Patents

Literature

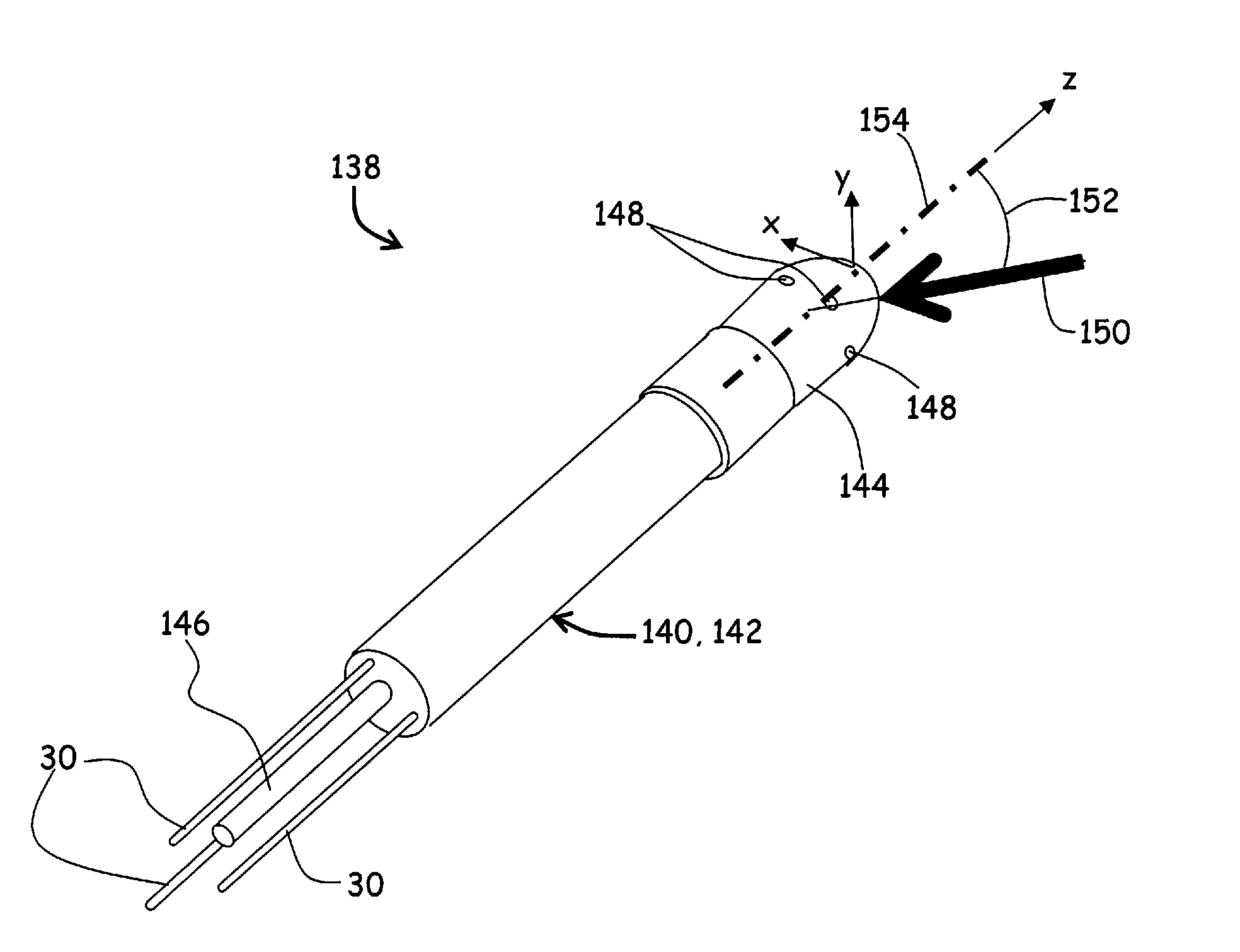

798 results about "Thermal isolation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermal isolation definition, thermal isolation meaning | English dictionary. thermal. n an imaginary line round the earth running through the point on each meridian with the highest average temperature.

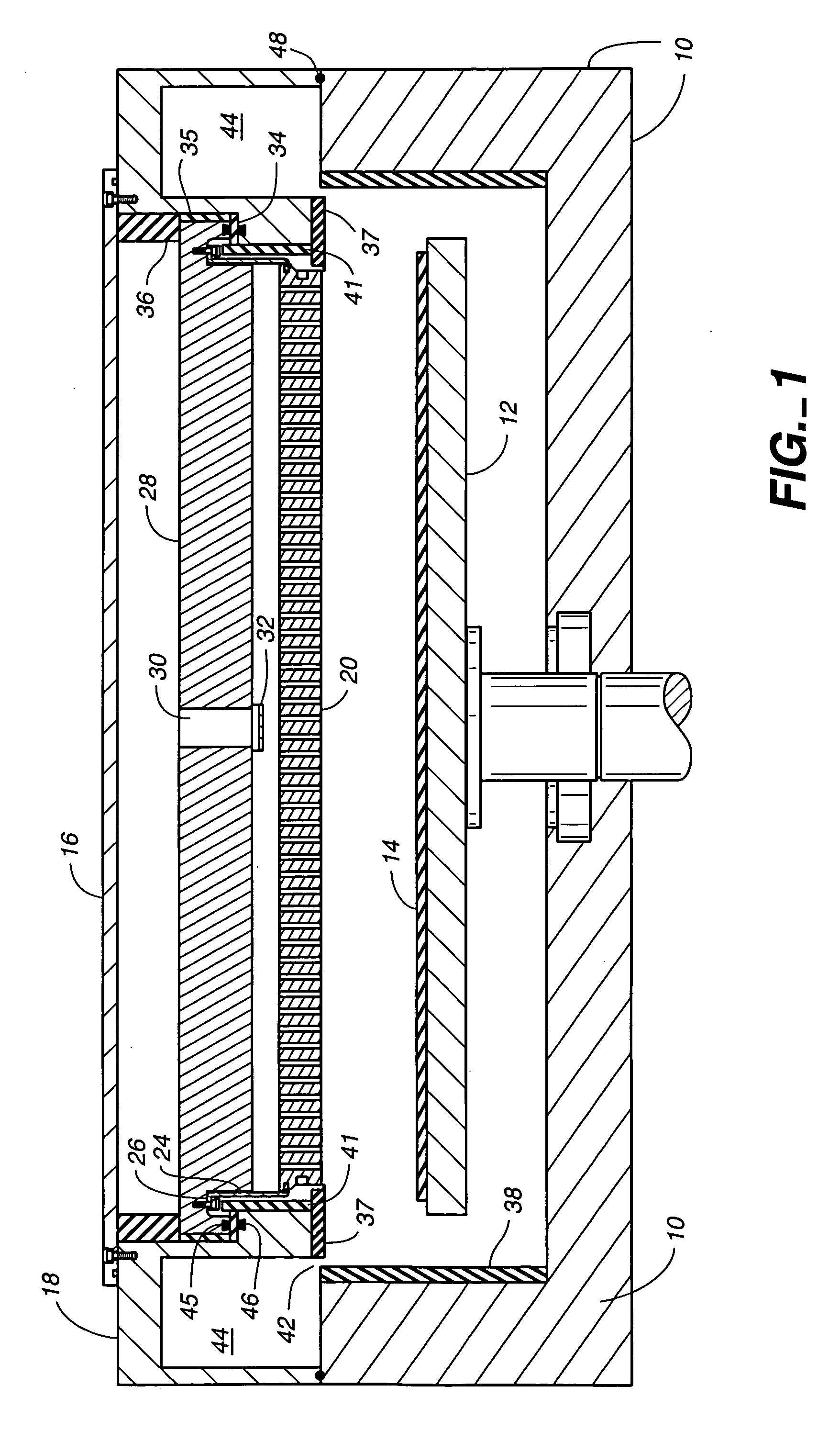

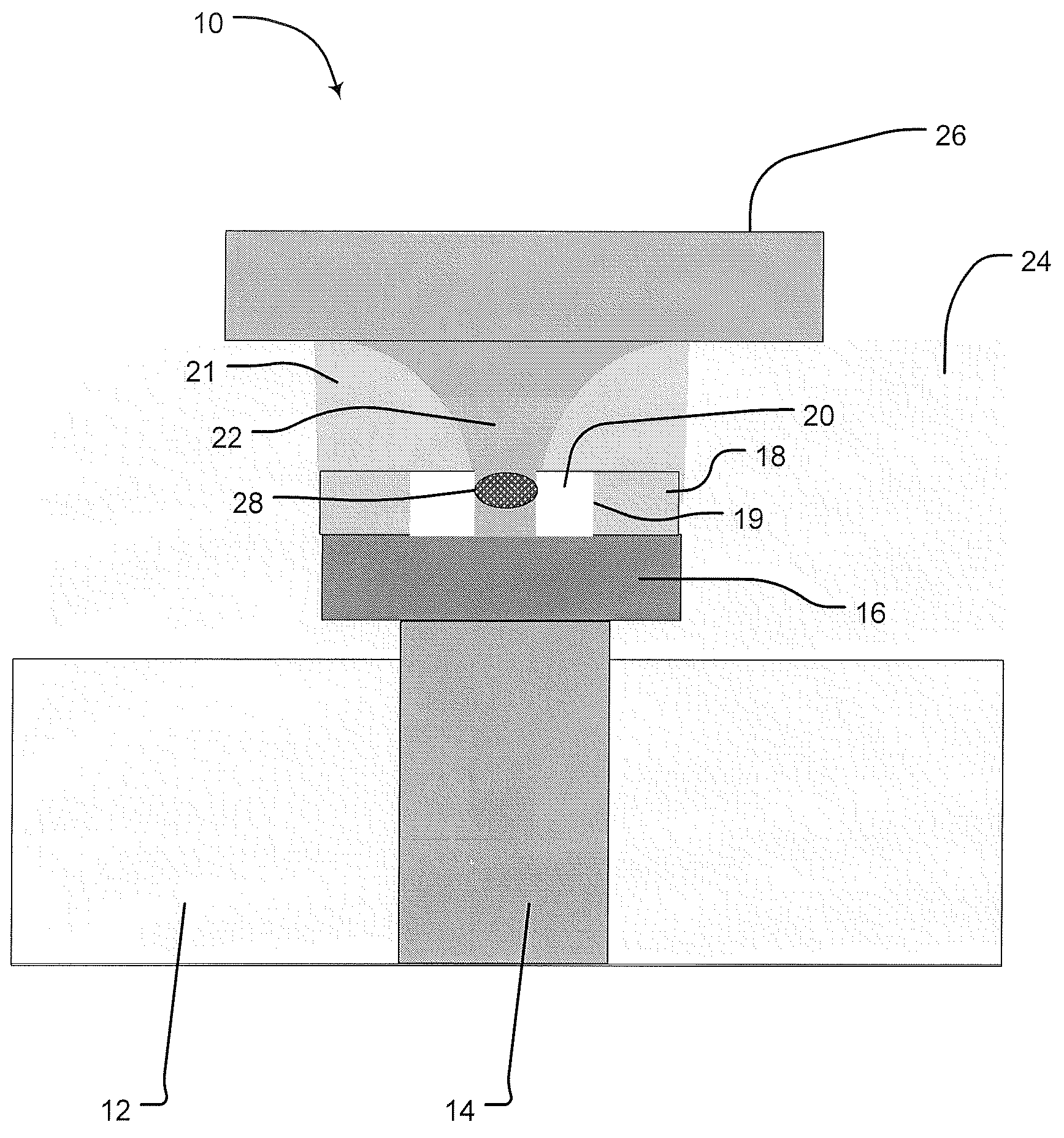

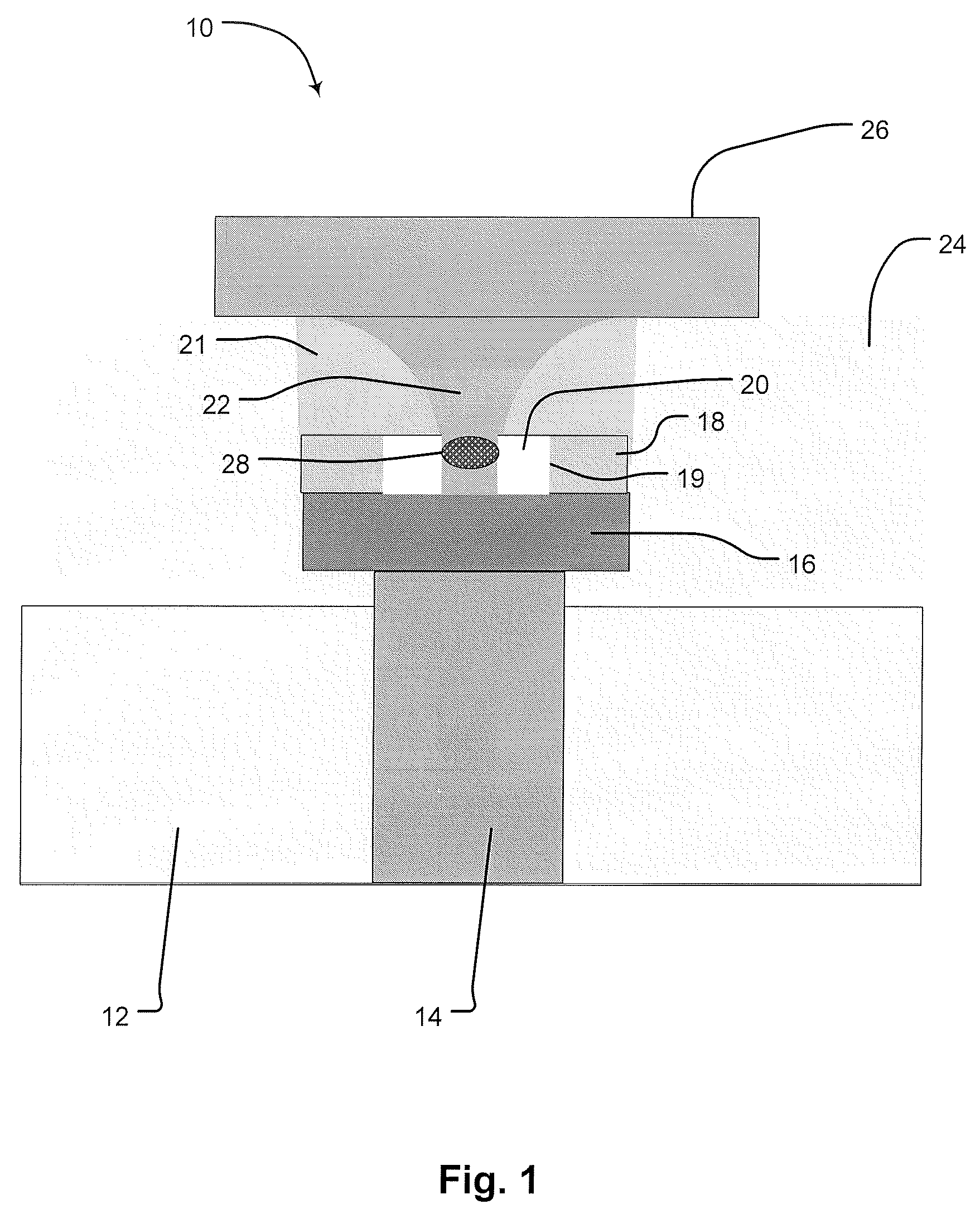

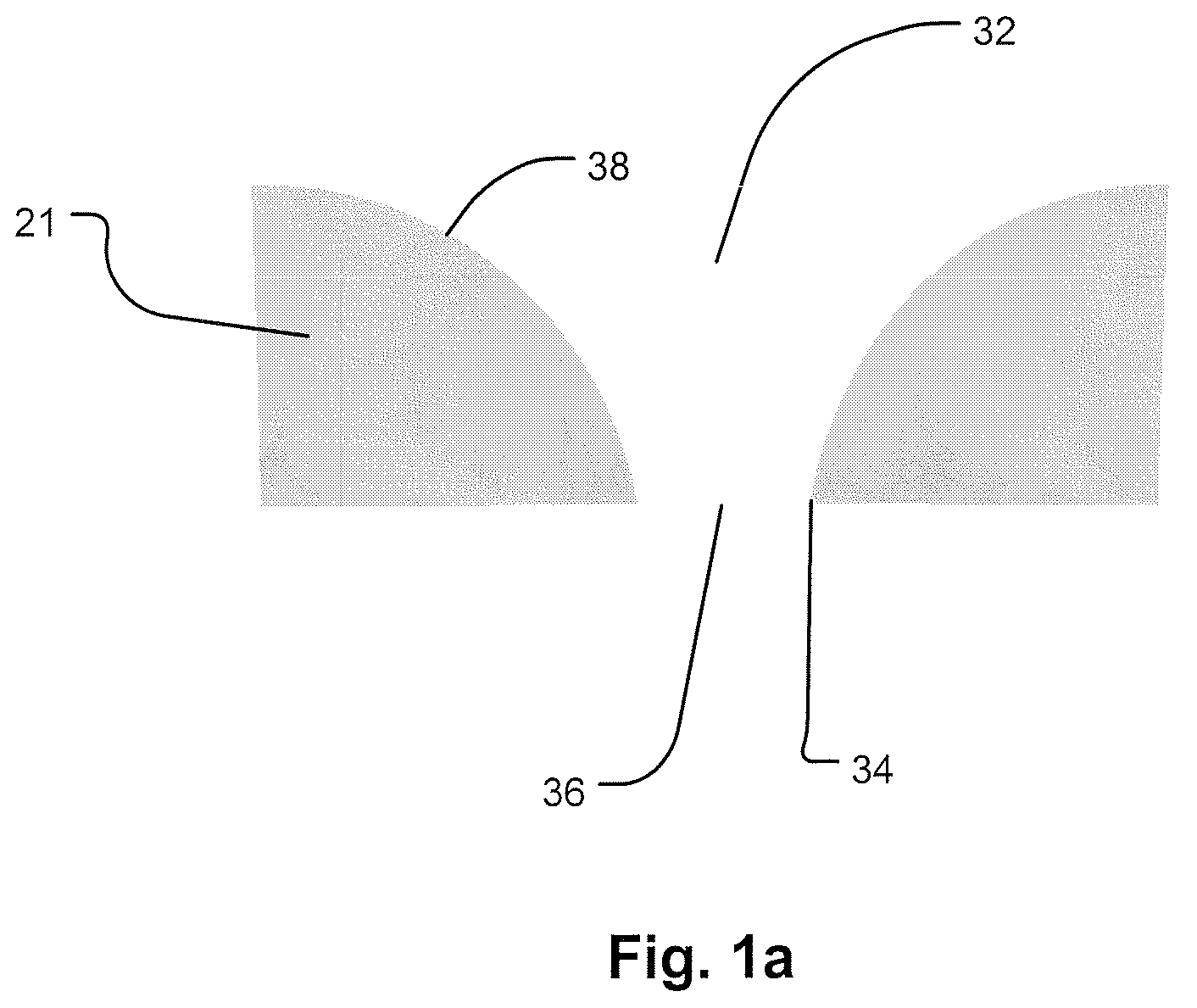

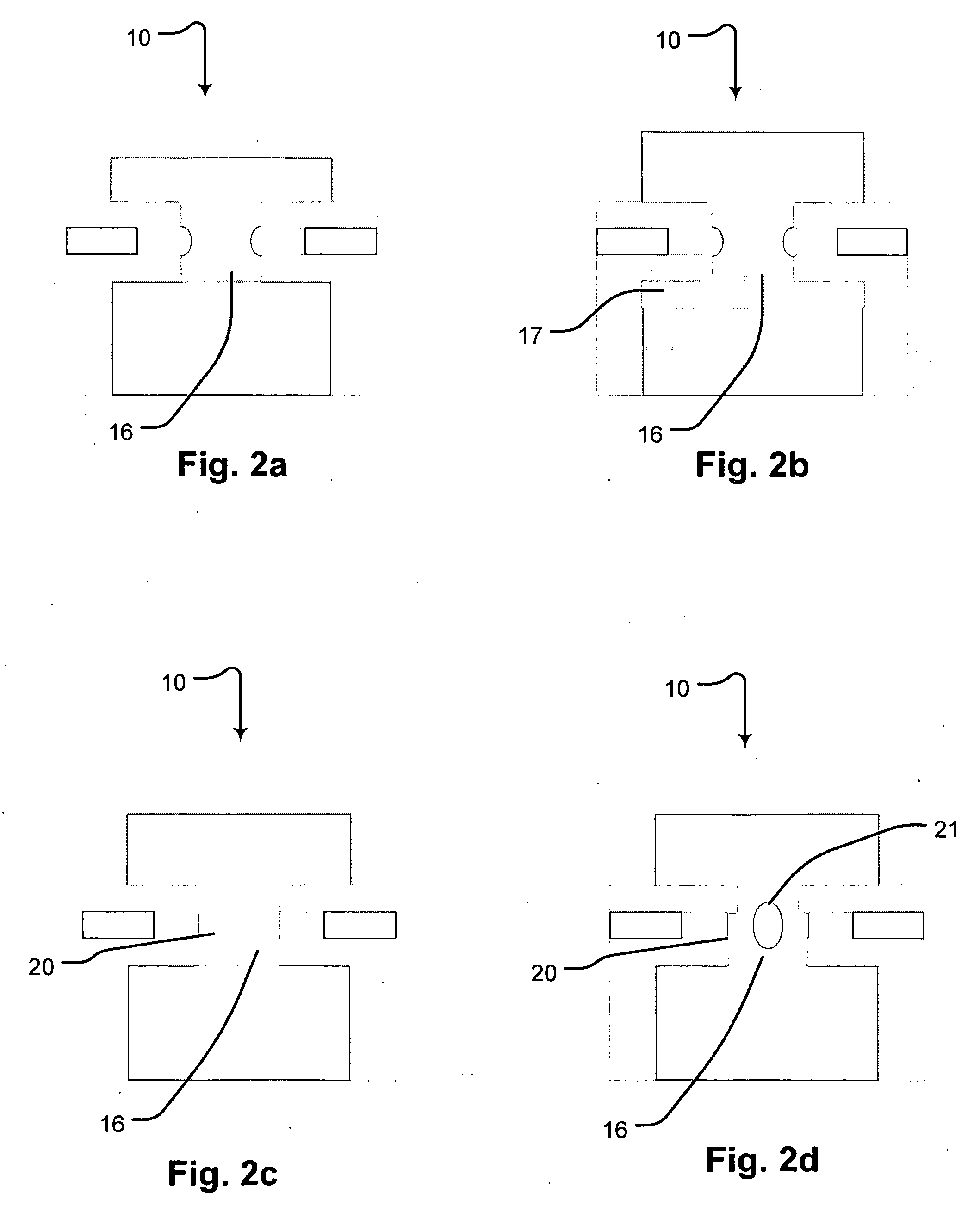

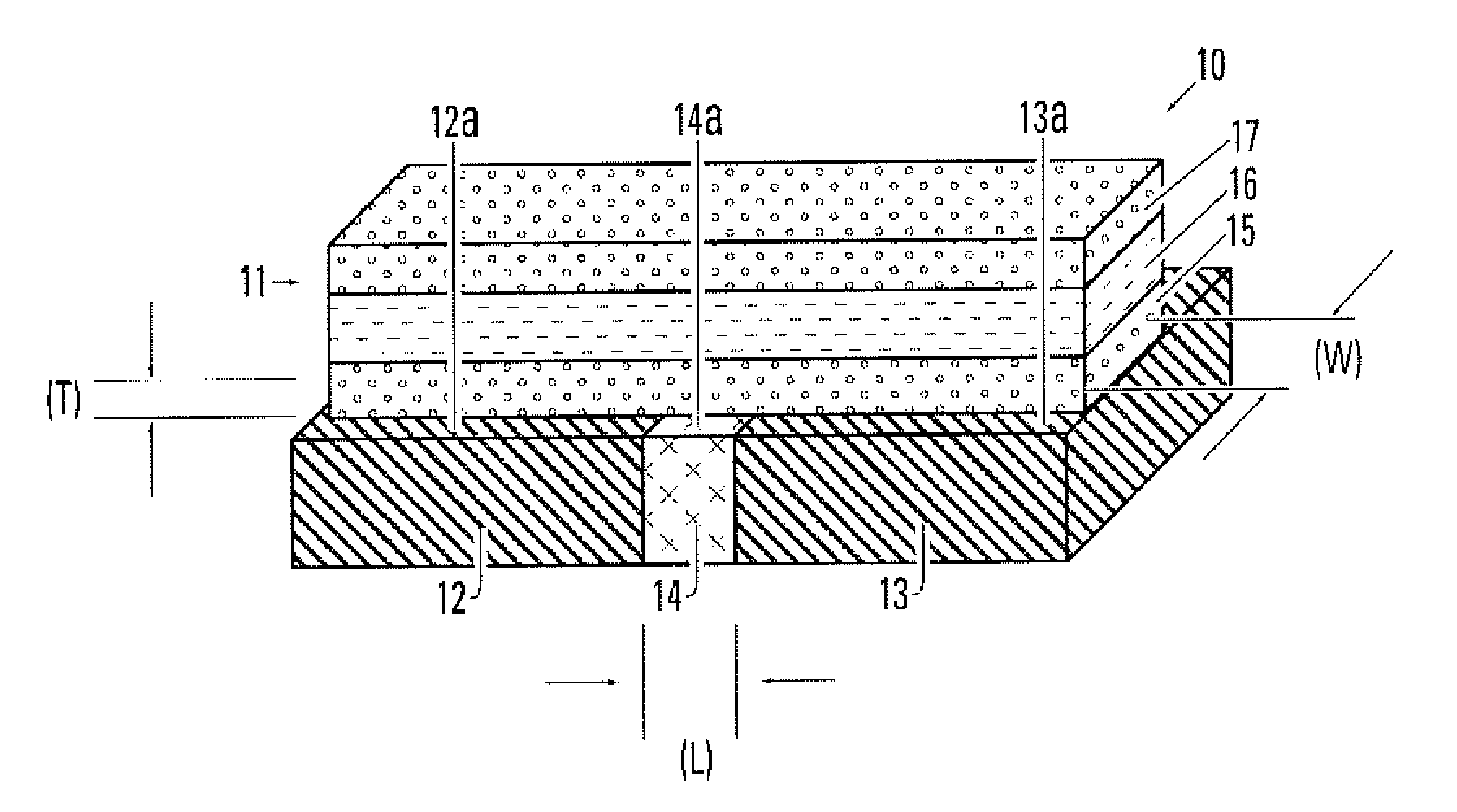

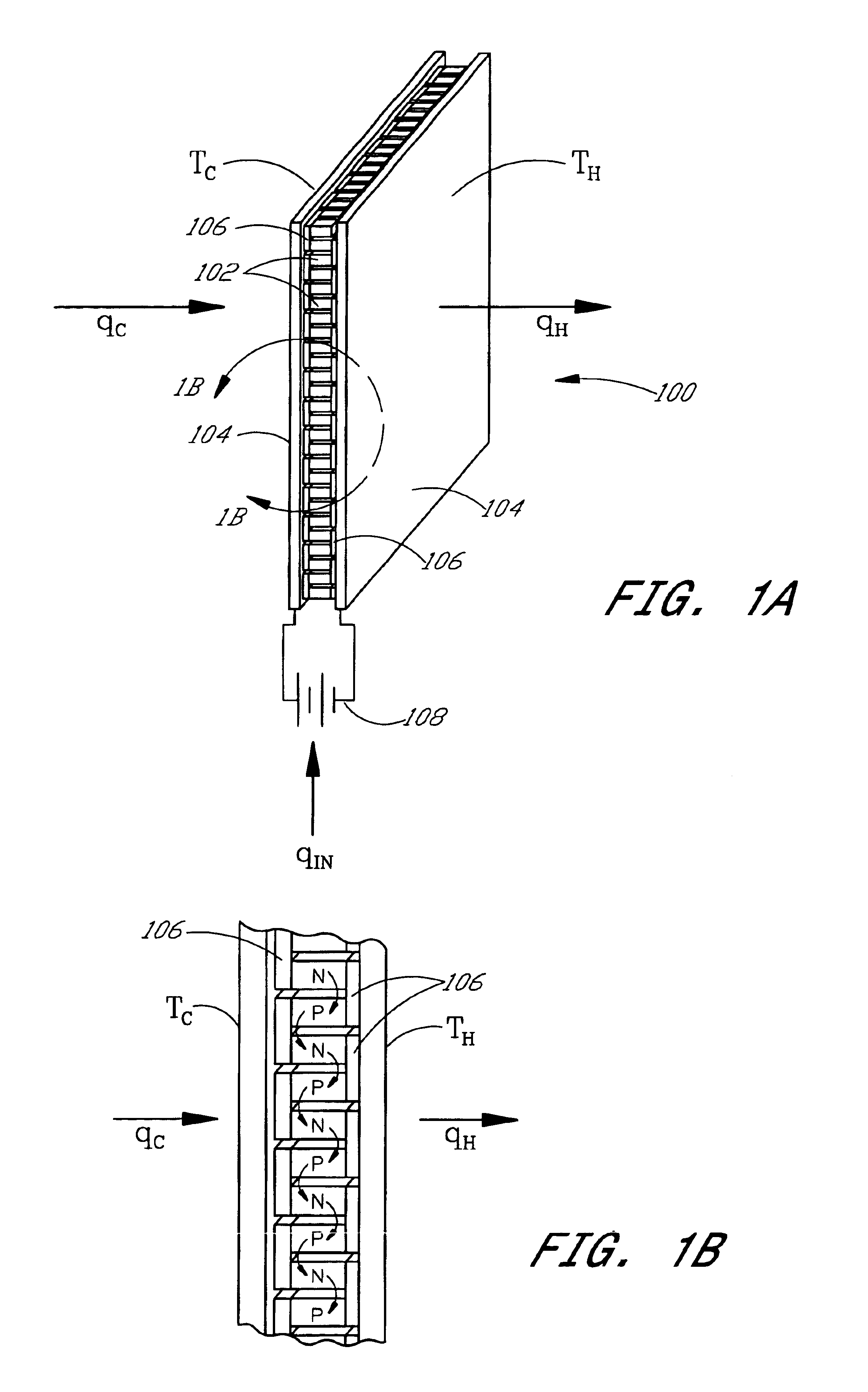

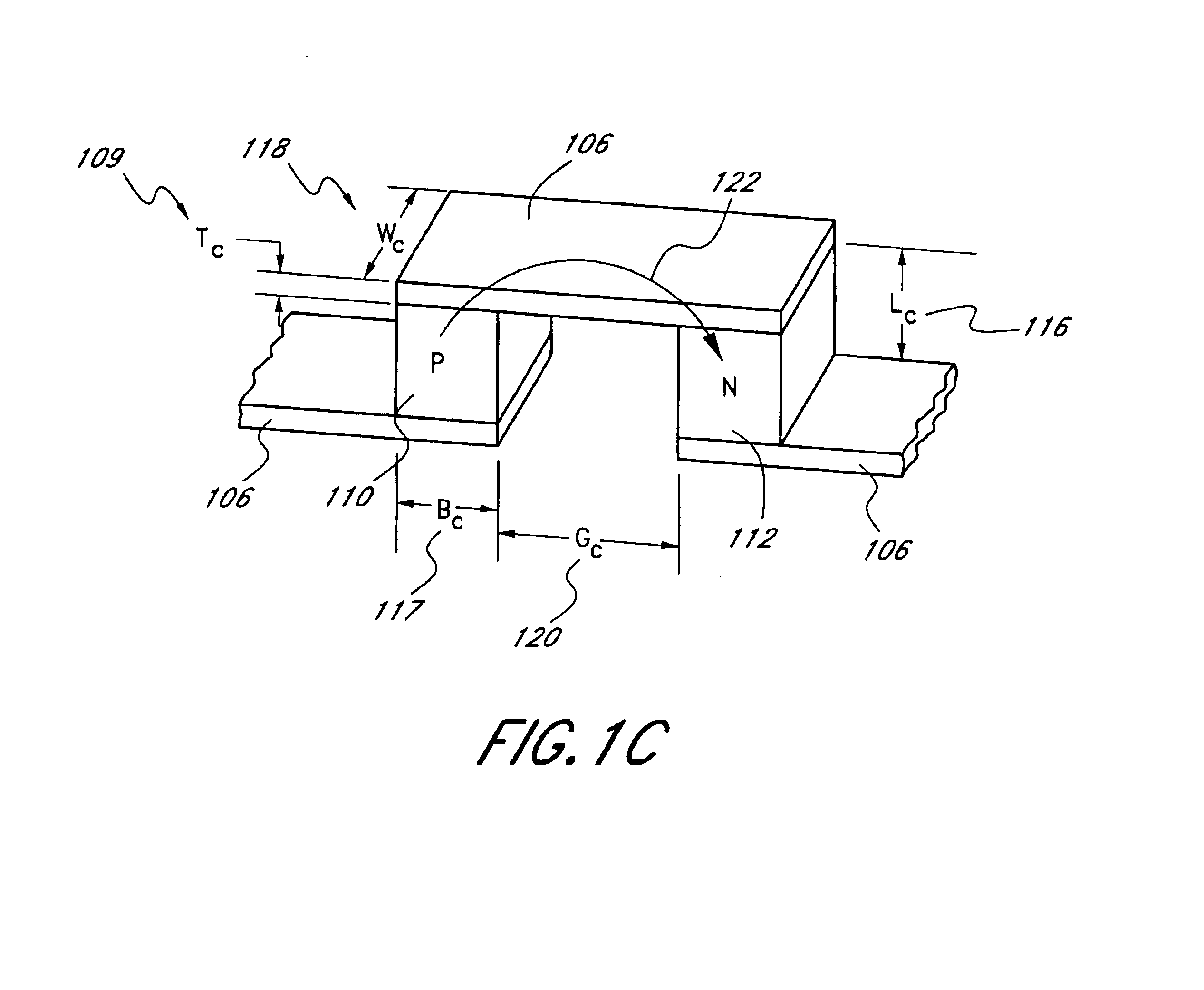

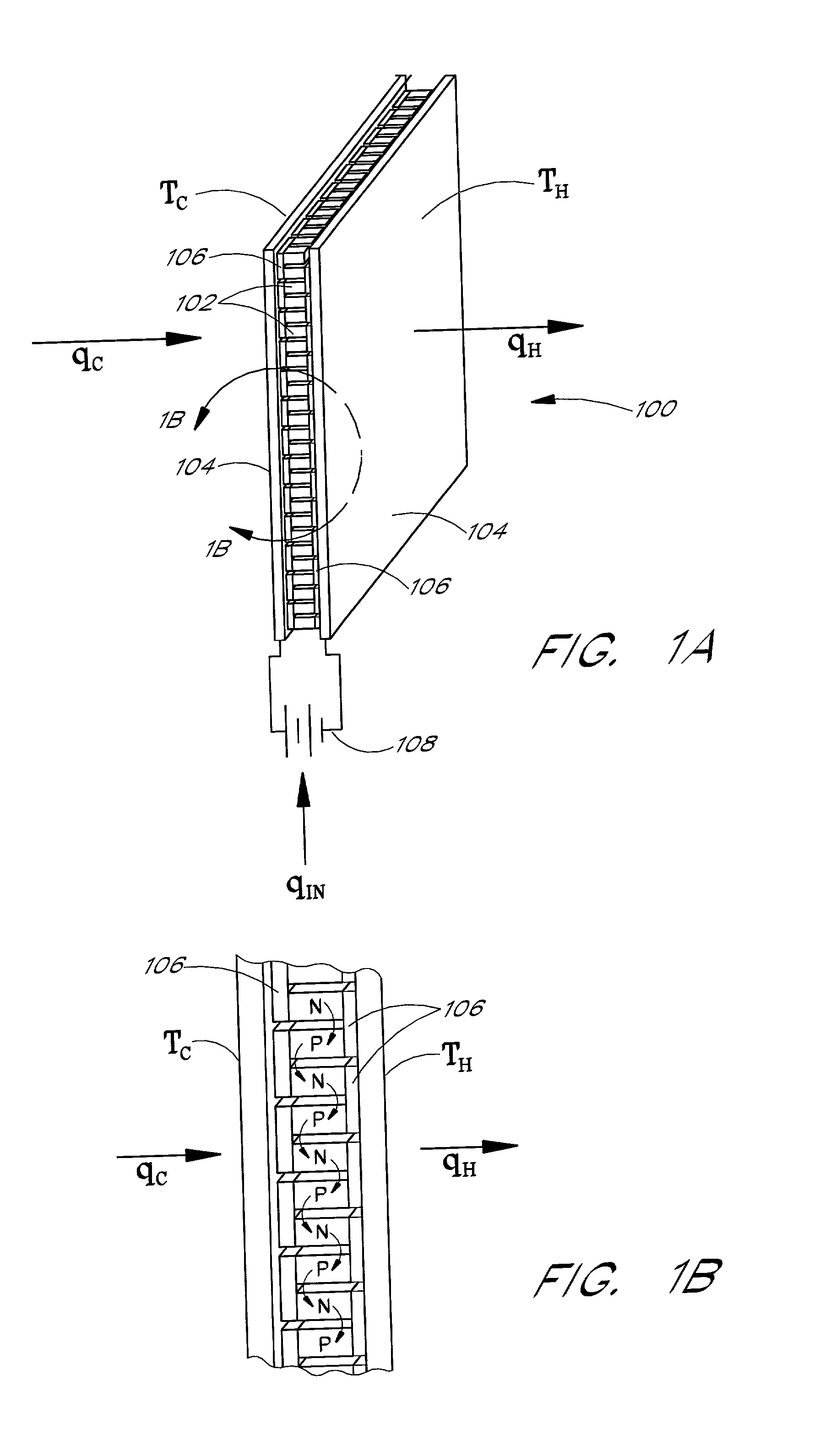

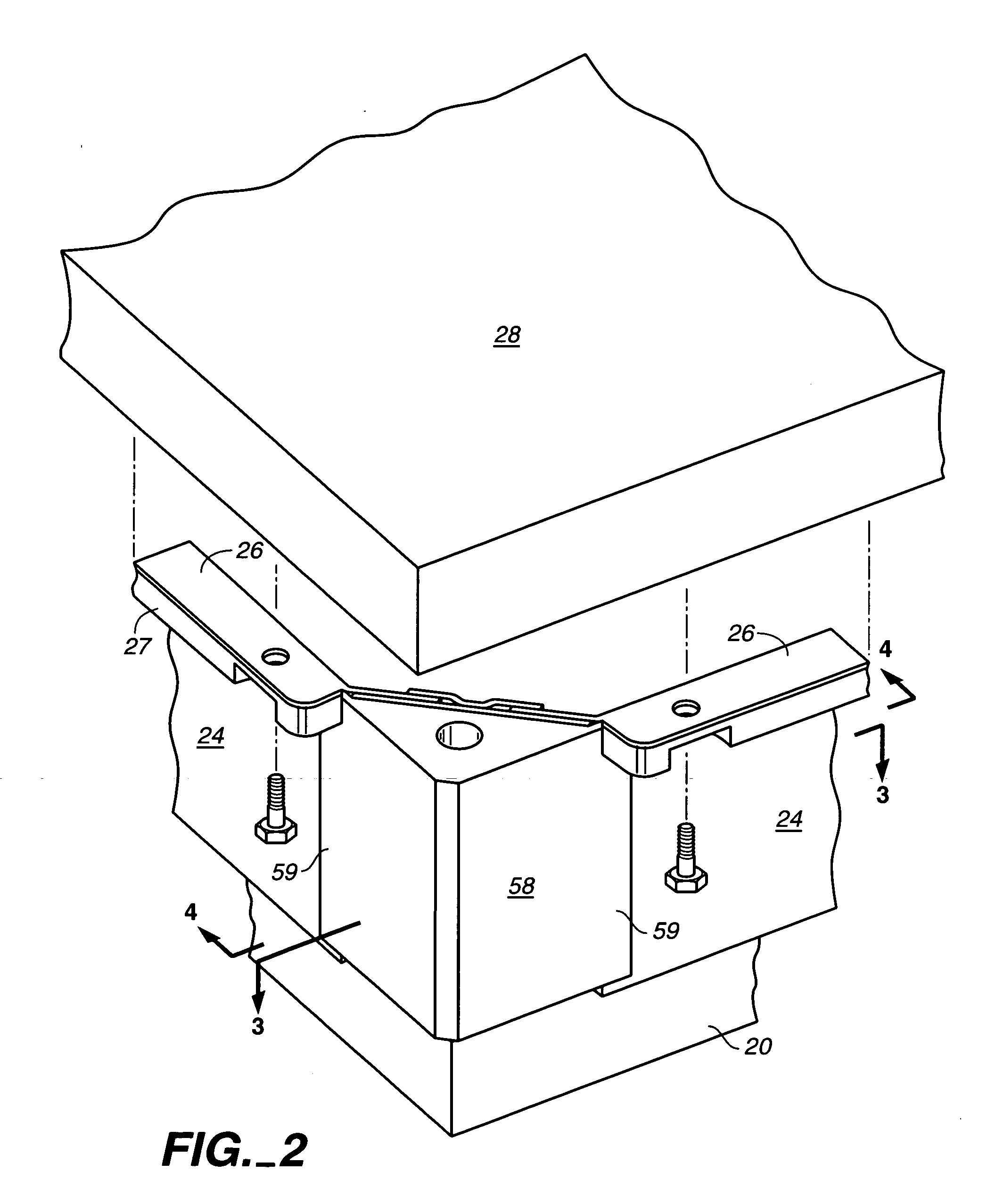

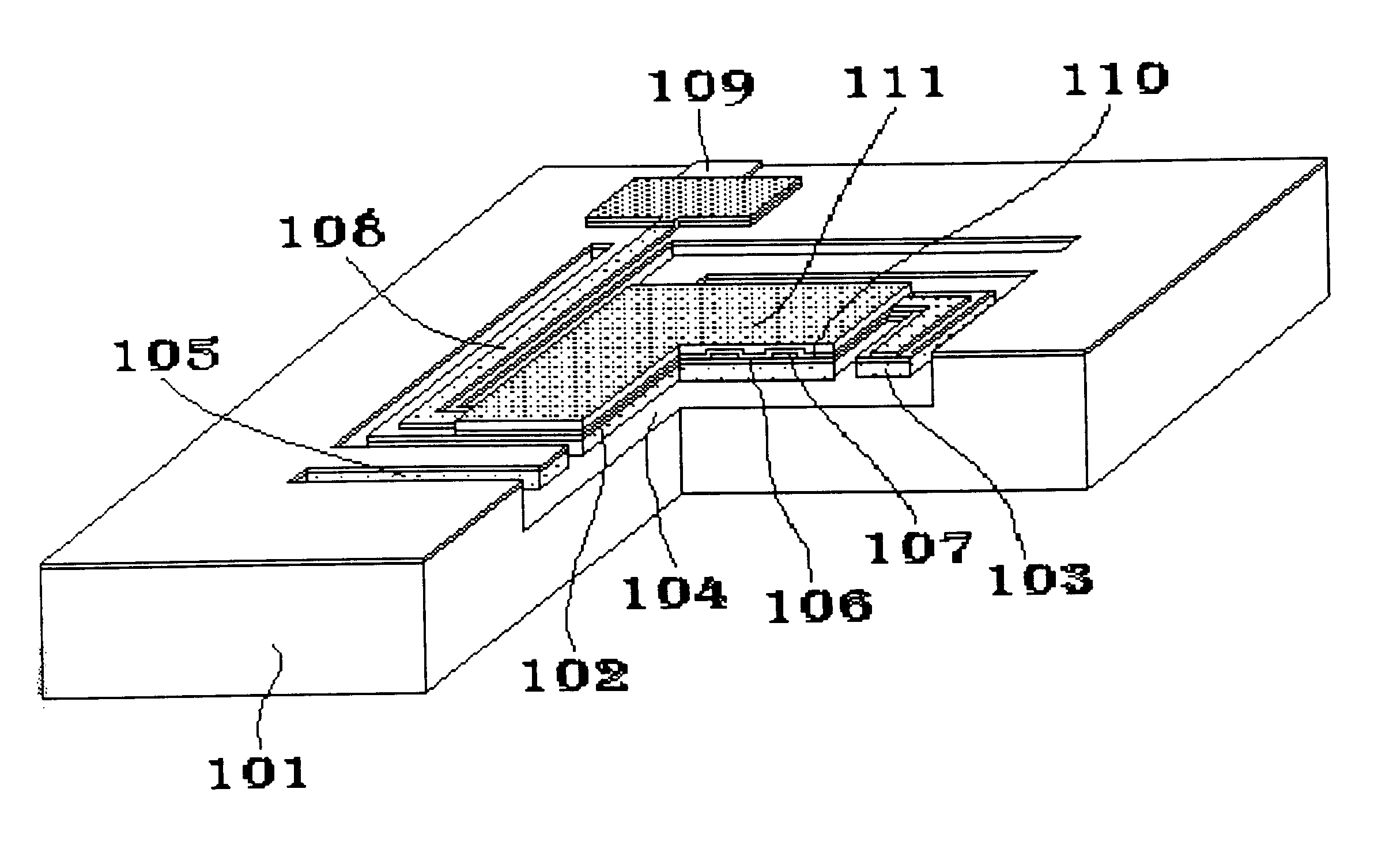

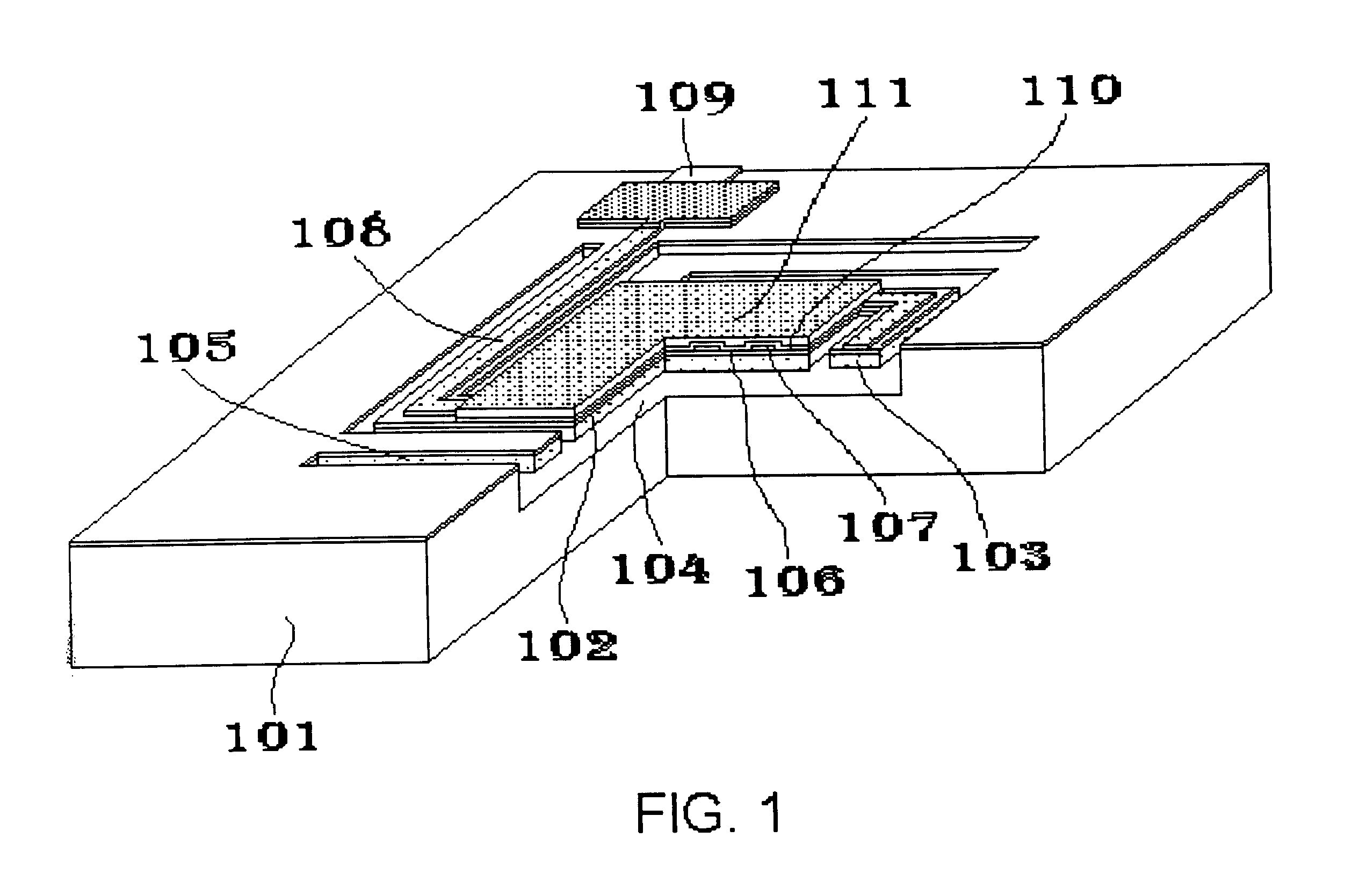

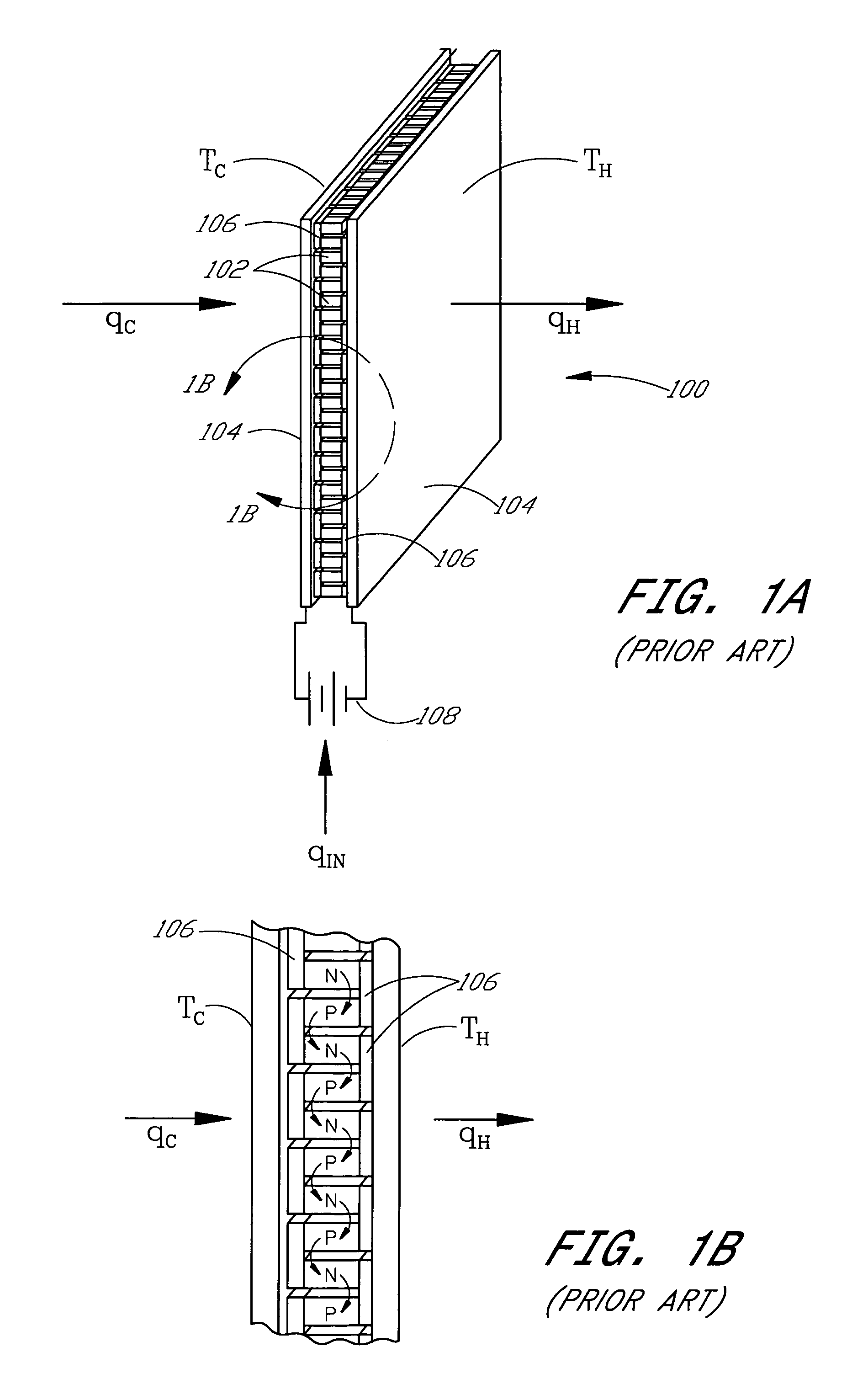

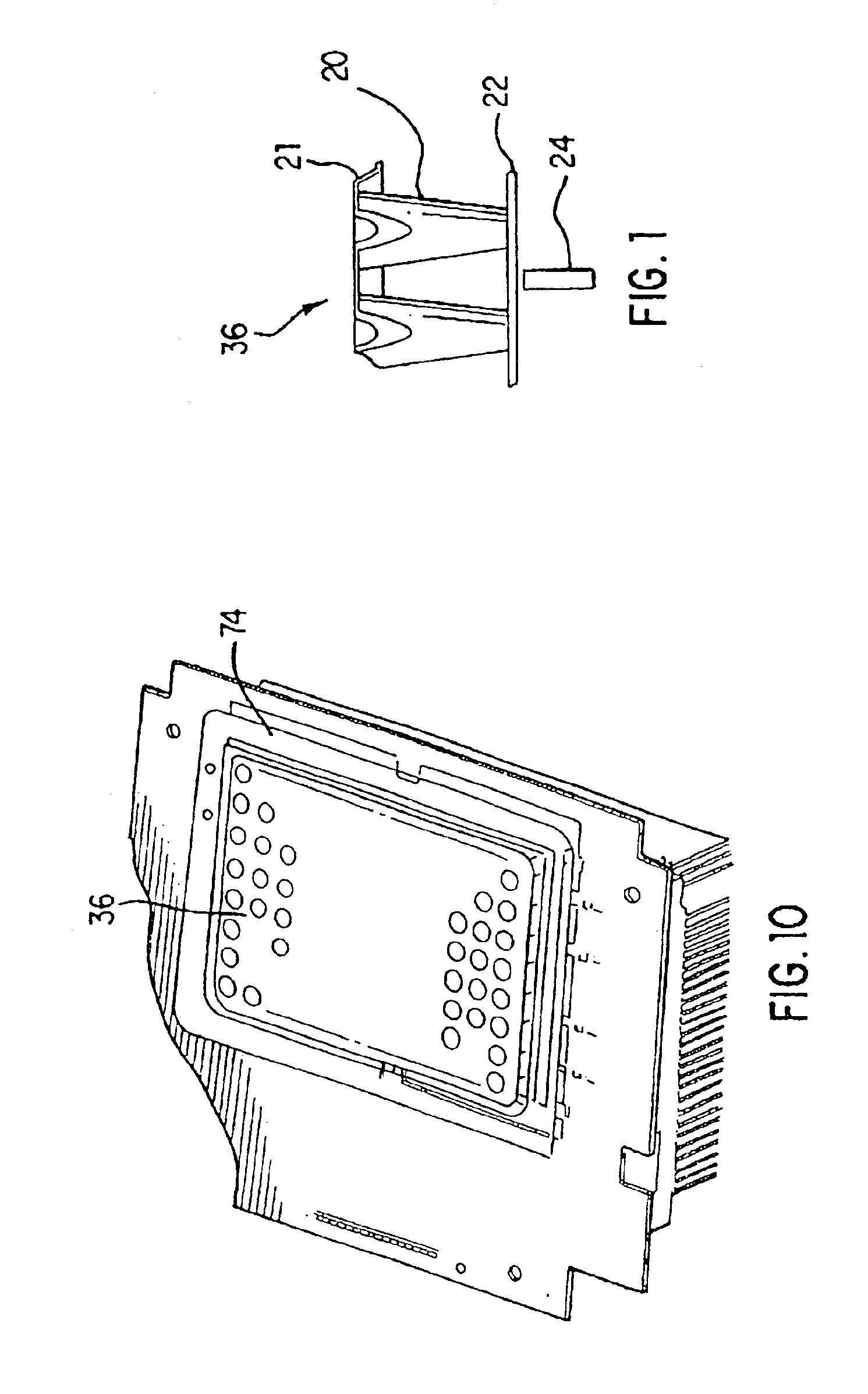

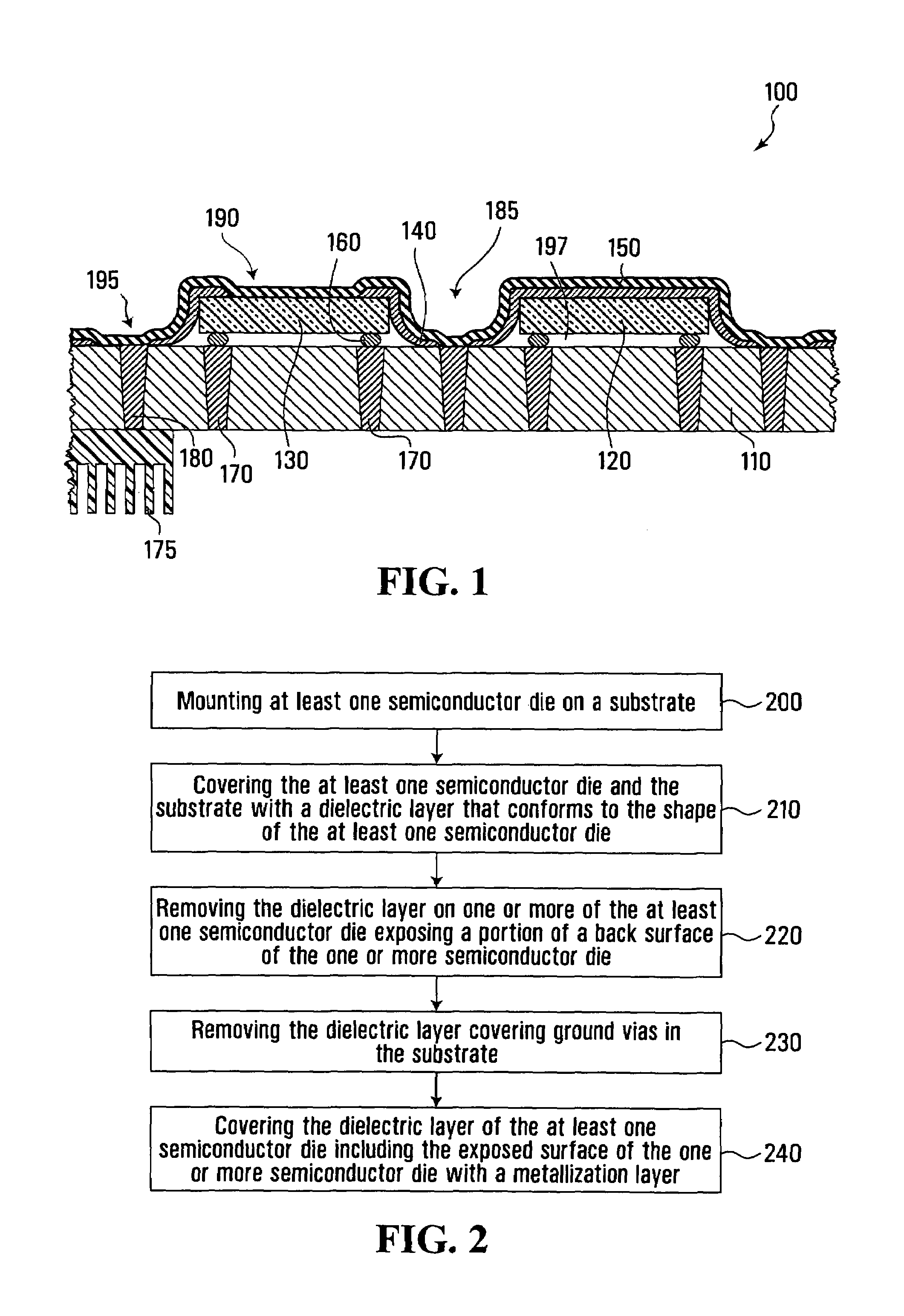

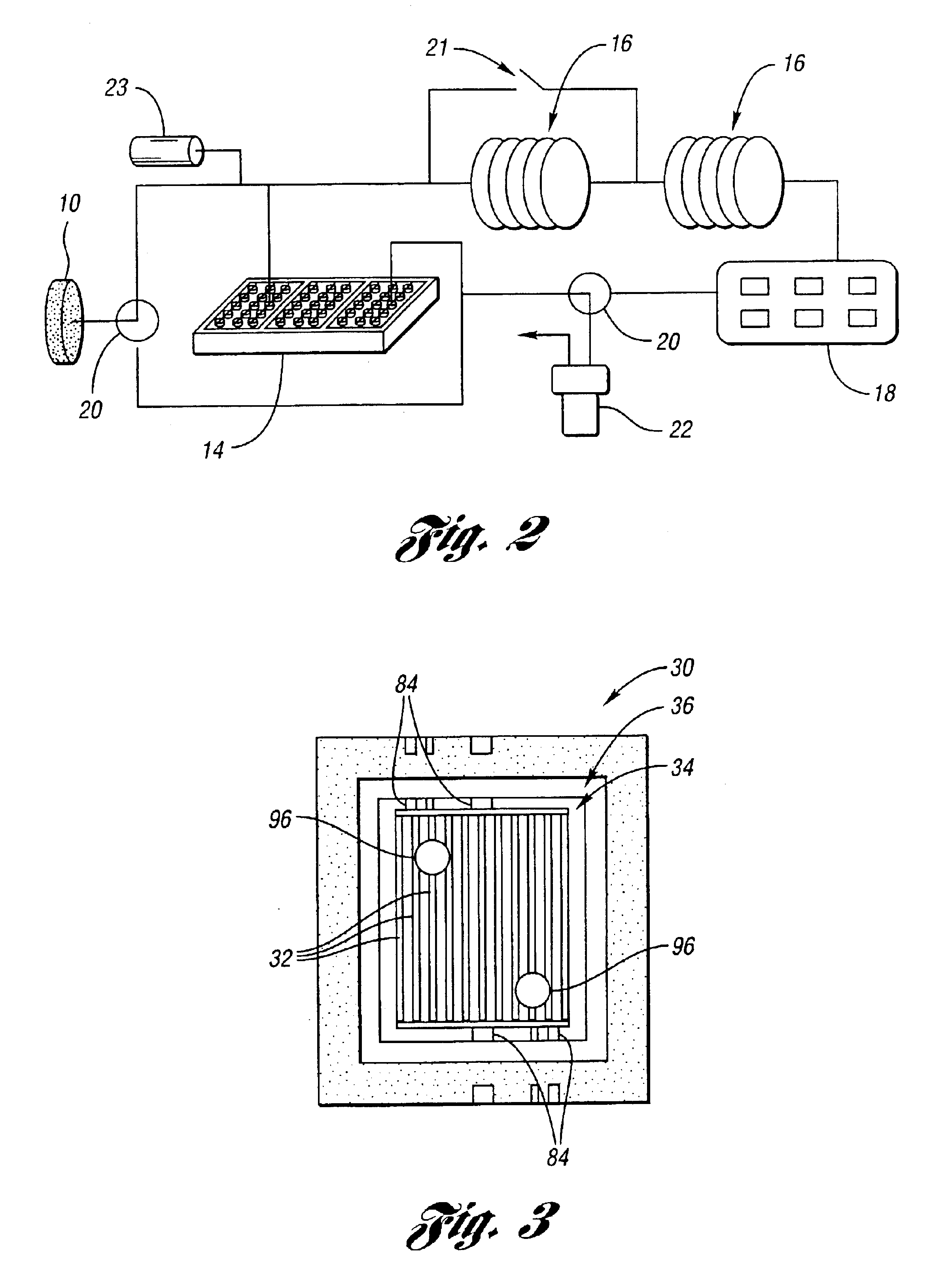

Efficiency thermoelectrics utilizing thermal isolation

InactiveUS6539725B2Thermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentThermal isolationElectrical resistance and conductance

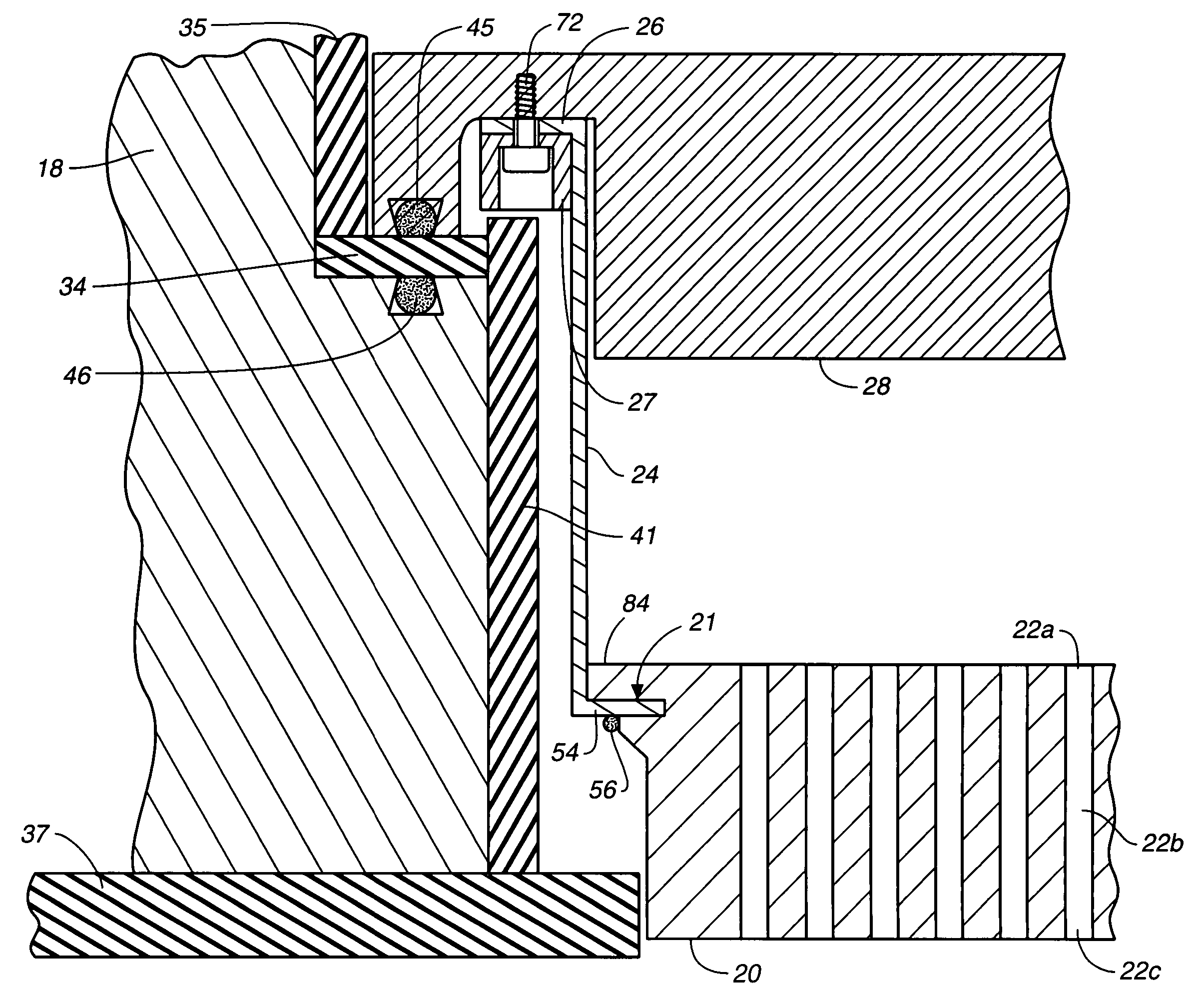

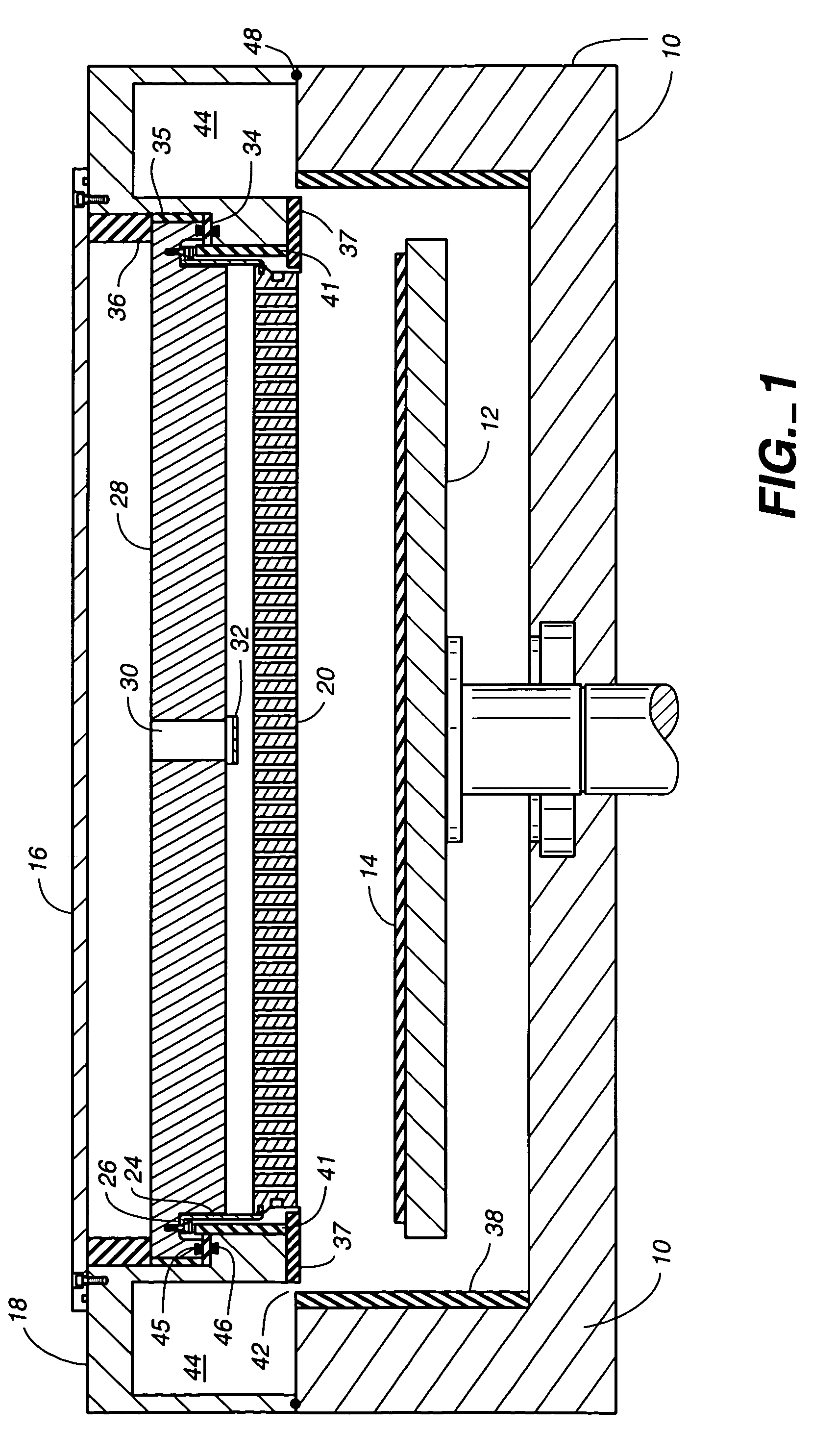

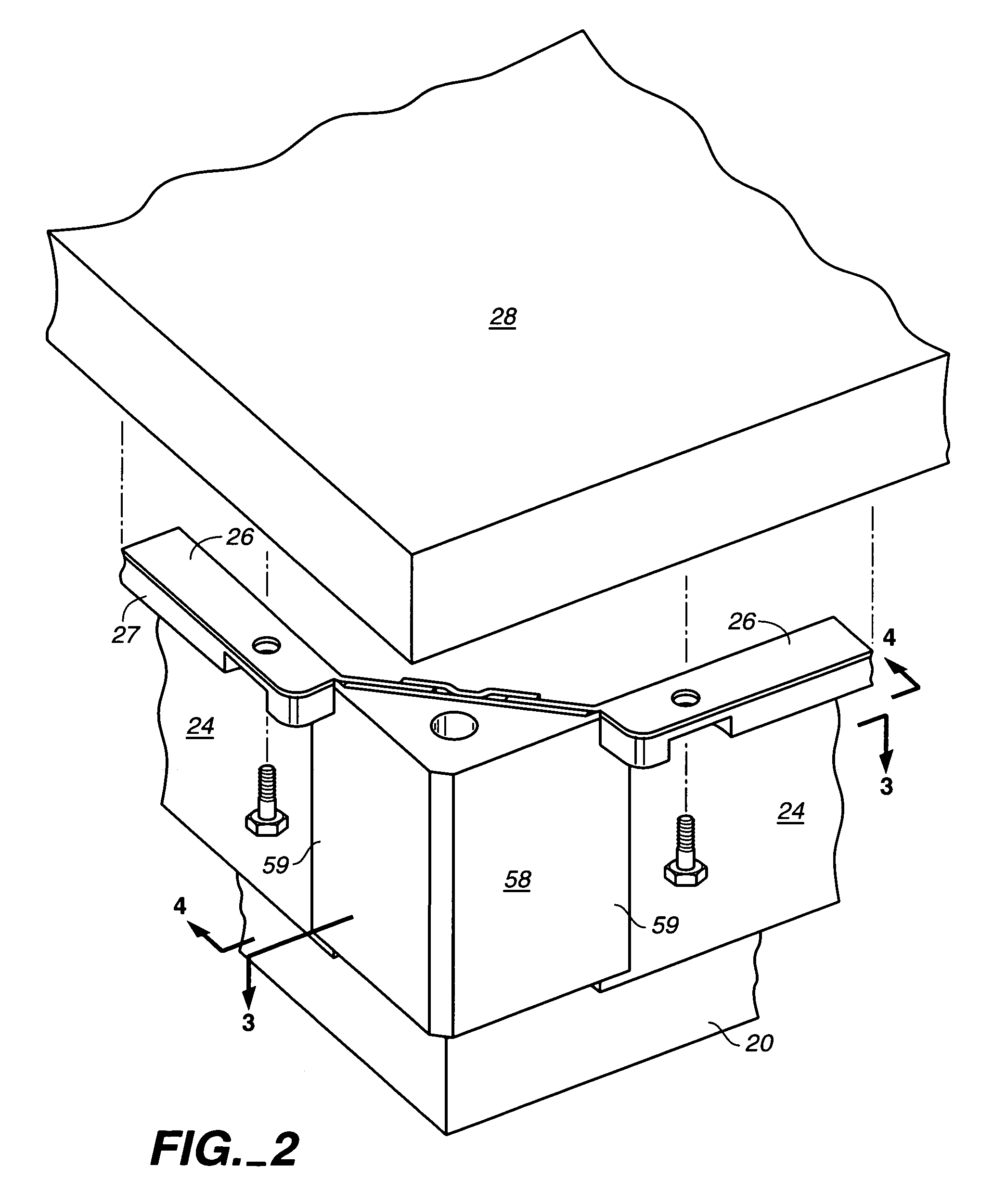

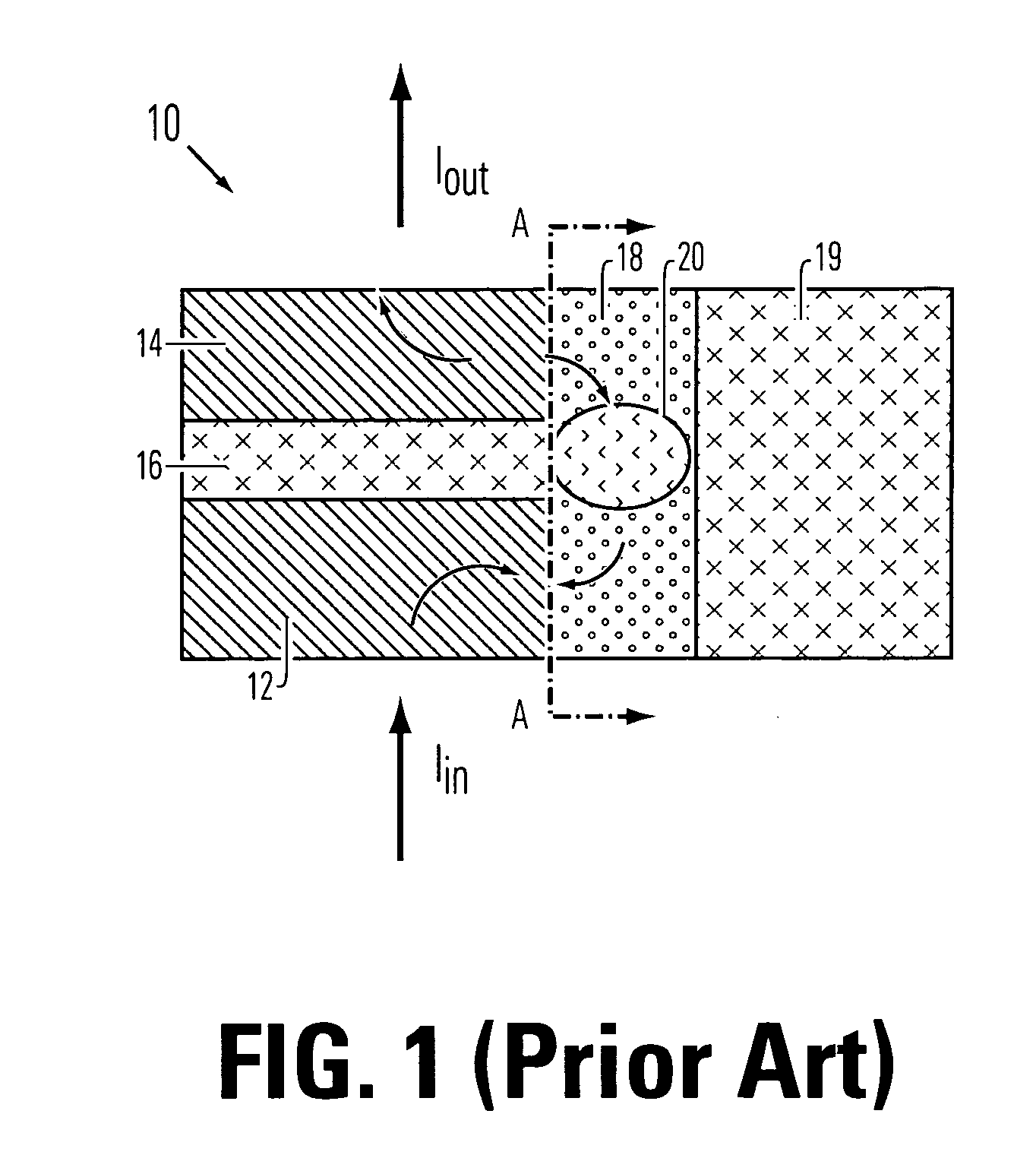

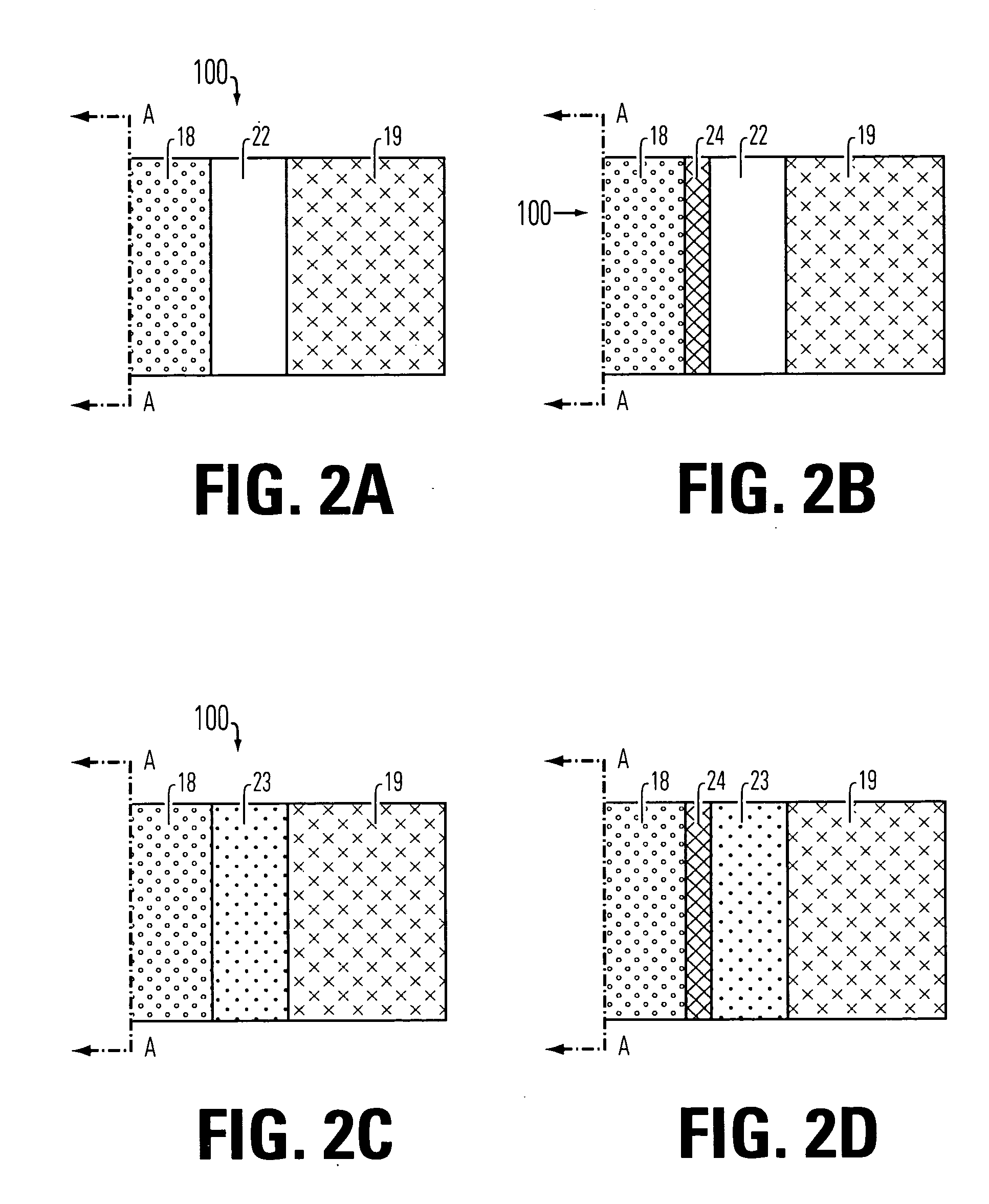

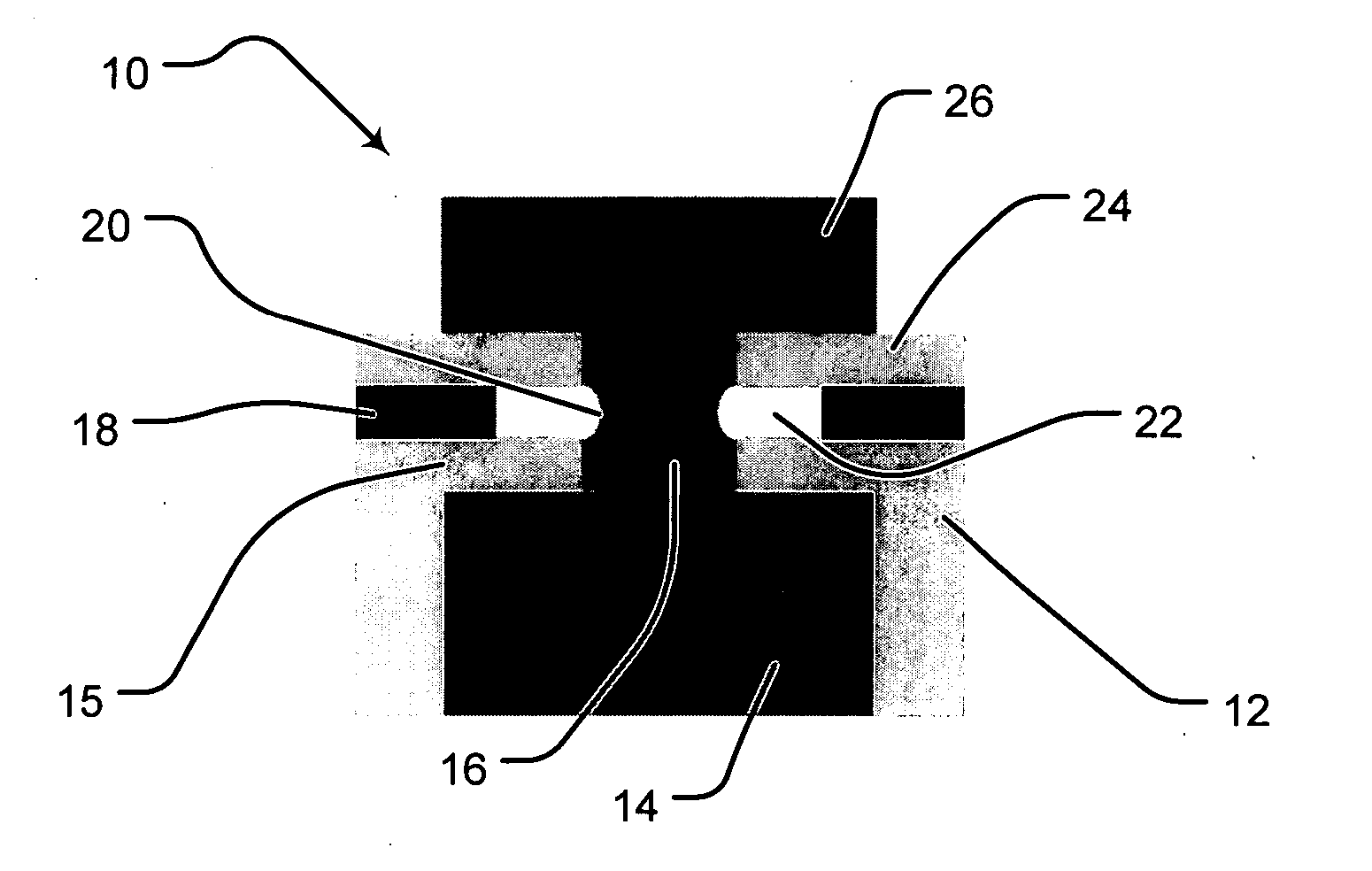

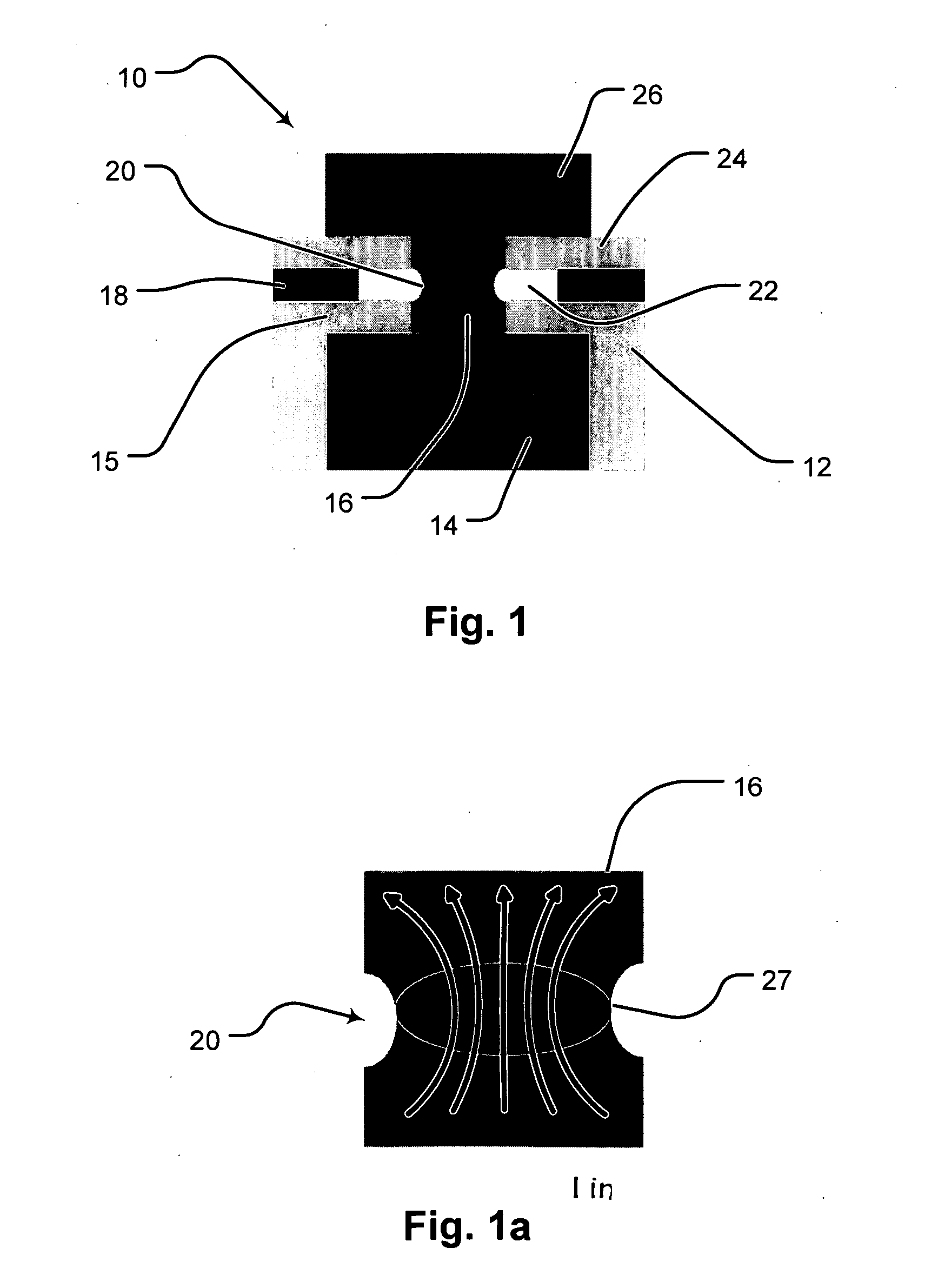

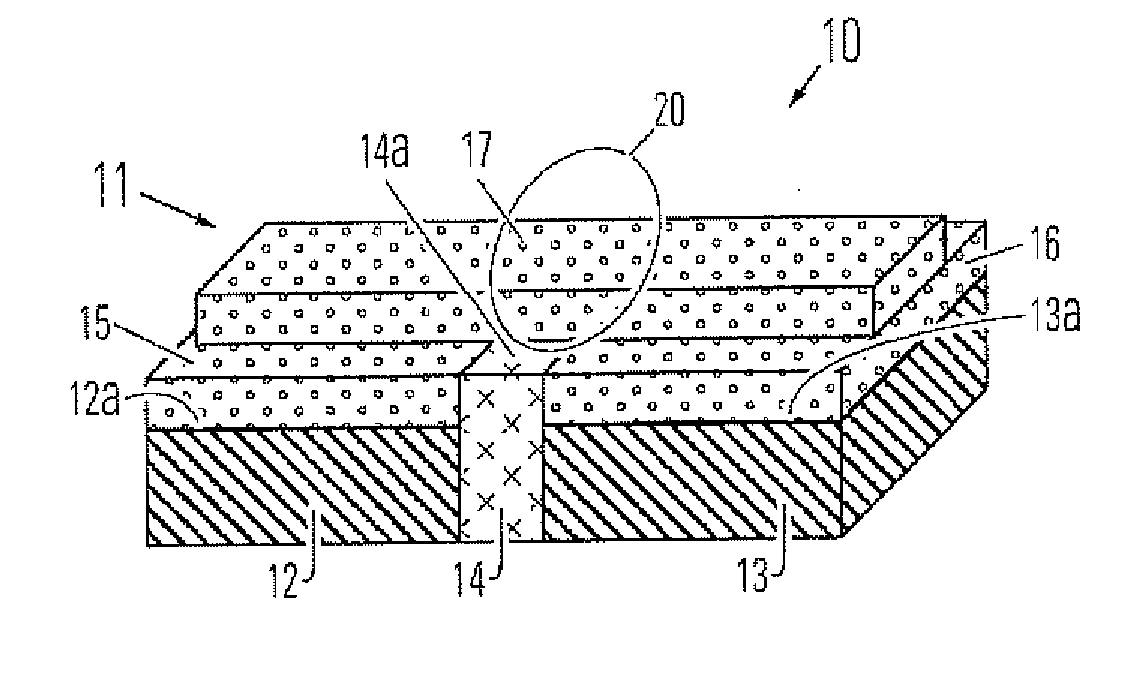

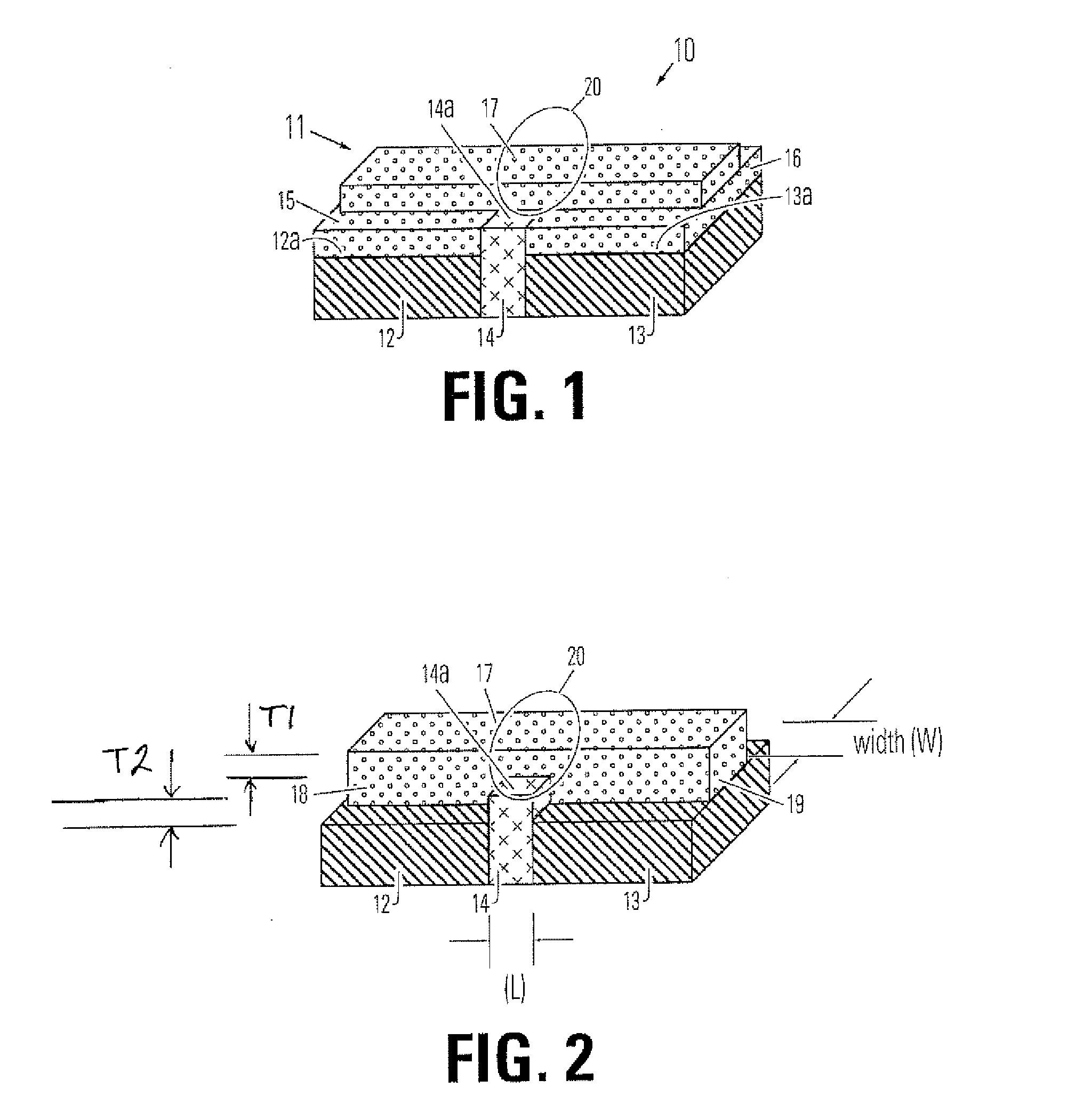

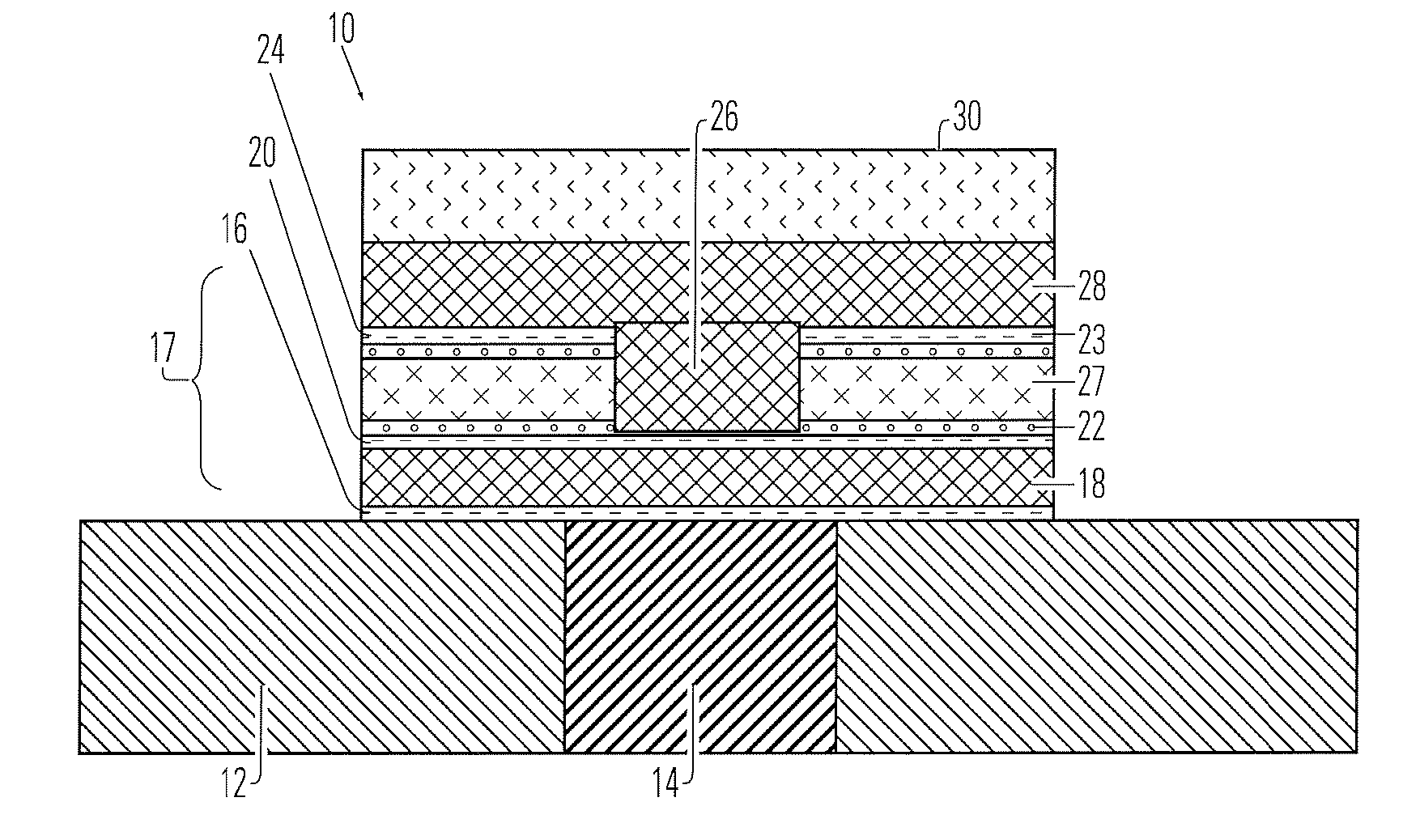

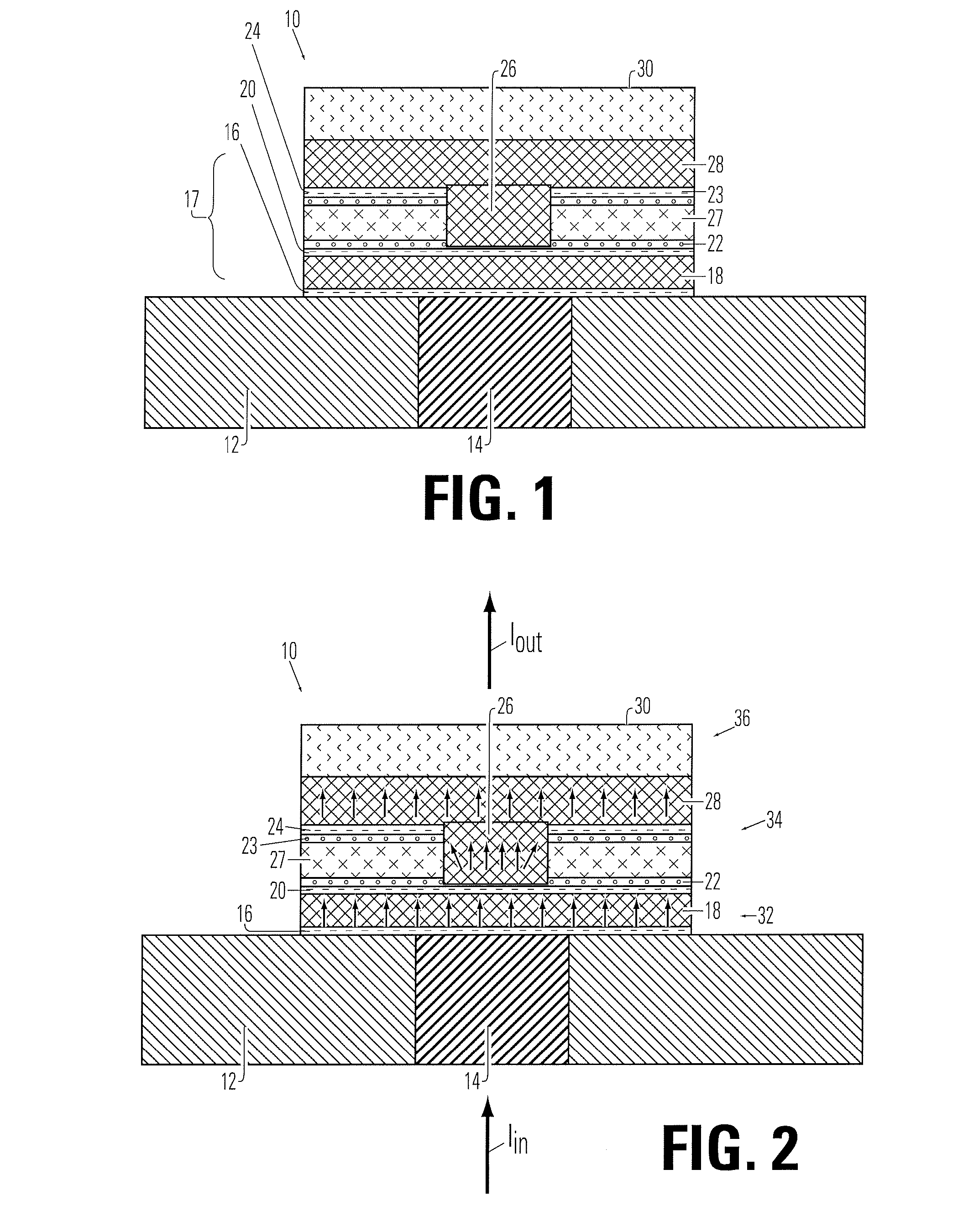

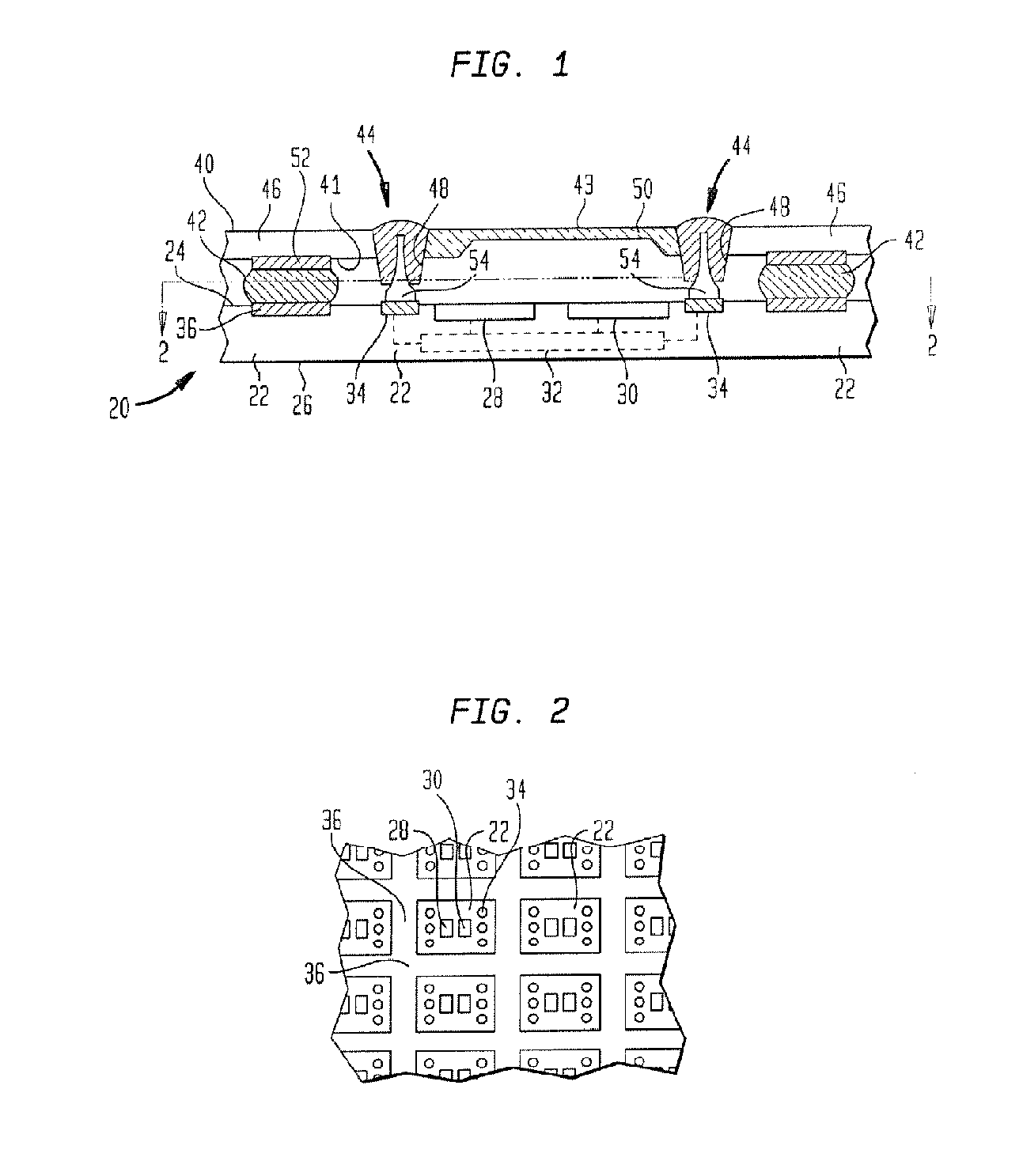

An improved efficiency thermoelectric system and method of making such a thermoelectric system are disclosed. Significant thermal isolation between thermoelectric elements in at least one direction across a thermoelectric system provides increased efficiency over conventional thermoelectric arrays. Significant thermal isolation is also provided for at least one heat exchanger coupled to the thermoelectric elements. In one embodiment, the properties, such as resistance or current flow, of the thermoelectric elements may also be varied in at least one direction across a thermoelectric array. In addition, the mechanical configuration of the thermoelectric elements may be varied, in one embodiment, according to dynamic adjustment criteria.

Owner:GENTHERM INC +1

Suspended gas distribution plate

InactiveUS7017269B2Avoid distortionAvoid crackingElectric discharge tubesSemiconductor/solid-state device manufacturingThermal isolationEngineering

A gas inlet manifold for a plasma chamber having a perforated gas distribution plate suspended by flexible side walls. The flexible suspension minimizes mechanical stress due to thermal expansion of the gas distribution plate. In another aspect, the suspension provides thermal isolation between the gas distribution plate and other components of the chamber.

Owner:APPLIED MATERIALS INC

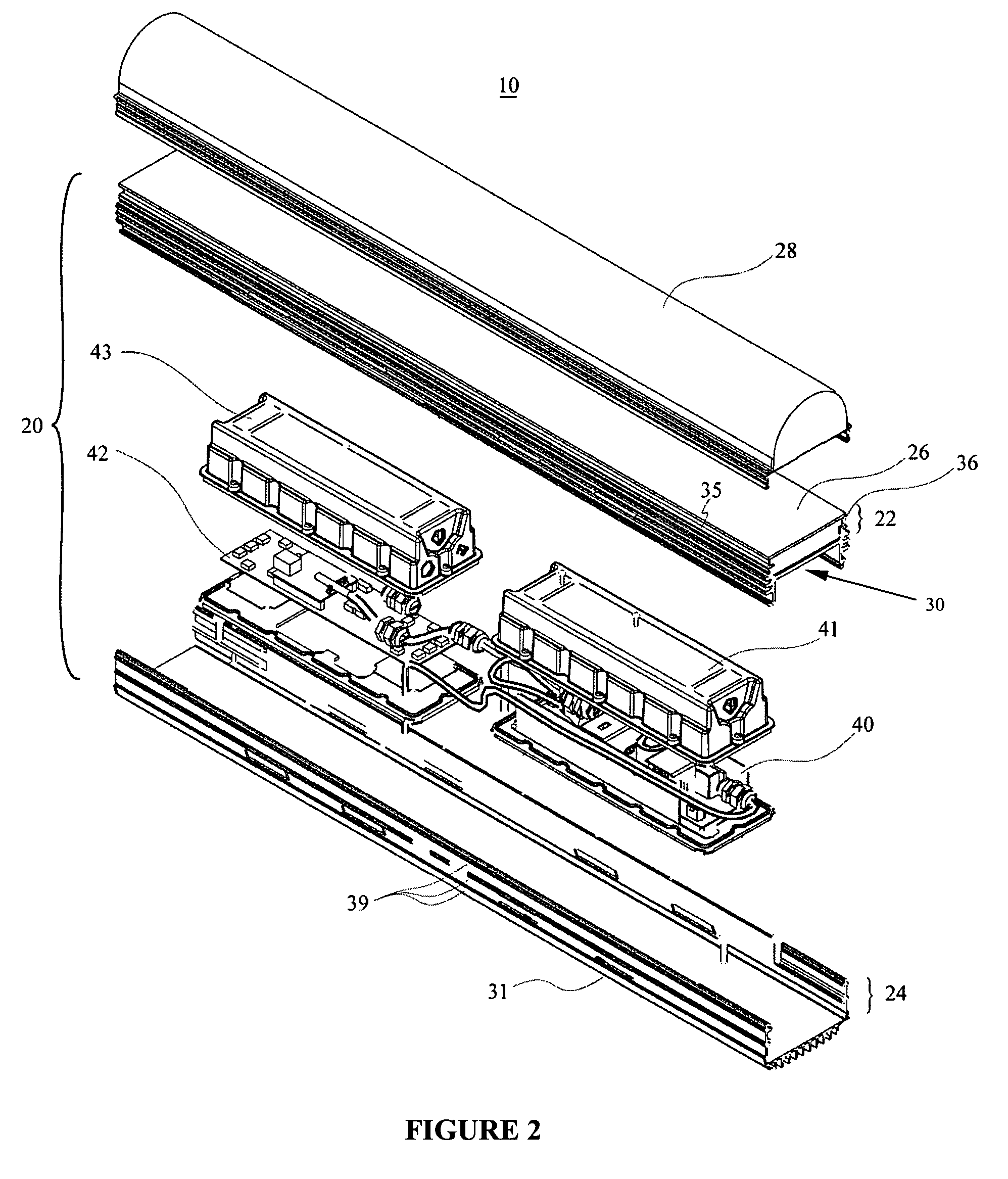

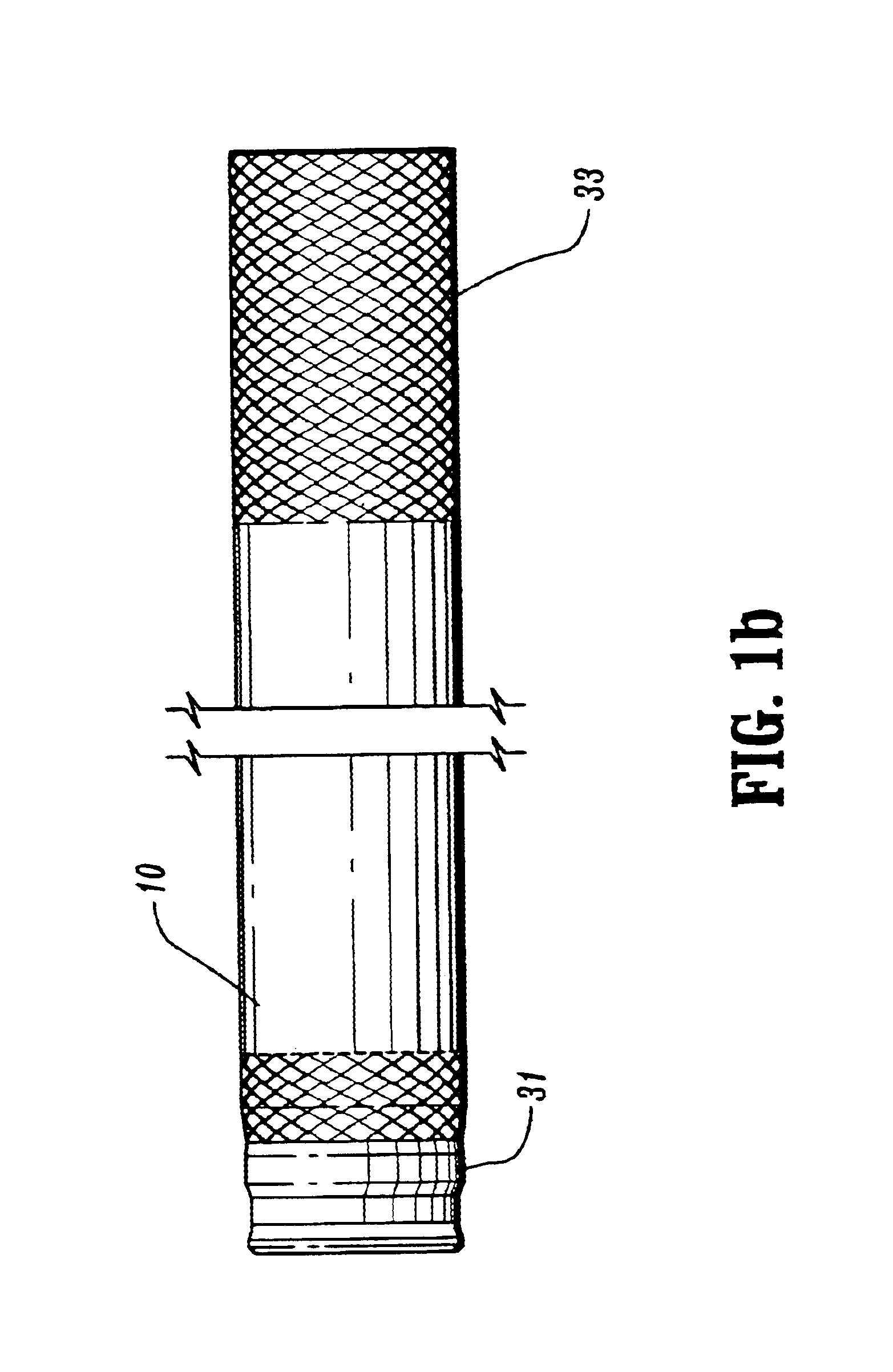

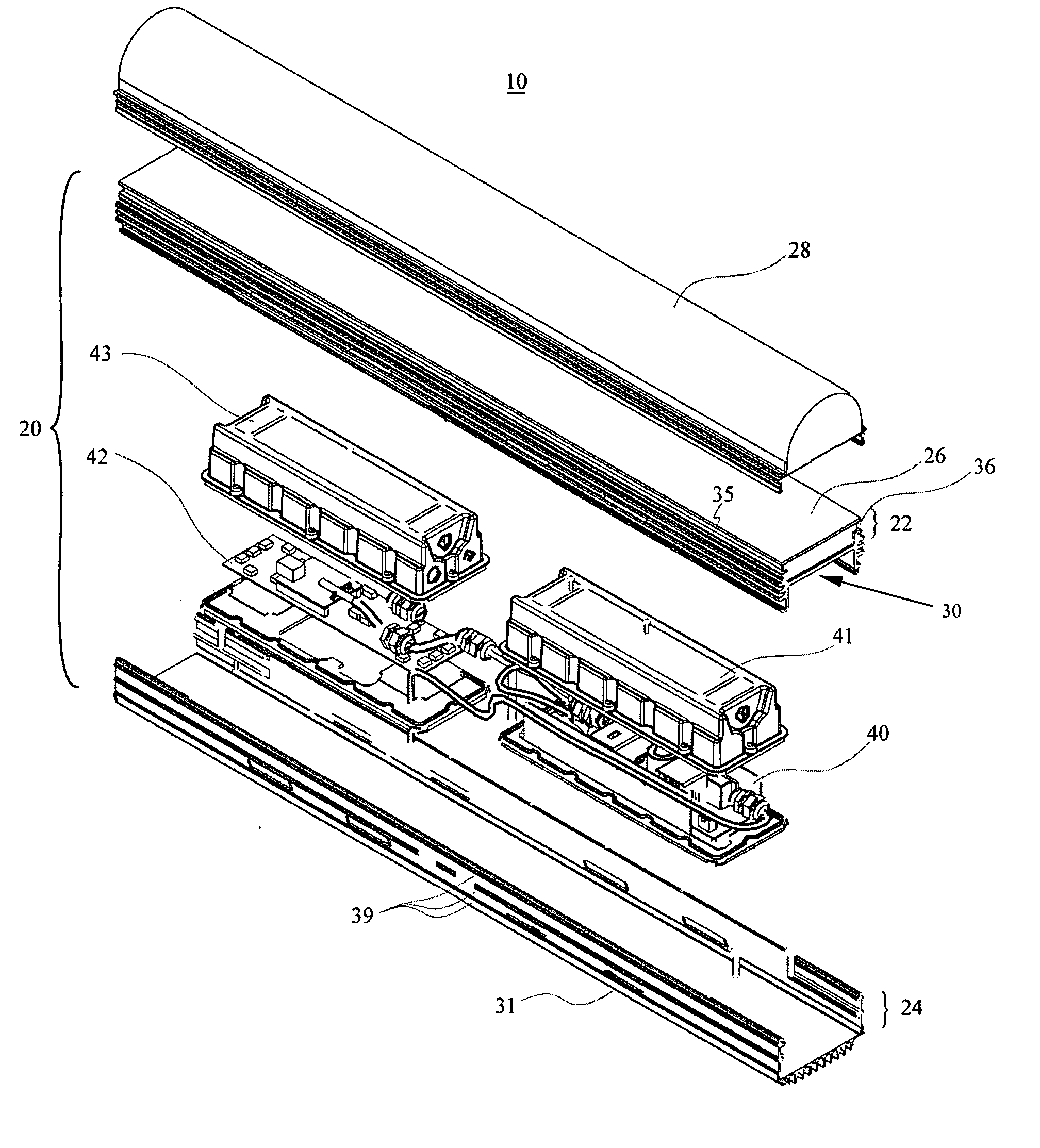

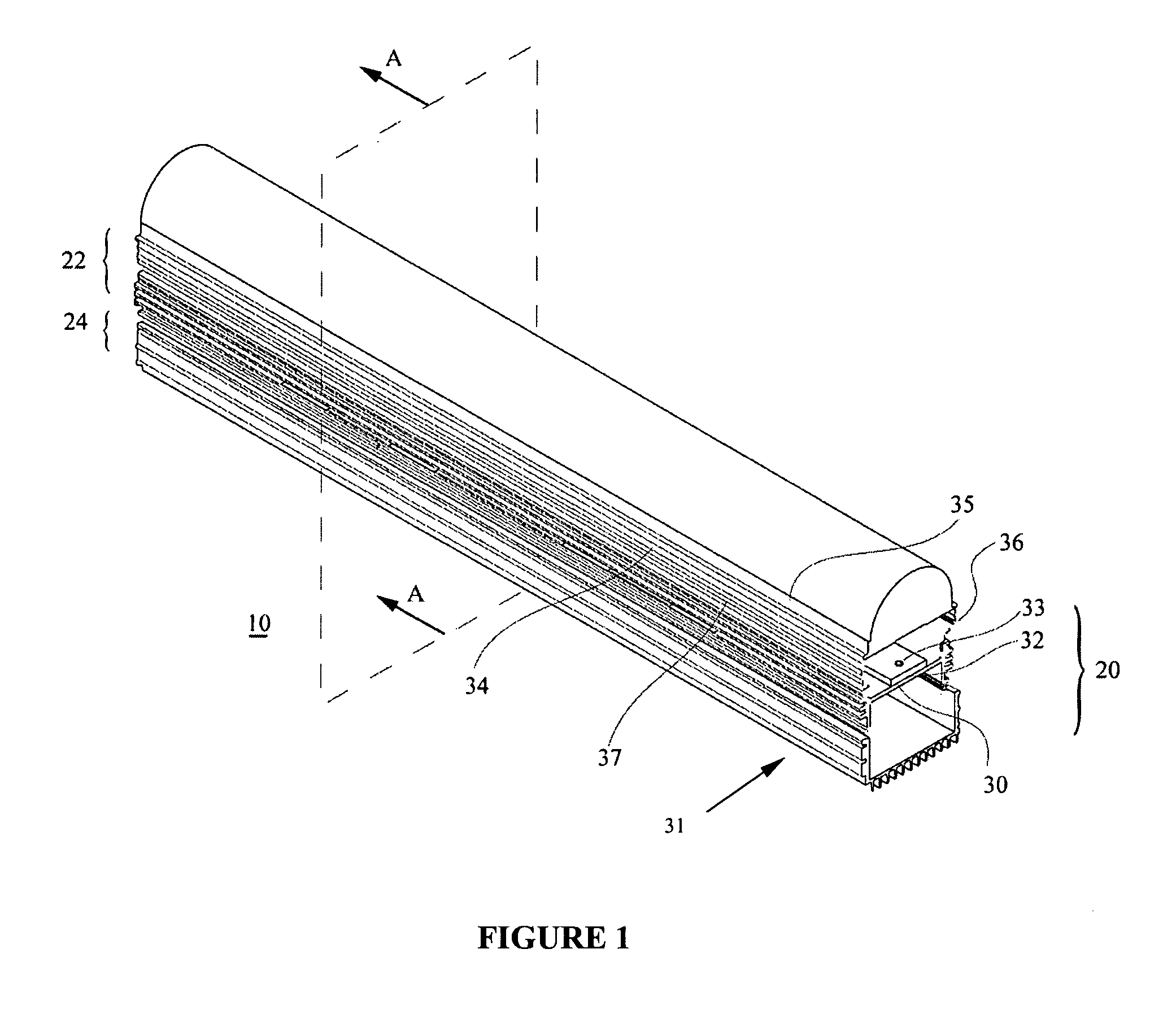

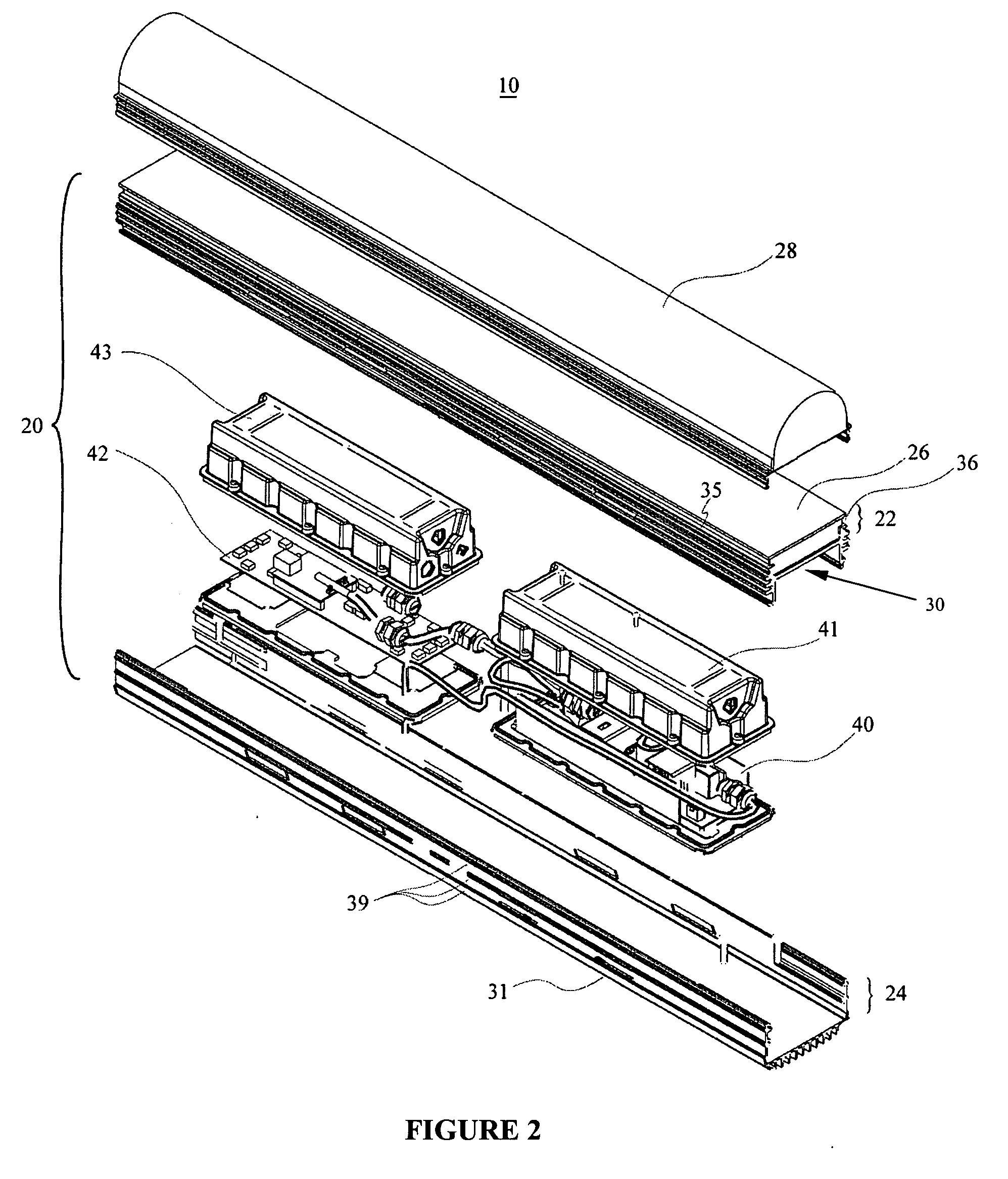

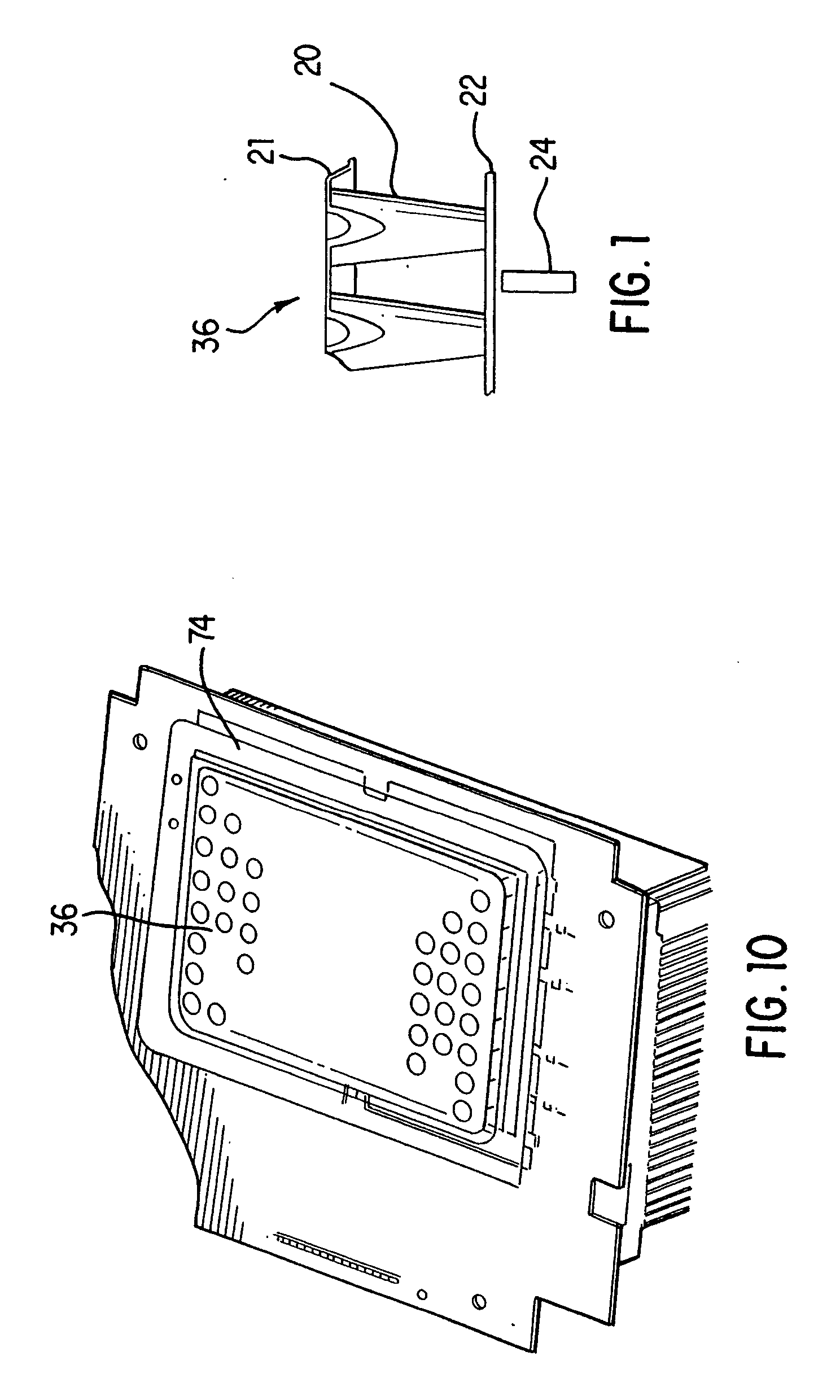

Directly viewable luminaire

ActiveUS7267461B2Constant brightnessPlanar light sourcesMechanical apparatusThermal isolationPoint light

Owner:SIGNIFY HLDG BV

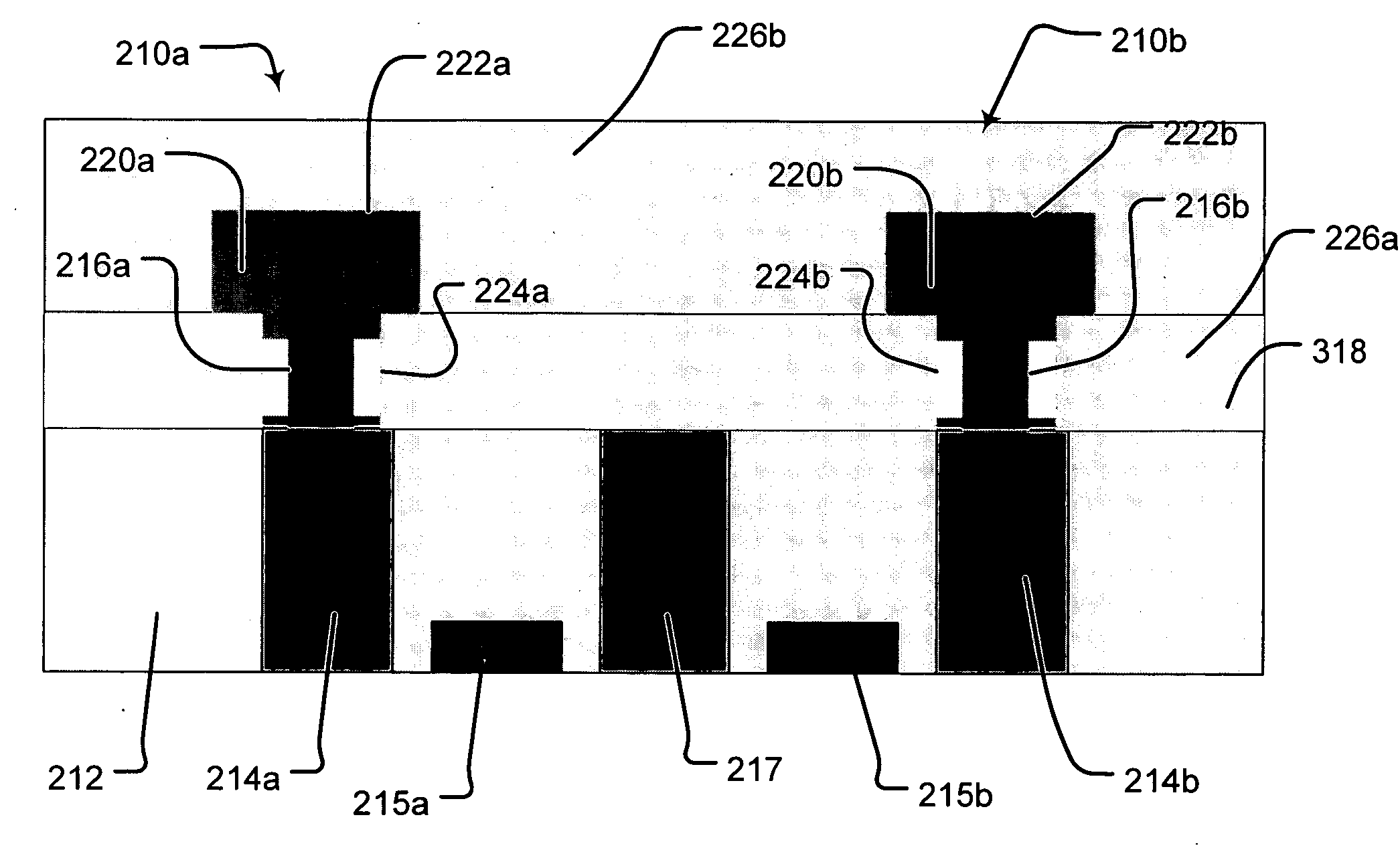

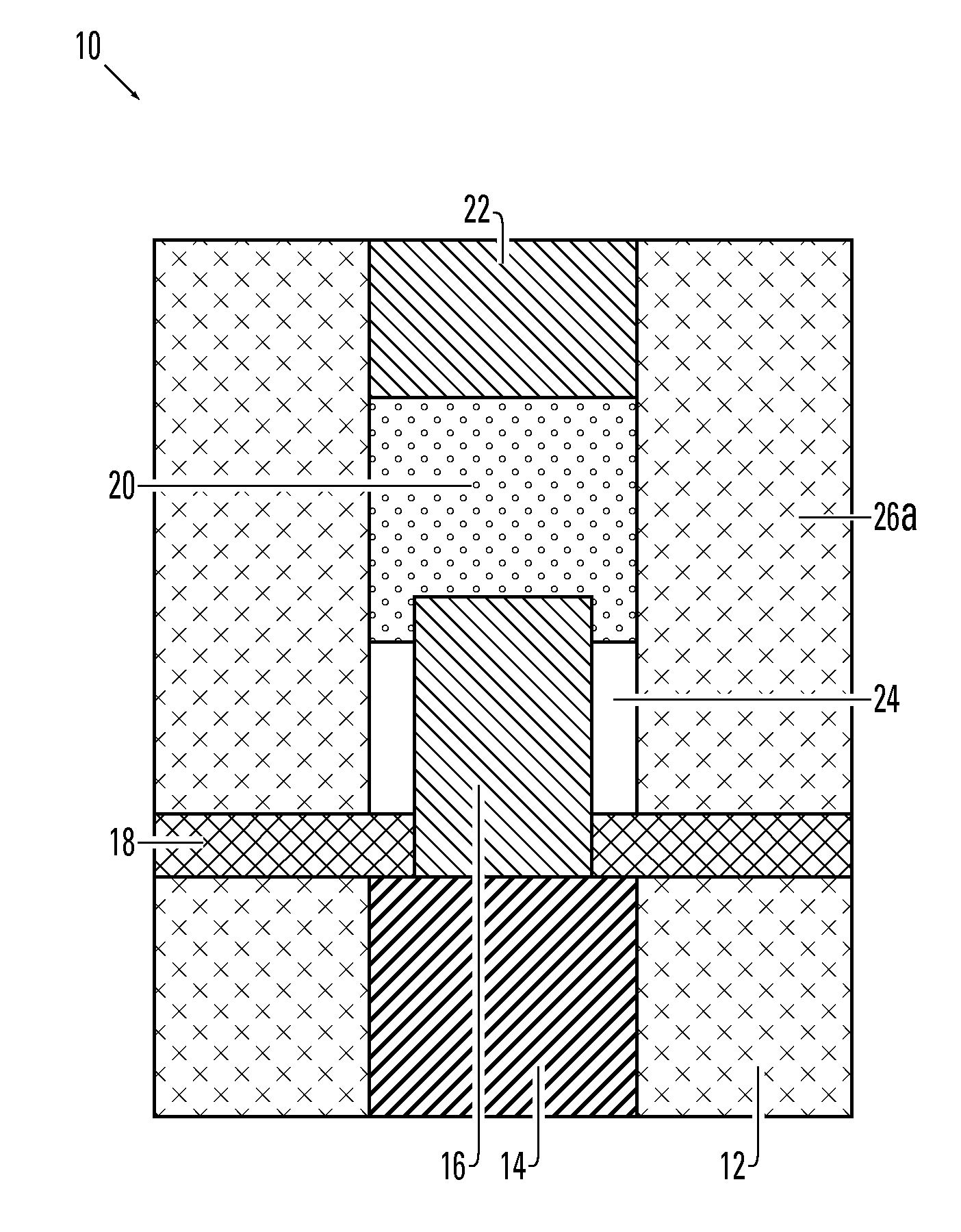

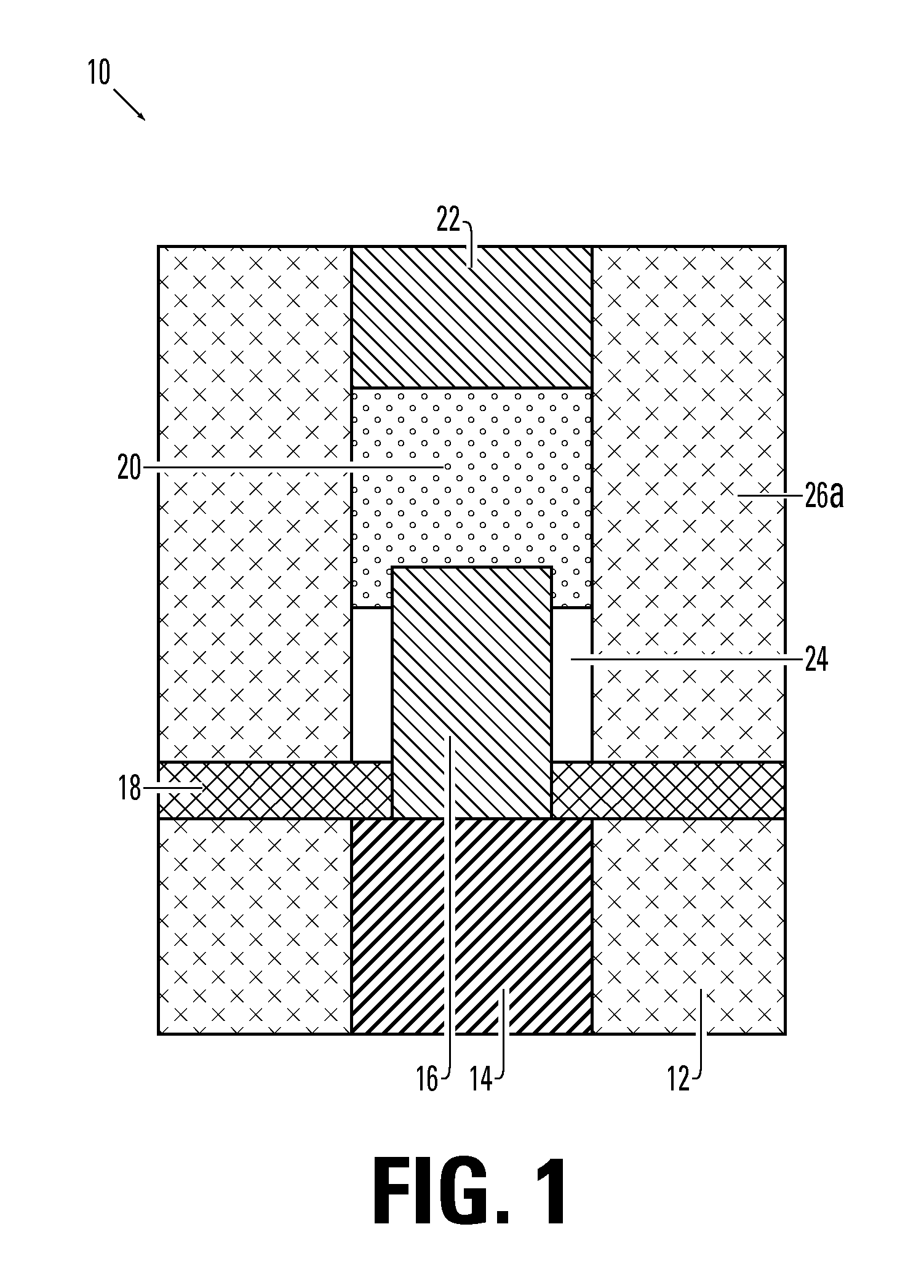

Method for Forming Self-Aligned Thermal Isolation Cell for a Variable Resistance Memory Array

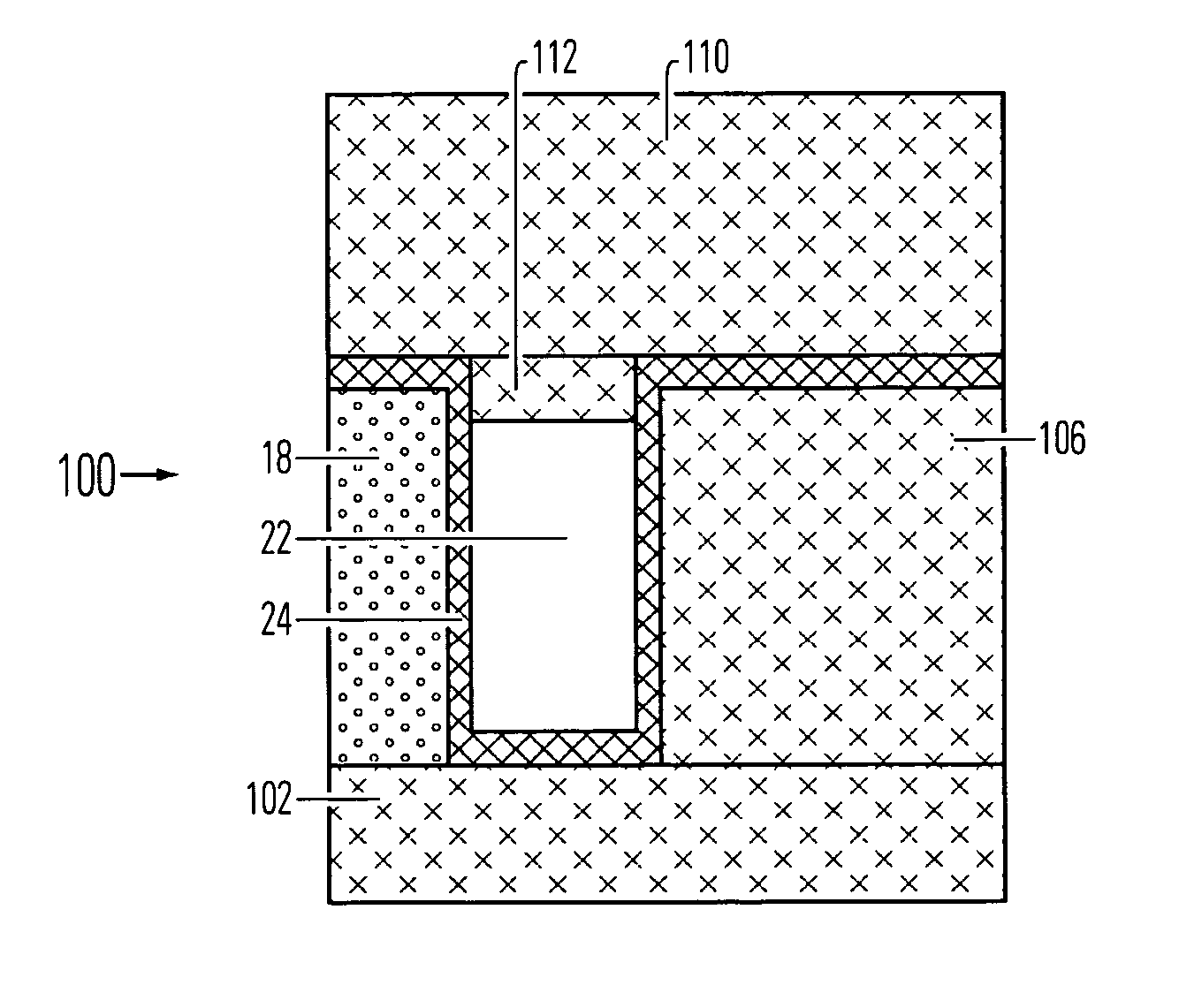

A non-volatile method with a self-aligned RRAM element. The method includes a lower electrode element, generally planar in form, having an inner contact surface. At the top of the device is a upper electrode element, spaced from the lower electrode element. A containment structure extends between the upper electrode element and the lower electrode element, and this element includes a sidewall spacer element having an inner surface defining a generally funnel-shaped central cavity, terminating at a terminal edge to define a central aperture; and a spandrel element positioned between the sidewall spacer element and the lower electrode, having an inner surface defining a thermal isolation cell, the spandrel inner walls being spaced radially outward from the sidewall spacer terminal edge, such that the sidewall spacer terminal edge projects radially inward from the spandrel element inner surface. ARRAM element extends between the lower electrode element and the upper electrode, occupying at least a portion of the sidewall spacer element central cavity and projecting from the sidewall spacer terminal edge toward and making contact with the lower electrode. In this manner, the spandrel element inner surface is spaced from the RRAM element to define a thermal isolation cell adjacent the RRAM element.

Owner:MACRONIX INT CO LTD

Suspended gas distribution manifold for plasma chamber

InactiveUS7484473B2Avoiding distortion and crackingImprove spatial uniformityElectric discharge tubesSemiconductor/solid-state device manufacturingThermal isolationProduct gas

Owner:APPLIED MATERIALS INC

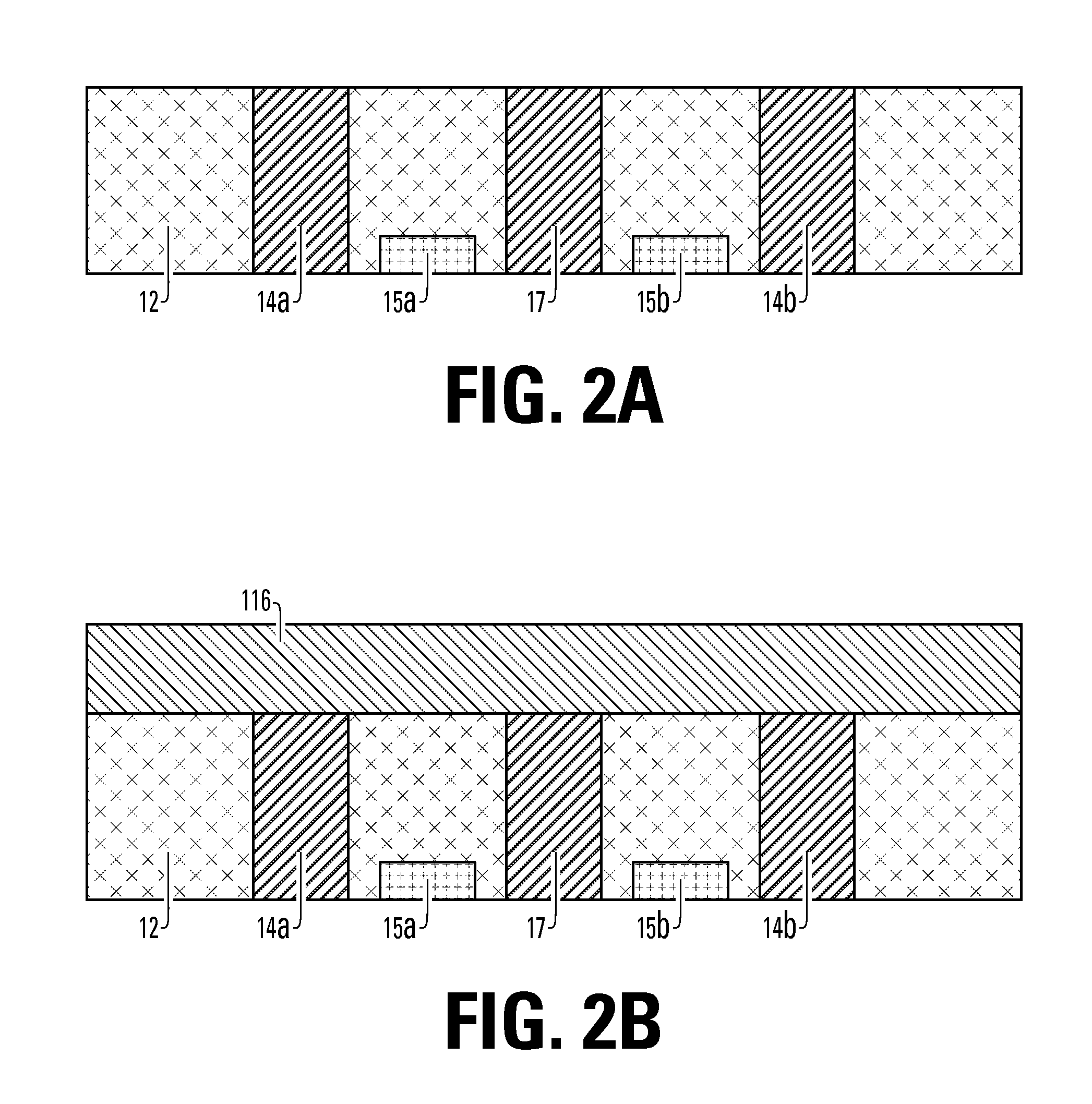

Thermal isolation for an active-sidewall phase change memory cell

ActiveUS20070115794A1Improve insulation performanceMechanical recordingRecord information storageDielectricThermal isolation

A phase change memory device with improve thermal isolation. The device includes an electrode stack, including a first and second electrode elements, generally planar in form, separated by and in mutual contact with a dielectric spacer element, wherein the electrode stack includes a side surface; a phase change element having a bottom surface in contact with the electrode stack side surface, including electrical contact with the first and second electrode elements; and dielectric fill material surrounding and encasing the memory device, wherein the dielectric fill material is spaced from the phase change element, such that the phase change element and the dielectric fill material define a cavity adjacent the phase change element, and wherein the cavity contains a low pressure environment.

Owner:MACRONIX INT CO LTD

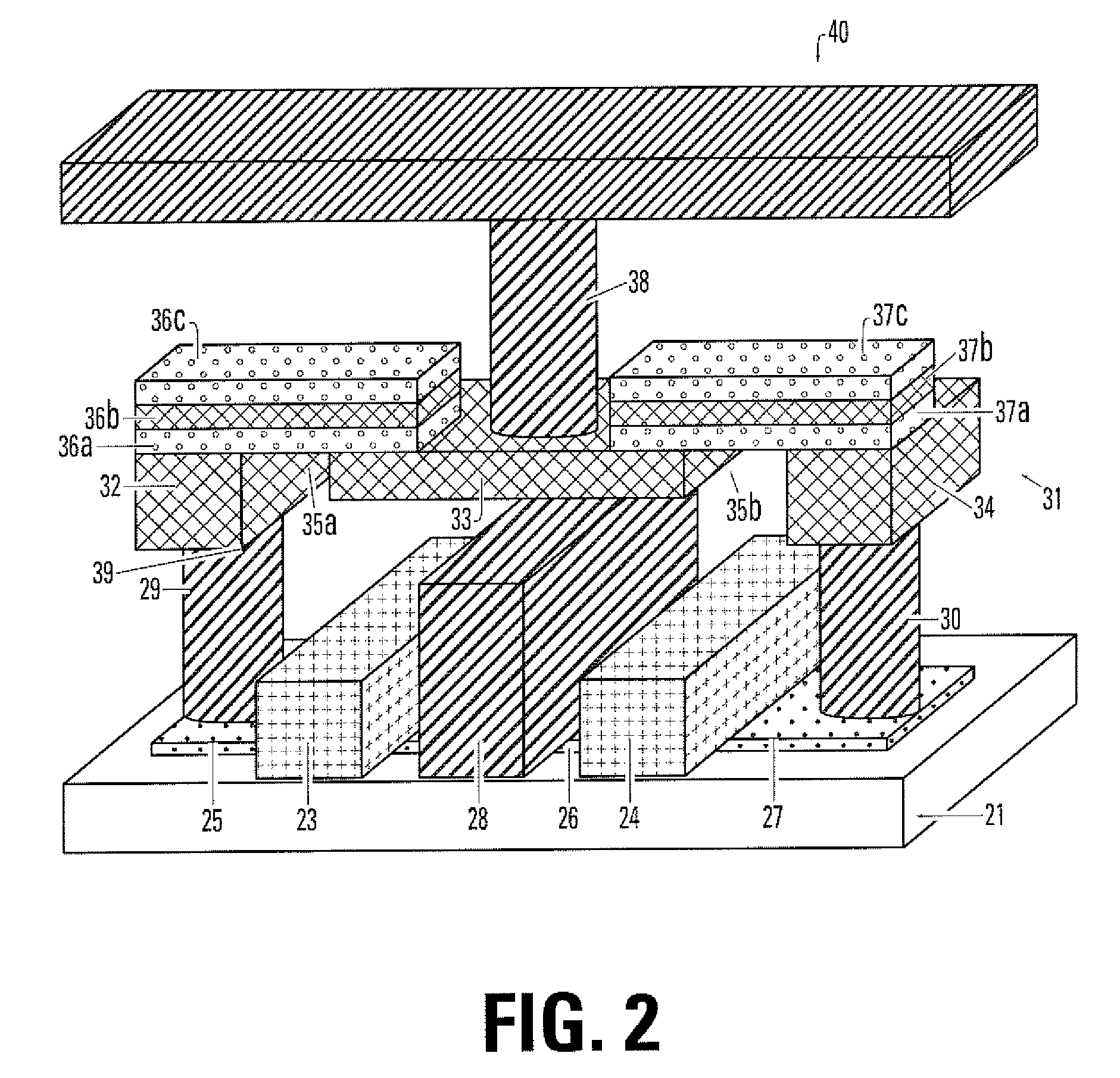

Vacuum cell thermal isolation for a phase change memory device

ActiveUS20070126040A1Improve insulation performanceSemiconductor/solid-state device manufacturingSemiconductor devicesThermal isolationPhase-change memory

A memory device with improved thermal isolation. The memory cell includes a first electrode element, having an upper surface; an insulator stack formed on the first electrode element, including first, second and third insulating members, all generally planar in form and having a central cavity formed therein and extending therethrough, wherein the second insulator member is recessed from the cavity; a phase change element, generally T-shaped in form, having a base portion extending into the cavity to make contact with the first electrode element and making contact with the first and third insulating members, and a crossbar portion extending over and in contact with the third insulating member, wherein the base portion of the phase change element, the recessed portions of the second insulating member and the surfaces of the first and third insulating members define a thermal isolation void; and a second electrode formed in contact with the phase change member.

Owner:MACRONIX INT CO LTD

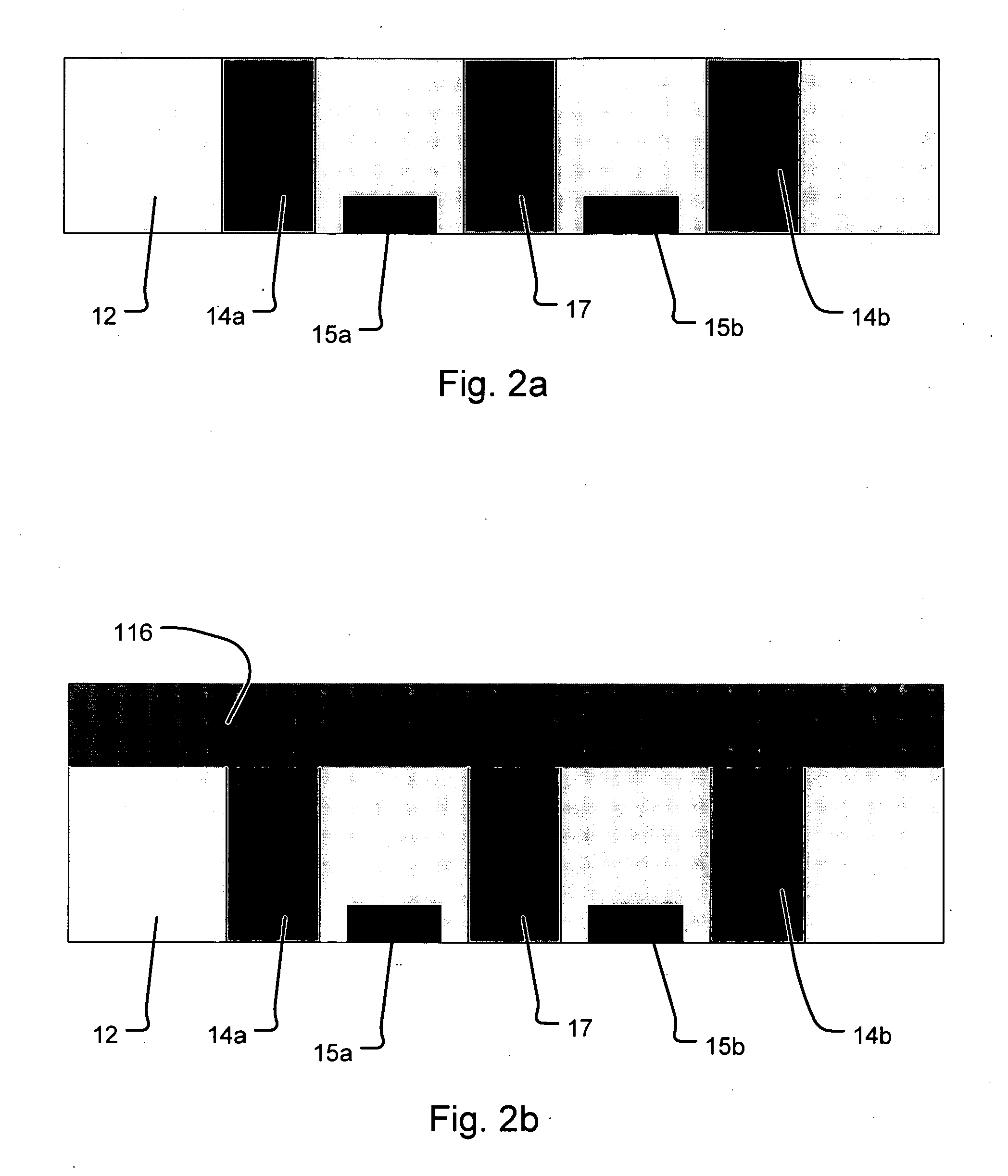

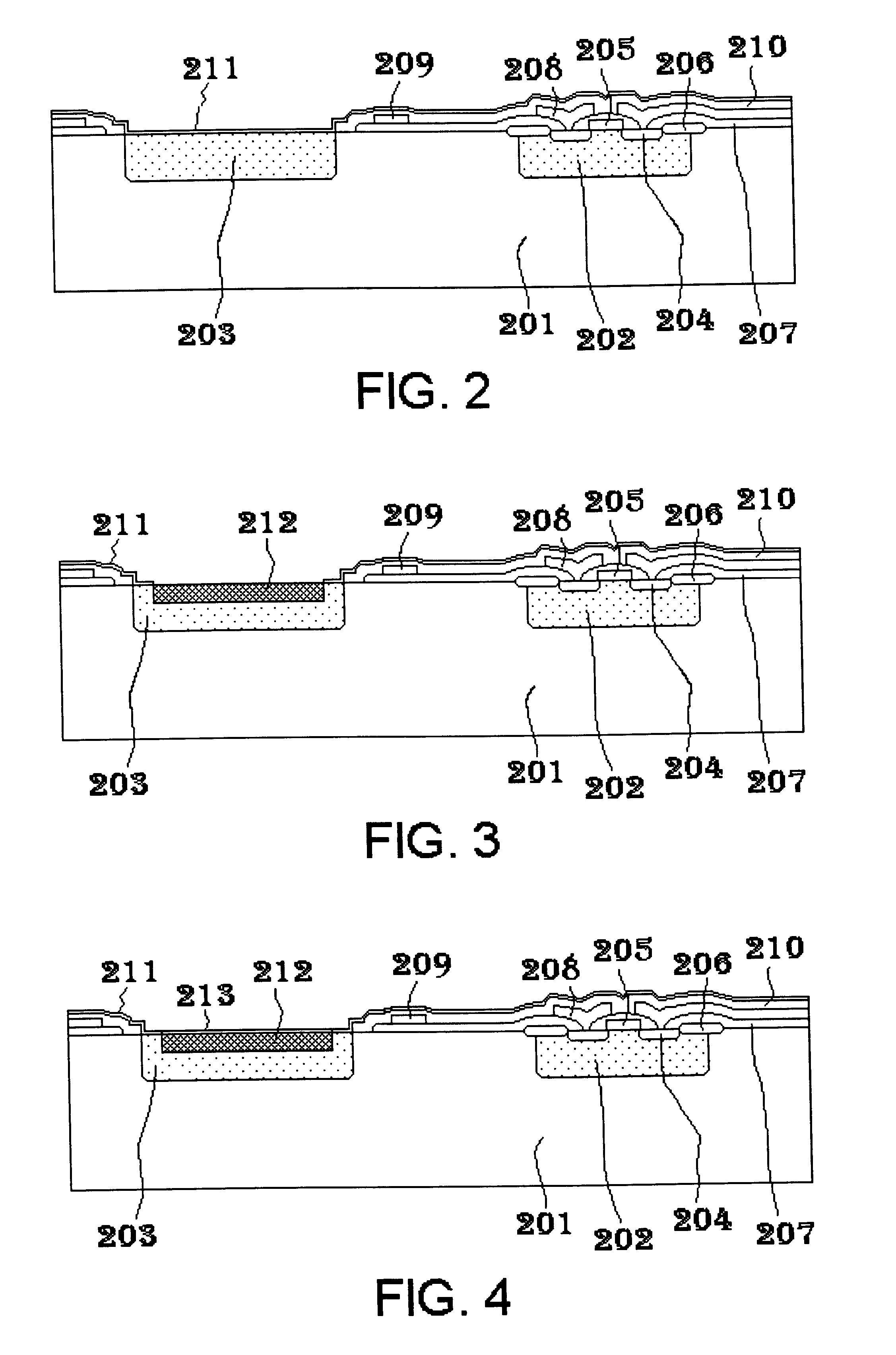

Thin film fuse phase change cell with thermal isolation layer and manufacturing method

ActiveUS20060284214A1Simple structureReduce power consumptionSolid-state devicesDigital storageThermal isolationEngineering

A memory device comprising a first electrode having a top side, a second electrode having a top side and an insulating member between the first electrode and the second electrode. The insulating member has a thickness between the first and second electrodes near the top side of the first electrode and the top side of the second electrode. A bridge of memory material crosses the insulating member, and defines an inter-electrode path between the first and second electrodes across the insulating member. An array of such memory cells is provided. The bridge comprises an active layer of memory material on the first side having at least two solid phases and a blanket of thermal insulating material overlying the memory material having thermal conductivity less than that of an overlying electrically insulating layer.

Owner:MACRONIX INT CO LTD

Thin Film Fuse Phase Change Cell with Thermal Isolation Pad and Manufacturing Method

ActiveUS20070131922A1Simple structureSmall reset currentSolid-state devicesSemiconductor/solid-state device manufacturingThermal isolationEngineering

A memory device comprising a first electrode having a top side, a second electrode having a top side and an insulating member between the first electrode and the second electrode. The insulating member has a thickness between the first and second electrodes near the top side of the first electrode and the top side of the second electrode extends outwardly from the top sides of the first and second electrodes defining a wall of insulating material having top side. A bridge of memory material crosses the insulating member over the top of the wall, and defines an inter-electrode path between the first and second electrodes across the insulating member. An array of such memory cells is provided. The bridge comprises an active layer of memory material on the top side of the wall, having at least two solid phases and a layer of thermal insulating material overlying the memory material having thermal conductivity less than a thermal conductivity of the first and second electrodes.

Owner:MACRONIX INT CO LTD

Touch Sensing Catheter

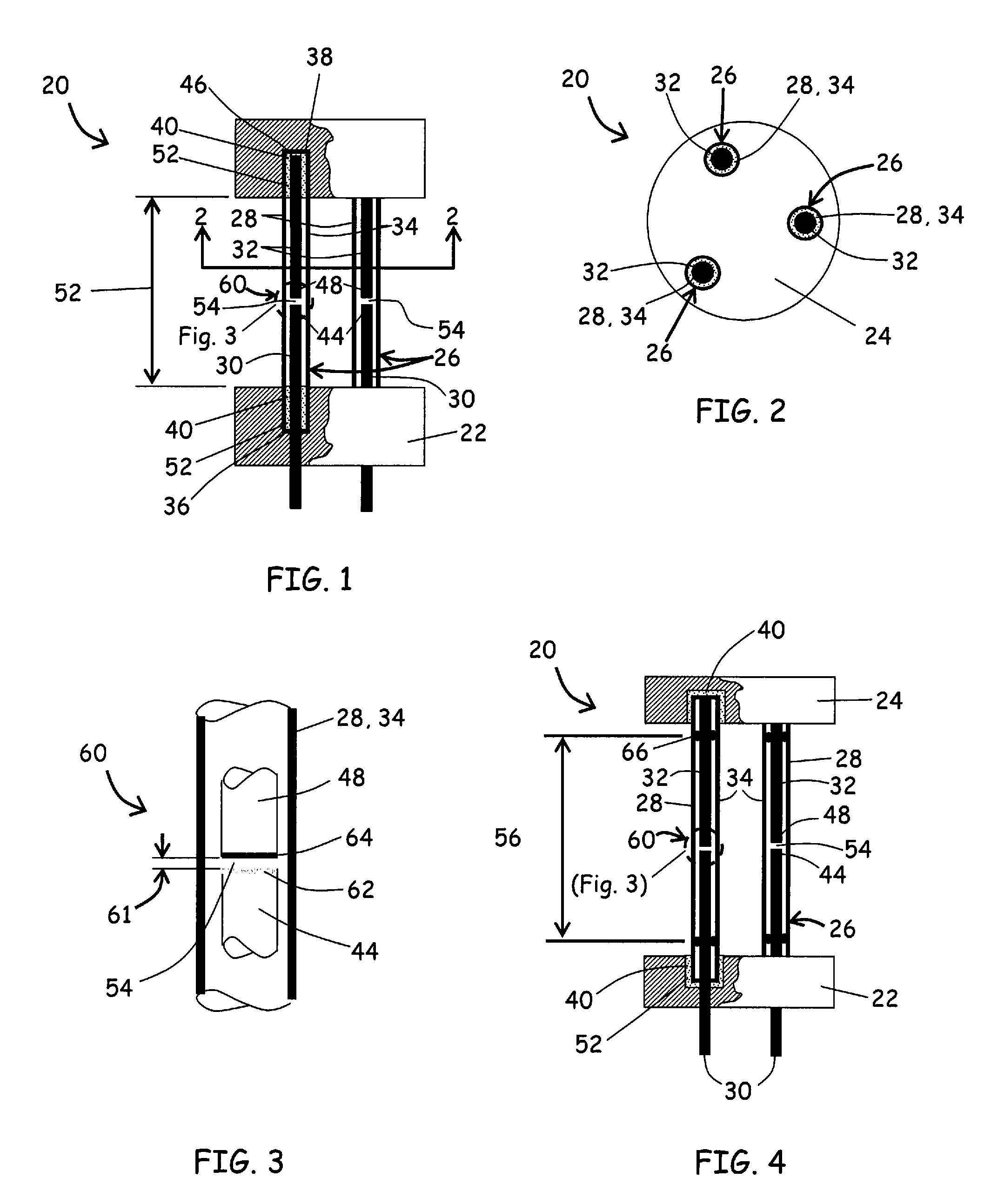

ActiveUS20080294144A1Moderate effectReduce potential temperature gradientStrain gaugeEndoscopesThermal isolationTouch Senses

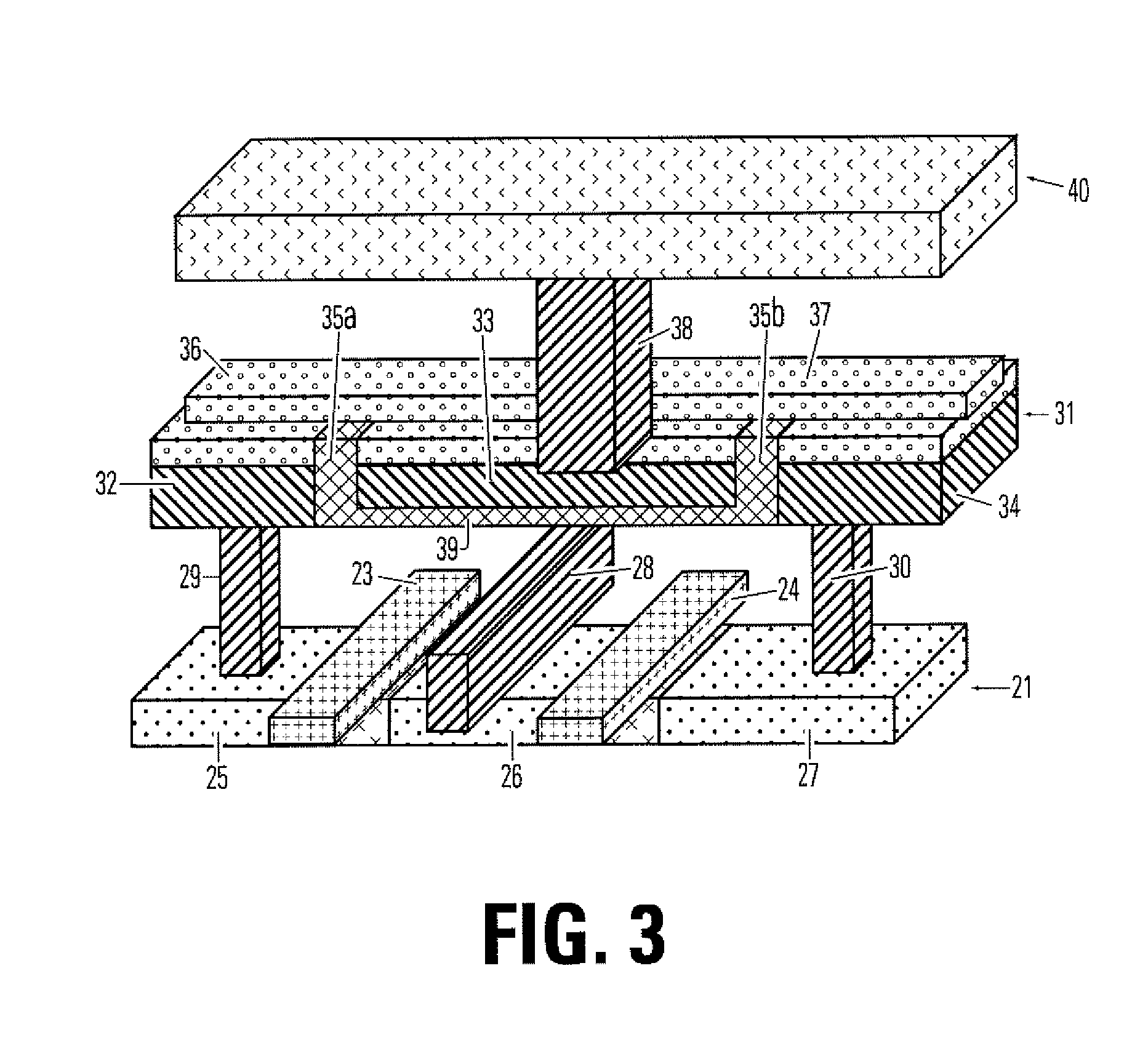

A touch sensing catheter having a strain sensor assembly that may resolve the magnitude and direction of a force exerted on a distal extremity of the catheter, the strain sensor assembly being substantially insensitive to bulk temperature changes. A deformable structure having a plurality of optical fibers associated therewith that are strained by the imposition of a contact force transferred thereto. The optical fibers cooperate with the deformable structure to effect variable gap interferometers, such as Fabry-Perot resonators, that vary in operative length when a force is exerted on the deformable structure. The strain sensor assembly is rendered insensitive to bulk temperature changes by matching the coefficient of thermal expansion of the deformable body with that of the optical fibers. The strain sensor assembly may also be configured to mitigate the effects of thermal gradients using various thermal isolation techniques.

Owner:ST JUDE MEDICAL INT HLDG SARL

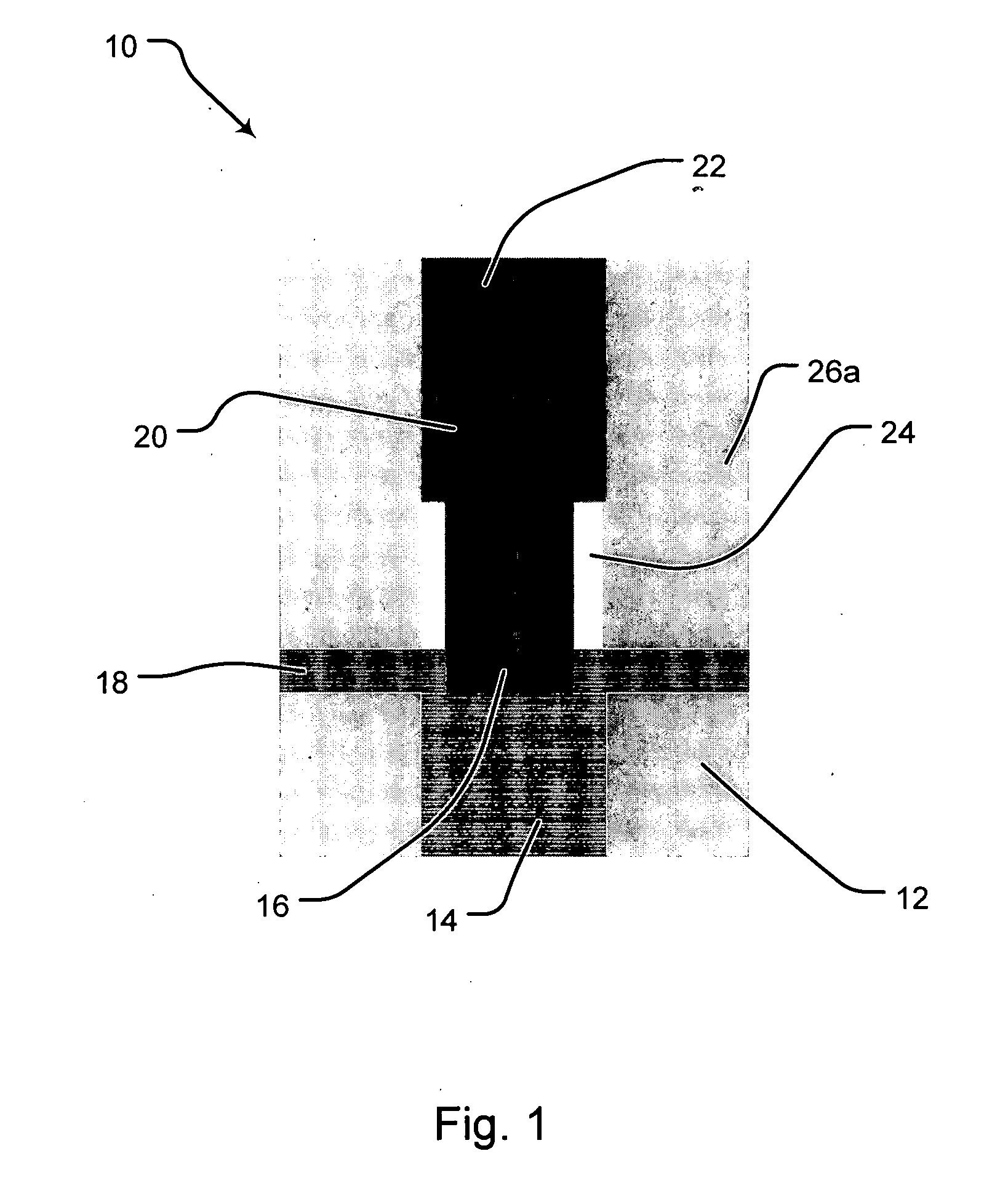

Vacuum jacketed electrode for phase change memory element

ActiveUS20070158862A1Improve insulation performanceTransistorSolid-state devicesThermal isolationPhase-change memory

A memory device having a vacuum jacket around the first electrode element for improved thermal isolation. The memory unit includes a first electrode element; a phase change memory element in contact with the first electrode element; a dielectric fill layer surrounding the phase change memory element and the first electrode element, wherein the dielectric layer is spaced from the first electrode element to define a chamber between the first electrode element and the dielectric fill layer; and wherein the phase change memory layer is sealed to the dielectric fill layer to define a thermal isolation jacket around the first electrode element.

Owner:MACRONIX INT CO LTD

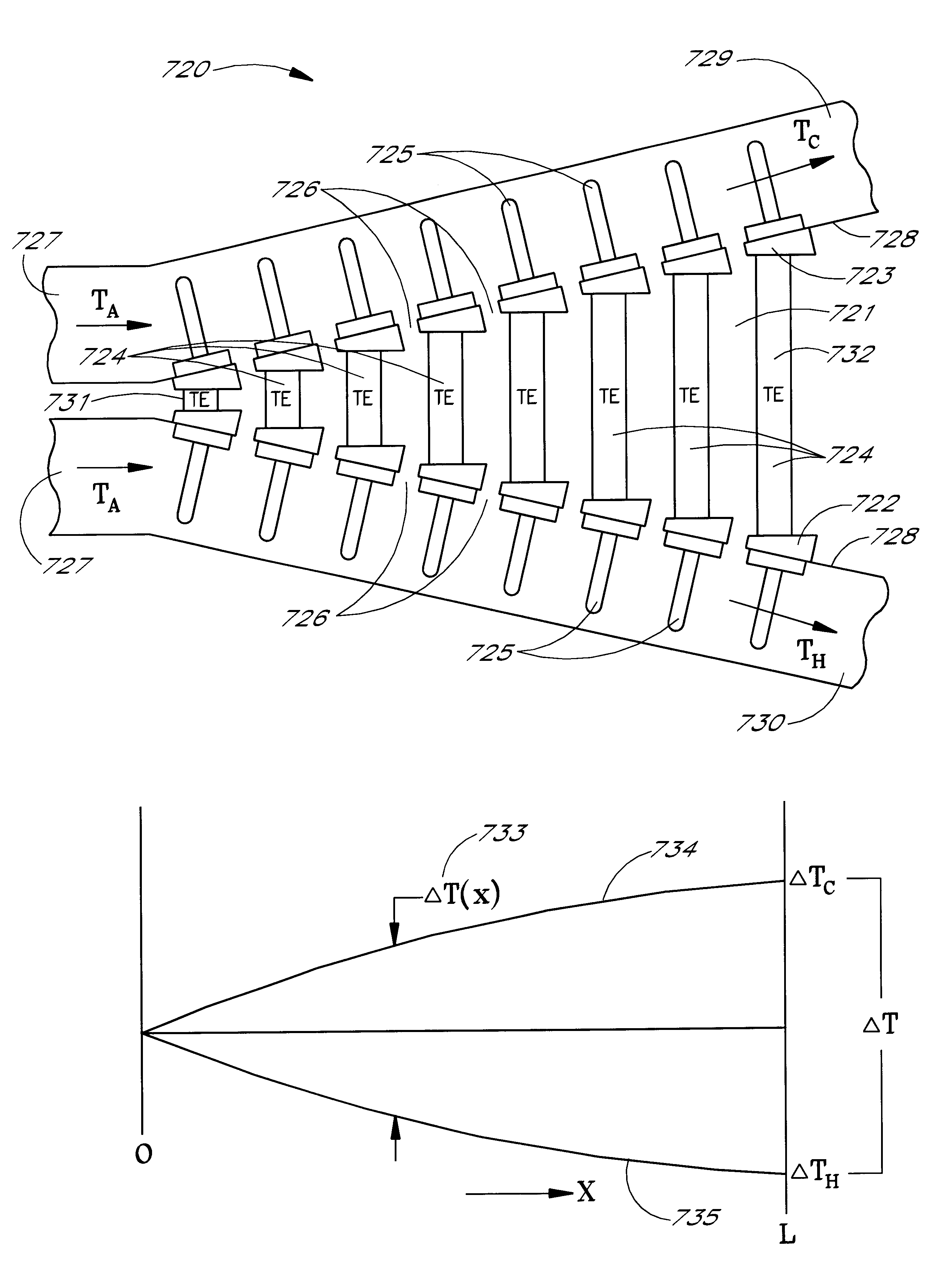

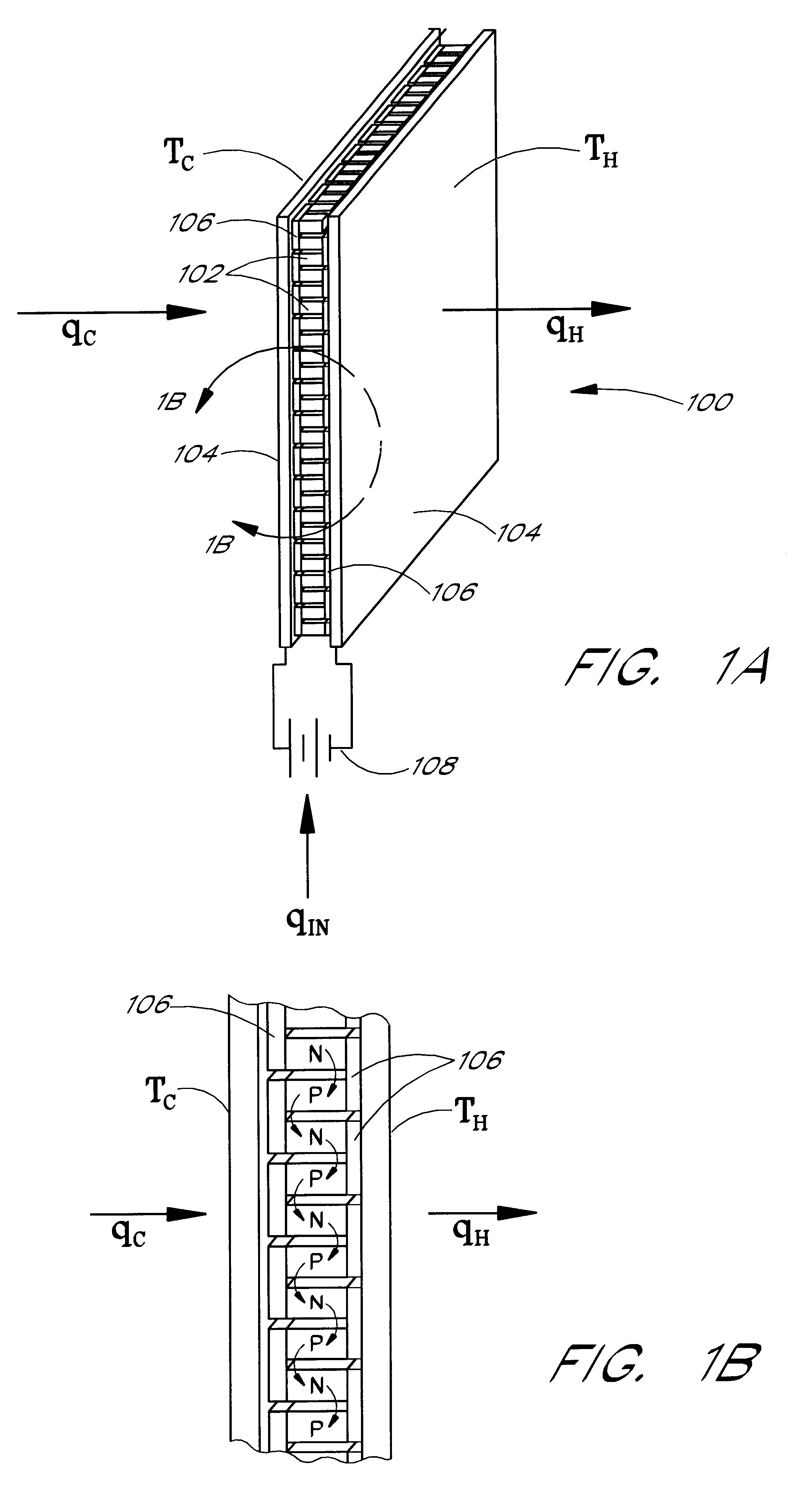

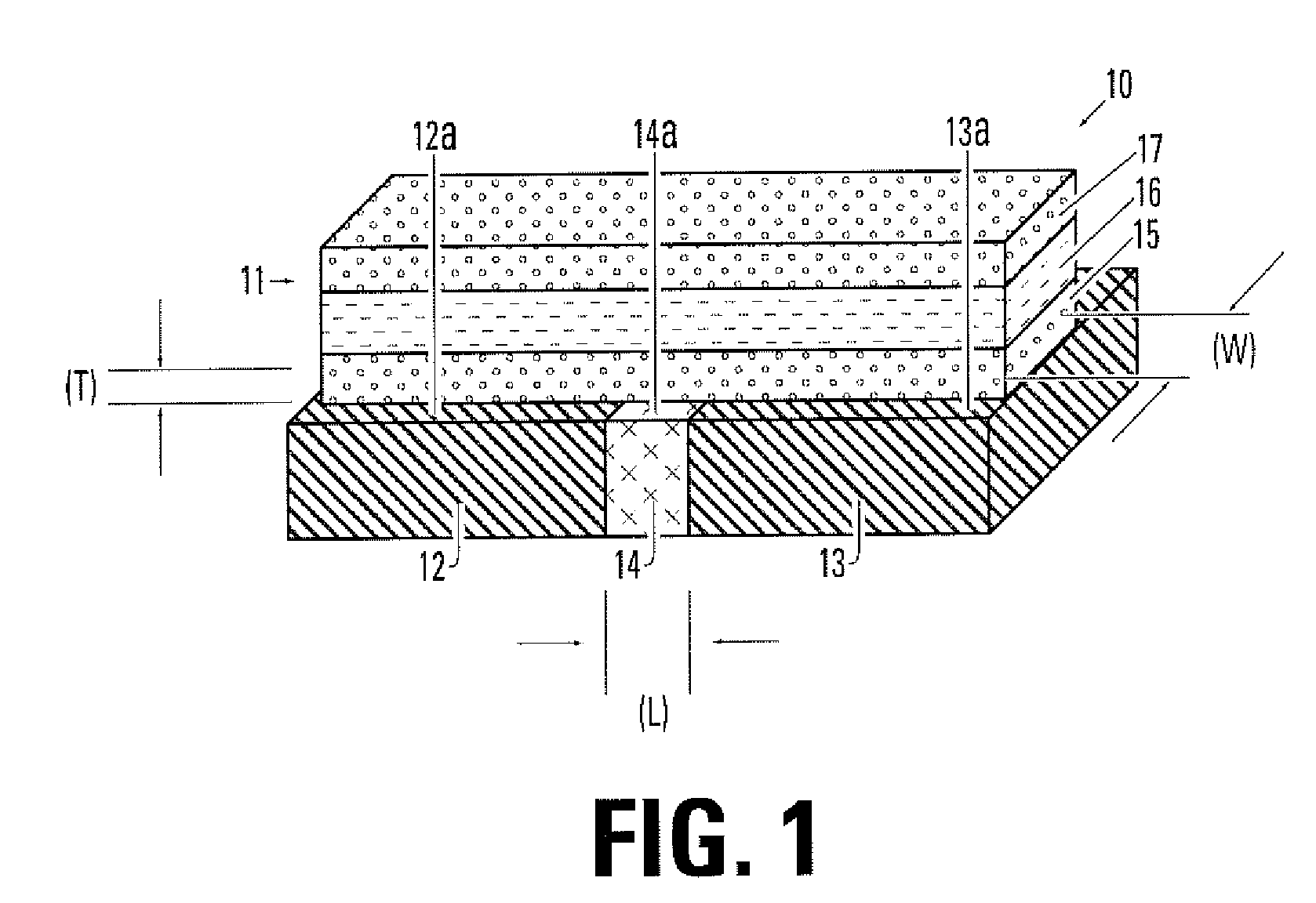

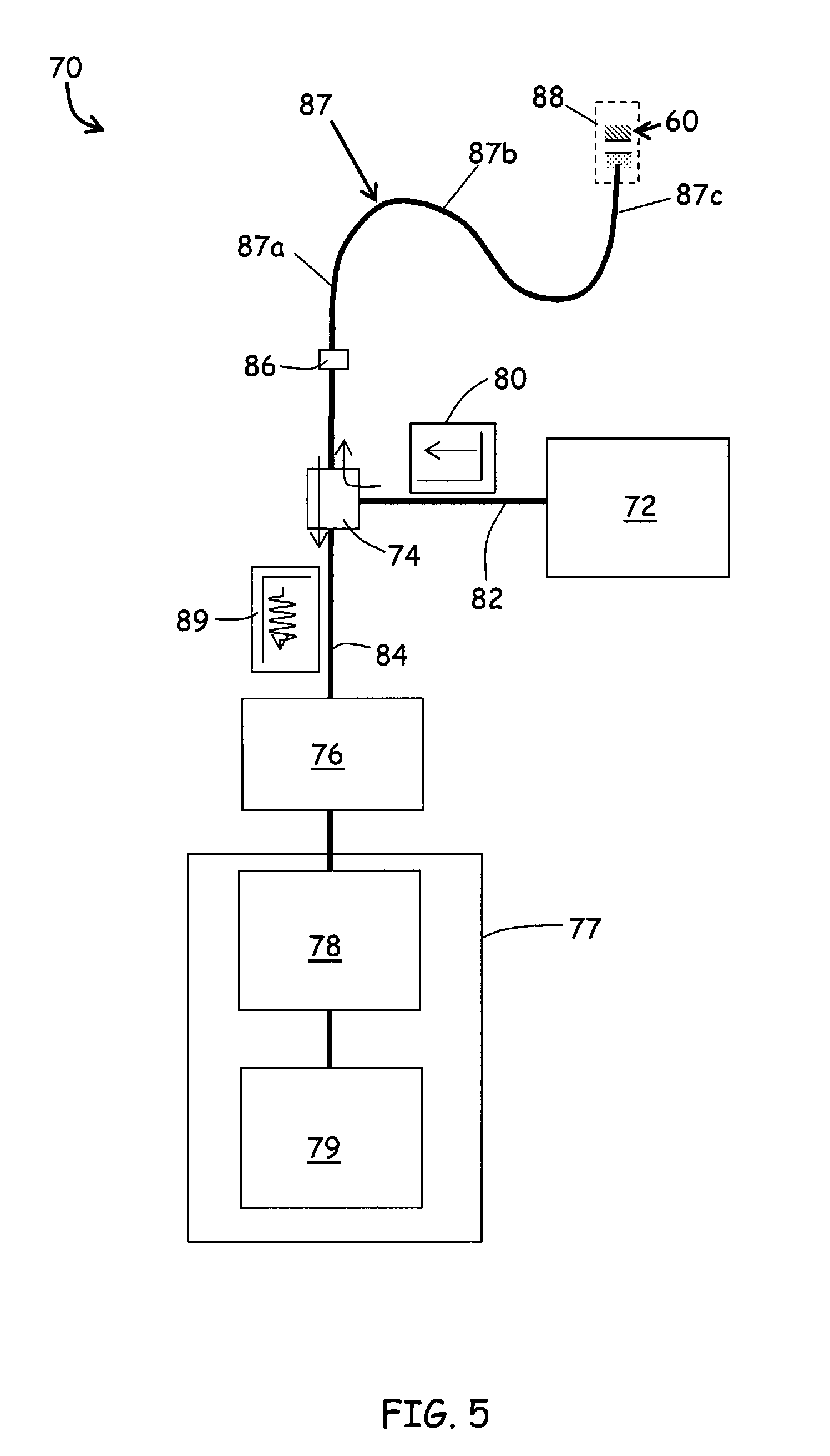

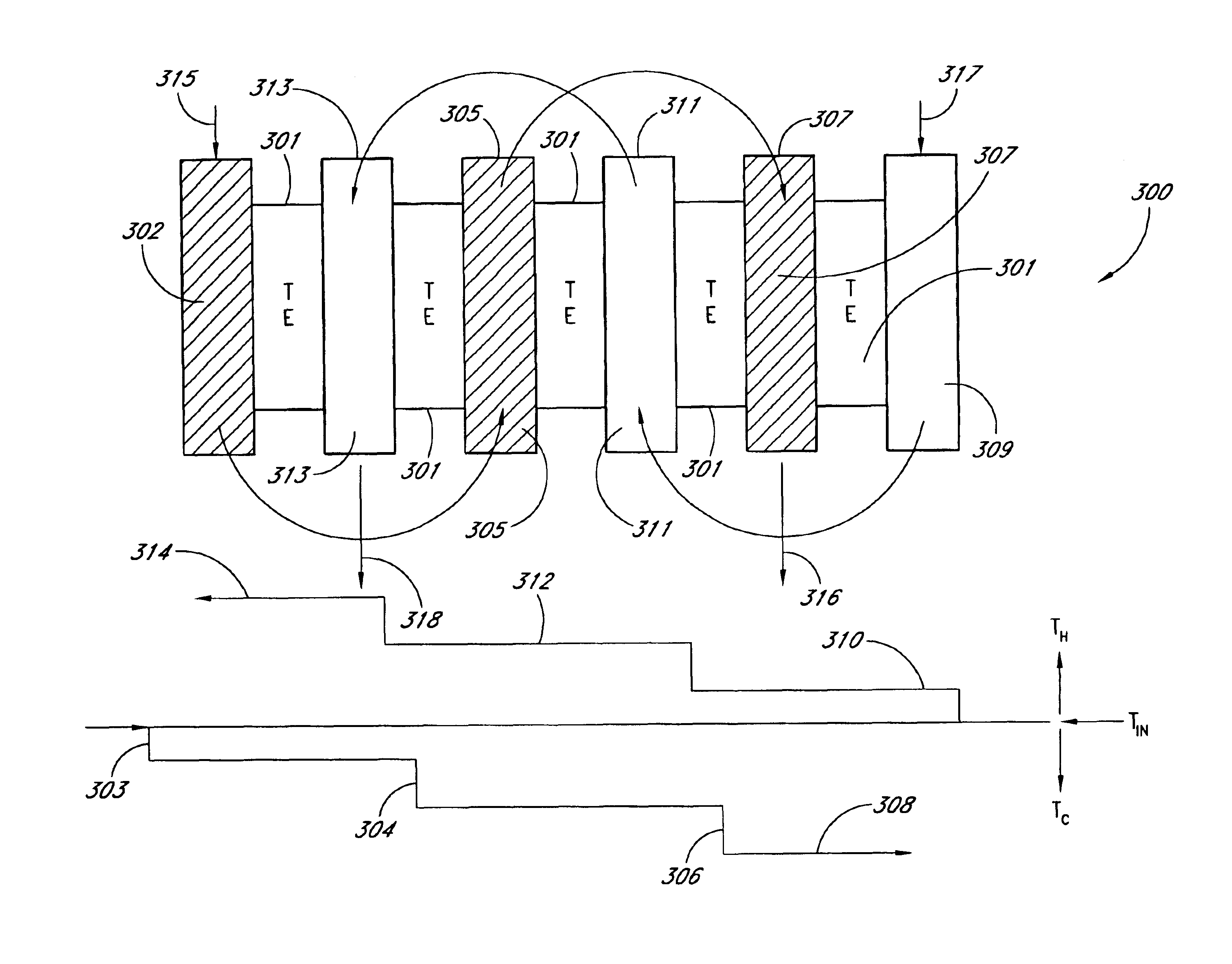

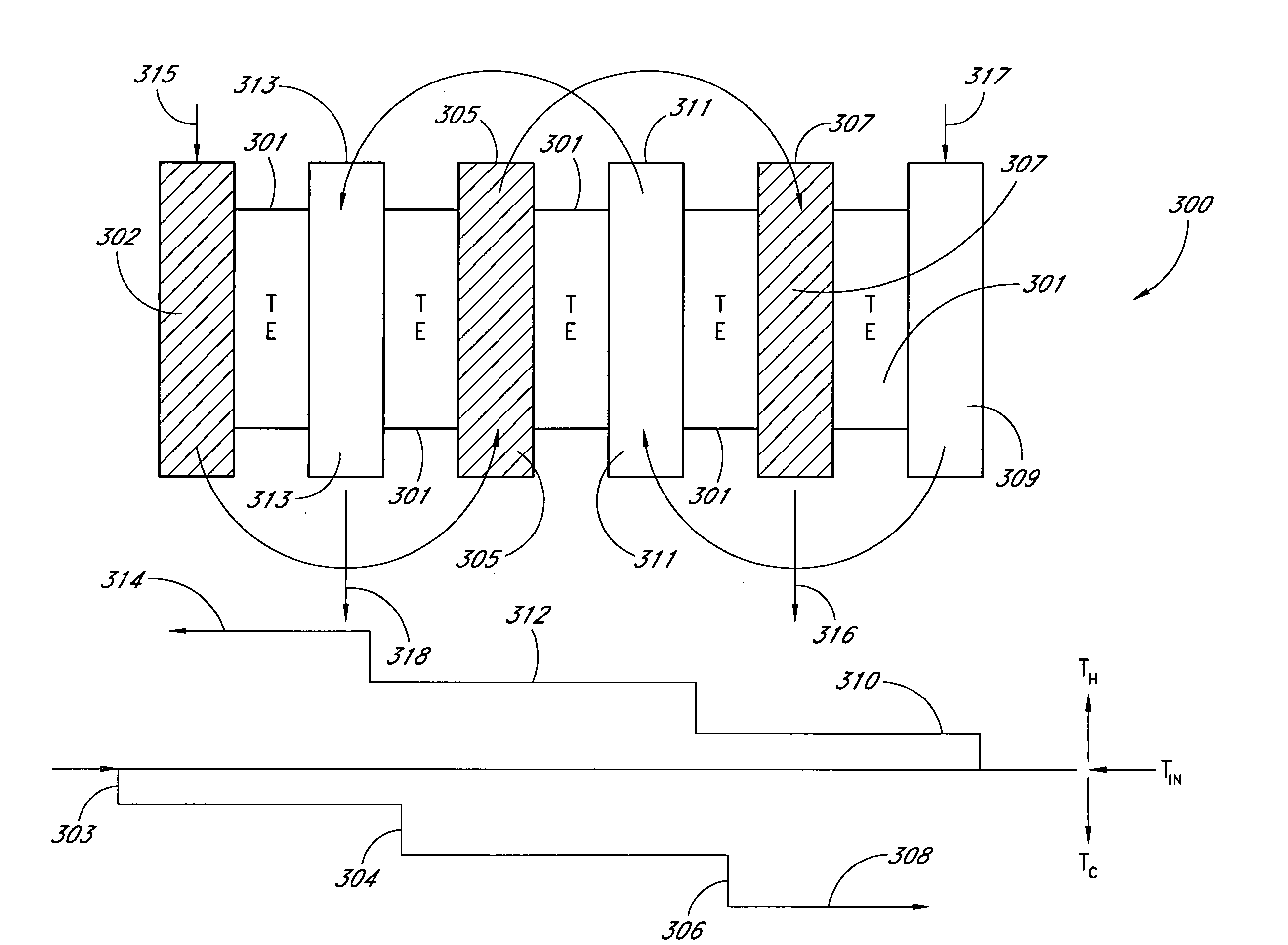

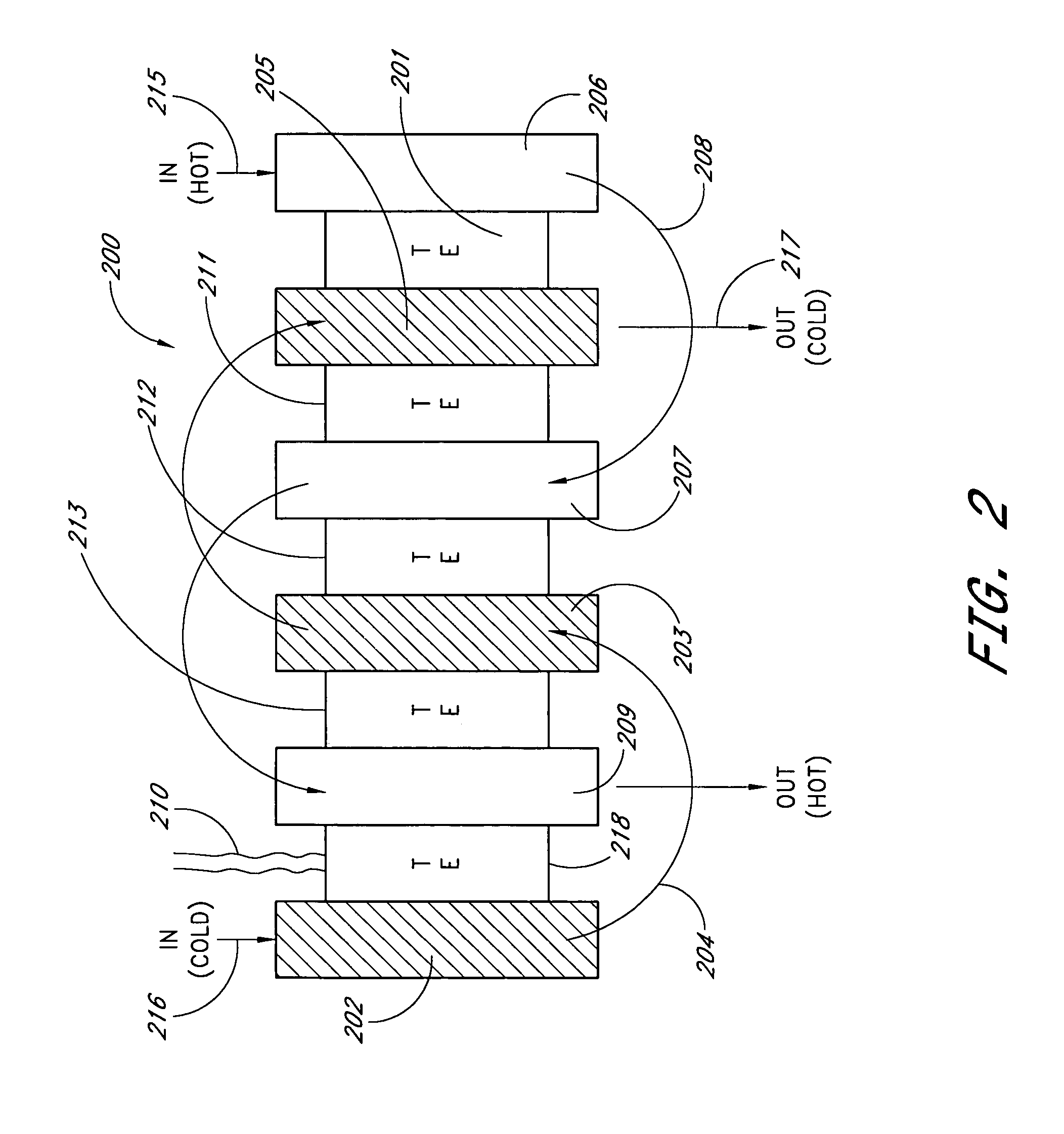

High power density thermoelectric systems

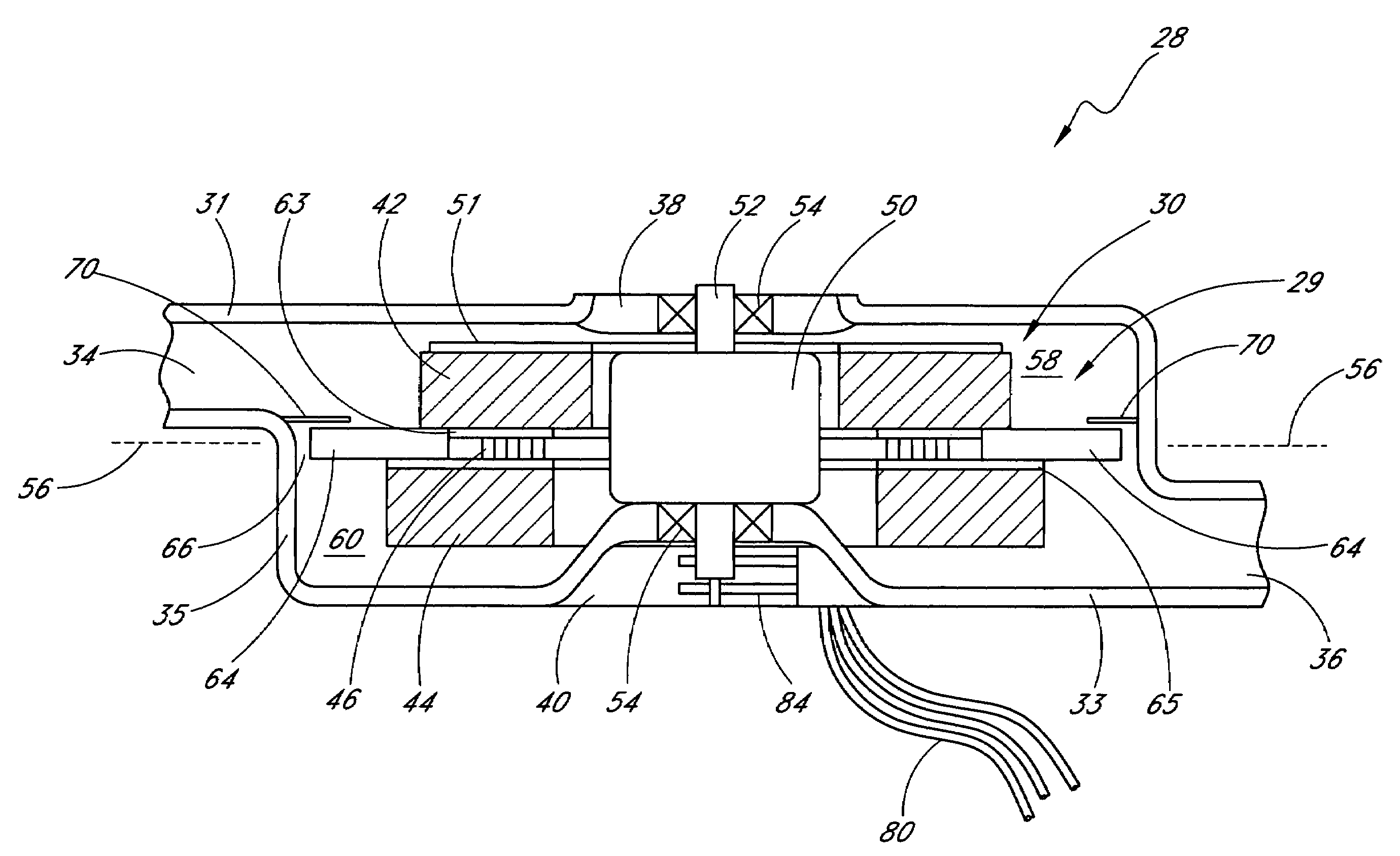

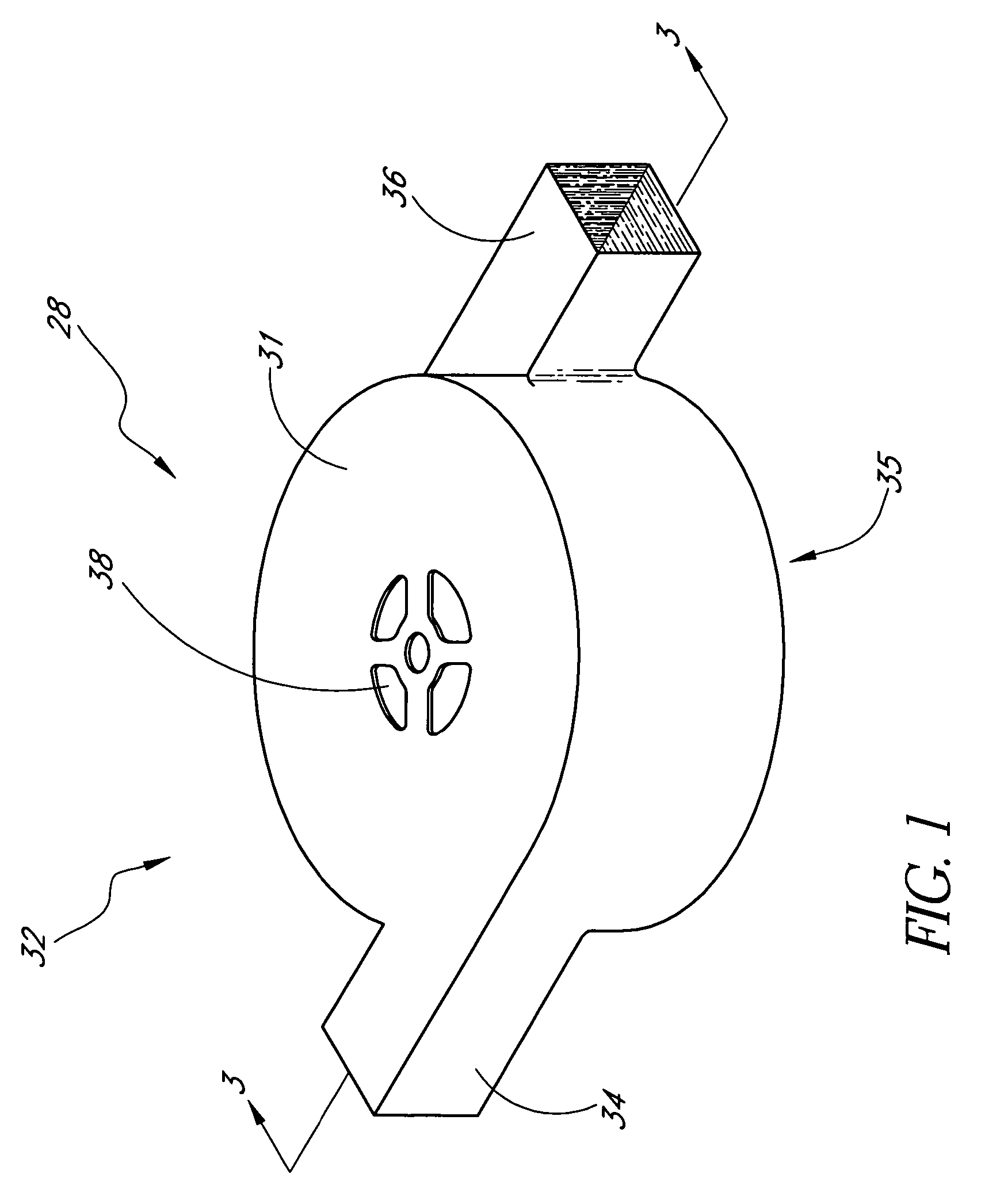

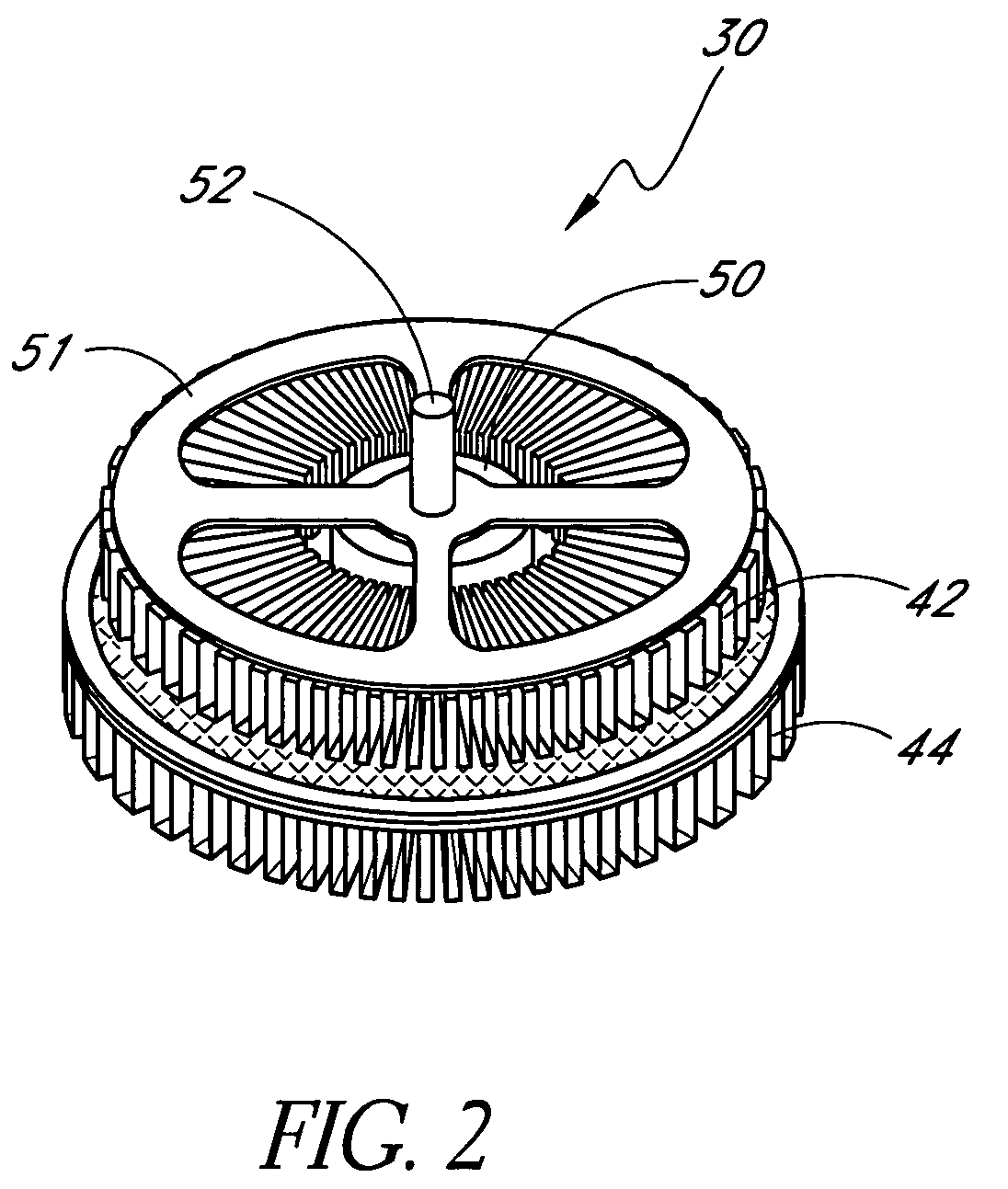

InactiveUS6959555B2Low costMaintaining and improving efficiency gainThermoelectric device with peltier/seeback effectDomestic cooling apparatusThermal isolationThermoelectric materials

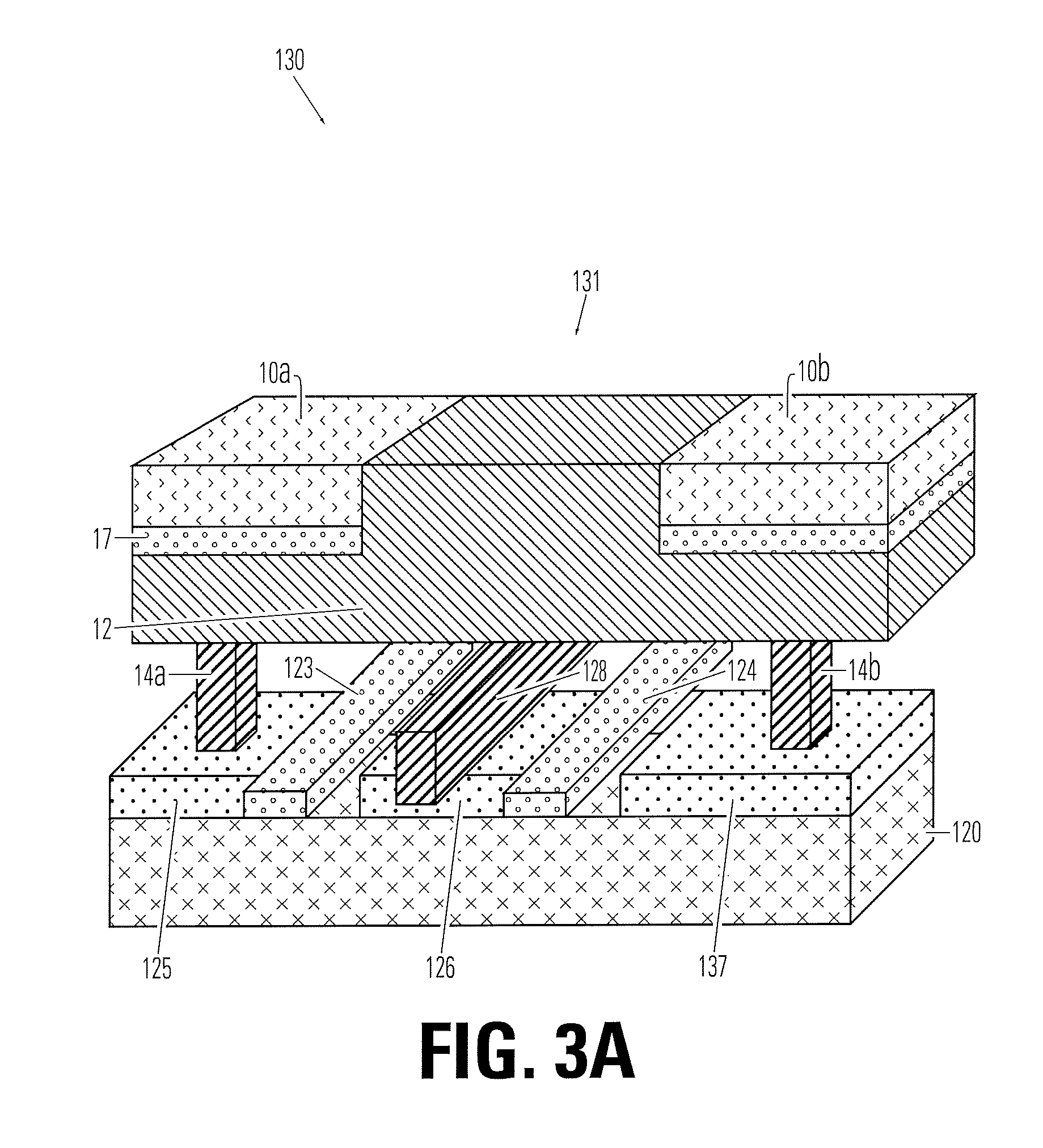

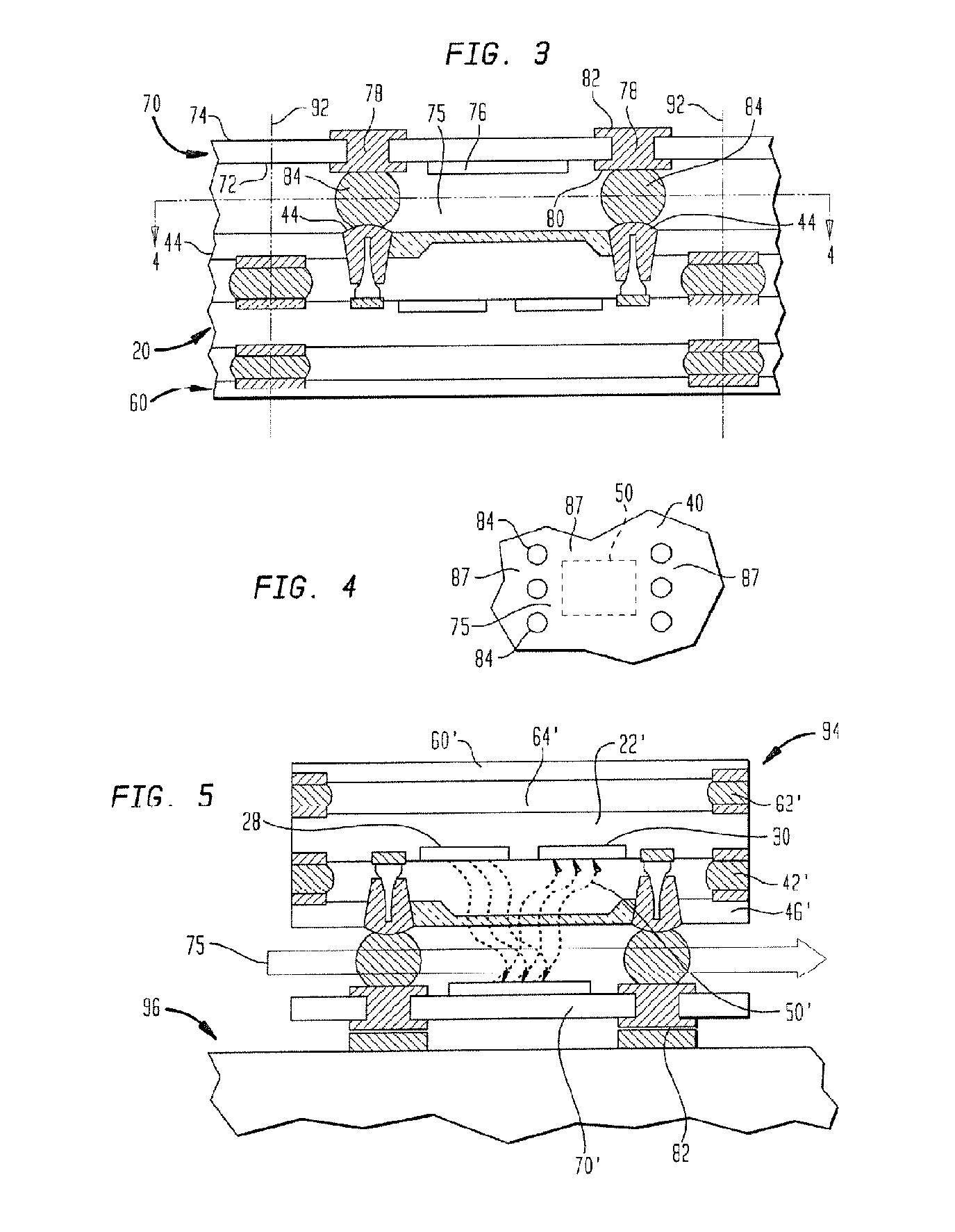

A number of compact, high-efficiency and high-power density thermoelectric systems utilizing the advantages of thermal isolation are described. Such configurations exhibit high system efficiency and power density. Some configurations exhibit a substantial reduction in the amount of thermoelectric material required.

Owner:GENTHERM INC

I-shaped phase change memory cell with thermal isolation

InactiveUS20080043520A1Solid-state devicesSemiconductor/solid-state device manufacturingThermal isolationPhase-change memory

A memory device includes two electrodes, vertically separated and having mutually opposed contact surfaces, between which lies a phase change cell. The phase change cell includes an upper phase change member, having a contact surface in electrical contact with the first electrode; a lower phase change member, having a contact surface in electrical contact with the second electrode; and a kernel member disposed between and in electrical contact with the upper and lower phase change members. The phase change cell is formed of material having at least two solid phases, and the lateral extent of the upper and lower phase change members is substantially greater than that of the kernel member. An intermediate insulating layer is disposed between the upper and lower phase change members adjacent to the kernel member.

Owner:MACRONIX INT CO LTD

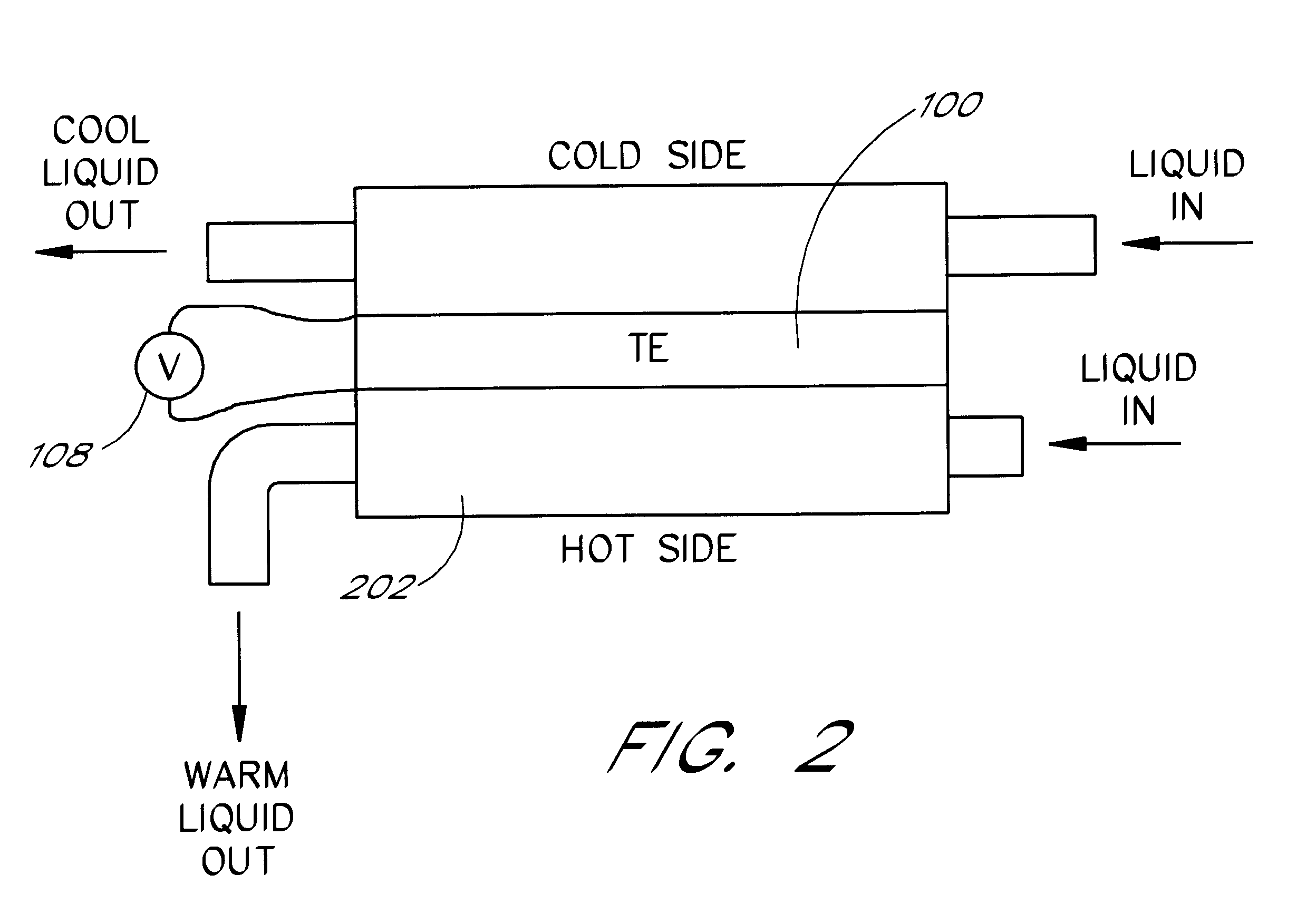

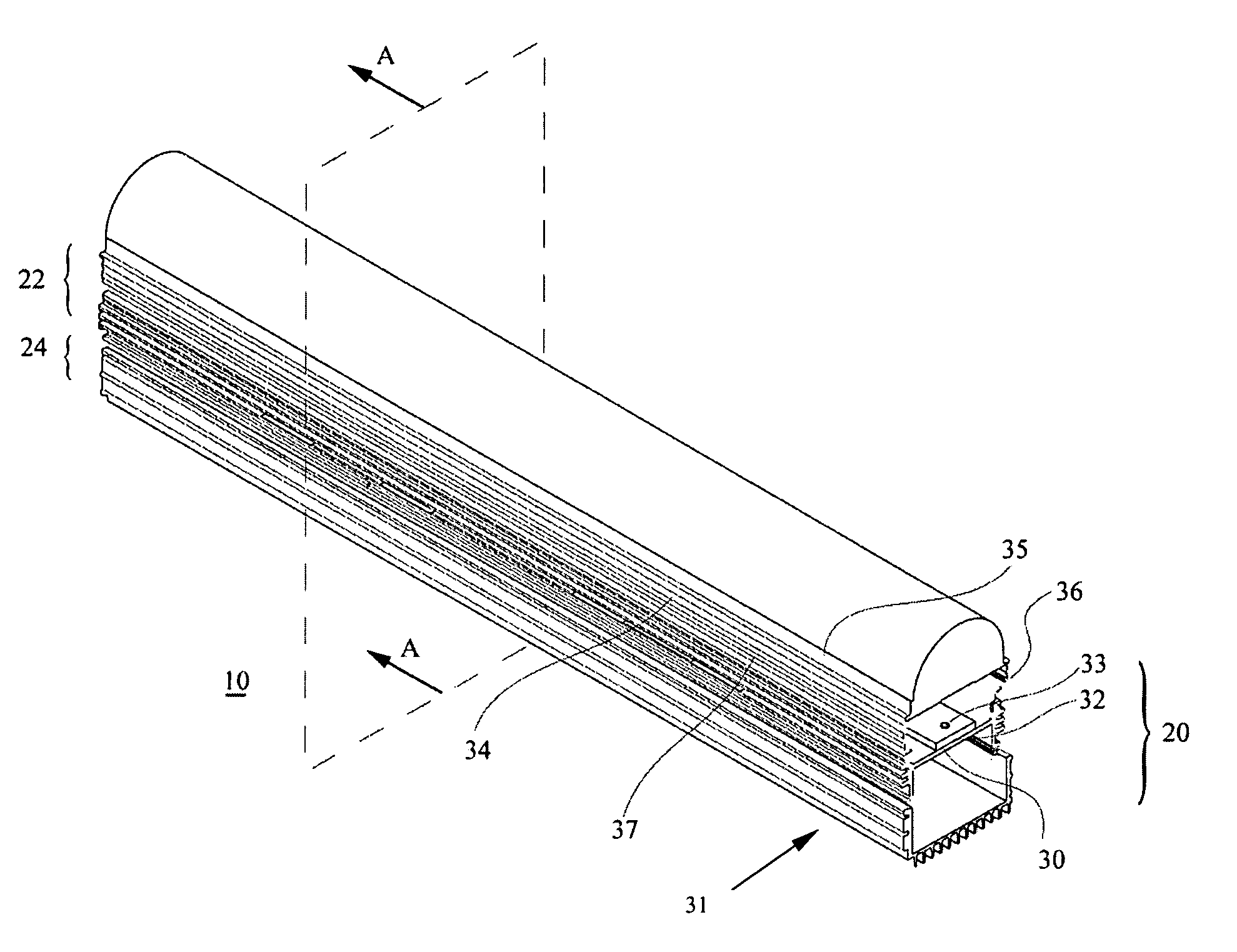

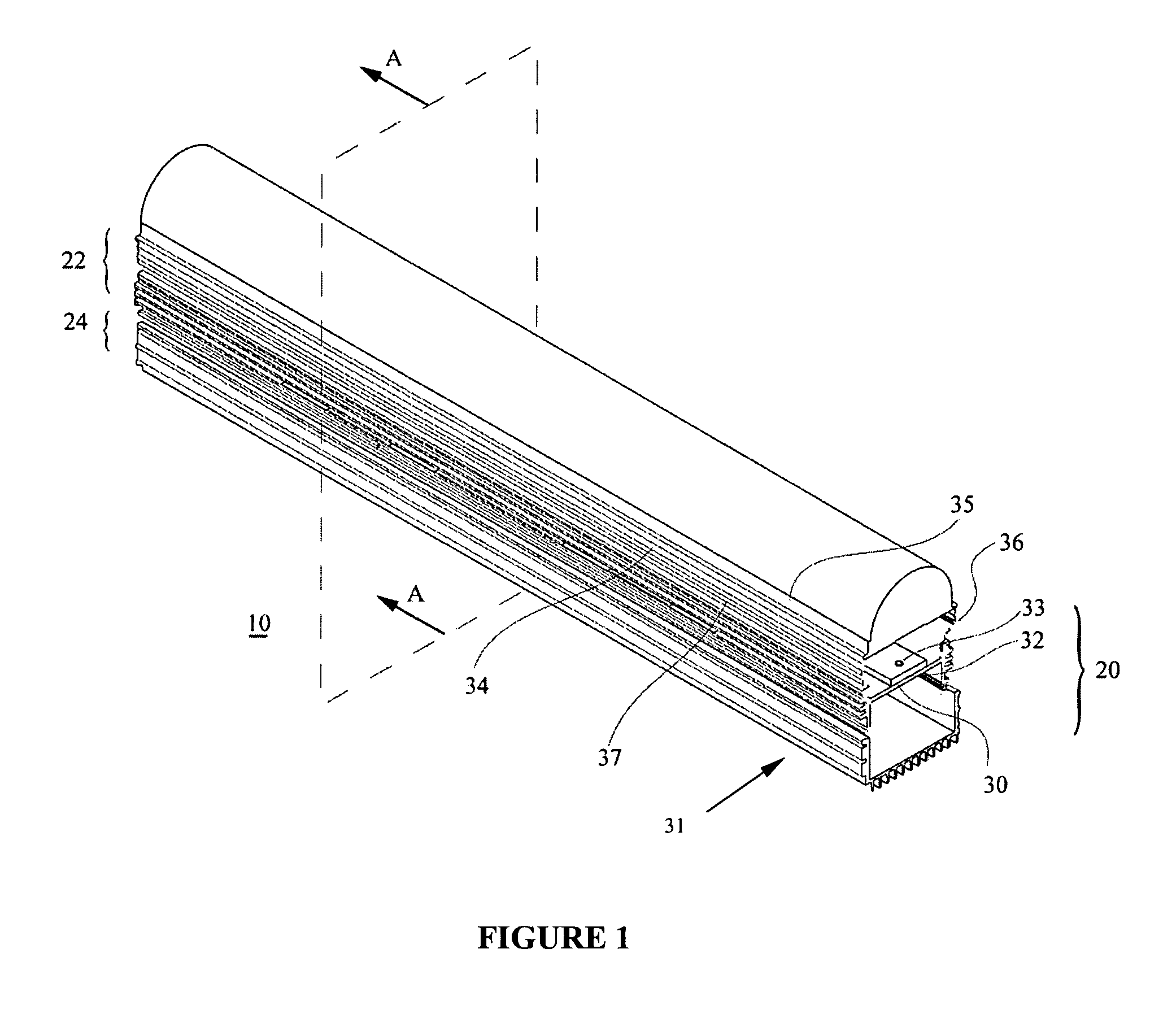

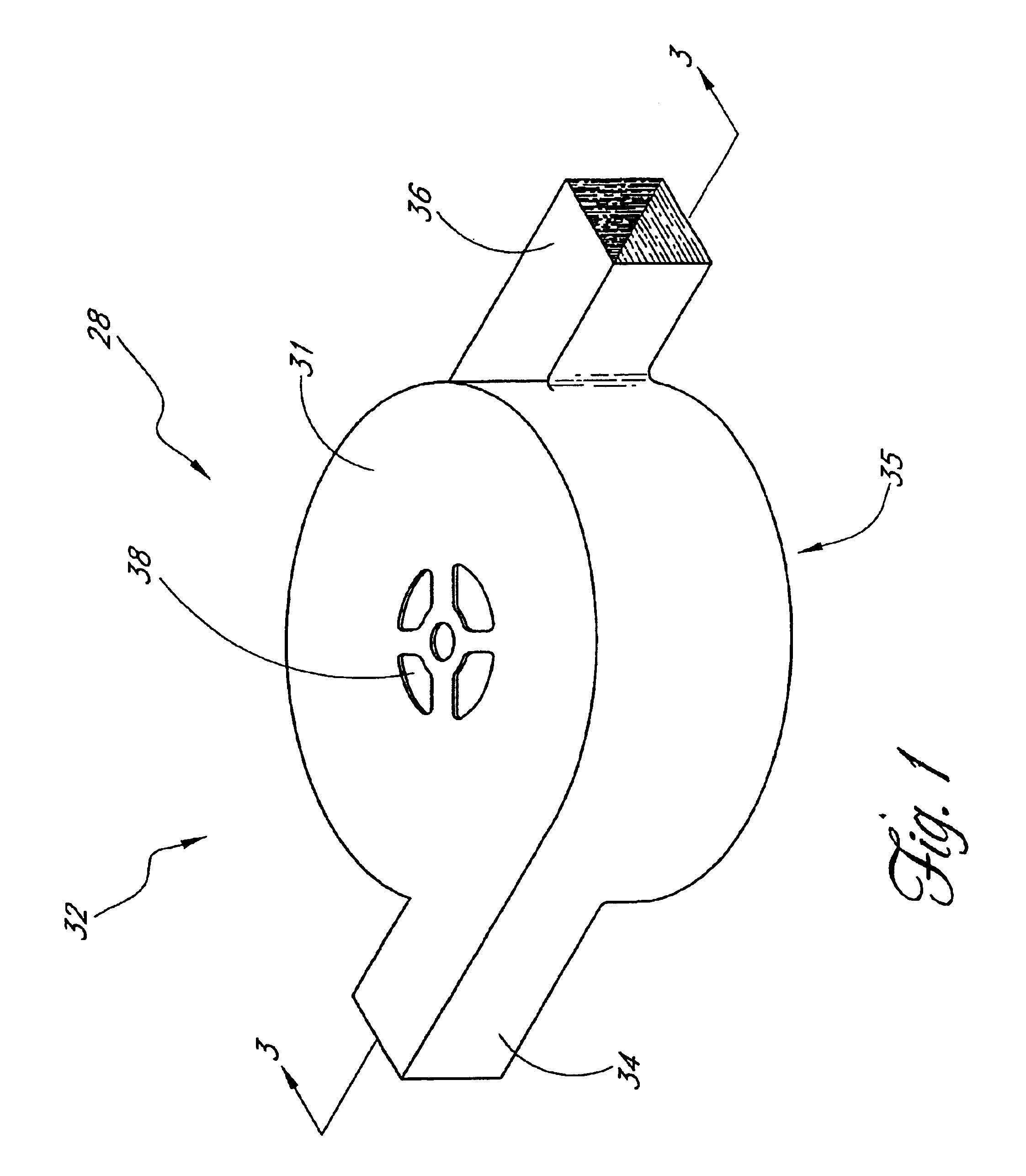

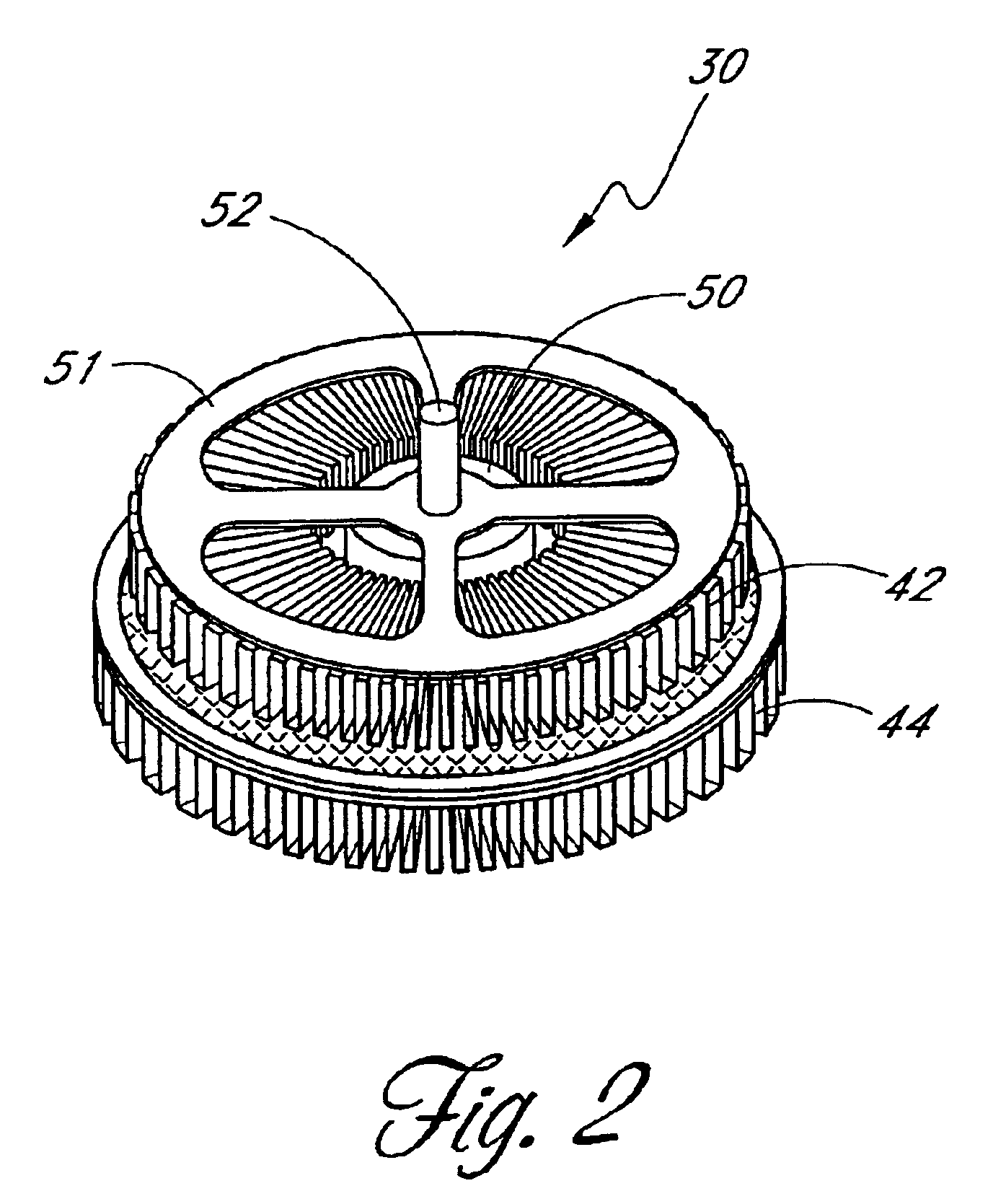

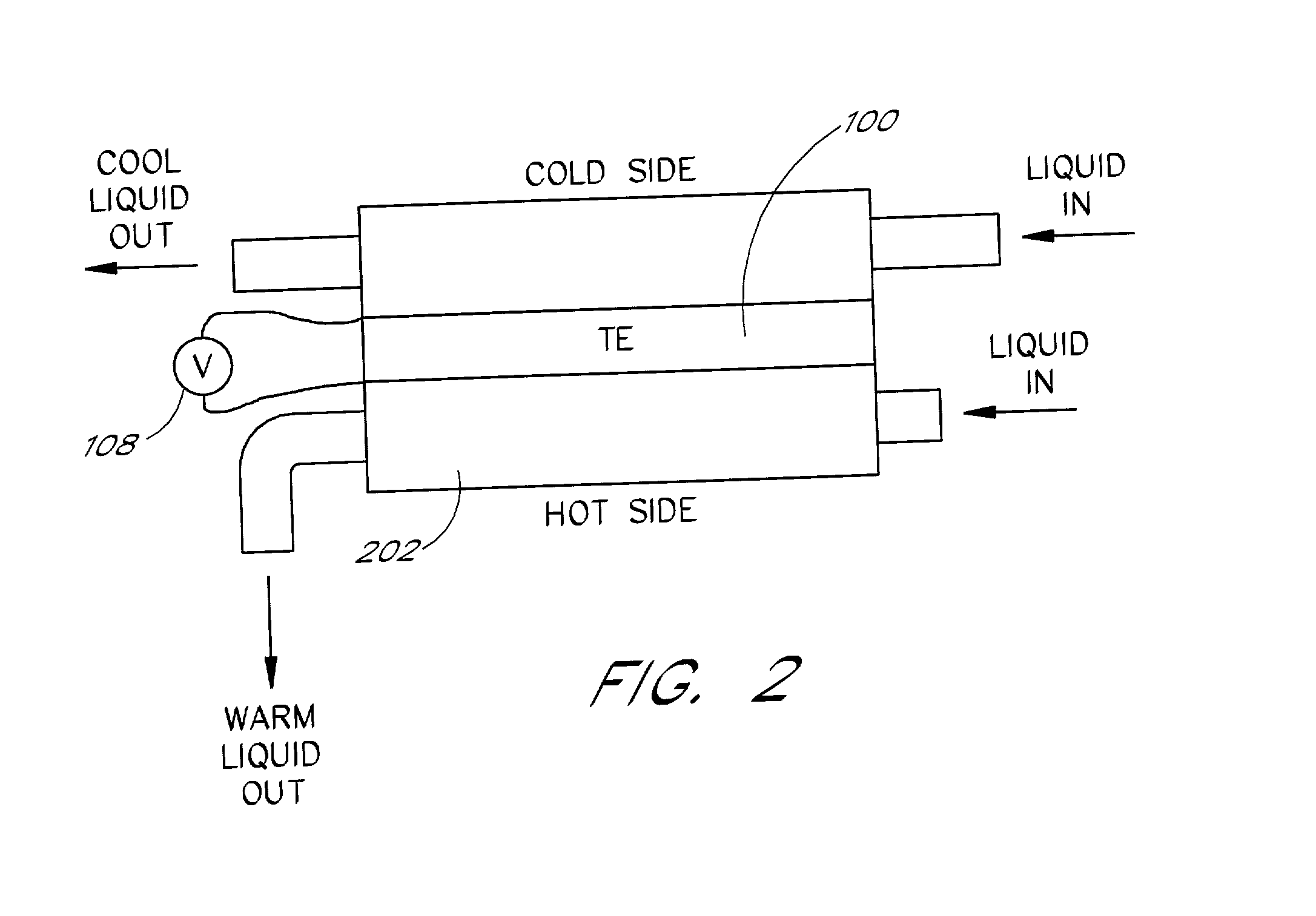

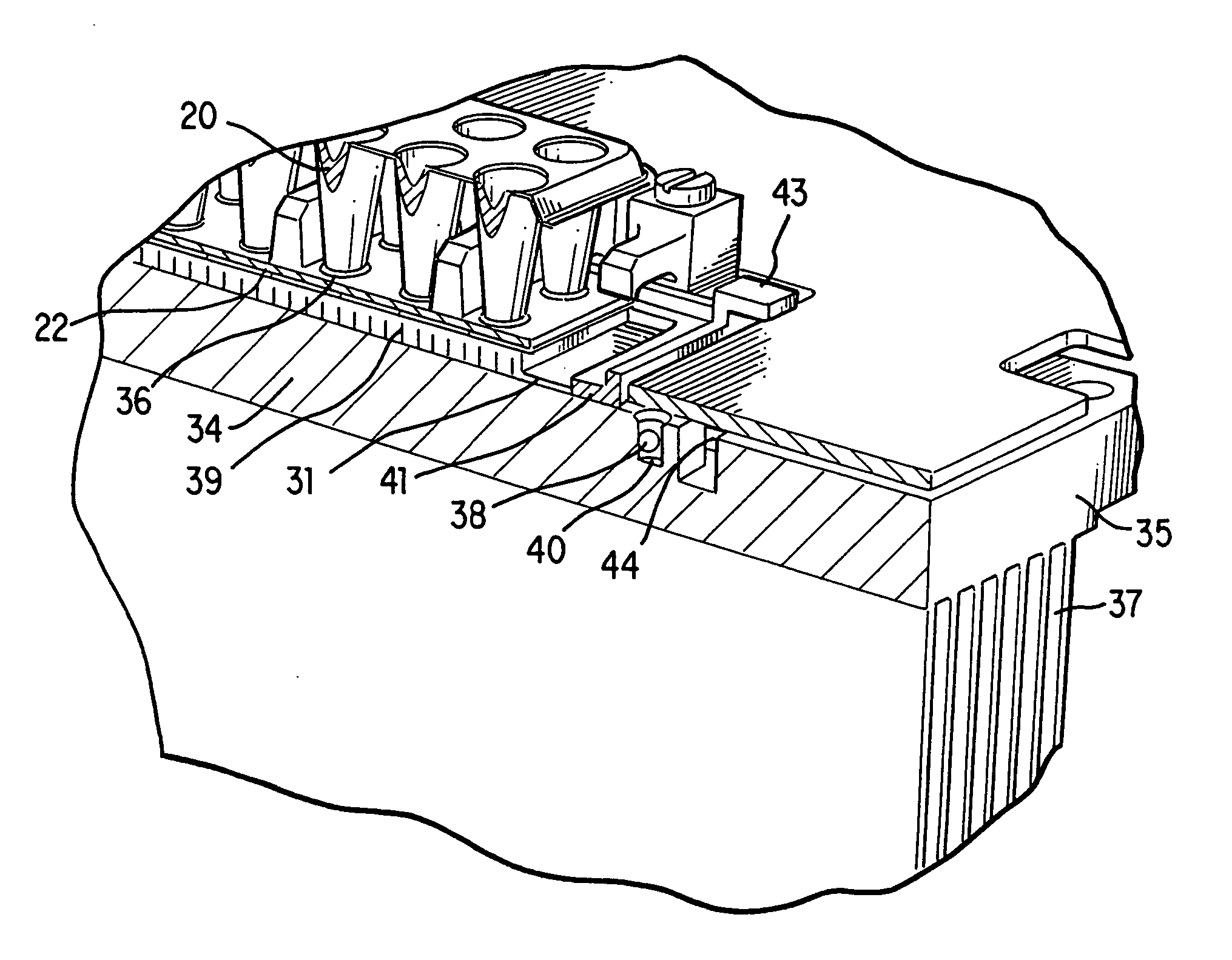

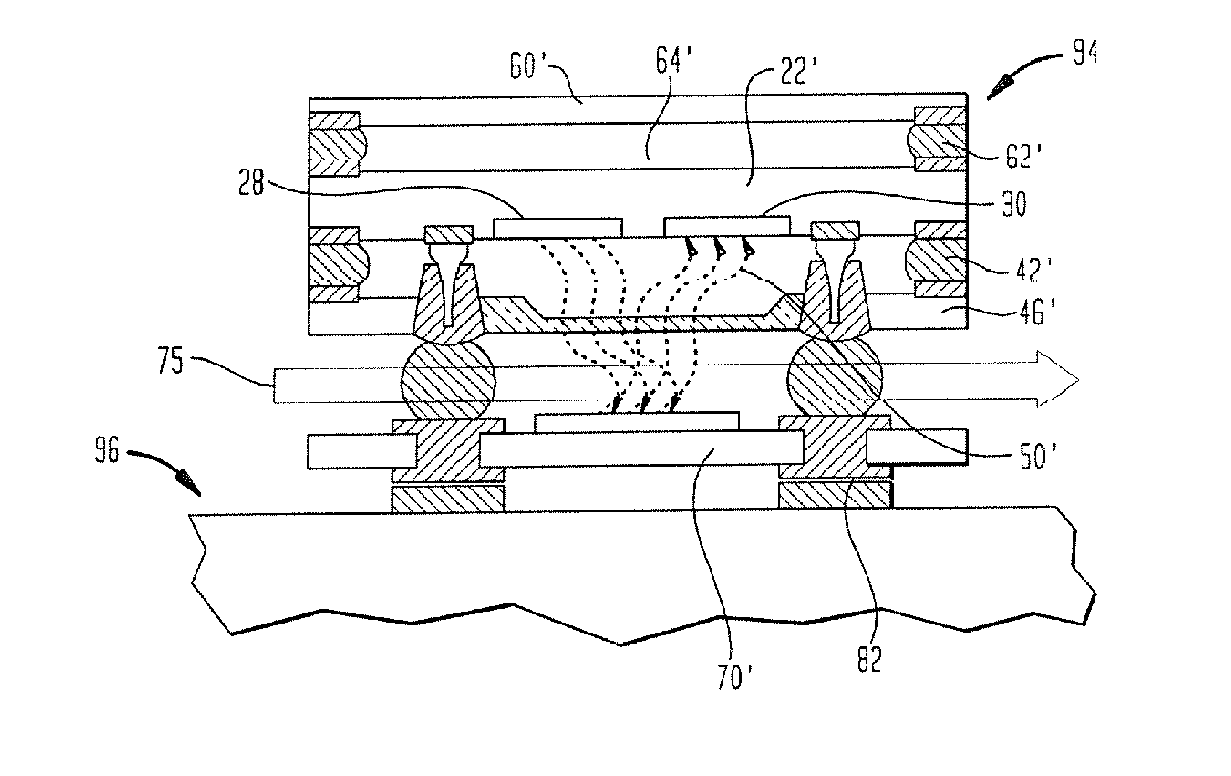

Thermoelectric heat exchanger

InactiveUS6907739B2Air-treating devicesSeat heating/ventillating devicesThermal isolationEngineering

Disclosed is a system for thermally conditioning and pumping a fluid. The system includes a thermoelectric heat exchanger having a thermoelectric device configured to pump heat. Heat exchangers are provided for transferring heat to and from the thermoelectric device and for generating a fluid flow across the thermoelectric device. The conditioned fluid may be placed in thermal communication with a variety of objects, such as a vehicle seat, or anywhere localized heating and cooling are desired. Thermal isolation may also be provided in the direction of flow to enhance efficiency.

Owner:GENTHERM INC

Efficiency thermoelectrics utilizing thermal isolation

InactiveUS20020139123A1Thermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentThermoelectric materialsThermal isolation

An improved efficiency thermoelectric system and method of making such a thermoelectric system are disclosed. Significant thermal isolation between thermoelectric elements in at least one direction across a thermoelectric system provides increased efficiency over conventional thermoelectric arrays. Significant thermal isolation is also provided for at least one heat exchanger coupled to the thermoelectric elements. In one embodiment, the properties, such as resistance or current flow, of the thermoelectric elements may also be varied in at least one direction across a thermoelectric array. In addition, the mechanical configuration of the thermoelectric elements may be varied, in one embodiment, according to dynamic adjustment criteria.

Owner:GENTHERM INC +1

Suspended gas distribution manifold for plasma chamber

InactiveUS20050000432A1Minimize gas leakagePermit some movementElectric discharge tubesSemiconductor/solid-state device manufacturingThermal dilatationThermal isolation

A gas inlet manifold for a plasma chamber having a perforated gas distribution plate suspended by a side wall comprising one or more sheets. The sheets preferably provide flexibility to alleviate stress in the gas distribution plate due to thermal expansion and contraction. In another aspect, the side wall provides thermal isolation between the gas distribution plate and other components of the chamber.

Owner:APPLIED MATERIALS INC

Microbolometer infrared sensors

InactiveUS6359276B1High mechanical strengthReduce residual stressSolid-state devicesMaterial analysis by optical meansThermal isolationMicrobolometer

A microbolometer infrared sensor utilizes a porous silicon bridge as its thermal isolating and mechanical supporting structure. Porous silicon formed from single crystal silicon on lightly doped p-type silicon has a thermal conductivity lower than silicon dioxide and silicon nitride, and, therefore, when used as a mechanical supporting structure, can offer better thermal isolation performance. The porous silicon layer can be fabricated much thicker than silicon dioxide and silicon nitride membranes since there is almost no residual stress therein. A thicker porous silicon bridge has higher mechanical support strength. The porous silicon process is a low temperature process. It facilitates a fabrication strategy of microelectronics first and micromechanics last.

Owner:TU XIANG ZHENG

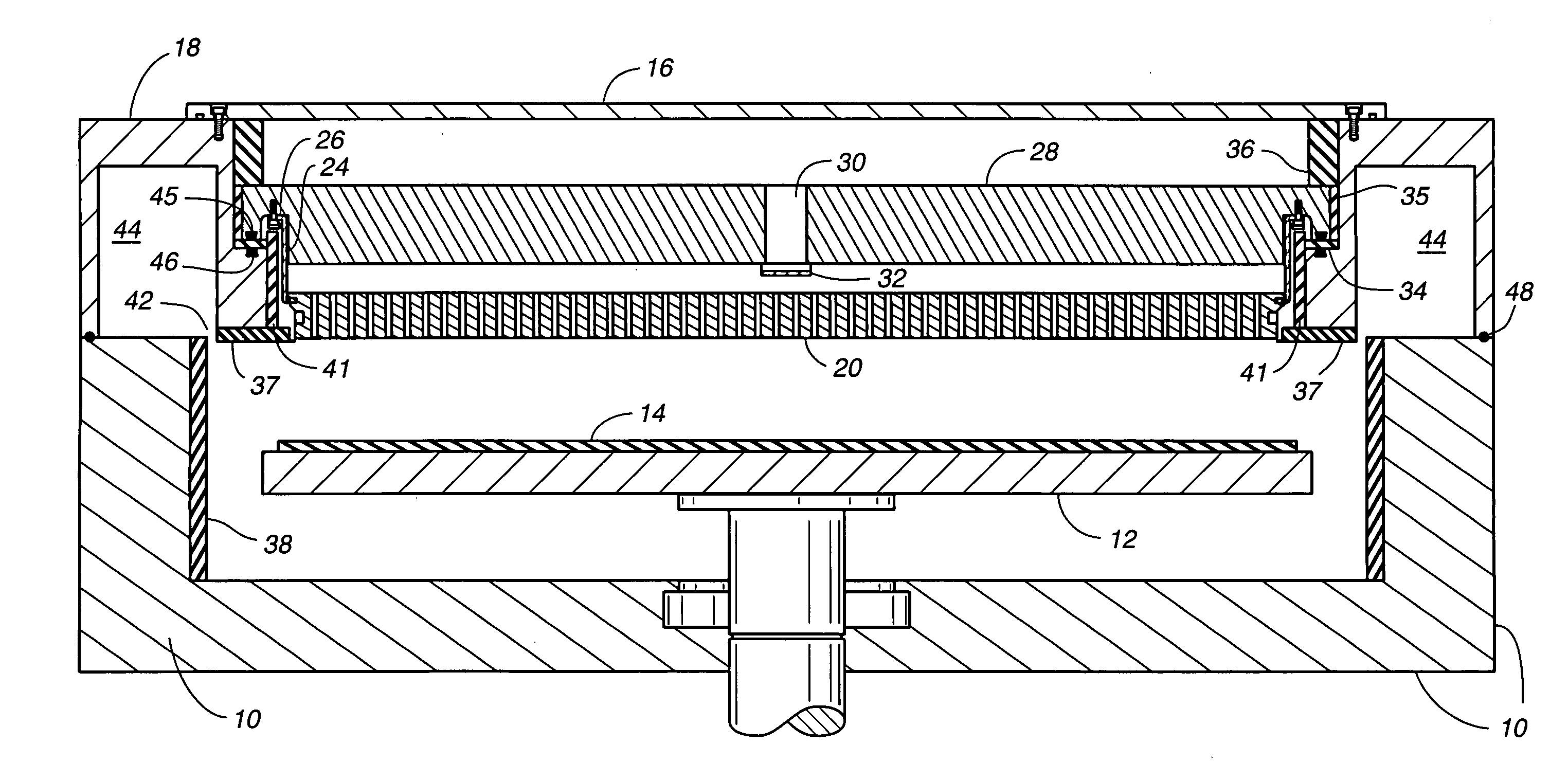

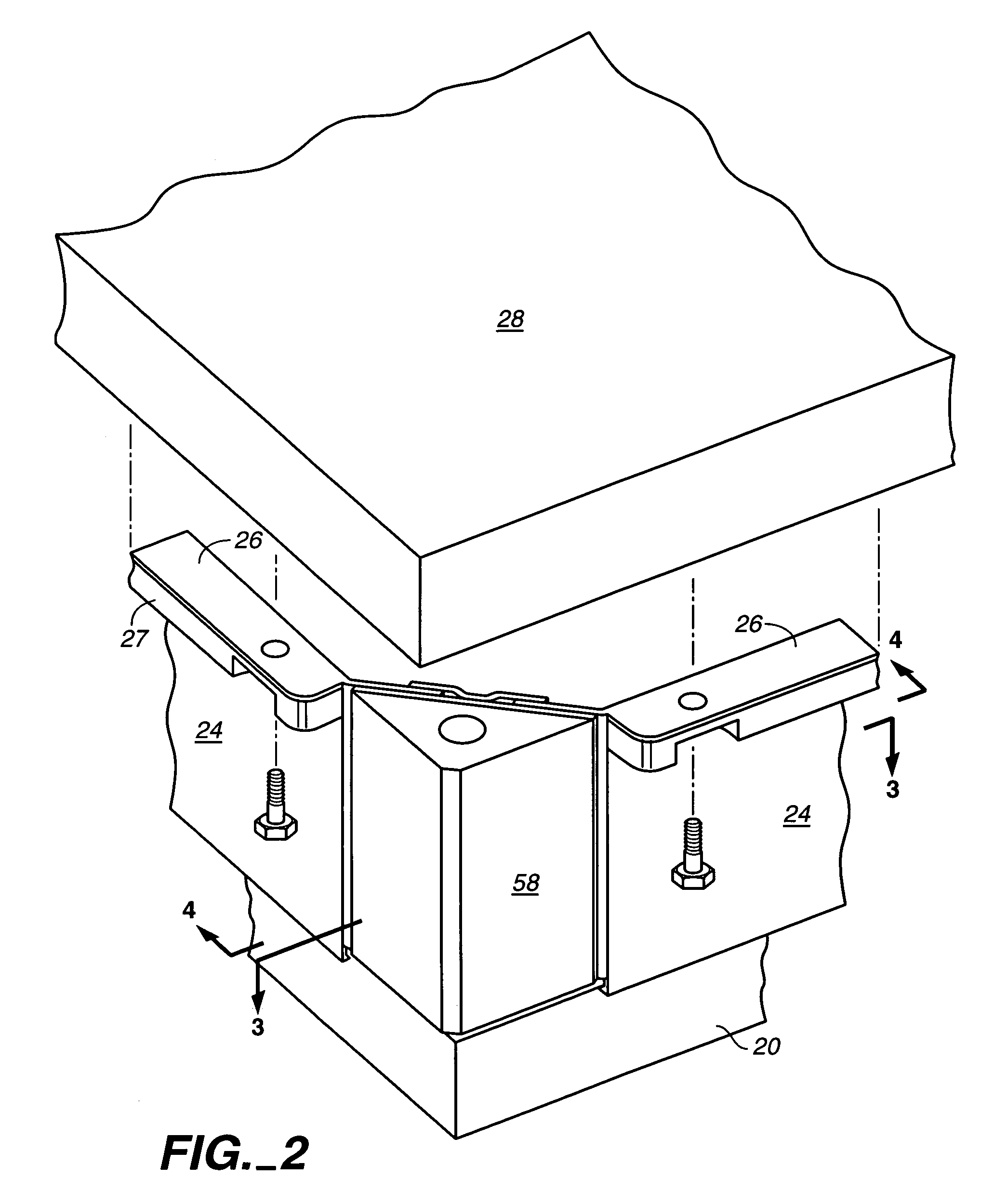

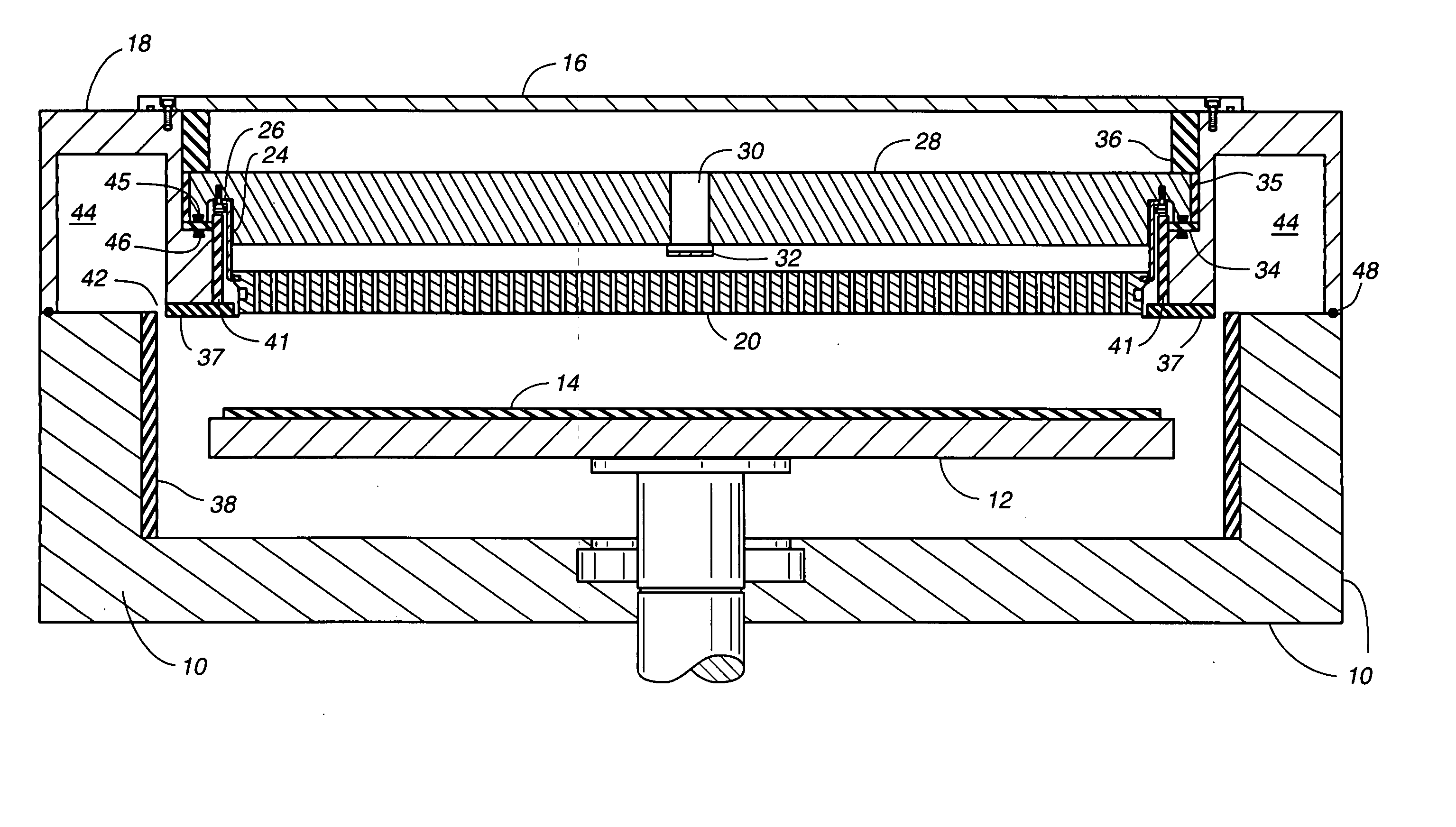

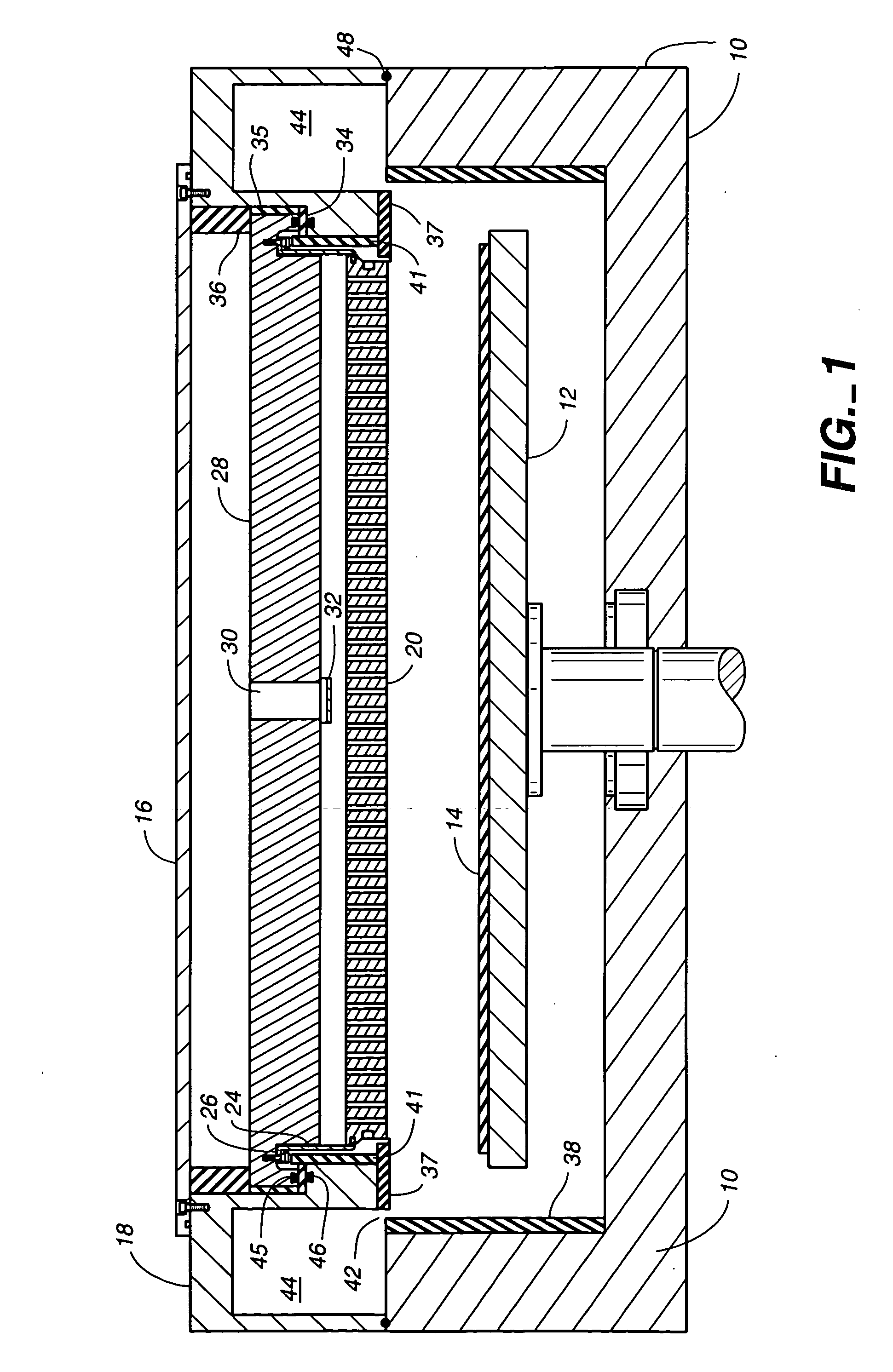

Compact, high-efficiency thermoelectric systems

InactiveUS7231772B2High densityImprove efficiencyThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentThermal isolationEngineering

A number of compact, high-efficiency thermoelectric system utilizing the advantages of thermal isolation in the direction of a working medium flow or movement, in manufacturable systems, are described. Such configurations exhibit high system efficiency and power density. Several different embodiments and applications are disclosed utilizing a plurality of thermoelectric modules or thermoelectric elements sandwiched between heat exchangers.

Owner:GENTHERM INC

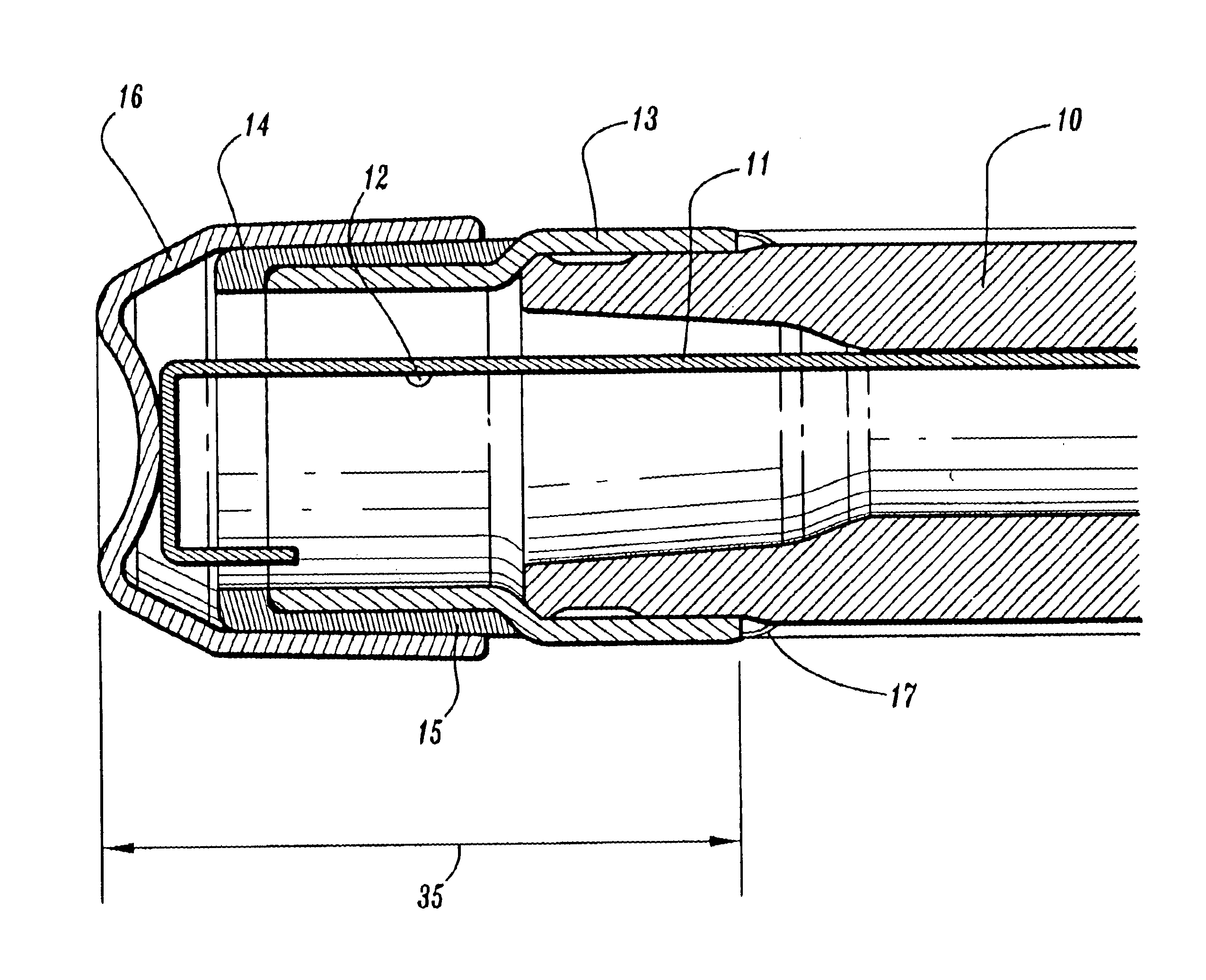

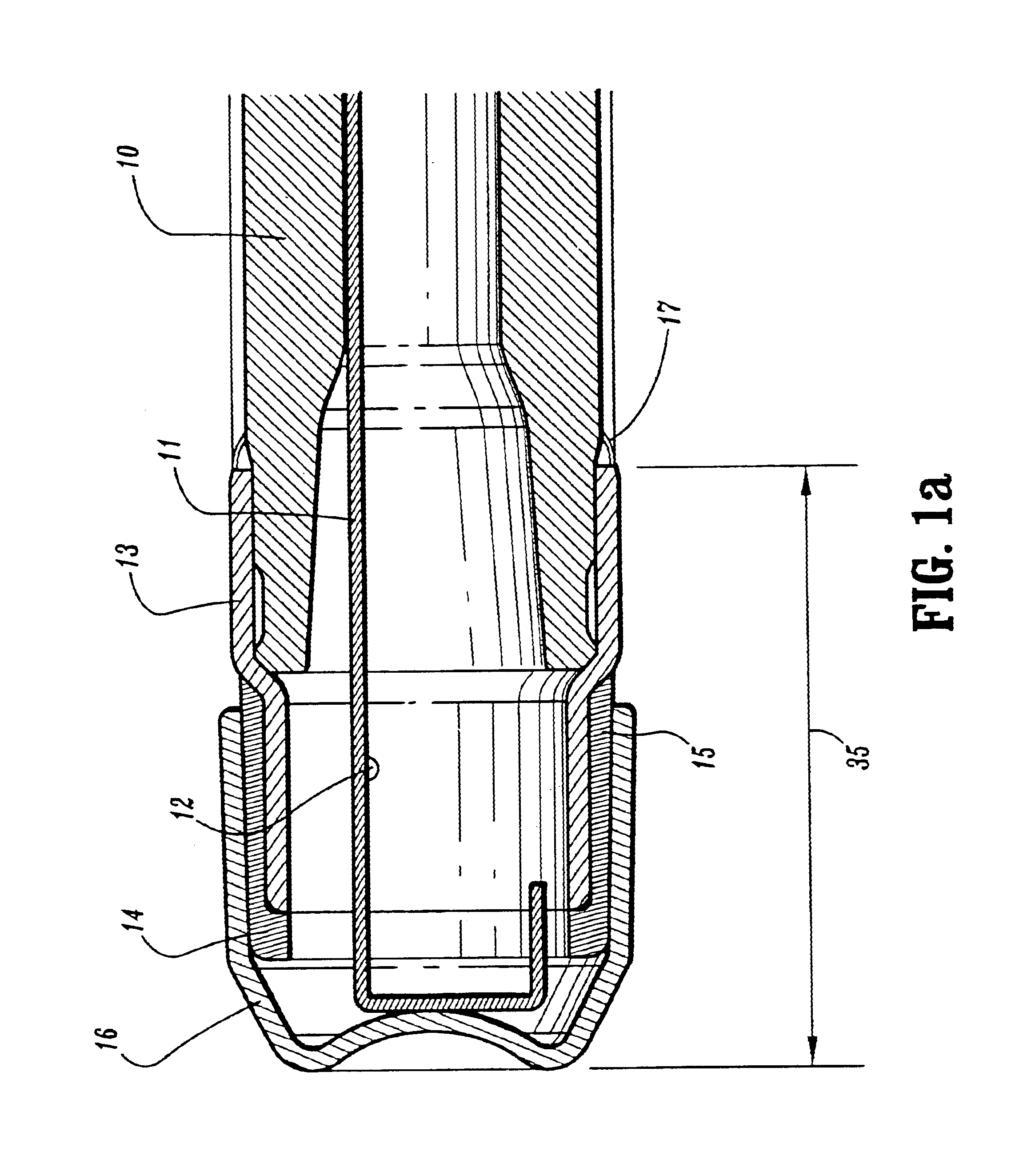

Probe tip thermal isolation and fast prediction algorithm

InactiveUS6839651B2Increase temperatureQuickly reachThermometer detailsRadiation pyrometryThermal isolationPrediction algorithms

A prediction type electronic thermometer having an actively controlled heater element thermally isolating the probe tip from the probe shaft. Rapid and accurate temperature measurements are made using predictive algorithms. Control circuitry reads input from the temperature sensing element to compute best heater control signals so that the temperature of the probe shaft rapidly follows changes in the temperature of the probe tip. Thermal isolation between probe shaft and tip impedes heat flow from the heater element to the tip providing more accurate measurements. Rapid and accurate management of shaft temperature allows heat from the patient being measured to be most efficiently transmitted to the temperature sensor element resulting in very fast temperature measurements.

Owner:CARDINAL HEALTH IRELAND UNLTD

Directly viewable luminaire

ActiveUS20050207166A1Constant brightnessPlanar light sourcesMechanical apparatusThermal isolationPoint light

The present invention provides a luminaire comprising an housing having thermally separate compartments for an electronics portion and a lighting portion. These thermally separate compartments can provide a means for providing thermal isolation between the respective components, namely the electronics portion and the lighting portion. In this manner thermal interaction between these portions can be reduced, thereby improving performance of the luminaire. The lighting portion comprises a plurality of light-emitting elements and further includes optics for the manipulation of illumination created by the light-emitting elements. A power supply for supply of energy to the light-emitting elements and a controller for controlling application of energy from a power source to the light-emitting elements is provided in the electronics portion and can be thermally separated within the electronics portion. Moreover, an optical device comprising two linear diffuser elements can be used to further improve the light emission characteristics of the light-emitting elements thereby providing a directly viewable luminaire wherein the illumination produced by point light sources appears uniform along the length of the luminaire.

Owner:SIGNIFY HLDG BV

Thermoelectric heat exchanger

Disclosed is a system for thermally conditioning and pumping a fluid. The system includes a thermoelectric heat exchanger having a thermoelectric device configured to pump heat. Heat exchangers are provided for transferring heat to and from the thermoelectric device and for generating a fluid flow across the thermoelectric device. The conditioned fluid may be placed in thermal communication with a variety of objects, such as a vehicle seat, or anywhere localized heating and cooling are desired. Thermal isolation may also be provided in the direction of flow to enhance efficiency.

Owner:GENTHERM INC

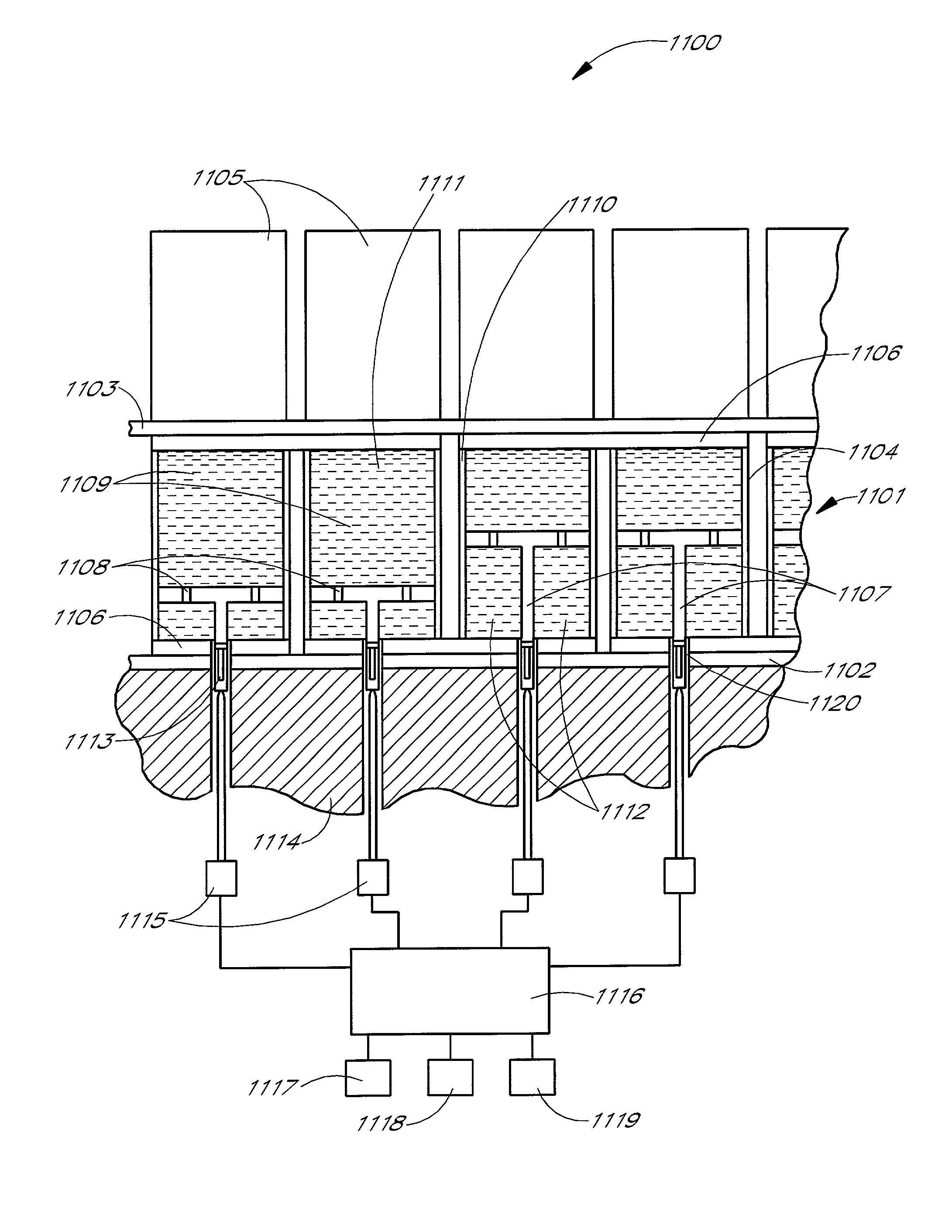

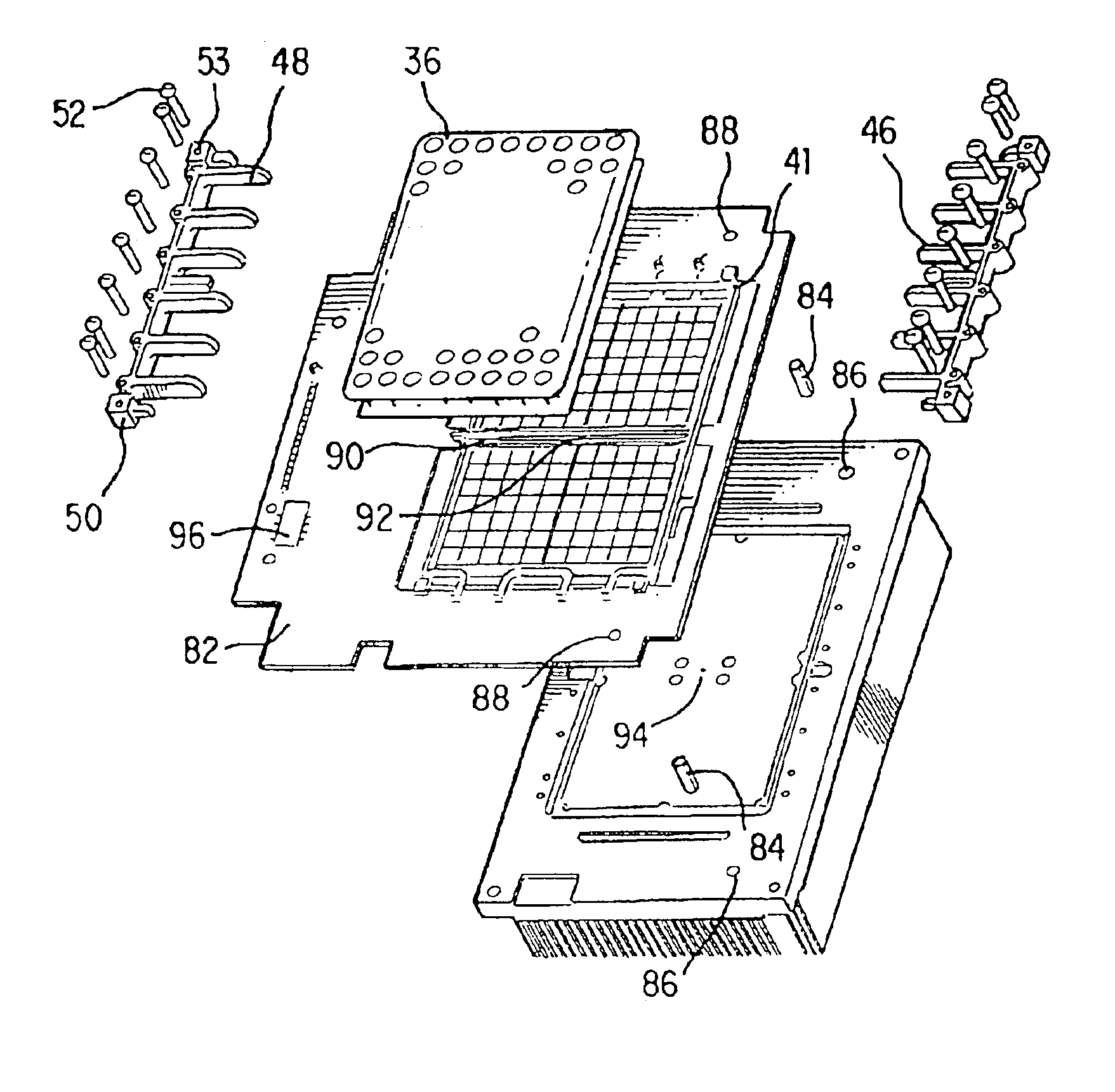

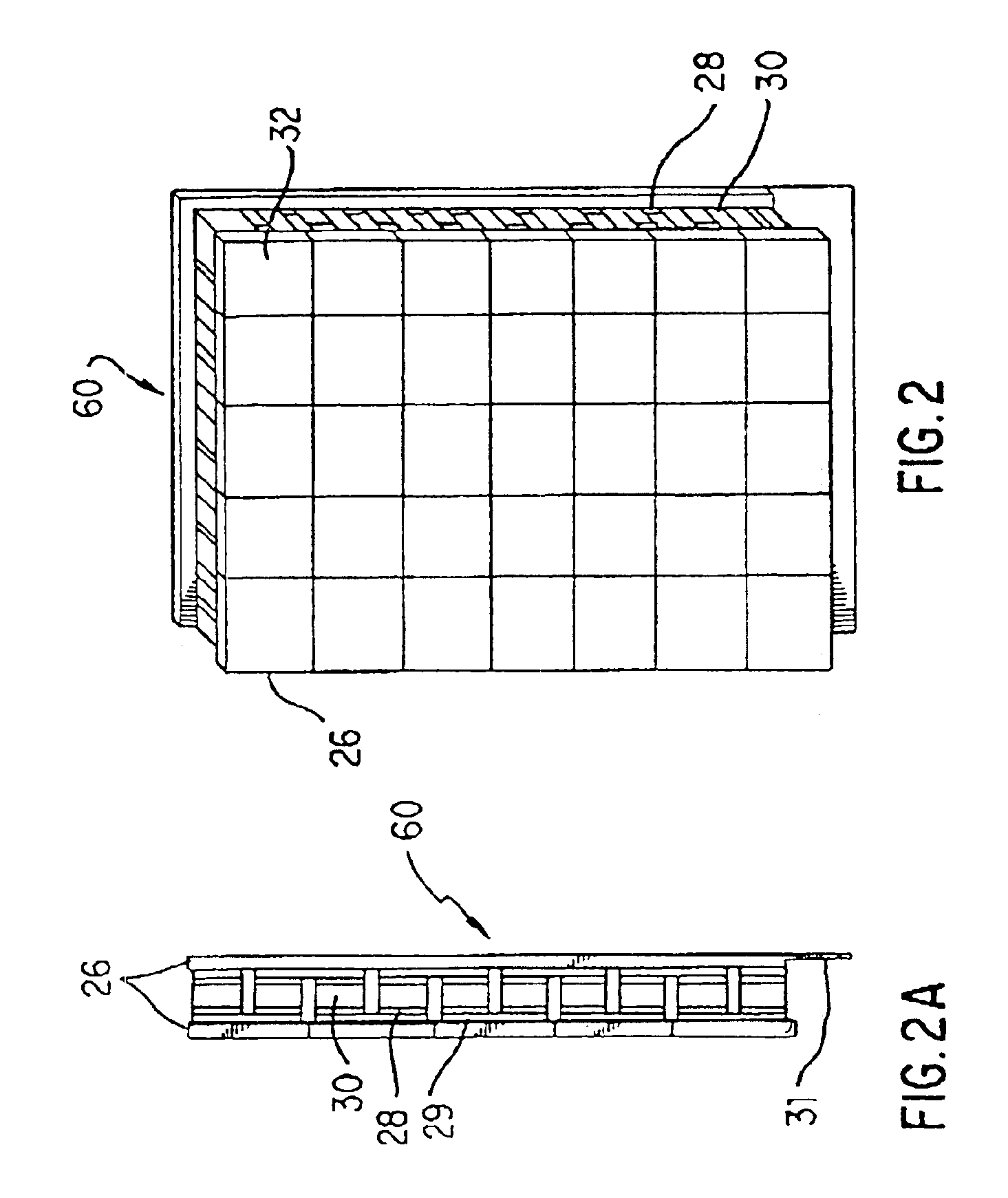

Thermal cycler for PCR

InactiveUS7133726B1Limit heat conductionMinimize thermal non-uniformityHeating or cooling apparatusThermoelectric device with peltier/seeback effectThermal isolationEvaporation

An instrument for PCR comprising an assembly, a heated cover, and a computer. The assembly can include a sample block, Peltier devices, and a heat sink, clamped together. The sample block temperature can be changed by controlling the Peltier devices with the computer. A perimeter heater can be used to in prove thermal uniformity. A heated platen can push down onto tube caps to apply a minimum force for seating the tubes. The force can be applied about the periphery of the tube caps to prevent distortion of the caps. The platen can be heated to provide thermal isolation and prevent evaporation from the surface of the sample. The software can include diagnostics to compensate for variation in thermoelectric coolers such that all instruments can perform identically.

Owner:APPL BIOSYSTEMS INC

Thermal cycler for PCR

InactiveUS20050145273A1Limit heat conductionMinimize thermal non-uniformityHeating or cooling apparatusThermoelectric device with peltier/seeback effectThermal isolationThermoelectric cooling

An instrument for performing highly accurate PCR employing an assembly, a heated cover and an internal computer. The assembly is made up of a sample block, a number of Peltier thermal electric devices and heat sink, clamped together. The sample block temperature is changed exclusively by the thermoelectric devices controlled by the computer. The sample block is of low thermal mass and is constructed of silver. The Peltier devices are designed to provide fast temperature excursions over a wide range. The heat sink has a perimeter trench to minimize edge losses and is adjacent to a continuously variable fan. A perimeter heater is used to improve the thermal uniformity across the sample block to approximately ±0.2° C. A heated platen pushes down onto the tube caps to apply a minimum acceptable force for seating the tubes into the block, ensuring good thermal contact with the block. The force is applied about the periphery of the tube caps to prevent distortion of the caps during thermal cycling. The platen is heated to provided thermal isolation from ambient conditions and to prevent evaporation from the surface of the sample into the upper portion of the sample tube. A control algorithm manipulates the current supplied to the thermoelectric coolers such that the dynamic thermal performance of the block can be controlled so that pre-defined thermal profiles for the sample temperature can be executed. The sample temperature is calculated instead of measured using a design specific model and equations. The control software includes calibration diagnostics which permit variation in the performance of thermoelectric coolers from instrument to instrument to be compensated for such that all instruments perform identically. The block / heat sink assembly can be changed to another of the same or different design. The assembly carries the necessary information required to characterize its own performance in an on-board memory device, allowing the assembly to be interchangeable among instruments while retaining its precision operating characteristics. The instrument has a graphical user interface. The instrument monitors the thermoelectric devices and warns of changes in resistance that may result in failure.

Owner:APPL BIOSYSTEMS INC

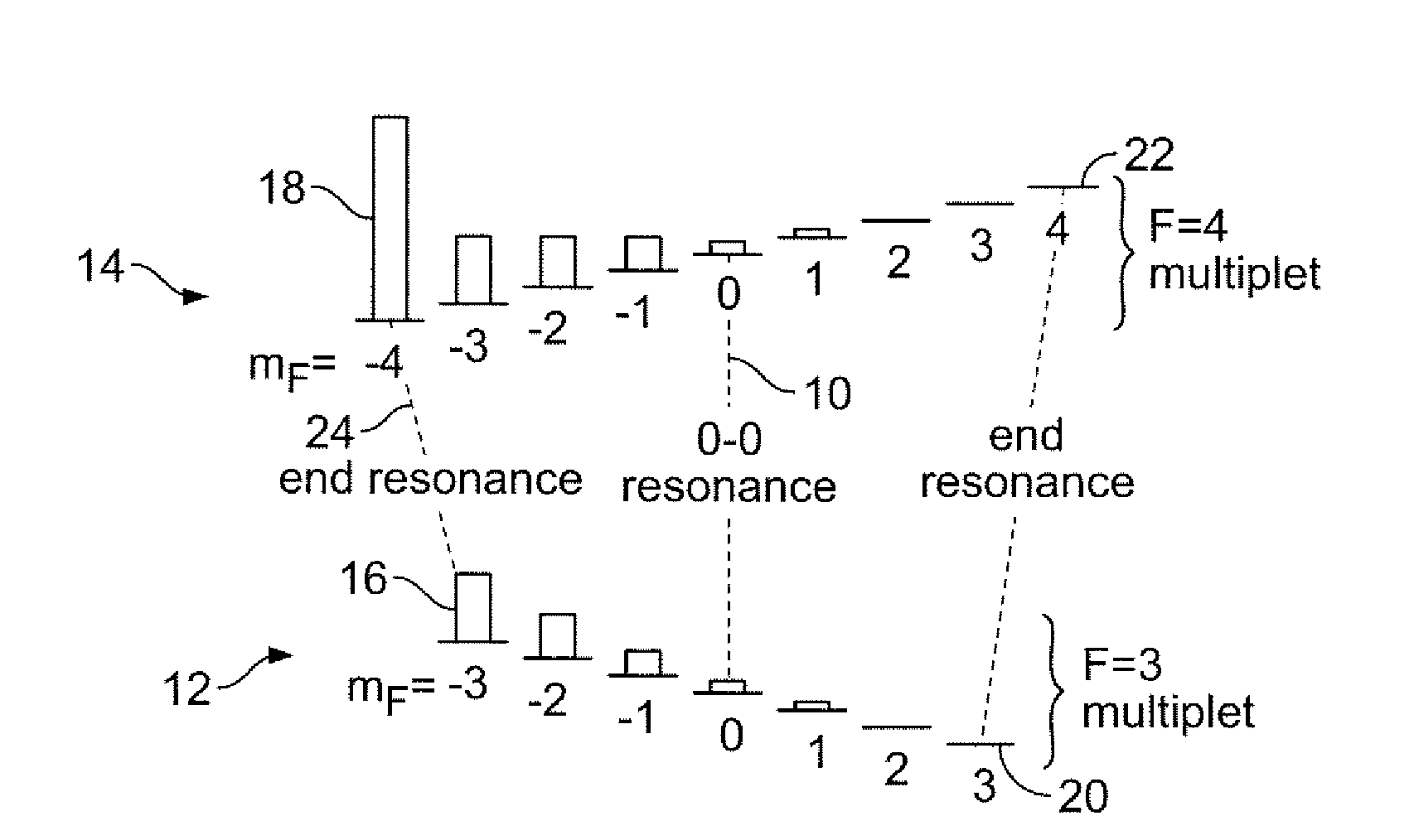

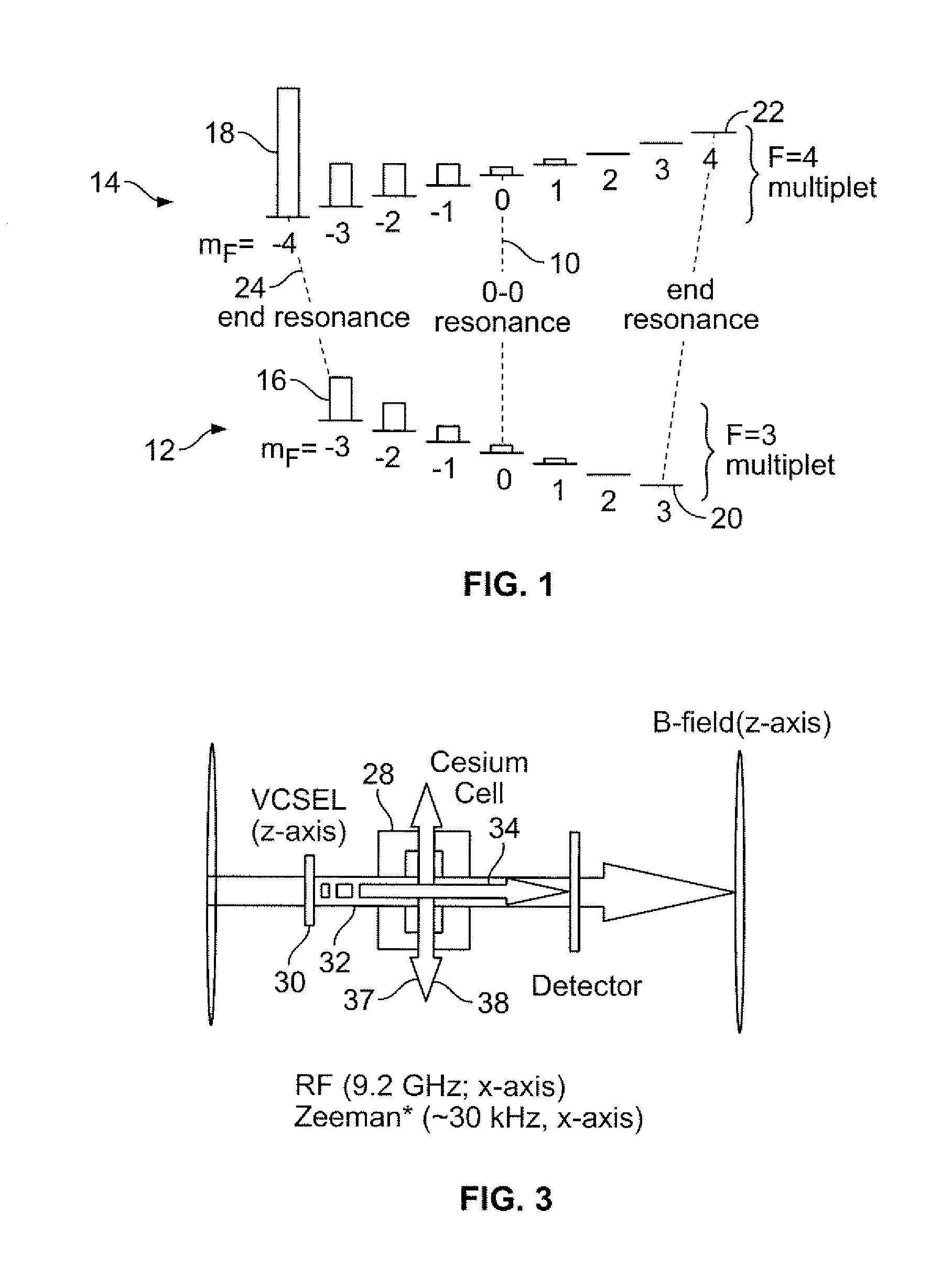

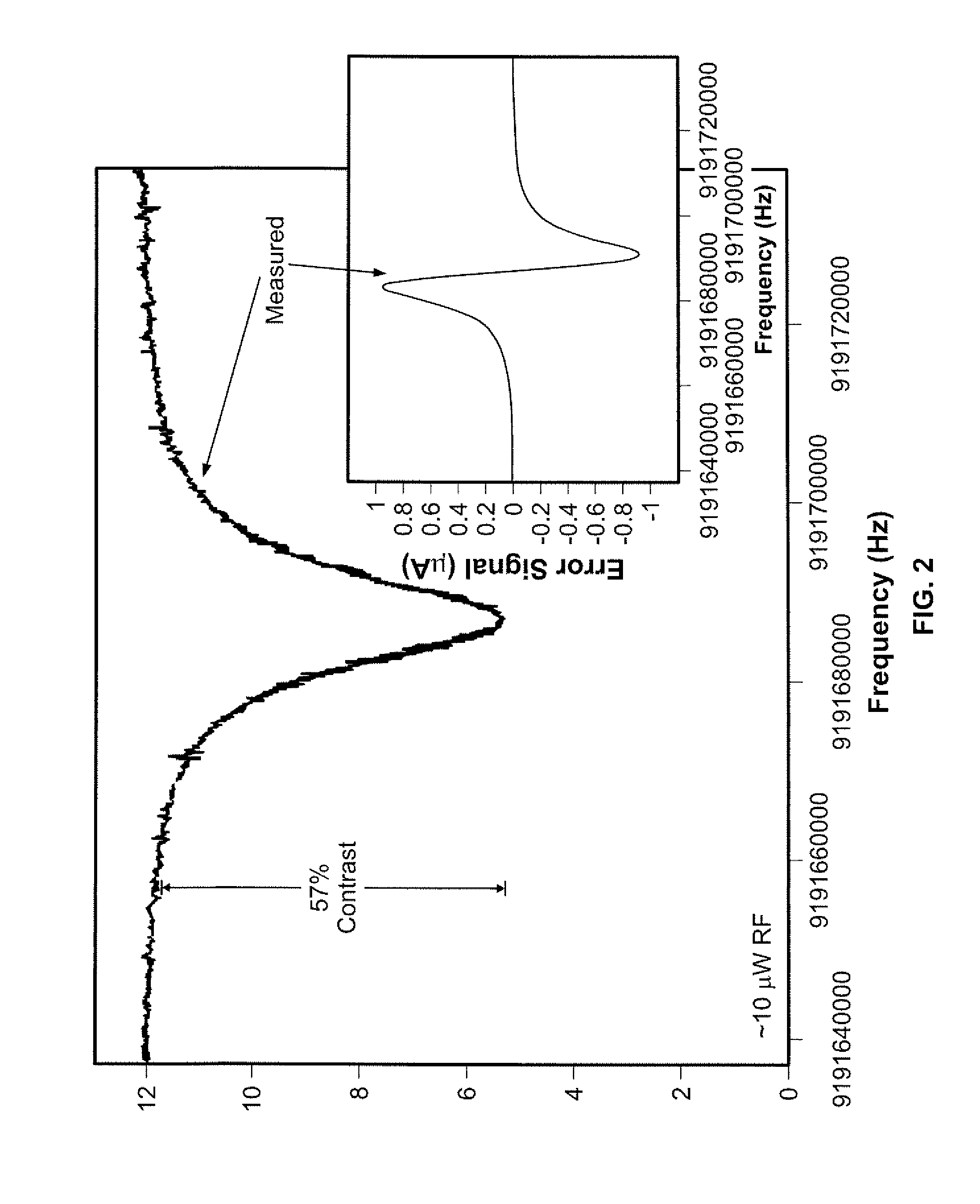

Batch-fabricated, rf-interrogated, end transition, chip-scale atomic clock

InactiveUS20070247241A1Increased signal noiseApparatus using atomic clocksPulse automatic controlThermal isolationVertical-cavity surface-emitting laser

A chip scale atomic clock is disclosed that provides a low power atomic time / frequency reference that employs direct RF-interrogation on an end-state transition. The atomic time / frequency reference includes an alkali vapor cell containing alkali atoms, preferably cesium atoms, flex circuits for physically supporting, heating, and thermally isolating the alkali vapor cell, a laser source for pumping alkali atoms within the alkali vapor cell into an end resonance state by applying an optical signal along a first axis, a photodetector for detecting a second optical signal emanating from the alkali vapor cell along the first axis, a pair of RF excitation coils for applying an RF-interrogation signal to the alkali atoms along a second axis perpendicular to the first axis, a pair of bias coils for applying a uniform DC magnetic field along the first axis, and a pair of Zeeman coils for applying a Zeeman interrogation signal to the alkali atoms and oriented and configured to apply a time-varying magnetic field along the second axis through the alkali vapor cell. Another flex circuit is used for physically supporting the laser source, for heating the laser source, and for providing thermal isolation of the laser source. The laser source can be a vertical cavity surface emitting laser (VSCEL). The bias coils can be Helmholtz coils.

Owner:SRI INTERNATIONAL

Vacuum jacketed electrode for phase change memory element

ActiveUS7479649B2Improve insulation performanceDigital storageBulk negative resistance effect devicesThermal isolationPhase-change memory

Owner:MACRONIX INT CO LTD

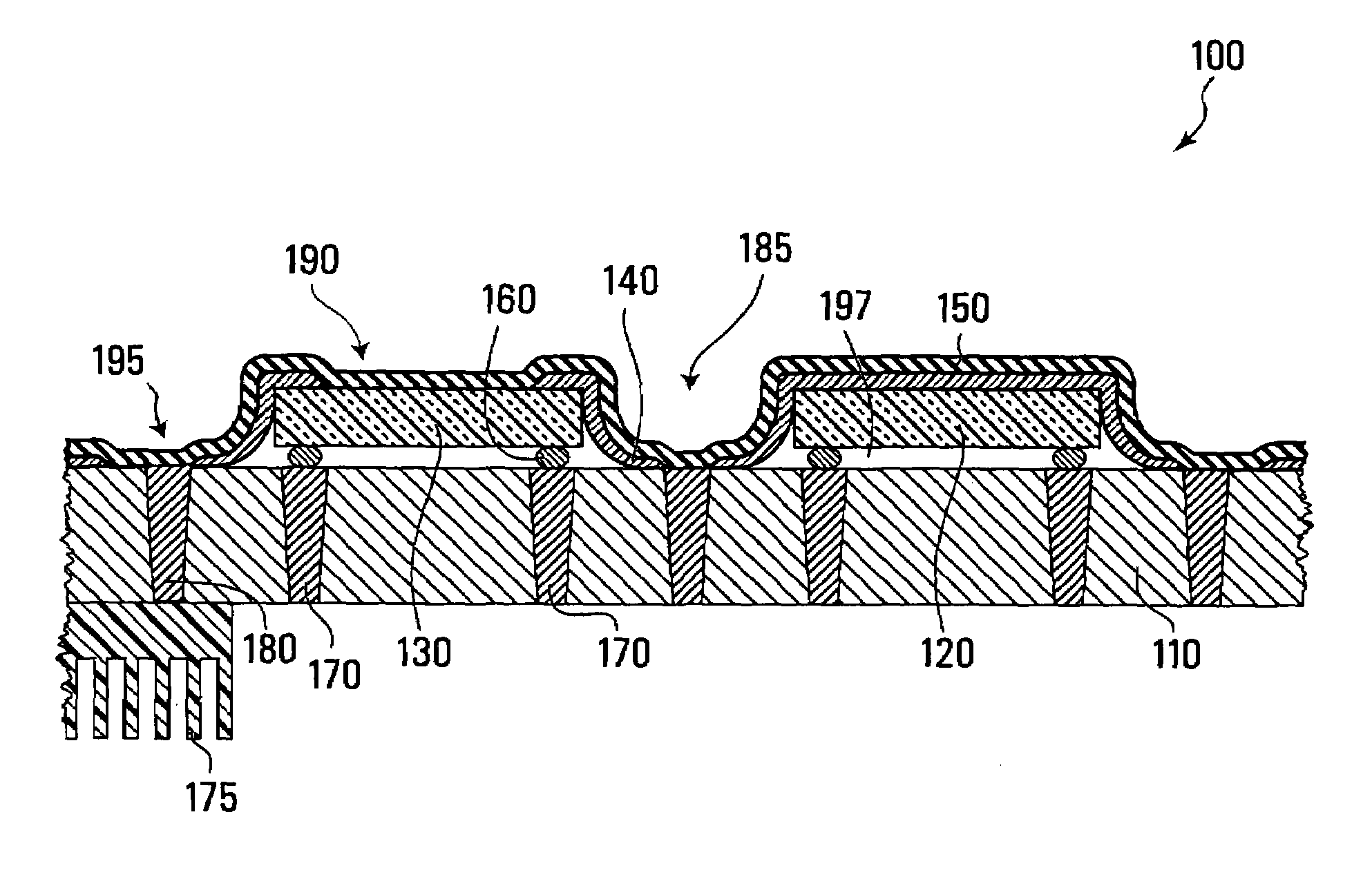

Wafer level microelectronic packaging with double isolation

InactiveUS20060081983A1Improved thermal isolationSemiconductor/solid-state device detailsSolid-state devicesThermal isolationAnalyte

A microelectronic package may include front and rear covers overlying the front and rear surfaces of a microelectronic element such as an infrared sensor and spaces between the microelectronic element and the covers to provide thermal isolation. A sensing unit including a microelectronic package may include a reflector spaced from the front cover to provide an analyte space, and the microelectronic element may include an emitter and a detector so that radiation directed from the emitter will be reflected by the sensor to the detector, and such radiation will be affected by the properties of the analyte in the analyte space. Such a unit provides a compact, economical chemical sensor. Other packages include elements such as valves for passing fluids into and out of the spaces within the package itself.

Owner:TESSERA INC

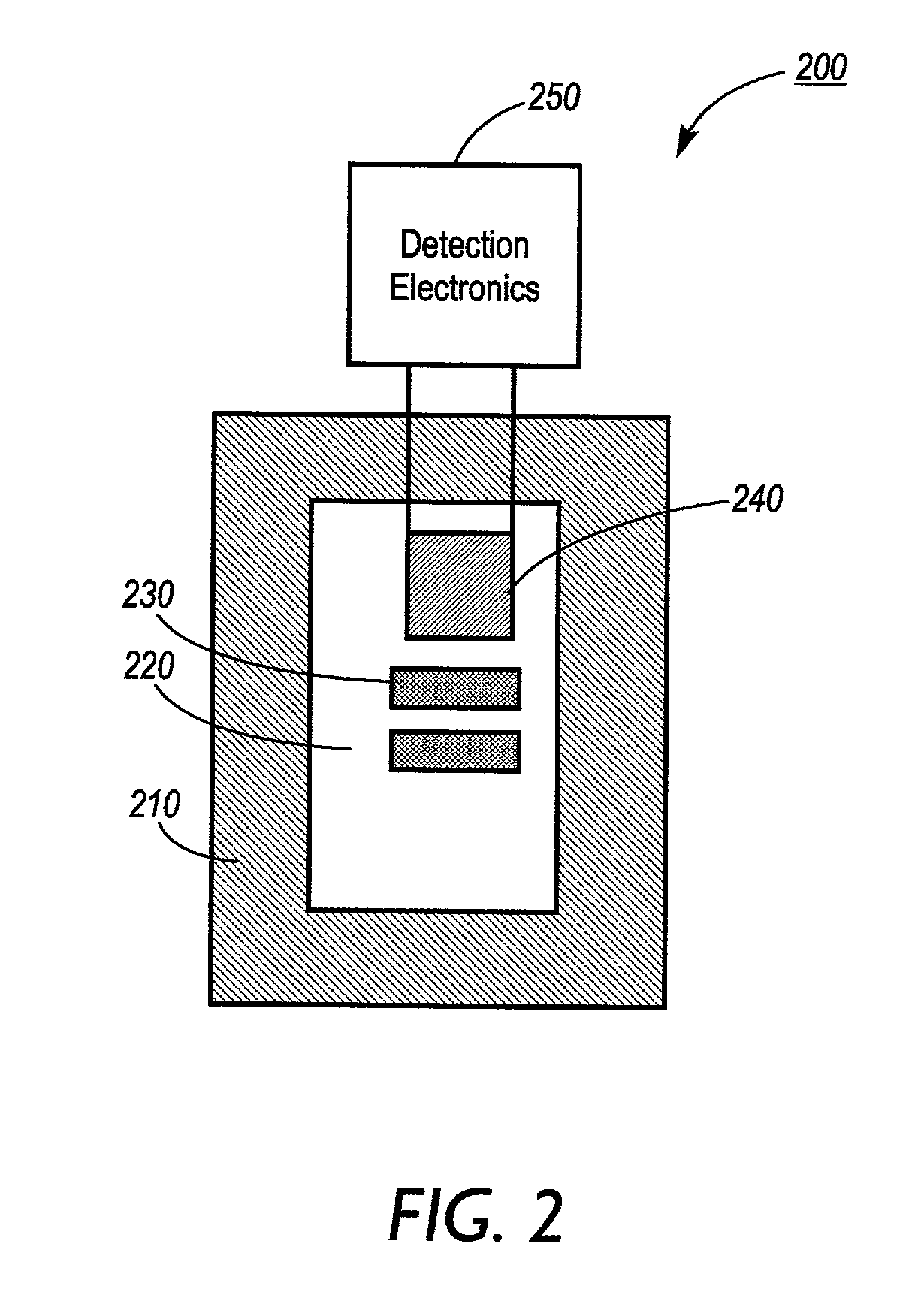

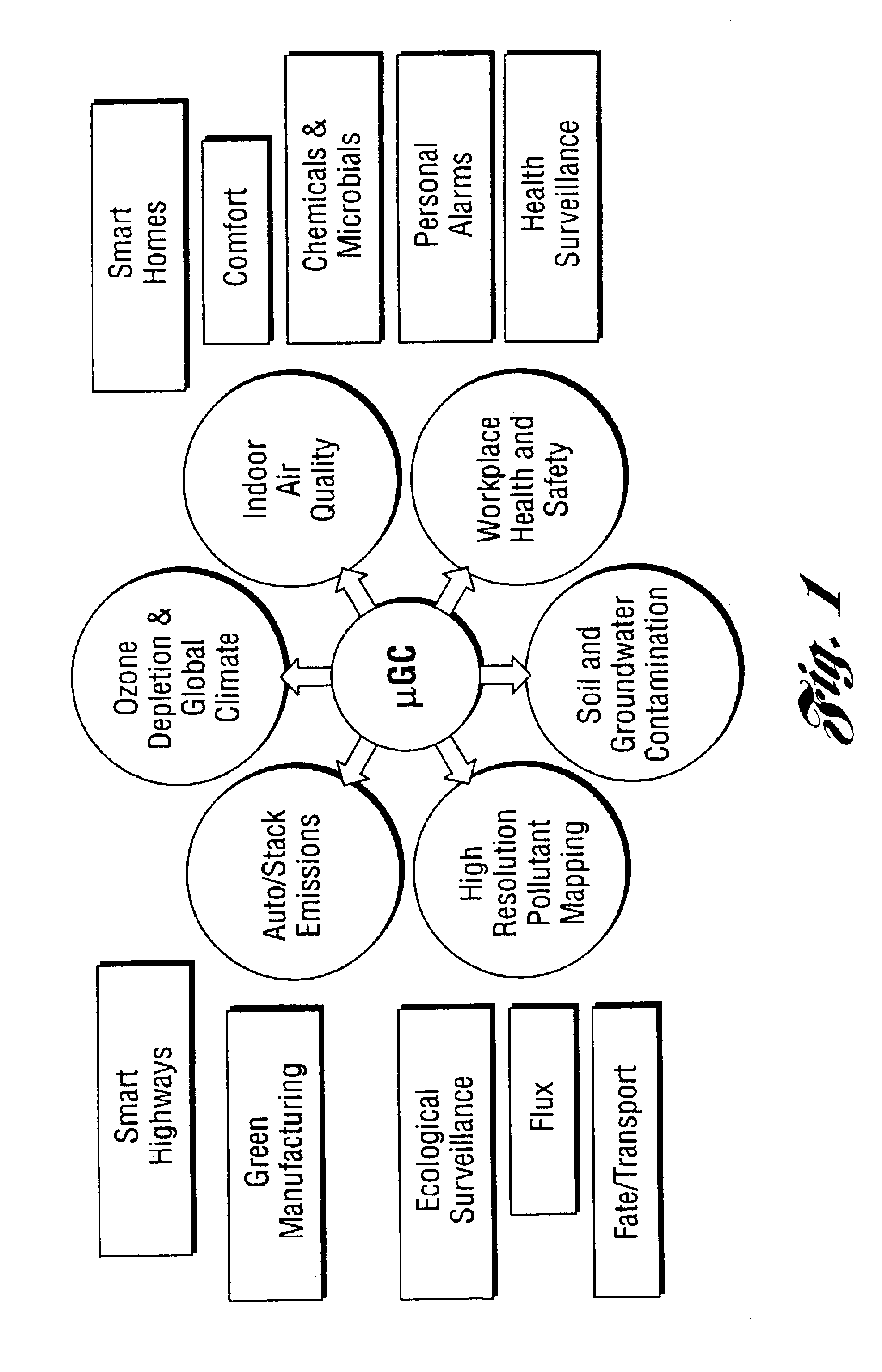

Apparatus and method for a nanocalorimeter for detecting chemical reactions

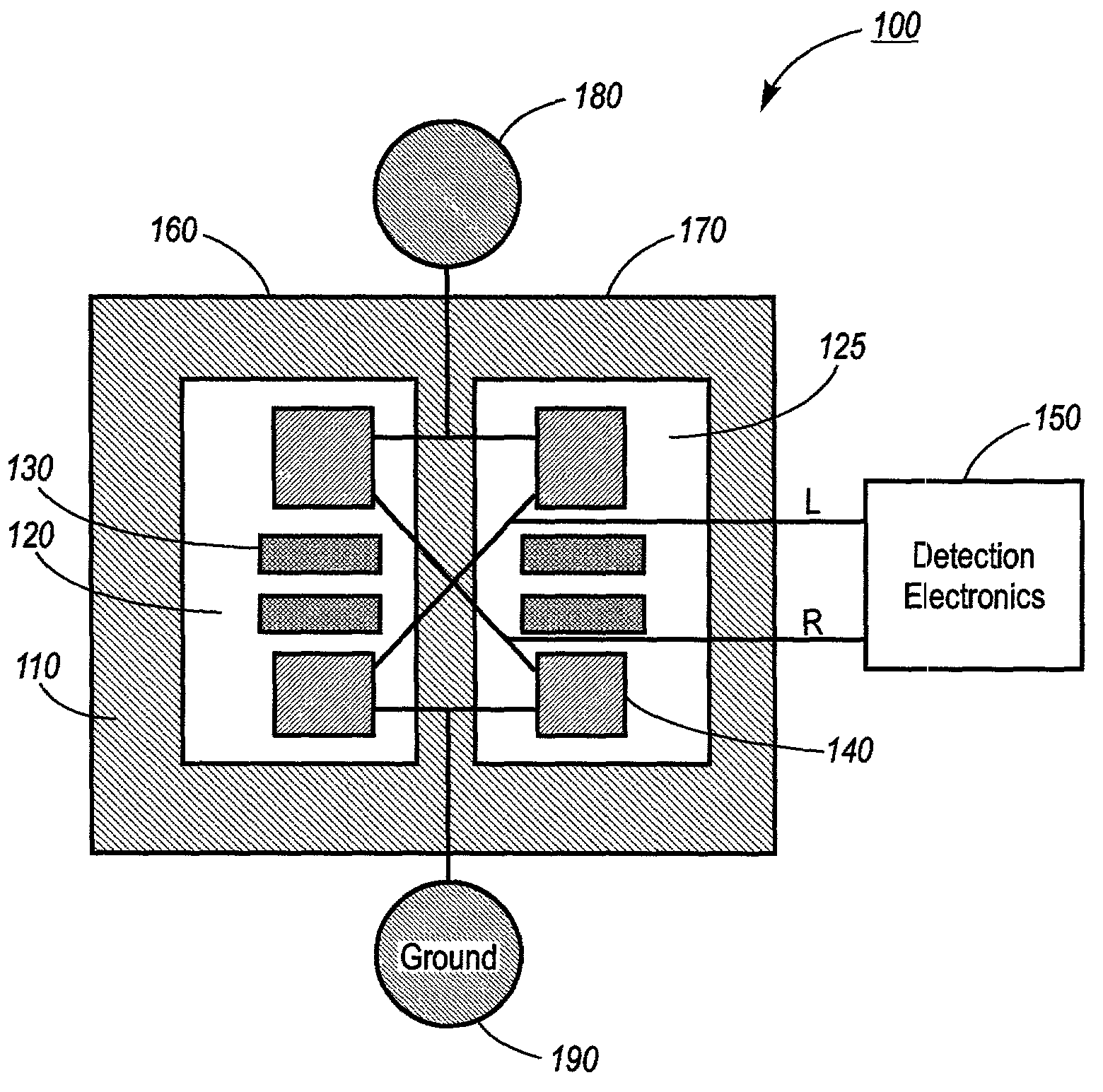

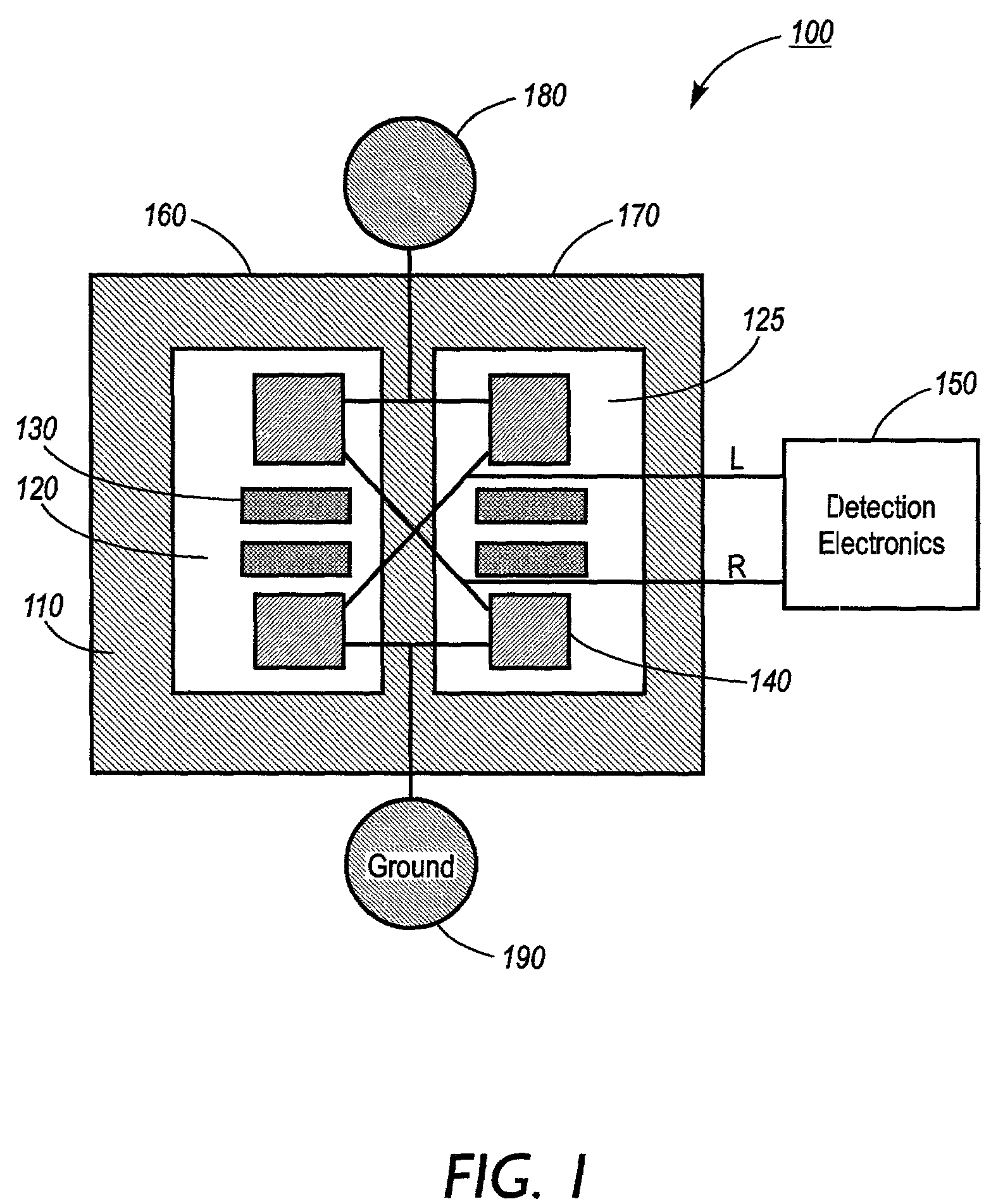

ActiveUS7141210B2Microbiological testing/measurementMaterial heat developmentThermal isolationChemical reaction

A nanocalorimeter array for detecting chemical reactions includes at least one thermal isolation region residing on a substrate. Each thermal isolation region includes at least one thermal equilibration region, within which resides a thermal measurement device connected to detection electronics.

Owner:XEROX CORP

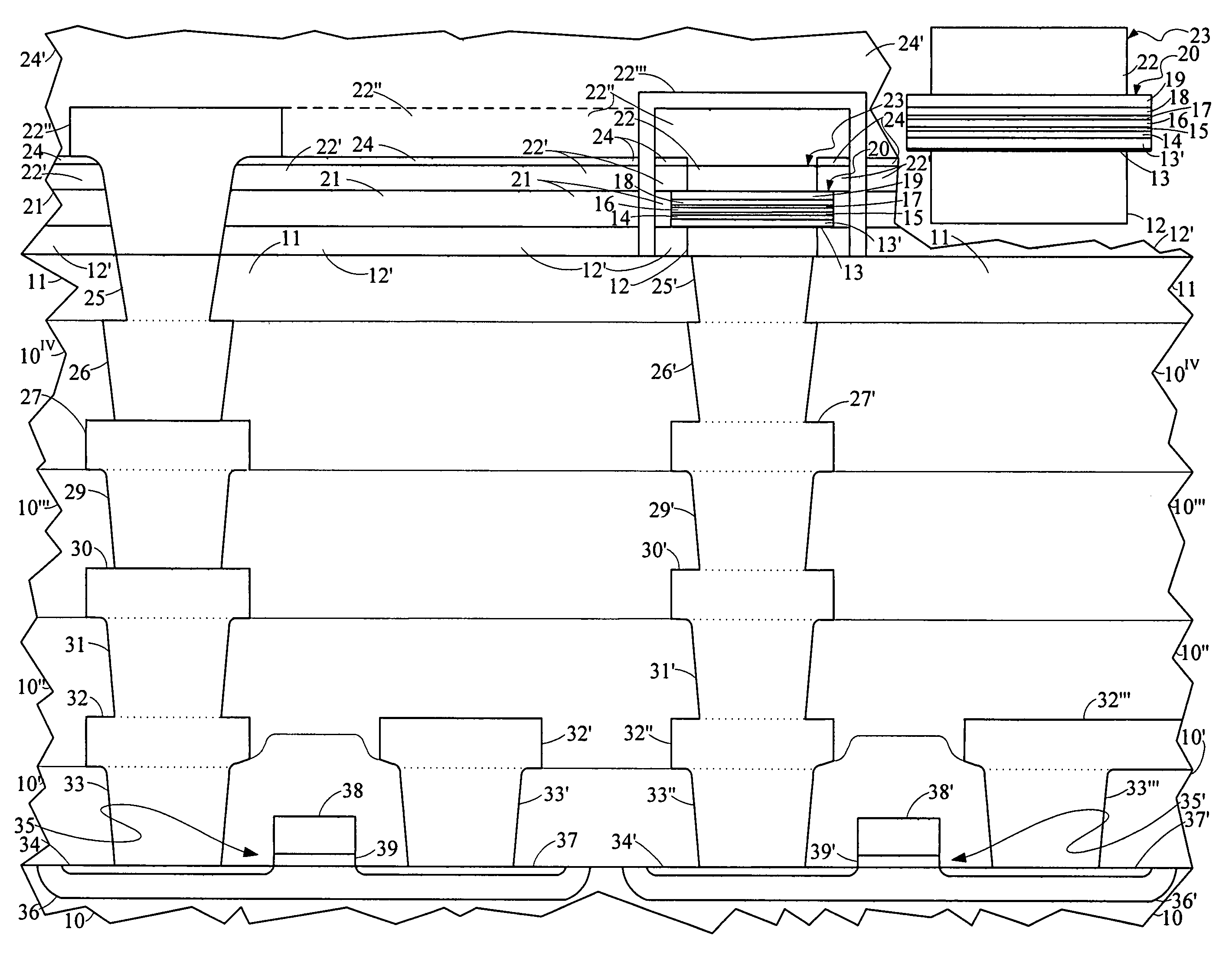

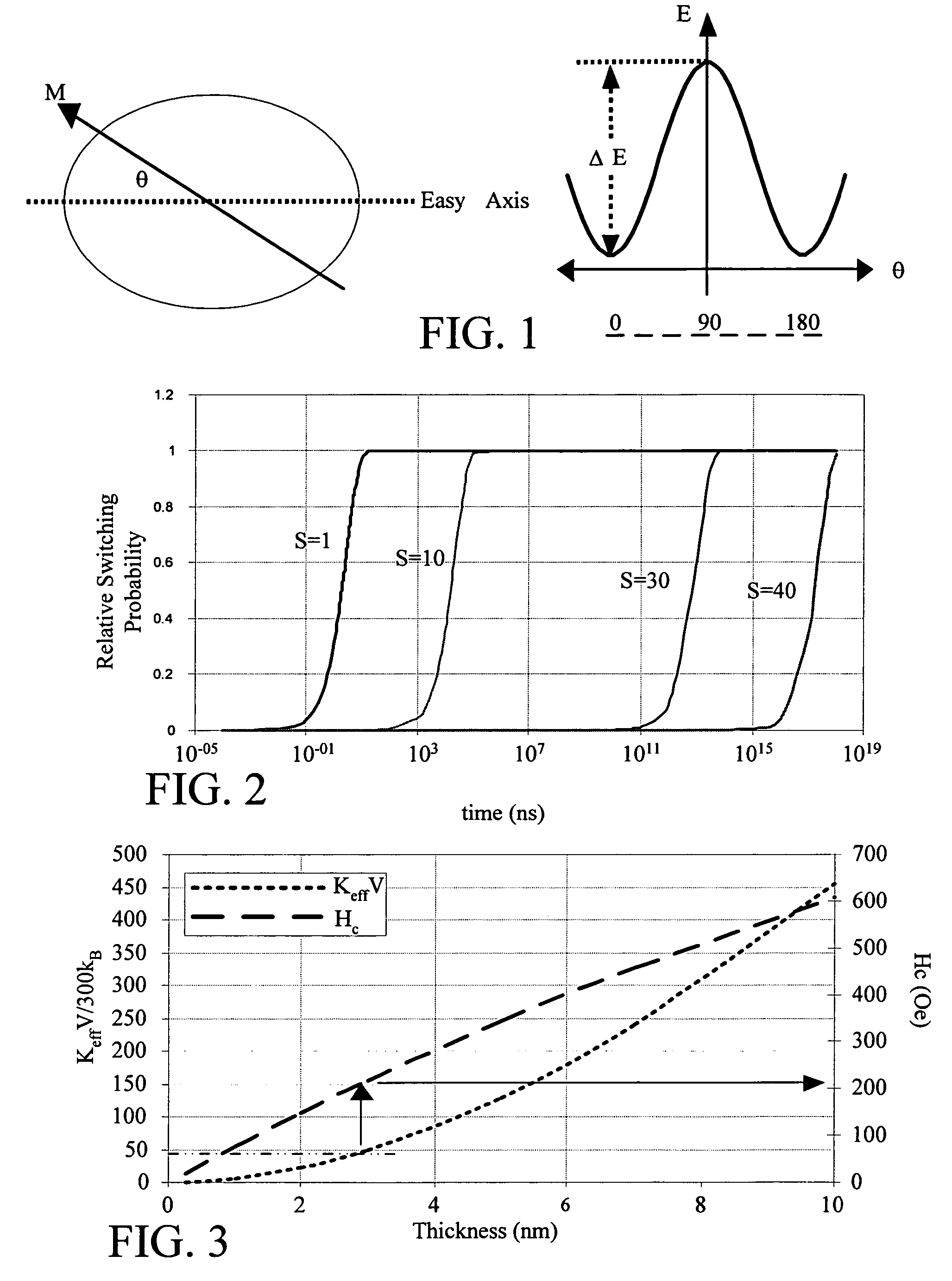

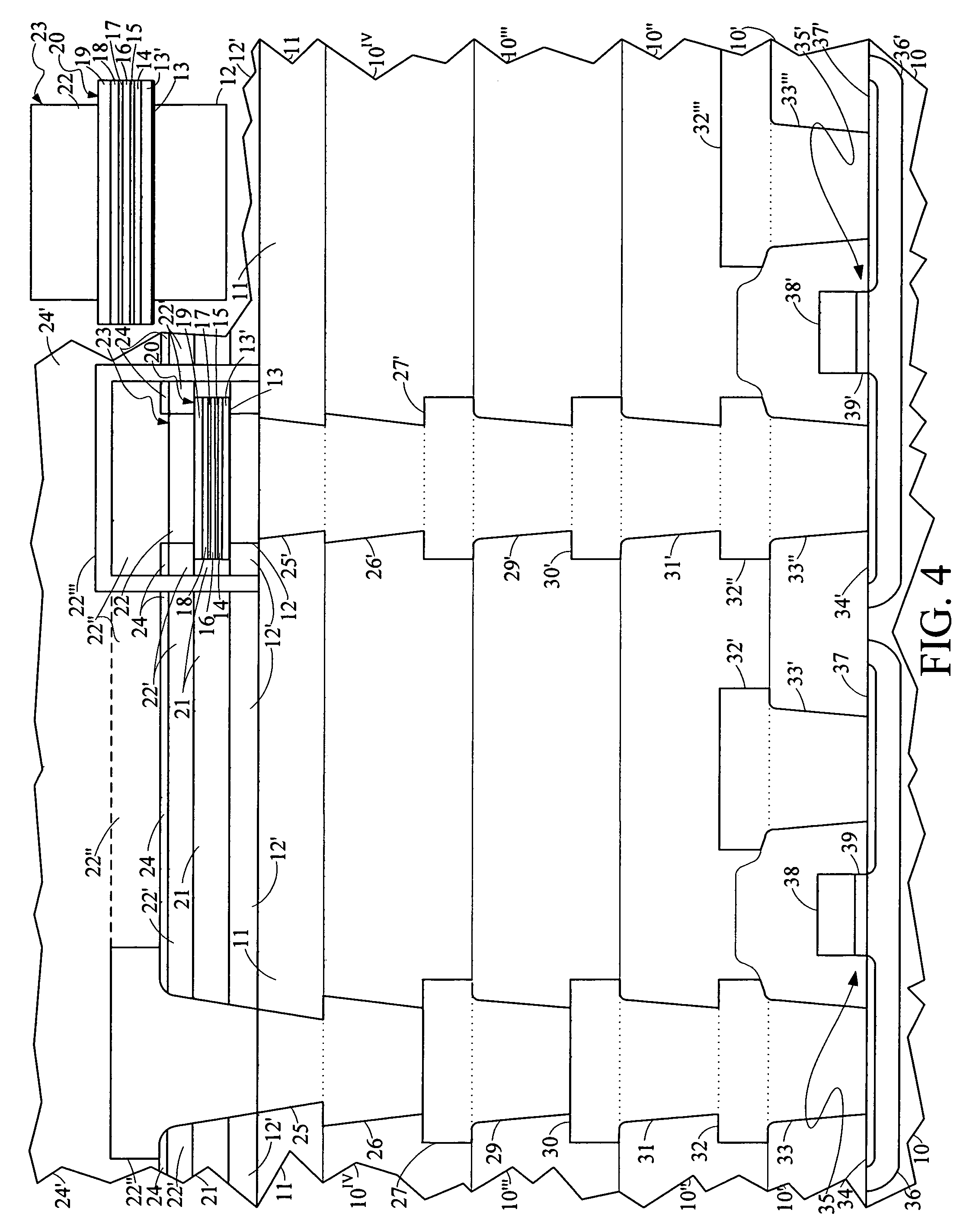

Thermomagnetically assisted spin-momentum-transfer switching memory

A ferromagnetic thin-film based digital memory having a substrate supporting bit structures that are electrically interconnected with information storage and retrieval circuitry and having first and second oppositely oriented relatively fixed magnetization layers and a ferromagnetic material film in which a characteristic magnetic property is substantially maintained below an associated critical temperature above which such magnetic property is not maintained. This ferromagnetic material film is separated from the first and second fixed magnetization films by corresponding layers of a nonmagnetic materials one being electrically insulative and that one remaining being electrically conductive. Each bit structure has an interconnection structure providing electrical contact thereto at a contact surface thereof substantially parallel to the intermediate layer positioned between the first contact surface and the substrate. A plurality of word line structures located across from a corresponding one of the bit structures on an opposite side. Electrical current selectively drawn through each of these bit structures and its interconnection structure can cause substantial heating of that bit structure to raise temperatures thereof while being above temperatures of at least an adjacent said bit structure because of sufficient thermal isolation.

Owner:NVE CORP

Methods for integrated circuit module packaging and integrated circuit module packages

ActiveUS7445968B2Impedence networksSemiconductor/solid-state device detailsThermal isolationComputer module

Owner:SKYWORKS SOLUTIONS INC

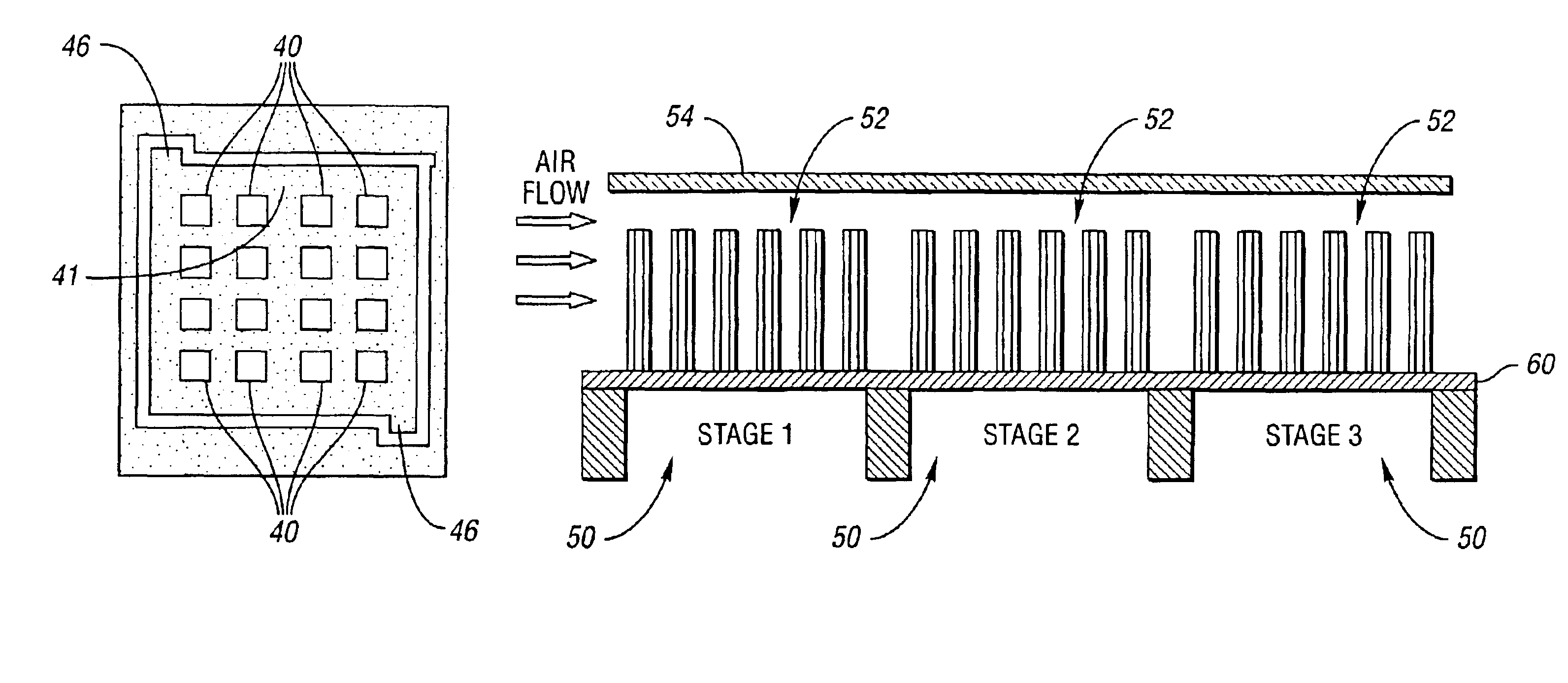

Microelectromechanical heating apparatus and fluid preconcentrator device utilizing same

InactiveUS6914220B2High porosityIncrease surface areaComponent separationBaking ovenThermal isolationEngineering

A microelectromechanical heating apparatus and fluid preconcentrator device utilizing same wherein heating elements of the apparatus are sized and spaced to substantially uniformly heat a heating chamber within a heater of the apparatus. Tall, thermally-isolated heating elements are fabricated in Si using high aspect ratio etching technology. These tall heating elements have large surface area to provide large adsorbent capacity needed for high efficiency preconcentrators in a micro gas chromatography system (μGC). The tall heating elements are surrounded by air gaps to provide good thermal isolation, which is important for a low power preconcentrator in the μGC system.

Owner:RGT UNIV OF MICHIGAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com