Patents

Literature

106results about How to "Adapt to deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anionic emulsified modified asphalt and preparation method thereof and anionic high-adhesiveness waterborne asphalt waterproof coating

ActiveCN109575310AGood dispersionHigh strengthConjugated diene hydrocarbon coatingsChloropene polymer coatingsFiberCarbon fibers

The invention discloses anionic emulsified modified asphalt and a preparation method thereof and anionic high-adhesiveness waterborne asphalt waterproof coating. The anionic emulsified modified asphalt is prepared from, by mass, 50-70 parts of matrix asphalt, 1-20 parts of a polymer modifier, 0.5-2 parts of nano carbon fibers, 2-5 parts of a surface modifier, 1-2 parts of an anionic surfactant, 0.1-0.8 part of a pH regulator and 20-40 parts of water. A film formed by the waterproof coating has excellent creep performance and extending performance and is capable of well sealing cracks of a baselayer to effectively resist cracking caused by base layer settlement, deformation and the like, water channeling is prevented, and reliability of an upper waterproof roll is improved.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

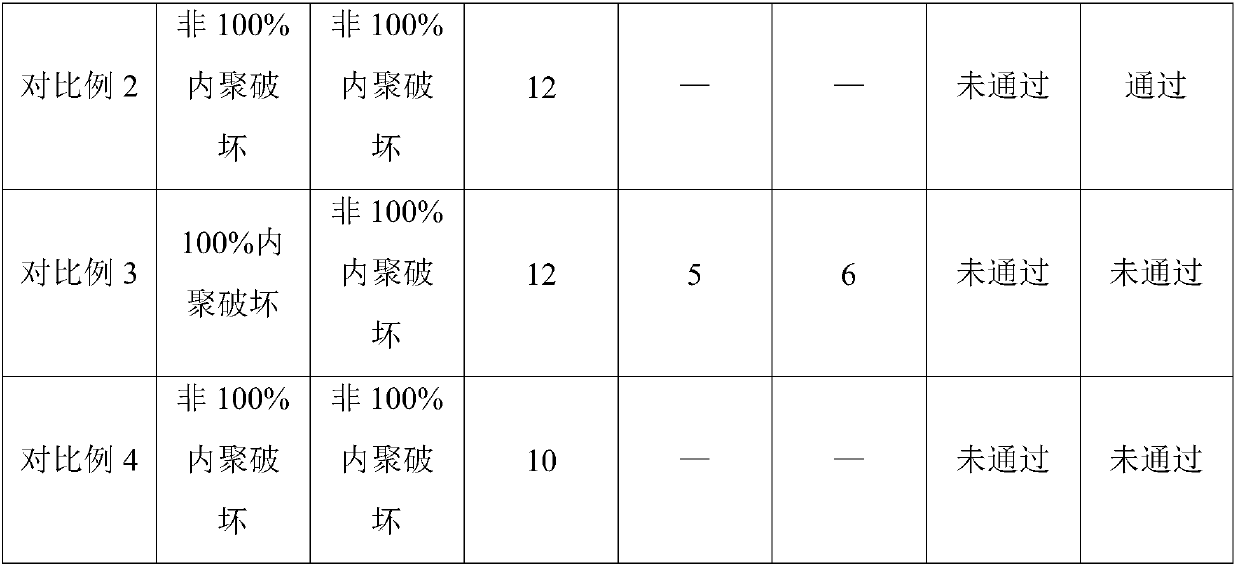

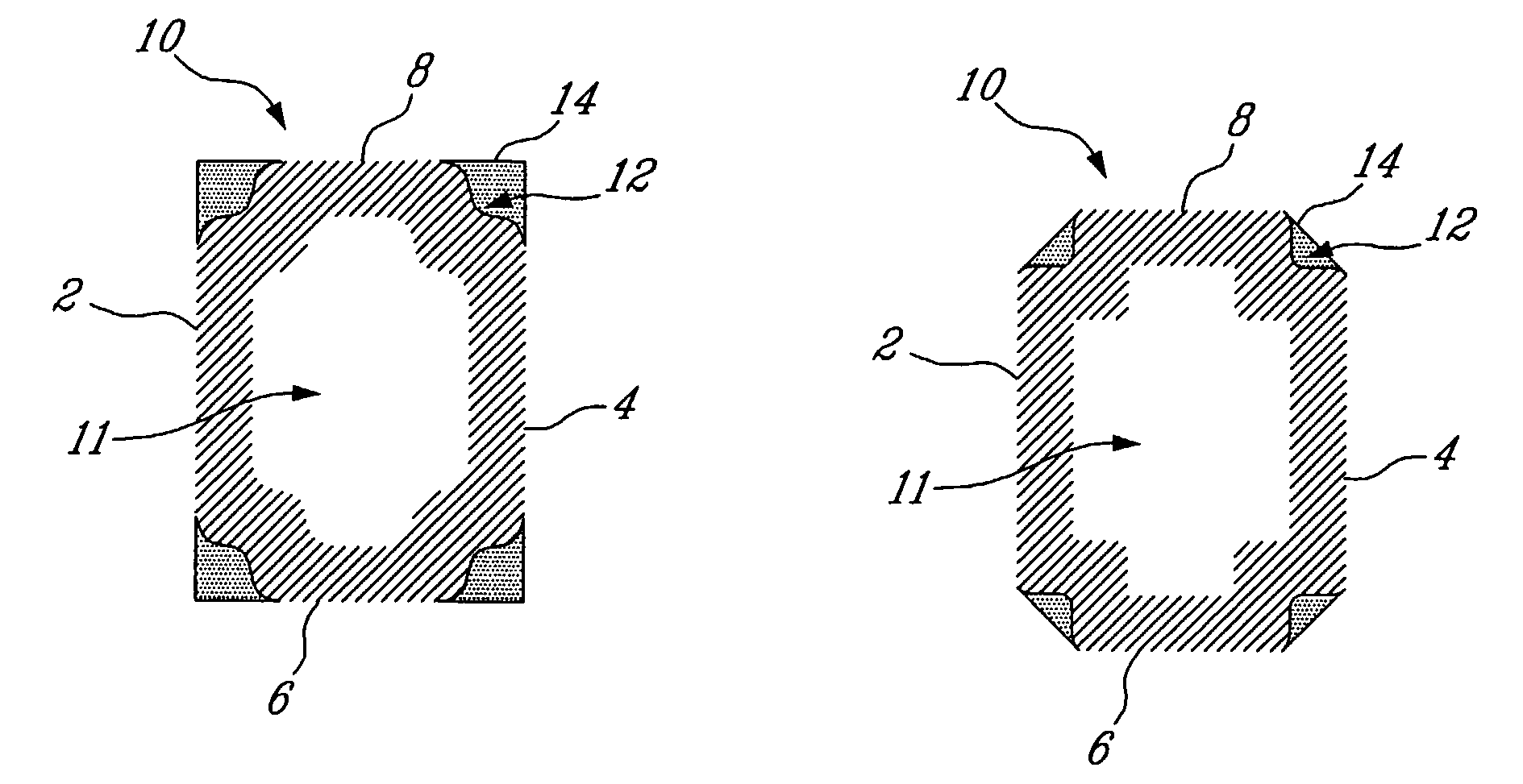

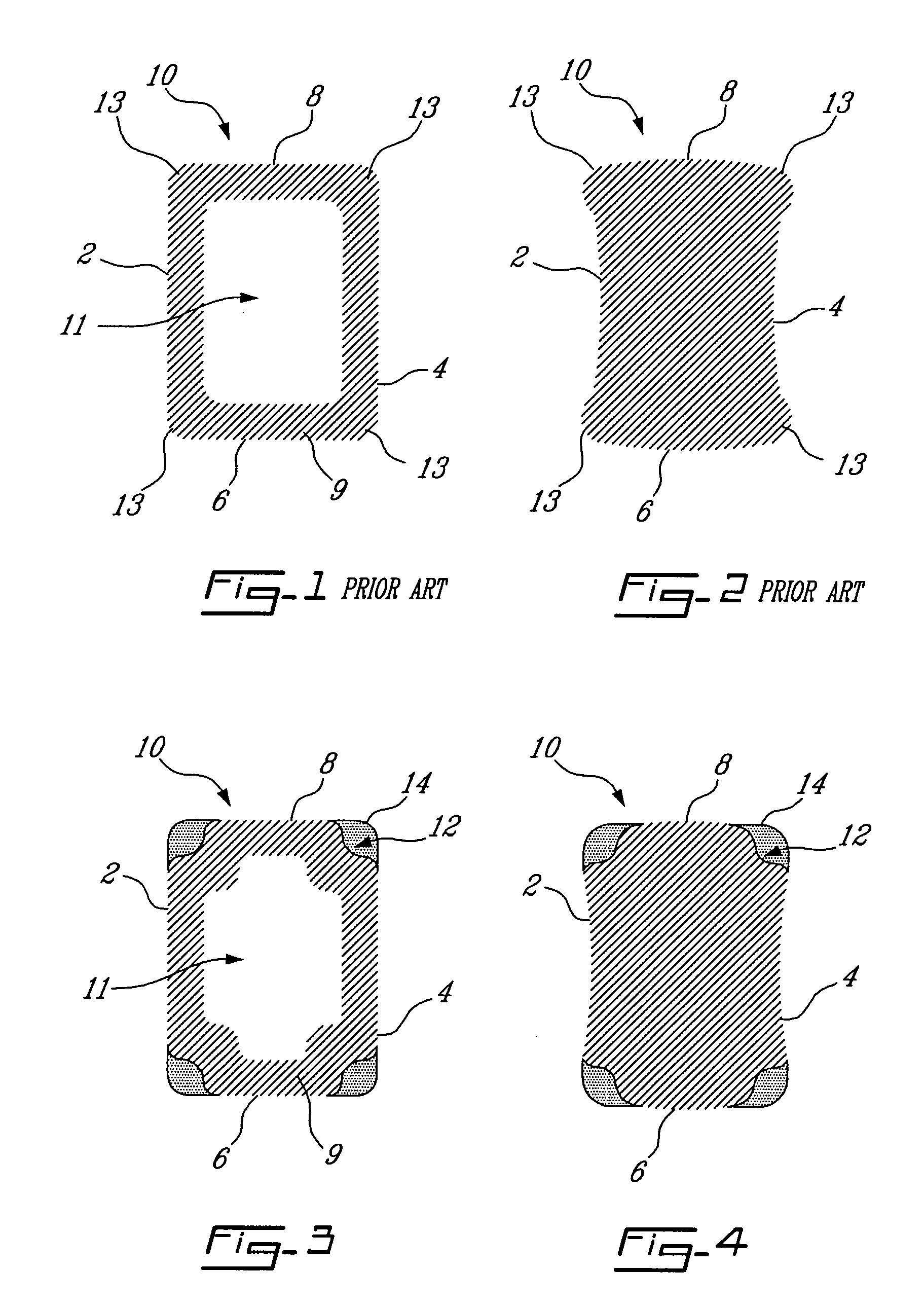

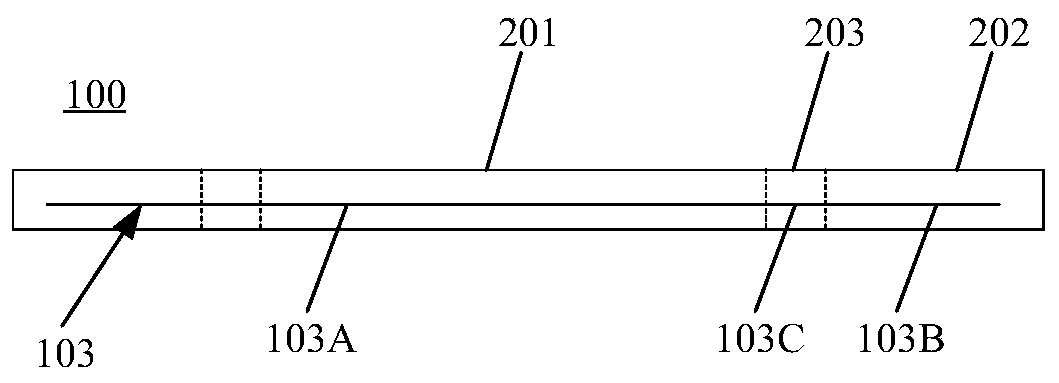

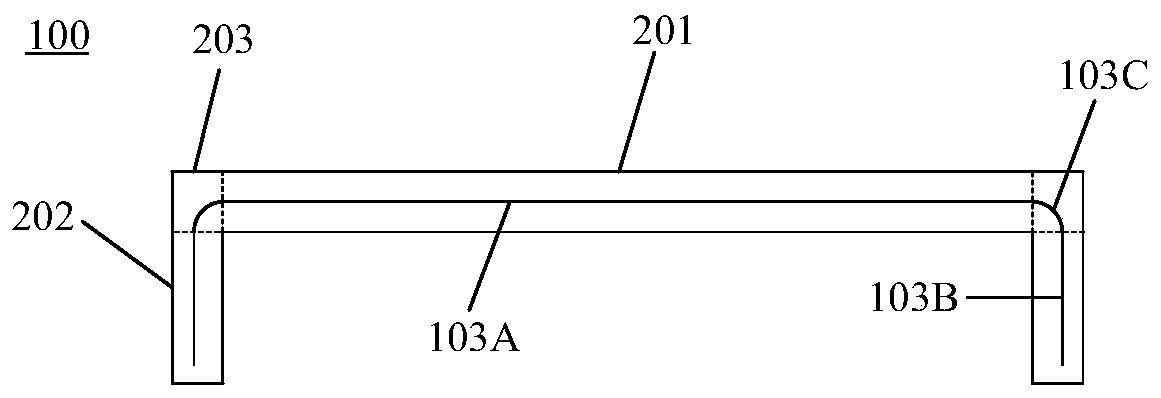

Sports apparatus shaft and blade with added impact protection and method of making same

The invention pertains to sports shafts to other sports equipment subjected to impact thereon. The longitudinal edges of the sports shaft are replaced with elastomeric material so as to create a series of bumpers along the longitudinal edges providing increased protection and longevity to the stick. The invention also pertains to the blade, as in hockey stick blade, wherein the top surface of the blade is provided with an elastomeric material so as to create a bumper on the top surface. The invention also pertains to a method of fabricating said sports shaft.

Owner:SPORT MASKA

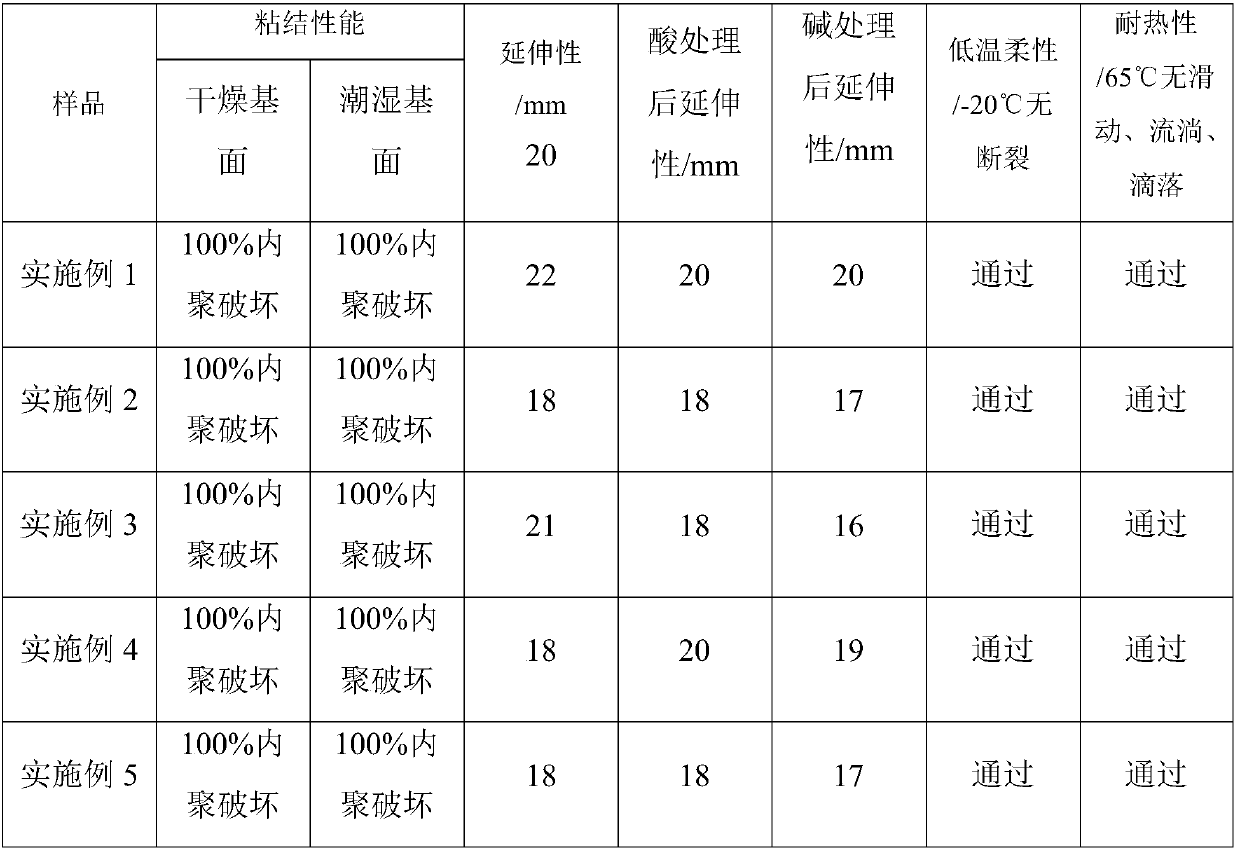

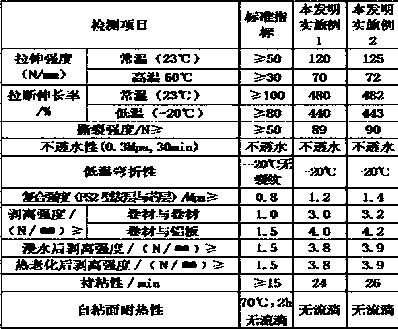

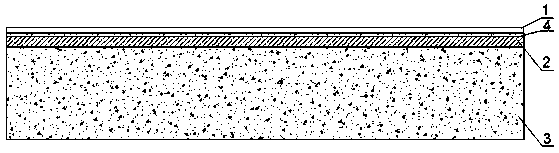

High initial adhesion self-adhering waterproof roll and preparation method

InactiveCN104263261AAvoid punctureAdapt to deformationNon-macromolecular adhesive additivesFilm/foil adhesivesAdhesiveAnti ageing

The invention discloses a high initial adhesion self-adhering waterproof roll which is characterized by comprising the following components in percentage by mass: 35-55% of petroleum asphalt, 5-25% of a softening agent, 5-25% of a modifier, 2-8% of an adhesive, 0.1-2% of a surfactant, 0.1-3% of an anti-aging agent and 5-20% of a filling agent.

Owner:包头市草原驼峰防水材料有限公司

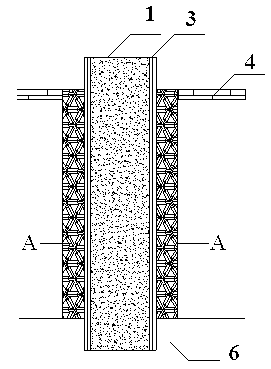

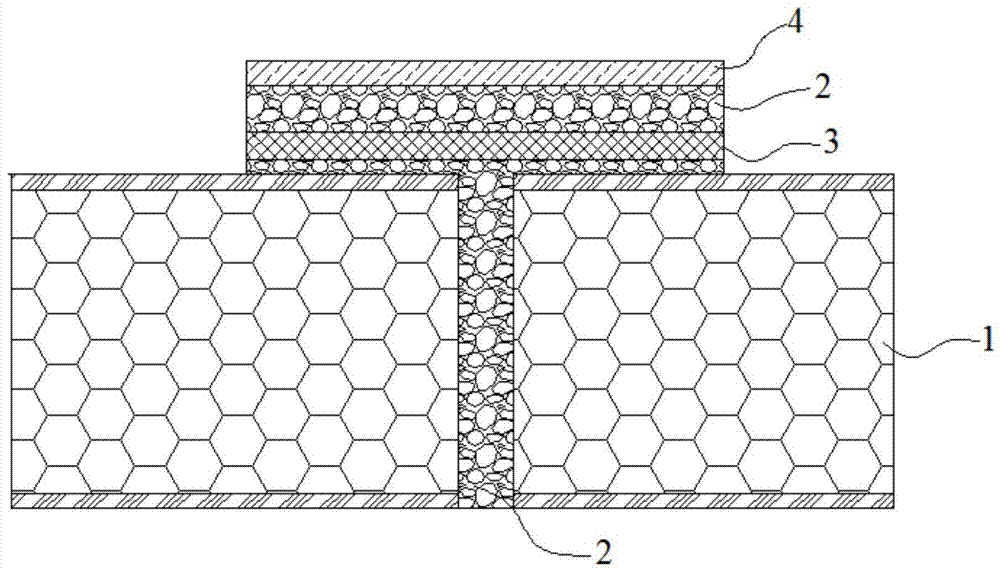

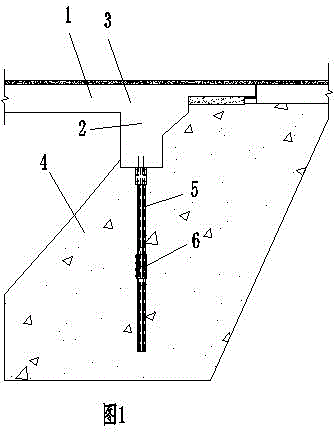

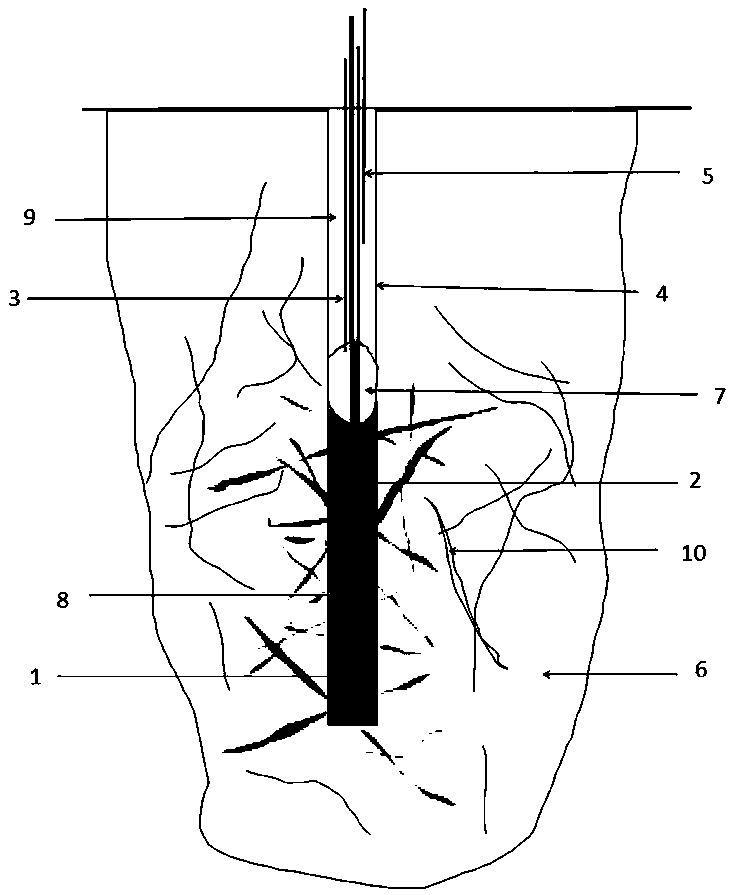

Casing draining end bearing pile for treating liquefied foundation and construction method

InactiveCN102995622AImprove bearing capacityTimely dissipation of excess pore water pressureBulkheads/pilesSoil preservationCrushed stoneEngineering

The invention discloses a casing drawing end bearing pile for treating a liquefied foundation and a construction method. The casing drawing end bearing pile for treating the liquefied foundation is that a pile body comprises an inner plastic pipe, an outer plastic pipe, a blind drain, concrete and a geotextile; a casing pile is an end bearing pile; a drilling machine is adopted and is used for drilling a hole so as to insert the outer plastic pipe which is wrapped by the geotextile into a foundation bearing course; the annular draining blind drain of which the diameter is slightly smaller than that of the outer pipe is placed on the inner side of the outer plastic pipe, so as to form a vertical draining channel; the inner plastic pipe is placed on the inner side of the annular draining blind drain; the concrete is poured into the inner plastic pipe to form the pile; and a gravel cushion layer is paved at the top of the pile along the horizontal direction, thus forming a horizontal draining channel. By adopting the casing draining end bearing pile for treating the liquefied foundation and the construction method, the bearing capacity of the pile is improved under the same amount of used concrete, the application range is wide, and the casing draining end bearing pile is applicable to the treatment of a general wear foundation and the liquefied foundation; the horizontal draining channel and the vertical draining channel are provided for foundation liquefying, and thus the possibility that the foundation is liquefied is reduced; and the casing draining end bearing pile is reasonable in structure, good in pile forming effect, low in cost and convenient to construct, and realizes the effects on foundation treatment and seismic hardening.

Owner:HOHAI UNIV

Foamable phenolic resin strengthening and filling material for coal mine

ActiveCN102558763AAdjustable curing speedCured body with high strengthUnderground chambersTunnel liningOrganic acidUrea

The invention relates to a foamable phenolic resin strengthening and filling material for coal mine. In the foamable phenolic resin strengthening and filling material for coal mines, a component A is one of inorganic acid and organic acid or a mixture of inorganic acid and organic acid; and a component B is prepared by mixing 90 to 100 weight parts of urea modified phenolic resin with solid content of 65 to 90 weight percent, 6 to 10 weight parts of composite fire retardant, 0 to 15 weight parts of foaming agent, 1 to 5 weight parts of stabilizing agent, 1 to 15 weight parts of cosolvent, 2 to 16 weight parts of antistatic agent and 10 to 30 weight parts of plasticizer, stirring at the temperature of between 30 and 50 DEG C and reacting for 0.5 to 2 hours. When the foamable phenolic resin strengthening and filling material is used, the component A and the component B are mixed and injected into a coal (rock) layer according to the weight ratio of (1-2) : 1 and permeated into small cracks to expand and generate curing reaction for strengthening and sealing the region. According to the foamable phenolic resin strengthening and filling material for coal mines, the compressive strength is more than 40 MPa; the bonding strength is more than or equal to 3.0 MPa; and the foaming coefficient is less than or equal to two times. The foamable phenolic resin strengthening and filling material for coal mines can meet the requirement of coal mine on safety production and can be applied to the industries such as hydroelectric powder, buildings, mining, traffic and the like.

Owner:SHANXI ZHAOXIN BIO TECH

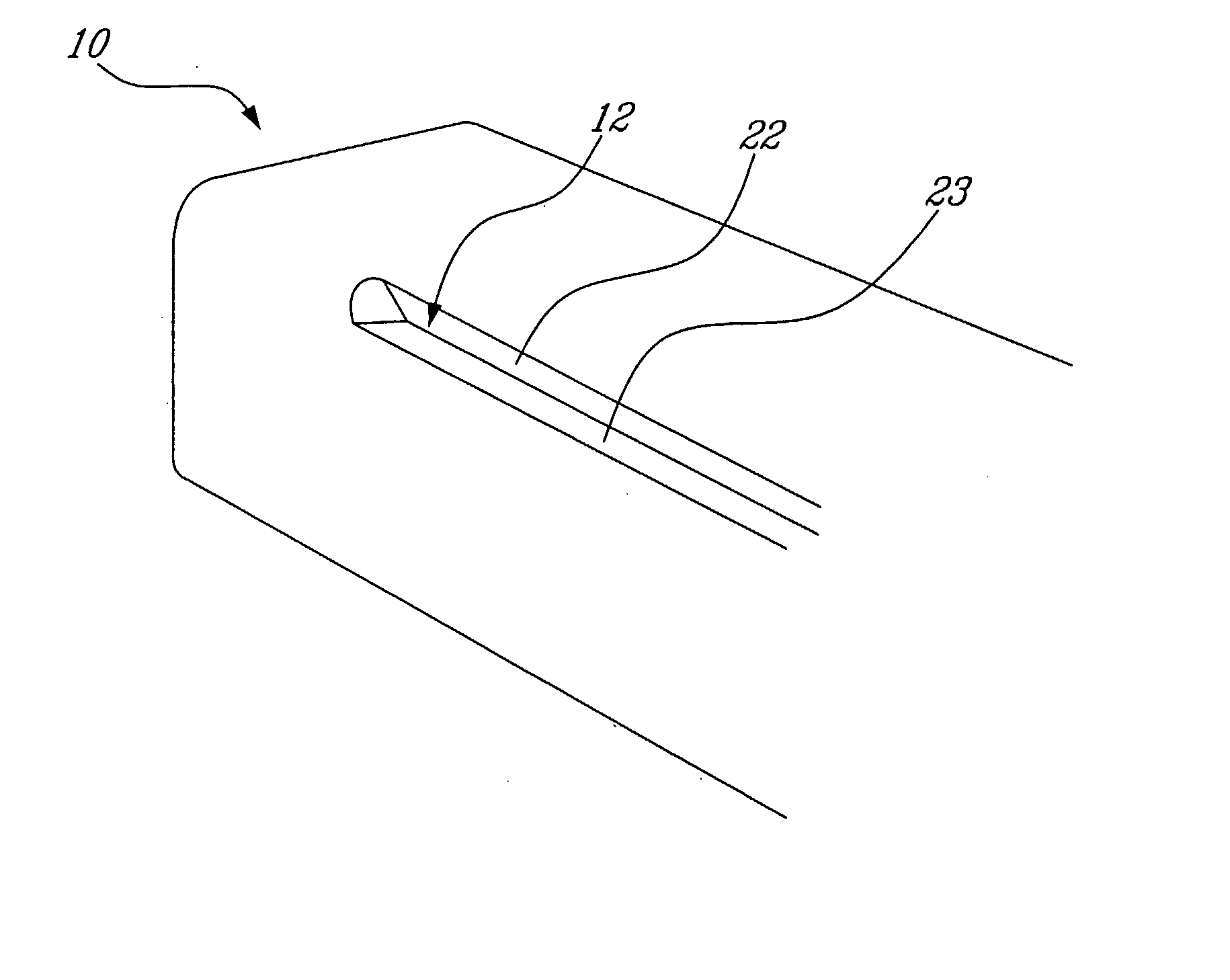

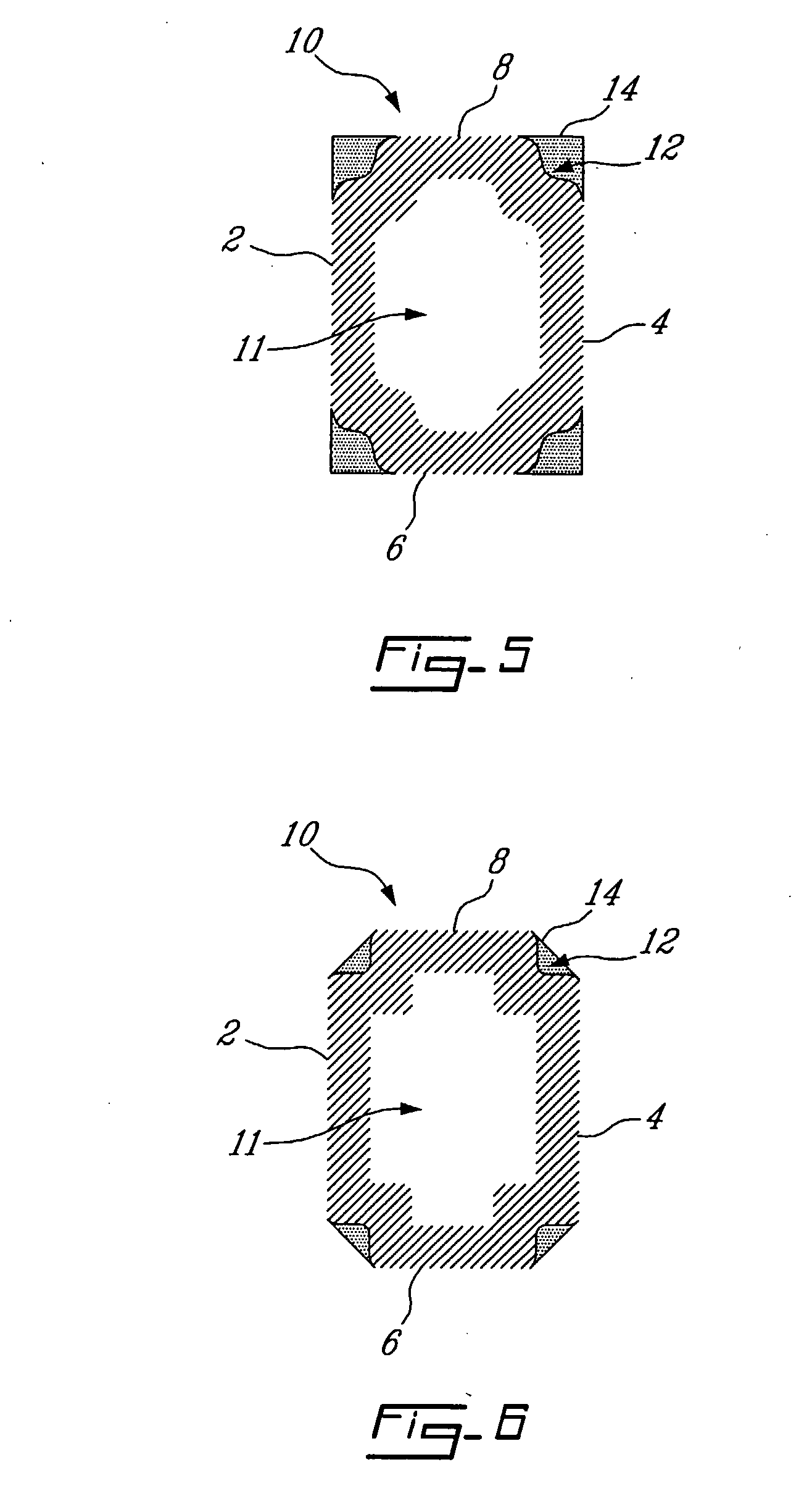

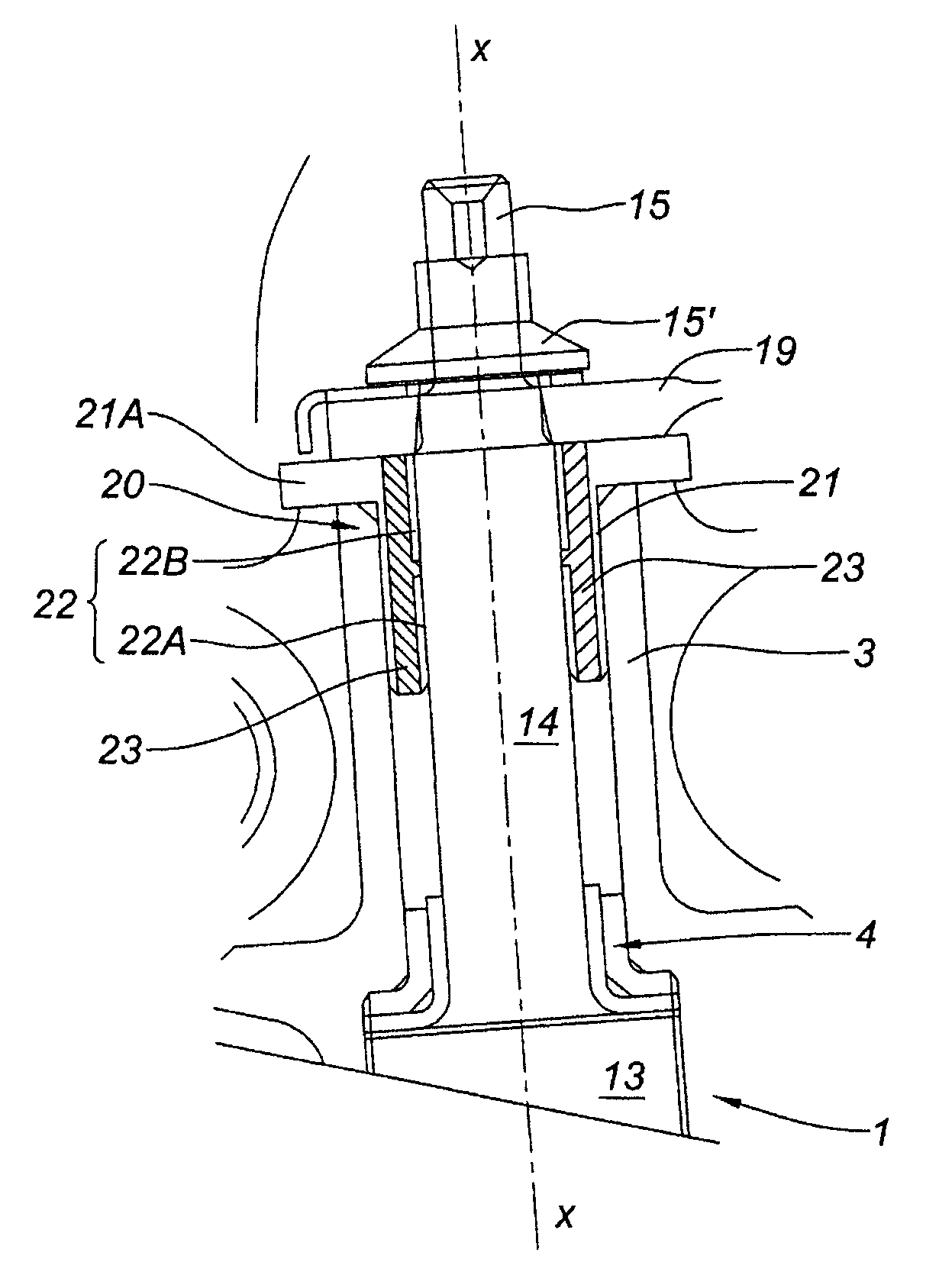

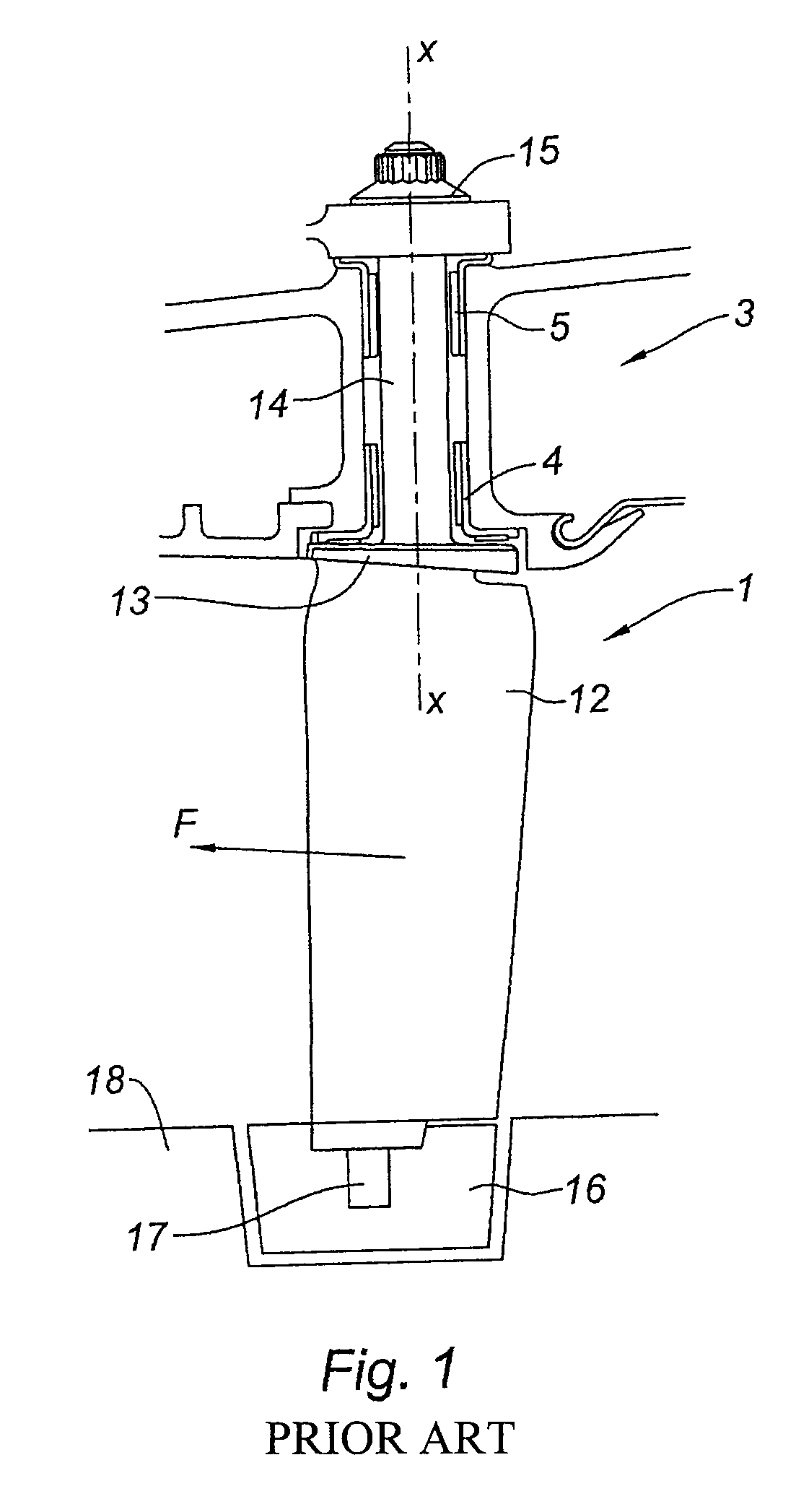

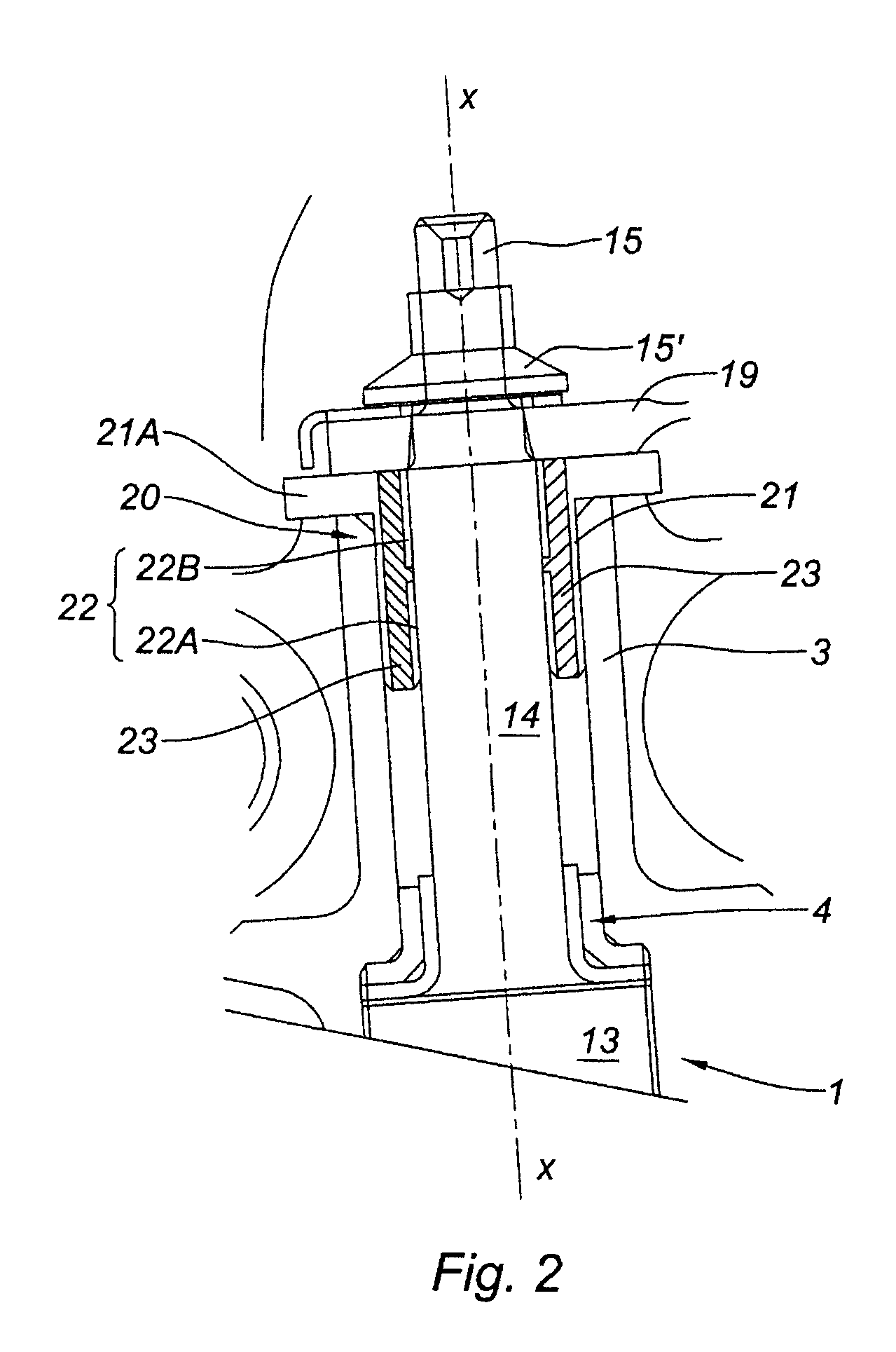

Bearing for variable pitch stator vane

ActiveUS8038387B2Increase the effective areaReduced component wearWind motor controlPump componentsEngineeringMechanical engineering

A bearing for a turbomachine variable pitch stator vane pivot mounted in a bore of the turbomachine casing is disclosed. The bearing includes an inner bushing secured to the pivot and an outer bushing secured to the bore. An elastomeric material is inserted between the inner bushing and the outer bushing to allow the vane to pivot about its axis and absorb at least some of the flexing of the pivot at right angles to the axis. The design makes it possible to reduce bearing bushing wear.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Sports apparatus shaft and blade with added impact protection and method of making same

The invention pertains to sports shafts to other sports equipment subjected to impact thereon. The longitudinal edges of the sports shaft are replaced with elastomeric material so as to create a series of bumpers along the longitudinal edges providing increased protection and longevity to the stick. The invention also pertains to the blade, as in hockey stick blade, wherein the top surface of the blade is provided with an elastomeric material so as to create a bumper on the top surface. The invention also pertains to a method of fabricating said sports shaft.

Owner:SPORT MASKA

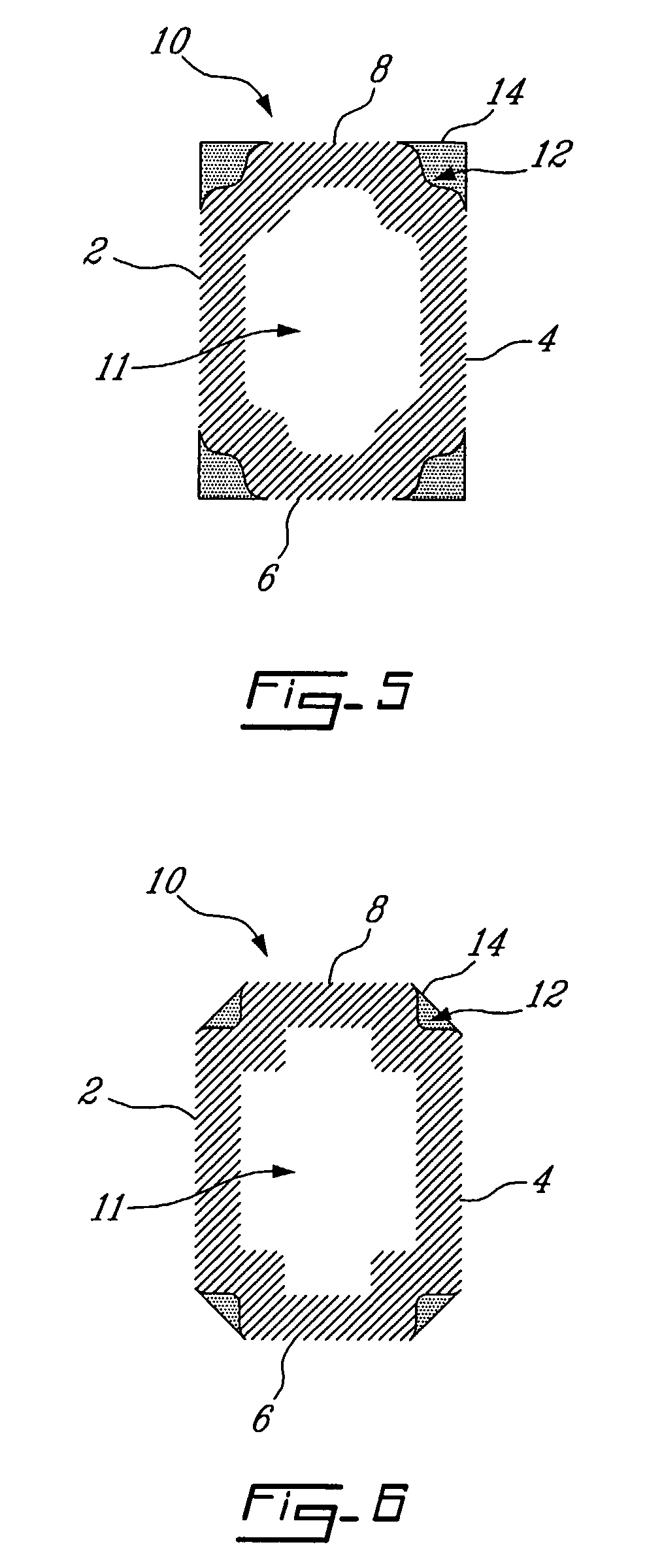

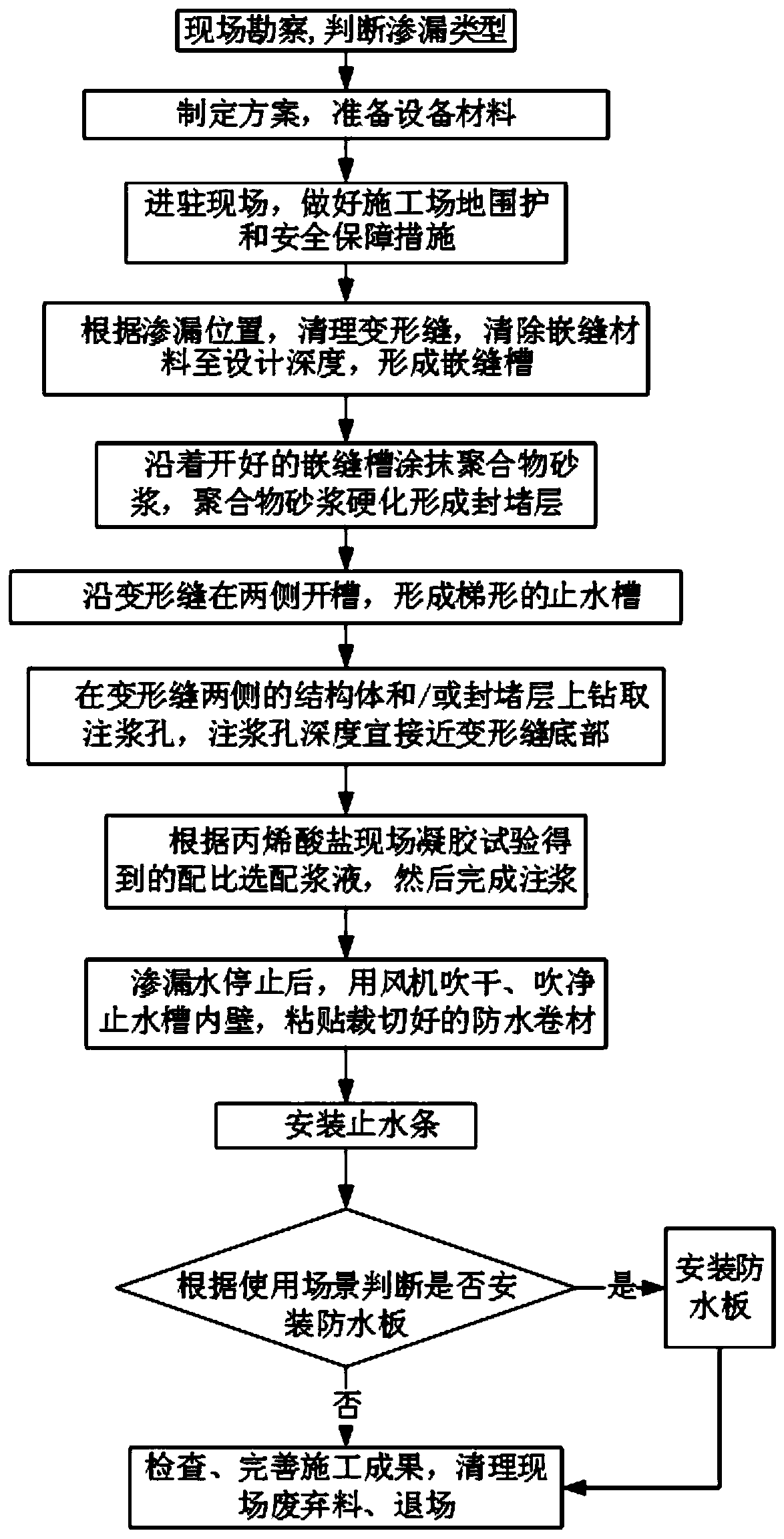

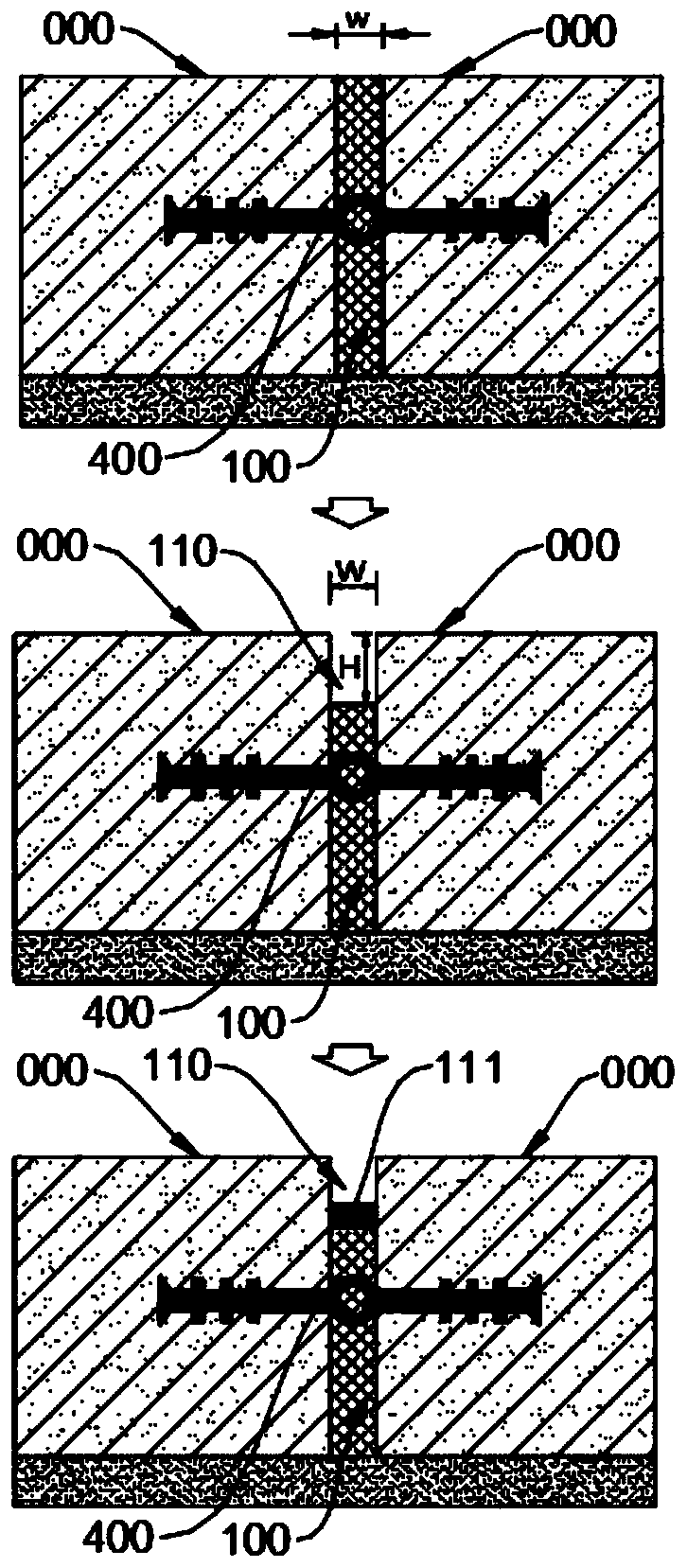

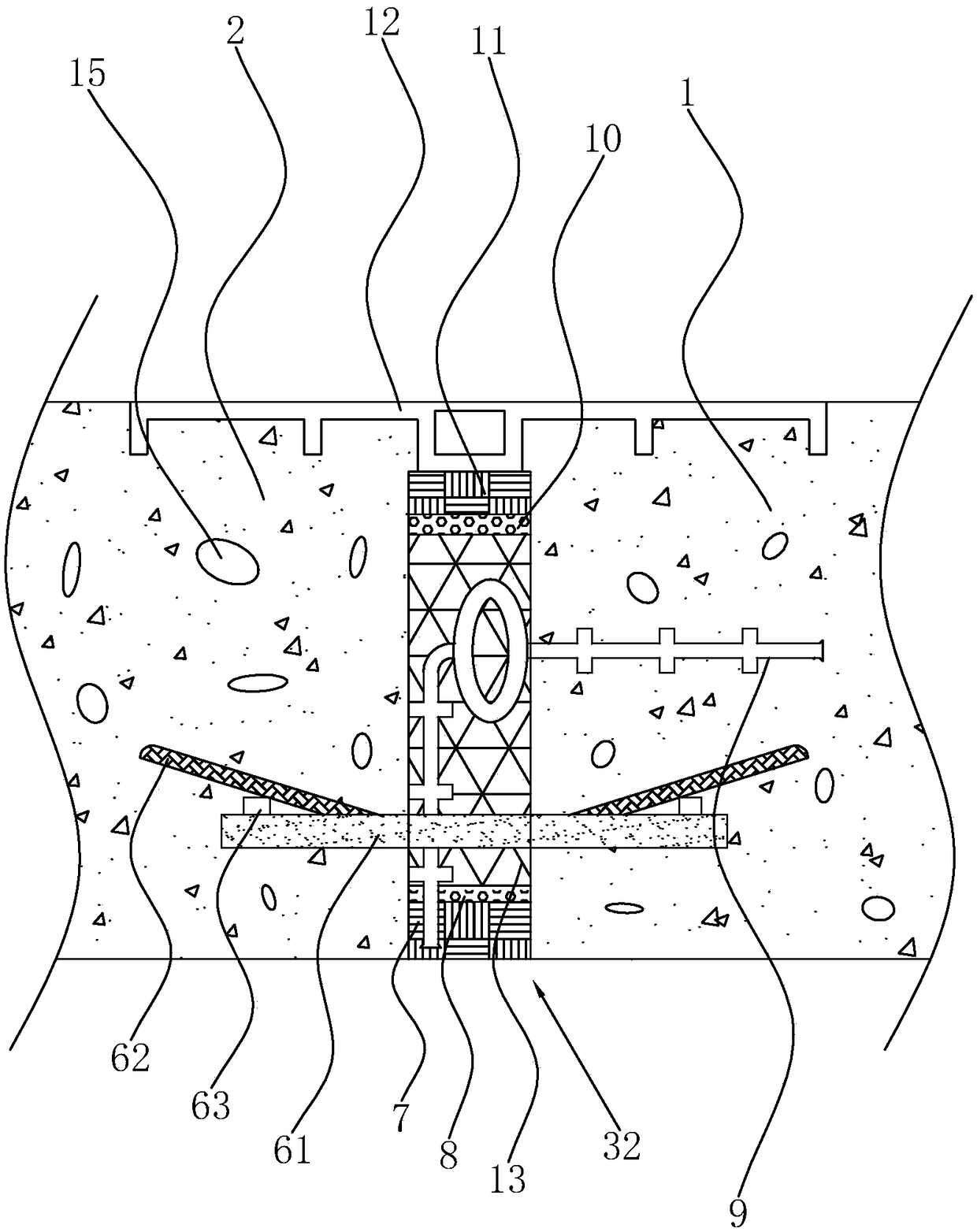

Deformation joint treatment method and deformation joint waterproof structure

InactiveCN110629800AEasy to manageBroaden applicationArtificial islandsProtective foundationWater leakageWater seepage

The invention relates to the field of water leakage treatment of building joints, in particular to a deformation joint treatment method and a deformation joint waterproof structure. The deformation joint treatment method comprises the steps that 1, on-site survey is conducted; 2, the type of deformation joint leakage is determined based on the result of the on-site survey; and 3, a construction plan is made based on the type of the deformation joint leakage. According to the deformation joint treatment method, the on-site survey is firstly conducted, information of the deformation joint is collected, the width and length of the deformation joint, the location and cause of water seepage, the number of water seepage points, the amount of water seepage, and the damage condition of a water stop are obtained; the type of the deformation joint leakage is determined based on the location and cause of water seepage, the number of water seepage, the amount of water seepage, and the damage condition of the water stop; according to the determined type of the deformation joint leakage, a targeted construction plan is made to better treat the leakage. According to the deformation joint treatment method, a flexible waterproof structure is formed, in the process of water blocking, a water blocking material can passively adapt to the deformation of the structure, and the problem of water leakage caused by the material damage due to the deformation of the structure is alleviated.

Owner:SUBWAY OPERATION TECH R & D CENT BEIJING SUBWAY OPERATION CO LTD +1

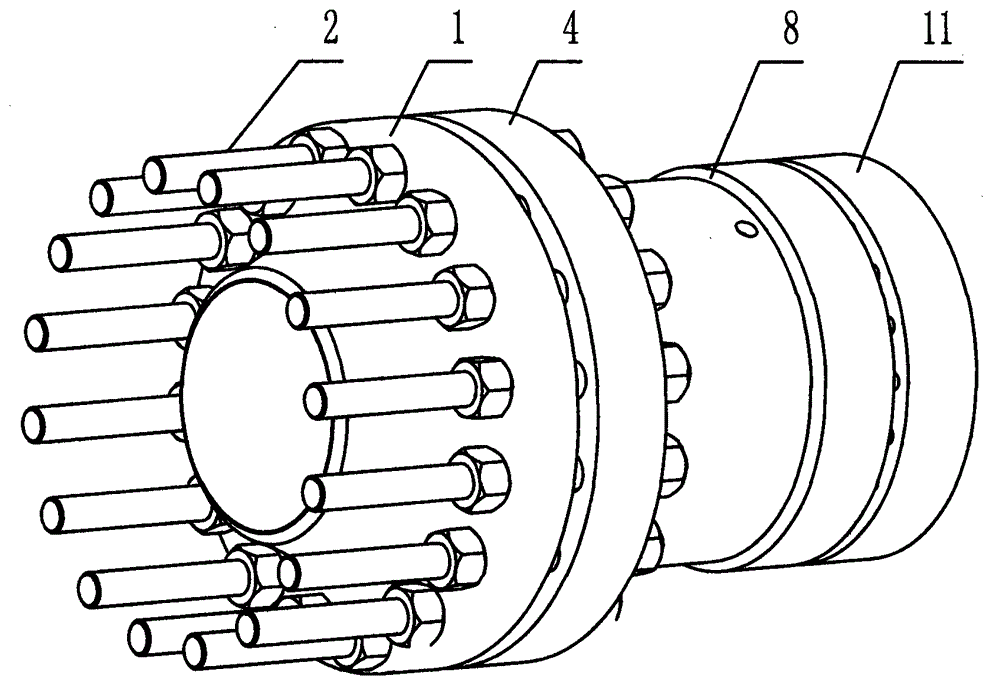

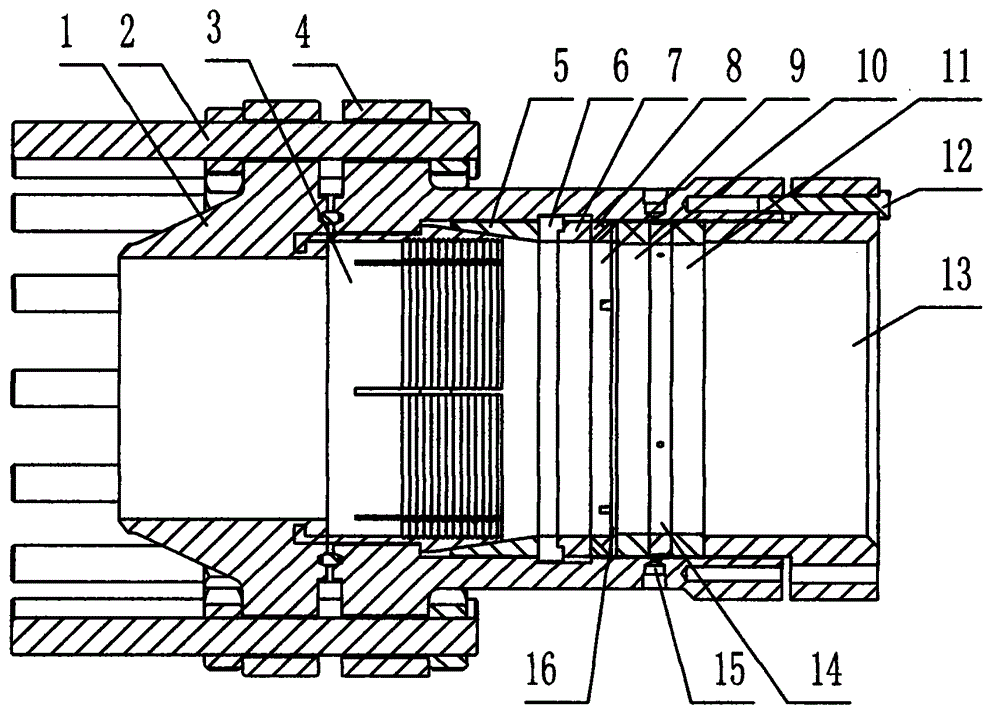

Quick pipeline connecting flange

The invention relates to a quick pipeline connecting flange comprising a flange body. The flange body is cylindrical, and the outer edge of the front end is provided with screw holes and bolts being in butt joint with and fixed to a butt flange. The quick pipeline connecting flange is characterized by being further provided with a clamping component group clamping the flange body to the outer wall of a connected pipeline and a sealing component group sealing the flange body and the outer wall of the pipeline; the clamping component group is arranged on the inner wall of the outer end of the flange body, the sealing component group is arranged on the inner wall of the inner end of the flange body, and the outer periphery of the clamping component group is attached into the groove of the inner wall of the outer end of the flange body; the outer periphery of the sealing component group is fixed to the inner wall of the inner end of the flange body and connected and fixed to the flange body through the bolts at the rear end. The clamping component unit is provided with a slip and a slip sleeve; the sealing component group is provided with a locking ring, a rubber ring and a butting flange sequentially from outside to inside. The quick pipeline connecting flange is applicable to pipelines, in particular to maintenance of underwater submarine pipelines, and has the advantages of high working efficiency, reliable sealability and firmness, high adaptability, maintenance cost saving and the like.

Owner:周庆涛

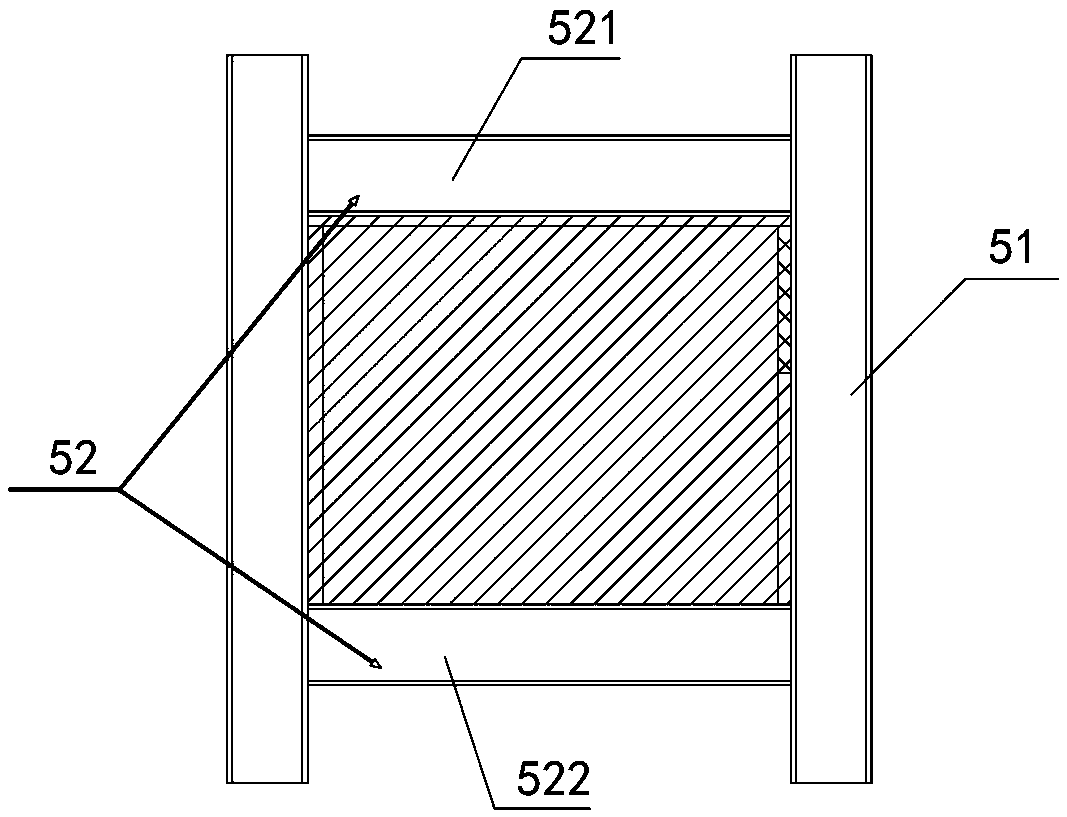

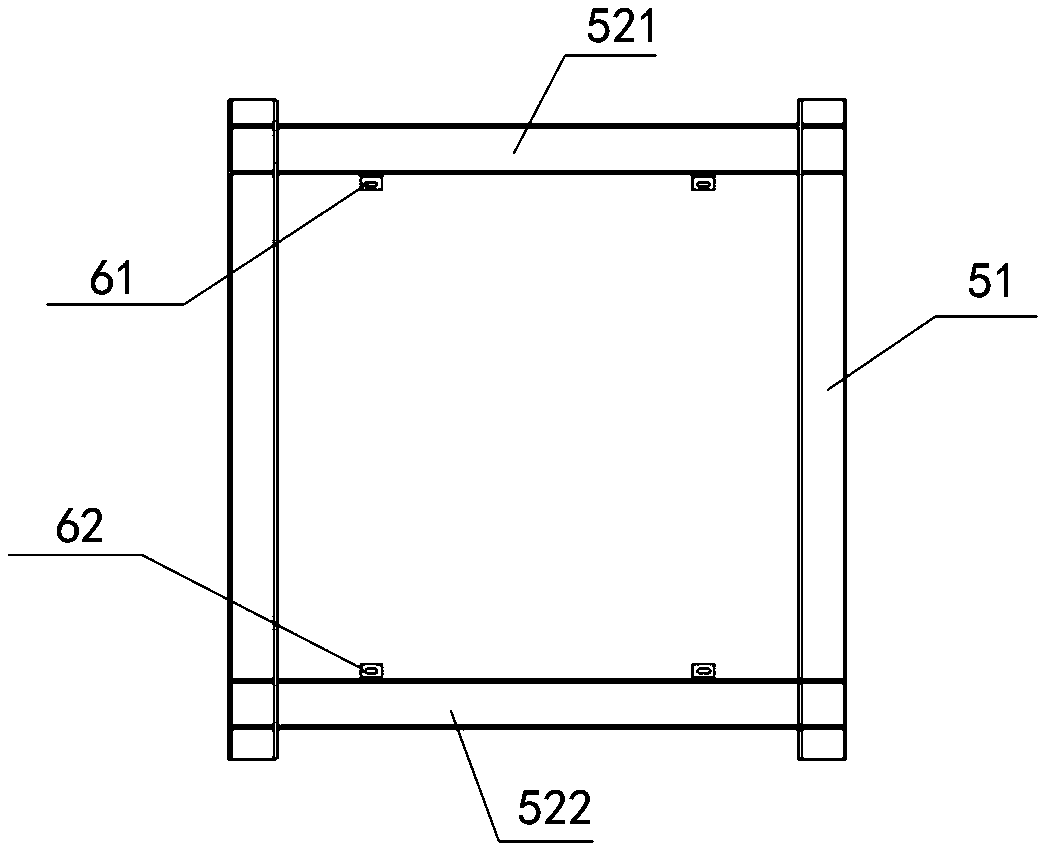

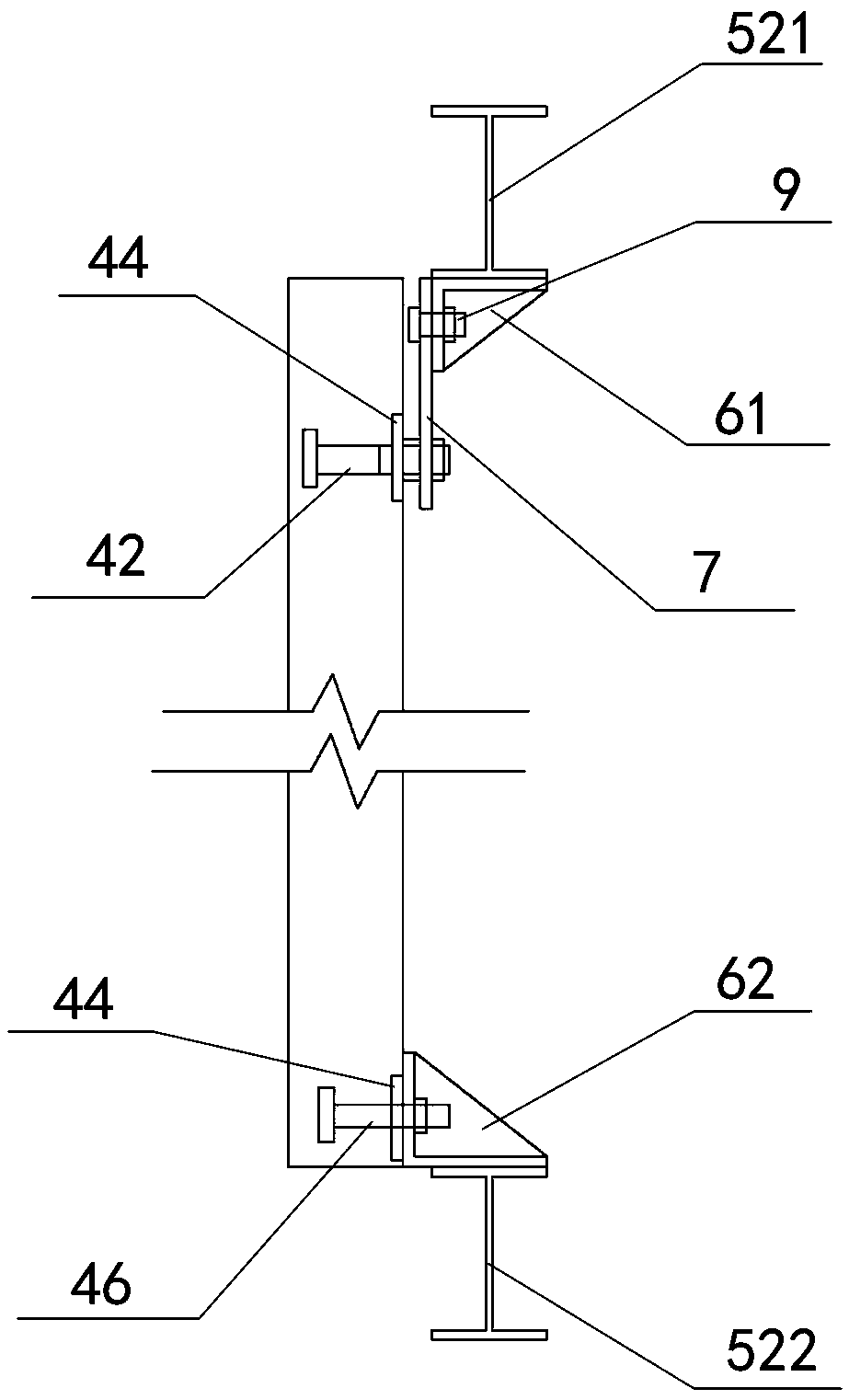

Externally-hung infilled wall structural system of steel framework, assembly-type infilled wallboard and construction method

ActiveCN108978949AGuaranteed co-morphingGuaranteed not to moveWallsClimate change adaptationMetallurgyStructural system

The invention relates to an externally-hung infilled wall structural system for an assembly-type steel framework. The system comprises the rectangular steel framework and the infilled wallboard. The steel framework is formed by connection of steel framework columns and steel framework beams. The inside of an upper steel framework beam at the upper part is connected with first angle iron connectingpieces by welding. The inside of a lower steel framework beam is connected with second angle iron connecting pieces by welding. The infilled wallboard is arranged outside the steel framework and connected between the upper steel framework beam and the lower steel framework beam. Four corners of the infilled wallboard are equipped with first screw rods and second screw rods in a pre-buried manner.The bottom of each rectangular connection board is connected with a first screw rod. The top of each rectangular connection board is connected with the upper steel framework beam through a third screw rod. Each second screw rod is connected with each second angle iron connecting piece. In case of a horizontal earthquake, the wallboard and the steel framework are deformed so that anti-earthquake performance is improved. During the force-bearing process of screw rods, surrounding concrete is not affected so that concrete is prevented from cracking.

Owner:新疆中鼎建设集团有限公司

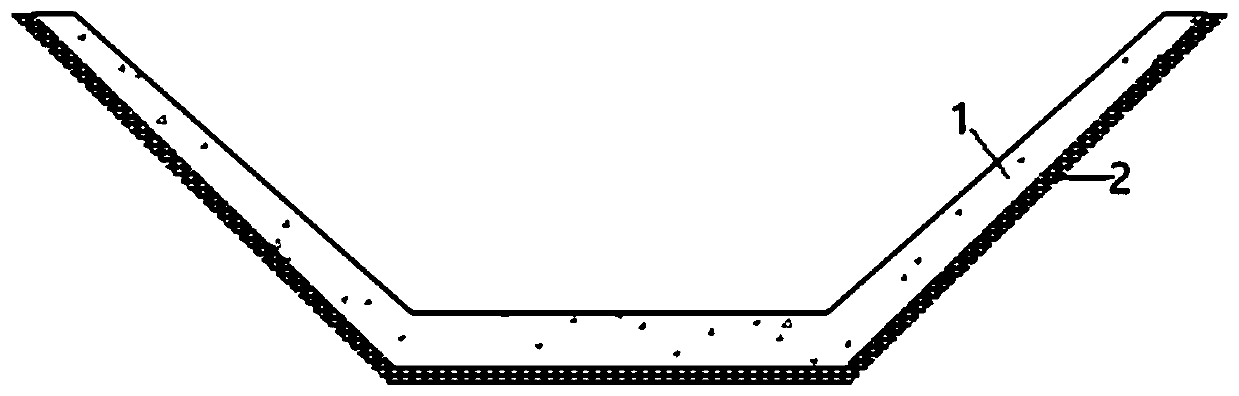

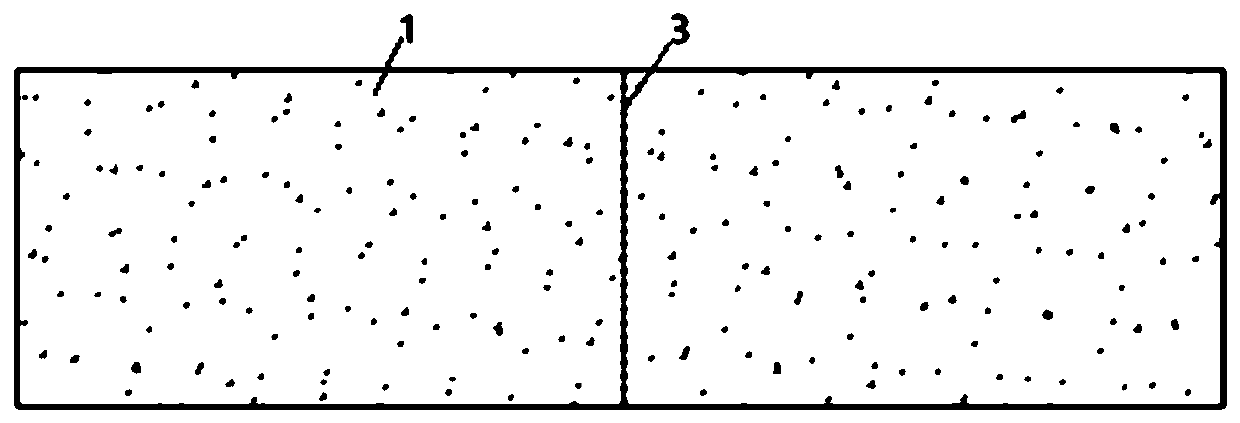

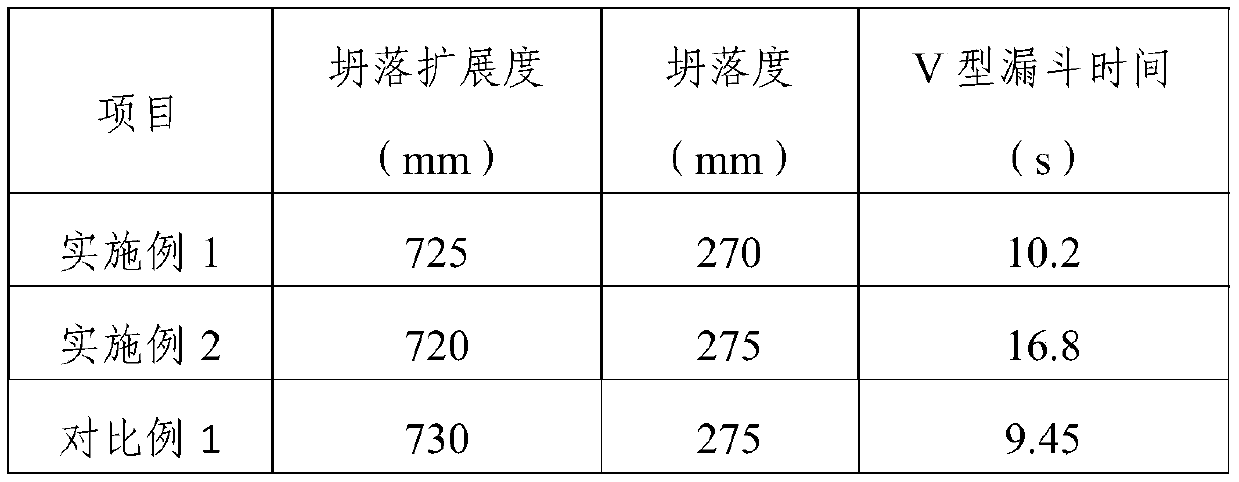

Self-compaction rubber concrete canal lining and preparation method therefor

ActiveCN110698127AImprove ductilityImprove impermeabilityArtificial water canalsFreeze thawingStructural engineering

The invention relates to a self-compaction rubber concrete canal lining and a preparation method therefor. The self-compaction rubber concrete canal lining comprises a canal lining main body, whereinthe canal lining main body is prepared from self-compaction rubber concrete. The lining material provided by the invention can be used for effectively improving high brittleness and low compliance ofthe conventional concrete linings and effectively improving the ductility, impervious waterproofing performance, salt corrosion resistance, freeze-thaw resistance and surrounding soil mass deformationadaptability of lining structures. In addition, the lining material can be filled and compacted in a lining die without bumping down in a poured-in-place process, so that construction steps are simplified, and the schedule of construction is accelerated. The self-compaction rubber concrete canal lining provided by the invention has better popularization and application prospects.

Owner:CHINA AGRI UNIV

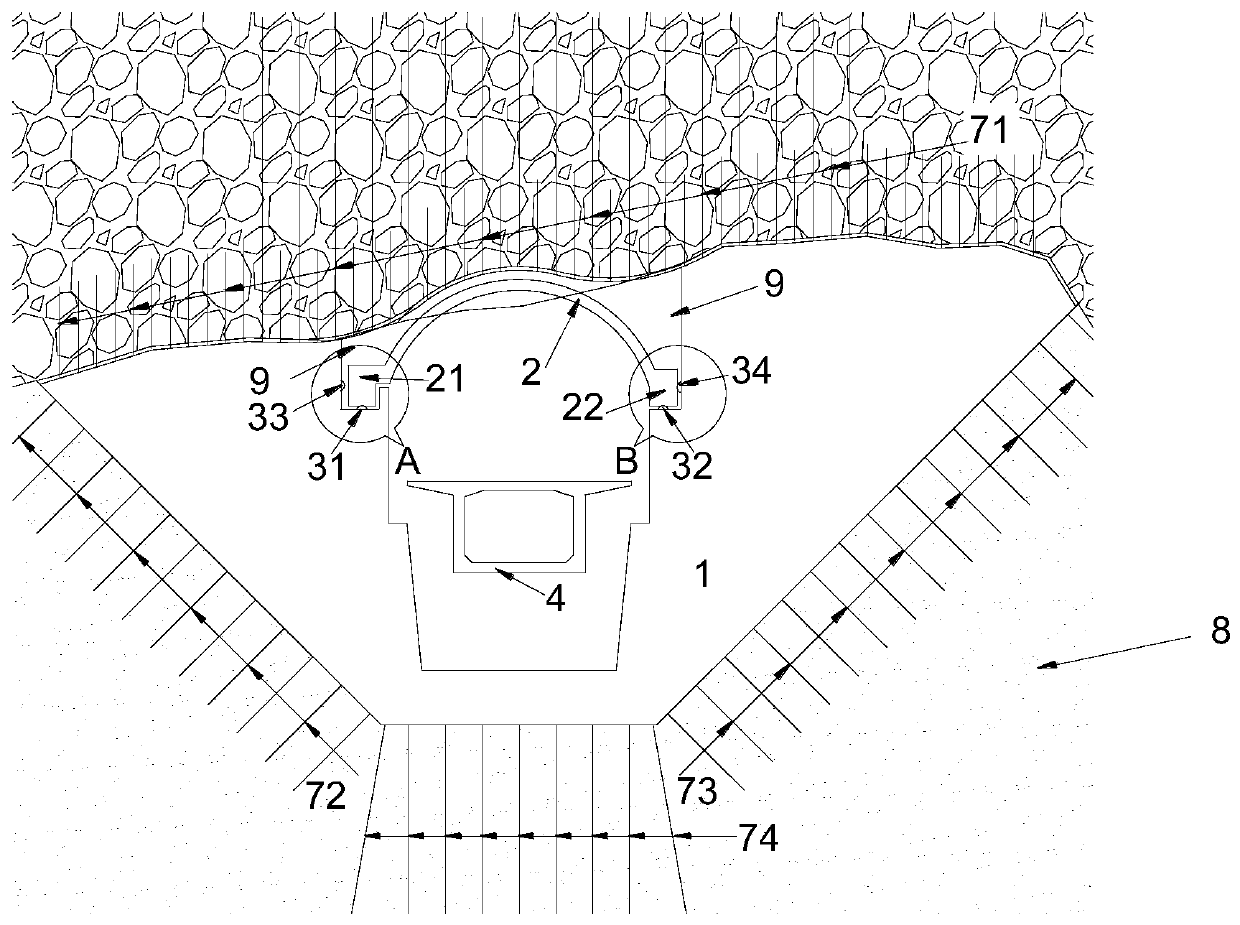

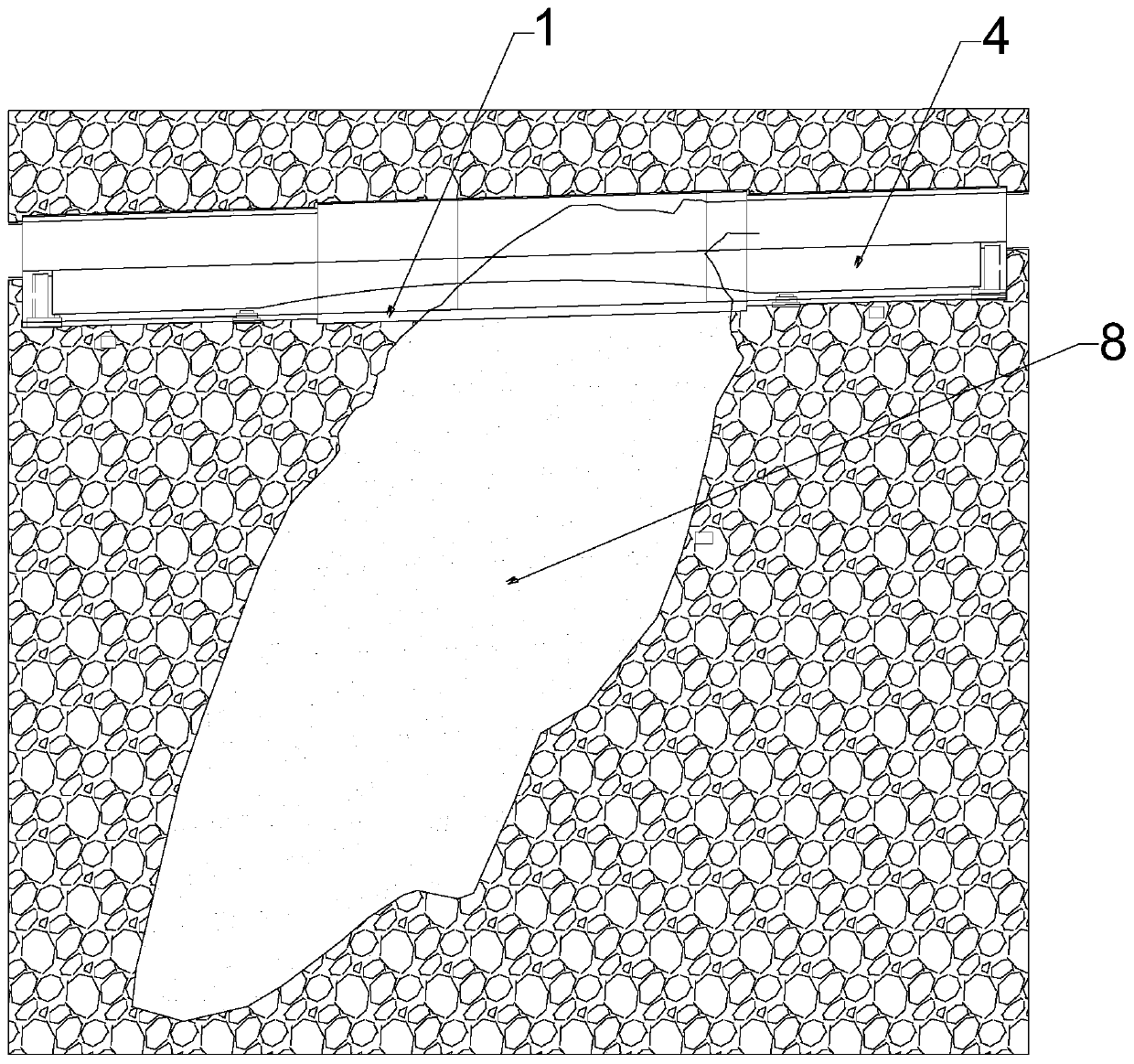

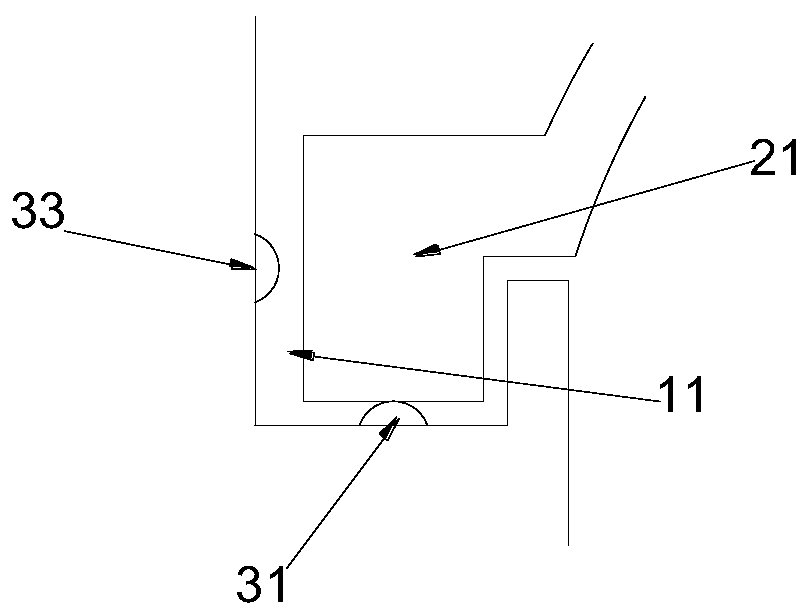

Open cut tunnel structure of simply supported arch of tunnel traversing huge karst cave and construction method thereof

PendingCN111396095AStable supportAchieve separationUnderground chambersMaterial fill-upArchitectural engineeringKarst

The invention relates to the field of karst tunnels, in particular to an open cut tunnel structure of a simply supported arch of a tunnel traversing a huge karst cave and a construction method thereof. The structure comprises a U-shaped substrate, an arch part simply supported arch, a vault backfill body and a bridge beam plate. The tops of two sides of the U-shaped substrate are in contact with upper surrounding rocks, a slot I is formed in one side of the inner wall of the U-shaped substrate, and a slot II is formed in the other side of the U-shaped substrate; the vault backfill body fills aspace among the upper surrounding rocks of the arch part simply supported arch; a side substrate I and a side substrate II are separately arranged on two sides of the arch part simply supported arch;the side substrate I is placed in the slot I and can shift vertically and transversely in the slot I; the side substrate II is placed in the slot II and can shift vertically and transversely in the slot II; and the bridge beam plate is placed in a space encircled by the arch part simply supported arch and the U-shaped substrate, and two ends of the bridge beam plate are located on stable foundations at two ends of the karst cave. The construction method is used to construct the structure. The open cut tunnel structure achieves dynamic and static separation and can avoid excessive structural settlement caused by dynamic and static load coupling.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

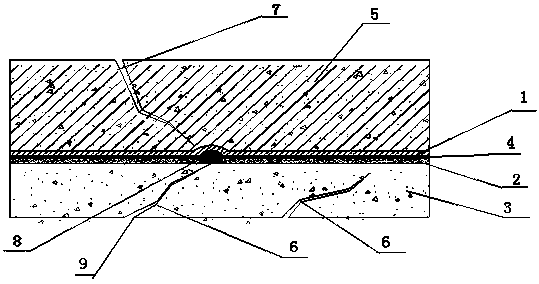

Construction technique of waterproof heat-insulation integrated system

The invention discloses a construction technique of a waterproof heat-insulation integrated system. The construction technique comprises the following steps: (1) processing a base layer; (2) popping up a plate paving control line at the surface of the base layer; (3) cutting the plates; (4) coating heated rubber asphalt coating on the base layer according to the control line; (5) paving the cut plates on the rubber asphalt coating, and vibrating and discharging; (6) performing crack-pouring sealing on the crack between adjacent plates by the rubber asphalt coating, and smear the rubber asphalt coating at both sides of the crack, paving a grid cloth, and coating the rubber asphalt coating to completely cover the grid cloth; covering a film surface with reflecting function on the rubber asphalt coating again. The waterproof heat-insulation integrated system prepared by the construction technique is free from water channeling, water absorption and water inflow; the heat insulation and waterproof problems are solved in one step; thus the construction technique is simplified, the system risk is reduced, and the comprehensive energy-saving effect is greatly improved.

Owner:SHENZHEN ZHUOBAO TECH

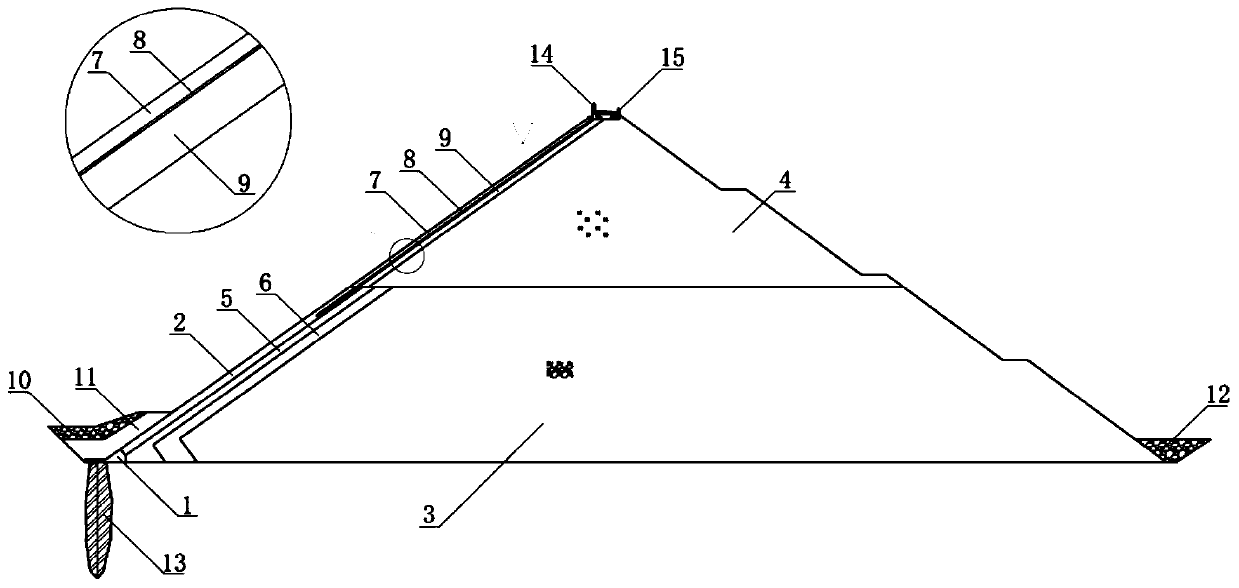

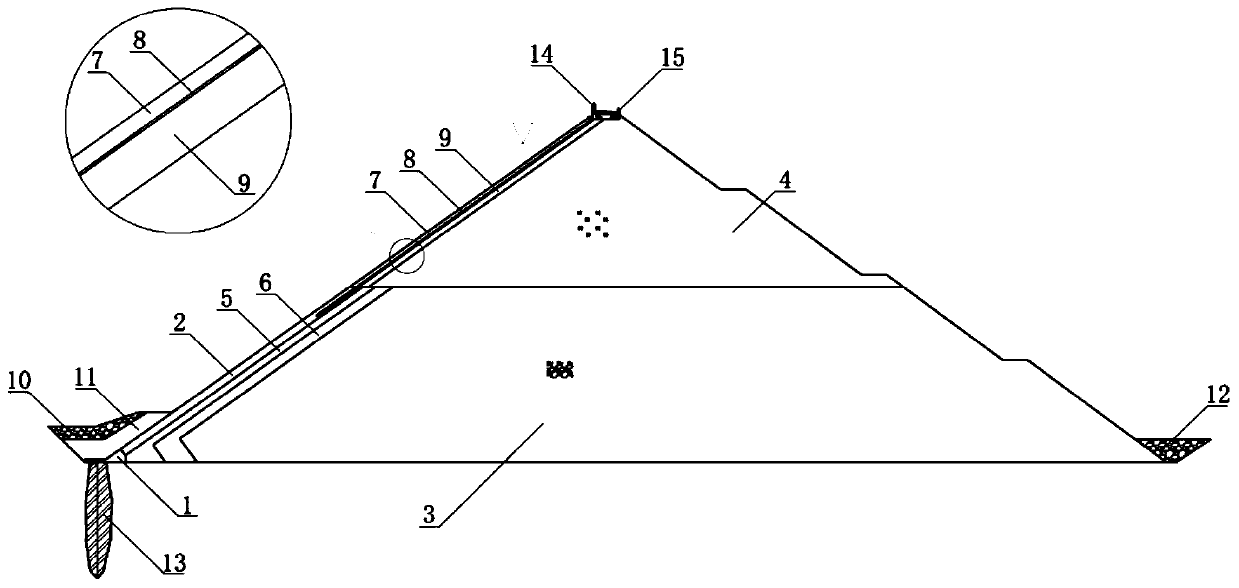

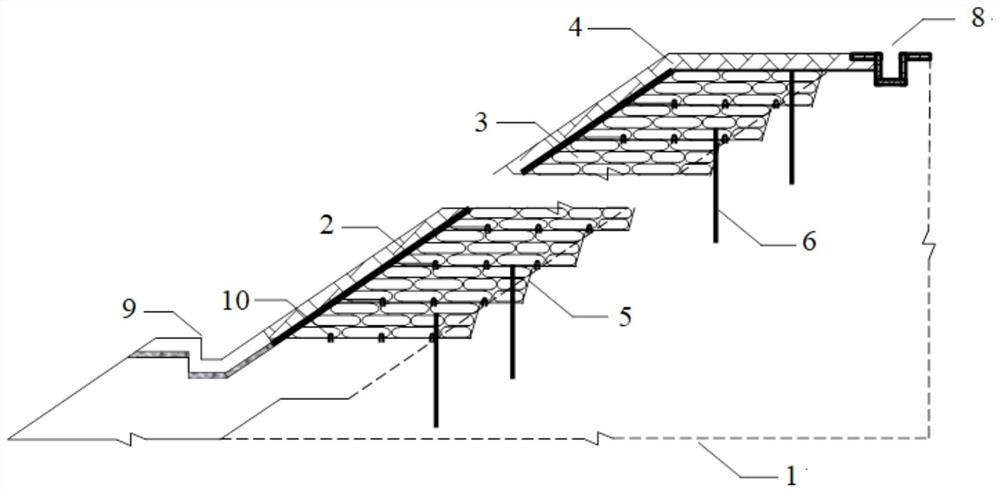

Concrete faced rock-fill dam seepage-proofing structure

PendingCN110042800AImprove ductilityAdapt to deformationEarth-fill damsRock-fill damsRockfill materialGeomembrane

The invention discloses a concrete faced rock-fill dam seepage-proofing structure. The concrete faced rock-fill dam seepage-proofing structure includes a high-strength reinforced geomembrane, a concrete face plate, curtain grouting, rock ballast cover weight, a transition material, a cushion area, a main rockfill area, a secondary rockfill area and the like. An upper half part of a traditional concrete face plate is changed into a high-strength reinforced polyethylene geomembrane structure, and watertightness of the geomembrane is utilized to play a seepage-proofing role. The secondary rockfill area adopts a rockfill material with large deformation modulus, and the geomembrane can adapt to the deformation of a subsequent secondary rockfill area. The concrete faced rock-fill dam seepage-proofing structure is simple in shape, high in construction speed, low in requirements for building stones in the secondary rockfill area and convenient to construct.

Owner:CHINA WATER RESOURCES BEIFANG INVESTIGATION DESIGN & RES

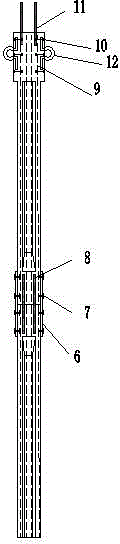

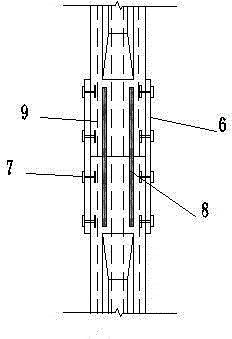

Method for improving integral type bridge abutment sustaining pile stress performance by H-shaped concrete pile

The invention relates to a method for improving integral type seamless bridge and bridge abutment pile foundation stress performance by an H-shaped concrete pile, and belongs to the field of bridges. The method comprises the following steps that (1) a sustaining pile is simulated through a finite element software and compared with an experiment pile, under the condition that the sustaining pile is in accordance with the experiment pile, the section of the sustaining is designed to an H-shaped section which enables a pile body to have optimal stress performance, and the strong axis and the weak axis of the H-shaped section are clear; (2) concrete with super high toughness is prepared; (3) moulding and bar laying are carried out, a concrete sustaining pile with super high toughness is divided into multiple units to be prefabricated, the end section of each unit is in a rectangular shape, and the middle section of each unit is in an H shape; (4) the multiple units are connected into a whole through connecting steel plates and bolts, the connecting position gradually changes from the solid rectangular section segment to the H-shaped section segment, and multiple threaded rods stretches out and at least stretches into the one fourth position of the next unit; (5) multiple threaded shearing nails are arranged on the pile head of the sustaining pile, and cast-in-place is carried out on the whole bridge abutment. The method can effectively reduce the horizontal anti-thrust rigidity of the pile, significantly increase the durability of the pile, and save the high maintenance cost.

Owner:FUZHOU UNIV

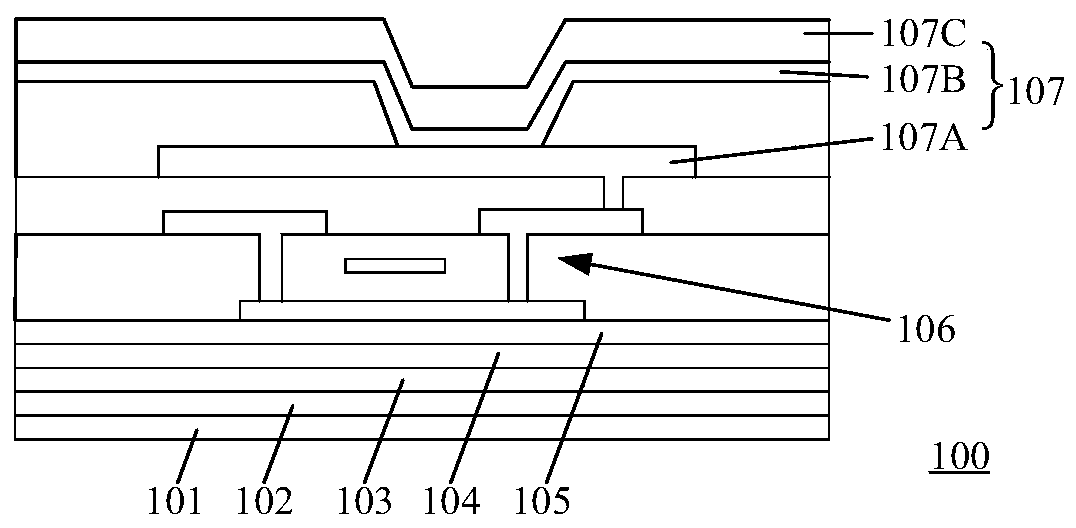

Display substrate, manufacturing method thereof, display panel and manufacturing method thereof

ActiveCN110085657AHigh strengthImprove reliabilityFinal product manufactureSolid-state devicesTransitional RegionEngineering

Owner:BOE TECH GRP CO LTD +1

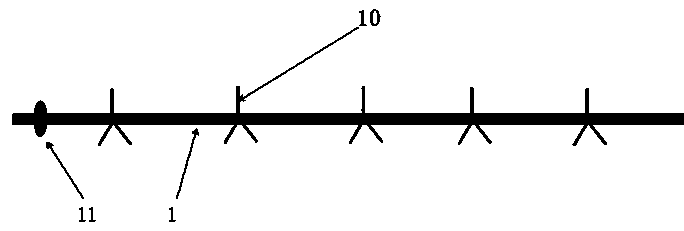

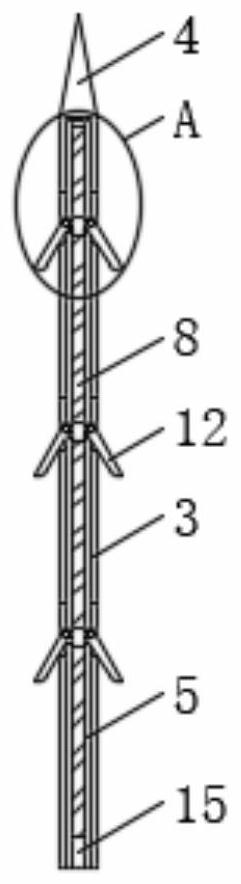

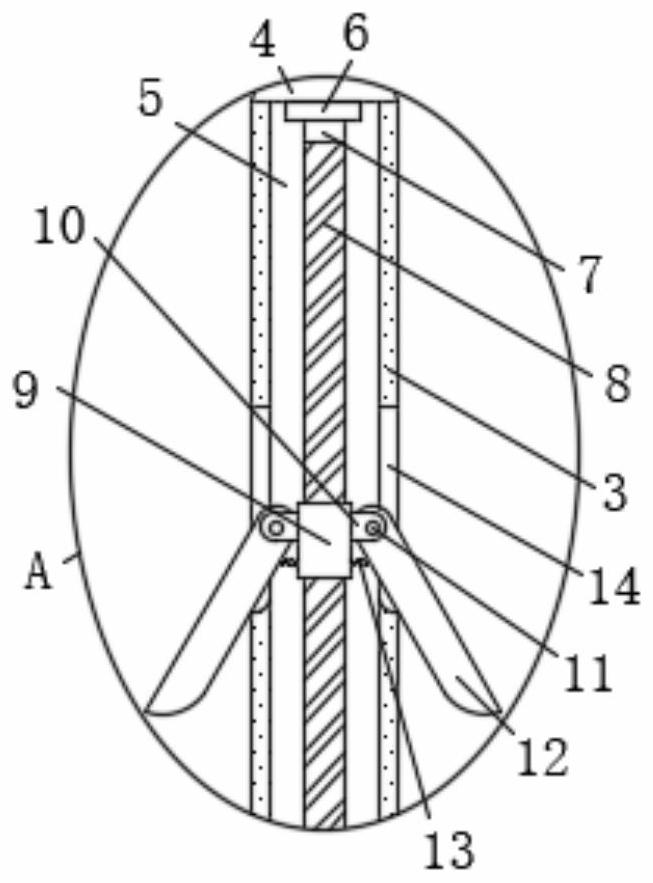

Pre-stressed anchor rod support anchoring device and method

InactiveCN109723478AAvoid adverse reactionsSimple processBulkheads/pilesAnchoring boltsDrill holePre stressing

The invention provides a new method for pre-stressed polymer anchor rod support of rock-soil anchoring. The new method comprises the following steps that a drill hole position is determined; drillingis carried out and sundries in a hole are cleared away; contaminants on the surface of a rod body are cleared away, a bracket is welded and centered, and a hole sealing cloth bag is bundled up; the rod body is put into the drill hole; a polymer is injected into the hole sealing cloth bag to seal the hole, the polymer is injected into an anchoring section; pre-stress tensioning and locking are carried out; effective pre-stress is monitored, after pre-stress locking is carried out for 24 hours, the situation of pre-stress loss is observed, and if the pre-stress loss exceeds 10% of the designed tensioning force, compensation tensioning and locking are carried out; concrete slurry is casted, and hole sealing is carried out. The new method has the advantages that the use is rapid and safe, thetime is saved, a rock-soil body can be rapidly anchored, the permeability coefficient is very low, antiseptic treatment does not need to be carried out specially on the rod body, the rod body has a certain flexibility and is suitable for the deformation of the rock-soil body better, the bonding strength of the rod body with a matrix is greater than that of concrete, and the method is more suitablefor engineering needing to be reinforced rapidly.

Owner:ZHENGZHOU UNIV +1

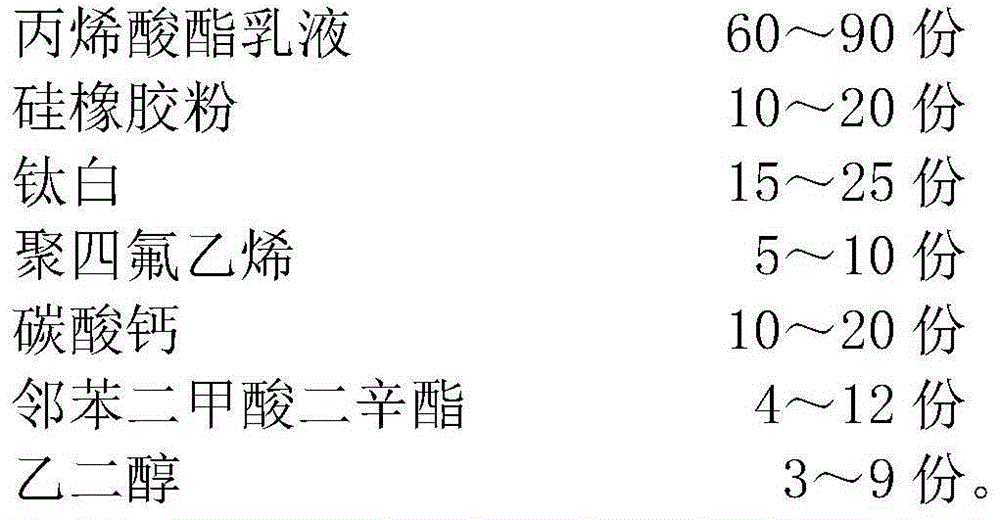

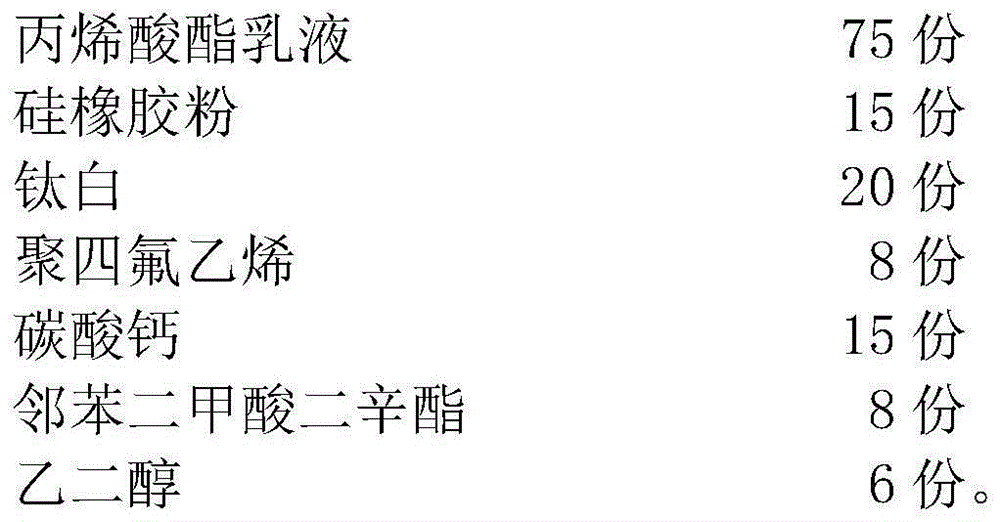

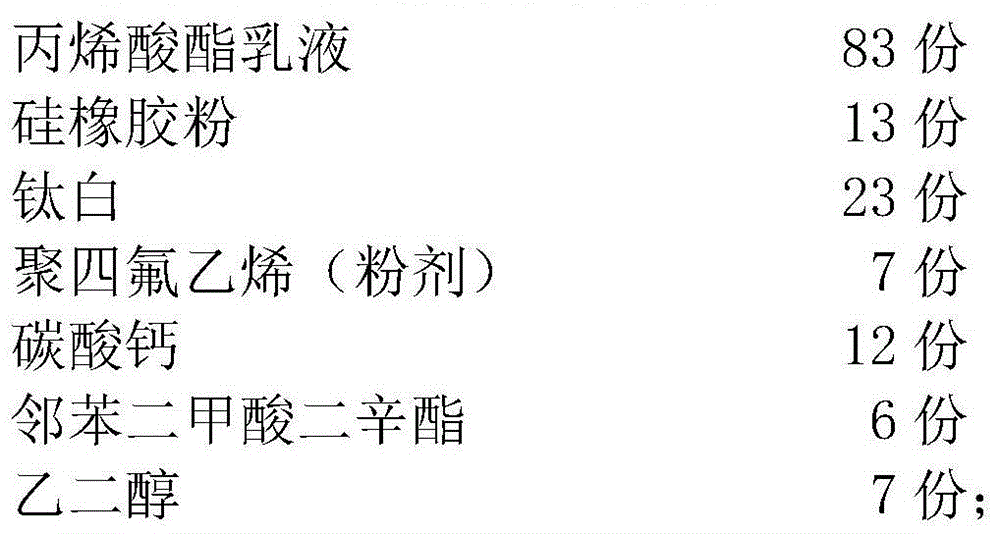

Single-component acrylate waterproof coating

The invention relates to the technical field of coatings, in particular to a single-component acrylate waterproof coating. The single-component acrylate waterproof coating is prepared from the following raw materials in parts by weight: 60-90 parts of acrylate emulsion, 10-20 parts of silicon rubber powder, 15-25 parts of titanium dioxide, 5-10 parts of polytetrafluoroethylene, 10-20 parts of calcium carbonate, 4-12 parts of dioctyl phthalate and 3-9 parts of ethylene glycol. The single-component acrylate waterproof coating has the characteristics of high elasticity, high ductility, high bonding strength and good low-temperature flexibility, has excellent corrosion resistance, light resistance and weather resistance, has no toxin and odor and has no pollution to the environment.

Owner:GUILIN HEXIN WATERPROOF DECORATION MATERIAL

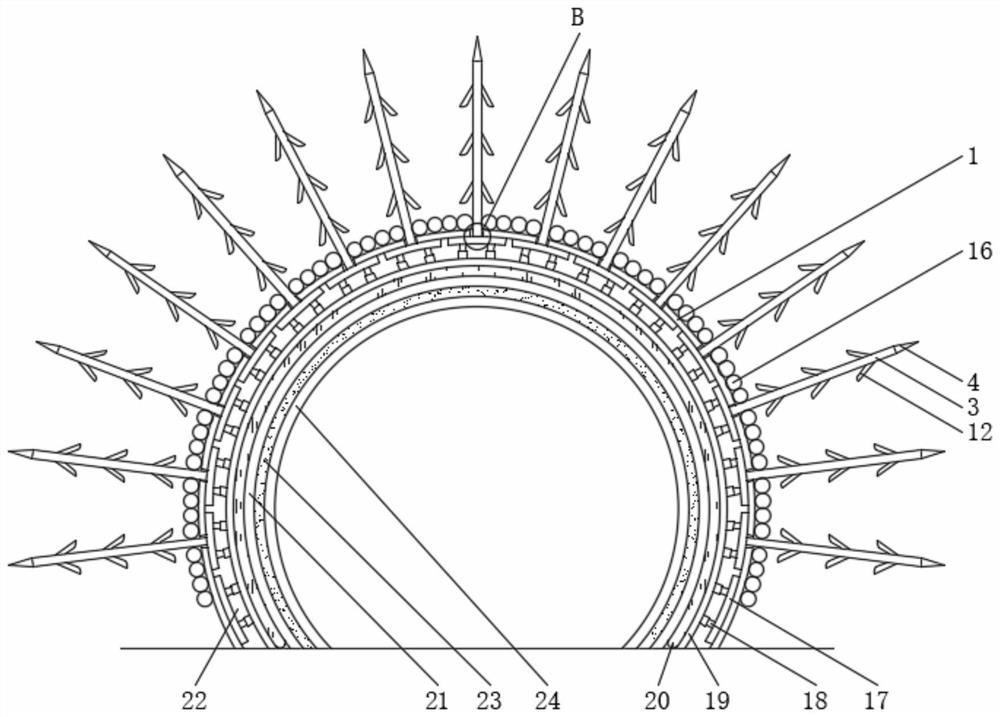

Double-layer primary support structure of weak surrounding rock tunnel and construction method thereof

ActiveCN111764940AIncrease the bearing areaImprove the anchoring effectUnderground chambersTunnel liningMesh reinforcementArchitectural engineering

The invention discloses a double-layer primary support structure of a weak surrounding rock tunnel and a construction method thereof and belongs to the technical field of tunnel construction. The double-layer primary support structure of the weak surrounding rock tunnel comprises a single-layer mesh reinforcement. The outside arc face of the single-layer mesh reinforcement is provided with anchorholes. Anchor rods are inserted into the anchor holes. According to the double-layer primary support structure of the weak surrounding rock tunnel, by means of mutual cooperation of the designed anchor rods, connection holes, bearings, rotating shafts, threaded rods, threaded cylinders, fins, pin shafts, limiting holes, an outer layer interrupted type arch frame, buffering devices, an advanced flexible net-structure protective cover, a buffering air cushion layer and other structures, by changing the position relationship between the fins and the anchor rods, the stress area of the anchor rodscan be effectively increased, and then the anchorage effect of the anchor rods on the overall structure can be effectively improved; and meanwhile, the adopted flexible connection relationship can effectively weaken the degree of the problems that deformation time is long, the deformation amount is large, the deformation speed is rapid, the time of duration is long, a large area of surrounding rock extrudes and invades into a limitation bound, and the support cracks or damages severely.

Owner:浙江省衢州市交通建设集团有限公司

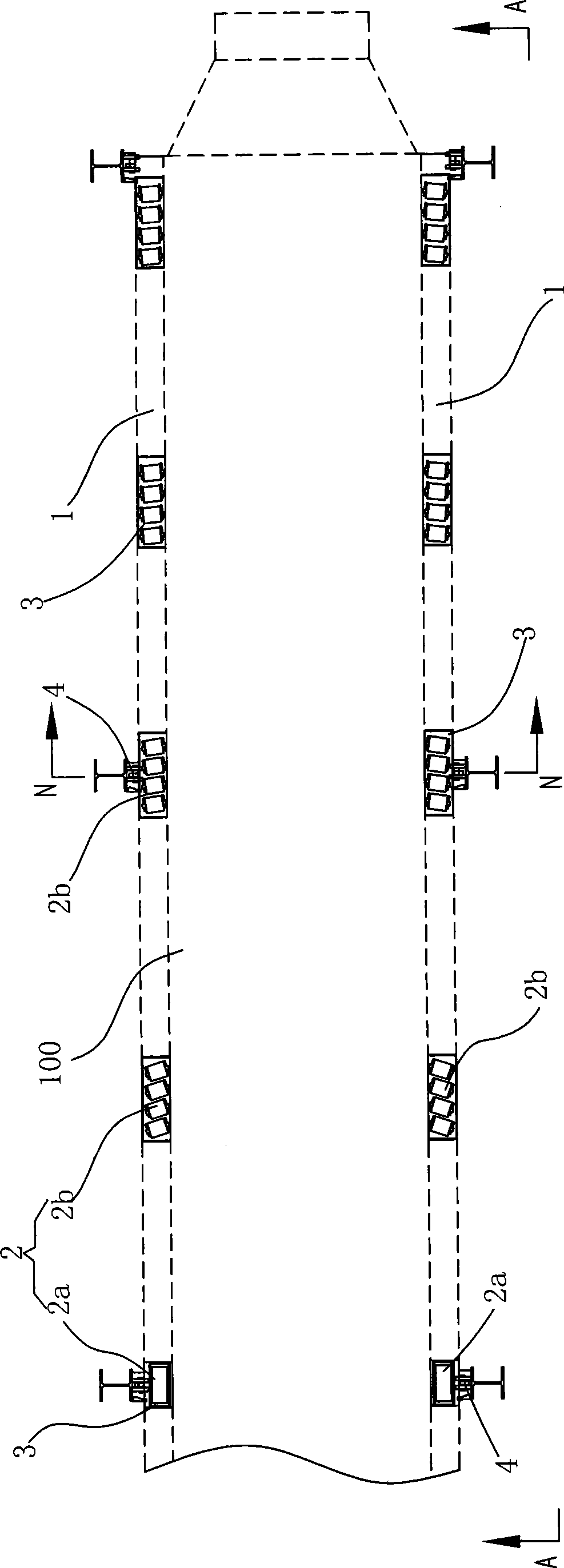

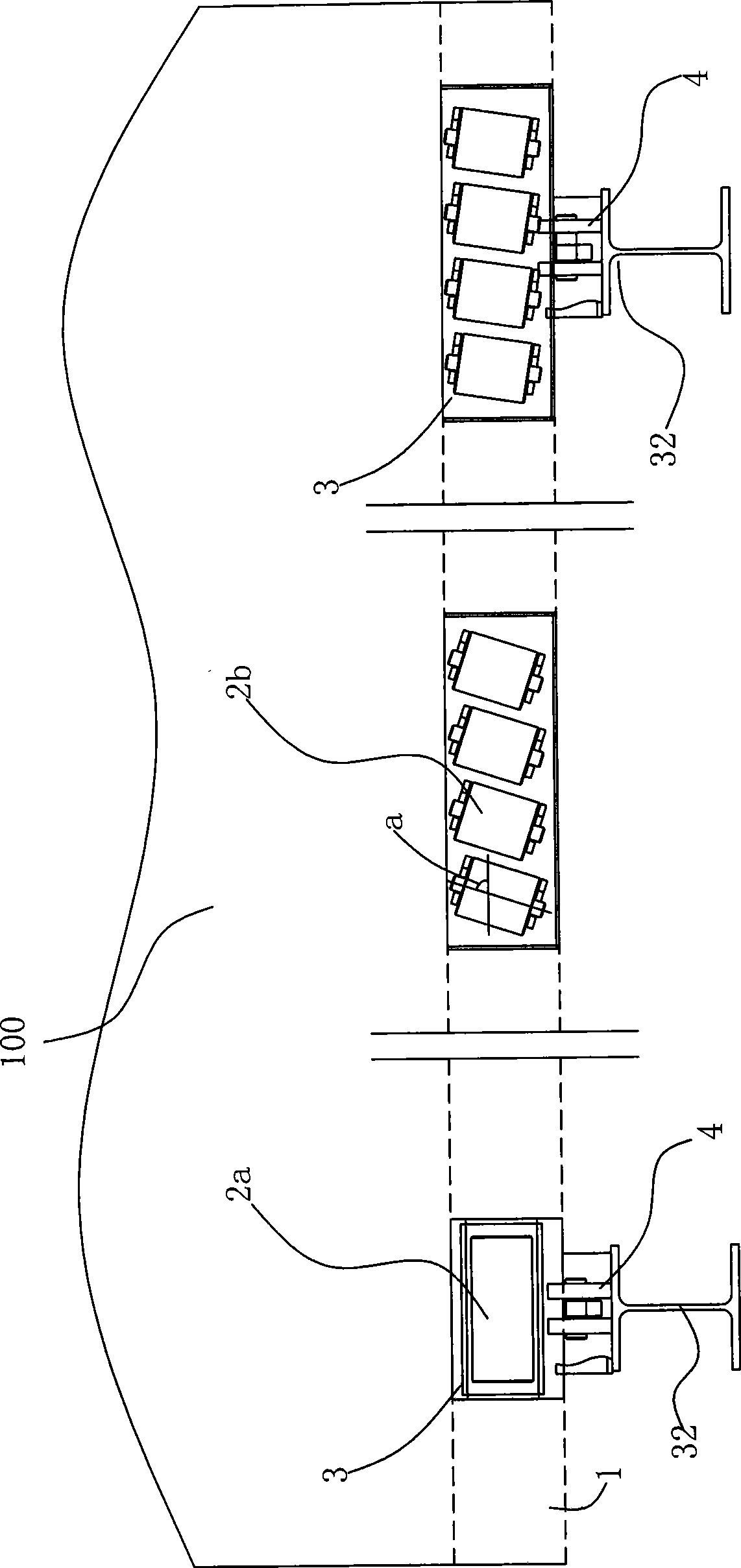

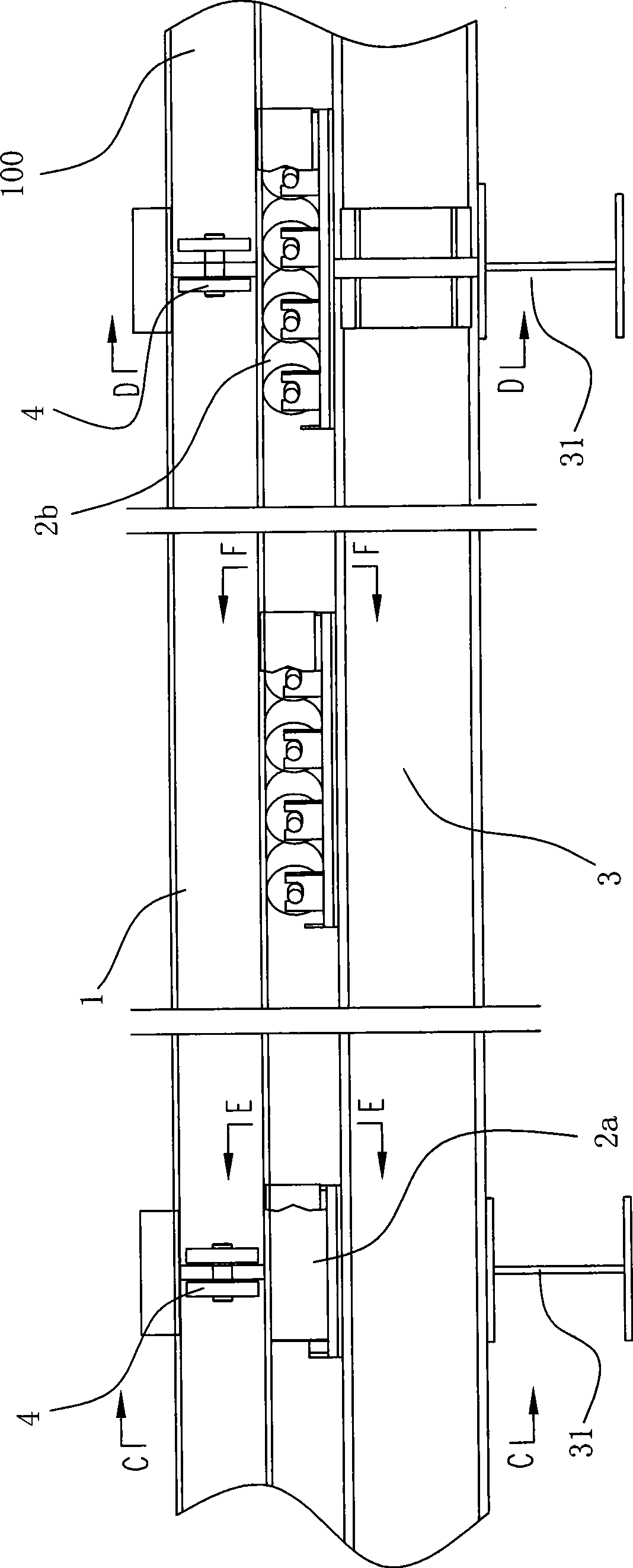

Supporting device for supporting waste heat boiler

ActiveCN101469862AAvoid damageAdapt to deformationBoiler supporting/setting arrangementsEngineeringWaste heat

The invention discloses a supporting device for supporting waste heat boiler, comprising brackets suitable for being mounted one two sides of the waste heat boiler body respectively; base parts respectively arranged on two sides of the waste heat boiler body; supporting rollers capable of rolling arranged on the base parts for supporting the brackets. According to the invention, the structure is simple, the mounting and the dismounting are convenient, the deformations caused by being heated on each direction of the waste heat boiler can be compensated and adapted simultaneously, and the safety and the reliability of the support are high.

Owner:CHINA ENFI ENGINEERING CORPORATION

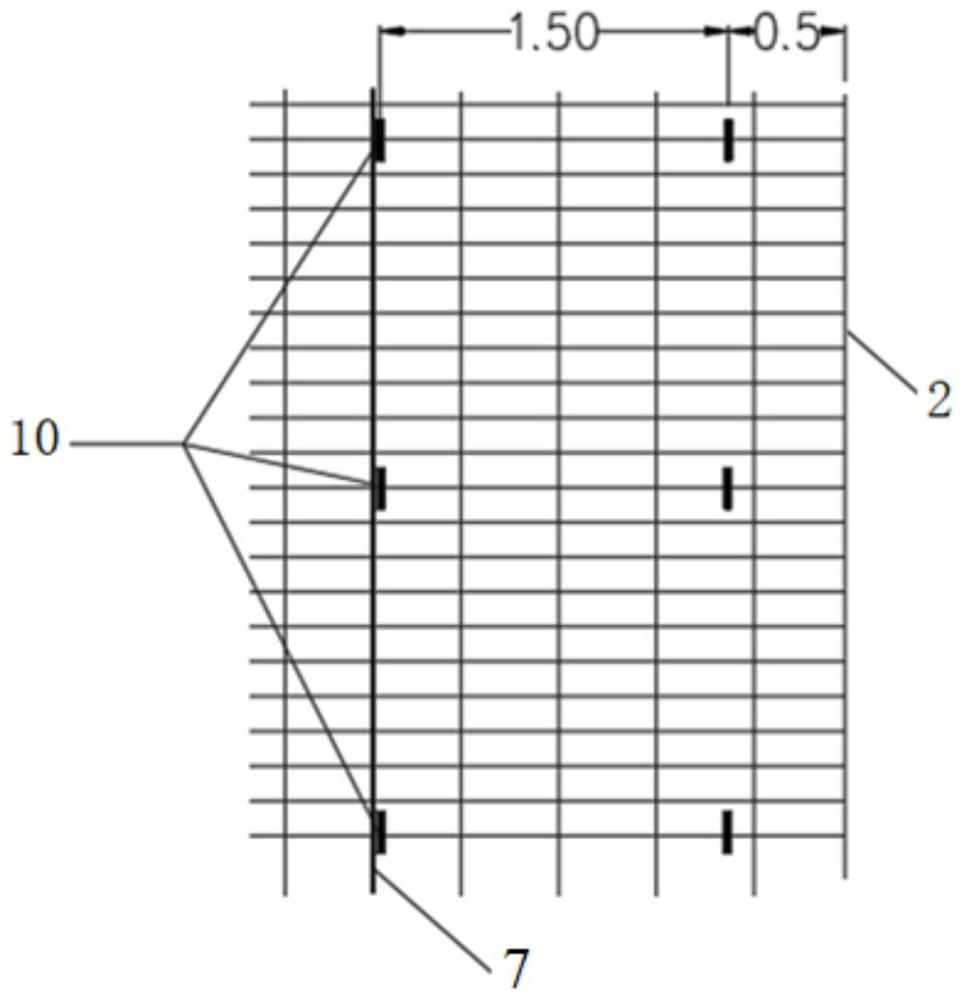

Rapid repairing structure for shallow landslide of above-second-level soil slope and construction method thereof

InactiveCN113322984AAdapt to deformationImprove repair effectEmbankmentsExcavationsSoil scienceLandslide

The invention discloses a rapid repairing structure for a shallow landslide of an above-second-level soil slope and a construction method thereof. According to the repairing structure, a step is excavated on a landslide part of a landslide body, multiple layers of backfill bagged soil are constructed on the step in a filling manner, and geogrids are laid at the bottom of each layer of backfill bagged soil; reserved parts of the geogrids are reversely wrapped along the backfill bagged soil on the upper portions of the geogrids and tensioned to the required tensile strength, the geogrids are fixed to the top face of the backfill bagged soil through U-shaped nails to form reverse wrapping, and the reverse wrapping geogrids and the geogrids adjacent to the upper layer are fixedly connected through U-shaped nails and are both fixed to the top face of the corresponding backfill bagged soil; and a plurality of steel bars are implanted into the bottom of a reinforced body formed by combining the backfill bagged soil and the geogrids. The repairing structure plays a supporting role, meanwhile, energy dissipation is achieved on expansion deformation generated by soil in the slope through self deformation, the repairing effect is good, construction is easy and convenient, the technical requirements for personnel are low, the construction period is short, the number of machines is small, risks are low, cost is low, and environment friendliness is achieved.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

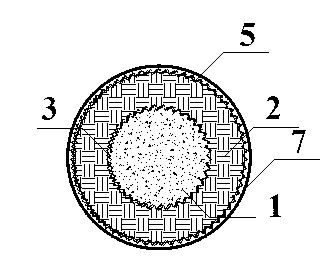

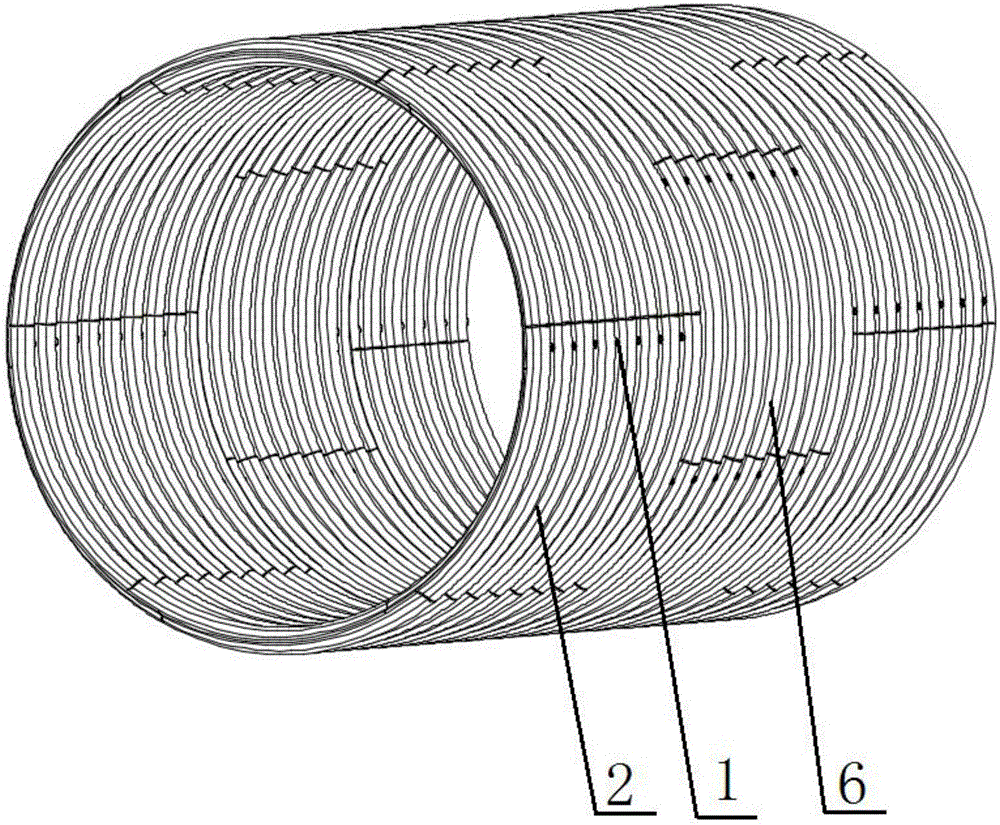

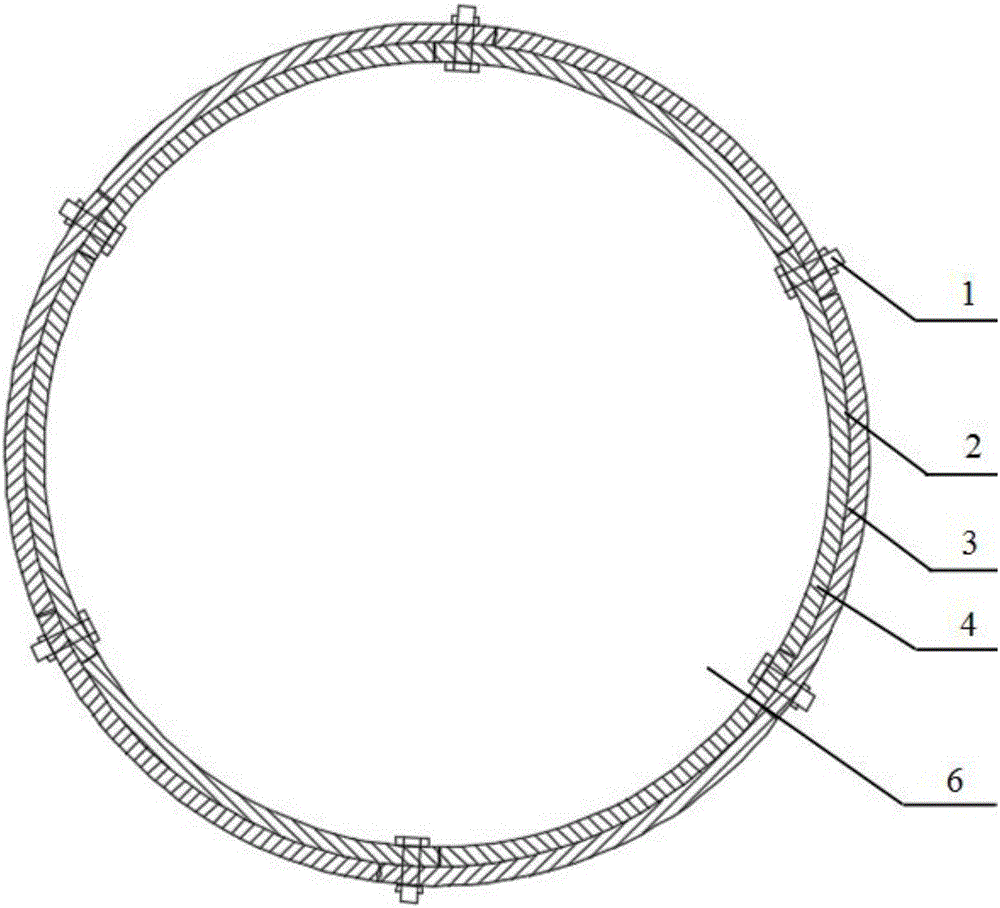

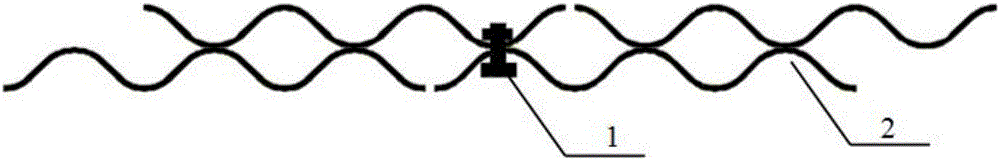

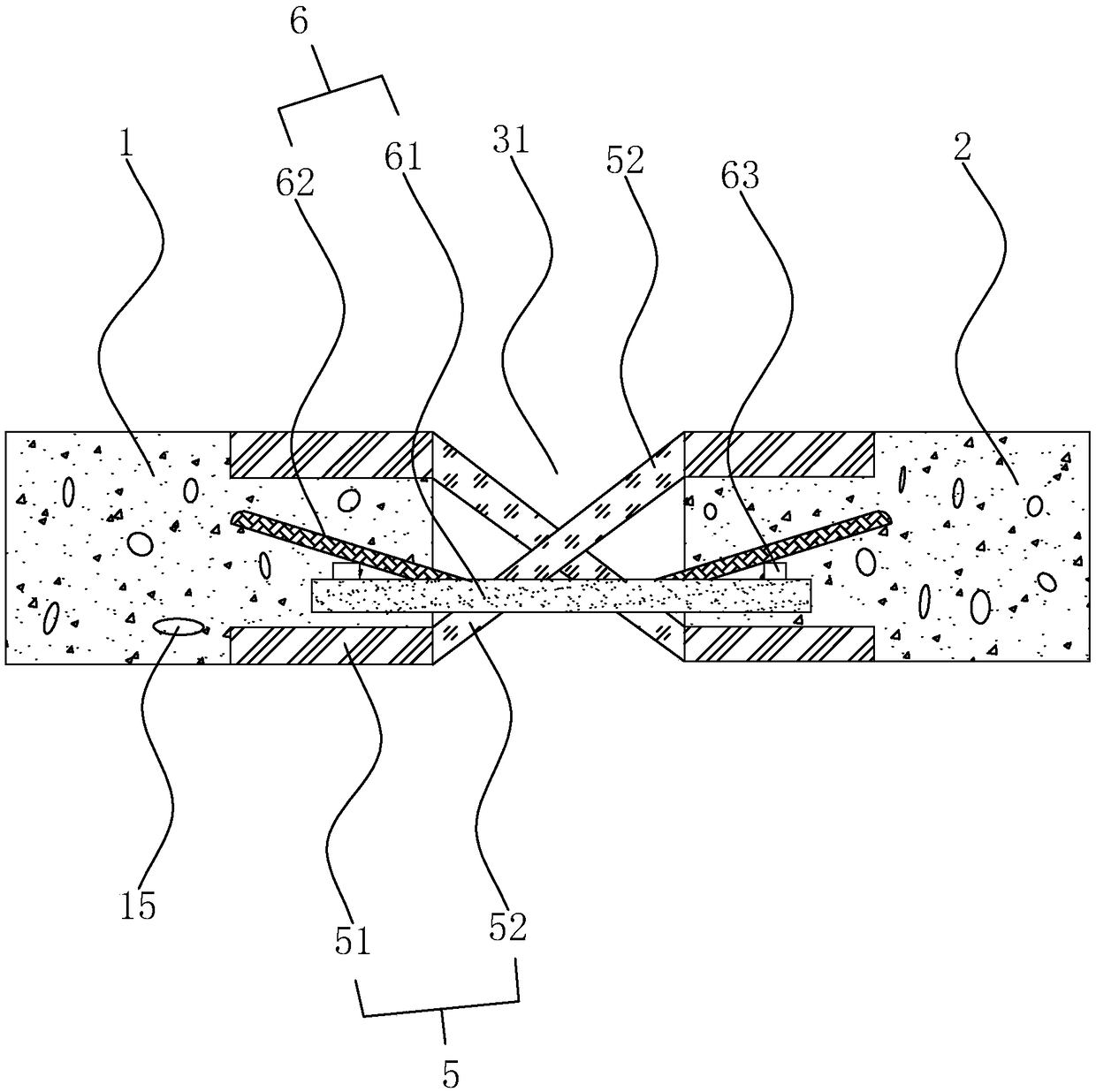

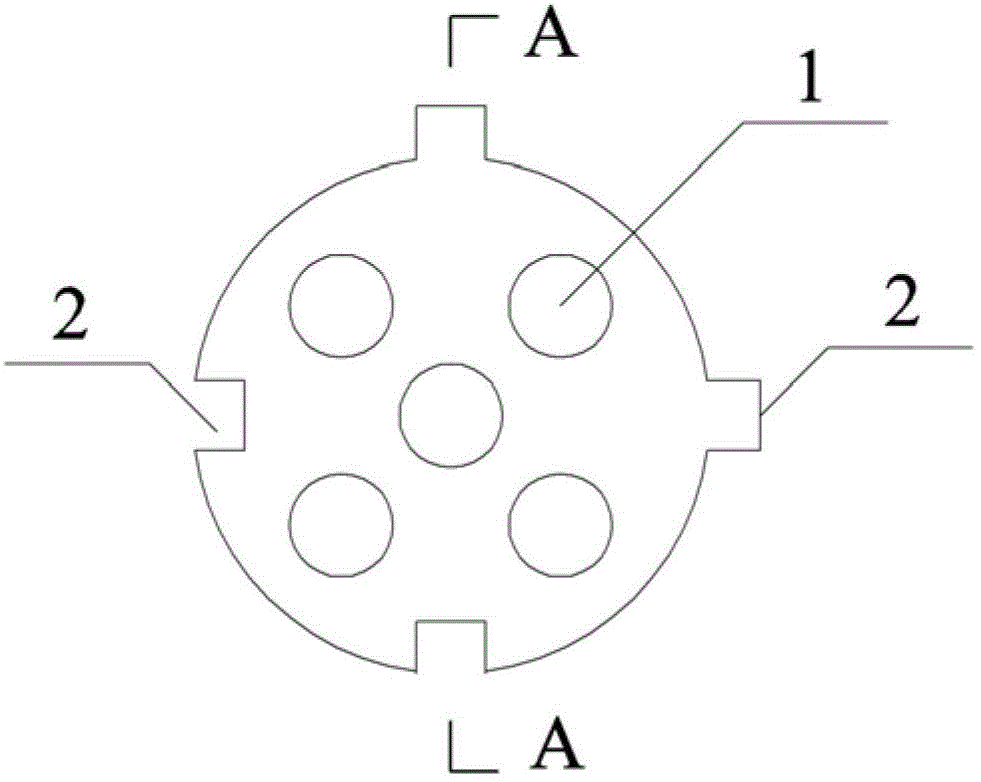

Circular assembling type double-wall corrugated closed steel corrugated culvert pipe

PendingCN106120581AAdapt to deformationSolve the problem of culvert damageGround-workCarrying capacityDouble wall

A circular assembling type double-wall corrugated closed steel corrugated culvert pipe comprises closed double-wall corrugated pipe segments. Each closed double-wall corrugated pipe segment is composed of two corrugated shaped steel plates, and the two corrugated shaped steel plates are welded to form the closed double-wall corrugated pipe segment and serve as an outer wall and an inner wall of the corresponding closed double-wall corrugated pipe segment respectively; six closed double-wall corrugated pipe segments are mutually spliced to form a circular pipe ring, the outer walls and the inner walls of every two adjacent closed double-wall corrugated pipe segments are mutually spliced, and the splicing positions are fixed through a row of bolts; and multiple circular pipe rings are mutually spliced to form an integral corrugated culvert pipe. The circular assembling type double-wall corrugated closed steel corrugated culvert pipe has the characteristics of high strength, high carrying capacity and the like, and as the body of a culvert and a bridge, when being compared with a concrete pipe culvert, the circular assembling type double-wall corrugated closed steel corrugated culvert pipe has the advantages of simpleness in construction, convenience in maintenance, long in service life, high ability of adapting to the foundation deformation and the like, and is worth popularizing.

Owner:河北驰特轨道交通设备有限公司

Basement connection portion crack preventing structure

InactiveCN108374437AFirmly connectedReduce generationArtificial islandsProtective foundationBasementEngineering

The invention discloses a basement connection portion crack preventing structure which comprises an internal connecting part, an external connecting part and a deformation buffer slit. A settlement buffer zone is arranged at the bottom of the deformation buffer slit, the internal connecting part and the external connecting part at two sides of the deformation buffer slit are in snap joint, and ananti-crack waterproof assembly is arranged at the top of the deformation buffer slit. The settlement buffer zone comprises reinforcing belts; each reinforcing belt comprises a connecting section and an anti-shear section, since the connecting section of the reinforcing belt has difference in vertical height, the anti-shear section is oblique; the connecting sections refer to a rigid connectors buried in the internal connecting part and the external connecting part and the anti-shear sections refer to elastic connectors. According to the arrangement, the anti-shear sections refer to elastic parts having a certain deformability and can reduce the probability of cracking of the settlement buffer slit; besides, the snap joint can increase adhesion stress between the two parts so that settlement of the basement connection portion can be synchronous to the utmost extent; the anti-crack waterproof assembly arranged at the top can reduce crack and water seepage further; therefore, the whole basement connection portion has excellent anti-crack and waterproof effect.

Owner:浙江联建工程设计有限公司

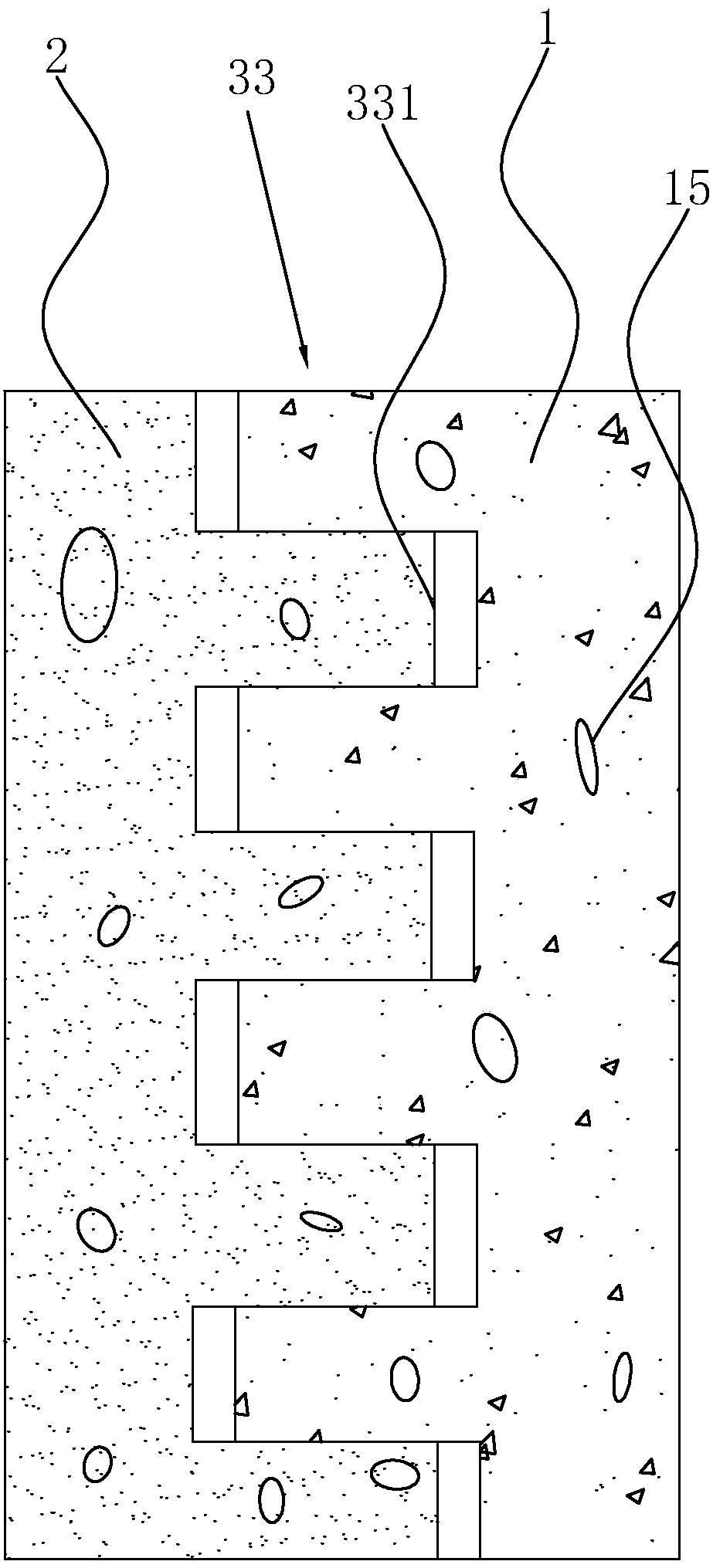

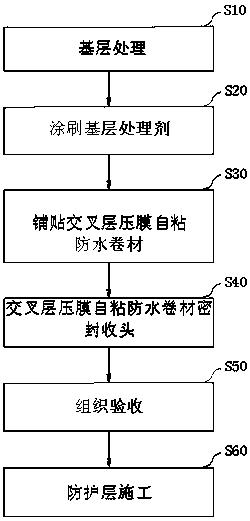

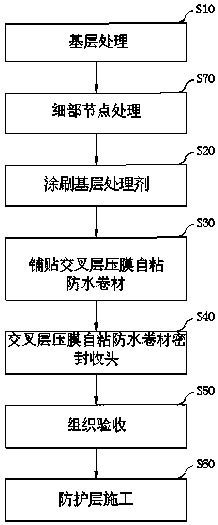

Waterproof construction technology for sidewalls of utility tunnel

InactiveCN109056802AAdapt to deformationEasy to useArtificial islandsProtective foundationUtility tunnelProtection layer

The invention relates to the technical field of infrastructure construction, and provides a waterproof construction technology for sidewalls of a utility tunnel. The waterproof construction technologycomprises the following steps of step S10, carrying out substrate processing; step S20, painting a substrate treating agent, uniformly stirring the substrate treating agent, and uniformly painting the substrate treating agent on a substrate; step S30, paving a self-adhered waterproofing roll with a cross laminated membrane, removing a first isolating membrane on the self-adhered waterproofing roll with the cross laminated membrane, making a bonding surface of the self-adhered waterproofing roll with the cross laminated membrane face the substrate and adhering to the substrate; step S40, sealing the self-adhered waterproofing roll with the cross laminated membrane and closing up, making the tail ends of the periphery of the self-adhered waterproofing roll with the cross laminated membraneextend into a vertical wall groove, fixing by metal beads, and sealing by seal paste; S50, carrying out tissue acceptance; and S60, carrying out protection layer construction. During the constructionof the self-adhered waterproofing roll with the cross laminated membrane, as long as the first isolating membrane is removed, the self-adhered waterproofing roll with the cross laminated membrane canbe firmly adhered to the substrate, the use is very convenient, and meanwhile, a waterproof effect is excellent.

Owner:CHINA 19TH METALLURGICAL CORP

Finishing method for improving lamination degree of coating and crust leather

The invention relates to the technical field of leather making chemistry and engineering and provides a finishing method for improving the lamination degree of a coating and crust leather. According to the finishing method, non-ionic polyurethane resin without charges and a non-ionic oil wax auxiliary agent are selected as main body materials of a finishing agent; the surface tension of a finishing agent is reduced so that the leveling property and the permeability are improved; a technology is balanced and primary and secondary aspects in each phase and each operation are grasped; the lamination degree of the coating and the crust leather is improved; an ideal thin film is formed on the surface of the crust leather through the finishing agent and a shell is not easy to form after the coating is repeatedly bent or stretched; the non-ionic oil wax auxiliary agent has good filling and covering effects and can be used for improving the flatness and fineness of a particle surface of the crust leather; injuries on the particle surface of the crust leather are covered; the grading rate and utilization rate of the crust leather are improved.

Owner:XINGYE LEATHER TECH CO LTD

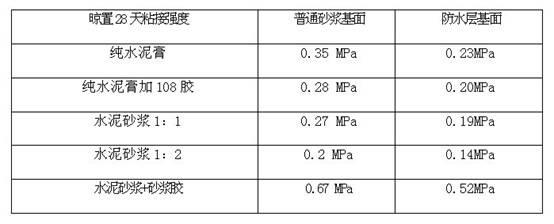

Mortar glue

The invention discloses mortar glue. The mortar glue comprises the following components in parts by weight: 17.5 parts-32.5 parts of vinyl acetate glue powder or acrylic acid glue powder, 3.5 parts-6.5 parts of methylcellulose and / or guar gum, 0.35 part-0.65 part of mineral oil and / or organosilicon, 48.3 parts-89.7 parts of calcium carbonate and / or quartz sand and 0.35 part-0.65 part of water reducer. By using the mortar glue, the difficult problems that when cement plaster is fixed on building materials such as ceramic tile and the like, the bond is not firm, empty drum, crack and falling are generated, property is unstable, and the like. The construction performance is good after the mortar glue is added to the cement plaster, the cement plaster has no droop and no sagging, and airing and regulating time is long. Bricks and walls do not need to be wet in the construction process of the cement plaster in which the mortar glue is added, and construction is consistent, thereby improving construction efficiency. The mortar glue disclosed by the invention has the advantages of no toxicity and no peculiar smell, and belongs to environment-friendly products.

Owner:广州雷邦仕化工建材有限公司

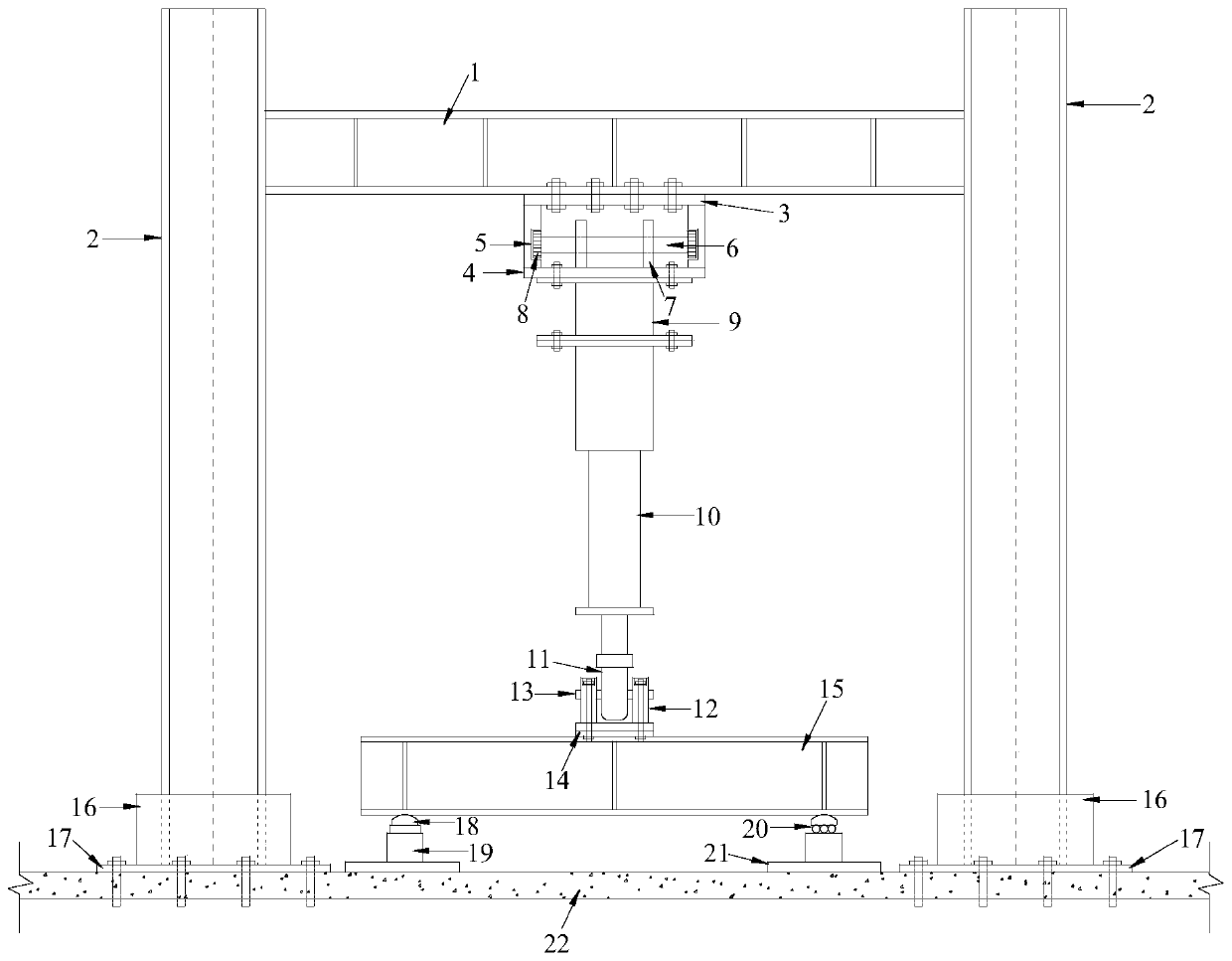

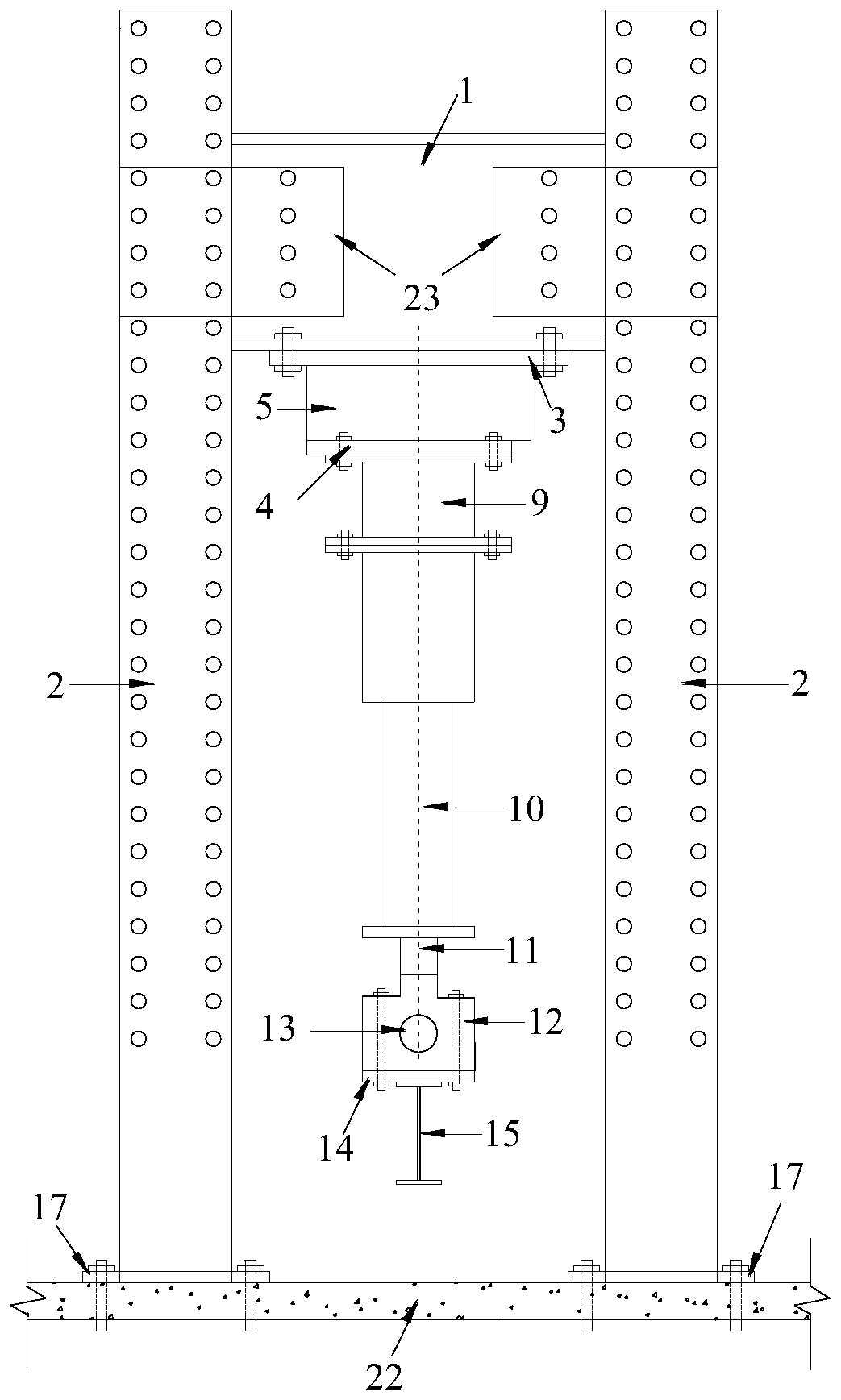

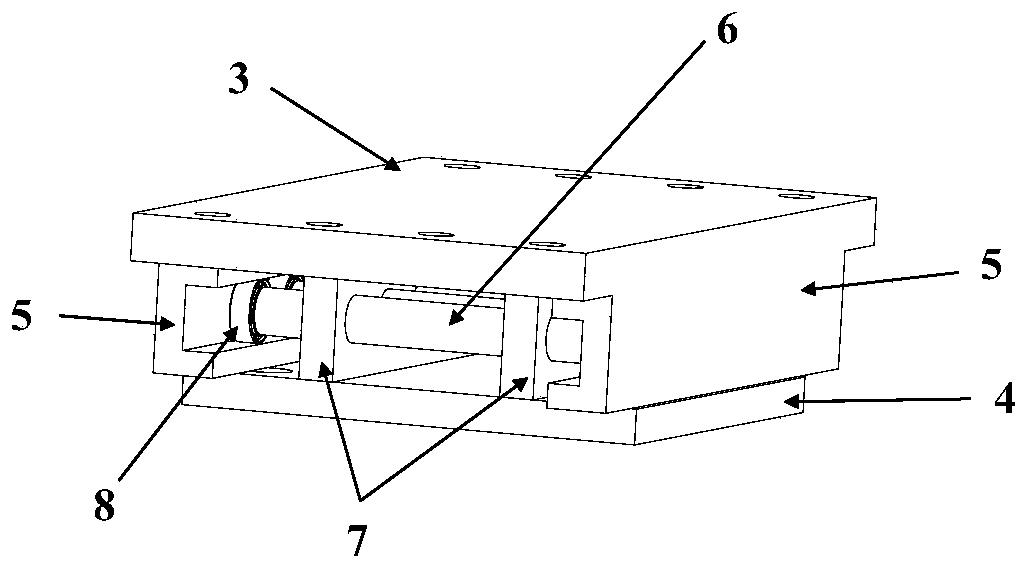

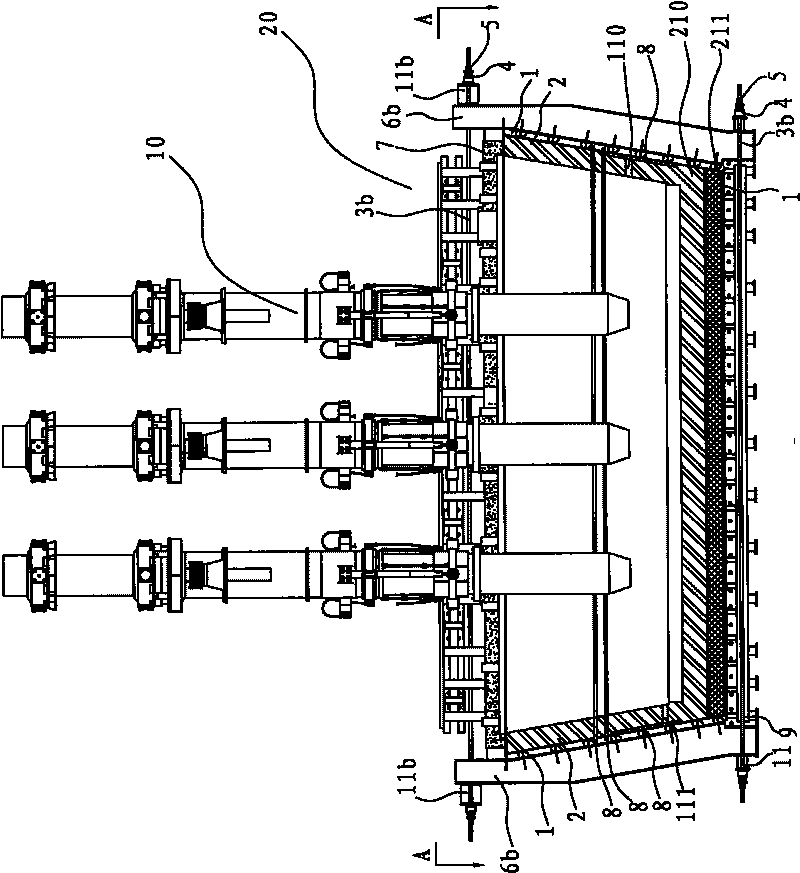

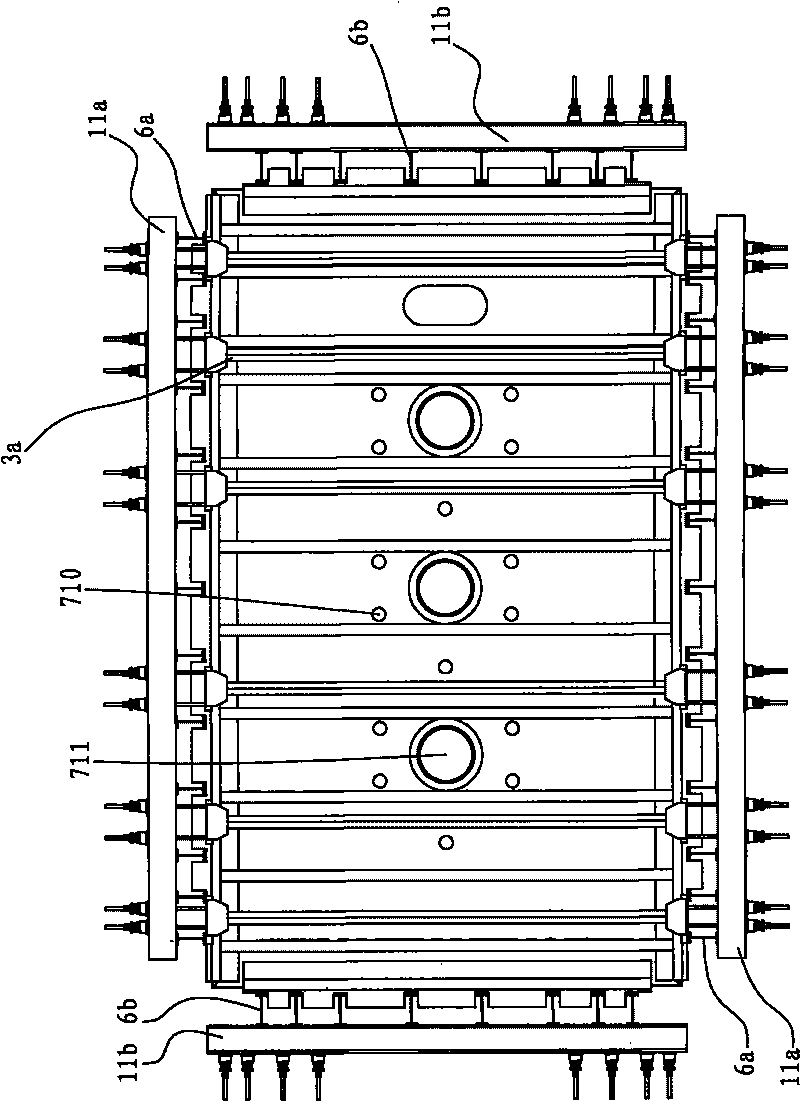

Loading device for overall stability test of horizontal steel curved beam

ActiveCN110987624ASimple structureOptimize the installation methodMaterial strength using tensile/compressive forcesClassical mechanicsMechanical engineering

The invention belongs to the related technical field of steel structures, and particularly discloses a loading device for overall stability test of a horizontal steel curved beam. The loading device comprises a counter-force frame unit, a sliding unit, a pressure sensor and a loading unit, wherein the counter-force frame unit is used for supporting the loading device; a top flat plate of the sliding unit is connected to the counter-force frame unit, sliding grooves are fixed to the left side and the right side of the top flat plate, and a sliding assembly is connected to a bottom flat plate and drives the bottom flat plate to slide in the length direction perpendicular to the horizontal steel curved beam. The upper side of the pressure sensor is connected to the bottom flat plate, and thelower side is connected to the loading unit. According to the invention, the sliding unit is arranged between the counter-force frame unit and the pressure sensor, when the horizontal steel curved beam generates lateral displacement, the pressure sensor and the loading unit can be driven to slide in the direction perpendicular to the length direction of the horizontal steel curved beam, so that the loading direction is always vertically downward in the loading process, and meanwhile, the constraint on the lateral displacement of the horizontal steel curved beam is released.

Owner:HUAZHONG UNIV OF SCI & TECH

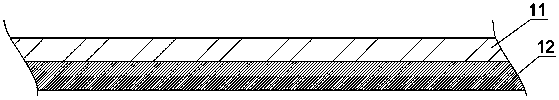

Composite waterproof structure and preparation method thereof

ActiveCN108859344ANo delaminationStrong chemical bondSynthetic resin layered productsLaminationPolymer modifiedSurface layer

The invention discloses a composite waterproof structure and a preparation method thereof, and belongs to the field of building waterproof materials. The composite waterproof structure is prepared from a waterproof coil layer, a reaction type macromolecular elastic coating layer and a waterproof base layer in turn from top to bottom, wherein the waterproof coil layer is prepared from an upper surface layer and a self-sticking material layer in turn from top to bottom; the self-sticking layer is self-sticking polymer modified asphalt. According to the composite waterproof structure and the preparation method thereof disclosed by the invention, separation between the coating and the coil is avoided, and the waterproof effect is perfect.

Owner:四川省威盾新材料有限公司

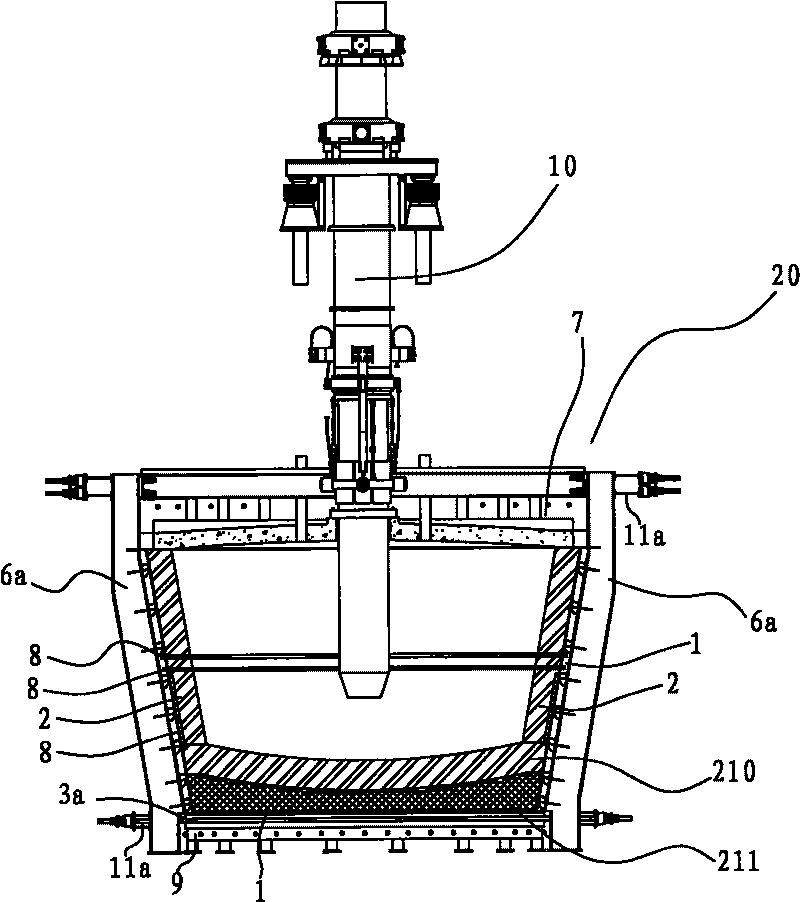

Electric furnace

ActiveCN101762152APromote expansionStable expansionLighting and heating apparatusElectric arc furnaceSlag

The invention relates to an electric furnace which comprises a furnace body, an elastic frame and an electrode, wherein the furnace body, of which the side walls incline inwards from top to bottom, comprises a furnace shell and a furnace cover; the furnace shell is provided with a product discharge port and a slag discharge port; the top end of the furnace shell is opened, and the side walls and the bottom wall of the furnace shell are provided with a refractory material layer; the furnace cover is arranged on the top end of the furnace shell to cover the opened top end of the furnace shell; the elastic frame is arranged outside the furnace shell to hoop the furnace shell; the electrode extends into the furnace body after penetrating the furnace cover from the top of the furnace body, and can move from top to bottom. The electric furnace of the invention has good integrated expansibility of the furnace body, i.e. the furnace body is expanded stably, uniformly and synchronously so that the service life of the furnace body is prolonged, the maintenance operation is reduced, and the cost is decreased.

Owner:CHINA ENFI ENGINEERING CORPORATION

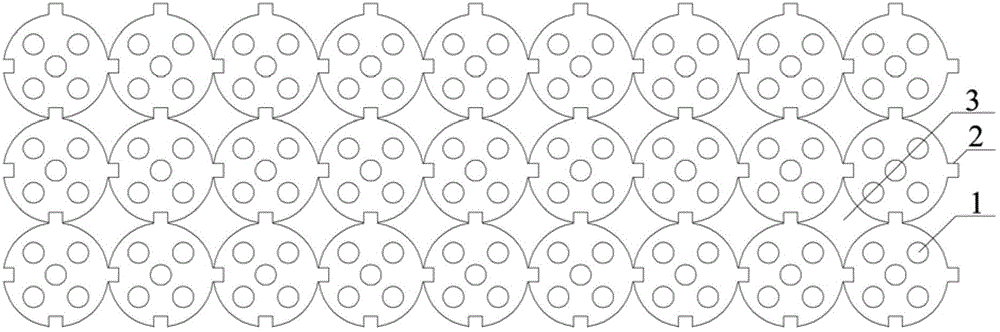

Ecological type fence plate

The invention relates to an ecological type fence plate. The profile outline of the ecologic type fence plate is a cylindrical block, the bottom surface and the top surface are planes, four convexo-concave gaps are symmetrically distributed on the side surface and are axially symmetrical up and down as well as left and right, and adjacent two gaps are the same or different; each fence plate is provided with at least one ventilation hole; the material of the fence plate is reinforced concrete; and a layer of broken-stone cushion layer is arranged below the fence plate, and seaweed is planted in the gap between fence plates. The fence plate is good in integrity and stability, and simple in construction, is suitable for sandy coast frost zone, and can be produced in an industrialized and standardized manner. The proper seaweed is planted in the gap between the fence plates, thereby meeting the ecological landscape requirement; the novel fence plate is regular in size, can be produced in the industrialized and standardized manner; and the construction period is shortened.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com