Patents

Literature

215results about How to "Less seams" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

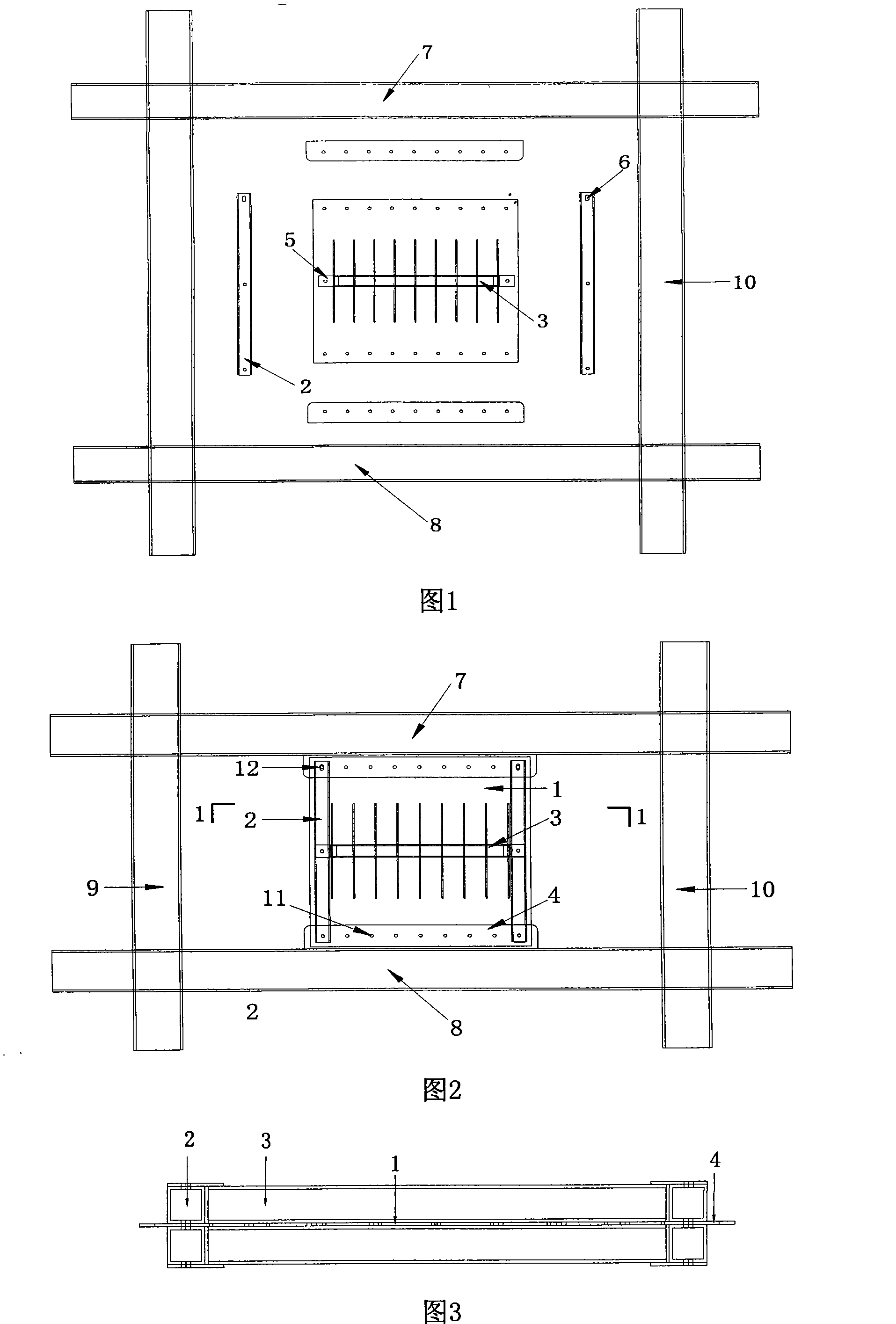

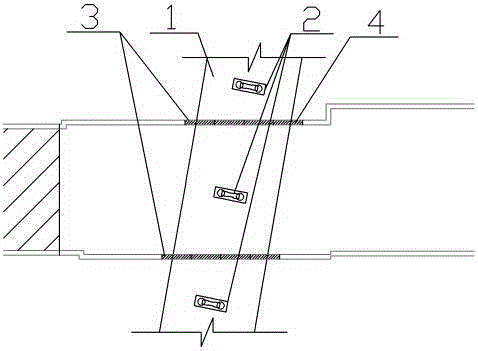

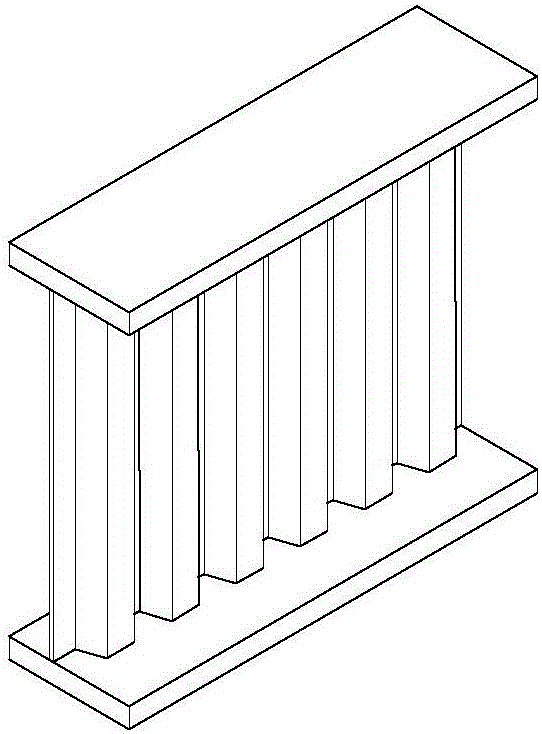

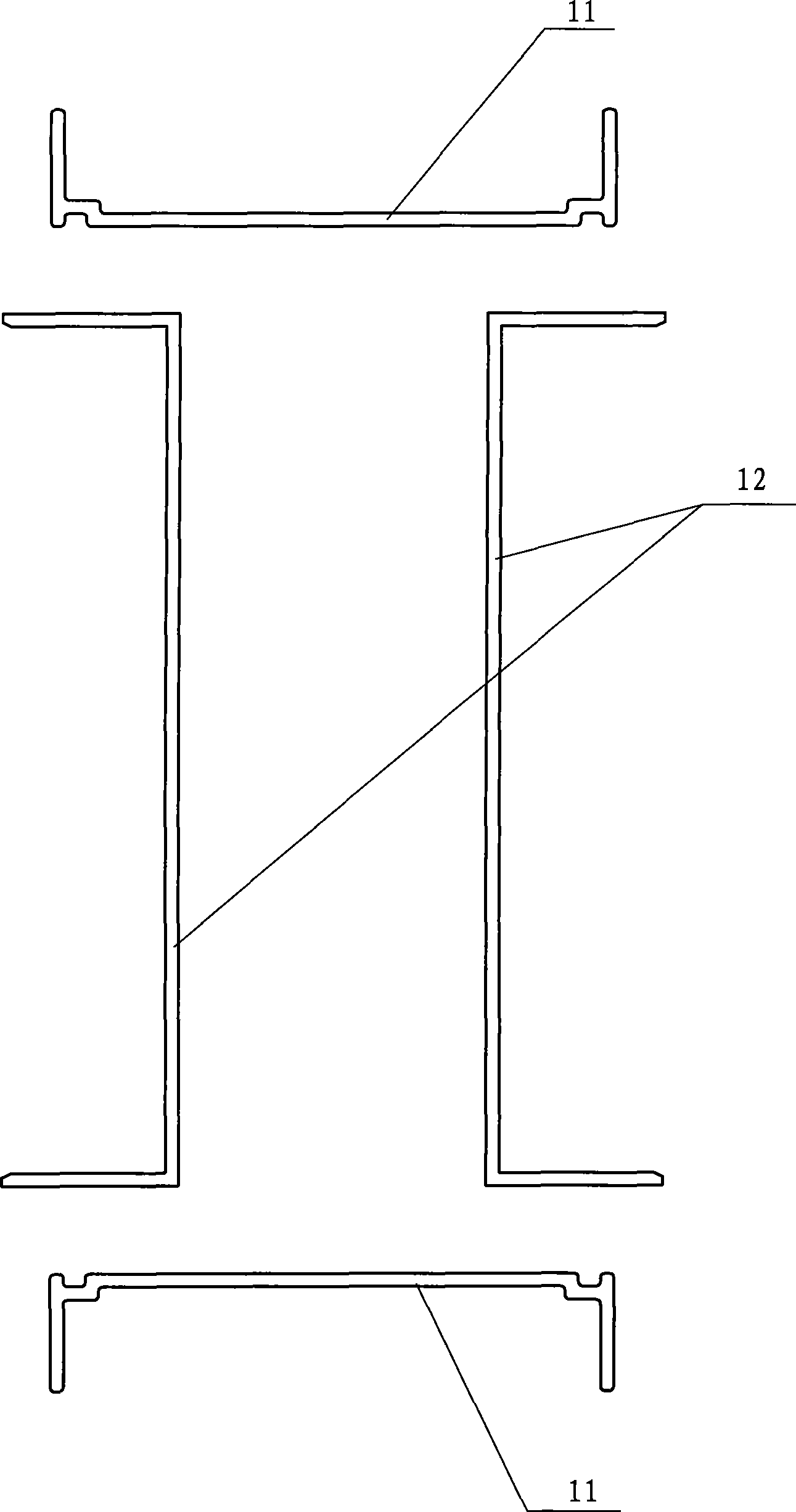

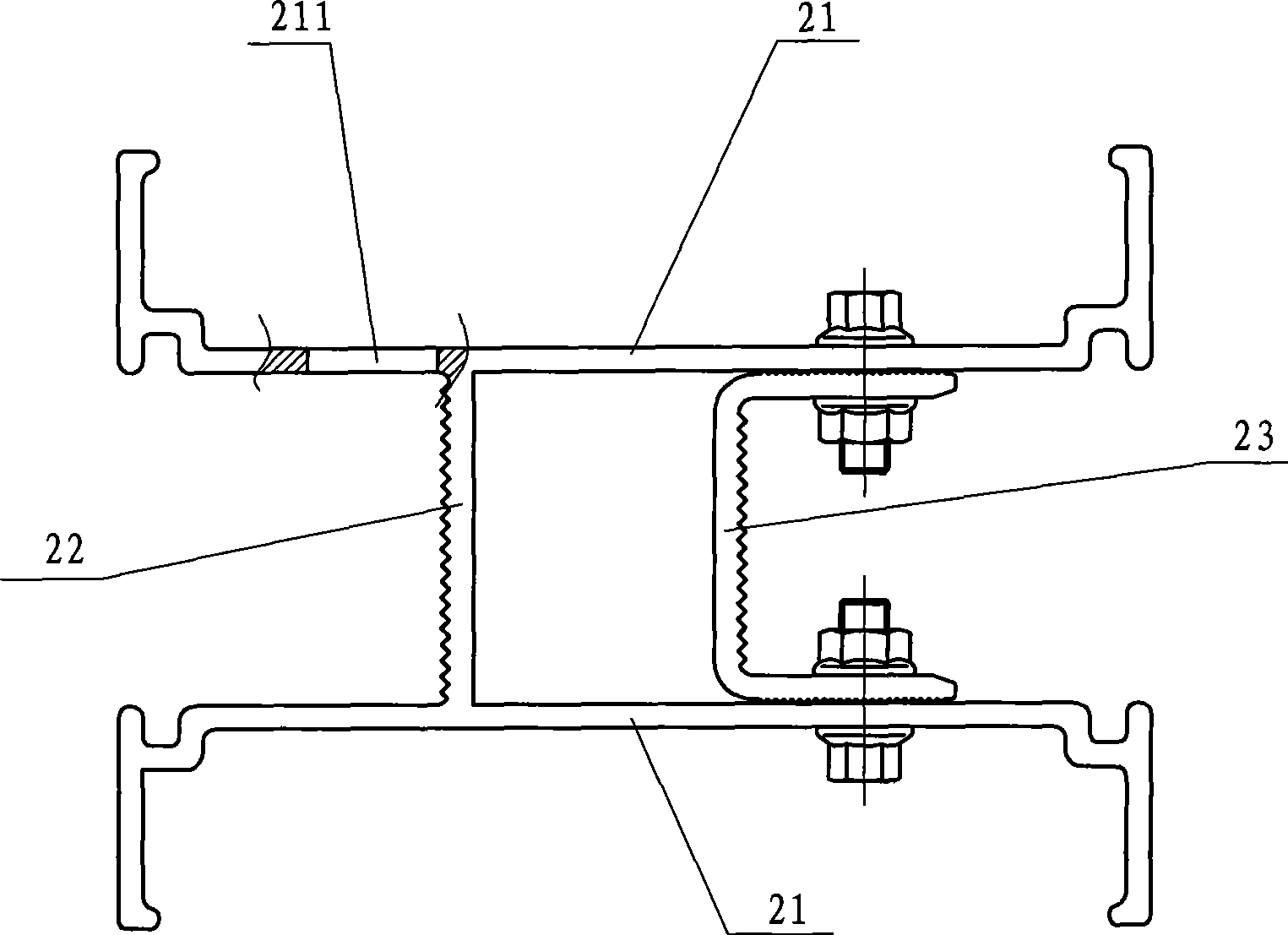

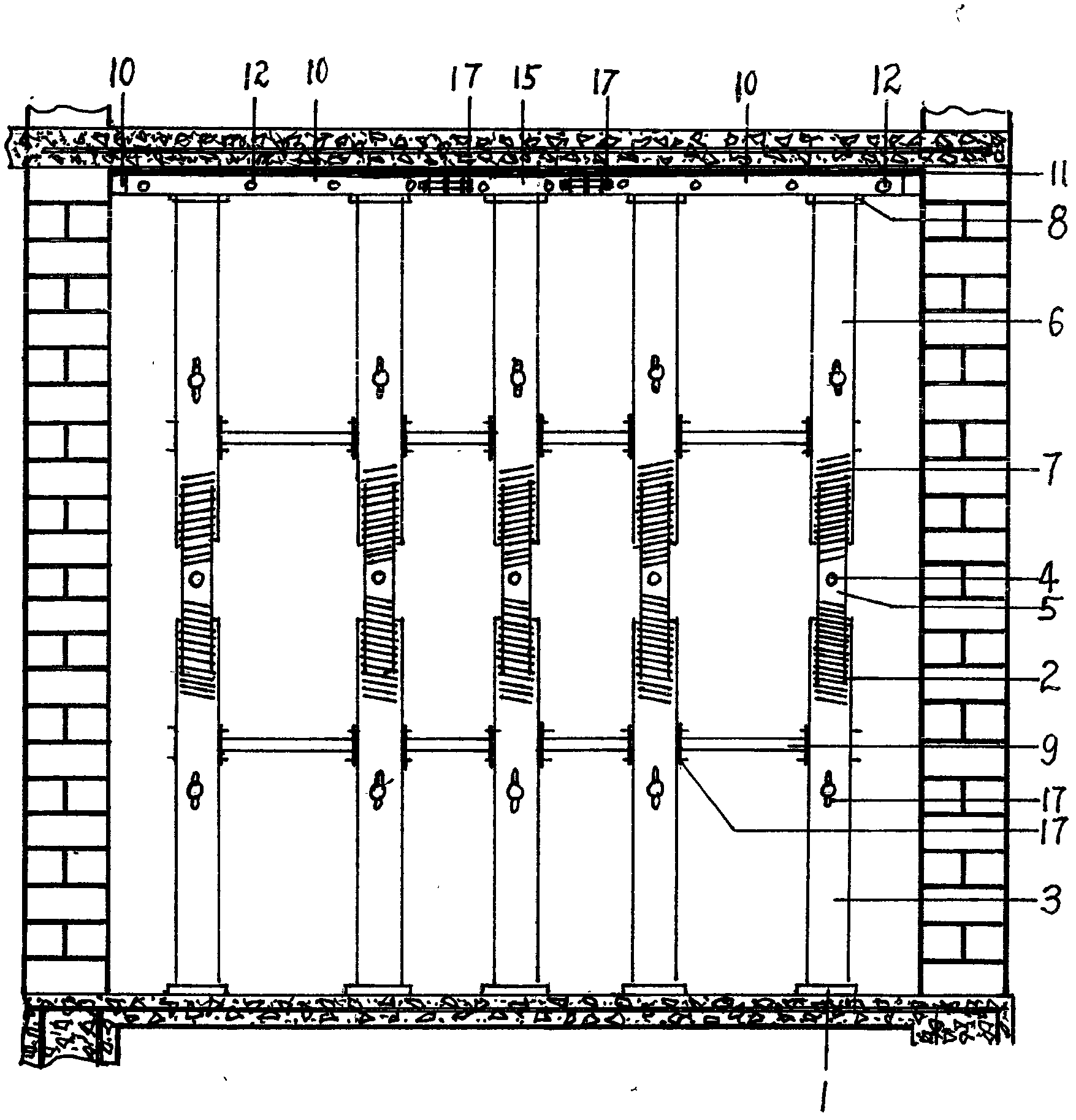

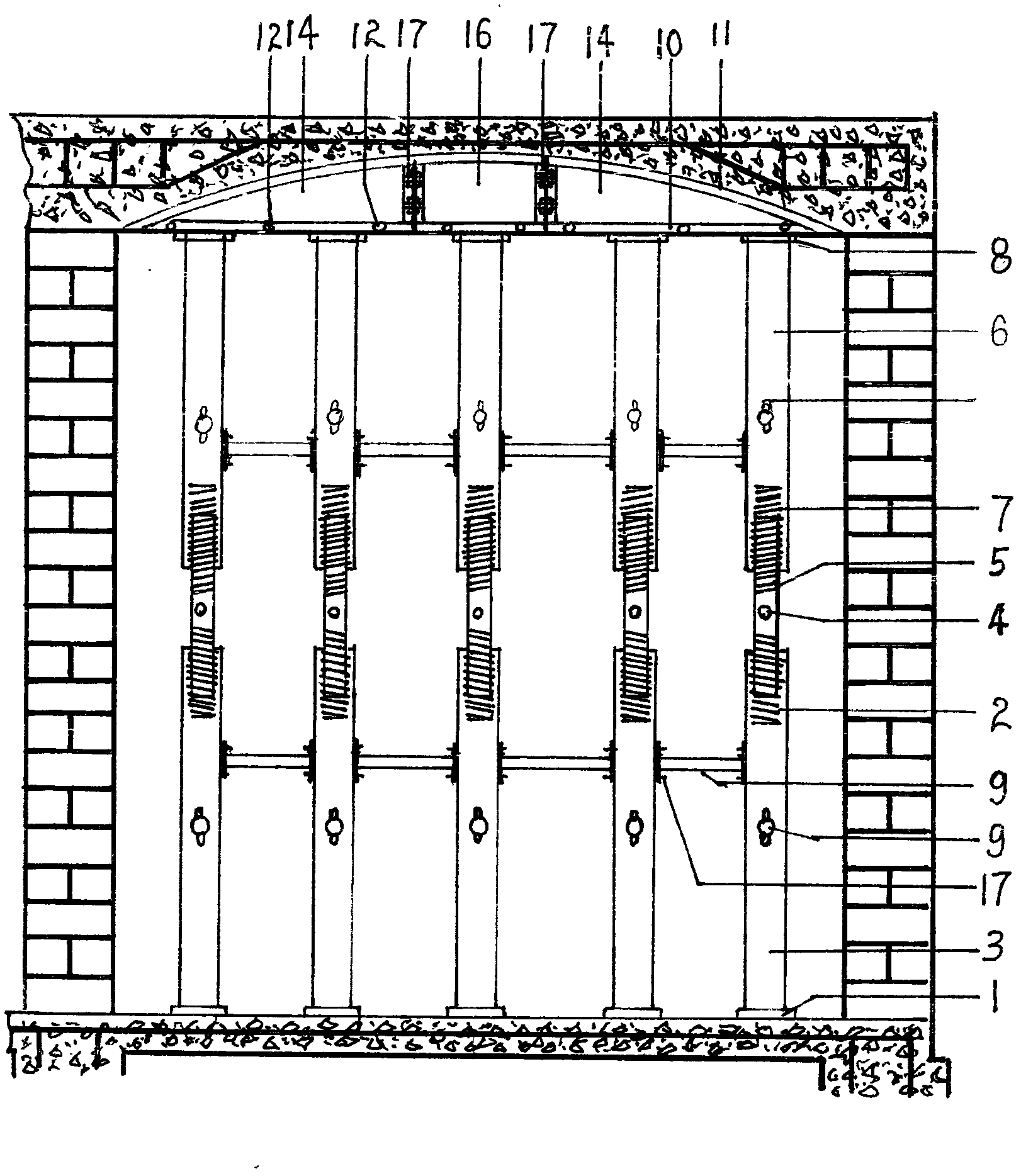

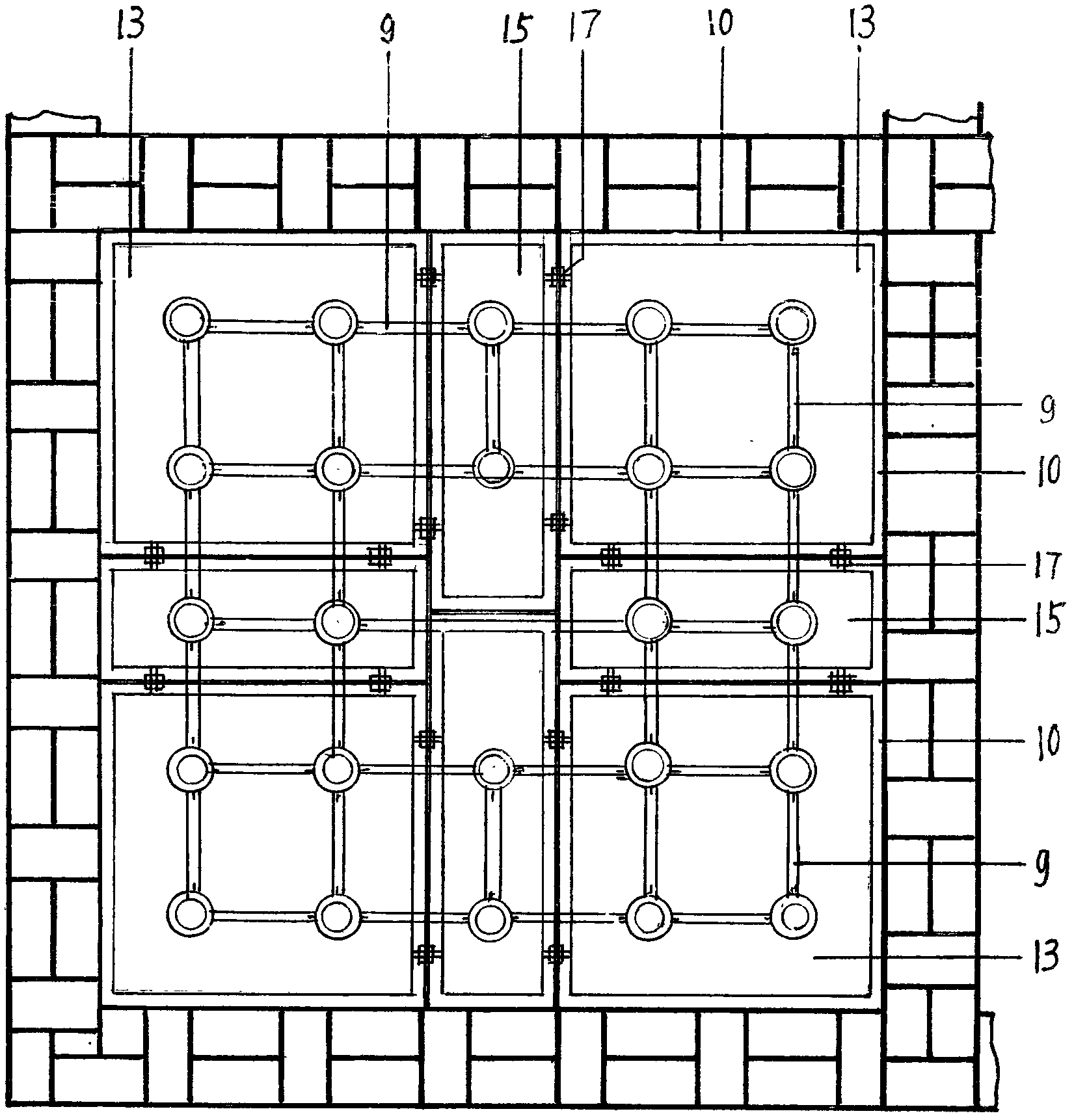

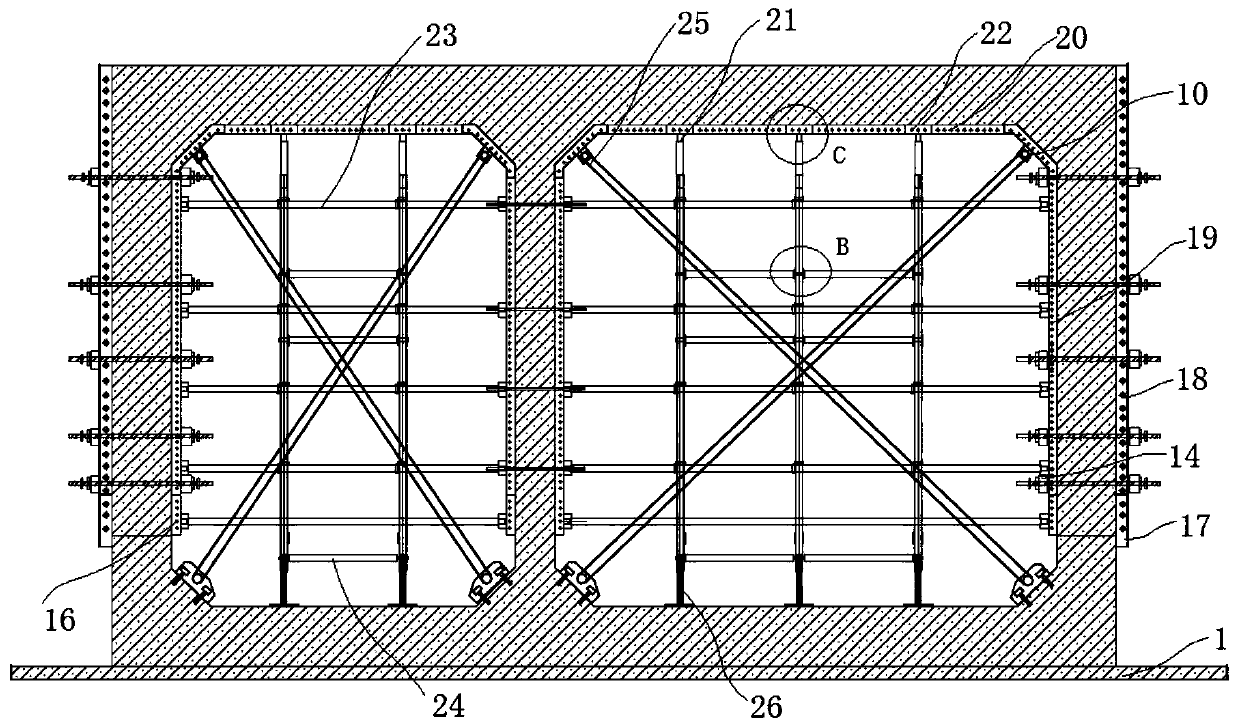

Steel joist constrained vertical seam steel plate shear force wall

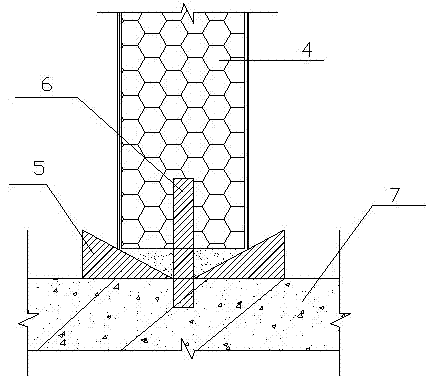

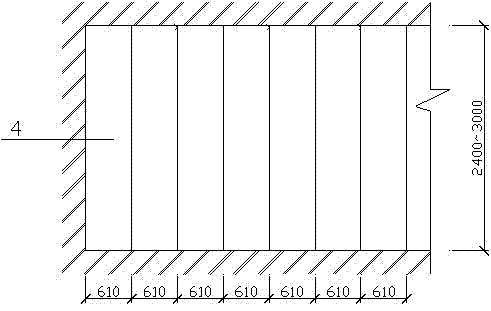

The invention belongs to the technical field of structural engineering, in particular to a steel keel restricting steel slab shear wall with vertical seam which comprises external periphery components, an embedded steel slab with vertical seam and a stiffening rib system, wherein the external periphery components are a frame beam and a frame column, the embedded steel slab with vertical seam adopts steel with low yield point and high ductility or steel with high strength and high ductility, the stiffening rib system comprises general section material, such as a vertical stiffening rib and a horizontal stiffening rib, the embedded steel slab with vertical seam is connected with the edge frame beam through a buttcover slab, an elliptical hole which is opened on the position between the vertical stiffening rib and the buttcover slab is to provide enough sliding space for a screw bolt to penetrate, and the embedded steel slab is connected with the horizontal stiffening rib and the vertical stiffening rib through a common screw bolt. The steel keel restricting shear wall which is provided by the invention is a novel lateral force resisting component of a multiple and high rise building steel structure or other structures, which has the advantages of less slit, low cost, convenient construction and the like, and has good aseismic behavior, ductility and hysteresis energy dissipation capacity, which is a superior aseismic energy dissipating component.

Owner:TONGJI UNIV

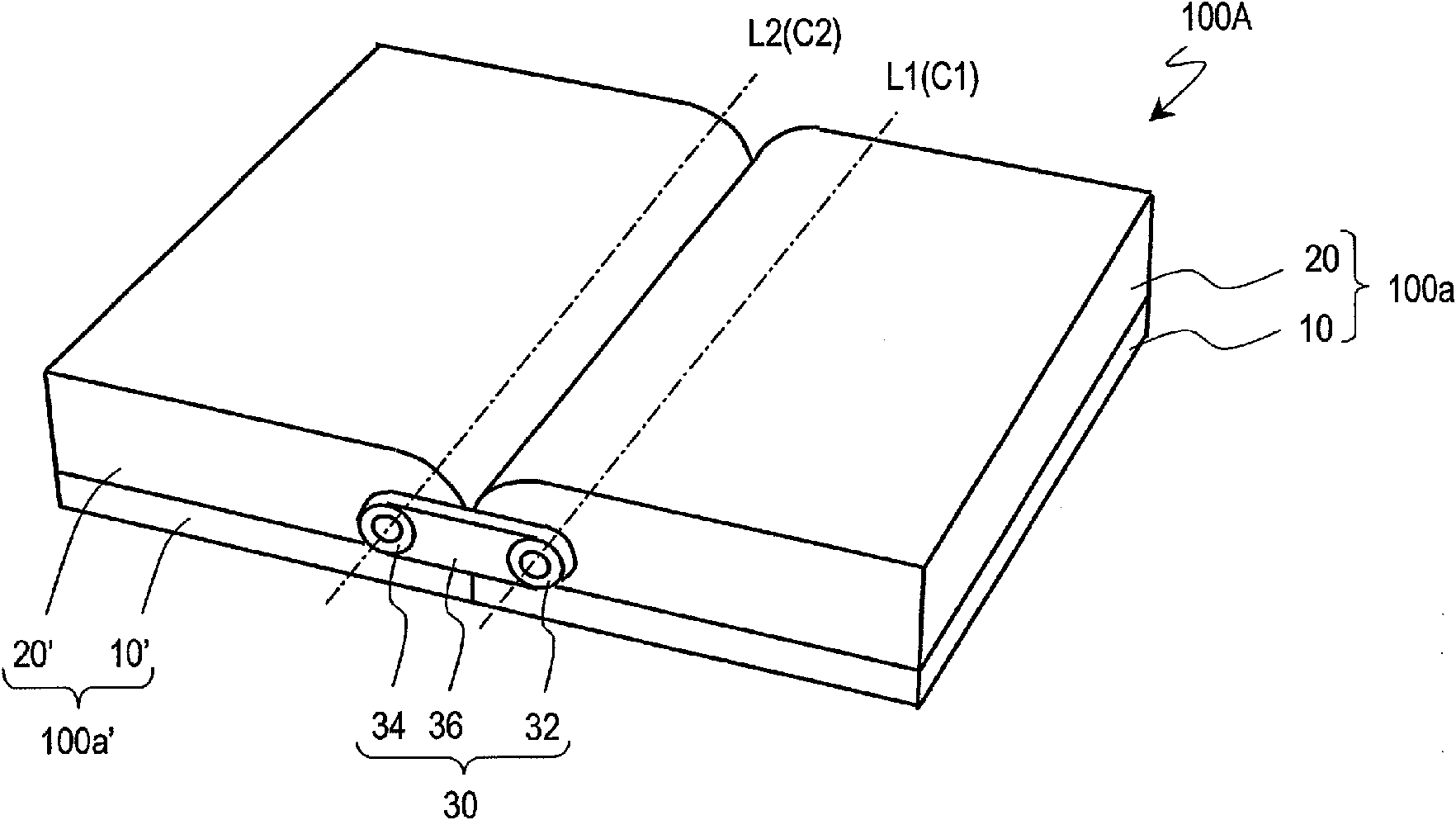

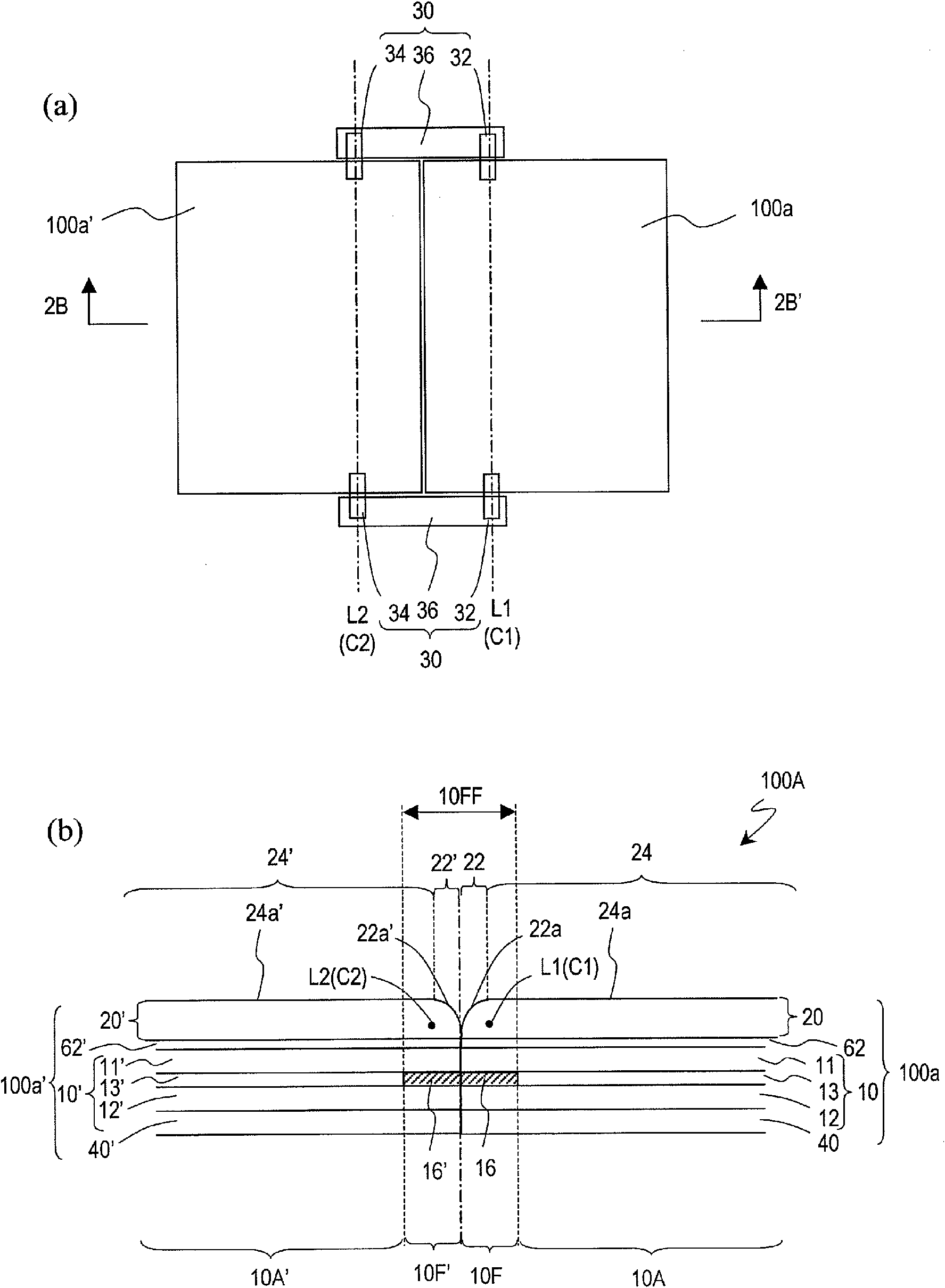

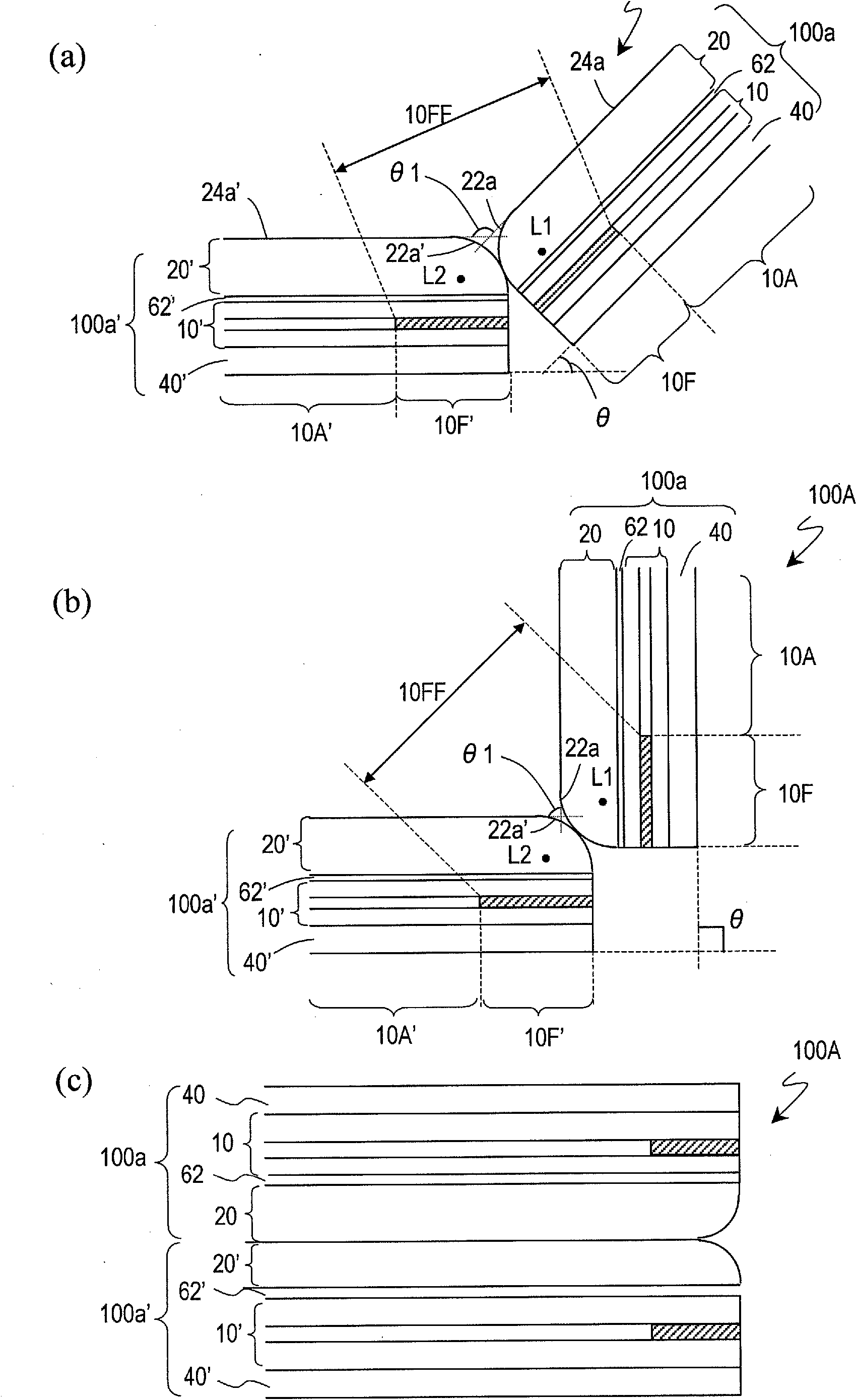

Display device

InactiveCN102473363ALess seamsDetails for portable computersNon-linear opticsDisplay deviceComputer science

A foldable display device (100A) is provided with: first and second display units (100a, 100a'); and biaxial hinge device (30) which connects the first and second display units such that the first and second display units can rotate about first and second rotating axes (L1, L2). The first and second display units respectively have first and second display panels (10, 10') and first and second translucent covers (20, 20'). The first and second translucent covers respectively have: first and second flat plate portions (24, 24') having flat observer-side surfaces (24a, 24a'); and first and second curved surface portions (22, 22') having observer-side surfaces (22a, 22a') as parts of the columnar curved surfaces having the first and second center axes (C1, C2) as respective center axes. The first and second rotating axes of the biaxial hinge device accord with the first and second center axes. Thus, the foldable display device having a small image joint in a state between the opened state and the closed state is provided.

Owner:SHARP KK

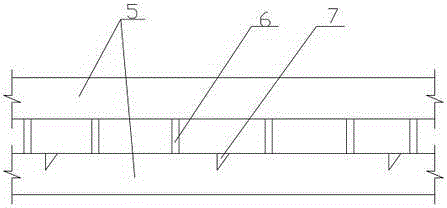

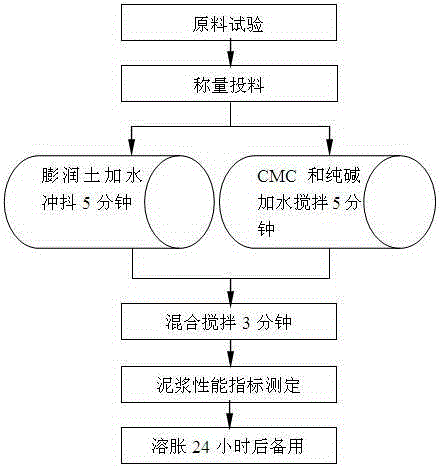

Construction method of underground continuous wall below viaduct

The invention relates to a construction method of an underground continuous wall below a viaduct. The method specifically includes the first step of staking out in a survey, the second step of guiding wall manufacturing, the third step of width adjustment of the underground continuous wall, the fourth step of slurry preparation, the fifth step of grooving construction, the sixth step of reinforcement cage manufacturing, hoisting and releasing, the seventh step of concrete grouting, the eighth step of repeatedly executing the fifth step, the sixth step and the seventh step till construction of a to-be-formed single-width undergrou nd continuous wall construction unit ends, and the ninth step of underground continuous wall joint processing. By means of the construction method, construction of the underground continuous wall can be fast completed while the quality and the quantity are guaranteed, and a viaduct pier will not be affected. Compared with a cast-in-situ bored pile construction method, the construction method has the beneficial effects that construction speed is high in the construction progress, stratum disturbance is small, and therefore the influences on the viaduct pier are small.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

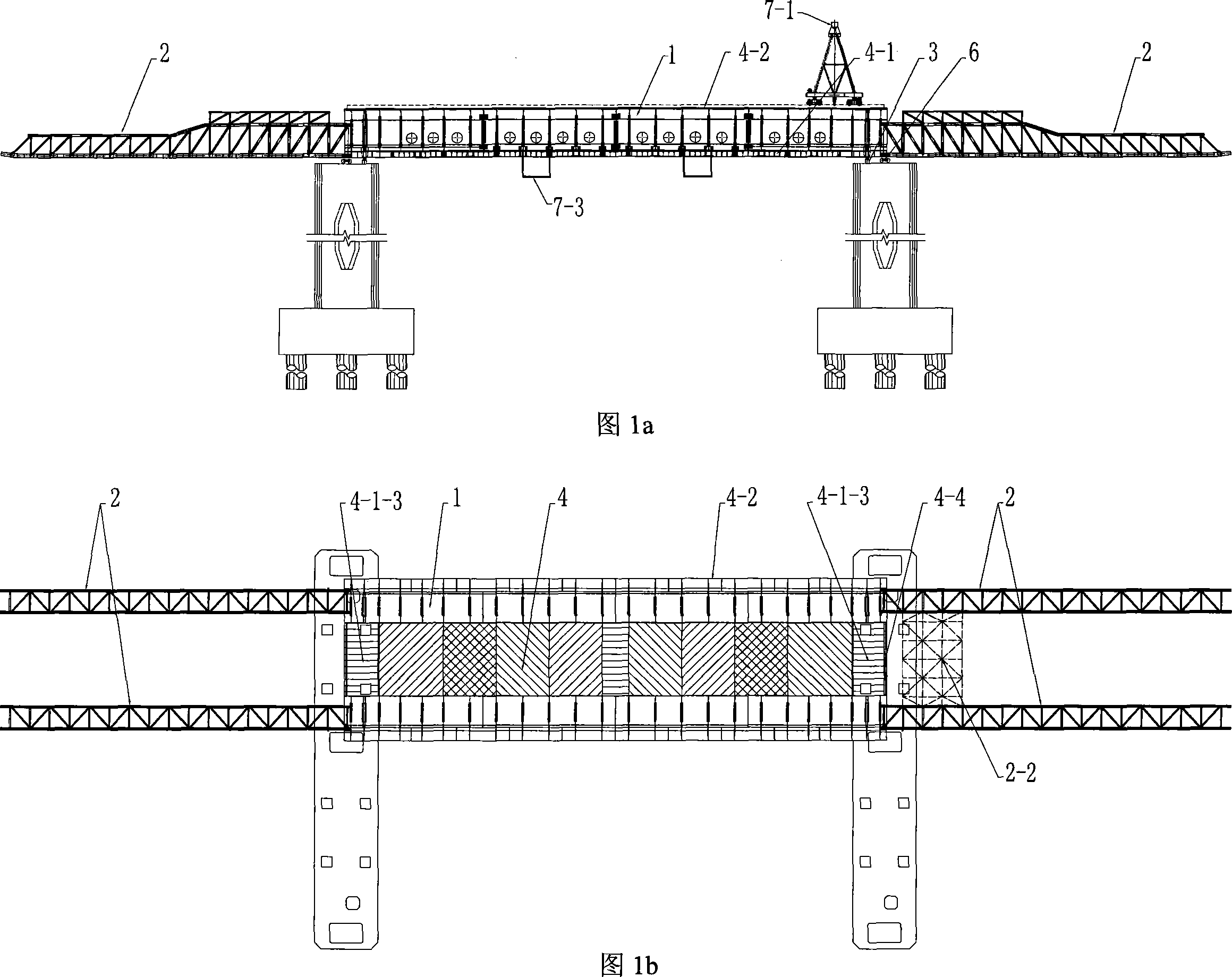

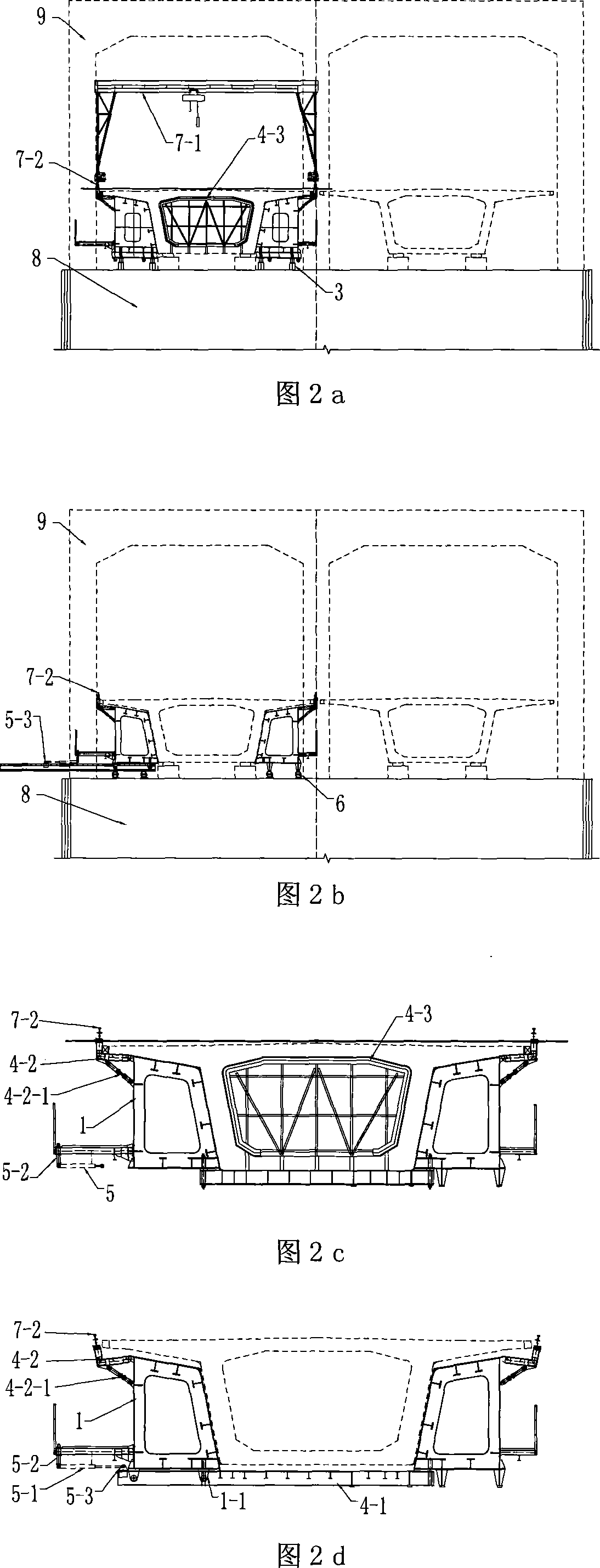

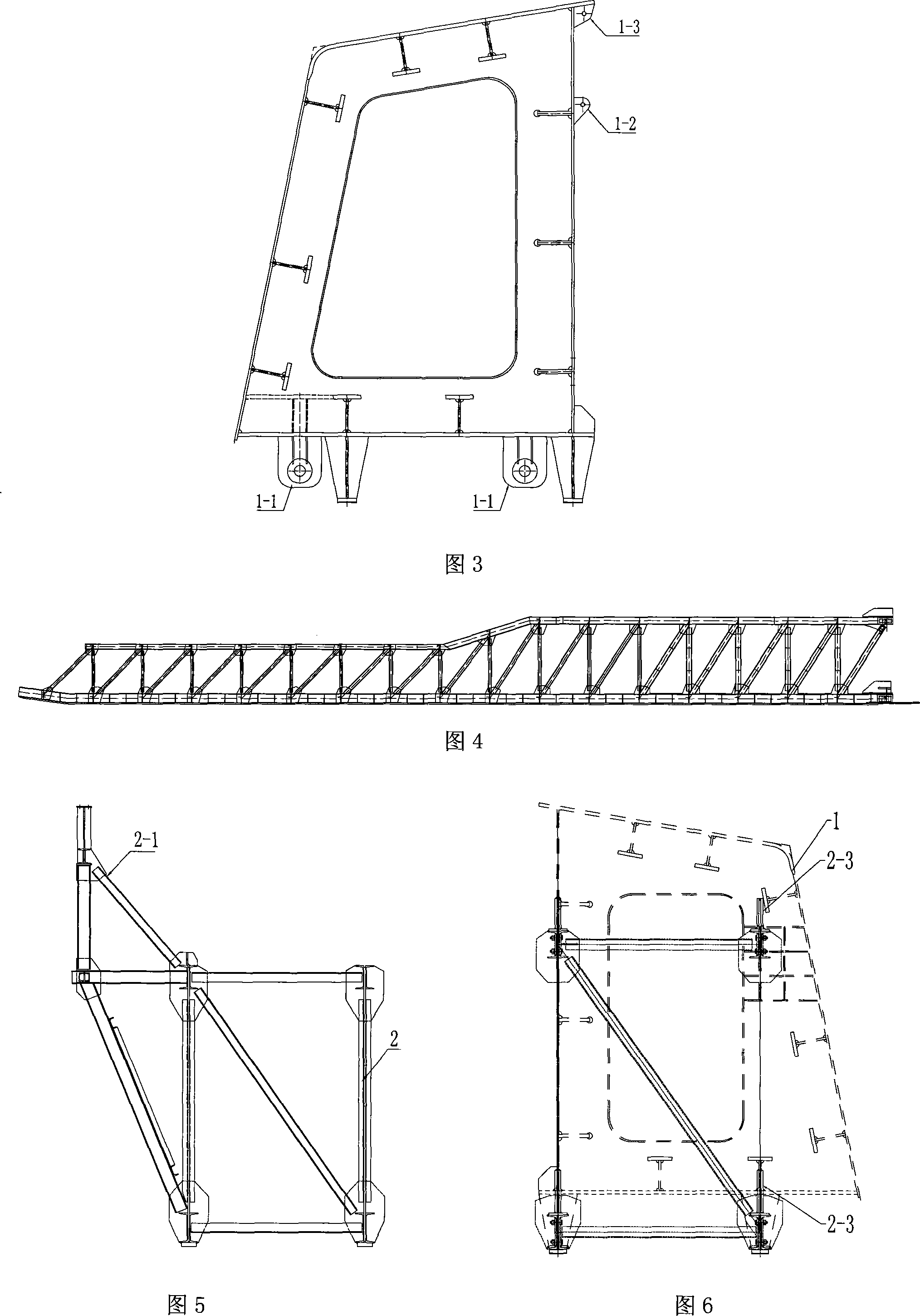

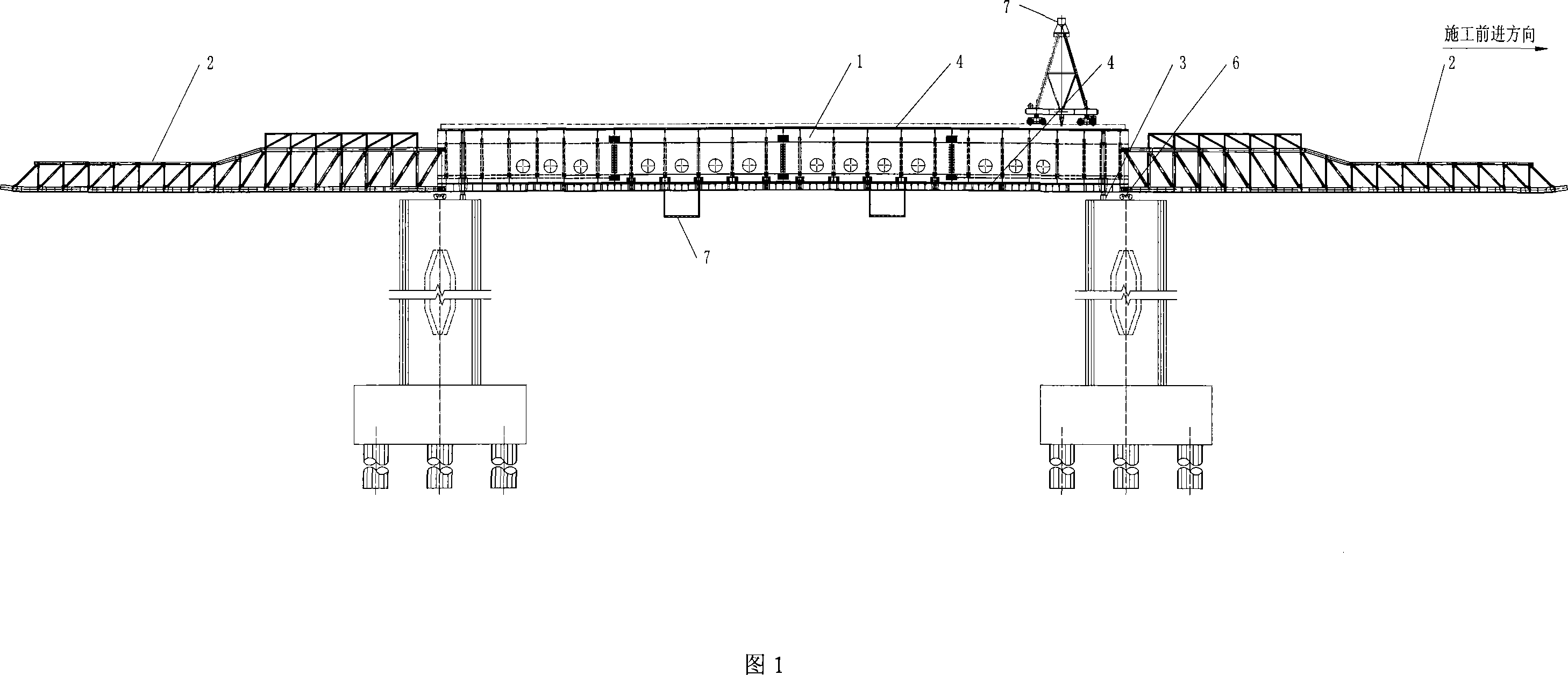

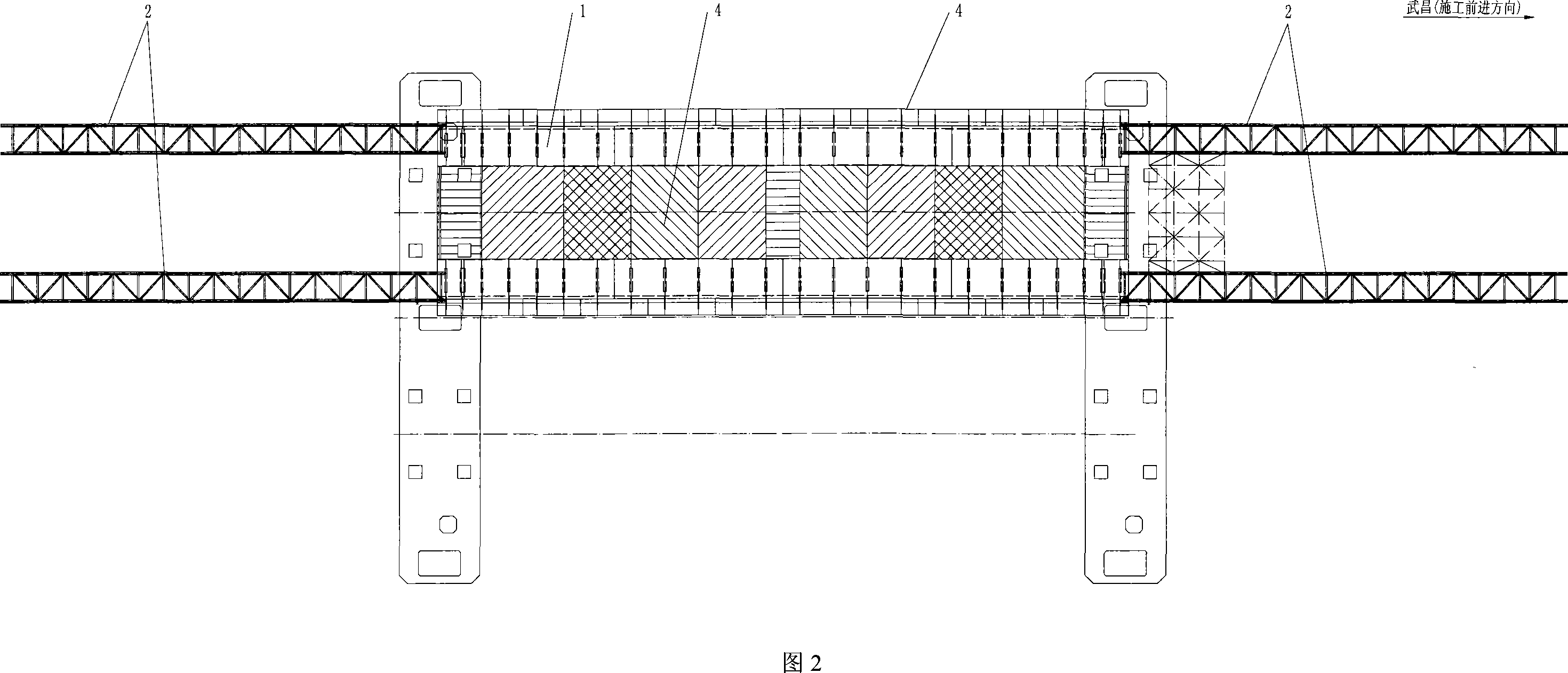

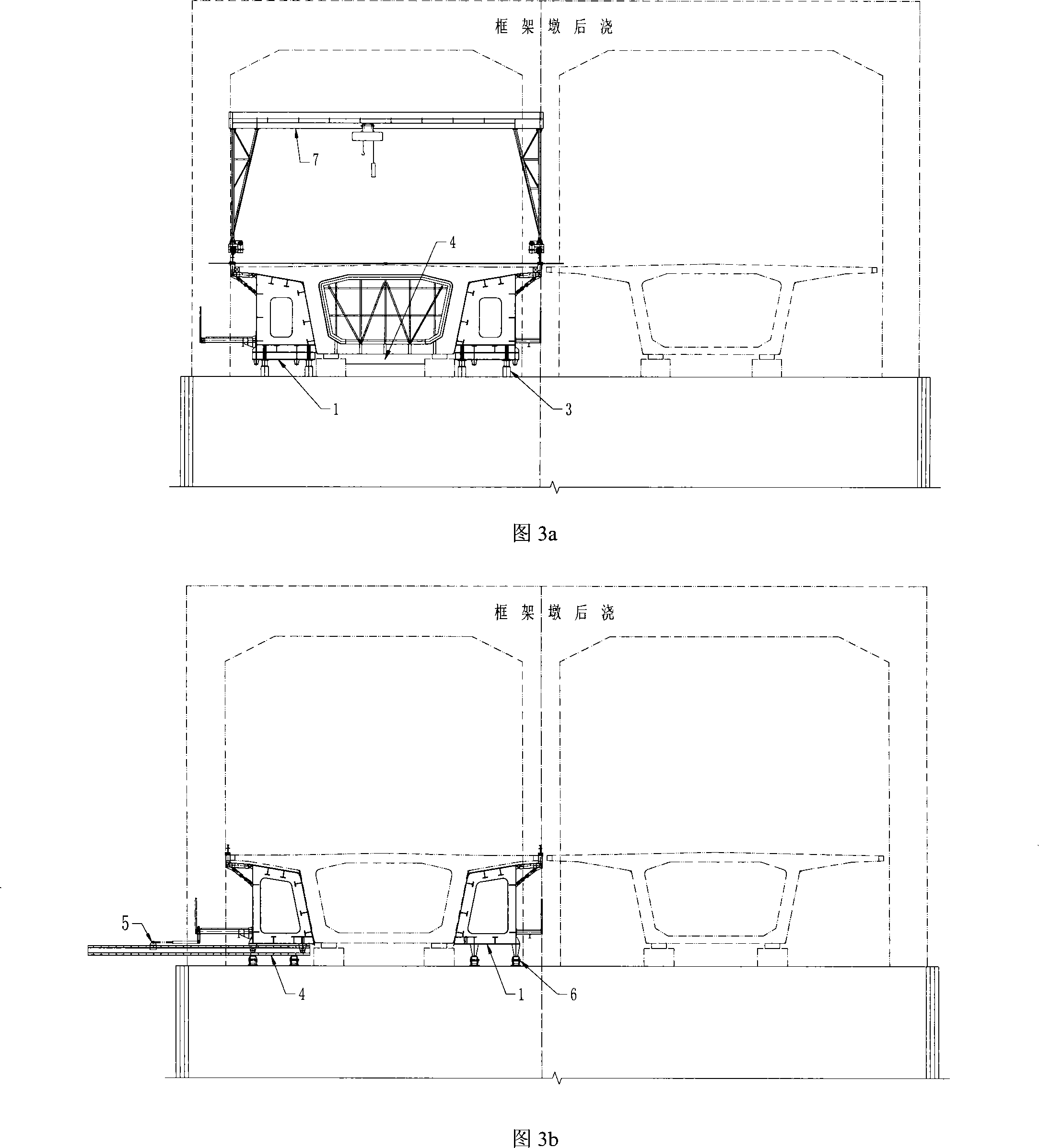

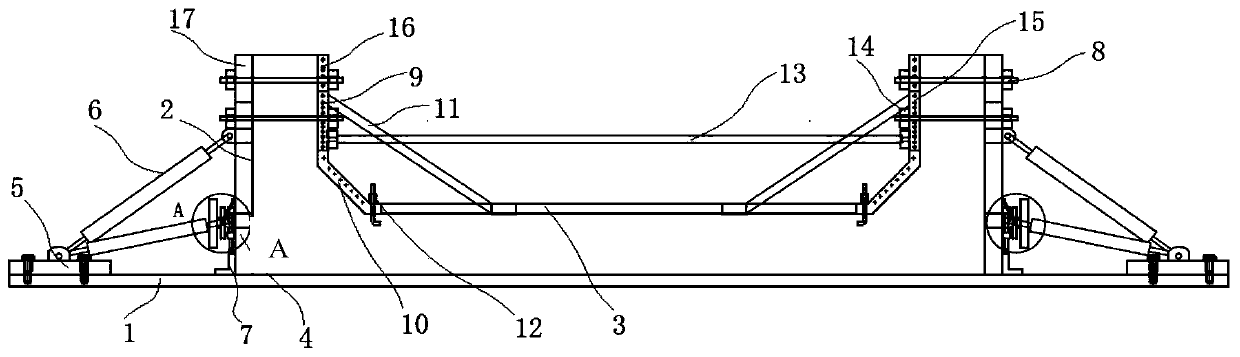

Abnormal shape steel case and orthotropic plate bottom formwork combined type moving die carrier framework and construction method thereof

ActiveCN101117791ALower the altitudeSolve the problem of running through holesBridge erection/assemblyBridge materialsPush and pullSelf locking

A heterotype steel box and an orthogonal heterology plate bottom mold combined moving mould base and a construction method are provided, the load bearing beam of the moving mould base is the beam of the heterotype steel box, and a top plate and an inner web plate are the outer mould of a concrete box beam; the bottom mold employs orthogonal heterology structure, high toughness and low height, through opening and closing by flat pushing at one side, and line feed is performed in the space between the concrete box beam and a pier shaft. The main beam of the moving mold base is directly supported at the pier top, with the self-locking hydraulic jacket to transmit the load and adjust the height, the transverse moving of the moving mold base is finished at the pier top, and therefore, a steel structure landing leg is not required. The longitudinal moving of the moving mold employs a steel strand and a continuous hydraulic jacket for pushing and pulling, power for the longitudinal moving is located at the front pier top, and removes the difficulty of the application of a bridge fabrication machine for a railway and a road bridge, is the construction equipment for the concrete box beam of the railway passenger line and used in the road bridge.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

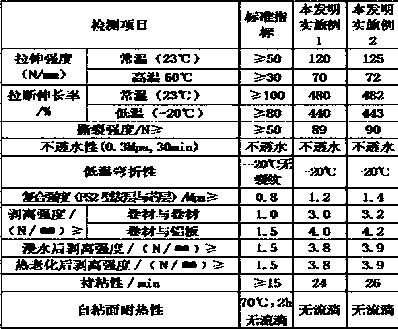

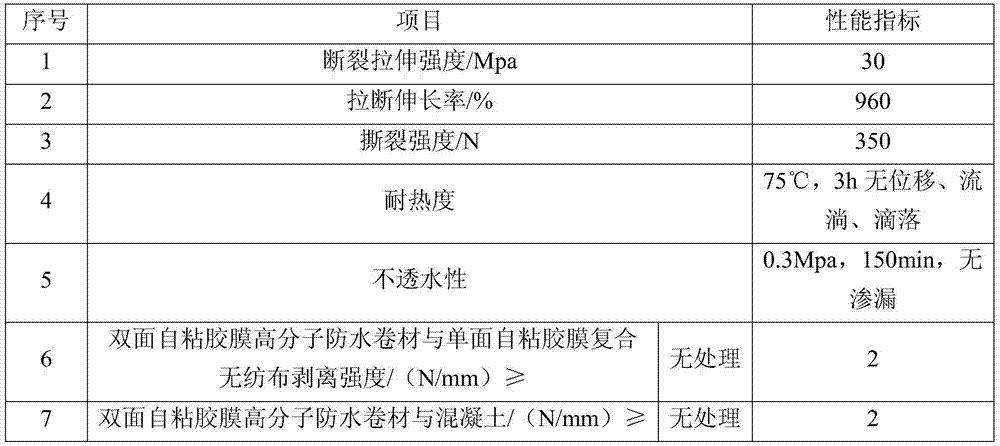

High initial adhesion self-adhering waterproof roll and preparation method

InactiveCN104263261AAvoid punctureAdapt to deformationNon-macromolecular adhesive additivesFilm/foil adhesivesAdhesiveAnti ageing

The invention discloses a high initial adhesion self-adhering waterproof roll which is characterized by comprising the following components in percentage by mass: 35-55% of petroleum asphalt, 5-25% of a softening agent, 5-25% of a modifier, 2-8% of an adhesive, 0.1-2% of a surfactant, 0.1-3% of an anti-aging agent and 5-20% of a filling agent.

Owner:包头市草原驼峰防水材料有限公司

Construction method for assembling light energy-saving composite wallboards on separation wall

InactiveCN102777045ALight in massQuality improvementWallsBuilding material handlingLight energyChisel

The invention discloses a construction method for assembling light energy-saving composite wallboards on a separation wall, wherein the light energy-saving composite wallboards have the advantages of high strength, stable seismic performance and reliable quality. The construction method comprises the following steps: firstly laying side lines of the wall body of the separation wall and fixing the positions of openings of doors and windows; drilling holes in a main structure at a mounting face of the separation wall and implanting reinforcing steel bars; drilling holes in side vertical faces of the composite wallboards; after sizing, erecting the composite wallboards in a way of being aligned to mounting lines on the floor, splicing the composite wallboards orderly according to a splicing sequence, driving wooden wedges into the lower part of battens, wherein the wooden wedges are used for adjusting position so that the battens are arranged in place; fixing the composite wallboards firmly and then driving each composite wallboard into a building surface slantwise at the angle of 45 degrees by using a steel chisel, so as to achieving an anchoring effect; applying mortar for flattening; and finally carrying out maintenance.

Owner:LONGXIN CONSTR GRP

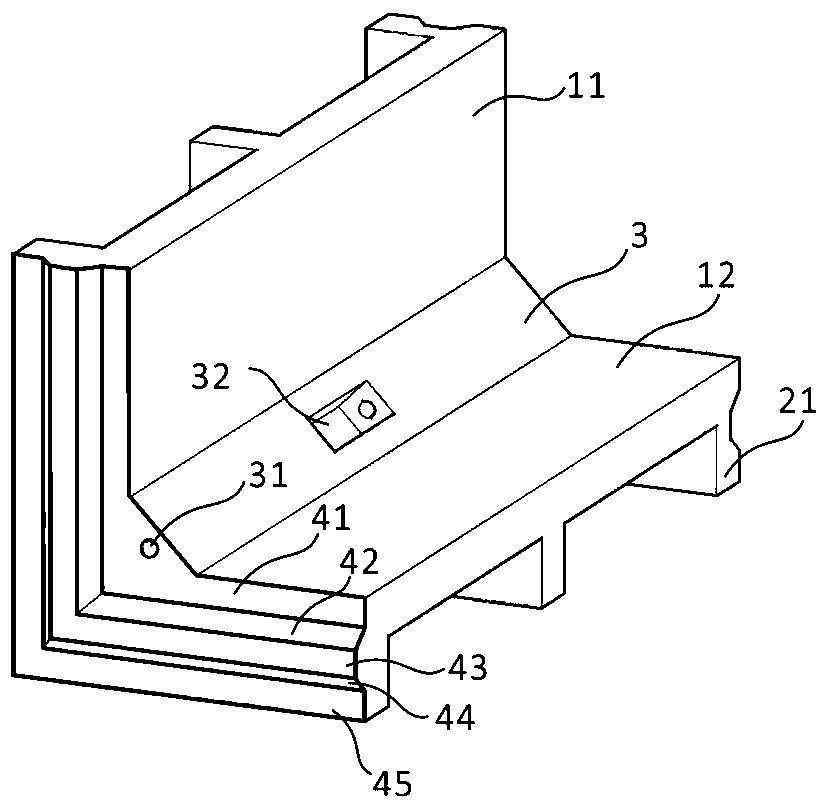

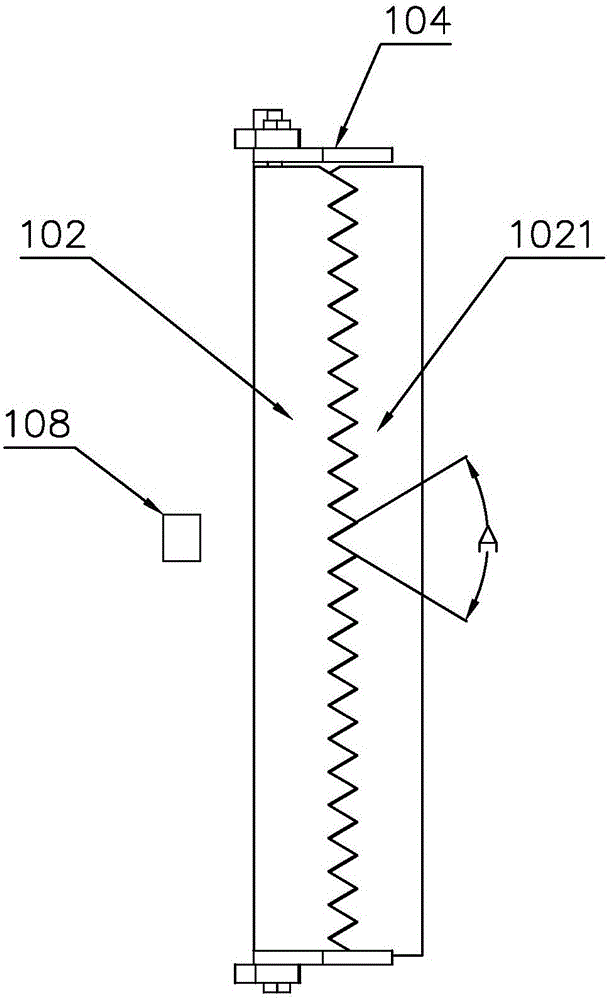

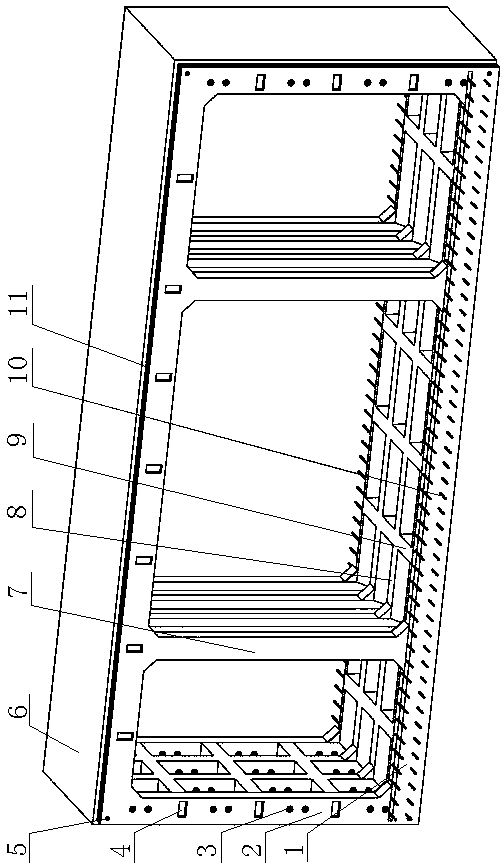

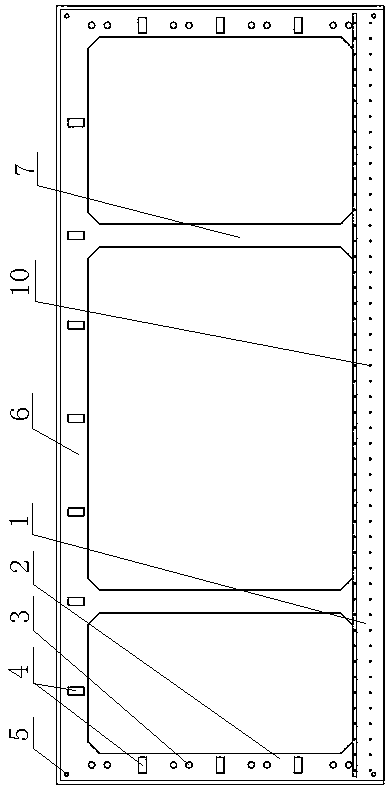

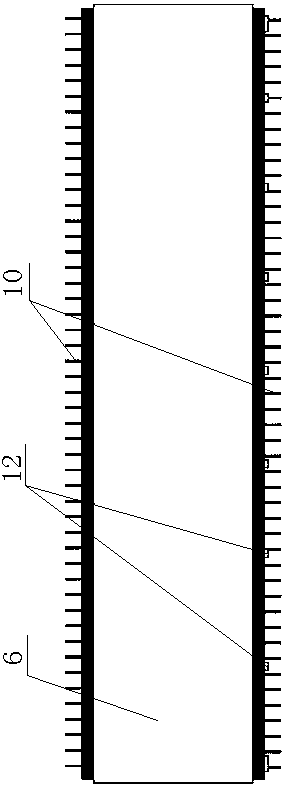

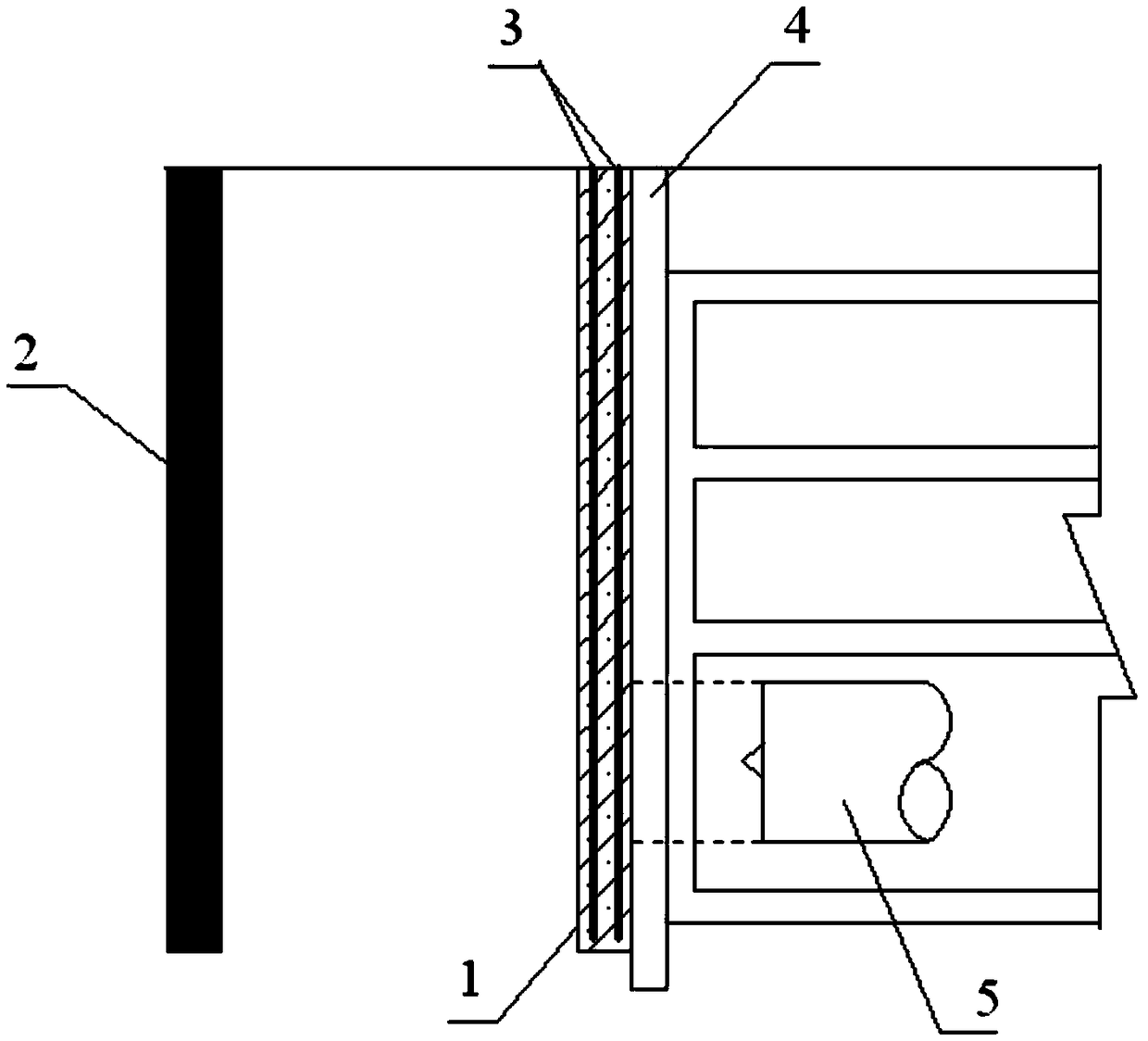

Clasp type intensive bus groove shell

The invention belongs to power transmission equipment, and relates to a shell structure of an intensive bus groove, in particular to a clasp type intensive bus groove shell. The clasp type intensive bus groove shell comprises an upper cover plate, a lower cover plate and a fixed lateral plate which is connected between the two cover plates and deviates to one side, the two cover plates and the fixed lateral plate are made of aluminum alloy profile with an integral structure, the position deviating to the other side between the two cover plates is provided with a movable lateral plate with C-shaped section, and hems of the upper end and the lower end of the movable lateral plate are connected and fixed with the cover plates through bolts or rivets; and the two hem edges of the movable lateral plate are folded outwards to form two sealed grooves positioned at the outside, the bottoms of the sealed grooves are provided with gland strips, the edges of the upper cover plate and the lower cover plate are inserted into the sealed grooves and pressed on the gland strips, and the edges of the upper cover plate and the lower cover plate and the side walls of the sealed grooves are provided with clasps which are mutually matched. The clasp type intensive bus groove shell has the advantages of simple structure, convenience for mounting and good waterproof effect.

Owner:WETOWN ELECTRIC GRP CO LTD

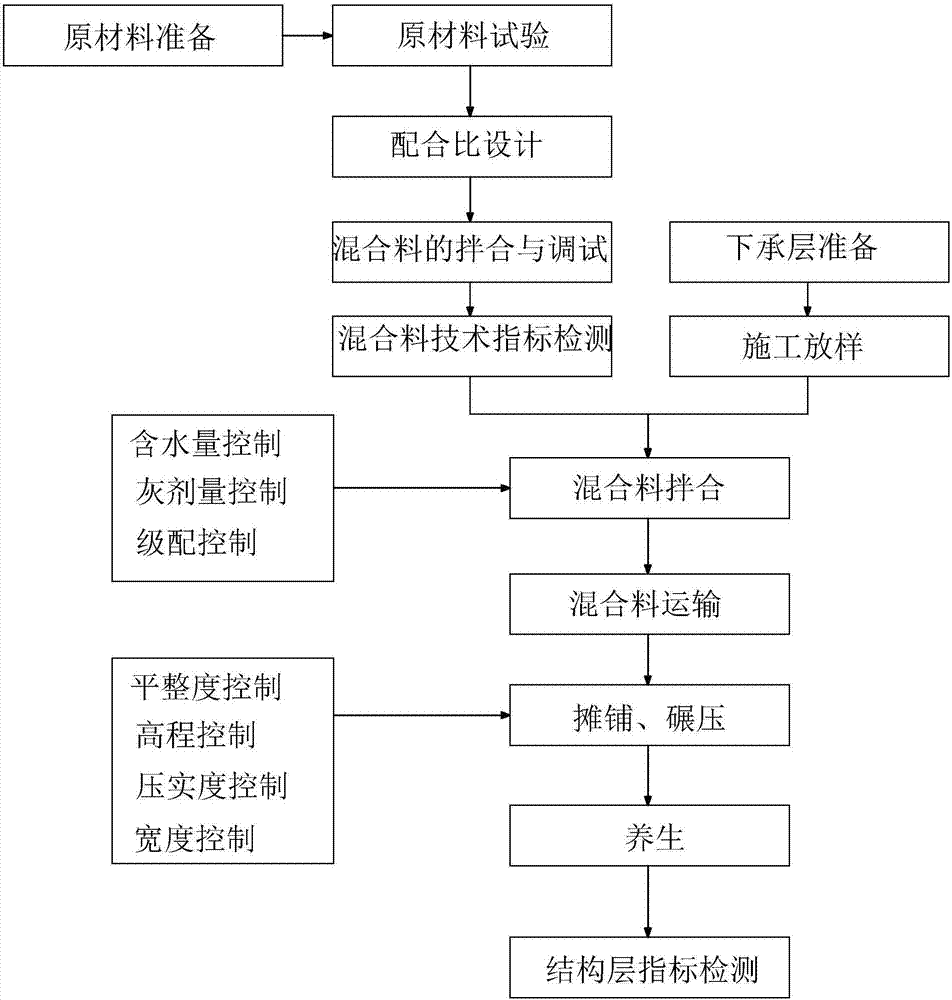

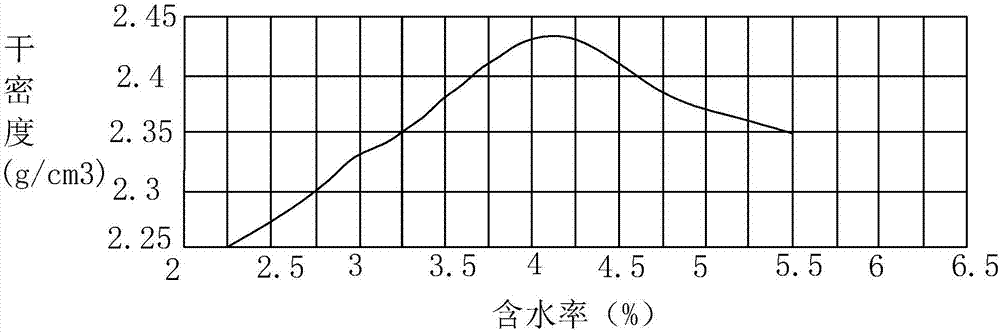

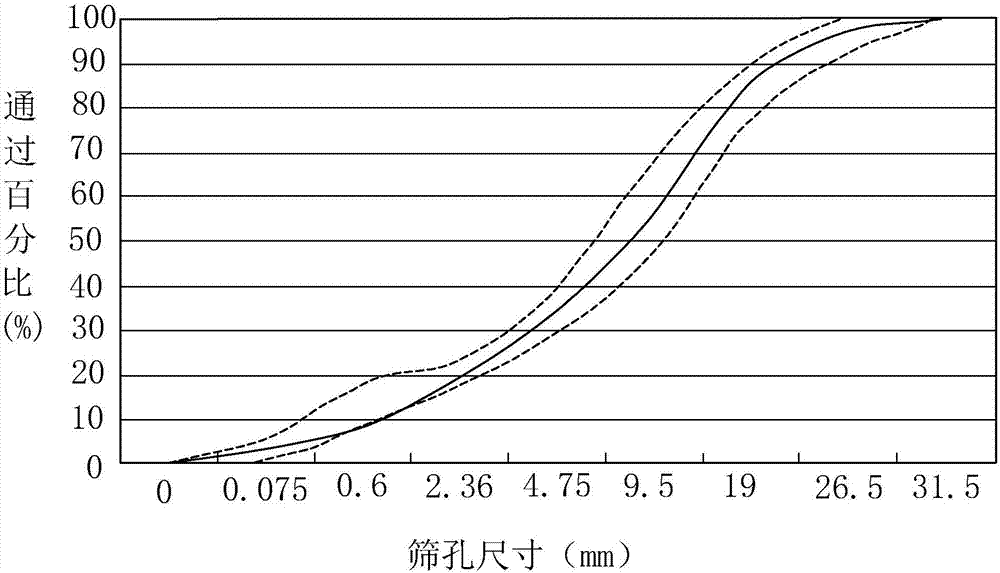

Construction method of crack-resisting cement stabilized crushed stone base course

InactiveCN106894308AEasy to useImprove water stabilityIn situ pavingsClimate change adaptationScreedFreeze thawing

The invention discloses a construction method of a crack-resisting cement stabilized crushed stone base course. The problems that at present, contraction fissures of a traditional cement stabilized crushed stone are many, the surface is prone to loosening after freeze-thaw, the defects of the construction mode exist in the construction side, and therefore large-area cracks and freeze-thaw are generated in the subsequent process of the road surface are solved. According to the key points of the technical scheme, the construction method comprises the following steps that (a), the crack-resisting cement stabilized crushed stone base course comprises a collected material, 3%-5% of cement and water, the curve of the screen hole size of the collected material and the passing percentage is in an S shape; (b), a mixture is mixed; (c), the mixture is conveyed; (d), the mixture is paved, specifically, square timber cushion blocks are put under a paver screed plate in advance, and mixture paving adopts two pavers to synchronously operate in an echelon formation mode; (e), the mixture is grinded; and (f), curing is conducted, specifically, a curing film or geotechnical cloth is covered to conduct hydrating curing, so that the surface of the cement stabilized course keeps a moist state all the time, and the cement stabilized crushed stone base course with the crack-resisting property being obviously improved is obtained.

Owner:昆山市交通工程集团有限公司 +1

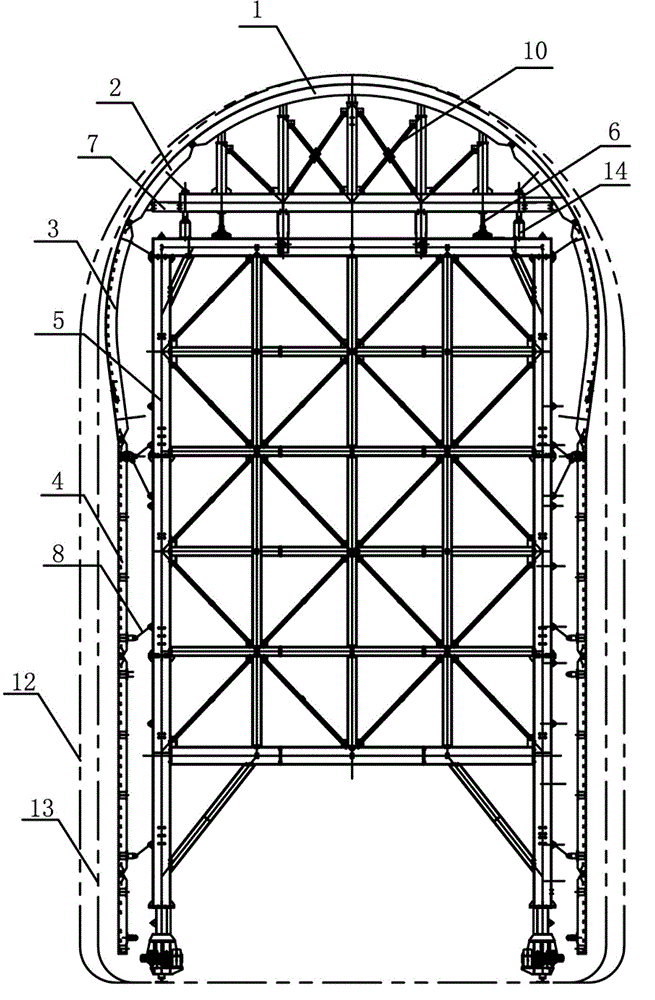

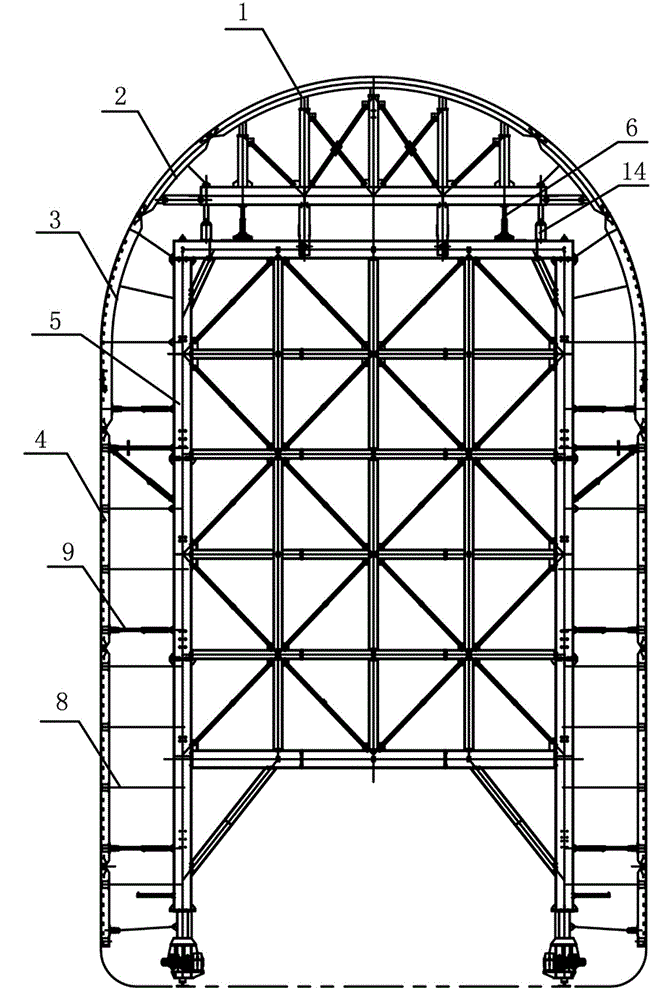

Narrow-beam transition section steel mould trolley for tunnel and construction method

ActiveCN104453949AImprove construction qualityEasy to shrinkUnderground chambersTunnel liningMaterials scienceNarrow beam

Owner:CHINA GEZHOUBA GRP THREE GORGES CONSTR ENG CO LTD

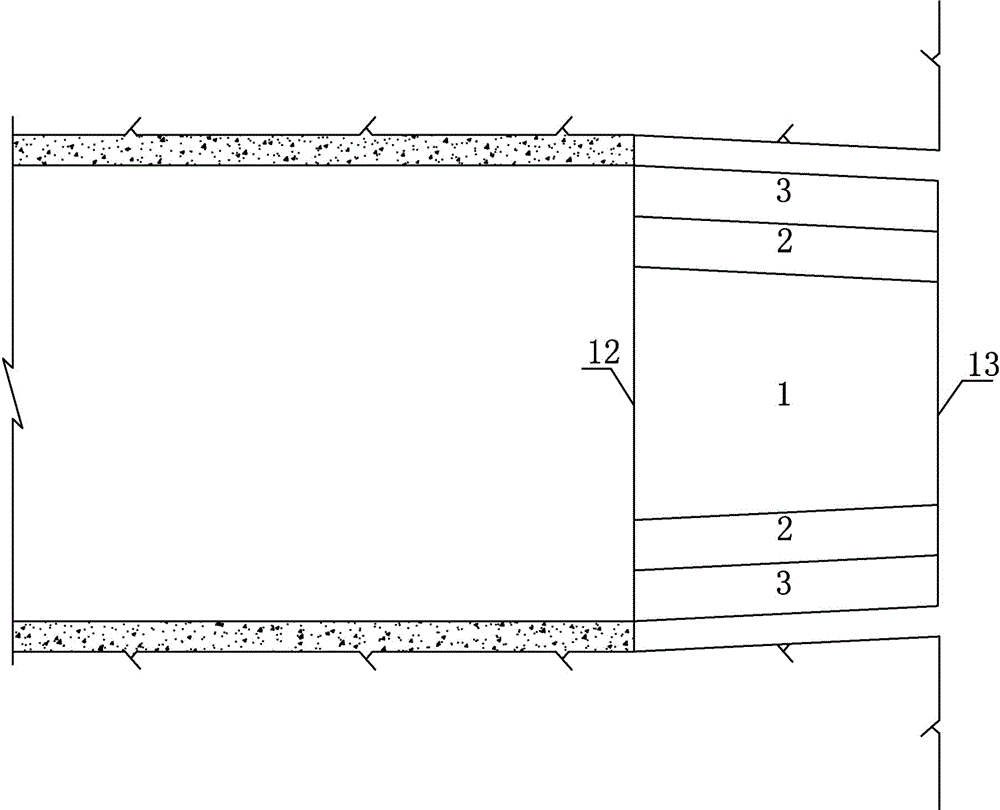

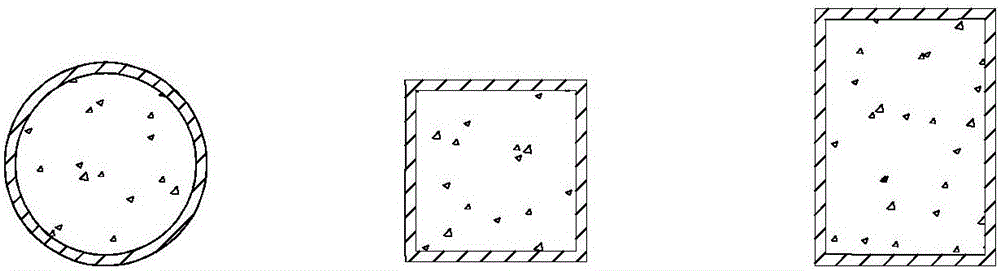

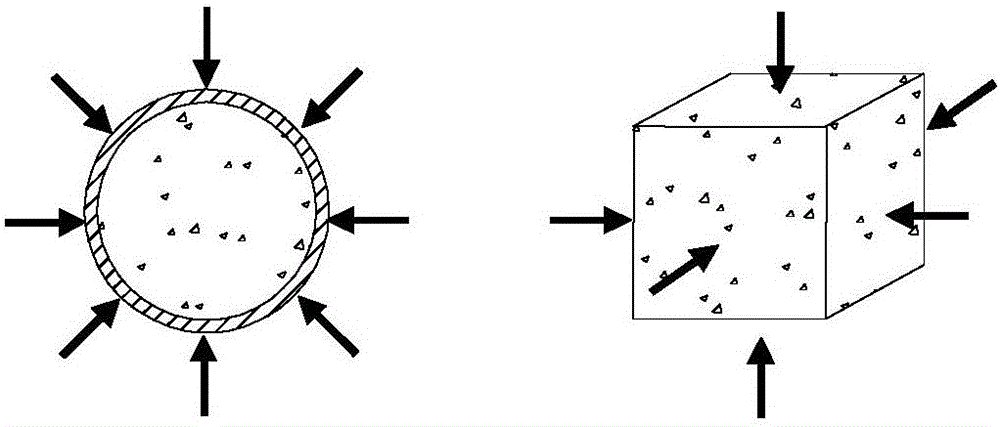

Very-high performance concrete prefabricated assembled pipe gallery and construction method

PendingCN107859065AReduce dosageLose weightArtificial islandsUnderwater structuresPre stressArchitectural engineering

The invention discloses a very-high performance concrete prefabricated assembled pipe gallery and a construction method. The pipe gallery is formed by inserting and splicing a plurality of concrete rectangular culvert monomers which are integrally formed front and back; each of the rectangular culvert monomers comprises a side plate, a bottom plate, a top plate and a partition plate; reinforcing rib structures are arranged on the outer side surfaces of the side plate and the top plate; axil angles are arranged at the connections of the side plate and the bottom plate and the side plate and thetop plate; prestress locking devices are arranged at the axil angles; inserting structures which are matched are arranged at the front and back ends of each of rectangular culvert monomers; and the inserting structures are waterproof devices. The construction method comprises the following steps: 1) preparation of the prefabricated rectangular culvert monomers; 2) excavation and support of foundation pits; 3) foundation treatment and cushion ply paving; 4) hoisting of the prefabricated rectangular culvert monomer sections; 5) penetrating and tensioning of the prestress ribs in position; 6) waterproof experiment of the pipe gallery; and 7) soil mass backfilling. The pipe gallery material dosage is reduced greatly, the self weight is reduced greatly, and the very-high performance concrete prefabricated assembled pipe gallery is convenient to transport and hoist, few in step, short in construction period and good in waterproofness and durability.

Owner:HUNAN UNIV

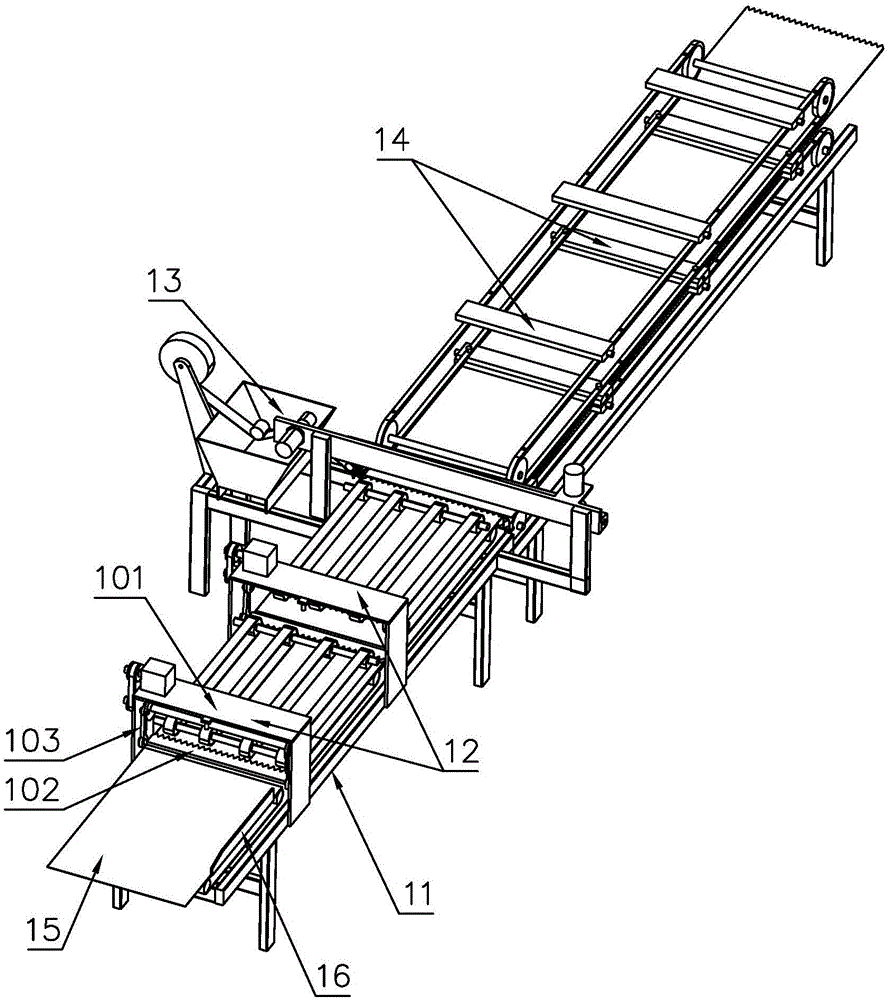

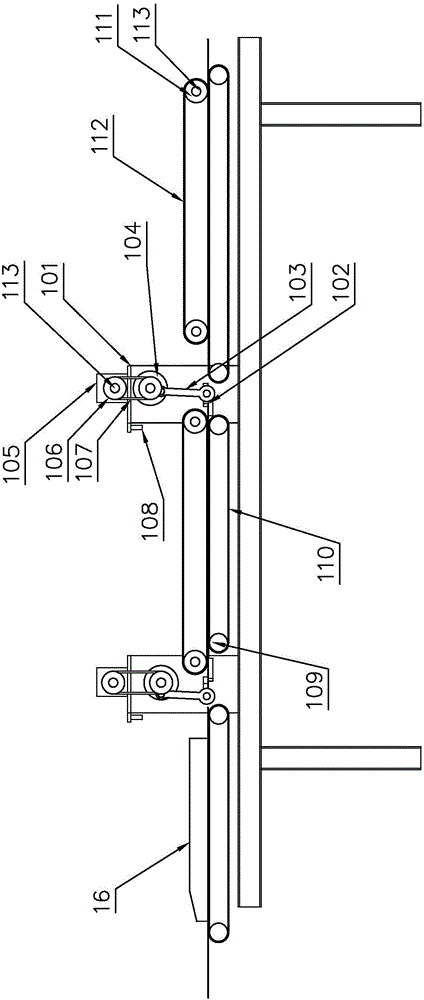

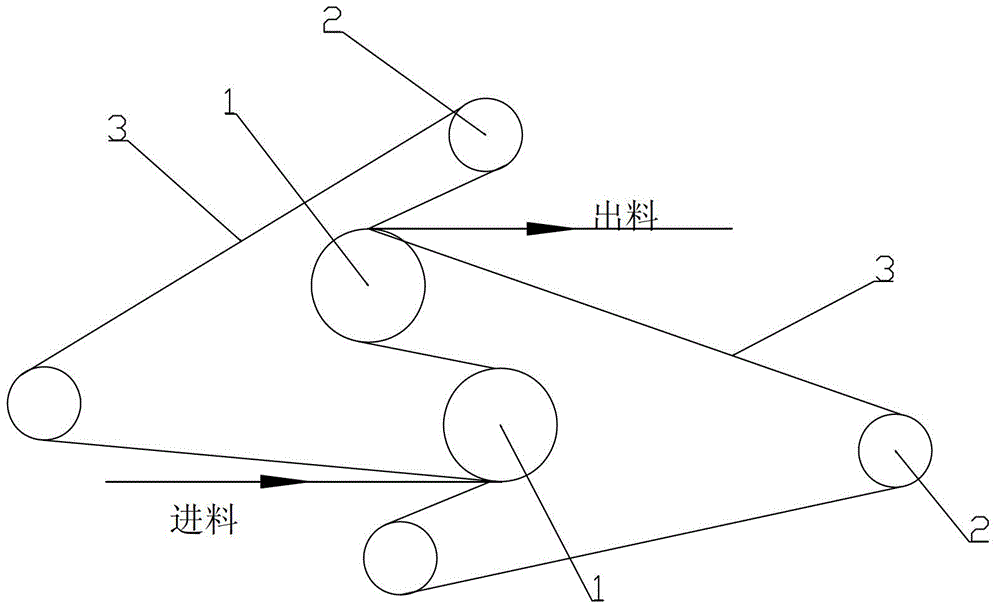

Fast tooth joint vertical veneer continuous splicing machine and splicing process thereof

ActiveCN105922370AGuaranteed StrengthMeet the needs of useOther plywood/veneer working apparatusPlywood pressesWoven fabricHot press

The invention discloses a fast tooth joint vertical veneer continuous splicing machine and a splicing process thereof. The fast tooth joint vertical veneer continuous splicing machine comprises a rack, a comb tooth mechanism, a butt joint mechanism and a hot-pressing forming mechanism; the comb tooth mechanism comprises a supporting frame, comb teeth, a cutting board base, a connection rod, an eccentric wheel, a motor, a synchronous belt wheel, a synchronous belt, a photoelectric switch, a carrier roller, a carrying and conveying belt, a transmission roller, a transmission belt and a transmission shaft; the butt joint mechanism is arranged on one side of the comb tooth mechanism and comprises a support, a glue pond, non-woven fabric, a gluing roller, a conveying roller brush, a cross beam, a pressing roller, a pressing roller supporting base, a clamp, a supporting arm, a traction base, an adjusting gap block and a motor; and the hot-pressing forming mechanism is arranged on one side of the butt joint mechanism and comprises a hot-pressing block, a clamping belt and a hot-pressing roller. The fast tooth joint vertical veneer continuous splicing machine makes veneer form spliced veneer large in breadth after the veneer is subjected to butt joint of the comb teeth and vertical splicing of the non-woven fabric before use, the strength of the position of a joint of spliced plates is guaranteed, and the using requirement of plywood veneer is met.

Owner:山东昶兴智能科技有限公司

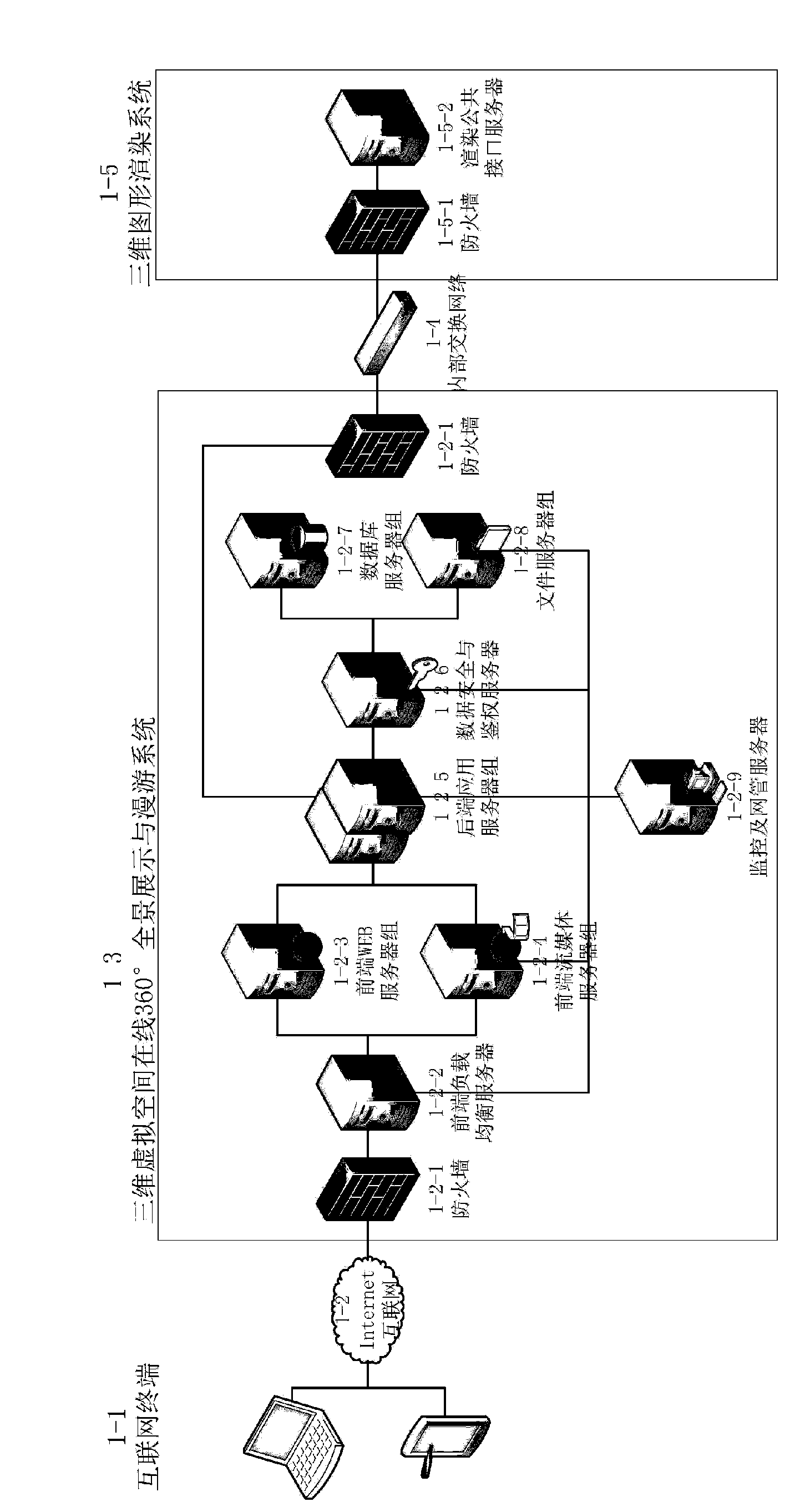

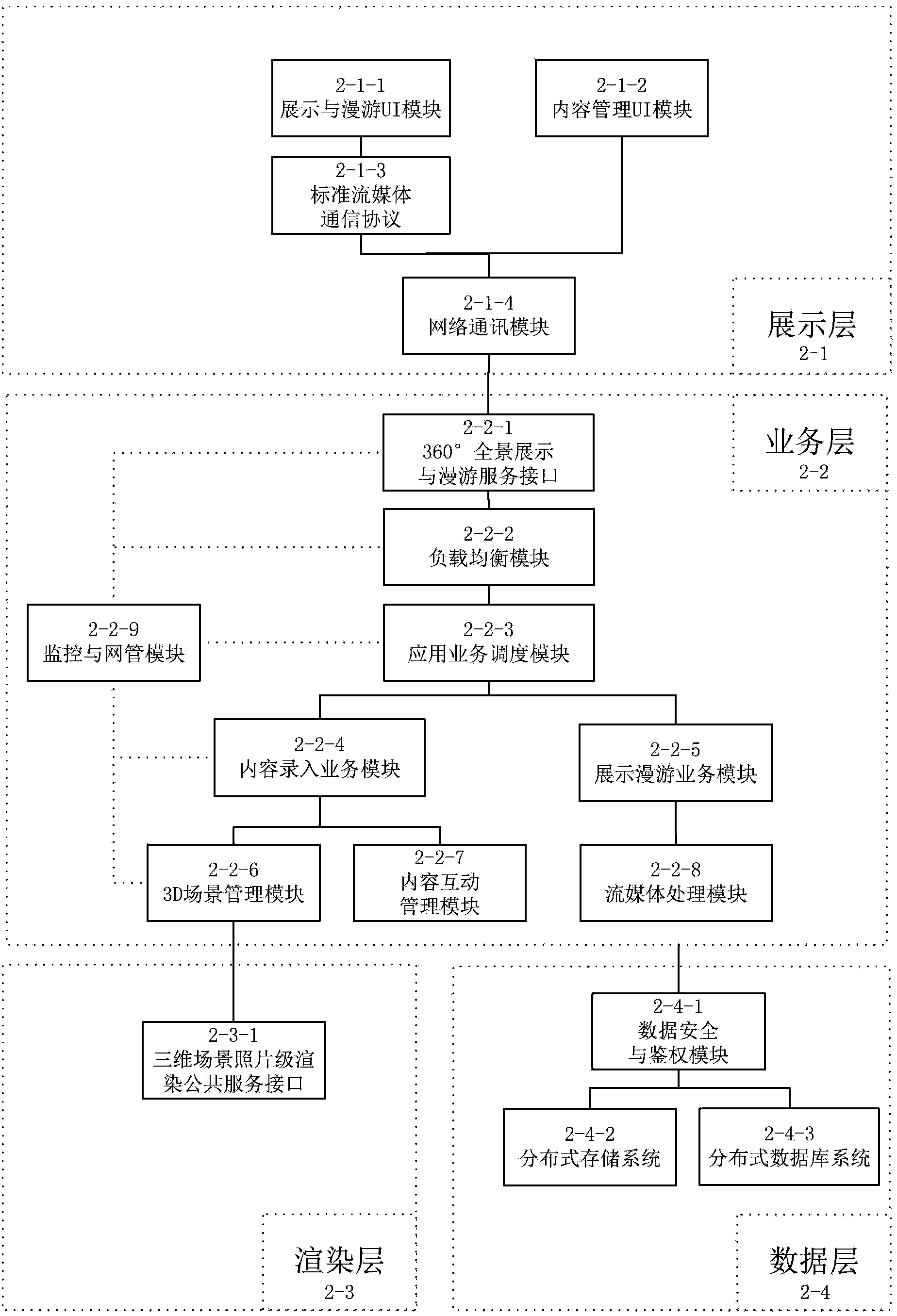

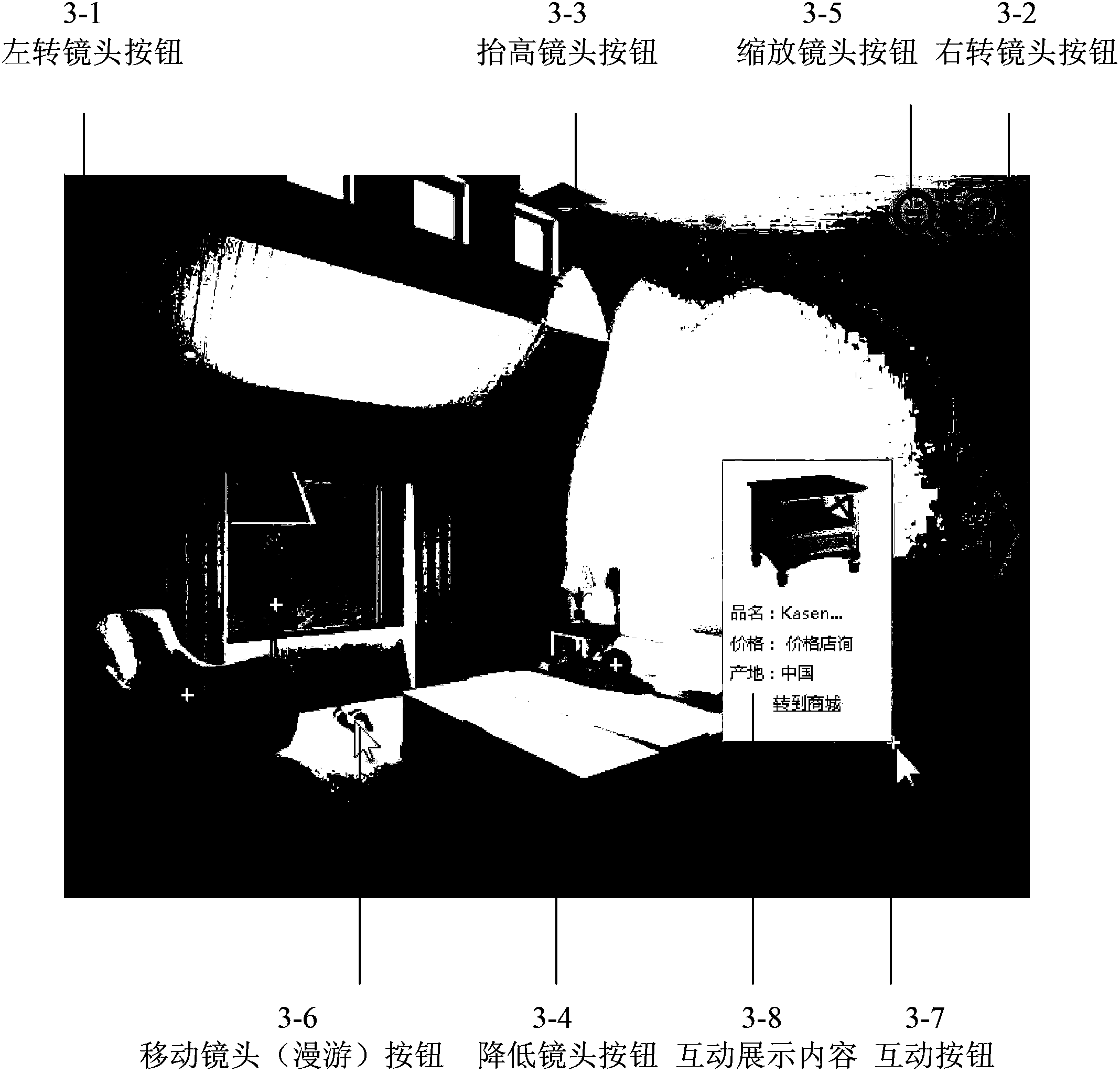

Implementation method and system for on-line panorama showing, immersion type roaming and man-machine interaction of three-dimensional scene

ActiveCN103401875AProjection formula continuousLess seamsTransmissionInput/output processes for data processingRoamingThree-dimensional space

The invention discloses an implementation method and system for on-line panorama showing, immersion type roaming and man-machine interaction of a three-dimensional scene. A 'three-dimensional scene-two-dimensional picture' mapping method based on globular projection is provided, and more three-dimensional space information such as depth is described on the two-dimensional panoramic picture and the attached description file, so that the defects that a traditional 360-degree panorama is only showed, and is not subjected to immersion type roaming and man-machine interaction are broken through, a novel 360-degree panorama showing and immersion type roaming technology with high plotting quality and high freedom degree of a camera is formed, and a novel man-machine interaction function is added on the basis of showing and roaming to meet the business application requirement.

Owner:JIANGSU CUDATEC TECH CO LTD

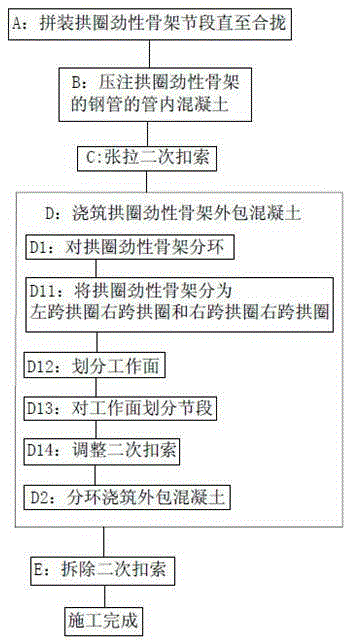

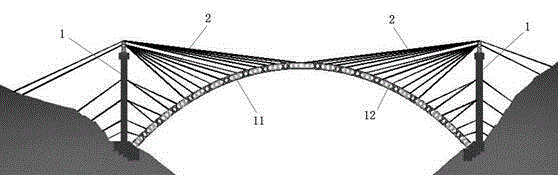

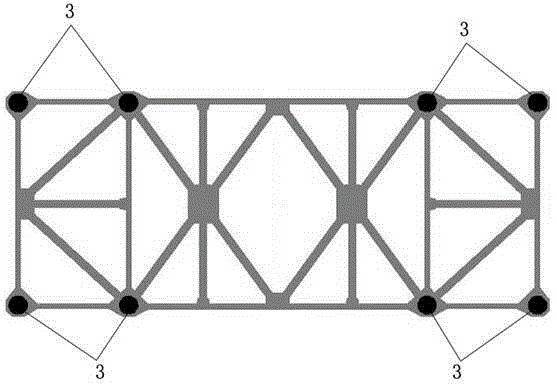

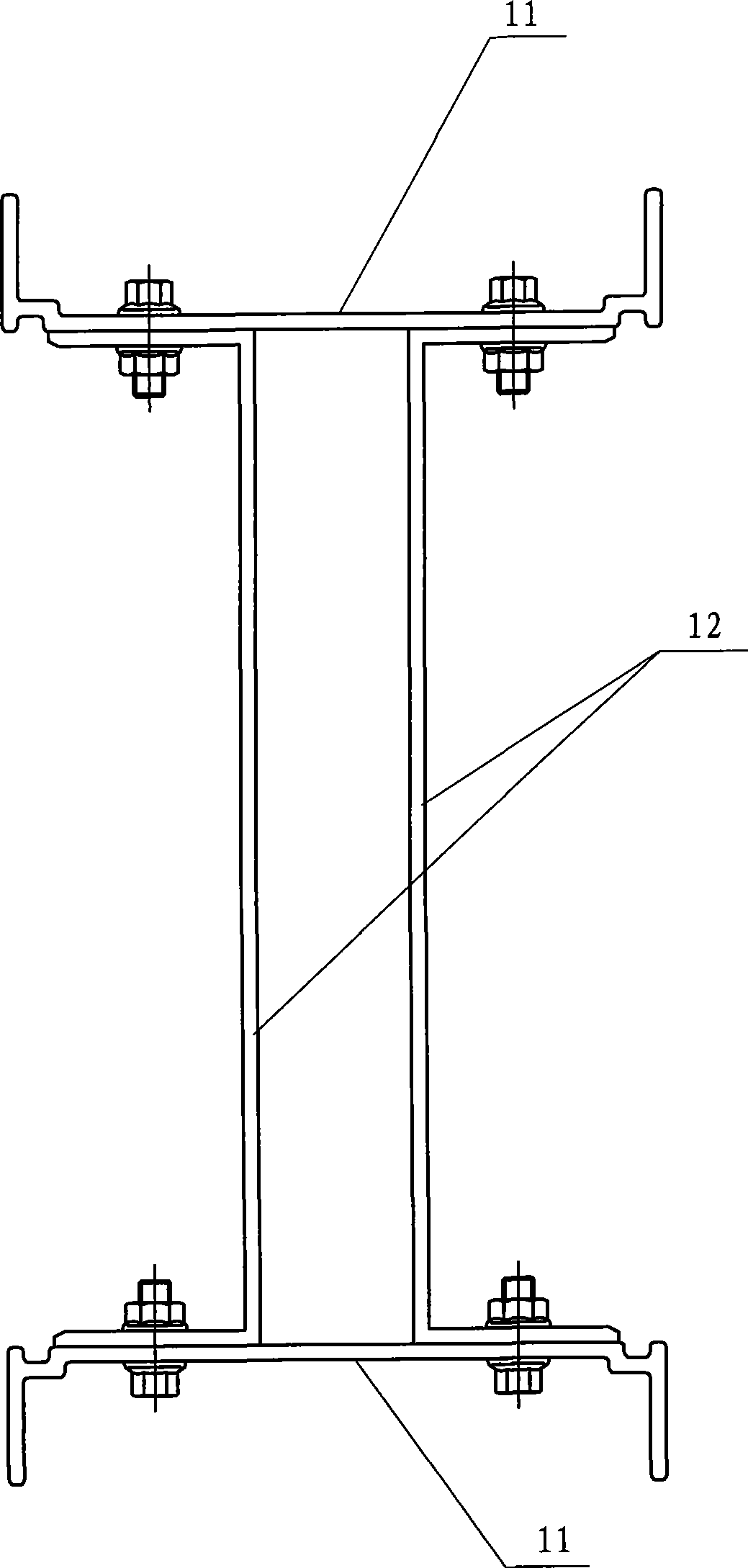

Arching method for stiff skeleton concrete arch bridge

ActiveCN105350442AReduce construction costsReduce construction difficultyBridge erection/assemblyArch-type bridgeBridge engineeringArchitectural engineering

The invention belongs to the technical field of bridge engineering, and particularly relates to an arching method for a stiff skeleton concrete arch bridge. The arching method sequentially includes the following steps that A, segments of an arch ring stiff skeleton are spliced till the segments are folded; B, concrete in steel pipes of the arch ring stiff skeleton is pressed and poured; C, secondary fastening cables are tensioned; D, outer wrapped concrete of the arch ring stiff skeleton is poured; and E, the secondary fastening cables are detached. According to the arching method, due to tensioning of the secondary fastening cables, in the outer wrapping pouring process, no other supporting components need to be arranged for supporting the arch ring stiff skeleton; firstly, the construction cost is reduced, and the construction difficulty is lowered; meanwhile, due to the fact that the fastening cables are used for tensioning the arch ring stiff skeleton, the occupied space is smaller than that of other supporting manners during connection of the fastening cables and an arch ring; and blocking in the following concrete pouring process is reduced, and following concrete pouring construction is further facilitated.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Toothed mating surface case for compact bus groove

The invention belongs to a transmission facility, which relates to a housing structure for a compact bus duct, in particular to a sawtooth mating surface housing for a compact bus duct. The sawtooth mating surface housing for the compact bus duct comprises an upper cover plate, a lower cover plate and a fixed side plate connected between the two cover plates and biased towards one side. The two cover plates and the fixed side plate are made of aluminum alloy sectional bars in monolithic construction. A flexible side plate with C-shaped cross section is arranged between the two cover plates, and is biased towards the other side. The folded edges at the upper end and the lower end of the flexible side plate are fixedly connected with the cover plates through bolts or rivets. The cross sections of the junction surfaces between the folded edges, the upper cover plate and the lower cover plate are in the shape of saw teeth meshed with each other. The housing structure has the advantages of simple structure, convenient installation and effective watertightness.

Owner:WETOWN ELECTRIC GRP CO LTD

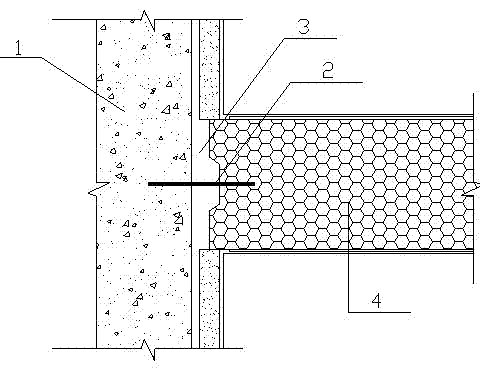

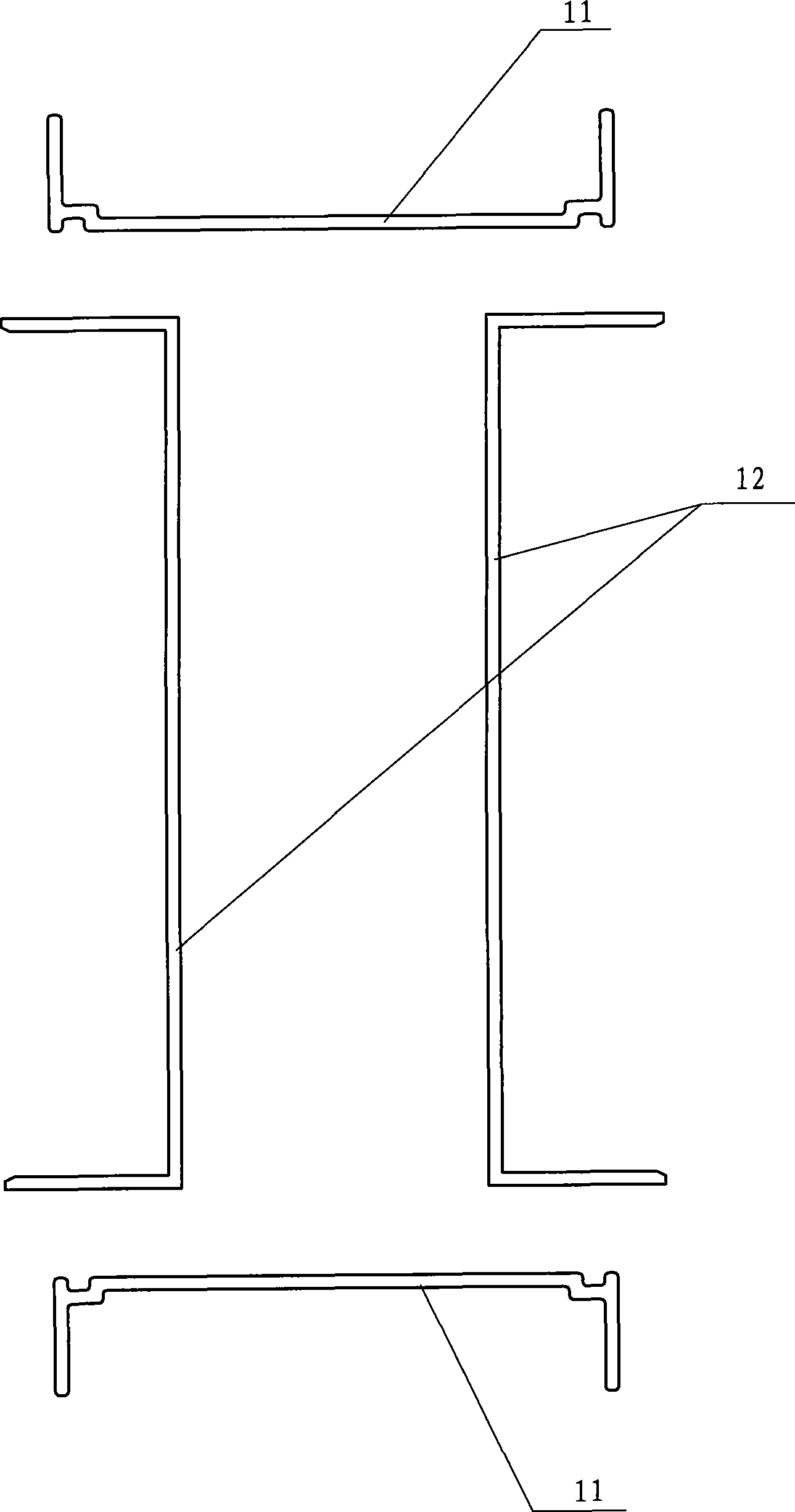

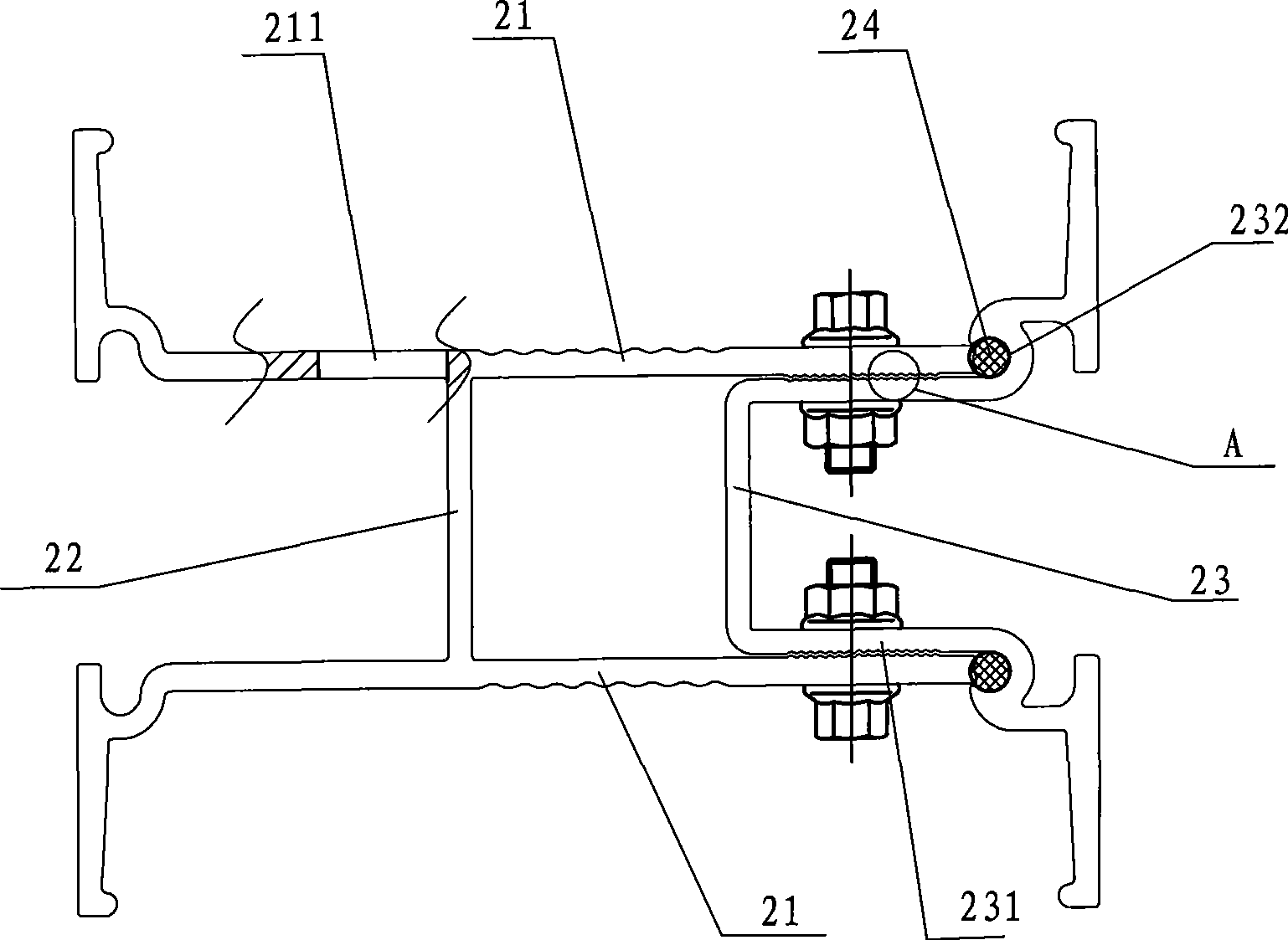

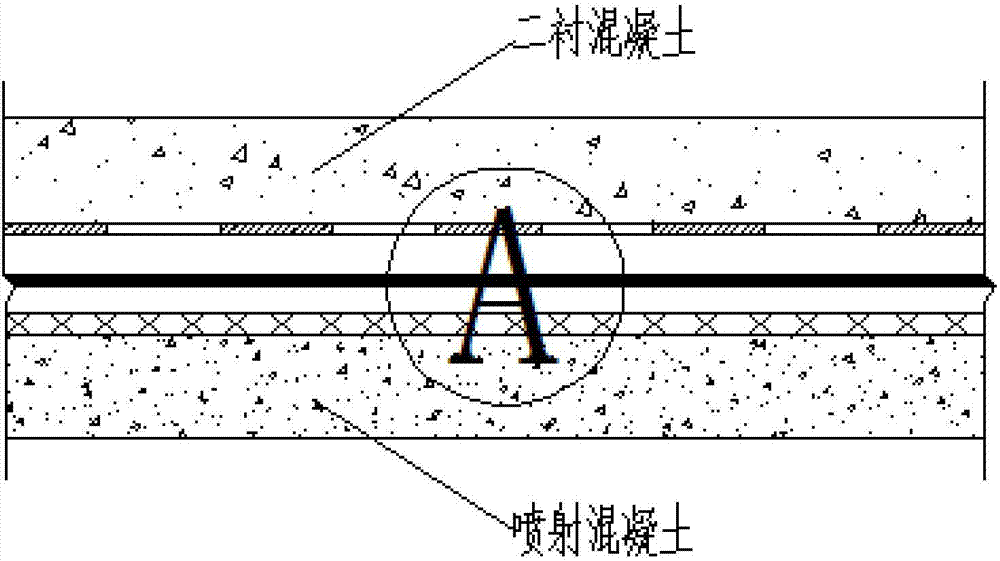

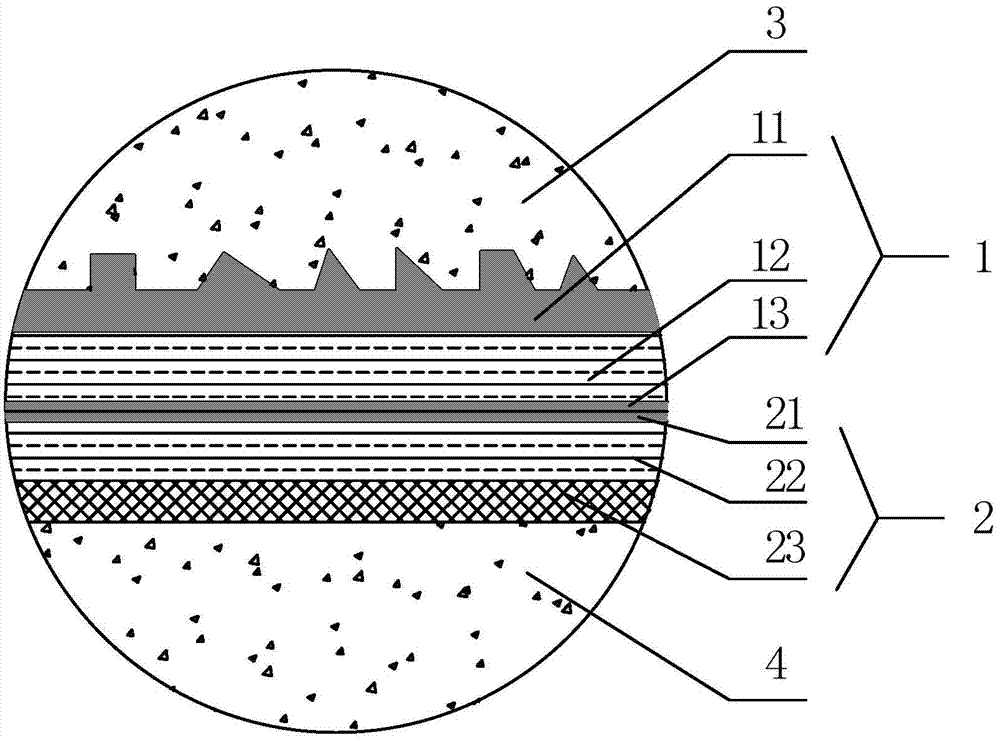

Self-adhesive composite waterproof layer for tunnel and paving method of self-adhesive composite waterproof layer

ActiveCN104847382AIncreased waterproof barrierWith waterproof functionUnderground chambersTunnel liningShotcretePolymer

The invention belongs to the technical field of waterproof materials and the paving methods thereof and specifically relates to a self-adhesive composite waterproof layer for a tunnel and a paving method of the self-adhesive composite waterproof layer. The waterproof layer is composed of a double-faced self-adhesive film polymer waterproof roll and single-rolled self-adhesive film composite non-woven cloth; the double-faced self-adhesive film polymer waterproof roll orderly comprises a bituminous adhesive layer, a polymer waterproof material layer and a self-adhesive layer from top to bottom; the single-rolled self-adhesive film composite non-woven cloth orderly comprises a self-adhesive layer, a polymer waterproof material layer and a non-woven cloth layer from top to bottom; the self-adhesive layer of the double-faced self-adhesive film polymer waterproof roll is glued with the self-adhesive layer of the single-rolled self-adhesive film composite non-woven cloth. The self-adhesive composite waterproof layer for the tunnel is used for solving the problems of waterproof plate tear and back voids of secondary lining concrete due to uneven surface of the primary support shotcrete, and the waterproof layer is securely attached on the structural surface of the primary support shotcrete and the secondary lining concrete permanently and securely in an effective and economic manner.

Owner:SHIJIAZHUANG INST OF RAILWAY TECH

Synthesized pipe rack with frame composite structure

ActiveCN105821903AAvoid lateral instabilityHigh strengthArtificial islandsUnderwater structuresWeb structureEngineering

The invention discloses a synthesized pipe rack with a frame composite structure. The synthesized pipe rack comprises unit plate pieces positioned on the upper and lower surfaces, and side unit plate pieces positioned on two side surfaces; the unit plate pieces and the side unit plate pieces are combined and spliced to form unit pipe sections; the unit pipe sections are axially spliced to form the synthesized pipe rack; the unit plate pieces consist of plates, hollow second pipes positioned at two ends, and hollow first pipes positioned at the other two ends; the side unit plate pieces consist of plates, and hollow second pipes positioned at two ends; the second pipes are axial splicing ends of the unit pipe sections; and in splicing of the synthesized pipe rack, the first pipes form longitudinal beams of the synthesized pipe rack, and the adjacent second pipes are connected with each other to form a skeleton structure of the synthesized pipe rack. The longitudinal beams and the skeleton structure of the pipe rack bear main loads; a bridge steel web structure is formed to enhance the shearing resistance of the pipe rack, and is skillfully used; based on dual enhanced structures, the bearing capacity is greatly improved; and under the same filling height, wall plates with the structures are thinner, and materials are saved.

Owner:NANJING LIANZHONG CONSTR ENG TECH

Ultra-high-performance concrete prefabricating and splicing integration pipe gallery system and construction method

ActiveCN107842035AIncrease stiffnessImprove bearing capacityArtificial islandsUnderwater structuresArchitectural engineeringPipe

The invention provides an ultra-high-performance concrete prefabricating and splicing integration pipe gallery system which is formed by splicing a plurality of prefabricated sections. Each prefabricated section is prepared through ultra-high-performance concrete. Each prefabricated section is composed of a side plate, a bottom plate, a top plate and a partition plate. Each partition plate is fixed between the corresponding bottom plate and the corresponding top plate. The adjacent prefabricated sections are overlapped through ultra-high-performance concrete patches. The invention further discloses a construction method of the pipe gallery system. According to the integration pipe gallery system, the prefabricated sections of the integration pipe gallery system are made of materials like the ultra-high-performance concrete with high strength, high tenacity and high durability, the structure of the ultra-high-performance concrete patches and the like is combined, rigidity, bearing capacity and waterproof performance of a pipe gallery are improved, the wall thickness of the prefabricated sections is reduced compared with that of a traditional pipe gallery system, the dead weight of the pipe gallery is reduced remarkably, and transporting and hoisting are convenient. The material use amount of the pipe gallery is low to be 50% of that of the traditional pipe gallery system, the comprehensive production cost is reduced by 10-50% correspondingly, rigidity is large, the system is suitable for regions with poor foundation geologic conditions, the construction period of the pipe gallery system is short, and the influence on the construction environment is small.

Owner:HUNAN UNIV

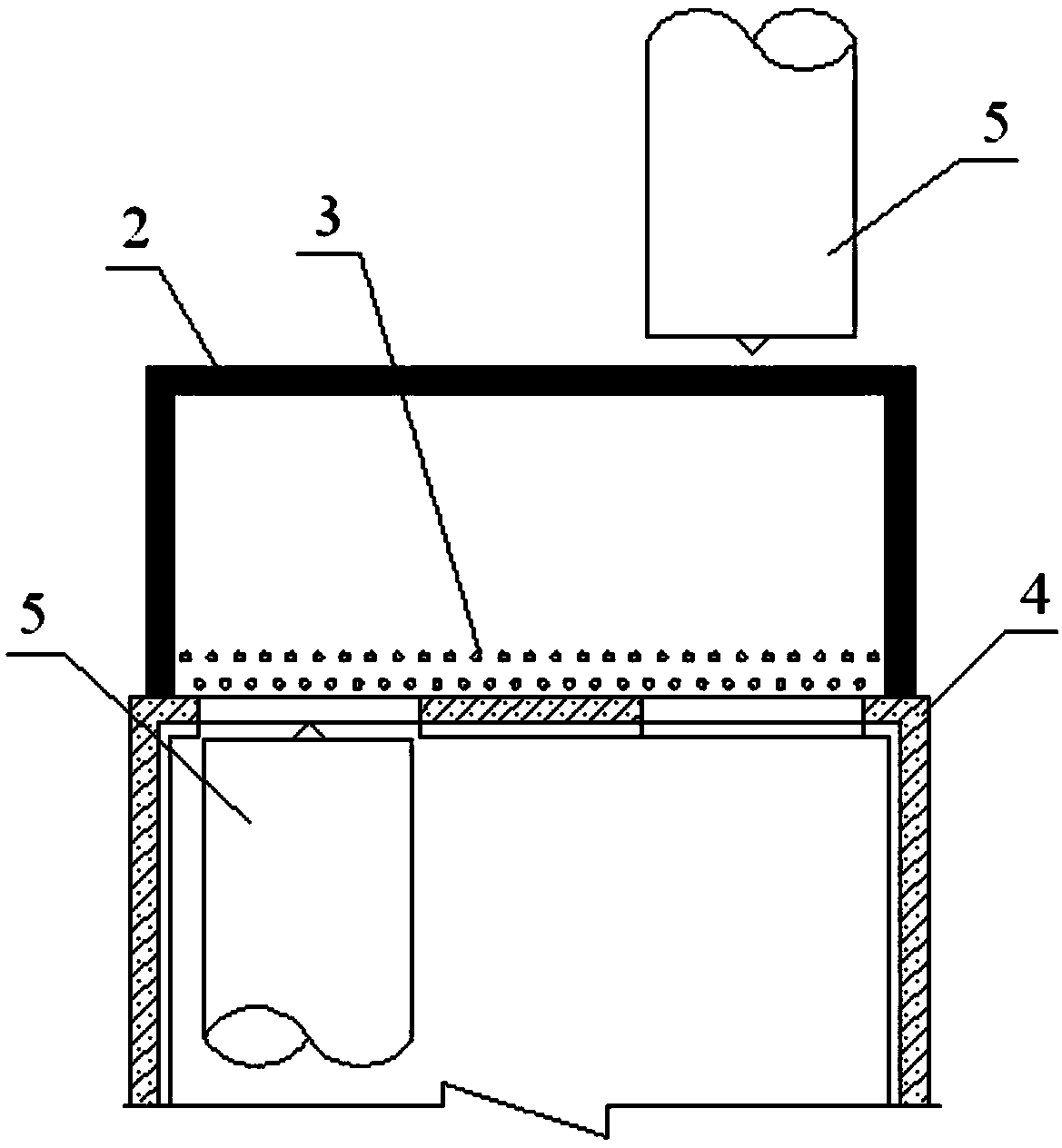

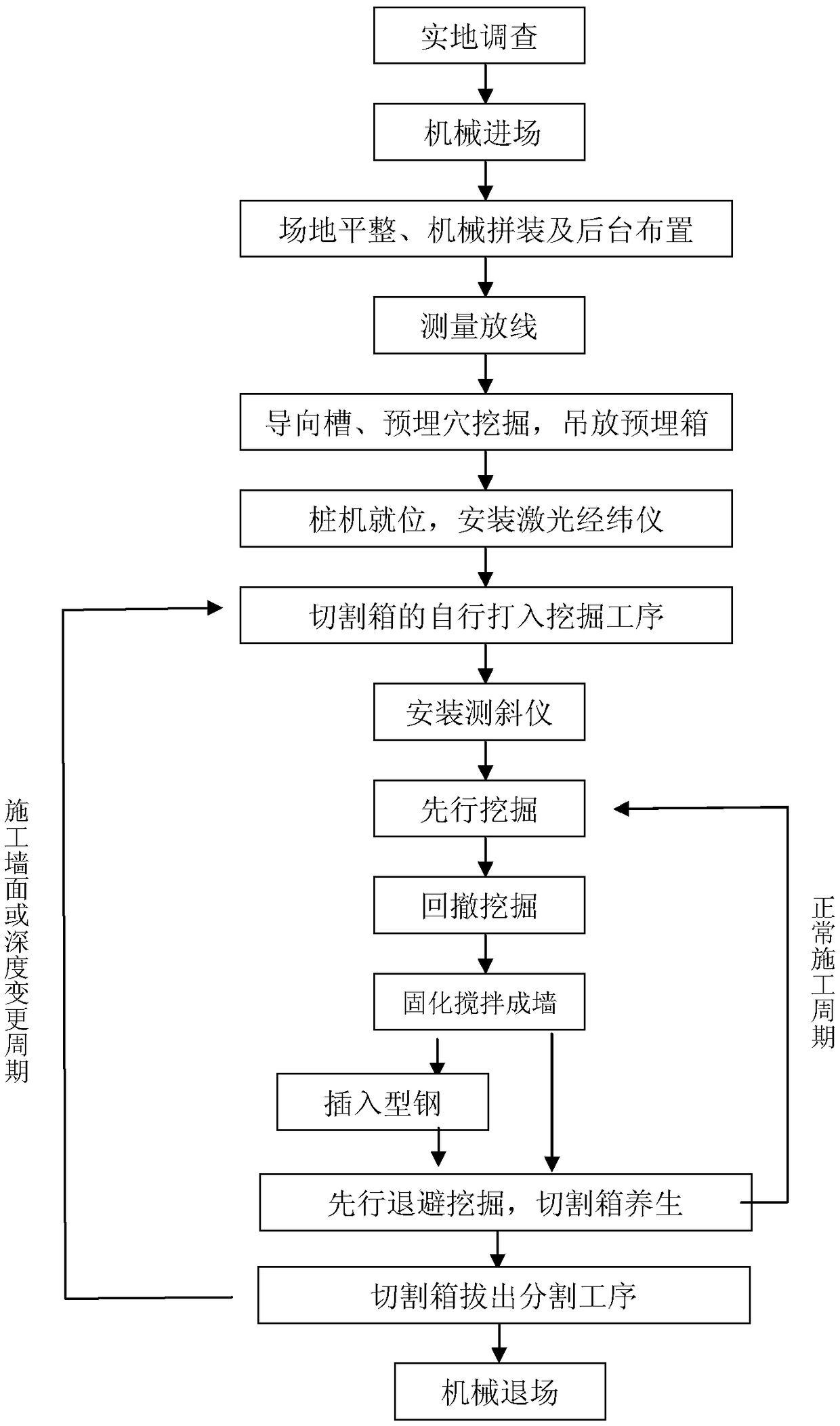

Joint reinforcement structure for shield tunnel end and a construction method

PendingCN109209396AGuaranteed accuracyImprove digging effectUnderground chambersTunnel liningSoil mixingEngineering

The invention discloses a joint reinforcement structure for a shield tunnel end and a construction method. The joint reinforcement structure is a rectangular box structure as a whole, and the rectangular box structure is formed by reinforcement structures surrounded on four sides. The reinforcement structure near a foundation pit is a frozen soil wall, and the reinforcement structures on the remaining three sides are cement soil continuous walls. The method includes a first step of construction of cement soil continuous walls by using a TRD method to construct continuous walls of cement soil with a three-cycle method; a second step of construction of vertical frozen soil wall by firstly, drilling of freezing holes, installing a freezing station at the same time; after confirming that the freezing meets the door chiseling condition, starting to break a hole wall, forcibly unfreezing before a shield main machine enters into the hole, pulling out a vertical freezing tube after the shieldmain machine completes entering and exiting the hole, and grouting. The joint reinforcement structure has the beneficial effects that strong construction practicability, convenient construction quality control and outstanding reinforcement effect. Compared with a traditional cement-soil mixing piles reinforcing method, the method saves cost and greater promotion and application value is ensured.

Owner:HAINAN UNIVERSITY

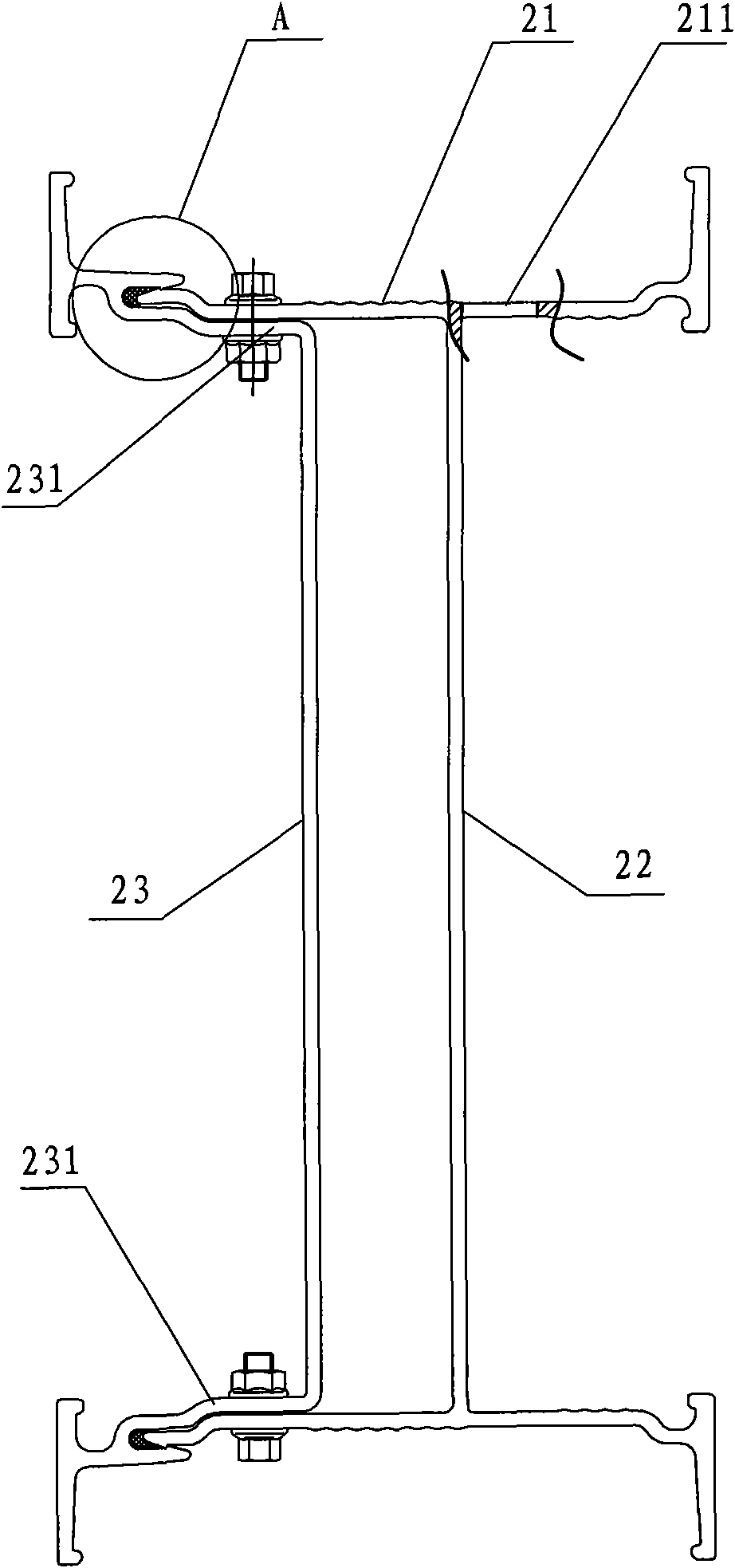

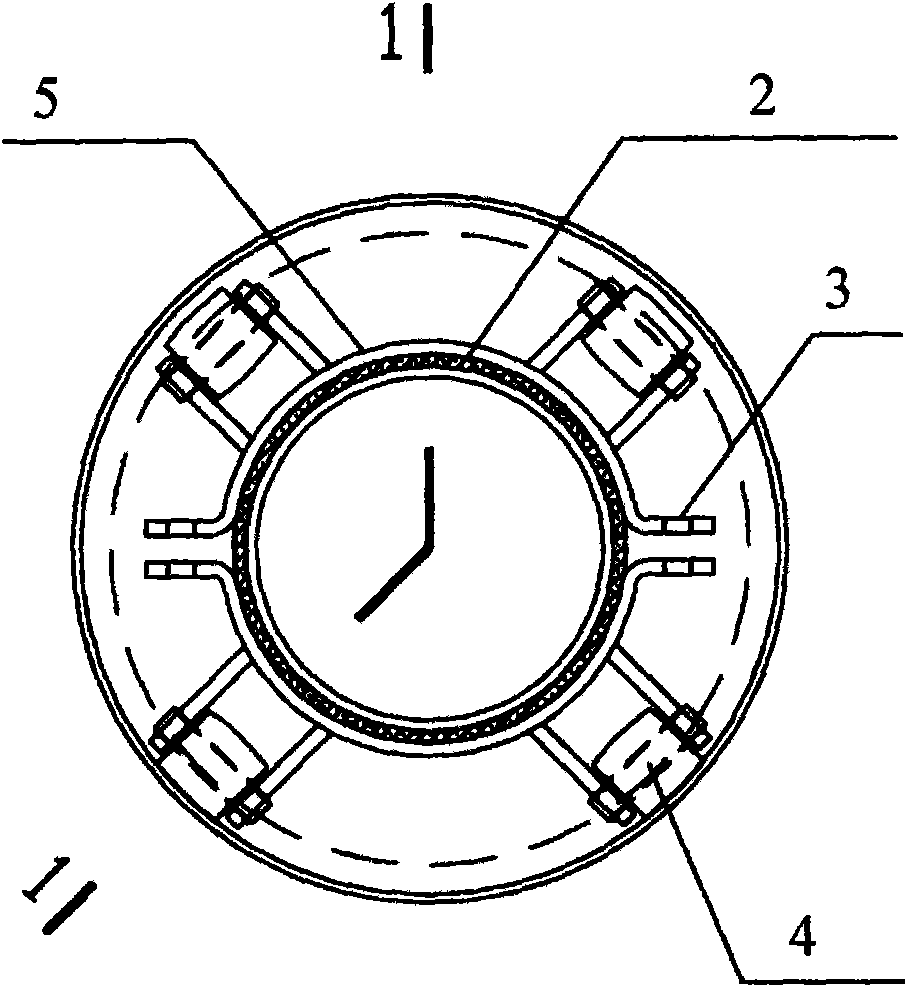

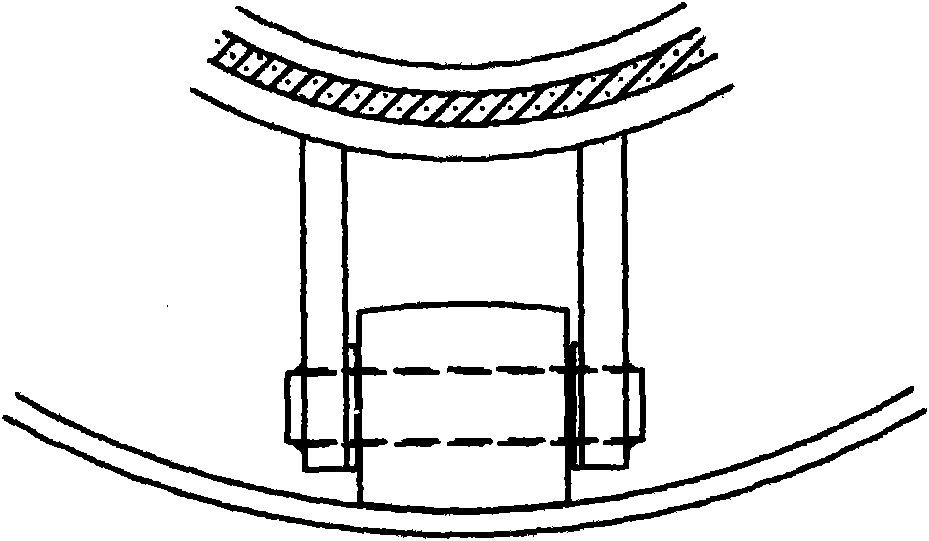

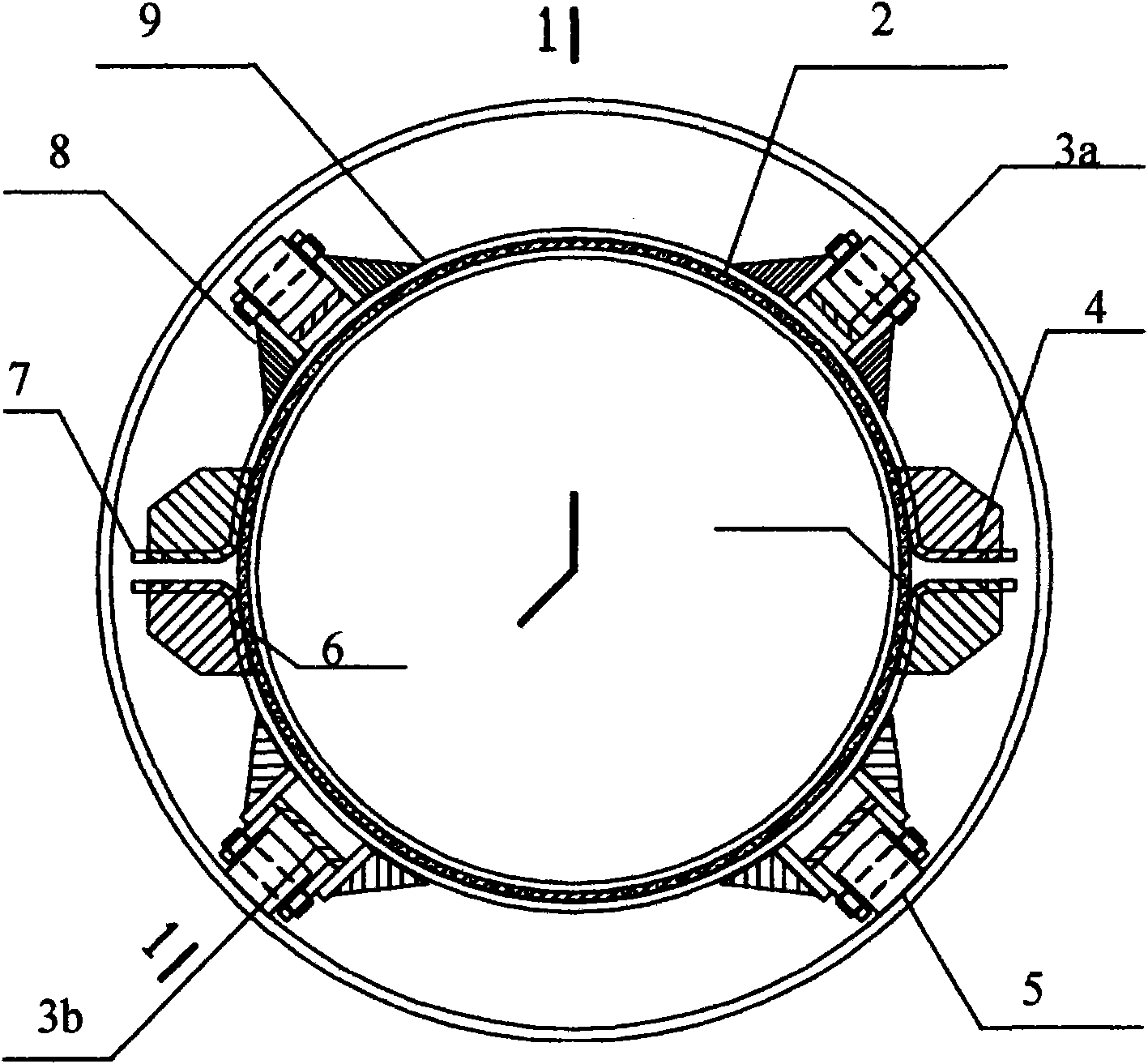

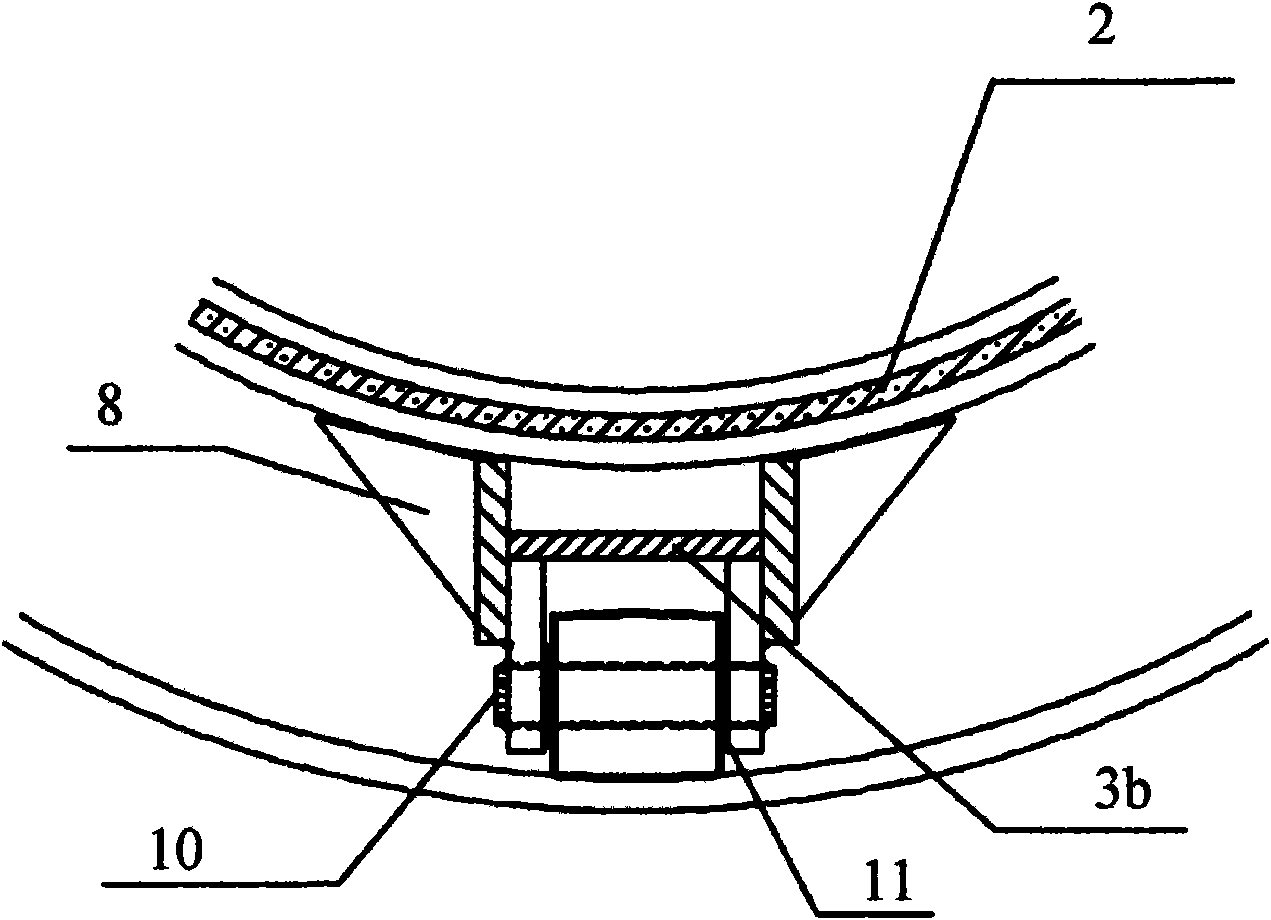

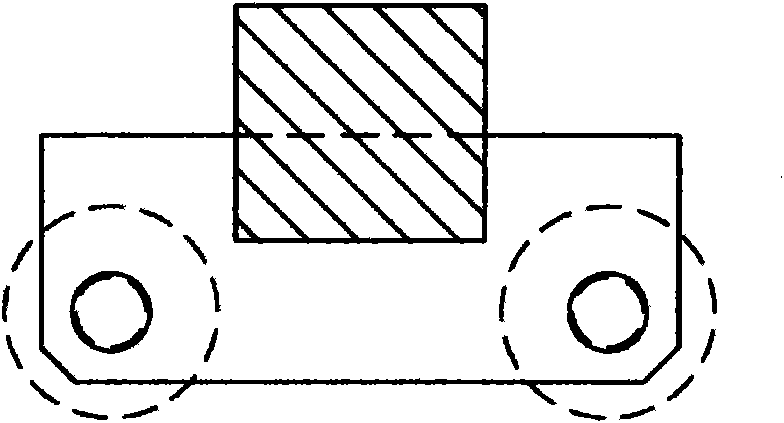

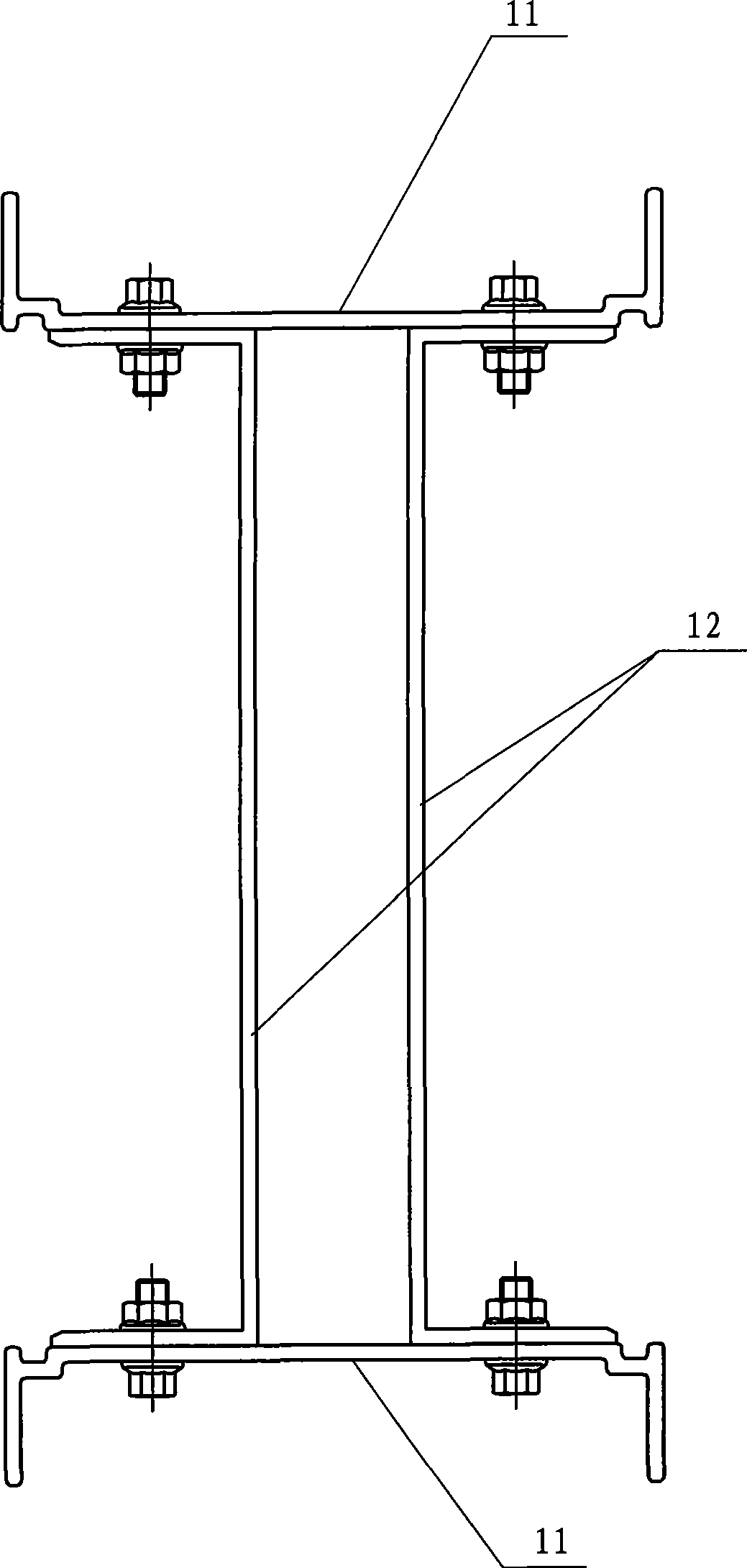

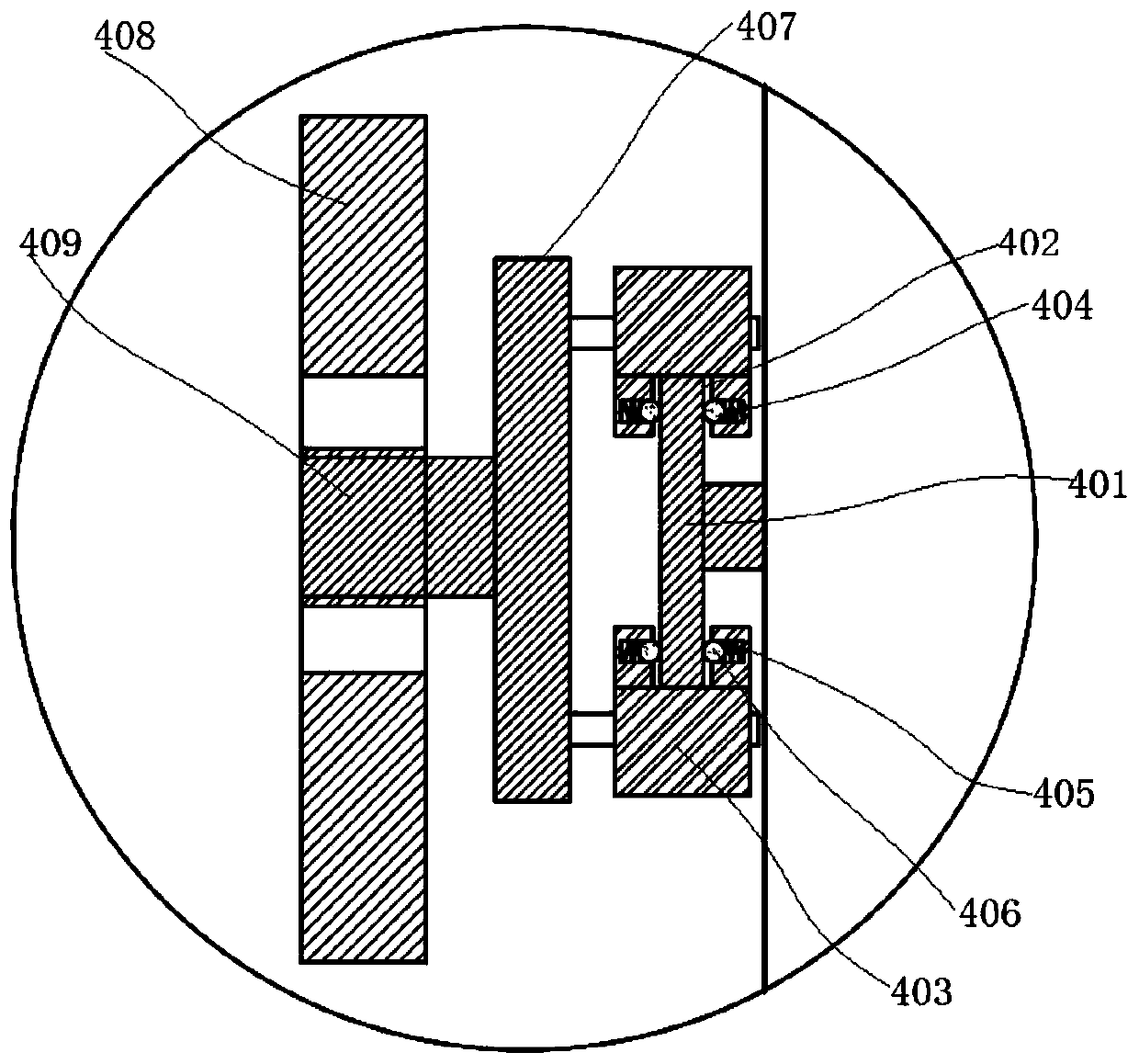

Steel-sleeve steel steam insulation pipe and rolling supporting mechanism thereof

InactiveCN101666419AReduce processImprove insulation effectPipe supportsThermal insulationRolling resistanceEngineering

The invention relates to a steel-sleeve steel steam insulation pipe and a rolling supporting mechanism thereof, wherein the nominal diameter of an inner sleeve steel pipe of the steel-sleeve steel steam insulation pipe is DN 250-DN 500. The rolling supporting mechanism comprises an upper steel hoop, a lower steel hoop, two upper idler wheels and two lower idler wheels, wherein the upper idler wheels and the lower idler wheels are respectively arranged on the upper steel hoop and on the lower steel hoop and distributed symmetrically; the end parts of the upper steel hoop and the lower steel hoop are clamped tightly by bolts; and when the axes of the inner sleeve steel pipe and an outer sleeve steel pipe are overlapped, the two lower idler wheels and the inner wall of the outer sleeve steelpipe are contacted in a rolling friction way, and fit-up gaps are left between the upper idler wheels and the inner wall of the outer sleeve steel pipe. The steel-sleeve steel steam insulation pipe comprises the inner sleeve steel pipe, the outer inner sleeve steel pipe, the rolling supporting mechanism, insulation material and heat-preservation material, wherein the external diameter of the heat-preservation layer is smaller than the internal diameter of the outer sleeve steel pipe and an air layer is formed between the heat-preservation layer and the sleeve steel pipe. The rolling supportingmechanism has small friction force, therefore, the stress of the rolling supporting mechanism and the inner sleeve steel pipe is reduced.

Owner:刘毅 +1

Steel-sleeve steel steam insulation pipe and rolling supporting mechanism thereof

The invention relates to a steel-sleeve steel steam insulation pipe and a rolling supporting mechanism thereof, wherein the nominal diameter of an inner sleeve steel pipe of the steel-sleeve steam insulation pipe is DN 600-DN 700. The rolling supporting mechanism comprises an upper steel hoop, a lower steel hoop, two upper idler wheels arranged on the upper steel hoop and distributed symmetrically, and four lower idler wheels arranged on the lower steel hoop and distributed symmetrically, wherein the four lower idler wheels are evenly divided into two groups; the end parts of the upper steel hoop and the lower steel hoop are connected by bolts; and when the axes of the inner sleeve steel pipe and an outer sleeve steel pipe are overlapped, the four lower idler wheels and the inner wall of the outer sleeve steel pipe are contacted in a rolling friction way, and gaps are left between the two upper idler wheels and the inner wall of the outer sleeve steel pipe. The steel-sleeve steel steaminsulation pipe comprises the rolling supporting mechanism and also comprises insulation material positioned between the rolling supporting mechanism and the inner sleeve steel pipe, heat-preservation material with the external diameter smaller than the internal diameter of the outer sleeve steel pipe, an air evaporation valve arranged on the outer sleeve steel pipe, and erosion resistant coatingsleeved outside the outer sleeve steel pipe. The rolling supporting mechanism has small friction force, therefore, the stress of the rolling supporting mechanism and the inner sleeve steel pipe is reduced.

Owner:刘毅 +1

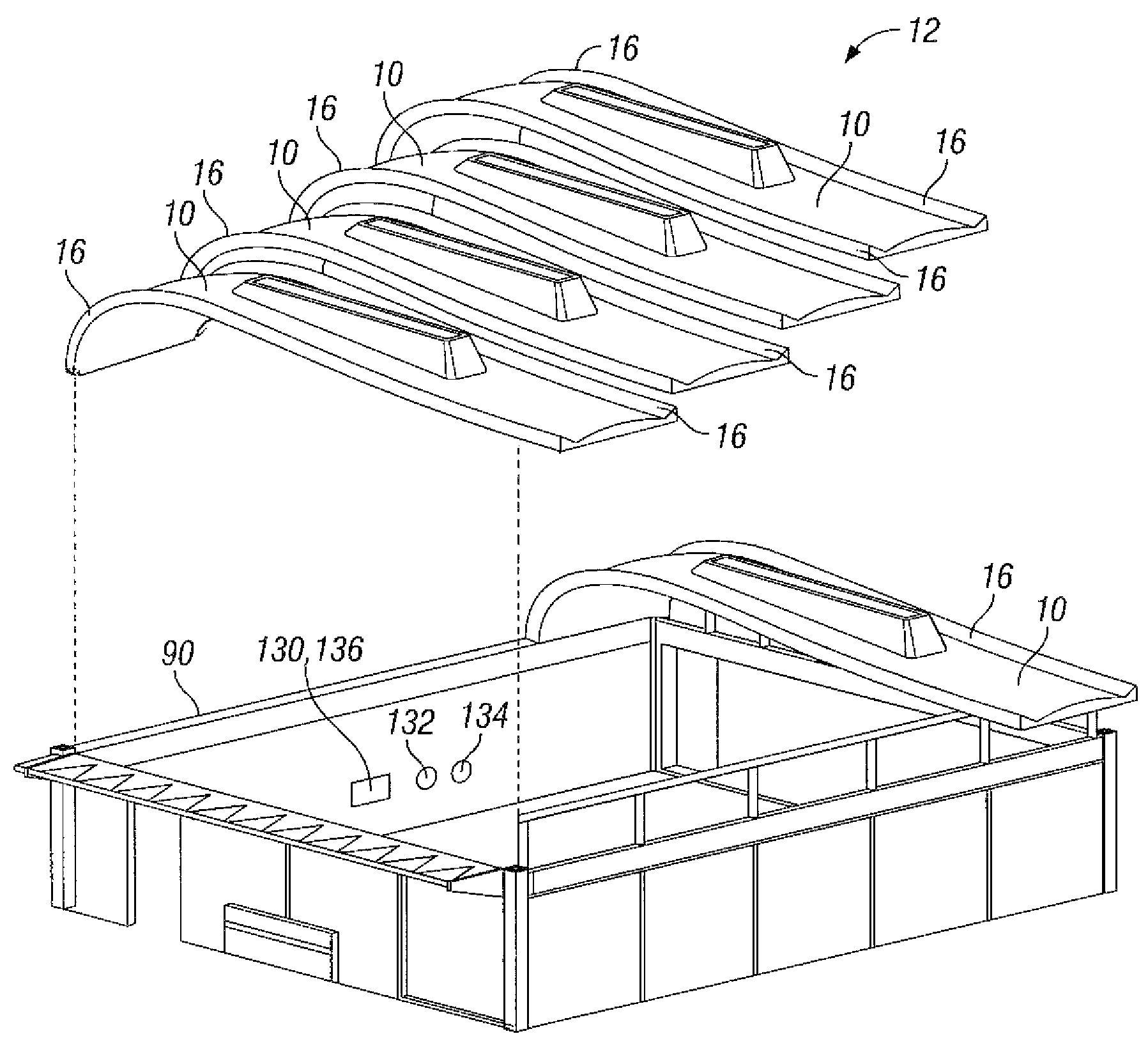

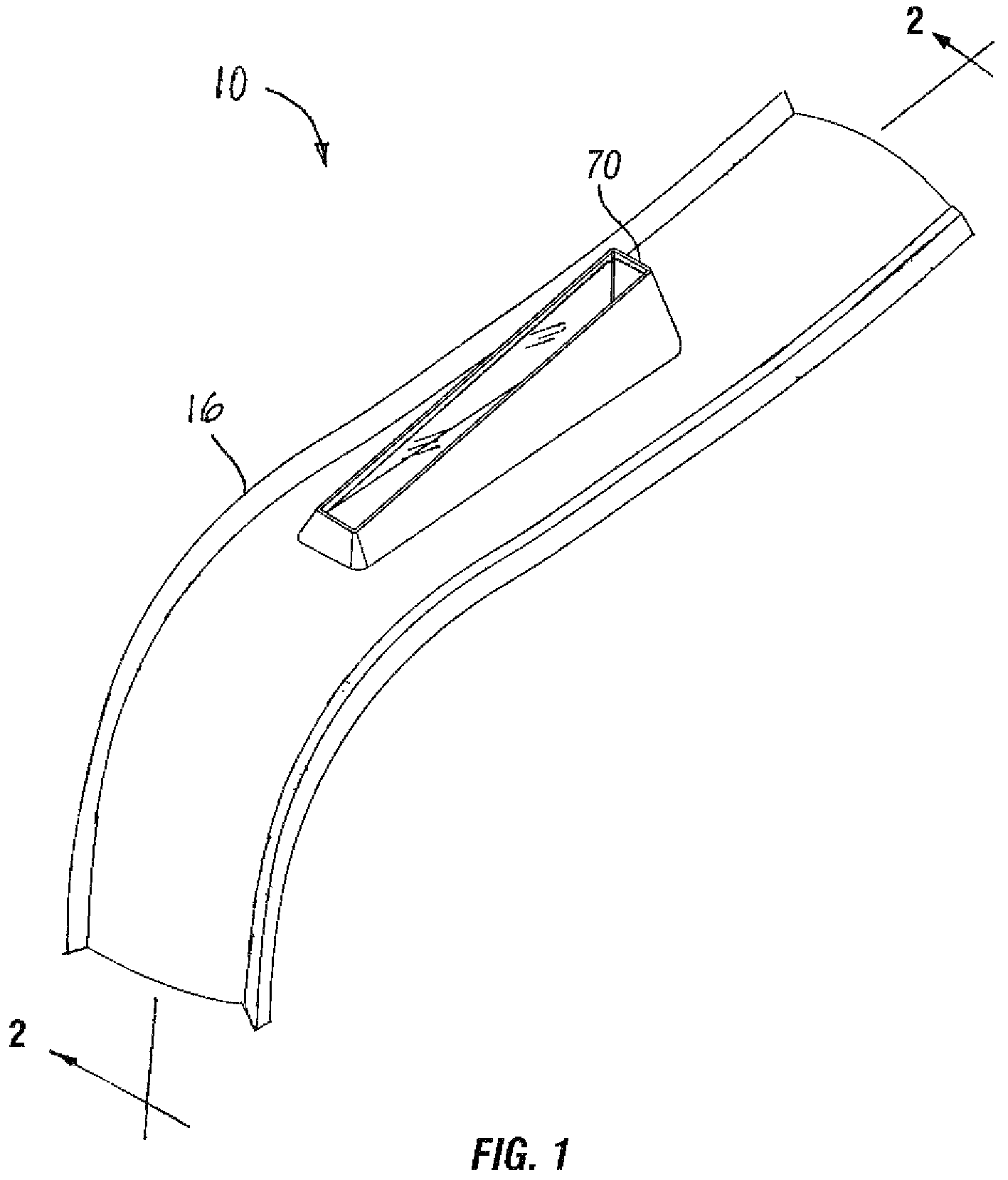

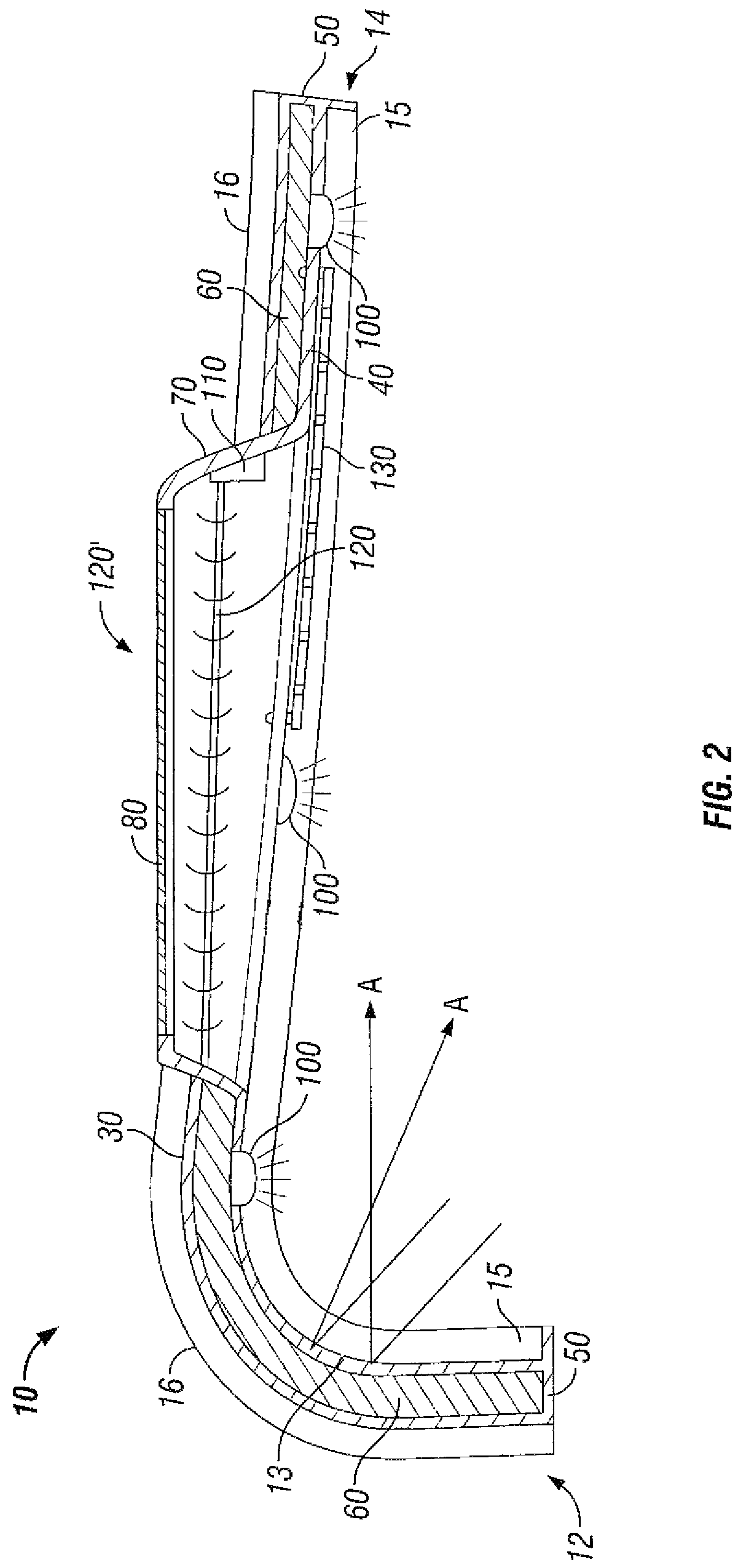

Modular roof structural units and use thereof

InactiveUS8381449B1Easy to useImproved strength to weight ratioLighting applicationsRoof covering using slabs/sheetsInterior spaceEngineering

A building structure has a generally horizontally disposed modular roof made-up of a plurality of side-by-side roof units which are mutually joined. Each roof unit is constructed as a pair of spaced apart rigid skins shaped in such manner as to eliminate additional supporting structure and which are joined along mutual edges of the pair of skins and forming an interior space filled with a thermal insulator. One end of each of the roof units is curved in a downward arc. A skylight frame protrudes above an upper one of the pair of skins, the frame supporting an upwardly facing window. An electrical circuit includes LED lamps mounted in a lower one of the pair of skins with its illumination directed downwardly. The circuit may also include a motorized shade or a liquid crystal shade for limiting natural light transmission through the window.

Owner:HODGETTS CRAIG +1

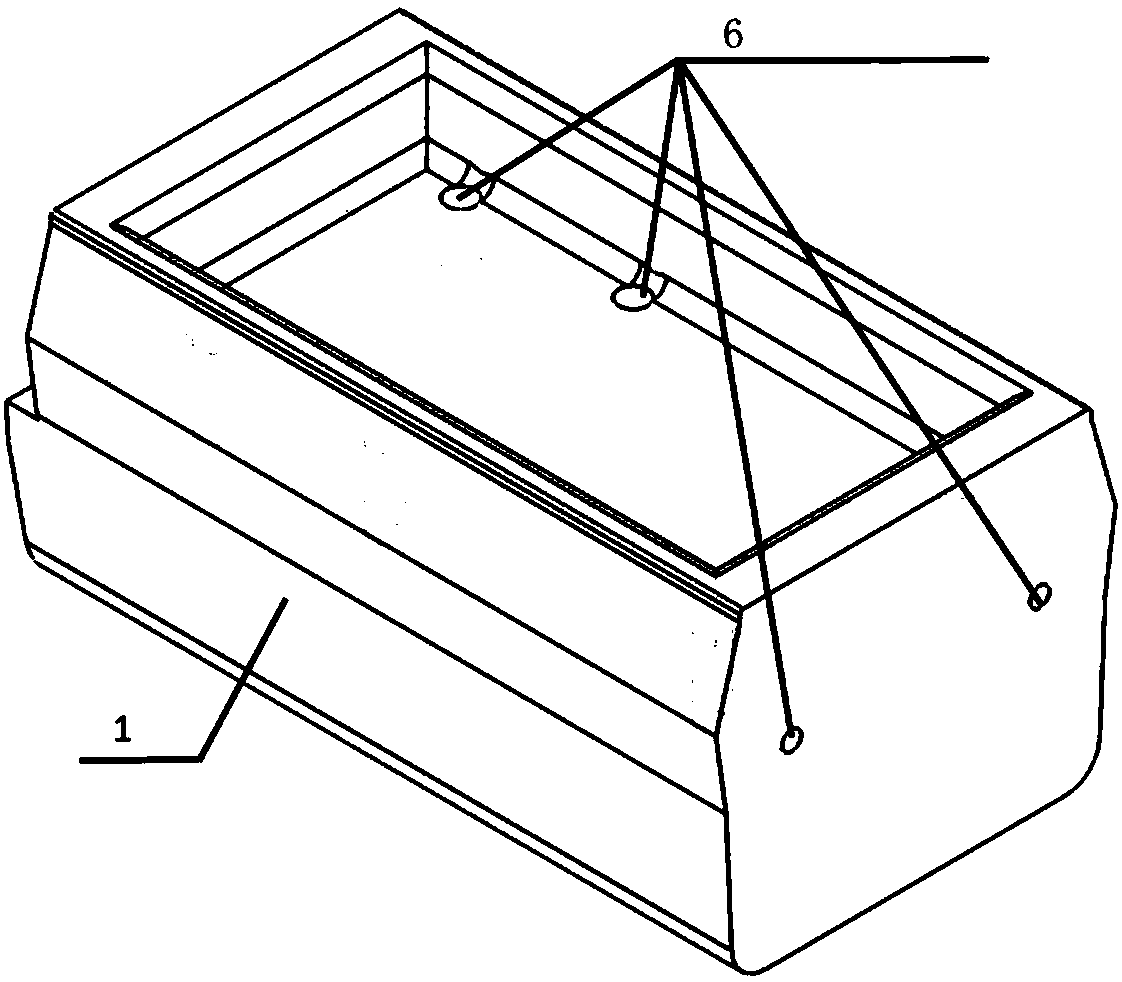

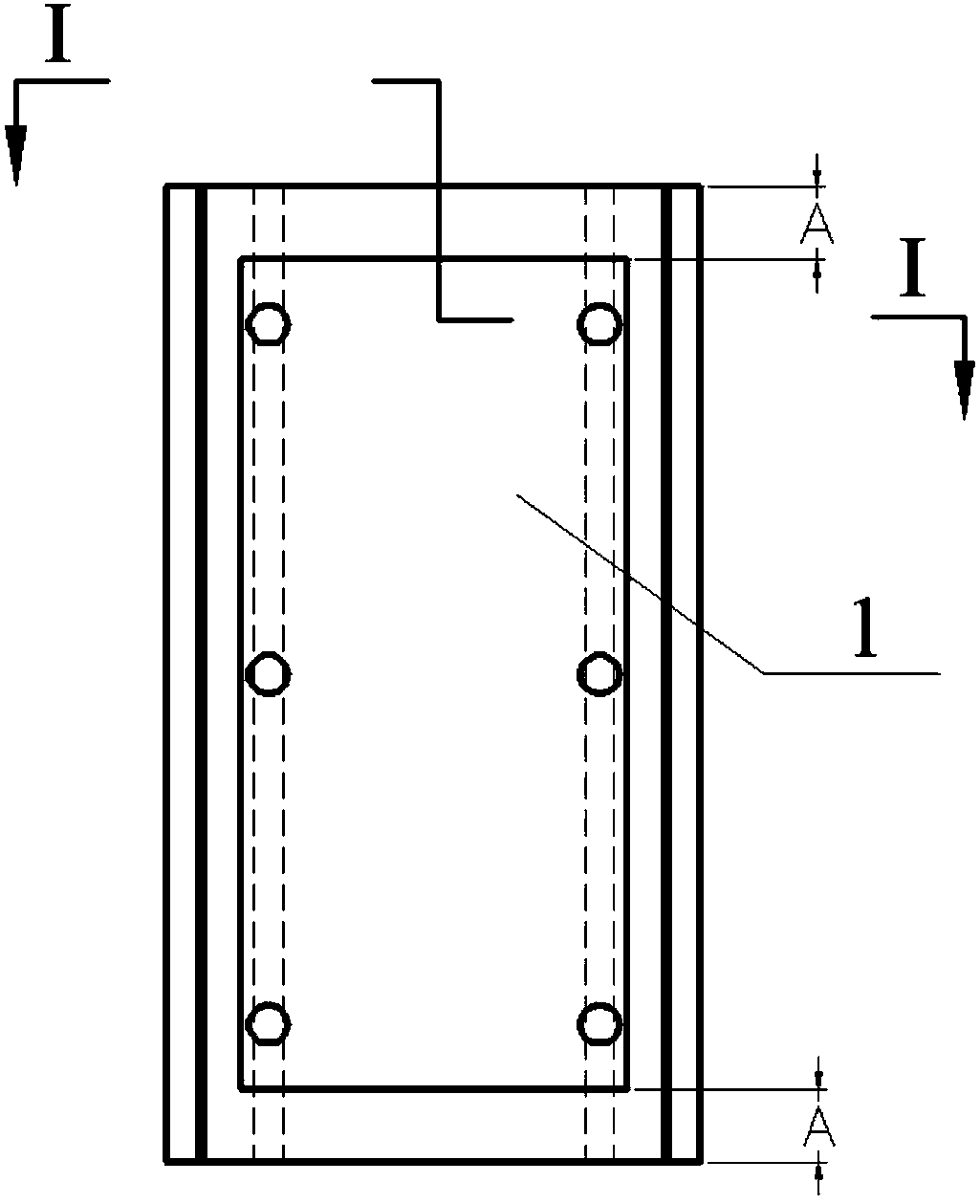

Compact bus groove case

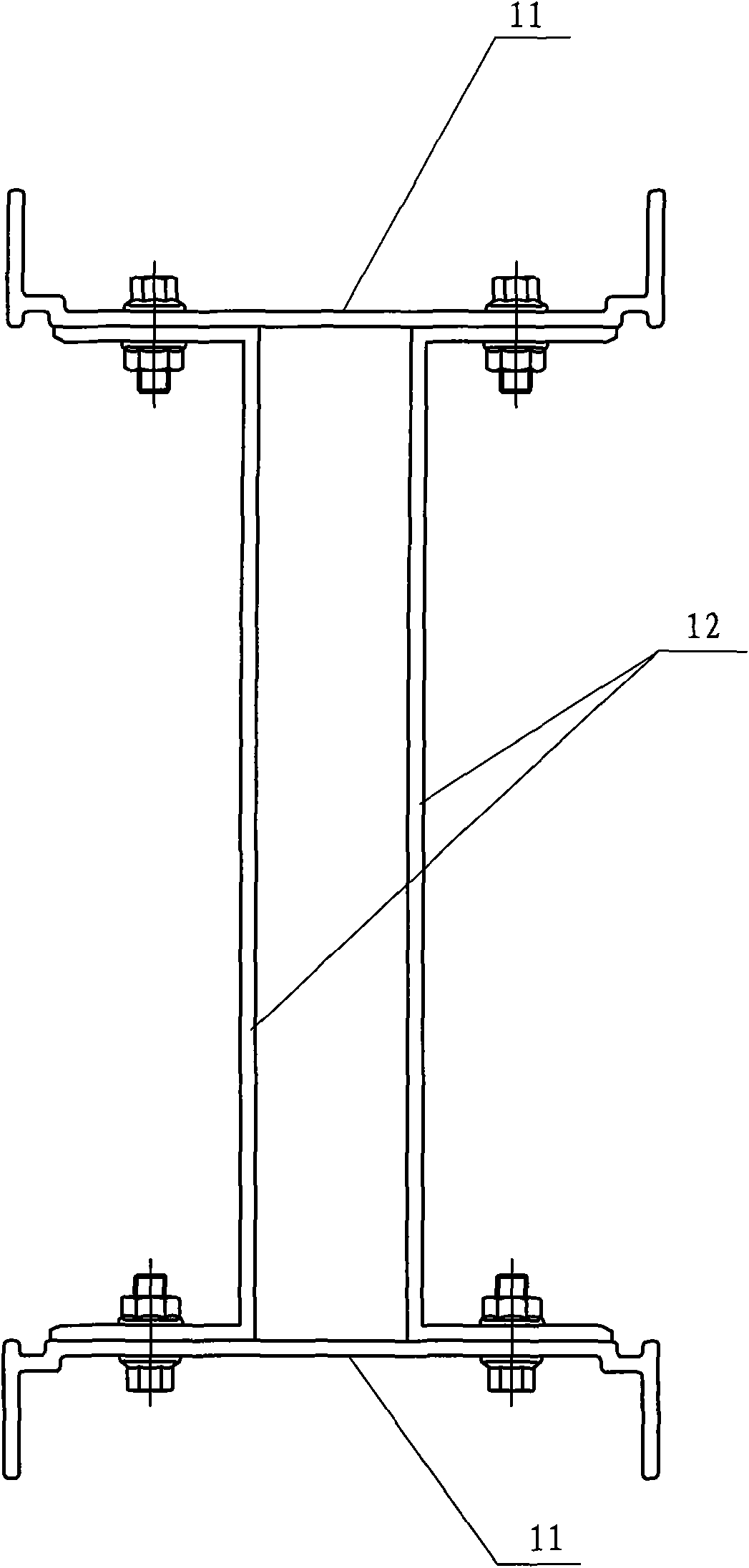

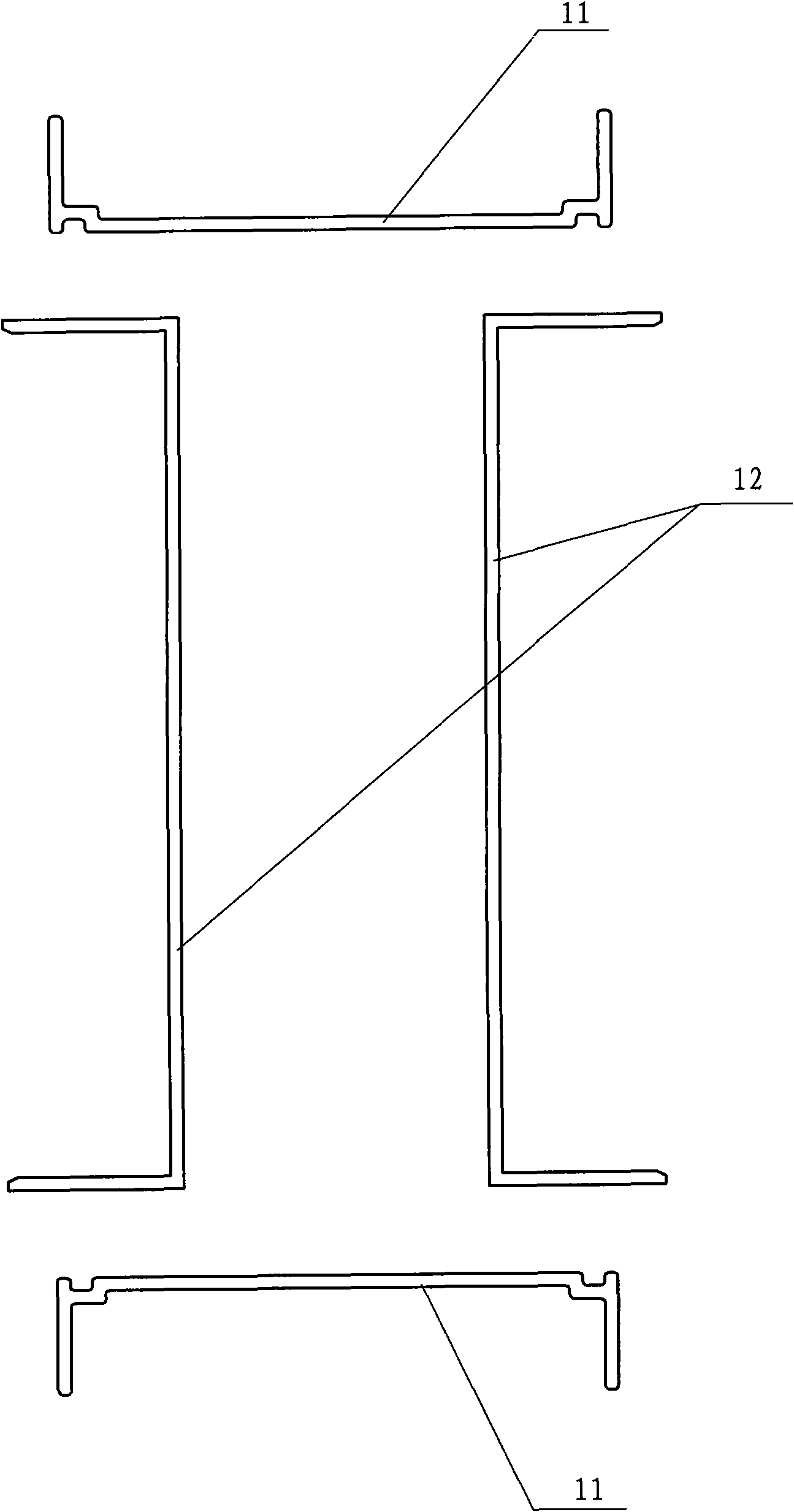

InactiveCN101478132ALess seamsPrevent infiltrationOpen bus-bar installationsArchitectural engineeringAlloy

The invention belongs to transmission facility, which relates to a compact bus duct housing, which comprises an upper cover plate, a lower cover plate and a fixed side plate connected between the two cover plates and biased towards one side. The two cover plates and the fixed side plate are made of aluminum alloy sectional bars in monolithic construction. A flexible side plate with C-shaped cross section is arranged between the two cover plates, and is biased towards the other side. The folded edges at the upper end and the lower end of the flexible side plate are fixedly connected with the cover plates through bolts or rivets. The compact bus duct housing has the advantages of simple structure, convenient installation and effective watertightness.

Owner:WETOWN ELECTRIC GRP CO LTD

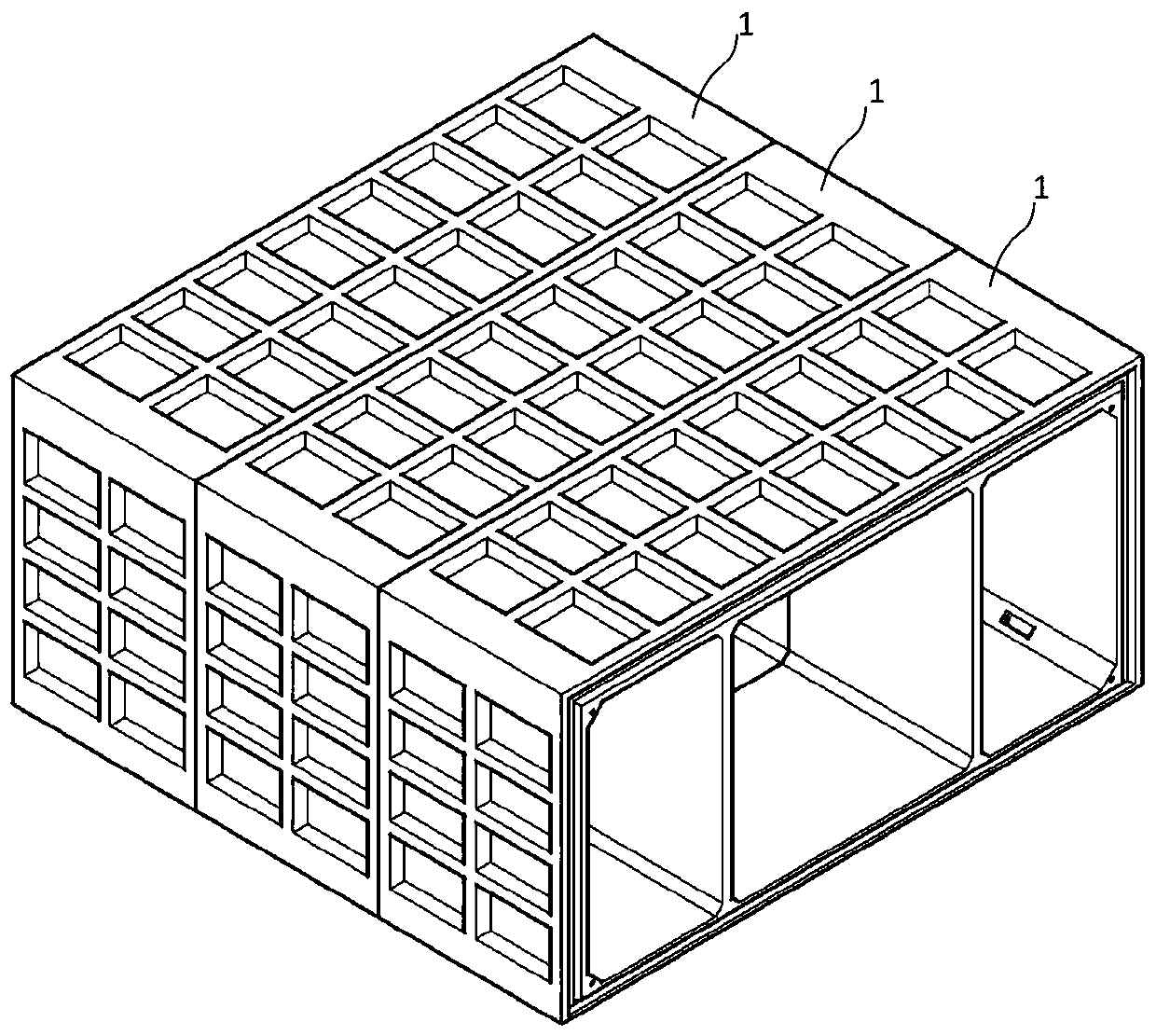

Assembly technology of adjustable supporting columns and eight type modularized steel floor slab moulds

InactiveCN103255929AImprove integrityHigh strengthForms/shuttering/falseworksShoresReinforced concreteFloor slab

Disclosed is an assembly technology of adjustable supporting columns and eight type modularized steel floor slab moulds. According to the technical scheme, the supporting columns with adjustable heights and the eight type modularized steel floor slab moulds are assembled into reinforced concrete cast floor slab templates of rooms. The assembled templates are high in wholeness and strength, few in joints and capable of preventing leakage and loss of cement paste during concrete casting and vibrating, and the construction quality can be effectively guaranteed. The assembly technology has the advantages that the disassembly speed is fast during construction, the process is simple, working hours are saved, the engineering progress and the generality are improved, the reusability is high, the problem that non-planar cast templates are assembled difficultly is well solved particularly, valuable wood resources are saved simultaneously, the environment is protected, and economic benefits are large.

Owner:TIANJIN SANCHUN TECH

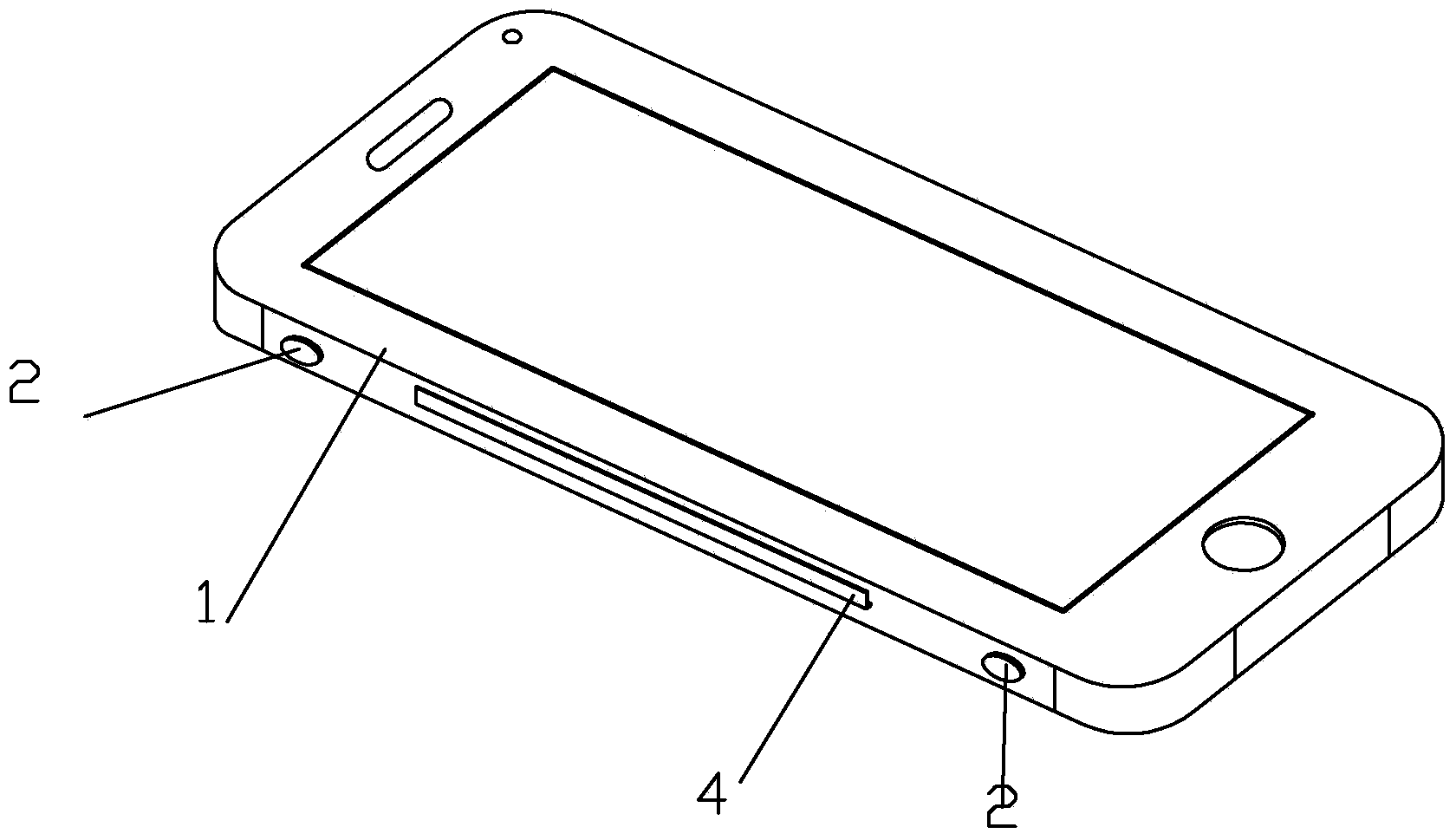

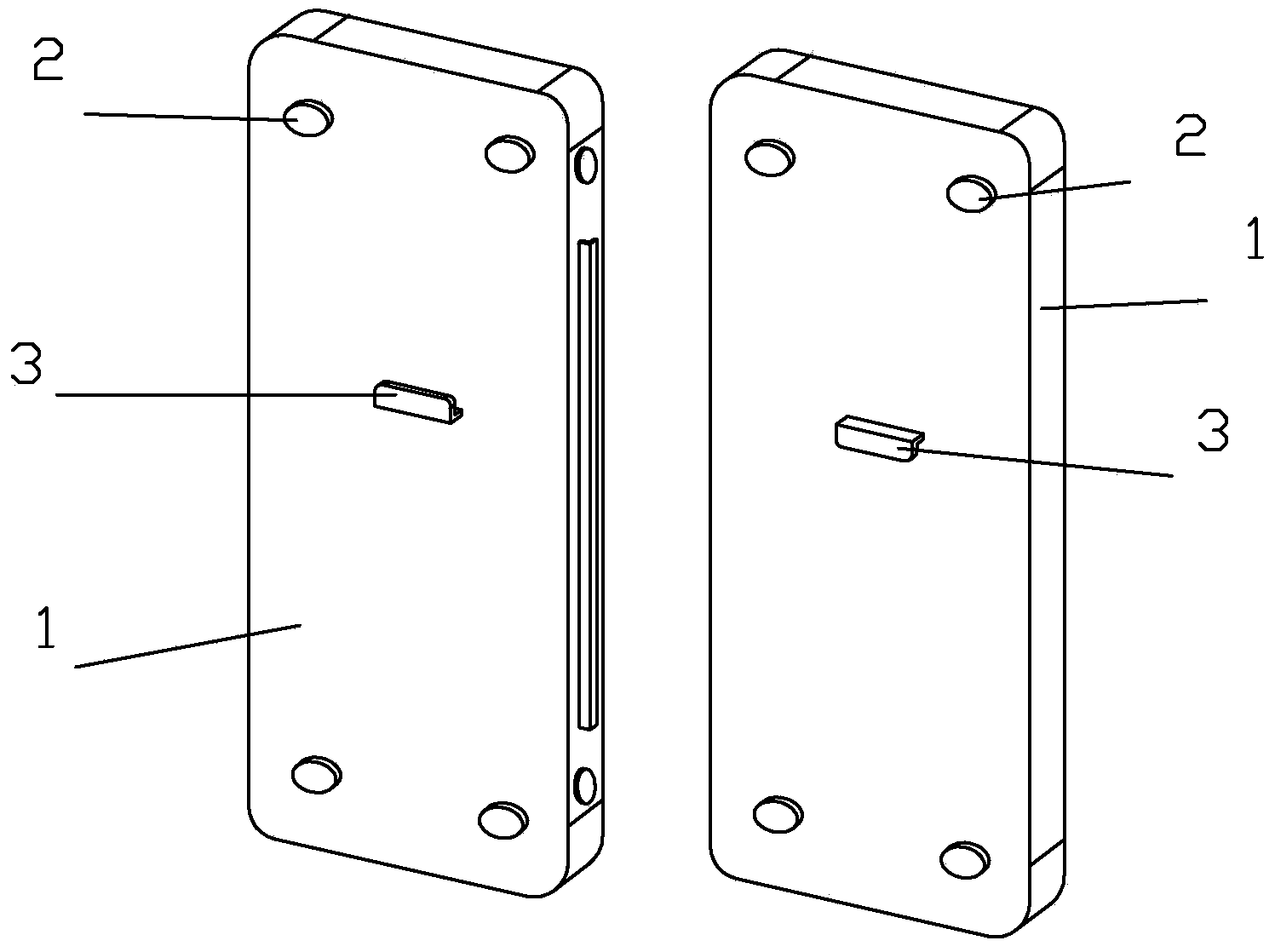

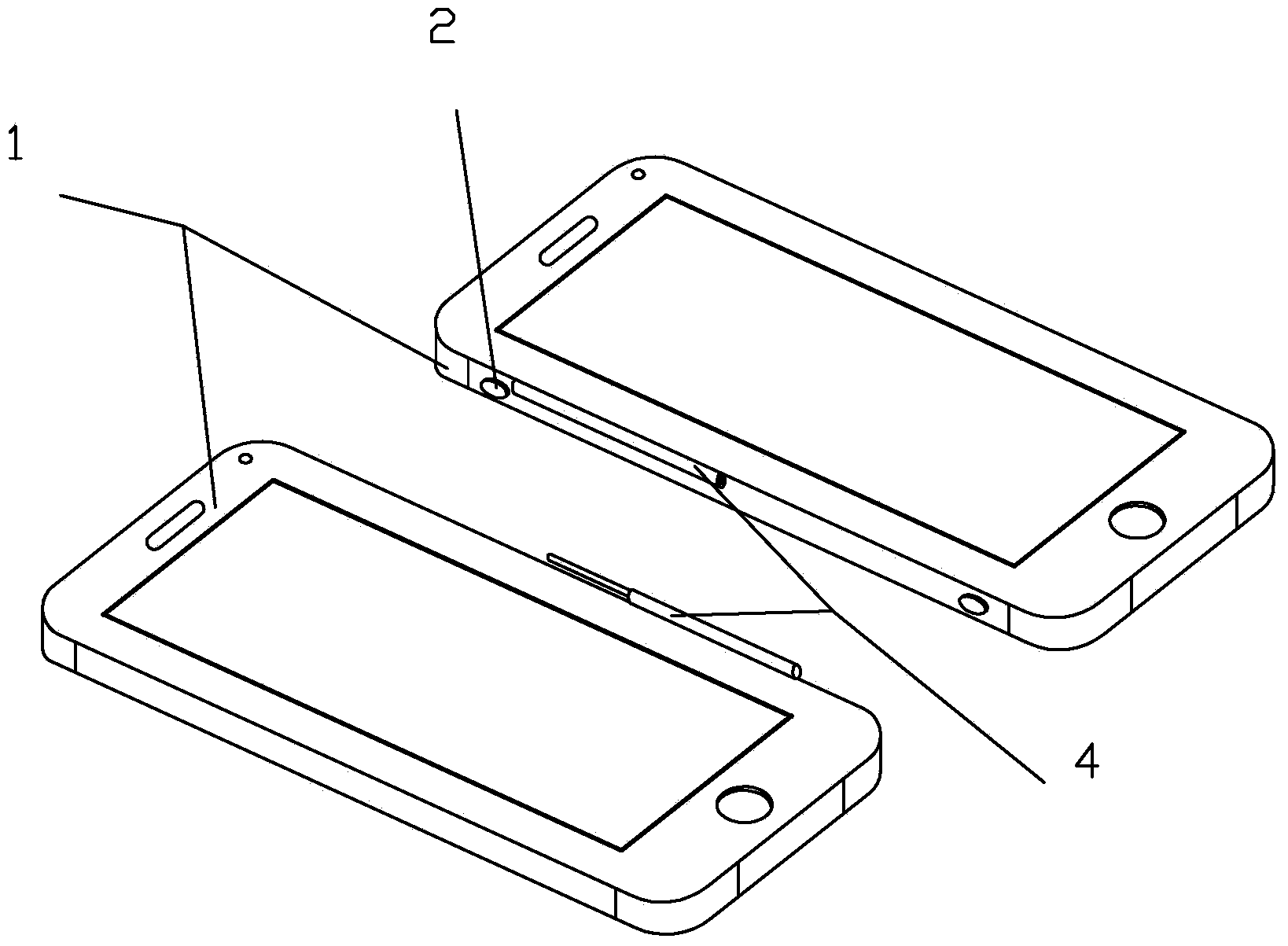

Split screen mobile phone assembly and method for split screen display

InactiveCN103986809AEasy to readIncrease entertainmentTelephone set constructionsAgricultural engineeringMobile phone

The invention discloses a split screen mobile phone assembly and a method for split screen display. The split screen mobile phone assembly comprises the same type of mobile phone bodies, and the four corners of the back of each mobile phone body are respectively and fixedly provided with a strong magnet, and first connecting parts are detachably arranged in the middles of the backs of the two mobile phone bodies. The side faces, not on the same side, of the two mobile phone bodies are respectively provided with two strong magnets. Second connecting parts are detachably arranged in the middles of the side faces. A mobile phone is used independently or used in a double-screen mode through the first connecting parts and the second connecting parts. The functions of free detachment and switching using are achieved.

Owner:QINGDAO TIANFANG AIJIUJIU BUSINESS

A manufacturing method of a PVC marble-imitated plate

InactiveCN104827689ASave spaceImprove wear resistanceFlat articlesPlastic materialsPrecipitated calcium carbonate

The invention relates to the technical field of stone plastic and particularly discloses a manufacturing method of a PVC marble-imitated plate. The method includes following steps of: smashing reclaimed materials of PVC products or templates to obtain a smashed PVC main material; adding ground calcium carbonate, precipitated calcium carbonate, a stabilizing agent, an ACR modifier, a CPE flexibilizer, titanium dioxide, stearic acid 1801 and paraffin into the PVC main material, mixing and stirring to obtain a mixture; adding the mixture into a twin-screw extruder, and extruding to obtain a PVC marble-imitated plate with a certain specification through an extrusion die head; cooling the PVC marble-imitated plate to obtain the formed PVC marble-imitated plate. The method is advantageous in that problems namely color fading and deformation, and the like, of stone plastic materials in traditional techniques are overcome; and the PVC marble-imitated plate has advantages of light weight, wear resistance, flame retardance, skid resistance, moisture resistance, and the like.

Owner:陕西金禾农业科技有限公司

Beam-form unified movable mould frame

InactiveCN101205702ASolve the technical problems of viasReduce investmentBridge erection/assemblyAbnormal shapedBox girder

The invention discloses a beam-mold type movable die carrier which is large-scale construction equipment used in the construction of box beams of upper structures of bridges of railways and highways. A load-bearing beam of the movable die carrier is a special cross-section steel box, a top plate and an inner web of the movable die carrier are taken as external molds of a concrete box beam; a bottom die adopts a low height orthotropic plate structure and is opened and closed by single-side horizontal push. The beam-mold type movable die carrier is particularly suitable for construction under wide pier shaft conditions.

Owner:CHINA MAJOR BRIDGE ENG

Method for manufacturing composite foamed plastic template

InactiveCN101722642AReduce the disadvantages of large heat shrinkageLess seamsFlat articlesFiberThermal insulation

The invention provides a method for manufacturing a composite foamed plastic template, and the composite foamed plastic template is composed of an upper surface, a lower surface layer and a core layer and has the following raw material proportioning: as for the upper surface layer and the lower surface layer, olefin plastics accounts for 40-90% of the raw materials and the filler accounts for 5-40% of the raw materials; as for the core layer, the glass fiber or plant fiber accounts for 10-60% of the raw materials while foaming agent is 0.2-3%, temperature regulator is 0.6-5%, and lubricant is 0.3-2%.The concrete processing procedures comprise pre-treatment, preparation of the core layer, the preparation of the upper surface layer and the lower surface layer and the like. The invention overcomes the defect that the plastic template only has rigidity without toughness; the product can be three-layer or multi-layer so as to enable the structure to be more reasonable, and the foaming materials are arranged in the middle, thus having the advantages of light weight, large rigidity, cold resistance, high temperature resistance and thermal insulation, high inventory turns, corrosion prevention, acid-base resistance and easy demoulding, reducing the shortcoming of large thermal shrinkage for plastics, having the capability of being customized in any size and reclaimed by 100%, reducing the joints of building wallboards, further smoothing and leveling the walls, saving materials and the like.

Owner:靳培军

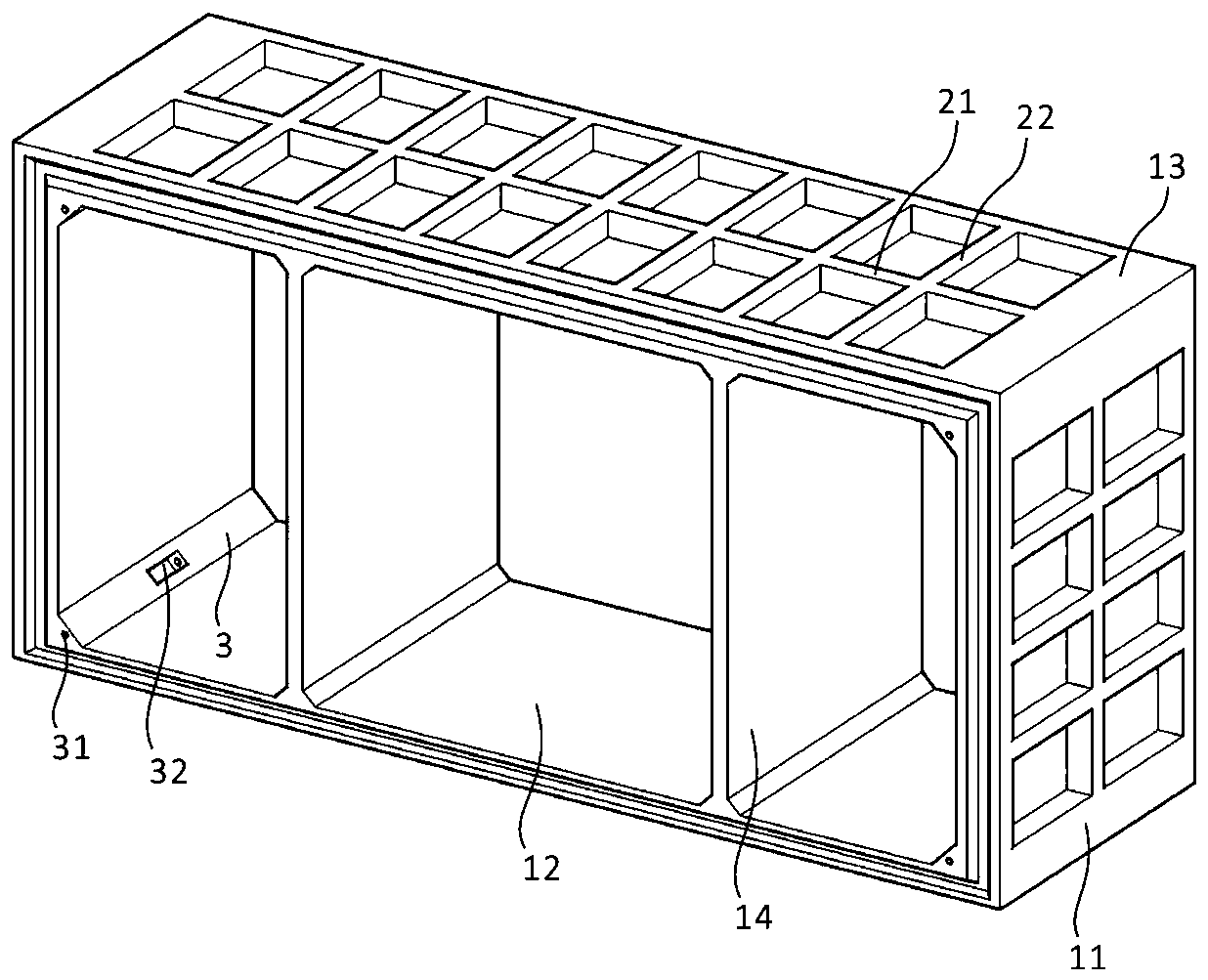

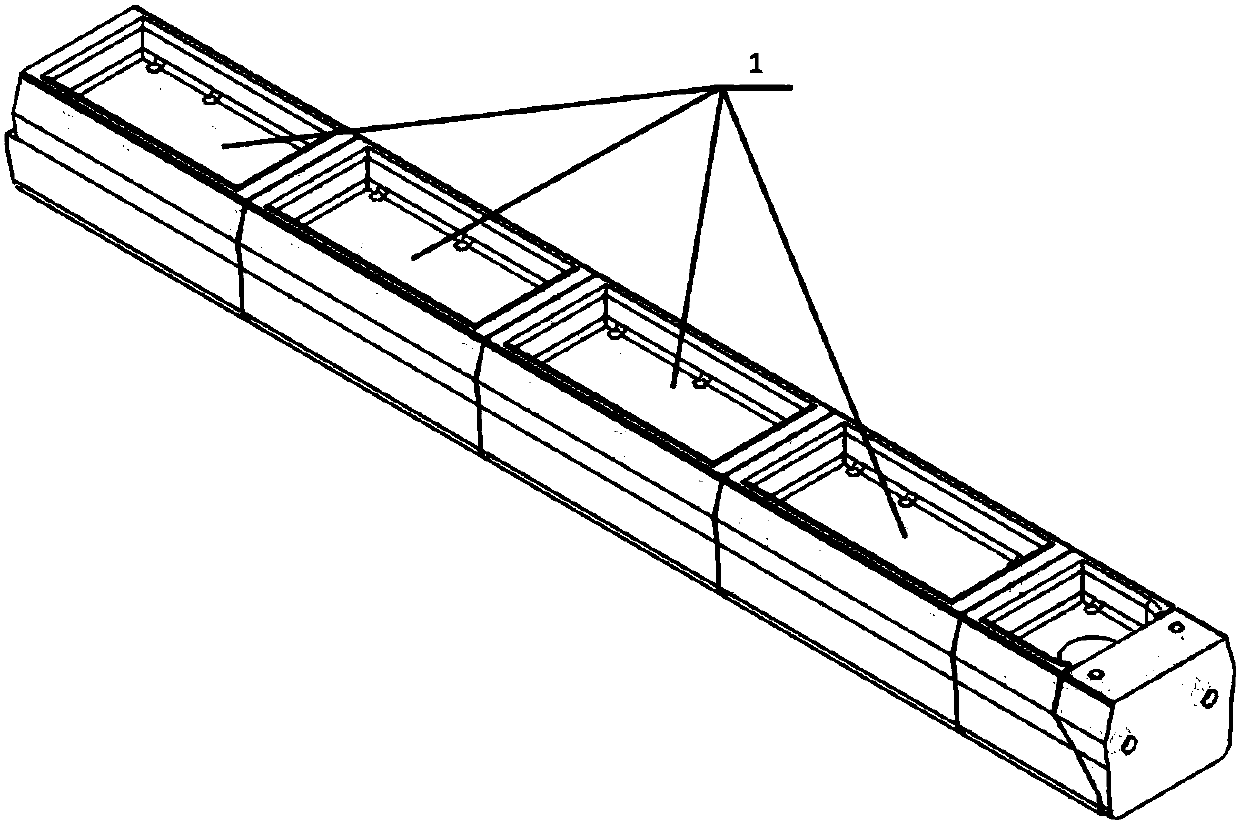

Aluminum formwork supporting system for comprehensive pipe rack

PendingCN111364505ALess seamsEasy to assemble and disassembleArtificial islandsForms/shuttering/falseworksSupporting systemButt joint

The invention provides an aluminum formwork supporting system for a comprehensive pipe rack. The aluminum formwork supporting system involves a bottom formwork structure and a top formwork structure,wherein the bottom formwork structure comprises a concrete cushion layer, a guide wall outer formwork, bottom face formworks and guide wall inner formworks; the guide wall outer formwork comprises a plurality of aluminum alloy outer formwork units distributed in the longitudinal direction of the pipe rack and connecting pieces enabling every two adjacent outer formwork units to be in butt joint, and a guiding and supporting mechanism and a moving mechanism are arranged on the outer side of each outer formwork unit; and the top formwork structure comprises outer wall formworks, inner wall formworks, a top face formwork, a top support, transverse supporting rods, longitudinal supporting rods and horizontal connecting rods. According to the forming characteristics, a large number of aluminumformworks can be adopted, the mode that the bottom and the top of the pipe rack are separately poured is adopted, and inclined supporting rods and the longitudinal supporting rods can be arranged on the formed bottom surface of the pipe rack without being arranged on a formwork, the formwork can be circulated, and specific construction can be achieved without a plurality of sets of formworks.

Owner:BEIJING MUNICIPAL ROAD & BRIDGE +1

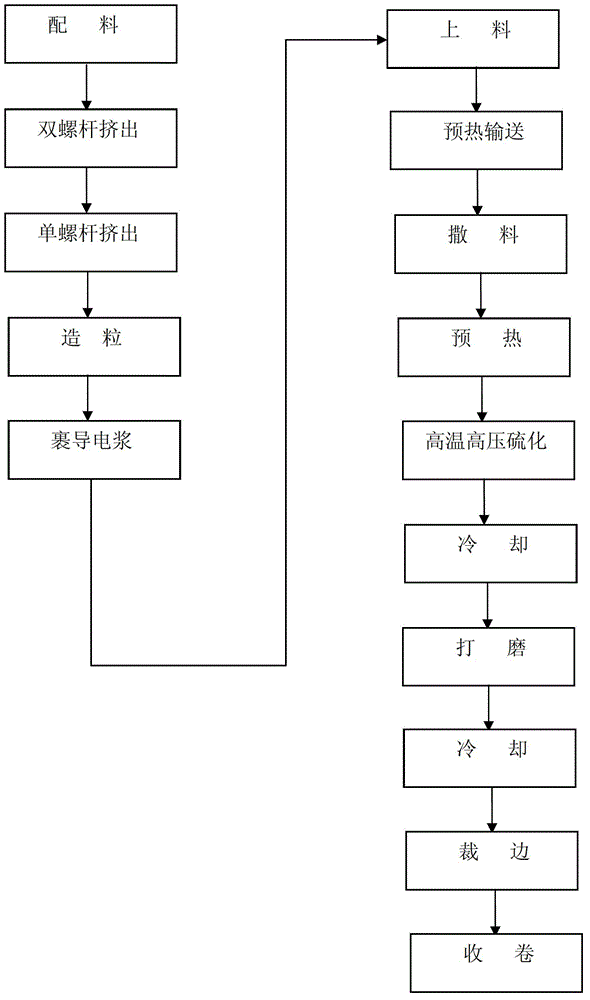

Preparation process of anti-static polyvinyl chloride (PVC) homogeneous through-core coiled material floor board

ActiveCN102873809AExtended service lifeUniform conductivityCovering/liningsVulcanizationPolyvinyl chloride

The invention relates to a preparation process of an anti-static polyvinyl chloride (PVC) homogeneous through-core coiled material floor board. The preparation process includes the following steps: PVC particles are prepared through a PVC granulating process; conductive slurry is wrapped on the surfaces of the PVC particles and dried, and a layer of conductive thin film is respectively formed on the surfaces of the PVC particles; or electric conductors are evenly mixed in the PVC particles; the PVC particles wrapped by the conductive thin film or the PVC particles mixed with the electric conductors are put into a drum-type vulcanizer to be molded through vulcanization; and aftertreatment is processed. The preparation process of the anti-static PVC homogeneous through-core coiled material floor board has the advantages of being simple in manufacturing process, good in stability, long in service life of the manufactured floor board, even in conductivity performance, small in joint during pavement, clear and natural in pattern and strong in third dimension. The dimension of the manufactured floor board can be 2.0m*50m generally or can be longer.

Owner:江苏丰树新材料科技股份有限公司

An energy-saving door lining brick for a coke oven

The invention relates to a door structure of a coke oven, and particularly relates to an energy-saving door lining brick for a coke oven. The door lining brick includes a lining brick main body, a glaze surface, a web and fastening members. The lining brick main body is provided with at least one concave type hollow structure, and is provided with fastening member connecting holes. The glaze surface is hung on the external surface, in contact with coke, of the lining brick main body. The wed covers the concave type hollow structure. The upper surface of the lining brick main body is in close contact with the web. The web and the lining brick main body are fastened through the fastening members so that the concave type hollow structure becomes a sealed cavity. The bottom of the web is coated with a coating. Heat-reflecting coating having high reflectivity is adopted by the coating. The lining brick is a fire-resistant precast block lining brick, and has a height of 500-2000 mm. The lining bricks are arranged into a row up and down and are tightly mounted inside an oven door frame. The lining brick can greatly reduce the present oven door thickness, reduce the temperature of the external wall of an oven door, reduce heat loss and save energy.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com