Erection method of large-span continuous steel truss arch

A large-span, steel truss technology, applied in the erection/assembly of bridges, bridge construction, bridges, etc., can solve problems such as large reaction force of supports, inability to meet stress requirements, and difficulty in realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

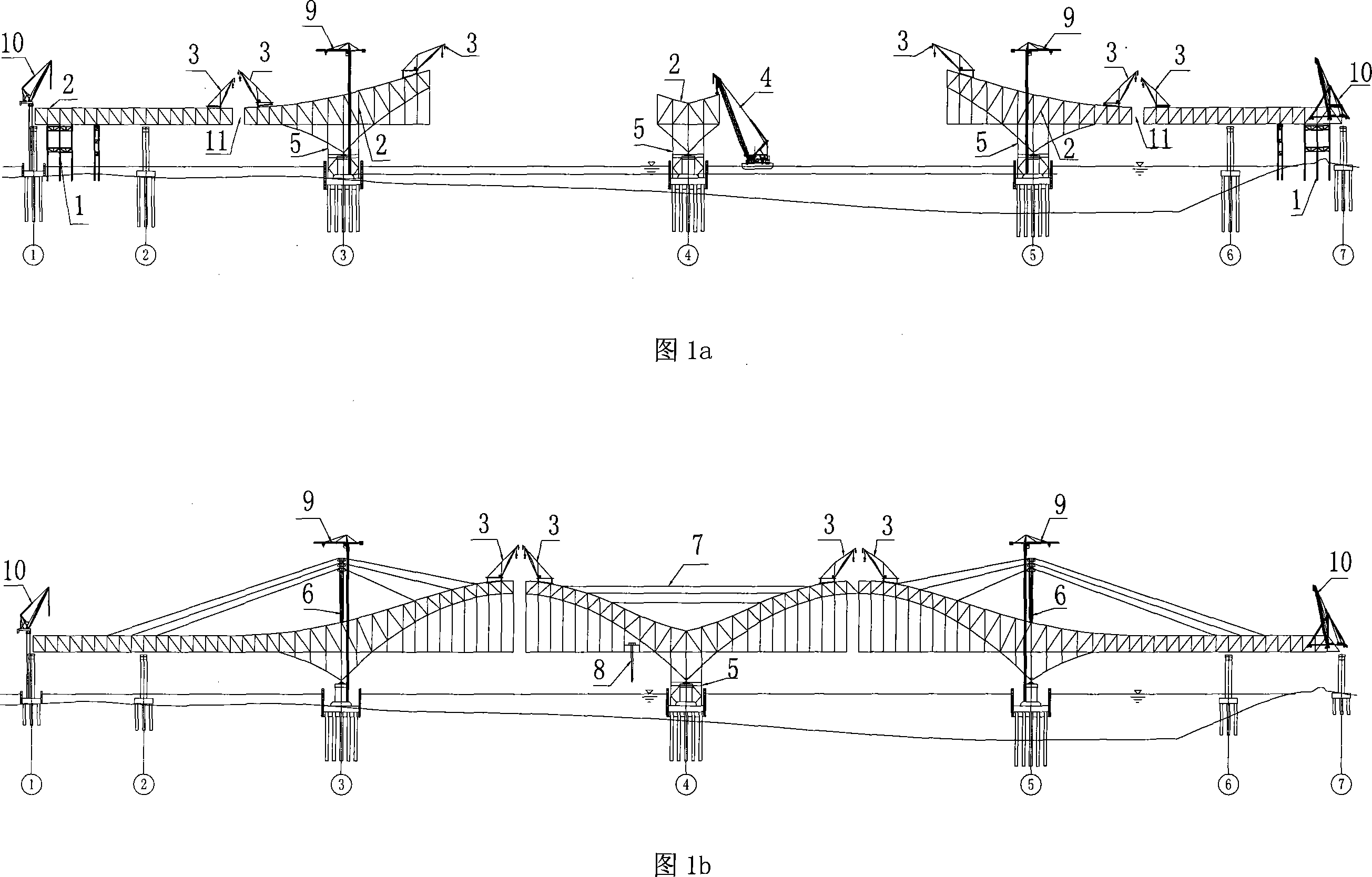

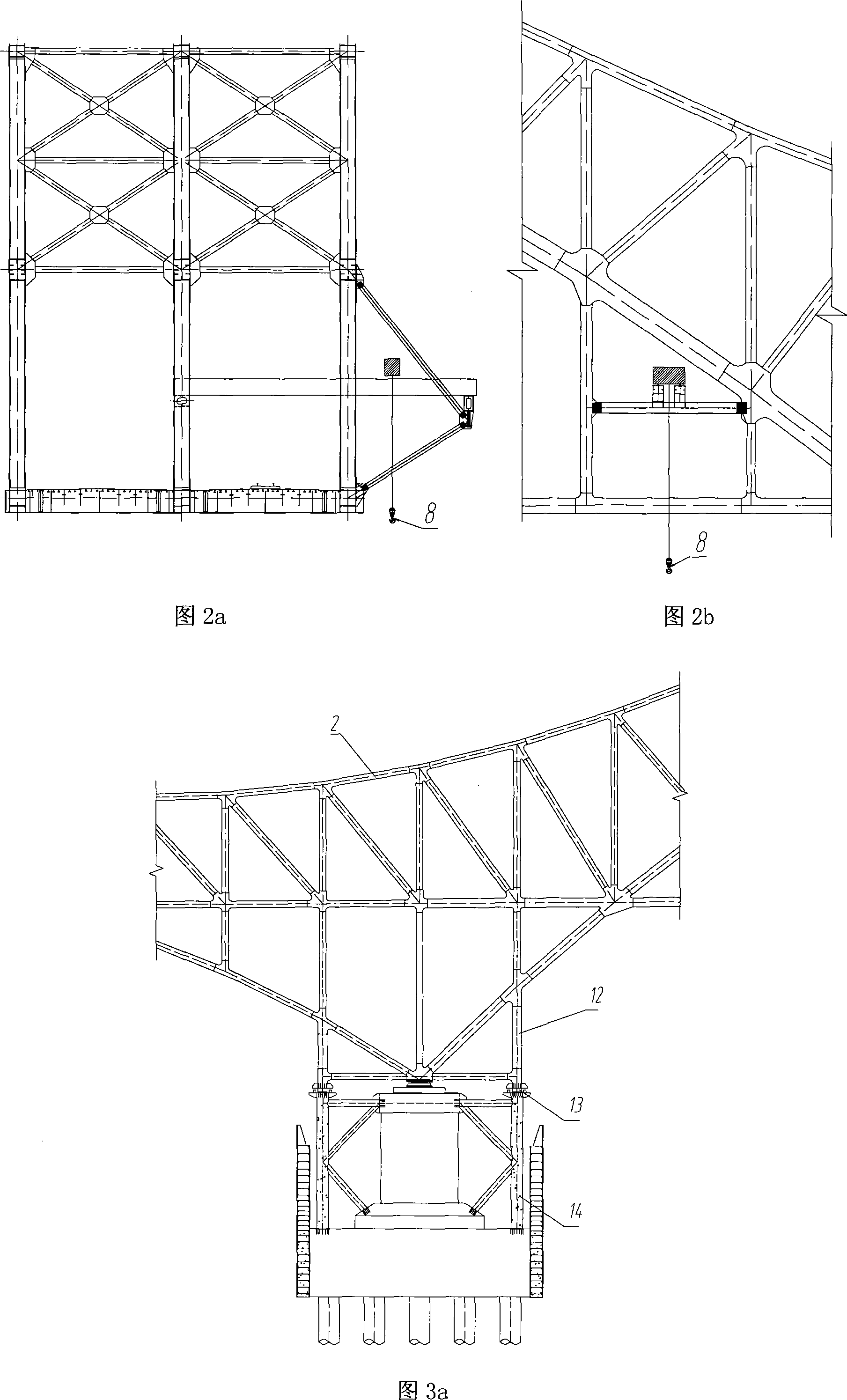

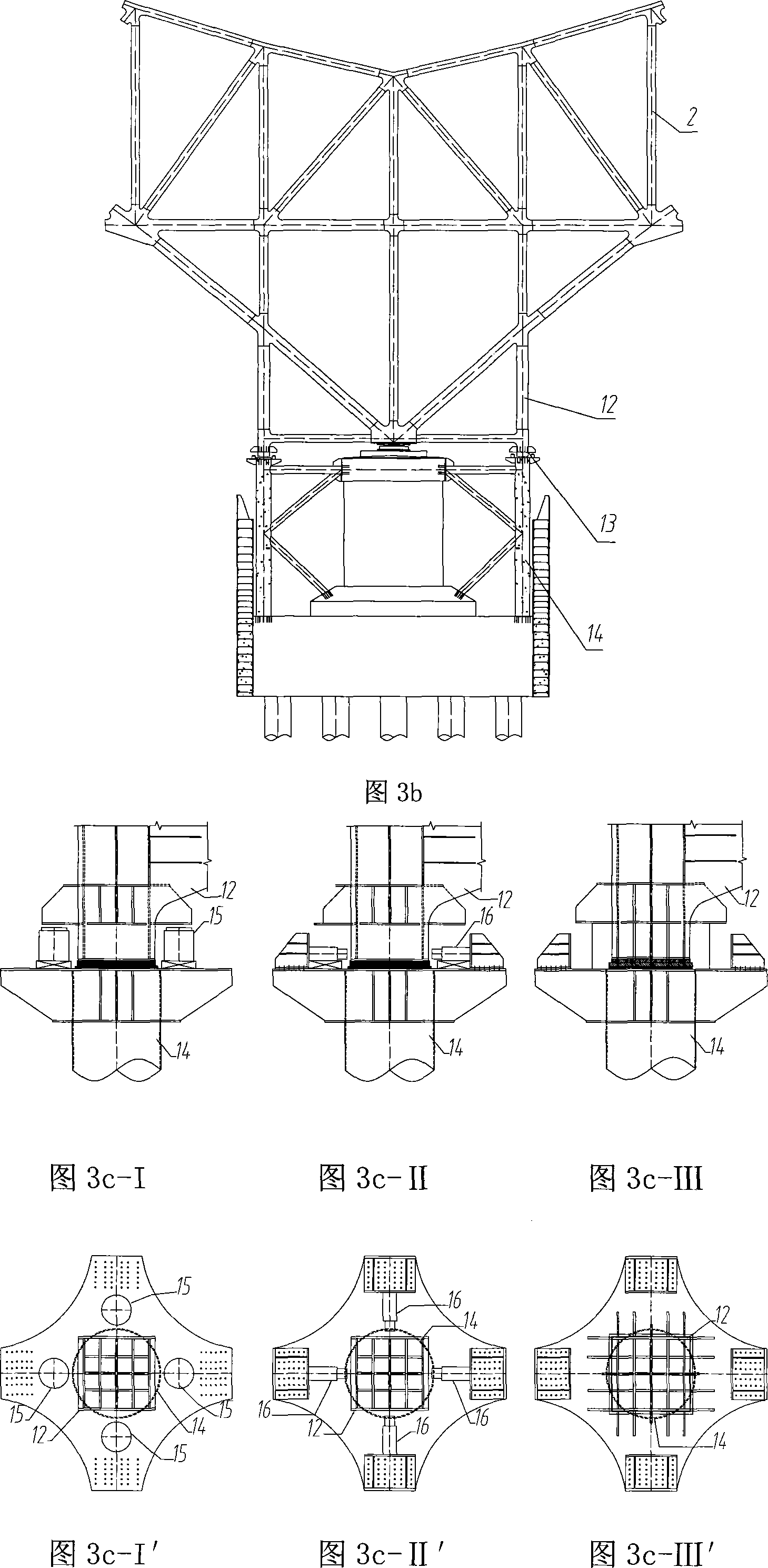

[0033] The construction method of the long-span continuous steel truss arch is mainly composed of: side span steel truss girder installation, pier side bracket 5 installation, sling tower 6, main span steel truss arch installation, and closing.

[0034] 1. Installation of side span steel truss girders

[0035] The installation of the steel truss starts from pier ①, install the initial internode steel truss 2 on the temporary support pier 1 from pier ① to pier ②, and assemble the girder crane 3 on the steel truss that has been erected. The machine 3 starts to erect the beam toward the pier ② direction. After the erection reaches the top of the pier ②, it is fully cantilevered and installed until the steel truss between the pier ② and the pier ③ closes the dragon mouth 11. A steel truss member lifting station 10 is set beside the pier ①, which is responsible for loading and supplying the rod members for cantilever installation.

[0036] 2. Bracket beside the pier

[0037] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com