Carbon nano tube wave absorbtion mateirla of surface carried with magnetic alloy particle and preparation method thereof

A carbon nanotube and magnetic alloy technology, applied in nanostructure manufacturing, nanotechnology, nanotechnology and other directions, can solve the problems of low surface reactivity, large surface curvature, inability to design and assemble magnetic metal alloy coatings, etc. It is not easy to uniformly deposit on carbon nanotubes, and the preparation process is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

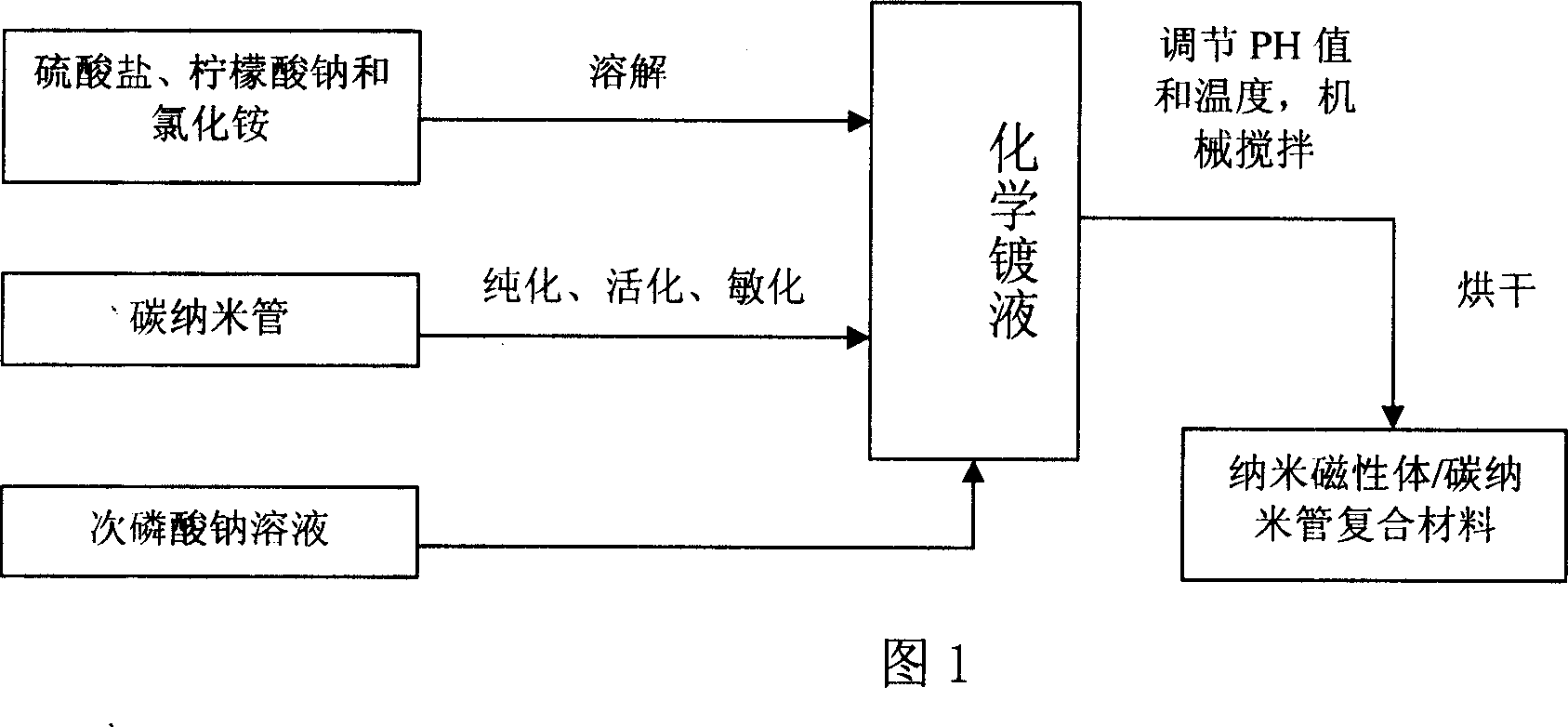

[0030] Weighed 9.706 grams of analytically pure nickel sulfate and 6.780 grams of cobalt sulfate according to the weight ratio, and added 8.912 grams of trisodium citrate and 12 grams of ammonium chloride, and dissolved them in deionized water to form 200 milliliters of chemical plating solution. 0.2 grams of multi-walled carbon nanotubes were purified, activated, and sensitized according to the process in the preparation step 1, and then placed in the prepared chemical plating solution and mechanically stirred. Pour 50 ml of the additional reducing agent sodium hypophosphite (12.847 g) solution into it, then add ammonia water drop by drop with constant stirring until the pH value is about 8, and dilute to 300 ml. Under the condition of 70°C water bath, stir mechanically until the reaction is completed. After the electroless plating is completed, it is cleaned, filtered and dried. A NiCo nanomagnetic body / carbon nanotube composite material was obtained.

[0031] Disperse the...

Embodiment 2

[0033]Weighed 11.121 grams of analytically pure ferrous sulfate and 5.312 grams of nickel sulfate according to the weight ratio, and added 8.912 grams of trisodium citrate and 12 grams of ammonium chloride, and dissolved them in deionized water to form 200 milliliters of chemical plating solution. 0.2 grams of single-walled carbon nanotubes were purified, activated and sensitized according to the process in the preparation step 1, and then placed in the prepared chemical plating solution and mechanically stirred. Pour 50 ml of the additional reducing agent sodium hypophosphite (12.847 g) solution into it, then add ammonia water drop by drop with constant stirring until the pH value is about 8, and dilute to 300 ml. Under the condition of 70°C water bath, stir mechanically until the reaction is completed. After the electroless plating is completed, it is cleaned, filtered, and dried, and then placed in a protective atmosphere at 450°C (the argon flow in the mixed gas is 2000scc...

Embodiment 3

[0036] Weigh 3.370 grams of analytically pure ferrous sulfate, 11.866 grams of cobalt sulfate, and 1.601 grams of nickel sulfate according to the weight ratio, and add 8.912 grams of trisodium citrate and 12.000 grams of ammonium chloride, and dissolve them in deionized water to form a chemical Plating solution 200 ml. 0.2 grams of double-walled carbon nanotubes were purified, activated and sensitized according to the process in the preparation step 1, and then placed in the prepared chemical plating solution and mechanically stirred. Pour 50 ml of the solution of sodium hypophosphite (12.847 g) prepared separately, and then add ammonia water drop by drop with continuous stirring until the pH value is about 9, and dilute to the specified volume of 300 ml. Under the condition of 80°C water bath, stir mechanically until the reaction is completed. After the electroless plating is completed, it is cleaned, filtered, and dried, and then placed in a protective atmosphere at 450 ° C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com