Patents

Literature

773 results about "Thermal compression" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermal Compression Therapy eliminates the need for ice and offers precise temperature to the affected area. This type of cold therapy can help to reduce edema related to burns, sprains and other causes. It can also help with lymphedema from venous stasis ulcers, CVI, dvt, vascular compression,...

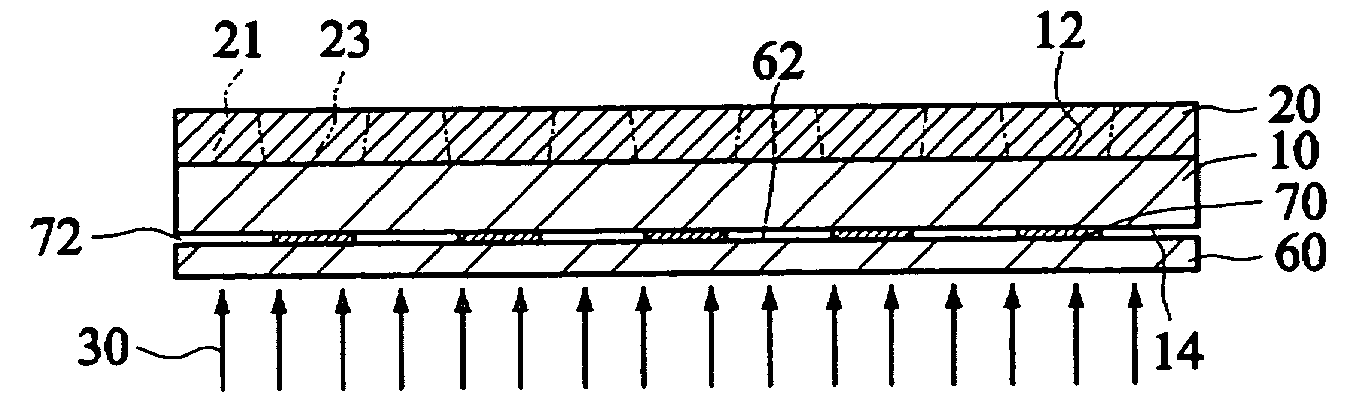

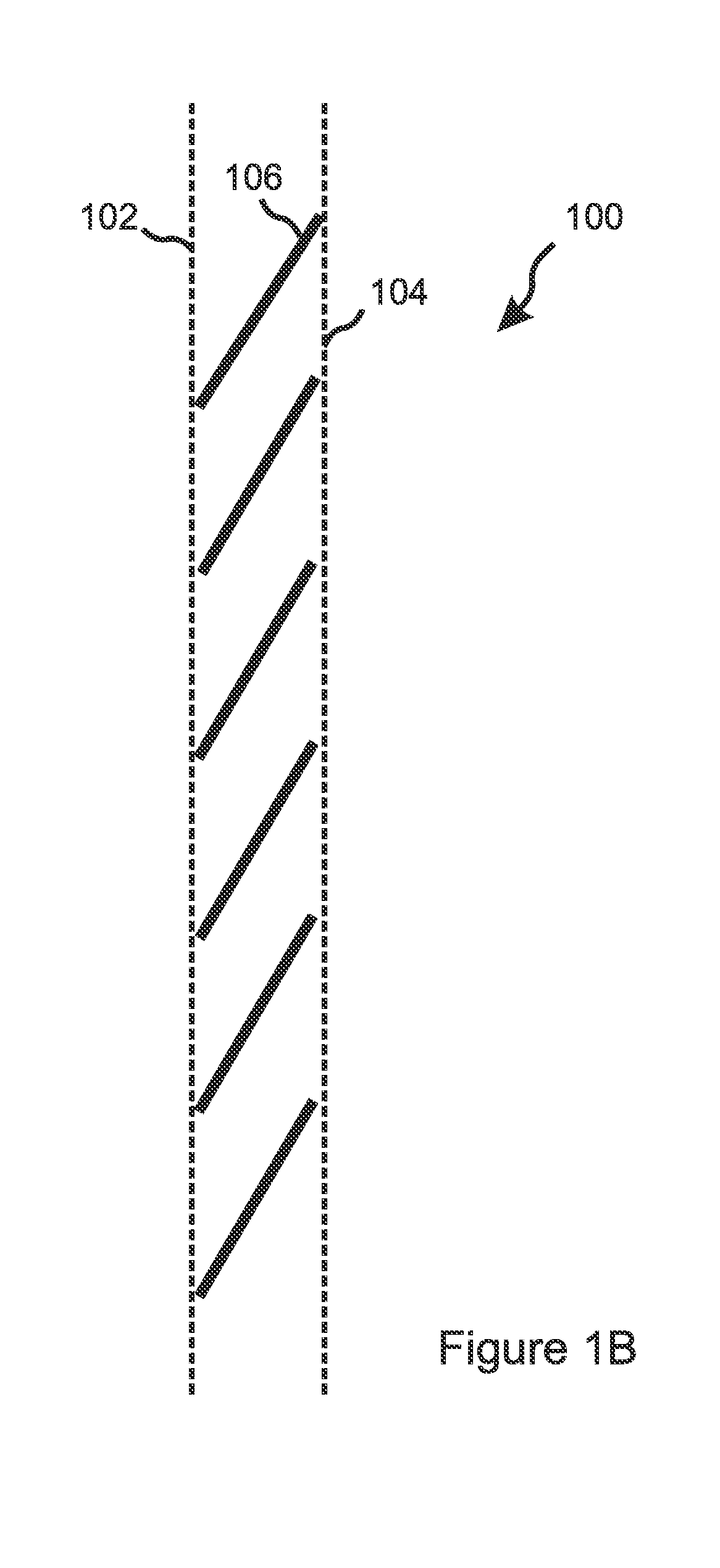

Space-variant waveplate for polarization conversion, methods and applications

InactiveUS20070115551A1Improve optical qualityPhotomechanical apparatusPolarising elementsPupilOptical polarization

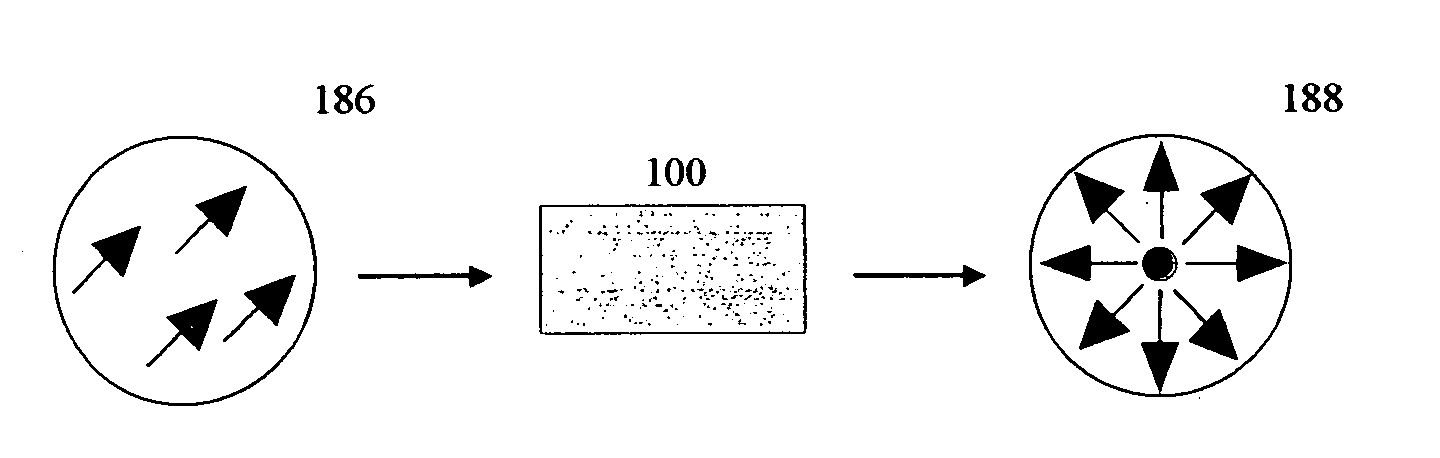

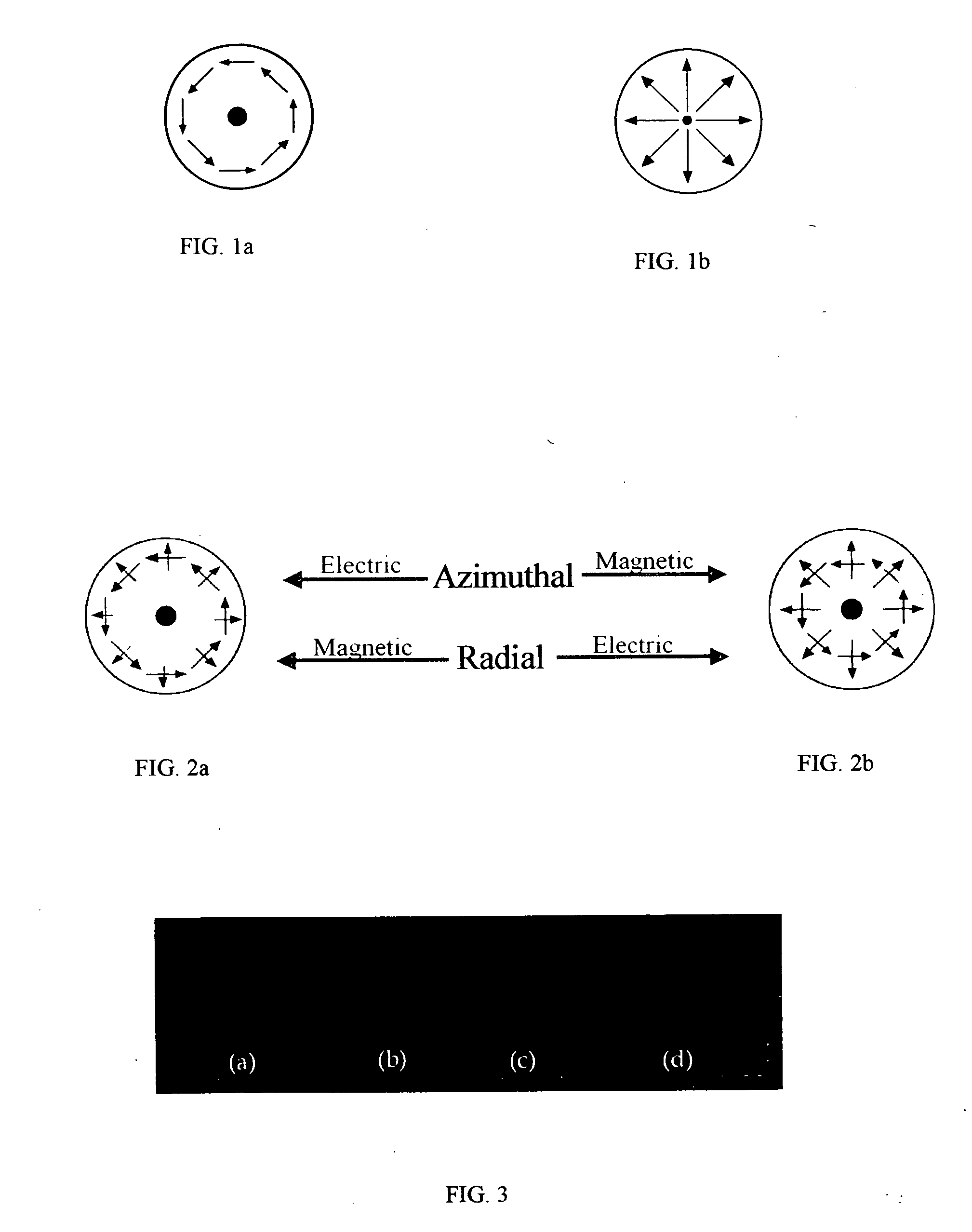

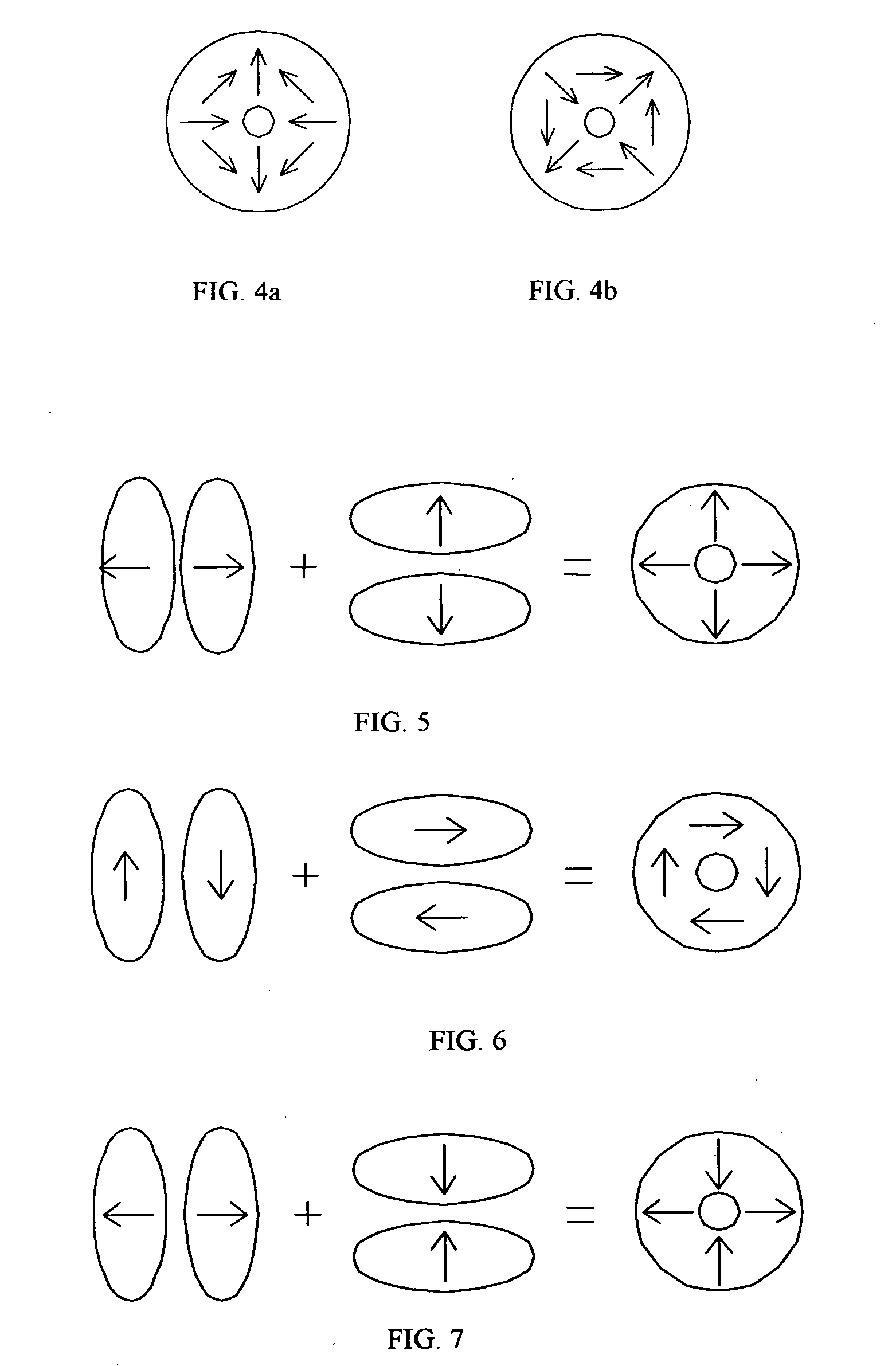

Embodiments of the invention are directed to apparatus and methods for converting spatially homogeneously polarized light into spatially inhomogeneously polarized light having a fast axis orientation that varies in a smooth and continuous manner over a pupil aperture. A space-variant waveplate referred to herein as a polarization converter includes an optically transmissive window characterized by a symmetric stress birefringence that provides at least λ / 4 retardance and, more particularly, λ / 2 retardance over an annular region centered about the optical axis of the window. Structural embodiments of the polarization converter include a mechanical compression housing and a thermal compression housing. Radially and azimuthally polarized vortex beams including cylindrical vector beams and counter-rotating beams can be generated from uniformly plane polarized input beams propagating through the polarization converter. Low-order polarization vortex beams can be optically combined to produce higher-order scalar vortex beams. Embodiments of the invention are also directed to various optical illumination and imaging systems utilizing the apparatus and methods described herein.

Owner:SPILMAN ALEXIS +1

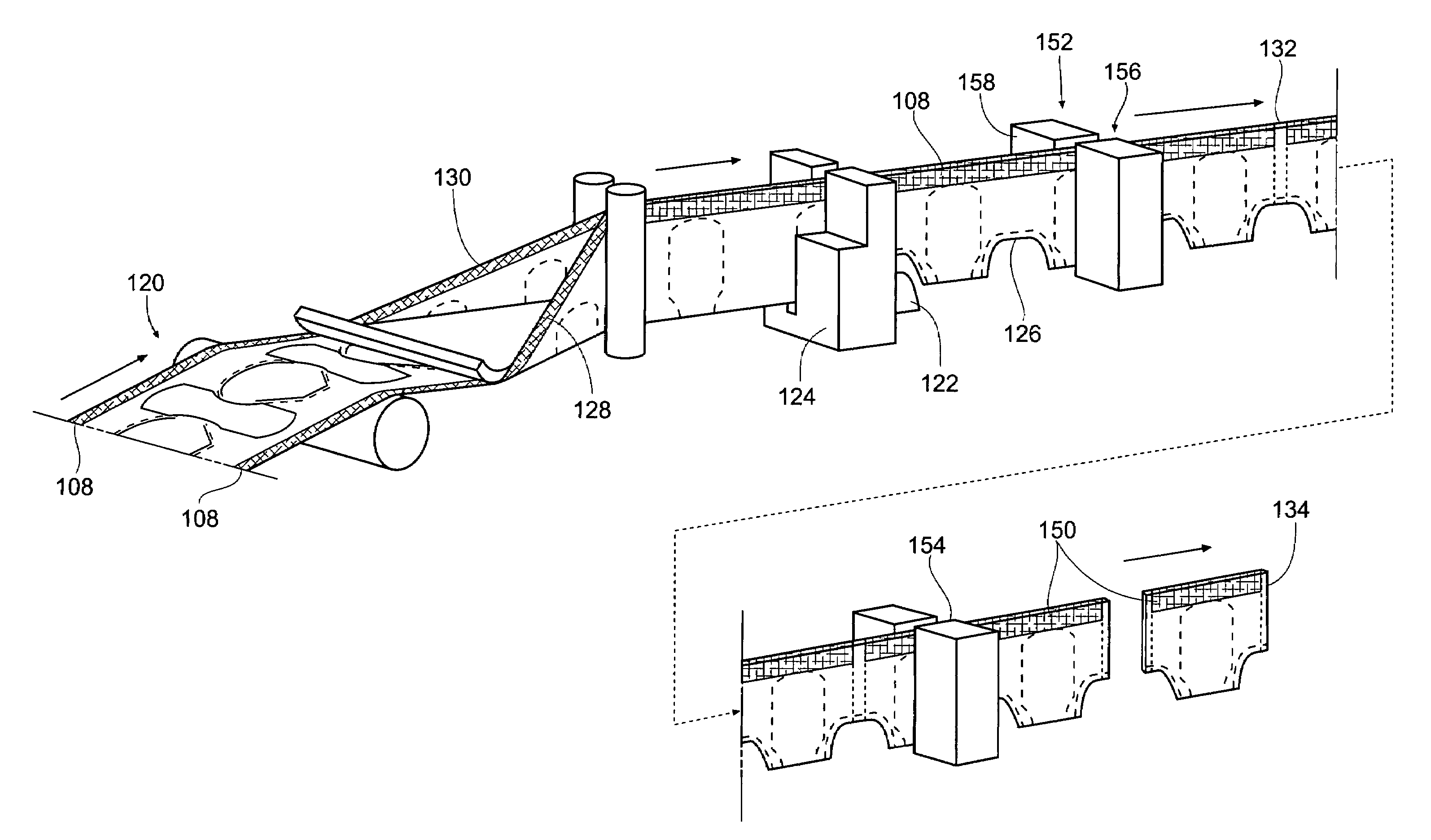

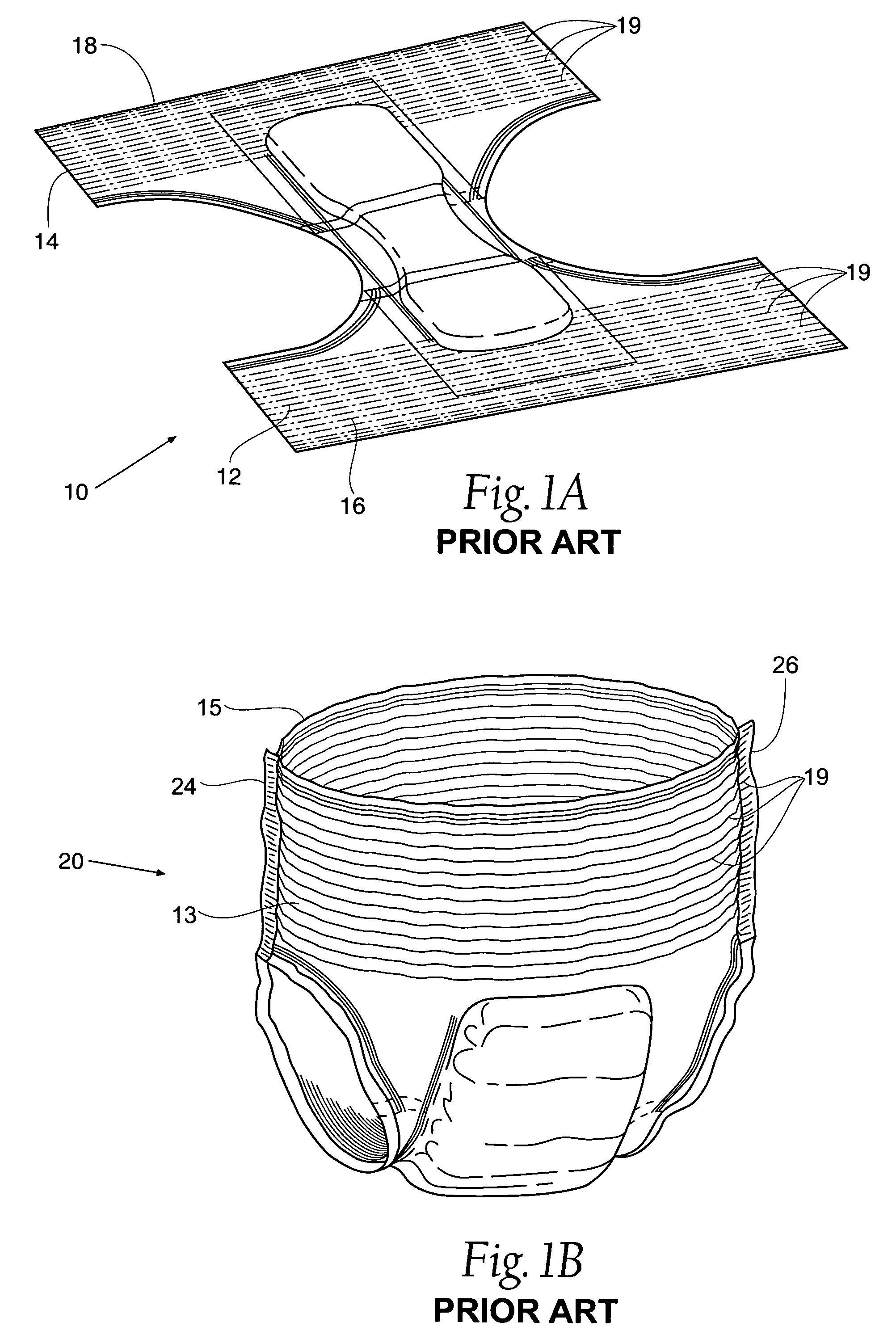

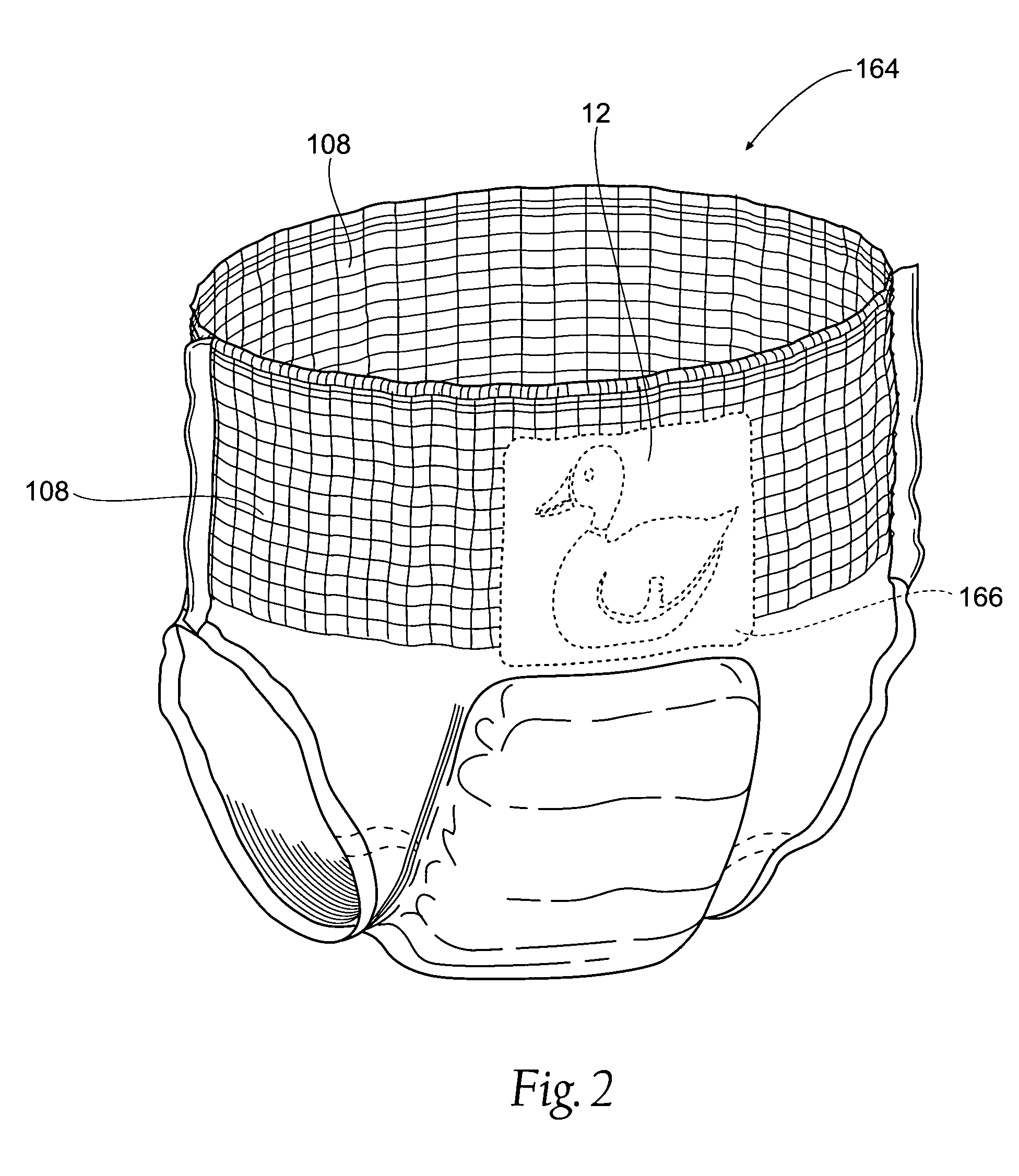

Apparatus and method for cutting elastic strands between layers of carrier webs

InactiveUS7708849B2Retain its shapeQuicker and easy placement of elastic materialLamination ancillary operationsLaminationThermal compressionBiomedical engineering

Owner:CURT G JOA

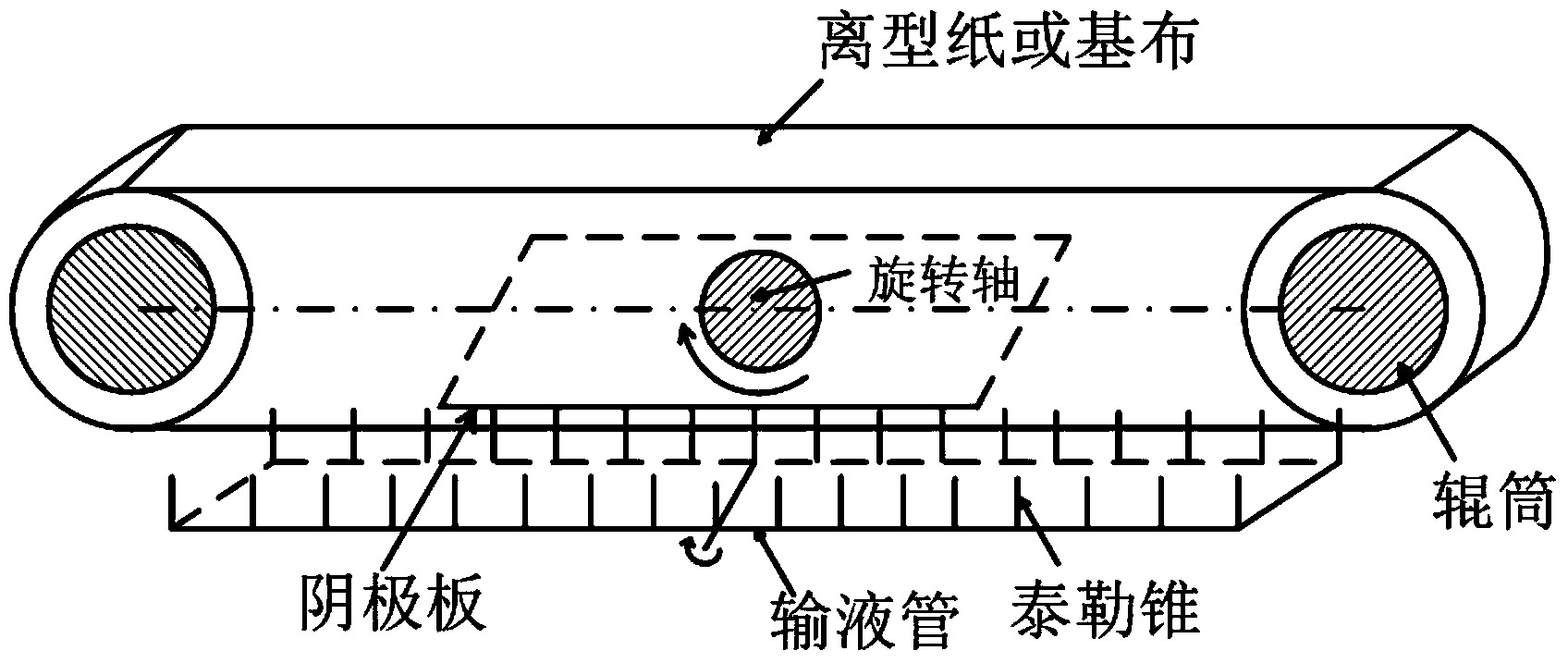

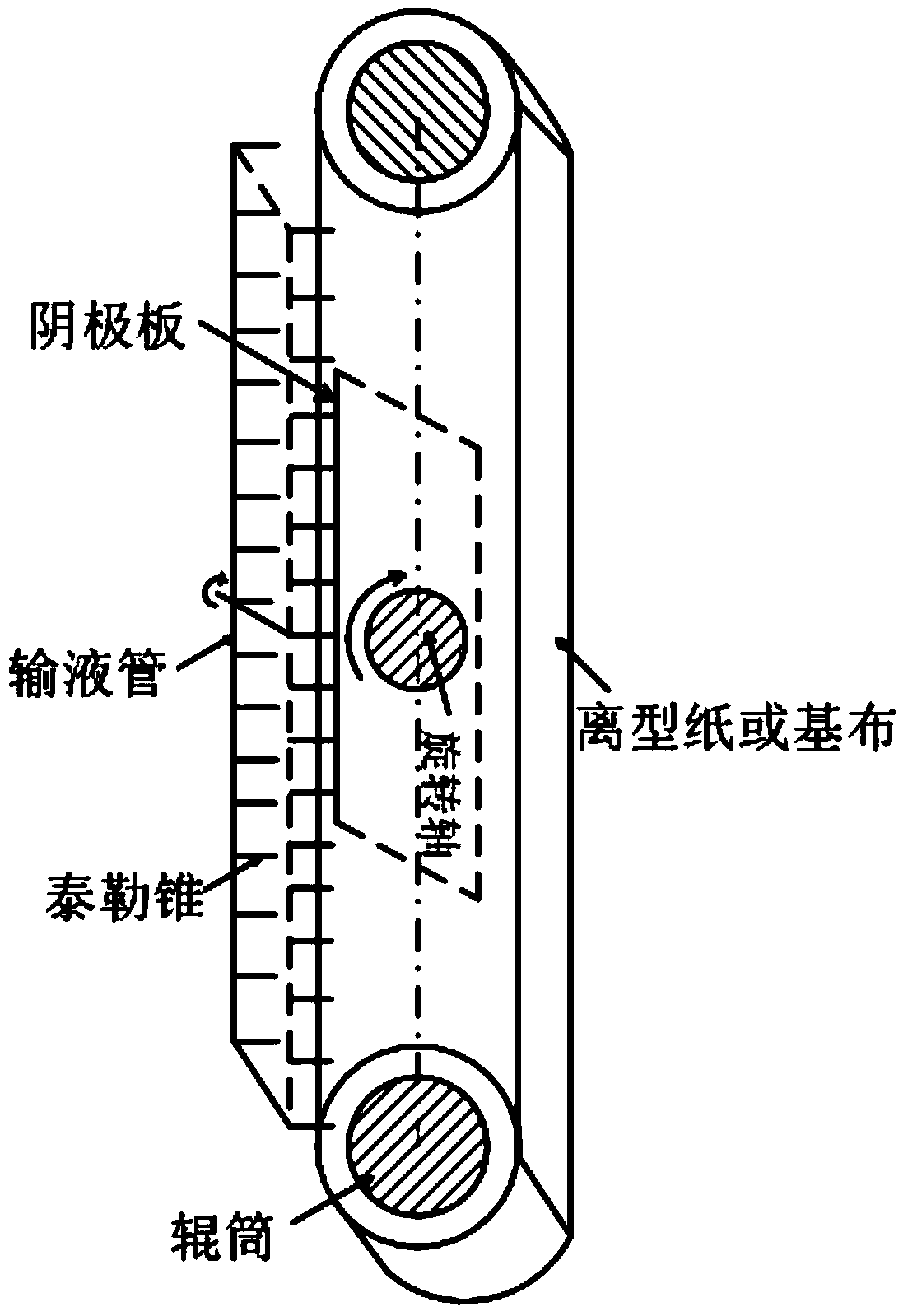

Electrostatic spinning nanofiber membrane as well as preparation method thereof

InactiveCN103437071AIncrease productivityReduce energy consumptionNon-woven fabricsChemical industryFiber

The invention provides an electrostatic spinning nanofiber membrane as well as a preparation method thereof. The electrostatic spinning nanofiber membrane provided by the invention comprises a fiber membrane obtained by electrostatically spinning a high-melting-point polymer and a fiber membrane obtained by electrostatically spinning a low-melting-point polymer, wherein the difference on the melting points of the high-melting-point polymer and the low-melting-point polymer is not less than 10 DEG C. The electrostatic spinning nanofiber membrane provided by the invention is multipurpose and can be applied to the fields such as biomedicines, energy and chemical industry, gas and liquid filtration, waterproofness and windproofness, windproofness and heat insulation, moisture permeability and ventilation, environmental management and semiconductor sensors. According to the electrostatic spinning nanofiber membrane provided by the invention, electrostatic spinning is respectively carried out on the high-melting-point polymer and the low-melting-point polymer, and the high-melting-point polymer fiber membrane and the low-melting-point polymer fiber membrane obtained are composited and hot-pressed to obtain the electrostatic spinning nanofiber membrane. The preparation method provided by the invention is high in production efficiency and low in energy consumption, and is suitable for industrial production.

Owner:ZHEJIANG WEIXING IND DEV

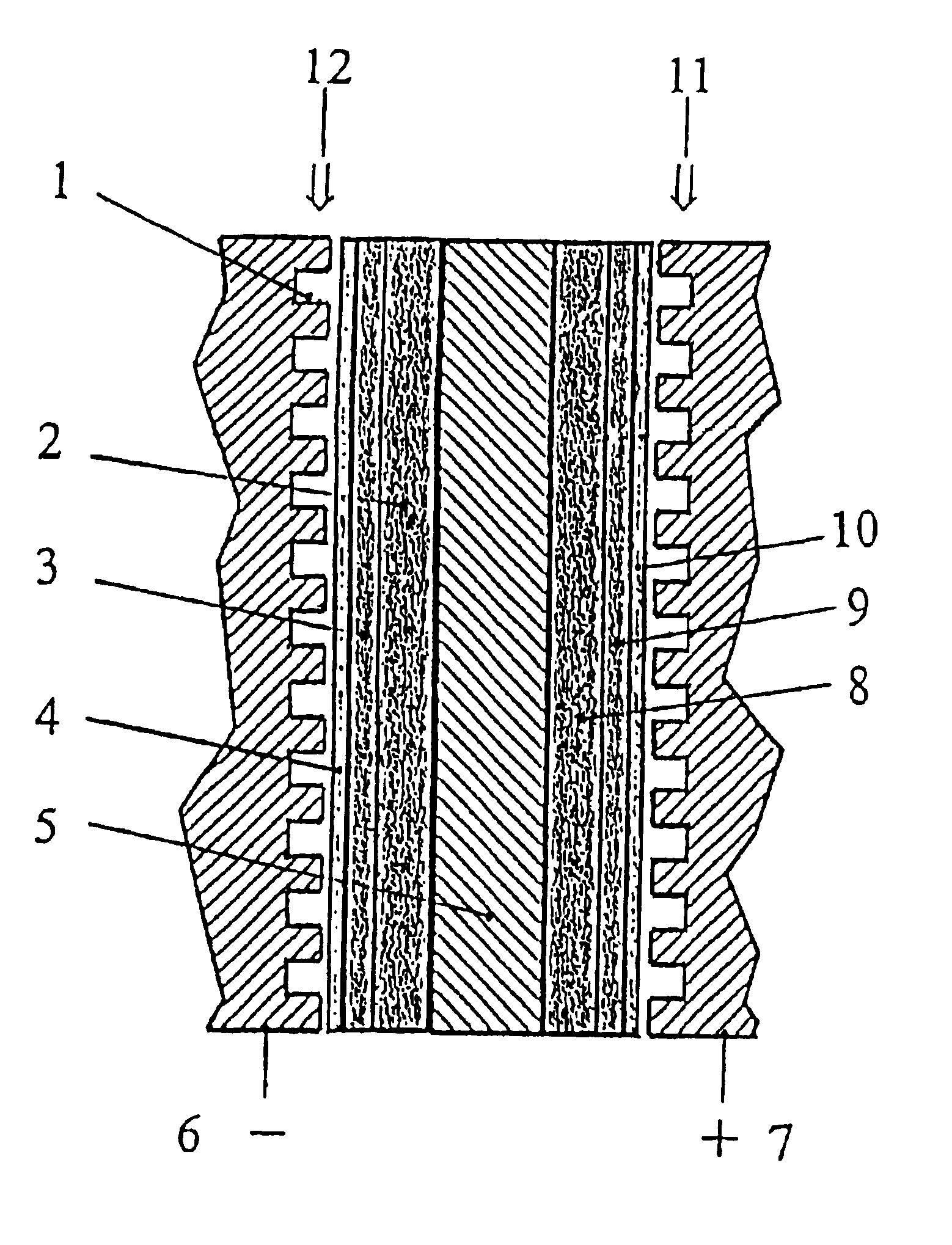

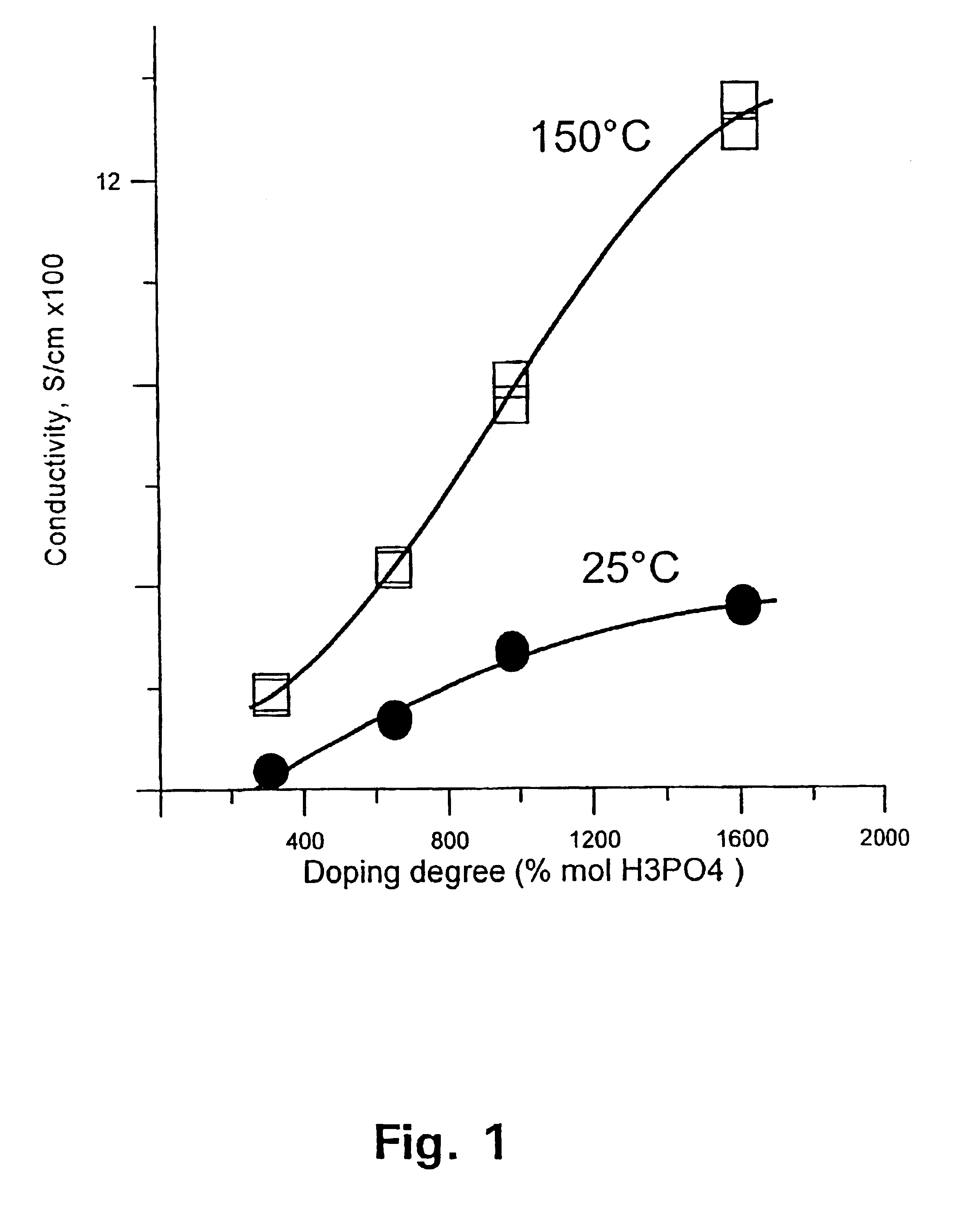

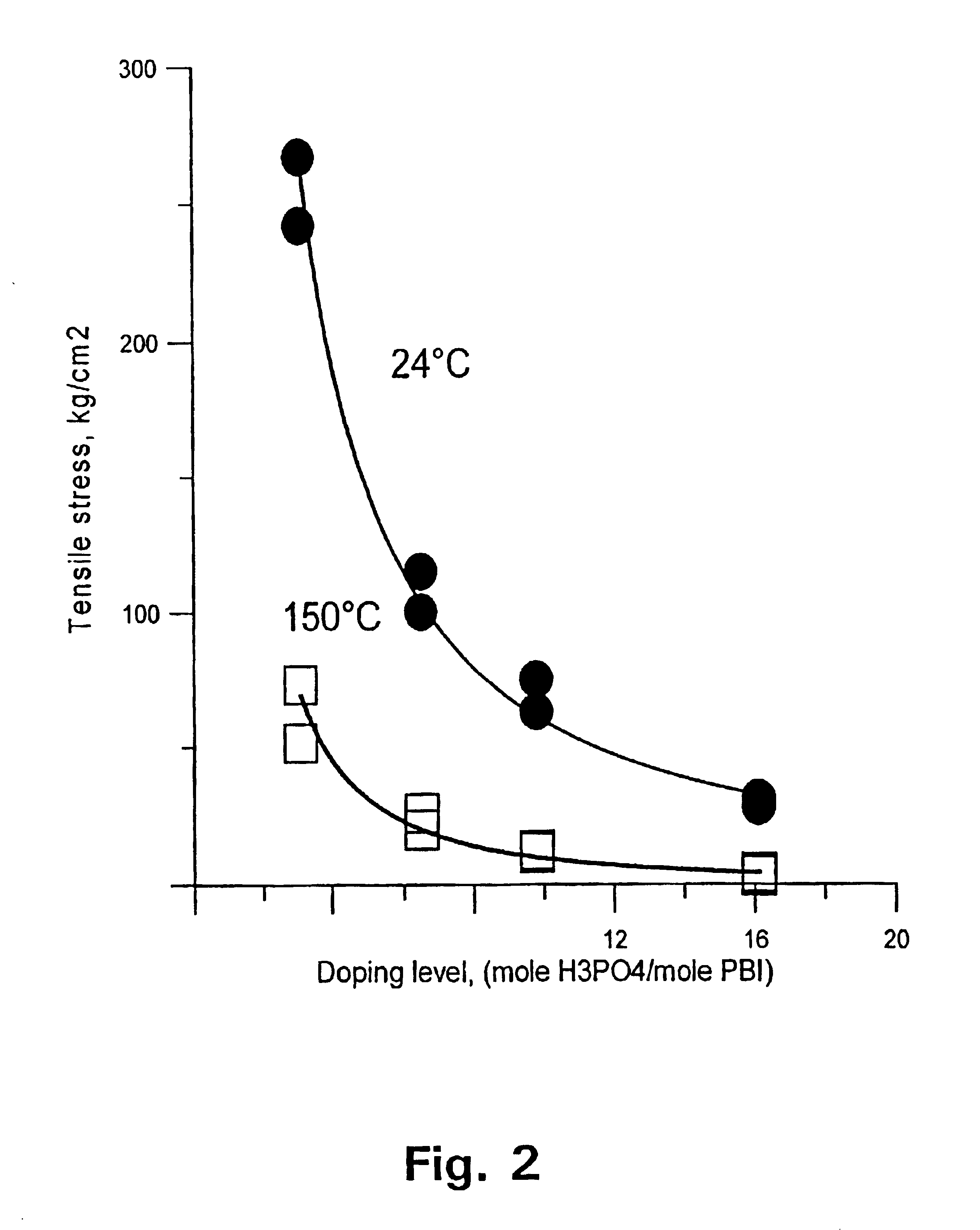

Polymer electrolyte membrane fuel cells

InactiveUS6946211B1Improve performanceImprove toleranceSolid electrolytesPrimary cellsThermoplasticGas diffusion electrode

A method for preparing polybenzimidazole or polybenzimidazole blend membranes and fabricating gas diffusion electrodes and membrane-electrode assemblies is provided for a high temperature polymer electrolyte membrane fuel cell. Blend polymer electrolyte membranes based on PBI and various thermoplastc polymers for high temperature polymer electrolyte fuel cells have also been developed. Miscible blends are used for solution casting of polymer membranes (solid electrolytes). High conductivity and enhanced mechanical strength were obtained for the blend polymer solid electrolytes. With the thermally resistant polymer, e.g., polybenzimidazole or a mixture of polybenzimidazole and other thermoplastics as binder, the carbon-supported noble metal catalyst is tape-cast onto a hydrophobic supporting substrate. When doped with an acid mixture, electrodes are assembled with an acid doped solid electrolyte membrane by hot-press. The fuel cell can operate at temperatures up to at least 200° C. with hydrogen-rich fuel containing high ratios of carbon monoxide such as 3 vol % carbon monoxide or more, compared to the carbon monoxide tolerance of 10-20 ppm level for Nafion®-based polymer electrolyte fuel cells.

Owner:DANISH POWER SYST

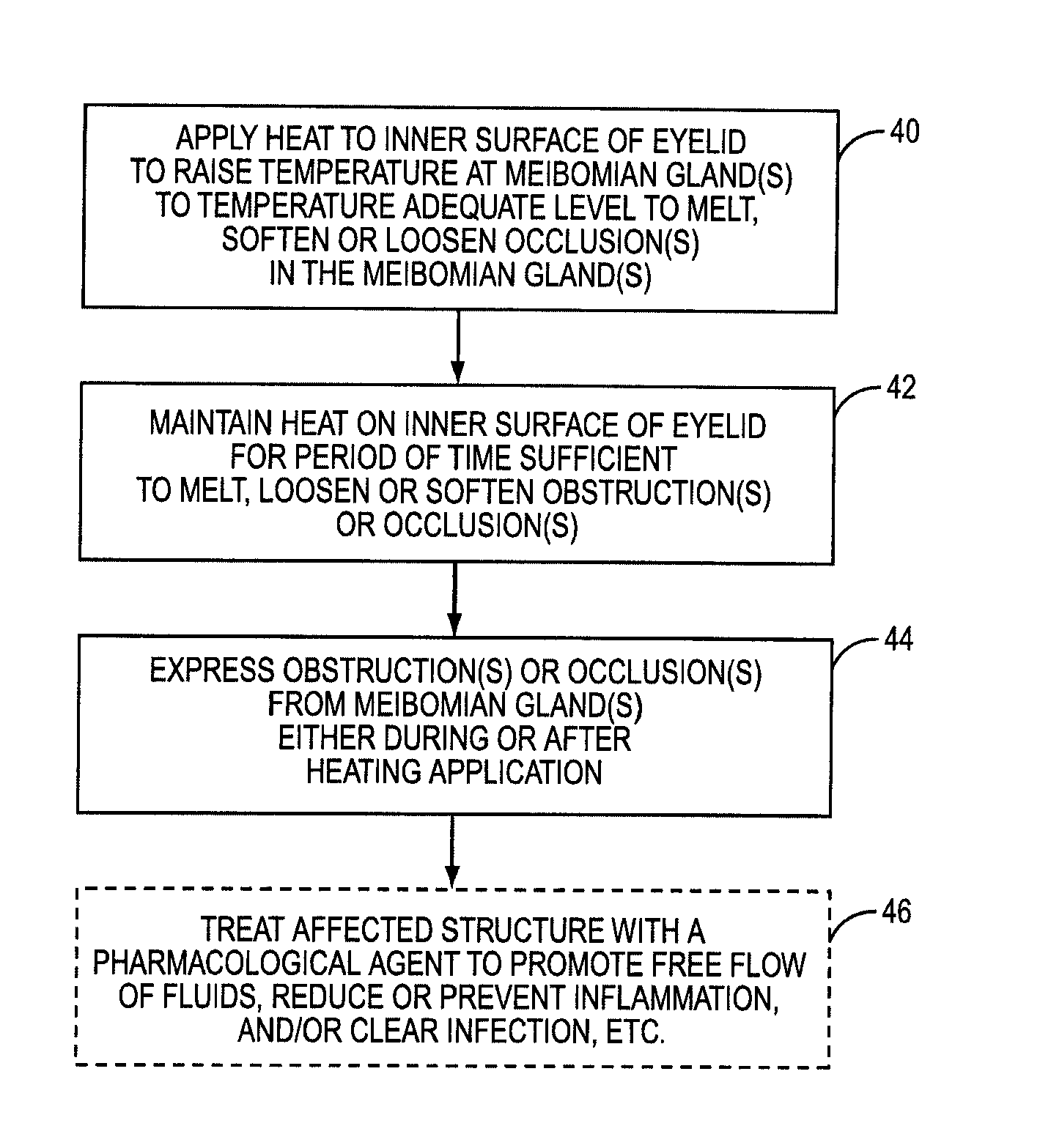

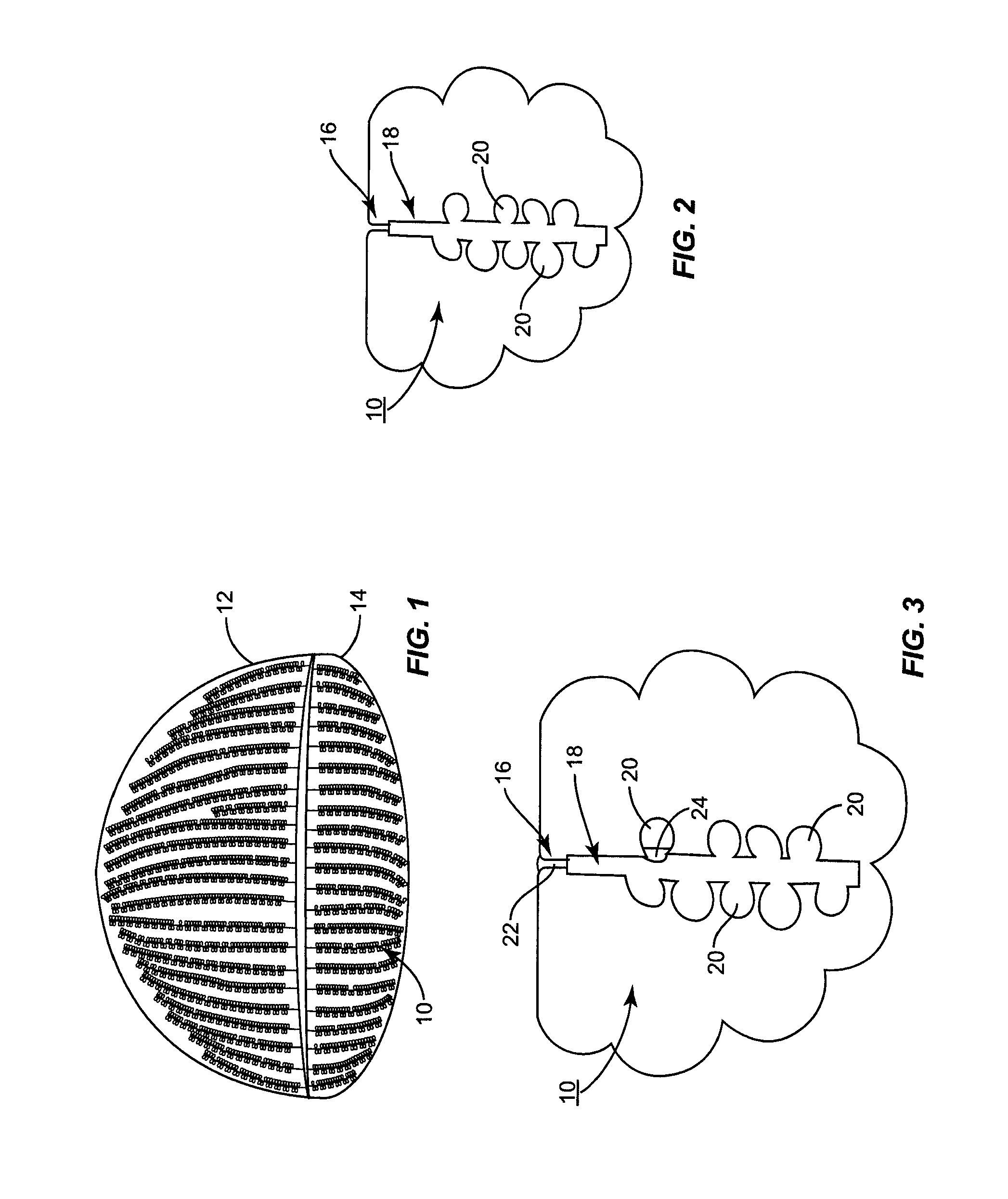

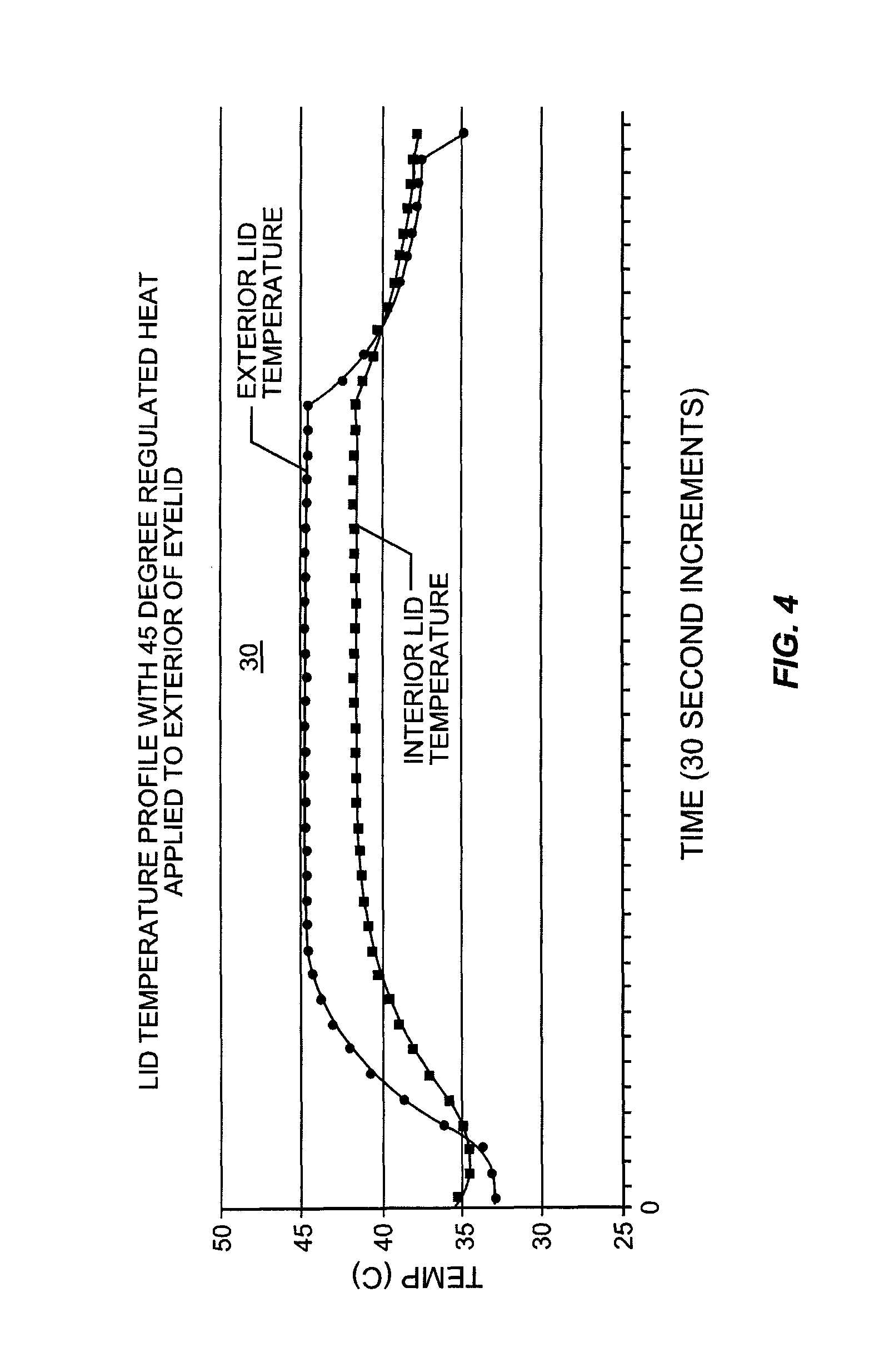

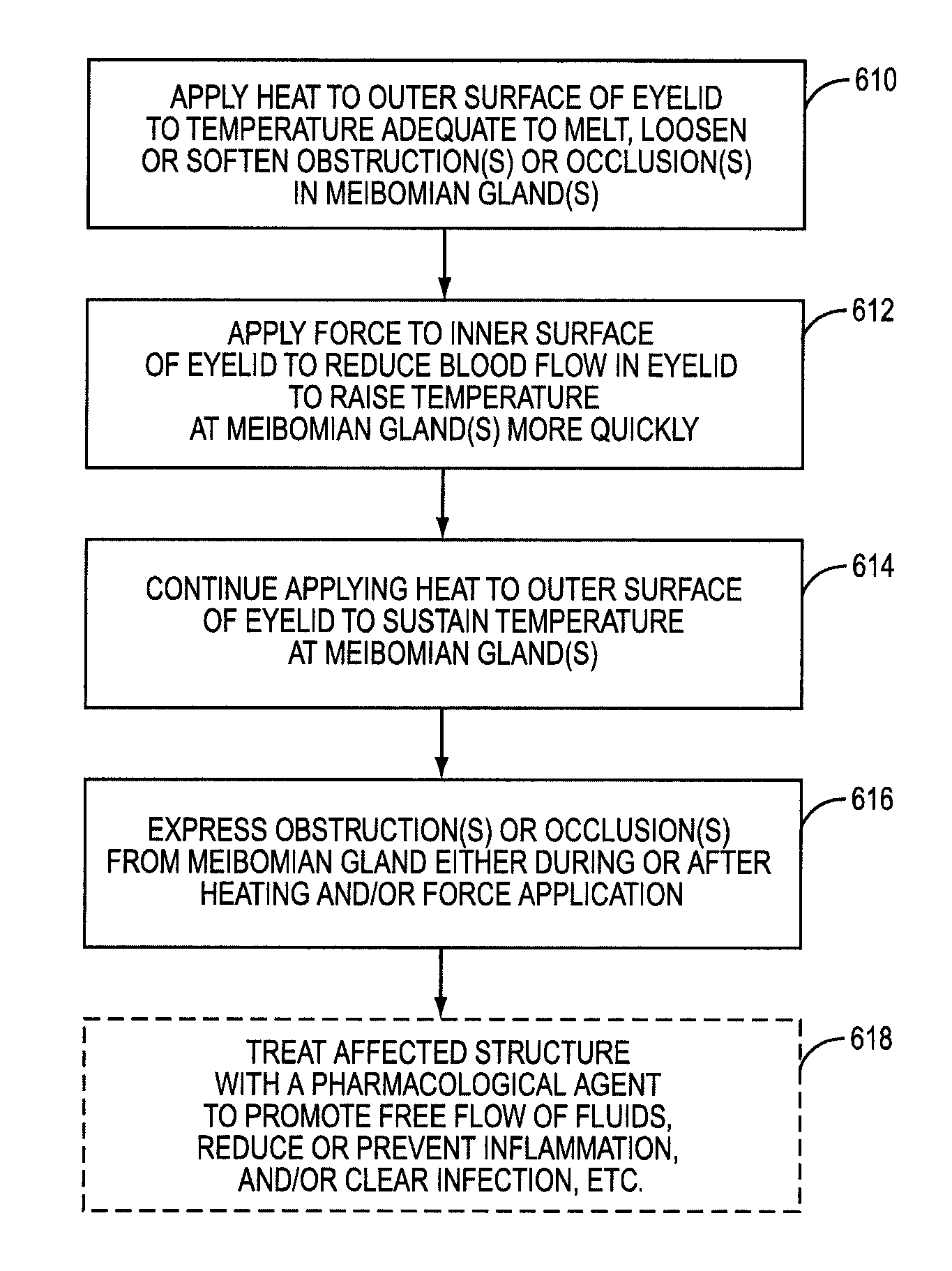

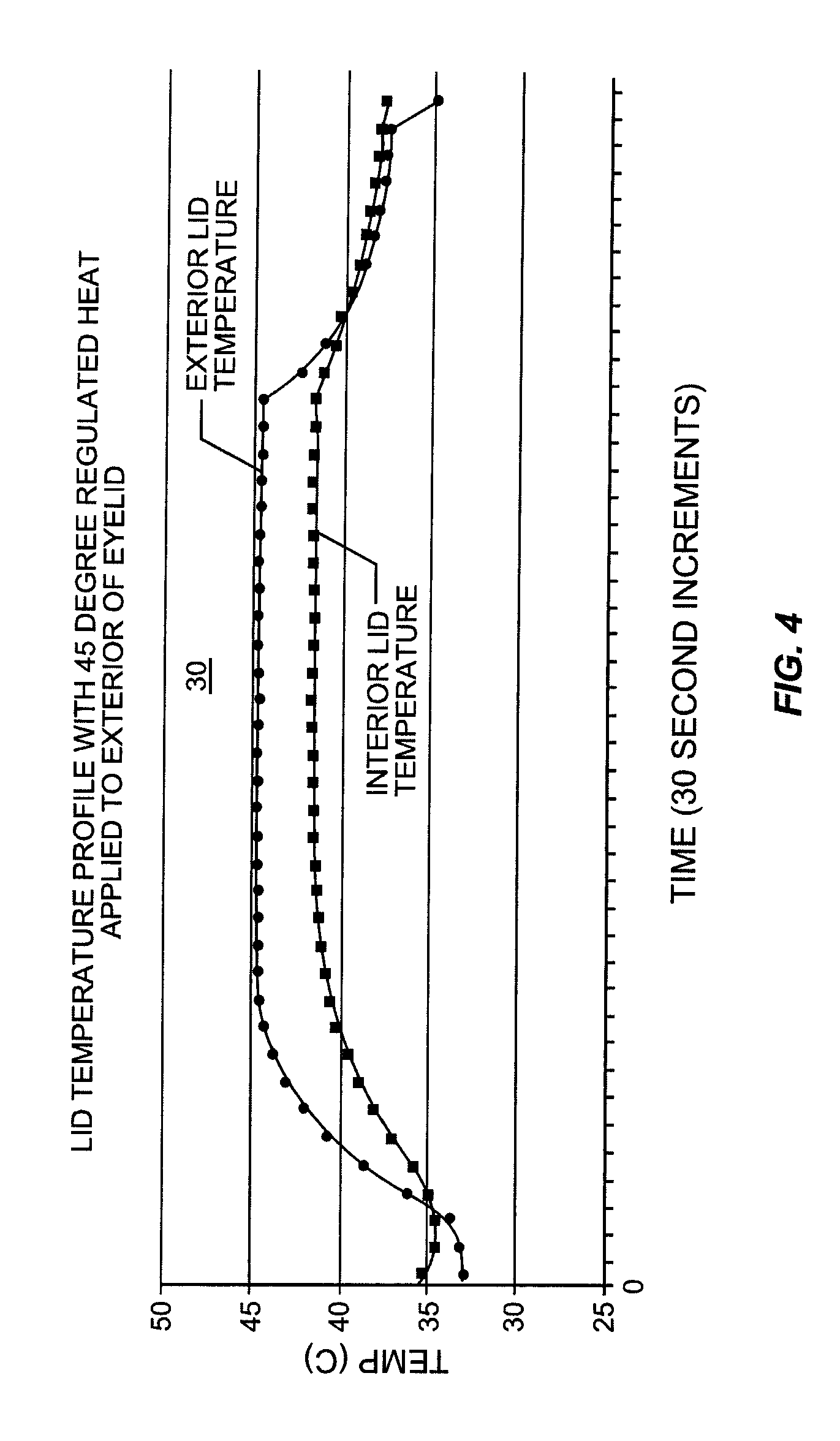

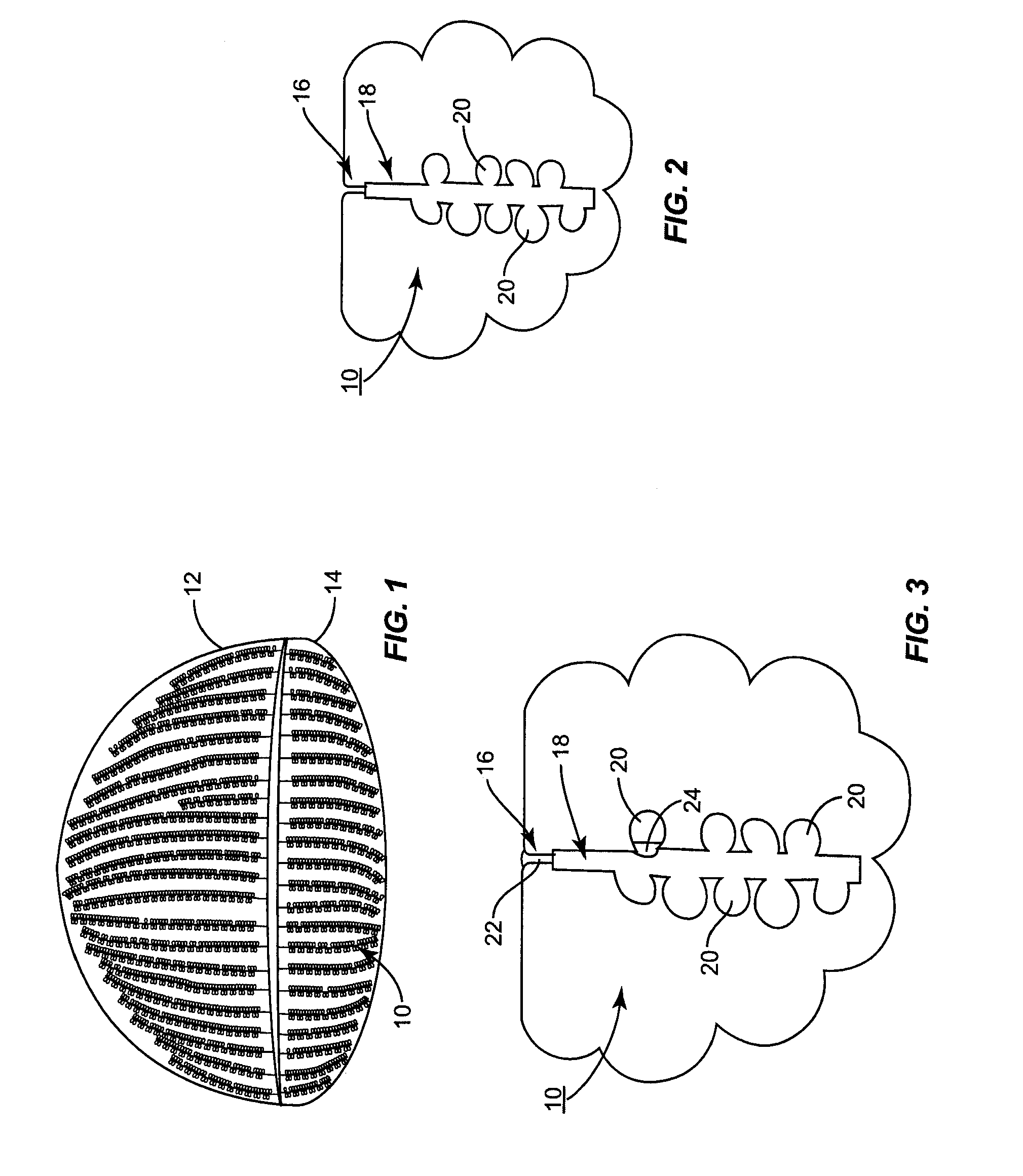

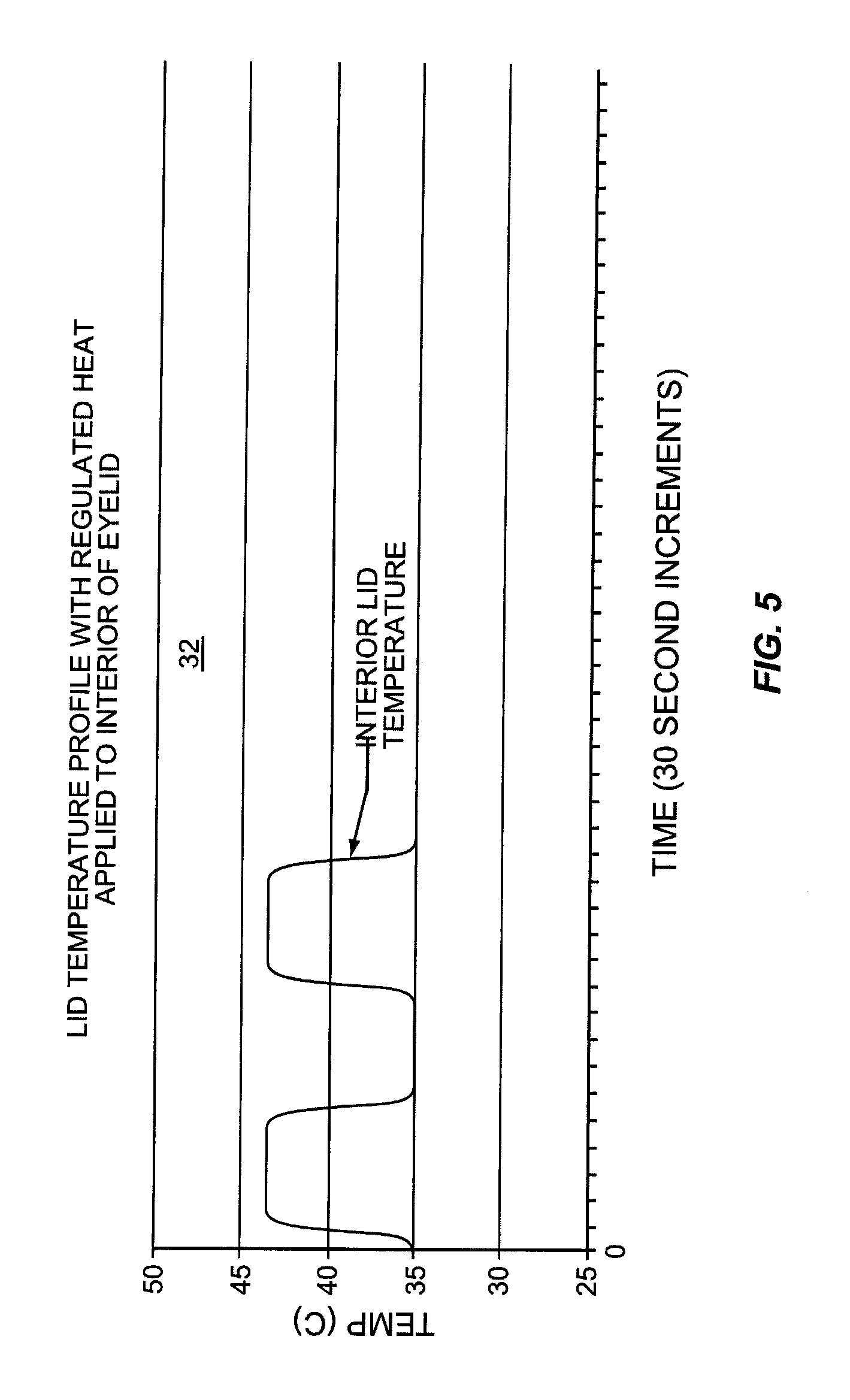

Inner eyelid heat and pressure treatment for treating meibomian gland dysfunction

ActiveUS7976573B2Effectively and efficiently raiseImprove sebum flowUltrasound therapyEye surgeryMedicineThermal compression

A method of treating meibomian gland dysfunction. Heat is applied to the inside of the eyelid to provide conductive heat transfer to the meibomian glands. The application of heat assists in the expression of obstructions or occlusions in the meibomian glands to restore sufficient sebum flow to the lipid layer to treat dry eye. Temperatures at the meibomian glands reach desired levels more quickly and efficiently when heating the inside of the eyelid. Reaching such higher temperature levels may be instrumental in removing obstructions in the meibomian glands. Less time may also be required to reach desired temperature levels when applying heat to the inside of the eyelid. A force may also be applied to the inside of the patient's eyelid to improve conductive heat transfer and reduce blood flow in the eyelid that causes convective heat loss. Thus, the application of force can further increase the temperature level and / or reduce the time to reach desired temperature levels for removing obstructions.

Owner:TEARSCIENCE INC

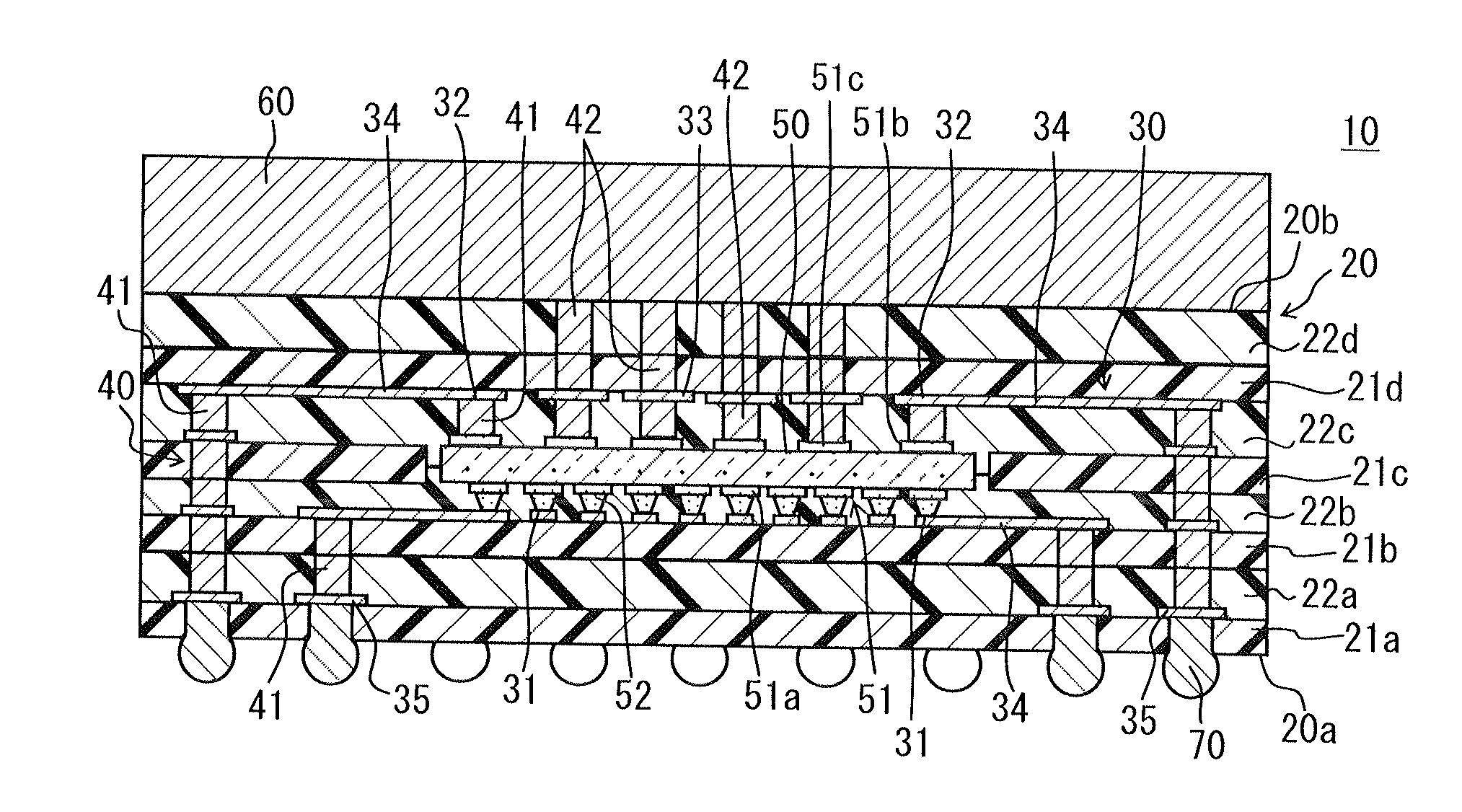

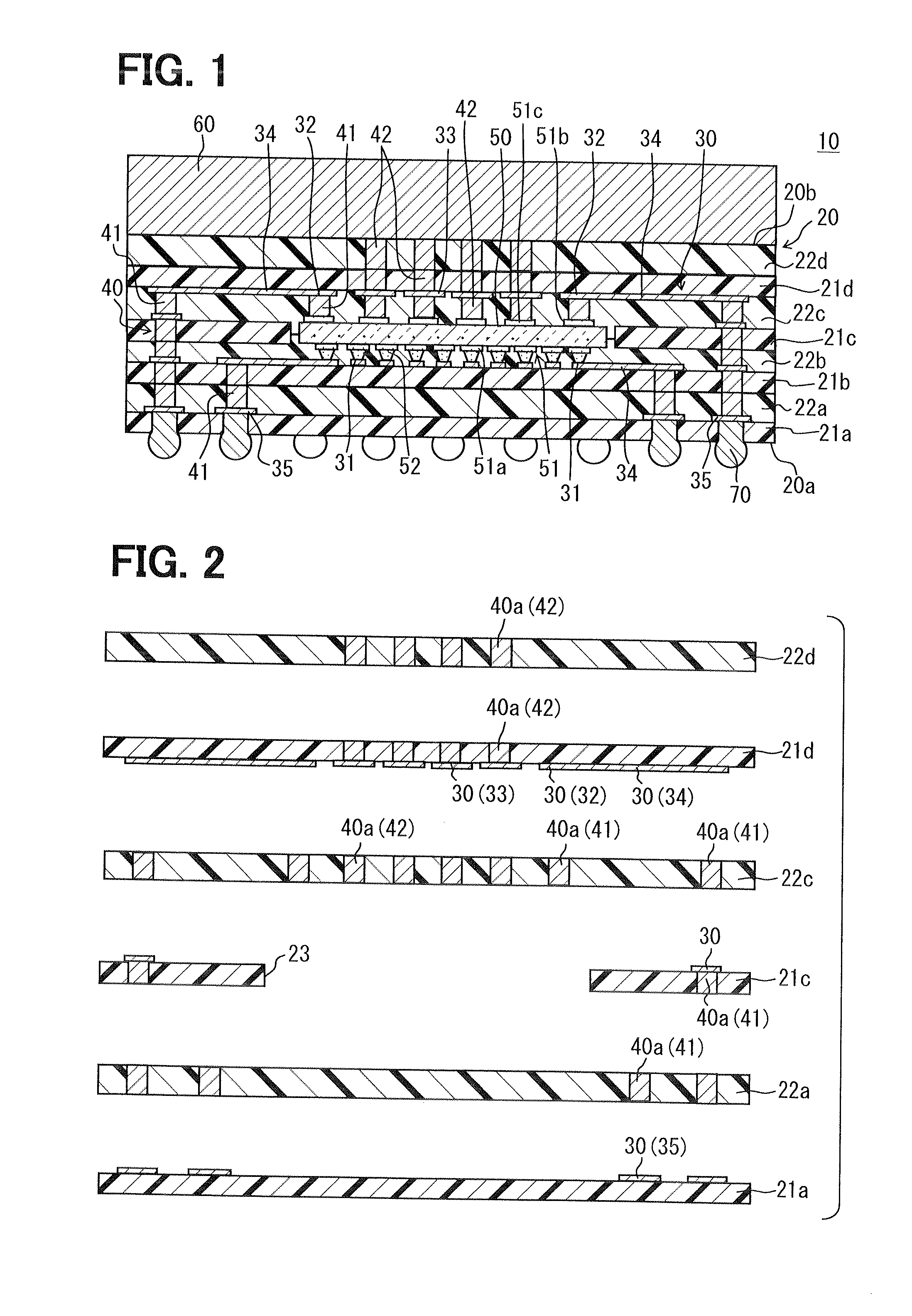

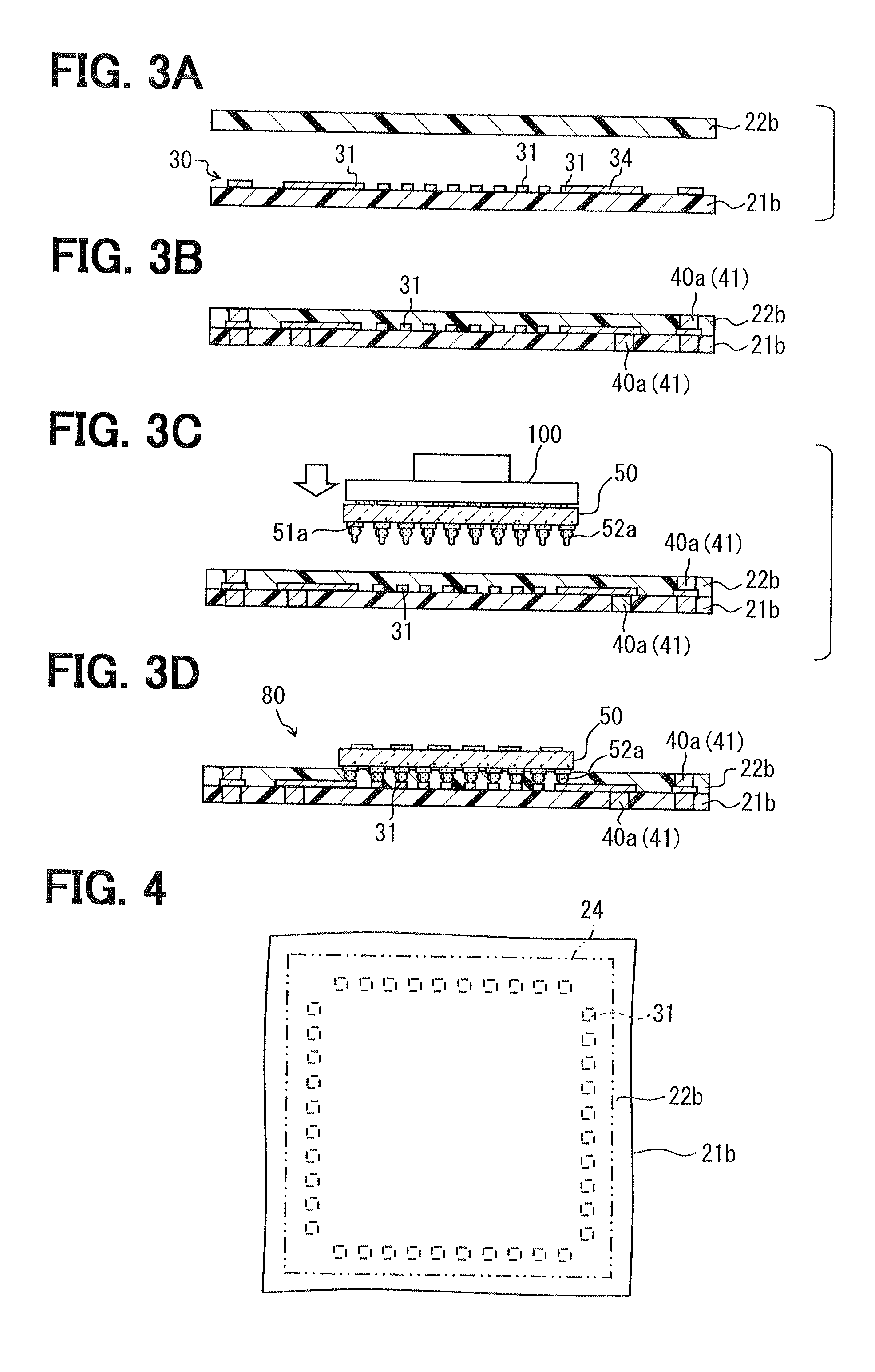

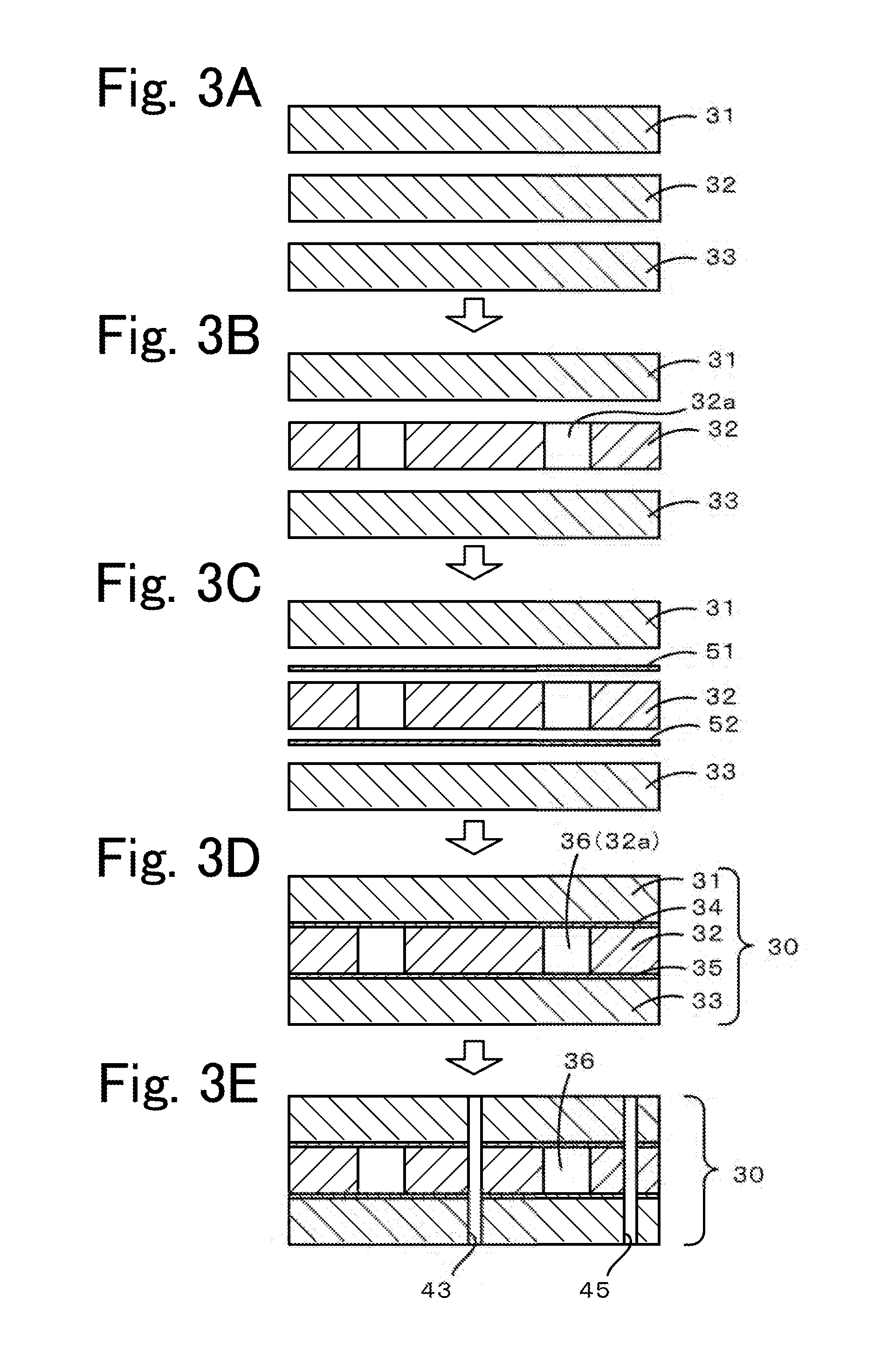

Manufacturing method of semiconductor chip-embedded wiring substrate

InactiveUS20110244636A1Simple manufacturing processShorten production timeSemiconductor/solid-state device detailsPrinted circuit aspectsSemiconductor chipThermal compression

With respect to a substrate including a first film, on a surface of which a pad is formed, a second film made of thermoplastic resin is a thermal compression bonded to a pad formation surface of the substrate. A stud bump formed on a semiconductor chip is stuffed into the second film while melting the second film and is pressure welded to the pad by application of pressure and heat. The melted second film seals between the semiconductor chip and the substrate. Then, multiple resin films are stacked with the substrate and the second film to form a stacked body. In a pressurizing and heating process, the multiple resin films, the substrate and the second film are integrated at one time so that the stud bump is bonded to the pad.

Owner:DENSO CORP

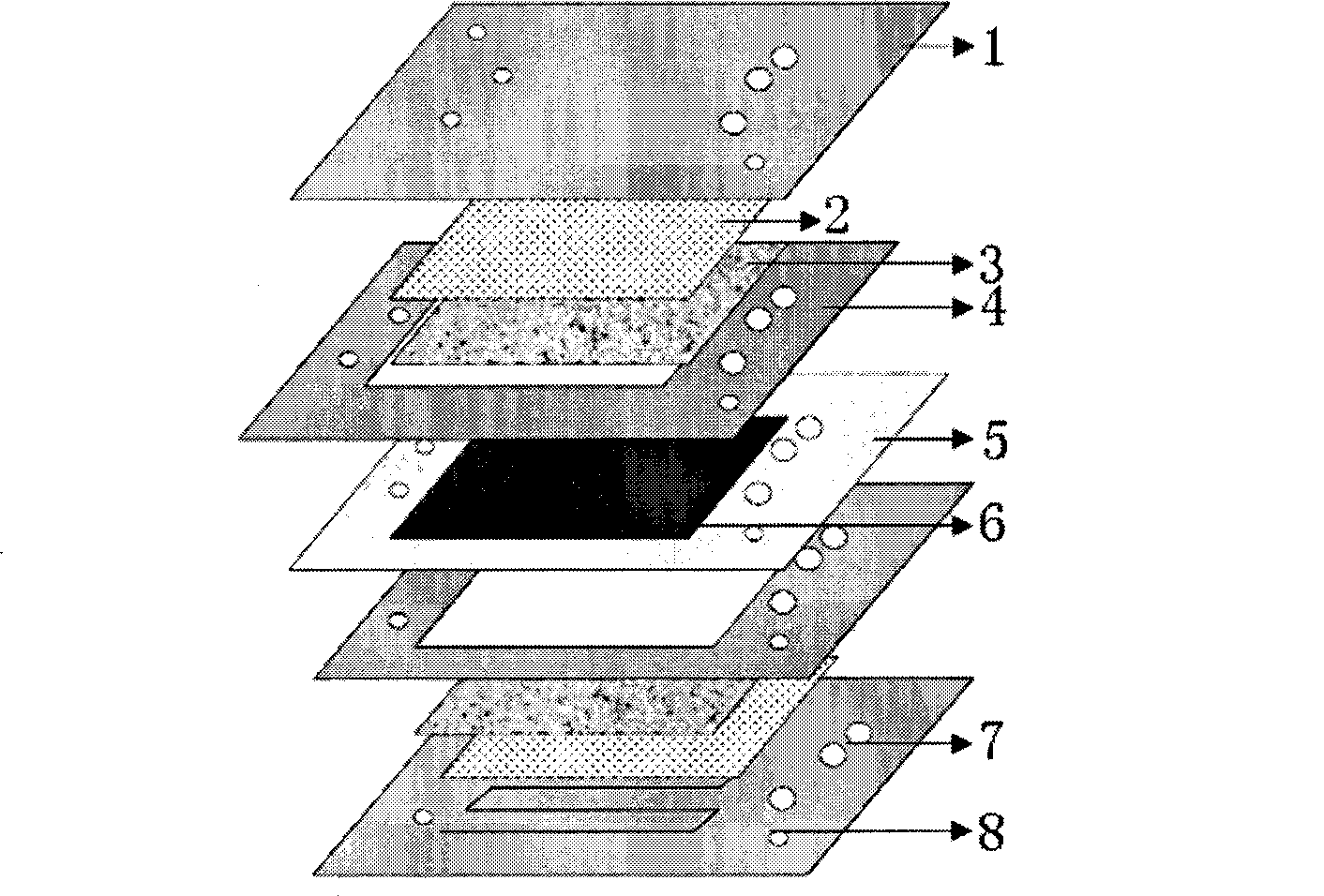

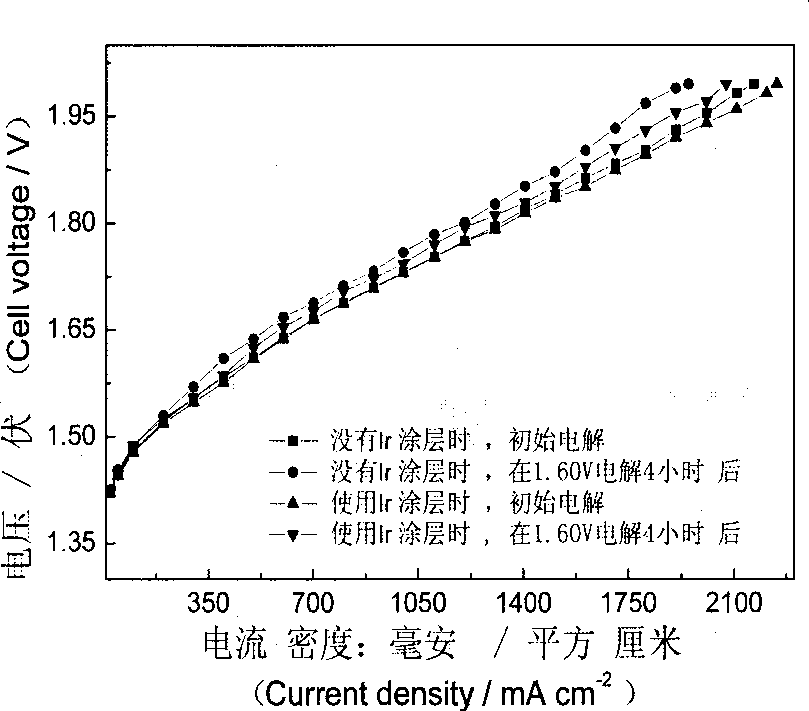

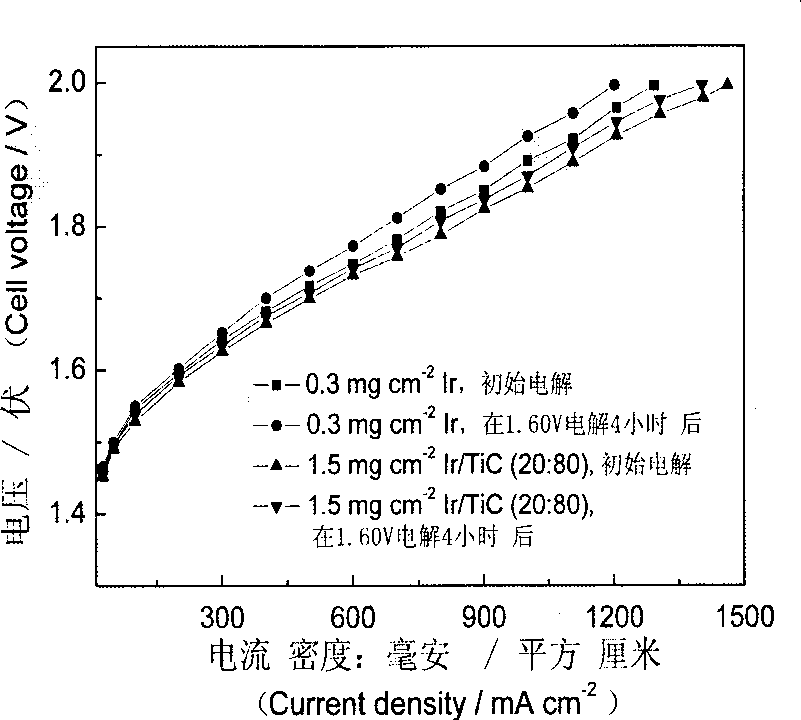

Membrane electrode for proton exchange membrane water electrolysis battery and preparation thereof

InactiveCN101388463AReduce loadReduce contact resistanceCell electrodesSolid electrolyte fuel cellsNano catalystElectrolysis

The invention discloses a proton exchange membrane water electrolyte battery membrane electrode and a process for preparation thereof, which belongs to the technical field of preparing hydrogen gas through electrolyzing water, wherein the proton exchange membrane water electrolyte battery membrane electrode comprises a polymer electrolyte membrane, an anode catalyst layer, a cathode catalyst layer, an anode diffusion layer, a cathode diffusion layer, a support layer and a flow field plate, wherein hydrophilic thin layer structures which are formed by catalyst are respectively brushed on both surfaces of the polymer electrolyte membrane. Anode catalyst is noble metal or metallic material, and the diffusion layer is carbon material or metallic material. A catalyst layer and the relative diffusion layer and the support layer are compacted in a titanium plate to prepare membrane electrode through utilizing external force under normal temperature. The invention lowers the load of catalyst, improves the operating factor of catalyst, avoids the deformation of membranes in the process of heat pressing, and is drawn supported from the catalytic and corrosion resistance property of an anti-corrosion diffusion layer with catalytic property, and the electrolytic property and the stability of a battery are improved. The invention has the advantages of simple technique, convenient operation and excellent repeatability.

Owner:SHANGHAI JIAO TONG UNIV

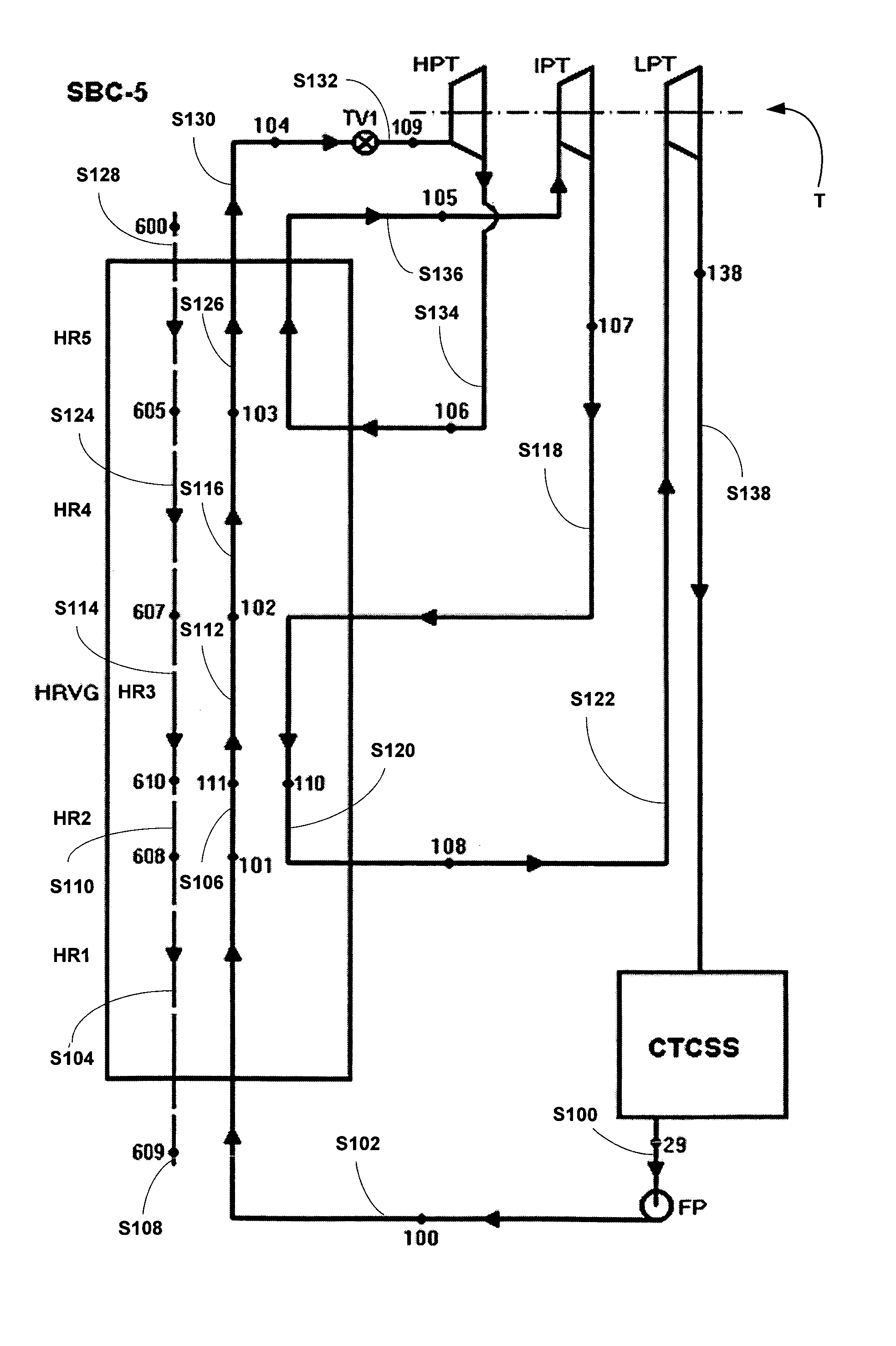

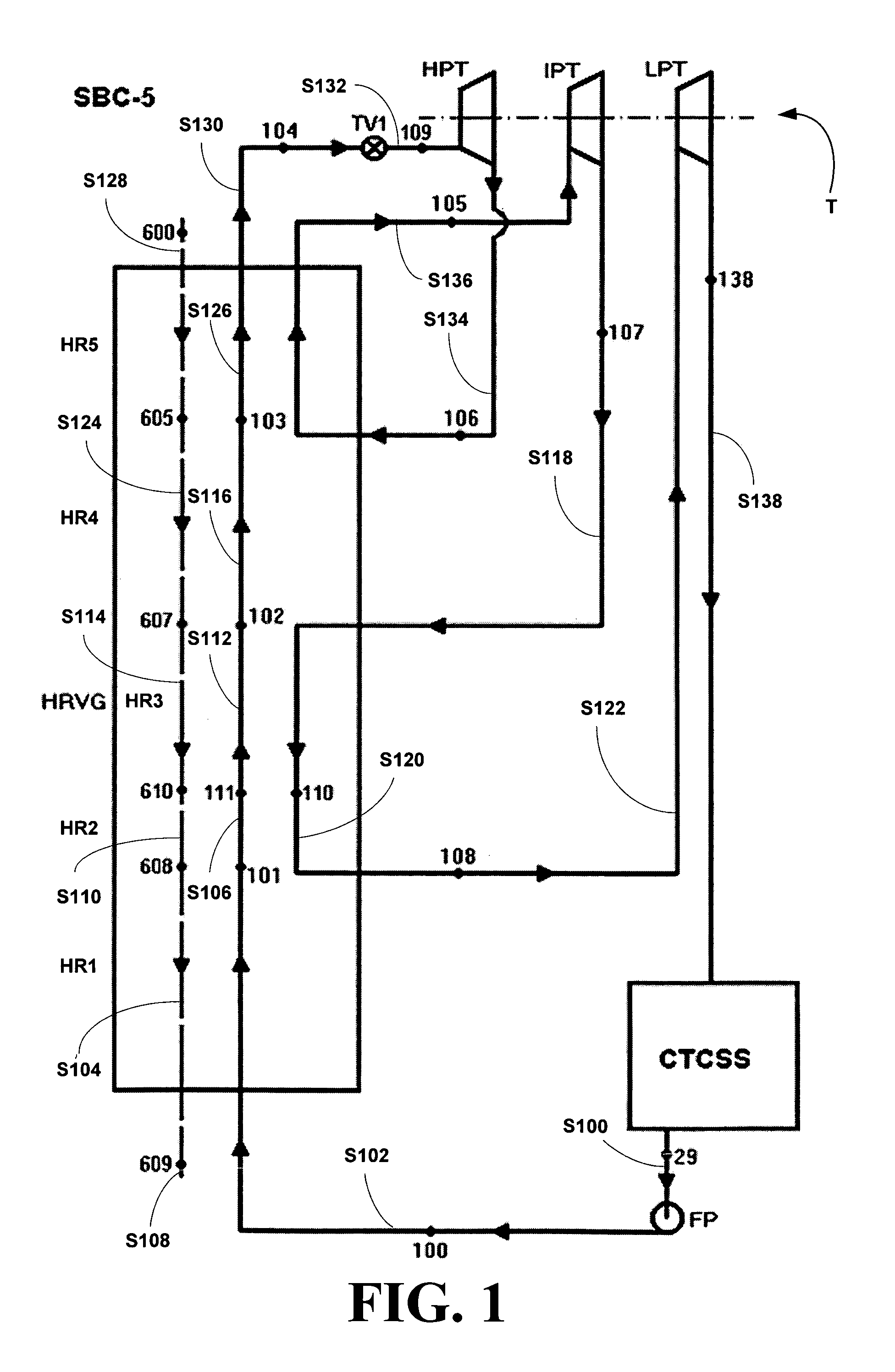

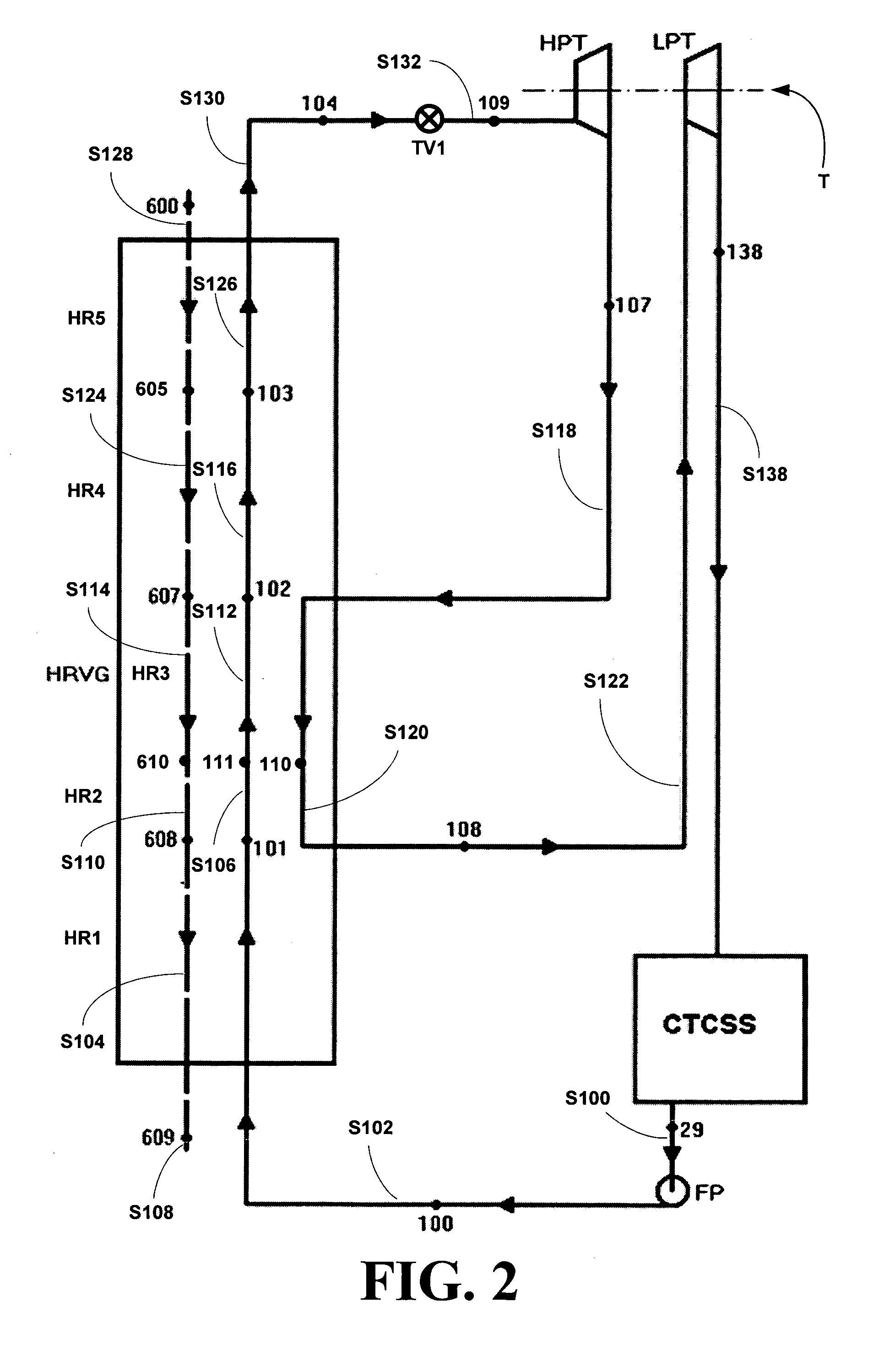

System and apparatus for power system utilizing wide temperature range heat sources

Owner:KALINA POWER LTD

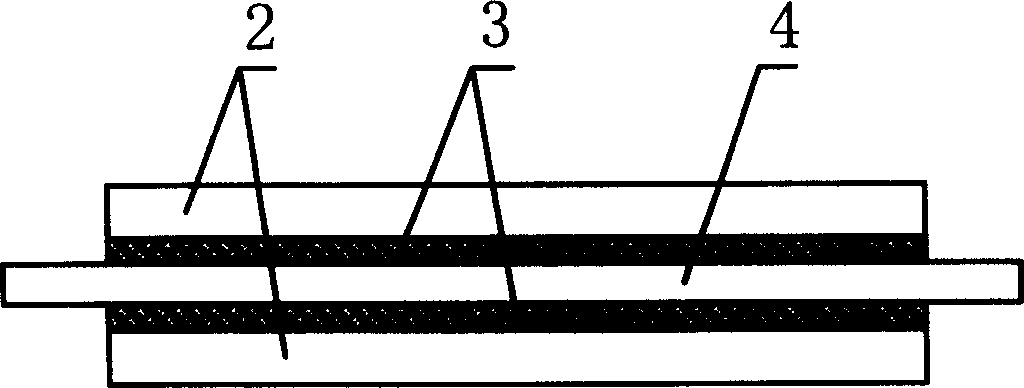

High shielding effect information leakage preventing glass

InactiveCN1482853AContainment leakImprove visibilityMagnetic/electric field screeningScreening apparatusHuman bodySheet film

The invention discloses a glass for prevention of information leakage which comprises glass, metal mesh and polycarbonate film, wherein two layers of polycarbonate films are arranged on each side of the metal mesh, a layer of glass is adhered on the outboard of the polycarbonate film by thermal compression bonding to form a unitary. The invention can effectively prevent information leakage, and diminishes the possible injury by the electromagnetic wave to the human body. íí

Owner:北京安方电磁屏蔽技术开发中心

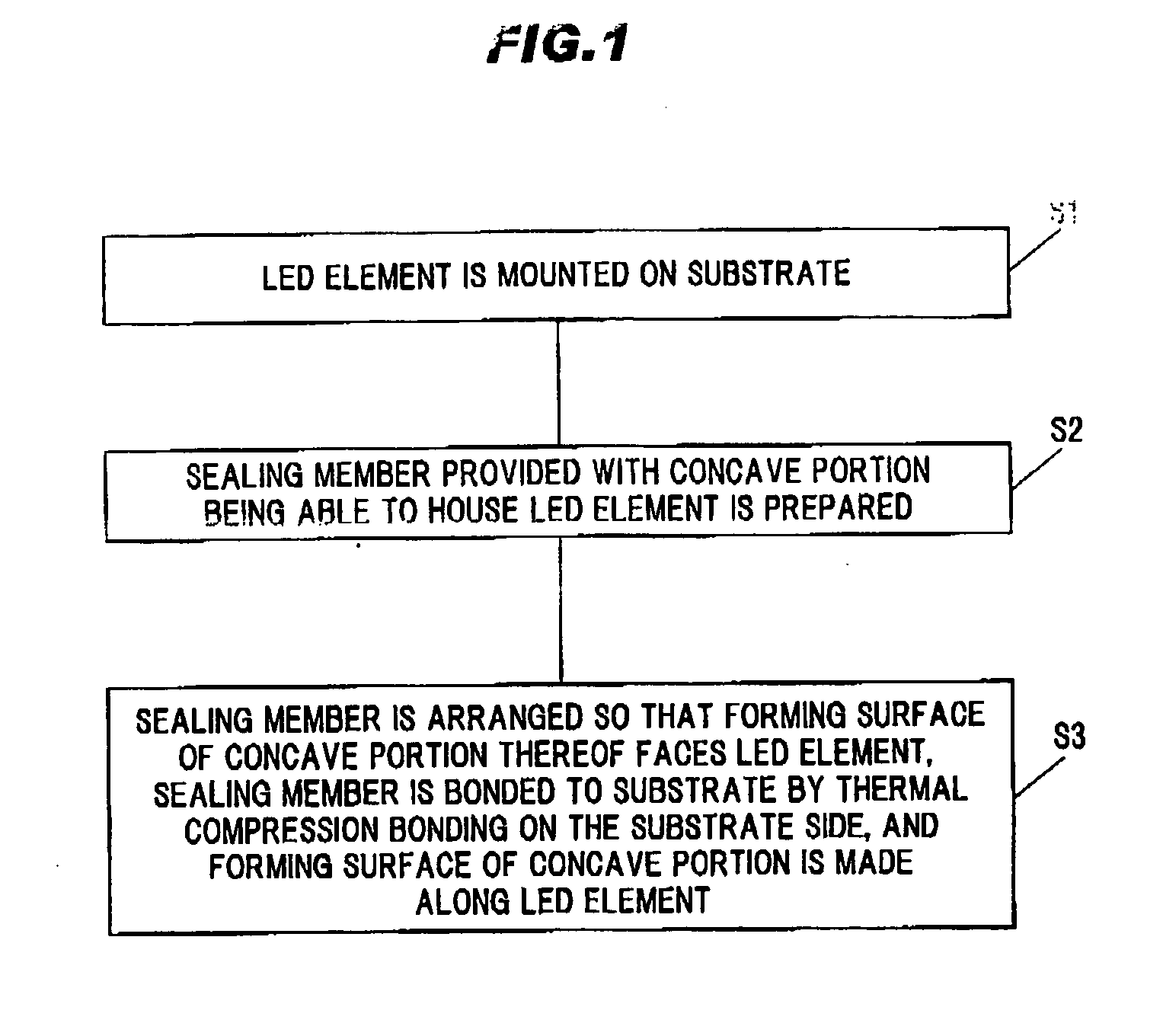

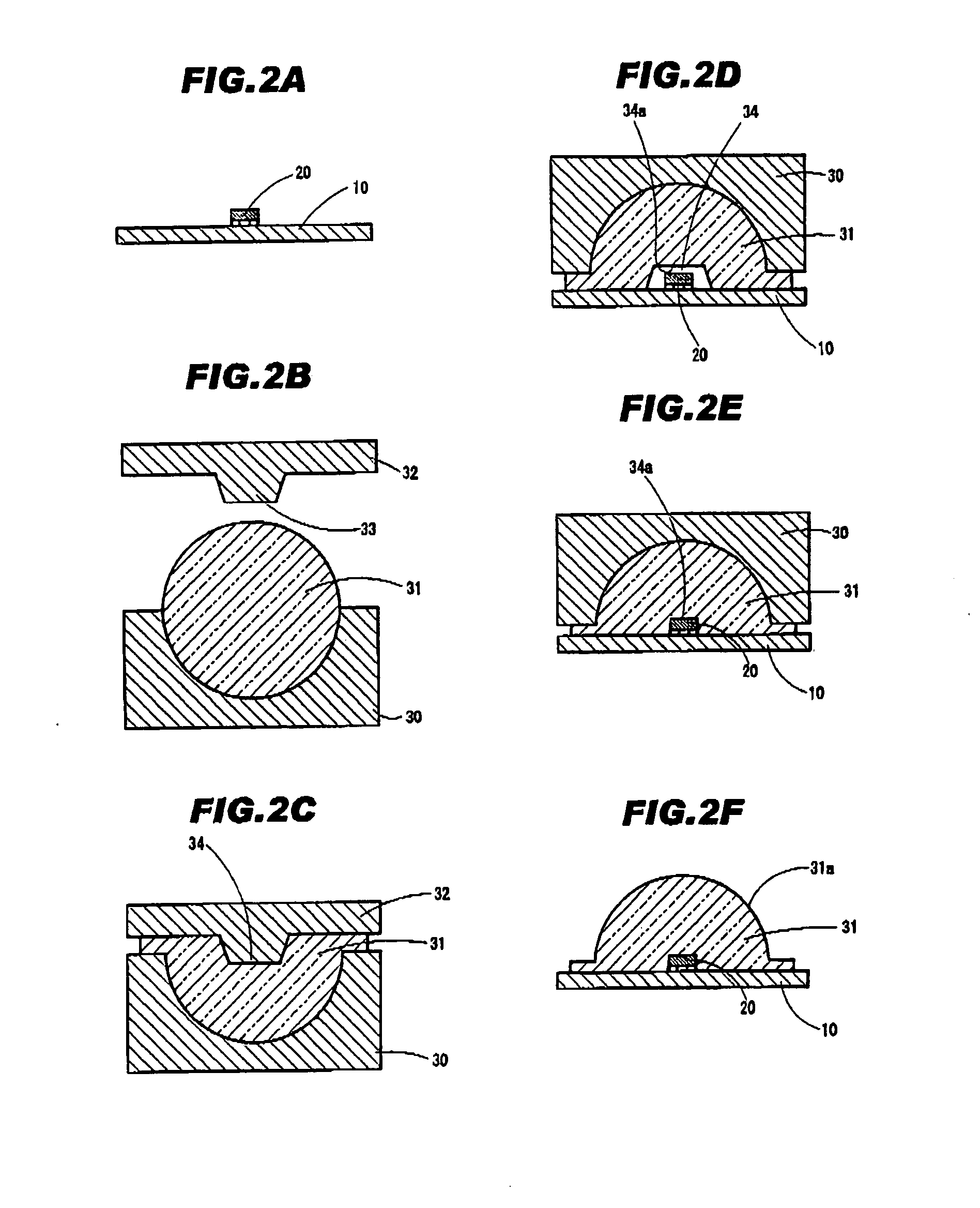

Method of manufacturing led lamp

ActiveUS20100244071A1Prevented from being directly pressedFlat surfaceSolid-state devicesSemiconductor/solid-state device manufacturingThermal compressionEngineering

A method of manufacturing a LED lamp that is formed by sealing a LED element mounted on a substrate with glass, includes a mounting process for mounting the LED element on the substrate, a sealing member preparation process for preparing a glass sealing member that includes a concave portion being capable of housing the LED element, and a sealing process wherein the sealing member is arranged so that a forming surface of the concave portion faces the LED element, the sealing member is bonded to the substrate by thermal compression bonding, and the forming surface of the concave portion is made along the LED element.

Owner:TOYODA GOSEI CO LTD

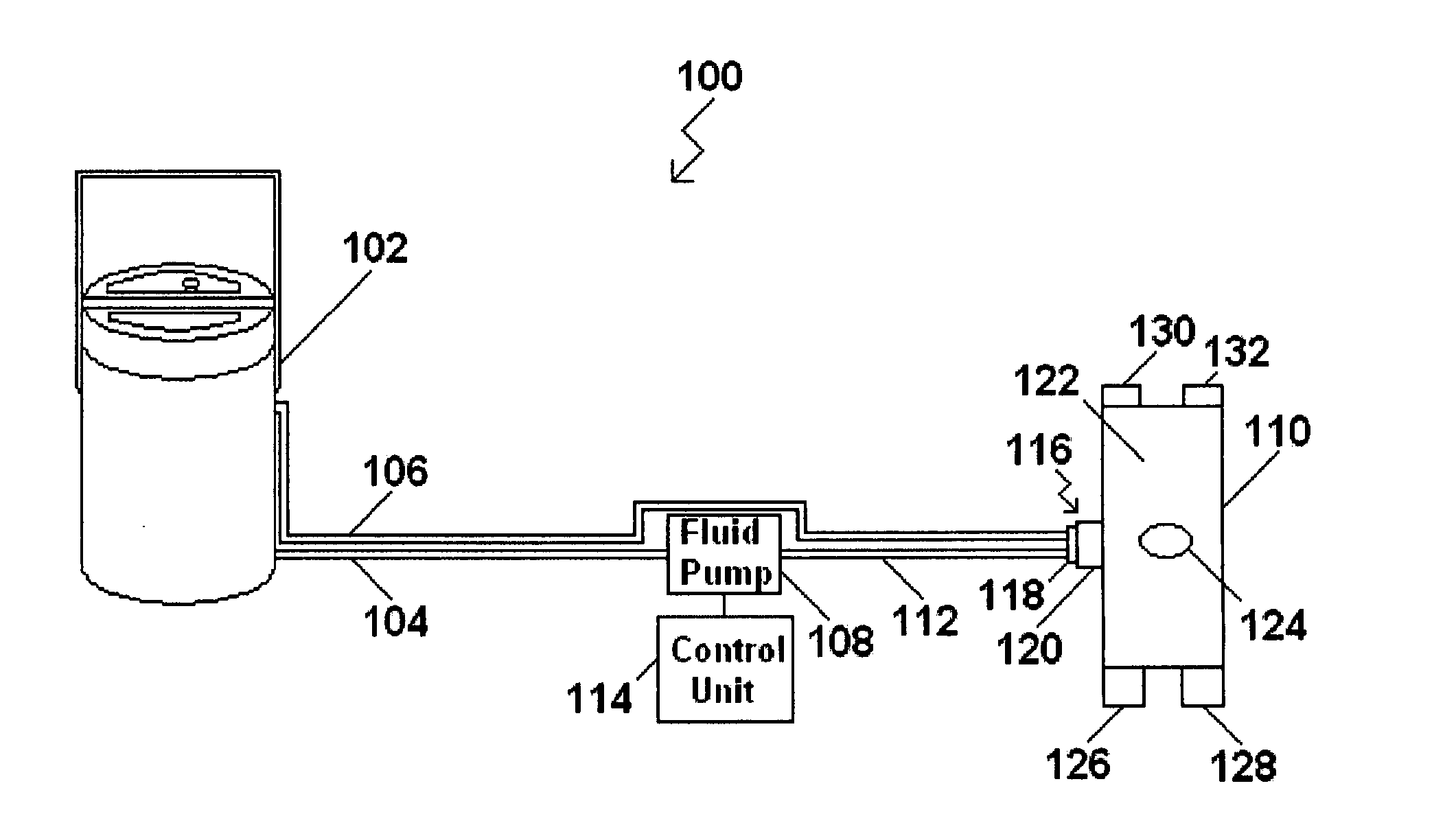

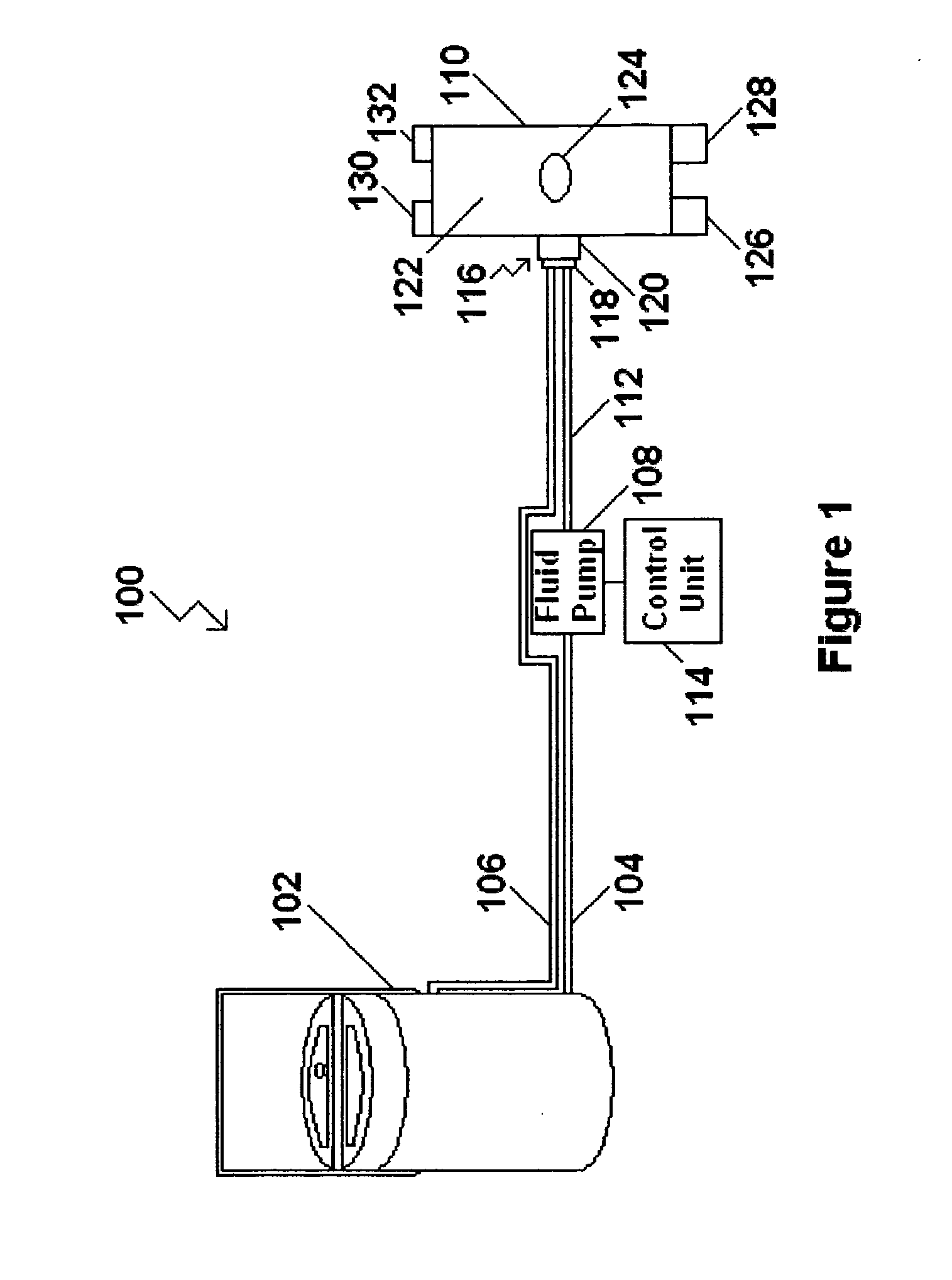

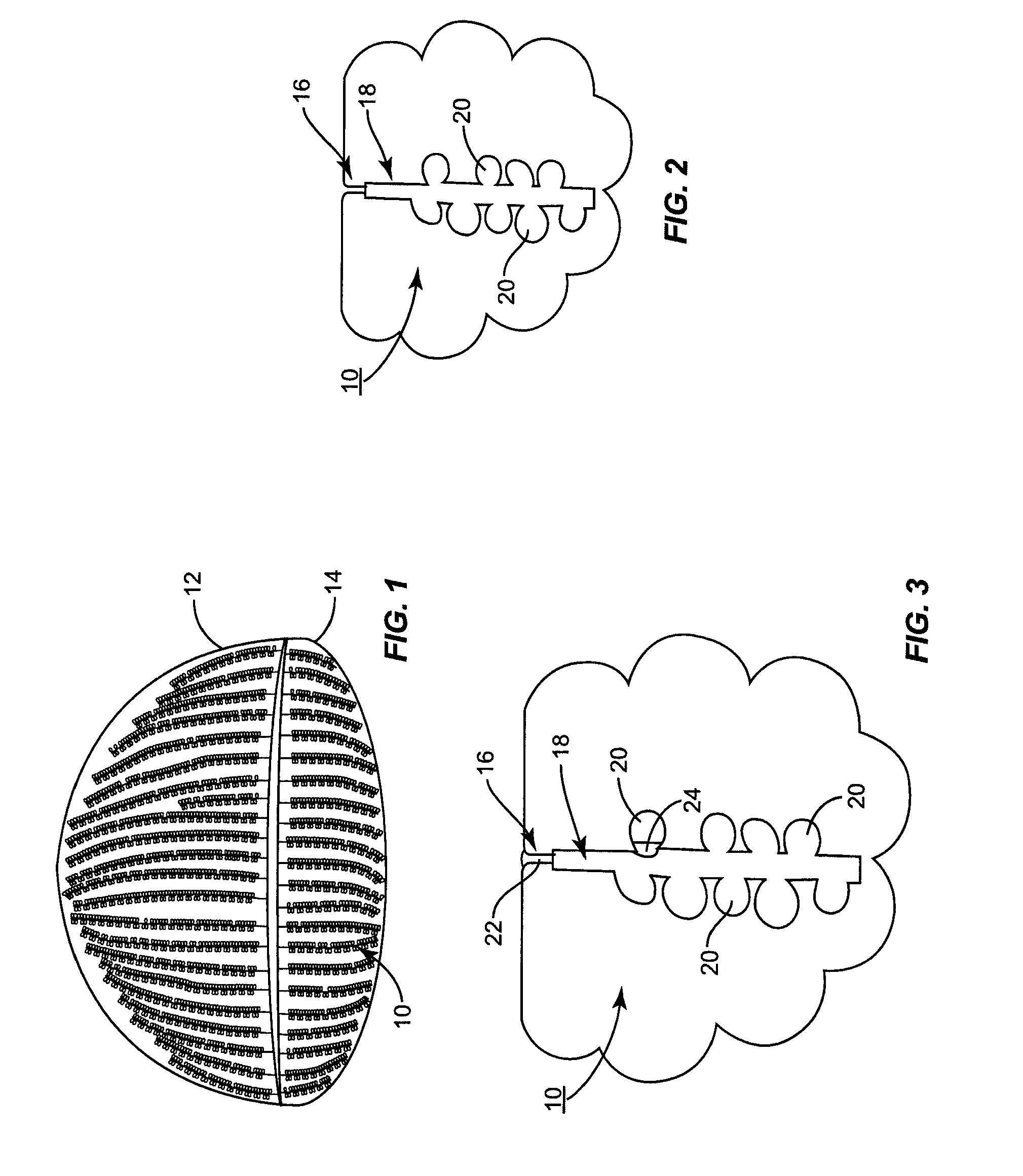

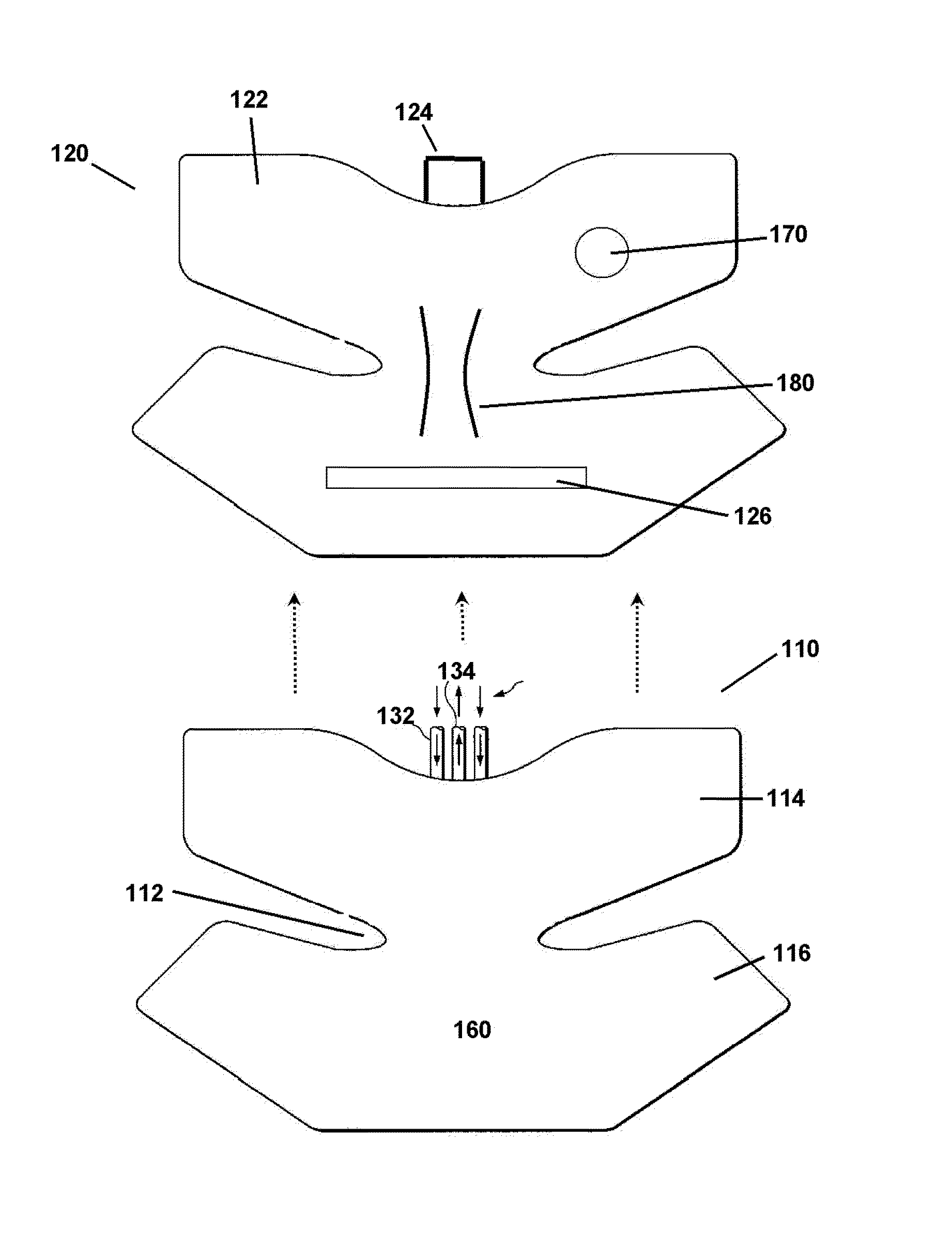

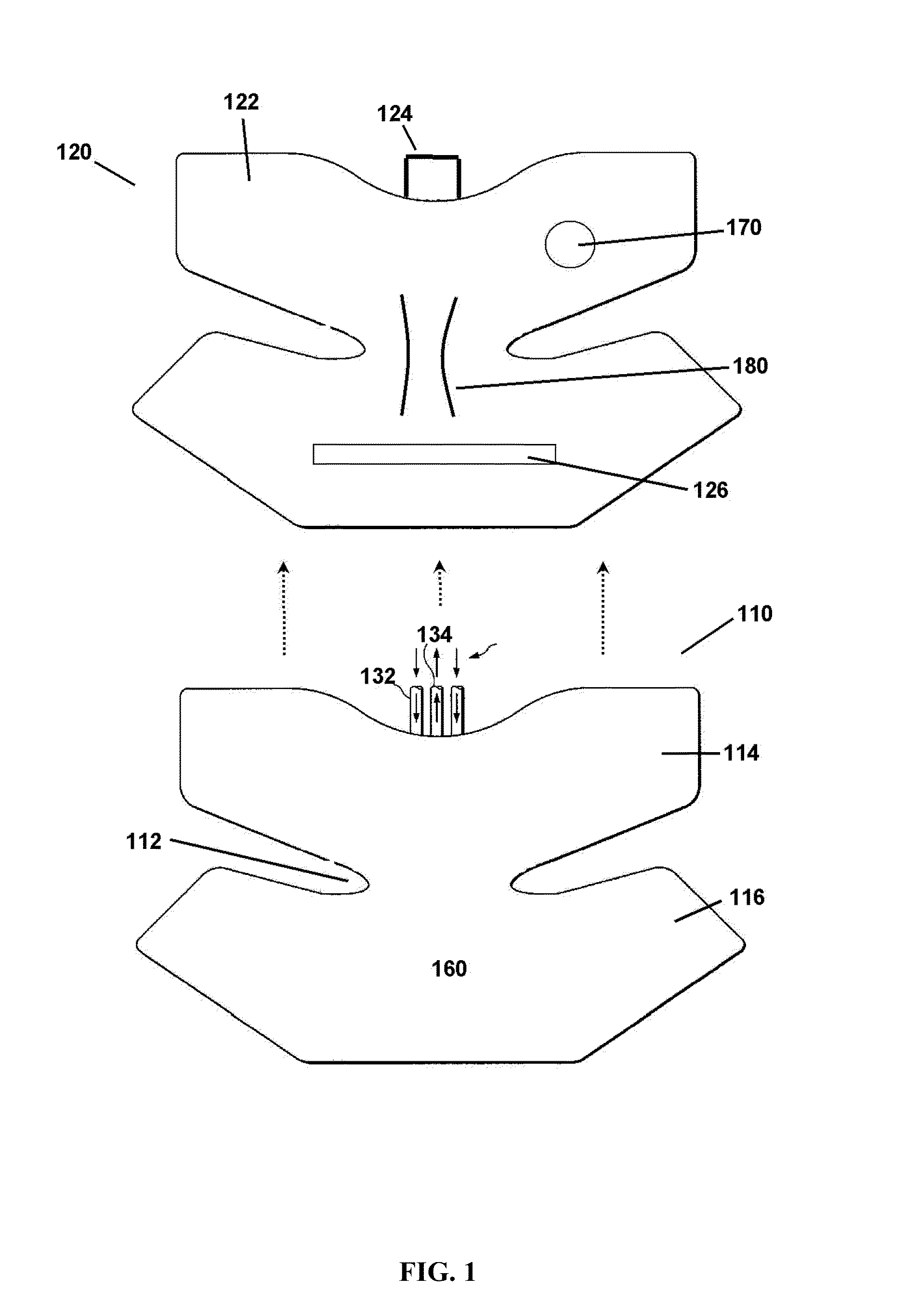

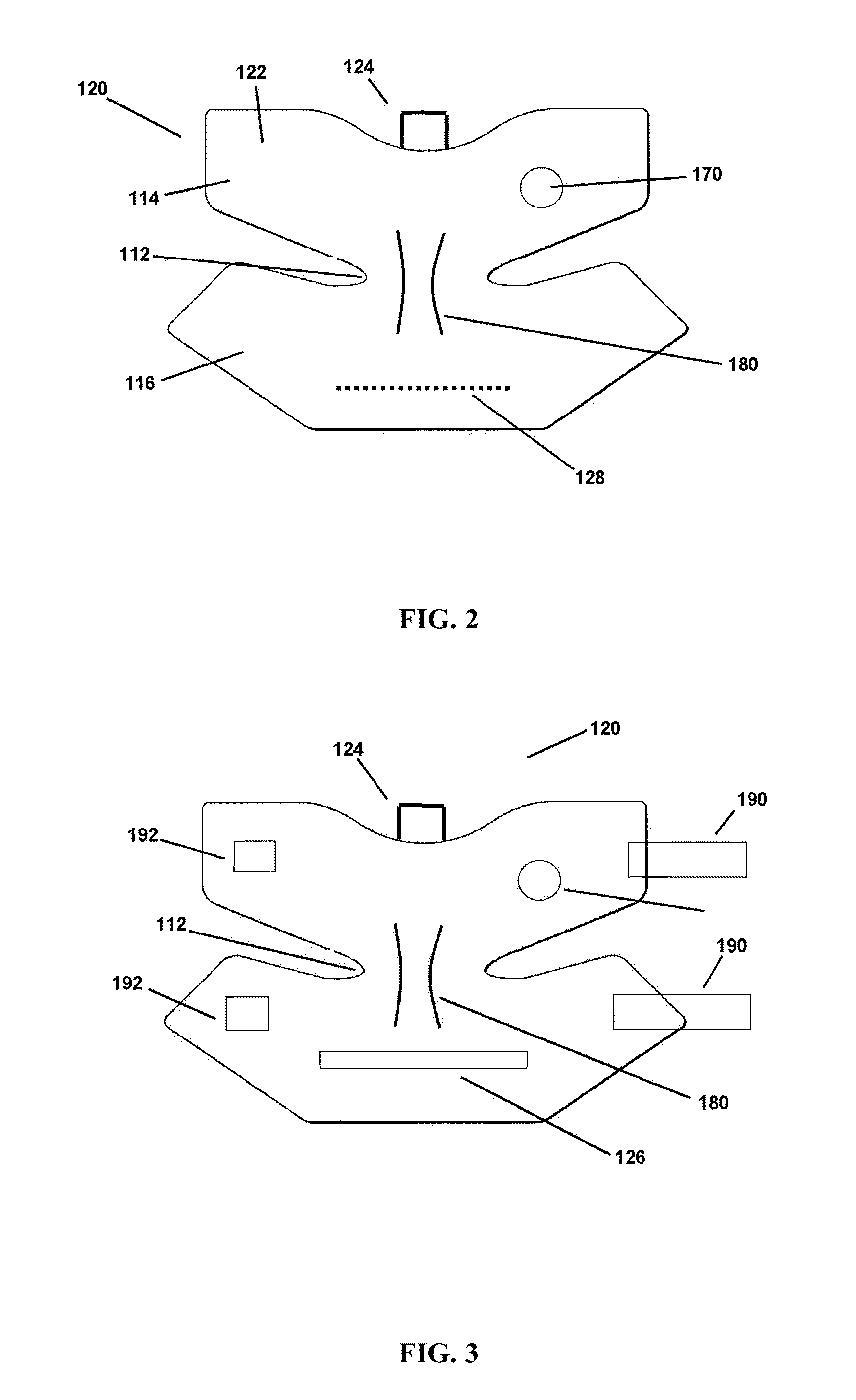

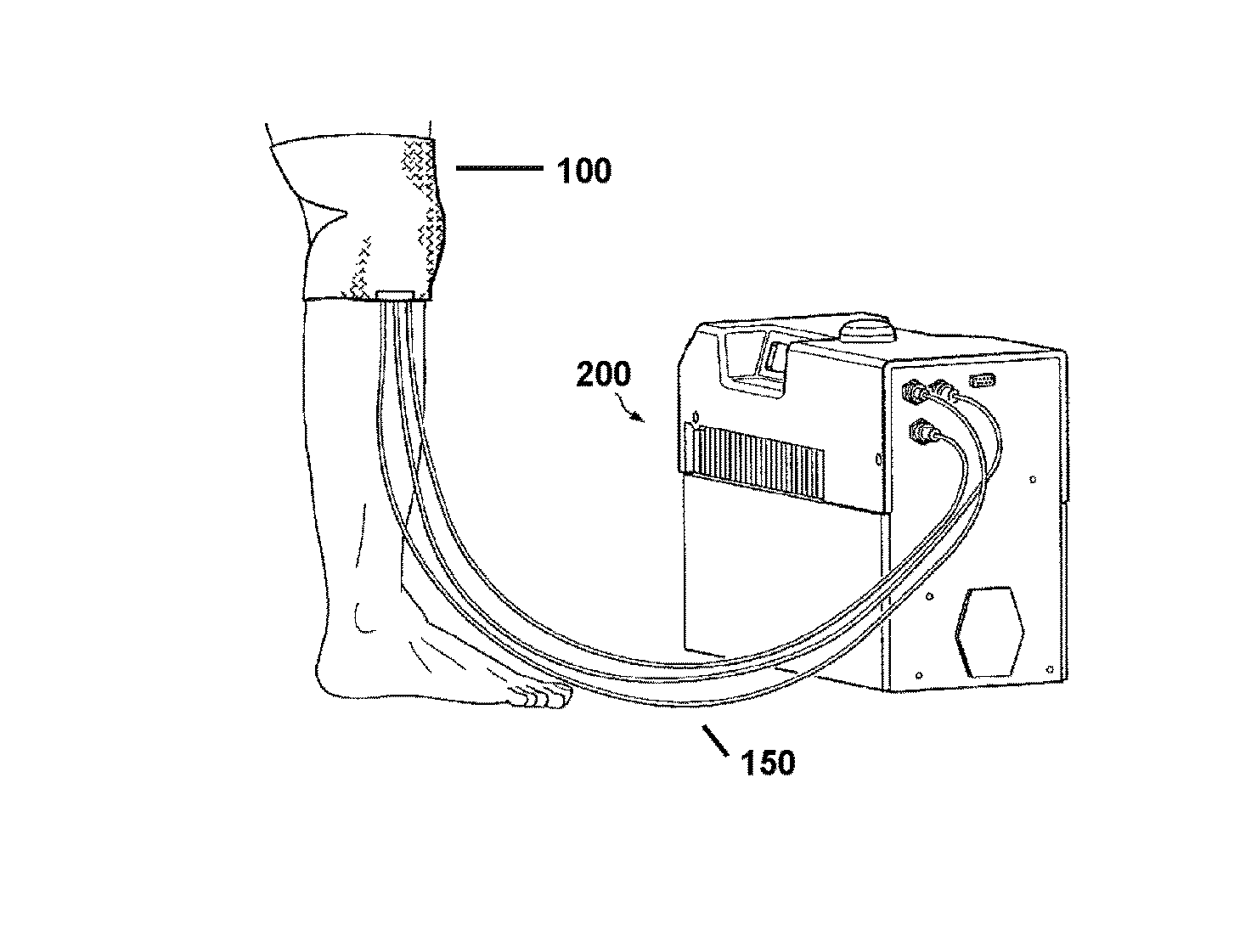

Thermal joint and bone compression system

InactiveUS20050033390A1Easy and quick connectionAvoid pressureTherapeutic coolingTherapeutic heatingMedicineThermal compression

A thermal compression system adapted to encompass a knee or any other portion of a limb is disclosed. The thermal compression system includes a container that has a fluid output line and a fluid input line. A fluid pump is connected with the fluid output line of the container and a fluid input of a cuff. The cuff is designed to be attached to an area of the body being treated. The pump fills the cuff with fluid and the fluid may exit the cuff through a fluid output of the cuff that is connected with the fluid input line of the container.

Owner:MCCONNELL DEAN EDWARD

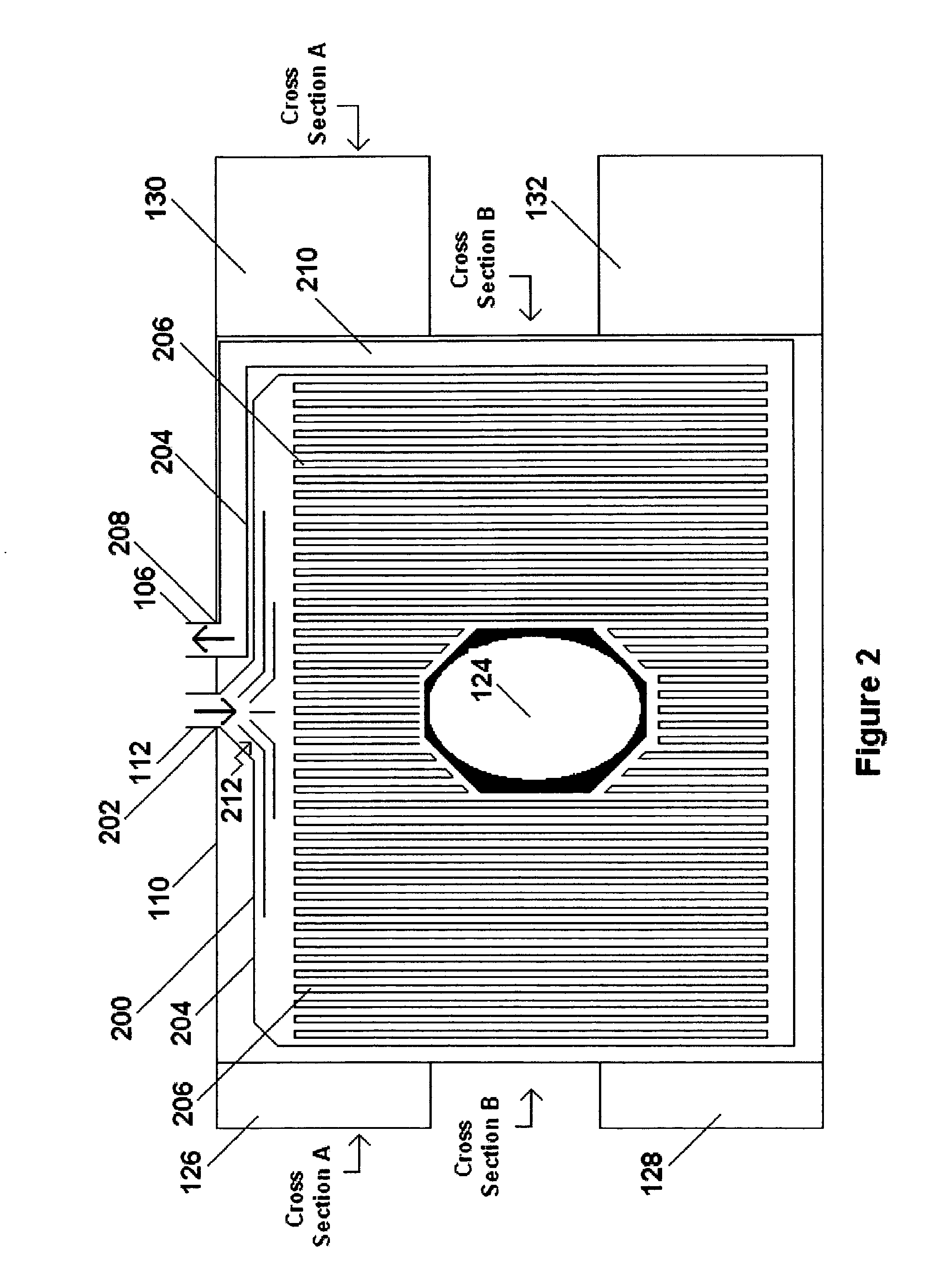

Outer eyelid heat and pressure treatment for treating meibomian gland dysfunction

InactiveUS7981147B2Effectively and efficiently raiseImprove sebum flowAntibacterial agentsBiocideMedicineThermal compression

Owner:TEARSCIENCE INC

Multiple channel micro-flow control chip, process for making same and use thereof

InactiveCN1699984ALow costChannel wide and deepBiological testingMaterial electrochemical variablesEtchingFluorescence

The invention relates to a micro flow control chip in the leading edge field of analytical chemistry, which has the characters of small volume, fast analysis. Although micro flow control chip integrated with laser evoked fluorescence detection can do 384 channels high-pass measuring, it isn't reported multichannel electric chemistry measuring from now on. The invention provides a multichannel micro flow control chip, which adopts high molecular material polymethyl methacryate, and fabricates monocrystalline silicon core by using the technology of photo etching and etching, and microchannel adopts hot-press method or polymerization. It integrals the measuring electric pole channel onto the chip. It can fill functional material into electric pole and control the distance of working electric pole and separating channel.

Owner:FUDAN UNIV

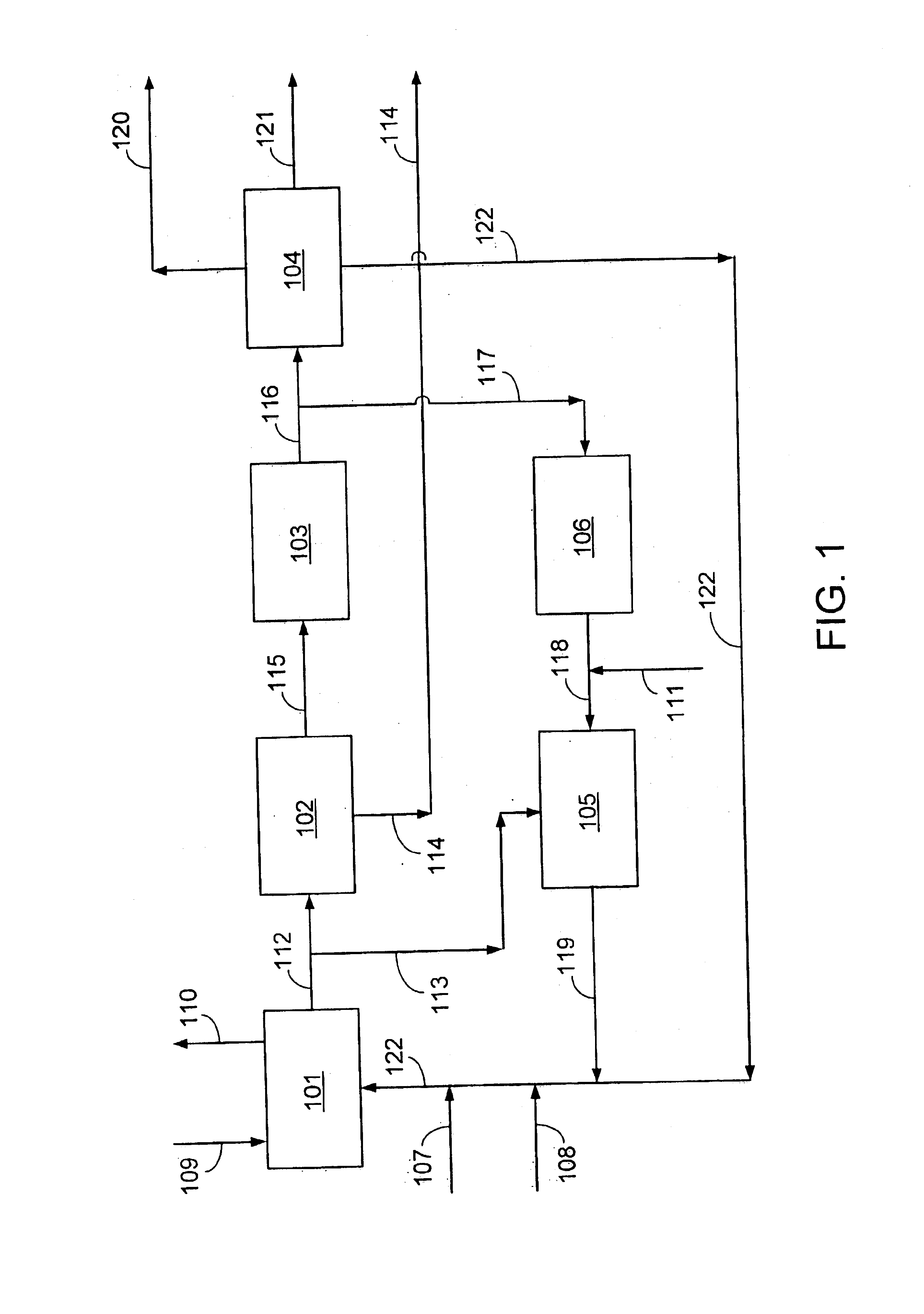

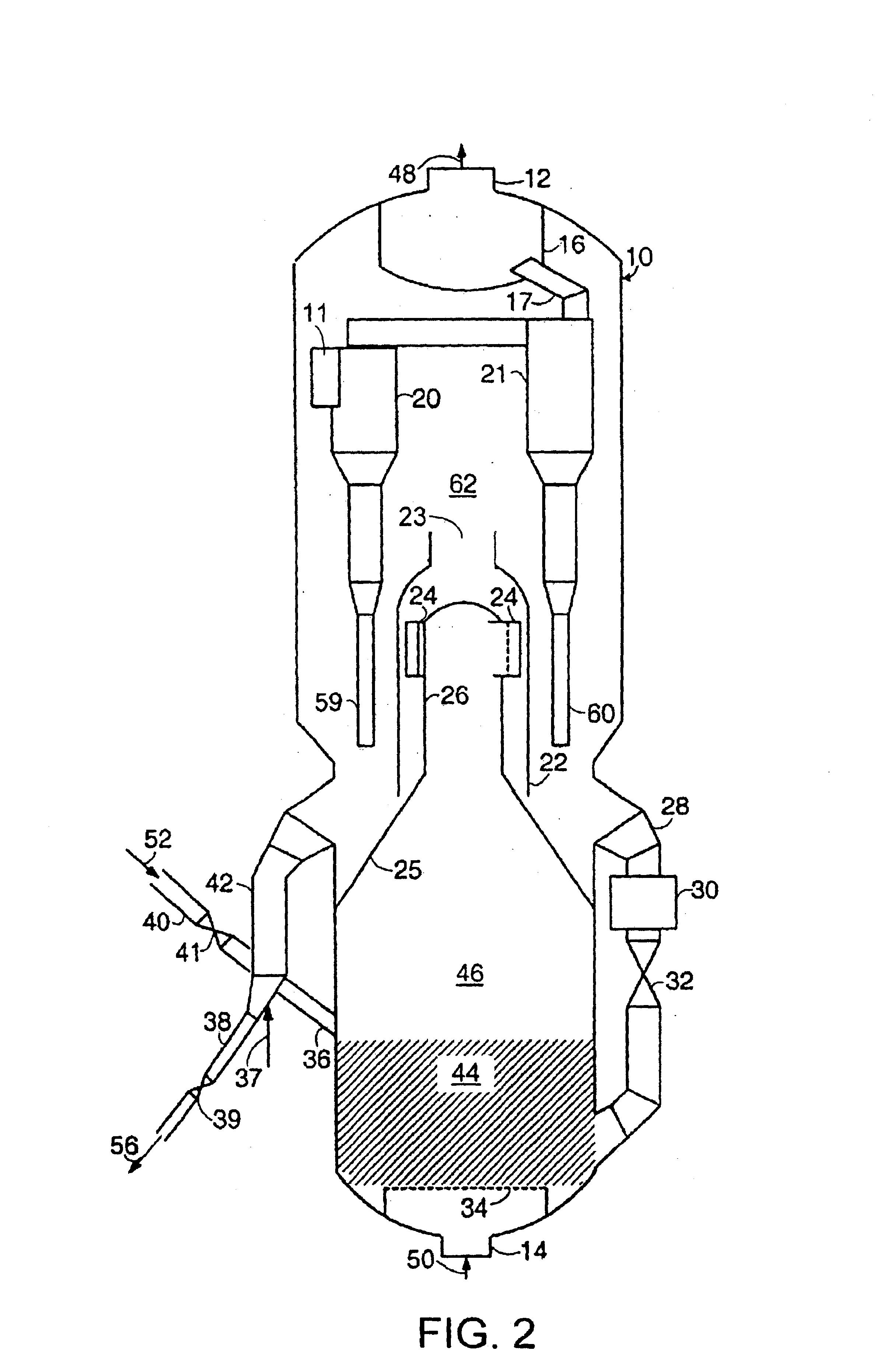

Start-up of a methanol-to-olefin process

InactiveUS6872867B1Low costAvoid expensesMolecular sieve catalystCatalystsMotor driveThermal compression

A catalytic conversion process using a fluidized conversion zone, which requires a minimum superficial gas velocity to function properly, and a motor-driven, capacity-limited product compressor zone is started up using a thermal compressor by establishing two start-up gas recirculation circuits, one using the product compression zone running at high pressure to recirculate about 40 to 60 vol-% of the effluent gas stream from the conversion zone and the other running at low pressure and carrying the remaining portion of the effluent gas stream from the fluidized conversion zone where the high pressure circuit supplies motive gas to the thermal compression zone and the low pressure circuit supplies suction gas to the thermal compressor and the resulting compressed discharge gas enables the catalytic process to start up without the use of a dedicated motor-driven start-up compressor.

Owner:UOP LLC

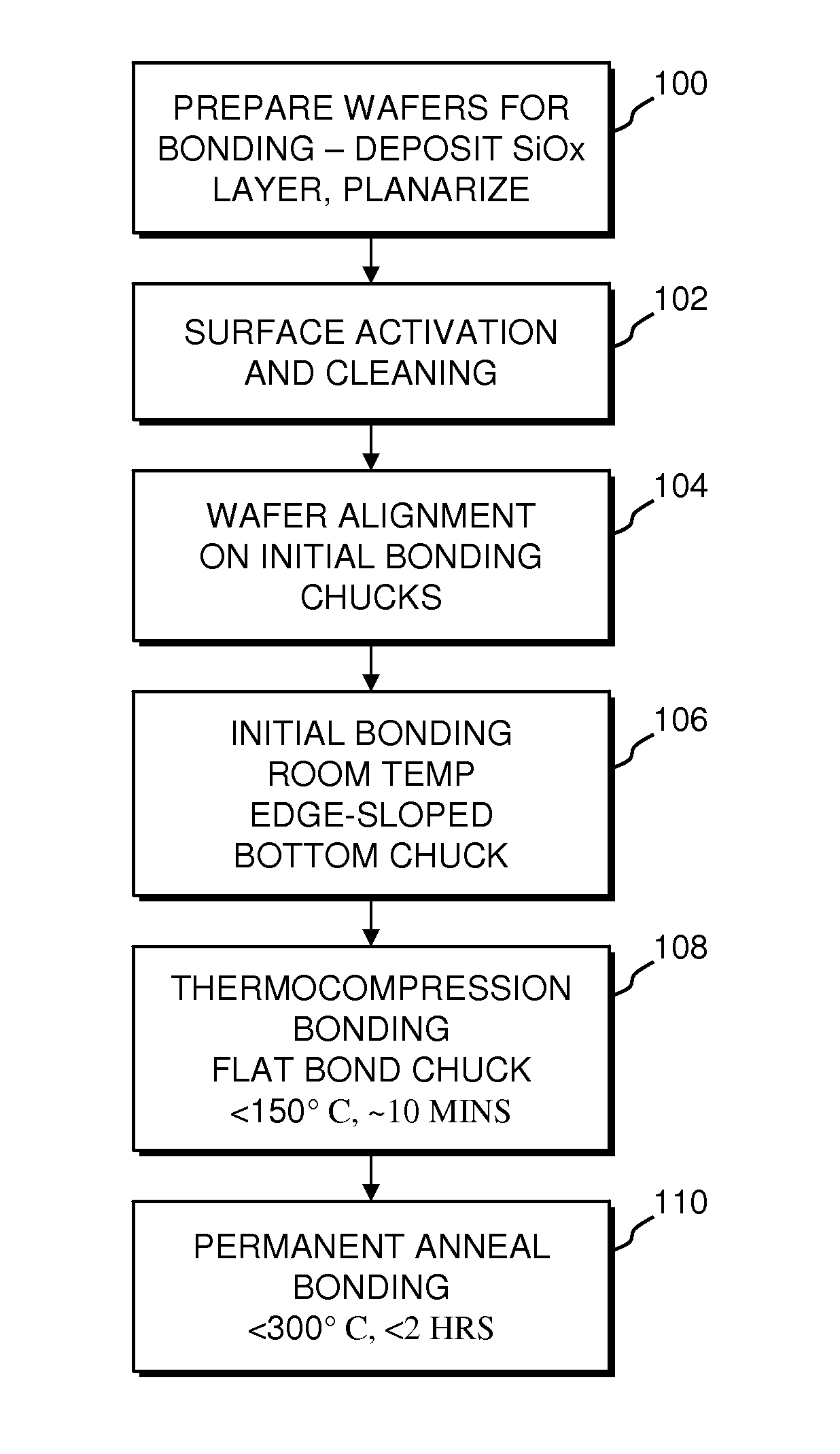

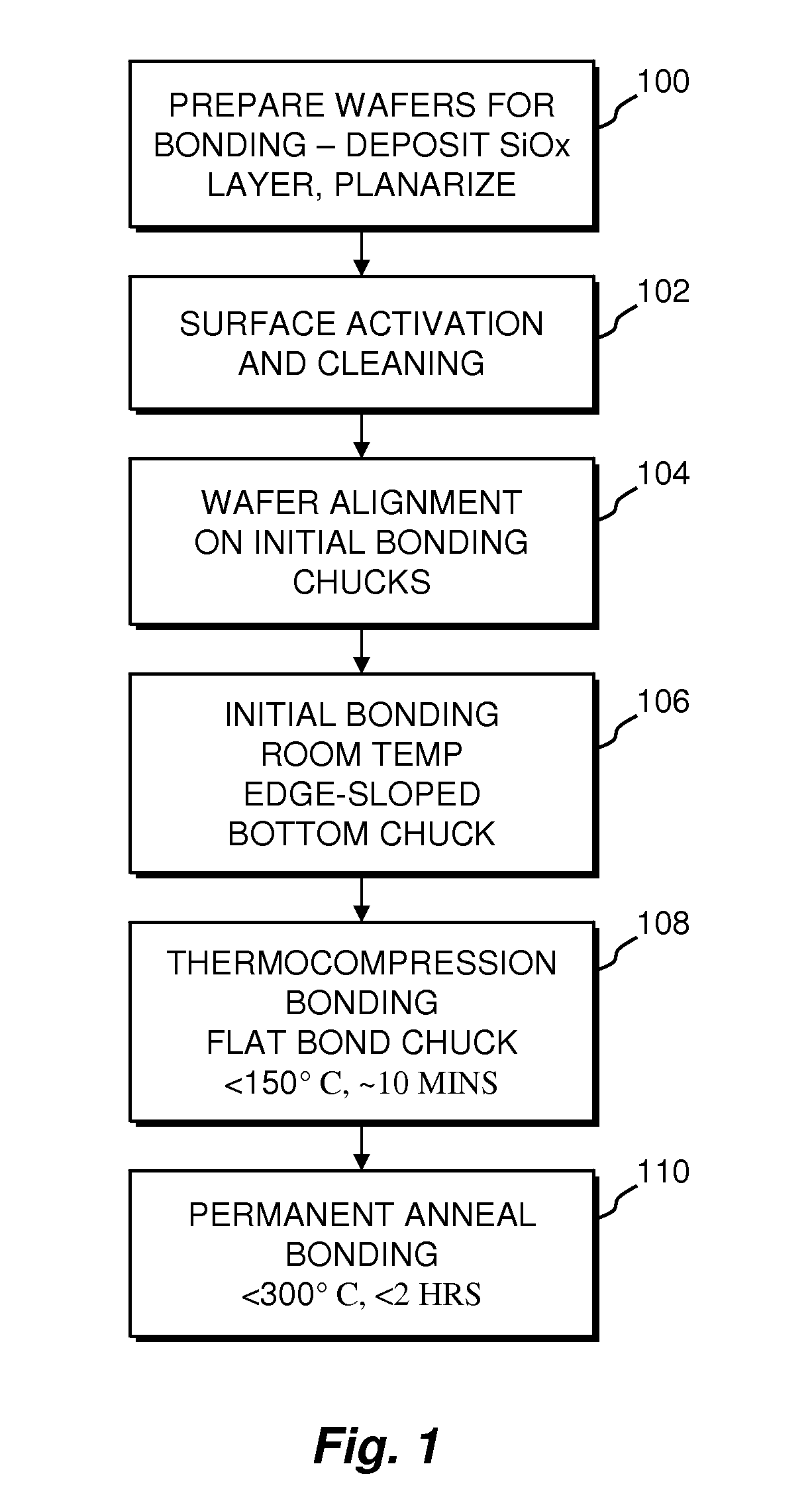

Wafer-to-wafer oxide fusion bonding

InactiveUS20140261960A1Reduce pressureEliminate gapsLamination ancillary operationsLaminationAtmospheric airThermal compression

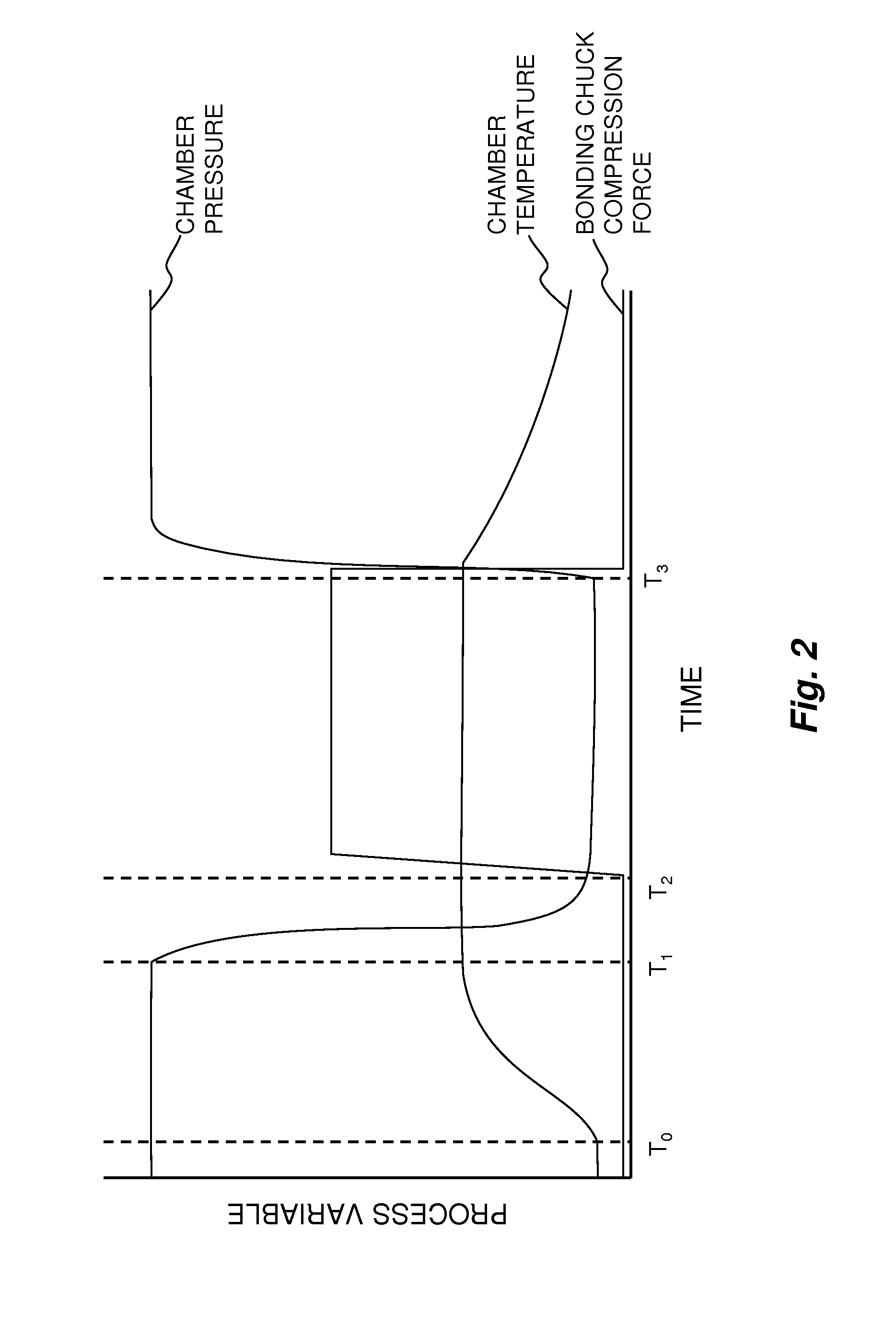

Oxide-oxide fusion bonding of wafers that includes performing a van der Waals force bonding process with a chuck having at least a flat central zone and an outer annular zone lower than the central zone, an edge portion of a mounted wafer is biased towards the outer annular zone. The van der Waals bonding wave is disrupted at the outer annular zone, causing an edge gap. A thermocompression bonding process is performed that includes heating the bonded wafers to a temperature sufficient to initiate condensation of silanol groups between the bonding surfaces, reducing the atmospheric pressure to cause degassing from between the wafers, applying a compression force to the wafers with flat chucks so as to substantially eliminate the edge gap, and performing a permanent anneal bonding process.

Owner:IBM CORP

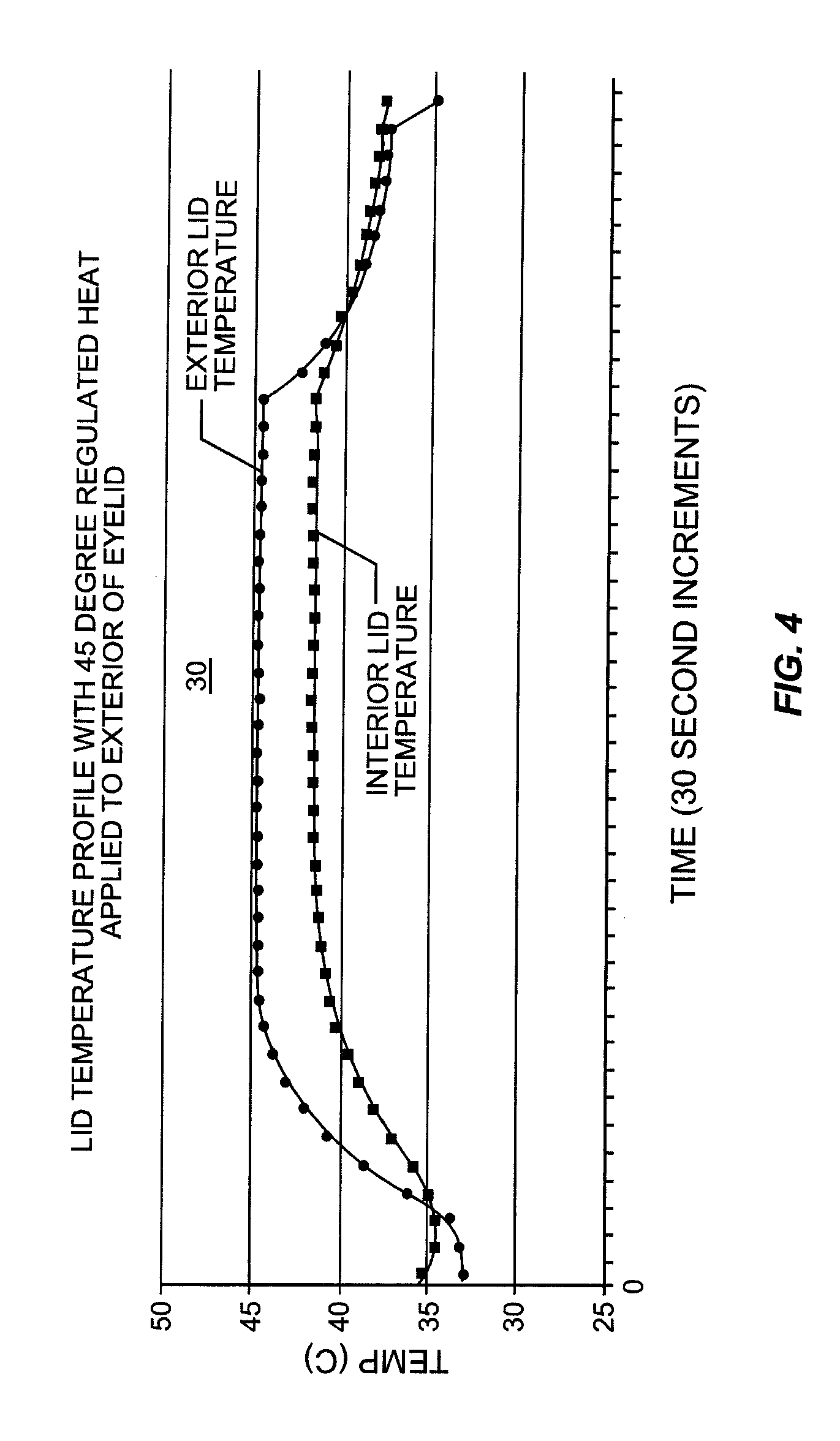

Outer eyelid heat and pressure treatment for treating meibomian gland dysfunction

ActiveUS20080132978A1Increase temperatureImprove conductive heat transfer efficiencyAntibacterial agentsOrganic active ingredientsMedicineThermal compression

A method of treating meibomian gland dysfunction. Heat is applied to the outside of the eyelid to provide conductive heat transfer to the meibomian glands. The application of heat assists in the expression of obstructions or occlusions in the meibomian glands to restore sufficient sebum flow to the lipid layer to treat dry eye. A force may also be applied to the outside of the patient's eyelid to improve conductive heat transfer and reduce blood flow in the eyelid that causes convective heat loss. Thus, the application of force can further increase the temperature level and / or reduce the time to reach desired temperature levels for removing obstructions or occlusions. Reaching increased temperature levels may improve the melting, loosening, or softening of obstructions or occlusions in the meibomian glands while reducing the amount of time to reach desired temperature levels and / or aid in reducing discomfort to the patient during treatment.

Owner:TEARSCIENCE INC

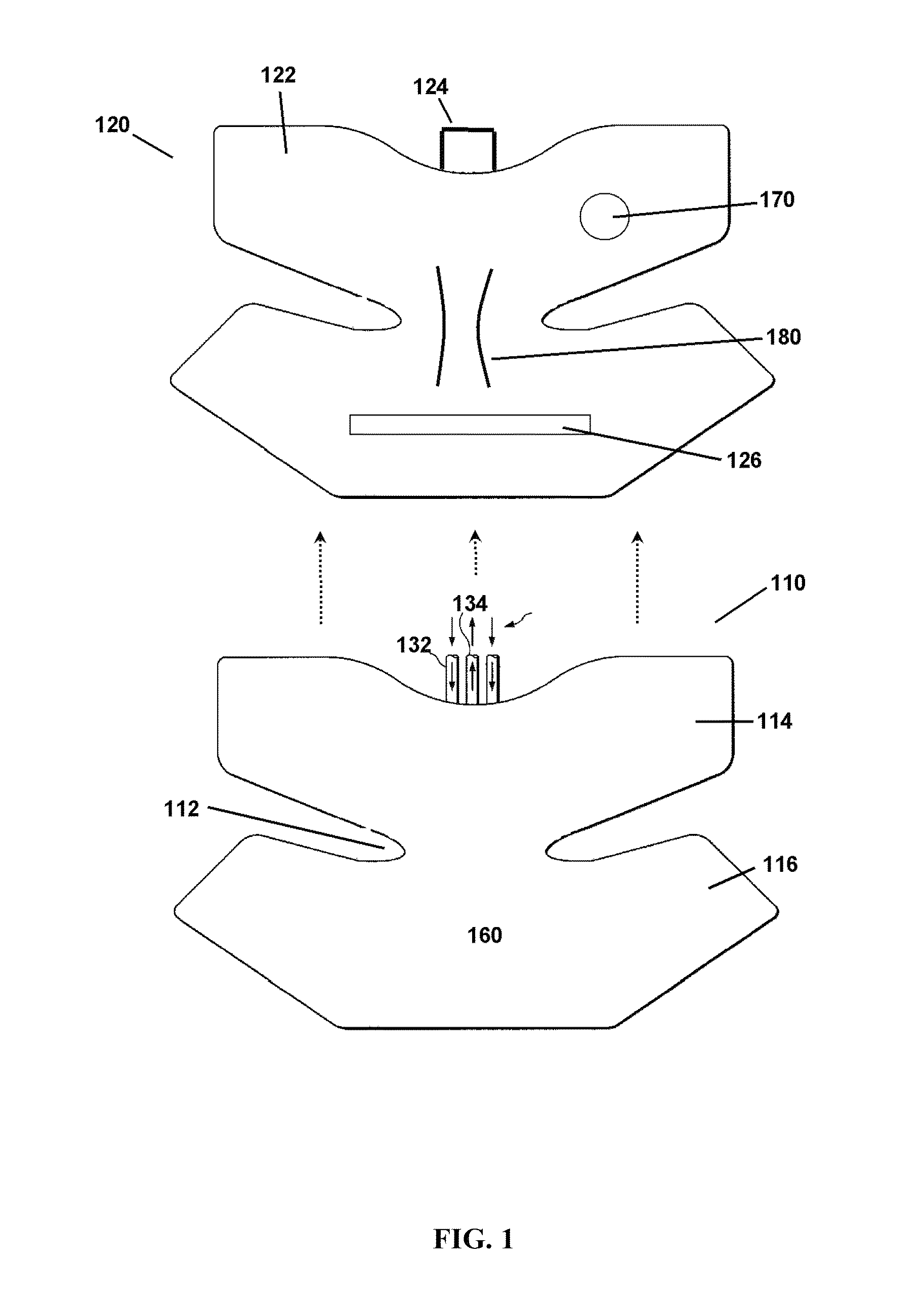

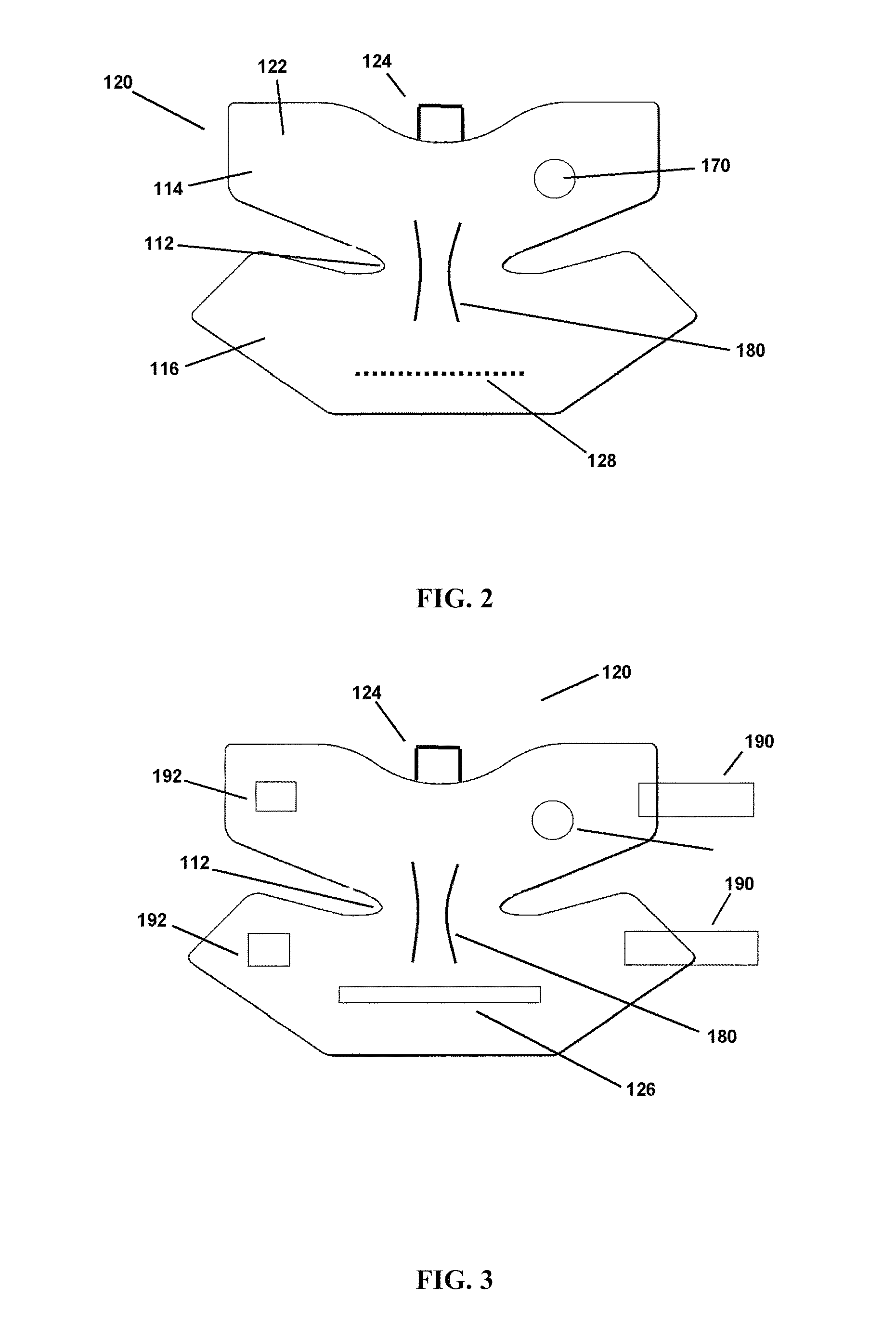

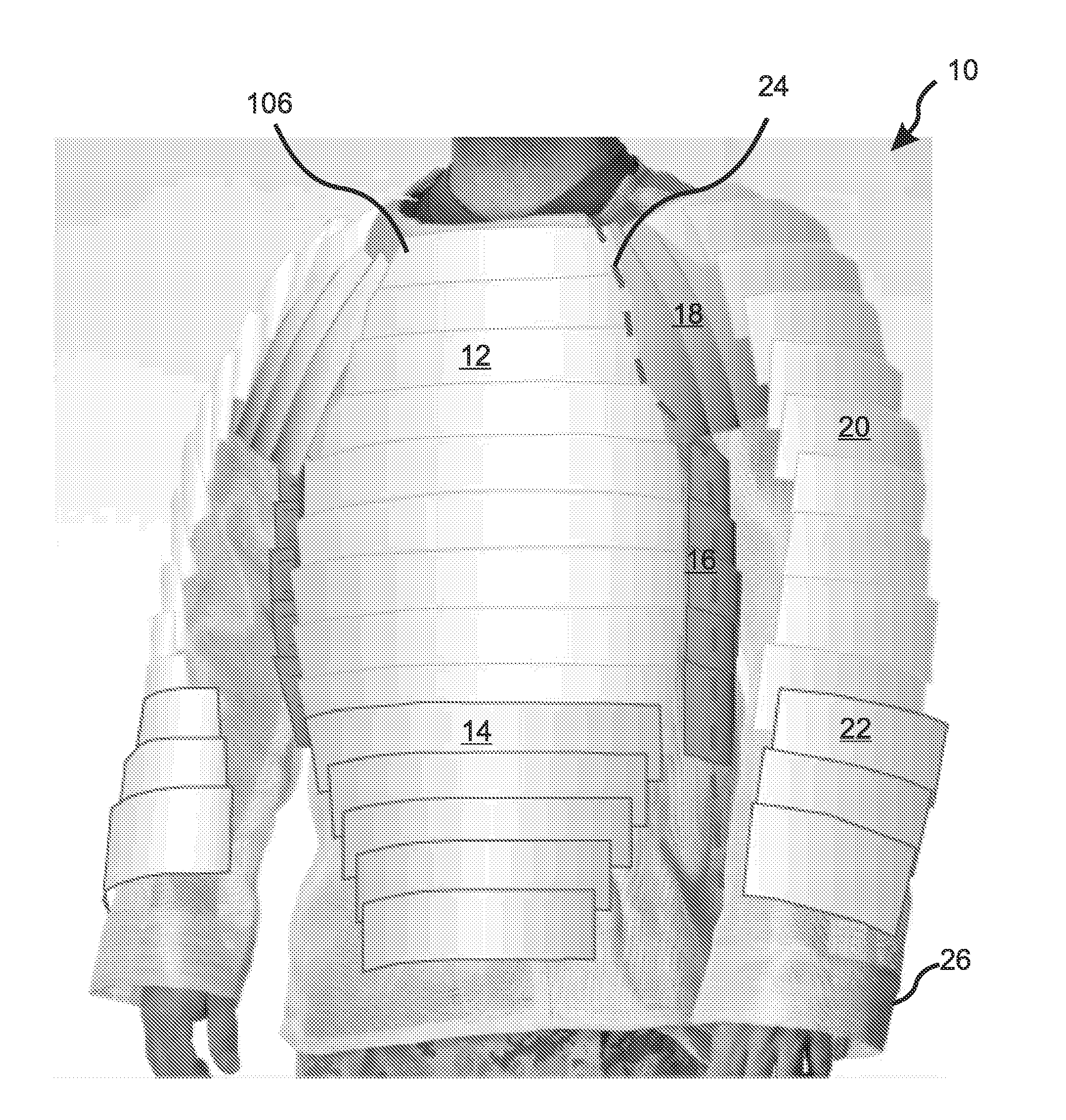

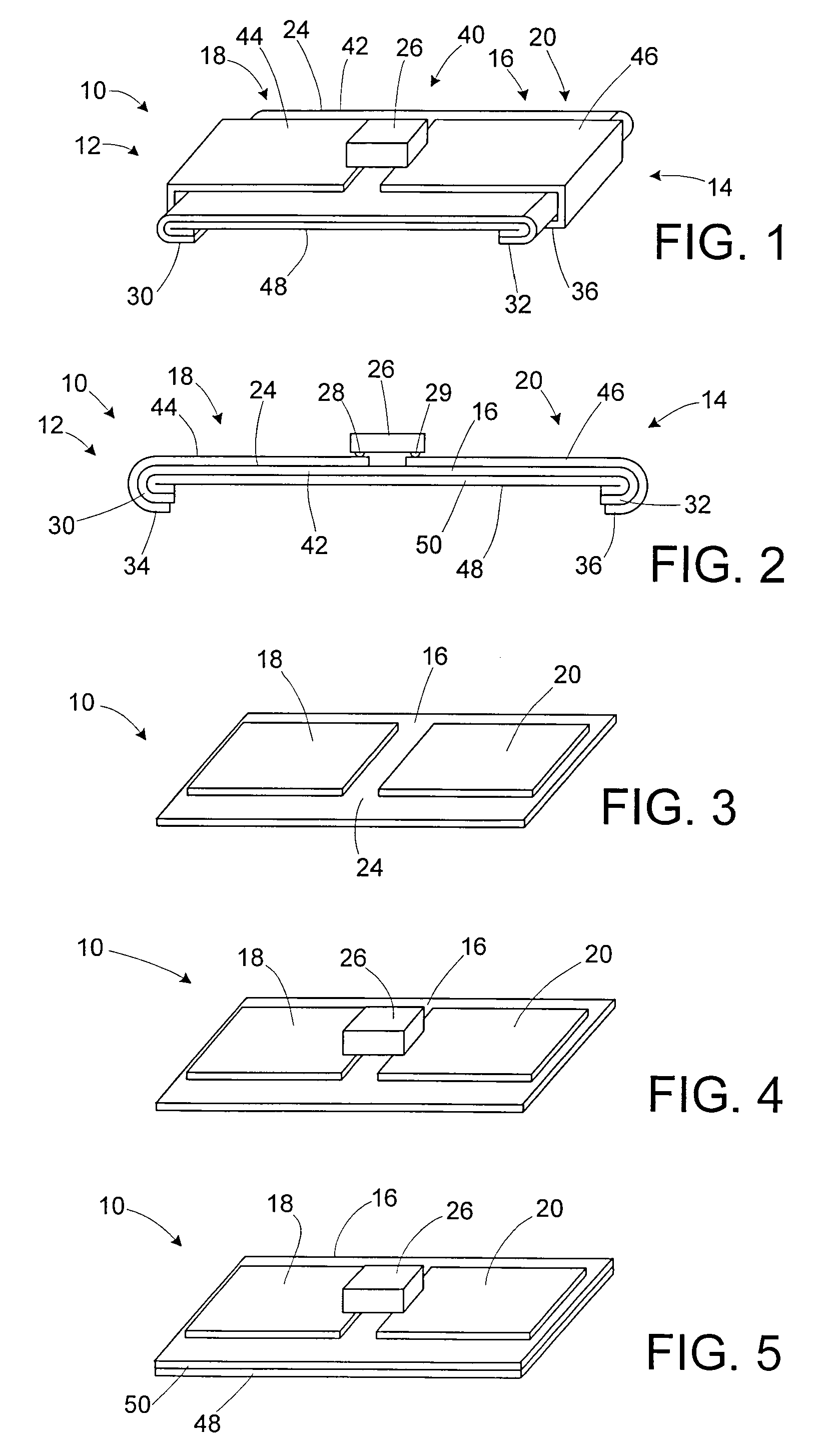

Thermal compression therapy apparatus and system

InactiveUS8444581B1Easy to useBlood stagnation preventionPneumatic massageCompression therapyThermal compression

A combined heating, cooling, and compression therapy system is provided. The system is configured for automated use with a controller. The system can have a core with separate channels for providing cold and heat and compression therapy; a cover for receiving the core; and a skin sensitive temperature node attached to the core cover.

Owner:MALDONADO MEDICAL

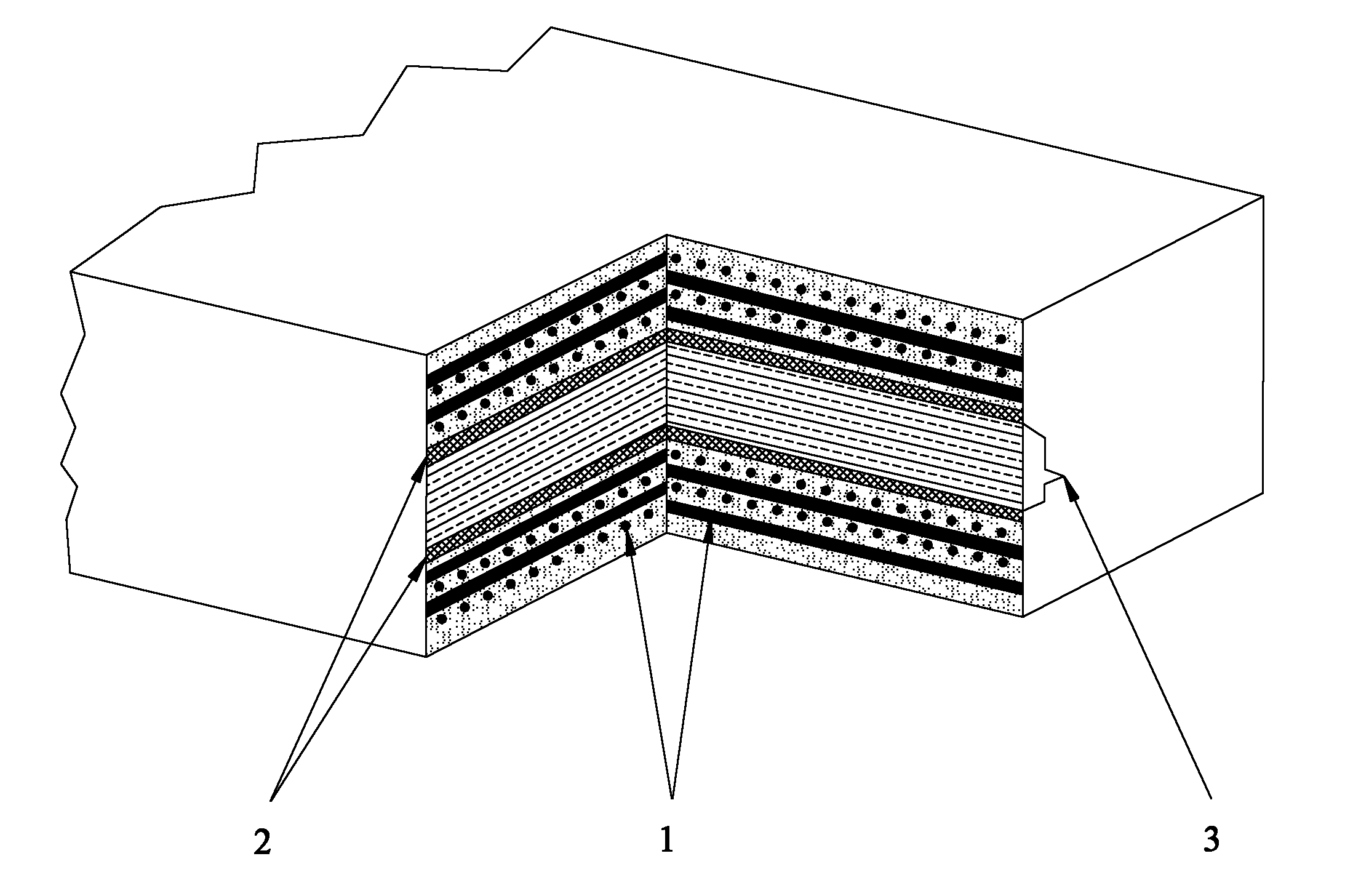

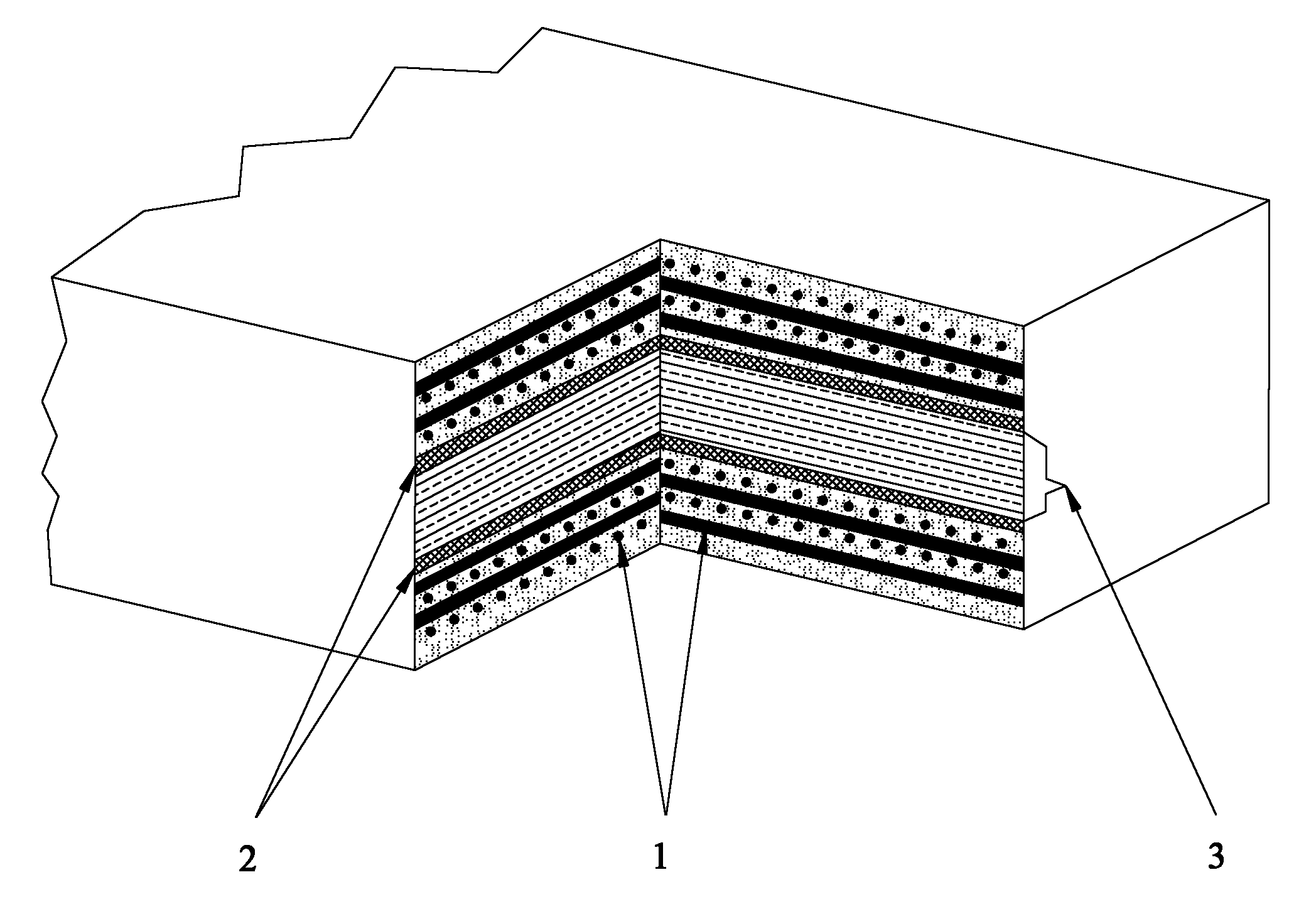

Building template reinforced by composite of continuous fiber plastic coated belt material and preparation method thereof

ActiveCN102127964AHigh impact strengthExcellent compression resistance, crack resistance and deformation resistanceSynthetic resin layered productsWood layered productsFiberThermal compression

The invention discloses a building template reinforced by composite of a continuous fiber plastic coated belt material, which has the advantages of favorable mechanical property and complete waterproof and dampproof properties and can be recycled more than a hundred of times. In the composite reinforced building template of the continuous fiber plastic-coated belt materials, a wooden oriented structural board is used as a core layer, a macromolecular adhesive membrane and 2-4 layers of continuous fiber plastic-coated belt materials are outwards sequentially and flatly paved and fixed on the two sides of the wooden oriented structural board symmetrically to form multilayer-combined composite reinforced building template of the continuous fiber plastic-coated belt materials, with a sandwich structure, wherein surface resin on one face of the macromolecular adhesive membrane is polypropylene resin, the surface resin on the other face of the macromolecular adhesive membrane is maleic anhydride modified polypropylene resin, a macromolecular adhesive membrane face with the surface resin of the maleic anhydride modified polypropylene resin is laminated with the wooden oriented structural board as the core layer, and a macromolecular adhesive membrane face with the surface resin of the polypropylene resin is adhered to a thermoplastic resin plastic-coated layer of the continuous fiber plastic-coated belt materials through thermal compression; and the continuous fiber plastic-coated belt materials are manufactured by coating thermoplastic resin on continuous fiber warp-knitted unidirectional cloth, and the fiber content of the continuous fiber plastic-coated belt materials is 20-60%.

Owner:JIANGSU QIYI TECH

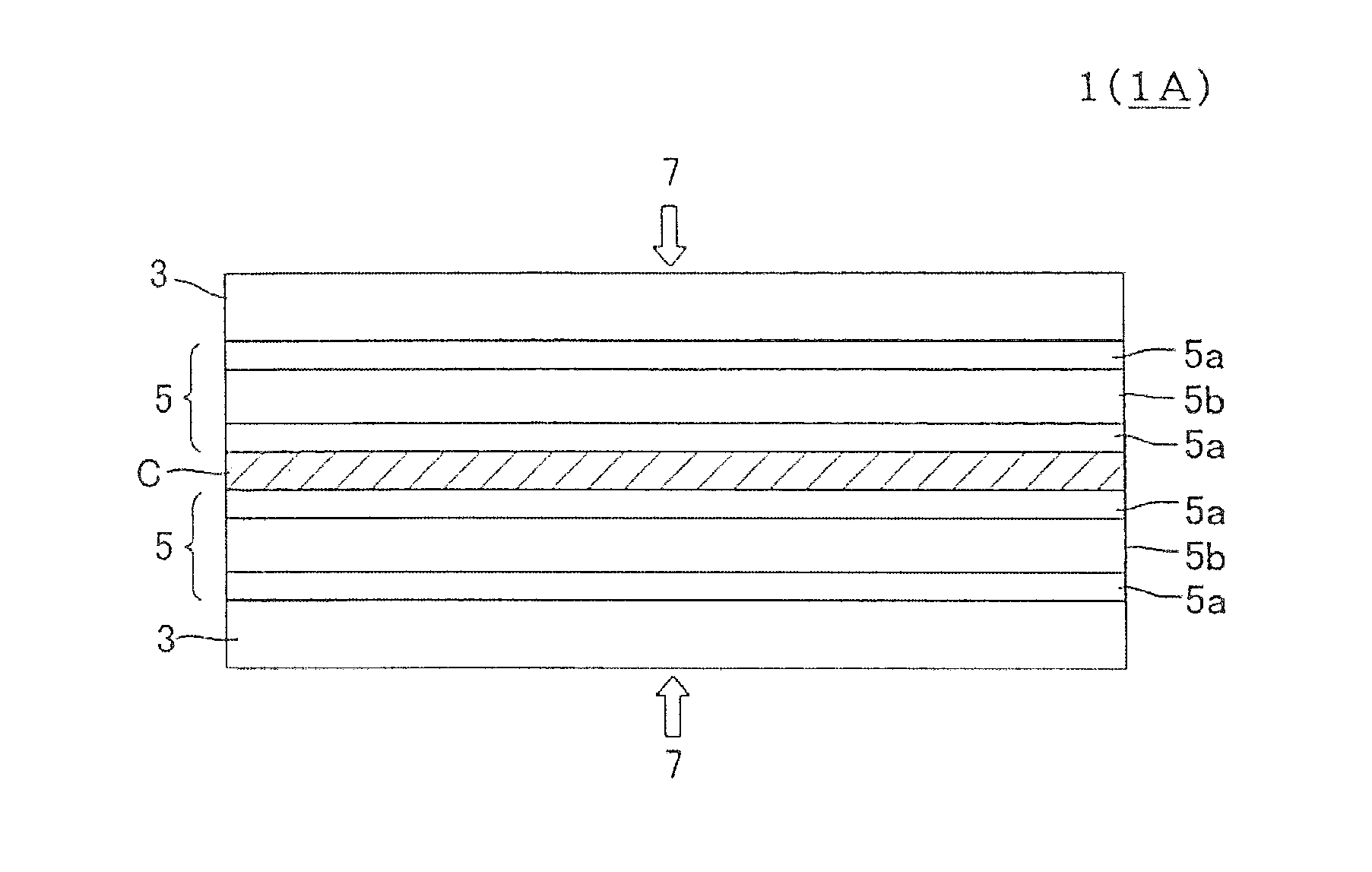

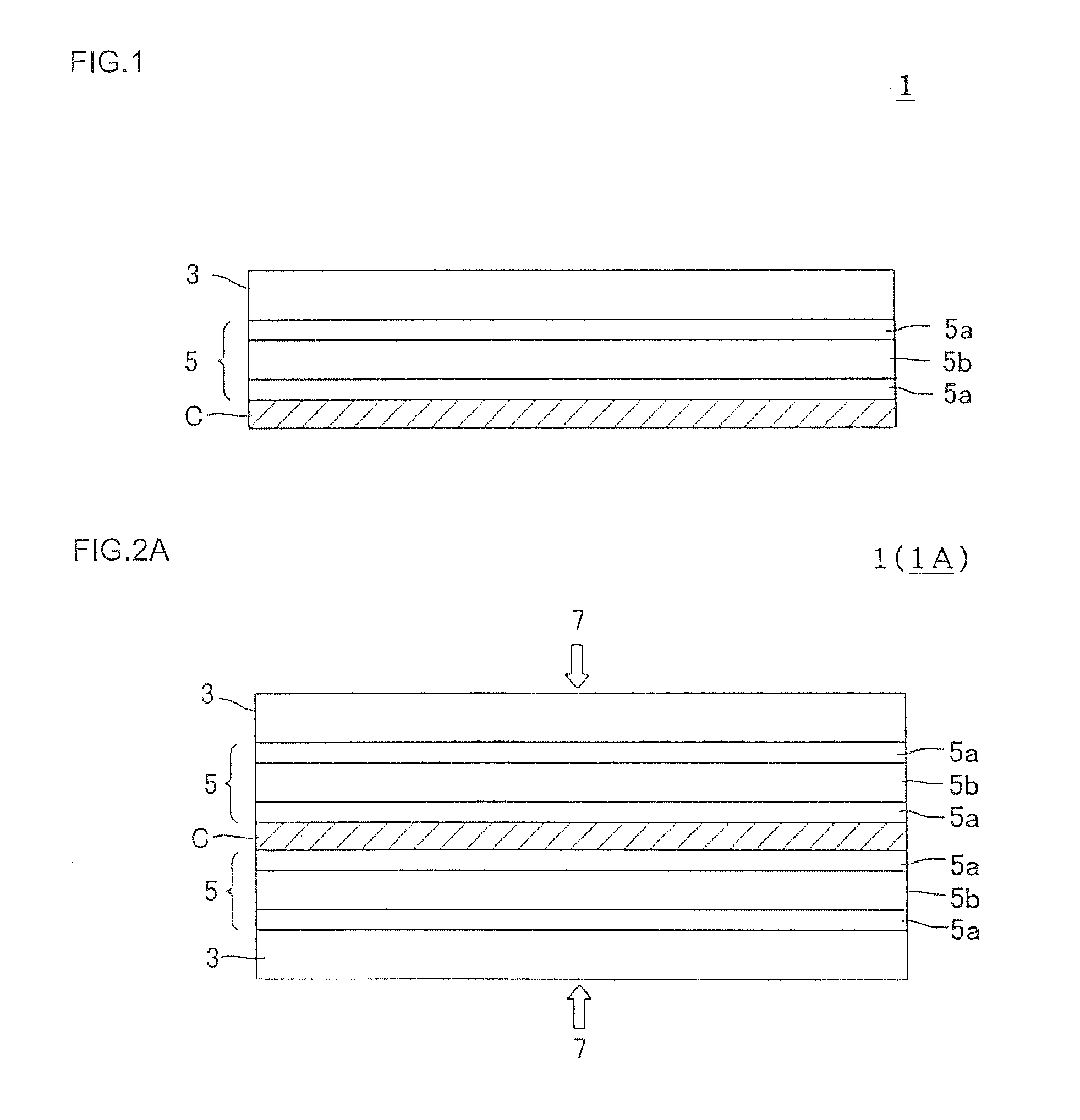

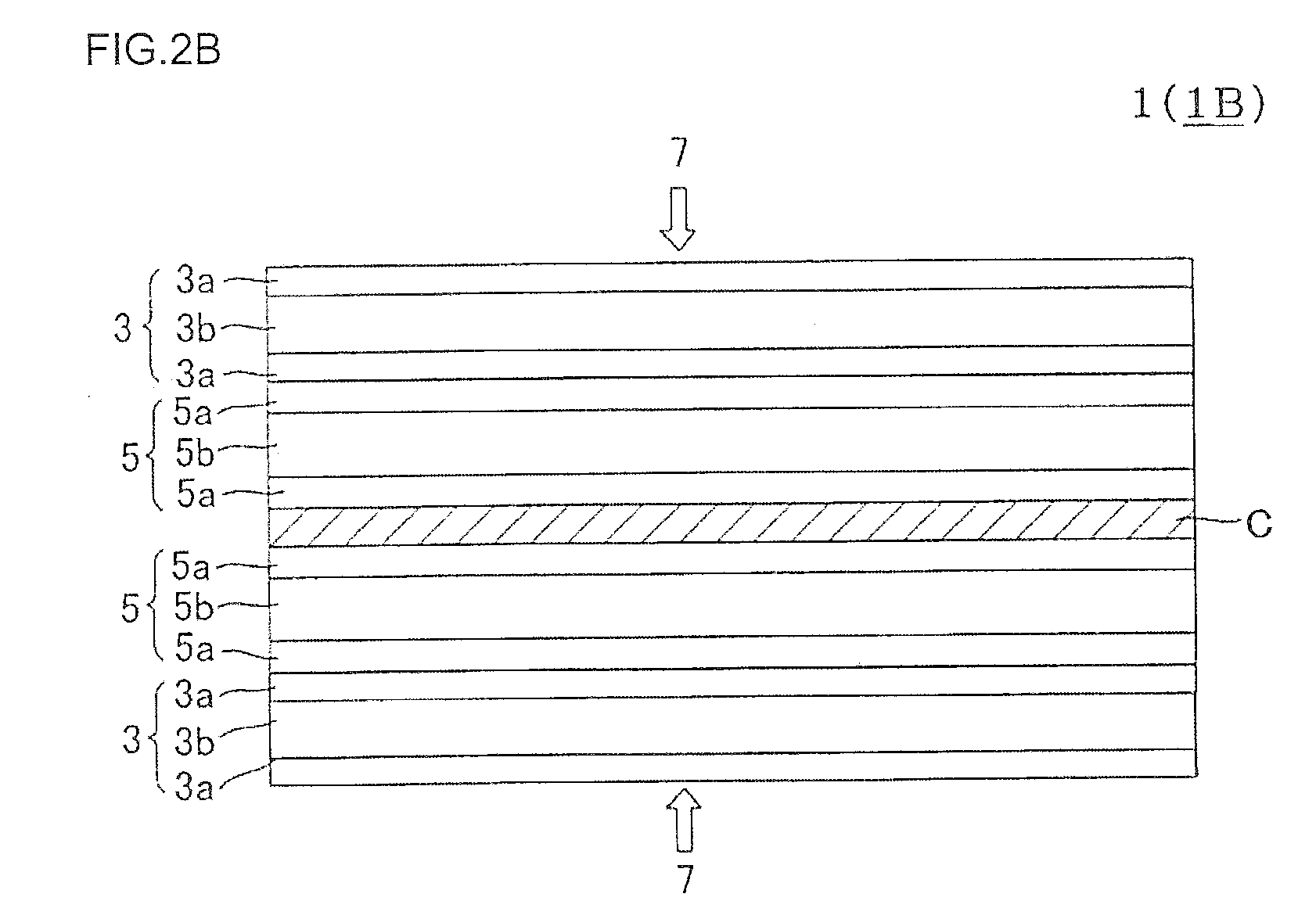

Multilayer laser-markable sheet for electronic passport and electronic passport

InactiveUS20120164419A1Improve laser marking effectIncrease contrastOther printing matterDuplicating/marking methodsEngineeringLaser light

A multilayer laser-markable sheet for an electronic passport includes three sheets of a sheet A / a multilayer sheet B / a sheet C as a basic constitutional unit. The sheet A includes a transparent polycarbonate resin composition including a thermoplastic polycarbonate resin and a laser light energy absorbing agent, the multilayer sheet B includes a transparent thermoplastic resin including a thermoplastic polycarbonate resin, at least one layer of the skin layers and the core layer of the multilayer sheet B including at least one selected from a dye and a pigment. The sheet C includes a sheet or a laminate sheet. The multilayer laser-markable sheet for an electronic passport has excellent laser markability and high contrast, can achieve clear letters, symbols and images, and further has excellent thermal adhesiveness, transparency, sheet conveyance property, releasability from a die after thermal press, thermal resistance, foldability and wear resistance.

Owner:JAPAN COLORING

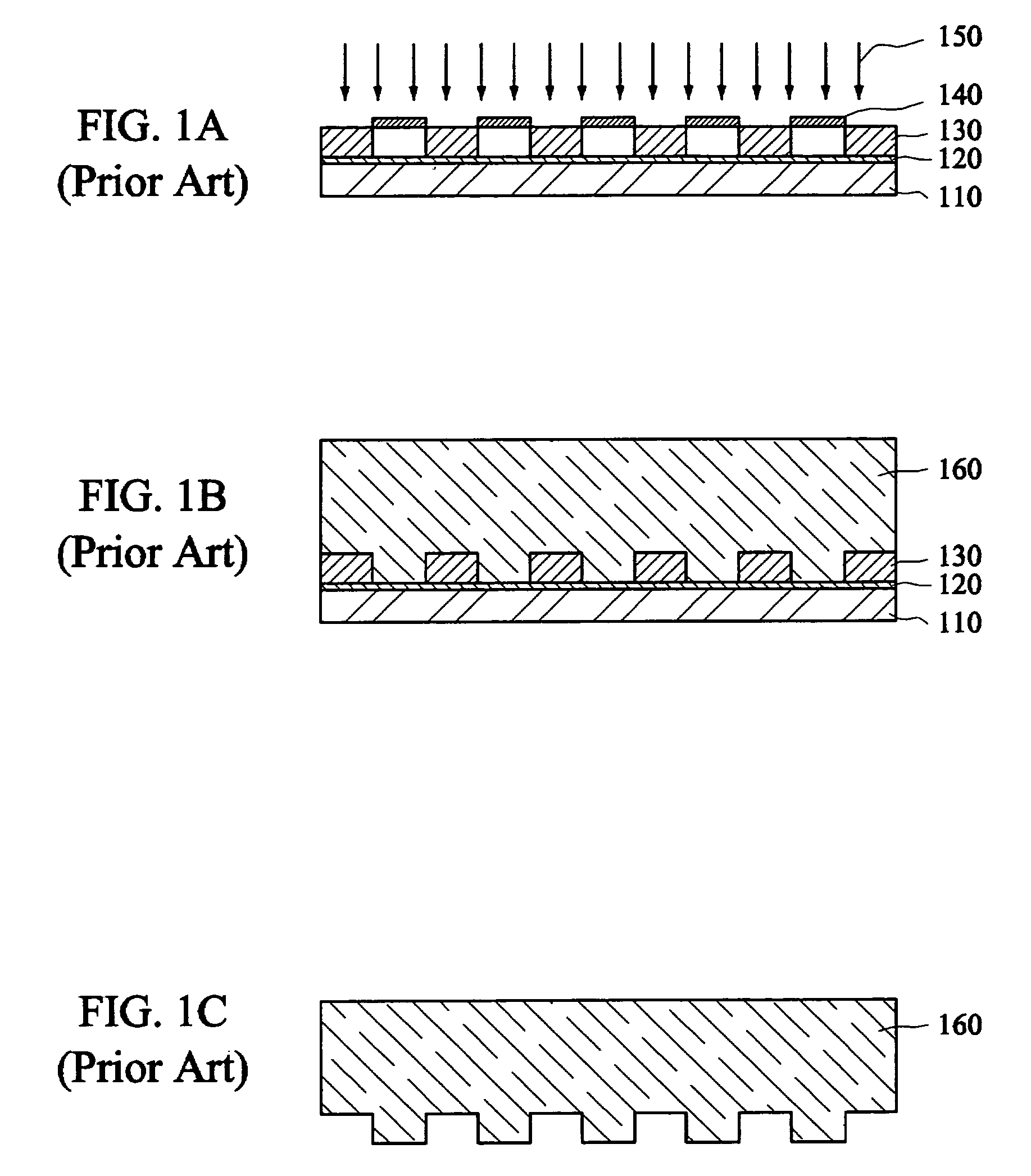

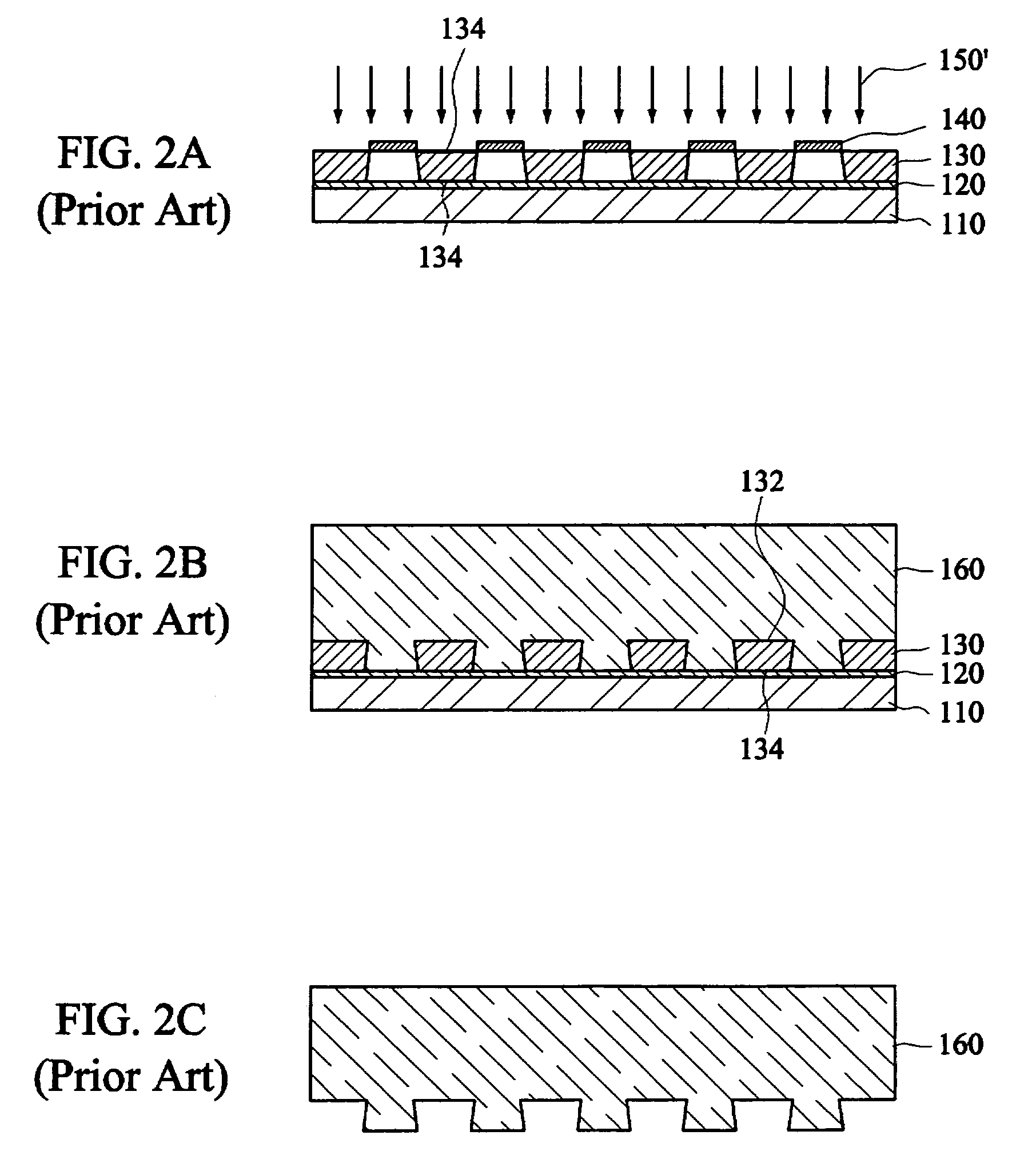

Method of manufacturing a LIGA mold by backside exposure

InactiveUS20060275711A1Low costPhotomechanical exposure apparatusMicrolithography exposure apparatusLIGAThermal compression

A method of manufacturing a LIGA mold by backside exposure includes the steps of: disposing a mask layer at a side of a first substrate, wherein the first substrate is transparent to a predetermined light source and has a front side and a backside; forming a photoresist layer on the front side of the first substrate; providing the predetermined light source to illuminate the backside of the first substrate so as to expose the photoresist layer to form an exposed portion and an unexposed portion; removing the unexposed portion to form a patterned structure on the photoresist layer; forming a metal layer on the patterned structure of the photoresist layer and the first substrate; and removing the photoresist layer and the first substrate to remain the metal layer as the LIGA mold, which is good in a de-molding procedure of a hot embossing process.

Owner:NATIONAL TSING HUA UNIVERSITY

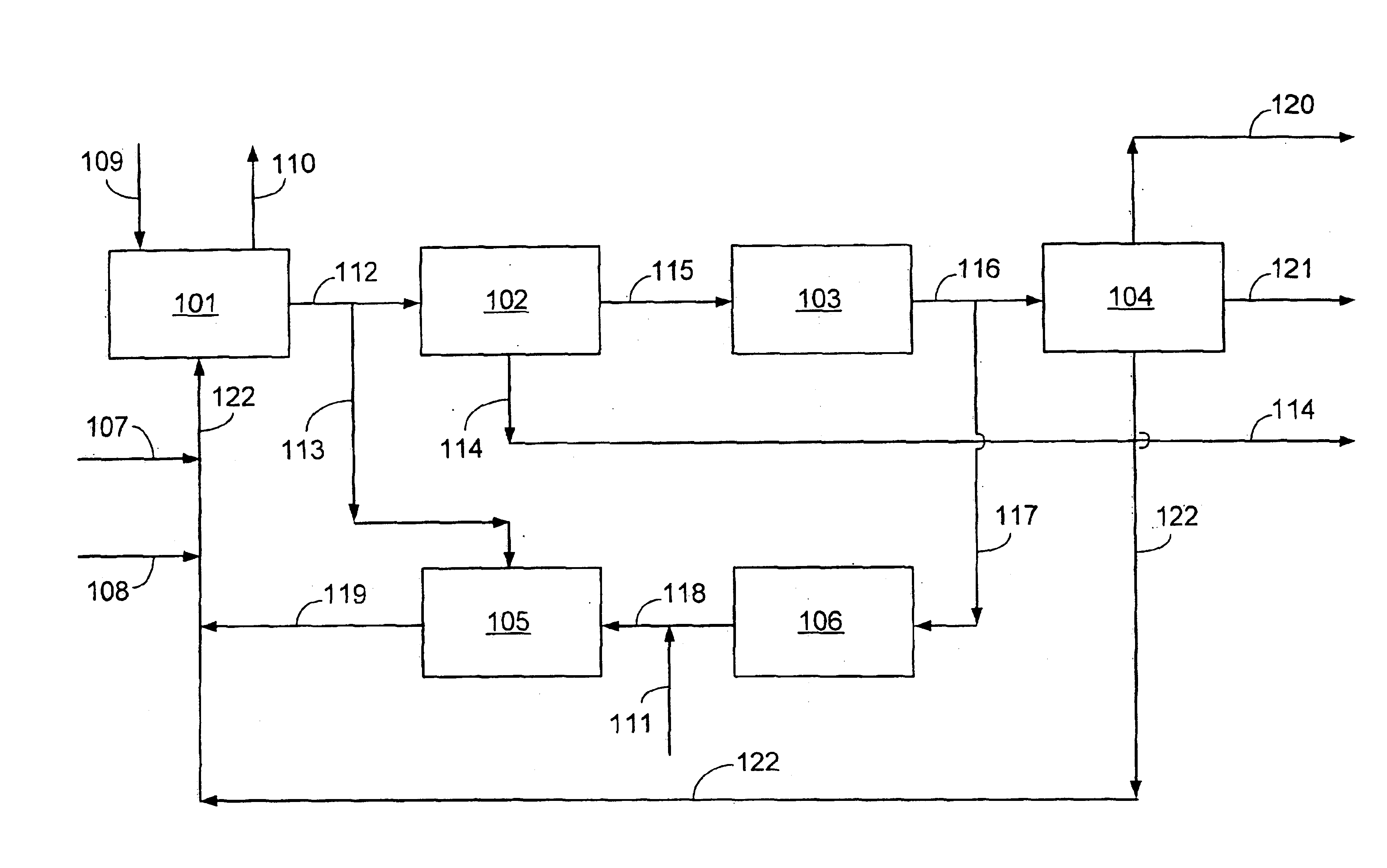

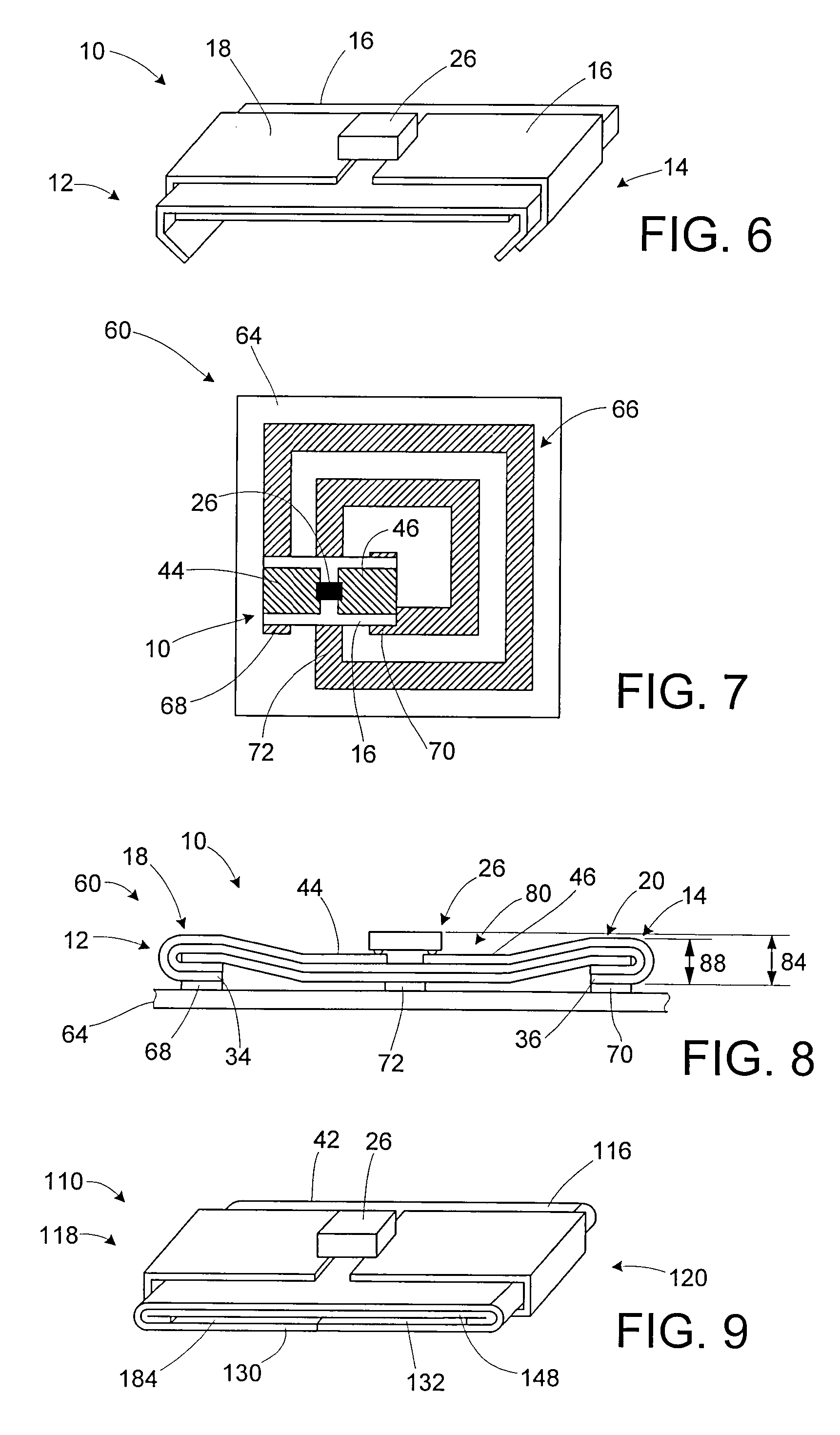

System and method for thermal compression therapy

A method for providing a combined DVT and compression therapy to a patient is provided. The method includes providing a control unit configured to condition heat transfer fluid and to selectively provide a compressed gas, providing a thermal compression device that is mountable to a select portion of the patient, and programming the control unit to supply heat transfer fluid to the thermal compression device and to supply compressed gas to the thermal compression device.

Owner:THERMOTEK

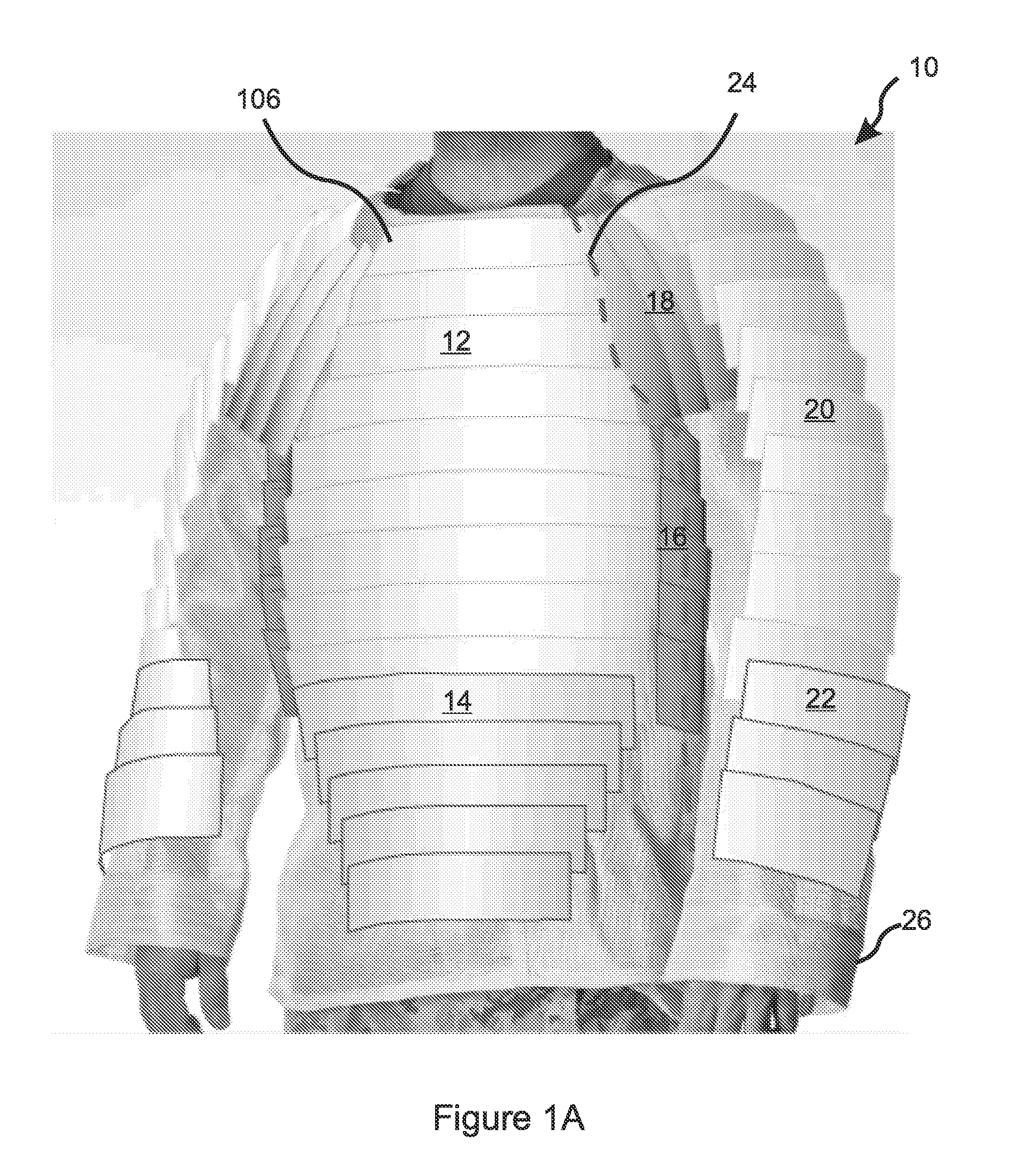

Thermally vented body armor

InactiveUS20120159680A1Stable positionMinimum wasted massArmourPersonal protection gearThermal compressionExcessive weight

A modular and field adaptable body armor system includes a plurality of flexible, air-permeable, thermally vented plates arranged in fixed relationships that pro-vide flexible, modular, field-adaptable protection for the torso and extremities without excessive weight or heat bur-den. The TVA plates include protective cards suspended in a parallel, louvered relationship between inner and outer mesh layers, thereby permitting air to flow therebetween while providing a flexible, compressible, modular barrier that protects the torso and extremities against projectiles. In embodiments, the outer mesh layer resists penetration and compresses cards together to intercept a projectile that would otherwise pass therebetween. Protective cards can include thermally pressed and flexed laminated UHMWPE. TVA panels can be removed and exchanged in the field according to the requirements of each mission. In embodiments, the TVA plates are laced together and / or attached to an underlying fabric carrier garment.

Owner:WARWICK MILLS INC

Foldable RFID device interposer and method

ActiveUS20080315992A1Electrical apparatus contructional detailsSubscribers indirect connectionCapacitanceAdhesive

An RFID device interposer has folded ends that bring conductive lead end portions of conductive leads of the interposer to an underside of the interposer. The central conductive lead portions of the conductive leads remain on an upper surface of a dielectric substrate of the interposer. The folded ends of the interposer may be held together with an adhesive, or with thermal compression bonding. The interposer may also have an additional conductive material layer on an underside of the dielectric substrate. The conductive material layer may be capacitively coupled to the conductive leads of the interposer. The interposer may be tuned by varying the pressure used to secure the folded ends. This may be used to provide a better impedance match between a chip of the interposer, and the conductive leads and an antenna to which the interposer is coupled.

Owner:AVERY DENNISON CORP

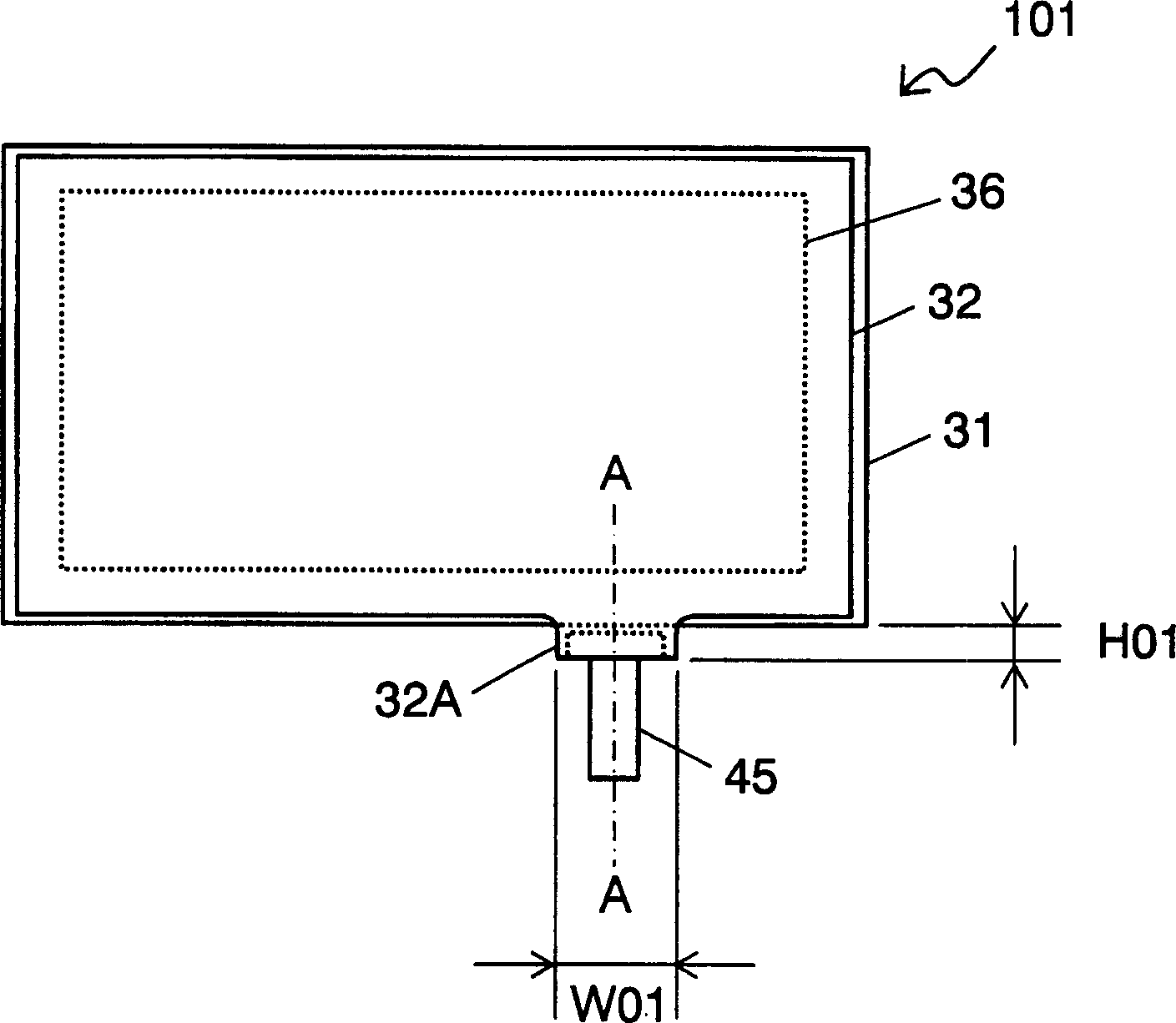

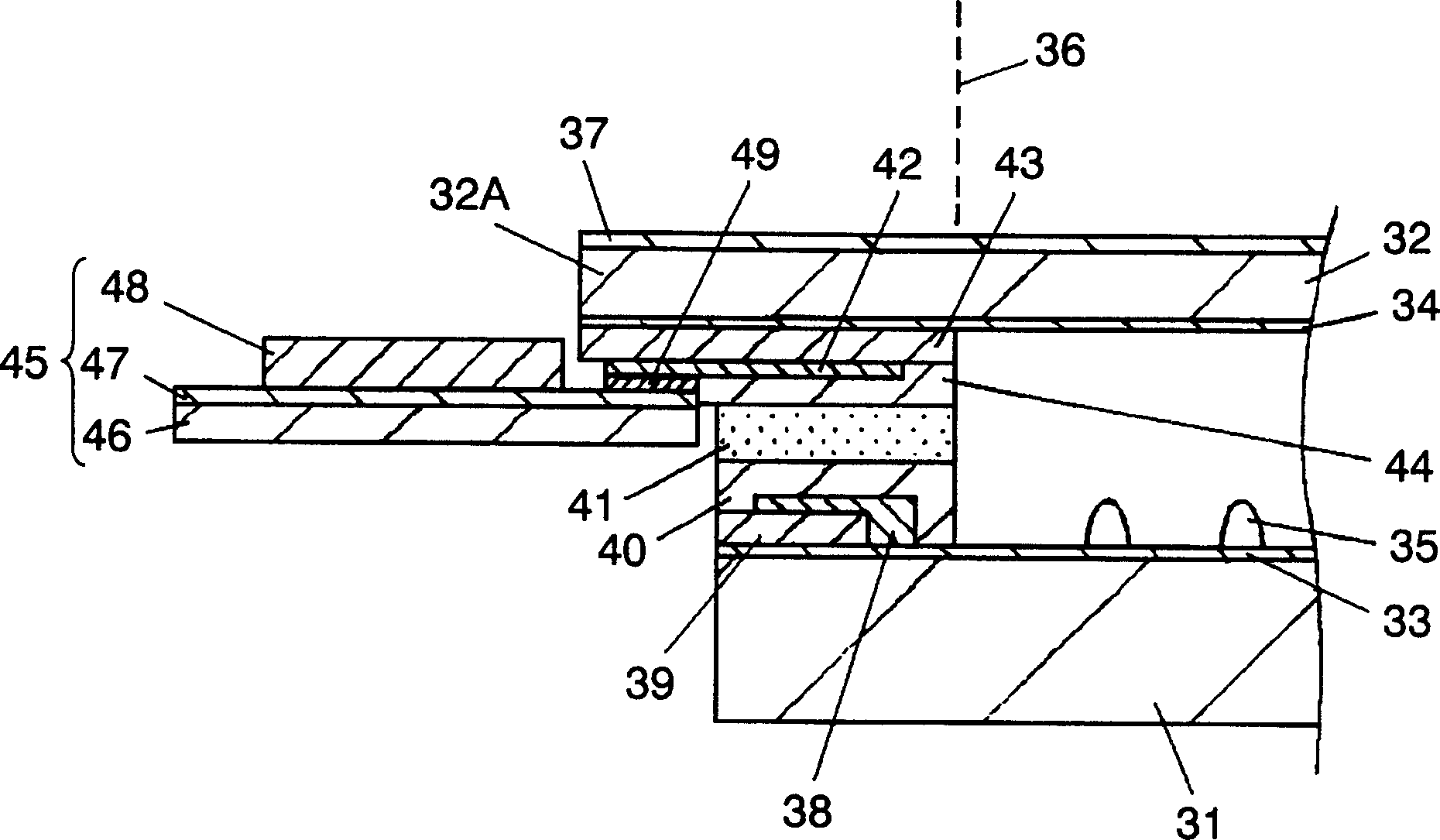

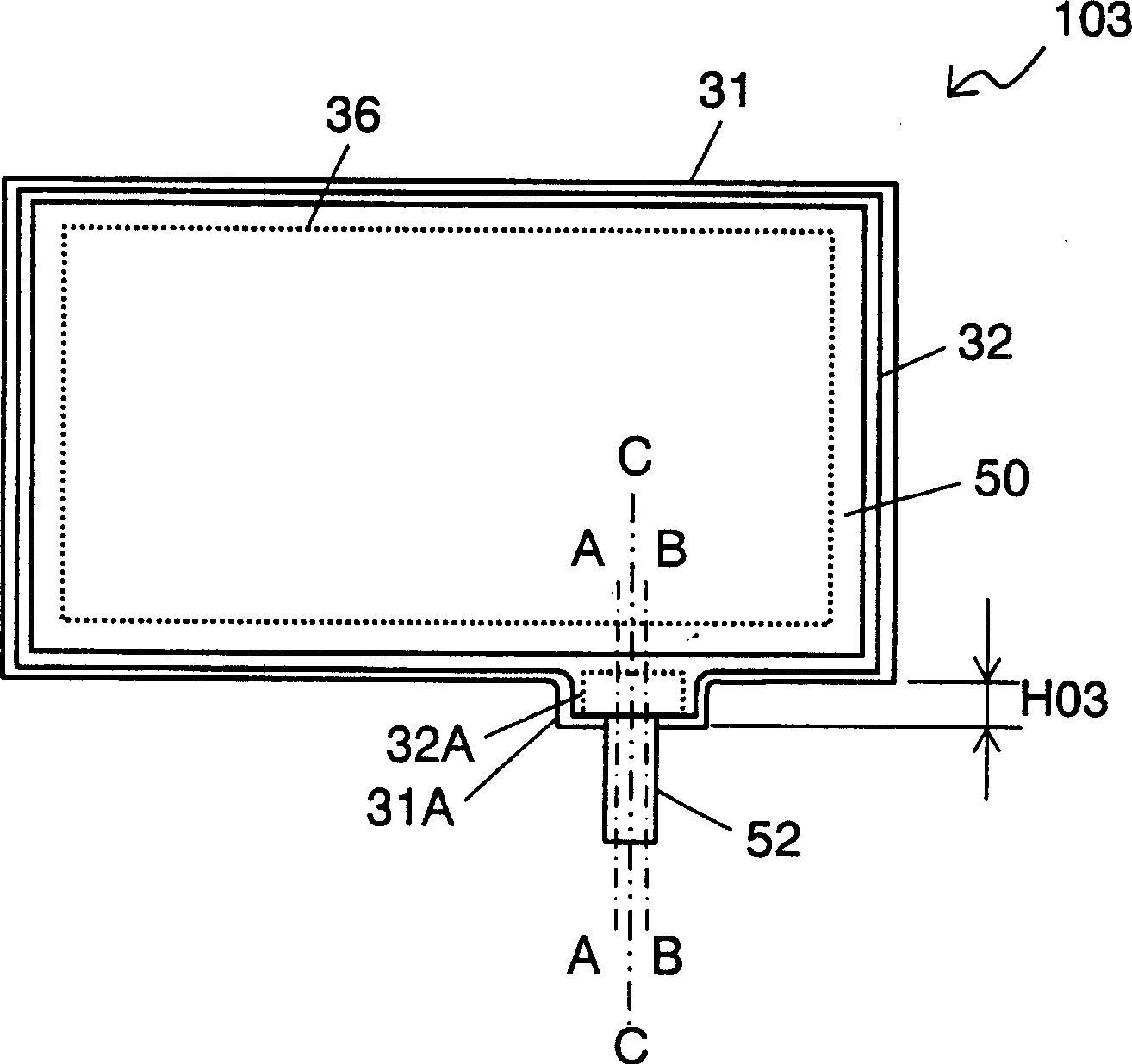

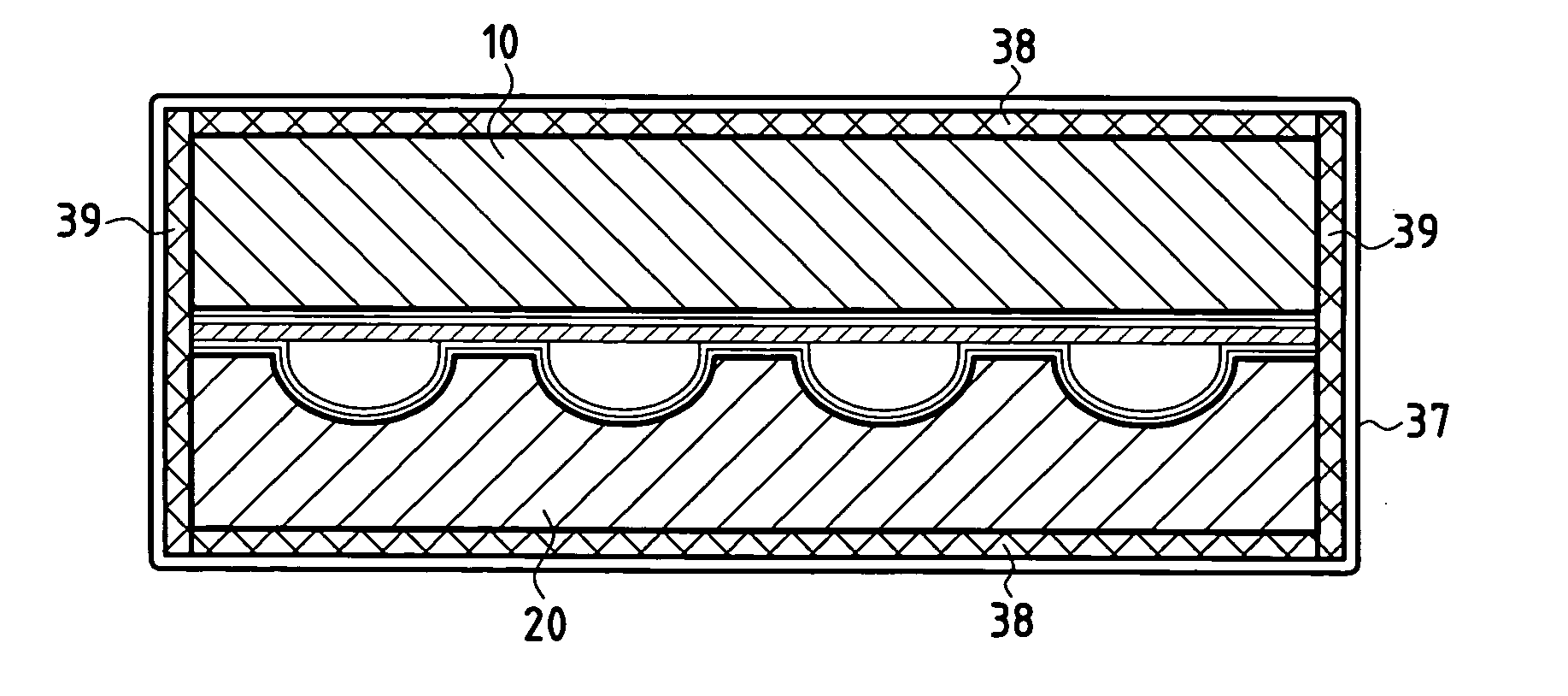

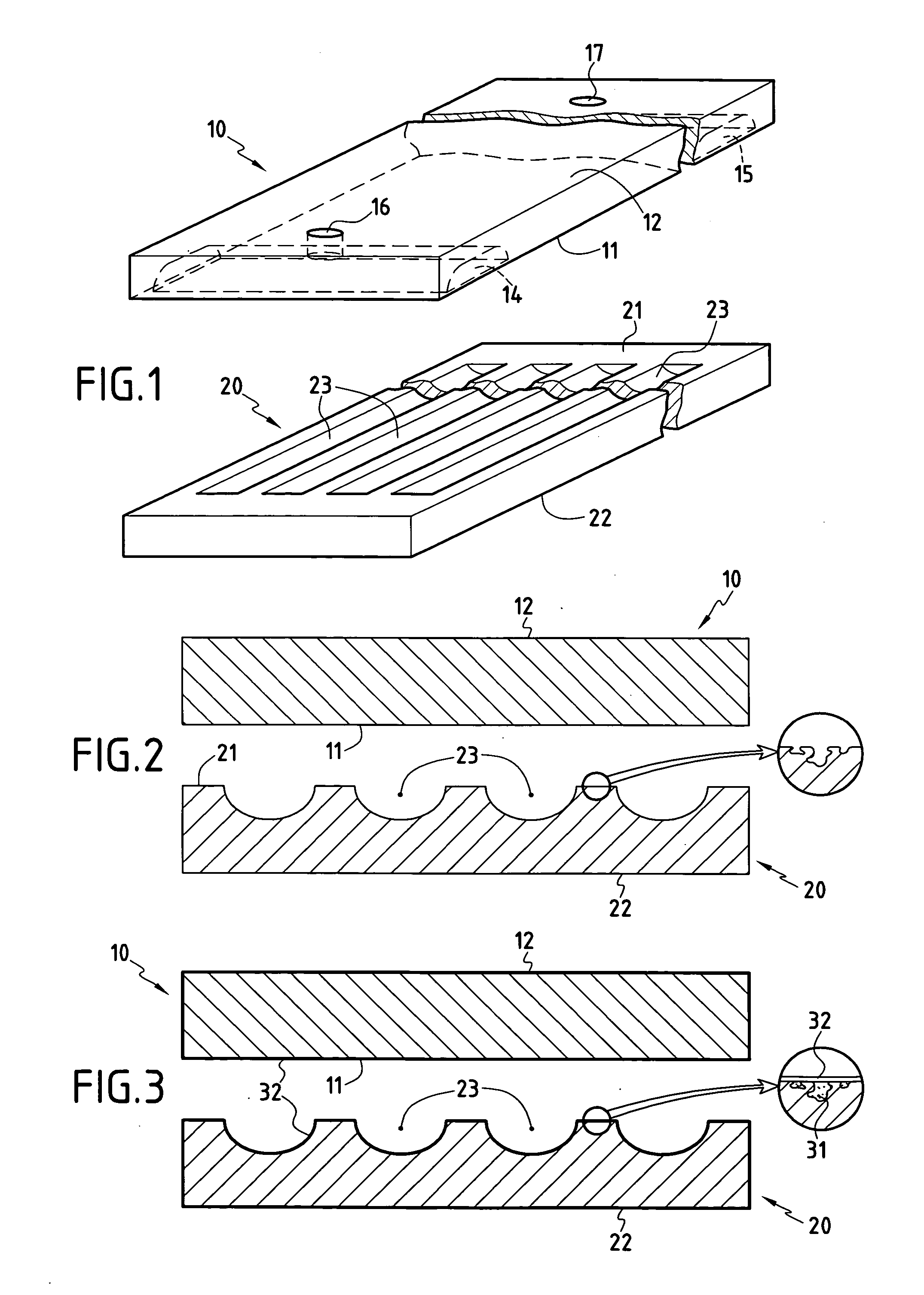

Touch panel and liquid crystal display apparatus using the same

InactiveCN1614624AInput/output for user-computer interactionPrinted circuit assemblingLiquid-crystal displayElectrical connection

The present invention provides a touch panel, which is constituted by providing a protruding part (32A) on a second transparent substrate (32), bonding a flexible wiring board (45) to the protruding part (32A) by thermocompression, and In the parts other than the part (32A), the size and weight of the equipment to be mounted are realized by narrowing the width of the frame edge. In addition, by sticking a sheet-like member such as a polarizing plate (50) to the upper surface portion of the second transparent substrate (32) except the area of the protruding portion (32A), the action from the sheet-like member to the FPC (52) is alleviated. Stress on the bonded portion is applied to improve the electrical connection stability of the FPC (52).

Owner:PANASONIC CORP

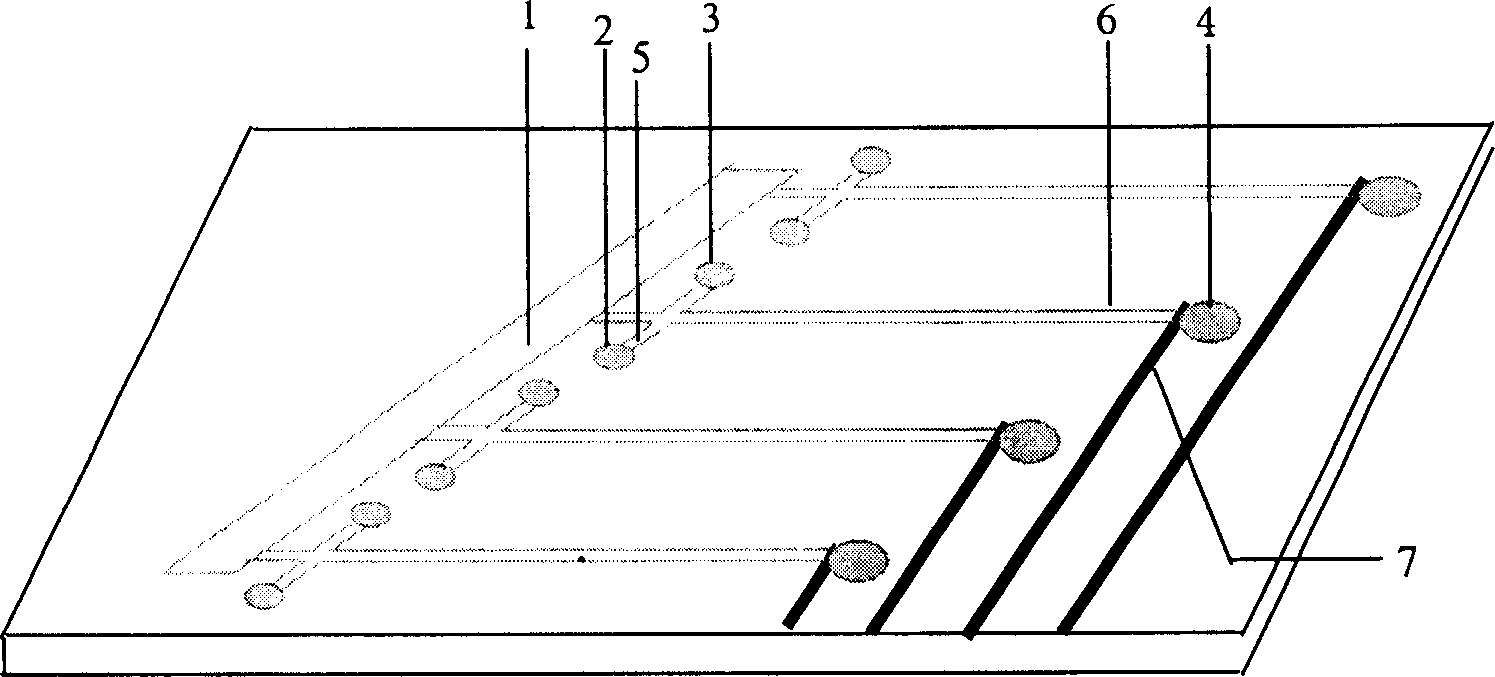

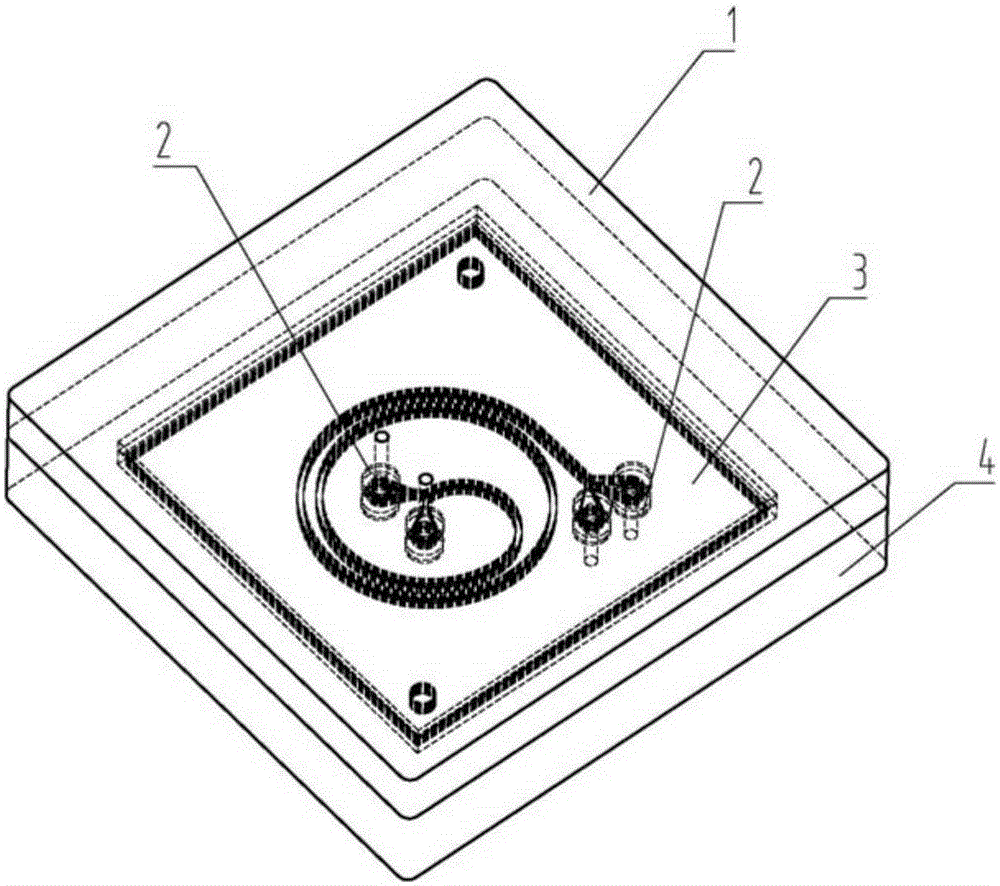

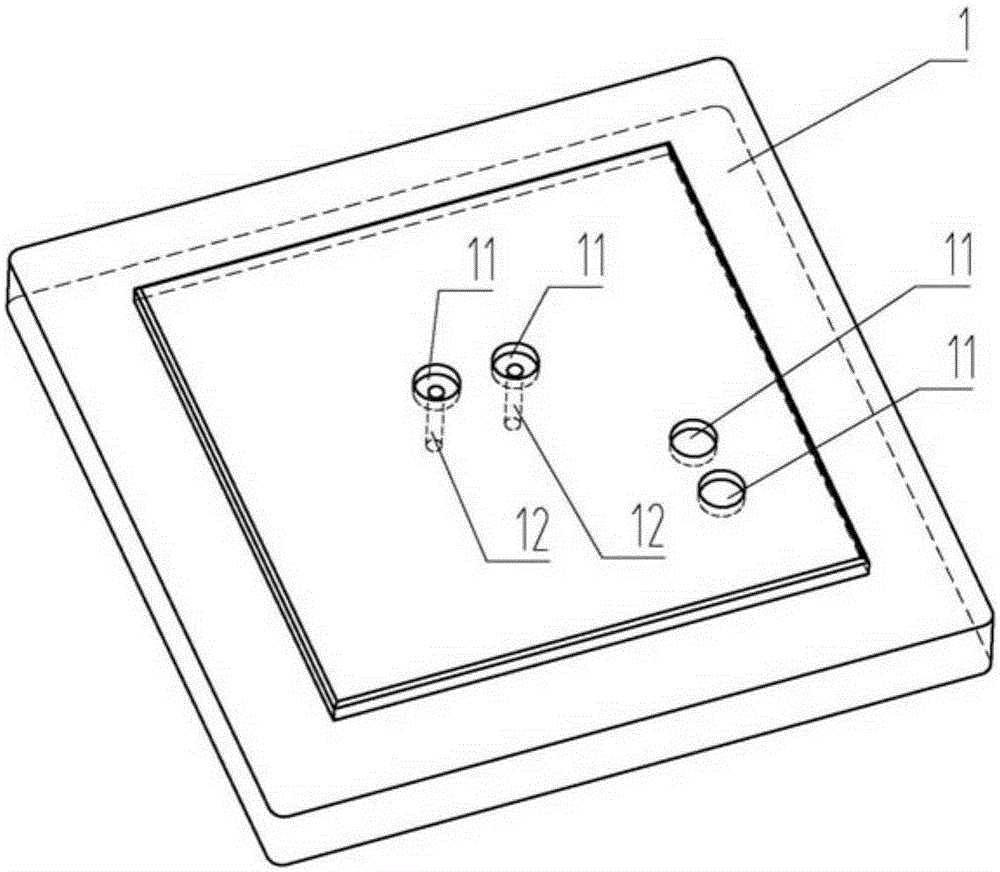

Clamping-piece-type microfluidic device and manufacturing method

ActiveCN105214747AEasy to purchaseLow costLaboratory glasswaresBiochemical engineeringThermal compression

The invention discloses a clamping-piece-type microfluidic device and a manufacturing method. The clamping-piece-type microfluidic device comprises a cover plate, sealing gaskets, a microfluidic chip assembly and a bottom plate; a sample inlet and a cover plate sealing gasket groove are formed in the cover plate; the microfluidic chip assembly is composed of a laminating film and a microfluidic chip with a microfluidic channel, and a liquid inlet hole, a liquid outlet hole and a positioning hole are formed in the microfluidic chip assembly; the bottom plate is provided with a sample outlet, a bottom plate sealing gasket groove and a positioning column; the sealing gaskets are arranged in the sealing gasket grooves formed in the cover plate and the bottom plate. The manufacturing method comprises an injection molding process method of the cover plate and the bottom plate, a laser direct writing method of the microfluidic chip, a laminating and bonding method of the microfluidic chip assembly and a hot-press assembly method of the microfluidic device. The clamping-piece-type microfluidic device is simple in structure and manufacturing method, low in cost, high in finished product rate and suitable for both one-piece making for laboratory scientific research and commercial mass production.

Owner:SOUTHEAST UNIV

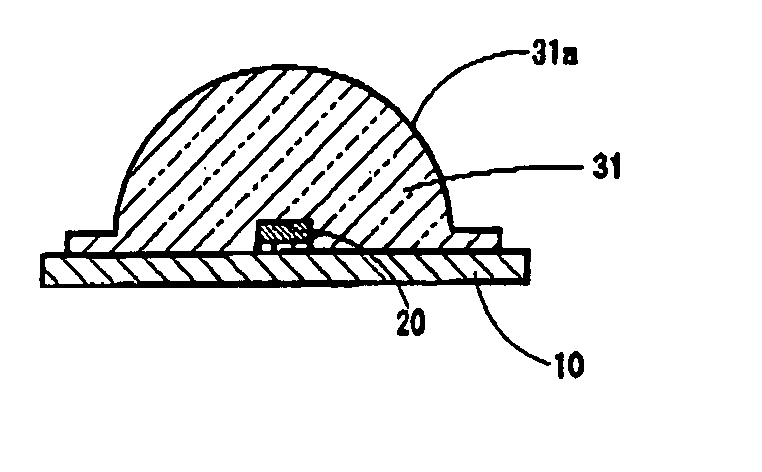

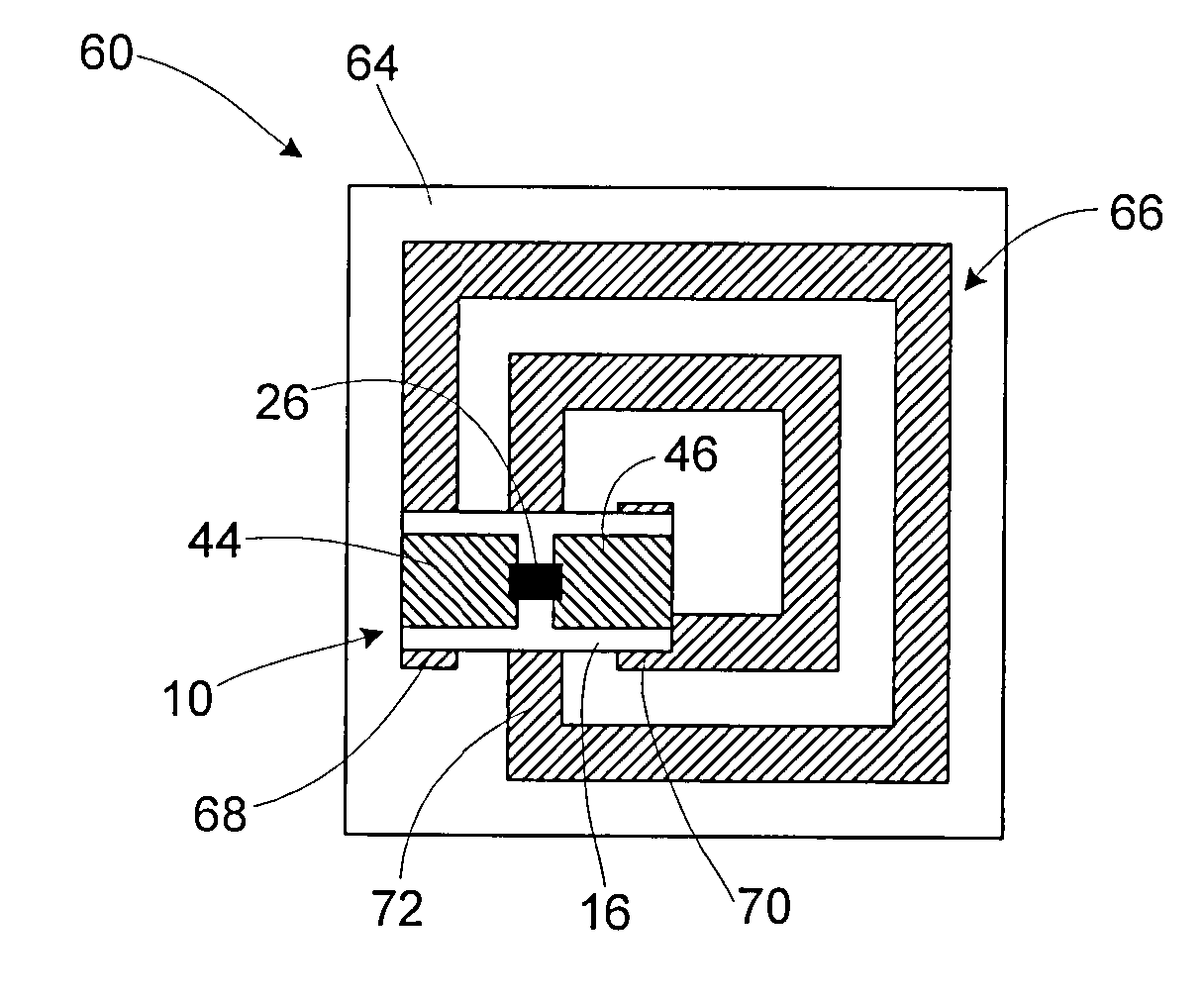

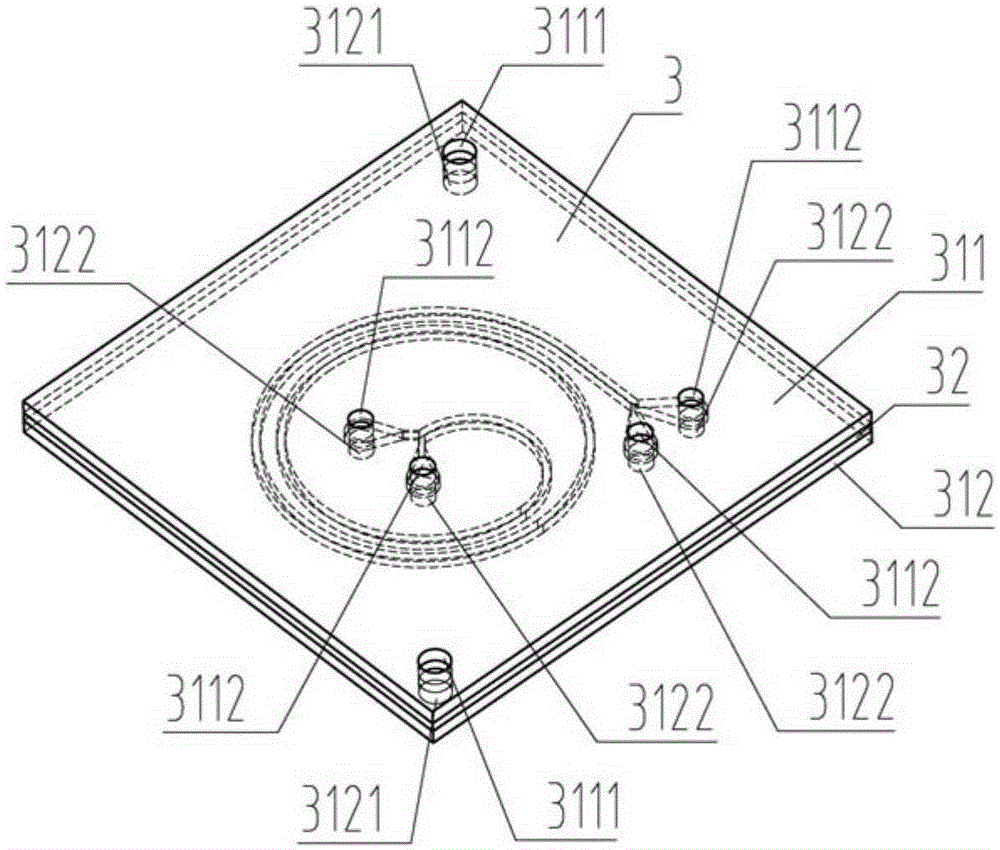

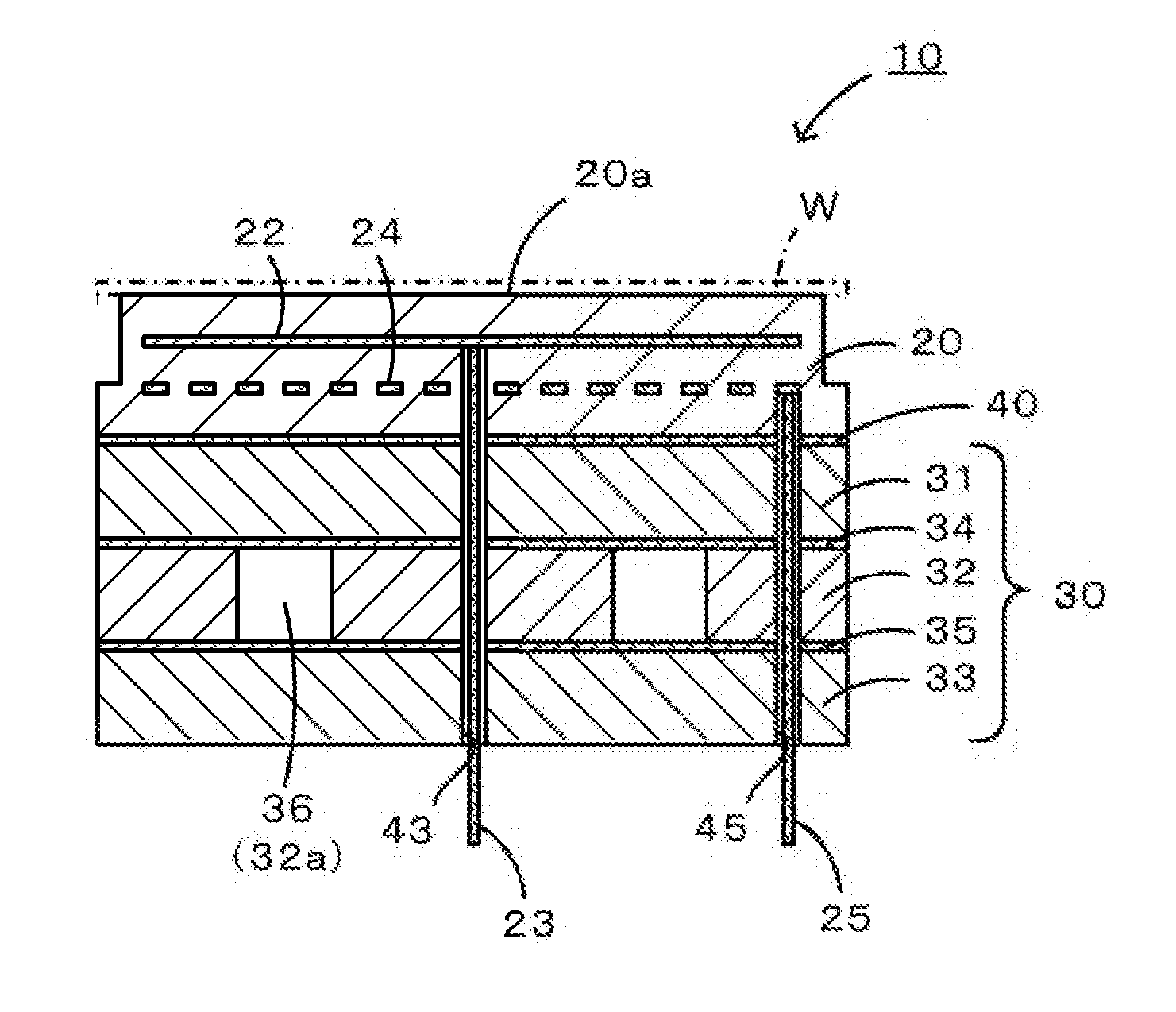

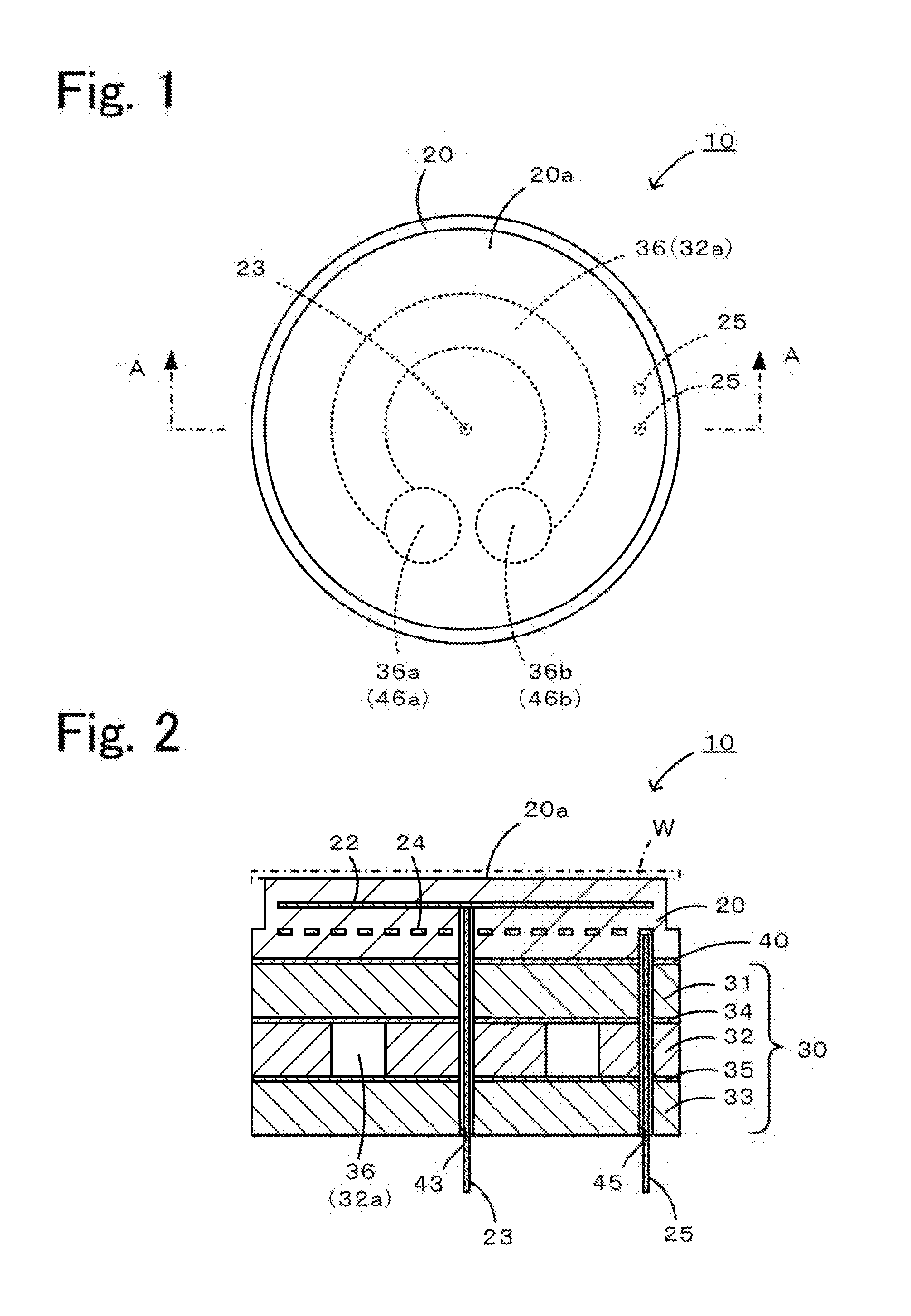

Cooling plate, method for manufacturing the same, and member for semiconductor manufacturing apparatus

ActiveUS20150077895A1Small differenceImprove conductivitySoldering apparatusSolid-state devicesThermal compressionManufactured apparatus

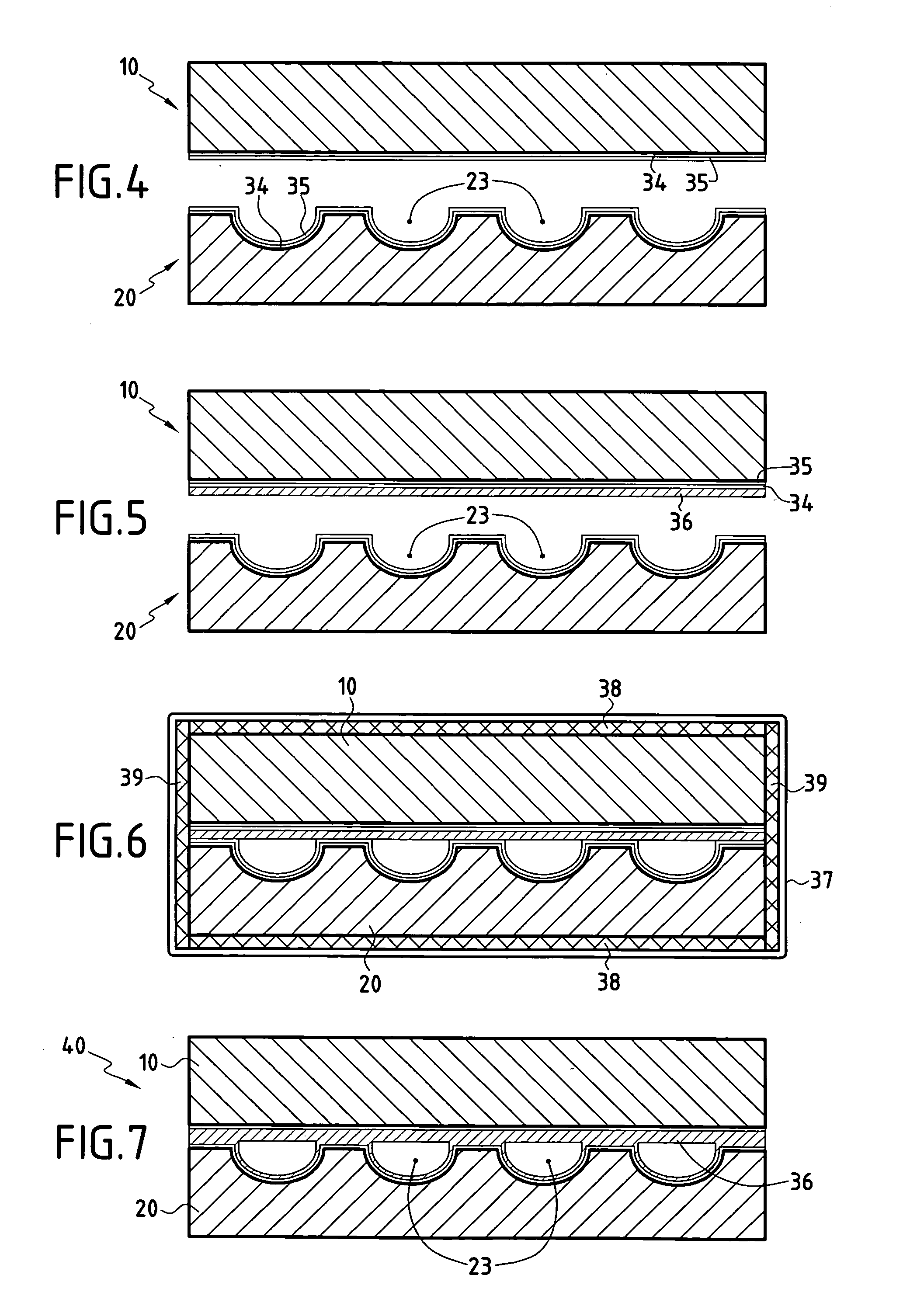

A member 10 for a semiconductor manufacturing apparatus includes an alumina electrostatic chuck 20, a cooling plate 30, and a cooling plate-chuck bonding layer 40. The cooling plate 30 includes first to third substrates 31 to 33, a first metal bonding layer 34 between the first and second substrates 31 and 32, a second metal bonding layer 35 between the second and third substrates 32 and 33, and a refrigerant path 36. The first to third substrates 31 to 33 are formed of a dense composite material containing Si, SiC, and Ti. The metal bonding layers 34 and 35 are formed by thermal compression bonding of the substrates 31 to 33 with an Al—Si—Mg or Al—Mg metal bonding material interposed between the first and second substrates 31 and 32 and between the second and third substrates 32 and 33.

Owner:NGK INSULATORS LTD

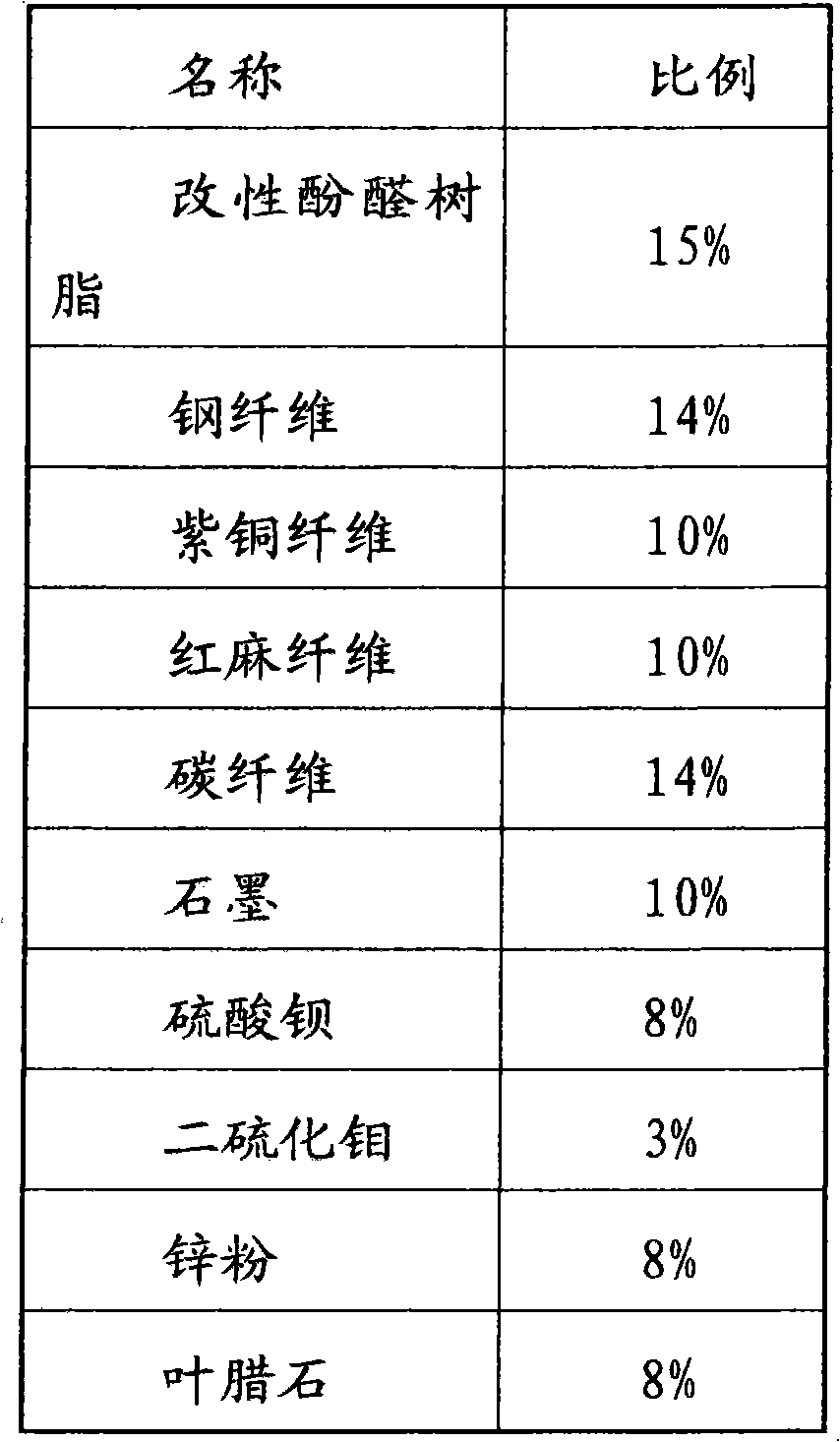

Manufacture method of automobile brake pad

ActiveCN102678798AImprove performanceMeet the use requirementsOther chemical processesFriction liningThermal compressionShock resistance

The invention discloses a manufacture method of an automobile brake pad, comprising the following steps of: mixing, and filling a friction material into pores of a porous metal material by a vacuum filling method, so that a friction material blank can be formed; injecting, and adding the friction material blank into an injector to inject into a compacting mould, wherein the injector is a screw rod-rotatable injector; compacting the friction material blank in the mould to prepare a friction block blank, wherein in the process of compacting, keeping the hot-press temperature at 148-152DEG C, the hot-press pressure at 23MPa, and keeping the pressure for 5 minutes; cutting the prepared friction block blank into a brake pad friction block according to the required size, and putting the friction block and the steel back in the mould to be compacted and shaped into a brake pad blank; and thermally treating the brake pad blank to prepare the brake pad, wherein the thermal treatment temperature of the thermal treatment technology is 160DEG C, and the thermal treatment time is 2 hours, and cooling along with a furnace.. The manufacture method has the benefit effects that the abrasive resistance and shock resistance of the automobile brake pad can be improved.

Owner:JIANGSU ANJIE AUTO PARTS

Method of manufacturing an active cooling panel out of thermostructural composite material

InactiveUS20050077341A1Effective and durableReduce usageContinuous combustion chamberNuclear energy generationMetal coatingCombustion chamber

A metal coating is formed on the inside face of a first thermostructural composite material part presenting indentations forming channels, and also on the inside face of a second thermostructural composite material part for being applied against the inside face of the first part, and the first and second parts are assembled together by bonding said inside faces together by hot compression, in particular by hot isostatic pressing, thereby obtaining a thermostructural composite material cooling panel having integrated fluid flow channels. The invention is applicable to making heat exchanger walls such as the walls of combustion chambers in aircraft engines, or the diverging portions of rocket engines, or plasma confinement chambers in nuclear fusion reactors.

Owner:SNECMA PROPULSION SOLIDE

Flow-guiding member unit and its production method

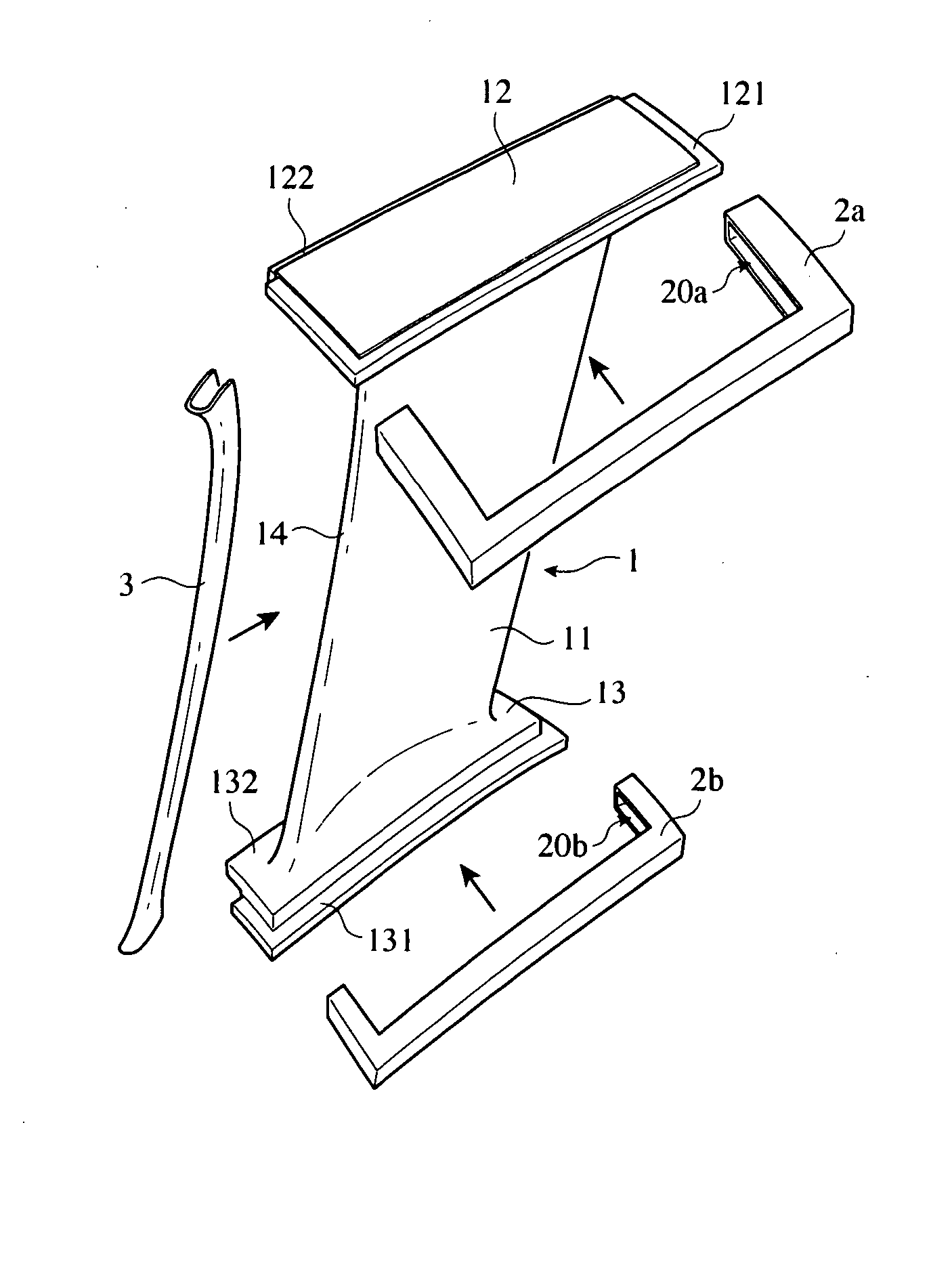

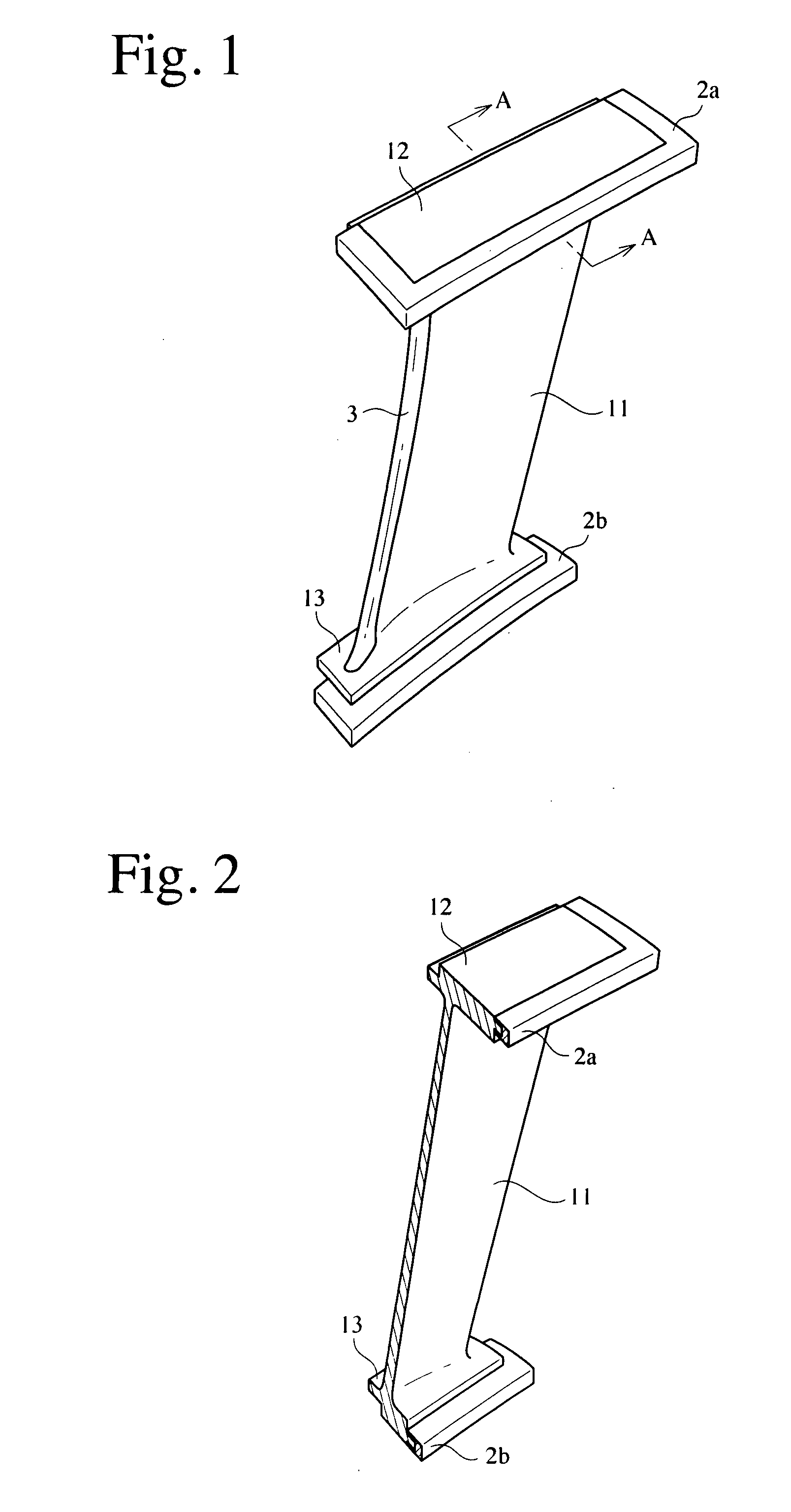

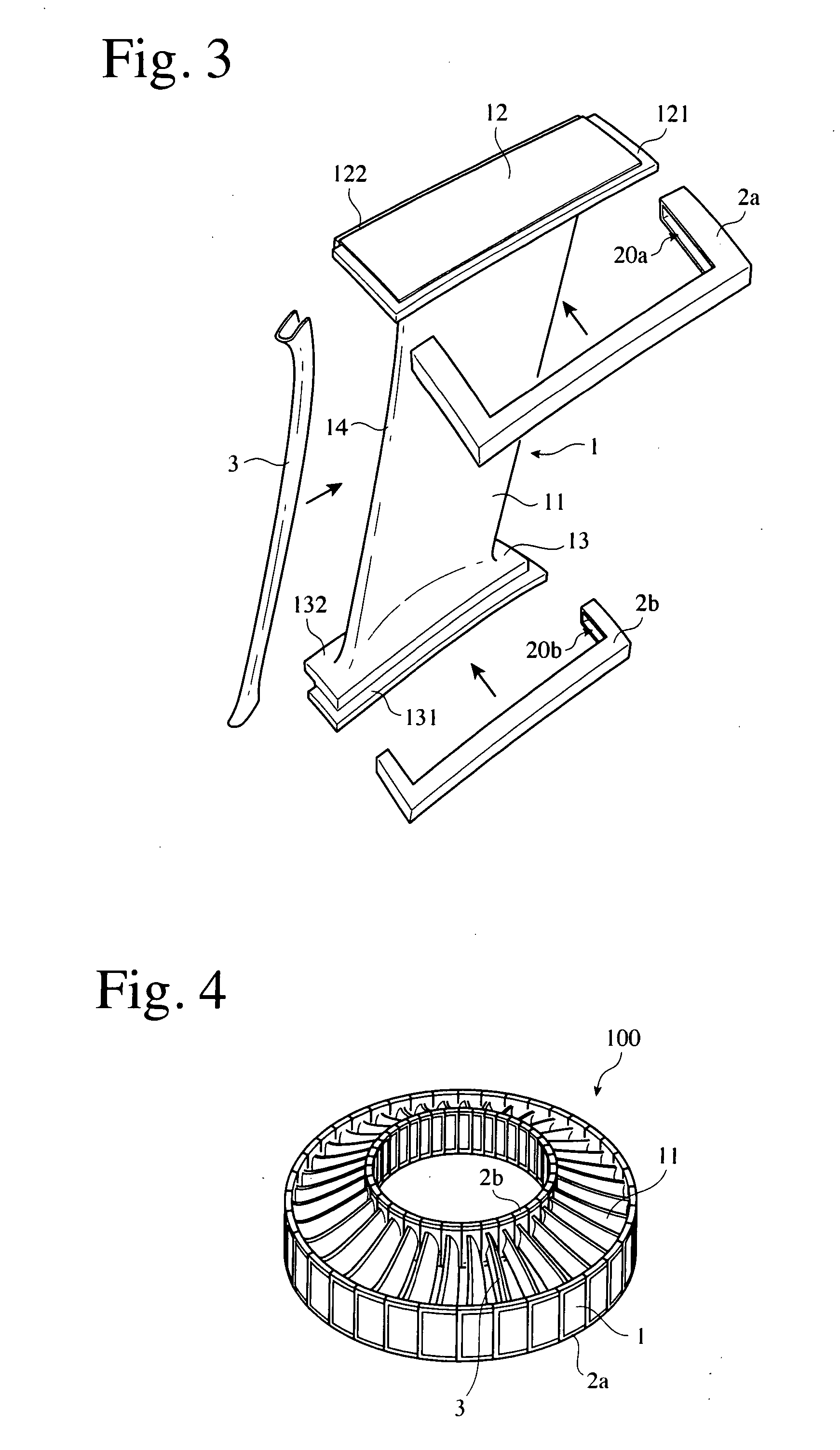

ActiveUS20080038113A1High mechanical strengthEasy to replacePump componentsMouldsFiberThermoplastic elastomer

A flow-guiding member unit used for assembling a flow-guiding member comprising pluralities of vanes, an outer platform and an inner platform, the unit comprising an integral body member comprising one vane portion, an outer platform portion, and an inner platform portion, a first elastic member attached to a step of the outer platform portion, and a second elastic member attached to a step of the inner platform portion, the body member being formed by the thermal compression of sheet-molding compounds or fiber-reinforced resin pellets, and the first and second elastic members being made of a thermoplastic elastomer.

Owner:HONDA MOTOR CO LTD

Method for preparing membrane electrode for hydrophilicity and hydrophobicity-adjustable proton exchange membrane fuel battery on the basis of catalyst/membrane technology

The invention relates to a method for preparing a membrane electrode for a hydrophilicity and hydrophobicity-adjustable proton exchange membrane fuel battery on the basis of a catalyst / membrane technology, comprising the following steps of: mixing deionized water and a hydrophobizing agent and then adding an alcohol-containing proton conduction polymer solution in the mixture and uniformly mixing to prepare a hydrophobizing agent and proton conduction polymer solution dispersion; wetting a catalyst by using the deionized water; adding the hydrophobizing agent and proton conduction polymer solution dispersion in the wet catalyst for dispersion to prepare catalyst slurry; coating the catalyst slurry on two mediums and drying by heating to obtain two mediums with catalytic layers through thermal processing; placing a proton exchange membrane between the catalytic layers of the two mediums with the catalytic layers and respectively shifting the catalytic layers on the two mediums to the two surfaces of the proton exchange membrane through thermal compression to obtain a catalyst-covering proton exchange membrane assembly; and placing the assembly between two gas diffusion layers and then making the assembly into the membrane electrode through the thermal compression, wherein the two surfaces of the proton exchange membrane exactly face the two gas diffusion layers.

Owner:武汉理工新能源有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com