Patents

Literature

536 results about "Reuse rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Application programming interface automatic test method, system, device and storage medium

ActiveCN107729243ASimplify the way you writeWrite implementationSoftware testing/debuggingApplication programming interfaceTest requirements

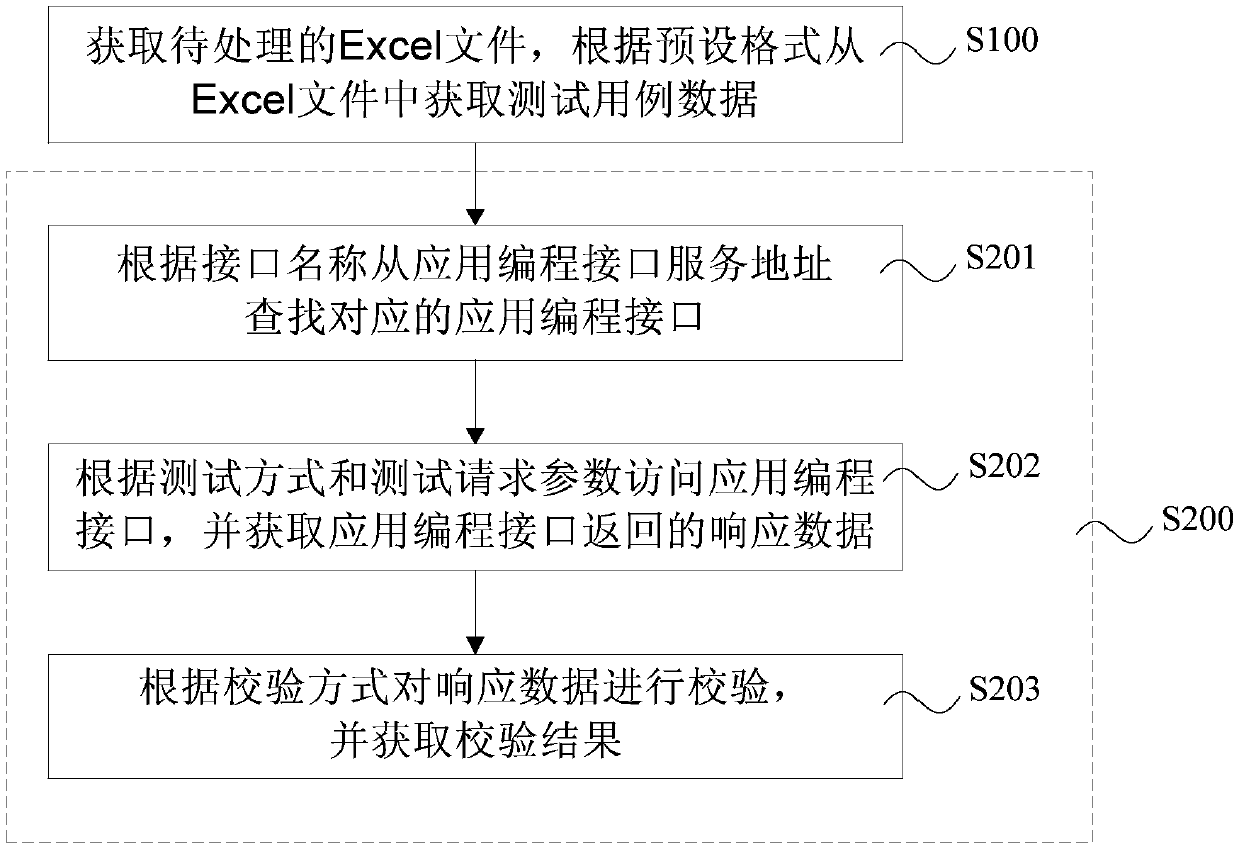

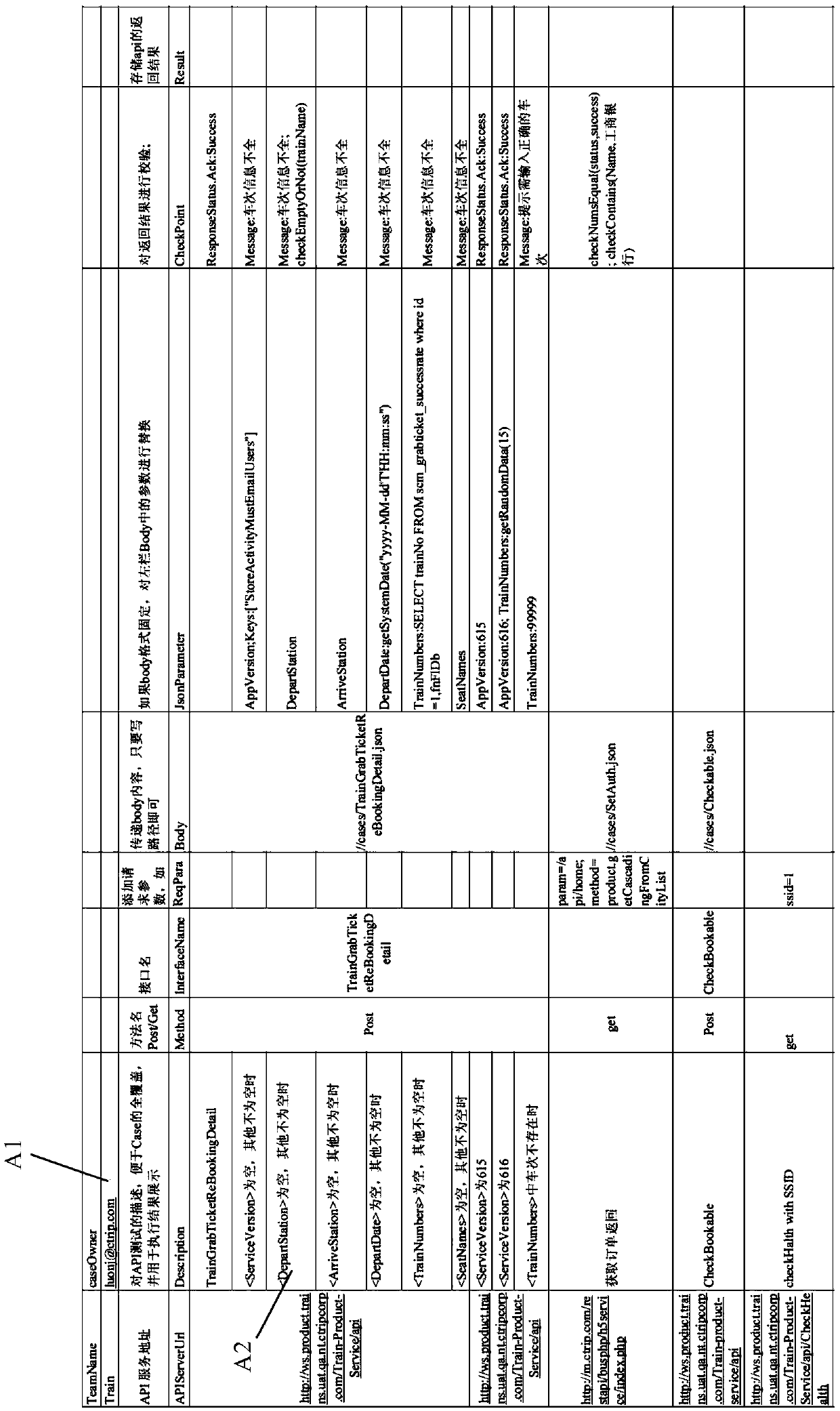

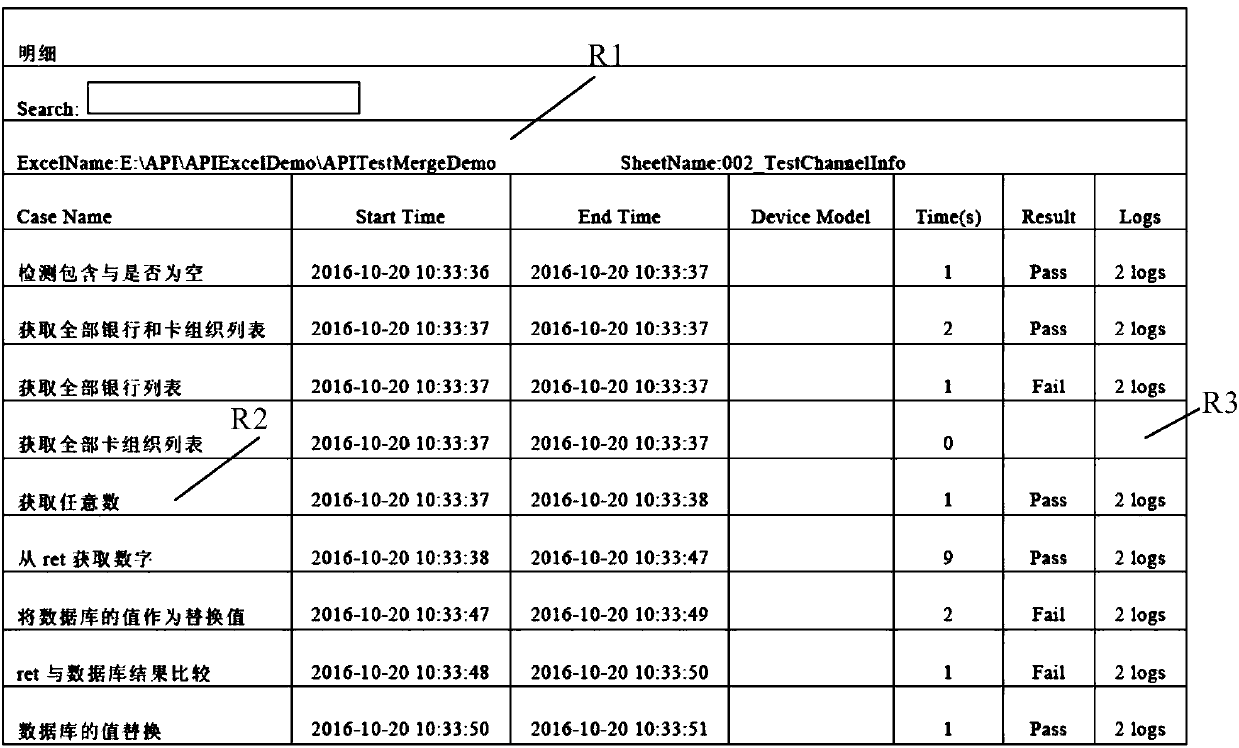

The invention provides an application programming interface automatic test method, system and device, and a storage medium. The application programming interface automatic test method includes the following steps: obtaining Excel files to be processed; obtaining test case data from the Excel files according to a preset format, wherein the test case data includes a test name corresponding to each test case, an application programming interface service address, an interface name, test modes, test request parameters, and verification methods; and executing each test case according to the test case data. The method simplifies the writing method of the test case, and the tester can complete the the writing method of the test case by only filling in the corresponding position data in Excel, without the need of understanding the code itself. The existing test report of a preset format is modified into the test report corresponding to each test case according to the data in the Excels, which improves the conversion rate of the test case, and improves the reuse rate of the test case through the reuse of the test report.

Owner:上海携程金融信息服务有限公司

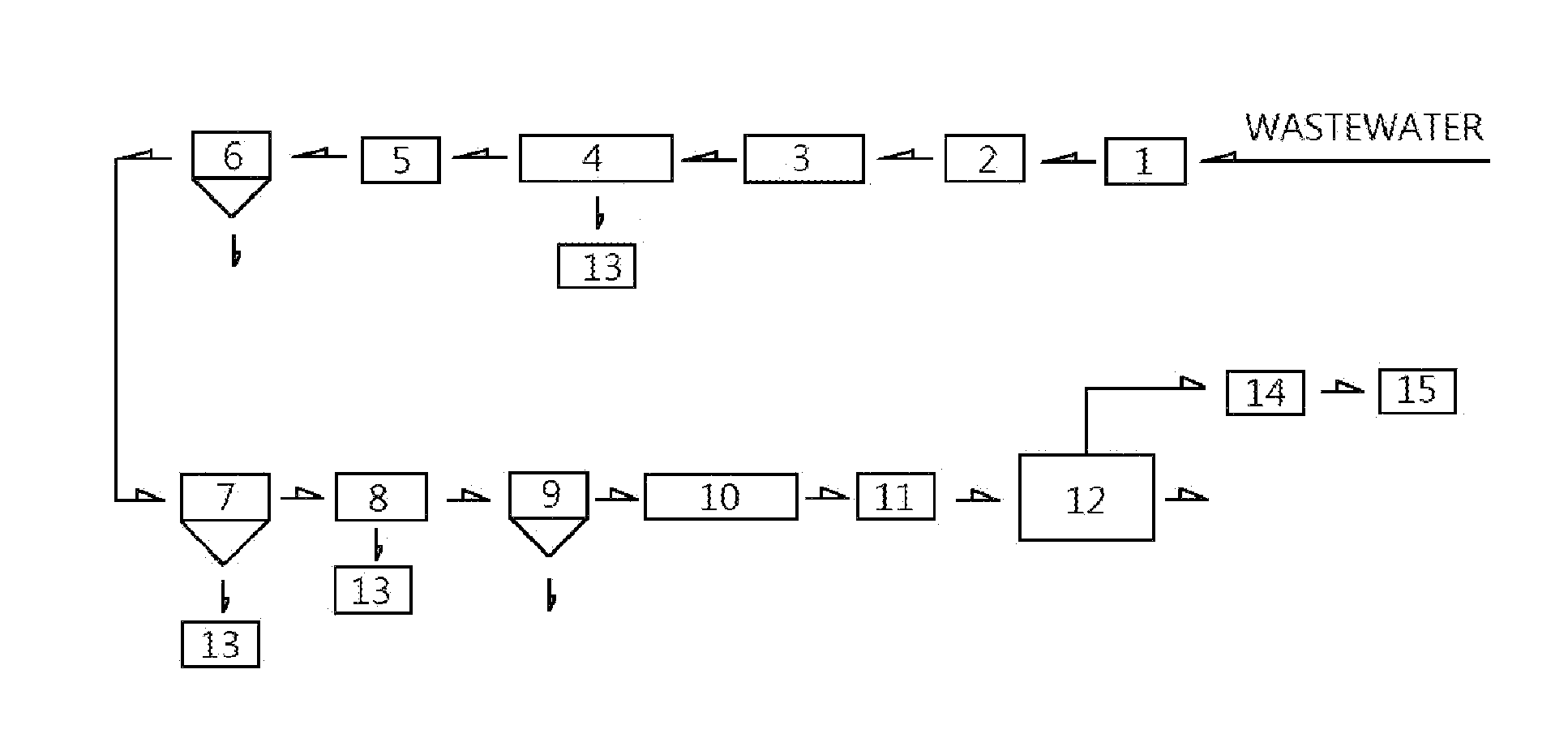

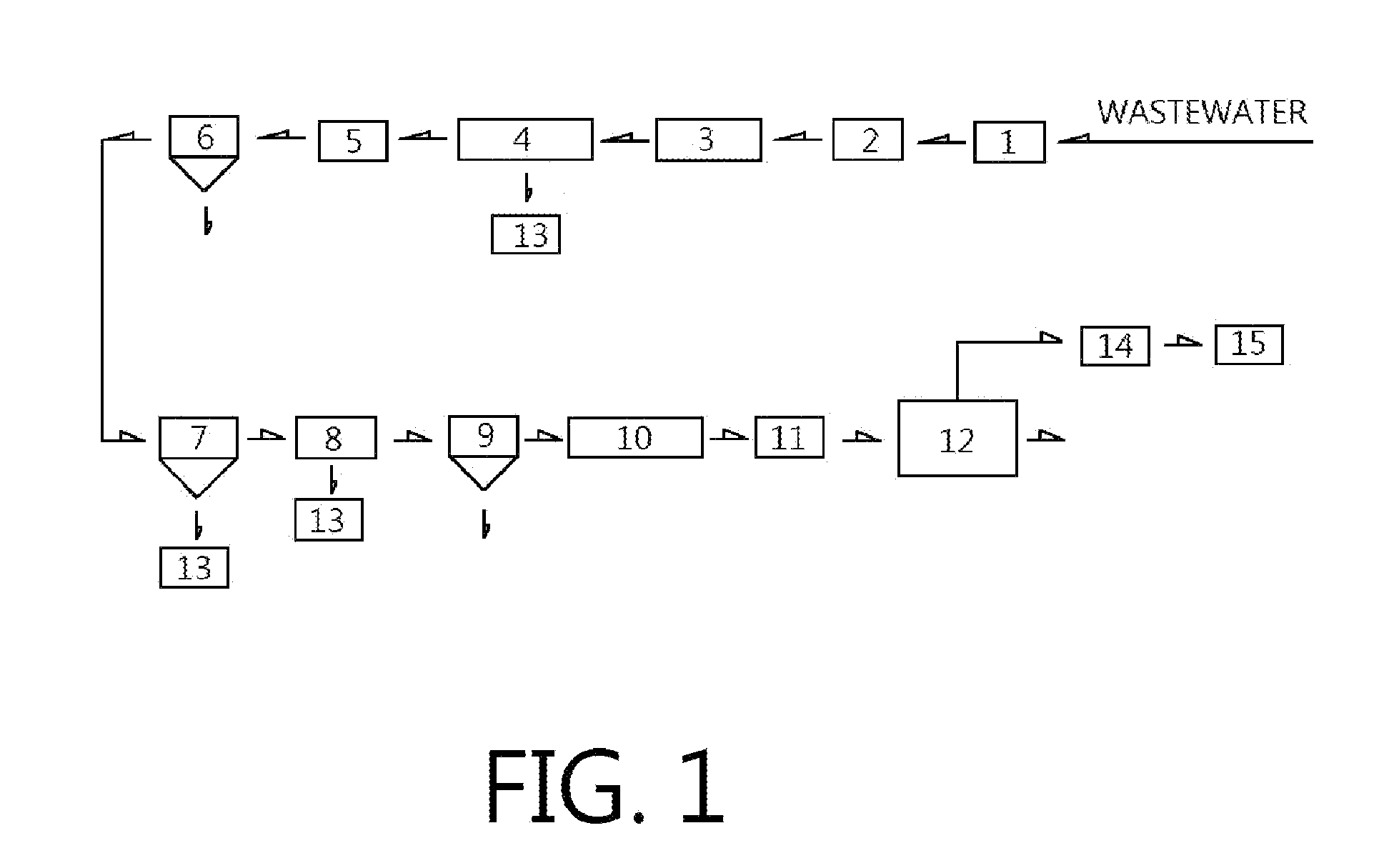

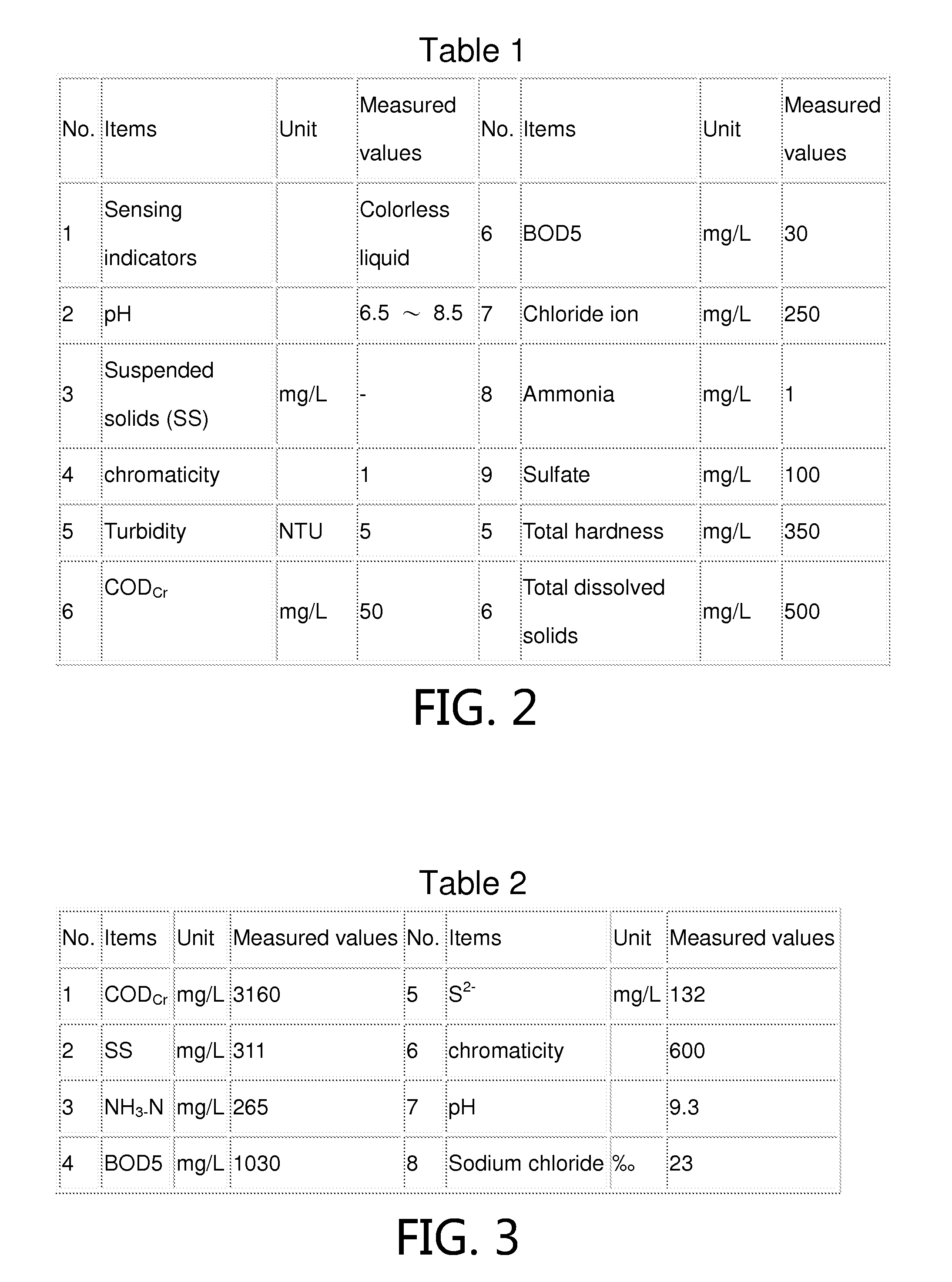

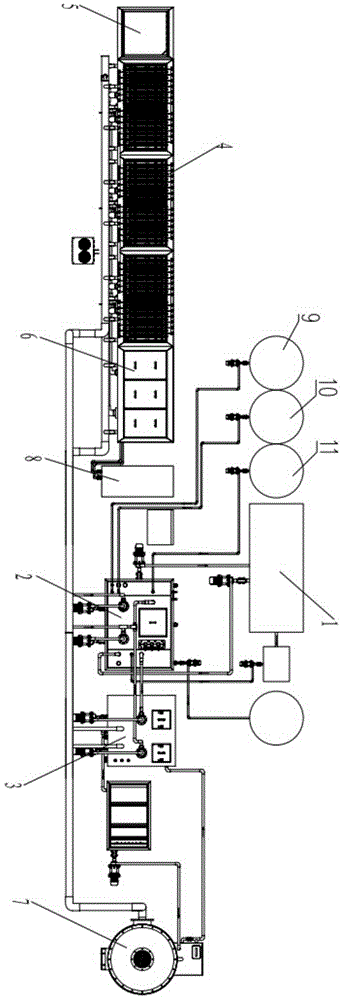

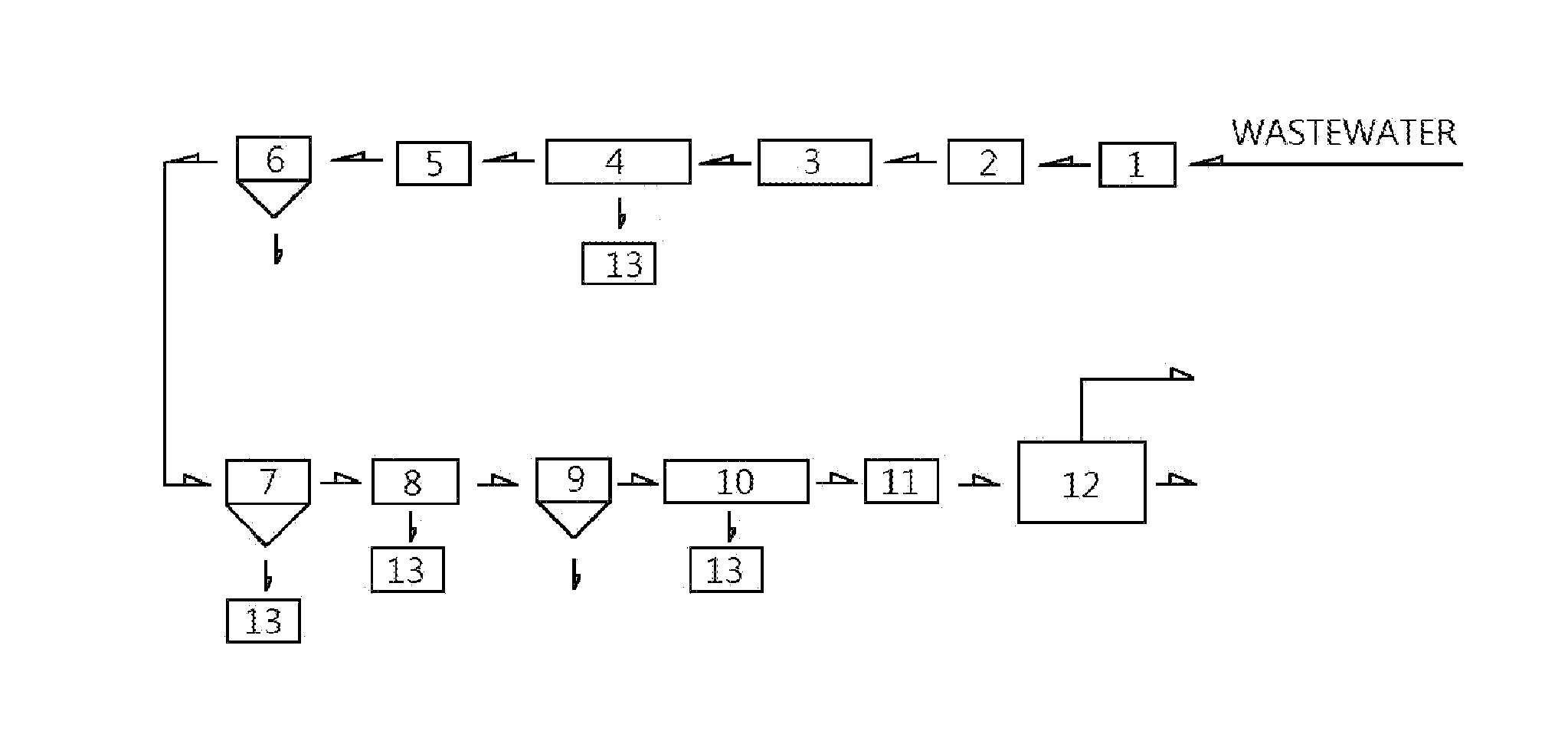

Treatment system and treatment method for biochemical effluent of industrial wastewater

InactiveCN107651794AEfficient removalHigh recovery rate of fresh waterGeneral water supply conservationTreatment involving filtrationHigh concentrationFiltration

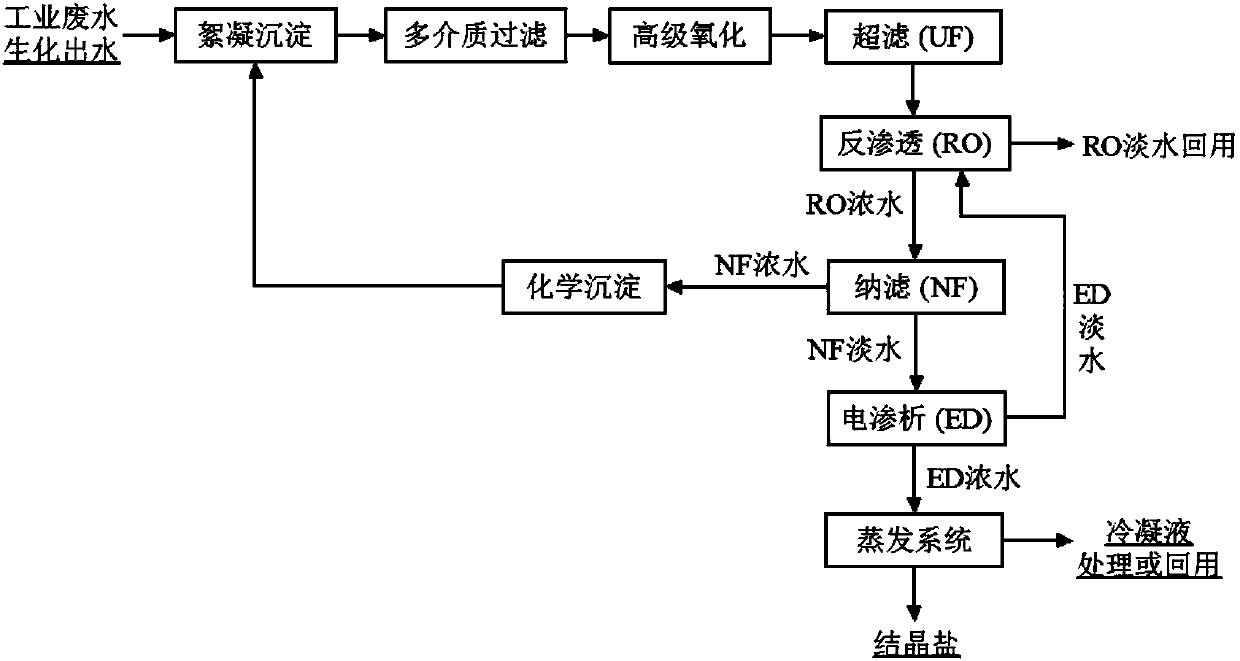

The invention provides a treatment system and treatment method for biochemical effluent of industrial wastewater. The treatment system comprises a flocculation sedimentation unit, a filtration unit, an advanced oxidation unit, an ultrafiltration unit, a reverse osmosis unit, a nanofiltration unit, an electrodialysis unit and an evaporation unit which are sequentially connected; and the water production outlet of the ultrafiltration unit is connected with the water inlet tank of the reverse osmosis unit, and the concentrated-water outlet of the reverse osmosis unit is connected with the water inlet of the nanofiltration unit. According to the invention, the treatment system and the treatment method utilize the coupling and synergistic effects of a physical-chemical method and a membrane technology to overcome the limitation of using a single technology, and the advanced treatment and desalination reuse of the industrial wastewater are realized; and the treatment system and the treatmentmethod have the advantages of strong adaptability to raw water, a high recovery rate of fresh water, a high concentration multiple of concentrated water, low energy consumption of evaporation and crystallization and the like, greatly improve the reuse rate of the industrial wastewater, reduce the amount of wastewater discharging, can be applied to the deep treatment and desalination reuse of various effluent wastewater, and promote the promotion and application of the technology in related industries.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

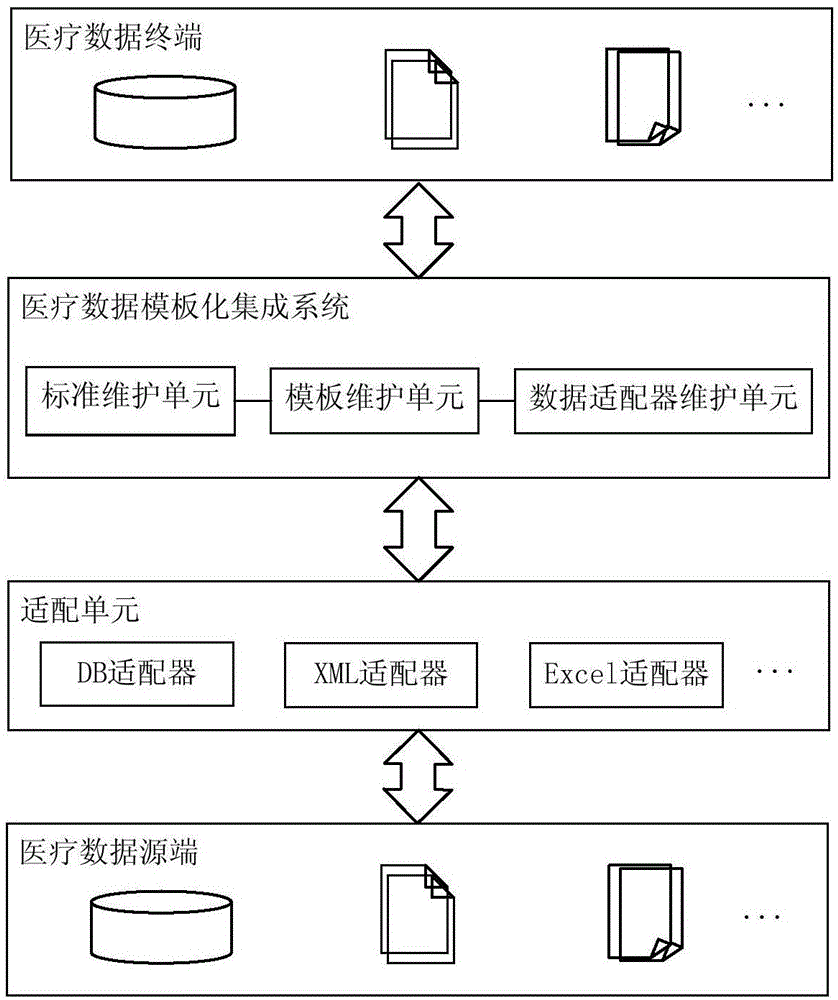

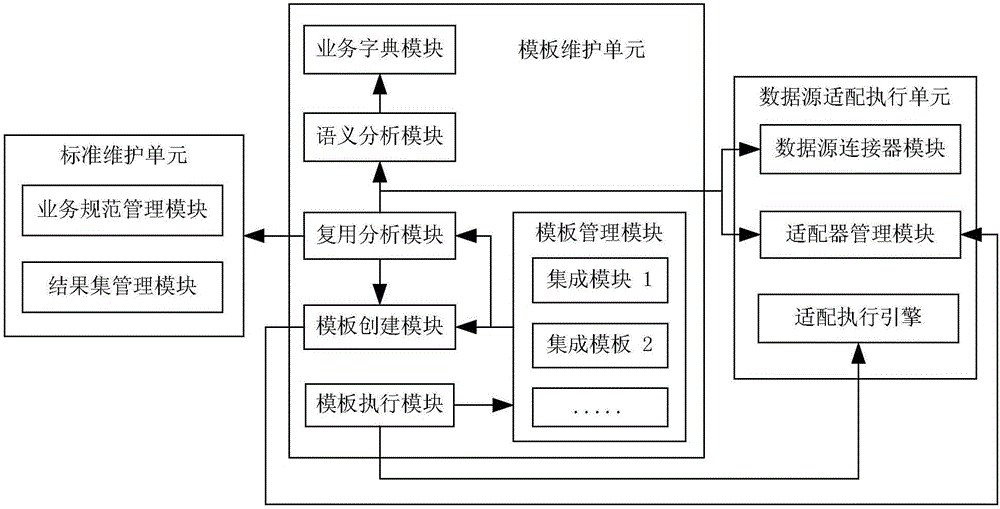

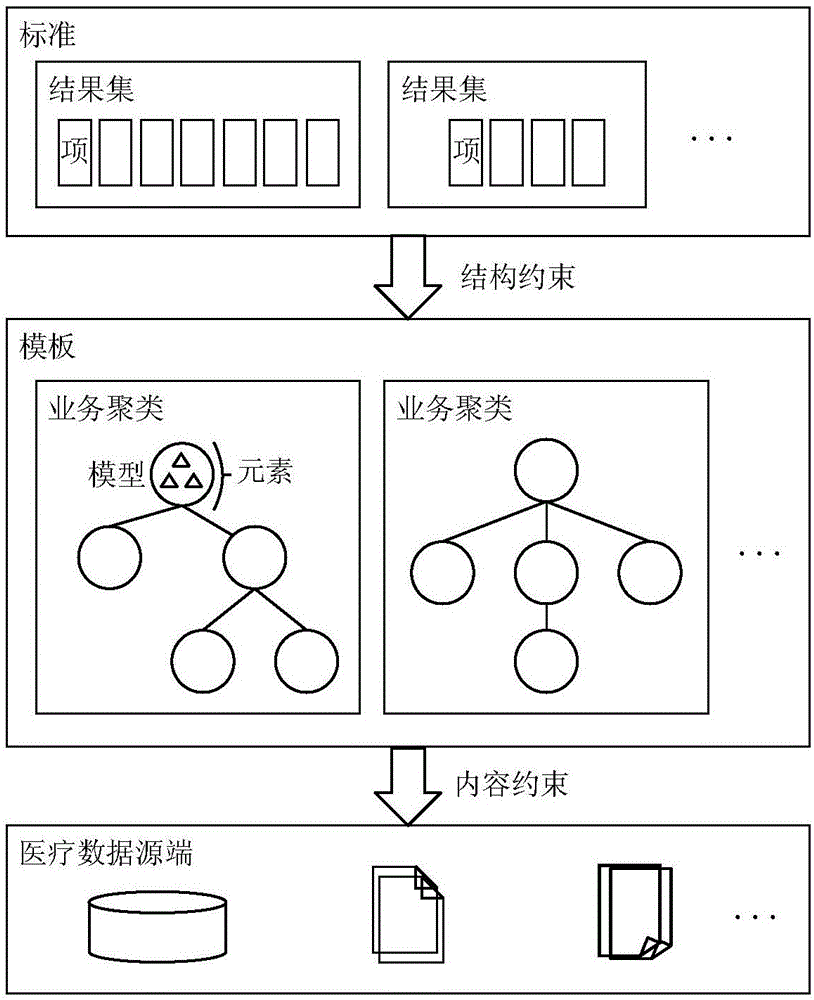

Templated integration system and method for medical information system data

InactiveCN106777970AEfficient integrationStrong industry attributesMedical data managementSpecial data processing applicationsData setMedical treatment

The invention provides a templated integration system and method for medical information system data and relates to the technical field of medical industry data integration. During the process of medical information system data integration, combined with target data standards and aimed at medical information system features (including manufacturers and versions, etc.), a reusable medical information system data integration template is established so as to realize data integration of different medical information systems (such as HIS, LIS, RIS, EMR,PEIS, etc.) Through solidification of special data set and the data conversion rules thereof, a reusable template for a certain medical information system during the process of multiple medical institution data integration is formed; at the same time, the different system templated integration process will enhance the adaptability of the template; a positive correlation between the reuse rate and completeness of the template is established; depending on the continuously improved and optimized template library resource, the implementation difficulty can be effectively reduced, the data integration efficiency can be increased, and the efficient and high quality development of medical information system integration programs is guaranteed.

Owner:BEIJING RUISOFT TECH CO LTD

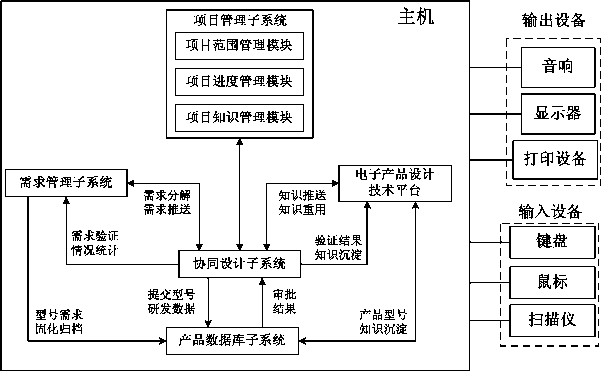

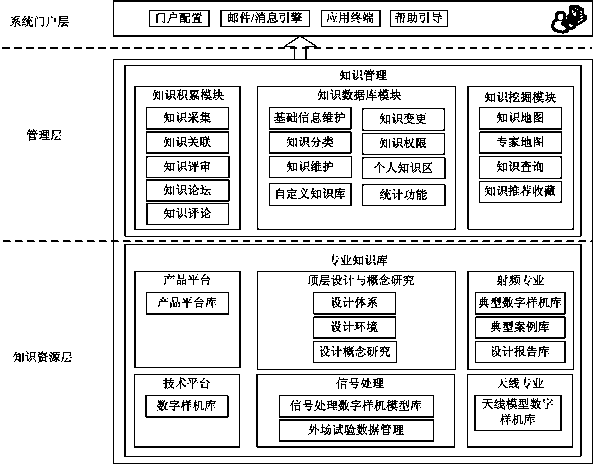

Knowledge-engineering-based automatic scheme generation and evaluation system and method

InactiveCN103646149AImprove reusabilityAchieve traceabilitySpecial data processing applicationsRequirements managementProject management

The invention discloses a knowledge-engineering-based automatic scheme generation and evaluation system. The automatic scheme generation and evaluation system comprises a project management subsystem, a demand management subsystem, a product database subsystem, a collaborative design subsystem and an electronic product design technology platform, wherein the project management subsystem is in charge of providing solving ideas and tools; the demand management subsystem is used for decomposing the product design demand, converting into task indicators and multi-level task sequences, realizing dependence mapping and providing real-time monitoring of the indicators; the product database subsystem is used for managing design data and setting data standards and regulations; the collaborative design subsystem plays the role of a bridge; the electronic product design technology platform is in charge of generalizing and managing typical data, design methods and digital prototype models of all products and pushing information to the collaborative design subsystem. A method comprises the steps of knowledge extraction and classification, professional knowledge base setting, knowledge-engineering-based platform construction and automatic design scheme generation and evaluation. According to the invention, knowledge engineering is introduced into the electronic product design, so that the reuse rate of knowledge and other resources is effectively improved, automatic generation and evaluation of product schemes are realized, the product research and development time is shortened and the intelligence degree is high.

Owner:SICHUAN UNIV +1

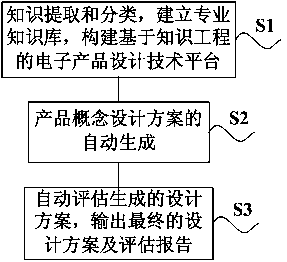

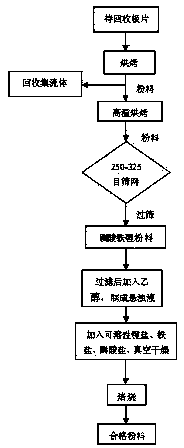

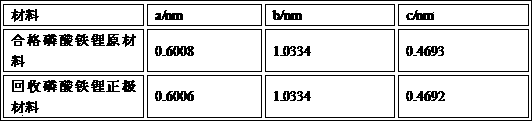

Method for recycling lithium iron phosphate wastes in manufacturing link of lithium iron phosphate batteries

ActiveCN104362408AImprove electrochemical performanceHigh reuse rateWaste accumulators reclaimingBattery recyclingDecompositionLithium-ion battery

The invention discloses a method for recycling lithium iron phosphate wastes in the manufacturing link of lithium iron phosphate batteries and relates to lithium ion batteries. The recycling method is characterized by comprising the following steps: after a pole piece to be recycled is put into a muffle furnace, baking is performed for 2-3h at the temperature of 400-600 DEG C, the decomposition of a binder fails, and an active material lithium iron phosphate and conductive agent powder completely fall off from a current collector aluminum foil; after the powder is put in the muffle furnace, baking is performed for 4-6h at the temperature of 650-800 DEG C, sieving is performed to obtain lithium iron phosphate power; filtering is performed, the lithium iron phosphate power is washed with deionized water, and an ethanol wetting agent after washing is added to obtain turbid liquid; soluble lithium salt, molysite and phosphate are proportionally mixed into an ethanol solution, the mixed solution is added into the turbid liquid for mixing, and vacuum drying is performed at the temperature of 120-140 DEG C; roasting is performed for 3-6h at the temperature of 650-850 DEG C in an inert gas atmosphere to obtain acceptable materials. The method has the advantages of being good in electrochemical performance of recycled materials, high in reuse rate and low in cost.

Owner:SHANDONG SACRED SUN POWER SOURCES

High-temperature-resisting easy collapse molding sand and preparation method thereof

InactiveCN103495693AImprove breathabilityImprove liquidityFoundry mouldsFoundry coresWet bondingSodium metasilicate

High-temperature-resisting easy collapse molding sand is made from, by weight, 240-280 parts of quartz sand, 50-55 parts of lightweight calcium carbonate powder, 20-30 parts of hollow ceramic microspheres, 10-15 parts of hollow glass microspheres, 40-55 parts of aluminum silicate powder, 25-30 parts of titanium dioxide, 35-40 parts of fluorite nano-powder, 30-40 parts of gypsum whisker, 60-70 parts of expanded perlite, 10-15 parts of talcum powder, 2-4 parts of sodium metasilicate, 1-2 parts of glucose powder, 1-2 parts of urea, 1-2 parts of chlorinated paraffin, and a proper amount of water. The materials such as the hollow ceramic microspheres and the hollow glass microspheres are used, so that the molding sand is fine in breathability and fluidity; meanwhile, the lightweight calcium carbonate, the glucose, the urea and the like are used, so that the molding sand is fine in high temperature collapsibility, high dry strength of sand molds, high in wet bonding power, excellent in sticking resistance and applicable to various hardening manners; drying time after CO2 hardening is shortened, and reuse rate of used sand can be increased significantly.

Owner:HEFEI CITY TENVER PRECISION CASTING

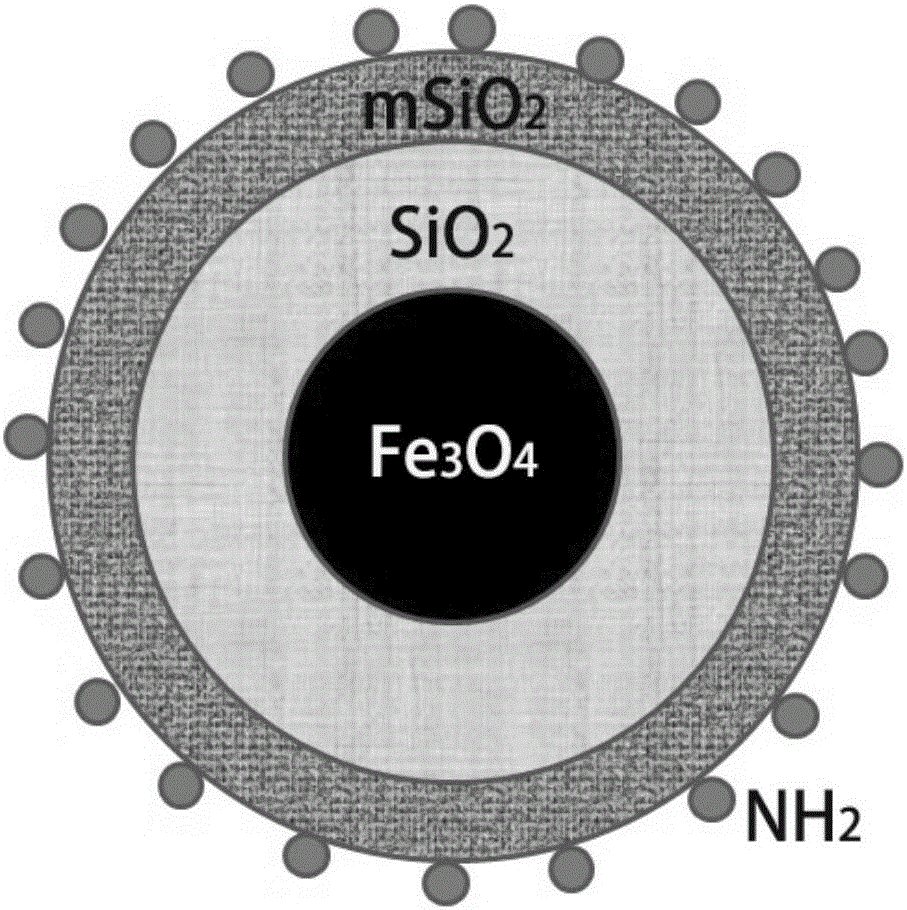

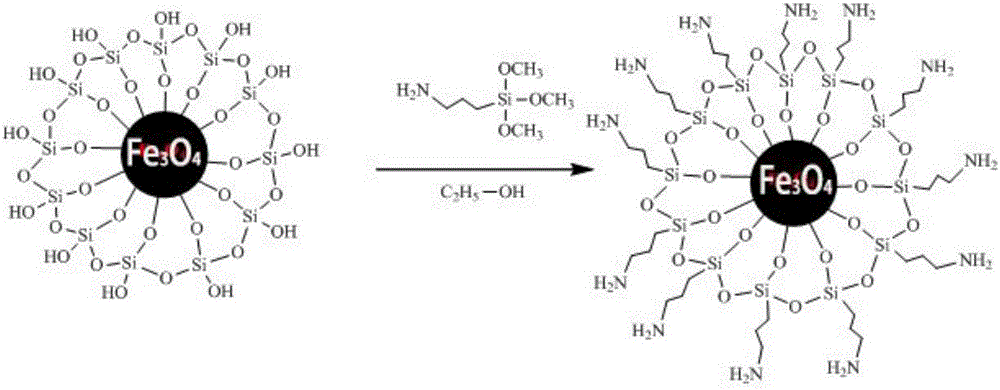

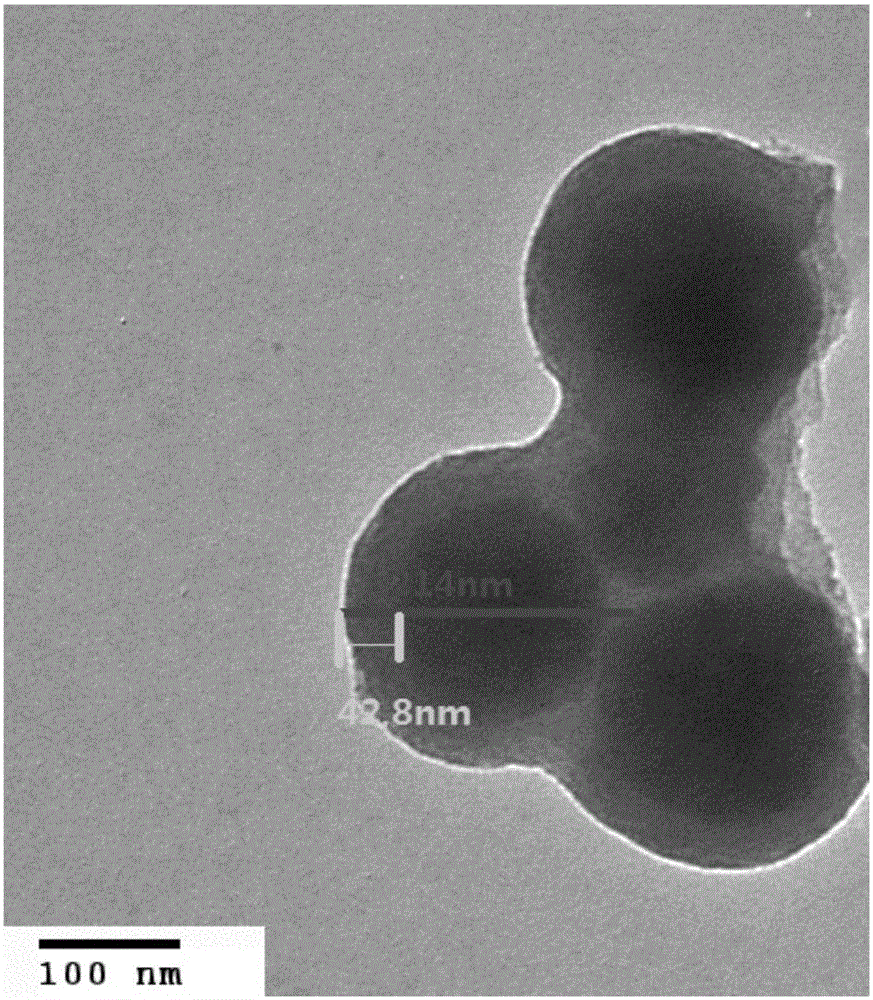

Preparation and application of amino modified Fe3O4@SiO2@mSiO2 composite particles with mesoporous structure

InactiveCN105964216AGood superparamagneticImproved saturation magnetizationOther chemical processesWater contaminantsSorbentSilanes

The invention relates to a preparation method of amino modified Fe3O4@SiO2@mSiO2 composite particles with a mesoporous structure. The preparation method comprises the steps: dispersing Fe3O4@SiO2 powder into a mixture solution of ethanol, deionized water, ammonia water and a template agent, so as to obtain a sol solution; then, dropwise adding TEOS into the sol solution, so as to prepare Fe3O4@SiO2@mSiO2 composite particles with the mesoporous structure; drying the Fe3O4@SiO2@mSiO2 composite particles, then, adding ethylene glycol into the dried Fe3O4@SiO2@mSiO2 composite particles, carrying out ultrasonic separation, then, adding a silane reagent, carrying out high-temperature refluxing while carrying out stirring so as to enable the silane reagent to be adsorbed into mesoporous pore passages of SiO2, carrying out a hydrolytic reaction, removing unreacted silane reagent or the silane reagent which is not adsorbed into the mesoporous pore passages, and finally, carrying out vacuum drying, thereby obtaining the amino modified Fe3O4@SiO2@mSiO2. According to the preparation method, SiO2 with a mesoporous structure serves as a shell layer, a nanoparticle Fe3O4 serves as a magnetic core, the stability in an acidic solution system is excellent, the difficult problem of the ordinary adsorbents that the separation is difficult after adsorption can be solved, the efficiency of adsorbing a target product is increased, and the reuse rate of an adsorbent is increased, so that the preparation method has good economic and environmental benefits.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Interface test method and device

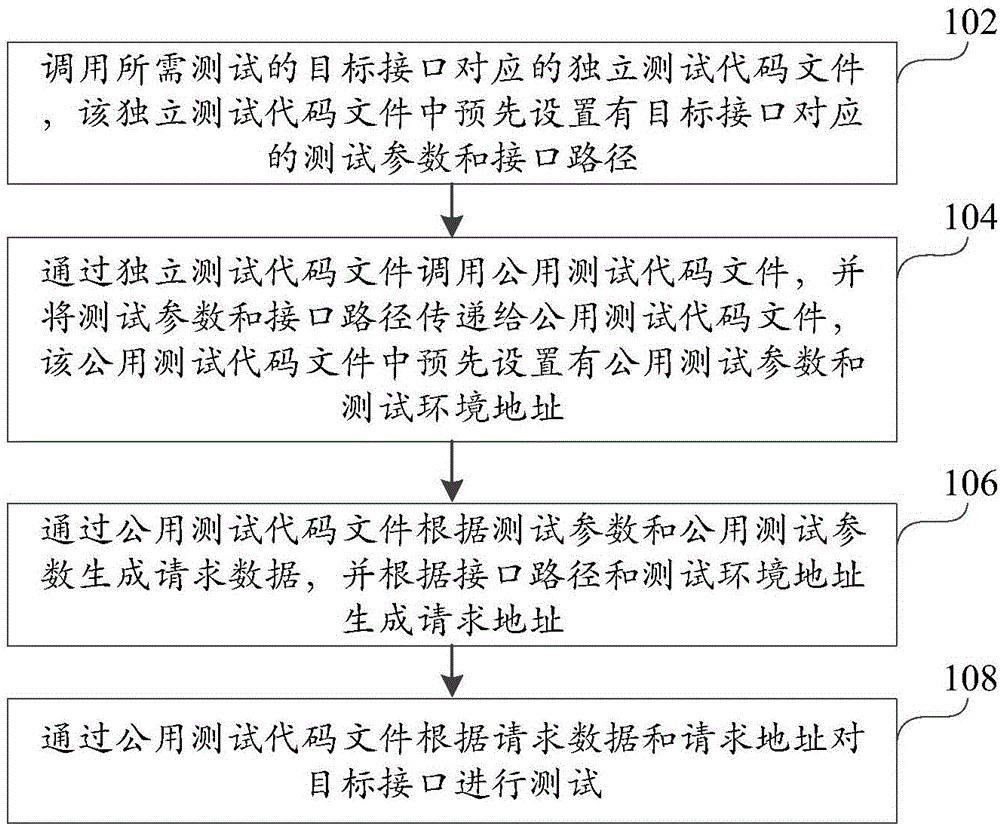

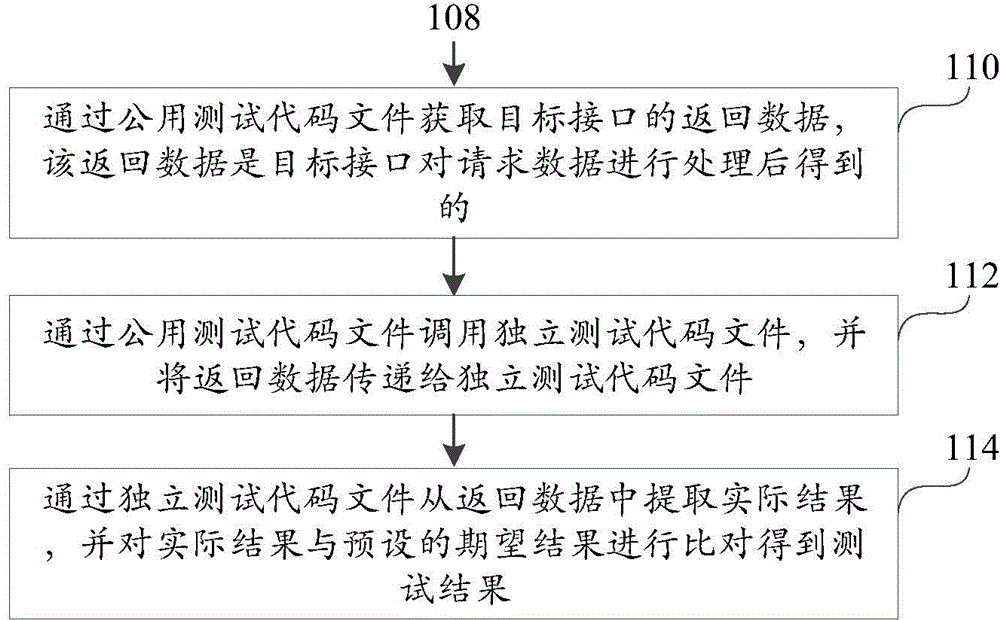

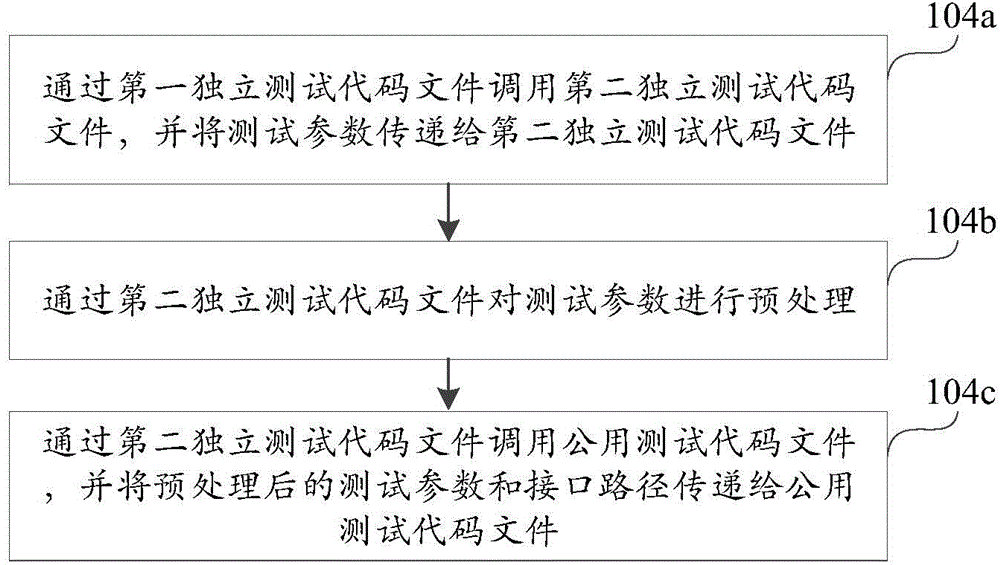

ActiveCN104615534ASolve the low reuse rateImprove reuse rateSoftware testing/debuggingAPI testingReuse rate

The invention discloses an interface test method and device and belongs to the field of testing technology. The method includes the step of calling an independent test code file corresponding to a target interface needing to be tested; the step of calling a public test code file through the independent test code file and transmitting test parameters and an interface path corresponding to the target interface to the public test code file; the step of generating request data through the public test code file according to the test parameters and public test parameters and generating a request address according to the interface path and a test environment address; the step of testing the target interface through the public test code file according to the request data and the request address. The problem that the reuse rate of test codes is low when interface testing is conducted through correlation techniques is solved; different independent test code files and the same public test code file are configured for different interfaces, and test codes needed for different interfaces are planned and managed in a unified mode, so that the reuse rate of the test codes is increased.

Owner:GUANGZHOU KUGOU TECH

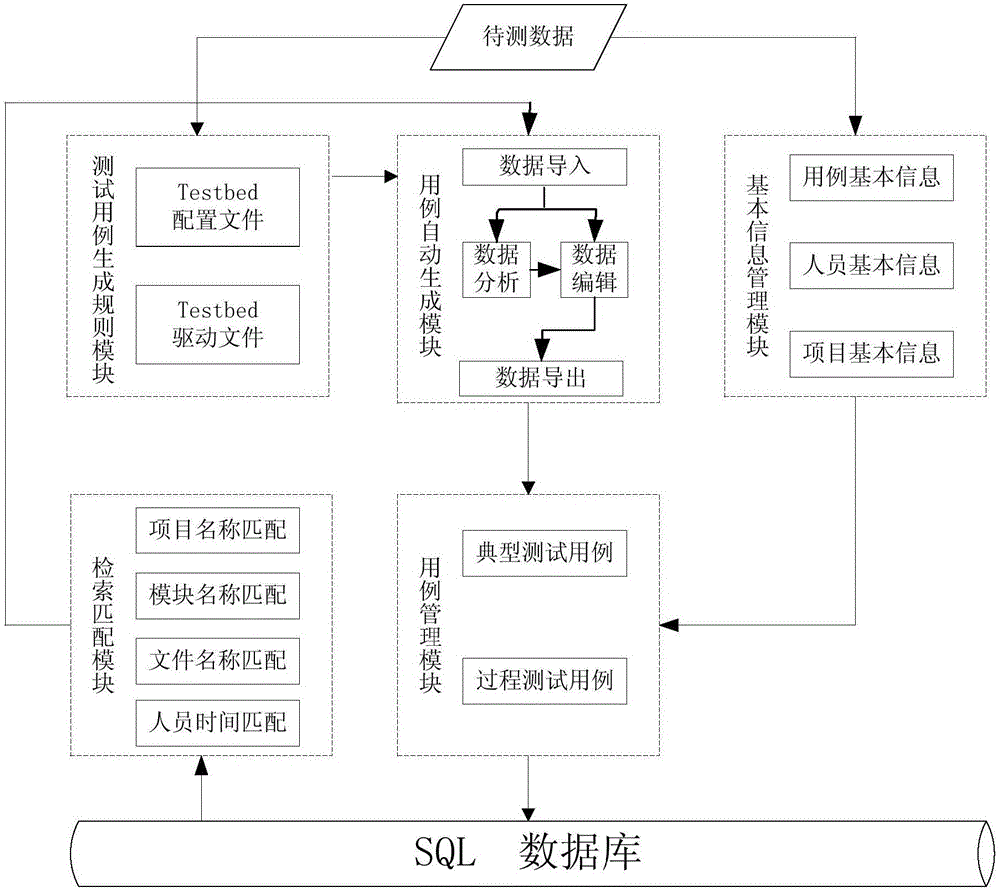

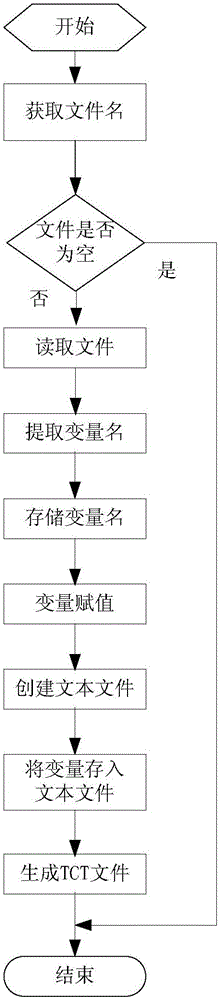

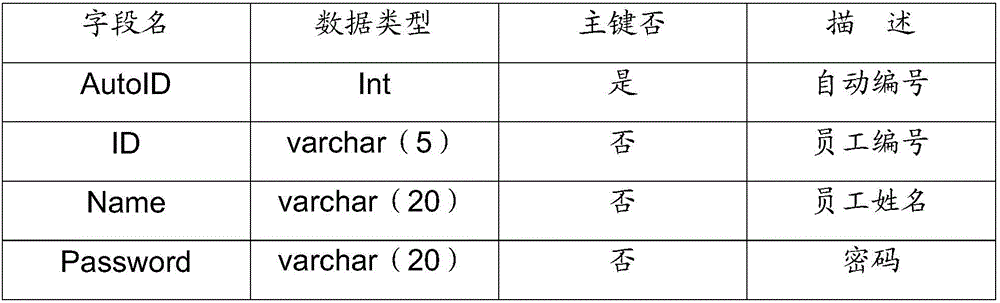

Software unit test case management system

ActiveCN106326122AImplement component managementImprove versatilitySoftware testing/debuggingTest qualityReuse rate

The invention discloses a software unit test case management system which comprises a case automatic generation module, a basic information management module, a retrieval match module and a case management module, wherein the case automatic generation module achieves the functions of data import, data analysis, data edition and data export, can generate a batch test case TCF file and import the file into a test tool to be executed automatically; the case management module can match test cases with basic information to form a process test case and a typical test case in the case management module, form a test case set, manage the test case set and facilitate the re-edition and reuse of the test cases; the retrieval match module can quickly and efficiently retrieve the finished test cases. For the characteristics that embedded servo software is large in code quantity and high in similarity, the software unit test case management system is high in automation degree and comprehensive and standard in test case, improves the unit test efficiency and the test quality, also improves the reuse rate of the test cases, and reduces the labor cost.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS +1

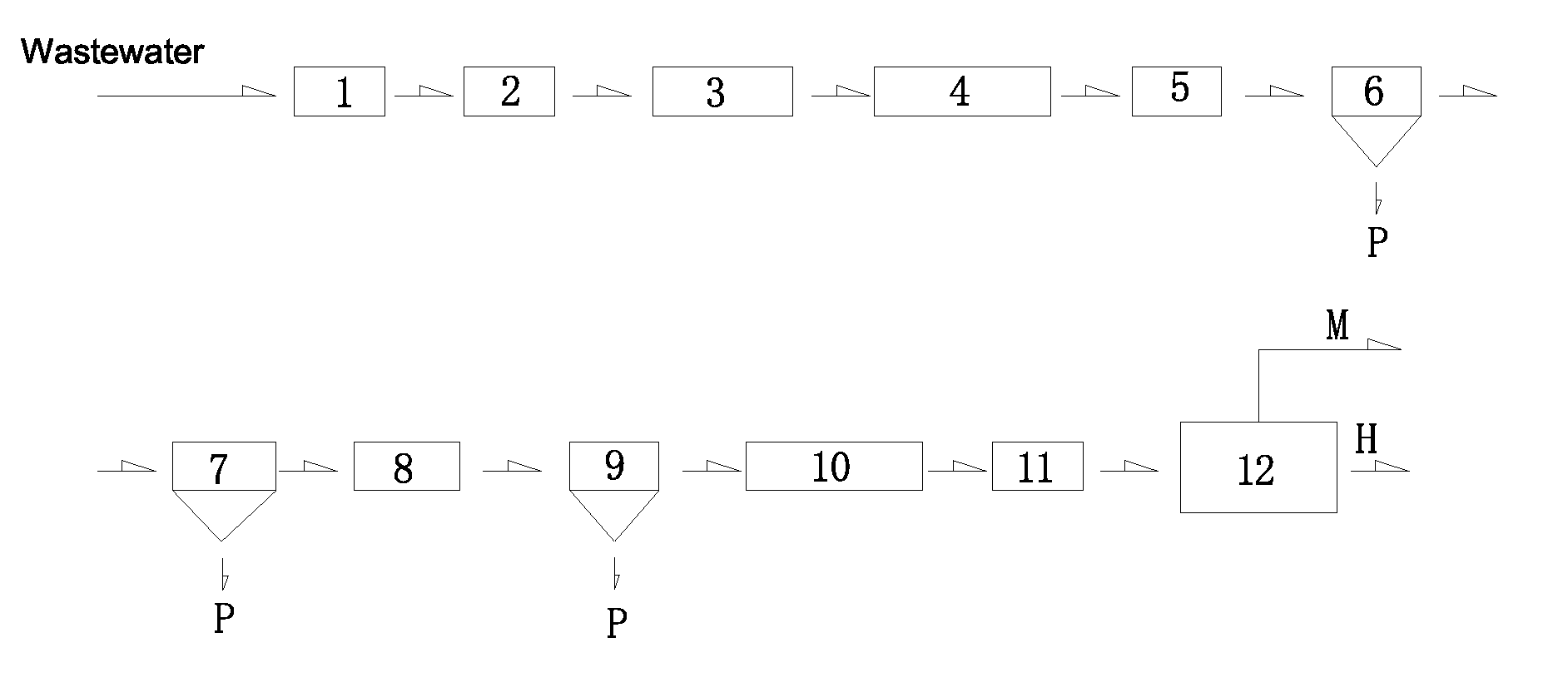

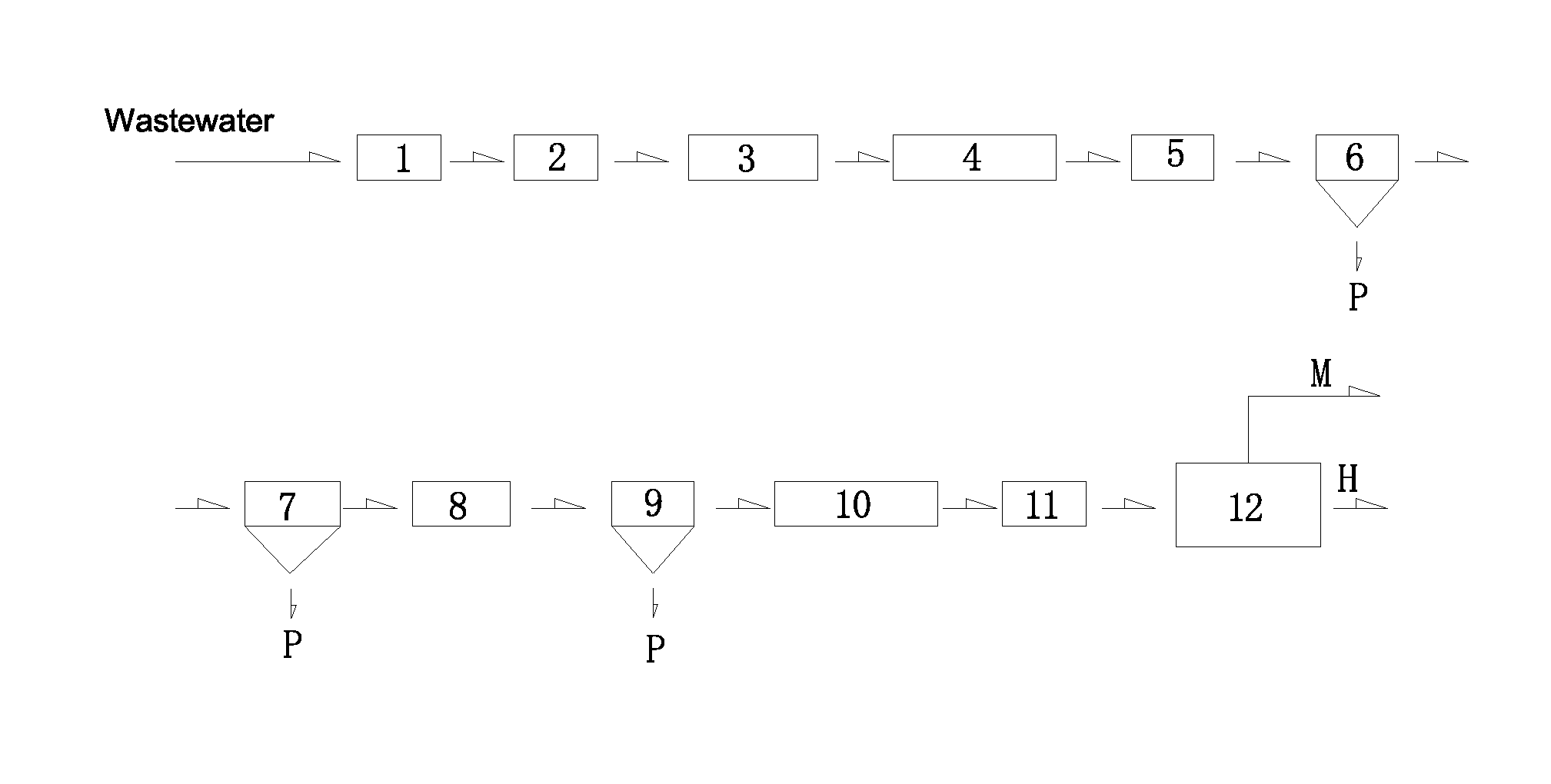

Printing and dyeing wastewater treatment and reuse apparatus and method therefor

InactiveUS20130256218A1Reduce the amount requiredReduce consumptionTreatment using aerobic processesPaint waste treatmentFlocculationElectrolysis

A printing and dyeing wastewater treatment and reuse apparatus includes a coarse filter, a regulation pool, a hydraulic sieve, a desulfurization pool, a nanocatalytic electrolyzer, a flocculation pool, a flocculation tank, a settling pool, a flotation device, a biochemical pool, a secondary settling pool, a secondary nanocatalytic electrolyzer, a fine filter, a compressor, a nanomembrane assembly, and a recycling pool. Also provided is a printing and dyeing wastewater treatment and reuse method including steps of desulfurization, nanocatalytic electrolysis, flocculation, biochemical treatment, secondary catalytic electrolysis, filtration, and separation by membrane. The invention allows high CODCr removal rate, reduced chemical agent consumption, reduced sludge formation, thorough treatment, and high water reuse rate.

Owner:BOYING XIAMEN SCI & TECH

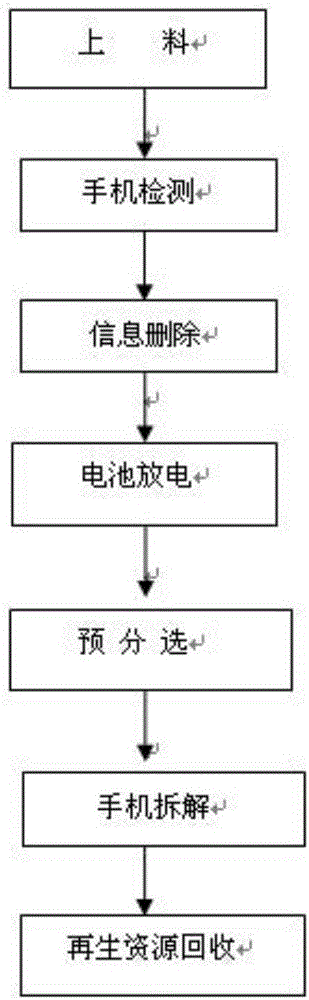

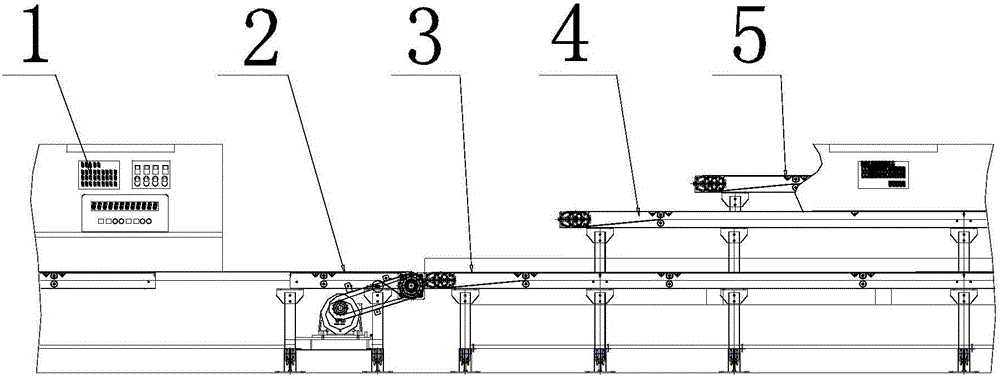

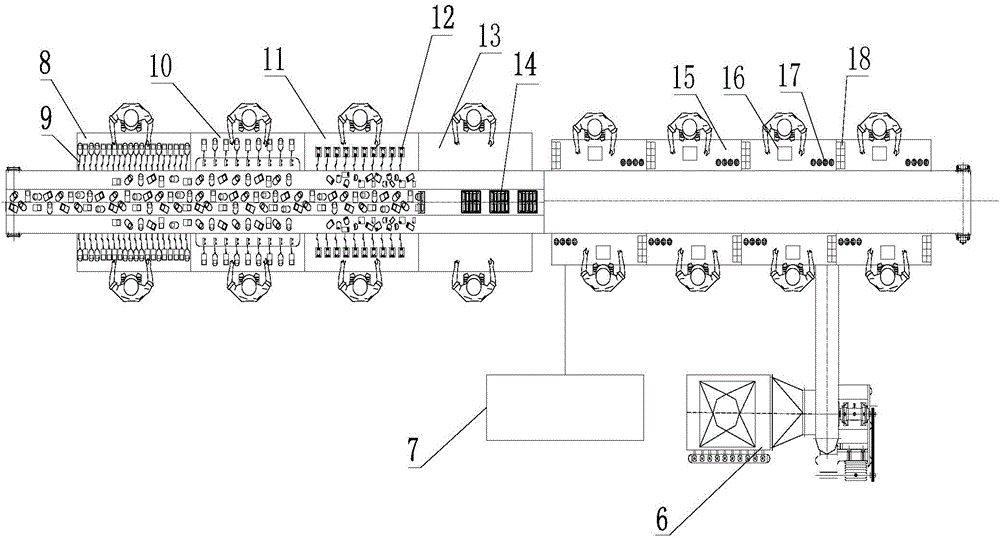

Technology and equipment for disassembling waste mobile phone

ActiveCN105710115AEasy to recycleUnique process methodSolid waste disposalElectronic waste recyclingEconomic benefitsOperation safety

The invention discloses technology for disassembling a waste mobile phone and used equipment. The technology comprises the whole process including treatment of the waste mobile phone by feeding through a belt conveyor, mobile phone detection, information deletion, battery discharging and artificial presorting in a mobile phone presorting region, mobile phone disassembling, recovery of materials and accessories after disassembly in a classifying manner and dedusting in a working field. The used equipment for disassembling the waste mobile phone mainly comprises a presorting belt conveyor, a disassembling belt conveyor, a detection workbench, an information deletion workbench, a battery discharging workbench, an artificial presorting workbench, a disassembling workbench, a mobile phone classifying quantization tool box and a usable component recovery box. With adoption of various special equipment and tools, the technology and the equipment can ensure the accessories of the waste mobile phone to be well disassembled and have the advantages of unique technological method, safety and reliability in operation, high disassembling efficiency, good disassembling effect, increase in resource reuse rate, low energy consumption, long service life of the equipment, dramatic economic benefit, smoothness in technological process, reduction in labor intensity of workers and the like.

Owner:滁州伟峰资源回收设备有限公司

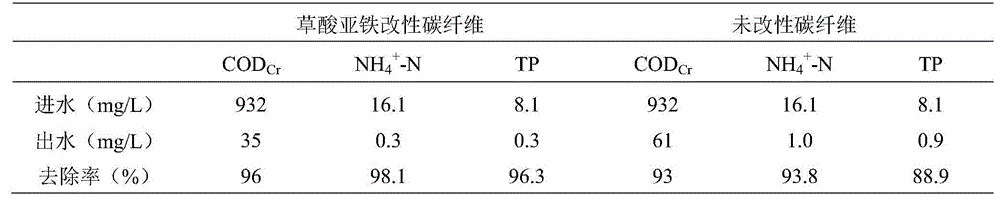

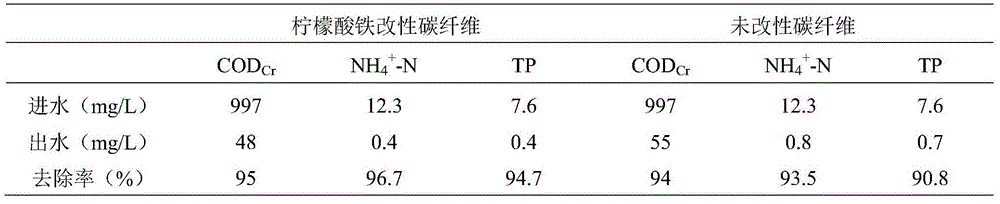

Excellent and efficient carbon fiber biofilm carrier modification method

InactiveCN104803471AGood biocompatibilityGood flexibilitySustainable biological treatmentBiological water/sewage treatmentFiberCarbon fibers

The invention discloses an excellent and efficient carbon fiber biofilm carrier modification method and aims to improve water treatment performance of carbon fibers used as biofilm carrier materials. A basic raw material is the carbon fibers; the modification method mainly comprises steps as follows: firstly, acid oxidation treatment is performed on the carbon fibers, so that surfaces of the carbon fibers are ensured to have sufficient functional groups for preparation for iron carrying; then an organic iron solution is used as a modifying agent, surface modification is performed on the carbon fibers with a liquid phase impregnation method, and an organic-iron-modified carbon fiber biofilm carrier material with the surface containing the iron element is prepared. The preparation method is simple and easy to implement, prepared organic-iron-modified carbon fibers can keep original excellent performance of the carbon fibers, the surface roughness and the hydrophilicity are significantly improved, the film colonization cycle is short, the microbial activity is improved, time required for water treatment is short, removal rates of COD, ammonia nitrogen and total phosphorus are obviously increased, the outgoing water quality is good in stability, and the reuse rate is higher.

Owner:HANGZHOU INST OF ADVANCED MATERIAL BEIJING UNIV OF CHEM TECH

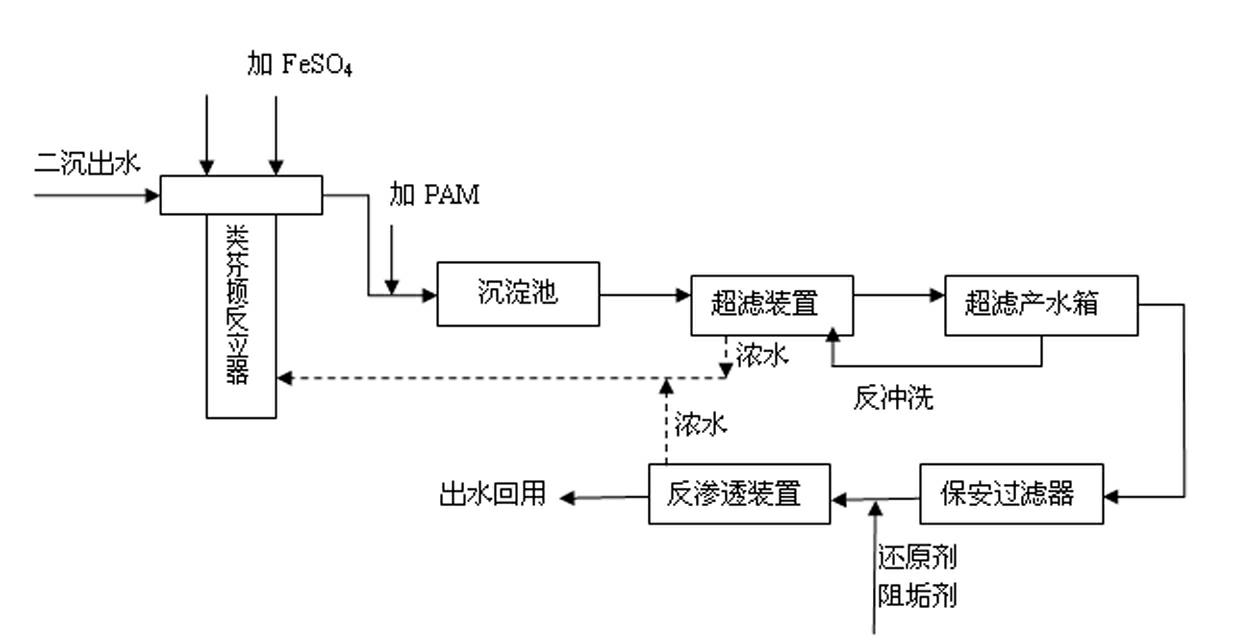

Advanced treatment process for fermented pharmaceutical waste water

InactiveCN102358651AImprove processing efficiencyImprove reuse rateWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentChemical treatmentUltrafiltration

The invention belongs to the technical field of waste water treatment, particularly relates to an advanced treatment process for fermented pharmaceutical waste water, which comprises the following steps: placing the pharmaceutical waste water after being subject to bio-chemical treatment into a Fenton reactor to perform oxidation treatment, and performing coagulating precipitation, ultra-filtration and reverse osmosis. The advanced treatment process for the fermented pharmaceutical waste water overcomes the shortcoming that limitation of potential of hydrogen (pH) in a Fenton method needs to be adjusted in the waste water treatment of biopharmaceutical industry, operation is simple, waste water treatment efficiency and reuse rate are high, and operating cost is low.

Owner:ZHENGZHOU UNIV

Desulfurization wastewater treatment system

ActiveCN105502790AImprove stabilityRealize quality reuseTreatment involving filtrationWater/sewage treatment bu osmosis/dialysisWater treatment systemFiltration

The invention relates to a desulfurization wastewater treatment system. The system is used for treating desulfurization wastewater from a desulfurization system, and comprises a pretreatment system, a membrane treatment system and an evaporative crystallization system which are arranged sequentially, wherein the pretreatment system is used for pre-treating desulfurization wastewater, the membrane treatment system is used for deeply treating the pretreated desulfurization wastewater, and the evaporative crystallization system is used for vaporizing and crystallizing the concentrate in the membrane treatment system to obtain crystalline salt. According to the desulfurization wastewater treatment system, the pretreated desulfurization wastewater is treated by a nano-filtration treatment system to separate monovalent and divalent ions, so that quality-divided recycling of desulfurization wastewater can be realized, and the reuse rate of water can be improved; and the water output from a reverse osmosis system is used to wash the nano-filtration treatment system, so that the dosage of a softening agent in a softening and clarifying system and the dosage of a scale inhibitor in the nano-filtration treatment system can be respectively reduced.

Owner:HANGZHOU WATER TREATMENT TECH DEV CENT

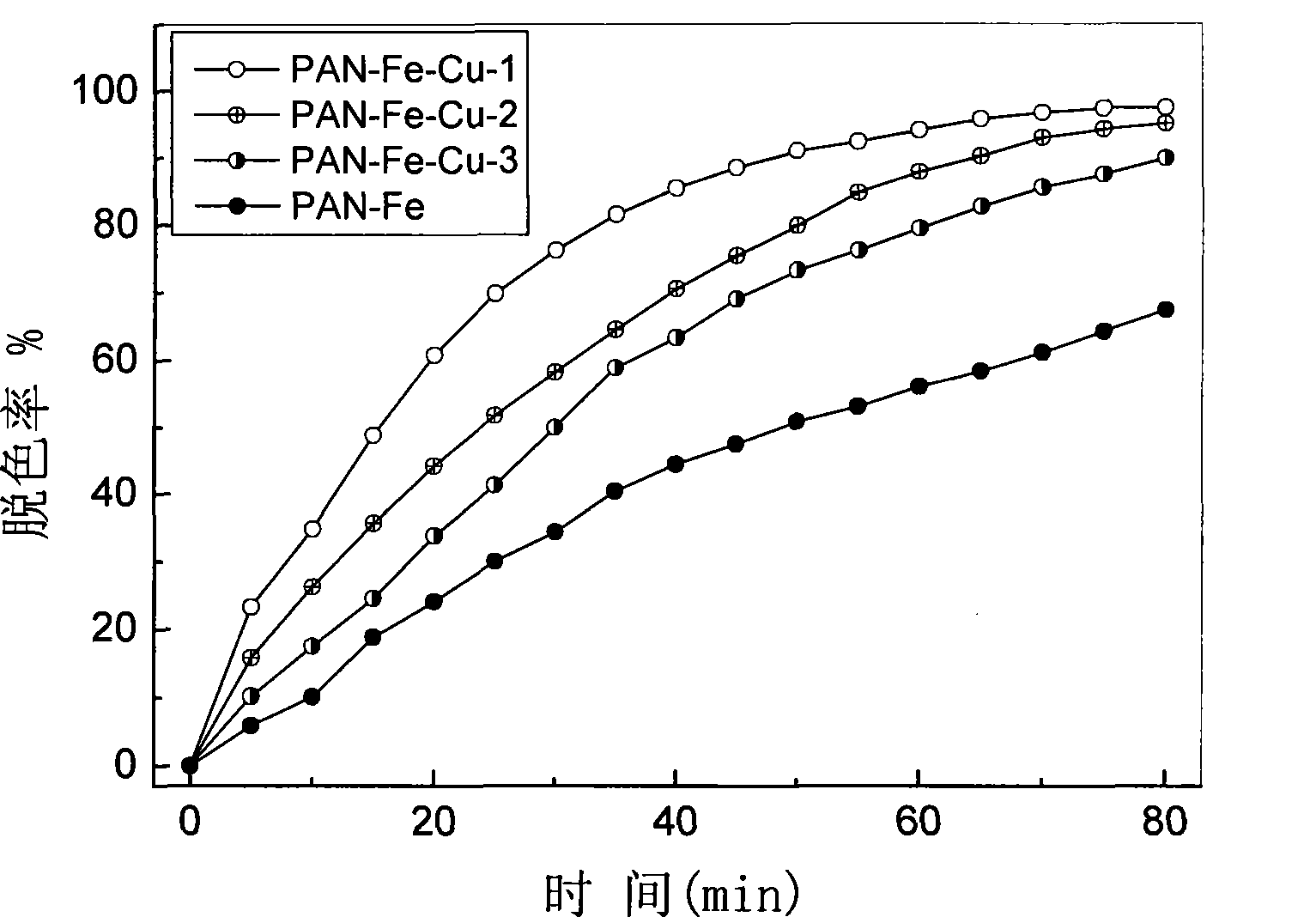

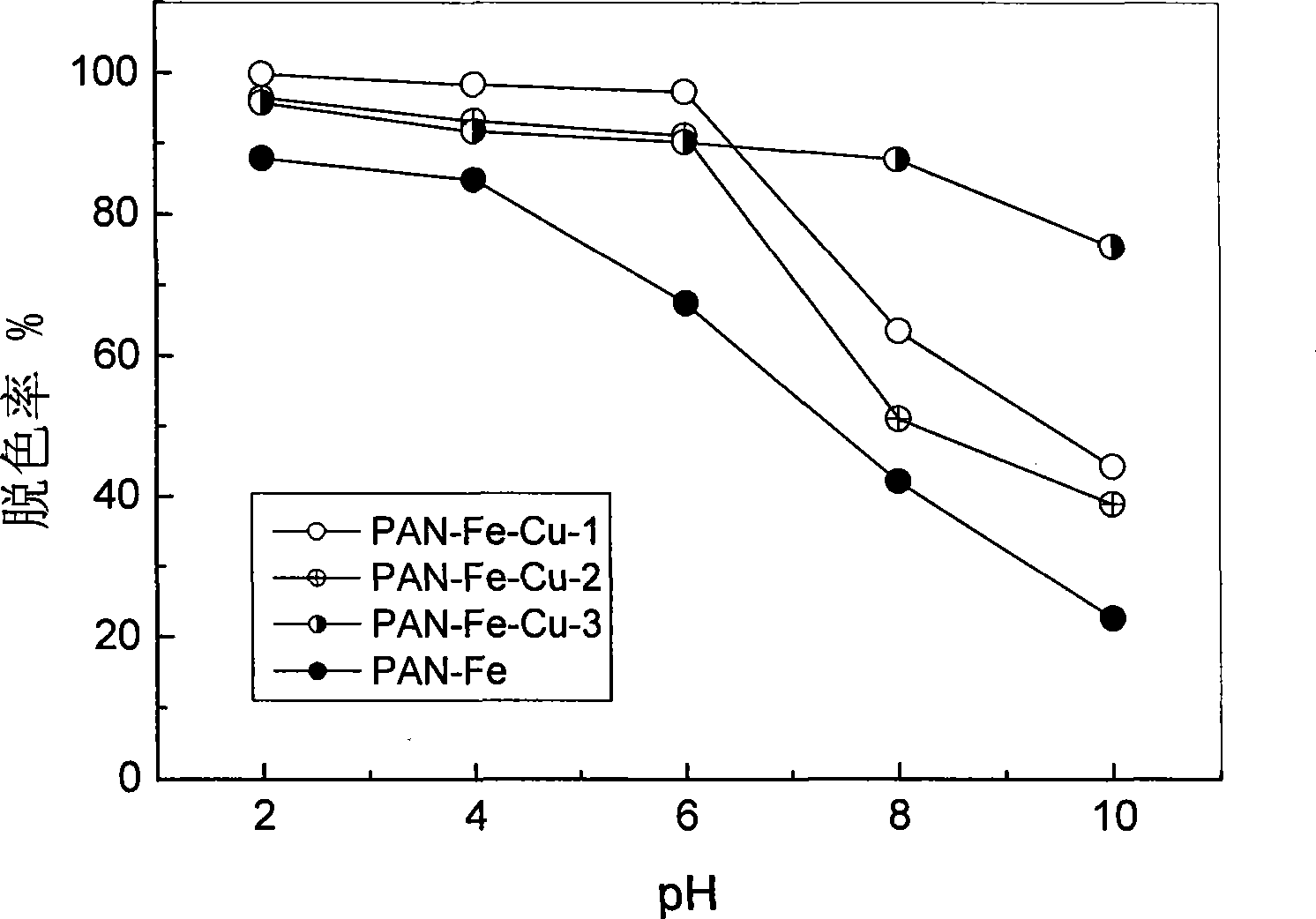

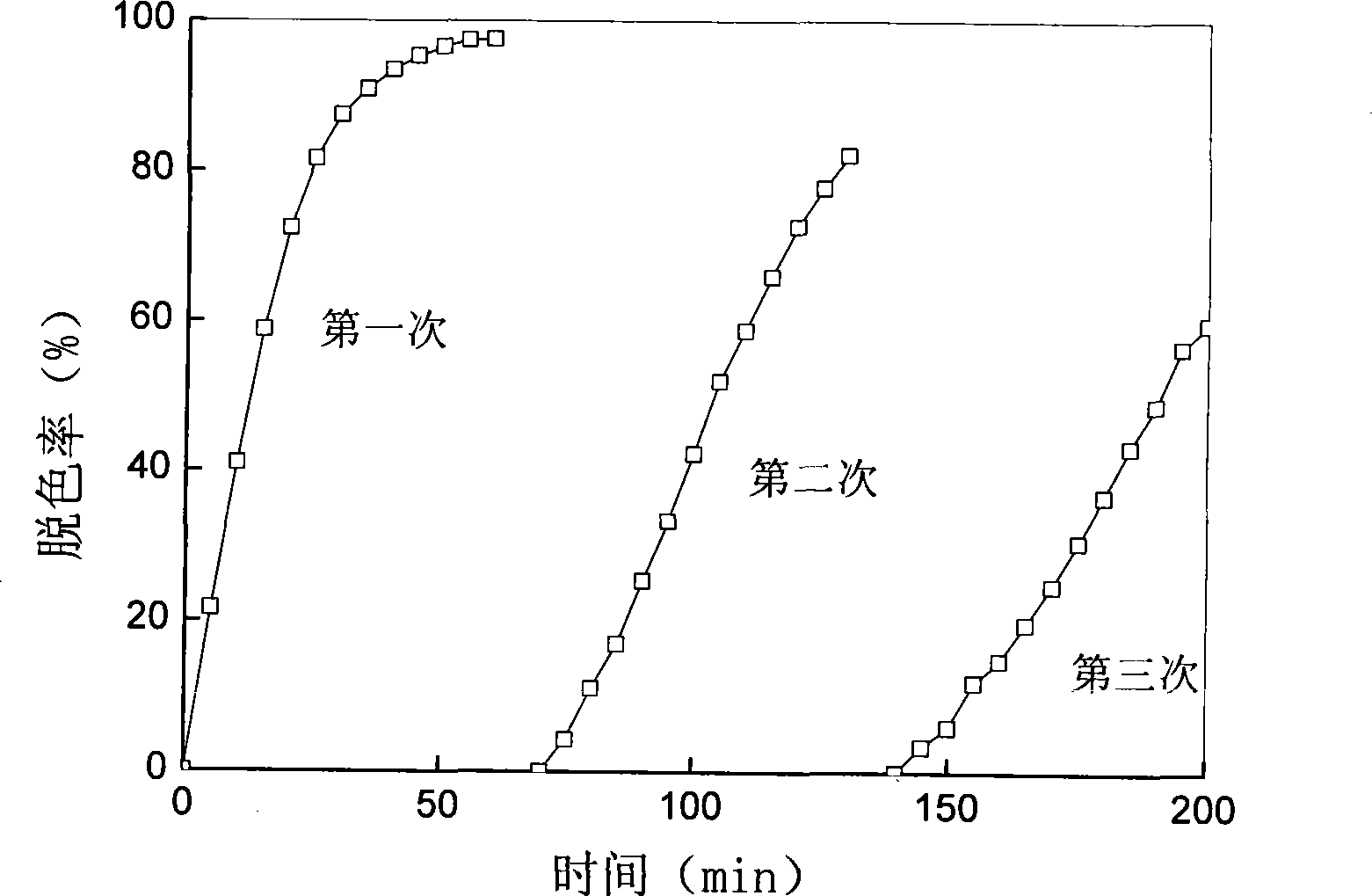

Polyacrylonitrile fiber duplex metal complexes catalyst and preparation method thereof

InactiveCN101362102AHigh catalytic activityHigh reuse rateOrganic-compounds/hydrides/coordination-complexes catalystsWater/sewage treatment by oxidationHydrazine compoundHydroxylamine Hydrochloride

The invention relates to a polyacrylonitrile fiber bimetallic complex catalyst and a preparation method thereof. The catalyst is characterized in that the appearance is between brownish yellow and yellowish green and is fiber-shaped; and the catalyst is formed by polyacrylonitrile fiber which is modified by hydrazine hydrate and hydroxylamine hydrochloride, and a coordination compound of iron ion and copper ion, wherein, the contents of iron ion and copper ion are 11.60mg / g to 26.10mg / g and 11.15mg / g to 28.30mg / g respectively. The preparation method adopts the following steps: 1. the pre-treatment of the polyacrylonitrile fiber; 2. modified reaction of the hydrazine hydrate of the polyacrylonitrile fiber and hydroxylamine hydrochloride; 3. the preparation of mixed solution of iron ion and copper ion; 4. the coordination reaction of the modified polyacrylonitrile fiber and metal ions; therefore, the fiber-shaped polyacrylonitrile fiber bimetallic complex catalyst with the color between brownish yellow and pale green is obtained. The catalyst has good catalytic activity, is applicable to the degradation of dyes in the basic printing and dyeing wastewater and has high reuse rate.

Owner:TIANJIN POLYTECHNIC UNIV

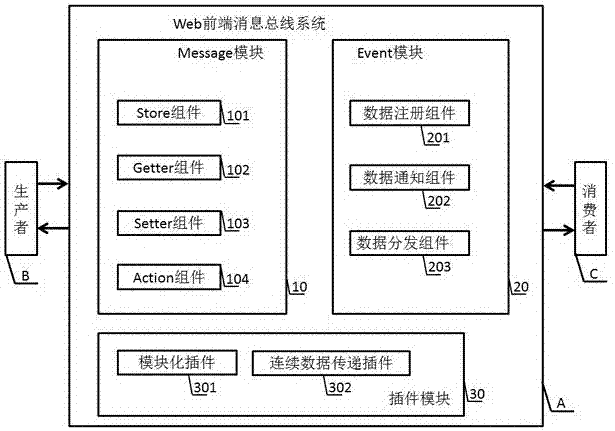

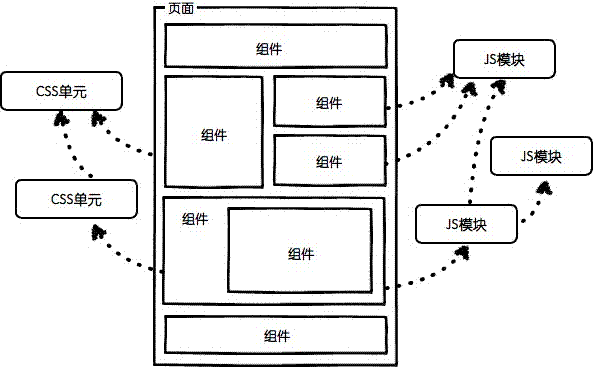

Web front end message bus system

ActiveCN107291523AImprove robustnessDegree of decouplingInterprogram communicationMemory systemsComputer hardwareEcological environment

The invention discloses a Web front end message bus system, relates to the technical field of information, and especially relates to the technical field of Web front end control. The Web front end message bus system is composed of a Message module, an Event module and a plug-in module. The Message module is composed of a Store component, a Getter component, a Setter component and an Action component. The Event module is composed of a data register component, a data notification component and a data distribution component. The invention aims at solving the problem of communication among Web front end components, a set of unified standard is defined for the communication among the Web front end components, and each component performs communication by using a unified communication mode. For Web front end configuration, the components are developed by focusing on the Web front end message bus system, the Web front end technology ecological environment and technology stack inside enterprises are formed, the reuse rate of the Web front end components is increased, production efficiency of project development is improved, and project operation cost is also reduced.

Owner:BEIJING ACT TECH DEV CO LTD

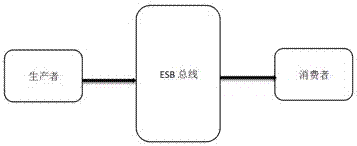

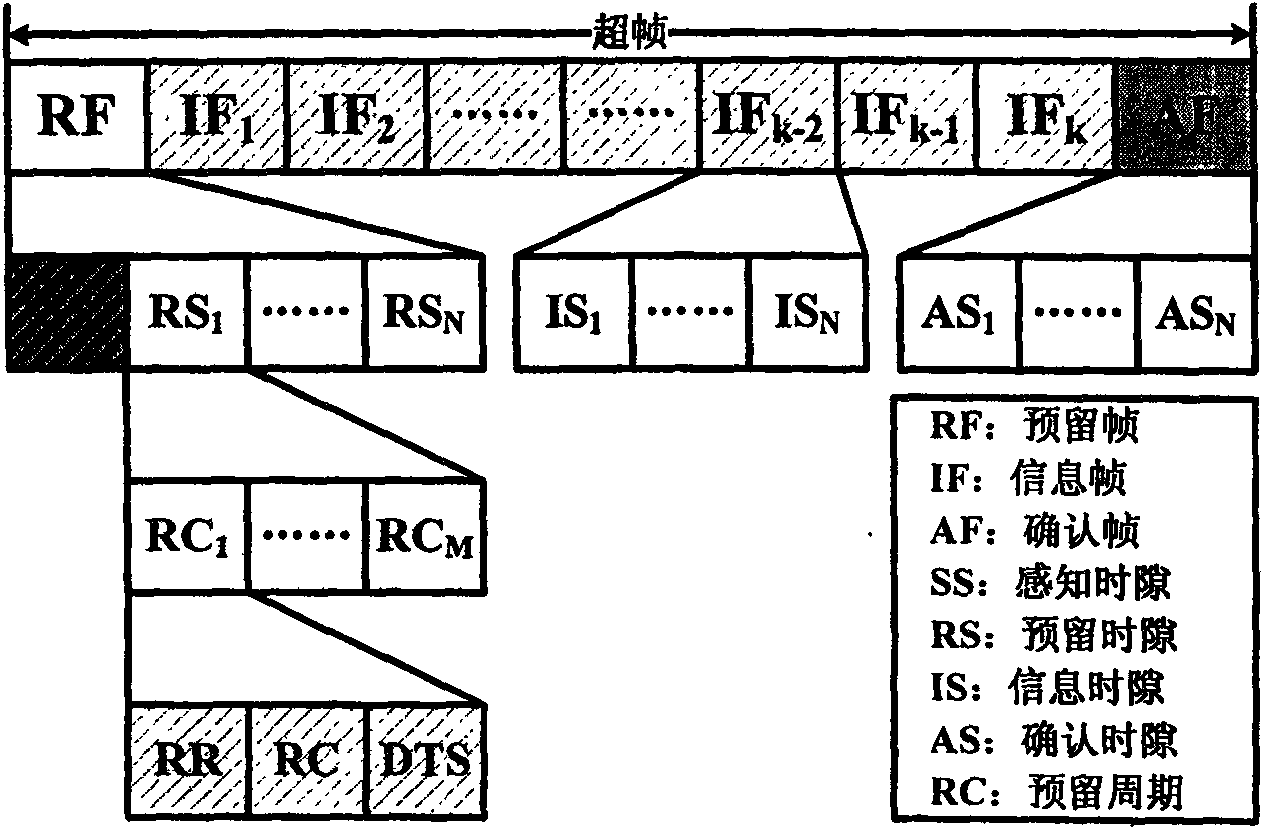

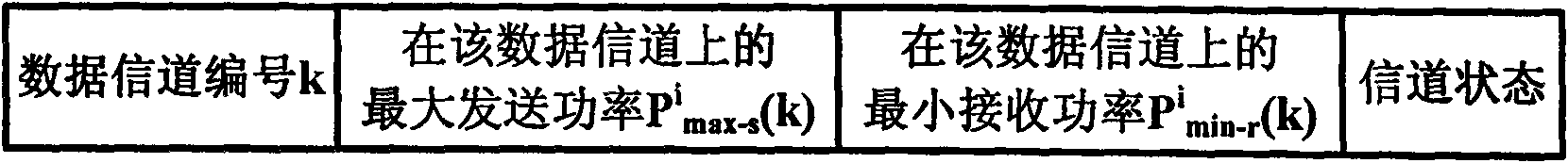

Implement method of power control cognition MAC protocol based on time division multiple access (TDMA)

InactiveCN101651969AReduce the probability of collisionAchieve protectionNetwork traffic/resource managementNetwork topologiesFrequency spectrumCode division multiple access

The invention discloses an implement method of power control cognition MAC protocol based on time division multiple access (TDMA). The method comprises the following steps: adopting strict time slot division, finishing time slot allocation among node pairs by a three-way handshake manner, namely, reserving application, reserving confirmation and deciding sending; realizing collision-free transmission in node communication process; and introducing a power control mechanism to improve the reuse rate of cyber space. The method can eliminate problems of multiple channels hiding a send terminal, multiple channels hiding a receiving terminal and multiple channels exposing terminals, and can dramatically decrease the impact on network performance brought by the problem of multiple channels hidingthe send terminal. The simulation result indicates, compared with dynamic spectrum access MAC (DSA-MAC) protocol, the invention can effectively enhance network throughput and decrease access time delay with the increment of network business volume.

Owner:XI AN JIAOTONG UNIV

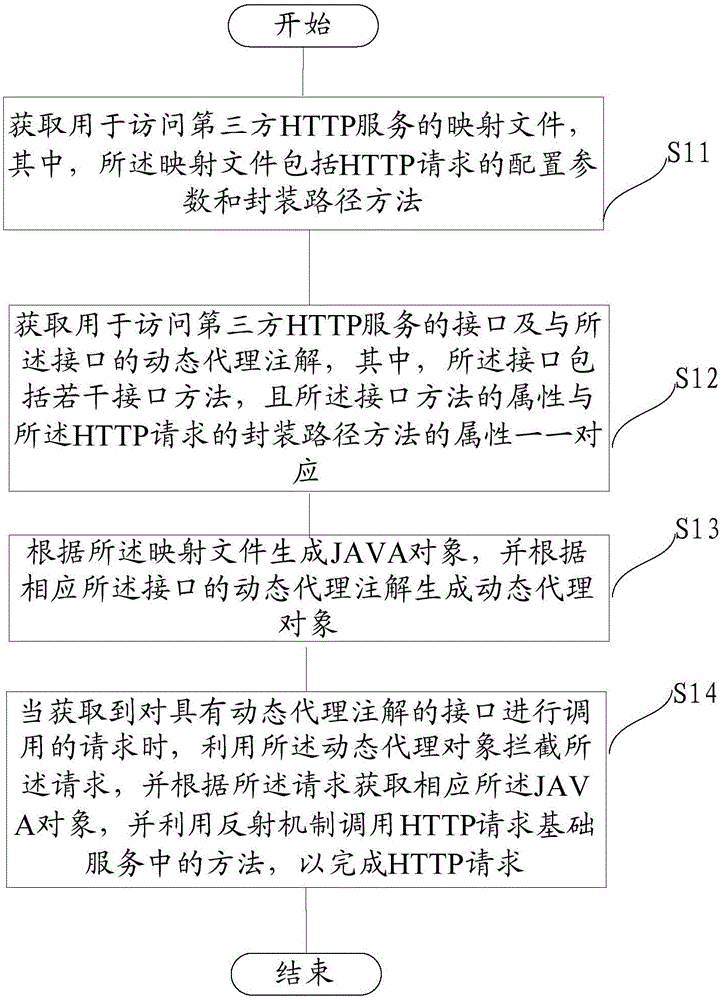

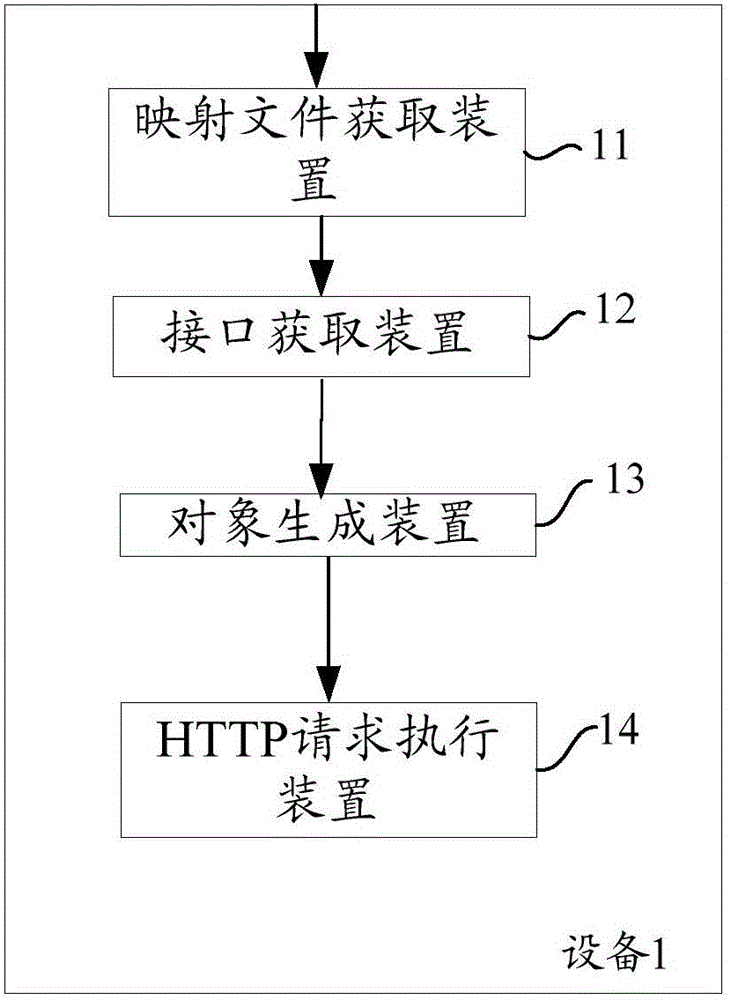

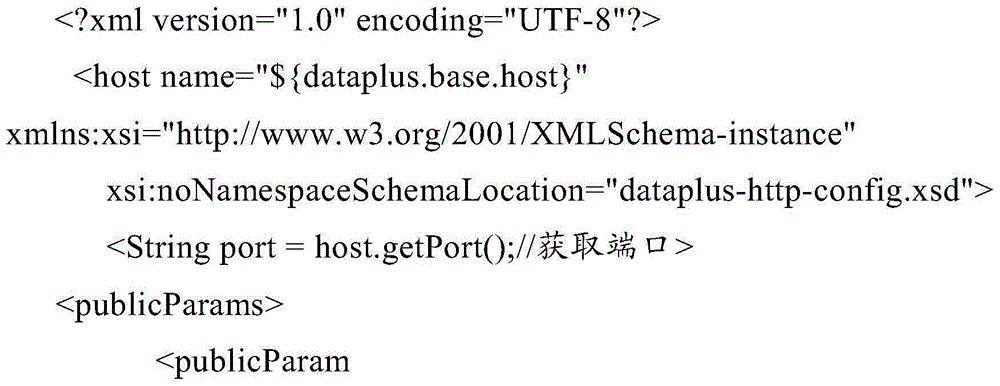

Method and equipment for uniform mapping of HTTP requests

ActiveCN106354481ARealize one-time development and multiple reuseSimplify development difficultySpecific program execution arrangementsThird partyJava object

The invention aims to provide a method and equipment for uniform mapping of HTTP requests. A configuration content is independent from a business logic content by obtaining a mapping file used for access to third party HTTP service, the mapping file corresponds to an interface, a corresponding JAVA object is generated according to the mapping file, a reflection proxy note corresponding to a corresponding interface is called according to the requests so as to generate a dynamic proxy object, when the HTTP requests are performed, the dynamic proxy object can process the requests by use of the JAVA object generated according to the mapping file, a method in HTTP request basis service is called, and the HTTP requests are completed, so that one-time development and multiple-time reuse of the mapping file are realized. Accordingly, HTTP request calling is realized under the conditions that the development difficulty is simplified and the reuse rate is improved.

Owner:ALIBABA GRP HLDG LTD

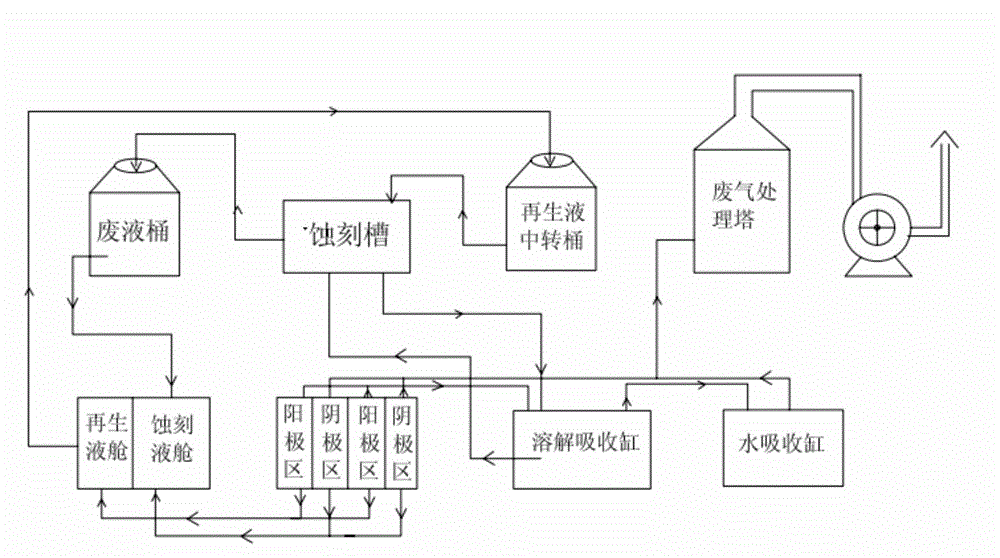

Device and process for electrolytically extracting copper in acidic etching liquid

InactiveCN104630825ASolve the problem of energy consumptionSolve the problem of low reuse ratePhotography auxillary processesProcess efficiency improvementElectrolysisHigh energy

The invention provides a device and a process for electrolytically extracting copper in an acidic etching liquid. The device comprises an etching tank, a waste liquid barrel, a copper extraction unit, a dissolving absorption jar and a water absorption jar, wherein the etching tank is connected with the waste liquid barrel which is connected with the copper extraction unit; the copper extraction unit comprises an etching liquid chamber, a regenerated liquid chamber and an electrolytic reaction chamber; the electrolytic reaction chamber is divided into a cathode area and an anode area at an interval by use of a composite high-molecular ionic membrane; the anode area is connected with the dissolving absorption jar by use of an exhaust pipeline, while the cathode area is connected with the water absorption jar by use of an exhaust pipeline; the dissolving absorption jar is in circular connection with the etching tank. The device is reasonable in structure, and the process is complete; the problems of high energy consumption and low reuse rate of electrolytic copper extraction from the acidic etching liquids in the prior art are solved; the quality of the cathode copper is improved, and meanwhile, material waste is reduced and the reuse rate is increased.

Owner:KUNSHAN MEIYUANDA ENVIRONMENTAL PROTECTION TECH

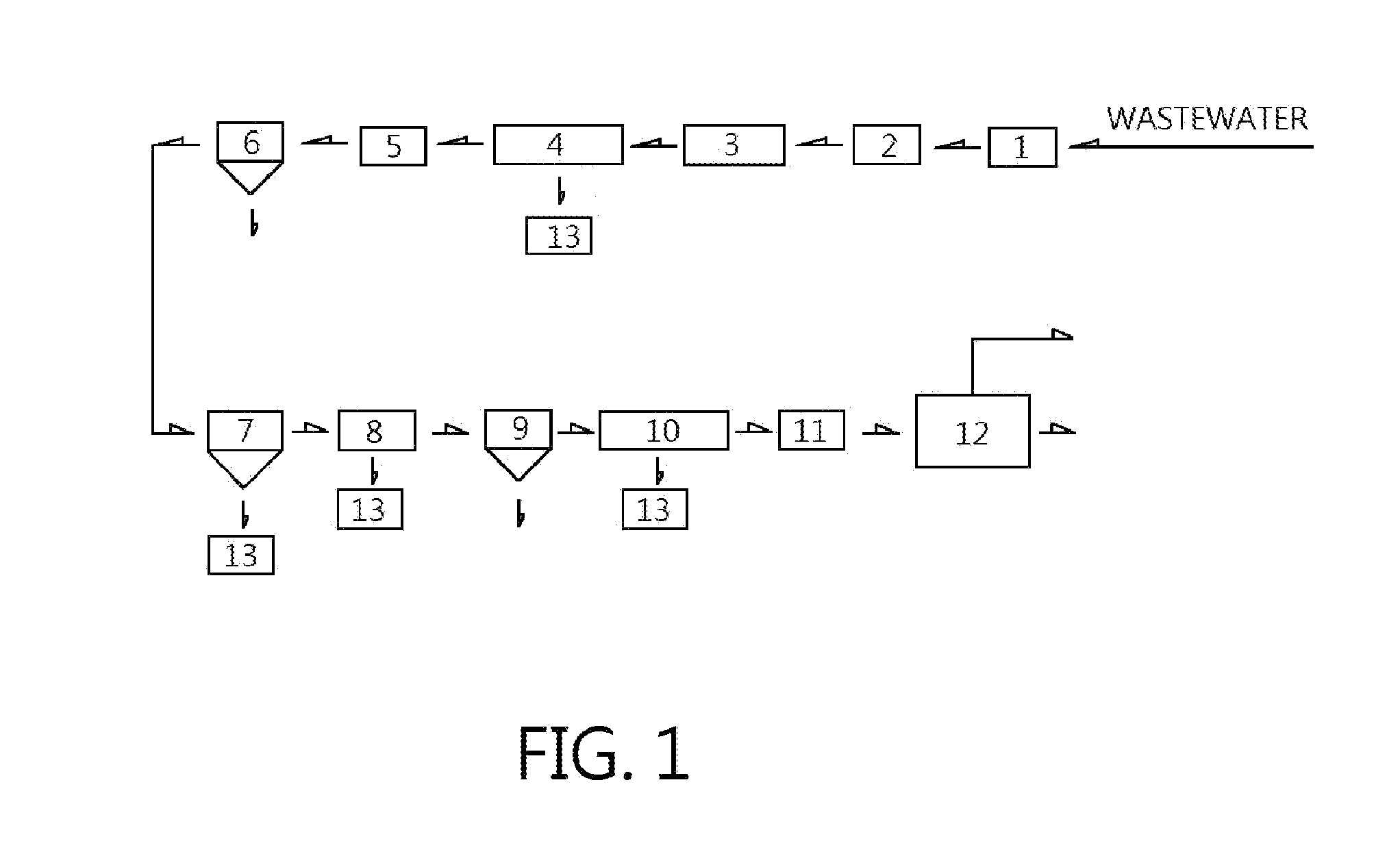

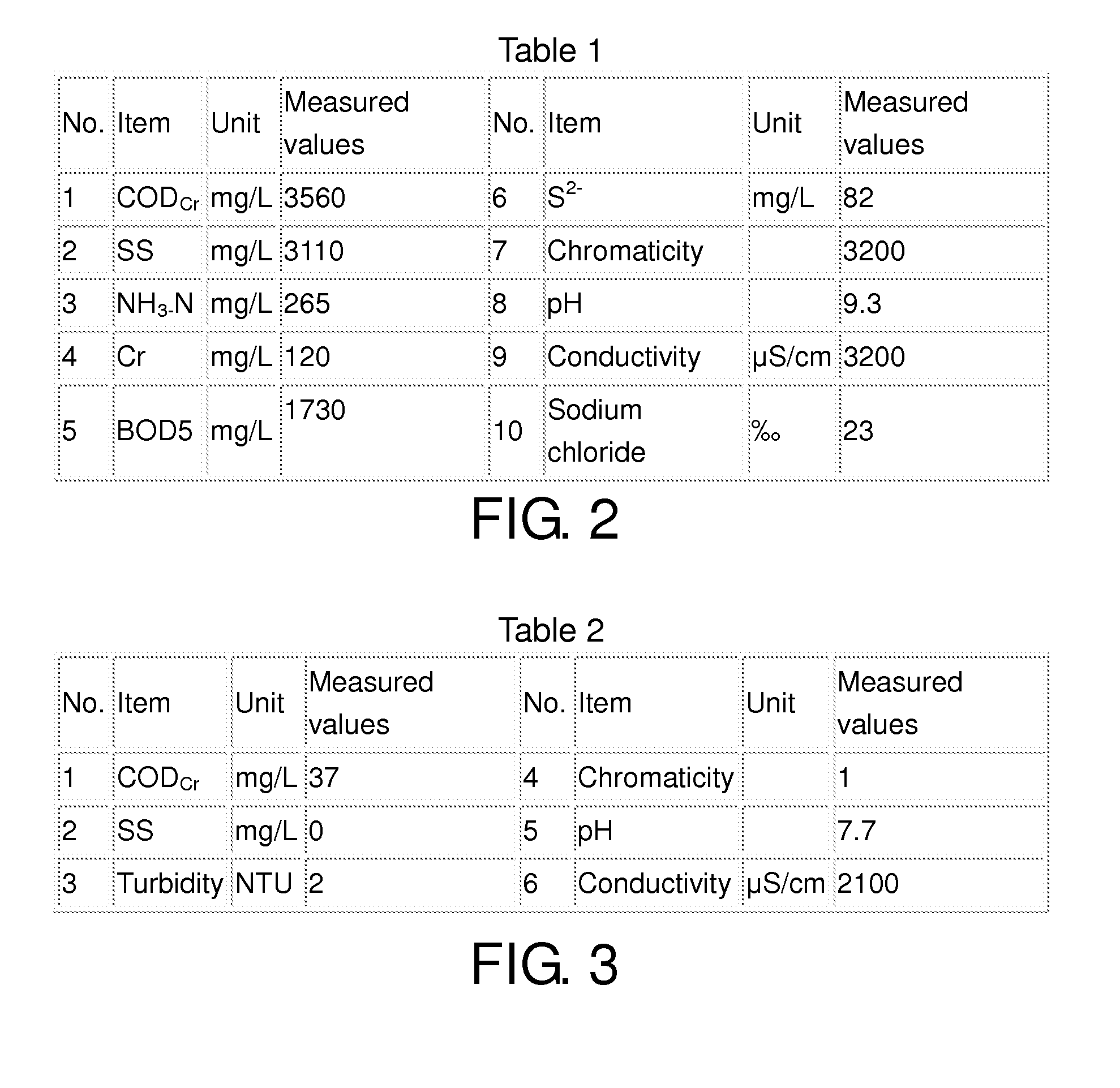

Tanning wastewater treatment and recycling method based on nano-catalytic electrolysis technology and membrane technology

InactiveUS20130206692A1High removal rateLow chemical consumptionTreatment involving filtrationSolid sorbent liquid separationFlocculationElectrolysis

A tanning wastewater treatment and recycling method based on nano-catalytic electrolysis technology and membrane technology relates to a tanning wastewater treatment. The tanning wastewater treatment and recycling method based on the nano-catalytic electrolysis technology and the membrane technology and a device thereof has a high COD removal rate, a low chemicals consumption, few sludges, thorough treatment, and a high reuse rate of water. The tanning wastewater treatment and recycling device based on the nano-catalytic electrolysis technology and the membrane technology includes: a coarse grid filtering machine, a regulating pool, a hydraulic sieve, a nano-catalytic electrolytic machine, a reaction pool, a sedimentation pool, an air flotation device, a biochemical pool, a secondary sedimentation pool, a secondary nano-catalytic electrolytic machine, a filter and a membrane system. The method includes: nano-catalytic electrolysis, flocculation, biochemical treatment, secondary catalytic electrolysis, filtration, and membrane filtration.

Owner:BOYING XIAMEN SCI & TECH

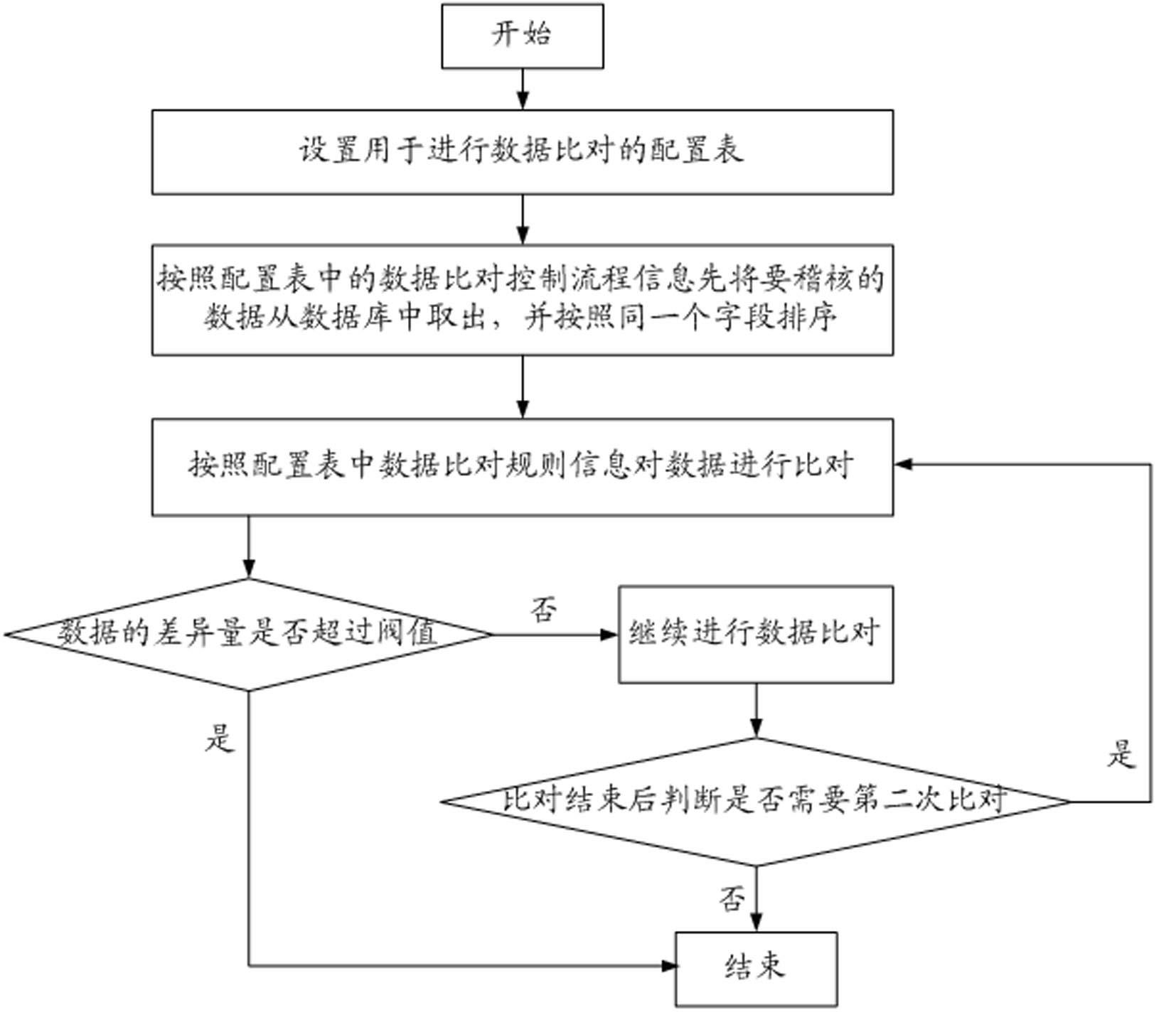

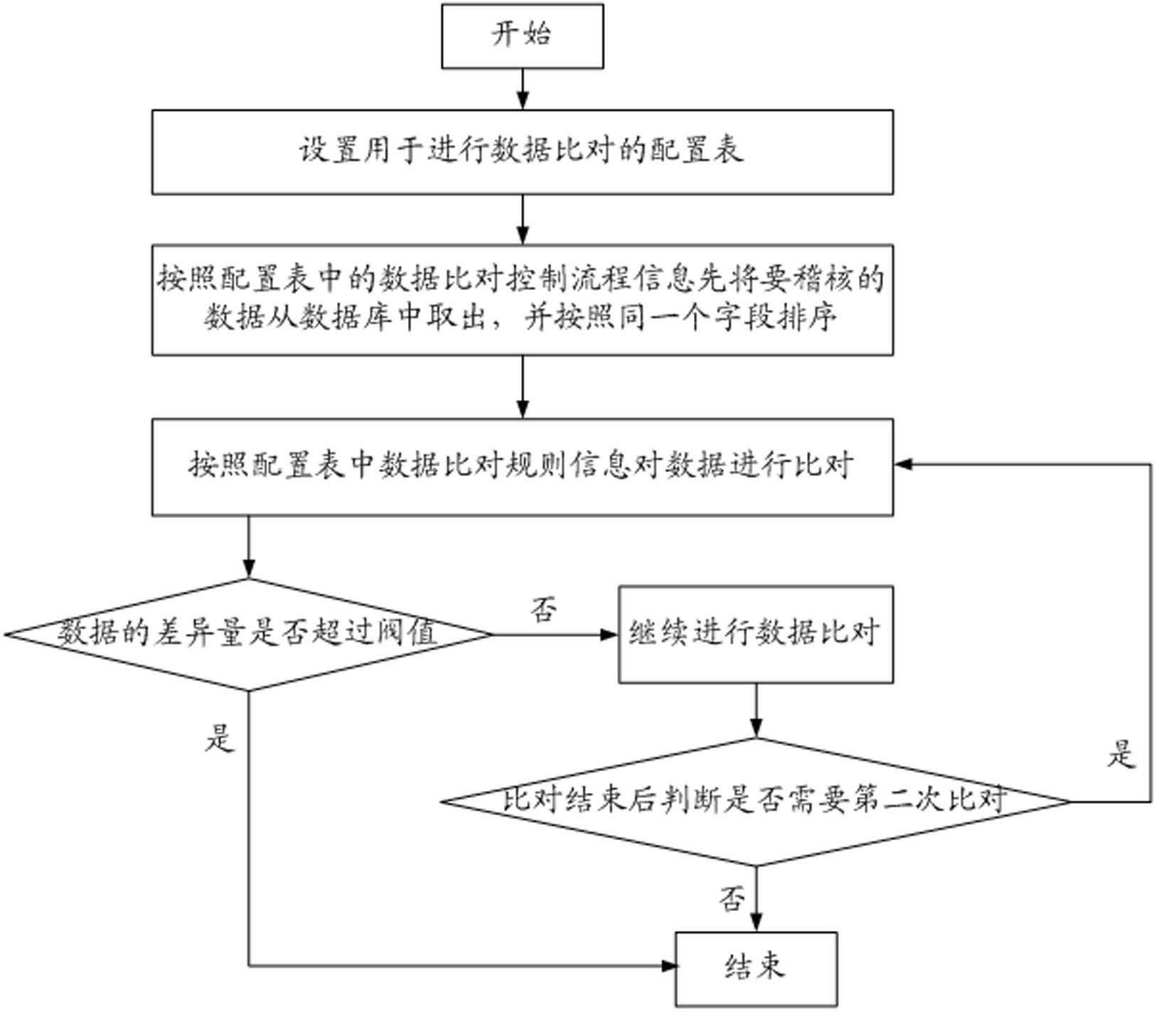

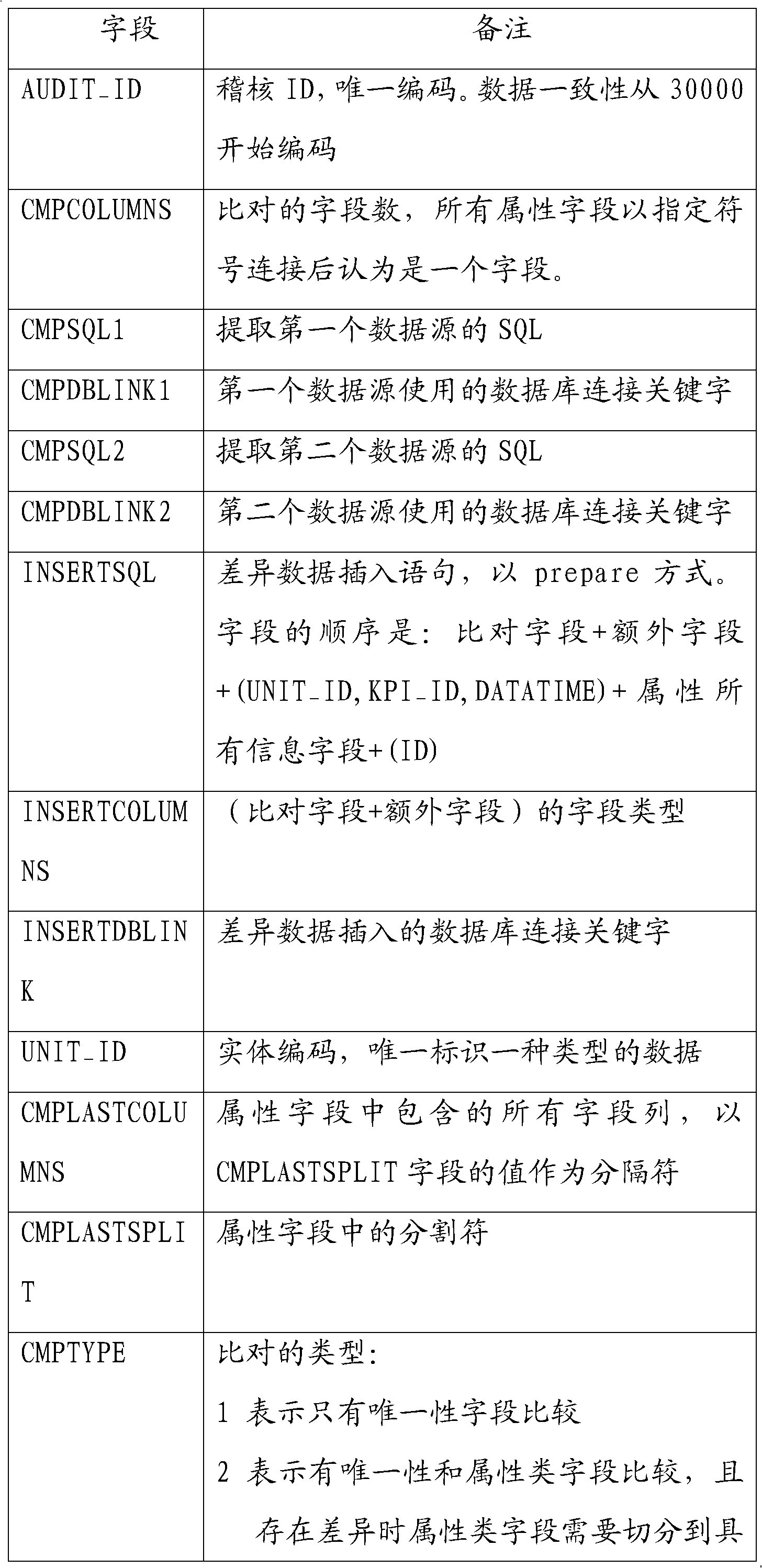

Data comparison method

InactiveCN102184190AFaster thanImprove reusabilitySpecial data processing applicationsControl flowValue set

The invention relates to a data comparison method. The data comparison method comprises the following steps of: 1, setting a configuration table for data comparison, wherein the configuration table comprises data comparison control flow information, address information of a data comparison content and data difference threshold value information; 2, extracting data to be checked from a database at first according to the data comparison control flow information in the configuration table, and sequencing the data according to a same field, wherein the field comprises an index field and a property field; 3, comparing the data according to data comparison rule information in the configuration table; 4, judging whether a difference of the data is greater than a data difference threshold value set in the configuration table, if the difference of the data is greater than the data difference threshold value set in the configuration table, recording a comparison result of the data, and if the difference of the data is not greater than the data difference threshold value set in the configuration table, keeping comparing the data; and 5, judging whether second comparison is required according to the property of the data after the comparison, if the second comparison is not required, storing the comparison result, and if the second comparison is required, returning to the step 3. The data comparison method has the advantages that: because the data comparison is uniformly managed by the configuration table, the comparison speed and the reuse rate are high.

Owner:北京思特奇信息技术股份有限公司

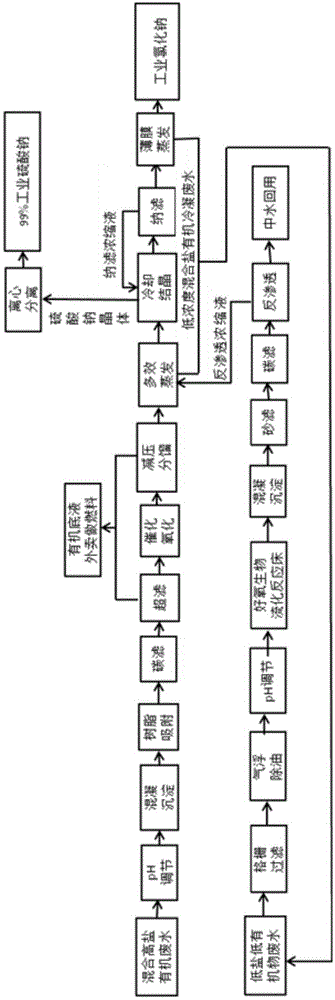

Treatment method and treatment system for high-concentration mixed salt organic wastewater

ActiveCN105254141AQuality improvementImprove reuse rateMultistage water/sewage treatmentAlkali metal chloridesHigh concentrationFractionation

The invention provides a treatment method for high-concentration mixed salt organic wastewater. The treatment method for the high-concentration mixed salt organic wastewater comprises the following steps: carrying out coagulating sedimentation on the high-concentration mixed salt organic wastewater, so as to obtain sediments and mixed liquor; carrying out vacuum fractionation on the mixed liquor, so as to obtain fraction and fractional distillate; carrying out evaporative crystallization on the fractional distillate, so as to obtain sodium salt and low-concentration mixed salt organic condensate wastewater; carrying out aerobic biological treatment on the low-concentration mixed salt organic condensate wastewater, so as to obtain low-concentration organic wastewater; carrying out reverse osmosis treatment on the low-concentration organic wastewater, so as to obtain treated wastewater and a reverse osmosis concentrate solution; and carrying out evaporative crystallization on the reverse osmosis concentrate solution, so as to obtain sodium salt, wherein the high-concentration mixed salt organic wastewater contains sodium salt, heavy metal ions and organic matters. The treatment method for the high-concentration mixed salt organic wastewater has the advantages that the sodium salt in the wastewater can be efficiently recycled, treated wastewater can meet industrial usage requirements, reuse rate is high, and zero wastewater discharge is realized. The invention also provides a treatment system for the high-concentration mixed salt organic wastewater.

Owner:安徽中飞科技有限公司

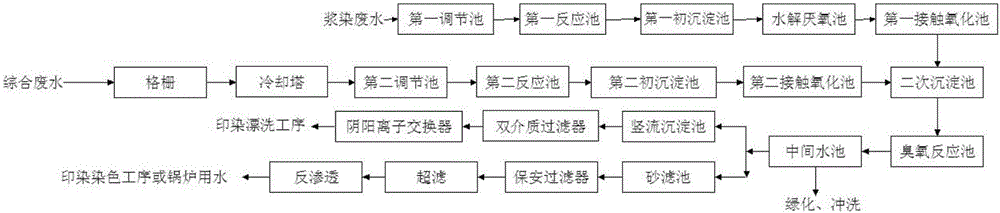

Complex printing and dyeing wastewater quality-divided treating and reusing integrated technology

ActiveCN105859055AReduce work intensityProtection securitySpecific water treatment objectivesWater contaminantsTextile printerWater use

The invention relates to a complex printing and dyeing wastewater quality-divided treating and reusing integrated technology. The technology comprises two parts of quality-divided treating and quality-divided reusing, the whole technical process is realized through an automatic detection and control mode. For the characteristics that wastewater in a textile printing and dyeing garden is large in water quality change, high in chromaticity, difficult to biologically decompose and high in inorganic salt content, an existing efficient ozonation technology, an ultrafiltration-reverse osmosis membrane technology, an economical biochemical treatment technology, a double-tower filtration technology and an cation and anion exchange technology are integrated and optimized, for meeting the water quality requirement of water used in all processes of the garden, and efficient and low-cost treatment of the printing and dyeing wastewater is achieved by means of quality-divided treating and quality-divided reusing. Compared with a traditional treatment technology, though the water is more complex, high in chromaticity and difficult to decompose, treatment cost is lower, and the reuse rate of reclaimed water is larger and can reach 70-80%.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Tanning wastewater treatment and reuse apparatus and method therefor

InactiveUS20130256224A1Reduce the amount requiredReduce consumptionTreatment using aerobic processesTreatment involving filtrationFlocculationElectrolysis

A tanning wastewater treatment and reuse apparatus includes a coarse filter, a regulation pool, a hydraulic sieve, a desulfurization pool, a first nanocatalytic electrolyzer, a flocculation pool, a first settling pool, a flotation device, a biochemical pool, a second settling pool, a second nanocatalytic electrolyzer, a fine filter, and a compressor. Also provided is a tanning wastewater treatment and reuse method includes the steps of desulfurization, first nanocatalytic electrolysis, flocculation, biochemical treatment, second catalytic electrolysis, and filtration. The invention allows high CODCr removal rate, reduced chemical agent consumption, reduced sludge formation, thorough treatment, and high water reuse rate.

Owner:BOYING XIAMEN SCI & TECH

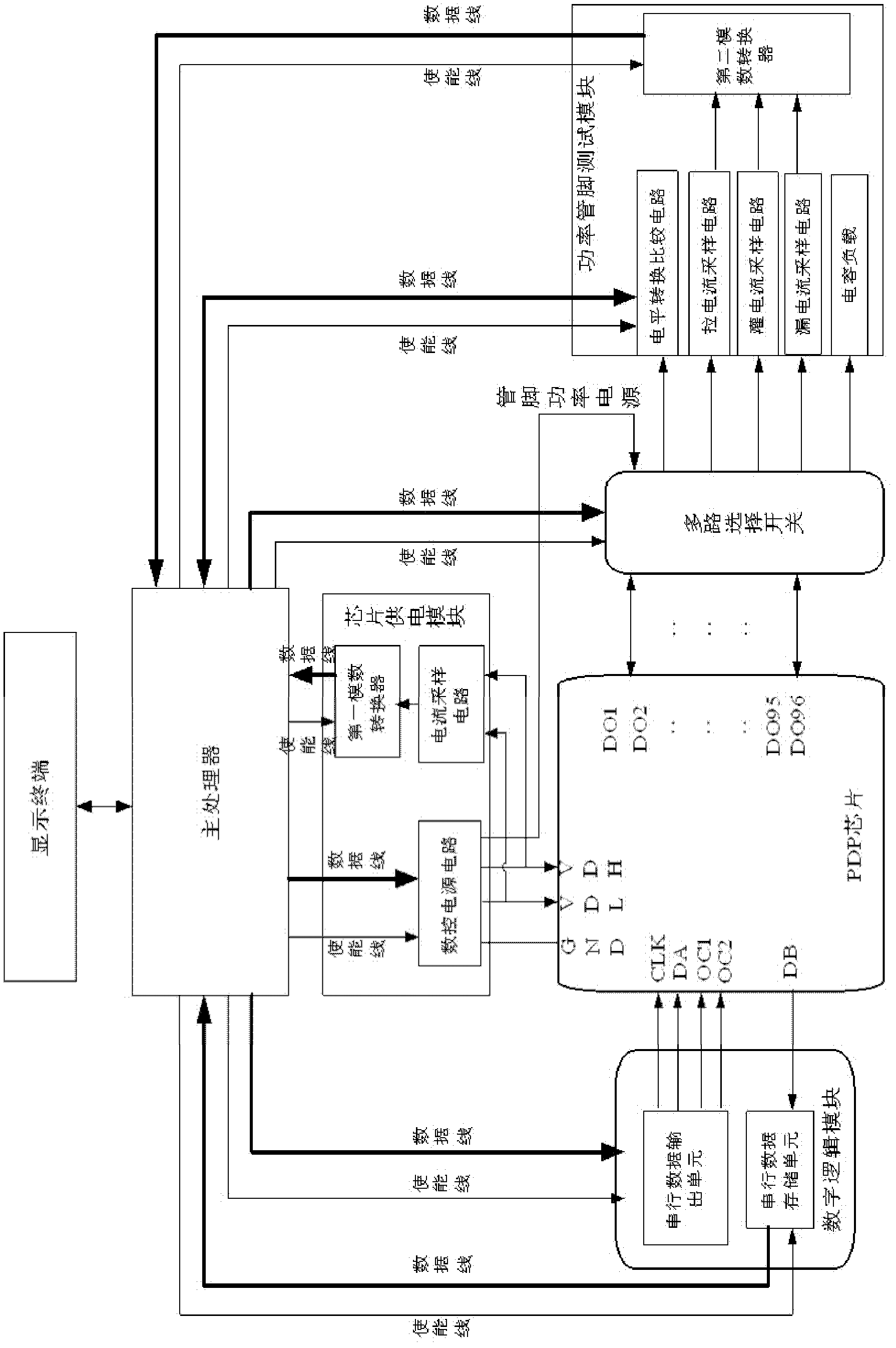

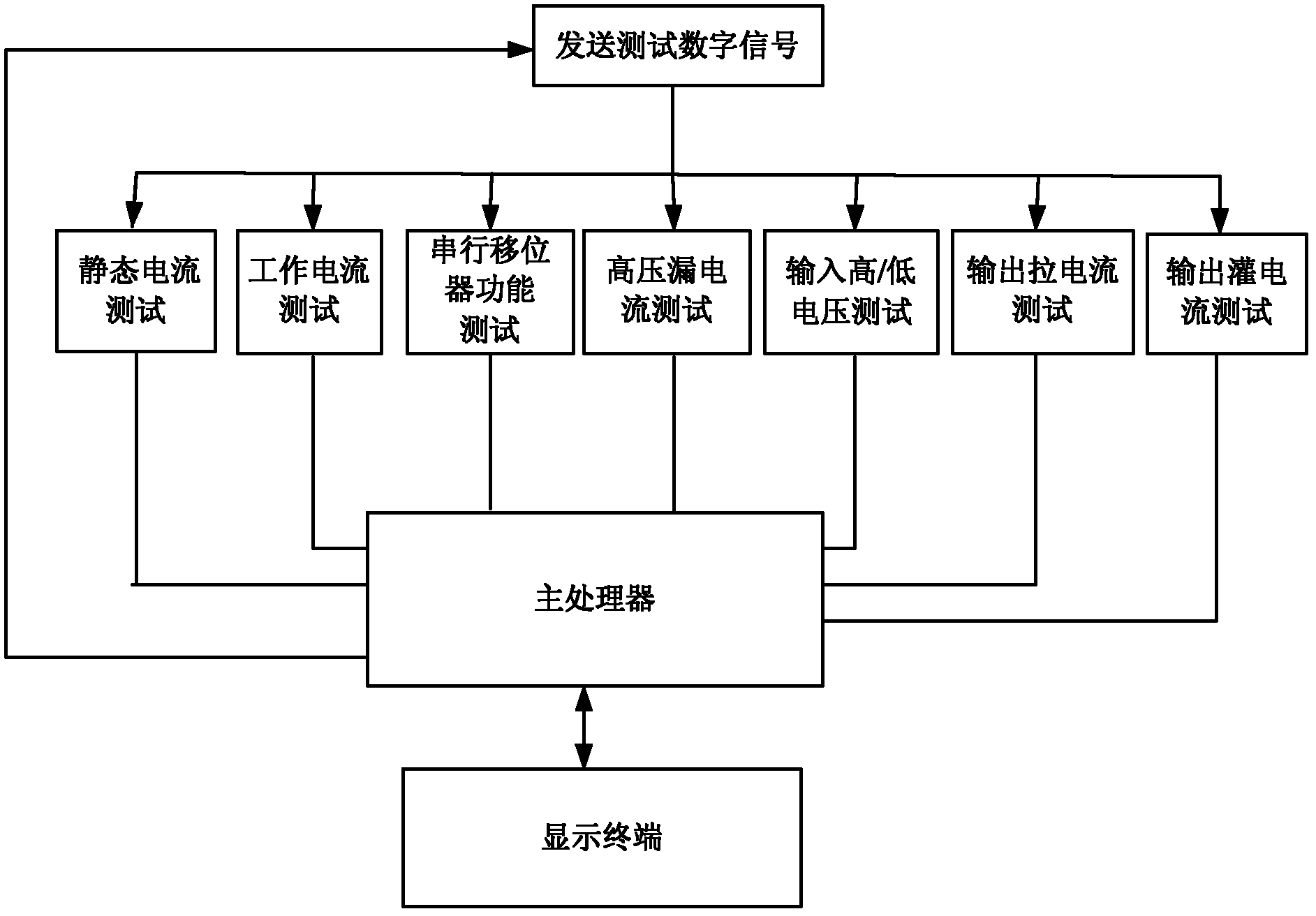

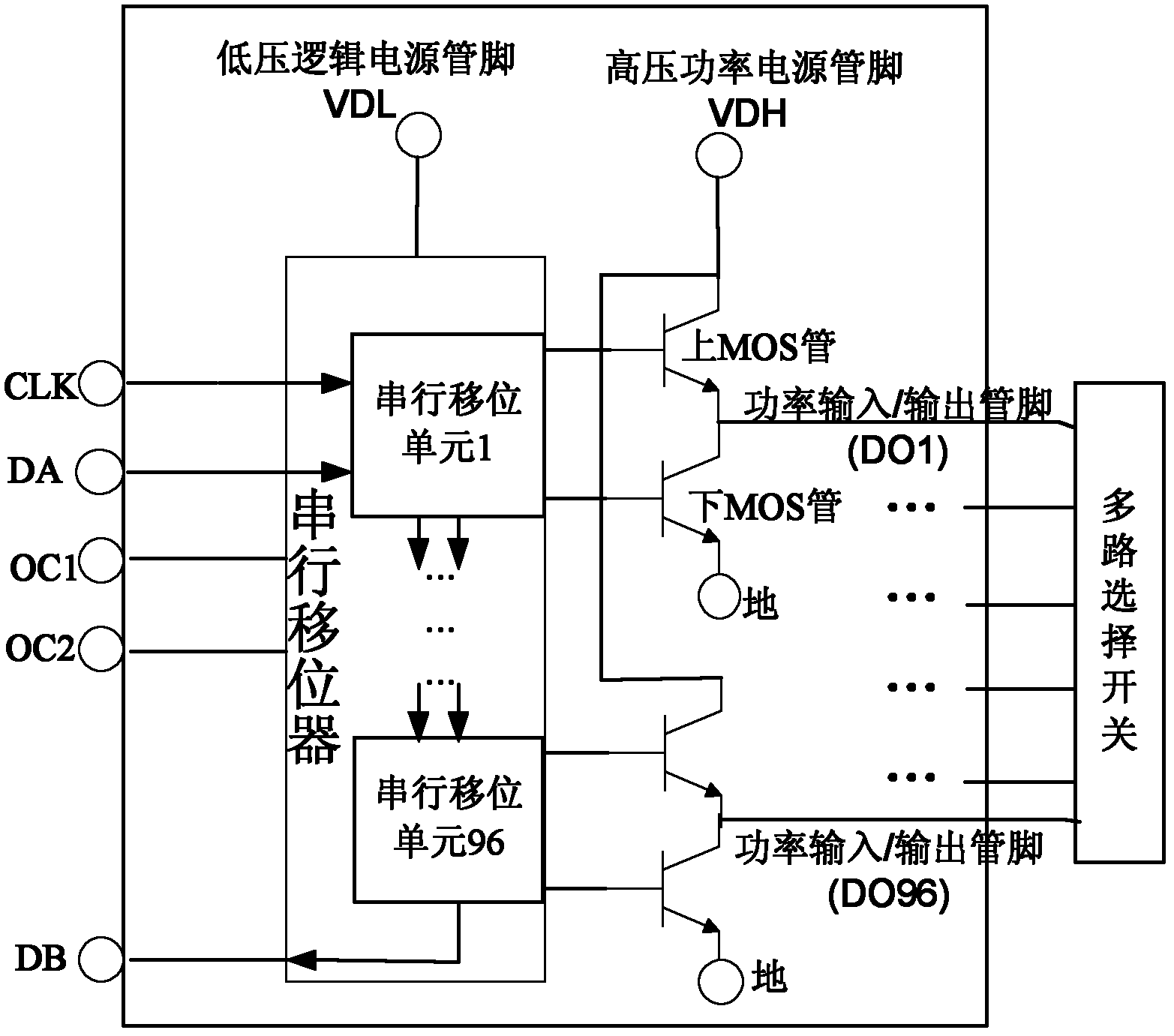

Device for testing plasma scanning driver ic

ActiveCN102540058ANot easy to damageImprove test efficiencyDigital circuit testingTest efficiencyFunctional testing

The invention relates to the field of integrated circuit testing, and discloses a device for testing a plasma scanning driver ic, which includes a main processor, a digital logic module, a chip power supply module, a multiway select switch, a power pin test module and a display terminal, and can be used for performing one or more tests for a PDP chip including a quiescent current test, a working current test, a serial shifter functional test, a high-voltage leakage current test, a source current output test, a sink current output test and a high / low voltage input test. The device provided by the invention has the advantages of high testing efficiency, short consumed time and high precision during the test verification process, is high in reuse rate, and has the advantages of simplicity in testing and high coverage rate, has low possibility of damaging the device in case of automatic measurement, and greatly reduces the testing cost.

Owner:HANGZHOU SILAN MICROELECTRONICS

Bamboo magnesite cement composite plate and its manufacture method

InactiveCN101323188ASufficient supplyHigh strengthSolid waste managementMouldsCement compositesFilling materials

The invention discloses a bamboo magnesite cement composite board and a manufacturing method thereof. The existing plates are inferior in composite characteristics of intensity, rigidity, density and smoothness and inferior in reuse rate. The chip material and the magnesite cement are taken as the raw materials in the invention. The bamboo strip or bamboo filament is embedded into the magnesite cement as the reinforced material; the chip material is mixed into the cement and taken as the filling material. The magnesite cement is taken as the bonding and reinforcing material to mix the three kinds of materials, which form sandwich layer of the plates. The prefabricated bamboo mat and finish coat are pasted to the upper and lower surfaces and the hot compacting is carried out. The manufacturing method of the invention reduces raw material consumption of bamboo and improves complex utilization rate of recourses. The plates have the advantages of high strength, high hardness, high smoothness, middle density, etc. The product made by the manufacturing method can be broadly used in templet, wrapping plate, partition plate, carriage plate, etc.

Owner:郎雨

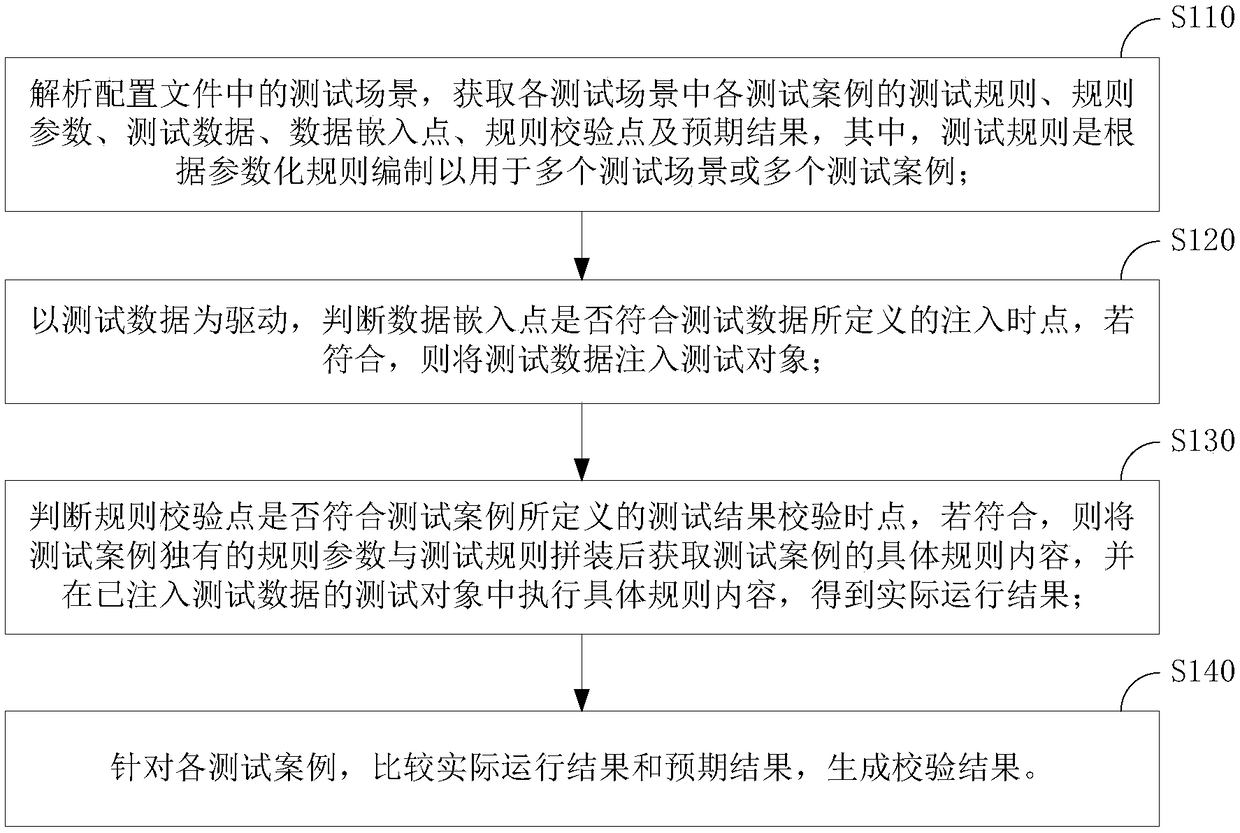

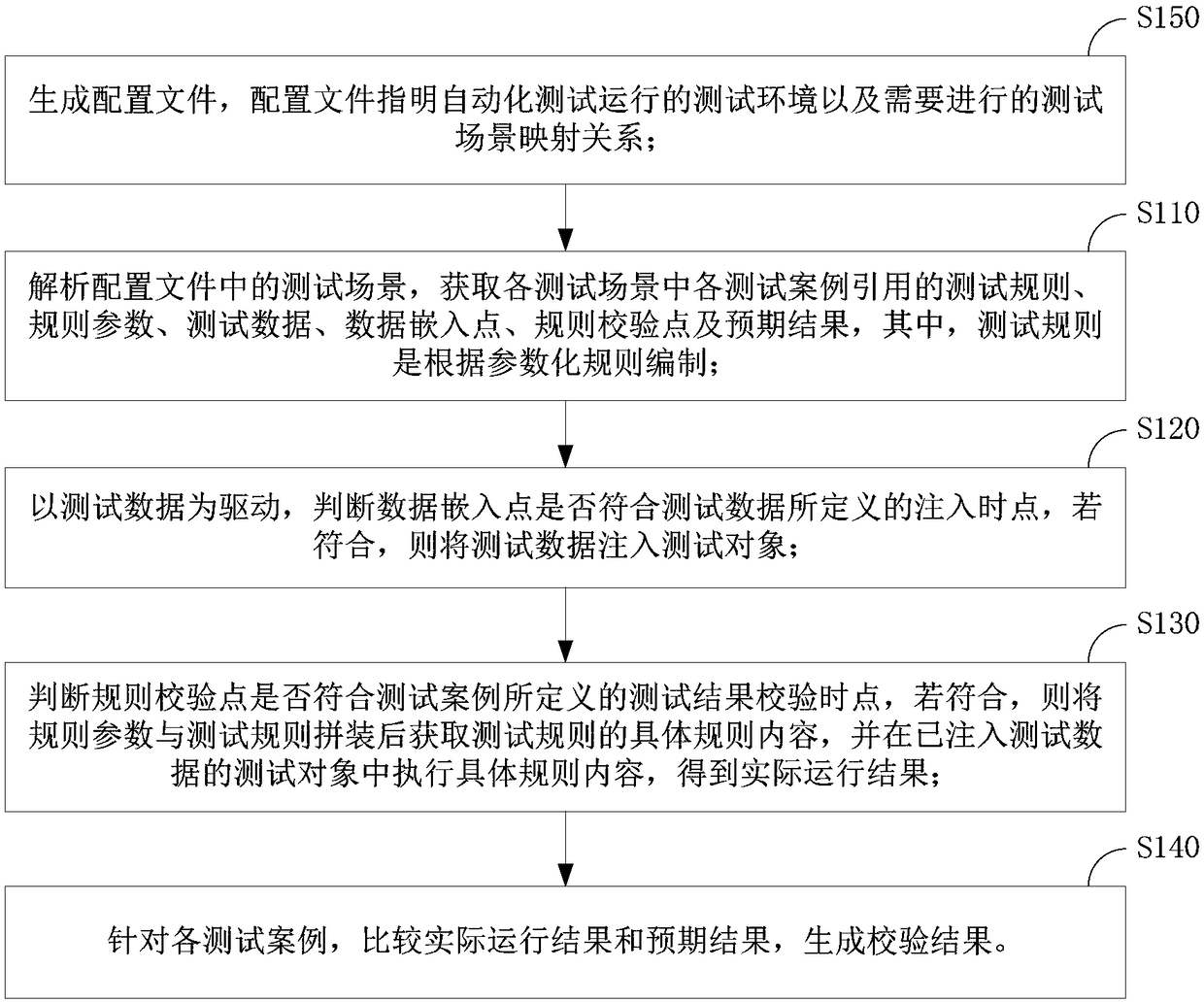

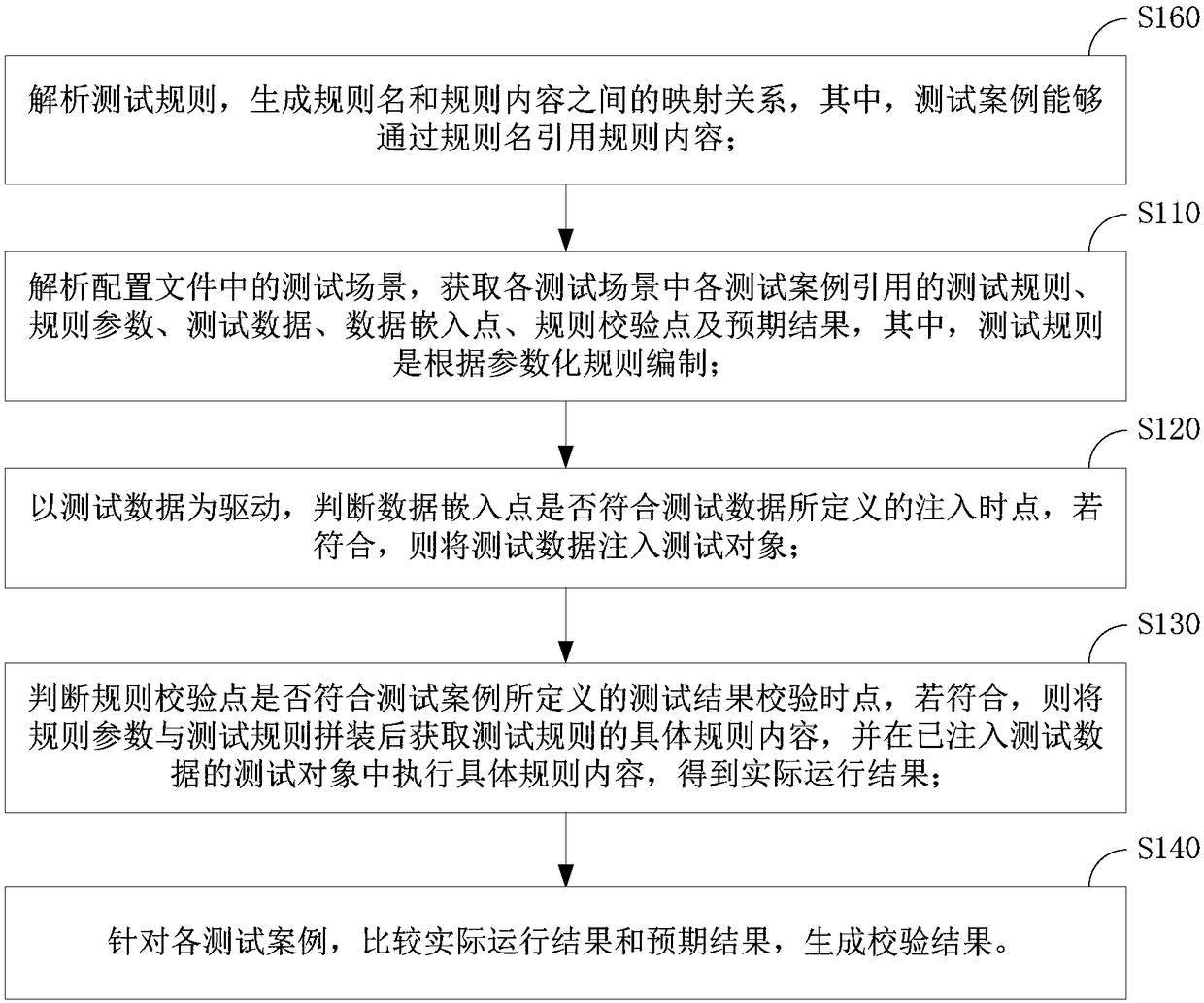

Automated test assertion method and device, storage medium and equipment

ActiveCN108614770AImprove reuse rateImprove maintainabilitySoftware testing/debuggingTest scriptCheck point

The invention provides an automated test assertion method and device, a storage medium and equipment. The method includes: obtaining test rules, rule parameters, test data, data embedding points, rulechecking points and expected results of all test case in a test scene, wherein the test rules are compiled according to parameterization rules to be used for multiple test scenes or multiple test cases; using test data as a drive to judge whether a data embedding point meets an injection time point defined by the test data, and if yes, injecting the test data into a test object; judging whether arule checking point meets a test result checking time point defined by a test case, and if yes, assembling unique test parameters and test rules of the test case, and then obtaining specific rule contents of the test case, and executing the specific rule contents in the test object, into which the test data are already injected, to obtain an actual running result; and comparing actual running results and the expected results for all the test cases to generate a checking result. The method can improve a test script reuse rate.

Owner:INDUSTRIAL AND COMMERCIAL BANK OF CHINA

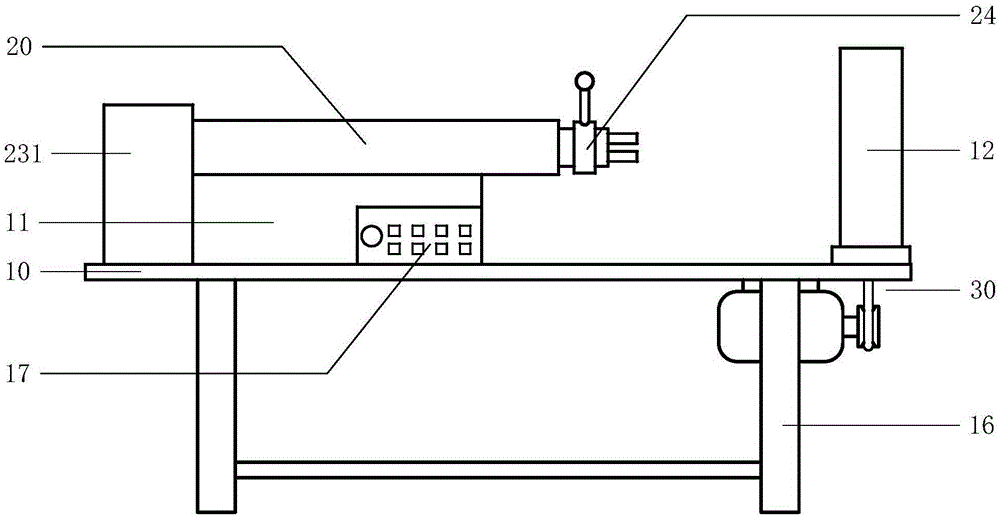

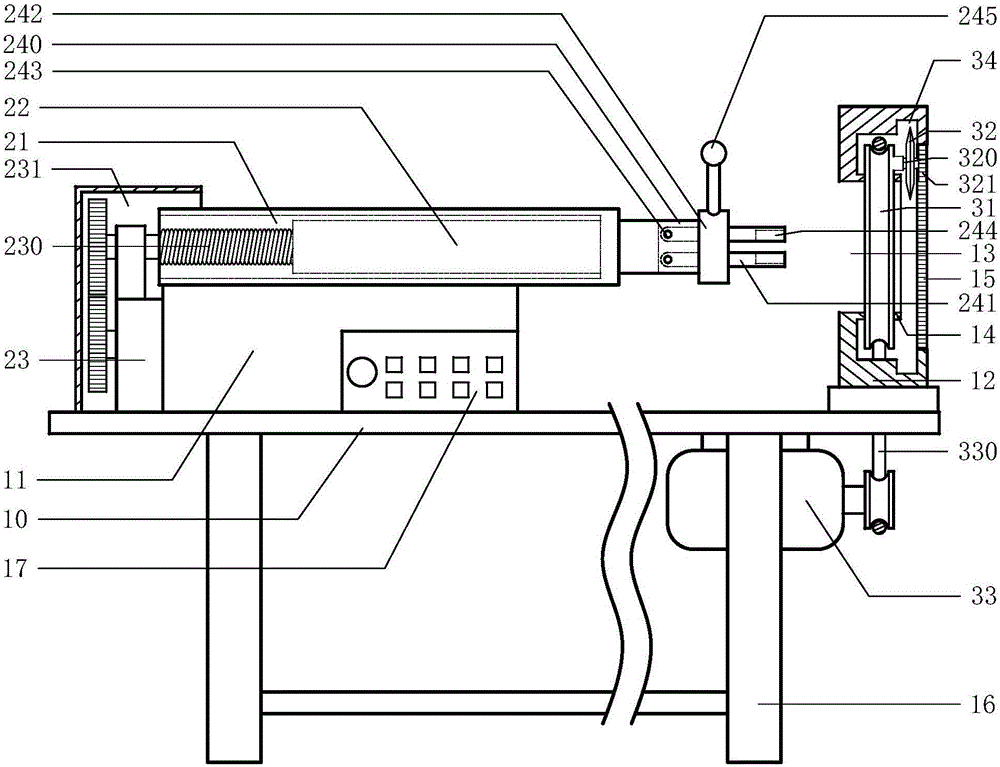

Plastic bottle cutter

A plastic bottle cutter comprises a working operation table, a transverse bottle pushing machine and an annular bottle cutting machine. A push-pull machine frame is arranged at one end of the working operation table. A cutting machine frame is arranged at the other end of the working operation table. The transverse bottle pushing machine is installed on the push-pull machine frame and structurally comprises a positioning sleeve, a telescopic ejector rod and a telescopic driving machine. A bottle mouth opening and closing clamp is arranged at one end of the telescopic ejector rod. The annular bottle cutting machine comprises a wheel type cutter rest, an annular cutter and a rotary wheel driving machine. Plastic bottles are cut into various specifications of plastic strips through the annular cutter, the plastic strips are used for weaving vegetable baskets, shopping bags, package bags, foot pads, vehicle mats and other daily supplies, environment pollution can be reduced, and life of people can be facilitated. Thus, the plastic bottle cutter is reasonable in structure, easy to control and capable of increasing the plastic bottle reuse rate.

Owner:固镇县涛声农机技术有限公司

Video synthesis method, video playing method, video modification method, video synthesis system and equipment

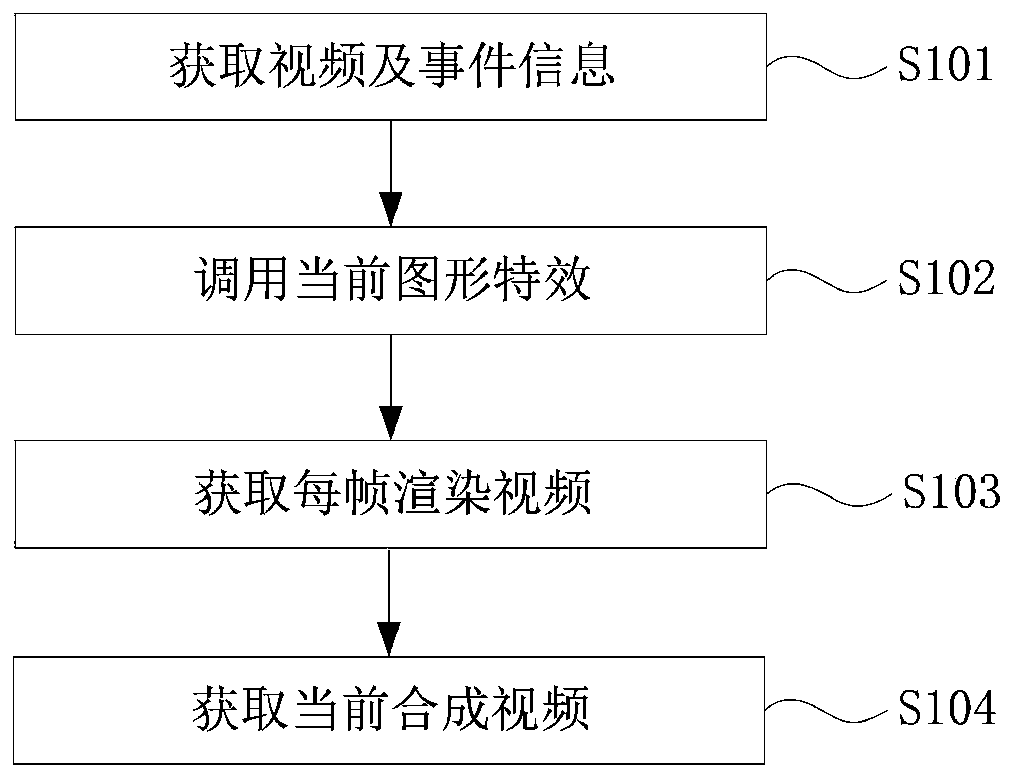

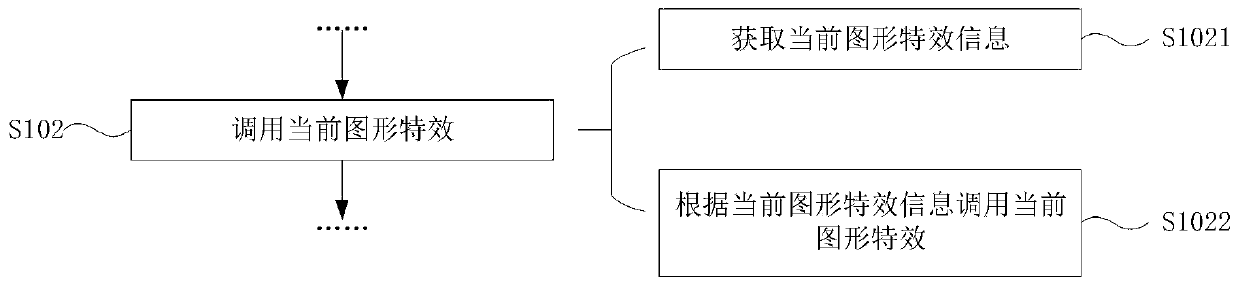

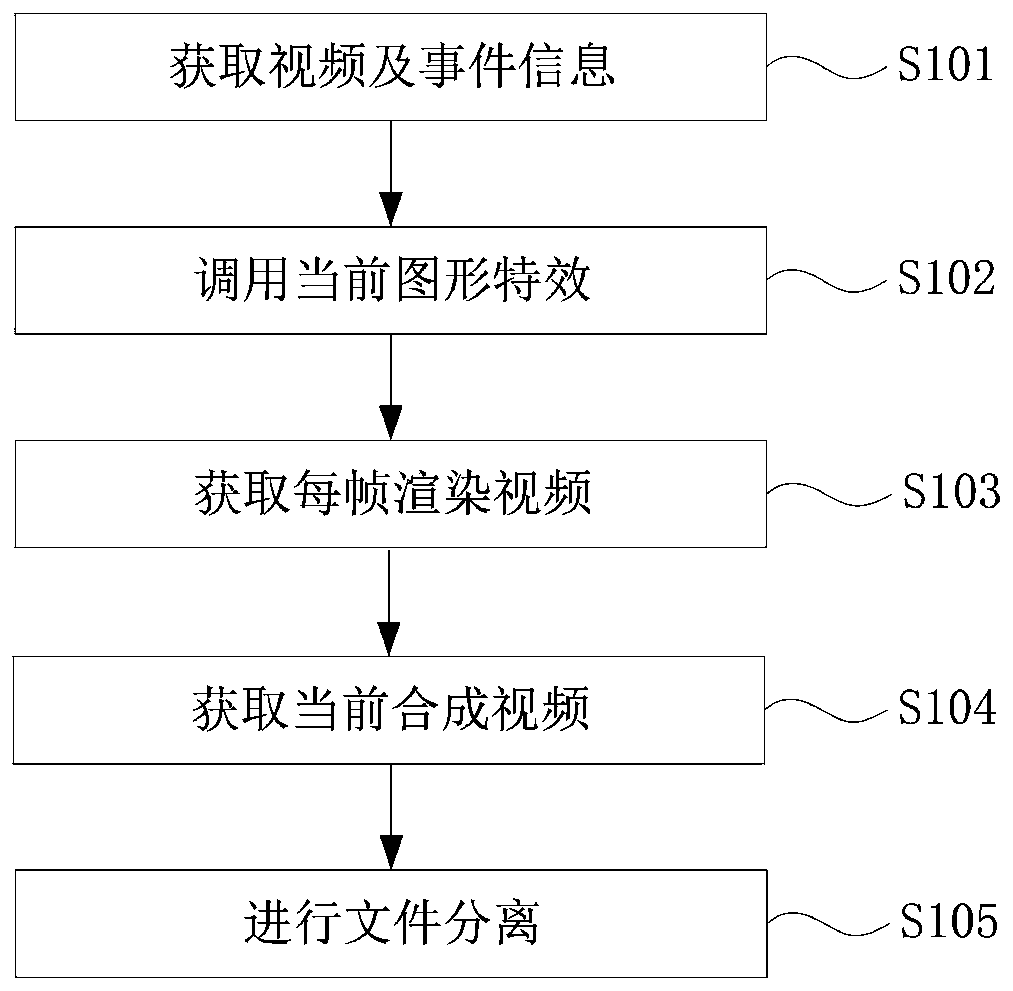

InactiveCN110049371AIncrease diversityImprove interactivityTelevision system detailsColor television detailsGraphicsSynthesis methods

The invention discloses a video synthesis method. The method comprises the steps of obtaining each frame of video and obtaining current event information corresponding to each frame; and calling the current graphic special effect according to the current event information; rendering each frame of video corresponding to the current graphic special effect according to the current graphic special effect to obtain each frame of rendered video; synthesizing each frame of video and each frame of rendered video according to the recording time line to obtain a current synthesized video. The inventionalso discloses a video synthesis method, a video playing method, a video modification method, a video synthesis system and video synthesis equipment. Event information and special effect information are classified, so that short videos or videos can be edited after being synthesized or uploaded to a network, and the reuse rate of recording materials is increased. Meanwhile, the dynamic special effect can be multiplexed when the video is played, so that the dynamic interaction can be realized when the video is played, and the diversity and interactivity of video display are improved.

Owner:北京比特星光科技有限公司

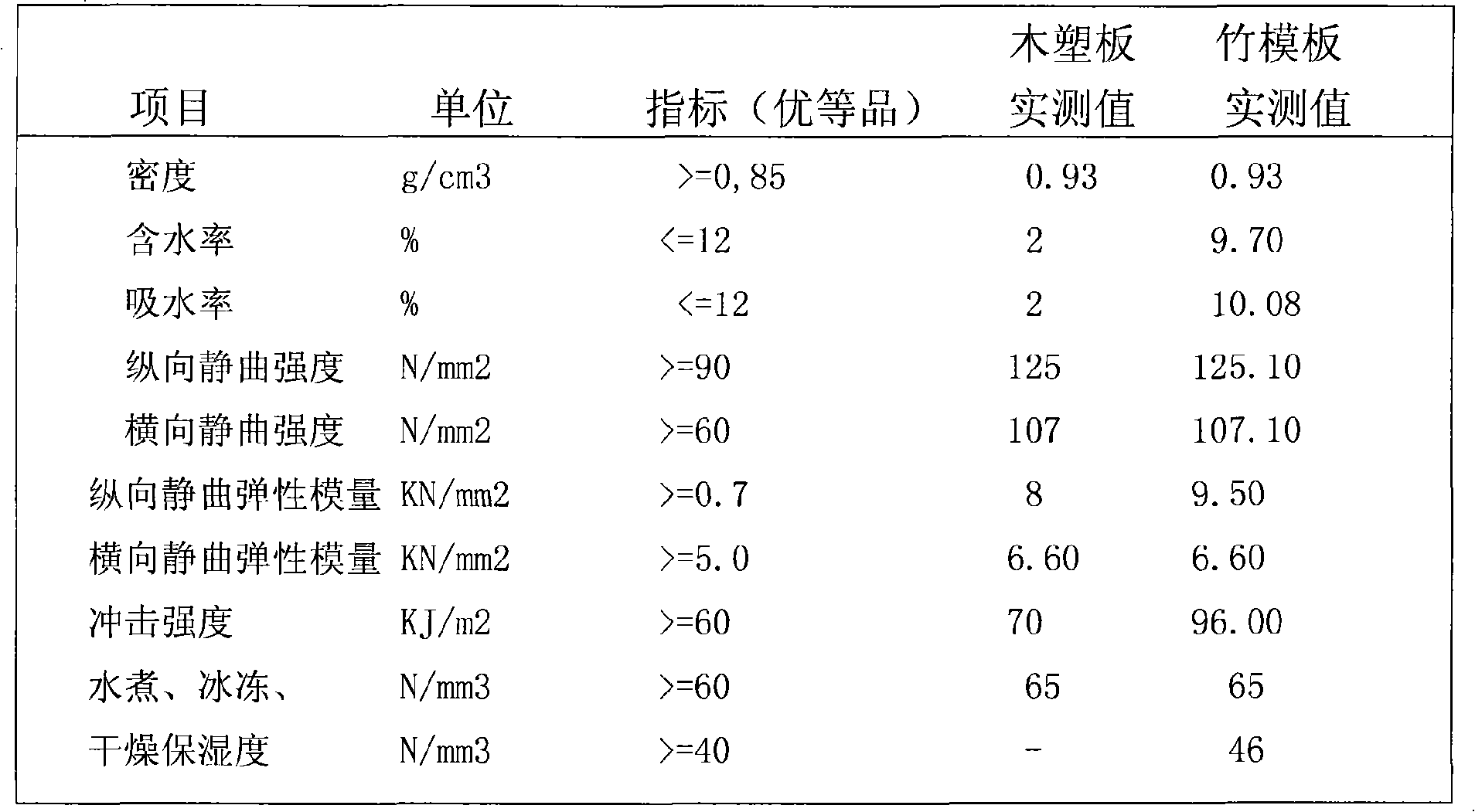

Wood plastic boards and method for making same

The invention discloses a wood-plastic board material and a production method thereof. The material is produced by a raw material with the following weight portions: 50 to 70 portions of polyethylene and polypropylene, 20 to 40 portions of crushed straw, old clothes and chemical fiber scrapped parts, 5 to 8 portions of slag powder or clinker, and 0.2 to 0.5 portion of additive. The production method is as follows: the blending-pulverizing is performed, and the weighing pavement is carried out after the crushing; the raw material is sent into a hotpress at a temperature of between 130 and 190 DEG C and at the pressure of between 12 and 18MPa, for 20 to 30 minutes, the cooling shaping is performed at a dropped temperature of between 50 and 70 DEG C for 10 to 20 minutes, and the product is taken out after the hotpress is opened. The material has excellent performances such as flame retardation, heat insulation, water proofness, acid and alkali resistance and so on, does not use glue during the hot press molding, has no pollution of formaldehyde, no toxicity and no smell, can be reclaimed for 100 percent, has simple maintenance and high reuse rate, and is a decorative building material with high strength, good elasticity and bending resistance; and the production method has high finished product rate, simple process, less investment and energy conversation.

Owner:韩进军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com