Patents

Literature

158results about How to "Good magnetic performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

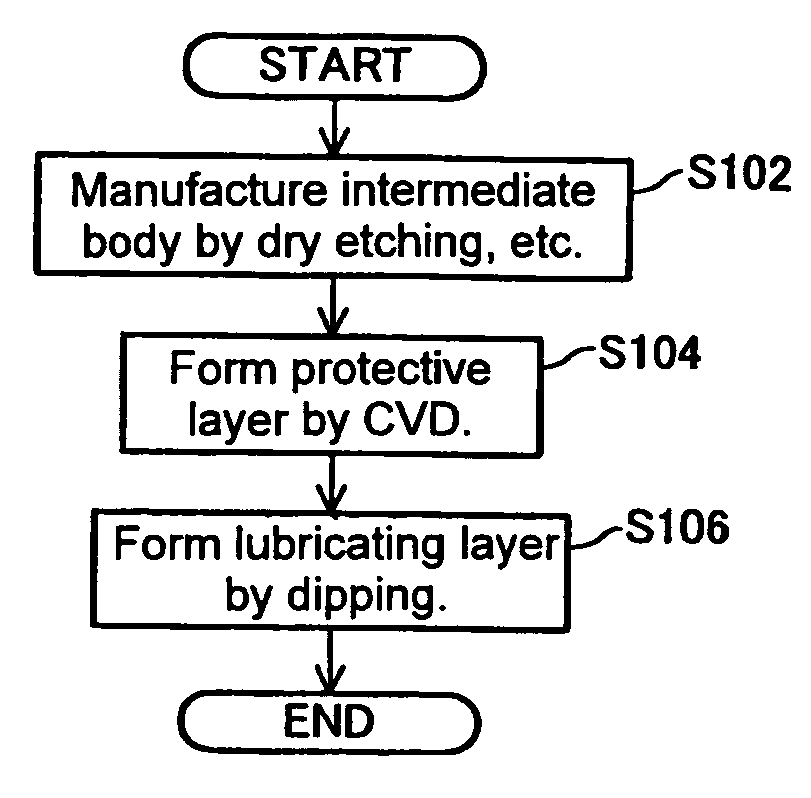

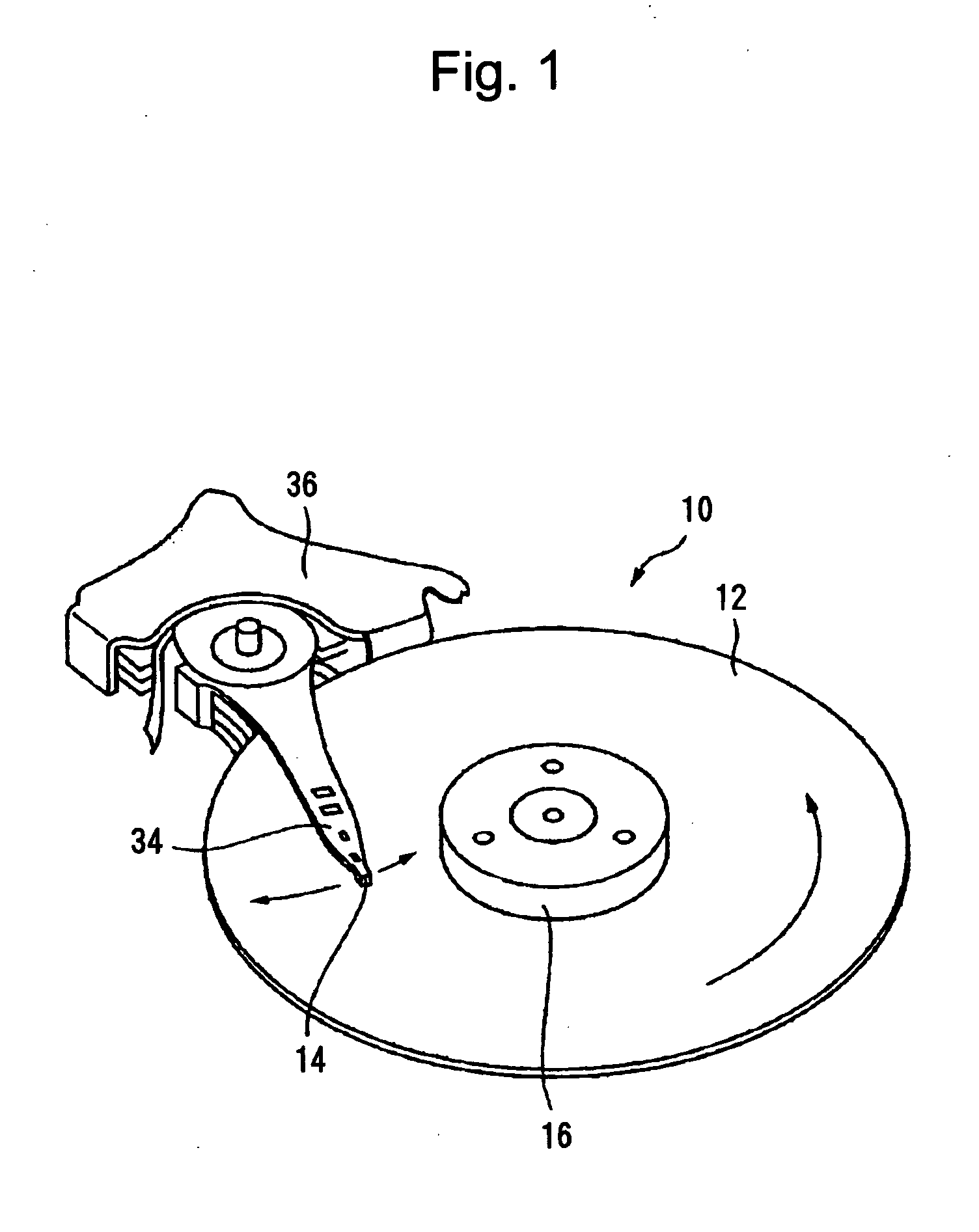

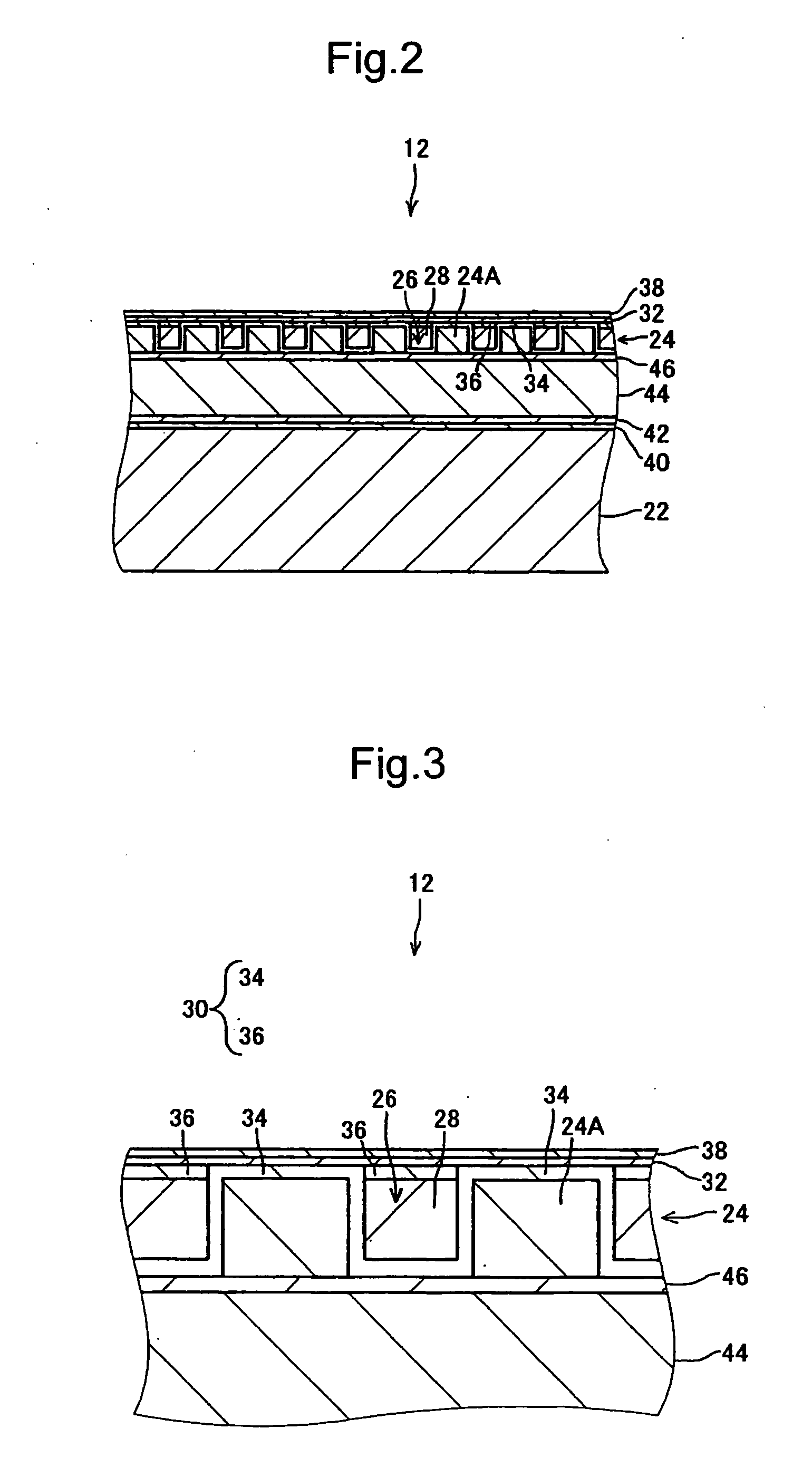

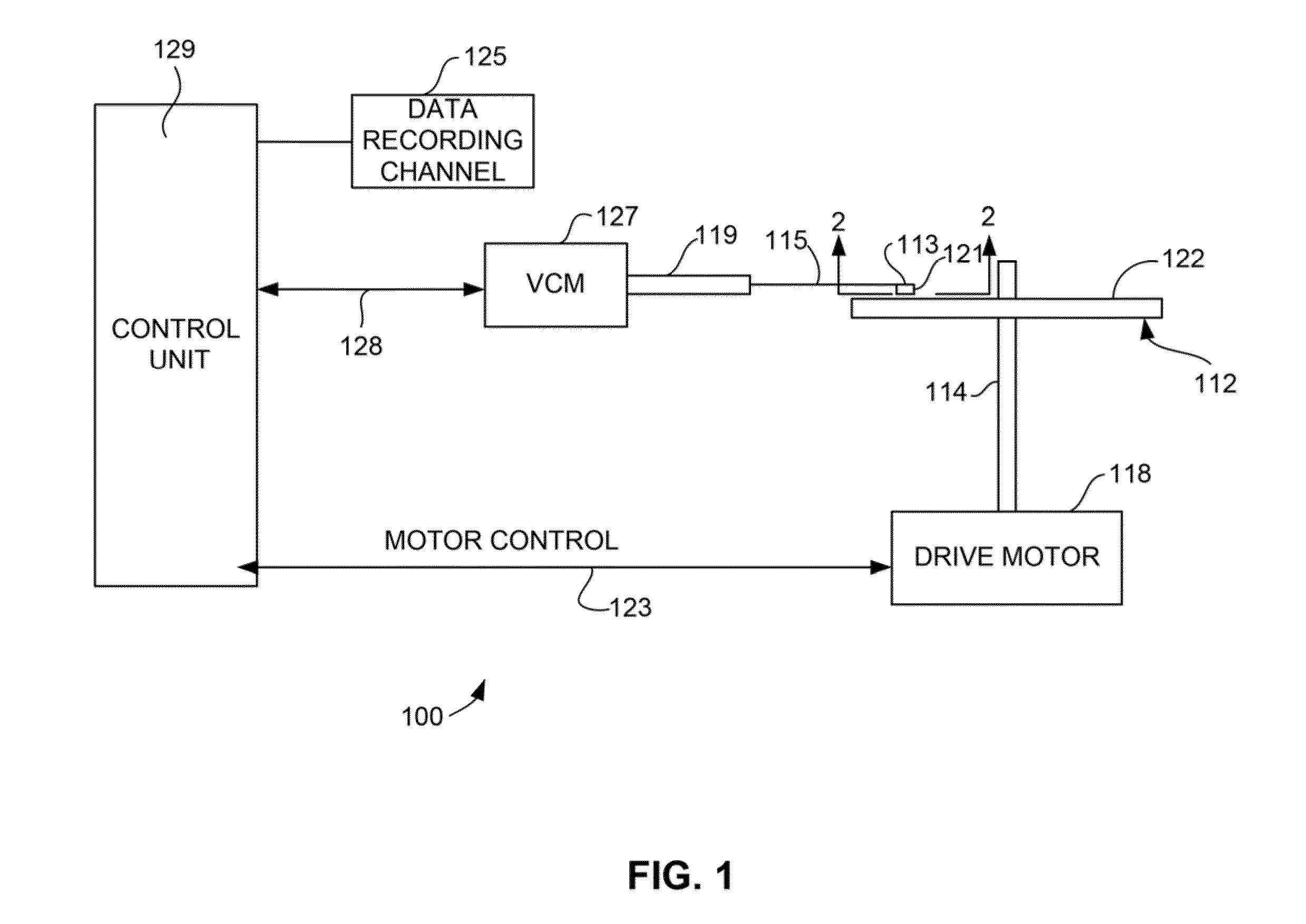

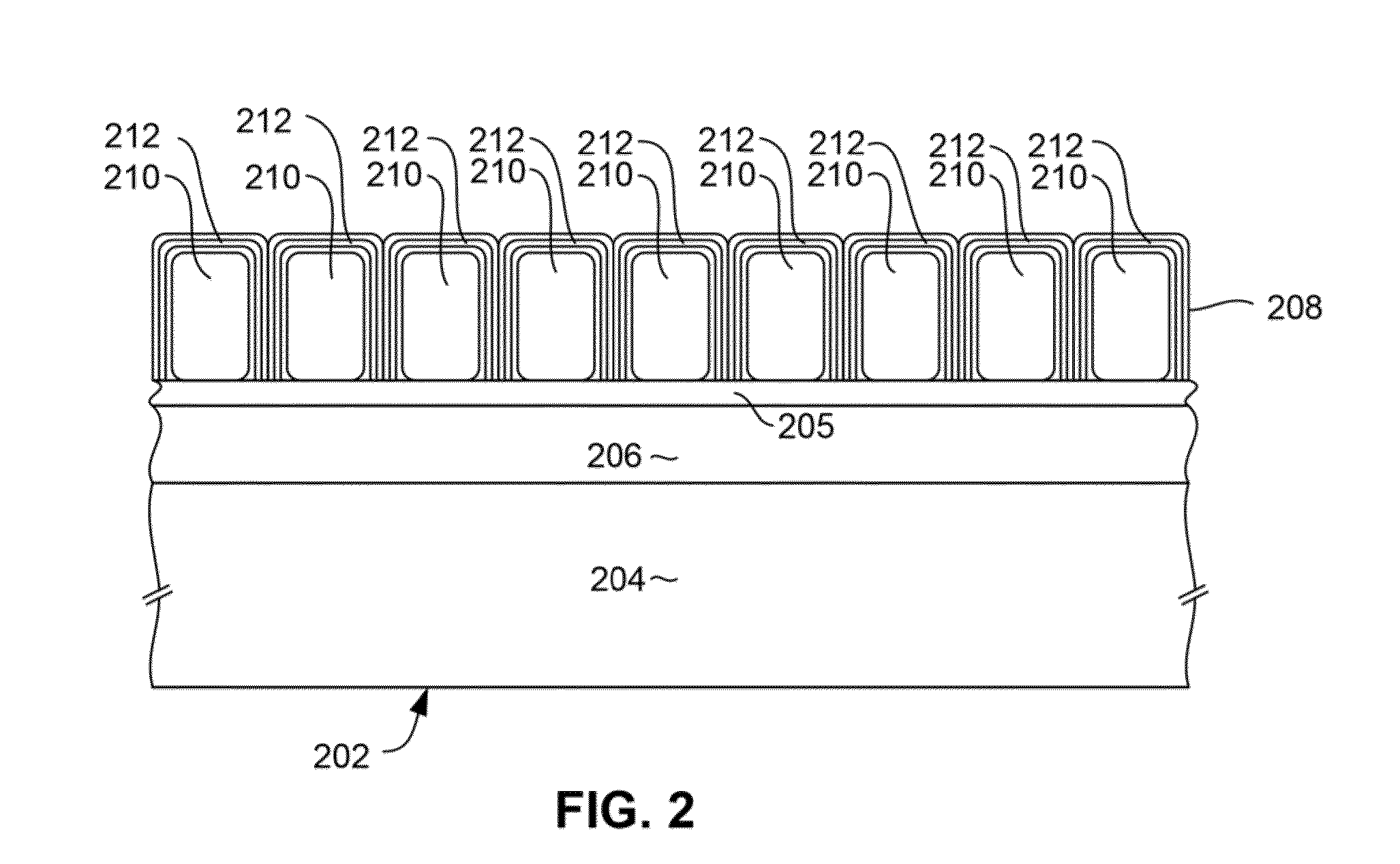

Magnetic recording medium, magnetic recording and reproducing apparatus, and manufacturing method of magnetic recording medium

InactiveUS20060183004A1Good magnetic performanceImprove reliabilityManufacture head surfaceElectrical transducersEngineeringRecording layer

A magnetic recording medium is provided which includes a recording layer formed in a concavo-convex pattern including recording elements formed as convex portions, provides a good flying performance of a magnetic head, and has high reliability. A magnetic recording and reproducing apparatus including that magnetic recording medium and a manufacturing method of that magnetic recording medium are also provided. The magnetic recording medium includes: the recording layer formed in a predetermined concavo-convex pattern over a substrate, the recording elements being formed as convex portions of the concavo-convex pattern; filling elements with which concave portions between the recording elements are filled; a conductive film which has a smaller electric resistivity than the filling elements and is formed over the filling elements; and a protective layer which covers the recording elements and the filling elements and is in contact with an upper surface of the conductive film.

Owner:TDK CORPARATION

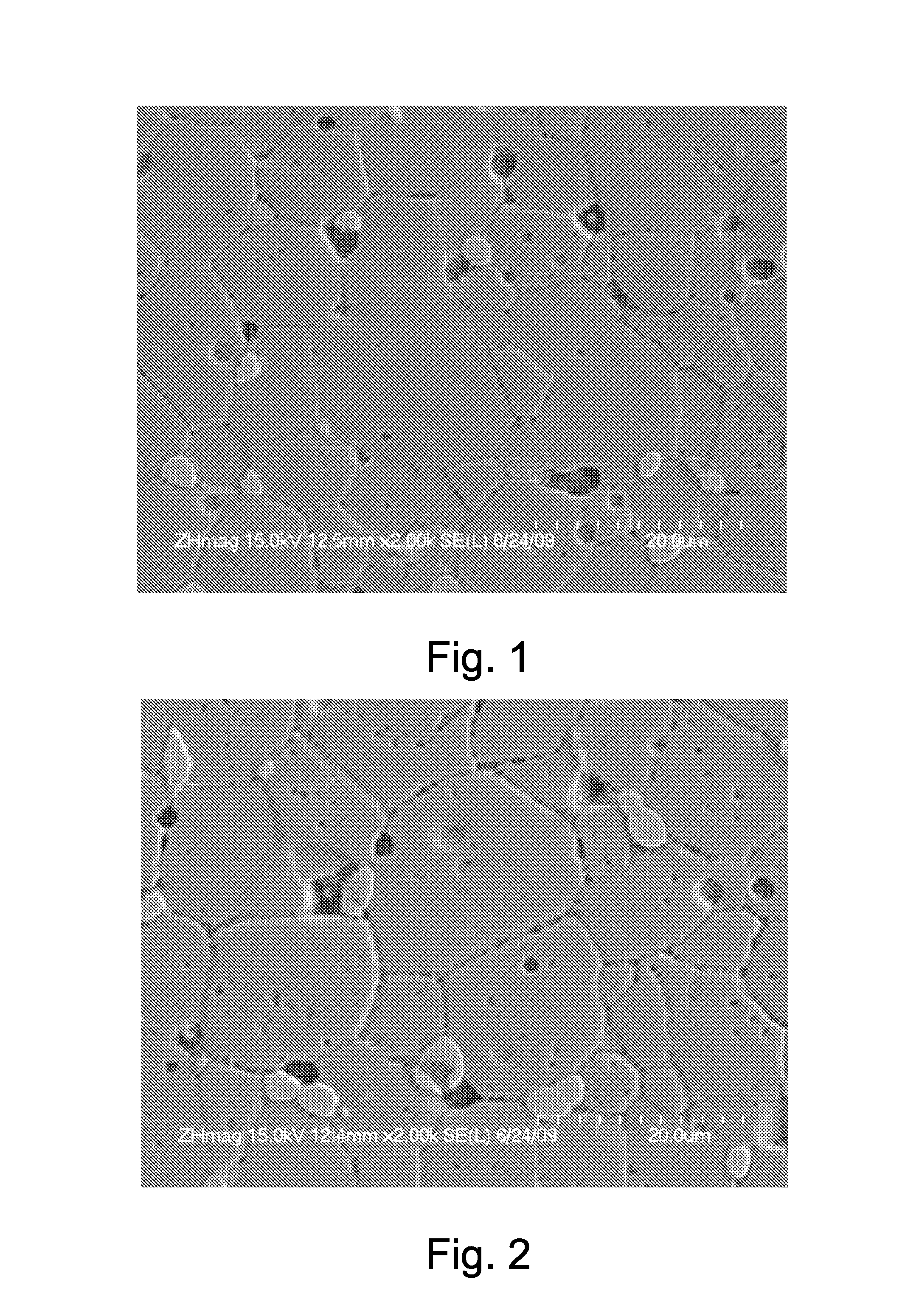

Magnetic fibre and manufacture method thereof

ActiveCN101649503AStrong magnetismWith shielding electromagnetic wavePhysical treatmentFilament/thread formingFiberMagnetization

The invention discloses a magnetic fiber and a manufacture method thereof. The magnetic fiber has a sheath core structure in the volume ratio of a sheath to a core bing 3:7-7:3 and is characterized inthat the fiber sheath layer material comprises the following components in percentage by weight: 57-89.7 percent of sheath layer polymer, 10-40 percent of magnetic powder and 0.3-3 percent of bulkingagent; and the fiber core layer material comprises the following components in percentage by weight: 80-97.5 percent of core layer polymer, 2-15 percent of metal power and 0.5-5 percent of coupling agent. The manufacture method of the magnetic fiber adopts the magnetic fiber components in percentage by weight and comprises the following processes: 1. preparing the magnetic fiber sheath layer material; 2. preapring the magnetic fiber core layer material; 3. preparing a sheath core composite magnetic fiber and spinning the sheath layer material and the core layer material obtained in the step 1and the sep 2 according to the volume ratio of the fiber sheath to the fiber core being 3:7-7:3 into a long fiber thread or a short fiber thread; 4. carrying out fiber magnetization processing and magnetizing the long fiber thread or the short fiber thread obtained in the step 3 in the magnetic field strength of 11,000 gausses for 0.05-2 minutes.

Owner:TIANJIN POLYTECHNIC UNIV

FePt-C BASED MAGNETIC RECORDING MEDIA WITH ONION-LIKE CARBON PROTECTION LAYER

InactiveUS20130114165A1Reduce thicknessImproves protection against corrosion againstDisposition/mounting of recording headsProtective coatings for layersMagnetic mediaThin layer

A magnetic media for magnetic data recording having a plurality of magnetic grains protected by thin layers of graphitic carbon. The layers of graphitic carbon are formed in a manner similar to onion skins on an onion and can be constructed as single monatomic layers of carbon. The thin layers of graphitic carbon can be formed as layers of graphene or as fullerenes that either cover or partially encapsulate the magnetic gains. The layers of graphitic carbon provide excellent protection against corrosion and wear and greatly reduce magnetic spacing for improved magnetic performance.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

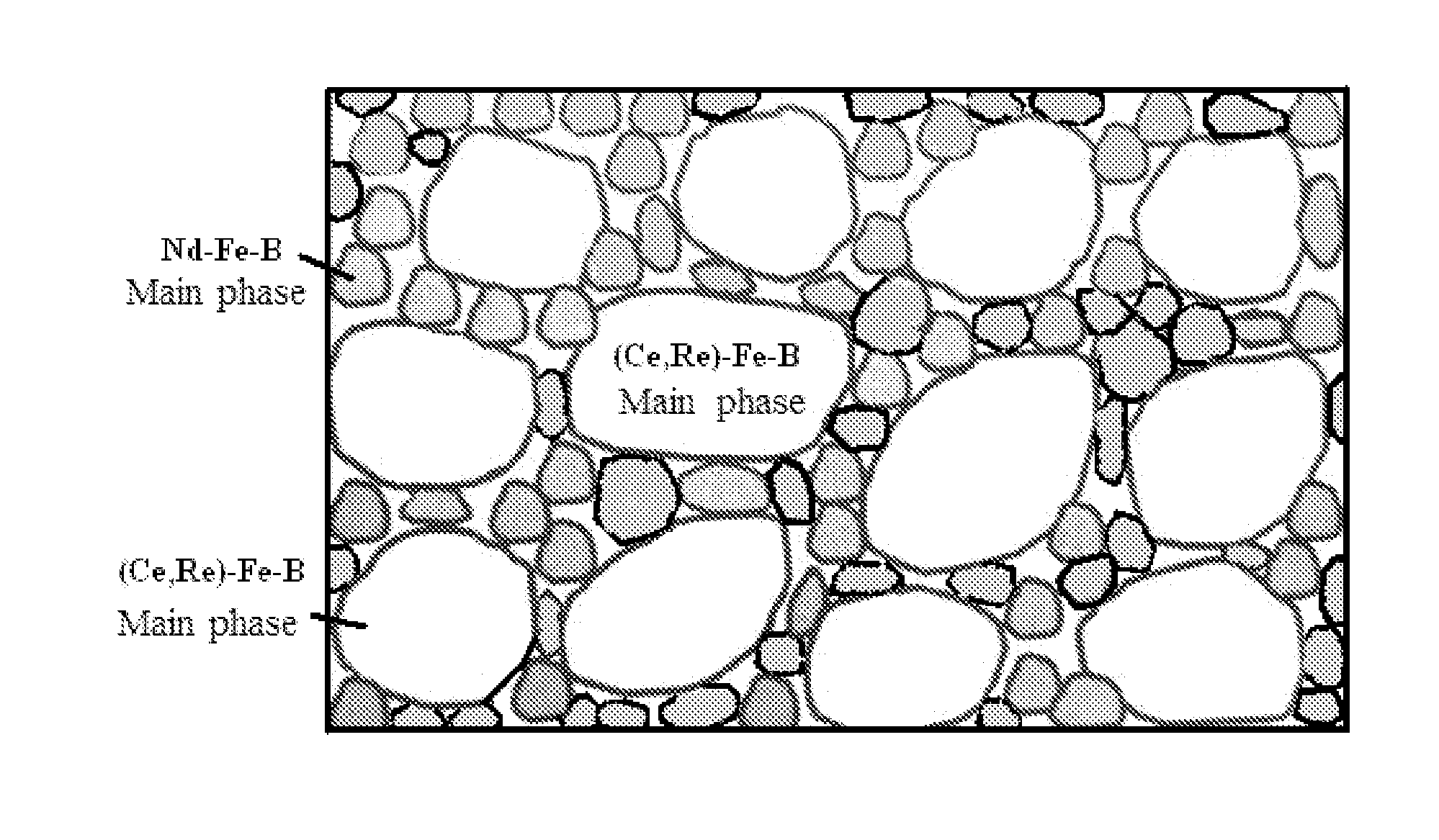

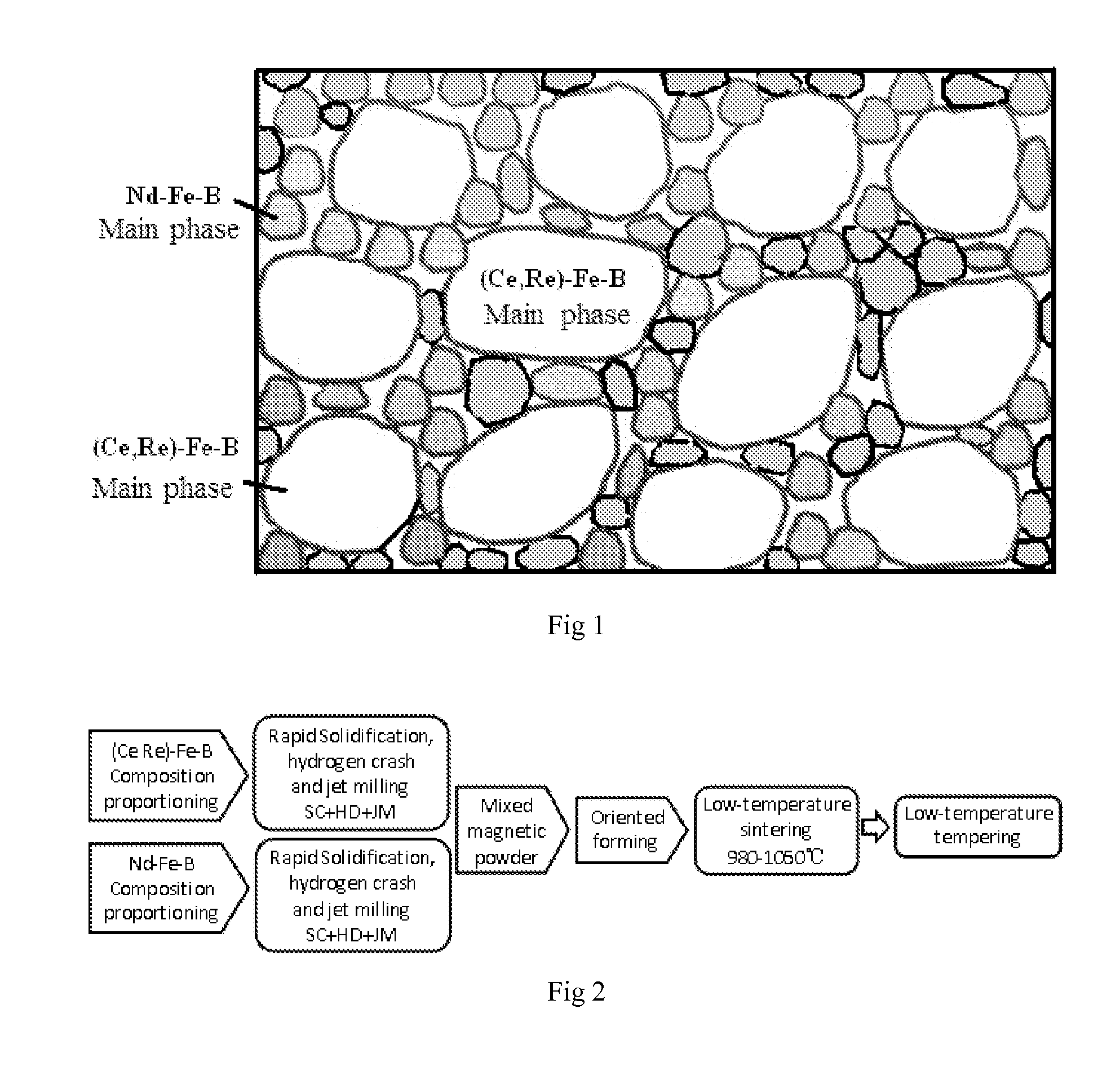

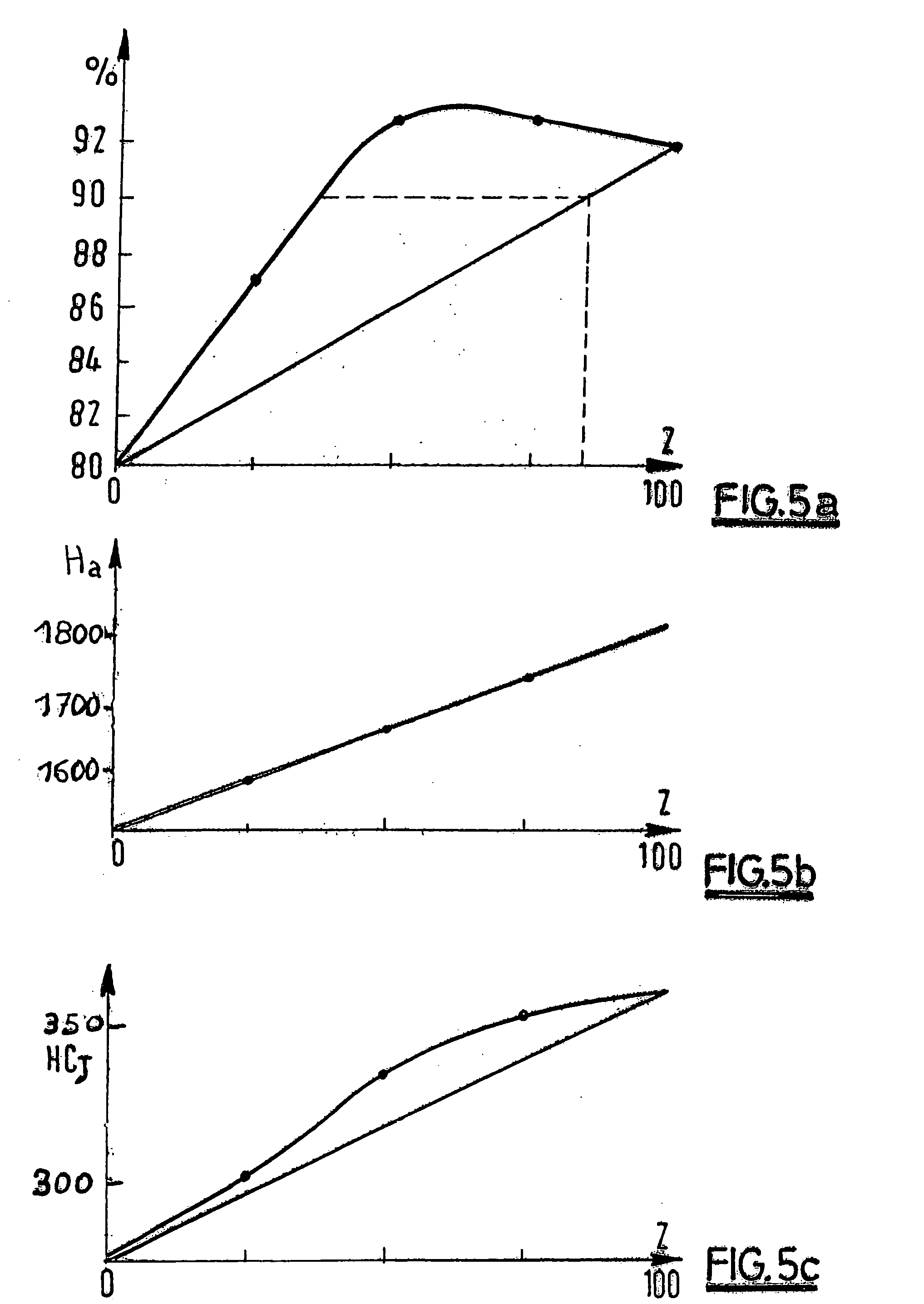

Low-Cost Double-Main-Phase Ce Permanent Magnet Alloy and its Preparation Method

ActiveUS20140065004A1Low costReduce manufacturing costInorganic material magnetismInductances/transformers/magnets manufactureRare earthAlloy

The invention discloses a low-cost double-main-phase Ce permanent magnet alloy and its preparation method, and belongs to technical field of rare earth permanent magnet material. The Ce permanent magnet alloy has a chemical formula of (Cex,Re1-x)aFe100-a-b-cBbTMc in mass percent, wherein 0.4≦x≦0.8, 29≦a≦33, 0.8≦b≦1.5, 0.5≦c≦2, Re is one or more selected from Nd, Pr, Dy, Tb and Ho elements, and TM is one or more selected from Ga, Co, Cu, Nb and Al elements; the Ce permanent magnet alloy has a double-main-phase structure with a low HA phase in (Ce,Re)—Fe—B and a high HA phase in Nd—Fe—B. The double-main-phase Ce permanent magnet alloy of the present invention prepared by using a double-main-phase alloy method greatly lowers the production cost of magnet while maintaining excellent magnetic performances.

Owner:CENT IRON & STEEL RES INST

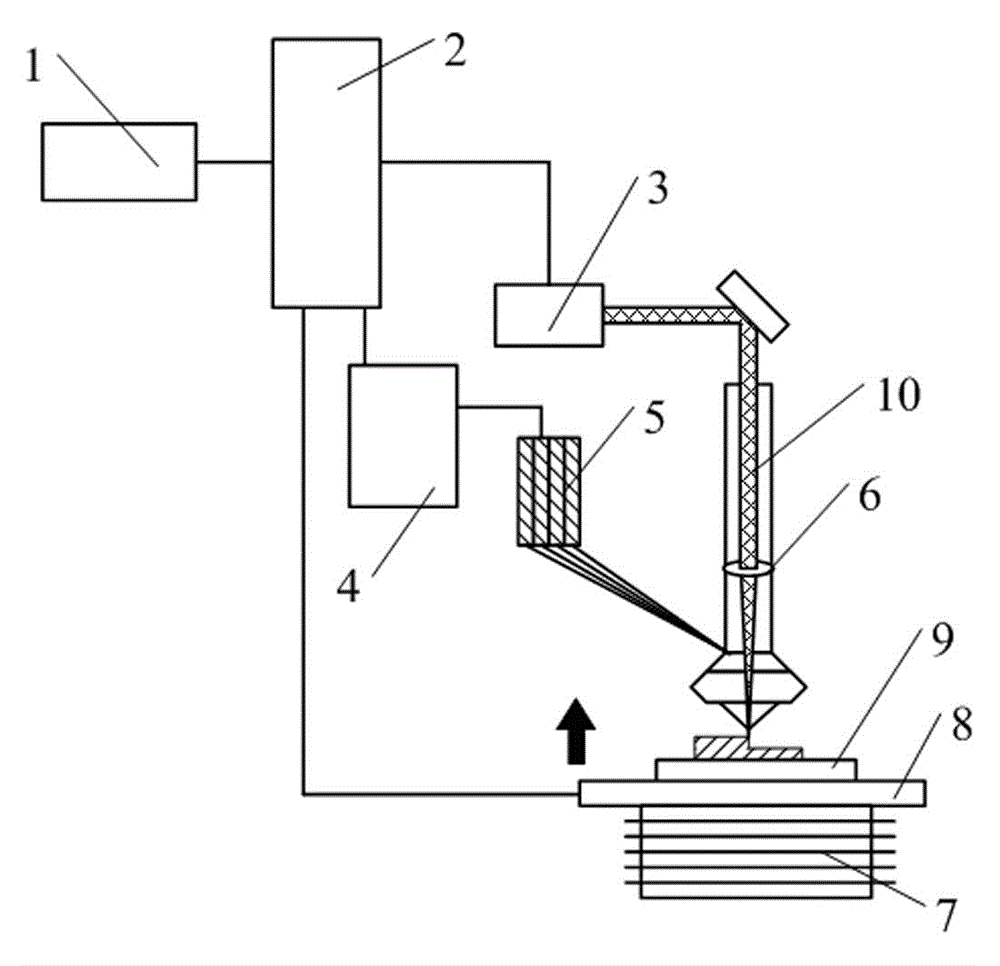

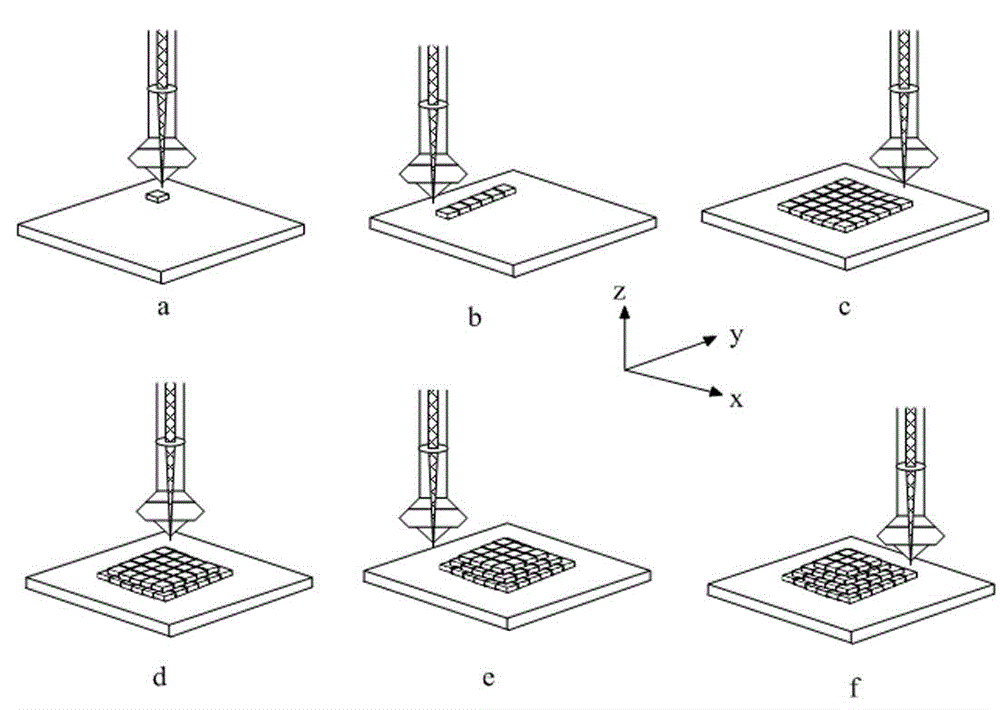

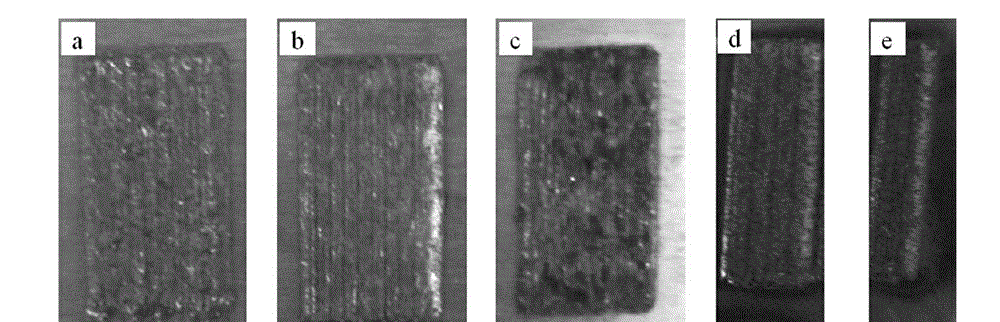

Method for preparing rare earth permanent magnet through laser additive fast forming and sintering in hot isostatic pressing mode

ActiveCN104377027ASave raw materialsReduce production processInorganic material magnetismInductances/transformers/magnets manufactureRare earthHigh pressure

The invention provides a method for preparing a rare earth permanent magnet through laser additive fast forming and sintering in a hot isostatic pressing mode, and belongs to the technical field of materials. The method comprises the following steps that (1), Nd / Pr / Dy-Fe-B micro powder is prepared; (2), programs are compiled in a control computer of a 3D printing device; (3), a base plate is installed on a work table, laser power is adjusted, and the spot size is controlled; (4), high-pressure nitrogen or argon is utilized for blowing the Nd / Pr / Dy-Fe-B micro powder into a feeding pipeline, and the conveying capacity is adjusted; (5), the Nd / Pr / Dy-Fe-B micro powder is sprayed on the base plate, an electromagnet is used for exerting a magnetic field, and laser is irradiated on the Nd / Pr / Dy-Fe-B micro powder on the base plate; scanning and sintering are sequentially carried out according to the programs to obtain a magnet rough blank; (6), the magnet rough blank is sintered in the hot isostatic pressing mode. A product obtained through the method can be directly used after the surface defects such as uneven surfaces and oxide skin are removed through polishing, and post-processing working procedures of slicing, polishing, wire-electrode cutting and the like are not needed.

Owner:NORTHEASTERN UNIV

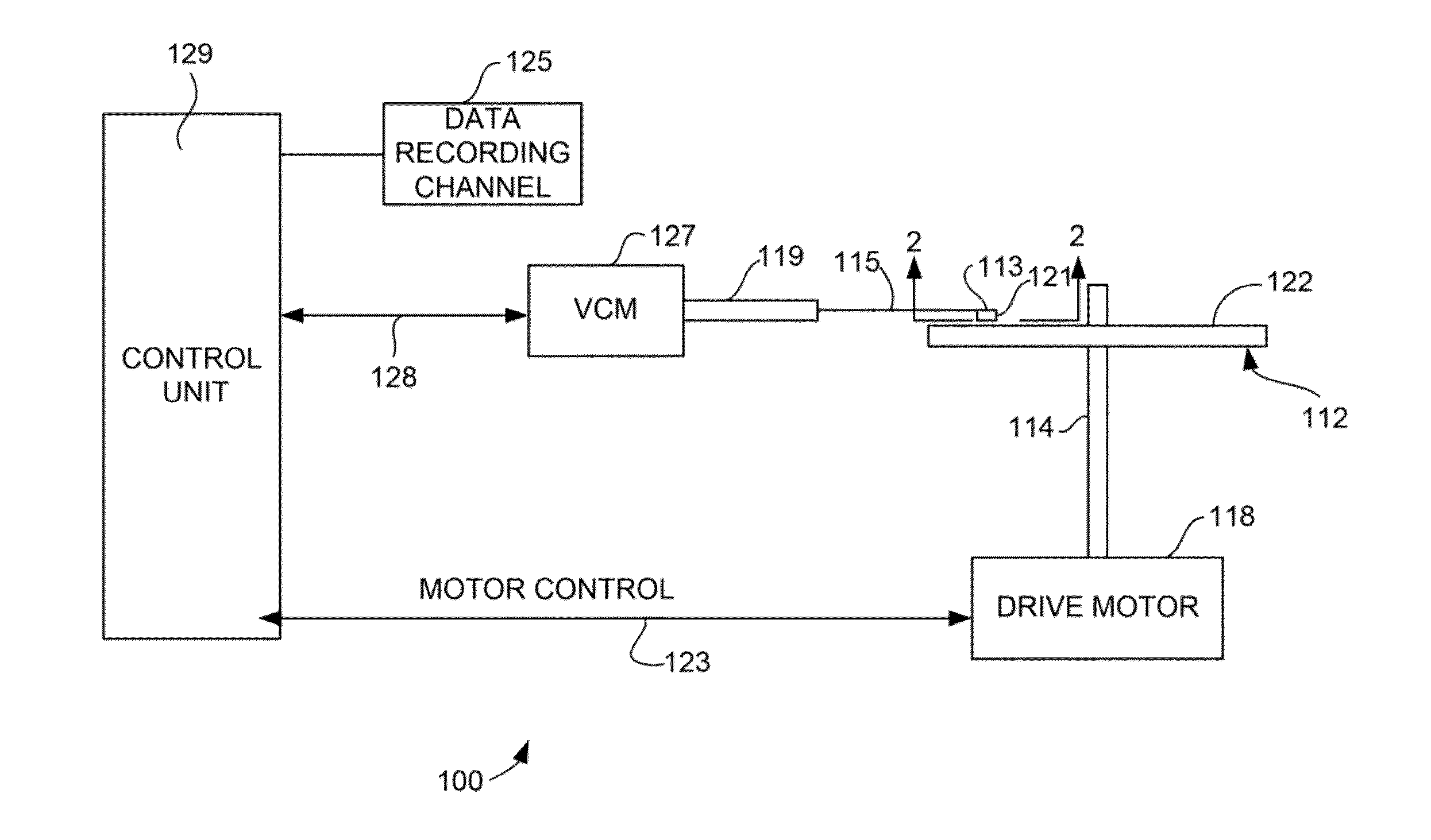

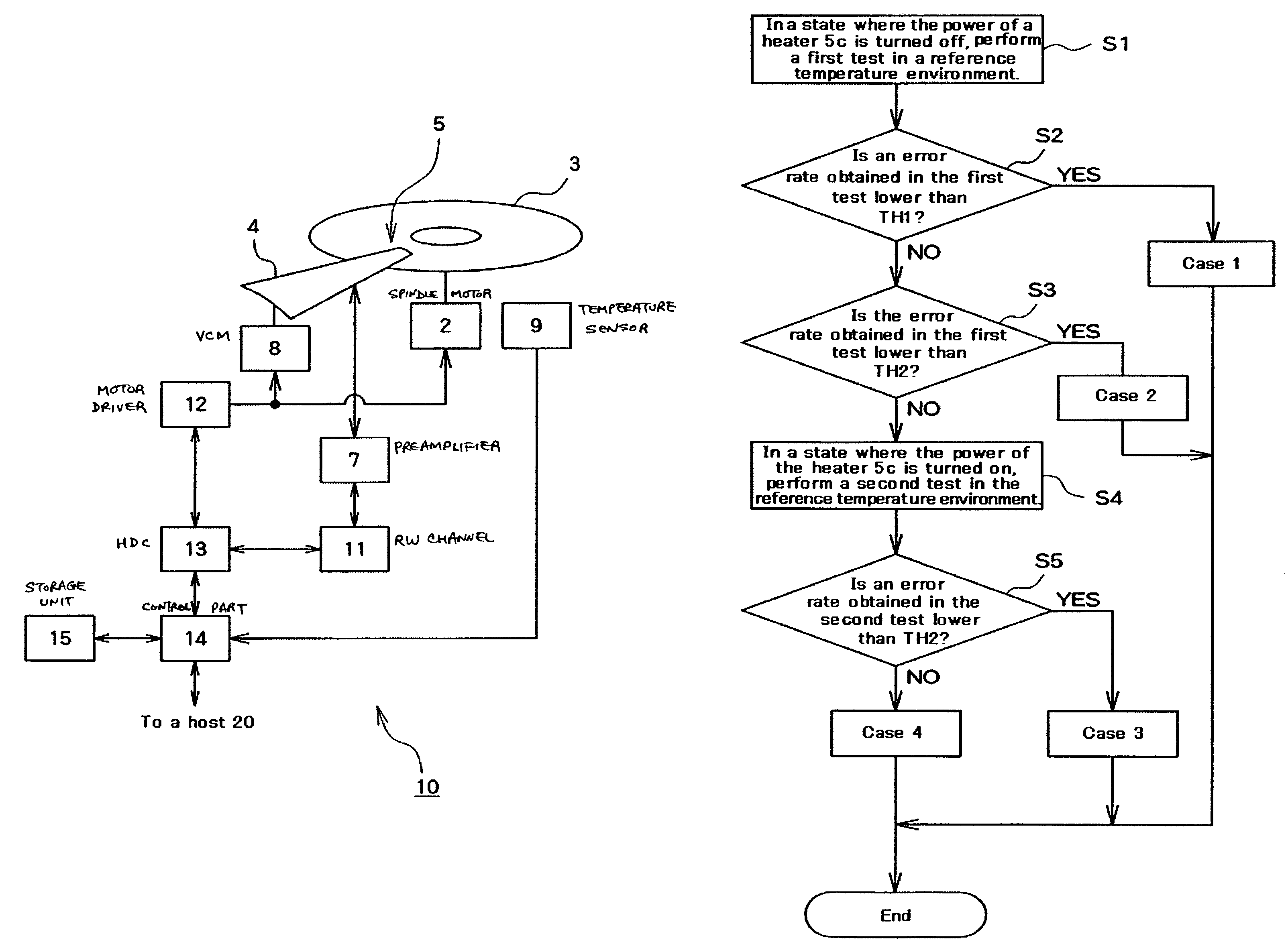

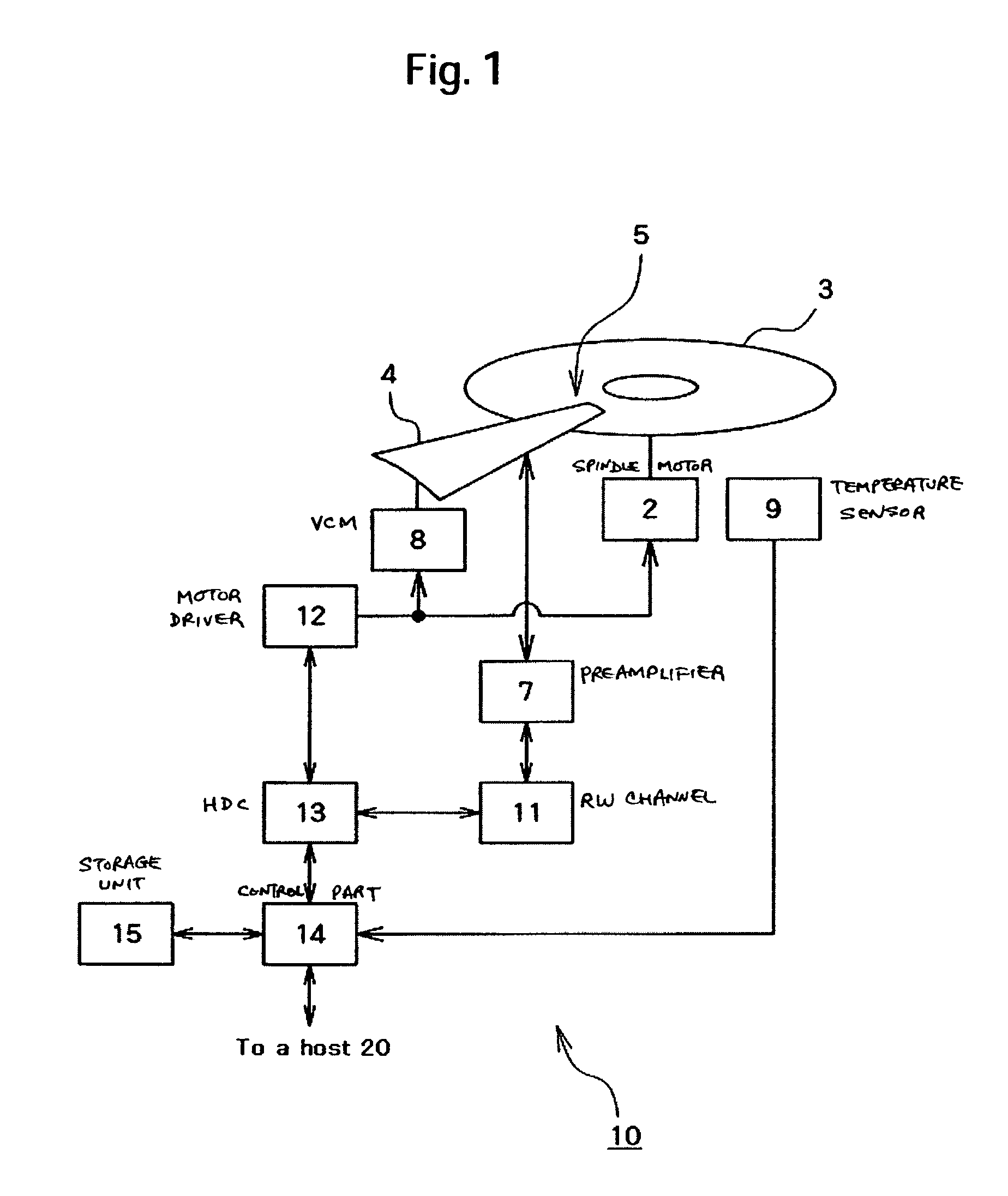

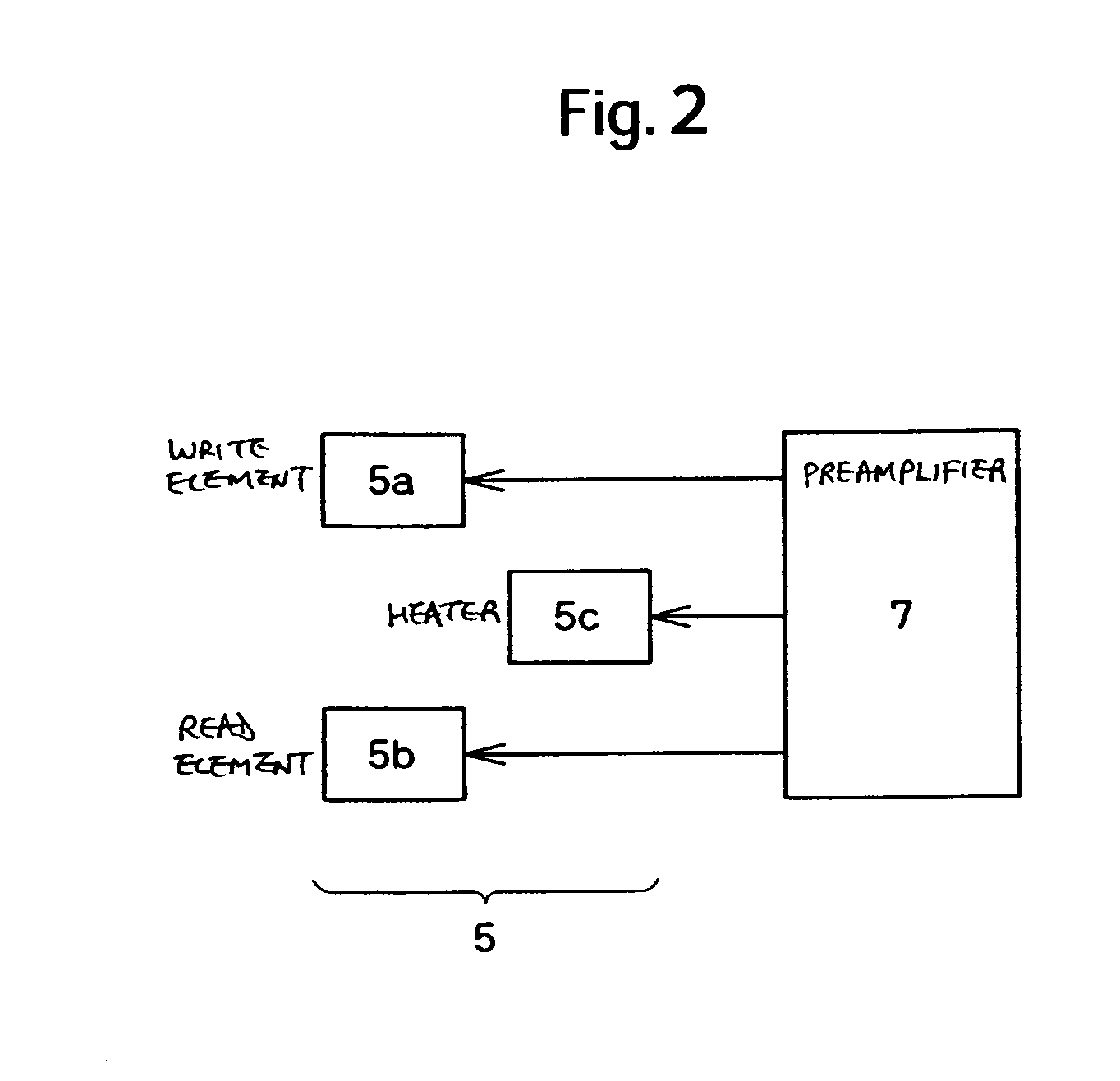

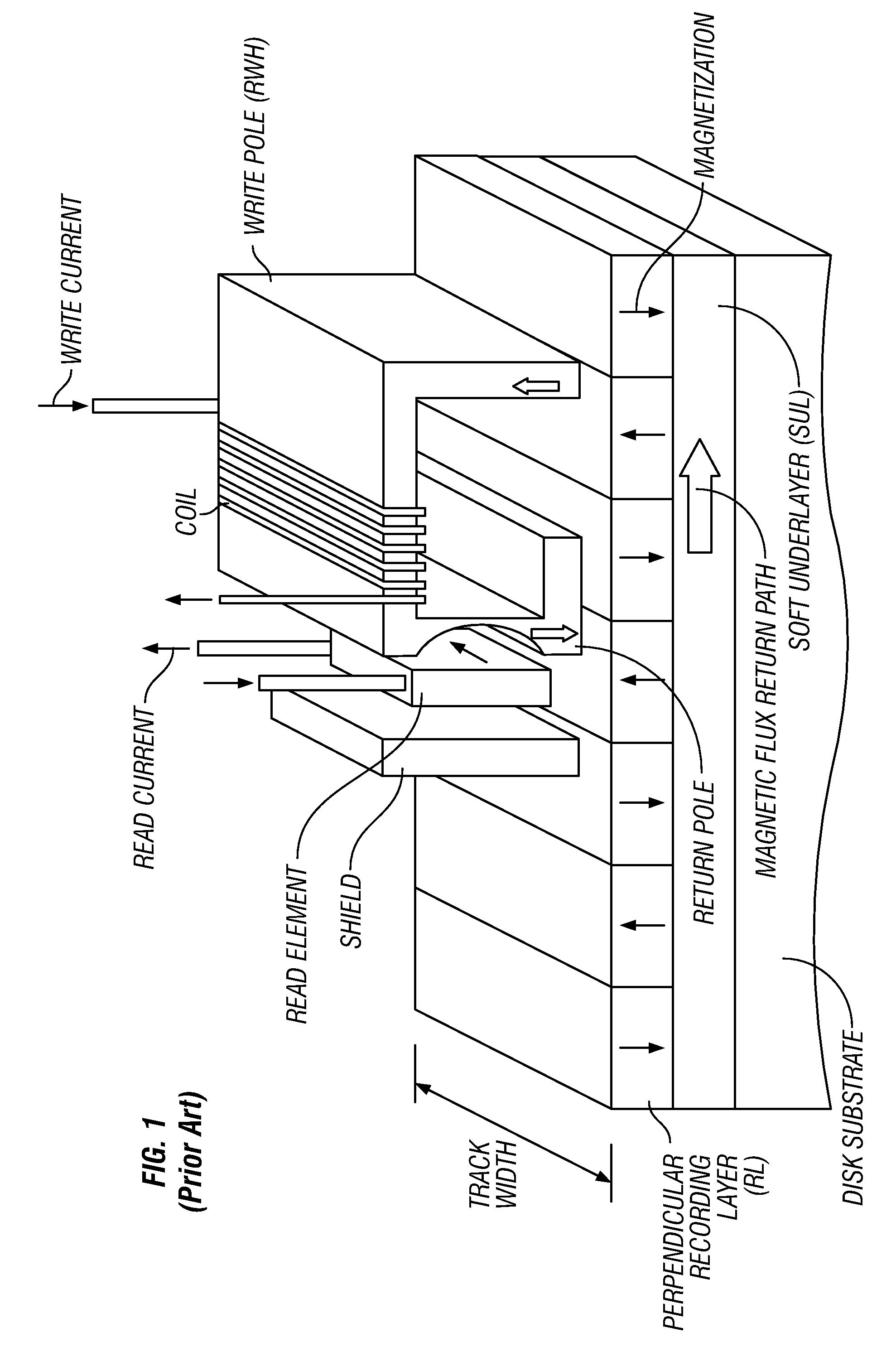

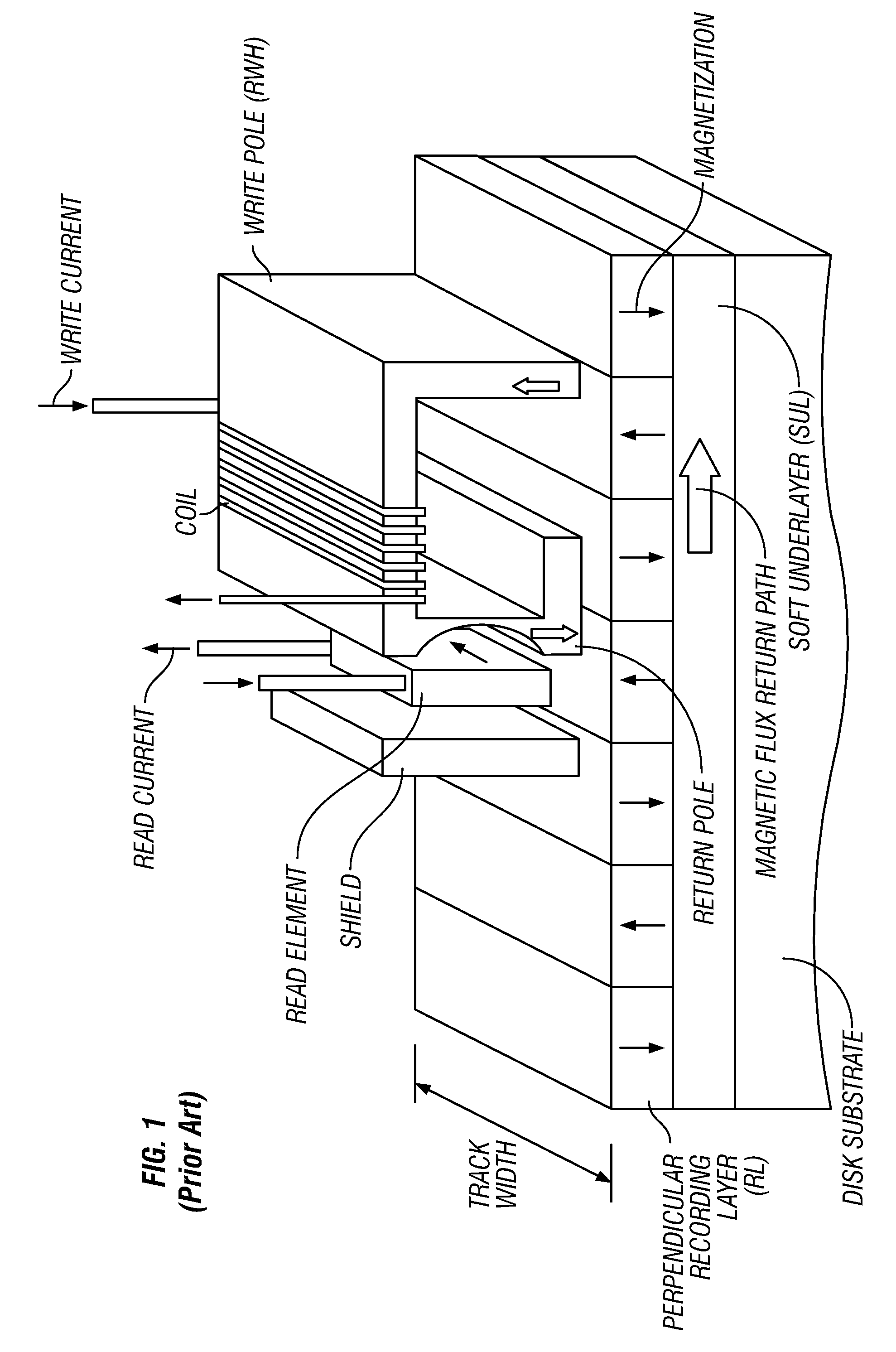

Magnetic disk drive with heater to control flying height and manufacturing method thereof

InactiveUS7480115B2Good magnetic performanceImprove performanceDriving/moving recording headsUndesired vibrations/sounds insulation/absorptionEngineeringFlying height

Embodiment of the invention improve the productivity of a magnetic disk drive that controls the flying height of a magnetic head by use of a heater. According to an embodiment, in a method for manufacturing a magnetic disk drive that writes / reads information to / from a magnetic disk medium by use of a magnetic head including a heater adapted to control the flying height, the read and write performance of the magnetic head is tested; a heating condition used at the time of heating by the heater is determined on the basis of the test results; and a control parameter that specifies the amount of heating by the heater in the determined heating condition is determined.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Rare earth permanent magnet and its preparation

ActiveUS20110036458A1Efficient productivityGood magnetic performancePermanent magnetsInorganic material magnetismRemanenceProduction rate

A rare earth permanent magnet is prepared by disposing a powdered metal alloy containing at least 70 vol % of an intermetallic compound phase on a sintered body of R—Fe—B system, and heating the sintered body having the powder disposed on its surface below the sintering temperature of the sintered body in vacuum or in an inert gas for diffusion treatment. The advantages include efficient productivity, excellent magnetic performance, a minimal or zero amount of Tb or Dy used, an increased coercive force, and a minimized decline of remanence.

Owner:SHIN ETSU CHEM CO LTD

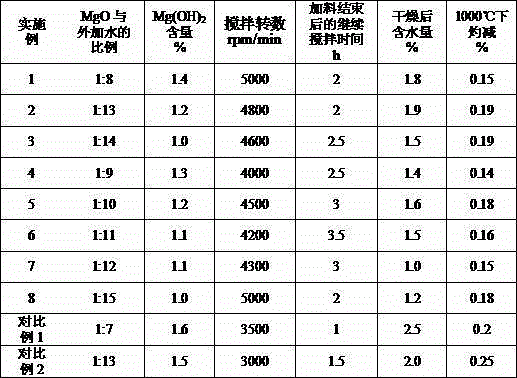

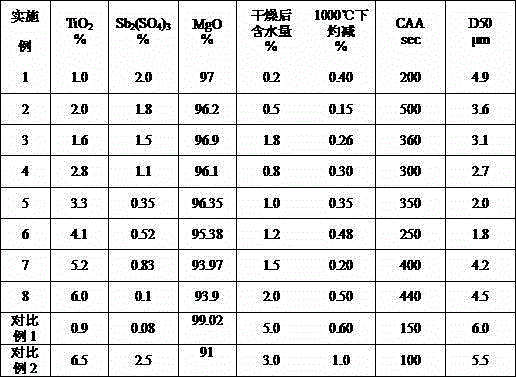

Annealing separant for high-magnetic-induction oriented silicon steel and preparation method thereof

The invention relates to an annealing separant for high-magnetic-induction oriented silicon steel, which is composed of the following raw materials in percentage by weight: 1-6% of TiO2, 0.1-2% of Sb2(SO4)3 and the balance of MgO. Water is additionally added, wherein the MgO:water ratio is 1:(8-15). The preparation method comprises the following steps: mixing the MgO and water; adding TiO2, and stirring sufficiently and uniformly; adding the Sb2(SO4)3, and stirring; and continuing stirring for not less than 2 hours for later use. The annealing separant enables the high-magnetic-induction oriented silicon steel to have favorable magnetic induction property and bottom quality, has favorable insulating property, is suitable for the operating requirements of high-capacity transformers, and can lower the concession rate of the product.

Owner:武汉钢铁有限公司

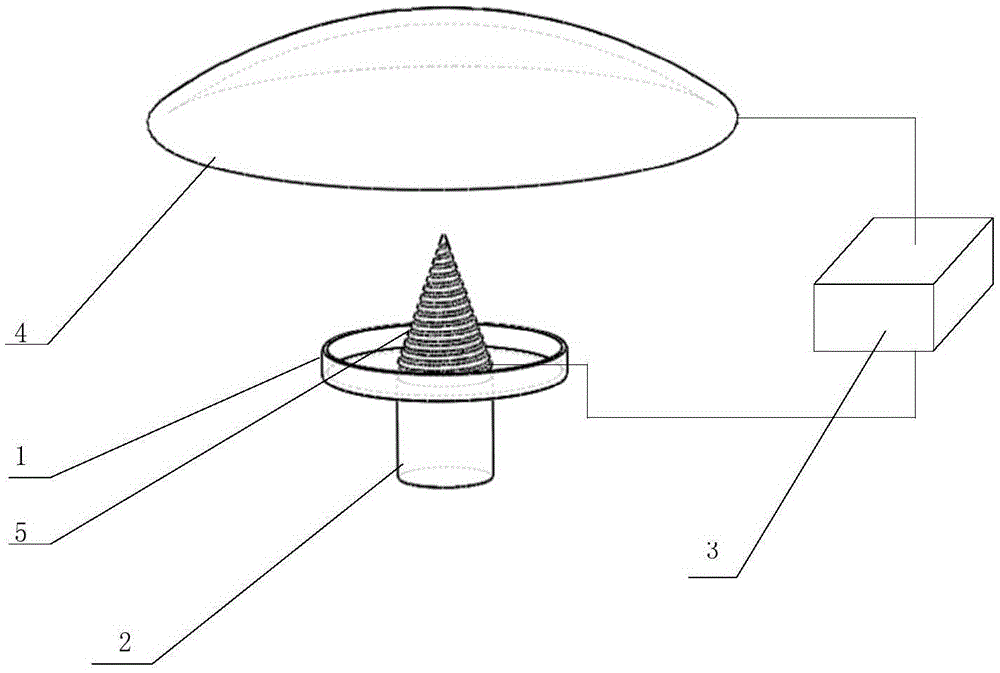

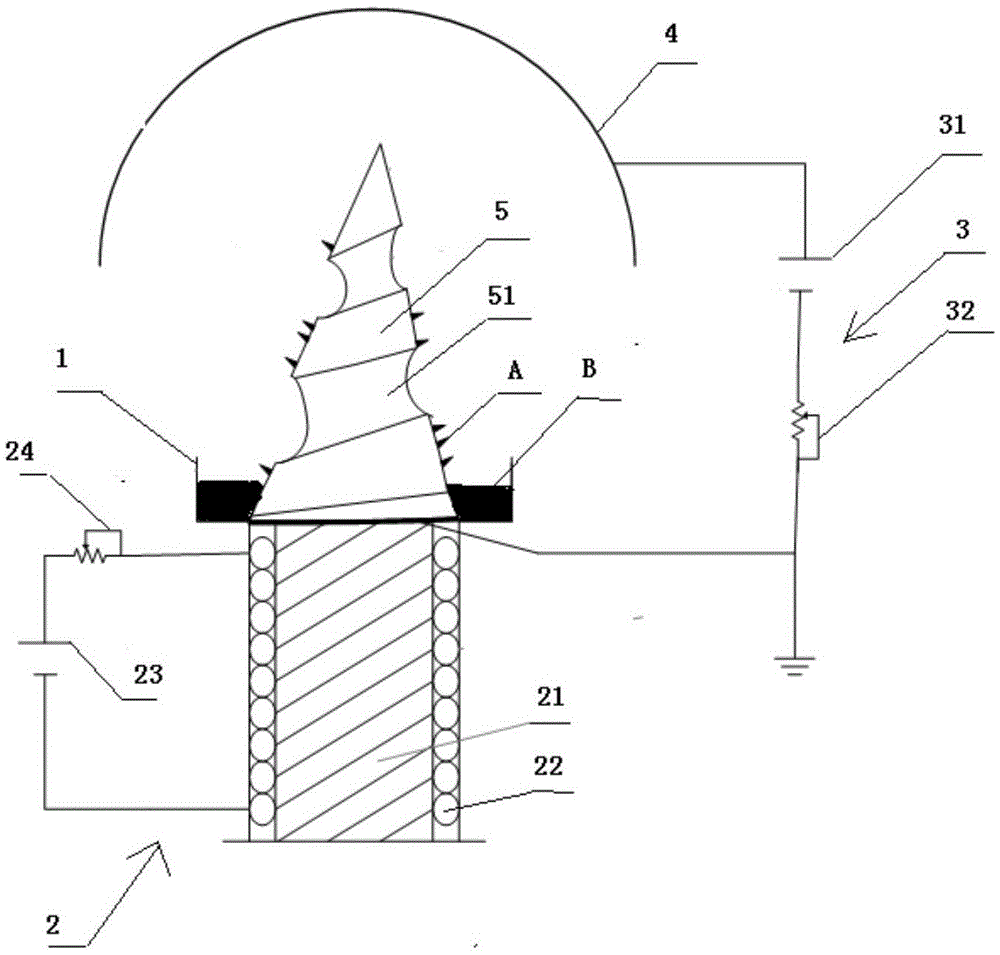

Polymer solution-based magnetofluid self-assembly needle-free electro-spinning device and nanofiber electro-spinning method thereof

InactiveCN105568407AAchieving Self-Spiral RisingUnified specificationsElectro-spinningMonocomponent synthetic polymer artificial filamentNeedle freeFiber

The invention discloses a polymer solution-based magnetofluid self-assembly needle-free electro-spinning device which comprises a groove. The device further comprises a controllable magnetic field generation module, a high-voltage electric field generation device, a conductive fiber receiving device used for collecting cellosilk, and at least one conductive and magnetic conductive cone tower. The surface of the cone tower is provided with a threaded groove ascending spirally along the cone tower. The polymer solution-based magnetofluid self-assembly needle-free electro-spinning device is simple in structure, operation is controllable and easy to control, and processing efficiency is high. Meanwhile, the invention further provides a nanofiber electro-spinning method achieved through the needle-free electro-spinning device. According to the method, the aim of controlling jetting of polymer solution-based magnetofluid is achieved by controlling electric and magnetic fields. The method is controllable, easy to control and good in control accuracy.

Owner:SUN YAT SEN UNIV

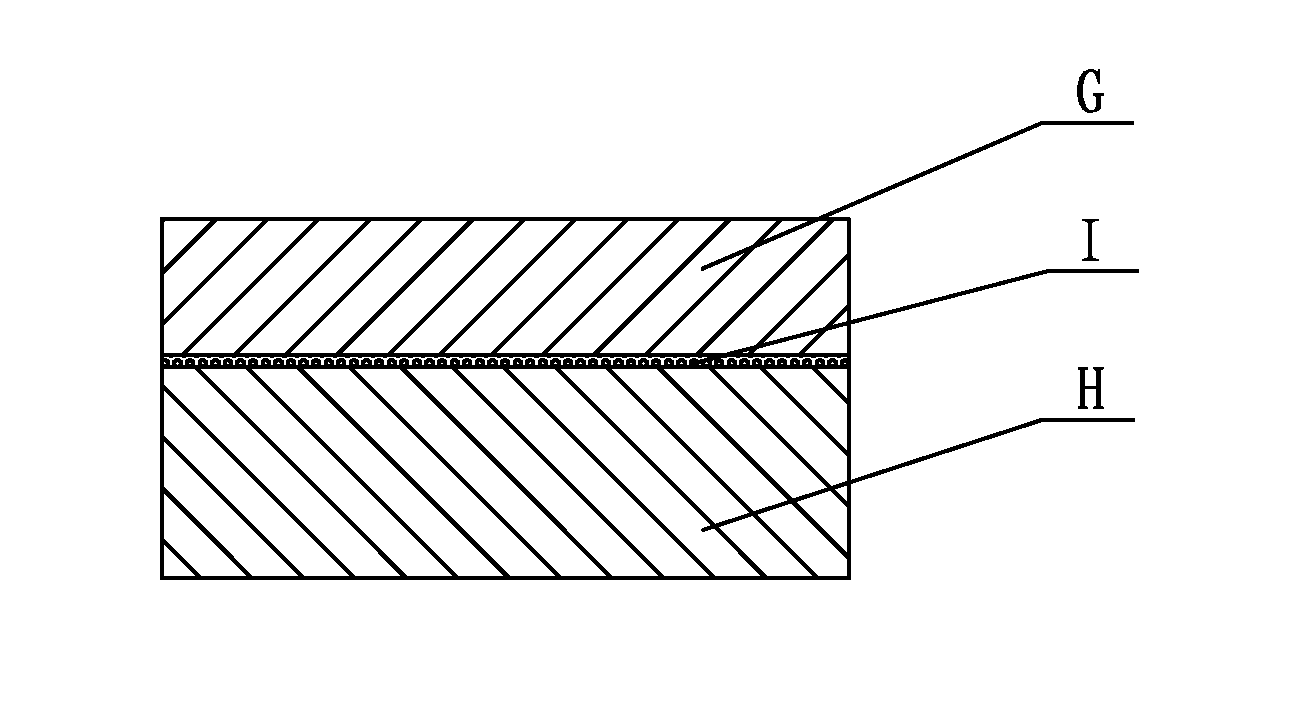

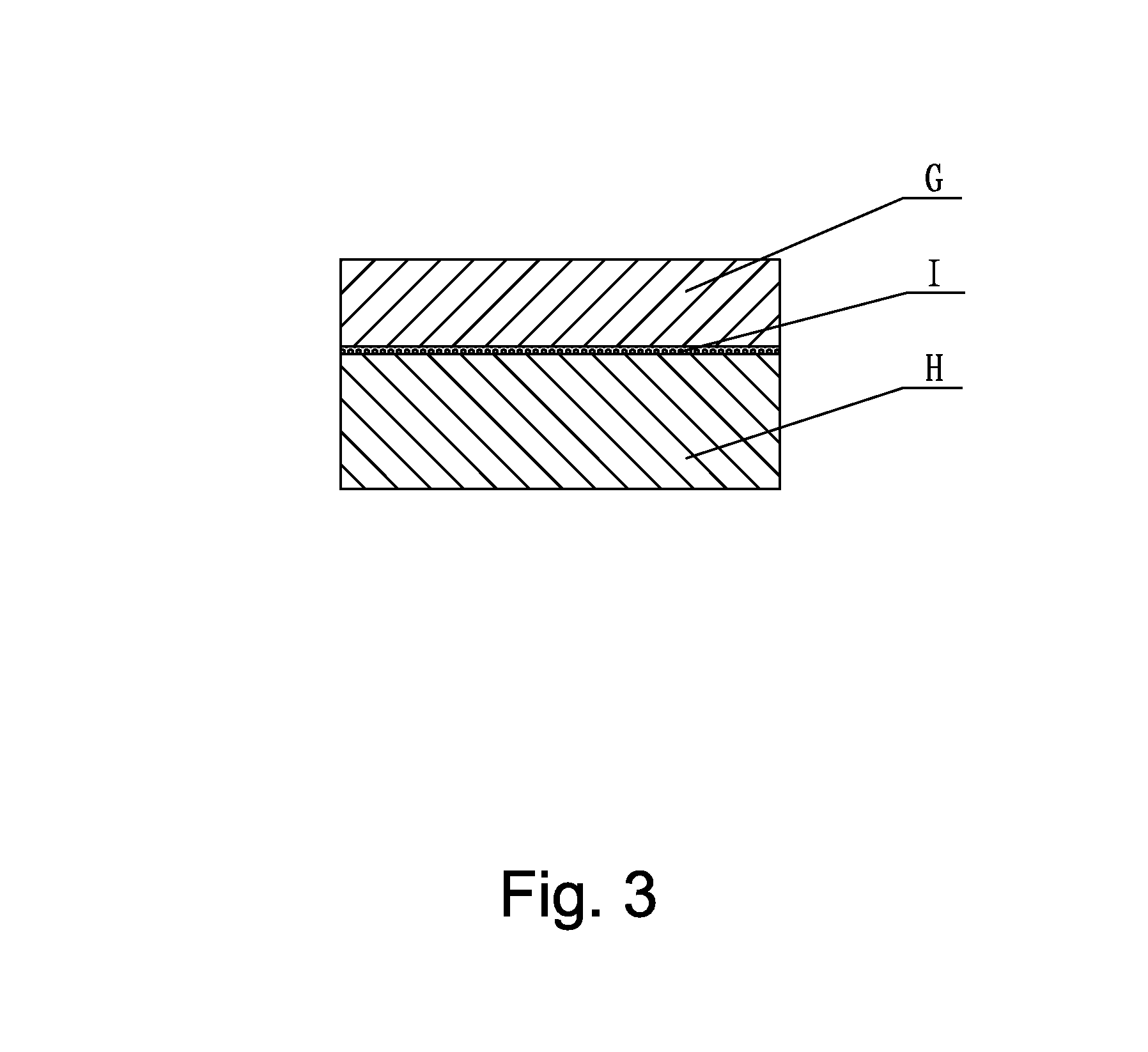

R-Fe-B based magnet having gradient electric resistance and method for producing the same

InactiveUS20130093551A1Reduce lossesImprove efficiencyPermanent magnetsInductances/transformers/magnets manufactureHigh resistanceElectrical resistance and conductance

An R—Fe—B based magnet having gradient electric resistance and a method for producing the same are provided. The magnet includes an exterior layer (G) and a main body layer (H). The exterior layer (G) is connected with the main body layer (H) via a sintered layer (I). The oxygen content in the exterior layer (G) is higher than the oxygen content in the main body layer (H), so the electrical resistivity of the exterior layer (G) is not lower than the electrical resistivity of the main body layer (H). The R—Fe—B based magnet having gradient electric resistance is capable of maintaining high resistance and excellent magnetic performance simultaneously.

Owner:YANTAI ZHENGHAI MAGNETIC MATERIAL CO LTD

Rare earth permanent magnet and its preparation

ActiveUS20110036457A1Efficient productivityGood magnetic performancePermanent magnetsInorganic material magnetismRemanenceProduction rate

A rare earth permanent magnet is prepared by disposing a powdered metal alloy containing at least 70 vol % of an intermetallic compound phase on a sintered body of R—Fe—B system, and heating the sintered body having the powder disposed on its surface below the sintering temperature of the sintered body in vacuum or in an inert gas for diffusion treatment. The advantages include efficient productivity, excellent magnetic performance, a minimal or zero amount of Tb or Dy used, an increased coercive force, and a minimized decline of remanence.

Owner:SHIN ETSU CHEM CO LTD

Rare earth permanent magnet and its preparation

ActiveUS20110036460A1Efficient productivityGood magnetic performancePermanent magnetsInorganic material magnetismRemanenceProduction rate

A rare earth permanent magnet is prepared by disposing a powdered metal alloy containing at least 70 vol % of an intermetallic compound phase on a sintered body of R—Fe—B system, and heating the sintered body having the powder disposed on its surface below the sintering temperature of the sintered body in vacuum or in an inert gas for diffusion treatment. The advantages include efficient productivity, excellent magnetic performance, a minimal or zero amount of Tb or Dy used, an increased coercive force, and a minimized decline of remanence.

Owner:SHIN ETSU CHEM IND CO LTD

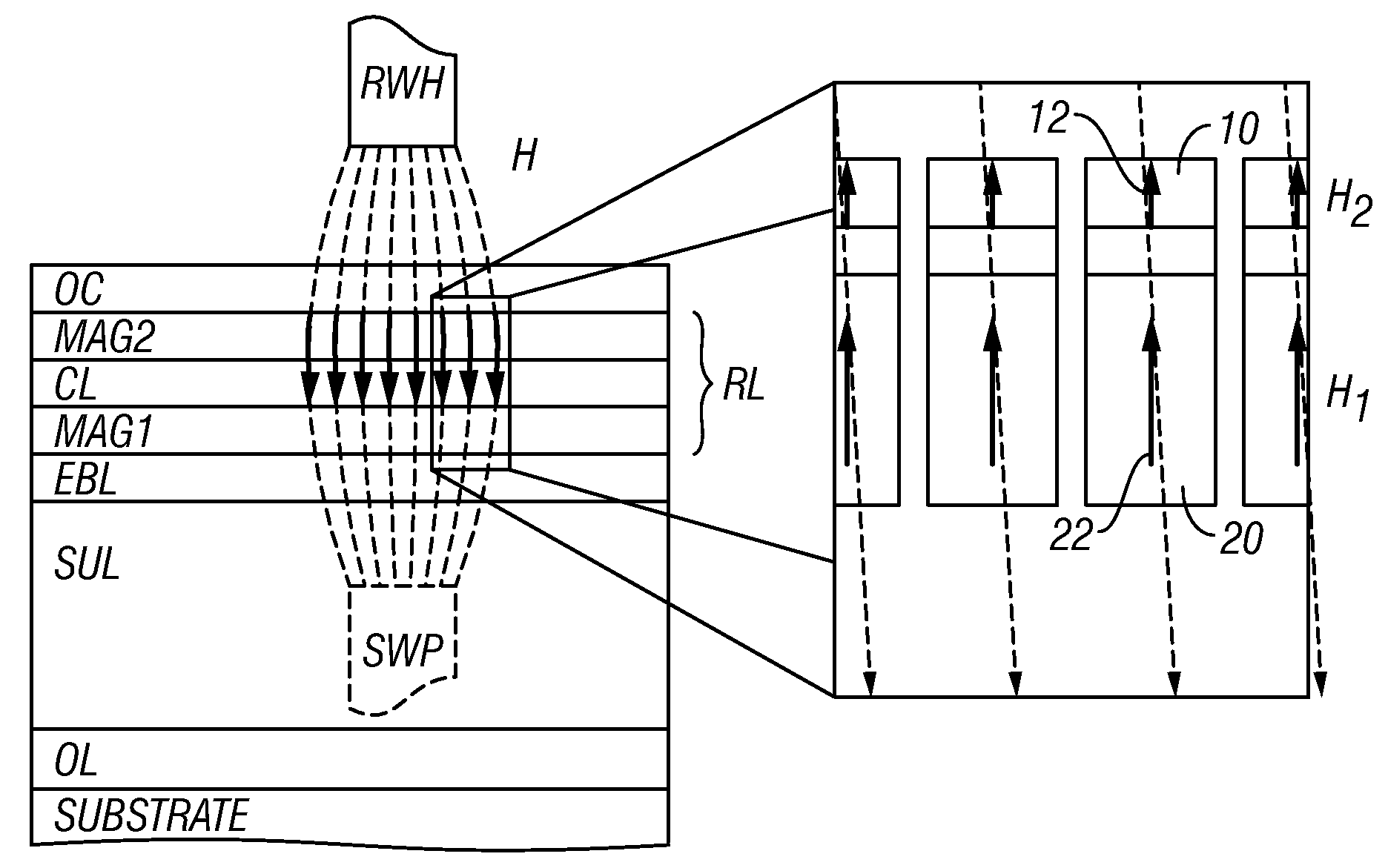

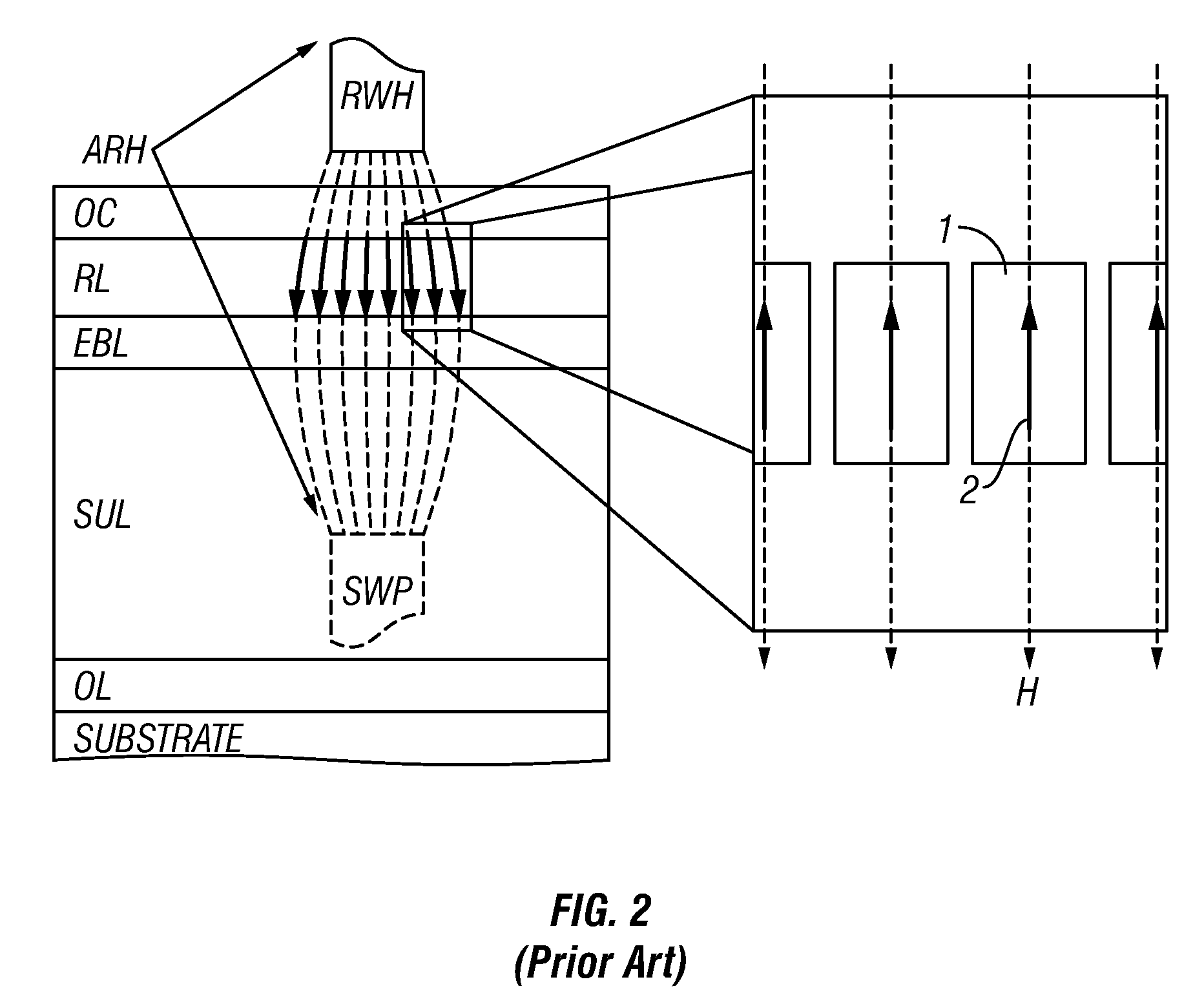

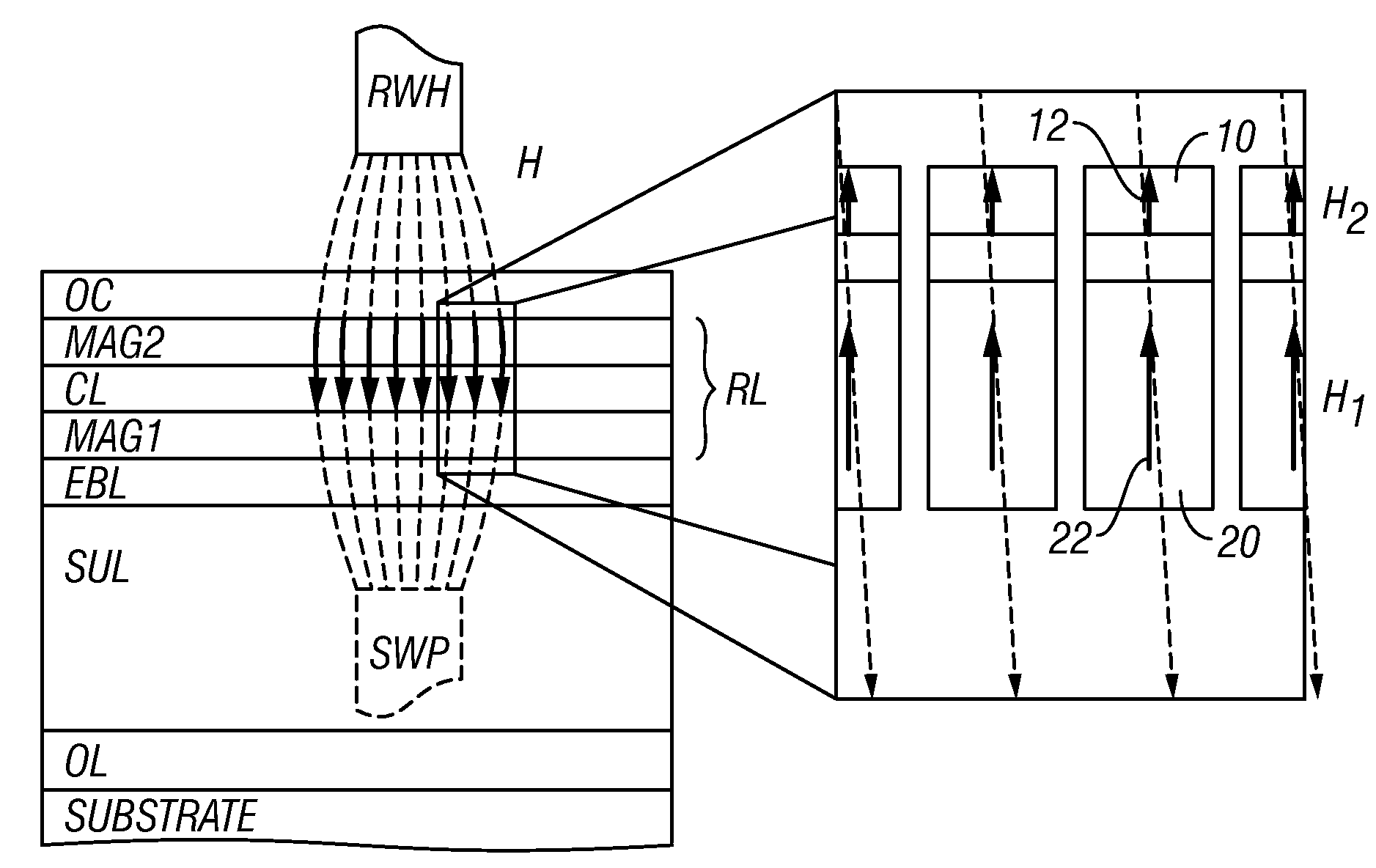

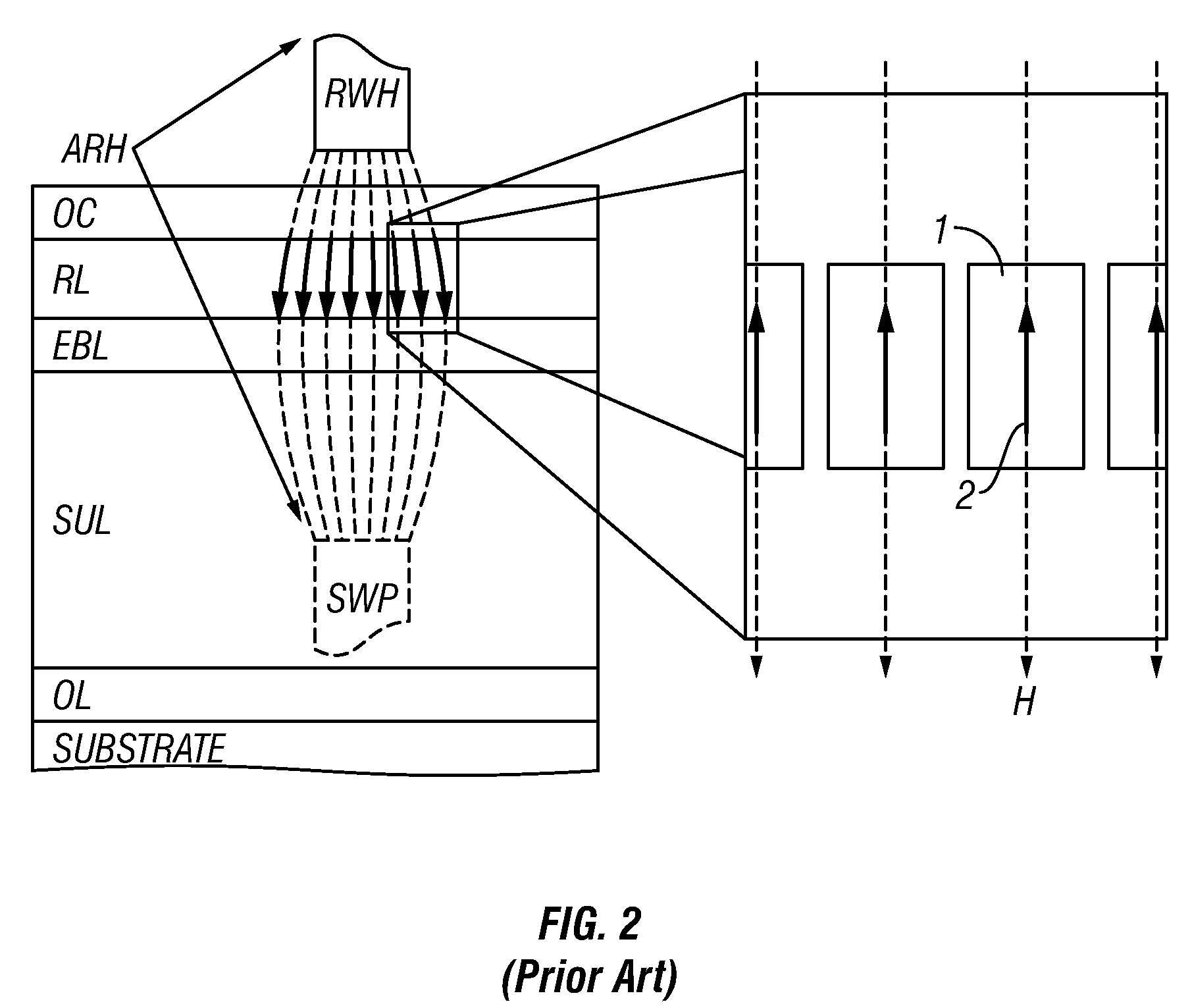

Perpendicular magnetic recording medium with exchange-coupled magnetic layers and improved coupling layer

InactiveUS20080254324A1Good magnetic performanceImprove corrosion resistanceRecord information storageMagnetic recordingCouplingAlloy

A perpendicular magnetic recording medium has an “exchange-spring” type magnetic recording layer (RL) with an improved coupling layer (CL). The RL includes the first or lower ferromagnetic layer MAG1, sometimes called the “media” layer, the second or upper ferromagnetic layer MAG2, sometimes called the “exchange-spring” layer, and the intermediate CL that provides ferromagnetic exchange coupling between MAG1 and MAG2. The CL is formed of NiCr or RuCr based alloys, or CoCr or CoCrB alloys with high Cr and / or B content (Cr plus B>about 25 atomic percent), or RuCoCr alloys with low Co content (<about 65 atomic percent). For each CL composition there is a CL thickness range that provides the optimal interlayer exchange coupling between MAG1 and MAG2. The selected CL materials provide an exchange-type perpendicular magnetic recording medium with good magnetic performance, while the relatively high amount of Cr of the CL improves the corrosion resistance of the medium.

Owner:WESTERN DIGITAL TECH INC

Perpendicular magnetic recording medium with exchange-coupled magnetic layers and improved coupling layer

InactiveUS7638210B2Good magnetic performanceImprove corrosion resistanceLayered productsRecord information storageCouplingAlloy

Owner:WESTERN DIGITAL TECH INC

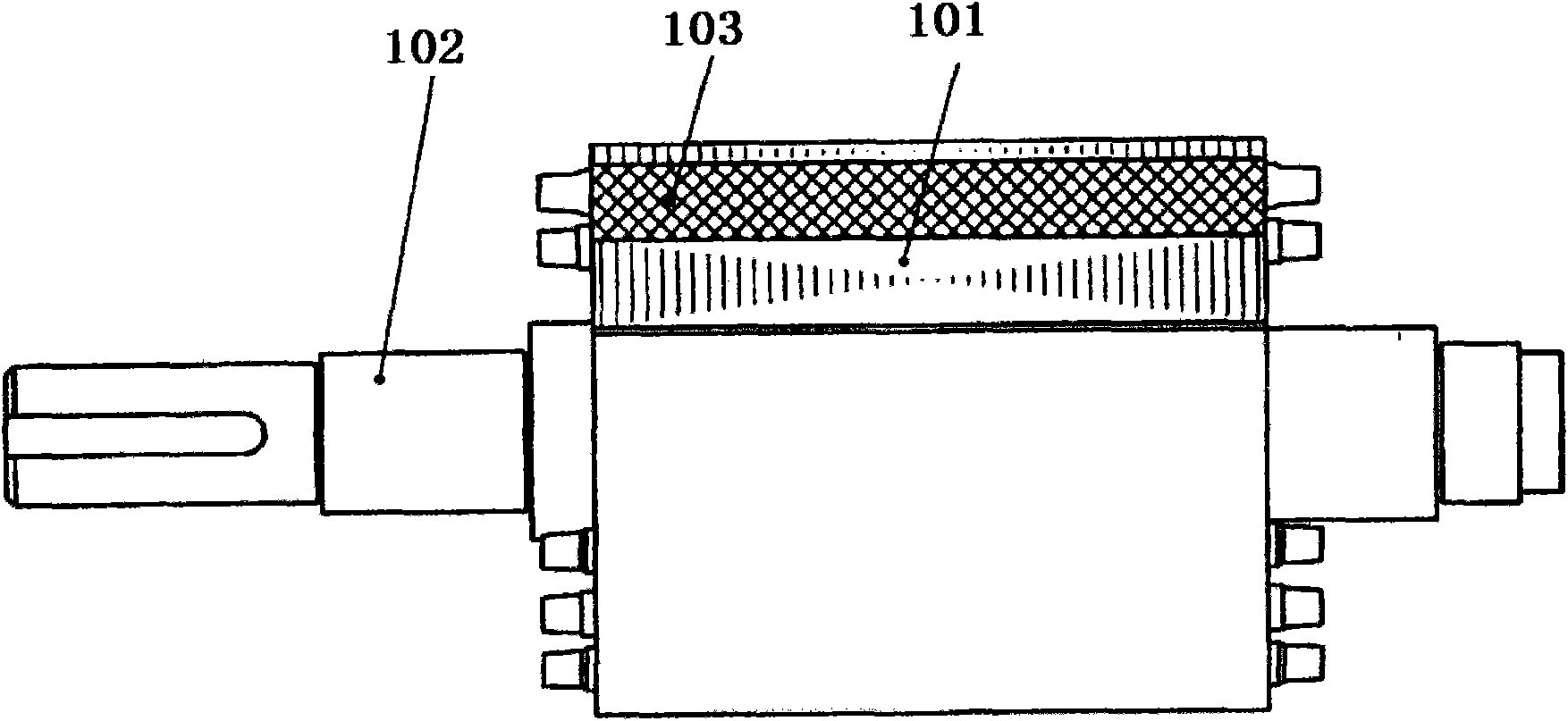

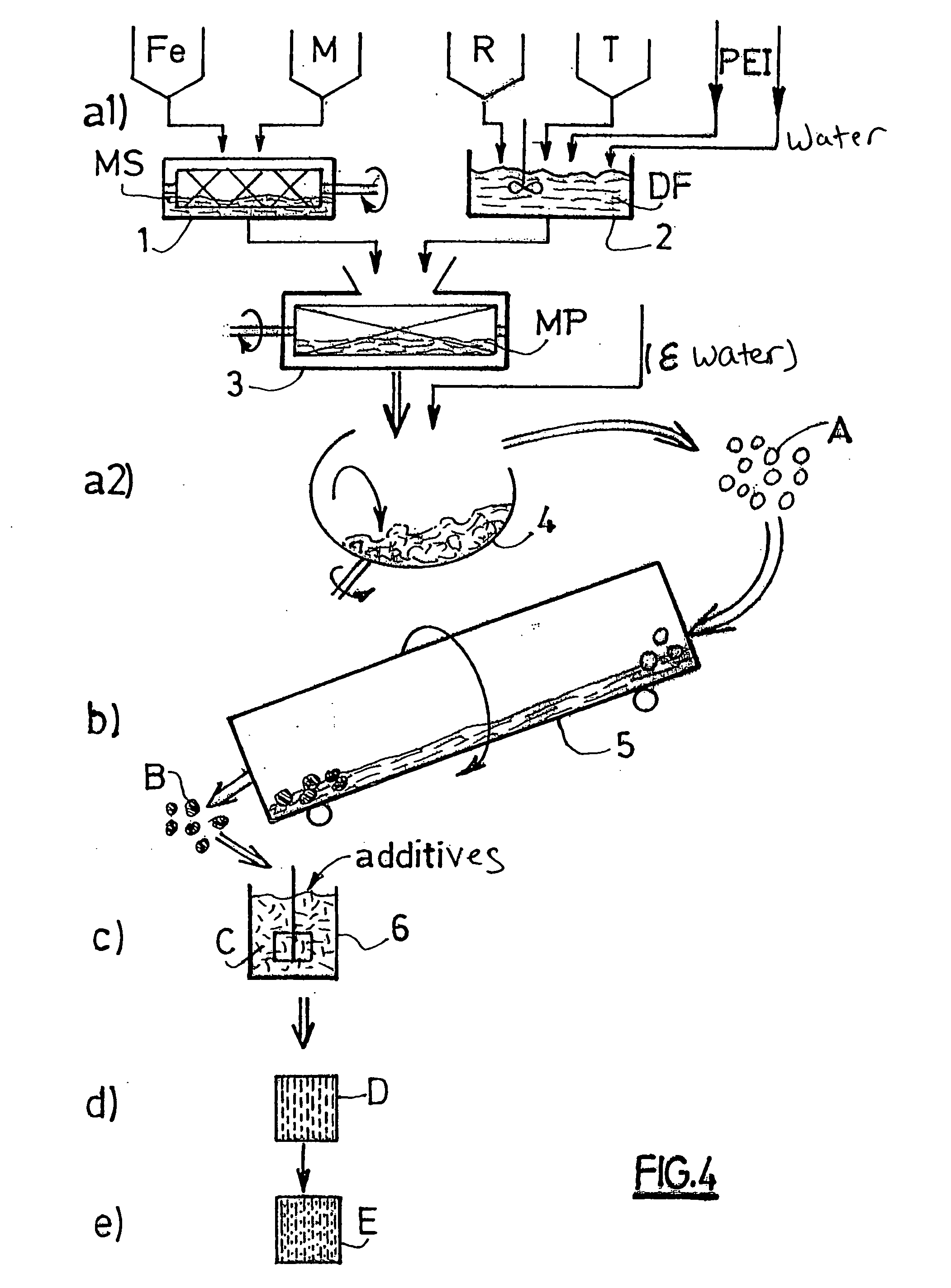

Process for fixing resin impregnated adhesive tapes for rotor

ActiveCN102468718AFacilitate conductionGood magnetic performanceManufacturing stator/rotor bodiesMagnetic circuit characterised by insulating materialsNon magneticElectrical tape

The invention discloses a process for fixing resin impregnated adhesive tapes for a rotor. In the process, a rotor iron core, a rotary shaft and magnets are adopted, wherein the rotor iron core is formed by laminating a plurality of rotor blades; and a plurality of magnet grooves and non-magnetic grooves are formed on the circumferential surface of the rotor iron core. The process comprises the following steps of: firstly, putting the rotor iron core into a baking oven, and pre-heating the rotor iron core; secondly, uniformly coating glue on the surface of the rotor iron core, and inlaying the magnets into the magnet grooves; thirdly, winding the resin impregnated adhesive tape on the surface of each magnet, and winding an insulating adhesive tape outside the resin impregnated adhesive tape; and finally, putting the rotor iron core into the baking box again, baking the rotor iron core to make the resin impregnated adhesive tape tightly wrap on the surface of the magnet, and thus obtaining a finished product for fixing the resin impregnated adhesive tapes for the rotor. The process for fixing the resin impregnated adhesive tapes for the rotor has the advantages that: the thickness of each resin impregnated adhesive tape can be a fraction of that of metal; an interval between the adhesive tape and the magnet can be quite smaller than the interval between a metal annular ring and the magnet; the friction between the rotor and a stator is greatly reduced; the conduction conversion rate of a magnetic field of a motor is higher; and the rotor can be polished and shaped.

Owner:腾禾精密电机(苏州)有限公司

Preparation method of filing type electromagnetic shielding silicon rubber

The invention provides a preparation method of filing type electromagnetic shielding silicon rubber. The preparation method includes the following steps that A, carbon fibers obtained after high-concentration hydrochloric acid activation and low-concentration hydrochloric acid acidification in sequence are placed in a plating solution containing nickel for nickel plating, and nickel-plated carbon fibers are obtained, wherein the molar concentration of high-concentration hydrochloric acid ranges from 4.0 mol / L to 6.0 mol / L, and the molar concentration of low-concentration hydrochloric acid ranges from 0.5 mol / L to 1 mol / L; B, the nickel-plated carbon fibers, a sulfurizing agent, white carbon black and carbon black are added to silicon rubber for rubber refining, and the electromagnetic shielding silicon rubber is obtained after sulfuration sample preparation. The high-concentration hydrochloric acid and the low-concentration hydrochloric acid are selected for activating and acidizing the carbon fibers, the situation that SnCl2 and PdCl2 are used for sensitization and activation is avoided, nickel plating cost is reduced, and environmental pollution is reduced.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

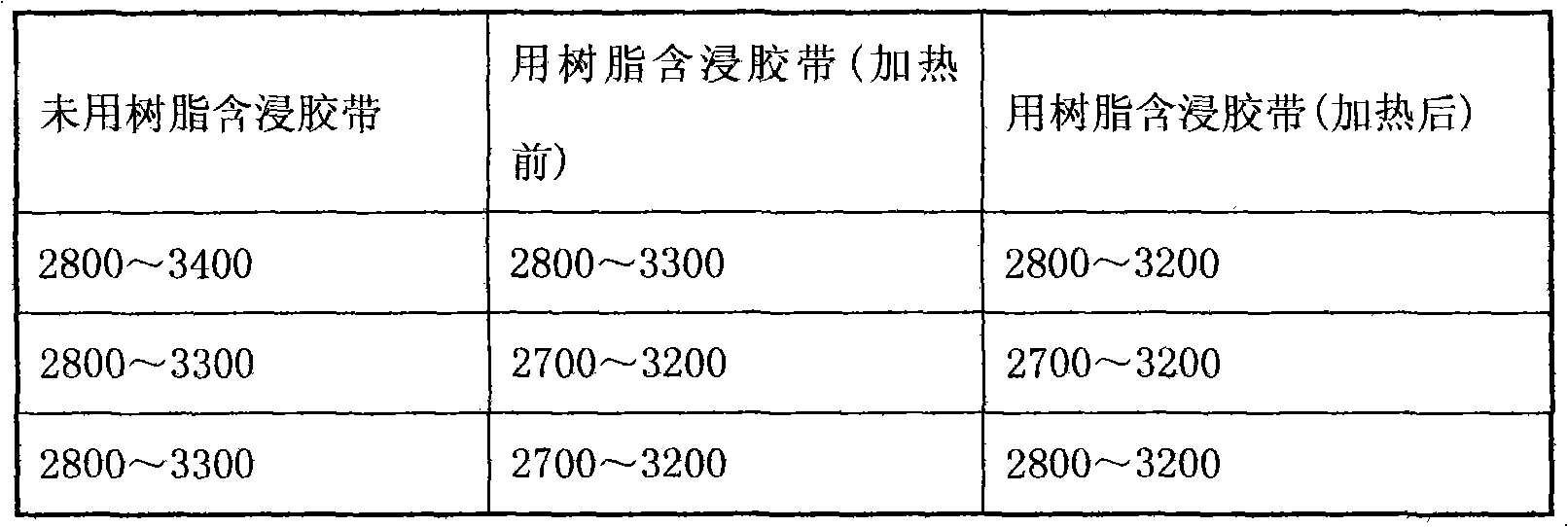

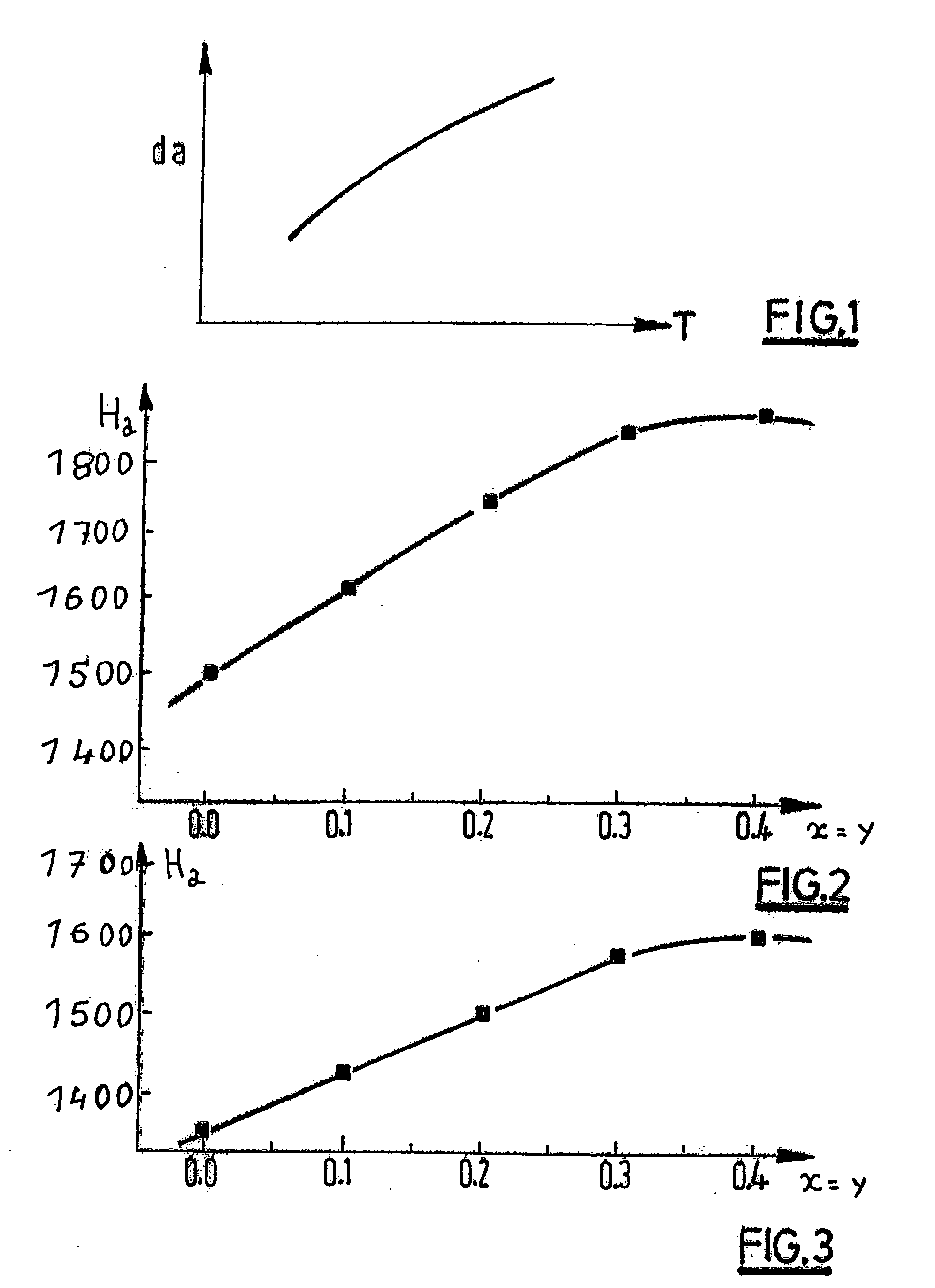

Manufacturing method for ferrite type magnets

InactiveUS20040151661A1Improve magnet performanceGood magnetic performanceIron oxides/hydroxidesInorganic material magnetismChemical compositionPowder mixture

A method for making ferrite magnets of formula M1-xRxFe12-yTyO19 including: a1) forming a powder mixture MP of related raw materials, a2) transforming into granules in green state A, b) calcining the granules in green state to form clinker B, c) wet ding clinker B to obtain a homogeneous dispersion of fine particles C, d) concentrating and compressing the particles under an orienting magnetic field to form an anisotropic green compact D, and e) sintering the green compact to obtain a sintered element E. In step a1), MP is formed from a dry mixture MS of M and Fe powder elements and a dispersion DF of raw materials related to elements R and T, and in step b) the granules in green state are calcined to obtain a clinker B which is homogeneous in chemical composition and size and with apparent low density, between 2.5 and 3.5.

Owner:UGIMAG SA

Preparation method for asphalt mixture capable of rapidly warming

The invention discloses a preparation method for an asphalt mixture capable of rapidly warming. The preparation method is characterized by comprising the following steps: placing pyrite cinder and a reducer in a ball mill and carrying out ball-milling, uniformly mixing the powder after the ball-milling with a mineralizer, then carrying out compression forming, drying, and calcining for 150-200min at 1250-1450 DEG C to prepare a wave-absorbing aggregate; proportioning heavy-duty road asphalt and the aggregate in the mass percentages of 4.6-6% and 94-95.4%, breaking the aggregate and then preheating at 180-200 DEG C, heating the heavy-duty road asphalt at 160-170 DEG C, and stirring and mixing the preheated aggregate with the heated heavy-duty road asphalt at 165-180 DEG C to prepare the asphalt mixture, wherein the aggregate is composed of, 75-100wt% of the wave-absorbing aggregate and 0-25wt% of a natural aggregate. The asphalt mixture prepared by the invention is good in microwave heating effect, and suitable for road de-icing, and road bituminous pavement maintenance and rapid repair.

Owner:SOUTHWEAT UNIV OF SCI & TECH

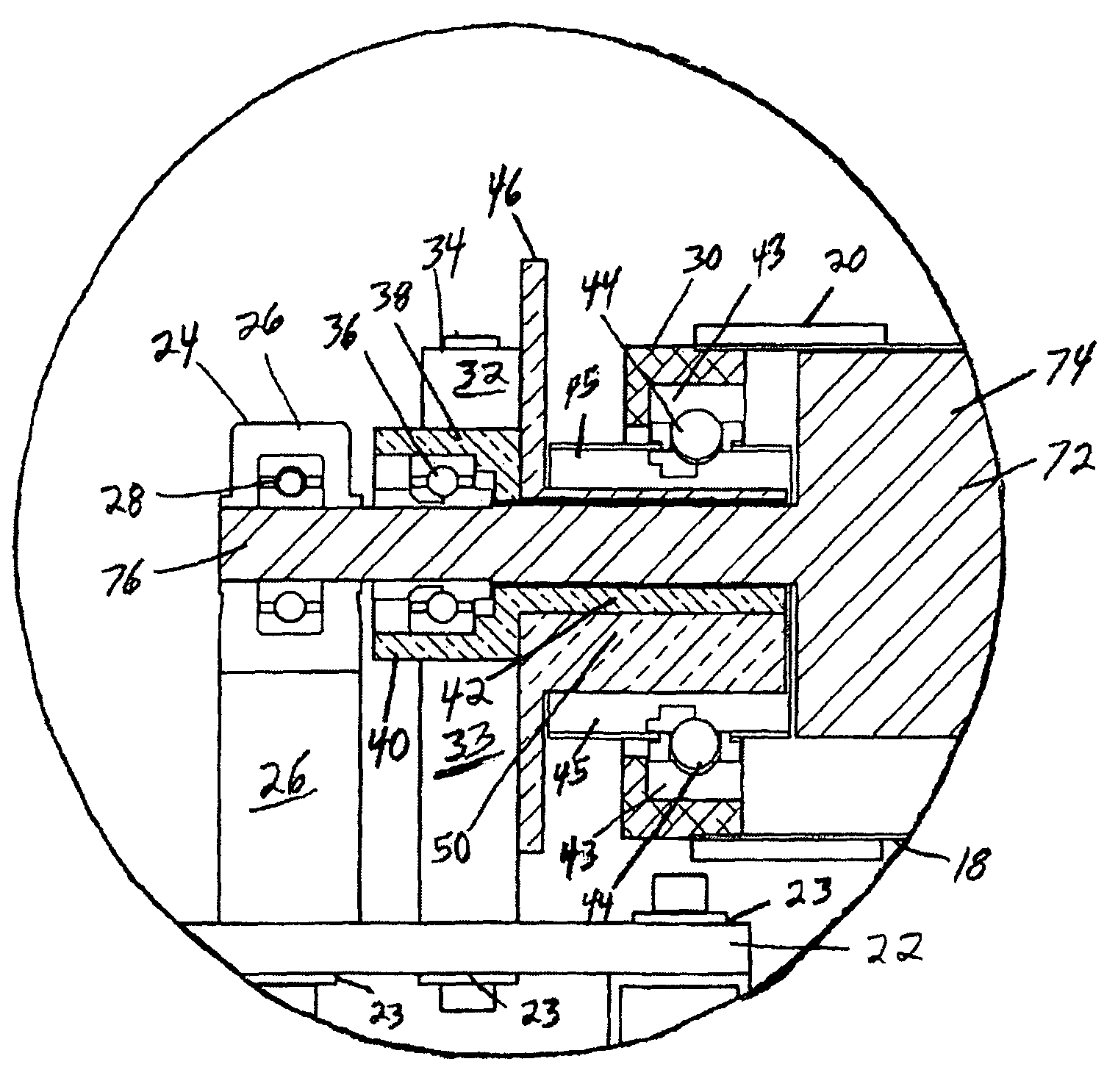

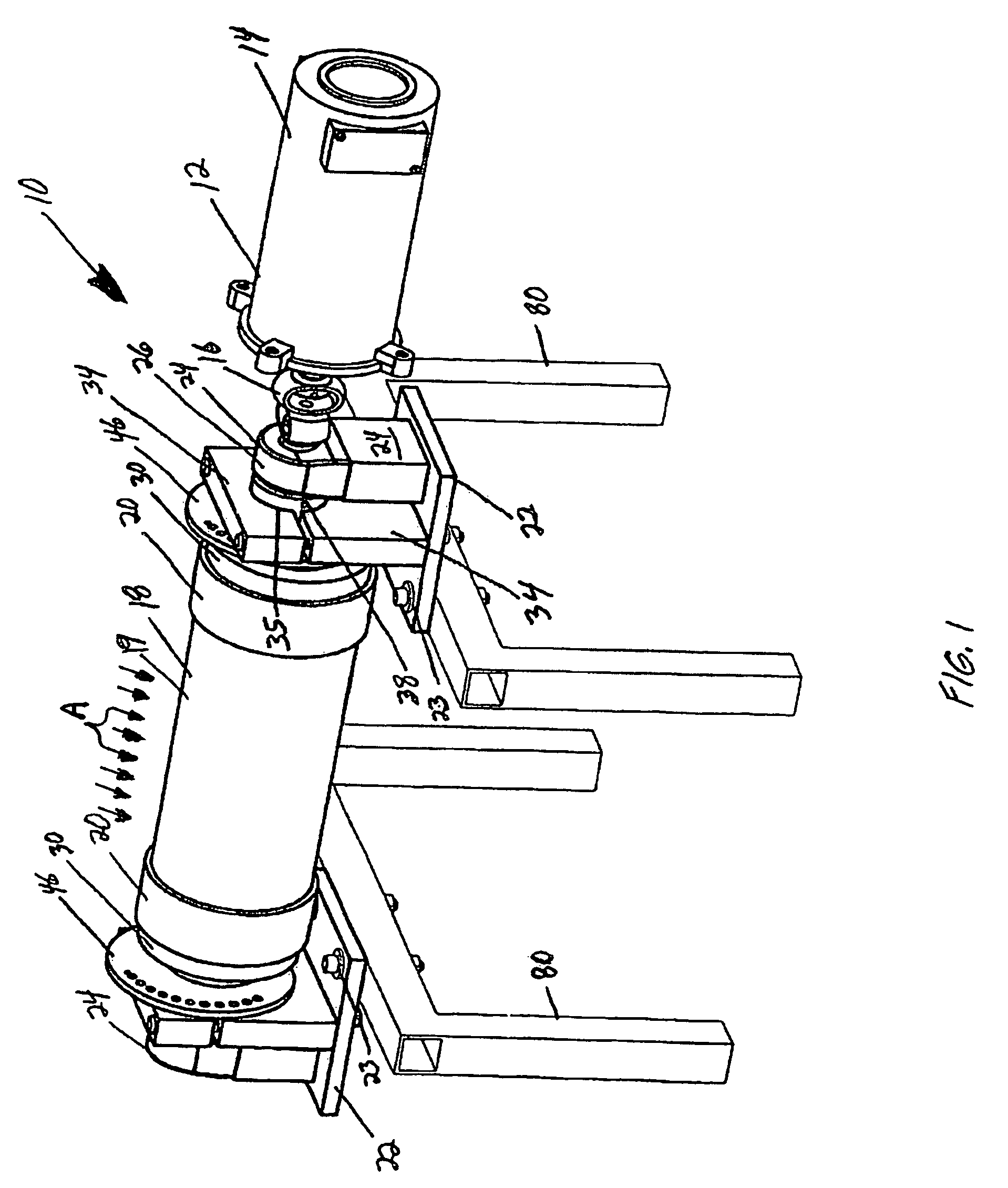

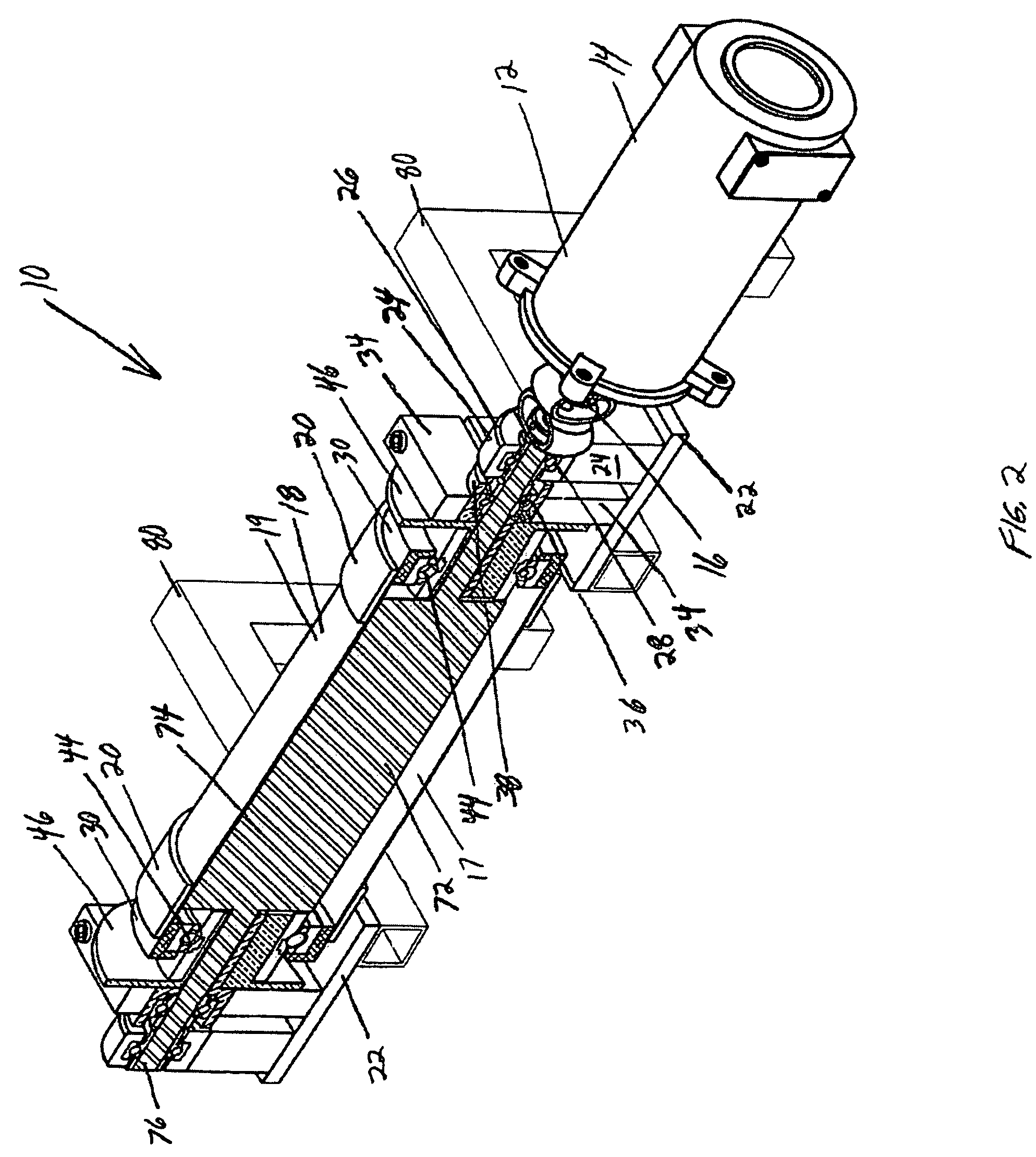

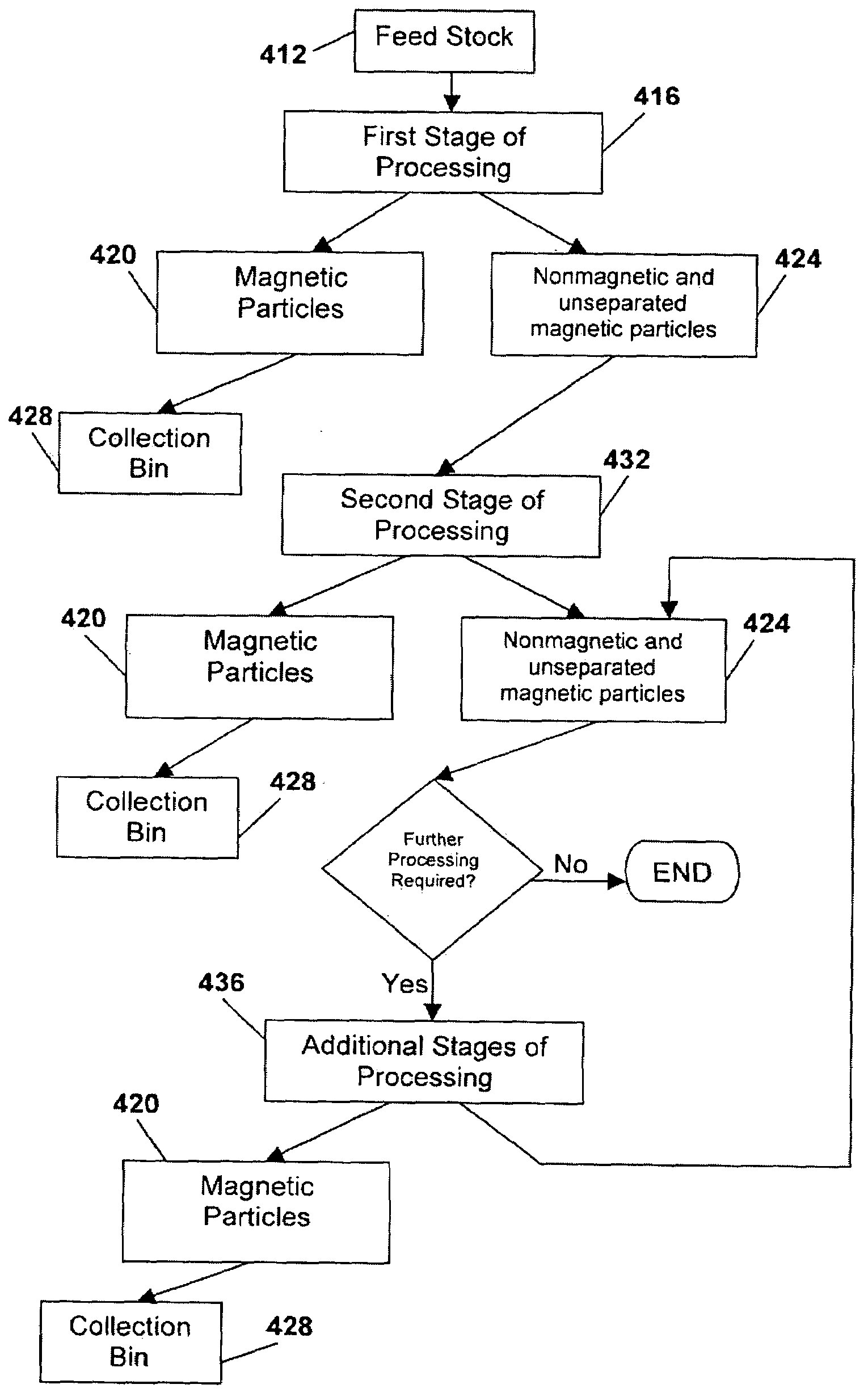

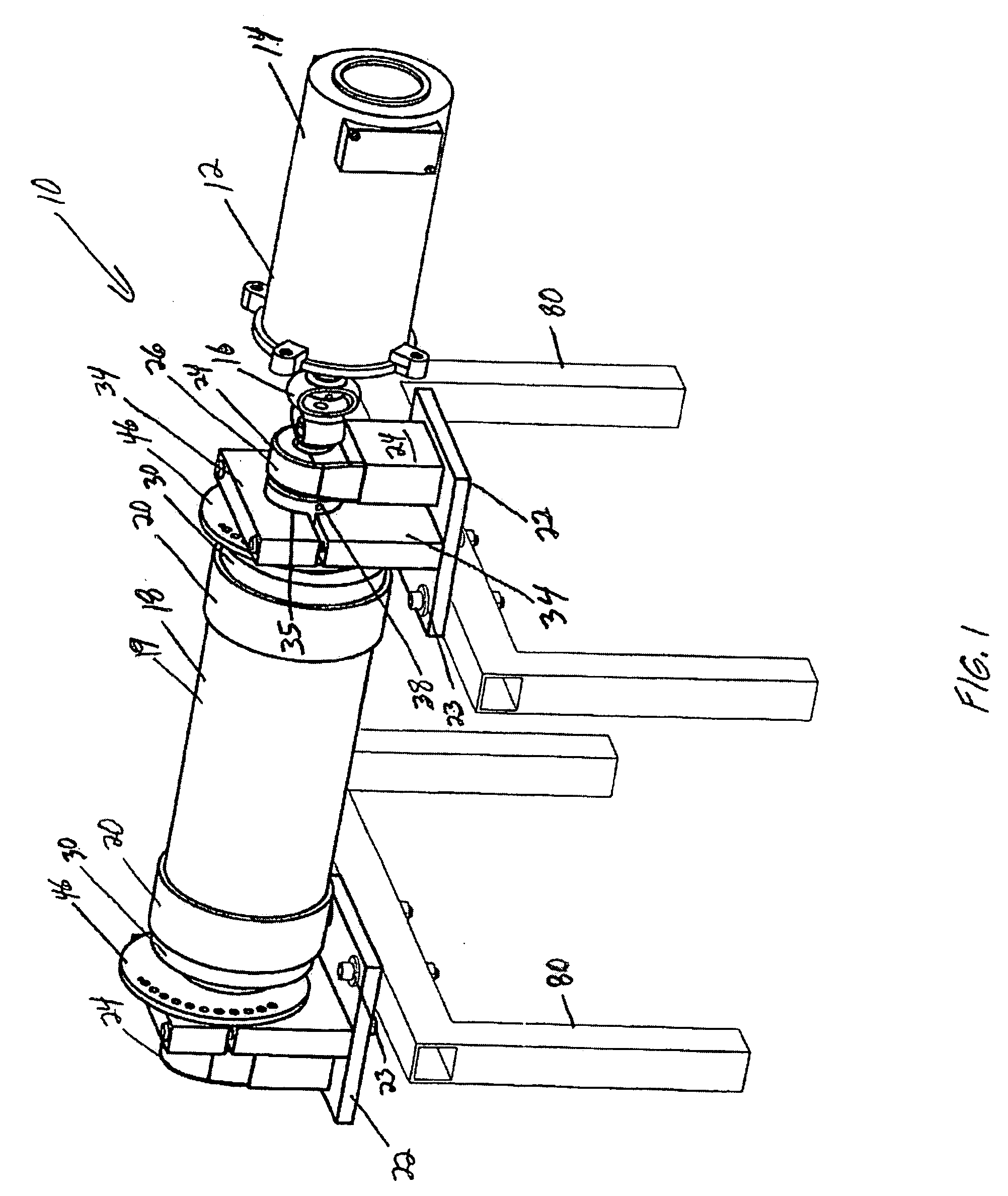

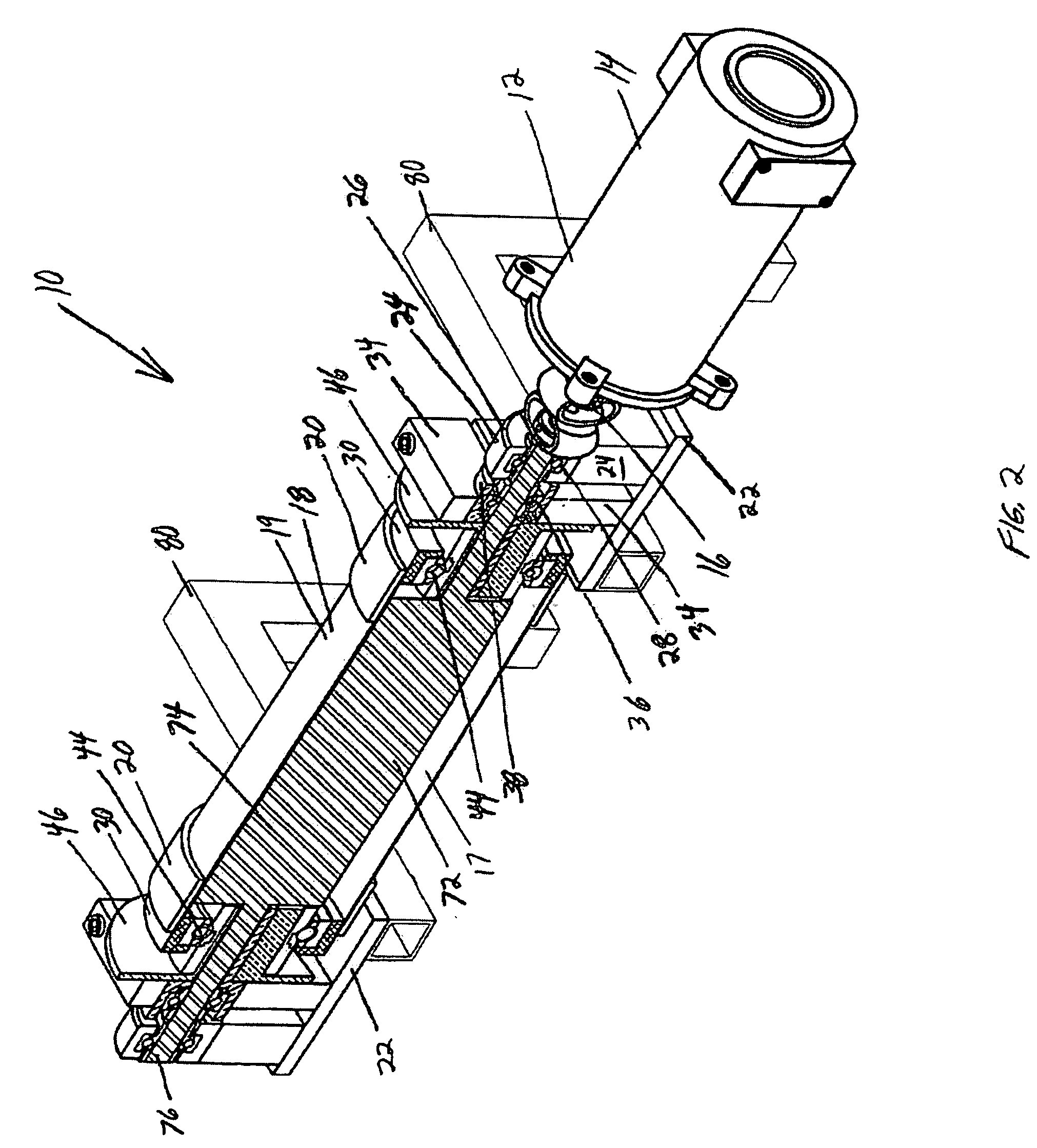

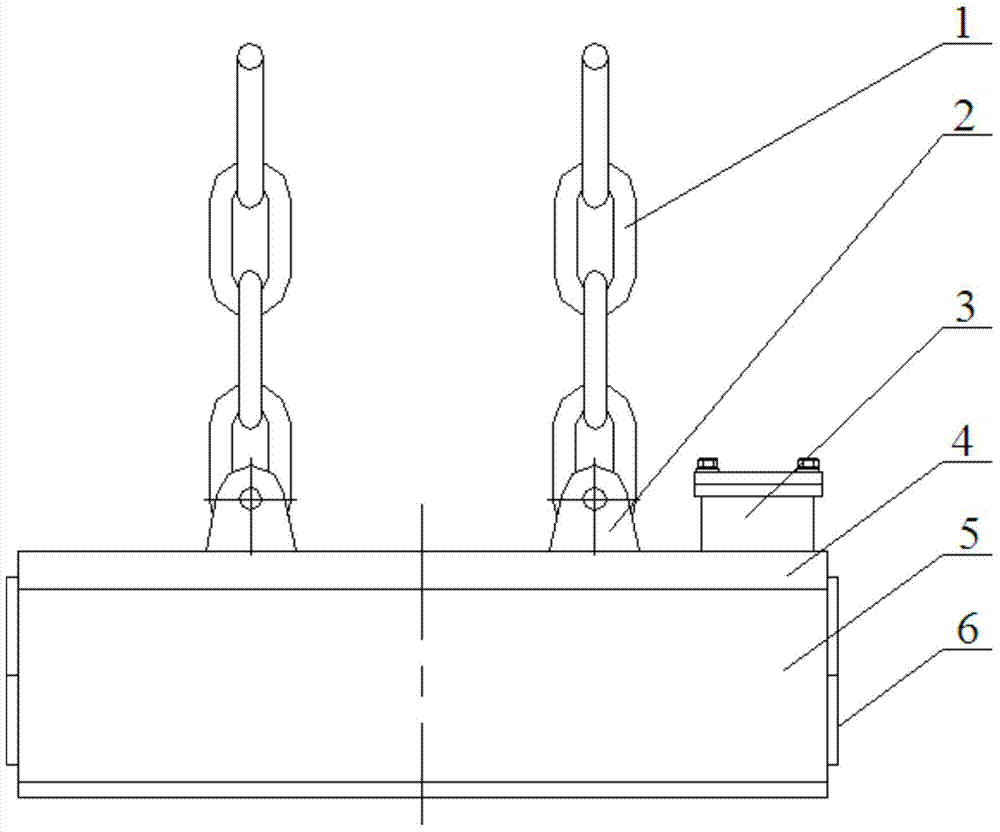

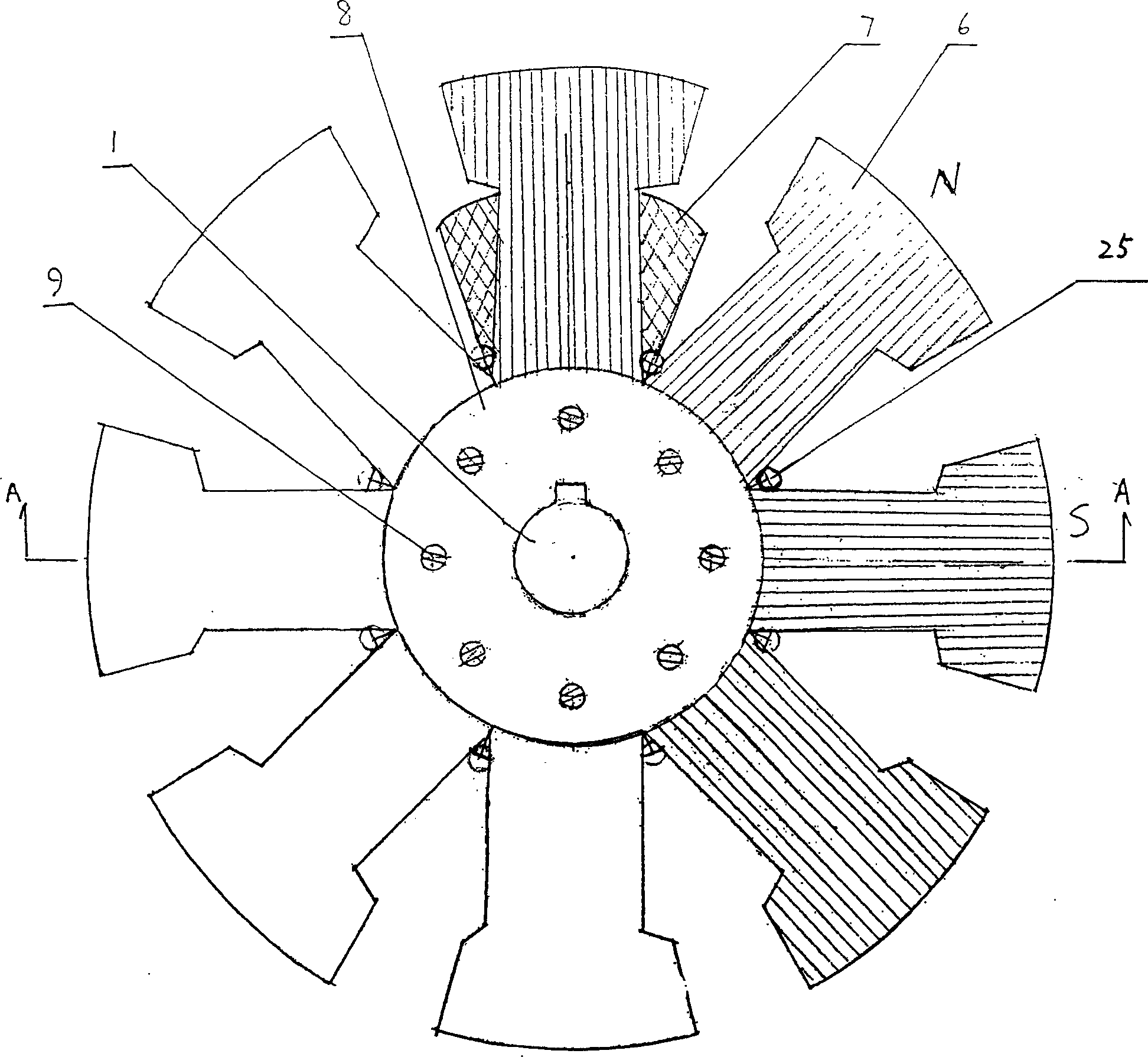

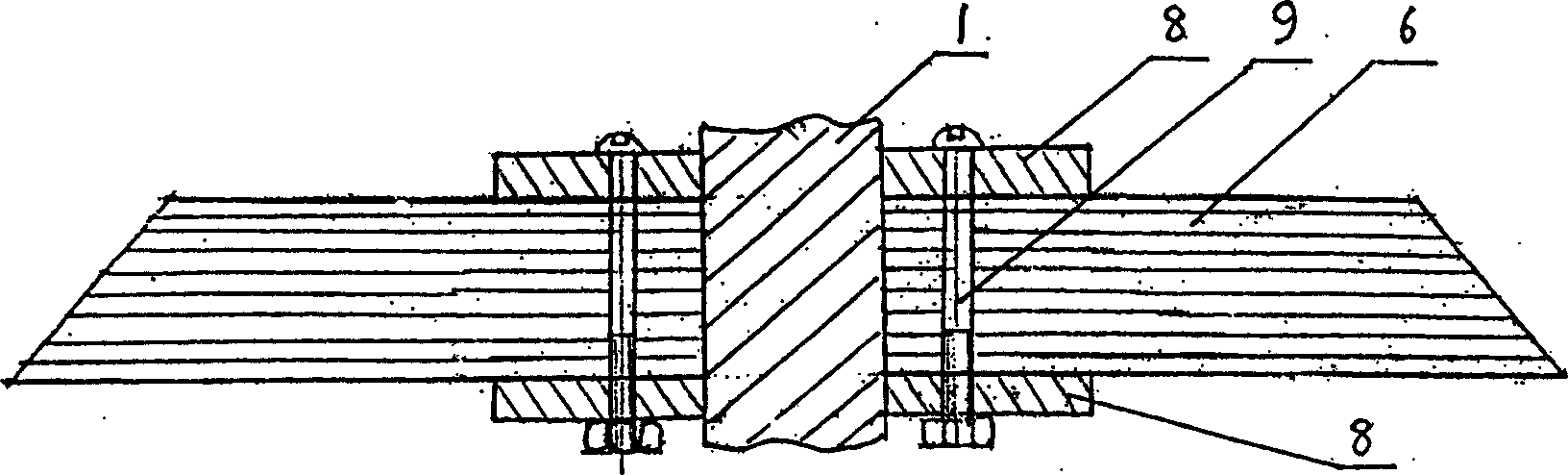

Beltless rare earth roll magnetic separator system and method

InactiveUS7841474B2Good magnetic performanceEasy to separateMagnetic separationMechanical energy handlingRare earthMagnetic separator

A material separator system and method for magnetically separating components of feedstock by directing the feedstock onto a thin rotating shell enclosing one or more rotating magnetic rolls capable of riding upon the interior of the shell. In one embodiment, a cam-and-bearing arrangement is used to permit the magnetic roll and shell each to rotate on its own independent axis. This provides the ability to adjust clearance, the line of contact, and the degree of contact between the magnetic roll and the shell. In another embodiment, a different arrangement provides the same capabilities. The system can be configured to drive a magnetic roll, which then drives the shell, or it can be configured to drive the shell, which then drives the magnetic roll. The system can also be configured as a retreater for retreating feedstock.

Owner:OUTOTEC OYJ

Beltless rare earth roll magnetic separator system and method

InactiveUS20100122940A1Good magnetic performanceEasy to separateMagnetic separationMechanical energy handlingRare earthMagnetic separator

A material separator system and method for magnetically separating components of feedstock by directing the feedstock onto a thin rotating shell enclosing one or more rotating magnetic rolls capable of riding upon the interior of the shell. In one embodiment, a cam-and-bearing arrangement is used to permit the magnetic roll and shell each to rotate on its own independent axis. This provides the ability to adjust clearance, the line of contact, and the degree of contact between the magnetic roll and the shell. In another embodiment, a different arrangement provides the same capabilities. The system can be configured to drive a magnetic roll, which then drives the shell, or it can be configured to drive the shell, which then drives the magnetic roll. The system can also be configured as a retreater for retreating feedstock.

Owner:OUTOTEC OYJ

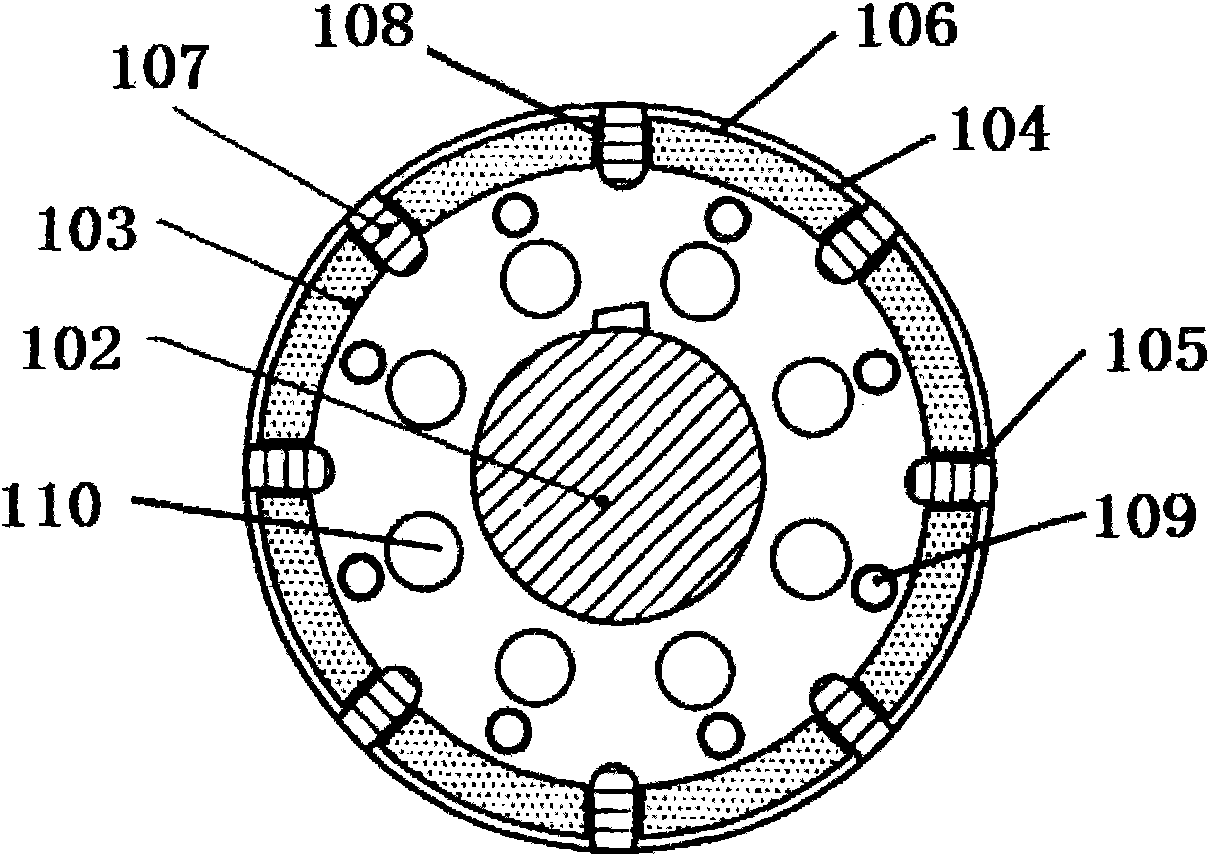

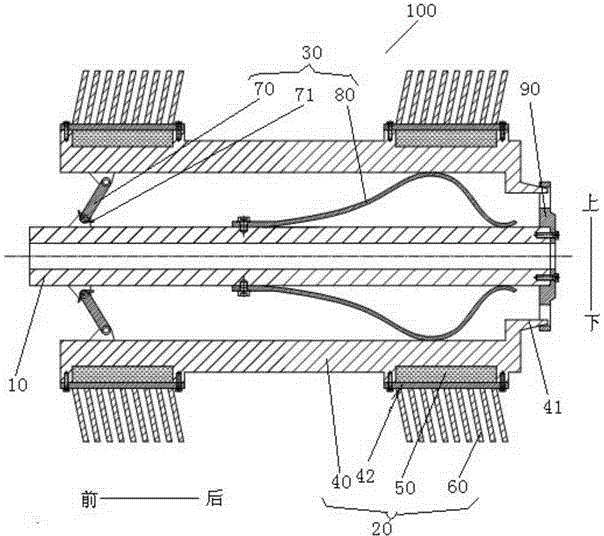

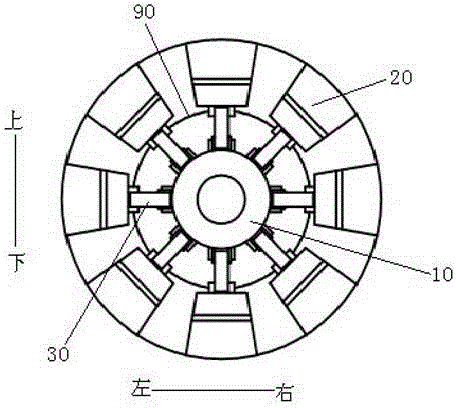

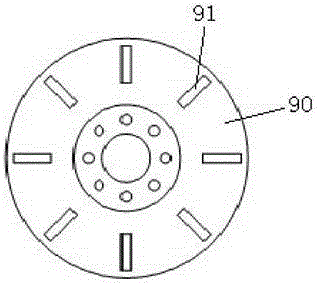

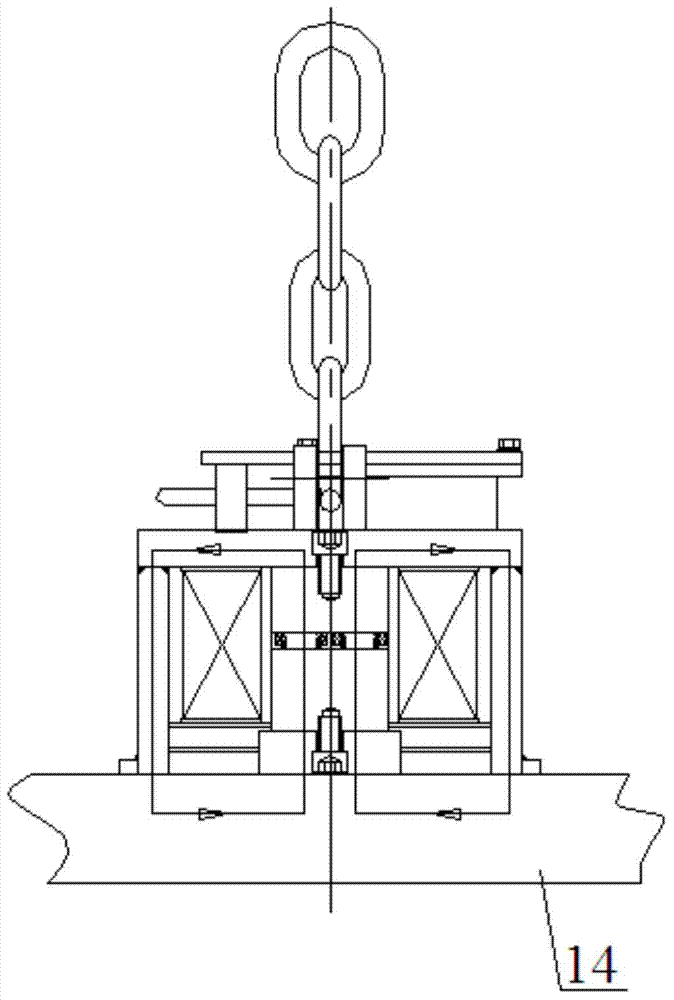

Three-dimensional magnetic flux leakage imaging detecting floated magnetizing component for pipeline

ActiveCN104061441AGuaranteed accuracyImprove accuracyMagnetic bodiesPipeline systemsEngineeringMagnetic flux leakage

The invention discloses a three-dimensional magnetic flux leakage imaging detecting floated magnetizing component for a pipeline. The floated magnetizing component comprises a mandrel, a plurality of floated magnetizing blocks and a plurality of supporting components, wherein the floated magnetizing blocks are arranged between the outer wall surface of the mandrel and the inner wall surface of the pipeline, and uniformly separated in the circumference direction of the mandrel; at least one part of each floated magnetizing block is propped against the inner wall surface of the pipeline; the floating and magnetizing block comprises a magnetizer, two magnetic pieces and a plurality of silicon steel sheets; the magnetizer extends in the axial direction of the mandrel and is column-shaped; the two magnetic pieces are respectively arranged on the outer wall surface of the magnetizer and arranged at an interval in the front-back direction; the silicon steel sheets are respectively connected with the two magnetic pieces; the free ends of the silicon steel sheets are respectively propped against the inner wall surface of the pipeline; the supporting components are respectively and movably arranged between the floated magnetizing blocks and the outer wall surface of the mandrel; each supporting component is propped against the inner wall surface of the magnetizer and the outer wall surface of the mandrel. The component is good in magnetoconductivity, simple in structure, good in applicability, and accurate in detection.

Owner:TSINGHUA UNIV

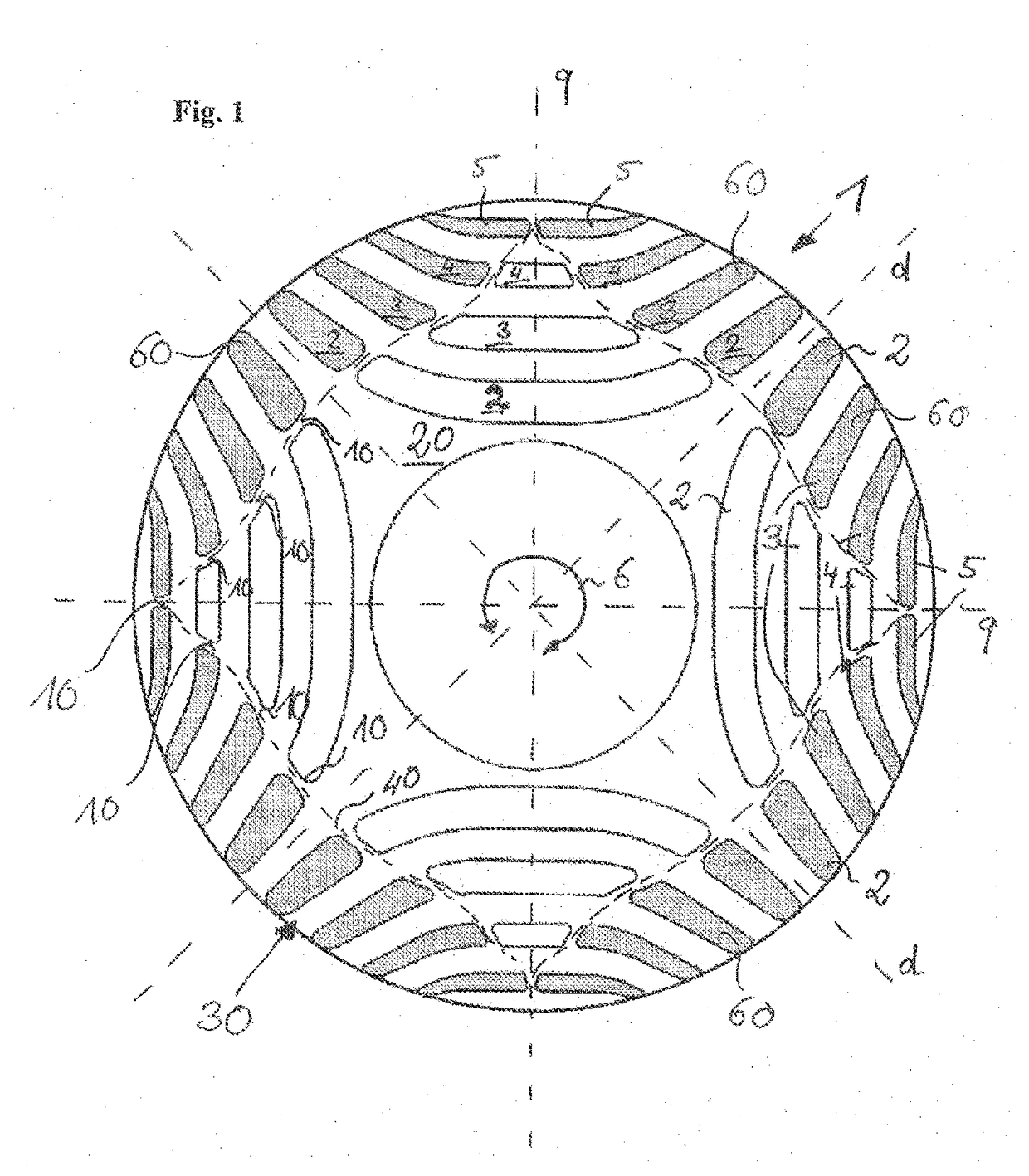

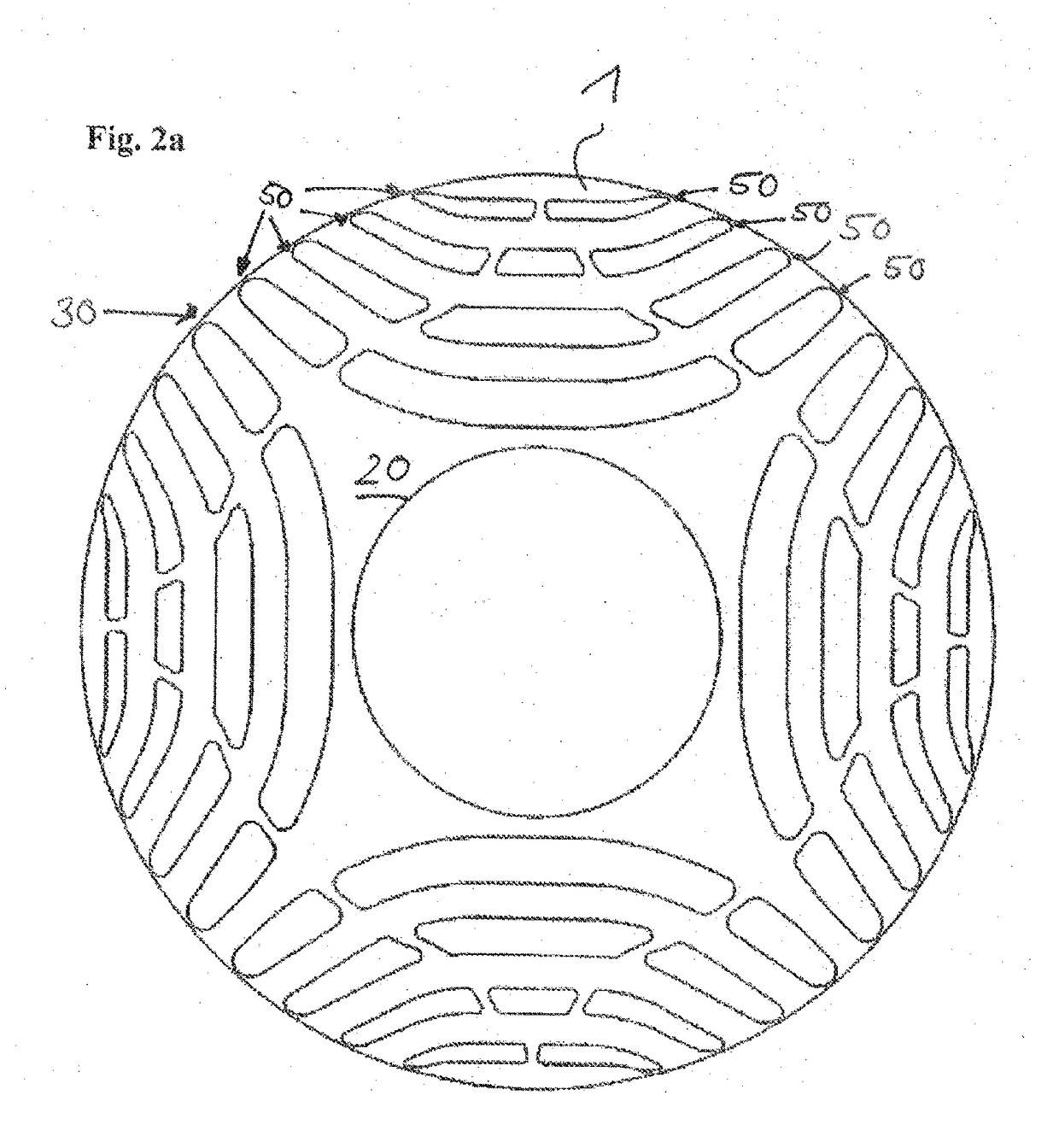

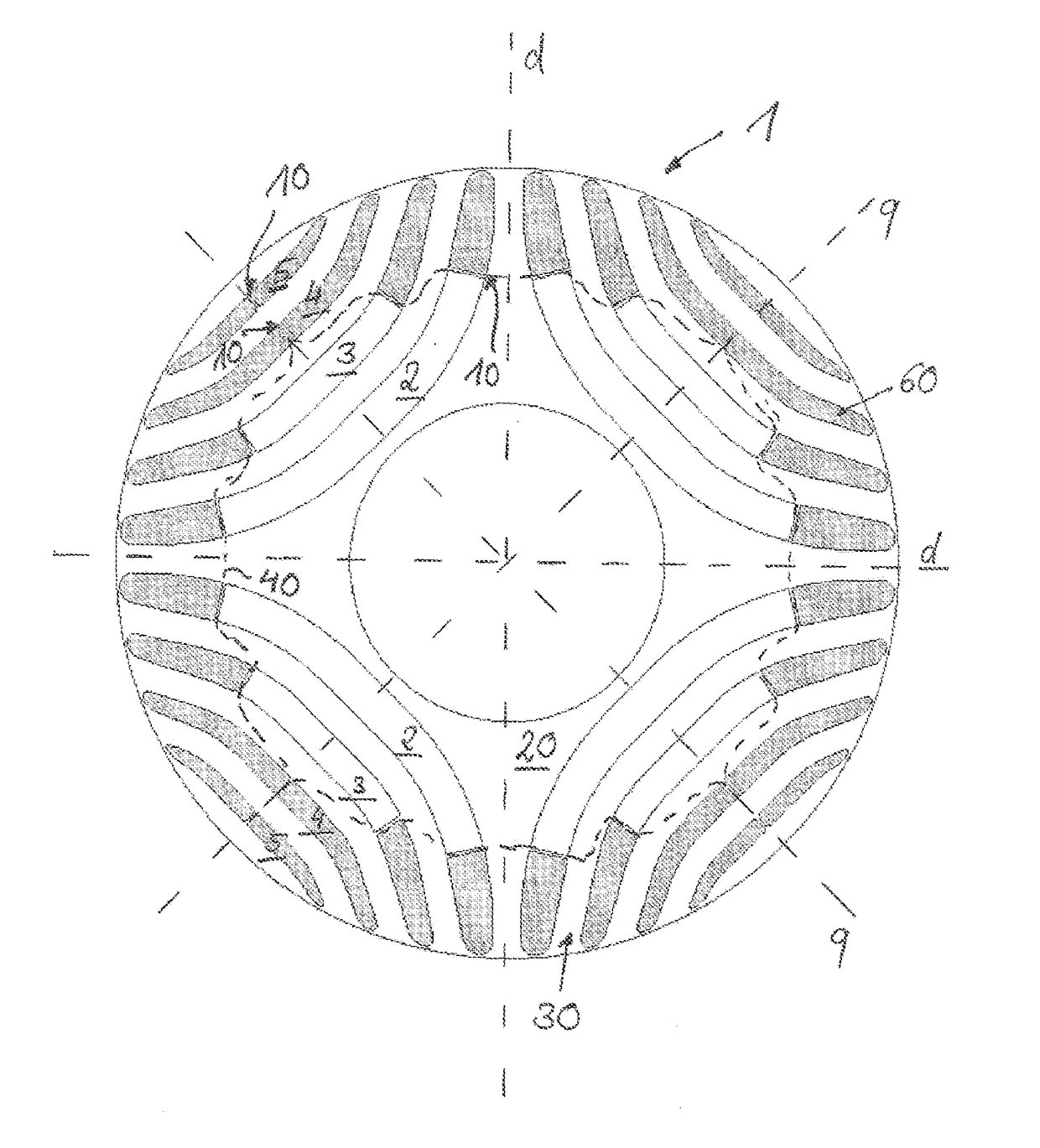

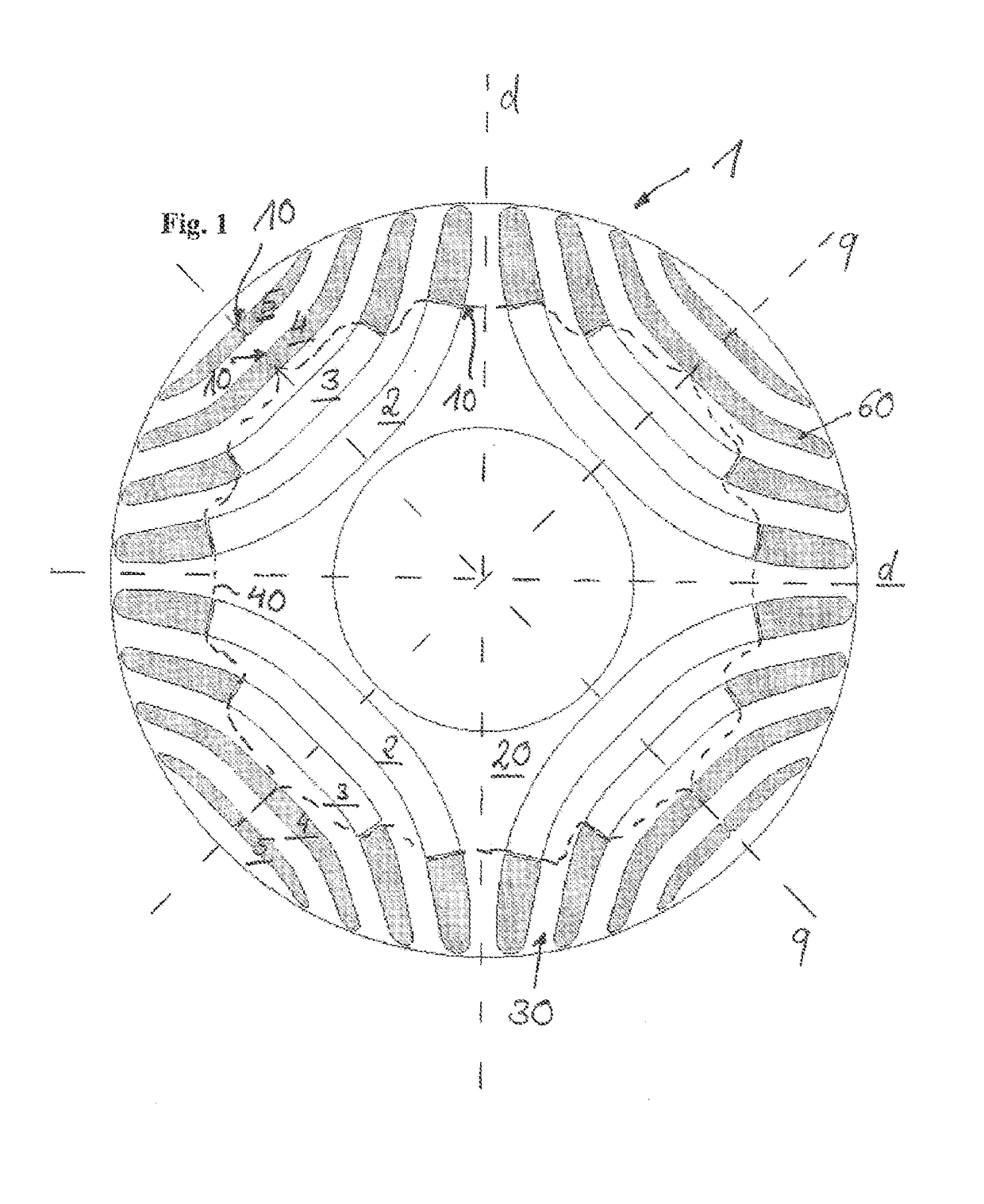

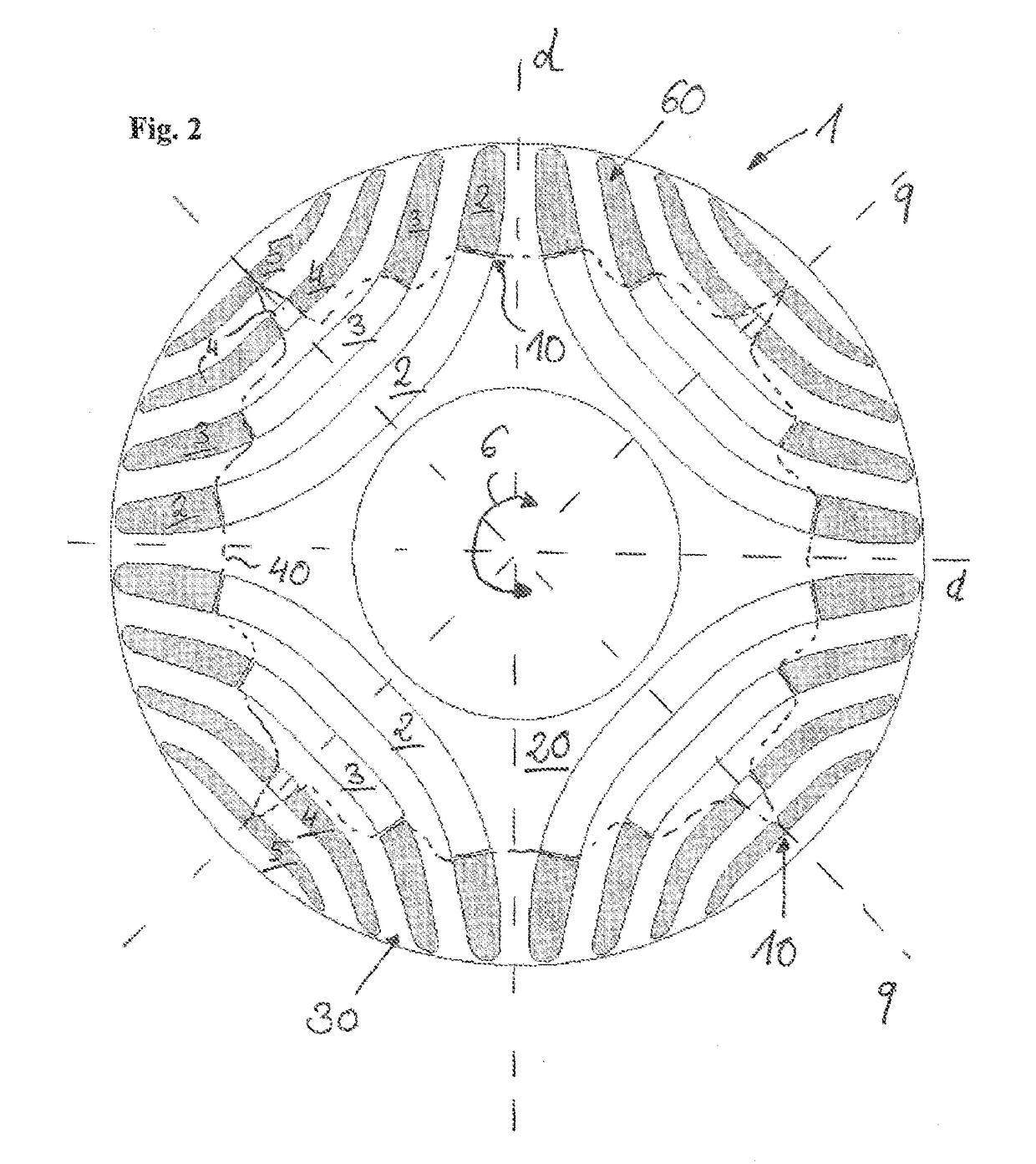

Rotor, Reluctance Machine and Method for Manufacturing the Rotor

ActiveUS20170237307A1Improve stabilityImprove the immunityMagnetic circuit rotating partsSynchronous motorsFilling materialsMechanical engineering

A rotor for a reluctance machine and a method of producing a rotor for a reluctance machine is provided. The rotor is formed as a soft magnetic element which is cylindrical in shape. The soft magnetic element has recesses for forming flux barriers, one or more flux barriers being at least partially filled with a filler material, and the filler material of said flux barriers extending up to the rotor periphery and forming part of the rotor periphery.

Owner:KSB AG

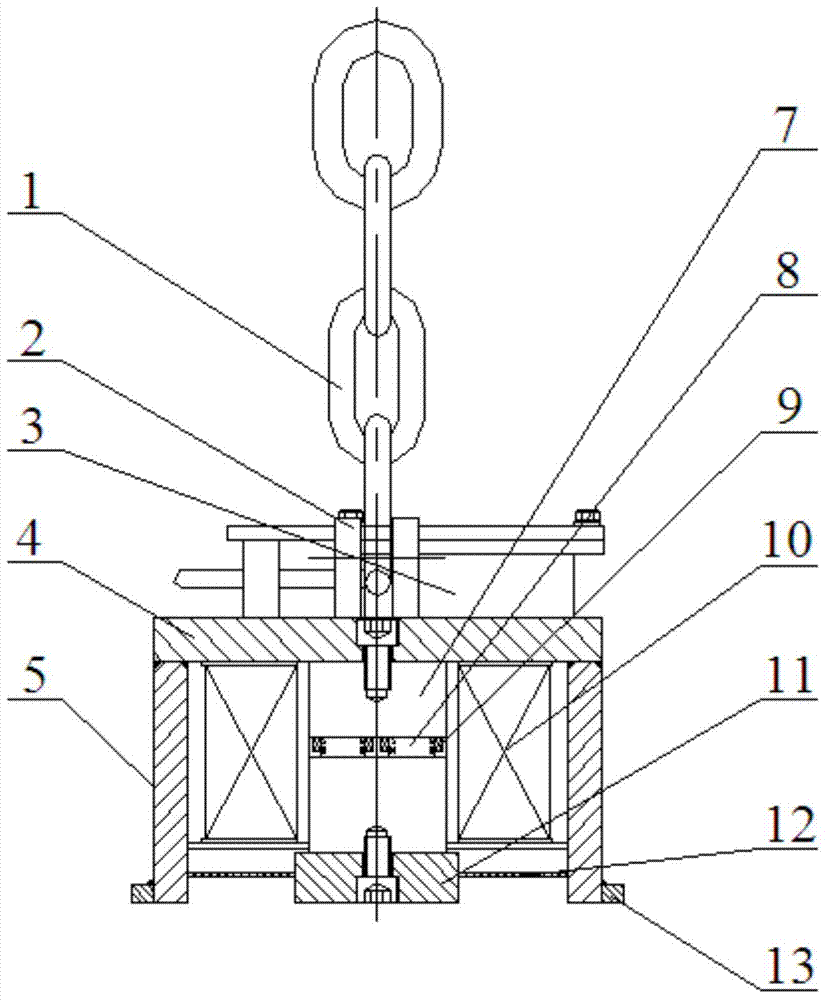

High-temperature-resistant electric control hoisting electro permanent magnet

InactiveCN104276506AOvercome sensitivityStrong suctionLoad-engaging elementsIntermediate frequencyMagnetic poles

The invention discloses a high-temperature-resistant electric control hoisting electro permanent magnet which comprises chains connected with hoisting equipment, lifting lugs arranged at the bottom ends of the chains, and an electro permanent magnet body fixedly connected to the bottom ends of the lifting lugs, wherein the electro permanent magnet body is of a sealed integrated structure consisting of a top plate, side plates, an end plate, an inner magnetic plate and a heat insulation plate; an iron core is arranged in the middle in the electro permanent magnet body; main excitation coils sleeve the outside of the iron core; a plurality of groups of magnetic steel are respectively arranged in the middle of the iron core; demagnetization coils respectively sleeve the outside of the multiple groups of magnetic steel; an outer magnetic pole is arranged at the bottom end outside the electro permanent magnet body; the top plate, the side plates, the outer magnetic pole, the inner magnetic plate, the iron core and the multiple groups of magnetic steel form a magnetic loop. According to the high-temperature-resistant electric control hoisting electro permanent magnet, current meeting different demands is generated by using electric control energy; during excitation, the high direct current is supplied; during demagnetization, the intermediate-frequency alternating current is supplied to the demagnetization coils; and therefore, extremely good and convenient control can be realized.

Owner:马鞍山起劲磁塑科技有限公司

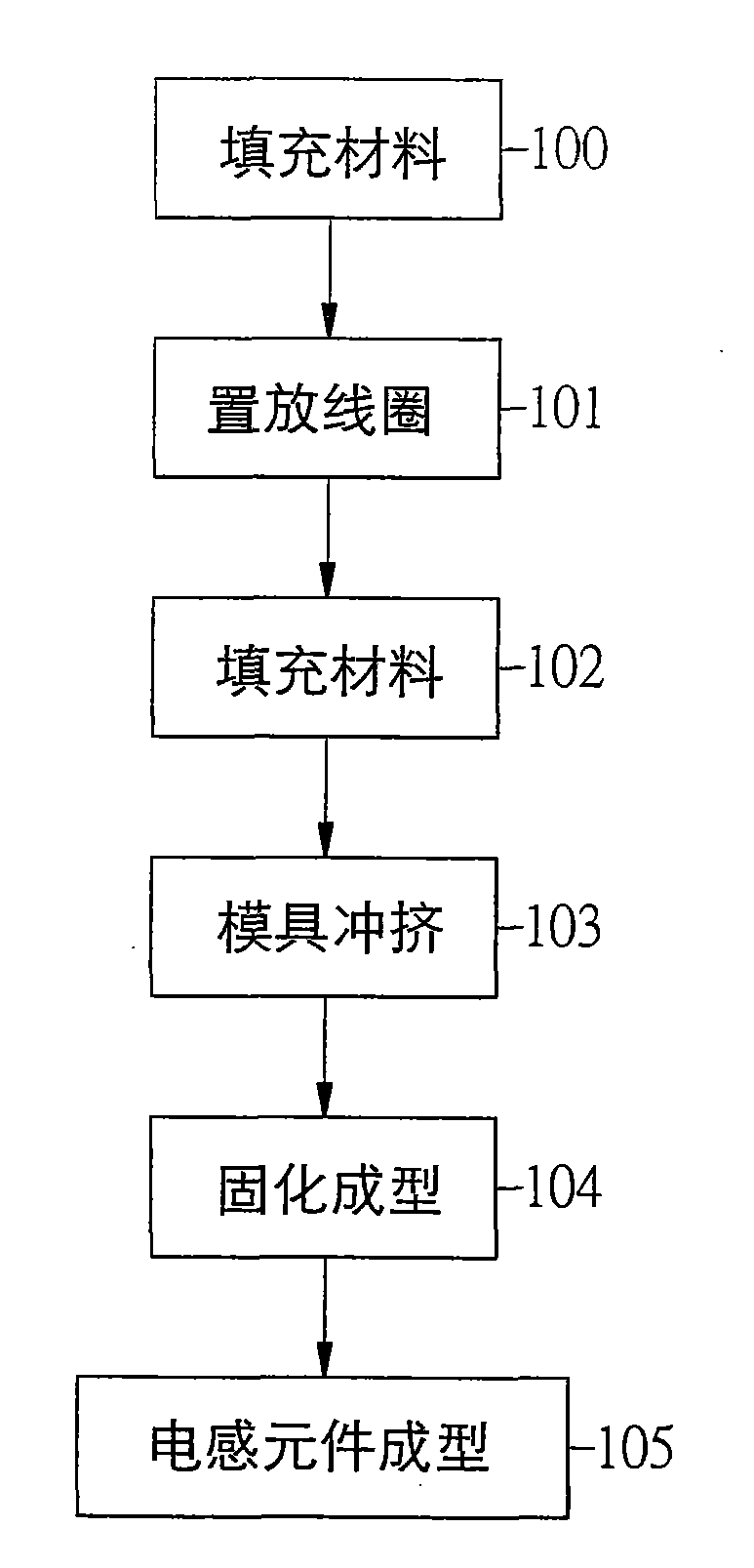

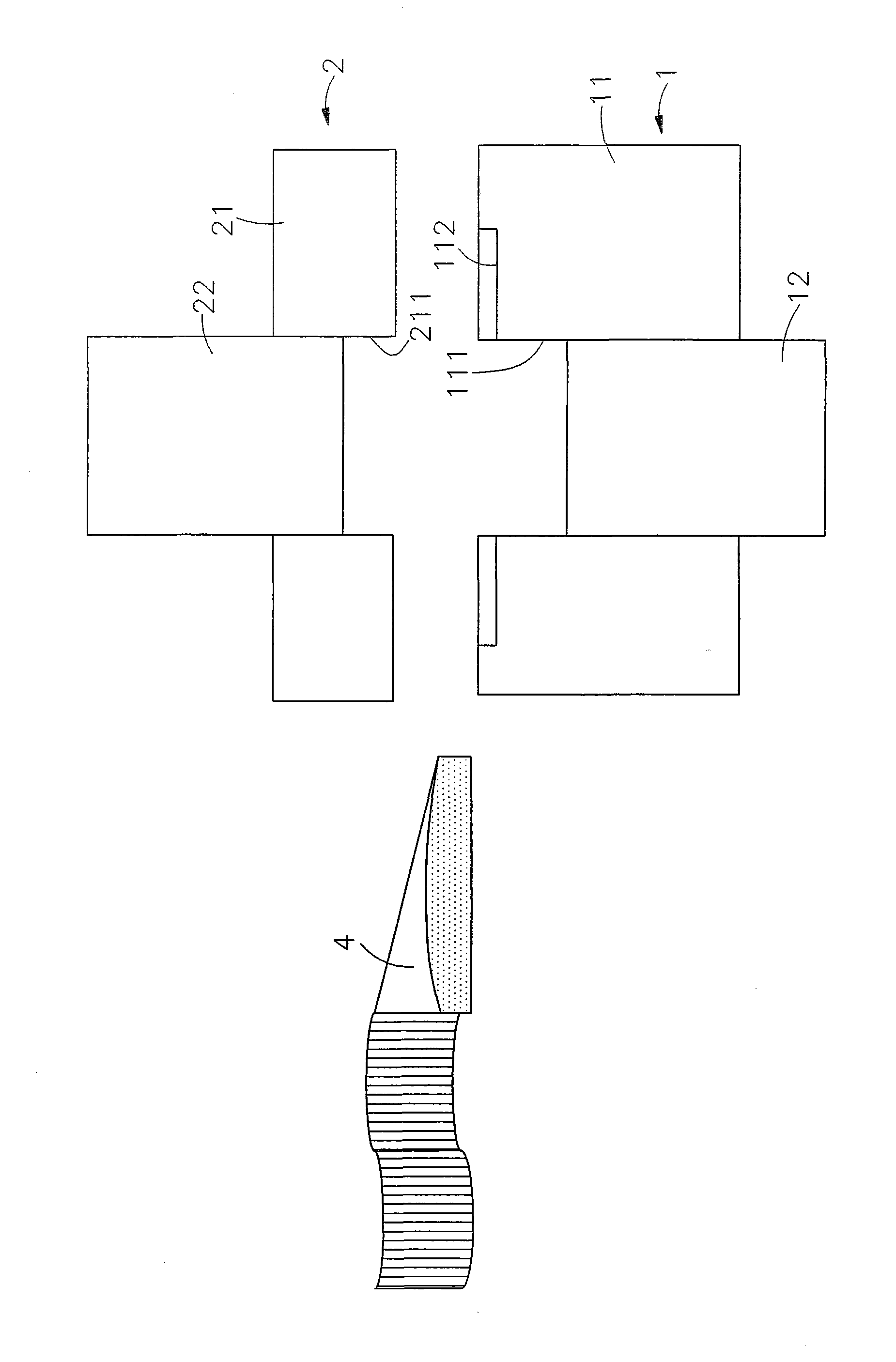

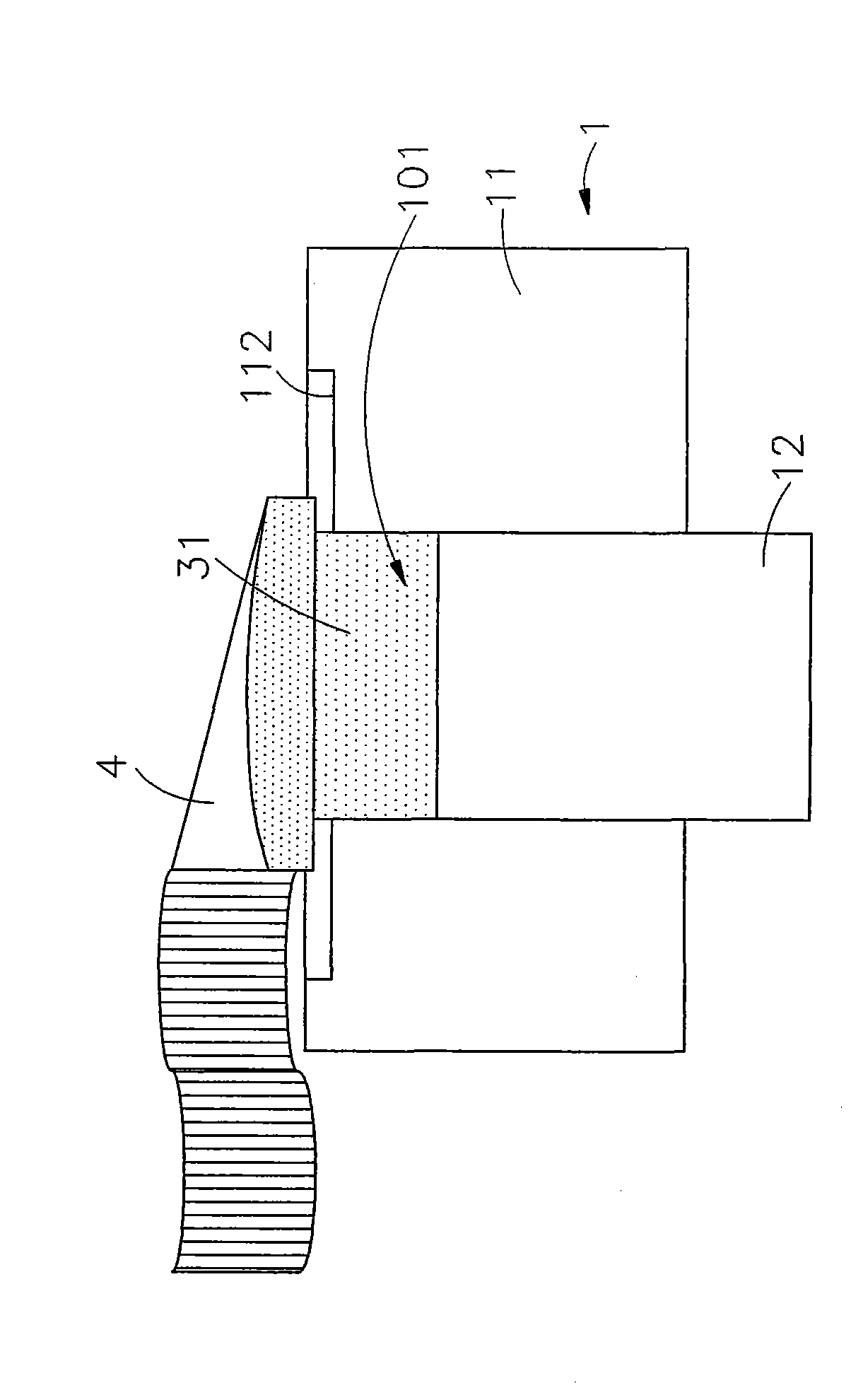

Method for manufacturing inductive element

InactiveCN102122560AReduce material costsAvoid it happening againInductances/transformers/magnets manufactureFixed signal inductancesSilicon alloyMetallic materials

The invention discloses a method for manufacturing an inductive element, comprising the steps of: manufacturing the inductive element by utilizing a die, wherein the die comprises a lower die core and an upper die core; causing the lower die core and the upper die core to relatively move to a filling position and an extrusion position along an axial direction; when the lower die core is located at the filling position, filling an iron silicon alloy material into a first space formed by the lower die core; placing a coil in the iron silicon alloy material in the first space and exposing an extension part of the coil out of the iron silicon alloy material; placing the upper die core at the filling position and filling the iron silicon alloy material into a second space formed by the upper die core to cover the coil body; then moving the upper and lower die cores to the extrusion position to ensure that the iron silicon alloy material is combined with the coil; and solidifying the iron silicon alloy material to ensure that the coil body is fixed in the iron silicon alloy material, wherein high magnetic conductivity is generated by matching the iron silicon alloy material with an integrated structure, the number of turns of the coil is reduced and the cost of the metal material of the coil is low so that the inductive element with low cost, low loss and high magnetic conductivity can be integrated.

Owner:TAIPEI MULTIPOWER ELECTRONICS

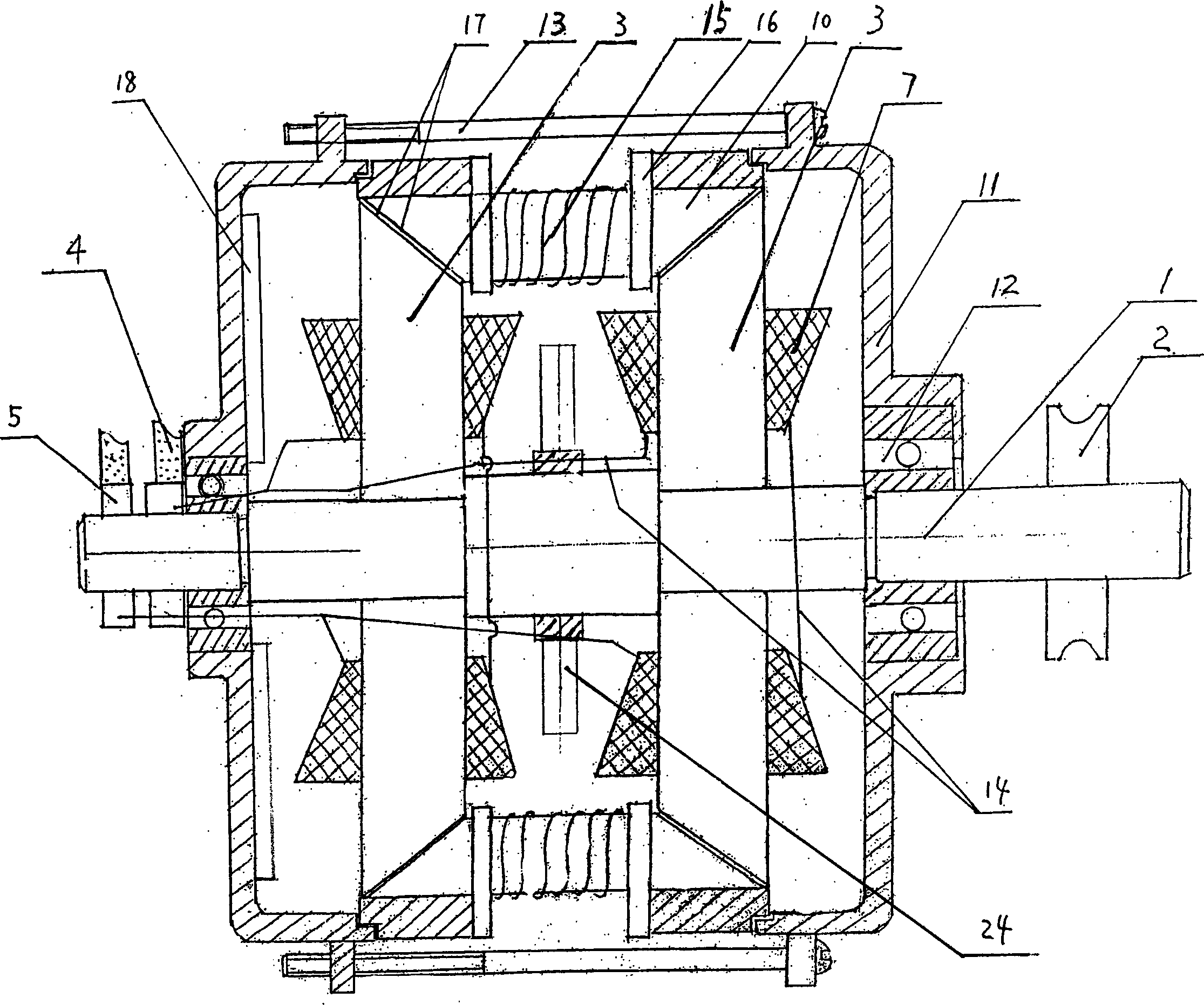

Automobile slotless AC electric generator

InactiveCN1556574AImprove efficiencyReduce temperature riseMagnetic circuit rotating partsMagnetic circuit stationary partsElectricityStator coil

The invention relates to a automobile slot-less alternate electric generator, which includes a stator, rotor and commutator, the rotor includes a rotary shaft, which is covered by the belt wheel, two polar plates and a sliding ring contacting to a carbon brush, the stator includes a stator iron core and stator coil winded out of the iron core, each polar plate of the rotor includes even magnetic polar arranged with radiating type evenly, each magnetic polar is overlapped and connected together with several pieces of cool rolling direction silicon steel plates, each plate is produced according to the orientation direction, each magnetic polar is winded with excitation coil, the winding direction of the joined excitation coils are reverse, the quantity of the stator is the integer times of 3 which is the quantity of the magnetic polar, the stator iron cores are arranged along the circle evenly, and fixed in the slots of the two ring plate, each stator iron core is connected together with several pieces of cool rolling direction silicon steel plates, each piece of cool rolling orientation silicon steel core is produced with the orientation direction, there has a gap between each magnetic polar and the stator iron core. The electricity generating efficiency reaches above 75%.

Owner:肖振霞

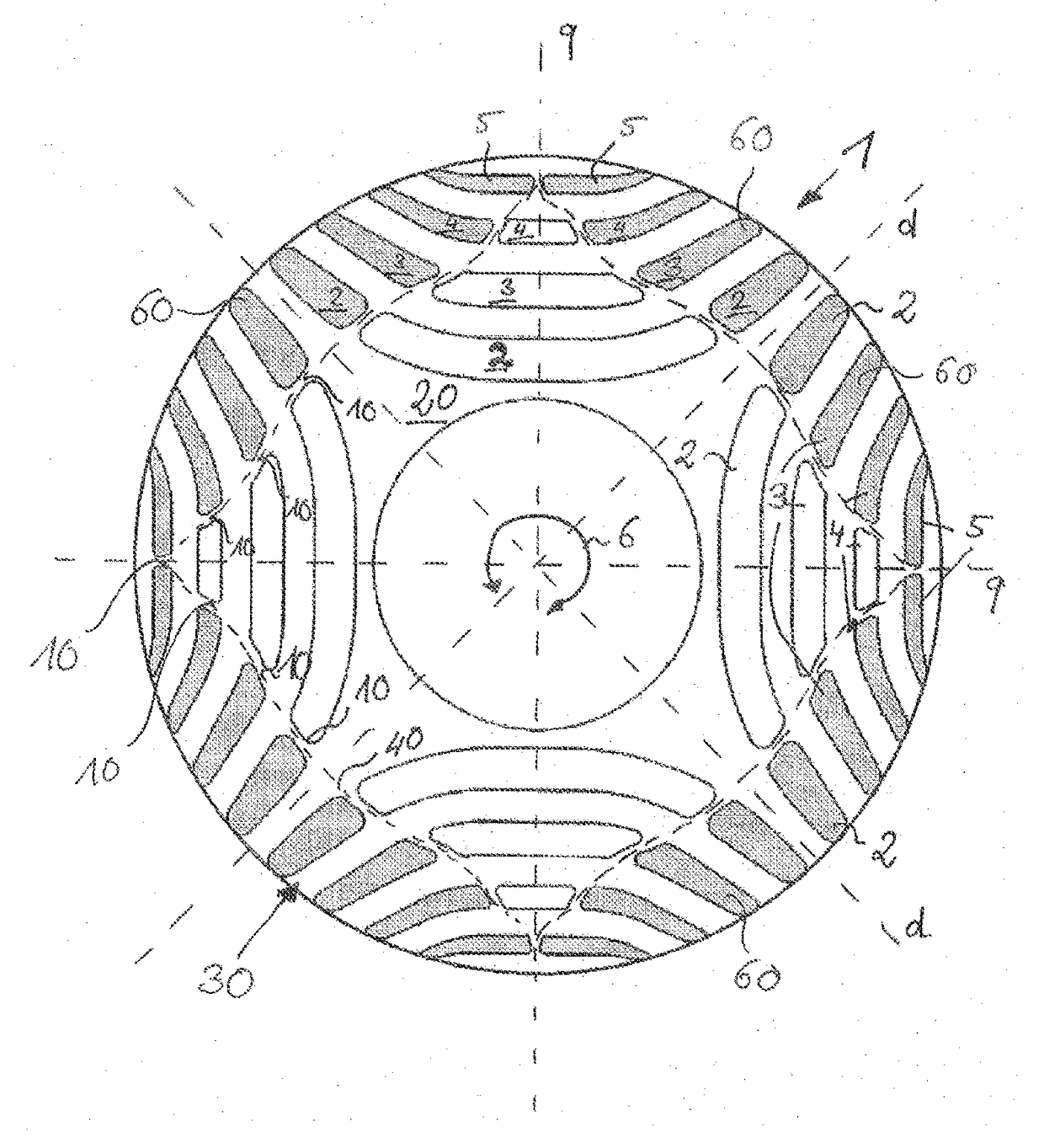

Rotor and Reluctance Machine

ActiveUS20170222505A1Small massOptimal degree of efficacyMagnetic circuit rotating partsSynchronous motorsFilling materialsPhysics

A rotor for a reluctance machine is provided. The rotor includes a soft magnetic element which is cylindrical in shape. The soft magnetic element has recesses forming flux barriers. At least part of the recesses are filled with an electrically conducting and magnetically non-conducting filler material such that a starting cage is formed in a peripheral region of the rotor. The ratio of the surface of the filled region of the flux barriers to the surface of the region of the unfilled flux barriers is at least 0.2 for at least one rotor cycle.

Owner:KSB AG

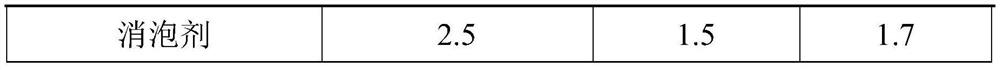

Photocureable magnetic-conductive and light-conductive pressure-sensitive adhesive, adhesive tape and preparation method of adhesive tape

PendingCN112226164AGood light guiding performanceGood magnetic performanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyPolymer science

The invention discloses a photocureable magnetic-conductive and light-conductive pressure-sensitive adhesive, an adhesive tape and a preparation method of adhesive tape. The pressure-sensitive adhesive comprises the following components in parts by weight: 30-40 parts of modified functional resin, 60-80 parts of aliphatic epoxy modified acrylate resin, 5-15 parts of functional monomer, 10-30 partsof diluent, 0.5-1 part of photoinitiator, 5-10 parts of light-conductive filler, 8-12 parts of magnetic-conductive filler, 1-3 parts of rheological agent, 0.5-1.8 parts of leveling agent, 1-2.5 partsof dispersant, 0.8-2.4 parts of coupling agent, 1-3 parts of a defoaming, 0.2-1 part of a chain transfer agent and 20-50 parts of tackifying resin. The light-conductive and magnetic-conductive adhesive disclosed by the invention has the advantages of excellent light-conducting property and magnetic-conducting property, light crosslinking, easy adhesion, easy stripping and certain temperature resistance, and can be widely applied to adhesion of various products needing light conduction and magnetic conduction.

Owner:恩平市盈嘉丰胶粘制品有限公司

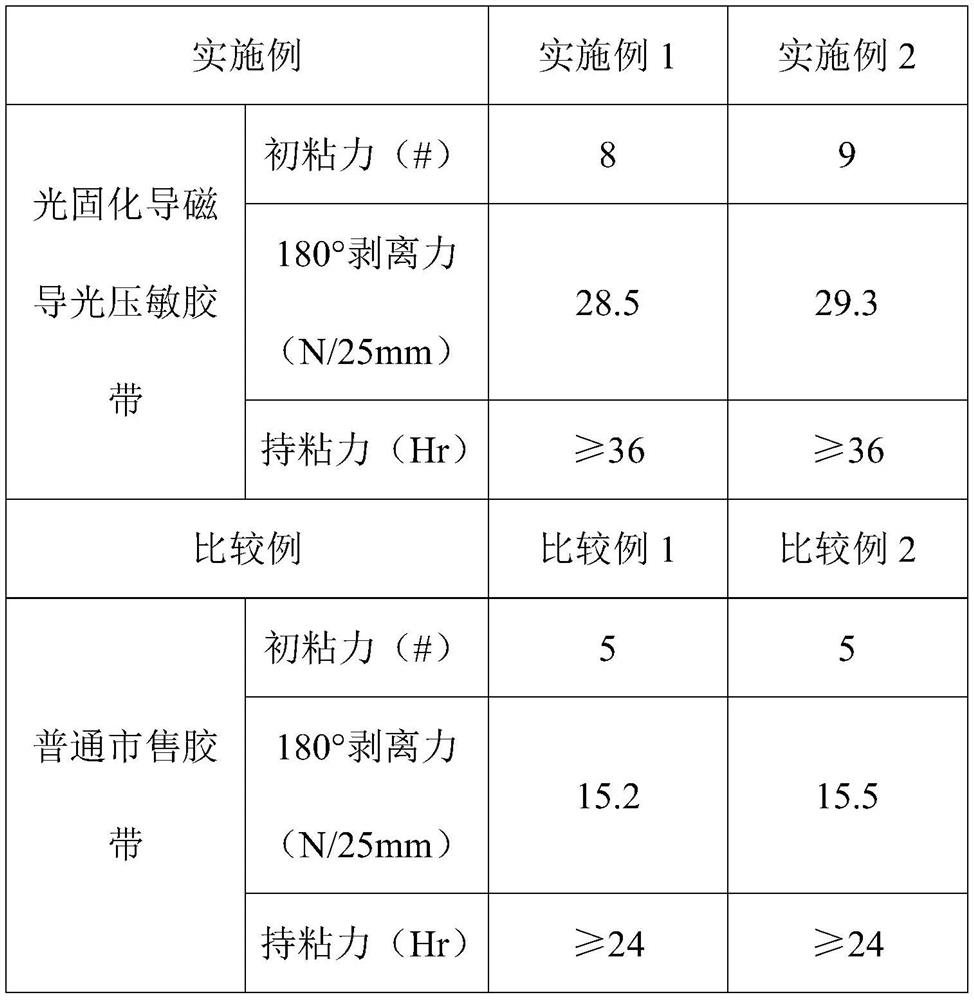

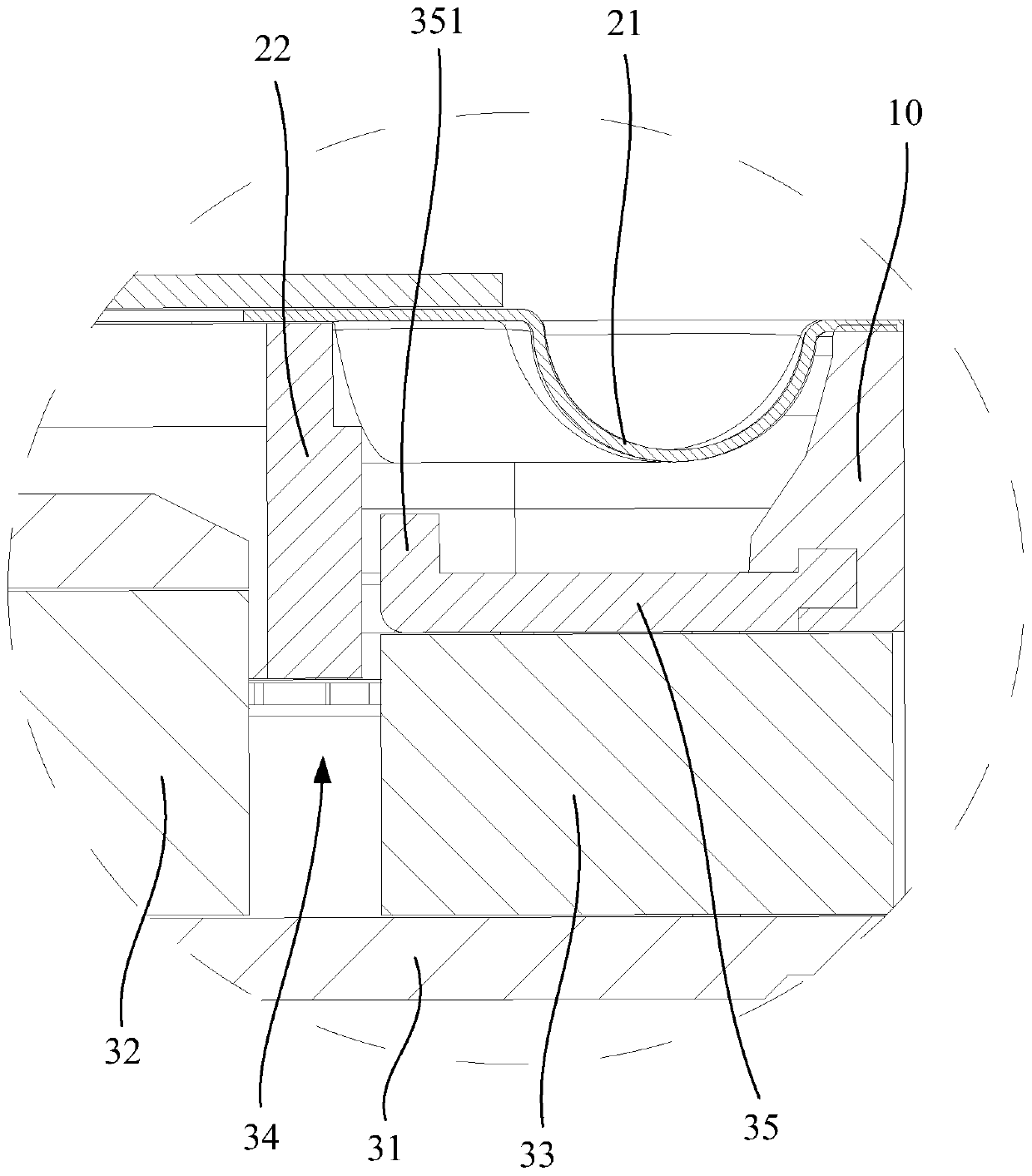

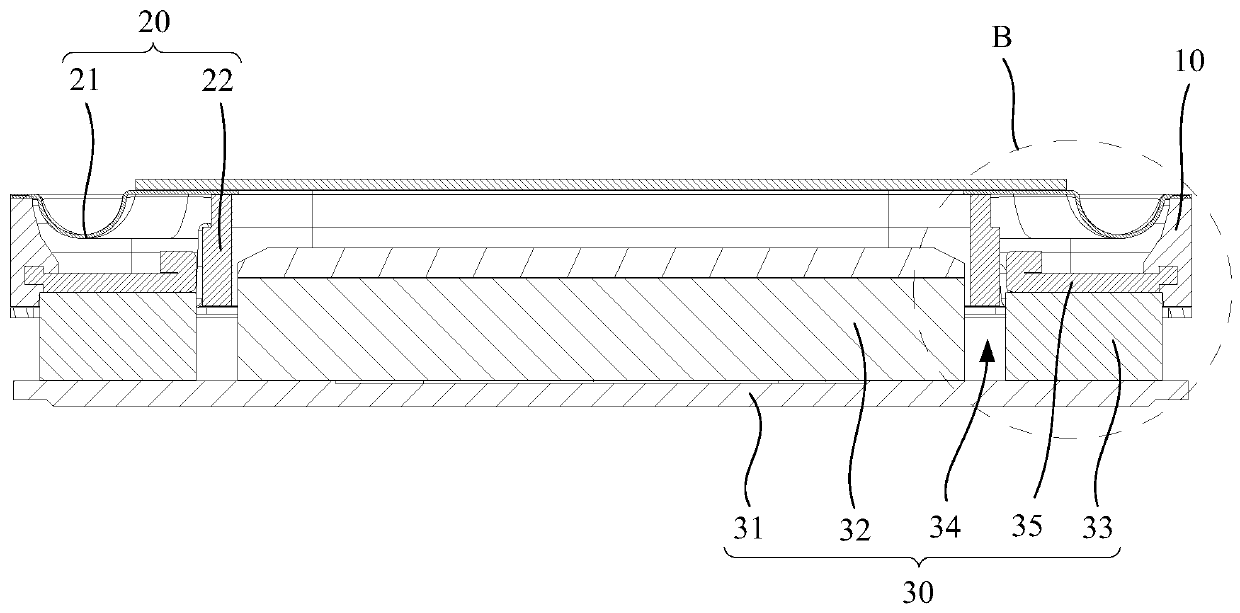

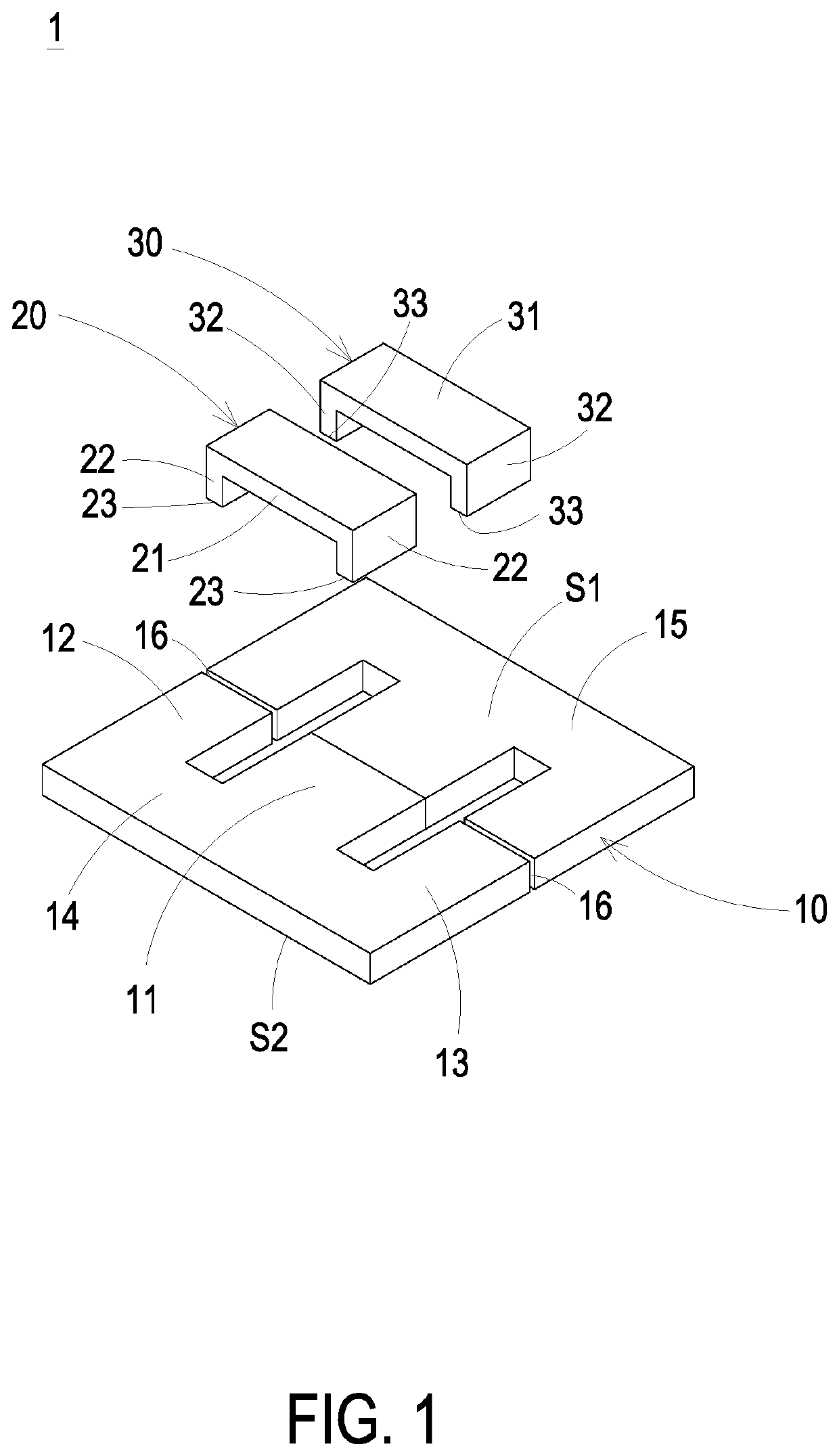

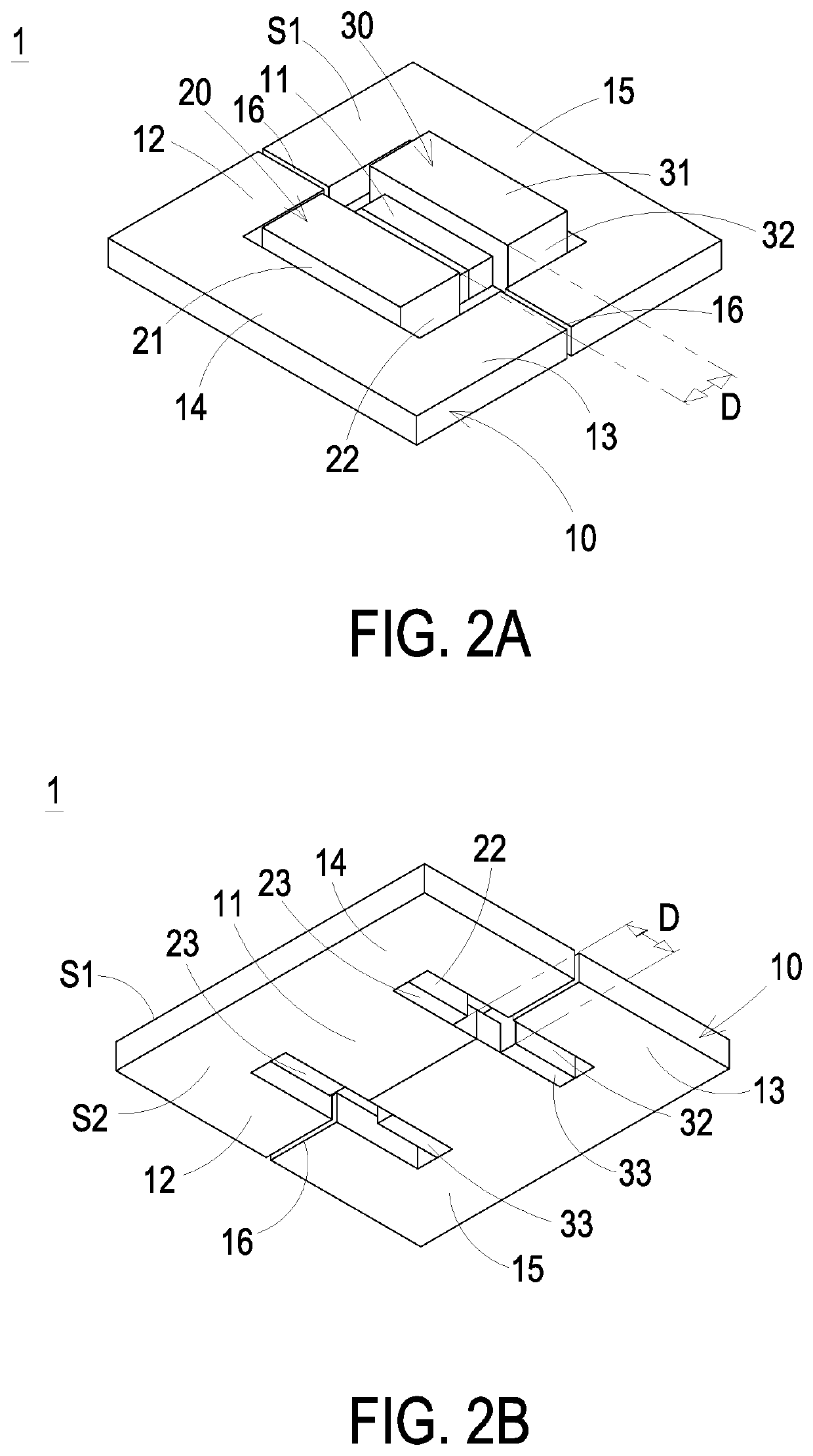

Sound production device and electronic equipment

ActiveCN110933570AIncreasing the thicknessLift coefficientMouthpiece/microphone attachmentsTransducer diaphragmsVoice coilElectronic equipment

The invention discloses a sound production device and electronic equipment. The sound production device comprises a shell, a magnetic circuit system and a vibration system, the magnetic circuit systemis arranged on the shell, comprises a side magnet and a side concentrating flux plate arranged at the upper end of the side magnet. A magnetic gap is formed on the inner side of the side magnet, thevibration system comprises a vibrating diaphragm connected with the shell and a voice coil arranged on the vibrating diaphragm, at least part of the voice coil extends into the magnetic gap, a bendingpart is arranged on one side, close to the magnetic gap, of the side concentrating flux plate, and at least part of the bending part is bent towards the direction of the vibrating diaphragm. According to the technical scheme of the invention, the vibration space of the diaphragm is not affected when the thickness of the part, close to the voice coil, of the side concentrating flux plate is increased.

Owner:GOERTEK INC

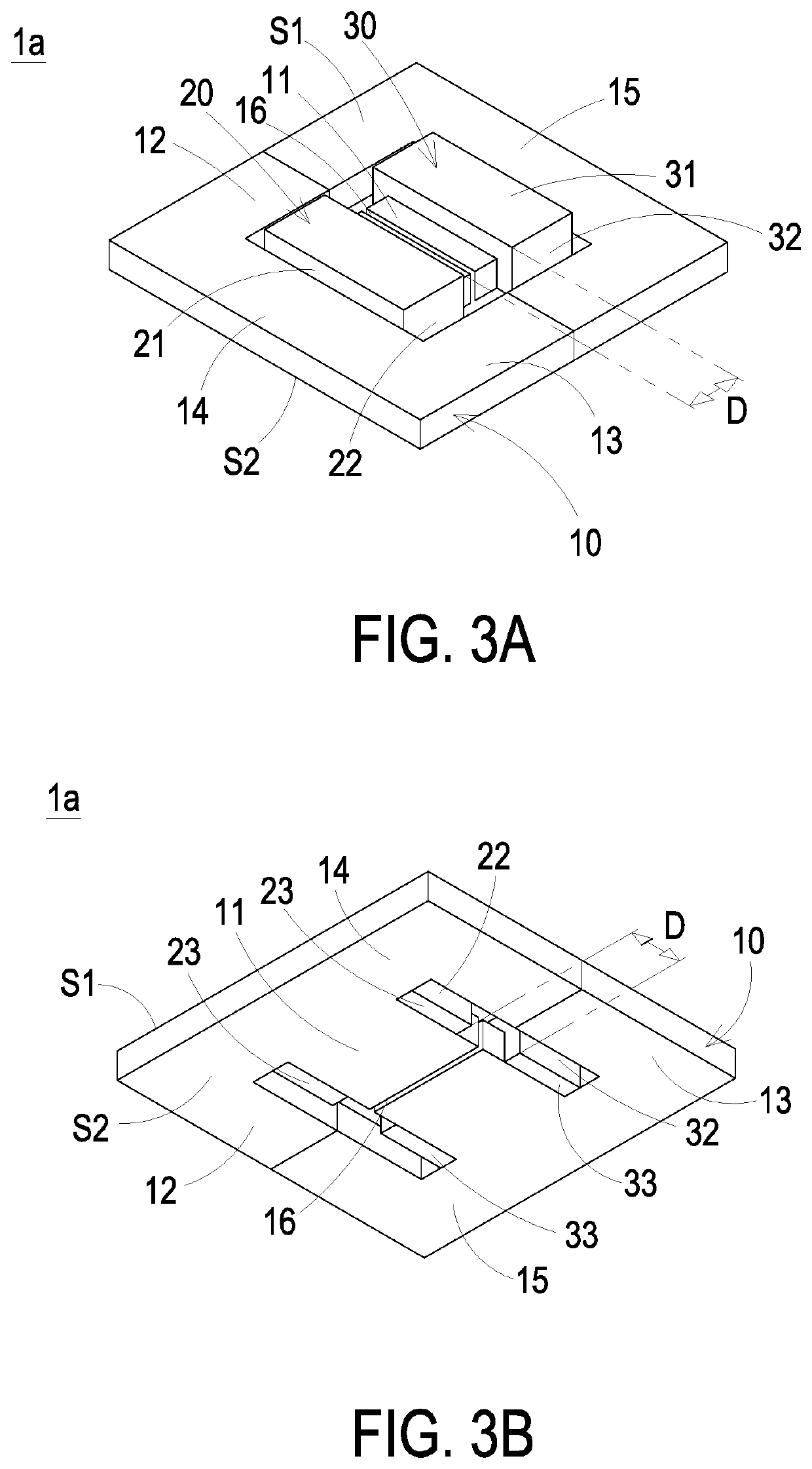

Magnetic component and power module

ActiveUS20190378643A1Reduce lossesHigh strengthTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresComputer moduleEngineering

A magnetic component and a power module using the same are provided. The magnetic component includes a magnetic core, a first winding set and a second winding set. The magnetic core includes two connecting portions connected through three magnetic columns to form two opposite sides. Each connecting portion includes a pair of first air gaps spaced apart by the middle magnetic column. The first winding set and the second winding set are made by a flat conductive body, respectively, and spaced apart at a distance. The first winding set includes two first conducting portions connected through a first horizontal portion. The second winding set includes two second conducting portions connected through a second horizontal portion. The first horizontal portion and the second horizontal portion are exposed to the first side, and the two first conducting portions and the two second conducting portions are extended to the second side.

Owner:DELTA ELECTRONICS SHANGHAI CO LTD

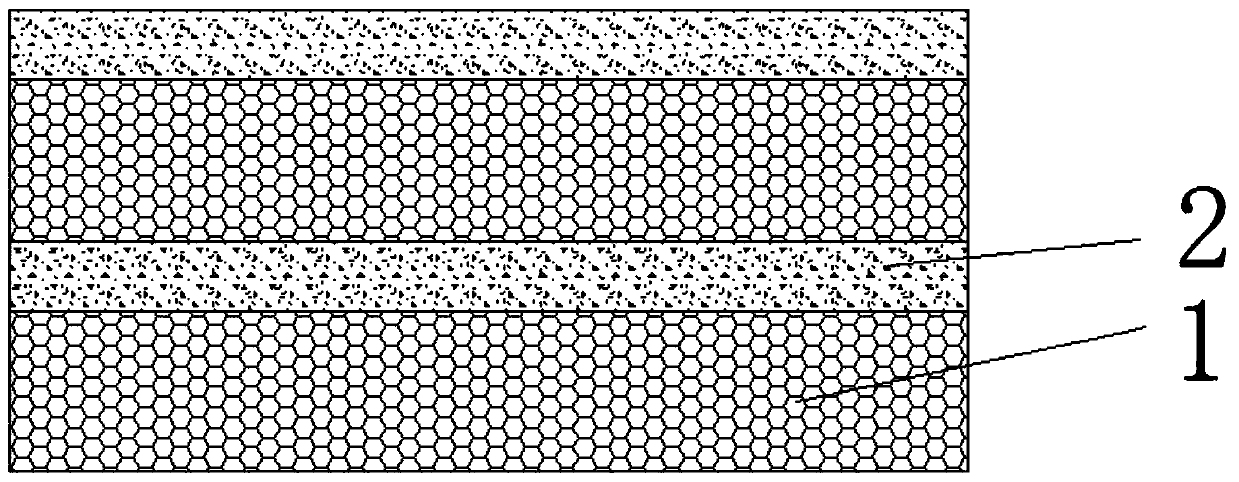

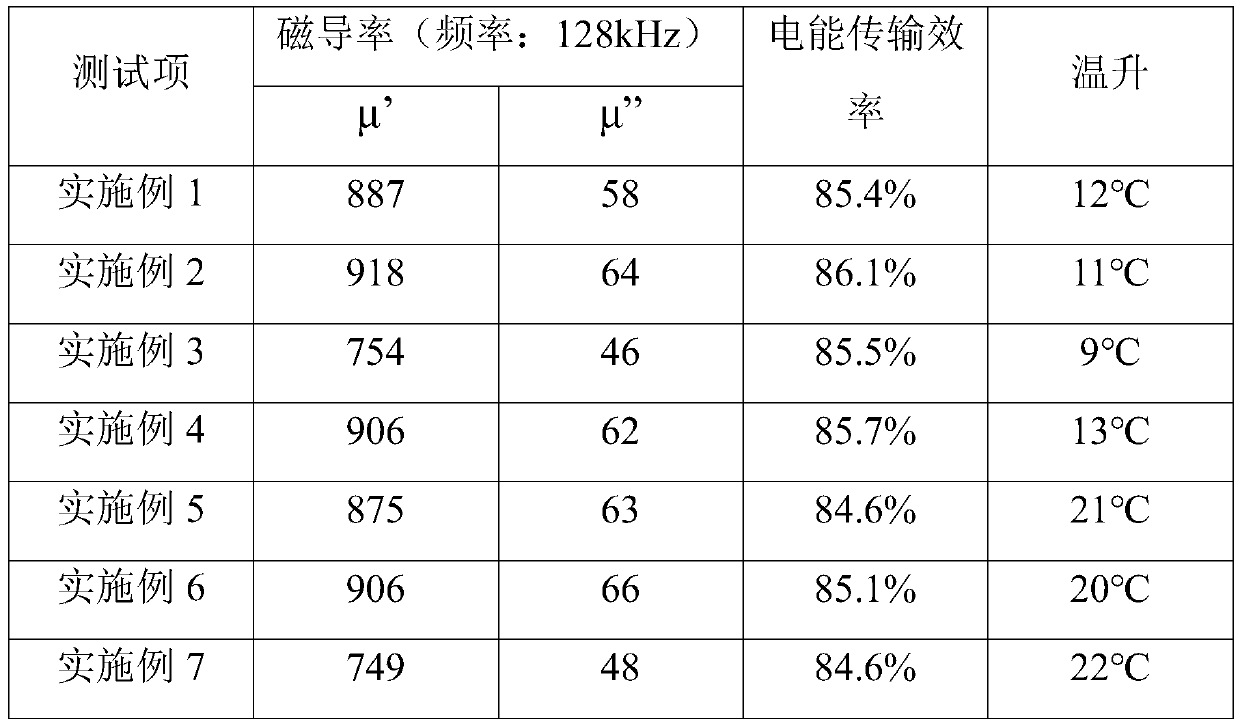

High-thermal-conductivity composite magnetism isolating sheet for wireless charging receiving end and preparation method thereof

ActiveCN110911114AReduce thermal resistanceImprove cooling effectTransformers/inductances coolingTransformersElectric resistivityThin sheet

The invention belongs to the technical field of wireless charging, and discloses a high-thermal-conductivity composite magnetism isolating sheet for a wireless charging receiving end and a preparationmethod of the high-thermal-conductivity composite magnetism isolating sheet. The composite magnetism isolating sheet for the high-thermal-conductivity wireless charging receiving end is a composite material formed by alternately compounding nanocrystalline sheets and a composite material layer, and the composite material layer comprises a thermal conductive filler, a magnetic conductive filler and a binder. According to the preparation method, the surface of the magnetic conductive powder is uniformly coated with the heat conductive powder, so that the electrical conductivity of the magneticpowder can be effectively reduced. And meanwhile, even if the composite magnetic powder has a bridging phenomenon in the composite material layer, the heat conductive powder with excellent insulativity on the surface of the magnetic powder can play a certain role in isolation, so that the resistivity of the composite layer is greatly improved, and the improvement of the charging efficiency of thesystem is facilitated.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com