Patents

Literature

564 results about "Diffusion effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Several factors that affect the rate of diffusion include temperature, density of the diffusing substance, medium of diffusion and concentration gradient Temperature : As temperature increases the average kinetic energy of particles increases. Greater kinetic energies lead to increased velocities.

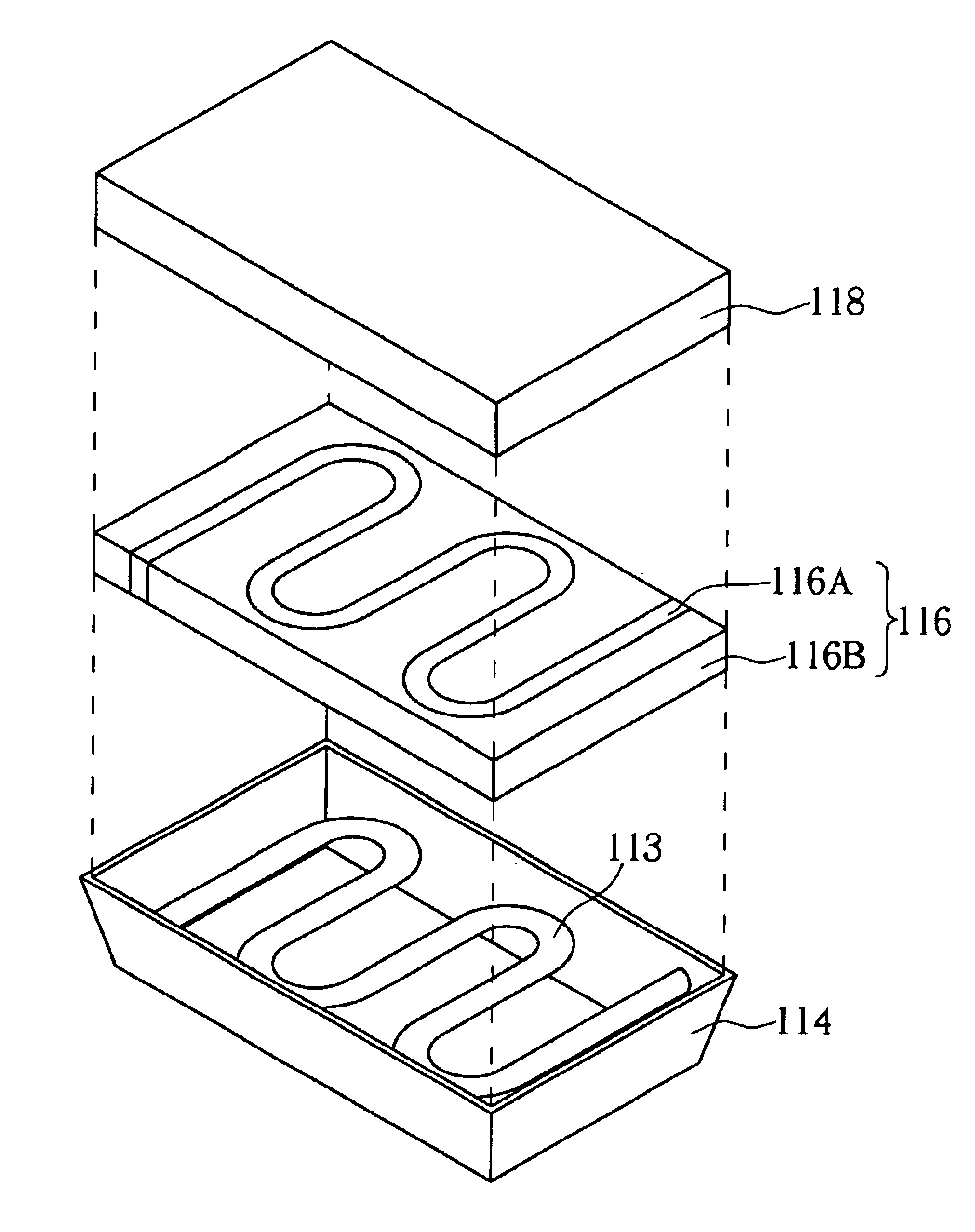

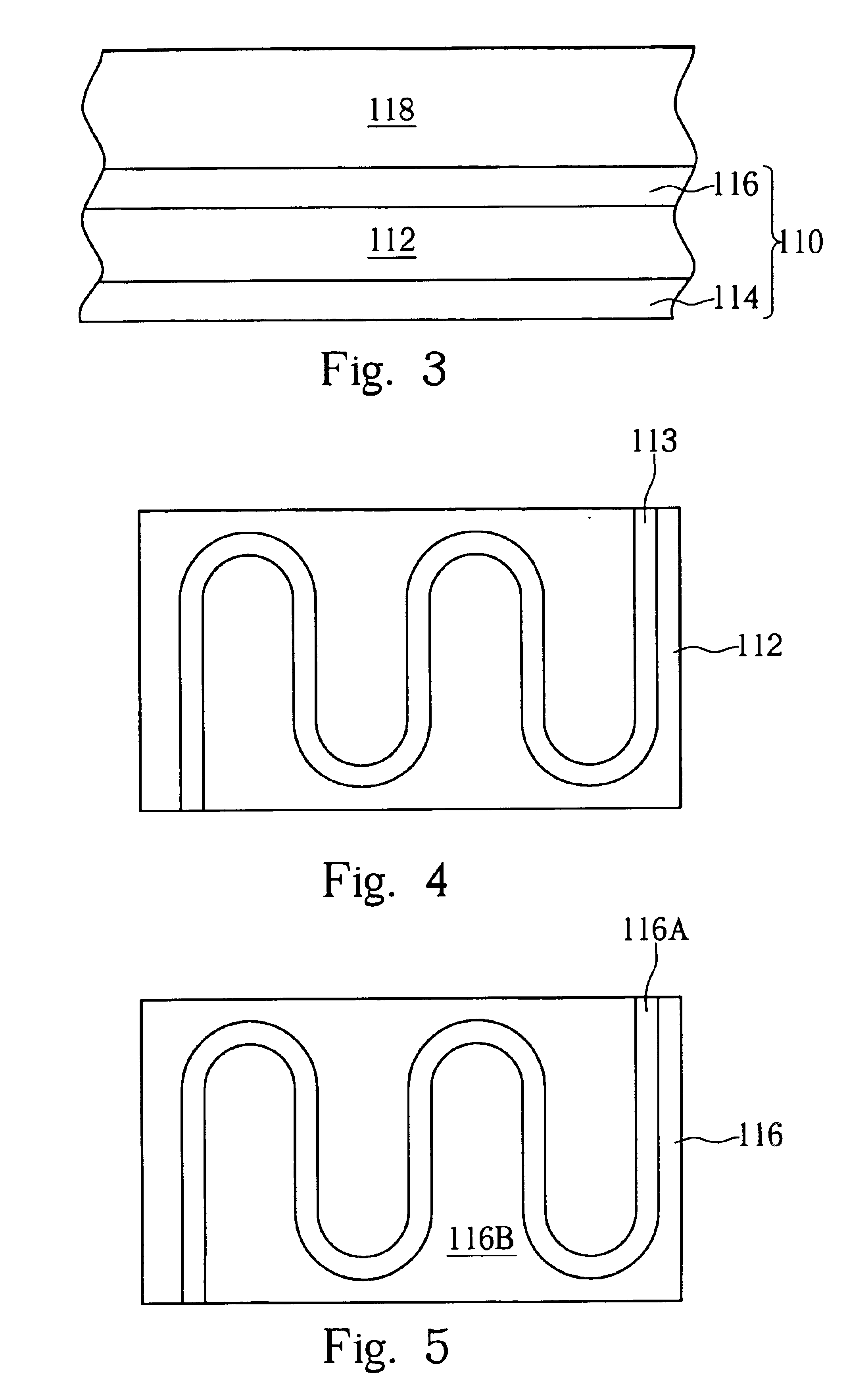

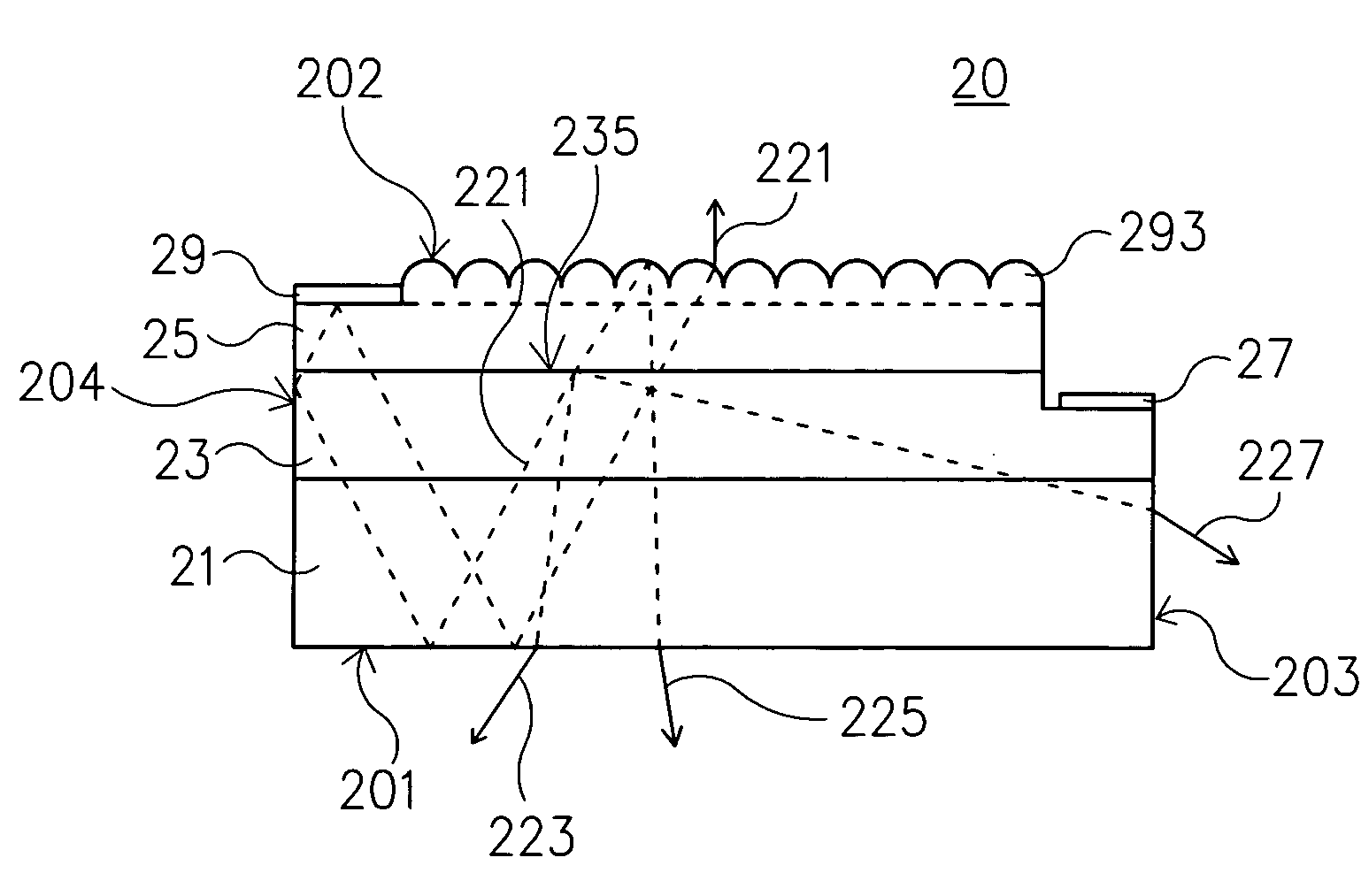

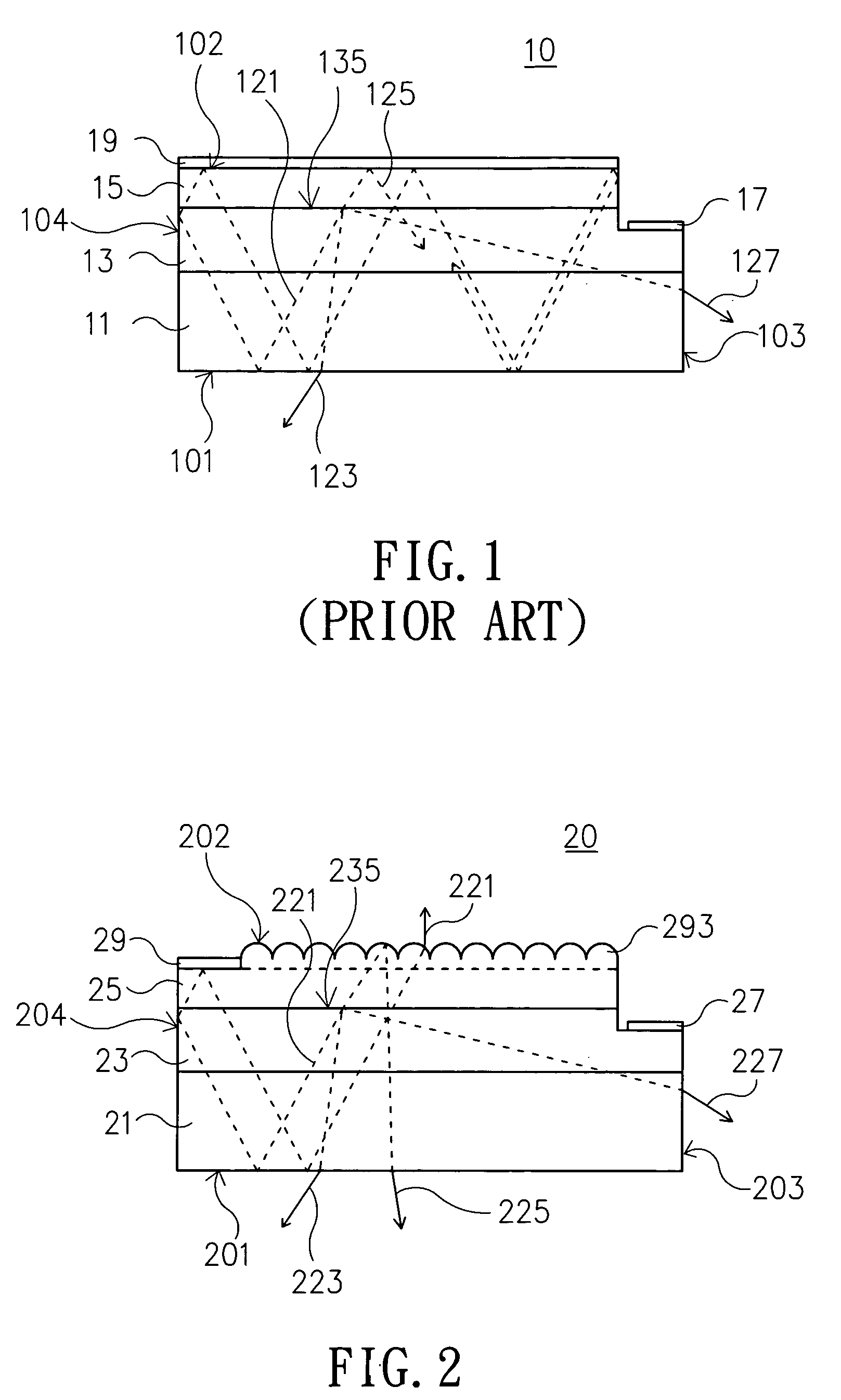

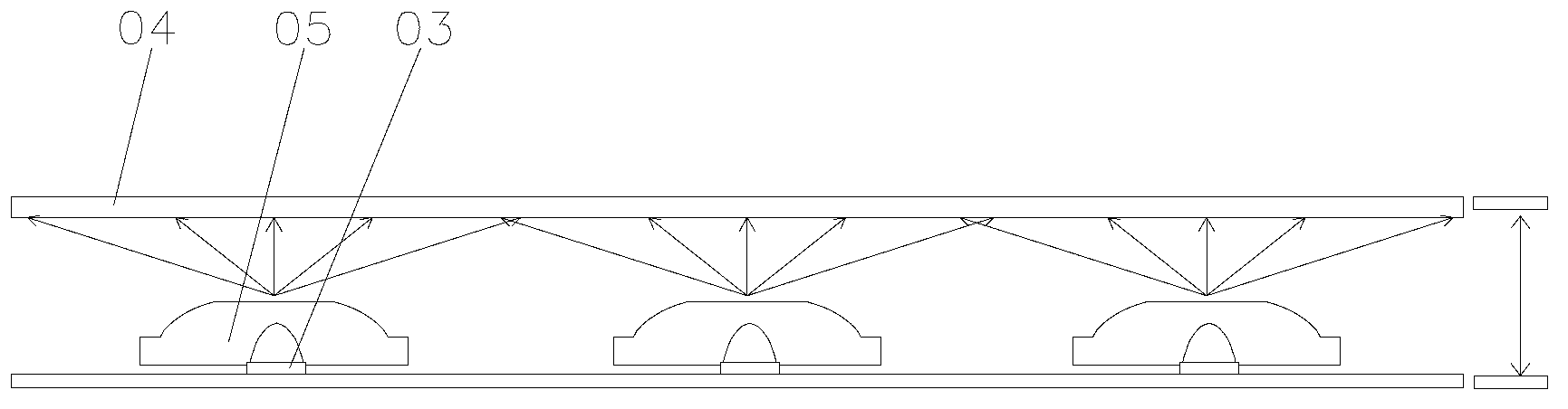

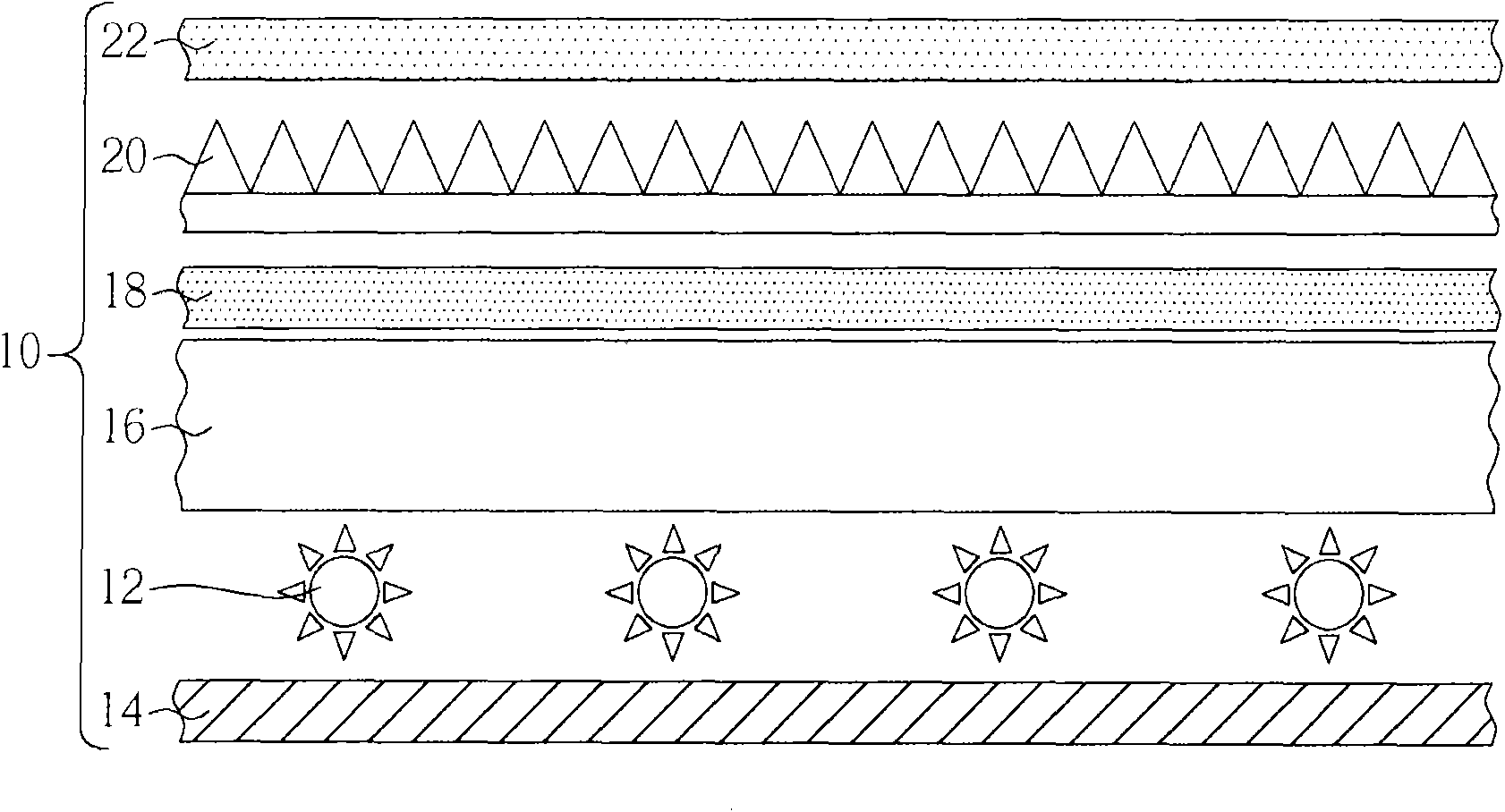

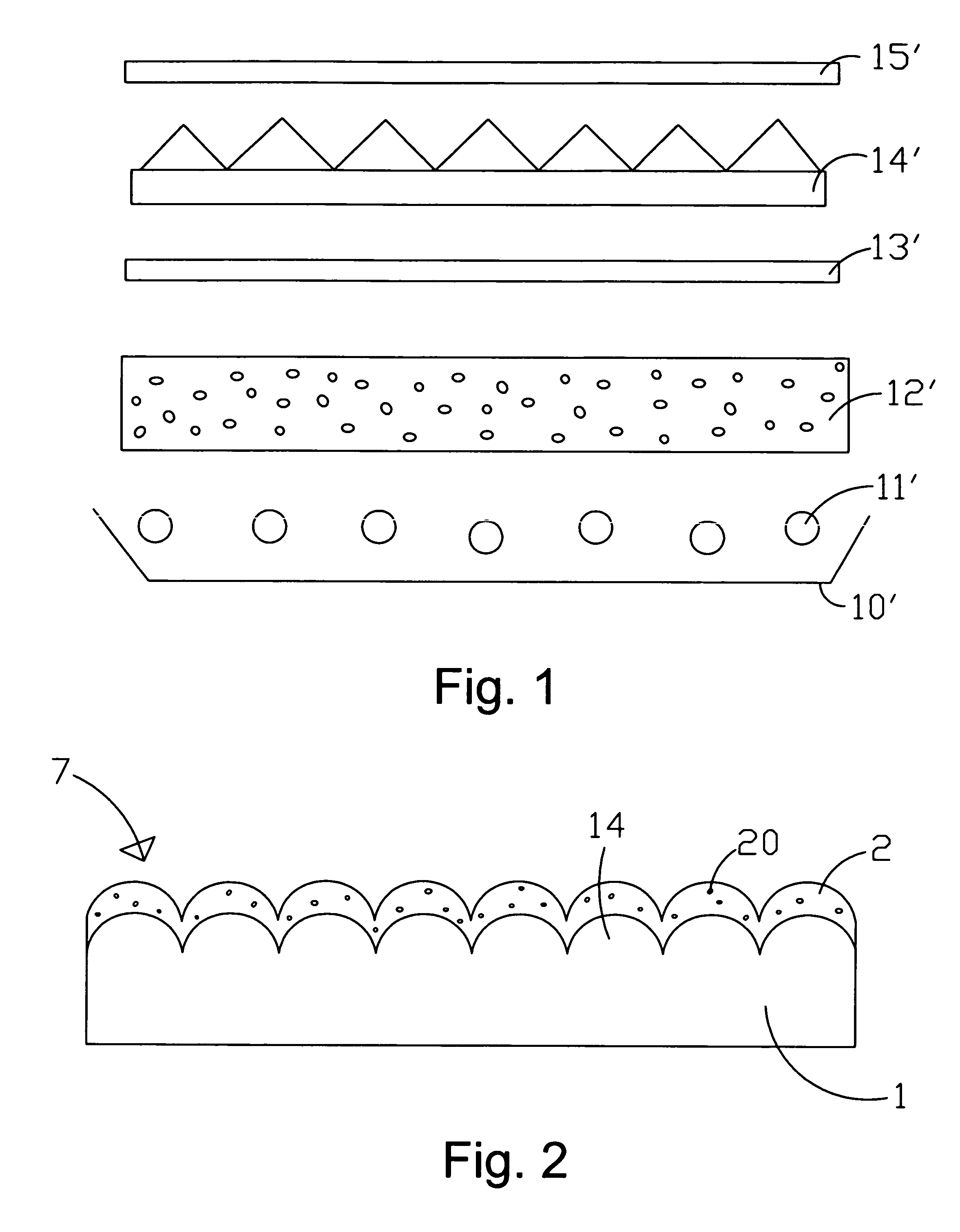

Back light unit including a diffuser with various diffusion effects

InactiveUS6861789B2Improve the scattering effectImprove uniformityStatic indicating devicesIncadescent envelopes/vesselsDiffusionScattering effect

A backlight unit is disposed beneath a display panel. The backlight unit includes an illumination means, which is used to provide a light source, and a diffuser positioned between the illumination means and the display panel, which is used to scatter the light generated by the illumination means. The diffuser, which is composed of liquid crystal particles and polymer, has a plurality of regions. The region thatis closer to the illumination means has greater scattering effect. In addition, the region with the greatest scattering effect has a shape corresponding to the illumination means.

Owner:INNOLUX CORP

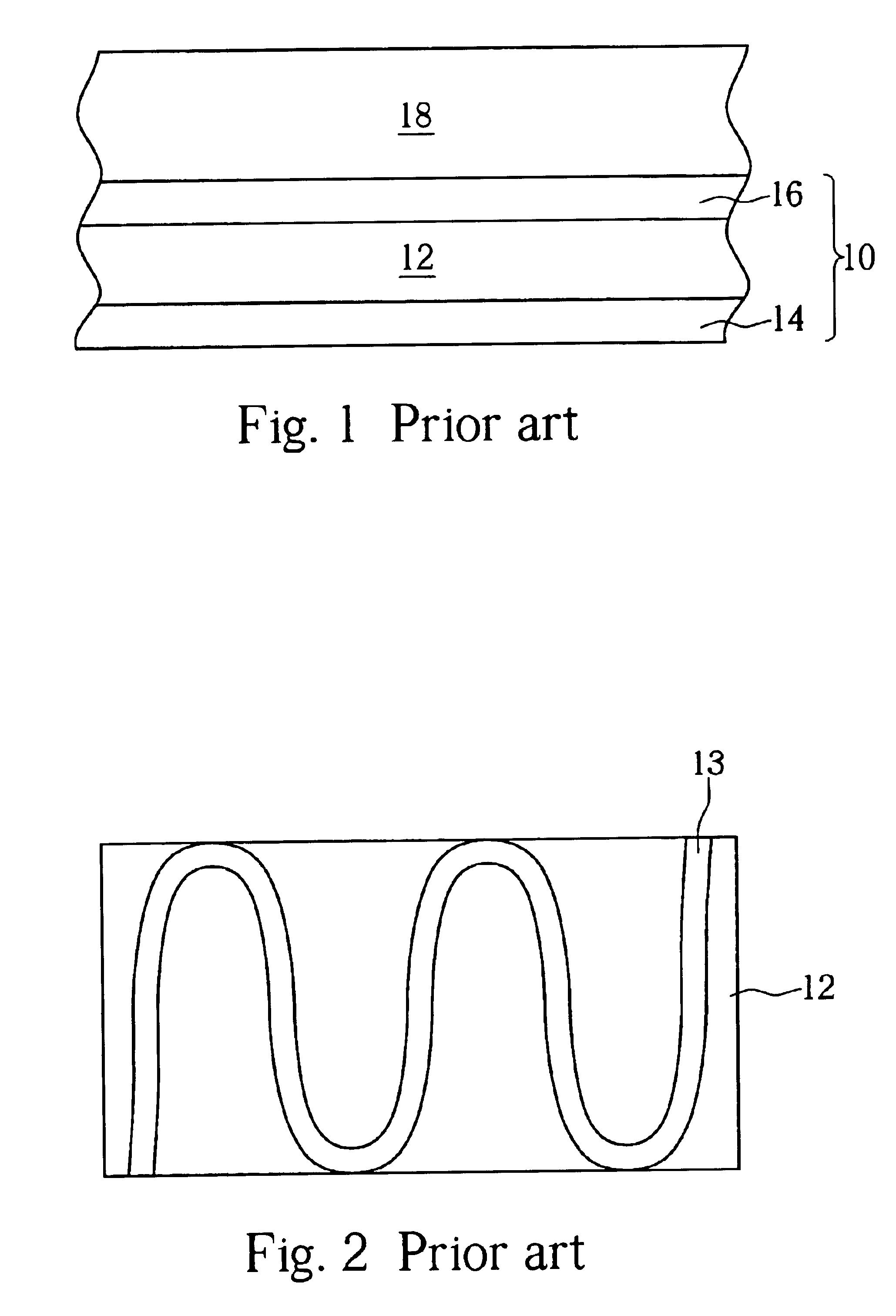

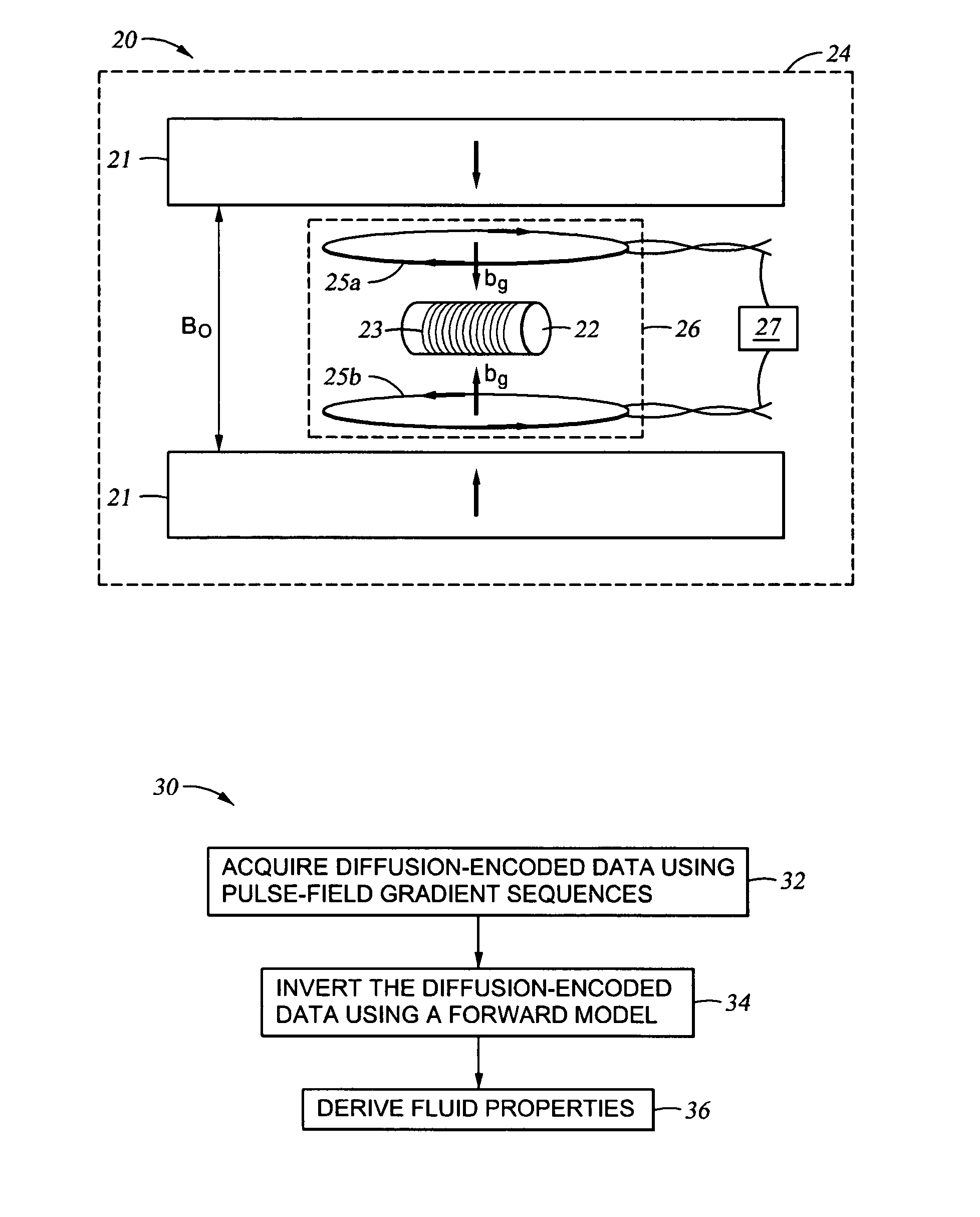

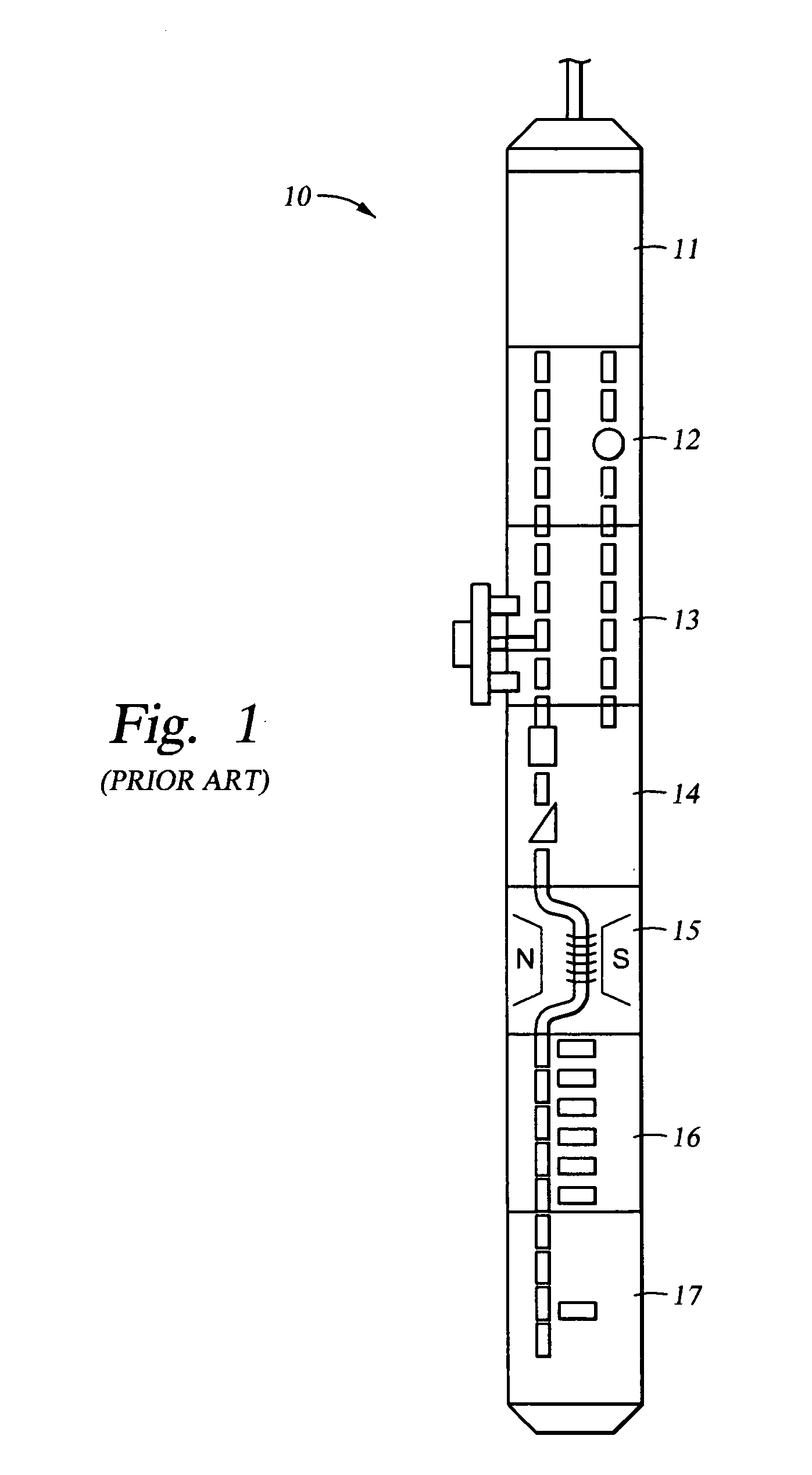

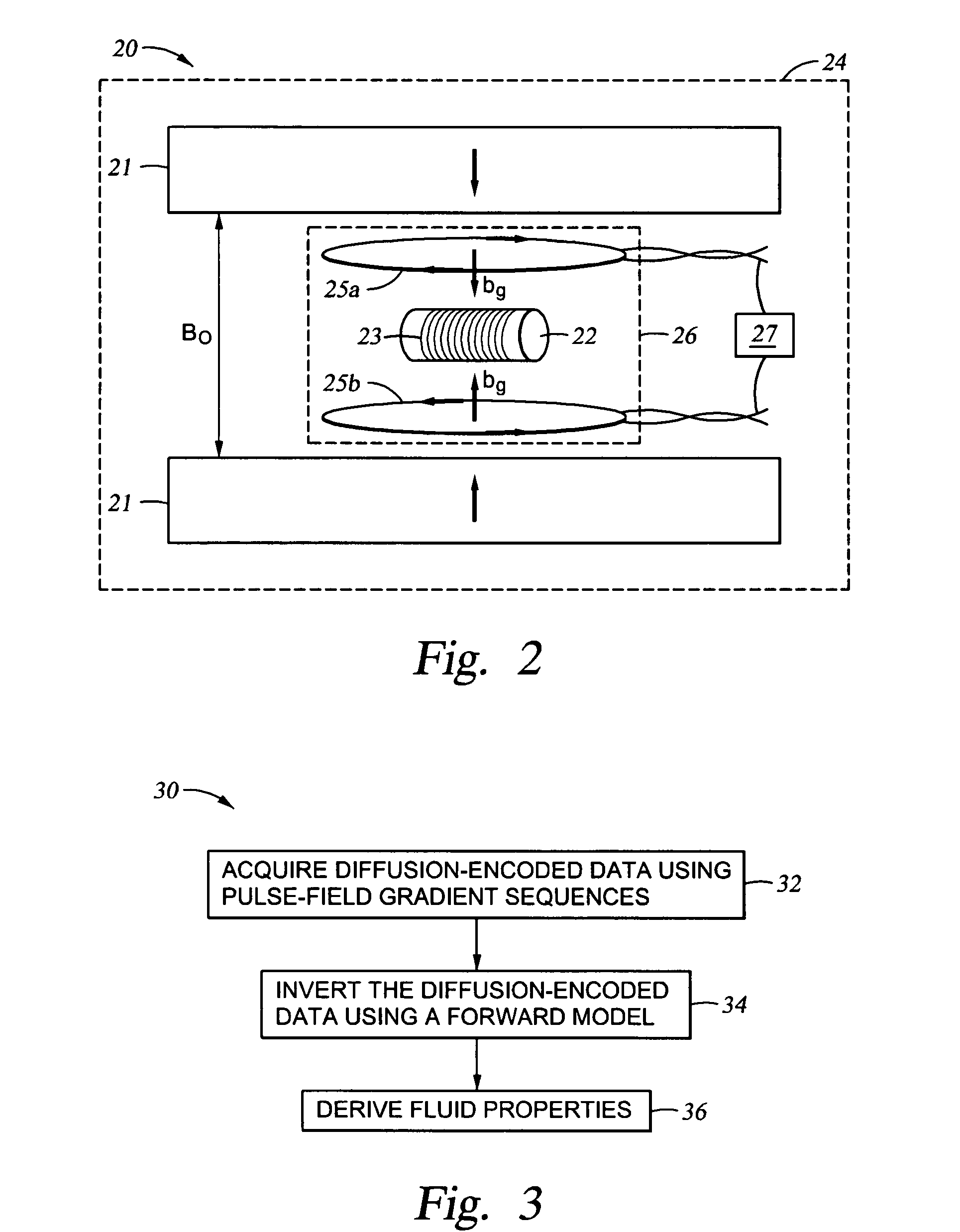

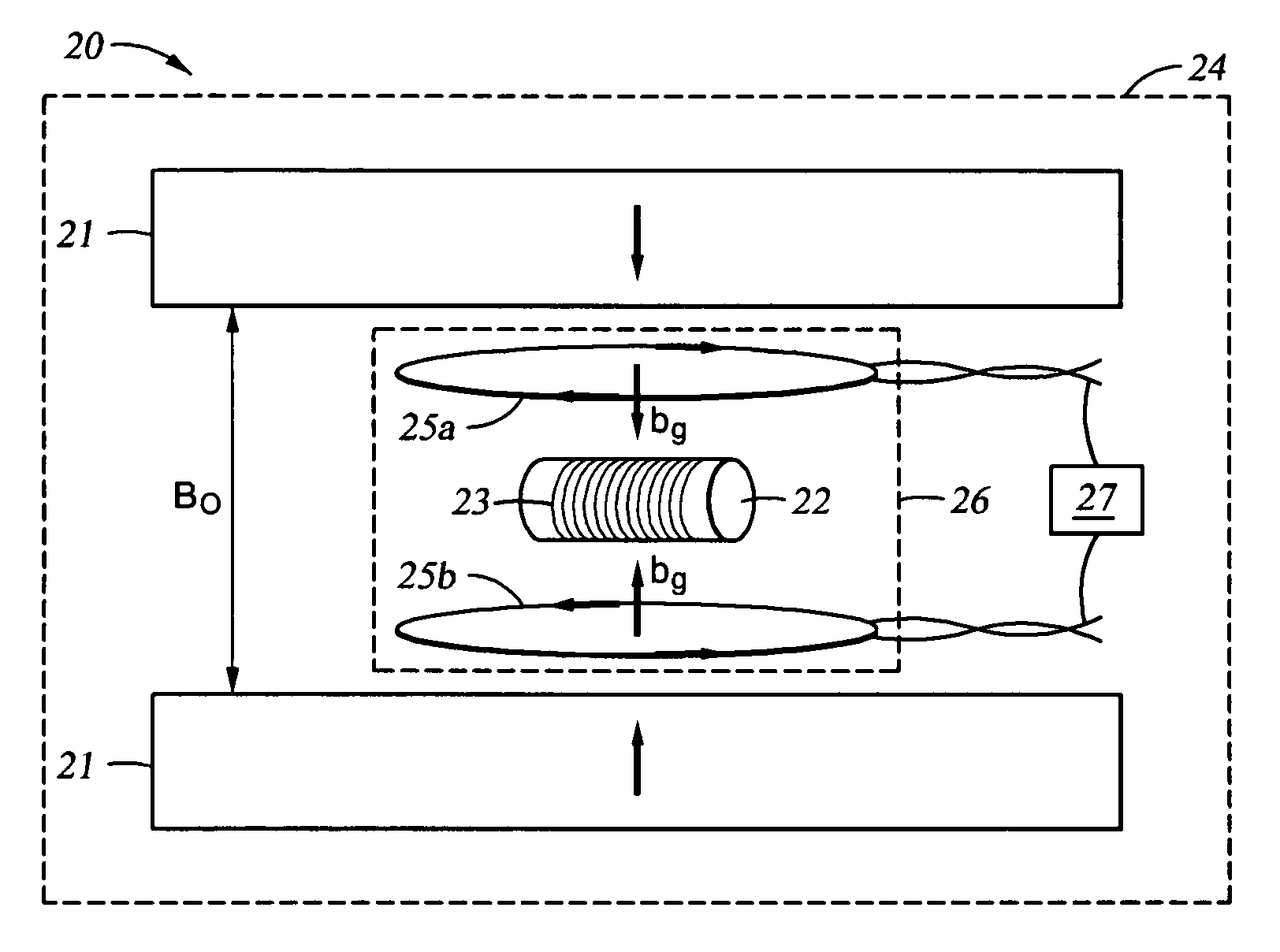

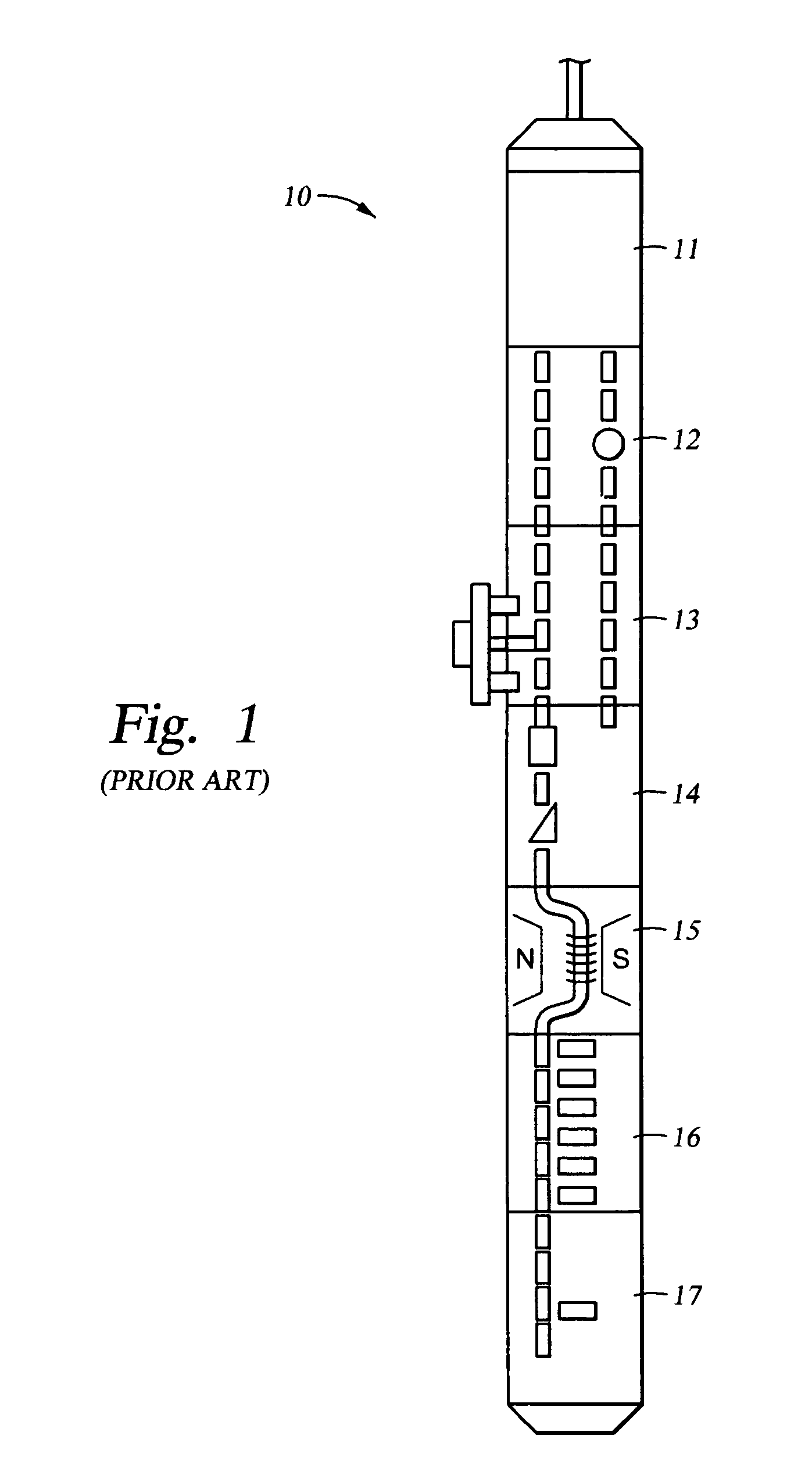

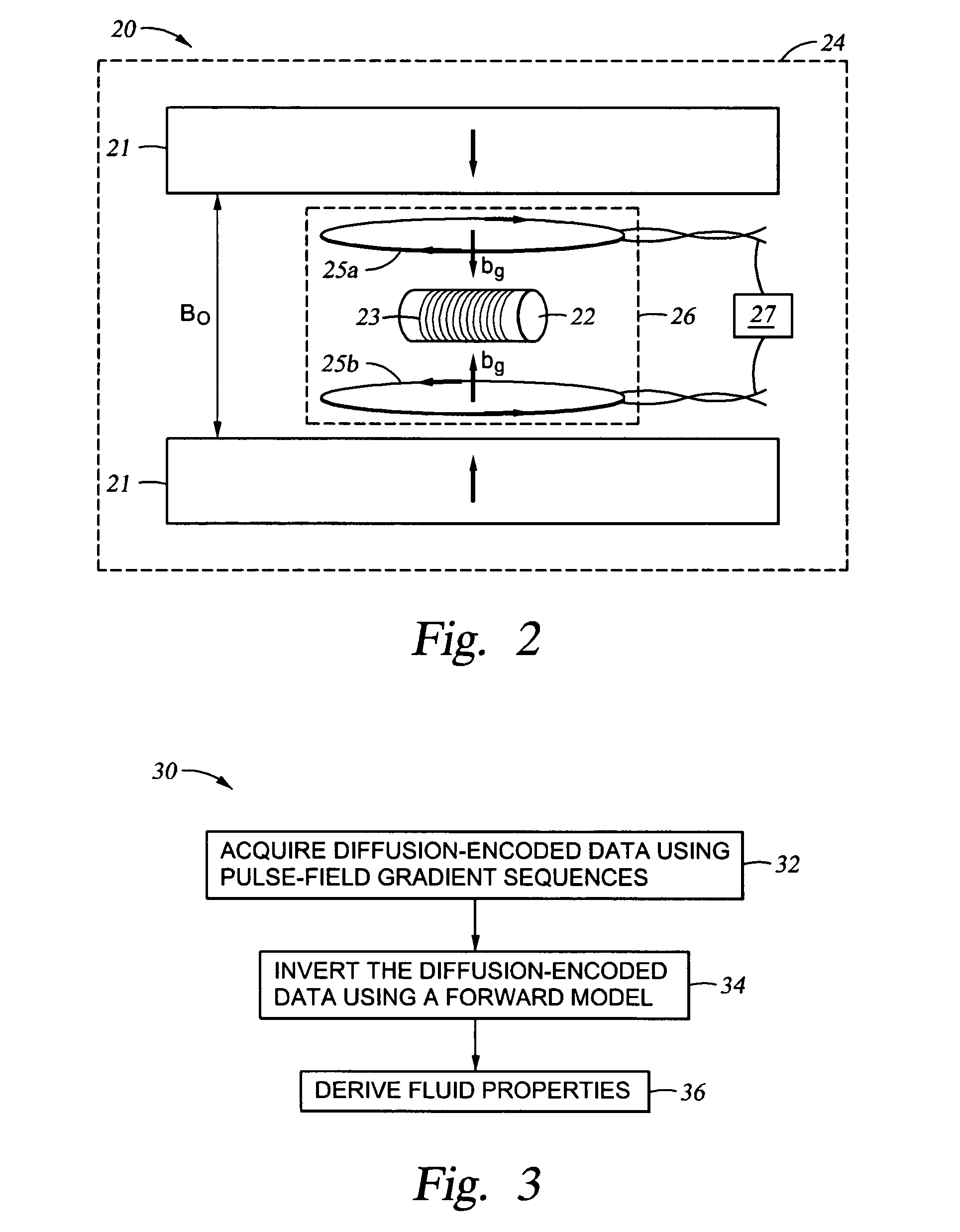

Method and apparatus for using pulsed field gradient NMR measurements to determine fluid properties in a fluid sampling well logging tool

InactiveUS20050270023A1Easy to detectRaise the ratioElectric/magnetic detection for well-loggingSurveyDiffusionNMR - Nuclear magnetic resonance

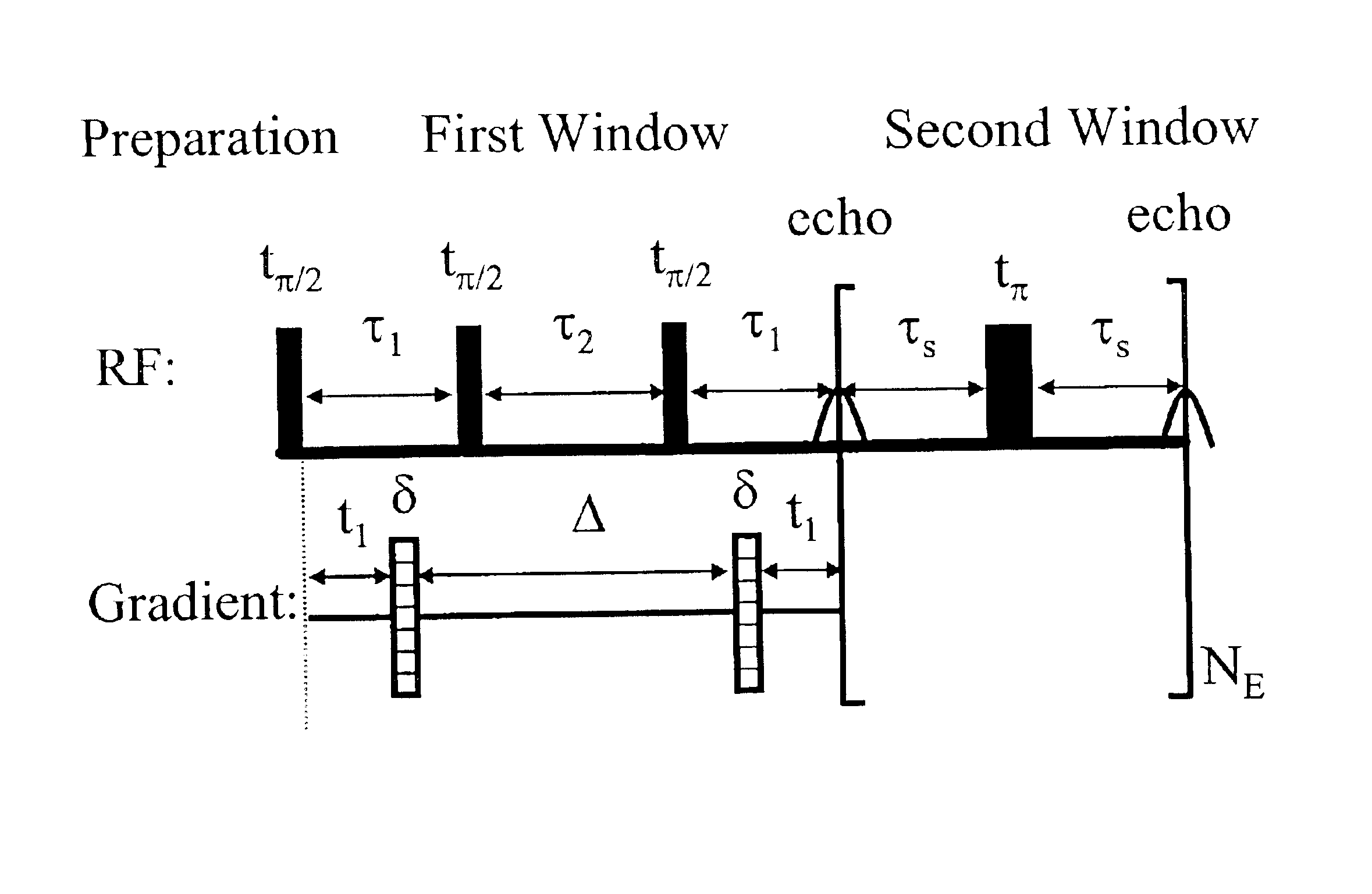

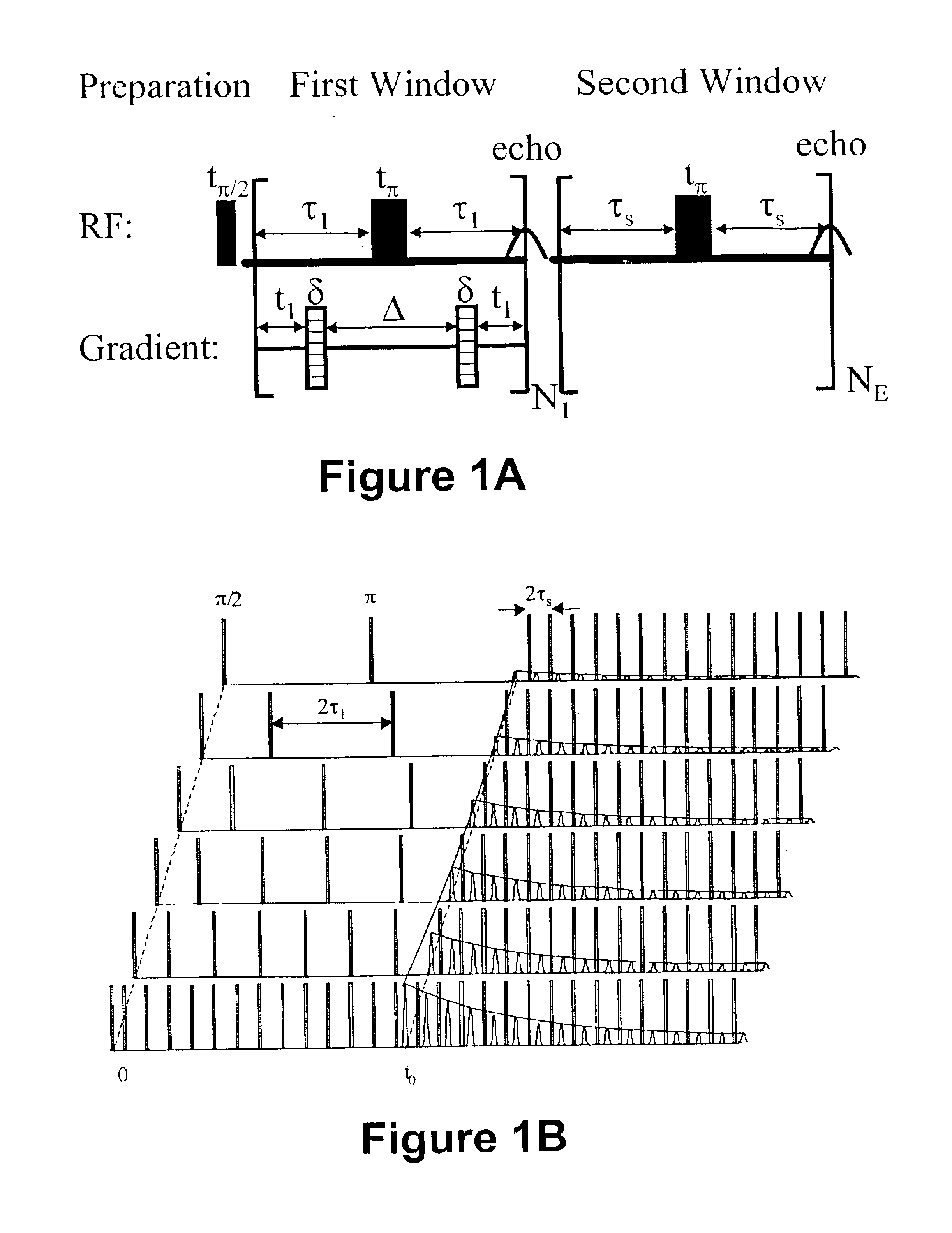

A method for determining a formation fluid property includes acquiring a suite of nuclear magnetic resonance (NMR) measurements of a fluid sample using a pulse sequence that includes pulsed field gradient pulses for encoding diffusion information, wherein each NMR measurement in the suite is acquired with a different value in a parameter in the pulsed field gradient pulses for producing a different diffusion effect, wherein the acquiring is performed in a formation fluid sampling tool in a borehole; inverting the suite of NMR measurements to produce a distribution function that relates diffusion properties of the fluid sample with an NMR property of the fluid sample; and determining the formation fluid property from the distribution function.

Owner:SCHLUMBERGER TECH CORP

Method and apparatus for using pulsed field gradient NMR measurements to determine fluid properties in a fluid sampling well logging tool

InactiveUS7053611B2Easy to detectRaise the ratioElectric/magnetic detection for well-loggingSurveyDiffusionNMR - Nuclear magnetic resonance

A method for determining a formation fluid property includes acquiring a suite of nuclear magnetic resonance (NMR) measurements of a fluid sample using a pulse sequence that includes pulsed field gradient pulses for encoding diffusion information, wherein each NMR measurement in the suite is acquired with a different value in a parameter in the pulsed field gradient pulses for producing a different diffusion effect, wherein the acquiring is performed in a formation fluid sampling tool in a borehole; inverting the suite of NMR measurements to produce a distribution function that relates diffusion properties of the fluid sample with an NMR property of the fluid sample; and determining the formation fluid property from the distribution function.

Owner:SCHLUMBERGER TECH CORP

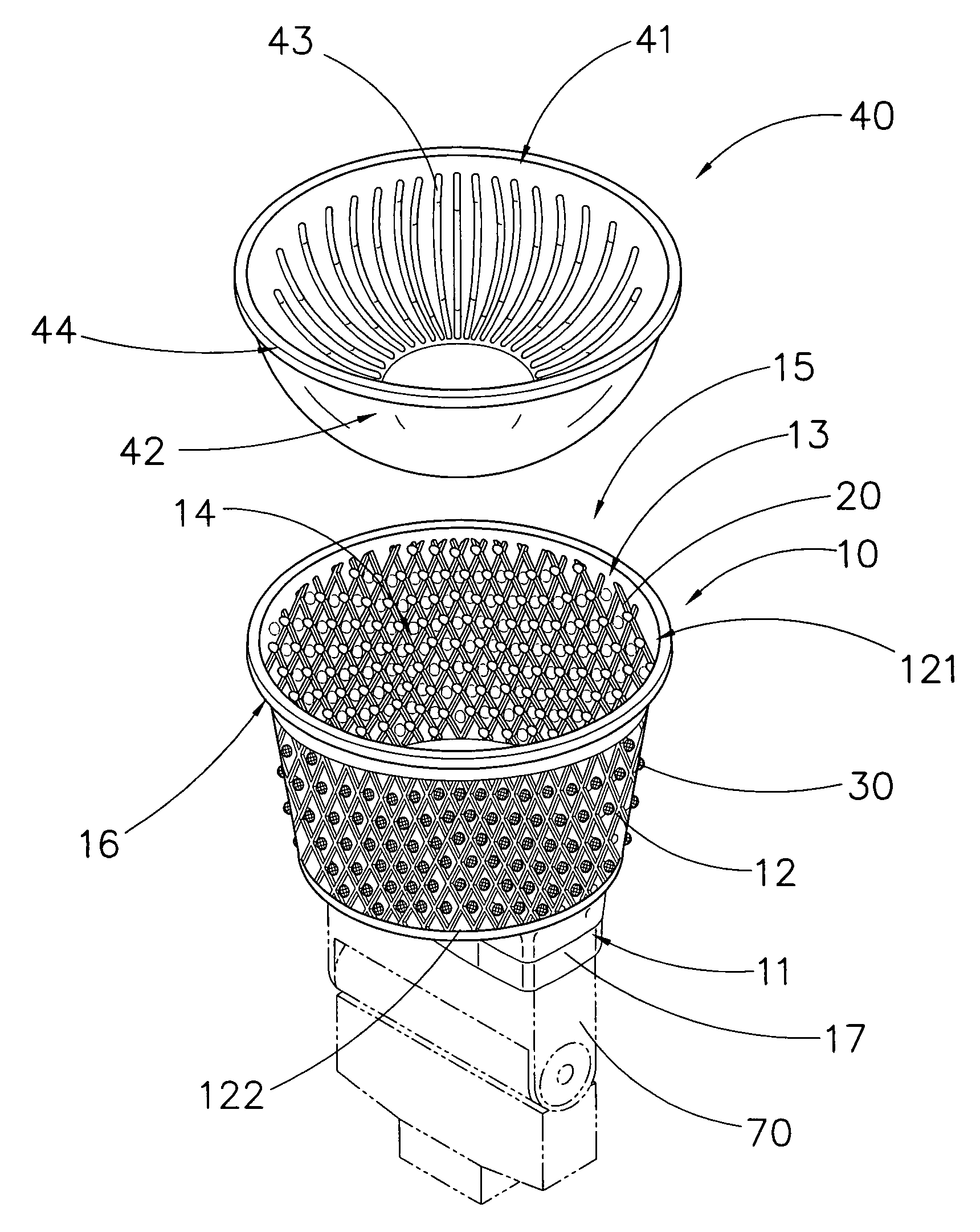

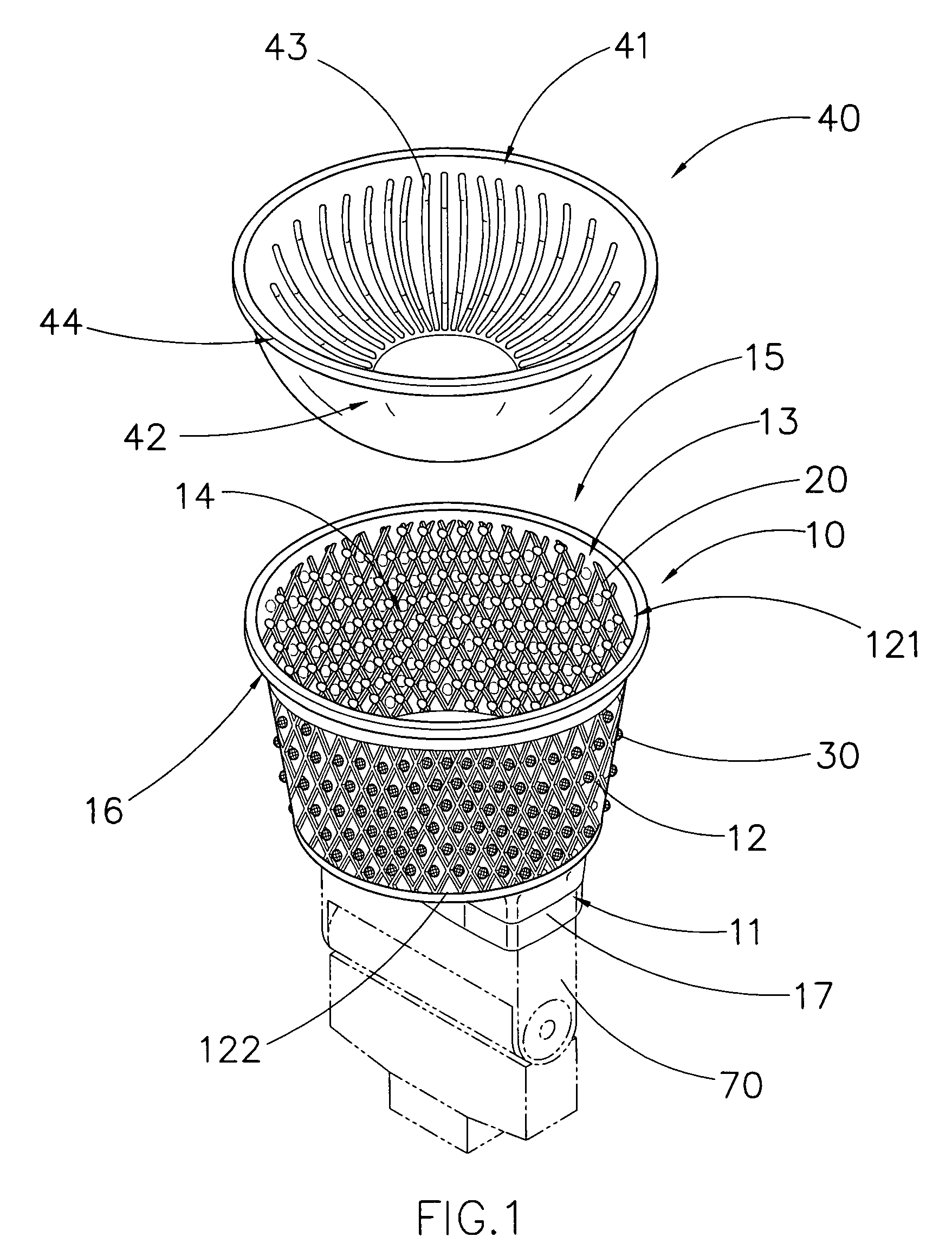

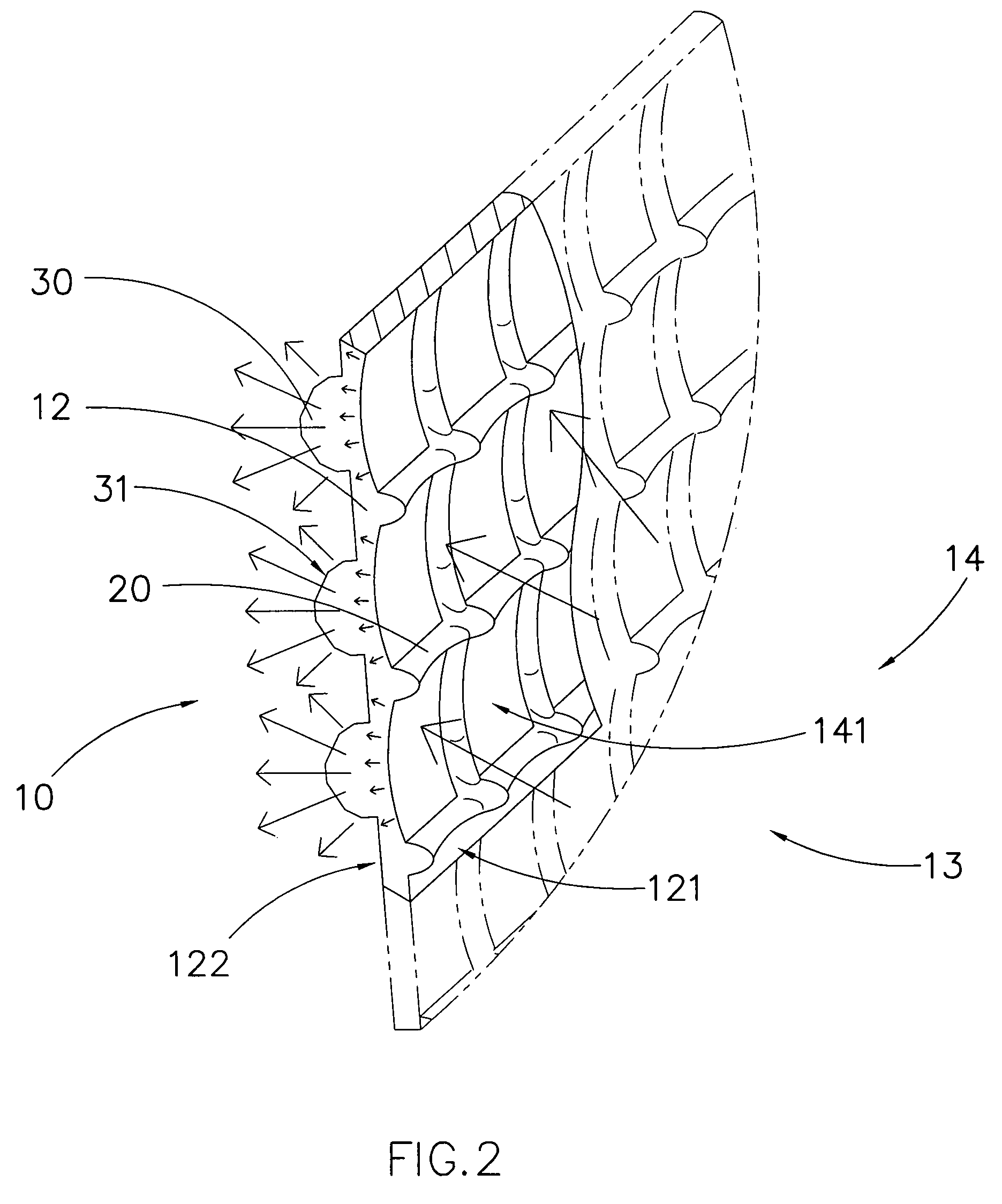

Photographic flashlight

InactiveUS7530701B2Improve lighting effectsMaximizing periodDiffraction gratingsLight fasteningsEffect lightLight diffraction

A light diffusion arrangement, for a photographic device having a flashlight, includes a diffuser housing, a plurality of diffracting mesh members, and a plurality of light diffusing elements. The diffuser housing has a light-admissible surrounding sidewall radially extended from a base portion to define a light diffraction cavity. The diffracting mesh members are integrally formed on an inner side surface of the surrounding sidewall of the diffuser housing, while the light diffusing elements are integrally formed on an outer side surface of the surrounding sidewall of the diffuser housing, wherein the diffracted light is arranged to impinge on the light diffusing elements from the light diffraction cavity, in such a manner that each of the light diffusing elements is adapted to diverge the diffracted light for diffusing the diffracted light, so as to provide a uniform light diffusion effect as an optimal lighting effect for the photographic device.

Owner:WHANG STUART A

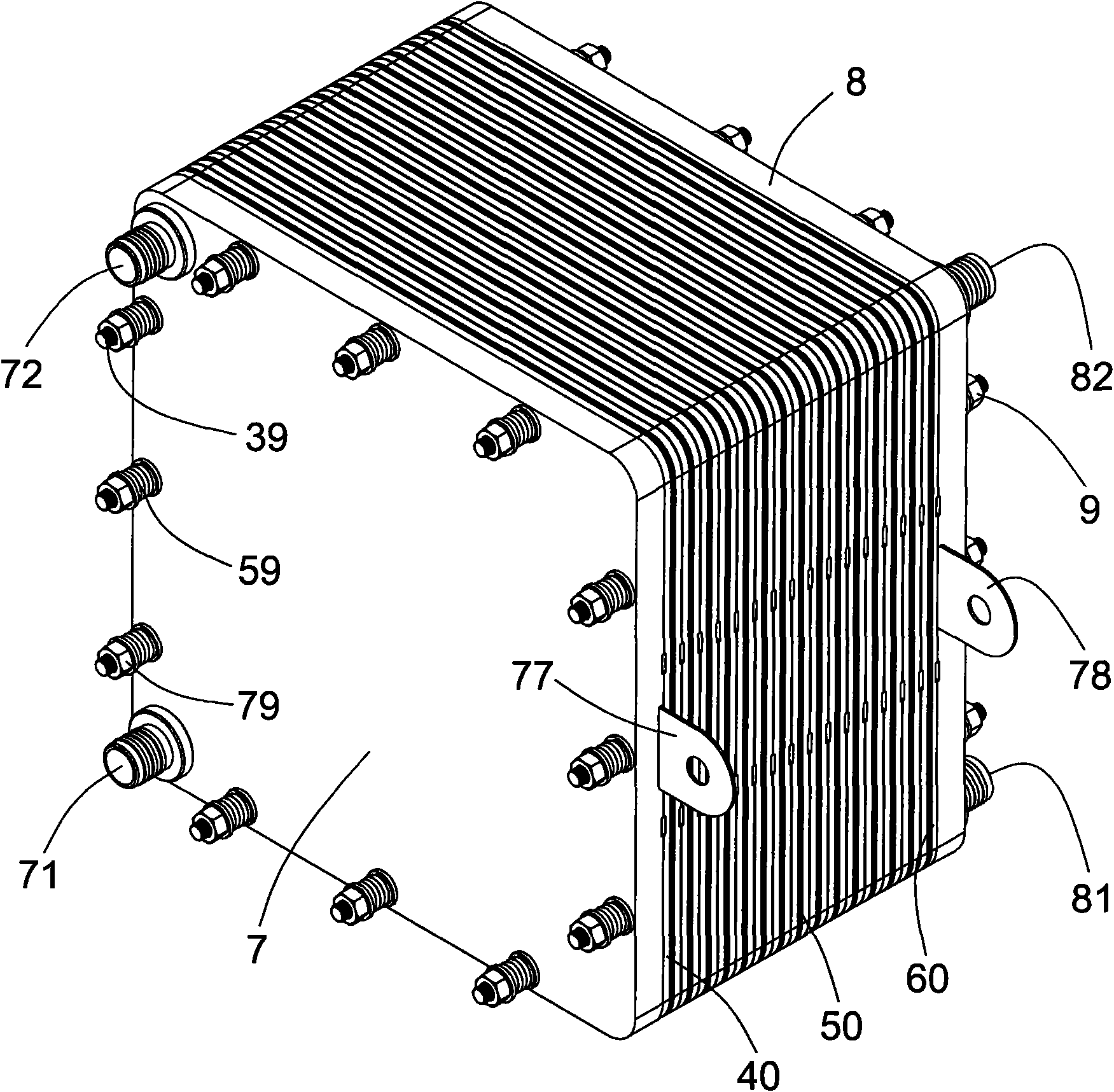

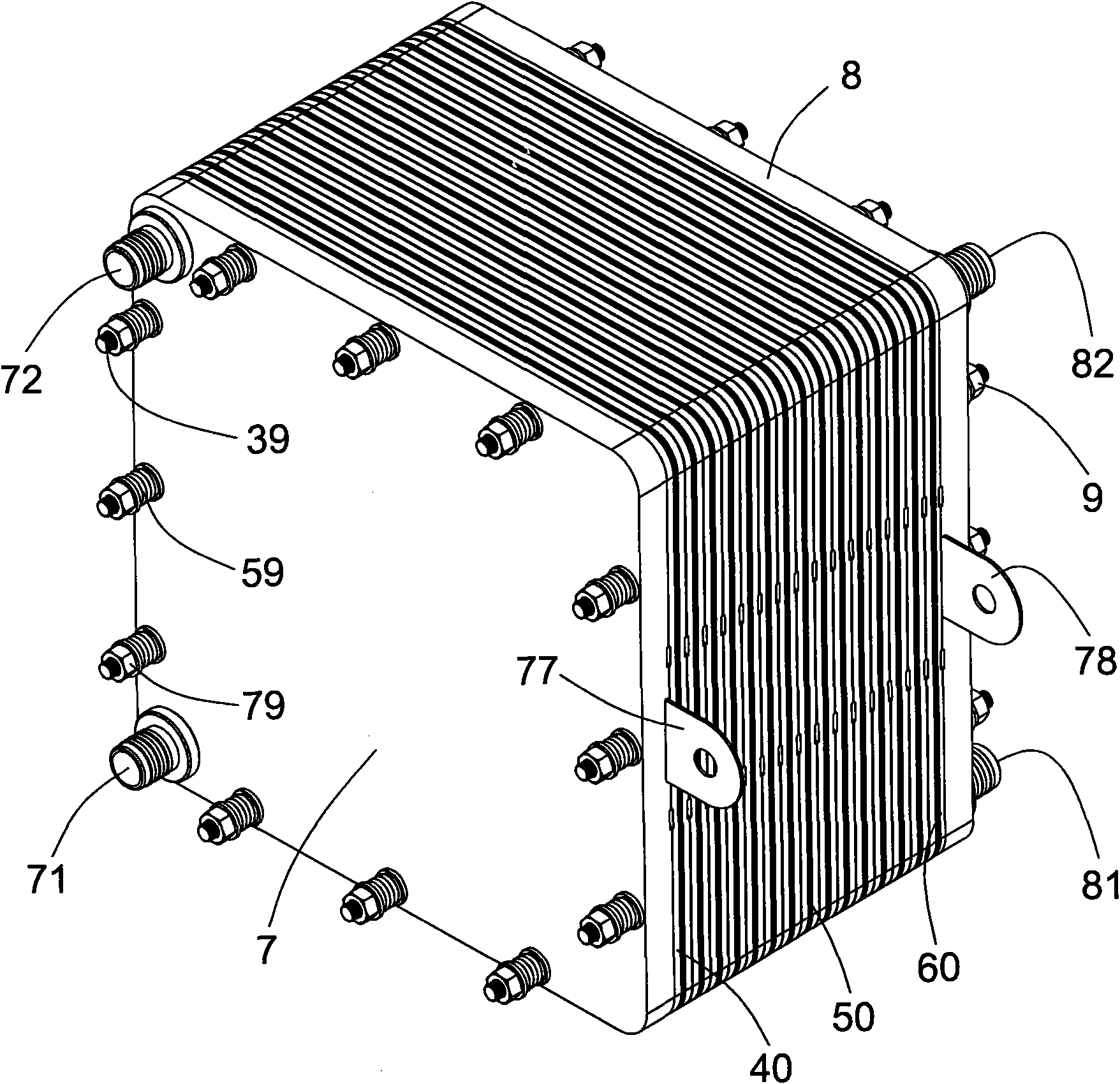

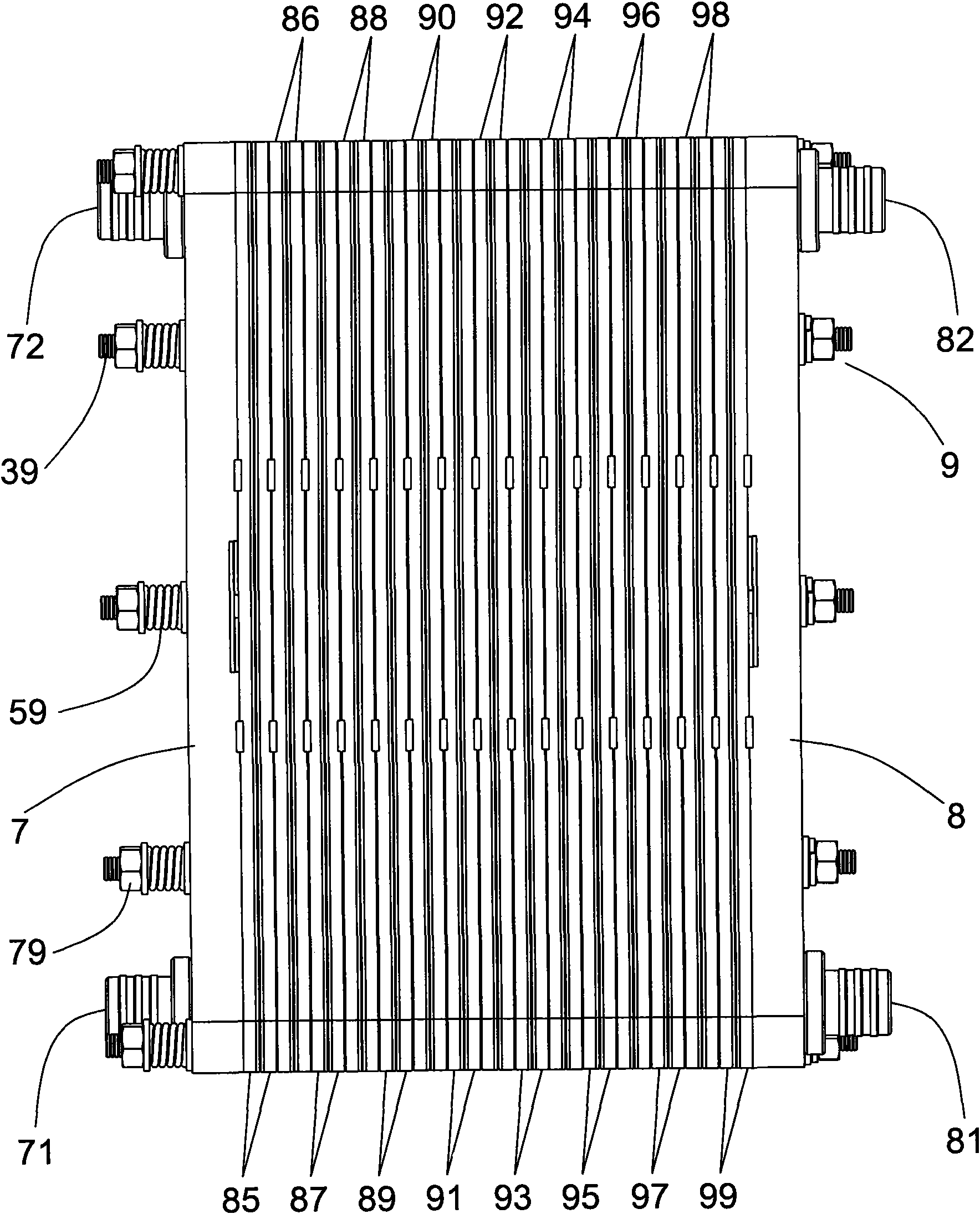

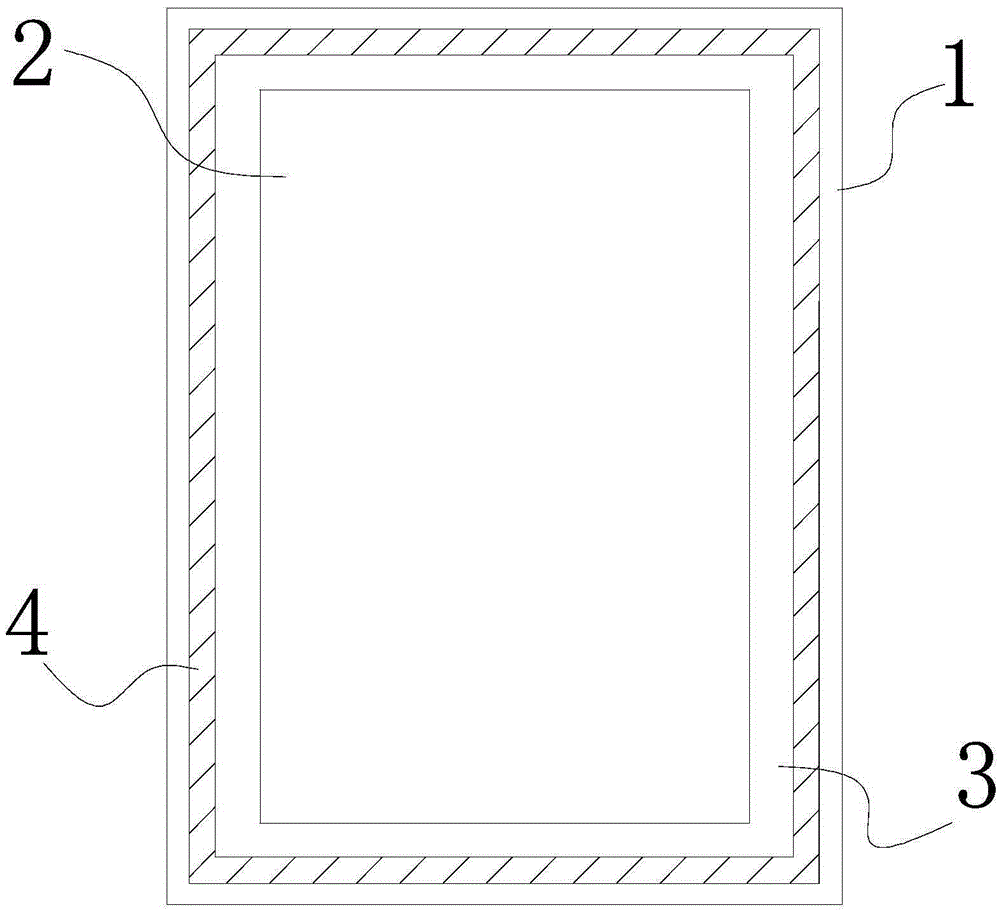

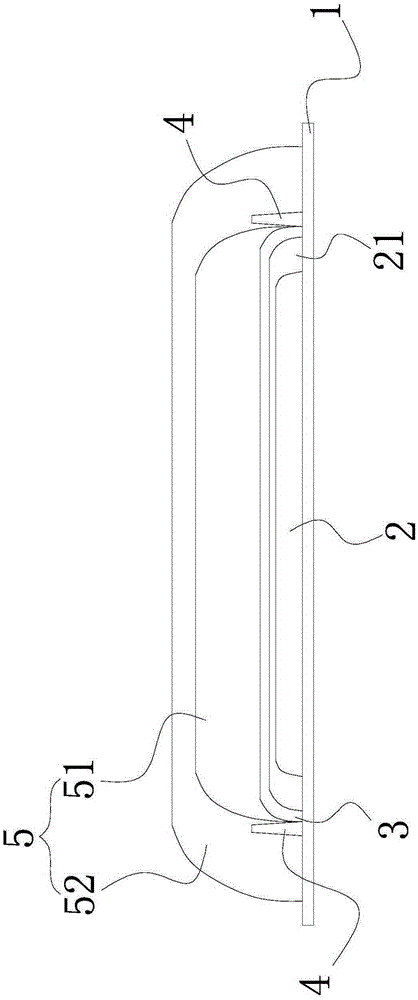

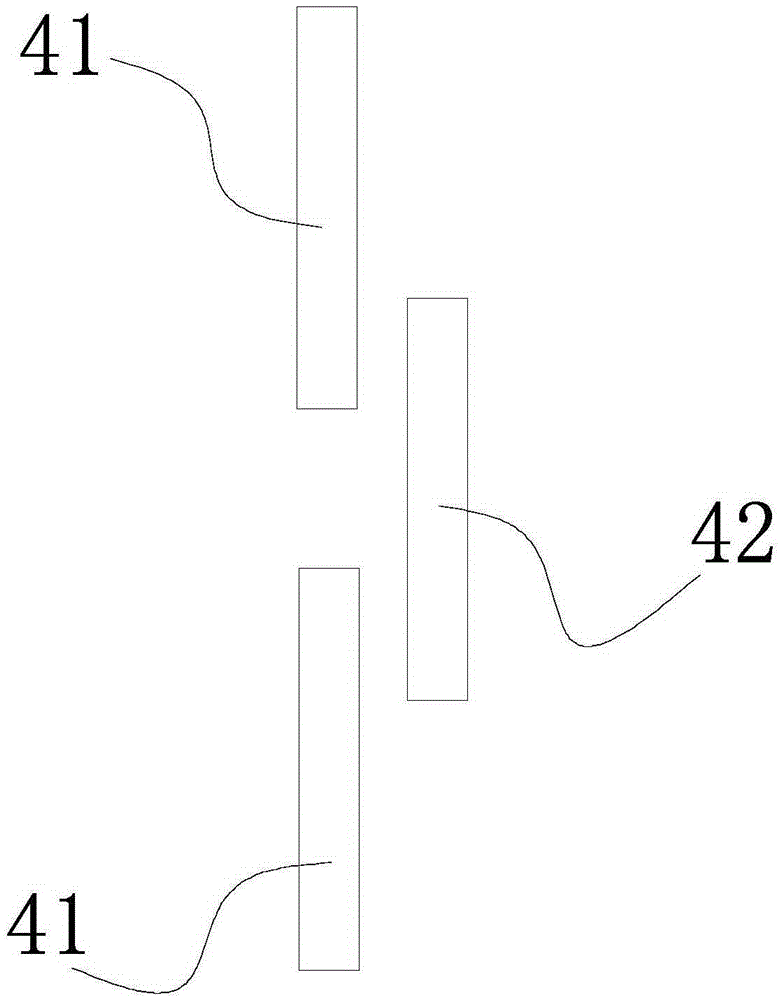

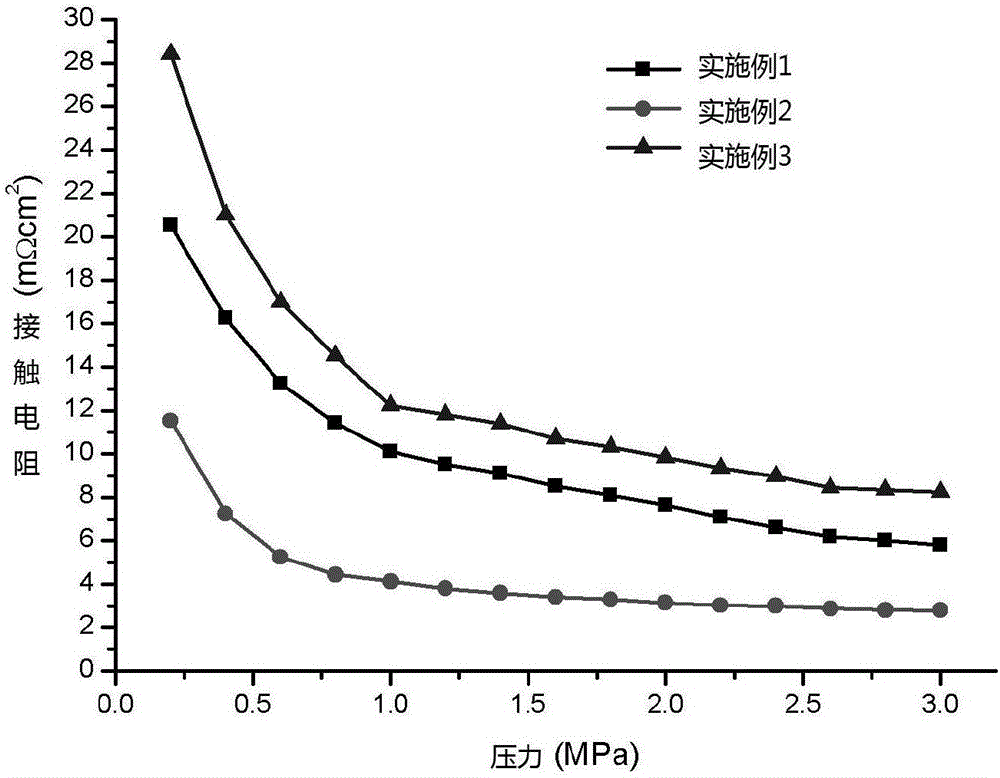

Flow battery

InactiveCN101814618AIncrease the lengthIncrease resistanceFinal product manufactureRegenerative fuel cellsInternal resistanceHigh energy

The invention relates to a flow battery. The flow frame boards of the flow battery are provided with liquid inlet holes and liquid outlet holes; the front surfaces of the flow frame boards are provided with liquid inlet branch flow channels and liquid outlet branch flow channels; one end of each liquid inlet branch flow channel is communicated with the liquid inlet holes, and the other end thereof is communicated with the inner frames of the flow frame boards; one end of each liquid outlet branch flow channel is communicated with the liquid outlet holes, and the other end thereof is communicated with the inner frames of the flow frame boards; the flow frame boards are alternately arranged according to a mode of front surface to front surface and back surface to back surface in sequence; an ion exchange film is clamped between the opposite front surfaces of the adjacent flow frame boards; a current-conducting plate is clamped between the opposite back surfaces of the adjacent flow frame boards; the edge of the inner frame of each flow frame board is provided with an annular chamfer; the current-conducting plate is arranged on the annular chamfer; and electrodes are arranged in the inner frames of the flow frame boards. The flow battery has fewer components, simple and compact structure, easy processing, convenient assembly, small thickness, small volume, small internal resistance, good transfer and diffusion effect of electrolyte, small self discharge current, big power density, high energy efficiency and low cost and can realize big-power and large-scale application.

Owner:GOLDEN ENERGY FUEL CELL

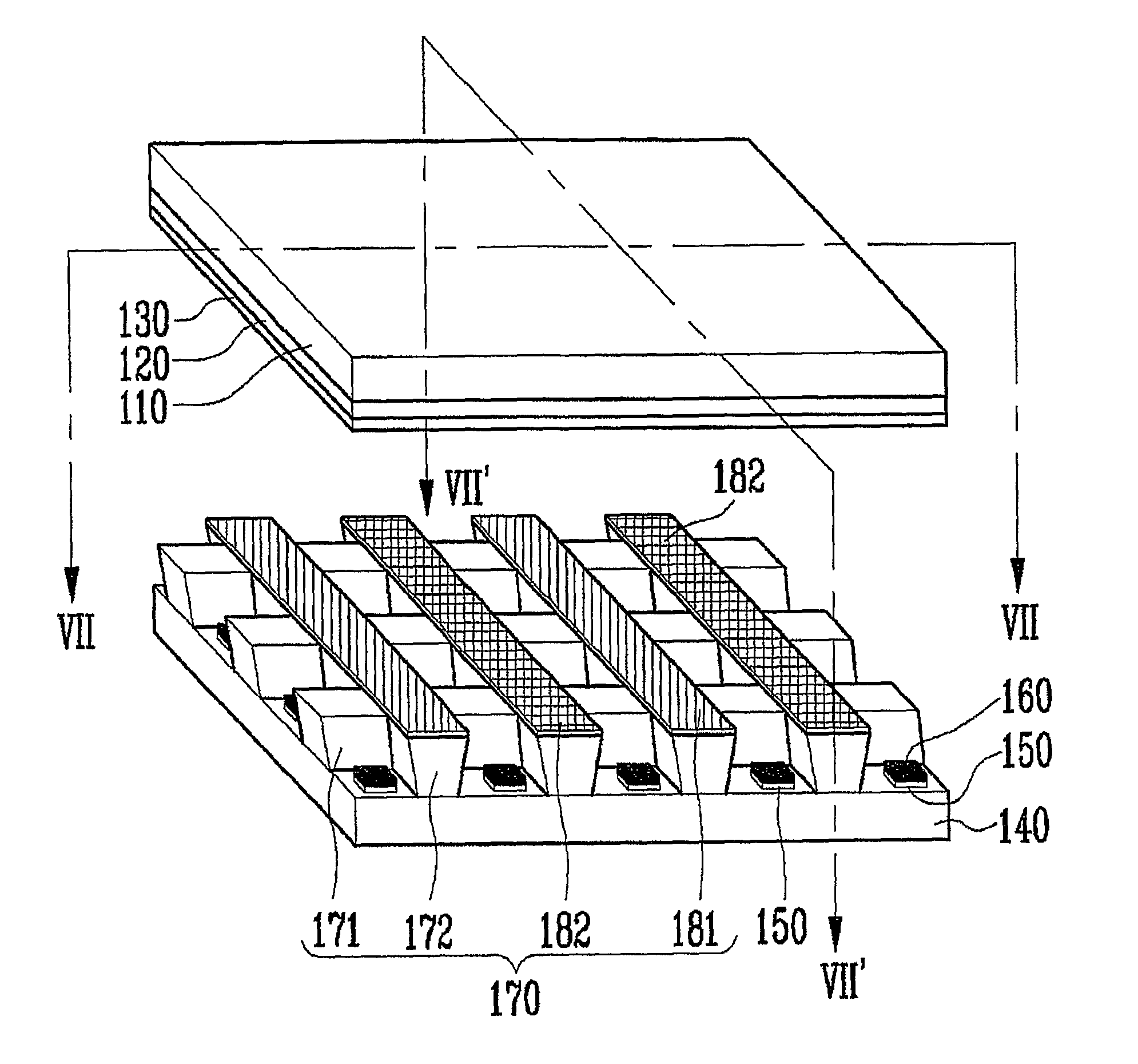

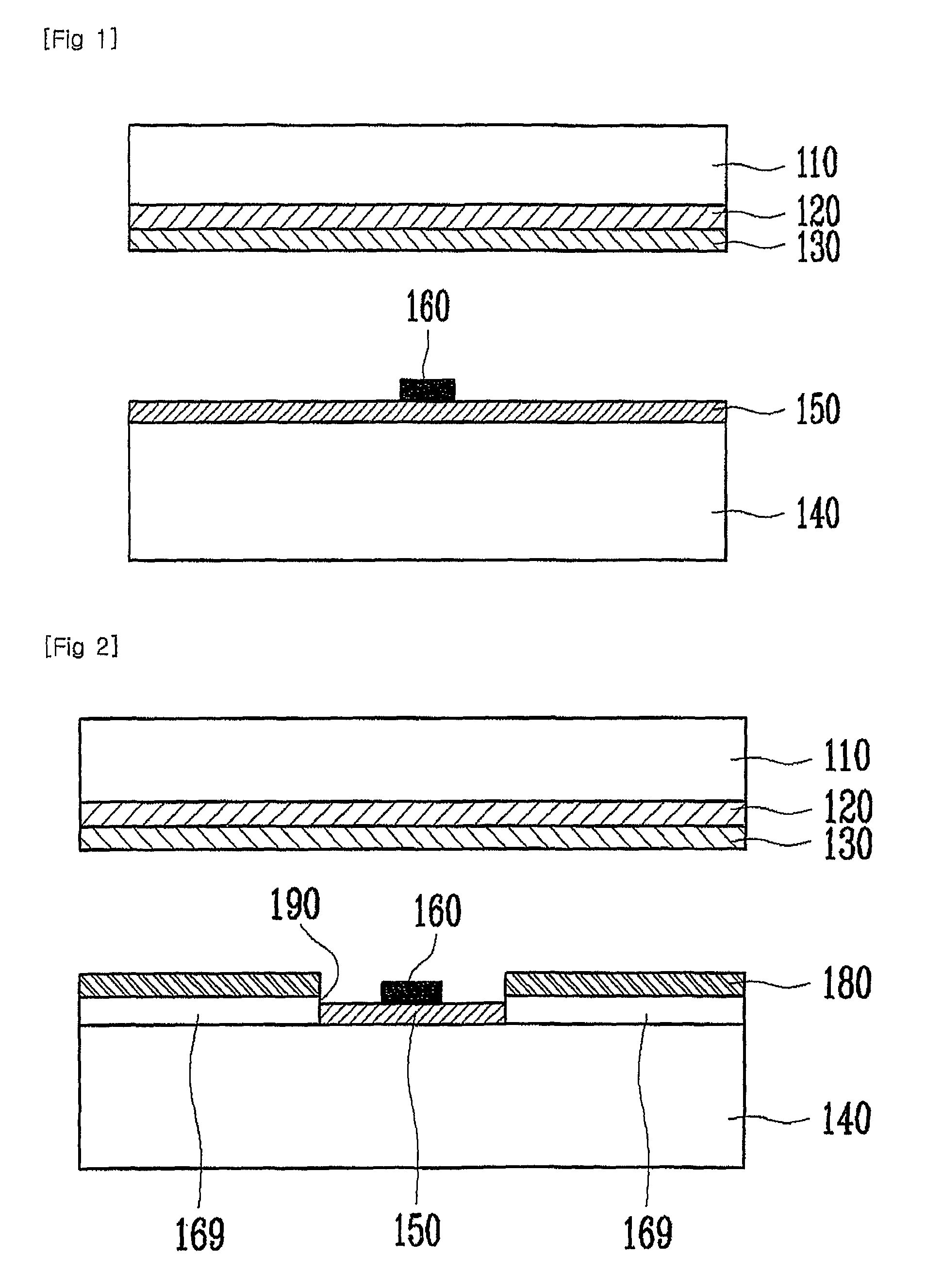

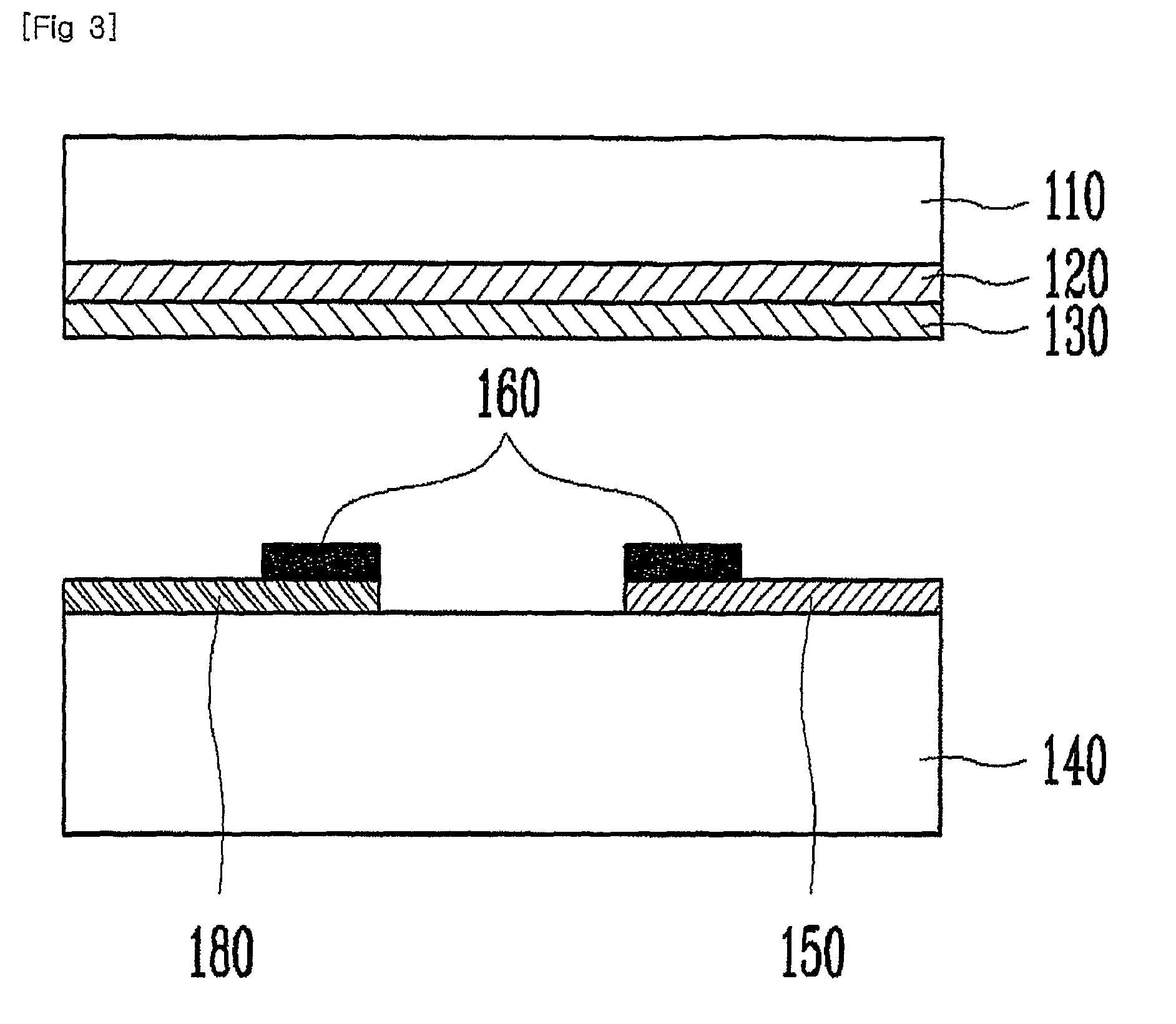

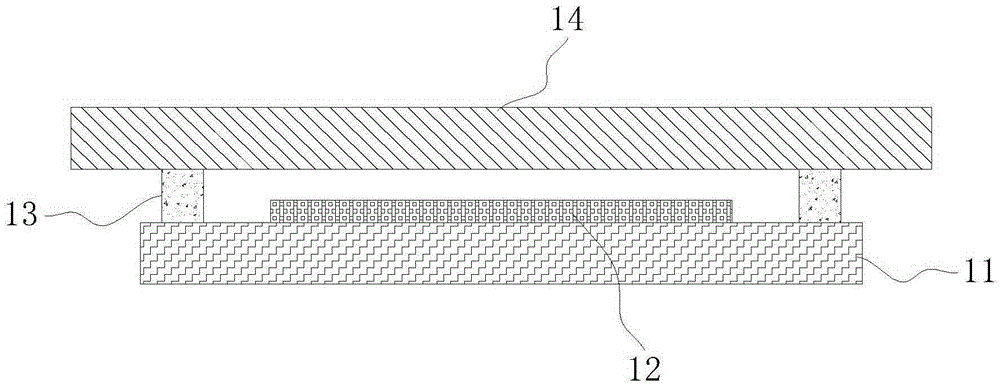

Flexible OLED display panel

ActiveCN105261712AAvoid scratchesPrevent crushingSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringWater block

The invention discloses a flexible OLED display panel, which comprises a flexible substrate, an OELD device, a first encapsulation layer, a barrier layer and a second encapsulation layer, wherein the OLED device is arranged on the flexible substrate; the first encapsulation layer is arranged on the flexile substrate and covers the OLED device; the barrier layer is arranged on the flexible substrate, surrounds the periphery of the first encapsulation layer, and comprises a plurality of discontinuous barrier units; the plurality of barrier units are arranged in a chain form; and the second encapsulation layer is arranged on the flexible substrate and covers the first encapsulation material and the barrier layer. The flexible OLED display panel is capable of effectively blocking the diffusion effect of atomic deposition coating and enhancing the water blocking capacity of a thin-film encapsulation on the periphery of the flexible OLED display panel; meanwhile, the reelability of the barrier layer is increased; the development requirement of the flexible OLED display panel is relatively well met; and an important idea is also provided for development of the flexible OLED display panel.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

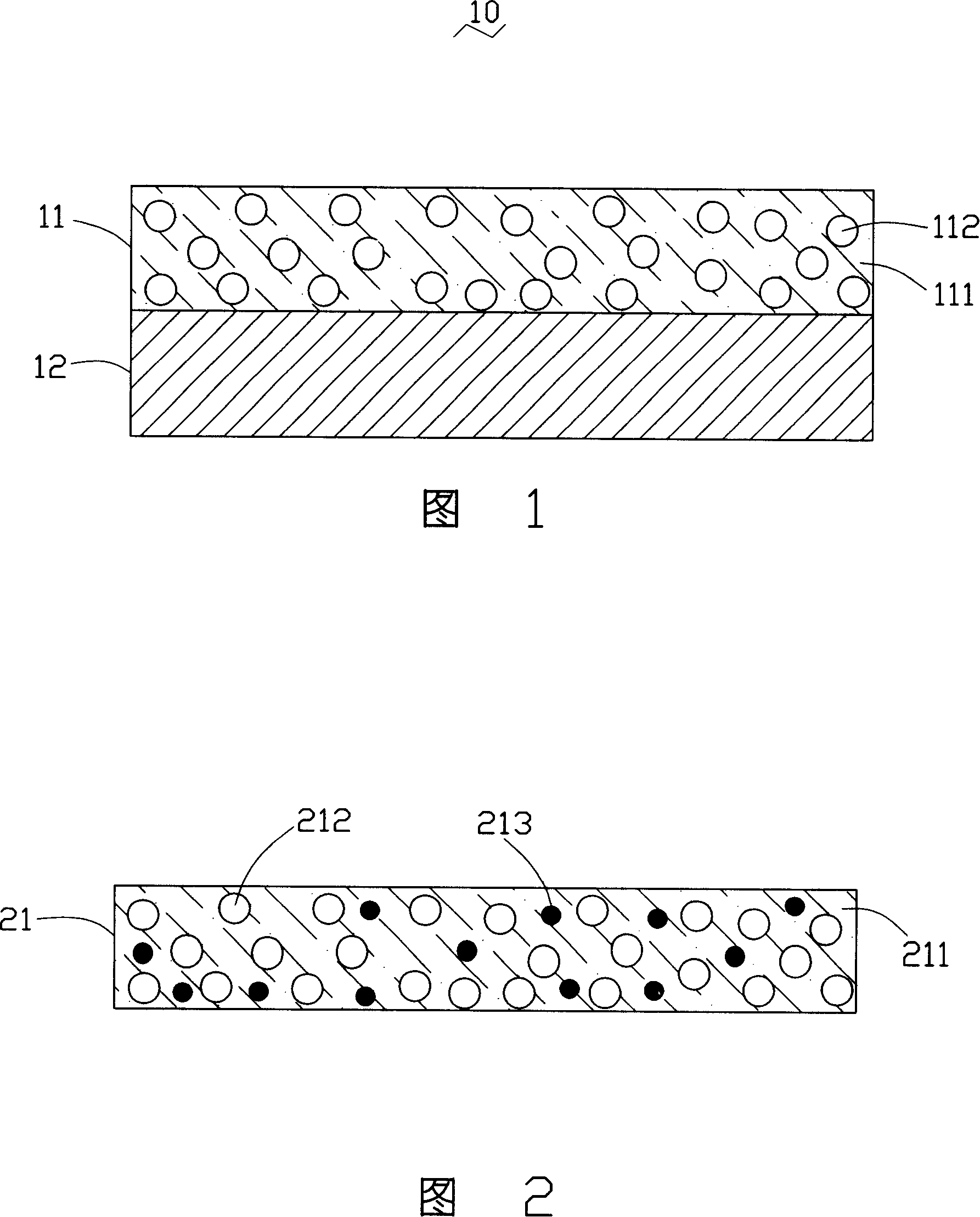

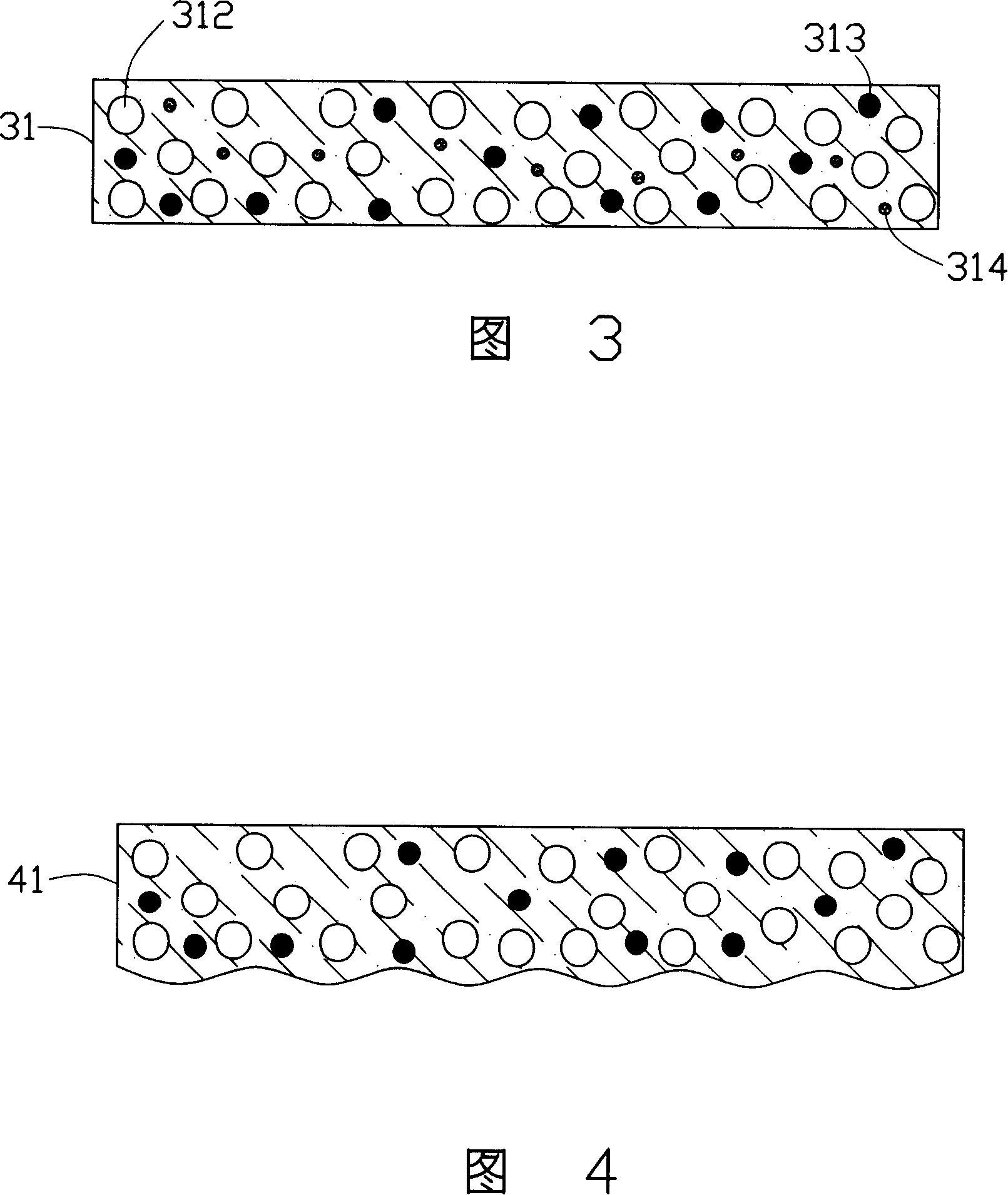

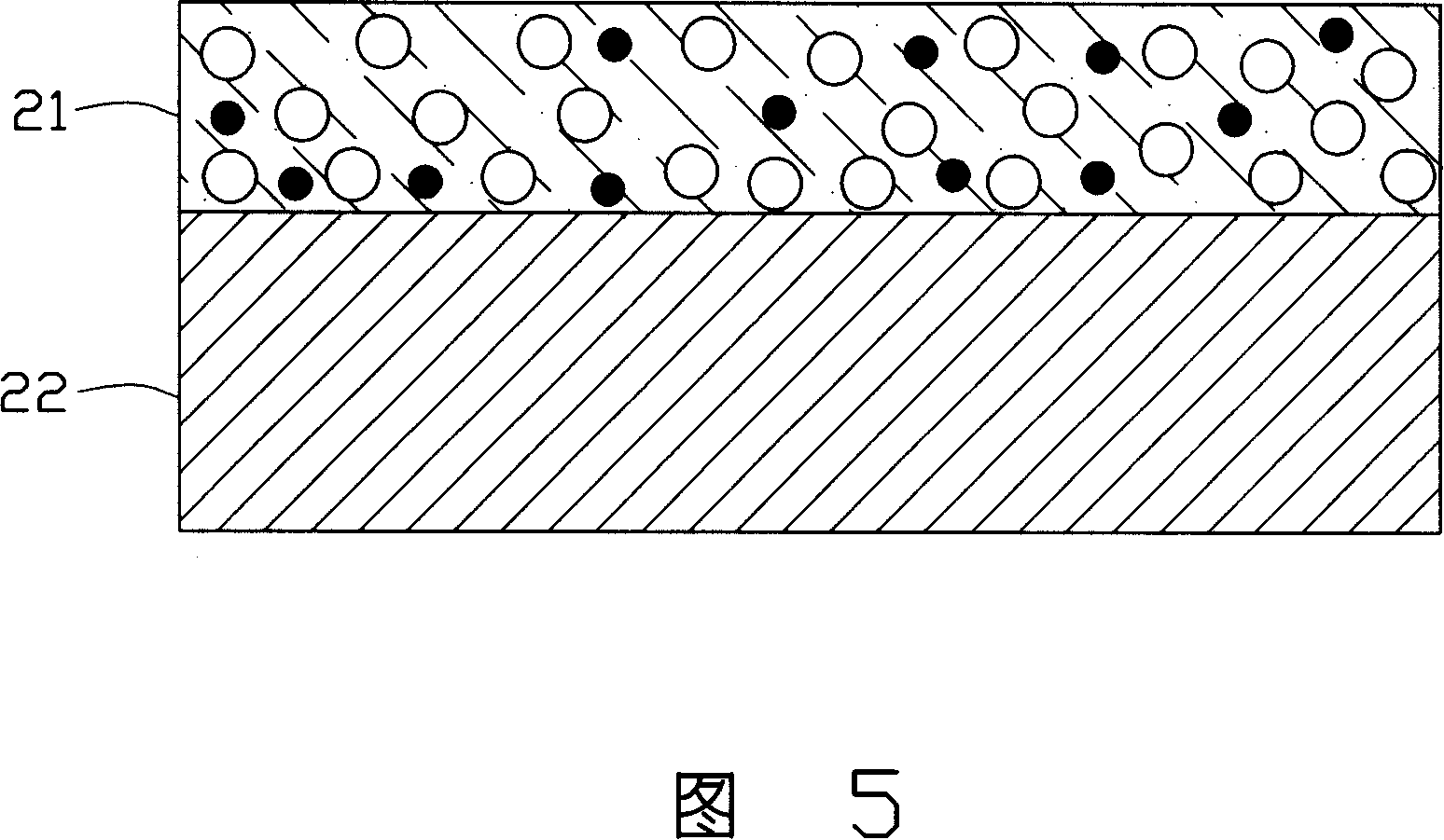

Pervasion piece

InactiveCN101118291AHigh refractive indexSpread evenlyDiffusing elementsSynthetic resin layered productsRefractive indexDiffusion layer

The present invention discloses a diffusion piece and comprises a diffusion layer. The diffusion layer consists of a transparent resin parent metal, as well as a first scattering particle and a second scattering particle doping in the transparent resin parent metal. The refractive index of the first scattering particle is smaller than the refractive index of the second scattering particle. The light diffusion effect of the diffusion piece is strong.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

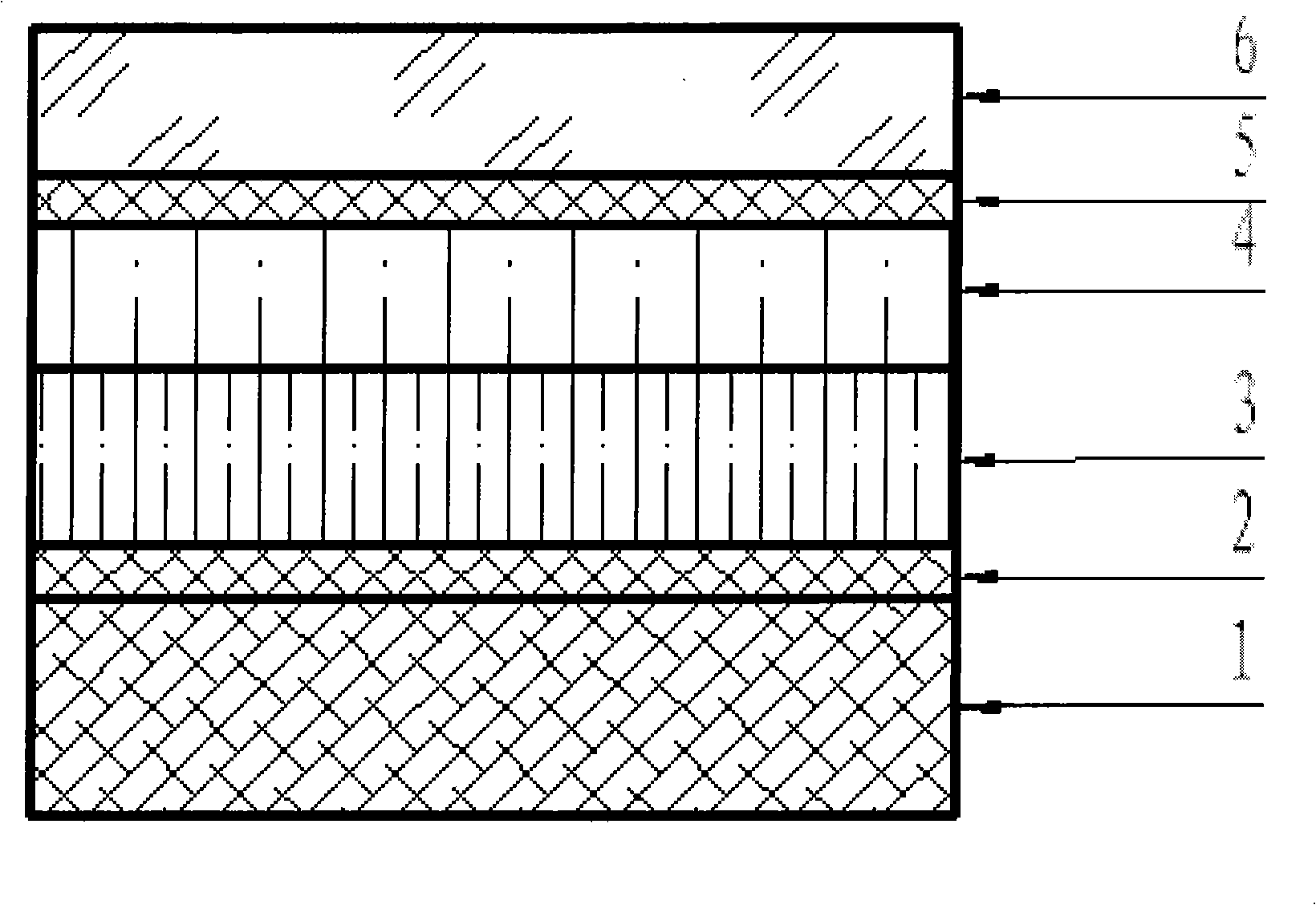

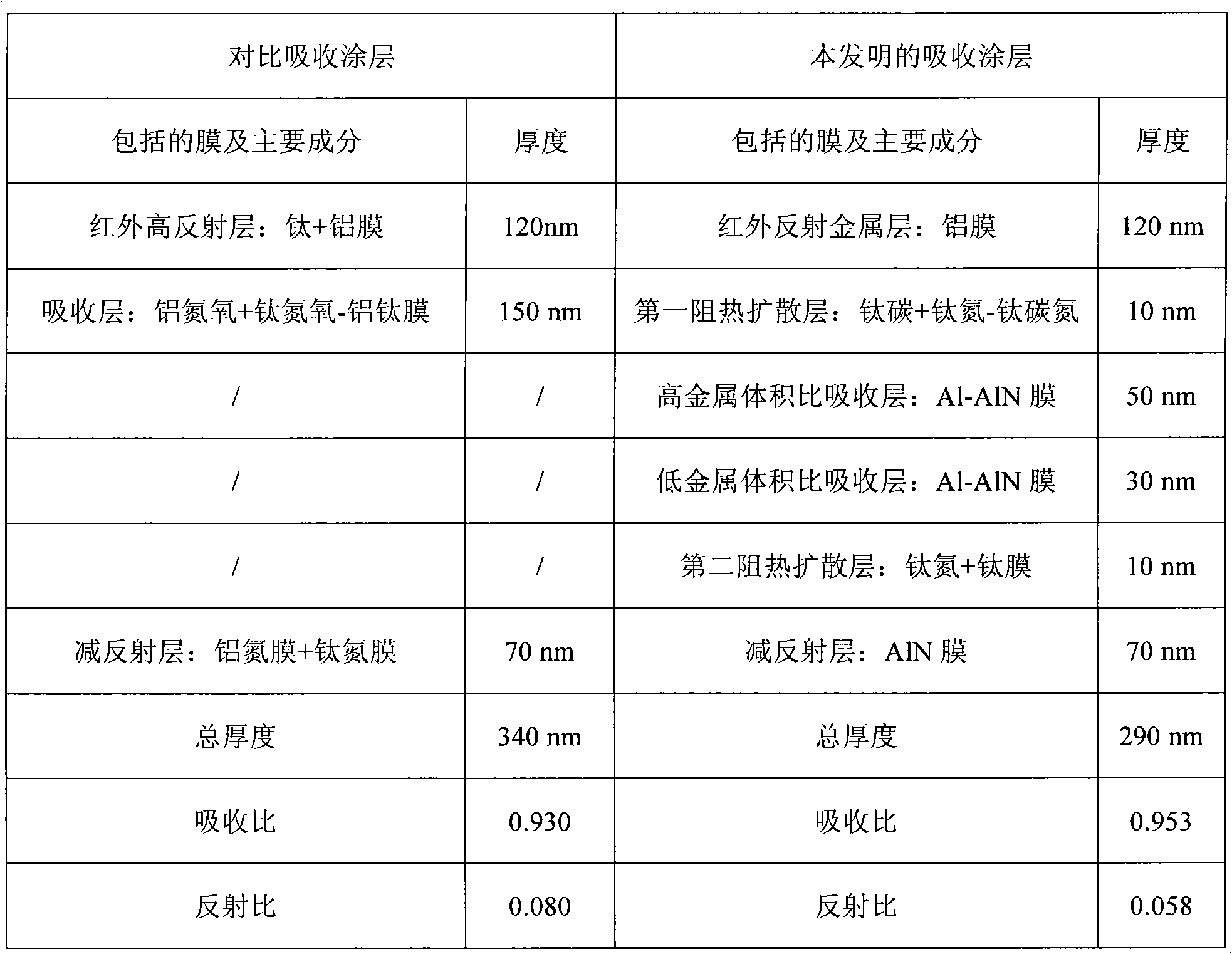

Solar selective absorption coating and preparing method thereof

InactiveCN101408354AComposition is stableImprove high temperature resistanceSolar heat devicesVacuum evaporation coatingSputteringHeat resistance

The invention relates to a solar selectivity absorbing coating which can prevent diffusion and have stable structure, belonging to the technical field of photothermal conversion utilization of solar energy; the absorbing coating, from top to bottom, sequentially comprises a metal substrate, an absorbing layer and a reflection reduction layer; the metal substrate is deposited by a first heat resistance diffusion layer which comprises TiC, TiN and TiCN; and the absorbing layer is deposited by a second heat resistance diffusion layer comprising TiN and Ti. The selectivity absorbing coating is generated by the spattering of a metal target in the gas. The solar selectivity absorbing coating has the beneficial effects that the thermal diffusion effect between coatings is effectively prevented, the structure is stable, the high-temperature resistance performance is good, the thermal efficiency is improved, the preparation method is simple and the production cost is low.

Owner:SHANDONG LINUO NEW MATERIAL +1

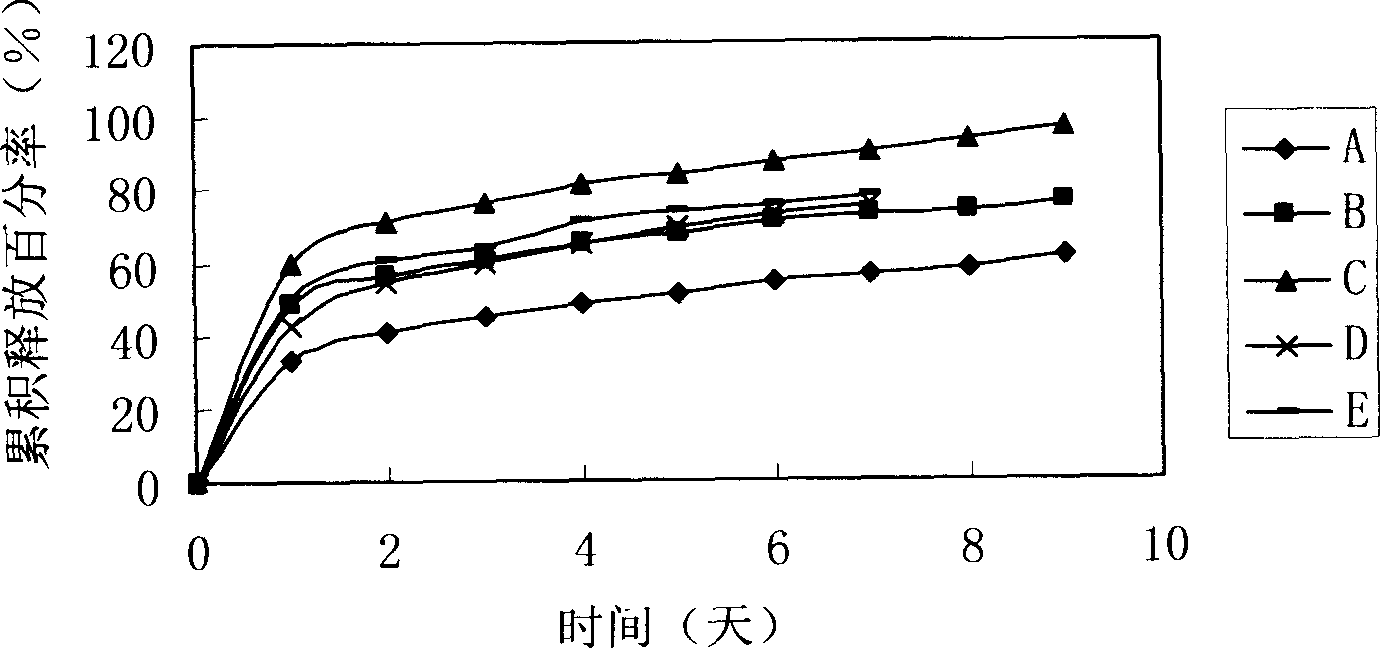

Temperature sensitive type water gel medicine release system and its preparing method

InactiveCN1899264AImprove stabilityAvoid structural damagePharmaceutical delivery mechanismPharmaceutical non-active ingredientsBiological macromoleculeMolecular medicine

The temperature sensitive hydro gel medicine releasing system and its preparation process belongs to the field of medicine technology. The medicine releasing system consists of carried medicine 0.1-30 wt%, temperature sensitive hydro gel 20-90 wt%, and high molecular weight polysaccharide 5-50 wt%. The medicine releasing system is prepared through a polysaccharide-temperature sensitive hydro gel compounding process, a polysaccharide-temperature sensitive hydro gel hydrophilic emulsifying process or a polysaccharide-temperature sensitive hydro gel emulsifying process. Owing to the retarding diffusion effect during solution-gel conversion, the present invention has raised medicine carrying amount, and improved medicine stability. The present invention provides simple and practical technological scheme for the controllable conveyance of biological macro molecular medicine and other treating components and the improvement of carried medicine release.

Owner:SHANGHAI JIAO TONG UNIV

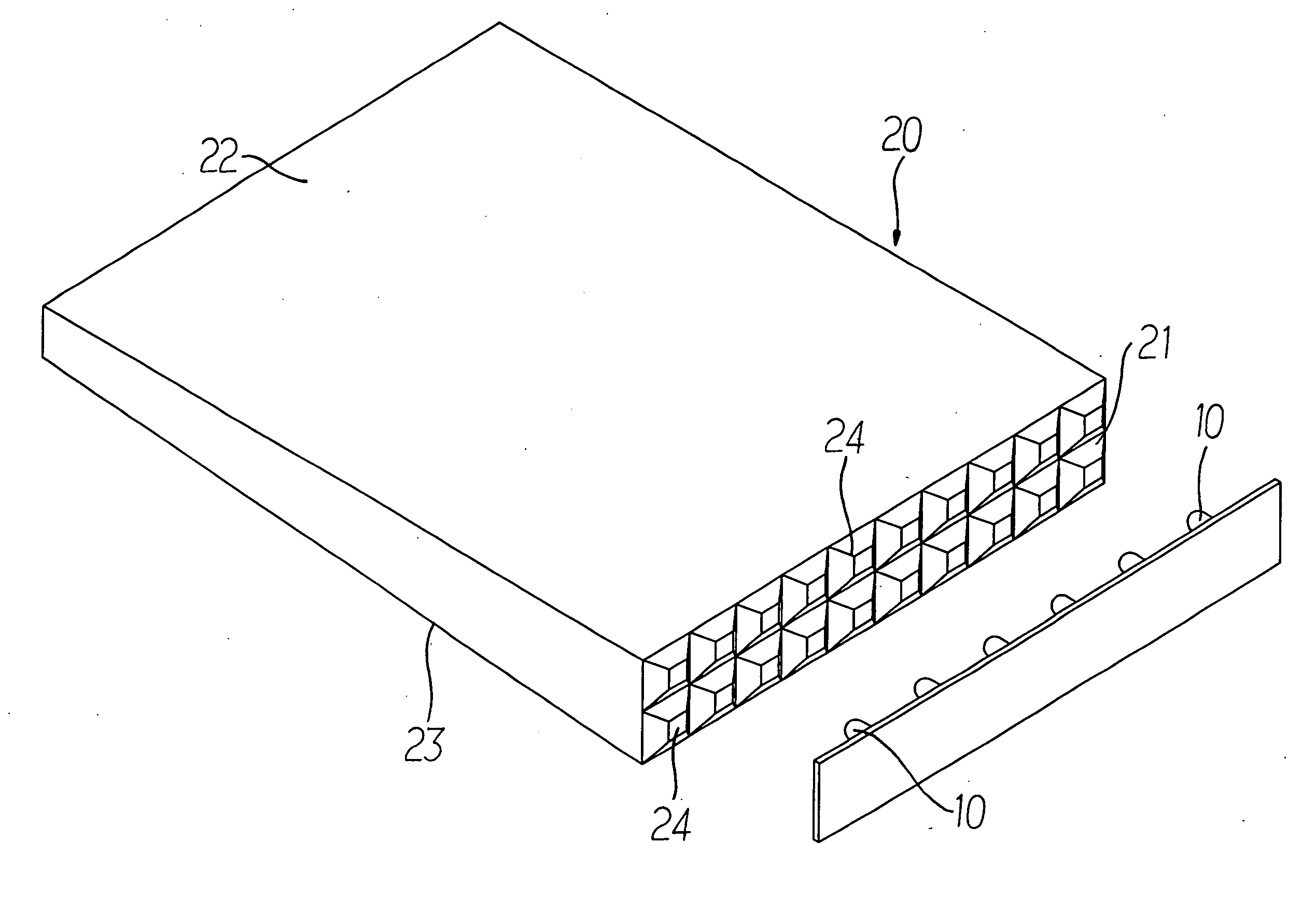

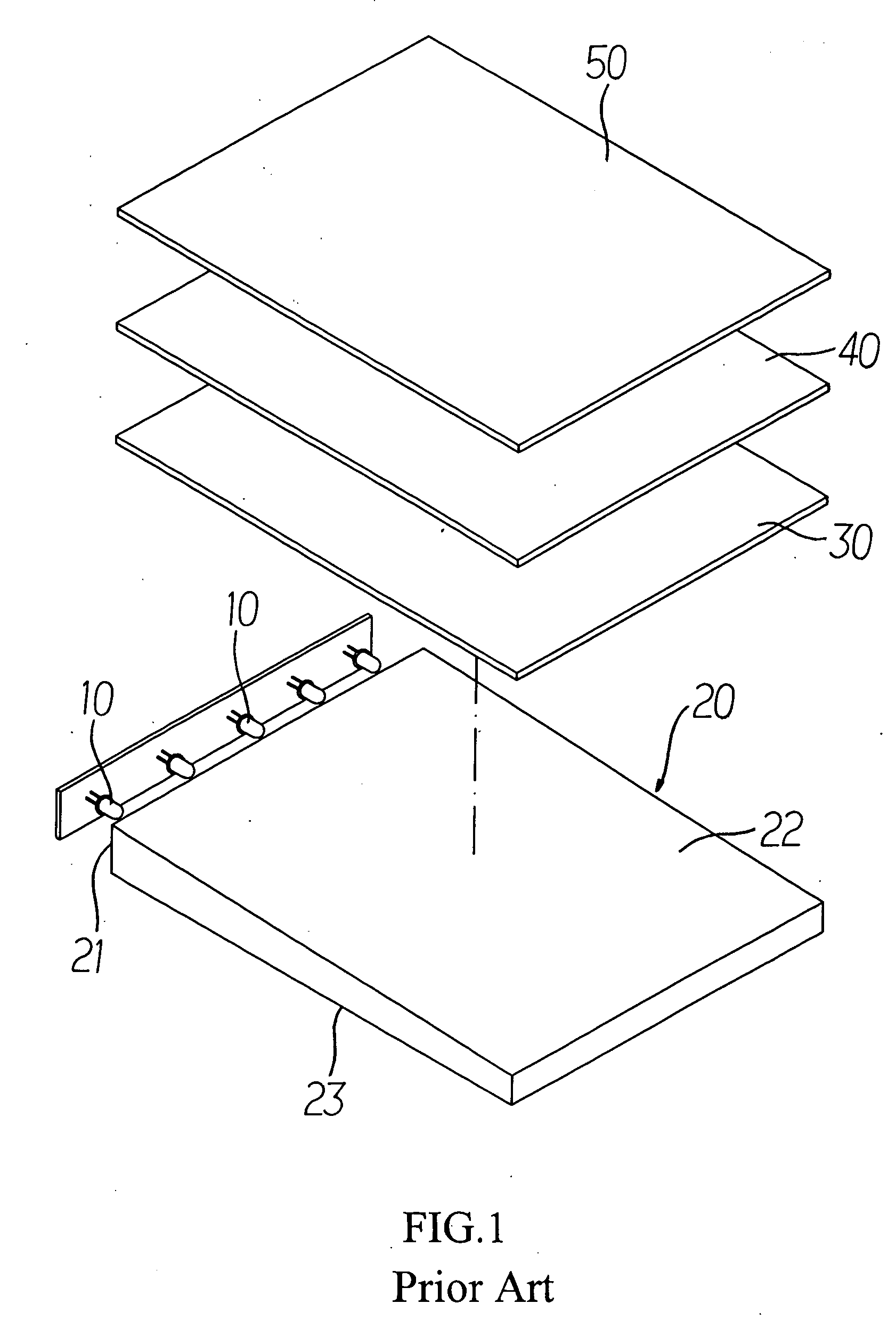

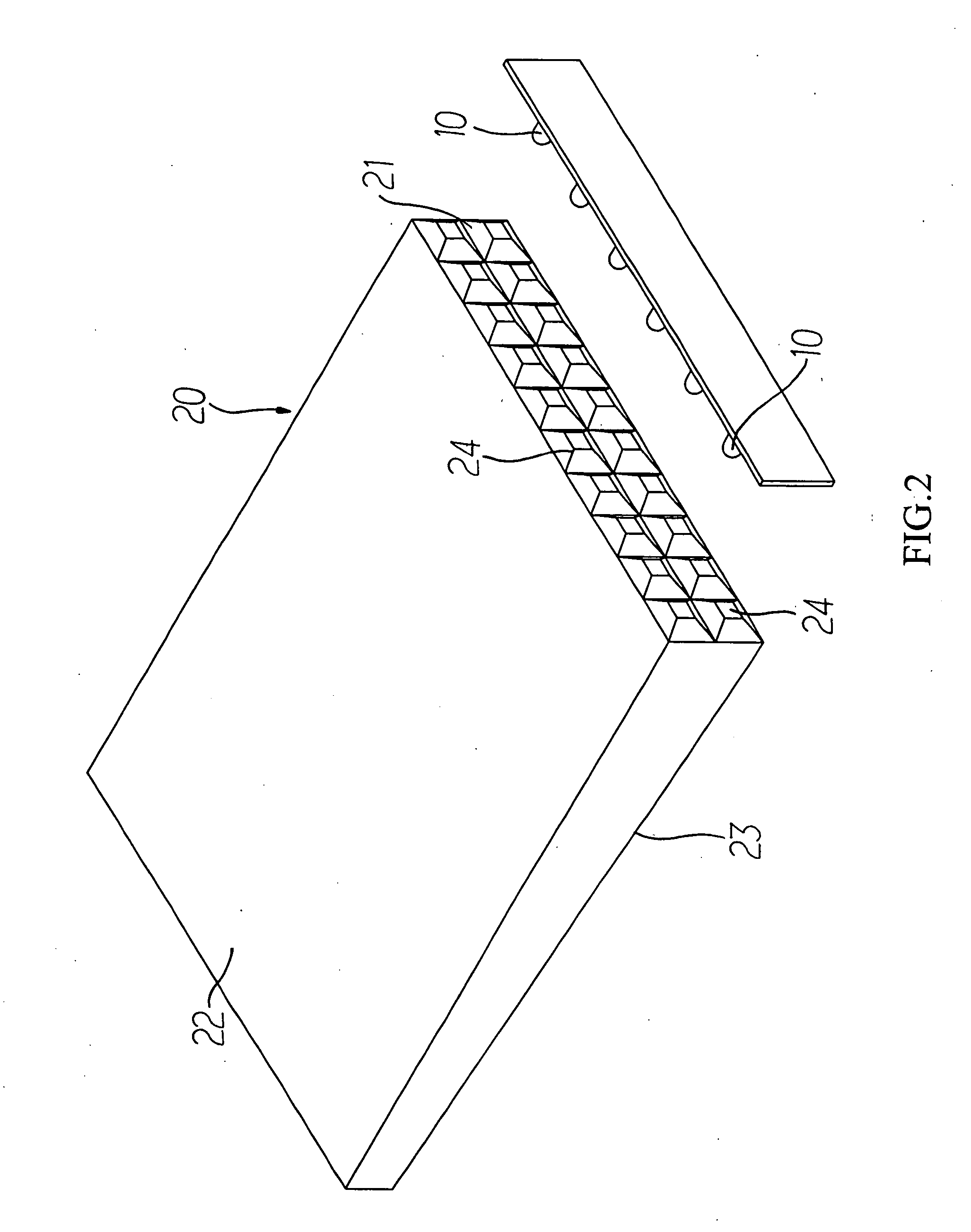

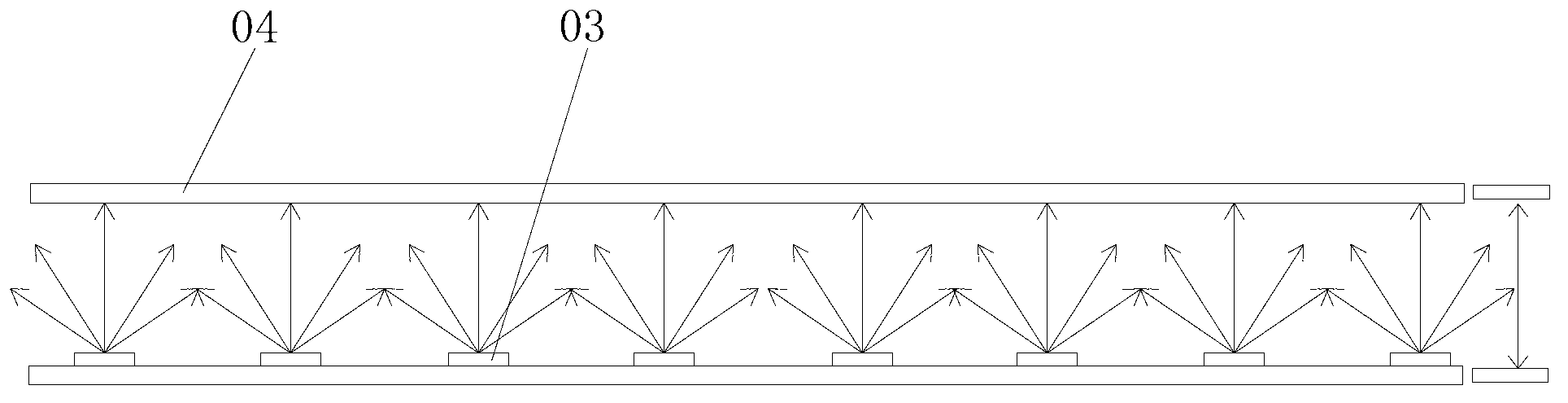

Incident assembly of light guide plate

InactiveUS20060203511A1Increase light sourceEven projectionOptical beam guiding meansPlanar/plate-like light guidesLight guideLight emitting device

A light guide plate includes an incident plane for receiving a light source of a light emitting device, a bottom surface connected to the incident plane, and an emergent plane corresponding to the bottom surface for outputting the light source of the light emitting device, and the light emitting device is installed on one side of the incident plane of the light guide plate; wherein the incident plane of the light guide plate has a structure consisted of a plurality of polyhedrons, such that an incident light of the light emitting device passes through the polyhedron structure to improve the light diffusion effect and make the light produced by the light emitting device evenly diffused towards the emergent plane of the light guide plate.

Owner:K-BRIDGE ELECTRONICS CO LTD

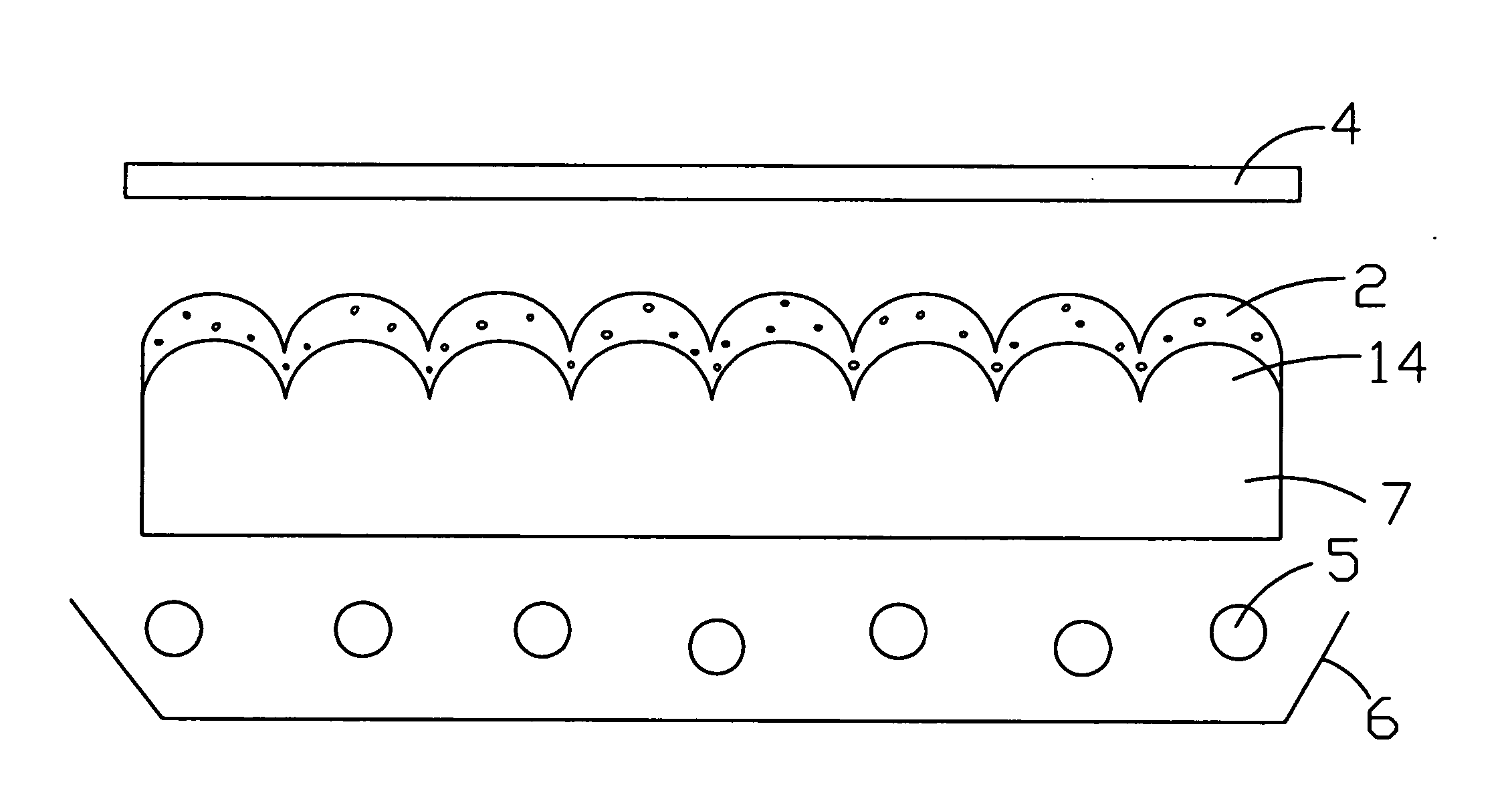

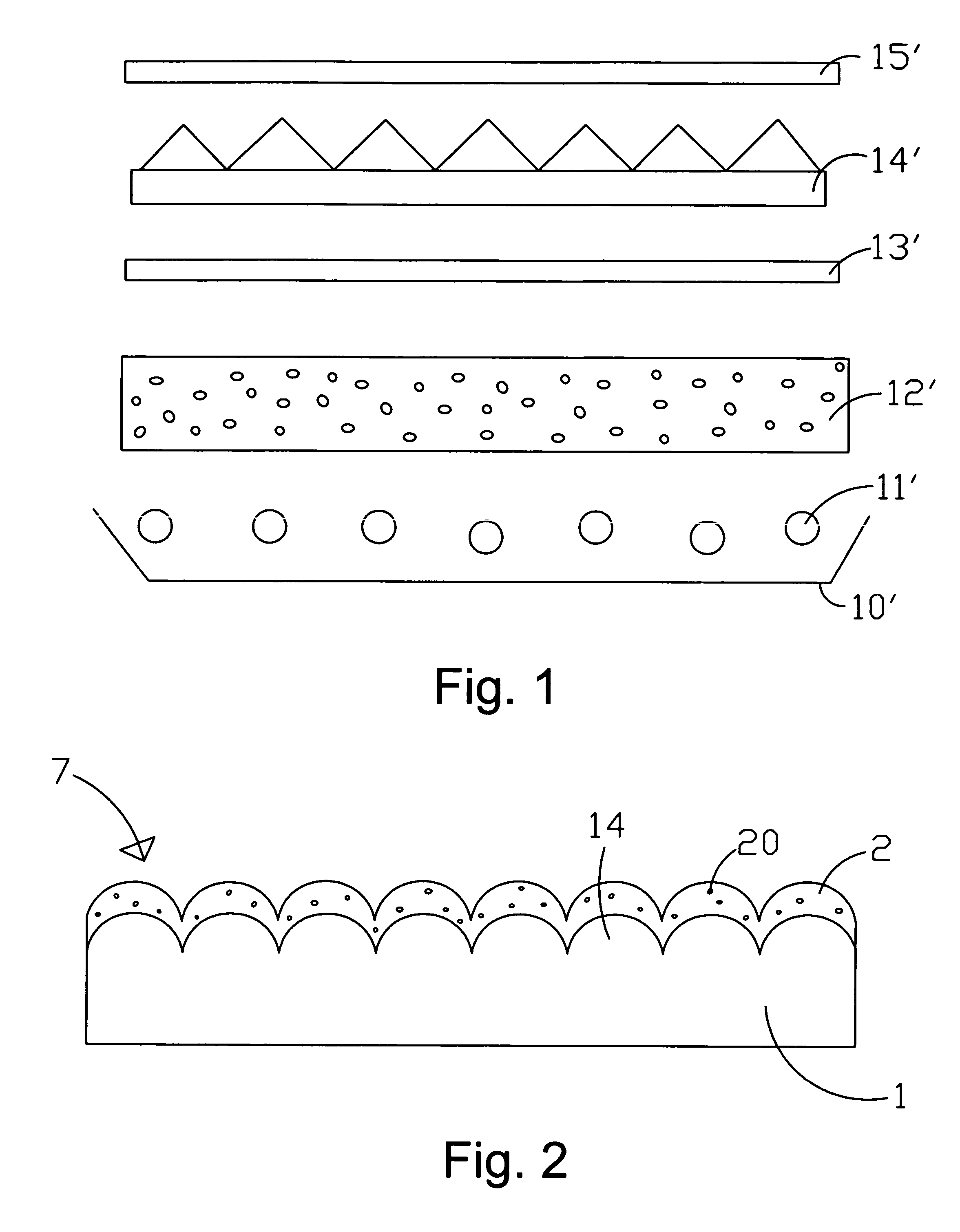

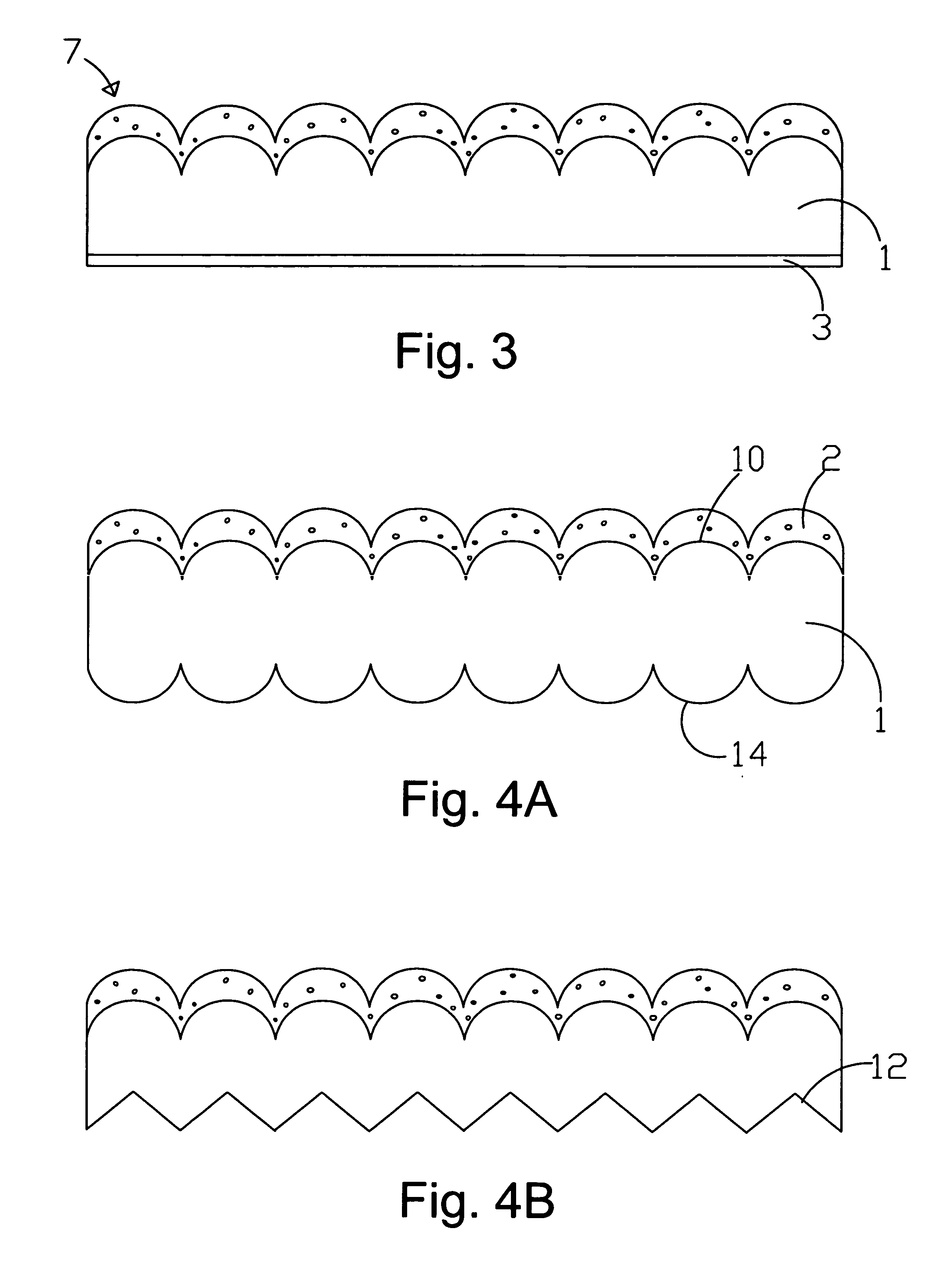

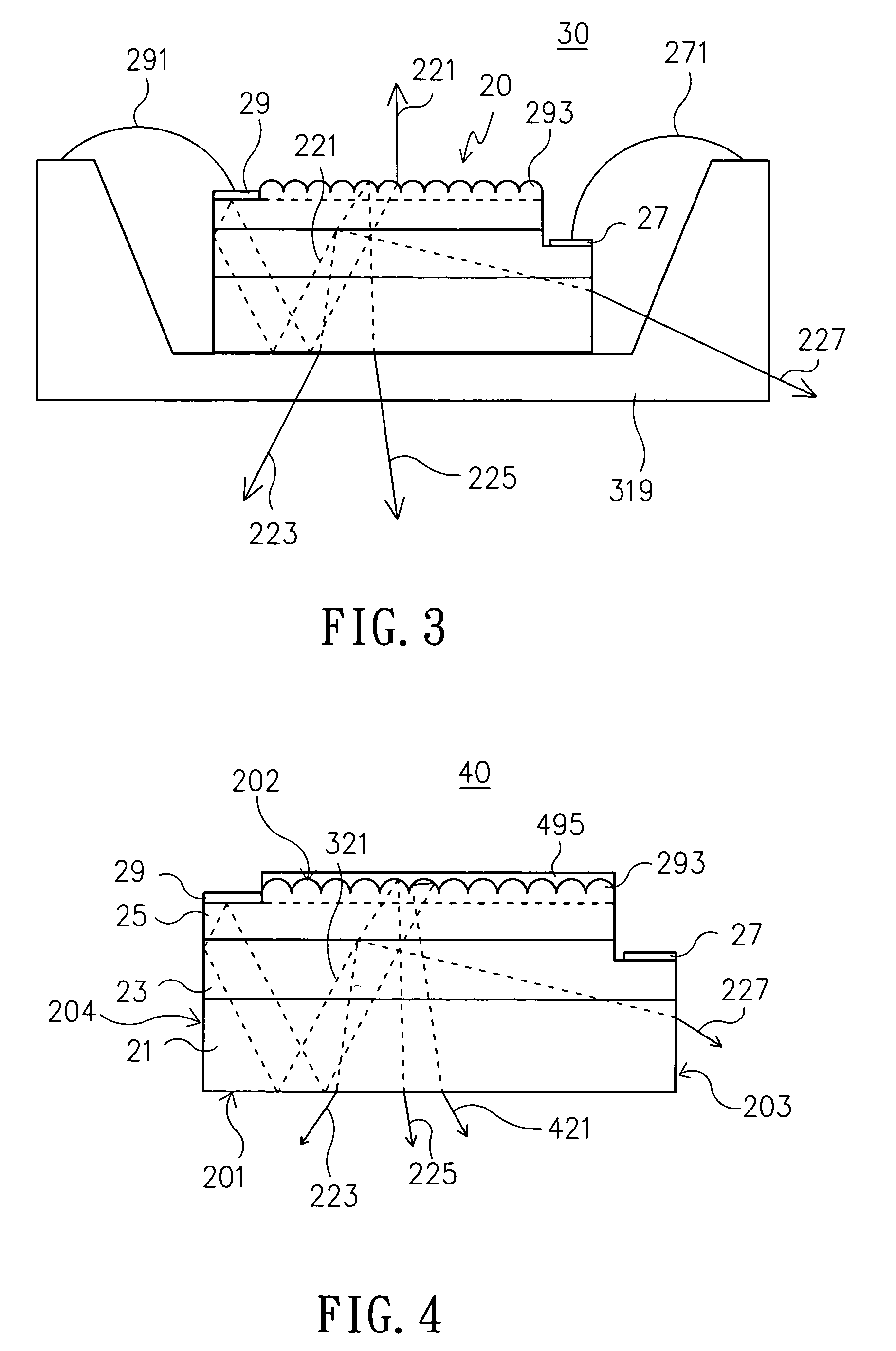

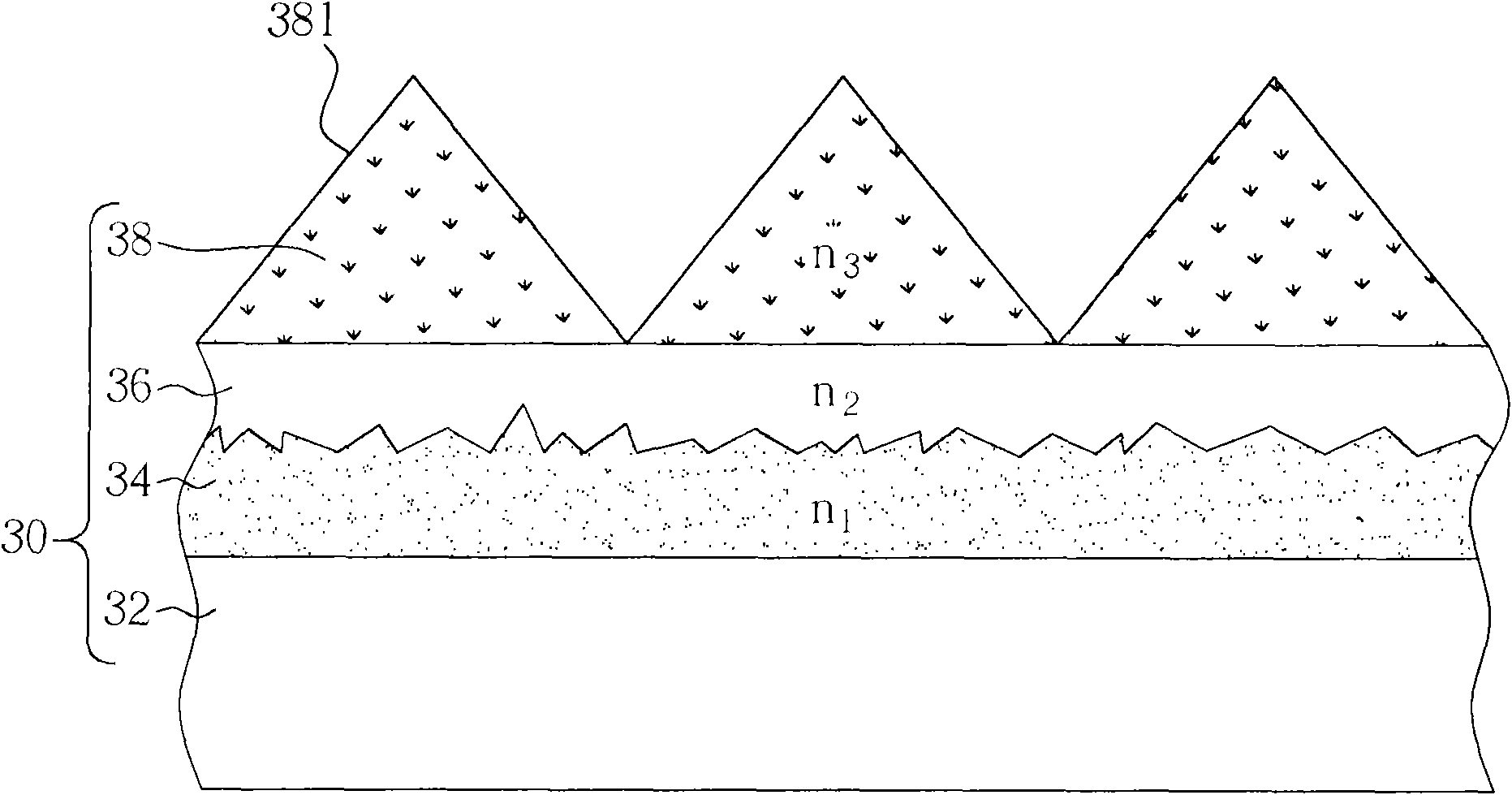

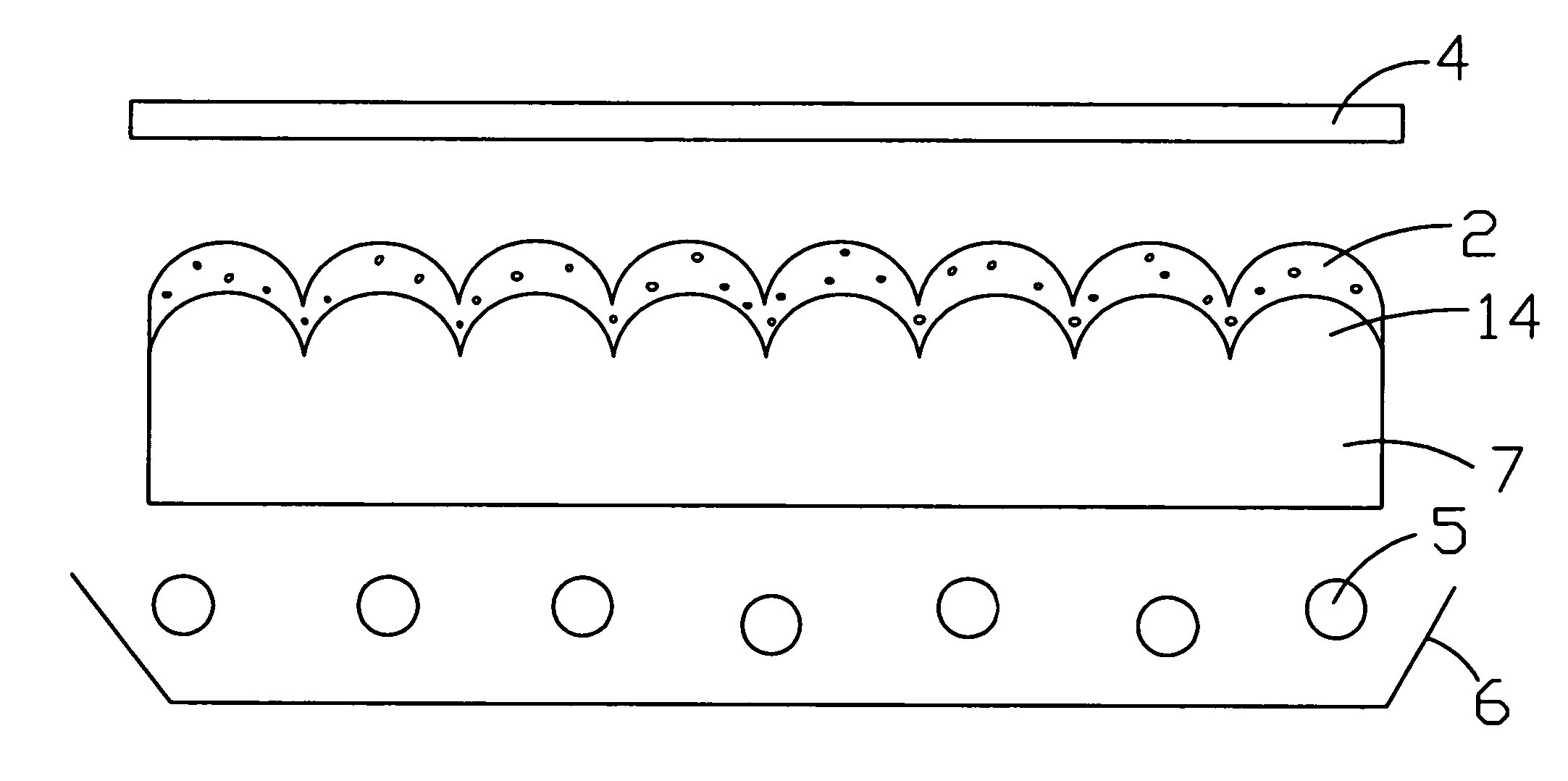

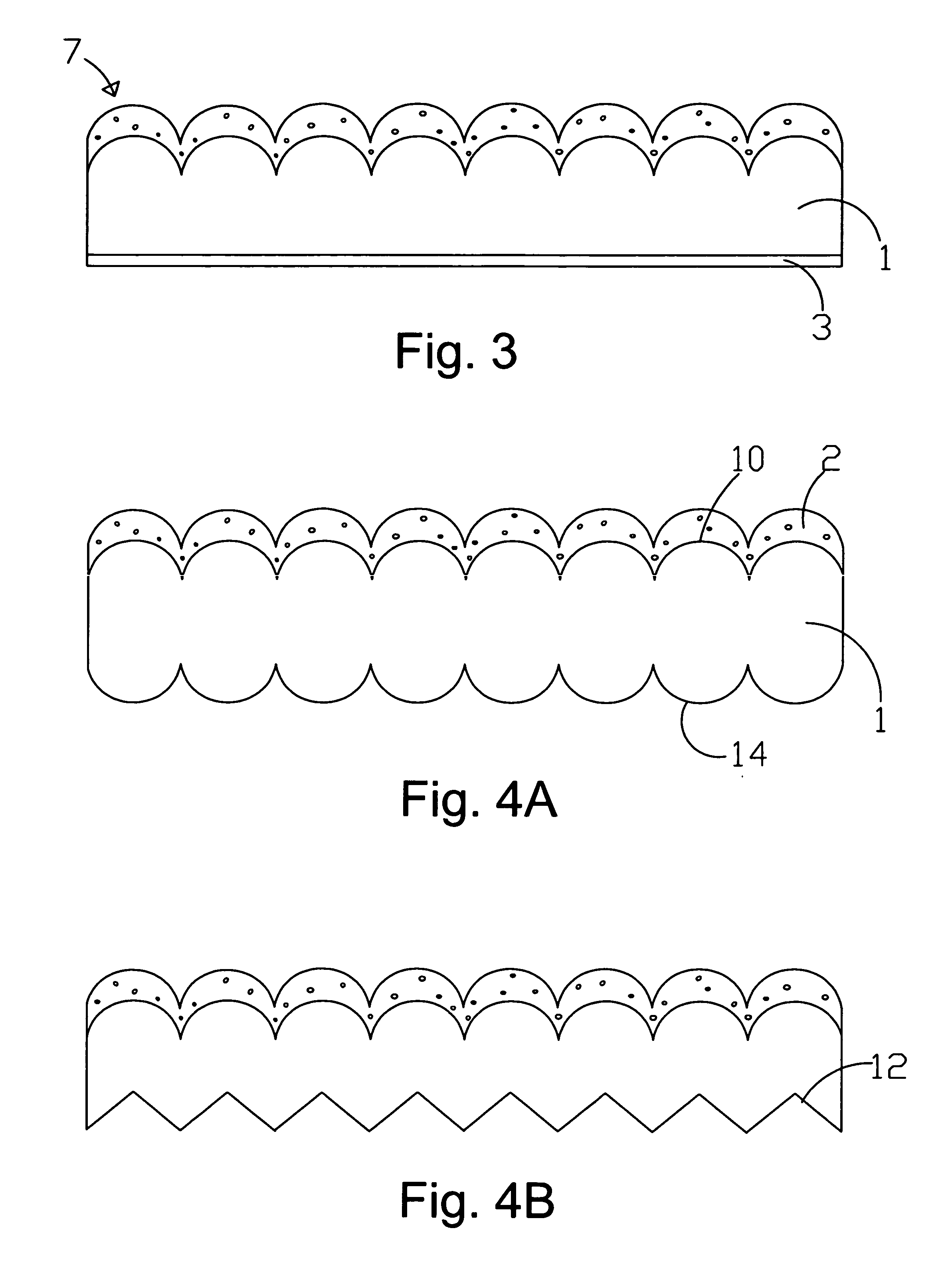

Diffuser plate with higher light diffusion efficiency and brightness

ActiveUS20070159699A1Improve diffusion efficiencyIncrease brightnessPrismsDiffusing elementsDiffusionLenticular lens

A diffuser plate with higher light diffusion efficiency and brightness applied to backlight module of Liquid Crystal Display TV (LCD TV) for providing uniform light is disclosed. An optical lens with a diffusion layer is disposed on one side of the substrate. The diffusion layer is arranged above the optical lens for enhancing diffusion effect. The other side of the diffuser plate can be a plane or having a lens structure. By Lenticular lens, the homogeneity of emitted light is improved so as to reduce the amount of diffusion particles being added into the diffusion plate Therefore, the light transmission is increased and the brightness is enhanced. Meanwhile, ability of shielding lamps is considered and Moiré effect is eliminated. Moreover, the diffusion layer is co-extruded on surface of the Lenticular lens together with the substrate so that the device is easy to be produced.

Owner:ENTIRE TECH CO LTD

Microbead-like dry granules, as well as preparation method and application thereof

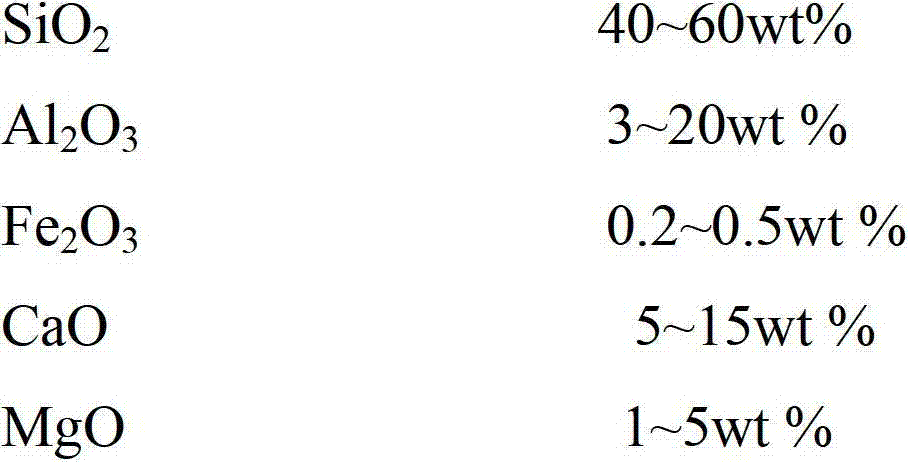

The invention belongs to a substance for being applied on the surface of a billet for forming a glaze and specifically relates to microbead-like dry granules, as well as a preparation method and an application thereof. The surfaces of the microbead-like dry granules are closed curved surfaces. The preparation method comprises the steps of taking ordinary dry granules or a fused block as raw materials / a raw material and processing through a flame floating method. A dry granular glaze ceramic tile is obtained by applying glaze slip prepared by the microbead-like dry granules on the surface of the billet and then firing. The microbead-like dry granules provided by the invention can greatly improve the specific gravity of the dry granules in a glaze material, the glaze material is good in flowability, and the loss of equipment caused by the irregular crystal dry granules can be further greatly reduced. Glaze spraying, glaze pouring, screen printing and rubber roll printing can be used for production process step of dry granular glaze cloth. The decorative surface of the produced dry granular glaze ceramic tile has a diffusion effect, and the artistic expression is stronger and richer.

Owner:GEAREX TECHN CERAMIC KUSN

Methods of decoupling diffusion effects from relaxation times to determine properties of porous media containing fluids

InactiveUS6833698B2Remove and minimizes effectElectric/magnetic detection for well-loggingMaterial analysis by using resonancePore fluidPorous medium

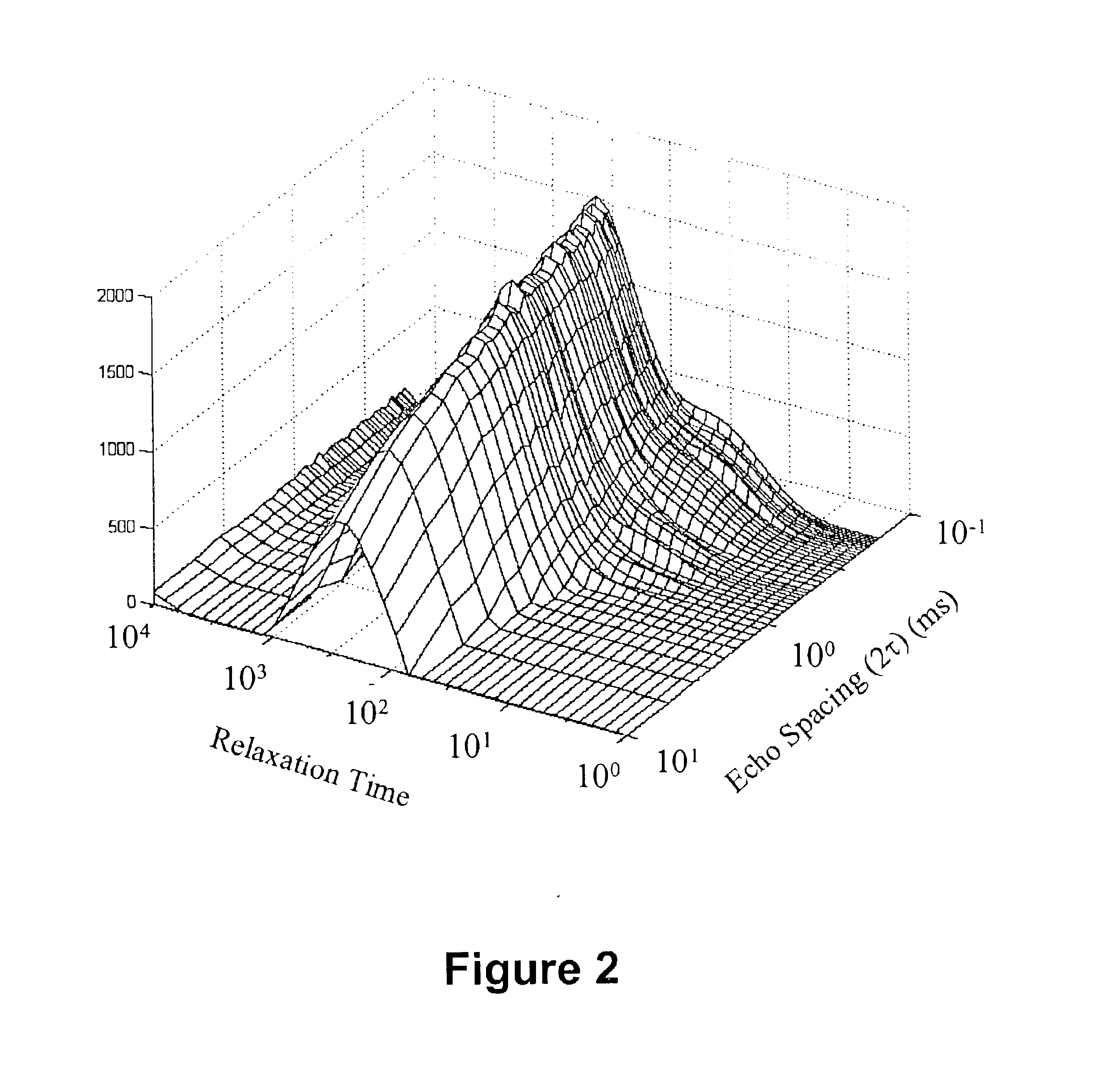

Novel pulse sequences are used to probe the properties of porous media, such as are found in subterranean formations and core samples. This use allows diffusion effects to be uncoupled from the overall T2 relaxation time of the sample. Properties such as internal field gradient and distribution of diffusion coefficients may be determined. A series of pulse sequences are applied to the media to be evaluated. The series of pulse sequences include first and second windows. The first windows include pulse sequences have varying characteristics, such as increasing echo spacing, while the second windows preferably utilize similar pulse sequences which have very small echo spacing. Apparent internal field gradient distribution and apparent diffusion coefficient may be determined as a function of T2 relaxation time. These properties are readily visualized in a two-dimensional map with a first axis being the apparent internal field gradient or alternatively the diffusion coefficient of pore fluids, a second axis being the T2 relaxation times, and the vertical amplitudes being proportional to the proton population. Other properties which may be determined from use of this method include porosity, pore size distribution, oil and water saturation, oil viscosity, oil wettability, and permeability. Also, a method for determining and plotting a T1-MAS 2D spectrum is provided where T1 relaxation time and chemical shift are plotted on x,y axes while intensity of proton population is displayed along a third axis.

Owner:CHEVRONTEXACO US

High-entropy alloy composite coating on metal bipolar plate of fuel cell and process

The invention relates to a high-entropy alloy composite coating on a metal bipolar plate of a fuel cell and a preparation method of the high-entropy alloy composite coating. The high-entropy alloy composite coating is prepared on the surface of the metal bipolar plate through adopting a closed-field unbalanced magnetron sputtering technology. The composite coating on the surface of a substrate of the metal bipolar plate is composed of a high-entropy alloy layer, a multi-component alloy-carbon transition layer and an amorphous carbon layer located on the outermost surface. Compared with the prior art, multi-component compounding is carried out by adopting a step-by-step transition method through sufficiently utilizing a high-entropy effect, a delaying diffusing effect and a cocktail party effect of a high-entropy alloy, and electrical conductivity and corrosion resistance of an amorphous carbon film. The modified metal bipolar plate provided by the invention has high film-substrate bonding force, corrosion resistance and electrical conductivity, so that utilization requirements of the metal bipolar plate of the fuel cell are met.

Owner:SHANGHAI DIANJI UNIV

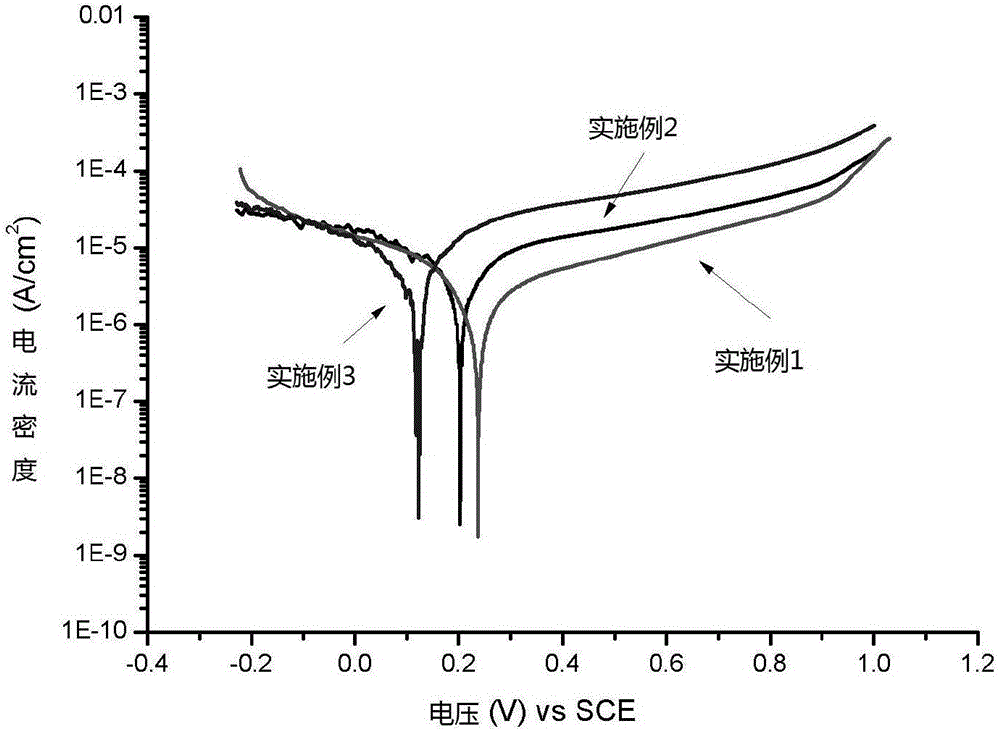

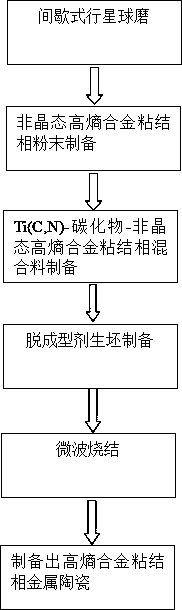

Preparation method for Ti(C,N)-based cermet with high-entropy alloy bonder phase

ActiveCN109022990AGood for maintaining relative contentKeep the relative contentWear resistantHigh entropy alloys

The invention discloses a preparation method for a Ti(C,N)-based cermet with a high-entropy alloy binder phase. The preparation method is characterized in that firstly, an amorphous high-entropy alloybinder phase powder with Co:Ni:Fe:Cu:Mn = 1:1:1:1:(0.3-1) is prepared by using an intermittent planetary ball mill; then, the amorphous high-entropy alloy binder phase powder is mixed with a hard phase powder by using a drum-type ball mill, and the prepared mixture is still in an amorphous state; lastly, microwave sintering at 1400-1450 DEG C is performed to allow the amorphous high-entropy alloybonder phase in the cermet to be crystallized, a transition process from the amorphous state to the crystalline state and the hysteretic element diffusion effect of the high-entropy alloy restrain the dissolution of the hard phase into the binder phase, and the binder phase of the cermet is the single-phase high-entropy alloy with a face-centered cubic structure; and thus, the cermet with the high-entropy alloy bonder phase is prepared. The preparation method overcomes the problem that during the existing preparation process of a cermet with a high-entropy alloy binder phase, a Ti(C,N) hard phase dissolves in a bonder phase, so that the relative content decreases and the grains of the hard phase are prone to abnormal growth, and finally insufficient mechanical properties of a hard alloy are caused. The preparation method can be used in cutting tools, wear-resistant parts and other fields.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

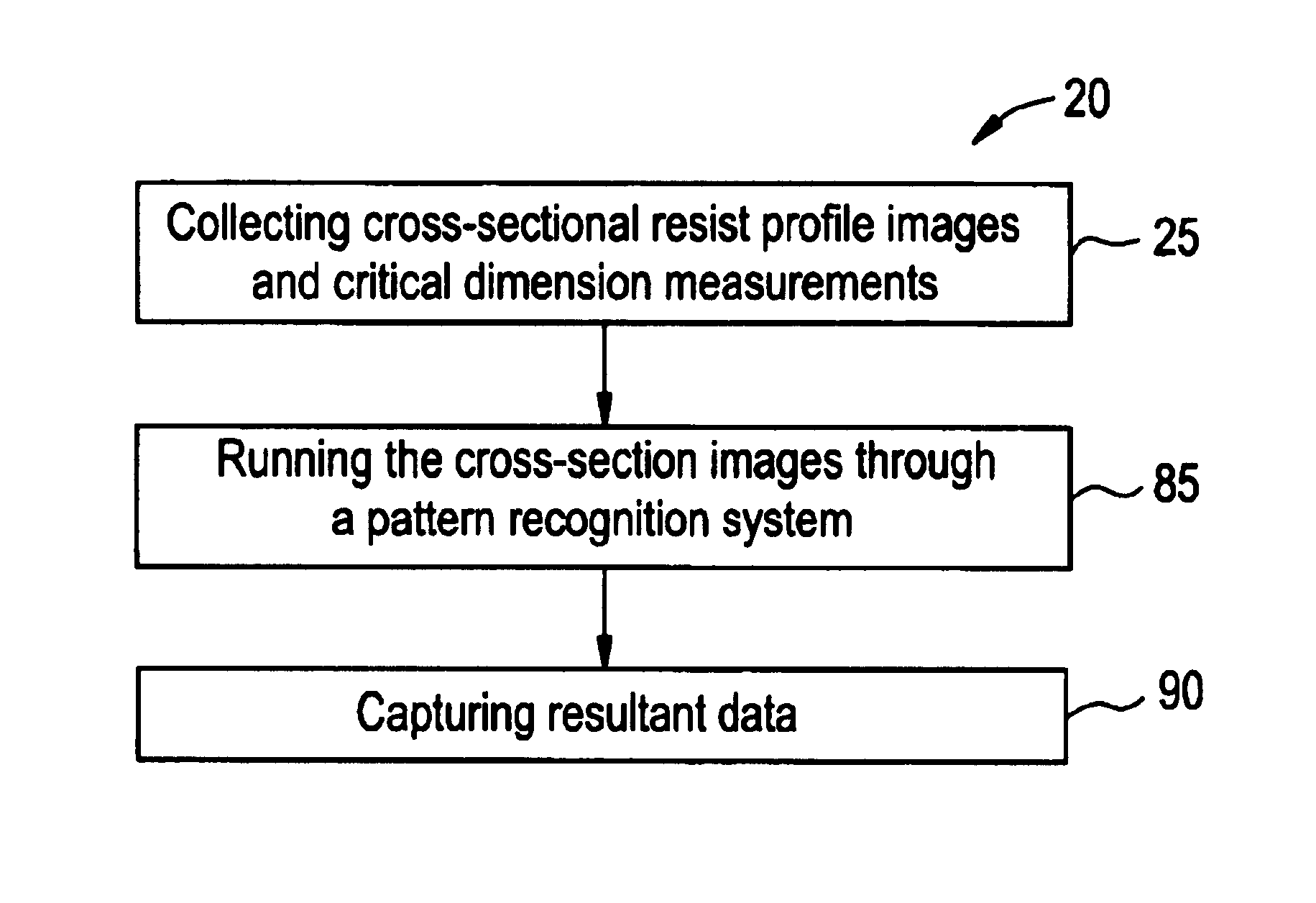

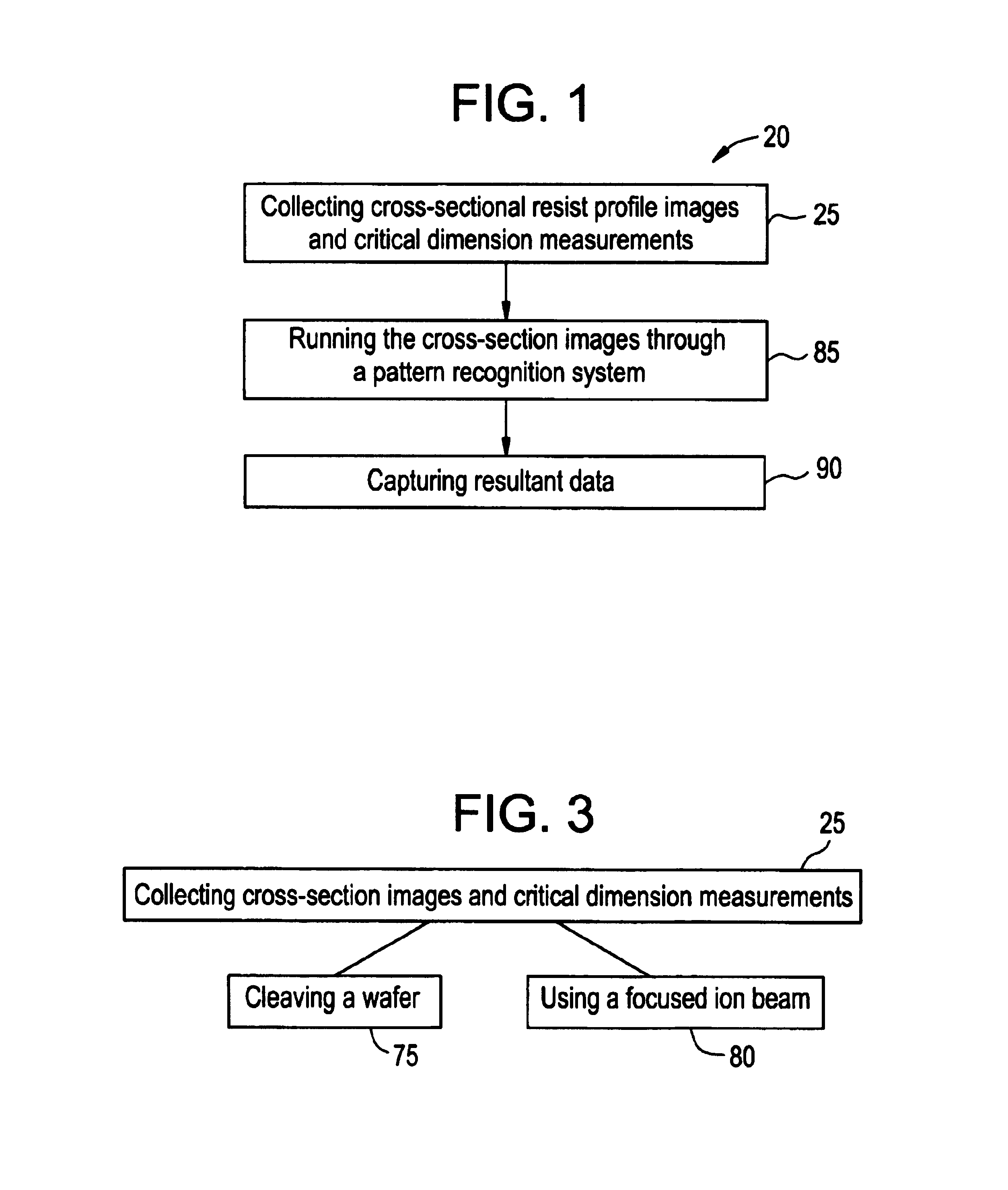

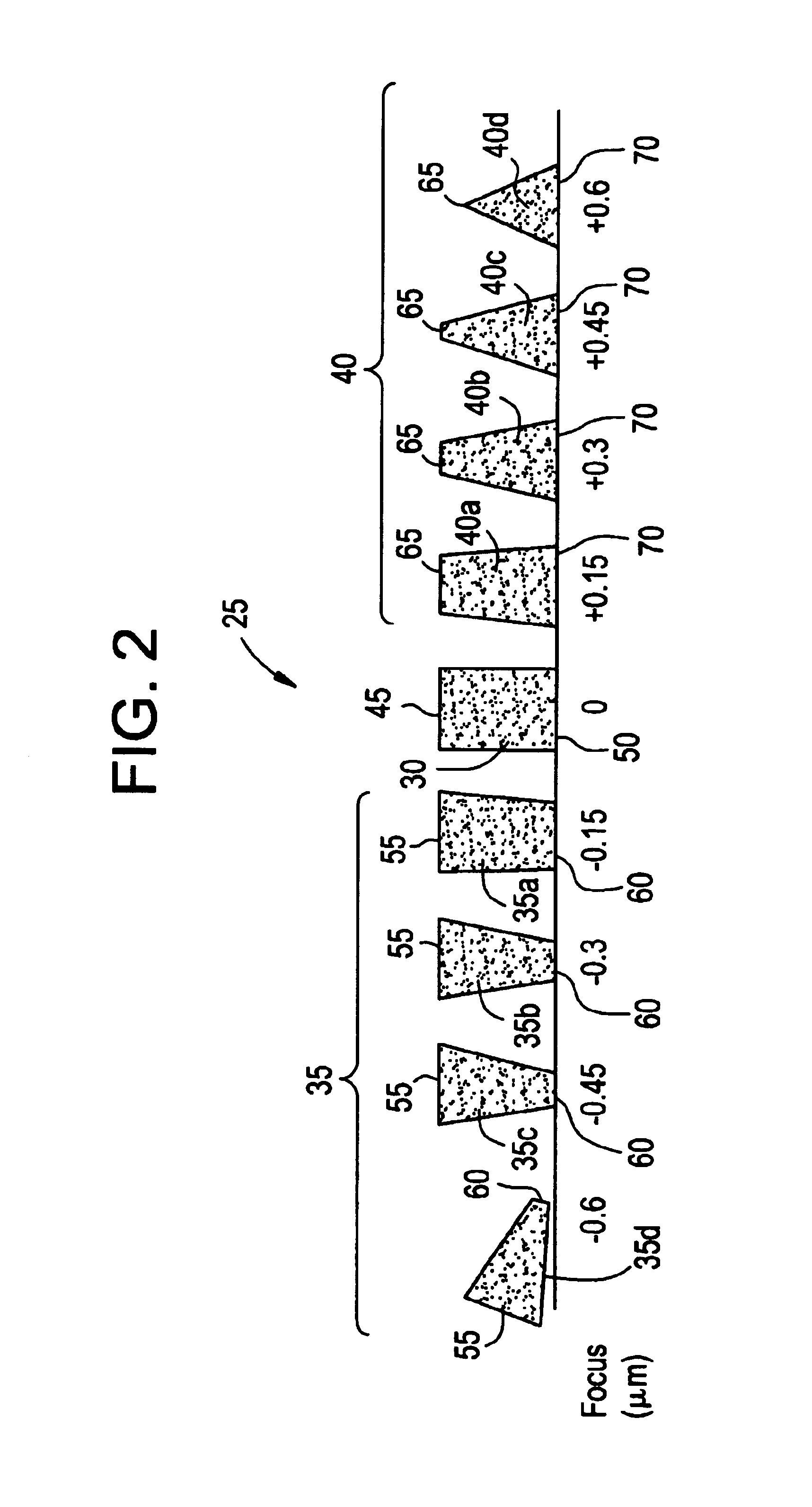

Method for improving OPC modeling

InactiveUS6934929B2Impacting accuracyCharacter and pattern recognitionSpecial data processing applicationsDiffusionCritical dimension

The invention provides a method for OPC modeling. The procedure for tuning a model involves collecting cross-section images and critical dimension measurements through a matrix of focus and exposure settings. These images would then run through a pattern recognition system to capture top critical dimensions, bottom critical dimensions, resist loss, profile and the diffusion effects through focus and exposure.

Owner:BELL SEMICON LLC

Field emission device

ActiveUS8018169B2Improve emission uniformityHigh voltageControl electrodesDischarge tube luminescnet screensField emission deviceGate insulator

Disclosed is a field emission device. The field emission device includes: an anode substrate including an anode electrode formed on a surface thereof and a fluorescent layer formed on the anode electrode; a cathode substrate disposed opposite to and spaced apart from the anode substrate, and including at least one cathode electrode formed toward the anode substrate and a field emitter formed on each cathode electrode; and a gate substrate having one surface in contact with the cathode substrate, wherein the gate substrate include gate insulators surrounding the field emitters and having a plurality of openings exposing the field emitters, and a plurality of gate electrodes formed on the gate insulators around the openings and electrically isolated from one another. Thus, when the trajectories of the electron beams emitted from the emitters are rapidly changed over time by a voltage difference between the gate electrodes, an electron beam-scanned area can be expanded due to residual images and the electron beam can be more uniformly emitted due to an electron beam scattering effect and a linear beam spreading effect, resulting in improved emission uniformity of the fluorescent layer.

Owner:ELECTRONICS & TELECOMM RES INST

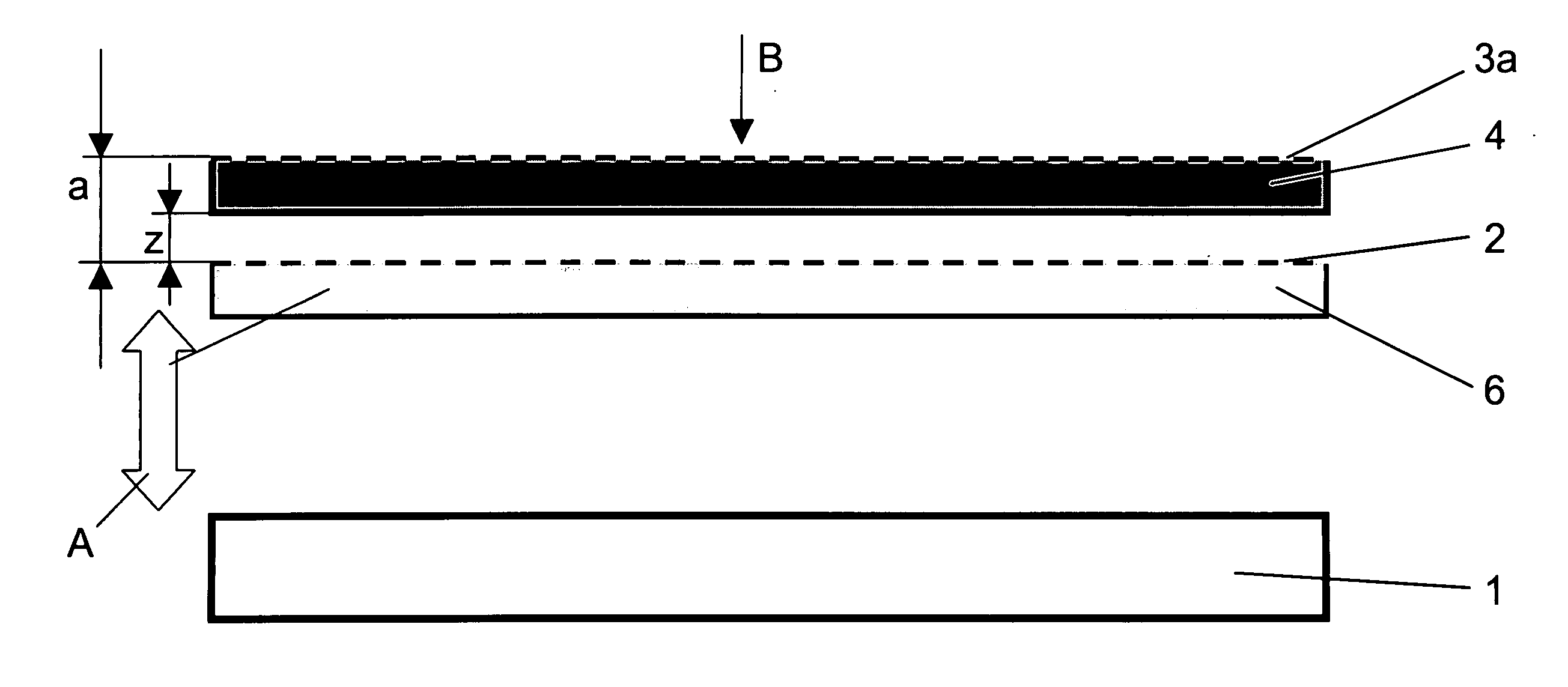

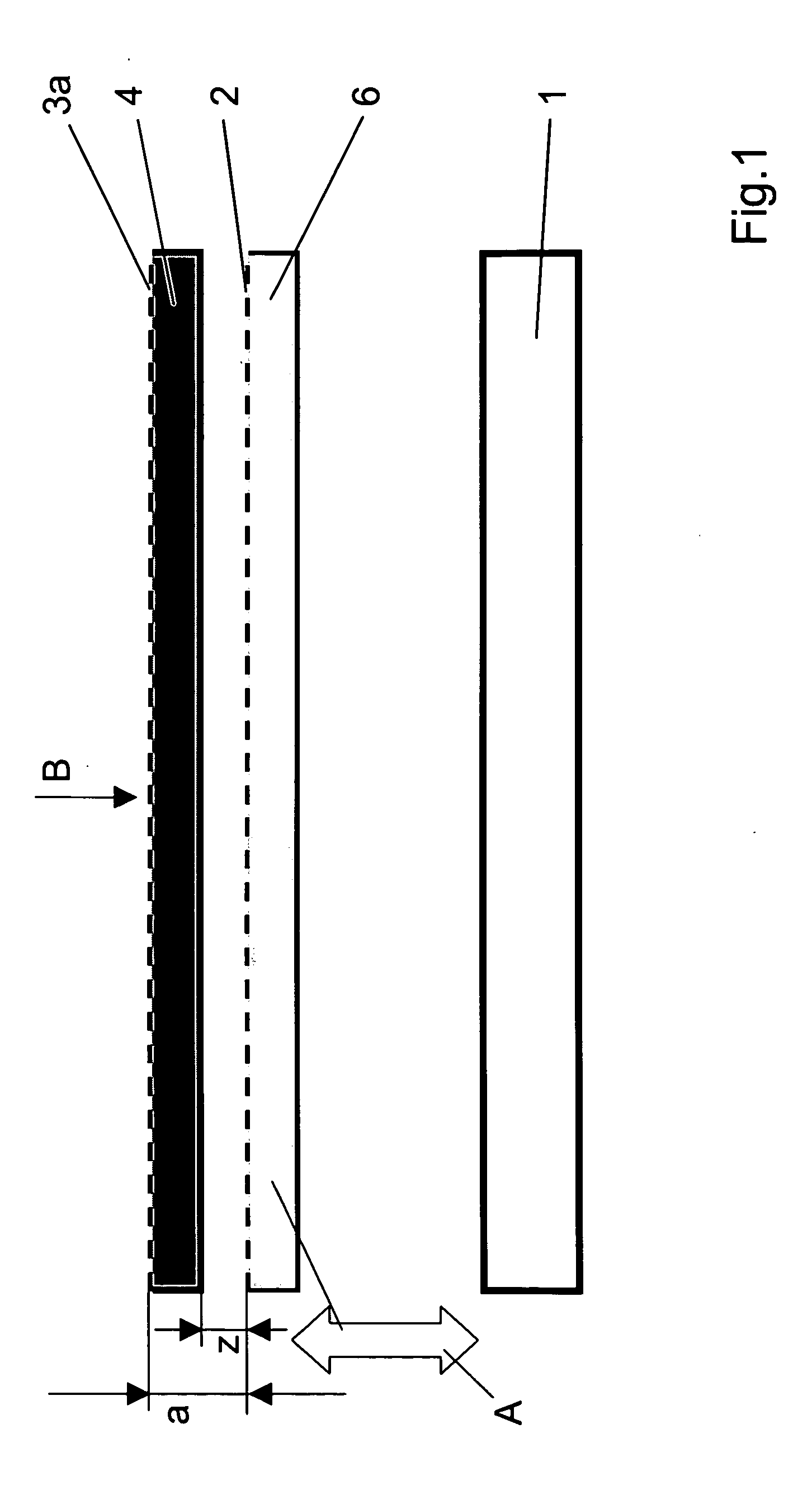

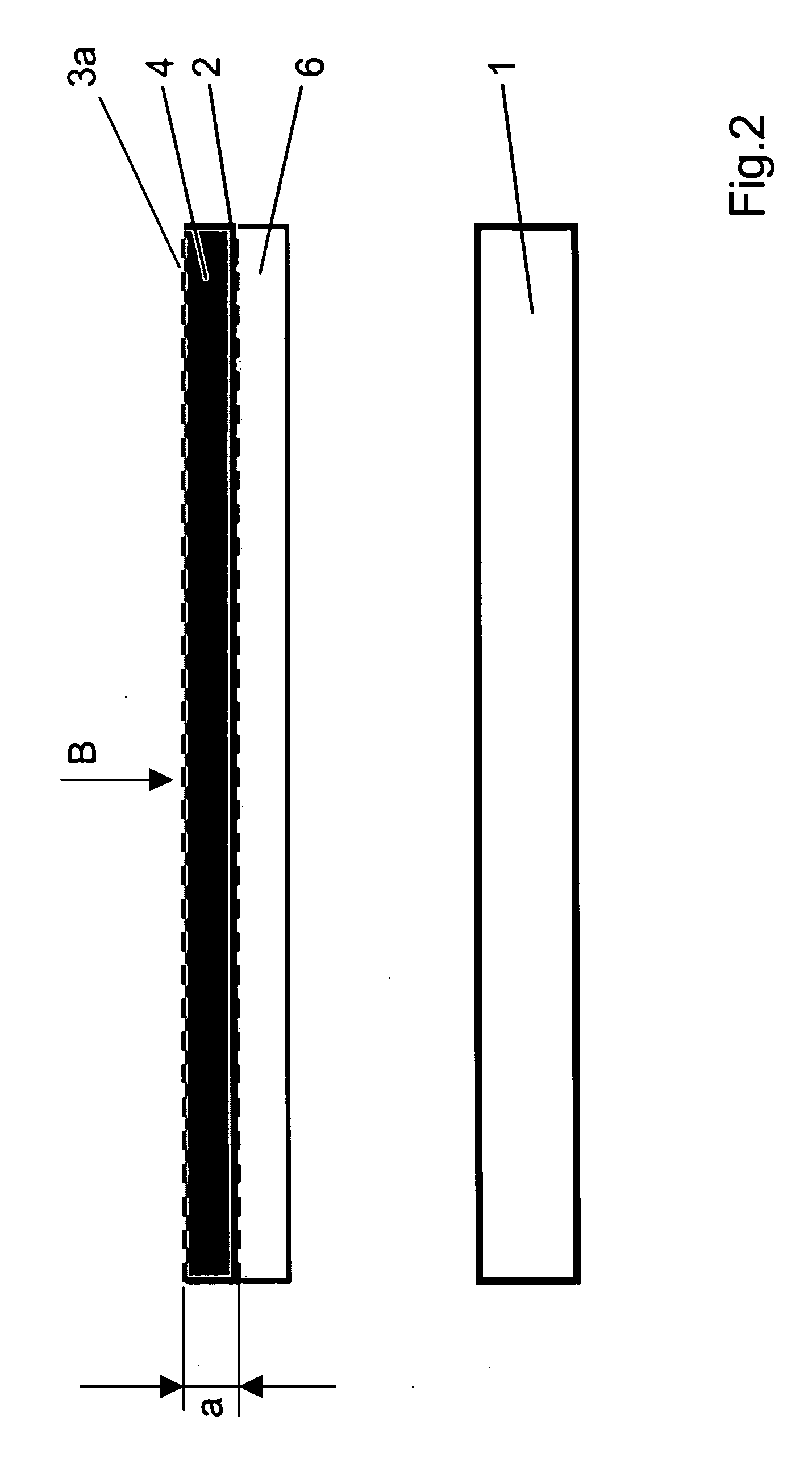

Arrangement for two-or three-dimensional display

InactiveUS20060192908A1Reduction of image brightnessSmall-viewing distanceSteroscopic systemsNon-linear opticsThree dimensional displayDiffusion effect

An arrangement for the display of images with selectable three-dimensionally visible or two-dimensional modes, including an illuminating device a filter array to impart a structure to the light a diffusing layer, and a transmissive image display device, with a variable distance a between the filter array and the diffusing layer, so that in a first position, the structure imparted by the filter array is essentially cancelled due to the light diffusion effect of the diffusing layer, and a two-dimensional image is shown, and the structure imparted by the filter array is essentially not cancelled, so that the image display device shows a three-dimensional image.

Owner:PHOENIX 3D

Light-emitting diode with micro-lens layer

InactiveUS20050199898A1Improve efficiencyIncrease brightnessSemiconductor devicesLight beamEngineering

A light-emitting diode with a micro-lens layer, includes a die substrate, a second epitaxy layer deposited on the top surface of the die substrate, a first epitaxy layer deposited on a portion of the top surface of the second epitaxy layer, a second electrode formed on a portion of the top surface of the second epitaxy layer, a first electrode formed on a portion of the top surface of the first epitaxy layer, and a micro-lens layer mounted on a portion of the top surface of the first epitaxy layer. The micro-lens layer can change the projection angle and the projection path of the light beams radiated within the light-emitting diode in virtue of the diffusion effect caused by the micro-lens, and thereby improving the light-drawing efficiency and the luminance of the light-emitting diode.

Owner:OPTO TECH

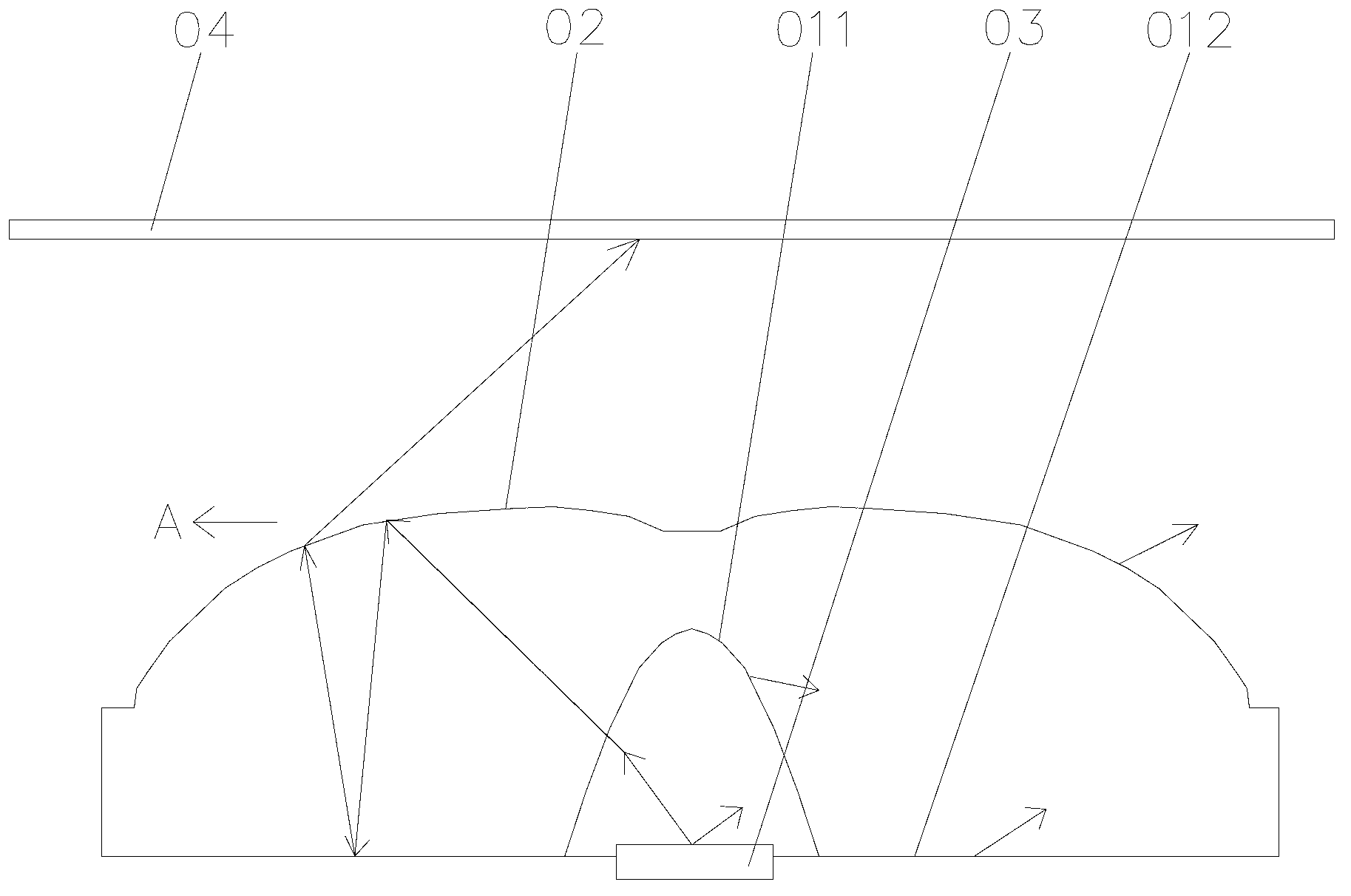

Secondary lens with bottom of curved surface structure

ActiveCN102705777AExtended Diffusion AngleImprove diffusivityCondensersIlluminated signsOptoelectronicsLighting system

The invention discloses a secondary lens with a bottom of a curved surface structure, which is rotationally symmetrical along with the central axis, comprising a bottom surface and an air light outlet surface connected with the bottom surface, wherein the air light outgoing surface is arranged above a point light source, and the bottom surface comprises a middle arc concave light inlet surface and a ring-shaped concave curved surface connected with the arc concave light inlet surface. According to the secondary lens in the invention, the bottom surface is a continuous curved surface which is formed by connecting the middle arc concave light inlet surface with the ring-shaped concave curved surface, so that the diffusion angle of the light source can be enlarged, the secondary lens is good in light ray diffusion effect, and the light ray reaching onto a receiving plate is more even; and the secondary lens in the invention is applicable to a backlight module, and is further applicable to an illumination system which needs the homogeneous diffusion effect of the light.

Owner:TPV DISPLAY TECH (XIAMEN) CO LTD

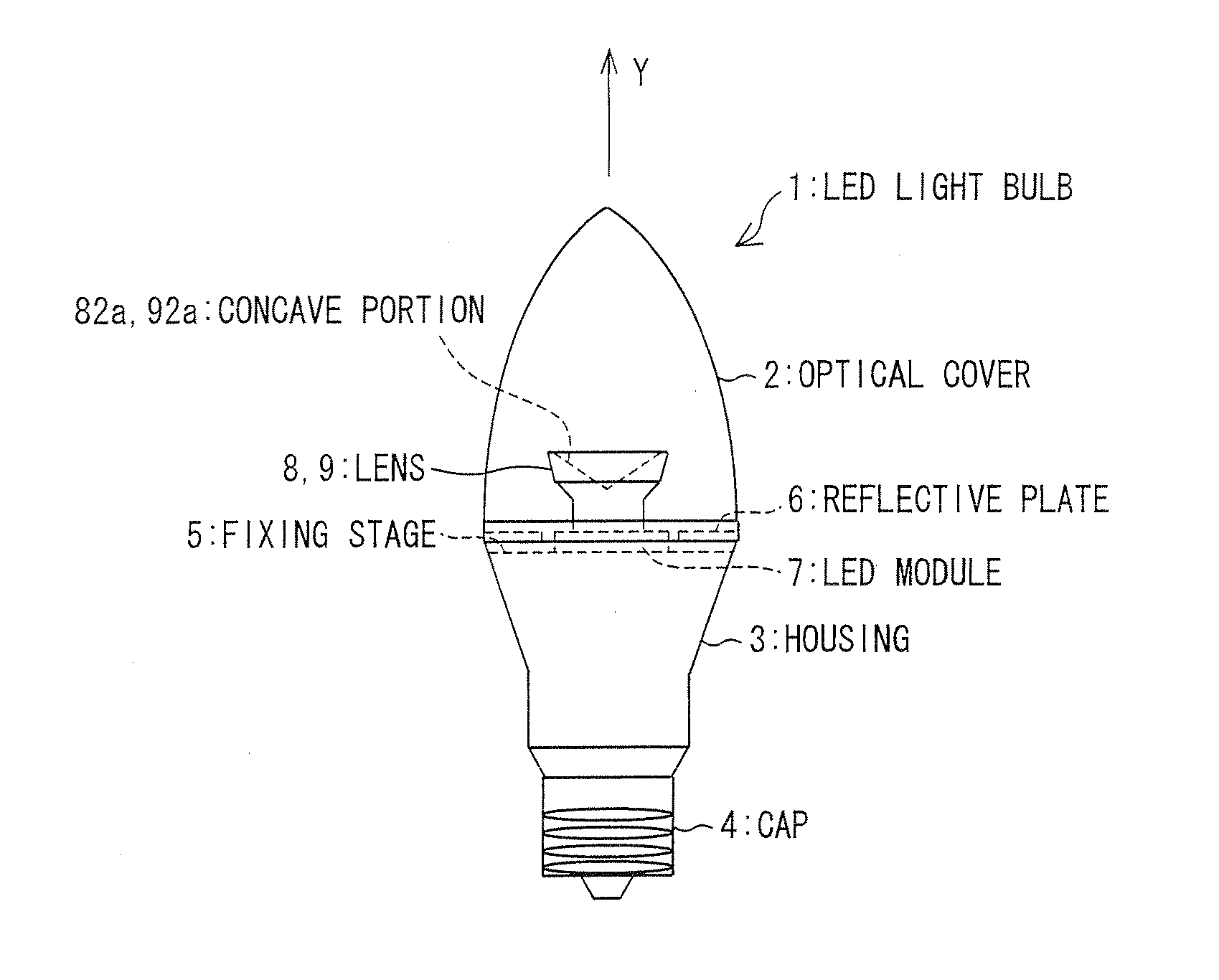

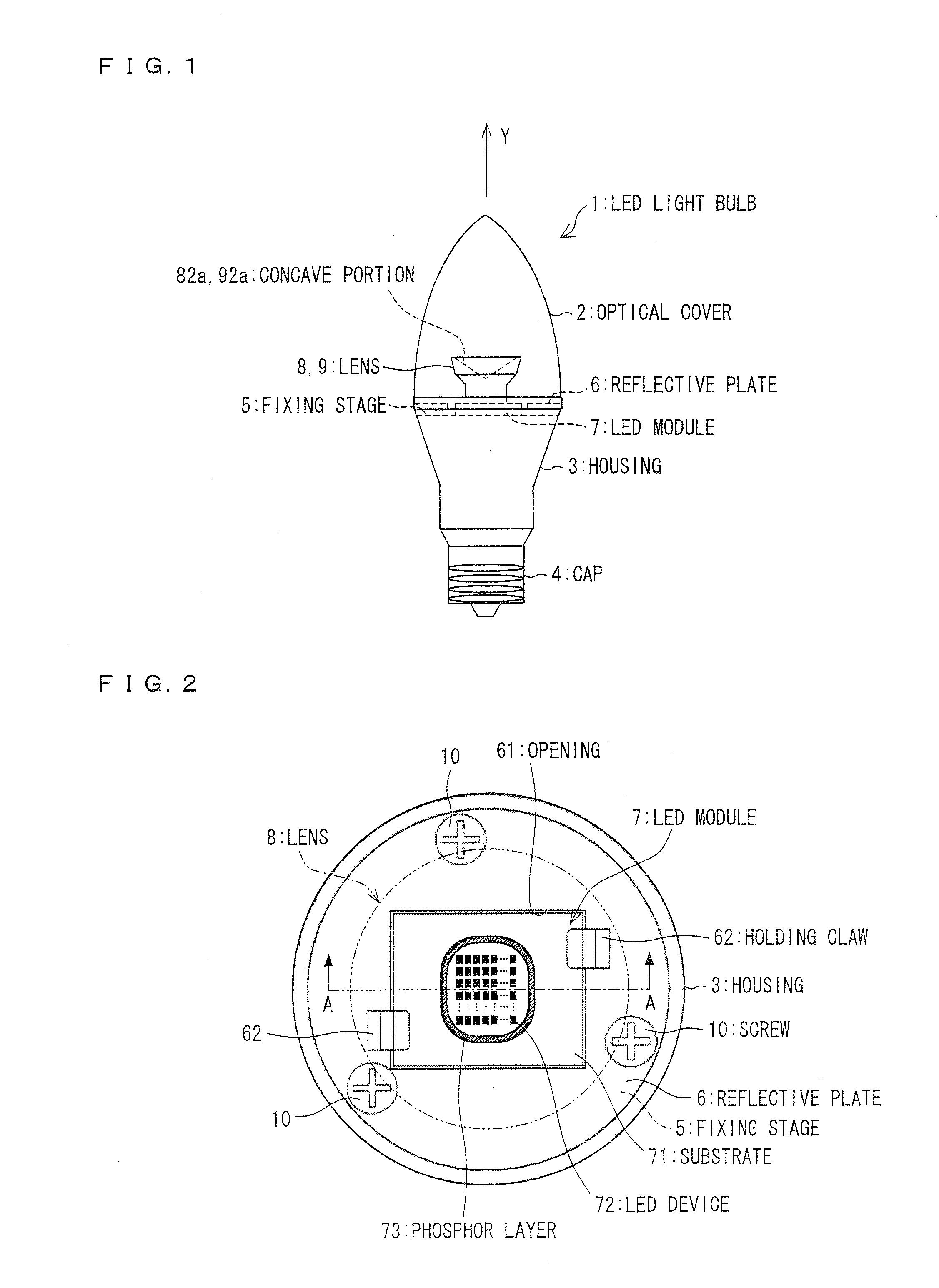

LED light bulb

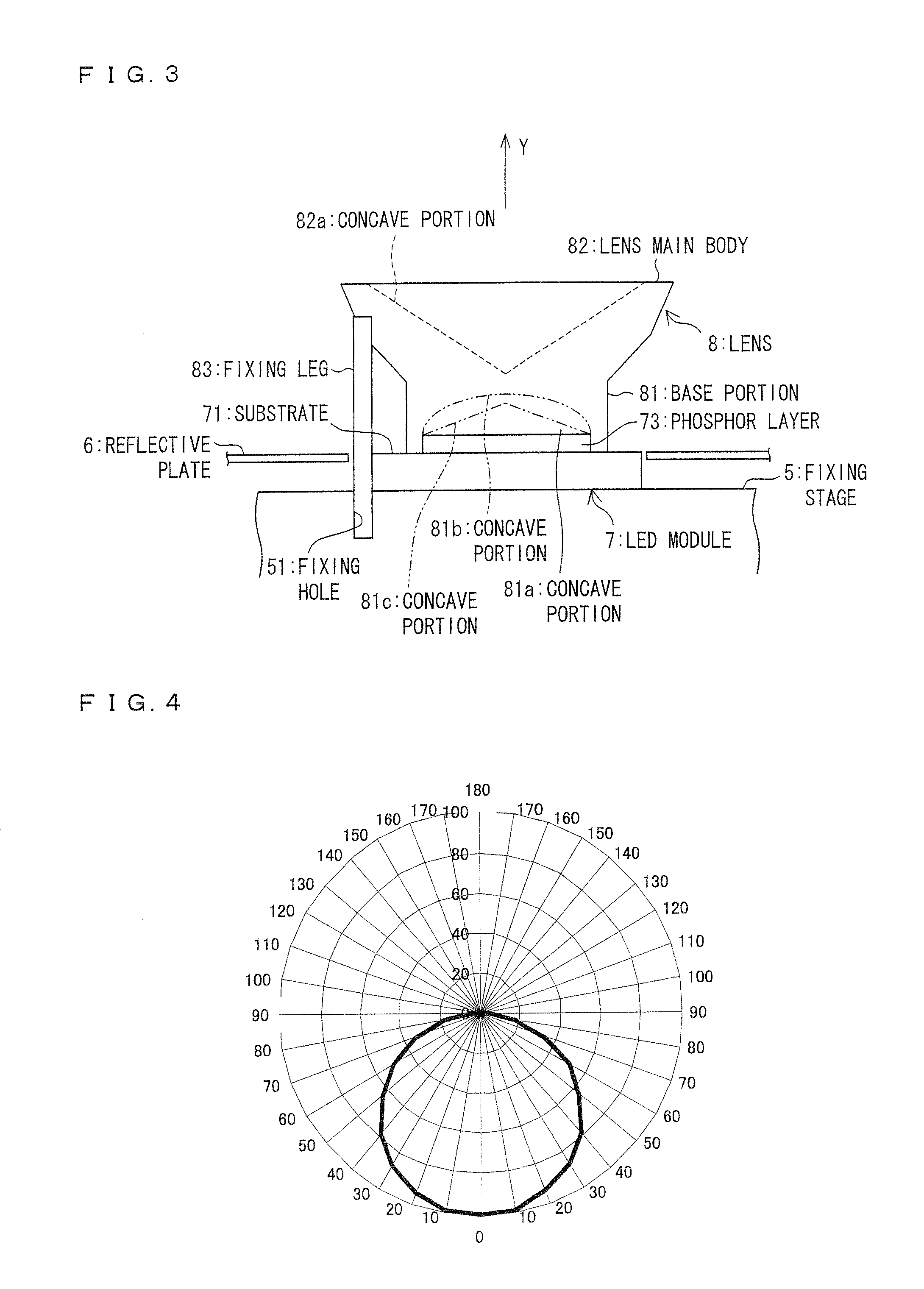

InactiveUS20110170299A1Light distribution can be easilyIncrease the light output ratioPlanar light sourcesPoint-like light sourceEngineeringLED lamp

In an LED light bulb, an LED module and a lens are disposed on a fixing stage provided to a housing. The lens has a concave portion at its top end. The concave portion forms a reflecting surface which reflects part of outgoing light from the LED module to (i) first directions perpendicular to a front emission direction of the outgoing light or (ii) second directions leaning to a cap beyond the first directions. Due to diffusion effect of an optical cover, part of the light reflected by the lens is emitted backward (toward the cap). This realizes an LED light bulb that distributes light over an entire circumference and has high output as well as high light output ratio.

Owner:SHARP KK

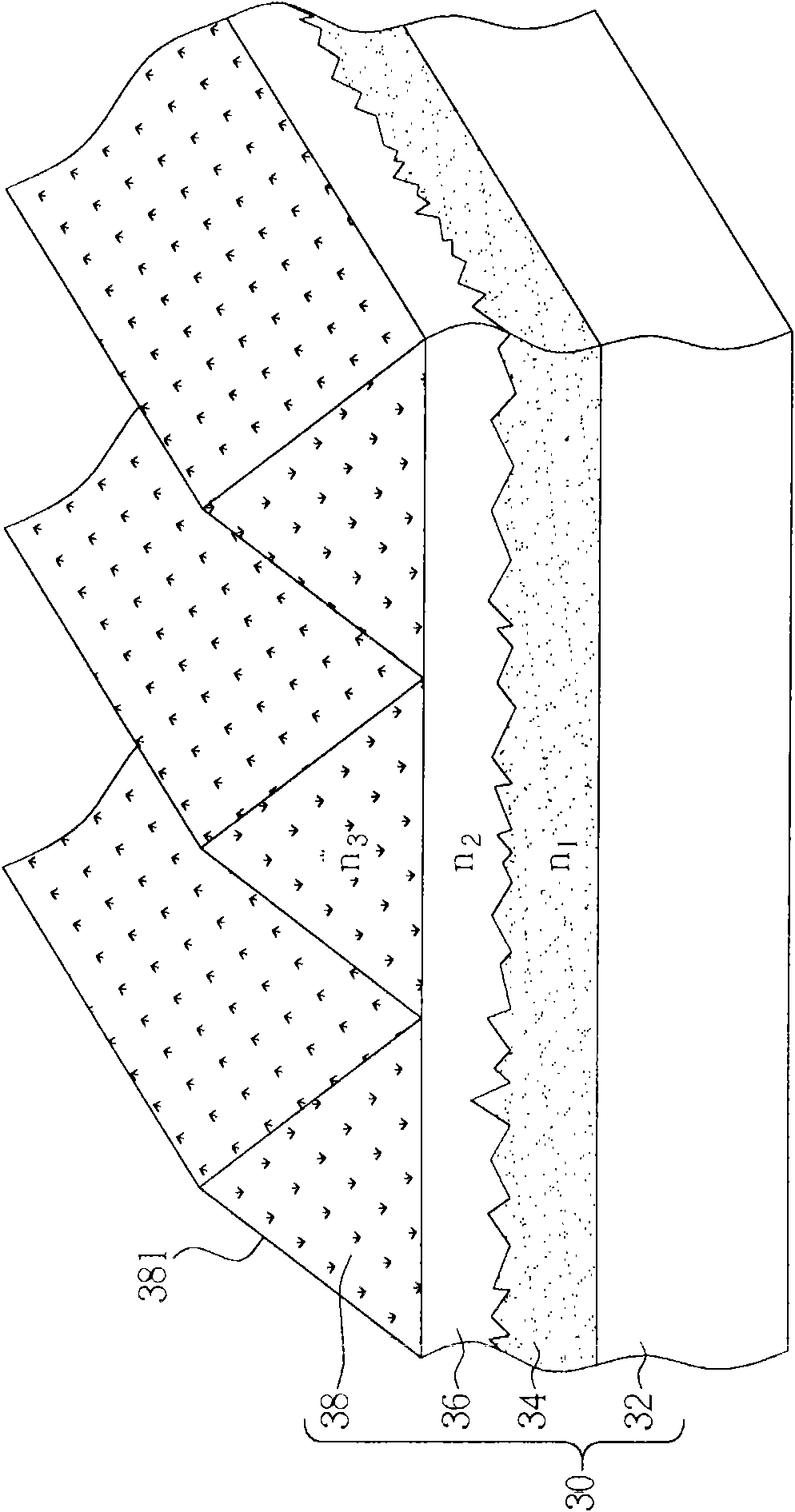

Compound optical film structure

InactiveCN101819289ATo achieve the diffusion effectDiffusion effect is effectivePrismsNon-linear opticsRough surfaceDiffusion

The invention relates to a compound optical film structure, comprising a transparent substrate, a diffusion layer, a flattening layer and a light collecting structure. The diffusion layer is arranged on the transparent substrate, wherein the diffusion layer has a first refractive index and a rough upper surface; the flattening layer is arranged on the upper surface of the diffusion layer, wherein the flattening layer has a second refractive index and a rough lower surface; and the light collecting structure is arranged on the flattening layer, wherein the light collecting structure has a third refractive index, the first refractive index is not equal to the second refractive index, and the second refractive index is not equal to the third refractive index. In the embodiment, the compound optical film structure can achieve the diffusion effect by utilizing the rough upper surface of the diffusion layer and controlling the difference of the refractive indexes of the diffusion layer and the flattening layer without providing an upper diffusion sheet. In addition, the effective light collection effect can be provided through arranging the light collecting structure and controlling the relations of the refractive indexes of the flattening layer, the light collecting structure and an external medium.

Owner:AU OPTRONICS CORP

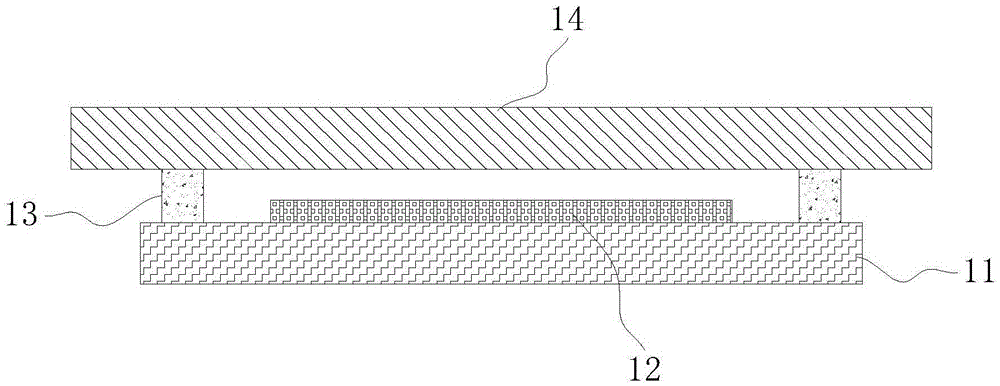

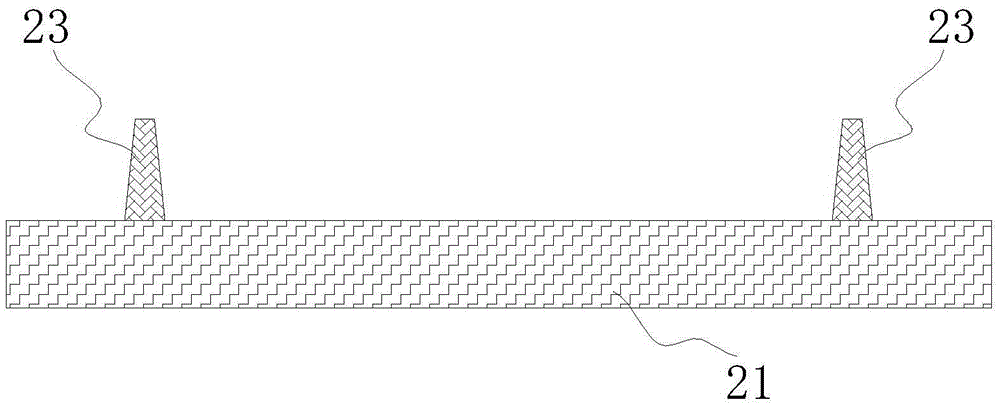

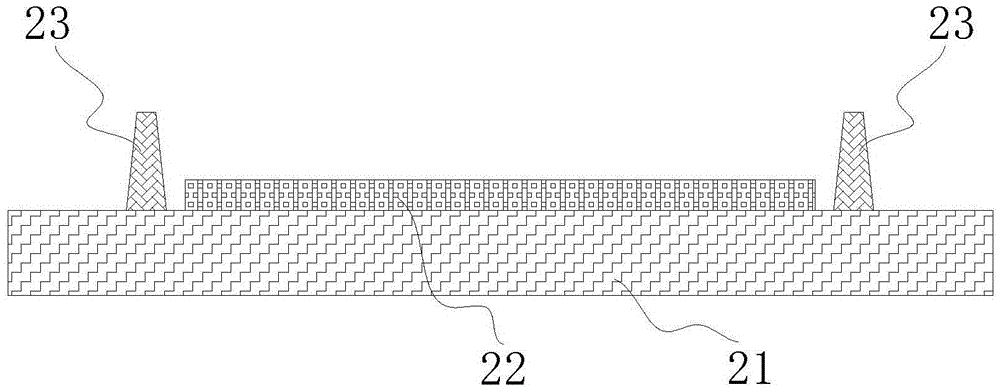

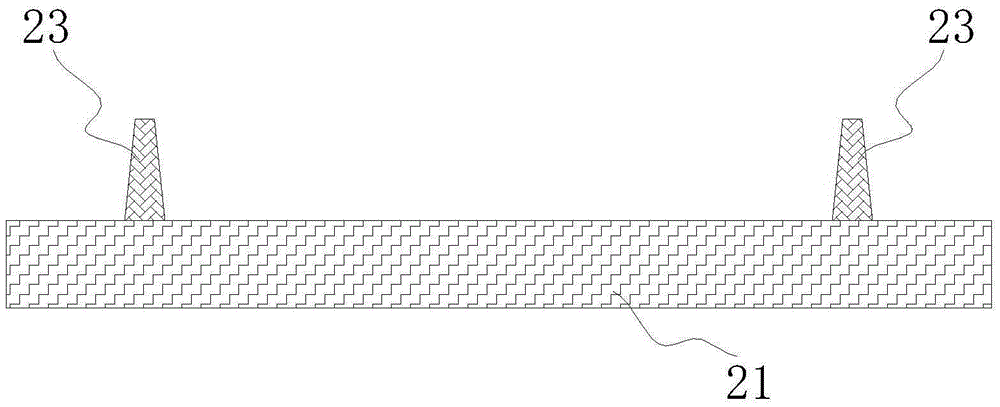

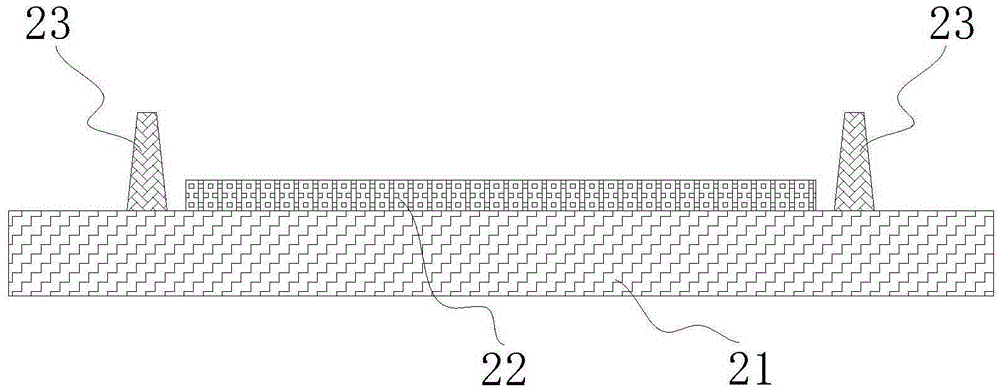

Packaging structure of display module and preparation method thereof

ActiveCN106848088AHigh mechanical strengthIncrease the number of water-blocking retaining wallsSolid-state devicesSemiconductor/solid-state device manufacturingFritDisplay device

The invention discloses a packaging structure of a display module and a preparation method thereof, relates to the technical field of display devices, and can be used for preparing display devices such as an AMOLED. The packaging structure of the display module and the preparation method thereof mainly sealedly protect the display module by a film packaging structure, namely, seal the display module by an inorganic film layer having a water oxygen prevention characteristic and transparency, and buffer the internal and external stresses of the film layer by preparing an organic module outside the inorganic film layer. When a flexible device is made, the film layer can be prevented from falling off due to the bending stress. Meanwhile, a bulge structure formed by multilayer stacking can effectively suppress the diffusion effect of an inorganic layer coating and increase the number of side water retaining walls of a film device, thereby effectively improving the packaging effect. The bulge structure supports a metal mask plate in the coating procedure and prevents damage to a substrate surface pattern. Additionally, the mechanical strength of the whole display device is effectively improved by using film packaging instead of glass Frit glue packaging technology.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

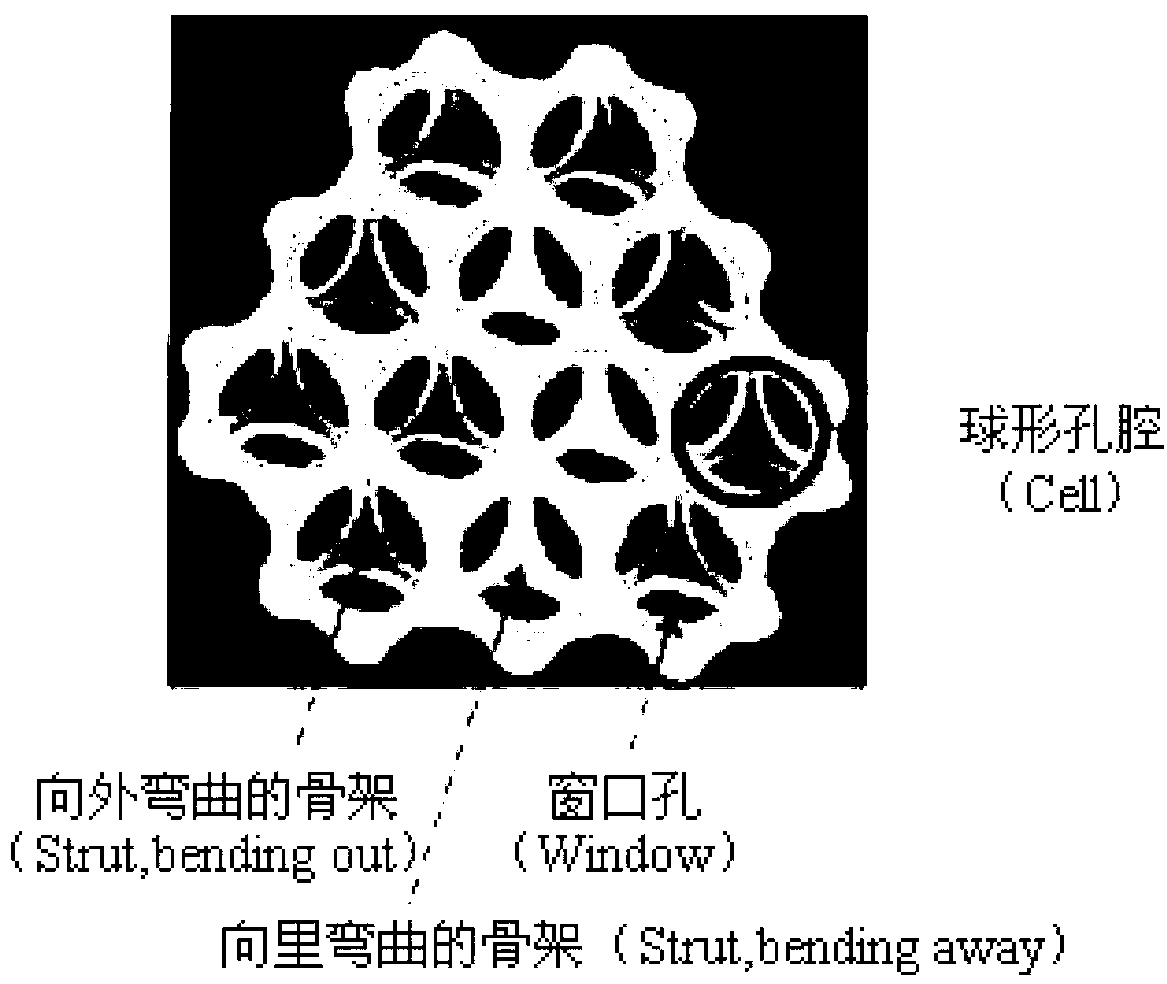

Cobalt-base catalyst adopting silicon oxide mesoporous foam as carrier, and application thereof

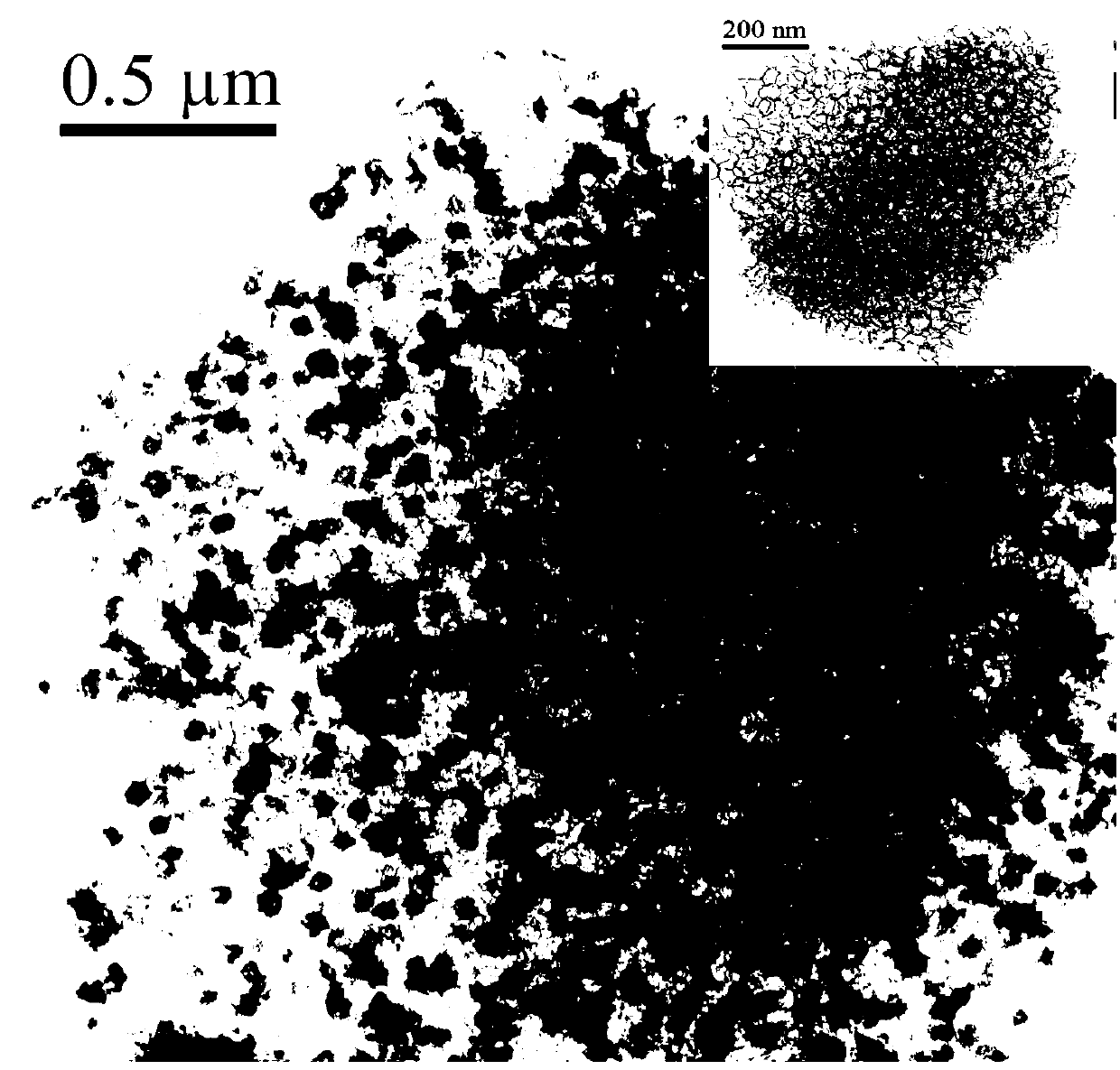

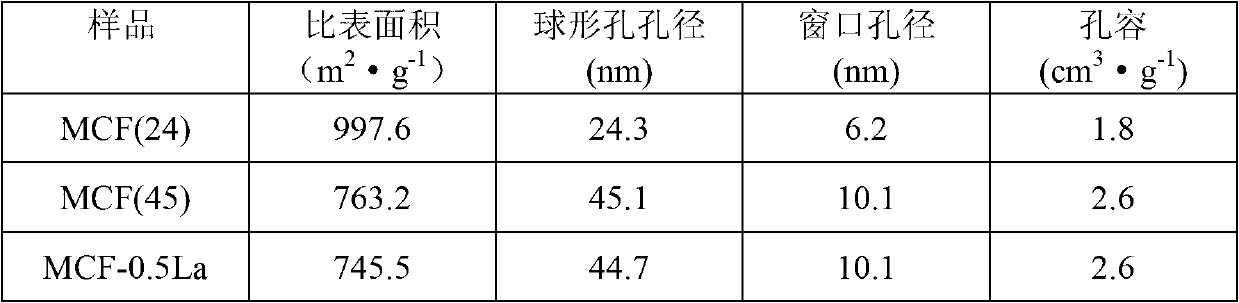

ActiveCN102728359AAvoid easy cloggingLarge specific surface areaLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsDispersityAdjuvant

The invention belongs to the technical field of novel Fischer-Tropsch synthesis catalyst preparation, and specifically discloses a preparation method for a cobalt-base catalyst adopting silicon oxide mesoporous foam MCF as a carrier, and an application of the cobalt-base catalyst in Fischer-Tropsch synthesis. According to the present invention, the carrier of the present invention has a three-dimensional ordered pore structure; the specific surface area of the carrier can be up to 1000 cm<2> / g; the pore size of the carrier can be adjusted in a range of 20-50 nm; the pore volume of the carrier is 1.5-3.0 cm<3> / g; the pore presents a spherical structure; the spherical pores are communicated through windows; the diffusion effect is good; the prepared catalyst has a high surface area; the active metal loading is high; and the active metal particles are uniformly dispersed, and the dispersity is good. Compared with the activity of the conventional silicon oxide carrier loaded cobalt-base catalyst, the activity of the cobalt-base catalyst of the present invention is increased by more than two times. In addition, the activity and the heavy hydrocarbon selectivity of the cobalt-base catalyst of the present invention are significantly increased compared with SBA-15 loaded cobalt-base catalysts having the same structured ordered structure, and the catalyst shows excellent performances after adjuvant element impregnating or doping.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

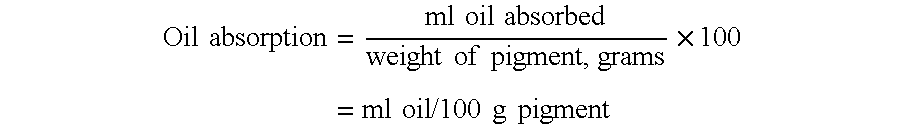

Novel silica- or silicate-based pigments for wrinkle-hiding cosmetic applications

InactiveUS20070258922A1Effective light diffusion and optical blurringSufficiently soft feelBiocideCosmetic preparationsWrinkle skinMedicine

Unique pigments that exhibit excellent light diffusion when applied to a person's skin within an appropriate medium as well as acceptable feel during such application are provided. To be most efficacious for this application, such pigments should meet specific criteria being a proper particle size, having irregular structure (i.e. not smooth), and a non-spherical shape. In such a manner, the subject pigments effectuate the desired ability to diffuse light when applied to skin (in a film of acceptable cosmetic composition) such that optical blurring takes place thereby preventing the appearance of wrinkles. The shape, particle size and irregularity of the pigments are necessary to permit maximum light diffusion effects. The particle size and particle size range also necessarily provides a feel that is sufficiently soft for skin applications. Specific types of pigments, as well as cosmetic formulations including such novel materials are also encompassed within this invention.

Owner:J M HUBER CORP

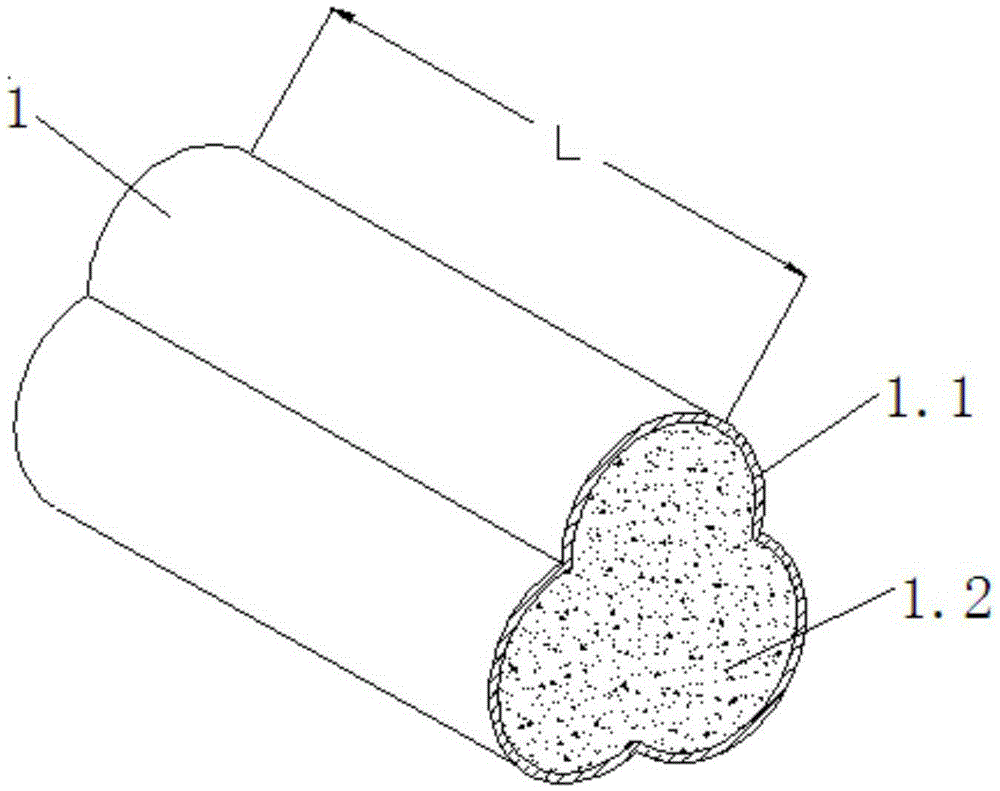

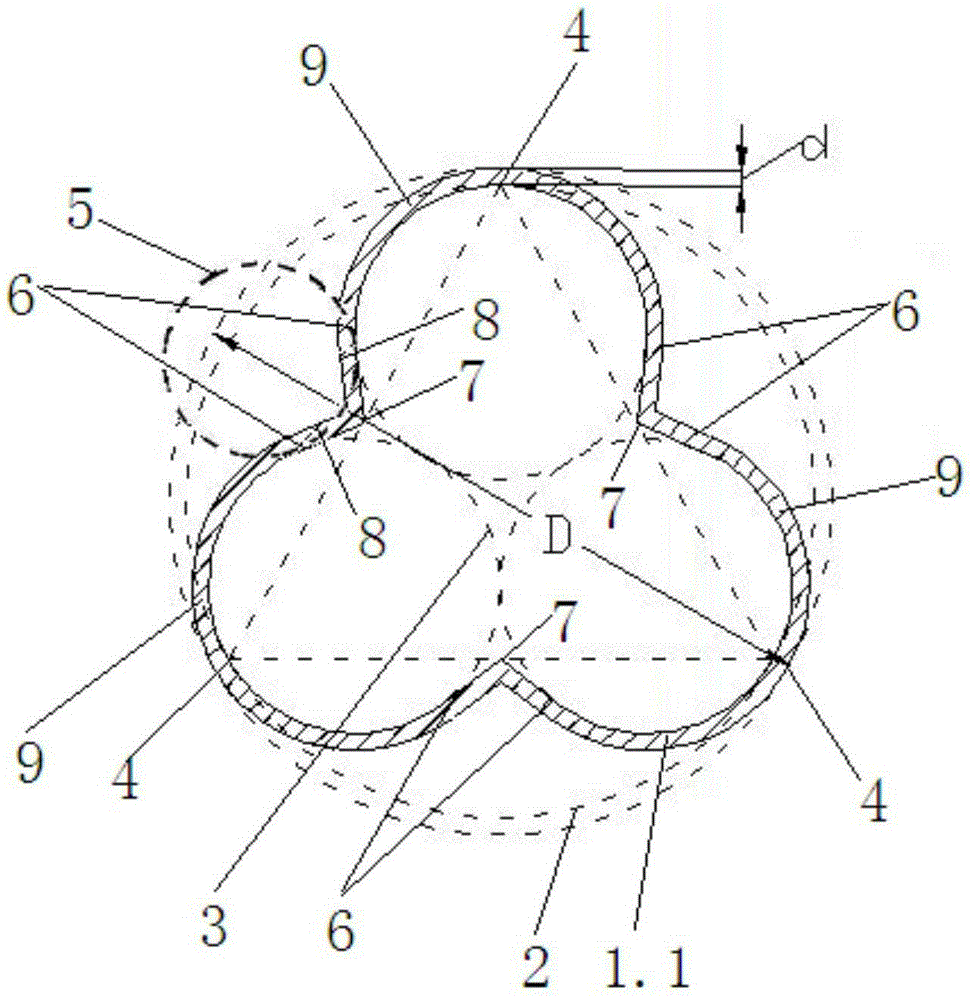

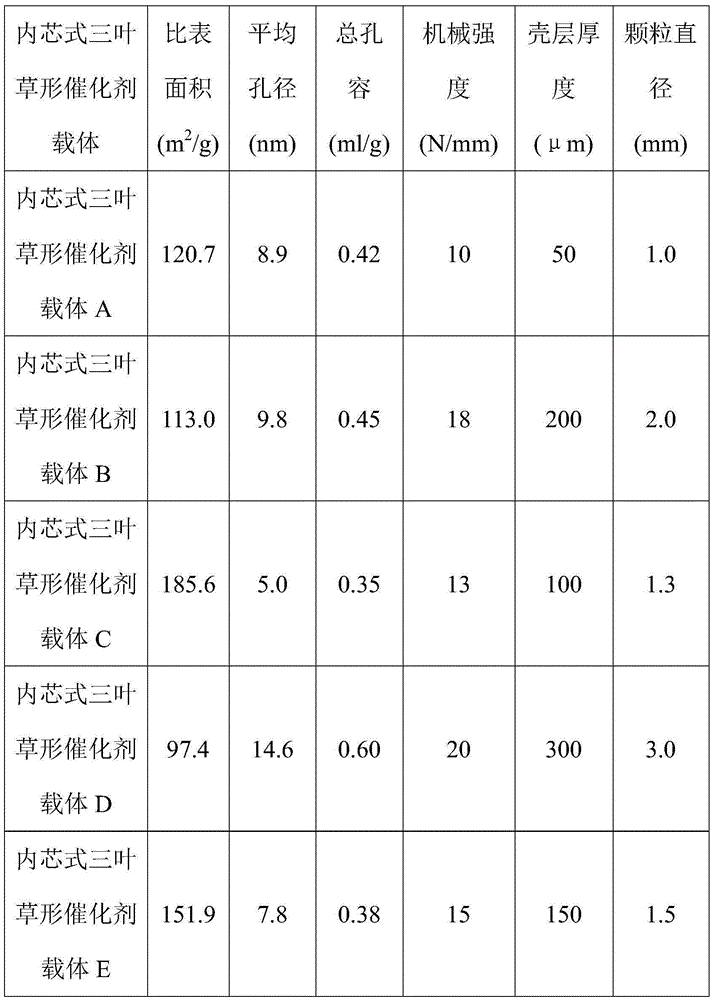

Inner core type cloverleaf-pattern catalyst carrier and preparation method and application thereof

ActiveCN105233880AIncreased crush strengthExtended service lifeCatalyst carriersLiquid hydrocarbon mixture productionEngineeringAqueous solution

The invention discloses an inner core type cloverleaf-pattern catalyst carrier and a preparation method and application thereof. The catalyst carrier comprises a catalyst carrier bar, and the catalyst carrier bar comprises an outer shell and an inner core. The cross section of the outer shell is in a hollow cloverleaf pattern, and the hollow part of the outer shell is filled with the inner core. The outer shell is made of a porous structure material. The inner core is made of a compact structure material, and the specific surface area of the inner core is smaller than 1 m<2> / g. The preparation method includes the steps that 1, Al2O3 powder which is of a porous structure is fully mixed with an aqueous solution containing an extrusion aid and a peptizing agent, so that a material I is obtained; 2, Al2O3 powder which is of a compact structure is fully mixed with an aqueous solution containing an extrusion aid and a peptizing agent, so that a material II is obtained; 3, after the material I and the material II are subjected to extrusion molding, drying and calcining are conducted. The catalyst carrier is applied to preparation of a Fischer-Tropsch synthesis catalyst. The catalyst carrier is high in anti-crush strength, large-scale industrial production can be achieved, the diffusing effect in the Fischer-Tropsch synthesis catalyst prepared through the catalyst carrier is small, methane selectivity is low and C5+ selectivity is high.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

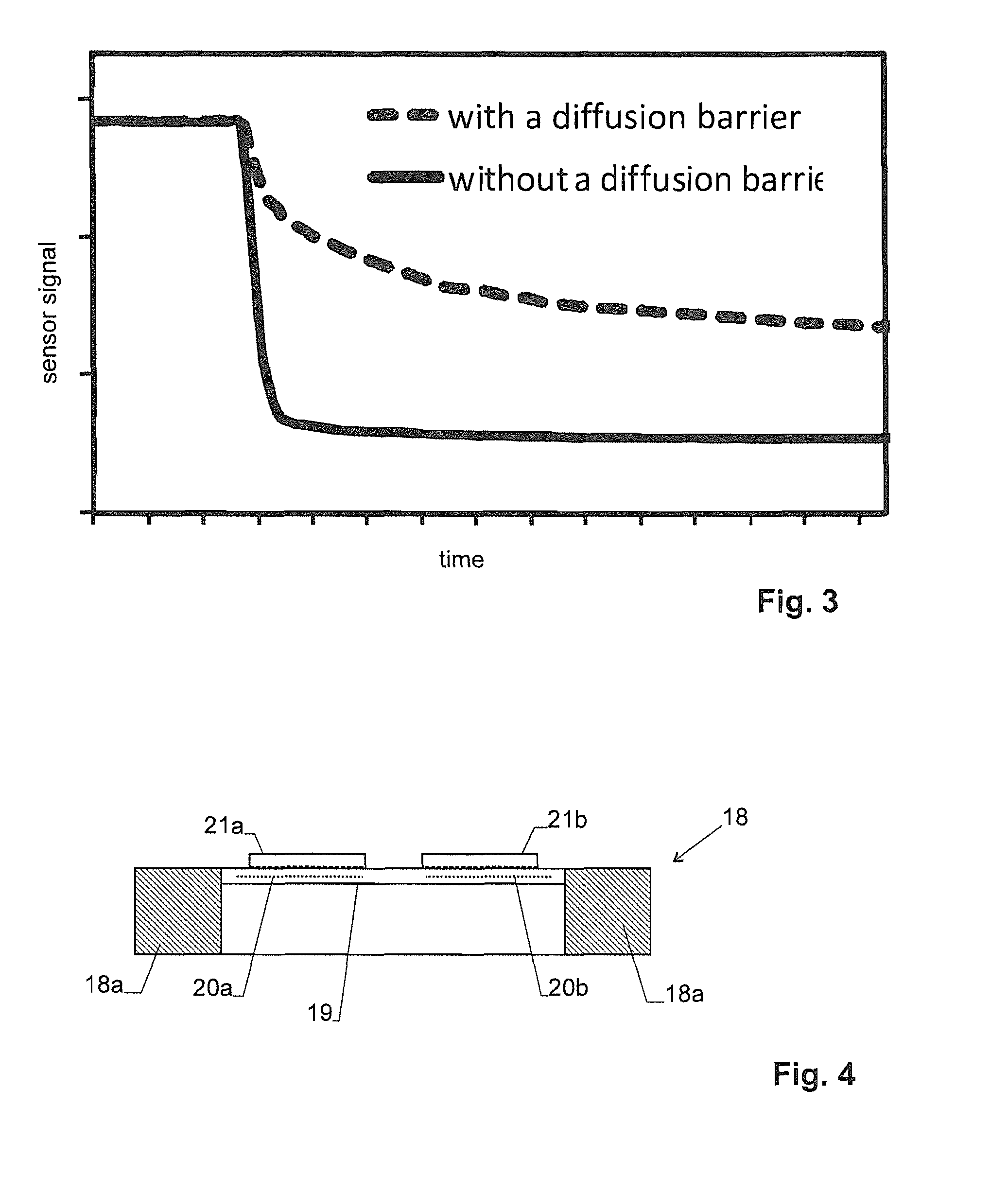

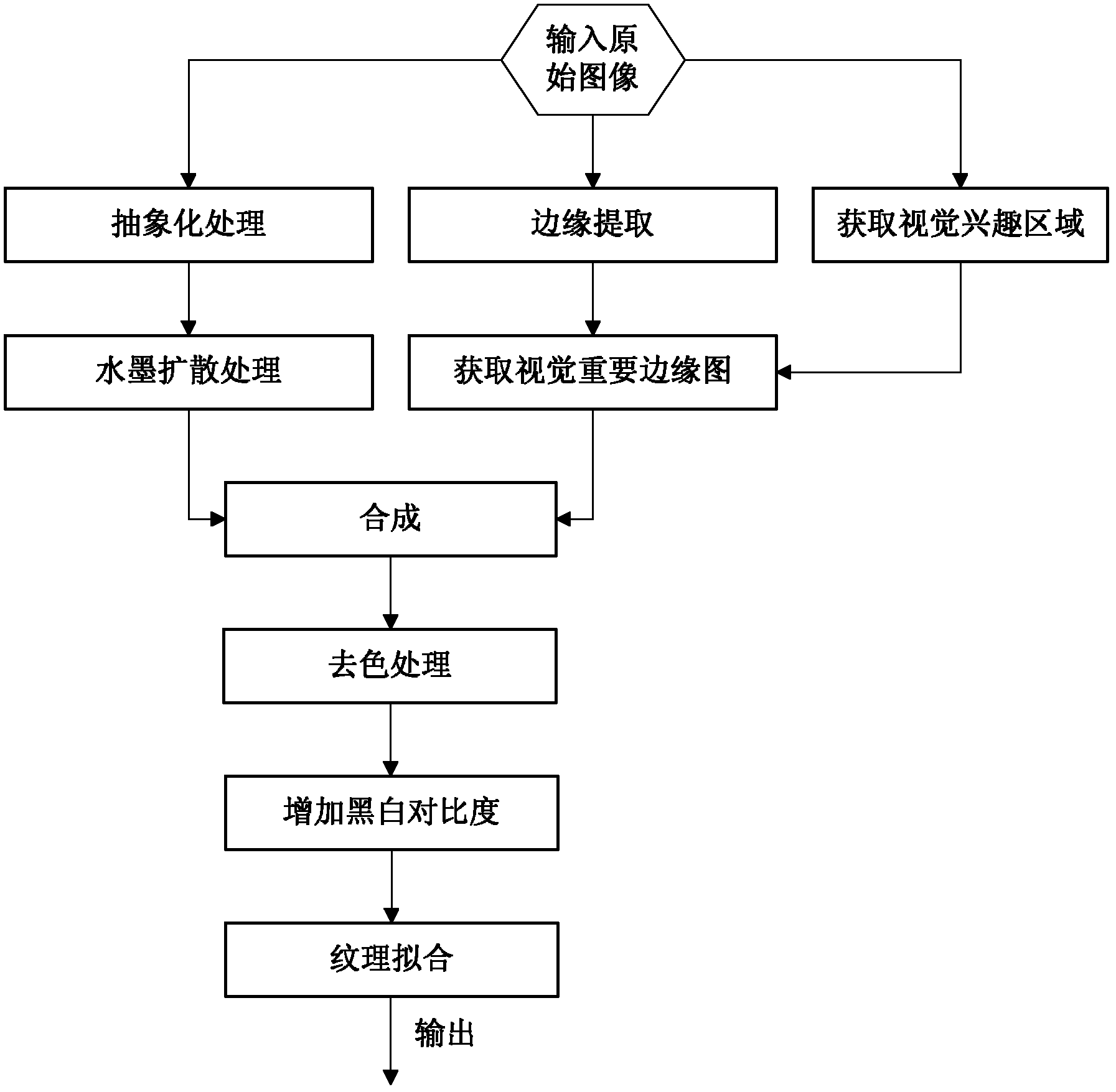

Diffusion based metal oxide gas sensor

ActiveUS20140212979A1Material analysis by electric/magnetic meansMaterial analysis by optical meansDiffusionAnalyte

A measuring device is provided for determining the type and / or concentration a gaseous analyte from a set of analytes in a gaseous carrier. It comprises a housing having a passage to a cavity. A gas sensor with a heated metal-oxide sensing layer is arranged in the cavity. In order to gain a better understanding of the type of the analyte, diffusion effects are exploited by taking into account that the diffusion process through the passage as well as the catalytic reaction rate at the metal-oxide sensing layer depend on the type of the analyte. These material parameters can be determined by taking several measurements in a non-steady state of the concentration of the analyte within the cavity or while varying the reaction rate.

Owner:SENSIRION AG

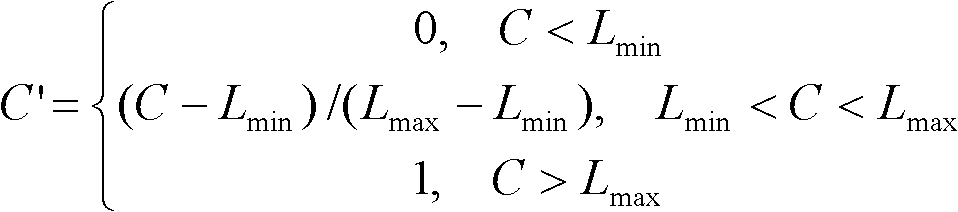

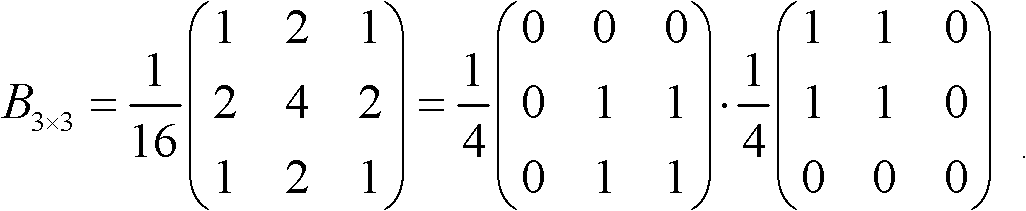

Image-based method for generating ink painting style image

InactiveCN102254333AFriendly interfaceRealistic effect2D-image generationComputer graphics (images)Edge extraction

The invention discloses an image-based method for generating an ink painting style image. The method comprises the following steps of: 1) inputting an original image, acquiring a visual attention distribution graph of the original image, performing edge extraction on the original image, and acquiring a visual important edge graph by using the visual attention distribution graph; 2) sequentially performing abstraction processing and ink diffusion processing on the original image to obtain an ink diffusion effect abstracted image; 3) combining the visual important edge graph with the ink diffusion effect abstracted image to obtain a color ink painting style image; 4) decolorizing the color ink painting style image, and increasing the black and white contrast of an ink painting to obtain a black and white ink painting style image; and 5) according to the internal texture of the black and white ink painting style image, performing texture fitting on the black and white ink painting style image to obtain the final ink painting style image. The method has the advantages of effect reality and high generating speed.

Owner:ZHEJIANG UNIV

Display module packaging structure and preparation method thereof

ActiveCN106848087AHigh mechanical strengthInhibit sheddingSolid-state devicesSemiconductor/solid-state device manufacturingSurface patternDisplay device

The invention provides a display module packaging structure and a preparation method thereof, and relates to the technical field of display devices. The display module packaging structure can be used for preparing related display devices such as AMOLEDs, a display module is sealed and protected by using a film packaging structure mainly, namely the display module is sealed by using a transparent inorganic film layer with a water and oxygen blocking characteristic, and inner stress and outer stress of the layer are buffered through the organic module prepared outside the inorganic film layer, and the film can be prevented from falling due to bending stress when the structure is used for manufacturing flexible devices. Meanwhile, a bulge structure formed by multi-layer stacking can effectively inhibit an inorganic layer coating film diffusion effect, the quantity of water-blocking baffle walls on the side face of the film device is increased, and the packaging effect can be effectively improved. Moreover, a role of supporting a metal mask is achieved in the film coating technology, and baseplate surface patterns are prevented from being damaged. Furthermore, film packaging is used for replacing a glass Frit glue packaging technology, so that the mechanical strength of the whole display device is effectively improved.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

Diffuser plate with higher light diffusion efficiency and brightness

ActiveUS7474464B2Improve efficiencyIncrease brightnessPrismsDiffusing elementsDiffusionLiquid-crystal display

A diffuser plate with higher light diffusion efficiency and brightness applied to backlight module of Liquid Crystal Display TV (LCD TV) for providing uniform light is disclosed. An optical lens with a diffusion layer is disposed on one side of the substrate. The diffusion layer is arranged above the optical lens for enhancing diffusion effect. The other side of the diffuser plate can be a plane or having a lens structure. By Lenticular lens, the homogeneity of emitted light is improved so as to reduce the amount of diffusion particles being added into the diffusion plate Therefore, the light transmission is increased and the brightness is enhanced. Meanwhile, ability of shielding lamps is considered and Moiré effect is eliminated. Moreover, the diffusion layer is co-extruded on surface of the Lenticular lens together with the substrate so that the device is easy to be produced.

Owner:ENTIRE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com