Patents

Literature

35879results about How to "Low running cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

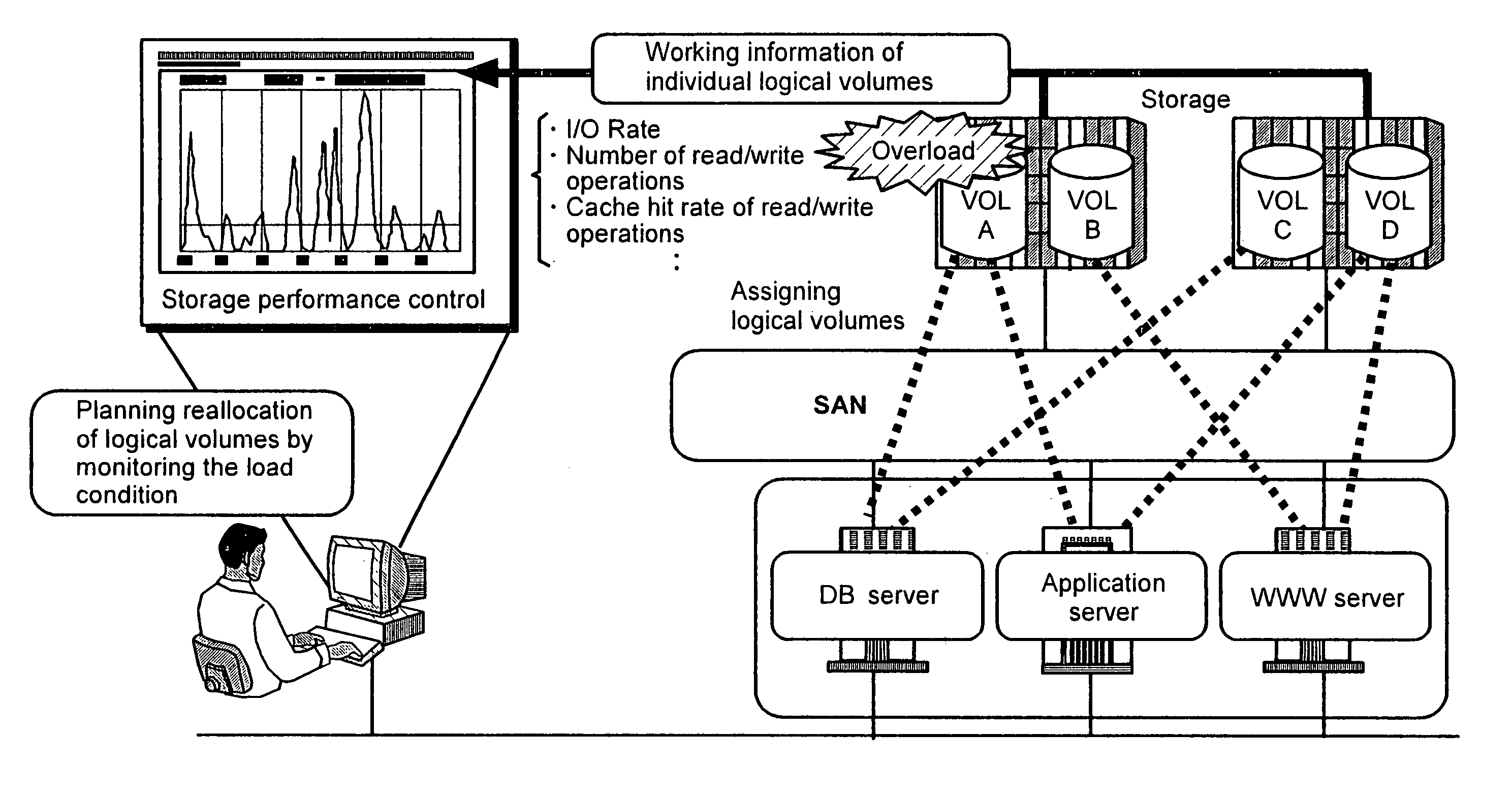

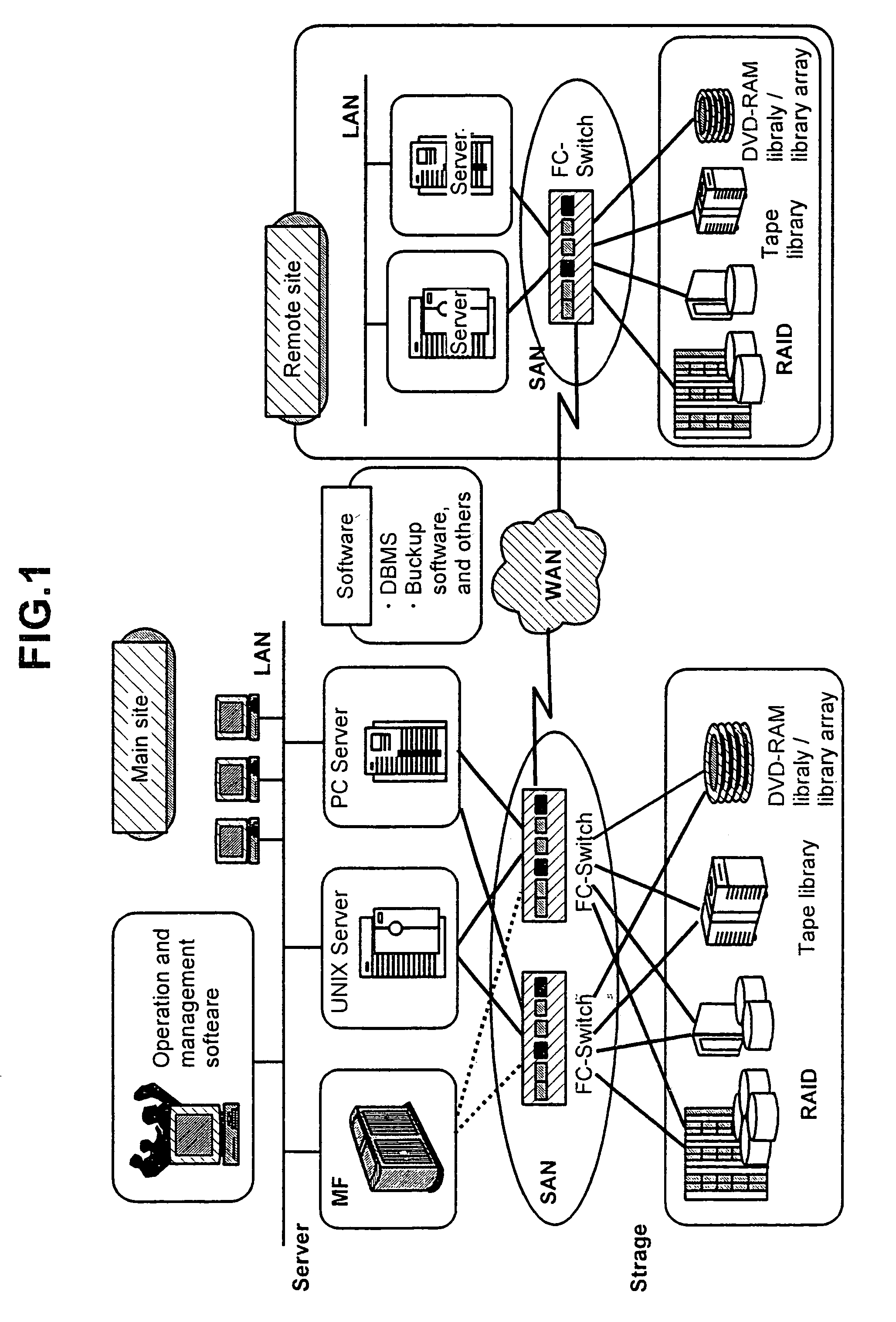

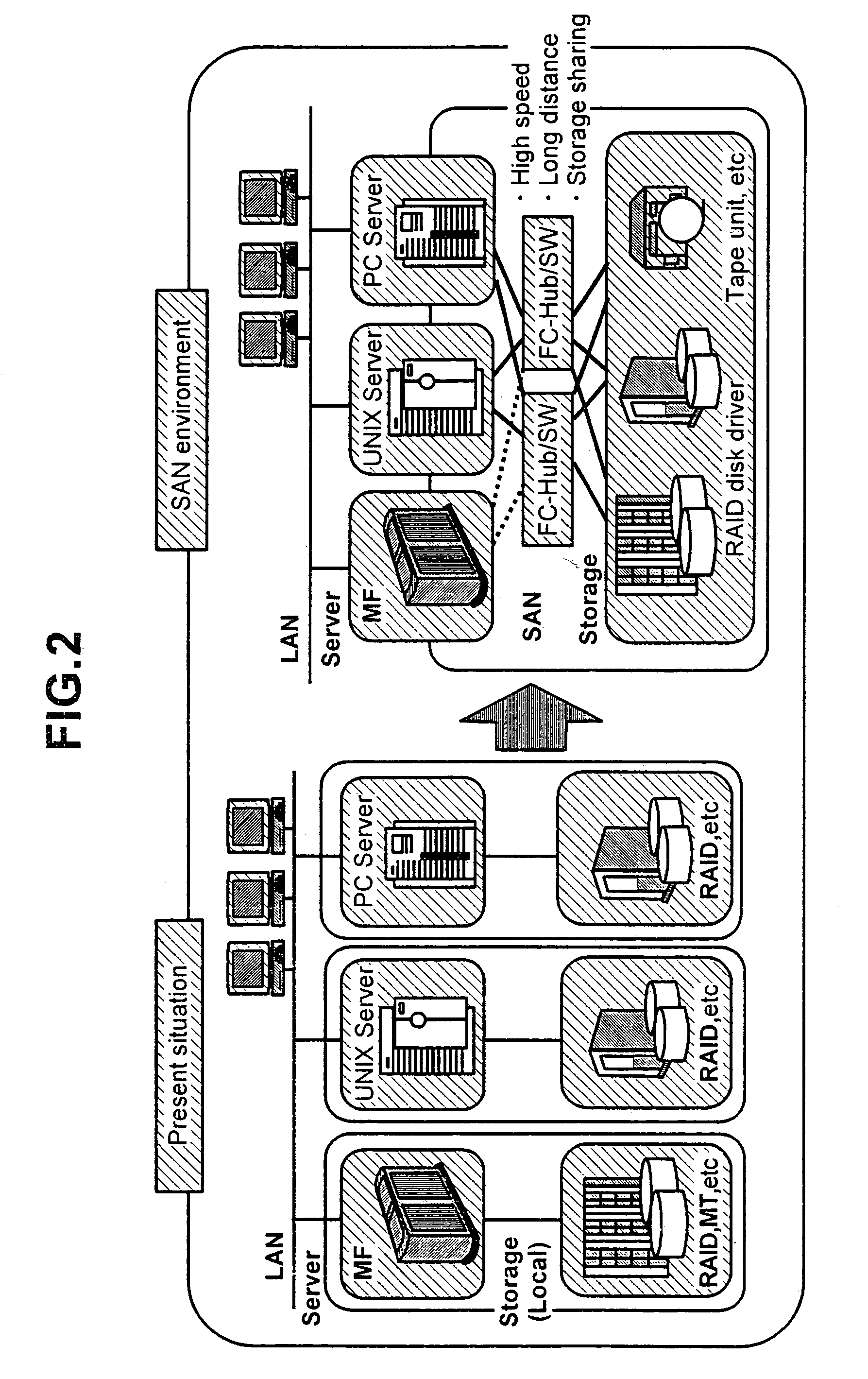

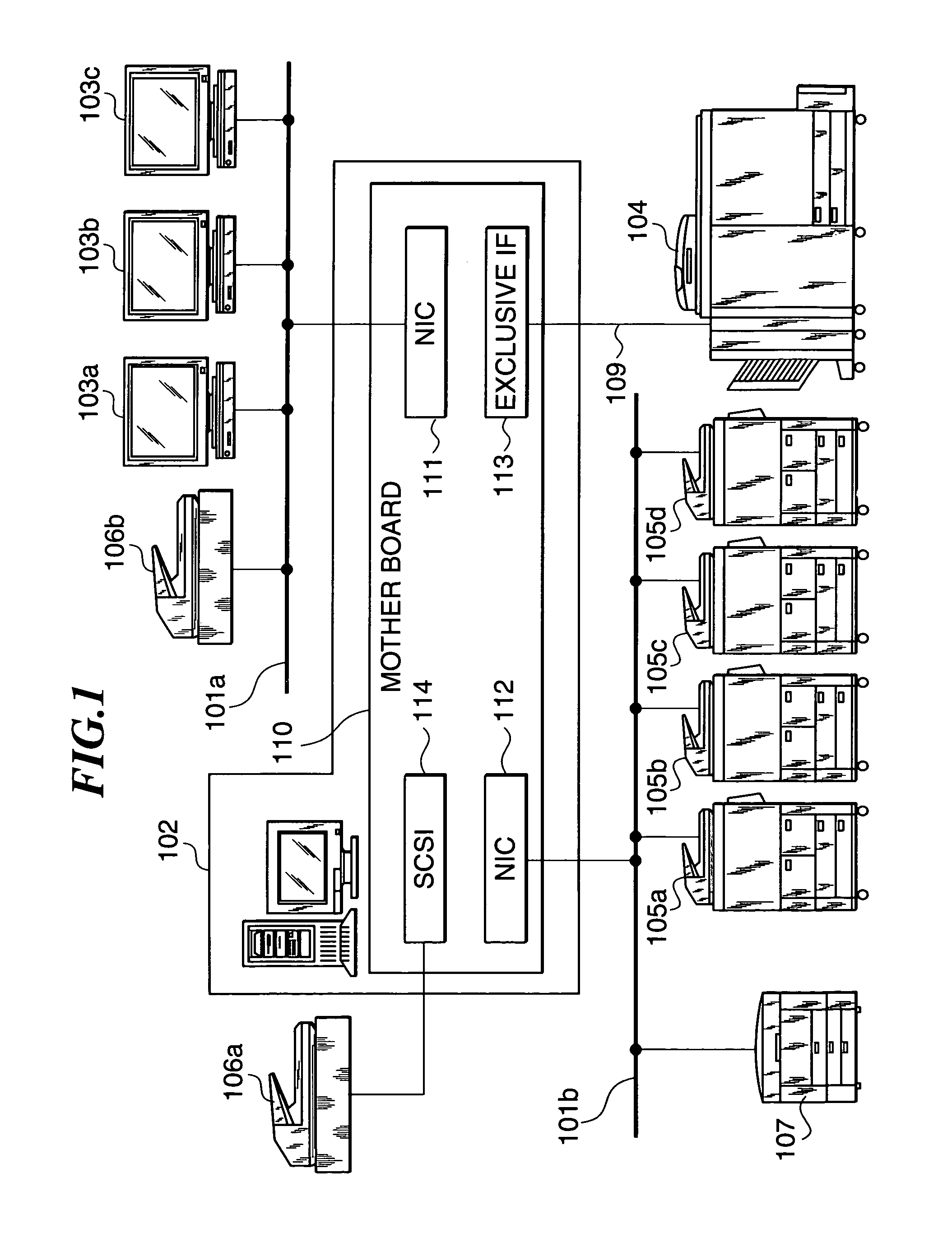

Computer system having a storage area network and method of handling data in the computer system

InactiveUS6950871B1Improve input performanceImprove output performanceDigital computer detailsSpecial data processing applicationsFiberStorage area network

In order to construct an integrated storage system by reinforcing collaboration of components or functions of a storage system in which a storage area network (SAN) is used, in a computer system having multiple client computers, multiple various servers, multiple various storages which keep data, and a local area network (LAN) which connects the computers and the servers, a storage area network (SAN) which lies between the servers and storages forms a switched circuit network which is capable of connecting any server and any storage through fiber channel FC switches. The computer system further includes a terminal which is equipped with operation and management software which performs storage management including management of logical volumes in the various storages, data arrangement, error monitoring, management of setting up the FC switches, and backup for data in the storages.

Owner:HITACHI LTD

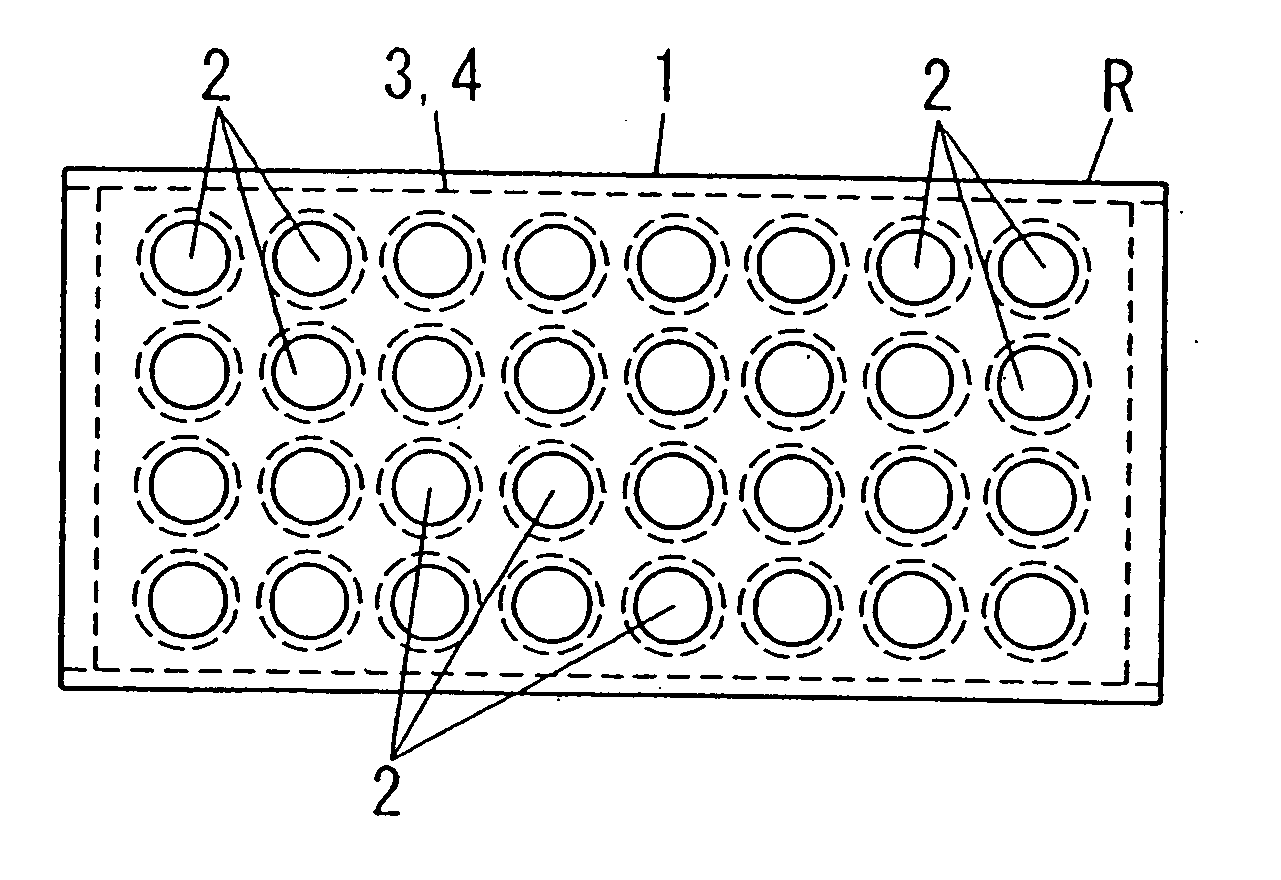

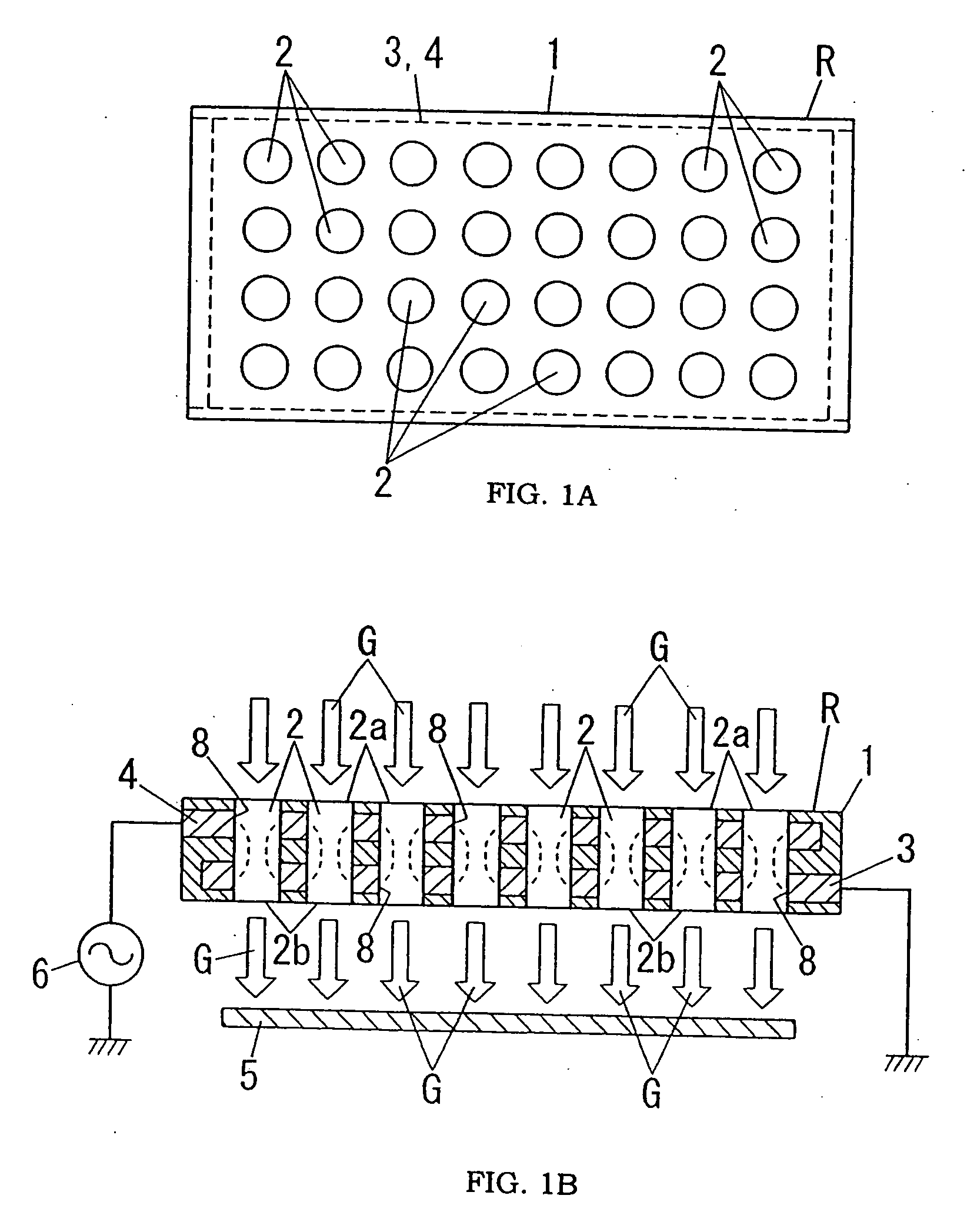

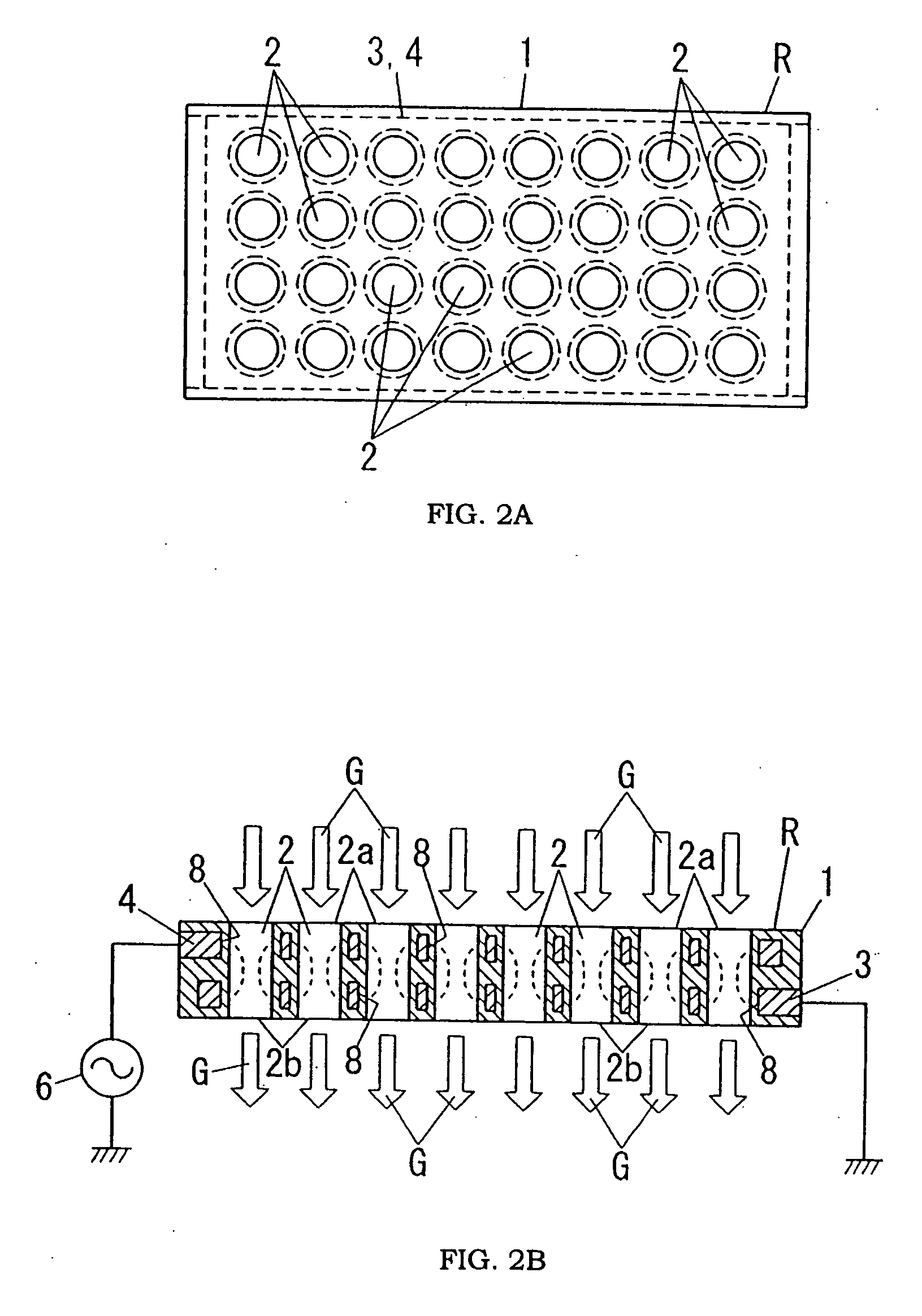

Plasma treatment apparatus, method of producing reaction vessel for plasma generation, and plasma treatment method

InactiveUS20060042545A1Large treatment areaLow gas consumptionMolten spray coatingElectric discharge tubesEngineeringVoltage

A plasma treatment apparatus is provided, which enables to increase a treatment area and provide good treatment uniformity. This apparatus comprises a pair of electrode plates having a plurality of through holes and an insulating plate having a plurality of through holes. The insulating plate is disposed between the electrode plates such that positions of the through holes of the electrode plates correspond to the positions of the through holes of the insulating plate. A plurality of discharge spaces are formed by the through holes of the electrode plates and the through holes of the insulating plate. By applying a voltage between the electrode plates, while supplying a plasma generation gas into the discharge spaces, plasmas are generated simultaneously in the discharge spaces, and sprayed on an object to efficiently perform a large-area, uniform plasma treatment.

Owner:MATSUSHITA ELECTRIC WORKS LTD

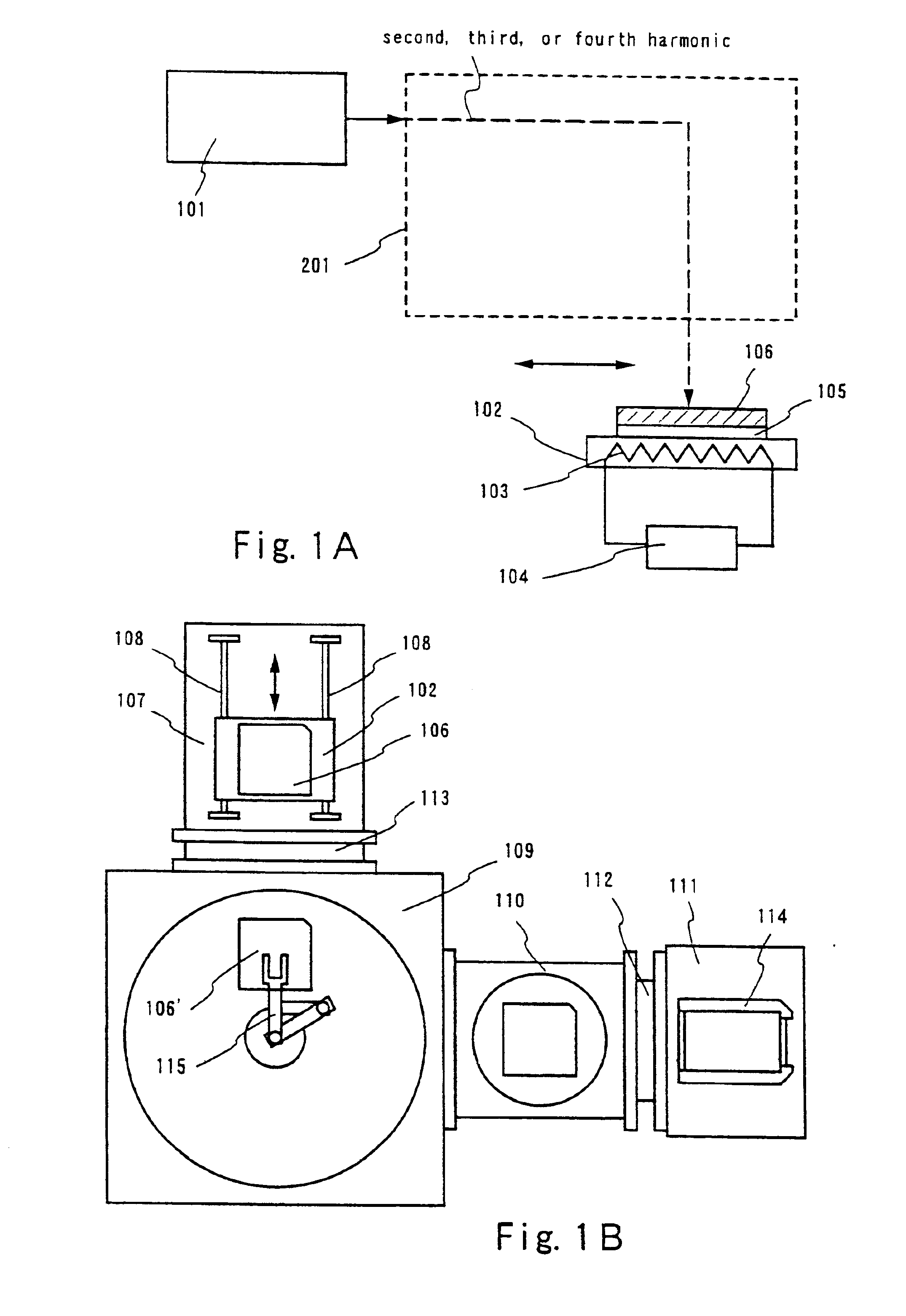

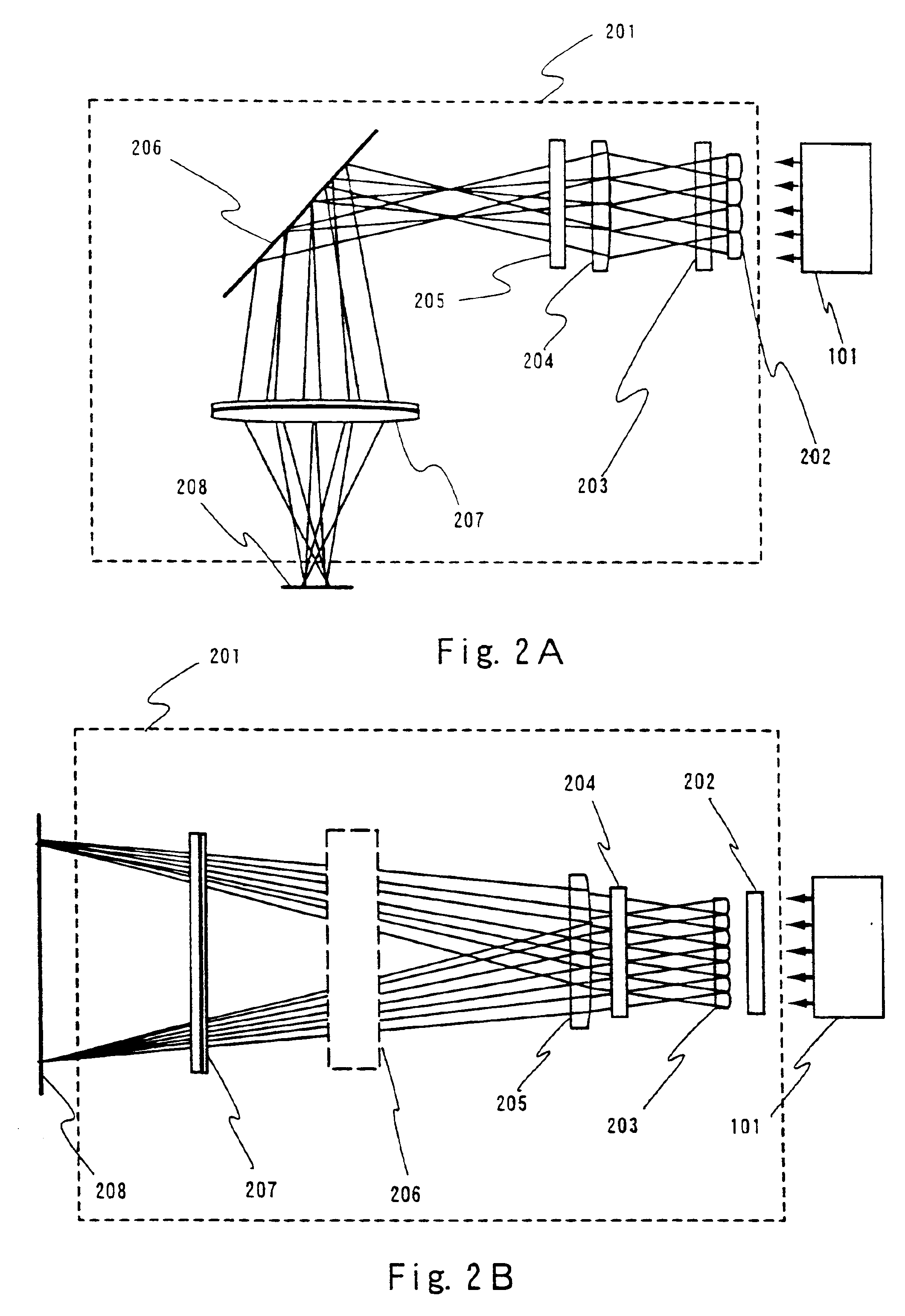

Laser apparatus, laser annealing method, and manufacturing method of a semiconductor device

InactiveUS6974731B2Large grainLow running costSolid-state devicesSemiconductor/solid-state device manufacturingLaser lightSolid-state laser

To provide a laser apparatus and a laser annealing method with which a crystalline semiconductor film with a larger crystal grain size is obtained and which are low in their running cost. A solid state laser easy to maintenance and high in durability is used as a laser, and laser light emitted therefrom is linearized to increase the throughput and to reduce the production cost as a whole. Further, both the front side and the back side of an amorphous semiconductor film is irradiated with such laser light to obtain the crystalline semiconductor film with a larger crystal grain size.

Owner:SEMICON ENERGY LAB CO LTD

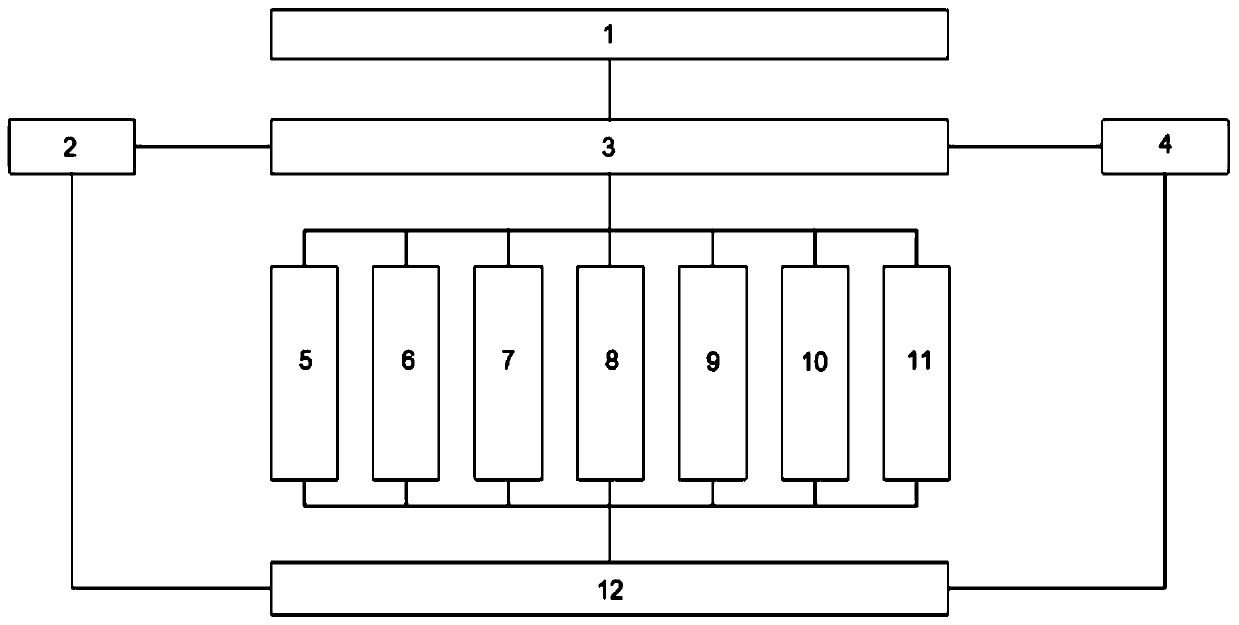

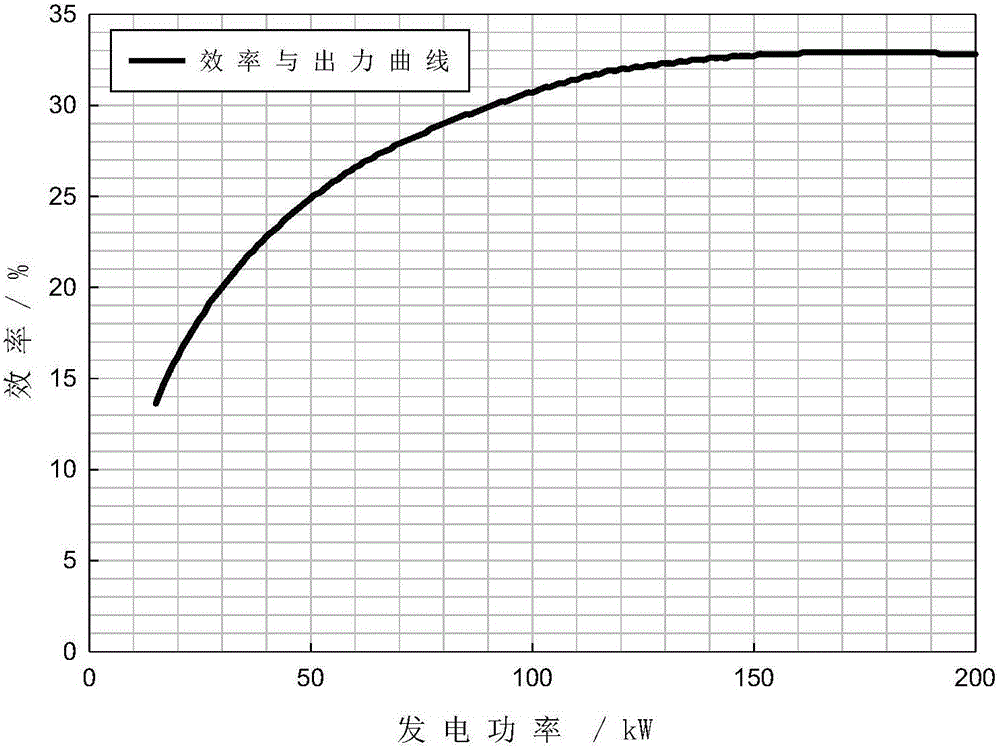

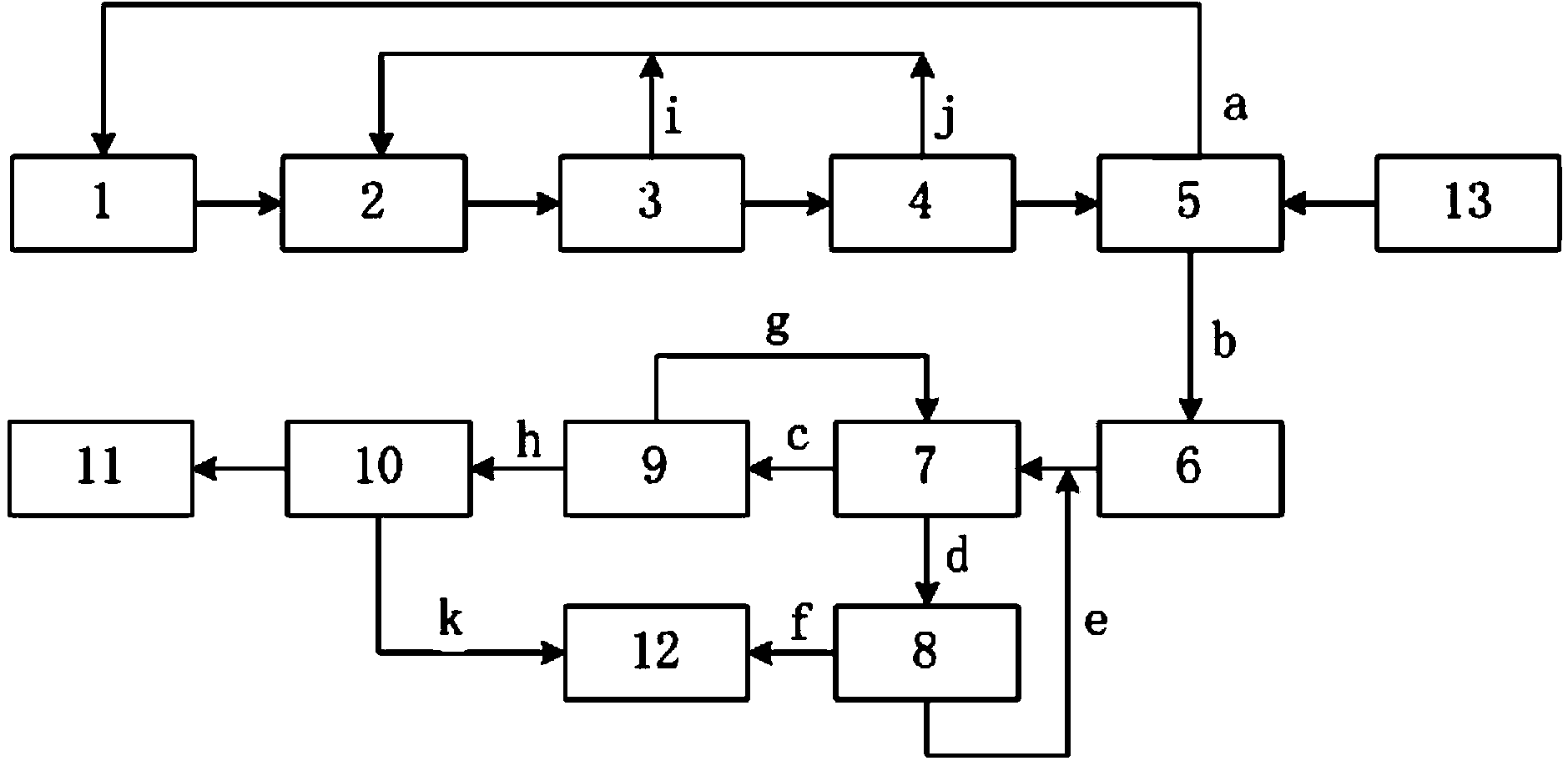

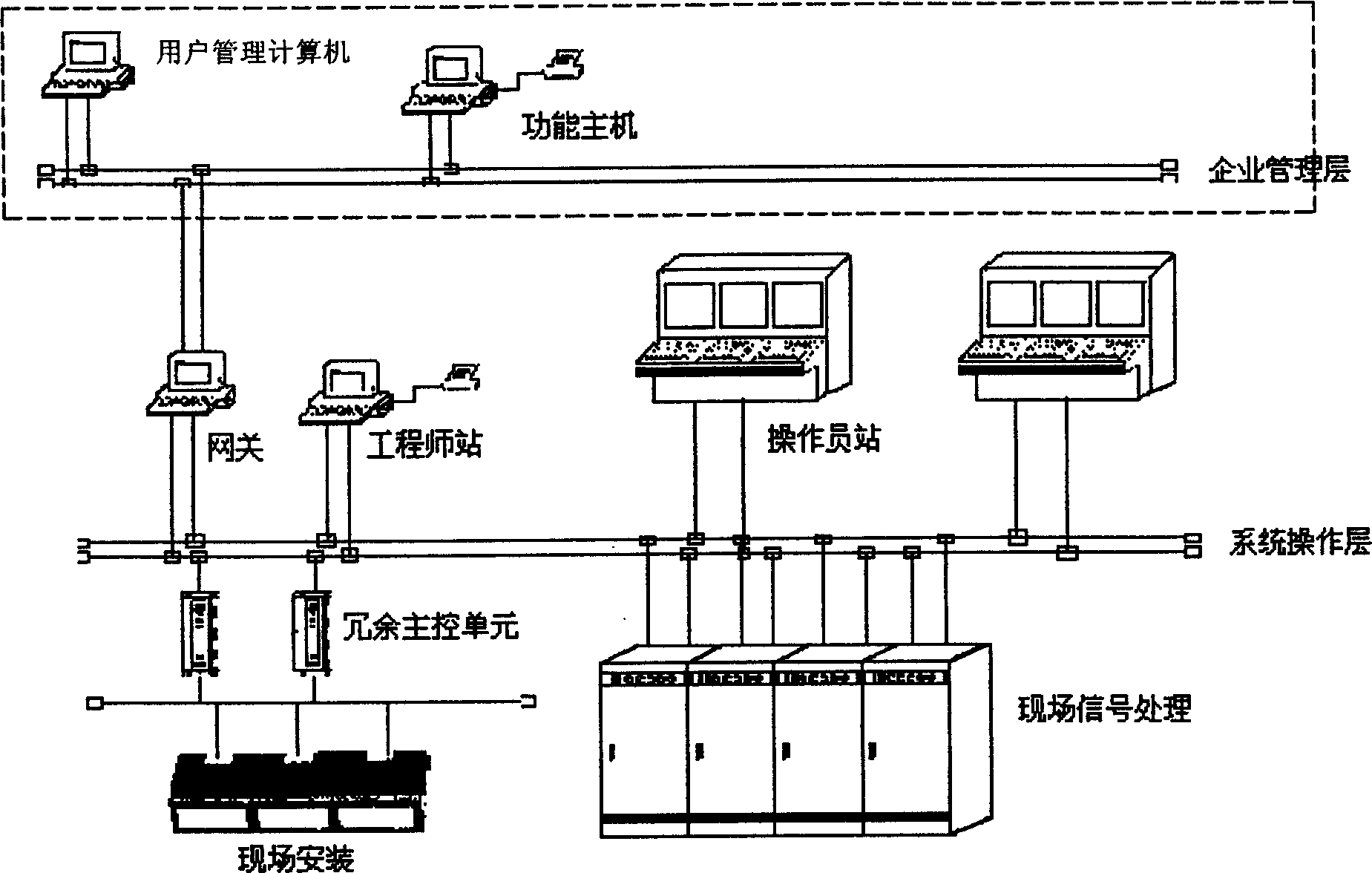

Minitype gas turbine generator wellhead shale gas supply device control system

PendingCN111350595AMeet the requirements of water hydrocarbon dew pointGuaranteed uptimeTurbine/propulsion fuel valvesGas turbine plantsMicro gas turbineHydrocarbon dew point

The invention discloses a minitype gas turbine generator wellhead shale gas supply device control system. A control protection system comprises a particle liquid drop control system, a temperature control system, a pressure control system, a liquid level control system, a water hydrocarbon dew point control system, a fine treatment control system and a system safety protection system which are independently arranged side by side, a working condition parameter signal acquisition system transmits acquired signals to a logic judgment command system, the logic judgment command system is correspondingly connected with a parameter setting system, the control protection system and a data storage remote transmission system, and a micro gas turbine power generation system is correspondingly connected with the parameter setting system, the control protection system and the data storage remote transmission system. The control system has the beneficial effects that stable control over the water hydrocarbon dew point is achieved, and normal and stable operation of the micro gas turbine is guaranteed; the pollution discharge is accurately controlled according to the fluctuation condition of theactual working condition, and the overall operation cost is reduced; and automatic liquid drainage under different working condition fluctuations is achieved, and the risks of tripping and blow-by arereduced.

Owner:JEREH OIL & GAS ENG

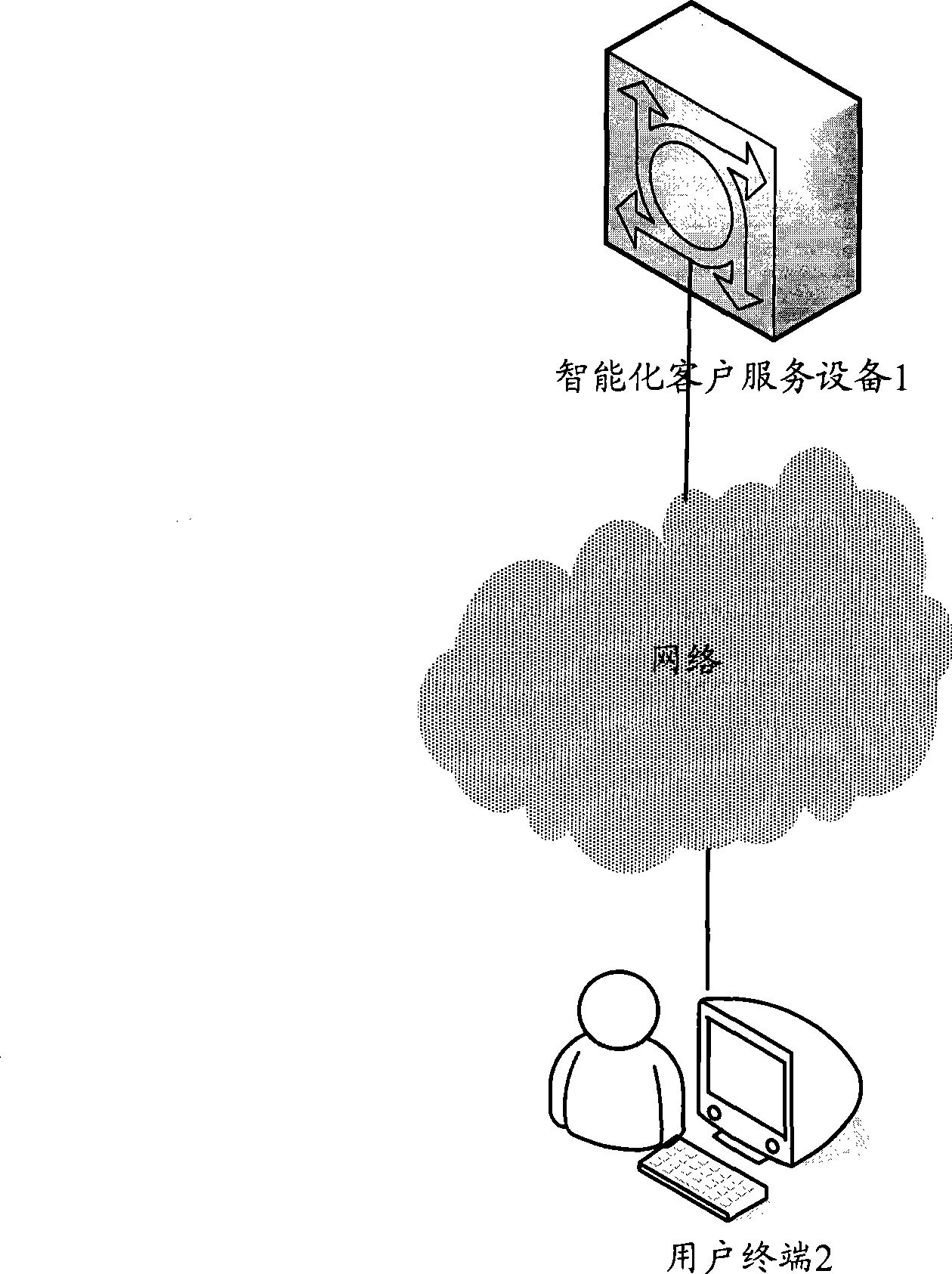

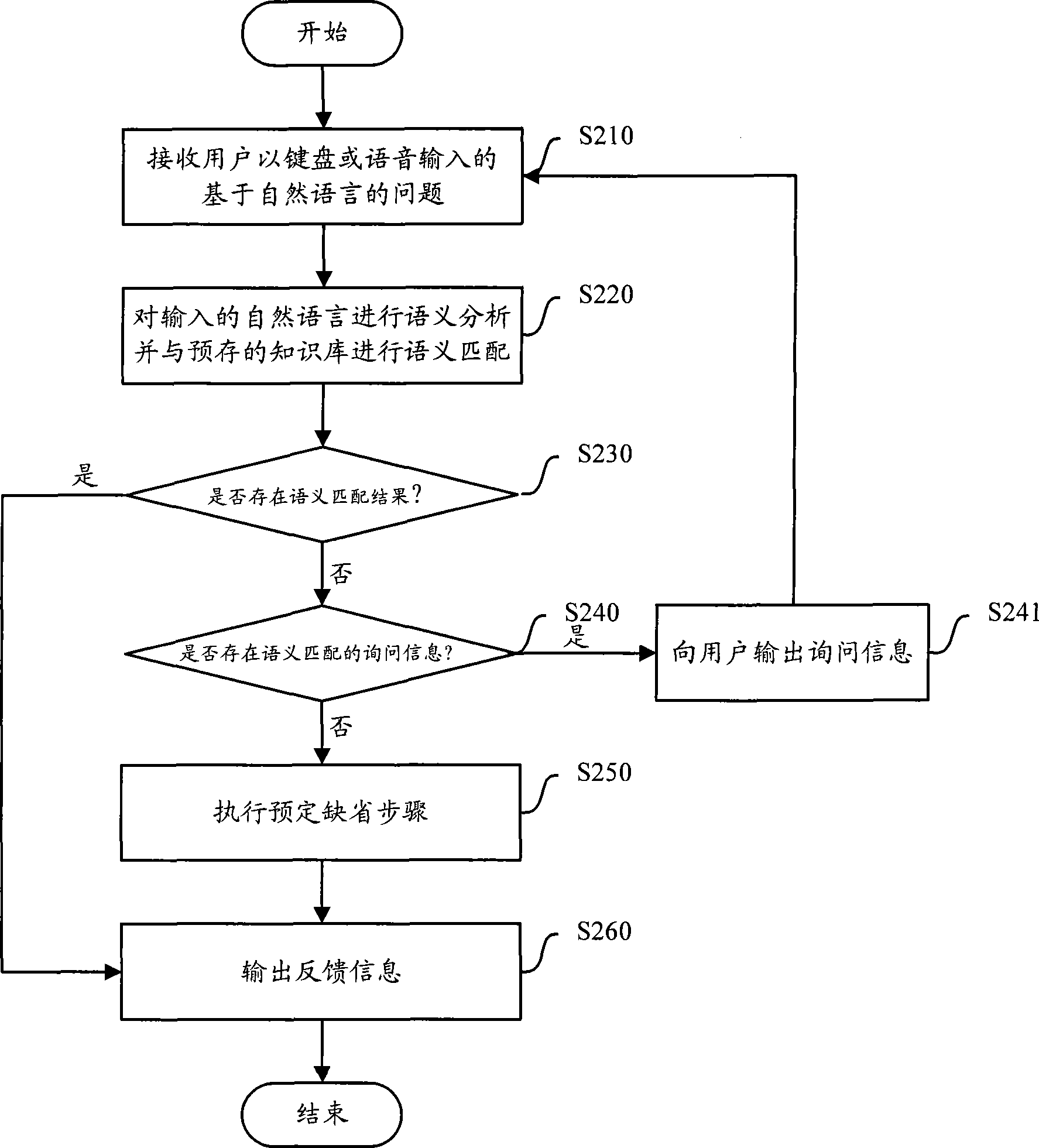

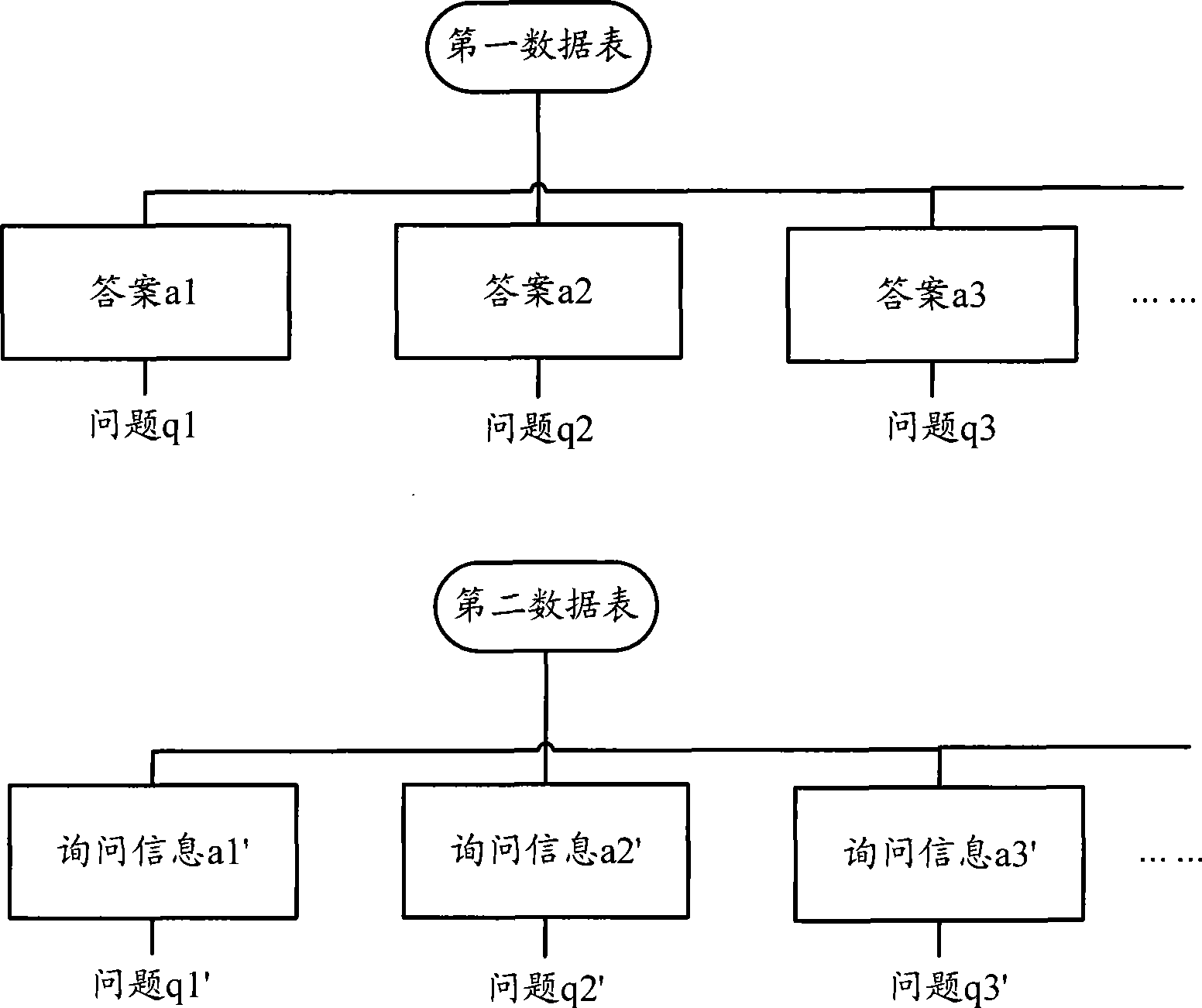

Method and equipment for implementing automatic customer service through human-machine interaction technology

ActiveCN101431573AReduce reinvestmentLow running costSpecial service for subscribersSupervisory/monitoring/testing arrangementsHuman–robot interactionHuman system interaction

The invention provides a method realizing automatic client service using human-computer interaction technique, and an equipment realizing the method. The method includes: receiving problem imported with nature language from the user, converting the nature language into information identified by the computer using human-computer interaction technique; outputting feedback information according withthe information identified for the computer. In addition, the invention also provides the equipment realizing the method.

Owner:SHANGHAI XIAOI ROBOT TECH CO LTD

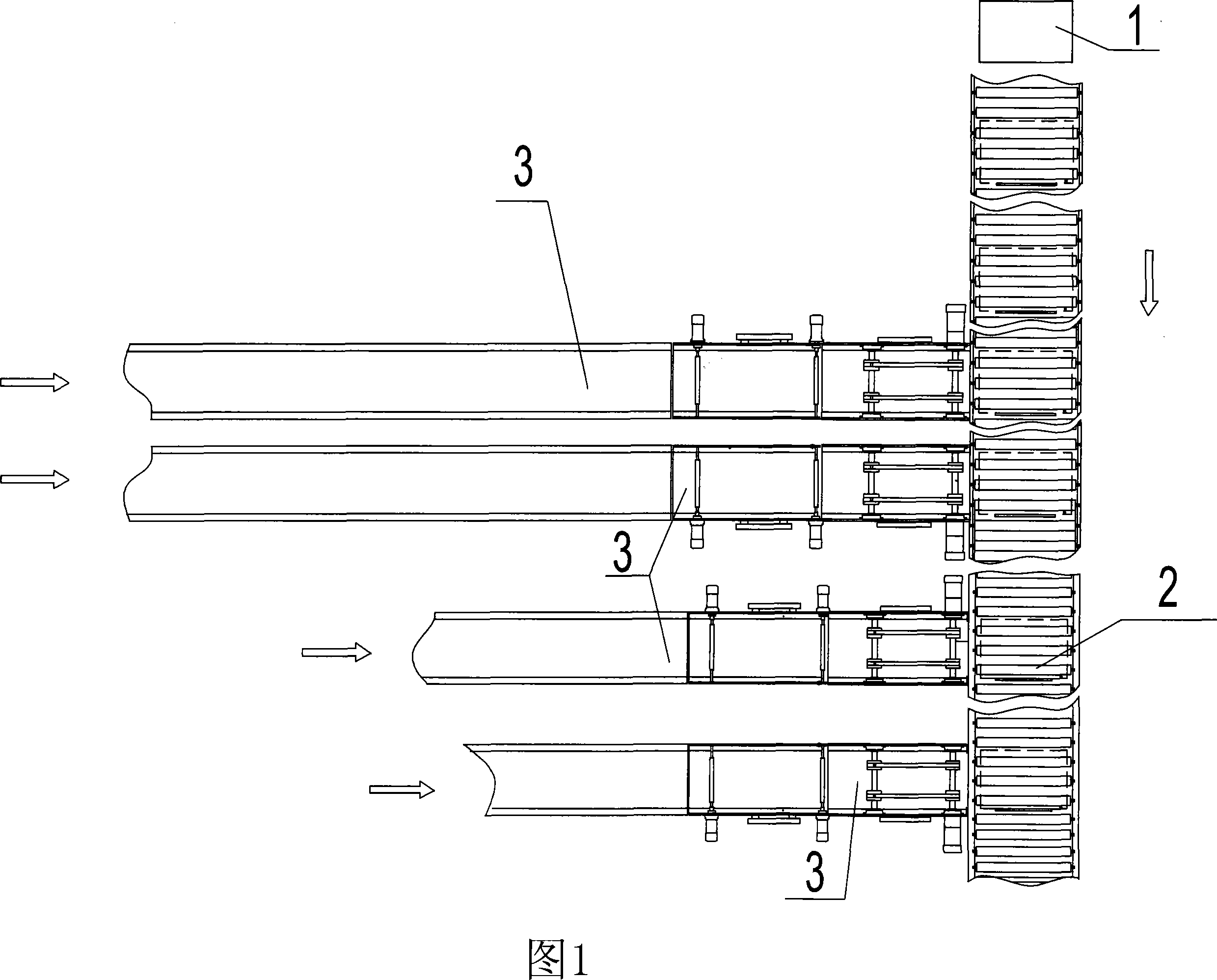

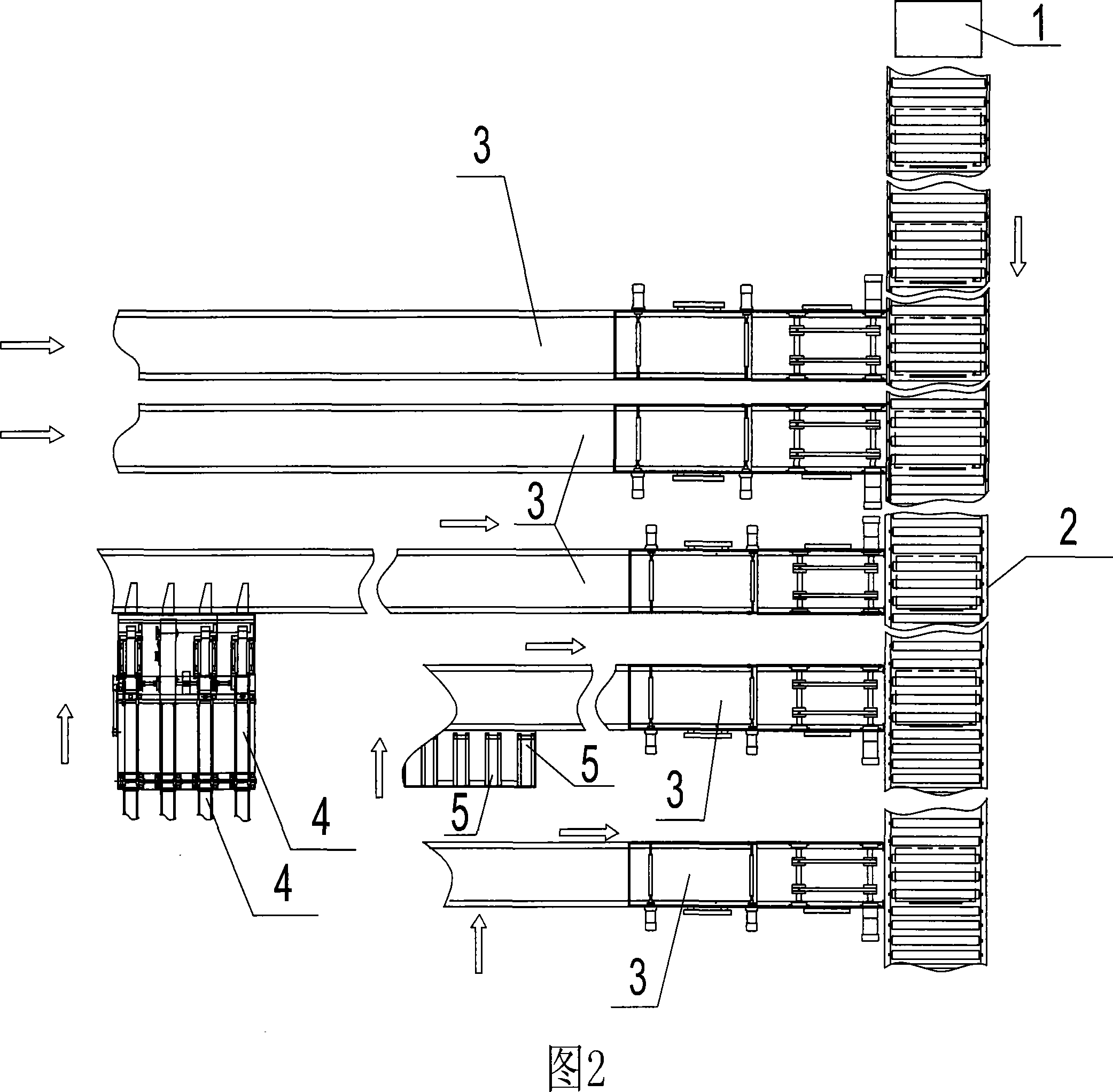

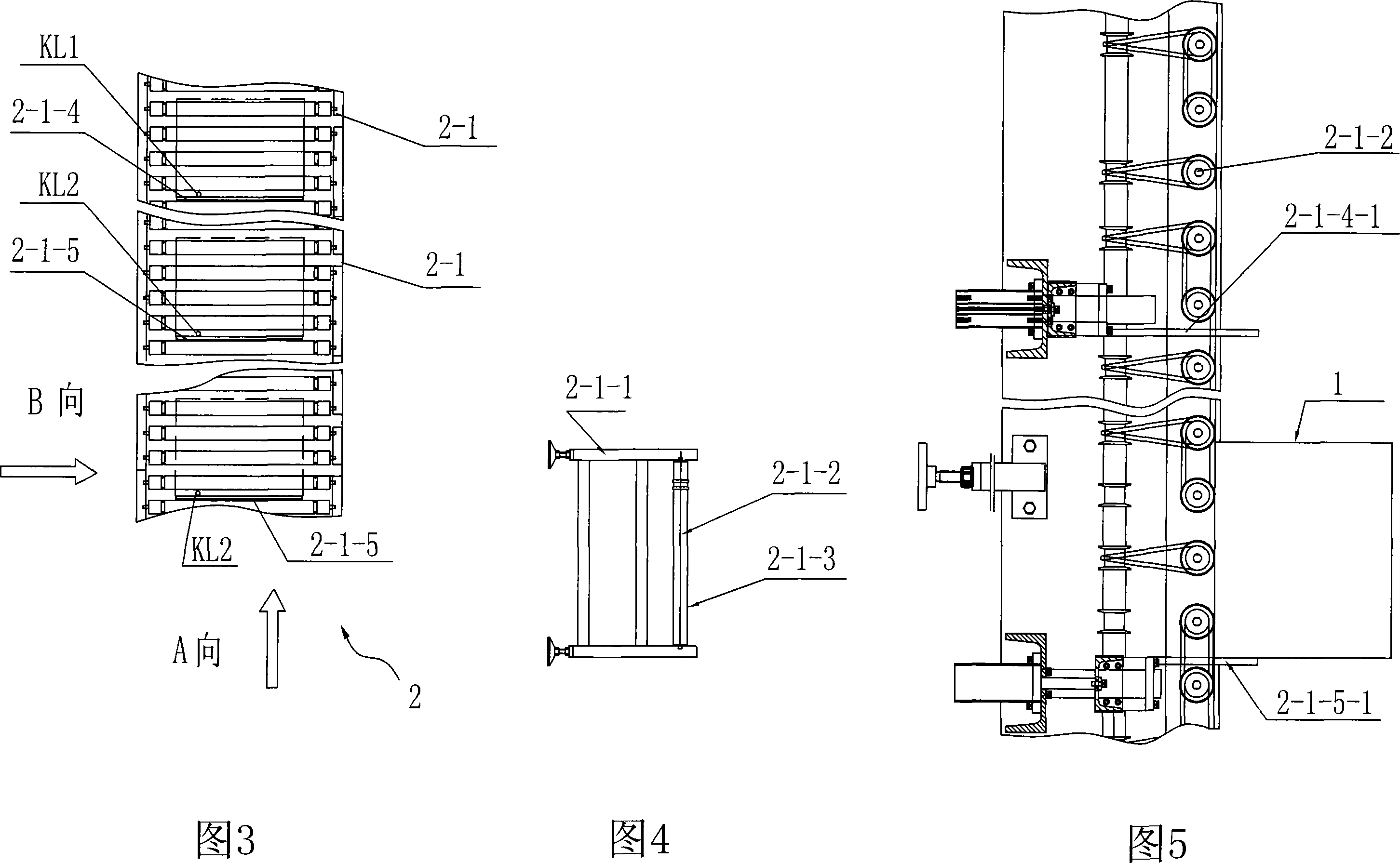

Goods sorting and split charging equipment and method thereof

InactiveCN101234677ASmall footprintReduce the number of employeesControl devices for conveyorsCo-operative working arrangementsElectronic control systemEngineering

The invention discloses an equipment for sorting and packaging goods and a method thereof, wherein, the equipment comprises turning box baskets, a box basket transporting device, a goods-providing device, a radio frequency reader, a wireless radio frequency card, an electronic control system and a system of computer information management, wherein, each box basket box has the wireless radio frequency card; a side on a stopping position of a plurality of box baskets on the box basket transporting device is provided with the goods-providing device; the radio frequency reader is arranged near the stopping positions for the box backsets on the box basket transporting device. The method comprises the following steps: A. configuring devices for the whole line and determining the brands and specifications of goods to be delivered; B. setting the information of device configuration as well as the brands and specifications of the goods; C. setting the allocation proposal; D. preparing and implementing the allocation proposal; E. starting the whole line and pre-allocation; F. inputting empty box baskets; G. applying the box baskets for delivery and allocation; H. unloading the baskets. The equipment for sorting and packaging goods has the advantages of high speed, reliable work, low operation cost, compact structure, and small land occupancy, so the invention is applicable for various goods delivery centers with different delivery requirements and scopes.

Owner:姜广峻

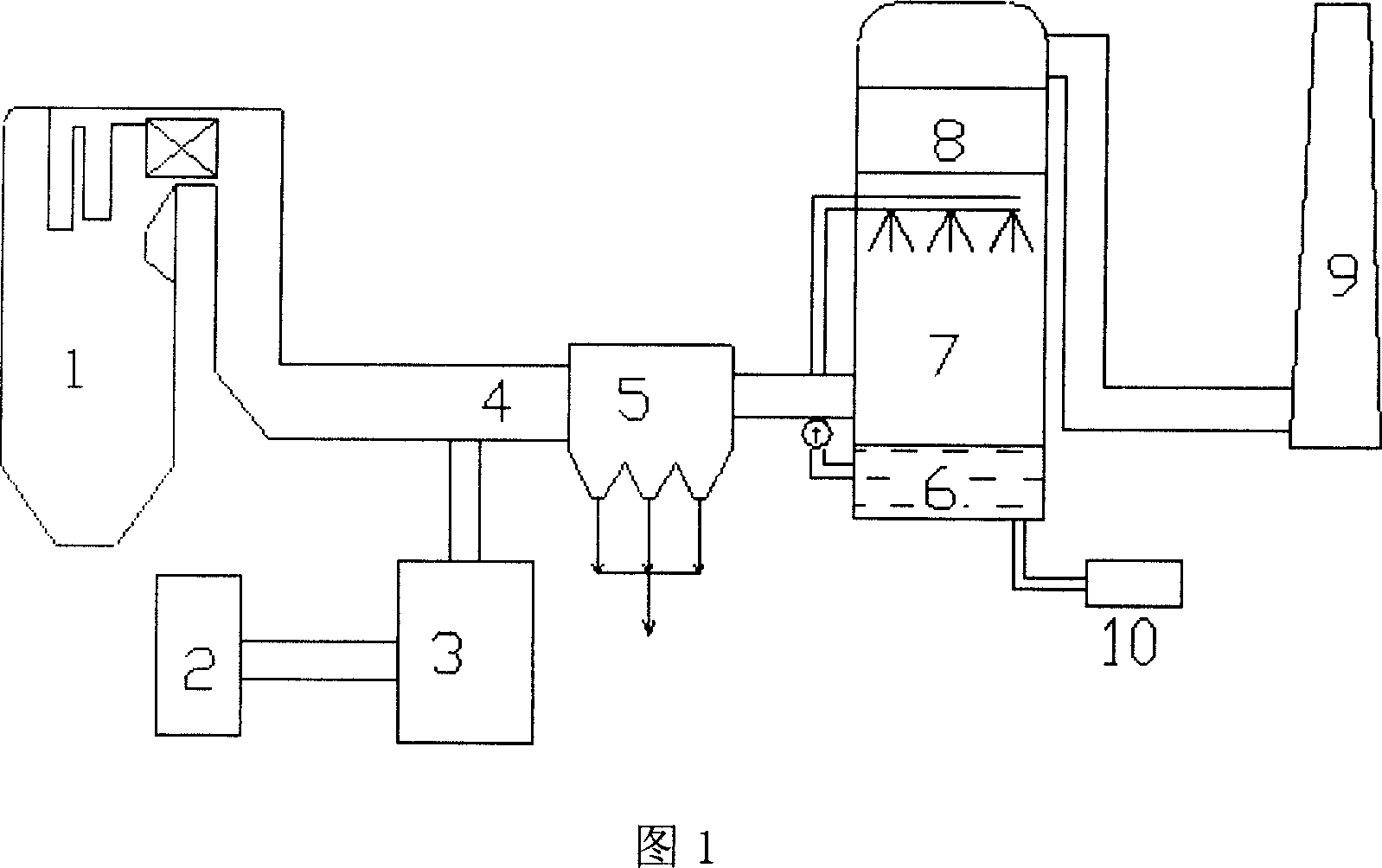

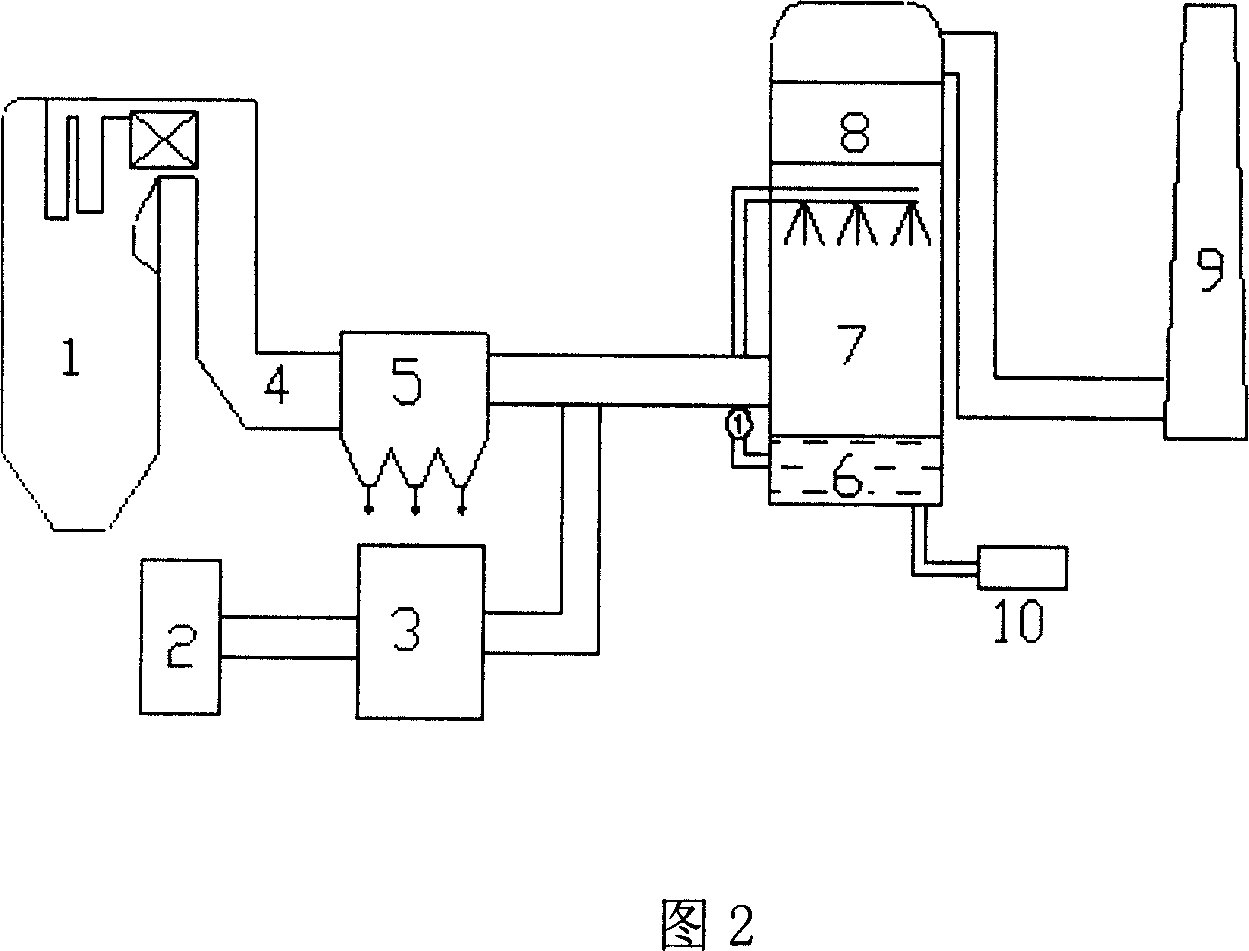

Device and method for coal-burning boiler fume ozone oxidation and simultaneous desulfurization and denitrification

InactiveCN1923341ALess investmentLow running costDispersed particle separationAir quality improvementFlueChemistry

The invention relates to a device for removing several pollutants of boiler smoke. Wherein, it comprises (1), before or after the static deduster 5 of smoke channel 4, ejecting into ozone O3 at low temperature section as 110-150Deg. C, while the ratio between ejected amount and nitrogen oxide is 0.5-1.5, to oxidize the low-level nitrogen oxide insoluble into soluble high-level nitrogen oxide, and the sulfur oxide is transformed into sulfur trioxide, and the reaction time is more then 0.5s; (3), feeding treated smoke into alkali washing tower 7 to wash, and absorbing high-level nitrogen oxide and sulfur oxide.

Owner:ZHEJIANG UNIV +1

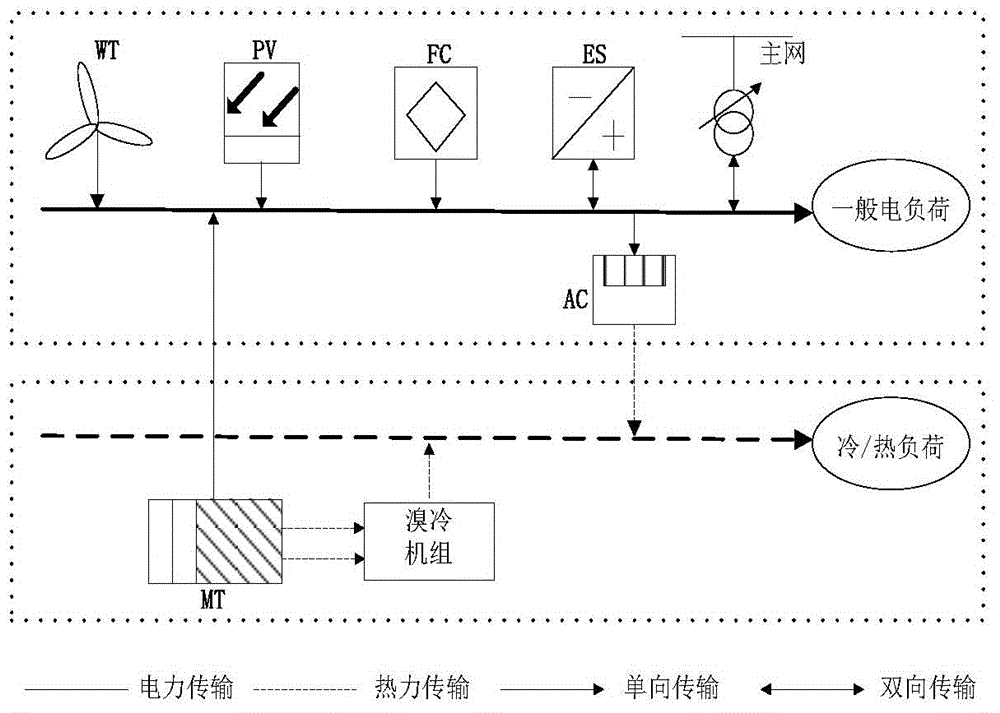

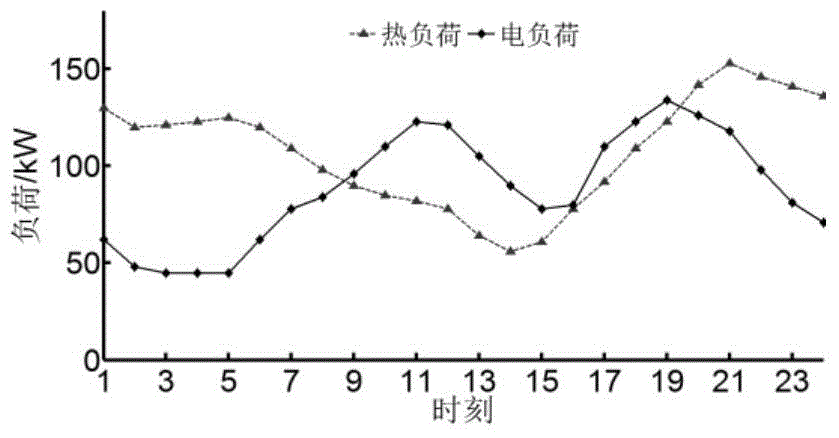

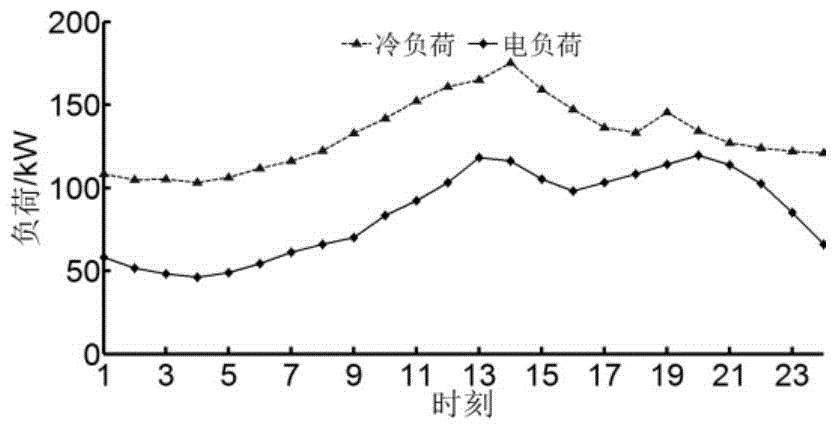

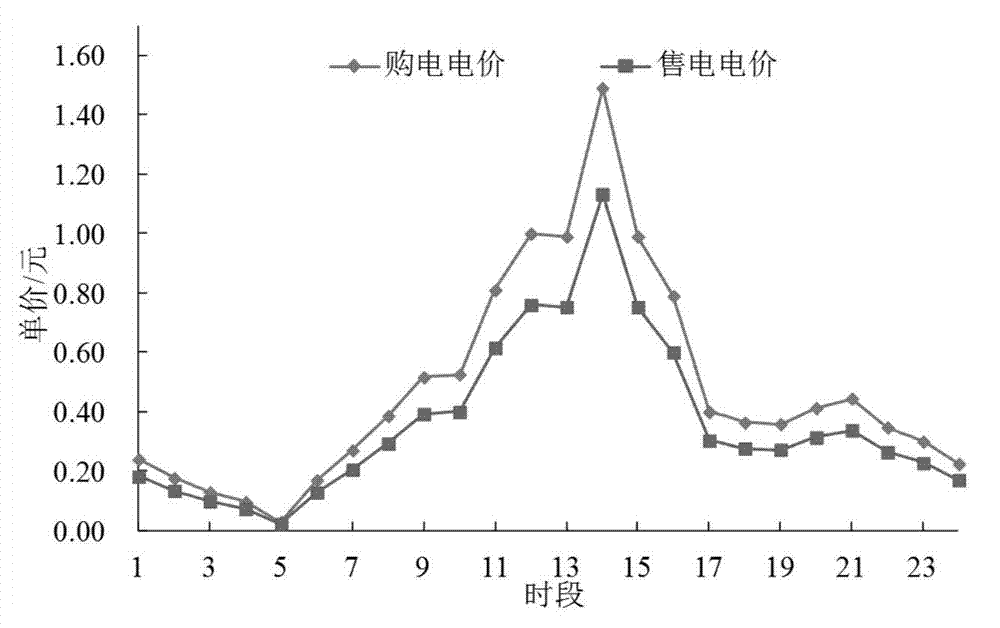

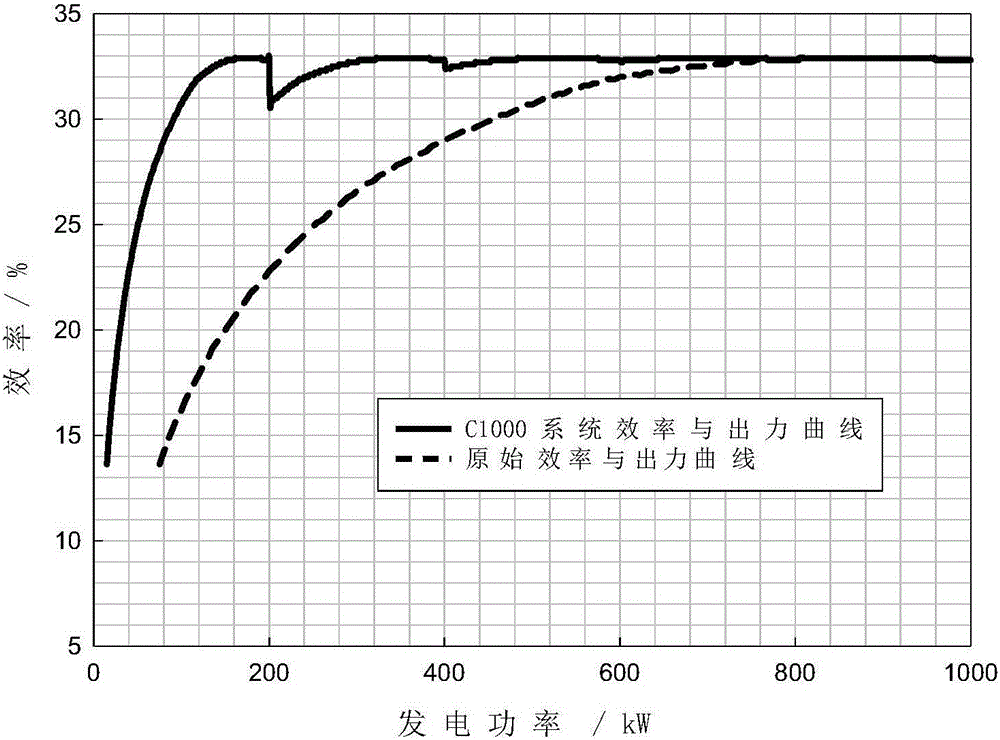

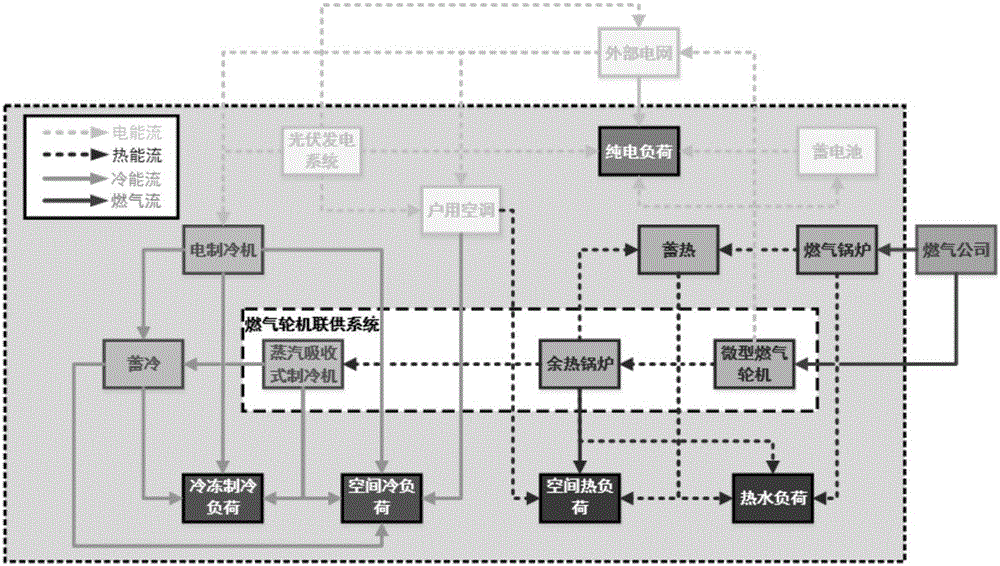

Microgrid operation optimizing method by considering combined supply of cooling, heating and power with stored energy operation strategy

InactiveCN104392286AIncrease revenue from electricity salesLow running costForecastingEnergy gradientMicrogrid

The invention discloses a microgrid operation optimizing method by considering combined supply of cooling, heating and power with a stored energy operation strategy.The microgrid operation optimizing method comprises the following steps of: establishing a CCHP (combined cooling heating and power) microgrid optimizing model; constructing a target optimizing function with a target of lowest generating cost under a microgrid grid-connected operation state; according to the established target optimizing function, comprehensively considering load level of front and time periods with an output trend of each micro power supply, and determining the operation principle of an energy storage unit and a fuel battery to determine the best operation mode of the whole CCHP system in a scheduling period. The microgrid operation optimizing method disclosed by the invention has the beneficial effects that the microgrid electricity selling profits can be effectively increased for energy storage optimization, obvious advantages are provided in lowering the operation cost of the microgrid; the energy resource utilization rate of the stem can be improved and the energy gradient utilization can be realized in comparison with the conventional heat-engine plant and thermal power plant, so that reference is provided for energy saving of the power system; moreover, the energy is saved and the emission is reduced, pollution of air pollutants is greatly reduced, and significance is achieved in improving environmental benefits.

Owner:SHANDONG UNIV

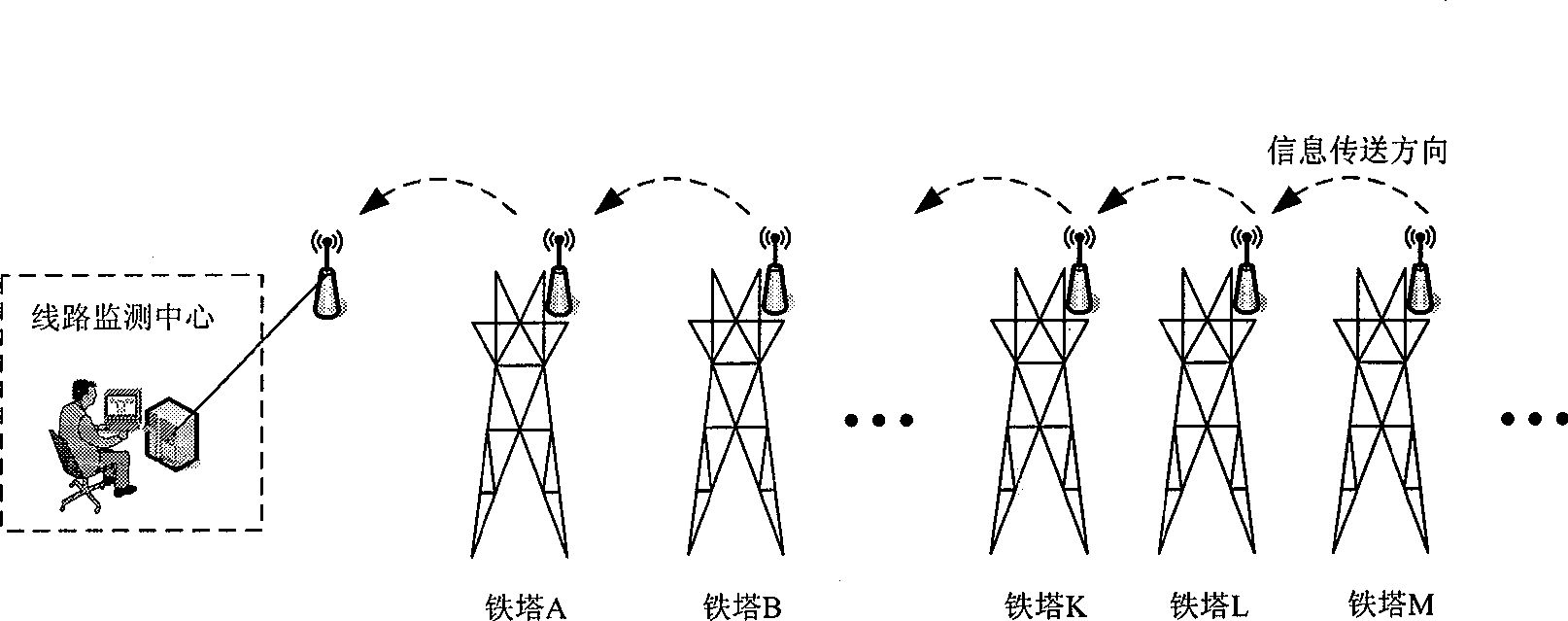

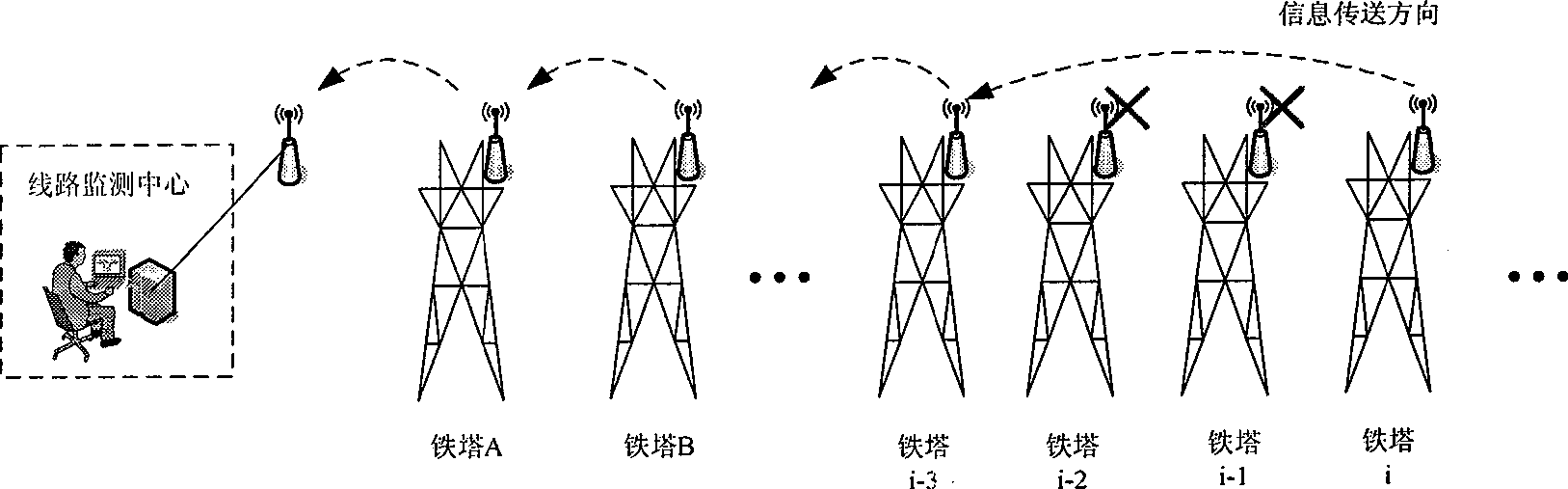

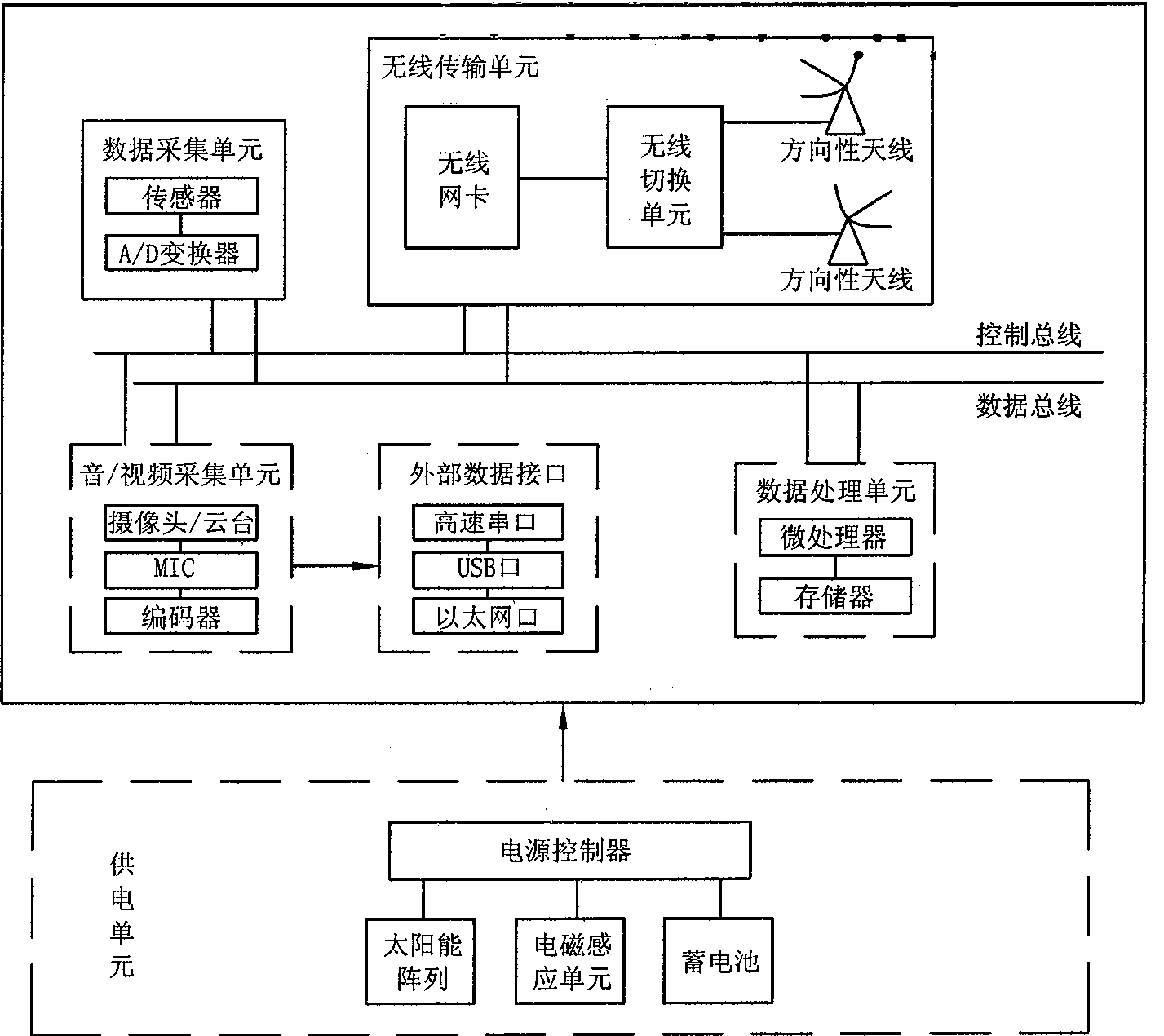

High voltage electricity transmission line monitoring method based on wireless communication and optical communication

InactiveCN101483567AEasy to implementFlexible deploymentCircuit arrangementsNetwork topologiesEngineeringHigh pressure

The invention relates to a high-tension transmission line monitoring method on the basis of wireless communication and photo-communication for overcoming the faults of limited functions, small band width, high running cost and low reliability in the prior art. The method comprises the following steps: 1. setting wireless monitoring nodes on the transmission line towers; selecting a particular tower along the line at an interval of 20-30 kilometers as a convergent point tower and simultaneously installing wireless monitoring nodes and photo-communication nodes on the convergent point tower and transforming plants on the two ends of the line; 2. the wireless monitoring nodes acquiring monitoring data, the wireless monitoring nodes of the towers in the area where the convergent point tower locates transmit the monitoring data to the photo-communication nodes on the convergent point tower by using a multi-hop forwarding method, each photo-communication node transmits the monitoring data to a monitoring center by using a multi-hop forwarding method. According to the invention, information monitored by thousands of sensors installed on towers of each level can be transmitted back to a junction centre for realizing the real-time monitoring of the whole high-tension transmission line.

Owner:NORTHWEST CHINA GRID

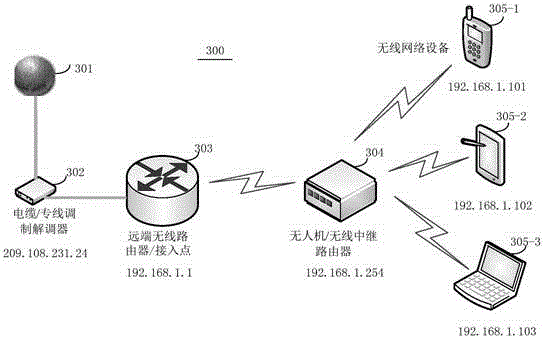

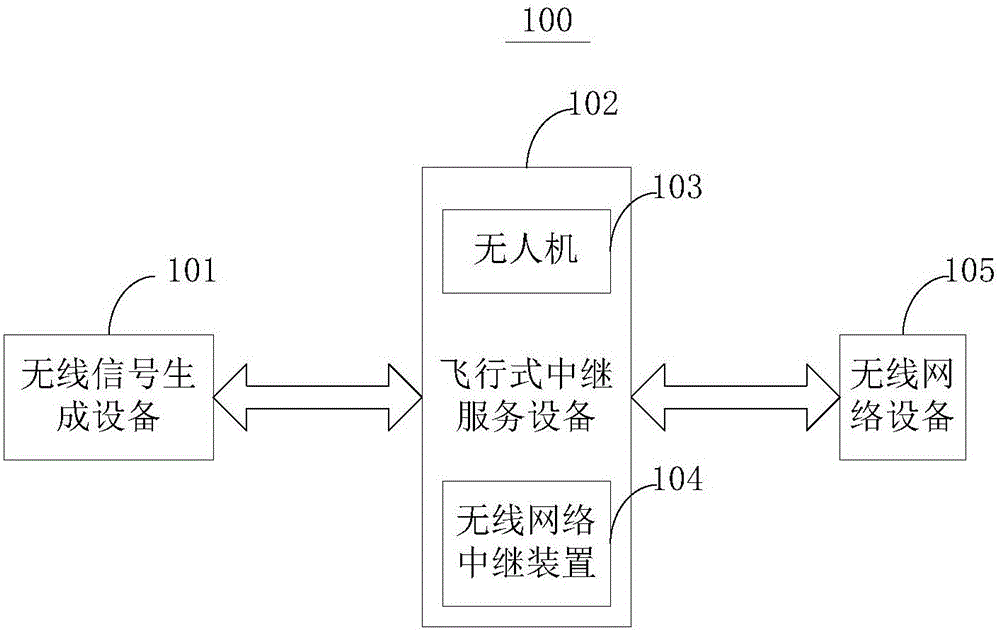

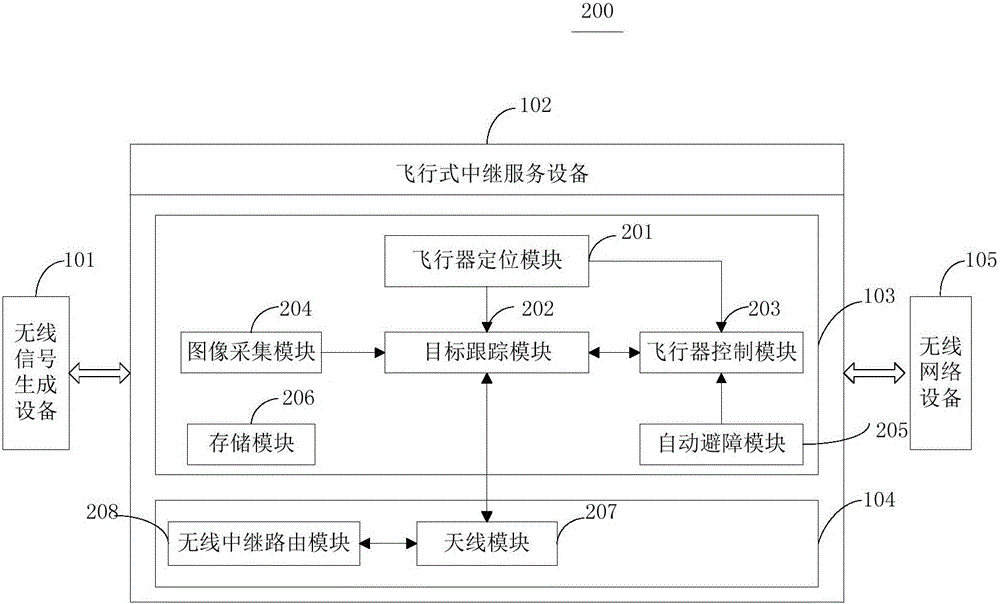

Intelligent relaying system and intelligent relaying method implemented by unmanned aerial vehicle

ActiveCN105071852AShort set up timeLow running costRadio transmissionIntelligent lightingWireless transmission

The invention discloses an intelligent relaying system and an intelligent relaying method implemented by an unmanned aerial vehicle, belonging to the technical field of unmanned aerial vehicle application. The system comprises a wireless signal generation device, a flying type relaying service device and a wireless network device. The flying type relaying service device is in wireless connection with the wireless signal generation device and the wireless network device, and comprises the unmanned aerial vehicle and an onboard wireless network relay, wherein the wireless signal generation device is suitable for generating wireless signals in a certain scope; the flying type relaying service device is suitable for realizing relaying amplification through the wireless signals, and the unmanned aerial vehicle is capable of intelligently controlling own flight status according to the needs of the wireless network device. According to the invention, the wireless network device needed to access to a near-end wireless network is tracked in real time by the unmanned aerial vehicle, the wireless signals of a remote wireless transmission network are amplified in a manner of relaying through the onboard wireless network relay, and thus, a fast, reliable, steady and high-efficiency network access service is provided for a tracking target.

Owner:杨珊珊

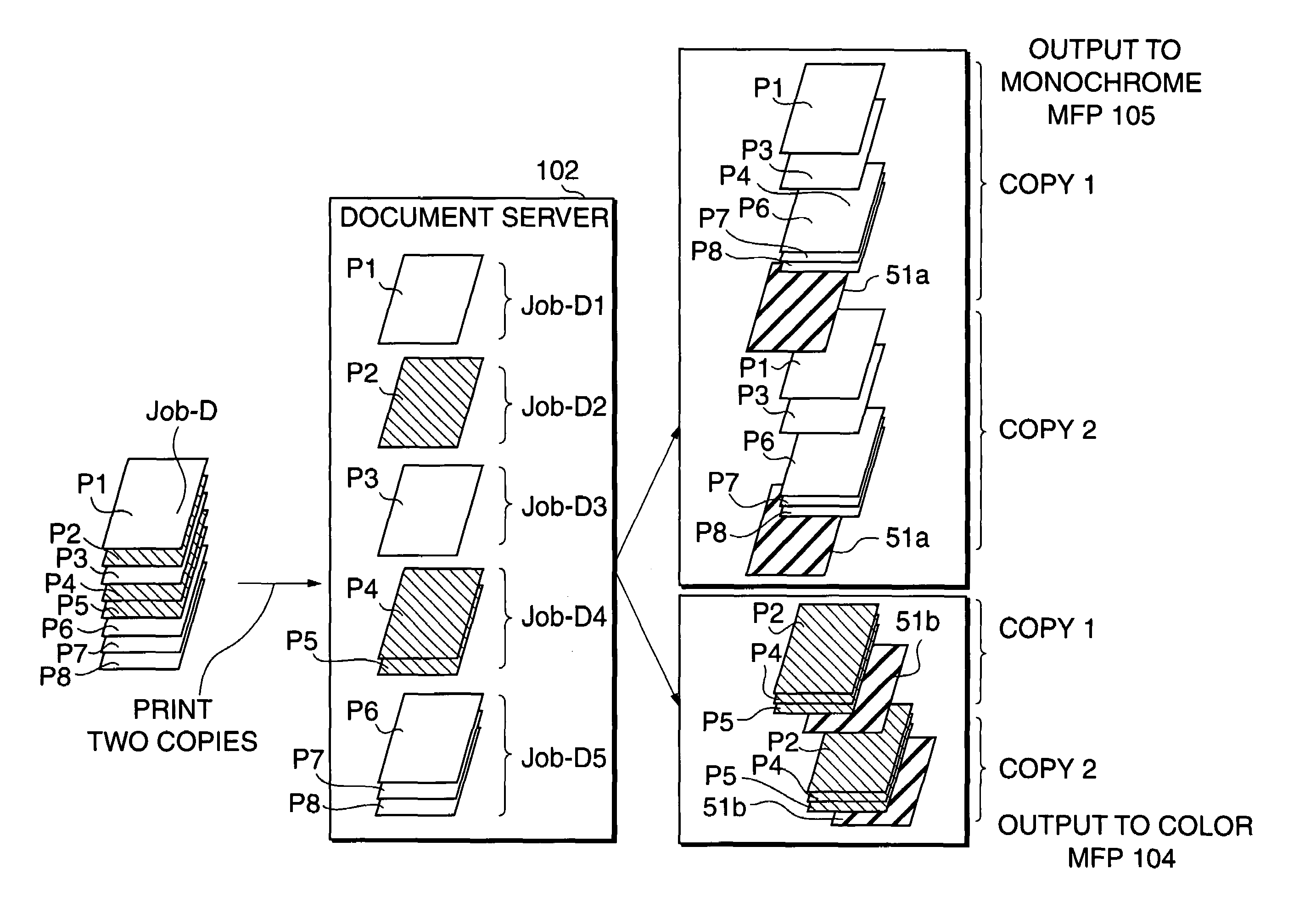

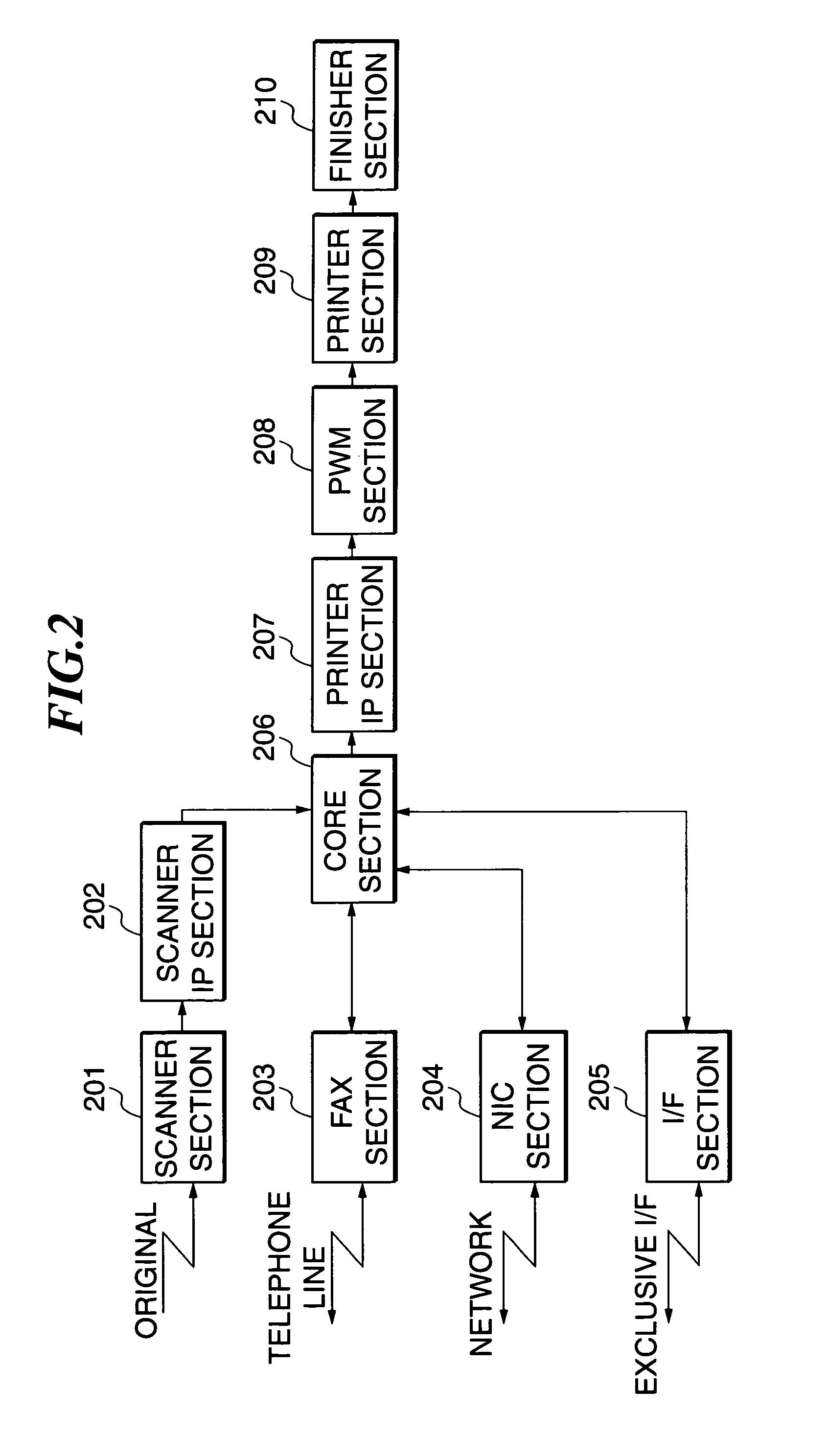

Image processing apparatus and system and control method therefor, image data processing method, image forming apparatus and control method therefor, controller therefor, and storage medium storing the control method for processing image data having different printing attributes

InactiveUS6985245B1Efficient executionA large amountDigitally marking record carriersDigital computer detailsImaging processingComputer graphics (images)

An image processing system having a plurality of image forming apparatuses and a method thereof separate a group of image data to be printed into a plurality of groups and transmitting the groups to the plurality of image forming apparatuses. A first image process is executed on the image data to be transmitted, and depending on printing attributes of the image forming apparatuses to which the image data are to be transmitted, a second process, which can be the same as or different from the first process, is executed. Further, the image data having the first attribute are formed on sheets from a first feeding unit while sheets from another feeding unit are inserted into the sheets with the first attribute at pages corresponding to image data of the group of image data having the second attribute.

Owner:CANON KK

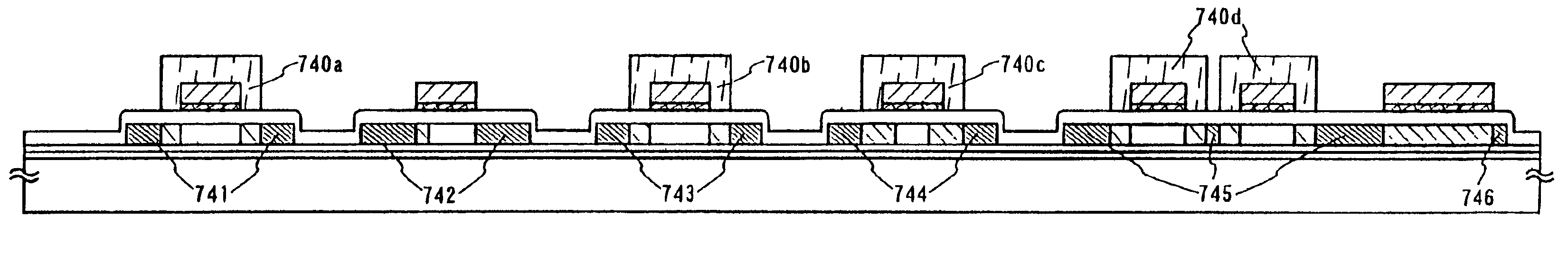

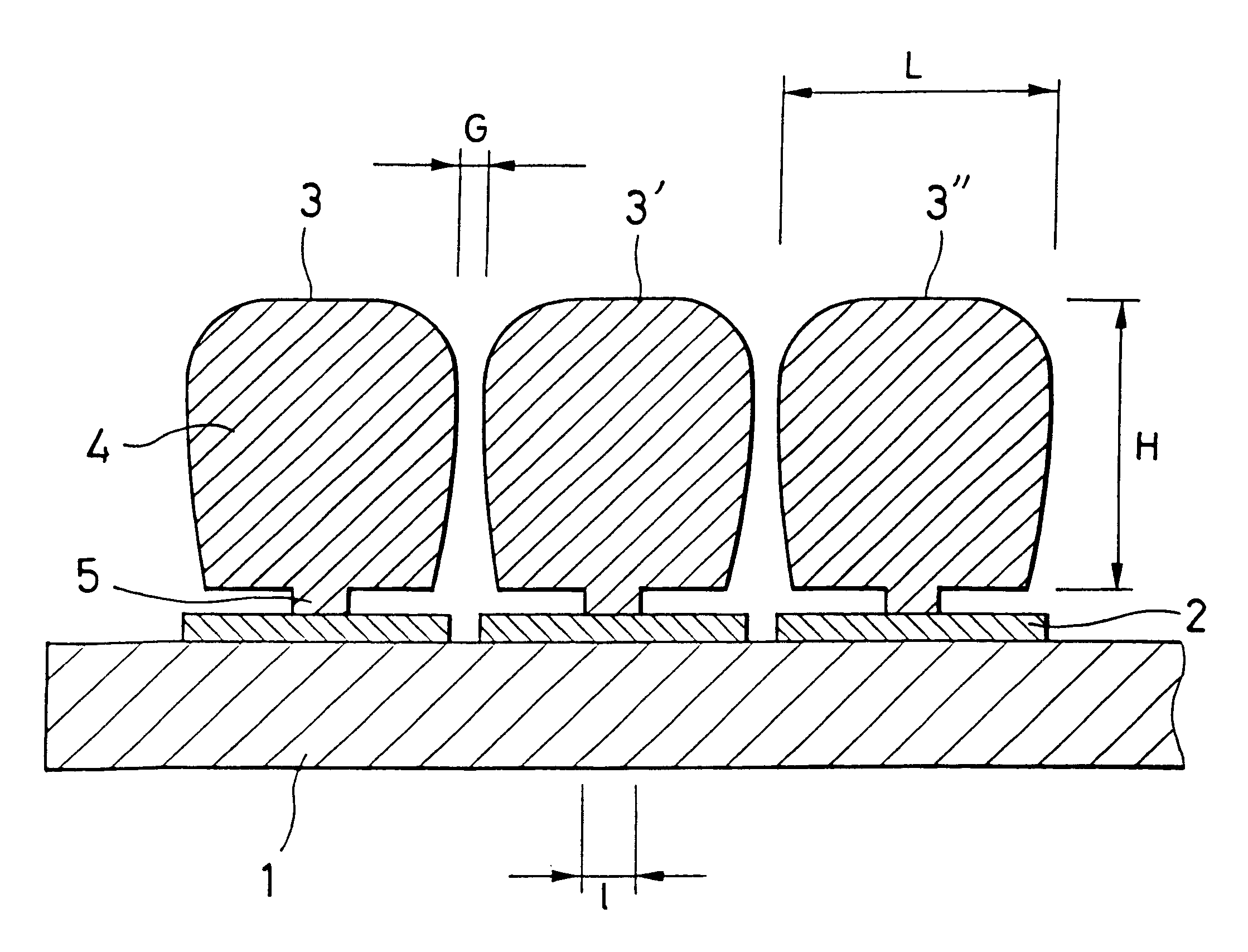

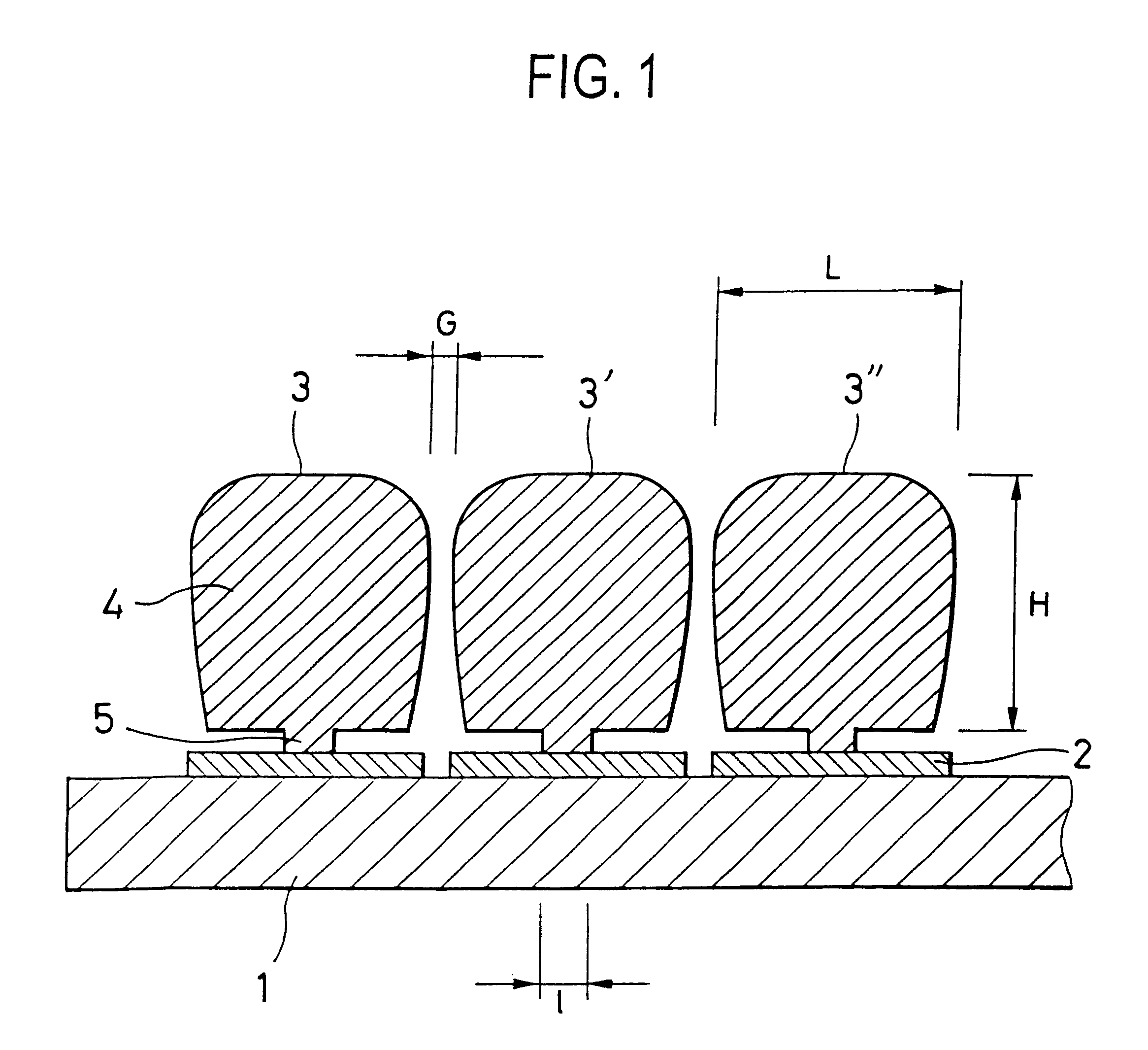

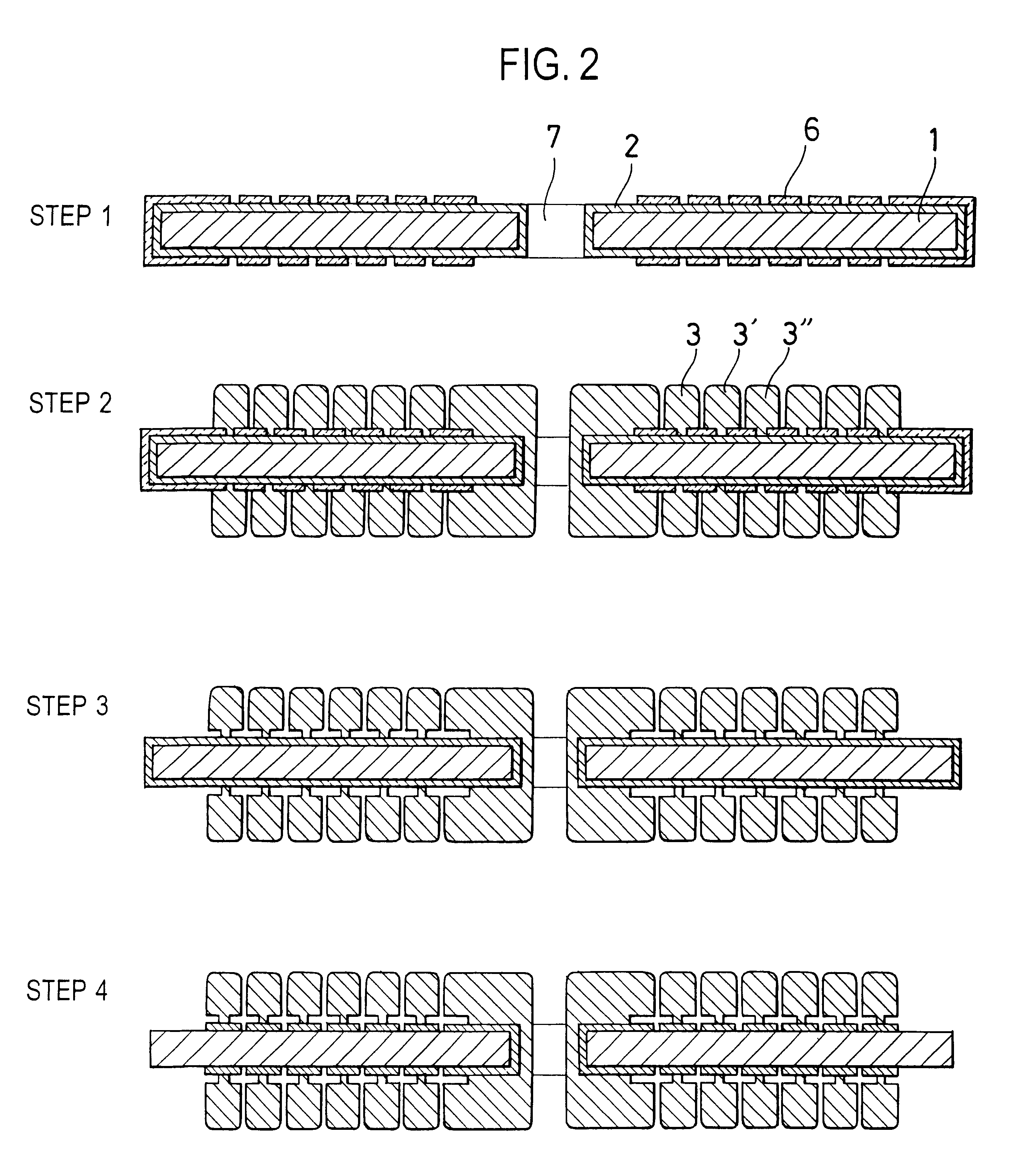

Planar coil and planar transformer, and process of fabricating a high-aspect conductive device

InactiveUS6600404B1Improve electrical performanceIncreases conductor thicknessTransformers/inductances coils/windings/connectionsPrinted circuit aspectsPlanar transformersPhysics

A planar coil including and insulating substrate, and a coil conductive filament having a thickness of 20 to 400 mum and formed on at least one surface of the insulating substrate, the coil conductive filament having a gap whose aspect ratio (H / G) is at least 1. The coil conductive filament has a cross-section in a substantially mushroom shape having a head and a neck, the head has a width (L) which is a least twice as large as a width (l) of the neck thereof, at most 1.5 times as large as a height of the head, and at least twice as large as a minimum spacing (G) between adjacent coil conductive filaments.

Owner:TDK CORPARATION

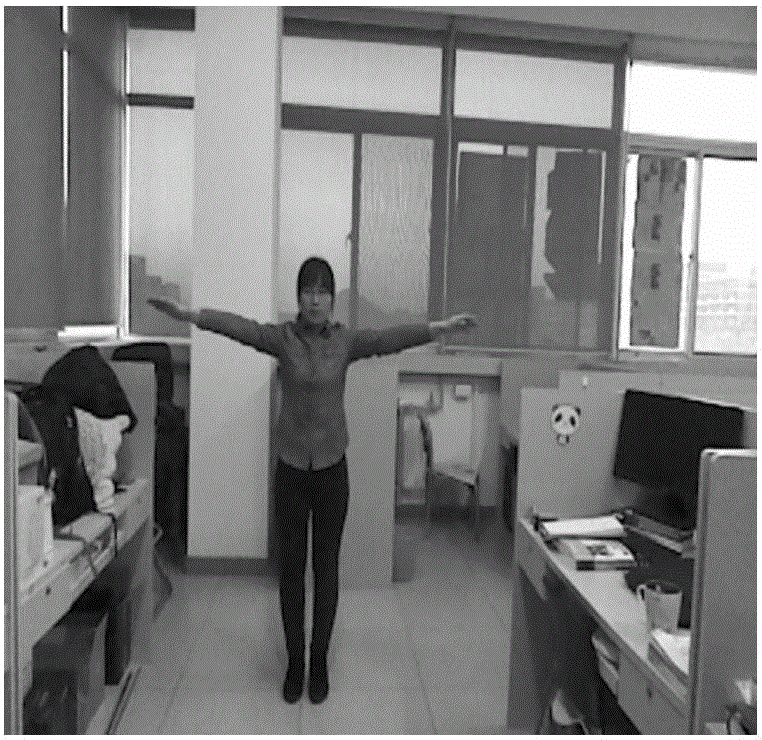

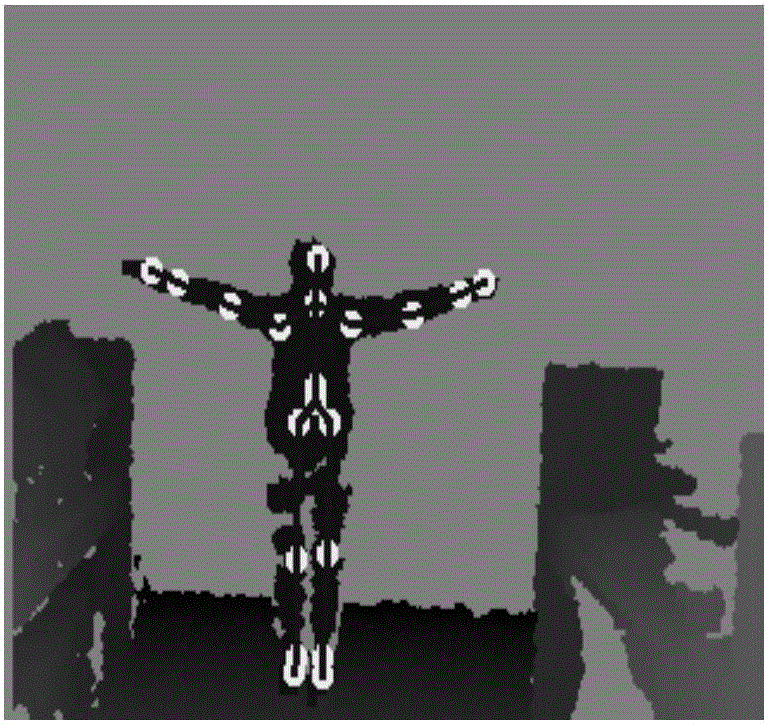

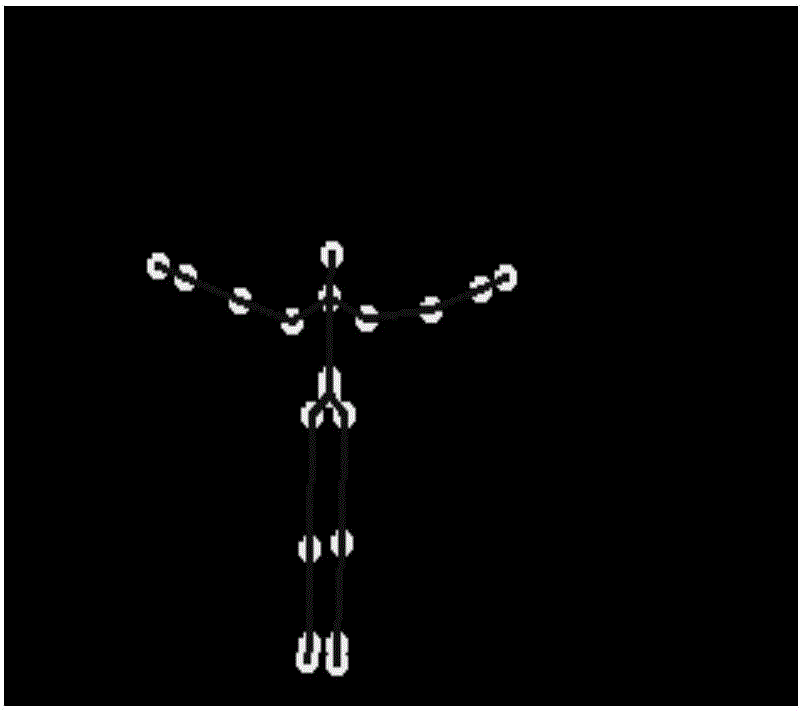

Human body motion recognition method based on three-dimensional bone information

ActiveCN106022213ALow light conditionsShade and other factors have little influenceThree-dimensional object recognitionHuman bodyData stream

The invention discloses a human body motion recognition method based on three-dimensional bone information. The method comprises the steps that color data stream, depth data stream and bone data stream of a number of individual samples of different sex and height are processed, wherein the individual samples make various motions; SVM models corresponding to all motions are constructed; the bone data stream of a recognized target which makes any motion within the acquisition range of a Kinect depth sensor is acquired; through the bone data stream, the distance between a normalized human body bone articulation point and a reference point and 14 vector angles are acquired; the data are respectively input to multiple SVM models; and a motion corresponding to the SVM model with the highest output probability is the motion of a recognition target. According to the invention, the Kinect depth sensor is used to acquire images; the method is less affected by light condition, shadow and other factors; the depth map and the bone information of a human body motion are acquired in real time; and a human body target in a scene can be accurately located.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY

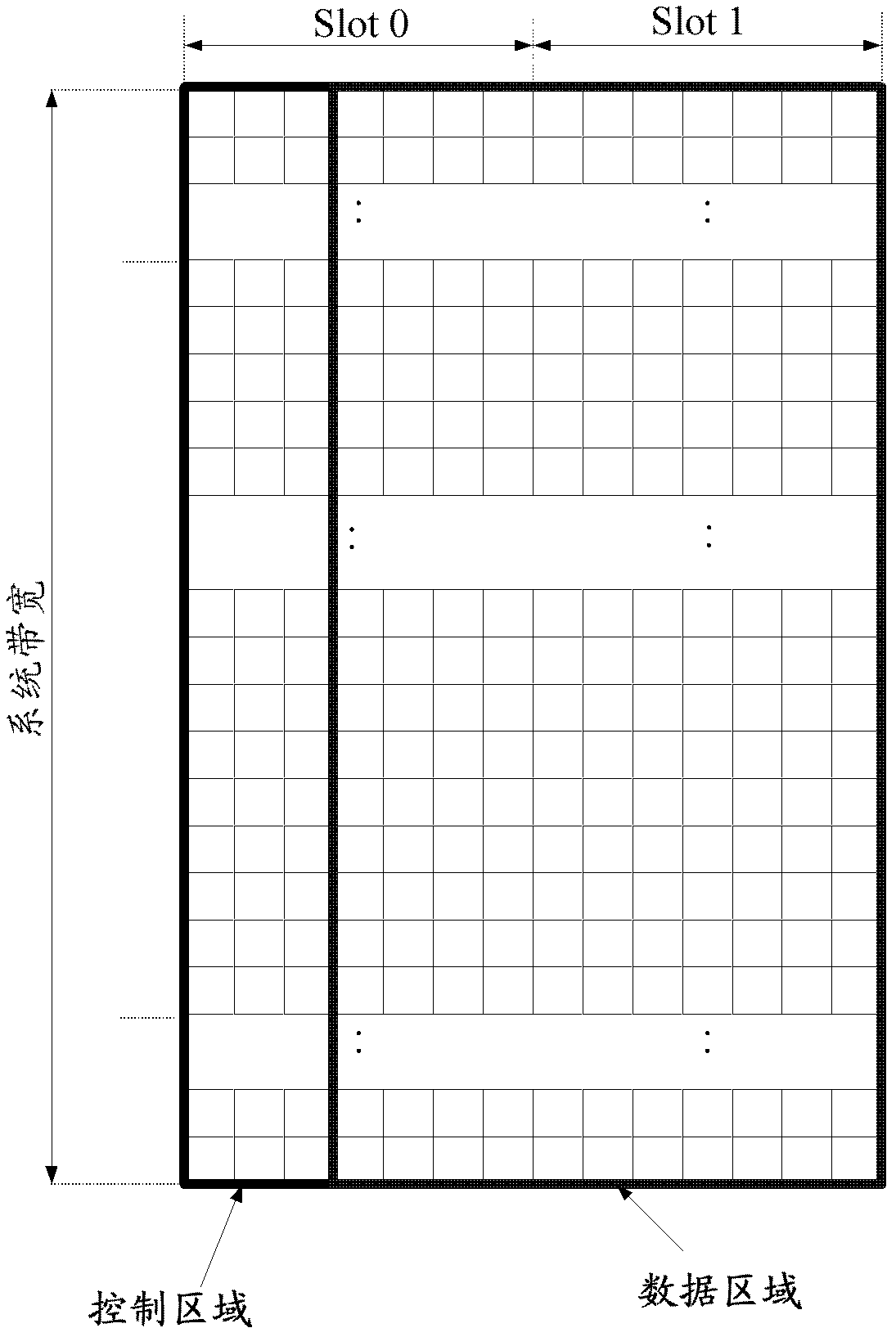

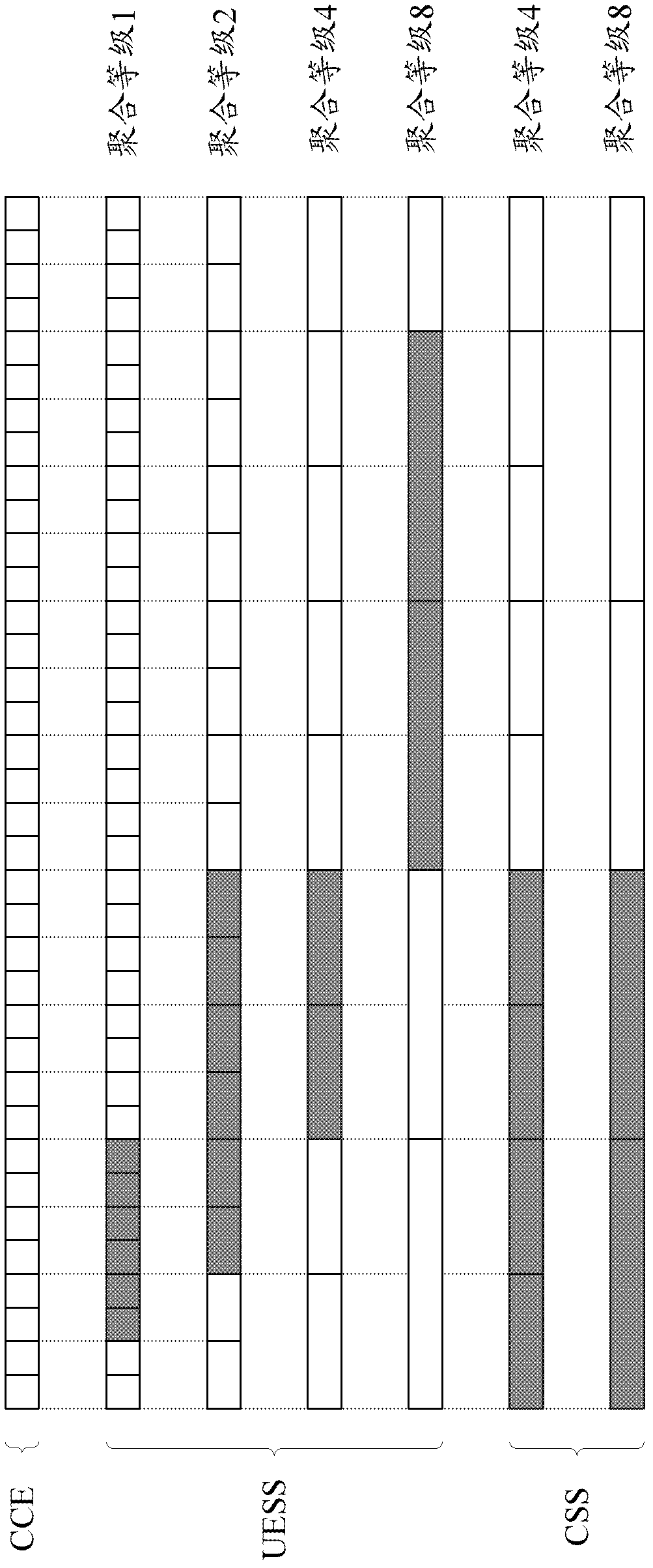

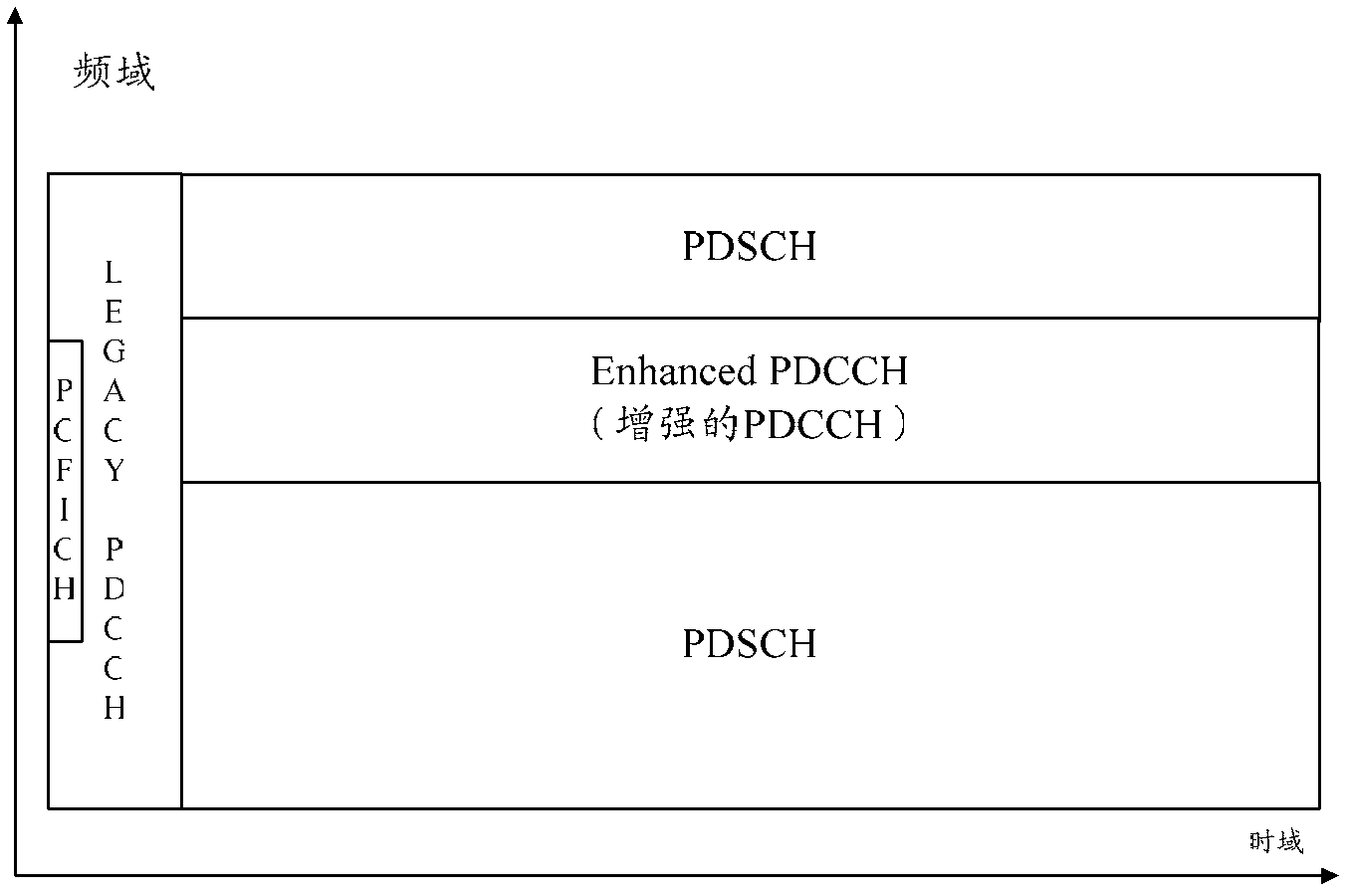

Method and device for transmitting DCI (downlink control information)

ActiveCN102573094AReduce overheadLow running costWireless communicationControl channelComputer science

The invention relates to the communication field and discloses a method and a device for transmitting DCI (downlink control information). The method comprises the following steps of: dividing E-PDCCH (extended physical downlink control channel) resources in a PDSCH (physical downlink shared channel) region into two types of candidate E-PDCCH, transmitting the terminal-exclusive DCI to a terminal by adopting the first type of the candidate E-PDCCH and at least transmitting the public DCI to the terminal by adopting the second type of the candidate E-PDCCH. Therefore, the signaling overhead when the public DCI is transmitted can be effectively reduced; and simultaneously, MTC (machine type communications) equipment can also be supported for running under working bandwidth which is lower than the bandwidth of a system, and the running cost of the system can be effectively reduced.

Owner:DATANG MOBILE COMM EQUIP CO LTD

Non-phosphorus compound scale and corrosion inhibitor for treatment of circulating cooling water

ActiveCN1621362AEasy to useIncrease the concentration factorScale removal and water softeningPhosphateTungstate

The composite phosphate-free scale inhibiting corrosion inhibitor for treating circular cooling water consists of scale inhibitor and corrosion inhibitor. The scale inhibitor consists of one or several of PASP, PVA, oxidized starch, polyacrylic acid, acrylic acid / acrylate copolymer and acrylic acid / acrylate copolymer with sulfo radical. The corrosion inhibitor consists of one or several of sodium salt / potassium salt / ammonium salt of organic salt, sodium / potassium / ammonium borate, nitrous organic matter, soluble molybdenate, soluble tungstate, soluble nitrate, soluble nitrite and soluble zinc salt. The composite scale inhibiting corrosion inhibitor has excellent scale inhibiting and corrosion inhibiting performance, is environment friendly, and is especially the treatment of hard circulation water with high calcium and high alkali content.

Owner:BEIJING YANHUA XINGYE TECH DEV +1

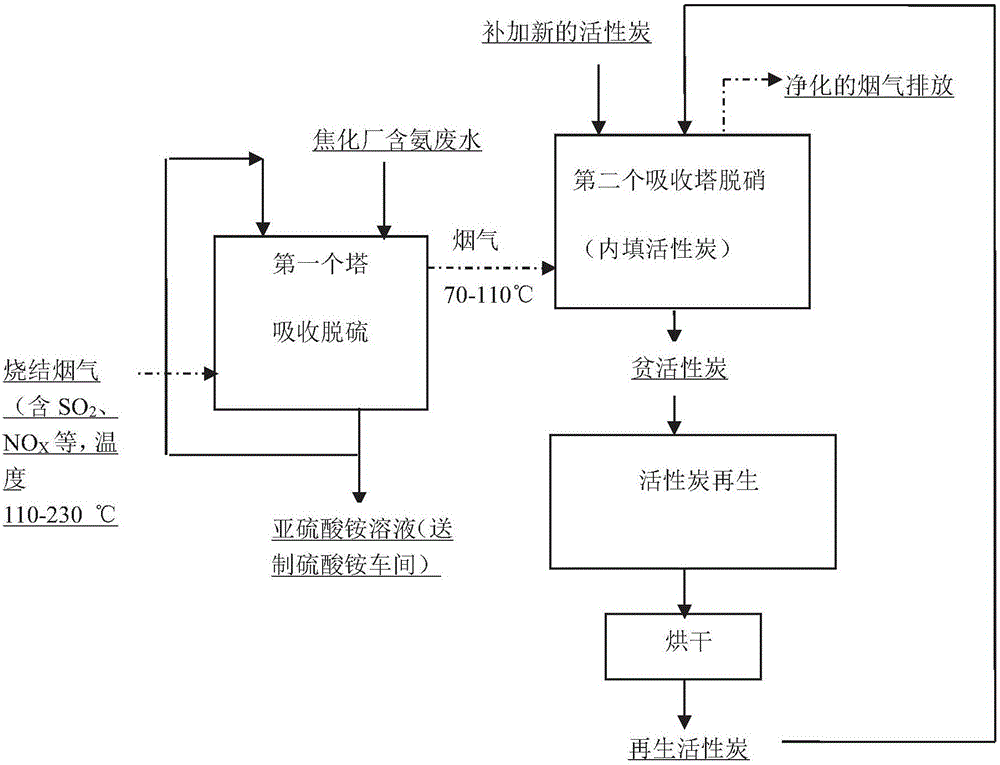

Ammonia-carbon combined desulfurization and denitration method for sintering flue gas

ActiveCN106621773AHigh mechanical strengthImprove recycling ratesGas treatmentOther chemical processesActivated carbonFlue gas

The invention discloses an ammonia-carbon combined desulfurization and denitration method for sintering flue gas. The sintering flue gas is desulfurized through ammonia-containing absorption liquid and then is adsorbed through activated carbon; the activated carbon is obtained by roasting carbonaceous materials and metallic oxide sources at a mass ratio of 2: 1 to 5: 1 at 850-1100 DEG C; the carbonaceous materials refer to semicoke or a mixture of coal and biomass. In the method, ammonia is cooperated with the activated carbon prepared through the method in use, desulfurization and denitration can be effectively achieved, secondary pollution is reduced, the process is cut short, and the treatment cost is reduced.

Owner:CENT SOUTH UNIV

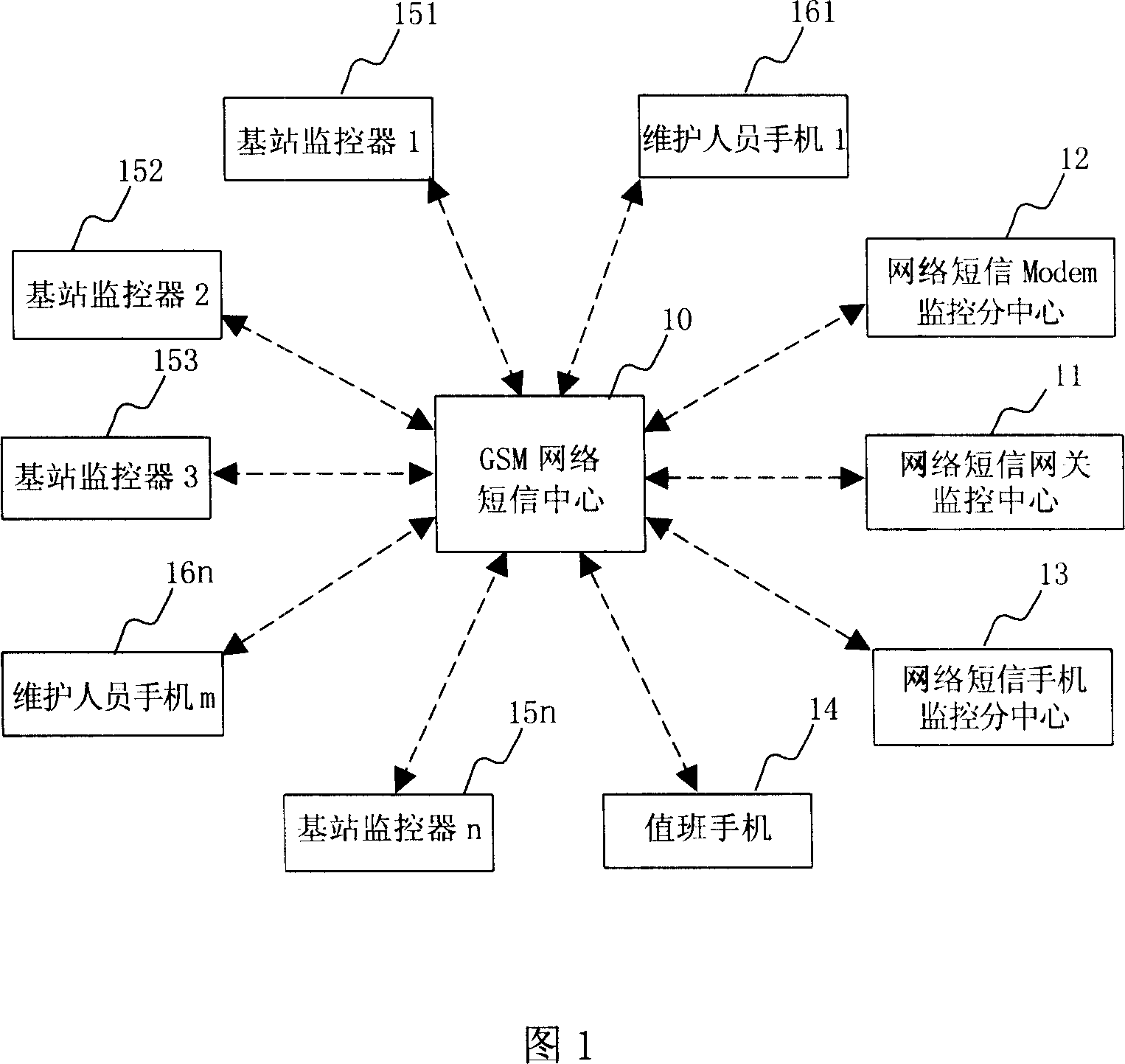

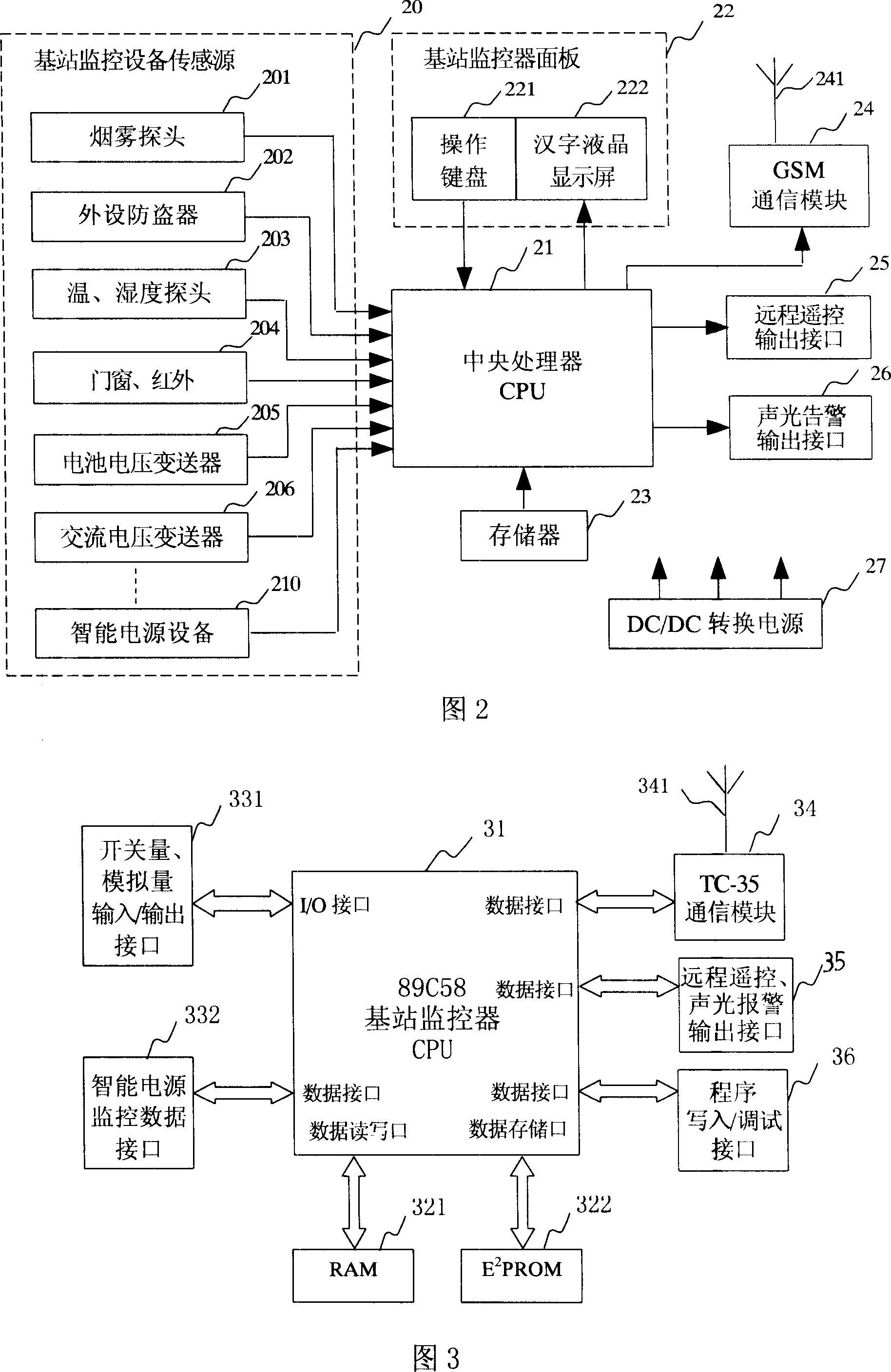

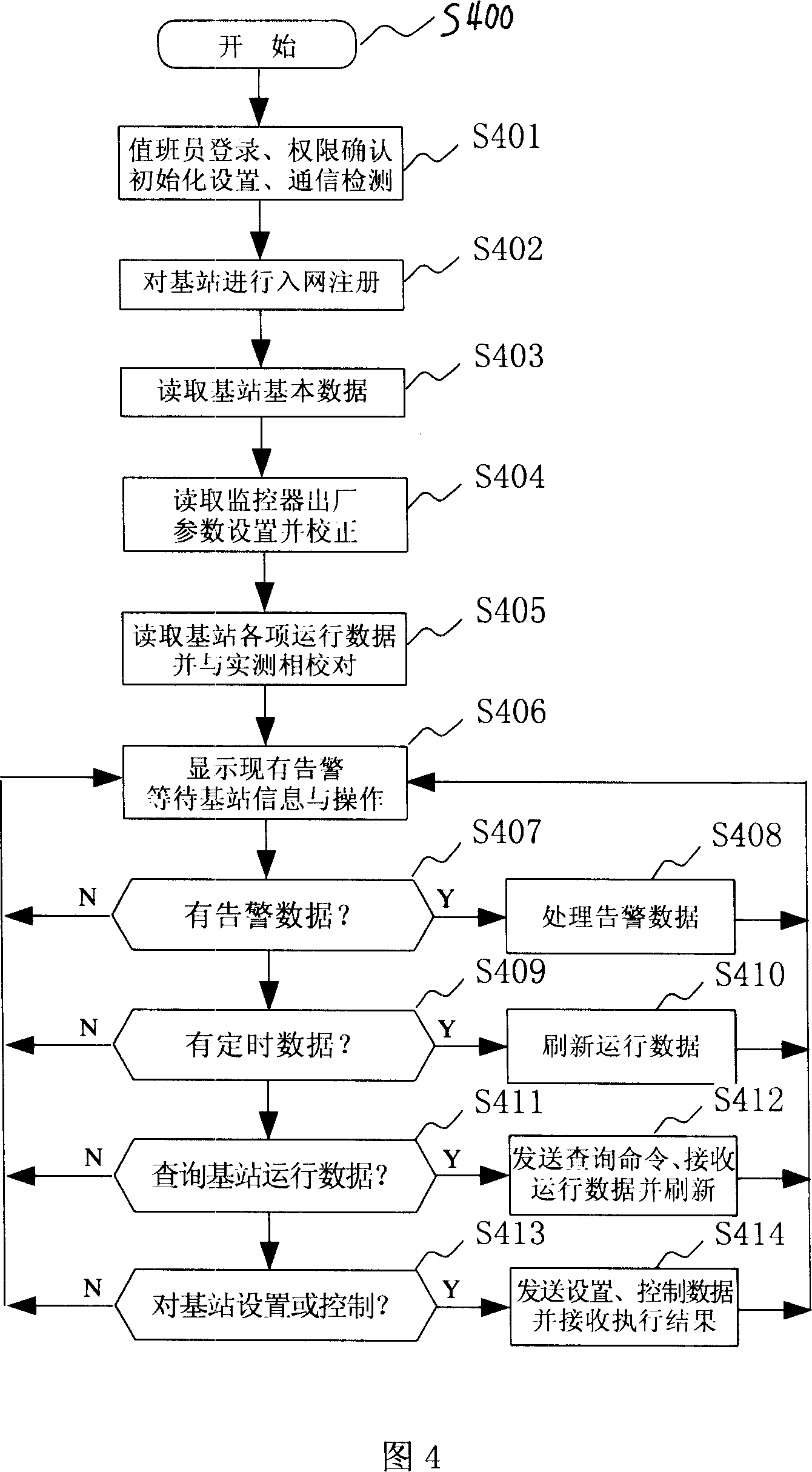

Method and system for transmitting monitoring data of communication base station

InactiveCN101014173ADetection speedEasy to masterTelephonic communicationRadio/inductive link selection arrangementsMonitoring methodsGSM

The invention relates to one digital mobile communication technique suitable for one transmission base station monitor method and system based on wireless mobile terminal, which uses GSM communication network short message channel to sort monitor data and to transmit on focus degree, wherein, the alarm information and inquire information send by real time and the operation information without alarm sends method and process technique to form alarm guide base station monitor system by network monitor center, base station and other human cell phone network.

Owner:姜宏伟

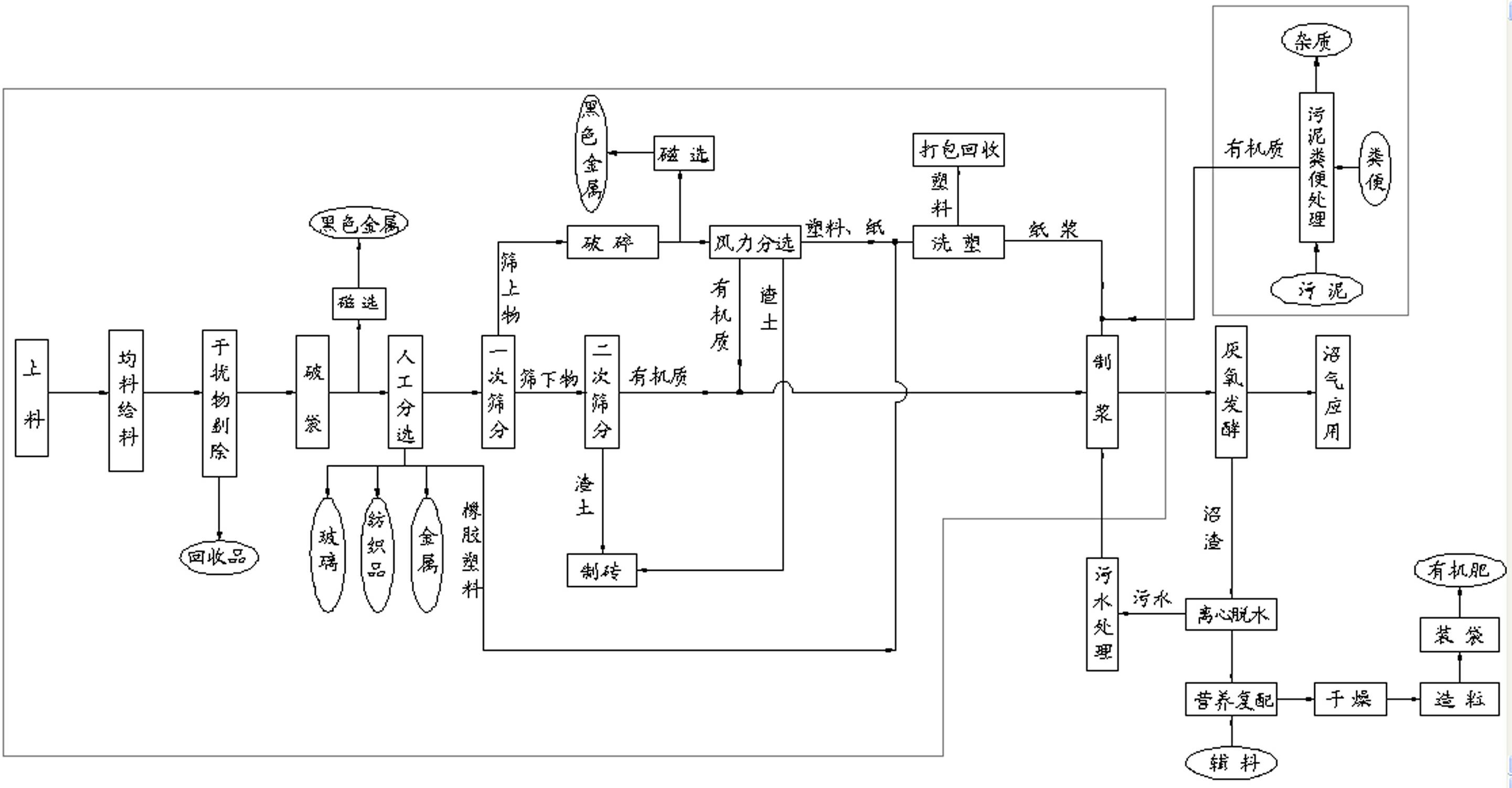

Comprehensive treating system for domestic wastes

InactiveCN102527701AIncrease productionImprove qualityBio-organic fraction processingWaste processingSludgeOrganic manure

The invention discloses a comprehensive treating system for domestic wastes. Reutilizing comprehensive treatment for mixed wastes is realized by the system according to a comprehensive sorting technology and a combined anaerobic fermentation technology, wherein the advanced sorting techniques, such as, crushing, magnetic separating, sieving, air classifying, and the like, are adopted in the comprehensive sorting technology; reutilized products, such as metal, plastics, organic matters, and the like, are screened out; the screened organic matters are prepared into slurry together with sludge and excrements and are then subjected to the combined anaerobic fermentation; the reutilized products, such as methane, organic fertilizer, and the like, can be produced under the action of anaerobic fermentation; and after the methane is purified, the methane is used for generating power, domestic fuel or vehicle-mounted fuel. According to the technology, the intensified treatment for organic wastes, such as domestic wastes, sludge, excrements, kitchen wastes, and the like, can be realized. The comprehensive treating system is high in mechanical and automated degree. Compared with the prior art, the comprehensive treating system has the advantages of simplification, effectiveness, less labor power, and the like.

Owner:BEIJING HAOHAI TIANJI TECH +1

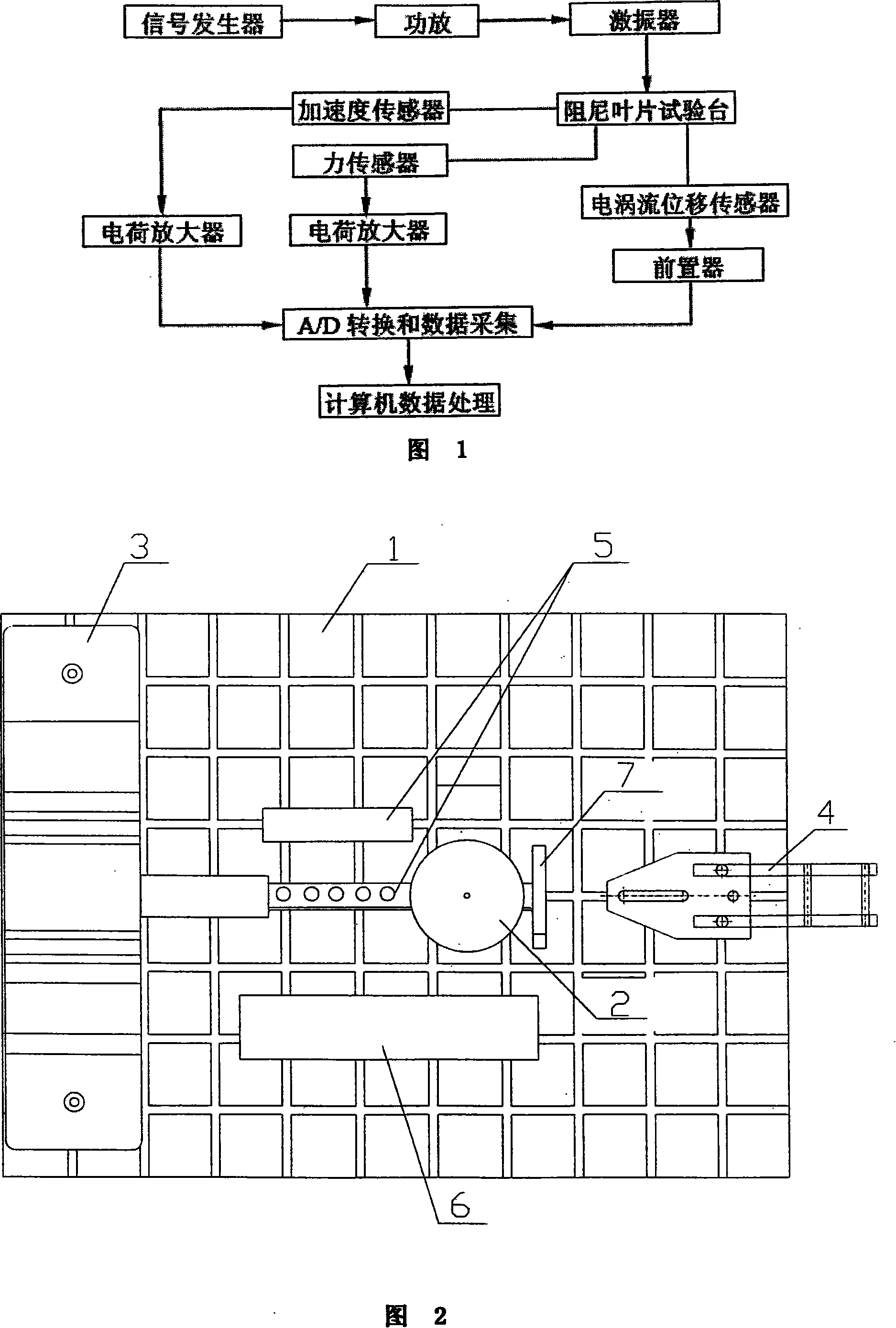

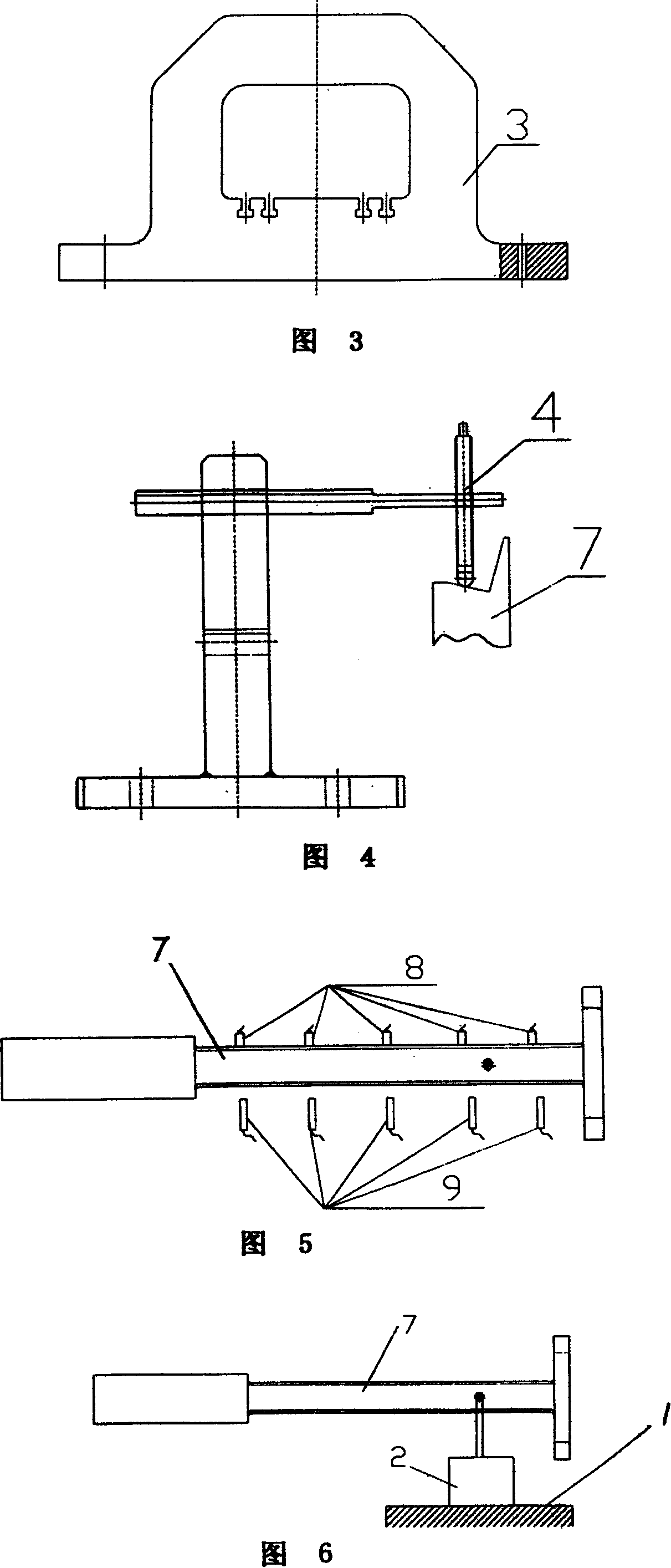

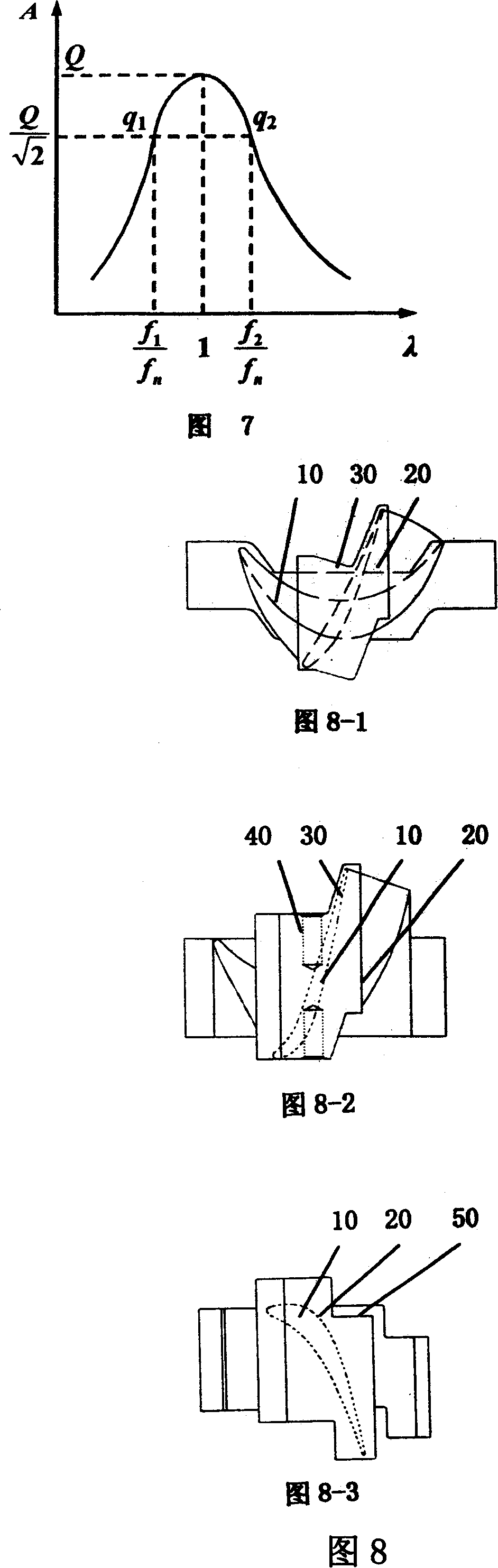

Turbine blade vibration test method and device

ActiveCN101122541AProven Vibration MechanismReasonable designVibration testingElasticity measurementMathematical modelEngineering

The invention discloses a steam turbine blade vibration test method and device. The method steps are that firstly, a blade force vibration status is analyzed and a blade excitation force mathematical model is built. Secondly, an excitation force is imposed on the blade by a vibration source. The frequency of the excitation force is regulated until resonance is generated between the blade and the vibration source. Vibration characteristics parameters values of the blade under the excitation force are measured. Thirdly, blade damping characteristics parameters, including modal damping ratio, damper contact stiffness and blade dynamic stress, are worked out according to the vibration characteristics parameters values. The device includes a test bed, a blade clamping mechanism arranged on the test bed, an excitation generator, a vibration parameter detector and a data processing system. The excitation vibration generator is fixed on the test bed. The excitation vibration head of the excitation vibration generator is fixed with the blade. Corresponding to the blade, the vibration parameter detector transforms the vibration signals of the blade into electric signals, which are input into the data processing system. The invention proves the vibration mechanism of the damping blade. A calculation model of the damping blade is constructed through the test parameters. Experience design is terminated. The blade design is standardized to step into a scientific design orbit.

Owner:DONGFANG TURBINE CO LTD +1

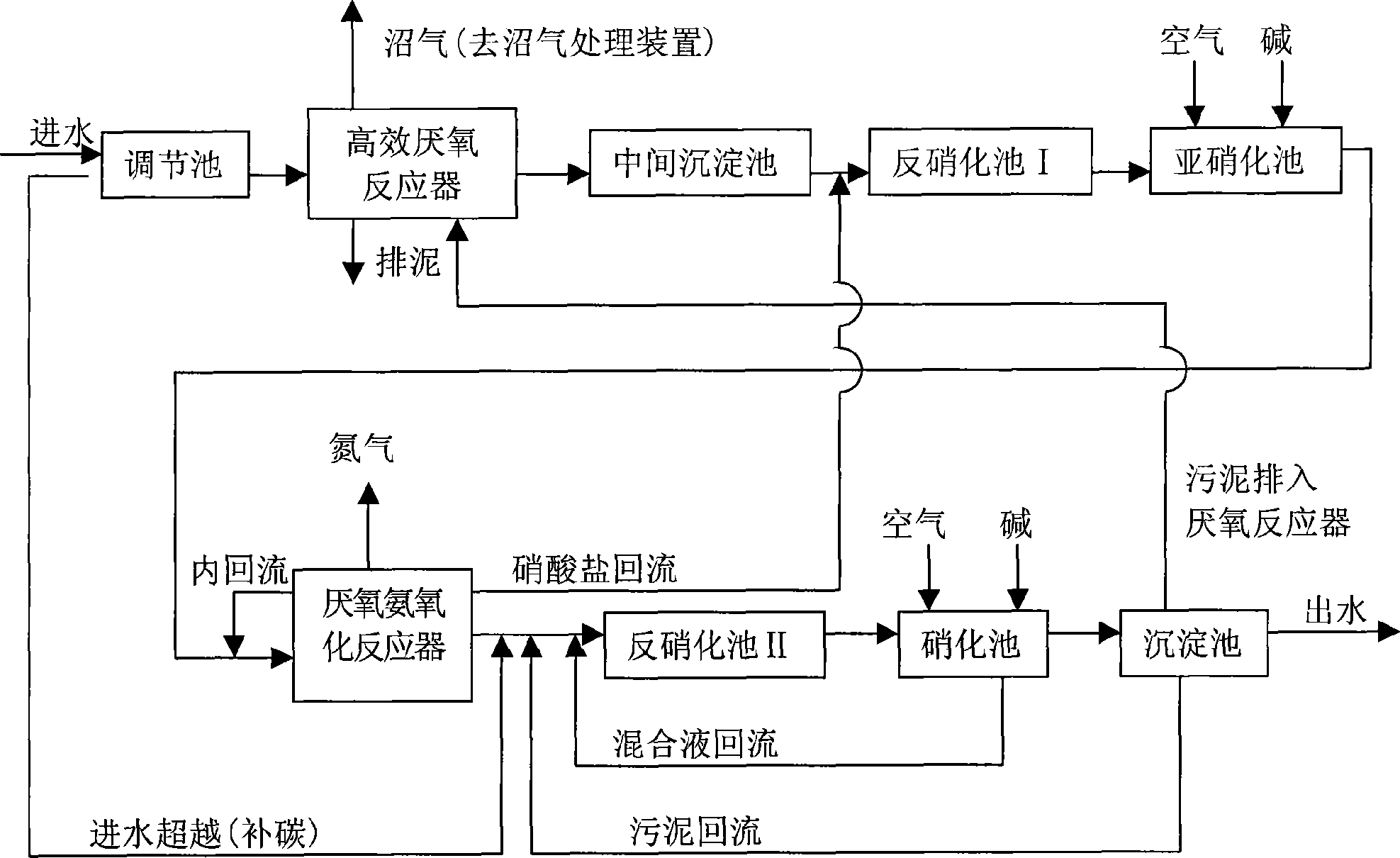

Deepness denitrogenation method for treating organic wastewater in high concentration

ActiveCN101050026AGuaranteed emission standardsThe process route is compactWater contaminantsTreatment with aerobic and anaerobic processesHigh concentrationTotal nitrogen

This invention discloses a method for deep denitrification treatment of high-concentration organic wastewater. The apparatus comprises an anaerobic decarbonization zone, an aerobic nitrosation / anaerobic ammoxidation denitrification zone, and a traditional nitrification / denitrification zone. In the anaerobic decarbonization zone, an anaerobic bioreactor is utilized to perform anaerobic biotreatment on the organic pollutants in raw water to remove the majority of organic matters. In the aerobic nitrosation / anaerobic ammoxidation denitrification zone, ammonia nitrogen and nitrite nitrogen are removed in the form of nitrogen gas. In the traditional nitrification / denitrification zone, nitrate in the water discharged from the aerobic nitrosation / anaerobic ammoxidation denitrification zone is subjected to denitrification and removed in the form of nitrogen gas. Excess organic matters are subjected to aerobic bioreaction and removed. The method can ensure COD; total nitrogen and ammonia nitrogen contents in the treated water are qualified for discharge. The method has such advantages as high decarbonization and denitrification efficiency, low energy consumption, and high running stability.

Owner:BEIJING MUNICIPAL RES INST OF ENVIRONMENT PROTECTION

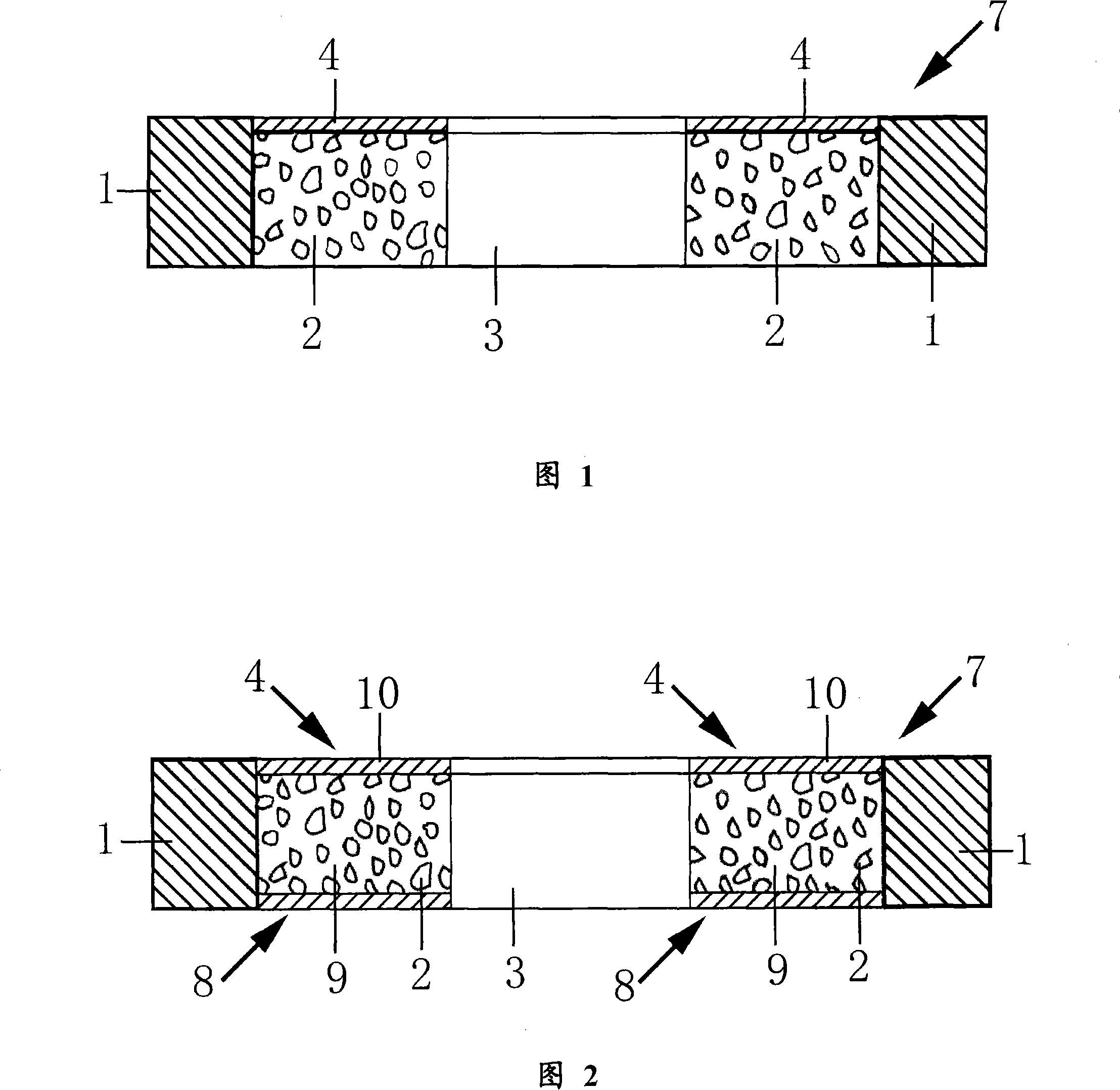

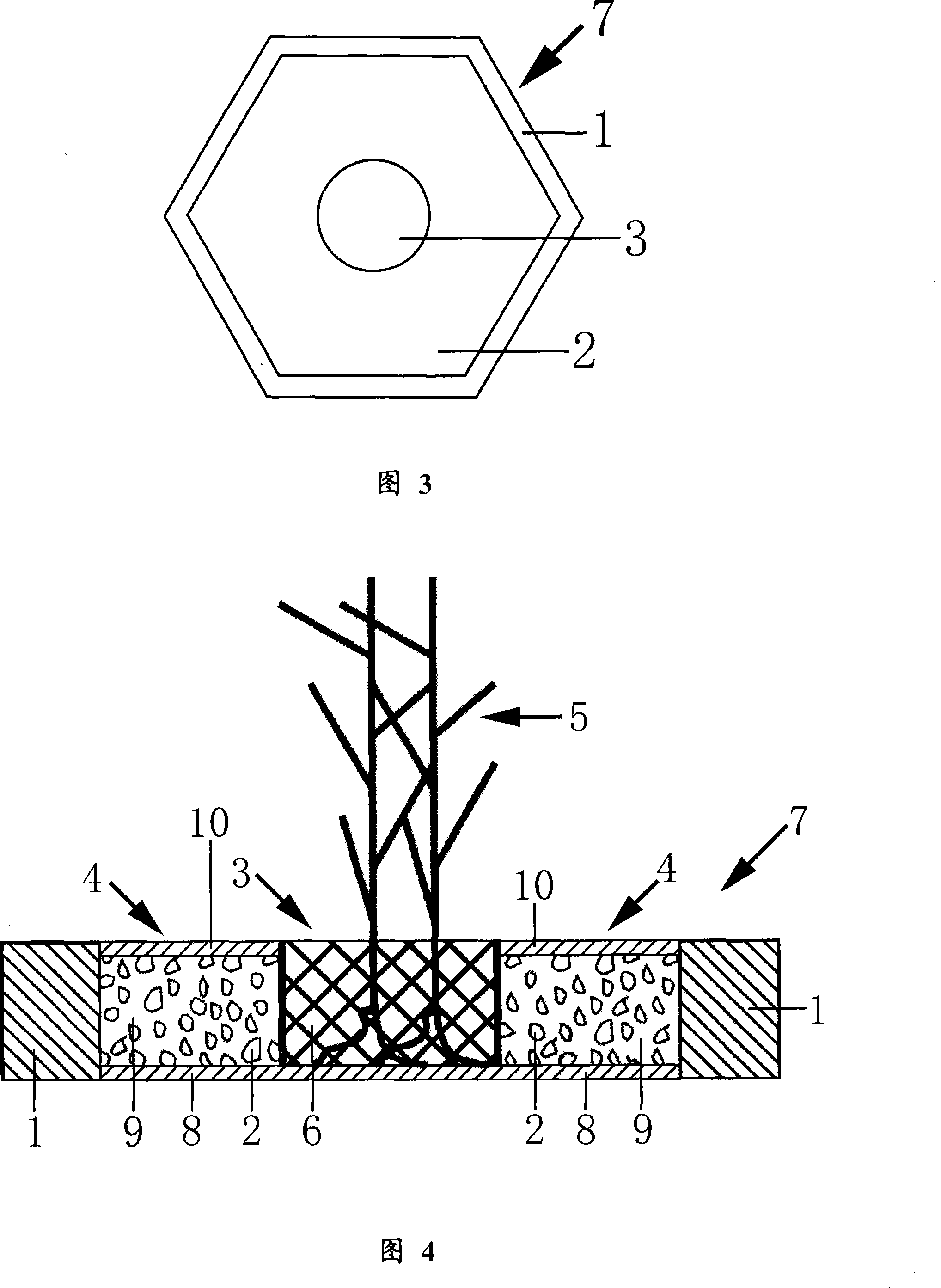

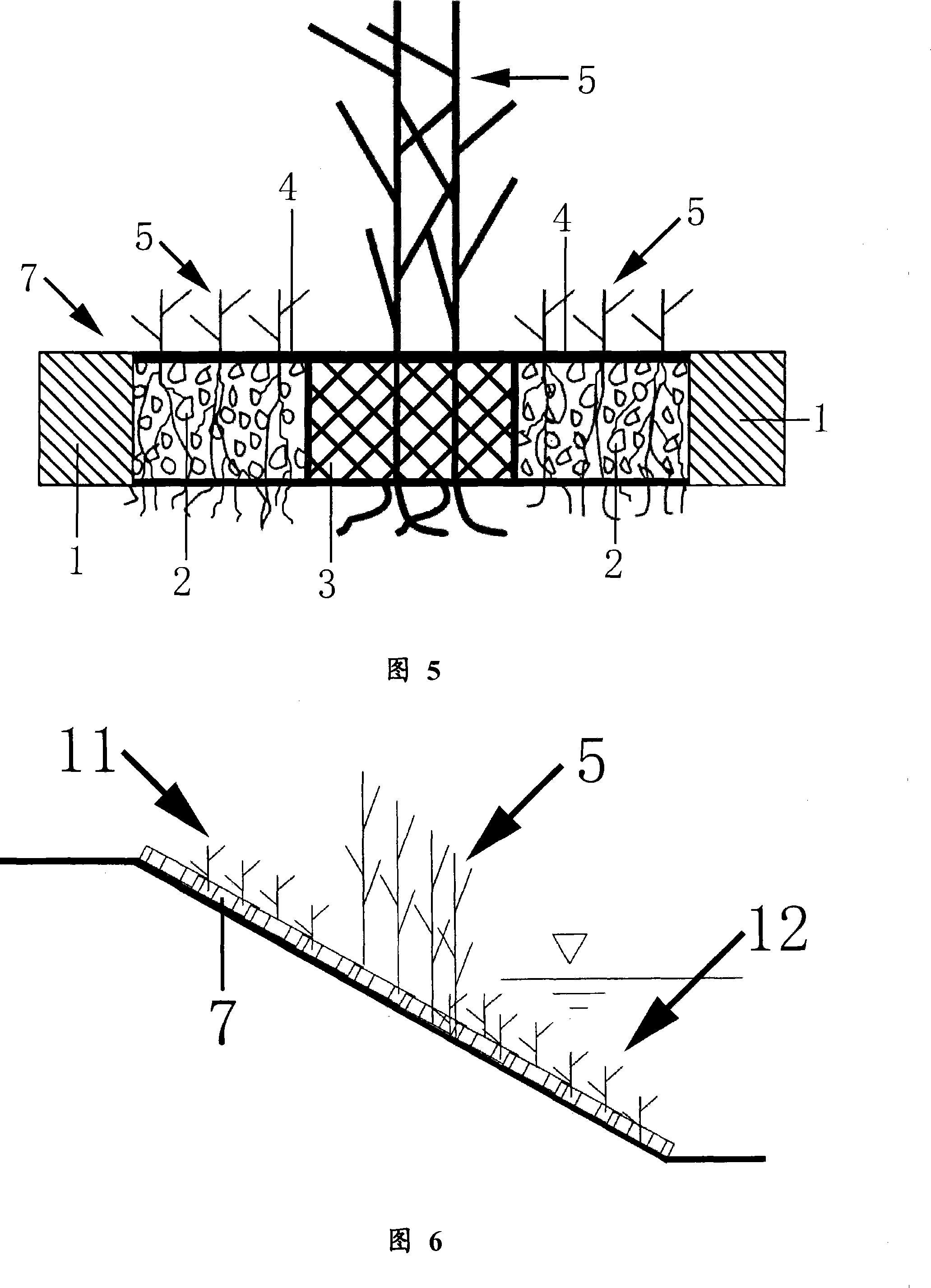

Ecological slope protection vegetation building blocks as well as making method and construction process

InactiveCN101200894APrevent collapseImprove the environmental landscapeSolid waste managementMixing operation control apparatusEngineeringLevee

The present invention relates to a building block of ecological slope protection vegetation, a fabrication method and a construction technique. The building block is composed of a growing bed body, a lath crib, planting troughs, a vegetation layer and a plant, the lath crib wraps the circumference of the growing bed body, the upper plane of the growing bed body is lower than the upper plane of the lath crib and concave, the vegetation layer is formed on the growing bed body, which matches the inner walls of the sectional area of the lath crib to form an integral building block, and more than one planting troughs are arranged on and run through the growing bed body. The design of the present invention is scientific, the structure is reasonable, the restoration of water ecology can reduce the operating cost, environment is improved, ecology is reinstated, harmonious natural beauty is enhanced, and the present invention is suitable for the nidification of small living creatures and the habitation and the survival of aquatic fishes, so that the cutting-off continuity of water and land regions is restored. The present invention is widely applied to channel slope protection, levee slopes, roadsides, airports, parks, public lands, household lawns, sports grounds, etc. The present invention is suitable for cold regions, damp regions, warm and damp intermediate zone, etc.

Owner:TIANJIN WATER RESOURCES RES INST +2

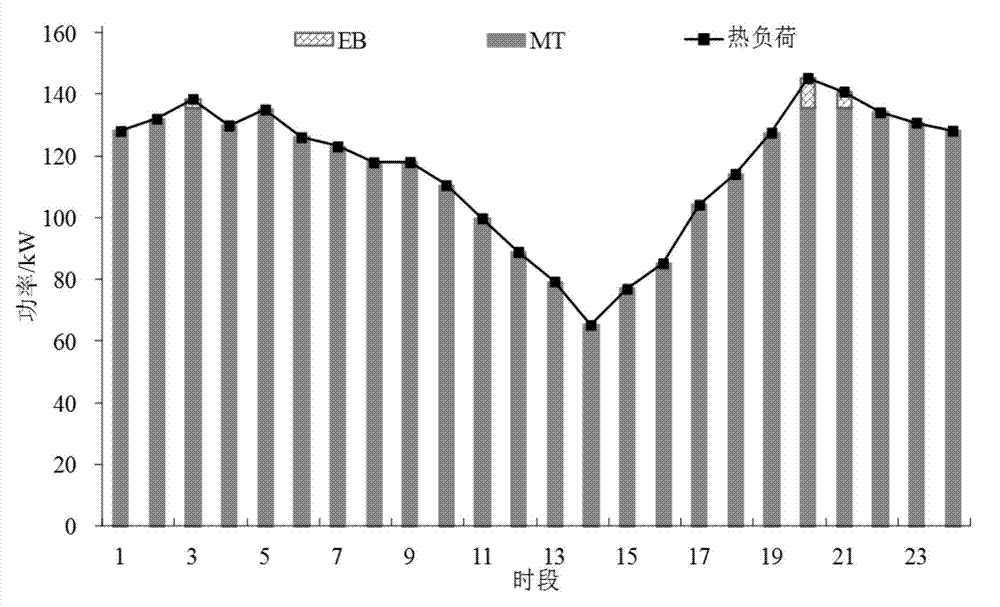

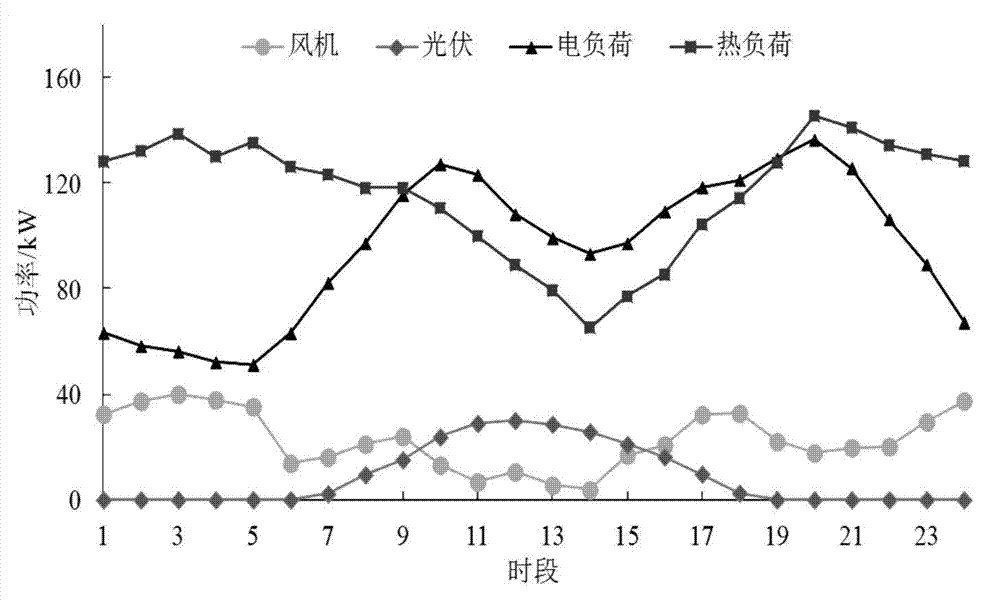

Microgrid running optimization system and method based on power and heat combined dispatching

ActiveCN104734168AIncrease profitLow running costEnergy storageAc network load balancingDistributed generatorInteger non linear programming

The invention discloses a microgrid running optimization system and method based on power and heat combined dispatching. Running restrains such as the output force characteristic, start, stop and climbing of a distributed type generator set and the charge and discharge characteristics of power and heat energy storage are comprehensively considered, a microgrid power and heat combined dispatching model containing a fan, a photovoltaic cell, a combined heat and power generation system, an electric boiler, a fuel cell and an energy storage (electrical energy storage and heat energy storage) is built, the 0-1 mixed integer nonlinear programming method is adopted for solving the optimal output force and total running cost of all units in the network, and power and heat dispatching contrastive analysis is carried out on the system and a traditional separated generation and combined generation optimization model. In addition, the influences of the heat and power reliability difference on the running are analyzed and discussed, and therefore the heat and power dispatching module is more reasonable, comprehensive and universal.

Owner:SHANDONG UNIV

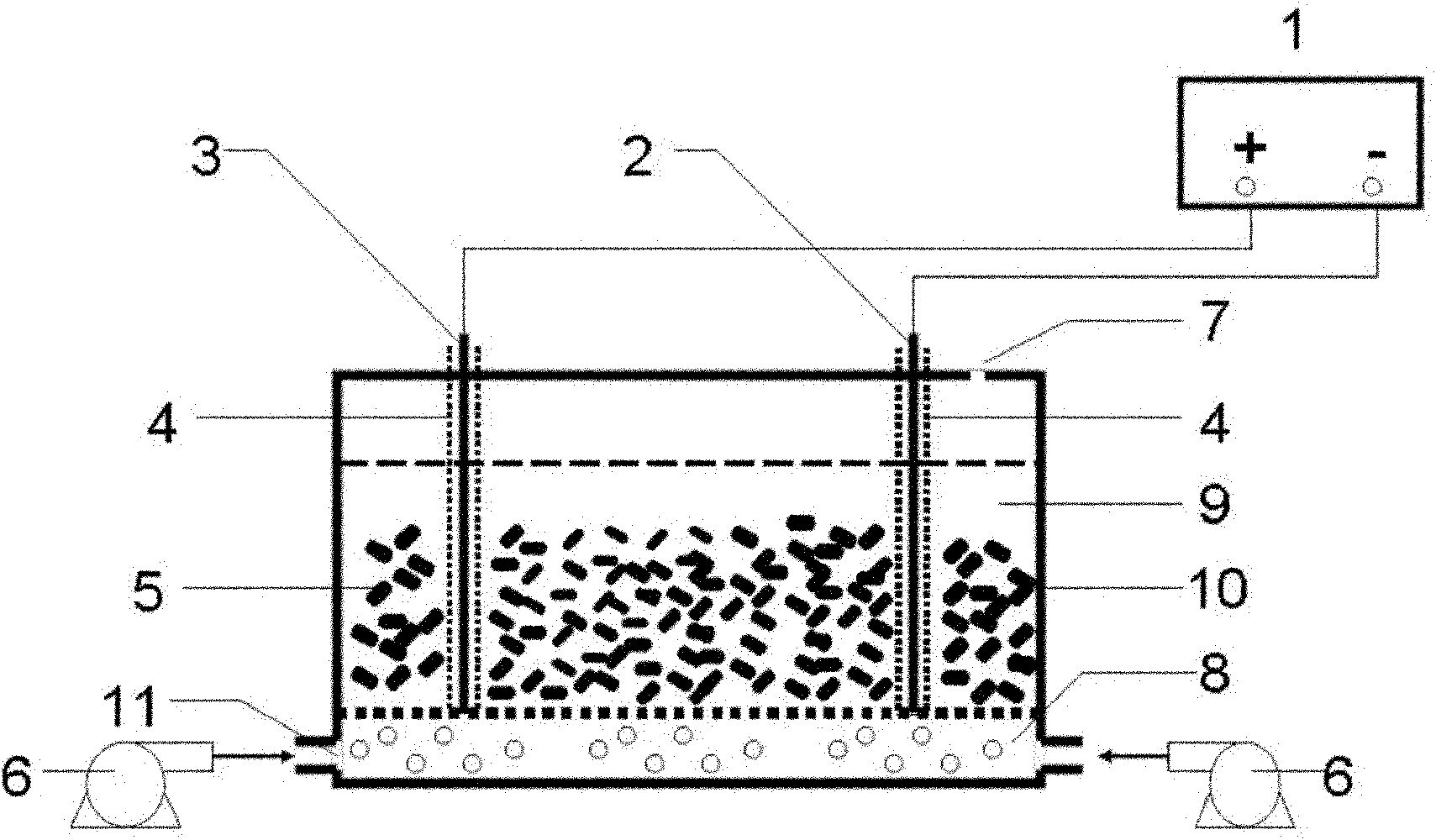

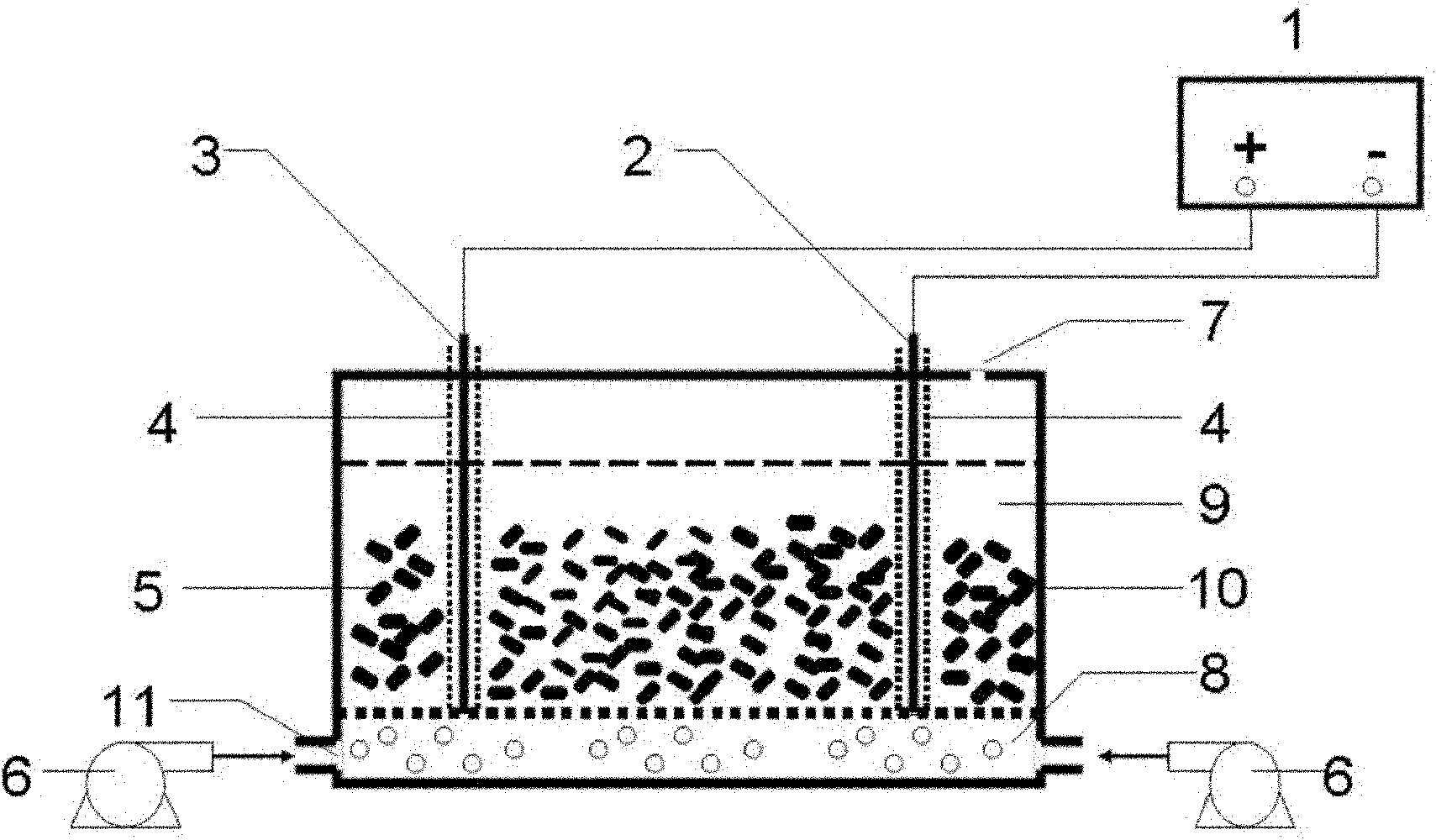

Method for removing organic matters in water by utilizing three-dimensional electrode electro-fenton and device thereof

InactiveCN102070230AIncrease contact areaExtension of timeWater/sewage treatment by oxidationFenton reagentFixed bed

The invention relates to a method for carrying out oxidation treatment on organic waste water by utilizing a three-dimensional electrode electro-fenton and a device thereof. The device comprises a reactor shell, a carbon material cathode, an iron plate anode, a three-dimensional particle electrode of a fixed bed, a direct-current voltage-stabilizing power supply, a microporous aeration plate and an air pump, wherein a reactor consists of a reaction chamber and a gas chamber; the carbon material cathode, the iron plate anode and the particle electrode are positioned in the reaction chamber at the upper part of the reactor; and the gas chamber is formed between the bottom of the reactor and the microporous aeration plate. After direct current is introduced, the iron anode is oxidized to generate iron ions, oxygen in the gas chamber is reduced on the surface of the cathode to generate hydrogen peroxide, and the iron ions and the hydrogen peroxide form a fenton reagent to oxidize and remove organic matters in waste water; and simultaneously, due to the particle electrode, the contact area and the contact time of the waste water and the fenton reagent are increased, and the mass transfer effect of the waste water in the reactor is reduced. The invention is applicable to treatment of various types of organic waste water, the equipment is compact, the operation is easy, the whole reactor is easy to control, and the requirements of an actual water treatment unit are met.

Owner:HUAZHONG NORMAL UNIV

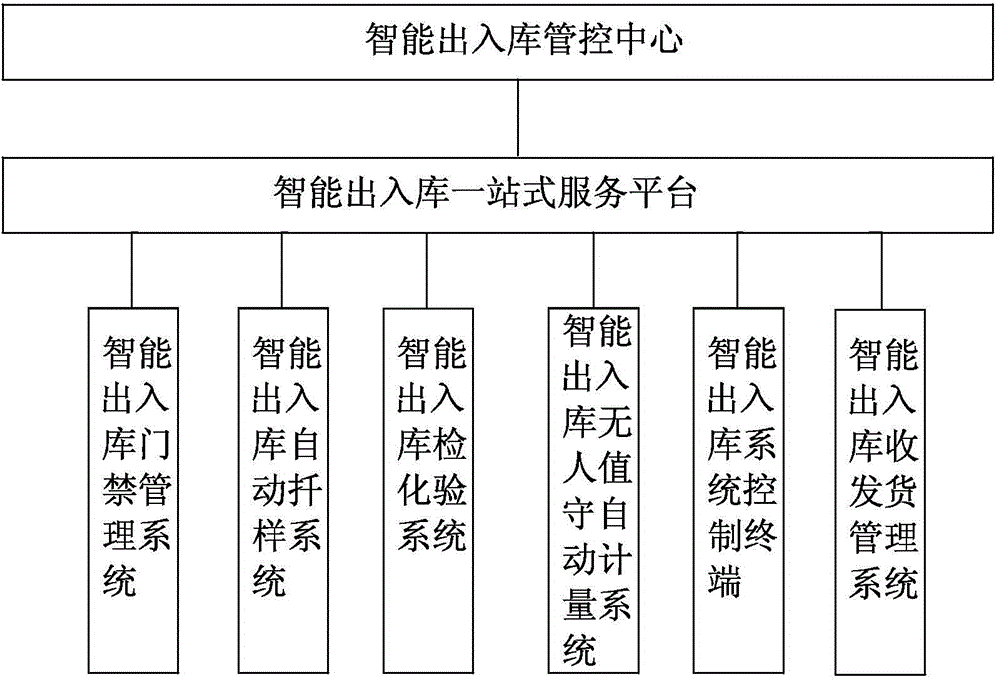

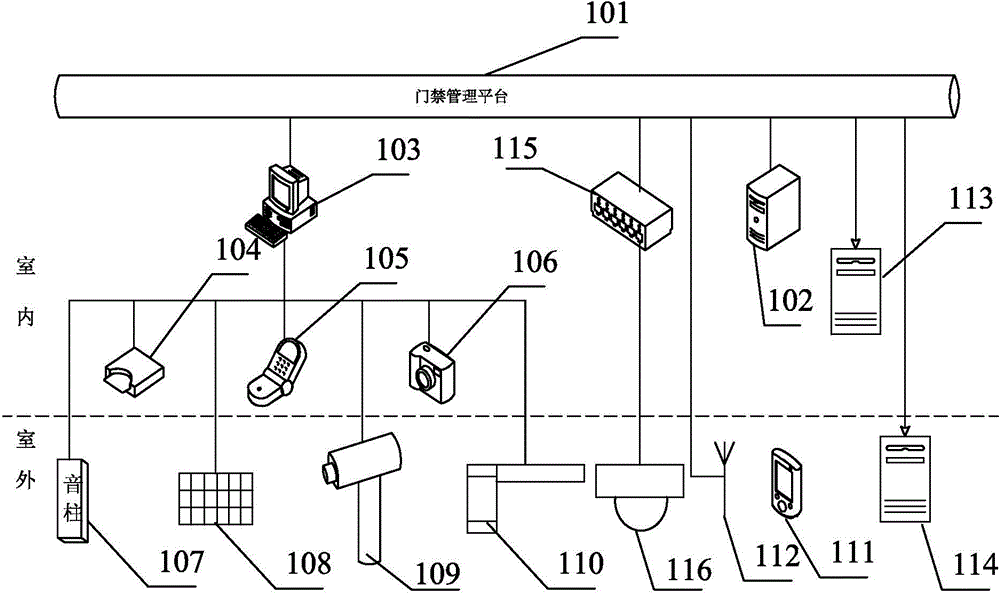

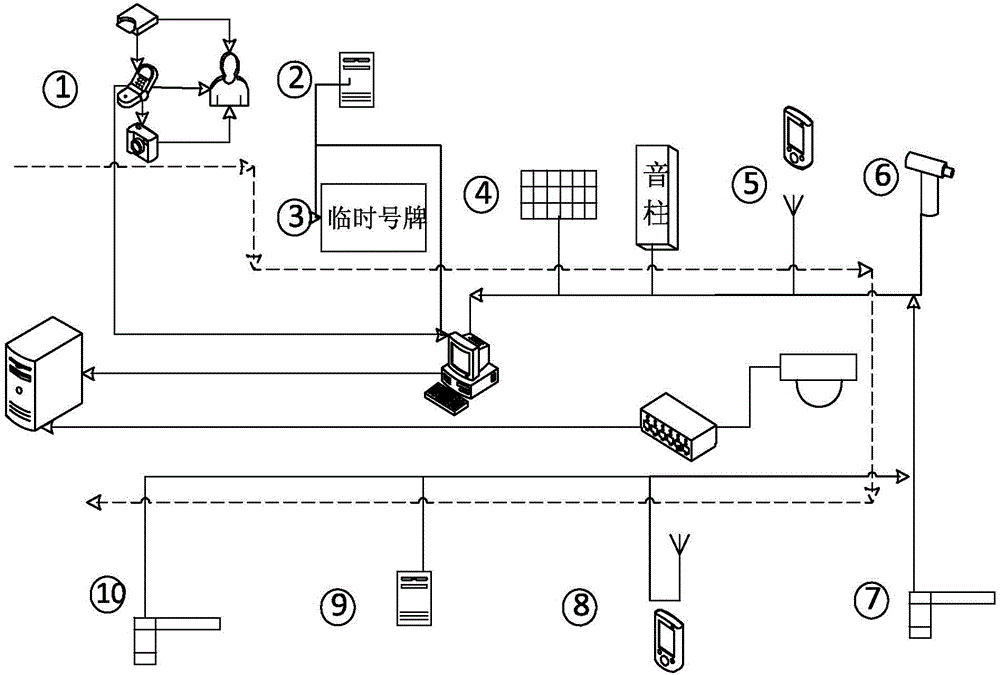

Intelligent depot output-input system of digital grain depot

ActiveCN103559605ASimplify business processesRealize paperless managementIndividual entry/exit registersLogisticsIntelligent managementComputer science

The invention discloses an intelligent depot output-input system of a digital grain depot. The intelligent depot output-input system of the digital gain depot comprises an intelligent depot output-input access control system, an intelligent depot output-input automatic sampling system, an intelligent depot output-input examination assay system, an intelligent depot output-input unattended operation automatic metering system, an intelligent depot output-input system control terminal, an intelligent depot output-input goods receiving-sending management system, an intelligent depot output-input system one-stop service platform and an intelligent depot output-input system control center. The intelligent depot output-input access control system, the intelligent depot output-input automatic sampling system, the intelligent depot output-input examination assay system, the intelligent depot output-input unattended operation automatic metering system, the intelligent depot output-input system control terminal, the intelligent depot output-input goods receiving-sending management system and the intelligent depot output-input system control center are connected with the intelligent depot output-input system one-stop service platform. According to the intelligent depot output-input system of the digital grain depot, a computer, the RFID internet of things technology, the communication technology and the information technology are converged together, networking, automation and intelligent management of the depot output and input are achieved, and labor participation is reduced.

Owner:JINAN JINZHONG ELECTRONICS SCALE +1

Economic optimization scheduling method for cold, heat and electricity combined supply type miniature energy grid

InactiveCN105869075AAchieve economically optimized operationImprove energy efficiencyData processing applicationsDesign optimisation/simulationSupply energyPower grid

The invention discloses an economic optimization scheduling method for a cold, heat and electricity combined supply type miniature energy grid. Various energy supply and energy storage devices in the cold, heat and electricity combined supply type miniature energy grid are analyzed, energy flow models of the devices are established, and a framework of the cold, heat and electricity combined supply type miniature energy grid is constructed based on energy exchange networks connected in a centralized mode; an economic optimization scheduling model of the cold, heat and electricity combined supply type miniature energy grid is established centered on the framework, and the model is solved with an interior point method based on Hessian matrix iteration according to the characteristics of the model. By scheduling the operation mode and output of all the energy supply devices in a smart grid park, economic optimization operation of the cold, heat and electricity combined supply type miniature energy grid is achieved. The energy optimization scheduling method is effective, practical and scientific, and application and popularization of energy conservation are promoted.

Owner:SOUTHEAST UNIV +2

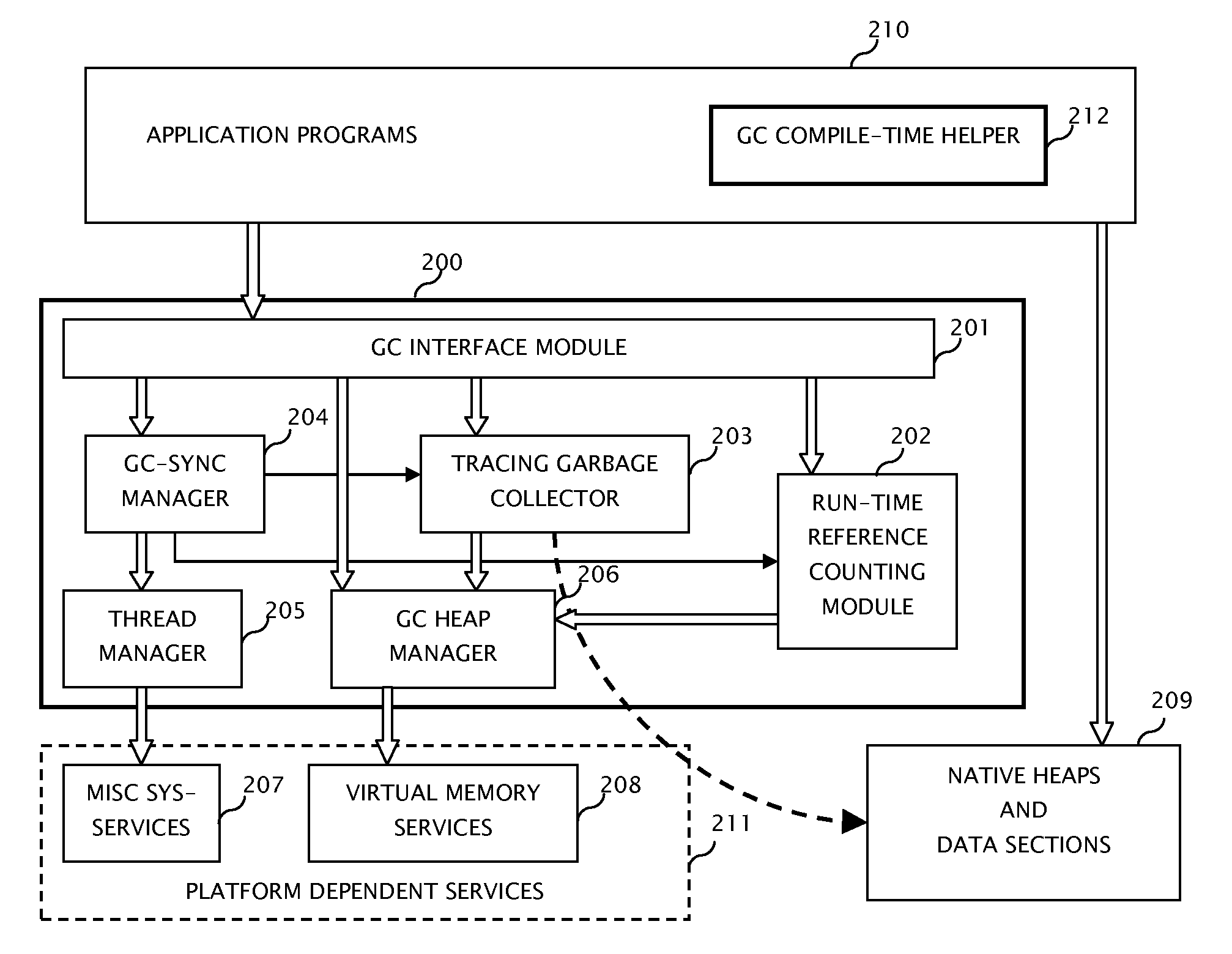

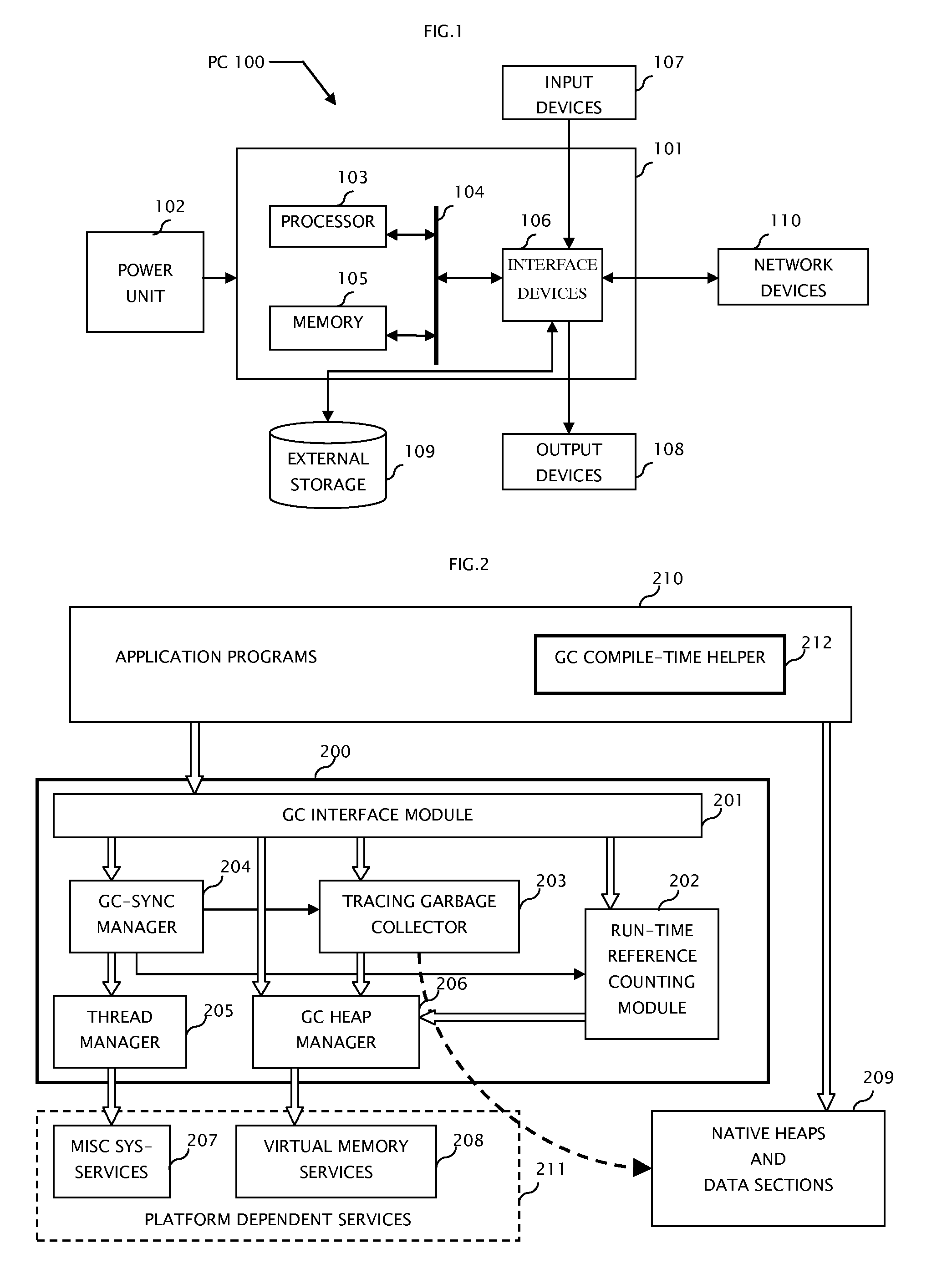

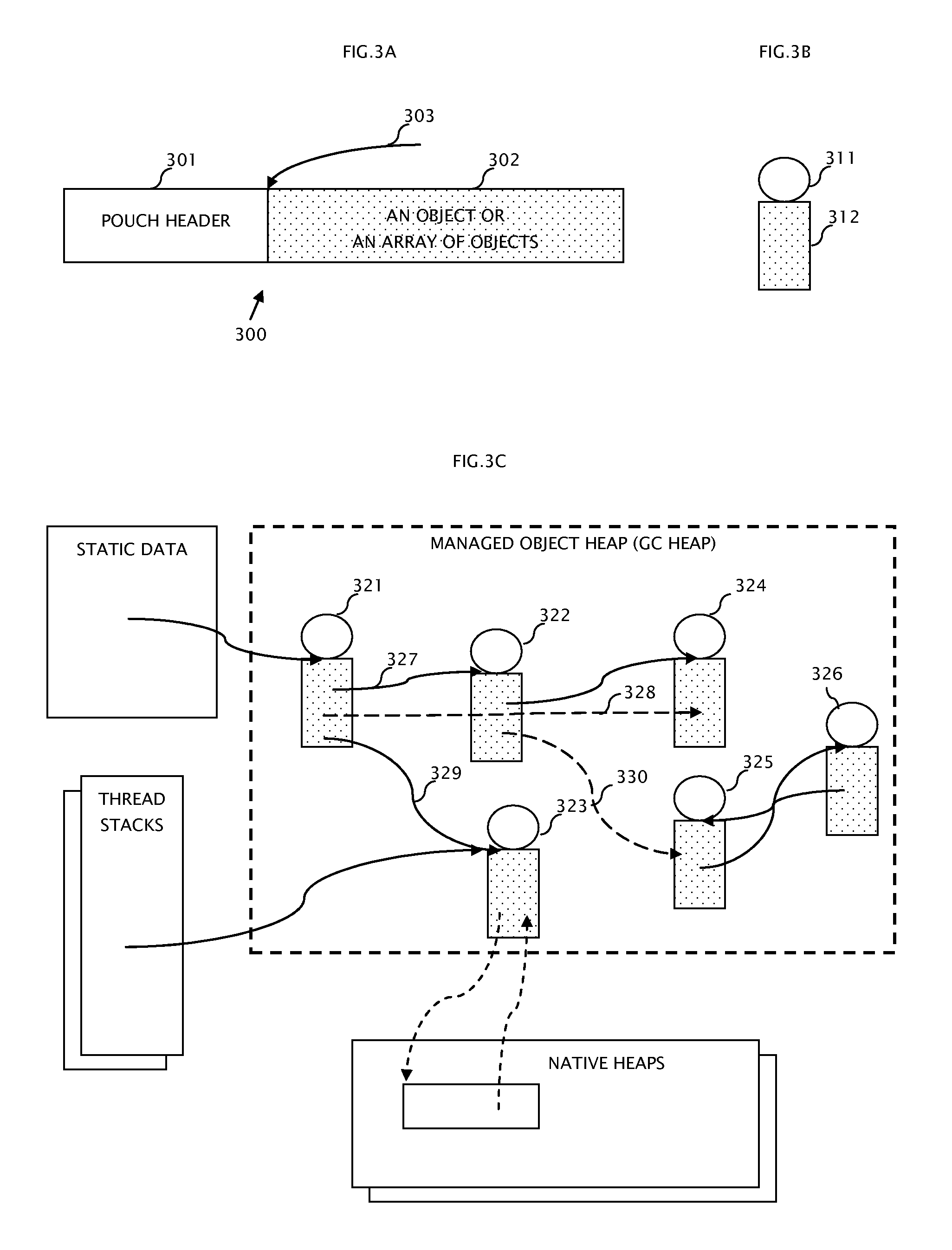

System and method for computer automatic memory management

ActiveUS7584232B2Eliminates all suspensionEnsure correct executionData processing applicationsSpecial data processing applicationsImmediate releaseWaste collection

The present invention is a method and system of automatic memory management (garbage collection). An application automatically marks up objects referenced from the “extended root set”. At garbage collection, the system starts traversal from the marked-up objects. It can conduct accurate garbage collection in a non-GC language, such as C++. It provides a deterministic reclamation feature. An object and its resources are released immediately when the last reference is dropped. Application codes automatically become entirely GC-safe and interruptible. A concurrent collector can be pause-less and with predictable worst-case latency of micro-second level. Memory usage is efficient and the cost of reference counting is significantly reduced.

Owner:GUO MINGNAN

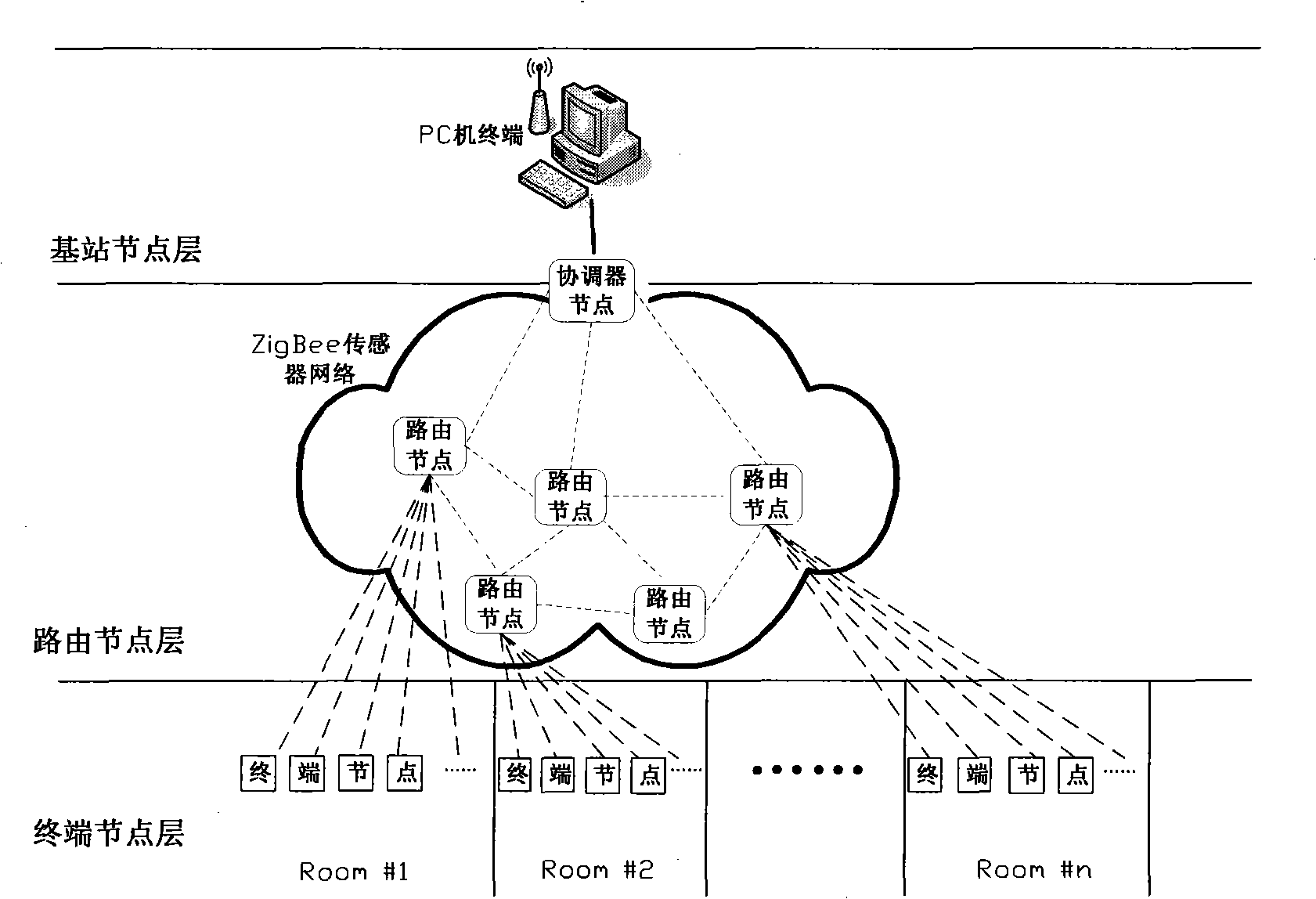

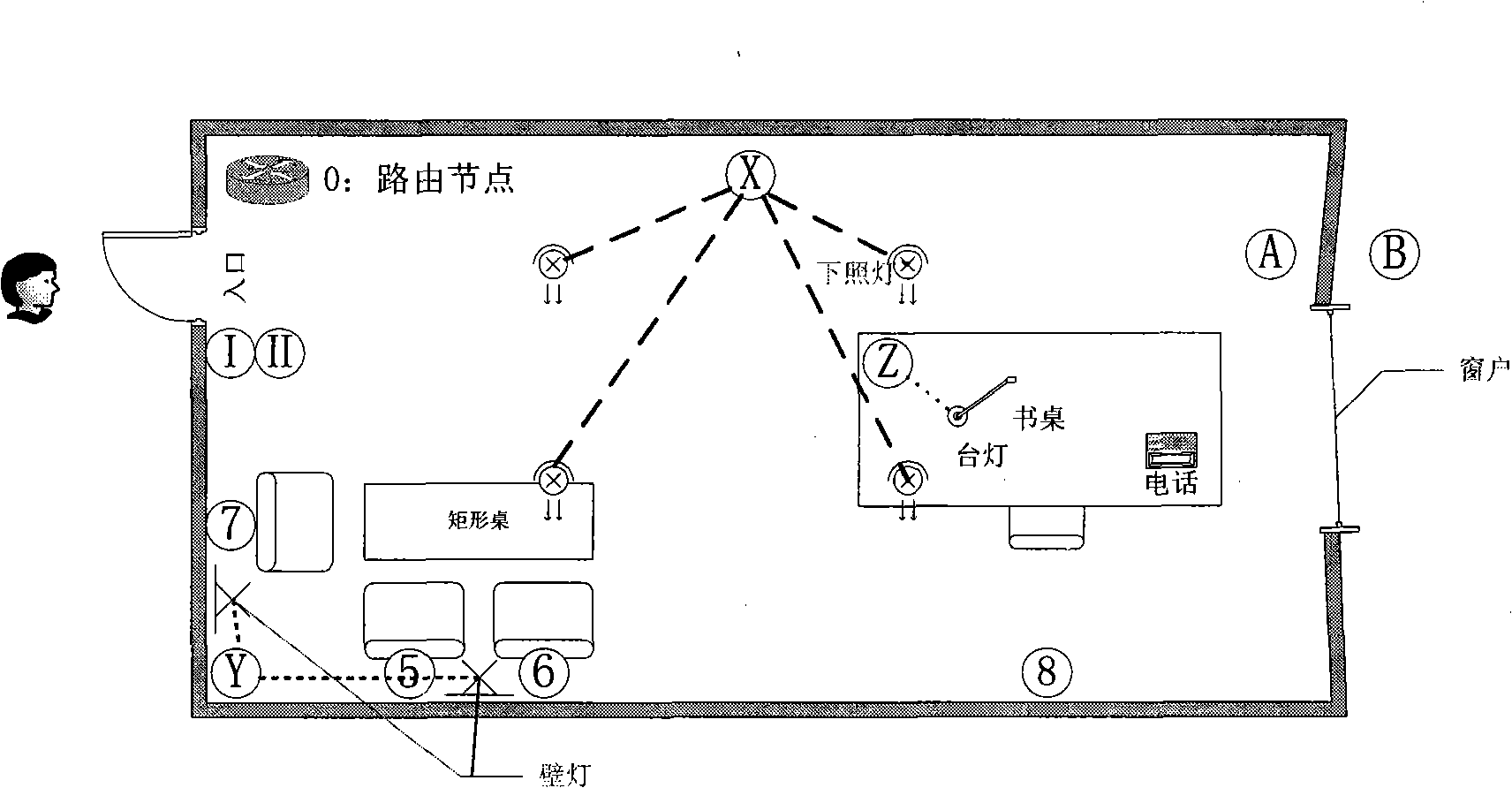

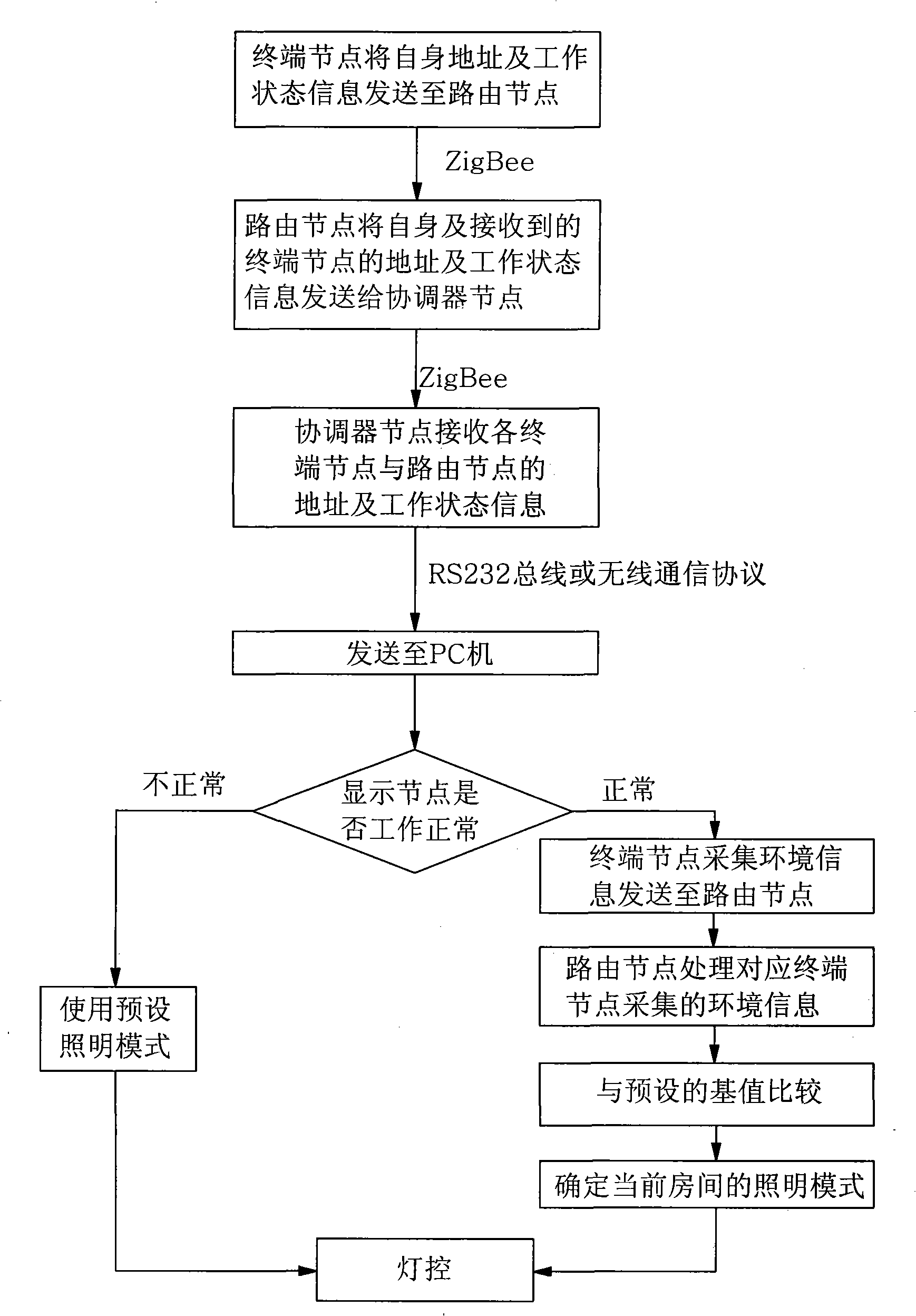

Energy-saving type interior illumination wireless intelligent control system and control method based on ZigBee sensing network

InactiveCN101282605AReduce wasteTo achieve the purpose of energy savingEnergy efficient ICTElectric controllersIlluminanceEffect light

The present invention provides energy-saving interior lighting wireless intelligent control system based on ZigBee wireless communication technology and the control method. The control method is comprises of ZigBee communication network composed of a plurality of wireless network nodes and PC machine; the wireless network node comprises coordinator node, route node and terminal node; the coordinator node is connected with the PC machine to compose lighting control center; the unique coordinator node and all the route nodes compose the two-level network; the route node and the terminal node in the room compose the lighting sub-system for controlling the lighting mode of each room; the lighting control center controls the state of each node of the lighting sub-system and the preset lighting mode; the lighting sub-system automatically controls the lighting mode in the current room according to the collected environmental information. The present invention causes the lighting control to be intelligent, ensures the illuminance consistency; and the luminaires have long life, convenient management, low maintenance cost and are energy conservation and environmental protection.

Owner:ZHEJIANG UNIV CITY COLLEGE

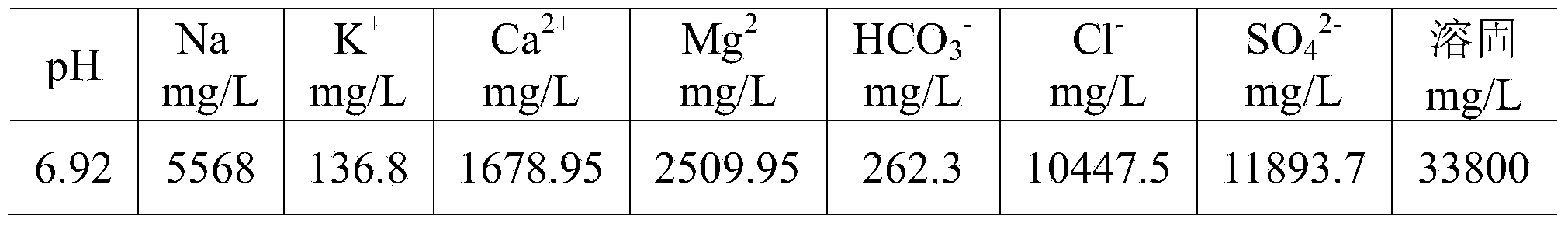

Desulfurization waste water recycling and zero discharge system and method

InactiveCN103979729ALimit concentrationEfficient separationMultistage water/sewage treatmentWater dischargeWastewater

The invention relates to a desulfurization waste water recycling and zero discharge system and method. The desulfurization waste water recycling and zero discharge system comprises a desulfurization tower, a filter and a nanofiltration device which are sequentially connected, wherein a scale inhibitor dosing device is arranged at the inlet of the nanofiltration device, the concentrated water outlet of the nanofiltration device is connected with the desulfurization tower, the fresh water outlet of the nanofiltration device is connected with a saline water concentrating device, the fresh water outlet of the saline water concentrating device is connected with a fresh water tank, the concentrated water outlet of the salt water concentrating device is connected with a crystallizer, and the condensed water outlet of the crystallizer is connected with the fresh water tank; a drying encapsulating machine is arranged at the solid outlet of the crystallizer. The desulfurization waste water recycling and zero discharge system has the advantages that desulfurization waste water discharged from the desulfurization tower is filtered and then is fed into the nanofiltration device, nanofiltration concentrated water returns to the desulfurization tower, nanofiltration fresh water is treated by virtue of the salt water concentrating device and then is crystallized by virtue of the crystallizer, the obtained fresh water is recycled in the fresh water tank, and salt is separated out, dried into crystallized salt and transported outside after being encapsulated, so that zero discharge of the desulfurization waste water is realized, quality of the recycled fresh water is improved, and a chemical agent and operating cost are saved.

Owner:XIAN TPRI WATER & ENVIRONMENTAL PROTECTION +2

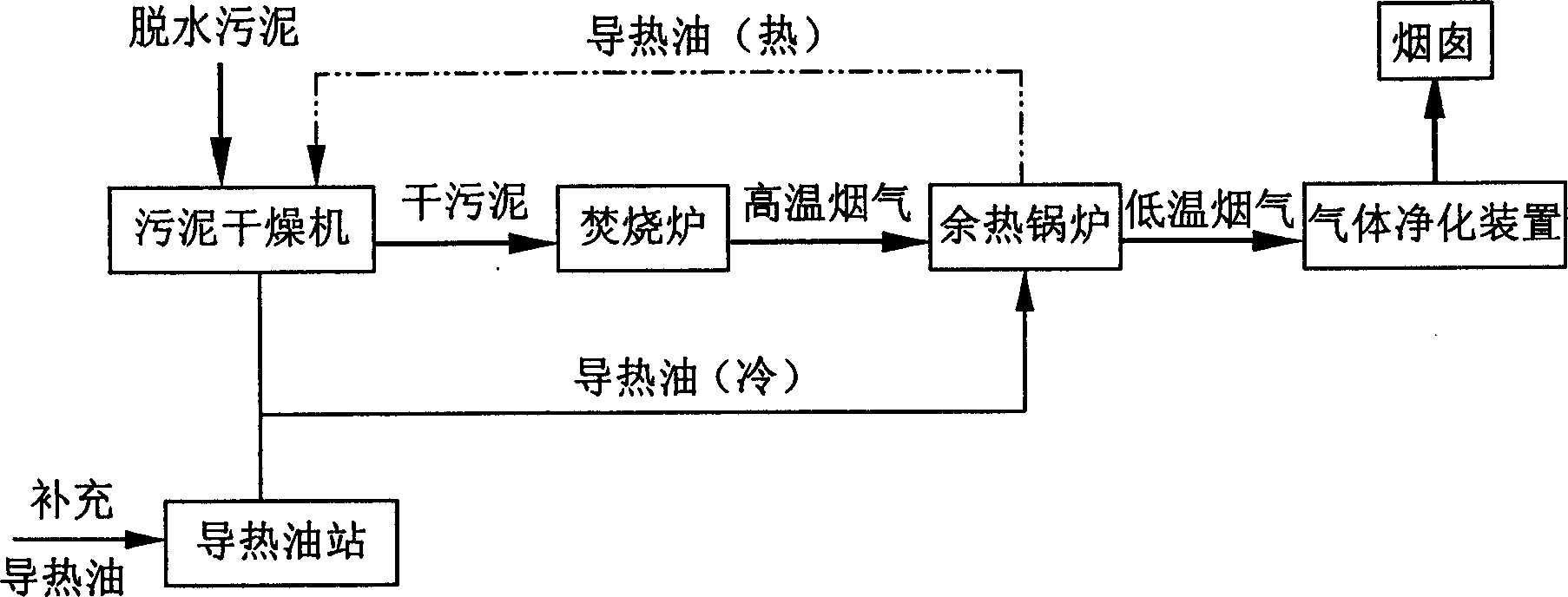

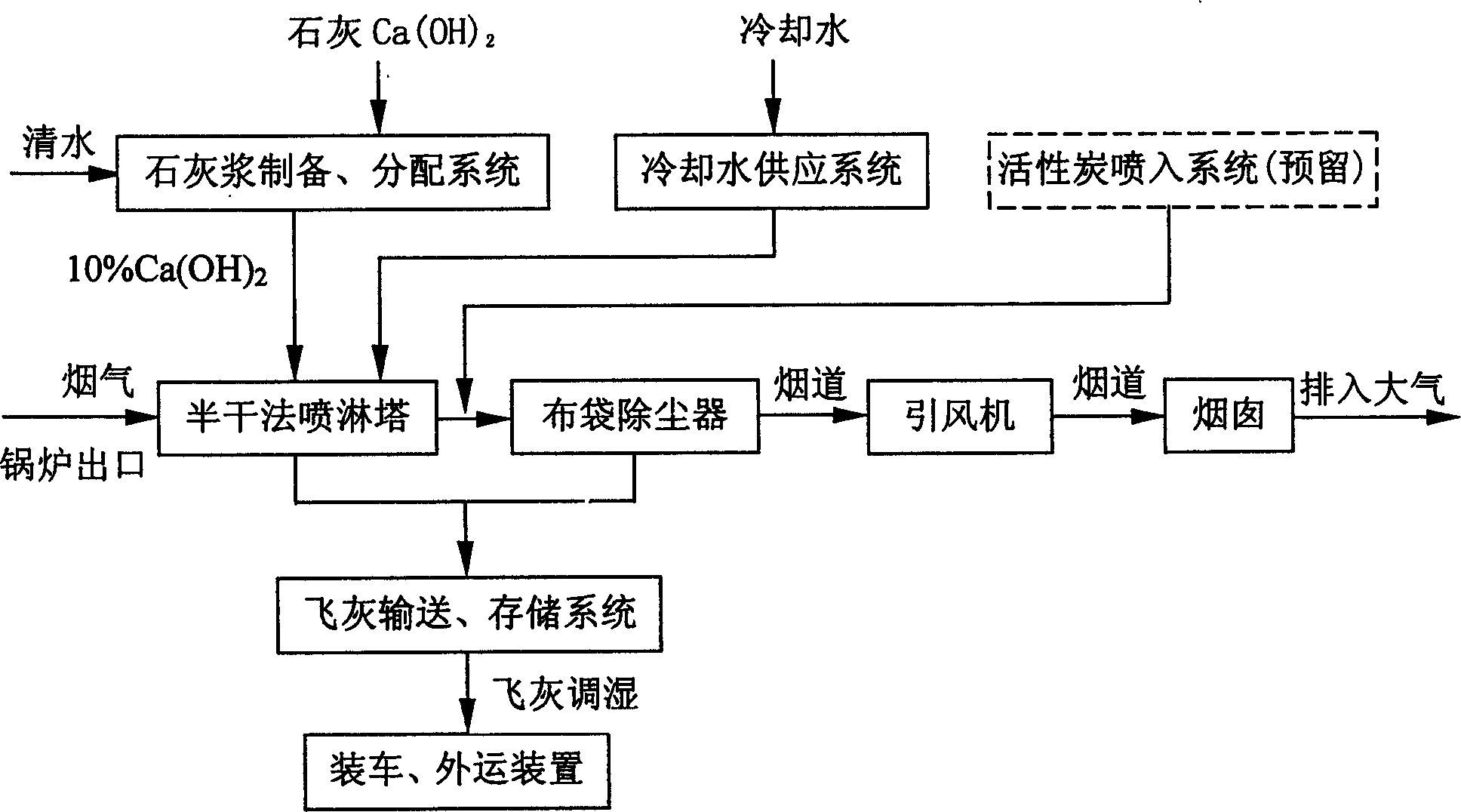

Sludge anhydration and burning process, and its systematic device

ActiveCN1800062ALow investment costLow running costSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationAir preheaterHeat conducting

The invention relates to a sludge drying and burning technique and its system devices, applying to the handling of active sludge in urban sewage treatment plants, its process flows through: wet sludge stock house, measuring bin, sludge mixer, sludge dryer, granular splitter, cooler, drying products storage bin, incinerator, smoke gas cleaning devices, which is characterized by: said incinerator is bubbling fluid bed incinerator with coal economizer, air heater fixed in its end part, high-heat smoke gas generated by burning is used to heat heat-conducting oil and cool air individually, and heat-conducting oil after being heated is transferred to sludge dryer through the circulating pump to dry wet-sludge. The invention is characterized by: take heat-conducting oil as heating medium, use the heat generated by burning dry sludge to heat heat-conducting oil and then dry wet-sludge to make full use of resources; the volume-reducing quantity after drying and burning could reach over 90%; the percentage of desulphurization in incinerator could reach 75% as a result of adopting two stage technology of sulfur removal, and the gross percentage of desulphurization meets national environmental legislation requirements. The invention accomplishes the resources, volume reduction, and innocence of sludge.

Owner:贵州筑信水务环境产业有限公司

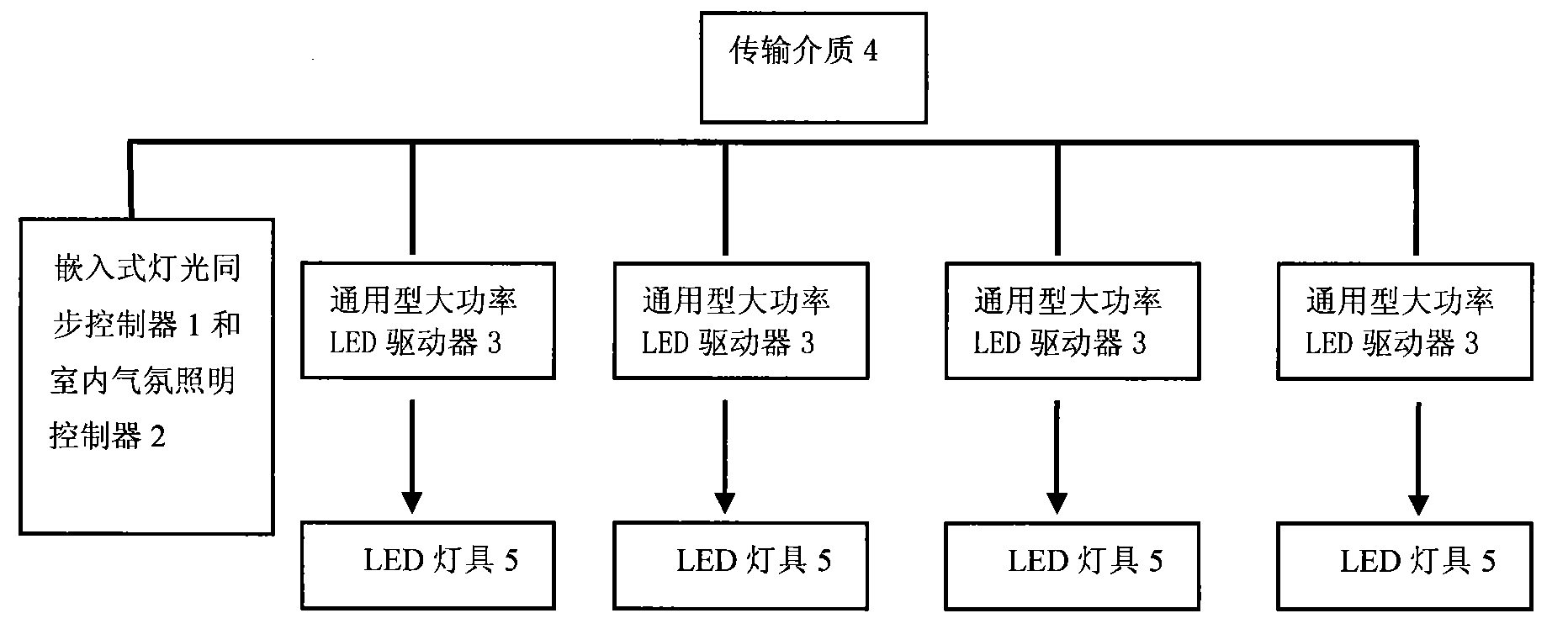

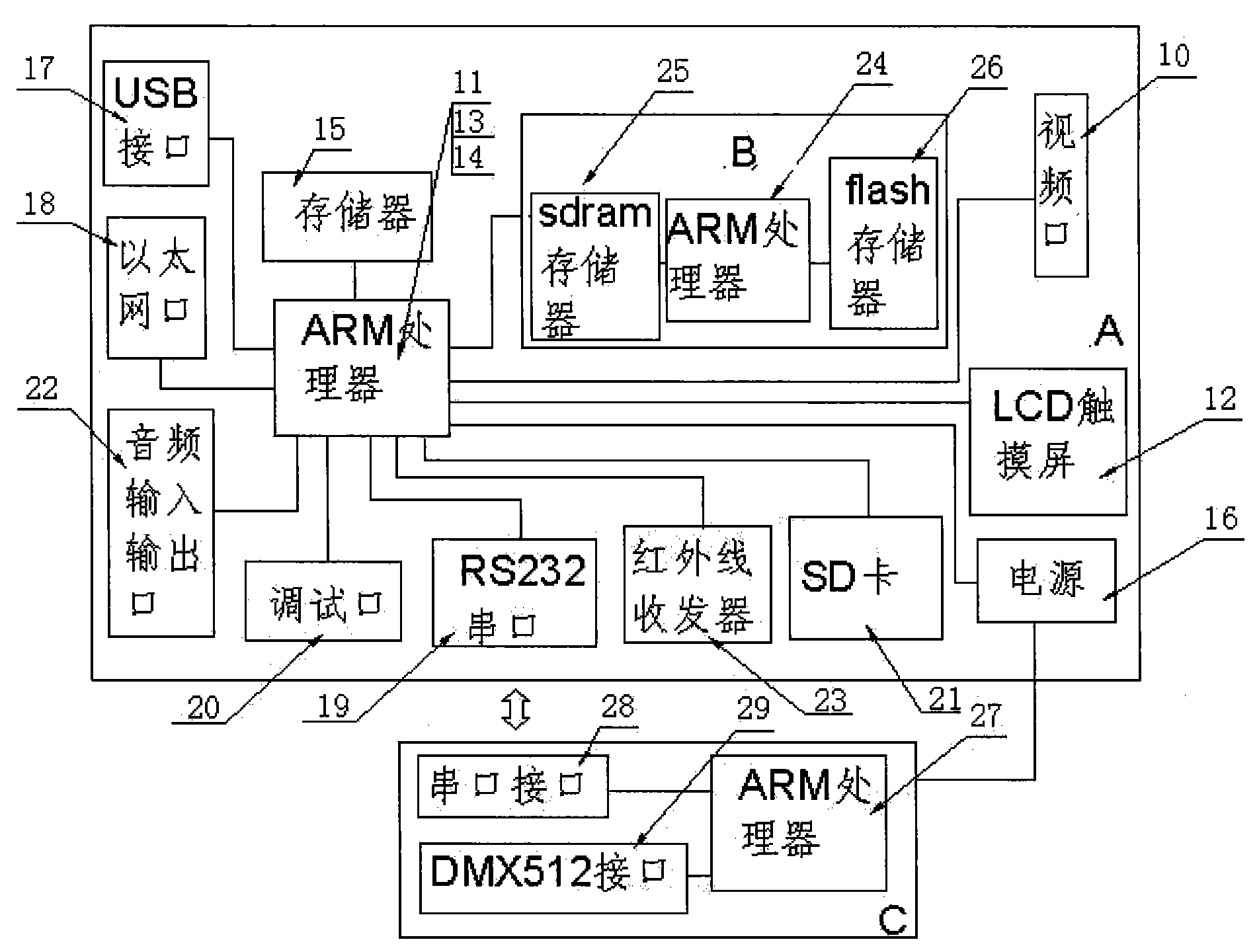

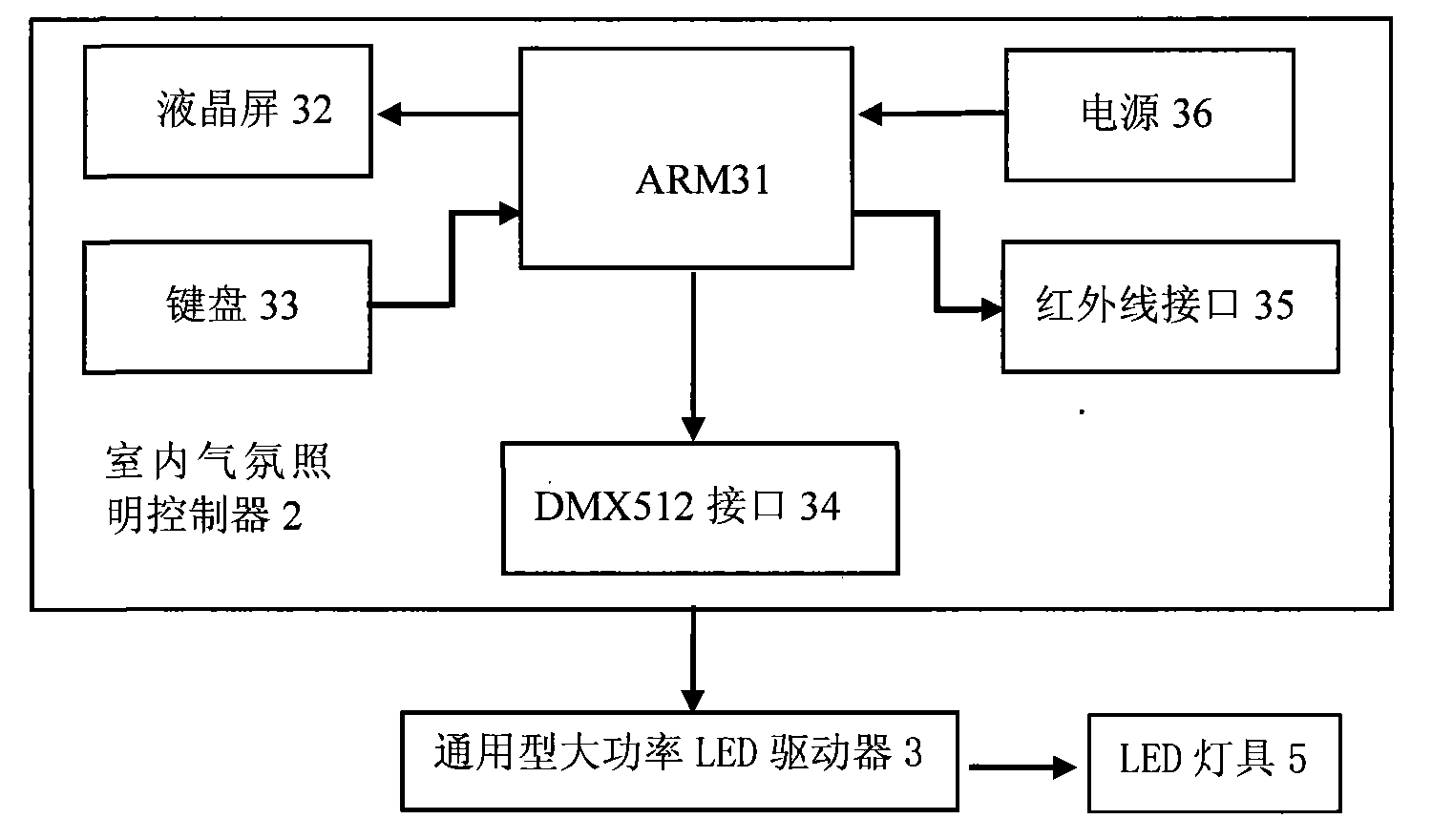

LED atmosphere illumination control system

InactiveCN101553065ABrightness adjustableColor adjustableElectric light circuit arrangementEnergy saving control techniquesAutomatic controlDMX512

The invention provides an LED atmosphere illumination control system, which adopts the standard DMX512 control protocol and a bus type network structure. A controller intensively controls all LED lamps. The system comprises an embedded light synchronous controller, an indoor atmosphere illumination controller, a general high-power LED drive, a transmission medium and the LED lamps. The system canperform scene mode control by network control mode, remote control mode, automatic control mode, manual control mode and various control modes; no less than nine scene modes are preset or can be freely set according to individual preference; digital diming can be achieved by an embedded program, and the illumination and the color tone of the light can be controlled precisely; and each lamp can beindependently controlled or can be controlled by networking. The system can ensure the evenness of the illumination effect while achieving the energy-saving illumination control and is widely applicable to local intensive illumination control of public places and families.

Owner:JIANGSU HANDSON INTELLIGENT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com