is formed on the surface on the mould by the blank in an adhered manner through carrying out hot forming processes successively including stretching, covering, stretching, heat preservation and creep deformation and the like on the stretching equipment. A machining method of the hot forming tool of the titanium alloy thin-wall part comprises eight steps. According to the invention, the heating efficiency, the process integration, the material formation and the formation precision of the titanium alloy thin-wall part in manufacture are greatly improved, so that the hot forming tool of the titanium alloy thin-wall part and the machining method of the hot forming tool have a practical value and a popularization value.

Owner:BEIHANG UNIV

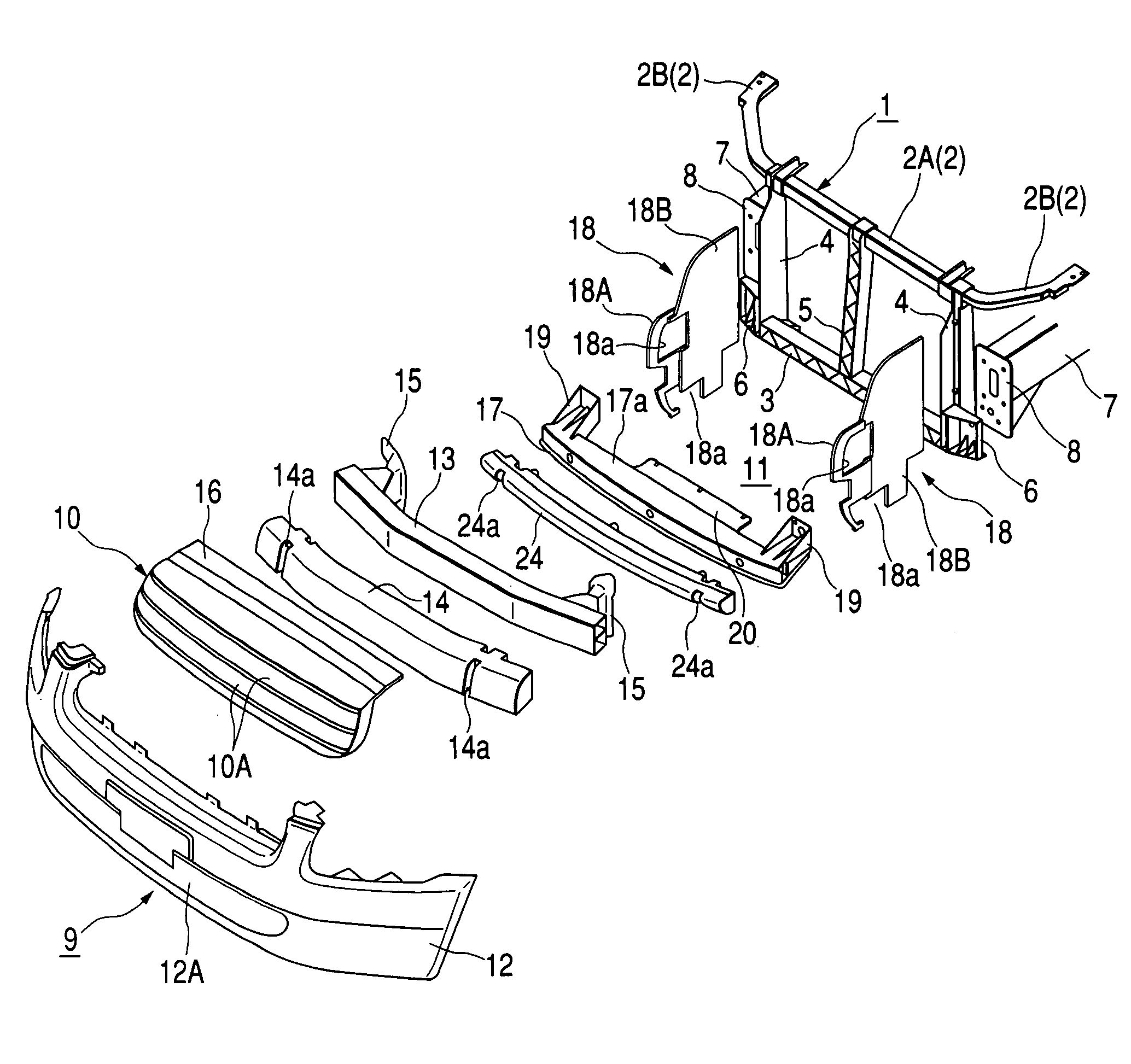

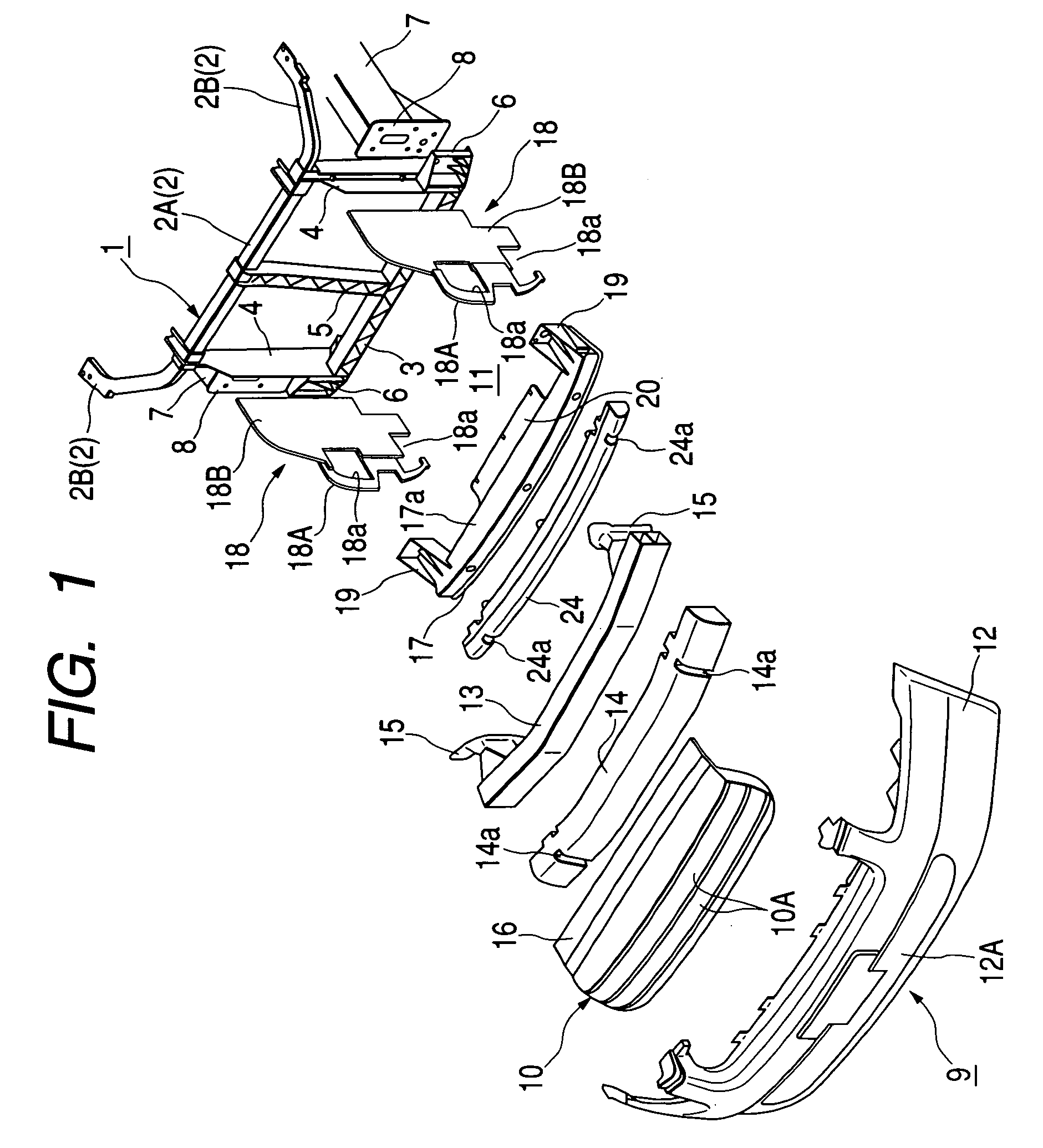

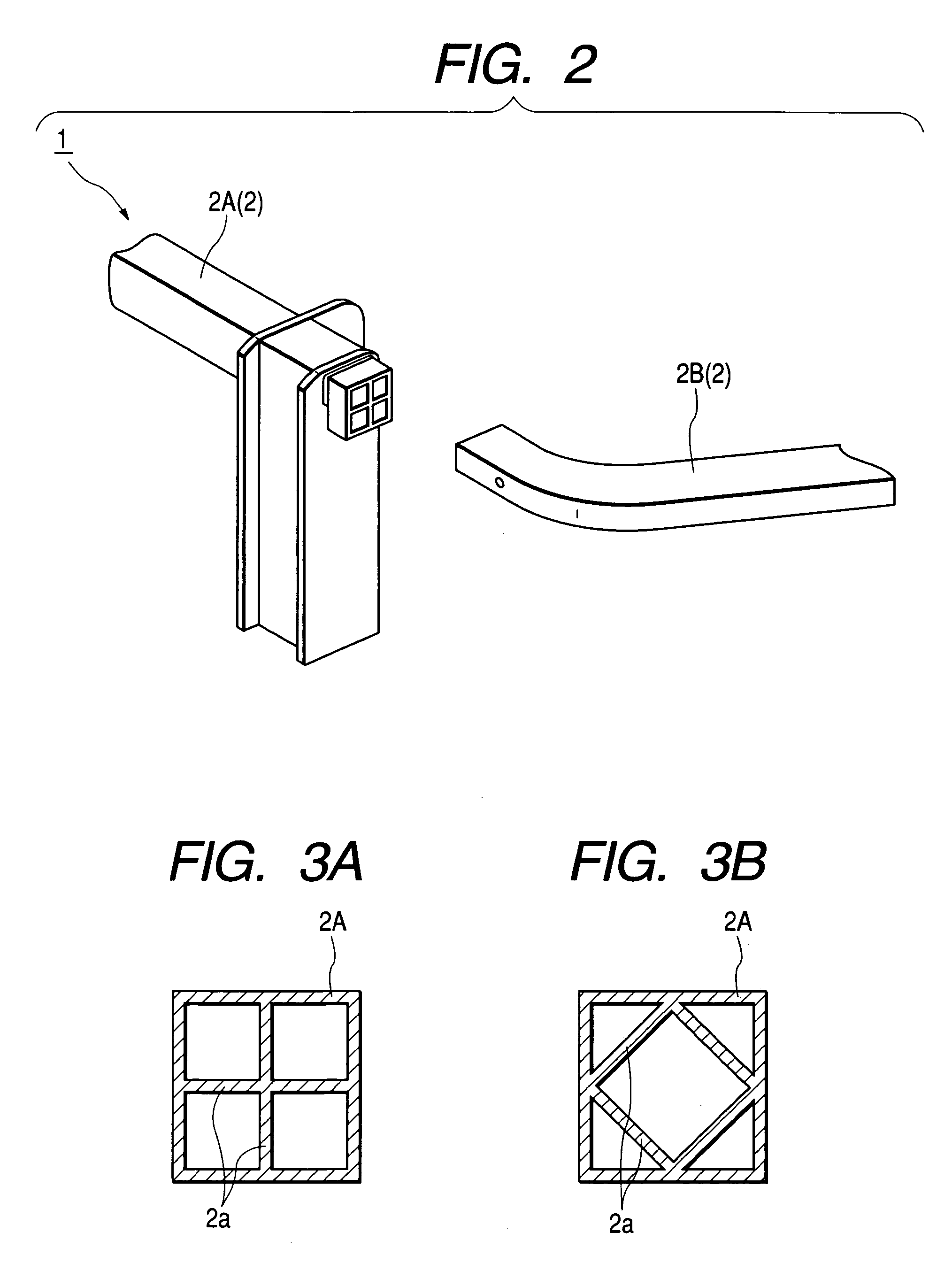

Structure of front portion of vehicle body

InactiveUS7114587B2Improve heating efficiencyImprove cooling efficiencyVehicle seatsSuperstructure subunitsEngineeringEngine room

A portion between a front end of an air guide plates, which forms an air duct portion, and the front exterior member of the vehicle is sealed by a seal portion. Therefore, hot air leaking from inside of an engine room, is positively prevented from being drawn into the air duct portion after it flows around the front end of the air guide plate.

Owner:CALSONIC KANSEI CORP

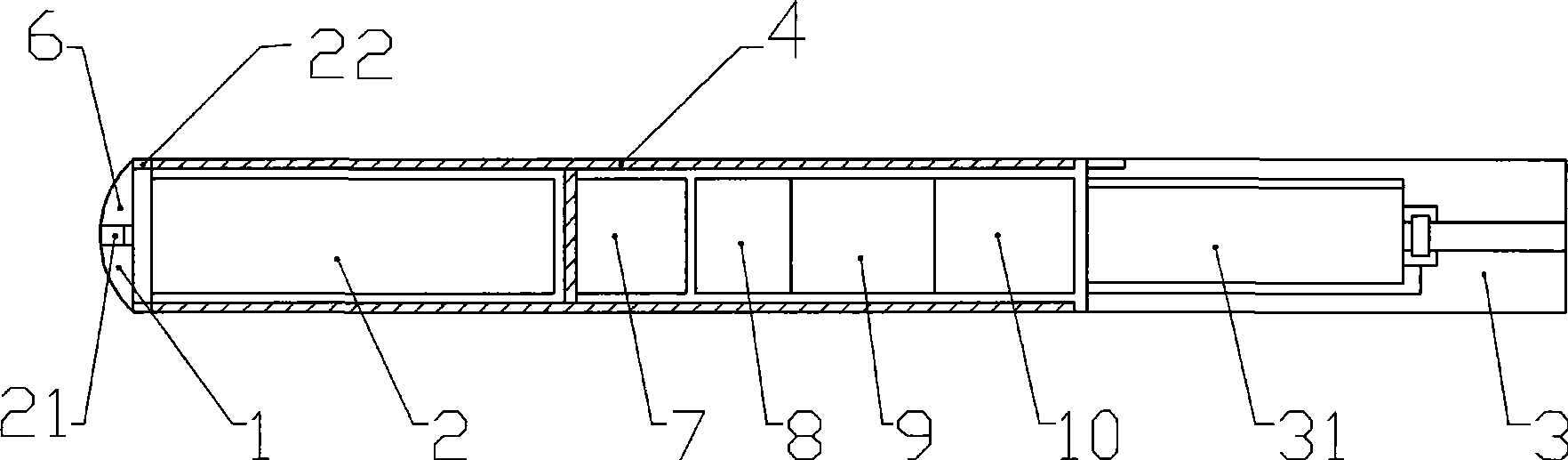

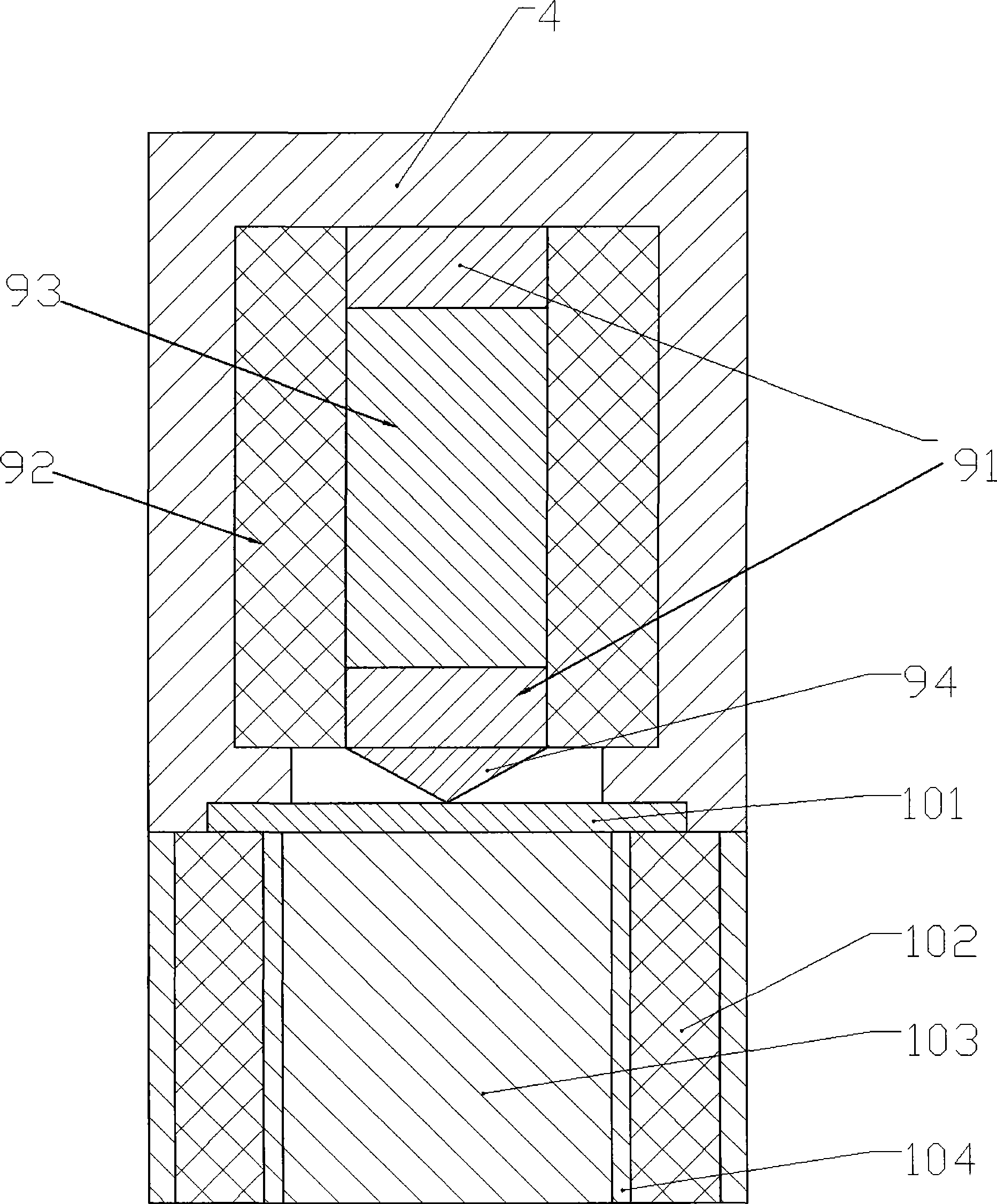

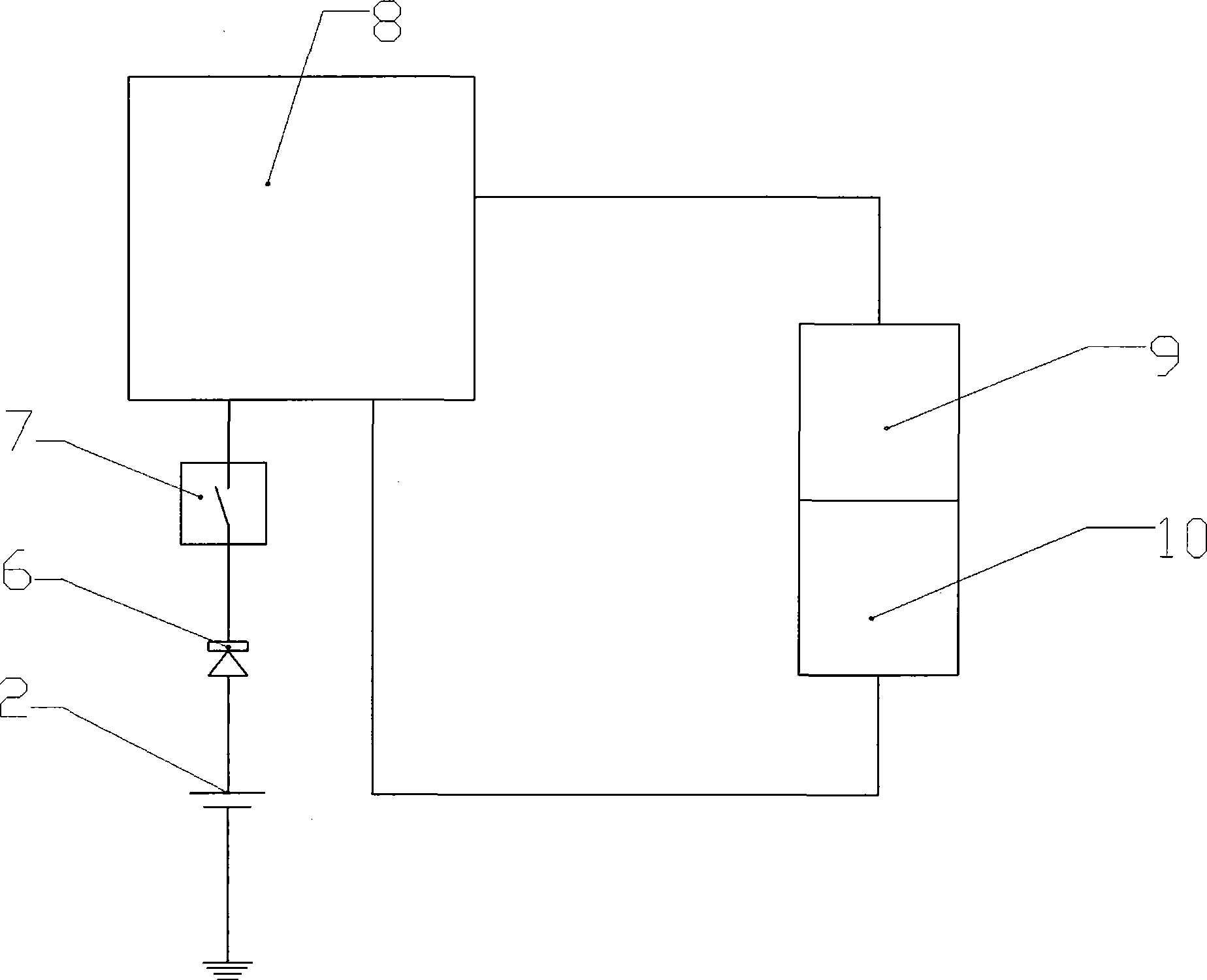

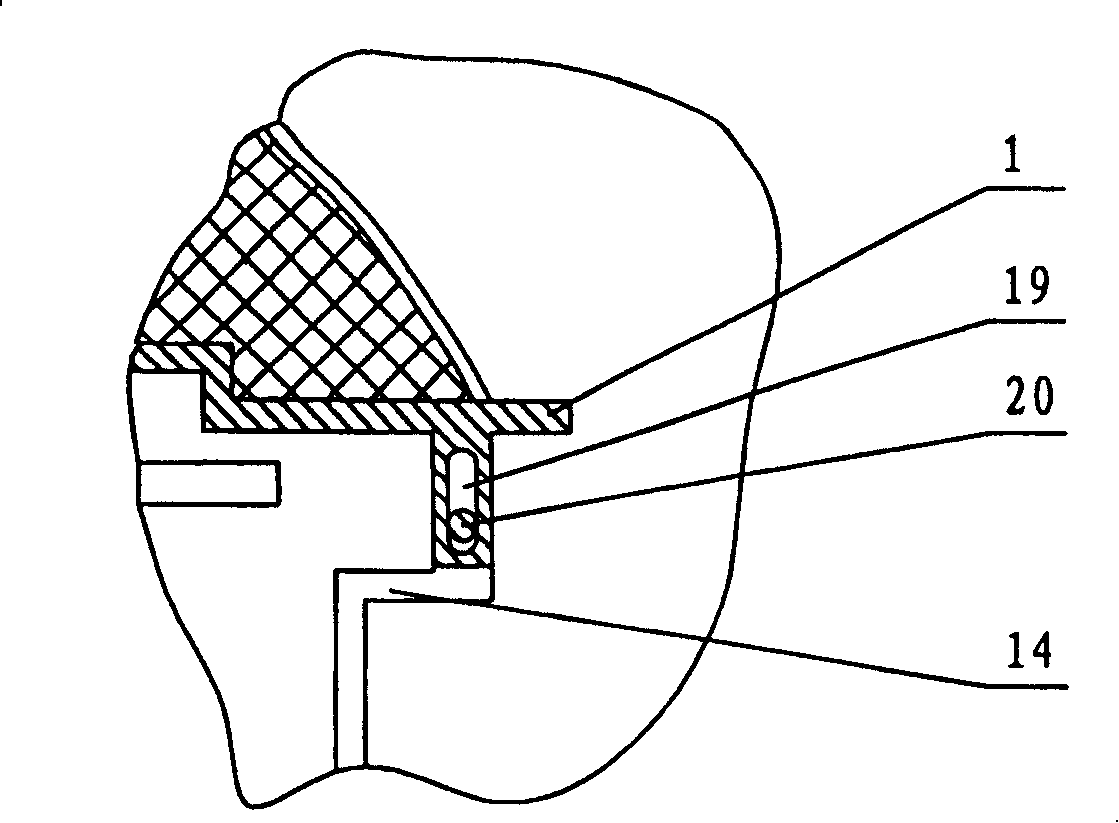

Sliding cover startup two-way heating and low-temperature baking smoking set

The invention discloses a sliding cover startup two-way heating and low-temperature baking smoking set which comprises a shell, a battery, a control board, a low-temperature baking ring and a sliding cover startup assembly, wherein a slide stroke of a sliding outer cover of the sliding cover startup assembly is provided with a first sliding position and a second sliding position; the sliding outer cover shields and is arranged at the outer side of a faucet and a metal sheet is separated from a thimble at the first sliding position; the sliding outer cover departs from the outer side of the faucet, the faucet is exposed and the metal sheet is in contact with the thimble at the second sliding position. Through the sliding cover startup assembly, on one hand, the sliding cover startup two-way heating and low-temperature baking smoking set can play a role in shielding the faucet in a non-use state; on the other hand, the sliding cover startup two-way heating and low-temperature baking smoking set can play roles in exposing the faucet and turning on a power supply at the same time through sliding towards one side in use, and has the advantages of being convenient to start, simple in operation, safe and durable.

Owner:CHINA TOBACCO YUNNAN IND

Low-temperature heating type electronic cigarette heater

A low-temperature heating type electronic cigarette heater comprises a heater component, a composite cigarette core and a cigarette holder portion. The composite cigarette core is consumable and cannot be reused, and the other portions are reusable; the composite cigarette core is composed of a core body and a filtering core in a combined manner and fills the heater component, the core body adopts natural plant fibers as the base material and is provided with tobacco aroma substances in an absorbed manner and tea polyphenol microcapsules, and the filtering core is tobacco paper filtering core compounded with bamboo fibers and is prevented from being carbonized during heating; a cigarette holder is connected to the heater component in a sleeved manner; the heater component comprises a connecting component, a supporting seat, a ceramic heating ring and a heat insulating sleeve. The composite cigarette core contacts with the ceramic heating ring in a cylindrical surface manner, the heating area is large, three ways, namely conduction, convection and radiation, of heat transfer during heating are provided, and the heating efficiency is high; the cigarette core releases contained tobacco ingredients through low-temperature heating, the taste is similar to that of a traditional cigarette, and toxics produced in the burning process can be avoided.

Owner:POWERTHINK (BEIJING) TECH CO LTD +2

Energy-saving heat supply system with function of reducing temperature of heat supply return water

InactiveCN106705185AIncrease profitReduce circulating water flowLighting and heating apparatusSteam useCooling towerTemperature difference

The invention discloses an energy-saving heat supply system with a function of reducing the temperature of heat supply return water, and belongs to the field of improvement of energy utilization efficiency. Heat exchange can be repeatedly carried out on heat sources by multistage heat exchangers, multistage absorption heat exchange units, multistage compression heat pumps and an ice making type refrigerator, accordingly, the heat supply areas can be enlarged, and the energy utilization efficiency can be improved. The energy-saving heat supply system has the advantages that the temperature of the return water of heat supply primary pipe networks can be reduced and reach 0 DEG C, the return water contains 10% of ice particles, accordingly, route heat loss of the return water of the heat supply primary pipe networks can be reduced, the temperature difference of the return water of the heat supply primary pipe networks can be increased and reaches 118 DEG C from the original 60 DEG C, the flow rate of circulating water of the heat supply primary pipe networks can be lowered, energy consumption of circulating pumps can be reduced, heat supply flow rates of a user side can be greatly increased, the delivery efficiency of the pipe networks can be improved, the heat supply scale can be expanded, waste heat of a cooling tower can be recycled, and the like.

Owner:DALIAN BAOGUANG ENERGY SAVING AIR CONDITIONING EQUIP

Heating device, non-combustion smoking set upon heating and constant temperature smoke releasing method

InactiveCN107183789APlay the role of thermal insulationImprove heating efficiencyTobacco devicesCombustionThermal insulation

The invention provides a heating device, a non-combustion smoking set upon heating and a constant temperature smoke releasing method. The heating device comprises a heating part shell body, one end of which is provided with an opening part, a heating part cover body arranged on the opening part, and an atomization part arranged inside the heating part shell body, wherein the vapor outlet end of the atomization part is connected to the heating part cover body through an end part thermal insulation fixing piece, and the side surface of the atomization part is wrapped with a side part thermal insulation assembly; an air flow gap used for the passage of an air flow is arranged between the side part thermal insulation assembly and the heating part shell body, and the air inlet end of the atomization part is communicated with the air flow gap. Since the atomization part of the heating device has a structure of being hung on the heating part cover body, the thermal insulation effects of the atomization part and the heating part shell body are improved; since the side part thermal insulation assembly and the end part thermal insulation fixing piece have thermal insulation effects on the atomization part, the heating efficiency of the atomization part is improved. The non-combustion smoking set upon heating can release smoke at a constant temperature, and can be charged.

Owner:SHANGHAI TOBACCO GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com