Patents

Literature

934 results about "Membrane technology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Membrane technology covers all engineering approaches for the transport of substances between two fractions with the help of permeable membranes. In general, mechanical separation processes for separating gaseous or liquid streams use membrane technology.

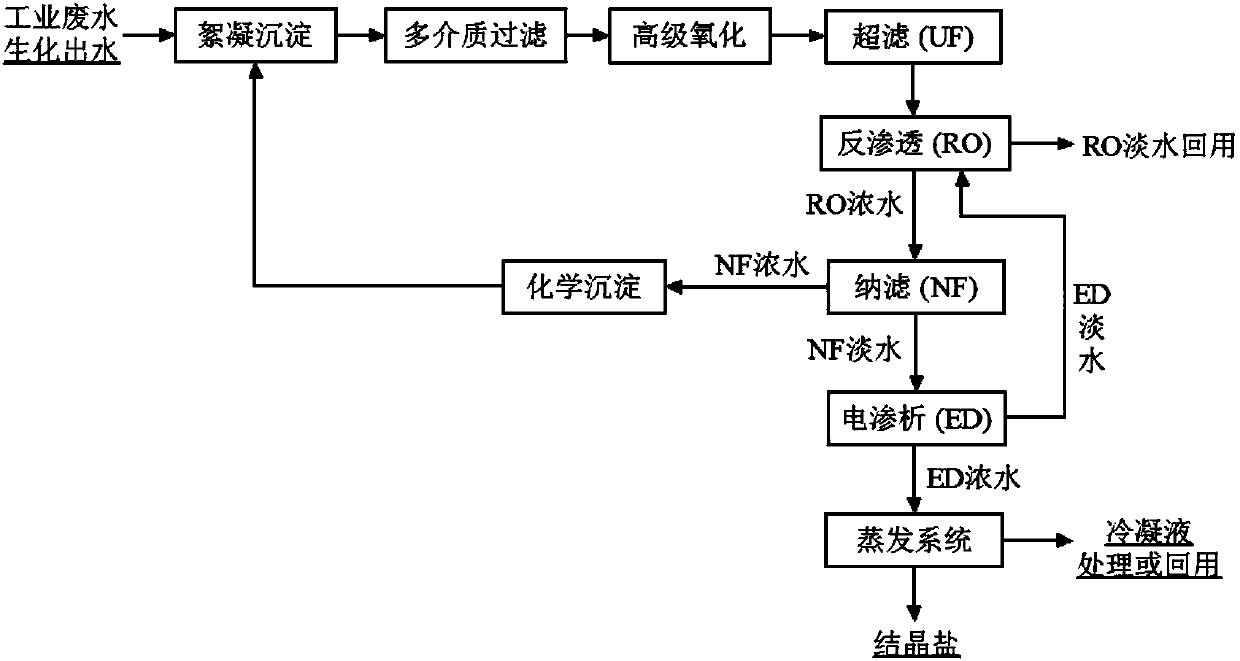

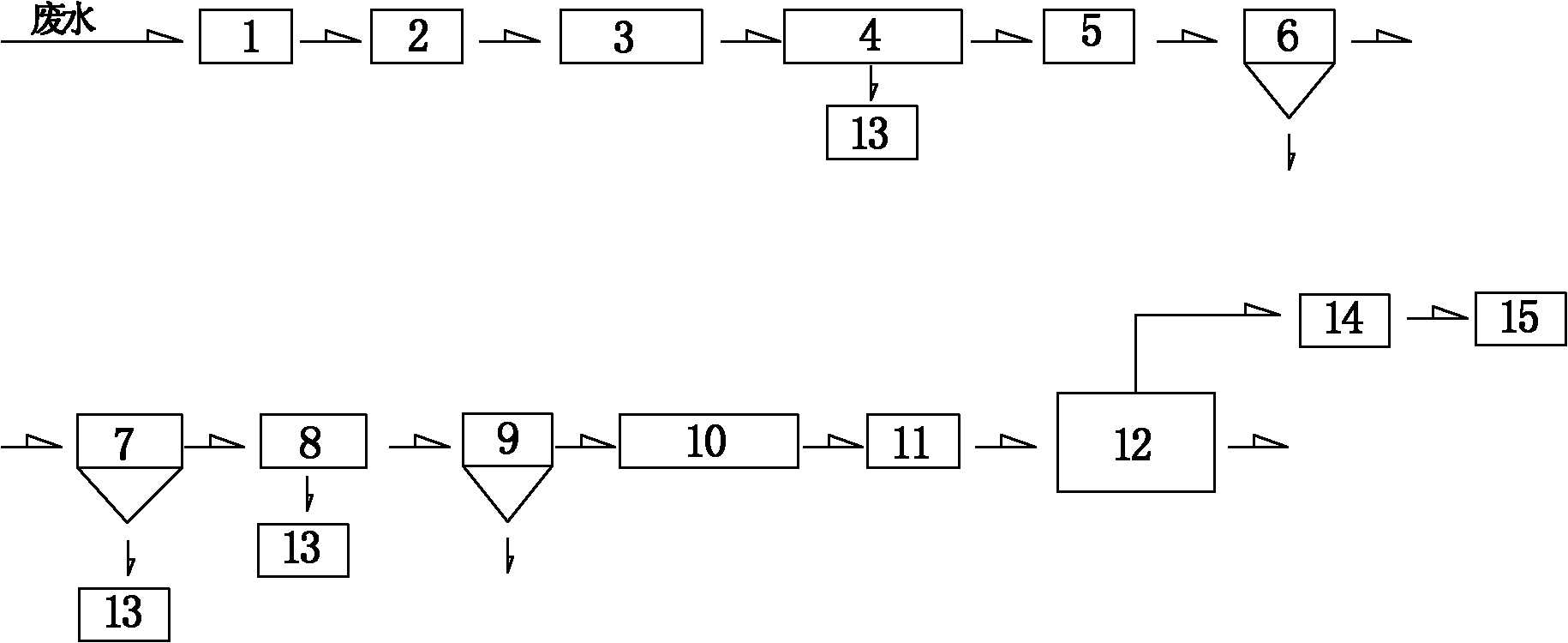

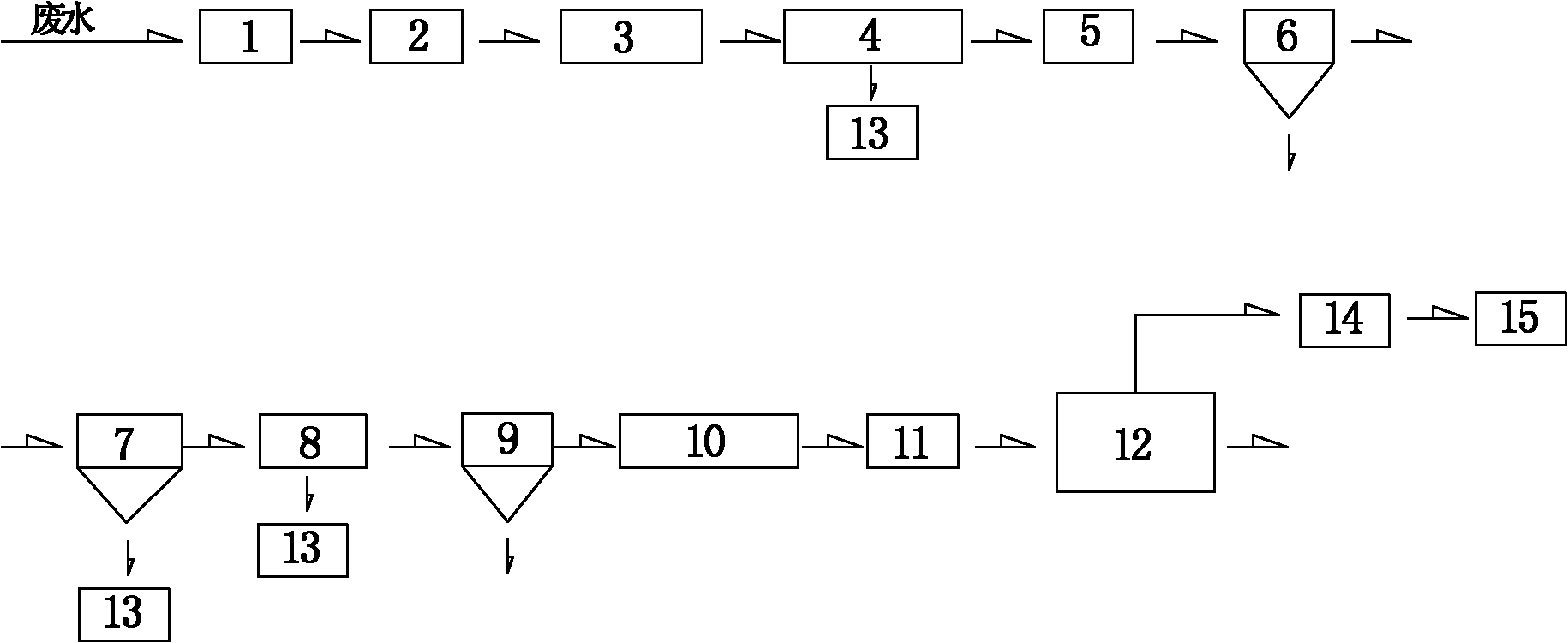

Treatment system and treatment method for biochemical effluent of industrial wastewater

InactiveCN107651794AEfficient removalHigh recovery rate of fresh waterGeneral water supply conservationTreatment involving filtrationHigh concentrationFiltration

The invention provides a treatment system and treatment method for biochemical effluent of industrial wastewater. The treatment system comprises a flocculation sedimentation unit, a filtration unit, an advanced oxidation unit, an ultrafiltration unit, a reverse osmosis unit, a nanofiltration unit, an electrodialysis unit and an evaporation unit which are sequentially connected; and the water production outlet of the ultrafiltration unit is connected with the water inlet tank of the reverse osmosis unit, and the concentrated-water outlet of the reverse osmosis unit is connected with the water inlet of the nanofiltration unit. According to the invention, the treatment system and the treatment method utilize the coupling and synergistic effects of a physical-chemical method and a membrane technology to overcome the limitation of using a single technology, and the advanced treatment and desalination reuse of the industrial wastewater are realized; and the treatment system and the treatmentmethod have the advantages of strong adaptability to raw water, a high recovery rate of fresh water, a high concentration multiple of concentrated water, low energy consumption of evaporation and crystallization and the like, greatly improve the reuse rate of the industrial wastewater, reduce the amount of wastewater discharging, can be applied to the deep treatment and desalination reuse of various effluent wastewater, and promote the promotion and application of the technology in related industries.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

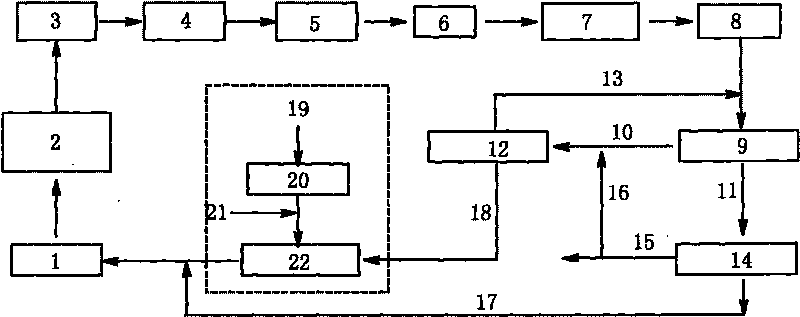

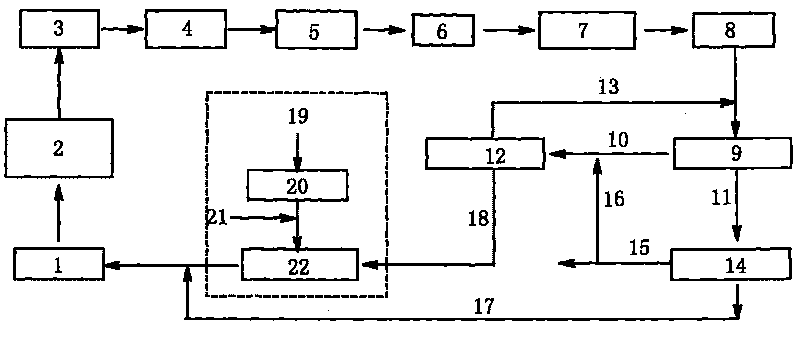

Method for producing propylene oxide

ActiveCN101735177AReduce investmentAchieve recyclingOrganic chemistryDispersed particle separationProcess designSodium hydroxide

The invention discloses a chemical production method, in particular a novel green production process for propylene oxide. In the method, the process design is carried out by using bipolar membrane, electrodialysis, antiosmosis, air flotation, heat exchange, oxidation, and other technology. In the production process, sodium hydroxide replaces the conventional calcium hydroxide and generates sodium chloride through reaction; the sodium chloride generates hydrochloric acid and sodium hydroxide by the bipolar membrane technology; and the hydrochloric acid is recovered, and the sodium hydroxide and water can be recycled. Therefore, no new sodium hydroxide is needed and no wastewater is discharged in the production of the propylene oxide. The sodium hydroxide is added at the preliminary stage of the production of the propylene oxide, and the input amount of the sodium hydroxide is controlled between 5 and 15 percent. The novel green production process for the propylene oxide has the advantages that: the recycling of the water, sodium chloride and sodium hydroxide is realized, the effects of zero discharge and input reduction of production materials are substantially achieved, and finally better social and economic benefits are achieved. The novel green production process for the propylene oxide can be widely applied to the chlorohydrin production in China.

Owner:HANGZHOU WATER TREATMENT TECH DEV CENT

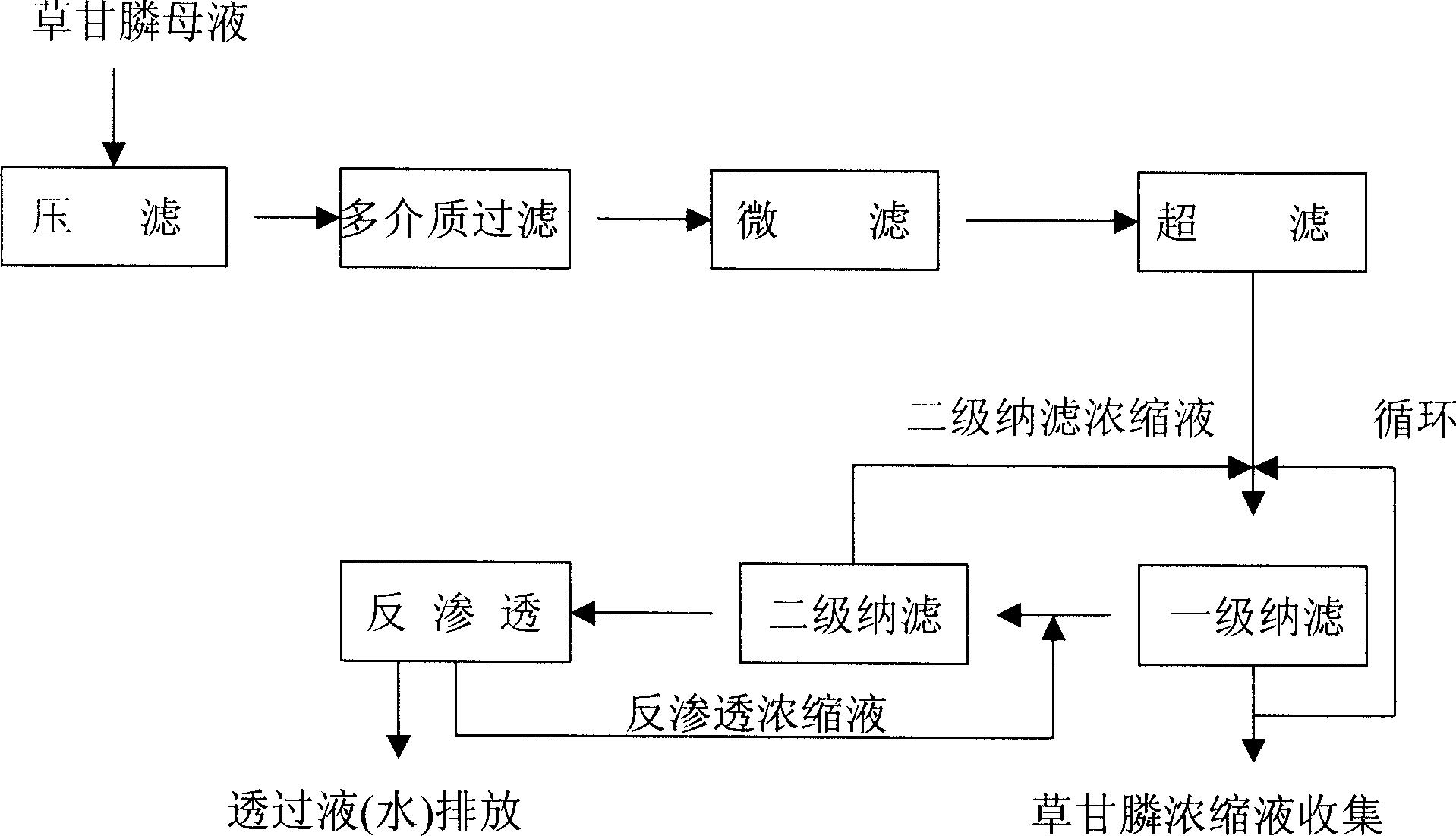

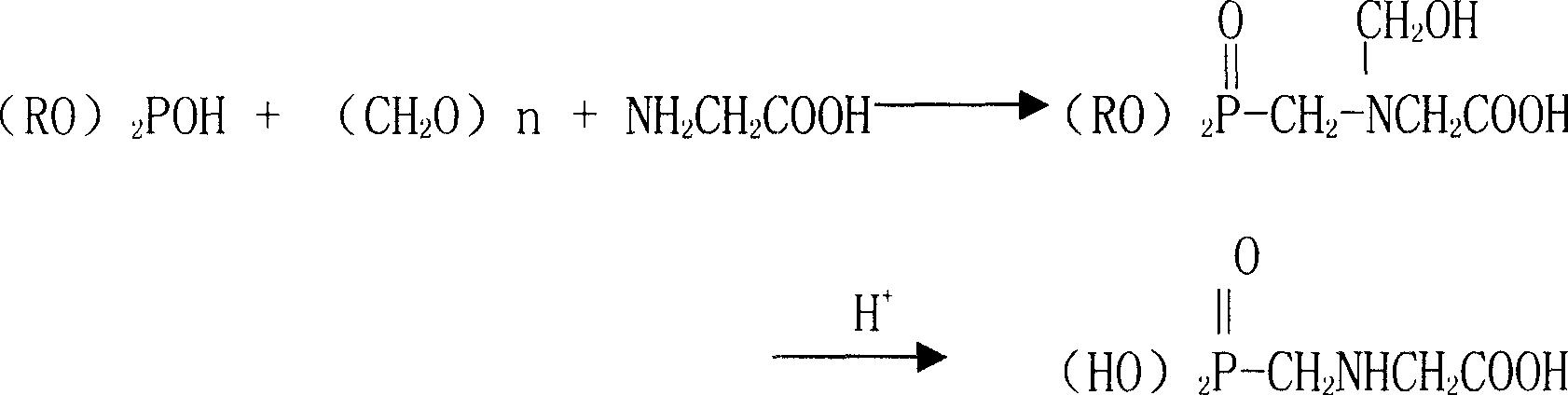

Process for separation and purification of glyphosate from glyphosate solution by membrane technology

InactiveCN1827626AAvoid decompositionQuality improvementBiocideGroup 5/15 element organic compoundsSolid componentDecomposition

The invention discloses a method for extracting glyphosate from heavy glyphosate stock solution by membrane separation technique. It consists of filtering the mother liquid, removing the solid component of the system, then according to the molecular structure, molecular mass, particle size and electric charge, from the big one to the small one, separating step by step by selecting appropriate hyperfiltration membrane, nanofiltration membrane and reverse osmosis membrane to obtain the effective composition of glyphosate. The invention unitizes the separation, concentration and the purification, and is performed at normal temperature. The barrier separation process is excellent in that it is of no change of phase, avoids the decomposition of glyphosate caused by high enrichment and concentration, effectively improves the product quality and yield rate, greatly reduces the energy consumption, is of consecutive operation, low operation cost, and it is energy-saving, highly effective, environment-friendly, furthermore, it can be operated by combining with routine thickening operating unit or be operated individually and is suitable for industrial continuous production.

Owner:捷马化工股份有限公司

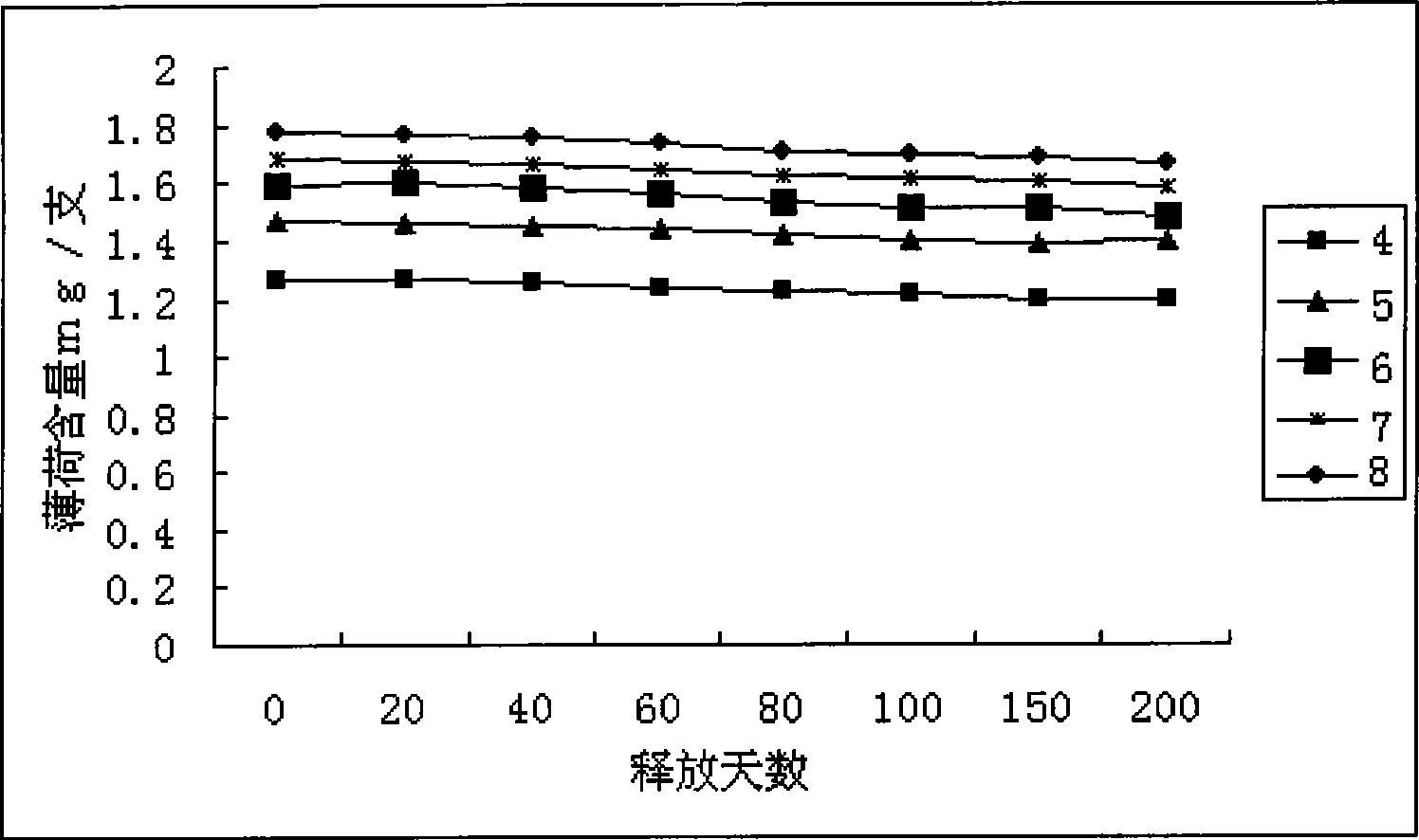

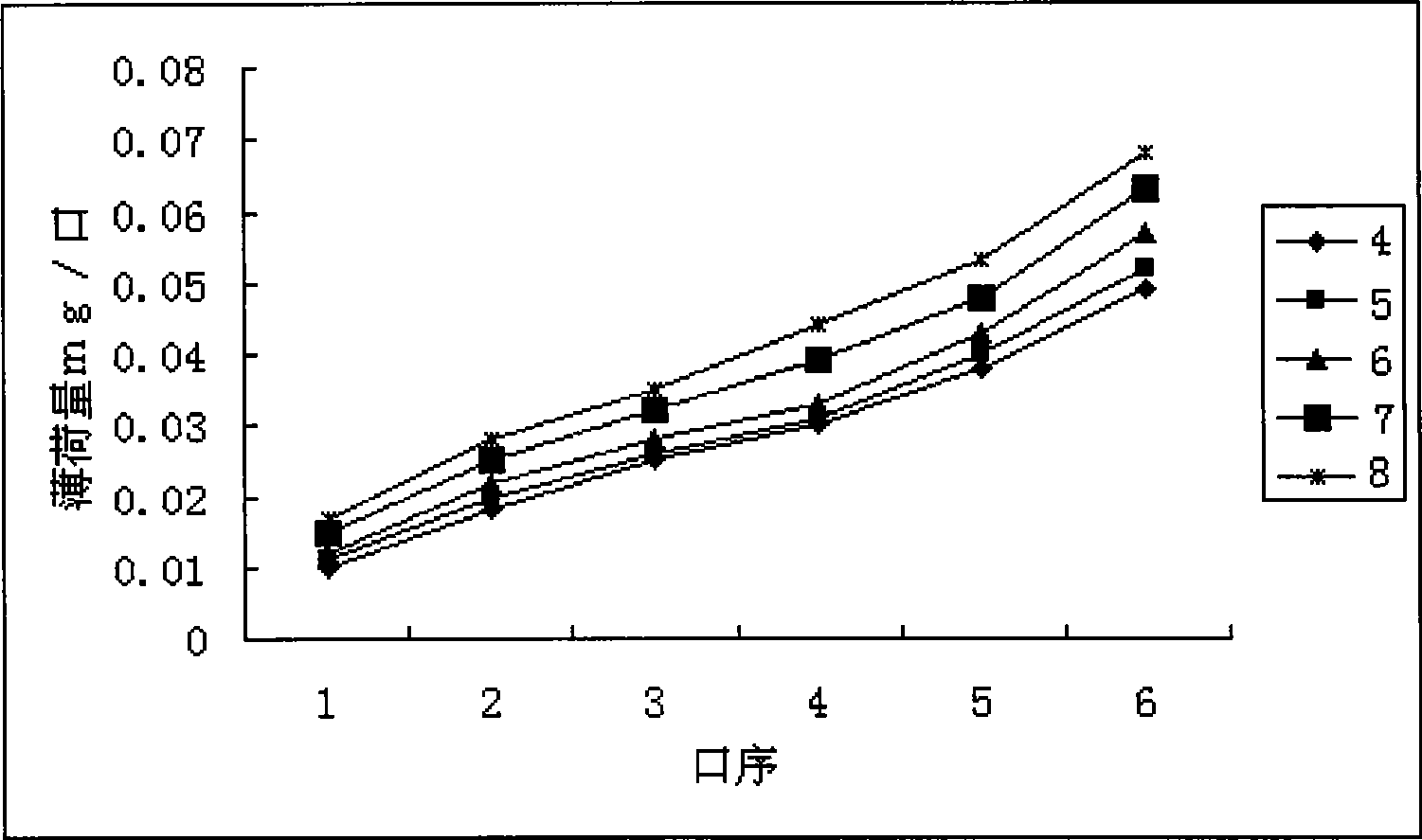

Cigarette filter tip rod capable of sustained releasing mint and production technique thereof

ActiveCN101390657AReduce volatilitySimple processTobacco smoke filtersMembrane technologyRoom temperature

The invention discloses a mint-releasing cigarette filter tip and a production technique thereof, relating to a cigarette filter tip and the production technique thereof. The mint-releasing cigarette filter tip contains tow material in which cotton thread infused with mint essence solution is wrapped; film-forming material solution is adsorbed at the outer layer of the cotton thread infused with mint essence solution; mint essence is added in the film-forming material solution; and the film-forming material includes natural macromolecular material and synthetic macromolecular material. The mint-releasing cigarette filter tip has the advantages that: 1, adopting membrane technology, mint is low in volatility at room temperature, so the mint can be effectively released when taking the cigarette;2, the production technique is simple; 3, the mint-releasing cigarette filter tip is not changed in performance; 4, the mint-releasing cigarette filter tip can be preserved for more than one year at room temperature; 5, the mint-releasing cigarette filter tip is low in cost.

Owner:HUBEI CHINA TOBACCO IND

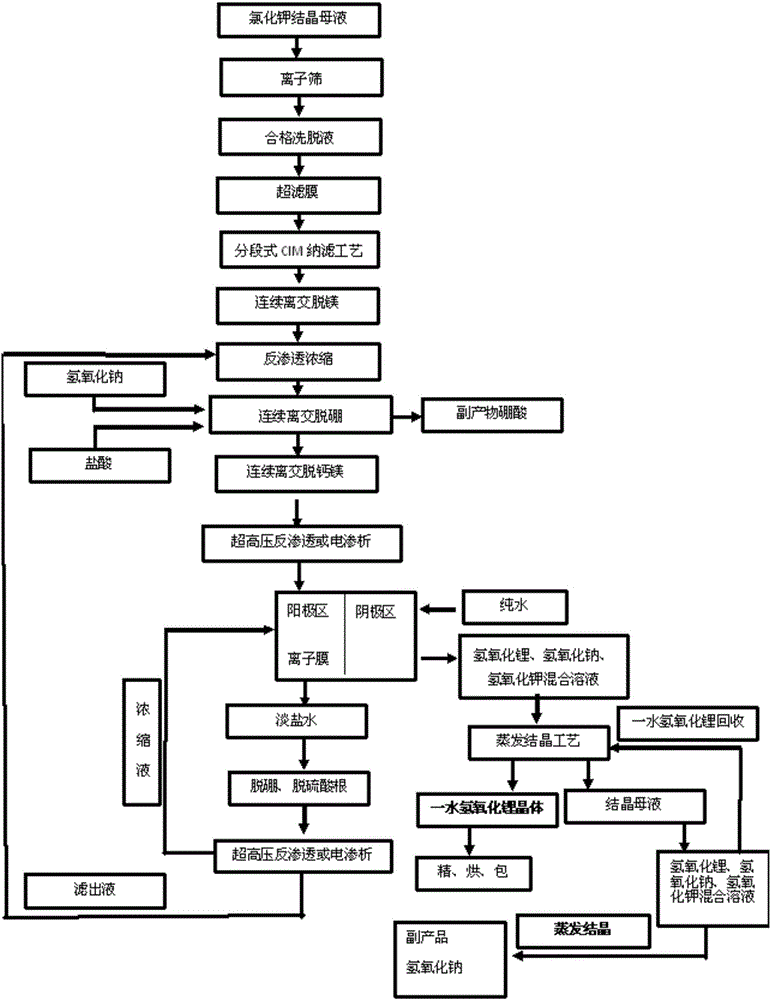

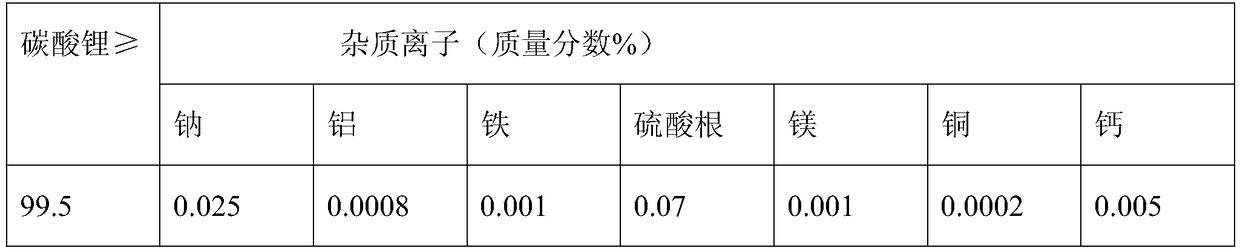

Production method of high-purity lithium hydroxide

ActiveCN106011917AHigh yieldReduce consumptionCellsBoron-oxygen compoundsLithium hydroxideUltrafiltration

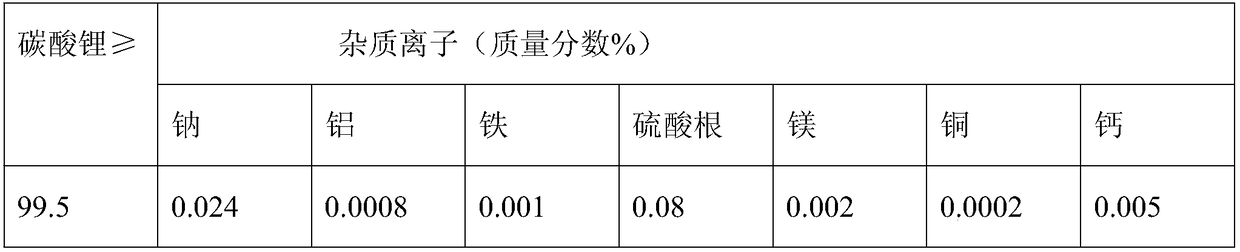

The present invention relates to a production method of high-purity lithium hydroxide. A crystallization mother liquor waste water is obtained after production of potassium chloride by using a salt lake bittern as the raw material, a magnesium-lithium ratio of the crystallization mother liquor waste water is 200-500:1, an eligible eluant is obtained through ion sieve adsorption and elution of the crystallization mother liquor waste water, and after treatment of the eluant through the ultrafiltration membrane technology, the sectional type nanofiltration technology, the external regeneration continuous hybridization technology and the reverse osmosis technology, a reverse osmosis concentrated solution is obtained. In the reverse osmosis concentrated solution, the content of magnesium ions is <=300 ppm, the content of lithium ions is 4-6 g / L, the content of sodium ions is 3-5 g / L, the content of calcium ions is <=5 ppm, the content of sulfate ions is 1-30 ppm and the content of boron is <=400 ppm. According to the production method provided by the present invention, the reverse osmosis concentrated solution is used as the raw material, the process comprises ultrahigh pressure reverse osmosis continuous hybridization for boron-removing, continuous hybridization for sulfate radical removing, ion-exchange membrane electrolysis, and crystallizing evaporation, and by using the hybridization boron-removing technology, the ion-exchange membrane electrolysis technology and the crystallizing evaporation technology, the high-purity lithium hydroxide is obtained, with the byproducts being the boric acid and sodium hydroxide. The process is continuous, controllable, high in extraction rate, low in production cost and easy to industrialize.

Owner:启迪清源(上海)新材料科技有限公司

Preparation technology of xylose

ActiveCN103409565AReduce manufacturing costReduce conductivitySaccharides productionUltrafiltrationHydrolysate

The invention provides a preparation technology of xylose, which mainly comprises the following technical steps: hydrolyzation, ultrafiltration purification, primary decoloring, electrodialytic deacidification and desalination, membrane concentration, primary evaporation and concentration, secondary decoloring, ion exchange refined desalting, secondary evaporation and concentration, crystallization, centrifugation, and drying to obtain a finished product xylose crystal. The technology has the advantages that the membrane technology is used to remove macromolecule impurities of colloid, protein, and the like in xylose hydrolysate, electrodialytic deacidification and desalination technology is used to lower the electric conductivity of an xylose solution, and meanwhile, neutralization and positive-negative-positive resin combined one-step purification process is removed to simplify the technical process; therefore, the manufacturing cost of xylose is lowered, meanwhile, the waste water discharge load of the manufacturing of xylose can be allowed to be lowered by more than 40%, and well environmental benefits and economic benefits are achieved.

Owner:SHANDONG FUTASTE

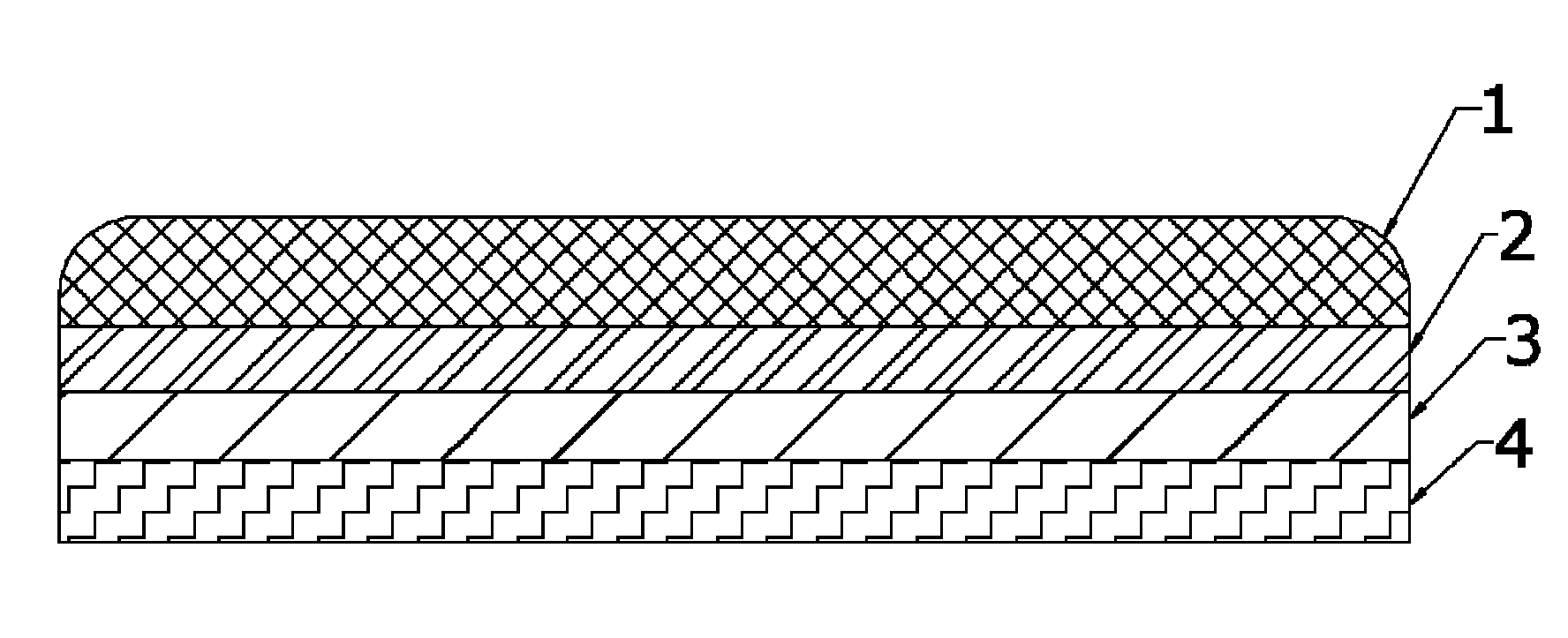

Preparation method and application of graphene oxide composite membrane

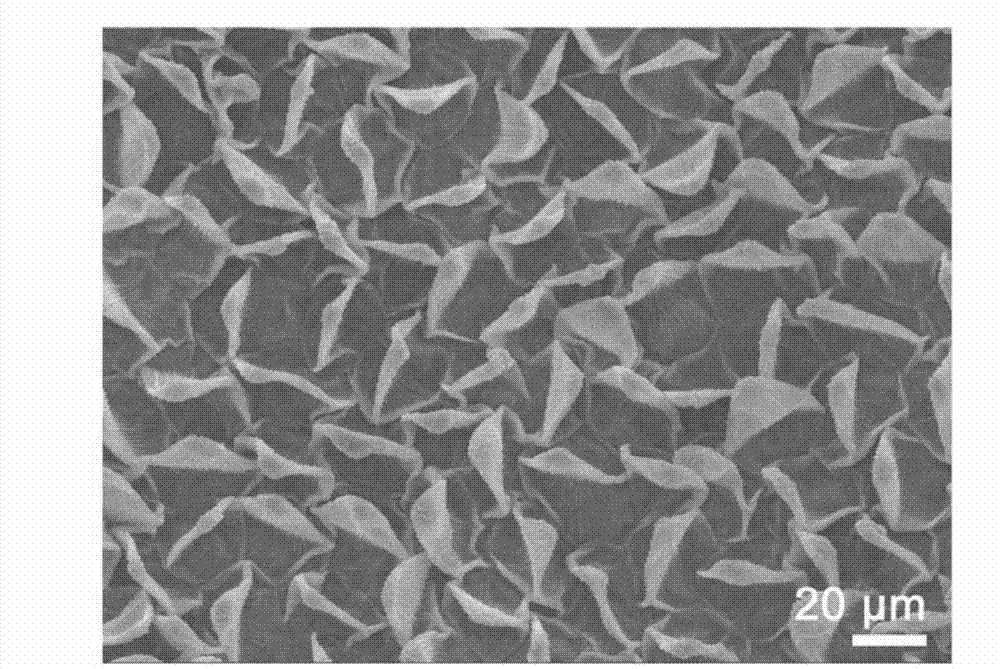

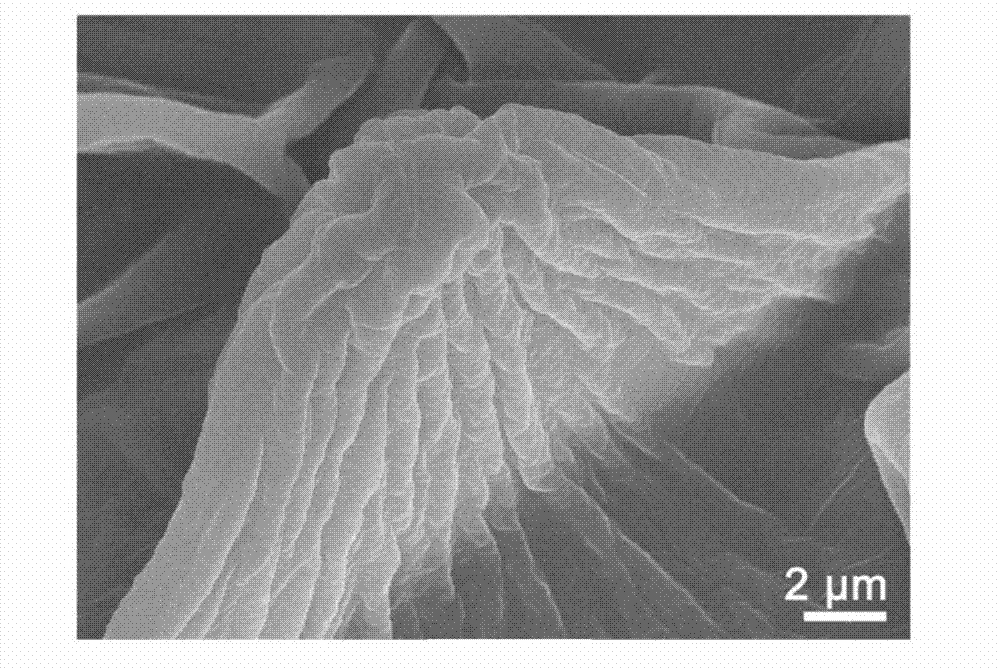

InactiveCN105727758AAdjustable spacingImprove performanceSemi-permeable membranesDispersed particle separationGas separationHummers' method

The invention discloses a preparation method and application of a graphene oxide composite membrane, and belongs to the technical field of gas separation membranes.The preparation method of the graphene oxide composite membrane comprises the steps that an aqueous dispersion liquid of graphene oxide is prepared through a Hummer method, and ultrasonic dispersion is conducted; metal salt or oxysalt is added, and heating and mixing are conducted; the surface of a micro-filtration membrane is covered with the prepared dispersion liquid through a vacuum filtration method; the membrane is put into a drying oven to be dried.The preparation method of the graphene oxide composite membrane has the advantages that the preparation method is simple, the thickness of the obtained membrane is smaller than 10 nm, the space between graphene sheet layers is adjustable, the obtained composite membrane is used for gas separation and has excellent comprehensive performance.Particularly, the graphene oxide composite membrane prepared from sodium tetraborate has high CO2 permeation flux and CO2 / CH4 and CO2 / N2 selectivity, and it is obtained through mixed gas tests under the humidifying condition that the CO2 permeation flux can reach 650 GPU, CO2 / CH4 selectivity is 75, and CO2 / N2 selectivity is 58.

Owner:TIANJIN UNIV

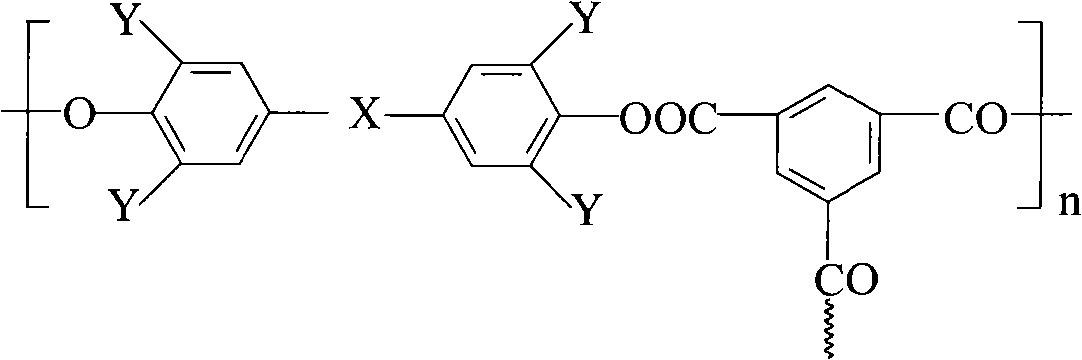

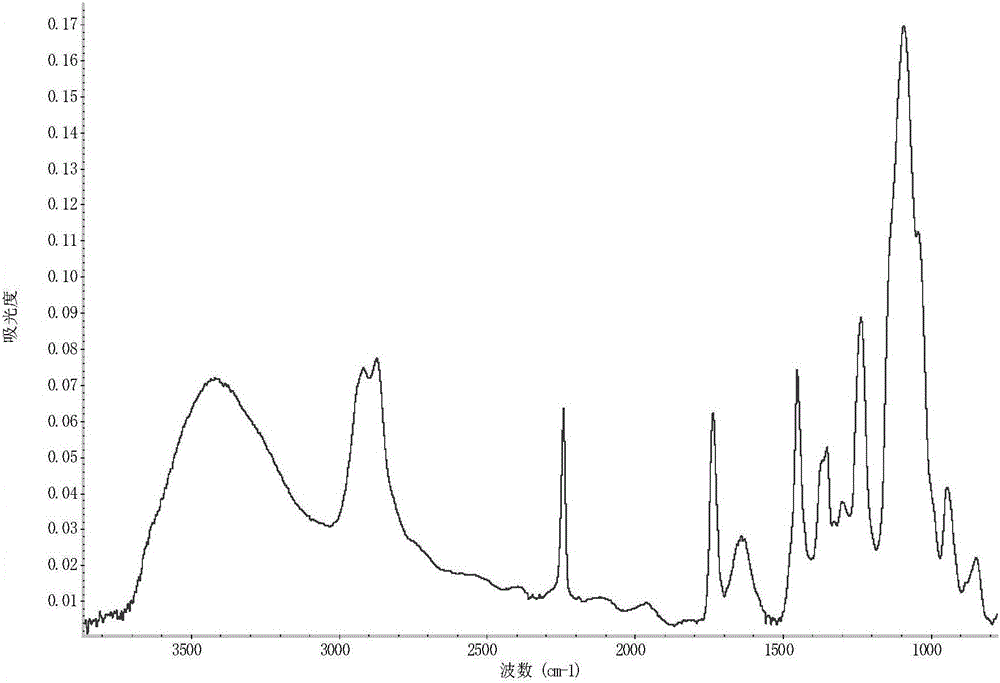

Carbon nano tube-polymer composite nanofiltration membrane and preparation method thereof

InactiveCN101890315AExcellent permeabilityExcellent selectivitySemi-permeable membranesMembrane technologyMembrane surface

The invention belongs to the field of membrane technology, and particularly relates to a carbon nano tube-polymer composite nanofiltration membrane and a preparation method thereof. The composite nanofiltration membrane is obtained by forming a layer of aromatic polymer functional cortex loaded with carbon nano tubes on a porous support membrane through the method of the invention. By using the method of the invention, the carbon nano tubes can be effectively loaded in the polymer functional cortex of a composite membrane, and the permeability and the selectivity of the prepared carbon nano tube-polymer composite nanofiltration membrane are superior to those of the membrane prepared by a traditional interfacial polymerization technology. The composite nanofiltration membrane surface functional cortex contains a great amount of carboxyl groups, and has higher permeability and desalinization ratio under a lower operation pressure. The preparation method of the invention has the advantages of simple operation process, mild reaction conditions, lower production cost and good application prospect of industrial production.

Owner:FUDAN UNIV

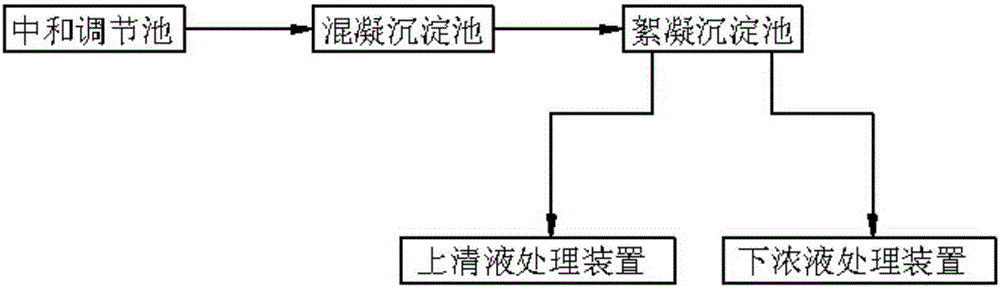

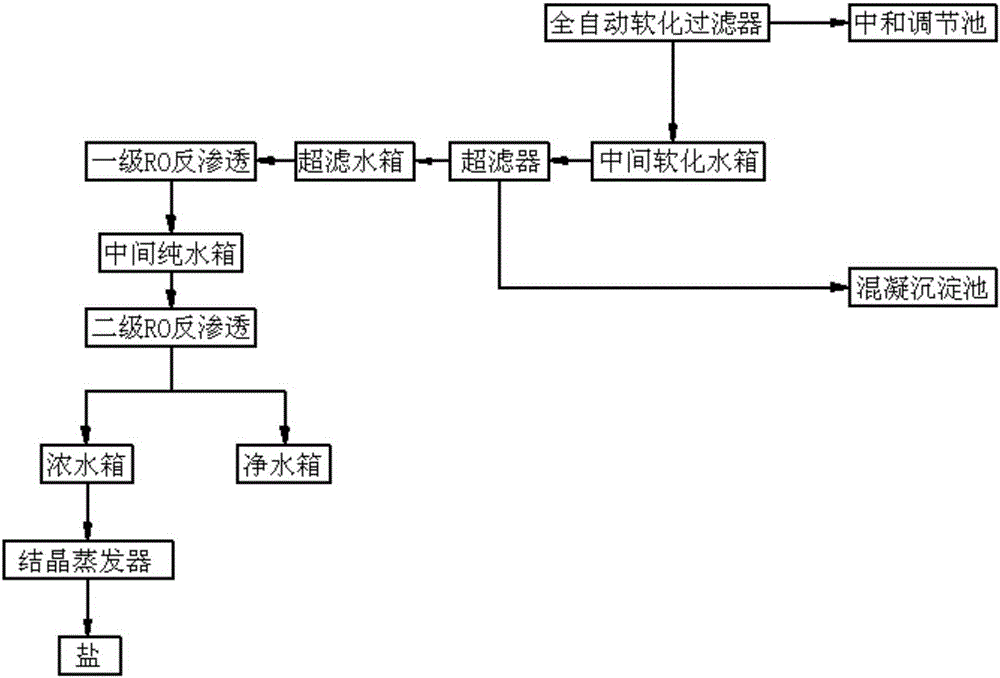

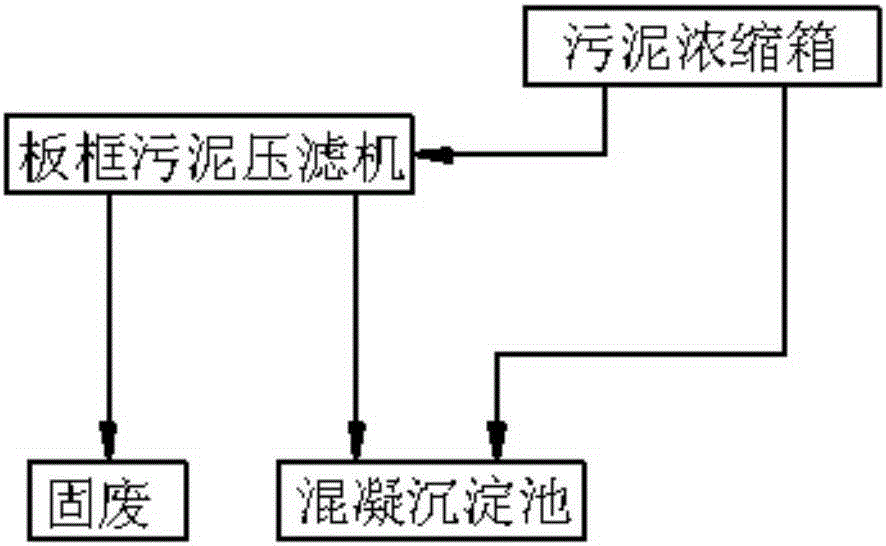

Desulphurization waste-water zero discharge processing system and technology

InactiveCN105174580AHigh removal rateReduce foulingSludge treatment by de-watering/drying/thickeningWaste water treatment from gaseous effluentsReverse osmosisSedimentation

A related desulphurization waste-water zero discharge processing system comprises a neutralization adjusting basin, a coagulation sedimentation basin and a flocculation sedimentation basin which are in successive connection. In the flocculation sedimentation basin, a supernatant formed in a specially-produced metering water channel flows into a supernatant processing device, and the lower dense liquid flows into a lower-dense-liquid processing device. The supernatant processing device comprises a full-automatic softening filter, an ultrafilter, a first-grade RO (reverse osmosis) device and a second-grade RO device; the outlet of the second-grade RO device is connected with a dense liquid tank and a pure water tank, pure water in the pure water tank is reusable, and a dense liquid in the dense liquid tank enters a crystallization evaporator for generating a salt. The lower-dense-liquid processing device discharges solid waste. Wastewater separated from a sewage concentration tank is discharged into the neutralization adjusting basin via a pipe for cyclic once-more processing. The technical scheme is combined with an advanced membrane technology, the technological flow is simple, energy-saving and environment-friendly, environment protection benefit is obviously increased, a new zero-discharge technology is realized, and the technical scheme possesses significant meaning on water pollution treatment.

Owner:天津市华通寰昊水务科技有限公司

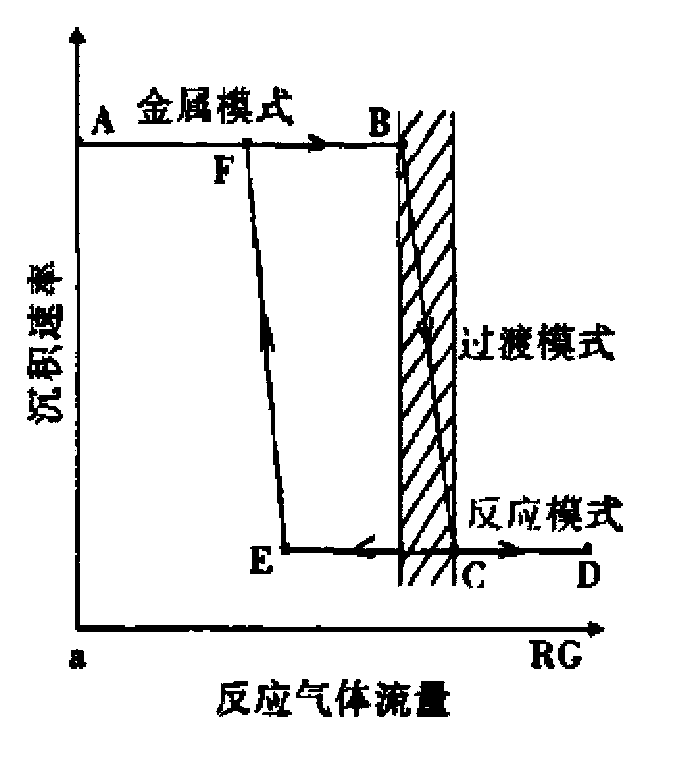

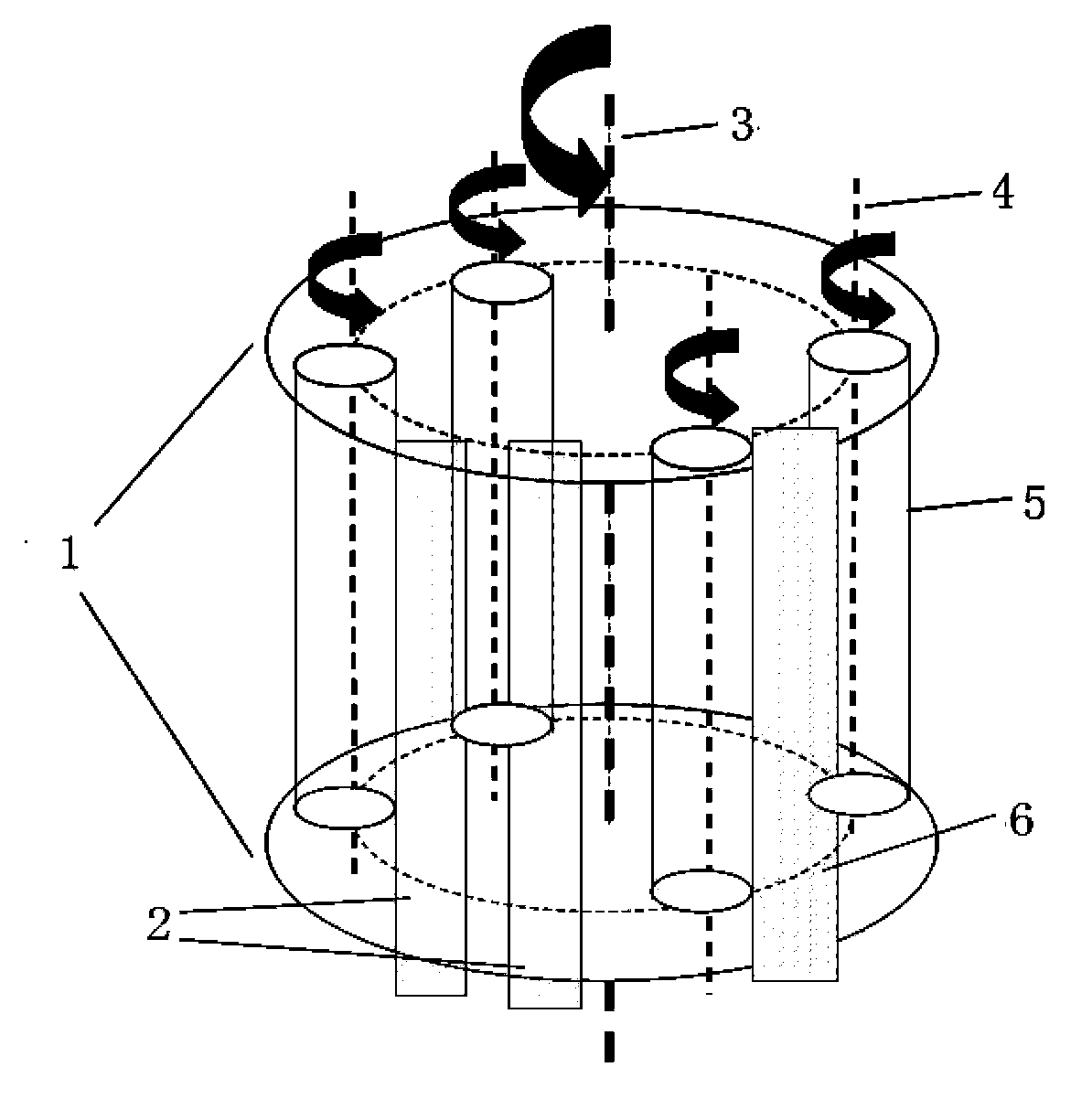

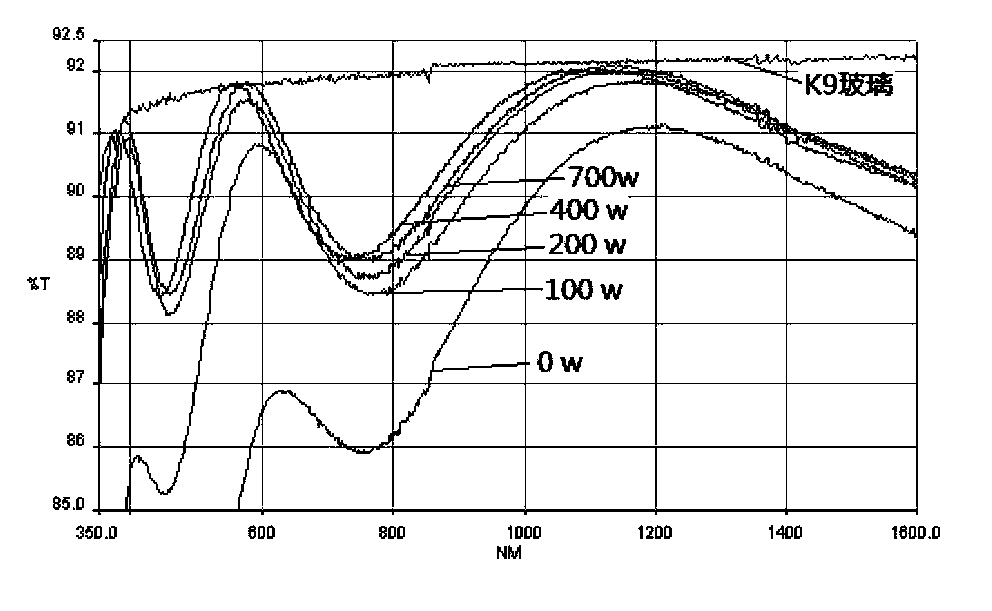

Plasma assisted magnetron sputtering depositing method

ActiveCN103668092ALow costStrong engineering magnificationVacuum evaporation coatingSputtering coatingIntermediate frequencyOptoelectronics

The invention relates to a plasma assisted magnetron sputtering depositing coating method. When a metal compound thin film is prepared by magnetron sputtering, in order to overcome target poisoning, anode disappearance and the like, an intermediate frequency or pulse direct current reaction magnetron sputtering method is common adopted. The invention provides a novel plasma assisted depositing method, wherein a plasma discharge area is additionally arranged in a vacuum chamber, a work rest rotates at a high speed along with a revolution plate which revolves at the same time, and when a workpiece rotates through the plasma discharge area, combination reaction is further carried out on the incompletely reacted ultrathin thin film and gas ions to obtain a compound thin film with a higher stoichiometric ratio, so that the depositing rate of the thin film is greatly improved. Compared with conventional plasma source assisted depositing technologies, the novel plasma generating technology provided by the invention is lower in cost and easy to amplify, can be used for the field of industrialized production on a large scale, and has an important application prospect.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

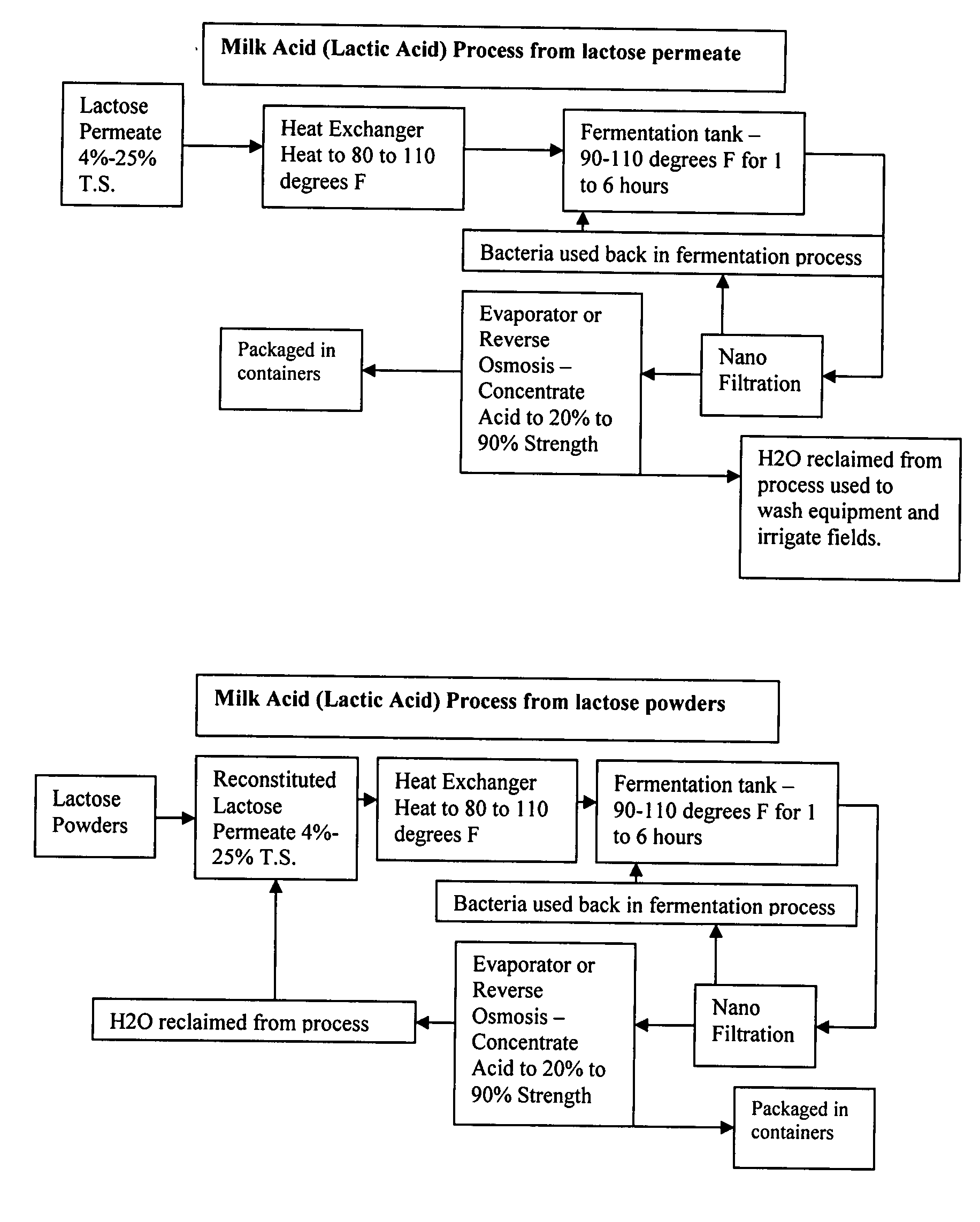

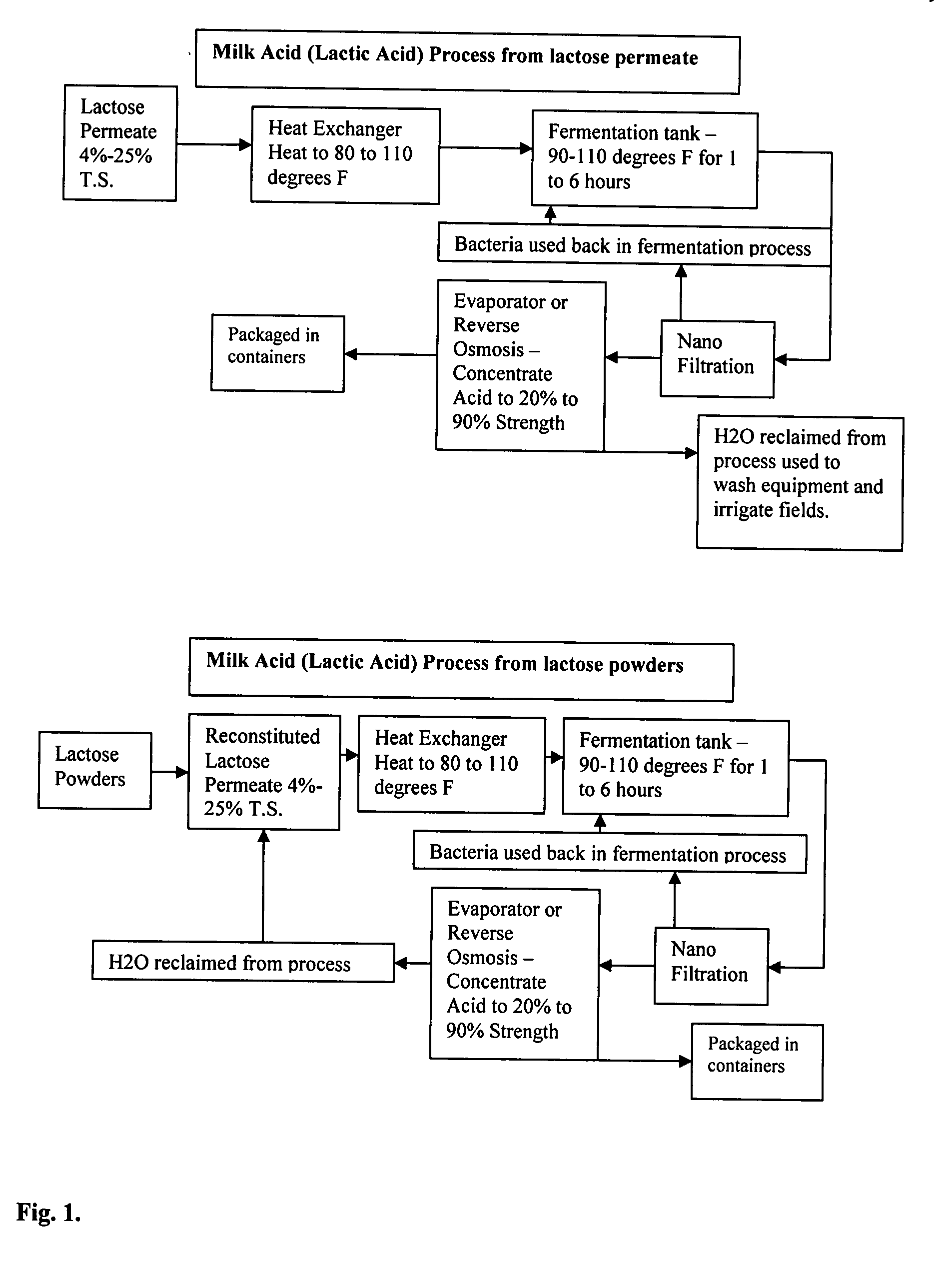

Novel manufacturing process for milk acid

The process consists of manufacturing milk acid from milk sugar by lactic fermentation process. The milk sugar is obtained as permeate from ultra-filtration of milk or from cheese or casein whey both in liquid, concentrate or dry form. The milk acid is separated and purified by a combination of membrane technology i.e., ultra-filtration / micro-filtration and nano-filtration. The purified milk acid is concentrated by evaporation, distillation or reverse osmosis.

Owner:PATEL RASHID +2

Method for extracting and preparing protein powder and enzymolysis product thereof from almond meal

InactiveCN102174071AKeep aliveIncrease added valuePeptide preparation methodsFermentationProtein solutionFood additive

The invention discloses a method for continuously extracting and preparing concentrated protein, separated protein and proteolysis products from almond meal. The method comprises the following steps of: degreasing and debitterizing residual oil meal obtained after almond oil is mechanically and coldly pressed, and then extracting with a low-concentration NaCl phosphate buffer solution to obtain the concentrated protein; preparing almond separated protein from the concentrated protein solution by applying an ultrafiltration membrane technology; preparing a proteolysis-almond polypeptide mixed solution from the separated protein solution by applying an enzymolysis technology; and ultrafiltering the polypeptide mixed solution by applying a membrane technology to obtain multifunctional active almond peptide with different class level molecular weights in sequence. The method has the advantages of simple process, strong operability and easiness in control of extracting conditions and can finish the extraction and preparation of the almond concentrated protein, the separated protein and the proteolysis products in sequence; and the obtained products have high purity and wide application and can be directly used as food additives, nutrition reinforcers, health care products, medicaments, and the like needed by the protein foods and different processing foods.

Owner:NORTHWEST A & F UNIV

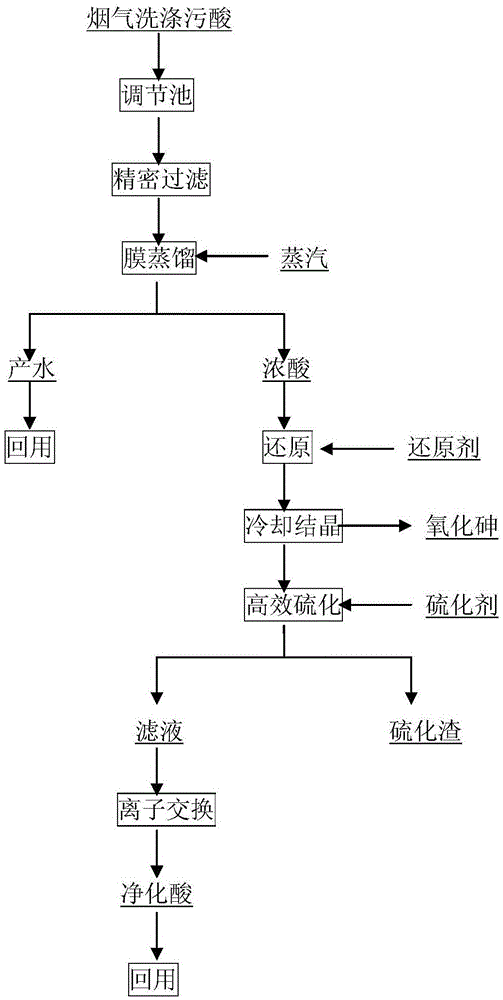

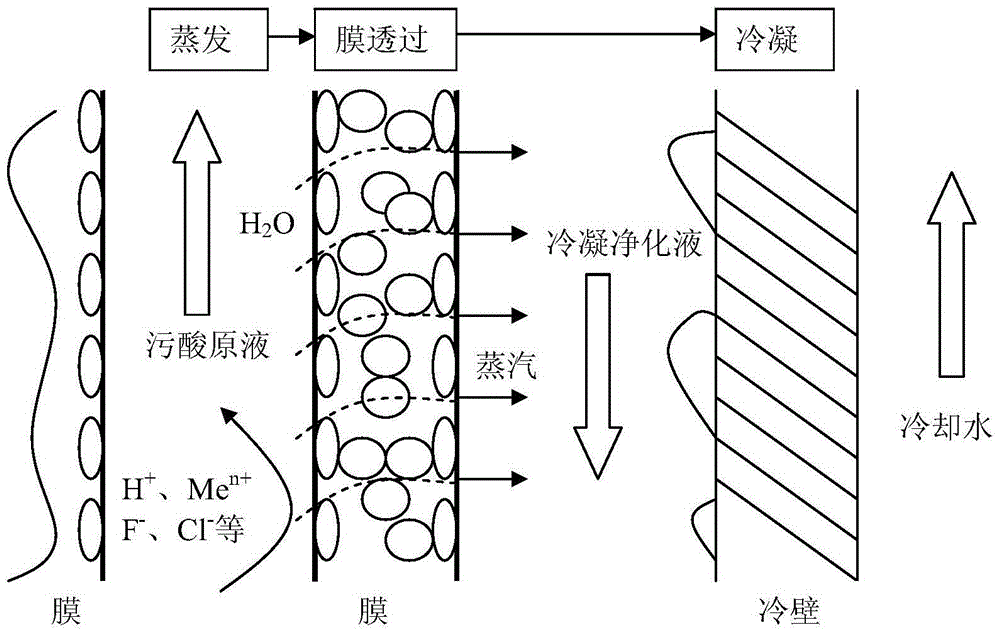

Method for purifying and recycling high arsenic polluted acid wastewater

ActiveCN105540973AEfficient separationQuality improvementWater contaminantsTreatment involving filtrationDistillationIon exchange

The invention provides a method for purifying and recycling high arsenic polluted acid wastewater. A main technique process comprises steps: filtering polluted acid, performing acid concentrating by membrane distillation and recycling condensed water, performing reduction on the concentrated acid, and then cooling to separate out arsenic trioxide, then sulfidizing to perform deep arsenic and heavy metal removing, and finally, removing fluorine and chlorine by ion exchange to obtain acid with low impurity and recycling for a system. The processing method effectively combines a traditional distillation technology and a membrane technology and can realize high quality recycle of purified water without affecting a smoke washing effect. The concentrated acid subjected to membrane distillation is subjected to efficient sulfidizing and then subjected to fluorine and chloride removing by ion exchange, thus providing guarantee for recycle of the concentrated acid. Enriching and concentrating of arsenic can be realized, the arsenic is reduced by a reducing agent, liquid is cooled and crystallized after reducing, 60 percent to 70 percent of arsenic is finally removed in a form of As2O3 from the polluted acid, the effective opening of the arsenic in a smelting system is realized, dosage of a subsequent sulfidizing or neutralizing agent can be greatly reduced, operation cost is reduced, an arsenic filter cake and waste residue are reduced, and secondary pollution risk to the environment is reduced.

Owner:CENT SOUTH UNIV +1

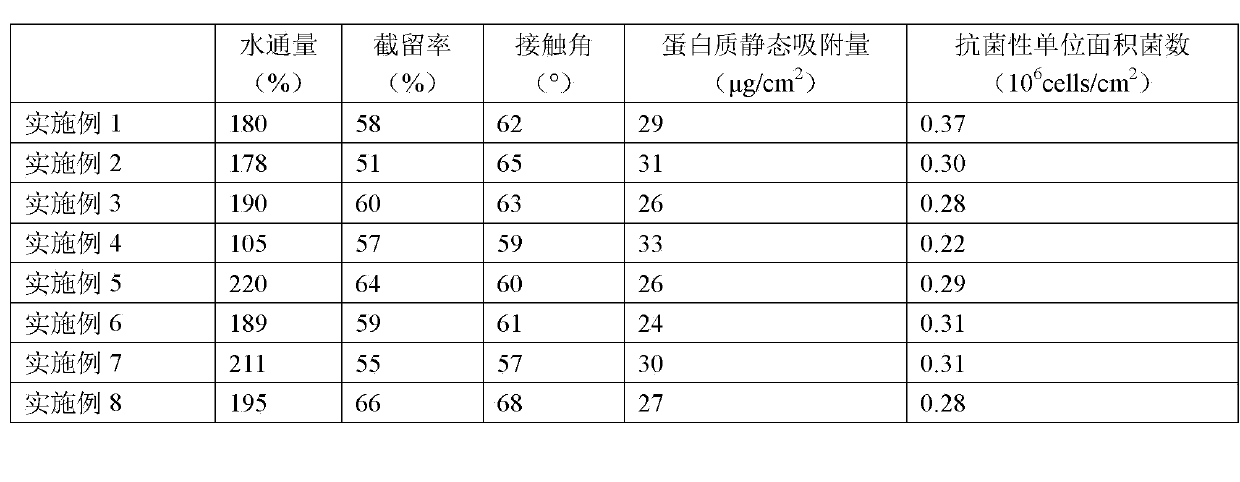

High strength nanometer modified ultrafilter membrane and preparation method thereof

ActiveCN103464004AReduce resistanceHigh strengthUltrafiltrationWater/sewage treatment bu osmosis/dialysisPolymer sciencePolyvinyl alcohol

The invention belongs to the field of ultrafilter membrane technology, and specifically relates to a high strength nanometer modified ultrafilter membrane and a preparation method thereof. The high strength nanometer modified ultrafilter membrane comprises following ingredients, by weight, 40 to 60 portions of polyvinylidene fluoride, 2 to 8 portions of polyvinylpyrrolidone, 5 to 10 portions of polyvinyl alcohol, 5 to 20 portions of polyethylene glycol and 0.05 to 0.5 portion of carbon nanotube. The high strength nanometer modified ultrafilter membrane is prepared by flat plate casting or electrospinning. The high strength nanometer modified ultrafilter membrane is high in strength and excellent in hydrophilicity, and possesses relatively high poriness. Resistance of the high strength nanometer modified ultrafilter membrane is reduced, water flux is increased, and service life of the high strength nanometer modified ultrafilter membrane is prolonged.

Owner:浙江金成环保科技工程有限公司

Superhydrophobic oleophobic modification method of porous membrane

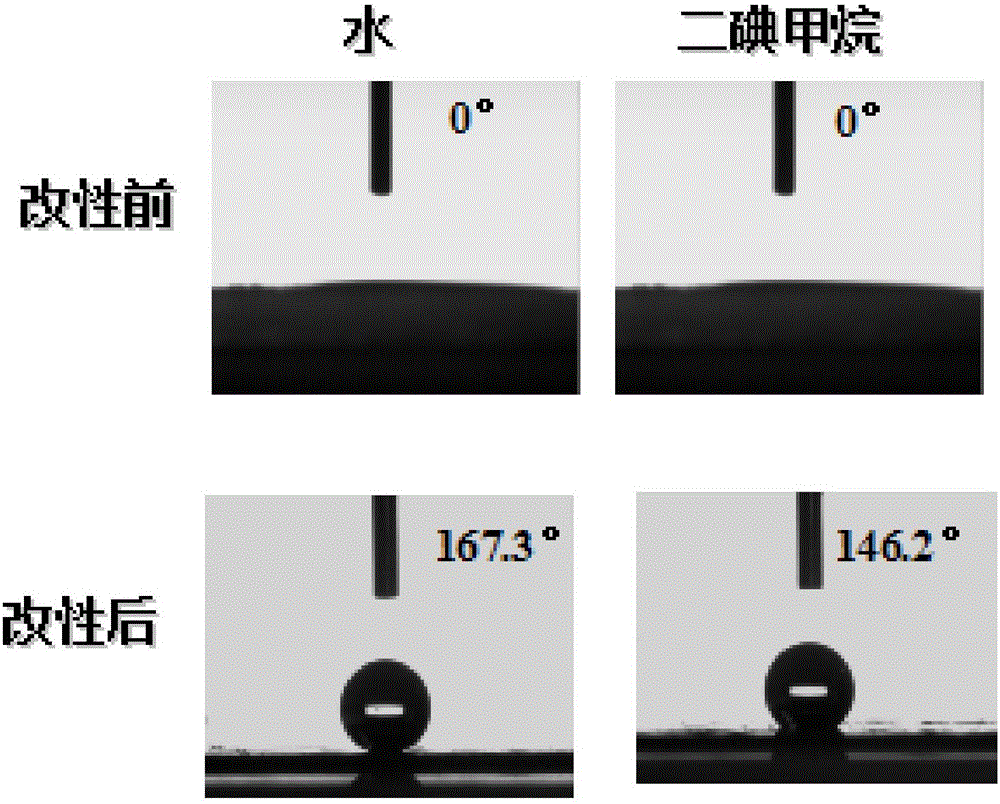

ActiveCN106390764AImprove stabilityImprove wear resistanceSemi-permeable membranesDiiodomethaneFiltration

The invention relates to a superhydrophobic oleophobic modification method of a porous membrane, and belongs to the technical field of separation membrane. According to the present invention, based on the self-cleaning bionic principle, fluorosilane-modified SiO2 nanoparticles having low surface energy are dispersed in an organic solution to prepare a uniform dispersion liquid, and a porous membrane is subjected to superhydrophobic oleophobic modification by using a dynamic filtration method to prepare the amphiphobic composite membrane having good stability, wherein the water contact angle of the amphiphobic composite membrane surface can achieve 167.3+ / -1 DEG C, the contact angle of diiodomethane can achieve 145.9+ / -1 DEG C, and the good amphiphobic property is presented; and method has characteristics of no requirement of complex equipment, simple and easy-performing process and short preparation period, and the prepared membrane has characteristics of high flux and good pollution resistance.

Owner:BEIJING UNIV OF TECH

Device and method for treating and recycling printing and dyeing wastewater

InactiveCN102050555AReduce dosageReduce consumptionTreatment using aerobic processesPaint waste treatmentFlocculationElectrolysis

Owner:BOYING XIAMEN SCI & TECH

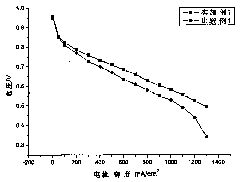

Method for preparing membrane electrode for hydrophilicity and hydrophobicity-adjustable proton exchange membrane fuel battery on the basis of catalyst/membrane technology

The invention relates to a method for preparing a membrane electrode for a hydrophilicity and hydrophobicity-adjustable proton exchange membrane fuel battery on the basis of a catalyst / membrane technology, comprising the following steps of: mixing deionized water and a hydrophobizing agent and then adding an alcohol-containing proton conduction polymer solution in the mixture and uniformly mixing to prepare a hydrophobizing agent and proton conduction polymer solution dispersion; wetting a catalyst by using the deionized water; adding the hydrophobizing agent and proton conduction polymer solution dispersion in the wet catalyst for dispersion to prepare catalyst slurry; coating the catalyst slurry on two mediums and drying by heating to obtain two mediums with catalytic layers through thermal processing; placing a proton exchange membrane between the catalytic layers of the two mediums with the catalytic layers and respectively shifting the catalytic layers on the two mediums to the two surfaces of the proton exchange membrane through thermal compression to obtain a catalyst-covering proton exchange membrane assembly; and placing the assembly between two gas diffusion layers and then making the assembly into the membrane electrode through the thermal compression, wherein the two surfaces of the proton exchange membrane exactly face the two gas diffusion layers.

Owner:武汉理工新能源有限公司

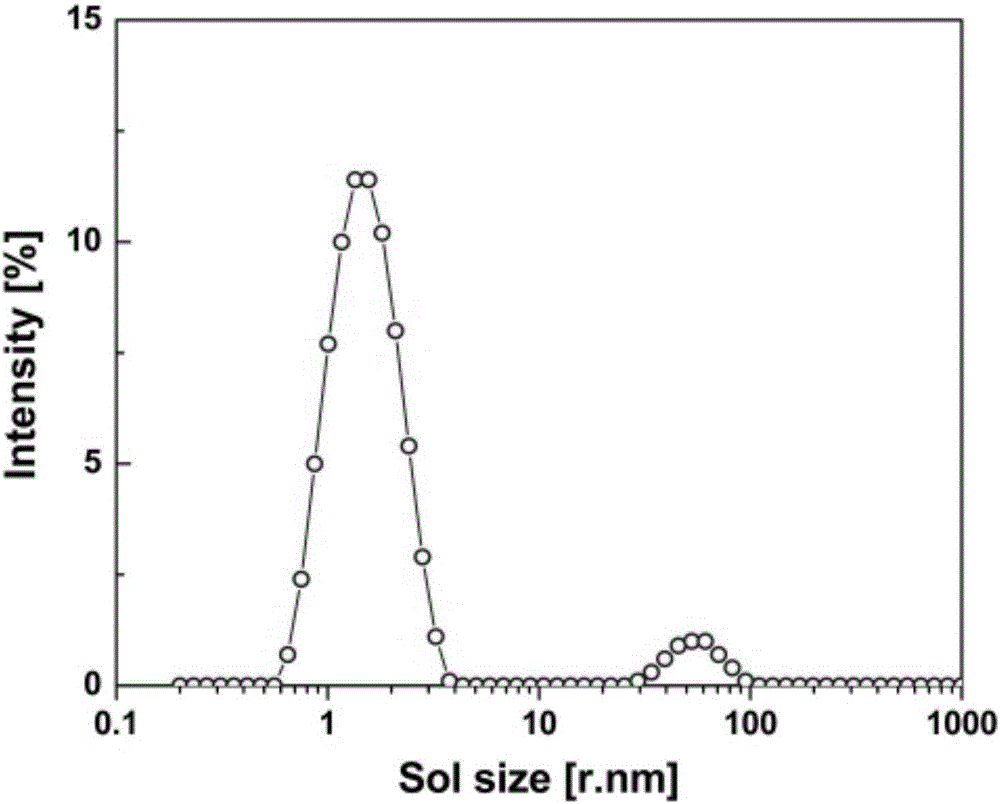

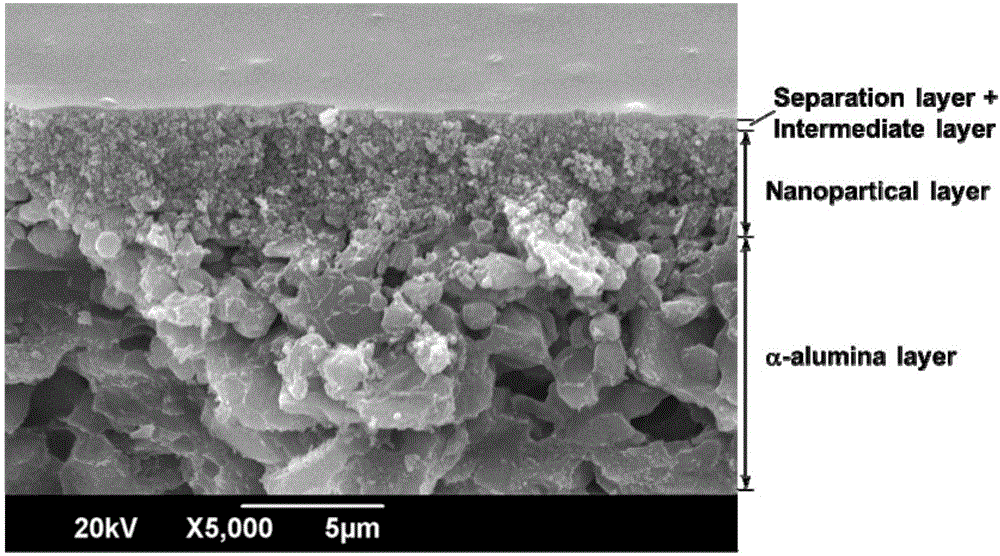

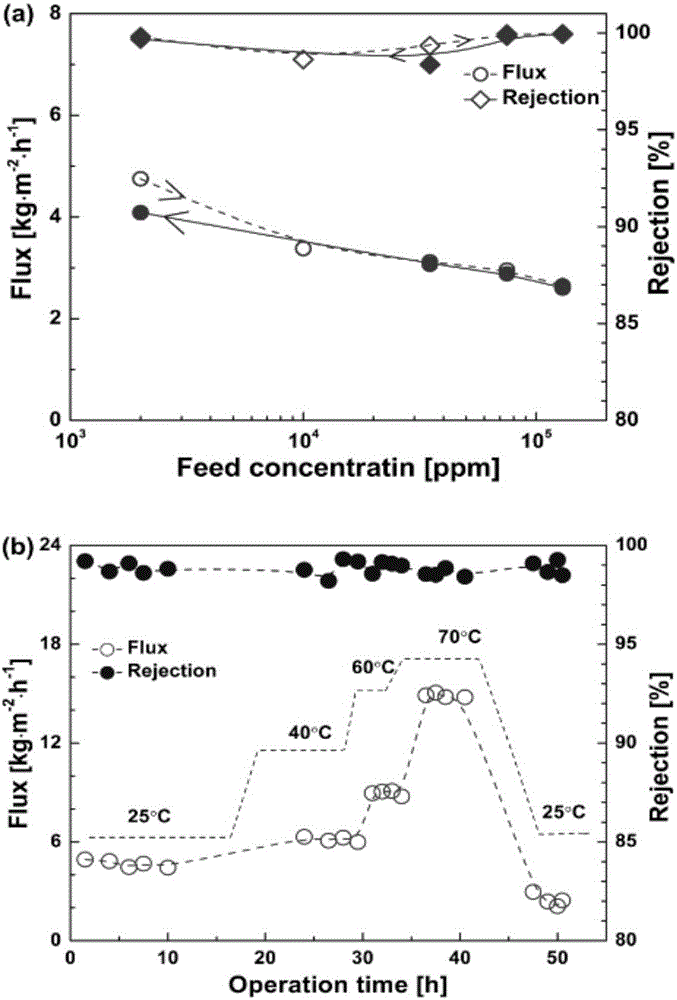

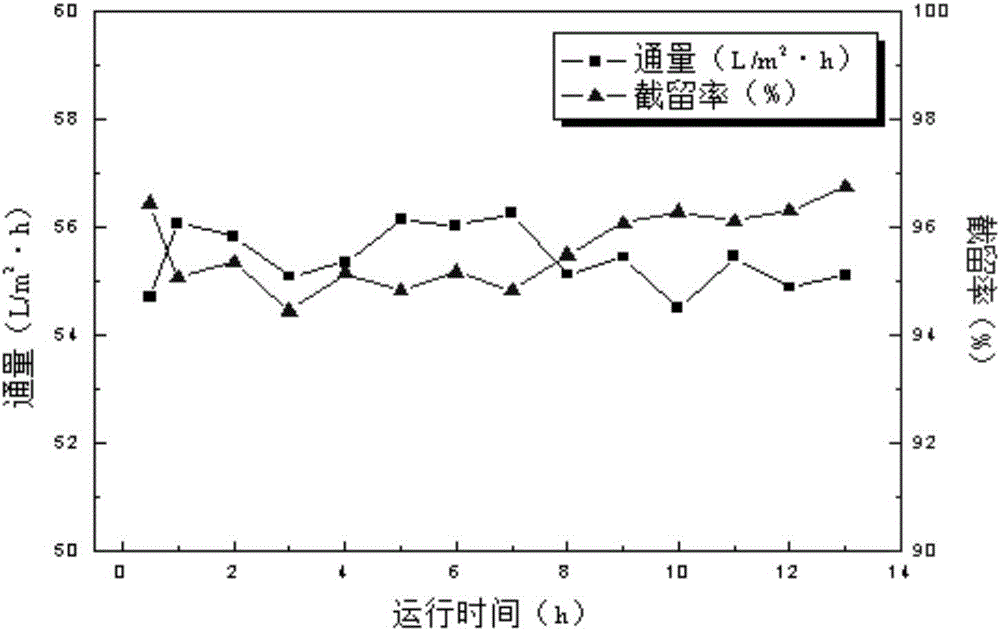

Preparation method of organosilicon film and application of organosilicon film in pervaporation treatment of high-salinity wastewater

ActiveCN106110909ARaise the saturated vapor pressureLow costSemi-permeable membranesGeneral water supply conservationReverse osmosisSilicon dioxide

The invention belongs to the technical field of pervaporation film separation, and particularly relates to a preparation method of an organosilicon film and application of organosilicon film in pervaporation treatment of high-salinity wastewater. An organosilicone source precursor is dissolved in absolute ethanol, deionized water is added, the mixture is stirred continuously, acid is added dropwise, and organosilicon sol is obtained; alpha-Al2O3 is dissolved in silicon dioxide-zirconium oxide sol at normal temperature and applied to a treated support, and silicon dioxide-zirconium oxide sol and organosilicon sol are applied and coated with a thermal applying method. The organosilicon film shows good hydrothermal stability during pervaporation desalination, has the advantages of high salt rejection rate, high water permeability and the like, and is particularly suitable for high-salinity wastewater difficult to treat with a reverse osmosis membrane technology.

Owner:CHANGZHOU UNIV

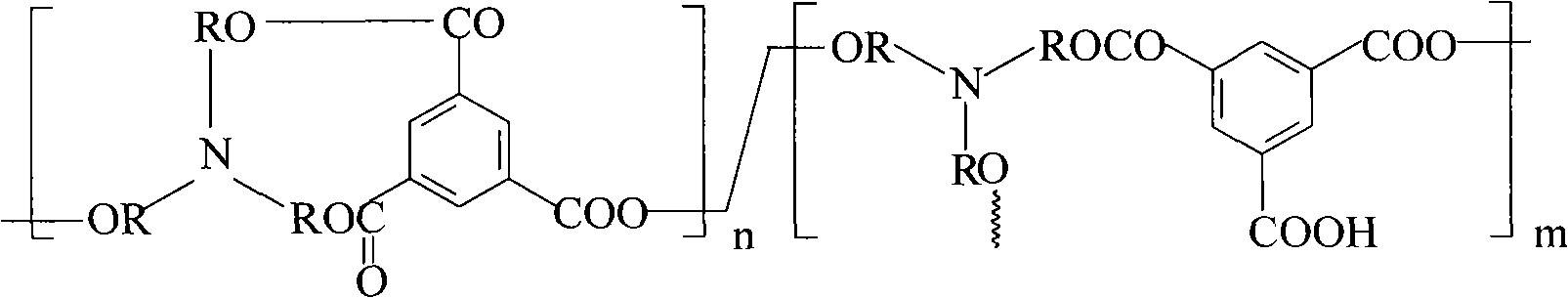

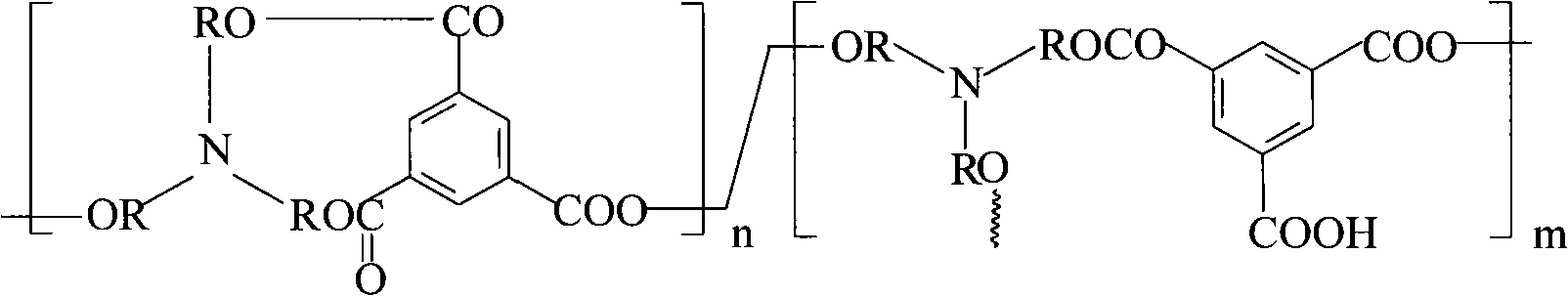

Crosslinked hyperbranched polyalcohol composite nano filter membrance and method of preparing the same

InactiveCN101254419ALow operating pressureReduce manufacturing costSemi-permeable membranesAlcoholMembrane technology

The invention belongs to the membrane technology field, in particular to a polyester composite nanofiltration membrane as well as the manufacturing method thereof. The composite membrane is characterized in that a layer of aromatic polyester functional cortex is compounded on a porous supporting membrane through multivariate alcohol amine and multivariate acyl chloride interfacial polymerization. The novel polyester composite nanofiltration membrane of the invention has low operating pressure, and the adopted multivariate alcohol amine has the advantages of innocuity, low price, easy availability, etc. Besides, as the functional cortex contains tertiary amine and carboxylic groups, the membrane surface can present different charge properties through adjusting the pH value of separated feed liquid, thereby being applicable to more industrial requirements. Furthermore, the production cost is low, the industrial production basis is good, and the application prospect is wide.

Owner:FUDAN UNIV

Livestock and poultry breeding wastewater treating technology

InactiveCN106007201AReduce SS contentEasy to settleSludge treatment by de-watering/drying/thickeningTreatment using aerobic processesPig farmsFeces

The invention discloses a livestock and poultry breeding wastewater treating technology and belongs to the technical field of treatment of livestock and poultry breeding waste. The method comprises the following steps of gravity sedimentation pretreatment, flocculation treatment, special ultrafiltration treatment, nanofiltration treatment, reverse osmosis treatment and aeration biological filter treatment. The membrane technology is used as the core, and a whole set of complete-process technology, which has the good separation and removal effect on organic matter, nitrogen, phosphorus and the like in livestock and poultry breeding wastewater, makes the processed waste water reach the pollution discharge standards in livestock and poultry breeding industry, and is wide in application range and suitable for livestock and poultry breeding wastewater zero discharge of various feces removal, is provided, wherein effluent can be recycled for washing hog houses, pig farm landscape water and toilets and the like.

Owner:嘉兴悟净环保科技有限公司

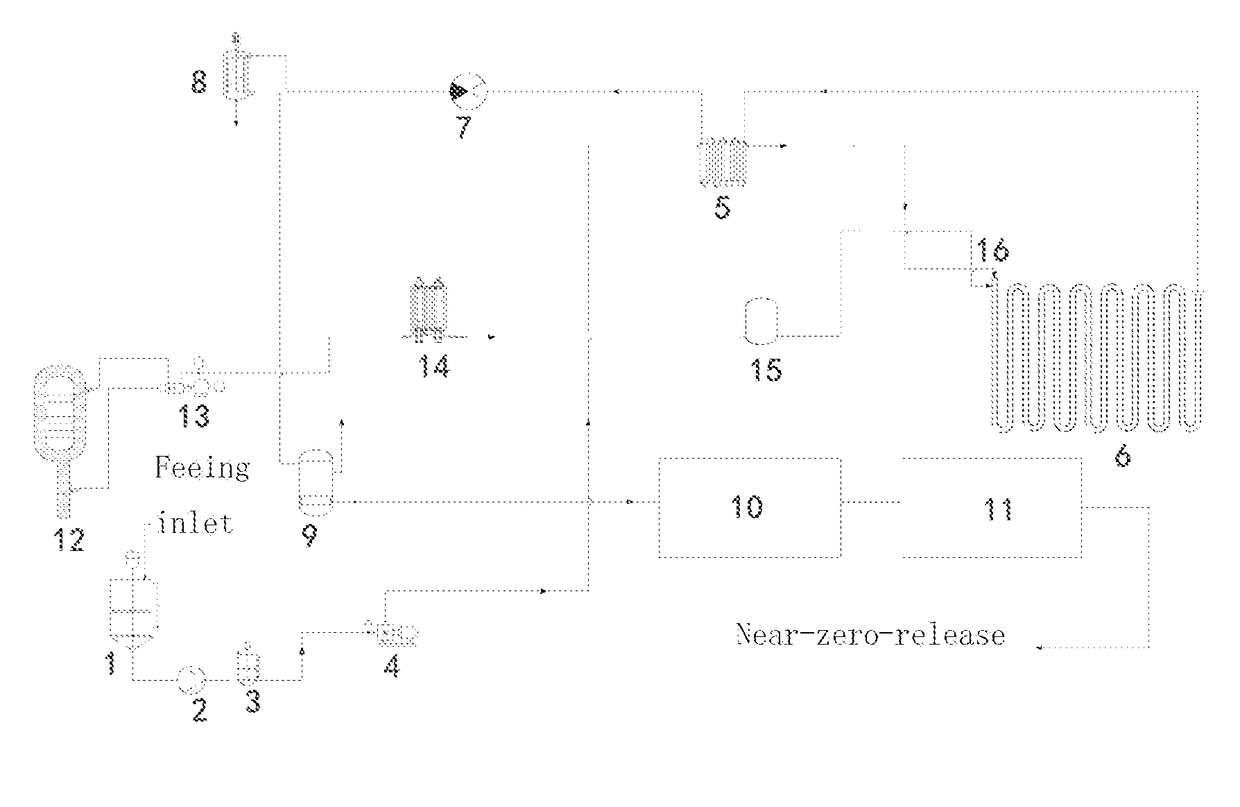

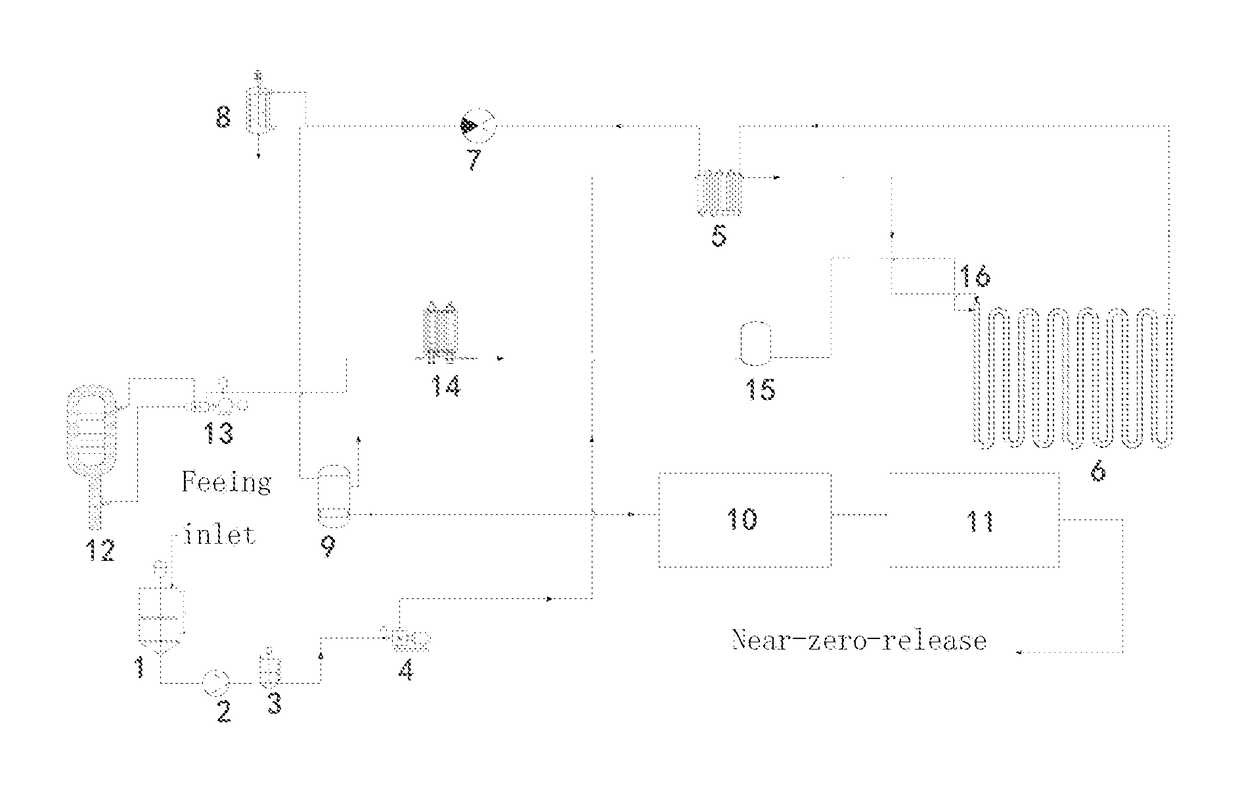

Near-zero-release treatment system and method for high concentrated organic wasterwater

ActiveUS20170267565A1Material efficiencySolve the real problemSludge treatmentSpecific water treatment objectivesSludgeEngineering

A near-zero-release treatment system and method for high concentrated organic wastewater is in the chemical engineering and environment protection field, whose core technology is SCWO. The wastewater and sludge are grinded by the homogeneous pump, pressurized by high-pressure plunger pump, transported to successive pipeline for preheating and mixing with the oxygen and undergoes SCWO reaction in the reactor. After pressure release in the pressure relief device, the reacted fluid passes through the self-cleaning filter and gas liquid separator for insoluble solid and gas separation; then enters the MVR for crystallization of the soluble salts to realize near-zero-release of the feeding. The regular water treatment technology (coagulation sedimentation, membrane biotechnology, membrane technology, etc.) is adopted to complement SCWO, which lowers the operating parameters of the reactor and cuts the operating cost by treating the remaining COD with regular water treatment technology.

Owner:XI AN JIAOTONG UNIV +1

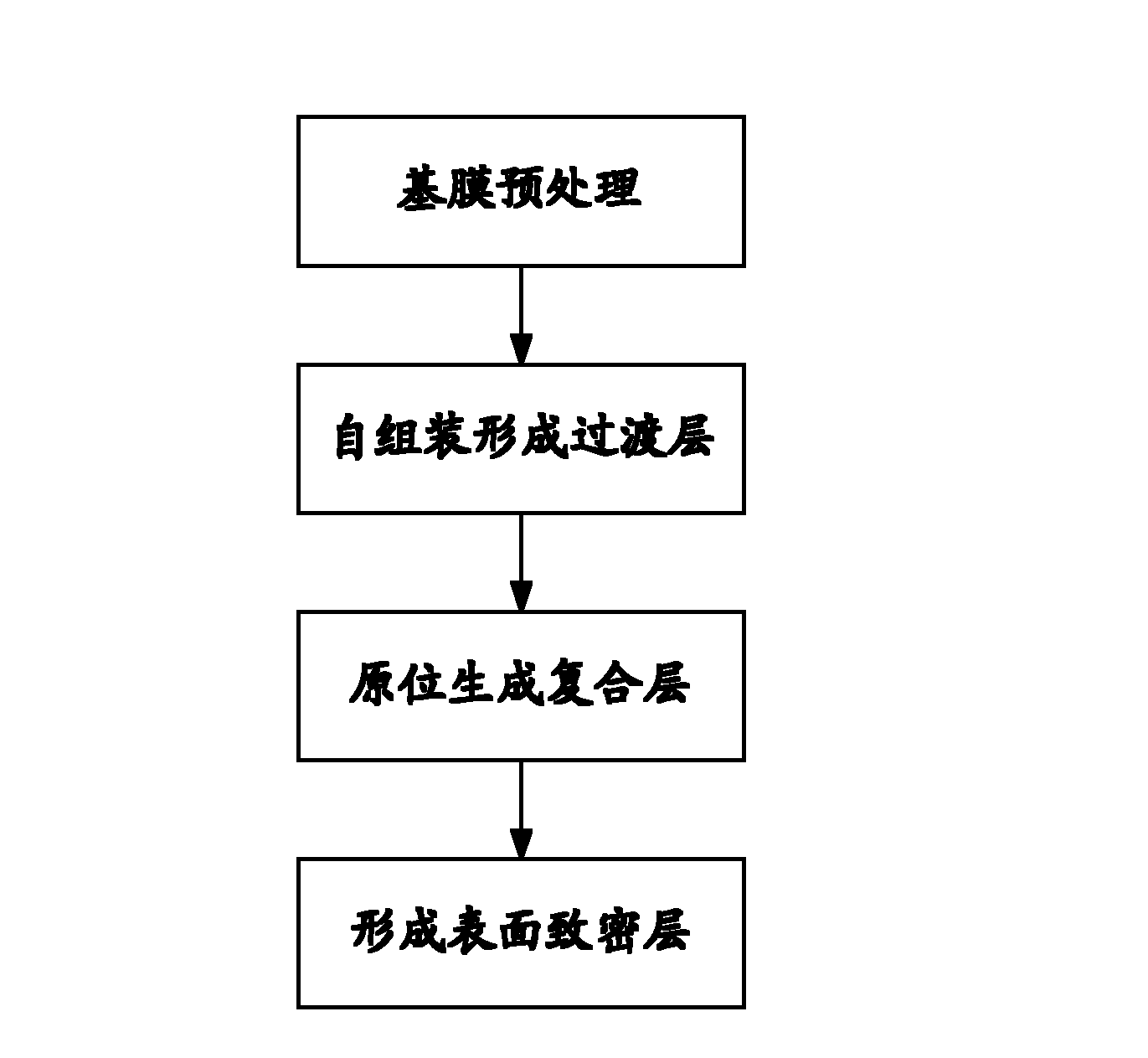

A high-temperature resistant precision molecular weight cut-off ultrafiltration membrane and a preparing method thereof

InactiveCN106166450AImprove performanceImprove high temperature resistanceSemi-permeable membranesMembrane technologyPhysical chemistry

The invention relates to the field of membrane technology, in particular to a high-temperature-resistant precision molecular weight cut-off ultrafiltration membrane and a preparation method thereof. The composition of raw materials and the definition of parameters in the preparation process of the base film ensure that the performance of the prepared wet base film is stable after the subsequent modification treatment, and can effectively improve its high temperature resistance; at the same time, combined with the modification process The definition of time, temperature and treatment method in the process makes the rejection rate of the ultrafiltration membrane to the molecular weight range of 2000-4000 reach more than 90%, which effectively improves the interception of the ultrafiltration membrane to low molecular weight substances and improves the quality of the filtration product .

Owner:VONTRON MEMBRANE TECH CO LTD

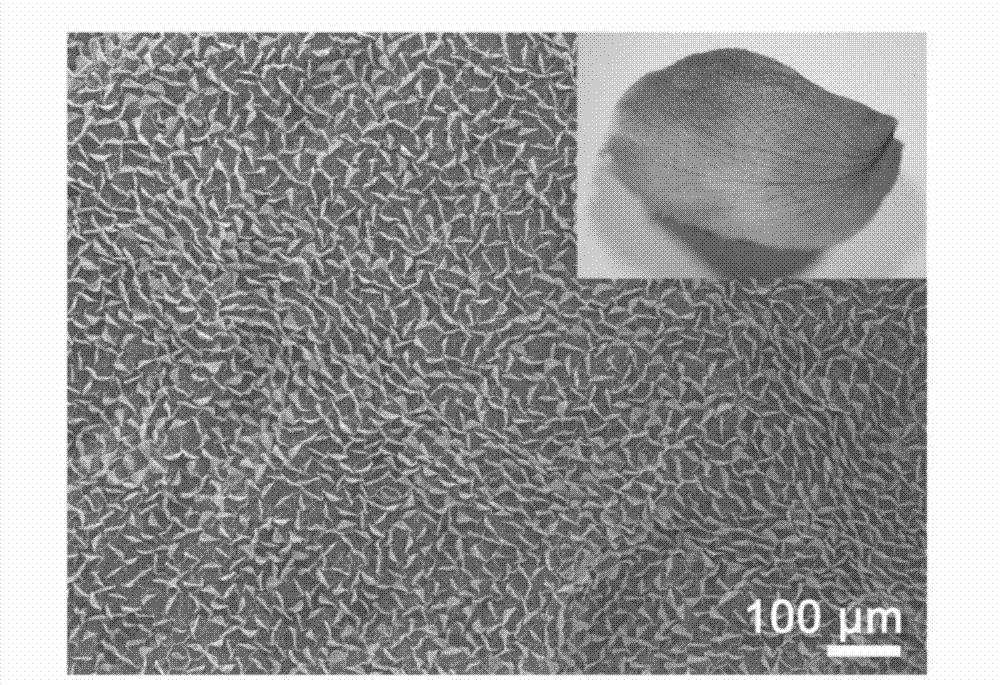

Enhanced Raman detection substrate based on natural biology super-hydrophobic structure surface and preparation method thereof

The invention belongs to the technical field of ultra-sensitive test analysis, and particularly relates to an enhanced Raman detection substrate which can be in mass production and is wide in application, efficient, environment-friendly and based on a natural biology super-hydrophobic structure surface and a preparation method thereof. The PVD (physical vapor deposition) and a self-assembly or chemical plating and coating film technology are utilized to cover a precious metal layer on the natural biology super-hydrophobic surface to form rough and hydrophobic surface enhanced Roman detection hot spot area so that the enhanced Raman detection substrate is formed. The natural super-hydrophobic structure surface is plant pedals, plant leaves or inset wings. The precious metal is gold or silver and the thickness of the precious metal layer ranges from 5 nm to 50 nm. The hydrophobic SERS (surface enhanced Raman scattering) detection substrate has high sensitivity, and the detection limit can reach 10-9. The enhanced Raman detection substrate draws materials from the natural hydrophobic biology surface, so that the sensitivity is high, the performance is stable, the cost is low, and the pollution to the environment is prevented.

Owner:JILIN UNIV

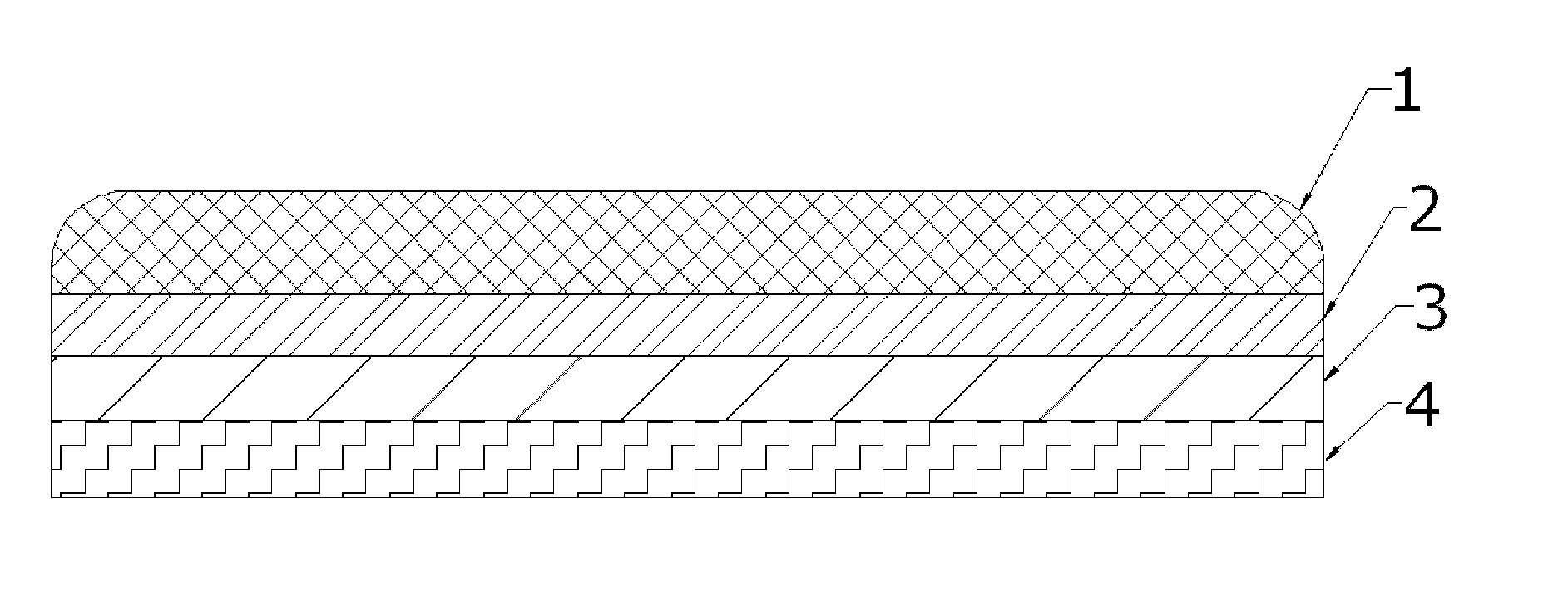

Inorganic/organic composite nanofiltration membrane and preparation method thereof

ActiveCN102553461AImprove performanceEasy to separateSemi-permeable membranesElectrolysisUltrafiltration

The invention belongs to the technical filed of membranes, particularly relates to an inorganic / organic composite nanofiltration membrane. The inorganic / organic composite nanofiltration membrane sequentially comprises a basement membrane, a transition layer, a composite layer and a compact layer, wherein the basement membrane is provided with an ultrafiltration membrane, the transition layer is formed on the surface of the basement membrane by cationic polyelectrolyte and anionic polyelectrolyte through electrostatic self-assembly, the composite layer is formed on the surface of the transition layer by a soluble calcium salt and a soluble carbonate in a in-situ way, and the compact layer is formed on the surface of the composite layer by the cationic polyelectrolyte and the anionic polyelectrolyte in a crosslink way. The precipitation and the in-situ formation of inorganic minerals are controlled through the identification of an inorganic matter precursor due to polyelectrolyte, thus the inorganic / organic composite nanofiltration membrane which is of a shell-simulation shape is obtained, and the inorganic / organic composite nanofiltration membrane is uniform and controllable and has a stable performance. The implementation processes are all carried out in normal temperature, an organic solvent is free, and the inorganic / organic composite nanofiltration membrane is environment friendly and has a good separating effect for Ca<2+>, Mg<2+> and dye molecules of which molecular weights are larger than 370 in water.

Owner:中科瑞阳膜技术(北京)有限公司

Method of producing chip copper interconnection high-purity copper sulfate electroplate liquid

A method for producing a chip copper interconnection high-purity copper sulfate electroplating solution of the present invention firstly includes an electrolysis step: in the process of electrolysis, an electrolytic cell is used, and an anode and a cathode are arranged in the electrolytic cell, the anode adopts an electrolytic copper plate, and the cathode Platinum plates are used, separated by a one-way membrane between the cathode and the anode, sulfuric acid is used as the electrolyte in the electrolytic cell, and metallic copper is dissolved by electrochemical methods; secondly, a superfiltration purification step is included to obtain a total amount of metal impurities less than 10PPM, high-purity copper sulfate mixed plating solution with organic impurities less than 10PPM. The present invention adopts a purification method combining electrochemistry and membrane technology. By adjusting process parameters and combining semiconductor ultra-purification and ultrafiltration technology, other indicators of the product can be controlled, and the product can be purified without evaporation and crystallization, and the qualified product can be directly produced. High-purity copper sulfate electroplating solution for copper interconnection.

Owner:SHANGHAI SINYANG SEMICON MATERIALS

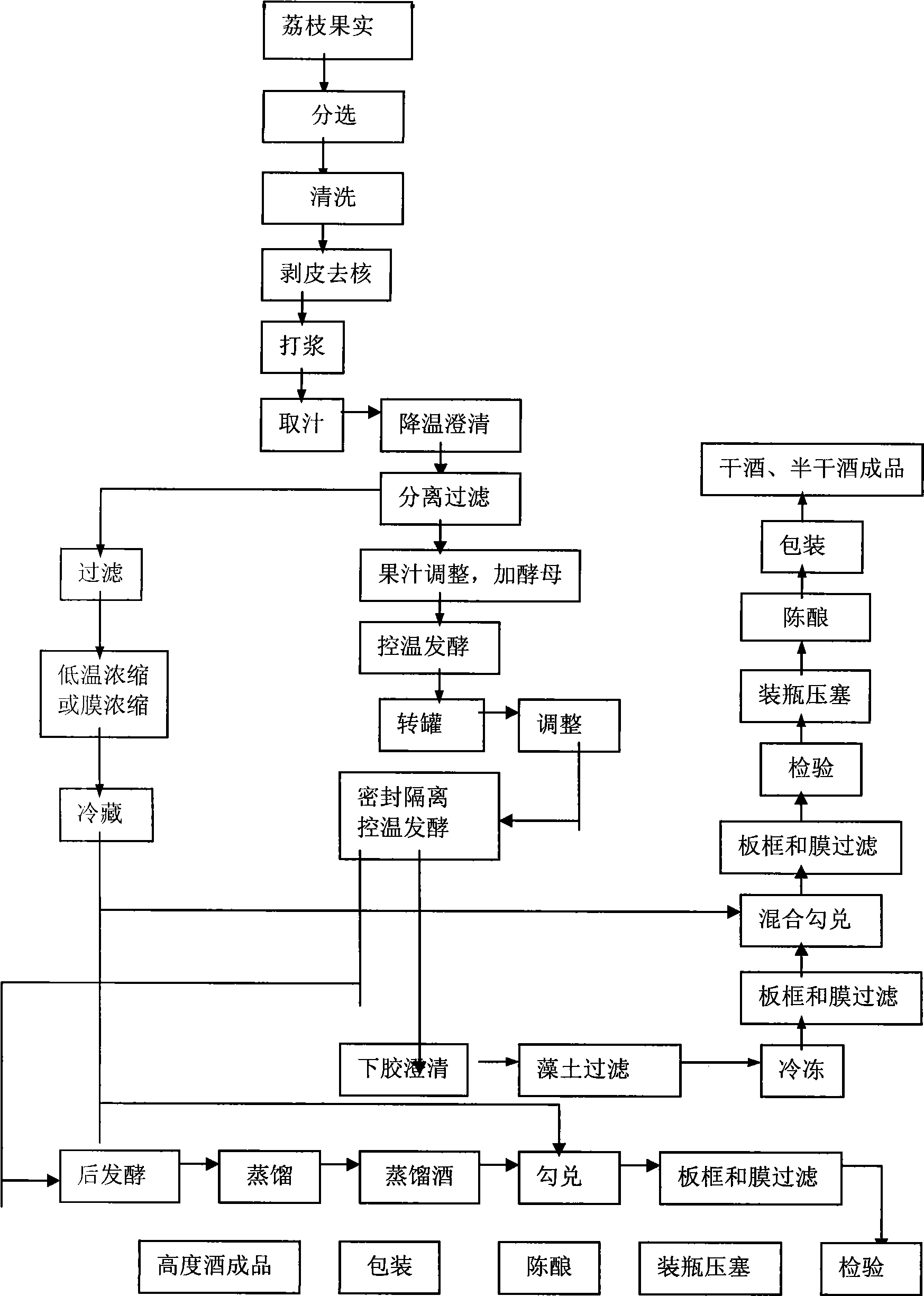

Wine-making preparation method adopting litchi fermentation

InactiveCN101531960ARaise the alcohol contentImprove the efficiency of fermentation to produce alcoholMicroorganism based processesAlcoholic beverage preparationSucroseSaccharum

The invention discloses a wine-making preparation method adopting litchi fermentation. The method comprises the following steps: adopting pollution-free excellent quality litchi pulp to make fruit juice concentrate by means of a low-temperature ice-crystal method or a membrane concentration method, and blending the fruit juice concentrate with high dry wine; adding highly concentrated fruit juice frozen by the low-temperature ice-crystal method or the membrane concentration method into the mixture to keep the typical aroma of litchi fruit wine; adopting yeast strain, lactic acid strain and acetic acid strain to carry out multi-strain coordinated fermentation and adjusting the fermentation conditions; accelerating fermentation and conversion by fruit sugar and glucose cooled after high-temperature acid conversion of sucrose to improve the quality of fermented wine liquid; making use of ultra low temperature cryoprecipitation and triple filtration sterilization to solve the problem of deposition of products during storage and transportation; and adopting non-thermal sterilization filtration and concentration membrane technology to avoid the influence on fruit wine quality caused by thermal sterilization. The wine-making preparation method can obtain a natural litchi fermented wine product with palateful quality.

Owner:广东岭南为多生命高科有限公司 +1

Process for producing high-purity kanjak mannan-oligosaccharides

The invention provides a method for preparing high- purity konjak mannan with production purity over 95%. It comprises following steps: taking konjaku flour as raw material, producing mannan through enzymolysis, centrifuging and filtering and microfiltering and purifying, desalting with ion-exchange technology, decoloring, odour- removing, cutting off macromolecule with ultrafiltering membrane technology from sugar liquid, spray drying and getting high purity konjak mannan with purity over 95%. The invention is characterize by employment of enzyme technology, ion- exchange technology, membrane technology system, simple operation, good separation effect, low cost, no chemical pollution, realization of industrial production. The product can not only be used as functional health care product, but aslo as high- grade food ingredient, medical intermediate, and high- grade feed addictive.

Owner:WUHAN TAIYUAN INVESTMENT GUARANTEE

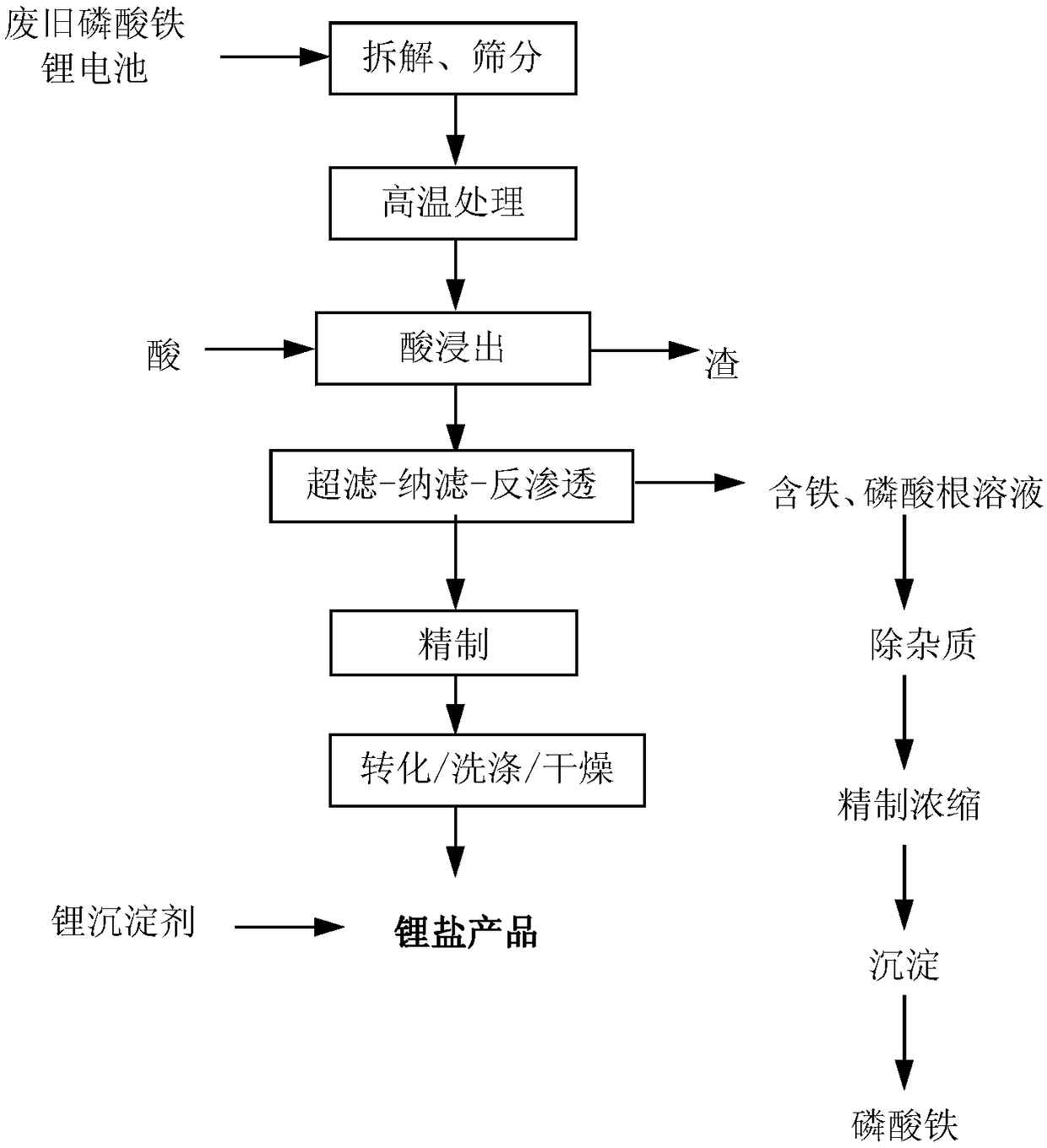

Method and system for recovering lithium from waste lithium iron phosphate battery

ActiveCN109207730AAdvanced separation technologyEasy to separateWaste accumulators reclaimingProcess efficiency improvementPregnant leach solutionLithium iron phosphate

The invention discloses a method and system for recovering lithium from a waste lithium iron phosphate battery. The method comprises the following steps that a positive plate is disassembled from thewaste lithium iron phosphate battery; a binder in the positive plate is removed, valuable metal elements in the positive plate are leached by an acid solution, and an acidified leaching solution is obtained; ultrafiltration treatment is carried out on the acidified leachate by using an ultrafiltration membrane; by using a nanofiltration membrane technology, lithium ions in the acidified leachate are separated from other cations different from lithium ions, a solution containing lithium and a solution containing other cations are obtained, and then a reverse osmosis technology is adopted for concentration and enrichment correspondingly, wherein the other cations comprise iron ions; and a lithium precipitant is adopted to precipitate and separate lithium ions in the lithium-containing solution, alkaline substances are adopted to precipitate and separate iron ions in the solution containing other cations, and lithium recovery is realized. According to the method and system, the ultrafiltration-nanofiltration-reverse-osmosis combined technology is adopted, and the method and system have the beneficial effects of simple process, environmental protection, less acid and alkali consumption, good and stable membrane separation effect and the like.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

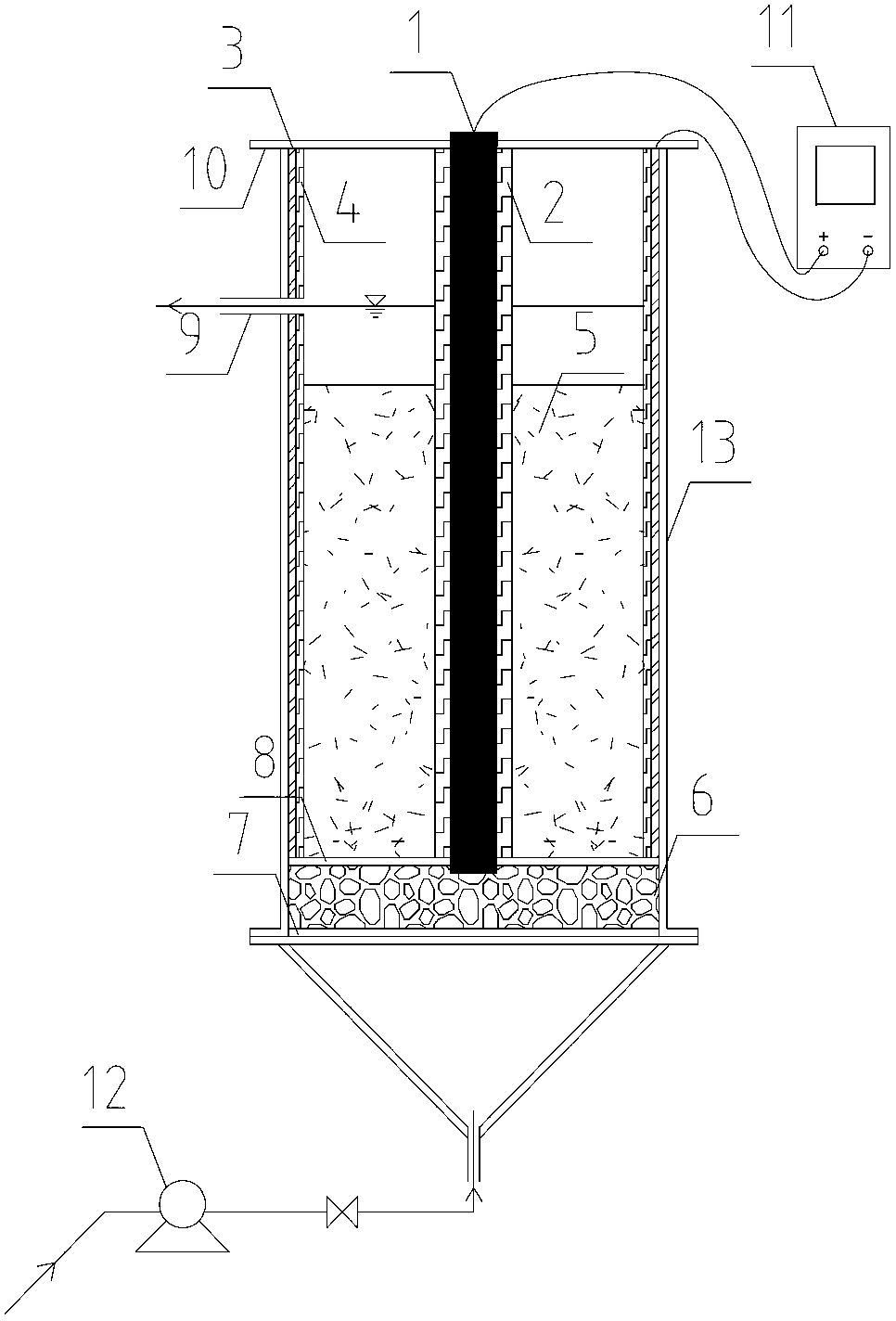

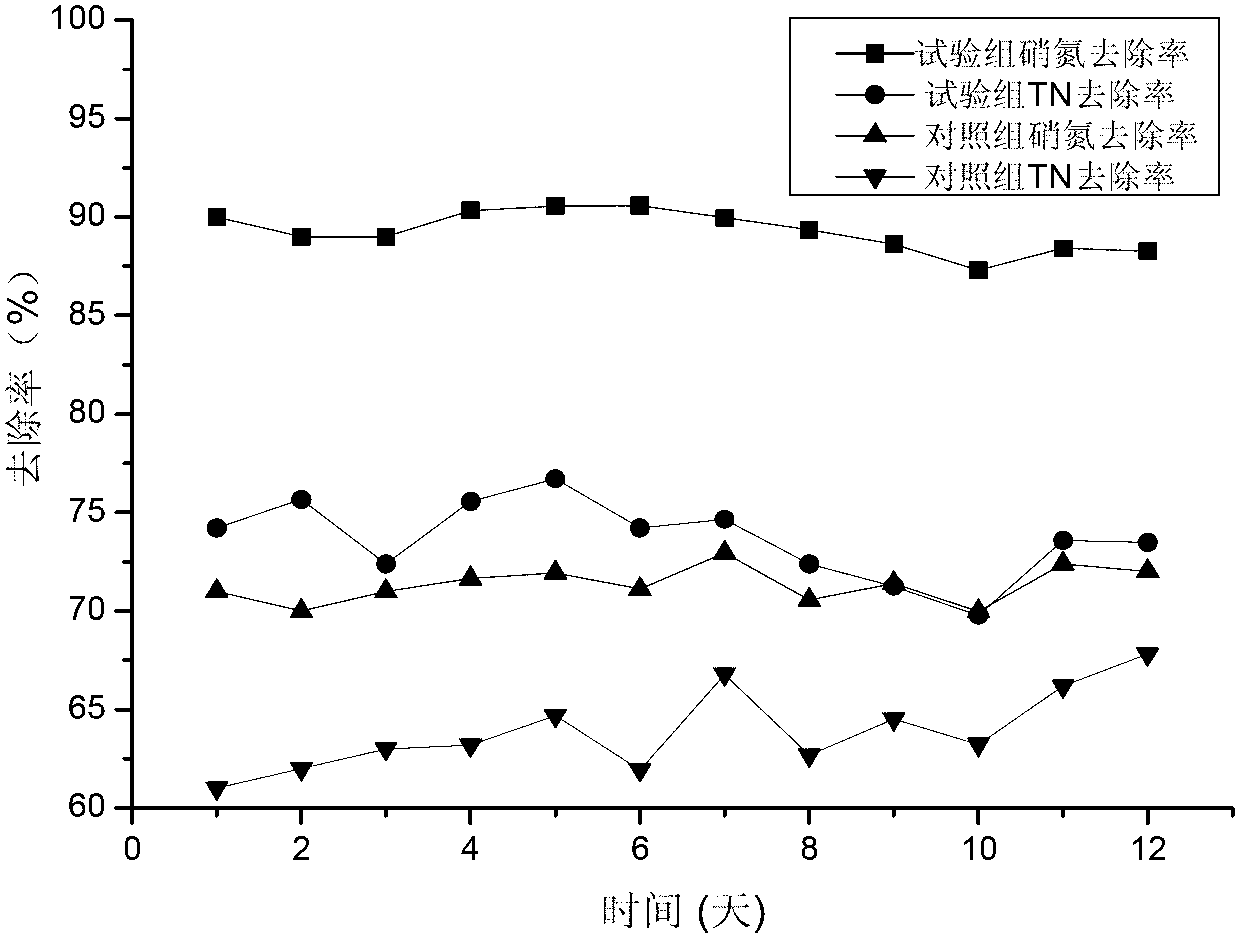

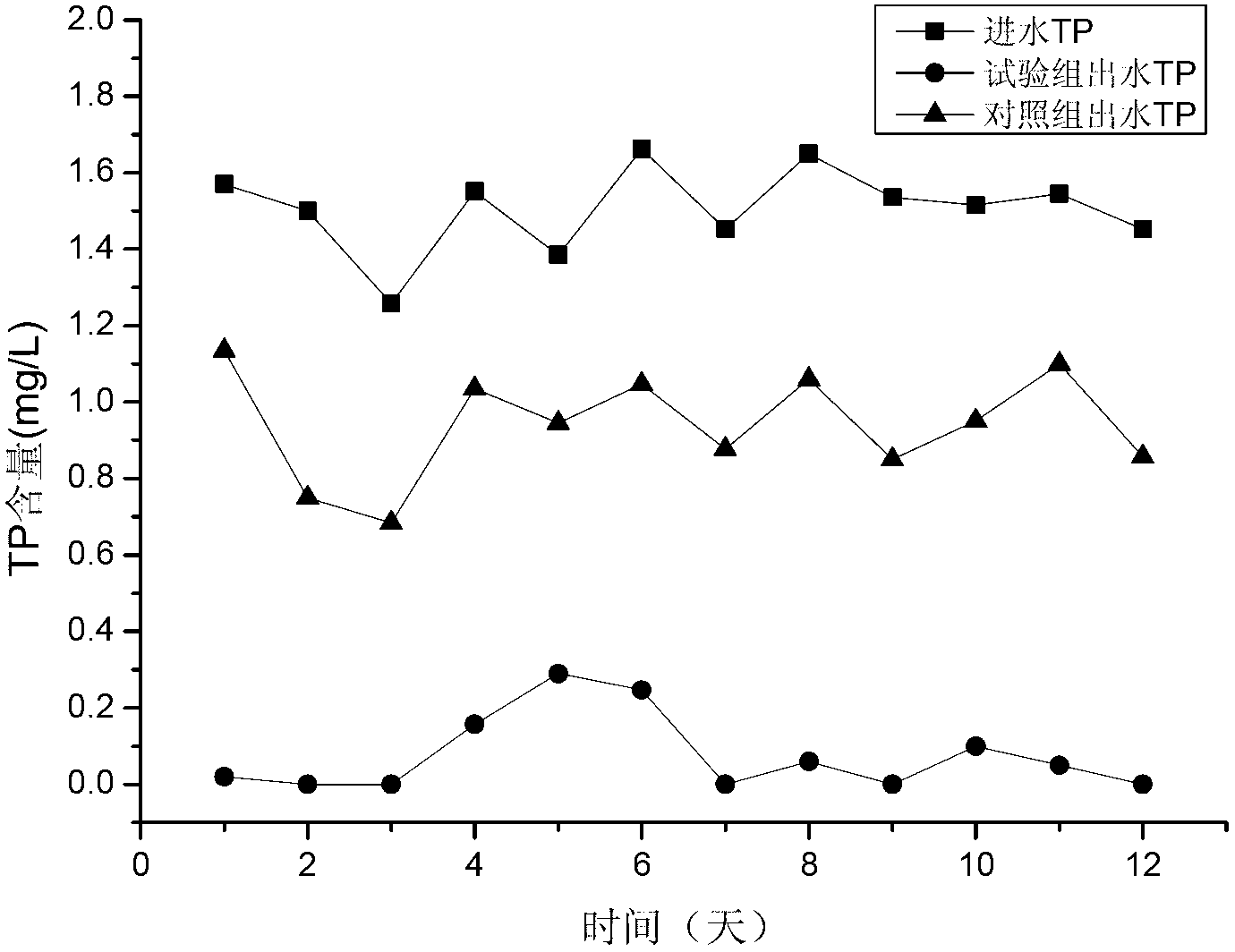

Reinforced nitrogen and phosphorus removal method suitable for reclaimed water with low carbon nitrogen ratio

InactiveCN103183402ATo promote metabolismEnhanced autotrophic denitrification processTreatment with anaerobic digestion processesWater/sewage treatment using germicide/oligodynamic-processElectron donorHydrolysis

The invention provides a reinforced nitrogen and phosphorus removal method suitable for reclaimed water with a low carbon nitrogen ratio, belonging to the field of environmental engineering. The reinforced nitrogen and phosphorus removal method is based on a three-dimensional electrode biochemical membrane technology. According to the reinforced nitrogen and phosphorus removal method, the nitrogen and phosphorus removal is reinforced through electrochemistry and biological denitrification coupled process, a graphite rod is used as the anode of a reactor, foamed nickel is used as the cathode of the reactor, and a sponge iron and activated carbon composite padding is filled between the anode and the cathode; under the action of electric currents, the cathode generates hydrogen for autotrophic denitrification by hydrogen bacteria, and the anode generates CO2 for providing an inorganic carbon source for microorganisms and buffering the pH value of the system; the sponge iron and activated carbon composite padding forms lots of micro-primary batteries, and sponge iron is corroded to generate hydrogen so as to provide lots of electron donors for the microorganisms, promote the growth and metabolism of the autotrophic microorganisms and reduce the requirements on an organic carbon source, and the sponge iron is beneficial to formation of anaerobic environments in the system; the nitrogen removal effect by autotrophic denitrification is reinforced through the process above; and the sponge iron is corroded to generate Fe<2+> and Fe<3+>, and the hydrolysis product of the sponge iron enables the phosphorus in yielding water to be substantially reduced.

Owner:BEIJING UNIV OF TECH

Method for preparing oligo xylose in high purity by using stalk as raw material, and using technique of enzyme and membrane

This invention discloses a method for preparing high-purity xylooligosaccharide from straw by using enzyme and membrane technology. The method comprises: steam-exploding straw, adding xylanase, hydrolyzing, centrifuging or filtering to obtain supernatant, performing nanofiltration or vacuum-concentration, acid-treating, centrifuging or filtering to obtain supernatant, performing active carbon adsorption, ultrafine filtration and ion exchange resin column adsorption, and concentrating or spray-drying to obtain high-purity xylooligosaccharide slurry or powder (xylooligosaccharide content is up to 70-95%). The residues of straw produced during xylooligosaccharide preparation can be used for papermaking, thus is environmentally friendly. Straw has an abundant resource, thus the cost is low. The method has such advantages as high treatment quantity, integrated operation, simple process, and high efficiency.

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com