Baking type atomization device and aerosol inhalation device

A technology of atomization device and inhalation device, which is applied in the directions of smoker's products, applications, tobacco, etc., can solve the problems of insufficient heat insulation, hot cigarette body, slow heating speed, etc., shortening baking time, improving heating efficiency, The effect of saving electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, so as to understand the essence of the present invention more intuitively.

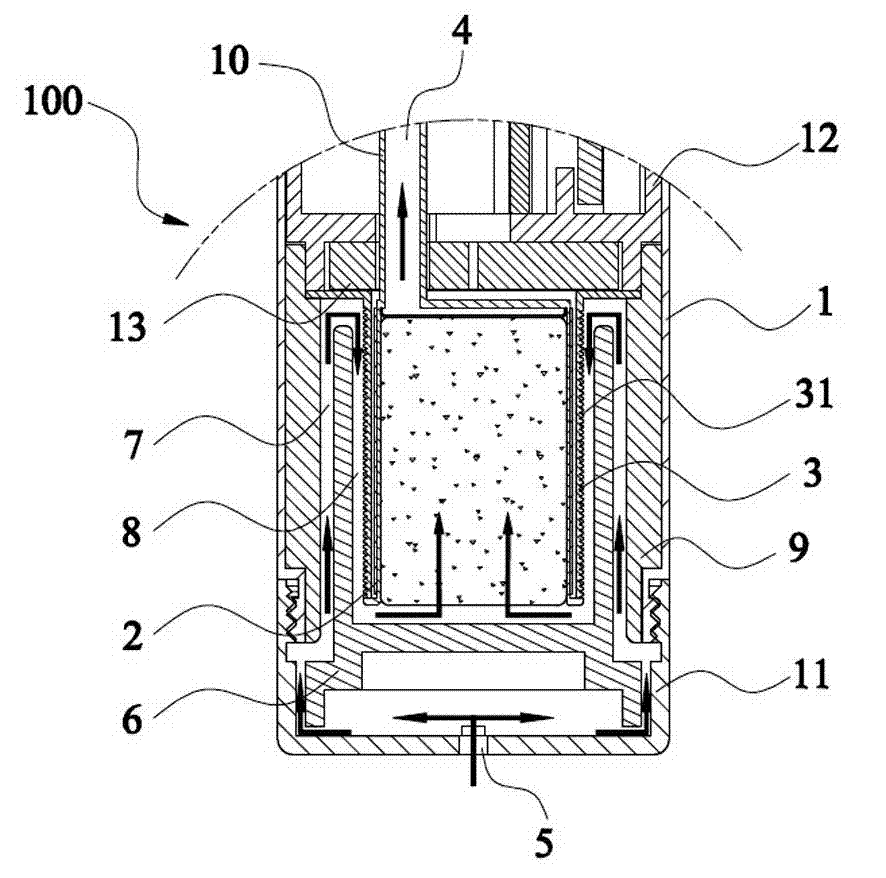

[0029] refer to figure 1 As shown, this embodiment provides a baking atomization device 100, which mainly includes a housing 1, a baking chamber 2 and a heating element 3 disposed in the housing 1, and one side of the baking chamber 2 is connected to an air outlet 4 , the other side communicates with an air inlet 5, and the heating element 3 is sleeved outside the baking chamber 2, wherein the baking chamber 2 is used to fill solid smoking substances such as tobacco and tobacco paste; the heating element 3 is used to generate heat, The solid smoke-generating material in the baking chamber 2 is roasted to generate smoke, air can enter through the air inlet 5, and the smoke is taken out from the air outlet 4 for people to inhale. Also includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com