Patents

Literature

472results about "Screening apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

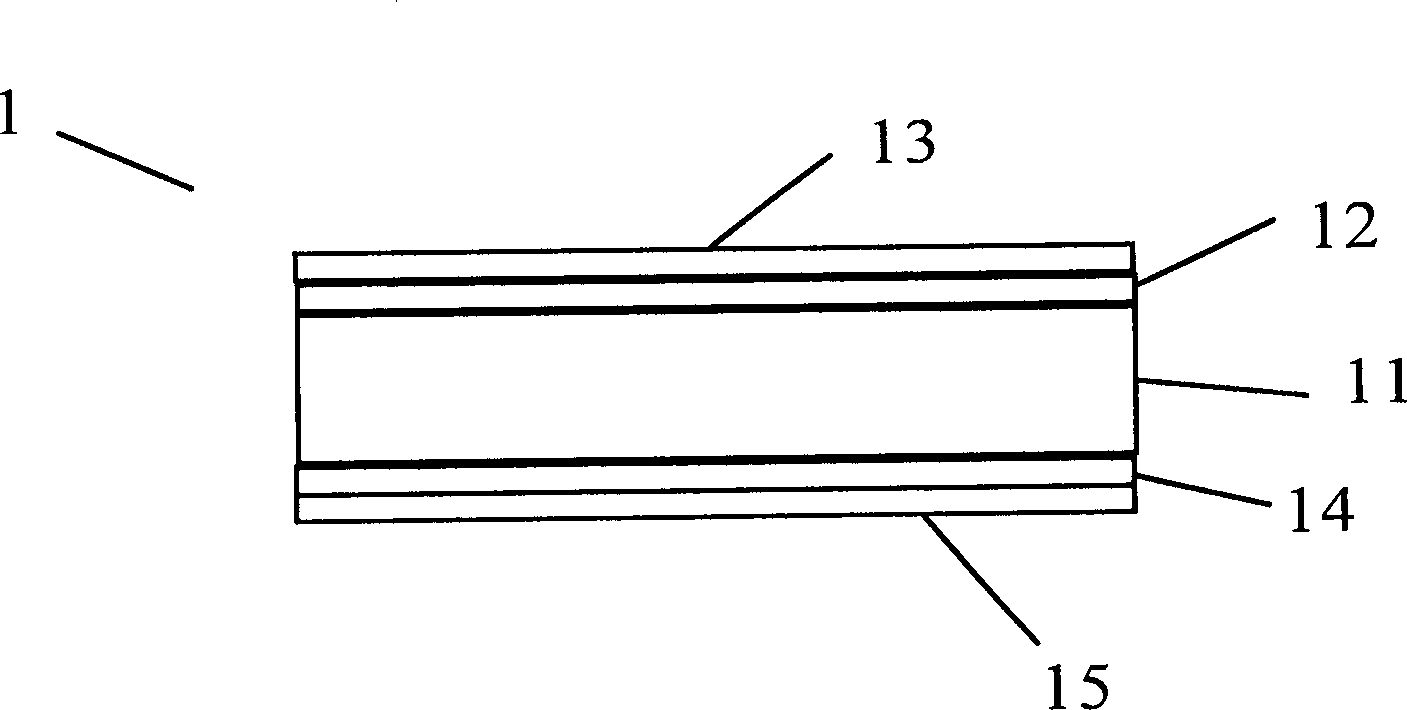

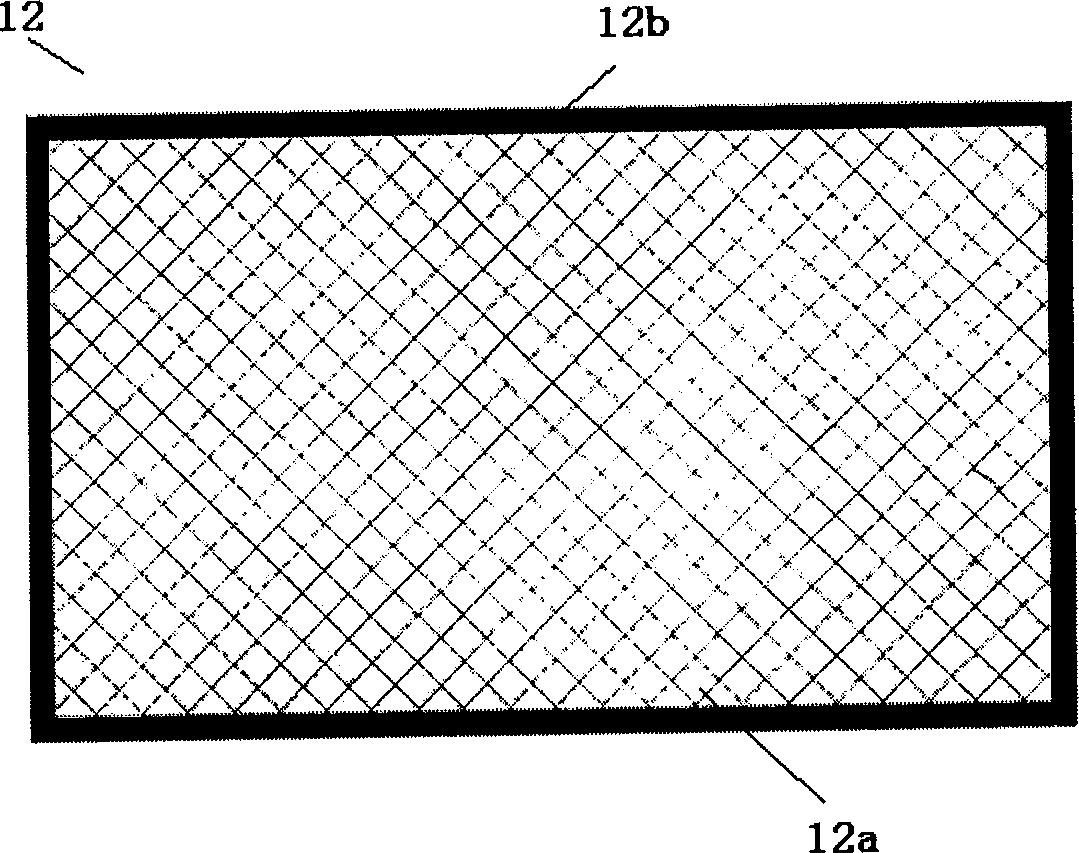

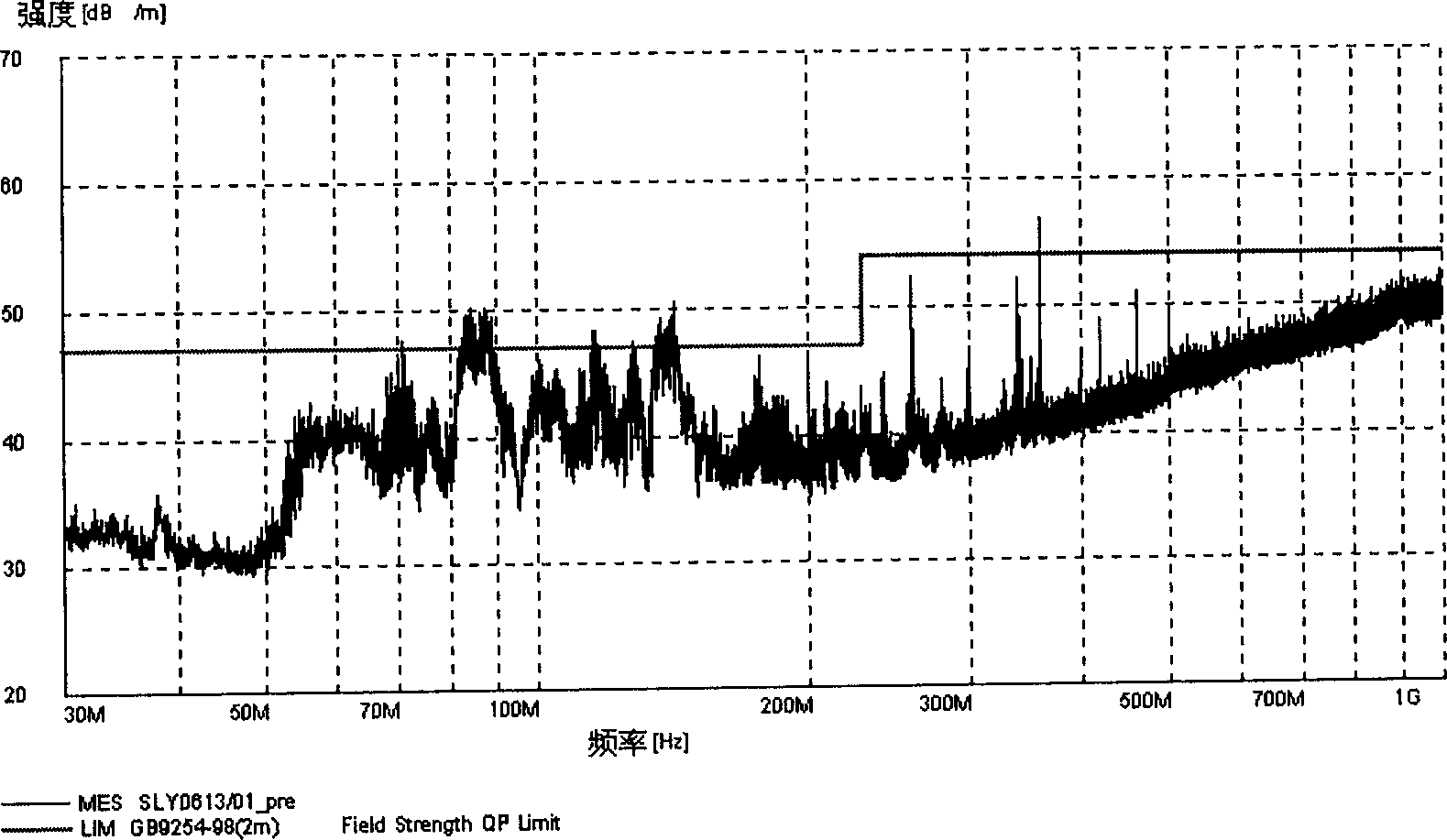

Electromagnetic shielded film and its manufacturing method

InactiveCN1870881AReduce consumptionReduce thicknessShielding materialsScreening apparatusLaser cuttingElectromagnetic shielding

The invention provides a kind of electromagnetic wave shielding films including: a film substrate with transparency on optical degree more than or equal to 87% and layers of metal net at least on one surface of the film substrate. The invention also provides a method including the following steps: first, a conductive layer is formed on the surface of film substrate by a method of physical vapor deposition, next, a metal layer is shaped on the conductive one by the technique of plating; then, metal reticular figure comes into being on such film substrate by laser-cutting technique. This invention can not only reduce the consumption of mental for electromagnetic shielding and avoid the use of solidifying glue between the layers of metal and film substrate, but also decreases the process steps to lower the cost of industrial production and increase productivity effectively.

Owner:72G INT

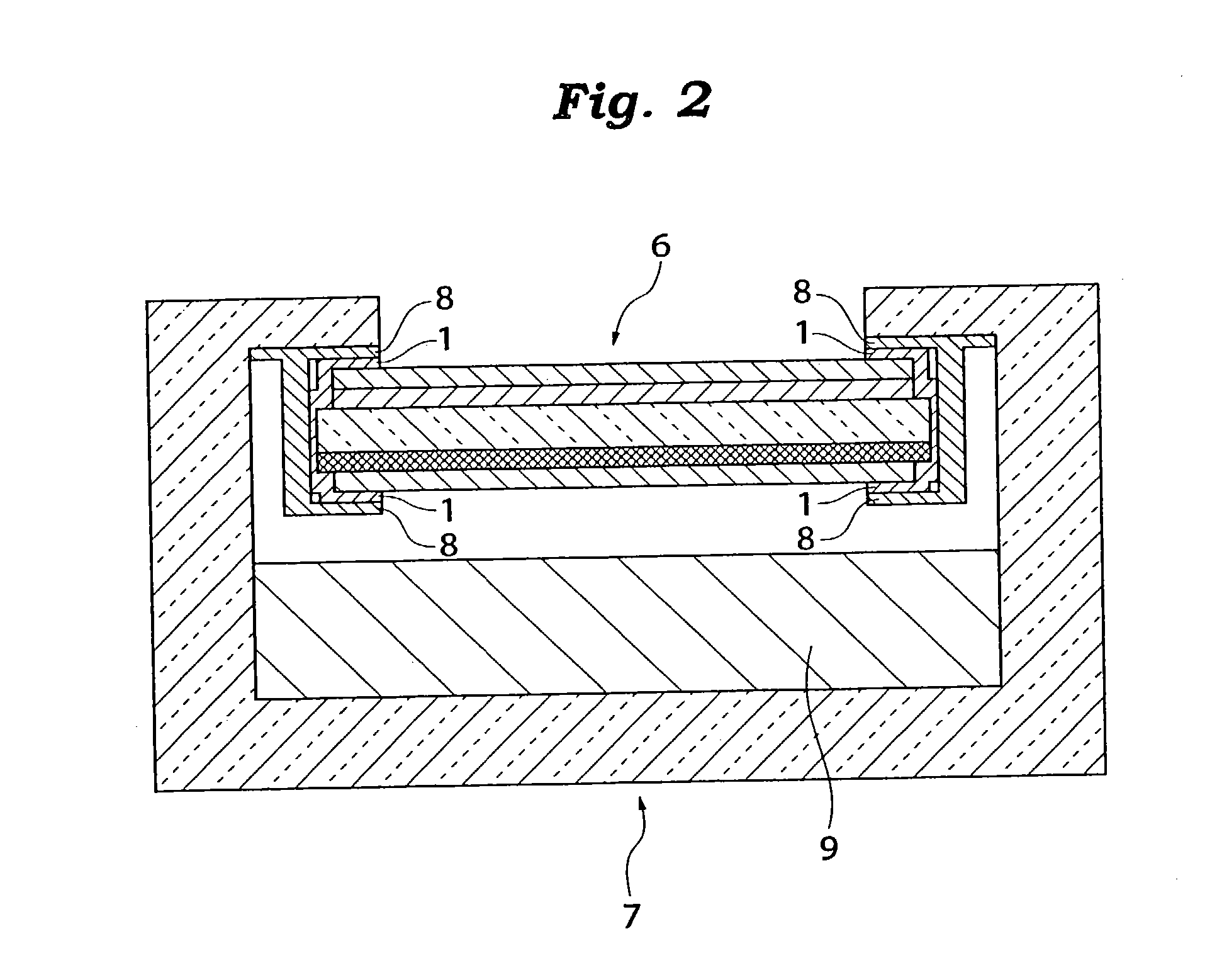

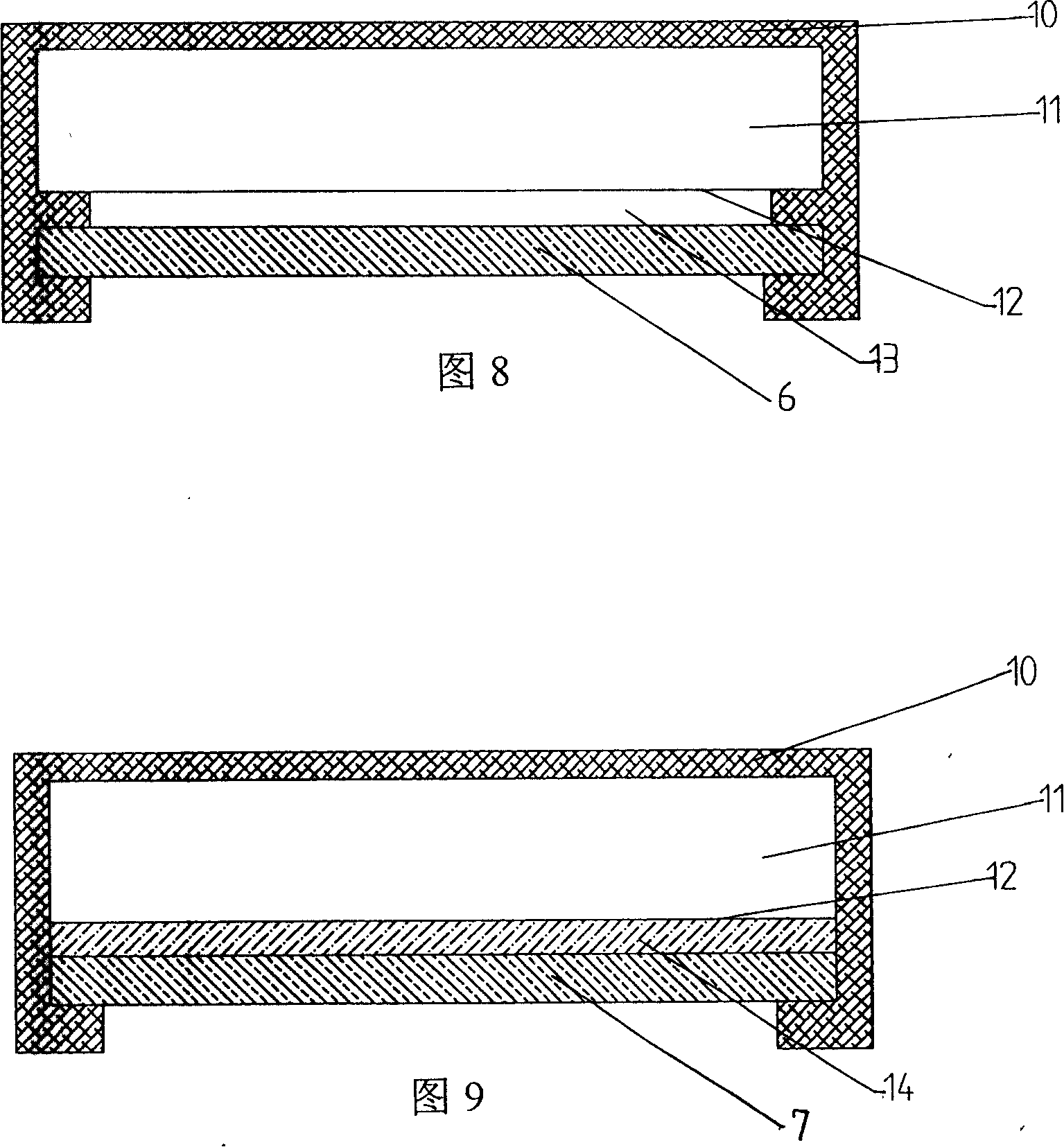

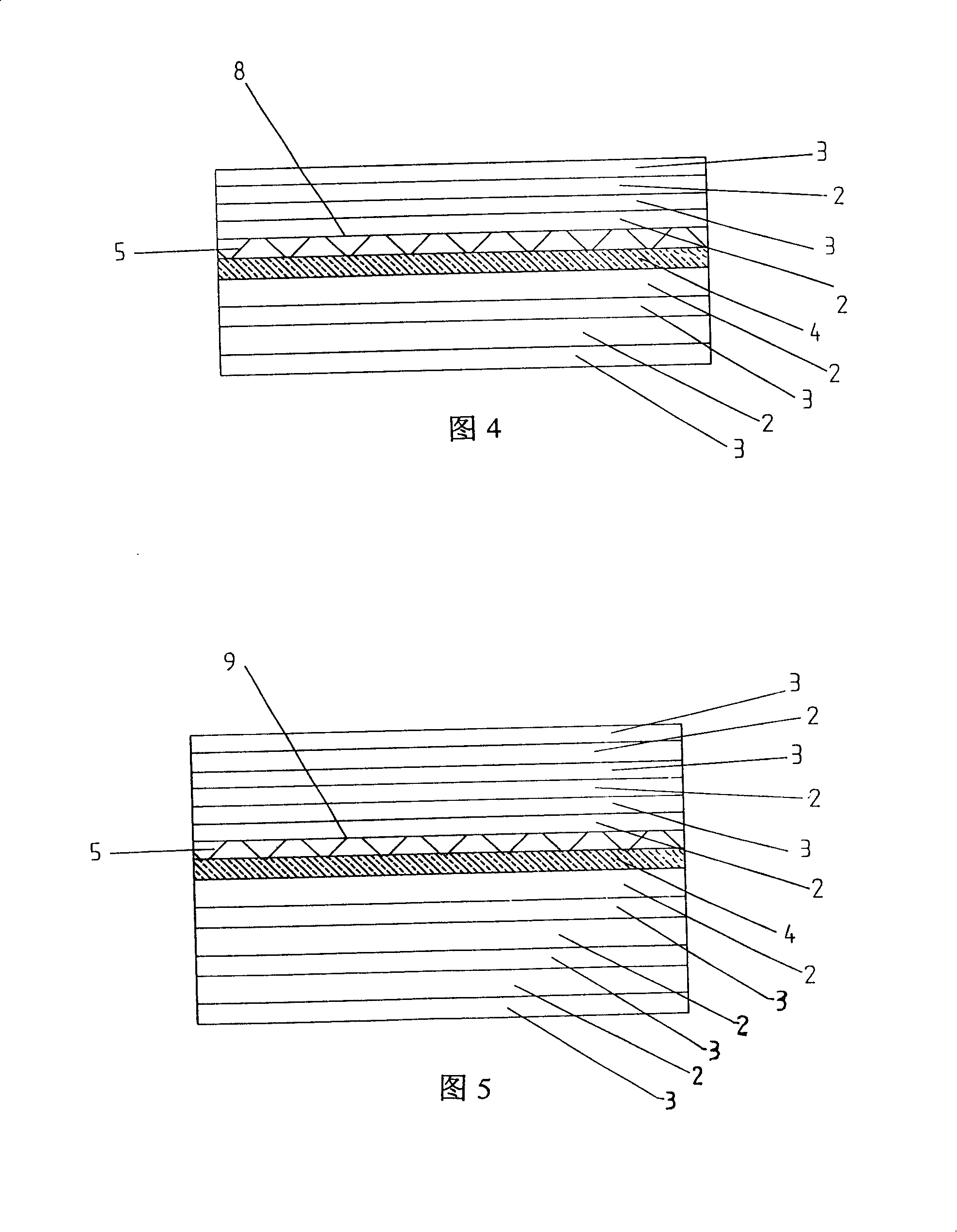

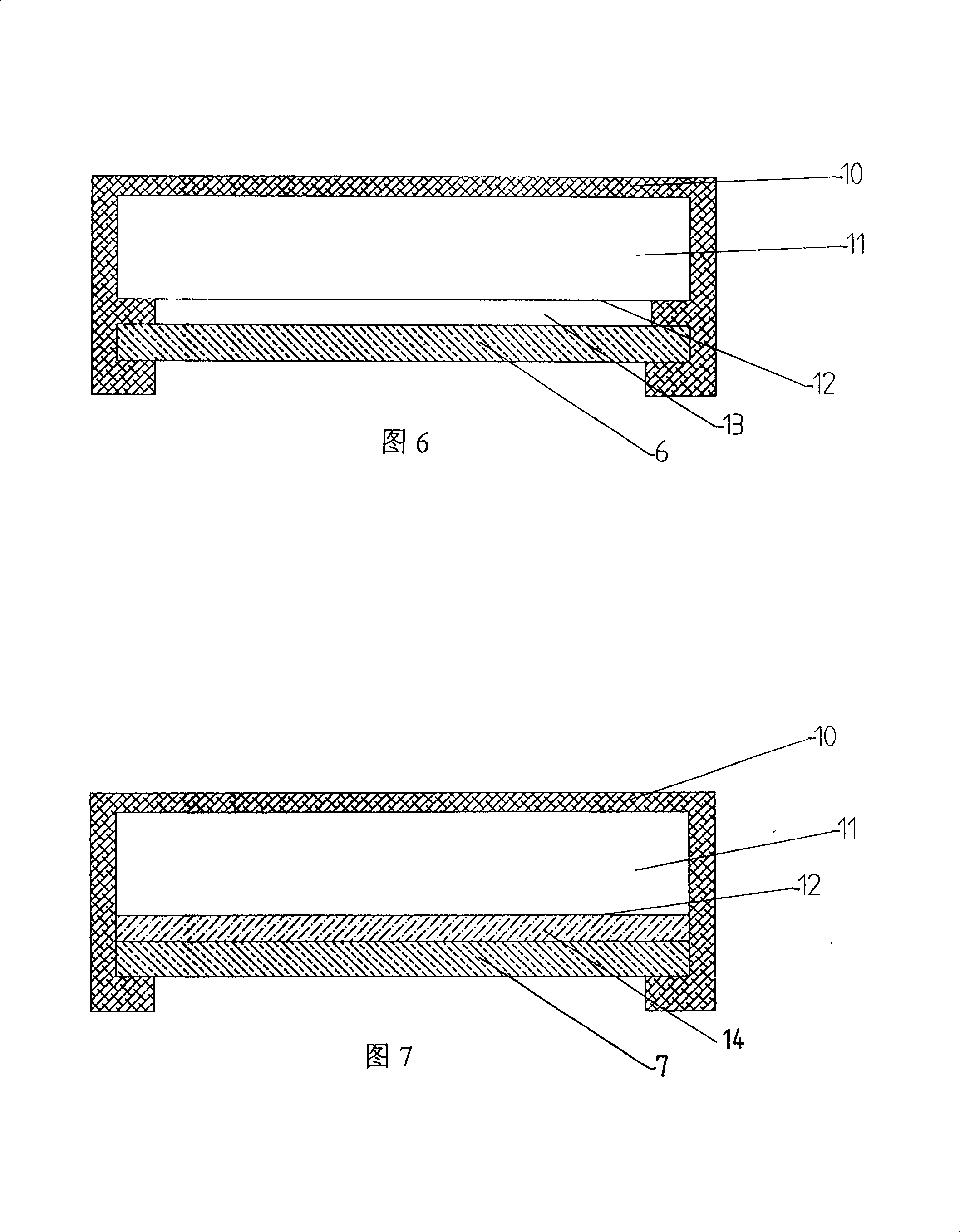

High shielding effect information leakage preventing glass

InactiveCN1482853AContainment leakImprove visibilityMagnetic/electric field screeningScreening apparatusHuman bodySheet film

The invention discloses a glass for prevention of information leakage which comprises glass, metal mesh and polycarbonate film, wherein two layers of polycarbonate films are arranged on each side of the metal mesh, a layer of glass is adhered on the outboard of the polycarbonate film by thermal compression bonding to form a unitary. The invention can effectively prevent information leakage, and diminishes the possible injury by the electromagnetic wave to the human body. íí

Owner:北京安方电磁屏蔽技术开发中心

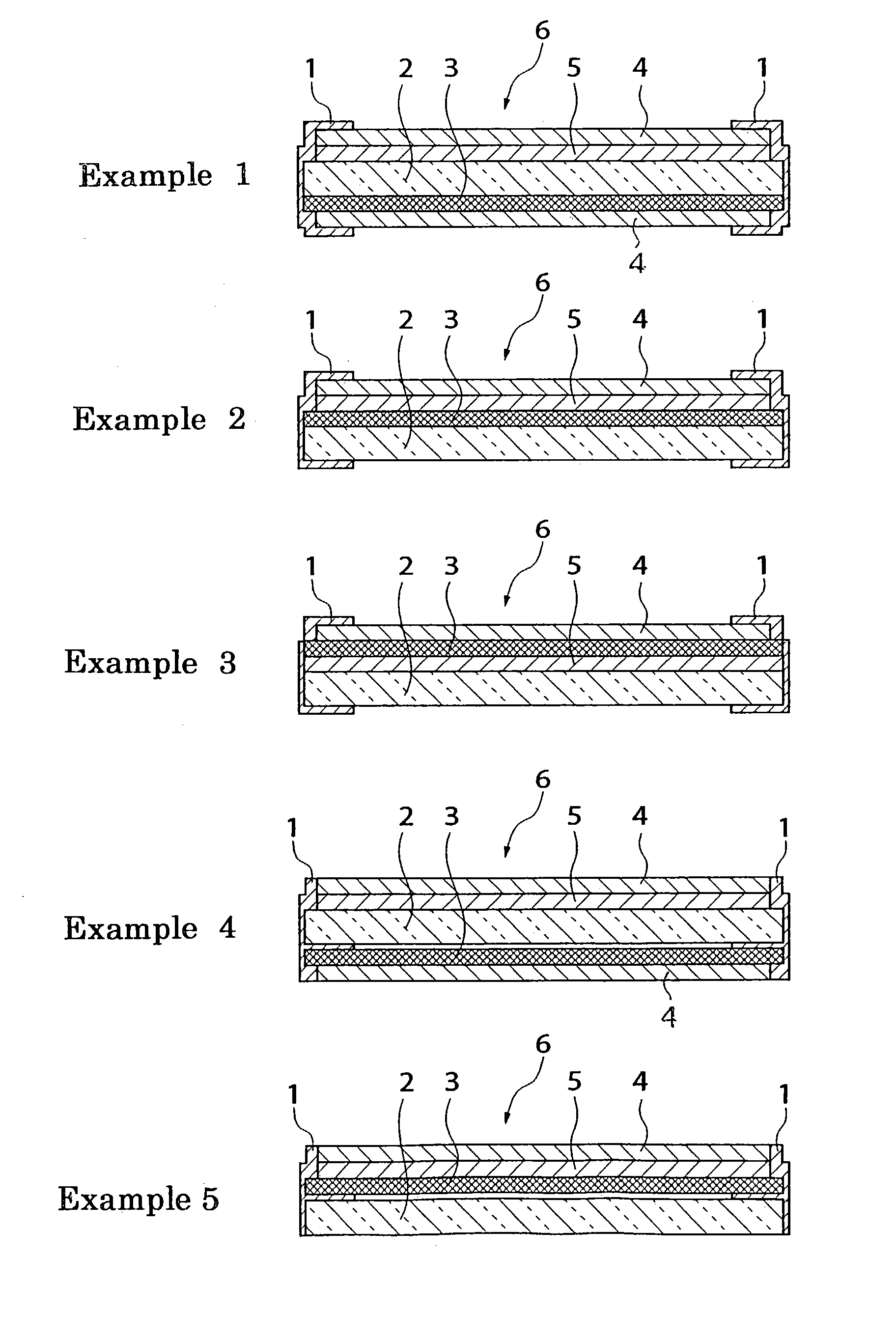

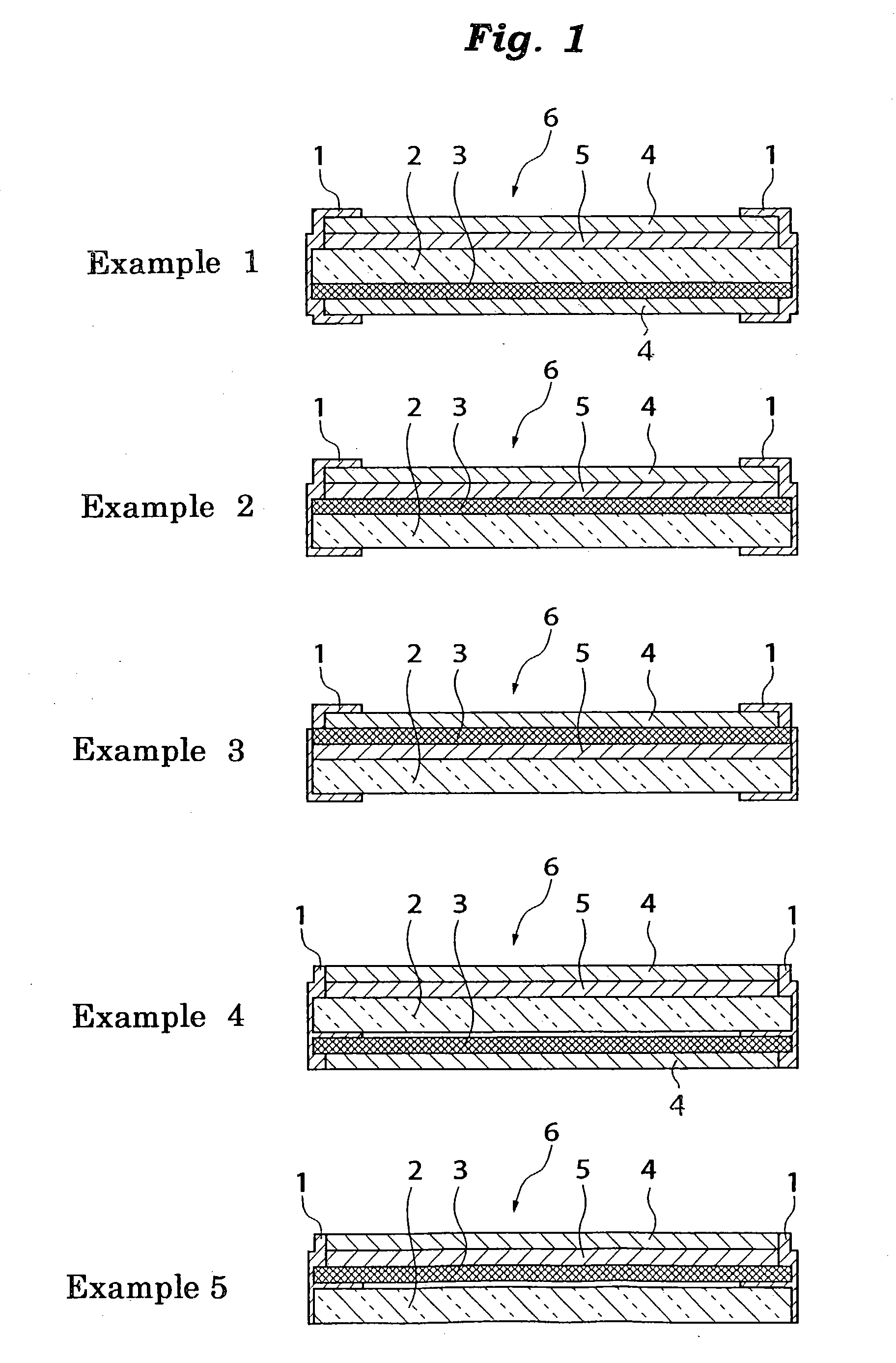

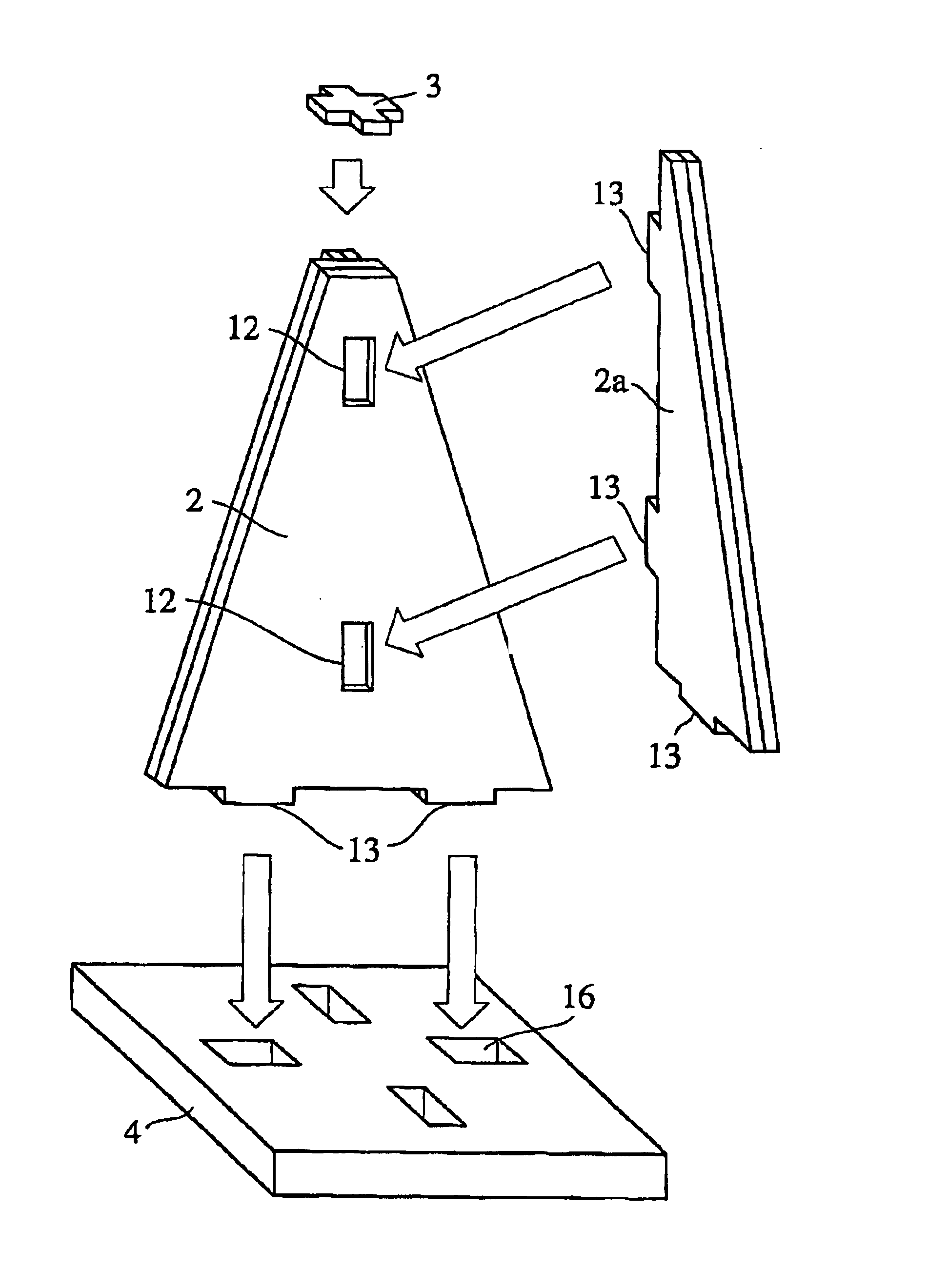

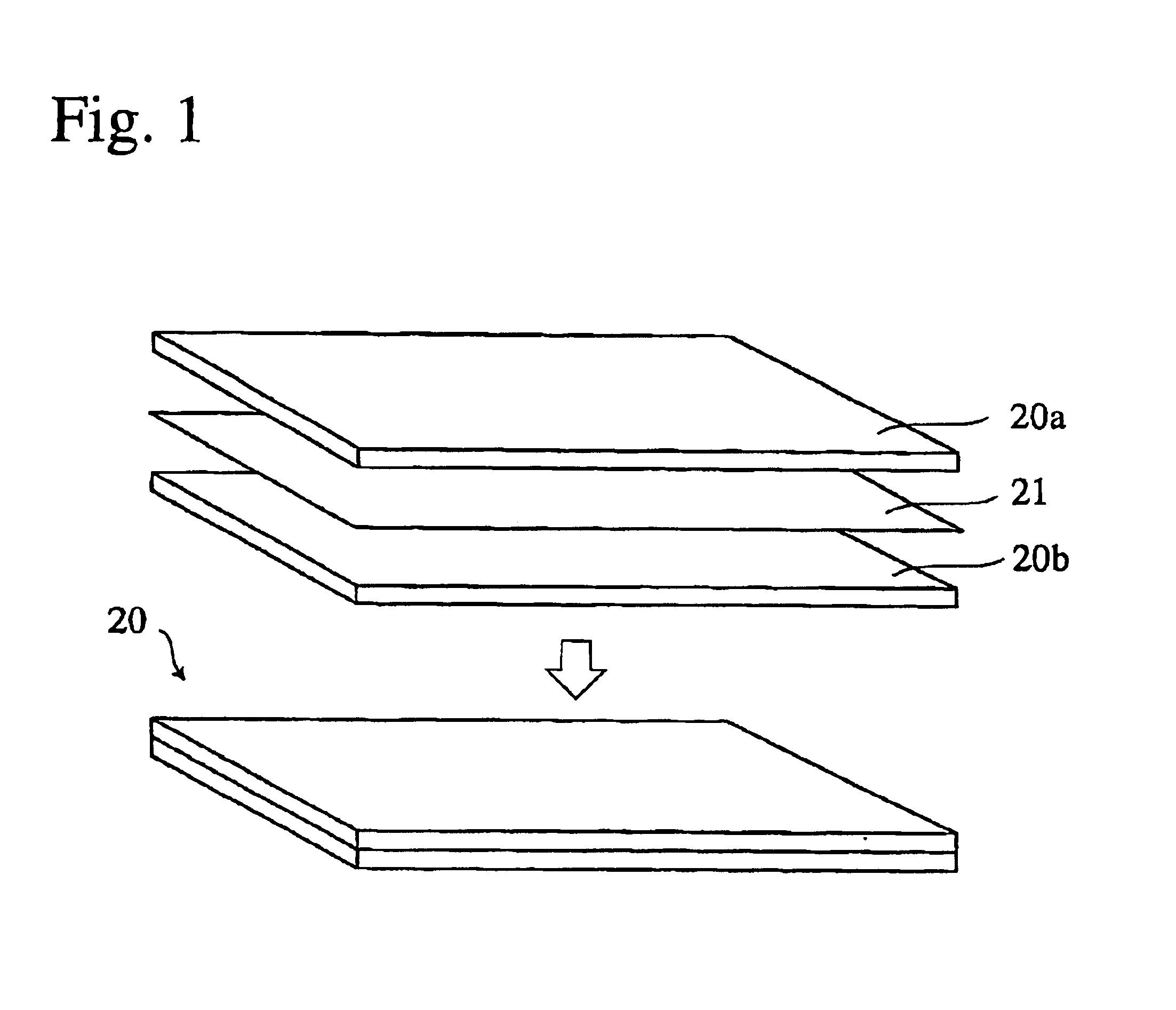

Transparent electromagnetic wave-shielding laminate for display, process for producing same and display unit

InactiveUS20040018375A1Improve production efficiencyMagnetic/electric field screeningScreening apparatusElastomerThermoplastic elastomer

There are disclosed a transparent electromagnetic wave-shielding laminate for display, the laminate comprising an electromagnetic wave-shielding layer wherein at least periphery of a terminal cross section of the layer and / or periphery of an edge thereof is covered with an electroconductive elastomer composition containing an electroconductive filler and a thermoplastic elastomer; a process for producing an electromagnetic wave-shielding laminate comprising bringing an electroconductive elastomer composition into contact with at least periphery of a terminal cross section of an electromagnetic wave-shielding layer and / or periphery of an edge of the layer, and in this state, heat press bonding the composition from a lamination direction and / or cross sectional direction to form an exposed portion on at least peripheral end of the laminate, the portion comprising the composition which is grounded to the layer; other processes for producing the same; and a display unit comprising the transparent electromagnetic wave-shielding laminate. The above laminate, which is producible in high production efficiency, is capable of following the unevenness on the electromagnetic wave-shielding laminate and on the display side grounding portion, thereby surely enabling grounding connection and electromagnetic wave-shielding.

Owner:NISSHINBO IND INC

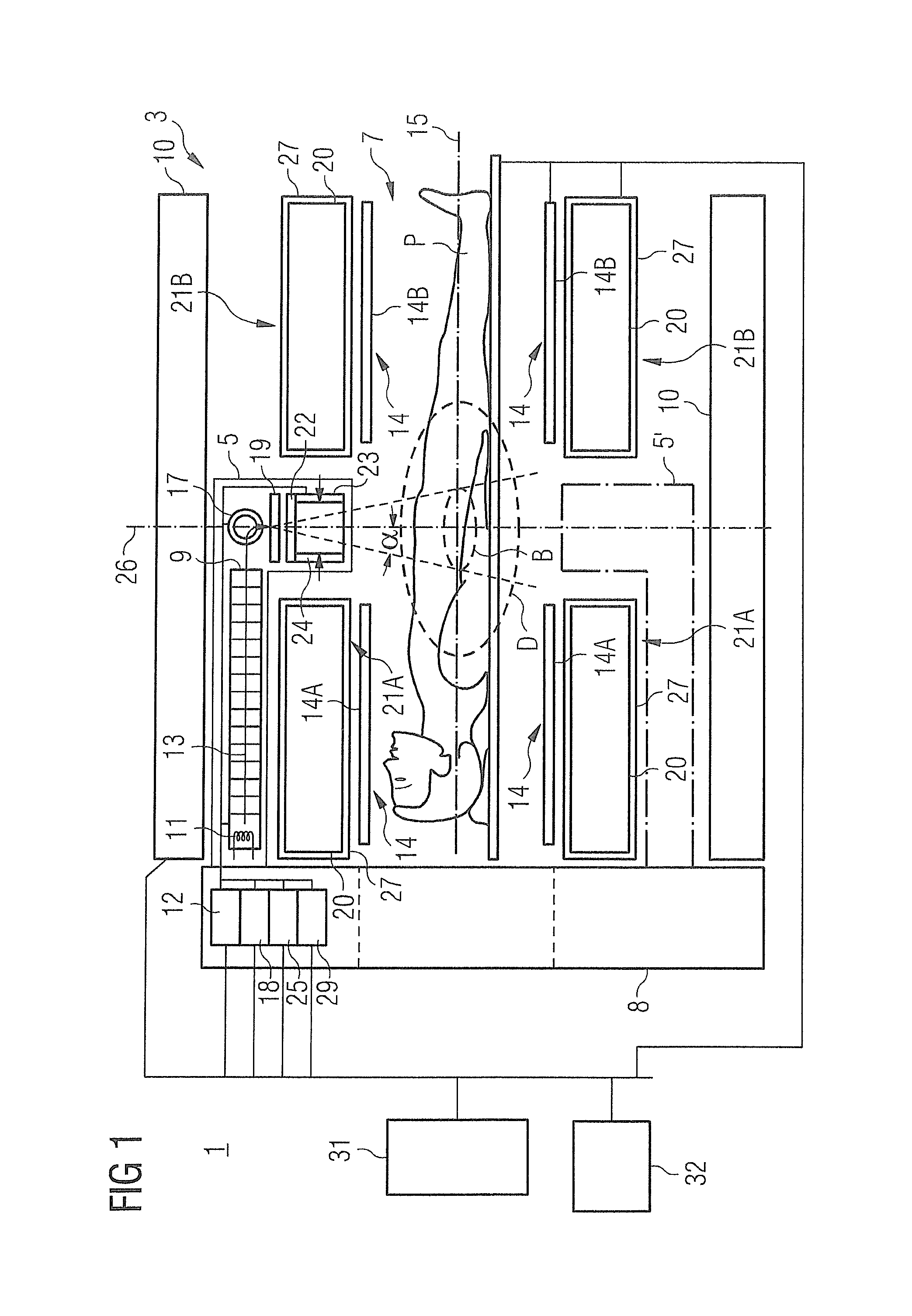

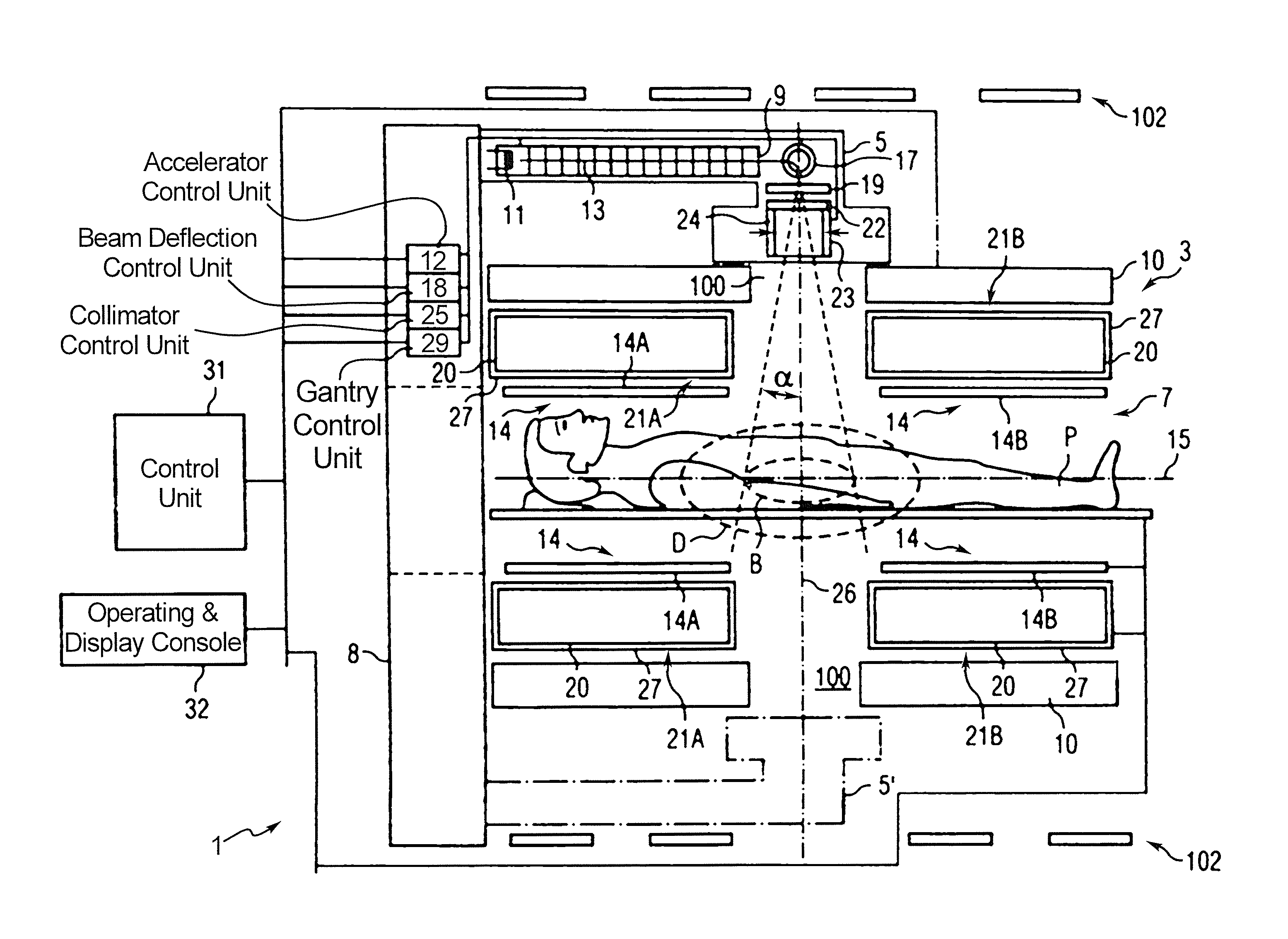

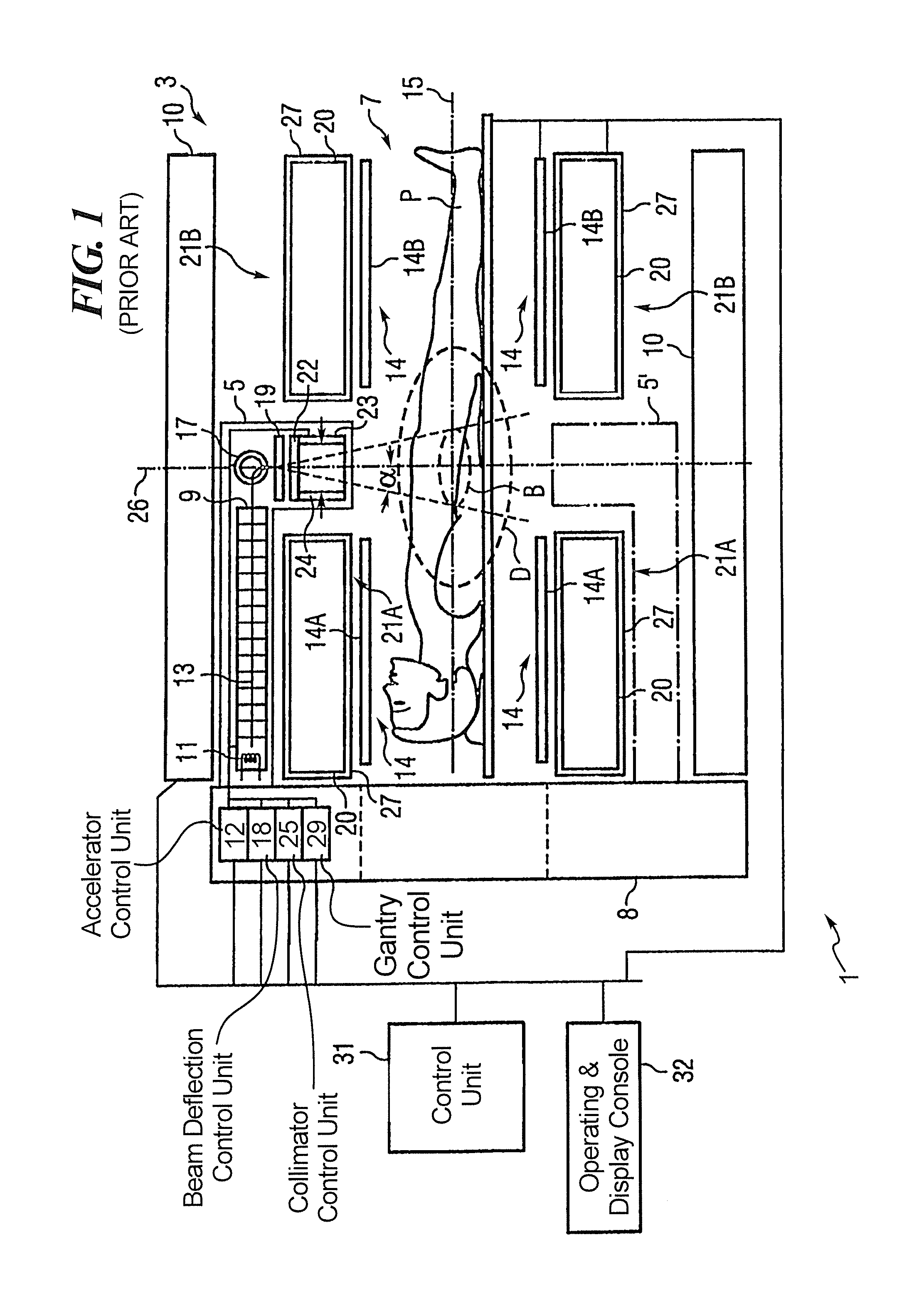

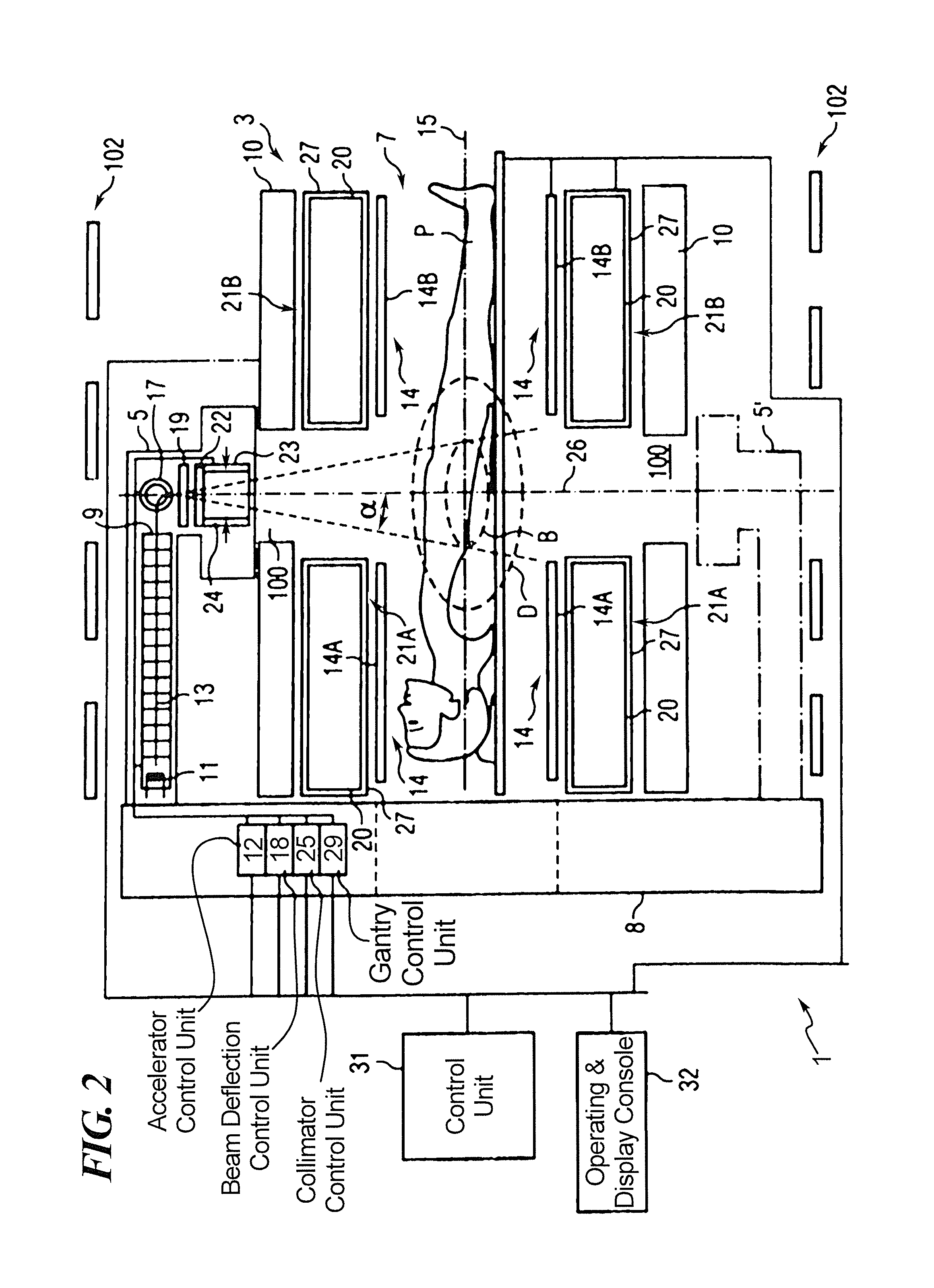

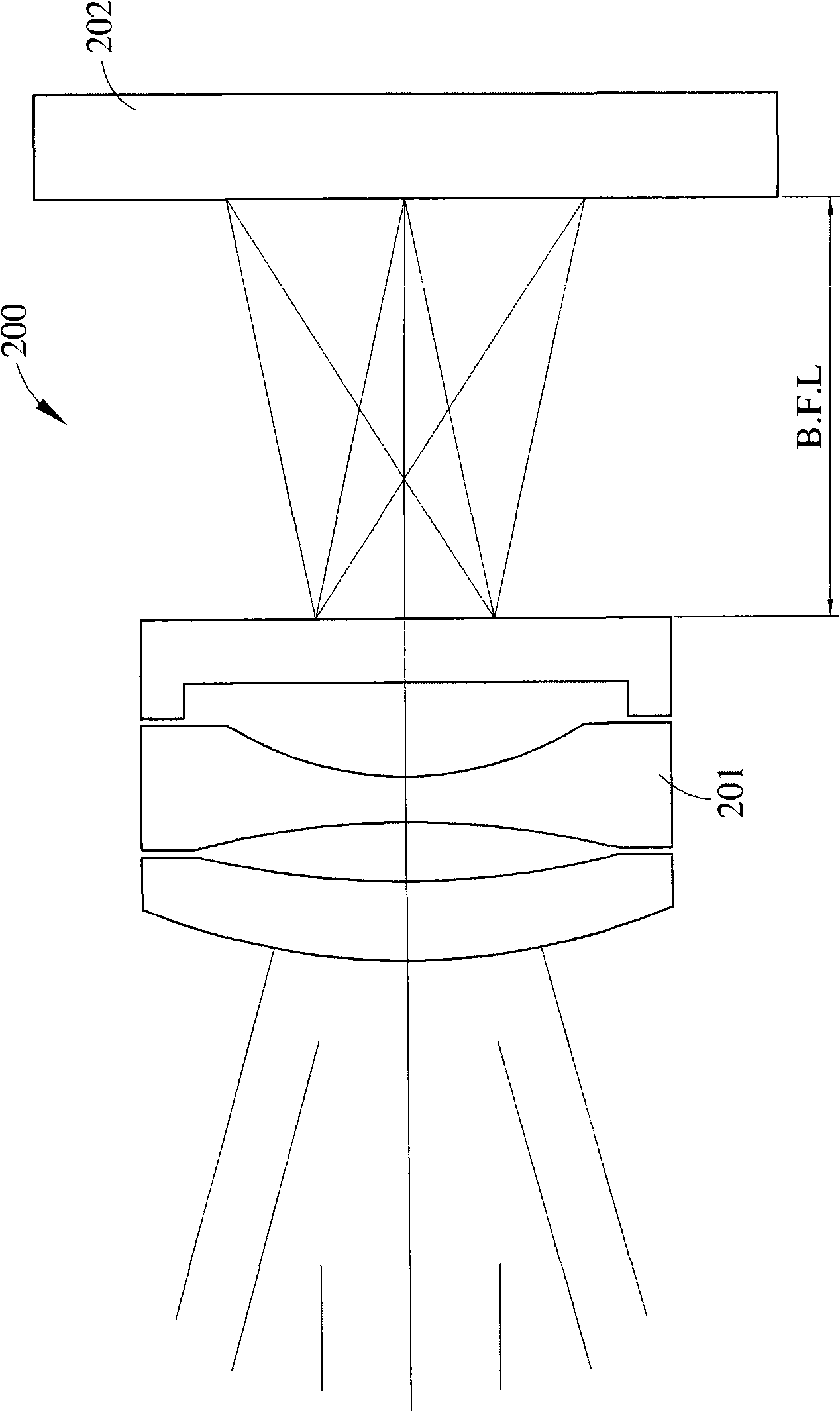

Combined MRI and radiation therapy system

ActiveUS20140135615A1Reduce the overall diameterWeakening rangeMagnetic measurementsScreening apparatusTherapeutic radiationElectron

A combined MRI and radiation therapy system has MRI imaging equipment and radiation therapy equipment. The MRI imaging equipment includes a shielded solenoidal magnet including a number of main magnet coils arranged coaxially along an axis, and a shielding arrangement arranged coaxially with the axis, at a greater radius from the axis than the main magnet coils. The radiation therapy equipment includes a LINAC assembly, that includes a linear electron accelerator arranged with an electron beam path parallel to the axis, and electron beam deflection arrangement and a target for generating a beam of therapeutic radiation. The linear electron accelerator is located at a position radially between the main magnet coils and the shielding arrangement.

Owner:SIEMENS HEALTHCARE GMBH

High light transmittance ratio transparent resin display protection panel and LCD device using same

InactiveCN101236264AImprove image qualityLow costScreening apparatusVacuum evaporation coatingLiquid-crystal displayDisplay device

The invention provides a high transmittance transparent resin display protection screen, comprising a transparent resin substrate, wherein, a double-layer antireflection filming layer of TiO2 and SiO2 or Nb2O5 and SiO2 is deposited in turn by adoption of the vacuum magnetron sputtering method on at least one surface of the transparent resin substrate, or a double-layer antireflection filming layer of TiO2 and SiO2 or Nb2O5 and SiO2 is overlapped and deposited in turn; a TiO2 / SiO2 double-layer filming layer or a Nb2O5 / SiO2 double-layer filming layer or a TiO2 / SiO2 multilayered overlapped filming layer or a Nb2O5 / SiO2 multilayered overlapped filming layer are formed in turn from the substrate to the outside. The protection screen of the invention can reduce reflectivity, improve transmittance and optical image effects, greatly reduce cost and fully improve the impact failure resistance of the display screen and become a safe protection screen. The invention also provides a liquid crystal display for the display protection screen.

Owner:甘国工

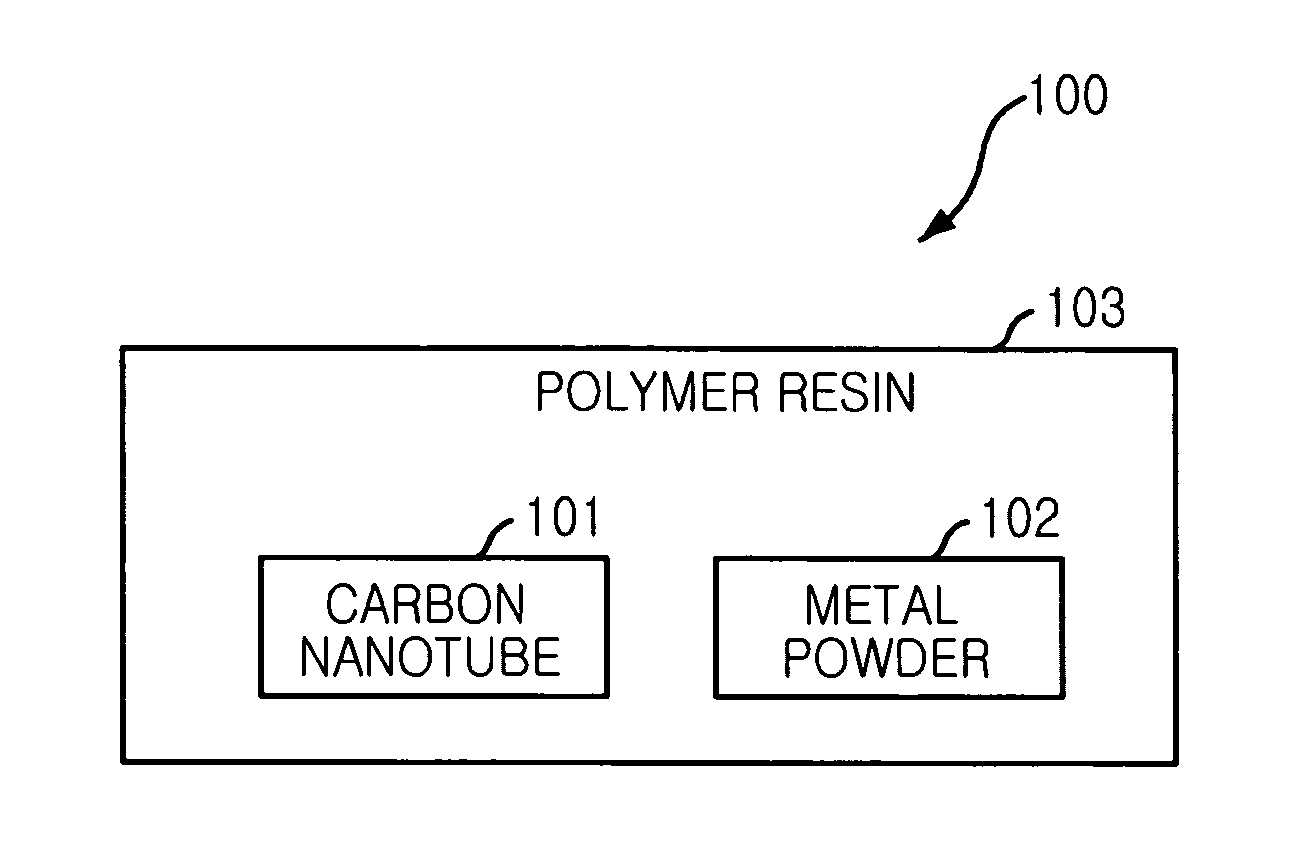

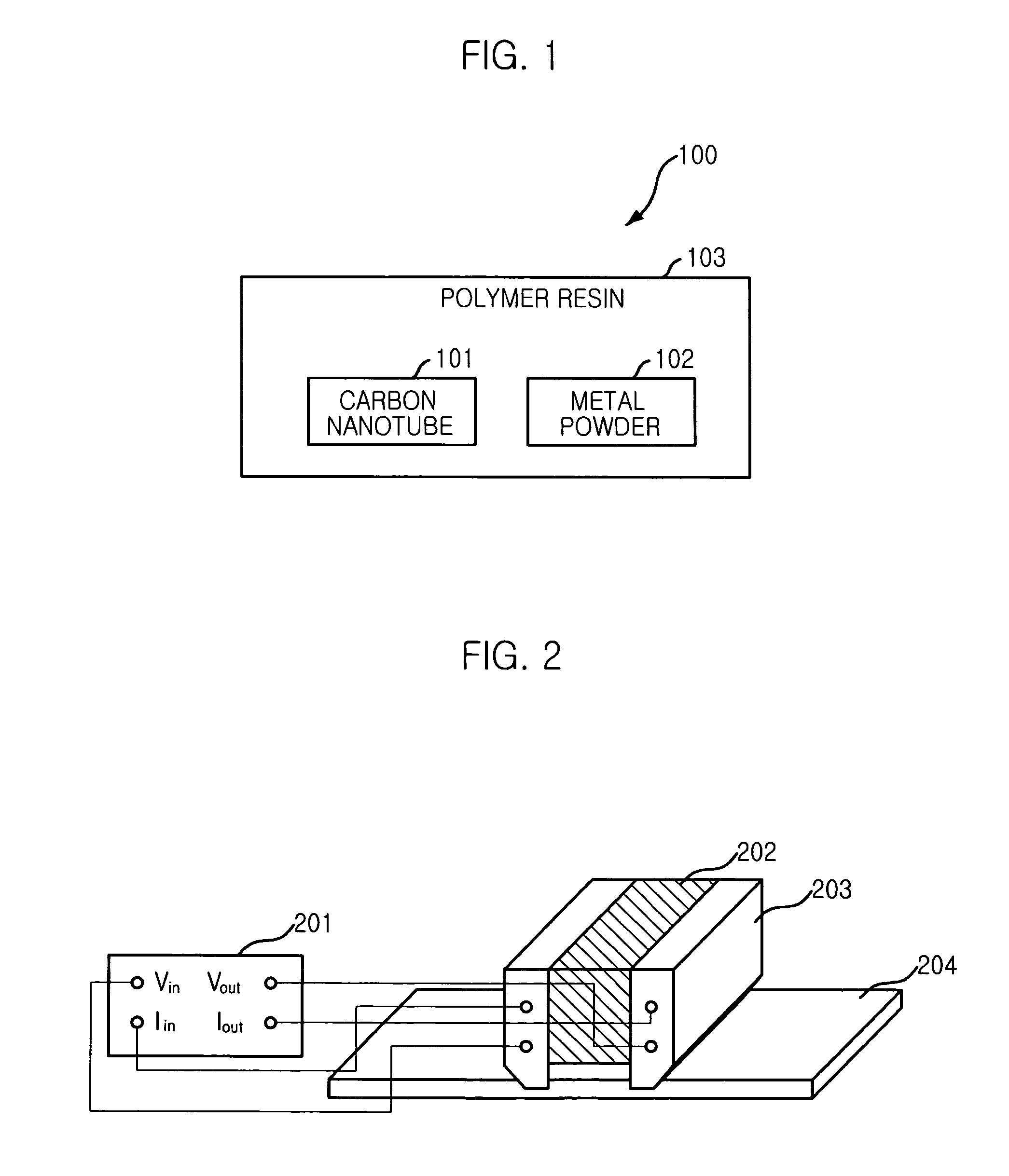

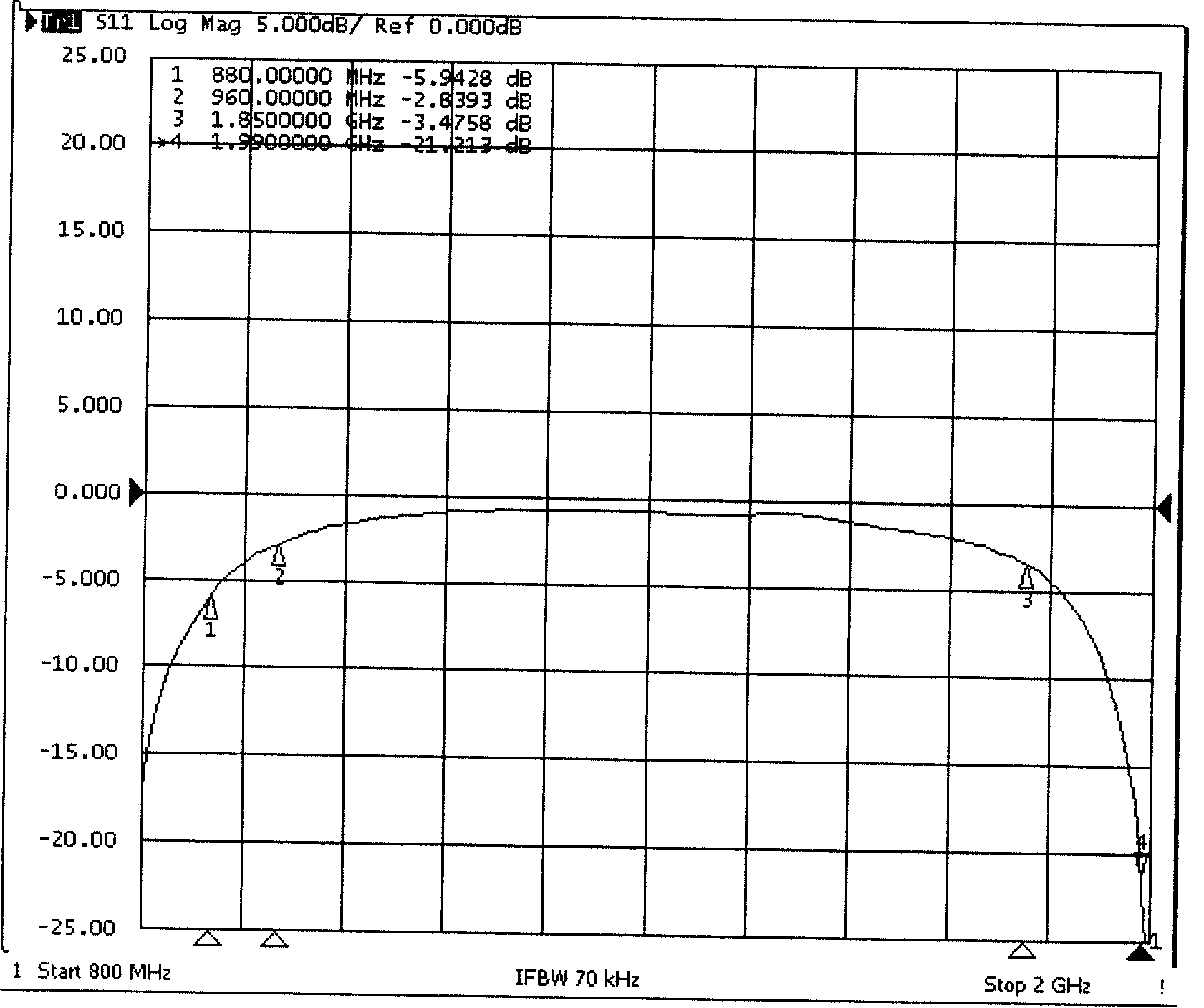

Electromagnetic shielding material having carbon nanotube and metal as electrical conductor

ActiveUS7588700B2Improved propertyMaterial nanotechnologyMagnetic/electric field screeningElectrical conductorPolymer resin

Disclosed is an electromagnetic shielding material with enhanced shielding effectiveness and mechanical property by employing a carbon nanotube and a metal as an electrical conductor. The electromagnetic shielding material includes a polymer resin for a matrix and two conductive fillers having a carbon nanotube and a metal, wherein a volume percent of the carbon nanotube ranges about 0.2% to about 10% and a volume percent of the metal powder ranges about 7.0% to about 30% so that the total volume percent of the conductive filler is in a range of about 7.2% to about 40%.

Owner:ELECTRONICS & TELECOMM RES INST

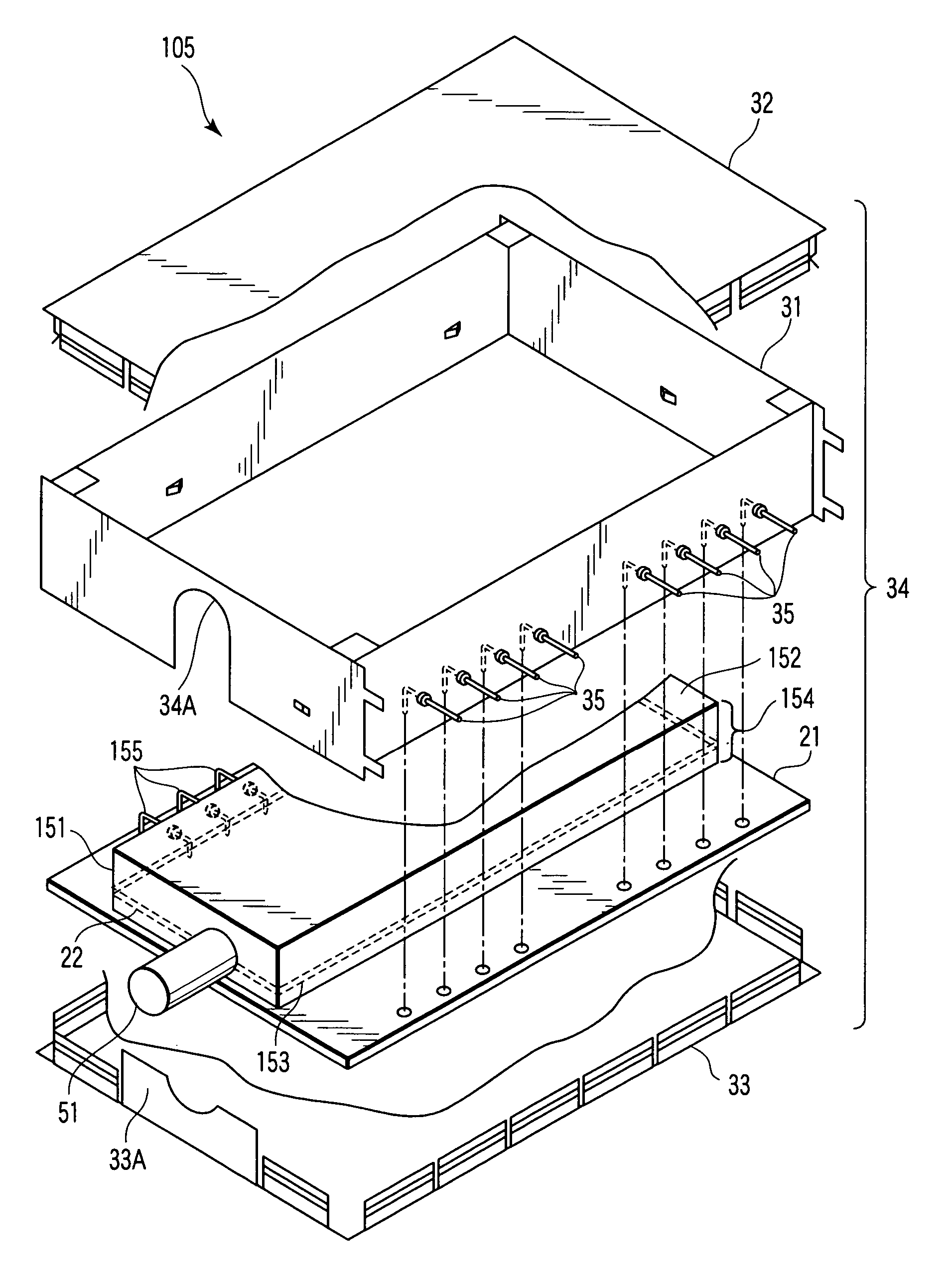

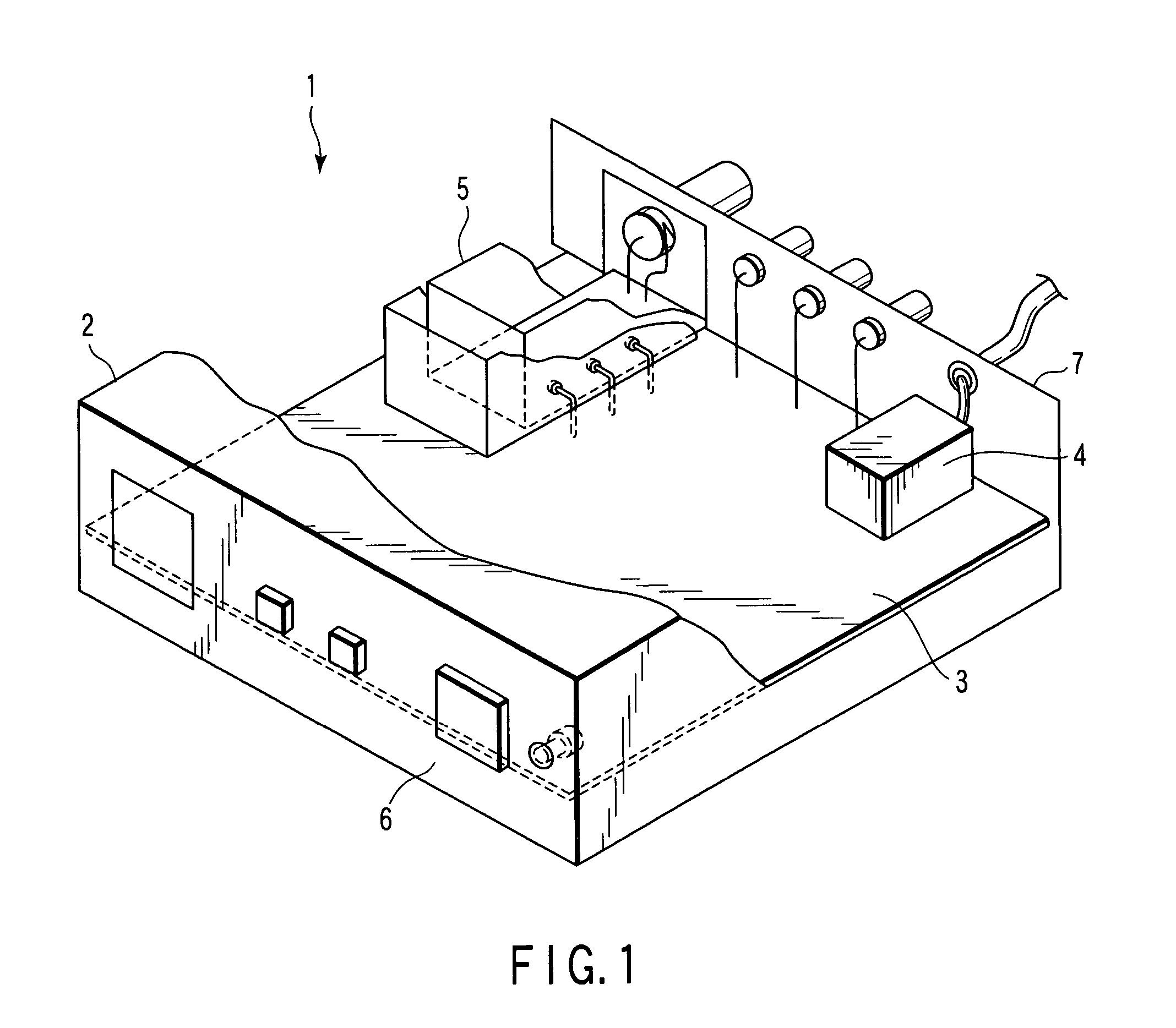

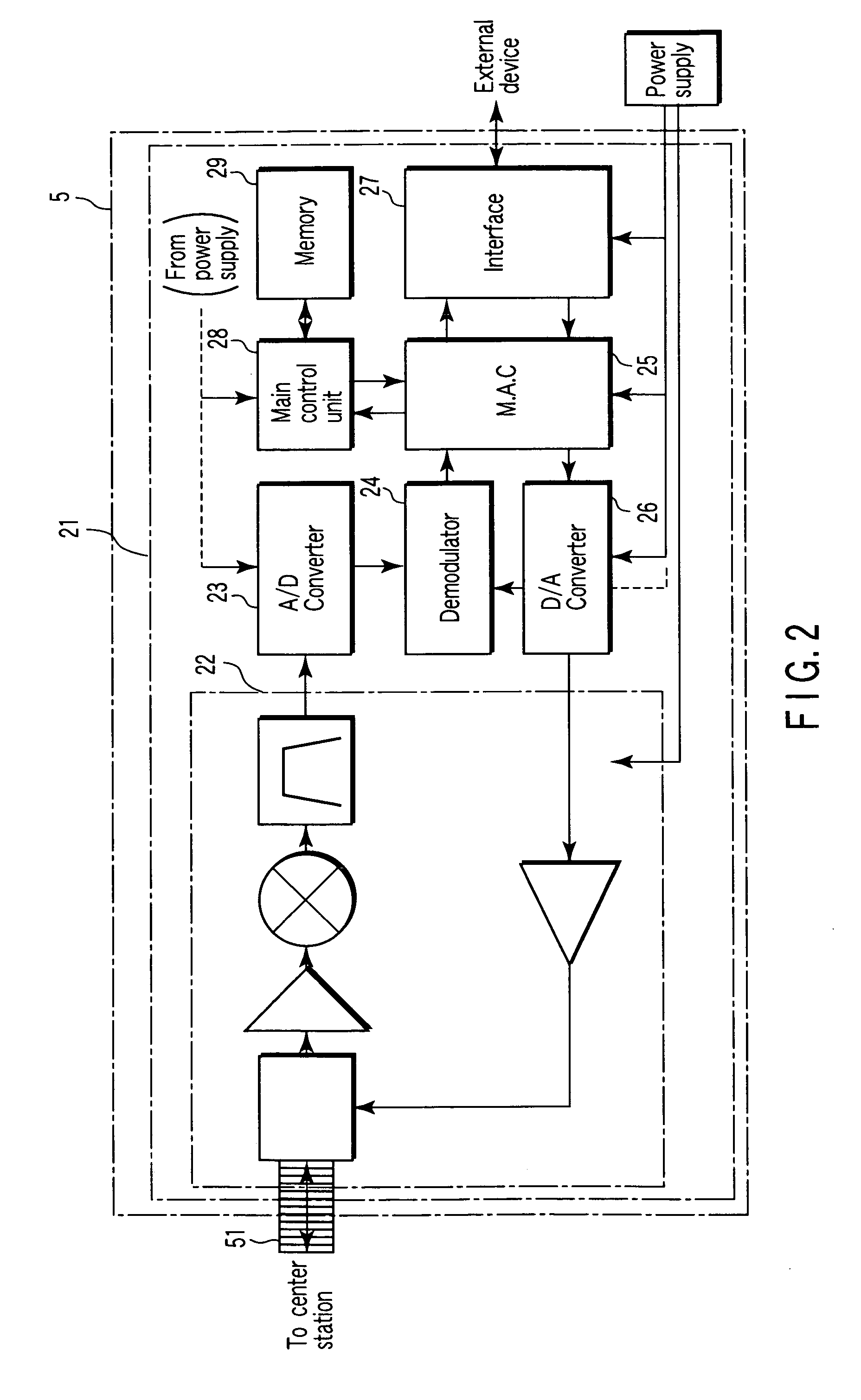

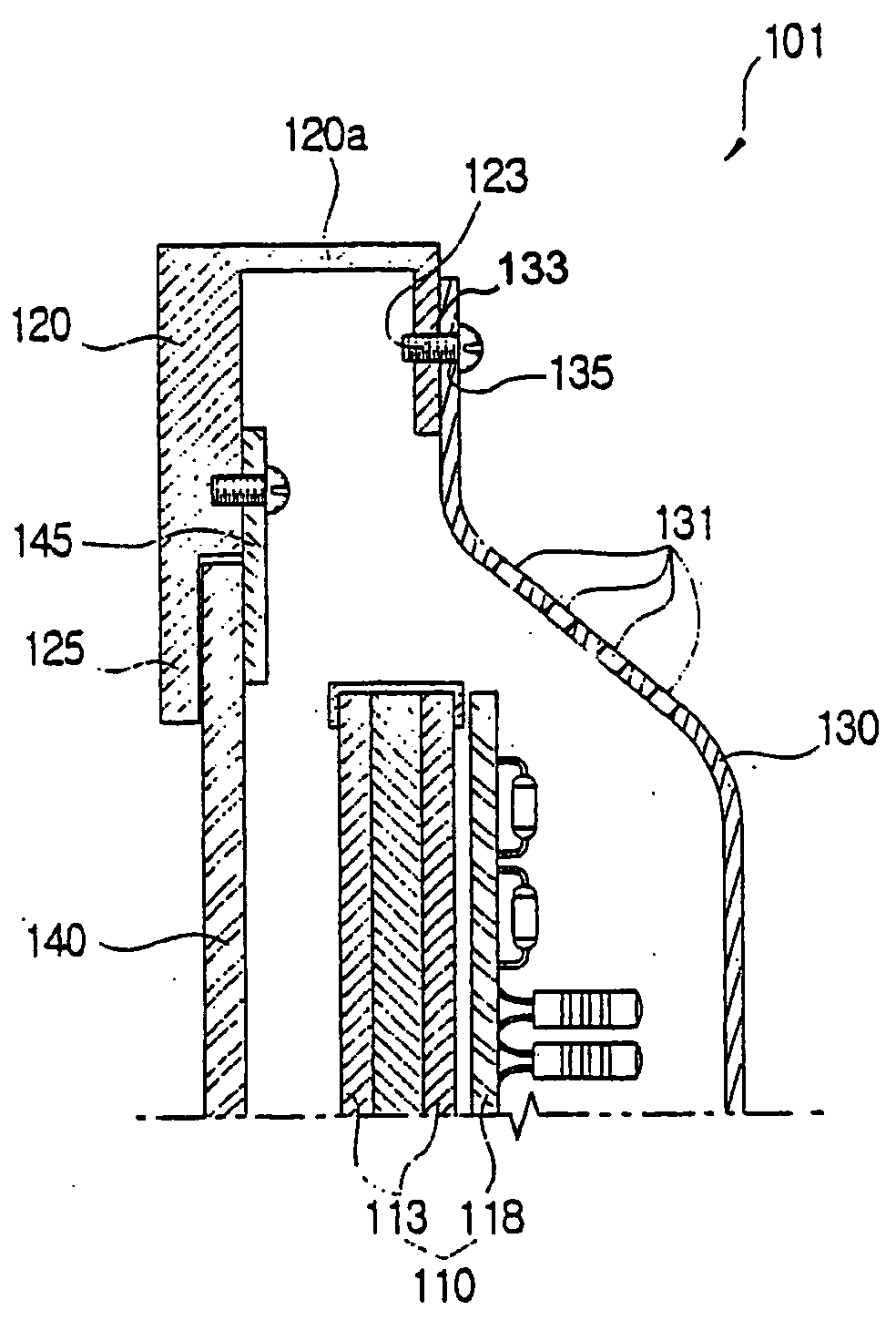

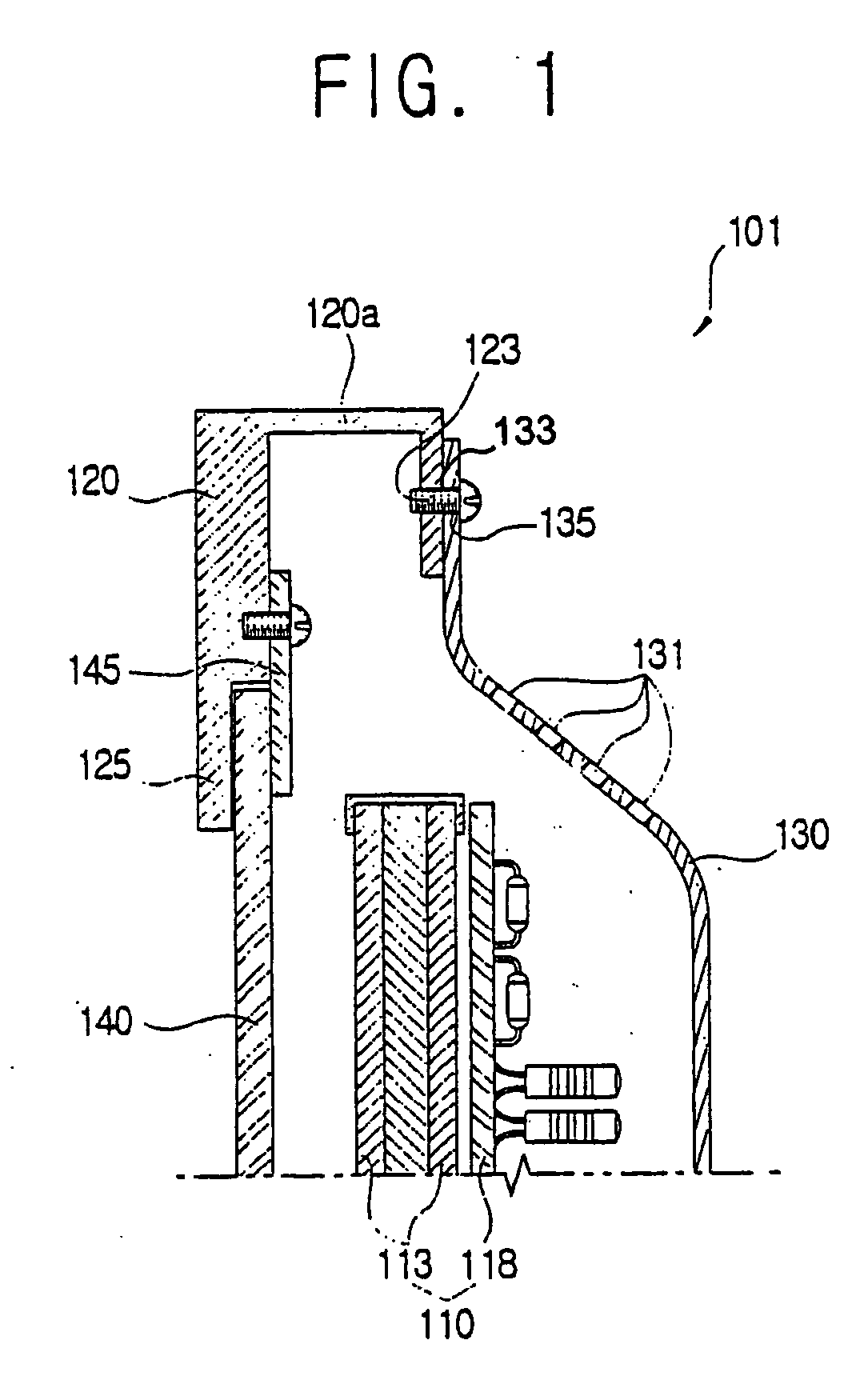

Cable modem module and transmitter-receiver

A cable modem module device includes a coaxial connector to transmit and receive high-frequency signals, a circuit board to which the coaxial connector is attached to protrude from its periphery in a direction parallel to its surface, and a first shield case formed in its portion corresponding to the coaxial connector with a cutout portion to avoid the coaxial connector so as to allow the circuit board to be housed from a direction perpendicular to the surface of the circuit board.

Owner:HISENSE VISUAL TECH CO LTD

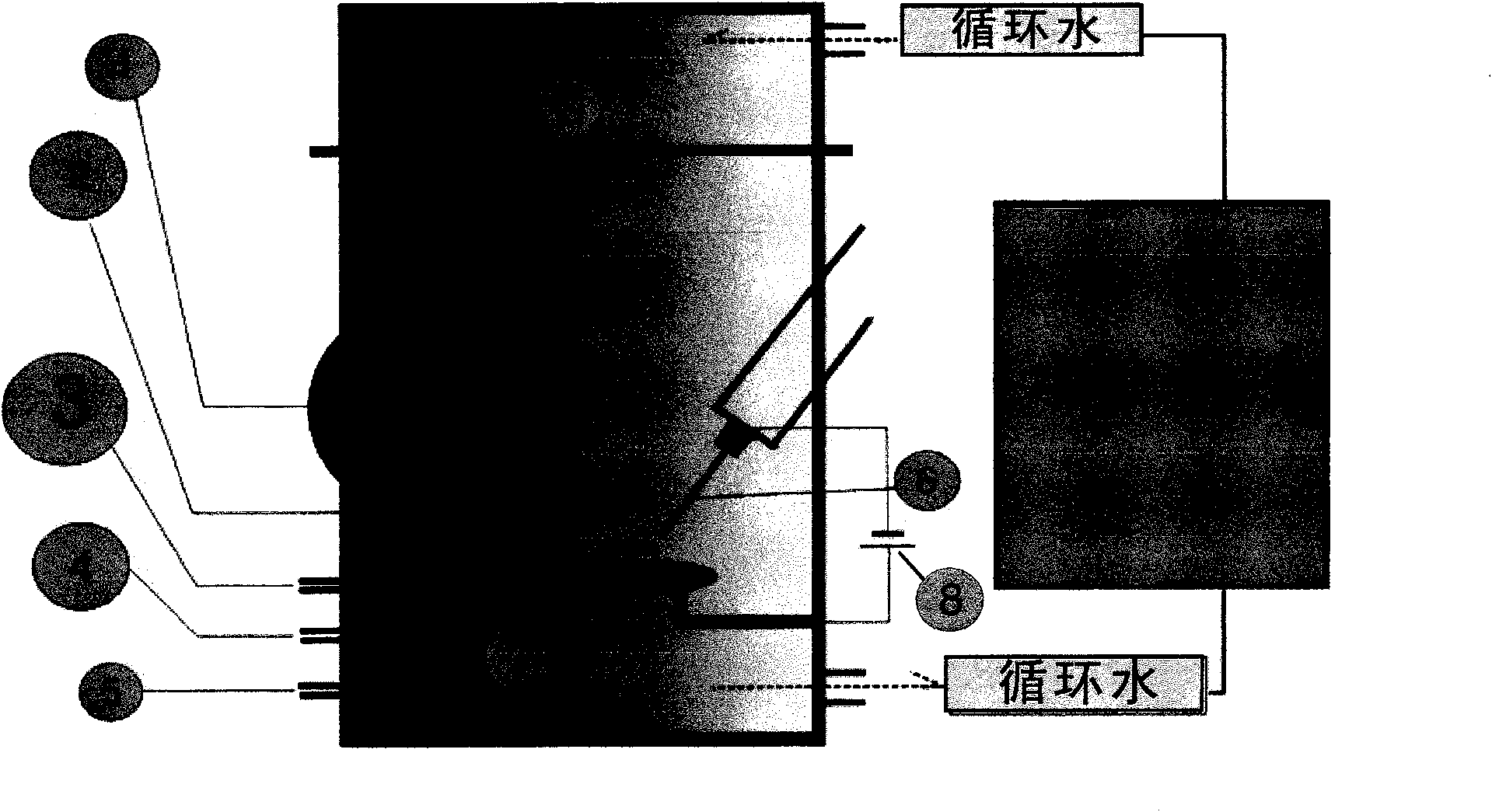

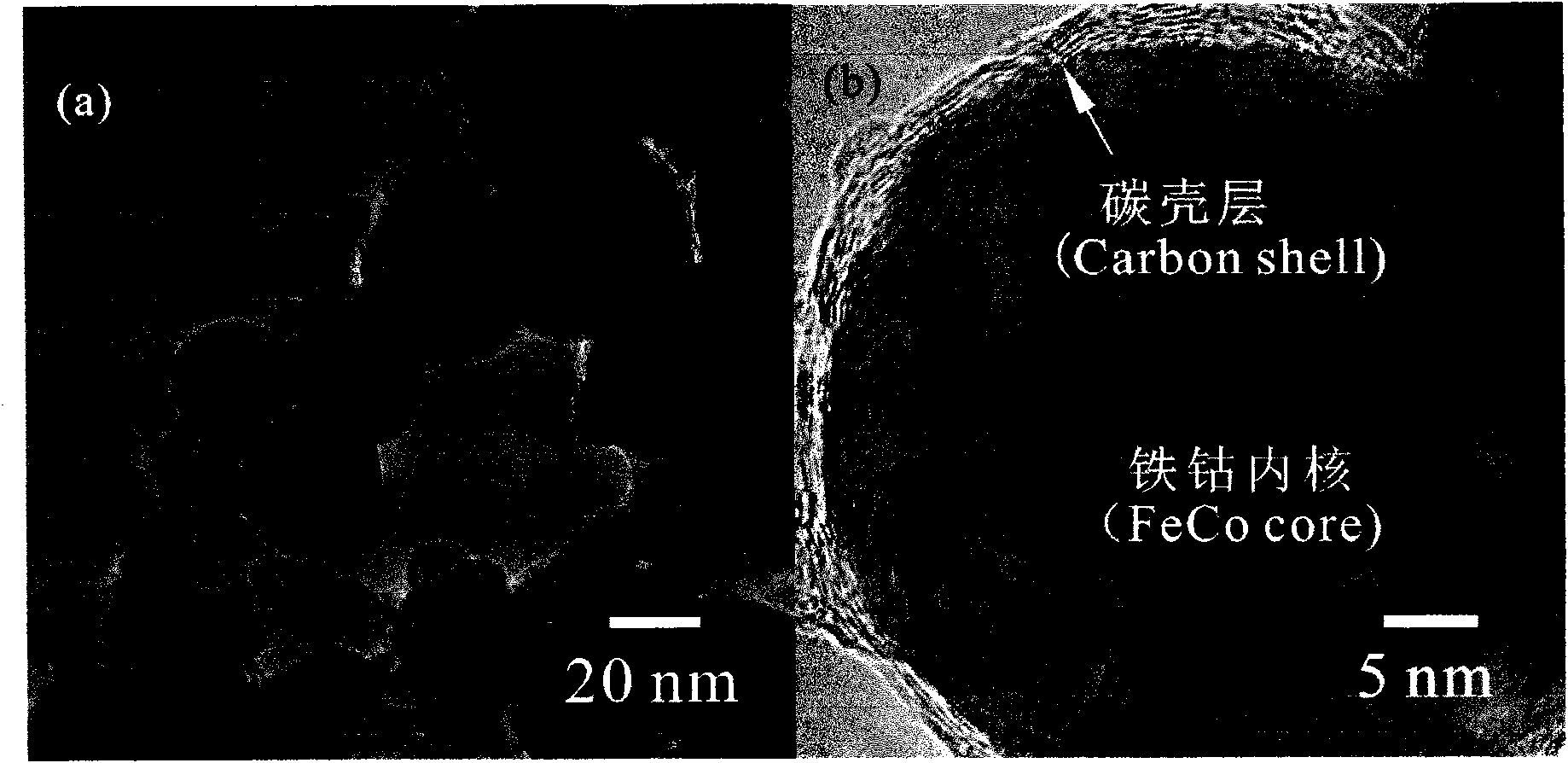

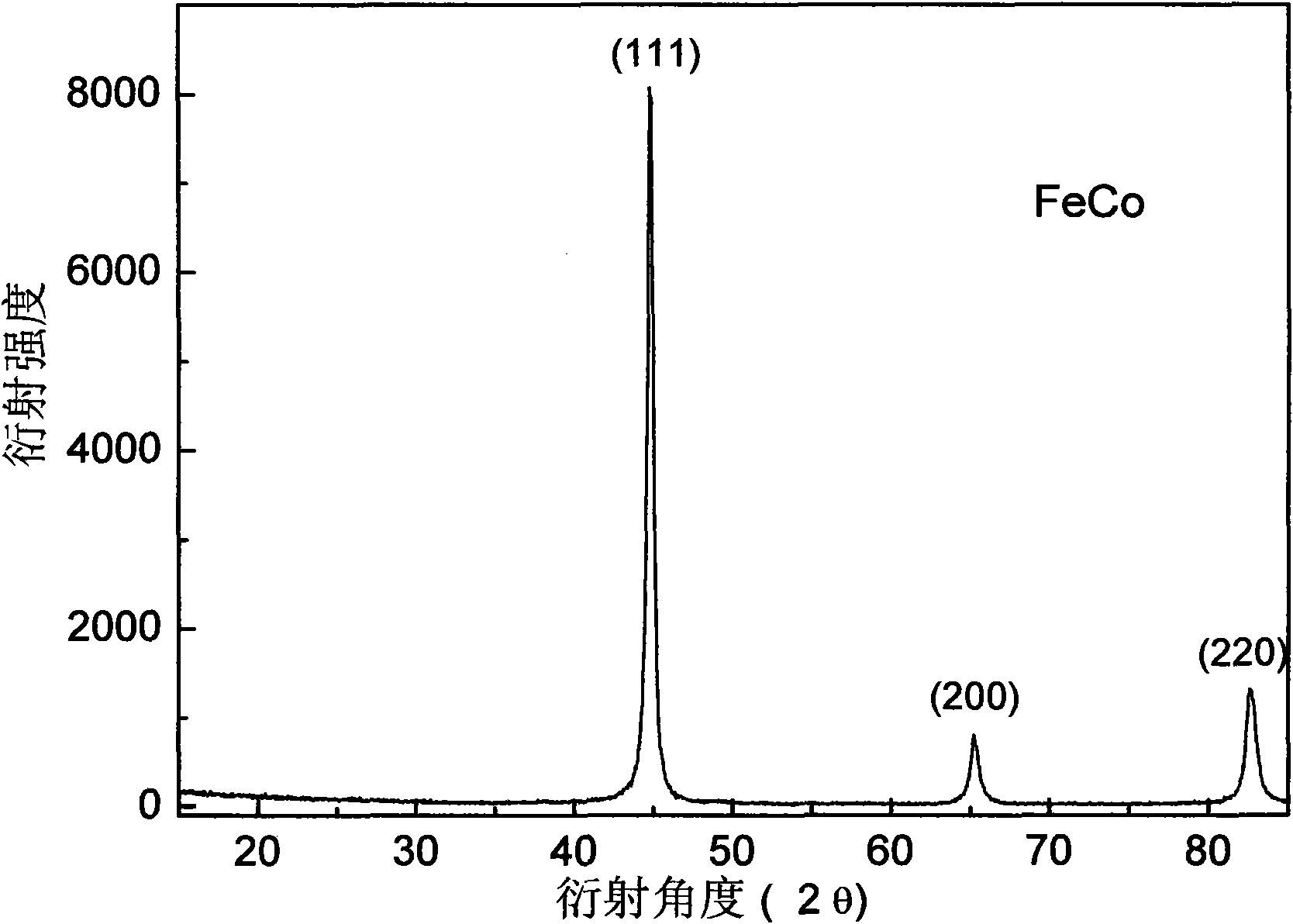

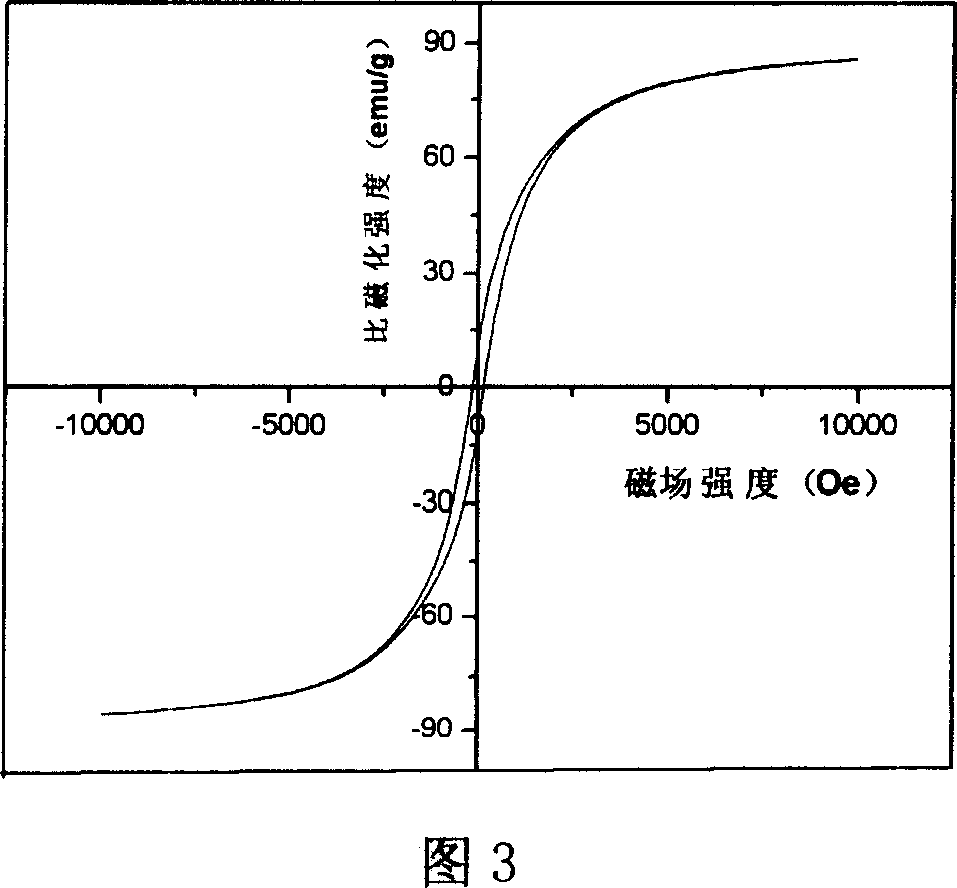

Method for preparing carbon-wrapped iron-cobalt nano wave-absorbing material

InactiveCN101567224AGood microwave absorptionImprove oxidation resistanceScreening apparatusPlasma techniqueOxidation resistantNanometre

The invention provides a method for preparing a carbon-wrapped iron-cobalt nano composite material with broad band and strong absorption. The composite material is prepared by adopting the technology that plasmas is generated by arc discharge of a negative electrode and a positive electrode under working gas, wherein the working gas is argon gas, simultaneously organic substances which can provide carbon elements and do not introduce impurities except C, H and O are added, the negative electrode is made of metals with high melting point and volatile difficulty such as tungsten and the like, and a target material for the positive electrode is iron-cobalt alloy, wherein the iron element accounts for 10 to 90 percent of alloy atomic. The carbon-wrapped iron-cobalt nano wave-absorbing material prepared by the method is a nano capsule formed by wrapping carbon outside the nano-scale iron-cobalt alloy; on one hand, a carbon shell layer is used as an oxidation resistant layer to increase the stability of a nano compound; and on the other hand, the carbon shell layer is used as a dielectric material and compounded with a magnetic iron-cobalt inner core so that the wave-absorbing property of the wave-absorbing material is superior to most classical ferrite and other most nano compound wave-absorbing materials.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

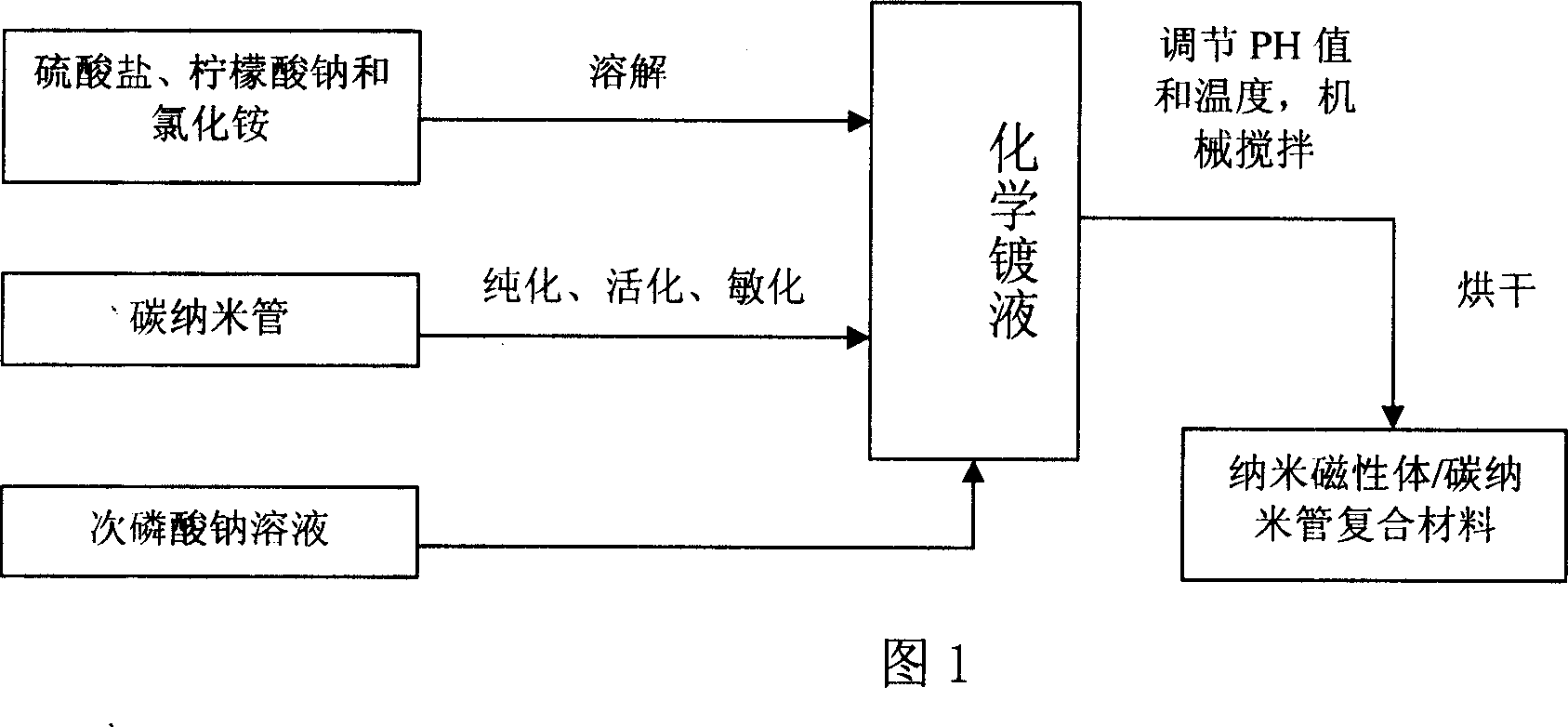

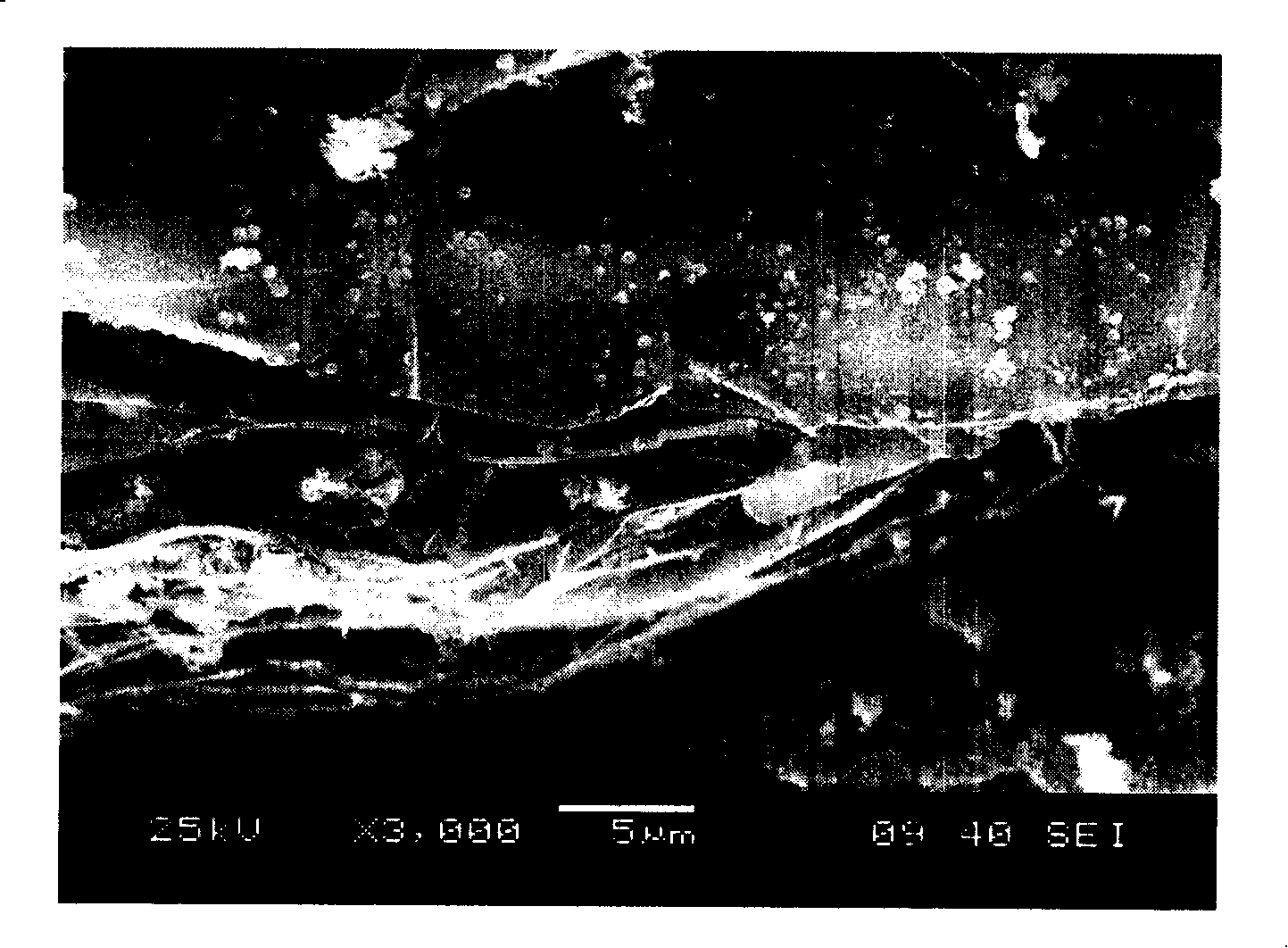

Carbon nano tube wave absorbtion mateirla of surface carried with magnetic alloy particle and preparation method thereof

InactiveCN101045533AGood electrical and magnetic propertiesSimple preparation processNanostructure manufactureScreening apparatusMicrowaveCarbon nanotube

A carbon nanotube carrying magnetic alloy particles on its surface and used as wave absorbing material is prepared through uniformly dispersing carbon nanotubes in the solution of the sulfate of Fe, Co and Ni, and oxidizing-reducing reaction for deposition the magnetic alloy particles on carbon nanotubes.

Owner:TSINGHUA UNIV

Display apparatus and method

InactiveUS20050117283A1Inhibit transferReduce probabilityStatic indicating devicesMagnetic/electric field screeningEngineeringMechanical engineering

Owner:SAMSUNG ELECTRONICS CO LTD

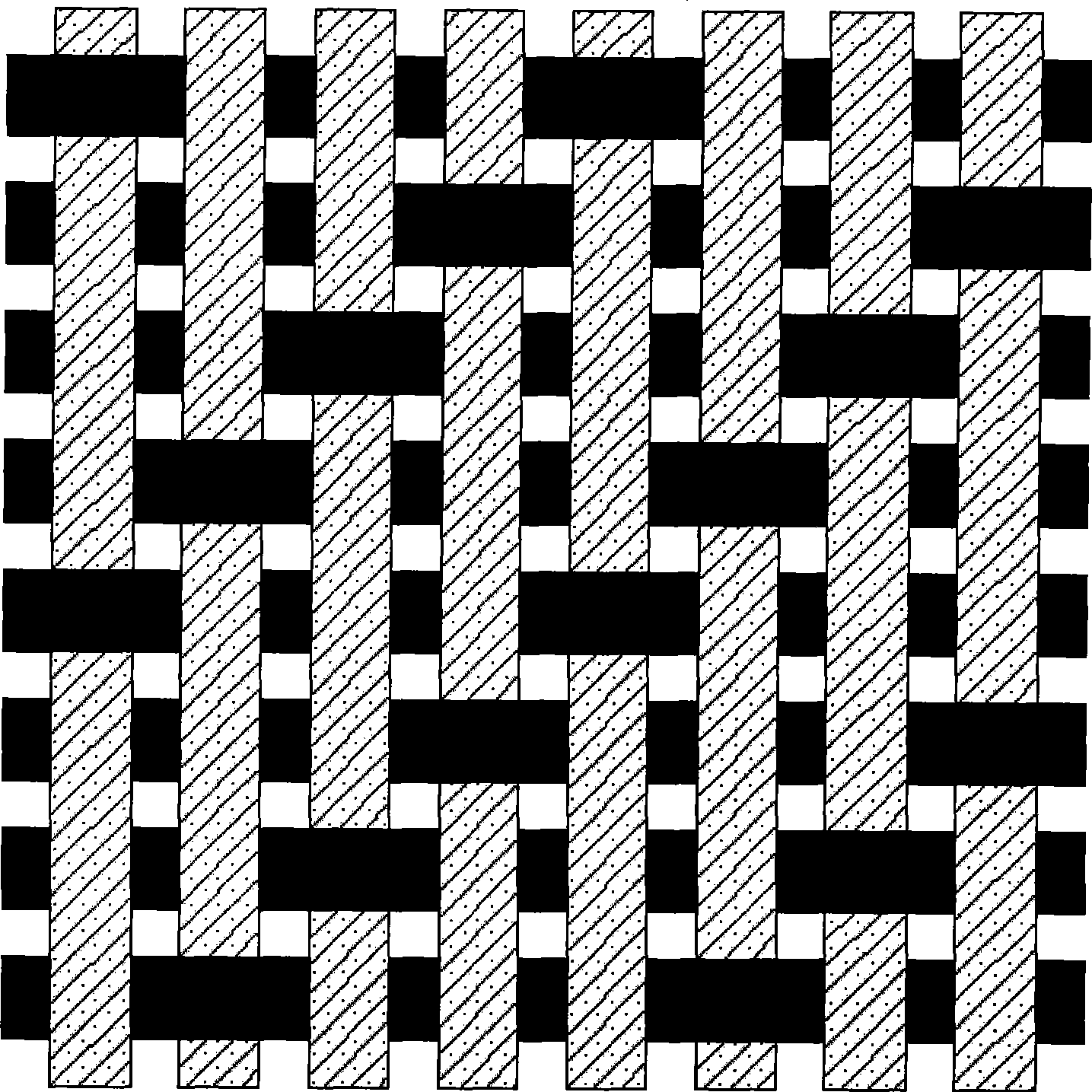

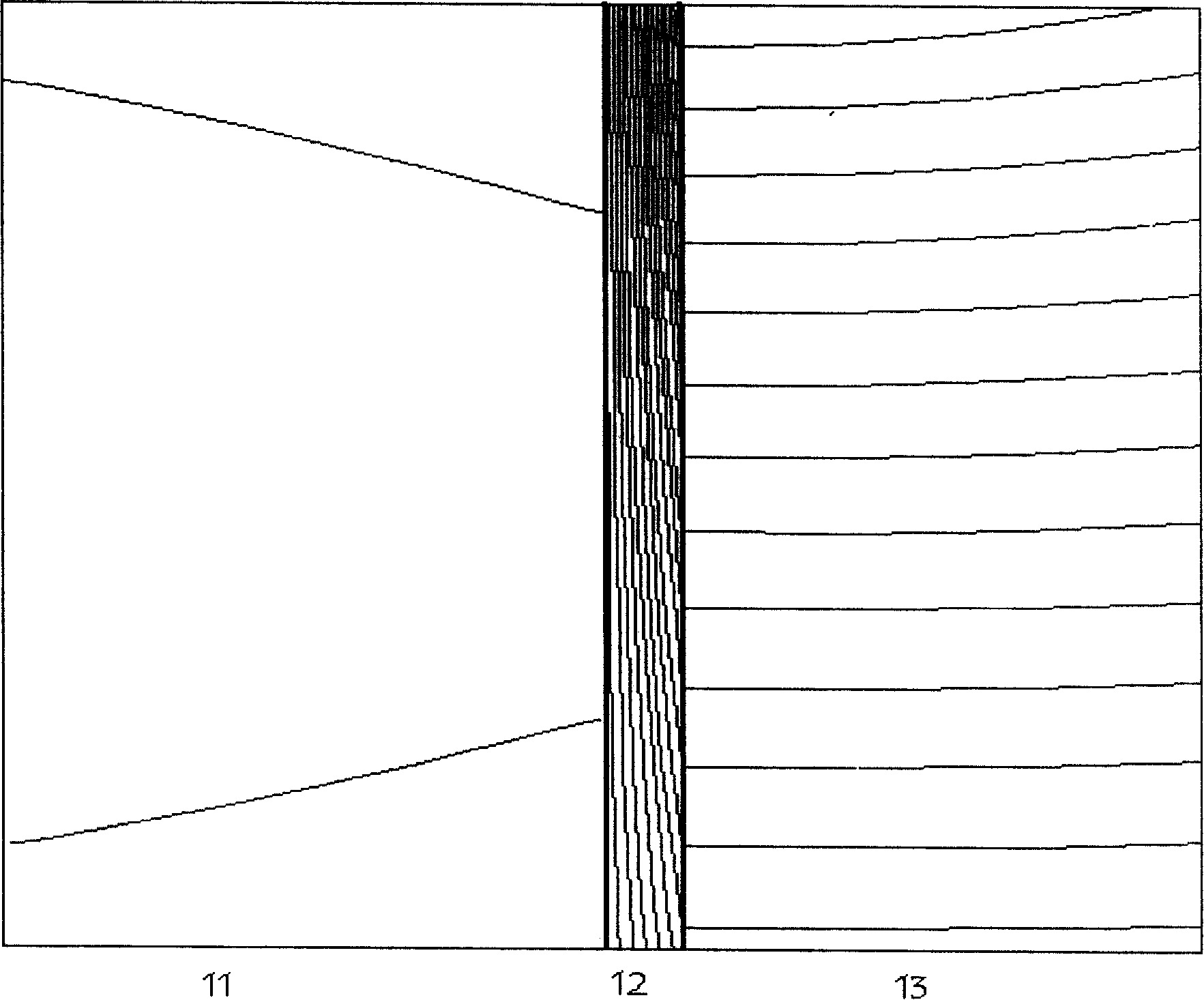

Magnetic field loomage as well as preparation method and application thereof

InactiveCN101423996ADecaying constant magnetic fieldAttenuation of extremely low frequency magnetic fieldsMagnetic/electric field screeningScreening apparatusYarnExtremely low frequency magnetic field

The invention relates to magnetic field shielding textile fabrics, a preparation method and application of the magnetic field shielding textile fabrics. The invention discloses the magnetic field shielding textile fabrics, which are formed by interlacing of permalloy wires and wearing yarns. The magnetic field shielding textile fabrics which are prepared by the permalloy wires can effectively attenuate a stationary magnetic field and a low-frequency magnetic field with DC - 300 Hz, are soft, can be cut, and can be applied to individual protection and magnetic field source shielding.

Owner:NAVY MEDICINE RES INST OF PLA

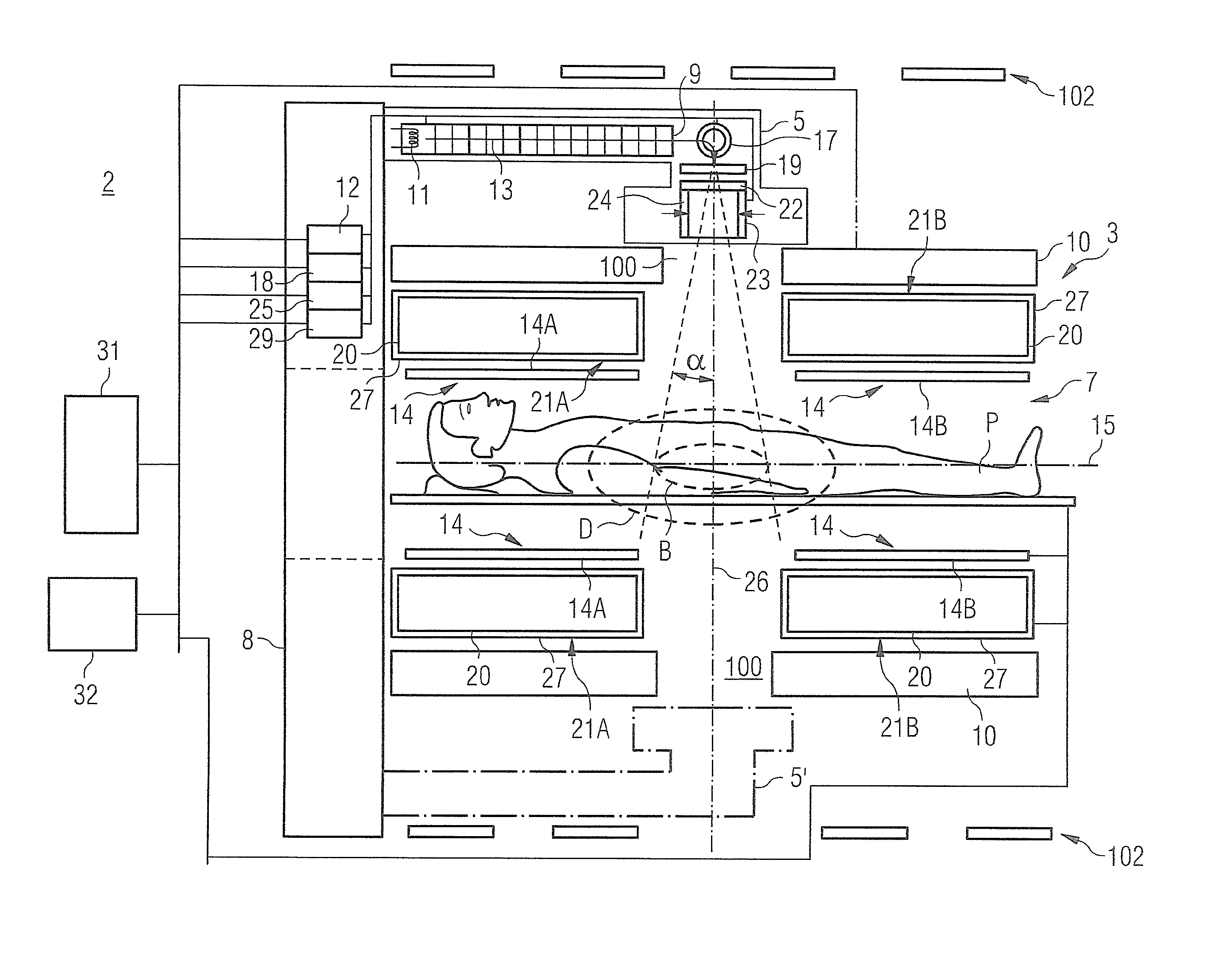

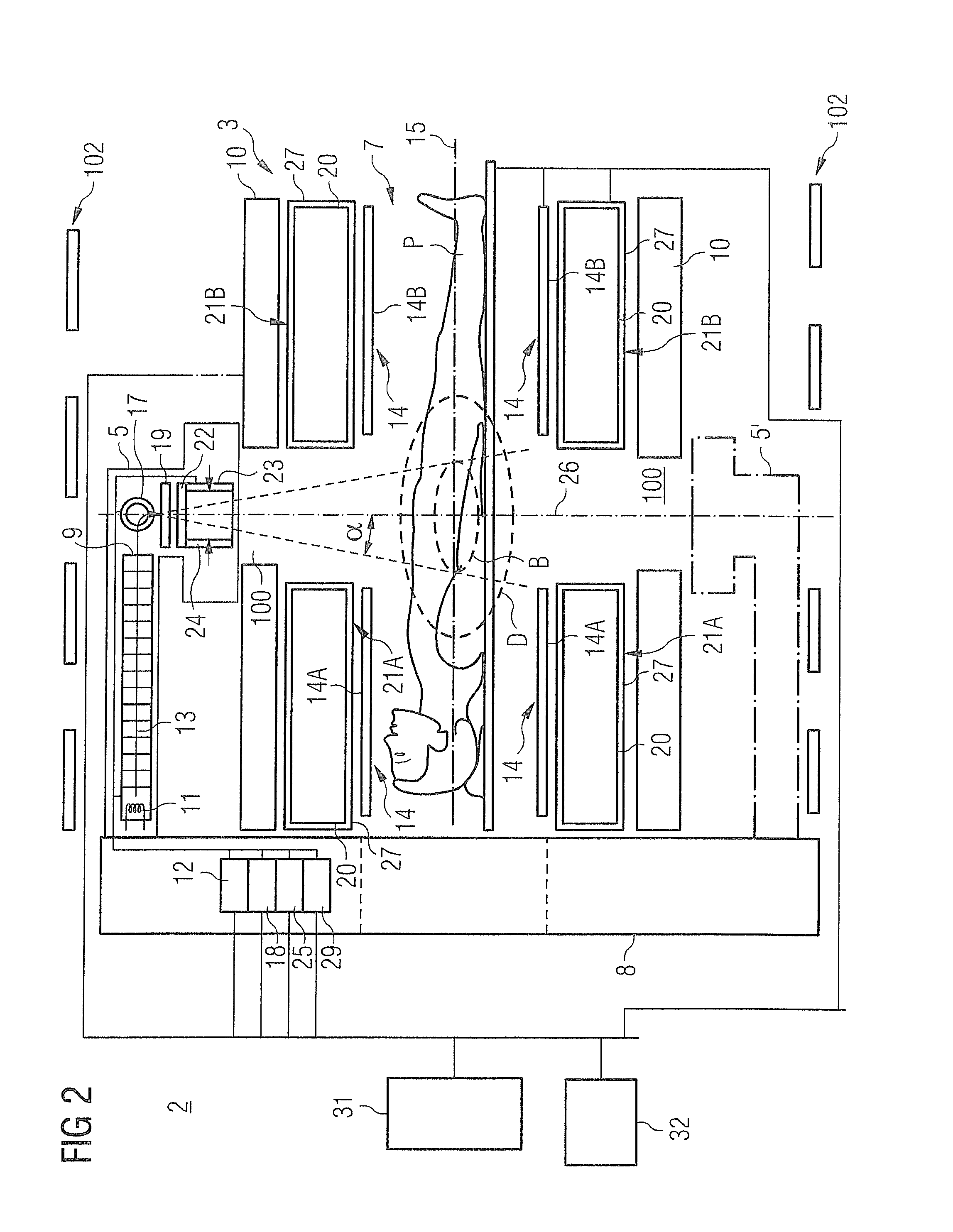

Combined MRI and radiation therapy system

ActiveUS9526918B2Reduce the overall diameterWeakening rangeScreening apparatusDiagnostic recording/measuringTherapeutic radiationElectron

A combined MRI and radiation therapy system has MRI imaging equipment and radiation therapy equipment. The MRI imaging equipment includes a shielded solenoidal magnet including a number of main magnet coils arranged coaxially along an axis, and a shielding arrangement arranged coaxially with the axis, at a greater radius from the axis than the main magnet coils. The radiation therapy equipment includes a LINAC assembly, that includes a linear electron accelerator arranged with an electron beam path parallel to the axis, and electron beam deflection arrangement and a target for generating a beam of therapeutic radiation. The linear electron accelerator is located at a position radially between the main magnet coils and the shielding arrangement.

Owner:SIEMENS HEALTHCARE GMBH

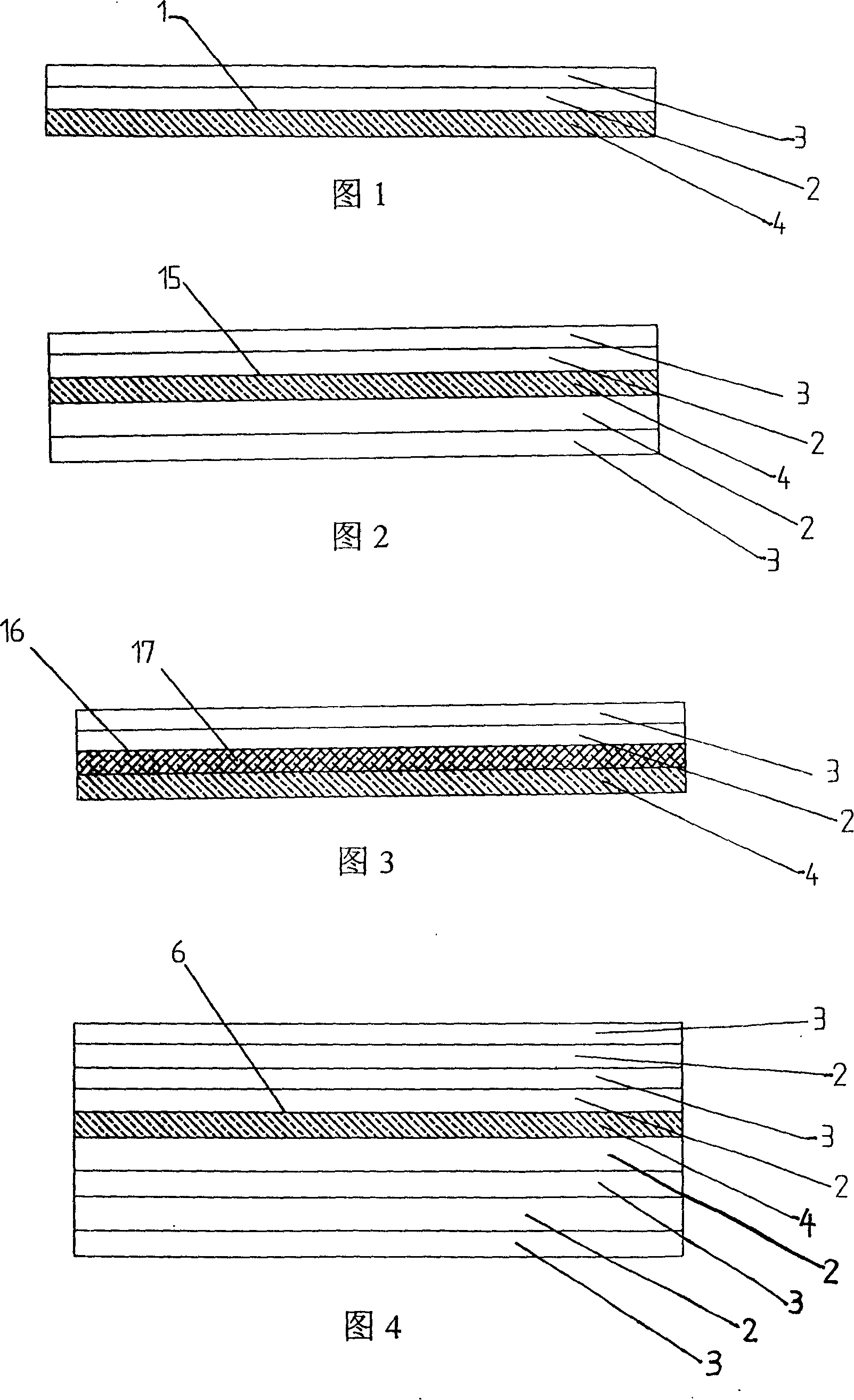

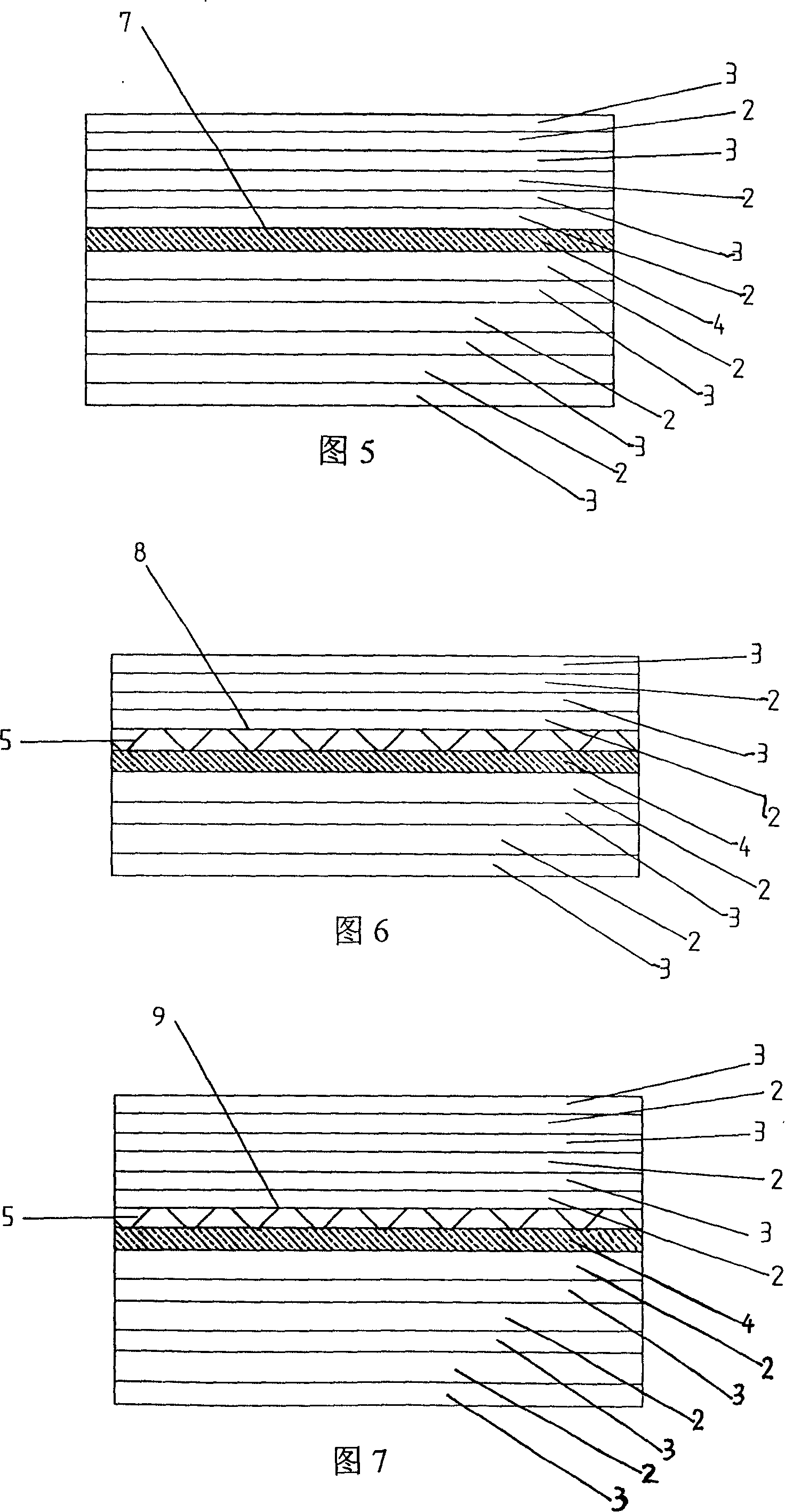

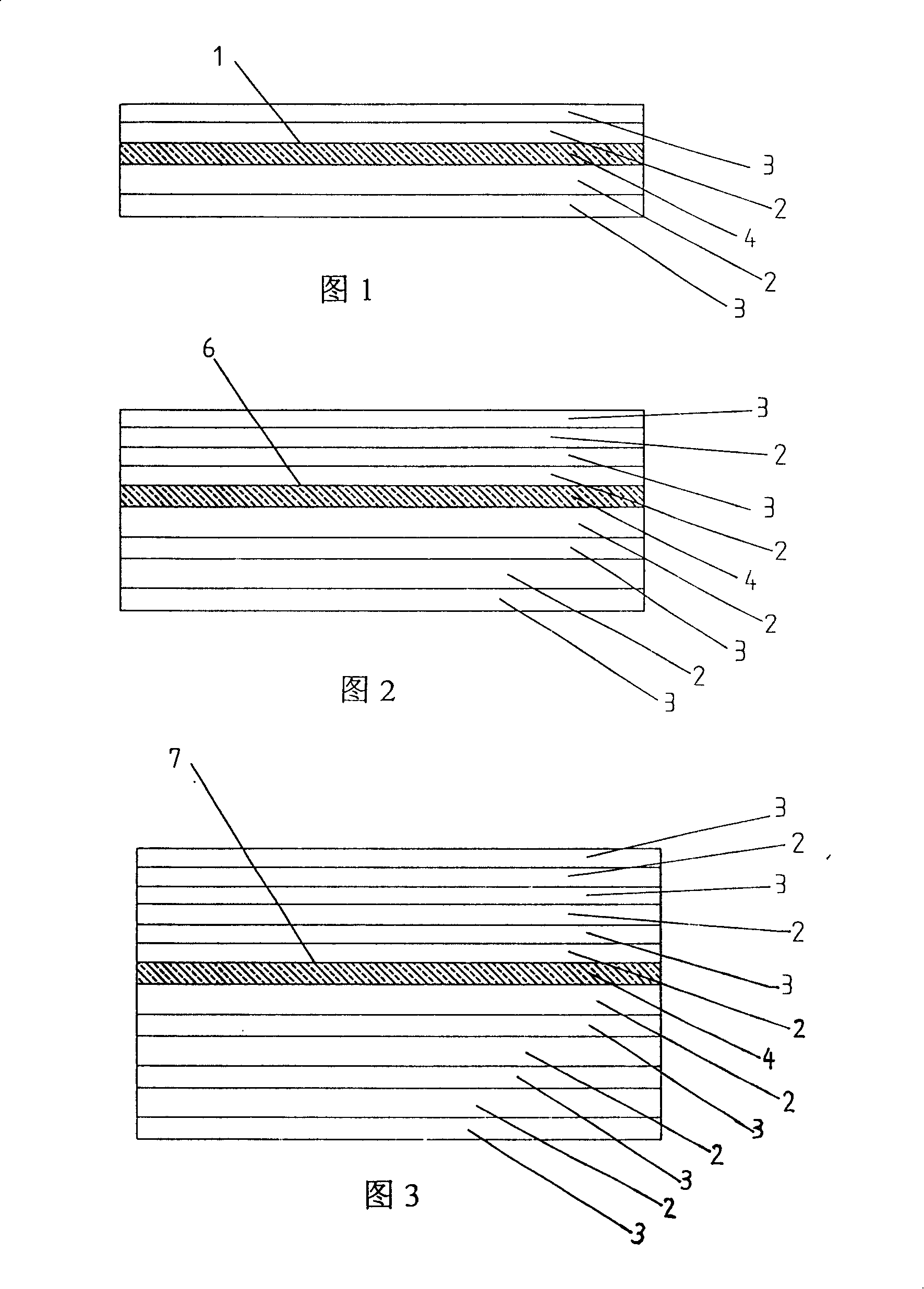

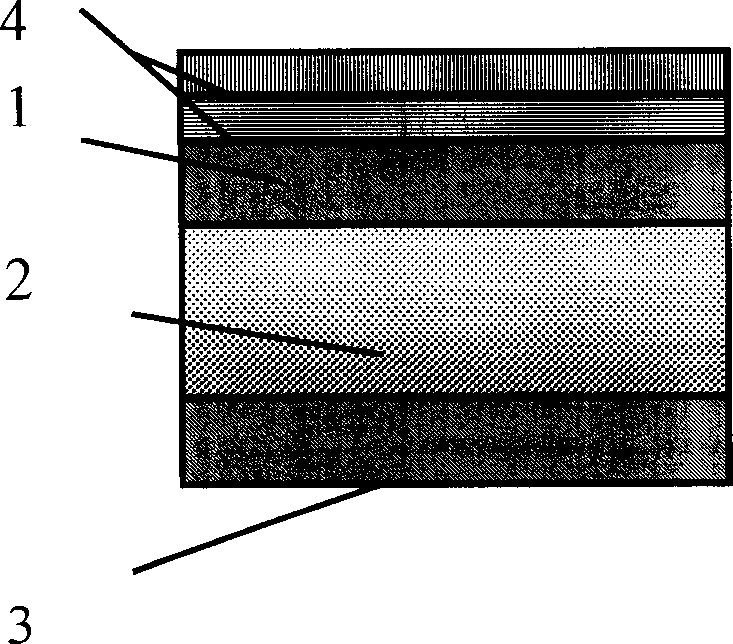

Anti-electromagnetic interference multilayer composite material and method for producing the same

InactiveCN101175394ALow resistivityStrong electromagnetic shieldingMagnetic/electric field screeningScreening apparatusBasementElectromagnetic interference

The present invention provides an anti electromagnetic interference multilayer composite materials, which comprises a plastic basement and a metal layer loaded on the plastic basement. The metal layer comprises at least three layers which are a first metal layer, a second metal layer and a third metal layer in turn from inside to outside. The first metal layer and the third metal layer are all formed by one of stainless steel, chrome and nickel. The second metal layer is formed by one of argentums, cuprum and aluminum. The multilayer composite materials provided by the present invention has a small resistivity with a resistance less than two ohm in the largest distance in an area, strong electromagnetism shielding capacity (the electromagnetism shielding capacity reaches up to 10 to 50 Debye), strong corrosion resistance and good combining power to the plastic basement. Even under the effect of brine corrosion, the metal layer in particular to the second metal layer is still firmly attached to the plastic basement. In addition, the metals forming the metal layer of the present invention are all routine and not expensive metals, so the cost of production is relatively low.

Owner:BYD CO LTD

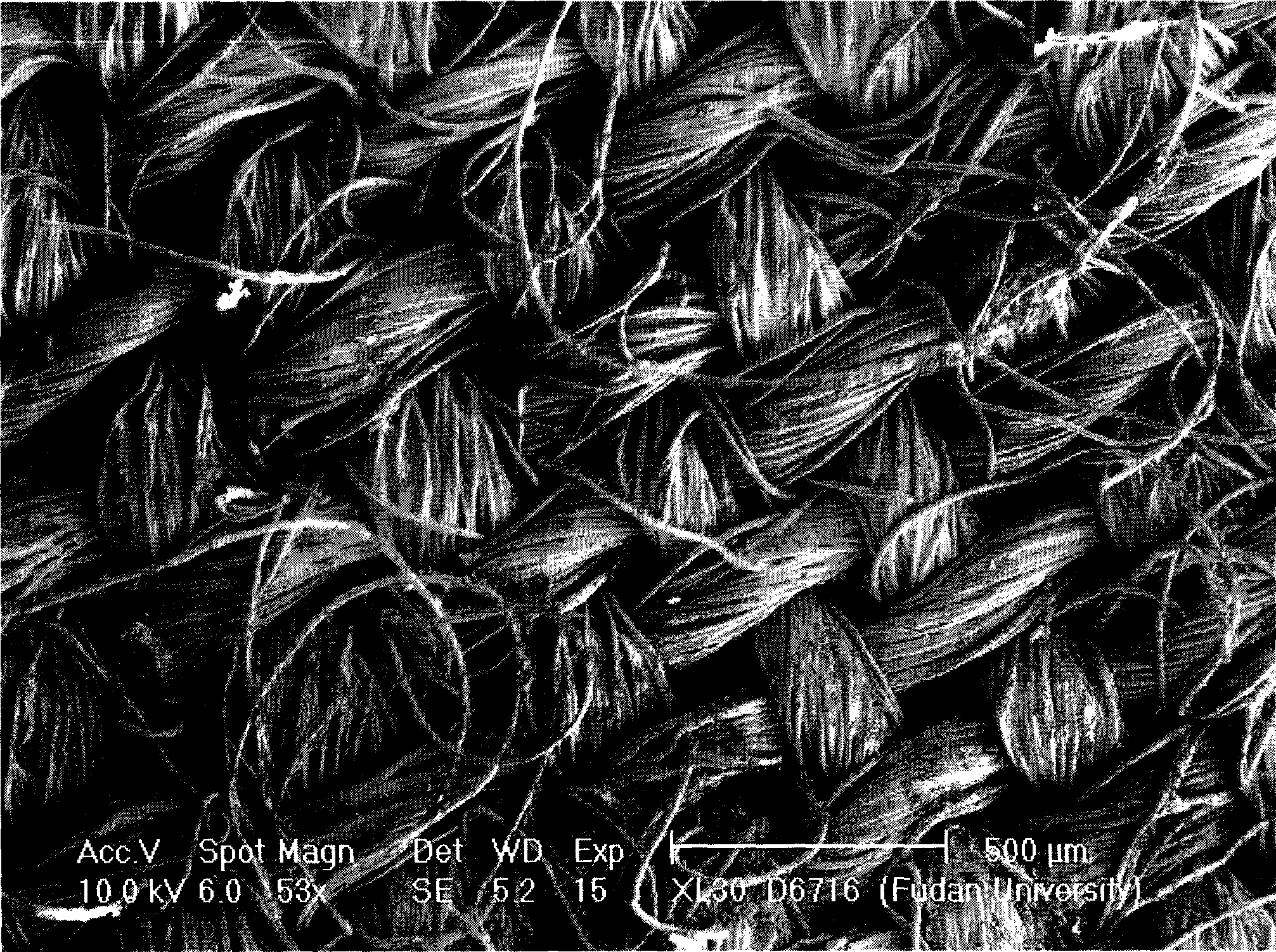

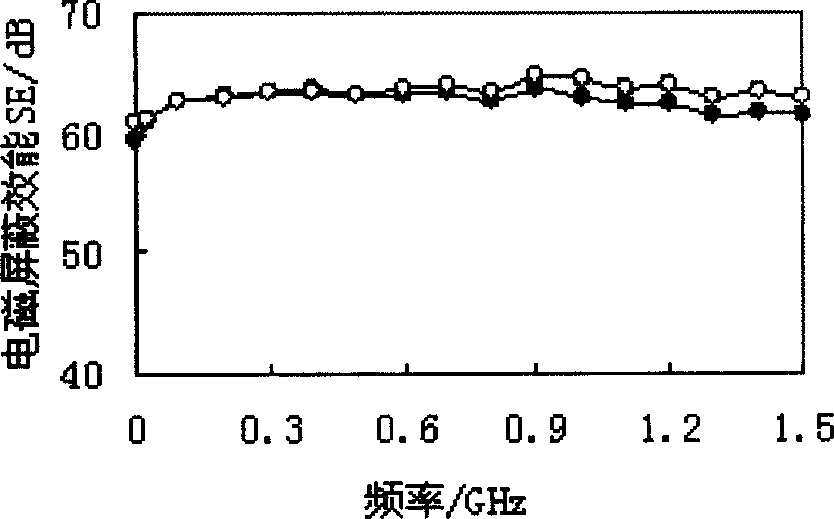

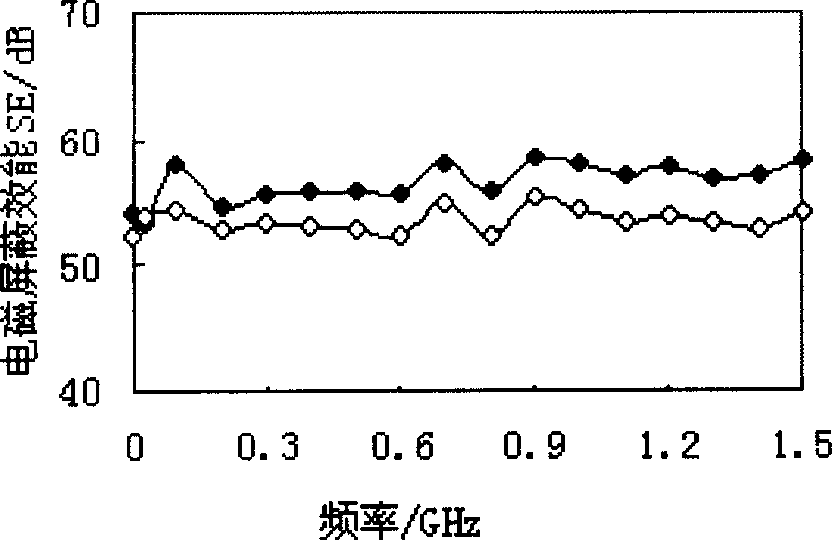

Preparation method of copper-clad electromagnetic wave shielding fabric

InactiveCN101532248AHigh bonding strengthImprove conductivityFibre typesScreening apparatusPolyesterAviation

The invention belongs to the technical field of electromagnetic wave shielding materials, and relates to a preparation method for copper-clad electromagnetic wave shielding fabric. The method comprises the following steps of: carrying out hydroxylation, sulfhydrylation and then chemical copper plating on the surface of polyester fabric and obtaining the electromagnetic wave shielding fabric; after the prepared electromagnetic wave shielding fabric is washed by an ultrasonic washing machine, the weight of the fabric is not changed, which shows that the copper plated on the surface and the fabric have good adhesivity, namely the fabric has strong washability; the washed fabric is in the range of 0.01MHz to 18GHz; and the efficiency of the electromagnetic wave shielding is larger than 54dB, namely the rate of radiation protection of the electromagnetic wave is larger than 99.999 percent. The fabric can be widely used for electromagnetic wave radiation-proof clothes and electromagnetic wave shielding of special departments including aviation, aerospace, military industry and communication, etc.

Owner:TAICANG BIQI NEW MATERIAL RES & DEV

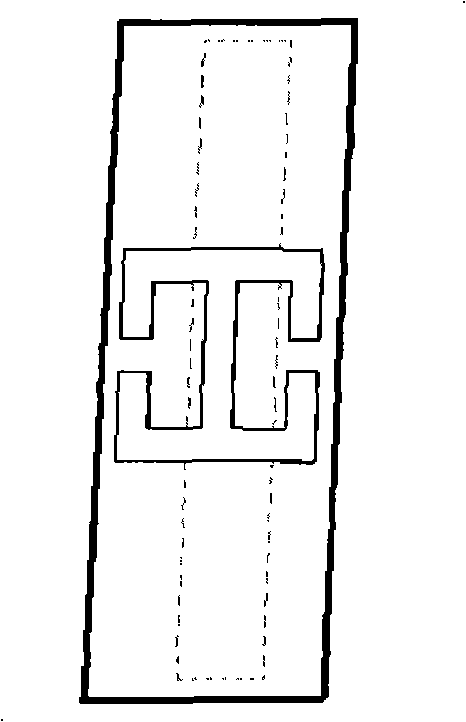

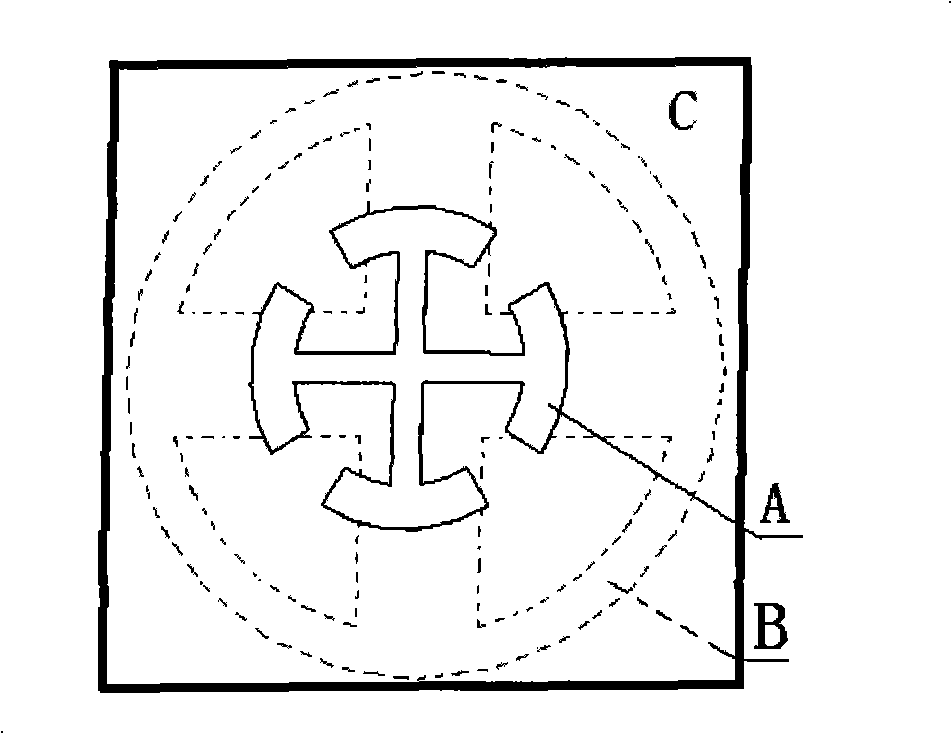

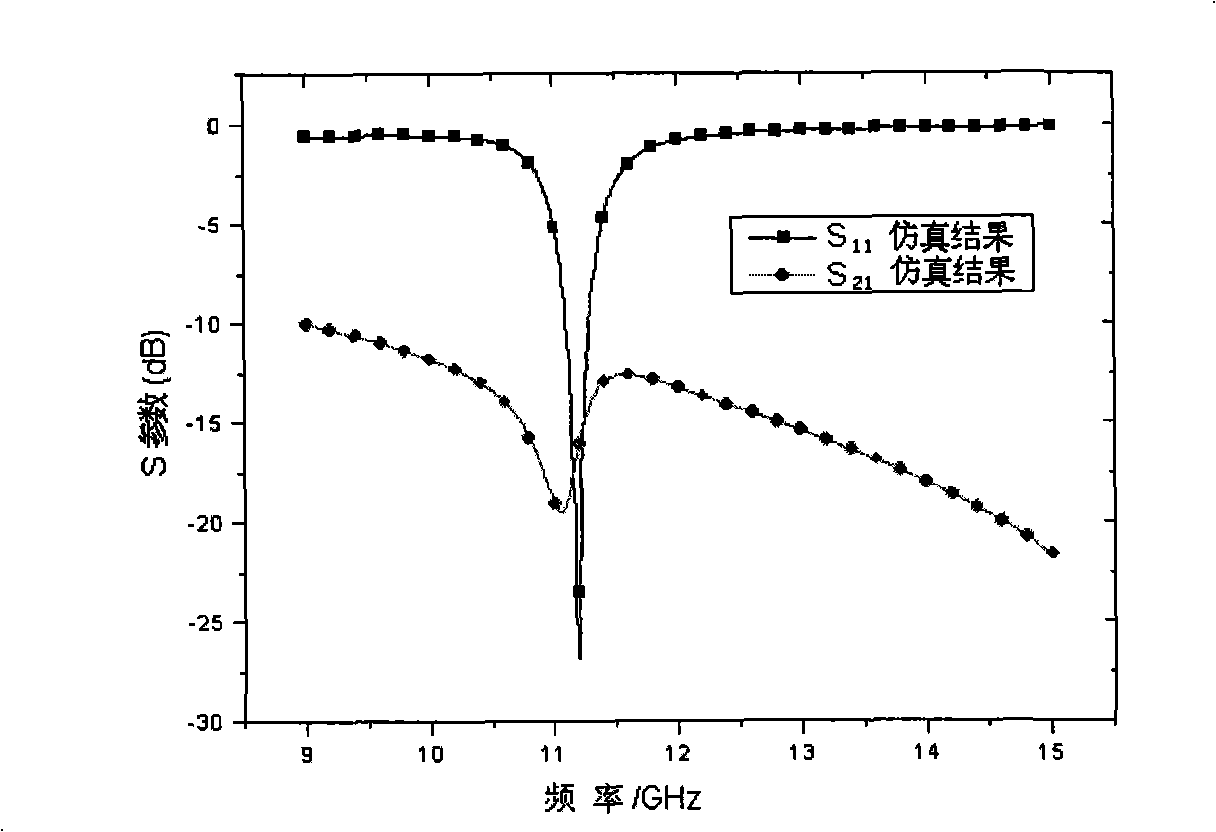

Slab wave-absorbing material

InactiveCN101540207APromote absorptionChange length widthScreening apparatusResonanceElectromagnetic field

The invention belongs to the technical field of electronic information and relates to electromagnetic fields and electromagnetic waves, in particular to a slab wave-absorbing material. The slab wave-absorbing material comprises unit wave-absorbing structures which are periodically arranged, wherein each unit wave-absorbing structure comprises a medium baseplate, a front metallic structure of the medium baseplate and a back metallic structure of the medium baseplate. The front metallic structure comprises 2 to 4 mutually crossed first metallic branch lines, and both ends of each first metallic branch line are respectively provided with a vertically connected linear or tangentally connected curved second metallic branch line. The back metallic structure comprises 2 to 4 mutually crossed first metallic branch lines, and both ends of each first metallic branch line are respectively tangentally connected with one circular ring-shaped second metallic branch line. Compared with the existing slab wave-absorbing material, the slab wave-absorbing material of the invention can absorb the electromagnetic waves in any polarization direction, and can better absorb in the wider incident angles of the electromagnetic field; and the electromagnetic resonance structures are mutually independent, can be separately adjusted, and have the characteristic of convenient syntonization.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

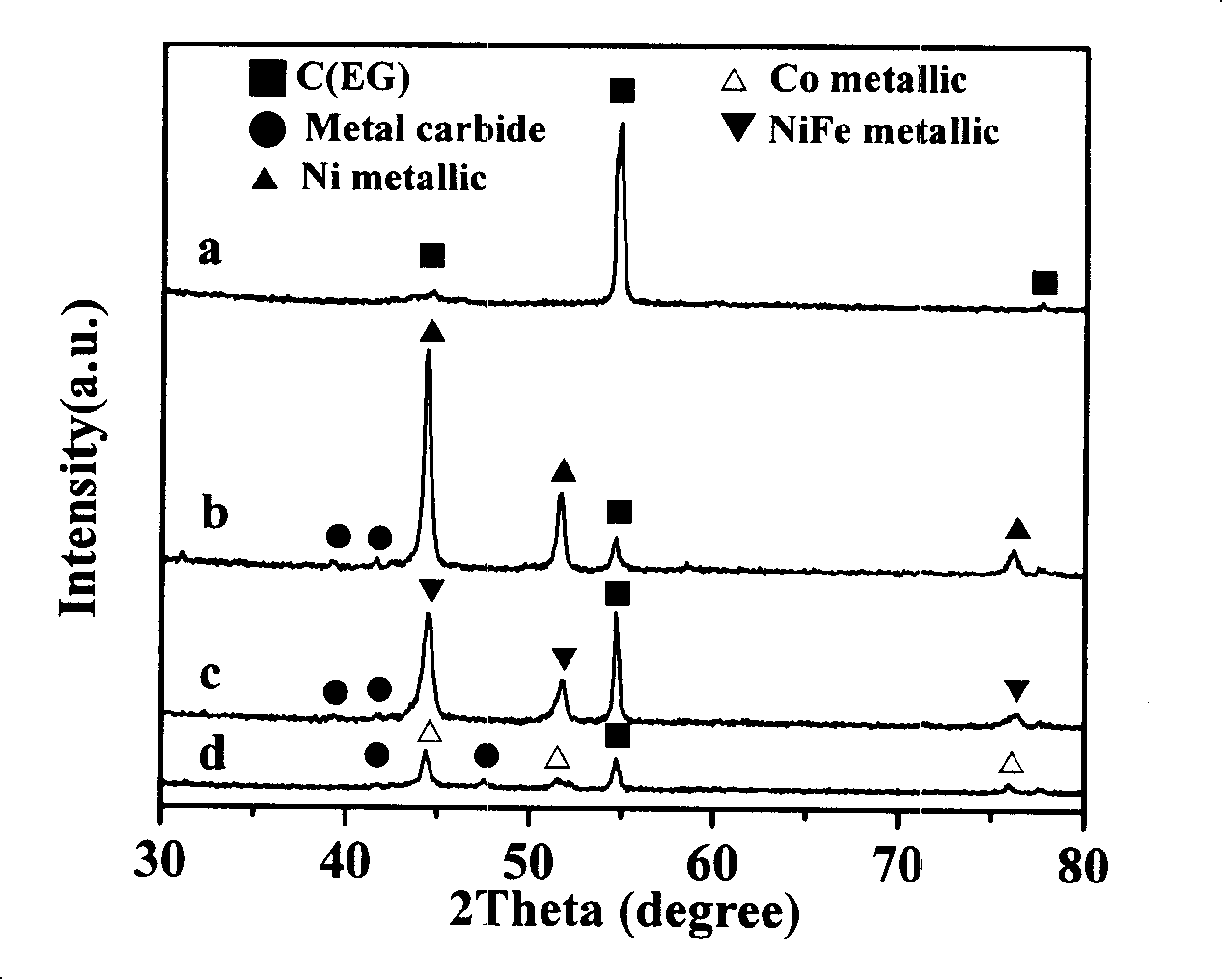

Method for preparing electromagnetic shielding light graphite based nanometer magnetic metal composite material

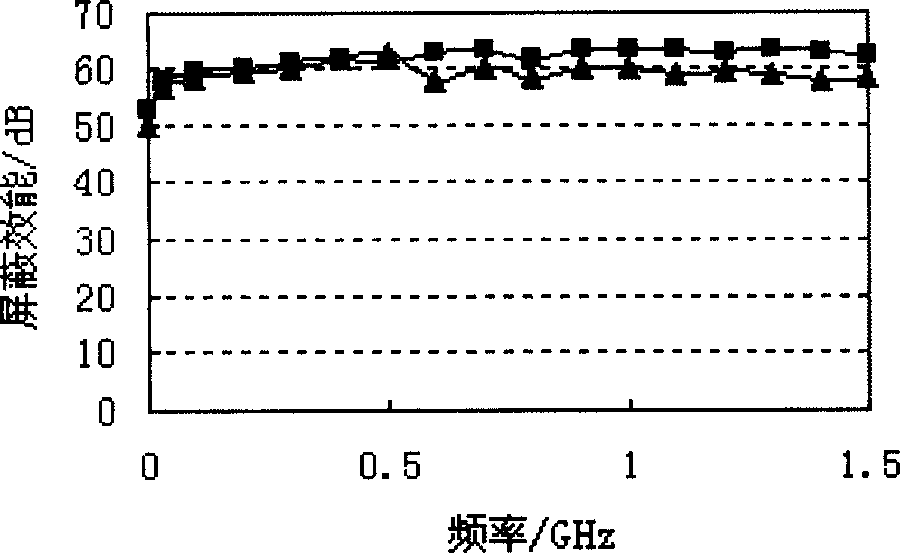

InactiveCN101179921AStir and disperse evenlyEnable mass manufacturingMagnetic/electric field screeningScreening apparatusLow frequency bandElectromagnetic shielding

The invention relates to a preparation method of a lightweight graphite-based nano-magnetic metal composite material used for electromagnetic shielding, which belongs to the related field of electromagnetic shielding materials; the precursor solution of expanded graphite and magnetic metal is mixed and stirred evenly, and dried after evaporating the solvent. The obtained mixture is treated in a reducing atmosphere at 300°C-1000°C, passivated with ordinary nitrogen and cooled to room temperature to obtain a composite material of expanded graphite and magnetic nanometer metal, and the relative content of the two can be adjusted. The composite material is light in texture, has excellent electromagnetic properties, and can be pressed into various shapes required. The material has excellent electromagnetic shielding performance in the range of 300kHz-1.5GHz, reaching 70-105dB, and the addition of magnetic metal improves the electromagnetic shielding performance of the expanded graphite in the low-frequency band. The method is simple and efficient, suitable for mass preparation, and the obtained product is expected to be applied in aerospace, military, electronic and electrical products.

Owner:NANJING UNIV

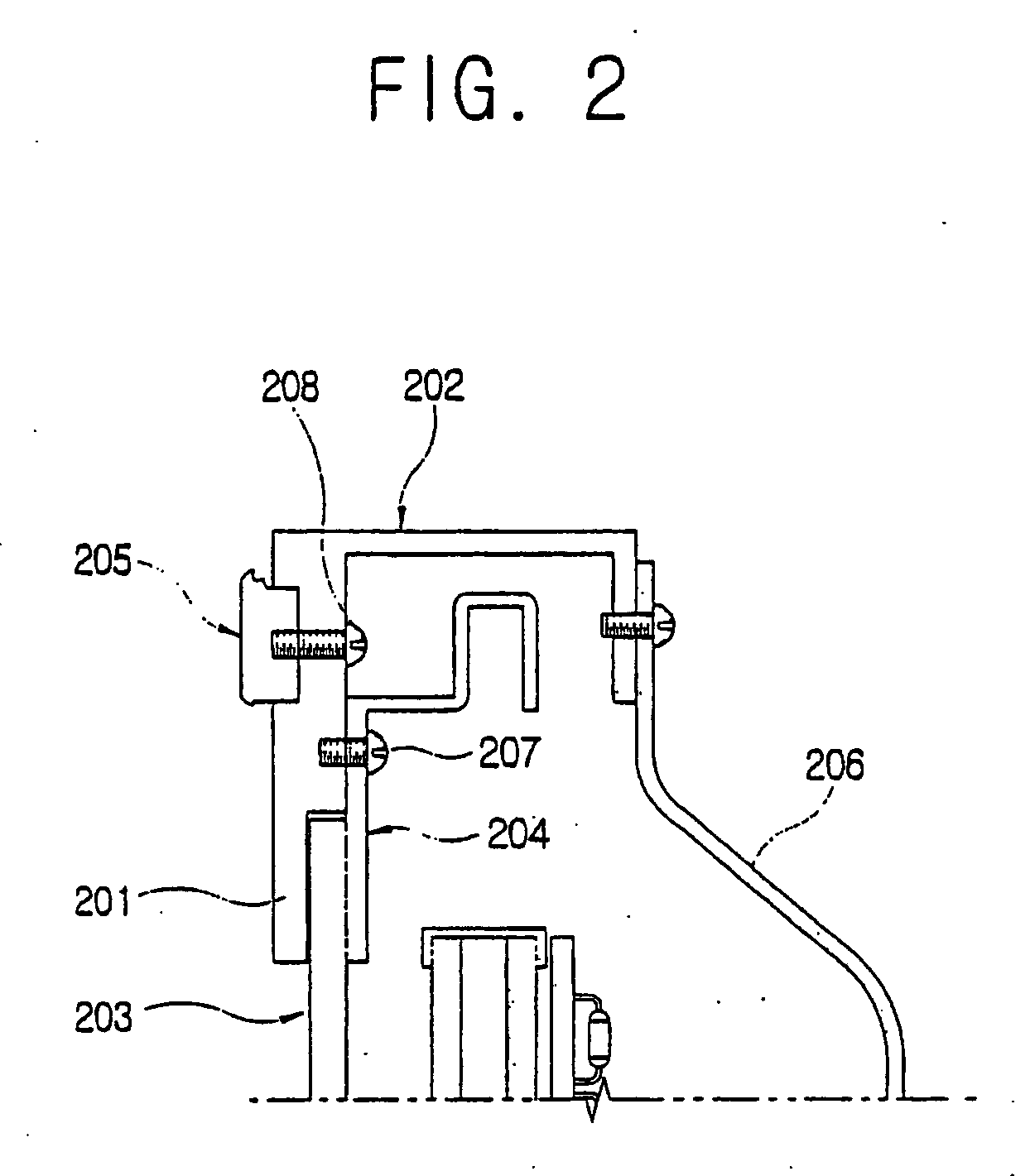

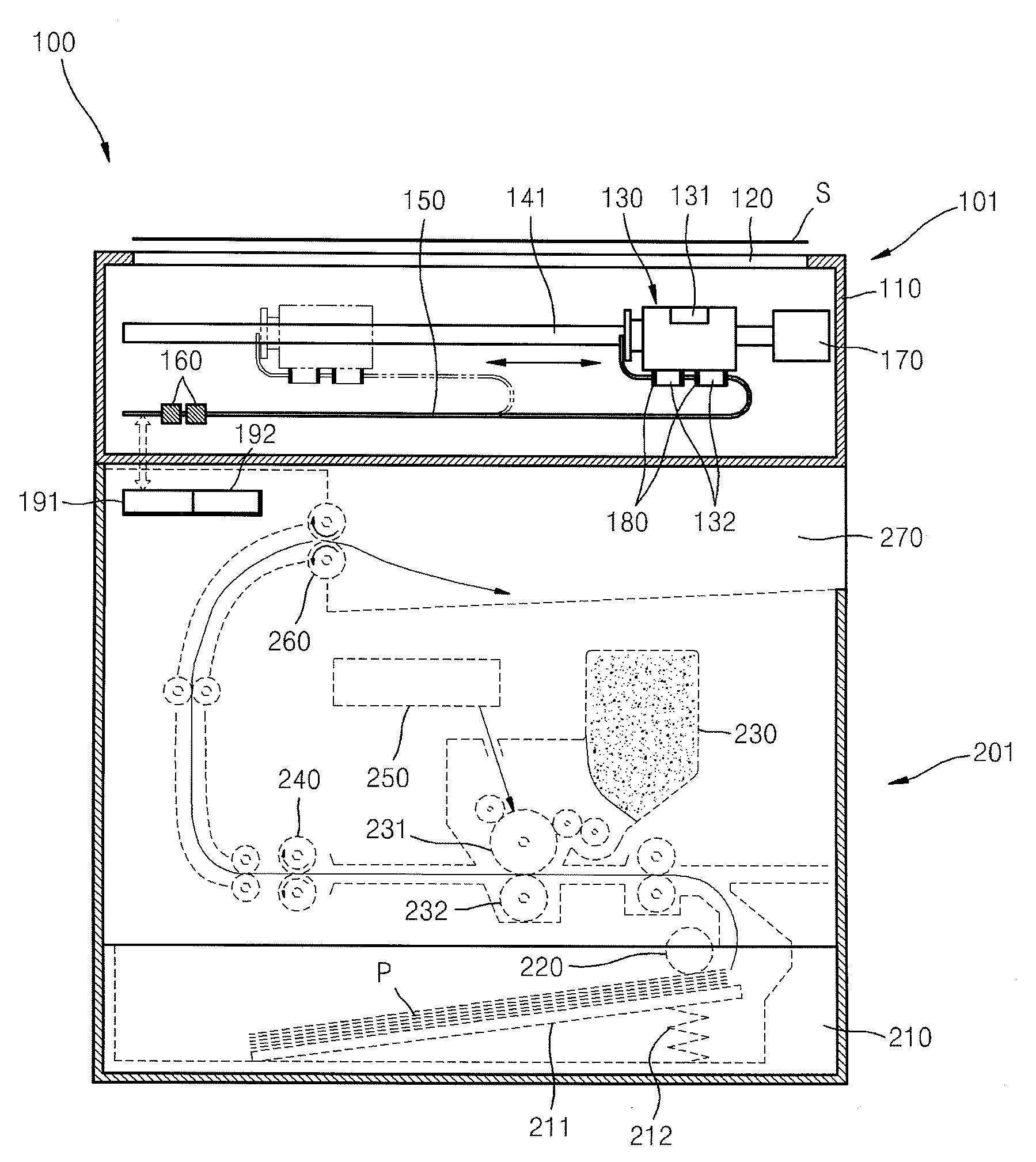

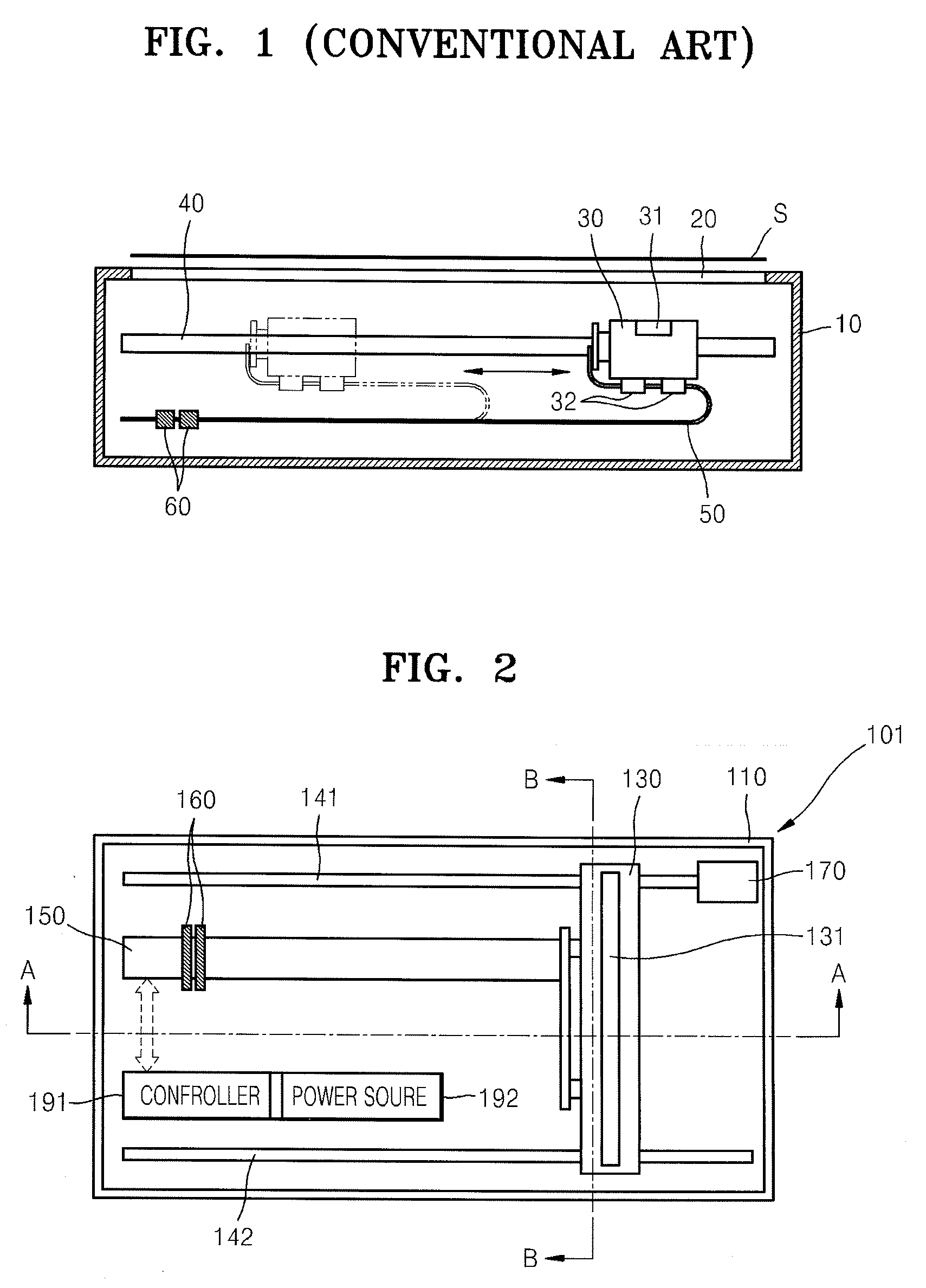

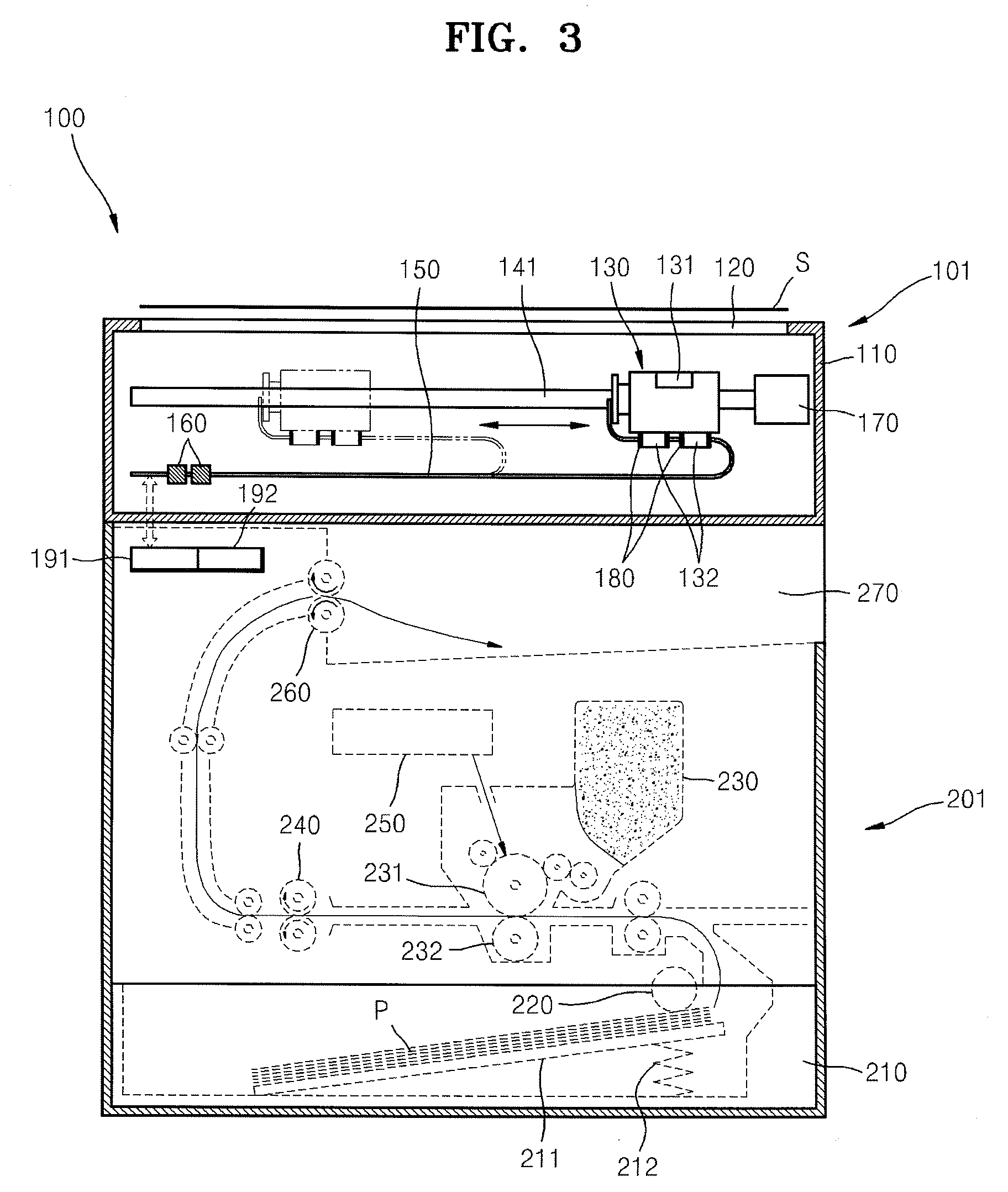

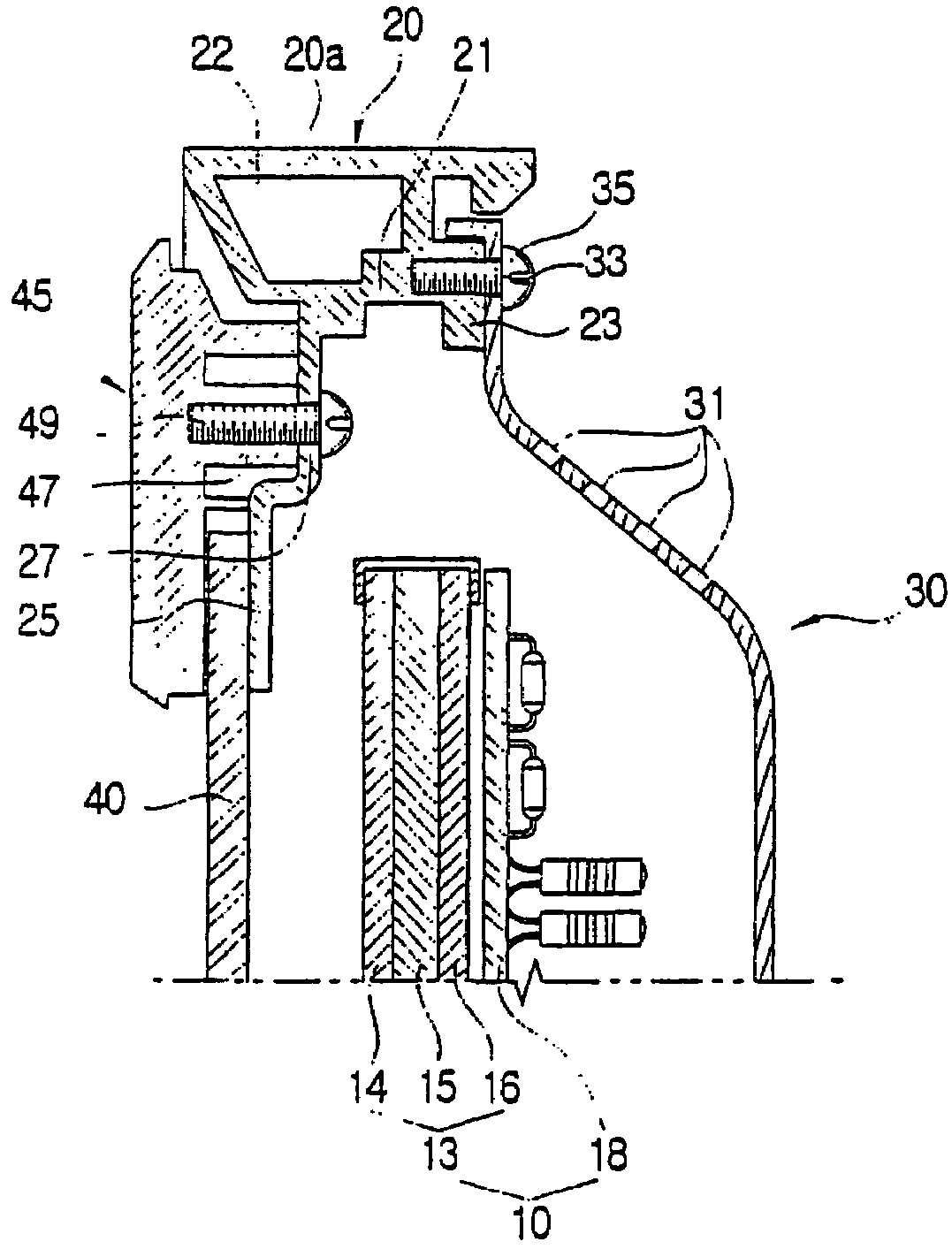

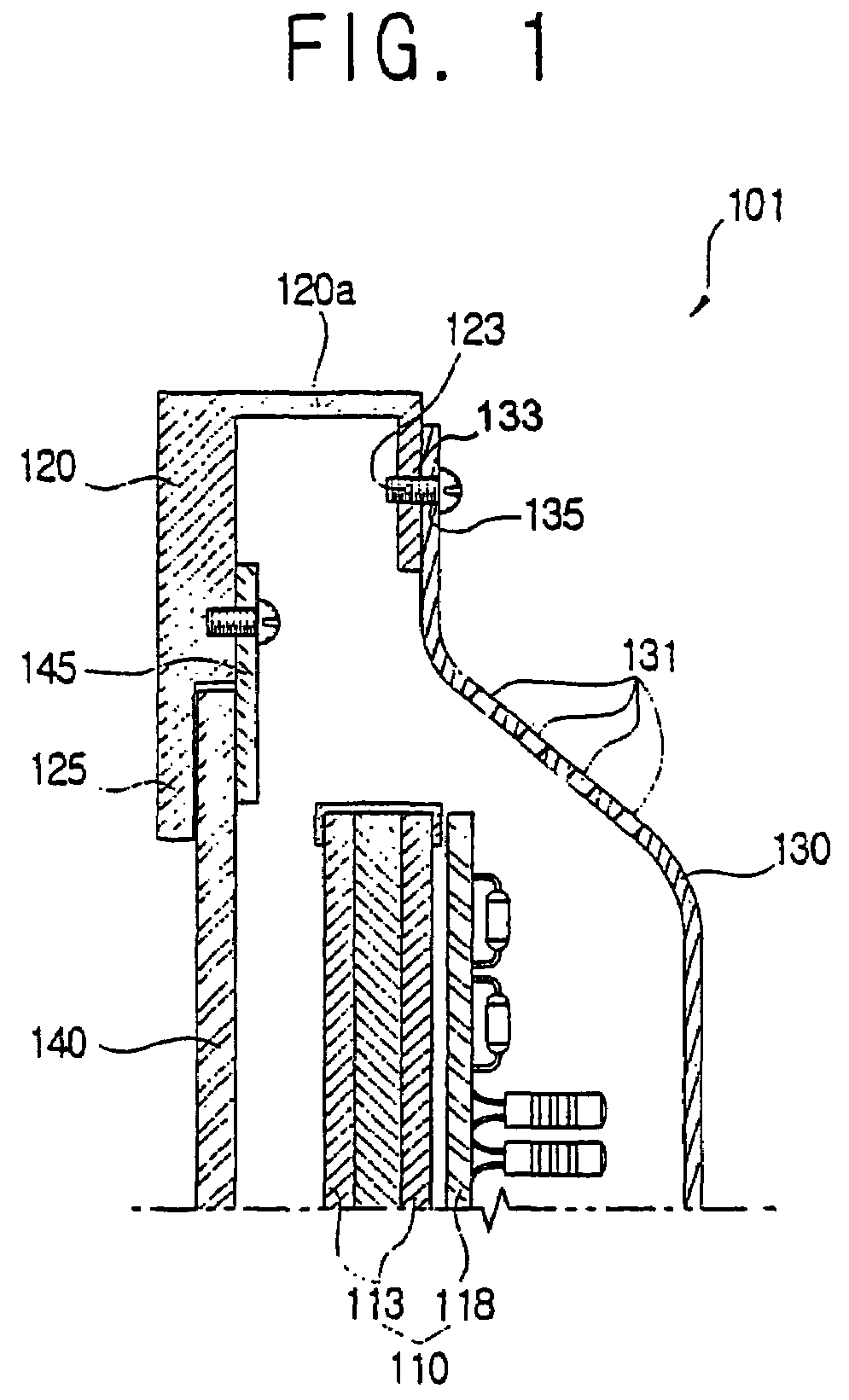

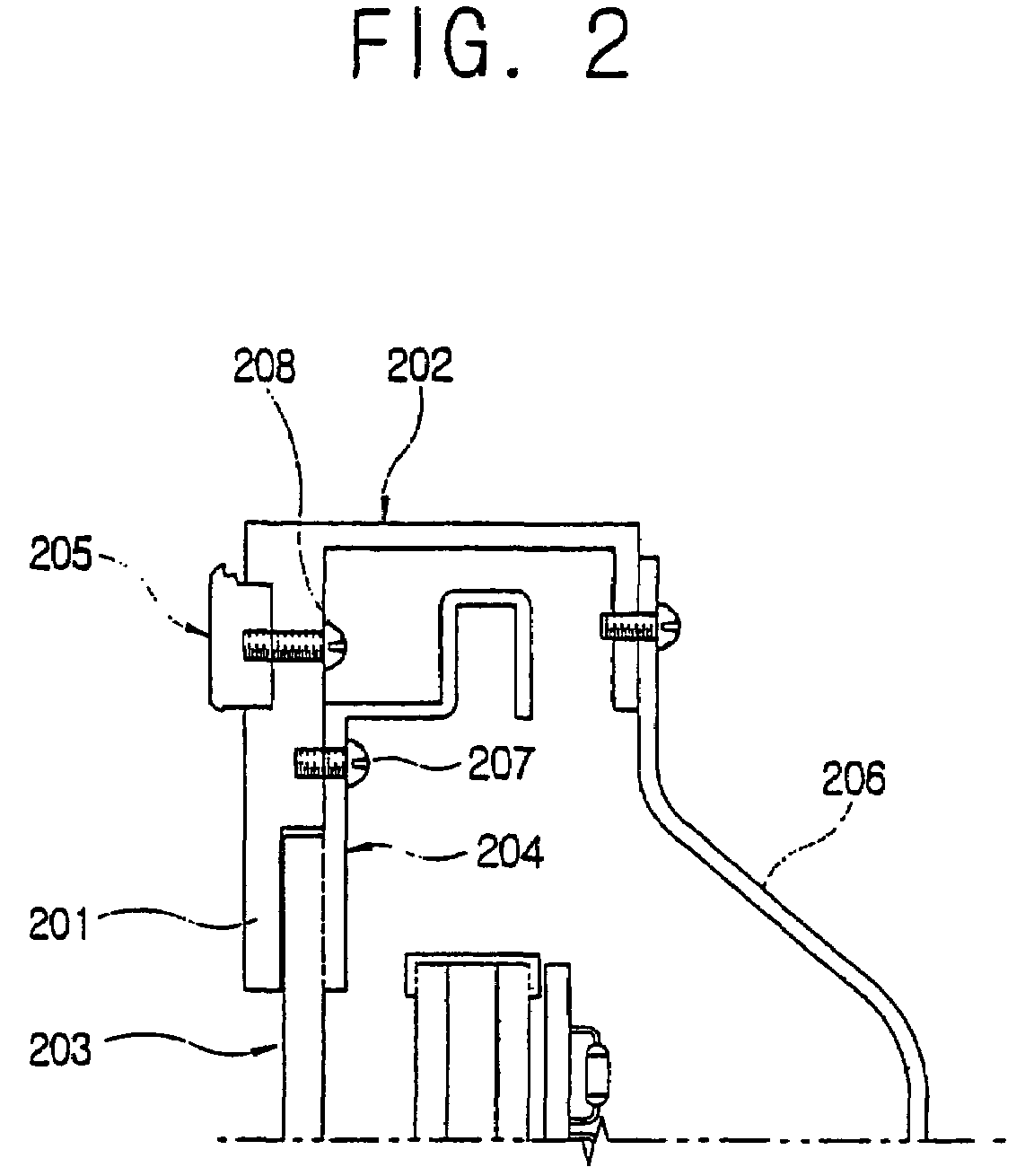

Scan unit having EMI noise blocking unit and image forming apparatus having the scan unit

ActiveUS20080316547A1Screening apparatusCharacter and pattern recognitionReciprocating motionElectromagnetic interference

A scan unit having an electromagnetic interference (EMI) noise blocking unit and usable with an image forming apparatus includes a document plate supporting a document, a reading module which is disposed under the document plate, performs a reciprocating motion, and includes an image sensor that reads an image of the document and generates an image signal in response to the read image, a flexible flat cable (FFC) which is connected to the reading module and functions as a transfer path of power and the image signal, and an EMI noise blocking unit which blocks noise that occurs when the image signal of the reading module is transmitted.

Owner:HEWLETT PACKARD DEV CO LP

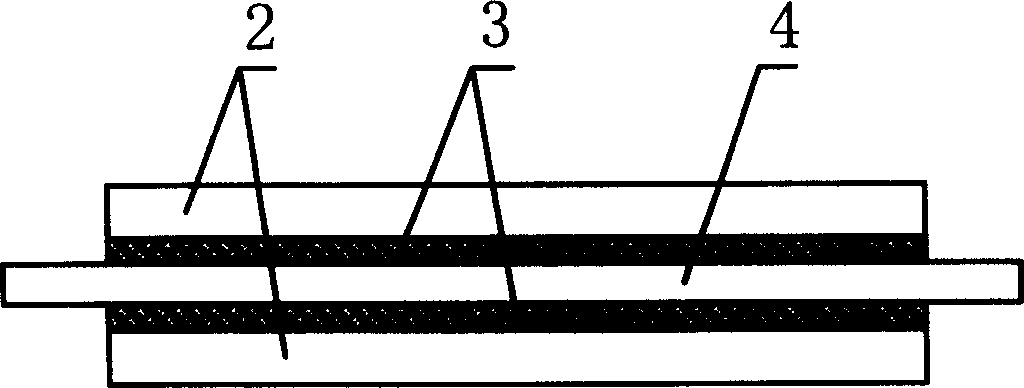

Composite electromagnetic screen film material and mfg. method thereof

InactiveCN1787114AMeet the needs of normal workLow costMagnetic/electric field screeningScreening apparatusComposite filmElectromagnetic shielding

The invention belongs to the field of magnetic material, relating to an electromagnetic shielding material and the making method thereof. The invention is a composite metallic film formed on a conductive substrate by multiple deposition in the water solution, and the obtained composite metallic film is 1-100 mum thick, and each layer of the composite metallic film is 1.1-99.9 mum thick, and the combination between the layers of the composite film is by chemical bond, and each layer is layered. The substrate can be stainless steel, copper plate, Ti plate, Al plate or one of the corrosion-resistant alloy plates, and also made of conductive glass, conductive plastics, polymer high molecular material, or other material; the composite metallic film comprises two or above different metallic film layers; each metallic film layer can be of copper, iron, iron-nickel alloy, nickel-cobalt alloy, iron-cobalt alloy or iron-cobalt-nickel alloy. The invention can shield the frequencies between 50Hz and 100 Hz and the shielding efficacy reaches above 70dB.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

High light transmittance ratio glass display protection panel and LCD device using same

InactiveCN101236263AIncrease brightnessNot scratchedScreening apparatusVacuum evaporation coatingLiquid-crystal displayOptical transmittance

The invention provides a high transmittance glass display protection screen, which comprises a transparent glass substrate, wherein, a double-layer antireflection filming layer of TiO2 and SiO2 or Nb2O5 and SiO2 is deposited in turn by adoption of the vacuum magnetron sputtering method on both surfaces of the substrate, or a multilayered antireflection filming layer of TiO2 and SiO2 or Nb2O5 and SiO2 is overlapped and deposited in turn; a double-layer filming layer of the TiO2 layer and the SiO2 layer, a double-layer filming layer of the Nb2O5 layer and the SiO2 layer, a multilayered overlapped filming layer of the TiO2 layer and the SiO2 layer or a multilayered overlapped filming layer of the Nb2O5 layer and the SiO2 layer are formed in turn from the substrate to the outside. The protection screen of the invention can reduce reflectivity, improve transmittance and optical image effects, greatly reduce cost and fully improve the impact failure resistance of the display screen and become a safe protection screen. The invention also provides a liquid crystal display using the glass display protection screen.

Owner:甘国工

Broad band multilayer foam wave-suction material and method for making same

InactiveCN1929731AAttached tightlyWon't fall offMagnetic/electric field screeningScreening apparatusBroadbandWide band

This invention relates to wide band multi-layer bubble wave absorptive materials and its process method in function materials technique. This invention forms single layer by open polyurethane bubble materials and wave absorptive materials.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Electromagnetic wave absorber

InactiveUS6784419B1Good formabilityExcellent electromagneticMagnetic/electric field screeningScreening apparatusElectromagnetic wave absorberClassical mechanics

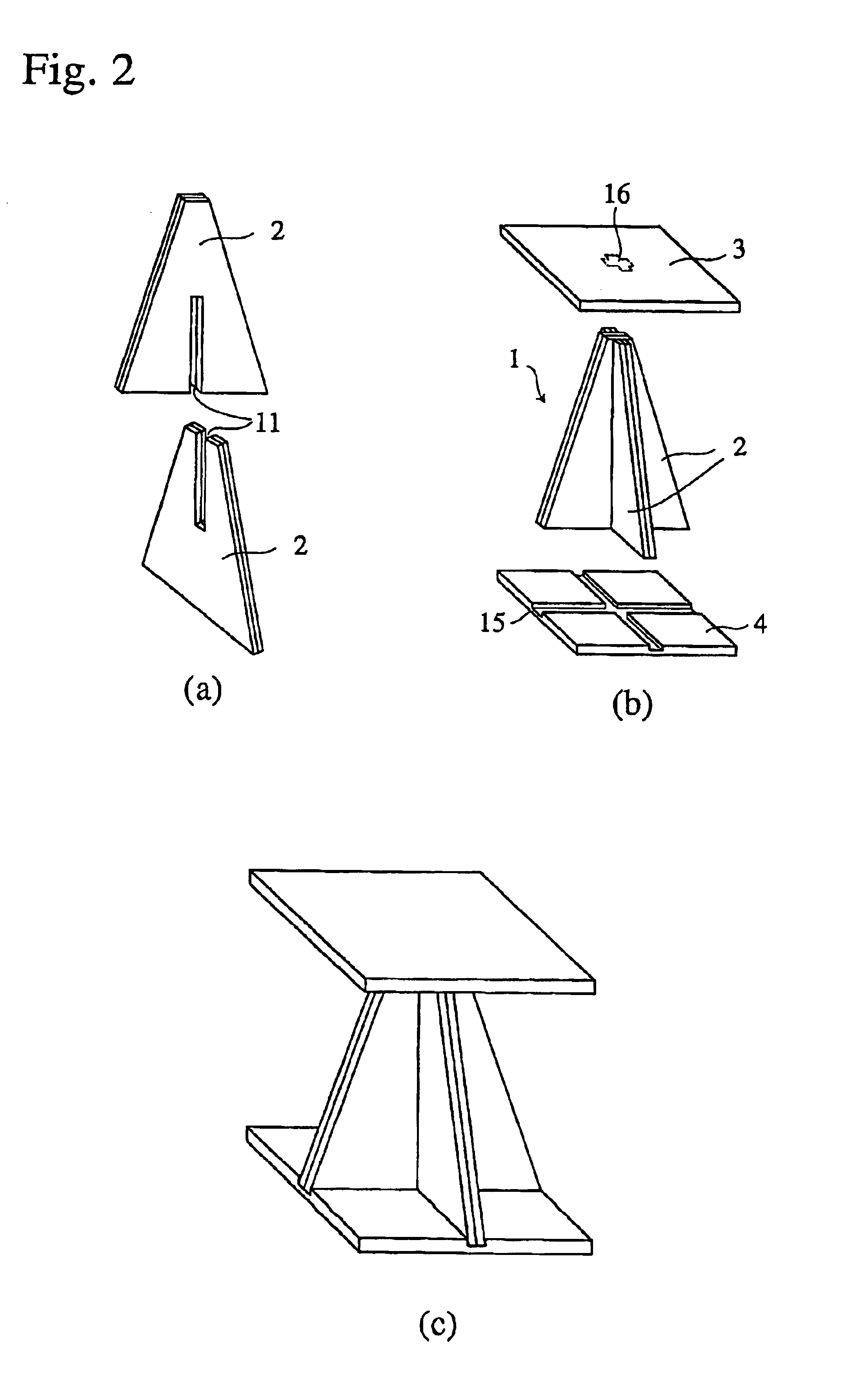

The present invention provides a flame-retardant electromagnetic wave absorber that exhibits excellent formability and electromagnetic wave-absorbing properties, and can be easily assembled and constructed. The electromagnetic wave absorber comprises a wave-absorbing body and a base plate supporting the bottom thereof, wherein the wave-absorbing body is formed in a pyramid shape by fitting polygonal wave-absorbing plates into each other.

Owner:RIKEN CO LTD

Display apparatus and method

InactiveUS7508654B2Inhibit transferReduce probabilityStatic indicating devicesMagnetic/electric field screeningComputer moduleEngineering

Owner:SAMSUNG ELECTRONICS CO LTD

A magnetic shielding device with multi-layer compound structure for shielding strong magnetic field

InactiveCN101166411AMagnetic/electric field screeningScreening apparatusNuclear detectionEngineering

Being in use for shielding strong magnetic field (MF), the magnetic shielding device with multilaminar composite structure solves issue that the design of magnetic shielding photomultiplier is unable to shield strong MF. Using multilaminar composite structure, the magnetic shielding device includes three layers from outer to inner: silicon steel assembly as middle layer, alloy assembly as inner layer, and solenoidal inductor as outer layer. The solenoidal inductor generates MF opposite to outer MF so as to weaken strong MF greatly. With higher saturation of MF, the silicon steel assembly reduces outer MF to a few Gauss further. Possessing quite high magnetic permeability of weak MF, the alloy assembly in innermost layer reduces residual MF to lower than 0.001 Gauss being far lower than level of earth MF. The invention makes shielded photomultiplier operate normally under strong MF. The invention has wide application in technical areas of nuclear electronics and nuclear detection.

Owner:INST OF HIGH ENERGY PHYSICS CHINESE ACADEMY OF SCI

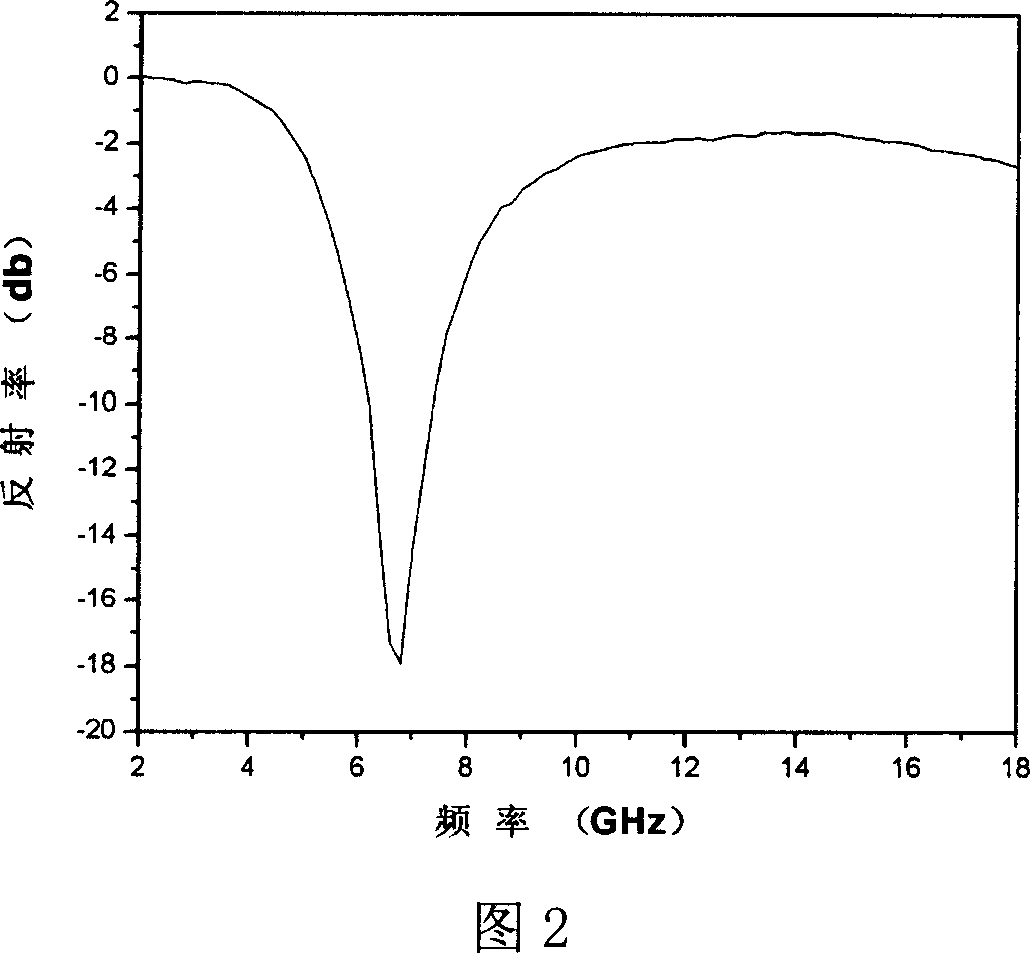

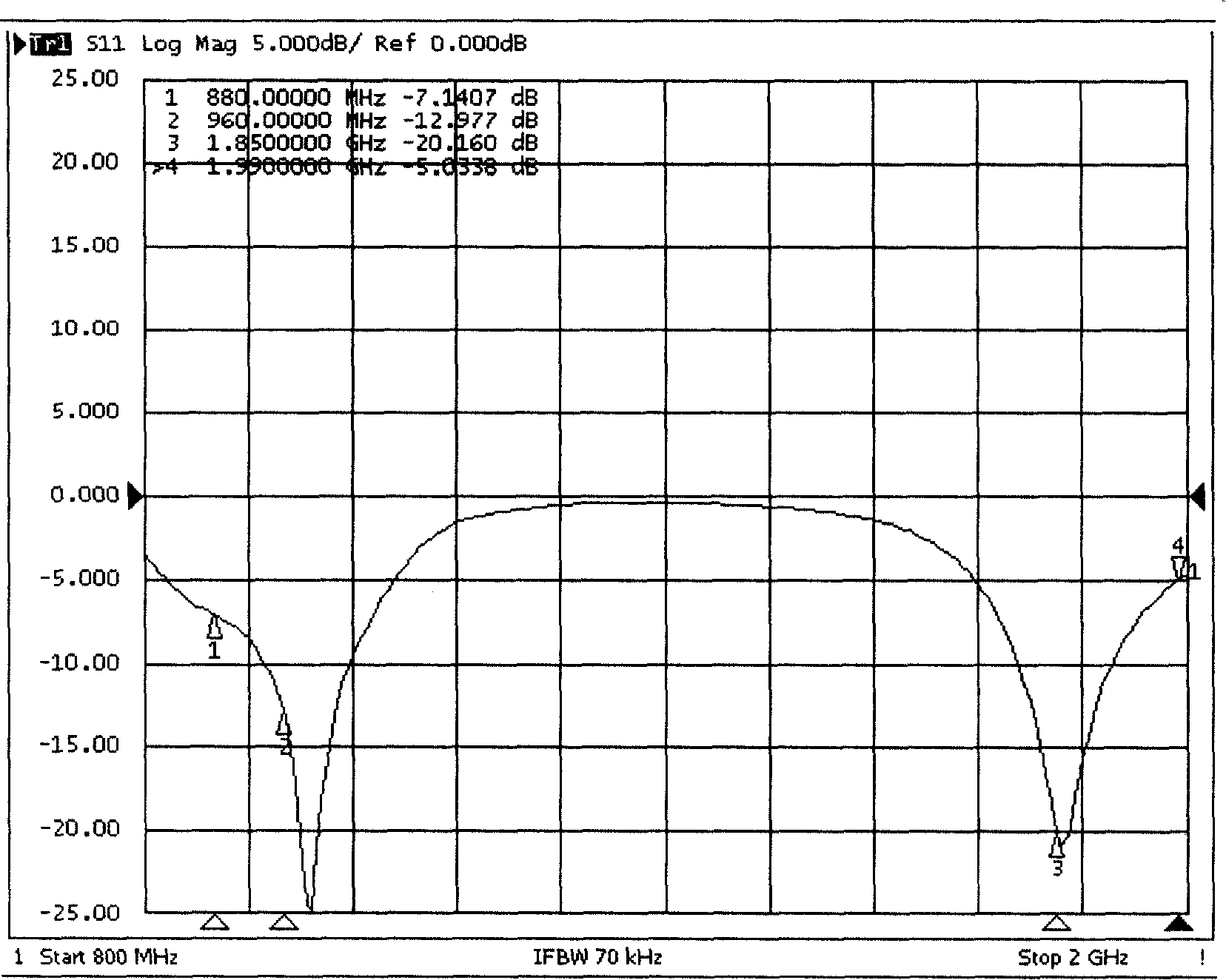

Preparation method of fiber metal matrix composite broadband light and slim type radar wave camouflage coating

ActiveCN101699564AImprove absorbing performanceGood broadband stealth effectLiquid surface applicatorsScreening apparatusCamouflageBroadband

The invention relates to a preparation method of fiber metal matrix composite broadband light and slim type radar wave camouflage coating. Coupling agent diluted by alcohol is coated on a metal plate, a plurality of polyacrylonitrile-based carbon fiber which has a diameter of 5-15 mu m, a length less than or equal to 1cm, and binder coated on the surface are uniformly adhered on the surface of the metal plate with both the longitudinal interval and the transverse interval being 0.5-1.5cm to form a carbon fiber layer and be dried for 2-4 hours, absorbing painting is sprayed on the carbon fiber layer in plural times to form an absorbing coating to be solidified for 5 hours in a baking oven of 60 DEG C to obtain the product. The invention adopts a multi-row transverse uniform arrangement of the carbon fiber having microwave scattering characteristic so as to absorb frequency bandwidth, and the absorbing coating has low density, high mechanical property, reflectivity within 8-18GHz being less than negative 8dB, strong absorbing performance as a whole, good camouflage effect, and high applicability to various weapons and military supplies and aerospace aircraft having high requirement on surface density.

Owner:江苏万华拓谷新材料科技有限公司

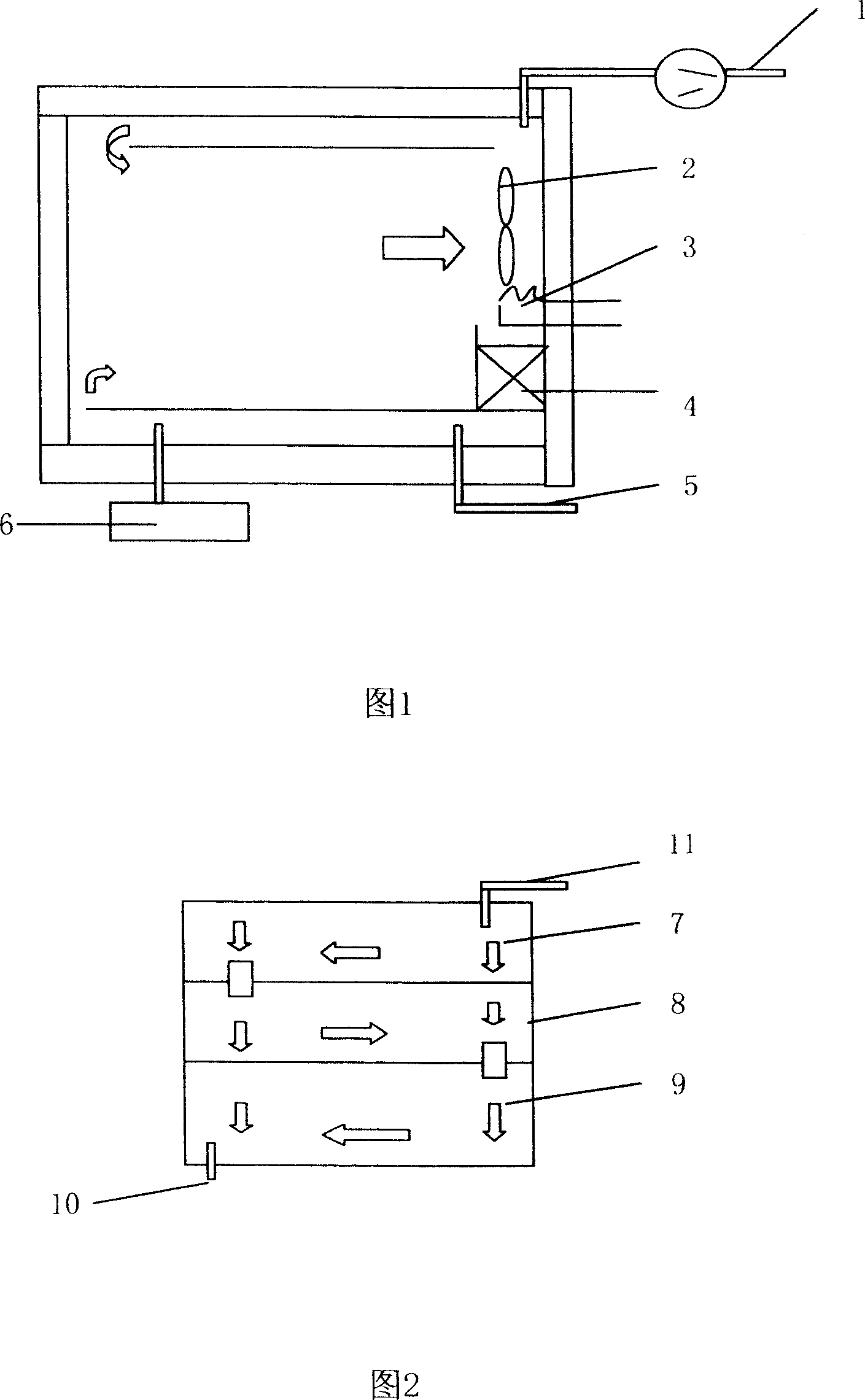

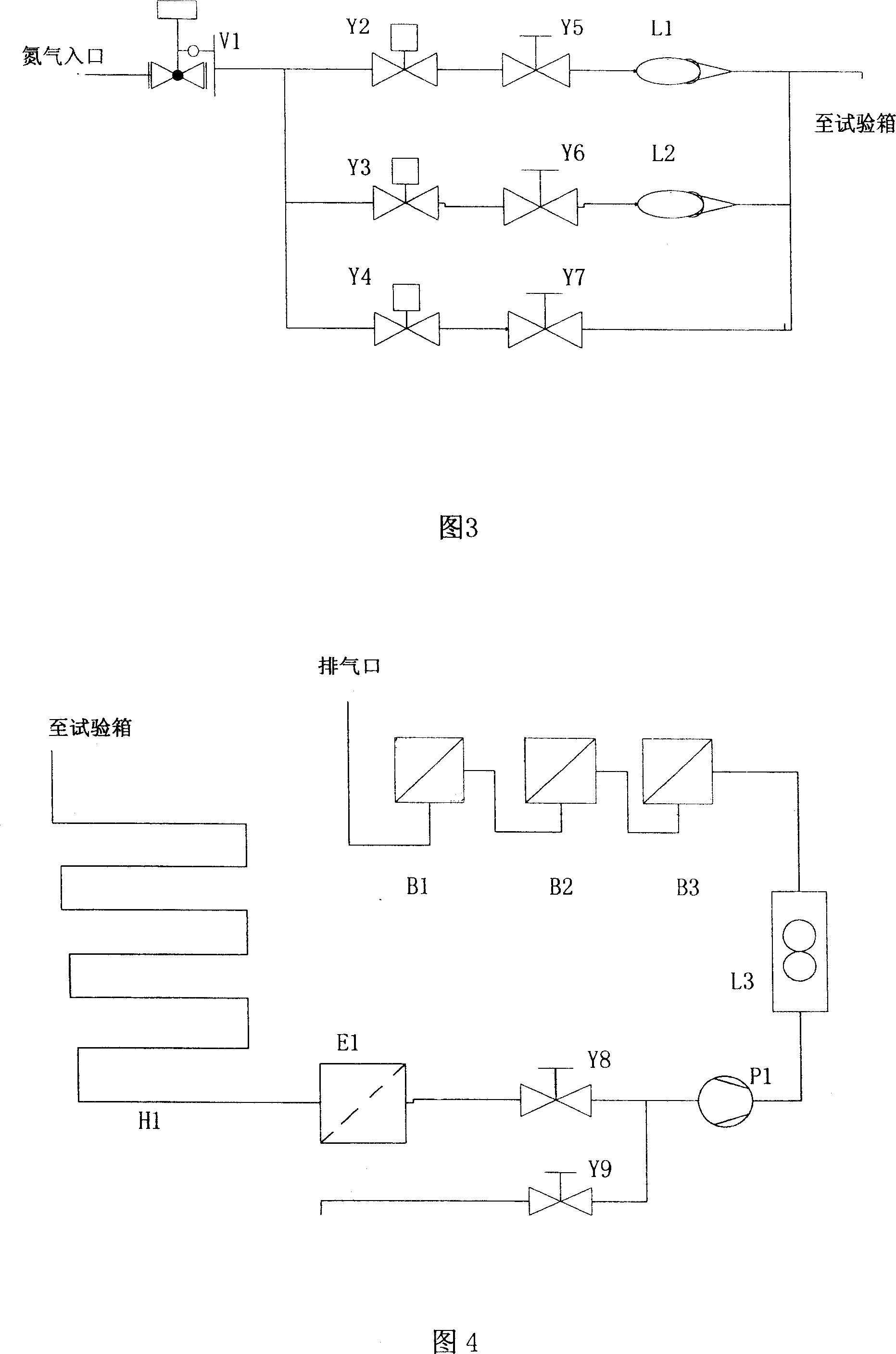

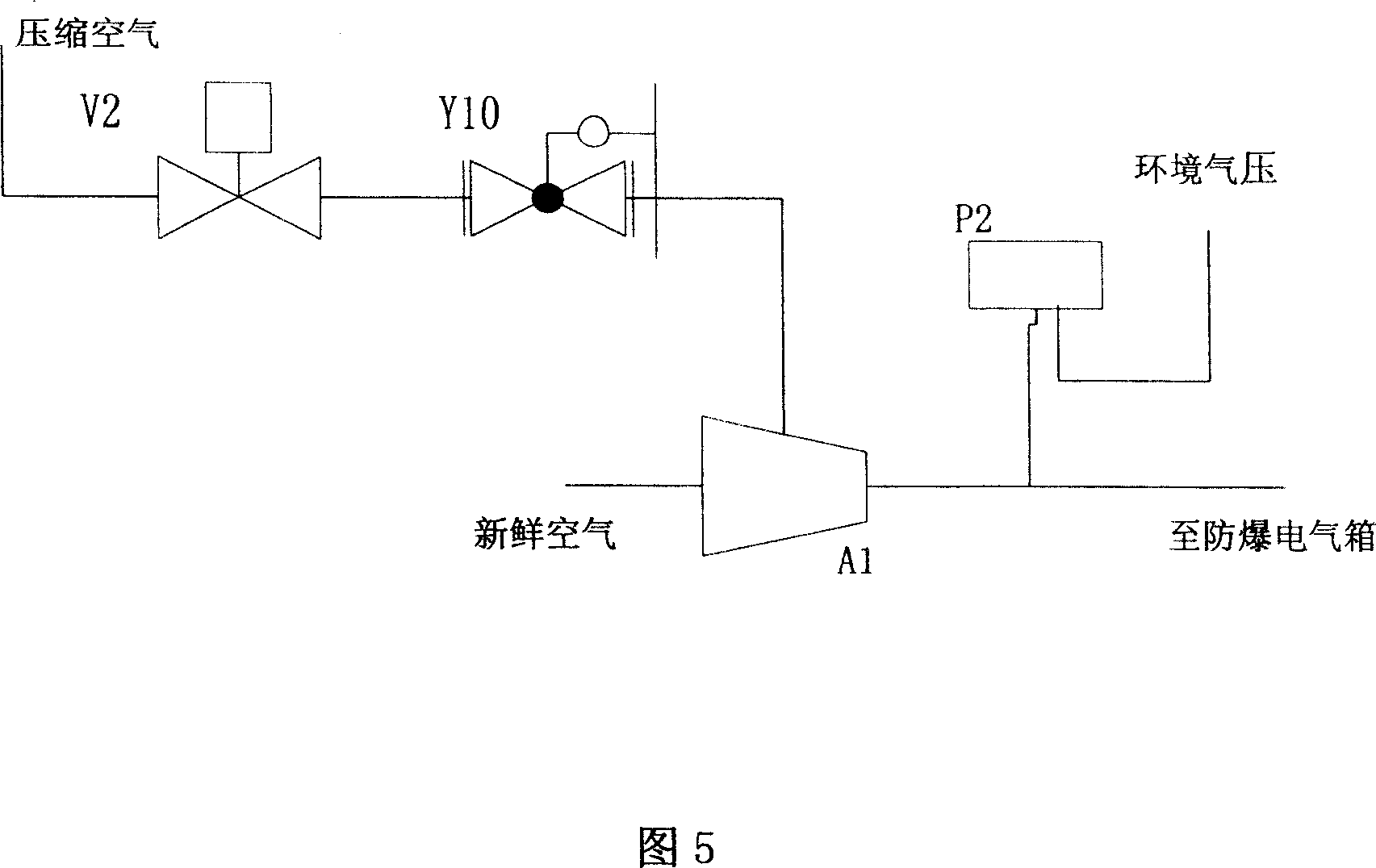

Explosion-proof high-low-temperature test chamber

The invention discloses an explosion-proof high and low temperature chamber for detecting auto parts performance, including samples explosion-proof box and electrical explosion-proof box; the said samples explosion-proof box has a nitrogen tank air loop outside, used to charge into nitrogen to the samples explosion-proof box, making oxygen content to largely 2%, and oxygen content exhausting and the detection circuit, for detecting the oxygen content in the box and the combustible gas content; the said electrical explosion-proof box is used for the power supply of the sample explosion-proof box and taking control, also including fresh air supply circuit to provide clean air to electrical explosion-proof box, and the power supply circuit to supply the said chamber. The invention can meet the load fuel testing requirements, and the security explosion-proof agrees with the national standards, and simple structure, low price.

Owner:UNITED AUTOMOTIVE ELECTRONICS SYST +1

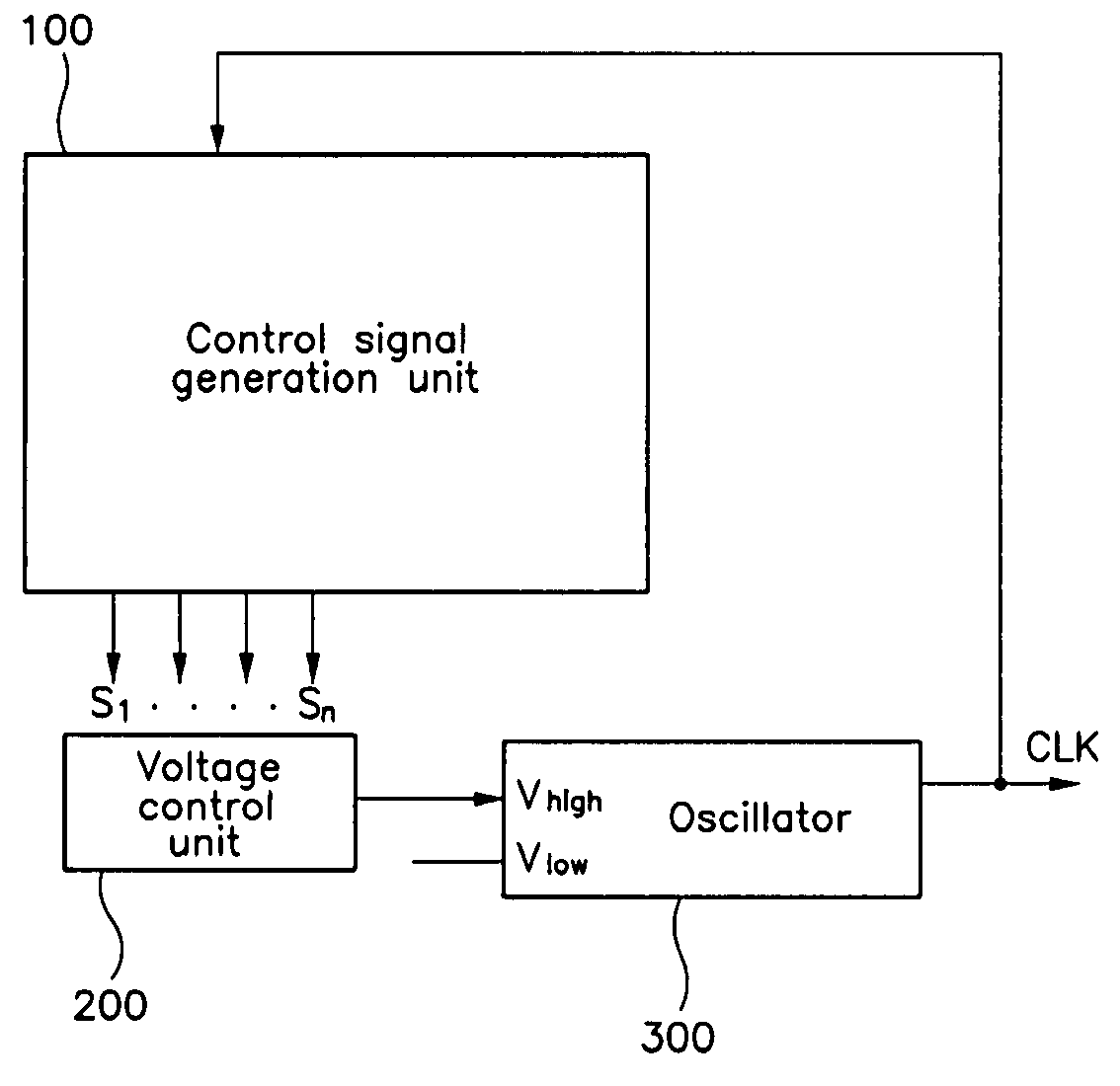

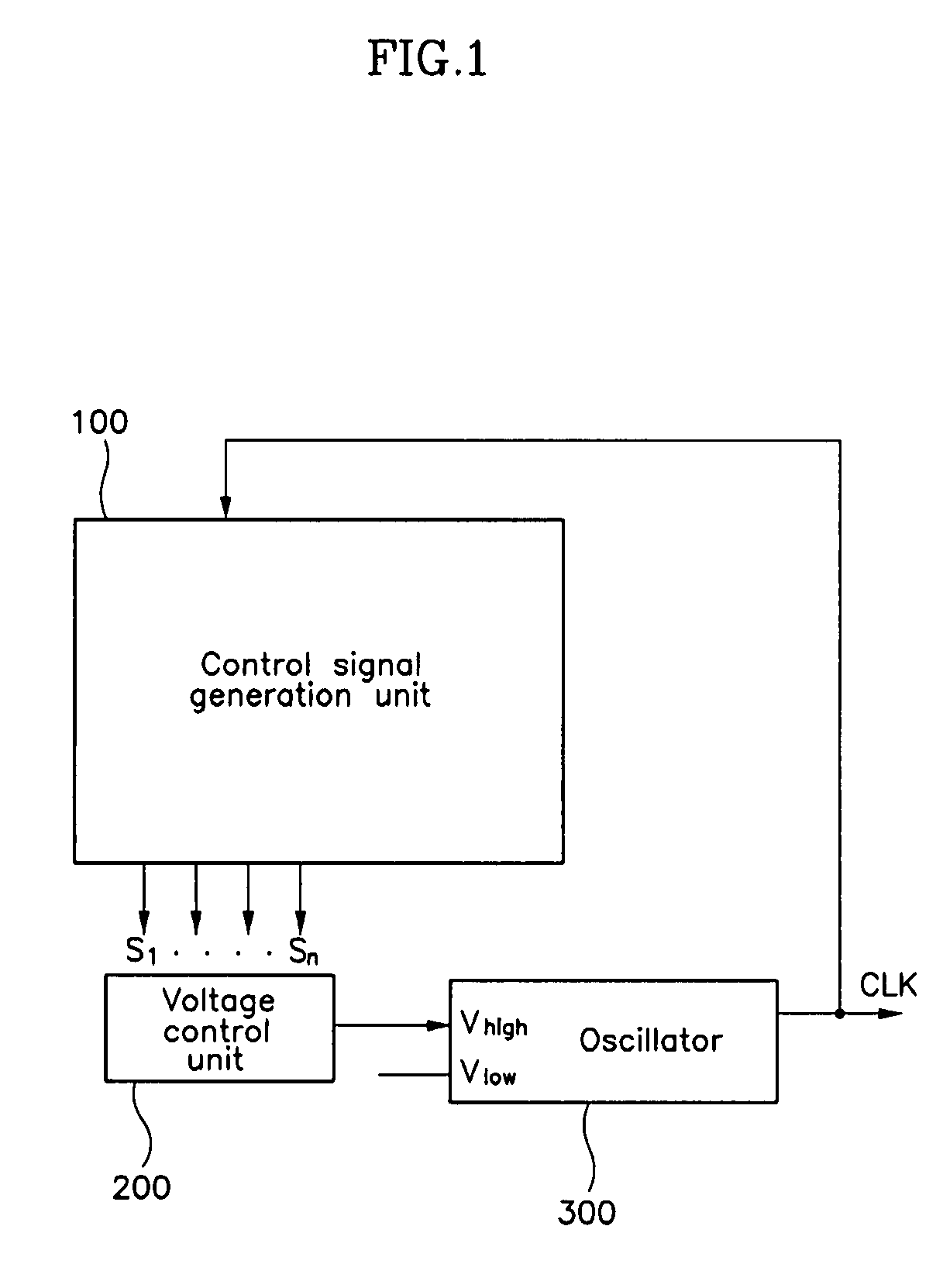

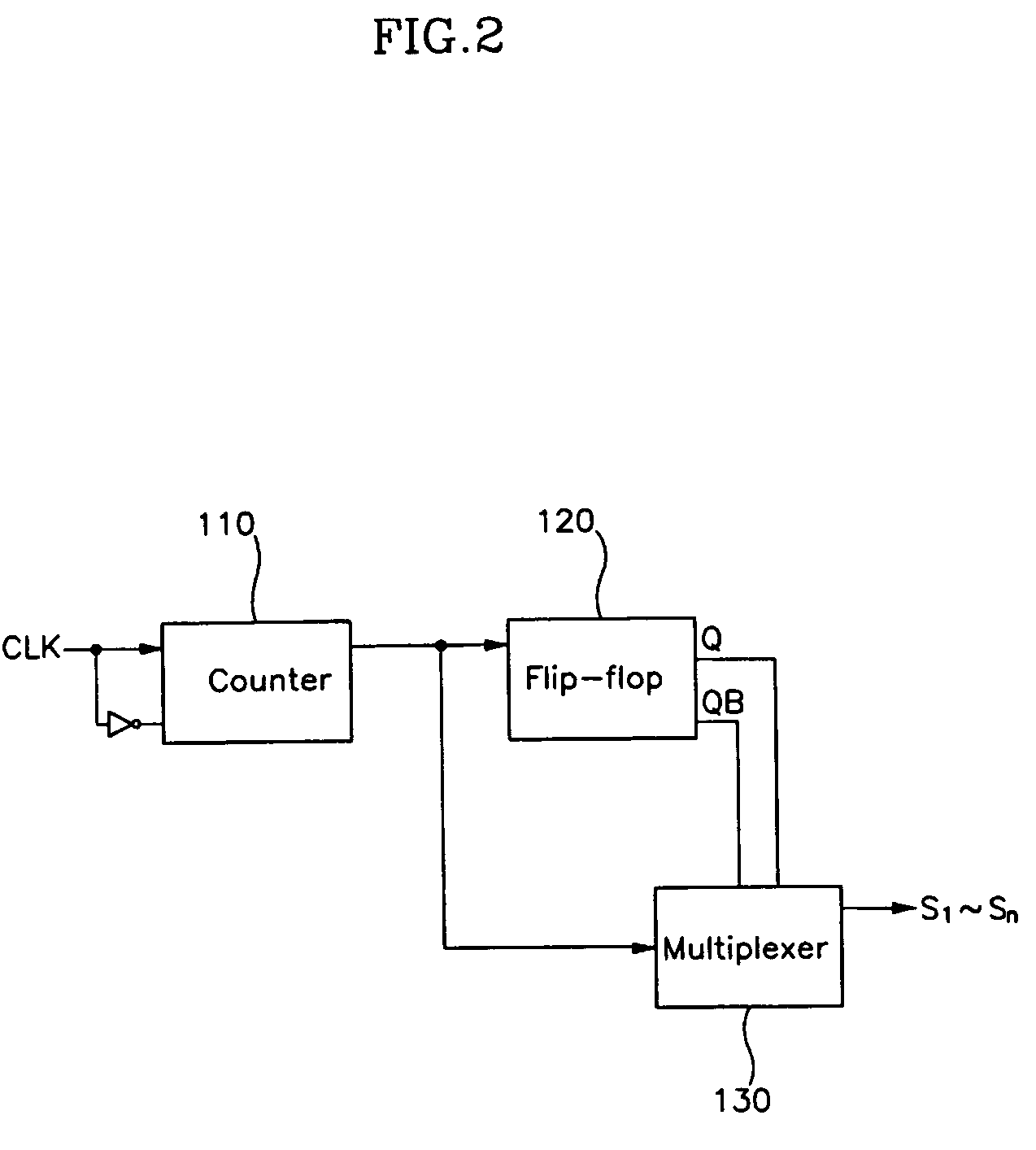

EMI cancellation method and system

In an EMI canceller, a control signal generation unit includes a counter, a second flip-flop, and a multiplexer. The counter outputs first and second output signals and includes first flip-flops in series. An output of the first flip-flop reverses at every cycle of the first and second output signals of a previous first flip-flop. An output of the second flip-flop reverses at every cycle of the first or second output signal of a final first flip-flop. The second flip-flop outputs third and fourth output signals. The multiplexer passes the first output signals of the first flip-flop as a control signal when the third output signal is a first level, and passes the second output signals as the control signal when it is a second level.

Owner:SEMICON COMPONENTS IND LLC

Ceramic microwave absorbing material and preparation method and application thereof

InactiveCN101665350AHigh surface hardnessScratch resistantScreening apparatusCooking vesselsMicrowaveUtilization rate

The invention discloses a ceramic microwave absorbing material and a preparation method and an application thereof. The ceramic microwave absorbing material comprises ceramic material powder and microwave absorbing powder, and the weight percentage of the components is as follows: 40 to 80 percent of ceramic material powder and 20 to 60 percent of microwave absorbing powder. The preparation methodof the ceramic microwave absorbing material comprises the following steps: 1) respectively weighing the ceramic material powder and the microwave absorbing powder according to weight percentage; 2) evenly mixing the ceramic material powder with the microwave absorbing powder to obtain compound wave-absorbing powder; 3) evenly mixing the compound wave-absorbing powder with methylcellulose and water to obtain the pulp of the ceramic microwave absorbing material; 4) forming the pulp to obtain a green body; and 5) drying the green body, and then sintering at high temperature to obtain the ceramicmicrowave absorbing material. The ceramic microwave absorbing material can be used for manufacturing ceramic microwave absorbing cooking equipment. The cooking equipment has high microwave utilization rate and heating efficiency; and food is not easy to be coked and is heated more uniformly. The preparation method of the ceramic microwave absorbing material has simple technique and low cost of raw material and processing.

Owner:MIDEA GRP CO LTD

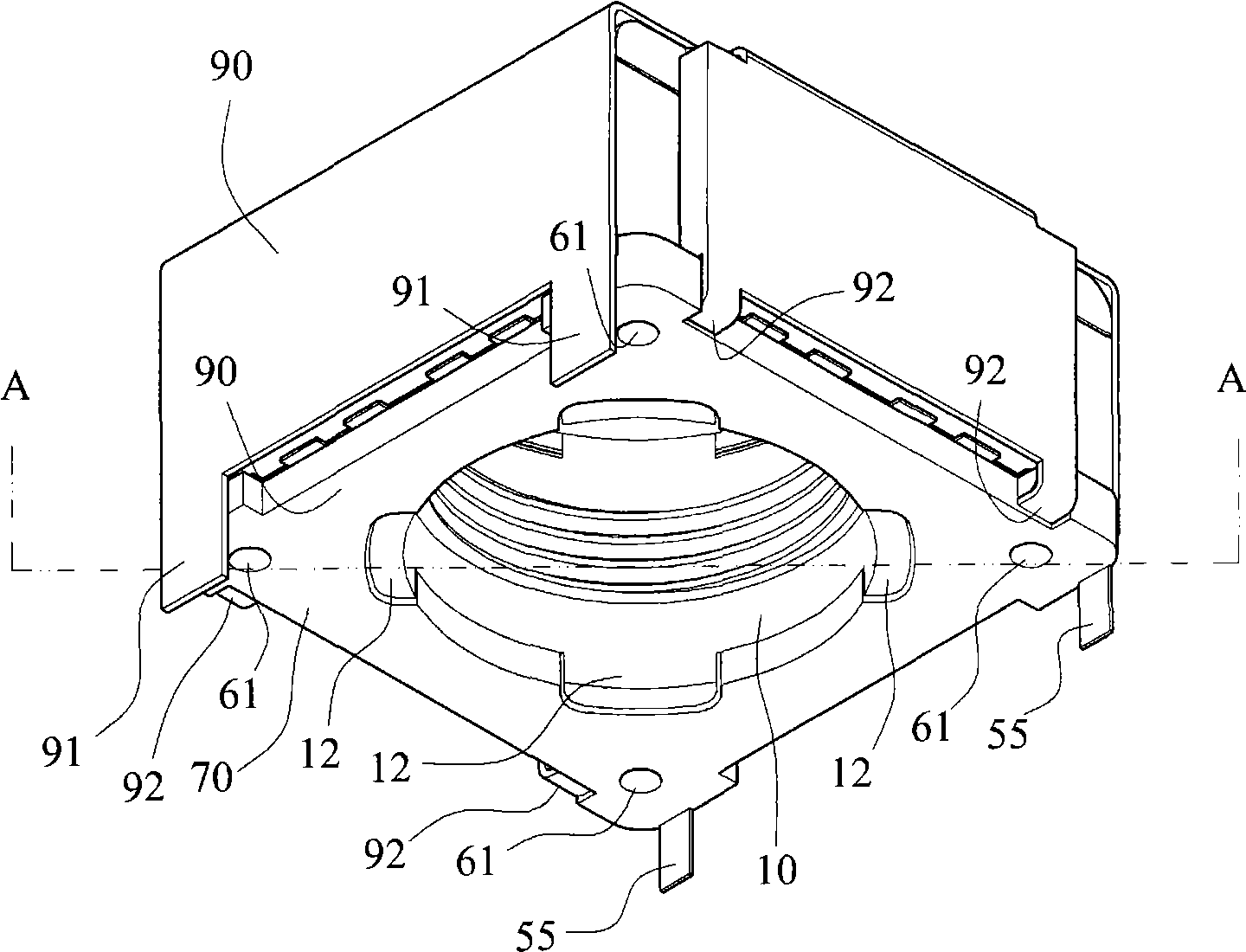

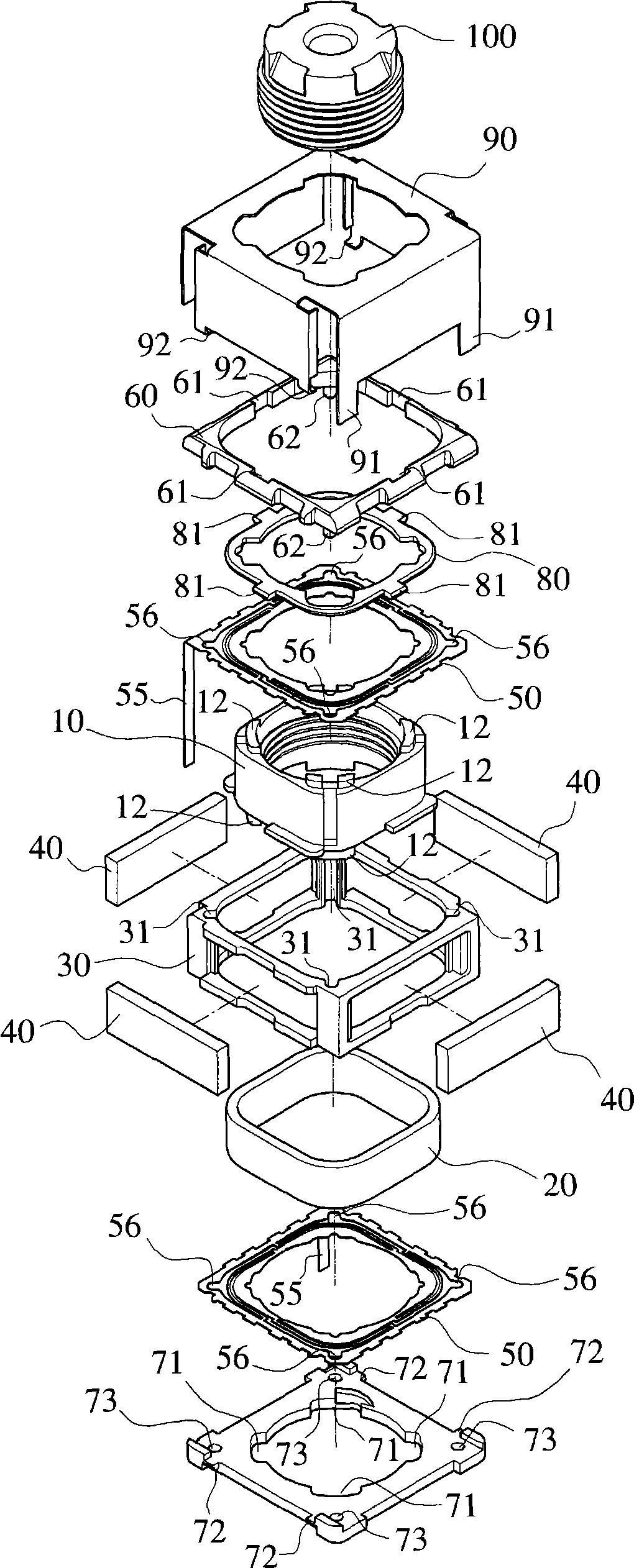

Electromagnetic interference preventing mechanism for micro-lens

ActiveCN101509996AAnti-electromagnetic effectImprove driving effectMagnetic/electric field screeningScreening apparatusCamera lensElastic component

The invention provides a mechanism for preventing electromagnetic interference of micro-lens, comprising a frame, around which four magnetism modules are arranged; a bearing seat which is used for bearing a micro-lens and externally covered with a coil pack; at least one elastic component, an external fixed part and an internal movable part of which mutually connects four groups of strings with ninety degrees, the external fixed part is connected with the frame, and the internal movable part is connected with the bearing seat, thus forming an elastic movable supporting bearing seat which is suspended at the center of the frame; an upper cover and a lower cover which are respectively arranged above and below the frame and fixedly connects the elastic component on the frame; a metal outer cover which covers the external parts of the upper cover, the elastic component, the bearing seat, the frame and the lower cover, and the bottom of the metal outer cover is provided with at least one conductive contact pin which is electrically connected to the ground, electromagnetic effect generated to the outside is insulated by the grounding mode, and the external electromagnetic interference and the electrostatic protection are also insulated.

Owner:TDK TAIWAN

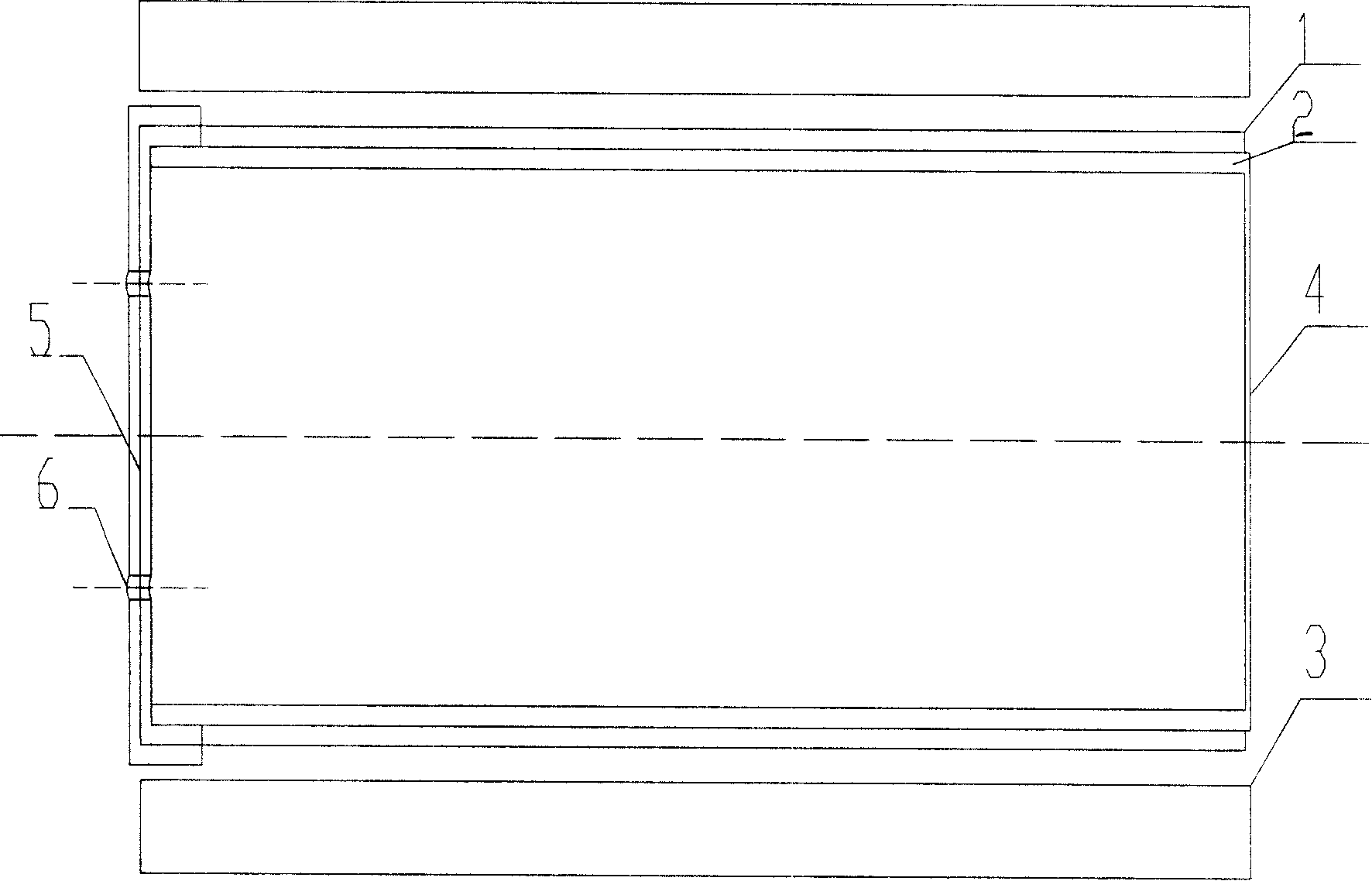

Electromagnetic shielded observation window

InactiveCN1429070ANot easy to gatherHigh transparencyMagnetic/electric field screeningScreening apparatusWire gauzeDielectric

A viewing window of electromagnetic shielding is composed of single layer or multiple layer of metal wire mesh, single layer or multiple layer of optical film in quantum well structure and transparent backing material as each layer of metal wire mesh is fabricated by metal thin wire flared-out in single set or multiple set, any two pieces of thin wires in each set of metal thin wire will be in the same plane as parallel to each other; optical film will be metal dielectric media multilayer film contained single layer of metal film or multiple layer of metal film and it is structured by inducible layer which consists of two layer of different transparent media films laid at two sides symmetrically and functional layer which will be compounded in between the inducible layers laid symmetrically as well as it will be embedded on the surface of microwave cavity to be closely compounded with the microwave cavity.

Owner:李宏强 +1

Making process of electromagnetically shielding composite wooden material

InactiveCN1772450AImprove shielding effectHigh bonding strengthMagnetic/electric field screeningScreening apparatusMetallic NickelCopper

The present invention belongs to the field of electromagnetically shielding material, is especially making process of electromagnetically shielding composite wooden material, and aims at raising electromagnetically shielding effect and simplifying the production process of electromagnetically shielding material. The making process of electromagnetically shielding composite wooden material includes the steps of activating wooden material, water washing, dispergation, washing with distilled water, chemically plating nickel and chemically plating copper. The electromagnetically shielding composite wooden material has high electromagnetic shielding effect and electromagnetic shielding efficiency up to 35-60 dB in the frequency range of 30 MHz to 1.5 GHz. The present invention has the advantages of simple technological process, wide material source and low production cost.

Owner:NORTHEAST FORESTRY UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com