Patents

Literature

296results about How to "Increase the concentration factor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for concentration of macromolecules

ActiveUS20060149042A1Reduce conductivityHigh final concentrationDepsipeptidesPeptide preparation methodsCell culture supernatantOragene

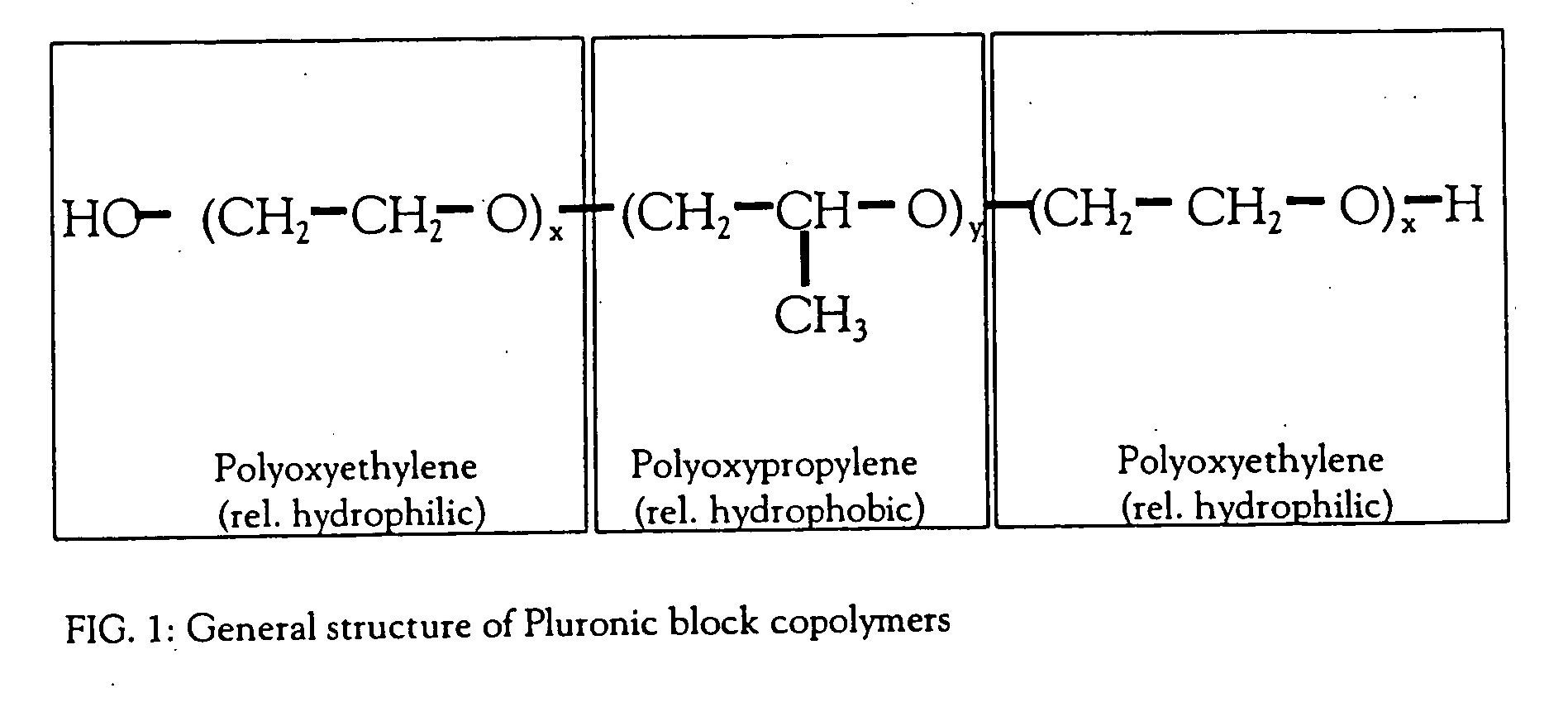

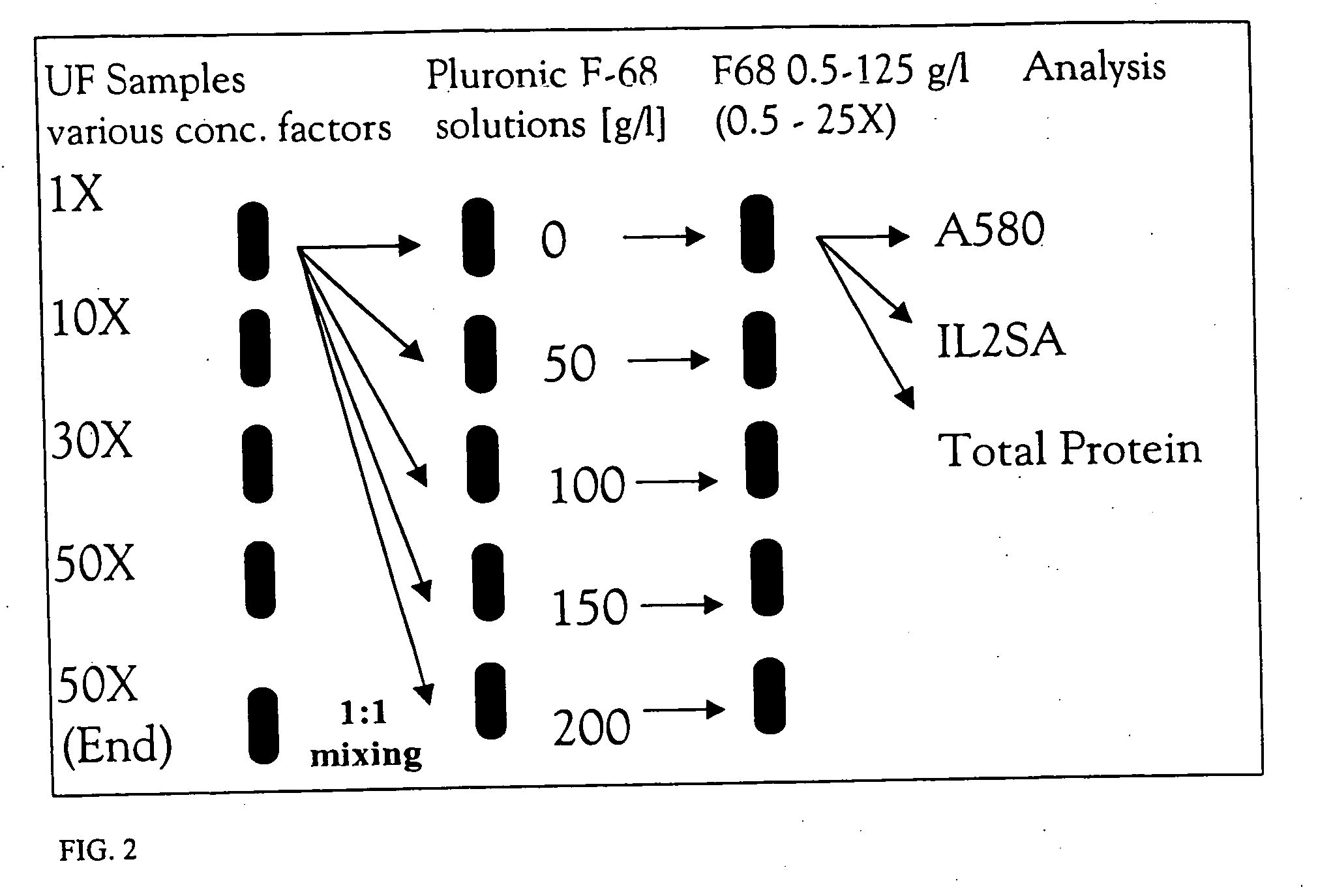

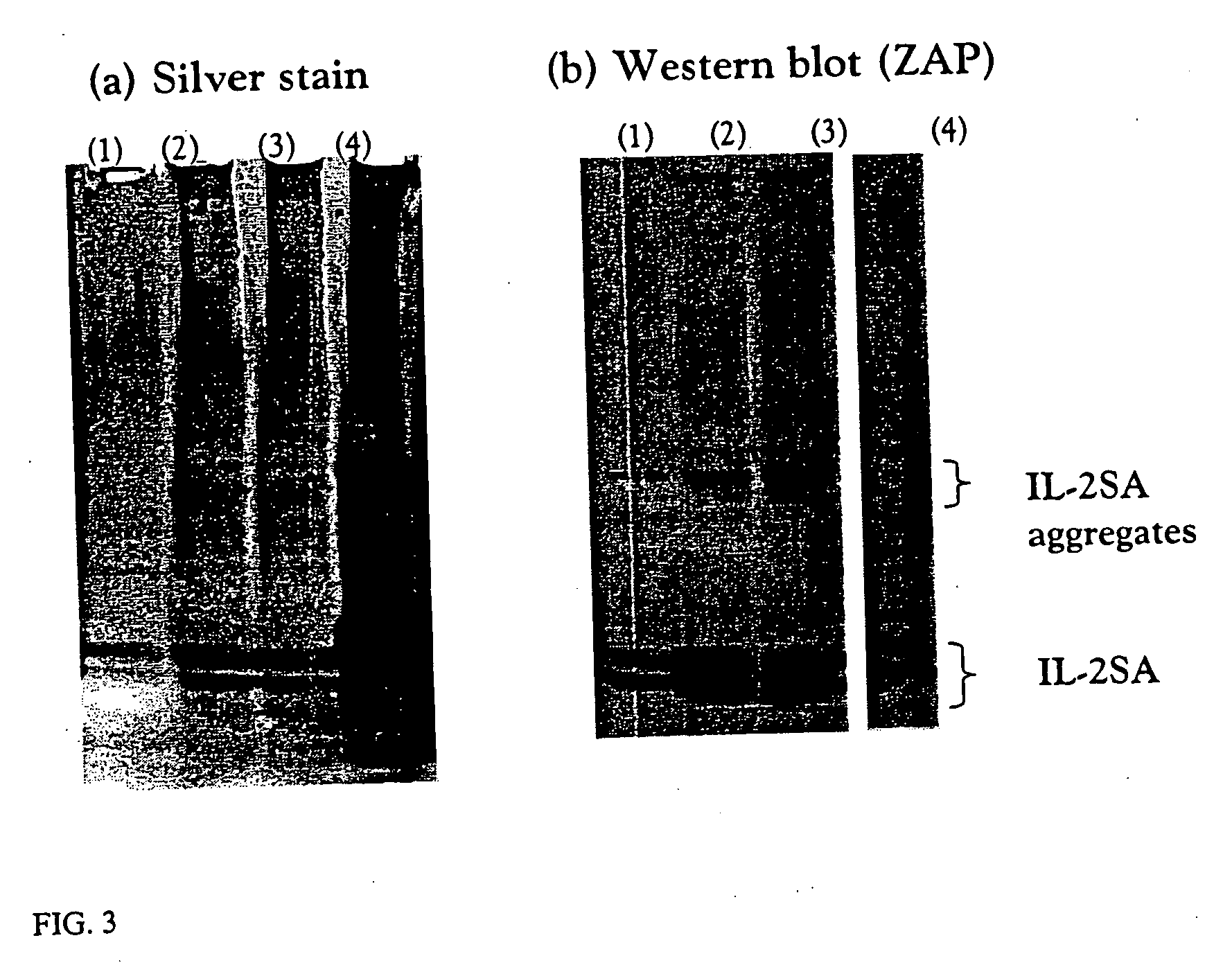

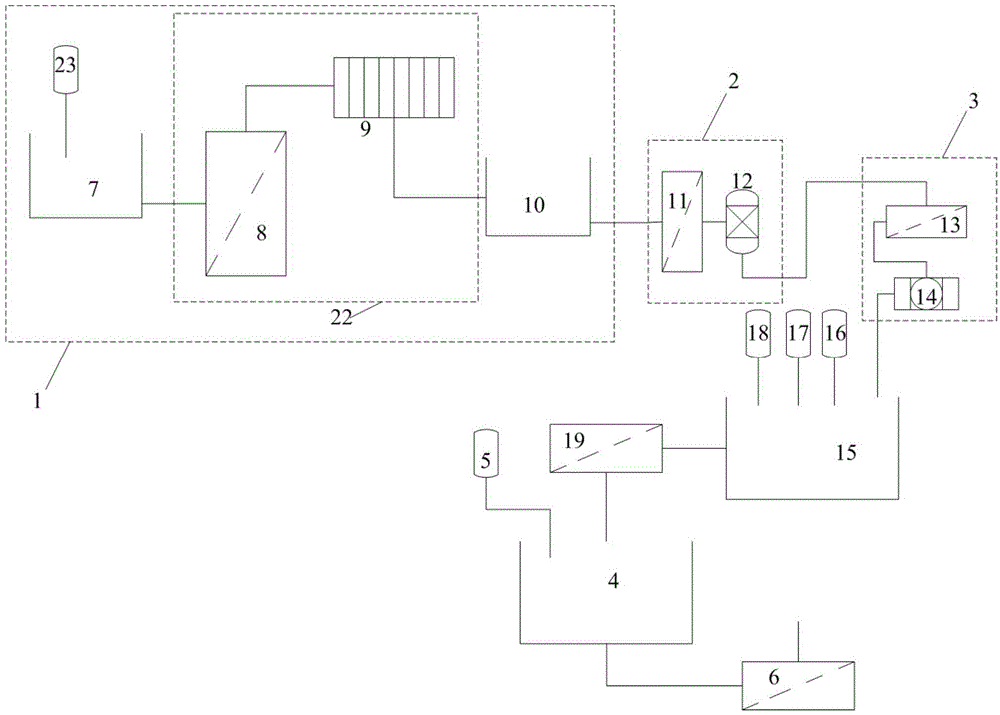

The invention provides methods for concentrating a macromolecule from a solution comprising the macromolecule and an organic polymer by first subjecting the solution to ultrafiltration to produce a first retentate solution, then adjusting the conductivity of the first retentate solution such that any protein precipitation induced by the organic polymer is essentially prevented to produce a second retentate solution, and then subjecting the second retentate solution to ultrafiltration. In a preferred embodiment, the conductivity is adjusted by diafiltration against water, suitable diluent or buffer. Preferably, the invention pertains to the concentration of solutions of native or recombinant proteins. The invention further pertains preferably to methods for the concentration of cell culture supernatant comprising a product protein and organic polymers of the Pluronic family of block co-polymers, and more preferably comprising Pluronic F-68 block co-polymer.

Owner:BAYER HEALTHCARE LLC

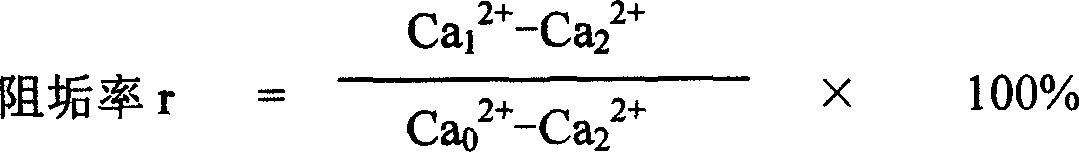

Non-phosphorus compound scale and corrosion inhibitor for treatment of circulating cooling water

ActiveCN1621362AEasy to useIncrease the concentration factorScale removal and water softeningPhosphateTungstate

The composite phosphate-free scale inhibiting corrosion inhibitor for treating circular cooling water consists of scale inhibitor and corrosion inhibitor. The scale inhibitor consists of one or several of PASP, PVA, oxidized starch, polyacrylic acid, acrylic acid / acrylate copolymer and acrylic acid / acrylate copolymer with sulfo radical. The corrosion inhibitor consists of one or several of sodium salt / potassium salt / ammonium salt of organic salt, sodium / potassium / ammonium borate, nitrous organic matter, soluble molybdenate, soluble tungstate, soluble nitrate, soluble nitrite and soluble zinc salt. The composite scale inhibiting corrosion inhibitor has excellent scale inhibiting and corrosion inhibiting performance, is environment friendly, and is especially the treatment of hard circulation water with high calcium and high alkali content.

Owner:BEIJING YANHUA XINGYE TECH DEV +1

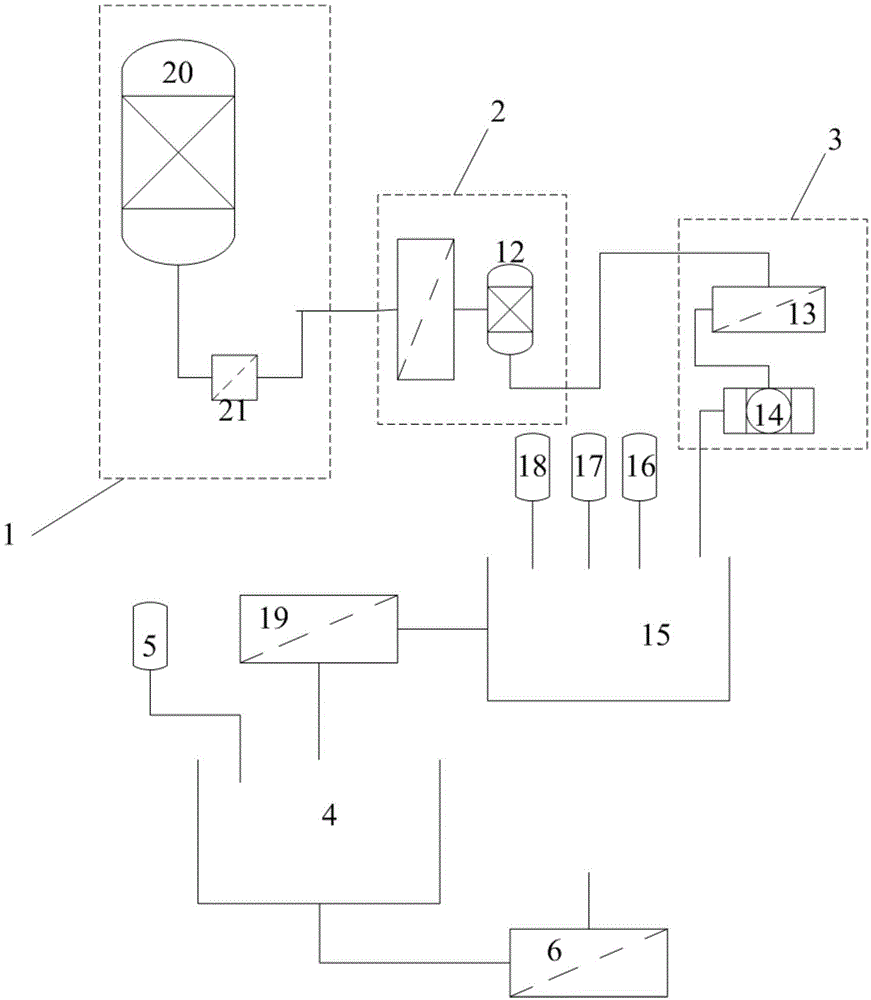

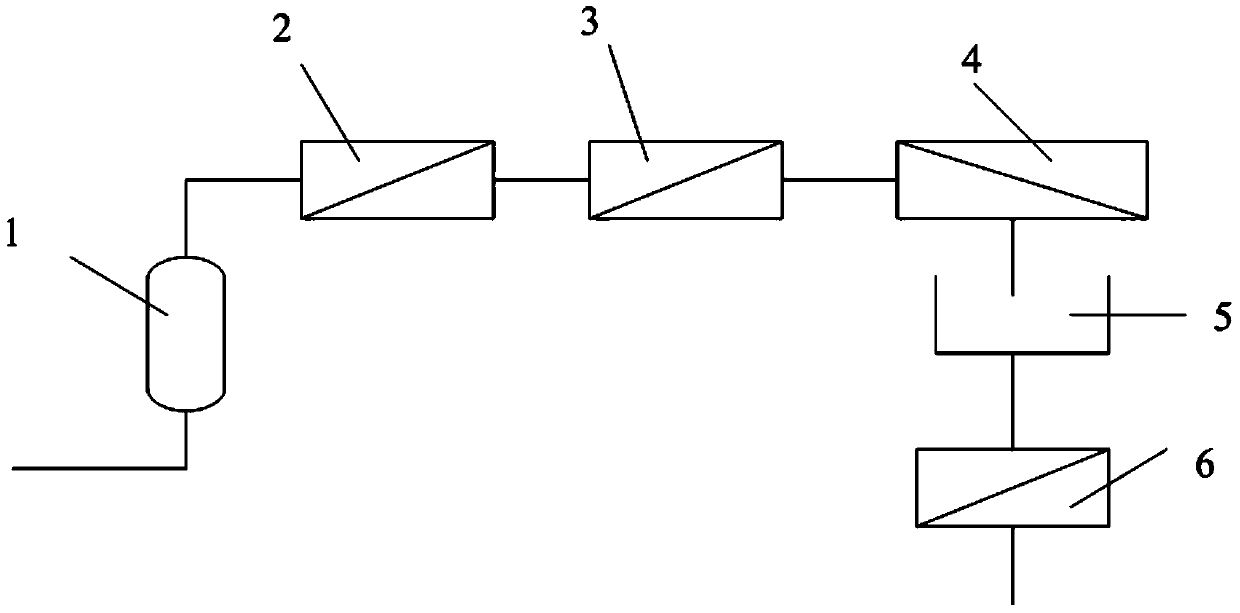

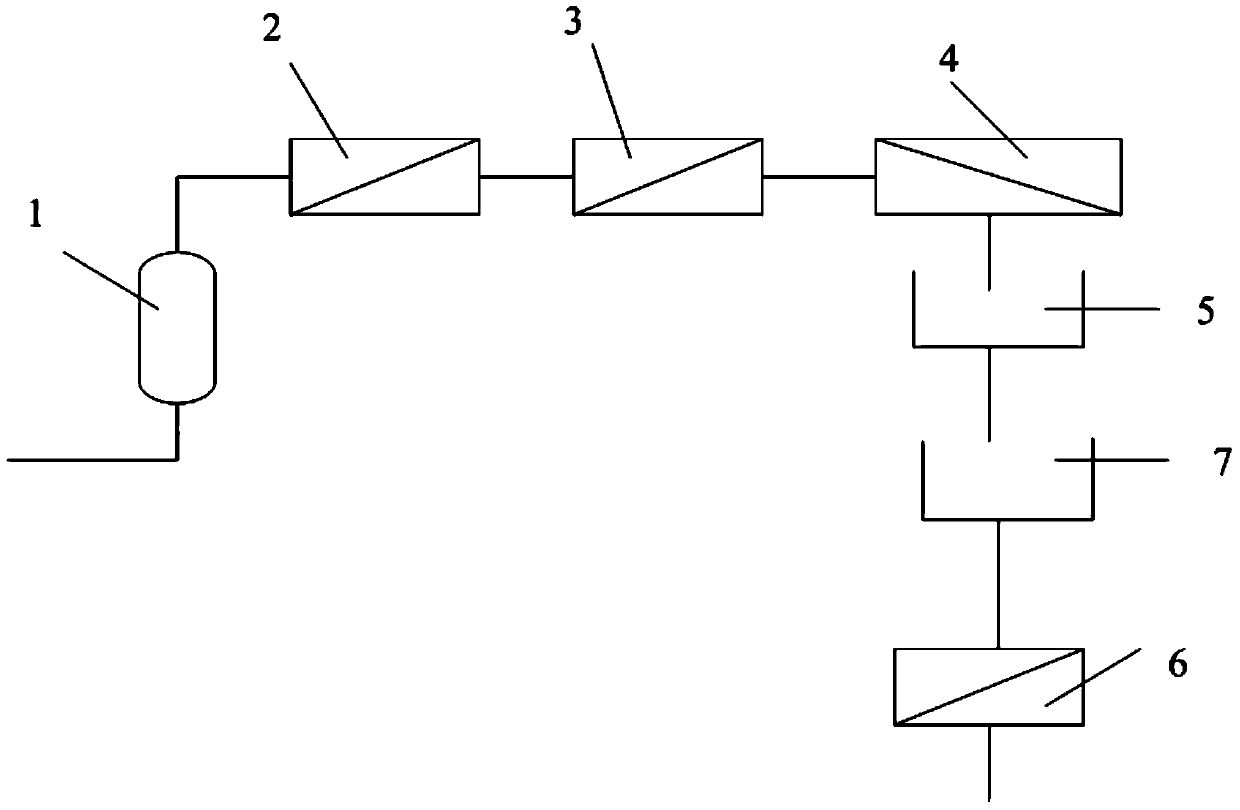

Process and device for extracting battery grade lithium from brine

ActiveCN104310446AIncrease the concentration factorHigh yieldLithium carbonates/bicarbonatesPhysical chemistryReverse osmosis

The invention relates to a process and a device for extracting battery grade lithium from brine. The process comprises the following steps: adding an adsorbent into the brine to adsorb lithium ions in the brine, intercepting the adsorbent by using a ceramic membrane filter, performing plate-frame pressure filtration on the ceramic membrane concentrated solution to obtain an adsorbent filter cake, washing and desorbing the adsorbent filter cake so as to obtain a desorption solution; removing magnesium in the desorption solution through a nanofiltration membrane system, entering the nanofiltration membrane permeate into an ion exchange resin tower for performing deep magnesium removal, concentrating through a reverse osmosis membrane, performing deep concentration in a DTRO membrane or electrodialysis equipment, evaporating the concentrated solution, adding BaCl2, Na2CO3 and NaOH into the solution, stirring, filtering in a ceramic membrane filter, performing plate-frame pressure filtration on the ceramic membrane filtrate, adding Na2CO3 into the clear liquid, preparing Li2CO3, washing Li2CO3 through a ceramic membrane, centrifuging, and drying, thereby obtaining the finished battery grade Li2CO3 product.

Owner:JIANGSU JIUWU HITECH

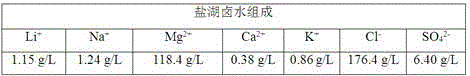

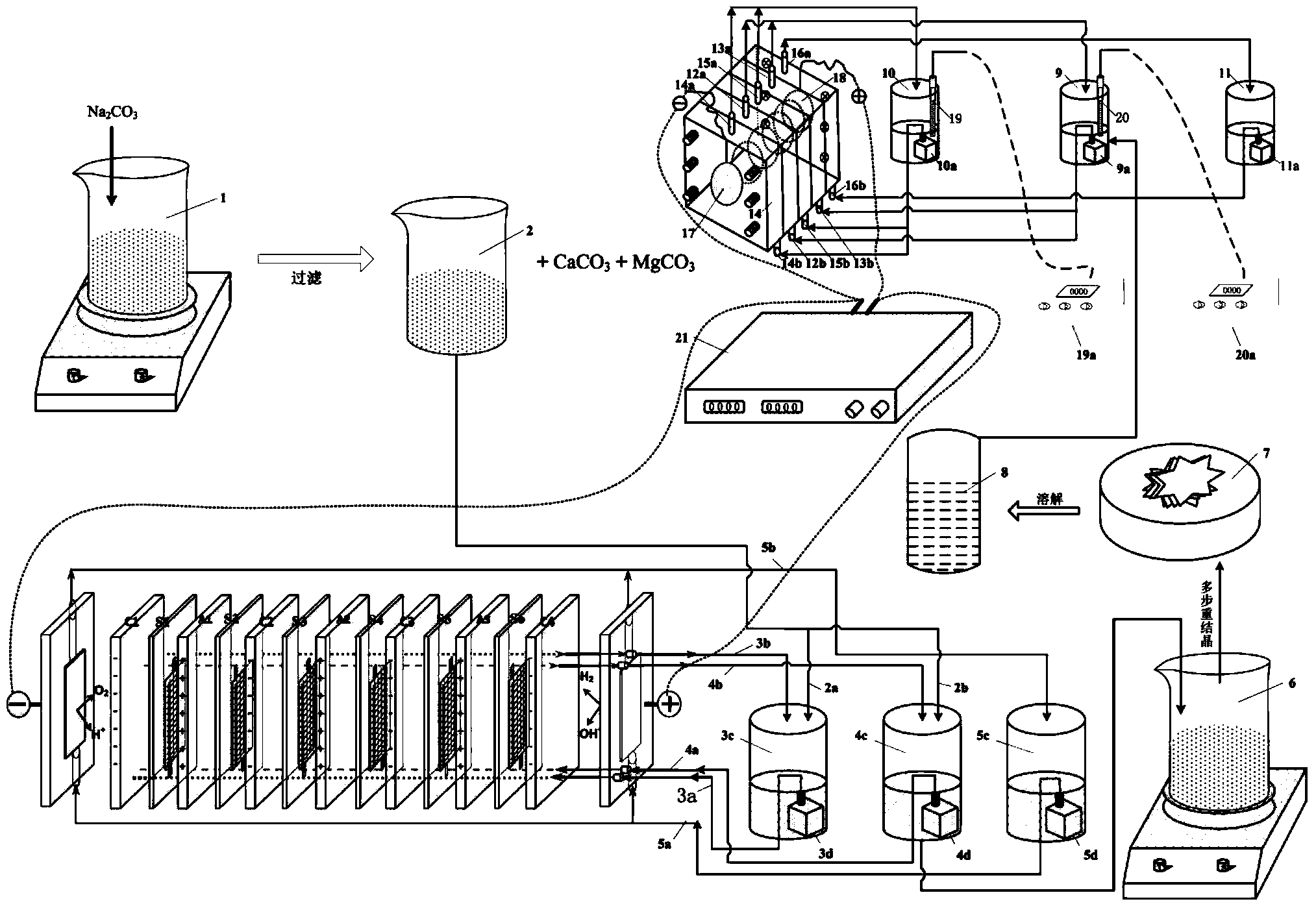

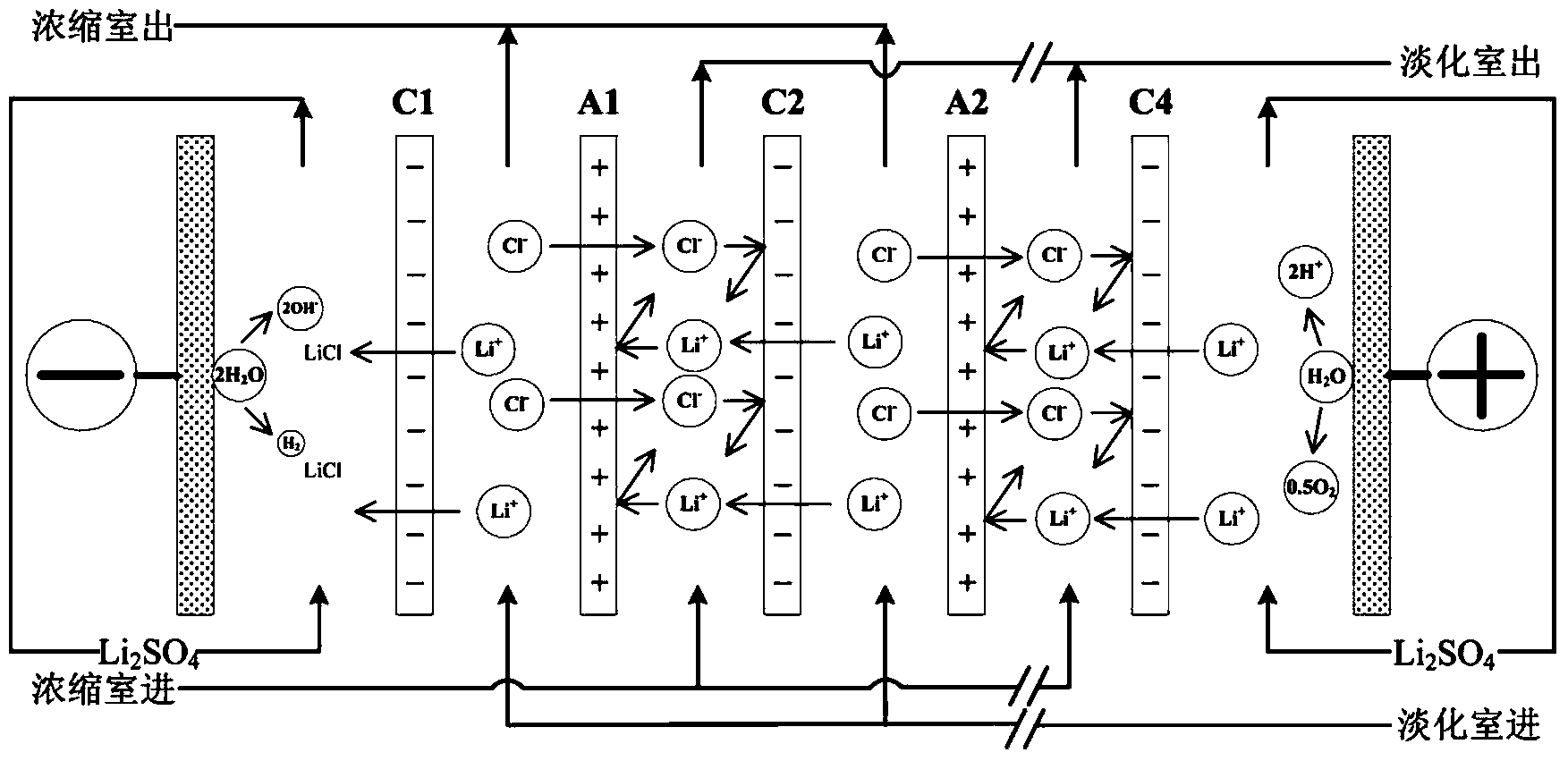

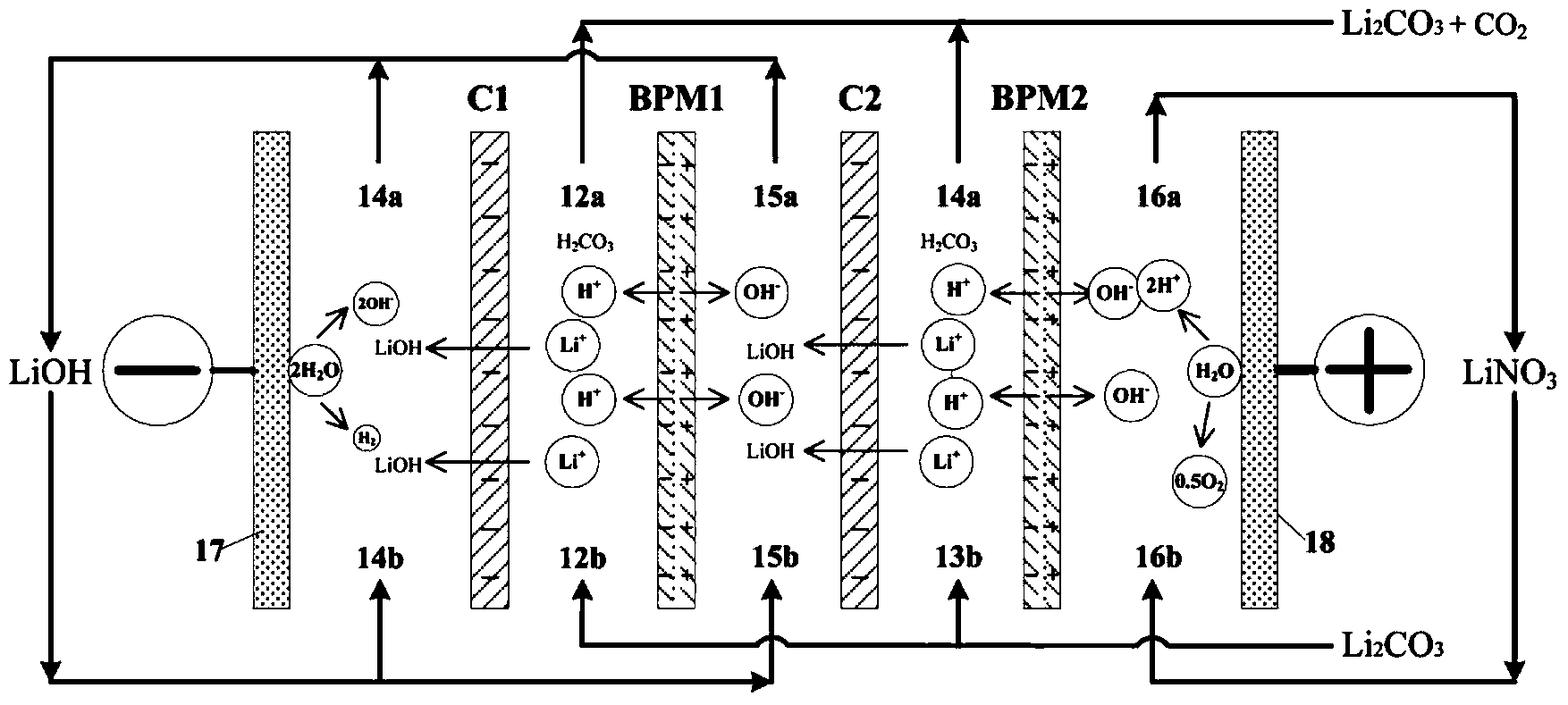

Method for extracting lithium hydroxide by salt lake brine

ActiveCN103864249AIncrease the concentration factorEasy extractionElectrolysis componentsMultistage water/sewage treatmentChemistryCalcium hydroxide

The invention discloses a method for extracting lithium hydroxide by salt lake brine. The method is characterized by comprising the following steps: firstly, removing calcium and magnesium ions in salt lake brine by adding sodium carbonate; concentrating the obtained brine with low lithium-magnesium ratio through ordinary electrodialysis to obtained concentrated brine; adding sodium carbonate to the concentrated brine and removing the calcium and magnesium ions again; adding sodium carbonate to obtain lithium carbonate through a multi-step crystallization method; preparing the lithium hydroxide by an electrolysis-bipolar membrane electrodialysis system after dissolving the lithium carbonate again. The traditional distillation process is replaced by ordinary electrodialysis, so that energy consumption is reduced, and the method is friendly to environment. In addition, the lithium hydroxide is produced by using an electrolysis-bipolar membrane electrodialysis technology, the defects of high energy consumption and low purity in the traditional lime method and electrolytic process are avoided, the capacity of the lithium hydroxide is improved, no waste residue is generated in the process, and the method is friendly to environment. Taken together, the method is simple to operate, low in energy consumption, friendly to environment, and expanded production is easy to achieve.

Owner:UNIV OF SCI & TECH OF CHINA

Composite corrosion-retarding antisludging agent for treating high-concentration multiple circulating water

InactiveCN101125715AGrowth inhibitionLimit metabolismScale removal and water softeningHigh concentrationCarboxylic acid

A compound inhibition antisludging agent is used for treating high-concentration circulation water, comprising a liquid part and a solid part. Based on that the total weight of the liquid part is deemed to be 100 percent, percentages of each component by weight are: organic phosphonic acid 5-40 percent, organic carboxylic acid 5-40 percent and water 20-90 percent; and based on that the total weight of the solid part is deemed to be 100 percent, percentages of each component by weight are: polymer with antisludging effect 5-35 percent, alkaline agent 45-80 percent, azoles 1-10 percent and zinc salt 1-10 percent. The concentrations of the liquid part and the solid part in the circulating water are that: the solid part: the dosage of the agent added into make-up water is 20-200mg / L; the liquid part: total phosphine kept in the circulating water system is 10-15mg / L. The invention has effects of inhibition, antisludging, sterilization and algae removal upon meeting the requirements of the state, can promote the concentration multiple of the circulating water system up to 7.5 or more and can be operated at normal temperature with good effect and without pre-membrane treatment.

Owner:上海潓溱环保科技股份有限公司

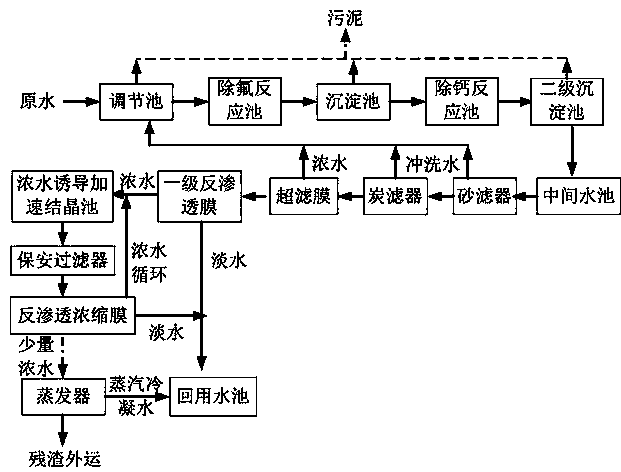

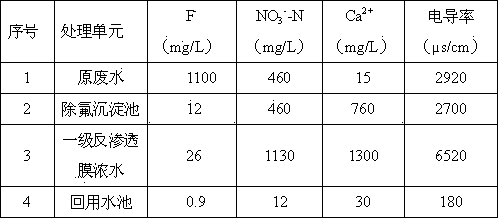

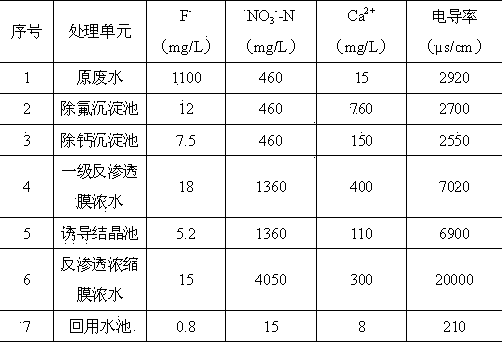

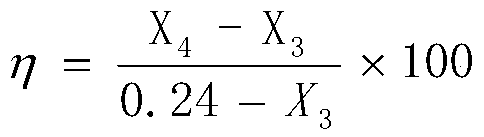

Method for realizing approximate zero discharge of high-fluorine-content and high-nitrogen-content battery production waste water in photovoltaic industry

ActiveCN103936218AReduced Possibility of ContaminationIncrease the concentration factorGeneral water supply conservationWater contaminantsIonEvaporator

The invention discloses a method for realizing approximate zero discharge of high-fluorine-content and high-nitrogen-content battery production waste water in the photovoltaic industry. The method comprises the following steps: feeding high-fluorine-content and high-nitrogen-content battery production waste water into a regulating tank for homogenizing; feeding into a fluorine-removing reaction tank, and feeding a reaction tank effluent into a sedimentation tank; feeding a supernatant in the sedimentation tank into a middle water tank; treating by virtue of a quartz sand filter and an active carbon filter, and feeding fresh water into a primary reverse osmosis membrane for treating; driving reverse osmosis membrane concentrated water to flow through a concentrated water induced acceleration crystallizing pond to precipitate calcium ions and fluorine ions in concentrated water on a seed crystal at a higher speed, effectively lower the concentrations of calcium ions and fluorine ions and increase the concentration multiple of a reverse osmosis concentration membrane, driving supernatant to flow through a cartridge filter, and feeding into the reverse osmosis concentration membrane for circularly concentrating; feeding a small amount of concentrated water on the reverse osmosis concentration membrane into an evaporator to greatly lower the evaporation cost, feeding steam condensed water into a recycling water tank for use as industrial water, and disposing evaporation residues as solid waste. In the entire process, no water pollutant is discharged.

Owner:JIANGSU PROVINCIAL ACAD OF ENVIRONMENTAL SCI

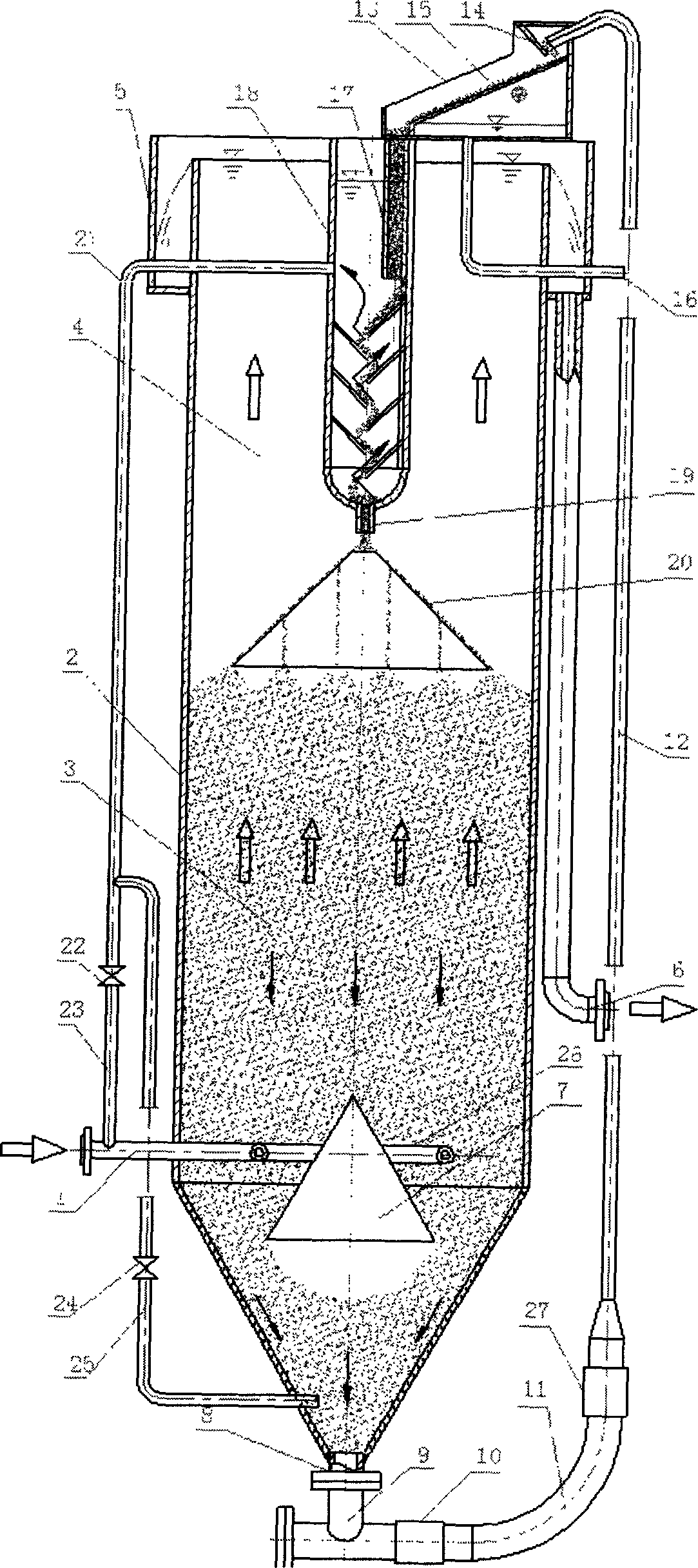

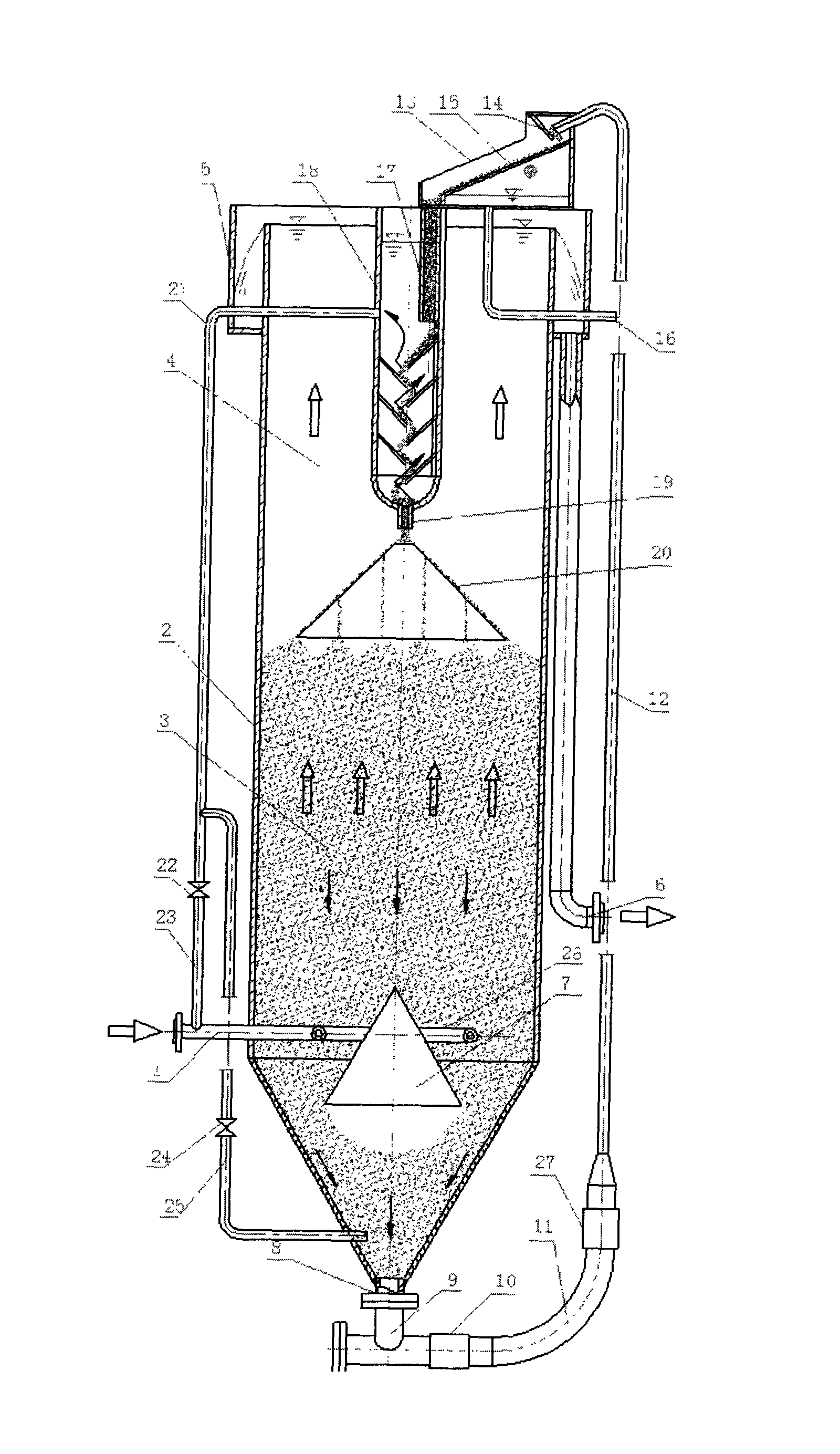

Method and device for extracting bitten lithium chloride

The invention relates to a method and a device for extracting bitten lithium chloride. The method specifically comprises the steps: 1, adsorbing lithium ions by bittern in a lithium-containing salt lake old brine pool through an aluminum salt adsorbing agent, desorbing by using water to obtain a desorbing solution; 2, filtering the desorbing solution by using a coarse filter; 3, filtering permeate of the coarse filter by using a nanofiltration membrane to obtain permeate of the nanofiltration membrane; 4, concentrating the permeate of the nanofiltration membrane by using a reverse osmosis membrane to obtain a reverse osmosis concentrated solution; and 5, carrying out baysalt or evaporating on the reverse osmosis concentrated solution to obtain lithium-containing concentrated brine. According to the method, the problems that the concentration multiple in a reverse osmosis station can not be increased, the baysalt efficiency is low and a plenty of reagents are consumed in precipitation in a conventional process for extracting lithium from brine can be solved, and the obtained lithium chloride solution is high in yield and high in purity.

Owner:JIANGSU JIUWU HITECH

Method for processing sewage from industrial cycle water

InactiveCN101172724AIncrease the concentration factorImprove running qualityScale removal and water softeningMultistage water/sewage treatmentFilter systemEnvironmental engineering

The invention relates to a method for treating industrial circulating water and sewage through the technology of a nano filter film. The invention is characterized in that one part of the sewage is used as the supplementing water of a circulating water system, while the other part is reused after being processed through a nano filter system after the sewage of the industrial circulating cooling water system is flocculated and precipitated and filtered; one part and the other part are added into the circulating water system after being mixed with a certain proportion so as to achieve the reuse of the industrial circulating water, thereby increasing the condensation times of the whole system, decreasing the water implementing quantity and the sewage discharge quantity of the system, and increasing the economic effect of the whole operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

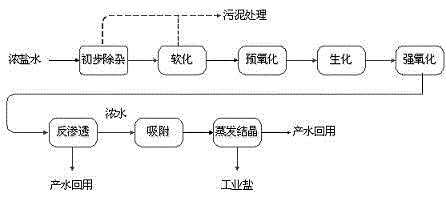

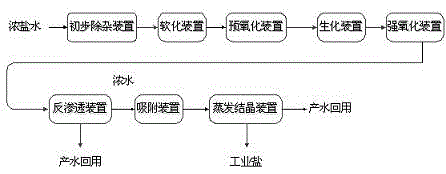

Method and device for realizing zero emission of strong brine

ActiveCN105541017ATake advantage ofEase of useGeneral water supply conservationWater treatment compoundsLoad resistanceEvaporation

The invention provides a method and a device for realizing zero emission of strong brine, overcoming the defects that the existing strong brine treatment technology is high in crystallized impurity salt treatment cost and severe in harm. The impurity removal, softening, pre-oxidation, biochemical and strong oxidation techniques are used for purifying the strong brine, the strong brine after being treated is pre-concentrated by adopting a reverse osmosis way, the reverse osmosis concentrated water is further purified by adopting an adsorption method, and finally the evaporation and quality-divided crystallization technology is used for separating the water to obtain industrial salt. By adopting the method and device, the zero emission of the strong brine is realized, the emission of dangerous waste is reduced, and the recycling is realized. Meanwhile, the general process is mature, the design is reasonable, the impact load resistance is relatively high, the chemical source is convenient, and the cost is low.

Owner:GO HIGHER ENVIRONMENT GRP CO LTD

Environment-friendly water quality stabilizer

InactiveCN1463935AGood inhibitory effectGood corrosion inhibitionScale removal and water softeningHigh concentrationWater quality

The environment protecting water quality stabilizer consists of scale inhibitor, corrosion inhibitor, assistant compounded together, and has the features of high efficiency, low toxicity and environment friendship. The water treating agent may be used in water system to produce corrosion inhibiting and scale inhibiting dispersion effect and may be used in the conditions of high hardness, high pHand high concentration multiple. The water treating agent may be used in circulating cooling water system with calcium hardness up to 750-1300 ppm, and in make-up water calcium hardness of 120 ppm, the concentration multiple may reach 10, being in zero-exhaust level.

Owner:CHUANHUA GRP

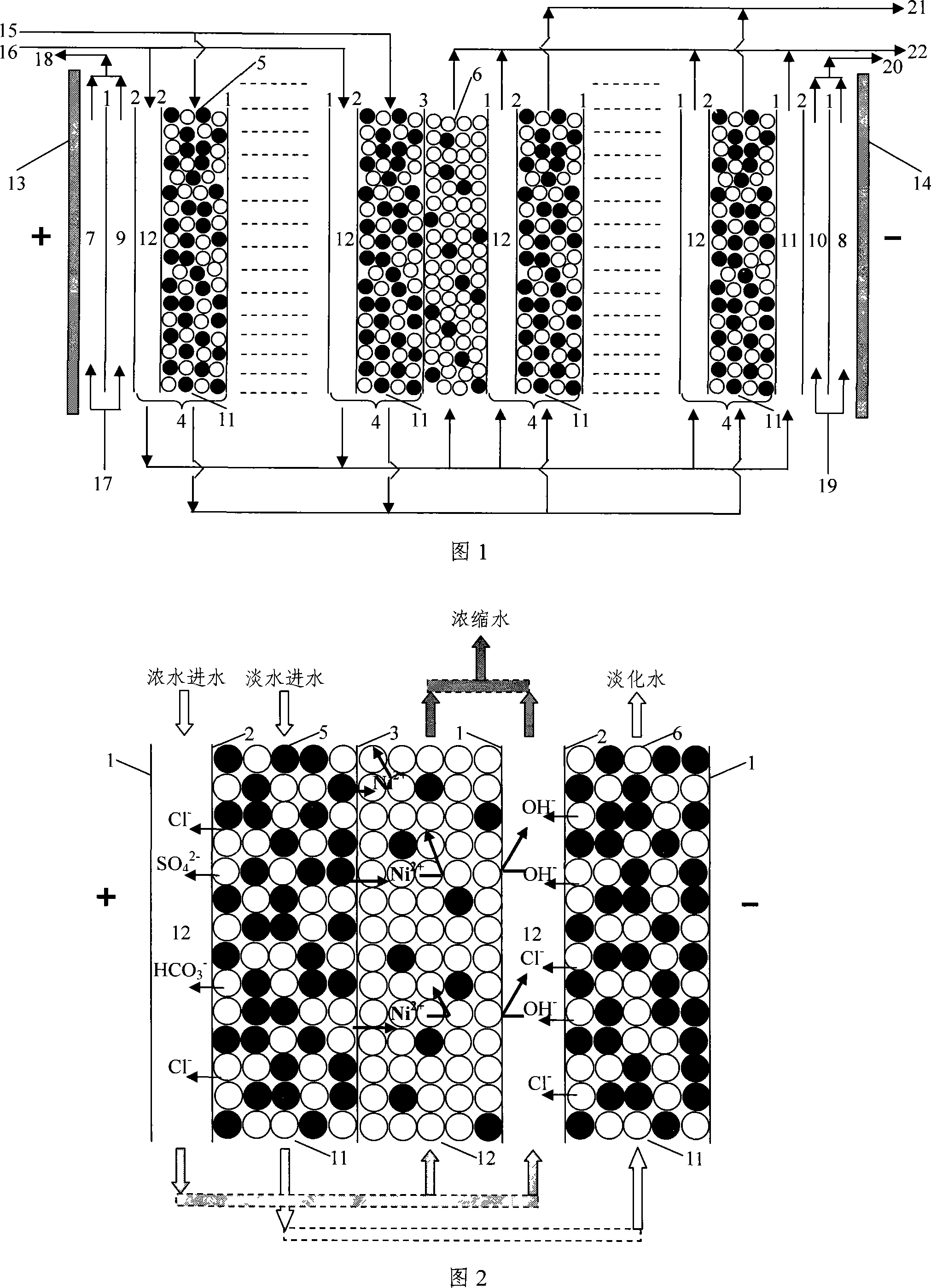

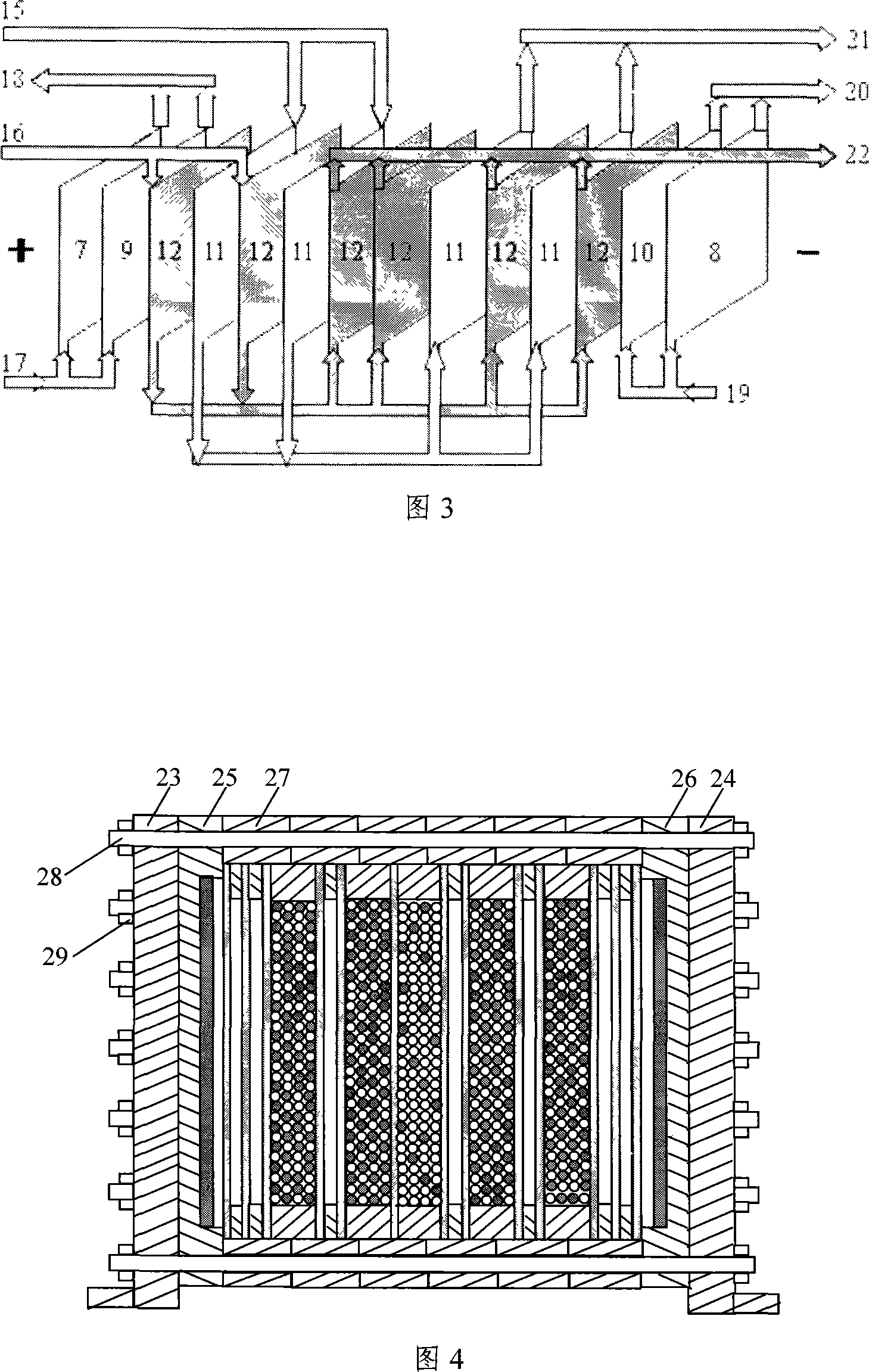

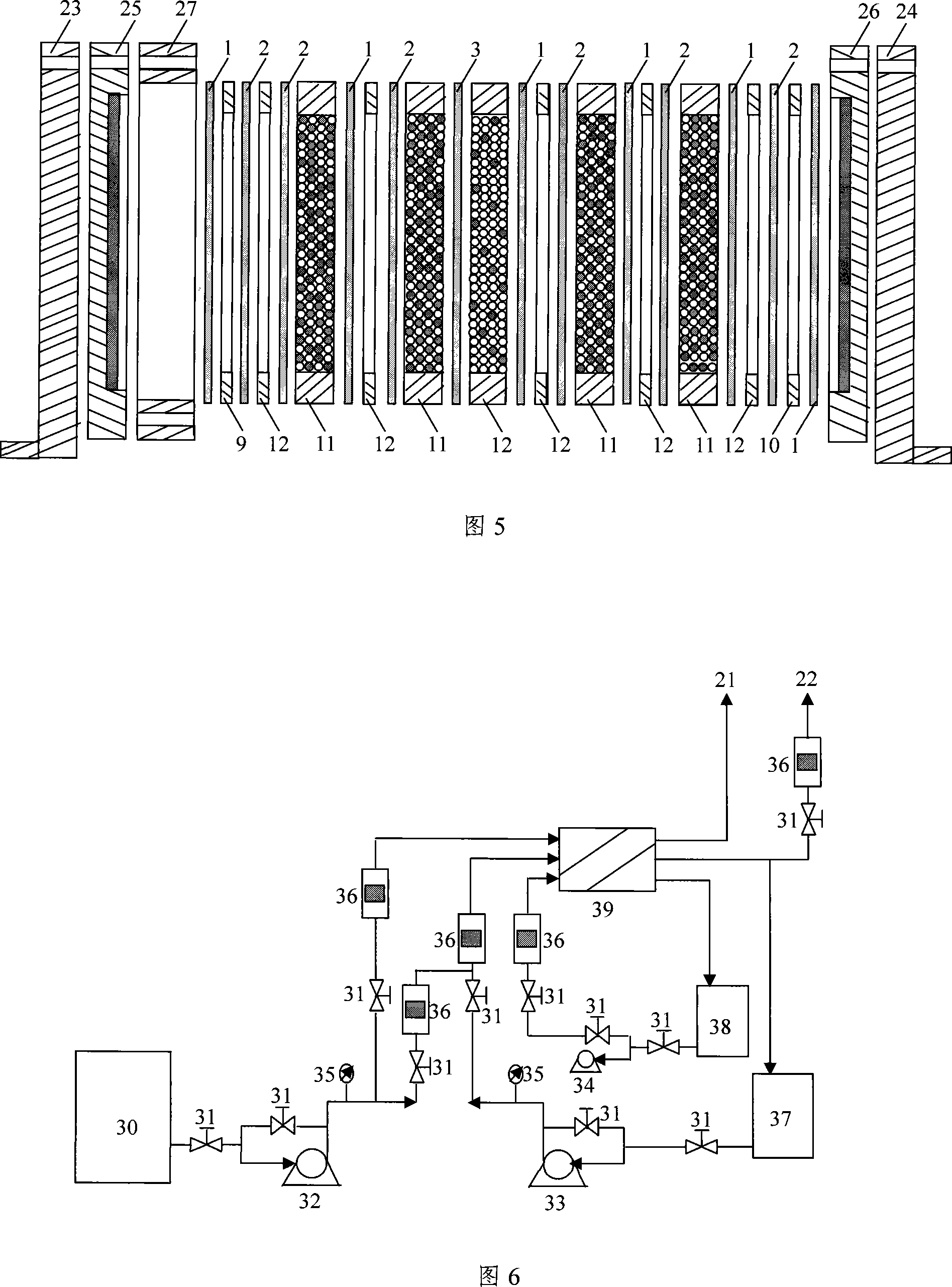

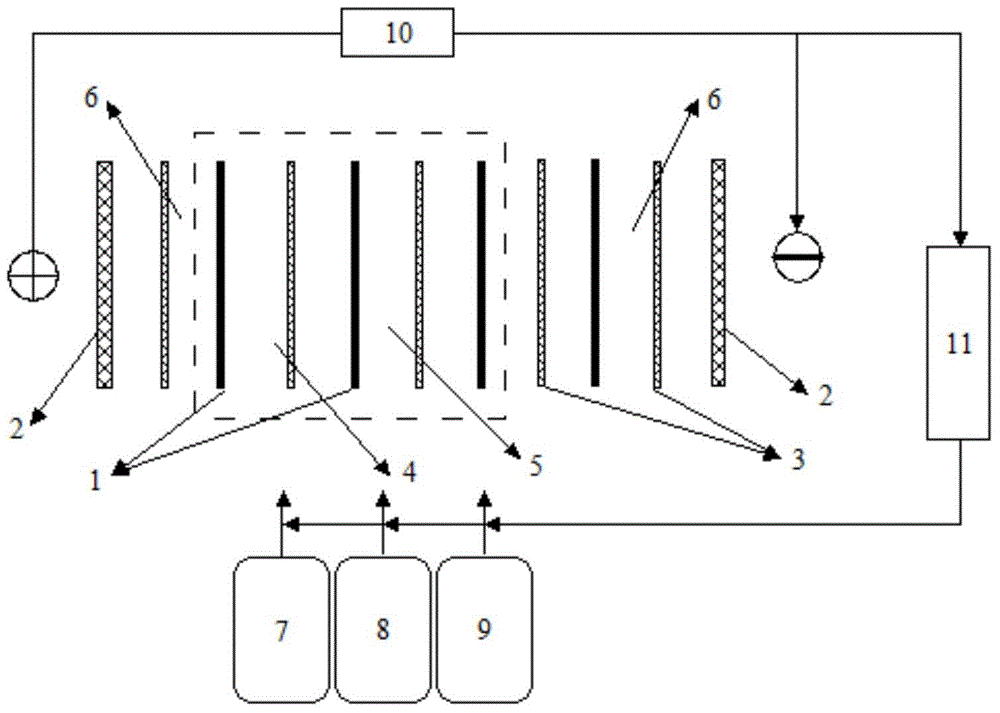

Electro-deionization method and device for synchronously concentrating and purifying heavy metal wastewater

InactiveCN101200325ALow flow resistanceImproved hydrodynamic propertiesDispersed particle separationWater/sewage treatment by ion-exchangeStrong acidsPollution

The invention relates to an electro-deionization method and device for concentrating and purifying heavy metal wastewater synchronously, belonging to a wastewater treatment technique, which adopts first-stage two-section or first-stage multi-section electro-deionization device, wherein the inner sides of the positive and negative poles are arranged with corresponding pole protection chambers, the desalting chamber is filled with large-hole strong-acid strong-base mixed bed resin with narrow particles distributed; cation exchange film is adopted as the direction-turning film, after direction-turning, two adjacent concentration chambers are arranged continuously, both are separated by cation exchange film, simultaneously after direction-turning, the first concentration chamber is filled with large-hole mixed bed resin with the volume of cathode resin more than 50 percent, the heavy metal wastewater to be treated enters the desalting chamber and the concentration chamber in two paths, the heavy metal ion and cathode in the desalted water flow are transferred into the concentration chamber so as to obtain the desalted water, the concentrated water flow is partially circulated or closely circulated so as to obtain the concentrated liquid of metal wastewater, thereby recycling valence metals and pure water resources synchronously and realizing zero emission and resource treatment of wastewater. Compared with the prior art, the wastewater treatment process has higher separation efficiency, more reliable operation, more convenient operation, continuous process operation and no secondary pollution.

Owner:NANKAI UNIV

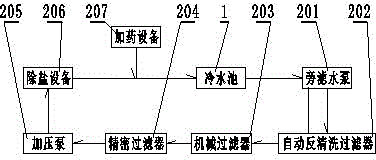

Energy-saving recycling combination system for industrial circulating cooling water

InactiveCN104478137AIncrease profitIncrease return water temperatureLighting and heating apparatusTreatment involving filtrationCooling towerWater quality

The invention discloses an energy-saving recycling combination system for industrial circulating cooling water. The system comprises two circulating cooling water systems, namely, a sealed-type circulating cooling water system and an open-type circulating cooling water system and specifically comprises a cold water tank, a water treatment process device, a cooling water supply pump, a pressure sensor, a flow sensor, a cooled device, an intermediate water tank, a lift pump, a cooling tower, a heat pump set, a hot water tank, a liquid-level sensor and an electronically controlled device and is an energy-saving and water-saving optimized combination system for industrial circulating cooling water. Serial-type water supply is adopted in the sealed-type circulating cooling water system, parallel-type water supply is adopted in the open-type circulating cooling water system, the utilization rate of the cooling water is increased to a maximize extent and the water supply amount of the cooling water is decreased. Since the system is provided with the water treatment process device, the water quality of the circulating water is improved, the sewage discharge capacity is decreased and the concentration multiple of the circulating water is increased. By arranging the heat pump set in the system, the low-temperature waste heat of the return water of the cooling water is effectively recovered, the evaporation amount is reduced and the effective utilization of the heat source is achieved and the system has important practical values.

Owner:CHINA FIRST HEAVY IND

Compound corrosion and scale inhibitor

InactiveCN105502704AHigh water saving rateReduce pollutionSpecific water treatment objectivesScale removal and water softeningHigh concentrationAzole

The invention provides a compound corrosion and scale inhibitor. The compound corrosion and scale inhibitor is a liquid preparation which is prepared by mixing a first liquid preparation with a second liquid preparation according to the ratio of 1:1; a compound preparation prepared from organic phosphonic acid, polycarboxylic acid, a dispersing agent and water is adopted as the first liquid preparation; a compound preparation prepared from solid agentia and water according to the weight ratio of 1:1 is adopted as the second liquid preparation, wherein a compound preparation which has the scale inhibition effect and is prepared from polymers, an alkaline agent, azoles and zinc salt is adopted as the solid agentia. The compound corrosion and scale inhibitor can achieve the effects of corrosion inhibition, scale inhibition and sterilization and algae removal which meet the national requirements, can be applied to a circulating cooling water system with the high concentration multiple, is convenient to put, does not need to be prefilmed, can be used at normal temperature and is good in using effect.

Owner:HEBEI AGRICULTURAL UNIV. +1

Preparation method of mango condensed thick juice

InactiveCN101543306AIncrease the juice yieldHigh retention rateFood preparationFood industryCellulase

The invention relates to a preparation method for mango condensed thick juice, belonging to the technical field of the application of enzyme engineering technology to the food industry. The method comprises the following steps: using fresh mangos as raw material, blanching, peeling, discarding kernels, protecting colors and pulping to obtain mango pulp; then, carrying out composite enzymolysis treatment of cellulose, glucamylase, pectase and acid protease, degerming and pressure filtering to obtain mango zymolyte juice; and concentrating, packaging, sterilizing and cooling to obtain the mango condensed thick juice product with the dissolvable solid content of 50 to 60 degrees Brix, the beta-renieratene content more than 4000 microgrammes / g and a pH value of 3.6 to 4.0. The invention has the advantages of scientific and reasonable technology, simple and convenient operation, high juice yield rate, high maintenance rate of nutrient contents, such as pulp, and the like, high degree of concentration and good color stability.

Owner:JIANGNAN UNIV

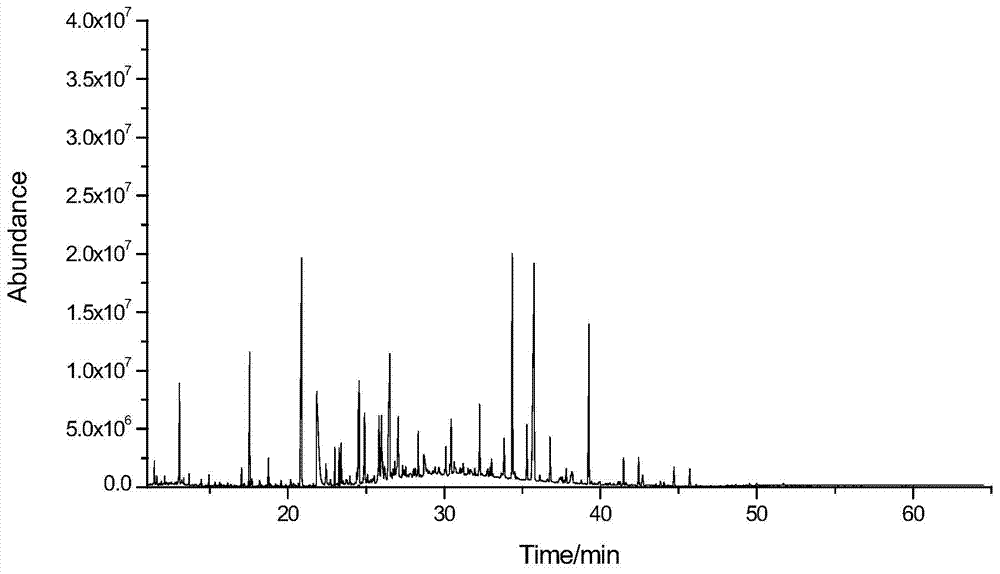

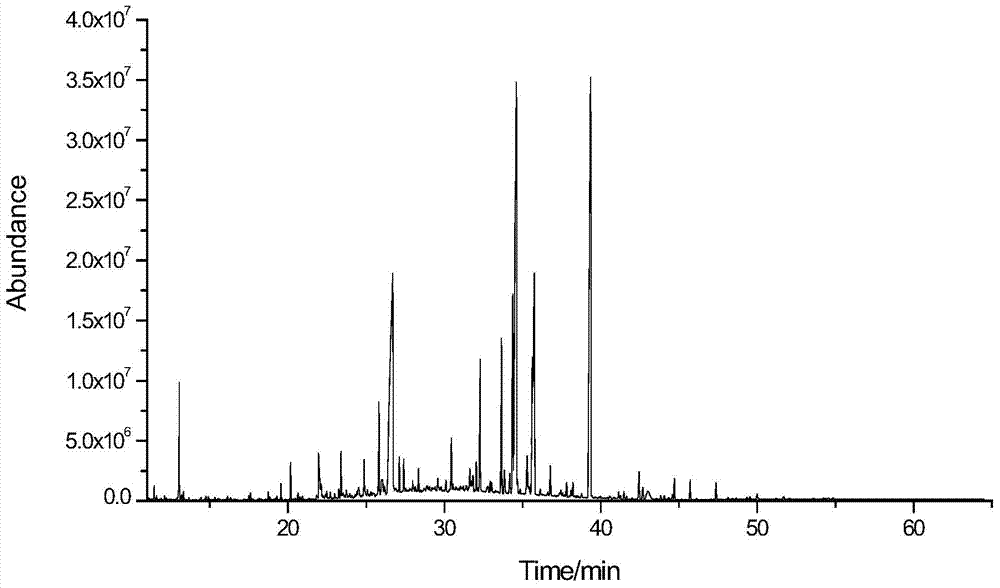

Method for extracting tobacco volatile and semi-volatile aroma components

InactiveCN104713965AStyle feature regulationStyle features are easy to followComponent separationOrganic solventClosed loop

The invention provides a method for extracting tobacco volatile and semi-volatile aroma components. The method comprises the following steps: removing a filter tip and cigarette paper from a cigarette to obtain a tobacco shred sample, and filling into a sample bottle to carry out heating balance; after balancing, continuously heating the sample bottle, and blowing the tobacco shred sample in the sample bottle with air prepared by an air pump; using a capture pipe to capture air obtained by blowing, and connecting the capture pipe, the sample bottle and the air pump into a closed loop; after finishing capture, taking off the capture pipe, adding an organic solvent, and eluting into a collecting bottle in several times to obtain the tobacco volatile and semi-volatile aroma components. The invention further provides a device for extracting tobacco volatile and semi-volatile aroma components. According to the method for extracting tobacco volatile and semi-volatile aroma components, provided by the invention, the volatile and semi-volatile aroma components are extracted from prepared cigarette tobacco shreds through adopting closed-loop gas. The method for extracting the volatile and semi-volatile aroma components from tobaccos is simple, feasible and efficient.

Owner:SHANGHAI TOBACCO GRP CO LTD

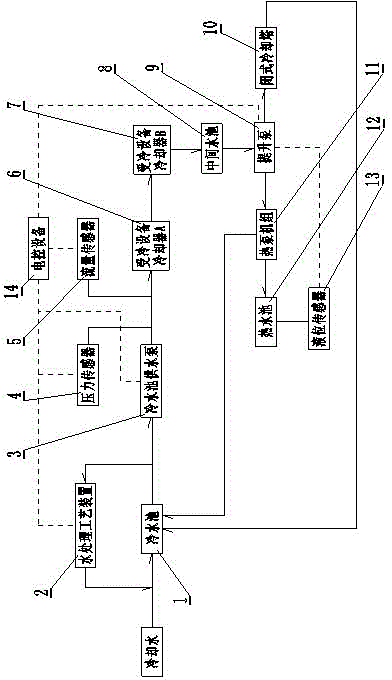

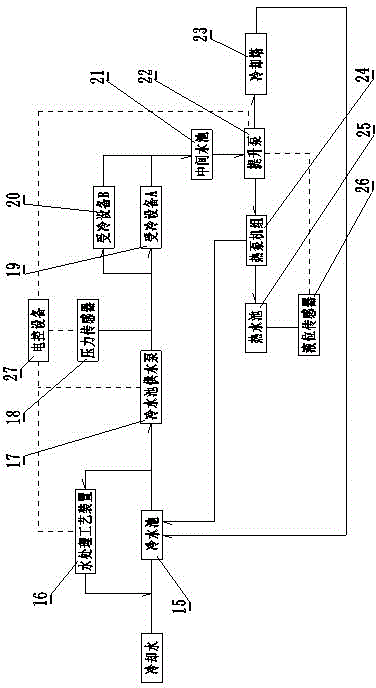

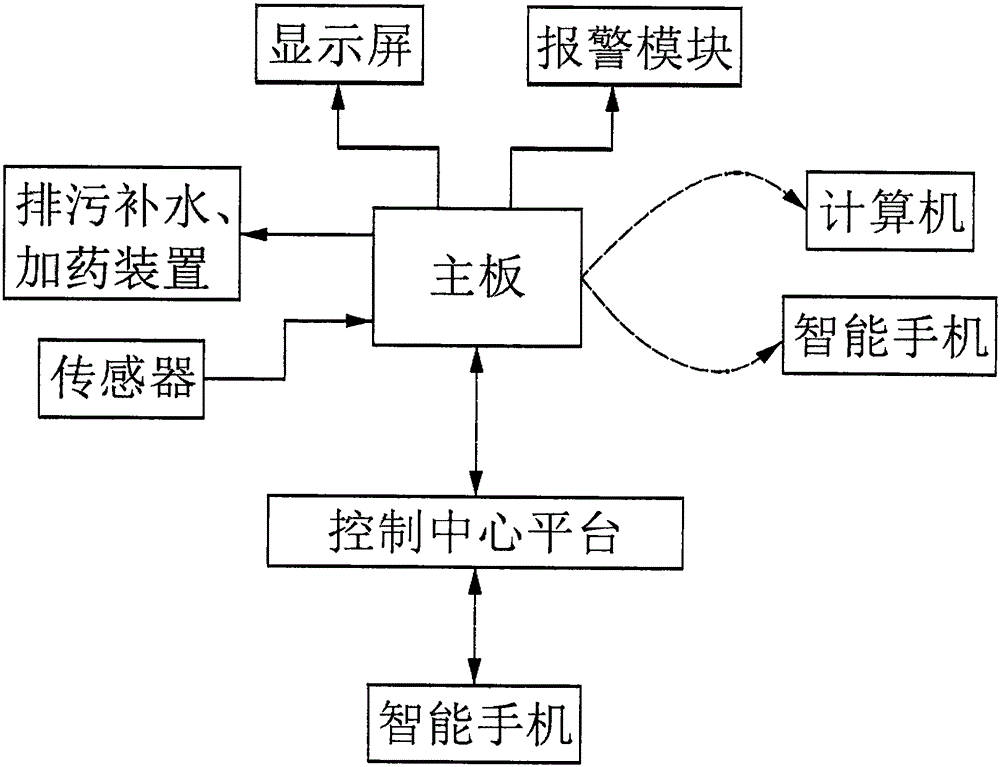

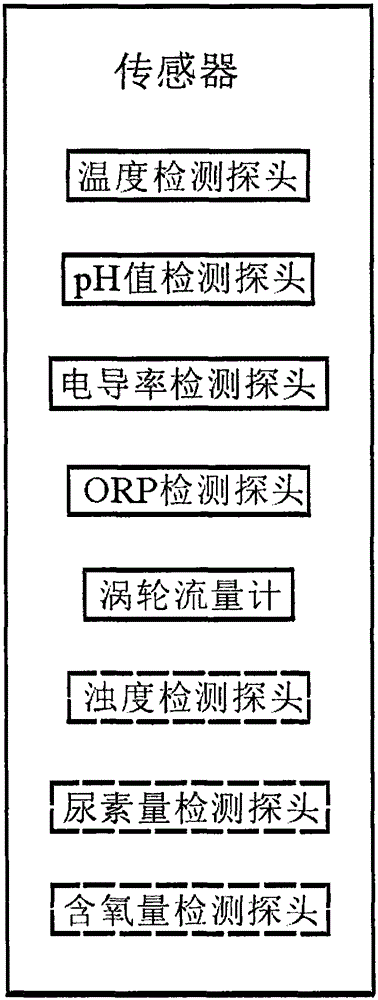

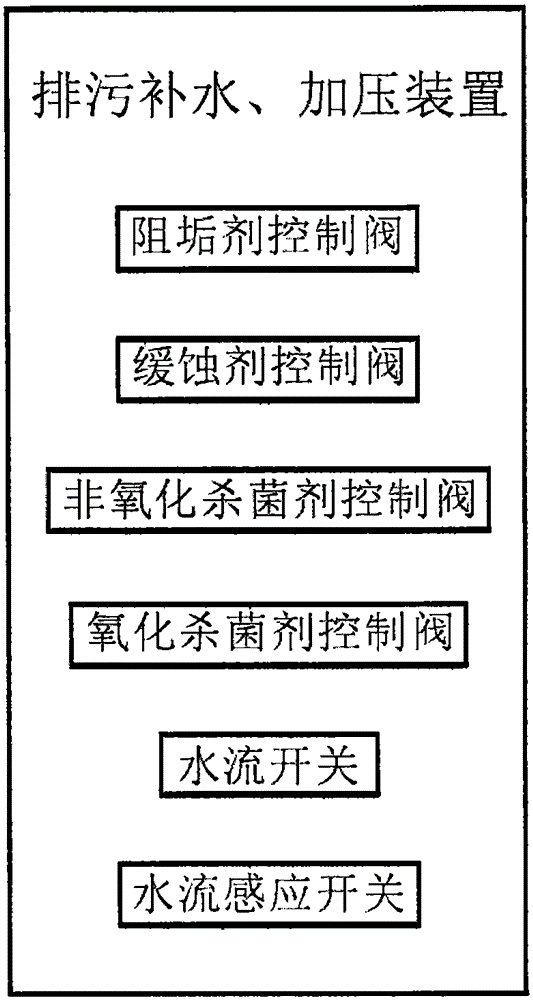

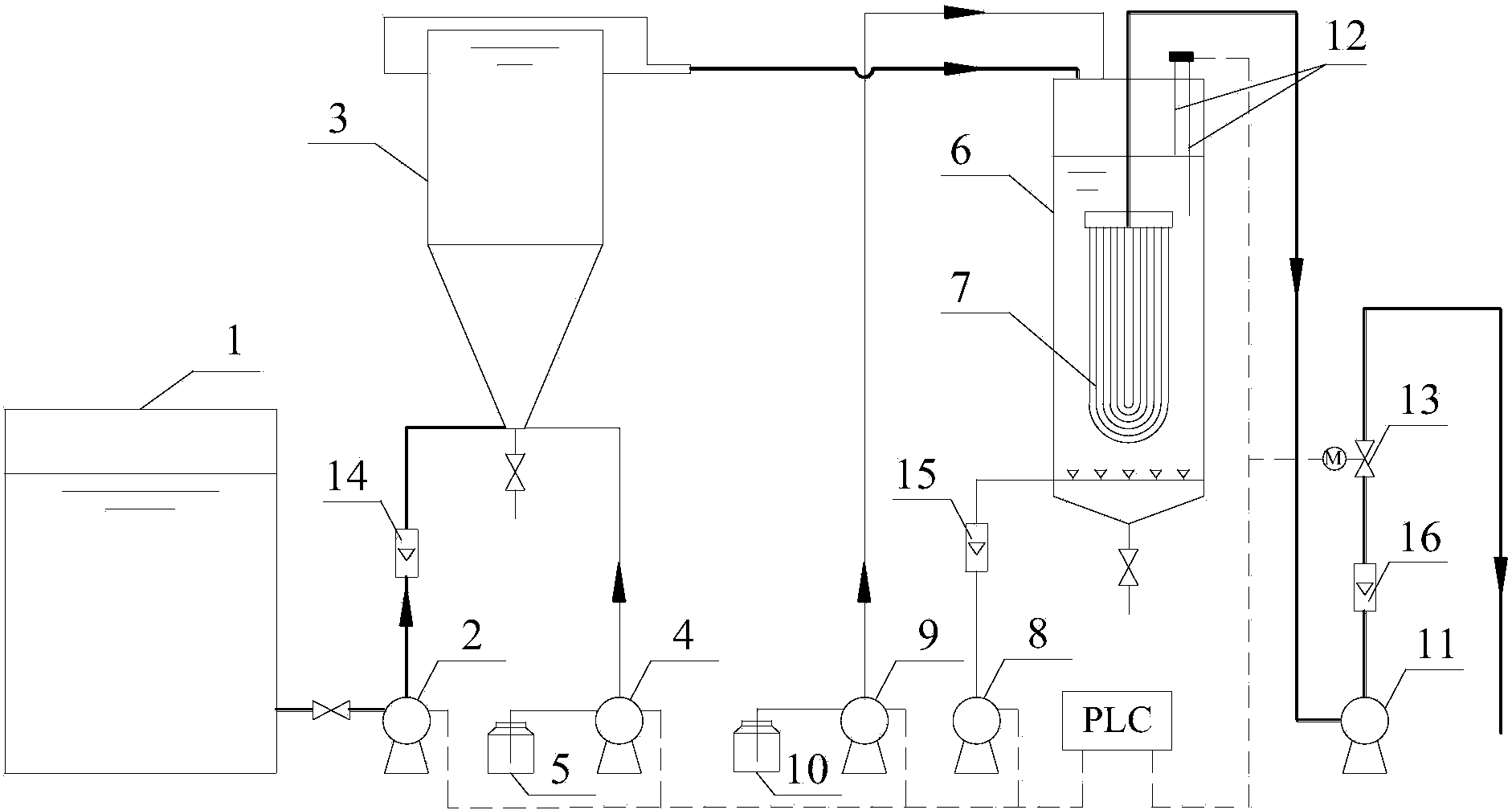

On-line intelligent network automatic water treatment detection and control system

InactiveCN105152364AImprove utilizationIncrease the concentration factorScale removal and water softeningWater/sewage treatment by neutralisationElectricityIntelligent Network

The invention discloses an on-line intelligent network automatic water treatment detection and control system which comprises a control center platform, a main board, a sensor, a pollution discharge, water replenishing and dosing device, an alarm module, a display screen, a computer and an intelligent mobile phone, wherein the output port of the sensor is connected with the input end of the main board, the output port of the main board is connected with the input end of the pollution discharge, water replenishing and dosing device, the output end of the main board is respectively connected with the display screen and the alarm module, the output end of the main board is connected with the computer or the intelligent mobile phone through the Internet or GPRS network, the main board and the control center platform are in bilateral interaction, and the control center platform and the intelligent mobile phone are in bilateral interaction. According to the invention, the sensor is used for detecting water quality data, and the opening and closing of the pollution discharge, water replenishing and dosing device are remotely controlled through the Internet, so that the electricity, water and chemical agents are furthest saved, the service life of an air conditioner is prolonged, the running cost of the air conditioner is lowered, and the environmental pollution is reduced.

Owner:中环清新人工环境工程技术(北京)有限责任公司

Processing technology for recovering and utilizing mother solution of glyphosate as resource

ActiveCN101659673AImprove throughputReduce flux decay speedGroup 5/15 element organic compoundsWater/sewage treatment bu osmosis/dialysisFiltrationCatalytic oxidation

The invention relates to a processing technology for recovering and utilizing the mother solution of glyphosate as a resource, which comprises the following concrete steps: firstly, preprocessing themother solution of glyphosate, and then, separating, concentrating and recovering the glyphosate by a membrane combination technique; returning the concentrated solution to a crystallization working section in the production process of the glyphosate after membrane filtration, thereby effectively recovering and utilizing the glyphosate resource; adsorbing the diluted solution with high efficiency,and further recovering and utilizing the glyphosate; and processing the adsorbed solution by catalytic oxidation with high efficiency to recover the sodium chloride resource with higher purity. The invention achieves the purposes of recovering and utilizing the glyphosate in the mother solution as a resource to the maximum extent and efficiency separating, recovering and utilizing the sodium chloride as a resource, has the advantages of economical technology, high efficiency, good system stability, high safety, easy operation, convenient industrial amplification, and the like, solves the problems of the soil salinization caused by applying water agents with high content of sodium chloride, the processing and disposal of solid wastes of the sodium chloride and the environment pollution, and effectively recovers and utilizes the resources of the glyphosate and the sodium chloride in the mother solution of the glyphosate.

Owner:NANJING UNIV OF TECH

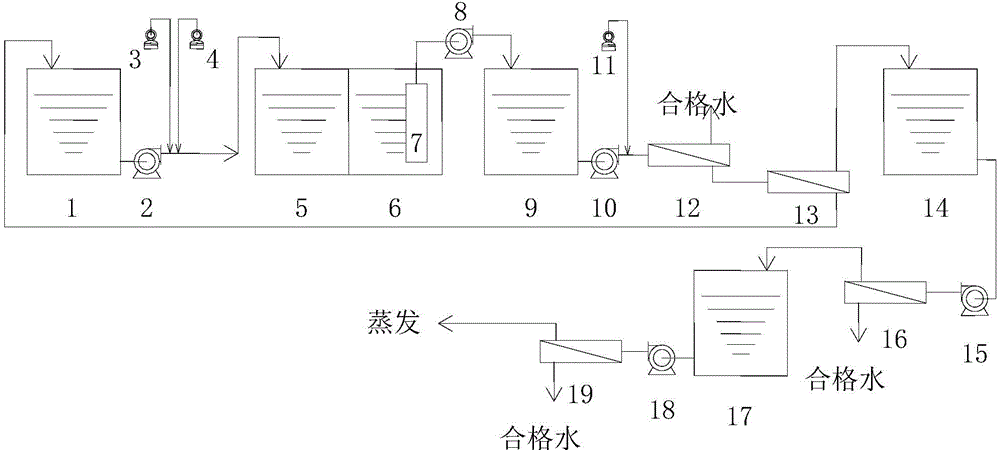

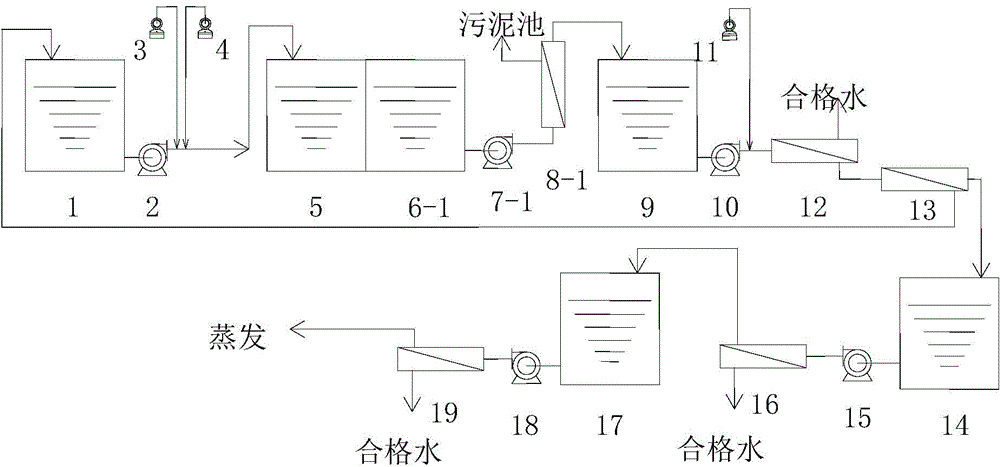

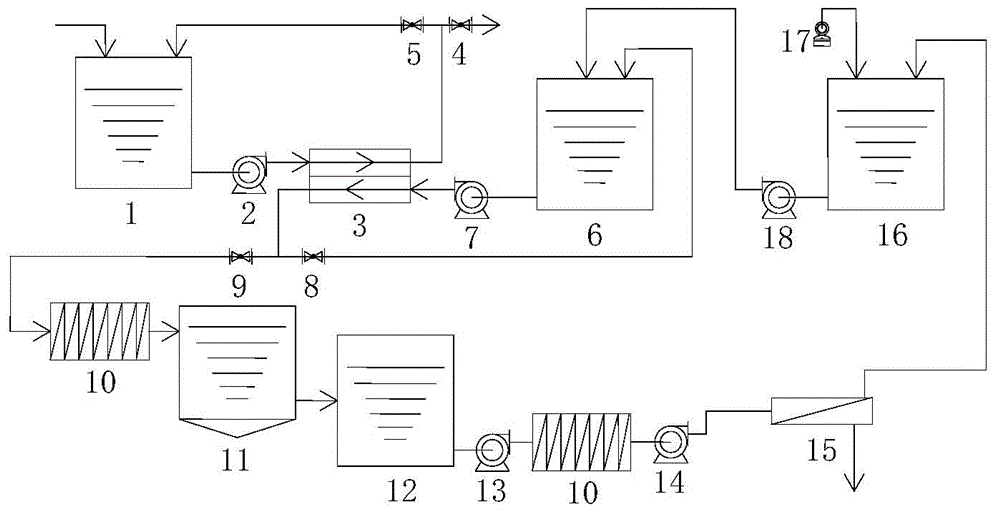

Method for treating reverse osmosis concentrated water and circulating wastewater by whole membrane method

ActiveCN104609610AReduce hardnessReduce salt contentScale removal and water softeningTreatment involving filtrationWater qualityProduced water

The invention discloses a method for treating reverse osmosis concentrated water and circulating wastewater by a whole membrane method, and belongs to the technical field of wastewater treatment and reclaimed water reuse. The method disclosed by the invention comprises the following steps: regulating the water amount and the water quality of wastewater by using a regulating tank; adding alkali to react with magnesium and calcium ions in a reaction tank to generate crystals of magnesium hydroxide and calcium carbonate; adding a mixed solution into a ceramic membrane filtering device; after the crystals of the magnesium hydroxide and calcium carbonate are filtered by a ceramic membrane, performing filter-pressing processing on a concentrated solution by using a plate frame; regulating the filtrate by adding an acid, and adding the regulated filtrate into a first-stage reverse osmosis device; recycling reverse osmosis pure water; adding the reverse osmosis pure water into a nano-filter; returning the concentrated water which is subjected to nano-filtration to the regulating tank; concentrating the water produced by the nano-filtration by using a second-stage reverse osmosis device; recycling the reverse osmosis produced water; further concentrating the concentrated water in a forward osmosis device; recycling the water produced by the forward osmosis; evaporating a trace amount of remaining concentrated water in an evaporator, and using the trace amount of remaining concentrated water in other ways, so as to finally realize zero emission of the wastewater.

Owner:山东泰禾环保科技股份有限公司

Polynary composite water treatment agent

ActiveCN1565994AIncrease the effective concentrationIncrease the concentration factorScale removal and water softeningChemistryCorrosion inhibitor

The invention relates to a polynary composite water treatment agent which mainly comprises terpolymer containing sulfonic acid radicals, organophosphorus acids, zinc salts and metal inhibitors, wherein the effective concentration weight ratio being 20-40 : 1-10 : 0.5-4 : 0-3.

Owner:PETROCHINA CO LTD

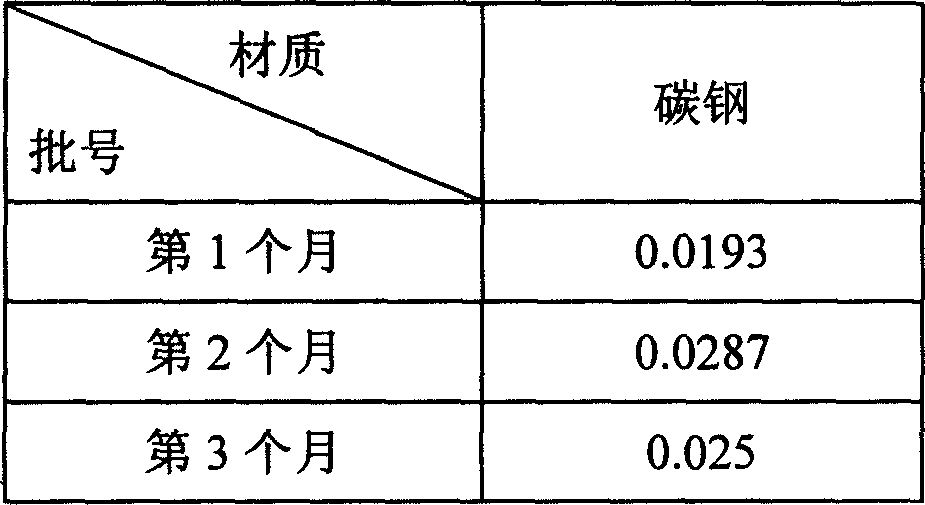

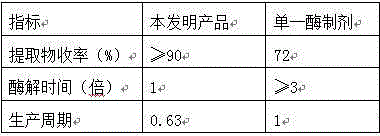

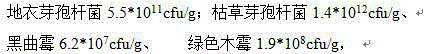

Complex enzyme preparation for extracting effective plant components and method for preparing complex enzyme preparation

InactiveCN105062990AHigh recovery rateRelease fullyMicroorganism based processesGlycosylasesBacillus licheniformisPectinase

The invention discloses a complex enzyme preparation for extracting effective plant components and a method for preparing the complex enzyme preparation. The complex enzyme preparation comprises components of glycanase, cellulase, pectinase, beta-glucanase and alpha-amylase. The activity of the glycanase is 3000IU / g, the activity of the cellulase is 2000IU / g, the activity of the pectinase is 20000IU / g, the activity of the beta-glucanase is 5000IU / g, and the activity of the alpha-amylase is 3000IU / g. The method for preparing the complex enzyme preparation includes symbiotically cultivating, extracting and concentrating bacillus licheniformis, bacillus subtilis, aspergillus niger and trichoderma viride according to certain proportions, then adding expanded plant protein carriers into the bacillus licheniformis, the bacillus subtilis, the aspergillus niger and the trichoderma viride; spraying mist at low temperatures to obtain the complex enzyme preparation. The complex enzyme preparation and the method have the advantages that the effective component recovery rate of complex enzymes can be increased as compared with a method for individually fermenting and producing various enzymes and then combining the various enzymes with one another, production technologies can be simplified, the production cycle can be shortened, the production cost can be lowered, the production efficiency can be greatly improved, the stability of the activity quality of final products can be guaranteed, and plant extraction complex enzyme production can be industrialized.

Owner:天津科建科技发展有限公司

Device for removing suspended matter in water

InactiveCN1597041AReduce the amount of waterIncrease the concentration factorLoose filtering material filtersGravity filtersWater qualitySewage

An apparatus for removing the suspended substance from water is a filter unit which is composed of cylindrical tank, overflow dam, water outlet tube, water inlet tube, water distributor, filtering material washer, fairing unit, filtering material distributor, cyclic filtering material lifting tube and air distributor. It features its additional suspended substance separator, between the outlet of said lifting tube and filtering material washer.

Owner:CHINA PETROLEUM & CHEM CORP +1

Circulating cooling water biological treatment method

InactiveCN104211185AIncrease the concentration factorImprove water qualityBiological water/sewage treatmentSulfurPurple Nonsulfur Bacteria

The invention discloses a circulating cooling water biological treatment method and belongs to the technical field of industrial water treatment. The method includes the steps of arranging a packed bed in a circulating cooling water tank for providing conditions for implantation of added microorganisms and disposing a circulation pump beside the circulating cooling water tank; adding four kinds of bacteria of yeast, purple non-sulfur bacteria, acetic acid bacteria and bacillus bacteria which are mixed in any proportion to the circulating cooling water tank, wherein the total monthly amount of the bacteria liquid is 0.05-1% of the water in a system; arranging a sludge removal pump in the circulating cooling water tank for regular sludge removal. Furthermore, the invention also provides a method for adjusting the pH of the circulating cooling water system. The circulating cooling water biological treatment method can improve the concentration multiple of the circulating cooling water, reduce the amount of make-up water of the circulating cooling water system, and is fast, easy, effective and environmentally friendly.

Owner:付永全 +3

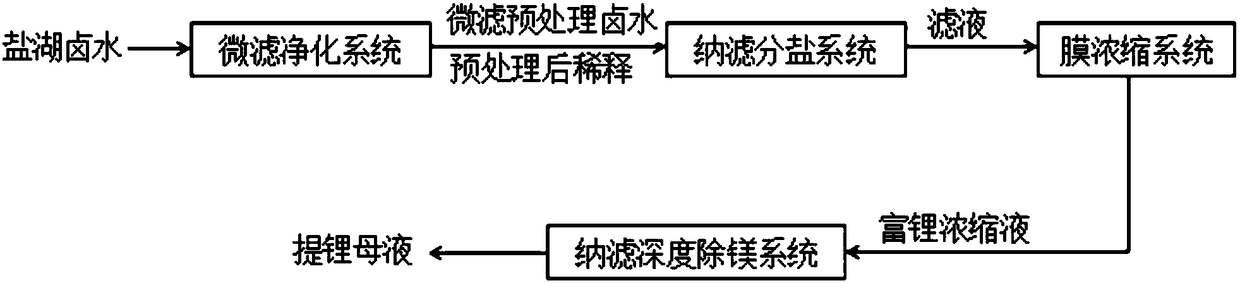

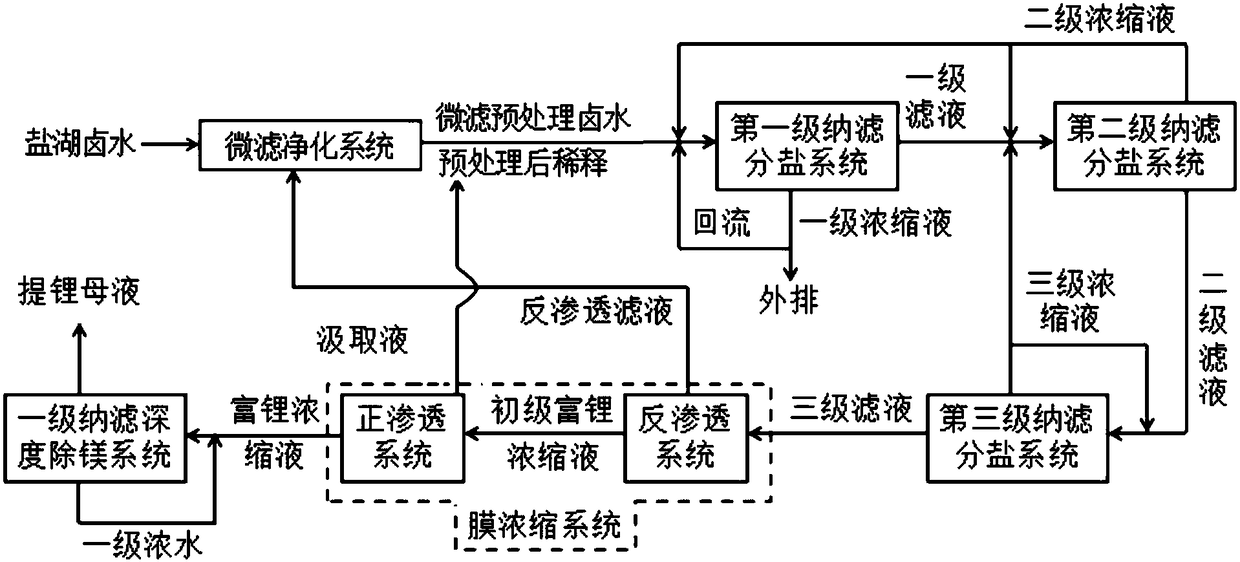

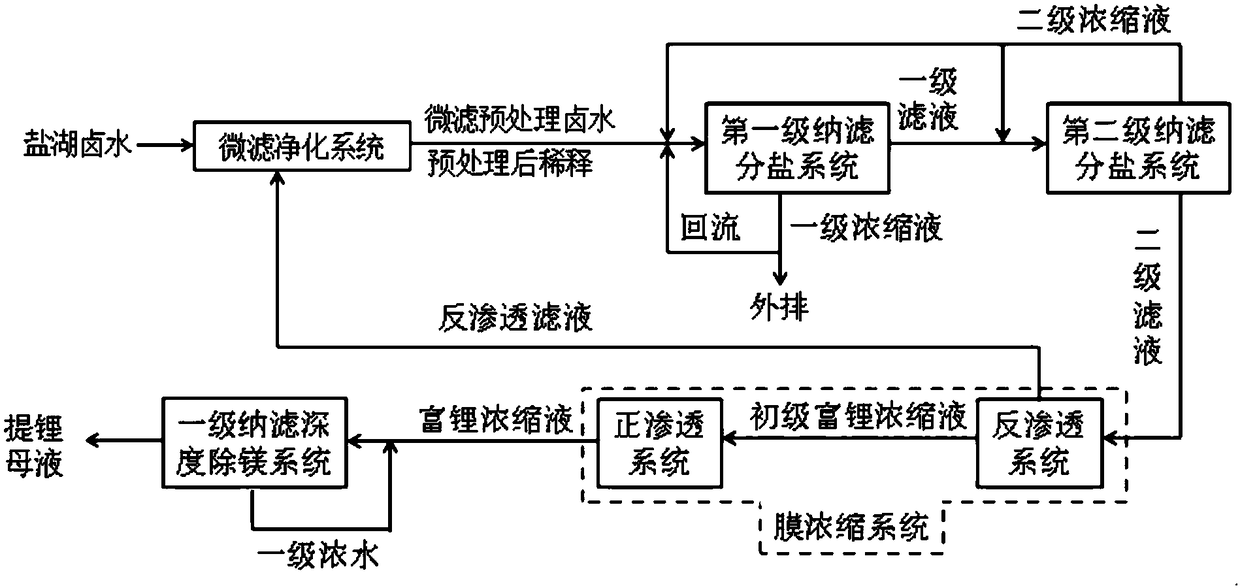

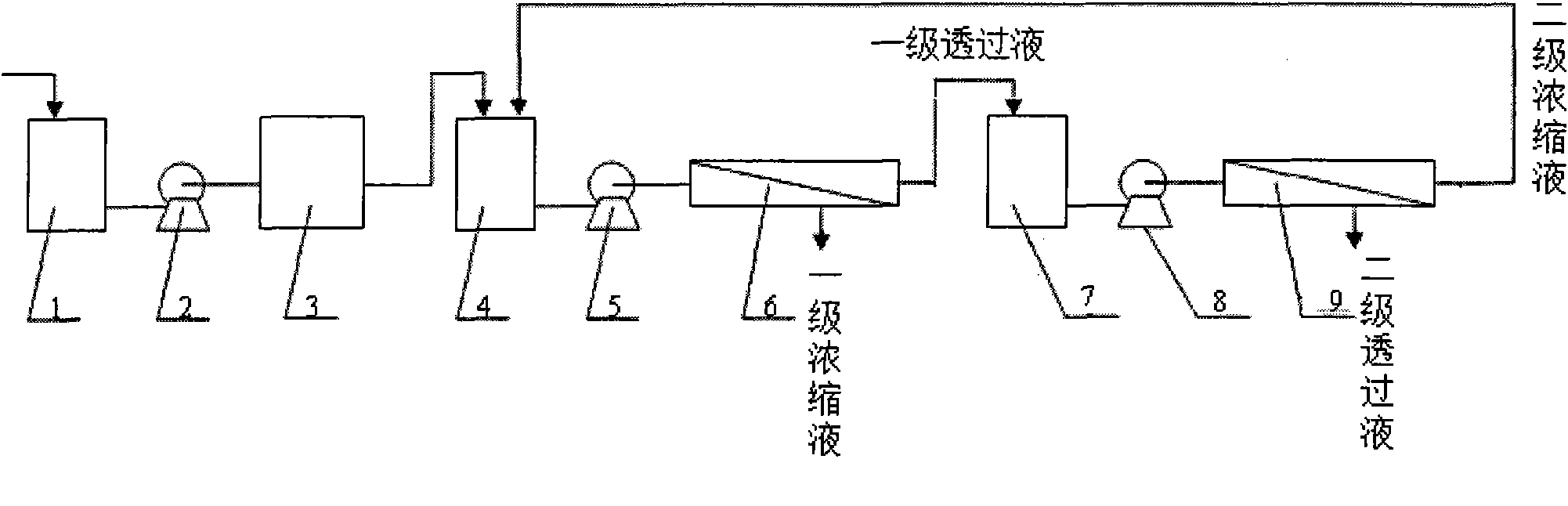

Total membrane separation method of producing lithium extracting mother liquor with multi-stage membrane concentration of salt lake brine

The invention discloses a total membrane separation method of producing a lithium extracting mother liquor with multi-stage membrane concentration of salt lake brine. The total membrane separation method comprises the following steps of (1) using a microfiltration purification system to perform pretreatment on the salt lake brine, removing suspended matters, colloid and other impurities in the salt lake brine, and then diluting the salt lake brine with fresh water to acquire microfiltration pretreated brine; (2) feeding the obtained microfiltration pretreated brine into a nanofiltration salt separation system, and performing separation to acquire a filtrate with monovalent cation as a priority and a concentrated solution with multivalent cation as a priority; (3) feeding the filtrate in the step (2) into a membrane concentration system, and performing concentration to obtain a lithium-enriched concentrated solution; and (4) feeding the lithium-enriched concentrated solution obtained inthe step (3) into a nanofiltration deep magnesium removing system, and performing deep magnesium removal with a nanofiltration membrane to obtain the lithium extracting mother liquor. The technologyis low in energy consumption, high in recovery rate, low in production cost, continuous and controllable in technology, high in reliability, low in magnesium-lithium ratio of the prepared lithium extracting mother liquor, high in lithium ion concentration and stable in quality and can be used for large-scale production.

Owner:西安金藏膜环保科技有限公司

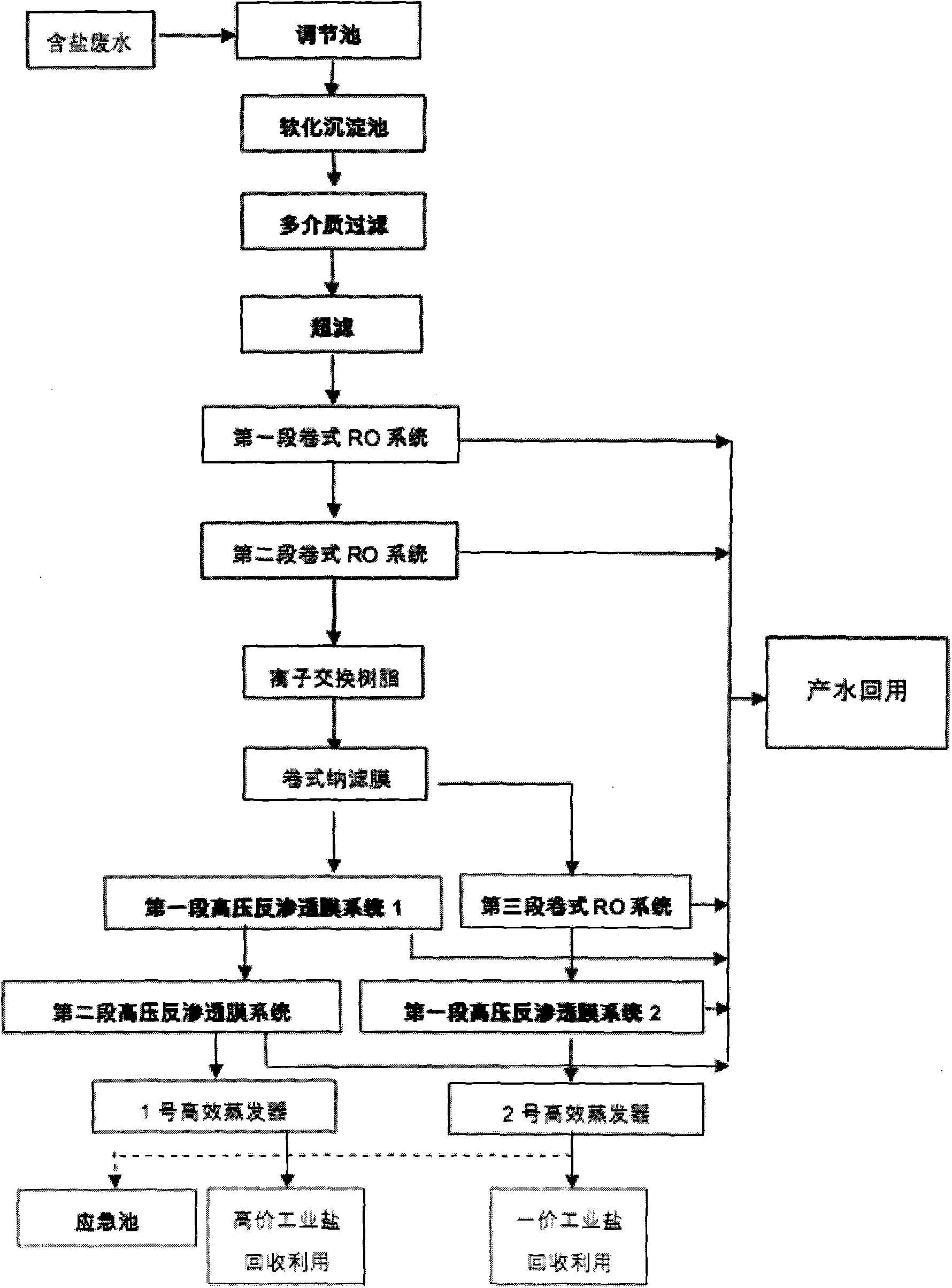

Salt-containing wastewater treatment method

ActiveCN103833172ASolve the problem of pollutionAvoid badWater/sewage treatment by ion-exchangeWater/sewage treatment bu osmosis/dialysisHigh concentrationIon exchange

The invention discloses a salt-containing wastewater treatment method. The wastewater goes through an adjusting tank, a softening sedimentation tank, a multi-medium filter, an ultrafiltration device, a first-section roll type reverse osmosis system, a second-section roll type reverse osmosis system, an ion exchange device, a roll type nanofiltration membrane device, a high-pressure reverse osmosis membrane system, a third-section roll type reverse osmosis system and an efficient evaporator. The treatment method disclosed by the invention has the advantages of strong anti-pollution capacity, solution of blocking problem, high concentration multiple, high recycling efficiency, high treatment efficiency, high automation degree, investment saving and low operation cost.

Owner:BEIJING NEWBIOLINK TECH DEV

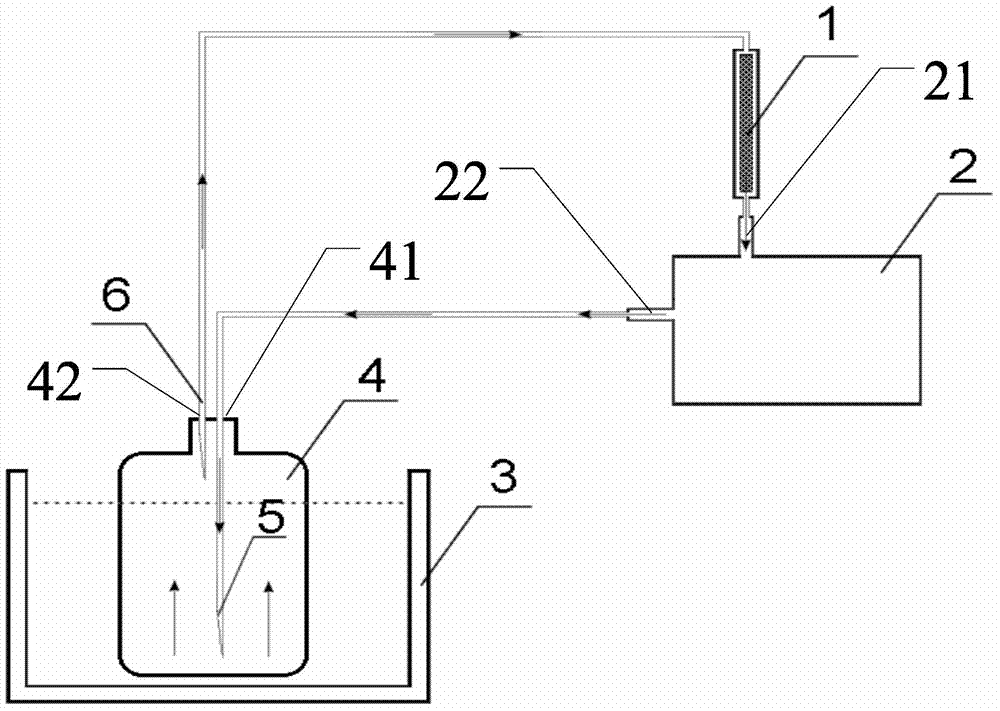

Forward osmosis absorption liquid using and recycling method and forward osmosis absorption device

InactiveCN104353361AReduce concentrationIncrease the concentration factorSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisHigh concentrationRecovery method

The invention discloses a forward osmosis absorption liquid using and recycling method and a forward osmosis absorption device, and belongs to the field of water treatment. According to the forward osmosis absorption liquid using and recycling method, raw material liquid is absorbed by the absorbing liquid in a forward osmosis device, so that in a raw material liquid concentration process, the absorbing liquid is an inorganic saline water solution and comprises dissolved sodium sulfate; the concentration of sodium sulfate is greater than 20wt%, and the temperature is 35-45 DEG C; the osmosis pressure of the absorbing liquid is 110-150bar; the recycling of the absorbing liquid comprises the processes of cooling crystallization and concentration recycling. By the use of the characteristic that the sodium sulfate solution is greatly different in dissolving degree due to different temperatures, the high-concentration sodium sulfate solution is used as the absorbing liquid, so that the concentration factor of the raw material liquid is increased as much as possible; when the absorbing liquid is recycled, a cooling crystallization device is added, and the concentration of sodium sulfate is reduced; under a condition of relative low pressure, the absorbing liquid is recycled by nano filtration or / and reverse osmosis concentration, and therefore, the energy consumption is low, and the cost is low; the investment and operation cost of equipment is lowered.

Owner:山东泰禾环保科技股份有限公司

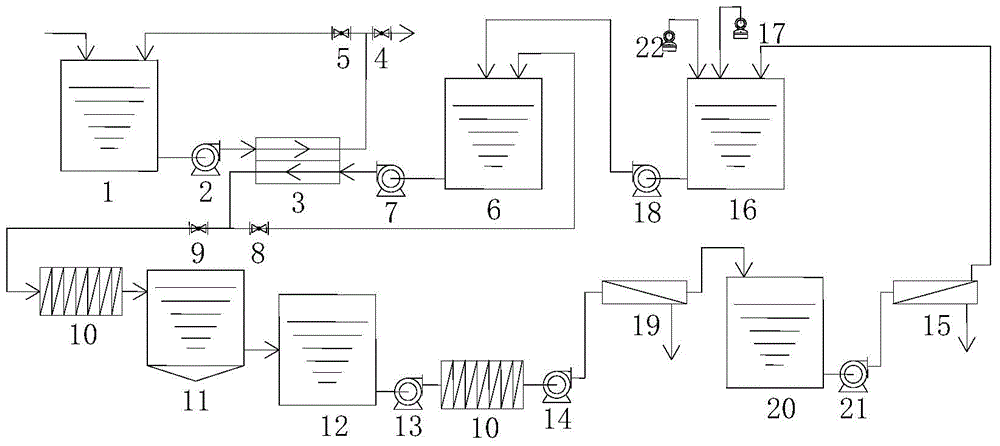

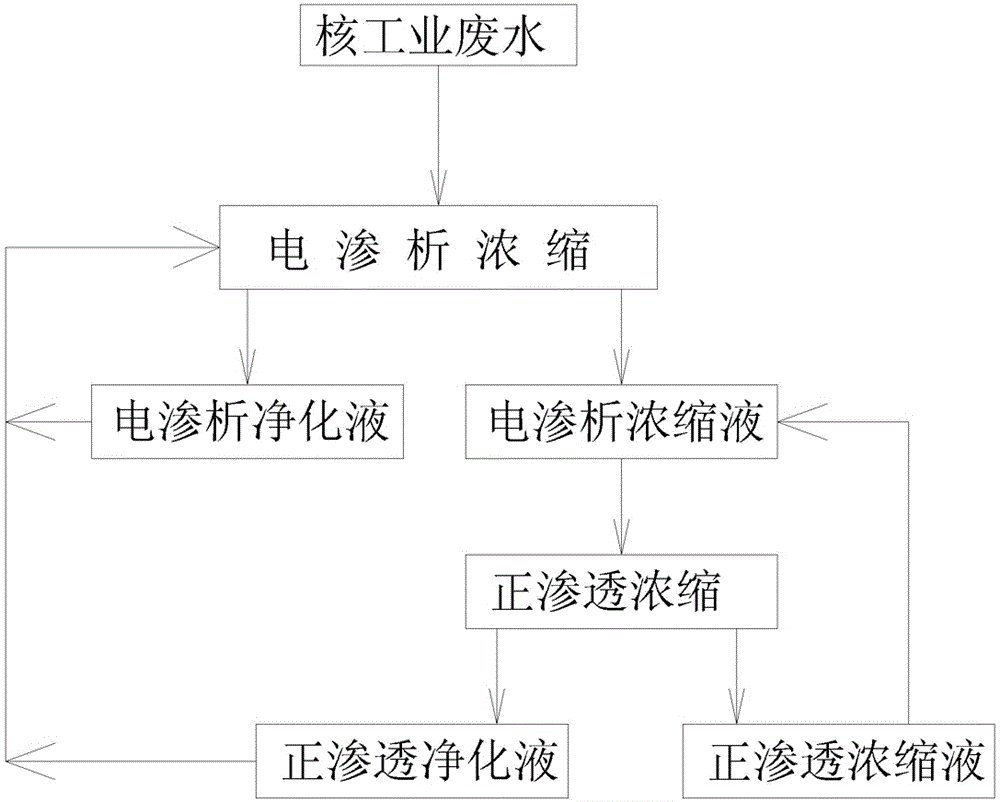

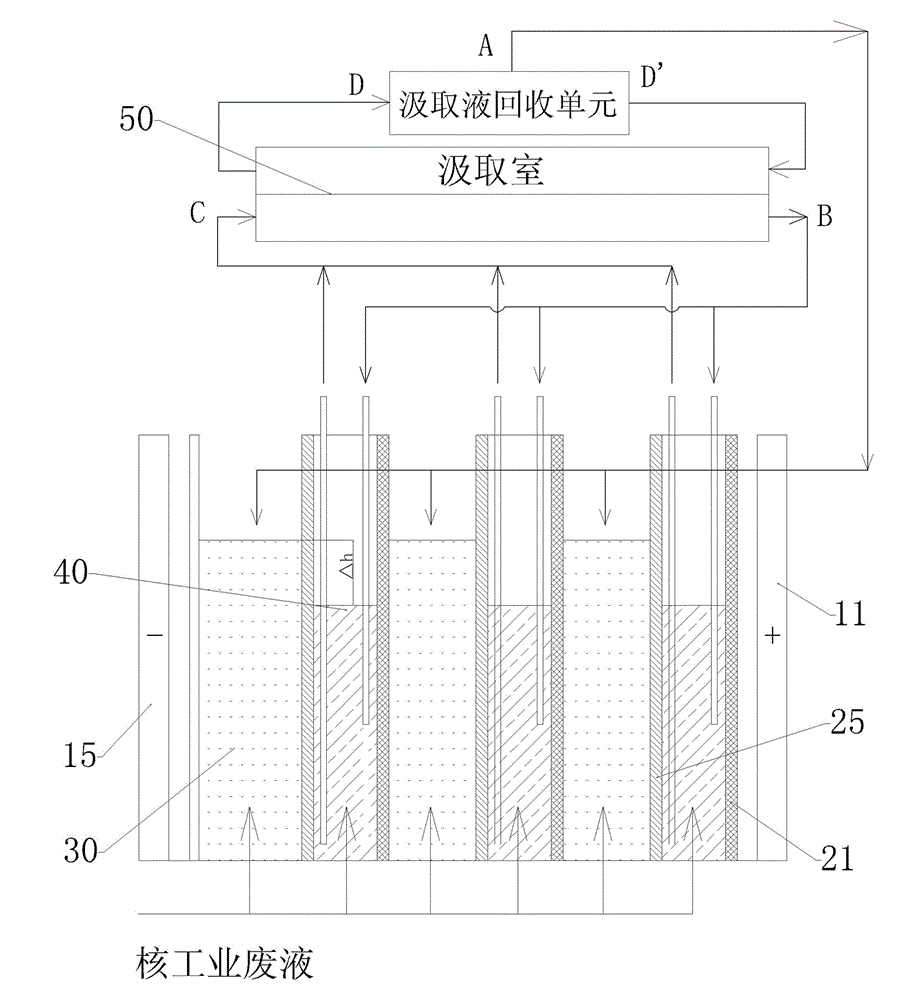

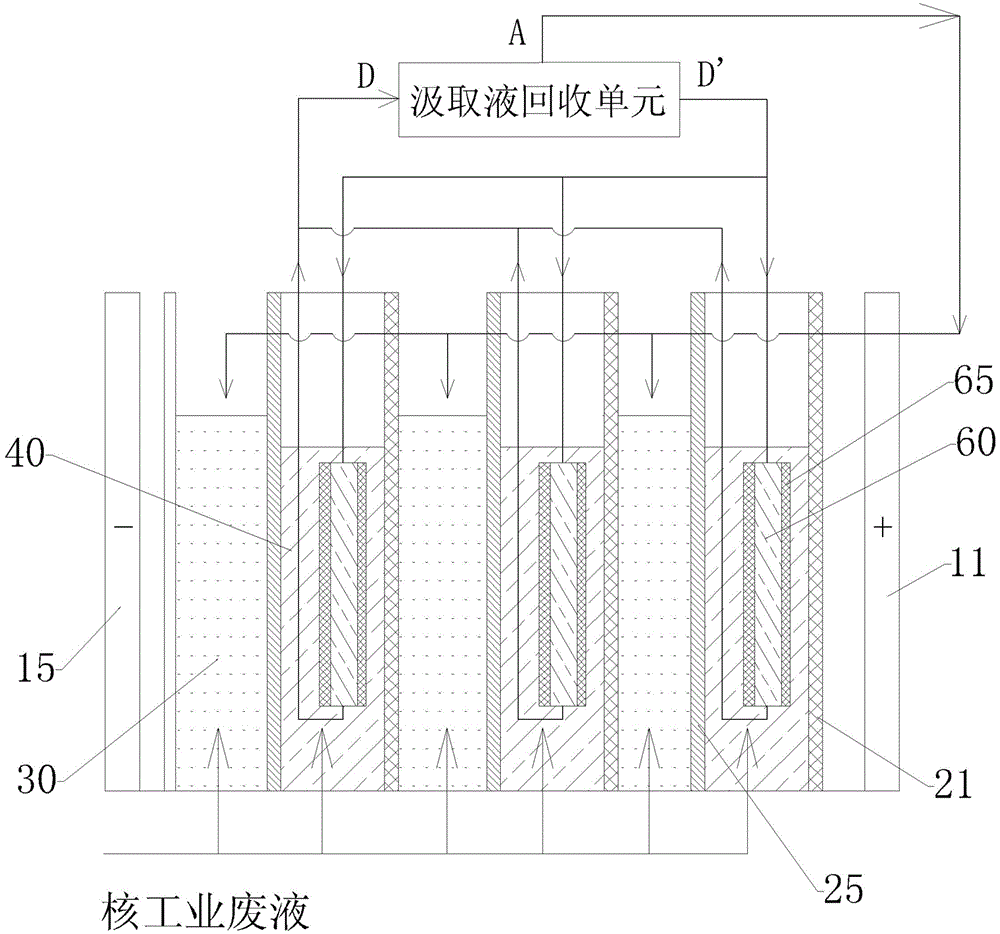

Method and system for decrement of concentrated solution in nuclear industry

ActiveCN104021834AIncrease the concentration factorMiniaturizationRadioactive decontaminationProcess engineeringNuclear chemistry

The invention discloses a method for decrement of a concentrated solution in the nuclear industry. The method specifically comprises the following steps: carrying out electroosmosis on radioactive wastewater in the nuclear industry to obtain an electroosmosis concentrated solution and an electroosmosis purified solution, wherein the PH value is 6-9, the saltness is 15-20g / L and the radioactive level is 3.7*10<4>Bq / L; separating the electroosmosis concentrated solution by a forward osmosis technology; returning a forward osmosis purified solution and a forward osmosis concentration solution after forward osmosis to an electroosmosis process, mixing the forward osmosis purified solution with the electroosmosis purified solution, and mixing the forward osmosis concentration solution with the electroosmosis concentrated solution; and synchronously and circularly carrying the above steps till the radioactive level of the electroosmosis purified solution is not higher than 60Bq / L, then, directly discharging the electroosmosis purified solution and exporting the electroosmosis concentrated solution for subsequent treatment. Through the coupling manner, the treatment efficiency of nuclear wastewater can be greatly improved, and the liquid level pressure difference deltah of a fresh water chamber and a concentrated water chamber is enlarged, so that positive and negative ions permeate to the concentrated water chamber more quickly.

Owner:TSINGHUA UNIV

Method and device for processing radioactive strontium-contained waste water

InactiveCN103714874AImprove decontamination factorIncrease the concentration factorRadioactive decontaminationFiberParticulates

The invention relates to a method and device for processing radioactive strontium-contained waste water. Chemical reactions are achieved between the radioactive strontium-contained waste water in a hydrocyclone and calcium carbonate seed crystals through hydrocycolone stirring and between the radioactive strontium-contained waste water in the hydrocyclone and sodium carbonate through hydrocycolone stirring, and therefore strontium carbonate is deposited on the surfaces of the calcium carbonate seed crystals and forms large-grain-size tight crystal particulate matter, and the large-grain-size tight crystal particulate matter rapidly sedimentates at the bottom of the hydrocyclone so that a part of radioactive strontium ions can be removed; small-grain-size strontium carbonate and small-grain-size seed crystals enter a membrane separator along with the supernatant to react with ferric chloride, the radioactive strontium ions are further removed after the particulate matter is separated through a hollow fibrous membrane, and therefore the radioactivity of discharged water is greatly lowered. The particulate matter formed through the method is large in grain size, compact in structure and good in sedimentation performance, the defects that the chemical precipitation method is low in decontamination factor and large in mud production amount are effectively overcome, the disadvantage that the membrane is seriously contaminated in the membrane separation process is also eliminated, and the method for processing the radioactive strontium-contained waste water is economical and practical.

Owner:TIANJIN UNIV

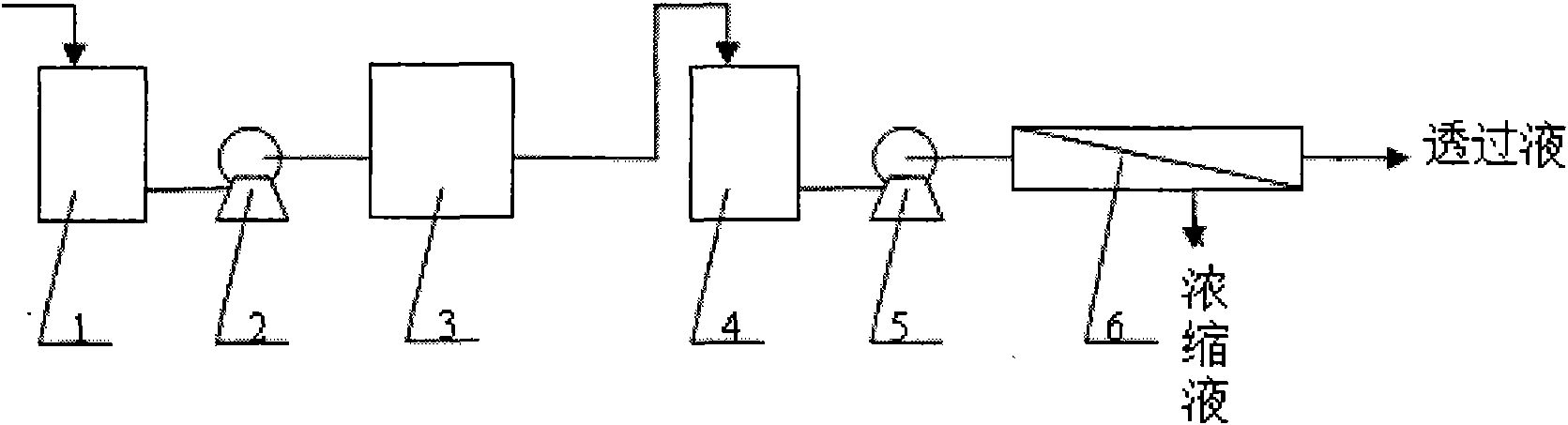

Treating method of ceftazidime mother liquor

InactiveCN101774709AConcentrated recovery is goodEfficient ConcentrationWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentSocial benefitsSeparation technology

The invention discloses a treating method for concentrating and separating ceftazidime mother liquor by using a membrane separation technology. The treating method mainly comprises the following steps: (1) carrying out pretreatment on the ceftazidime mother liquor to be treated, and removing fine suspended matters in the mother liquor; and (2) under the condition that the operation pressure is 0.5 to 4.0MPa, and the temperature is 10 to 80 DEG C, carrying out concentration and separation to a nanofiltration component for the ceftazidime mother liquor after pretreatment, obtaining concentrated liquor with the mass fraction of ceftazidime of more than 10 percent, collecting and then carrying out crystallization treatment; and the obtained permeate is discharged into a sewage treatment station for treatment. The treating method has the advantages of: effectively concentrating the ceftazidime mother liquor, not only recovering effective ingredient in the mother liquor, namely the ceftazidime, ensuring the quality of the ceftazidime, but also reducing the indexes of COD and BOD and the like discharged by the mother liquor, reducing the pollution and energy consumption, and having obvious economical and social benefits. The treating method can be widely applied in occasions needing to concentrate and recover the ceftazidime.

Owner:UNIV OF JINAN

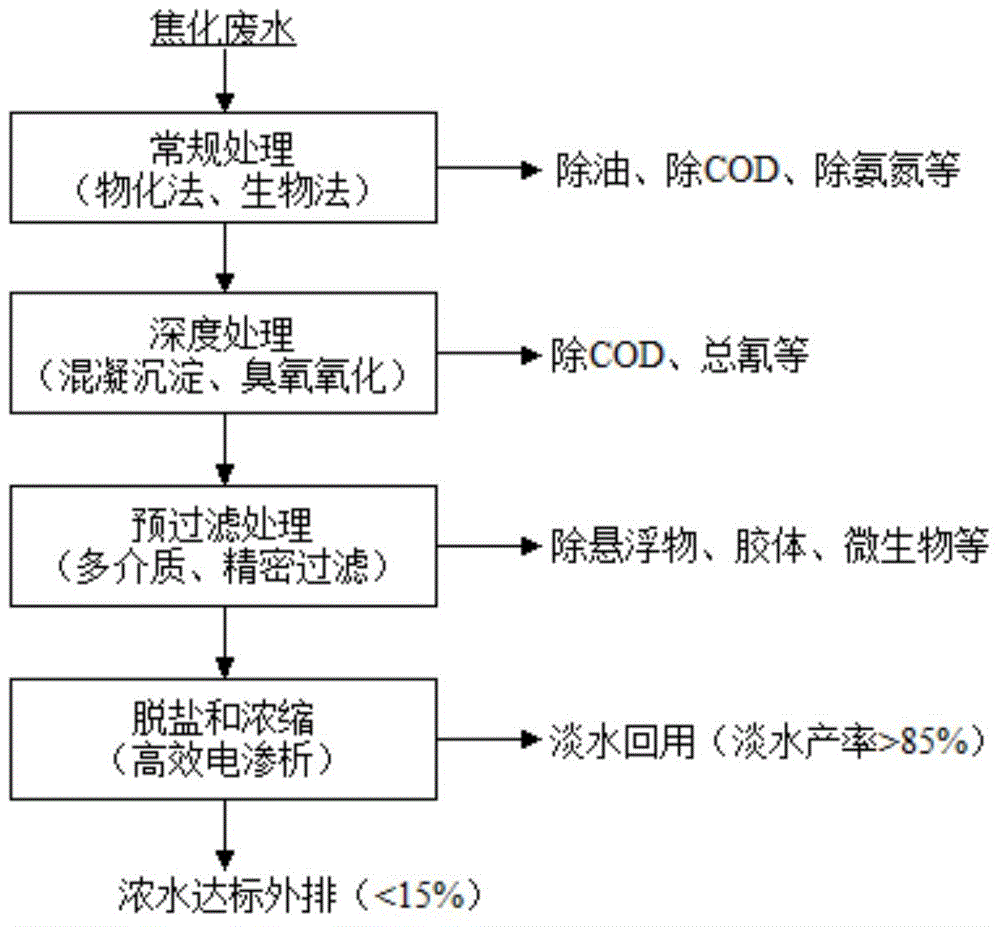

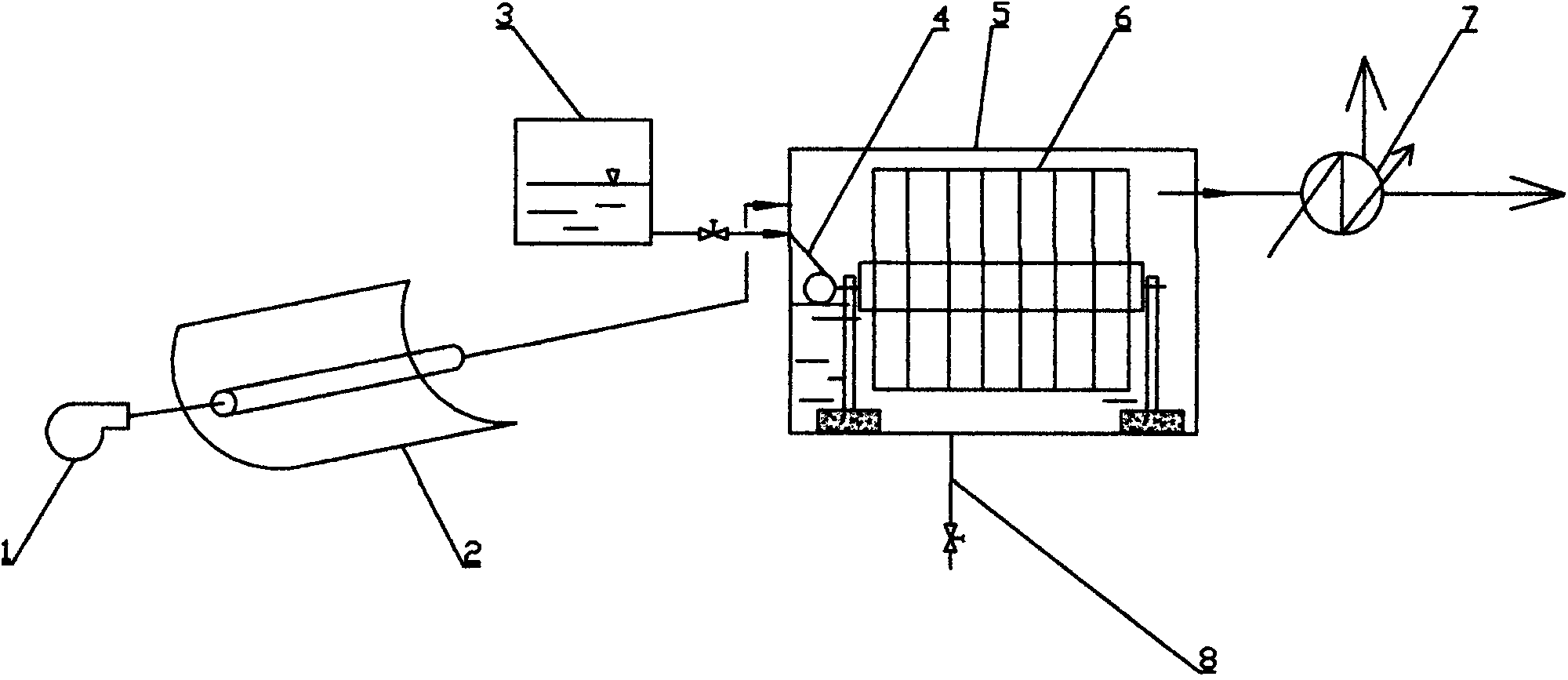

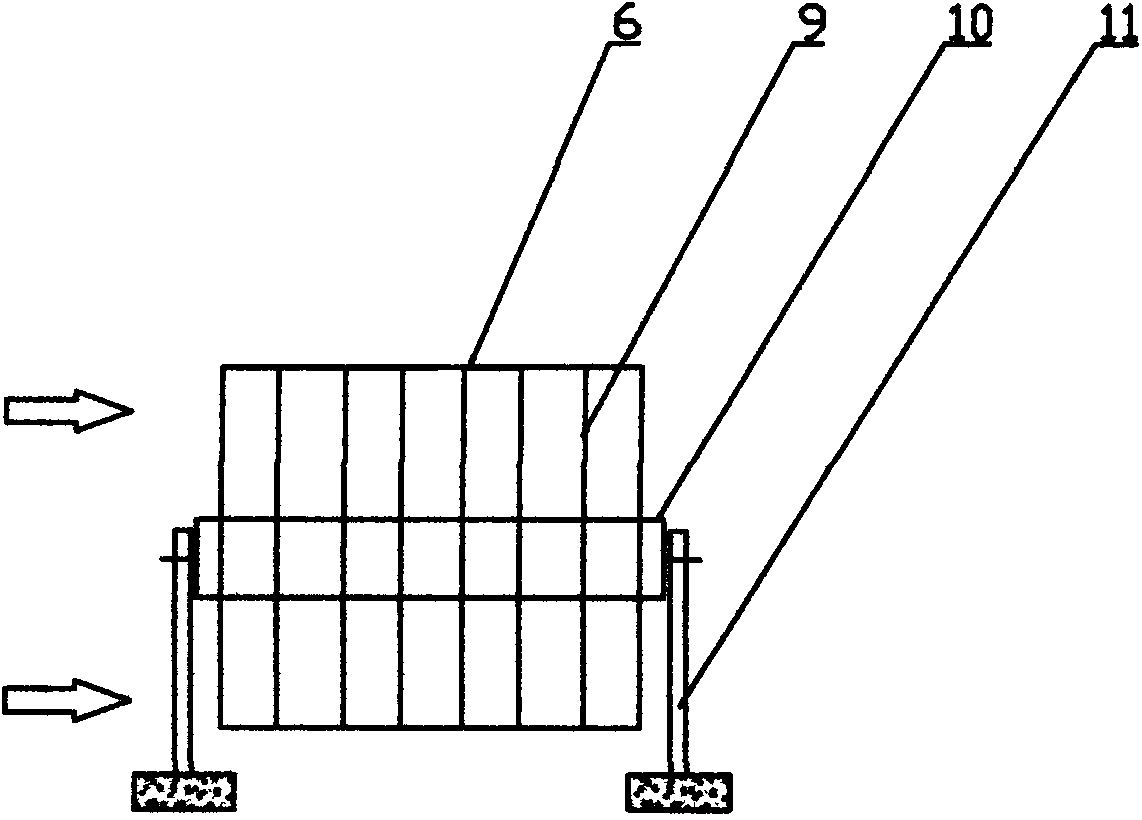

Efficient electrodialysis desalinizing device and method for coking wastewater

ActiveCN104478045AHigh freshwater yieldReduce concentrated water dischargeGeneral water supply conservationDispersed particle separationIon-exchange membranesChemistry

The invention relates to an efficient electrodialysis desalinizing device and method for coking wastewater. The device comprises a modified low-permeability anti-pollution ion exchange membrane, a corrosion-resistant titanium-based coating electrode with a low hydrogen and oxygen evolution overpotential, a waterproof and leakage-proof electric partition plate and an electrodialysis process control system for desalinizing coking wastewater, which are systematically integrated and optimized to construct an efficient electrodialysis device for desalinizing the coking wastewater. The method comprises the following step of deeply treating and desalinizing the coking wastewater by the efficient electrodialysis device, wherein freshwater is subjected to multi-stage desalination, so that the pre-treated coking wastewater reaches industrial reclaimed water standards, and the recovery rate of freshwater is over 85%; after being circulated and concentrated, the discharge amount of the concentrated water is smaller than 15% and discharged after the standards are achieved, and the system is stably operated. According to the device and the method for efficiently desalinizing by electrodialysis for coking wastewater disclosed by the invention, the problems such as a low freshwater recovery rate, great concentrated water discharge amount, severe membrane pollution, difficult long-term stable operation, and the like in the process of treating the coking wastewater by the conventional membrane technology are solved, and the engineering application of the electrodialysis technology in deeply treating and desalinizing the coking wastewater can be promoted.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

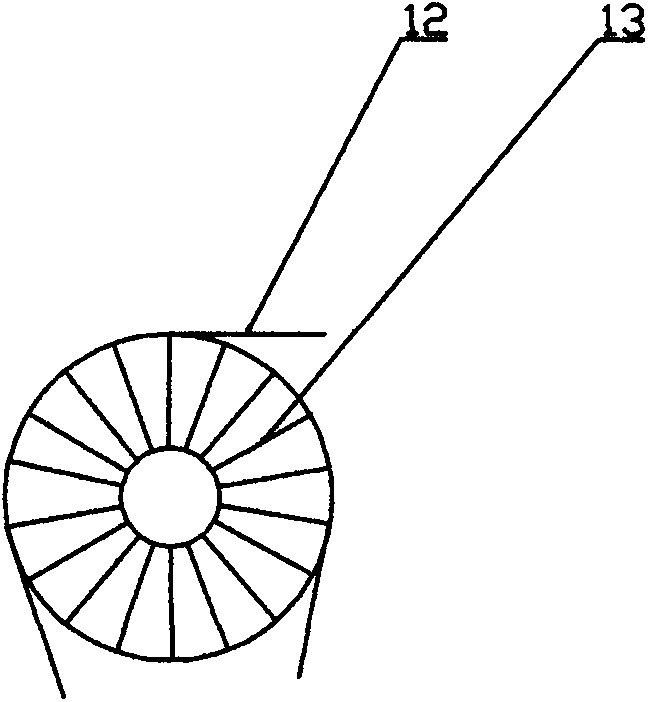

Solar seawater concentration desalting device and method

InactiveCN103641194AIncrease the concentration factorGuaranteed continuityGeneral water supply conservationSeawater treatmentHigh concentrationDistillation

The invention provides a solar seawater concentration desalting device and method. The device mainly comprises a fan, a concentrating solar air heater, an evaporator, a floating type absorbent cloth turntable and a condenser. A micro-evaporation environment is actively formed by use of an absorbent cloth net, and the hot air is quickly evaporated through the floating type absorbent cloth turntable immersed in the evaporator; and the absorbent cloth generates density difference in the evaporation process so that the floating type absorbent cloth turntable automatically rotates in the evaporator in a manner of deviating from the gravity center to realize continuous operation of the evaporation process. Since the evaporation process is not influenced by the boiling point elevation and the scaling of inorganic salts such as calcium carbonate and magnesium hydroxide, up-to-quadruple concentration evaporation of seawater can be realized. The device and method can be applied to the concentration treatment of seawater desalination, solar salt making in a solar field and inorganic wastewater. Compared with a common distillation evaporation and reverse osmosis technology, the treatment is not influenced by the salt content in water, and the device can be used for treating seawater / brackish water until a high-concentration salt-containing water body is obtained.

Owner:TIANJIN CHENGJIAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com