Patents

Literature

1767 results about "Spandrel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A spandrel is a triangular space, usually found in pairs, between the top of an arch and a rectangular frame; between the tops of two adjacent arches or one of the four spaces between a circle within a square. They are frequently filled with decorative elements.

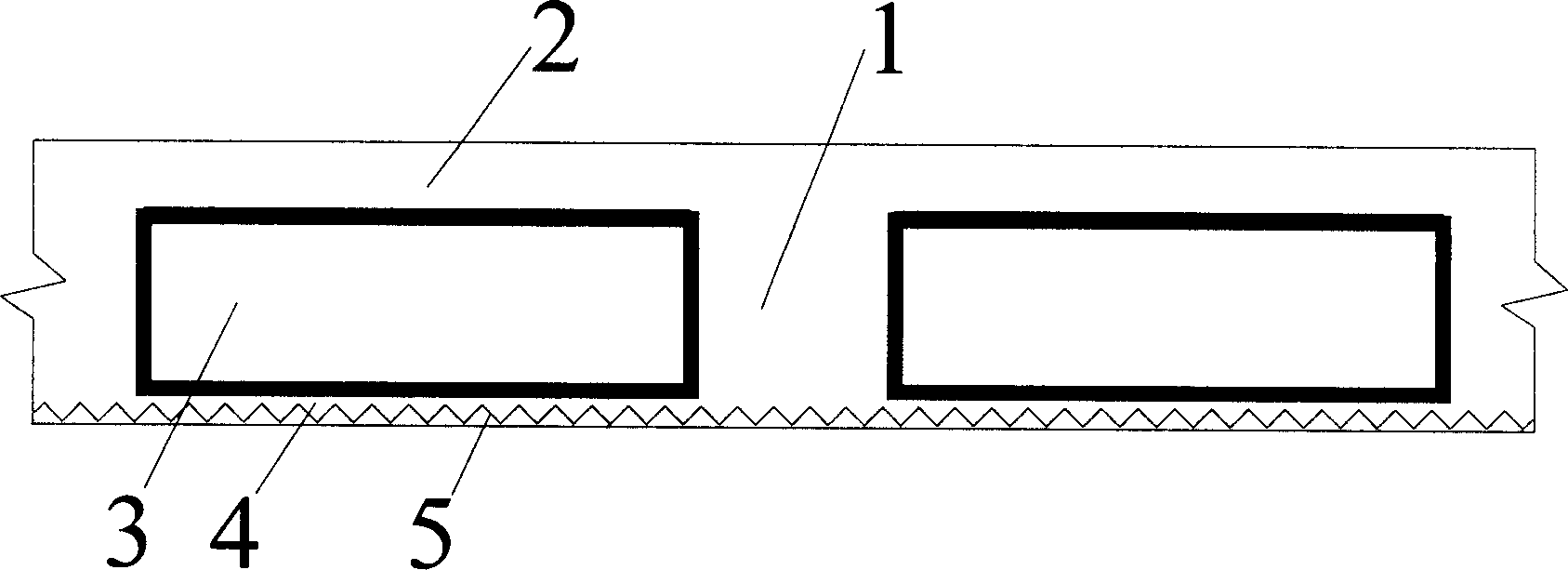

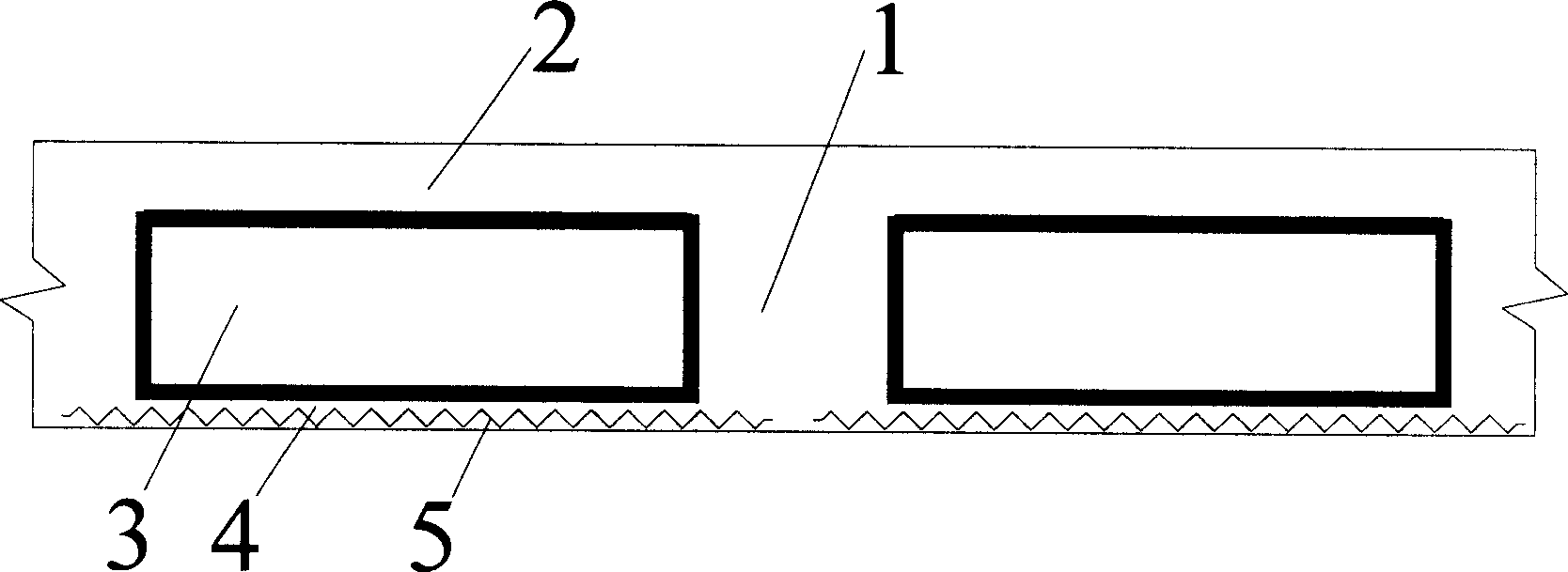

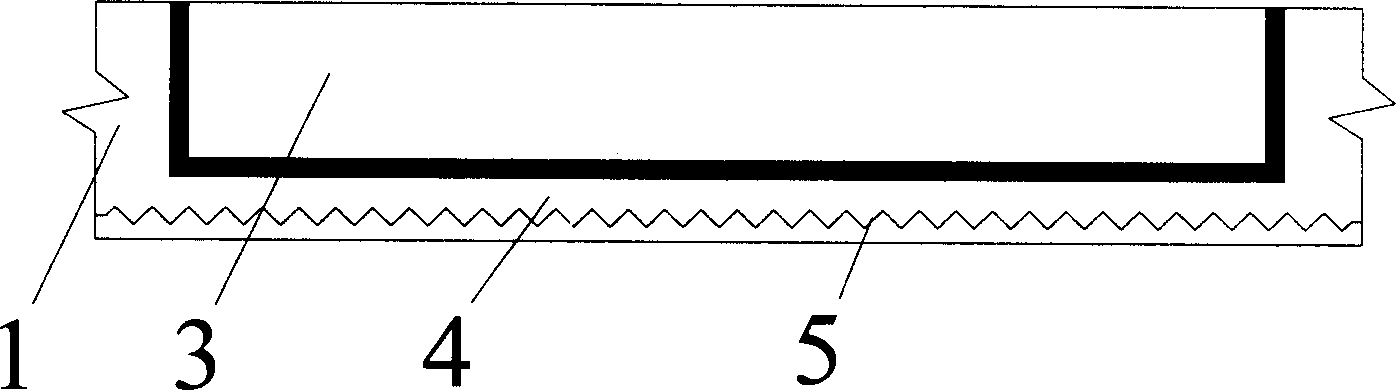

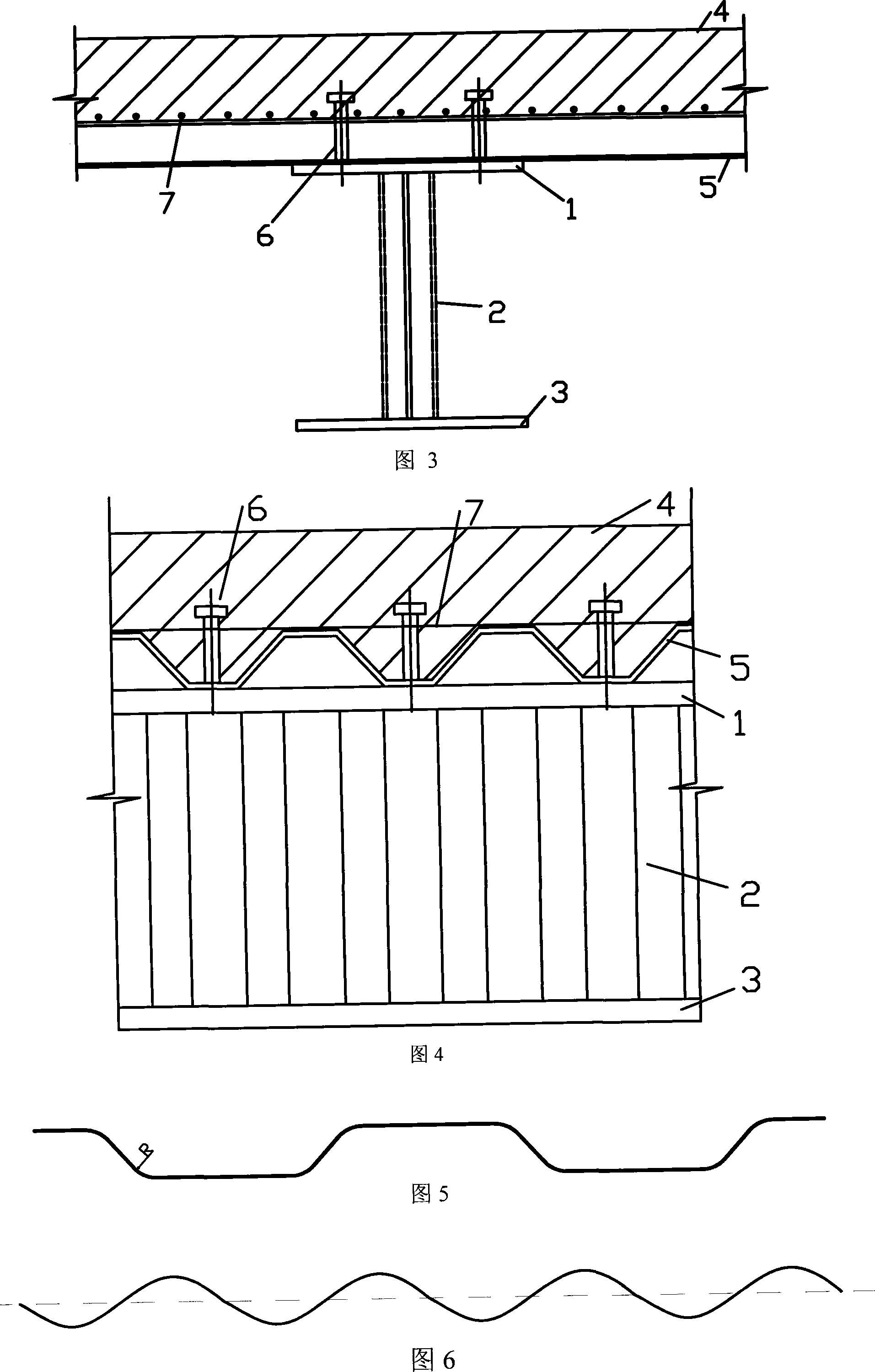

Hollow floor slab with small dense ribs and its production process

InactiveCN1637217ALarge spanSafe and reliable structureFloorsForms/shuttering/falseworksFloor slabLine tubing

The hollow floor slab includes column, solid belt, solid reinforced beam with dense ribs, reinforced facing board, and composite box with lower thin bottom board. The production process includes: a) laying and tying reinforcing steel bar in the floor slab formwork; b) laying the steel wire net and other reinforcing material; c) setting and fixing made composite thin box; d) tying reinforcing steel bar for the facing board; e) fixing reinforcing bars with iron wire; and f) embedding prefabricated pipeline inside the facing board and the dense ribs. The present invention may produce flat sealed floor slab cavity with dense ribs in once deposition.

Owner:HUNAN BDF ENERGY SAVING TECH

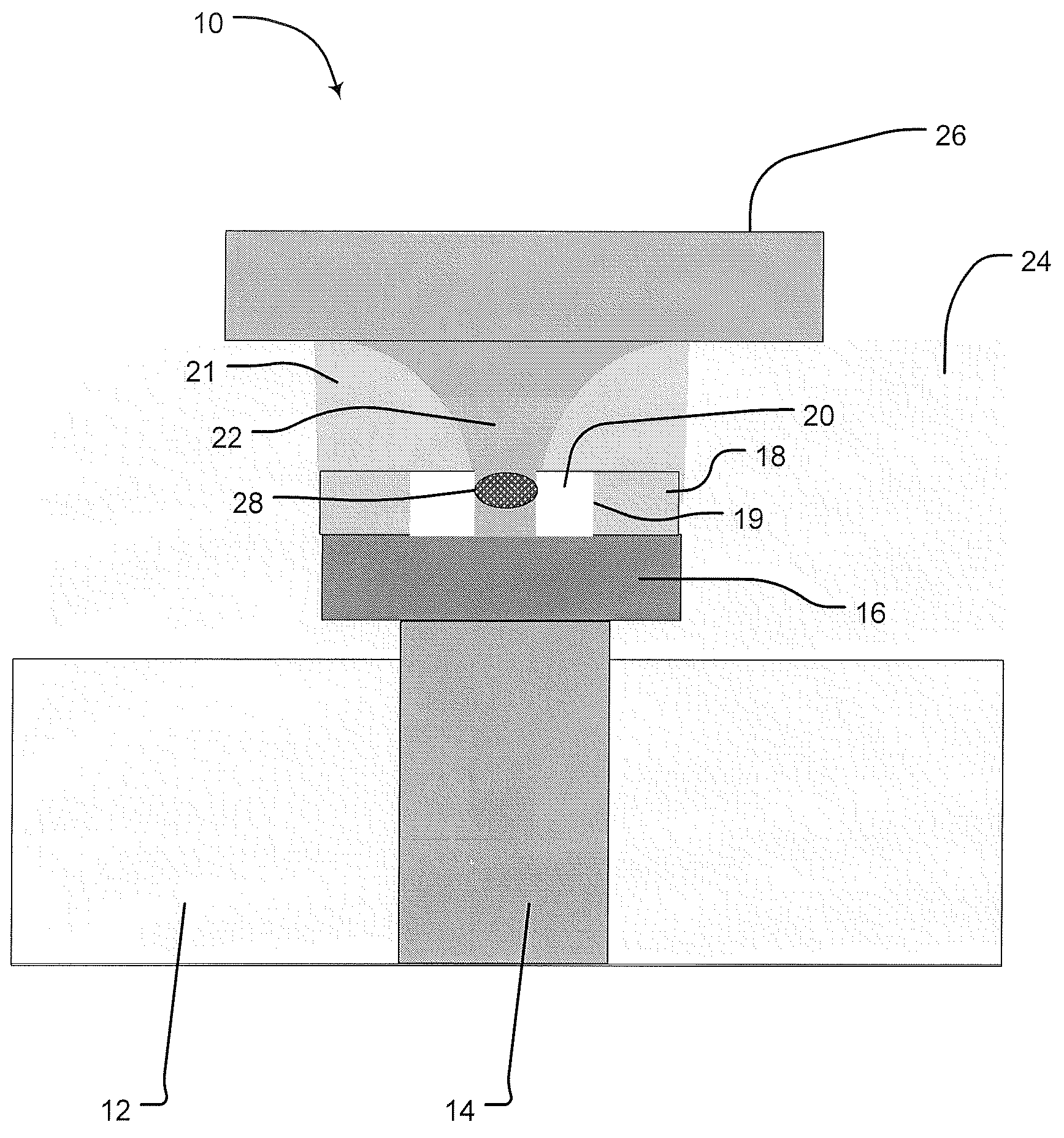

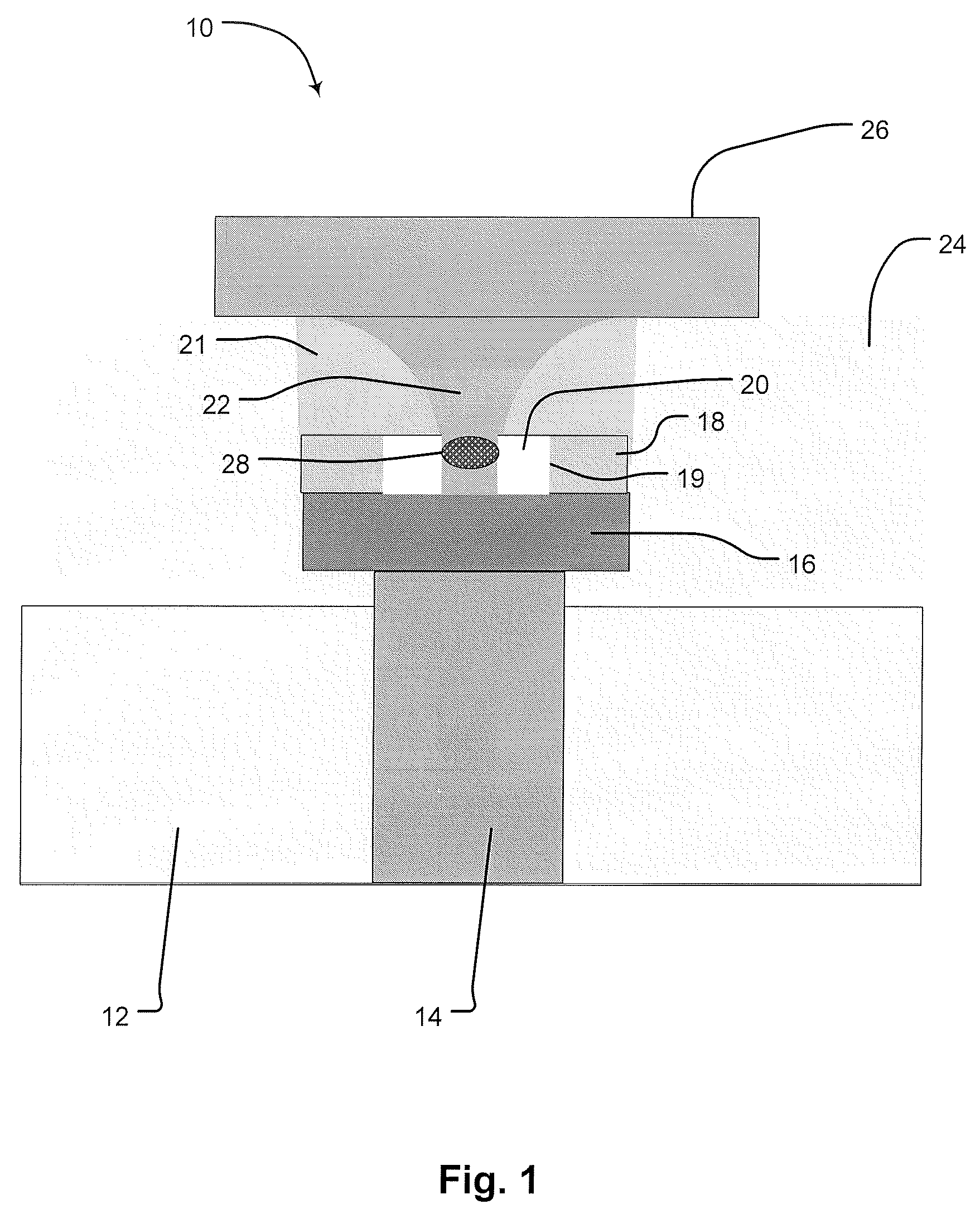

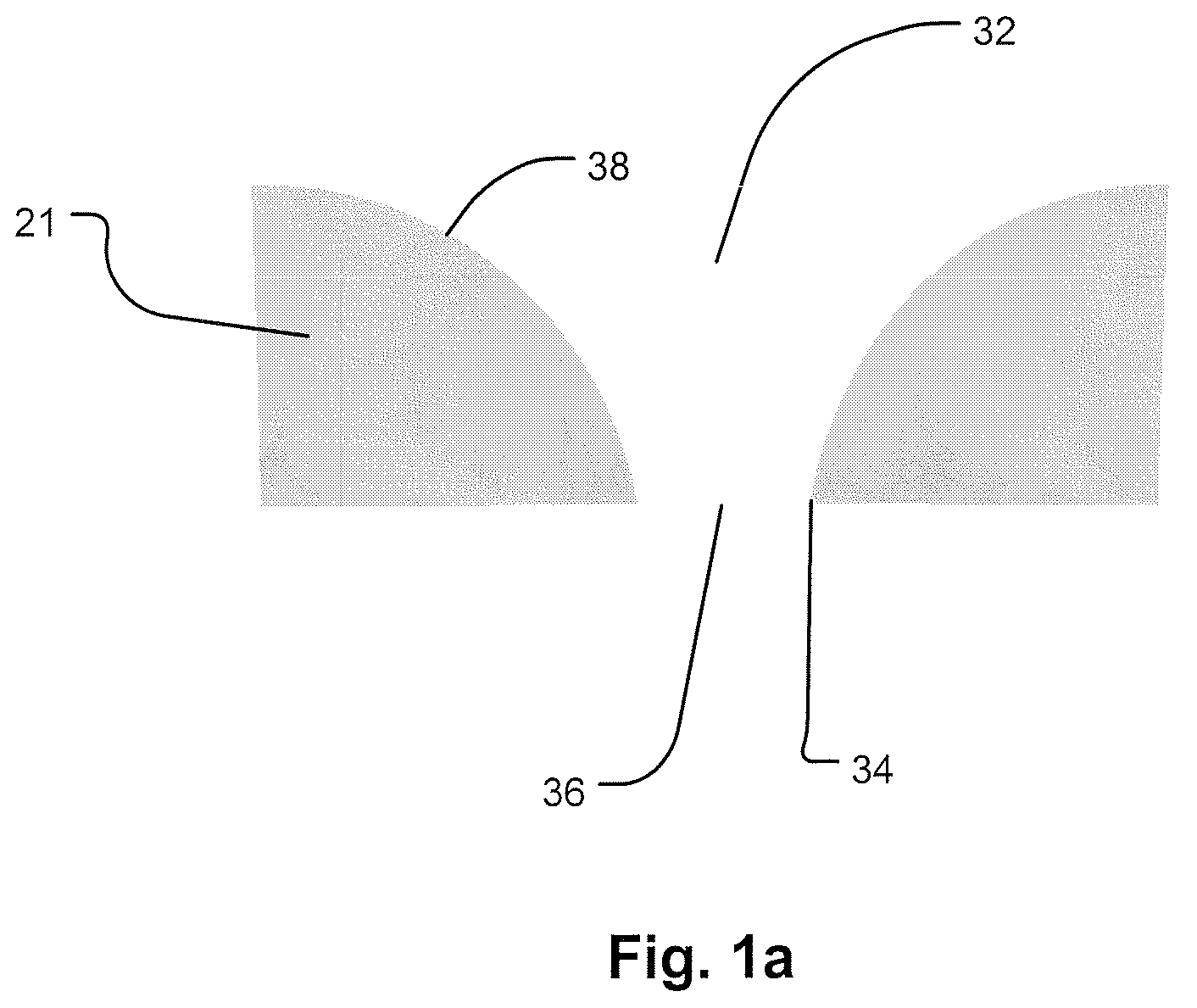

Method for Forming Self-Aligned Thermal Isolation Cell for a Variable Resistance Memory Array

A non-volatile method with a self-aligned RRAM element. The method includes a lower electrode element, generally planar in form, having an inner contact surface. At the top of the device is a upper electrode element, spaced from the lower electrode element. A containment structure extends between the upper electrode element and the lower electrode element, and this element includes a sidewall spacer element having an inner surface defining a generally funnel-shaped central cavity, terminating at a terminal edge to define a central aperture; and a spandrel element positioned between the sidewall spacer element and the lower electrode, having an inner surface defining a thermal isolation cell, the spandrel inner walls being spaced radially outward from the sidewall spacer terminal edge, such that the sidewall spacer terminal edge projects radially inward from the spandrel element inner surface. ARRAM element extends between the lower electrode element and the upper electrode, occupying at least a portion of the sidewall spacer element central cavity and projecting from the sidewall spacer terminal edge toward and making contact with the lower electrode. In this manner, the spandrel element inner surface is spaced from the RRAM element to define a thermal isolation cell adjacent the RRAM element.

Owner:MACRONIX INT CO LTD

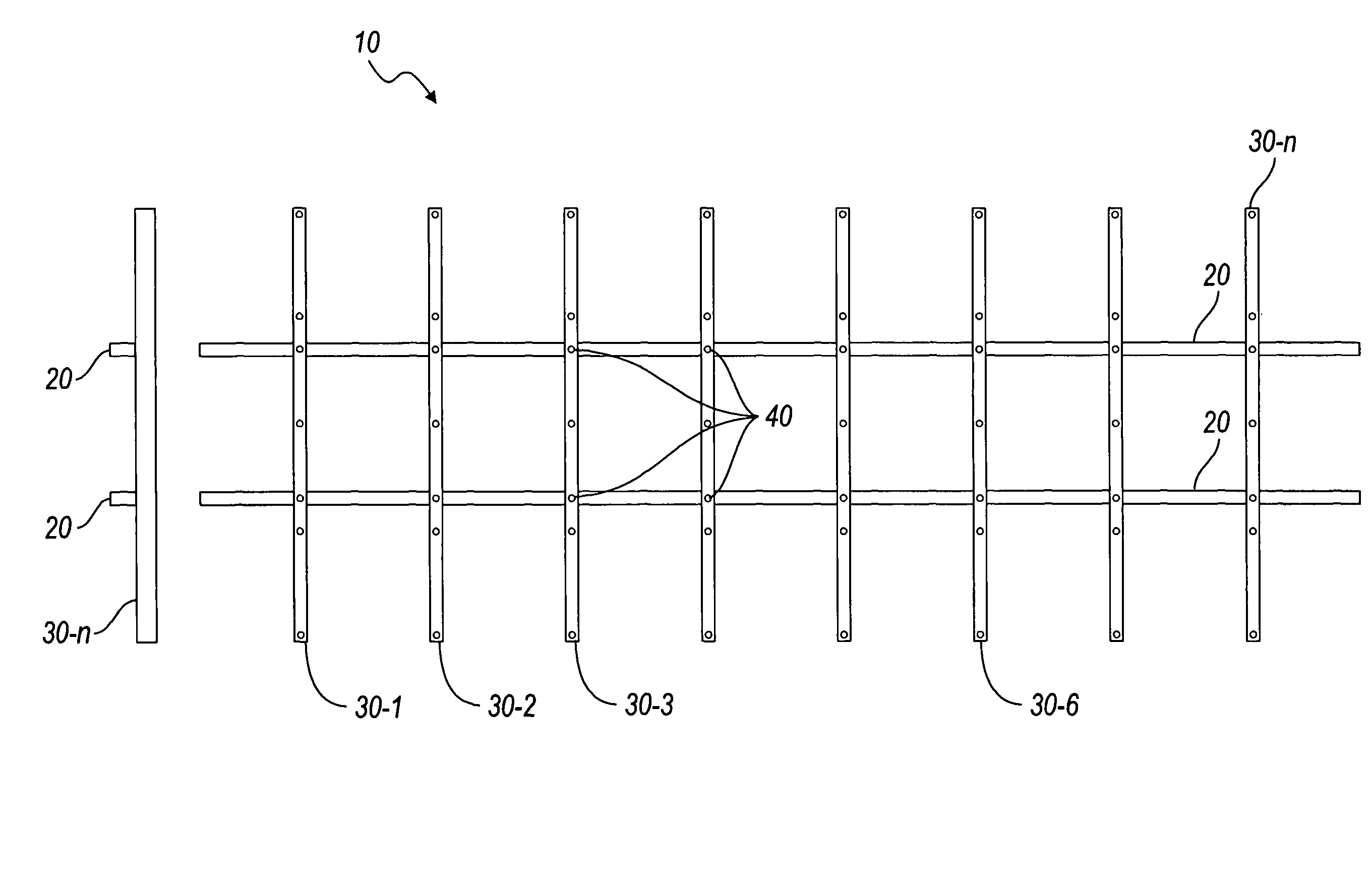

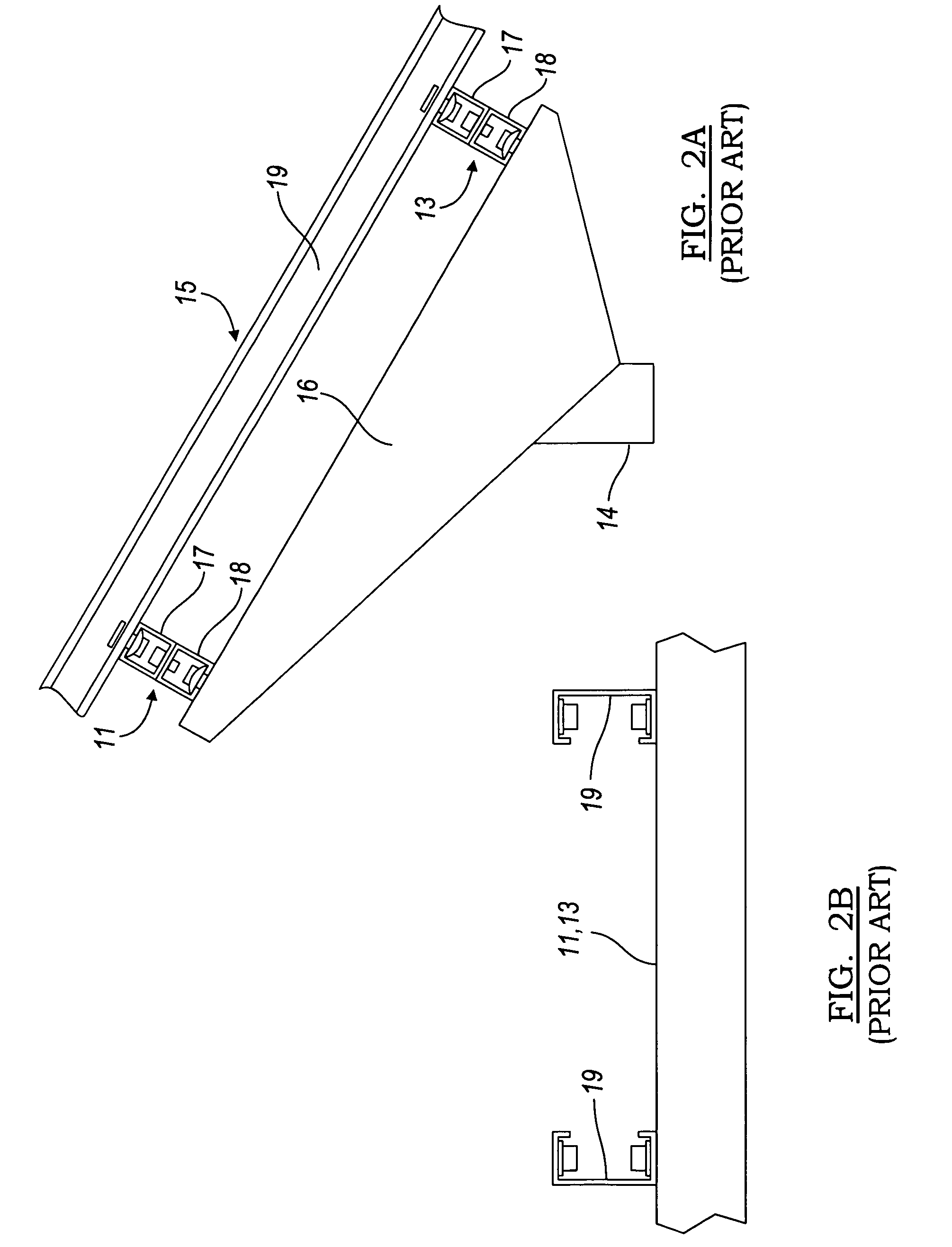

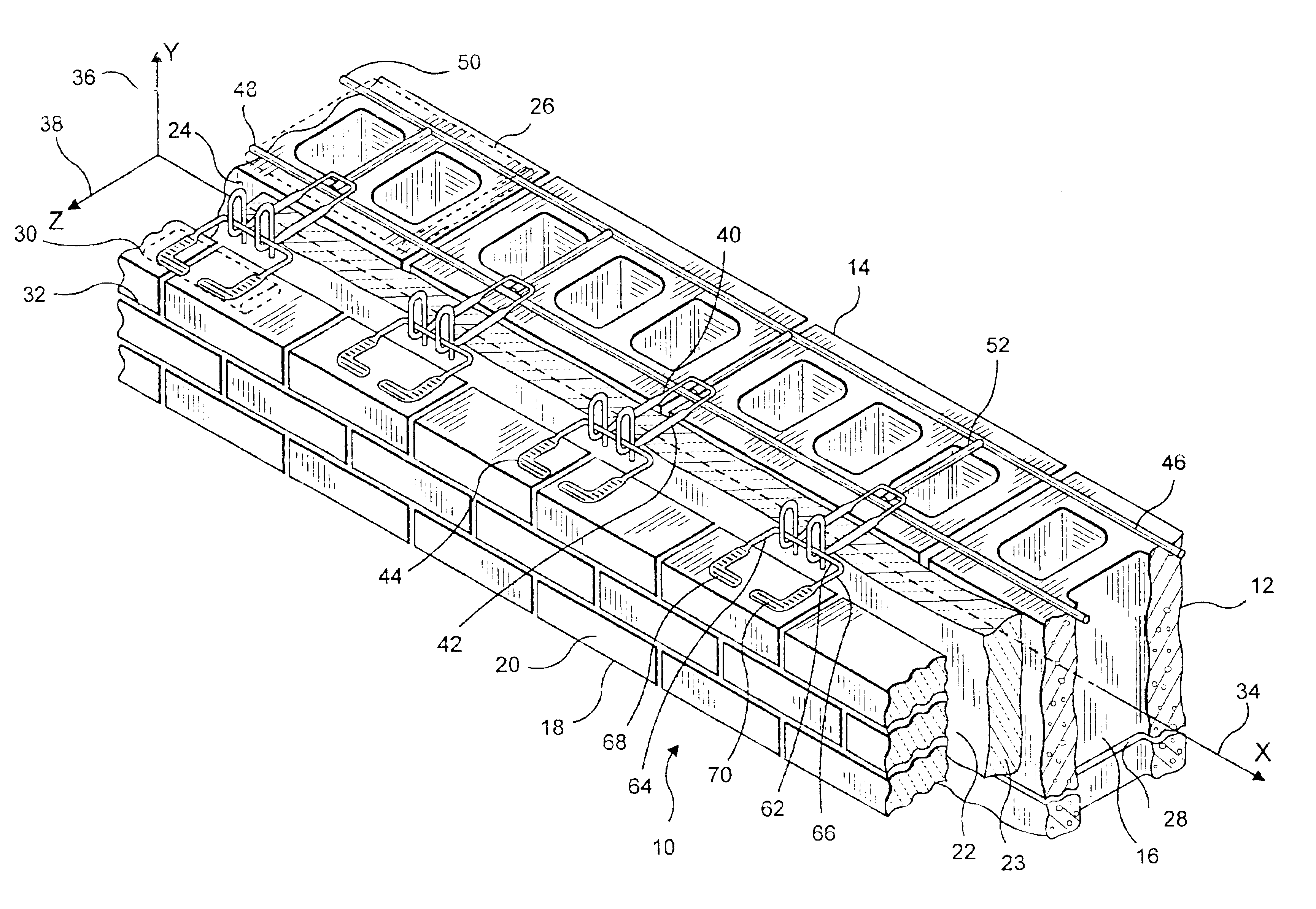

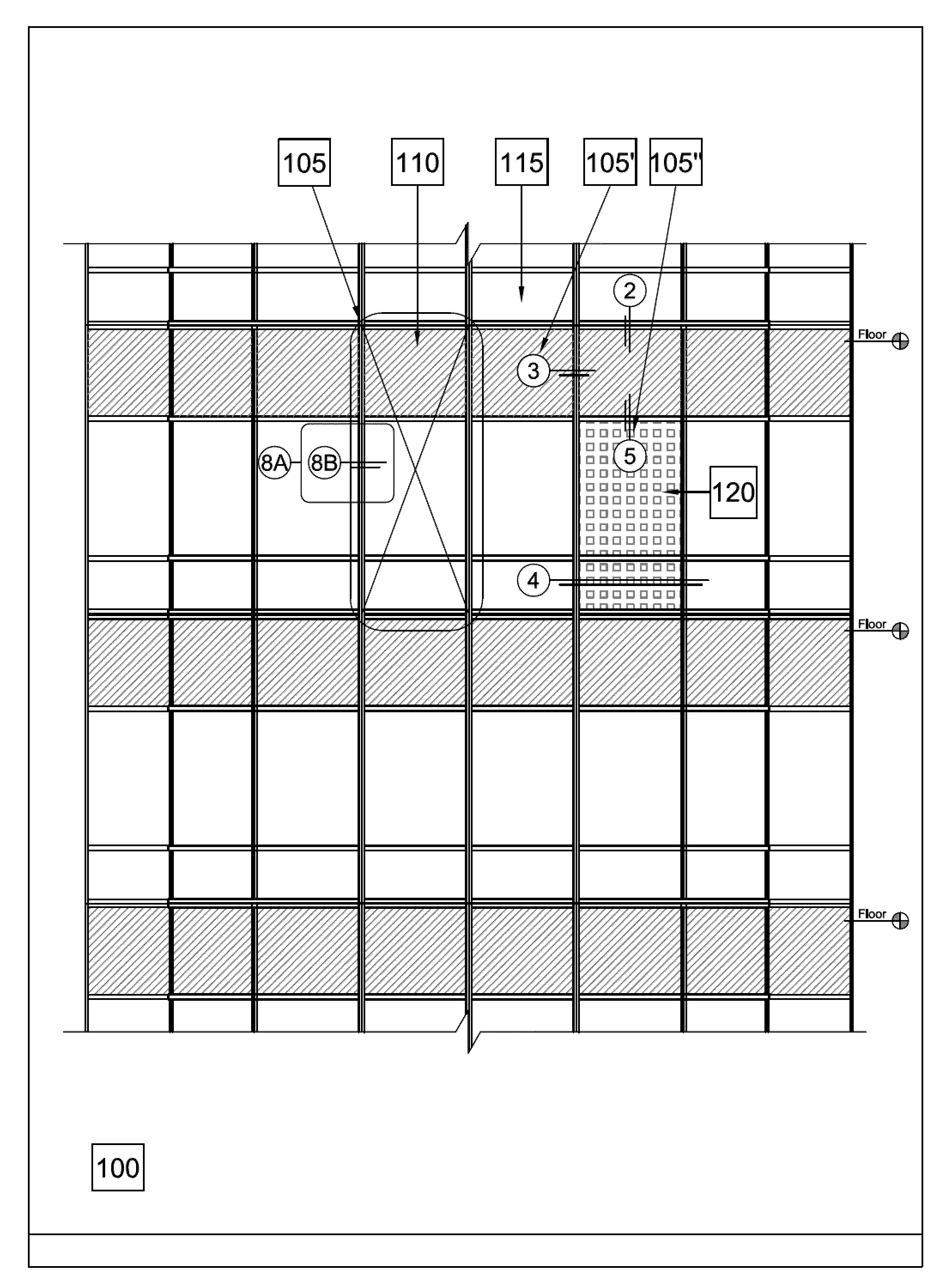

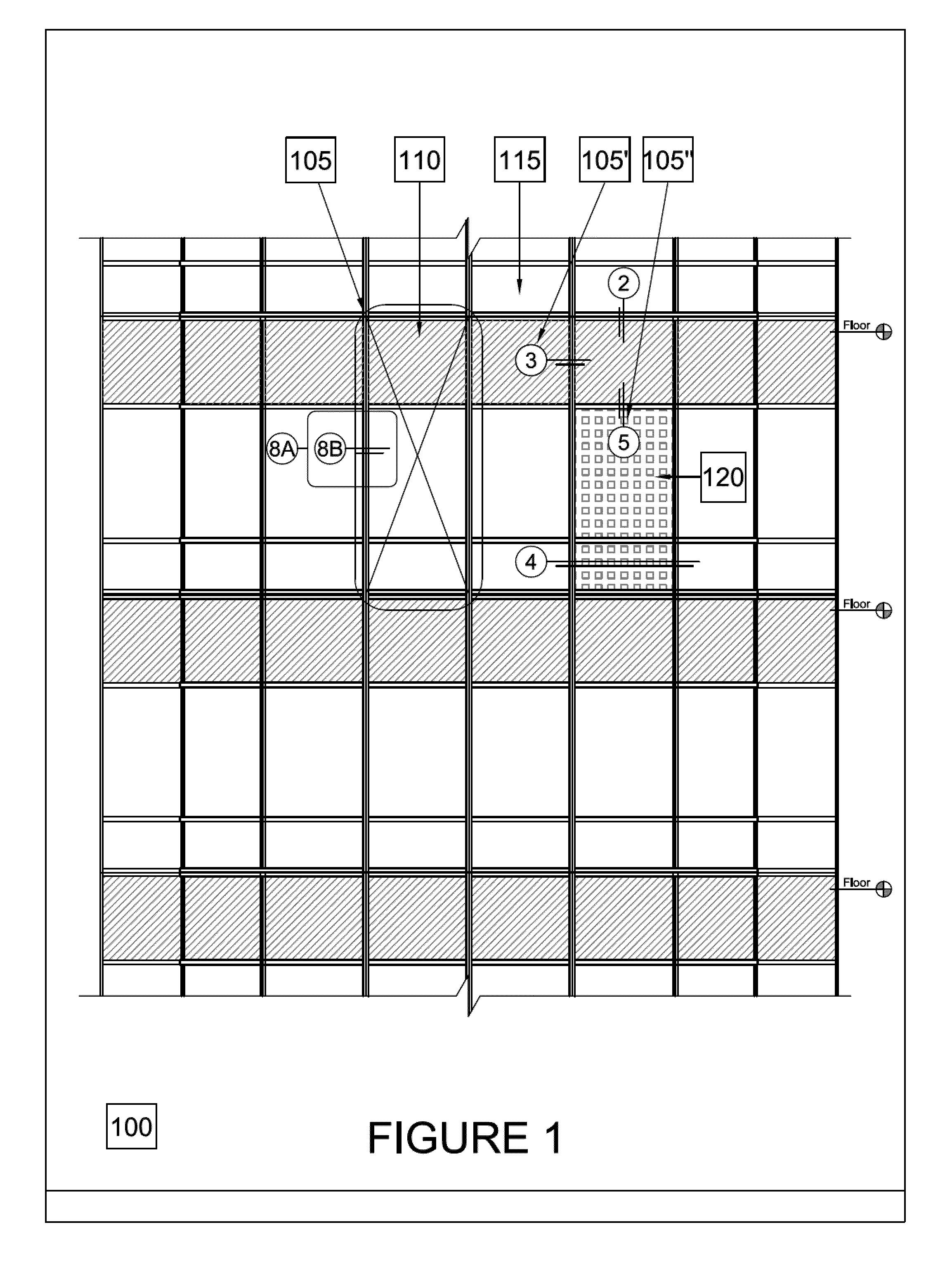

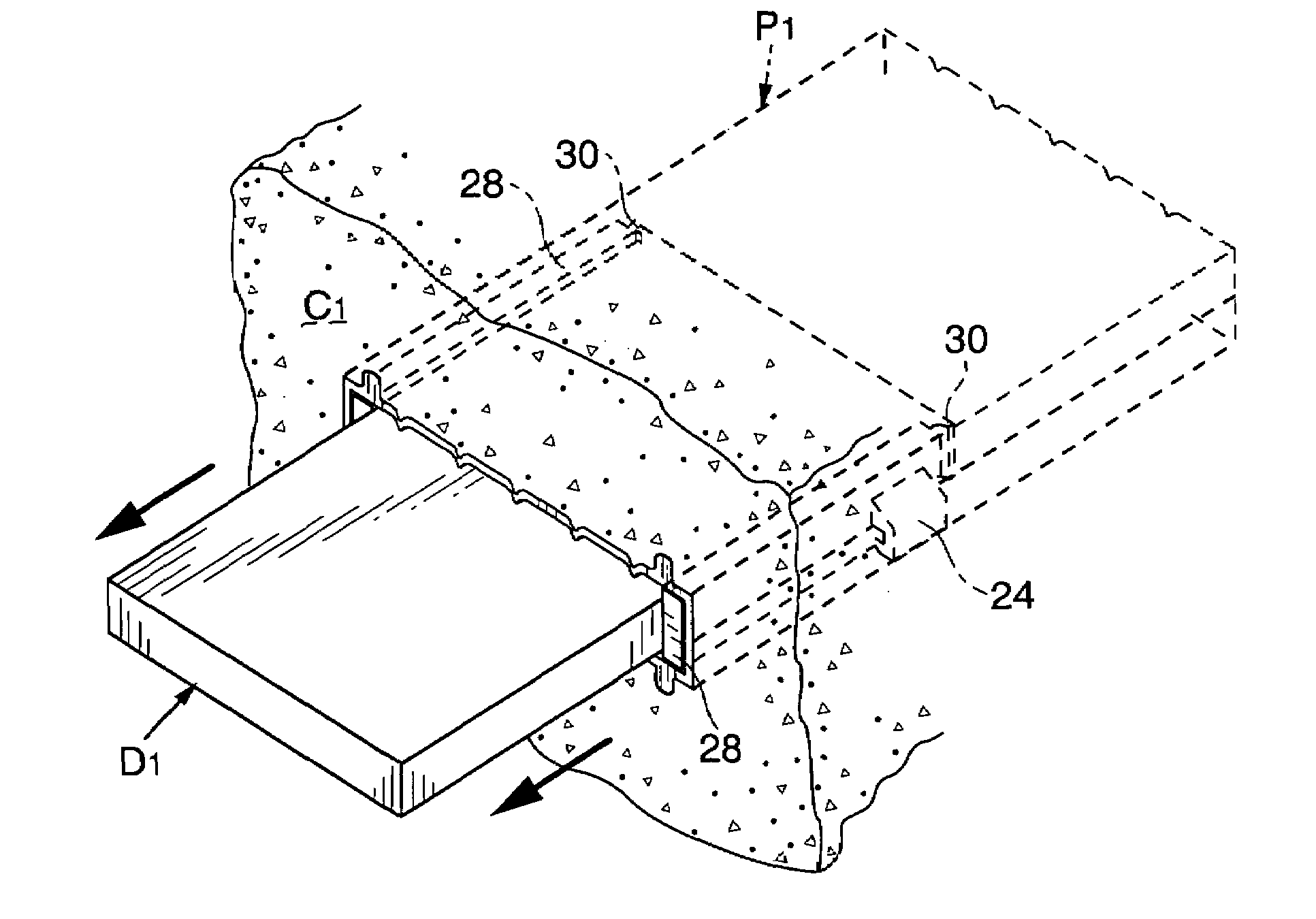

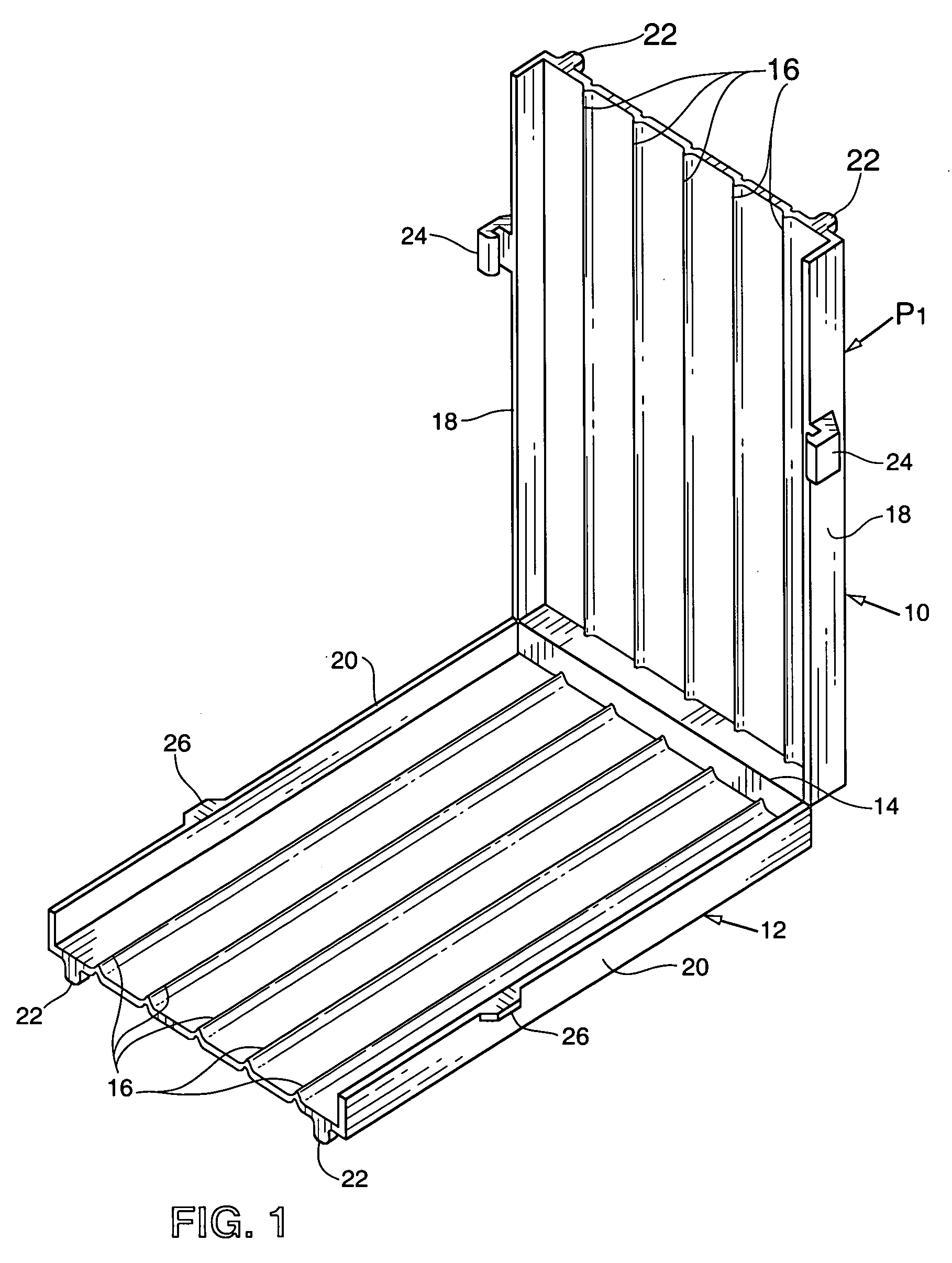

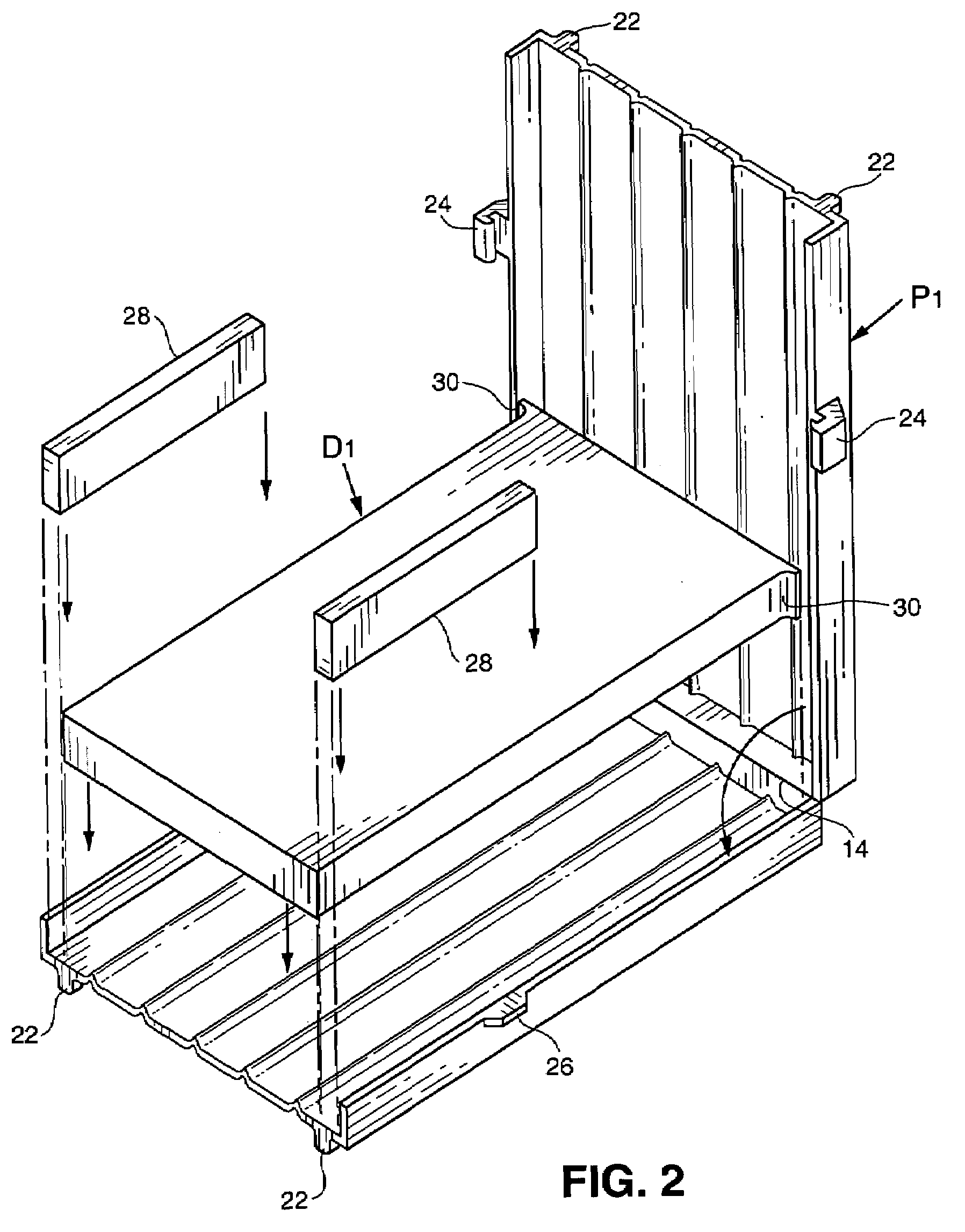

Support system for solar panels

ActiveUS8316590B2Easy to foldReduce spacingPhotovoltaic supportsSolar heating energyRow and column spacesSupporting system

An array of photovoltaic panels is supported in rows and columns spaced from one another using a foldable bi-directional span of support members. The support members include a plurality of support joists and support rails braced at an incline. Each support rail is tubular and generally rectangular, having a lower wall section with a T-slot channel for acceptance of the head of a bolt for adjustable attachment with the support joist. Also, the support rail may have a C-slot channel for retaining electrical wires. Clips are used to secure each panel to upper wall portions of underlying support rails. Each clip has a generally U-shaped gasket and is retained to a corresponding support rail through a threaded hole in a top wall of the support rail that receives a bolt or similar threaded fastener.

Owner:NORTHERN STATES METALS

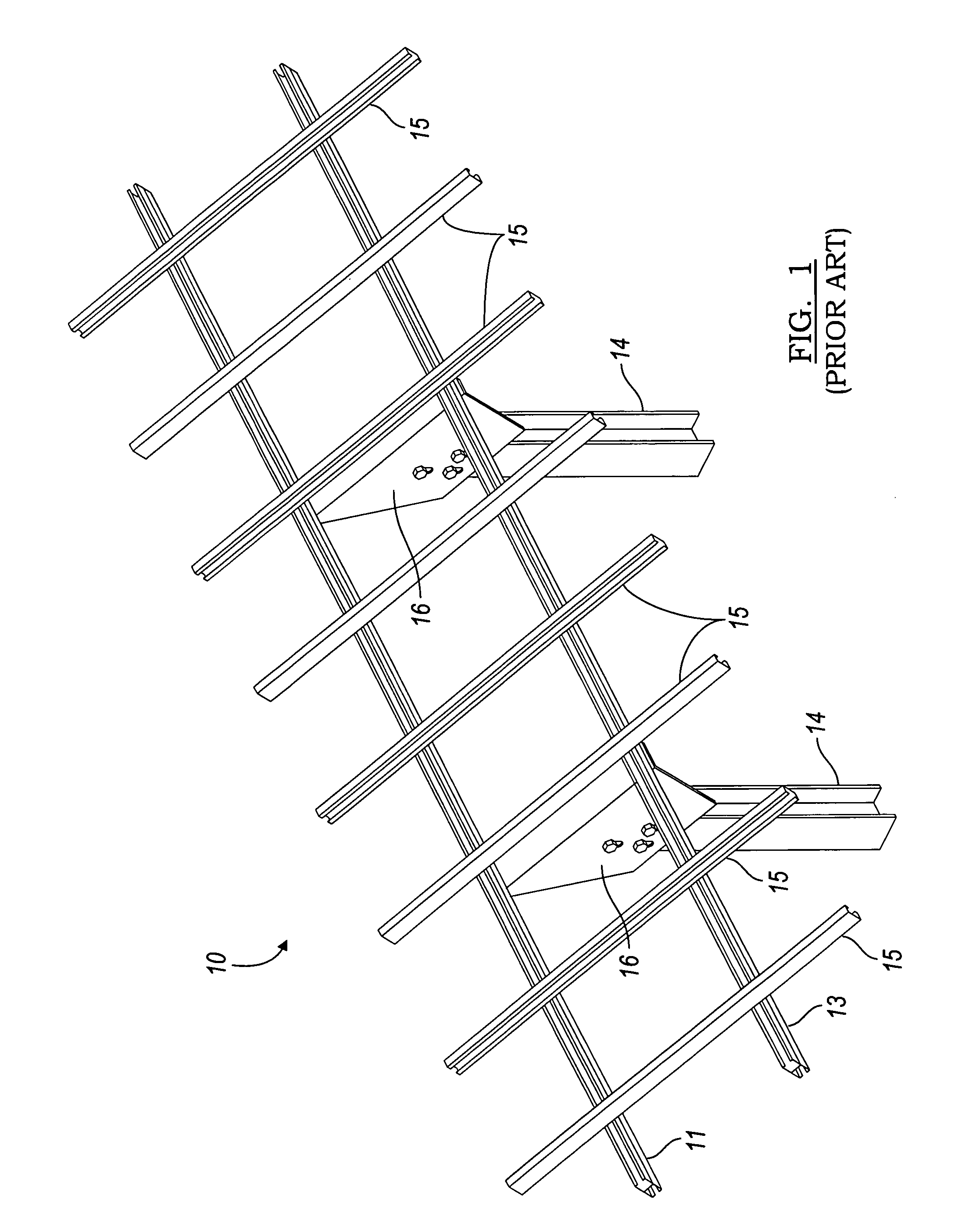

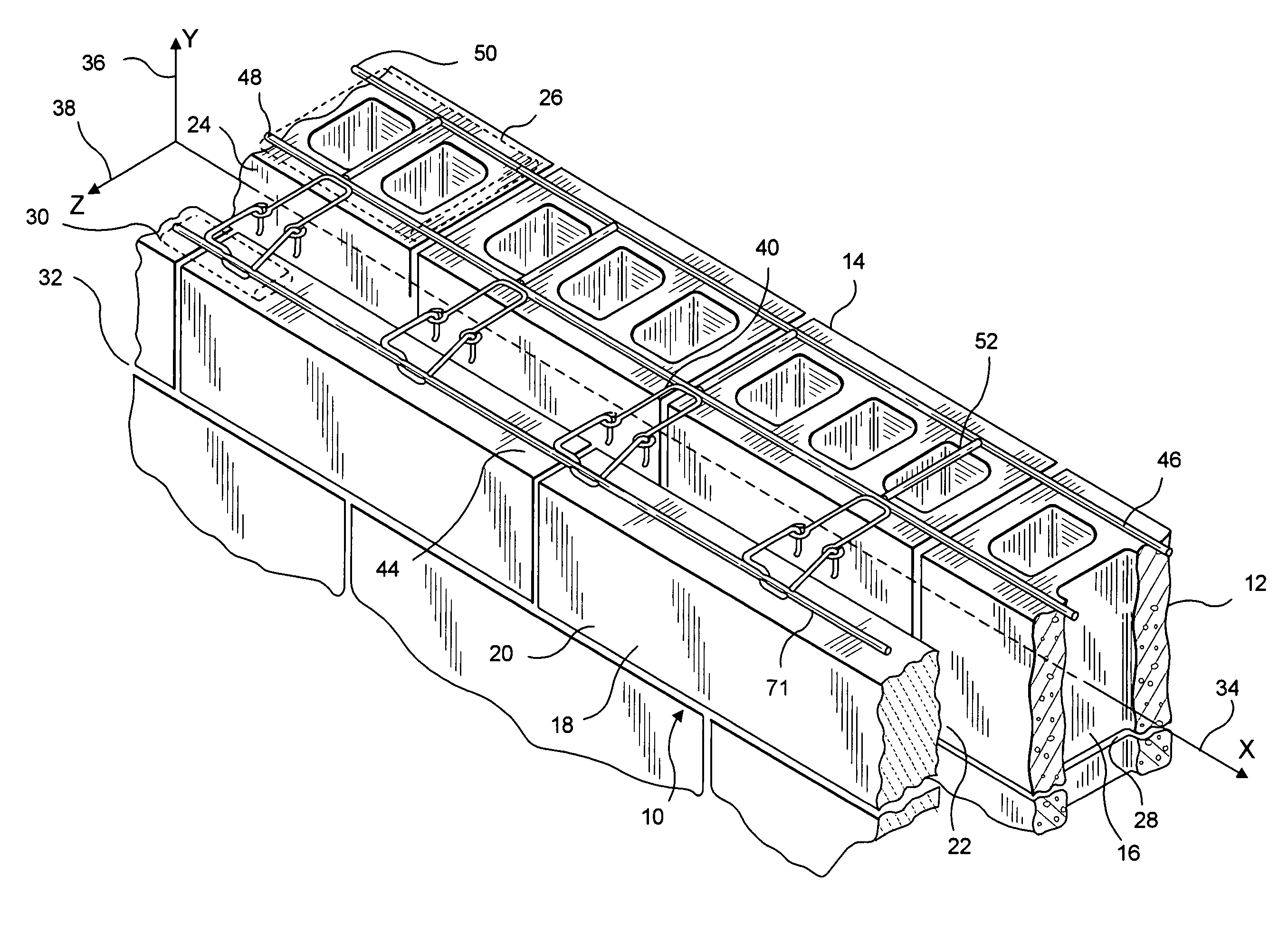

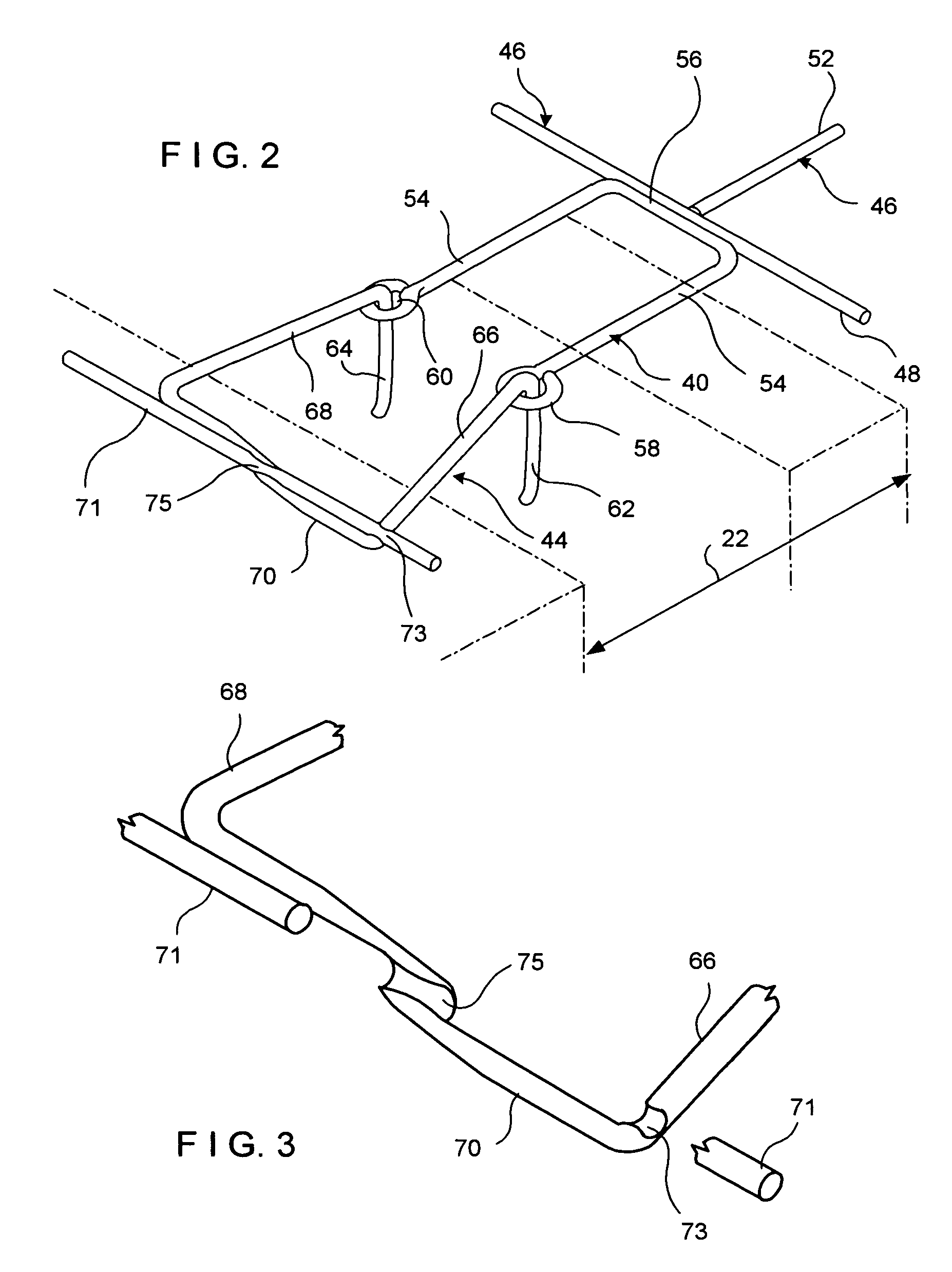

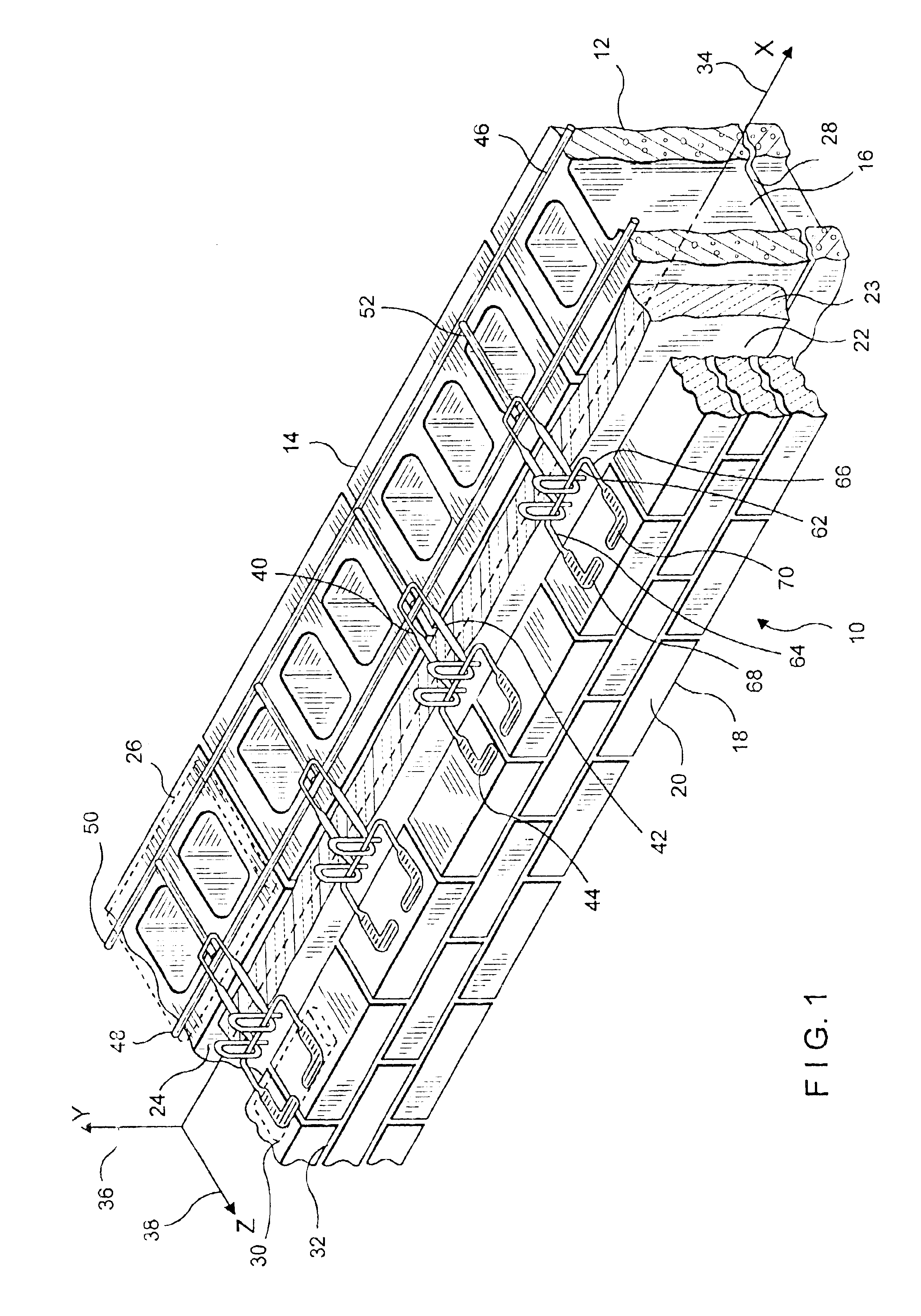

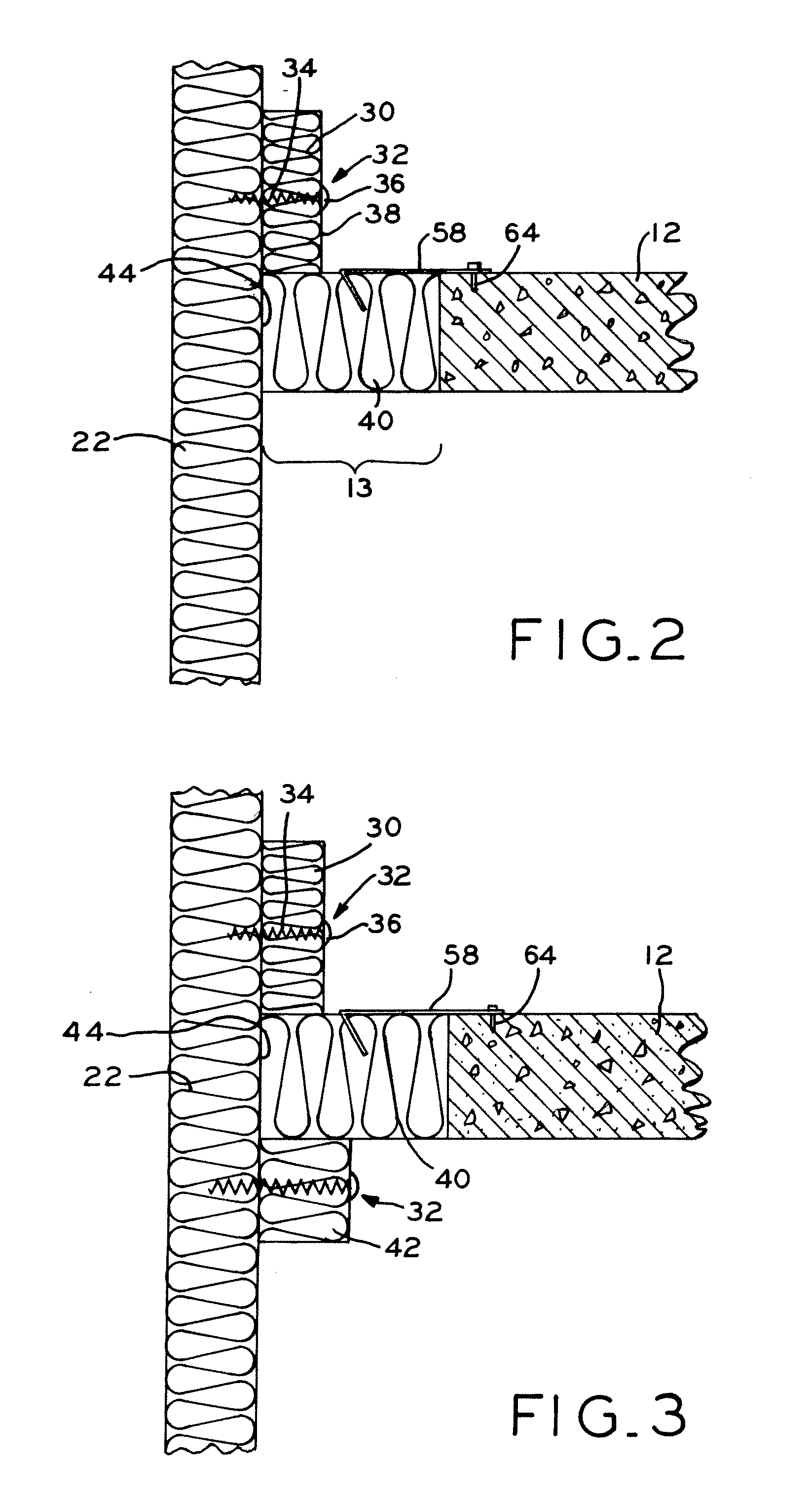

Snap-in wire tie

ActiveUS7325366B1Reduce manufacturing costLower unit costConstruction materialFloorsEngineeringCavity wall

A seismic construction system for a cavity wall is disclosed. The system is shown in three exemplary applications—a masonry backup wall with ladder- or truss-type reinforcement cooperating with a snap-in wire tie; a masonry backup wall with ladder- or truss-type reinforcement with a high-span wall anchor cooperating with a low-profile, snap-in wire tie; and a drywall backup wall with internal insulation, a sheetmetal wall anchor, and snap-in wire ties. The snap-in wire ties accommodate a continuous reinforcing wire for the outer wythe, which reinforcing wire snaps into the wire housings therefor with a predetermined force. With the interconnected wall and veneer anchors and the respective reinforcing elements a seismic construct is formed.

Owner:HOHMANN & BARNARD INC

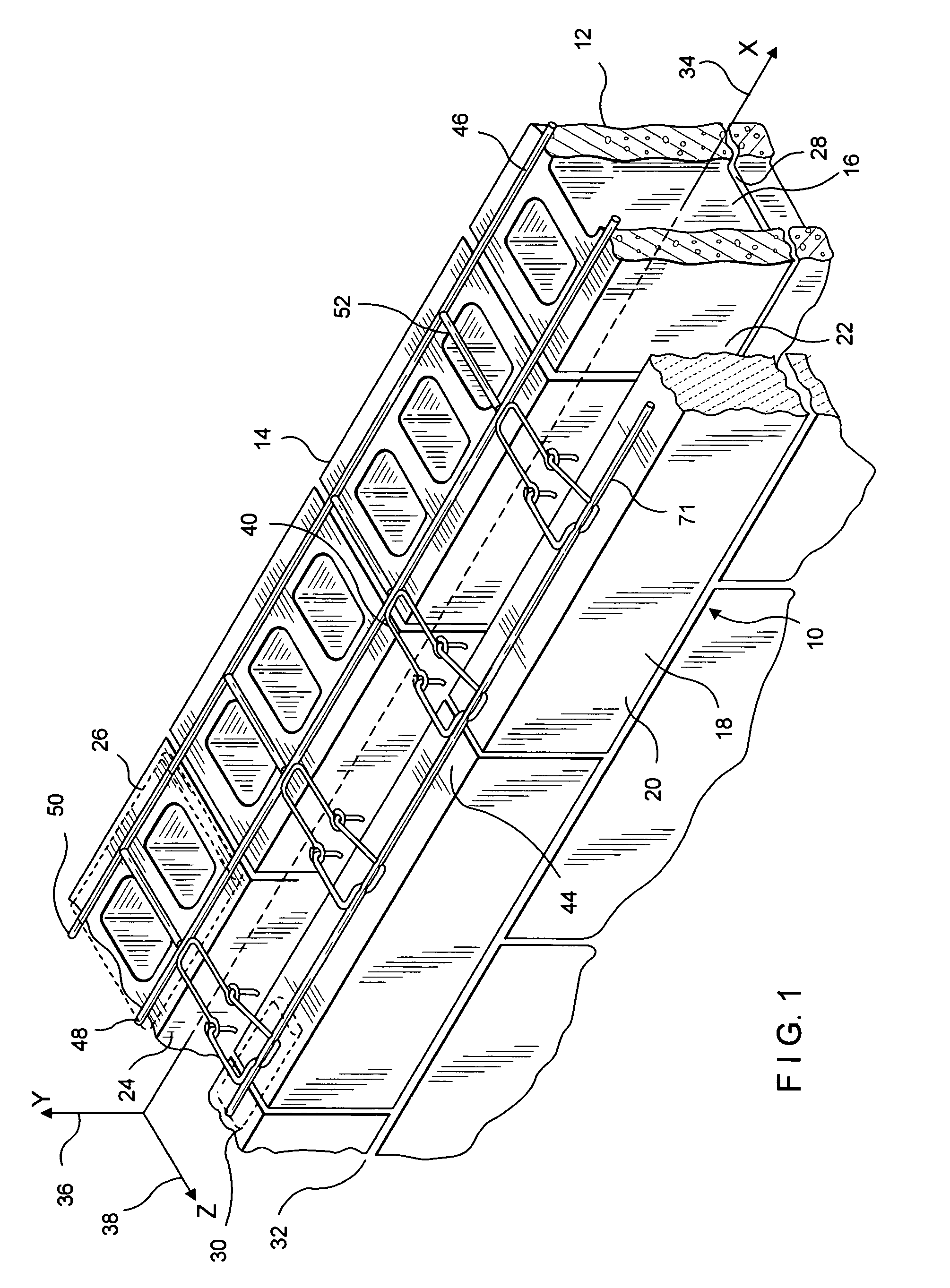

True-joint anchoring systems for cavity walls

InactiveUS6851239B1Improve evenlyReadily maintained verticalityStrutsConstruction materialMetal alloySingle plate

A high-span anchoring system is described for a cavity wall incorporating a wall reinforcement combined with a wall tie which together serve a wall construct having a larger-than-normal cavity. Further the various embodiments combine wire formatives which are compressively reduced in height by the cold-working thereof. Among the embodiments is a veneer anchoring system with a low-profile wall tie for use in a heavily insulated wall. The compressively reduced in height wall anchors protrude into the cavity through the seams, between insulation strips, which seams seal thereabout and maintain the integrity of the insulation by minimizing air leakage. Further, the eye wires extend across the insulation into the cavity between the wythes, and each accommodates the threading thereinto of a wire facing anchor or wall tie with either a pintle inserted through the eye or the open end of the veneer tie. The veneer tie is then positioned so that the insertion end is embedded in the facing wall. The close control of overall heights permits the mortar of the bed joints to flow over and about the wall reinforcement and wall tie combination inserted in the inner wythe and insertion end of the wall in the outer wythe. Because the wire formatives hereof employ extra strong material and benefit from the cold-working of the metal alloys, the high-span anchoring system meets the unusual requirements demanded thereof.

Owner:HOHMANN & BARNARD INC

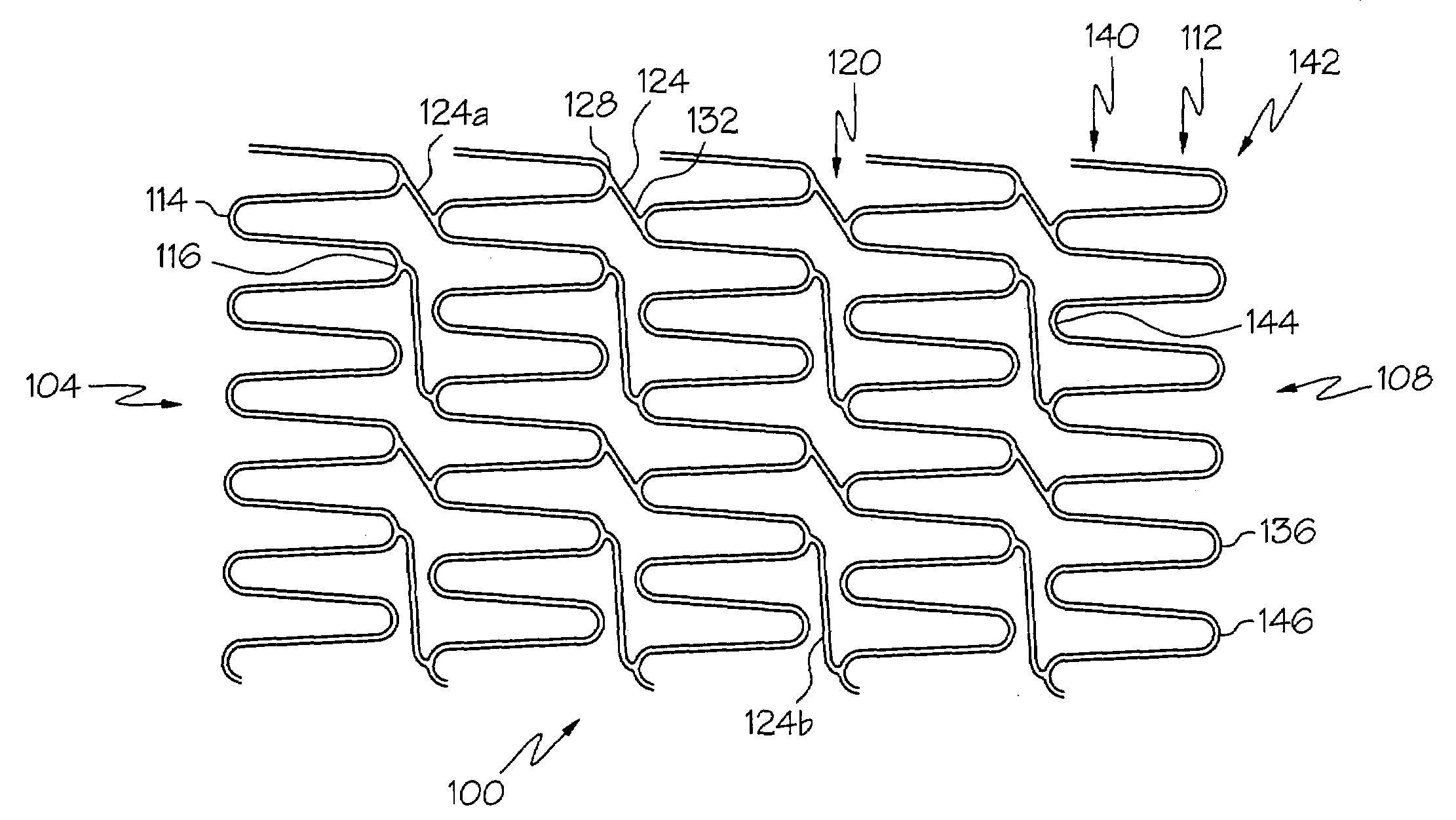

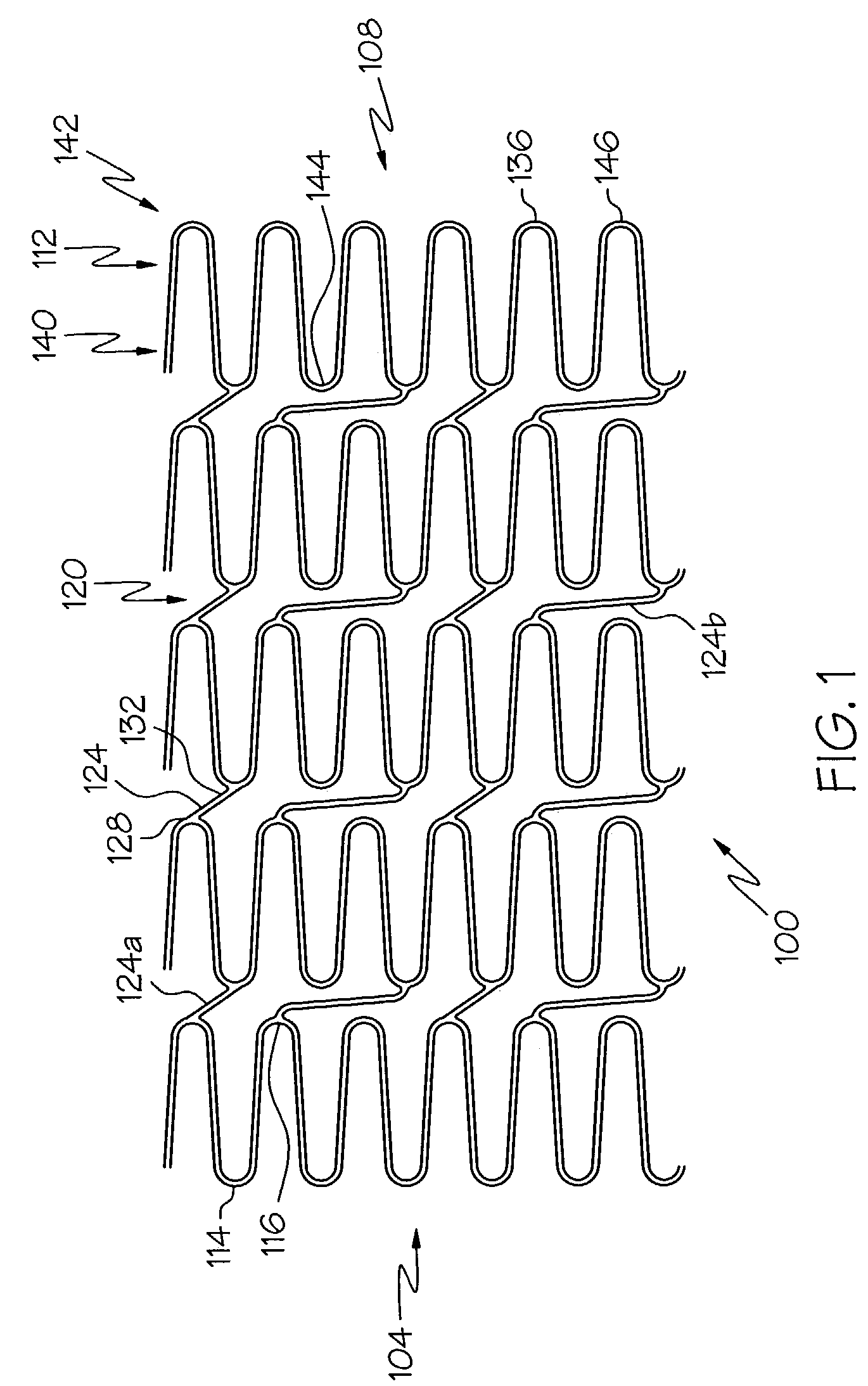

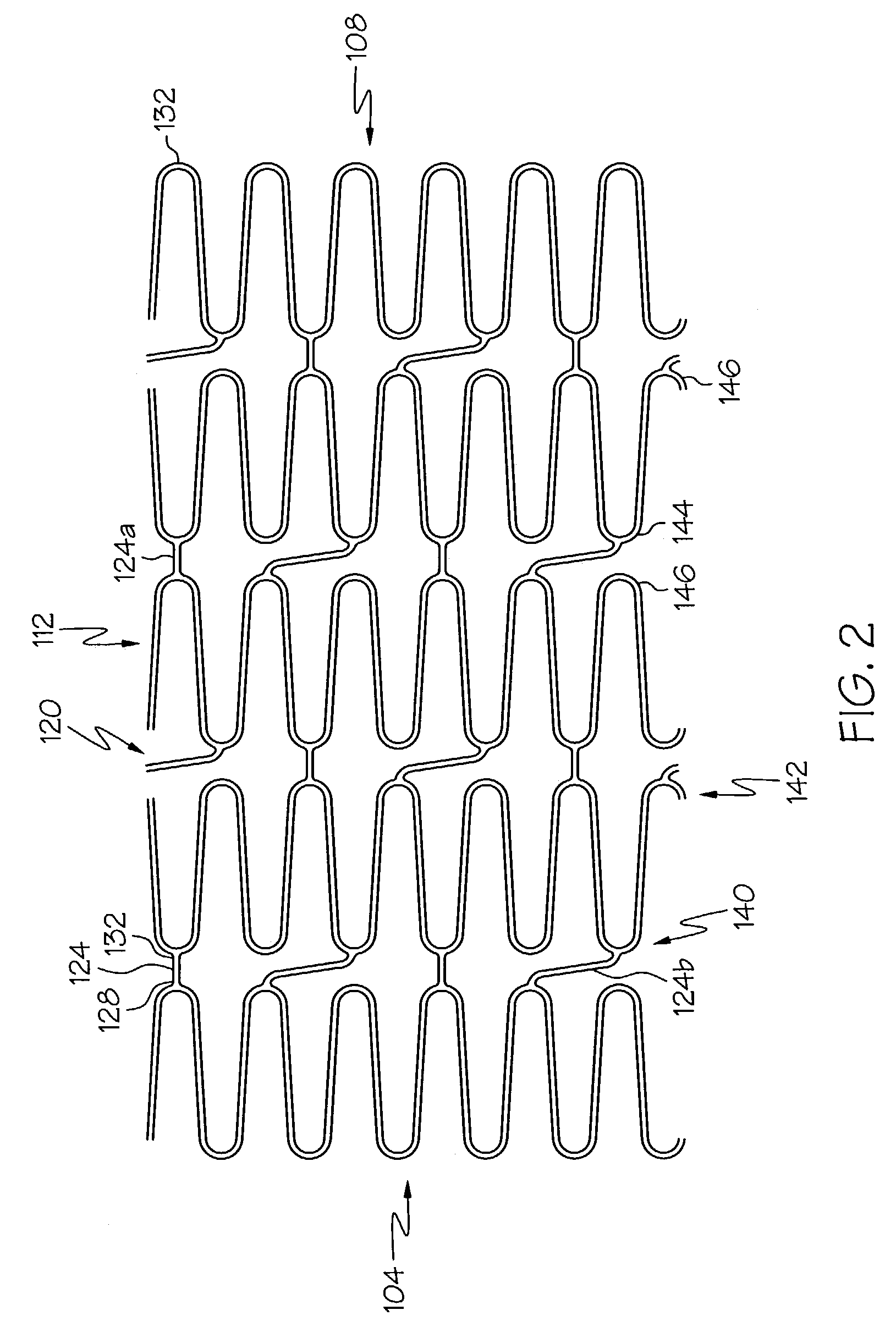

Varying circumferential spanned connectors in a stent

A stent comprises a plurality of serpentine circumferential bands and a plurality of connector columns. Each connector column is located between two adjacent serpentine circumferential bands and comprises a plurality connector struts. Each connector strut is connected at one end to one serpentine circumferential band and at another end to another serpentine circumferential band. Each connector column may contain multiple types of connector struts having varying circumferential spans. Each serpentine circumferential band may have sections which vary in amplitude and / or wavelength.

Owner:BOSTON SCI SCIMED INC

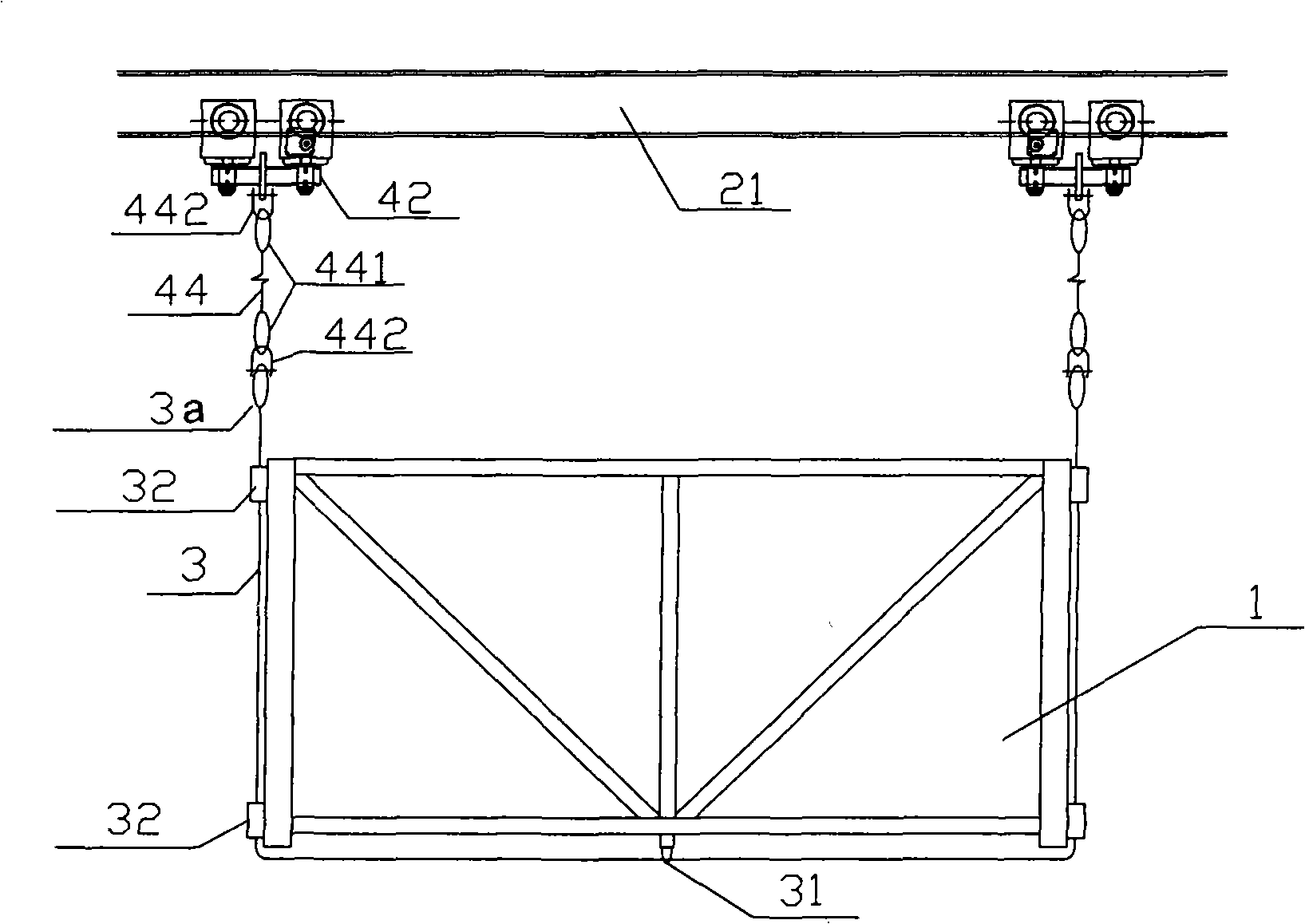

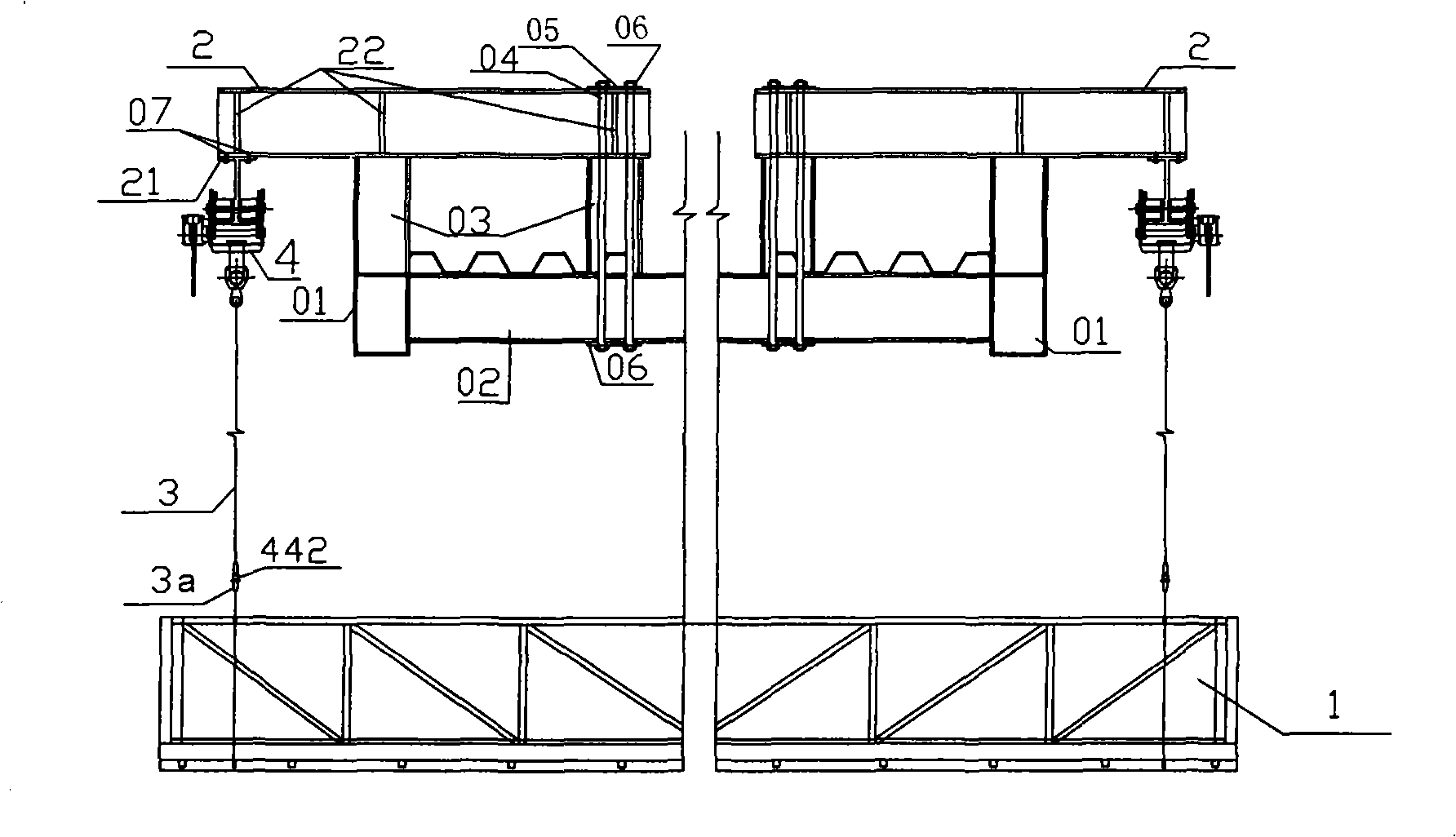

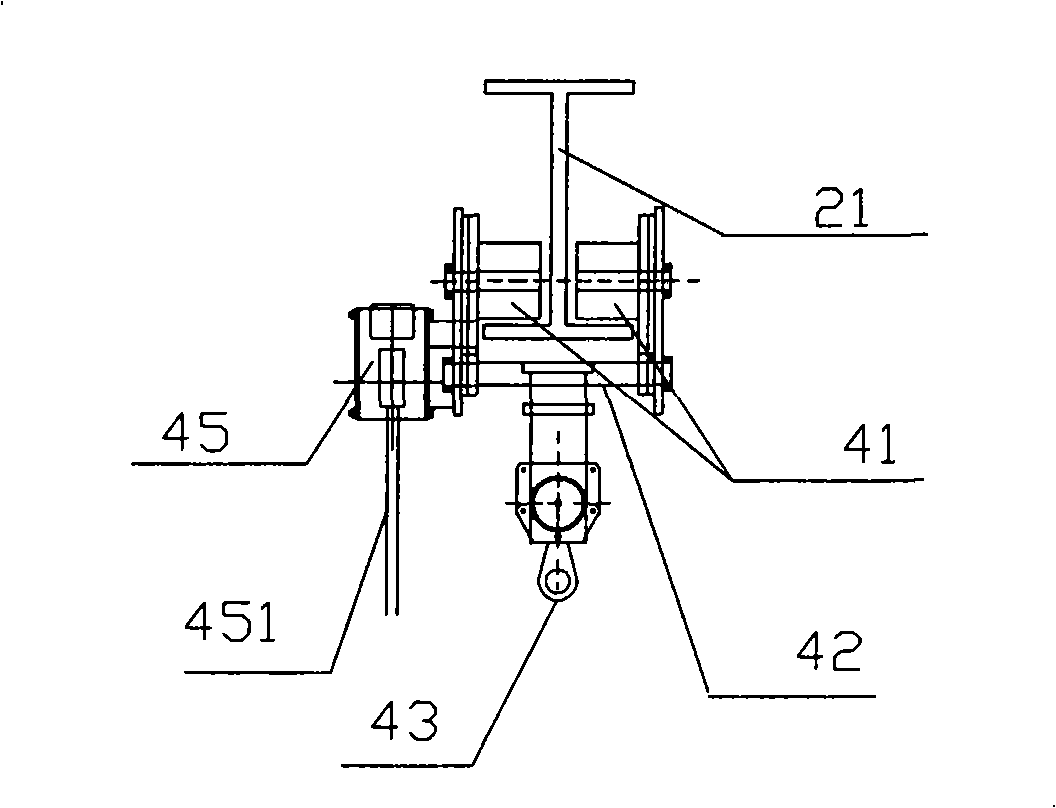

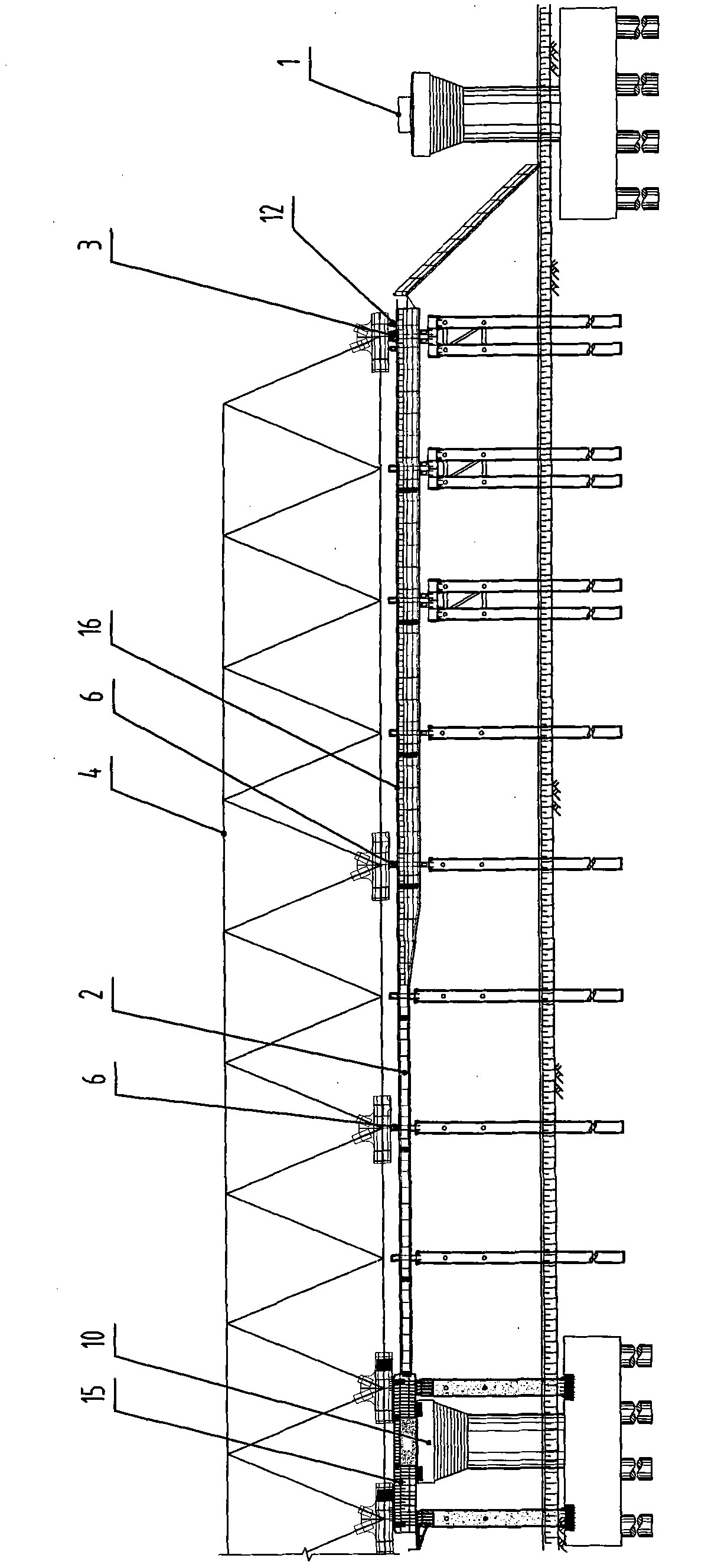

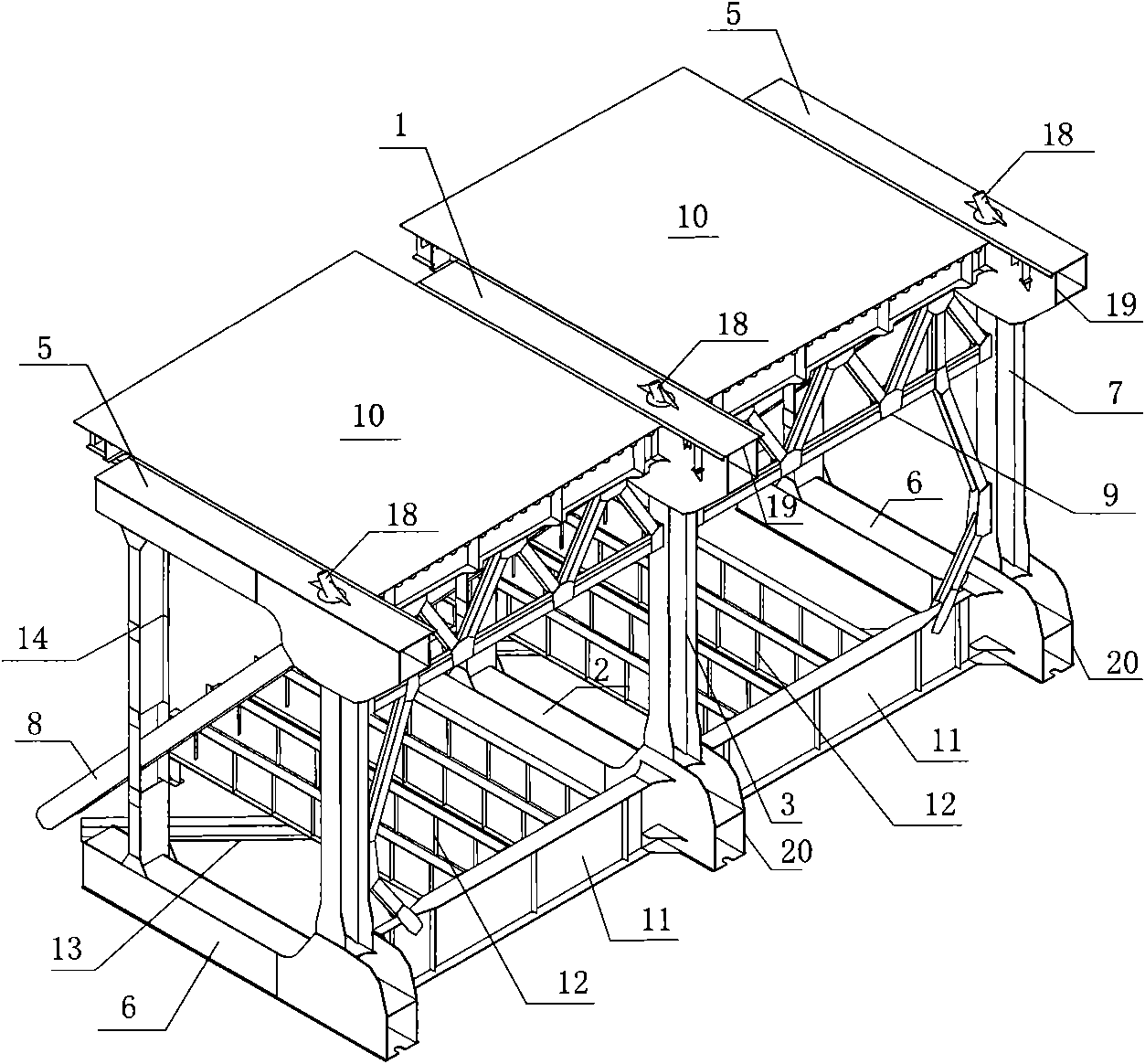

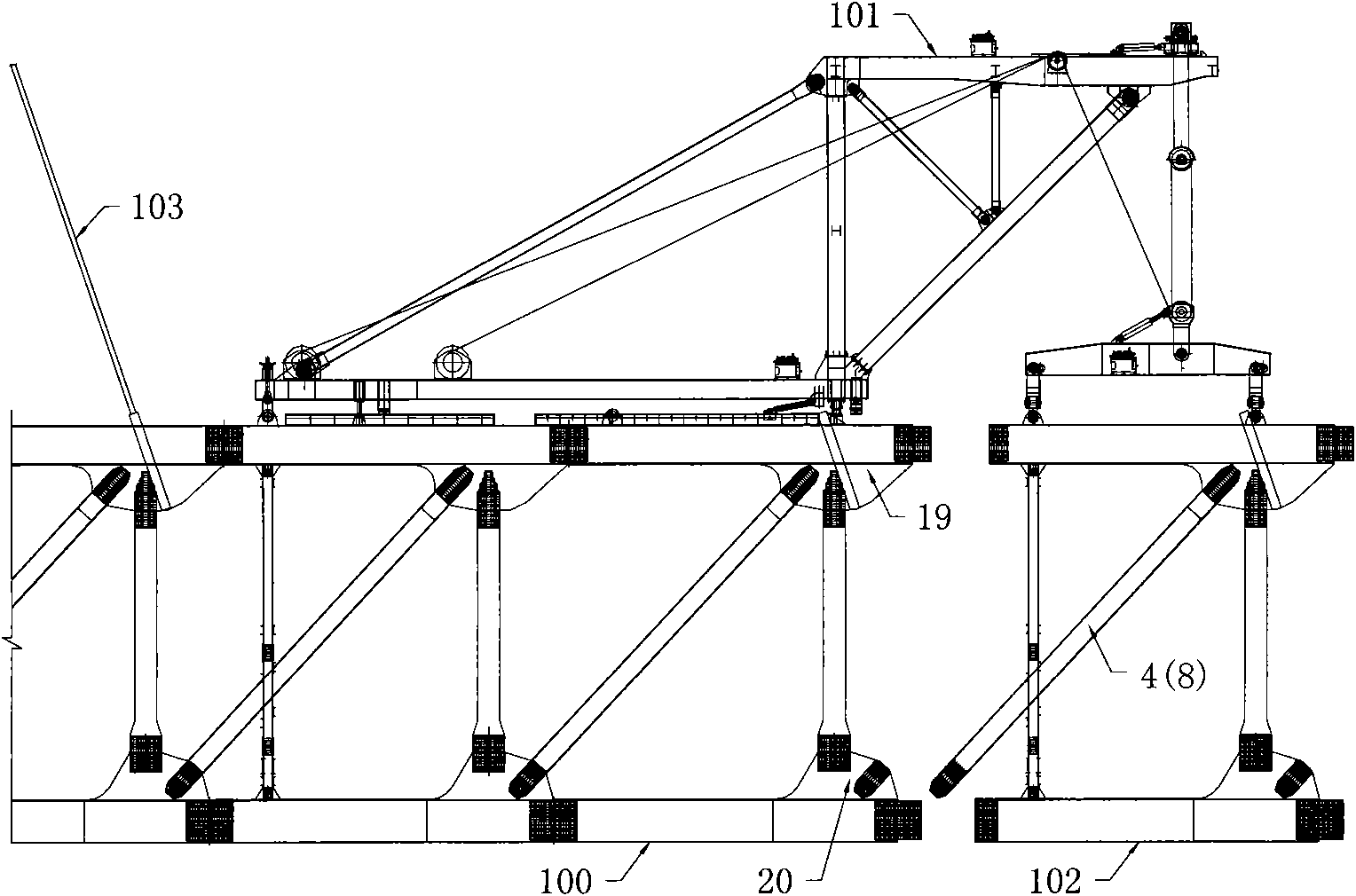

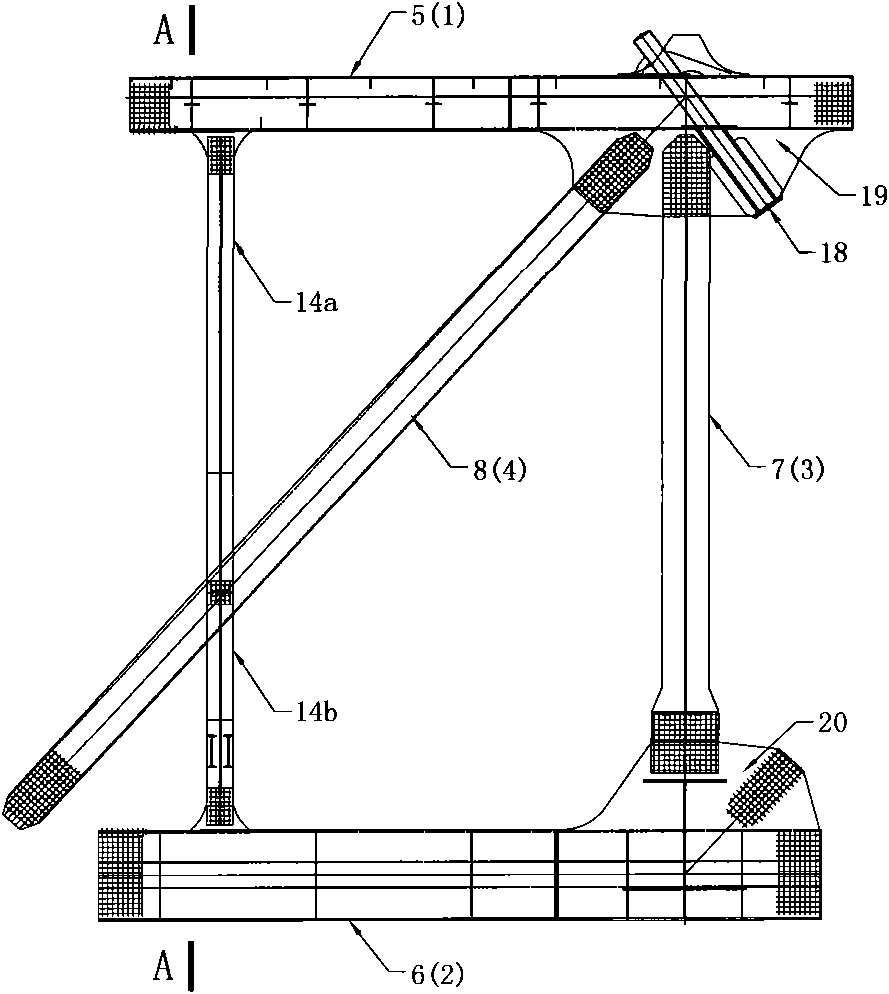

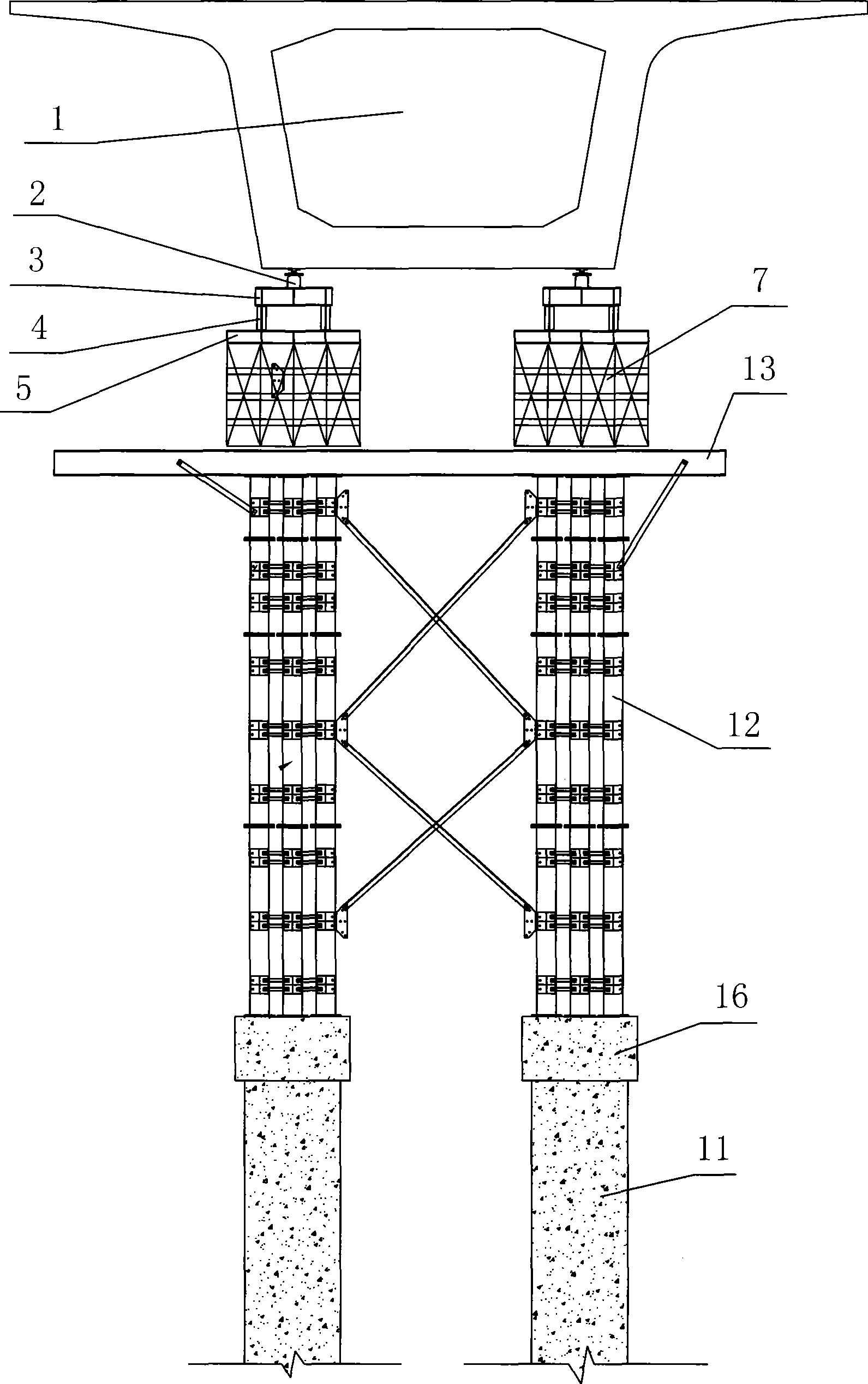

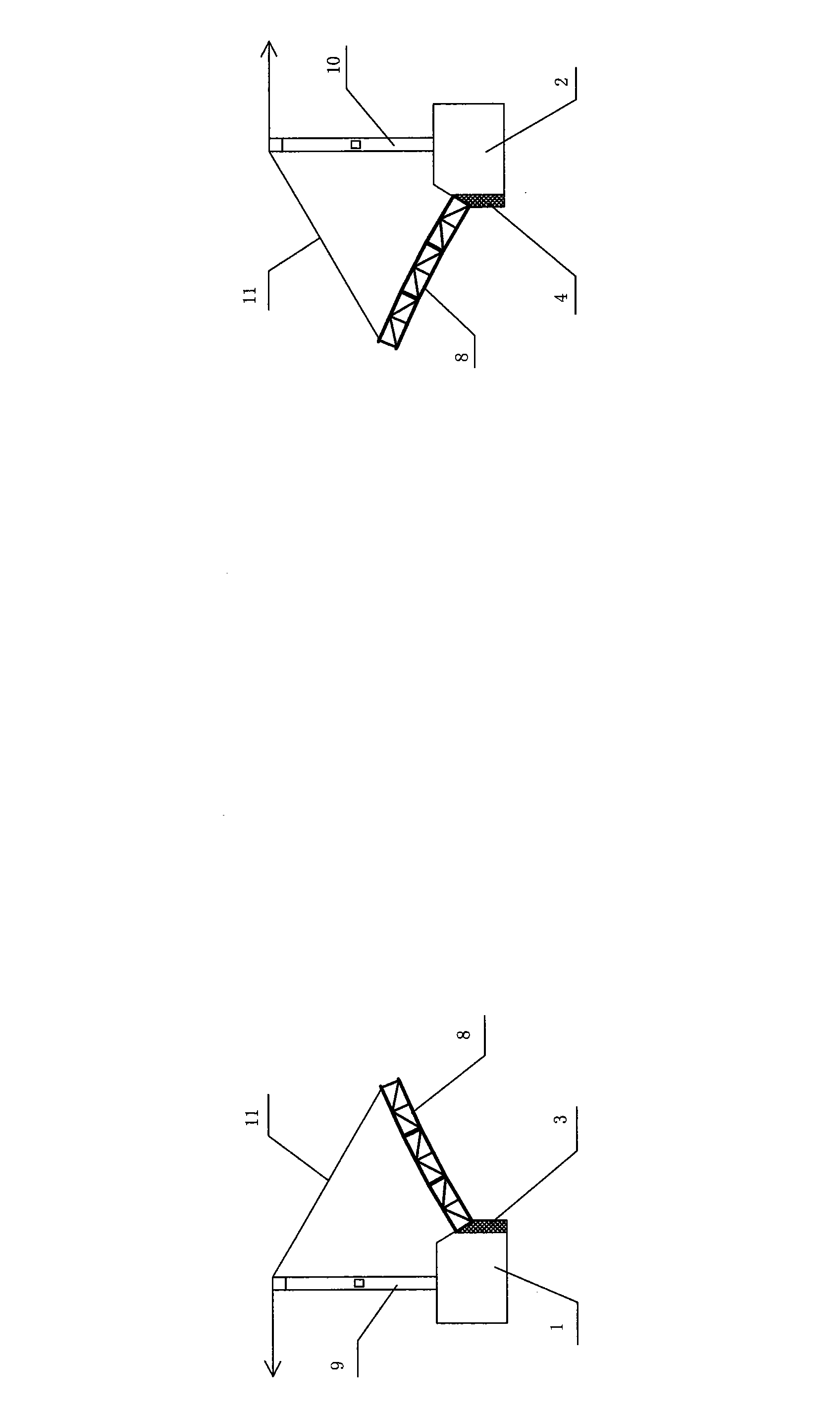

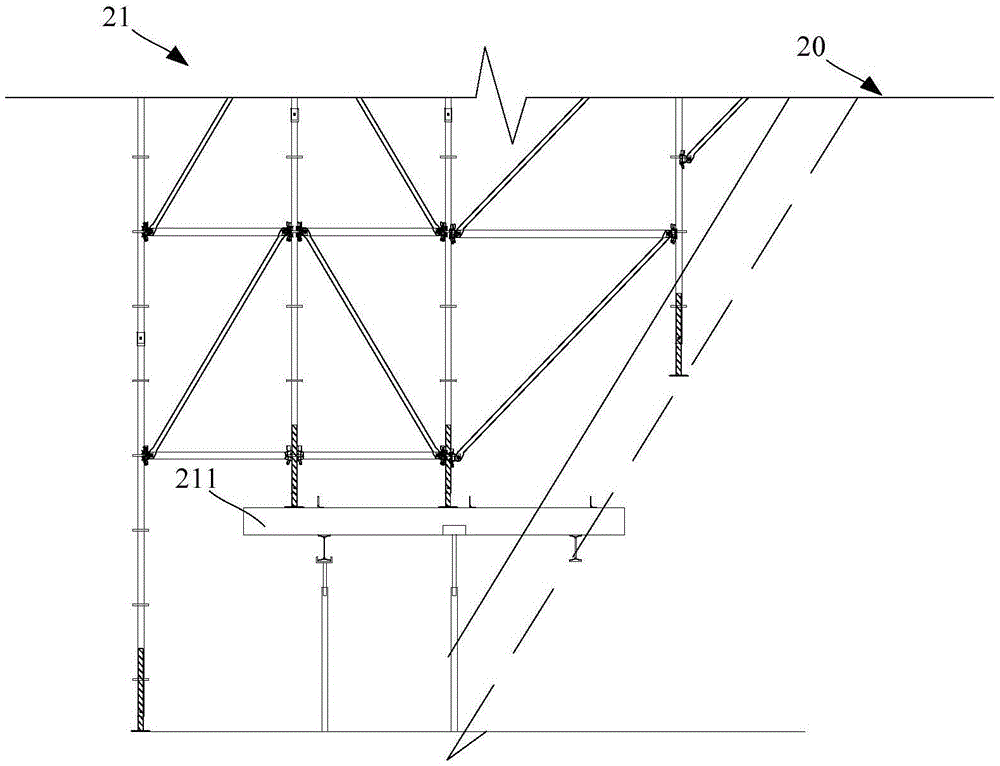

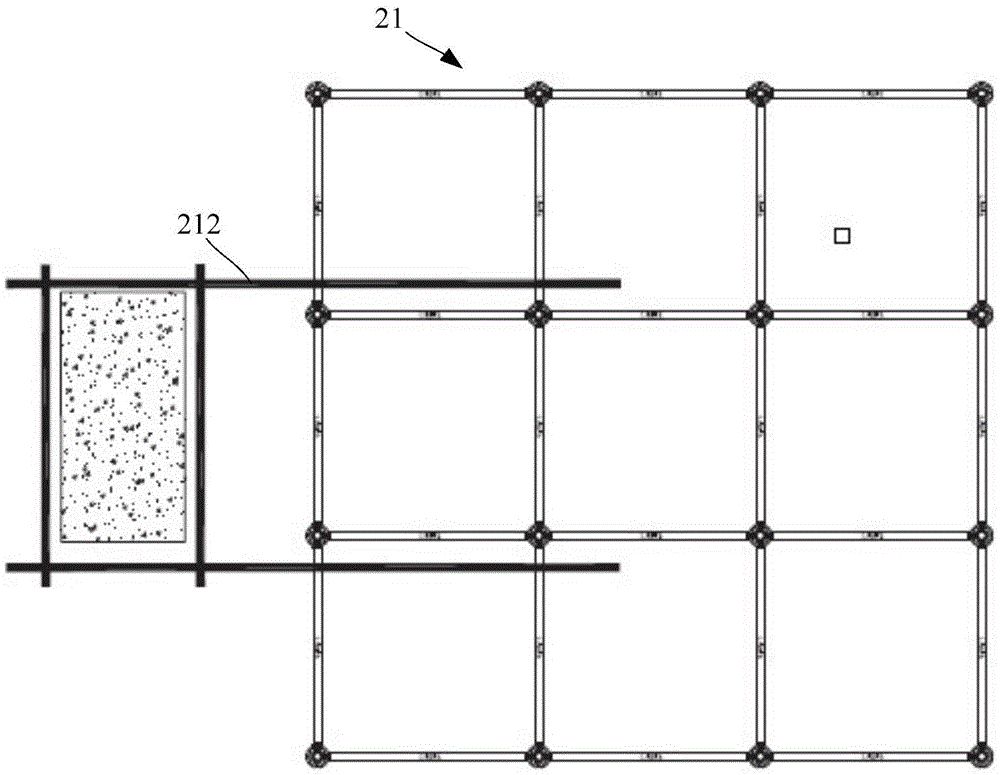

Hanger rail type electric hanging boat and high-rise long span house, bridge building construction method and use thereof

ActiveCN101514586AFirmly connectedImprove securityBridge erection/assemblyBuilding material handlingArchitectural engineeringLong span

The invention provides a hanger rail type electric hanging boat, comprising an overhung hanger rail fixed on a building main component, a construction operation hanging boat, a hanging boat horizontal walking system and a hanging boat lifting system, wherein the overhung hanger rail is fixed on the building main component, the hanging boat is fixed on the hanger rail via a walking device, and a detachable fixedly connecting structure is formed between the hanging boat and a hanger rod via the hanger rod. The invention further provides a method for high-rise building outside wall construction by the hanger rail type electric hanging boat, including a mounting method and a demolishing method. The use of the hanger rail type electric hanging boat and the construction method is further provided. The invention provides the safe and practical hanging boat with reasonable structure, thereby solving the problem that the hanging boat cannot move horizontally in the prior art, and facilitating outside wall ceiling construction of various special buildings such as long span vestibule.

Owner:JANGHO GRP

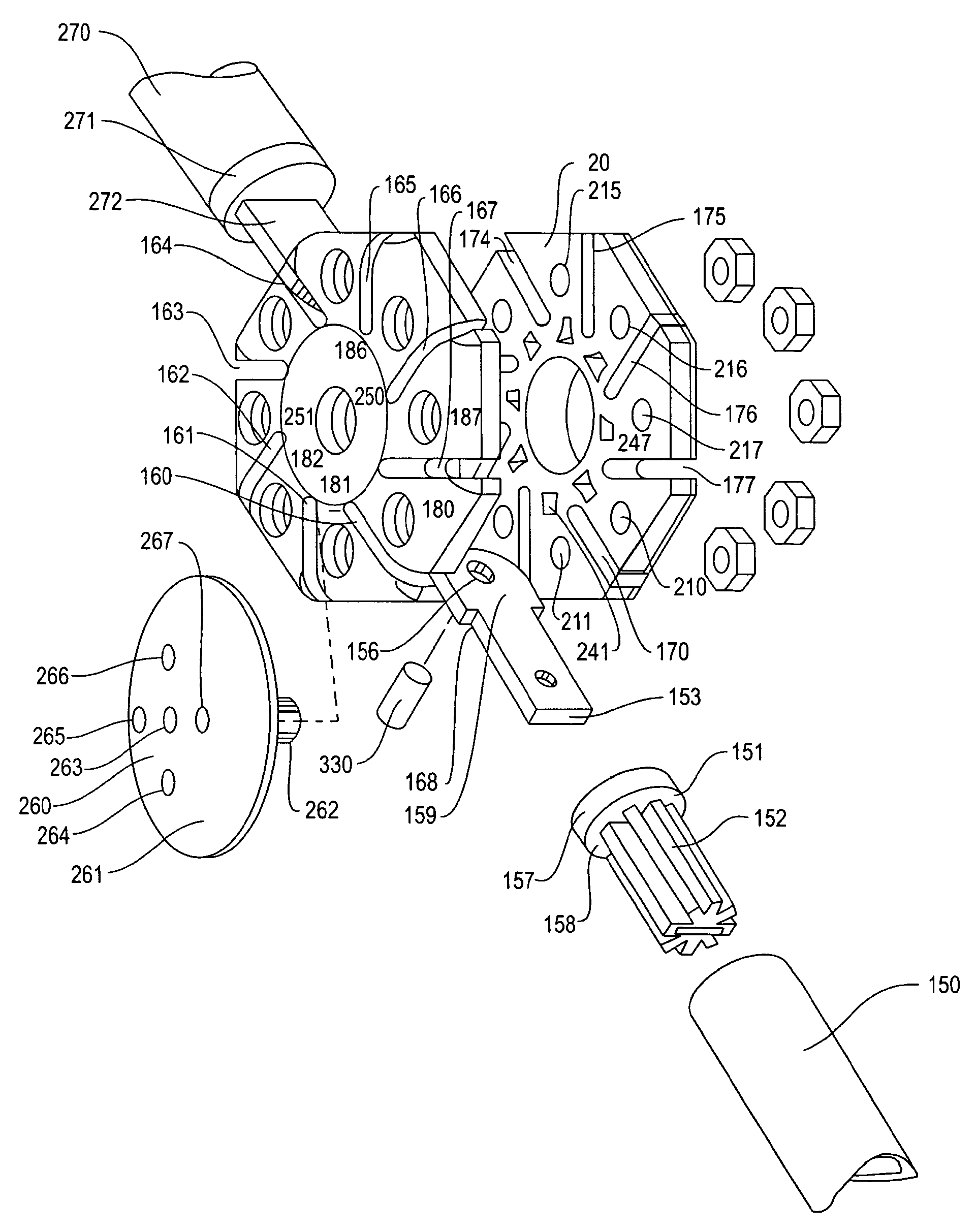

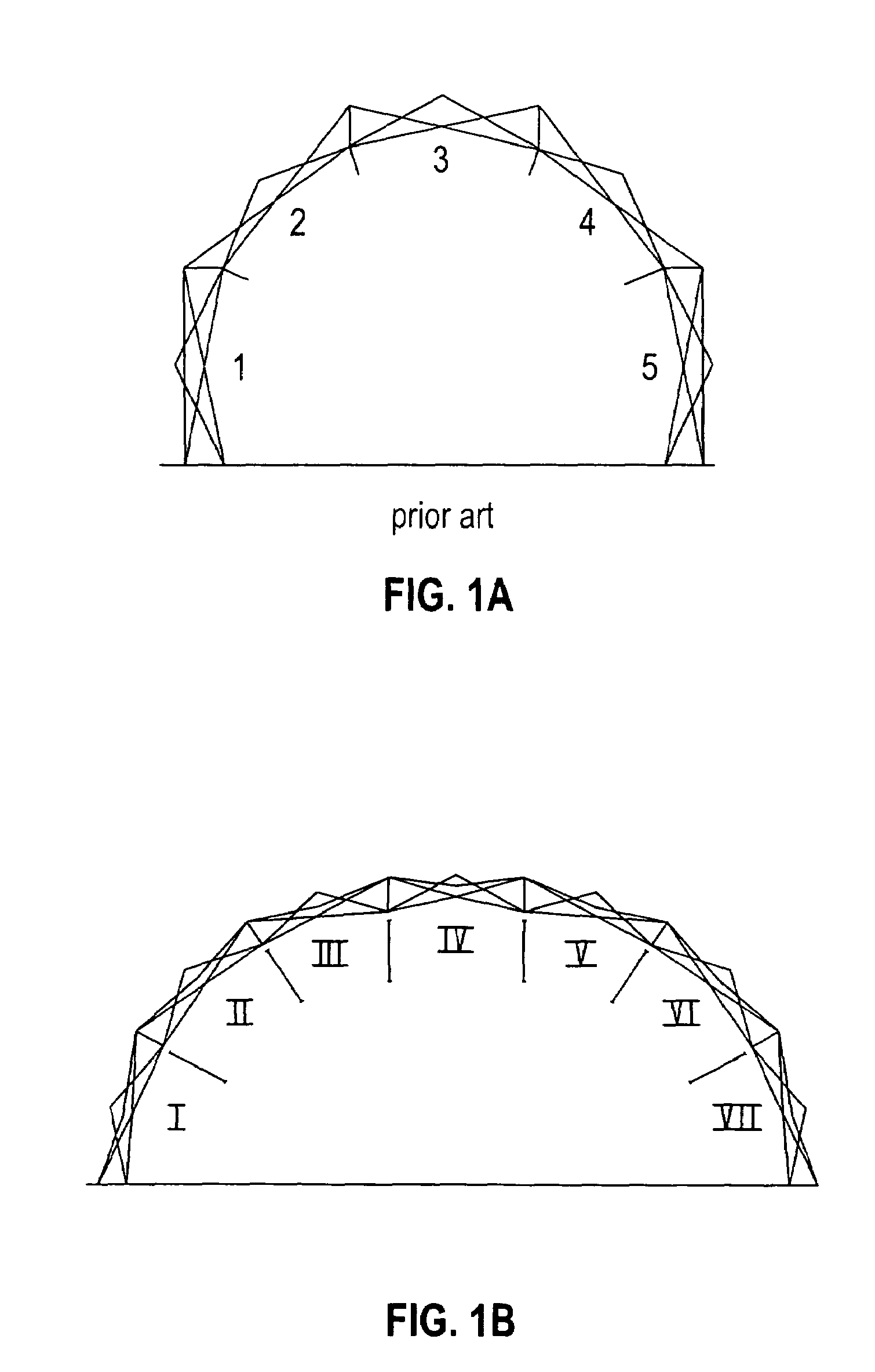

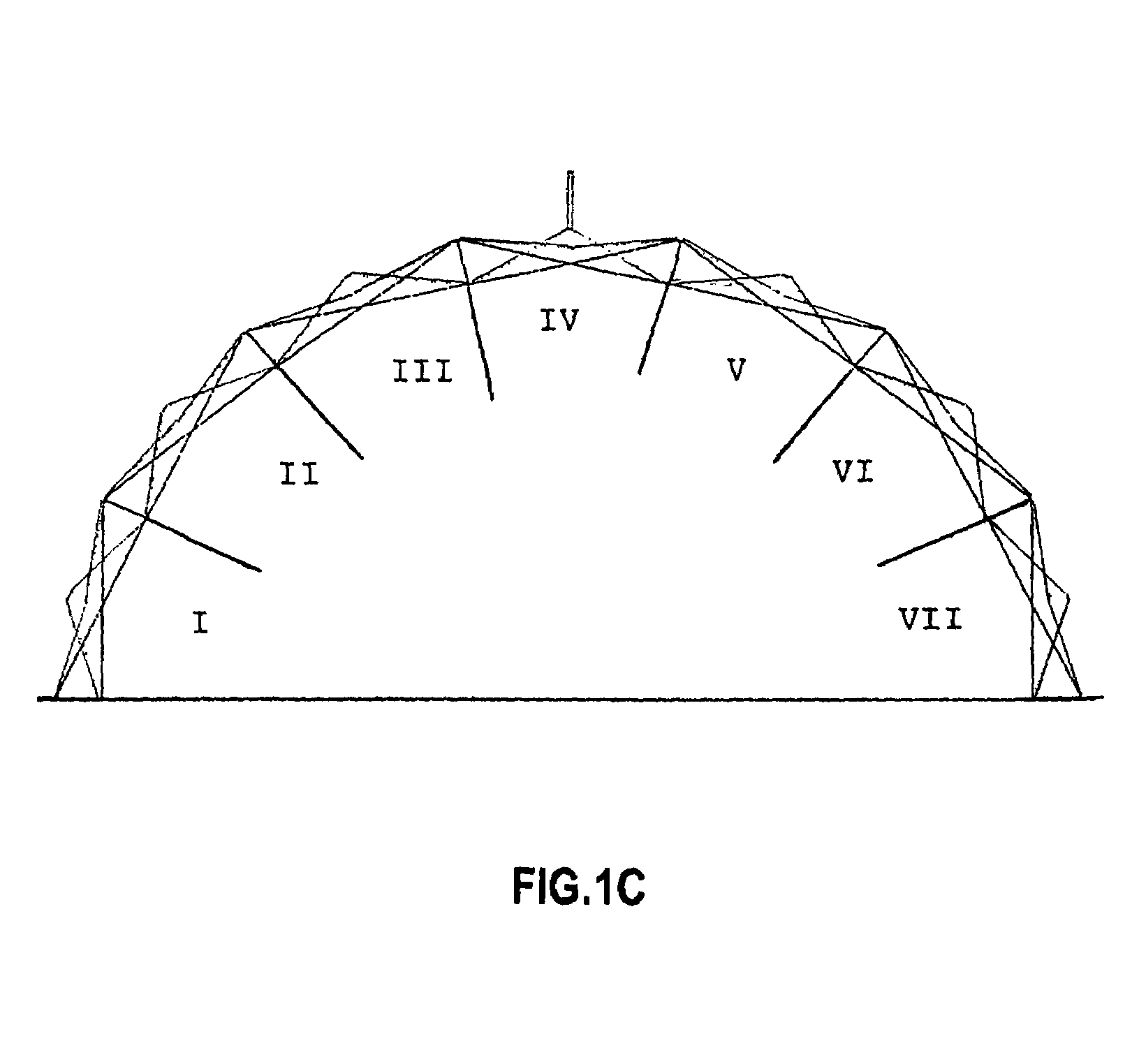

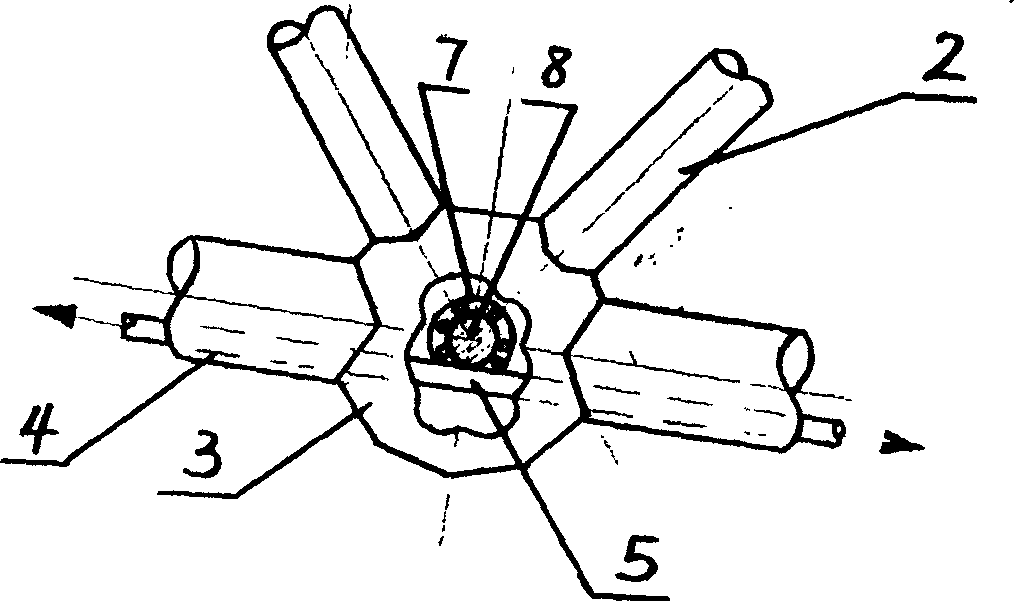

Articulating hub assembly

ActiveUS7481235B2Quick erection and strikingEasily fold in on themselvesBuilding roofsYielding couplingCombined useSpandrel

A collapsible self-supporting structure used in combination with an improved articulating hub assembly. The articulating hub assembly is used as a connector among tubular rod elements which together provide a generally tubular frame matrix used to erect a collapsible self-supporting prefabricated deployable structure where a clear span interior without supporting columns is required.

Owner:HDT EXPEDITIONARY SYST INC

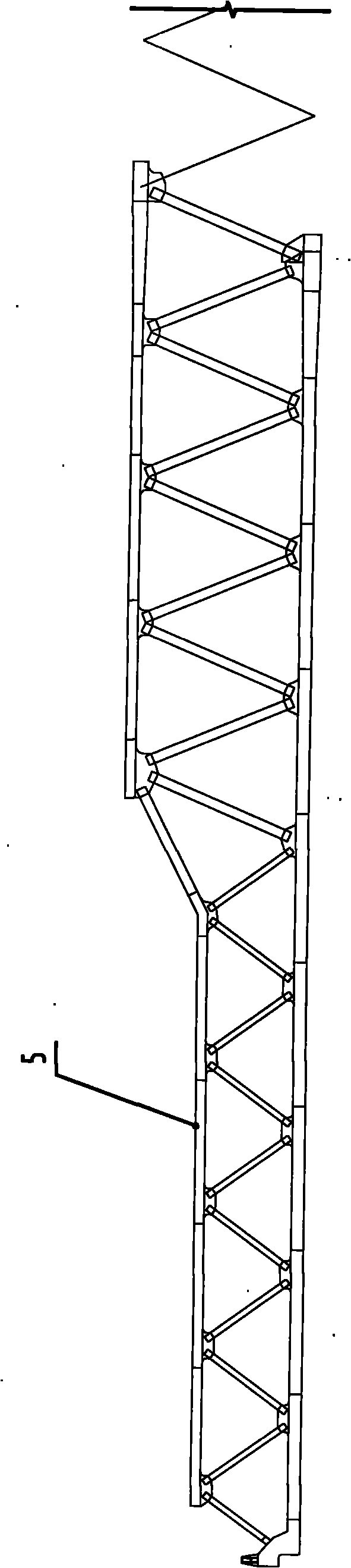

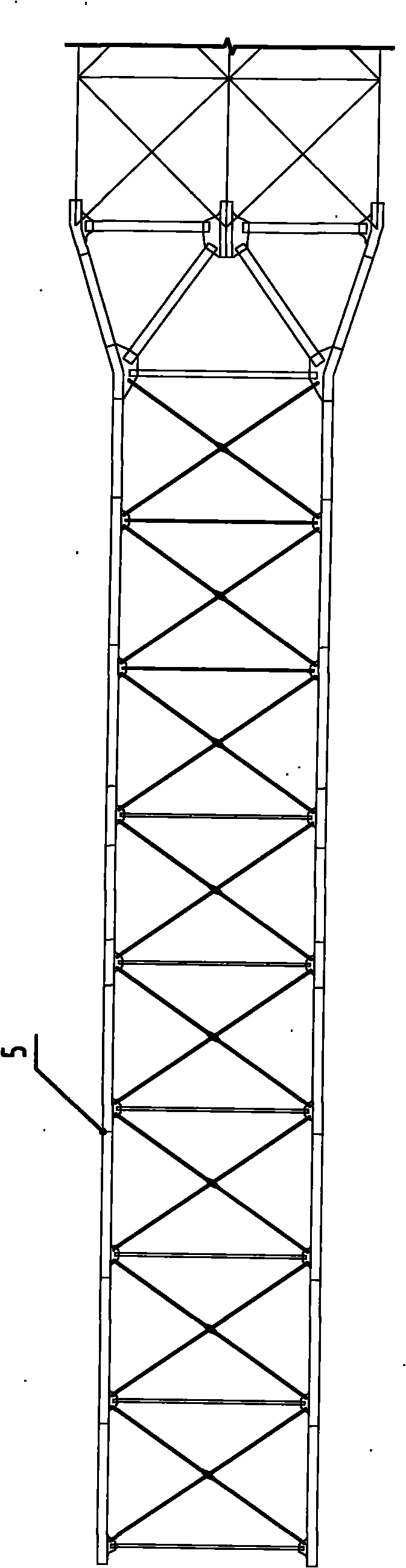

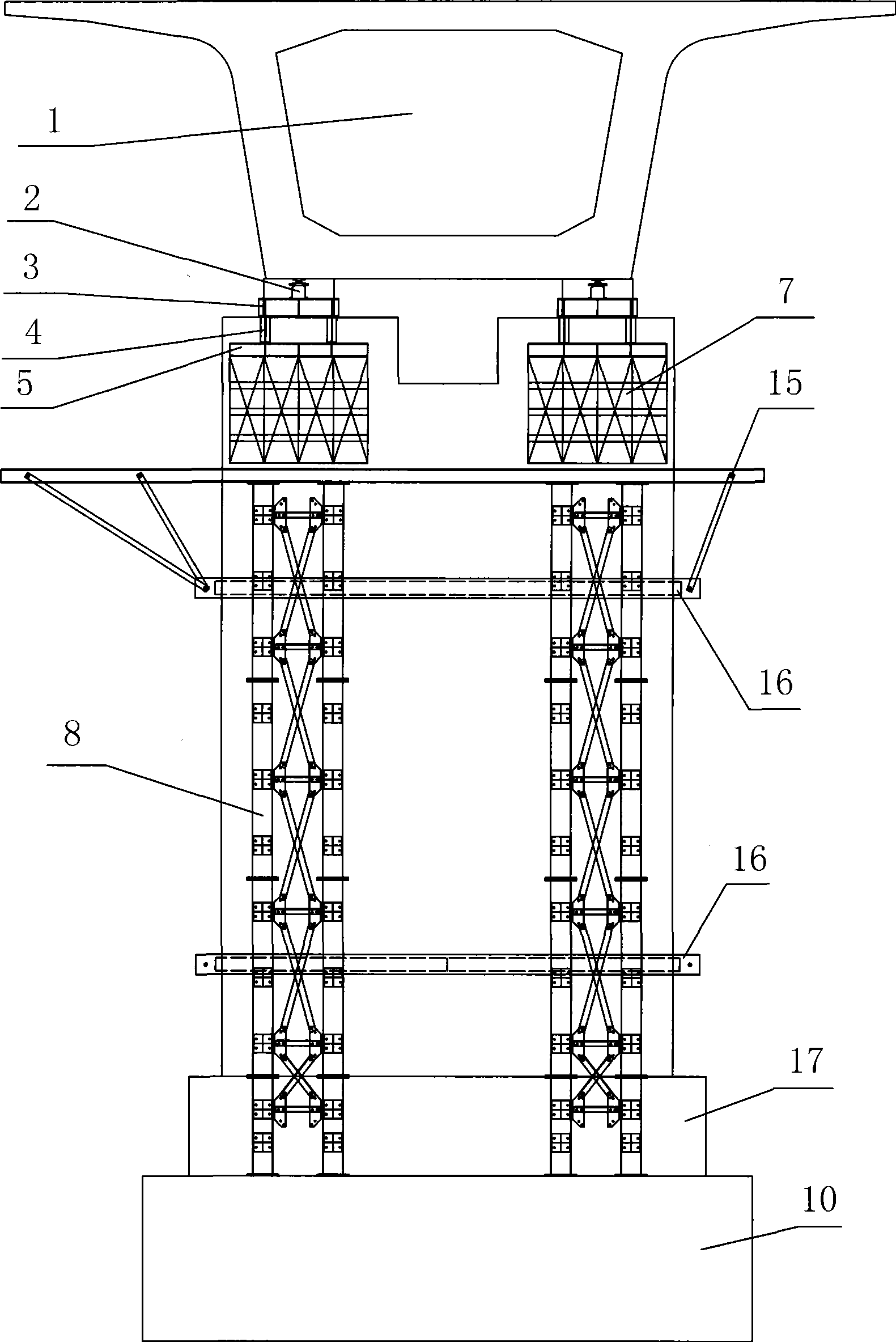

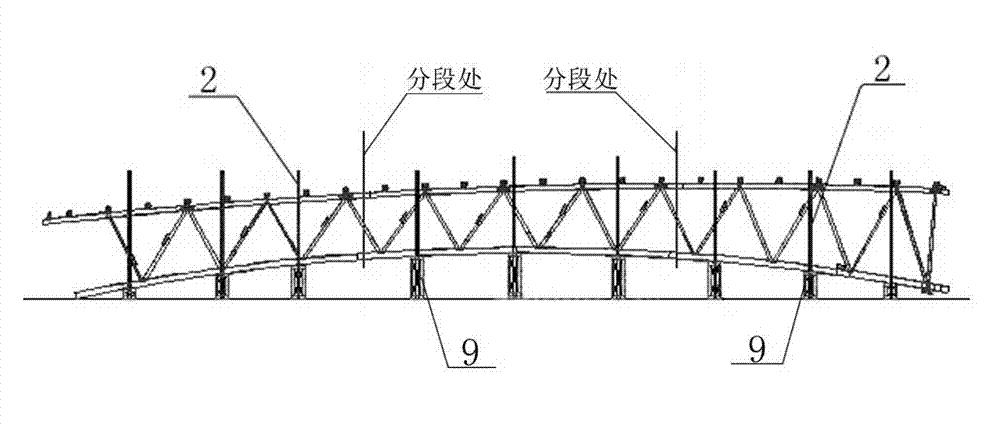

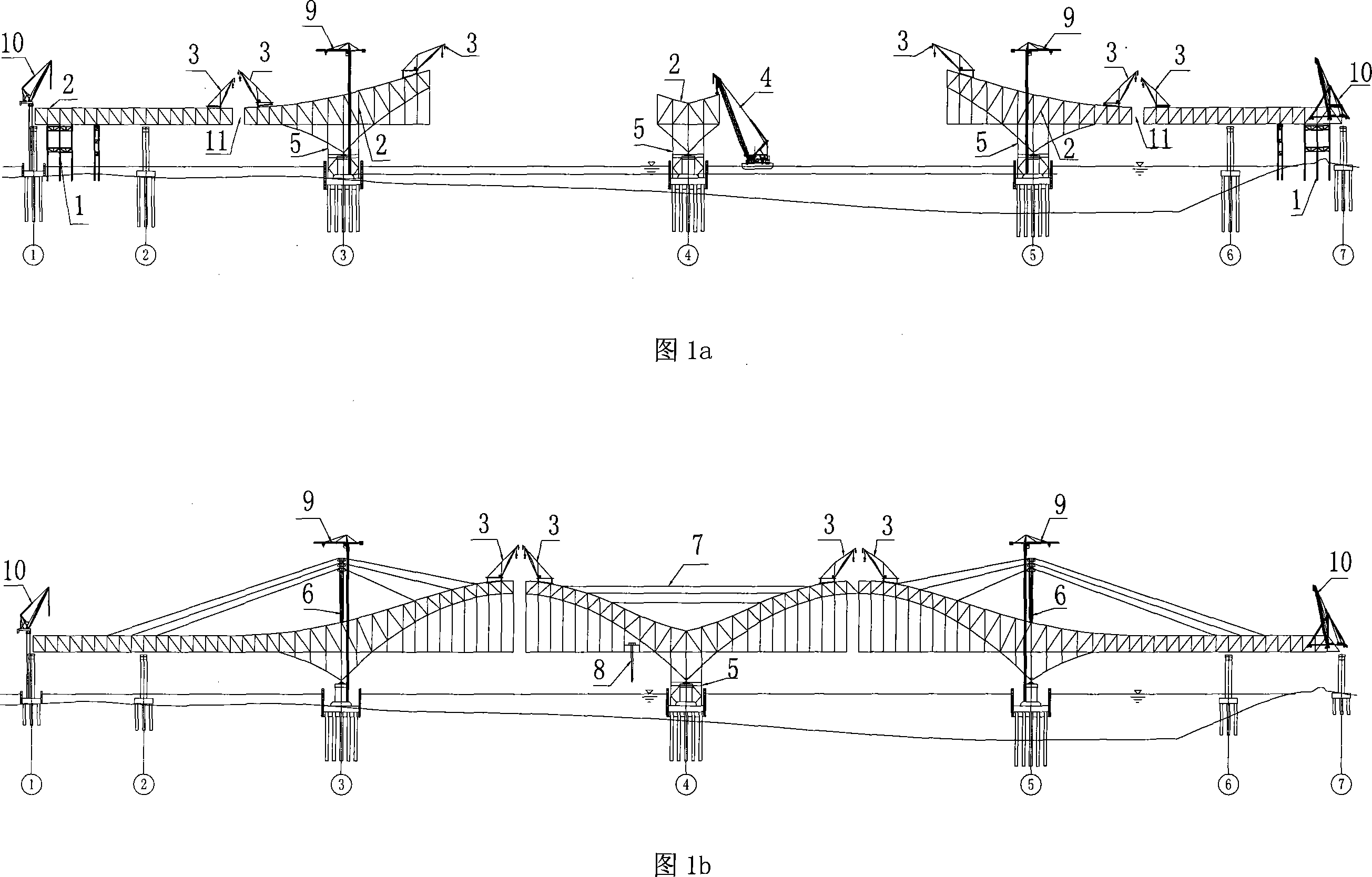

Multipoint synchronous push construction method for porous large-span continuous steel truss girder

ActiveCN101831874AEasy constructionReduce labor intensityBridge erection/assemblyControl systemEngineering

The invention discloses a multipoint synchronous push construction method for a porous large-span continuous steel truss girder, which comprises the following steps of: (1) assembling a steel truss girder assembling platform and a push slideway in a shoreside bridge pier position; (2) assembling a section of steel truss girder and a guide girder on the steel truss girder assembling platform; (3) installing a vertical jack for carrying out support conversion on the steel truss girder and then installing a continuous push jack, a steel strand and an electrohydraulic integrated control system; (4) operating the electrohydraulic integrated control system for carrying out push operation on the steel truss girder; and (5) after the push operation of the section of steel truss girder is finished, continuously assembling the steel truss girder on the steel truss girder assembling platform, carrying out next push operation, repeating the step for circulating operation and finishing the push construction of the porous large-span steel truss girder. The invention has the advantages of short construction period, safe construction, quality guarantee, low cost, and the like, realizes the push operation of the large-span steel truss girder, saves the construction cost, and reduces the pollution to a river channel.

Owner:1ST ENG OF CHINA ZHONGTIE MAJORBRIDGE GROUP +1

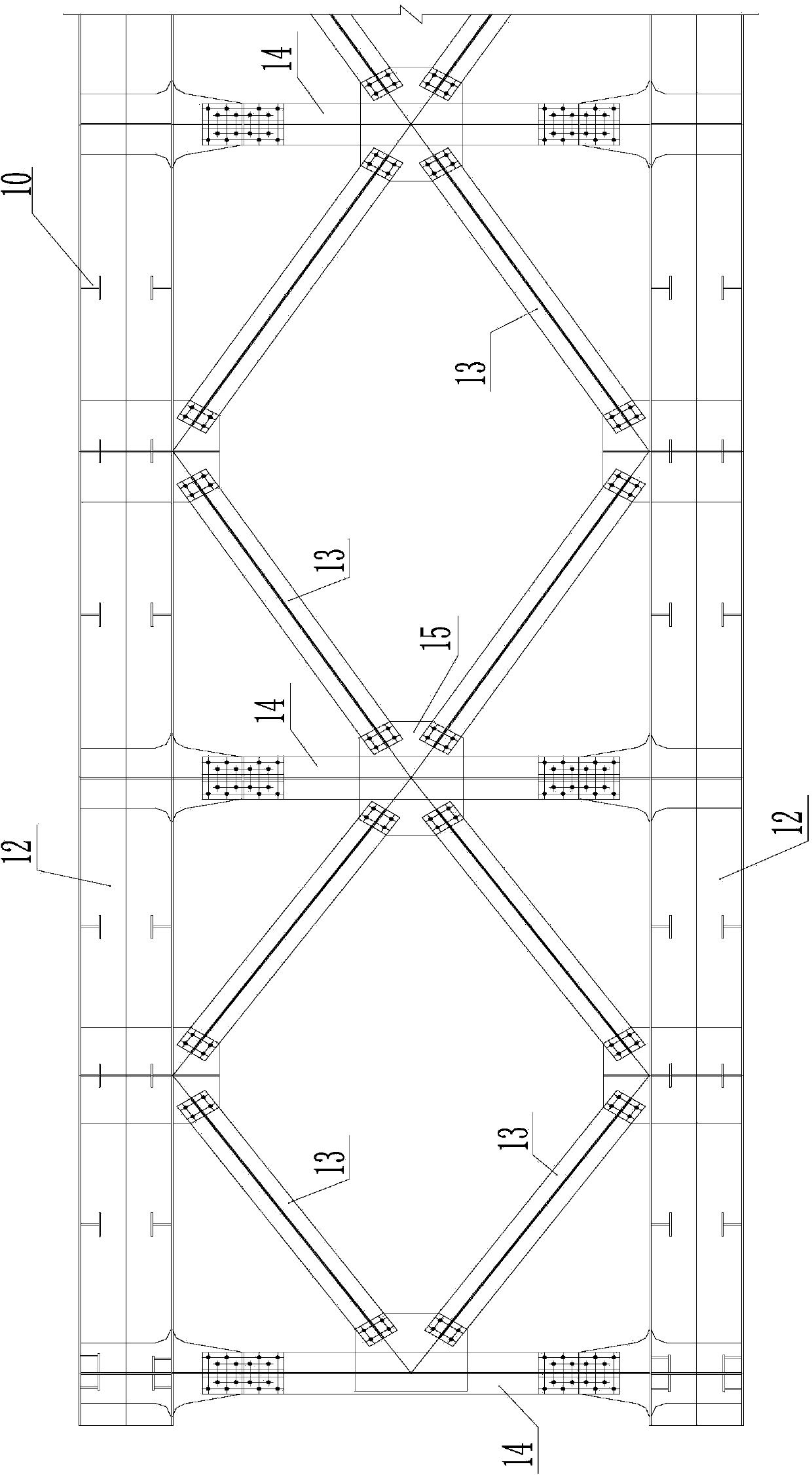

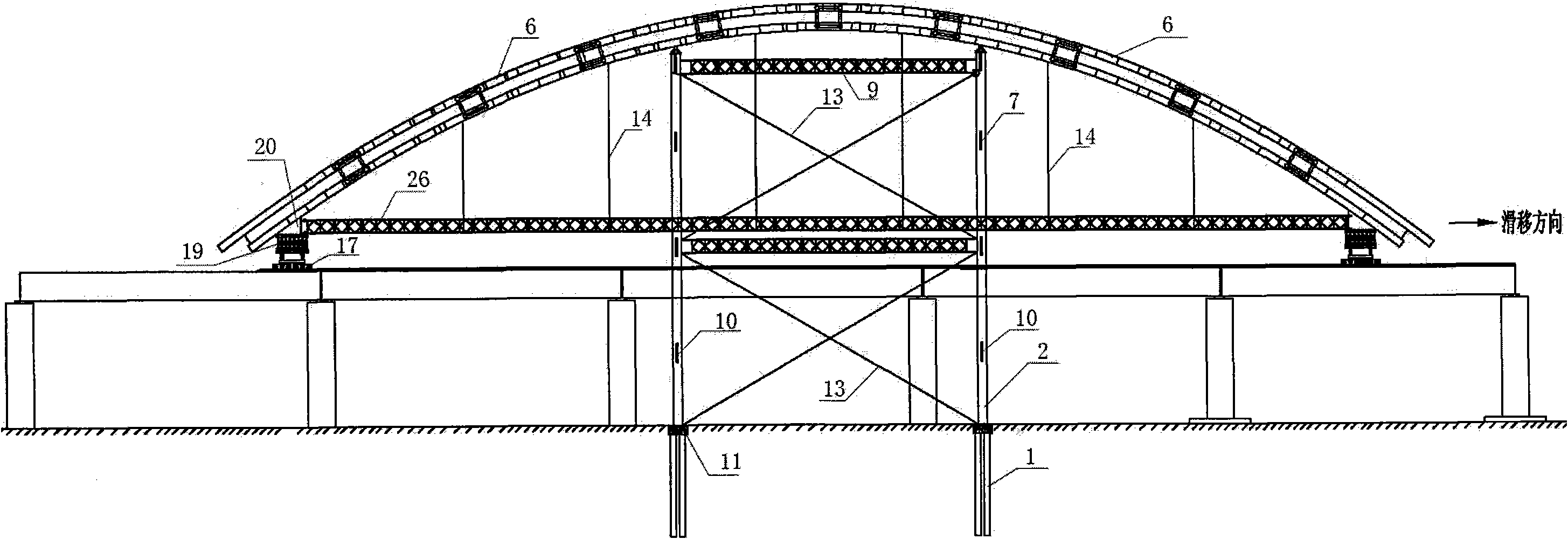

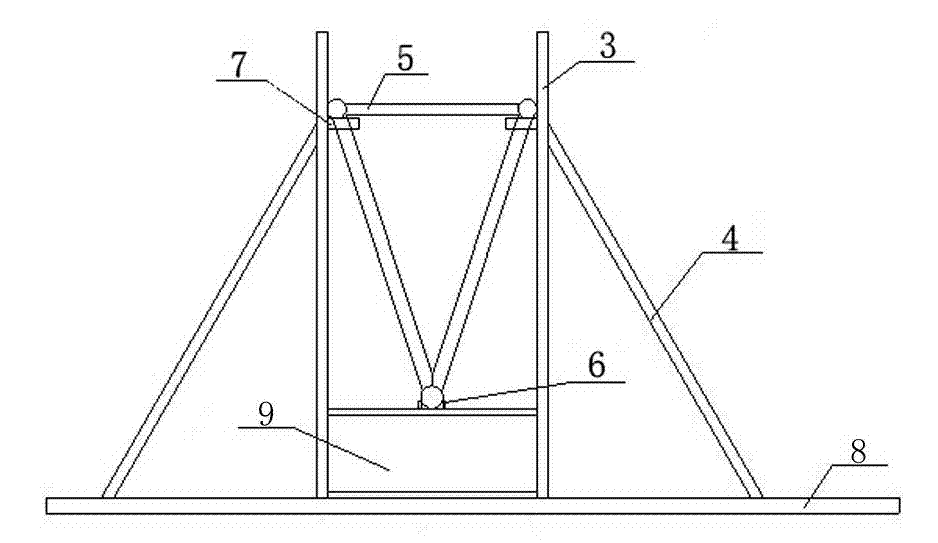

Segmental slipping and assembling process of overhead large-span steel structure

InactiveCN101725255AImprove installation accuracyFast constructionBuilding material handlingSpandrelSteel structures

The invention relates to a segmental slipping and assembling process of an overhead large-span steel structure, which is characterized by comprising the following steps of: firstly building a temporary track beam support, then arranging a slipping track beam and an assembling jig frame on the temporary track beam support, assembling a steel structure truss element on the jig frame according to drawing requirements, dismantling the assembling jig frame after the assembly is finished, pushing and slipping the steel structure truss element forwards along the a slipping track, moving the steel structure truss element to the expected position of the steel structure, then carrying out next span area steel structure truss element assembly on the emptied-out assembling jig frame, carrying out welding connection between the next span steel structure truss element and the previous element, slipping and pushing the steel structure truss elements to the expected position in sequence, analogizing the process in sequence till all steel structure slipping and assembly are finished, and finally unloading, landing and fixing to finish the whole installation work of the steel structure.

Owner:高申甫

Straddle type single-track double-box rectangular steel-concrete composite track beam structure

InactiveCN104213477AImprove carrying capacityIncrease lateral stiffnessRailway tracksBridgesEngineeringSpandrel

The invention relates to the field of track beams, in particular to a straddle type single-track double-box rectangular steel-concrete composite track beam structure. The straddle type single-track double-box rectangular steel-concrete composite track beam structure comprises two steel-concrete track main beams parallel to each other; the two steel-concrete track main beams are connected through crossbeams below and a low plain longitudinal; each steel-concrete track main beam comprises a steel beam structure with a box-type cross section and a concrete cuboid structure with a rectangular cross section; each concrete cuboid structure is positioned above the corresponding steel beam structure and is connected with the steel beam structure through shear nails; the span of each steel-concrete track main beam is 30-80 meters; the cross beams are I beams and are in bolt connection with cross beam connecting plates of the steel-concrete track main beams; the low plain longitudinal is a diamond truss, and plain main rod piece parts are respectively connected with the steel-concrete track main beams and the cross beams. The straddle type single-track double-box rectangular steel-concrete composite track beam structure can be suitable for building double-line large-span track beams, and the double-line large-span track beams are large in span, high in transverse stiffness and high in transverse stress performance structurally.

Owner:CHINA RAILWAY ENG CONSULTING GRP CO LTD

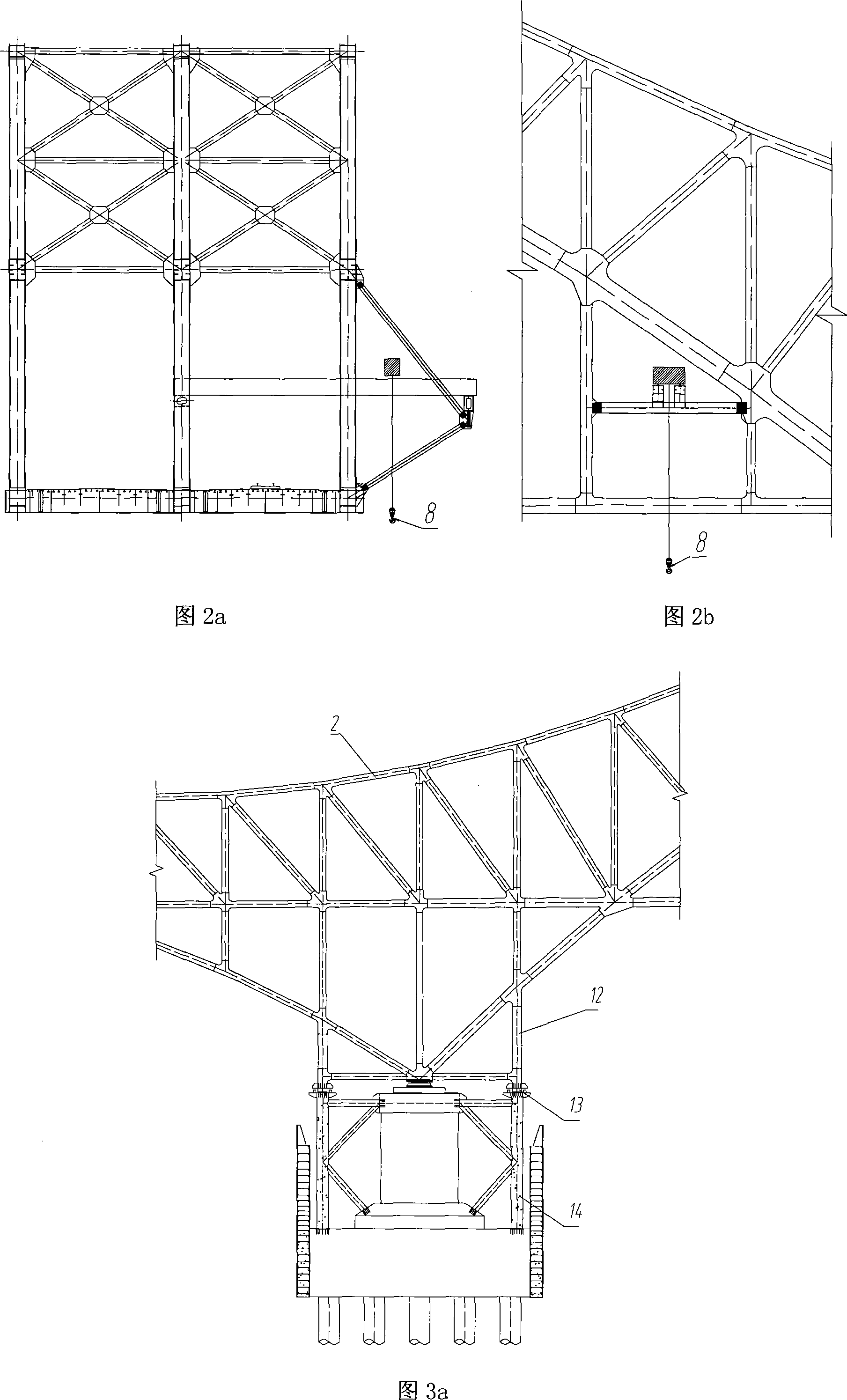

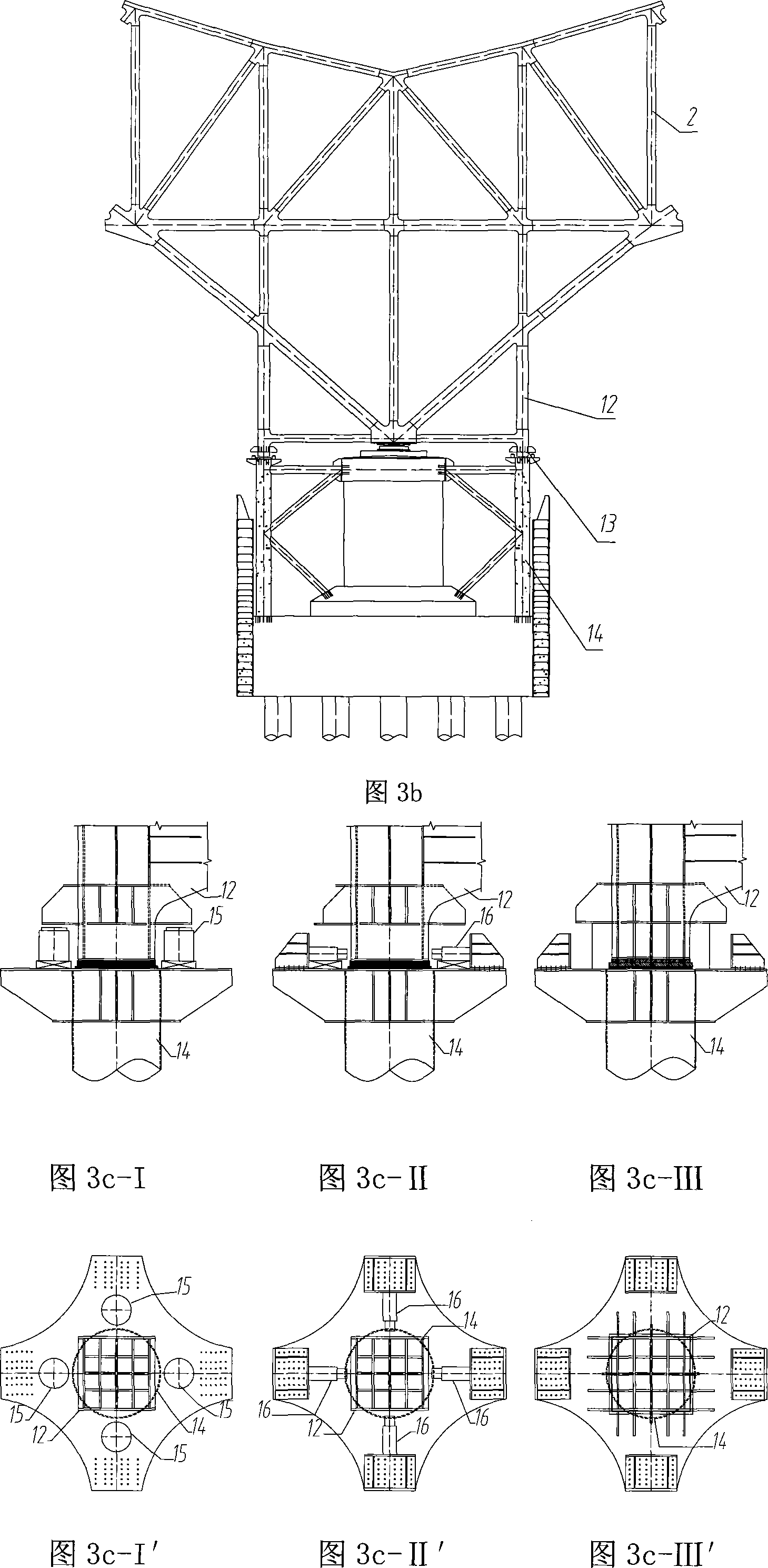

Three-truss main girder structure of highway and railway bi-purpose cable-stayed bridge and installation method thereof

ActiveCN101603288AImprove installation efficiencySave installation timeBridge erection/assemblyLoad-engaging elementsButt jointCable stayed

The invention relates to a three-truss main girder structure of a highway and railway bi-purpose cable-stayed bridge and an installation method thereof, relating to the technologies of designing and constructing a heavy load and long span highway and railway bi-purpose cable-stayed bridge. The structure of three main trusses comprises a middle truss piece and side truss pieces arranged on both sides of the middle truss piece, wherein an orthotropic slab and a transverse bracing truss are arranged between the upper edges of the middle truss piece and each side truss piece, and a railroad transverse girder, a railroad longitudinal girder and a horizontal bracing cross bridging are arranged between the lower edges of the middle truss piece and each side truss piece; and the invention provides the installation method adopting adaptive pre-splicing of multiple truss-sections, arrangement of temporary constructional rod pieces, integral lifting of each truss section and multi-node simultaneous alignment. The invention has the beneficial effects of: 1. pushing the highway and railway bi-purpose cable-stayed bridge to develop towards the direction of large span and heavy loading, 2. improving the installation efficiency and quality, 3. reducing the quantity of welding lines of construction sites, 4. innovatively practicing the multi-point simultaneous butt joint technology, 5. adopting the temporary rod pieces for solving the problems of unstability and large deformation in the processes of delivering and lifting the truss sections, 6. strengthening the adaptability of adjacent truss sections, and 7. solving the problems of inconsistent deformation of the middle and the side trusses and inconsistent centre-of-gravity positions of the truss sections.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD +1

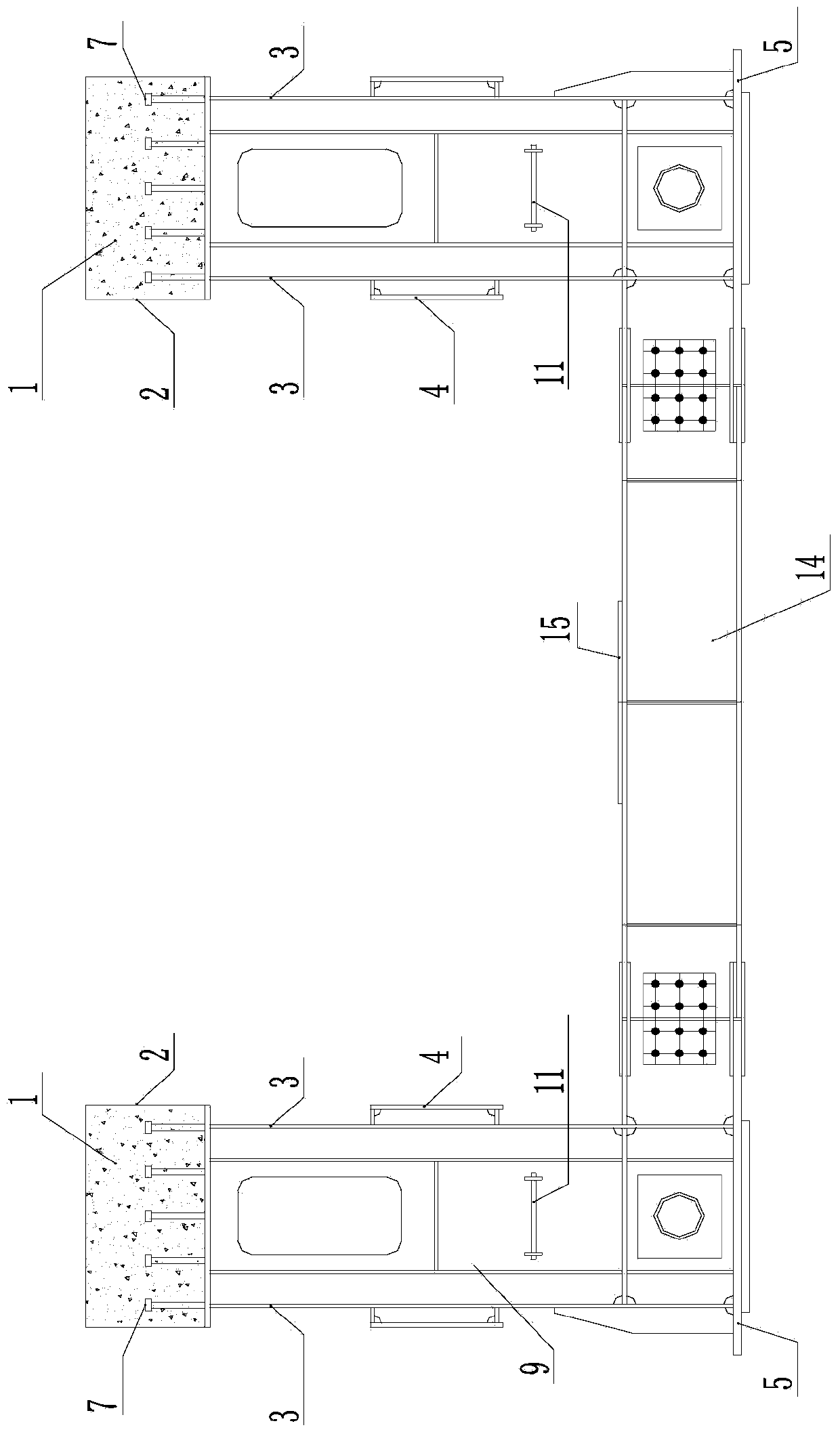

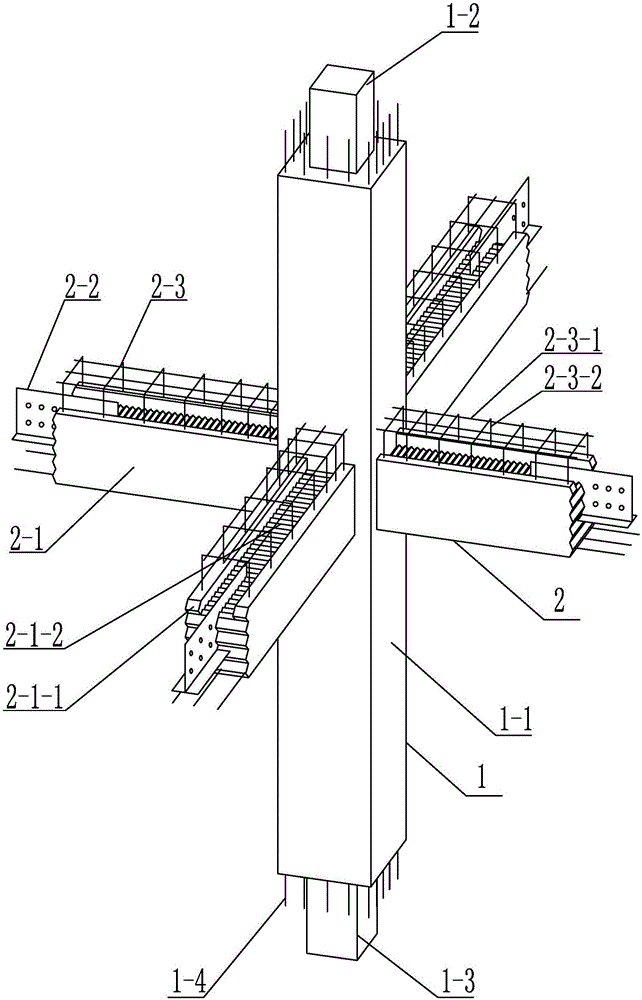

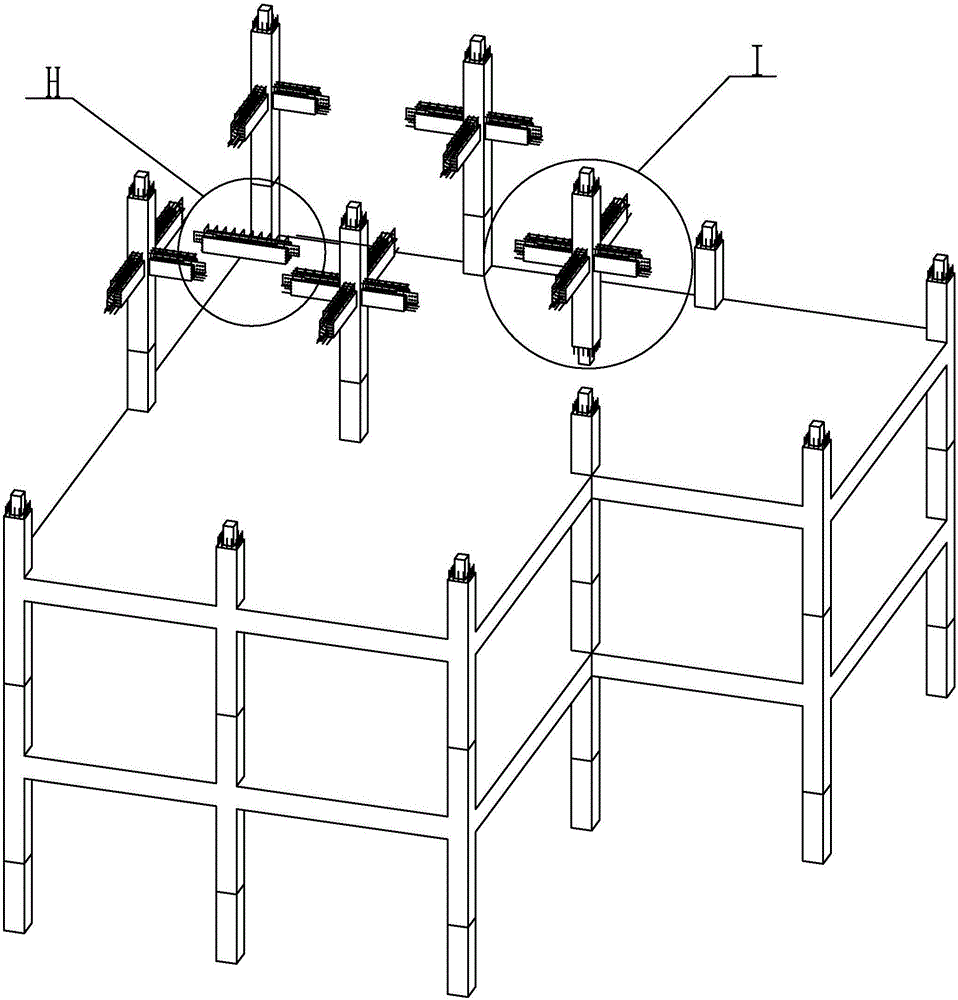

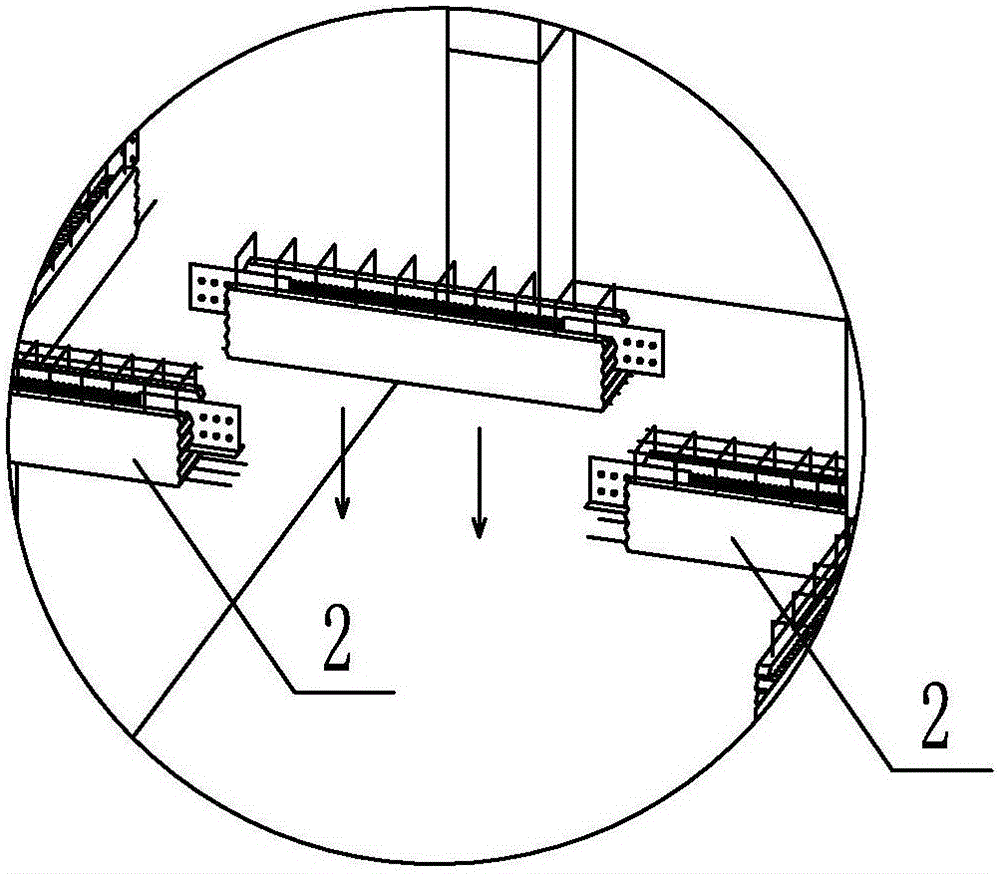

Single-layer prefabricated assembly type reinforced concrete beam-column joint

The invention relates to a prefabricated reinforced concrete beam-column joint, in particular to a single-layer prefabricated assembly type reinforced concrete beam-column joint. In order to solve the problem that the connection integrity of existing prefabricated beams and prefabricated columns is hard to guarantee, the prefabricated joint for one-piece casting manufacturing of a column section and part of beam sections is provided according to the concept of the point of inflection. The single-layer prefabricated assembly type reinforced concrete beam-column joint is formed by overall manufacturing of a vertical column section (1) and joint superposed beam sections (2) in a factory for prefabrication. A manufacturing method comprises the steps of beam-column longitudinal bar and stirrup binding, connector pre-burying, formwork erecting and concrete pouring and curing. The height of the vertical column section (1) of the joint is 1 / 2 of the storey height, and the length of each joint superposed beam section (2) is 1 / 3 of the span of adjacent columns. The vertical column section (1) comprises a pouring section (1-1), a concrete filled steel tube connector (1-2), a steel tube connector (1-3) and column section longitudinal bars (1-4). Each joint superposed beam section (2) comprises a groove-shaped pouring section (2-1), inverted-T-shaped structural steel connectors (2-2) and a reinforcement cage framework (2-3). The single-layer prefabricated assembly type reinforced concrete beam-column joint is applied to the construction industry.

Owner:HARBIN INST OF TECH

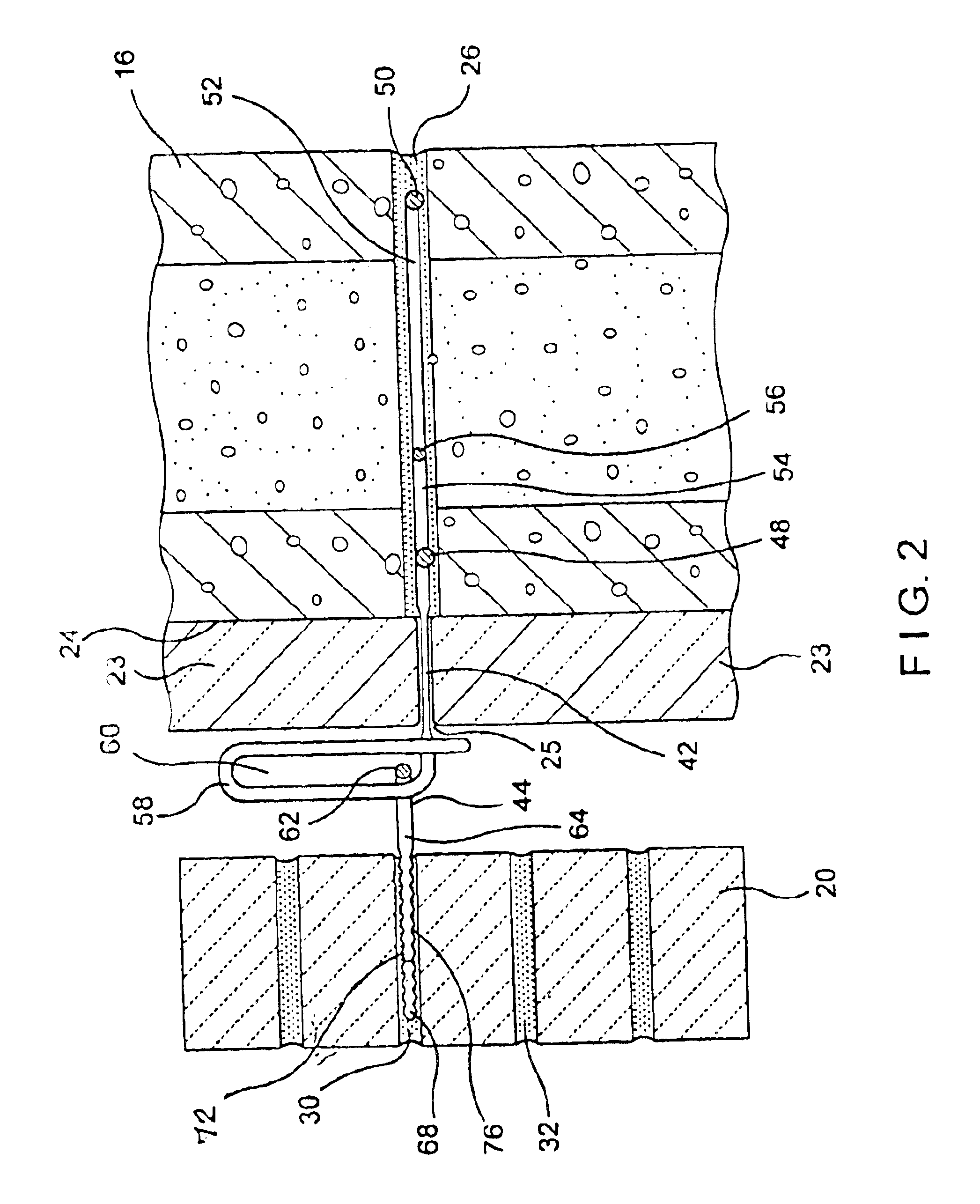

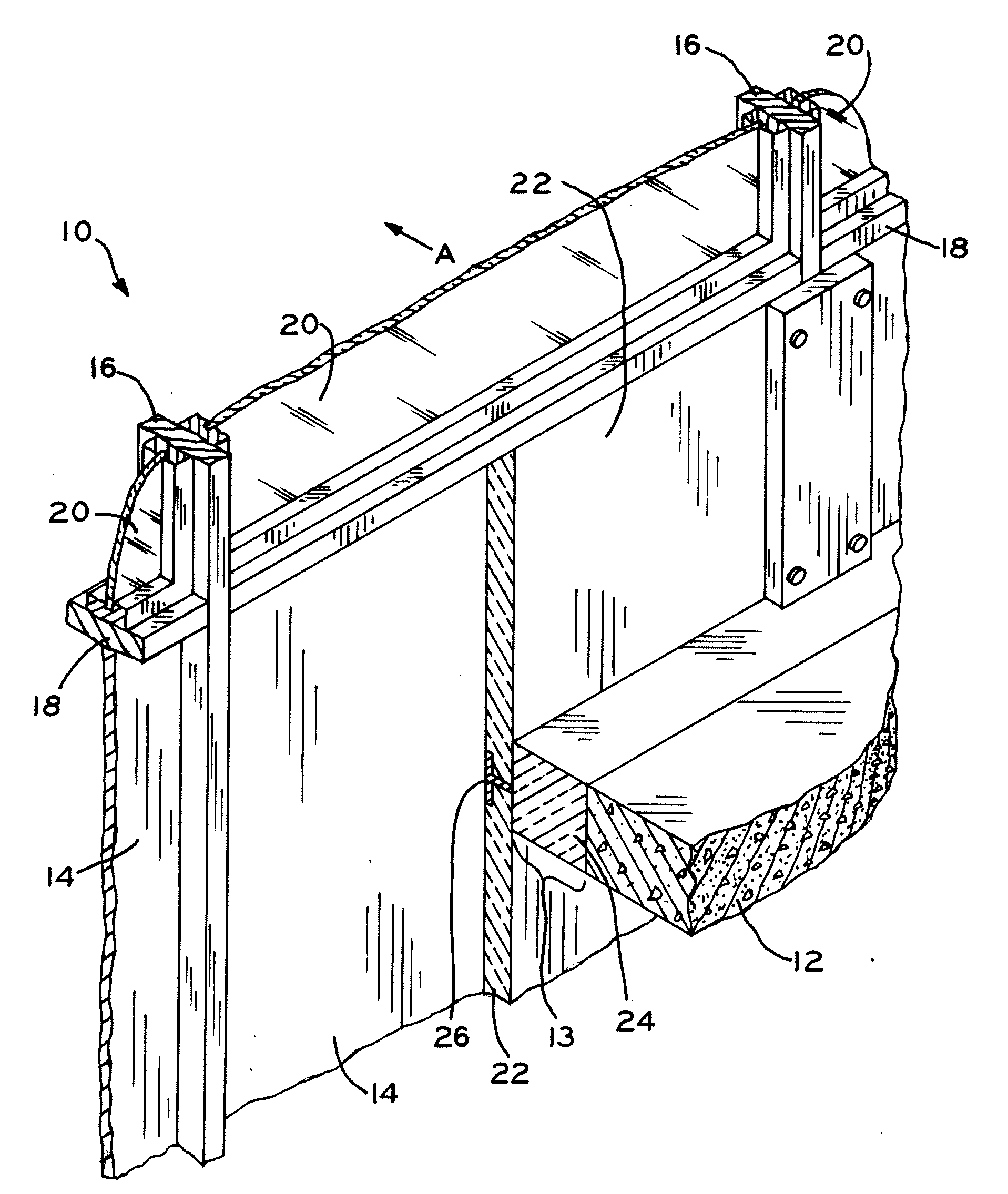

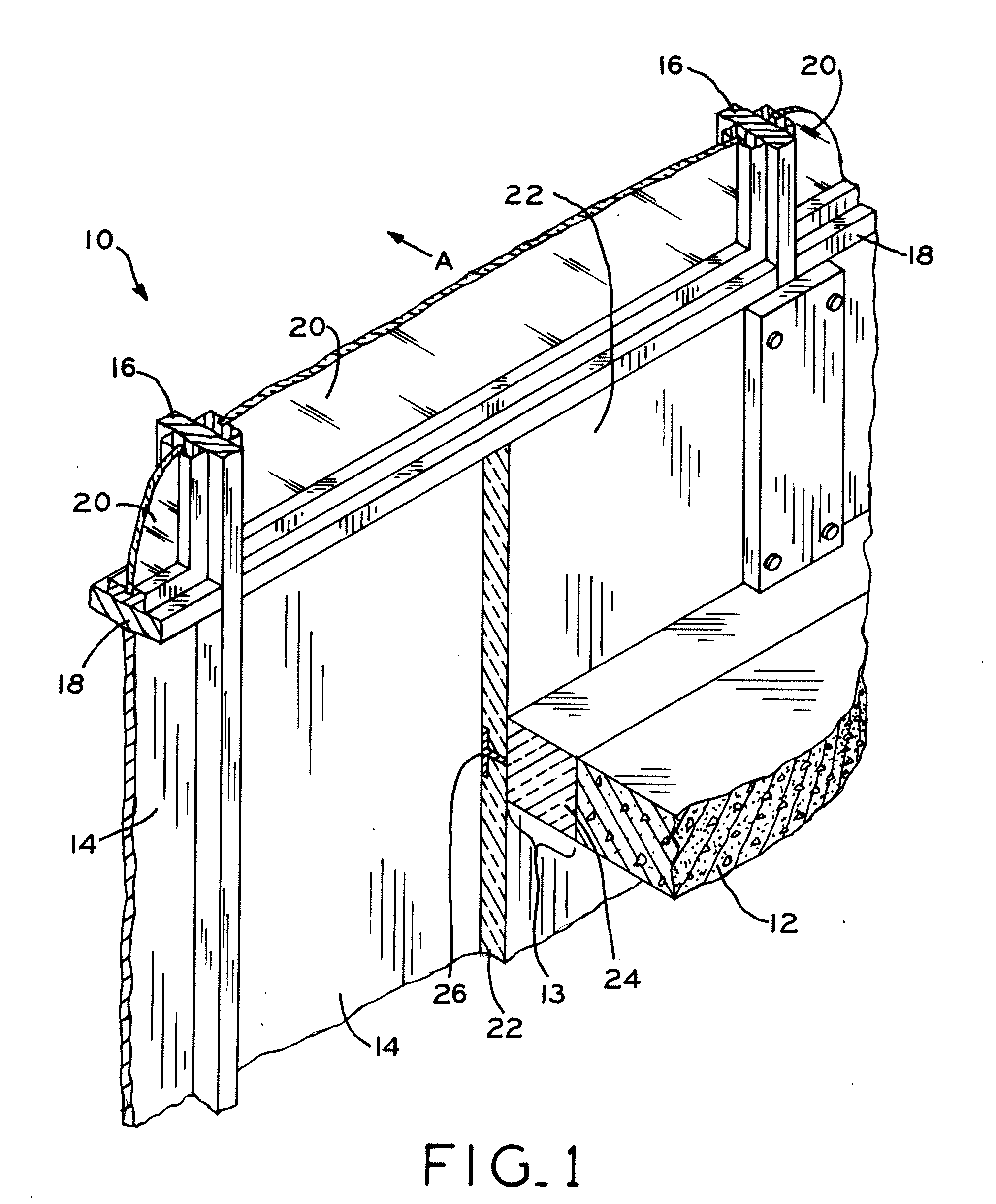

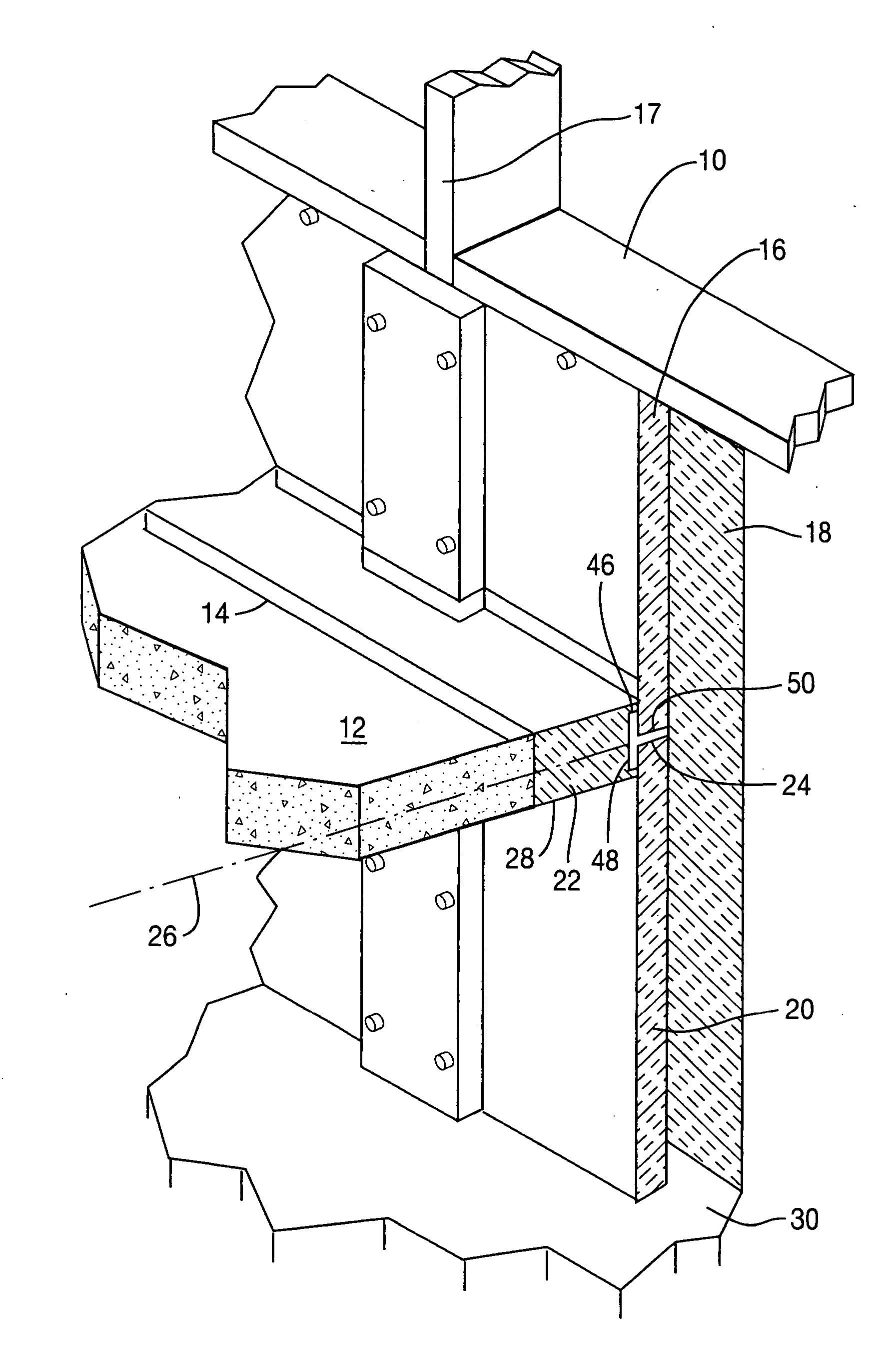

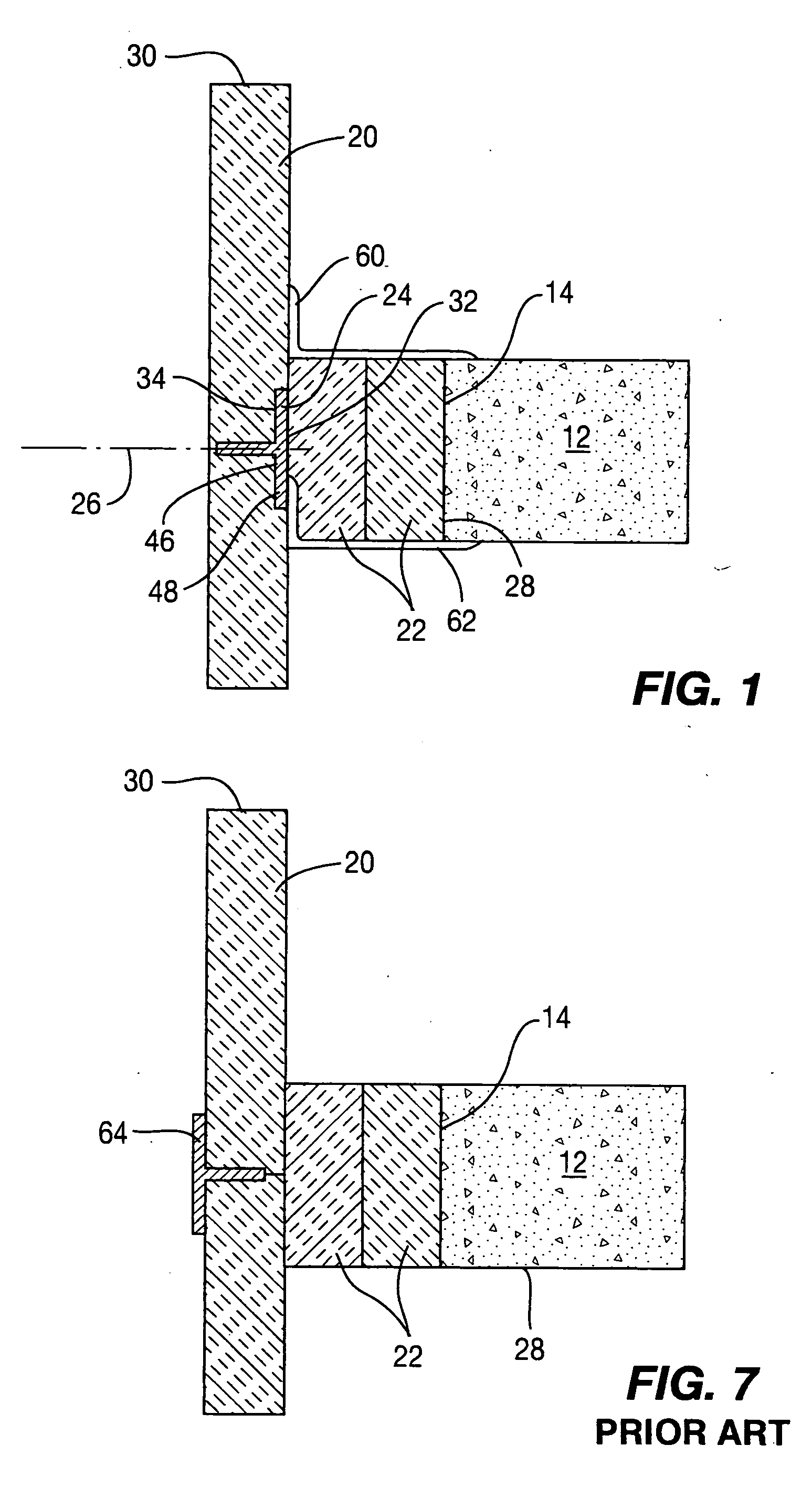

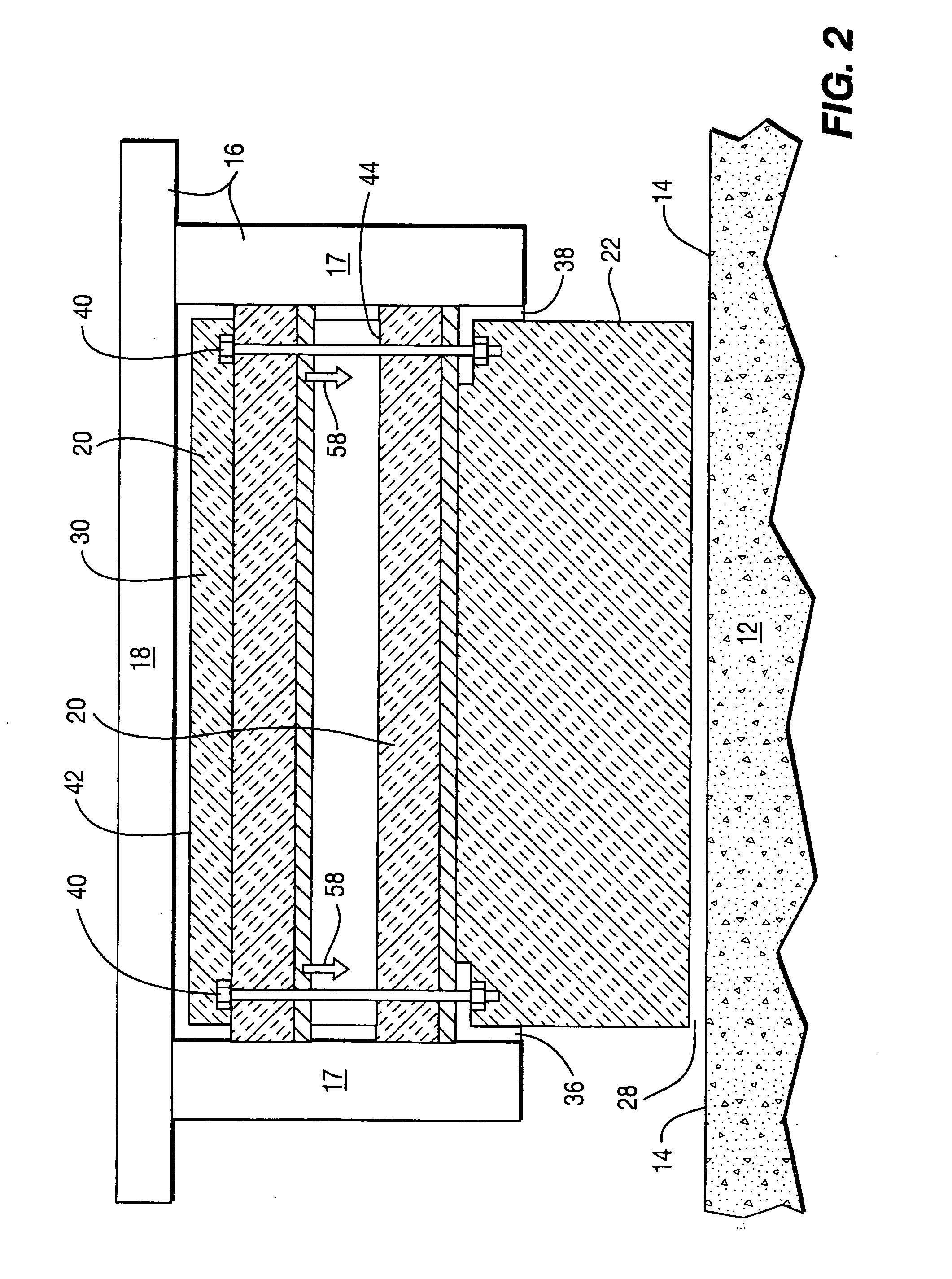

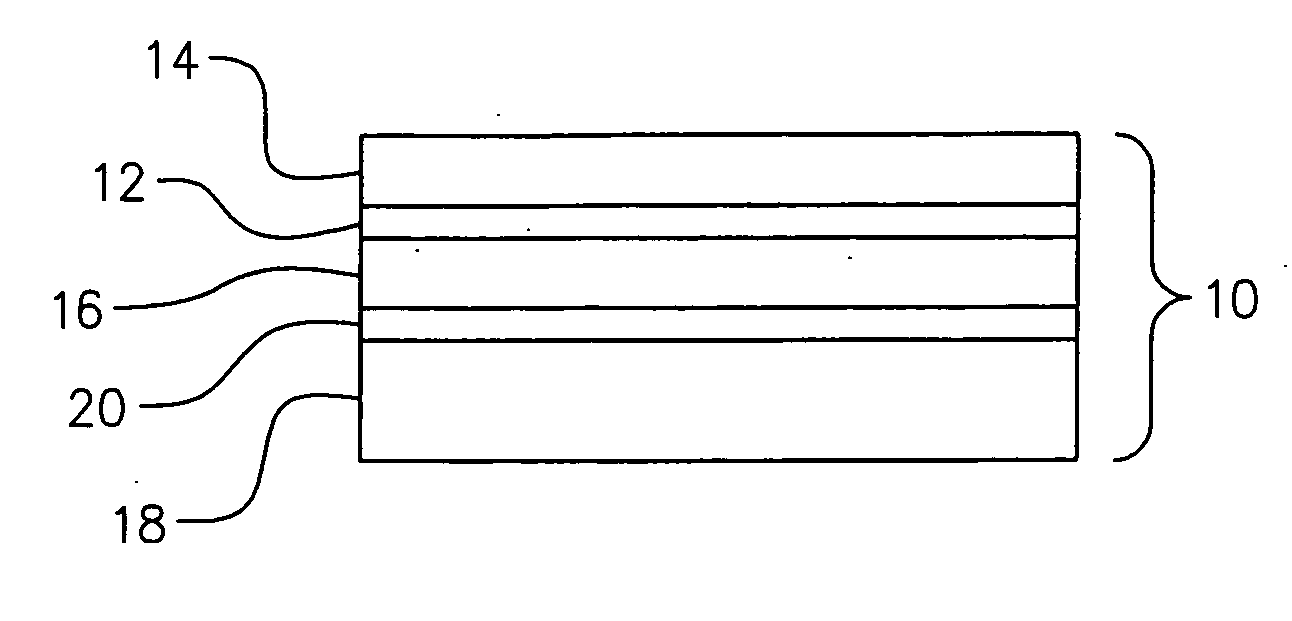

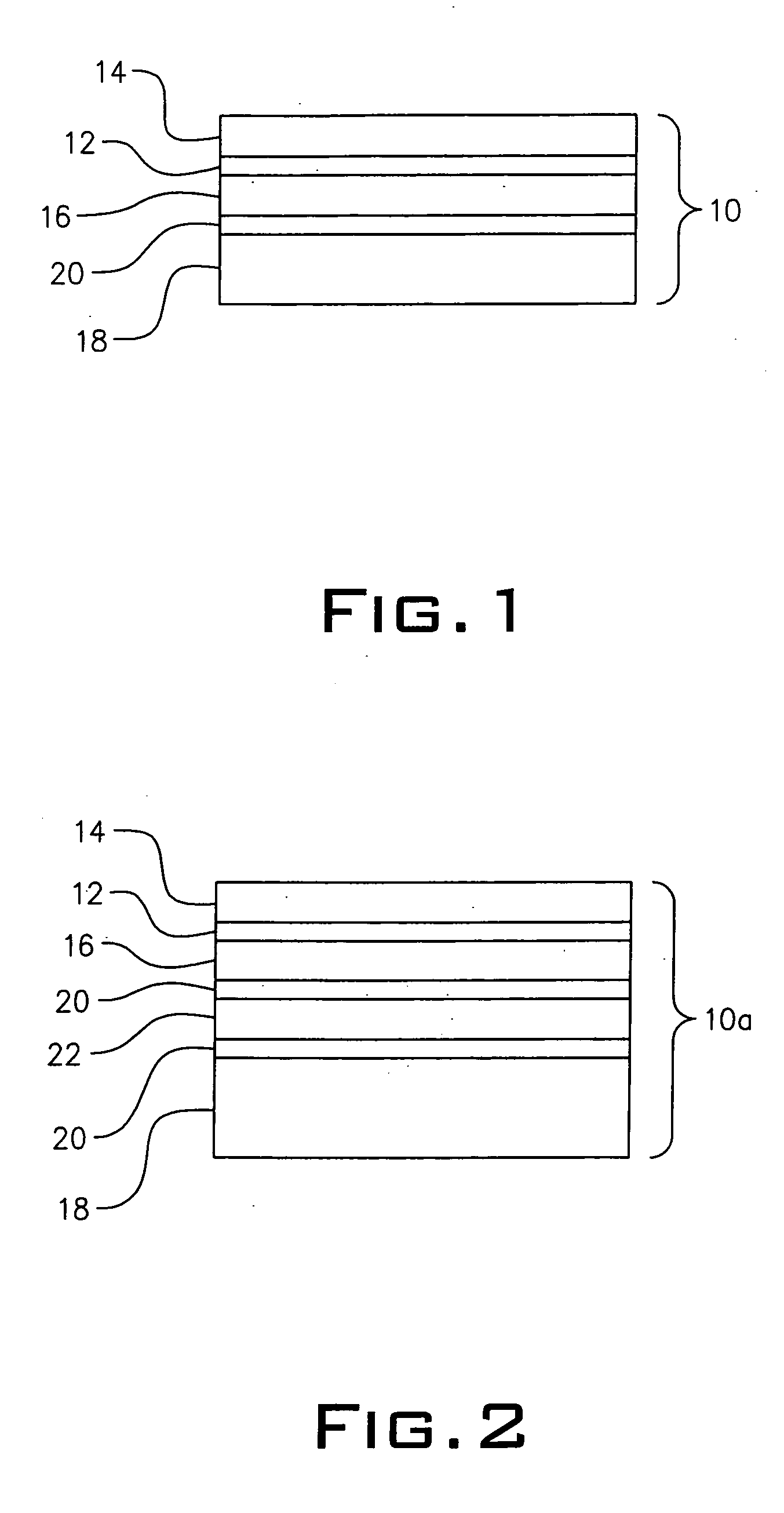

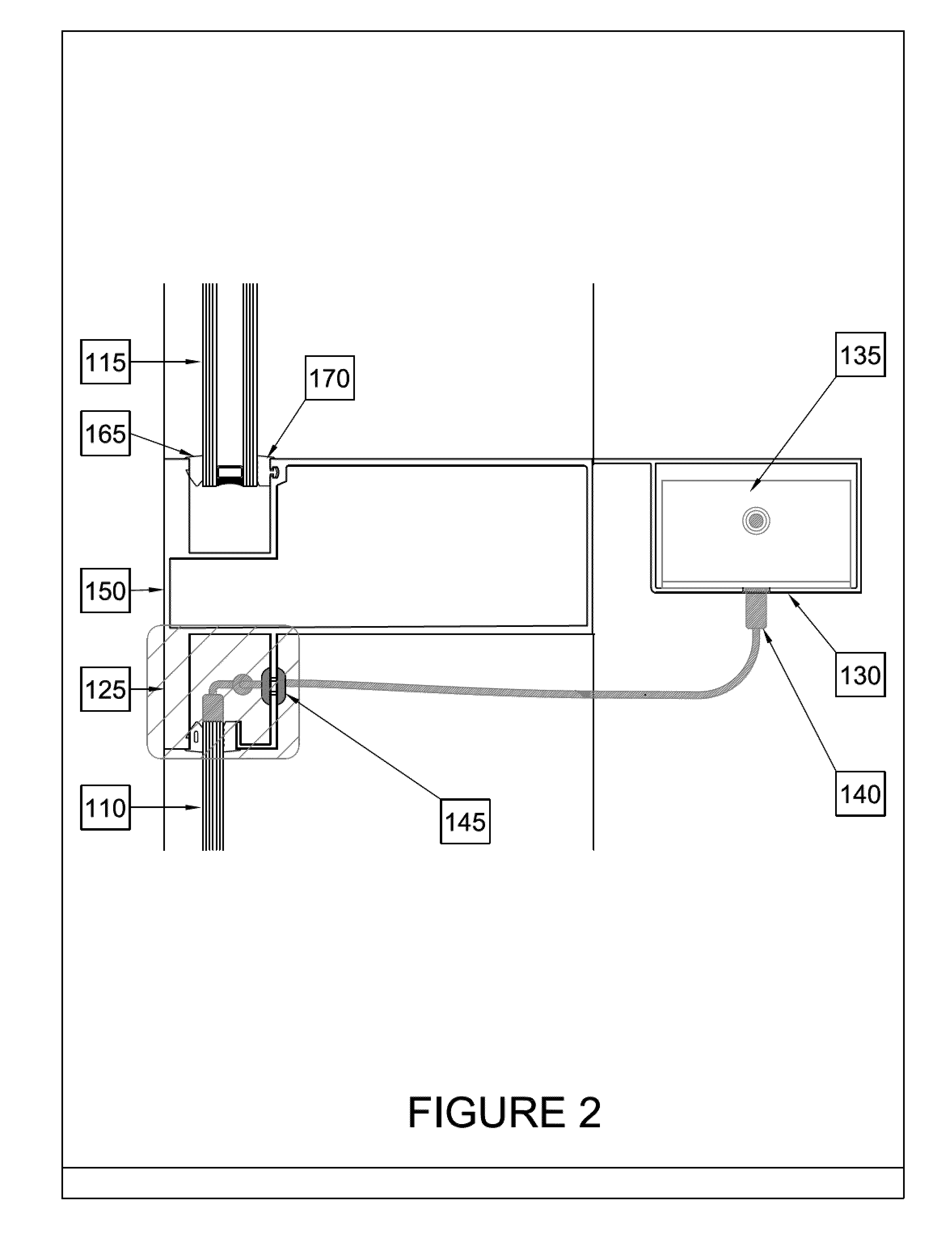

Methods and apparatuses for positioning and securing safing insulation

The present invention provides methods and apparatuses for securing safing insulation in the gap formed between a spandrel and a slab. Additionally, the present invention eliminates the need for stiffening tees and / or stiffening brackets. In one exemplary embodiment, the present invention utilizes a first portion of safing secured to spandrel insulation positioned in an exterior wall structure and a second portion of safing insulation positioned adjacent to the first portion of safing insulation and between the spandrel insulation and the slab. By fixedly securing the first portion of safing insulation to the spandrel insulation, any deformation of the spandrel insulation caused by the forces exerted by the compressed second portion of safing insulation on spandrel insulation results in the first portion of safing insulation moving with the spandrel insulation.

Owner:THERMAFIBER

Segment-assembling simply supported box girder movable falsework construction method

The invention discloses a segment assembled simple box girder movable trestle construction method. The required construction simple box girder has single hole or multiple holes, and is assembled by a plurality of longitudinal (i.e. along bridge direction) segment box grinders; the method comprises the following steps: prefabricating all the segment box girders for assembling the simple box girder in concentration; assembling and erecting the first hole grinder, which comprises the steps of: assembling and erecting the trestle (i.e. assembling platform), hanging the segments on to the assembling platform according to the assembling sequence and adjusting the arch degree, line style and position accurately, constructing the segments on the assembling platform by segment assembling construction technology until complete the whole hole grinder construction, and dismounting the trestle and moving to the next hole grinder; and performing the subsequent hole grinders in order according to the construction steps of the first hole grinder. the invention achieves the advantages of simple steps, low construction difficulty, short construction cycle and low onetime fund investment; can solves the practical problems existing in the segment assembling construction process of current large-span bridge fabrication machine.

Owner:CHINA RAILWAY FIRST GRP CO LTD

Means and method for fireproof sealing between the peripheral edge of individual floors of a building and the exterior wall structure thereof

InactiveUS20070204540A1Avoid overall overheatingIncrease ratingsBuilding roofsWallsFloor slabEngineering

A construction and a method for fireproof sealing between the outer edges of a floor and the exterior wall structure of a building which includes the placement of an insulation support member between the safing insulation positioned immediately around the floor edge, and the spandrel insulation extending between the vertical studs inside of the outer cladding. Safing insulation is normally compressed prior to placement, and this compression is maintained by positioning the insulation support member in abutment therewith. Also, by positioning the insulation support member between the safing insulation and the spandrel insulation, the support member itself is protected which enhances maintenance of the effective seal of the slot between the floor and the outer cladding. Also during installation, the insulation support member can be used to achieve a desired compression of the safing insulation by positioning it after initial positioning of the insulation member such that it is compressed during final installation of the insulation member.

Owner:SPECIFIED TECH

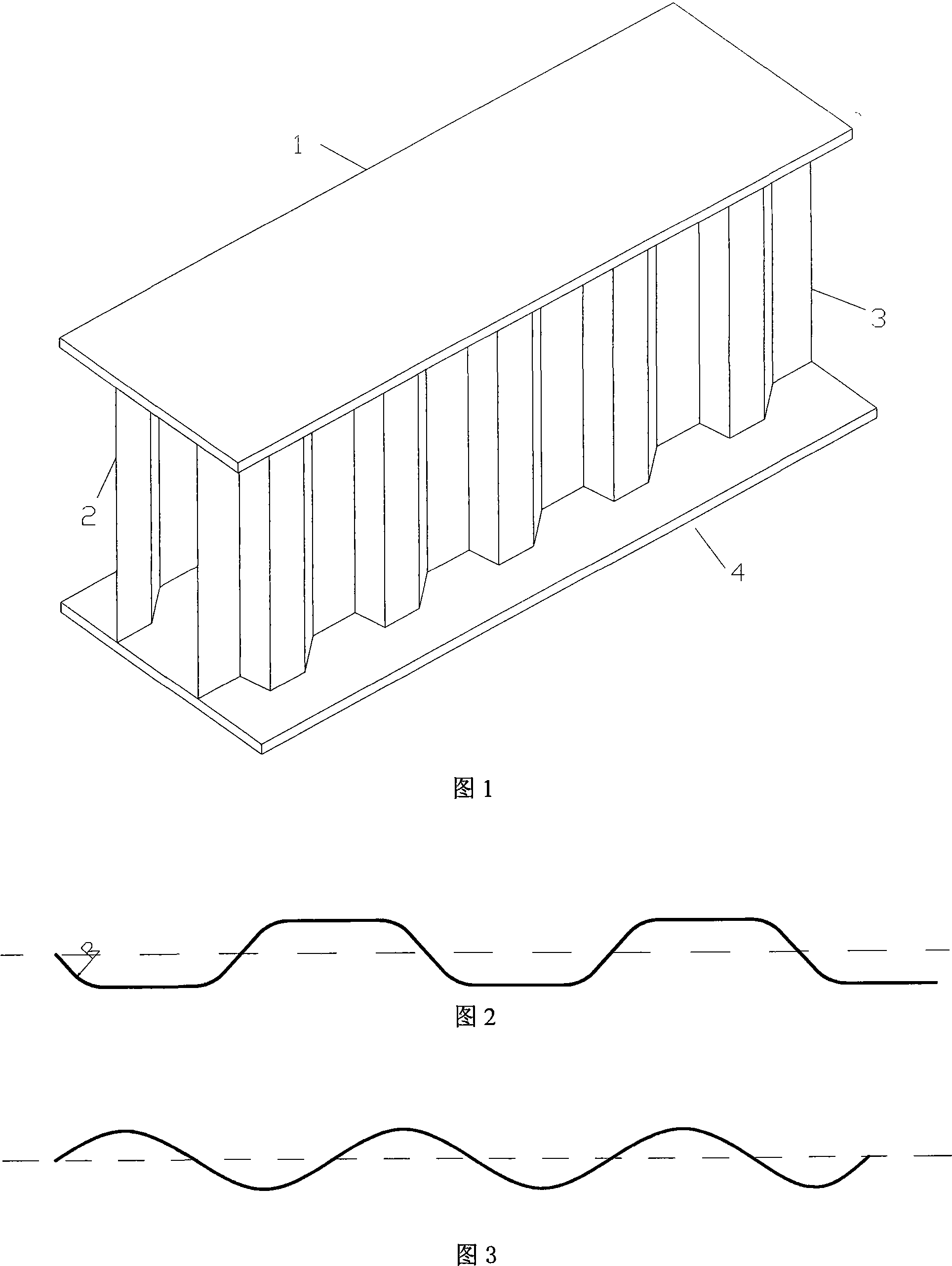

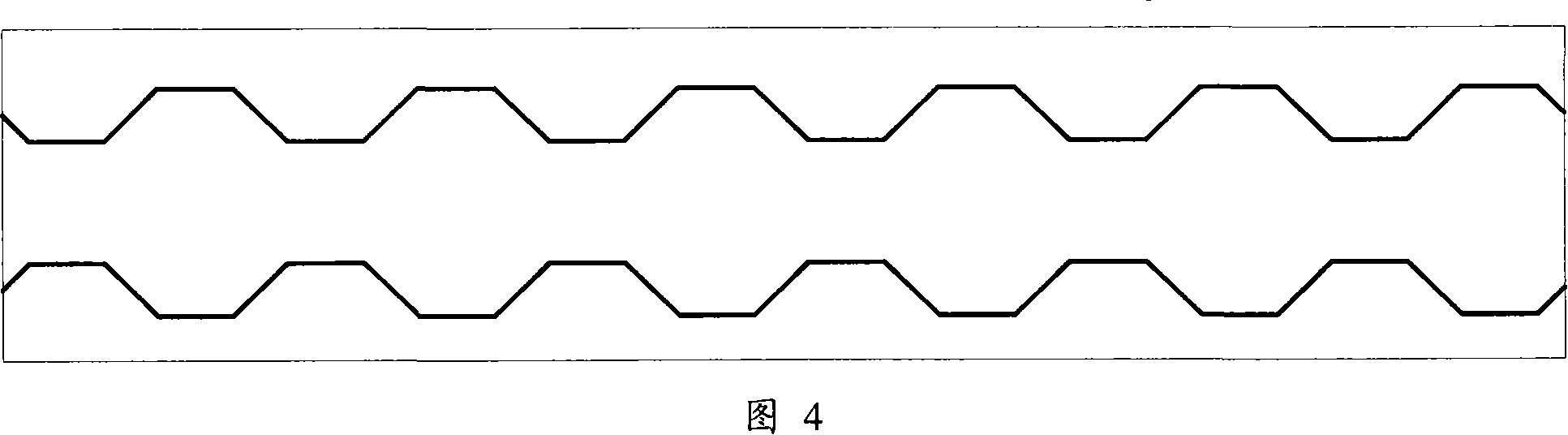

Double corrugated web plate steel box girder

The invention belongs to the technical field of building materials and in particular relates to a double undulated web slab steel box girder. The cross-section fracture shape is composed of a middle web slab, an upper flange and a lower flange which are integrated, wherein the upper flange is parallel to the lower flange, a double web slab is vertically located between the upper flange and the lower flange, the double web slab is arranged symmetrically and takes a honeycomb structure, the web slab and the flange slabs adopt one side fillet weld to connect, the web slab is an undulated web slab whose length direction are periodically repeated evenly or unevenly, and the undulated cross section takes circular arc angle trapezoid and sinusoidal curve. The product can replace products such as normal welded box steel girders, hot rolled H-shaped steel, I-shaped steel and the like, has wider usage compared with the products, and can realize maximization and can be used in the special fields and special places including the building of bridges with large spans, the manufacture of ships and the like.

Owner:TONGJI UNIV +1

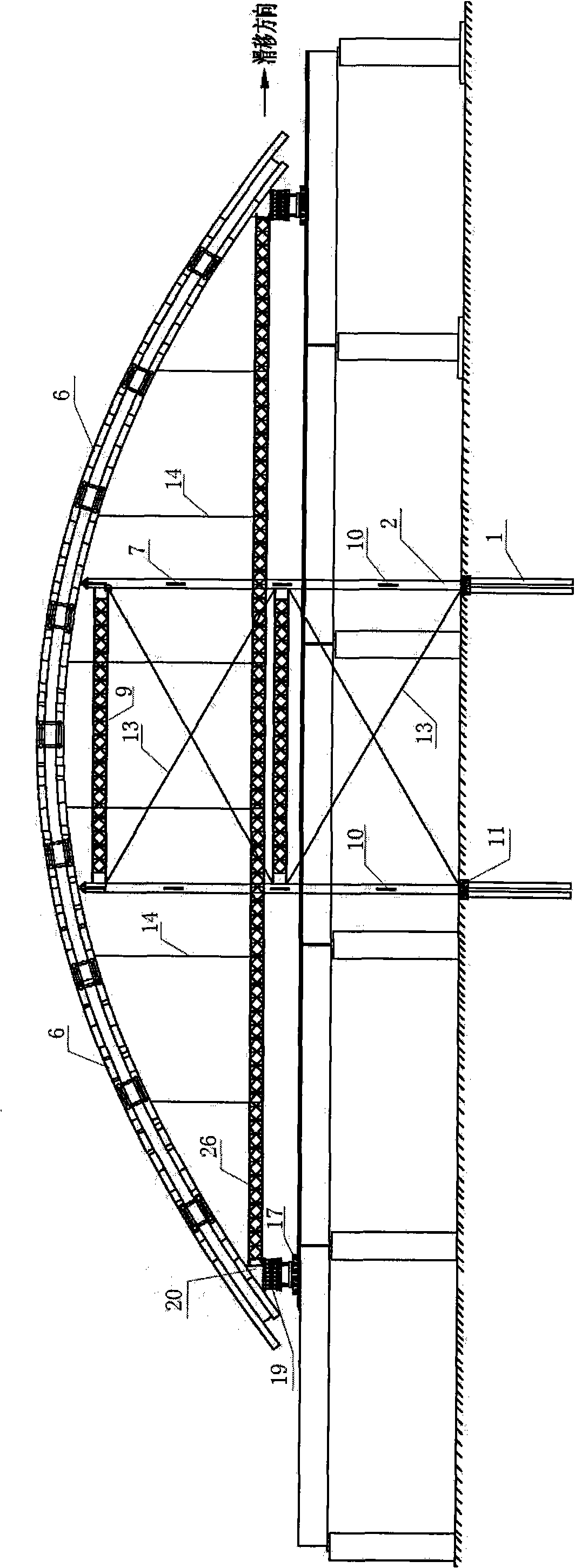

Construction method for integrally sliding large-span steel pipe arch of curved bridge

ActiveCN101935987AReduce occupancyReduce in quantityBridge erection/assemblyBridge engineeringConcrete beams

The invention relates to a construction method for integrally sliding a large-span steel pipe arch of a curved bridge, belonging to the field of bridge engineering construction. The method comprises the following steps: firstly, carrying out on-site splicing and welding on the manufacturing and installing sections of a steel pipe arch to form a large hoisting section; then installing a temporary arch-splicing support on a bridge-site longitudinal splicing site position, arranging arch ribs on the temporary arch-splicing support, and adopting an arch springing restraint device to preload arch springings after finishing splicing the steel pipe arch, thus enabling the steel pipe arch to form a stressed entirety; and finally, dismantling the temporary arch-splicing support, and adopting a pushing power system to realize integrally sliding the whole steel pipe arch into a proper position. The construction method of the invention has the advantages of small site occupation, integral hoisting of large sections, less hoisting subsection and less arch-splicing support amount, thus the construction cost is economical, the high-altitude welding quantity is less, the welding quality is ensured, the arch axis linetype control is easy, the steel pipe arch splicing and a concrete beam can be simultaneously constructed, arch splicing is carried out on an ectopic bridge site, the underbridge navigation is not influenced, the construction is safe and the construction progress can be quickened.

Owner:CHINA FIRST HIGHWAY ENG +1

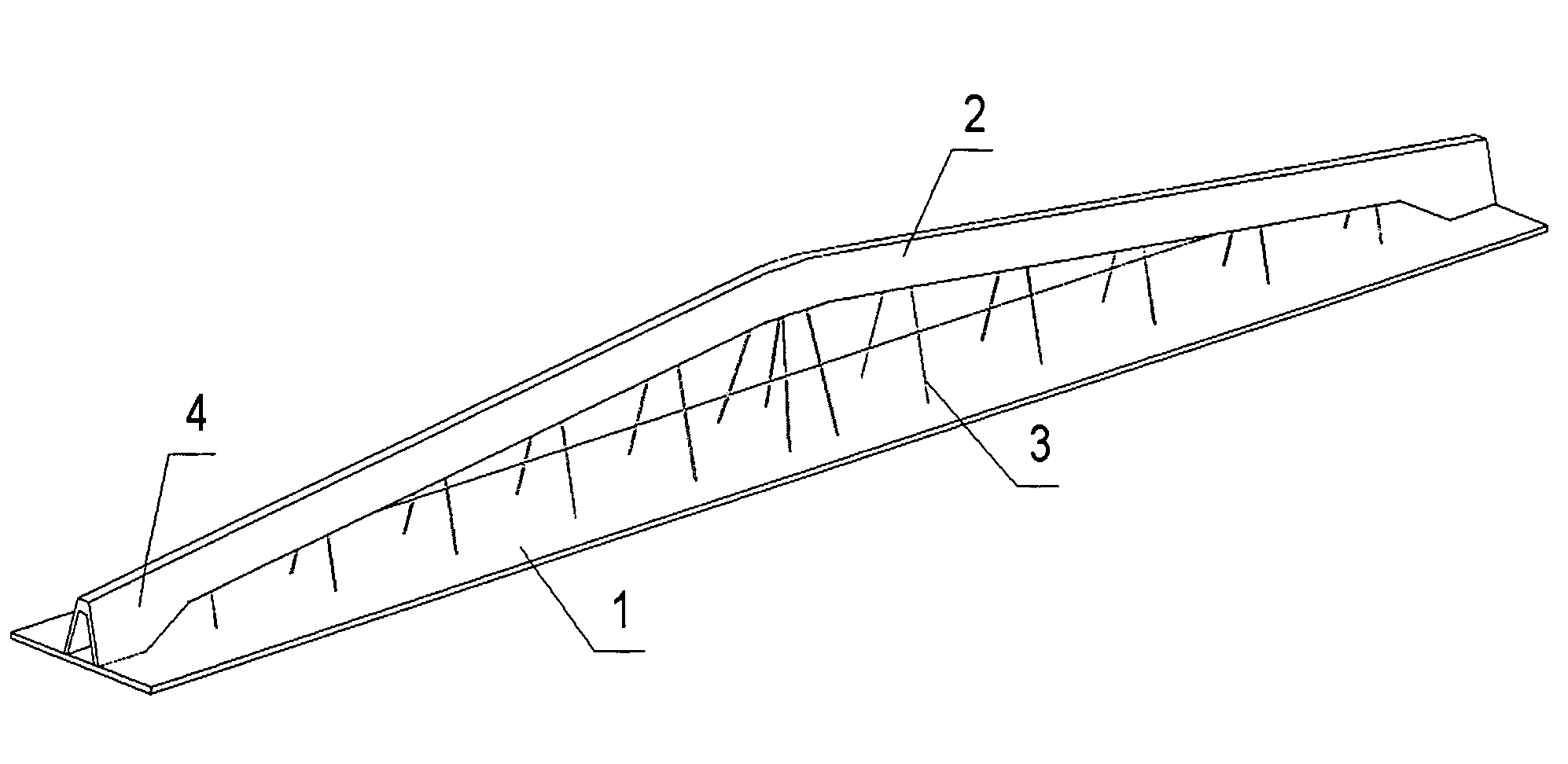

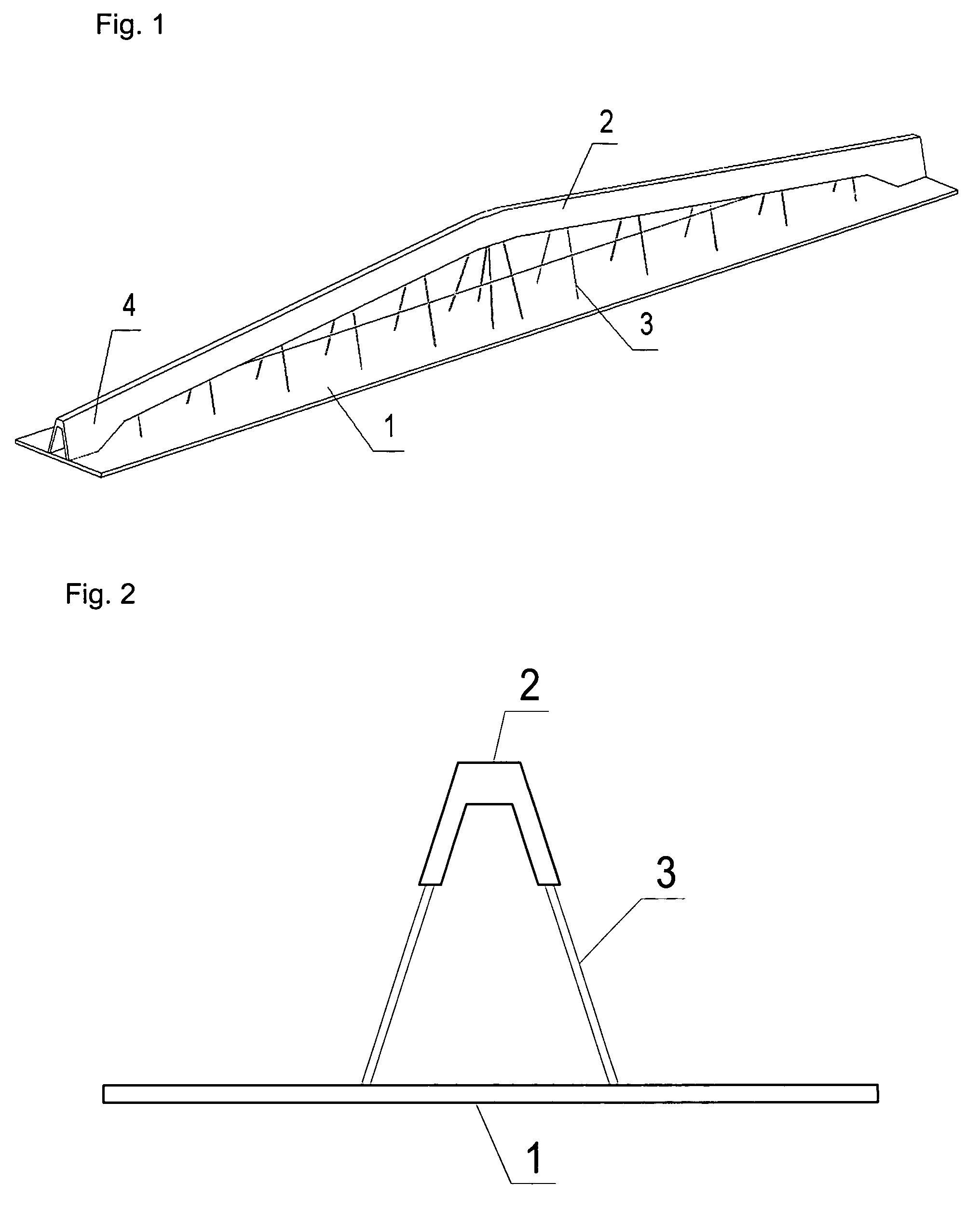

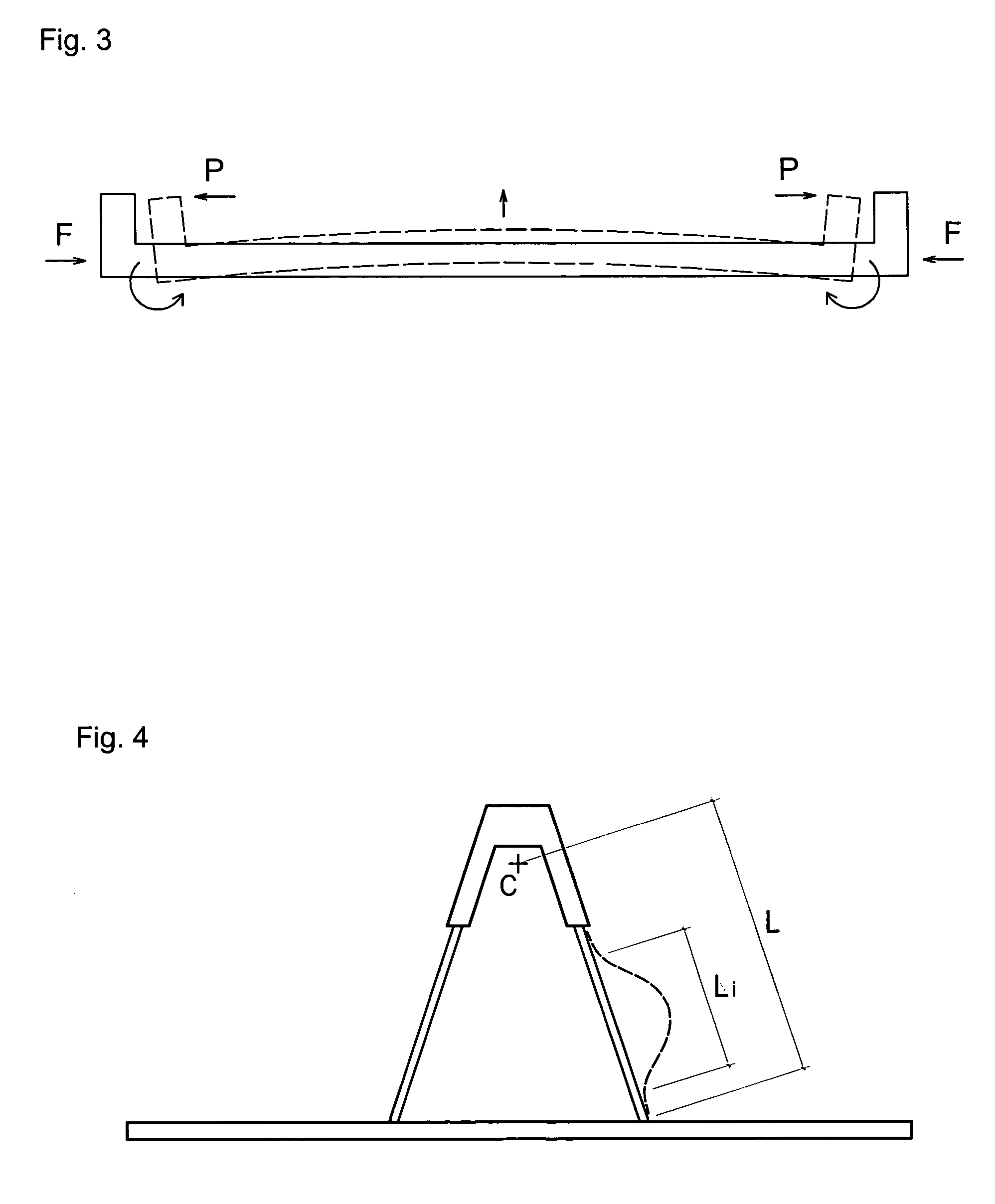

Indirectly prestressed, concrete, roof-ceiling construction with flat soffit

An indirectly prestressed concrete roof-ceiling construction is a prefabricated element for constructing large-span industrial buildings. The construction includes a distinctly wide and thin concrete soffit plate and an upper concrete girder of an inverse “V”-shaped cross section, interconnected by slender steel pipe-rods that are used to stabilize the upper girder against lateral buckling and to prevent the plate and the girder from getting closer or further away from each other. Prestressing of the soffit plate causes compression in the upper girder which passively (indirectly) pushes the ends of the construction, acting on some eccentricity over the center of gravity of the cross section, causing rotation of its ends, bending in that way the soffit plate upwards. There are two efficient methods of prestressing these constructions.

Owner:MARA INST D O O

Large-span steel truss arch construction method

InactiveCN101581074AGood effectImprove structural stabilityBridge erection/assemblyArch-type bridgeTerrainReinforced concrete

The invention relates to a large-span steel truss arch construction method. The invention is characterized in that the method comprises the following steps: 1) based on the alignment design of an main arch ring of a reinforced concrete arch bridge, if a main arch span of the reinforced concrete arch bridge is not more than 100m, an arc line is adopted as the line shape of a arch axis line of the steel truss arch; if the main arch span of the reinforced concrete arch bridge is more than 100m, a catenary line or a parabola curve is adopted as the line shape of the arch axis line of the steel truss arch; big samples of a first unit truss segment and a second unit truss segment are produced for steel truss arch ribs on a sample platform according to the scale of 1:1; 2) the inner side of a first main arch support is widened to form a first base of the steel truss arch, the inner side of a second main arch support is widened to form a second base of the steel truss arch; 3) the erection sequence of the unit truss segments is that: first arranging steel truss arch ribs on the upper course of a river, then arranging steel truss arch ribs in sequence to the lower course of the river; 4) the back arch elevation of the steel truss arch is adjusted to the level of the arch soffit elevation of the main arc ring. The construction method is not limited by the terrain condition and site condition of bridge location and is simple and easy to install and remove.

Owner:CHINA FIRST METALLURGICAL GROUP

Assembling and splicing installation method of large-span tube-truss roof beam

InactiveCN102777047AEasy to installGeometry is easy to controlBuilding material handlingEngineeringSpandrel

The invention relates to an assembling and splicing installation method of a large-span tube-truss roof beam. The assembling and splicing installation method comprises the following steps of: dividing a tube-truss roof beam into a roof beam middle span section, a roof beam left span section and a roof beam right span section; dividing the roof beam left span section and the roof beam right span section into a plurality of sub sections, welding respectively, and transporting to an installation field; manufacturing an assembling and splicing jig frame, sequentially arranging each sub section of the roof beam left span sections on the assembling and splicing jig frame, assembling, splicing and welding into the roof beam left span section; manufacturing the roof beam right span section in the same way; and respectively lifting the roof beam left span section and the roof beam right span section in place, welding and fixing, splicing, installing and fixing the roof beam middle span section, respectively abutting the roof beam middle section with the roof beam left span section and the roof beam right span section, leveling by a web member, welding, so as to form an integrative tube-truss roof beam. With the adoption of the assembling and splicing installation method, the geometric dimension of the whole tube-truss construction member is controllable; and due to the assembling and splicing process on the ground, the working efficiency is improved, the cost of large machineries is saved, the safety risk during the lifting process is avoided, in this way, the construction method is especially suitable for the installation of each large-span tube-truss roof beam.

Owner:河北二十冶建设有限公司

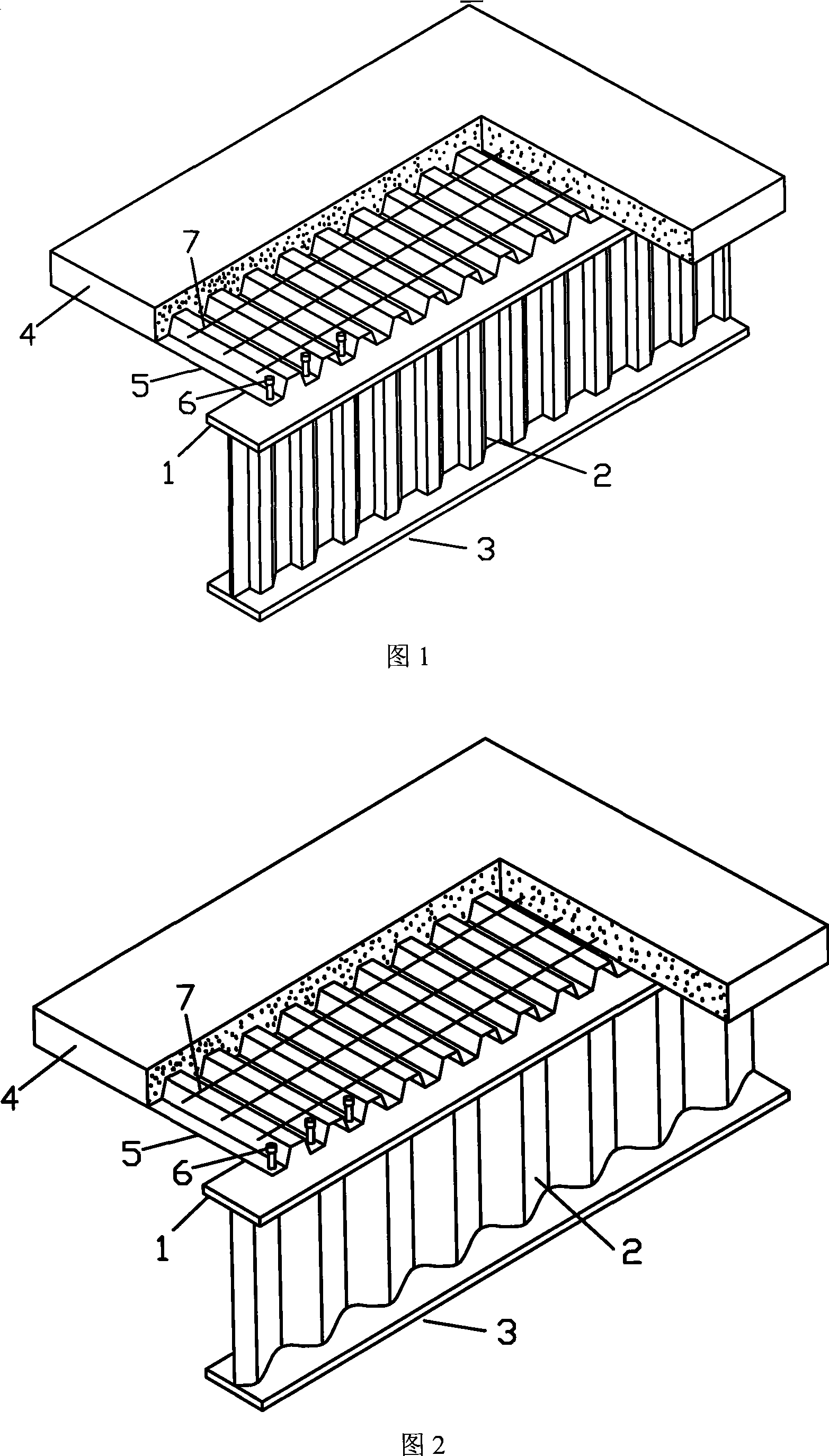

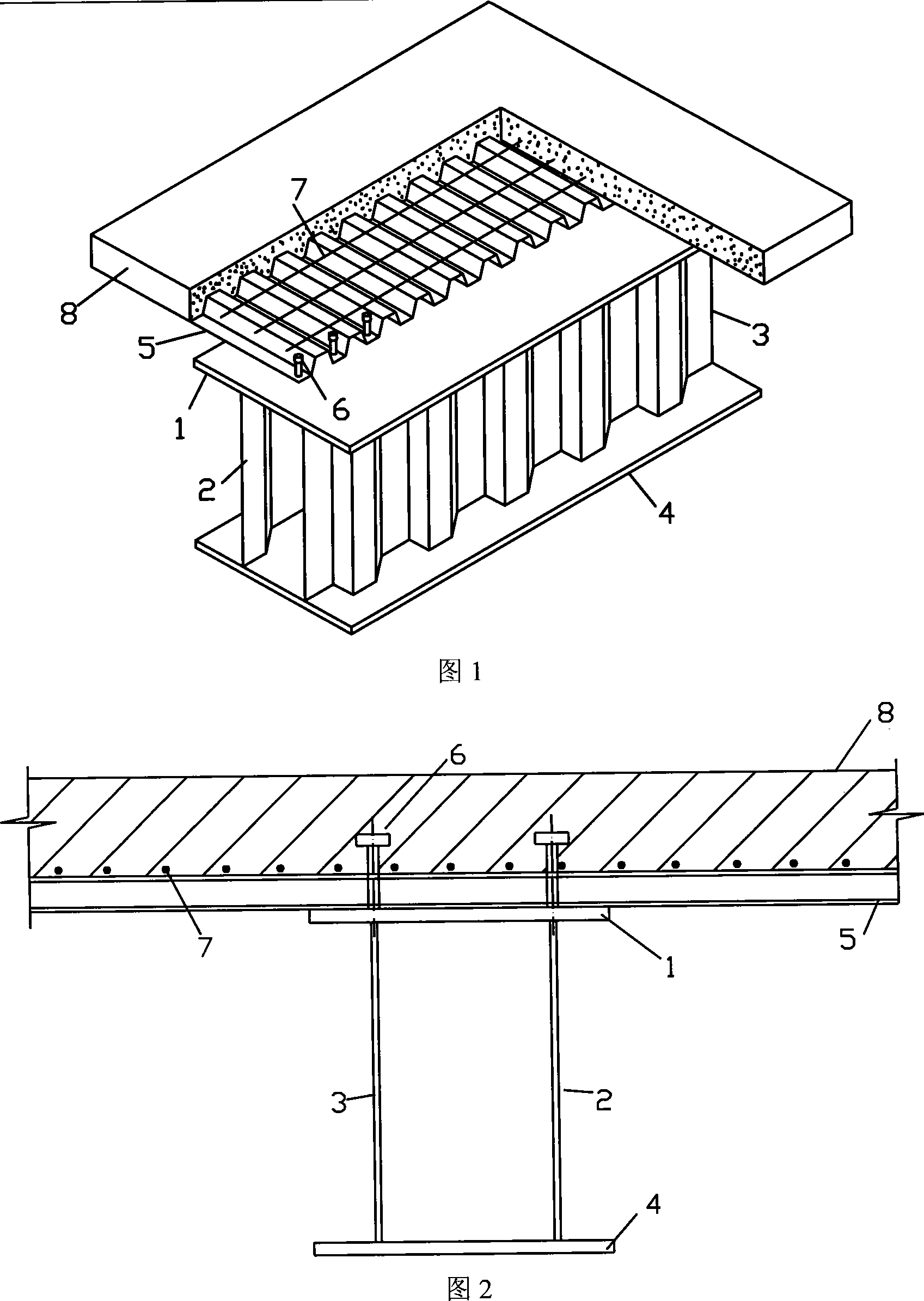

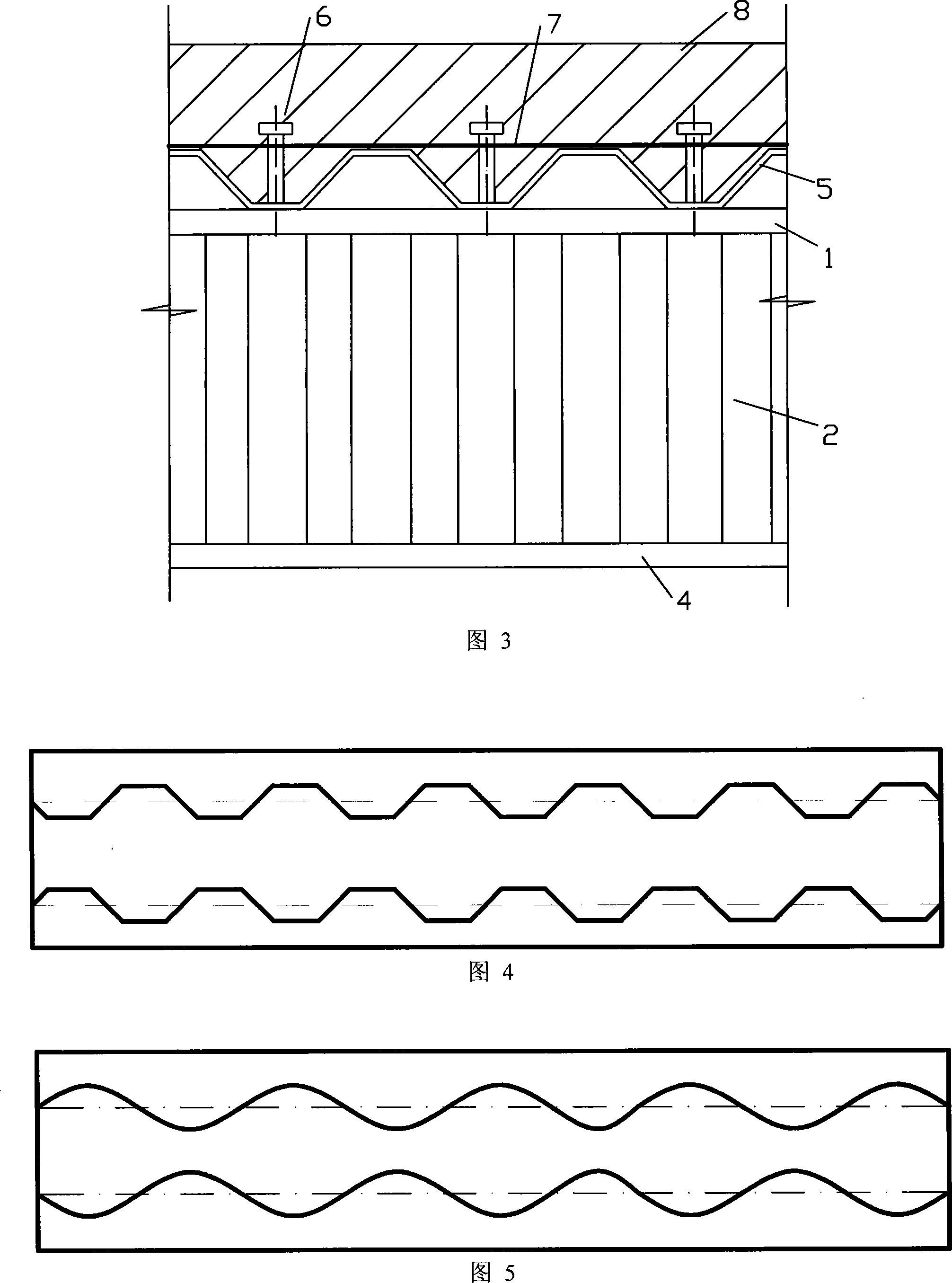

Corrugated sternum H-shaped steel composite beam

InactiveCN101225688APrecise positioningImprove carrying capacityLoad-supporting elementsFillet weldJoist

The invention relates to a corrugated web plate H-shaped profile steel composite bean, belonging to the technical field of building profile materials . The cross section port type comprises a corrugated web plate and an upper and lower flange joints. The upper flange is in parallel with the lower flange; the web plate is vertical to the upper flange and the lower flange; the web plate is connected with the flanges by single-sided fillet weld; the web plate is a trapezoid ripple or a sine curve ripple, wherein the lengthwise direction of the trapezoid ripple is repeated periodically. The upper part of a composite beam is a reinforced concrete swing plate and a profiled steel sheet. The upper flange, the reinforced concrete plate and the profiled steel sheet are connected by a plurality of studs; the reinforced concrete swing plate can be connected with the profiled steel sheet by additional lateral steel bar. The traditional hot-rolling joist steel and H-shaped profile steel composite beam can be replaced by the corrugated web plate H-shaped profile steel composite bean which has the wider application than joist steel and H-shaped profile steel composite beam; the maximization can be realized for special field and special location comprising the construction of large span industrial and civil building and large span bridge.

Owner:TONGJI UNIV

Double-ripple ventral shield steel case built-up beam

InactiveCN101220697APrecise positioningImprove mechanical propertiesFloorsLoad-supporting elementsSteel barSpandrel

The invention belongs to the technical field of architectural profiles and particularly relates to a double corrugated web steel box composite beam. The sectional shape of the invention is composed of two symmetrically arranged corrugated webs, a top flange and a lower flange. The top flange is parallel with the lower flange, the web is vertical to the top flange and the lower flange, the web and the flange are connected by single-side fillet joint, and the web has periodically repetitive trapezoidal wave or sinusoid wave along the length direction. The top of the composite beam is a reinforced concrete wing plate and a profiling steel plate. The top flange, the reinforced concrete slab and the profiling steel plate are connected each other by male pins, and a transverse reinforcement can be additionally used for the connection between the reinforced concrete wing plate and the profiling steel plate. The invention can replace the traditional hot rolled flange beam, H-beam composite beam and welded steel box composite beam; furthermore, the invention has wider application than the flange beam and the H-beam composite beam, and can realize maximization to be used in special fields and special places, including the construction of wide-span industrial and civilian buildings and wide-span bridges, etc.

Owner:TONGJI UNIV

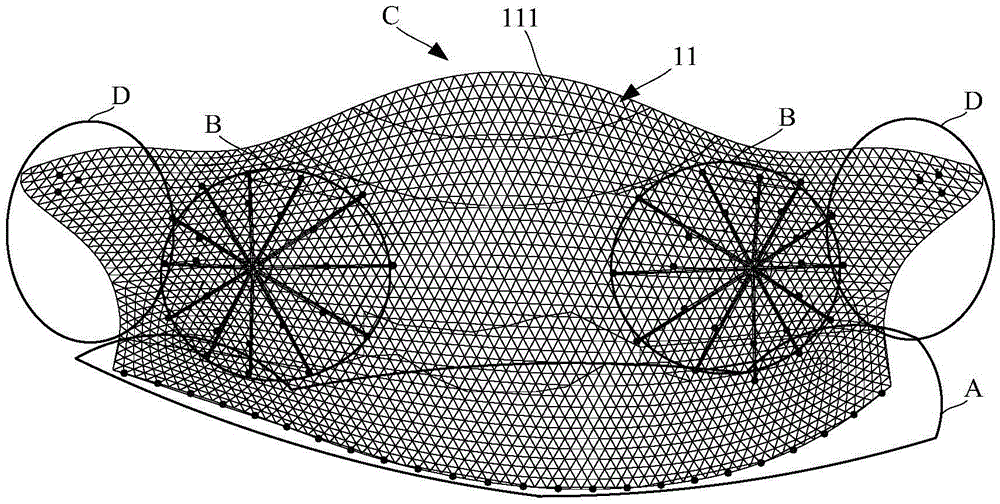

Construction method of special-shaped curved surface roof with large span and multiple curvatures

ActiveCN105569358AReduce installation difficultyShorten the construction periodBuilding roofsBuilding material handlingEngineeringSpandrel

The invention relates to a construction method of a special-shaped curved surface roof with a large span and multiple curvatures. The construction method comprises steps as follows: regional division is performed according to the shape of the special-shaped curved surface roof; structural rod pieces are assembled in a bulk area, and a first lattice shell structure is formed; structure units are hoisted in a unit mounting area, and a second lattice shell structure connected with the first lattice shell structure is formed; sliding tracks are laid on an operating platform in a sliding mounting area; lattice shell units are transported to the sliding mounting area through the sliding tracks for assembly, then a third lattice shell structure connected with the first lattice shell structure and the second lattice shell structure is formed, and accordingly, a lattice shell roof is formed; support pillars are arranged below the lattice shell roof, and the operating platform is dismounted. According to the construction method, the mounting area is divided, a mounting method combining bulk assembly of components, unit hoisting and lattice shell sliding is adopted, and the construction method has the advantages that the construction period is shortened, the construction cost is saved and the construction quality is improved.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD +1

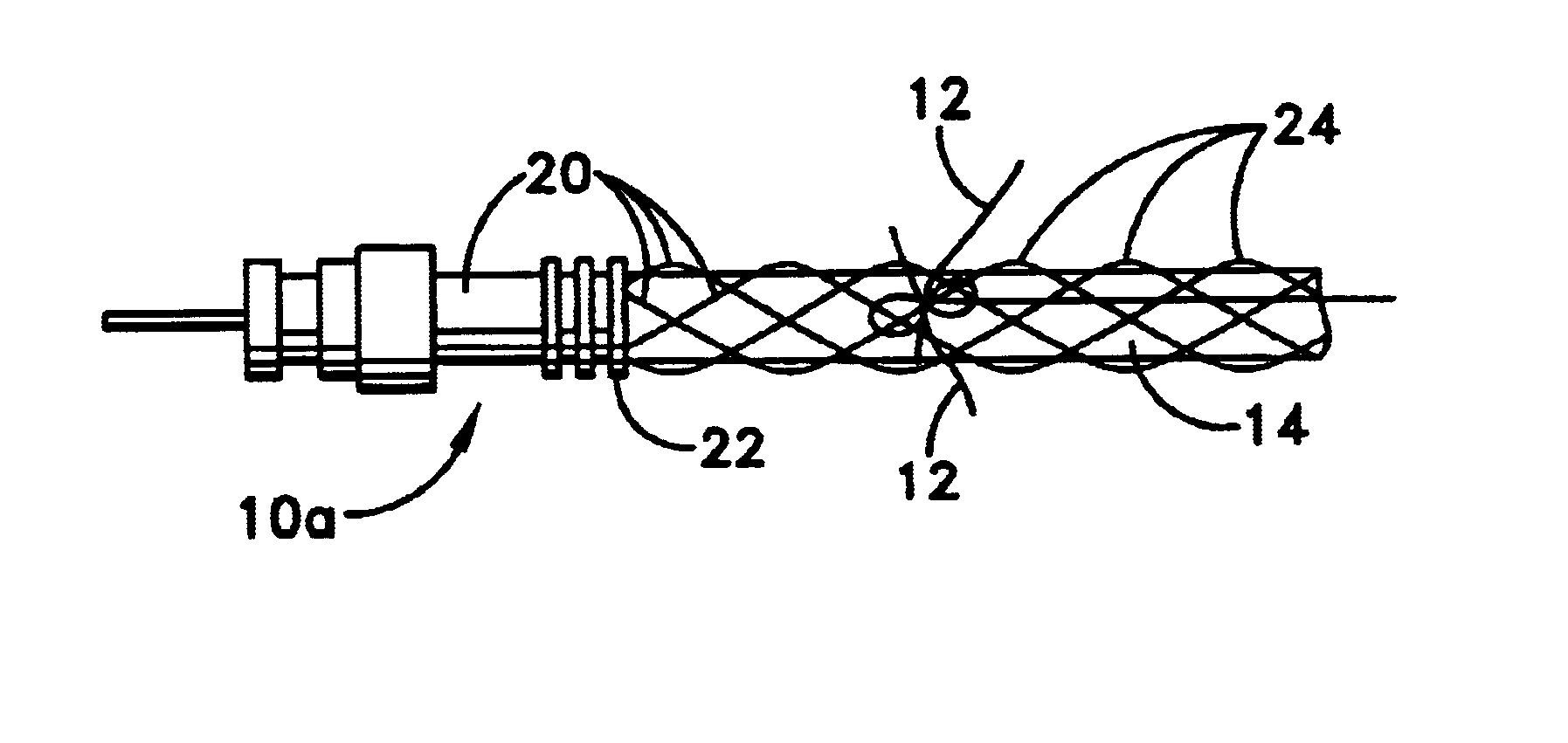

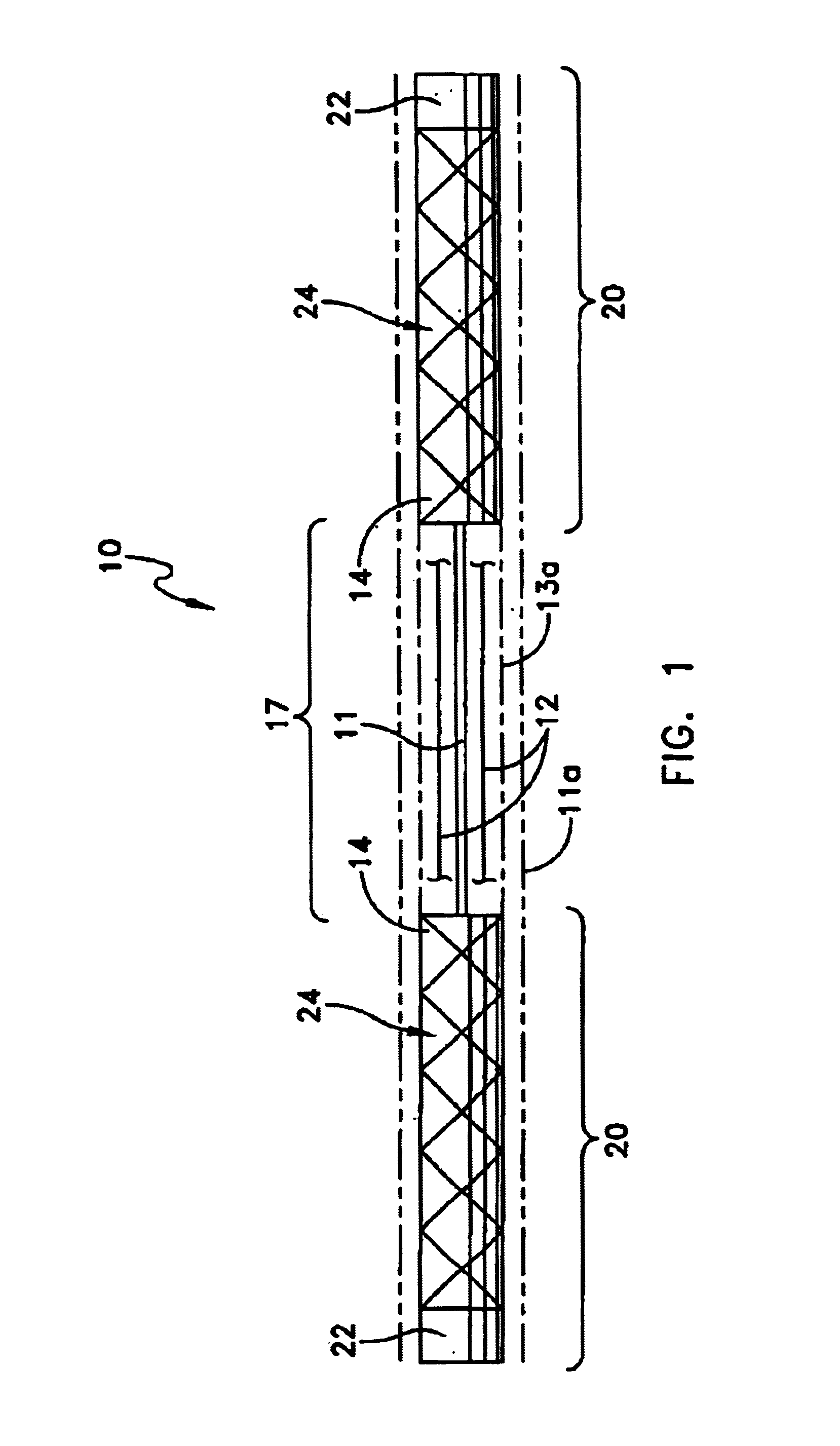

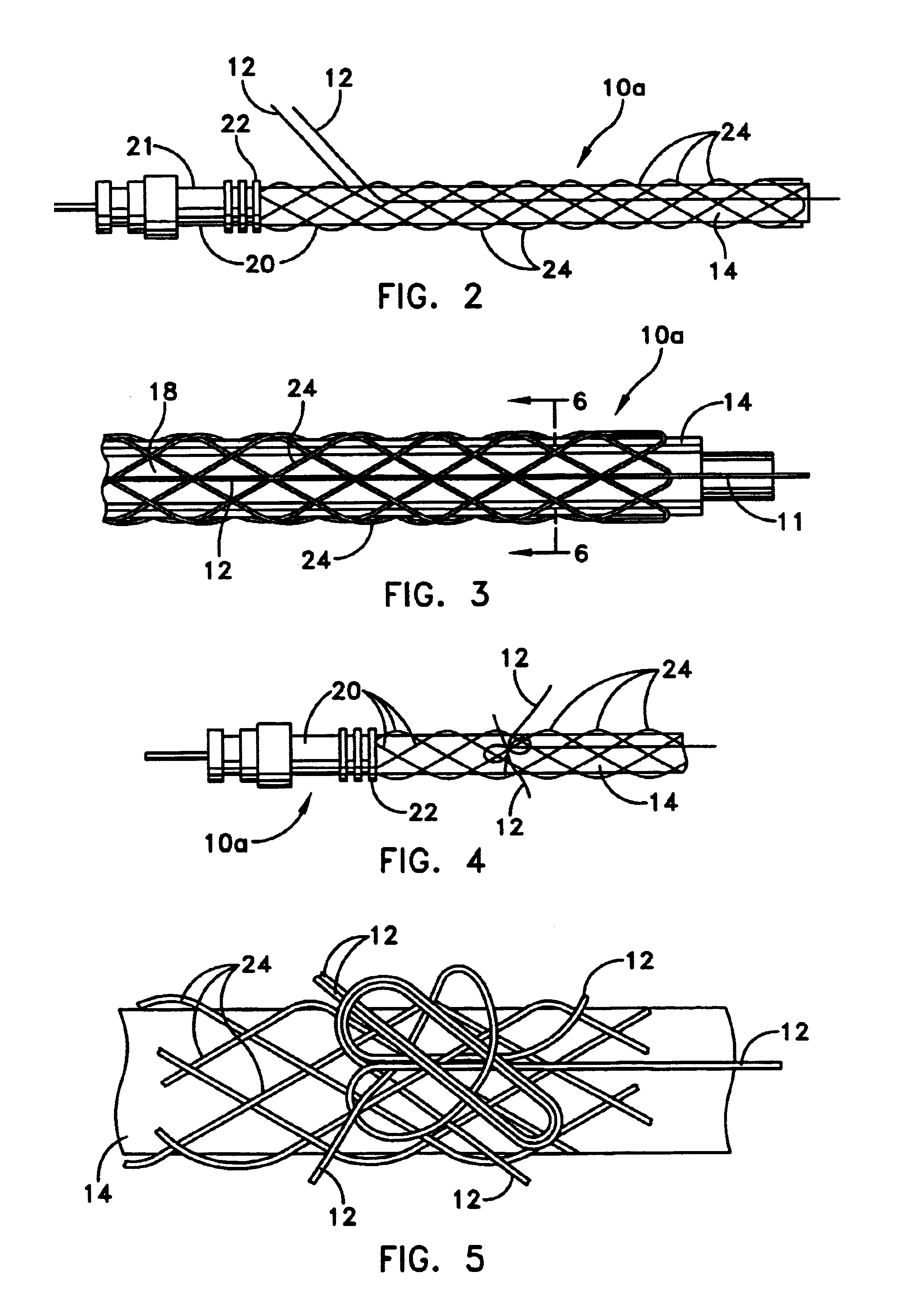

Strength strand construction for a longitudinal section of a cable

InactiveUS6992253B1Simple designHigh tensile strengthElectrically conductive connectionsAntenna adaptation in movable bodiesCoaxial cableCoaxial line

An assembly including a span of microwave signals flexible coaxial line, or other form energy transmission media, is provided with generally coextensive, non-metallic longitudinal strength strands to render greater tensile strength to the assembly. Marginal axial end sections of a coaxial cable span are potted in respective polyurethane grip foundation having longitudinal grooves. The grip foundations are inserted into an open-mesh-sleeve type cable-end grip device. The strength strands are seated in the grooves and interlaced in and out of the openings in the open-mesh-sleeves of the grip devices. Co-adjacent marginal end portions of the strength strands are bundled beyond the interlacing, and knotted to the open-mesh-sleeves of the grip devices. In forming the knots the bundled marginal end portions of the strength strands are entwined and bound together and with a pair of the crossing strands of the open-mesh-sleeve.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

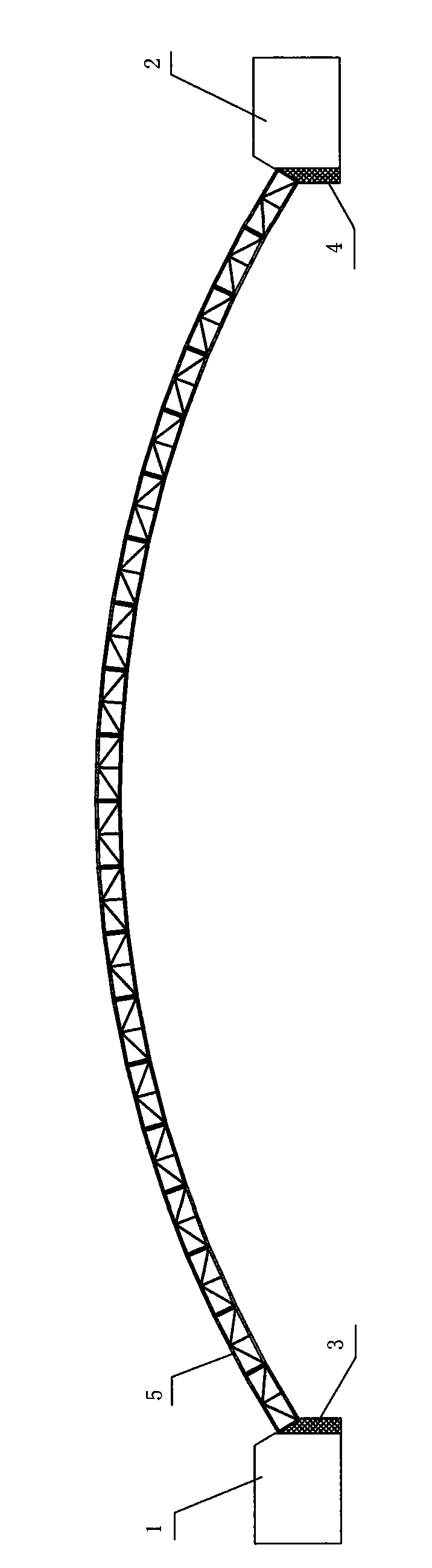

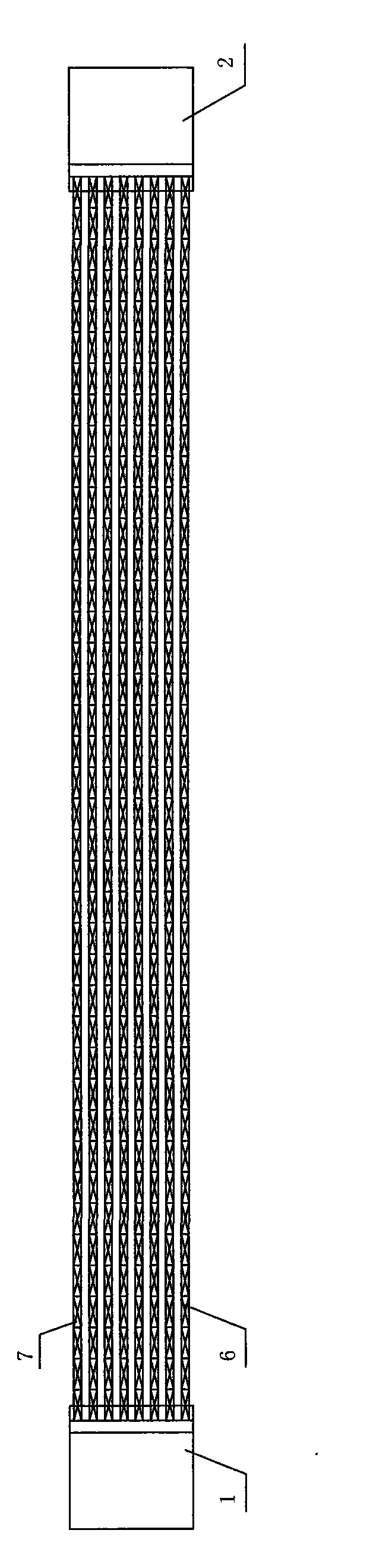

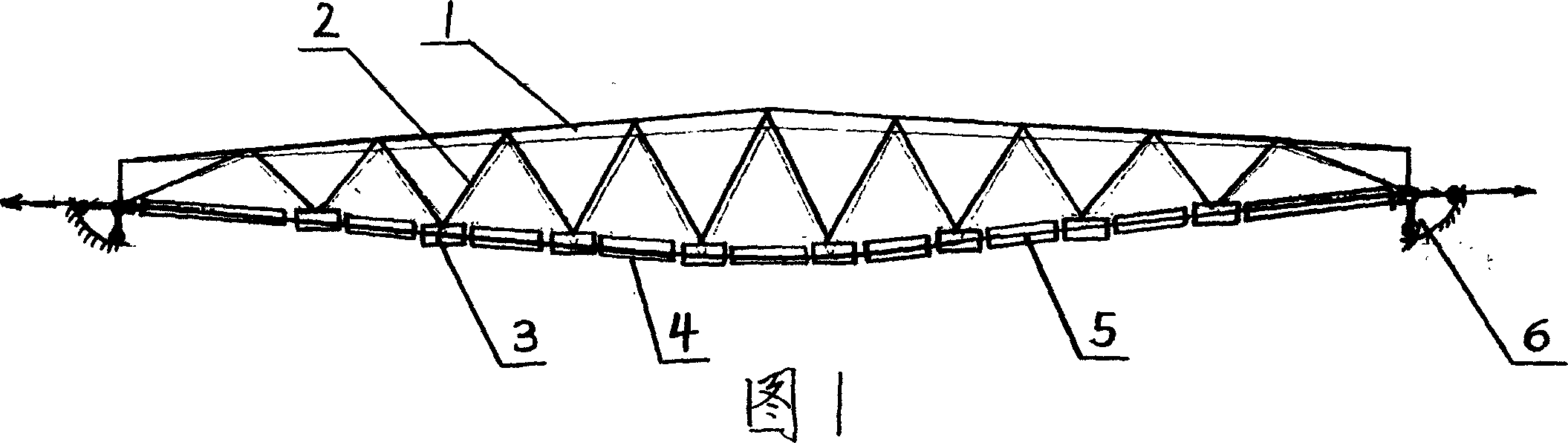

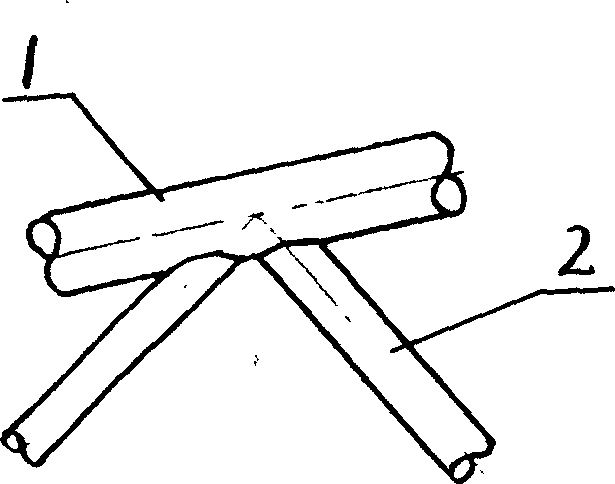

Method for fabricating new type tension chord truss frame in large span

InactiveCN1563626ARelieve pressureReduce the amount of structural steel usedGirdersJoistsArchitectural engineeringLong span

This is a method used to produce long span spread chord truss. It contains: To weld the belly rod on the upper spread chord rod, put the formed upper chord rod on the wording platform, fix the two ends of this chord rod on the fixed seat, then connect lower end of the belly rod with cover joint pipe, and between two cover pipes beforehand put a lower chord steel pipe. The steel rope pierce through every joint cover pipe and every lower chord steel pipe, then to spread out the steel rope, on the steel rope at the spreading straight, state weld every lower steel pipe with every joint cover pipe, keep the steel rope spread out straightly, then loose the two ends of the upper chord rod from platform, then long span spread chord truss is finished.

Owner:GUIZHOU UNIV

Method for manufacturing spandrel glass film with metal flakes

A film laminating adhesive is formed by admixing a polyester resin and encapsulated metallic flakes. The metallic flakes are encapsulated with a silane in a hydrolyzed condition modified with a surfactant or dispersion agent. A mounting adhesive is applied to an outside surface of a first clear PET film. A silicone liner is adhered to the outside surface. A second PET film is bonded to another side of the first clear film with the film laminating adhesive containing encapsulated metallic flakes to form the spandrel glass film composite adapted for bonding to a glass surface after removal of the silicone liner.

Owner:MADICO INC

Building integrated photovoltaic conversion system implemented in both vision and spandrel areas

Owner:ARCHITECTURAL GLASS & ALUMINUM CORP

Erection method of large-span continuous steel truss arch

ActiveCN101117792ATimely adjust the space positionImprove scalabilityBridge erection/assemblyTowerCantilever

An erection method of a large-span continuous steel truss arch, in the construction of a large-span continuous truss arch bridge, a bridge pier is taken as the foundation, a bracket beside the pier is arranged, a plurality of steel trusses with an interval on the top pier are arranged on the bracket beside the pier, and a double-suspension erection system is formed. A full-rotation beam erection lifting machine is positioned at the truss of the pier top, and truss bar is arranged one by one. After the suspension arm reaches a certain degree, a horizontal rope or a multi-layer tower with a suspended cable and a stay cable is arranged to maintain the double-suspension arm to extend forwards until closure.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

Pocket assembly for placing a flat dowel between cast in place concrete slabs

An assembly for use in the formation of adjacent concrete slabs to provide a flat rectangular dowel engaged between the slabs. The assembly comprises a pocket which is cast in place in the edge portion of the first slab to be formed, with the dowel fully confined within the pocket. After the formation of the first slab, the dowel is partially withdraw from the pocket and the second slab is formed in place against the first slab, with the dowel in spanning relationship to the respective slabs. In the preferred embodiments, the pocket comprises a monolithic plastic box having complimental generally rigid upper and lower sections movable between a closed condition defining the pocket therebetween and an open condition exposing the pocket interiorly. One edge of the pocket is formed with an opening through which the dowel passes as it moves between the fully confined and the partially withdrawn positions. In certain embodiments, a sealing element or door is provided to close the opening during the formation of the first slab. Seal elements are also provided to seal the pocket against the intrusion of concrete during the formation-of the second slab.

Owner:MMI PRODS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com