Patents

Literature

122 results about "Rockfill material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Optimization method of particle gradation of blasting rockfill materials based on fractal theory

InactiveCN102277859AImproved particle size distributionEarth-fill damsRock-fill damsRockfill materialFragment size

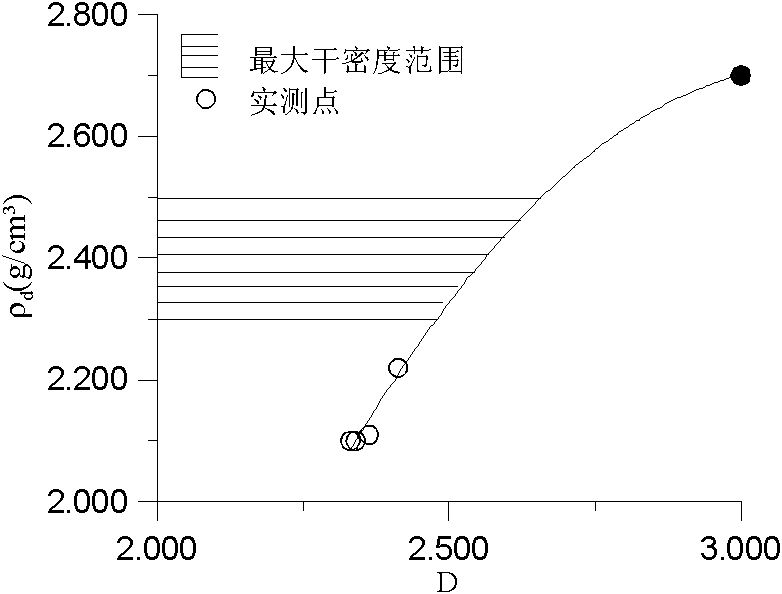

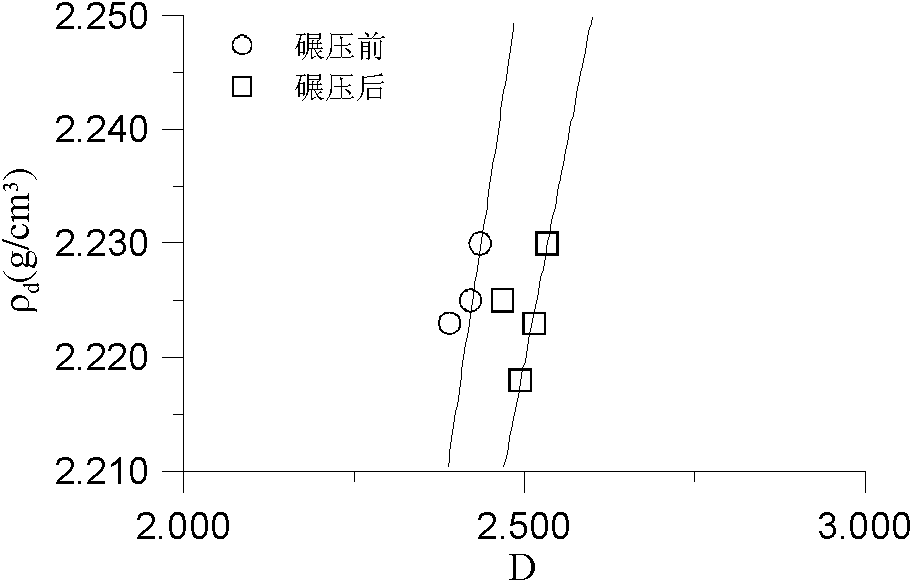

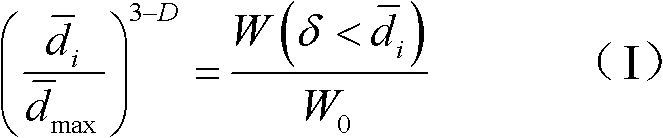

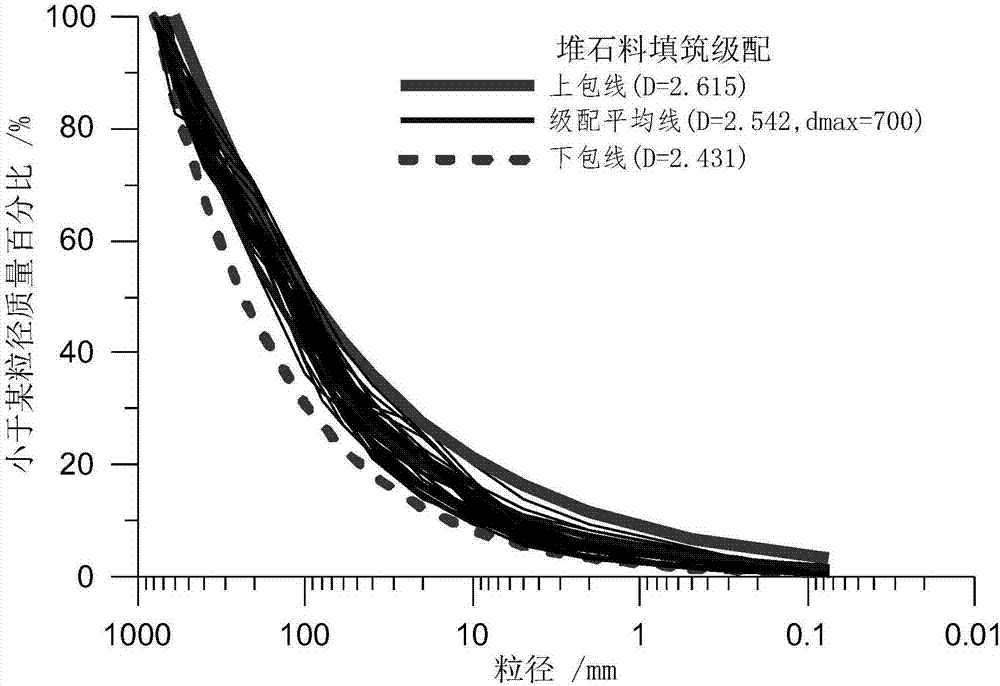

The invention provides a method for optimizing grain composition of a blasting rockfill material based on a fractal theory. The method is characterized by comprising the following steps of: establishing a function relation among the grain fractal dimension, compacted dry density and average particle size of the rockfill material, and further establishing a relation between a blasting scheme or parameter and the compacted dry density of a field rockfill material according to a correction Kuz-Ram model for forcasting the blasting fragment size distribution of a rock mass; and obtaining an optimal grain composition of a dam construction rockfill material which is easier to compact by adjusting the blasting scheme or parameter. The method can be applied to optimized design of the grain composition of the blasting rockfill material.

Owner:HOHAI UNIV

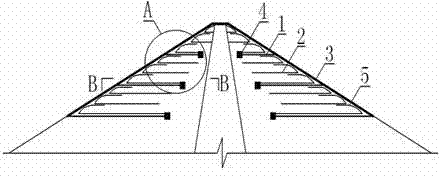

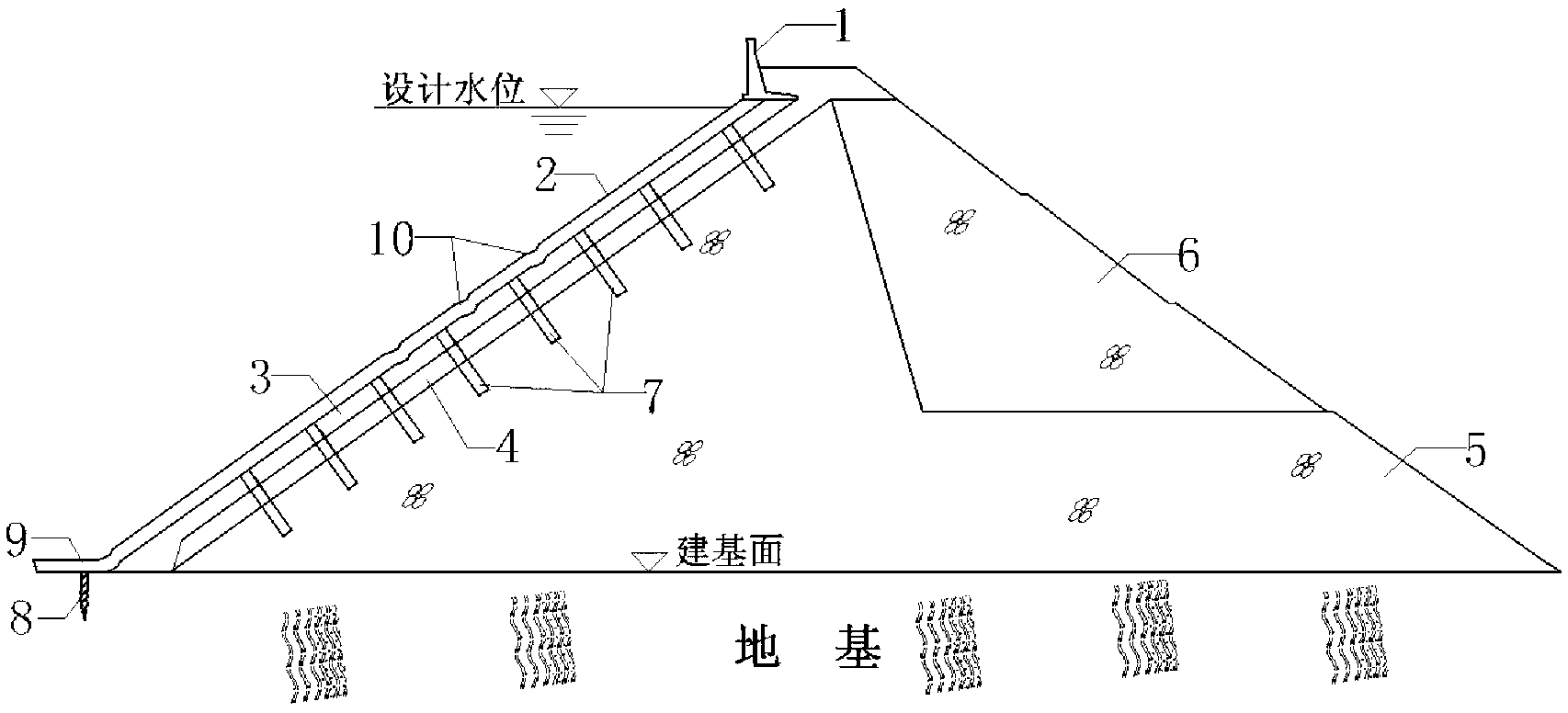

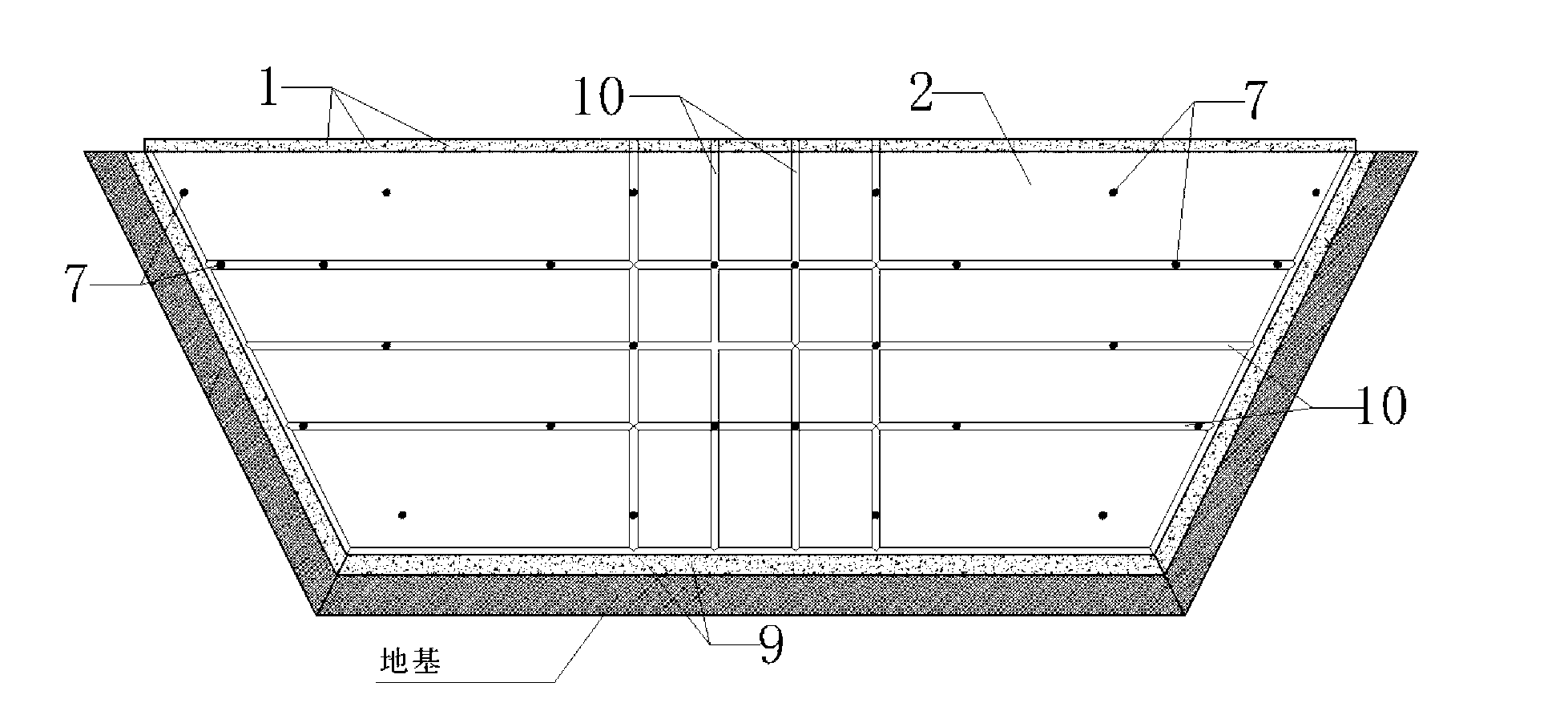

Anti-seismic measure and construction method of a high earth-rock dam

ActiveCN102261053ASmall sizeImprove skid resistanceEarth-fill damsRock-fill damsRockfill materialEarthquake resistant structures

The invention discloses an aseismatic structure of a high earth-rock dam and a construction method thereof, and an aseismatic structure is constituted by steel bars, geogrids, stainless steel meshes, precast concrete anchoring sections and geogrid wrapping sections. In rockfill in an upstream dam shell and a downstream dam shell within the range from the dam top to 1 / 5-1 / 4 of the height of the dam, a layer of the steel bars is laid every three layers of the rockfill according to the number of the compacted layers of the rockfill material, asphalt is further top-poured for performing anti-rusting treatment, one end of each steel bar is fixedly connected with the precast concrete anchoring section and the other end of each steel bar is hinged with the stainless steel mesh on the dam surface; and the geogrid is laid on the rockfill in each layer after compaction, and each geogrid is reserved on the dam surface for being turned and rolled onto the rockfill of the upper layer after roller compaction for forming the geogrid wrapping section; and the steel bars on the top surface of a core wall penetrate through the whole rockfill for connecting the stainless steel meshes on the upstream dam surface and the downstream dam surface. The aseismatic structure of the high earth-rock dam absorbs the advantages of flexible material and rigid material in the aseismatic aspect, the aseismatic performance is good, the construction is convenient, the construction progress is not affected, the size of a dam body is not increased and the aseismatic structure of the high earth-rock dam is economic and practical.

Owner:HOHAI UNIV

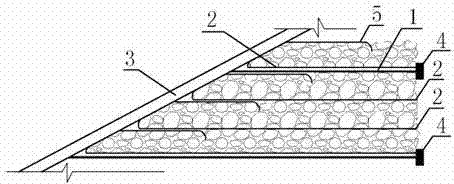

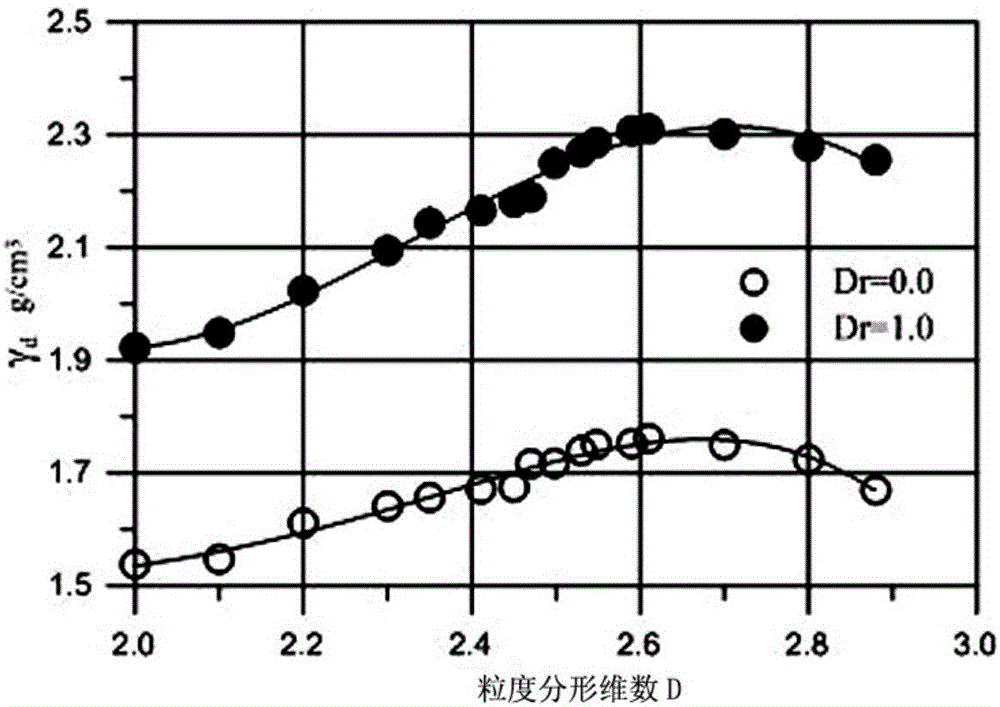

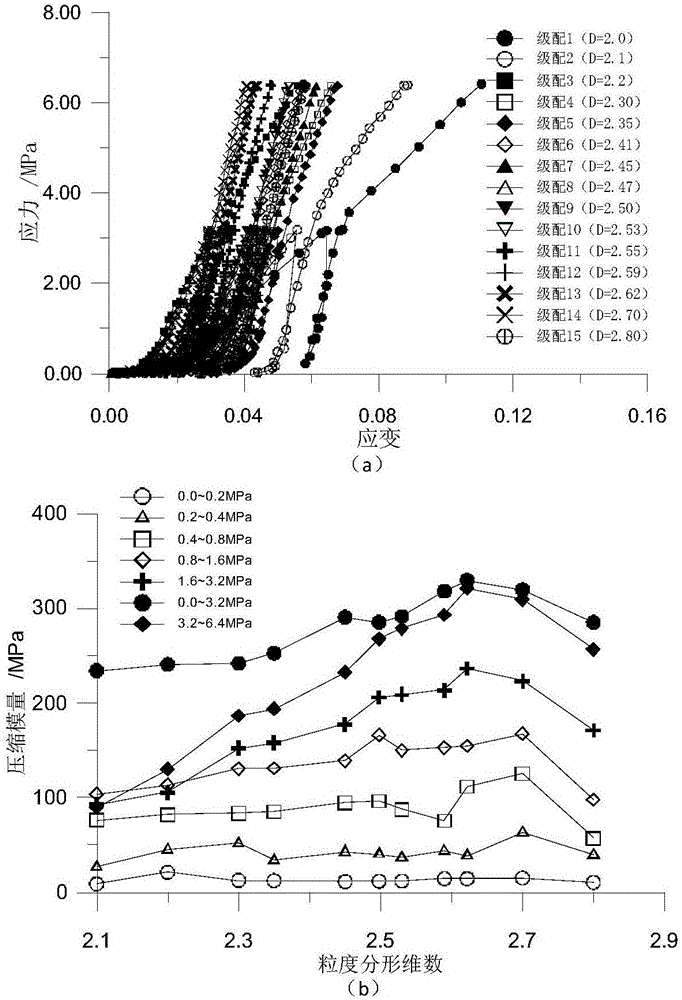

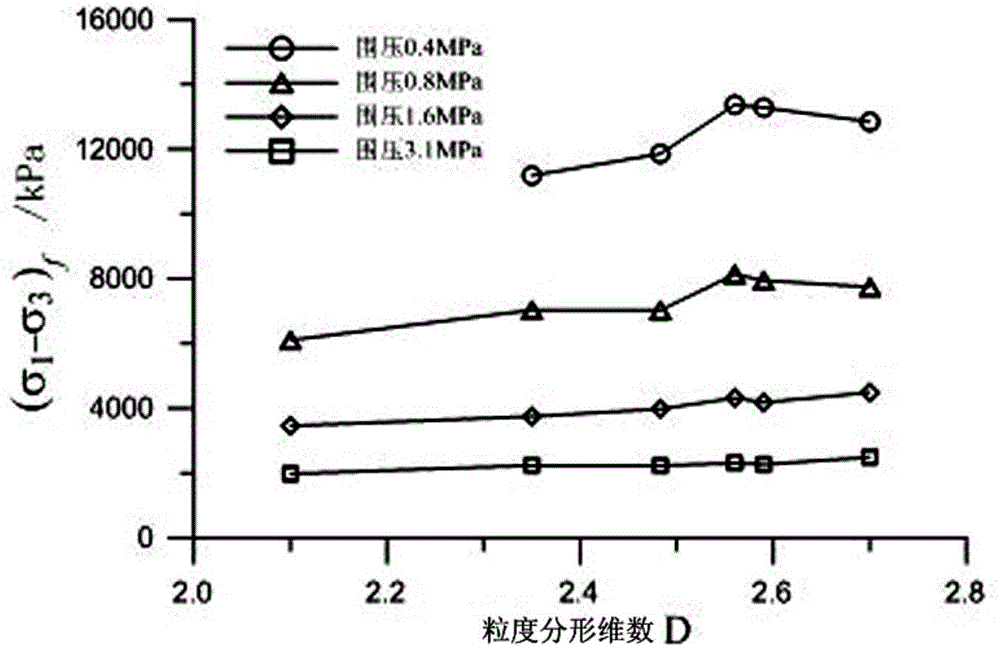

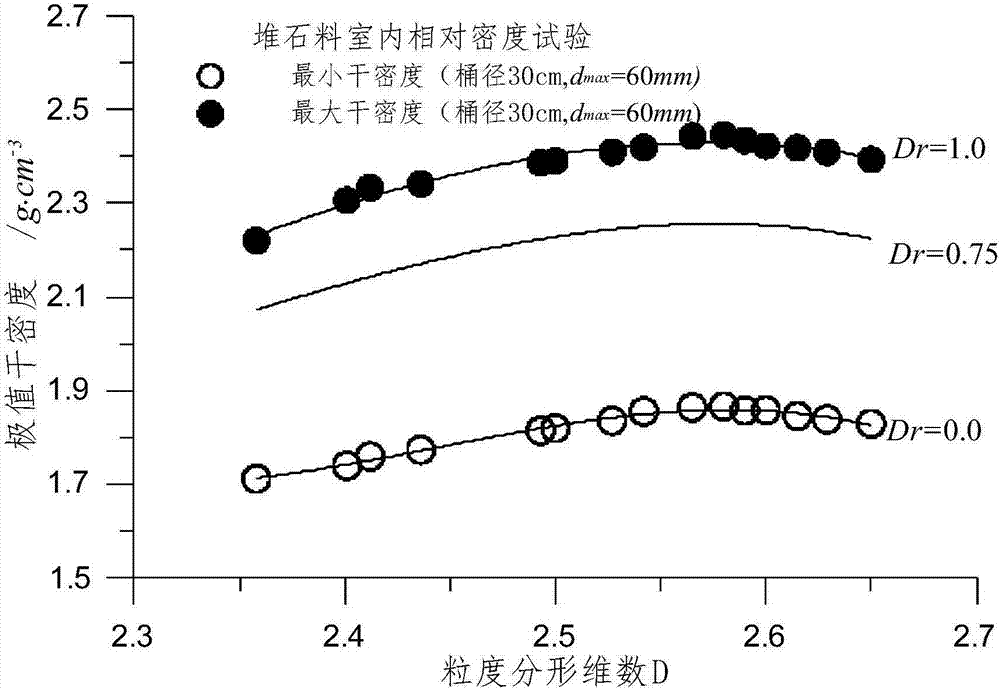

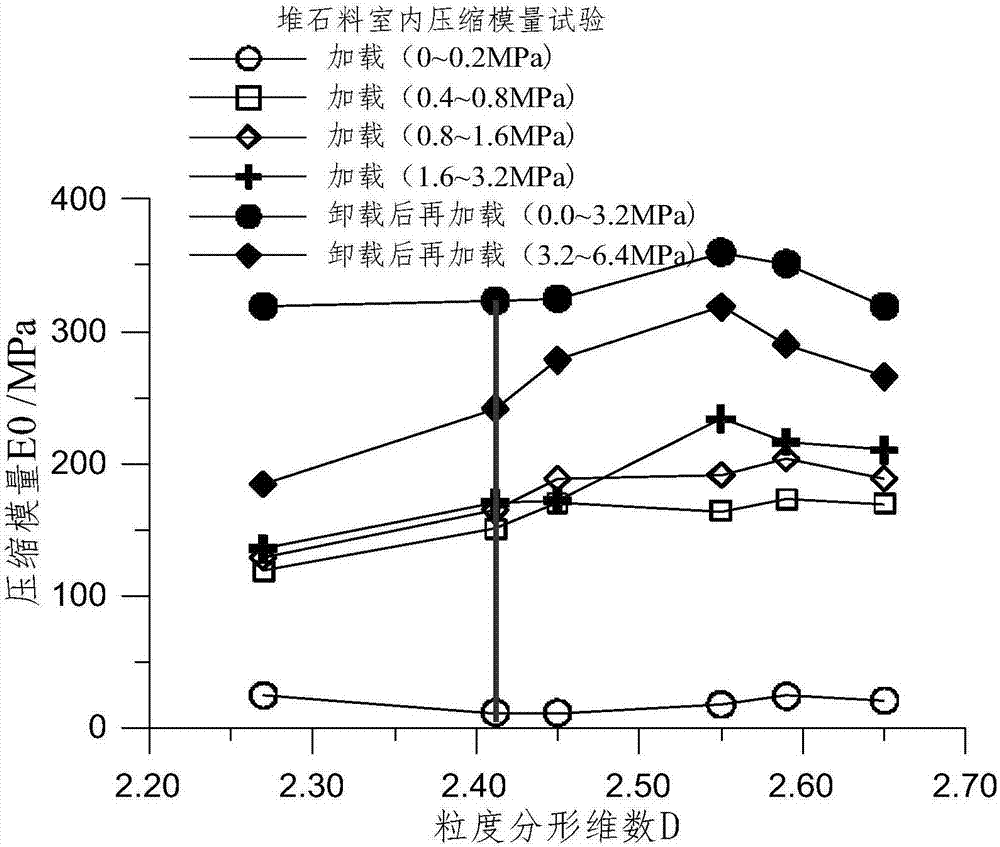

Earth and stone material grading optimization method based on fractal theory and physical mechanics test

The invention provides an earth and stone material grading optimization determining method which comprises the following steps of: changing granularity fractal dimension of earth and stone materials for the earth and stone materials with particle distribution meeting fractal distribution characteristics; preparing a grading earth and stone material sample with different particle size distribution functions; establishing a function relationship of extreme value dry density, modulus of compression, shearing strength and grading granularity fractal dimension through a field or indoor test; and regulating the granularity fractal dimension to obtain earth and stone material grading with a better filling relationship, easier compactness, higher modulus and strength. The earth and stone material grading optimization determining method can be used for a particle grading optimization design of rockfill materials and natural sand gravel materials.

Owner:HOHAI UNIV

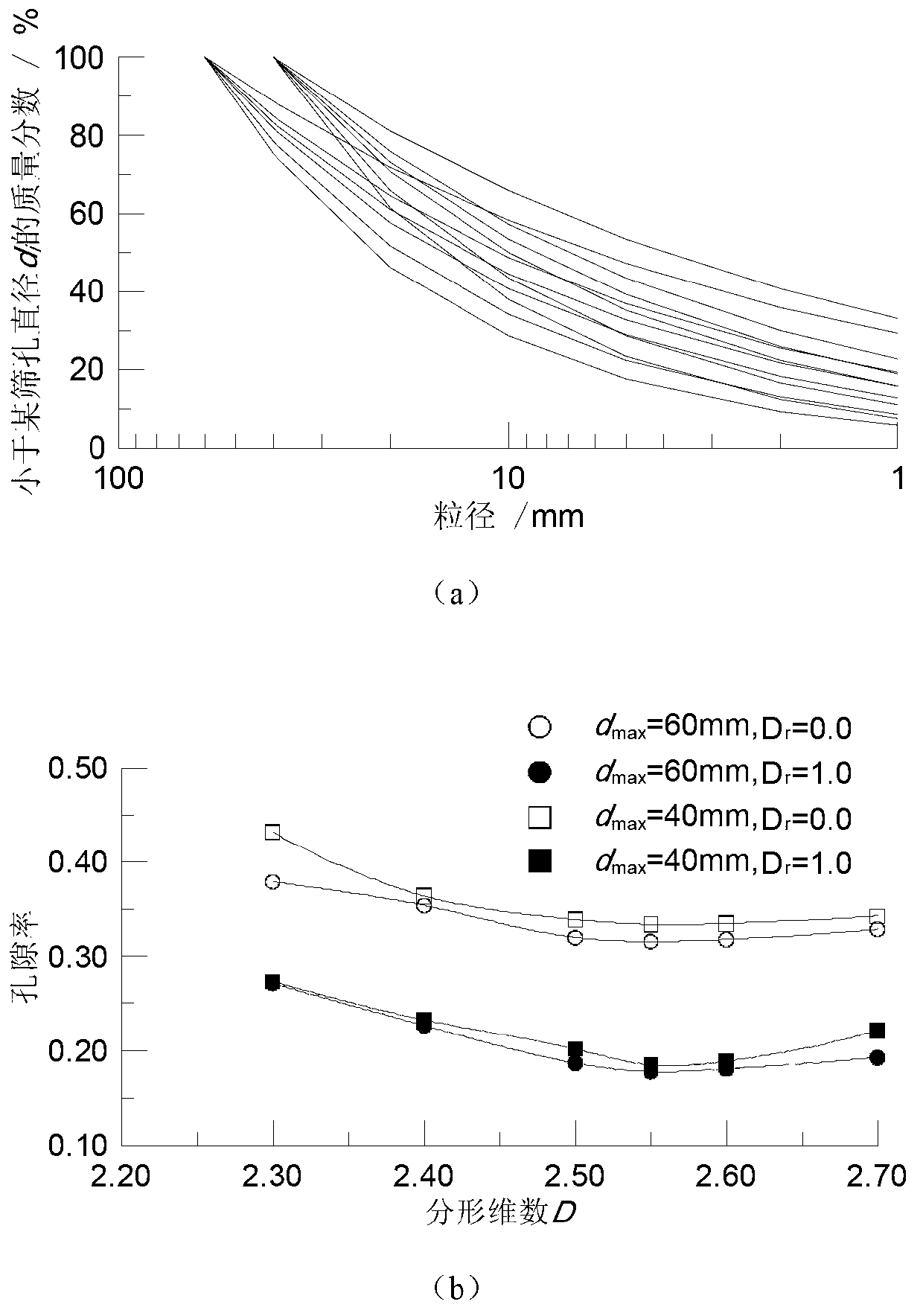

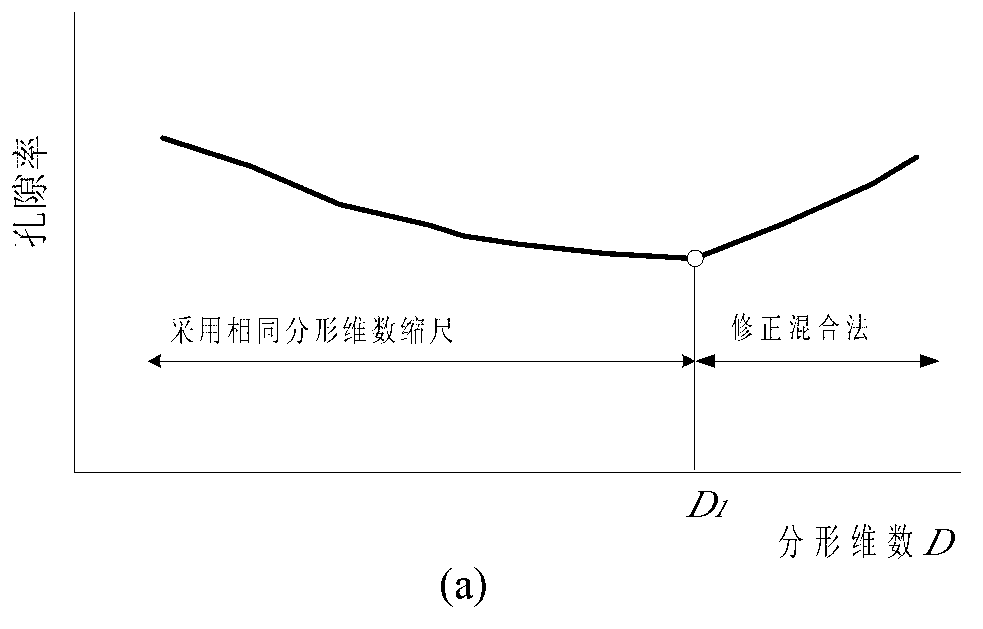

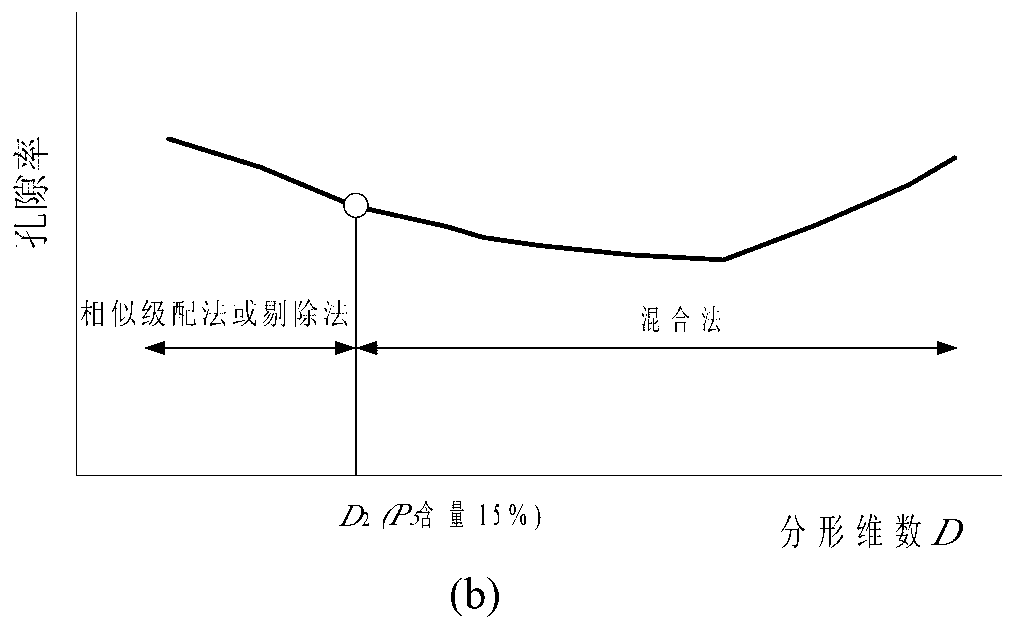

Coarse particle contraction rule method based on fractal theory

ActiveCN103134906AReduced scale effectOvercomes the disadvantage of being irrelevant to the largest particle sizeMaterial analysisRockfill materialAdditive ingredient

The invention discloses a coarse particle contraction rule method based on fractal theory. The coarse particle contraction rule method based on fractal theory is suitable for particle grade contraction of water conservation and civil engineering coarse particle, can effectively weaken coarse particle contraction effete. As for naturally formed sand-gravel material and generated blasting heap rockfill material through parameter design, the particle grading basically conform to Talbot grading curve, the particle size accord with fractal distribution, and good compacting performance is possessed. The coarse particle contraction rule method is based on the fractal theory, by introducing a grading parameter and a fractal dimension, and puts forward a contraction grading formula that physical mechanics condition is basically uniform on condition that original grading coarse particle appoints maximum control particle diameter dmax. The coarse particle contraction rule method based on the fractal theory specifically comprises the following steps: (1) calculating fractal dimension DO of the original grading; (2), through a relative density ratio test of corresponding ingredient of maximum control particle diameter, and determining a critical fractal dimension DL; (3) calculating grading parameter A according to relationship between the DO and the DL; (4) substituting the grading parameter A and the DO into the grading formula, and obtaining contracted target grading.

Owner:HOHAI UNIV

Method for determining rockfill material filling standards and detecting on-site filling quality based on fractal theory

ActiveCN107543775AControl filling qualityGuaranteed constructionParticle size analysisPermeability/surface area analysisPorosityRockfill material

The invention relates to a method for determining rockfill material filling standards and detecting on-site filling quality based on a fractal theory. The method comprises verifying a particle fractaldistribution model, building a relationship between grading parameters and dry density or porosity, building a relationship between grading parameters and a compressive modulus, determining rockfillmaterial filling grading or a grading envelope line satisfying compressive modulus requirements, acquiring a filling porosity index or an index range, carrying out a penetration test, detecting a permeability coefficient, if the permeability coefficient does not satisfy the permeability requirement, reducing and adjusting a grading range until the permeability coefficient satisfies the permeability requirement, and verifying whether the filling porosity under the condition of design relative density satisfies the filling porosity requirement. The method provides double control standards of porosity and relative density, controls rockfill body filling quality, comprehensively considers the influence produced by the grading of the rockfill material, the characteristics of the parent rock anda compaction degree on the deformability of the rockfill body, provides the reliable basis for the whole stability of the rockfill dam and effective deformation control and ensures the construction and operation safety of the dam.

Owner:HOHAI UNIV

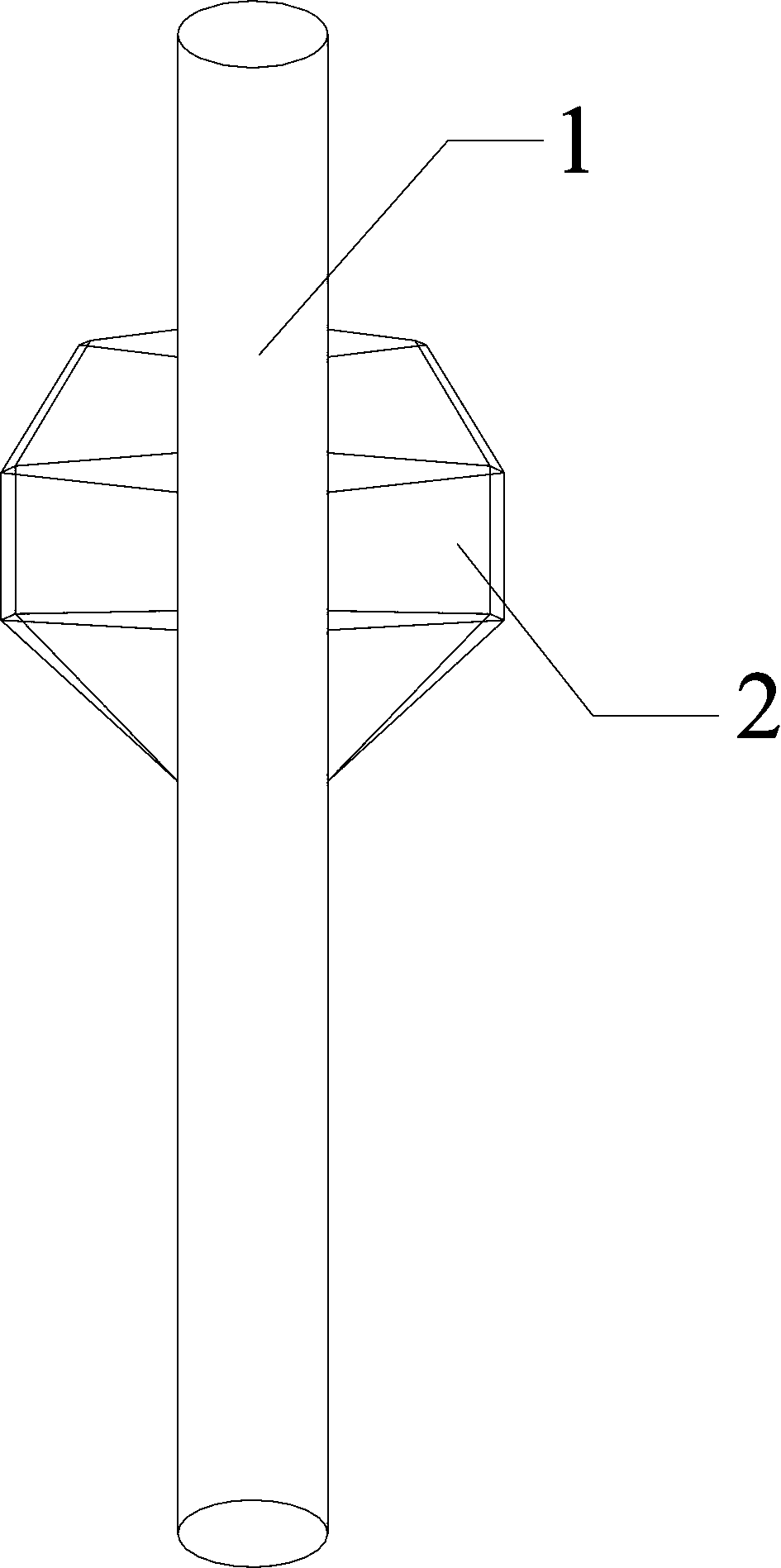

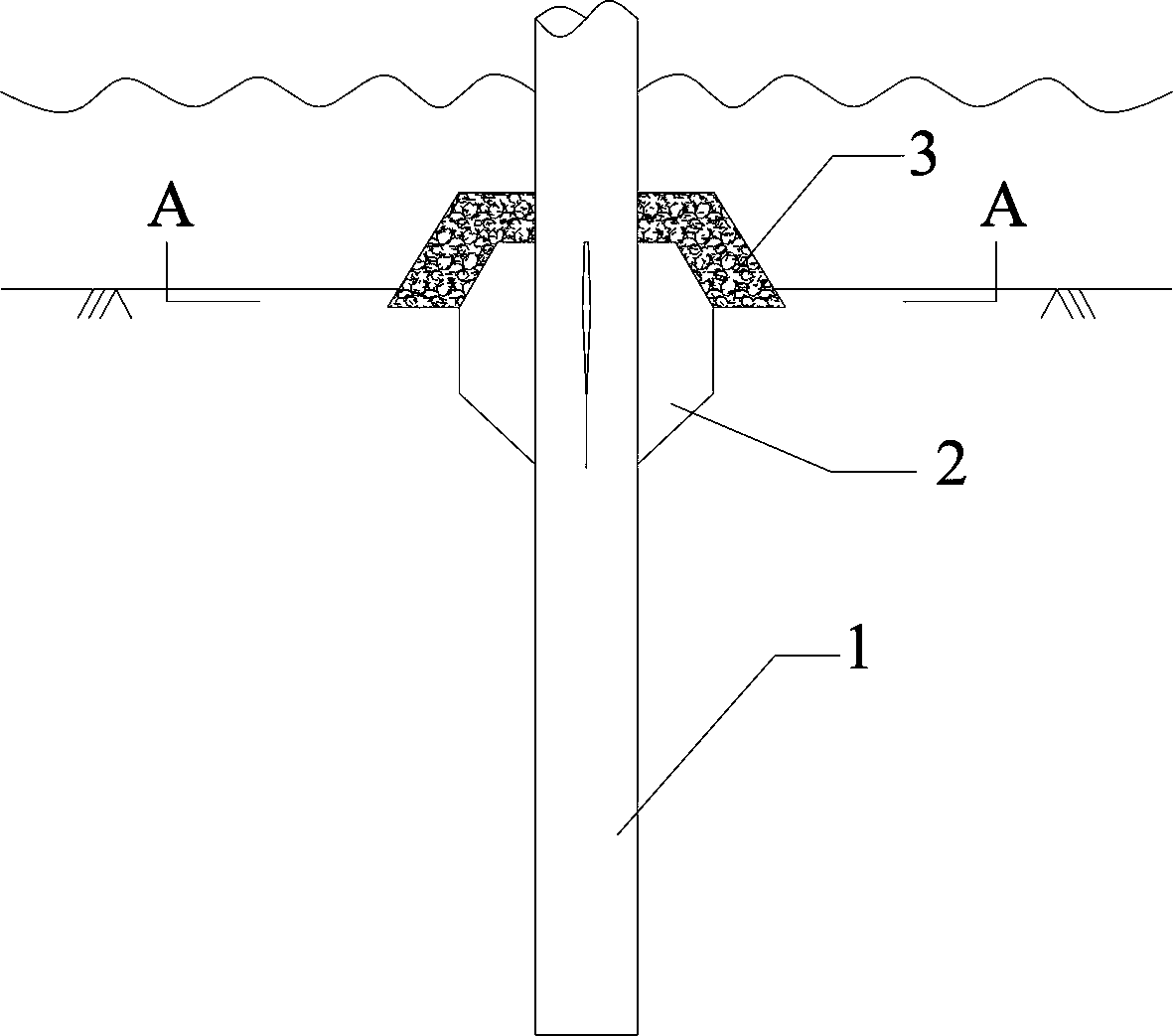

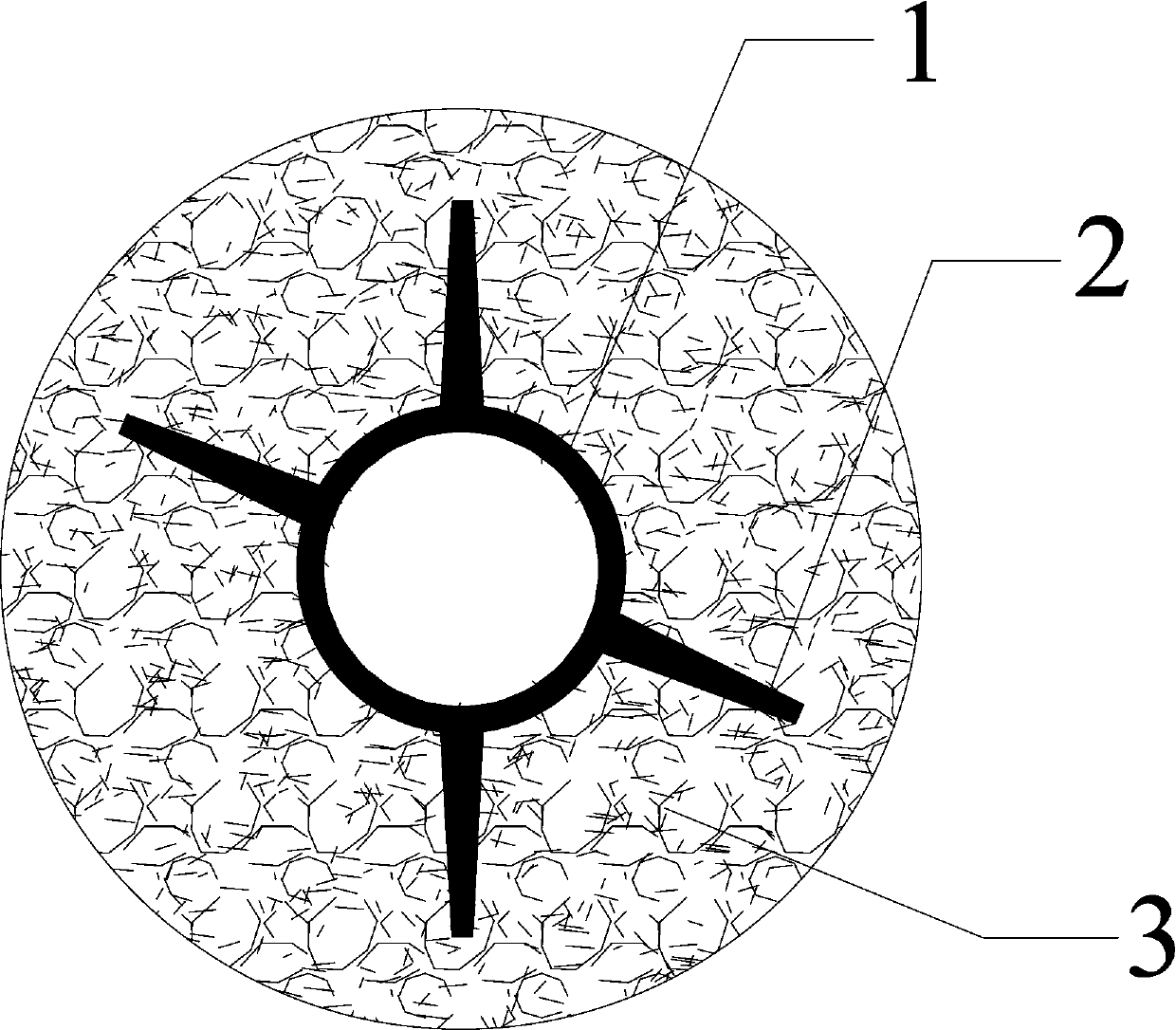

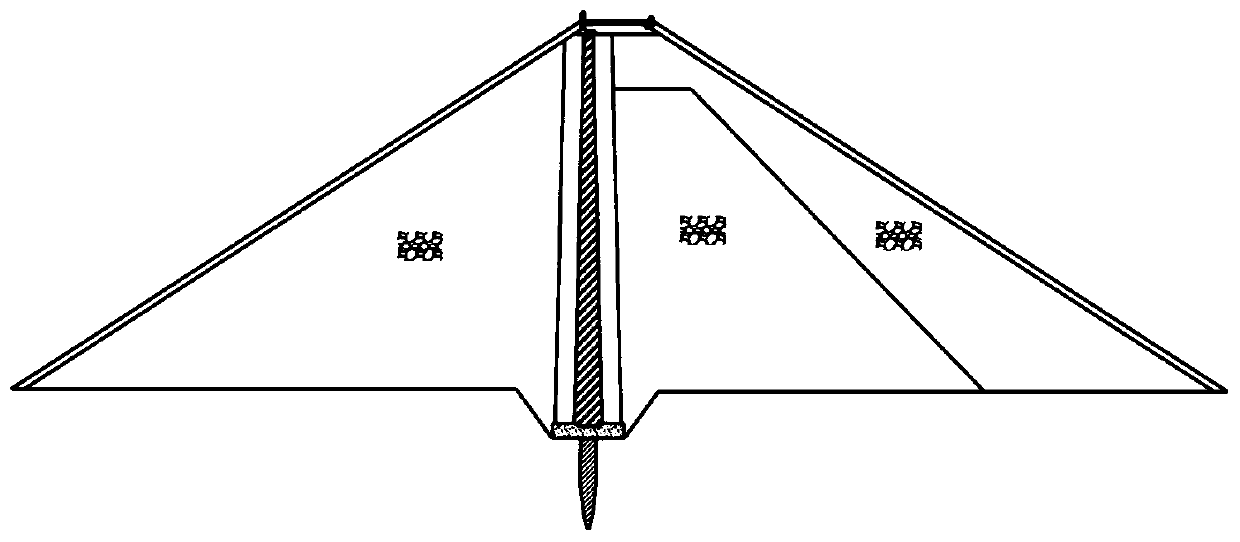

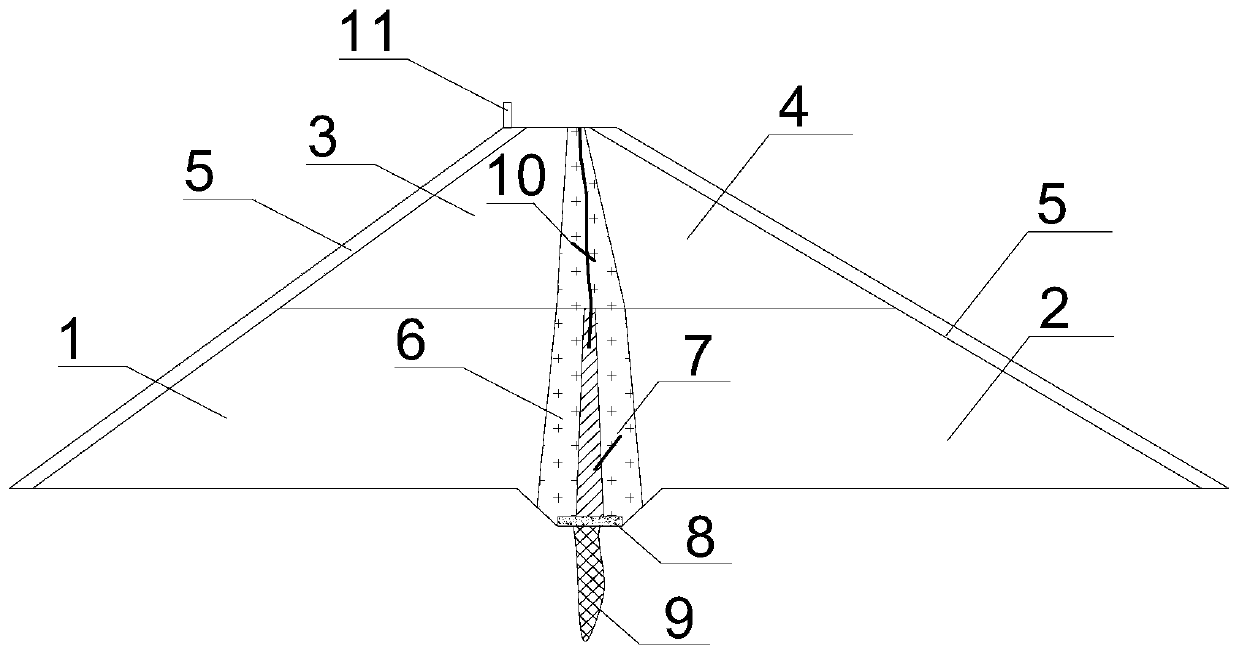

Offshore wind electricity single pile-wing plate-rockfill composite foundation and construction method thereof

PendingCN110984214AImprove carrying capacityFully mobilize resistanceFoundation engineeringRockfill materialStructural engineering

The invention discloses an offshore wind electricity single pile-wing plate-rockfill composite foundation and a construction method thereof. The foundation comprises a single pile, a wing plate and rockfill, the wing plate is of a conical structure, and is welded to the outer wall of a pile body, the rockfill is formed through dense stacking of the rockfill, the upper end of the wing plate is located in the rockfill, and the lower end of a pile wing is located on a seabed supporting layer. The construction method of the offshore wind electricity single pile-wing plate-rockfill composite foundation comprises the following steps of S1, determining the sizes of the single pile, the wing plate and the rockfill; S2, driving the single pile with the wing plate by the designed anchorage depth; and S3, stacking the rockfill on a seabed nearby the single pile. The problems of the low single pile bearing force, the large pile wing of the wing plate pile, serious foundation washing and the like can be solved, the single pile, wing plate and rockfill combination structure uses pile periphery soil resistance and rockfill friction force, the pile foundation bearing force can be improved, the pile foundation horizontal displacement can be reduced, the wing plate size is reduced, a wing plate stress mechanism is changed, washing of waves and ocean currents to seabed soil can be blocked, and safe and stable running of an offshore wind generation set can be ensured.

Owner:CHINA THREE GORGES CORPORATION

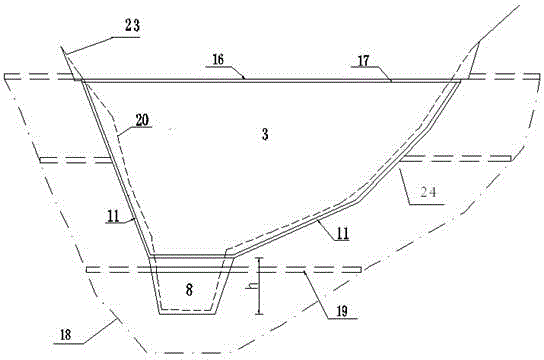

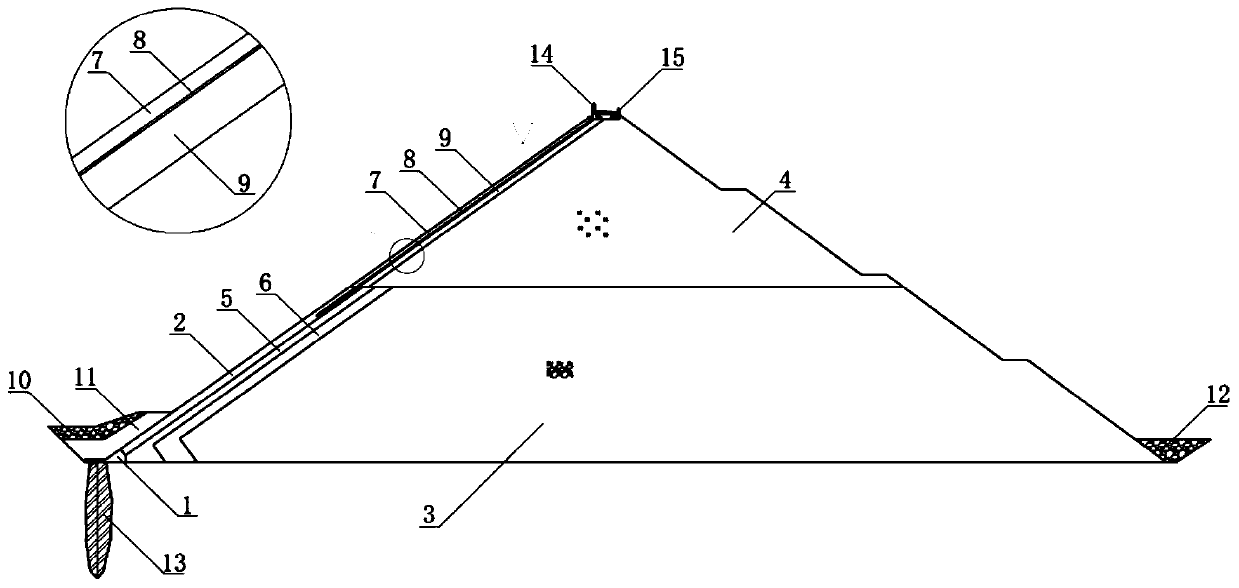

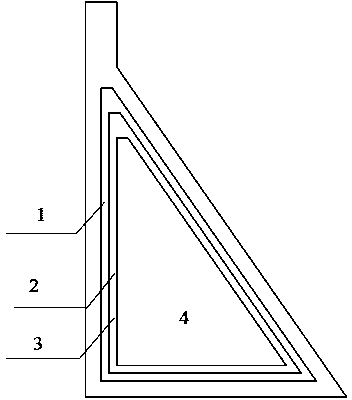

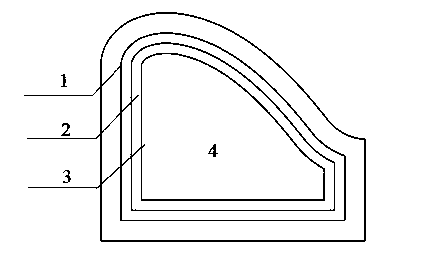

Extrusion-wall type geomembrane-faced rockfill dam

The invention discloses an extrusion-wall type geomembrane-faced rockfill dam, relates to the field of geomembrane-faced rockfill dam construction, and aims at face rockfill dams. The extrusion-wall type geomembrane-faced rockfill dam at least comprises a dam body, a geomembrane, an extrusion wall, a protective layer and a protective slop, and is characterized in that the dam body is trapezoidal, inclined planes on two sides of the dam body refer to an upstream side dam and a downstream side dam, and the surface of the upstream side dam is paved with the geomembrane; the extrusion wall is disposed on the downstream of the geomembrane, in other works, the extrusion wall is sandwiched between the geomembrane and the upstream side dam, and the protective layer and the protective slop are arranged on the upstream of the geomembrane. The extrusion-wall type geomembrane-faced rockfill dam aiming at the security problems of the ultral-high face rockfill dams has the advantages that both independent advantage and comprehensive advantages of the geomembrane, the extrusion wall and rockfill materials are fully exerted, reliability, durability, aseismicity and security of a dam seepage control structure are enhanced, and the dam has good social, economic and environmental ecological benefits.

Owner:POWERCHINA XIBEI ENG

Steel membrane concrete faced rockfill dam

ActiveCN103225285AAvoid influenceGuaranteed crack resistanceEarth-fill damsRock-fill damsCrack resistanceReinforced concrete

The invention discloses a steel membrane concrete faced rockfill dam which consists of a steel membrane concrete faces, a cushion layer zone, a transition zone, a main rockfill zone, a secondary rockfill zone, reinforced concrete toe boards, a wave prevention wall, anti-slip reinforcing steel bars, a grouting curtain and deformed inductive grooves, wherein the steel membrane concrete face is laid on the cushion layer zone of an upstream slope of a rockfill dam body; the top of the dam is provided with a reinforced concrete wave prevention wall; the bottom and the periphery of the dam body are provided with the reinforced concrete toe boards; the bottom at the front end of the dam body is provided with the curtain for grouting; the middle parts and the edges of the steel membrane faces are provided with groove-type deformed inductive grooves; the steel membrane faces on the top of the dam body extend into the reinforced concrete wave prevention wall; the bottom of the dam body and the steel membrane at the side part extend into the reinforced concrete toe boards; and the rear part of the steel membrane is provided with the anti-slip reinforcing steel bars. The steel membrane concrete faced rockfill dam provided by the invention has obvious advantages during the processes of construction, running, management and the like by adopting the steel membrane faces, and especially can well solve influences on faces by the deformation of rockfill materials of the dam body, so that the aspects of face crack resistance and seepage resistance as well as the dam body safety and the like are effectively ensured.

Owner:TIANJIN UNIV

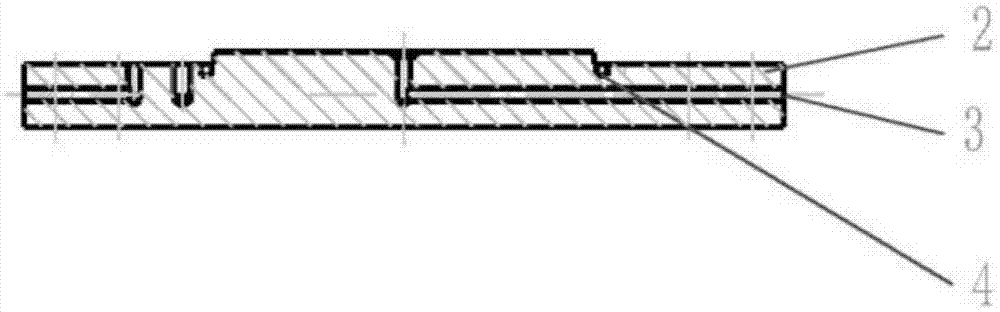

Single-molecule high polymer and rockfill material three-axis sample preparation equipment and application method

ActiveCN106198137APrevent penetrationFull chemical reactionPreparing sample for investigationRockfill materialChemical reaction

The invention discloses single-molecule high polymer and rockfill material three-axis sample preparation equipment and an application method. The equipment comprises a vacuum saturation cylinder and a base located in the vacuum saturation cylinder; a split mold is mounted on the base; a fixing sleeve is mounted at the top of the split mold; the fixing sleeve is fixed at the top of the split mold through a connecting rod; a lower permeable stone, and a rockfill material and a single-molecule high polymer, which are loaded by layers, are arranged on an inner wall of the split mold; a compacting device for impacting the rockfill material and the single-molecule high polymer is mounted in the split mold; second filter paper and a geotextile cover are arranged on the inner wall of the split mold; a water through hole is formed in the base. In a testing sample preparation process, the second filter paper and the geotextile cover are arranged at the inner side of the split mold and can be used for effectively preventing from a condition that high polymer and water have a chemical reaction and then penetrate into a mold formed in the inner side of the split mold so that a test sample is difficult to detach and the content of the high polymer in the test sample is changed.

Owner:HOHAI UNIV

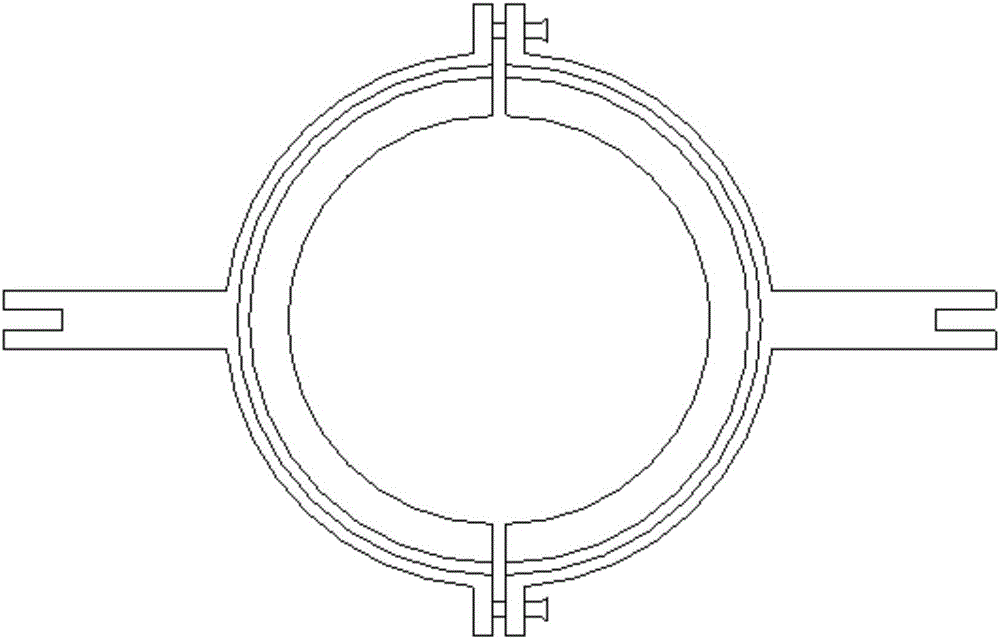

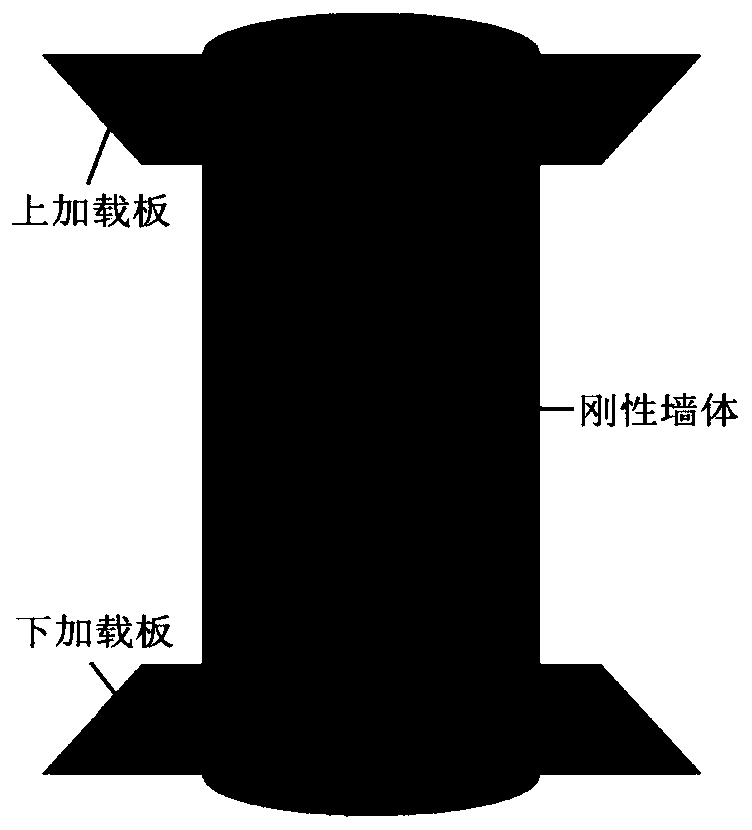

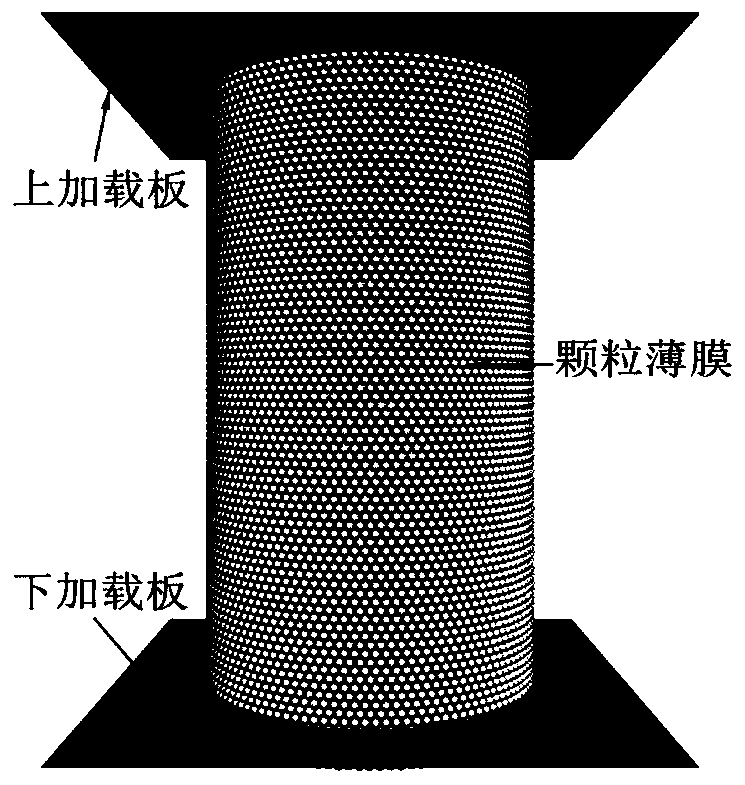

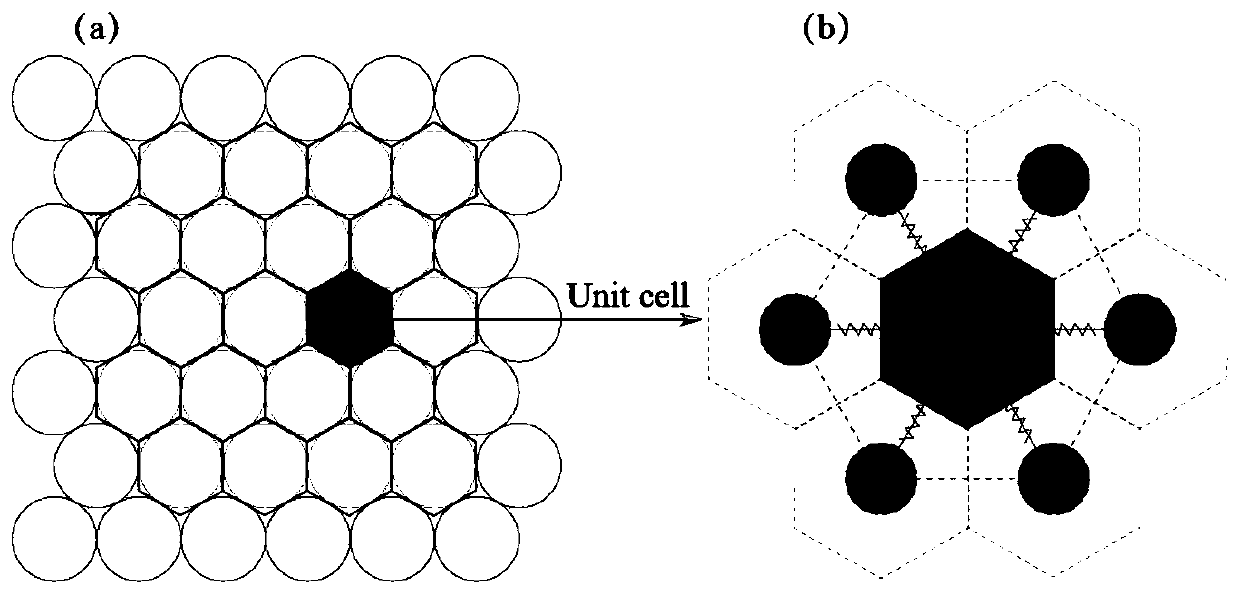

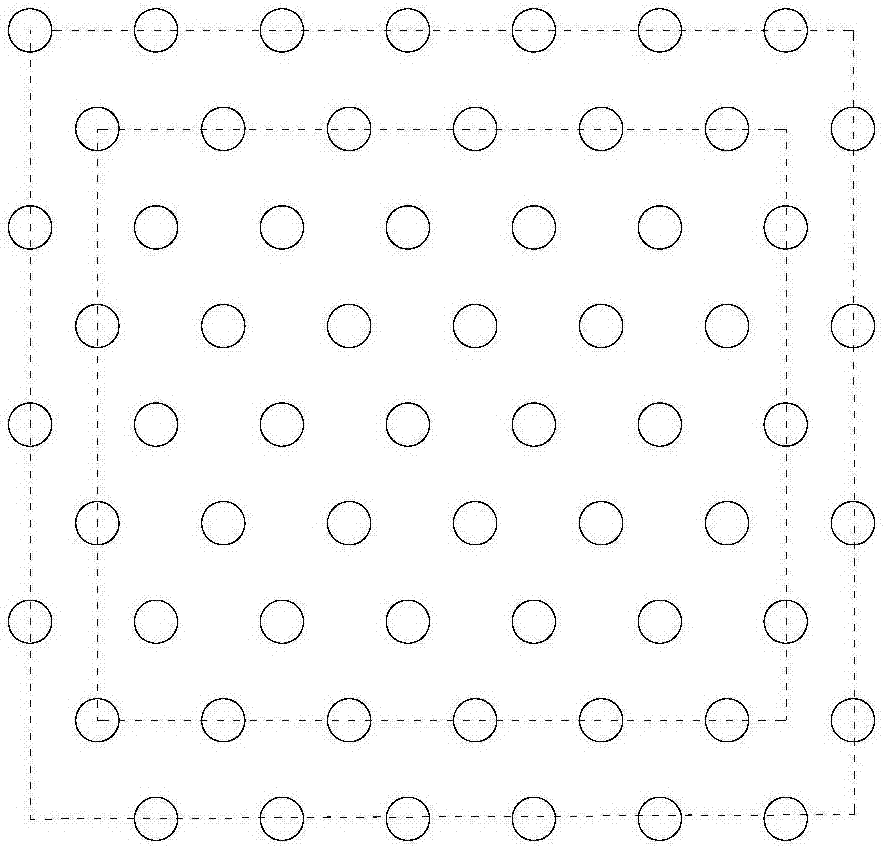

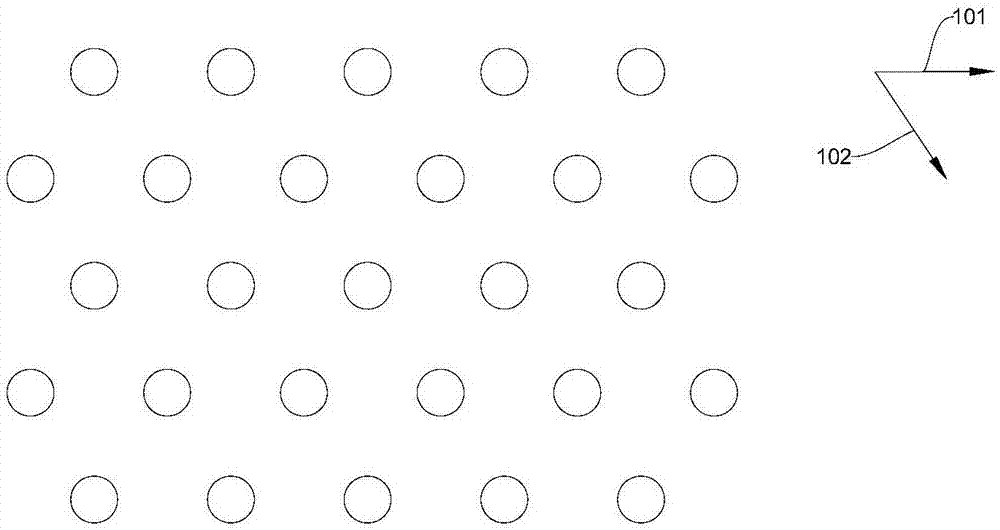

Discrete element simulation method for rock-soil triaxial test flexible film boundary

PendingCN110309536AStable and Accurate LoadingVolumetric deformations of snapping volumesDesign optimisation/simulationSpecial data processing applicationsDiscrete element simulationShape change

The invention discloses a discrete element simulation method for a rock-soil triaxial test flexible film boundary. The discrete element simulation method adopts a particle set arranged in a hexagonalhoneycomb structure to represent a flexible film, and a linear bonding model is adopted among particles, and an upper loading plate and a lower loading plate adopt rigid walls. The discrete element simulation method has the outstanding advantages that (1) the film particles can effectively represent parameters such as the elasticity modulus, the Poisson's ratio and the thickness of the physical film; (2) the film can be freely deformed in the sample loading process, and the hydrostatic confining pressure can be stably and accurately transmitted; and (3) the volume deformation of the sample canbe accurately recorded in real time in the loading process. The discrete element simulation method is simple in implementation process and suitable for simulating conventional triaxial tests of various granular materials such as sandy soil and rockfill materials. Practice shows that the discrete element simulation method can accurately simulate the shape change, the stress-strain relationship andthe volume strain condition of the sample in the triaxial test process of the granular material, and can provide powerful support for macroscopic parameter test and mechanical property research of the granular material.

Owner:CENT SOUTH UNIV

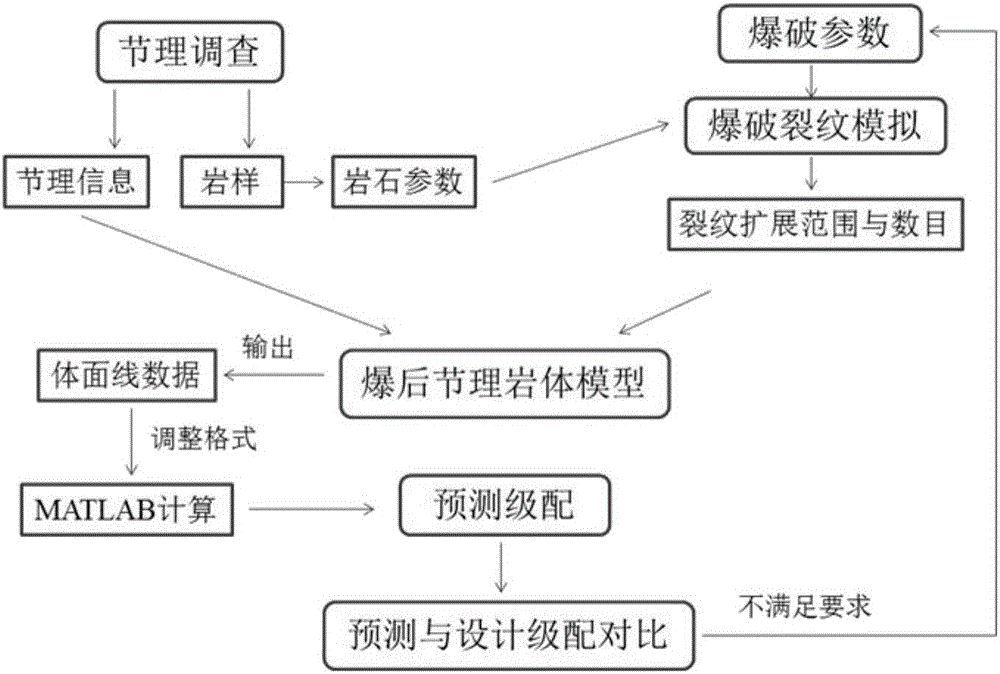

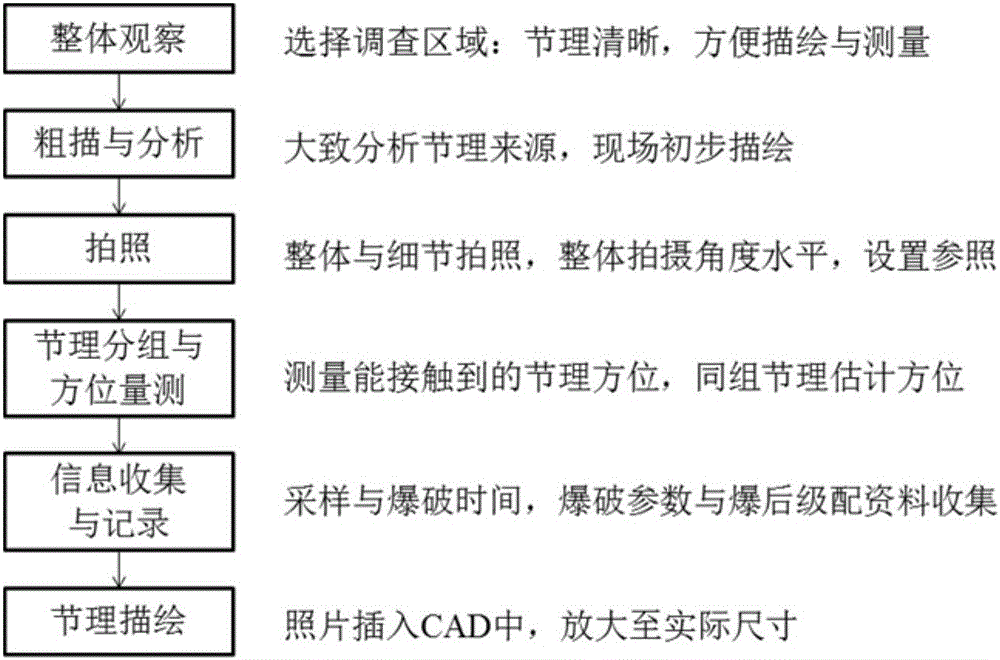

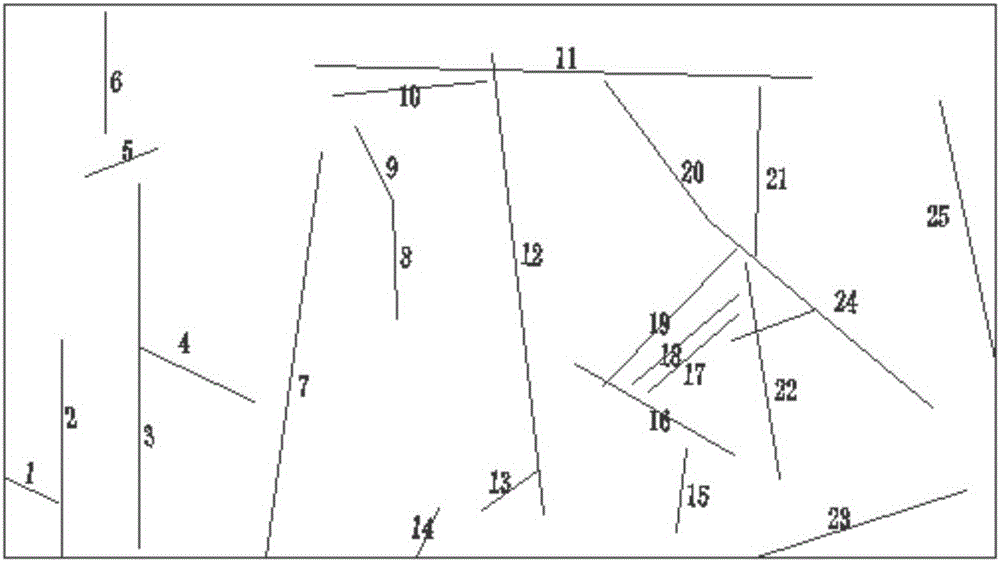

Rockfill material blasting grade prediction method for water-power engineering

ActiveCN106227913AEase of field applicationPractical Forecasting MethodsDesign optimisation/simulationSpecial data processing applicationsRockfill materialInvestigation methods

Owner:SICHUAN UNIV

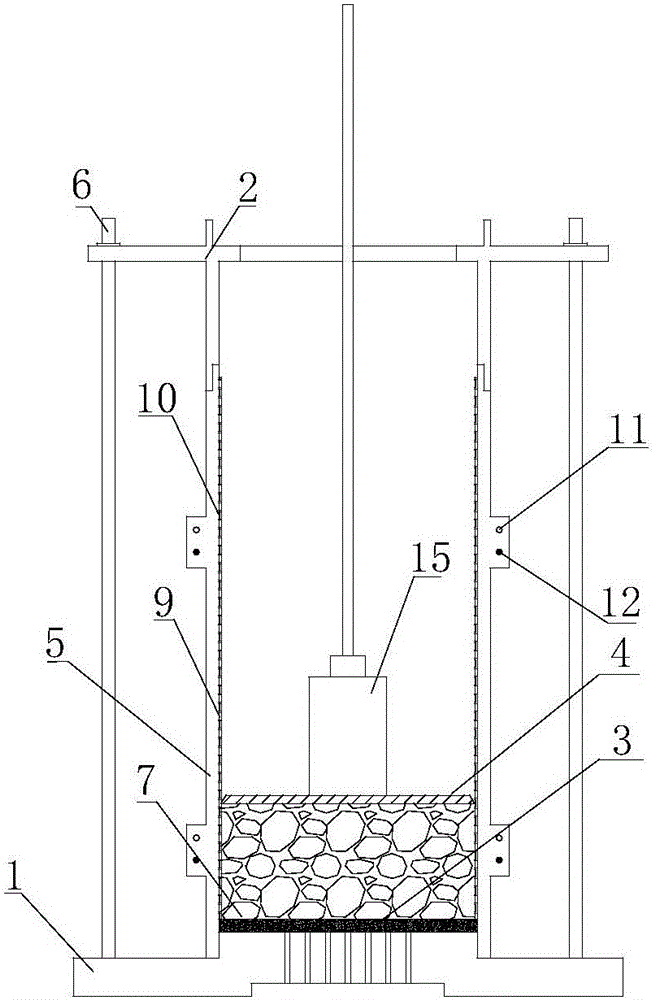

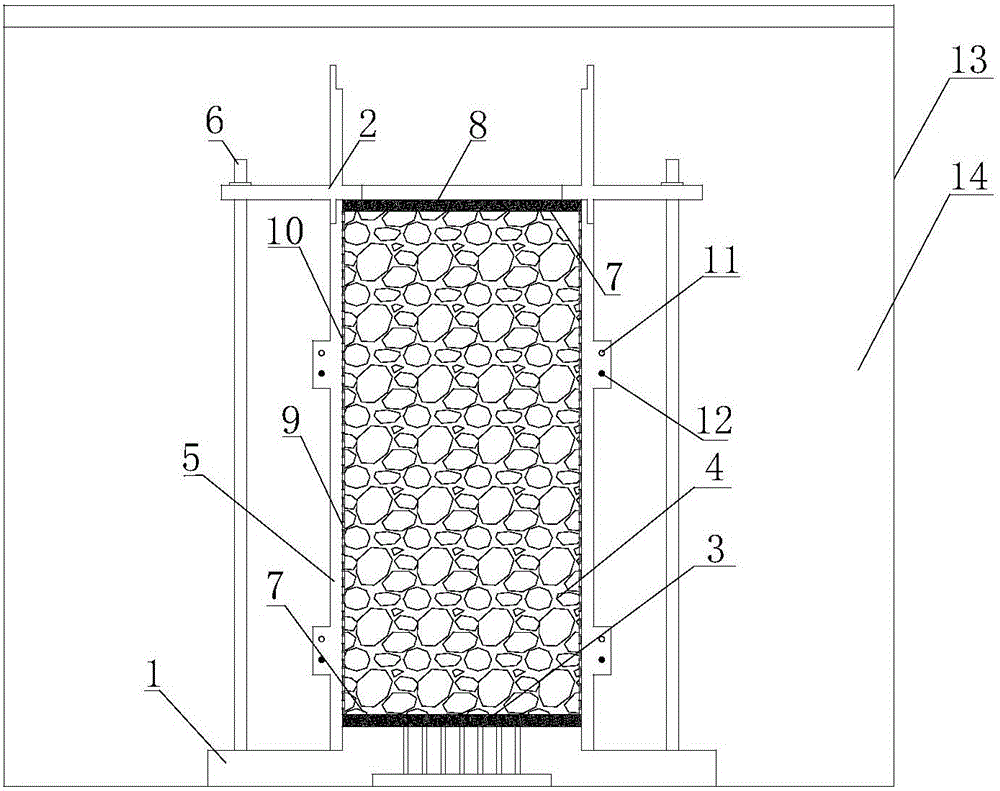

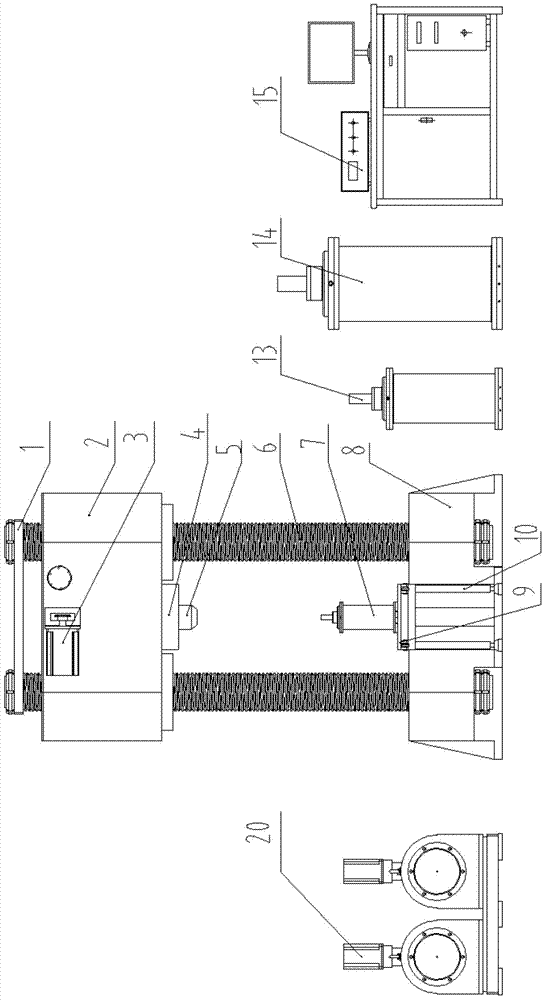

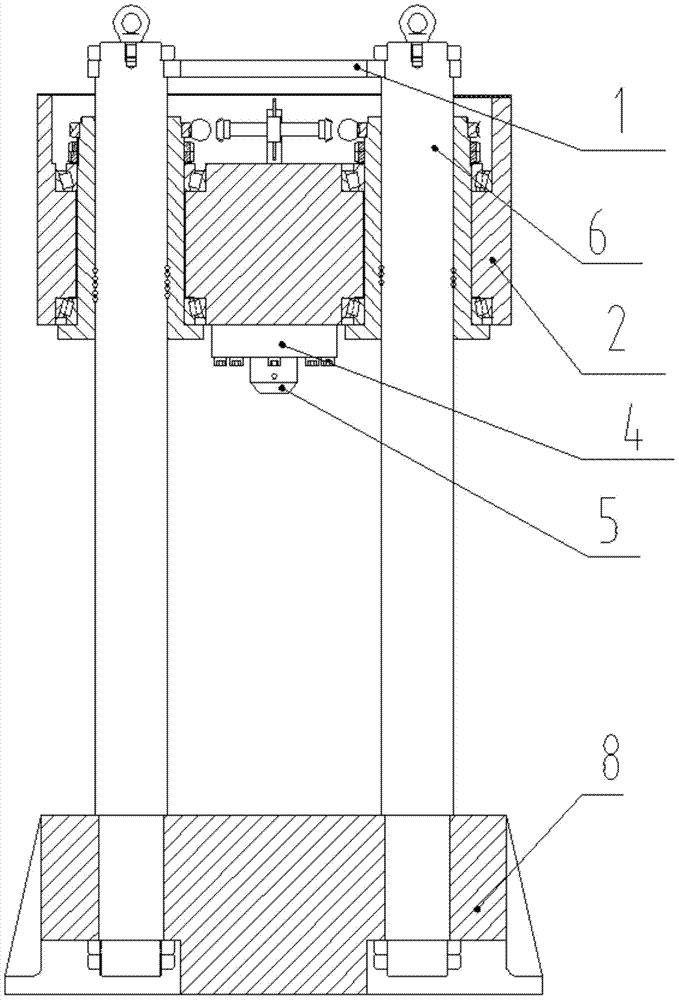

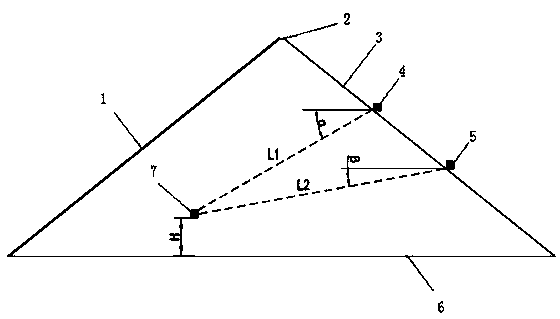

Large triaxial shear testing instrument for rockfill material degradation

ActiveCN103674736ARealize two-way independent high-precision controlAccurate measurementMaterial strength using steady shearing forcesRockfill materialClosed loop

A large triaxial shear testing instrument for rockfill material degradation is characterized by comprising a test mainframe, a confining pressure and pore pressure servo loading system, a temperature control system, a closed loop measurement and control system and a computer control and data acquisition system (15). The large triaxial shear testing instrument for rockfill material degradation adopts a multichannel closed loop controller to realize two-way independent high-precision control for axial loading and lateral loading of a servo motor and a reducer ball screw, and a mechanical property test for a rockfill material under a complex stress path can be carried out; the large triaxial shear testing instrument for rockfill material degradation adopts a cold and hot control device provided with a temperature control pump, an acid-base circulating device and an anti-corrosion pipeline, so that physical weathering and chemical weathering tests can be performed simultaneously; and the large triaxial shear testing instrument for rockfill material degradation adopts a differential displacement sensor and a diameter deformation measurement sensor, and accordingly, accurate measurement of a dynamic size change process in a dry and wet change process of a rockfill material test piece is realized.

Owner:NANJING HYDRAULIC RES INST

High-base asphalt concrete core wall dam

ActiveCN104099903AReduce stressIncrease stressWall damsGravity damsEarthquake resistanceRockfill material

The invention relates to a high-base asphalt concrete core wall dam. The high-base asphalt concrete core wall dam is characterized by comprising a high base, a core wall, a base of an anti-seepage asphalt concrete wall, two first transition areas, second transition areas, a first stone stacking area, a second stone stacking area, a riverbed low-compression material area and an anti-wave wall. The core wall is arranged on the base of the anti-seepage asphalt concrete wall, the base of the anti-seepage asphalt concrete wall is arranged on the high base, and the anti-wave wall is arranged at the top of the core wall; the first transition areas are respectively arranged on the upstream side and downstream side of the core wall and are tightly fitted to the core wall; the second transition areas are arranged on the outer sides of the two first transition areas; the heights of the first and second transition areas are the same as the height of the core wall; the height of the high base is larger than 10cm. Advantages and comprehensive superiority of the asphalt concrete, high base, low-compression material and stacked stone material are played completely, the problem of the feasibility of the high-base asphalt concrete core wall dam with narrow lower portion and wider upper portion is solved technically, and reliability, durability, anti-seismic performance and safety of a dam anti-seepage structure can be improved significantly.

Owner:POWERCHINA XIBEI ENG

Triaxial sample preparation device for hammer-type rockfill materials and use method

PendingCN106644649AImprove uniformityUniform densityPreparing sample for investigationRockfill materialEngineering

The invention discloses a triaxial sample preparation device for hammer-type rockfill materials and a use method. The triaxial sample preparation device comprises a sample preparation mechanism and a compaction mechanism, the sample preparation mechanism comprises a split mold, a sleeve ring, a base, a water permeation plate, a water permeation stone, a rubber sleeve, an O-shaped ring and a vacuum pump, the compaction mechanism comprises a compaction hammer, a compaction base plate, a guide rod, a measuring rod, a guide rod positioning instrument and a test ruler. According to the triaxial sample preparation device, bulk rockfill material samples are formed by the rubber sleeve adsorbing on a sample preparation barrel, the guide rod, the measuring rod and the test ruler are mutually matched, samples of the rockfill materials are prepared in an uniformly layered manner, the two mechanism are efficiently matched, samples of continuous gradation and single gradation rockfill materials are prepared, so that sample preparation is independent of a triaxial compression apparatus, and prepared samples have good uniformity.

Owner:TSINGHUA UNIV

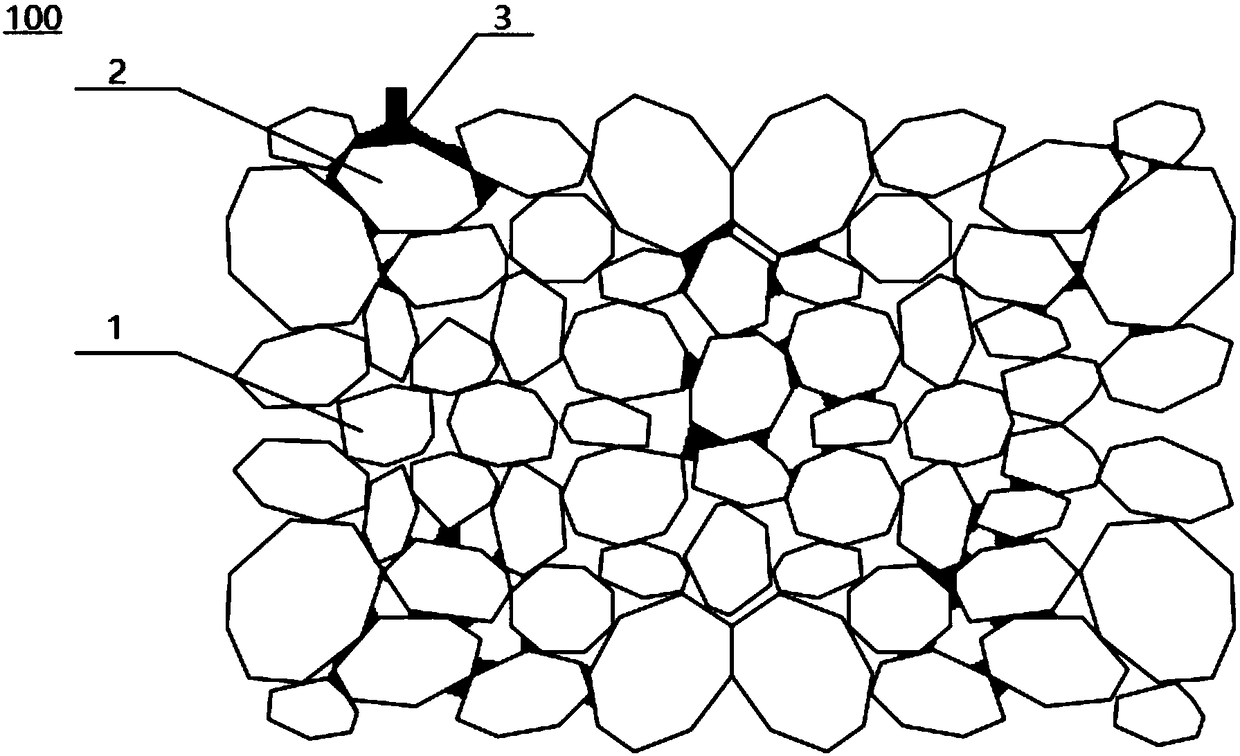

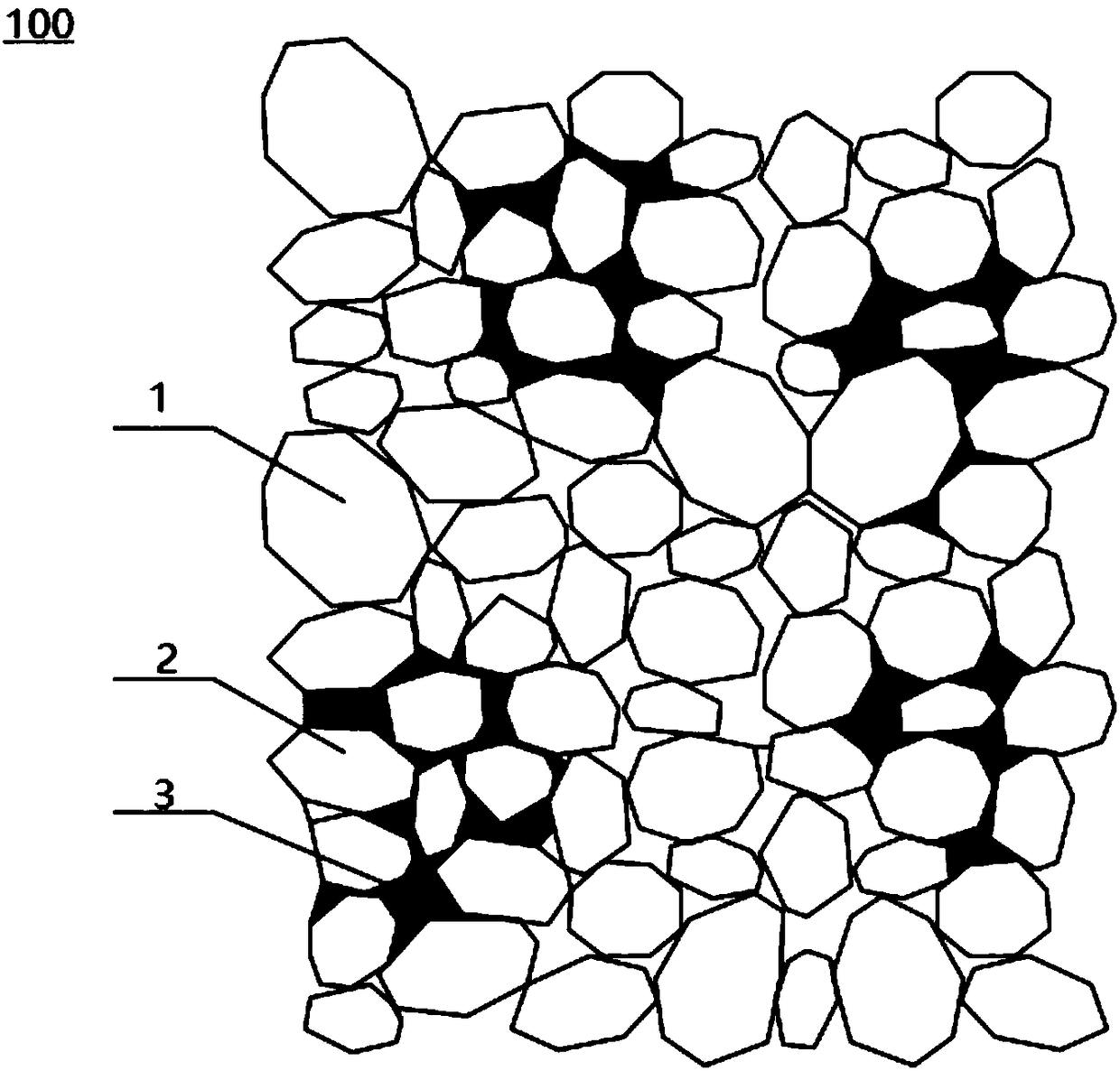

Structured cemented particulate material and preparation method thereof

ActiveCN108546007AMaintain ability to adapt to deformationHigh strengthSoil preservationRockfill materialDeformation modulus

The invention discloses a structured cemented particulate material and a preparation method thereof, the structured cemented particulate material comprises a granular material and a cemented granularmaterial, and the granular material is at least one of a rockfill material, a crushed stone material, sand gravel and a soil and stone material. The cemented granular material is obtained by filling aself-compacting cement-based cementing material into gaps of the granular material. Since the structured cemented particulate material comprises the granular material in the form of a granular body and a cementation body cemented granular material, the ability of the granular material to adapt to deformation is maintained, and the structured cemented particulate material has a large plastic deformation advantage. The cemented granular material is obtained by filling the granule gaps of the granular material with the self-compacting cement-based cementing material, the strength, rigidity and deformation modulus of the granular material can be improved, and by control of the fluidity, viscosity and pouring amount of the self-compacting cement-based cementing material, different cementationtypes, shapes and volumes of cemented granular materials can be obtained, and are suitable for different engineering conditions.

Owner:TSINGHUA UNIV

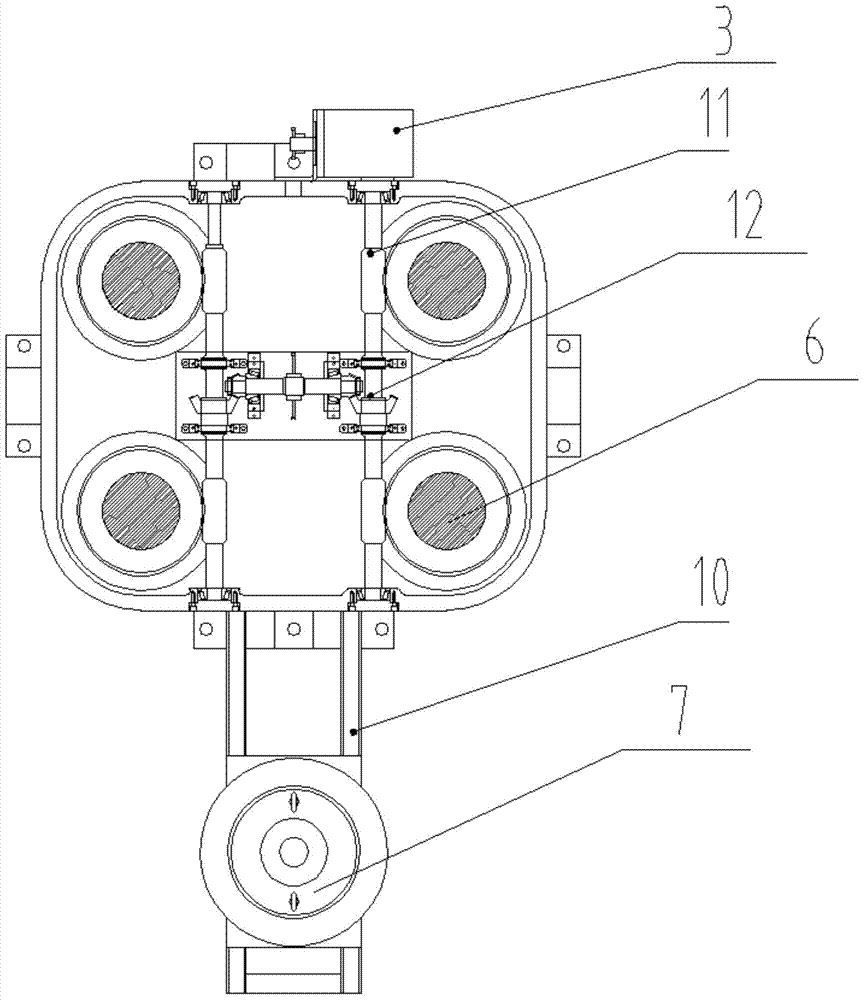

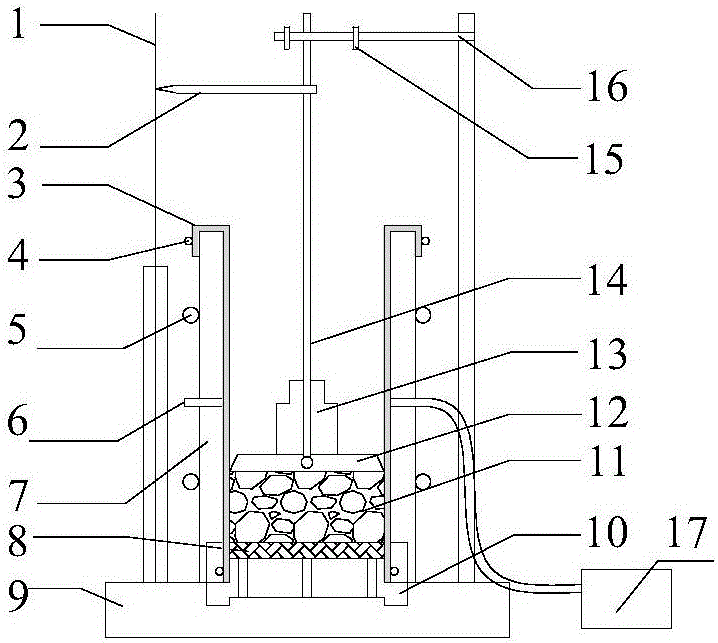

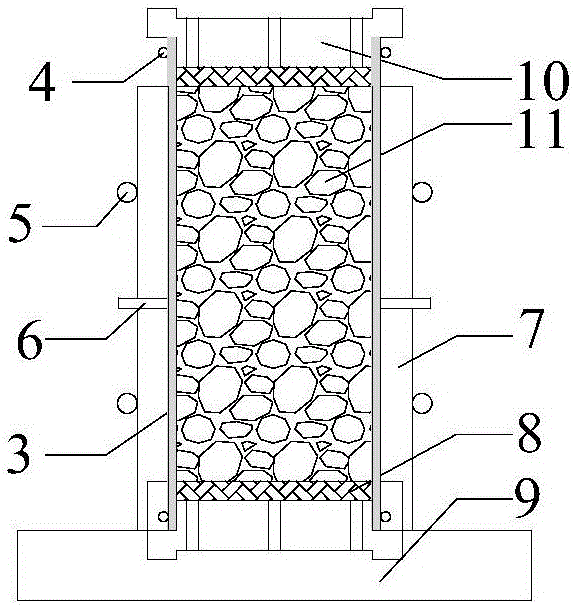

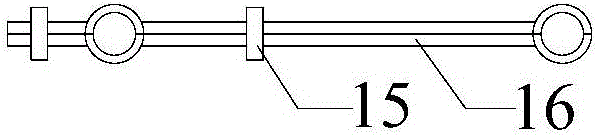

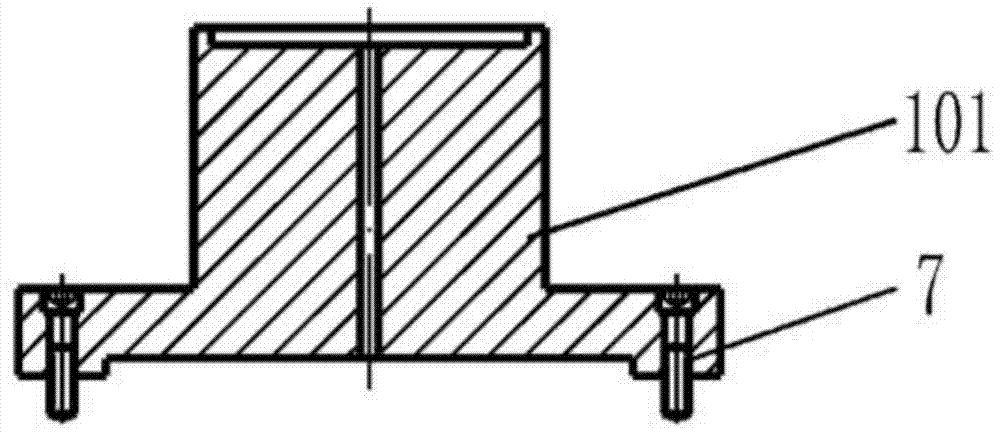

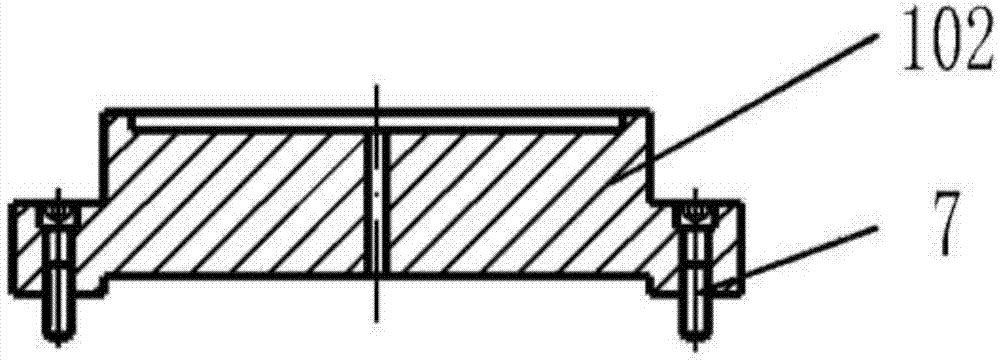

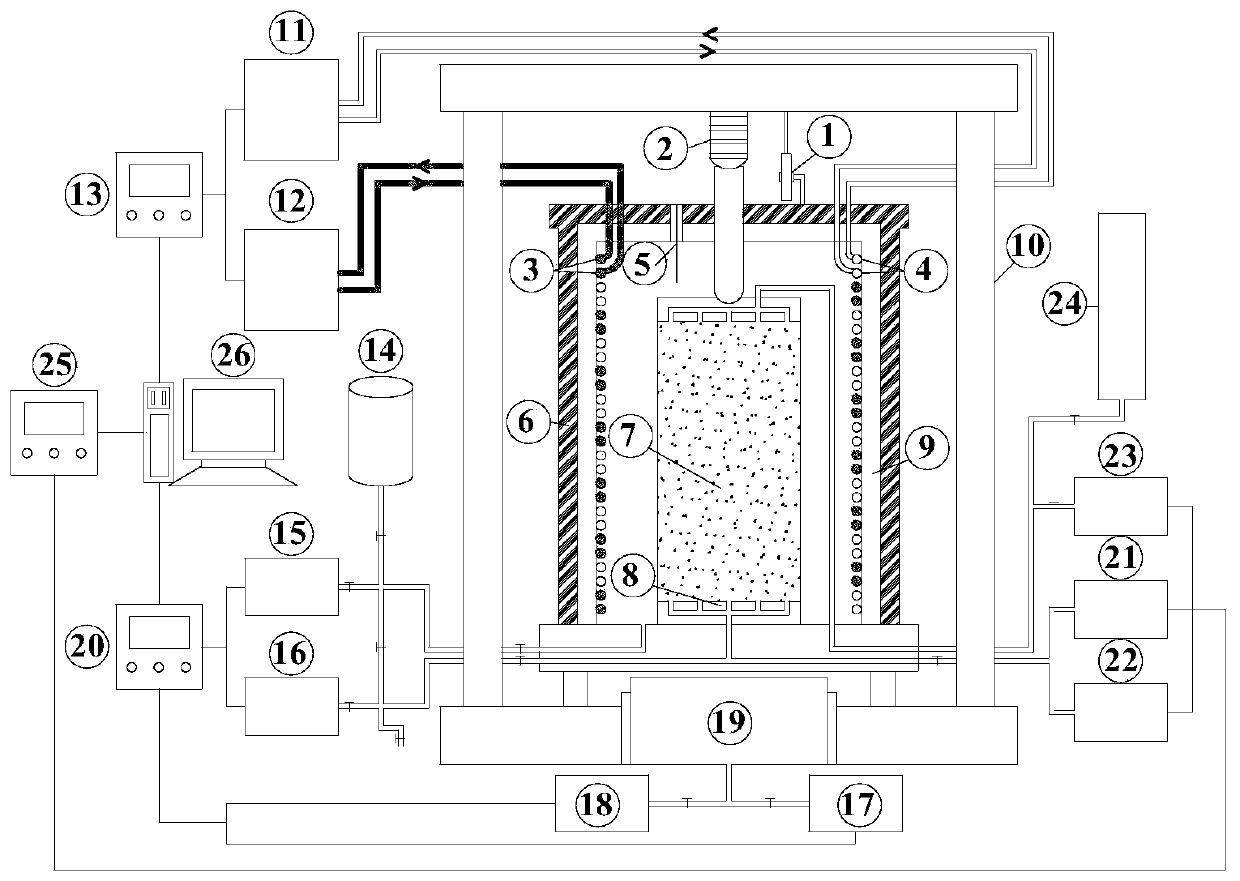

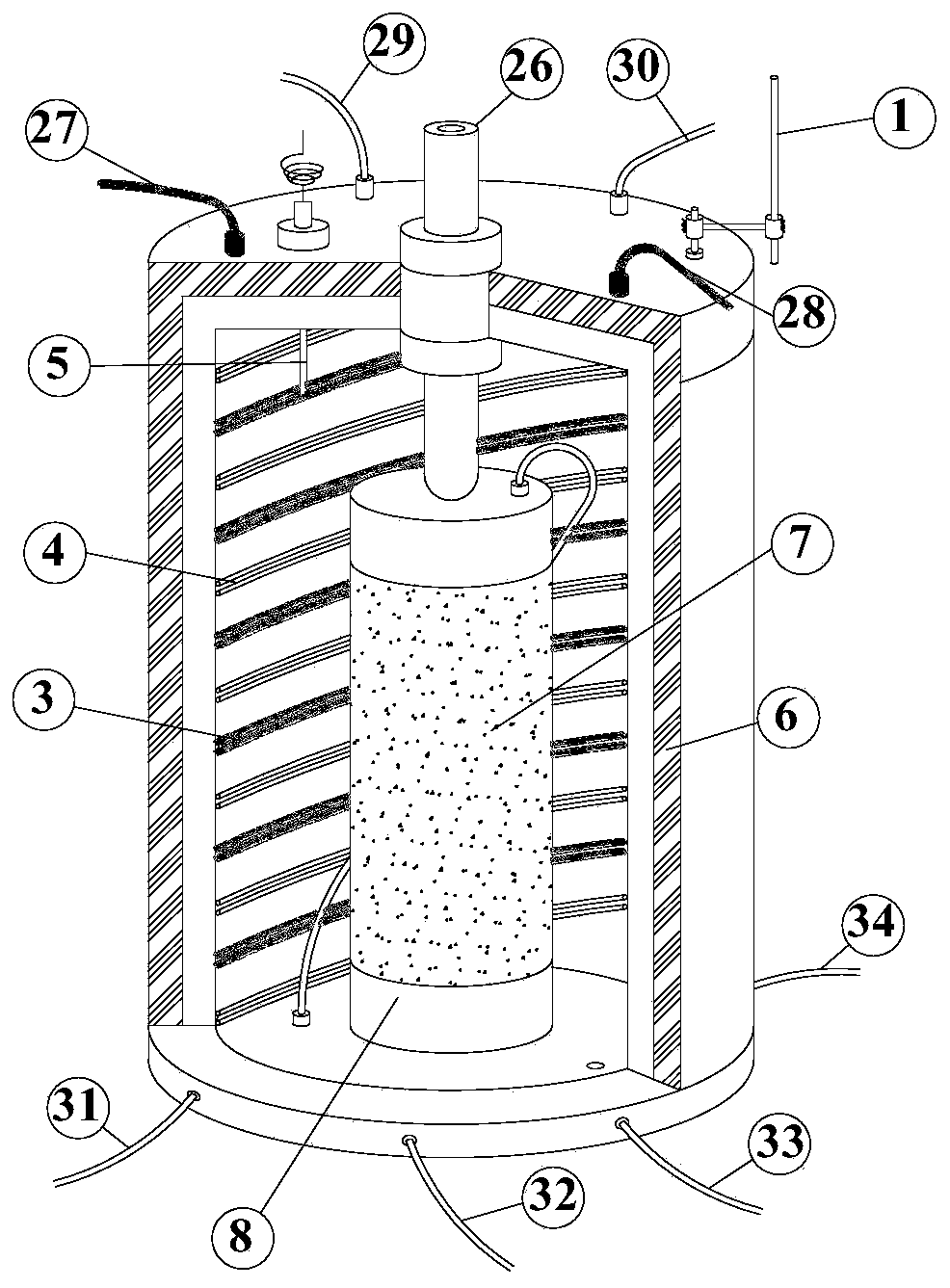

Multifunctional tester for anti-seismic property of rockfill material of high rockfill dam

ActiveCN103698492AWide range of stressAccurate measurementEarth material testingRockfill materialWater volume

The invention discloses a multifunctional tester for the anti-seismic property of a rockfill material of a high rockfill dam. The multifunctional tester comprises a lower pressure plate (1), a pressure chamber base (2), a pressure chamber (8), a support (10), an upper pressure plate (11), a pressure water volume self-balancing device (12), a loading rod (15), a guide sealing sleeve (16) and a rigid connection rod (25). The multifunctional tester for the anti-seismic property of the rockfill material of the high rockfill dam is capable of studying the scale effect of rockfill material dynamic property on the same device, effectively avoiding influence on test results by system errors between different devices, basically eliminating system deformation caused due to insufficient system rigidity and a gap between a sealant tape and a mechanical rotation mechanism, and realizing precise measurement in a dynamic changing process of volume deformation of rockfill material samples under high-frequency cyclic loadings.

Owner:NANJING HYDRAULIC RES INST

Concrete faced rock-fill dam seepage-proofing structure

PendingCN110042800AImprove ductilityAdapt to deformationEarth-fill damsRock-fill damsRockfill materialGeomembrane

The invention discloses a concrete faced rock-fill dam seepage-proofing structure. The concrete faced rock-fill dam seepage-proofing structure includes a high-strength reinforced geomembrane, a concrete face plate, curtain grouting, rock ballast cover weight, a transition material, a cushion area, a main rockfill area, a secondary rockfill area and the like. An upper half part of a traditional concrete face plate is changed into a high-strength reinforced polyethylene geomembrane structure, and watertightness of the geomembrane is utilized to play a seepage-proofing role. The secondary rockfill area adopts a rockfill material with large deformation modulus, and the geomembrane can adapt to the deformation of a subsequent secondary rockfill area. The concrete faced rock-fill dam seepage-proofing structure is simple in shape, high in construction speed, low in requirements for building stones in the secondary rockfill area and convenient to construct.

Owner:CHINA WATER RESOURCES BEIFANG INVESTIGATION DESIGN & RES

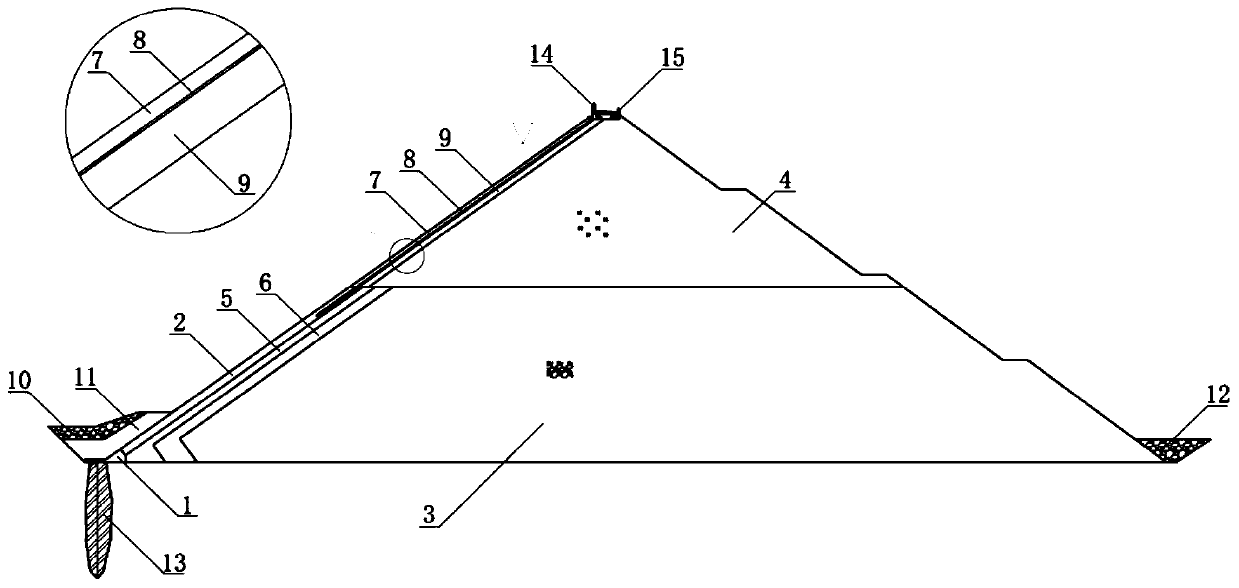

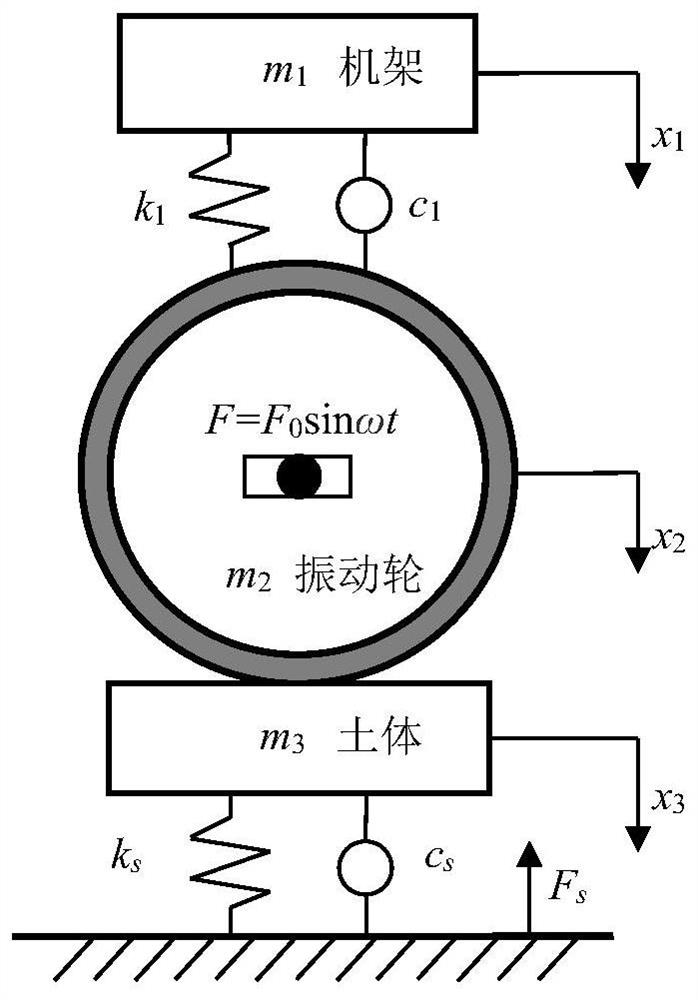

Rock-fill dam material compaction quality detection method based on soil body rigidity

ActiveCN112924310AImprove complianceImprove adaptabilityMaterial strength using repeated/pulsating forcesSoil scienceRockfill material

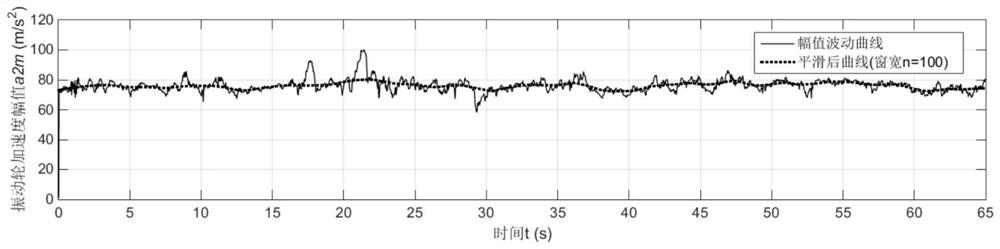

The invention discloses a rock-fill dam material compaction quality detection method based on soil rigidity, which comprises the following steps: in combination with the rolling characteristics of a rock-fill dam material, establishing a rolling machine-soil body vibration system three-degree-of-freedom kinetic analysis model capable of being applied to the rock-fill dam material, and obtaining the relationship between soil body parameters and the acceleration of the vibration system; obtaining the absolute value of the measured acceleration signal data of the vibration wheel, performing peak value selection and moving average, and obtaining the average amplitude a2m of the acceleration signal of the vibration wheel; by means of parameter sensitivity analysis, assuming that the soil body damping cs is always a damping value in an initial rolling state, and rapidly calculating the soil body rigidity to reflect the compaction quality of the rock-fill dam material in the vibration compaction process according to the obtained acceleration average amplitude a2m and the relation between the soil body parameters and the acceleration. The method disclosed by the invention can be applied to compaction quality field control and detection of fine materials such as clay core walls and the like, and also has a relatively good detection effect on coarse-grained materials such as rockfill materials and sand gravel materials.

Owner:中节能建设工程设计院有限公司 +2

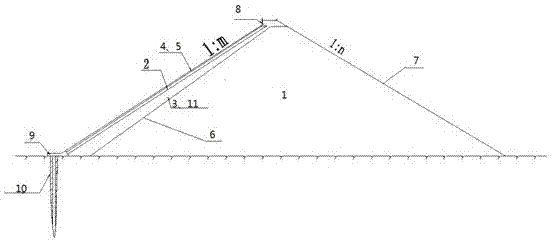

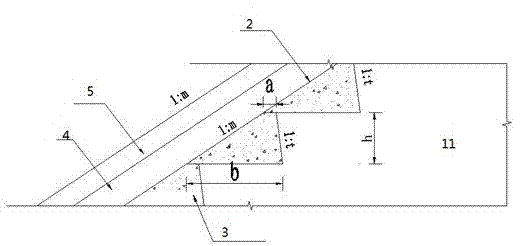

Method for composite geo-membrane sloping core cofferdam

InactiveCN104314089ASpeed up constructionEnsure safety during floodsFoundation engineeringSocial benefitsRockfill material

The invention discloses a method for a composite geo-membrane sloping core cofferdam. A buffer platform is reserved between an anti-seepage structure and a weir foot by moving a lower anti-seepage structure forwards, so that the synchronous construction of the lower anti-seepage structure and weir body filling is facilitated. A weir body comprises a weir body concrete extruding side wall, a weir body bedding material, a weir body transition material and a weir body rockfill material from upstream to downstream in sequence. The top of the lower anti-seepage structure is provided with anchoring concrete; the anchoring concrete is arranged after the weir top is filled to the top. The top and the bottom of a composite geo-membrane are provided with telescopic joints respectively and are anchored with the concrete at the weir top and the weir bottom respectively; the surface of the composite geo-membrane is protected by spraying the concrete. By using the method, conditions are created for parallel construction of the lower anti-seepage structure and the weir body filling, the weir body partition is simplified, the straight construction period is favorably shortened, the engineering construction progress is quickened, the engineering safety flood season is guaranteed, and the economic and social benefits are obvious.

Owner:SINOHYDRO BUREAU 14 CO LTD

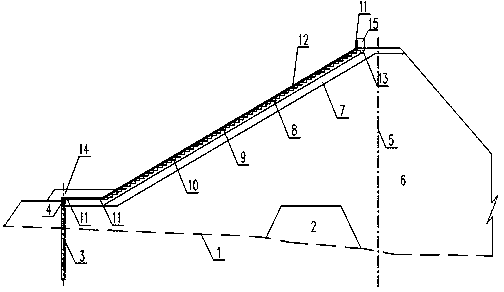

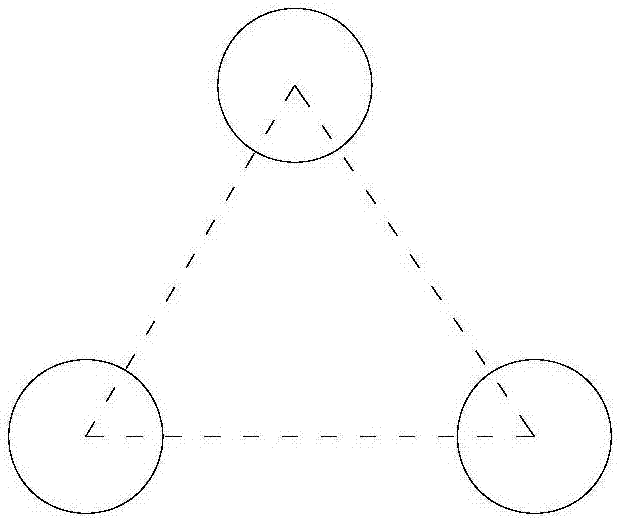

Earth and rockfill dam inner deforming non-contact monitoring method

ActiveCN103512546ALittle construction disturbanceStrong resistance to crushingMeasurement devicesRockfill materialDeformation monitoring

The invention discloses an earth and rockfill dam inner deforming non-contact monitoring method. Target measuring points are buried in an earth and rockfill dam body, the difference between the target measuring points and rockfill materials is large. A detecting instrument is arranged on the outer portion of a rockfill body or a dam inner gallery, the distance between the target measuring points and the detecting instrument is detected from different positions and different angles, according to the known position of the detecting instrument, the detecting distance between the detecting instrument and the target measuring points and the included angle between the detecting distance and a horizontal line, the initial positions of the target measuring points are determined, the real positions of the target measuring points are measured at specific time intervals, and the difference between the real positions measured each time and the initial positions is the variation value of deforming of a part in the dam body. The method solves a plurality of problems existing in a current inner deforming monitoring technology of the earth and rockfill dam, and the safety monitoring design and the monitoring method of earth and rockfill dams in China are changed fundamentally.

Owner:POWER CHINA KUNMING ENG CORP LTD

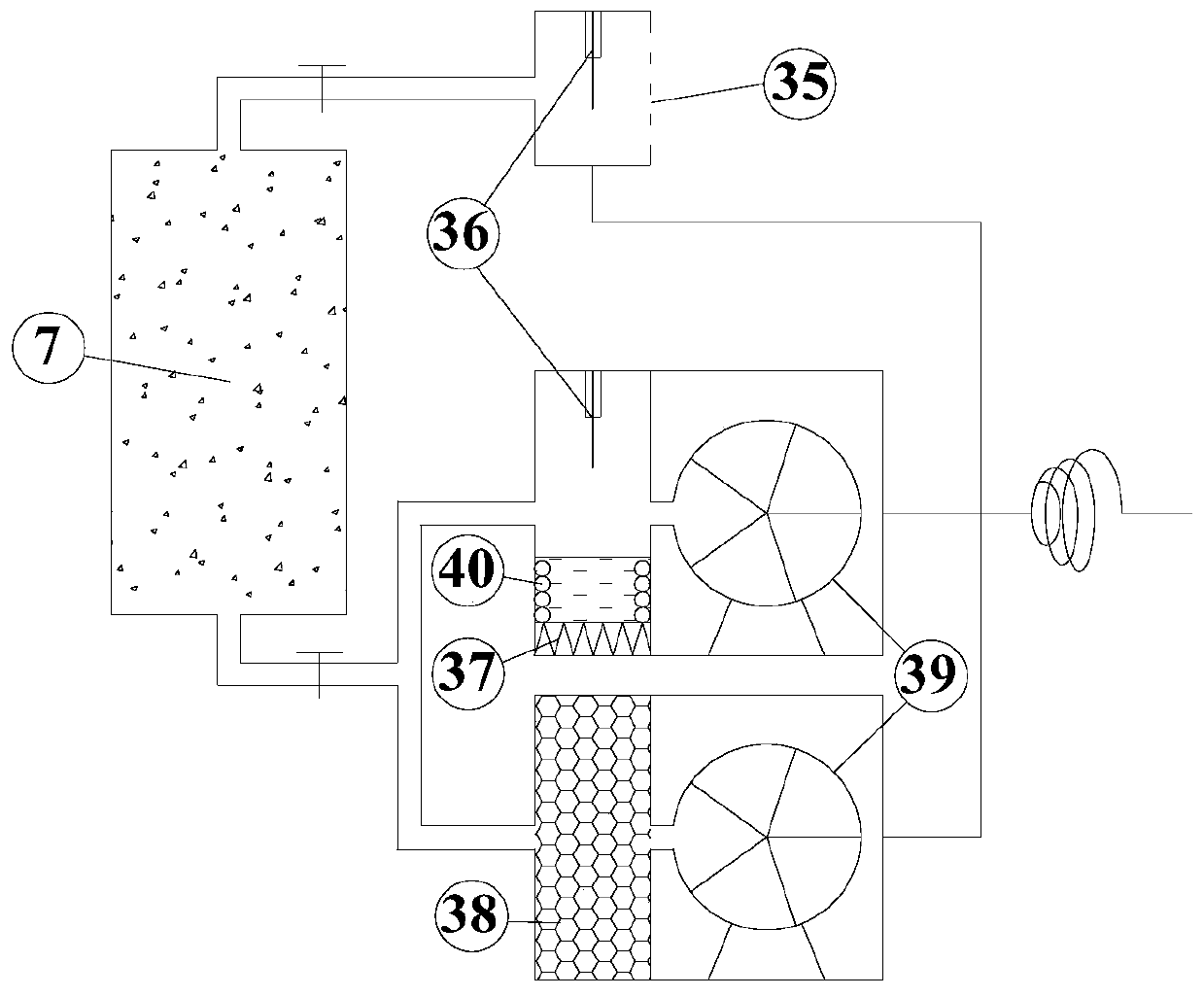

Rockfill material triaxial test device

InactiveCN109932249ARealize direct measurementReduce the impact of the scaling effectMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesTemperature controlRockfill material

The present invention discloses a rockfill material triaxial test device. The device comprises a loading system, a temperature control system, a humidity control system, and a data collection and control system. The loading system comprises a counter-force frame, a bearing device formed by a pressure cover in the counter-force frame, and a loading device formed by an ambient pressure actuator, a pore pressure actuator and an axle load combined controller. The humidity control system comprises a humidifying device, a drying device and a relative humidity measurement device. The test device is upgraded on the basis of a traditional triaxial apparatus to mainly improve the loading system and extend an ultrasonic wave humidifying system and a dry and wet circulatory system. The rockfill material triaxial test device can achieve the rockfill material triaxial test with high axle load, high ambient pressure, temperature control, relative temperature control, long-term loading and complete stress path loading.

Owner:HOHAI UNIV

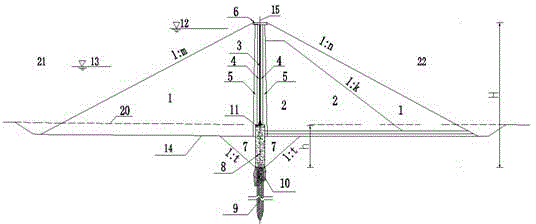

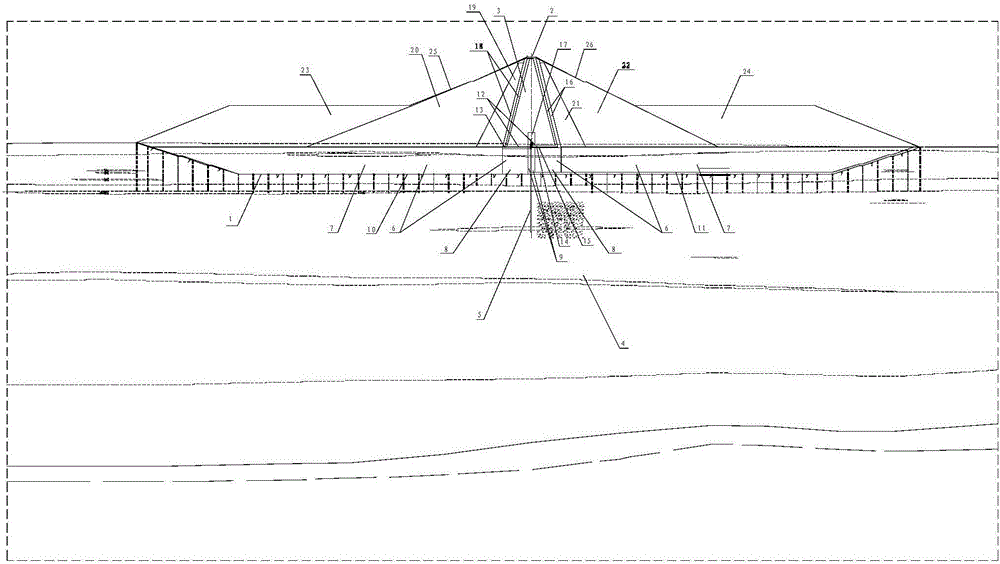

High dam structure built on deep overburden of soil material shortage area

ActiveCN106368176ABuild fastReduce dosageBarrages/weirsFoundation engineeringOverburdenRockfill material

The invention discloses a high dam structure built on a deep overburden of a soil material shortage area, and belongs to the technical field of design and construction of water conservancy and hydropower engineering buildings. The high dam structure provided by the invention has the advantages that the construction speed is high, the rare clay consumption is obviously lowered, and the construction cost is obviously reduced. The high dam structure comprises an excavation foundation pit, a clay core wall and a concrete diaphragm wall, and further comprises a foundation pit rockfill material back-filling layer, wherein the clay core wall is arranged in a dam body; the concrete diaphragm wall is arranged in the deep overburden; the foundation pit rockfill material back-filling layer is arranged in the excavation foundation pit; the clay core wall is arranged at the top of the foundation pit rockfill material back-filling layer; the concrete diaphragm wall penetrates through the foundation pit rockfill material back-filling layer in the vertical upward direction, and then is embedded into the clay core wall; and the bottom of the excavation foundation pit is reinforced by adopting a vibro-replacement stone column.

Owner:POWERCHINA CHENGDU ENG

Composite material dam

InactiveCN103437326AImprove anti-seepage effectHigh strengthEarth-fill damsRock-fill damsRoller-compacted concreteRockfill material

The invention discloses a composite material dam, comprising a concrete dam shell, wherein a rockfill material is filled in the inner cavity of the concrete dam shell; a cushion layer and a transition layer are orderly arranged from outside to inside between the inner wall of the concrete dam shell and the rockfill material. The composite material dam has the combined advantages of a rolled rockfill dam and a rolled concrete gravity dam, and is good in impermeability, small in size, simple and convenient for construction, low in manufacture cost, and simple and beautiful in appearance; the composite material dam is mainly applicable to low dams having the dam height of less than 50 m.

Owner:POWERCHINA ZHONGNAN ENG

Grouting reinforcement construction method and earth surface construction method

ActiveCN107035389ATargetedGuarantee the quality of groutingUnderground chambersTunnel liningRockfill materialSlurry

The invention relates to the field of buildings, in particular to a grouting reinforcement construction method and an earth surface construction method. The earth surface grouting reinforcement construction method comprises the following steps that grouting is conducted in a plurality of grouting holes in a hole-skipping grouting mode; and in the grouting process, curtain grouting is conducted on the grouting holes located on the periphery firstly, and then grouting is conducted on the internal grouting holes. Through adjustment of grout and the grouting sequence, pertinence is achieved on the grouting range, and the grouting quality is easy to ensure. The grouting reinforcement construction method is not limited by the operation space, by increasing resource commitment, tunnel excavation and earth reinforcement can be subjected to parallel construction, a bad geological section can be continuously and quickly passed, and the construction period is easy to ensure. The methods are suitable for tunnel construction of a pebble bed where the particle diameter is simplex, and no cementing material exists, and the methods are also suitable for construction of fill areas of manual backfill soil dirt such as a gobi material. The difficult problems of the cementing-free rockfill material area construction technology and construction of the fill areas of the manual backfill soil dirt such as the gobi material are solved.

Owner:XINJIANG BEIXIN ROAD & BRIDGE GRP +1

Construction method for double-wall corrugated pipe

The invention belongs to the technical field of corrugated pipe manufacturing, and particularly relates to a construction method for a double-wall corrugated pipe. The construction method comprises the following steps of (1), pipe trench excavation, specifically, when a pipe trench is excavated, the foundation elevation is controlled strictly, foundation undisturbed soil is not disturbed, in the mechanical excavation process, the foundation undisturbed soil with the designed elevation being 10-20 cm is maintained, and before a pipe is laid, manual excavation is performed to the designed elevation; (2), exchanging-fill, specifically, the excessively-excavated or disturbed part is subjected to changing-fill with natural rockfill materials with the size being 10-20 cm or gravel with the sizebeing 30-40 cm and leveled and tamped; (3), pipe examination, specifically, appearance examination is performed one by one according to stands of pipe products and connecting pieces of the pipe products, and the pipes not meeting the standards cannot be used as construction pipes; (4), installation, specifically, in the installation process, due to the fact that the burial depth of a drainage pipeof the project is small, manual pipe descending is adopted, the pipe descending is required to be steady and free of fierce collision with the trench wall and the groove bottom, an inserting openingof a bell and spigot is in the direction of the water flow, and a bellmouth of the bell and spigot is opposite to the water flow direction.

Owner:天津军勇利预应力制品有限公司

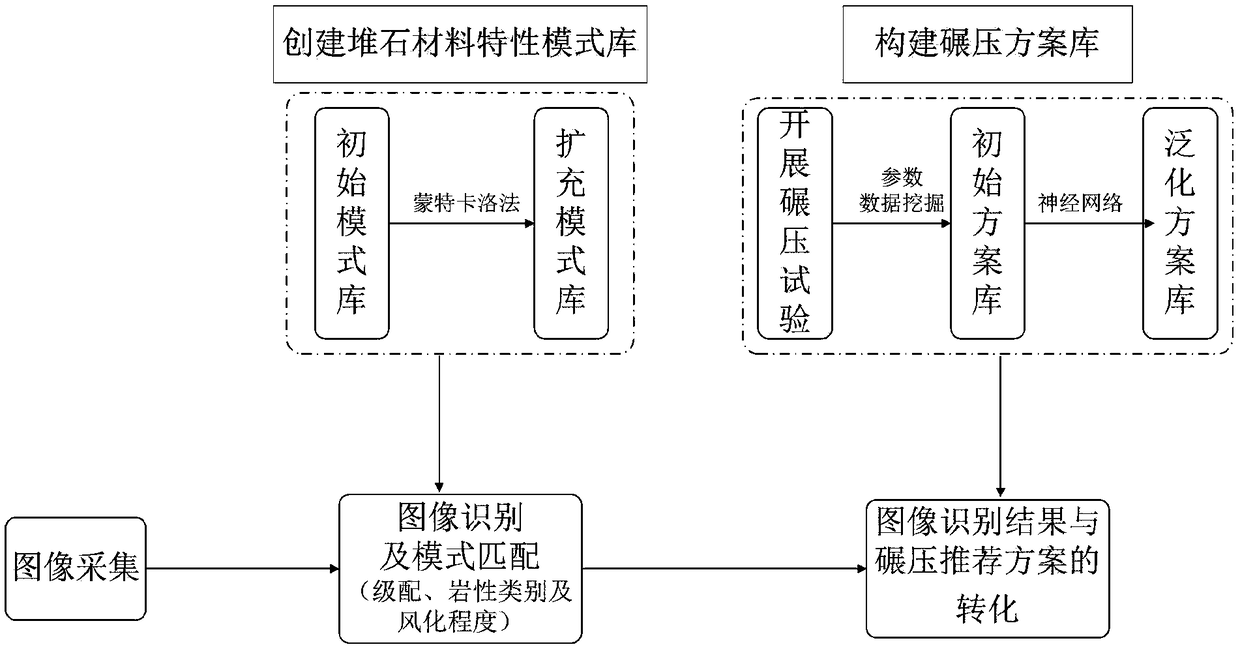

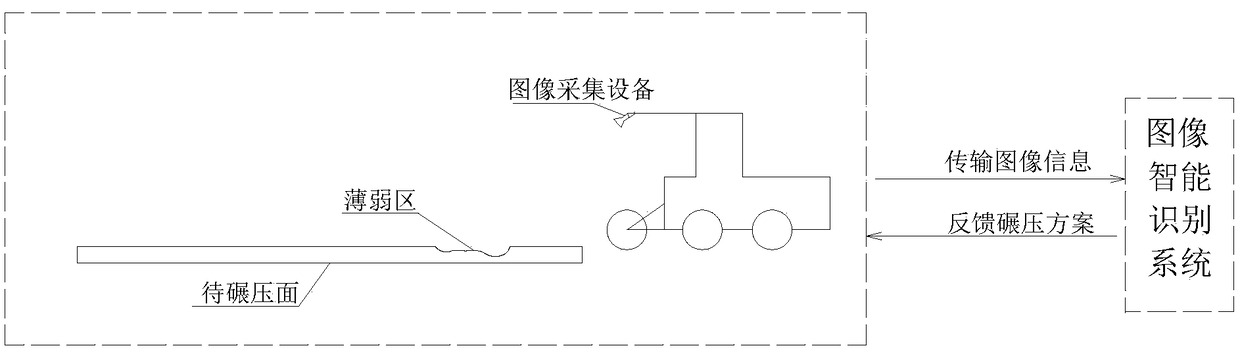

A method for adjusting a rockfill rolling scheme based on the technology of particle grading and visual identification of material composition

ActiveCN109165638AExperienceAvoid under-rollingGeometric CADImage analysisLithologyRockfill material

The invention discloses a method for adjusting a rock-fill rolling scheme based on the technology of particle grading and visual identification of material composition. The steps are as follows: 1, creating a characteristic pattern database of rockfill material: establishing that correspond relationship between the particle color, the texture distribution, the crack size and the lithology categoryand the weathering degree of the rockfill material in a sample image, and providing a database source for subsequent image matching; 2, image acquisition: taking photographs of that rock-fill material to be rolled and collecting images; 3, image recognition and pattern matching: carrying out digital processing on the collected images, and calculating the material gradation according to the gray value of the particle areas of different sizes; extracting material characteristics, and determining the characteristics of material lithology and weathering degree by matching with pattern database; 4, transformation of image recognition results and rolling scheme: firstly, constructing the rolling scheme database, and then, according to the results of image recognition and pattern matching, modifying and adjusting the rolling scheme by comparing with the rolling scheme database. The invention can adjust the rolling scheme and avoid under-pressure phenomenon.

Owner:HOHAI UNIV

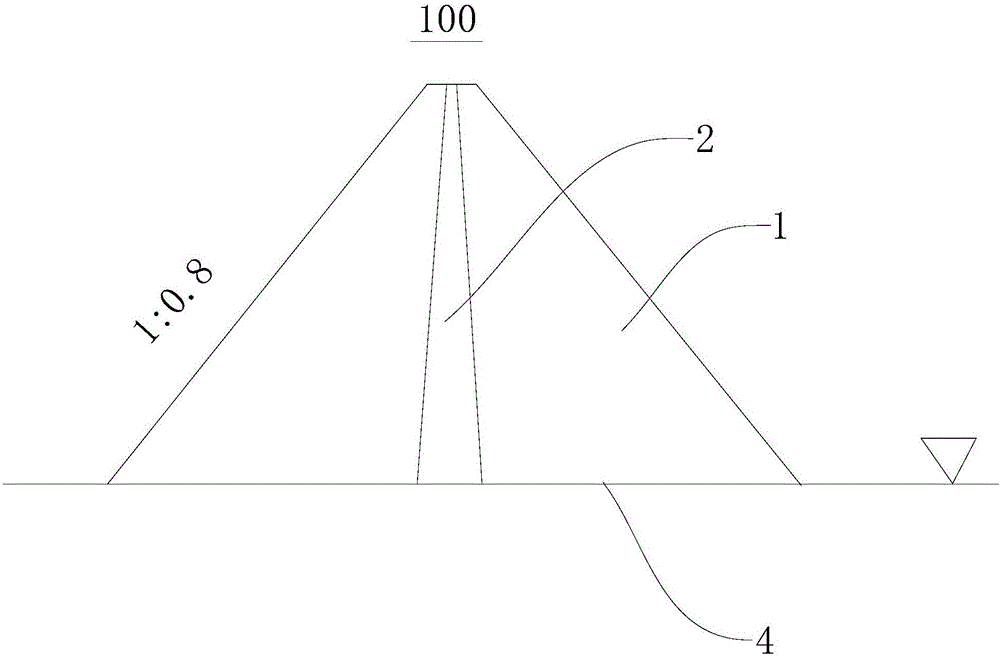

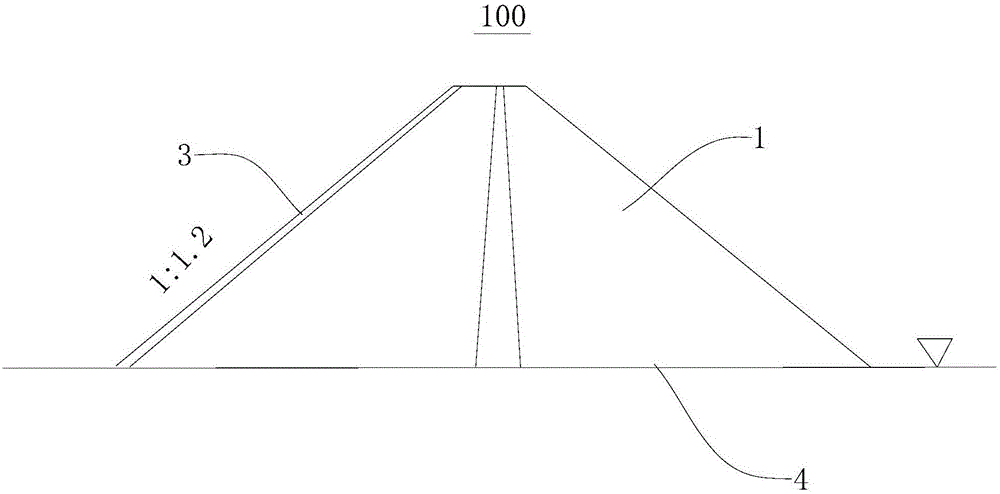

Cementing rock-fill dam

InactiveCN107524120AIncreased shear strengthIncrease elasticityEarth-fill damsRock-fill damsRockfill materialCanyon

The invention discloses a cementing rock-fill dam. The cementing rock-fill dam comprises a dam body and a seepage-proofing body. The dam body is of a ladder structure. The dam body is filled by cementing rock-fill materials. The seepage-proofing body adopts seepage-proofing body core walls or panels. The cementing rock-fill materials are dam construction materials formed by mixing rockfill materials with fine-grained soil screened out and cement or pouring mortar. The cementing rock-fill dam is filled by using the cementing rock-fill materials, the shear strength and elasticity modulus of dam body materials can be effectively improved, the dam body size and dam body non-uniform settlement are reduced, cracking of the seepage-proofing body can be effectively restrained, the cementing rock-fill materials can maintain the capacity that the rock-fill dam is adapted to deformation, the cementing rock-fill dam can be constructed on a flexible foundation and has a certain capacity of resisting overtopping flood so as to improve the safety of the dam, the construction technology is simple, the construction speed is high, and the project benefit is good; and the dam profile can be small, the project construction cost is low, and the adaptability to the ground foundation is higher, so that the cementing rock-fill dam can be built on topographies such as flexible dam bases and canyons.

Owner:TSINGHUA UNIV +1

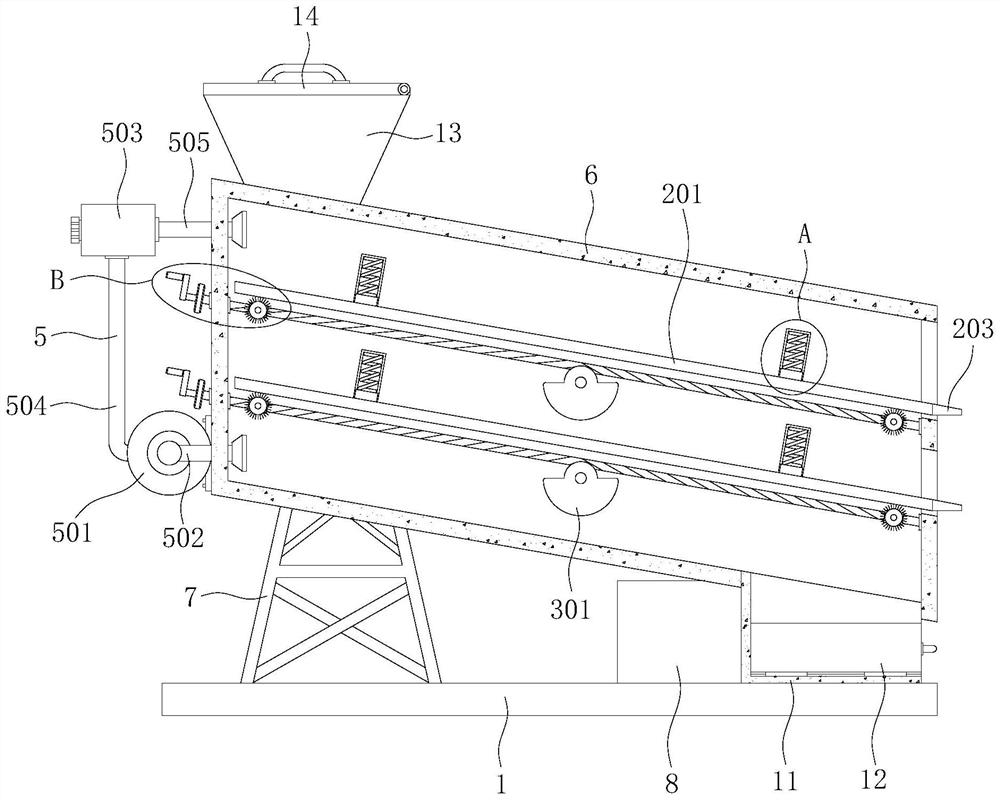

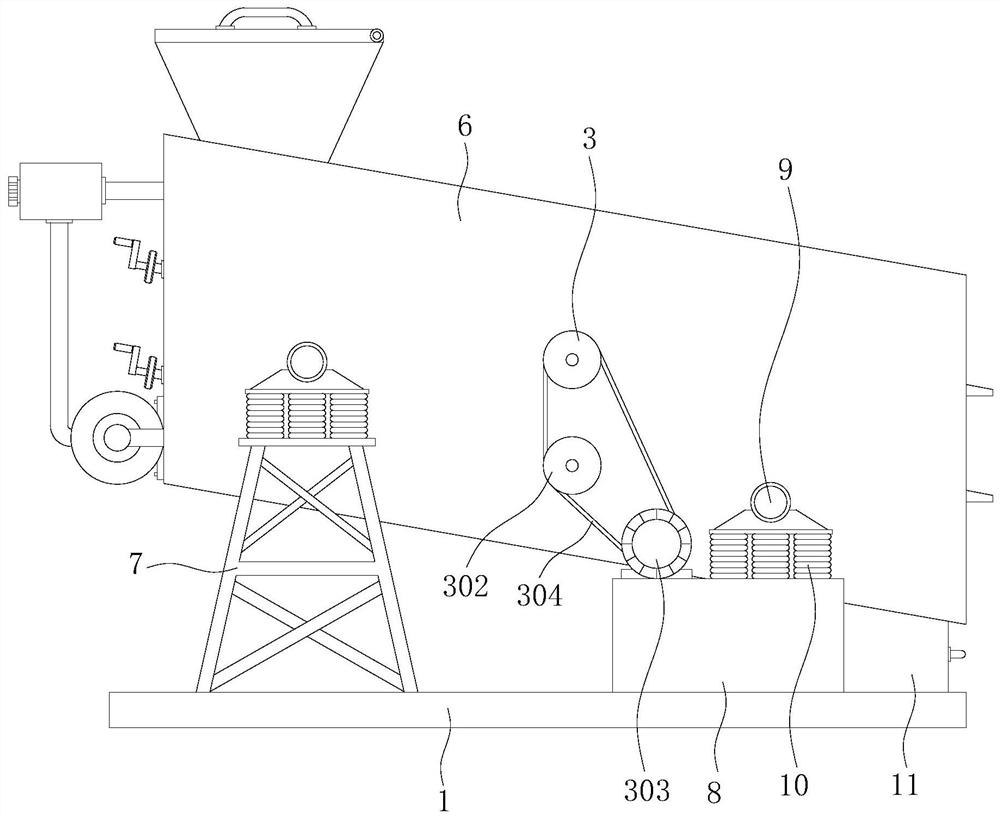

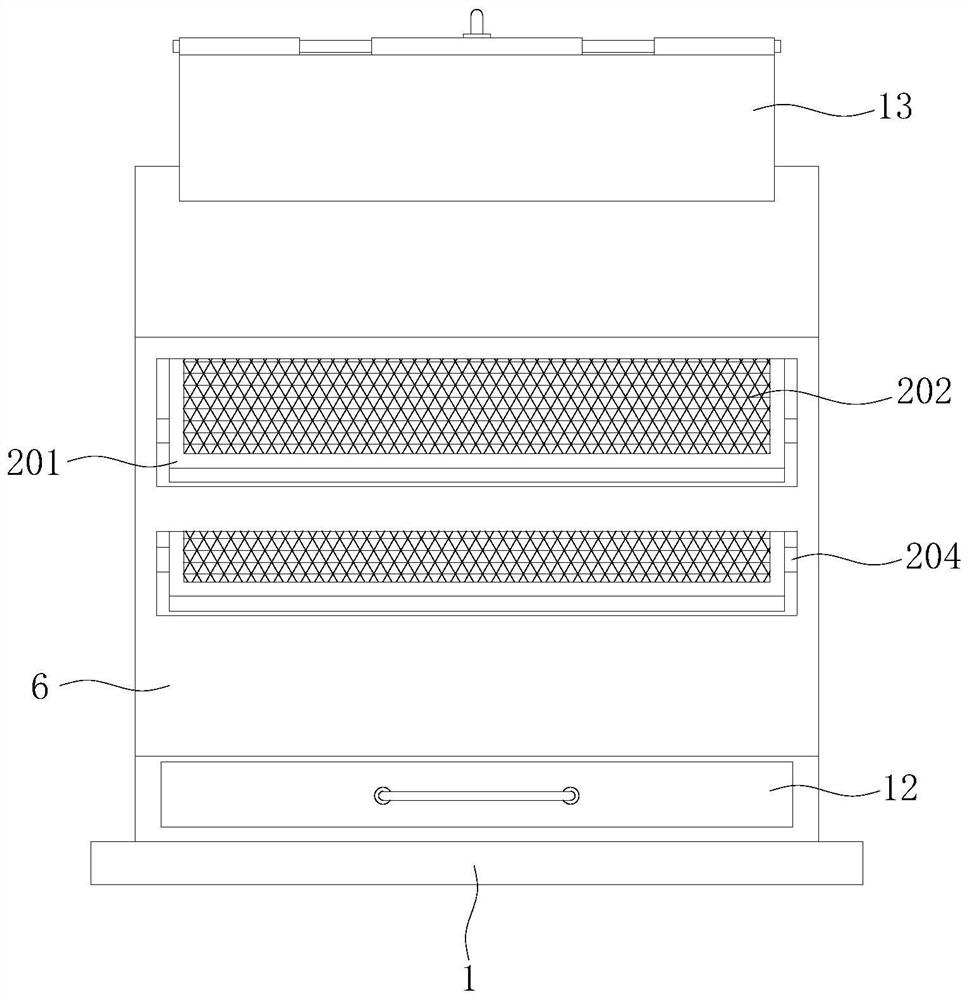

Multi-layer rockfill material screening device

InactiveCN112122107AEasy to cleanAvoid damageSievingDispersed particle filtrationRockfill materialDust control

The invention discloses a multi-layer rockfill material screening device, and relates to the technical field of mining machinery. The multi-layer rockfill material screening device comprises a workbench, wherein a screening mechanism, a vibration mechanism, a blockage cleaning mechanism, a dust removal feeding mechanism and a screening box are arranged on the workbench, two groups of holes are formed in the outer wall of one side of the screening box, two groups of supporting frames and two groups of fixing tables are welded to the outer surface of the top of the workbench, two groups of fixing bases are welded to the outer surfaces of the front side and the rear side of the screening box, and three groups of high-strength springs are welded to the outer surfaces of the tops of the supporting frames and the fixing tables. According to the multi-layer rockfill material screening device, an operator only needs to rotate a crank on a bidirectional threaded rod to clean rockfill materialsblocked on a screen, so that the influence on the screening operation of the device due to the blockage of the rockfill materials is reduced, the screening quality of the device is guaranteed, meanwhile, the service life of the device is prolonged, the stability maintenance cost is reduced, the operation is simple and convenient, and popularization and use are facilitated.

Owner:湖州吴兴花果山矿山机械有限公司

Mixed anti-seepage dam

PendingCN110939104ASimplify construction proceduresEven by forceEarth-fill damsRock-fill damsRockfill materialSoil science

The invention discloses a mixed anti-seepage dam. The mixed anti-seepage dam comprises an upstream lower rockfill material, a downstream lower rockfill material, an upstream upper rockfill material, adownstream upper rockfill material, a dry stone revetment, transition materials, an asphalt concrete core wall, a concrete base, curtain grouting and a wave wall, wherein the asphalt concrete core wall is arranged in the transition materials positioned between the upstream lower rockfill material and the downstream lower rockfill material; a high-strength reinforced geomembrane is arranged in thetransition materials positioned between the upstream upper rockfill material and the downstream upper rockfill material to replace the asphalt concrete core wall; the upper half part of a traditionalasphalt concrete core wall dam is changed into the high-strength reinforced polyethylene geomembrane, and the anti-seepage effect is achieved through the watertightness of the geomembrane; and the upstream rockfill material and the downstream rockfill material are rockfill materials with the large deformation modulus. The dam body is simple in form and high in construction speed, the requirementfor the upstream rockfill material and the downstream rockfill material is low, and the mixed anti-seepage dam has good popularization value for projects with insufficient dam building materials in dam site areas.

Owner:CHINA WATER RESOURCES BEIFANG INVESTIGATION DESIGN & RES

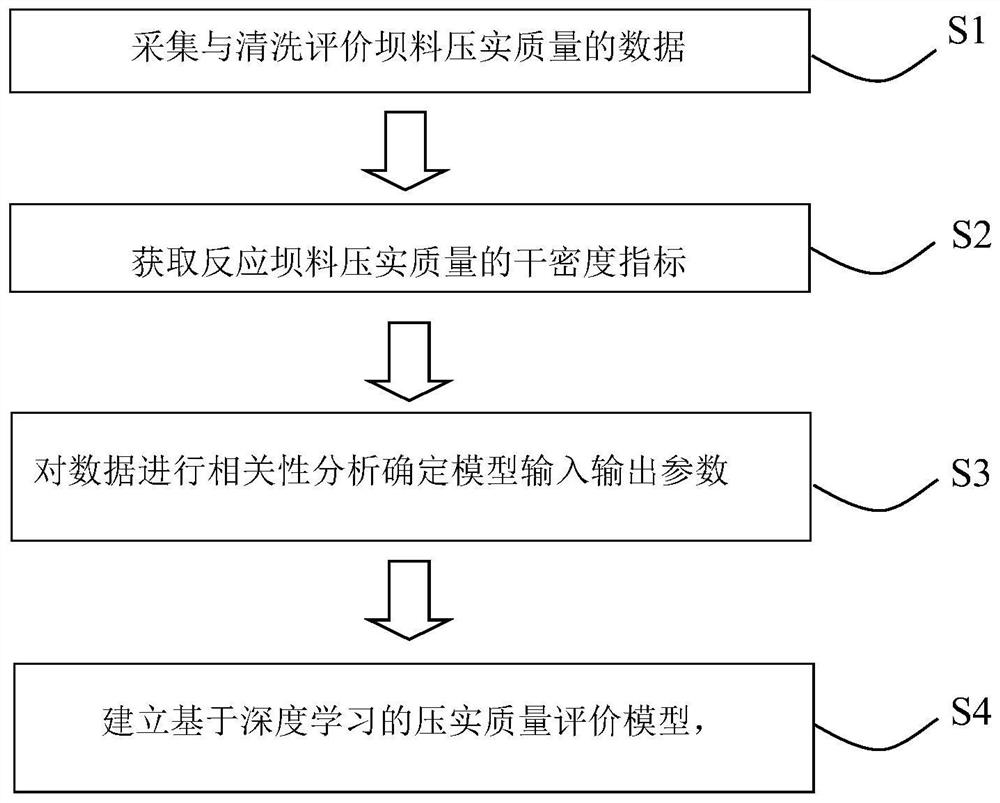

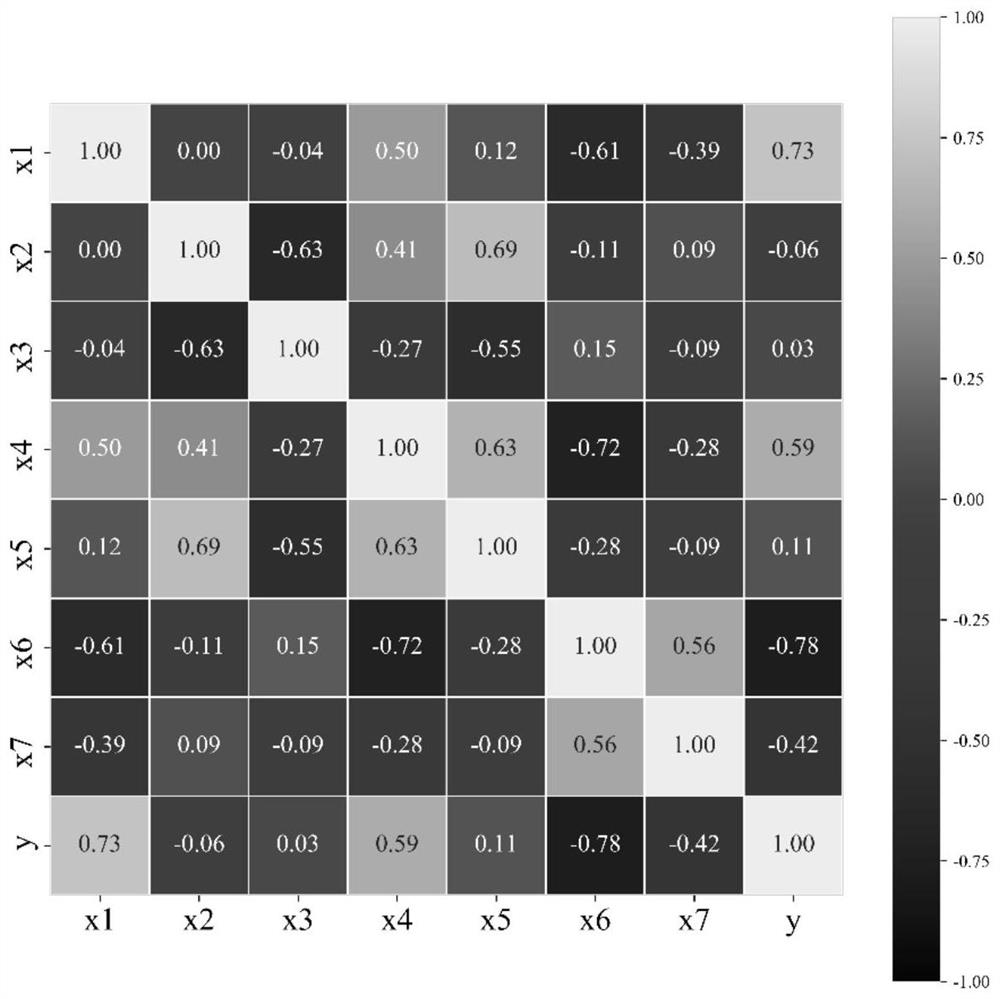

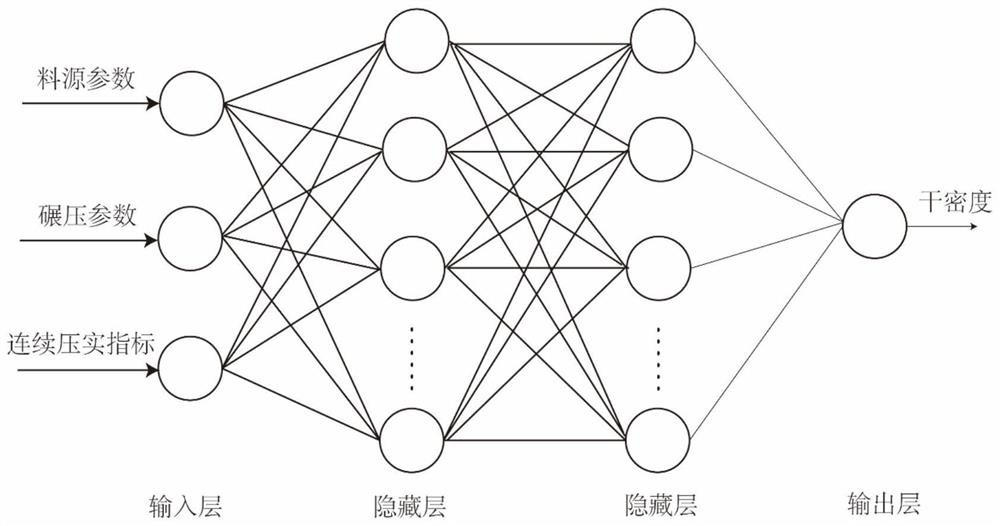

Earth and rockfill dam material compaction quality evaluation method

ActiveCN113640175AExtension of timeIncrease costUsing mechanical meansSpecific gravity measurementRockfill materialArchitectural engineering

The invention provides an earth and rockfill dam material compaction quality evaluation method. The method comprises the following steps: collecting and cleaning data for evaluating dam material compaction quality; obtaining a dry density index reflecting the compaction quality of the dam material; performing correlation analysis on the data for evaluating the compaction quality of the dam body to determine final model input and output parameters; and establishing a compaction quality evaluation model based on deep learning, and evaluating the compaction quality. According to the method, the influence of material source parameters, rolling construction parameters and continuous compaction indexes on the dam material compaction quality is fully considered, a deep learning method is utilized to construct a rockfill material compaction quality evaluation model based on the artificial neural network, the refined real-time quality control of the whole dam filling construction process is realized, human intervention is reduced, the construction quality is ensured, and the time and the cost of dam material compaction quality detection are greatly improved. The method can provide huge application potential and possibility for compaction quality control and engineering quality guarantee of earth and rockfill dam engineering under construction or to-be-constructed.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com