Preparation process of anti-static polyvinyl chloride (PVC) homogeneous through-core coiled material floor board

A technology of coiled flooring and preparation technology, which is applied in building construction, covering/lining, construction, etc. It can solve the problems of difficult control of thickness difference at splicing joints, difficulty in quality inspection of laying, troublesome construction and many seams, etc. Achieve the effect of clear and natural pattern, strong three-dimensional effect and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

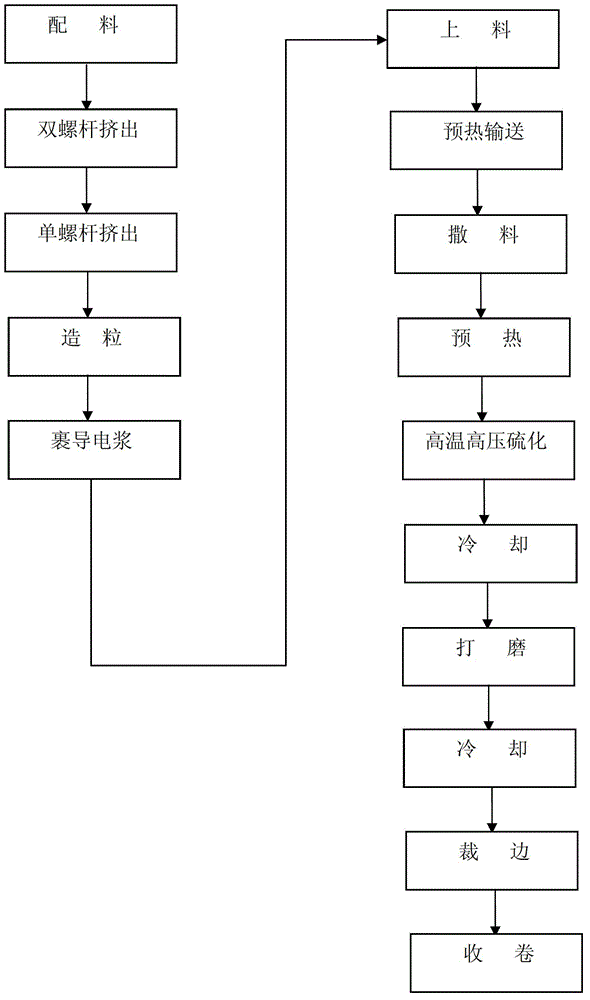

[0034] Such as figure 1 Shown, a kind of preparation technology of antistatic PVC homogeneous core permeable coiled material floor is characterized in that: has the following steps:

[0035] a) Put the raw material PVC, plasticizer, stabilizer, lubricant, colorant and filler into high

[0036] High-speed mixer, after mixing, enter the low-speed mixer to stir and disperse to make color masterbatch;

[0037] b) The raw material PVC, plasticizer, filler, and the color masterbatch prepared in the first step are conveyed through the screw

[0038] machine transported to the container, through the automatic measuring instrument, mixed according to the proportion, mixed and transported to

[0039] The twin-screw extruder is plasticized and then enters the single-screw extruder for extrusion, and is cut by eccentric water mist.

[0040] The diameter of the cut particles is 3~7mm, cooled by two-stage cyclone to collect PVC particles;

[0041] c) Wrap PVC particles with a layer of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com