Energy-saving recycling combination system for industrial circulating cooling water

A technology of circulating cooling water and a combined system, which is applied in cooling fluid circulation devices, applications, household appliances, etc., can solve the problems of low utilization rate of heat energy in the production process, waste of resources, thermal pollution of the atmospheric environment, etc., and is conducive to waste heat recovery, The effect of increasing the recycling rate, reducing the evaporation of water and heat energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

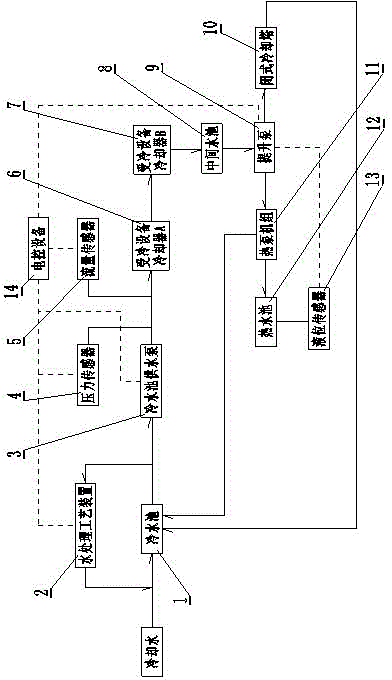

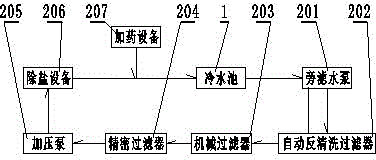

[0031] see figure 1 , image 3 , a metallurgical industry closed circulating cooling water system, consisting of cold water pool 1, water treatment process device 2, cooling water supply pump 3, pressure sensor 4, flow sensor 5, cooling equipment cooler A 6, cooling equipment cooler B 7. An intermediate pool 8, a lift pump 9, a closed cooling tower 10, a heat pump unit 11, a hot water pool 12, a liquid level sensor 13, and an electric control device 14. The cooling water is pressurized by the cooling water supply pump 3 from the cold water pool 1 and enters the cooler A 6 of the cooling equipment first through the cooling water supply pipeline. The cooler A 6 of the cooling equipment can be an air compressor, a hydraulic station, a water pump, a heat exchange The cooler of the equipment such as the cooling device indirectly cools the cooling equipment, and the outlet water is used as the water source and then enters the cooling equipment cooler B 7 in series through the pipel...

Embodiment 2

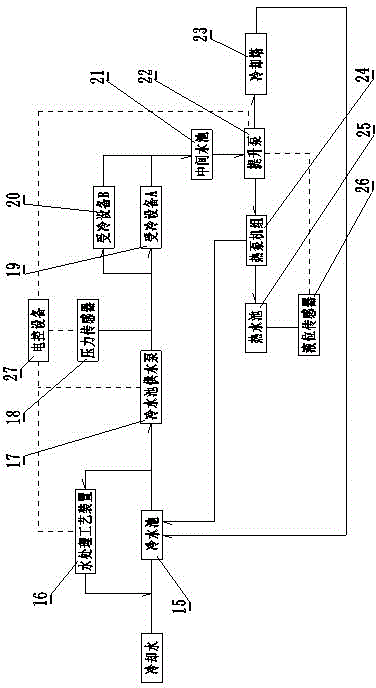

[0033] see figure 2 , Figure 4 , an open circulating cooling water system in the metallurgical industry, consisting of a cold water pool 15, a water treatment process device 16, a cooling water supply pump 17, a pressure sensor 18, a cooling equipment A 19, a cooling equipment B 20, an intermediate pool 21, a lifting Pump 22, cooling tower 23, heat pump unit 24, hot water pool 25, liquid level sensor 26, electric control equipment 27. The cooling water is pressurized by the cooling water supply pump 17 from the cold water pool 15 and directly enters the cooling equipment A 19 and the cooling equipment B 20 through the cooling water supply pipeline in parallel. The cooling equipment in this system is mainly used for ironmaking and steelmaking , continuous casting, hot rolling and other units of gas cleaning, slag flushing, flame cutting, spray cooling, quenching cooling, refining and dust removal, etc., the effluent returns to the middle pool 21 through pipelines. A pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com