High-entropy alloy composite coating on metal bipolar plate of fuel cell and process

A metal bipolar plate, high-entropy alloy technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as pinhole phenomenon, coating peeling failure, coating pitting corrosion, etc., to extend service life and improve resistance. Effects of Corrosive and Conductive Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

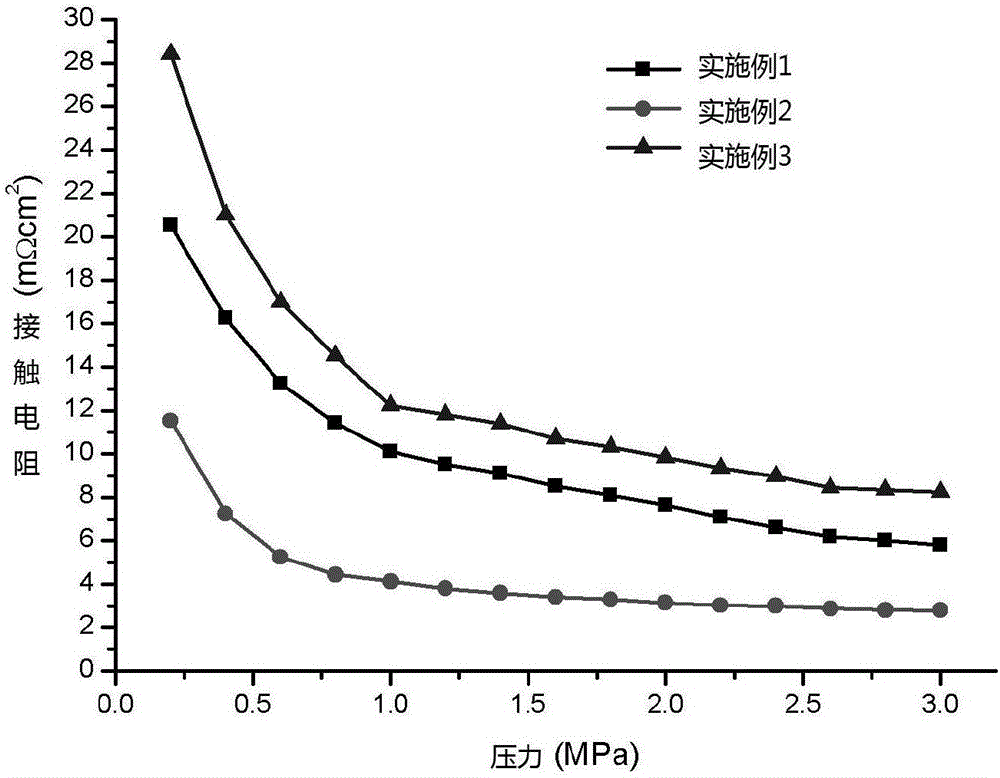

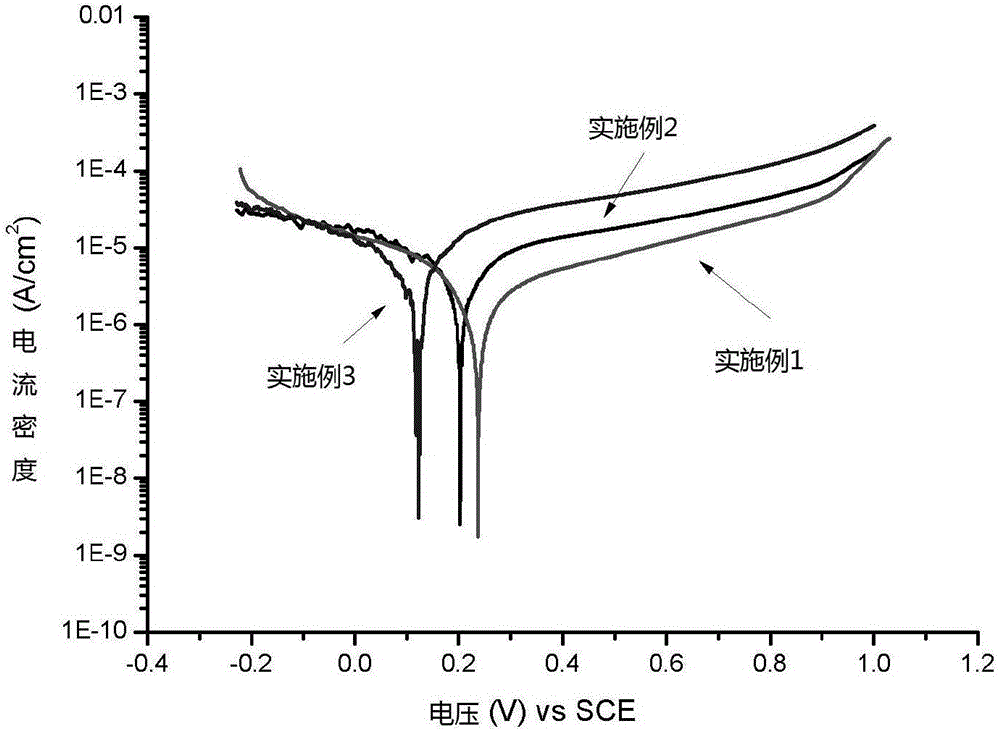

Embodiment 1

[0031] Using unbalanced magnetron sputtering equipment, the equipment is equipped with 4 DC sources, respectively installed 2 AlCrTaTiZr high-entropy alloy targets and 2 graphite targets. Put the 316 stainless steel substrate sample into the vacuum chamber of the coating machine after cleaning and drying, and vacuumize to 2.5×10 -5 torr, enter argon gas, apply bias voltage to -500V, and perform ion cleaning on the surface of the substrate sample to remove the passivation film on the surface of the stainless steel substrate; then adjust the bias voltage to -100V, high-entropy alloy target current 5A, on the substrate First deposit the bottom layer of high-entropy alloy on the surface; then gradually reduce the current of the high-entropy alloy target, and at the same time turn on the current of the graphite target, and gradually increase it to 6A, the bias voltage is -80V, and deposit the multi-element alloy-carbon mixed transition layer; finally turn off the high-entropy alloy ...

Embodiment 2

[0033] Using unbalanced magnetron sputtering equipment, the equipment is equipped with 2 radio frequency sources and 2 DC sources, among which AlCrFeMnNi high-entropy alloy targets are installed on the radio frequency sources, and 2 graphite targets are installed on the DC sources. Put the 316 stainless steel substrate sample into the vacuum chamber of the coating machine after cleaning and drying, and vacuumize to 2.5×10 -5 torr, enter argon gas, apply bias voltage to -450V, and perform ion cleaning on the surface of the sample to remove the passivation film on the surface of the stainless steel substrate; then adjust the bias voltage to -120V, and the power of the high-entropy alloy target is 300W. First deposit the bottom layer of high-entropy alloy; then gradually reduce the power of high-entropy alloy target, and at the same time turn on the current of graphite target, and gradually increase it to 3A, the bias voltage is -60V, deposit the multi-element alloy-carbon mixed t...

Embodiment 3

[0035] Using unbalanced magnetron sputtering equipment, the equipment is equipped with 2 RF sources and 2 DC sources, among which Ta-Nb targets and Ti-W targets are respectively installed on the 2 RF sources, and Zr targets are respectively installed on the 2 DC sources , Graphite target. Put the 316 stainless steel substrate sample into the vacuum chamber of the coating machine after cleaning and drying, and vacuumize to 2.5×10 -5 torr, enter argon gas, apply bias voltage to -550V, and perform ion cleaning on the surface of the substrate sample to remove the passivation film on the surface of the stainless steel substrate; then adjust the bias voltage to -80V, Ta-Nb target, Ti-W target Add power of 300W and 280W respectively, Zr target current is 4A, first deposit ZrTaNbTiW high-entropy alloy bottom layer on the substrate surface; then gradually reduce the Ta-Nb target, Ti-W target power, reduce the Zr target current, and turn on the graphite target at the same time The curr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com