Battery module and its manufacturing method

A battery module and battery technology, applied in battery pack components, circuits, electrical components, etc., can solve problems such as increased operating costs and more heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

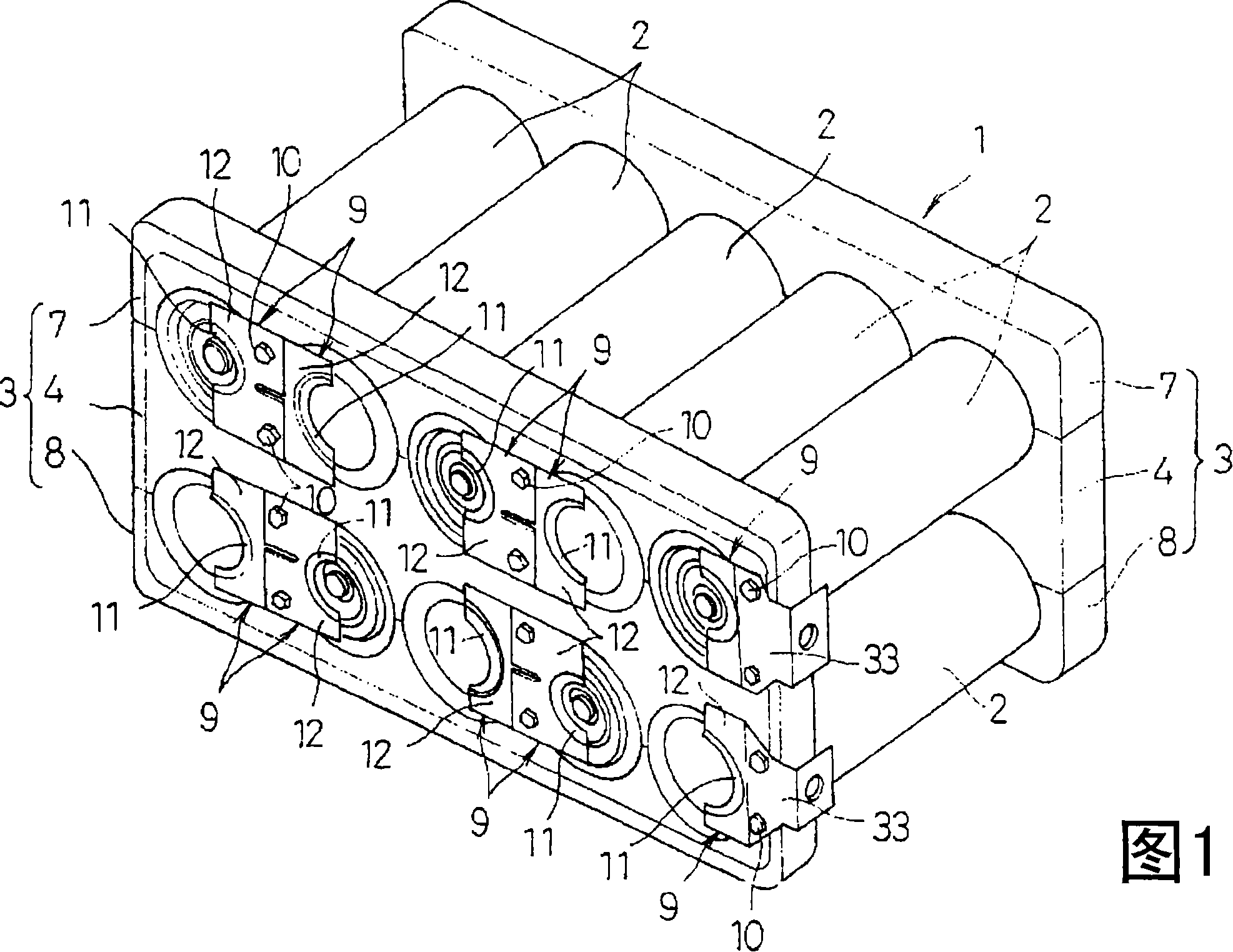

[0073] Hereinafter, best embodiments of the present invention will be described in detail with reference to the drawings. FIG. 1 is a schematic perspective view showing an appearance image of a battery module 1 according to one embodiment of the present invention. The battery module 1 is constituted as follows: a battery string is arranged in two sections, the upper and lower sections, and the battery string is formed by arranging 5 cylindrical batteries 2 parallel to the battery axis; 3. Both ends of the battery axial direction of the ten cylindrical batteries 2 in total are fixed and held. In addition, in this battery module 1, ten cylindrical batteries 2 are connected in a state in which the outer surfaces other than both ends are exposed to the outside. Compared with the structure, the heat dissipation effect is greatly improved.

[0074] In addition, in this embodiment, the case where a large cylindrical battery 2 such as a nickel metal hydride storage battery having a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com