Discrete element simulation method for rock-soil triaxial test flexible film boundary

A technology of triaxial test and simulation method, applied in the field of geotechnical engineering, can solve the problems such as the inability of the model to calculate and reasonably characterize the volume deformation of the triaxial test, the technical difficulty, the inability to simulate the parameters of the film material, etc., to achieve the simple and practical implementation process and the advantages Prominent and clear implementation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0117] The triaxial test parameters of this embodiment are as follows:

[0118]

[0119] see figure 1 , the simulation steps are as follows:

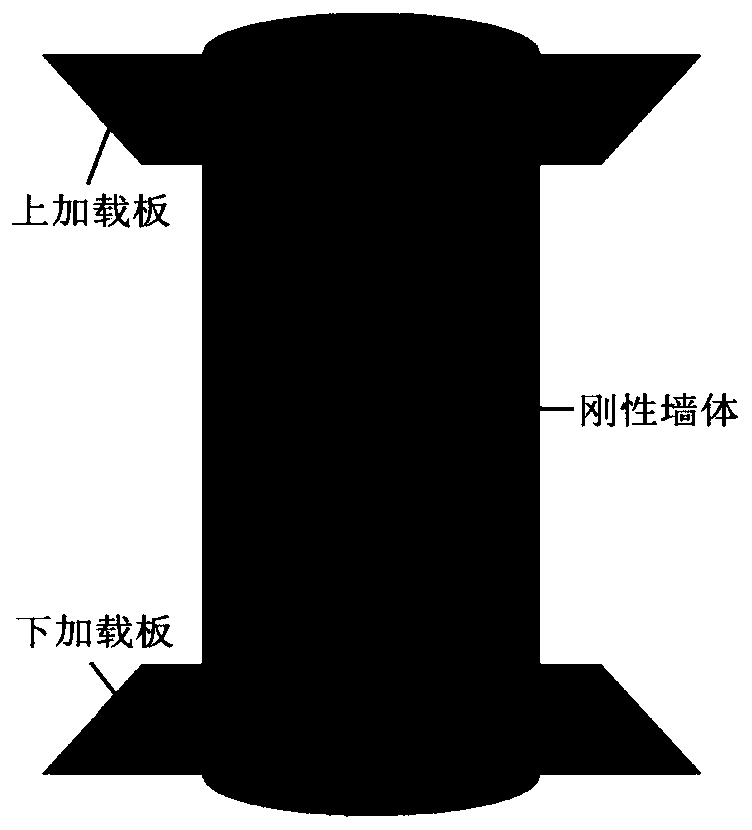

[0120] Step (1): Generate an initial sample. According to the test parameters, the sample is generated in a rigid cylindrical wall, and the upper and lower loading plates are rigid walls; the triaxial sample is loaded to 100kPa using a servo mechanism.

[0121] Step (2): Calculate the stiffness parameters of the film particles. The elastic modulus, Poisson's ratio and particle thickness of the film used in the test, the mesoscopic parameters of the film particles are calculated:

[0122]

[0123] Among them: K n and K s are the normal stiffness and tangential stiffness of the film particles, respectively; E, ν and t are the elastic modulus, Poisson's ratio and thickness of the test film, respectively.

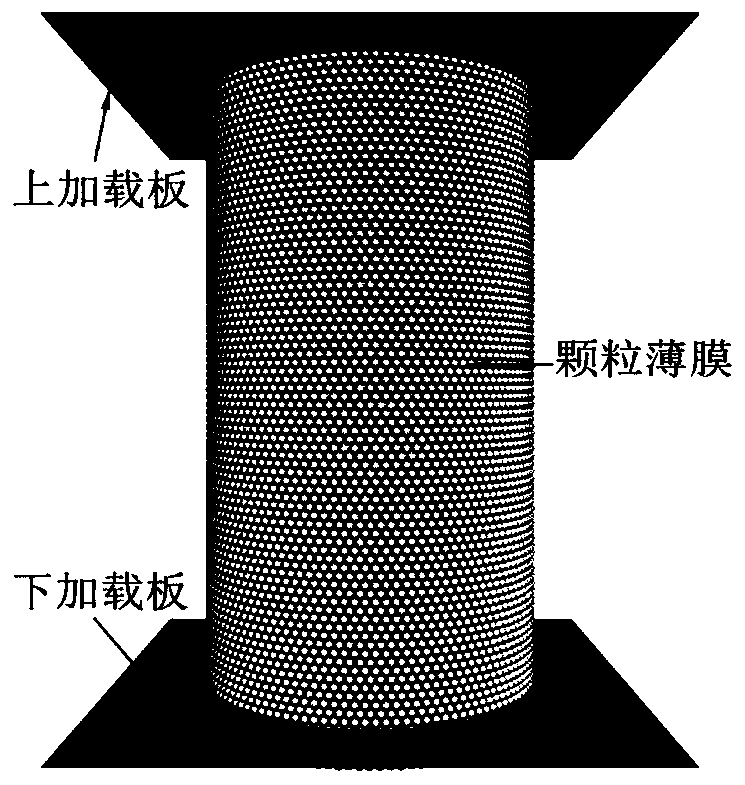

[0124] Step (3): Install the particle film.

[0125] 1) Delete the lateral rigid wall;

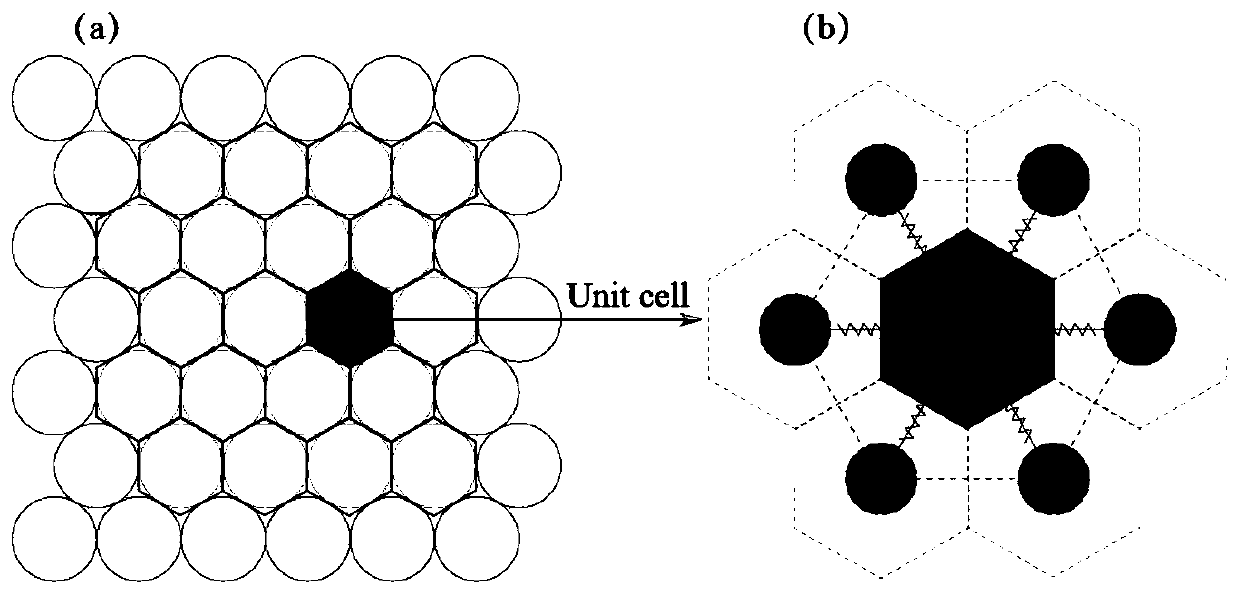

[0126] 2) if figure 2 As shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com