Patents

Literature

56results about How to "Improve magnet performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing r-fe-b based sintered magnet

ActiveUS20140352847A1Easy to operateLow production costInorganic material magnetismEncapsulation/impregnationRare-earth elementMetallurgy

A method for preparing an R—Fe—B based sintered magnet, including: preparing a R1—Fe—B-M sintered magnet having a thickness of between 1 and 10 mm; spraying a layer of Tb or Dy having a thickness of between 10 and 200 μm on each surface of the sintered magnet in a sealed box under an Ar atmosphere by hot spraying method; and transferring the sintered magnet coated with the layer of Tb or Dy to a vacuum sintering furnace, heating the sintered magnet at the temperature of between 750 and 1000° C. in a vacuum condition or under the Ar atmosphere, and allowing heavy rare earth element Tb or Dy to enter an inner part of the sintered magnet via grain boundary diffusion.

Owner:YANTAI ZHENGHAI MAGNETIC MATERIAL CO LTD

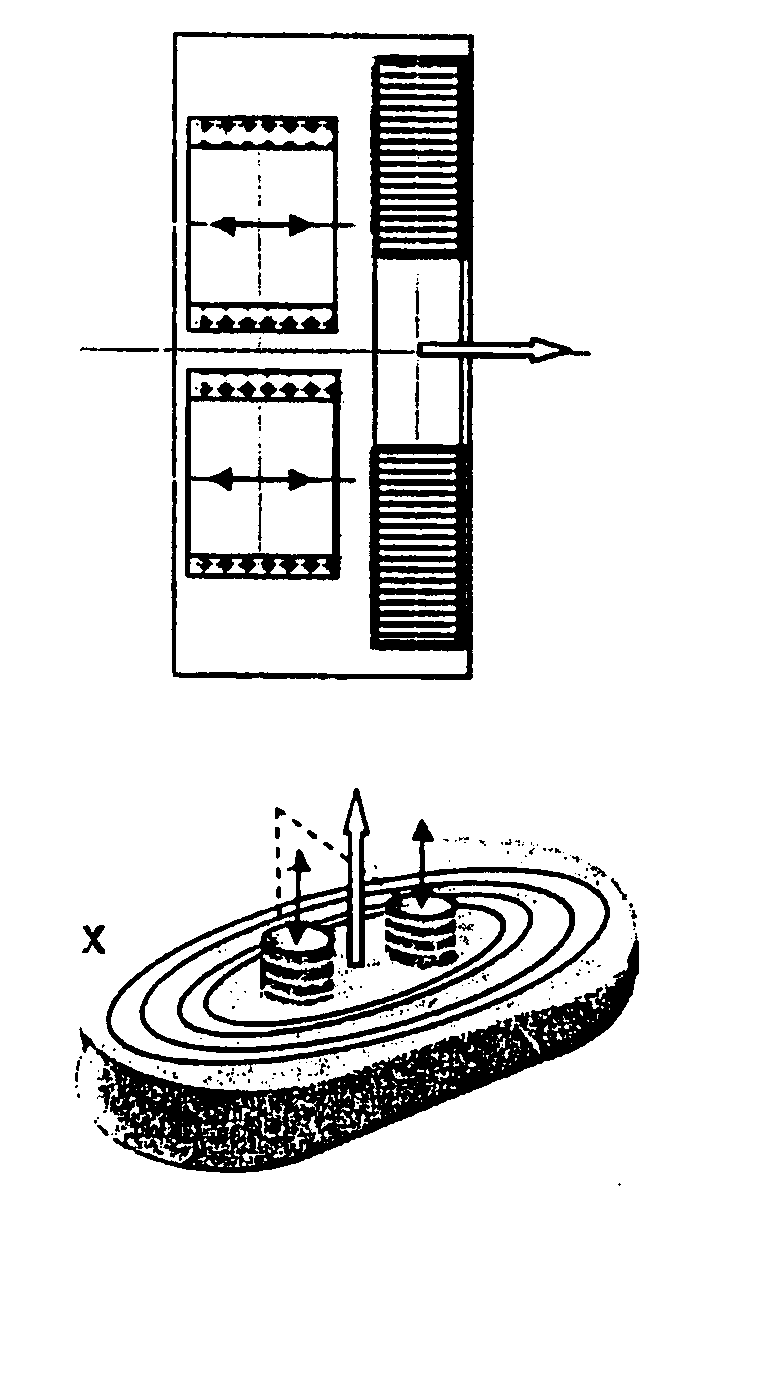

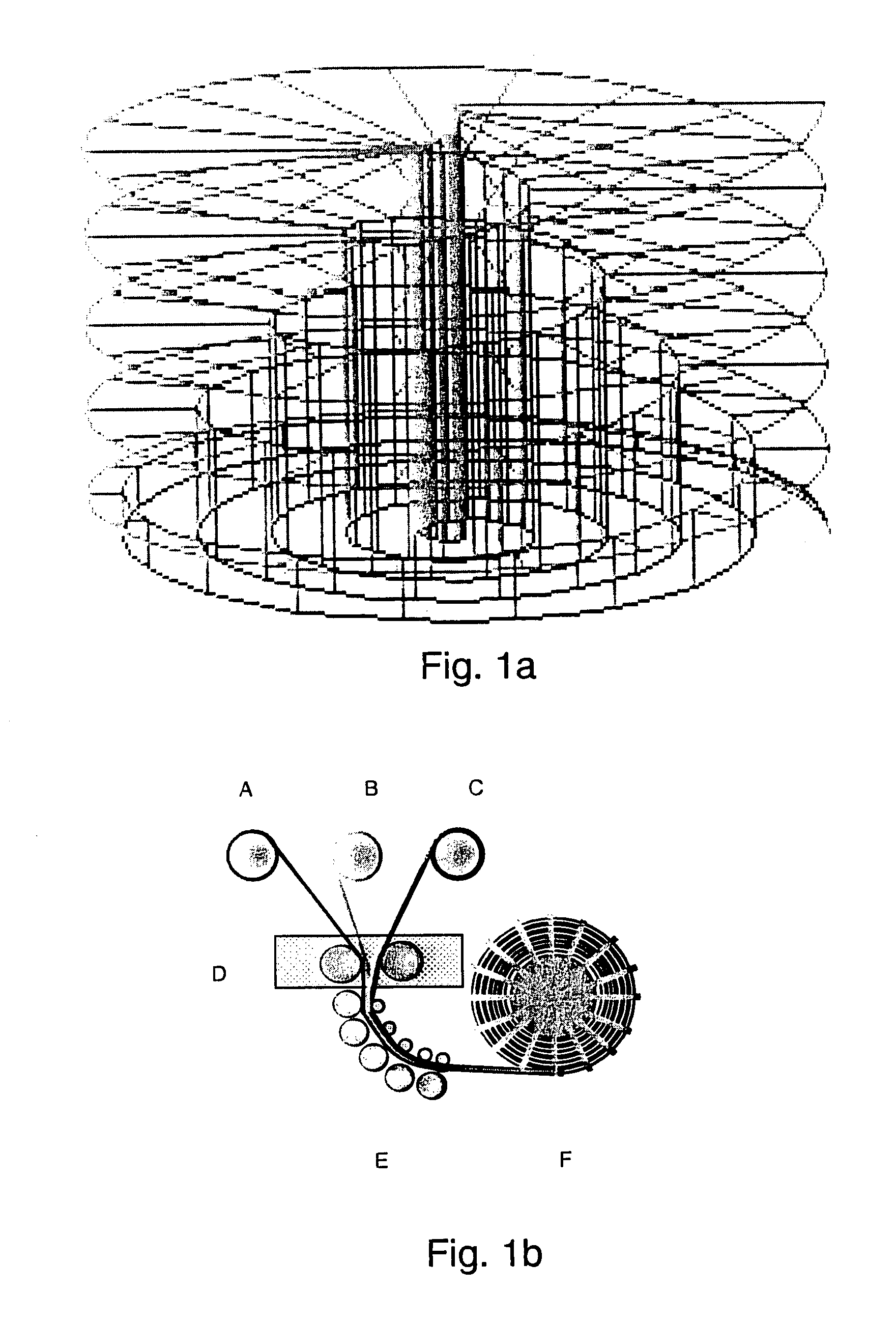

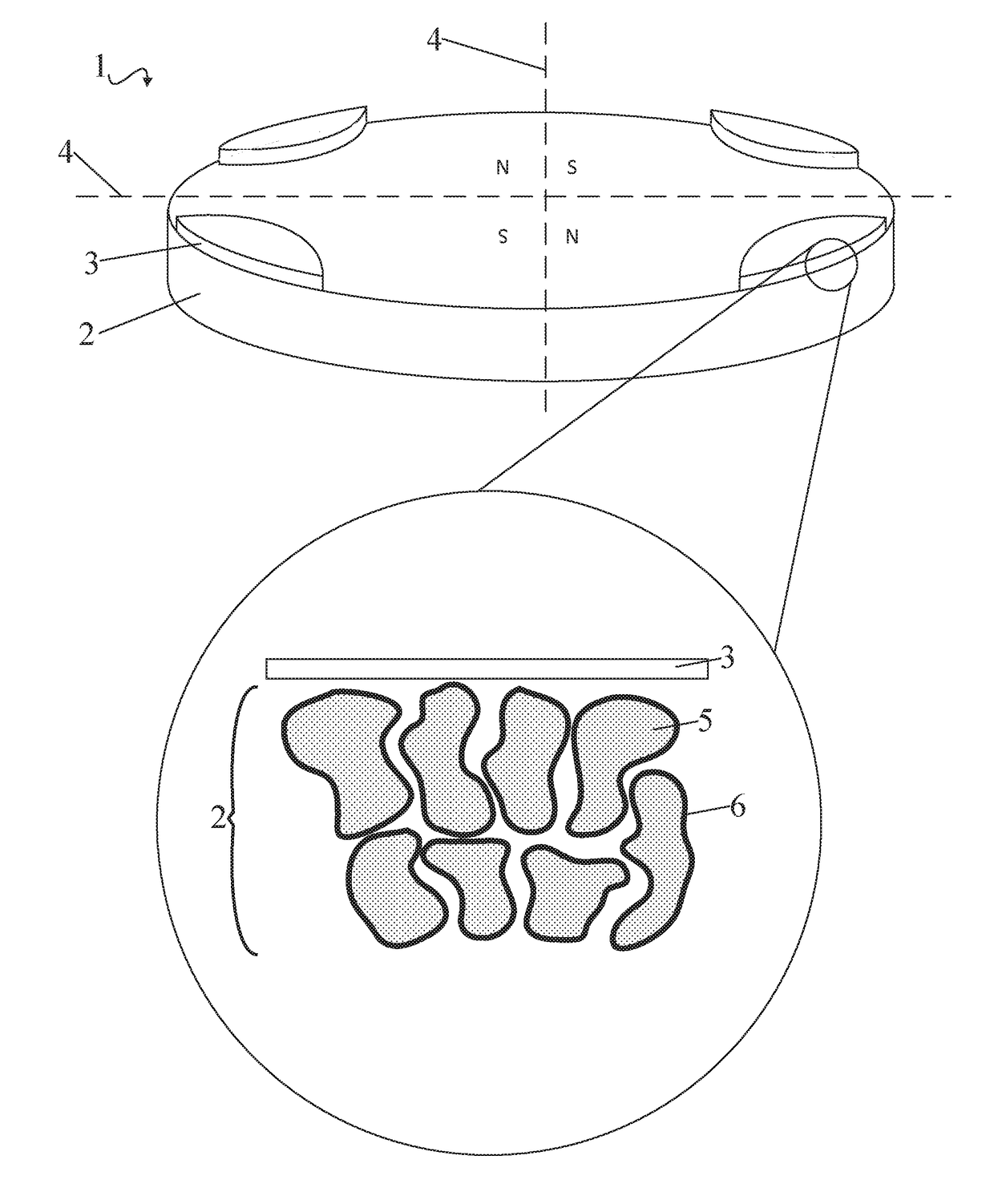

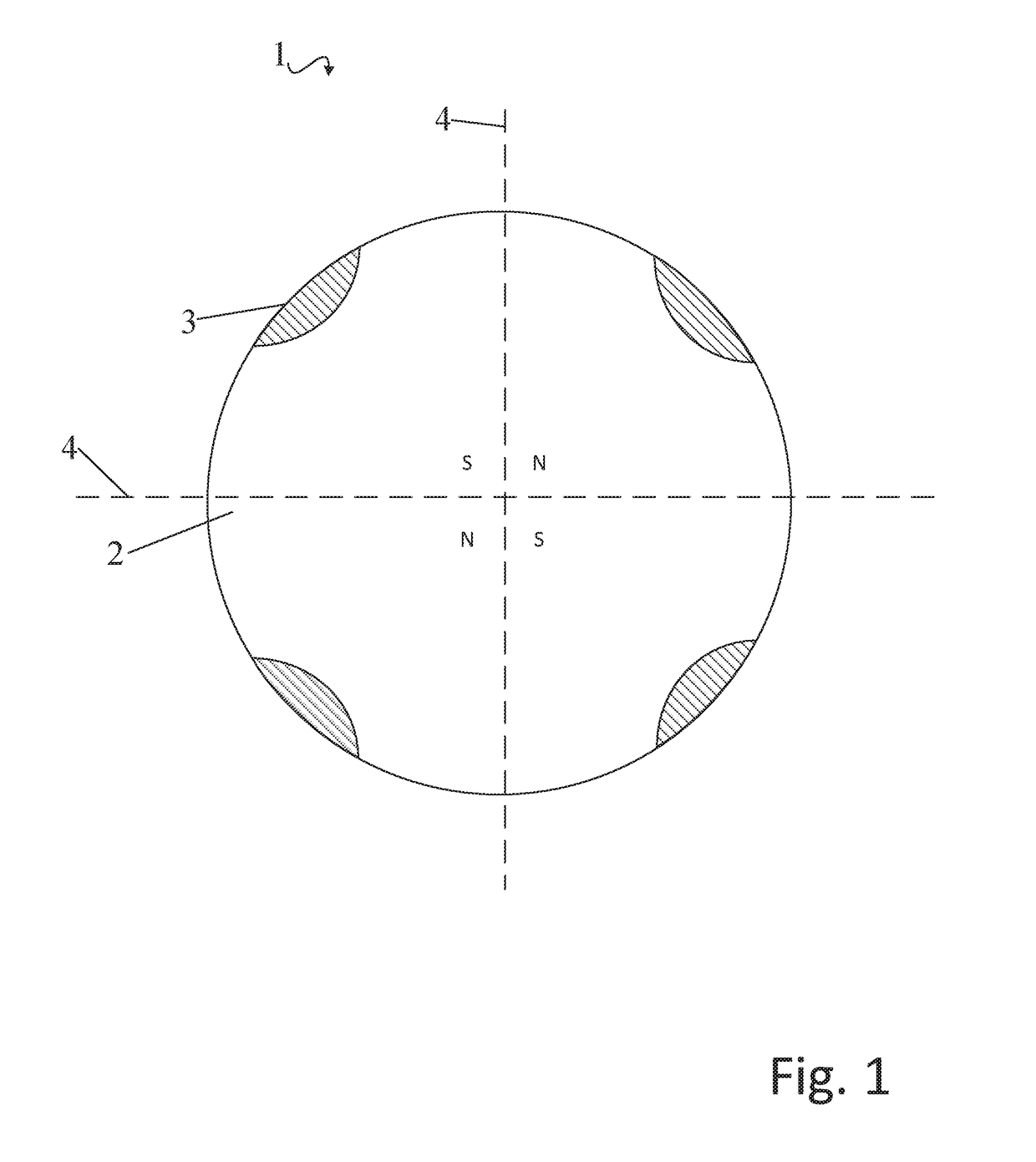

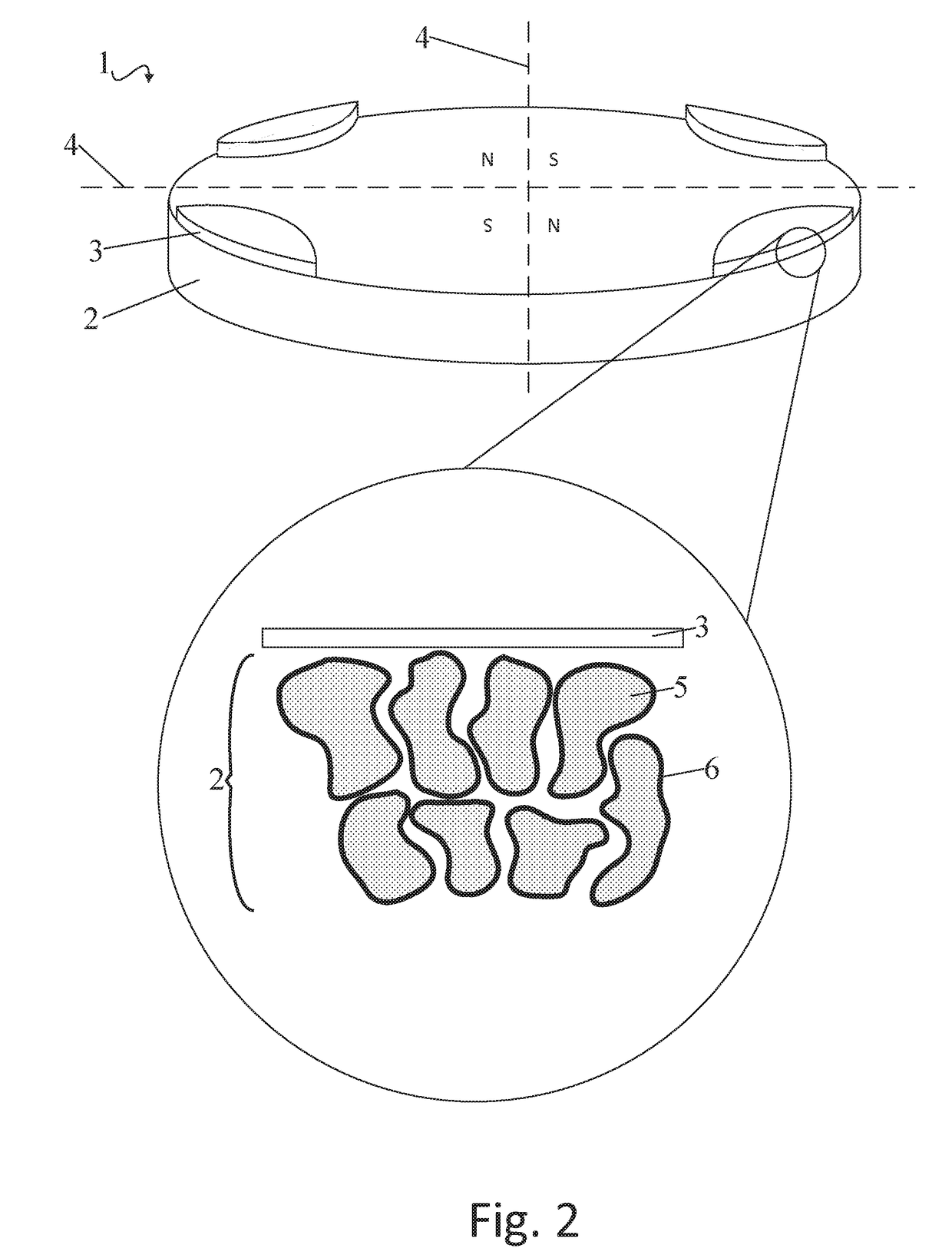

Magnetic Module

InactiveUS20120065073A1Improve stabilityReduce voltageWood veneer joiningInductances/transformers/magnets manufactureComputer moduleEngineering

A magnetic field source is provided comprising a support structure upon which is positioned a conducting surface path of superconductor material. The support structure has an at least partially radially overlapping layer of material arranged in a spiral. A corresponding conducting surface path of superconductor material is arranged on the surface of the support structure such that the conducting path has a first point for the introduction of current and a second point for the extraction of current.

Owner:3 CS

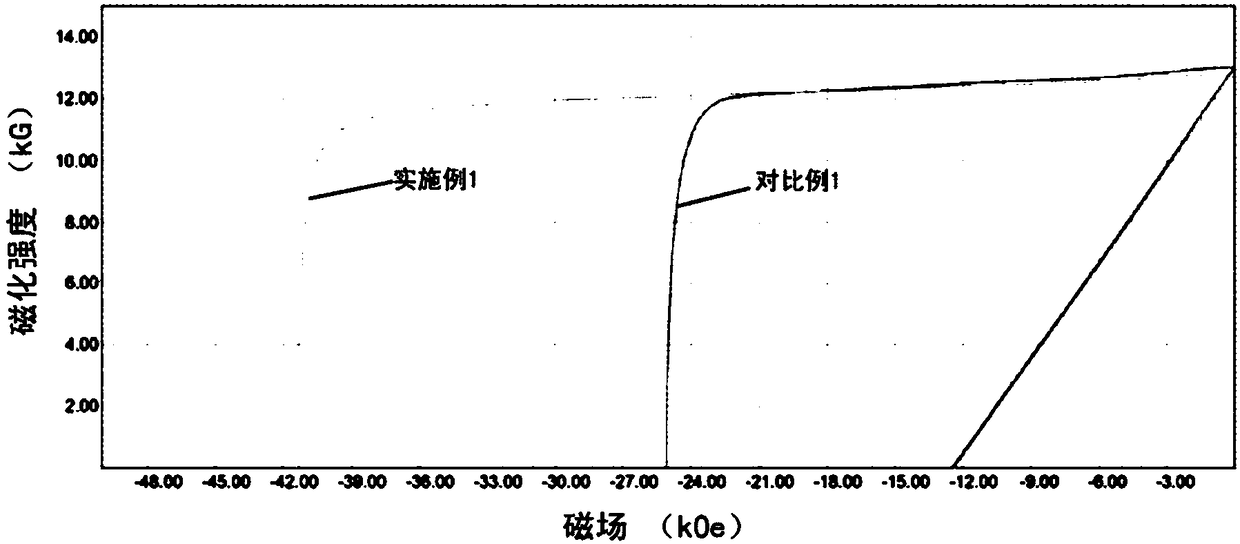

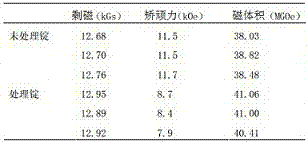

Rare earth permanent magnet material and preparation method thereof

ActiveCN108183021AReduce usageImprove performanceSolid state diffusion coatingInductances/transformers/magnets manufactureRare earthFluoride

The invention discloses a rare earth permanent magnet material and a preparation method thereof. The method comprises the steps of sintering treatment, diffusion heat treatment and tempering; during sintering treatment, composite powder for diffusion is laid on the surface of a neodymium-iron-boron magnetic powder layer and subjected to spark plasma sintering treatment, a neodymium-iron-boron magnetic body with a diffusion layer solidified on the surface is obtained, wherein the proportional expression of components of the composite powder for diffusion is H100-x-yMxQy, H is one or more of Dy,Tb, Ho and Gd metal powder, fluoride powder or oxide powder, M is Nd or Pr or Nd and Pr metal powder, and Q is one or more of Cu metal powder, Al metal powder, Zn metal powder and Sn metal powder; xis the atomic percent of the M component in the composite powder for diffusion, y is the atomic percent of the Q component in the composite powder for diffusion, x is within 0-20, and y is within 0-40. The preparation method is high in efficiency, good in diffusion effect and low in use amount of heavy rare earth.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

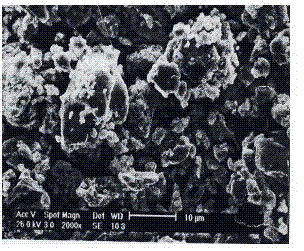

Method for producing a high-performance neodymium-iron-boron rare earth permanent magnetic material

ActiveUS20140328711A1Degree of alignment can be improvedIncrease oxygen contentTransportation and packagingMetal-working apparatusCycloneRare earth

In the method for producing a high-performance neodymium-iron-boron rare earth permanent magnetic material of the present invention, the degree of alignment of the magnet can be improved by preparing the pre-sintered alloy material, the particle size of the powder ground by the jet mill can be refined and the fine powder in the filter of the jet mill can be mixed with the powder collected by the cyclone collector by controlling the oxygen content of the jet mill and adding the nanoscale oxide fine powder. The present invention can significantly improve the utilization ratio of the material and the performance of the magnet, save the use of the rare earth, and especially the heavy rare earth, thereby protecting the scare resources.

Owner:SHENYANG GENERAL MAGNETIC

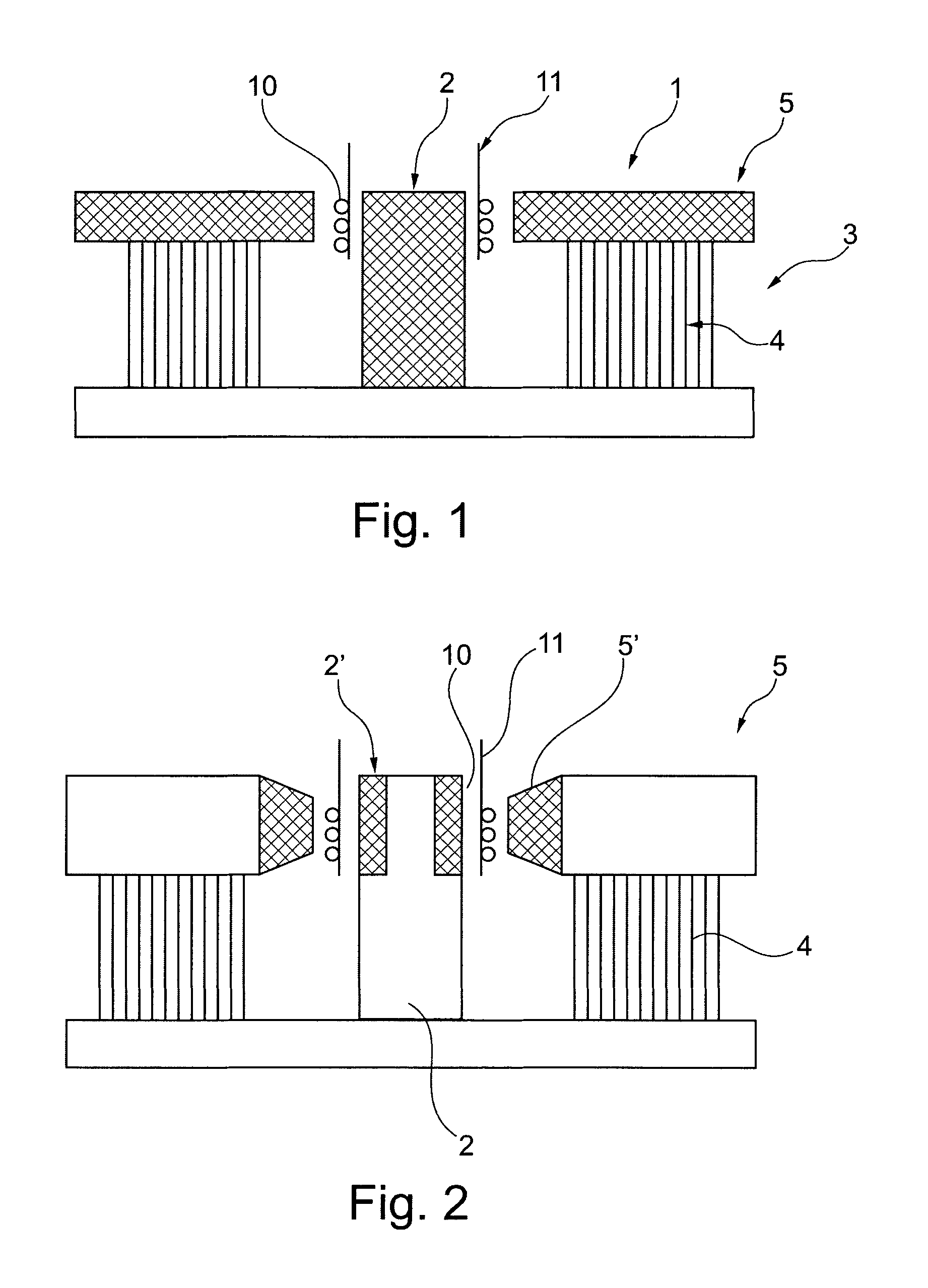

Neodymium iron boron magnetic material with excellent magnetic performance

InactiveCN103617855AHigh energy productImprove remanenceInorganic material magnetismNiobiumDysprosium

The invention discloses a neodymium iron boron magnetic material with the excellent magnetic performance. The neodymium iron boron magnetic material with the excellent magnetic performance is formed by a main-phase alloy and a secondary-phase alloy through mixing. The main-phase alloy comprises, by weight, 64.5-68.5% of iron, 1.0-1.2% of boron, 30.2-34.3% of neodymium, 0.05-0.4% of niobium and 0.1-0.4% of aluminum. The secondary-phase alloy comprises, by weight, 50.8-54.2% of iron, 0.8-1.2% of boron, 18.9-21.1% of neodymium, 12.8-16.3% of praseodymium, 8.9-11.1% of dysprosium and 0.8-1.2% of copper. The neodymium iron boron magnetic material prepared with the method has the excellent magnetic performance and high intrinsic coercivity.

Owner:NINGBO STAR MATERIALS HI TECH

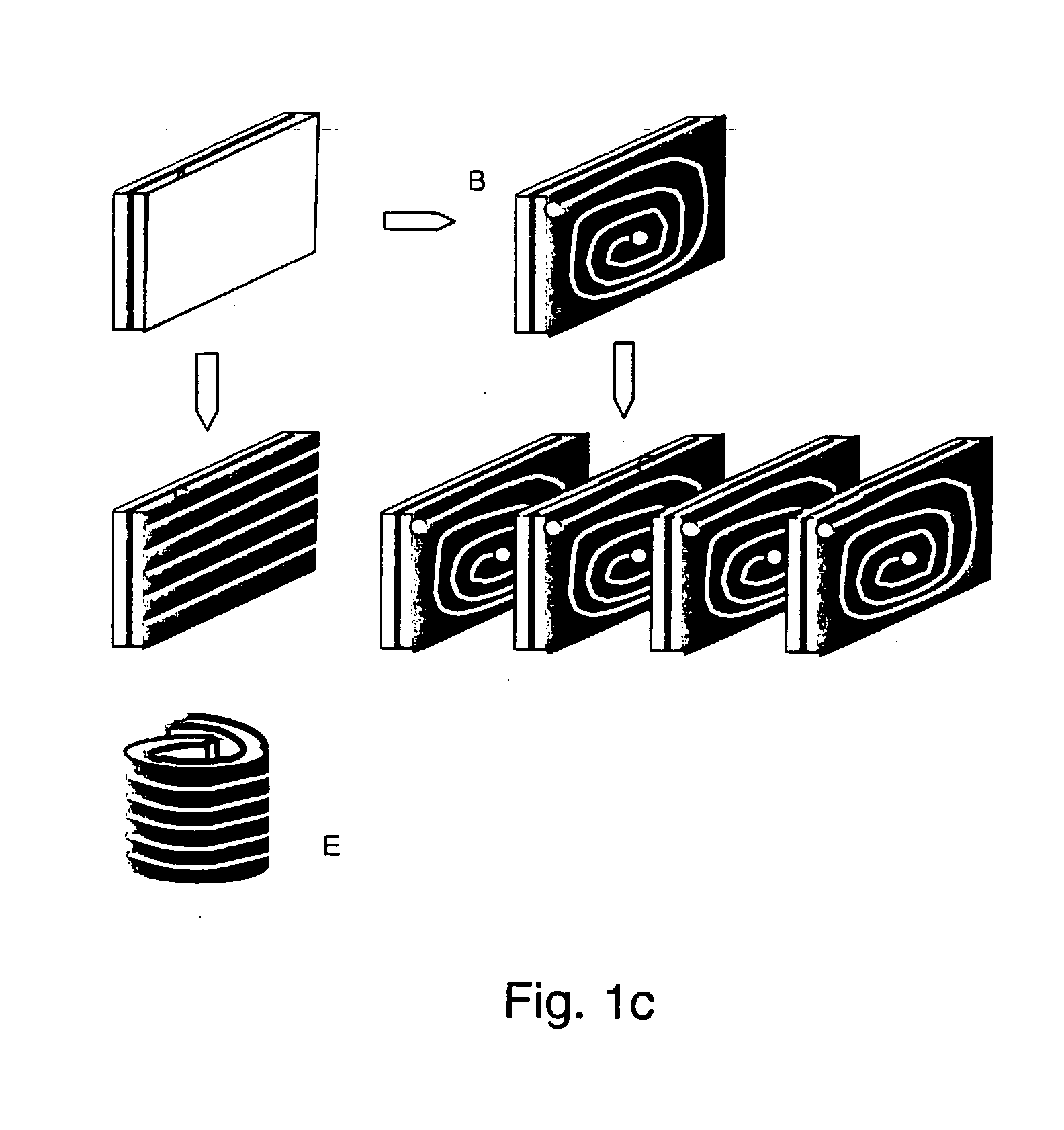

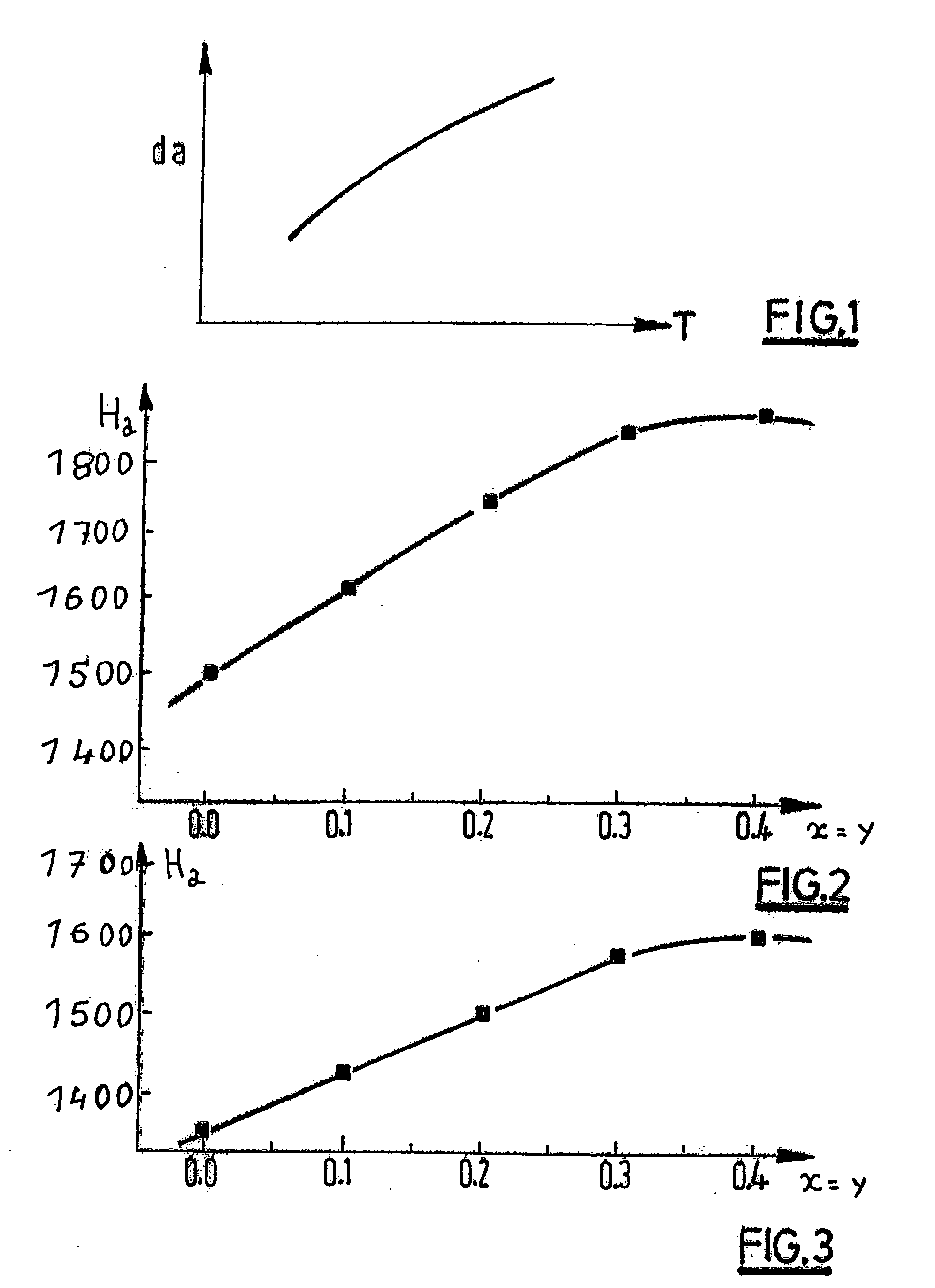

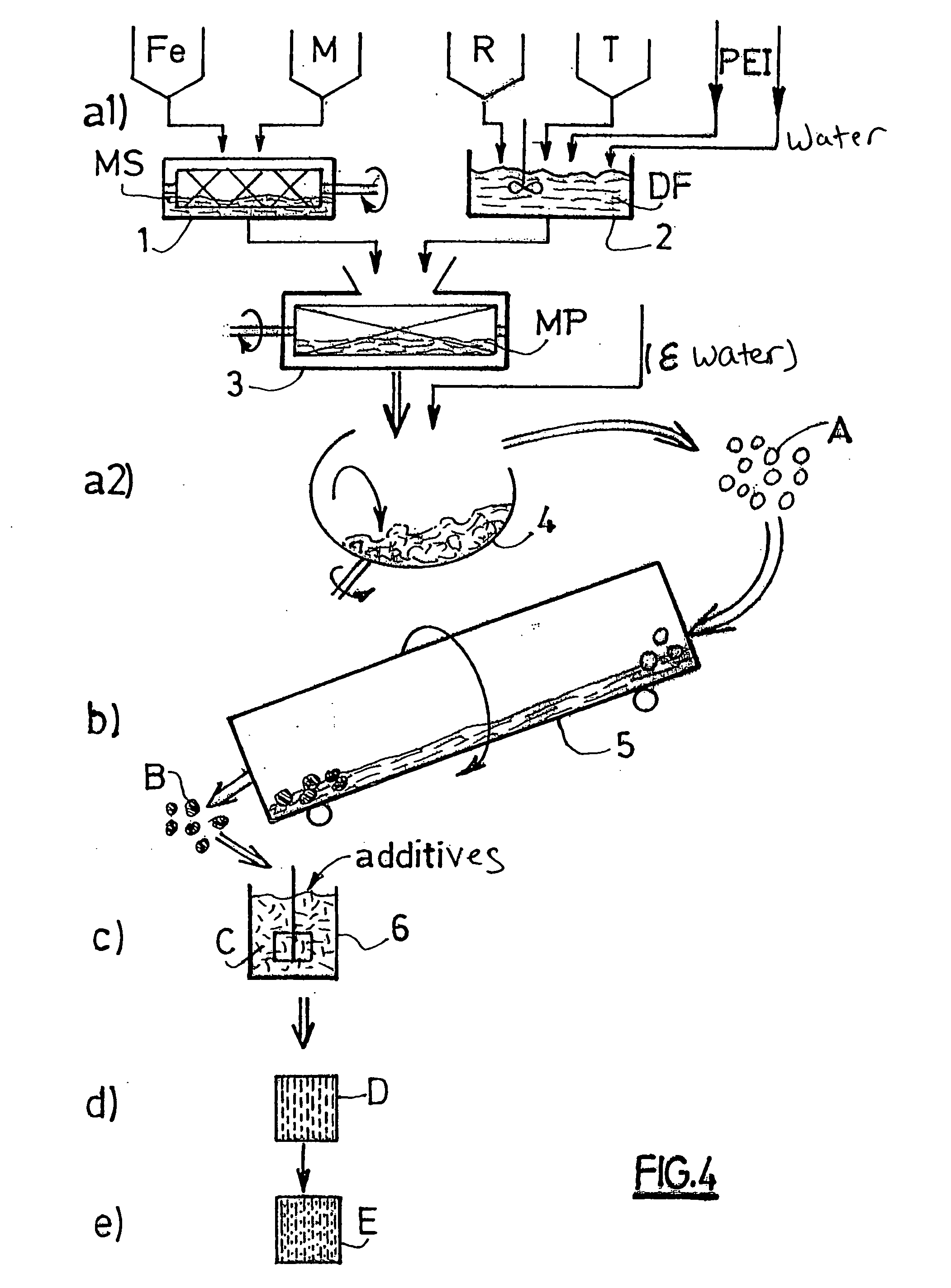

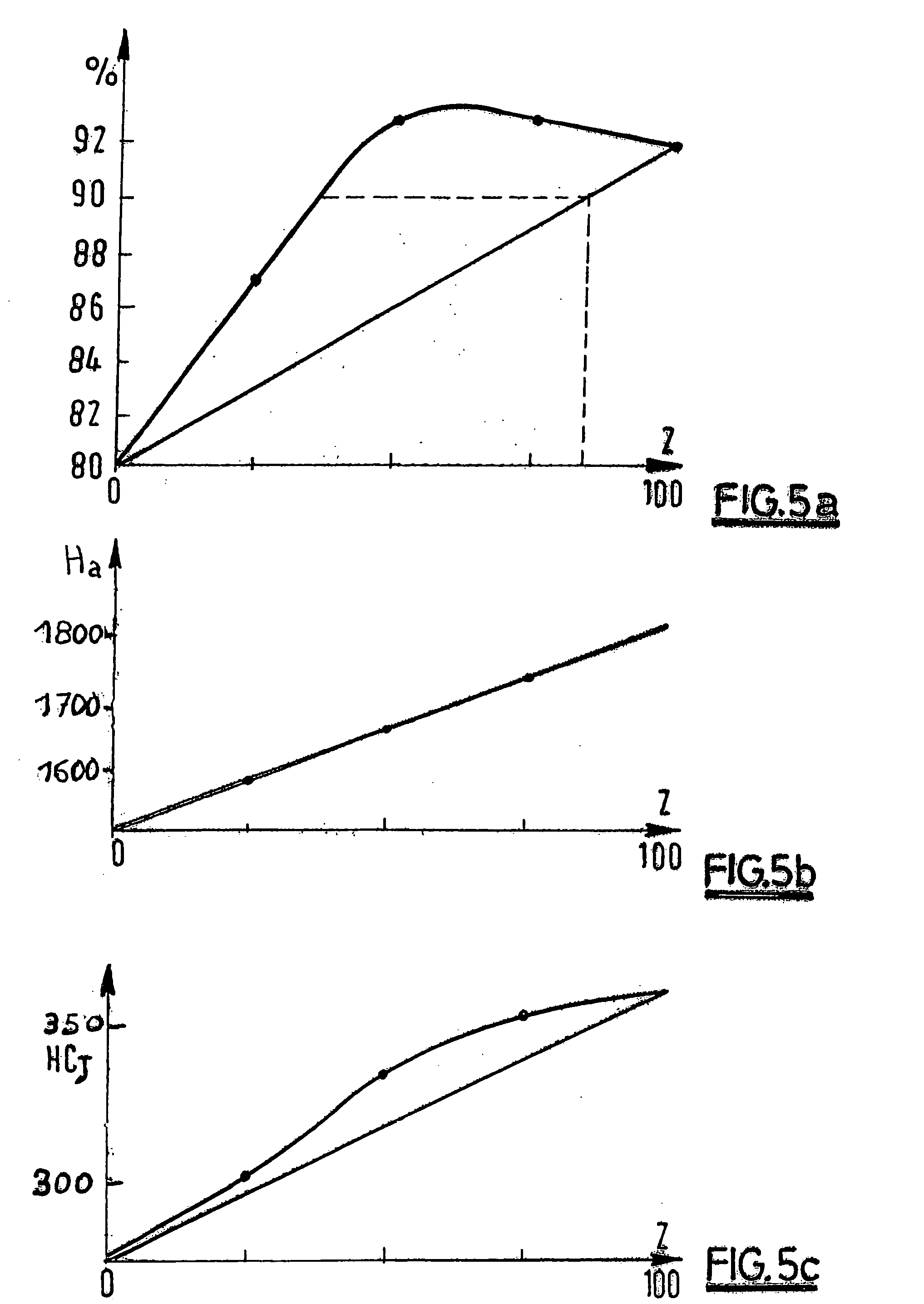

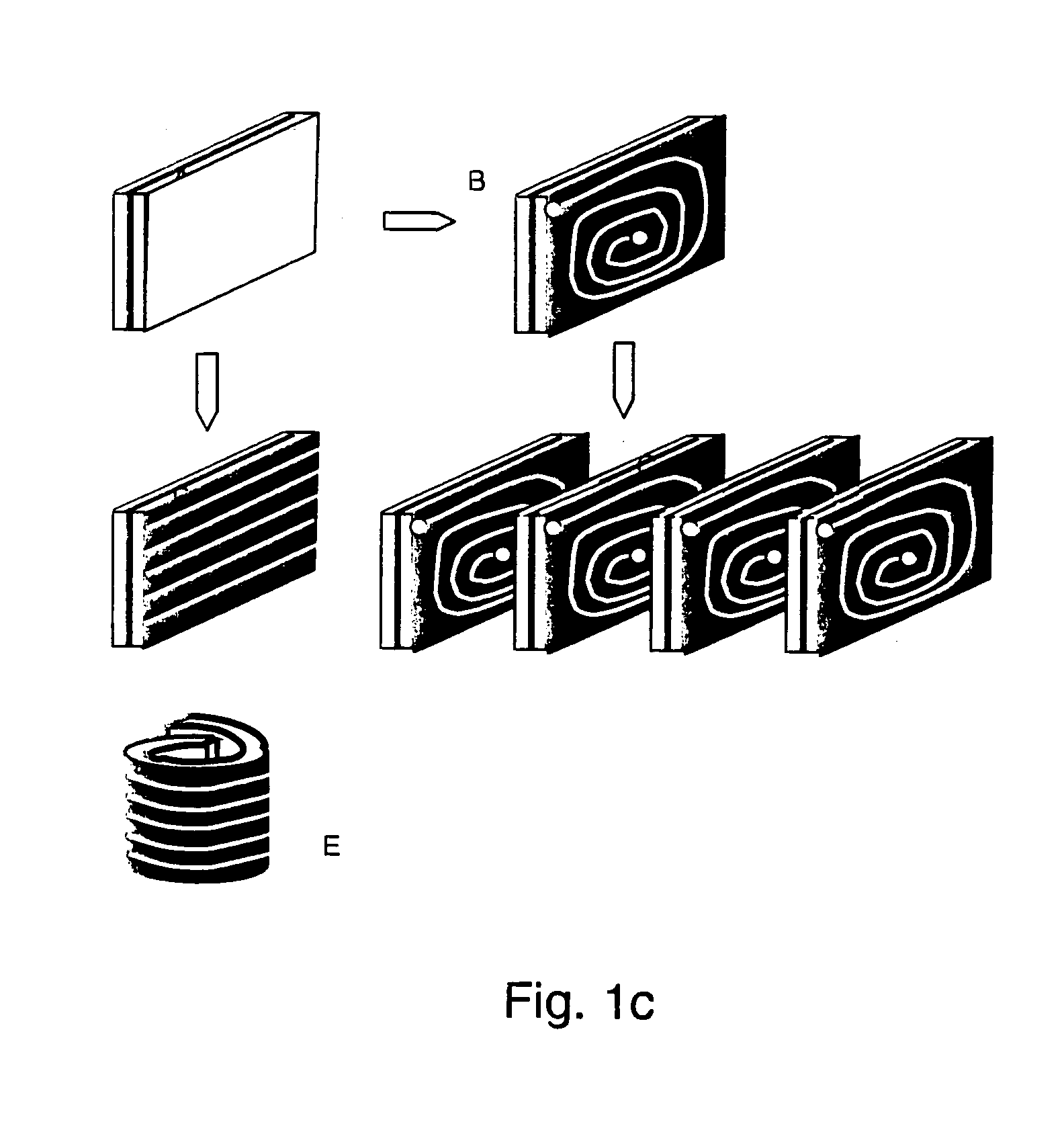

Manufacturing method for ferrite type magnets

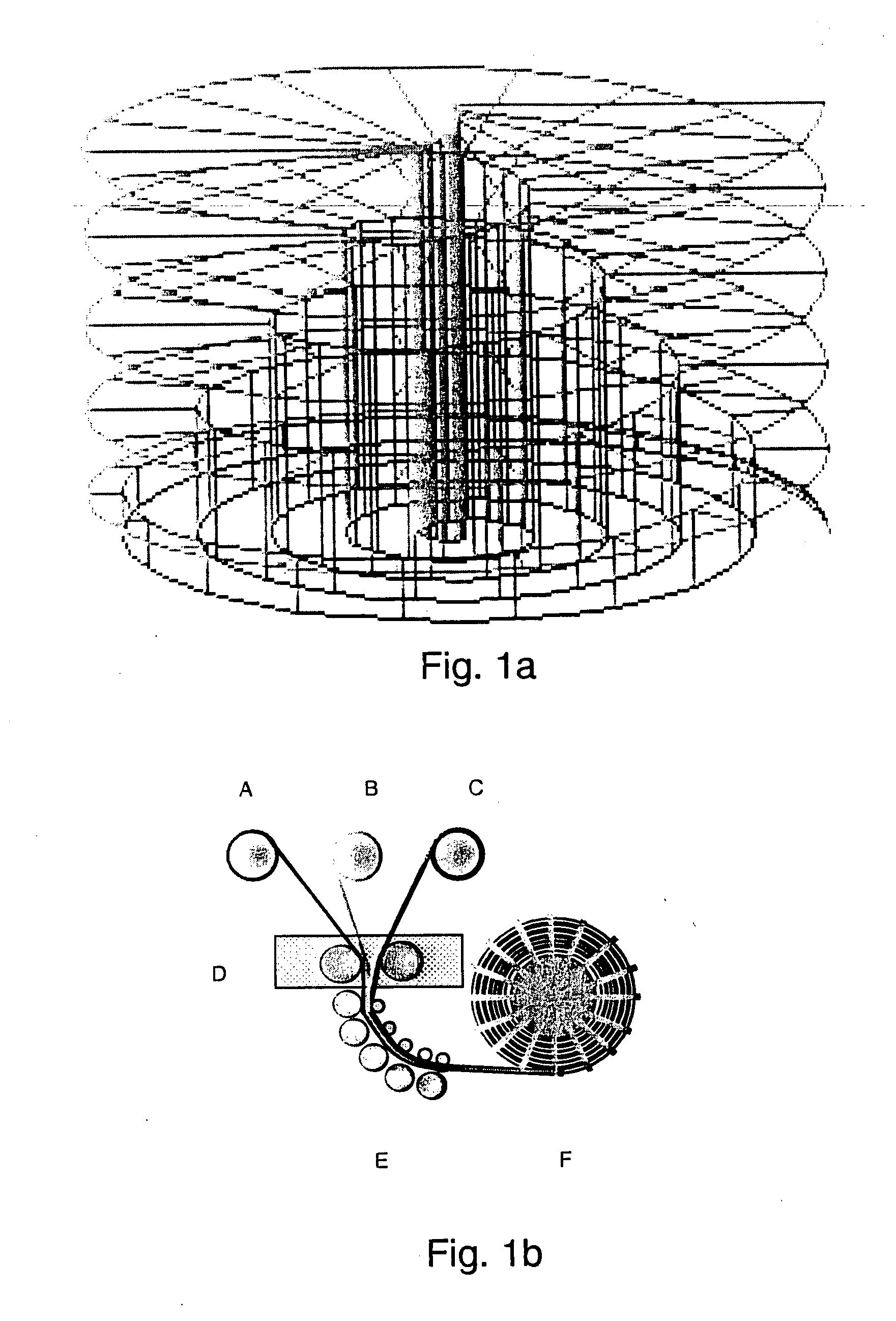

InactiveUS20040151661A1Improve magnet performanceGood magnetic performanceIron oxides/hydroxidesInorganic material magnetismChemical compositionPowder mixture

A method for making ferrite magnets of formula M1-xRxFe12-yTyO19 including: a1) forming a powder mixture MP of related raw materials, a2) transforming into granules in green state A, b) calcining the granules in green state to form clinker B, c) wet ding clinker B to obtain a homogeneous dispersion of fine particles C, d) concentrating and compressing the particles under an orienting magnetic field to form an anisotropic green compact D, and e) sintering the green compact to obtain a sintered element E. In step a1), MP is formed from a dry mixture MS of M and Fe powder elements and a dispersion DF of raw materials related to elements R and T, and in step b) the granules in green state are calcined to obtain a clinker B which is homogeneous in chemical composition and size and with apparent low density, between 2.5 and 3.5.

Owner:UGIMAG SA

Neodymium iron boron magnetic material strong in corrosion resistance

The invention relates to a neodymium iron boron magnetic material strong in corrosion resistance. The neodymium iron boron magnetic material strong in corrosion resistance is formed by a main-phase alloy and a secondary-phase alloy through mixing. The main-phase alloy comprises, by weight, 64.5-68.5% of iron, 1.0-1.2% of boron, 30.2-34.3% of neodymium, 0.05-0.4% of vanadium and 0.1-0.4% of aluminum. The secondary-phase alloy comprises, by weight, 50.8-54.2% of iron, 0.8-1.2% of boron, 18.9-21.1% of neodymium, 12.8-16.3% of tantalum, 8.9-11.1% of dysprosium and 0.8-1.2% of nickel. The neodymium iron boron magnetic material prepared with the method is excellent in corrosion resistance.

Owner:NINGBO STAR MATERIALS HI TECH

Antioxidant for sintering neodymium iron boron jet mill, and use method of antioxidant

InactiveCN104449740AReduced oxidation resistanceLoss is good for compensationInorganic material magnetismChemical inhibitorsMetallurgyStearic acid

The invention discloses an antioxidant for a sintering neodymium iron boron jet mill, and a use method of the antioxidant. The antioxidant consists of an antioxidation agent and an antioxidation assistant, wherein the antioxidation agent consists of one or several of 1-cetyl alcohol, trityl alcohol and zinc stearate and alcohol; and the antioxidation assistant is a mixture of aviation gasoline and petroleum ether. The use method comprises the following steps that (1) 30-65% of the total amount of the antioxidation agent and neodymium iron boron magnetic powder are uniformly mixed and then crushed via the jet mill; (2) fine mixing is performed, and the antioxidation assistant and the rest antioxidation agent are added and uniformly mixed; and (3) compression molding is performed and then antioxidant removal treatment is performed. The antioxidant can improve the antioxidation property of the sintering neodymium iron boron magnetic powder, greatly improve the lubricating property and the orientation degree of the magnetic powder, and improve the magnet property. The use method can reduce loss of the antioxidation agent caused by volatilization, and can ensure continuous antioxidation property of the neodymium iron boron magnetic powder in each production stage.

Owner:HUNAN AEROSPACE MAGNET & MAGNETO

Electromagnetic drive unit

ActiveUS20140169615A1Low generationLow electrical conductivityTransducer detailsLoudspeakerMagnetic flux

An electromagnetic drive unit for a loudspeaker of the type where an air gap is arranged in a magnet system such that magnetic flux lines are substantially linear across the air gap, and that a voice coil is arranged in said air gap, wherein the magnet system comprises a central yoke separated by said air gap from a ring-shaped magnet system, which magnet system at least comprises a bottom plate connected to said central yoke, and a magnet and a top plate, characterised in that at least a section of the central yoke corresponding to the extent of the air gap and at least a corresponding section of the top plate is made from a soft magnetic composite material.

Owner:DALI AS

Neodymium iron boron magnetic material with high coercivity

InactiveCN103617854AImprove intrinsic coercive forceImprove the characteristics of insufficient coercive forceMagnetic materialsCobaltBoron

The invention relates to a neodymium iron boron magnetic material with the high coercivity. The neodymium iron boron magnetic material with the high coercivity is formed by a main-phase alloy and a secondary-phase alloy through mixing. The main-phase alloy comprises, by weight, 64.5-68.5% of iron, 1.0-1.2% of boron, 30.2-34.3% of neodymium, 0.05-0.4% of molybdenum and 0.1-0.4% of gallium. The secondary-phase alloy comprises, by weight, 50.8-54.2% of iron, 0.8-1.2% of boron, 18.9-21.1% of neodymium, 12.8-16.3% of praseodymium, 8.9-11.1% of terbium, and 0.8-1.2% of cobalt. The neodymium iron boron magnetic material prepared with the method has high intrinsic coercivity.

Owner:NINGBO STAR MATERIALS HI TECH

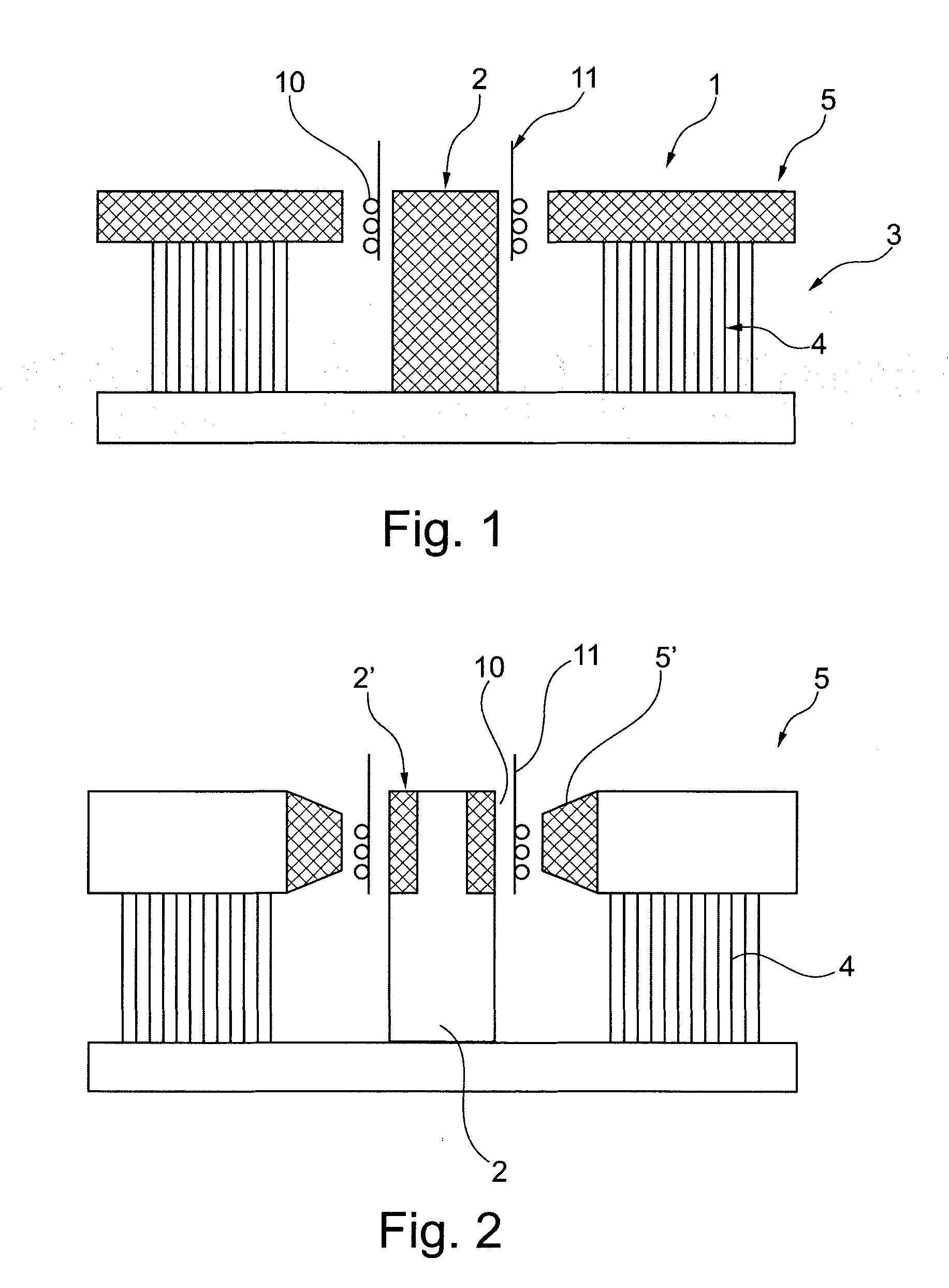

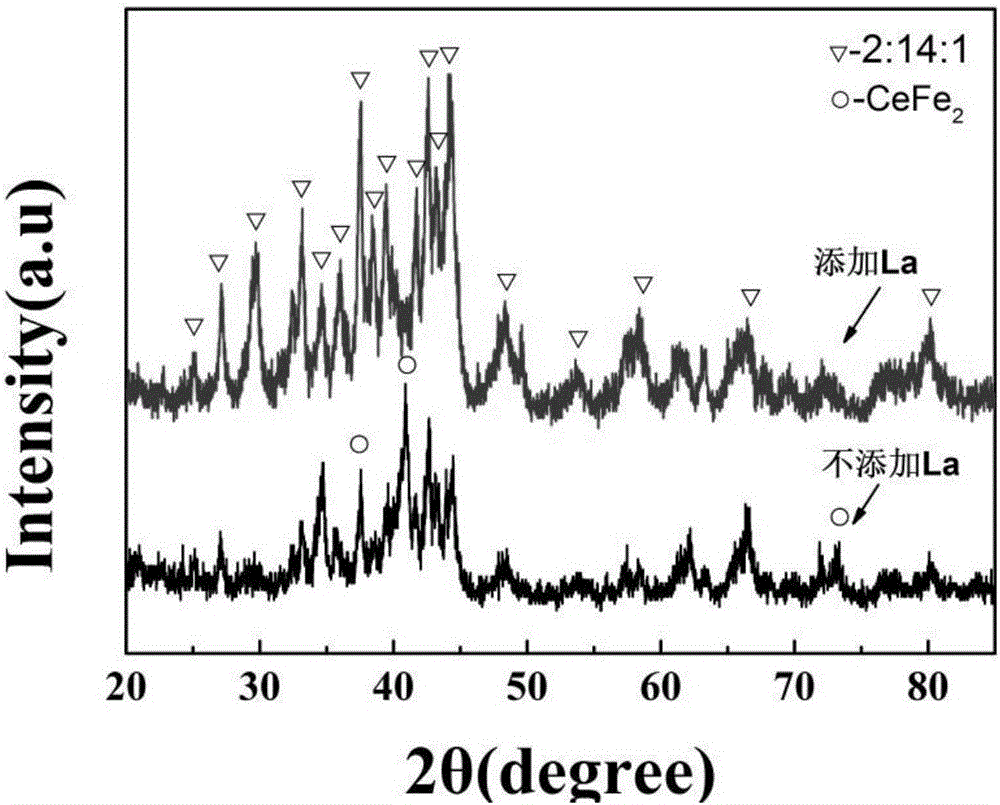

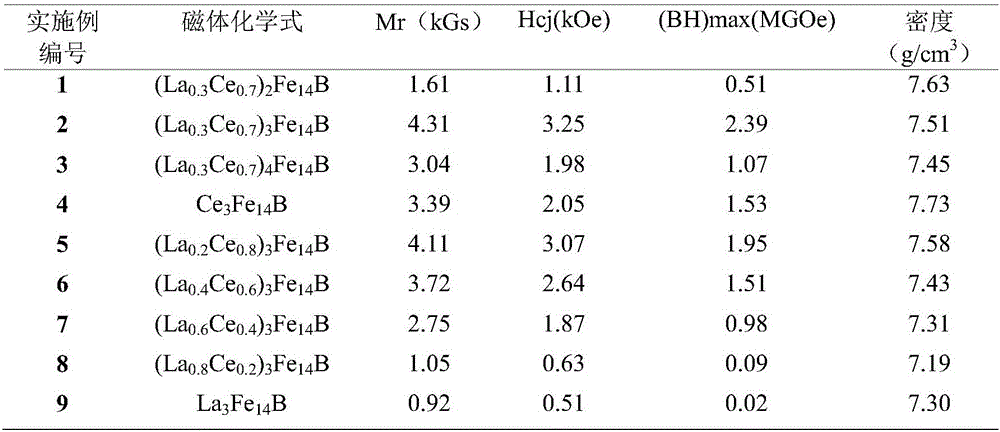

Method for preparing cheap light rare earth lanthanum cerium iron boron nano-crystal permanent magnet

ActiveCN106816249AInhibitionImprove magnetismInductances/transformers/magnets manufactureMagnetic materialsArgon atmosphereCerium

A method for preparing a cheap light rare earth lanthanum cerium iron boron nano-crystal permanent magnet belongs to the field of rare-earth permanent magnets. The method includes: performing matching according to (Lax / Ce1-x) yFe14B, x=0-1, y=2.0-4.0 element mole ratio, putting the matched material into a suspension smelting furnace, performing heating and smelting in the argon atmosphere, and acquiring an even ingot casting; performing mechanical grinding on the ingot casting to remove surface oxide, performing smashing, and filling the ingot casting fragments in a quartz tube; arranging the quartz tube filled with the ingot casting on a melt rapid quenching device to perform melting, spraying alloy fluid to a copper roller which is rotating at a high speed from a nozzle, allowing the alloy fluid to contact the copper roller to be rapidly cooled, and acquiring a rapid quenching band; and screening the rapid quenching band to remove impurities, smashing the rapid quenching band and performing screening, putting the smashed rapid quenching band in a die, putting the die in a discharging plasma sintering furnace, and performing hot pressing sintering at a suitable temperature and pressure. The method can easily achieve rapid sintering of materials, and can acquire compact ultra-fine crystal even nano-crystal sintering body.

Owner:BEIJING UNIV OF TECH

Magnetic module

InactiveUS8838193B2Avoid heat productionLow costSuperconductors/hyperconductorsMagnetsEngineeringElectrical current

A magnetic field source is provided comprising a support structure upon which is positioned a conducting surface path of superconductor material. The support structure has an at least partially radially overlapping layer of material arranged in a spiral. A corresponding conducting surface path of superconductor material is arranged on the surface of the support structure such that the conducting path has a first point for the introduction of current and a second point for the extraction of current.

Owner:3 CS

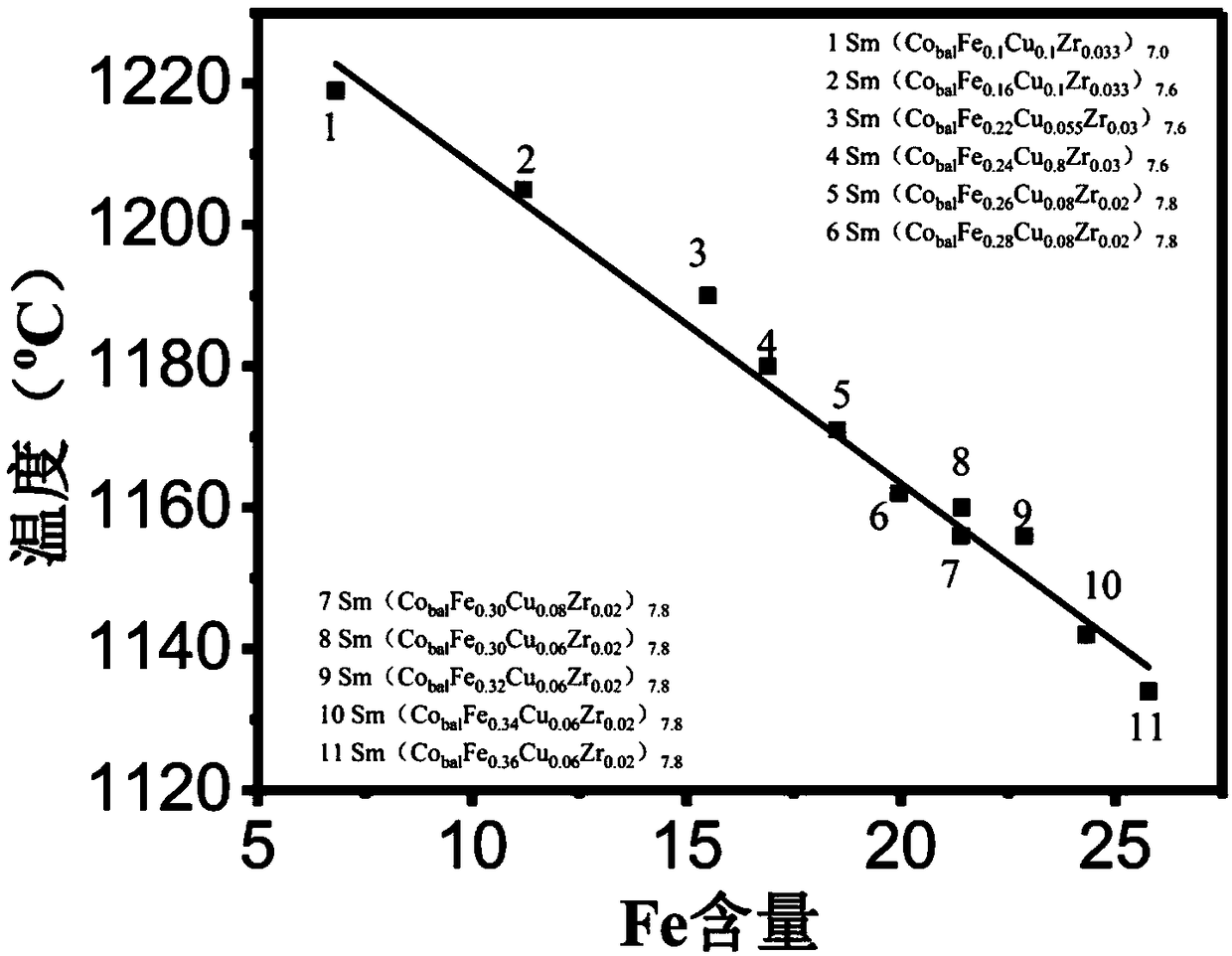

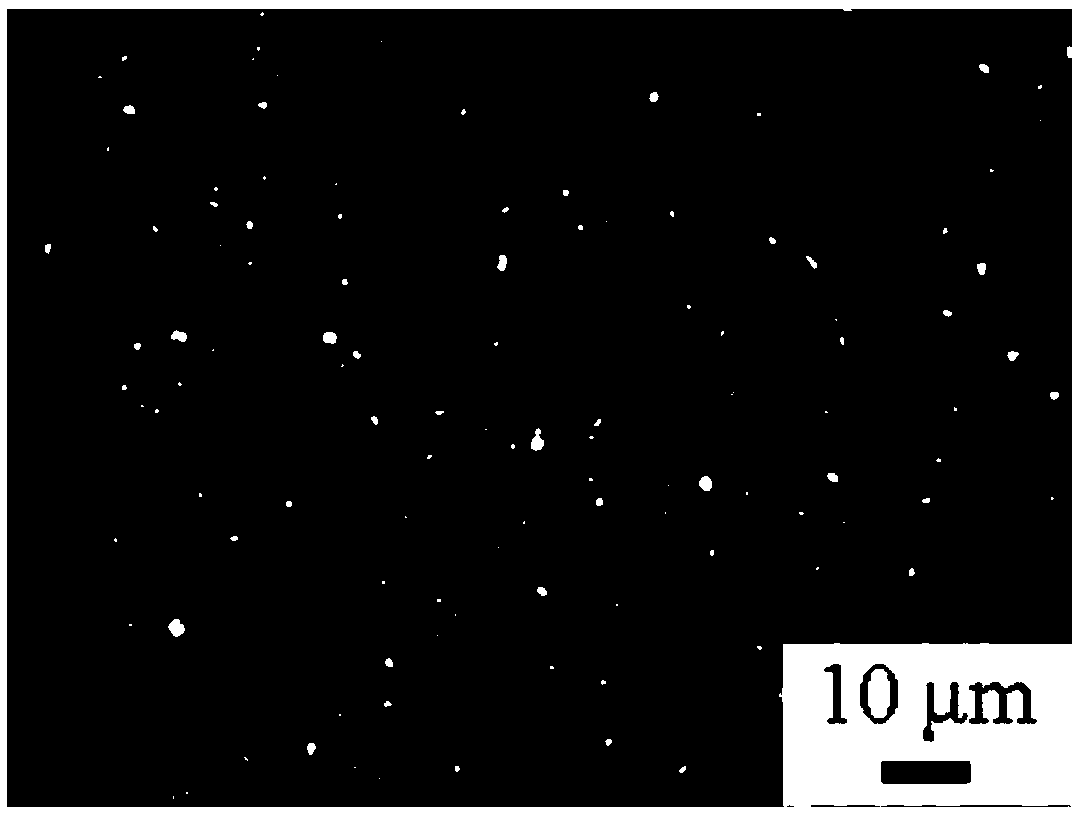

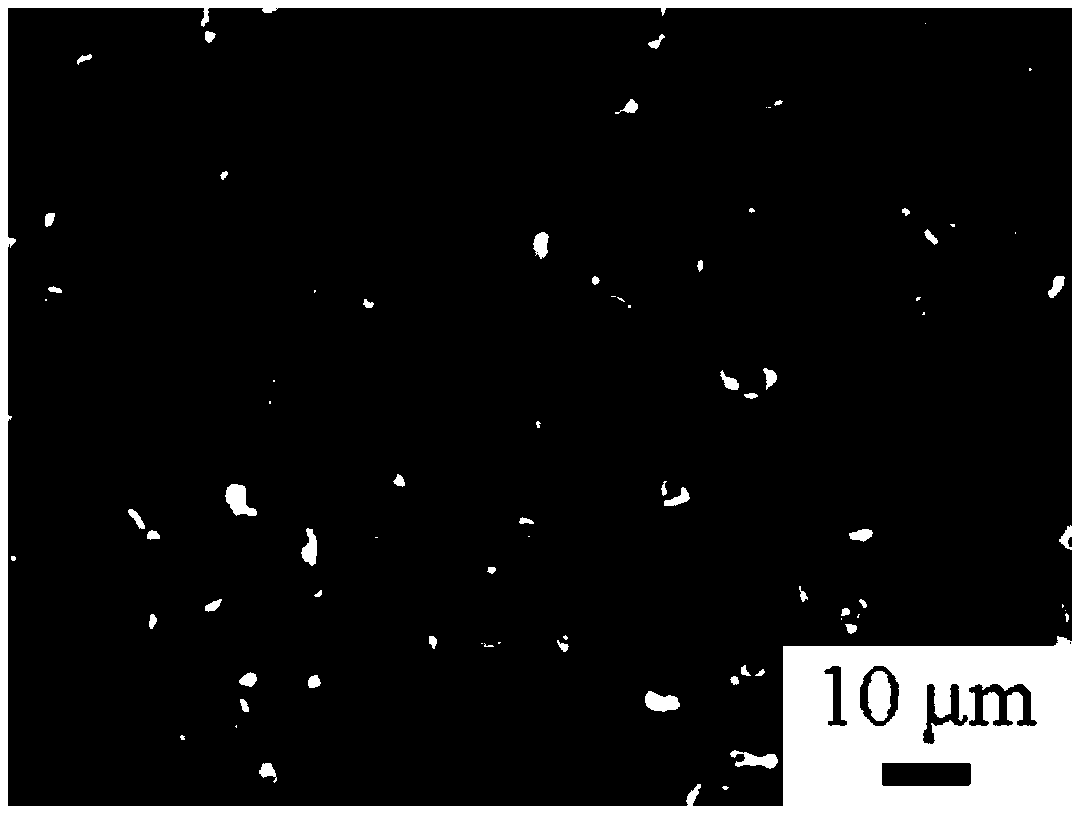

Samarium-cobalt magnet and method for improving solid solubility of Zr element

ActiveCN108777202AImprove stabilityImprove magnet performanceInductances/transformers/magnets manufactureMagnetic materialsSingle phaseSolid solubility

The invention discloses a samarium-cobalt magnet and method for improving the solid solubility of a Zr element. By adjusting a solid solution temperature to Tst=1248-4*WFe(%)+-3 DEG C, the precipitation of a Zr-rich second phase is suppressed, the Zr element is used for replacing a Fe-Fe atom pair in a high-temperature 1:7H phase, so that the c / a shrinkage ratio of samarium-cobalt magnet main phase 1:7H is higher than 1%, the stability of a high-temperature phase 1:7H structure is improved, and after solid solution at a Tst temperature, the solid solution state of the magnet is a single phase1:7H phase. A single phase 1:7H magnet conducts solid solution at the Tst temperature, a Zr-rich precipitation phase content is less than 1 vol. %, the performance of the magnet and the squareness ofa demagnetization curve are optimized, and the method can be used for preparing samarium-cobalt magnets with different iron content components.

Owner:BEIHANG UNIV

Preparation method of samarium-cobalt permanent magnet material

InactiveCN105931780AAdvantages of preparation methodLow hydrogen pressureInorganic material magnetismHydrogen pressureDehydrogenation

The invention relates to a preparation method of a samarium-cobalt permanent magnet material. A traditional 2:17 samarium-cobalt sintered magnet which cannot easily absorb hydrogen to break is prepared by combining a double-alloy technology and a hydrogen breaking technology. The method specifically comprises the following steps: (1) preparing a first alloy ingot with high iron content and low rare earth content and a second alloy ingot with high rare earth content and low iron content according to the ratio of various elements respectively; (2) carrying out hydrogen absorption and dehydrogenation on the first alloy ingot under 0.3-0.45MPa first hydrogen pressure to obtain first hydrogen broken powder, and carrying out hydrogen absorption and dehydrogenation on the second alloy ingot under 0.2-0.35MPa second hydrogen pressure to obtain second hydrogen broken powder; (3) carrying out airflow milling on the first hydrogen broken powder and the second hydrogen broken powder respectively to obtain first alloy powder and second alloy powder; and (4) mixing the first alloy powder and the second alloy powder evenly, and sequentially carrying out orienting compression, sintering solid solution and aging treatment to obtain the samarium-cobalt permanent magnet material.

Owner:WUXI NEW GREAT POWER ELECTRICAL MACHINE

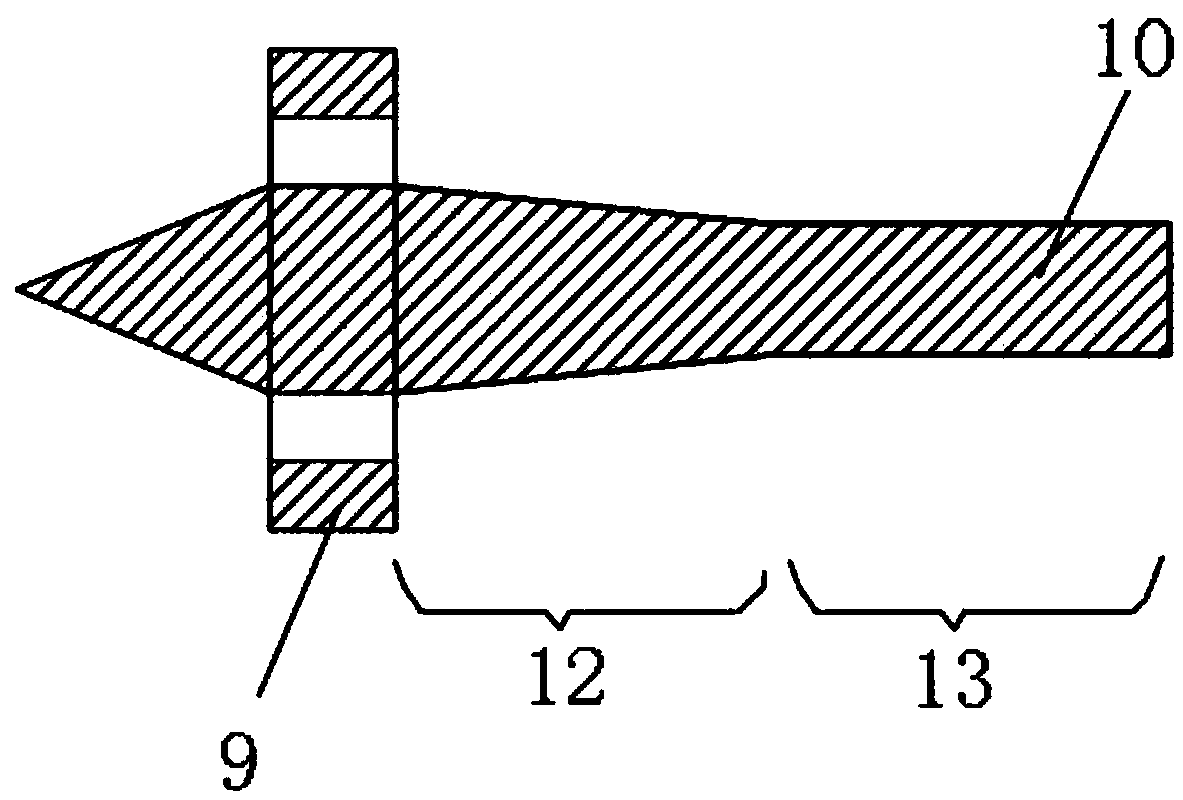

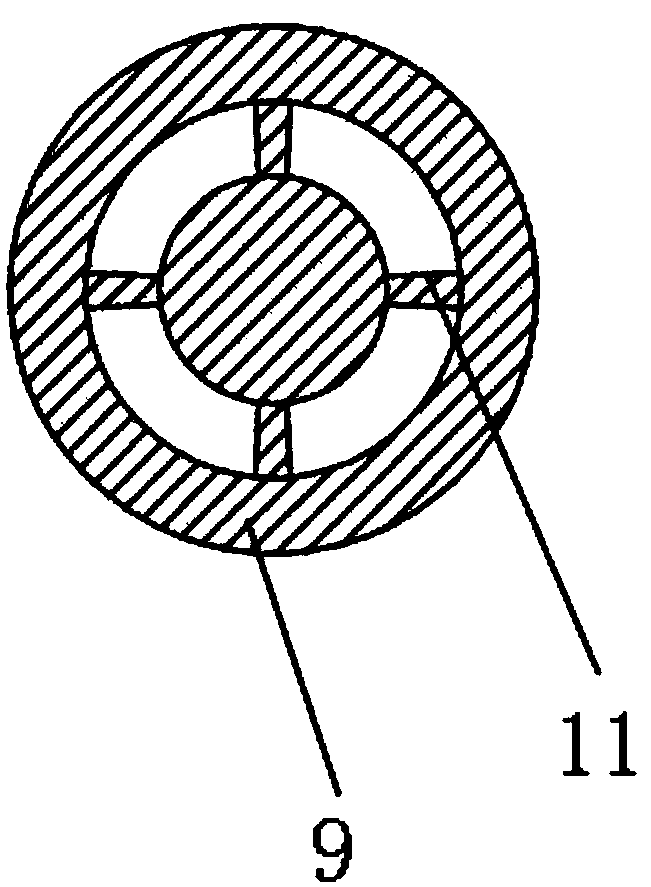

A method for continuously producing a hot extruded radiation ring

ActiveCN109166720AImprove pass rateImprove magnet performanceTransportation and packagingMetal-working apparatusAlloyQuenching

The invention relates to the technical field of manufacturing magnetic materials, in particular to a method for continuously producing a hot extrusion radiation ring, comprising the following steps: (1) preparing a nano composite phase fast-quenching belt by using a melt fast-quenching technology, and homogenizing and crushing the nano composite phase fast-quenching belt to prepare a hot-pressingmagnetic powder; (2), adding lubricant and mixing that homogeneou mixture, transferring the mixture to a hopper of a special extruder, and filling the mixture densely; (3) feeding into a continuous hot extrusion die, pressing into a hot pressing zone to obtain a full-density alloy, and then entering into a deformation zone to obtain a hot extrusion radiation ring. The invention skillfully places the hot pressing and the hot deformation of the hot extruding radiation ring in different segments in the same mold, The invention solves the problem that the hot-pressed radiation ring can not be continuously produced. The method has the advantages of high yield and material utilization ratio, uniform orientation, less grinding amount in the post-processing, greatly reducing the production cost and operation procedures, and is suitable for automatic batch production.

Owner:ZHEJIANG DONGYANG DMEGC RARE EARTH MAGNET CO LTD

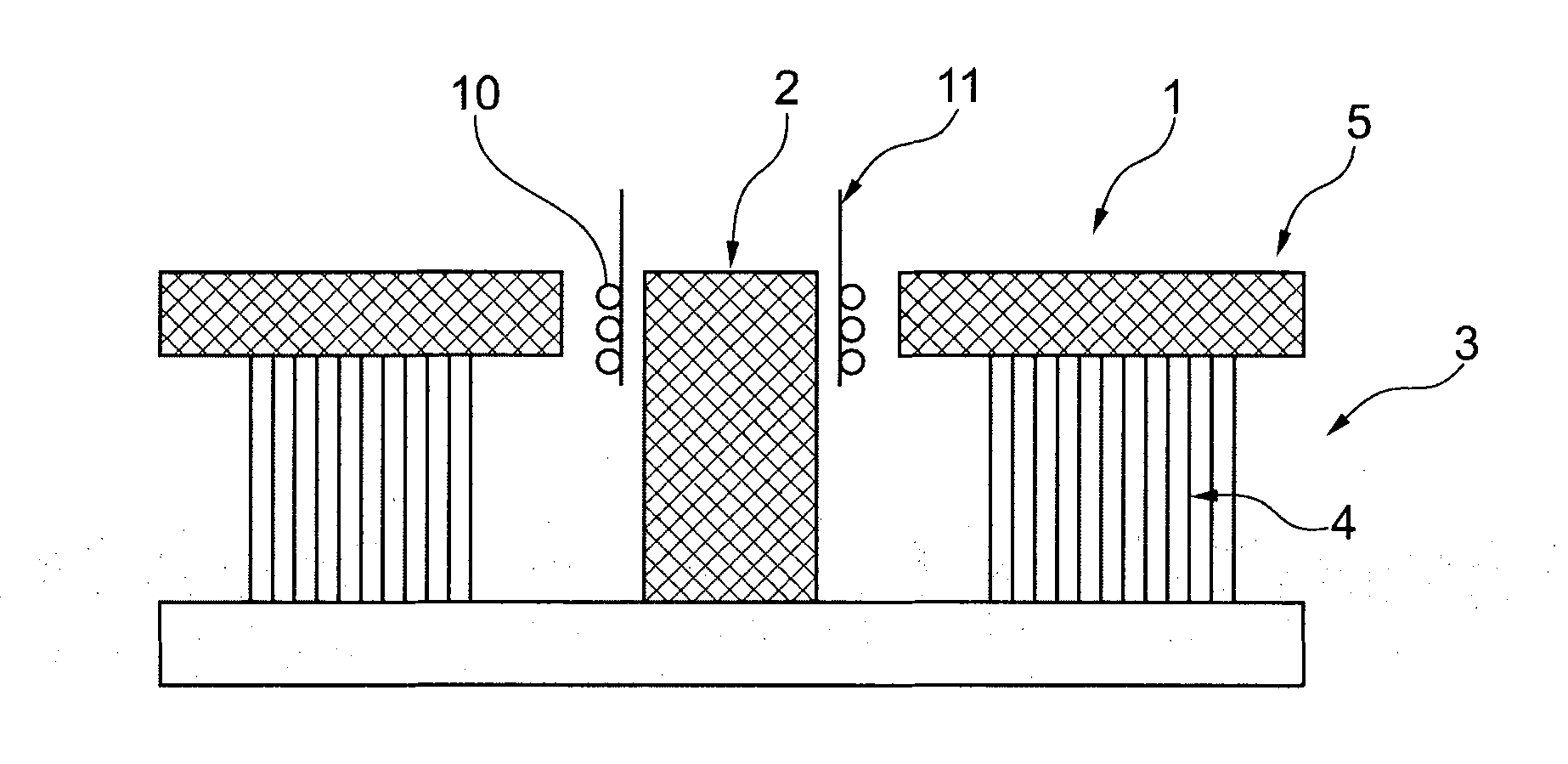

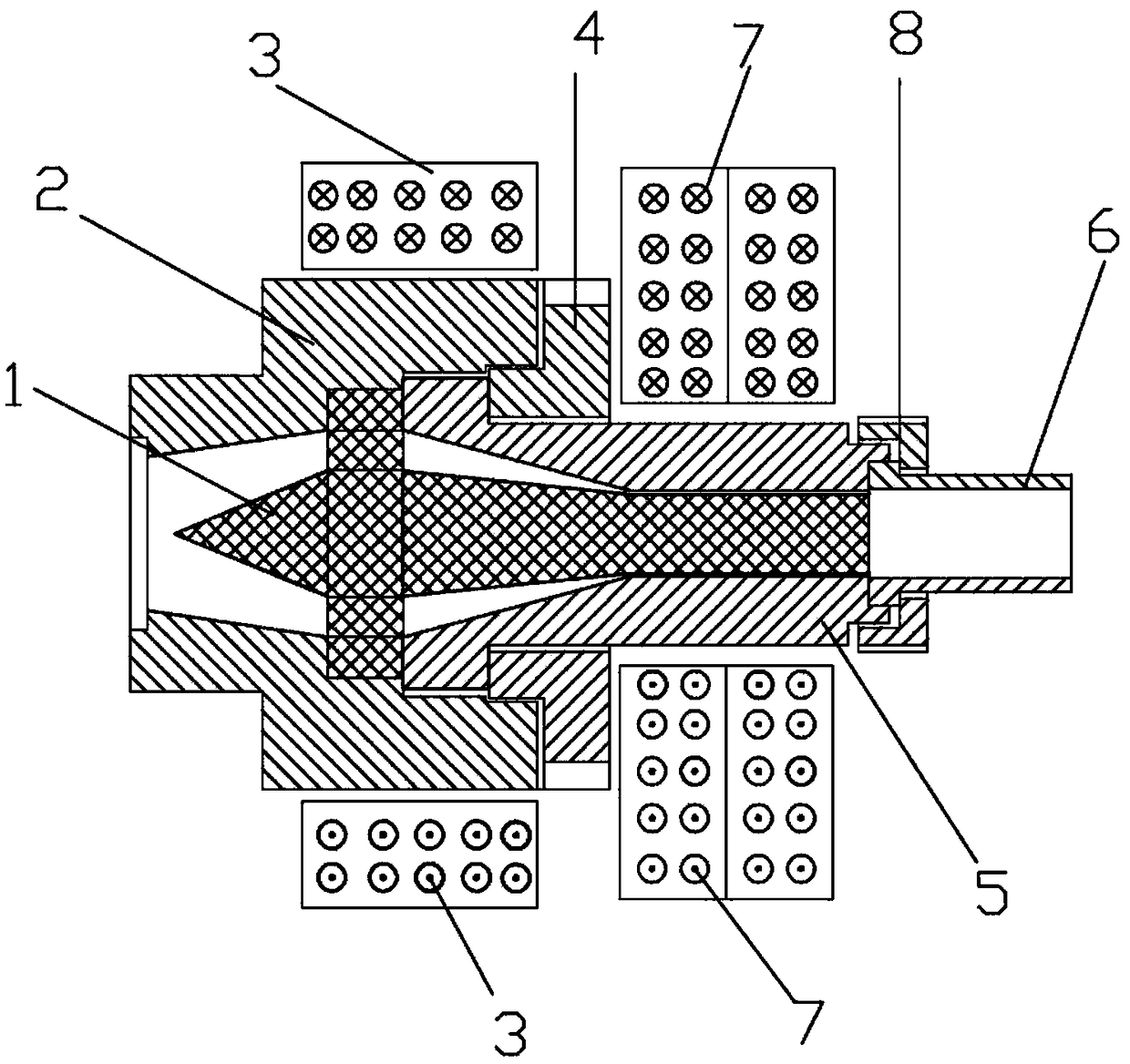

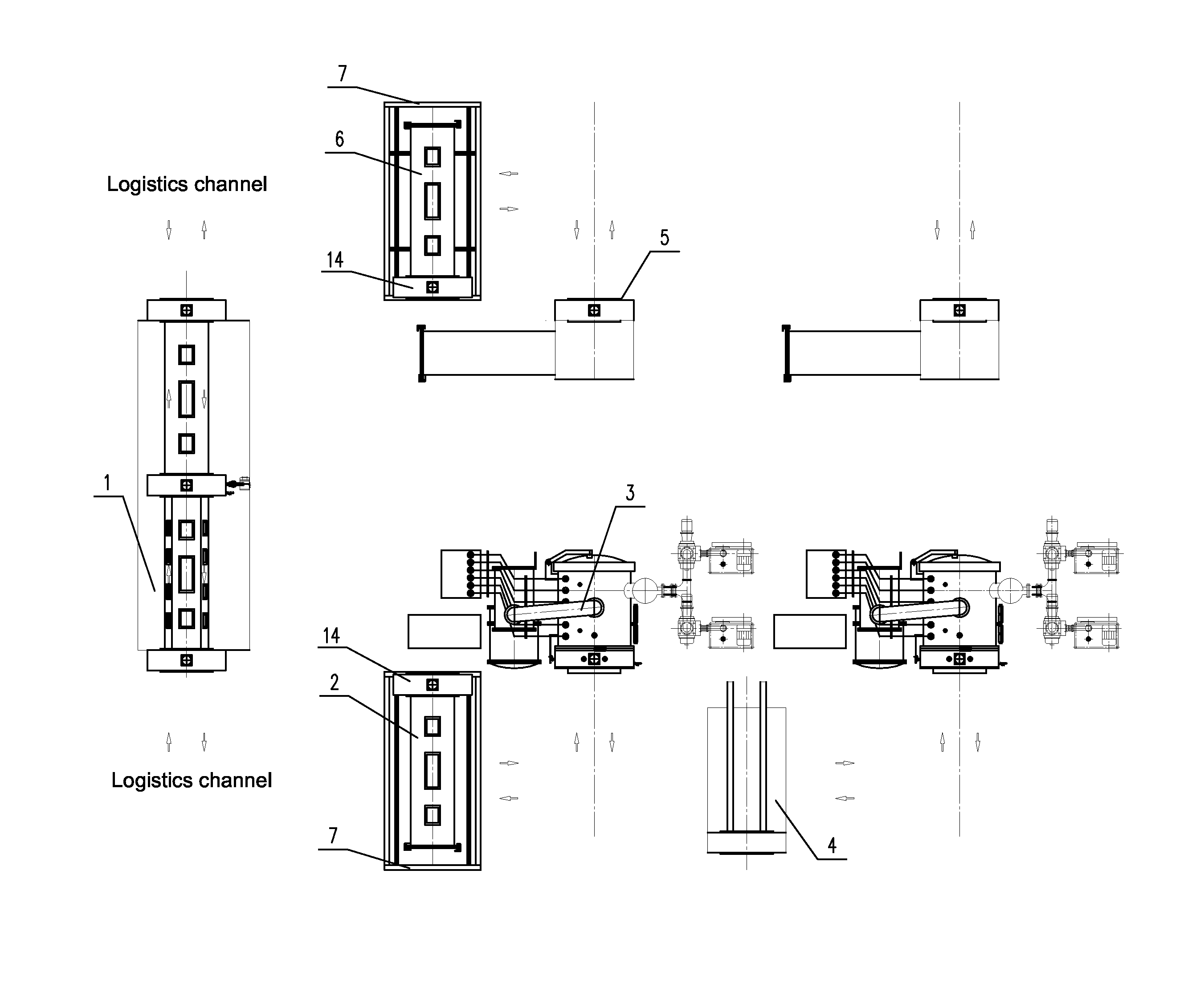

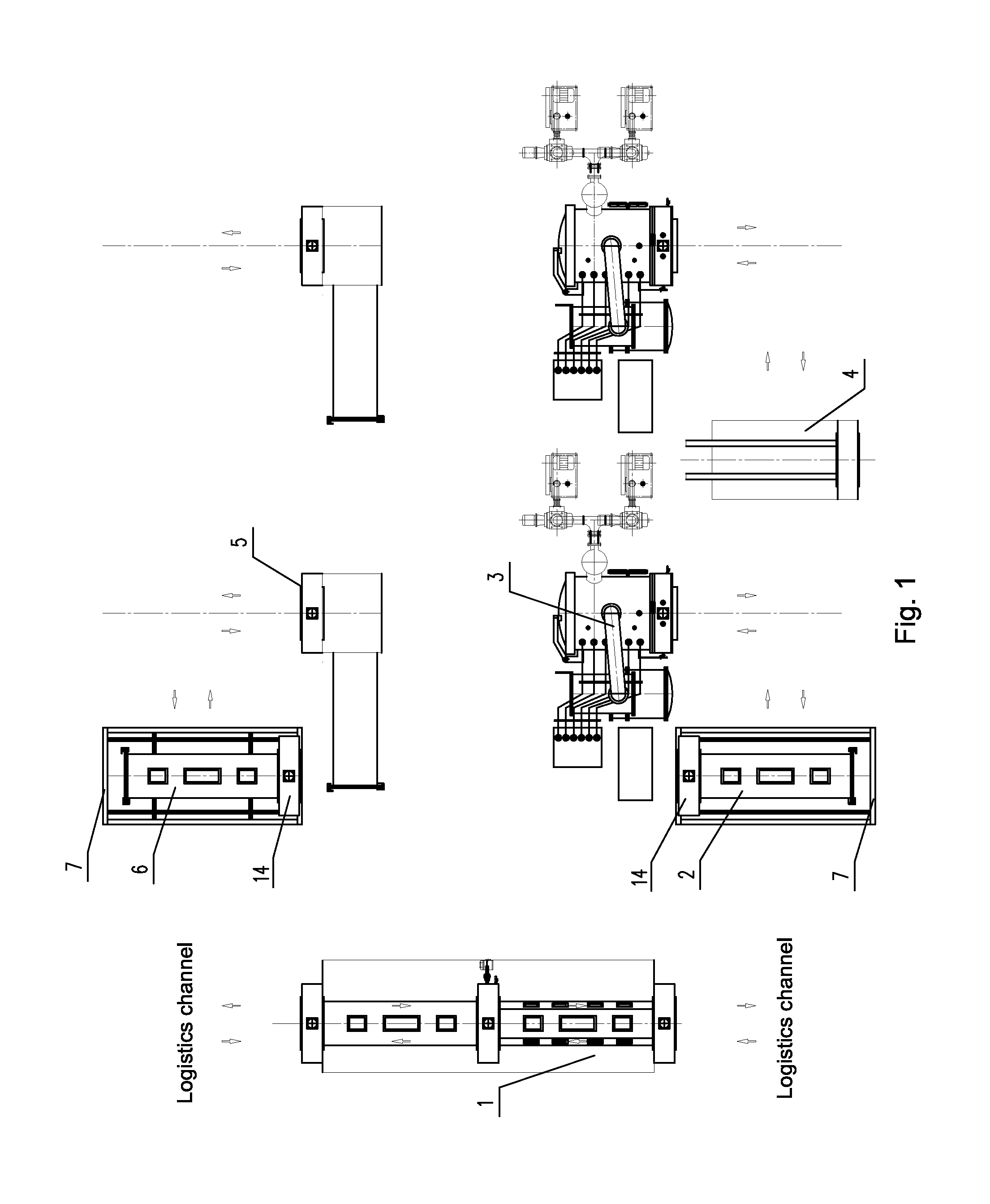

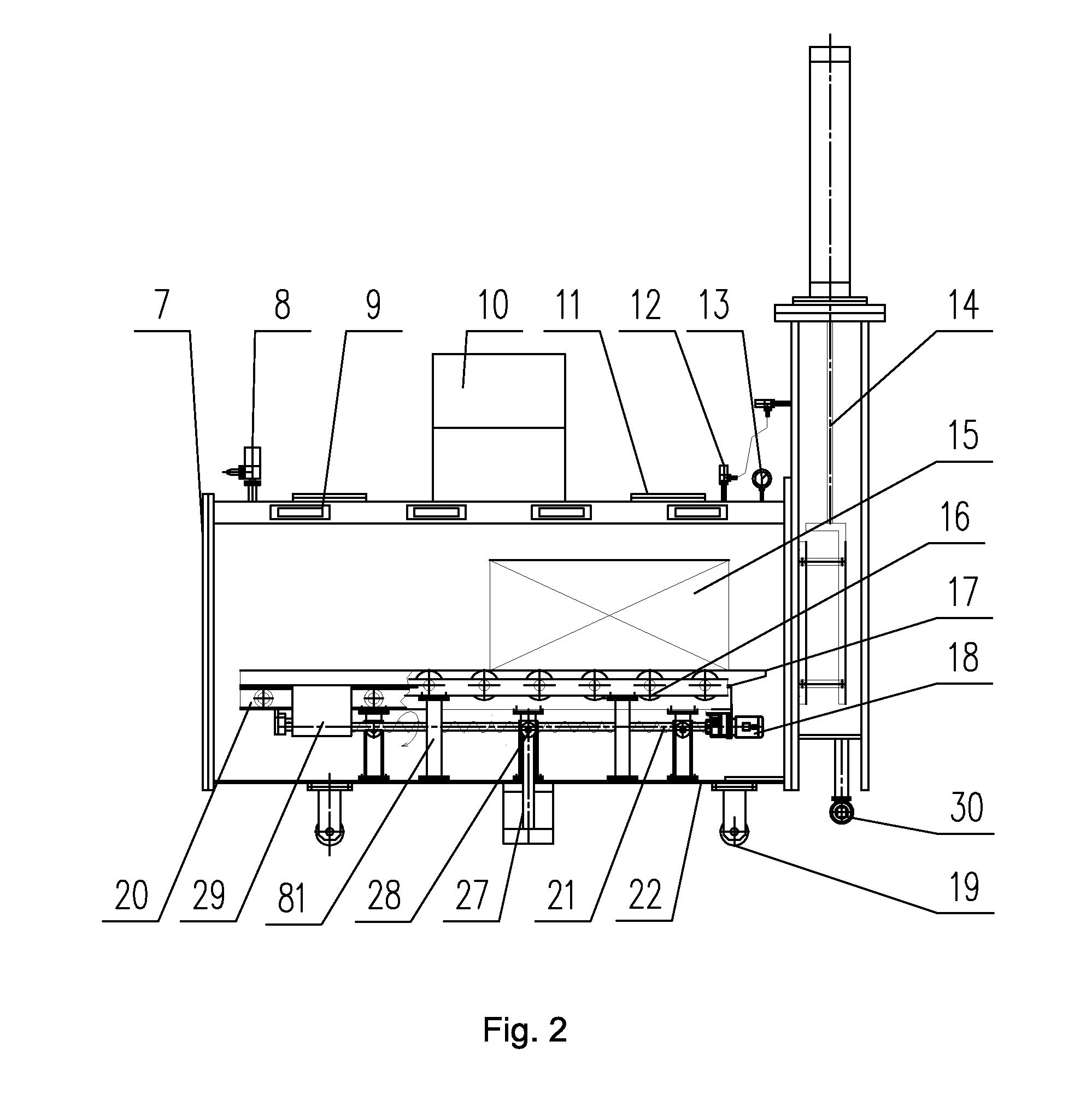

Method for flexibly sintering rare earth permanent magnetic alloy and sintering equipment thereof

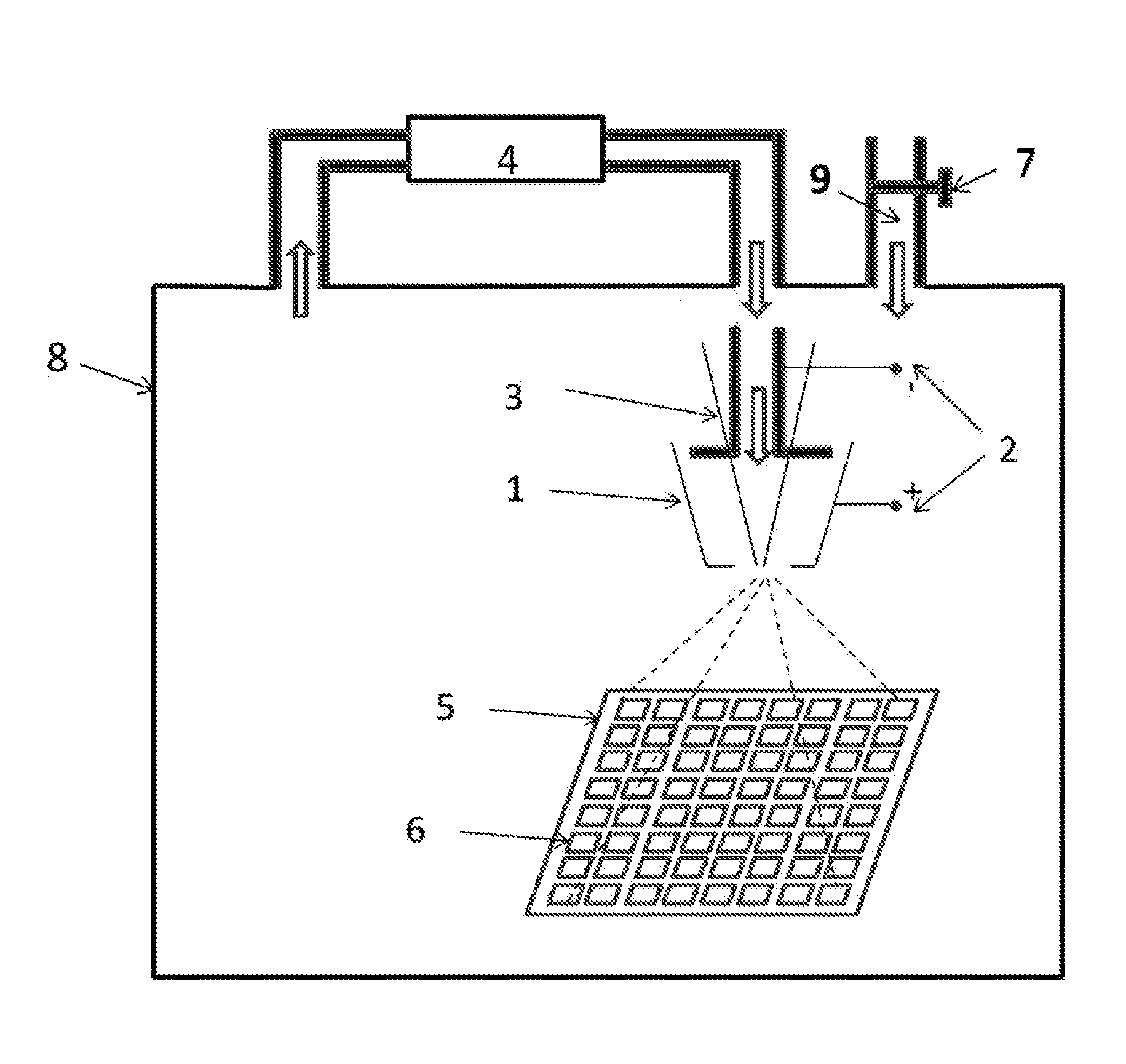

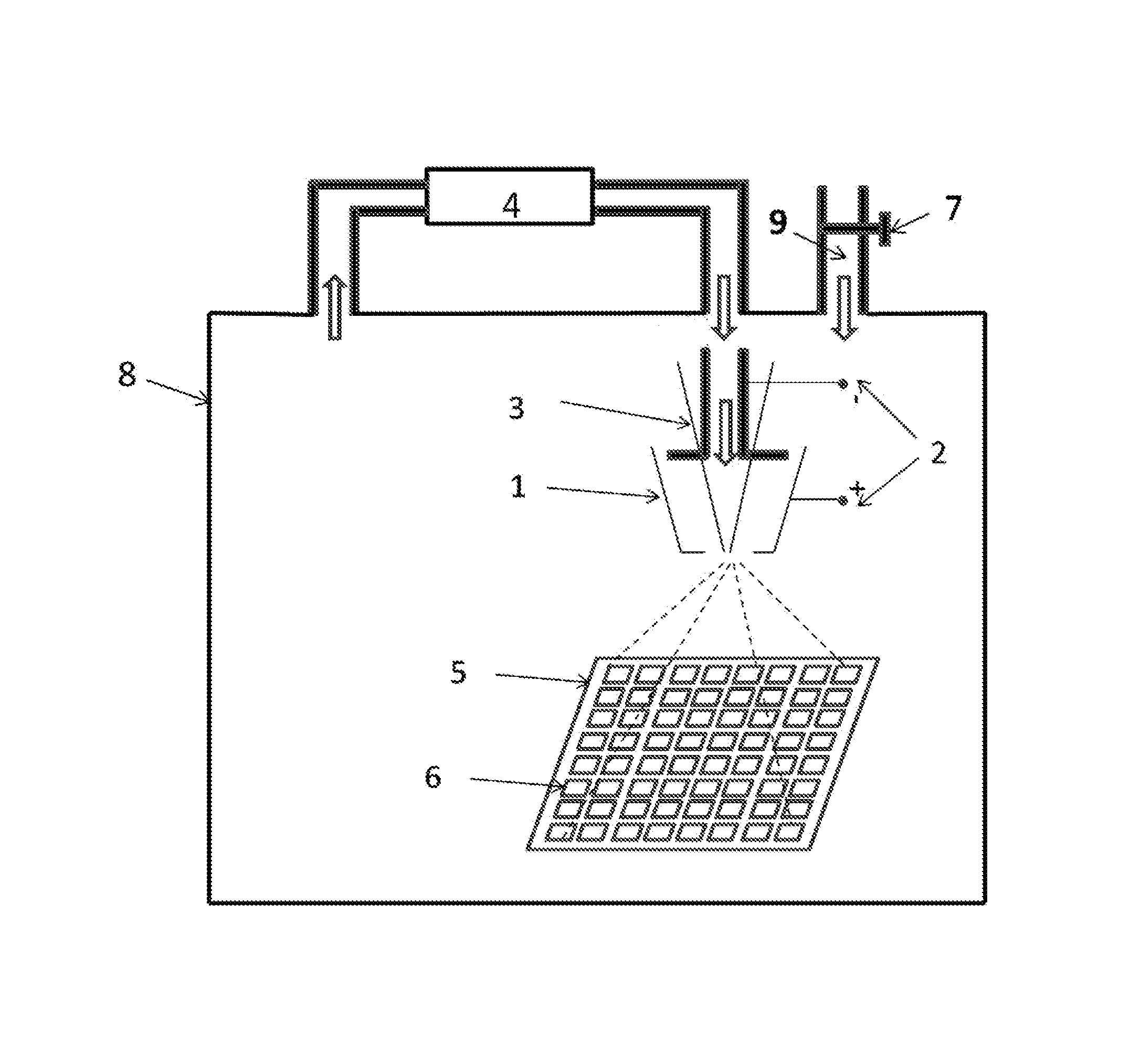

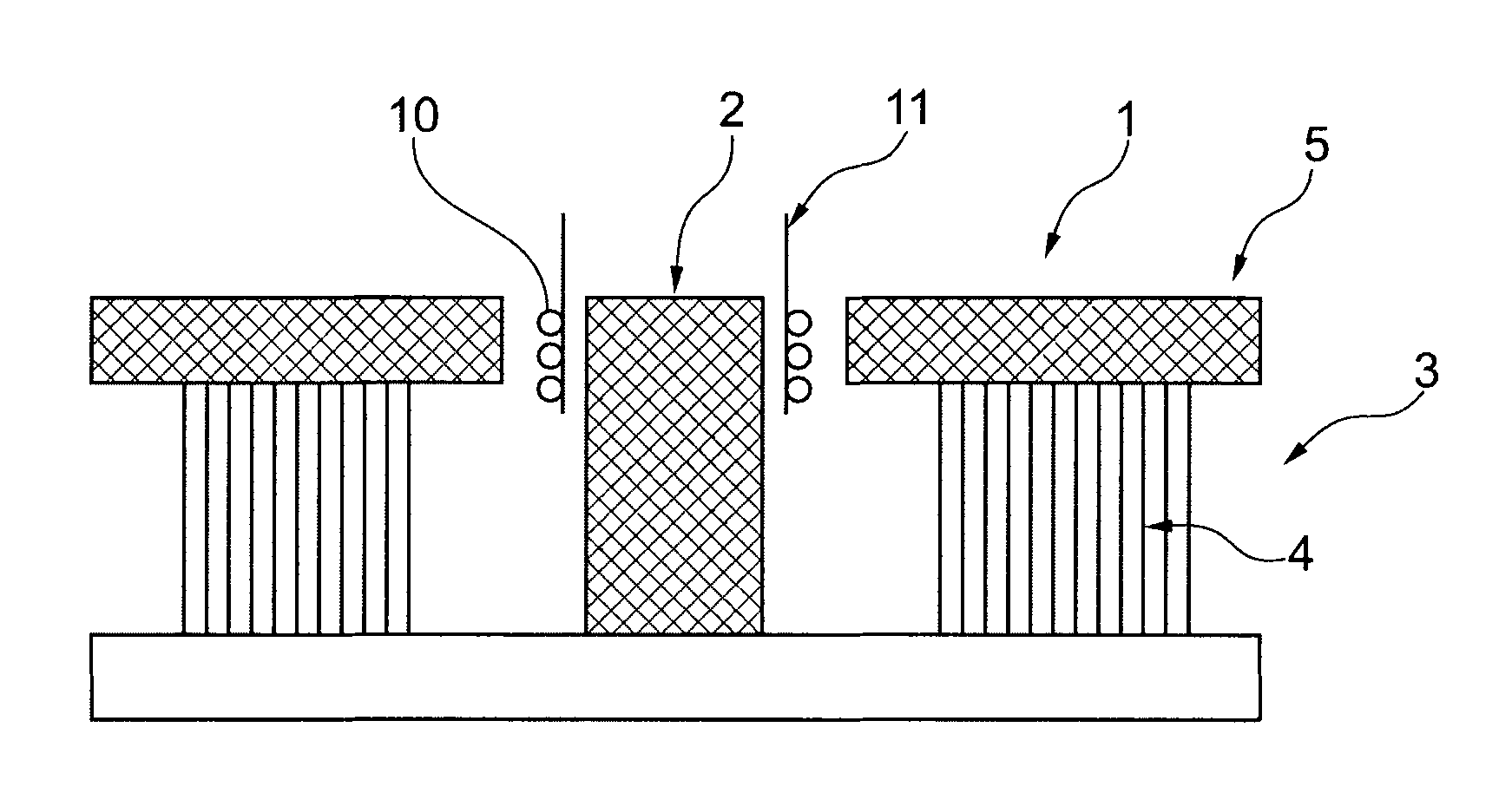

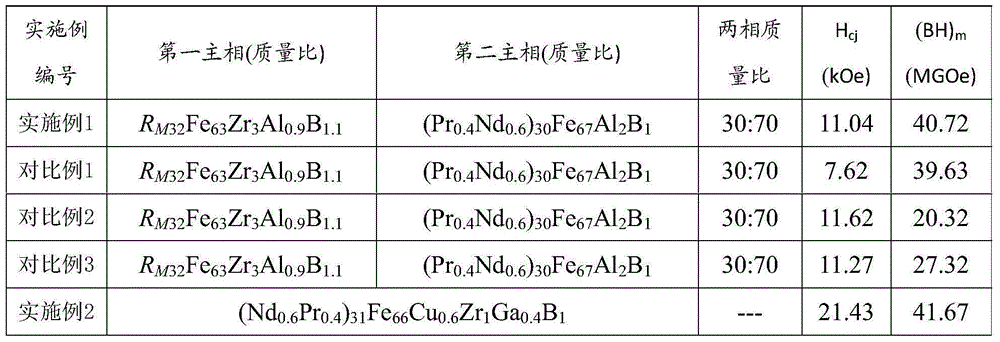

InactiveUS20140348690A1Automaticity improvedImprove magnet performanceMaintainance of heating chambersFurnace typesIsolation valveFine powder

A method for flexibly sintering rare earth permanent magnetic alloy comprises: (1) weighing fine powder of rare earth permanent magnetic alloy, loading the fine powder in moulds, and orientedly compacting the fine powder in a press machine and in inert atmosphere to obtain blanks and loading the blanks into charging boxes; (2) opening the two isolating valves connected with each other; wherein after a first rolling wheel transmission in the second conveying vehicle transfers the charging tray into the first chamber of the glove box, the two isolating valves are closed, and the second conveying vehicle leaves; (3) locking two matching flanges of the two isolating valves tightly; (4) locking matching flanges tightly; and (5) processing the blanks with heating and heat preservation according to a preset process curve; wherein the blanks are sintered at a highest temperature of 1200° C.

Owner:SHENYANG GENERAL MAGNETIC

Preparation method of soft magnetic ferrimagnetics

InactiveCN1152395CLow costEasy to processInorganic material magnetismInductances/transformers/magnets manufactureTetraglycol(Hydroxyethyl)methacrylate

The preparation method of magnetically soft ferrite magnet includes the following steps: in deionized water adding (wt%) 5-30% of mixture of ethylol methacrylate and tetraglycol diacrylate (according to the mixing weight ratio of 10-50:1), 0-20% of water-soluble macromolecular material, 3-20% of dispersing agent and 0.17-2% of initiating agent, mixing them and preparing them into monomer solution, adding the magnetically soft ferrite powder into monomer solution, mixing them to obtain suspension system, pouring the suspension system into foring mould, heating, heat-insulating, demoulding and drying so as to obtain the invented product. The described monomer aqueous solution is non-toxic, and the ammonium persulfate can be adopted as initiating agent.

Owner:SOUTH CHINA UNIV OF TECH

Neodymium iron boron magnetic material suitable for motor

InactiveCN103632788AImprove degassing effectCrystallize fastMagnetic circuit characterised by magnetic materialsMagnetic materialsCeriumTitanium

The invention relates to a neodymium iron boron magnetic material suitable for a motor. The neodymium iron boron magnetic material is prepared by main phase alloy and auxiliary phase alloy in a mixed mode, the main phase alloy is prepared by, by weight, 64.5-68.5% of iron, 1.0-1.2% of boron, 30.2-34.3% of neodymium, 0.05-0.4% of stibium and 0.1-0.4% of gallium, and the auxiliary phase alloy is prepared by, by weight, 50.8-54.2% of iron, 0.8-1.2% of boron, 18.9-21.1% of neodymium, 12.8-16.3% of titanium, 8.9-11.1% of lanthanum and 0.8-1.2% of cerium. The neodymium iron boron magnetic material prepared according to the technical scheme has the advantages of having the mechanical property suitable for the motor and solving the problem that magnetic material of the motor are prone to being lost.

Owner:NINGBO STAR MATERIALS HI TECH

Magnet

PendingUS20180197665A1Increase in coercivityImprove magnet performanceInductances/transformers/magnets manufactureMagnetic materialsDysprosiumRare-earth magnet

Magnets and systems, methods, and techniques for manufacturing magnets are provided. In some embodiments, methods of manufacturing magnets comprise providing a rare earth magnetic body depositing a bead of dysprosium or terbium metal onto a part of the magnetic body to form a magnet; and heat-treating the magnet. In some embodiments, a magnet is provided comprising a magnetic body and a bead of dysprosium or terbium metal. In some embodiments, the magnetic body contains grains of rare earth magnet alloy, and the bead of dysprosium or terbium metal is deposited onto a part only of a surface of the magnetic body.

Owner:DYSON TECH LTD

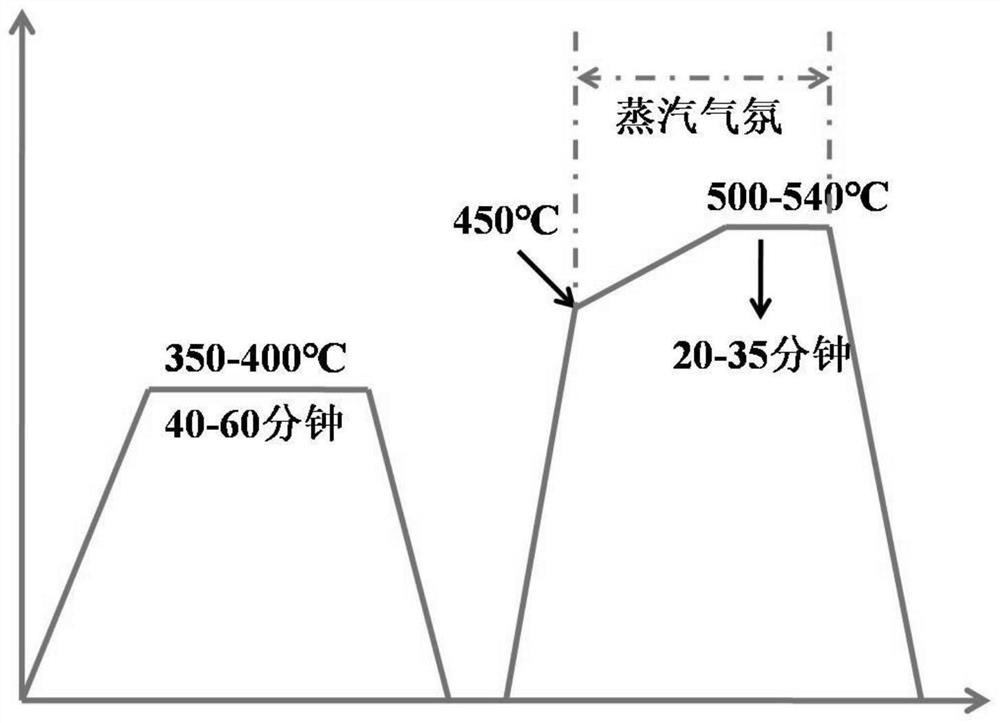

Preparation method of high-coercivity neodymium-iron-boron magnet

ActiveCN109590463AHigh strengthHigh energy productVacuum evaporation coatingSputtering coatingMetallurgyRare earth

The invention provides a preparation method of a high-coercivity neodymium-iron-boron magnet. According to the preparation method, graphene is added to a neodymium-iron-boron powder, so as to effectively improve the strength of the neodymium-iron-boron magnet. Modifier Li<4-2x>M<3x>Ti<5-x>O<12>C is used to improve the magnetic energy product of the neodymium-iron-boron magnet, so as to perfect andimprove the performance of the neodymium-iron-boron magnet. A rare-earth metal film is sputtered onto the surface of each powder particle by using the magnetron sputtering process; grain boundaries are diffused by means of pressing and sintering; rare earth metals enter the superficial layers of neodymium, iron and boron to improve the anisotropies of the neodymium, iron and boron, with the neodymium, iron and boron hardly affected; and therefore, the purpose of greatly improving the coercivity of the neodymium-iron-boron magnet can be achieved under the condition that remanent magnetism hardly decreases. In addition, the neodymium-iron-boron magnet is pre-sintered by means of stepped heating, so that the temperature gradients at the exterior and center of the neodymium-iron-boron magnetdecrease; and when the sintering temperature is reached, the temperature of the central part of a neodymium-iron-boron compact is allowed to reach the sintering temperature rapidly, so as to improve the density and magnetic properties of the sintered neodymium-iron-boron compact.

Owner:ZHEJIANG ZHONGHANG NEW MATERIAL

A kind of preparation method of samarium cobalt permanent magnet material

ActiveCN105304249BLow hydrogen pressureGood hydrogen absorption and crushing abilityInorganic material magnetismHydrogen pressureRare earth

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Rare earth permanent magnet material and preparation method thereof

PendingUS20200303120A1Improve coercive forceImproving coercive force characteristicSolid state diffusion coatingInductances/transformers/magnets manufactureRare-earth elementFluoride

The present invention discloses a rare earth permanent magnet material and a preparation method thereof The method comprises: a sintering treatment step: laying a composite powder for diffusion on the surface of a neodymium iron boron magnetic powder layer and carrying out spark plasma sintering treatment to obtain a neodymium iron boron magnet with a diffusion layer solidified on the surface thereof, wherein the compositional proportional formula of the composite powder for diffusion is H100-x-yMxQy, where H is one or more of a metal powder, a fluoride powder, or an oxide powder of Dy, Tb, Ho, and Gd, M is a Nd, Pr, or NdPr metal powder, and Q is one or more of Cu, Al, Zn, and Sn metal powders, x and y are respectively the atomic percentages of component M and component Q in the composite powder for diffusion, x is 0-20, and y is 0-40; and diffusion heat treatment and tempering steps. The method of the present invention has high efficiency, good diffusion effects, and reduced quantities of heavy rare earth elements.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

PPS-based permanent magnetic composite material and preparation method thereof

The invention discloses a PPS-based permanent magnetic composite material and a preparation method thereof. The raw materials comprise 85-95 wt% of magnetic powder subjected to surface treatment and 5-15 wt% of an adhesive; wherein the adhesive is prepared from the following materials in percentage by weight: 0.1-60.0 wt% of thermoplastic resin, 40.0-99.0 wt% of polyphenylene sulfide resin, 0.1-10.0 wt% of a compatilizer, 0.01-1.0 wt% of an antioxidant and 0.01-1.0 wt% of a lubricating agent; wherein the surface-treated magnetic powder is prepared by coating the surface of the magnetic powderwith a coating material, the coating material is a silane or titanate coupling agent, and the use amount of the coating material is 0.01-1.0 wt% of the mass of the magnetic powder. According to the invention, other thermoplastic resins are added into the PPS for blending to prepare an adhesive, so that the defects of difficult molding, brittleness, poor toughness and the like of the PPS-based magnet are effectively overcome.

Owner:赣州能之光新材料有限公司

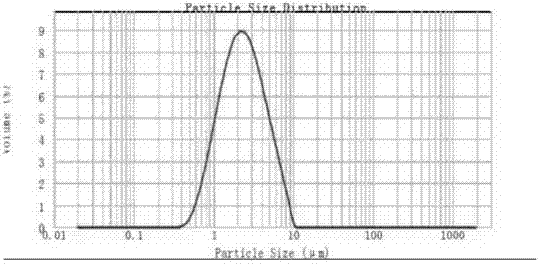

Method for producing a high-performance neodymium—iron—boron rare earth permanent magnetic material

ActiveUS9427804B2Prevent oxidationImprove magnet performanceTransportation and packagingMetal-working apparatusBoronFine powder

In the method for producing a high-performance neodymium-iron-boron rare earth permanent magnetic material of the present invention, the degree of alignment of the magnet can be improved by preparing the pre-sintered alloy material, the particle size of the powder ground by the jet mill can be refined and the fine powder in the filter of the jet mill can be mixed with the powder collected by the cyclone collector by controlling the oxygen content of the jet mill and adding the nanoscale oxide fine powder. The present invention can significantly improve the utilization ratio of the material and the performance of the magnet, save the use of the rare earth, and especially the heavy rare earth, thereby protecting the scare resources.

Owner:SHENYANG GENERAL MAGNETIC

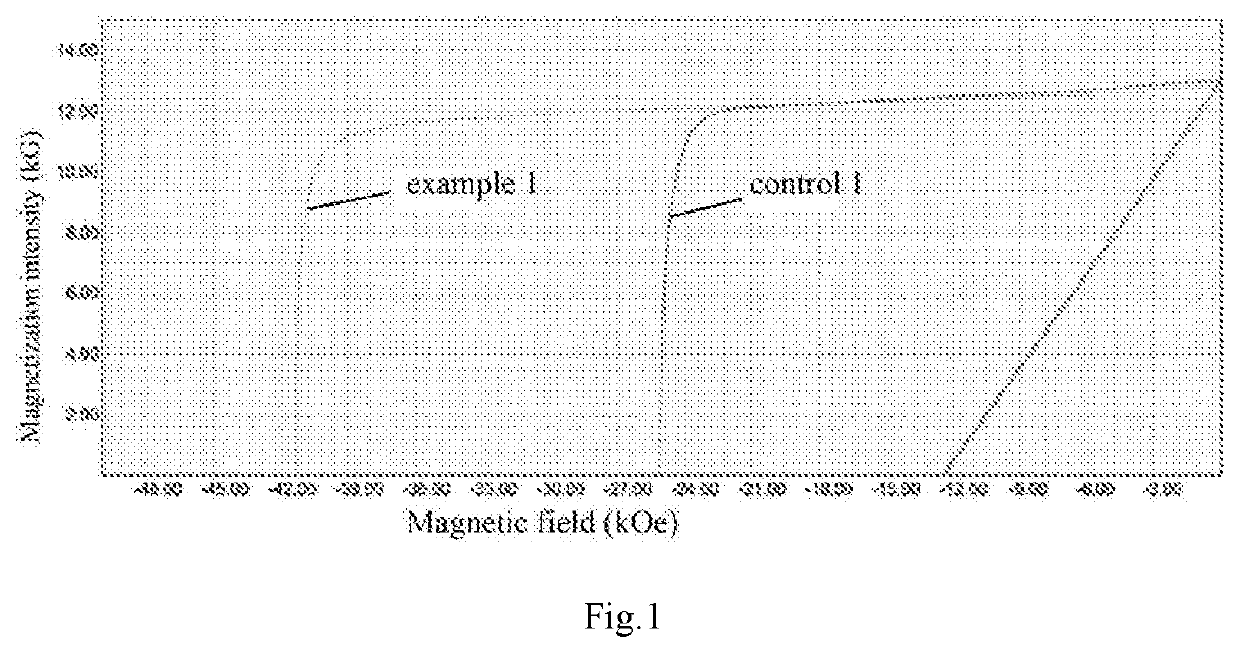

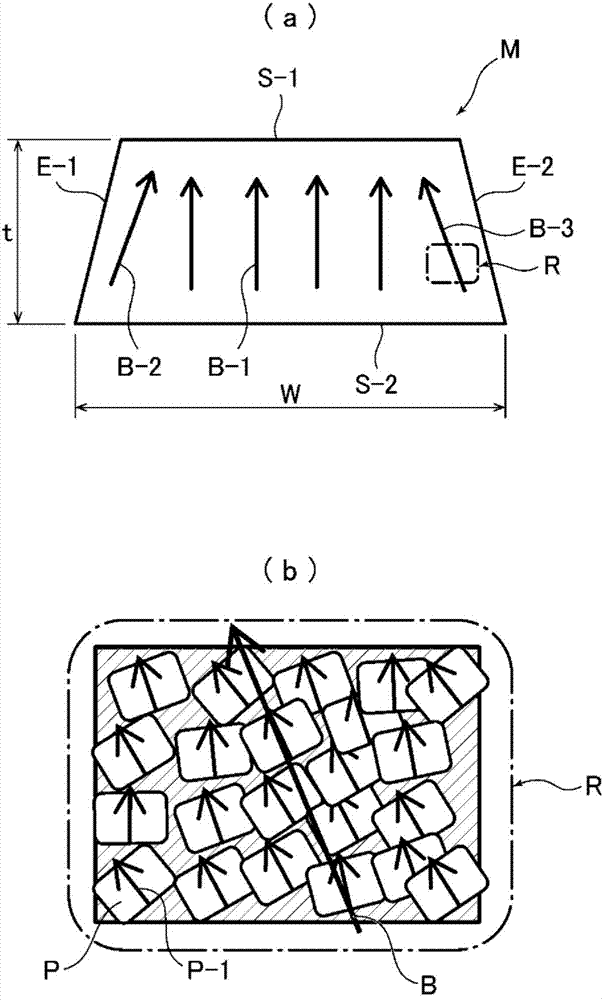

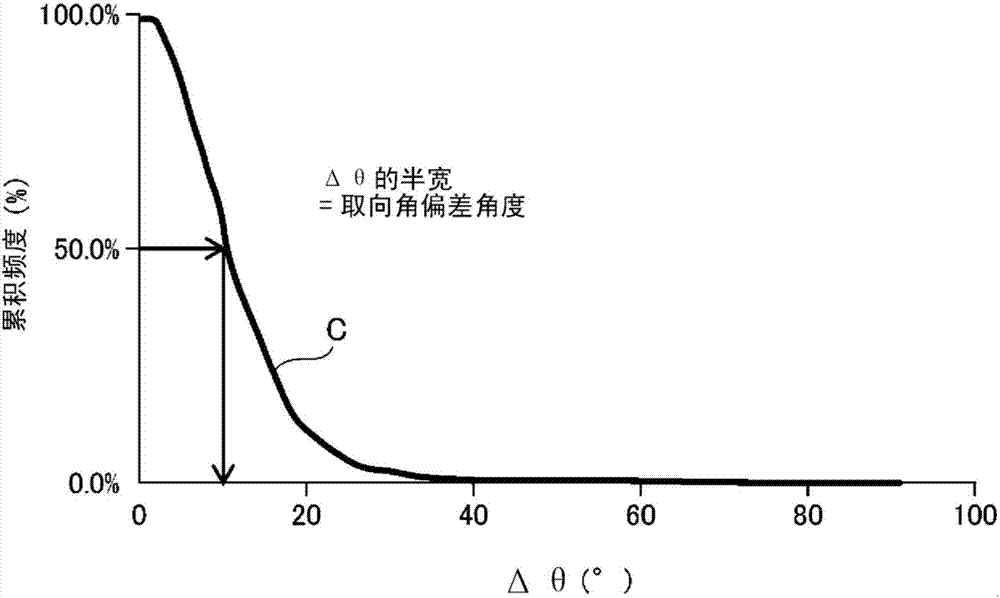

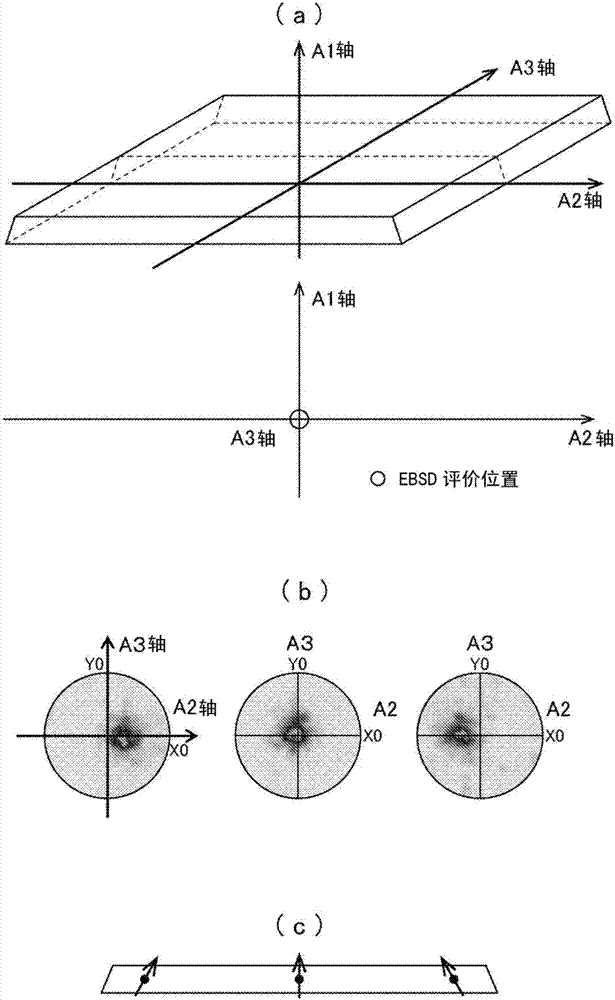

Sintered body for forming rare-earth magnet, and rare-earth sintered magnet

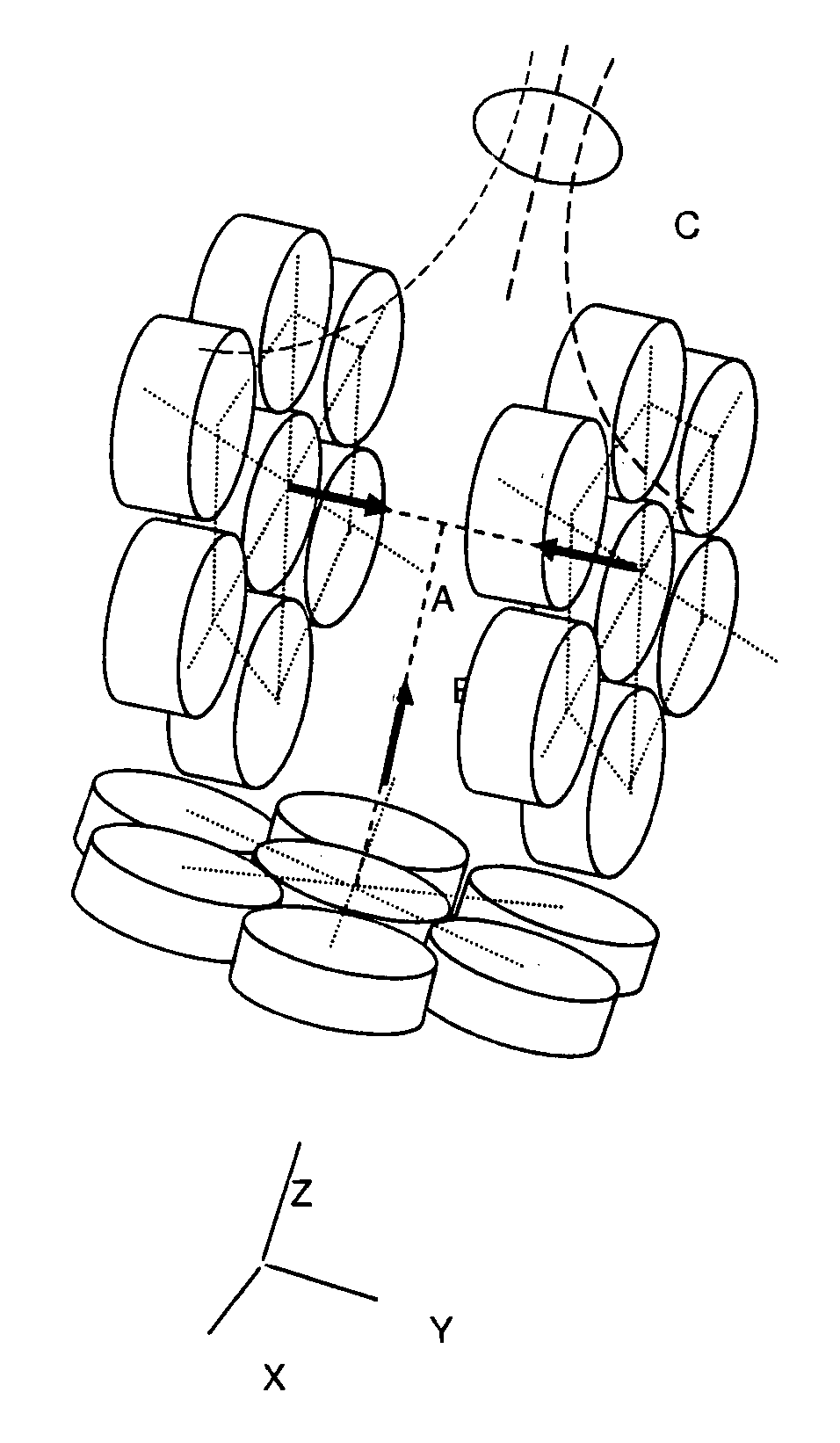

ActiveCN107430921AImprove magnet performanceHigh densityTransportation and packagingMetal-working apparatusSintered magnetsMagnetization

Provided are: a sintered body that forms a rare-earth magnet and is configured in a manner such that the divergence between the orientation angles of the easy axes of magnetization of magnet material particles and the orientation axis angle of the magnet material particles is kept within a prescribed range in an arbitrary micro-section of a magnet cross-section; and a rare-earth sintered magnet. This sintered body for forming a rare-earth magnet has two or more different regions exhibiting an orientation axis angle of at least 20 DEG, given that the orientation axis angle is defined as the highest-frequency orientation angle among the orientation angles of the easy magnetization axes, relative to a pre-set reference line, of a plurality of magnet material particles in a rectangular section at an arbitrary position in a plane including the thickness direction and the widthwise direction. The orientation-angle variance angle is 16.0 DEG or less relative to said orientation axis angle, given that the orientation-angle variance angle is defined on the basis of the difference between the orientation angles of the easy magnetization axes of the magnet material particles. One embodiment defines said section as a rectangular section containing 30 or more magnet material particles, and for example, containing 200 or 300 magnet material particles. It is preferable for the rectangular section to be a square. Another embodiment defines said section as a square section having 35[mu]m sides.

Owner:NITTO DENKO CORP

Electromagnetic drive unit

ActiveUS9036859B2Improve linearityEven harmonic distortionTransducer detailsDeaf-aid setsEngineeringLoudspeaker

An electromagnetic drive unit for a loudspeaker of the type where an air gap is arranged in a magnet system such that magnetic flux lines are substantially linear across the air gap, and that a voice coil is arranged in said air gap, wherein the magnet system comprises a central yoke separated by said air gap from a ring-shaped magnet system, which magnet system at least comprises a bottom plate connected to said central yoke, and a magnet and a top plate, characterized in that at least a section of the central yoke corresponding to the extent of the air gap and at least a corresponding section of the top plate is made from a soft magnetic composite material.

Owner:DALI AS

Preparation method of permanent magnet material

InactiveCN106270519AInhibit growthImprove magnet performanceMagnetic materialsHot isostatic pressingMagnet

The invention provides a preparation method of a permanent magnet material, comprising the steps of (1) preparing raw powder of permanent magnet material having a particle size of 0.01-5 Mum; (2) orient-forming the raw powder in the magnetic field 0.5-2 T under the protection an inert gas; (3), placing oriented magnet in a hot isostatic press, and pressing under 30-400 Mpa and 200-1100 DEG C for 0.1-4 h. After magnet powder is oriented, the magnet powder is subjected to hot isostatic sintering, the magnet is sintered with all-directional high pressure, it is possible to provide rapid sintering without a hot deformation process, and therefore, energy consumption is reduced and more excellent comprehensive permanent magnet performance is exhibited.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Magnetic powder

The invention discloses magnetic powder, which is composed of components according to the following mass parts: 1 to 7 parts of iron scale power, 2 to 7 parts of iron oxide red, 7 to 15 parts of barium salt, 5 to 18 parts of additive, and 8 to 17 parts of latent solvent. The magnetic powder produced according to the invention has good effect, and cannot be crush easily.

Owner:南通万宝磁石制造有限公司

Composite binder and method for preparing soft magnetic composite material by using same

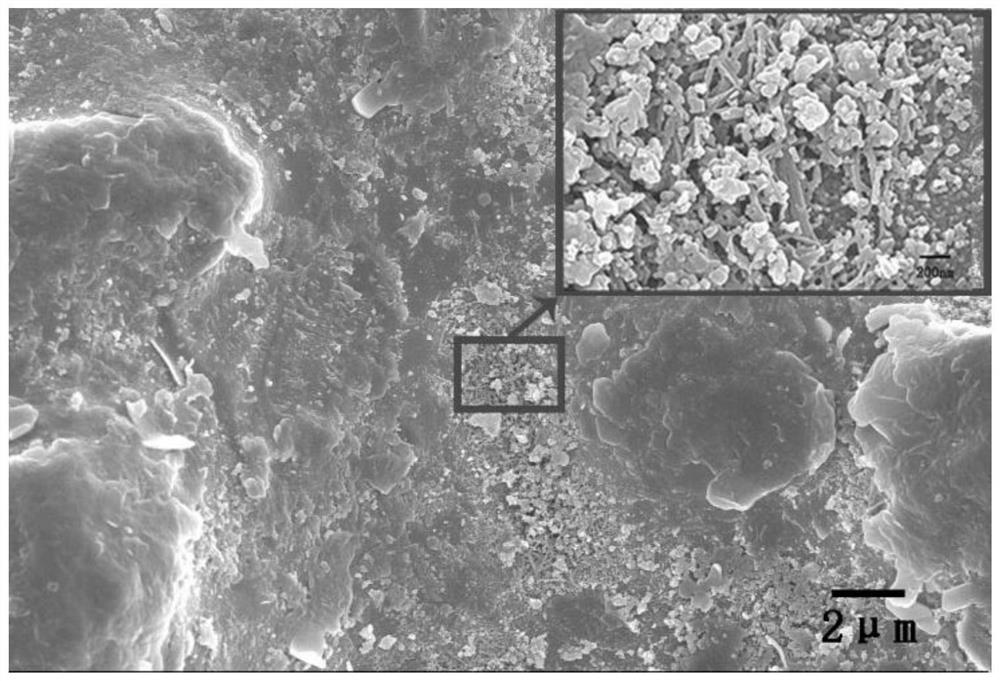

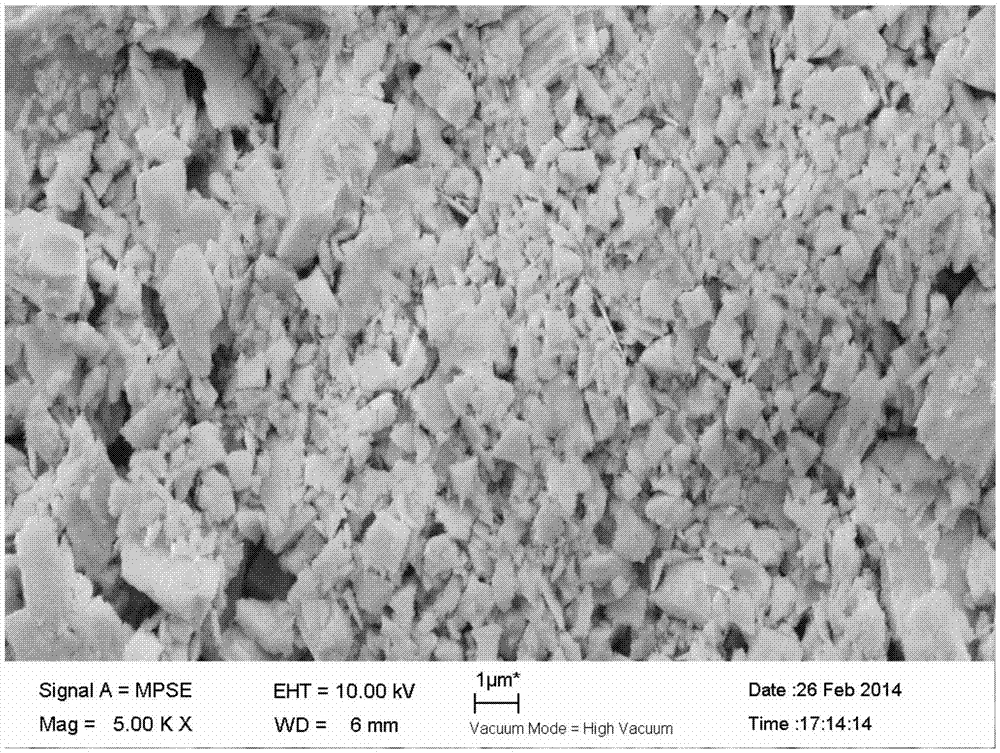

ActiveCN111872374AImprove mechanical propertiesHigh mechanical strengthTransportation and packagingMetal-working apparatusCarbon nanotubeUltrasonic oscillation

The invention relates to a composite binder and a method for preparing a soft magnetic composite material by using the same, and belongs to the technical field of soft magnetic material preparation. The composite binder is prepared by the following method including the steps of firstly, preparing an acetone solution of organic silicon resin, then adding carbon nanotubes accounting for 1%-5% of theweight of the organic silicon resin, and uniformly dispersing the carbon nanotubes in the acetone solution of the organic silicon resin through ultrasonic oscillation and mechanical stirring to formthe composite binder. Organic silicon resin molecules in the composite binder are adhered to the surfaces of the carbon nanotubes to form a net-shaped structure, and after coating with the composite binder, a net-shaped coating structure can be formed on the surface of iron powder, so that the volatility of the composite binder and a lubricating agent adhered to the net-shaped structure during annealing can be obviously reduced, a diffusion channel is provided for steam to enter a magnet, organic matters can be more effectively removed, a uniform and complete oxidation strengthening layer is formed, and the mechanical strength of the SMC magnet is greatly improved.

Owner:山东精创磁电产业技术研究院有限公司

Preparation method of high-performance neodymium-iron-boron permanent magnet

ActiveCN106898486AImprove magnet performanceInductances/transformers/magnets manufactureNeodymium iron boronOrganic solvent

The invention provides a preparation method of a high-performance neodymium-iron-boron permanent magnet. The preparation method comprises the following steps that firstly, rare-earth metal powder and an organic solvent are mixed according to a weight ratio of 1:5 and subjected to rod milling and filtration to obtain filtered rare-earth metal powder, wherein the organic solvent is C1-C4 monohydric alcohol and / or resin, and the weight percentage of the rare-earth metal powder to the organic solvent is larger than 80%; secondly, after filtration, the filtered rare-earth metal powder is sprayed on a neodymium-iron-boron permanent magnet sample through a spraying device under the air pressure of 0.15-0.4 MPA, and the neodymium-iron-boron permanent magnet with a rare-earth metal is obtained after natural drying.

Owner:TIANJIN SANHUAN LUCKY NEW MATERIAL CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com