Electromagnetic shield unit

An electromagnetic shielding and carbon fiber technology, applied in the field of electromagnetic shielding units, can solve the problems of high density, low cost of electromagnetic shielding paint, poor electromagnetic shielding effect, etc., and achieve the effect of improving wave absorption efficiency, good electrical conductivity and magnetic permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The application also discloses the preparation process of the above-mentioned electromagnetic shielding unit:

[0024] S1, Prepare the waveguiding layer

[0025] S2, heat-treating the carbon fiber to remove surface impurities; then configuring an electroplating solution, using a silver plate as the anode, and the heat-treated carbon fiber as the cathode, both the anode and the cathode are immersed in the electroplating solution, and the silver-plated carbon fiber is obtained by electroplating;

[0026] S3, soak the silver-plated carbon fiber in the diluted silane coupling agent for 1min, and cut the silver-plated carbon fiber into 3-5mm and 7-9mm lengths after drying; Rubber is used as the matrix, silver-plated carbon fiber is used as the filler, and isopropanol is used as the antifreeze agent to prepare the wave-absorbing layer;

[0027] S4, embedding the wave-absorbing layer inside the wave-guiding layer to obtain the electromagnetic shielding unit.

[0028] Wherein...

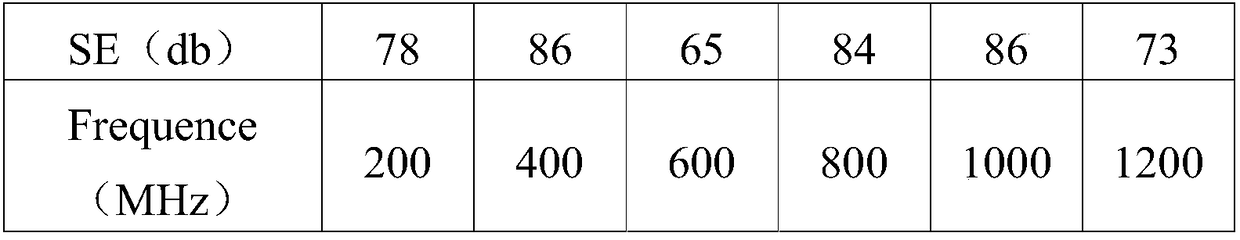

Embodiment 1

[0036] An electromagnetic shielding unit, the electromagnetic shielding unit is a double-layer structure, the outer layer is a wave-guiding layer, the inner layer is a wave-absorbing layer, the wave-guiding layer is made of a copper alloy sheet, and the wave-absorbing layer is based on silicon rubber , and filled with silver-plated carbon fibers, the carbon fibers are in the form of short rods, distributed randomly among them.

[0037] The preparation process of the electromagnetic shielding unit is:

[0038] S1, the waveguide layer is made of copper alloy sheet material, the copper content in the material is 76%, the iron content is 13%, the zinc content is 11%, and the thickness of the waveguide layer is 1mm;

[0039] S2. First, select carbon fiber with a density of 1.75g / cm and a diameter of 5 μm. Place the carbon fiber in a box furnace at 400°C for 30 minutes to remove surface colloidal impurities; then take silver sulfate, ammonium chloride, boric acid, dodecyl Prepare t...

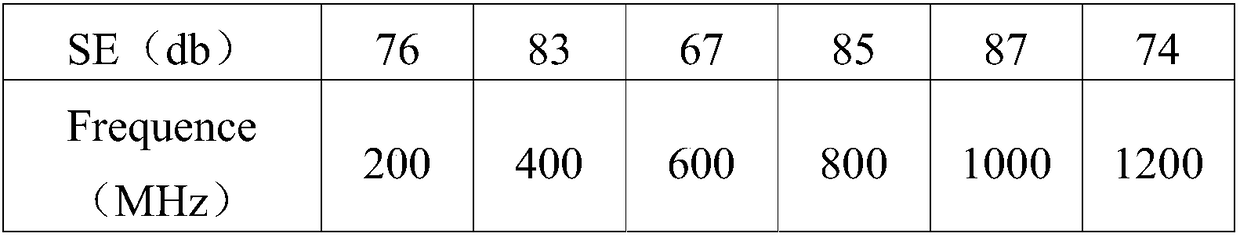

Embodiment 2

[0048] An electromagnetic shielding unit, the electromagnetic shielding unit is a double-layer structure, the outer layer is a wave-guiding layer, the inner layer is a wave-absorbing layer, the wave-guiding layer is made of a copper alloy sheet, and the wave-absorbing layer is based on silicon rubber , and filled with silver-plated carbon fibers, the carbon fibers are in the form of short rods, distributed randomly among them.

[0049] The preparation process of the electromagnetic shielding unit is:

[0050] S1, the waveguide layer is made of copper alloy sheet material, the copper content in the material is 76%, the iron content is 13%, the zinc content is 11%, and the thickness of the waveguide layer is 1mm;

[0051] S2. First, select carbon fiber with a density of 1.75g / cm and a diameter of 5 μm. Place the carbon fiber in a box furnace at 400°C for 30 minutes to remove surface colloidal impurities; then take silver sulfate, ammonium chloride, boric acid, dodecyl Prepare t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com