Construction method of underground continuous wall below viaduct

A technology of underground diaphragm wall and construction method, which is applied in the direction of sheet pile wall, foundation structure engineering, construction, etc., can solve the problems that underground diaphragm wall cannot adopt underground diaphragm wall construction method, the complexity of production site conditions increases, etc., and achieve good waterproof effect , small deformation, high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

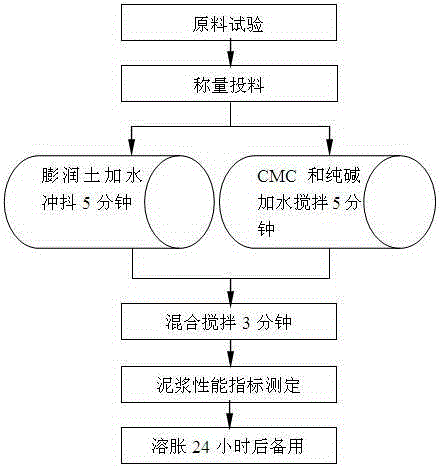

Method used

Image

Examples

Embodiment

[0041] A concrete application of the construction method of the underground diaphragm wall 2 under the viaduct of the present invention in the construction of the underground diaphragm wall 2 under the viaduct of Wusheng Road, the eleventh section of Wuhan Rail Transit Line 6, the following examples are descriptive, not limiting However, the protection scope of the present invention cannot be limited by this.

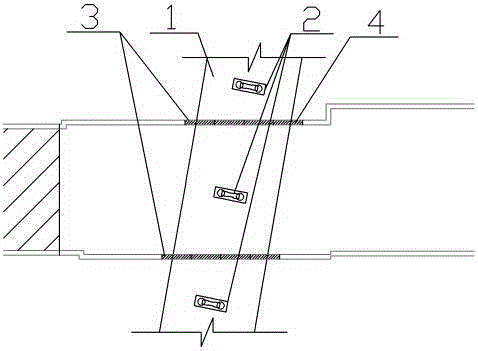

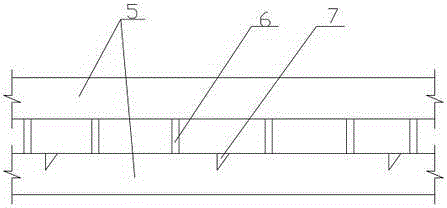

[0042] see figure 1 , The Wusheng Road overpass is a north-south straight viaduct, and the planning width varies from east to west along the line. The width of the bridge deck across the subway station range is 16m, and the clearance under the bridge is 4.2m. Wusheng Road Viaduct 21# pier 3 is located inside the main body of the subway station, and 20# and 22# pier 3 are located on both sides of the station. The width of the foundation pit under the viaduct 1 is 23.6m, and the depth of the foundation pit is about 24.6m. The minimum distances between the 3 caps of 20# a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com