Patents

Literature

3692 results about "Pier" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A pier, in architecture, is an upright support for a structure or superstructure such as an arch or bridge. Sections of structural walls between openings (bays) can function as piers.

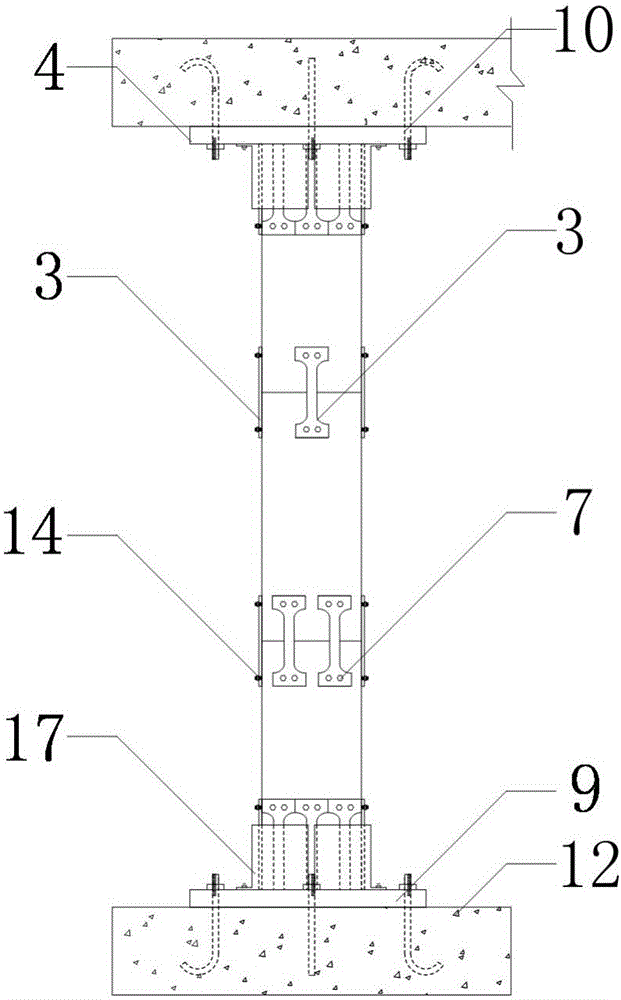

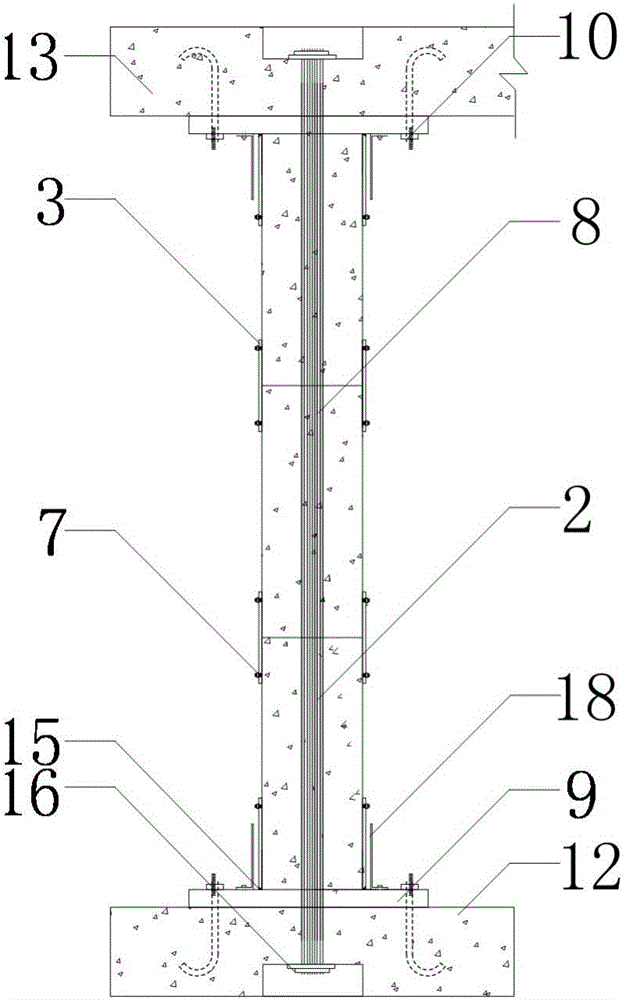

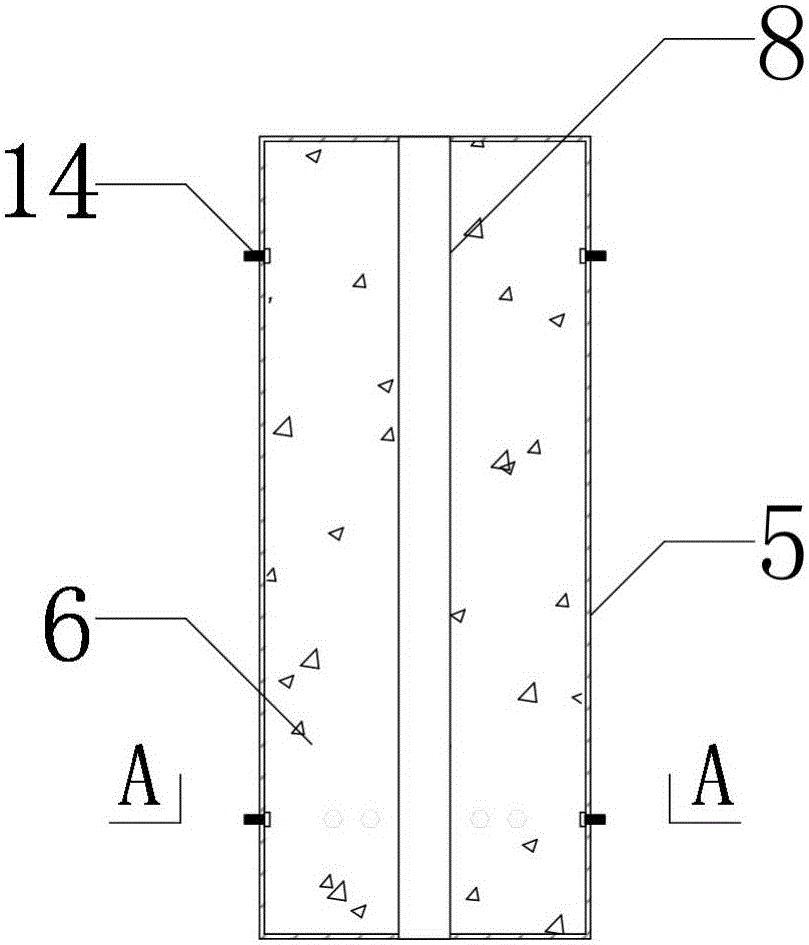

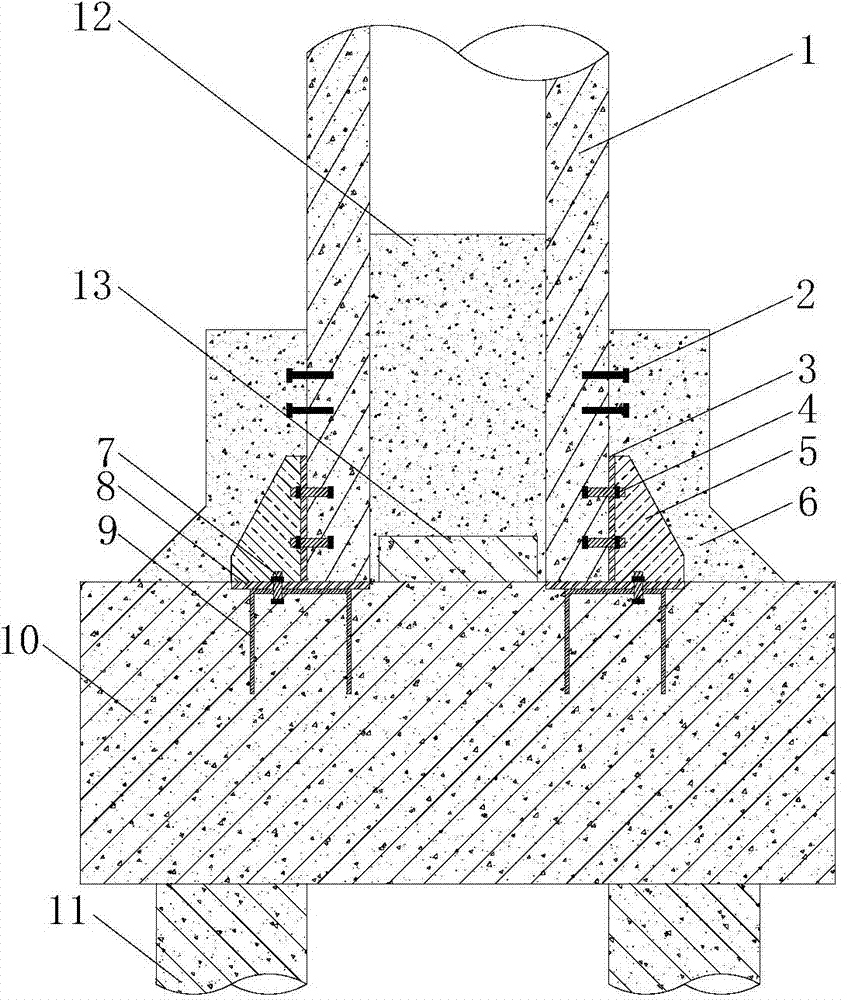

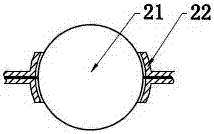

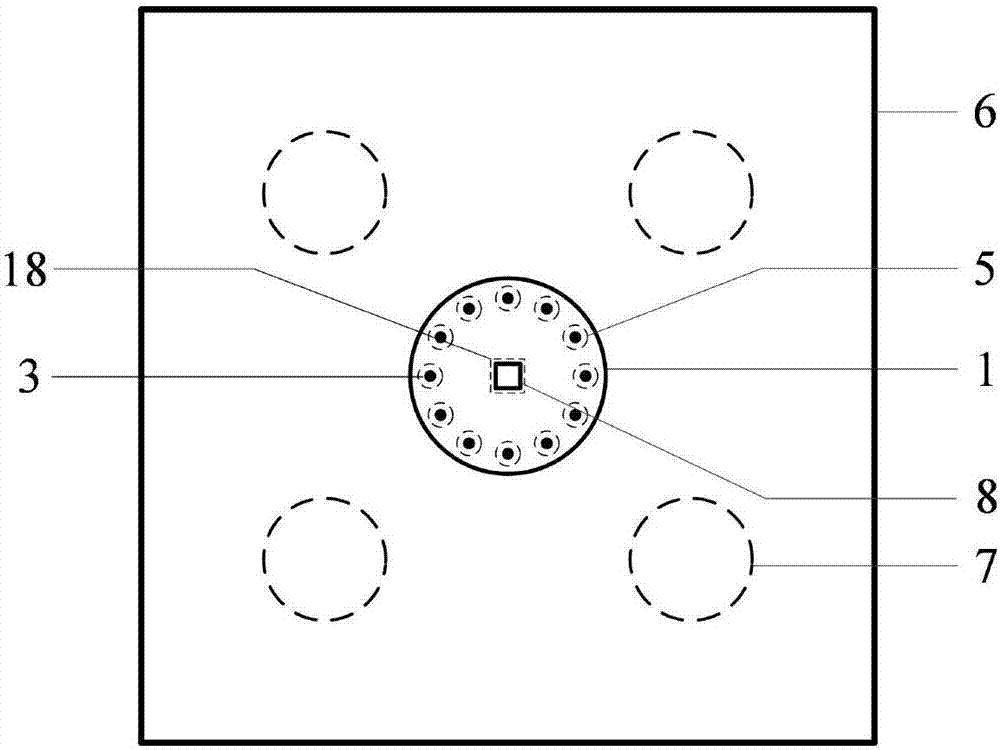

Damage-controllable self-resetting section prefabricated assembled steel pipe concrete bridge pier and manufacturing method thereof

ActiveCN105908621ASmall residual displacement after earthquakeImprove bearing capacityBridge structural detailsBridge erection/assemblyBridge engineeringHigh energy

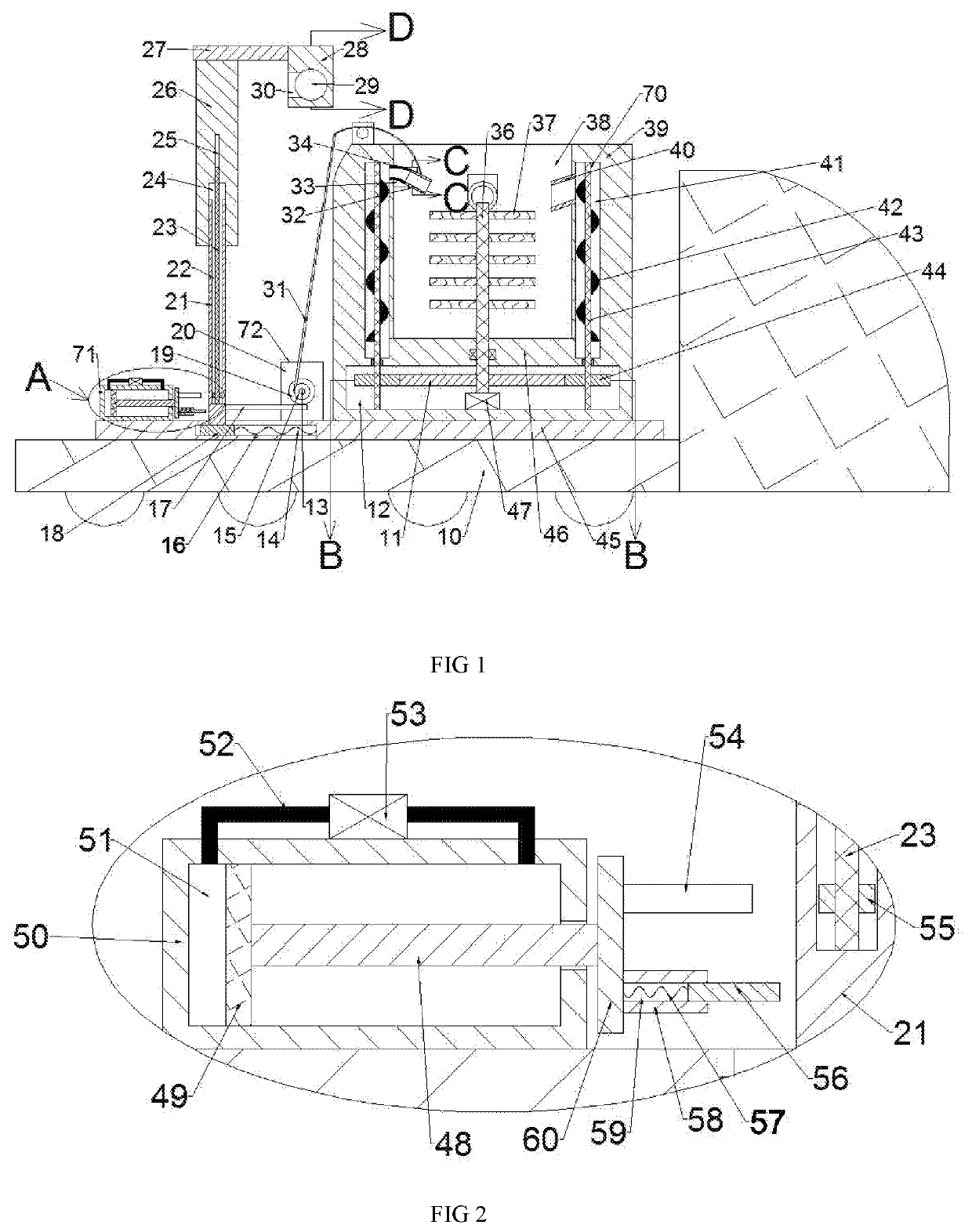

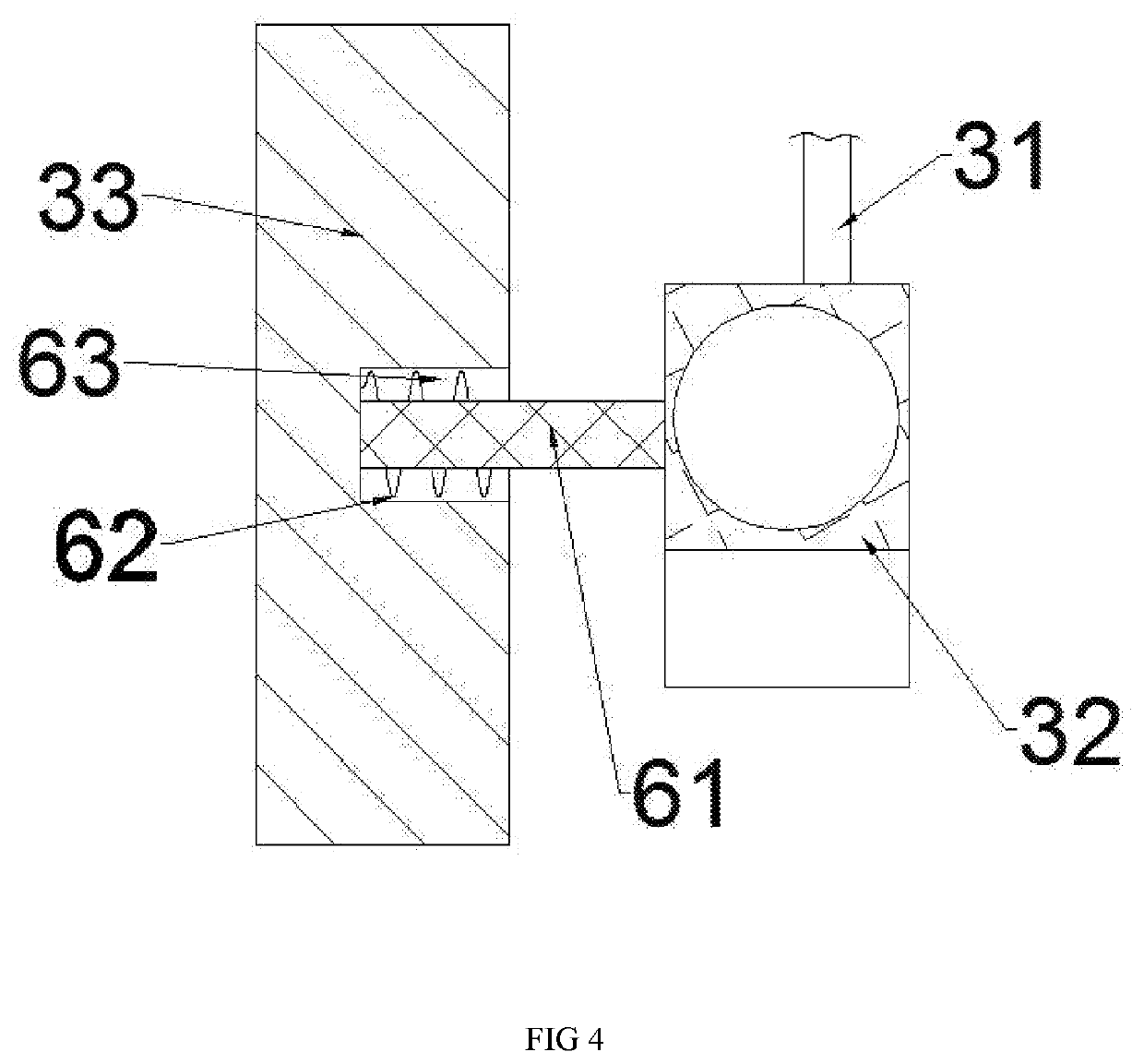

The invention discloses a damage-controllable self-resetting section prefabricated assembled steel pipe concrete bridge pier and a manufacturing method thereof, and belongs to the field of bridge engineering. An exposed node connecting piece consists of a foot plate, anchor bolts, end connecting plates and buckling restraining sleeves. A connecting plate is mounted between prefabricated steel pipe concrete sections through high-strength bolts; the exposed node connecting piece is connected with each of a cover beam and a bearing platform by utilizing the anchor bolts, and is connected with a prefabricated steel pipe concrete section through the high-strength bolts relying on the end connecting plates. A pre-stressed tendon penetrates through a section prefabricated steel pipe concrete pier; the two ends of the pre-stressed tendon are respectively anchored to the interiors of the bearing platform and the cover beam by using anchorage devices. The energy consumption-controllable self-resetting section prefabricated assembled steel pipe concrete bridge pier disclosed by the invention has the characteristics of small post-seismic residual displacement, high energy consumption capacity, controllable energy consumption, high assembling degree, convenience and quickness in construction process, greenness, high efficiency, energy conservation, environment friendliness, easiness in factory production, convenience and quickness in construction, and the like; the construction period of the pier can be remarkably shortened.

Owner:BEIJING UNIV OF TECH

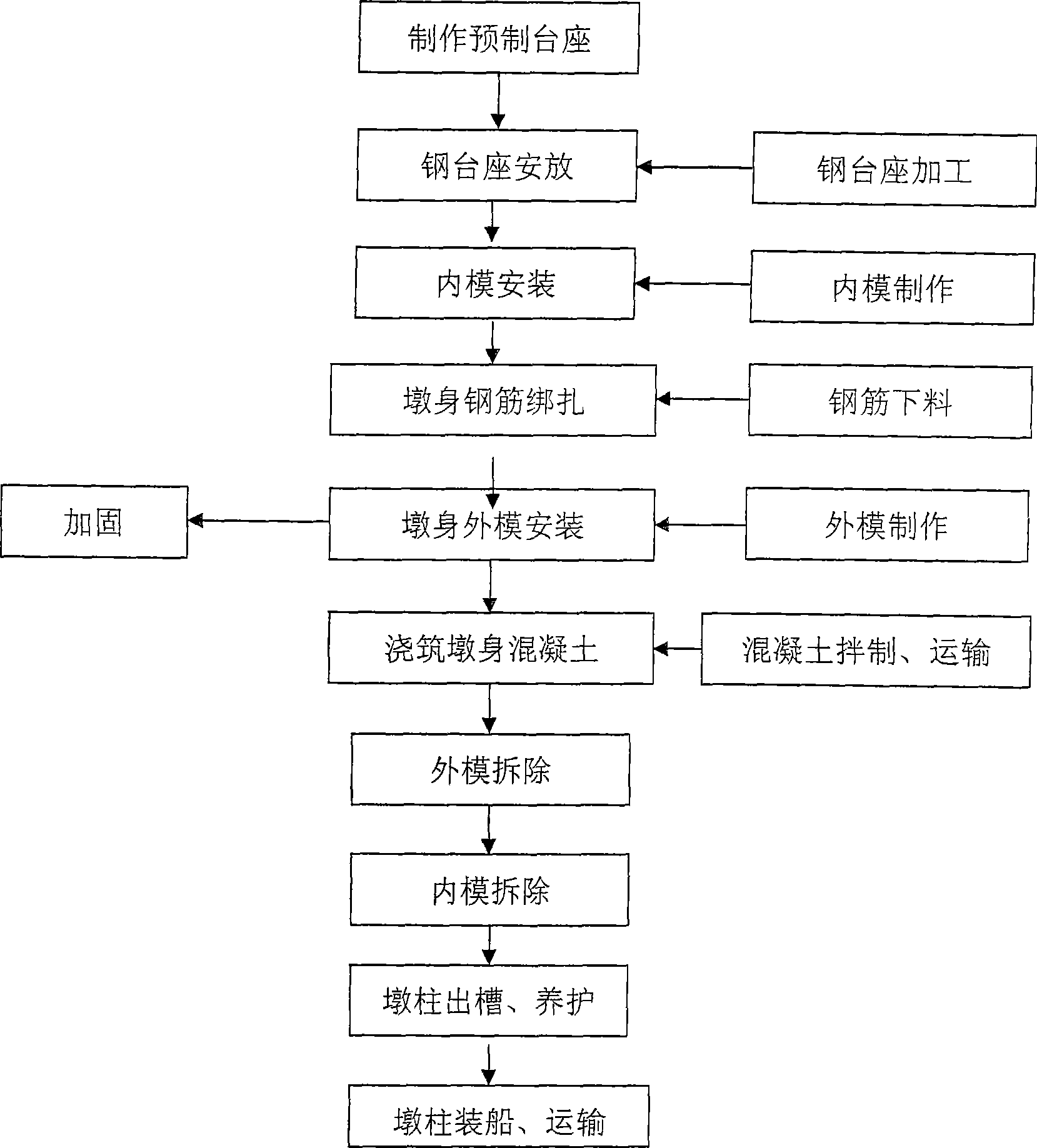

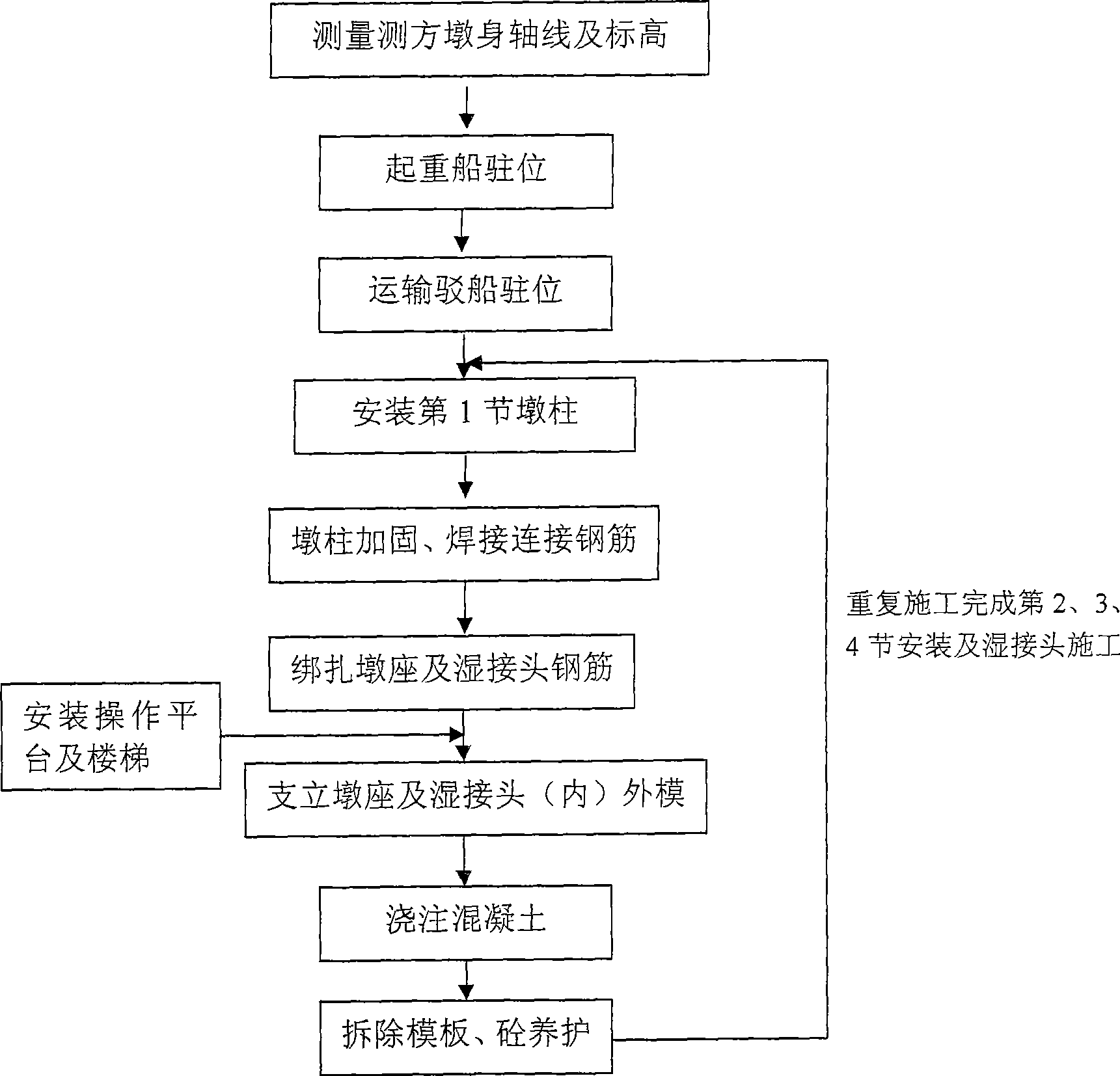

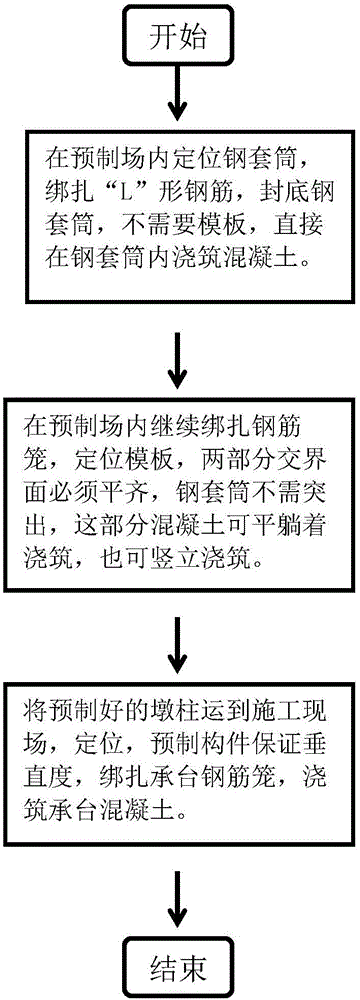

Pier column prefabrication splicing building technology

ActiveCN101429752AInspection is easy to implementImprove construction qualityBridge structural detailsBridge erection/assemblyHigh strength concreteBridge engineering

Owner:NO 1 ENG COMPANY CO LTD OF CCCC FIRST HARBOR ENG COMPANY +1

Assembled type pier column member with steel-concrete composite structure

InactiveUS20170356144A1Improve construction progressReasonable and convenient to constructBridge structural detailsBridge erection/assemblyPile capPre stress

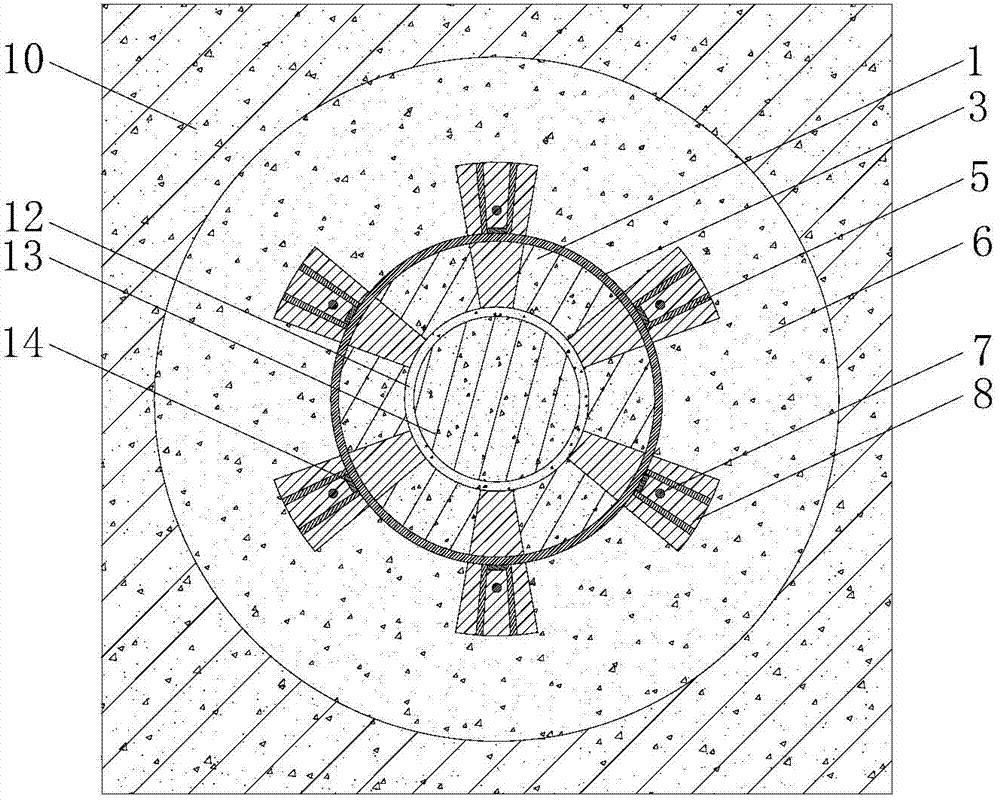

A segment-assembled type pier column member with a steel-concrete composite structure includes a reinforcement tube embedded in a pile cap, wherein the reinforcement tube is connected with a bottom of a lower segment of a hollow steel tube pier and is poured with concrete, and pier columns in upper and lower segments are reinforced by means of segment connecting and being embedded with local reinforcing meshes. A steel cross beam is connected with an upper segment of the hollow steel tube pier in an assembled way. A pre-stressed tensioning duct is reserved between the steel cross beam and the pier column in the upper segment.

Owner:HOHAI UNIV

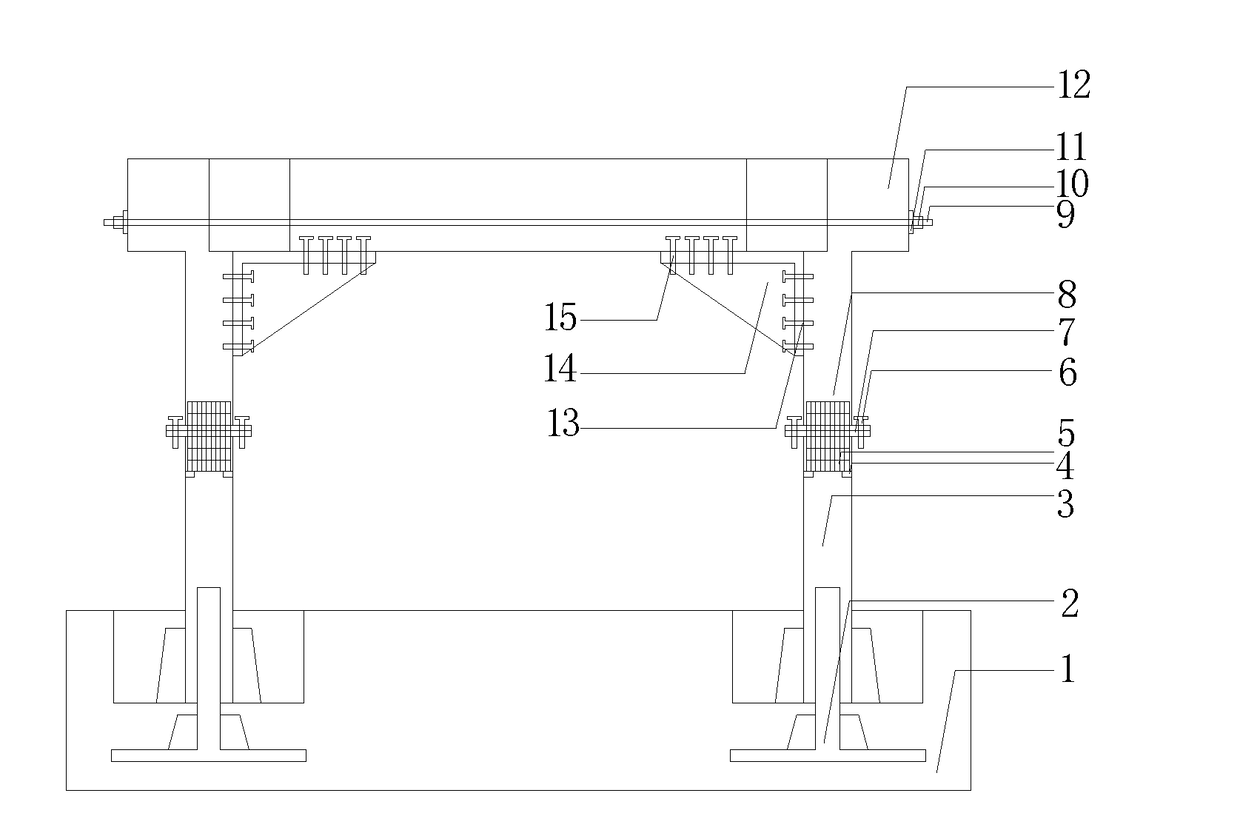

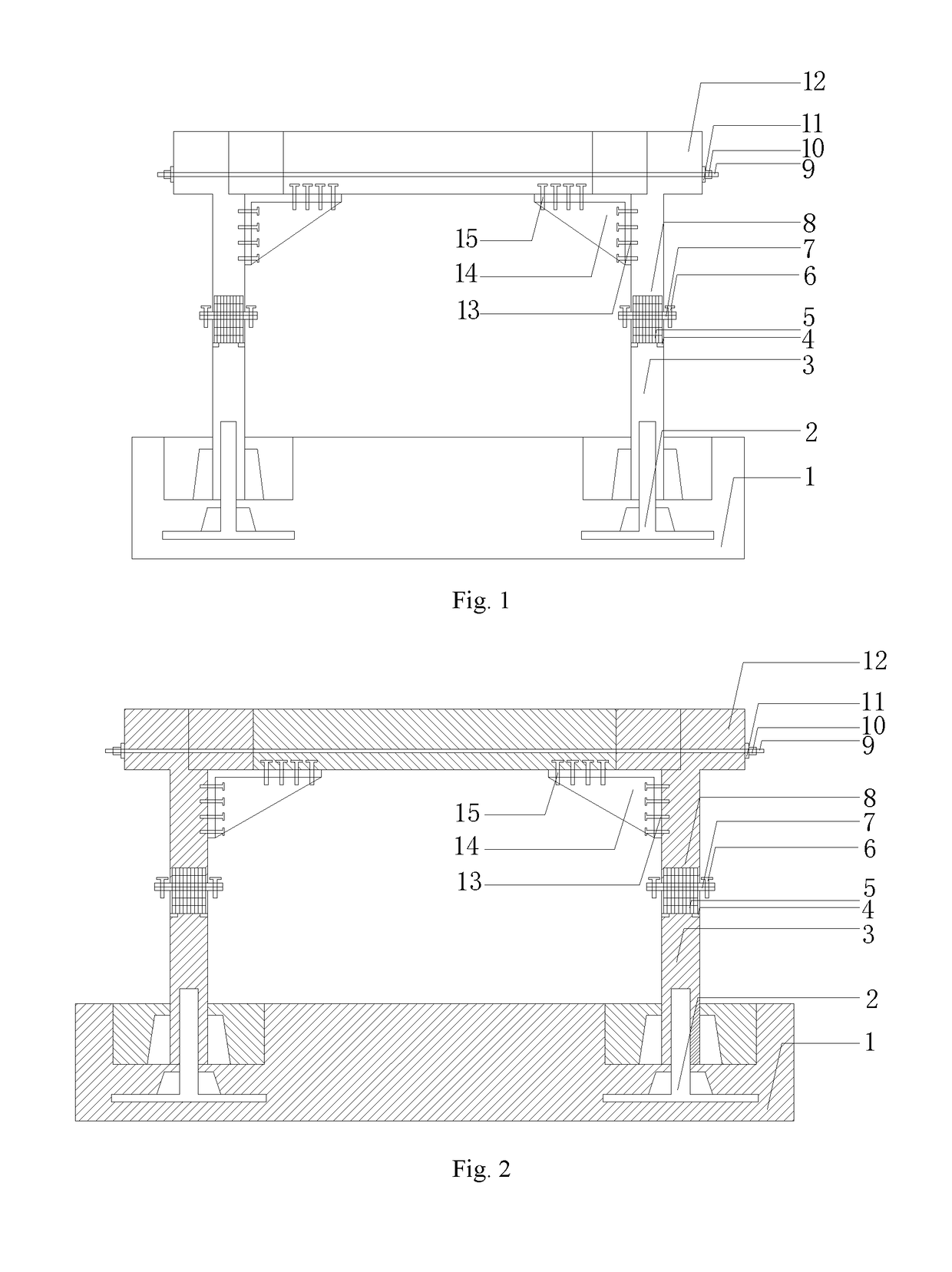

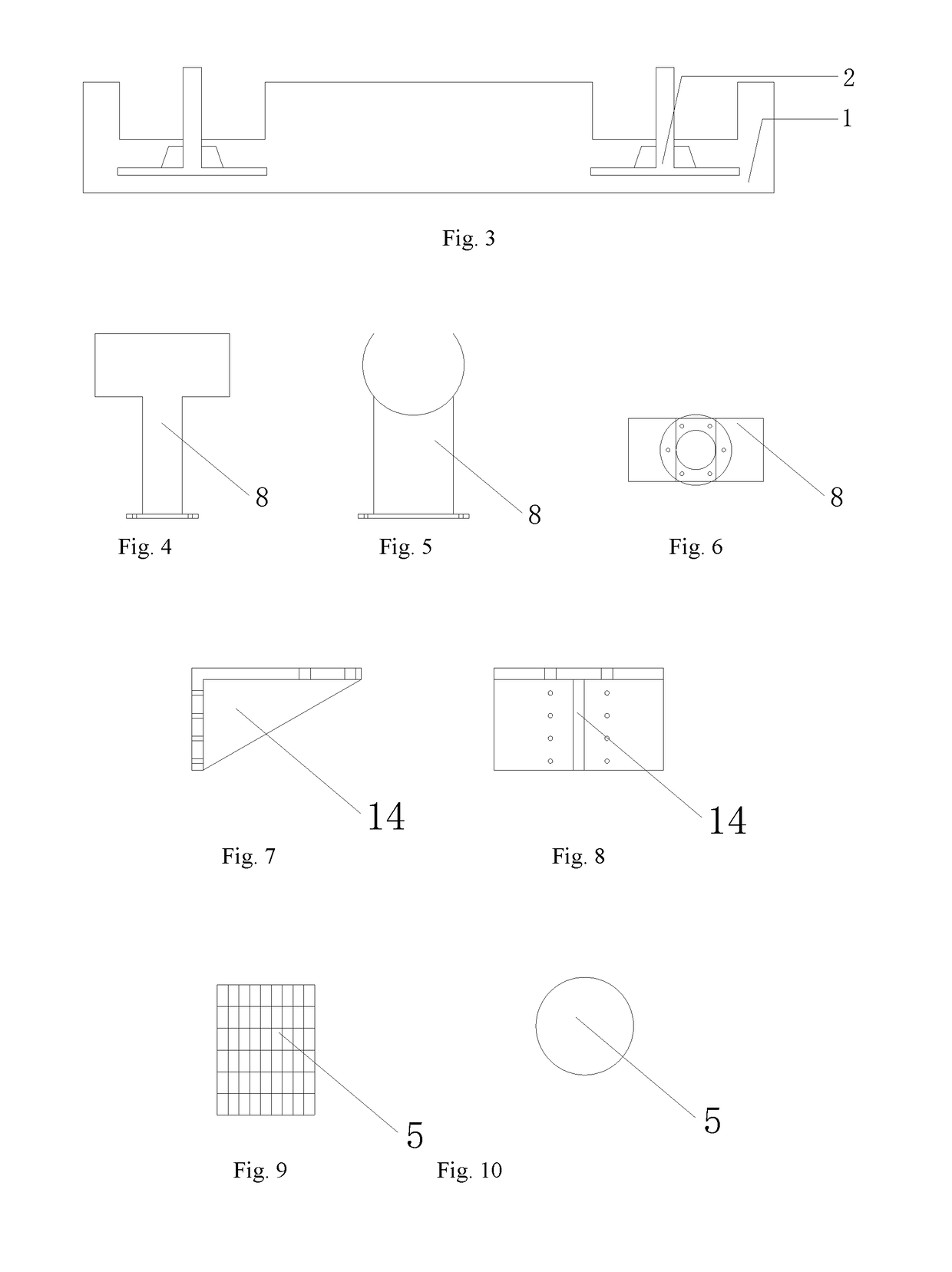

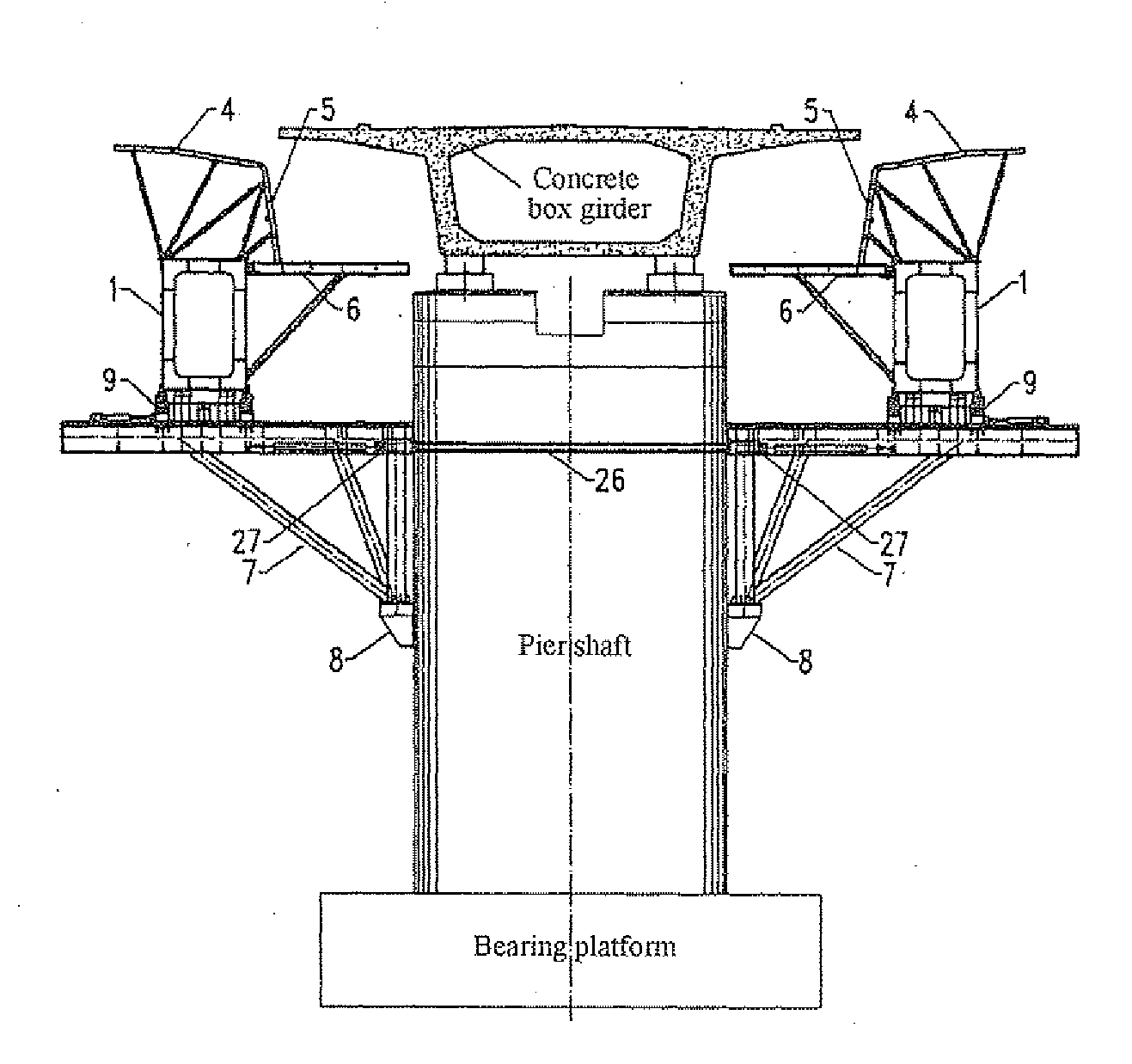

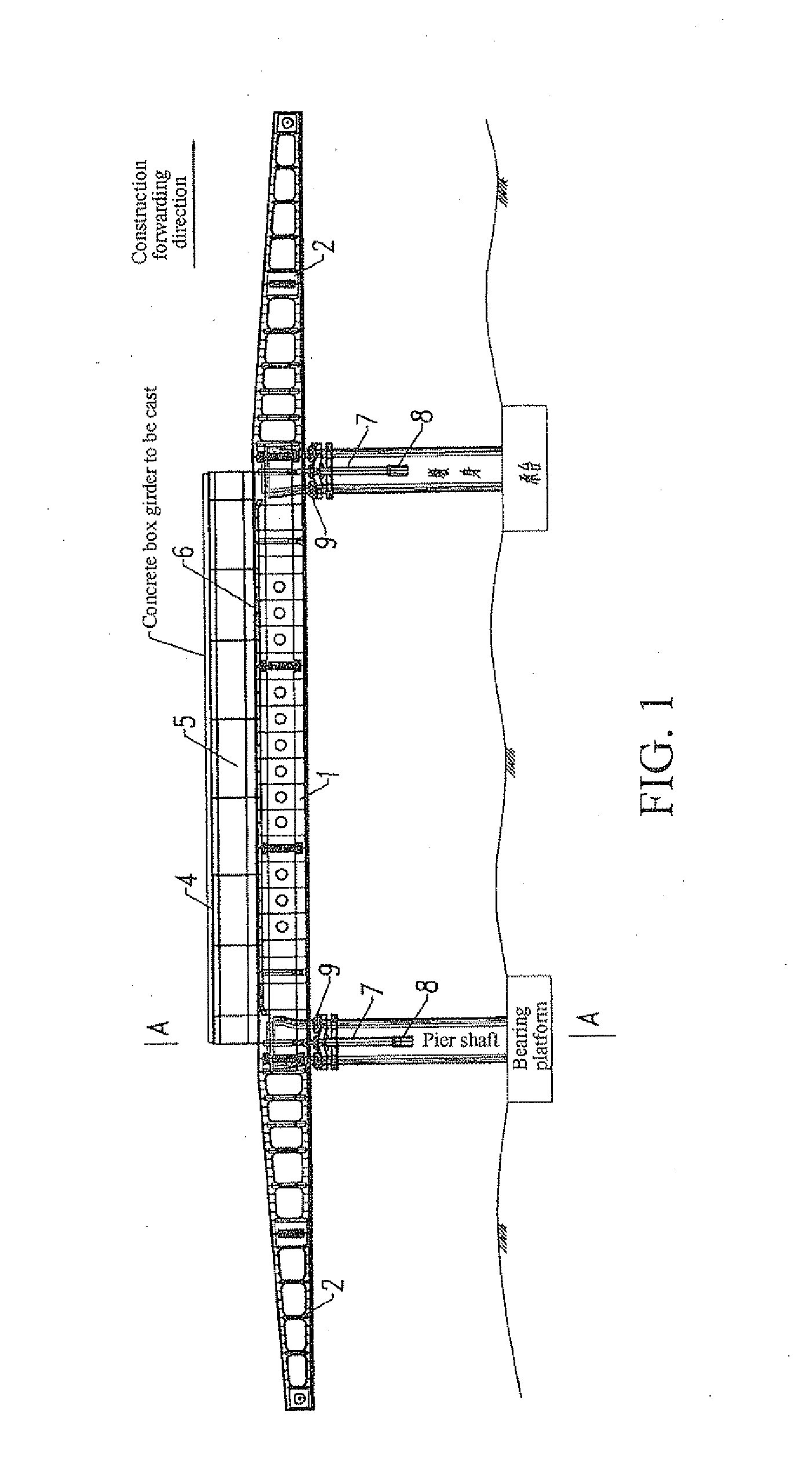

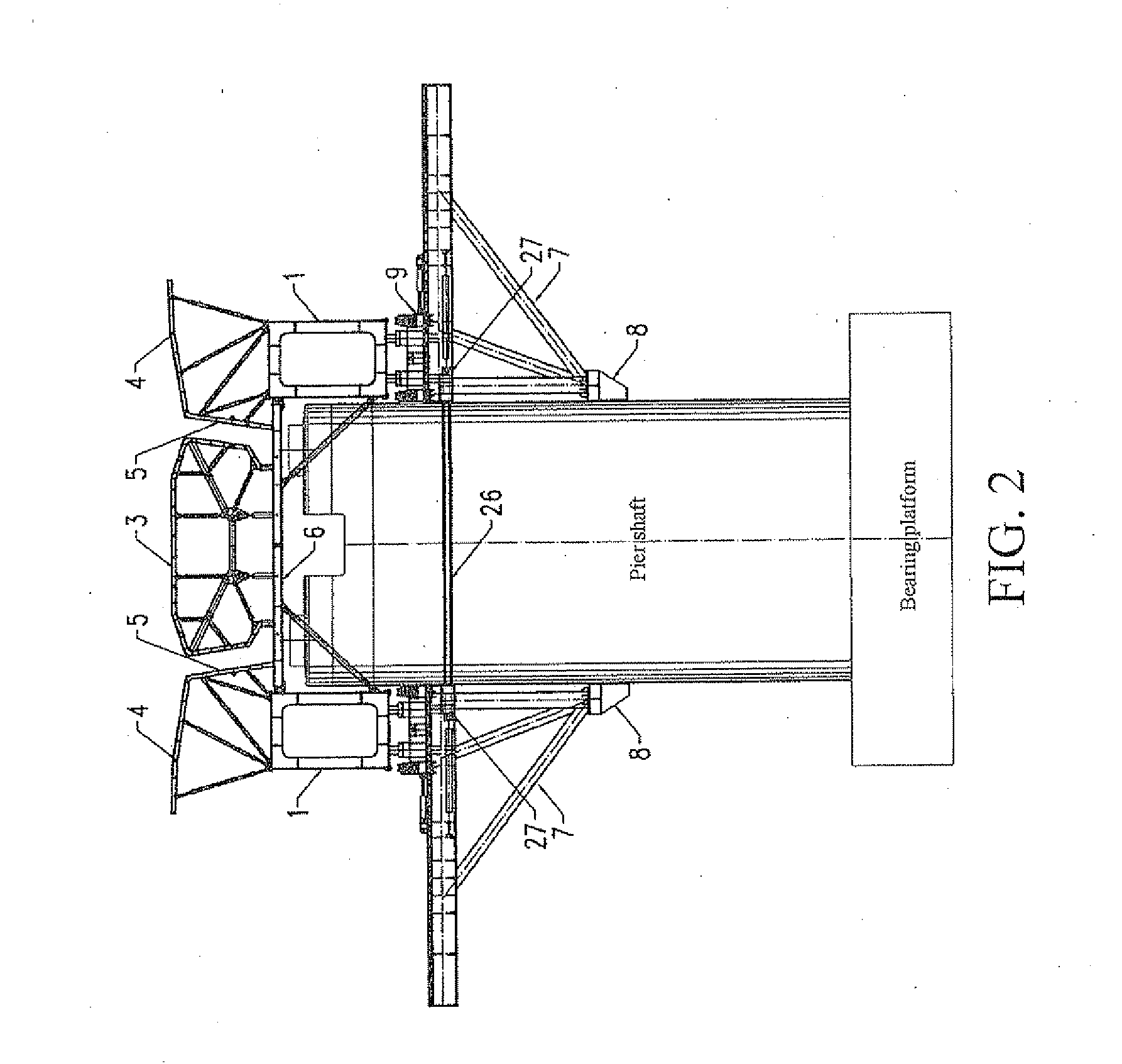

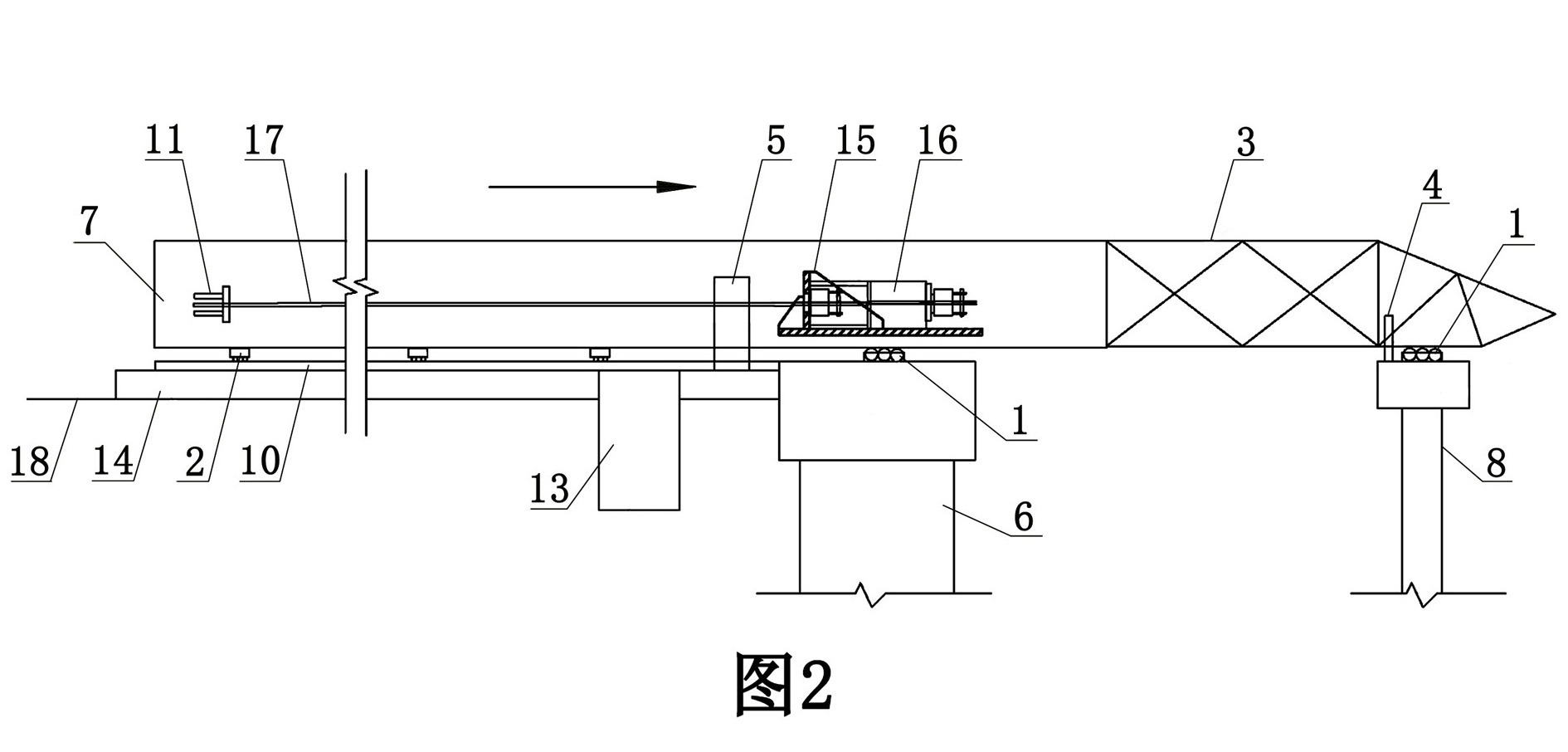

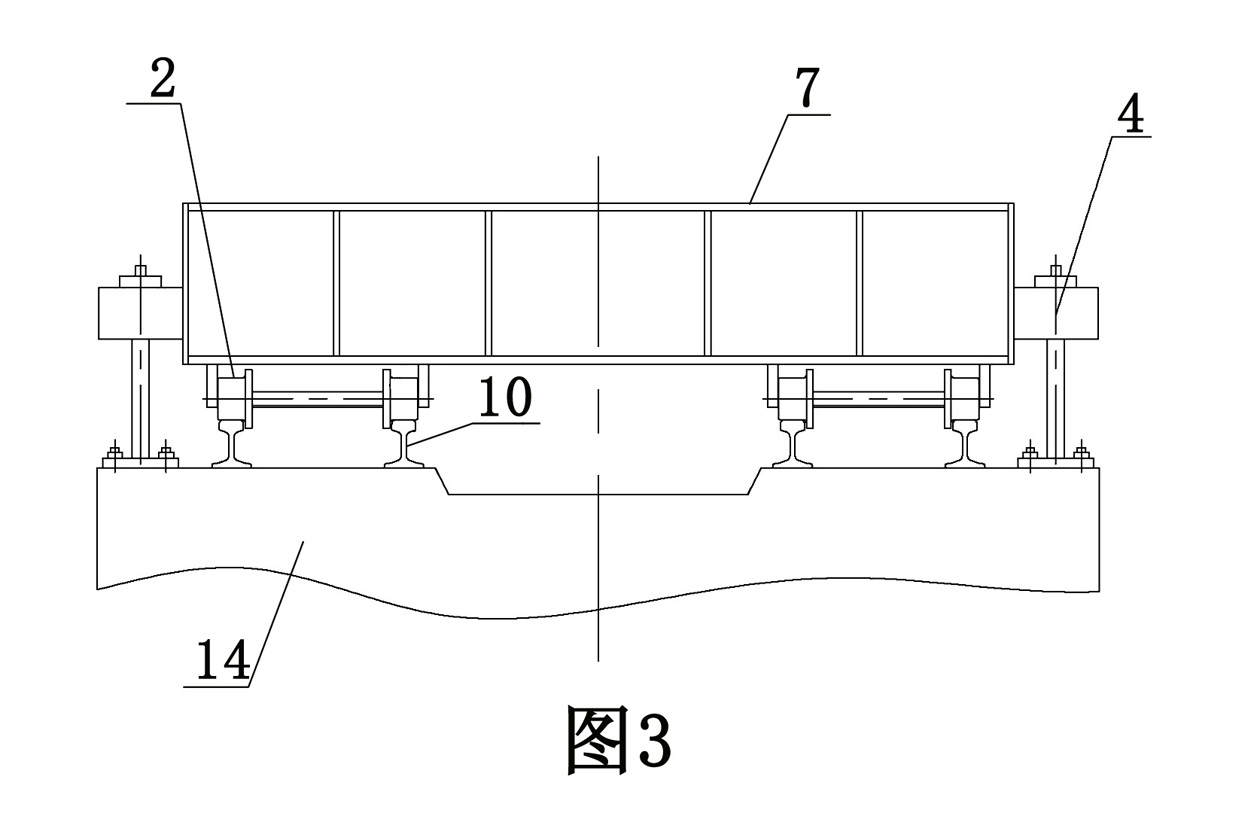

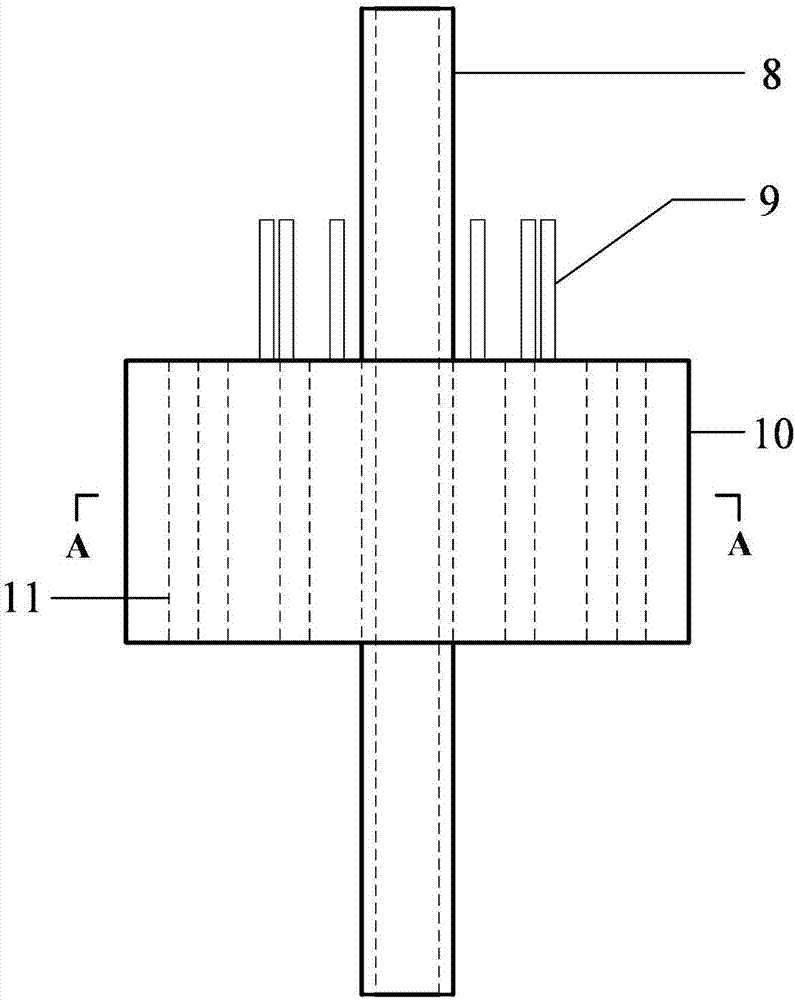

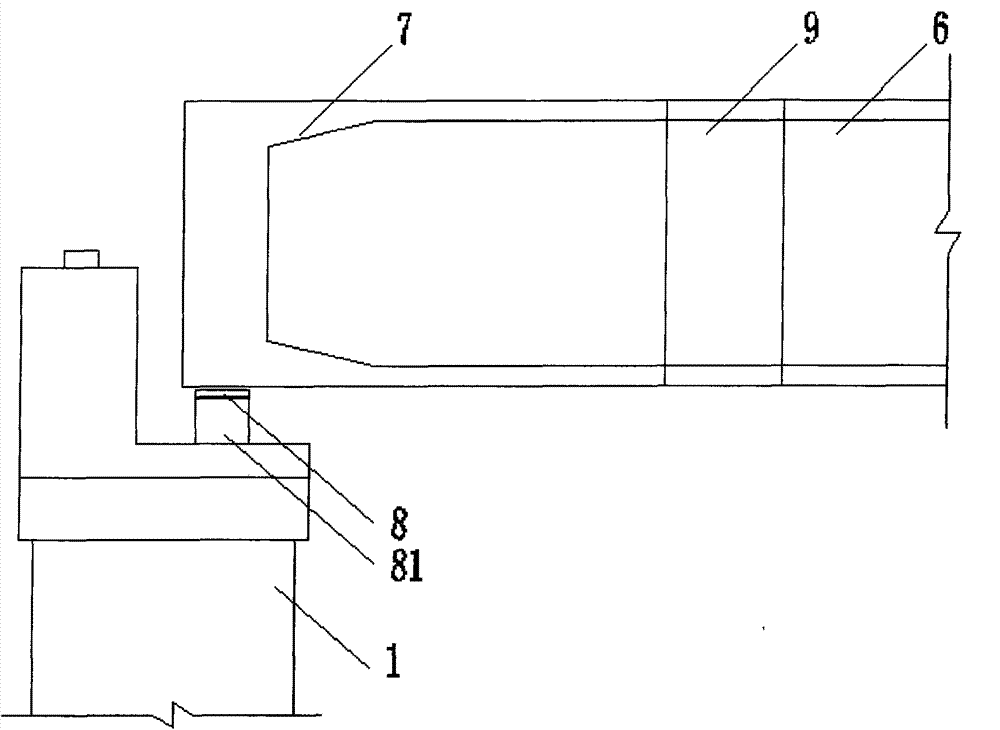

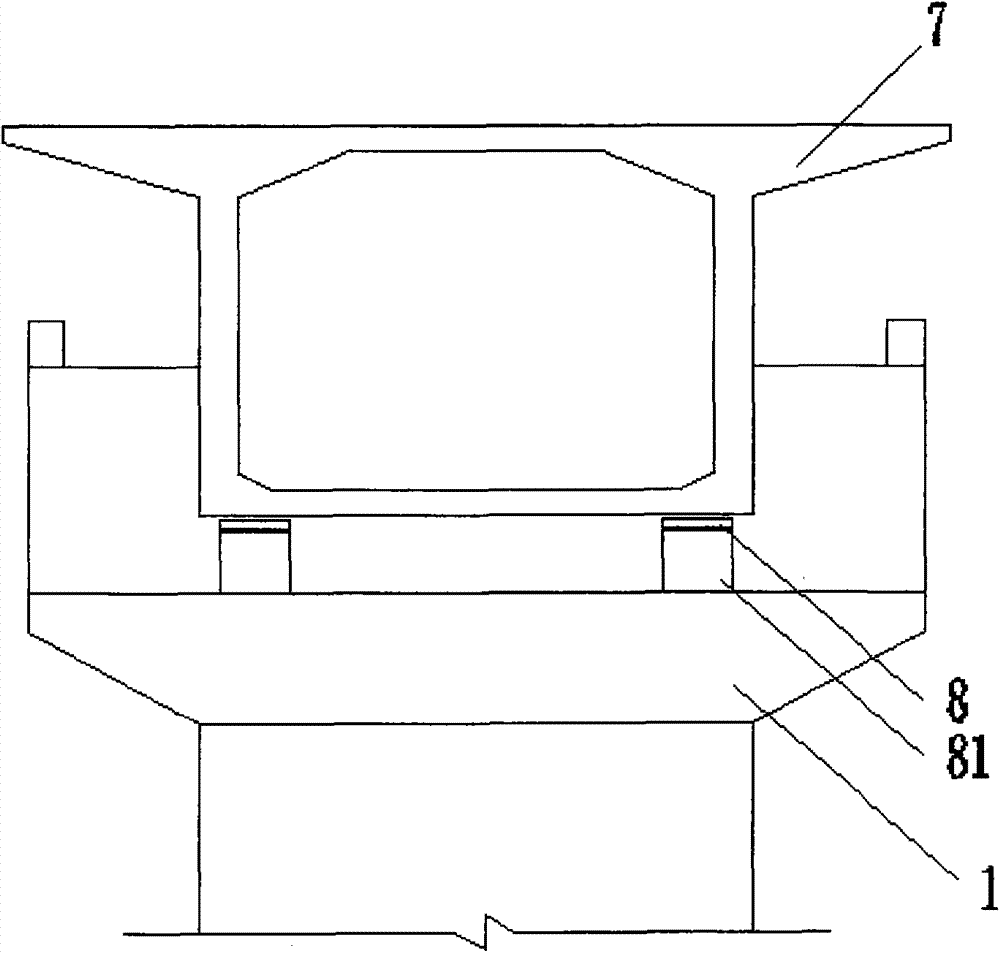

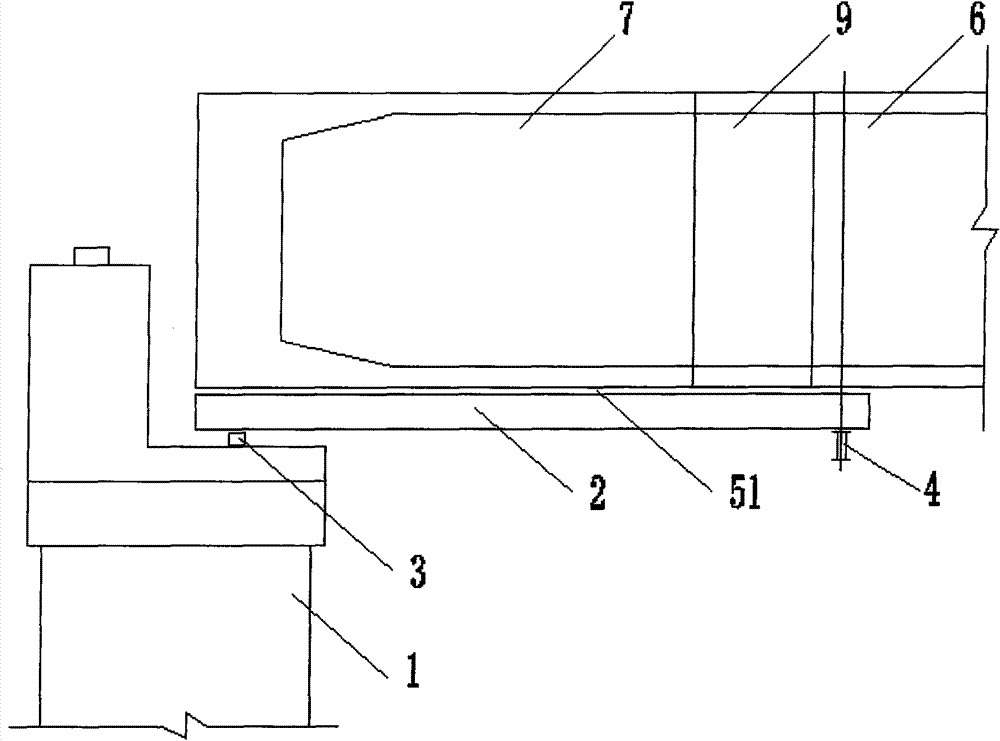

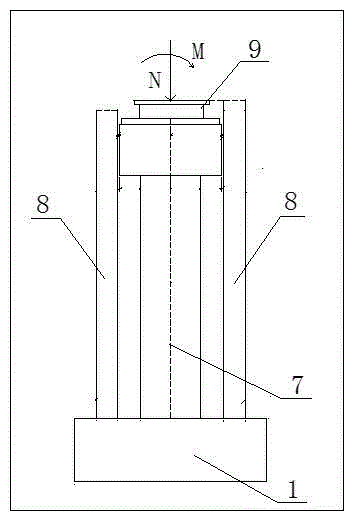

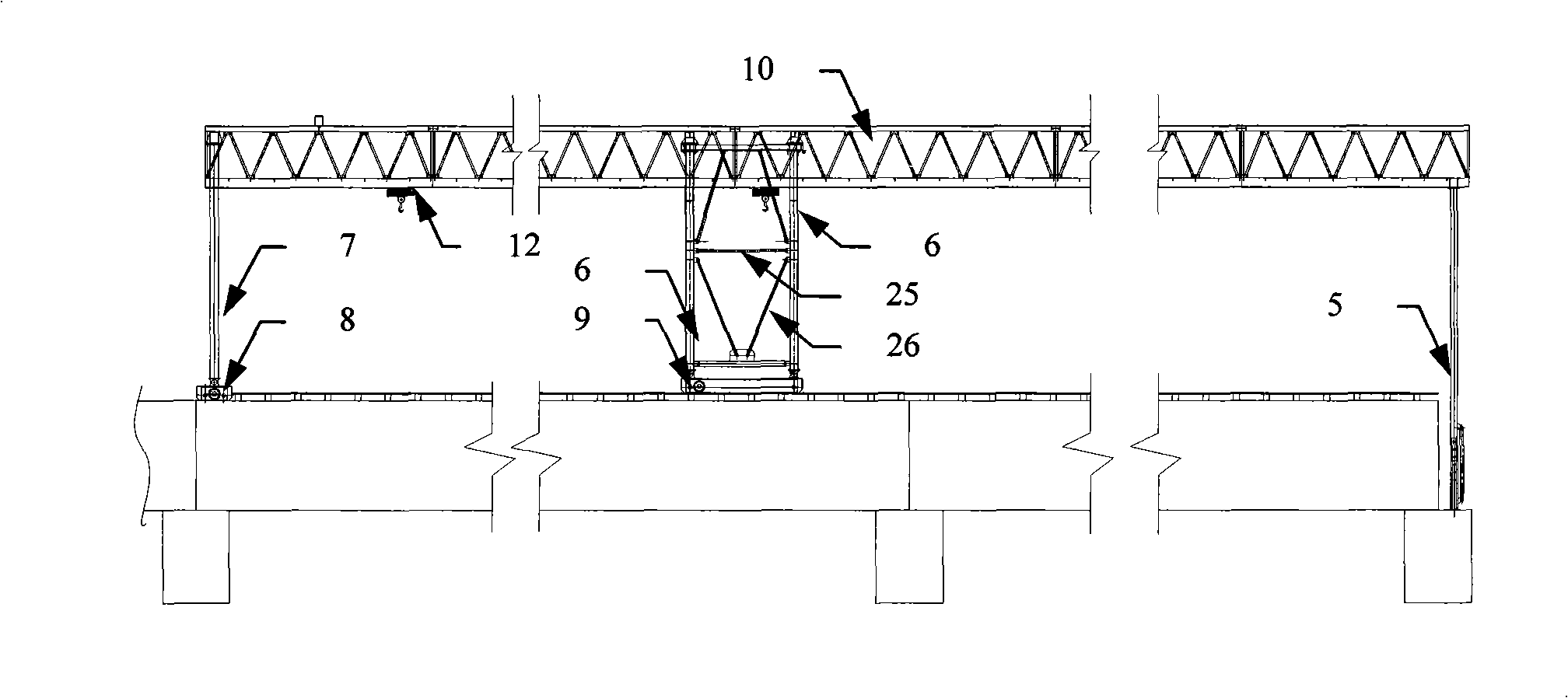

Upper-bearing typed movable formwork

ActiveUS20110133052A1Large dead weightIncreased footprintMouldsForms/shuttering/falseworksEngineeringBridge engineering

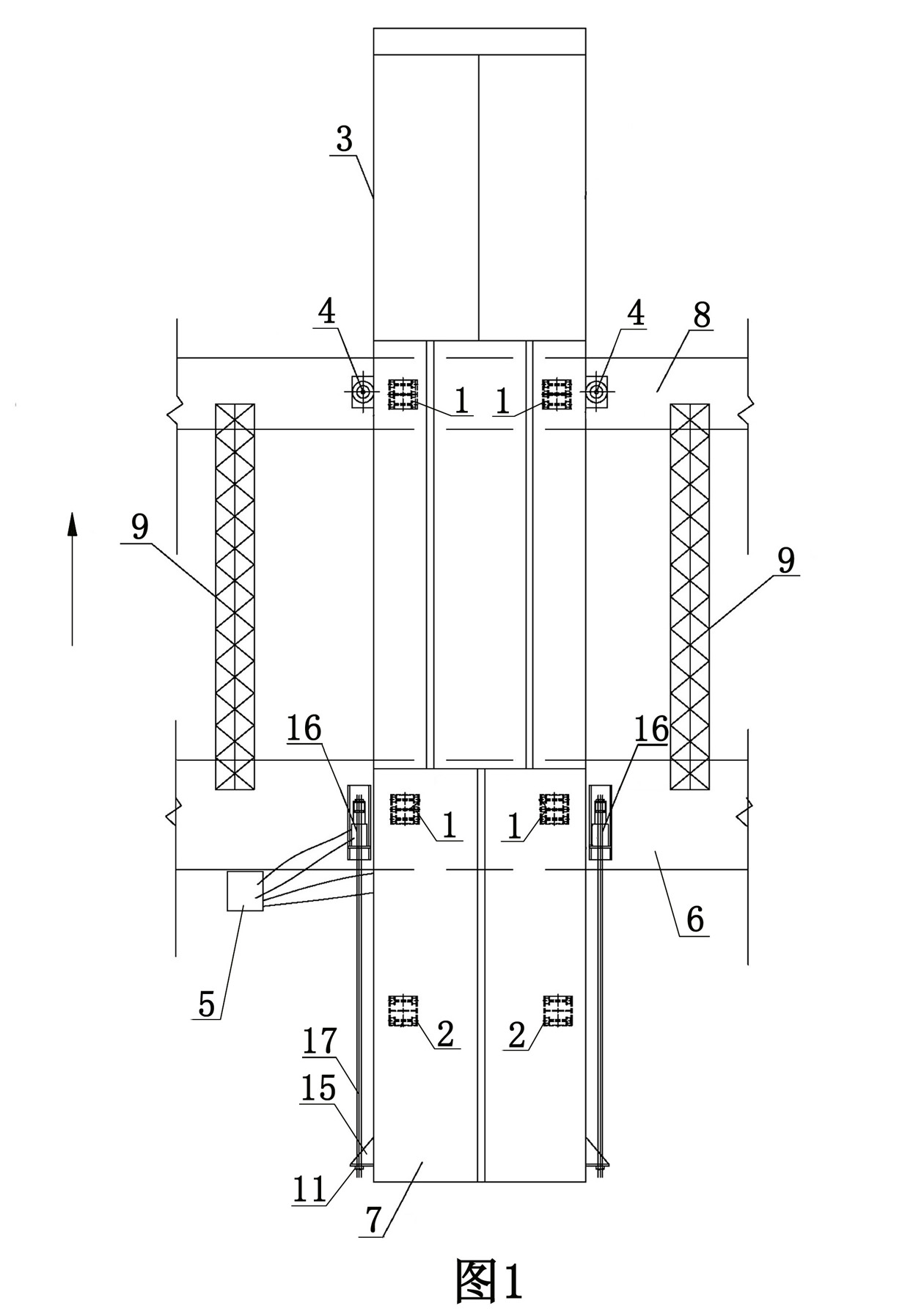

An upper-bearing typed movable formwork used for cast-in-situ of concrete box girder in bridge engineering, comprising left and right legs (7) which are respectively fixed on a pier, left and right longitudinal / transverse sliding mechanisms (9), bearing devices and a template system. The left and right longitudinal / transverse sliding mechanisms (9) are respectively arranged on the left and right legs (7) and can move horizontally along the left and right legs (7), the bearing devices are respectively fixed on the left and right longitudinal / transverse sliding mechanisms (9), the template system comprises a bottom formwork (6), an internal formwork (3), a left formwork and a right formwork, the bottom formwork (6) is formed by screw connection of a left bottom formwork and a right bottom formwork (6a,6b) which are symmetrical about the axis line of the concrete box girder, two ends of the bottom formwork are respectively fixed on two opposite internal side surfaces of the left main beam and the right main beam (1). The movable formwork also comprises a plurality of adjustable supporting rods (14) used for supporting the template system.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

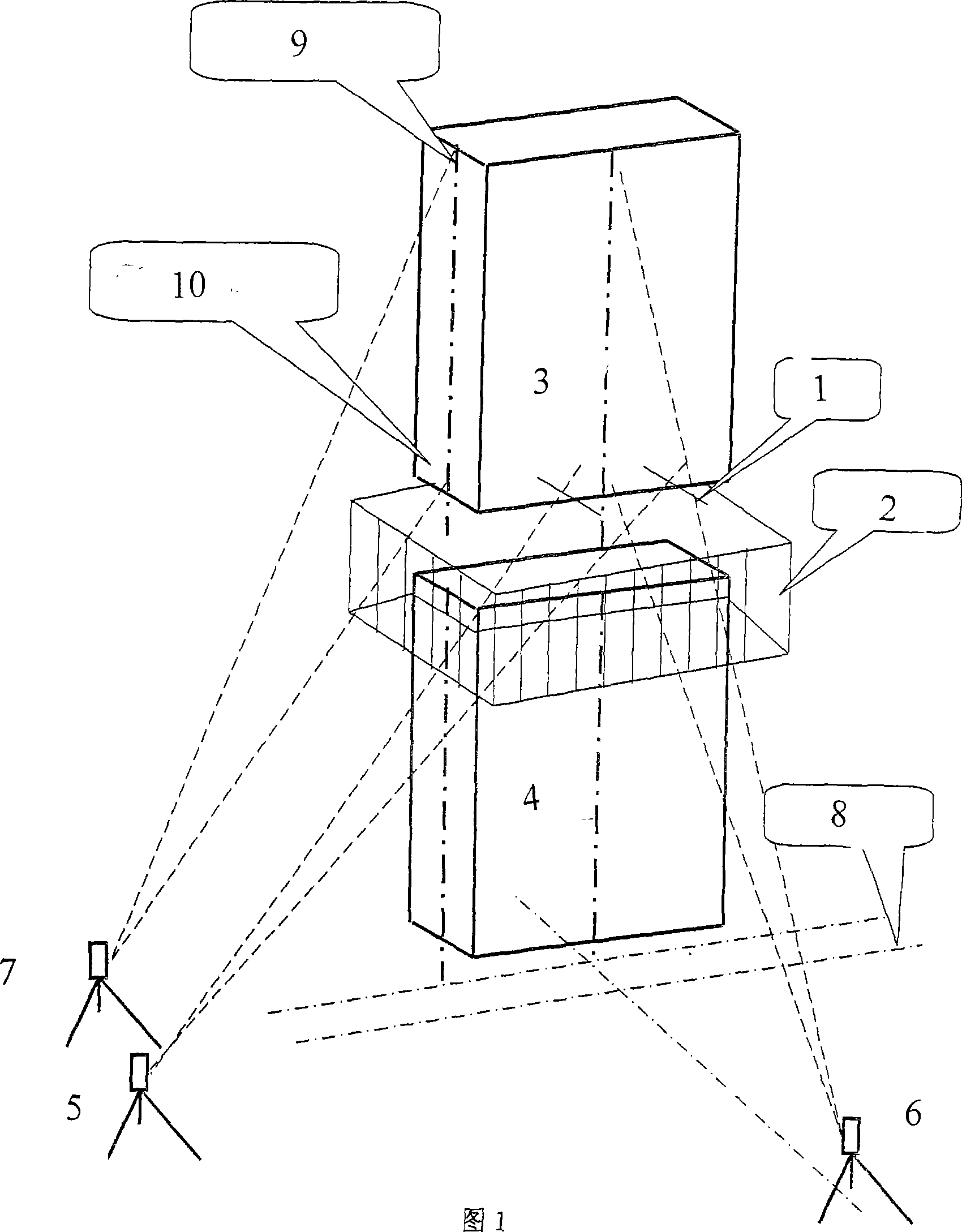

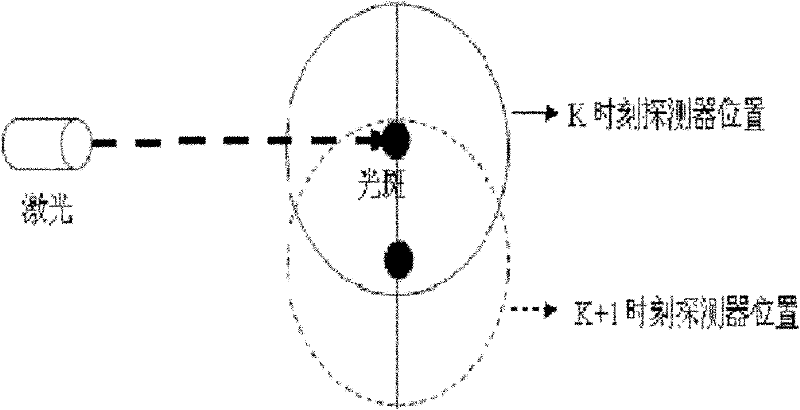

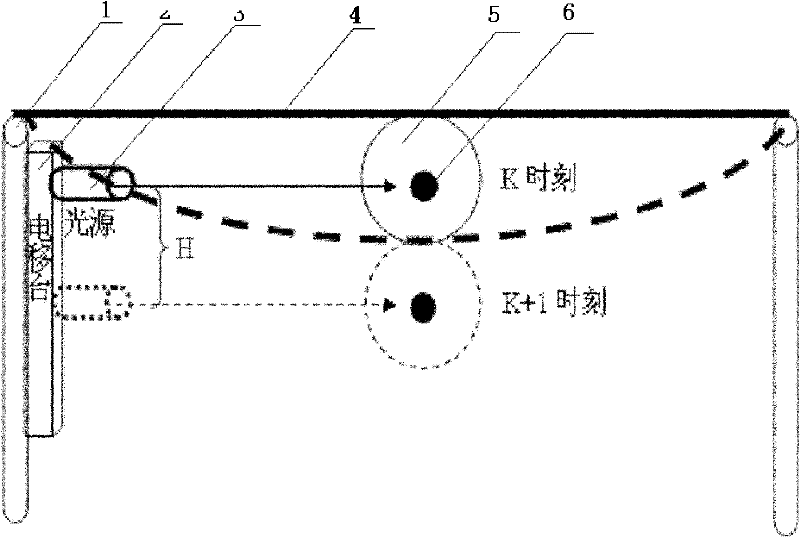

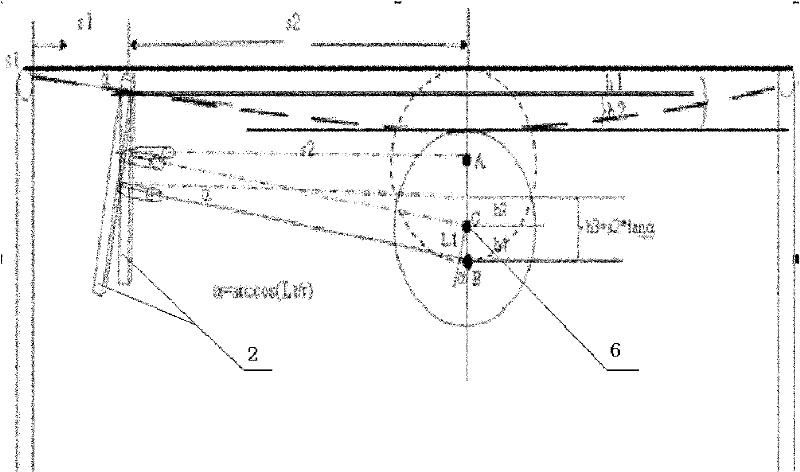

Method for testing deflection/longitudinal displacement change of bridge based on four-quadrant position detector

InactiveCN102564323AHigh precisionReal-time monitoring of security statusUsing optical meansFour quadrantsLight spot

The invention discloses a method for testing a deflection / longitudinal displacement change of a bridge based on a four-quadrant position detector. The method is characterized by comprising the following steps: firstly, the four-quadrant position detector is installed in the centre of the bridge or other points to be tested at the bottom of a bridge deck; a laser source is installed on a pier and / or a certain point below the bridge deck through an electric displacement table; then, testing is carried out by matching the four-quadrant detector with the laser source, so that the light spot of laser is over against the centre of the detector; when the deflection of the bridge deck changes, the four-quadrant detector longitudinally moves together with the point to be tested; the light spot position, formed on the four-quadrant detector, of the laser moves oppositely relative to the detector; and different position coordinates of the light spot on the detector before and after the deflection of the bridge changes and light spot position variable quantity on the four-quadrant detector, namely deflection position variable quantity of the point to be tested on the bridge deck can be calculated. The method disclosed by the invention has the advantages of simple structure, good controllability and high precision and is capable of realizing real-time online test of the deflection / longitudinal displacement of the bridge.

Owner:DALIAN MARITIME UNIVERSITY

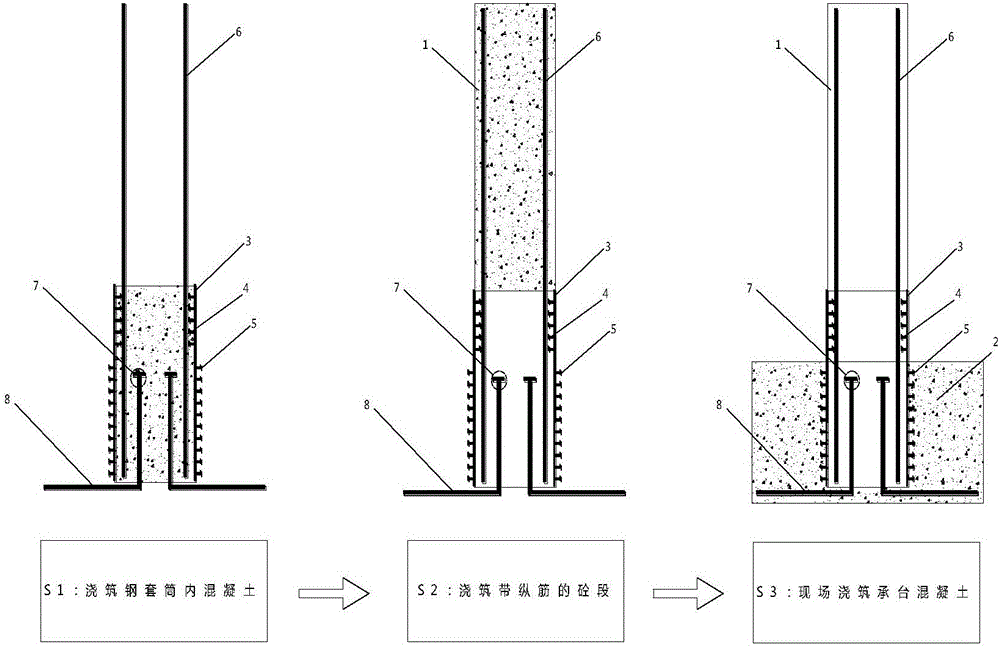

Bridge prefabricated hollow pier column post-poured connecting structure and construction method

InactiveCN104746422AGood connection performanceFast constructionBridge structural detailsFoundation engineeringEarthquake resistanceArchitectural engineering

The invention relates to a bridge prefabricated hollow pier column post-poured connecting structure. The bridge prefabricated hollow pier column post-poured connecting structure is characterized by comprising a prefabricated hollow pier column, a pier column foundation and a post-poured concrete pier wall, wherein connecting steel plates are pre-buried in the top surface of the pier column foundation, and an installation limiting block limiting the installation position of the prefabricated hollow pier column is arranged at the center of the pier column foundation; the prefabricated hollow pier column is fixed on the pier column foundation through the connecting steel plates; the prefabricated hollow pier column is wrapped by a steel protecting barrel, and a steel rib plate is arranged on the outer wall of the steel protecting barrel; the concrete pier wall is poured on the periphery of the bottom of the prefabricated hollow pier column, and the hollow position in the prefabricated hollow pier column is filled with a concrete filling core section formed by micro-expansion concrete. As the prefabricating process is adopted for the structure, the construction speed is high, connection strength is high, overall stress performance is good, anti-seismic performance is strong, and technological and economical benefits are good. The invention further discloses a construction method for the bridge prefabricated hollow pier column and foundation connecting structure.

Owner:柳州市建筑工程集团有限责任公司

Impact and vibration method for measuring natural frequency of bridge lower structure

InactiveCN1804563AEasy to operateEasy to testVibration measurement in solidsSubsonic/sonic/ultrasonic wave measurementFrequency spectrumEngineering

The invention relates to an impulse vibrating method for testing the bridge substructure natural frequency of vibration which uses avoirdupois weight to stroke the pier and tests the vibrating response of the pier to analyze and compute the natural frequency of vibration. It uses avoirdupois weight to stroke the pier top part and tests the speed and hastens response of the bridge. It usually dose multi-stroke and uses the recording wave mode superposition to dispel the noise to obtain the accurate response wave mode. It reads the response wave mode to do Fourier analysis to ascertain Fourier frequency spectrum and combines with the peak spectrum to ascertain the natural frequency of vibration of bridge.

Owner:BEIJING JIAOTONG UNIV

Device for performing incremental launching construction on bridge by using multi-roller sliding ways and construction method thereof

ActiveCN101818481AMeet the needs of climbingReduced longitudinal stiffness requirementsBridge erection/assemblyEngineeringSteel box girder

The invention discloses a device for performing incremental launching construction on a bridge by using multi-roller sliding ways and a construction method thereof. The device comprises a drawing part and a sliding part, wherein the drawing part comprises jack reaction supports, centre hole jacks, steel stranded wires, fixed end clampers, steel box girder reaction seats and an oil pump; the jack reaction supports are fixed on two sides at a predetermined position of a steel box girder of a structural pier; the centre hole jacks are arranged on the jack reaction supports; one end of each steel stranded wire is fixed with corresponding centre hole jack, while the other end is fixed on the corresponding steel box girder reaction seat through the corresponding fixed end clamper; and the sliding part comprises the multi-roller sliding ways fixed on the structural pier and a temporary pier in pairs, and further comprises a railway foundation and a steel guide way which are paved on a platform foundation, and a girder-transporting track run on the steel guide way. The device utilizes the mechanical characteristics of a roller structure so as to reduce requirements on the longitudinal rigidity of the temporary pier, satisfying needs on the climbing of vertical curves in the incremental launching process and greatly accelerating the incremental launching construction process.

Owner:BEIJING URBAN CONSTR ROAD & BRIDGE GROUP +1

Bridge and construction method thereof

ActiveCN102747677AImprove construction safetyShorten working timeBridge erection/assemblyButt jointArchitectural engineering

The invention relates to the field of construction, in particular to a bridge and a construction method thereof. The bridge and the construction method of the bridge are provided to overcome shortcomings in construction methods of existing bridges, a conventional sequence construction method of performing cast-in-place construction of a beam body after bridge pier construction is finished is changed into a parallel construction operation method of a bridge pier and the beam body. The bridge comprises the bridge pier and the beam body, and the beam body comprises a precast beam body and two side span connecting segments respectively in butt joint with the head end and the tail end of the precast beam body. The bridge pier comprises side piers supported on end sides of the side span connecting segments and main piers symmetrically arranged on two sides of the end of the precast beam body, and a load-bearing beam for supporting the precast beam body is connected between the two main piers positioned on two sides of the end of the precast beam body. The construction method has the advantages of achieving the effects of shortening operating time and reducing cost at once, being high in work efficiency, being not subjected to limitation of a conventional construction process, reducing high-altitude operation difficulty and dangerous sources and improving construction safety for workers.

Owner:CHINA RAILWAY NO 3 GRP CO LTD +1

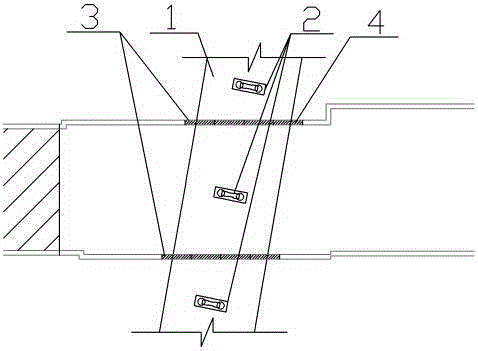

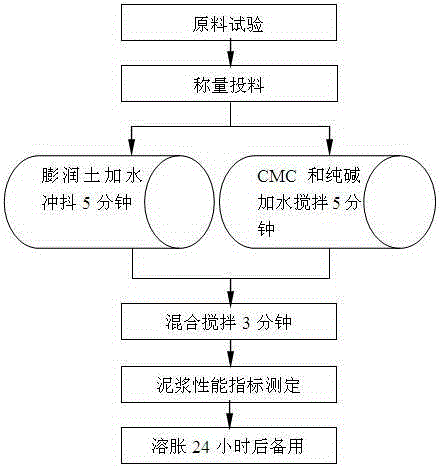

Construction method of underground continuous wall below viaduct

The invention relates to a construction method of an underground continuous wall below a viaduct. The method specifically includes the first step of staking out in a survey, the second step of guiding wall manufacturing, the third step of width adjustment of the underground continuous wall, the fourth step of slurry preparation, the fifth step of grooving construction, the sixth step of reinforcement cage manufacturing, hoisting and releasing, the seventh step of concrete grouting, the eighth step of repeatedly executing the fifth step, the sixth step and the seventh step till construction of a to-be-formed single-width undergrou nd continuous wall construction unit ends, and the ninth step of underground continuous wall joint processing. By means of the construction method, construction of the underground continuous wall can be fast completed while the quality and the quantity are guaranteed, and a viaduct pier will not be affected. Compared with a cast-in-situ bored pile construction method, the construction method has the beneficial effects that construction speed is high in the construction progress, stratum disturbance is small, and therefore the influences on the viaduct pier are small.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

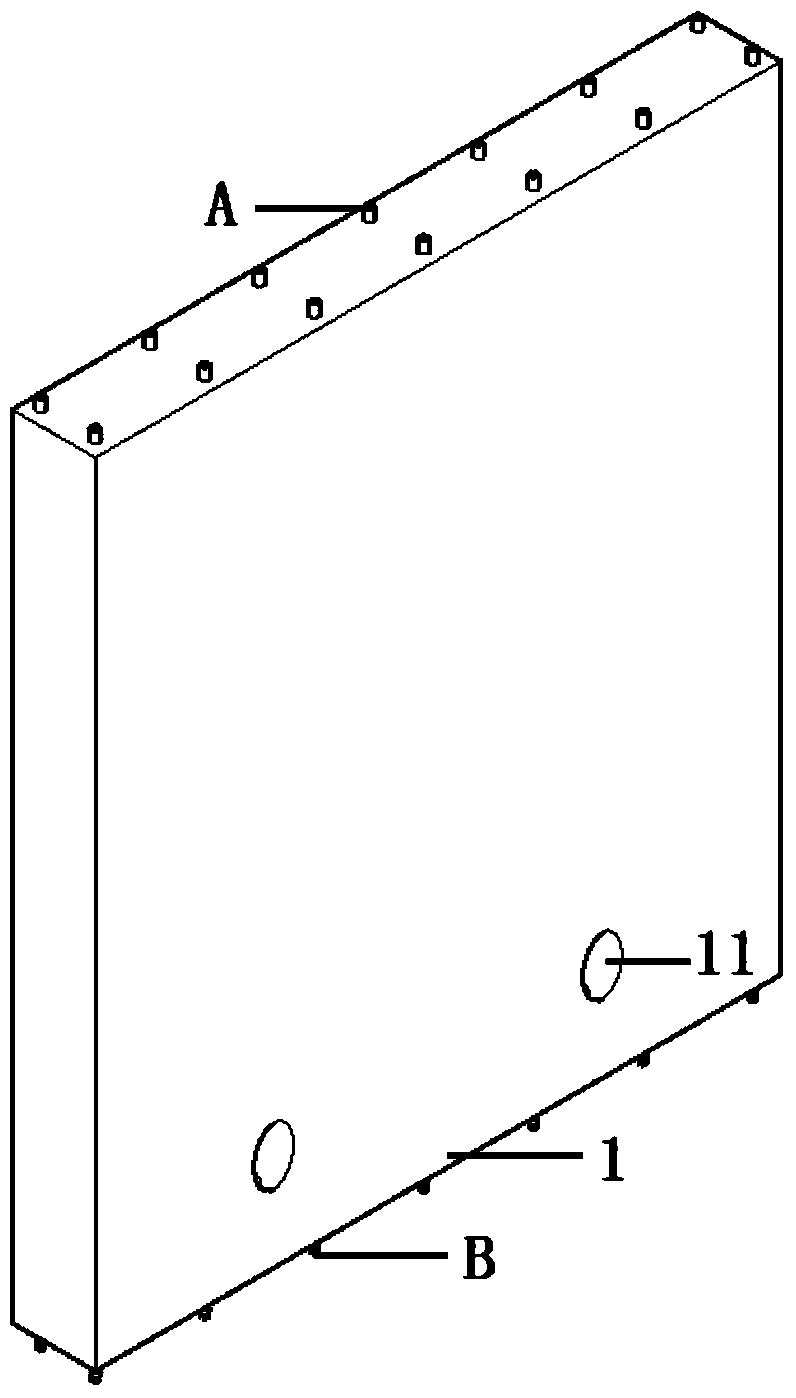

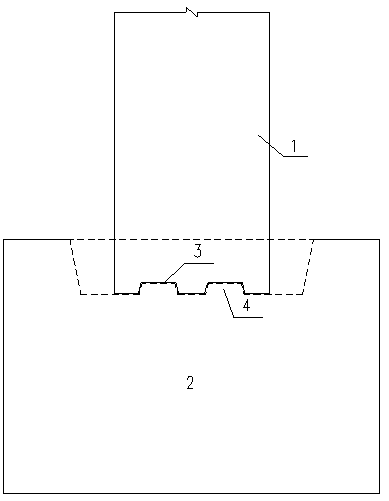

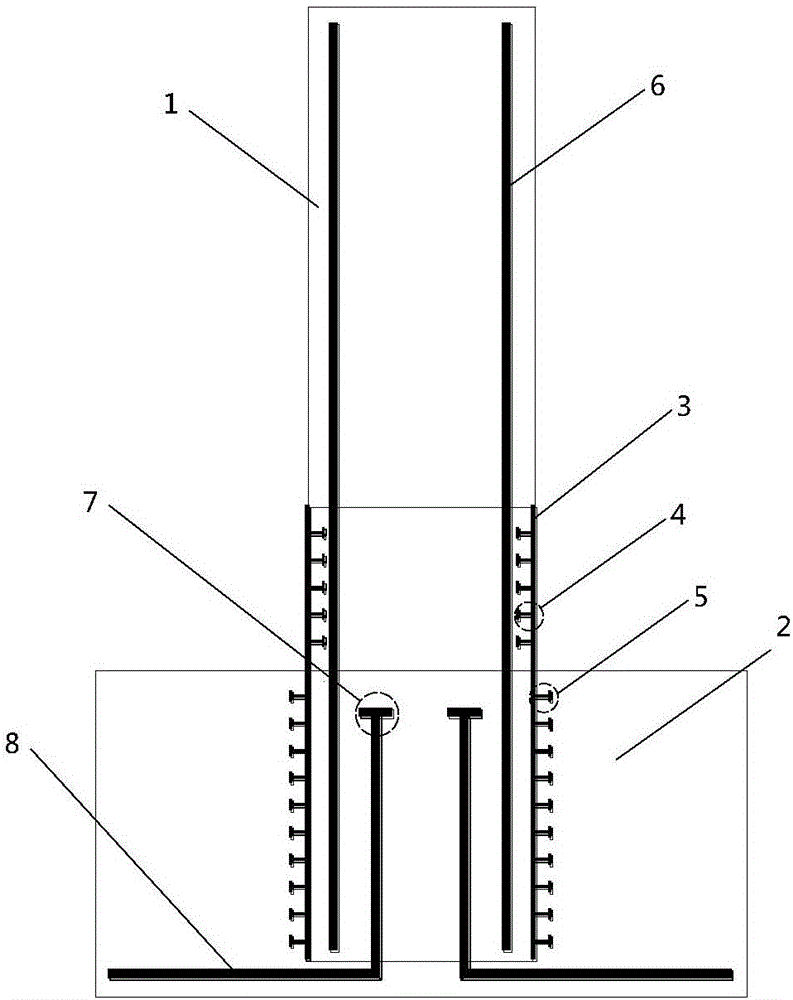

Bridge prefabricated hollow pier stud connecting structure and construction method thereof

ActiveCN104294753AReliable connection forceEasy constructionBridge structural detailsFoundation engineeringPre stressArchitectural engineering

The invention relates to a bridge prefabricated hollow pier stud connecting structure. The bridge prefabricated hollow pier stud connecting structure is characterized by comprising a pier stud foundation and a prefabricated hollow pier stud; the pier stud foundation is provided with an insertion groove for the prefabricated hollow pier stud, the cross section of the insertion groove is in the shape of a big-end-up trapezoid, and an installation locating block is arranged at the bottom of the insertion groove; the prefabricated hollow pier stud is arranged on the upper portion of the pier stud foundation, a T-shaped steel plate is arranged at the joint between the prefabricated hollow pier stud and the top face of an opening of the insertion groove, and gradienters are symmetrically arranged on rib plates of the T-shaped steel plate; a horizontal pre-stressed anchor cable is arranged in the pier stud foundation, a vertical pre-stressed anchor cable is arranged in the prefabricated hollow pier stud, and the hollow position of the prefabricated hollow pier stud is filled with micro-expansion concrete to form a concrete core segment. According to the bridge prefabricated hollow pier stud connecting structure, by the adoption of the precasting process, the construction speed is high, the mutual connection strength is high, the overall stress performance is good, and good technical and economic benefits are obtained. The invention further discloses a construction method of the bridge prefabricated hollow pier stud connecting structure.

Owner:ANHUI HIGHWAY ENG CORP

Automatic processing irrigation truck for concrete pier for bridge pier

InactiveUS20200114542A1Extend concrete transportation timeStable outputConcrete transportationServomotor componentsDrive shaftArchitectural engineering

The invention discloses an automatic processing irrigation truck for concrete pier for bridge pier, and includes a body plate, a bottom plate is fixed on the end surface of the body plate, and a storage block is fixed on the right side of the end surface of the bottom plate. A processing mechanism is provided in the storage block, and the processing mechanism includes a stirring cavity with an opening facing upward. The agitating chamber is used for containing concrete. The agitating chamber is provided with a rotatable drive shaft. Ten ten agitating rods are evenly fixed on the drive shaft. The device can be used for bridge pier during transportation. The processing of concrete, by means of stirring and spiral circulation, can not only make the processing fully, but also prevent the subsequent layering of the concrete, ensure the quality of the concrete, and use spiral transportation when needed.

Owner:ZHANG HUANGEN

Liftable self-propelled continuous pushing system for large-span steel box beam and construction method thereof

ActiveCN107151980AReduced midline deviationReduced quality damageHydro energy generationBridge erection/assemblyAuto regulationControl system

The invention discloses a liftable self-propelled continuous pushing system for a large-span steel box beam. The liftable self-propelled continuous pushing system for the large-span steel box beam comprises a automatically-positioning continuous pushing device, an automatic pier top slideway elevation adjusting device and a horizontal limiting and correcting device. By virtue of a highly automated control system, precise positioning and synchronous pushing are achieved, damage to the quality of a steel box structure is minimized, and a relatively good quality control effect is ensured. The invention further discloses a pushing construction method. Through arrangement of the automatically-positioning continuous pushing device and the automatic pier top slideway elevation adjusting device in a pushing construction technology, self-propelled advancement and precise positioning of the pushing device are achieved, lifting and mounting and dismounting operation procedures of mechanical equipment are saved, the operation of the construction technology is simplified, the technical difficulty is reduced, the on-site controllability is substantially improved, the construction time is shortened, the safety risks are reduced, and popularization and application are easy.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP OF THE FIFTH ENG +1

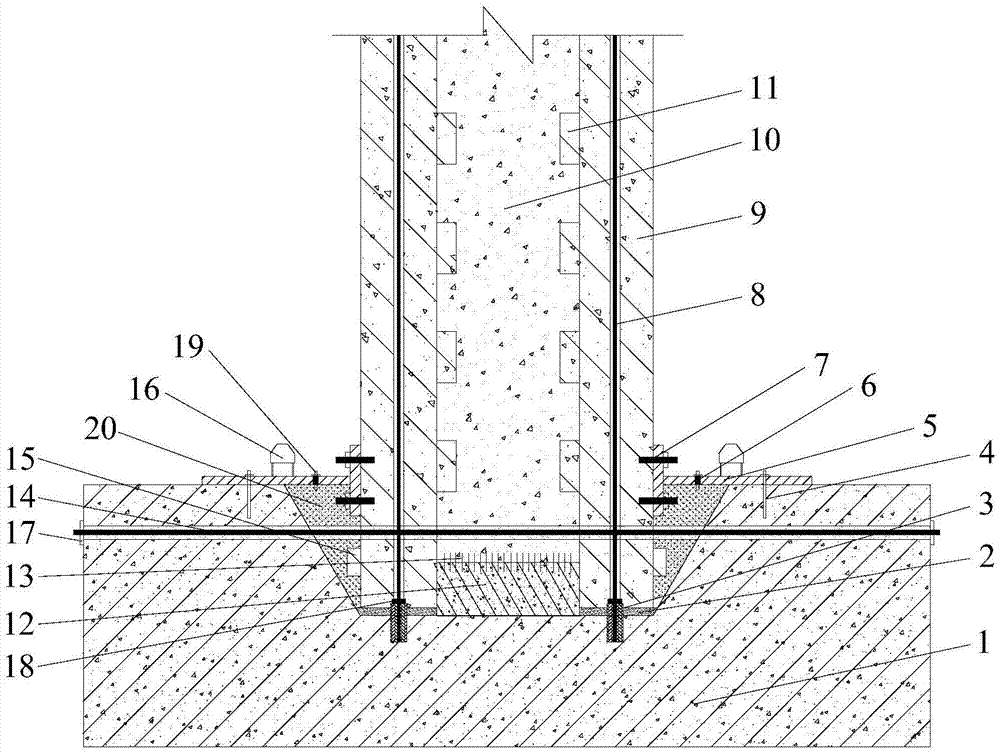

Joint connection mode for prefabricated spliced bridge pier with flexible layer arranged at bottom of pier and cushion cap and realization method thereof

The invention discloses a joint connection mode for a prefabricated spliced bridge pier with a flexible layer arranged at the bottom of the pier and a cushion cap and a realization method thereof. The flexible layer at the bottom of the prefabricated pier, longitudinal reinforcements extending out from the bottom of the prefabricated pier, pre-buried metallic bellows in the cushion cap, preserved grooves in the top face of the cushion cap and self-compaction high-strength micro-expansion grouting materials grouted through the metallic bellows are involved in the joint connection mode. An overlapped steel plate rubber layer is installed at the bottom of the bridge pier and formed with the bridge pier in a cast and prefabricated mode, the self-compaction high-strength micro-expansion grouting materials are grouted into the pre-buried metallic bellows in the cushion cap and overflow so that the grooves can be filled with the grouting materials, and then the longitudinal reinforcements extending out from the bottom of the prefabricated bridge pier are inserted into the pre-buried metallic bellows until the bottom of the prefabricated bridge pier is inserted into the grooves to be compacted. The construction mode is simple; the bridge pier is formed in a prefabricated mode, in this way, the on-site construction speed of projects is increased, and the quality of the projects is improved; due to the overlapped steel plate rubber layer arranged at the bottom of the prefabricated bridge pier, the ductility of the bridge pier can be obviously improved, and the damage degree of the plastic hinge region of a pier stud is reduced.

Owner:BEIJING UNIV OF TECH

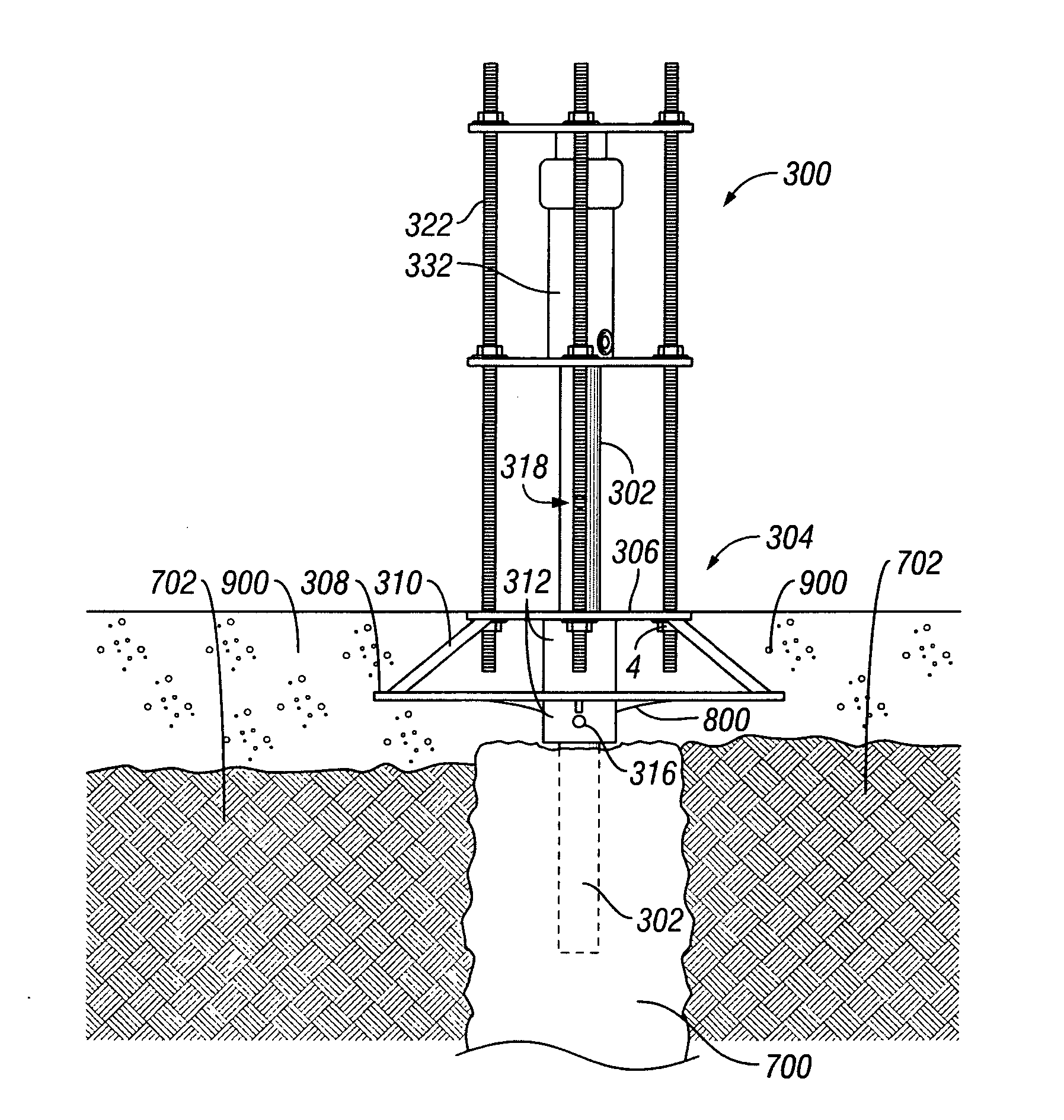

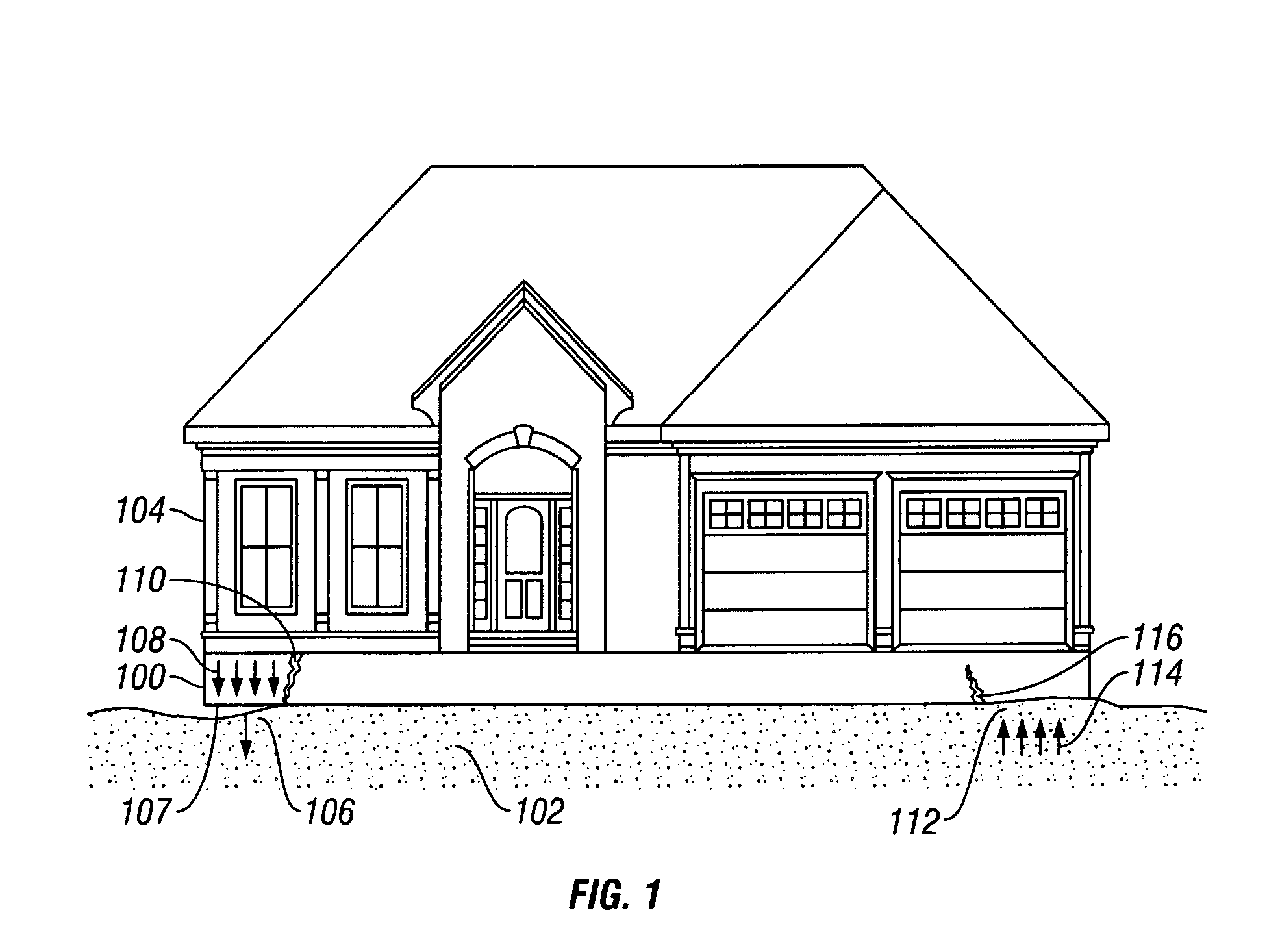

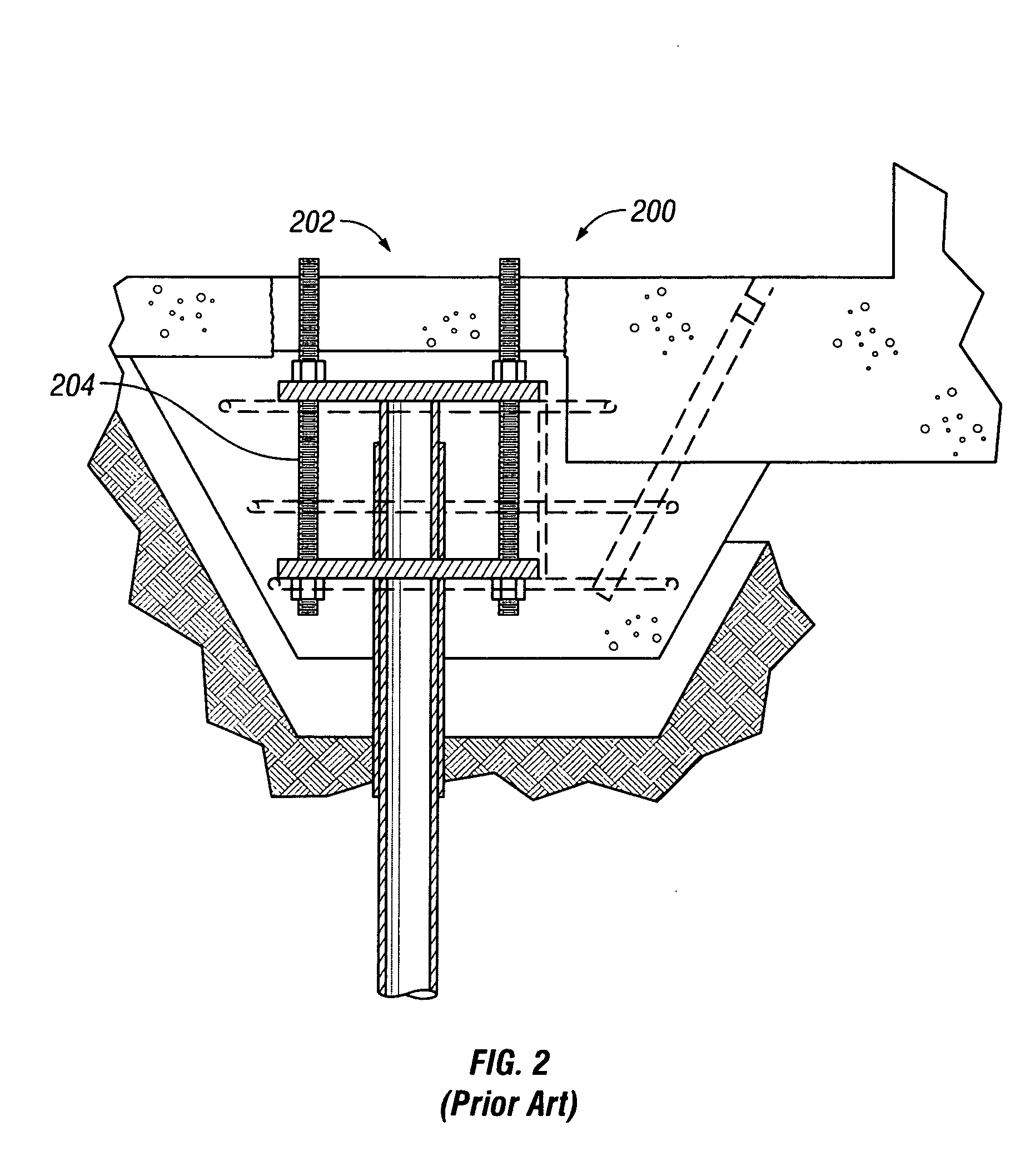

Foundation lifting assembly and method of use

A lifting assembly for raising, supporting, and stabilizing a foundation or other weighted member. An anchoring bracket, which is mounted to a piling or pier that has been driven into the ground below the location where the foundation is to be poured, is attached to a jacking assembly. The jacking assembly includes a bottom plate which rests on the upper end of the vertical support column, a hydraulic jack which rests on the bottom plate, and a top plate which is supported by the hydraulic jack. Concrete which will form the foundation is poured into the foundation mold and around the anchoring bracket which rests in said mold. The concrete foundation is allowed to cure. Support rods which are secured to the anchoring bracket and bottom and top plates, transfers the upward force generated by the hydraulic lift, from said top plate to said anchoring bracket, thus lifting the foundation to which the anchoring bracket is integrally attached.

Owner:ROBERTS WILSON D +1

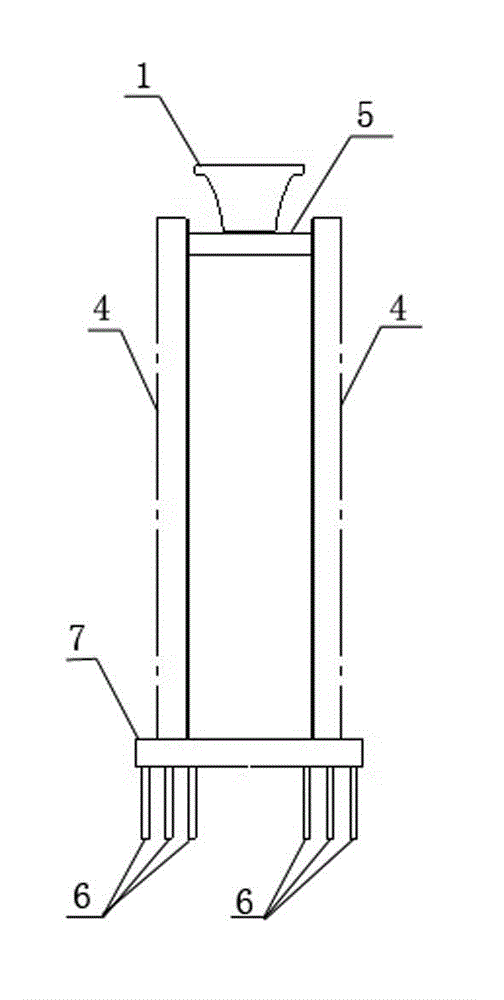

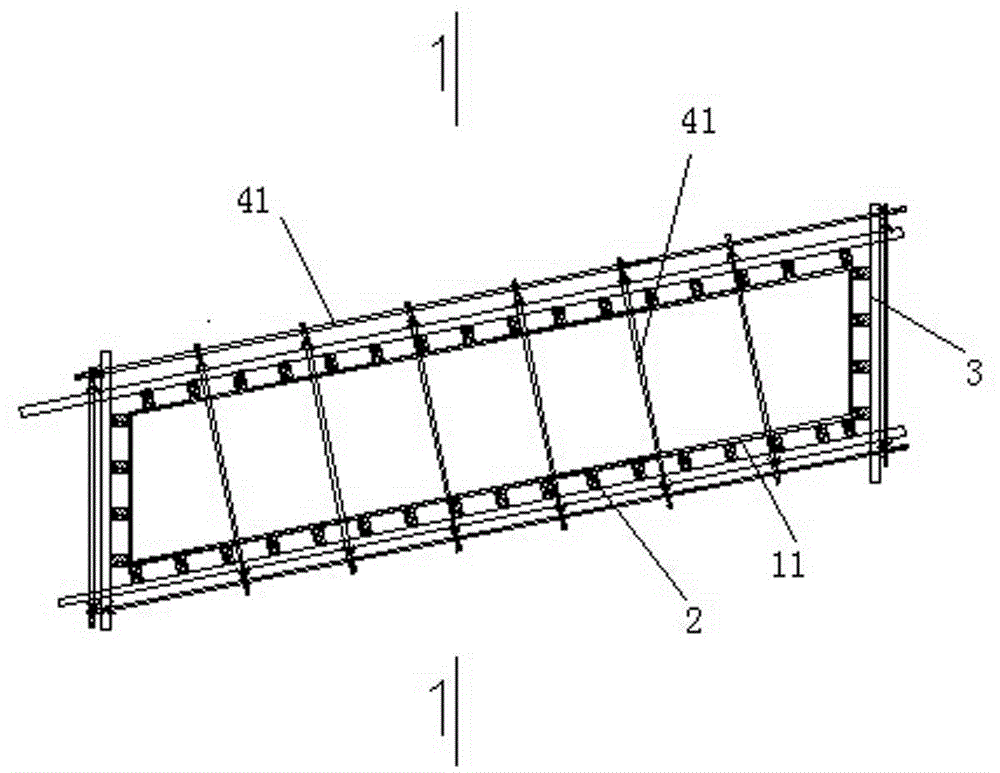

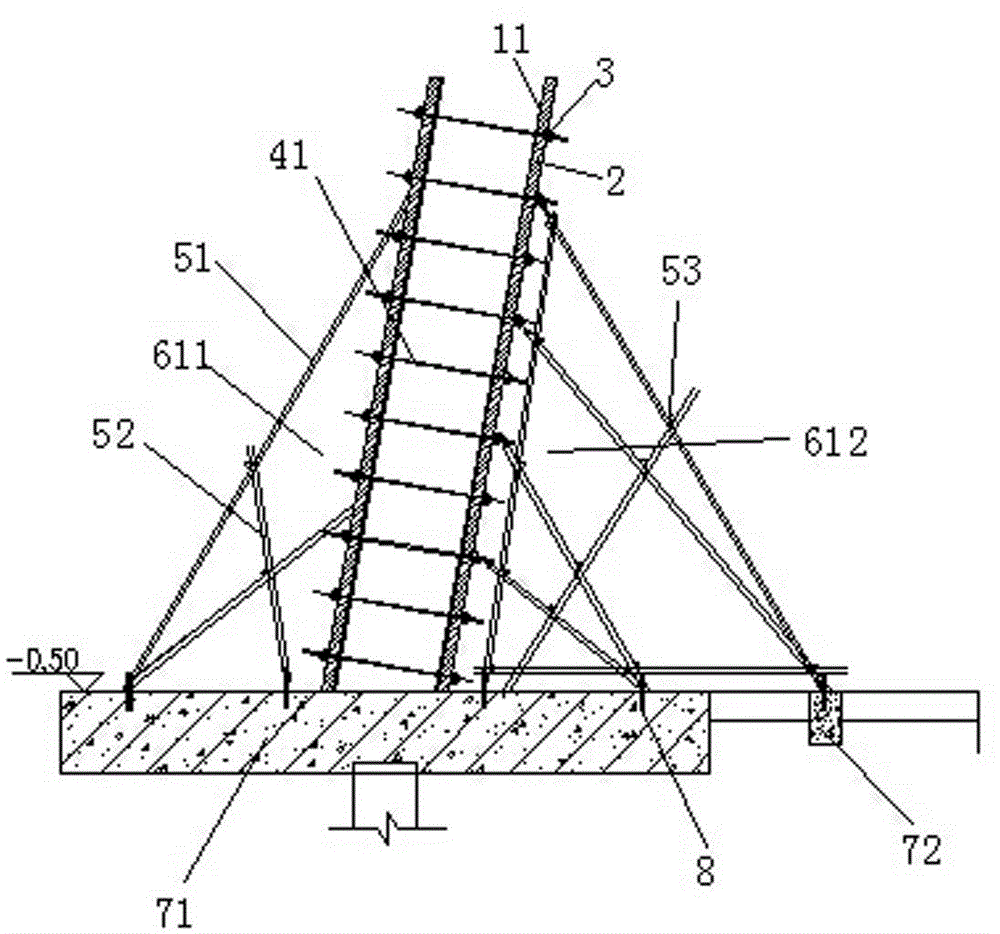

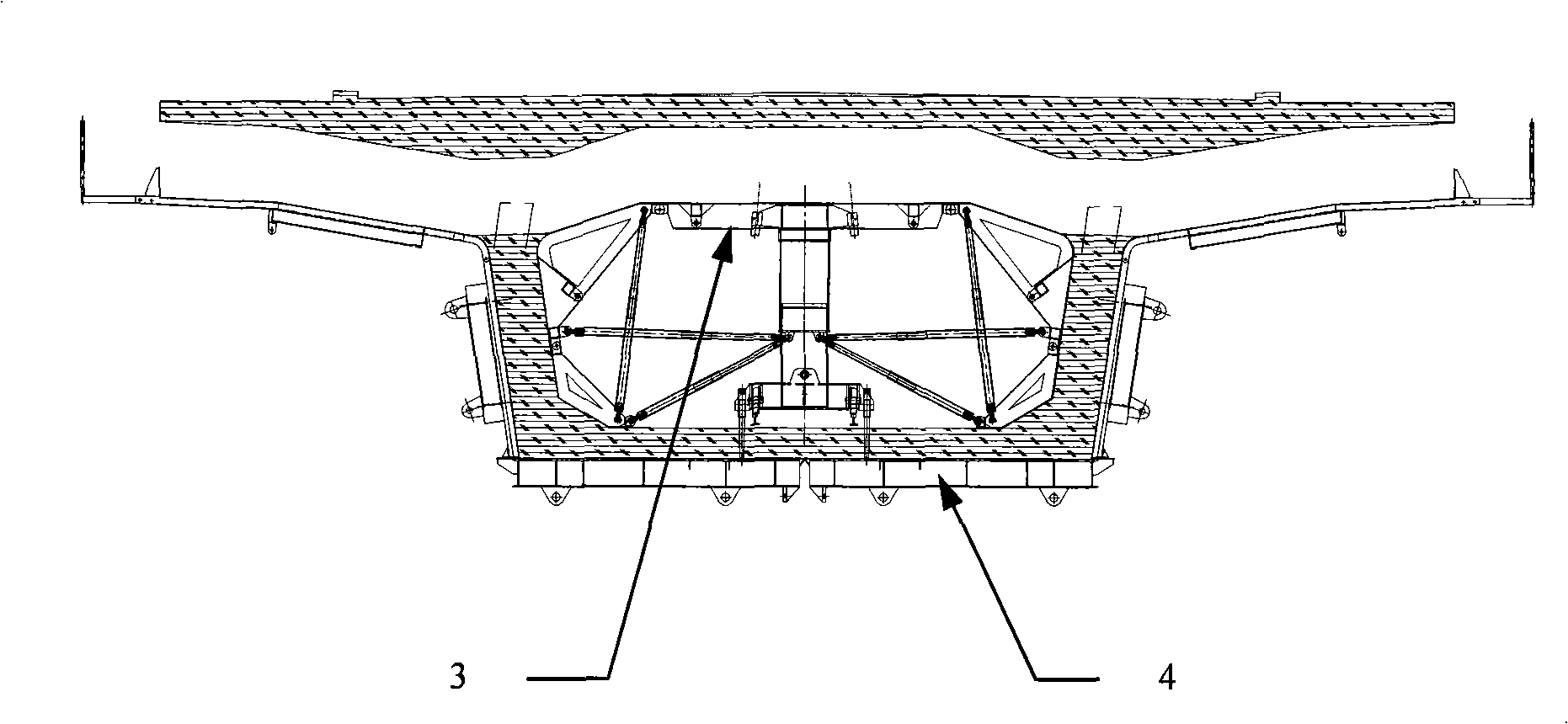

Method for mounting high pier, tower over-form construction reinforced bar and movable support thereof

InactiveCN101481944AEnsure safetyLow costForms/shuttering/falseworksBuilding reinforcementsRolloverReinforced concrete

The invention relates to a method for installing reinforcing steel for the rollover construction of a high pier and a tower and a moveable bracket thereof. The method for installing the reinforcing steel for the rollover construction of the high pier and the tower has the construction steps as follows: (1) according to the characteristics of the sections of the pier and the tower, a moveable bracket (2) matched with a pier body and a tower body is designed and processed, a movable bracket (3) and reinforcing steel (4) are installed, the moveable brackets are dismounted, a pier body moulding board or a tower body moulding board is installed, concrete (5)for the section of a pier body or the section of a tower body on which the reinforcing steel is bound is cast, hoisting equipment is used for installing the moveable brackets, and finally, the installation and the construction of the next section of reinforcing steel are carried out. The method for installing the reinforcing steel for the rollover construction of the high pier and the tower and the moveable bracket thereof greatly reduce the construction cost and the security risk, and have obvious efficiency of accelerating the engineering speed. The invention provides the method for installing the reinforcing steel and the moveable bracket, which are safe, reliable, economic and convenient, for the construction of the high pier and the tower with the constant section and variable section reinforced concrete used for a suspension bridge, a cable stayed bridge, a continuous rigid frame bridge, a continuous girder bridge and bridges of other types.

Owner:SICHUAN ROAD & BRIDGE GRP

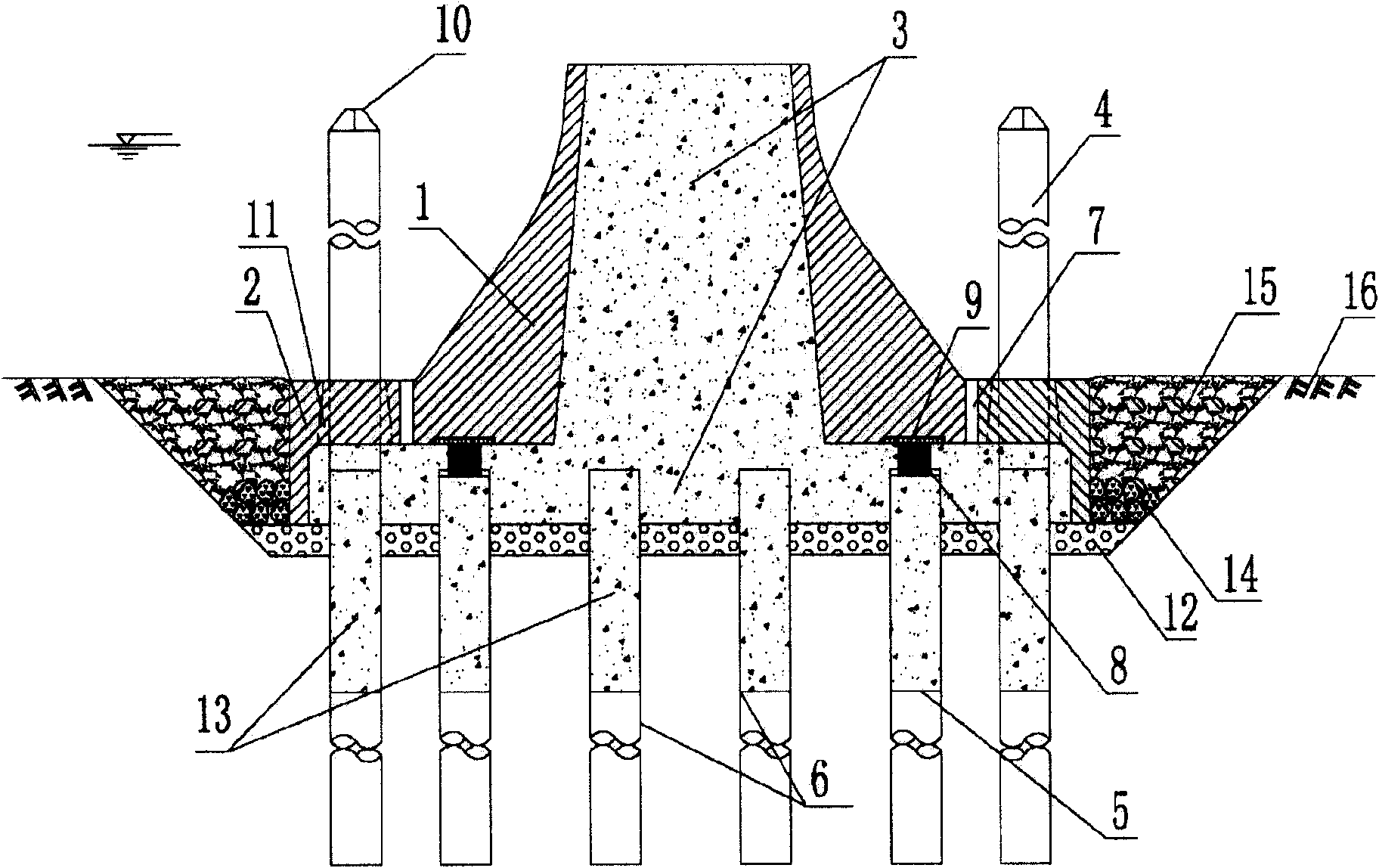

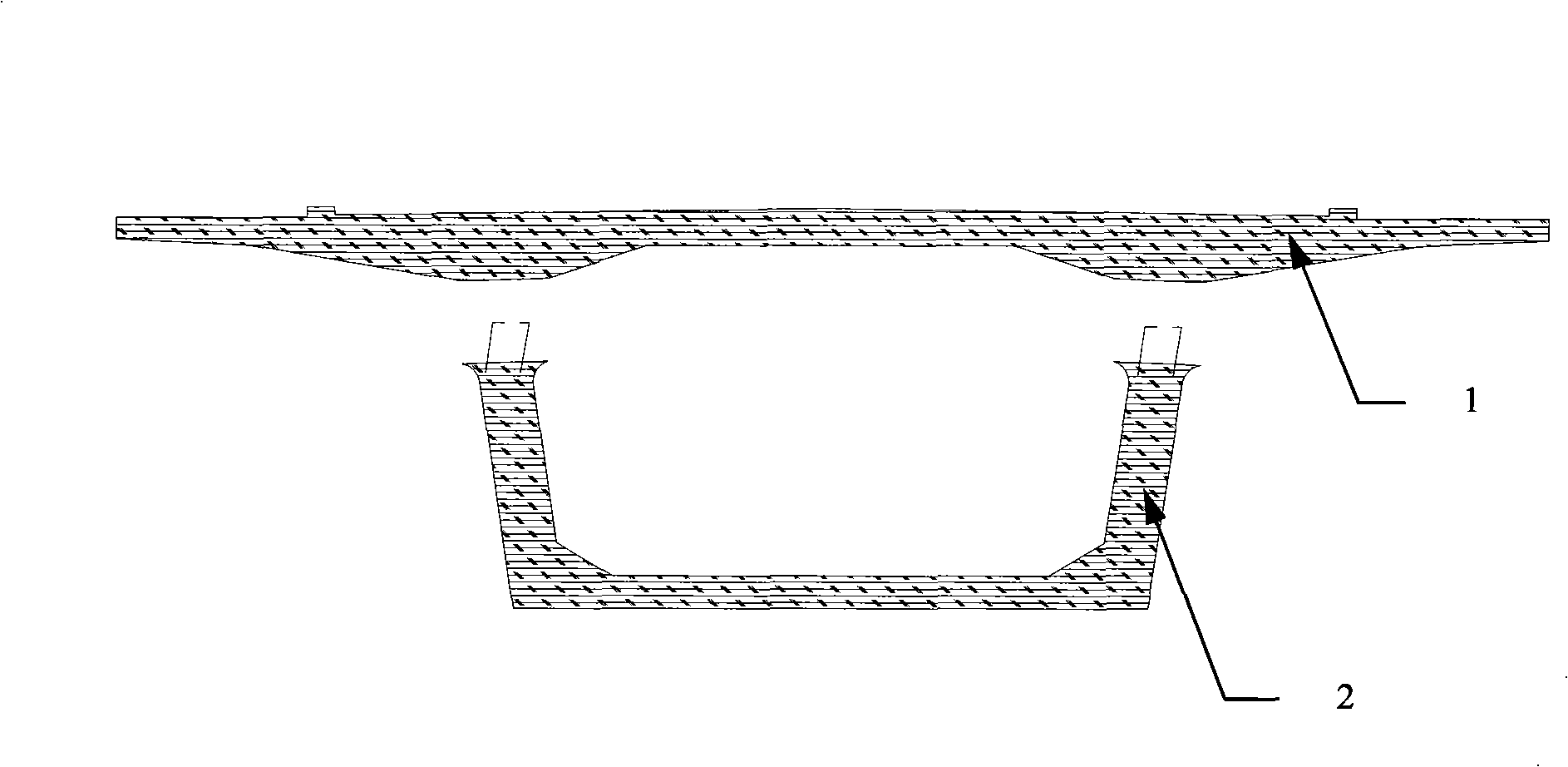

Bridge prefabricated foundation and bed-burying method thereof

InactiveCN101962956AReduce water resistanceGuarantee the construction qualityBridge structural detailsFoundation engineeringPilot holeUnderwater

The invention discloses a bridge prefabricated foundation and a bed-burying method thereof. The bridge prefabricated foundation consists of a bridge lower part pier body, an undercut bearing platform and a cavity formed by enclosing the pier body and the bearing platform. The undercut bearing platform is reserved with a guide hole, an exhausting recharging hole and a supporting liner plate. The bed-burying method comprises the following steps of: integrally prefabricating the lower part pier body and the bearing platform in a factory; excavating a foundation ditch, and then paving a crash pad layer; and sinking a pile which passes through the crash pad layer and is inserted into a sea (or river) bed. A range of 5 to 30 m below a designed height mark of the top of the pile and is filled with core filling concrete, and a supporting pile and a bearing pile are cut to the designed height mark underwater. The prefabricated foundation is positioned through a guide pile, and is placed on the supporting pile which is provided with a supporting component. The guide pile is cut underwater, and the cavity is poured with concrete to ensure that the prefabricated foundation is firmly connected with the pile. The top surface of the lower part pile body of the bridge prefabricated foundation must be higher than water surface and higher than a splash zone. The bearing platform of the prefabricated foundation is completely buried into the sea (or river) bed to ensure that the water resistance ratio can be reduced, the construction period can be shortened, the influence on the environment can be reduced, and the engineering cost is low.

Owner:CCCC HIGHWAY CONSULTANTS

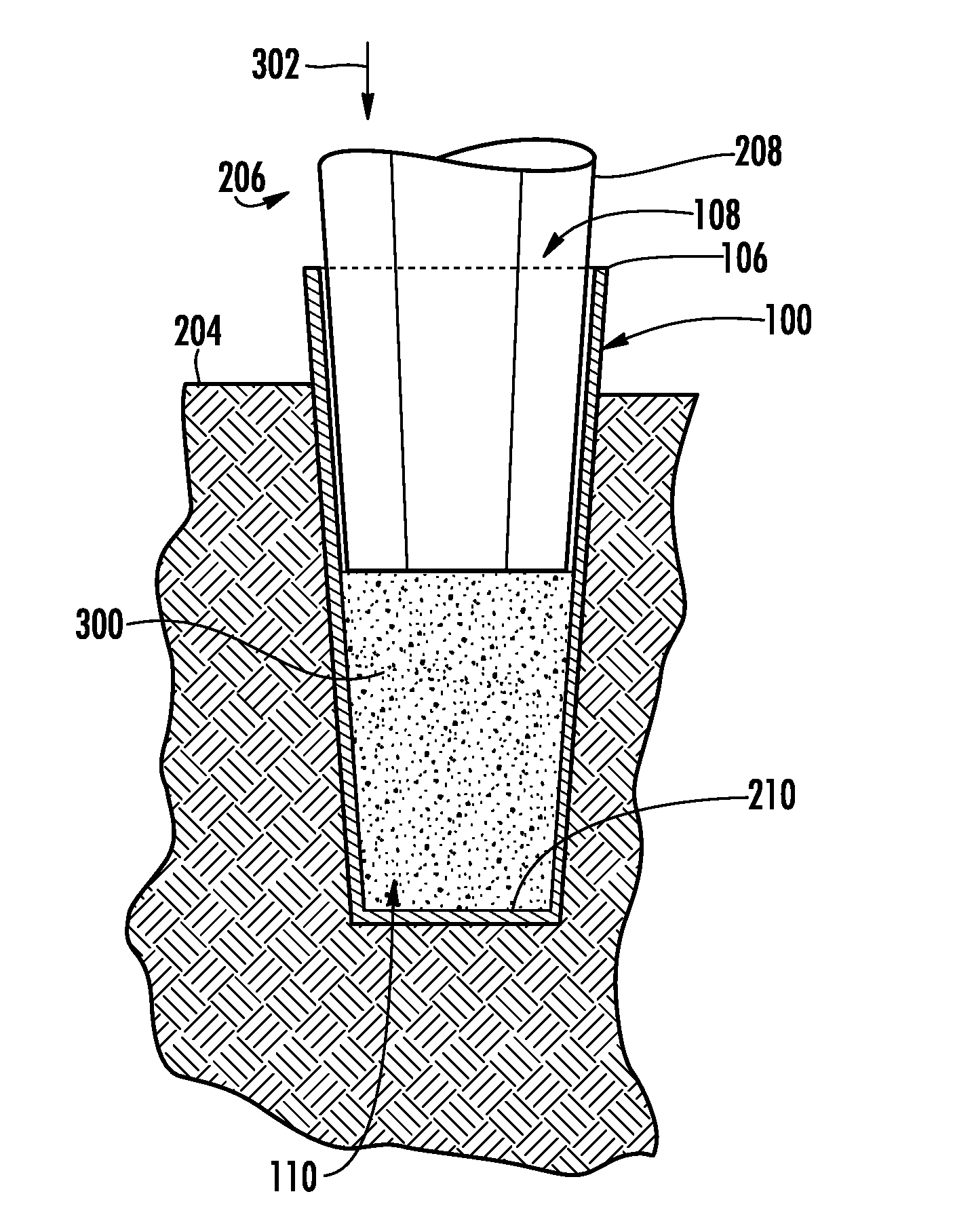

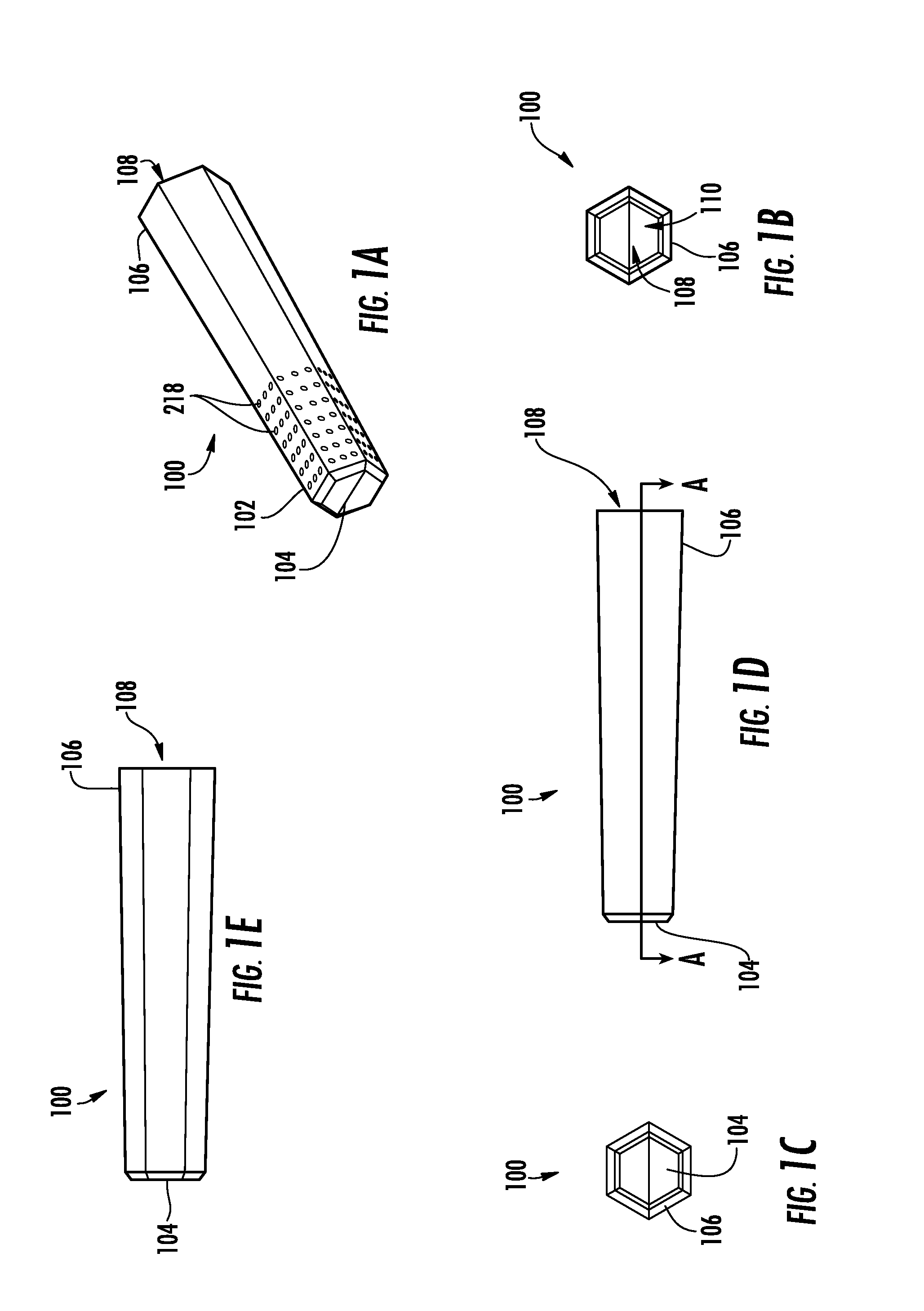

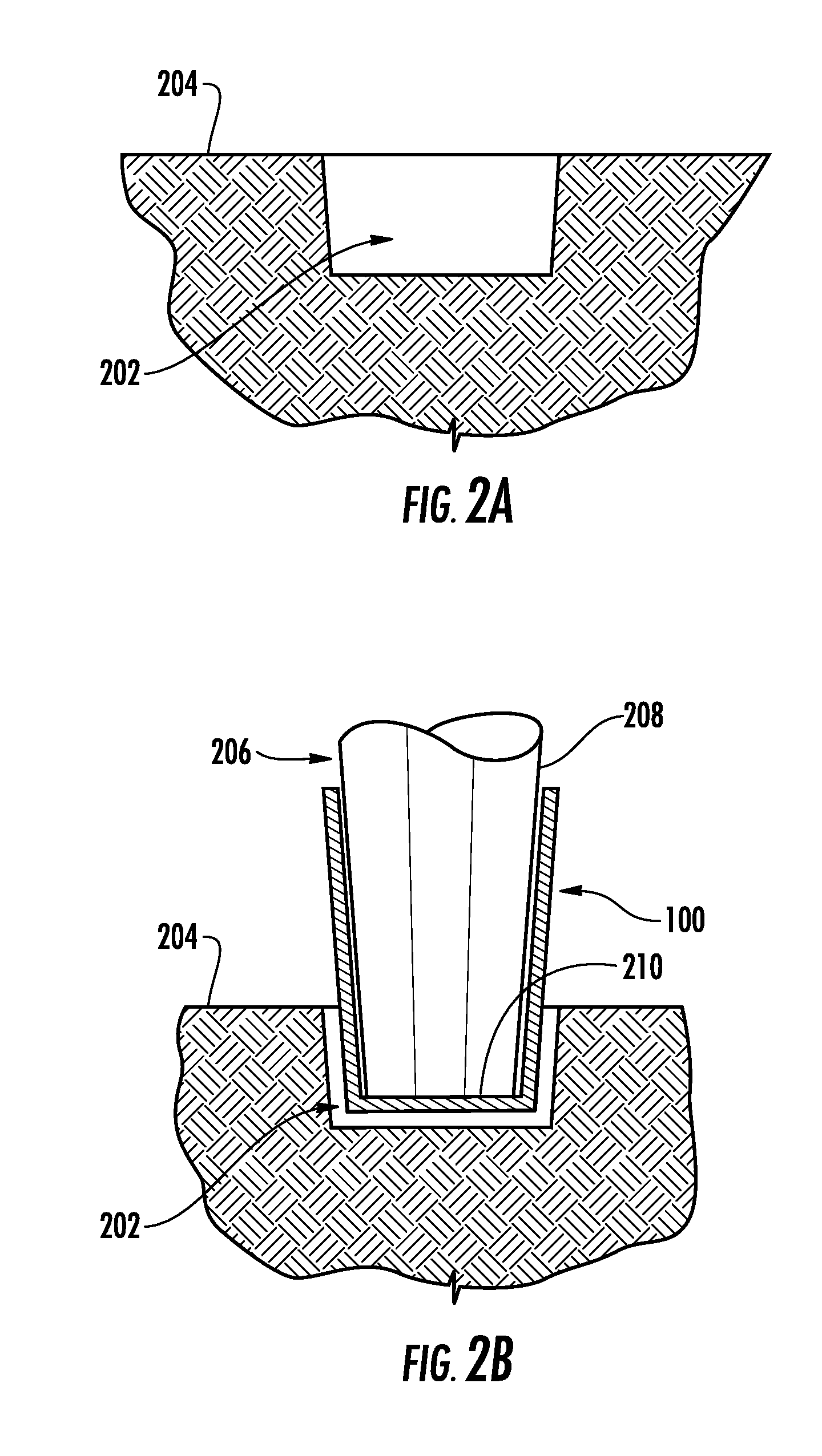

Extensible Shells and Related Methods for Constructing a Support Pier

Extensible shells and related methods for constructing a support pier are disclosed. A shell can define an interior for holding granular construction material and define an opening for receiving the granular construction material into the interior. The shell can be flexible such that the shell expands when granular construction material is compacted in the interior of the shell. A method may include positioning the shell in the ground and filling at least a portion of the interior of the shell with the granular construction material. The granular construction material may be compacted in the interior of the shell to form a support pier.

Owner:GEOPIER FOUND

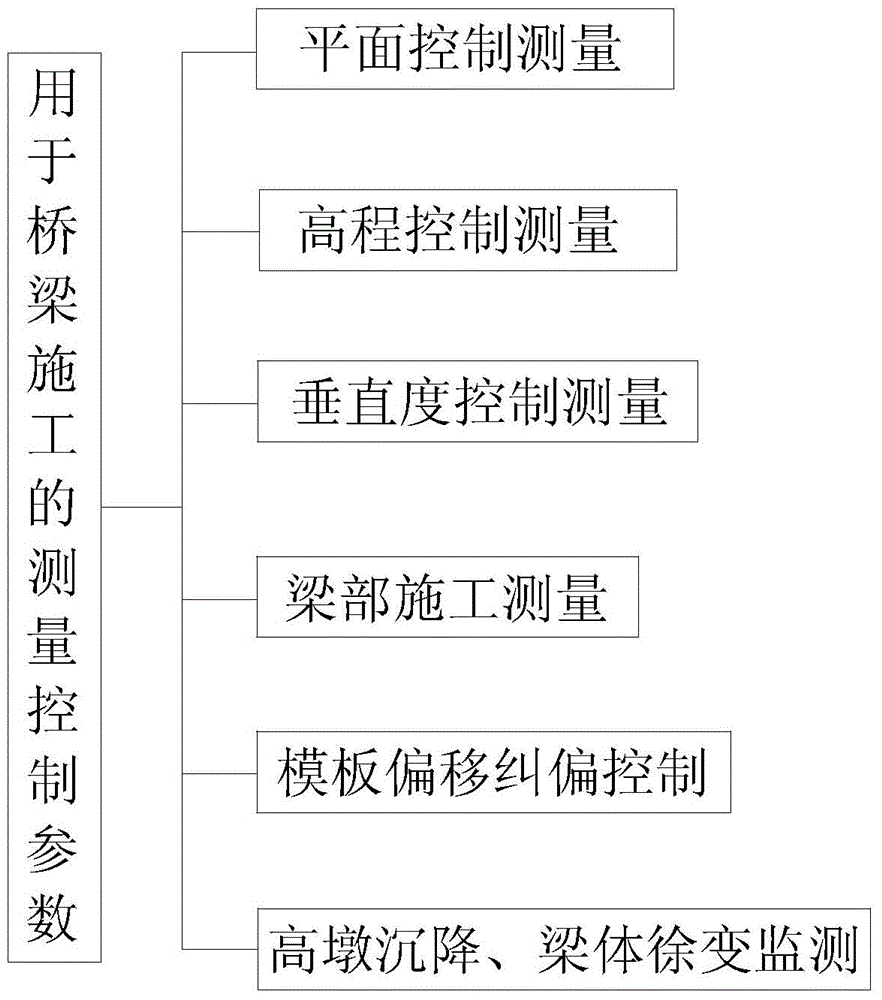

Measurement and control method for bridge construction

InactiveCN104457716AReduced measurement accuracyGuaranteed accuracySurveying instrumentsHeight/levelling measurementArchitectural engineeringControl theory

The invention discloses a measurement and control method for bridge construction. The measurement and control method comprises the measurement on the following parameters: plane control and measurement, elevation control and measurement, perpendicularity control and measurement, beam part construction measurement, template offset correction control, high pier sedimentation and beam body creep monitoring. By using the measurement and control method disclosed by the invention, all corresponding control measures and methods are proposed by analyzing all factors influencing the construction measurement accuracy, so that the influence of human factors on the construction accuracy is scientifically and effectively reduced, and the setting-out accuracy is effectively guaranteed; and the construction method is simple and reliable and the adaptability is wide.

Owner:中铁建生态环境有限公司

Hanging bracket supporting system of side-span cast-in-place section and implementation method thereof

ActiveCN103485283AReduce adverse effectsReduce dosageBridge erection/assemblyTerrainBridge engineering

Common methods of construction of side-span cast-in-place sections of long-span continuous bridges of bridge engineering can be summarized into a floor stand method, an attached support method, a hanging bracket method and the like. Due to the limits of terrain conditions, the overhang length and the carrying capacity of a cradle in the floor stand method, the attached support method, the cradle hanging bracket method, the length of a side-span cast-in-place section is often reduced to facilitate construction, and further the bridge structure is not reasonable. The invention provides a hanging bracket supporting system of a side-span cast-in-place section and an implementation method thereof, the hanging bracket supporting system of the side-span cast-in-place section and the implementation method thereof are free from the restrictive conditions of the terrain conditions, the overhang length and the carrying capacity of the cradle and are applicable to the construction of relatively long side-span cast-in-place sections. Besides, according to the hanging bracket supporting system of the side-span cast-in-place section and the implementation method thereof, the problems of small space and insufficient height between a bridge body of a cast-in-place section and a transitional pier are effectively solved, a supporting method of a hanging bracket between a cantilever end and a transitional pier top is provided, adverse effects of the cantilever end on the concrete of the side-span cast-in-place section due to circulating vibration of sunshine temperature differences can be avoided, construction quality control can be facilitated, the material utilization amount is small, and a feasible approach is provided for improvement on side-to-middle span ratio of bridges.

Owner:CHINA FIRST HIGHWAY ENG

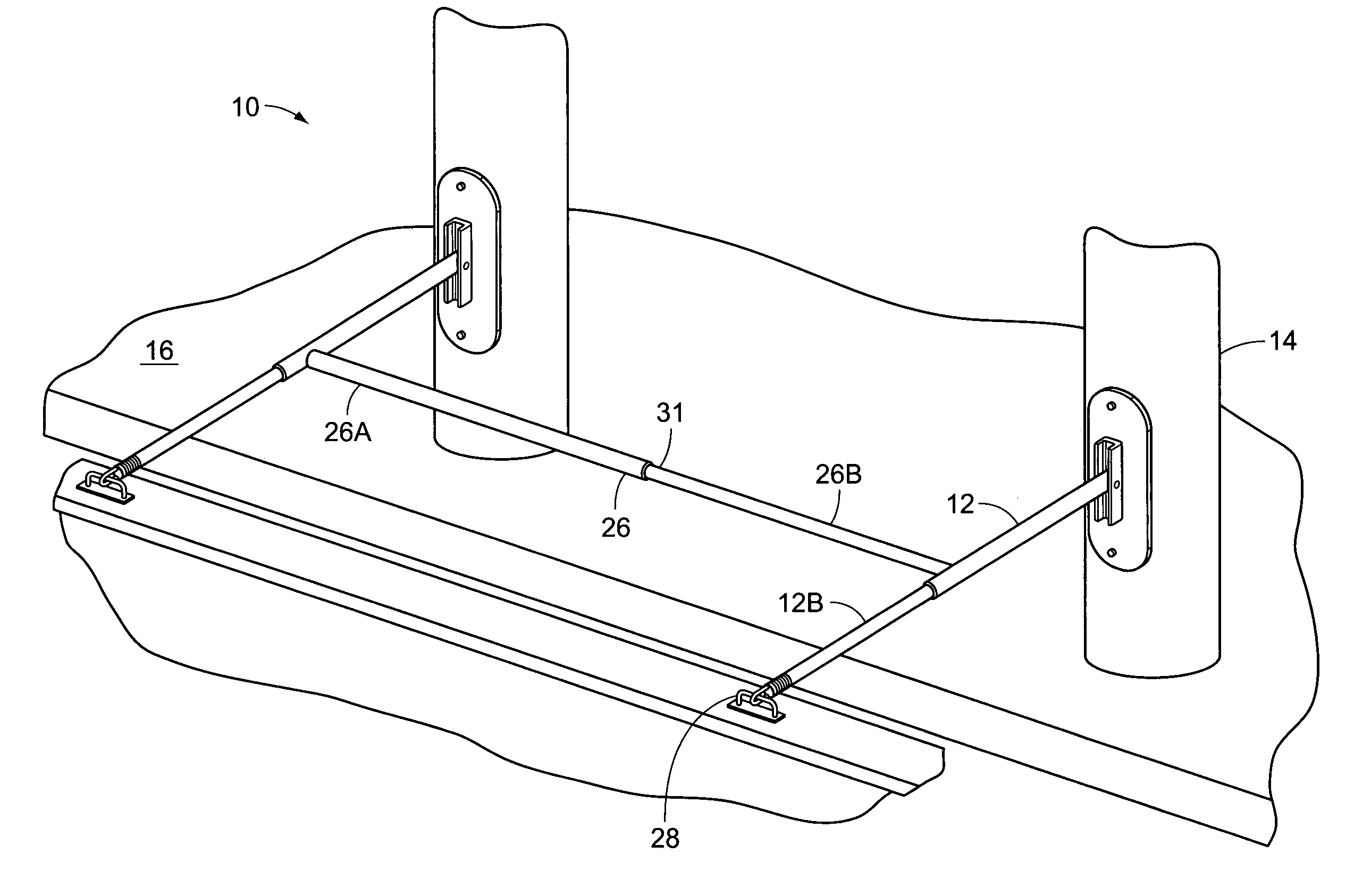

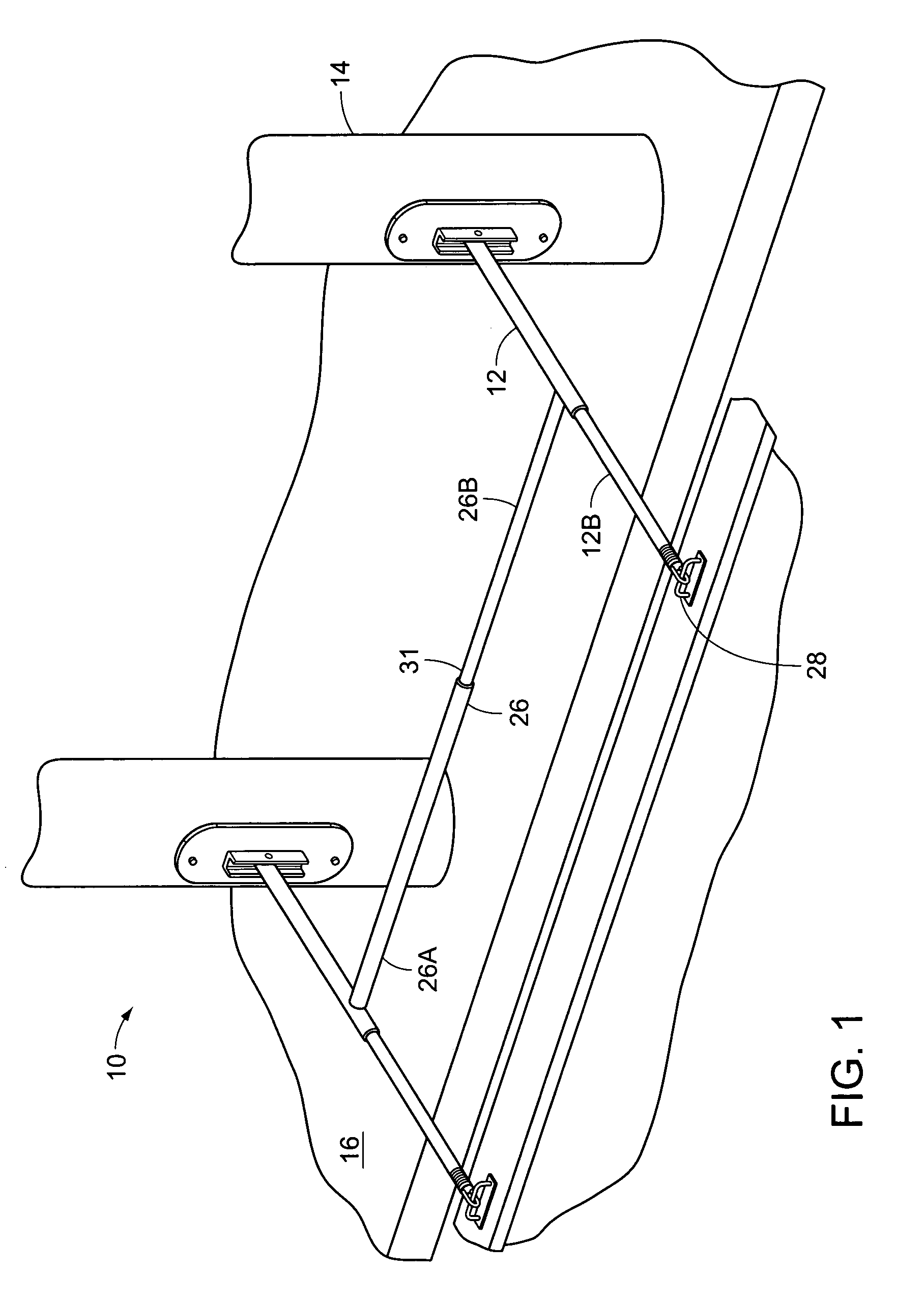

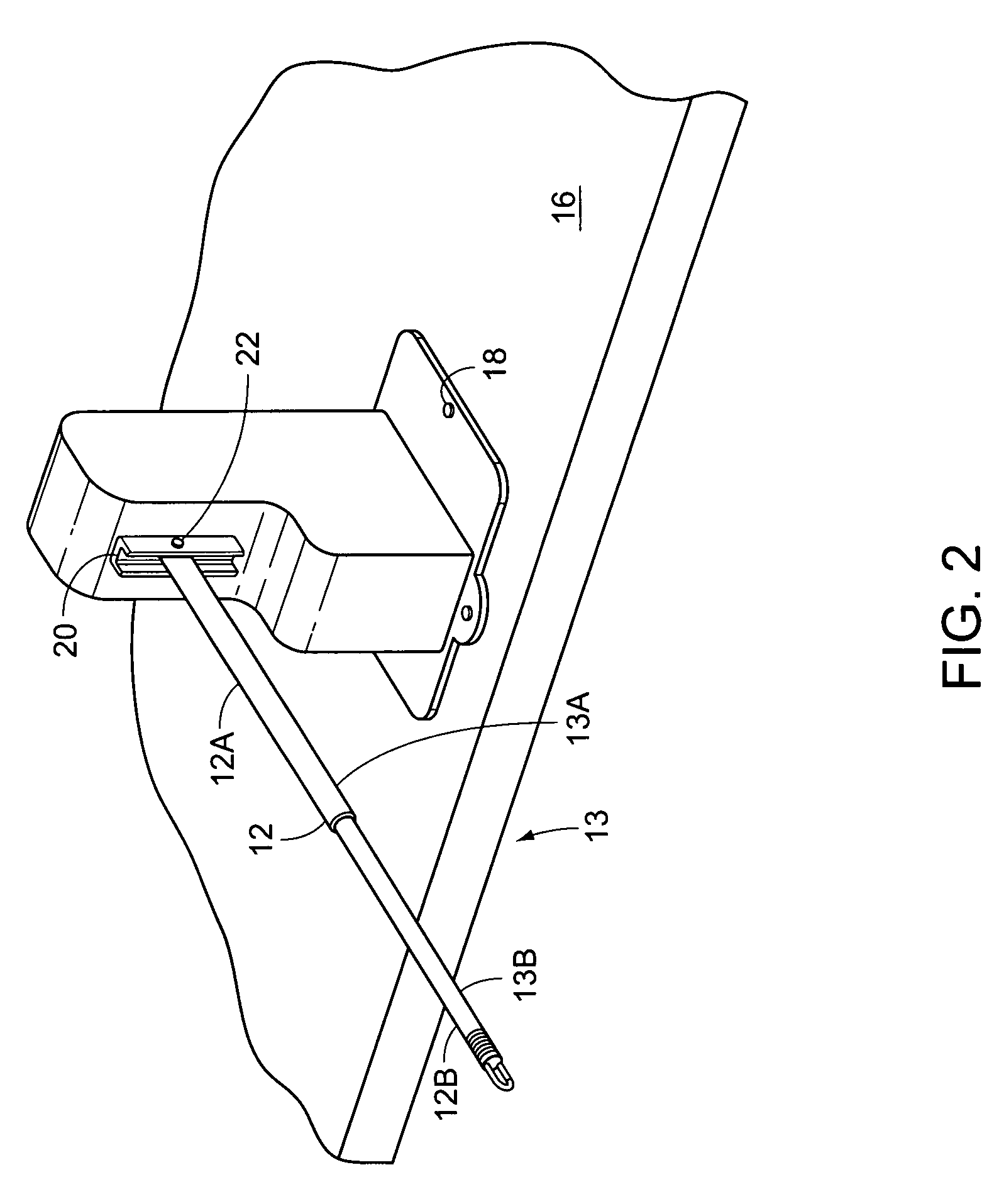

Docking apparatus which secures a boat to a pier

InactiveUS6962122B1Prevent movementGood adhesionWaterborne vesselsShipping equipmentMechanical engineeringOn board

This invention is a docking apparatus for small boats which secures the boat to a pier without use of ropes and fenders having two dock mounts securely affixed spaced apart to the pier and each having an elongated sleeve. Two docking poles each include a first end and a second end, and each have an extension arm which telescopes outwardly to reach the boat. The first ends are inserted within the elongated sleeve of the two docking mounts the second ends have a spring loaded snap clamp having an insertion opening. A stabilizer bar is secured centrally between the two docking poles. A pair of boat mounting cleats are attached to the boat and each have a hole. The insertion openings of the spring loaded snap clamps attach securely to the holes of the boat mounting cleats.

Owner:BOULDIN JR ALFRED

Horizontal rotating construction method for steel truss beam bridge

ActiveCN104652290AReasonable structureClear forceTruss-type bridgeBridge erection/assemblyReinforced concreteConstruction engineering

The invention discloses a horizontal rotating construction method for a steel truss beam bridge. The horizontal rotating construction method comprises the following steps: constructing a reinforced concrete pile foundation, a cushion cap, a slideway, a main pier and a cap beam in a rotating system by using a conventional construction technology, and mounting a rotating spherical hinge as a core part for rotating; mounting an upper rotating plate on the slideway for construction; constructing the main pier and the cap beam; mounting a permanent support saddle of the main pier; preparing safety measures before rotating; determining a weight scheme before rotating; preparing a jack; rechecking before rotating; performing rotating construction operation. Compared with other processes, the horizontal rotating construction method for the steel truss beam bridge, provided by the invention, has the advantages of high construction speed and low construction cost. The construction of a lower structure can be synchronously finished in the manufacturing process of a steel beam in a factory; the hoisting operation of symmetrical cantilevers can be performed when a spliced site is hardened to reach the traveling strength of cranes like crawler crane; main expenses are rental expenses of the cranes, so the cost is reduced.

Owner:NANTONG ROAD & BRIDGE ENG CO LTD +1

Precast concrete member connected by straight thread and pier head lock anchor grouting sleeve, and method for assembling same

The invention relates to a precast concrete member connected by a straight thread and a pier head lock anchor grouting sleeve, and a method for assembling the precast concrete member, belonging to the technical field of constructional engineering assembly concrete structures. The method of connecting by the straight thread and the pier head lock anchor grouting sleeve is adopted; one end of a reinforcing steel bar is processed into the straight thread (6), and the other end of the reinforcing steel bar is processed into a pier head (5); the inner wall of the end with smaller diameter of a connecting sleeve is processed into a thread (9) which is connected with the reinforcing steel by the straight thread (6) and is used for transmitting force; the inner wall of the end with larger diameter of the connecting sleeve is processed into a thread (16) which is connected with a matched plug ring (10) by an external thread (17); after grouting is carried out through a grouting hole, the original way that the tensile force of the reinforcing steel bar of a prefabricated part connected by grouting is transmitted mainly by bonding is changed by the reinforcing steel bar through lock anchor extrusion and bonding force transmission among the pier head of the reinforcing steel bar, the plug ring, grouting material and the sleeve. The safety and economical efficiency of the connection of the novel precast concrete member are improved.

Owner:CHINA CONSTR ENG DESIGN GROUP +1

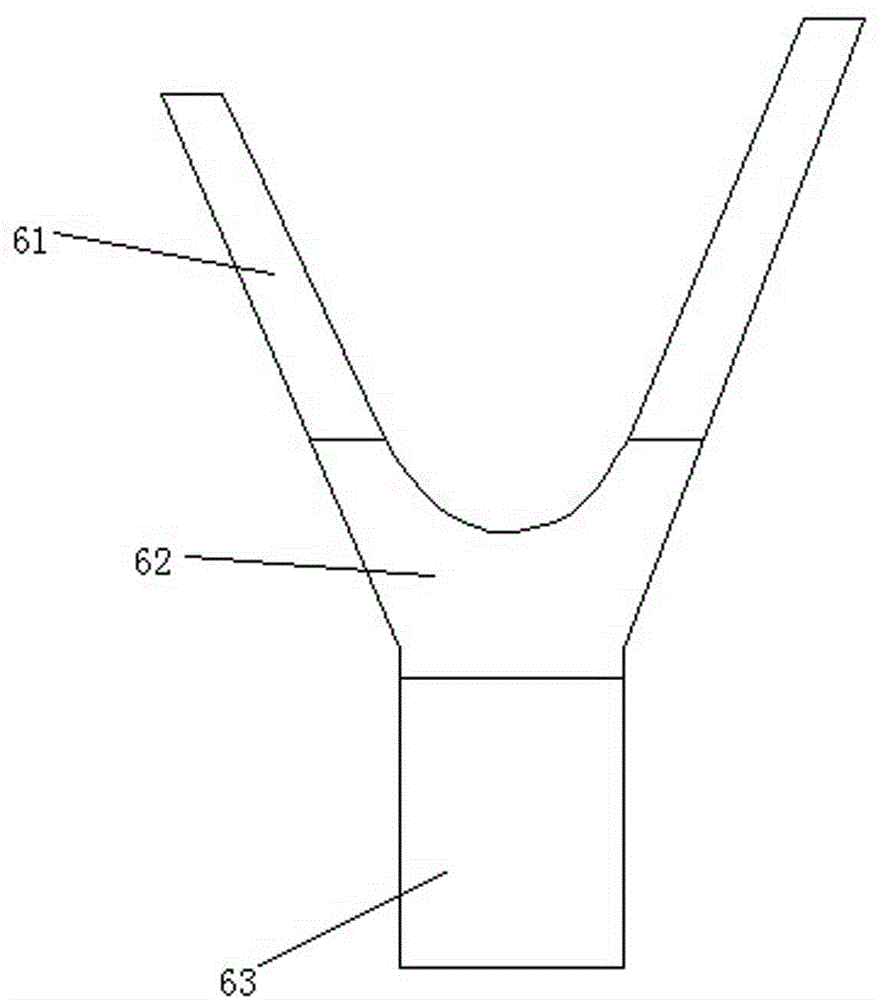

Y-type cast-in-place concrete column formwork system and construction method thereof

ActiveCN104088461AEasy positioning controlSolve the chamfering problemForms/shuttering/falseworksFloor slabArchitectural engineering

The invention discloses a Y-type cast-in-place concrete column formwork system. The formwork system is composed of a column root formwork system, a column handle formwork system and a branch column formwork system and comprises multi-layer plates, back edges, column hoops, split bolts, diagonal supporting rods, diagonal pull rods, horizontal pull rods and the like, and all the components are connected to form a whole to be fixedly supported on a floor slab or a plain concrete pier. The invention further discloses a construction method for the Y-type cast-in-place concrete column formwork system. The construction method includes the steps of model designing, sample machining, formwork manufacturing, hoisting, formwork and support reinforcing, positioning control and precision adjusting; when a formwork is installed at the proper position, construction of the column root formwork system is carried out first, then construction of the column handle formwork system is carried out and ultimately construction of the branch column formwork system is carried out. Y-type positioning control is facilitated due to the fact that corner angles are reserved; a wood formwork system is easy to splice and is suitable for structural components with various models, the forming effect of the components meets design requirements, and the manufacturing cost of the wood formwork system is low.

Owner:北京城建建设工程有限公司

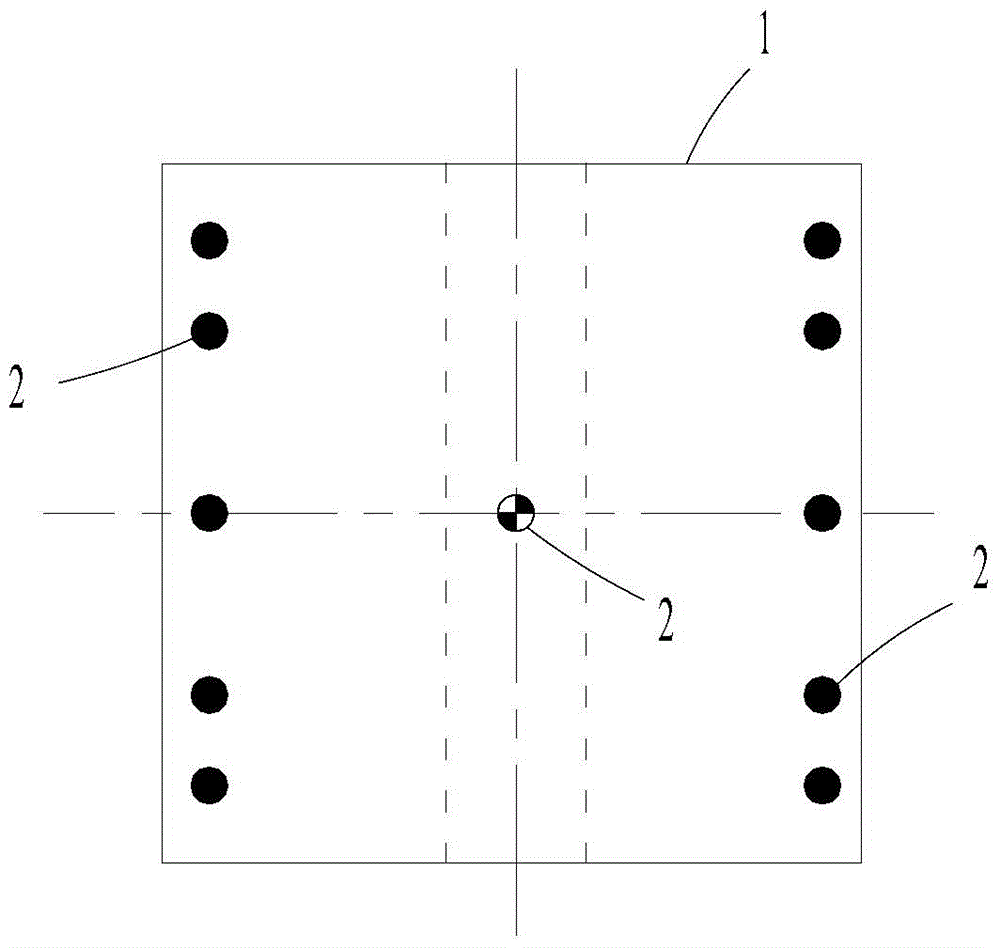

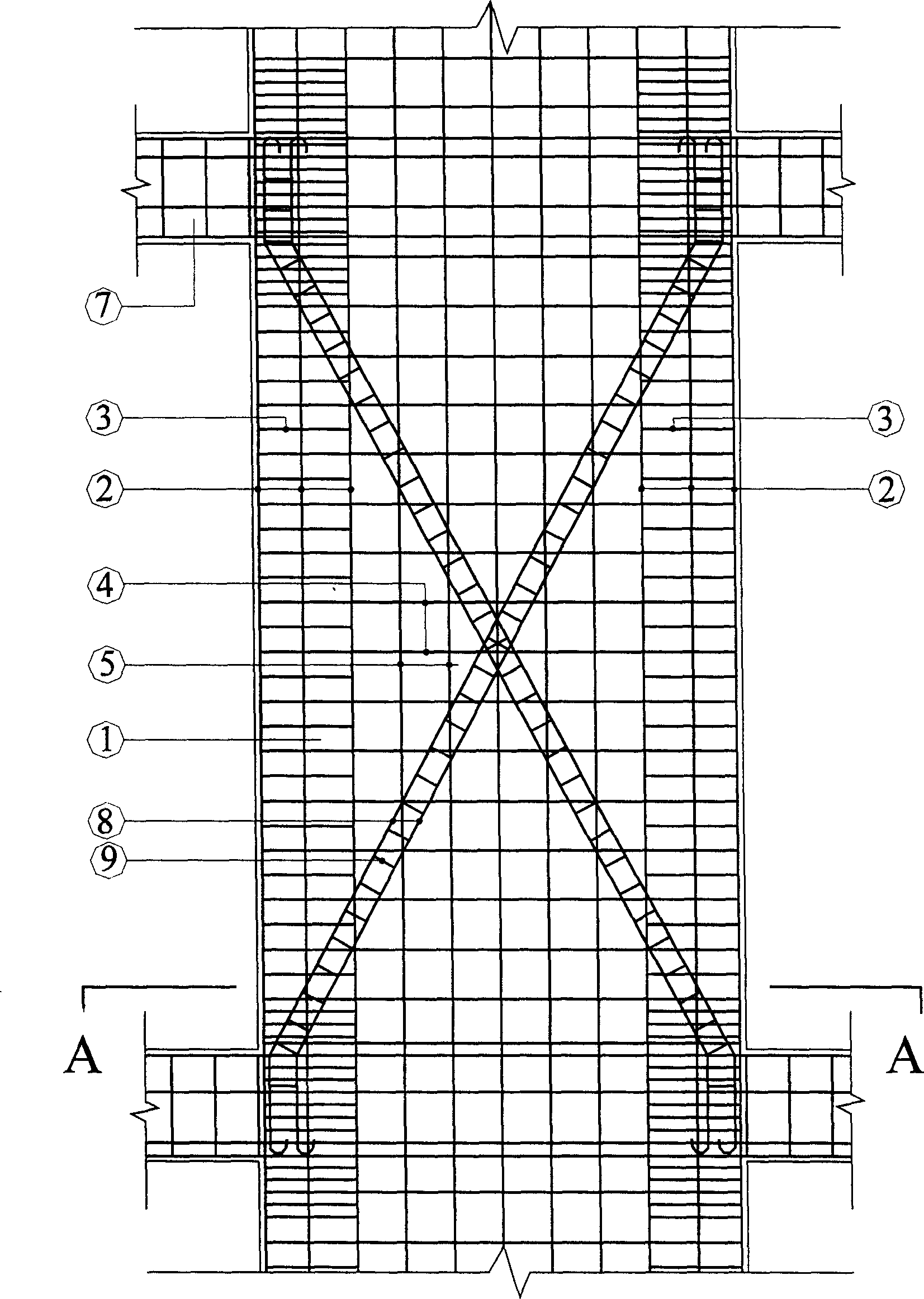

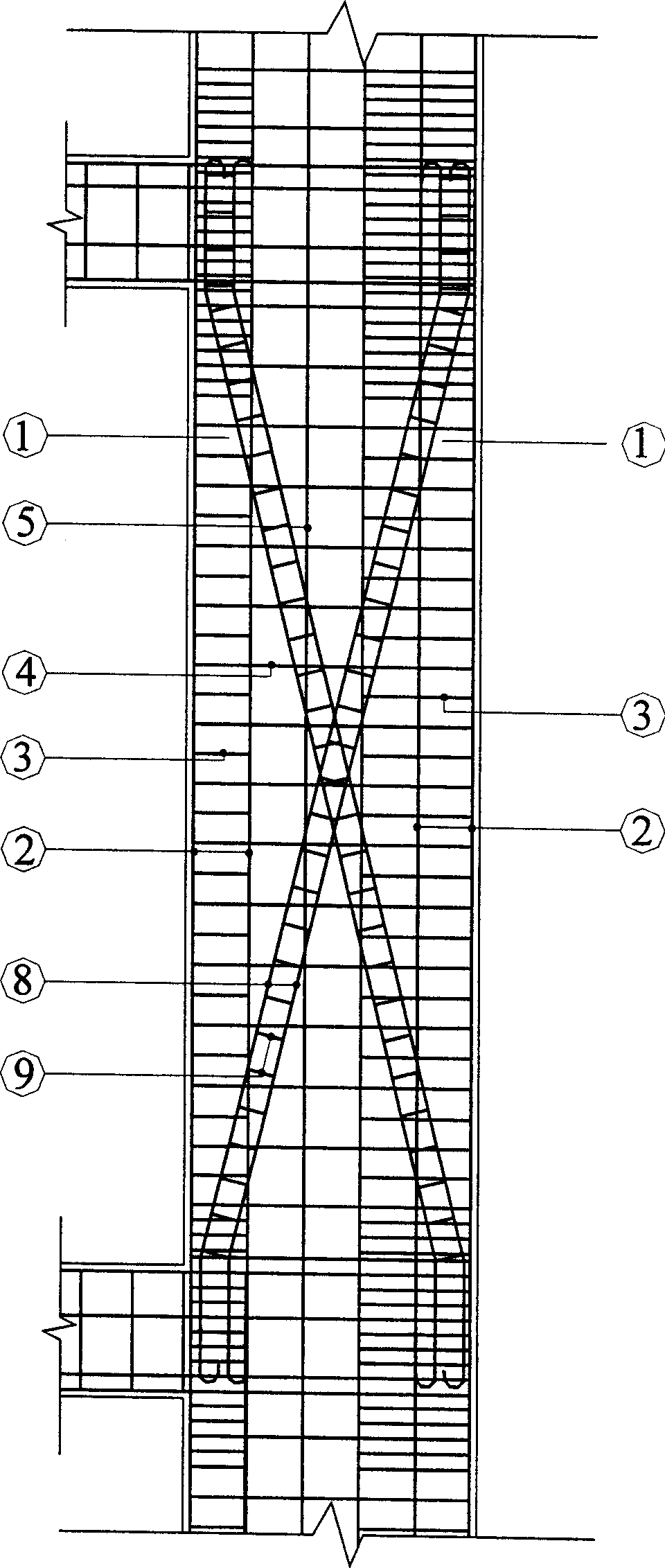

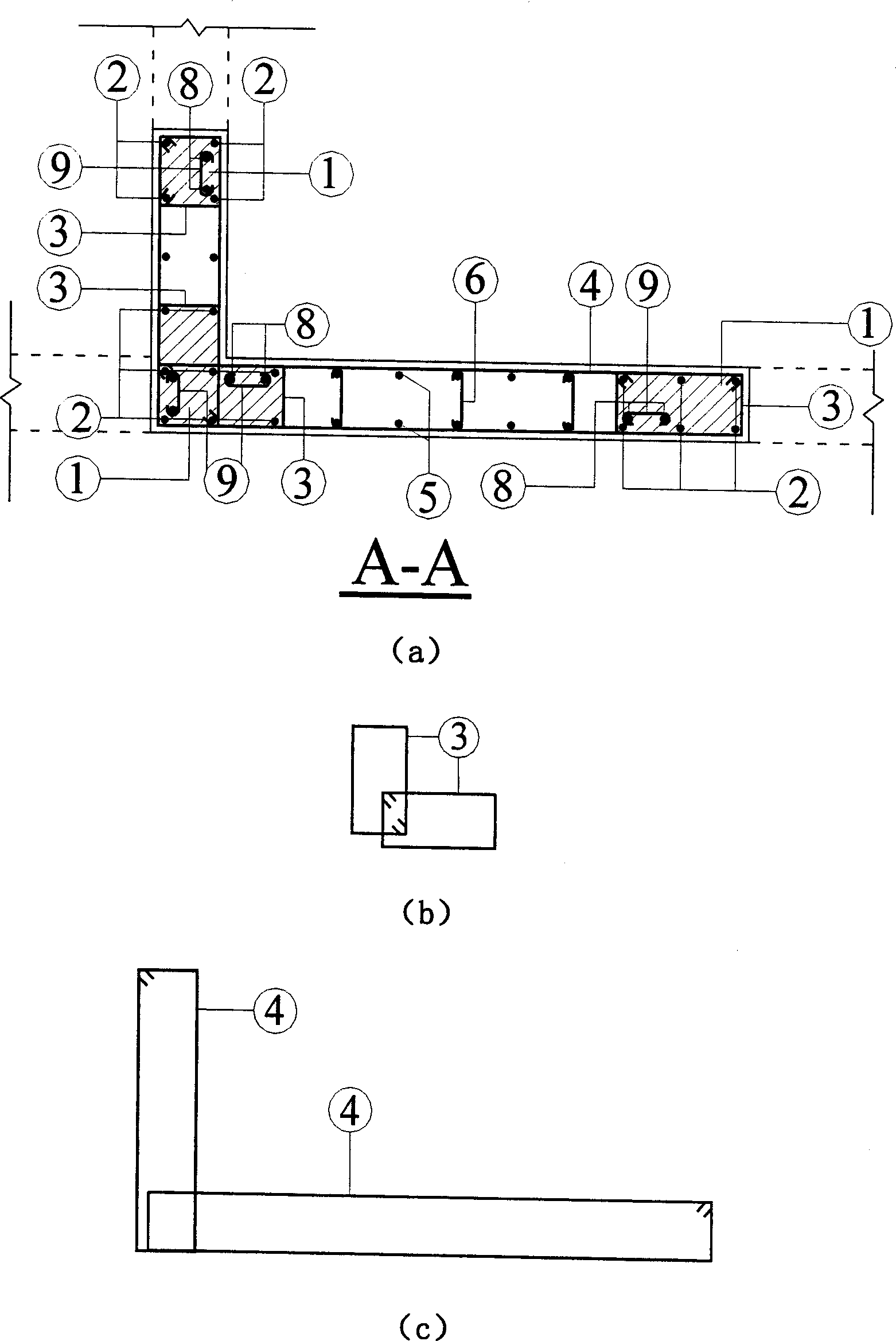

Profiled short-pier shear wall with rung steel bar support

InactiveCN1804264AExpand the crack distribution areaIncrease distribution areaWallsBuilding reinforcementsSteel barAbnormal shaped

The invention relates to a grid reinforced bar support special-shaped section short shearing force wall and relative producing method. The special-shaped section short shearing wall is formed by hidden post (1) and shearing wall plates. Wherein, it arranges reinforced bar network inside the wall plate and hidden posts at the end and corner of wall branches; when using two-row reinforced bars, the horizontal distributed reinforced bar (4) uses rectangle closed hoop reinforcement and adds intercross grid reinforced bar support between the reinforced bar network while said grid reinforce bar support is made by using drawing reinforced bar (9) to bond or weld the inclined reinforced bar beam (8); when the reinforced bar network uses single-row distributed bar, it arranges grid reinforced bar support at the two sides of reinforced bar network; it inserts hidden post (1) anchorage at the upper and lower ends of inclined reinforced bar beam (8); and both the web and swing wall branch have said grid reinforced bar support. Compared to general short shearing wall, the invention has improved anti-vibration ability, improved loading ability, higher ductility, higher torsional resistance, reduced side rigidity reduction and limited bottom shearing slide.

Owner:BEIJING UNIV OF TECH

Mine recyclable steel cylinder packing pier column and construction method thereof and method for gob-side entry retaining

ActiveCN102493823AEasy constructionSimple structureProps/chocksProtective coversMaterials scienceSteel cylinder

The invention relates to a mine recyclable steel cylinder packing pier column and a construction method thereof and a method for gob-side entry retaining, which belong to the field of mine laneway support. The steel cylinder packing pier column is a steel cylinder sand and stone packing pier column and consists of a height-adjustable steel cylinder mould and sand and stone packing which is filled in the steel cylinder mould, wherein the sand and stone packing is bulk sand or / and stones which are filled compactly, and also can contain other particulate matters; a filling opening is formed on the top of the steel cylinder mould; a discharging outlet is formed and an openable end cover of the discharging outlet is arranged on the lower part of the steel cylinder mould; two sides of the upper part of the steel cylinder mould are provided with support bases; the pier column is added with water and filled and constructed by a concrete injector; and the steel cylinder mould is taken as an outer wall of the pier column after being filled. The invention also provides a method for recycling the steel cylinder mould of the pier column and a self-advancing pneumatic vibration device. The pier column has a novel and practical structure, is readily available in materials, high in construction efficiency and low in support cost, and is easy to construct; the steel cylinder mould can be recycled for saving steel; and the yielding property of the support of the pier column is greatly improved to ensure that the pier column can meet the requirement that the influence of two-time mining is tolerated by the gob-side entry retaining well and is particularly suitable for the gob-side entry retaining.

Owner:兖矿能源集团股份有限公司

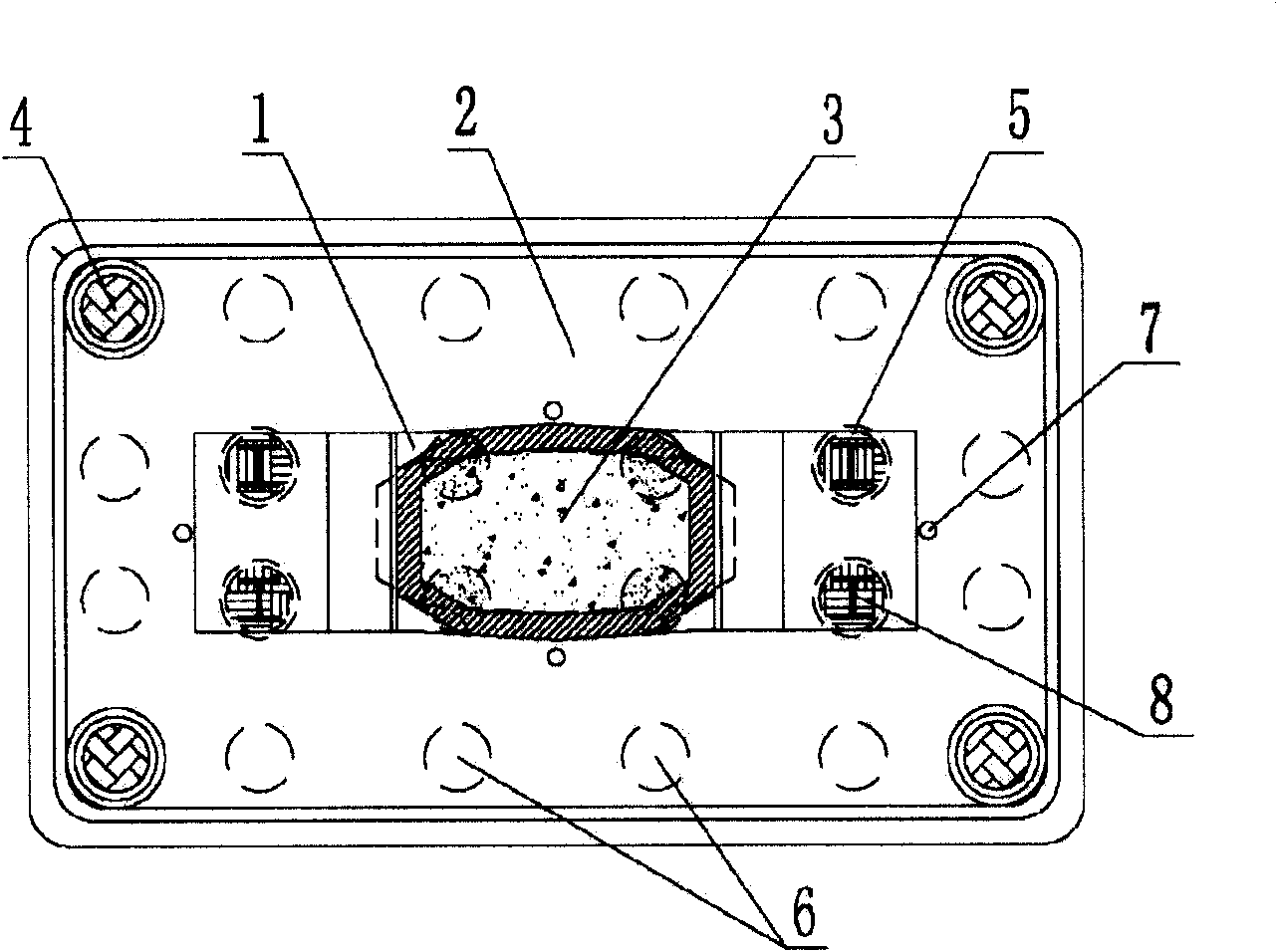

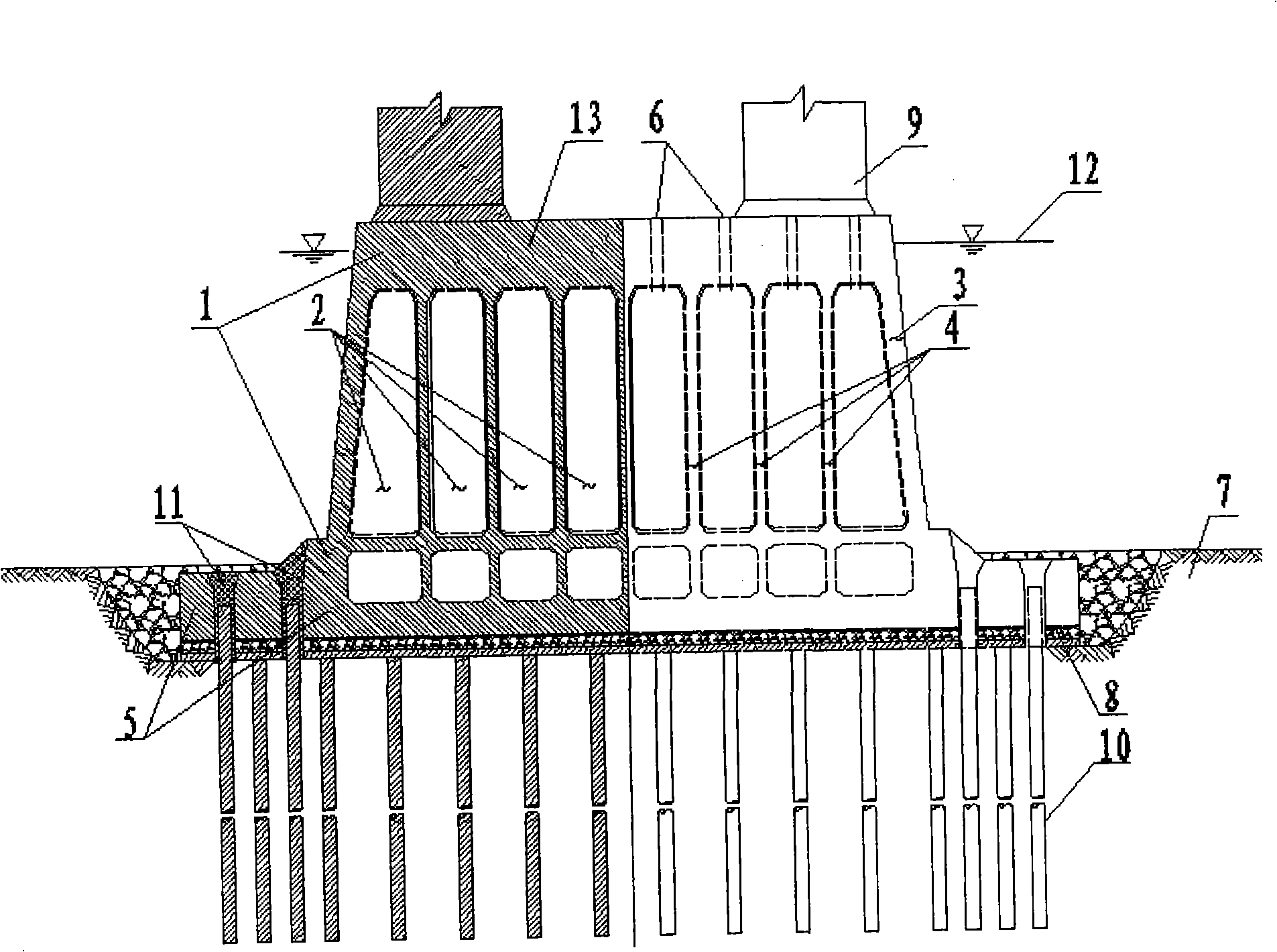

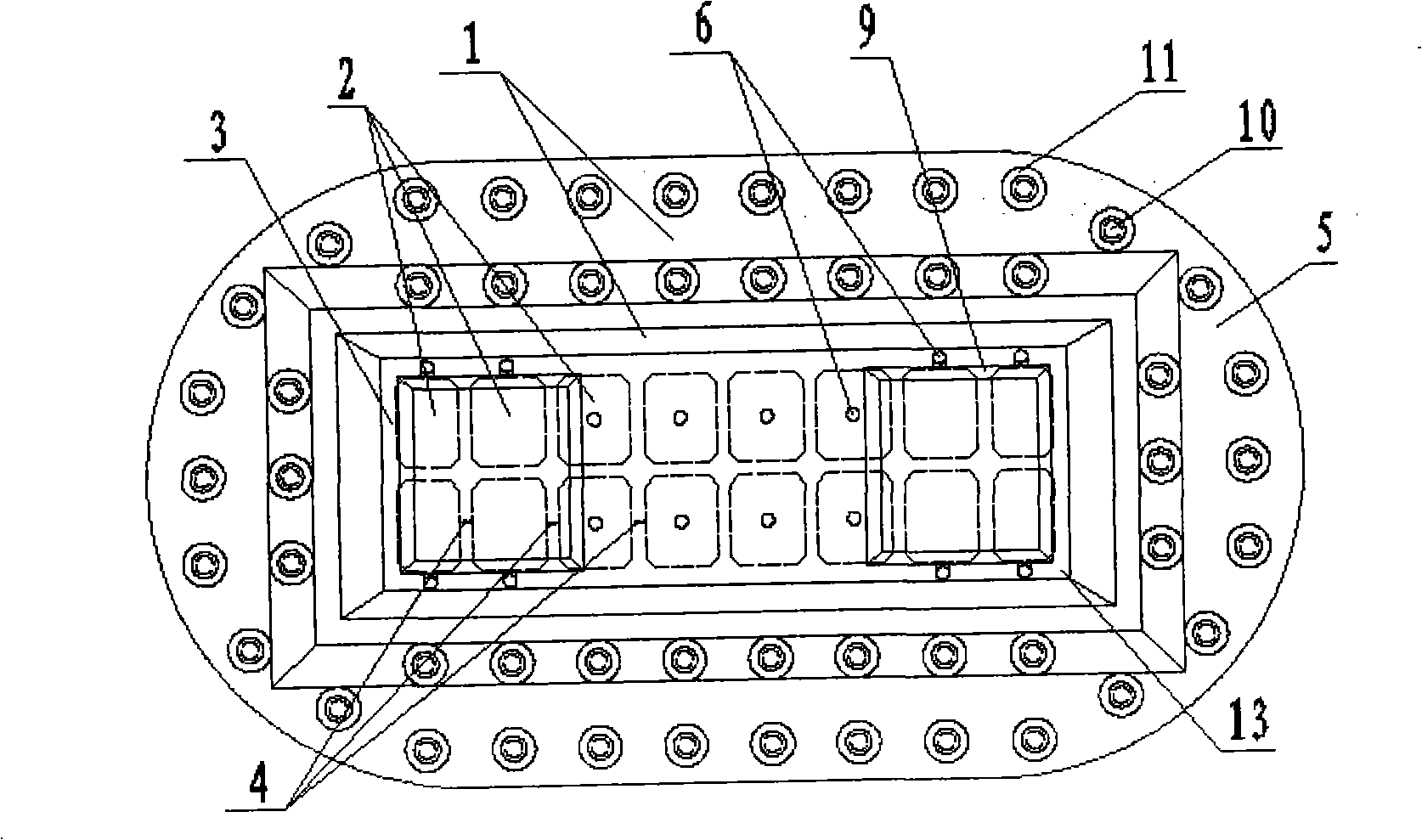

Steel cavity stranded caisson-pile inverse-way composite base and construction method

ActiveCN101294394AEffective control of settlementReduce settlementCaissonsBulkheads/pilesRiver bedEngineering

The invention relates to a composite foundation composed of a caisson with a steel cavity and piles constructed by the reverse operation method, and a construction method thereof, belonging to the bridge construction technology. The composite foundation comprises a caisson, a foundation bed, and piles. The caisson is composed of a steel cavity, an outer wall, an inner wall with a partition wall structure, a caisson cover, and a caisson bottom platform, wherein the caisson cover is preserved with water pumping and gas delivery holes, which are doubled as inspection holes. The caisson is arranged above the foundation bed and placed inside water, bridge piers are arranged on the caisson cover, the periphery of the caisson bottom platform is connected with the piles constructed by the reverse operation method, and the piles are inserted into the foundation bed and the sea bed or river bed through sinking pile preserved holes. After a foundation trench is excavated, a ship is located by riprapping to form the foundation bed, and the foundation bed is leveled by a platform type foundation bed riprapping leveling ship. The piles are connected with the caisson by pouring concrete in the preserved holes in the caisson. The inventive composite foundation utilizes the buoyancy force of the caisson steel cavity and considers the combined action of the piles, soil and the caisson to share partial external load by the sea bed or the river bed. The composite foundation optimizes the pile foundation design, reduces settlement during bridge service period, and reduces construction cost.

Owner:CCCC HIGHWAY CONSULTANTS

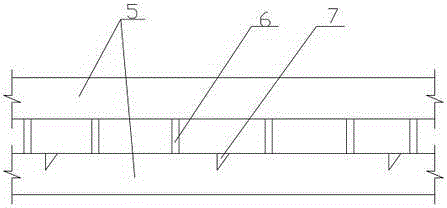

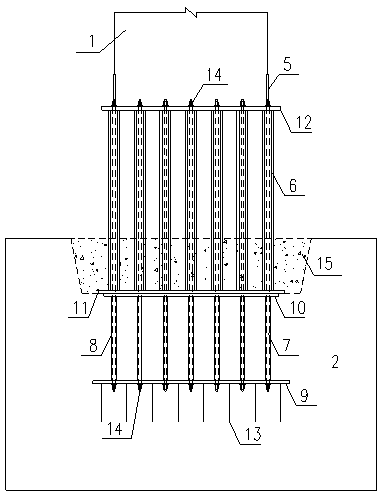

Lifting equipment and method of box girder integral steel reinforcement framework

InactiveCN101324055AImprove bridge building speedTravelling cranesBridge erection/assemblyDrive wheelArchitectural engineering

The invention provides a hoisting device and a hoisting method used for a box girder whole rebar frame, relating to the upper structure construction equipment of bridges. The hoisting device comprises a main beam a and a main beam b which are parallel and truss-structural; one end of the main beam a and one end of the main beam b are respectively connected with a front leg; the other ends of the main beam a and the main beam b are respectively connected with a rear leg; the middle parts of the main beam a and the main beam b are connected with at least a middle leg; the main beam a and the main beam b are respectively provided with at least two electric blocks which can move forwards and backwards along the main beam; the bottom of the rear leg is provided with a rear leg wheel box provided with a driving wheel; the bottom of the middle leg is provided with a middle leg wheel box provided with the driving wheel; the length of the front leg is more than that of the middle leg and the rear leg. The hoisting method of the invention replaces the sequential operation with parallel operation, and the box girder whole rebar frame can be hoisted in place on a girder surface with at least one cell cast in advance, then the box girder concrete is cast in-situ on the pier, thus being especially suitable for use matched with movable frames and effectively improving the bridge construction speed.

Owner:CHINA MAJOR BRIDGE ENG

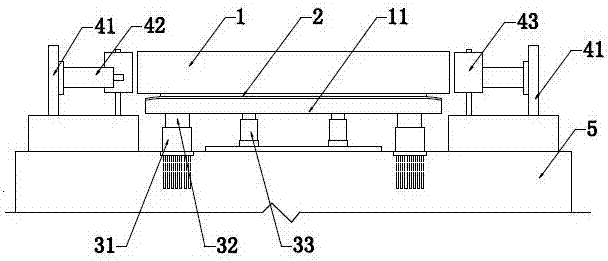

Prefabricated assembling bridge pier connecting device and construction method thereof

InactiveCN107806109AWith anti-collision protection functionSimple construction processFoundation engineeringArchitectural engineeringPier

The invention relates to a prefabricated assembling bridge pier connecting device and a construction method thereof. The prefabricated assembling bridge pier connecting device comprises a pier bottomconnecting device at the bottom of a prefabricated bridge pier and a pile-cap connecting pre-embedded device on the top of a cast-in-place pier cap; and connecting and fixing of the prefabricated bridge pier and the cast-in-place pier cap are achieved through up-down matching and installing of the pier bottom connecting device and the pile-cap connecting pre-embedded device. According to the prefabricated assembling bridge pier connecting device and the construction method thereof, the prefabricated assembling bridge pier with a connecting form of steel plate wrapping and U-shaped ribs and fine-rolling screw-thread steel is adopted, the construction process is simple and convenient; compared with other forms, the site construction process is less, the construction efficiency is greatly improved, and construction quality is ensured most effectively; safety and reliability are high, and the prefabricated assembling bridge pier connecting device and the construction method thereof can beapplied to areas with high seismic intensity; and the connecting structure has a certain anti-collision protection function to a bridge pier main body so that the prefabricated assembling bridge pierconnecting device and the construction method thereof can be widely popularized in city bridges.

Owner:CCCC FIRST HIGHWAY CONSULTANTS

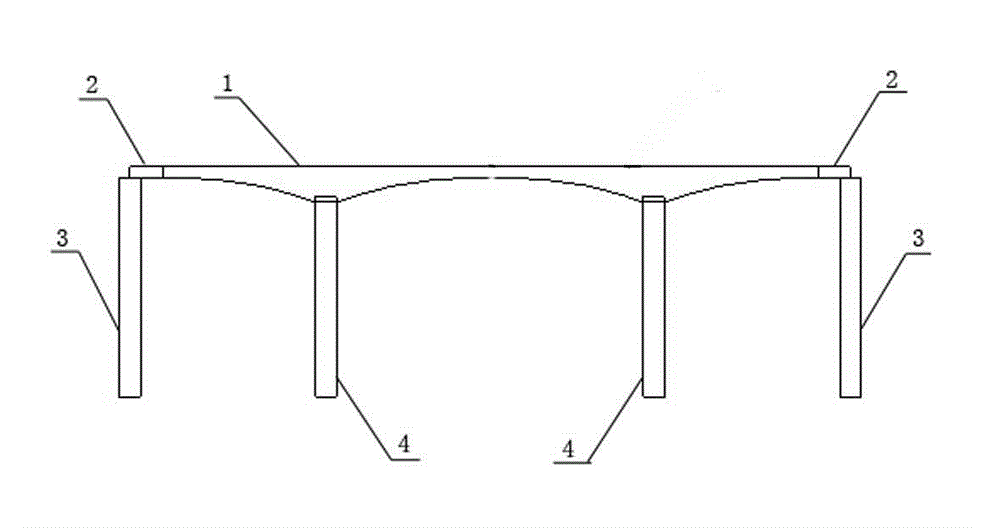

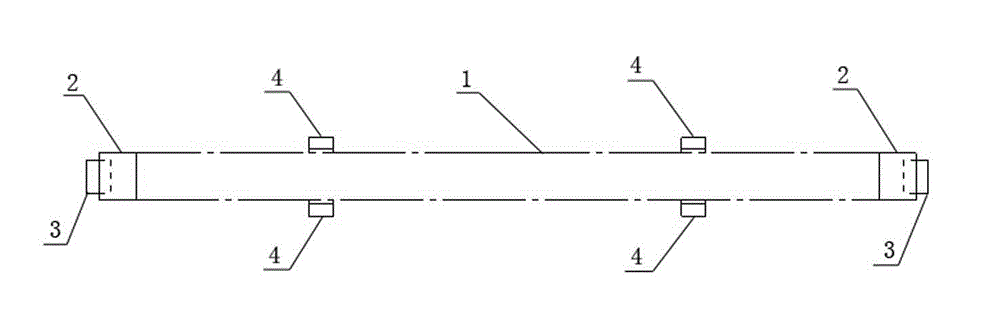

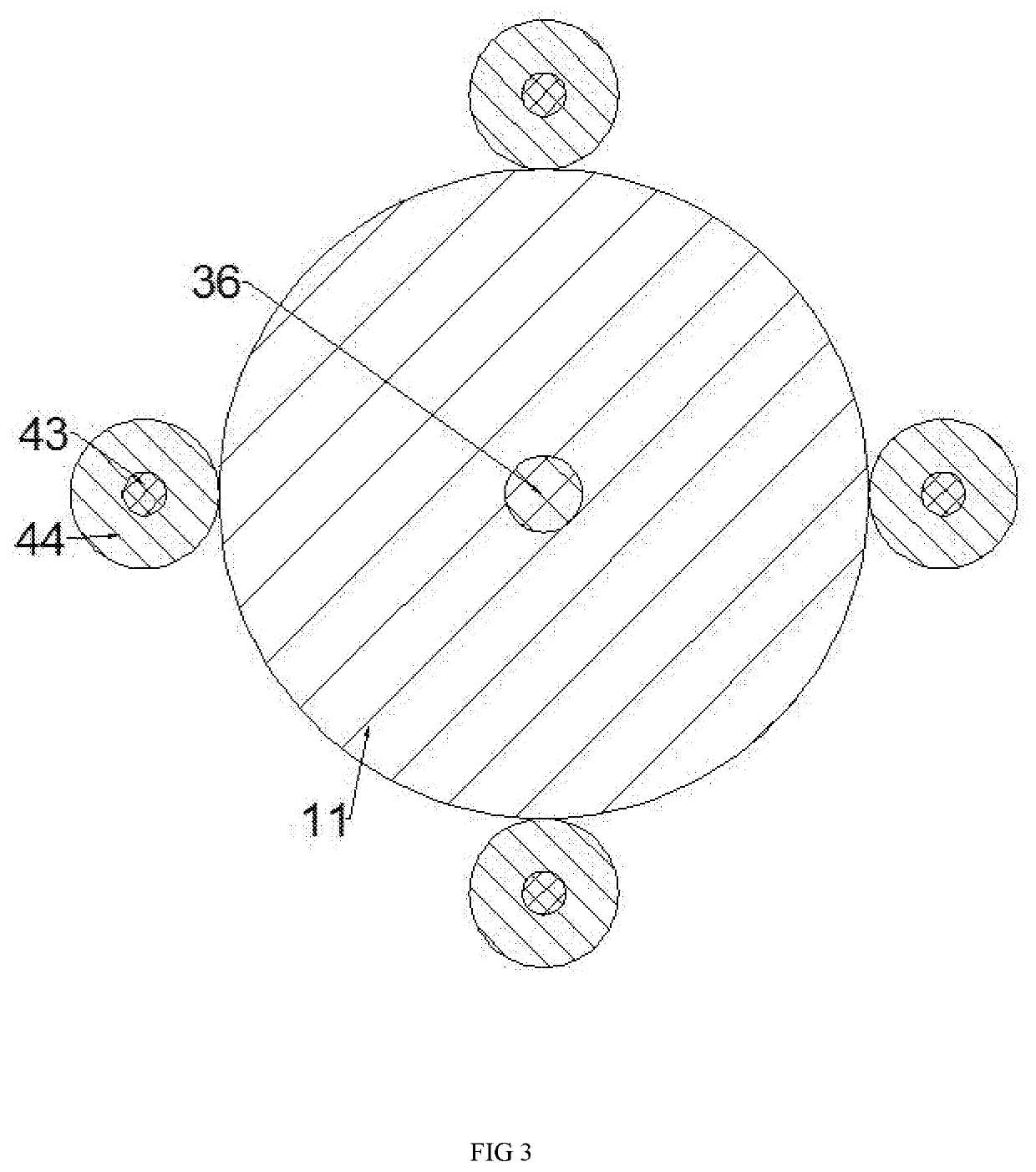

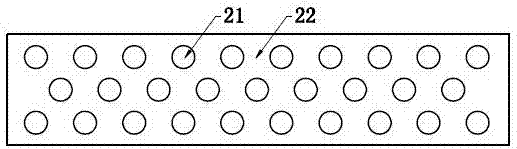

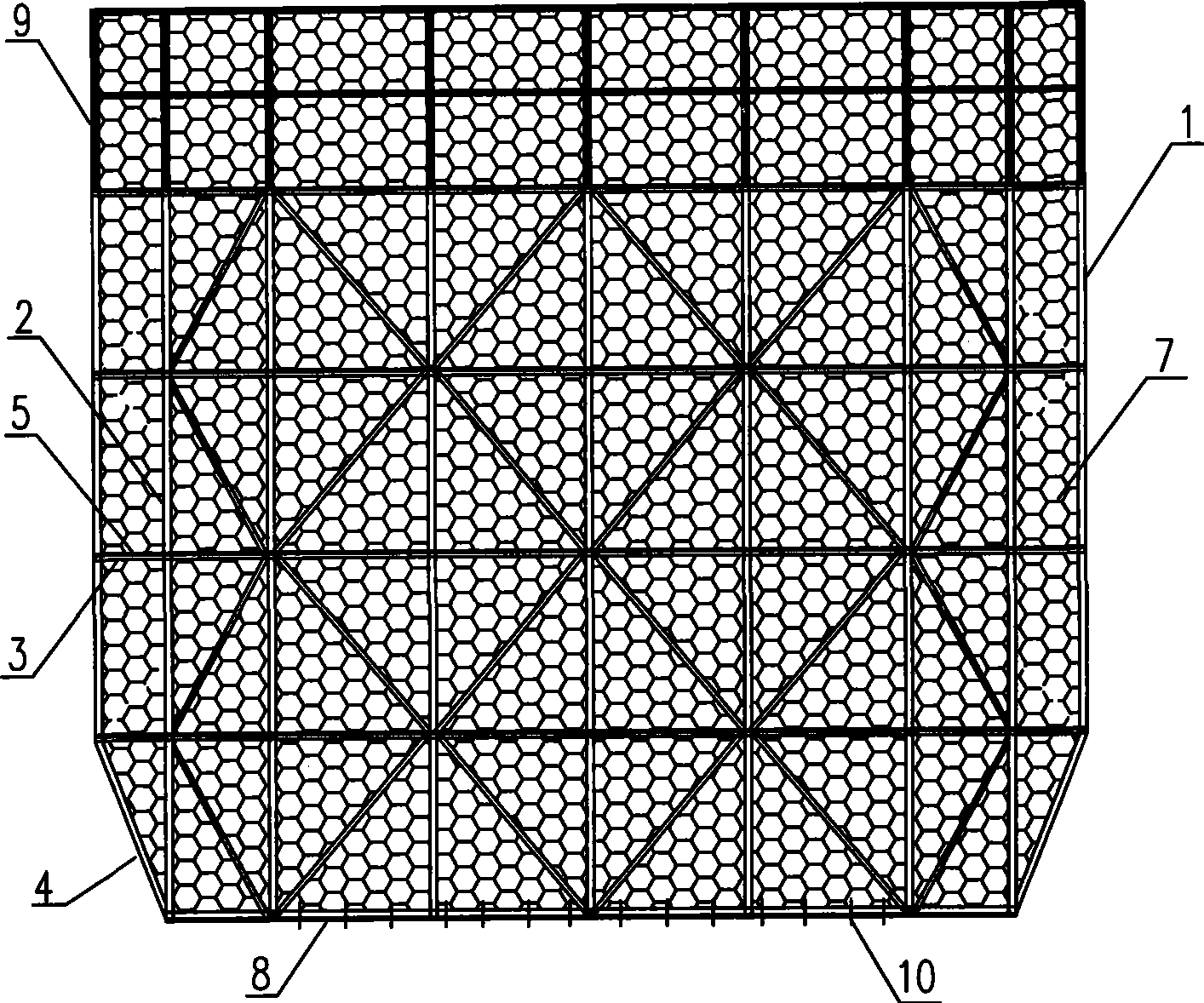

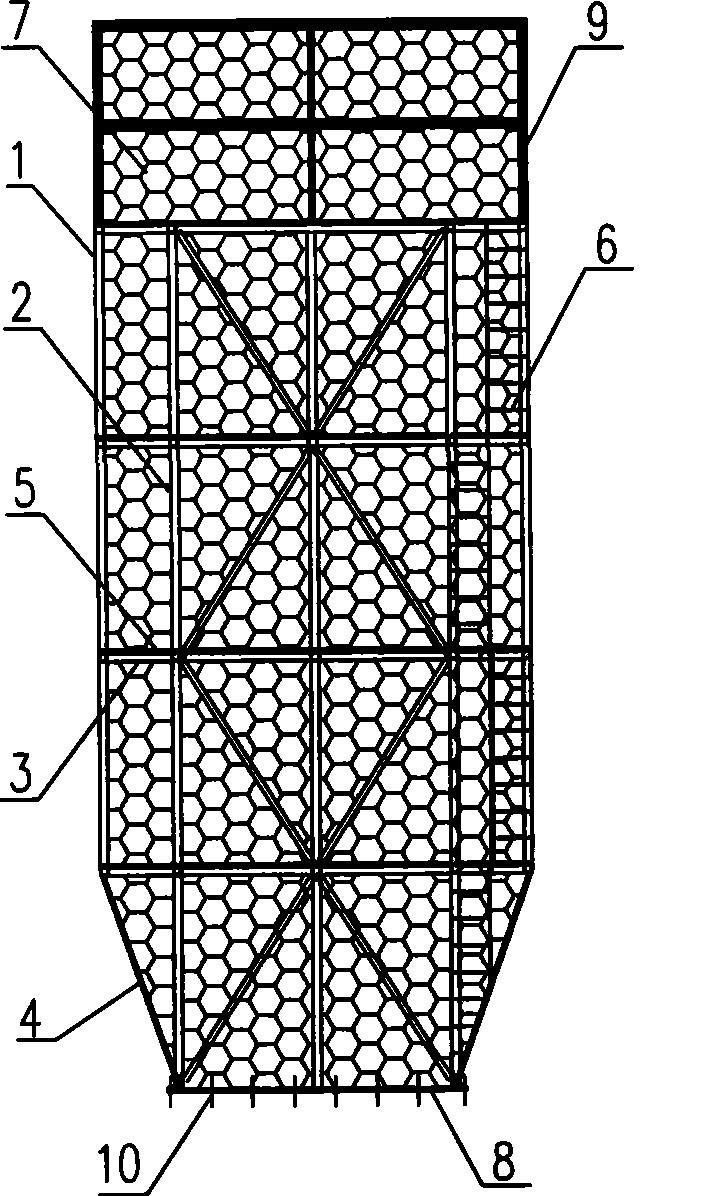

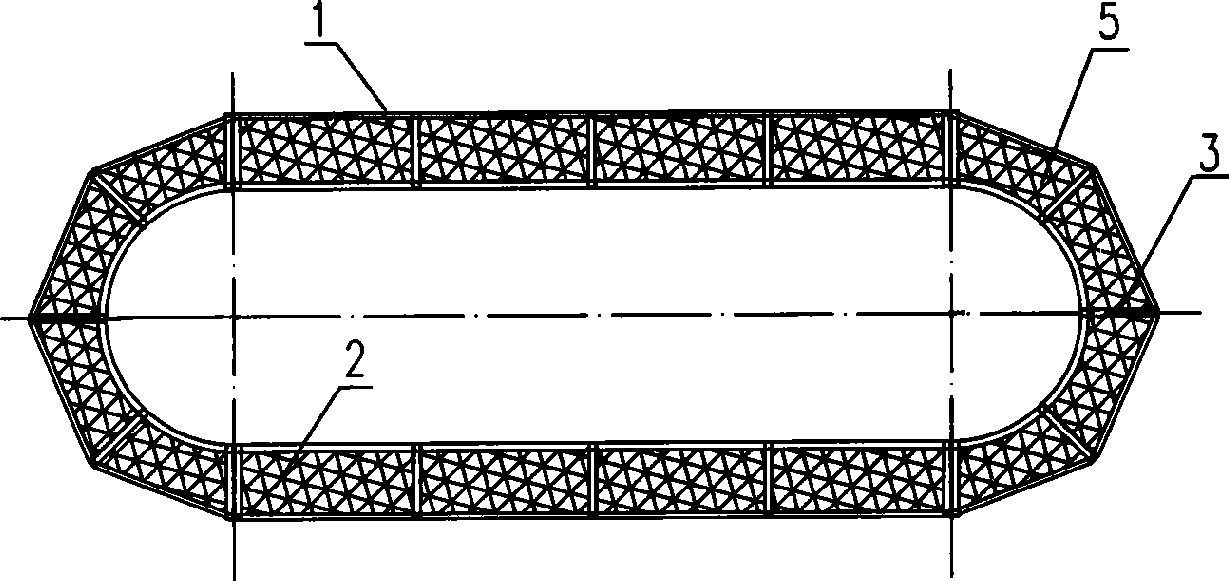

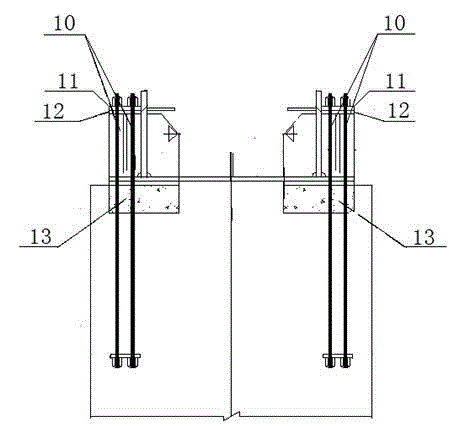

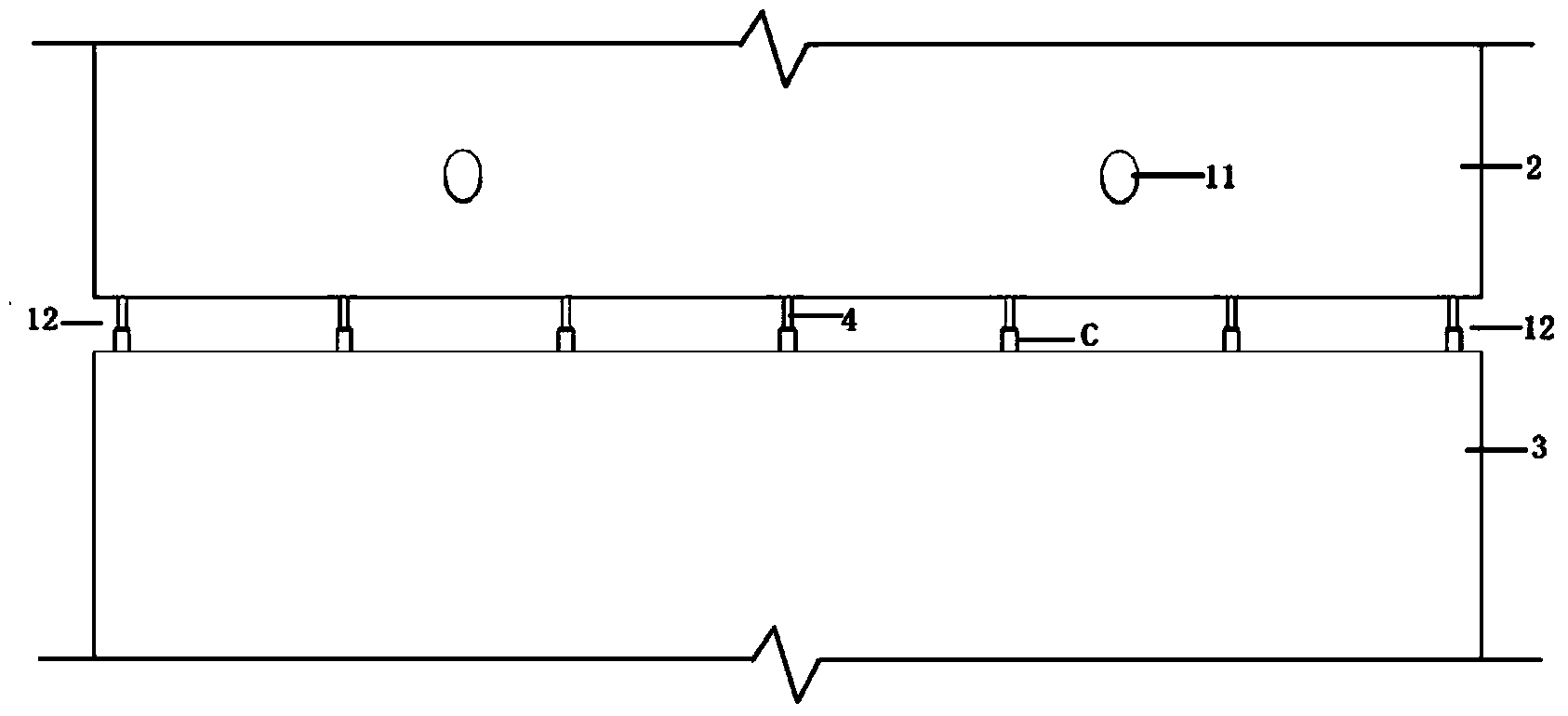

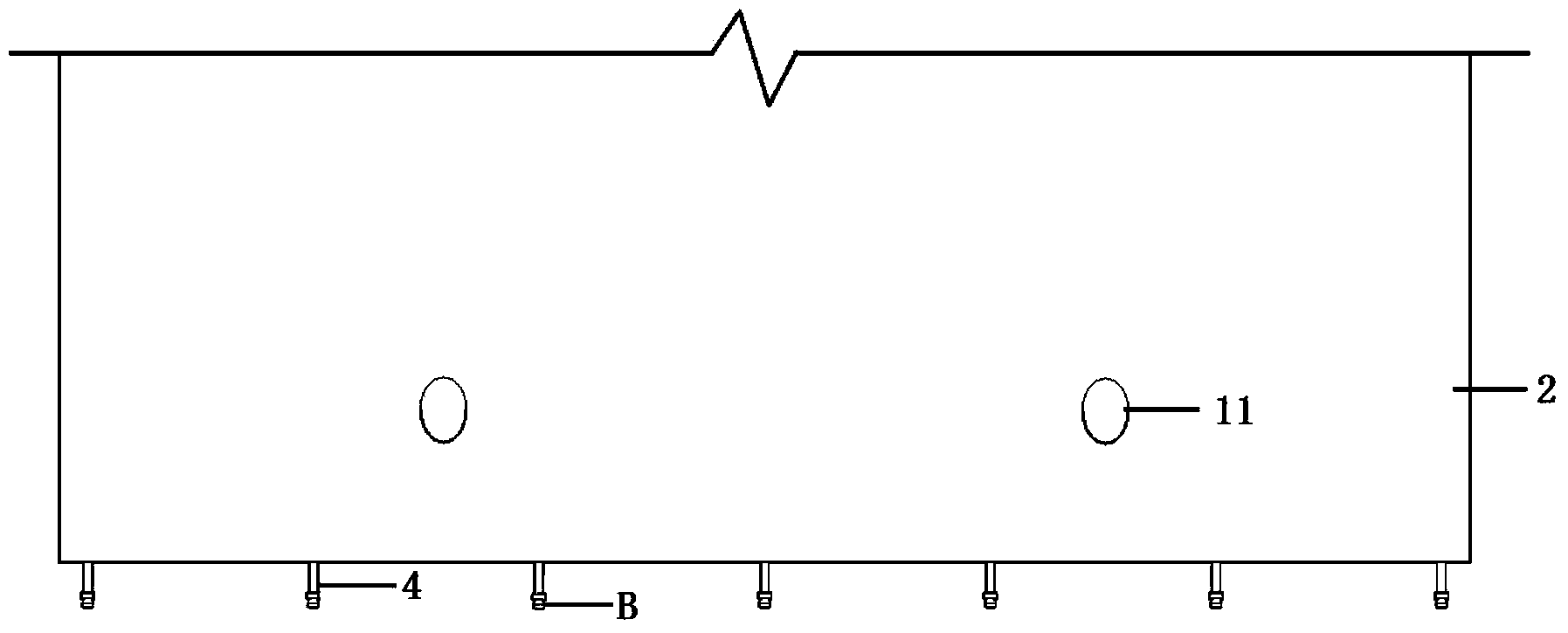

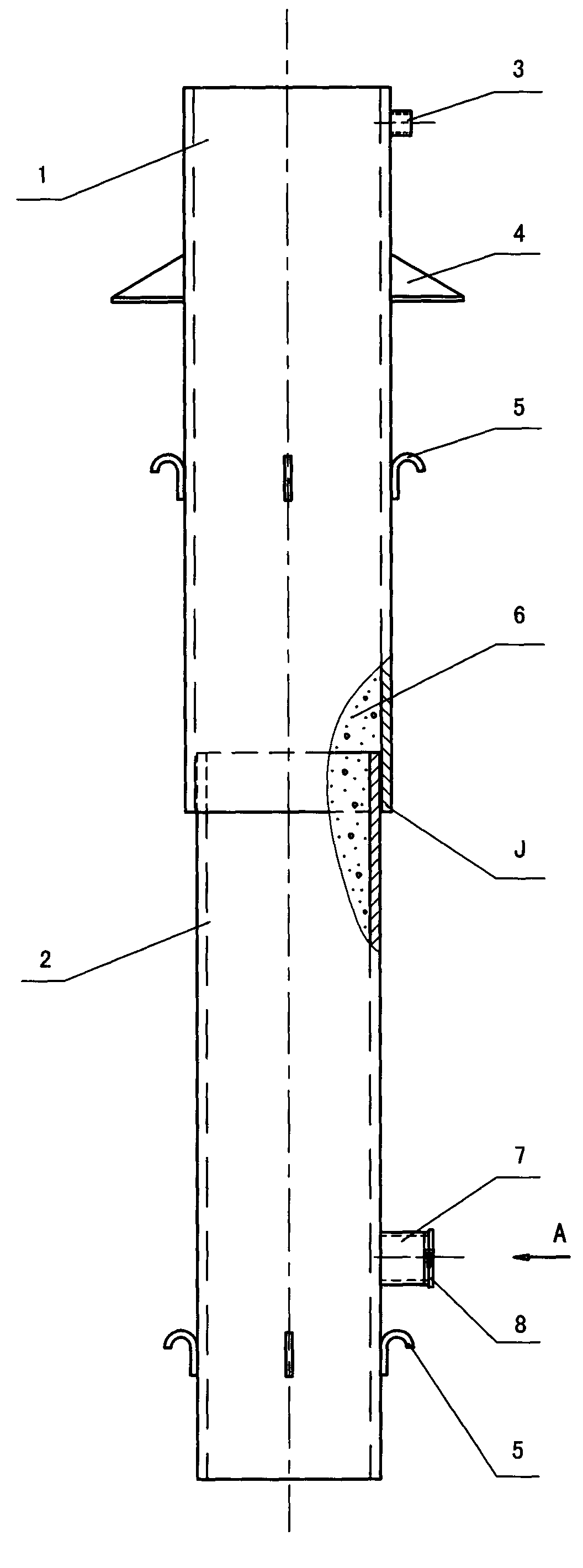

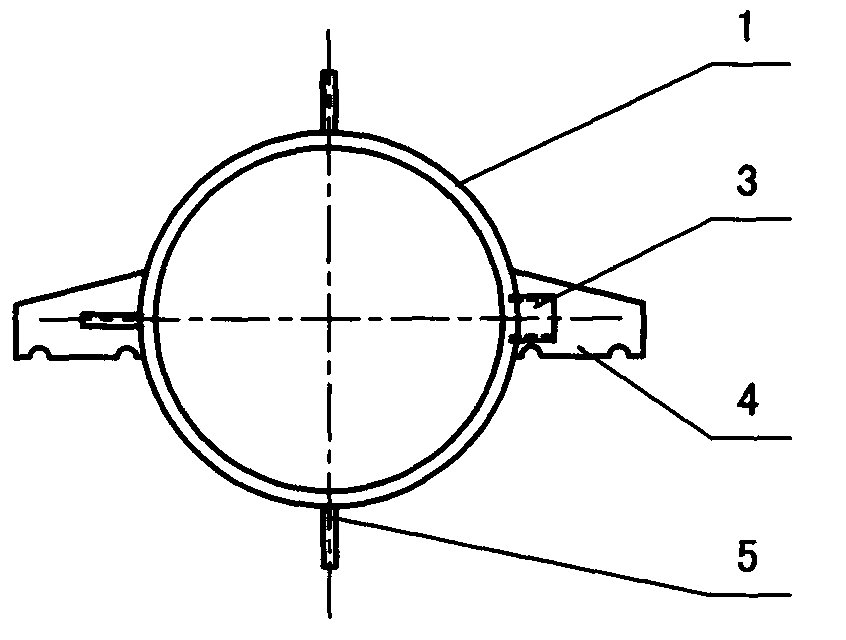

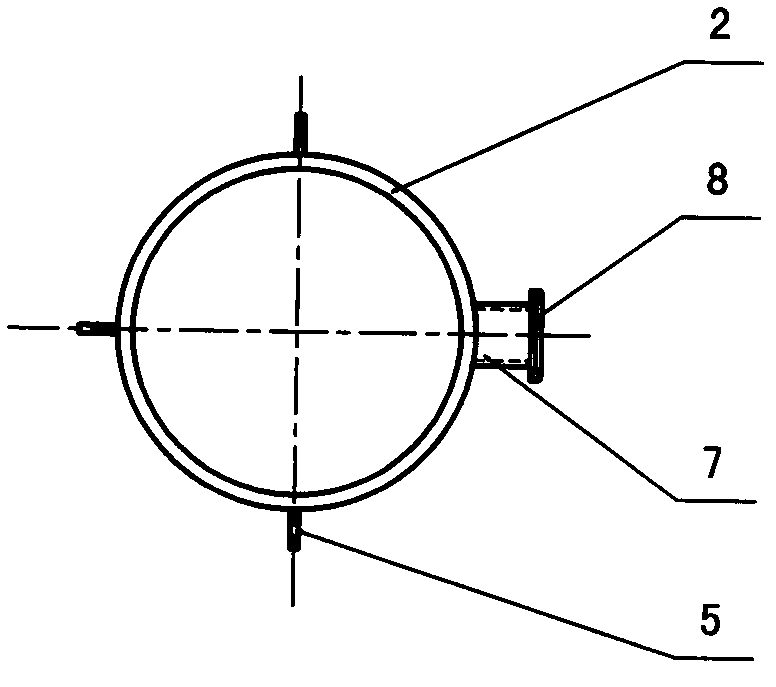

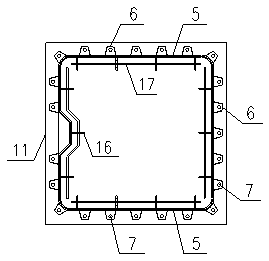

Steel sleeve prefabricated assembly type pier with shear nails

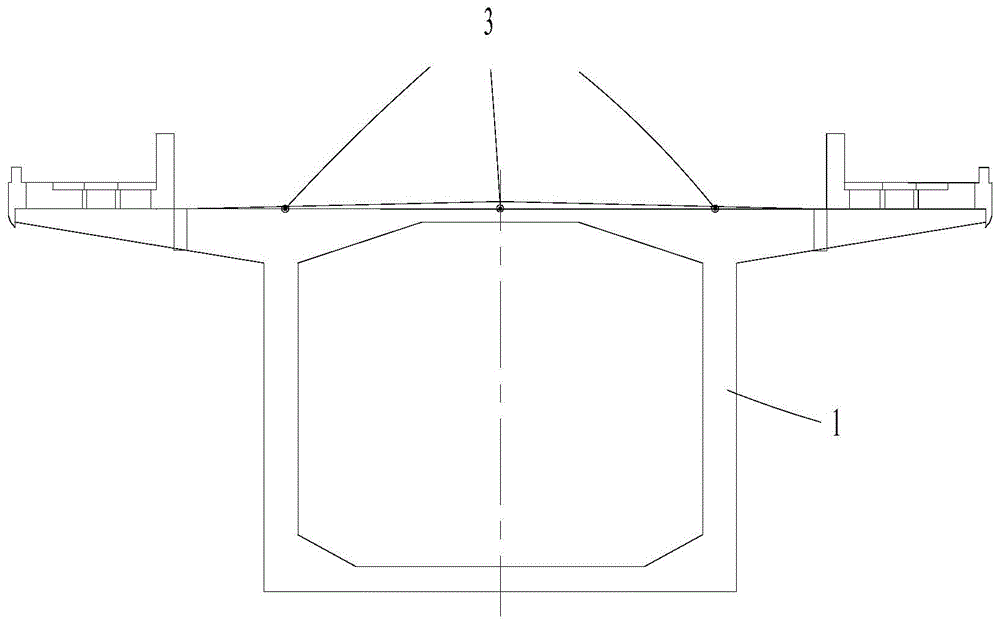

InactiveCN106192730AReduce workloadSave steelBridge structural detailsBridge erection/assemblyRebarPlastic hinge

The invention discloses a steel sleeve prefabricated assembly type pier with shear nails. The pier comprises a pier column 1 and a bearing platform 2. A steel sleeve 3 with the shear nails is connected with the bearing platform 2 and the pier column 1. The shear nails 4 on the part, connected with the pier column 1, of the steel sleeve are arranged on the inner side of the steel sleeve, and the shear nails 5 on the part, located in the bearing platform, of the steel sleeve are arranged on the outer side of the steel sleeve. Longitudinal ribs 6 embedded in a pier body are inserted into the part, located in the bearing platform 2, of the steel sleeve. The longitudinal ribs 6 and L-shaped rebars 8 are poured together, and an upsetting head 7 is reserved at the end, located in the bearing platform 2, of each L-shaped rebar 8. The steel sleeve with the shear nails is adopted for connecting the pier column and the bearing platform, a plastic hinge zone is wrapped with the steel sleeve in advance, the earthquake damage that a large amount of surface layer concrete peels off can be avoided, and the normal using performance can be restored through a little restoration work after earthquakes.

Owner:SHANGHAI INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com