Patents

Literature

22545 results about "Ingot" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An ingot is a piece of relatively pure material, usually metal, that is cast into a shape suitable for further processing. In steelmaking, it is the first step among semi-finished casting products. Ingots usually require a second procedure of shaping, such as cold/hot working, cutting, or milling to produce a useful final product. Non-metallic and semiconductor materials prepared in bulk form may also be referred to as ingots, particularly when cast by mold based methods. Precious metal ingots can be used as currency (with or without being processed into other shapes), or as a currency reserve, as with gold bars.

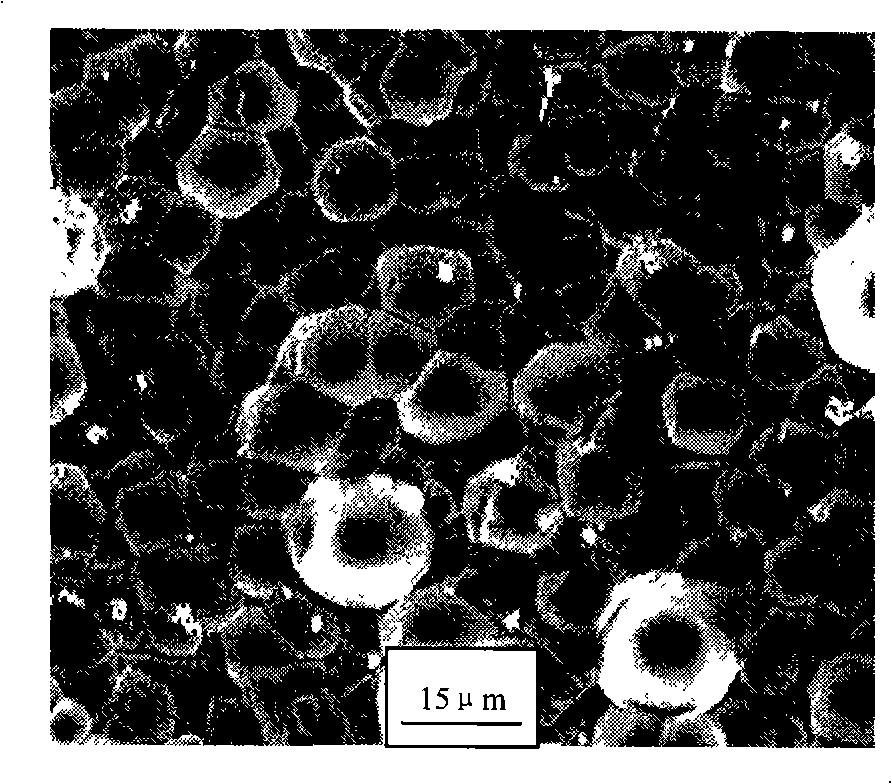

Copper alloy and process for producing the same

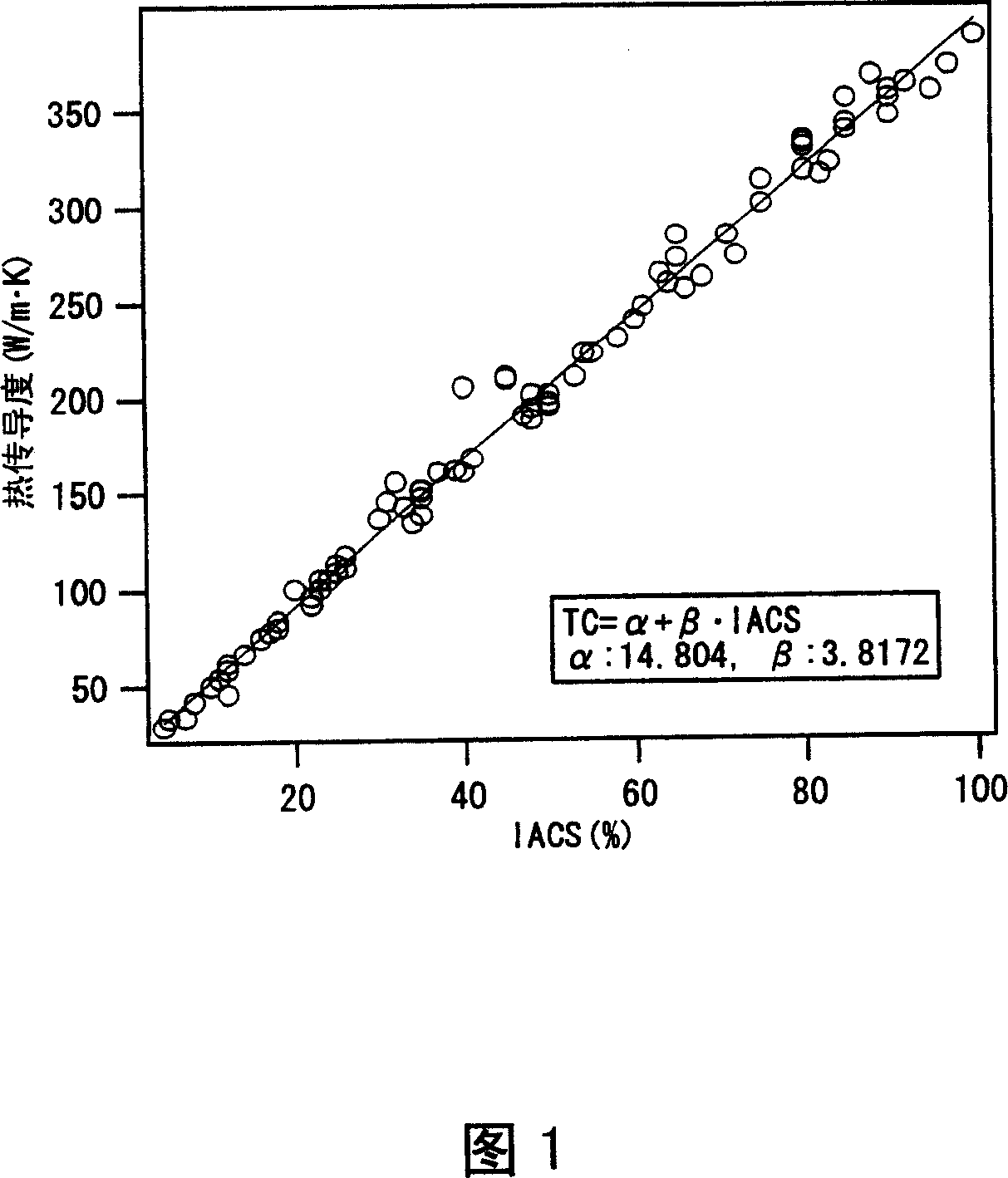

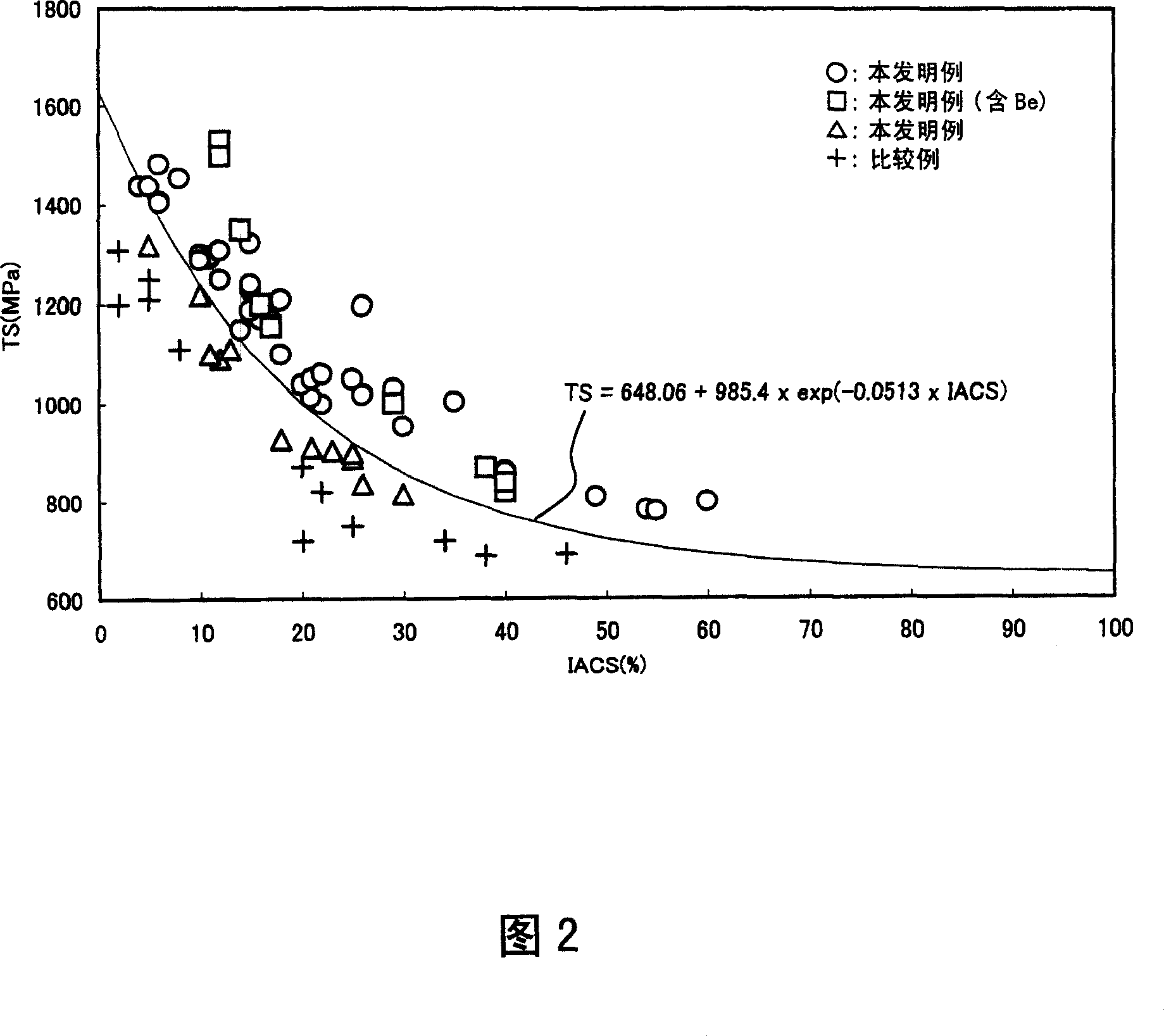

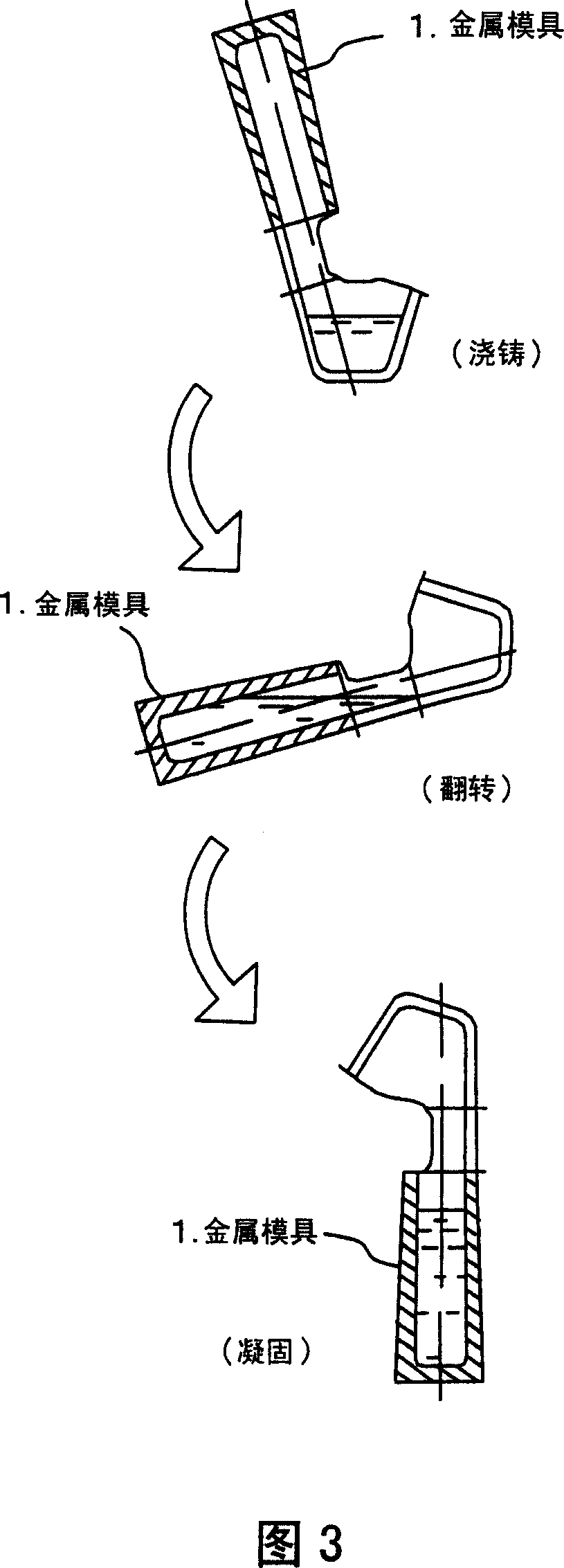

A copper alloy that has a specific chemical composition, the balance being Cu and impurities, in which the relationship between the total number N and the diameter X satisfies the following formula (1). This copper alloy is obtained by cooling a bloom, a slab, a billet or an ingot in at least a temperature range from the temperature of the bloom, the slab, the billet or the ingot just after casting to 450 DEG C, at a cooling rate of 0.5 DEG C / s or more. After the cooling, working in a temperature range of 600 DEG C or lower and further heat treatment of holding for 30 seconds or more in a temperature range of 150 to 750 DEG C are desirably performed. The working and the heat treatment are most desirably performed for a plurality of times. logN 0.4742 + 17.629 exp - 0.1133 X wherein N means the total number of precipitates and inclusions, having a diameter of not smaller than 1 [mu]m which are found in 1 mm 2 of the alloy; and X means the diameter in [mu]m of the precipitates and the inclusions having a diameter of not smaller than 1 [mu]m.

Owner:SUMITOMO METAL IND LTD

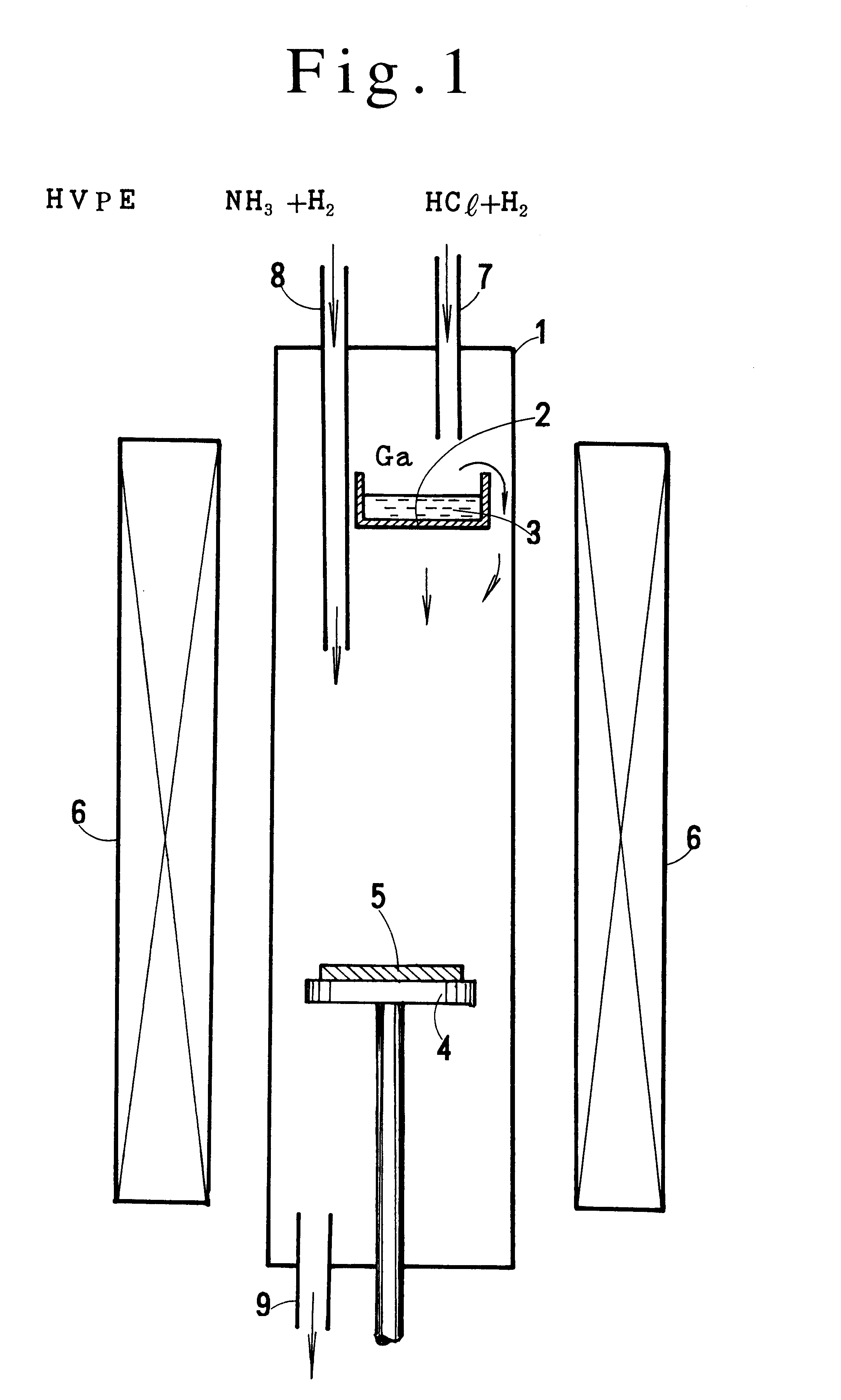

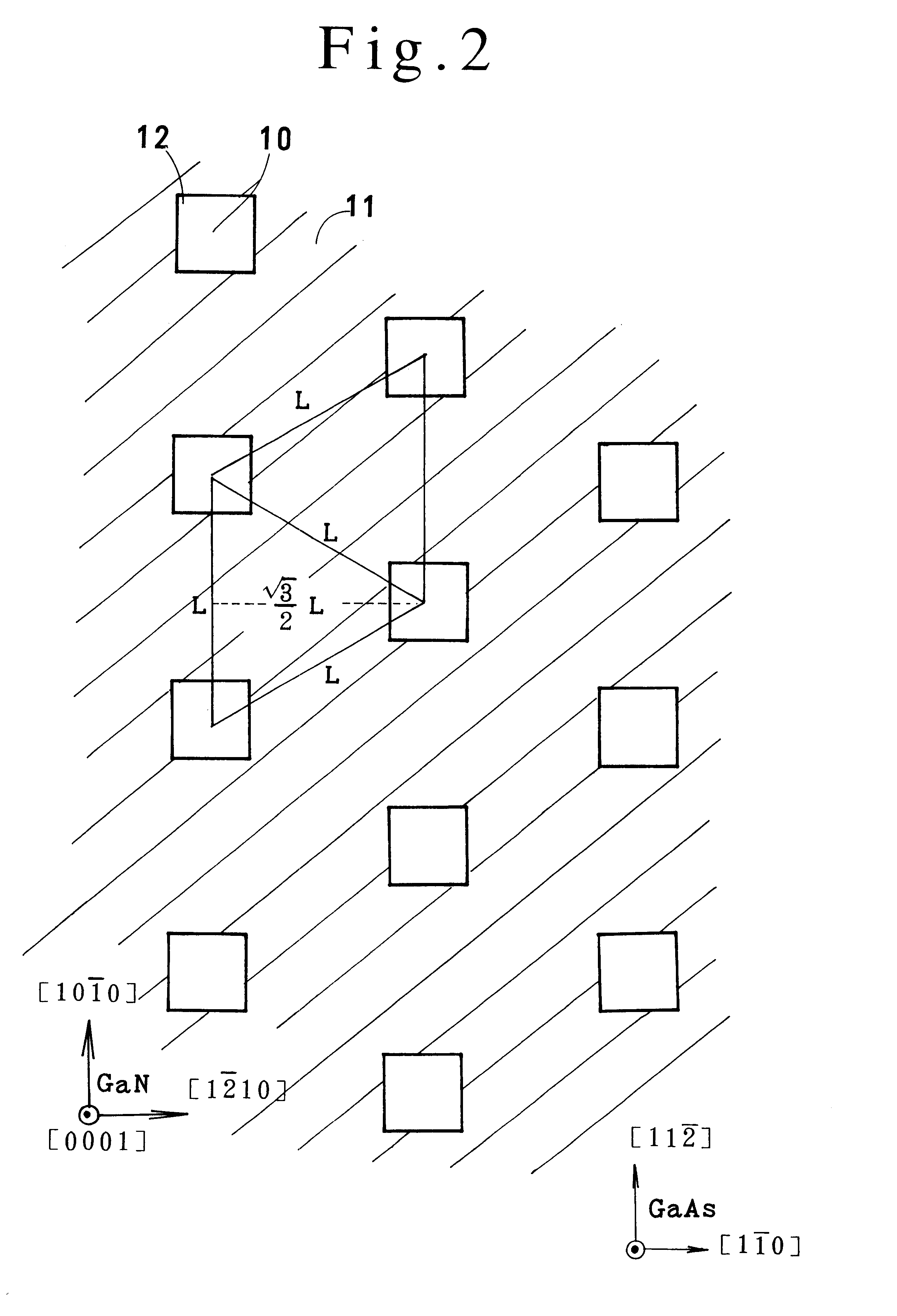

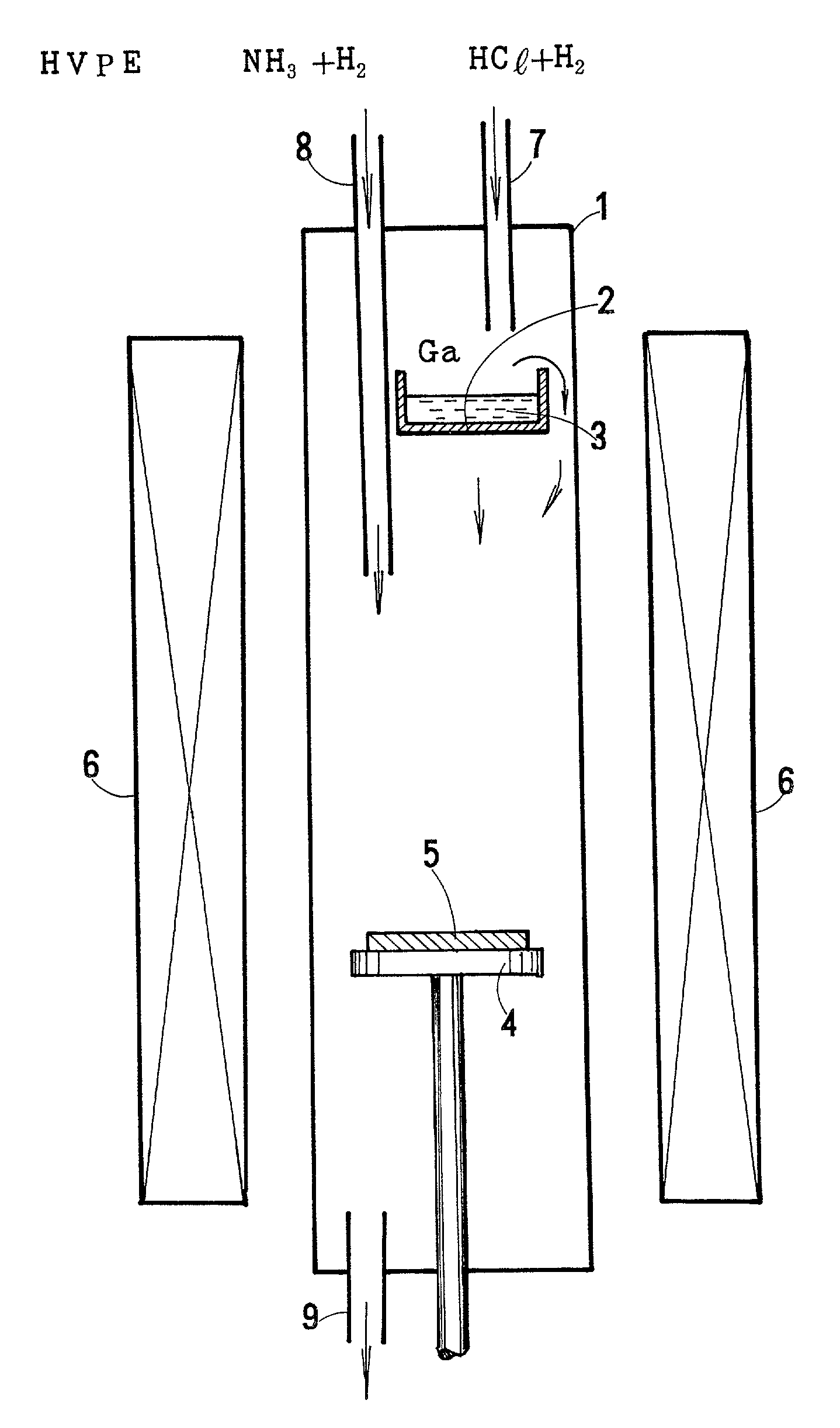

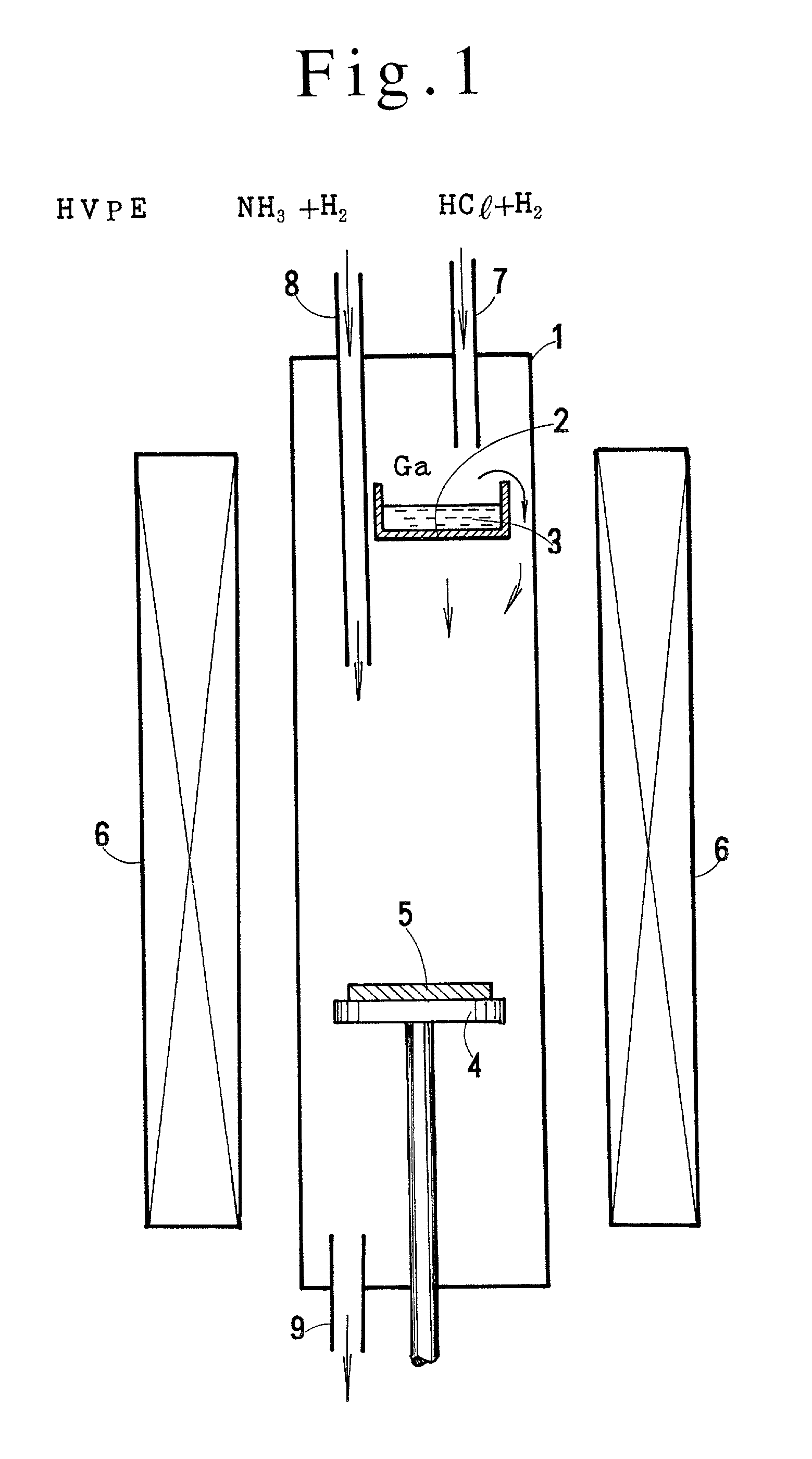

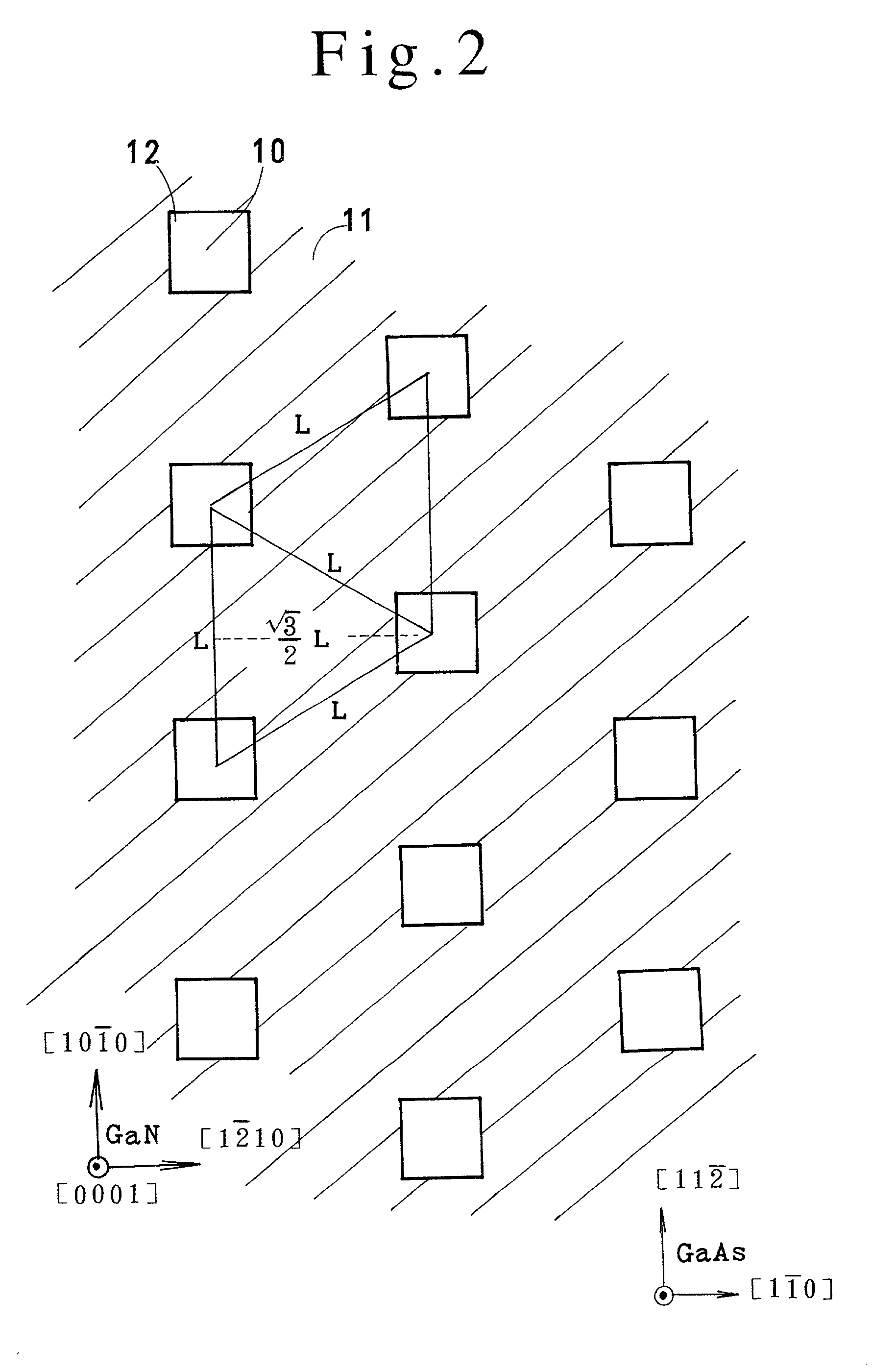

Method of producing a single crystal gallium nitride substrate and single crystal gallium nitride substrate

InactiveUS6468882B2Increase the number ofPolycrystalline material growthLaser detailsThreading dislocationsSingle crystal substrate

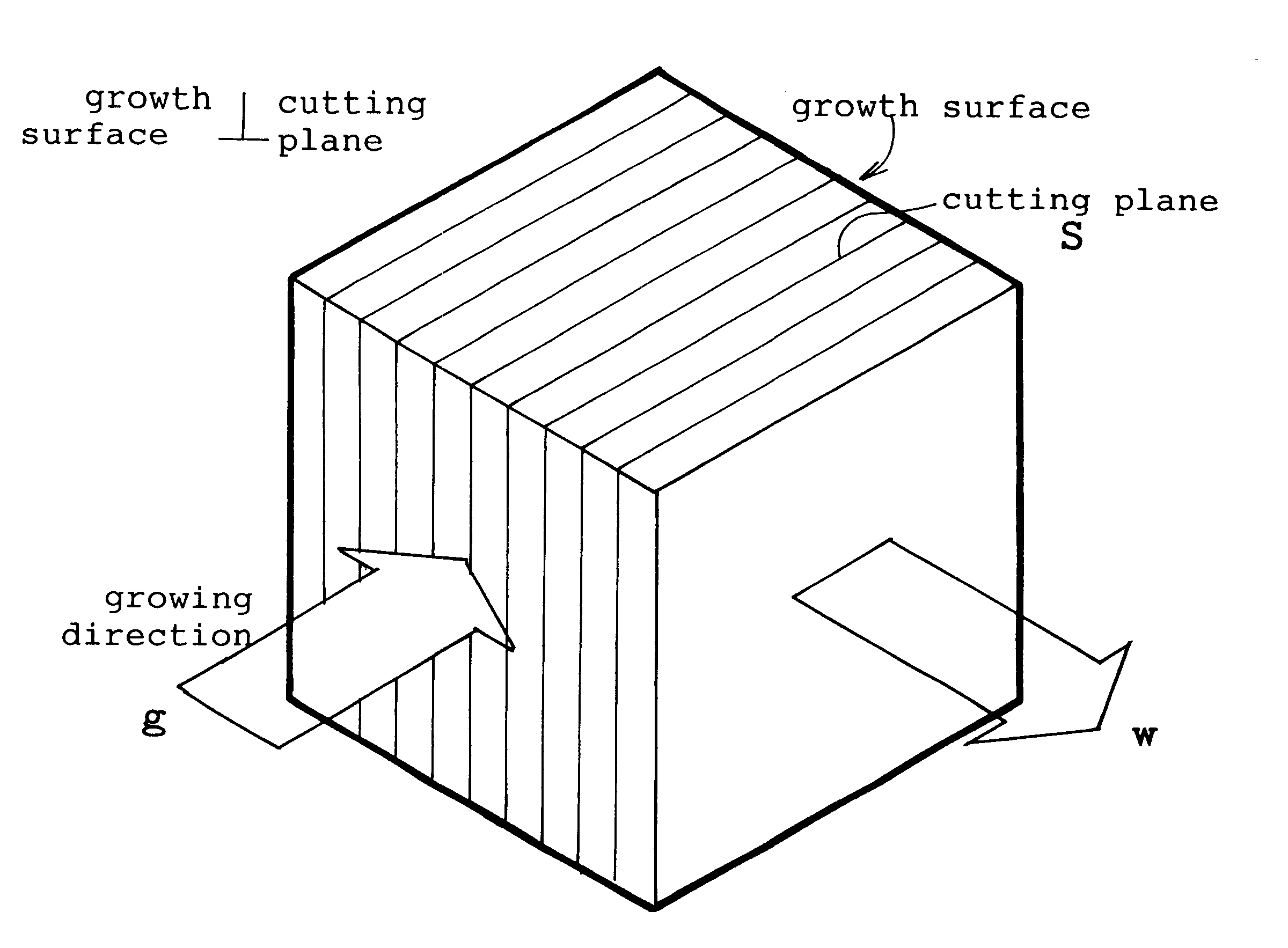

GaN single crystal substrates are produced by slicing a GaN single crystal ingot in the planes parallel to the growing direction. Penetration dislocations which have been generated in the growing direction extend mainly in the bulk of the GaN substrate. A few of the threading dislocations appear on the surface of the GaN substrate. GaN substrates of low-dislocation density are obtained.

Owner:SUMITOMO ELECTRIC IND LTD

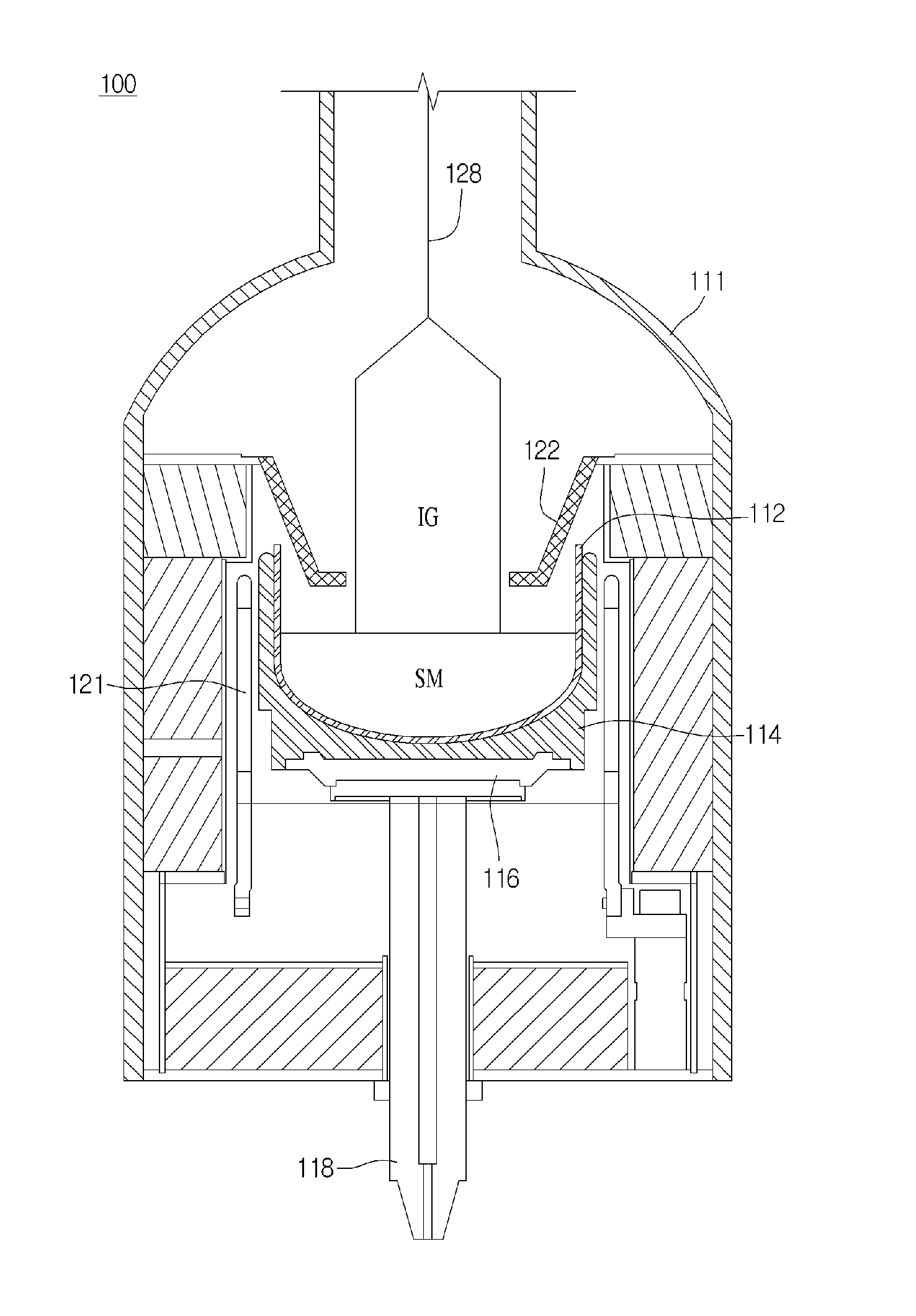

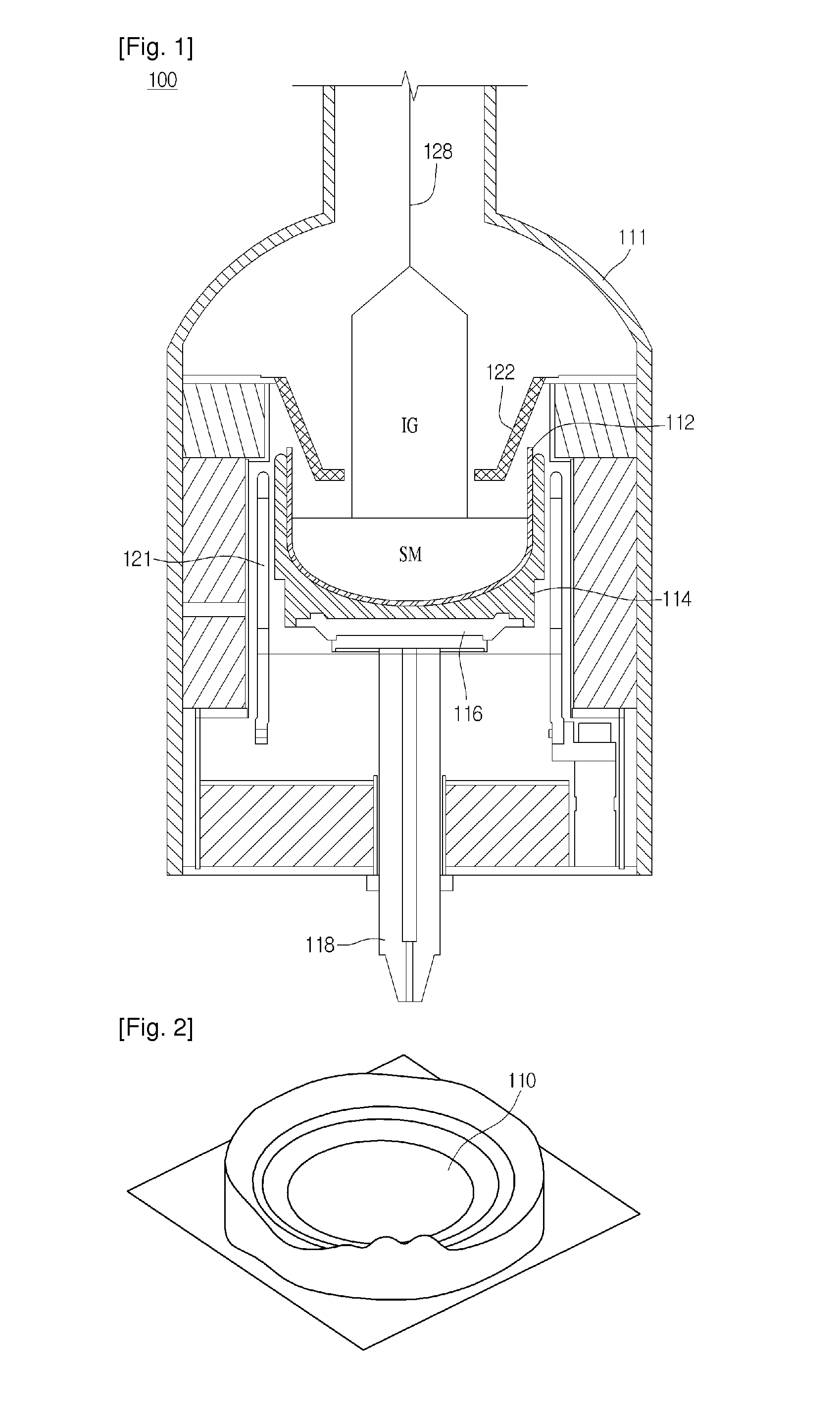

Method of manufacturing single crystal ingot, and single crystal ingot and wafer manufactured thereby

InactiveUS20140015108A1Increase productionPolycrystalline material growthSemiconductor/solid-state device manufacturingCrucibleIngot

A method of manufacturing a single crystal ingot, and a single crystal ingot and a wafer manufactured thereby are provided. The method of manufacturing a single crystal ingot according to an embodiment includes forming a silicon melt in a crucible inside a chamber, preparing a seed crystal on the silicon melt, and growing a single crystal ingot from the silicon melt, and pressure of the chamber may be controlled in a range of 90 Torr to 500 Torr.

Owner:LG SILTRON

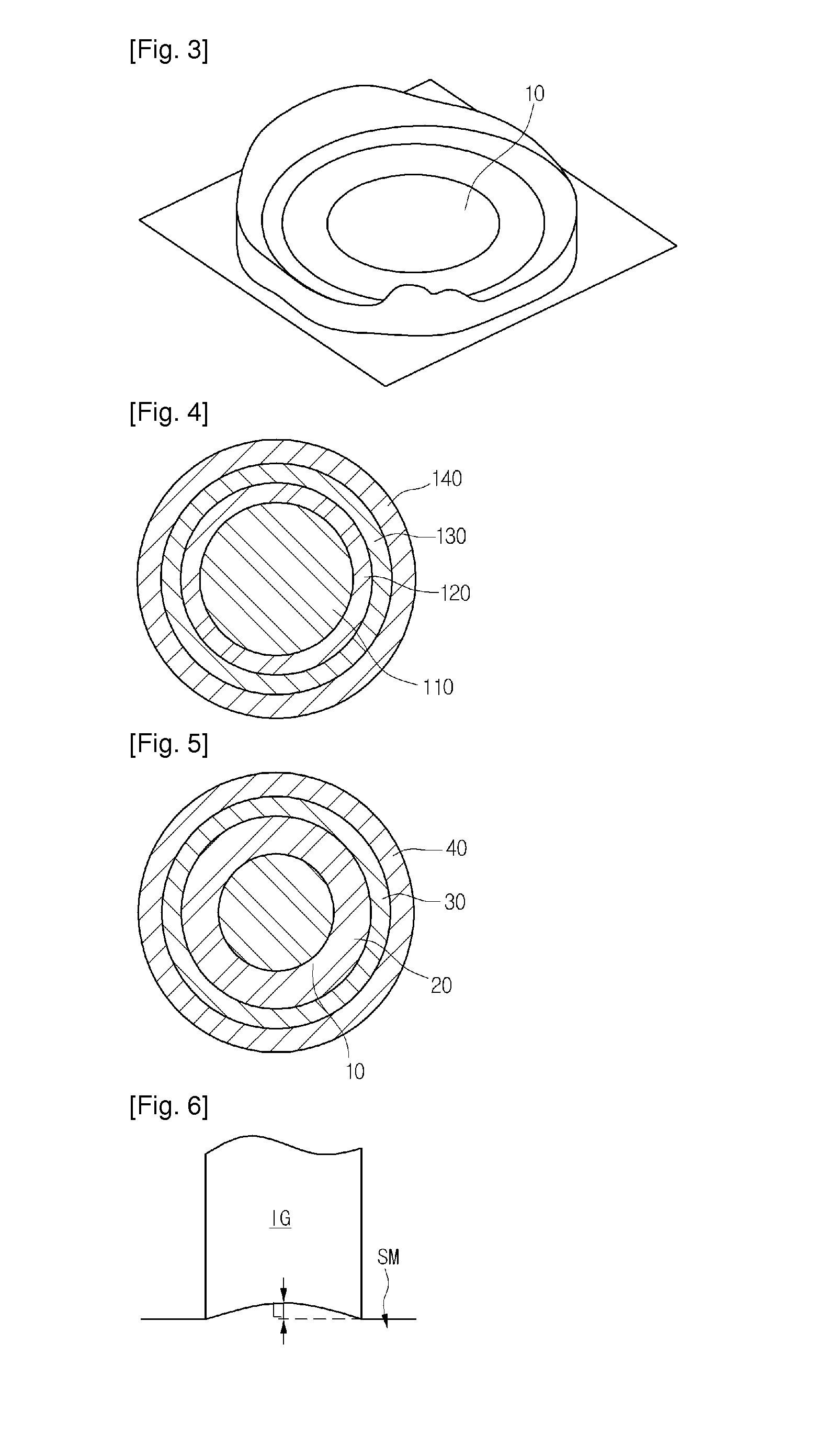

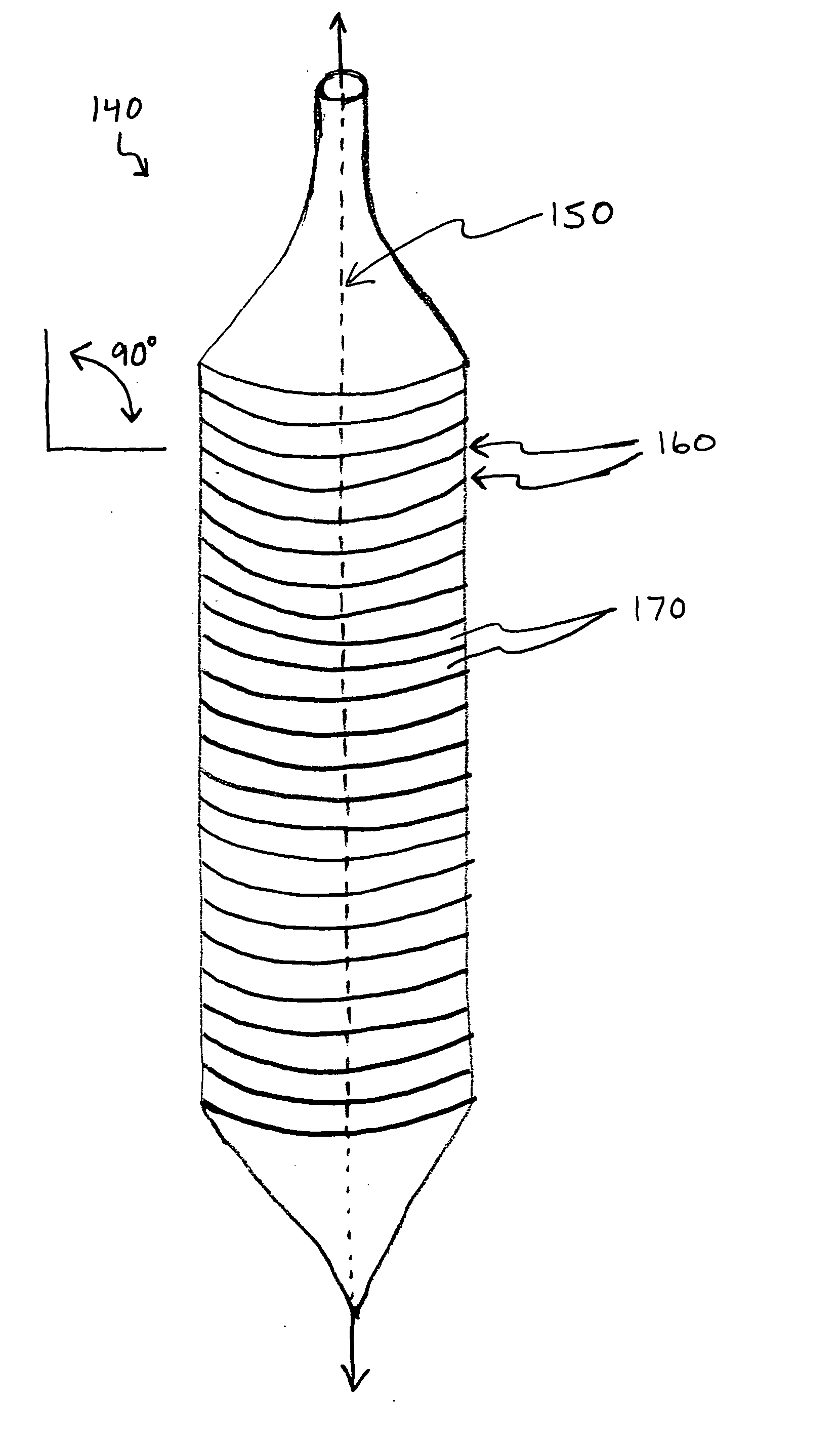

Method for casting composite ingot

ActiveUS20050011630A1Easy to controlImprove corrosion resistanceThin material handlingIngotMaterials science

A method and apparatus are described for the casting of a composite metal ingot comprising at least two separately formed layers of one or more alloys. An open ended annular mould has a feed end and an exit end and divider wall for dividing the feed end into at least two separate feed chambers, where each feed chamber is adjacent at least one other feed chamber. For each pair of adjacent feed chambers a first alloy stream is fed through one of the pair of feed chambers into the mould and a second alloy stream is fed through another of the feed chambers. A self-supporting surface is generated on the surface of the first alloy stream and the second alloy stream is contacted with the first stream such that the upper surface of the second alloy stream is maintained at a position such that it first contacts the self-supporting surface where the self-supporting surface temperature is between the liquidus and solidus temperatures of the first alloy or it first contacts the self-supporting surface where the self-supporting surface temperature is below the solidus temperatures of the first alloy but the interface between the two alloys is then reheated to between the liquidus and solidus temperatures, whereby the two alloy streams are joined as two layers. The joined alloy layers are then cooled to form a composite ingot. This composite ingot has a substantially continuous metallurgical bond between alloy layers with dispersed particles of one or more intermetallic compositions of the first alloy in a region of the second alloy adjacent the interface.

Owner:NOVELIS INC

Method of producing a single crystal gallium nitride substrate and single crystal gallium nitride substrate

InactiveUS20020028564A1Reduce misalignmentIncrease the number ofPolycrystalline material growthLaser detailsThreading dislocationsSingle crystal substrate

GaN single crystal substrates are produced by slicing a GaN single crystal ingot in the planes parallel to the growing direction. Penetration dislocations which have been generated in the growing direction extend mainly in the bulk of the GaN substrate. A few of the threading dislocations appear on the surface of the GaN substrate. GaN substrates of low-dislocation density are obtained.

Owner:SUMITOMO ELECTRIC IND LTD

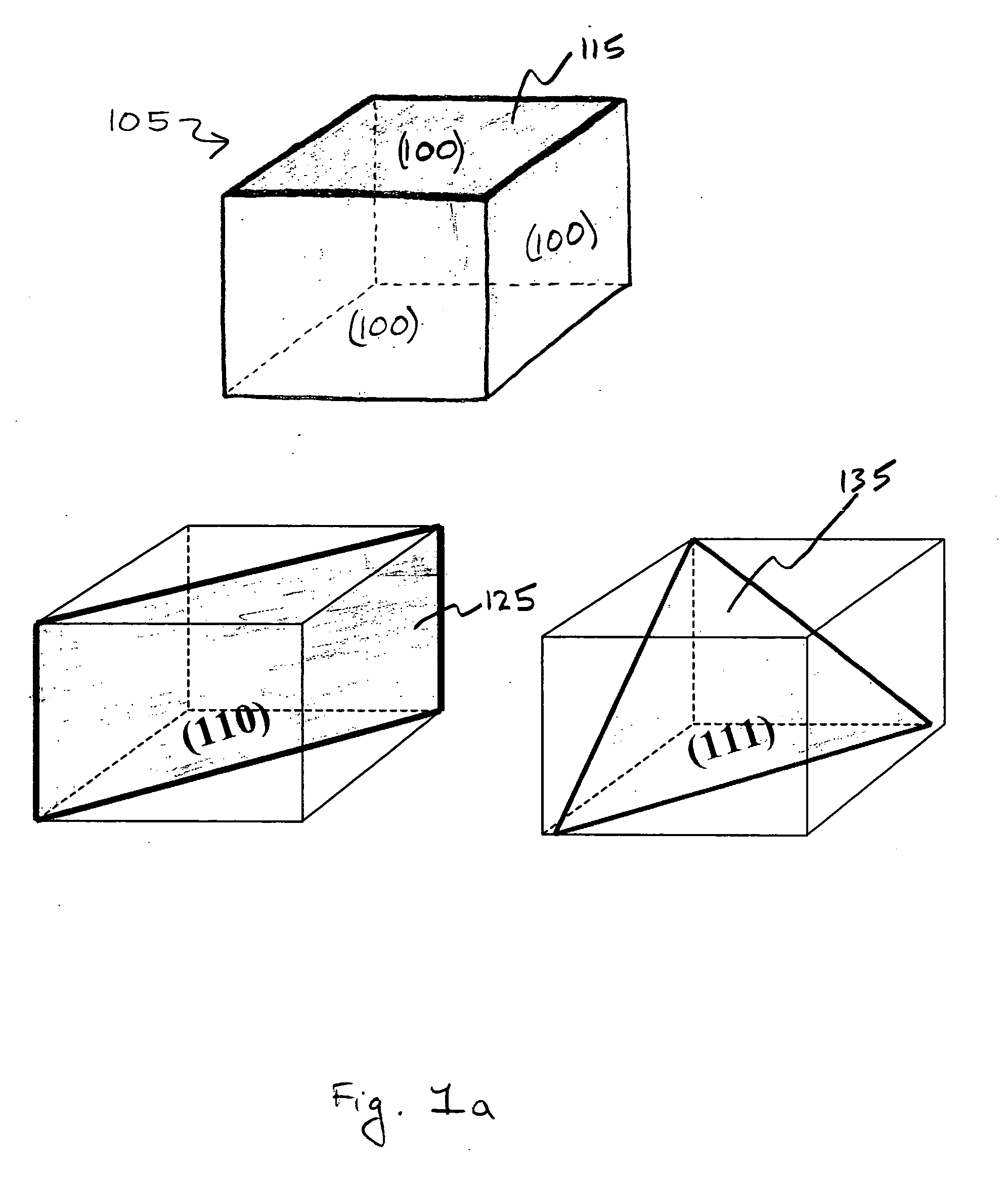

Semiconductor wafers with non-standard crystal orientations and methods of manufacturing the same

The crystal orientations of monocrystalline semiconductor wafers may be varied by four parameters. The first parameter is the type of crystal seed used to grow the monocrystalline semiconductor ingot from which the wafers are cut. The second parameter is the angle at which the wafer is sliced from the ingot. The third parameter is the crystal plane towards which the wafer is cut. And, the fourth parameter is the position of the orientation indication feature that is used to align the wafer during processing. Different combinations of these parameters provide variations of non-standard crystal orientations of monocrystalline semiconductor wafers and semiconductor-on-insulator substrates such as silicon-on-insulator.

Owner:INTEL CORP

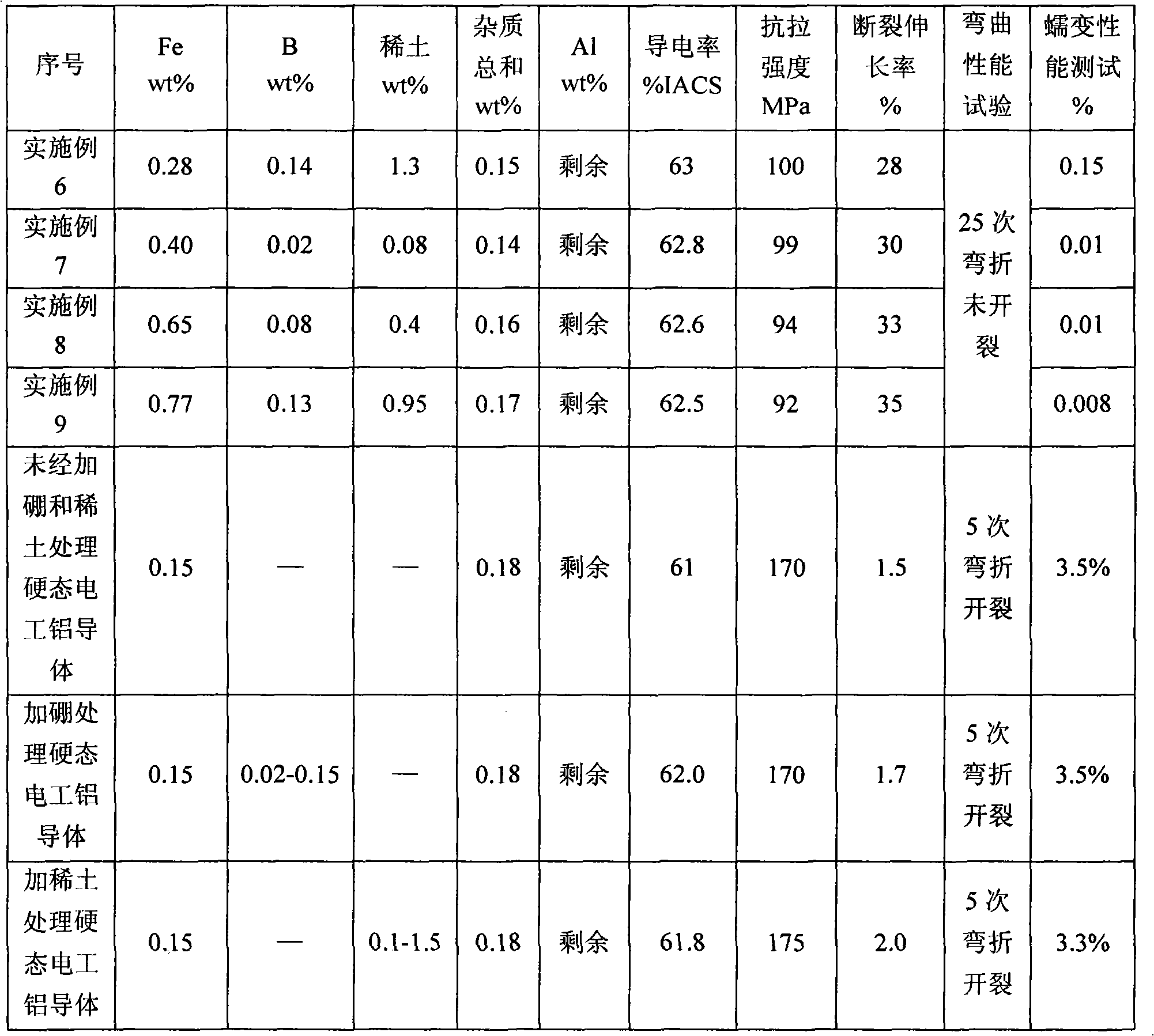

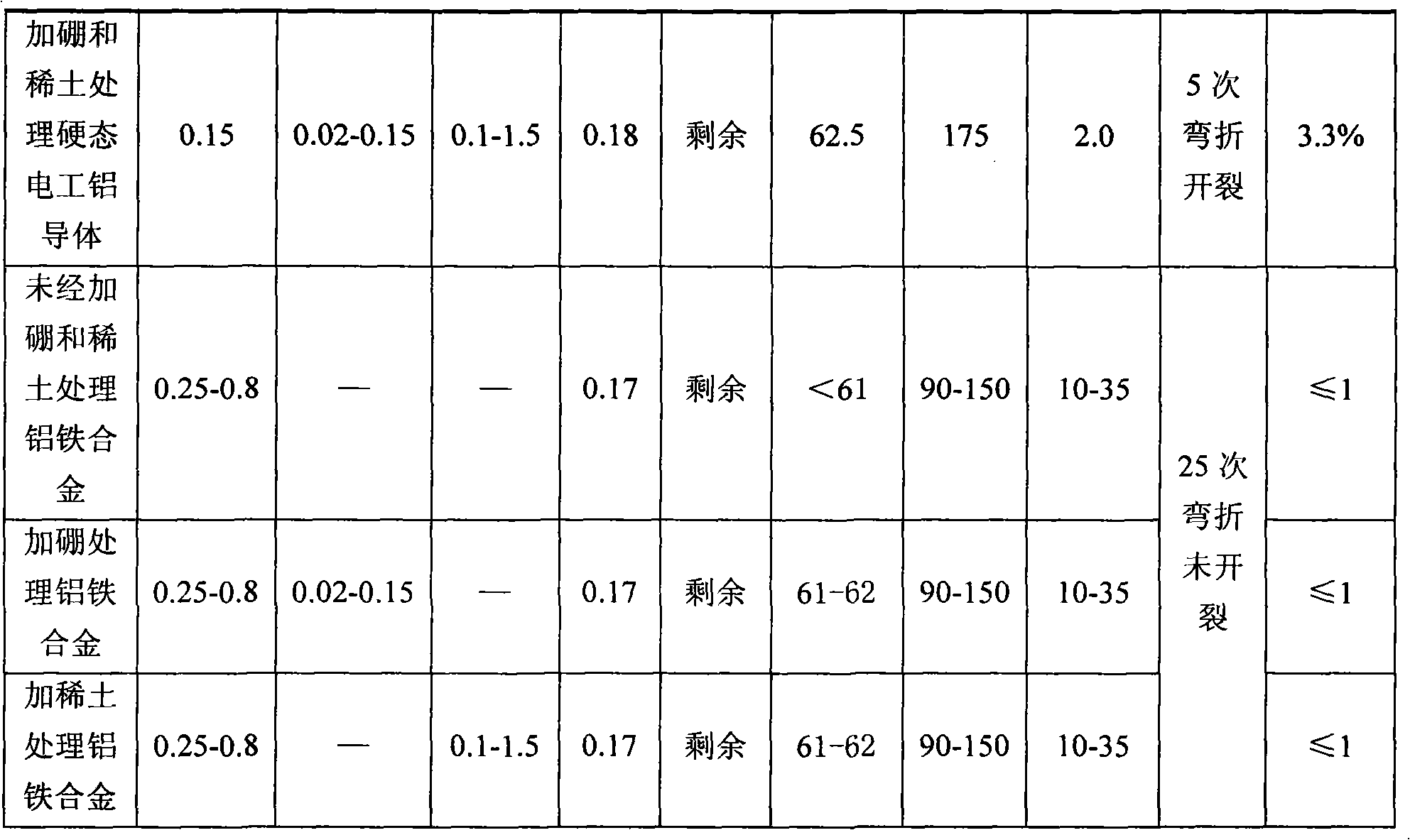

High-conductivity aluminum alloy material for cable and preparation method thereof

InactiveCN101886198ALittle impact on electrical performanceEasy to stretchMetal/alloy conductorsRare-earth elementPliability

The invention relates to a high-conductivity aluminum alloy material for a cable and a preparation method thereof. The aluminum alloy material comprises the following components in percentage by weight: 0.25-0.80 percent of iron element, 0.02-0.15 percent of boron element, 0.1-1.5 percent of rare earth element and the balance of aluminum and inevitable impurities. The aluminum alloy is formed by adding an aluminum alloy intermediate alloy, an aluminum-boron alloy and an aluminum-rare earth intermediate alloy into an aluminum ingot of which the purity is more than 99.80 percent by weight and carrying out a casting process and annealing treatment on the mixture. Compared with a common electric aluminum conductor, the prepared aluminum alloy conductor has more excellent conductive performance and the conductivity reaching or exceeding 62.5 percent IACS (International Annealed Copper Standard); the aluminum alloy conductor treated by using a special process has excellent flexibility and creep resistance; and compared with a common electric aluminum conductor, the prepared aluminum alloy material used as a cable extrusion insulating lead core is more energy-saving and safer.

Owner:ANHUI JOY SENSE CABLE

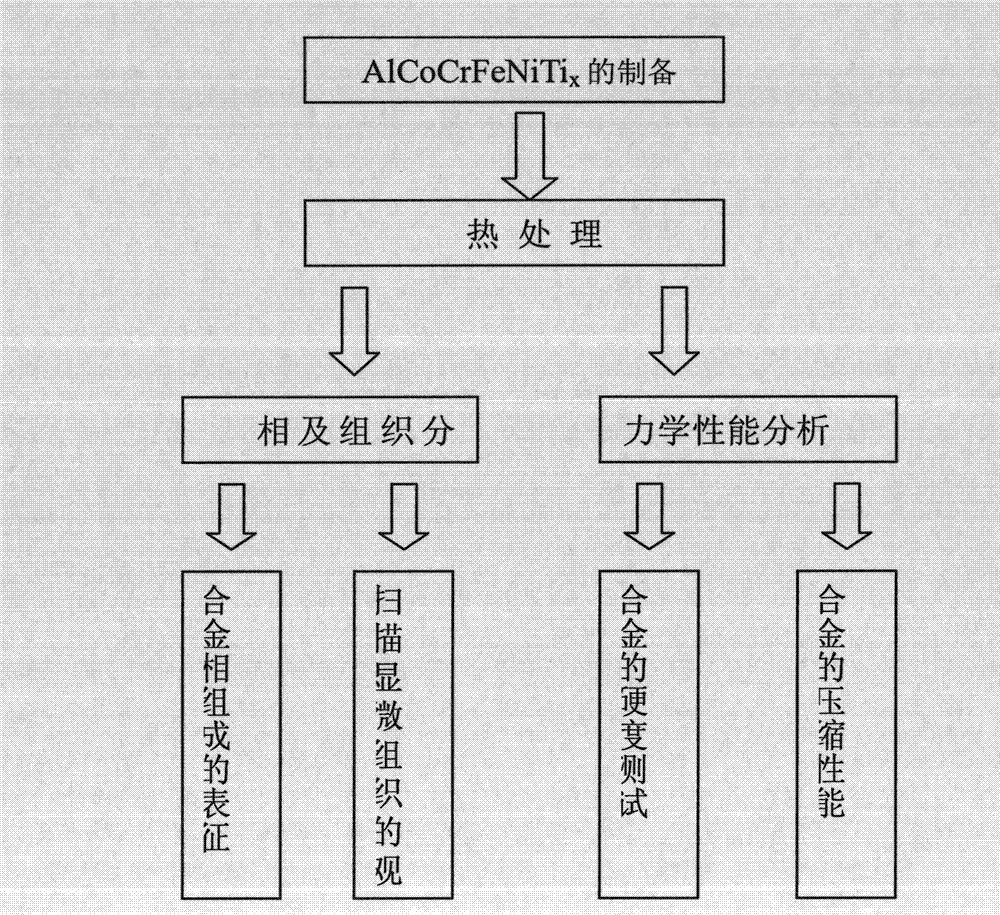

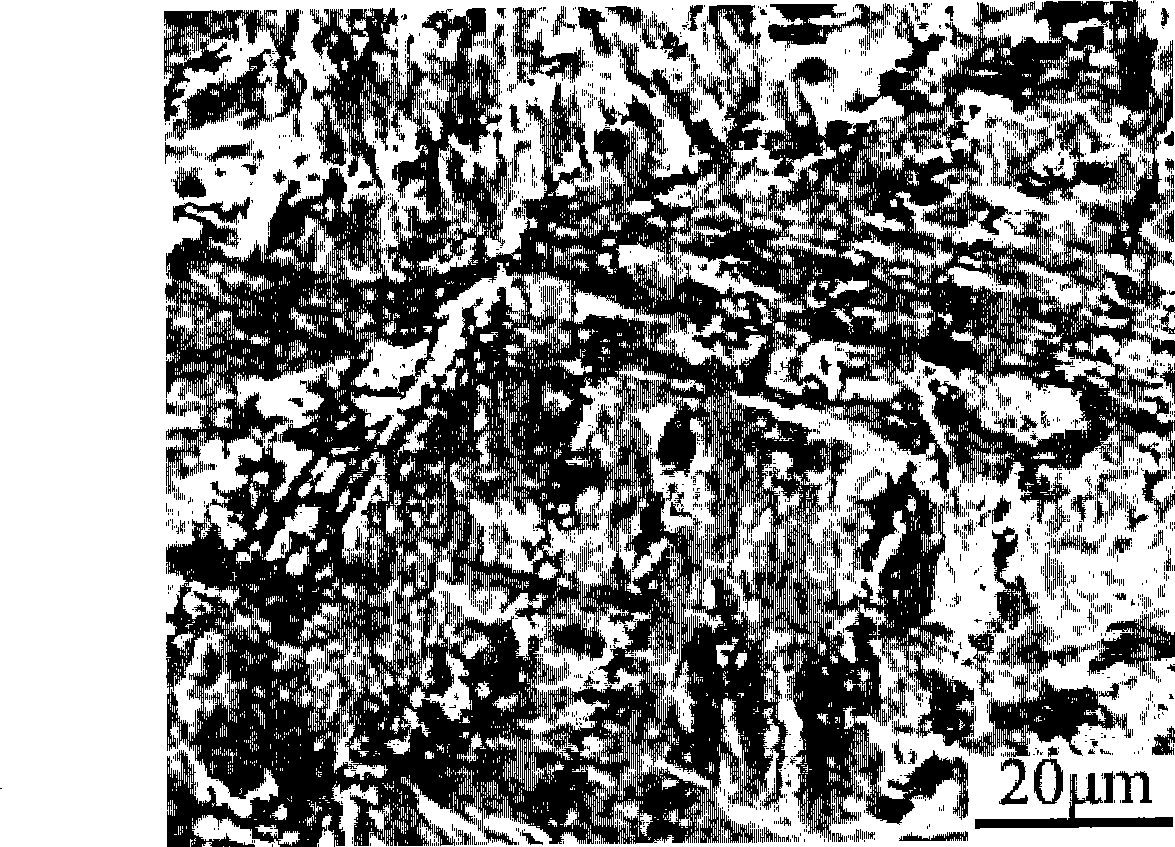

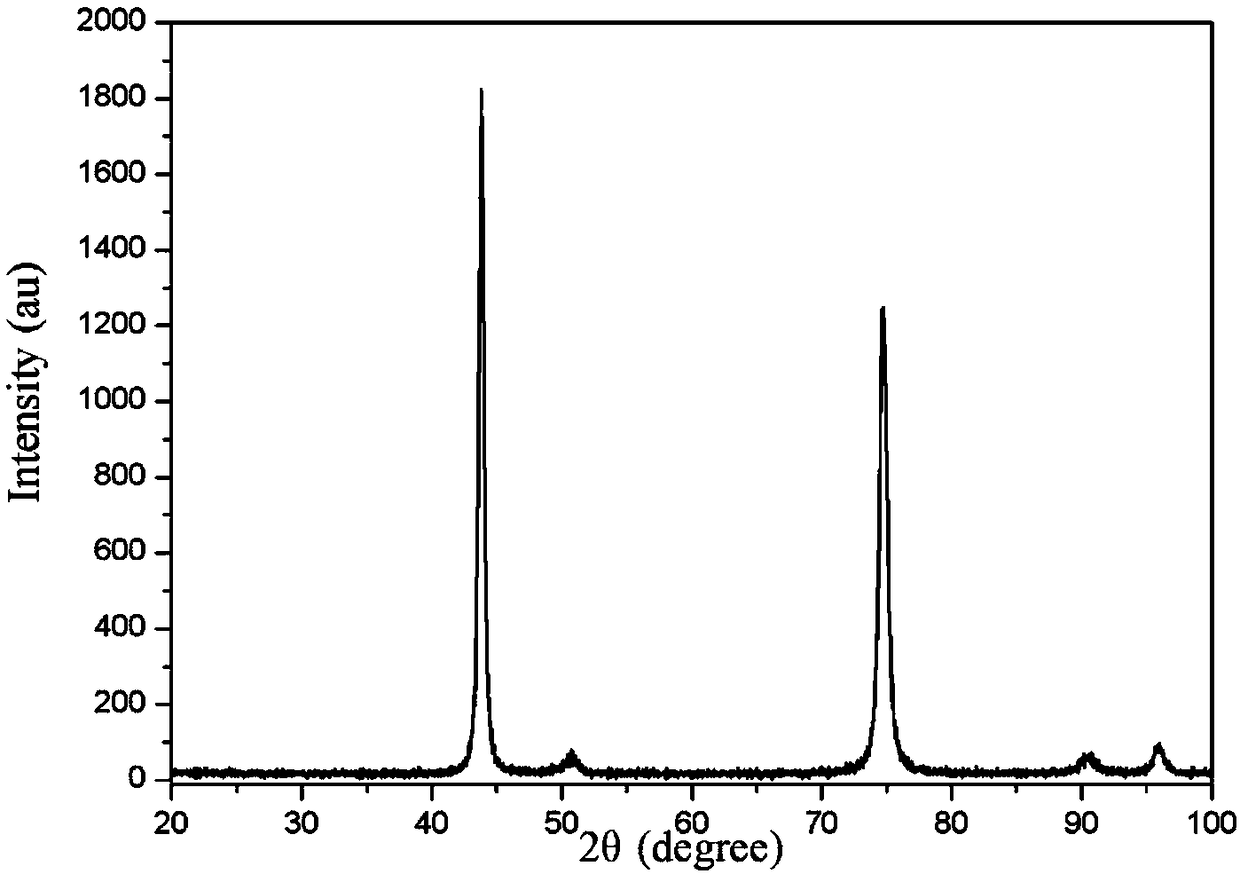

AlCoCrFeNiTix high-entropy alloy material and method for preparing same

The invention relates to a high-entropy alloy material and a method for preparing the same. The component of the high-entropy alloy material is AlCoCrFeNiTix, wherein x represents a molar ratio, and the value range is between 0.1-0.4. The method for preparing the material comprises: preparing raw materials, adopting the alloy smelting raw materials including Al, Co, Cr, Fe, Ni and Ti, and accurately weighing and proportioning according to the molar ratio; then, purifying oxide on a metal surface; putting the prepared raw materials into a tank in a water-cooling copper-formed mold smelting pool, vacuumizing, filling argon, controlling smelting current to be at about 250 ampere and smelting time for 30-60 seconds, turning an alloy block after alloys are fully mixed, putting an alloy ingot into a tank of a water-cooling copper-formed mold, regulating the smelting current, opening a suction casting air suction valve after the alloys are uniformly smelted, utilizing the negative pressure in a pump for suction casting, and taking out the alloy ingot after an alloy mould is cooled. Compared with the conventional crystalline state alloy, the high-entropy alloy material has relative high thermal stability, hardness, yield strength, breaking tenacity, plastic deformation and work hardening capacity.

Owner:TAIYUAN UNIV OF TECH

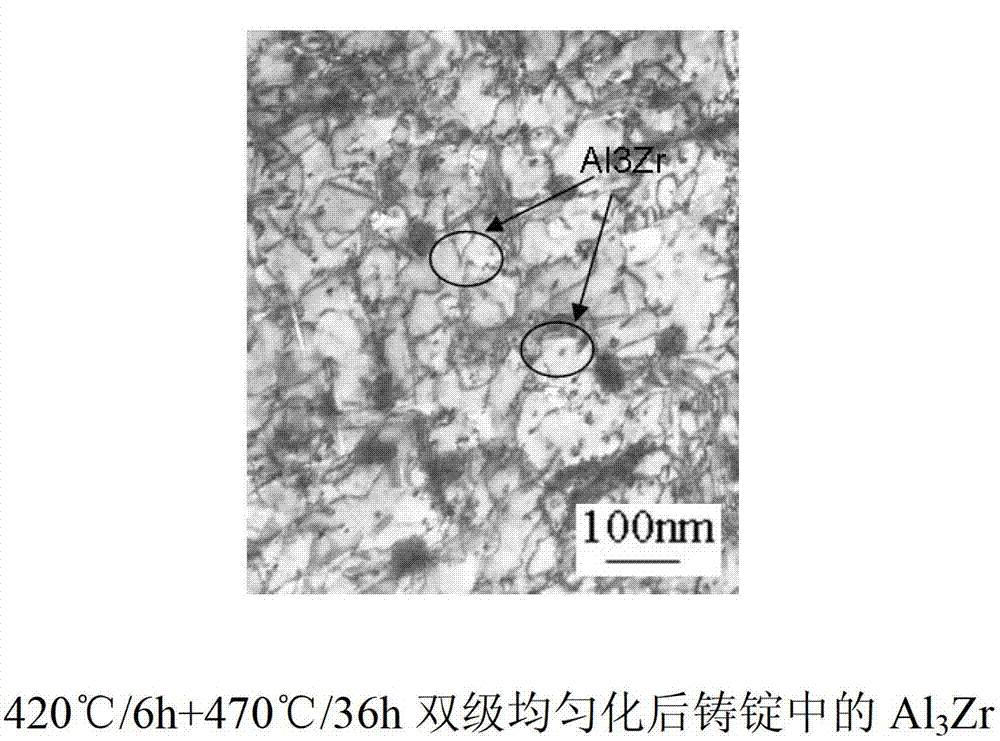

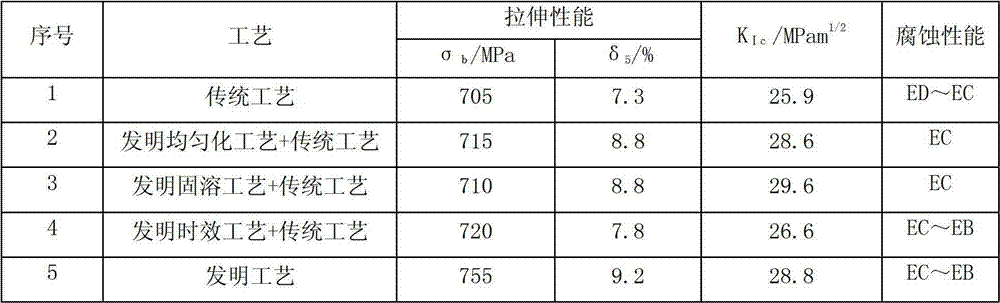

7000 series aluminum alloy material and preparation method thereof

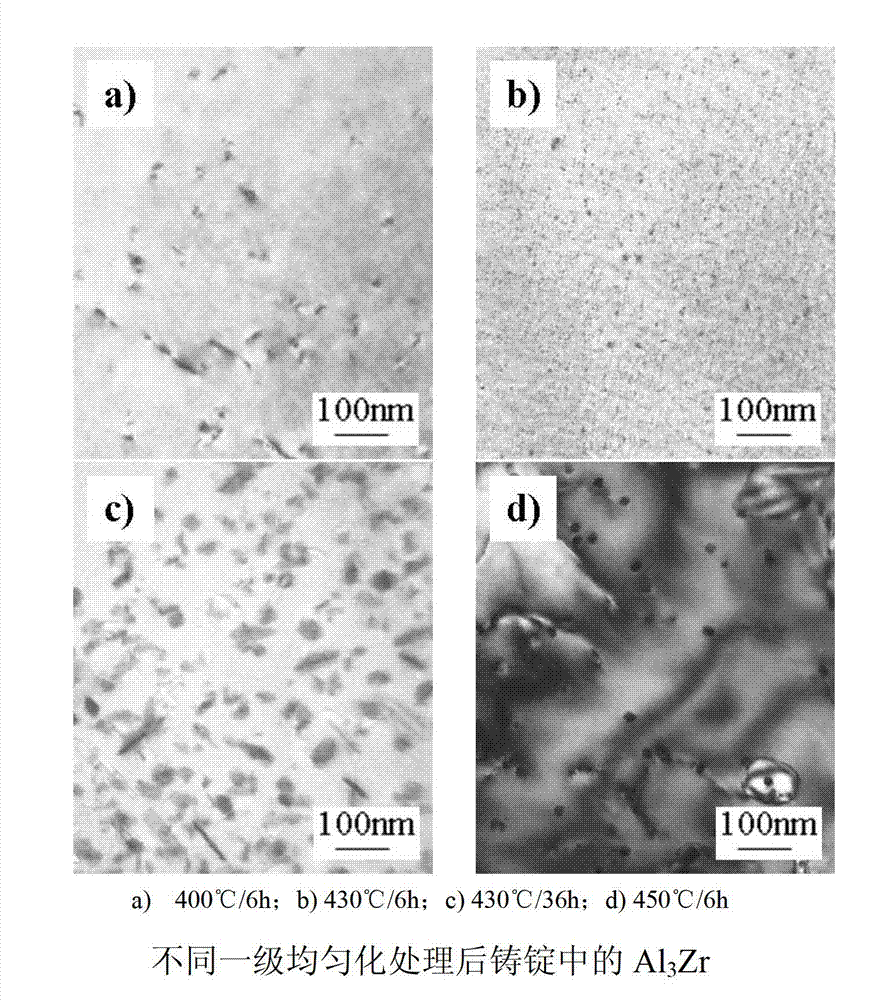

The invention relates to a 7000 series aluminum alloy material and a preparation method thereof. The aluminum alloy material has alloy components of, by weight: 7.6-11.0% of Zn, 1.2-3.0% of Mg, 1.3-2.6% of Cu, 0.04-0.30% of Zr, 0.10-0.60% of Cr, no more than 0.08% of Si, no more than 0.10% of Fe, no more than 0.10% of Ti, no more than 0.15% of total other impurities (wherein the content of single other impurity is no more than 0.05%), and balance of Al. The alloy elements Zr and Cr can be added optionally or simultaneously. The materials are prepared according to the alloy composition; the raw materials are molten; in-furnace refining and standing are carried out; and the material is cast into alloy ingots with required specifications. The alloy ingots are subjected to a preferable graded uniformization process, and is forged or extruded, such that the alloy ingots are molded; the molded materials are subjected to graded solid solution treatment, and are quenched; and artificial forced aging is carried out, such that the material can be processed into parts. The microstructures of the material are uniform, and the property of the material is stable. The ultimate tensile strength of the material can be more than 750MPa. The extensibility of the material is higher than 10%. The T-L direction KIc of the material reaches 28MPam1 / 2.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

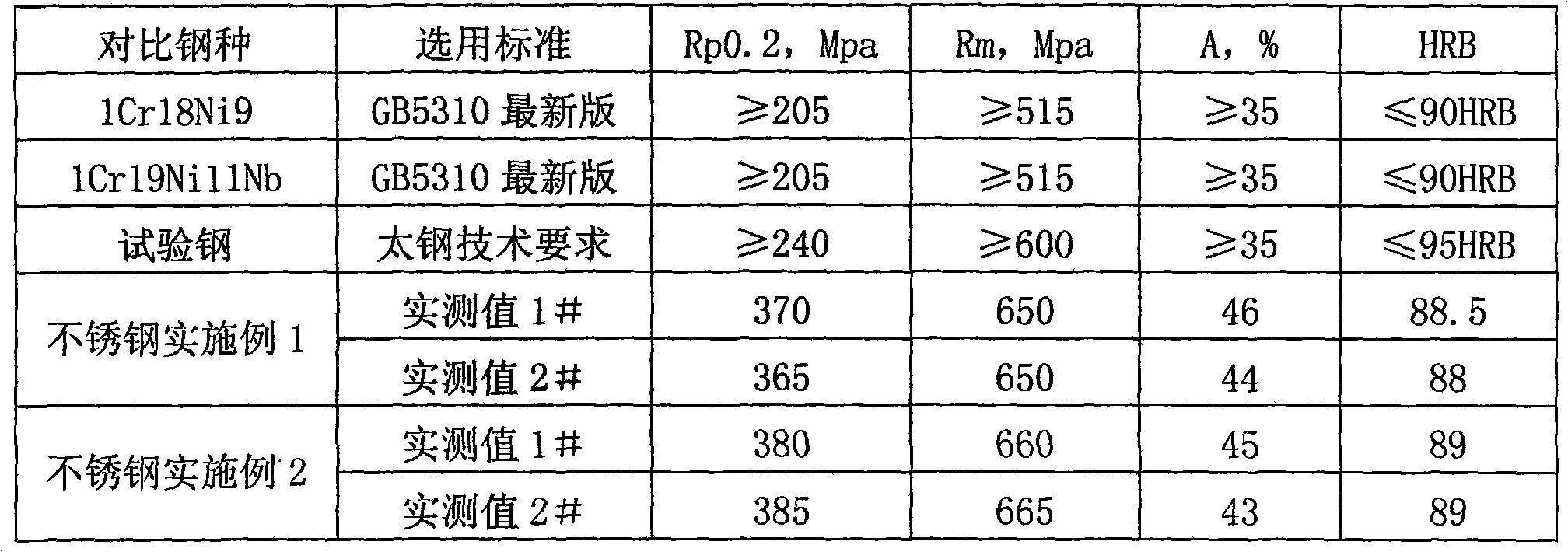

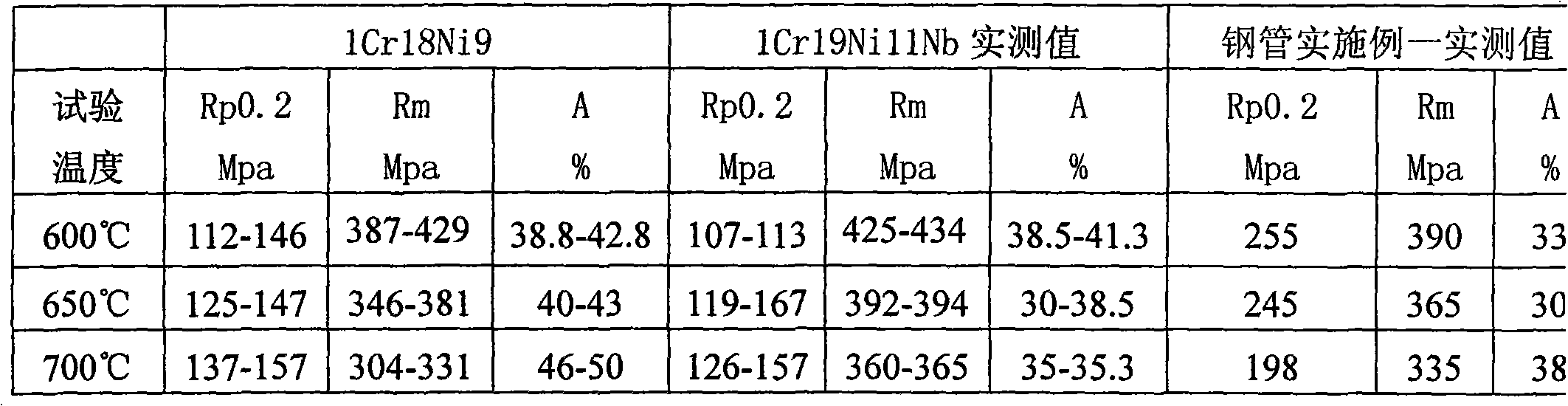

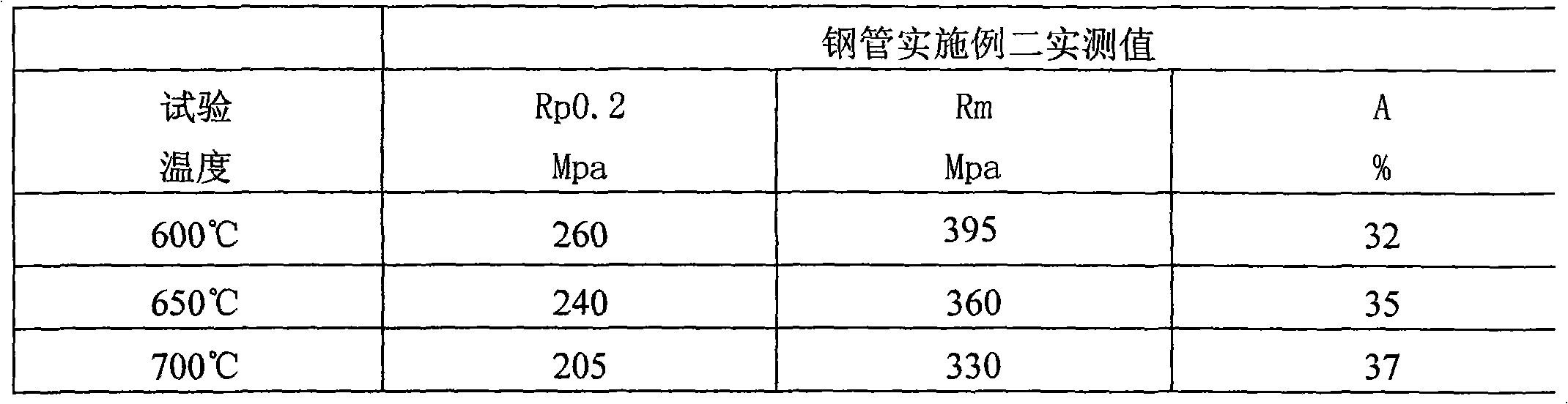

Austenitic stainless steel, steel tube thereof and manufacturing method thereof

ActiveCN101633999AImprove high temperature creep resistanceExcellent resistance to high temperature steam corrosionTemperature control deviceManufacturing convertersSS - Stainless steelIngot

The invention relates to an austenitic stainless steel, a steel tube thereof and a manufacturing method thereof, wherein the austenitic stainless steel and the stainless steel tube comprise the components by mass percent: 0.060-0.14% of C, more than 0 and less than or equal to 0.50% of Si, more than 0 and less than or equal to 1.00% of Mn, less than 0.040% of P, less than 0.015% of S, 17.00-20.00% of Cr, 8.00-11.00% of Ni, 2.50-4.00% of Cu, 0.30-0.60% of Nb, 0.15-0.50% of Mo, 0.15-0.50% of Co, 0.05-0.14% of N, 0.001-0.01% of B, the rest of Fe and unavoidable impurity. The manufacturing method of the steel tube comprises: smelting and pouring to form steel ingots or continuously cast bloom, processing bar material, preparing tubular billet and further processing the steel tube; the method comprises the steps: the heating temperature of processing the bar material is 1250-1270 DEG C, heating temperature of preparing the tubular billet is 1100-1220 DEG C, and the finished product solid solution temperature is 1120-1190 DEG C. The austenitic stainless steel tube has high temperature creep strength and corrosion resisting performance at the high temperature.

Owner:SHANXI TAIGANG ENG TECH +1

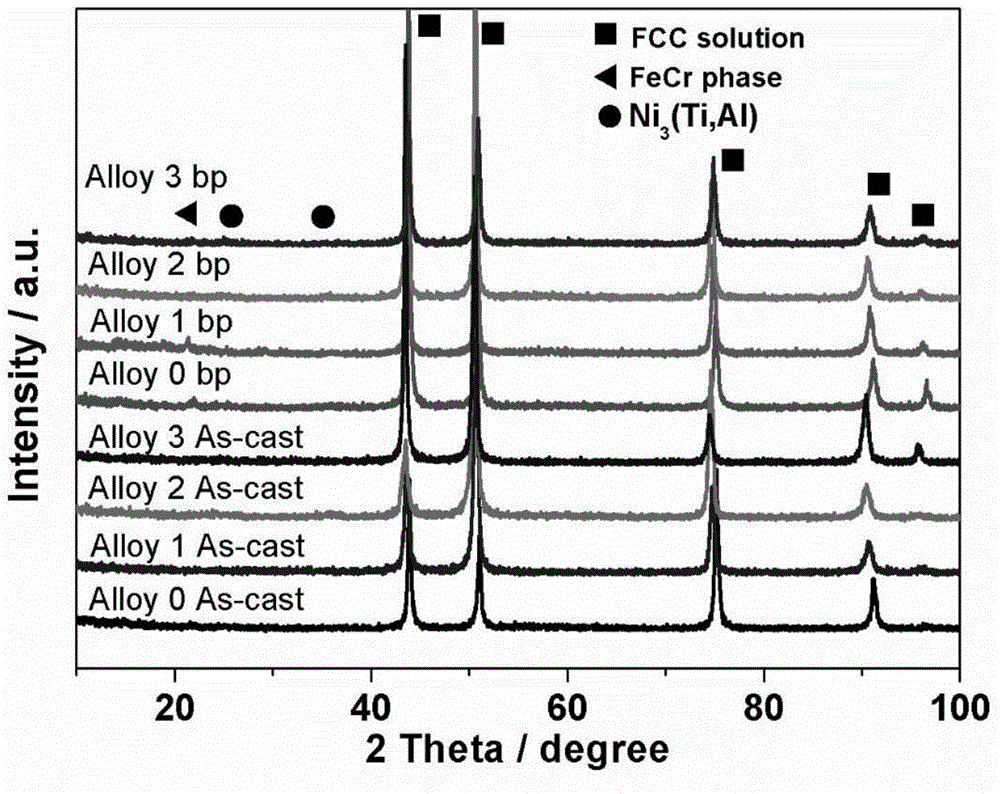

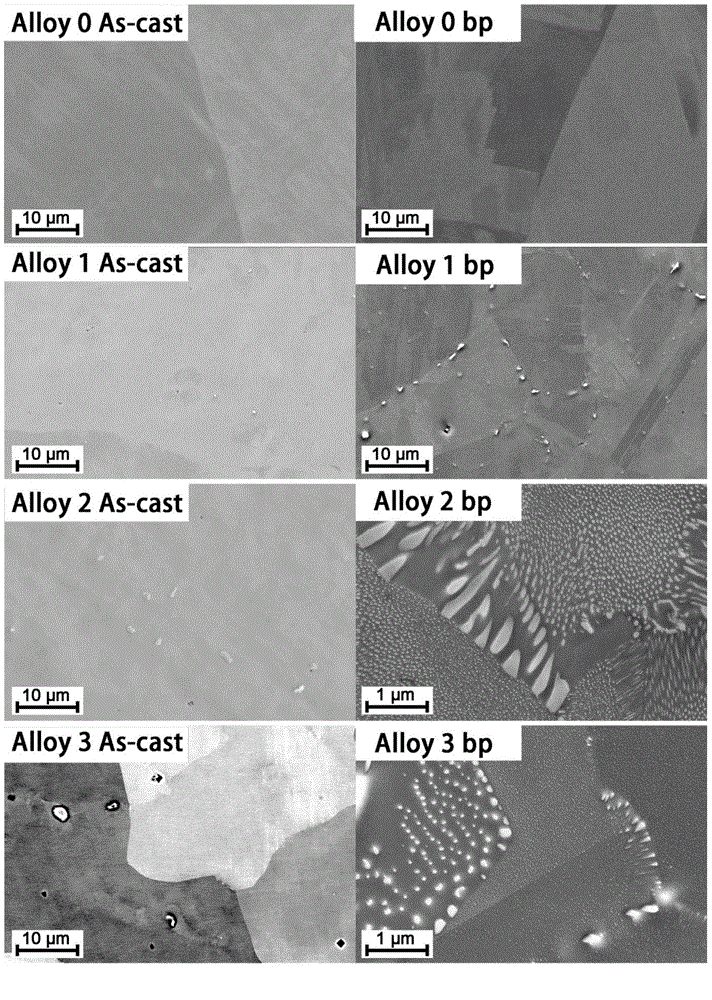

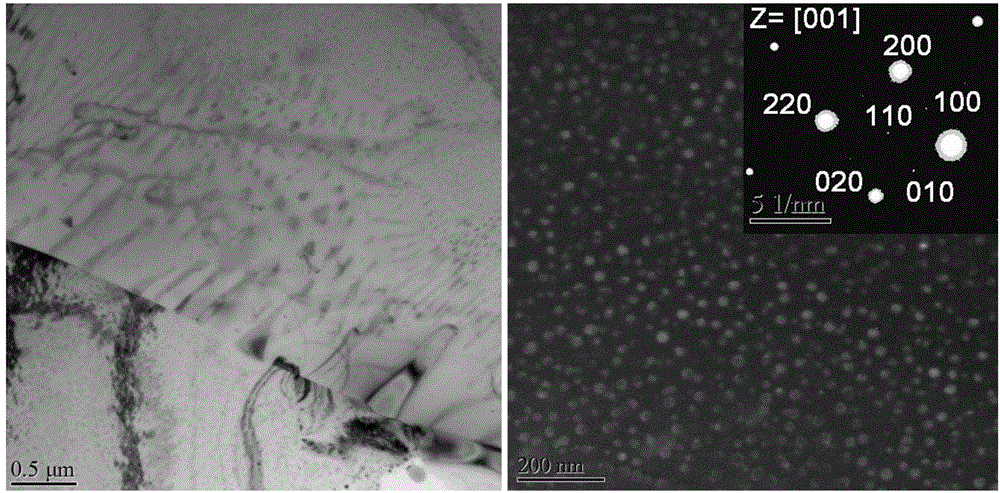

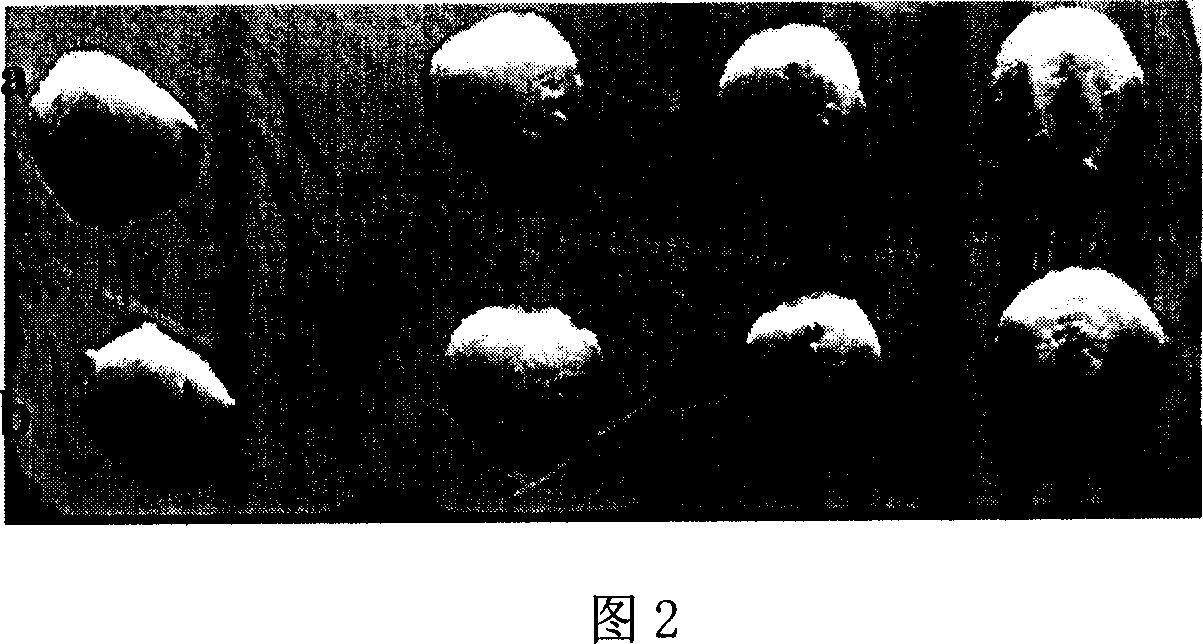

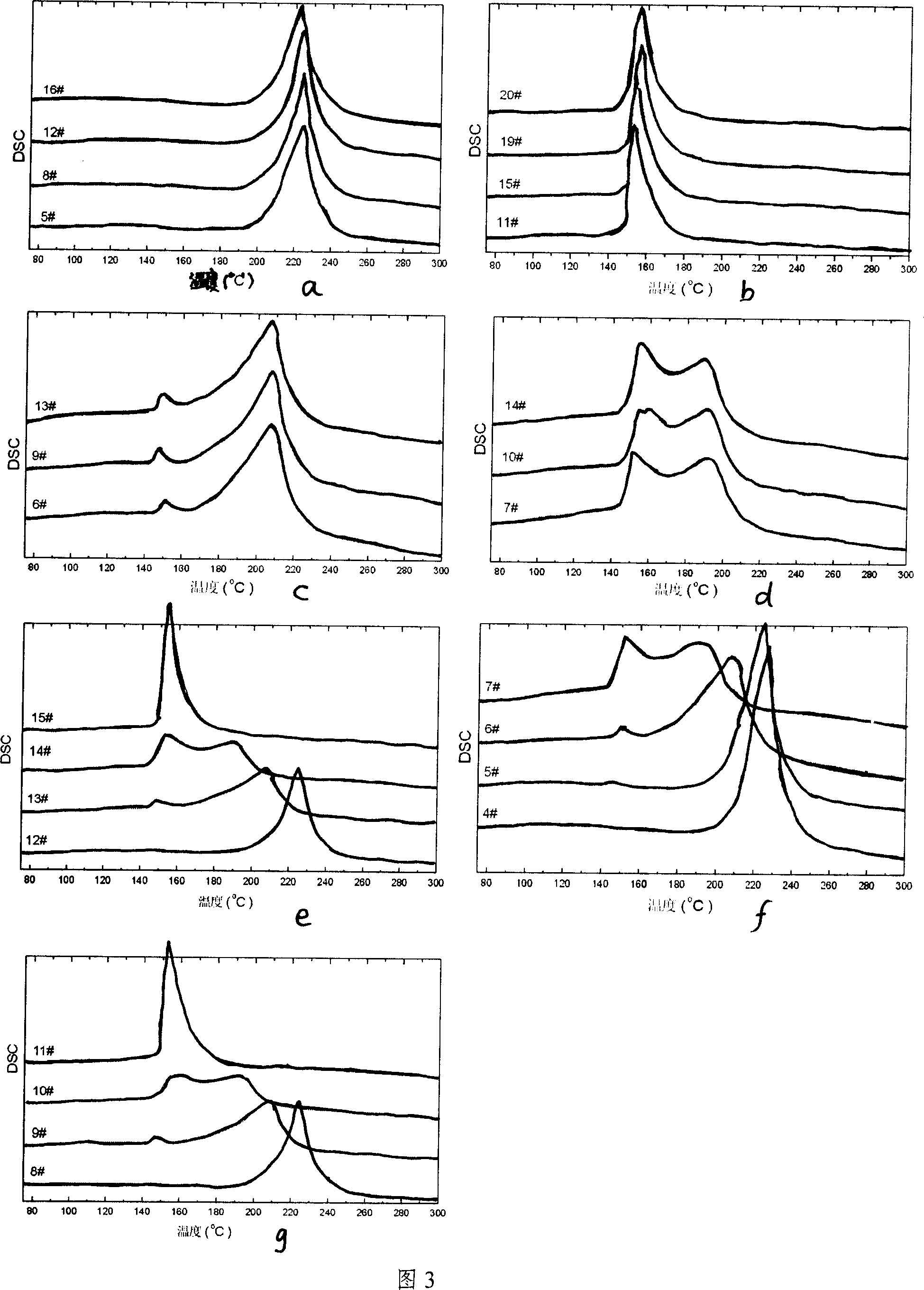

High-entropy alloy with dispersion nano-sized precipitate strengthening effect and preparing method thereof

ActiveCN104694808AWide range of ingredientsControl mechanical propertiesElectric arc furnaceHigh entropy alloys

The invention discloses high-entropy alloy with the dispersion nano-sized precipitate strengthening effect and a preparing method thereof. The method comprises the steps of removing oxidized skin of a metal material, and then conducting weighing and burdening accurately according to a ratio; conducing smelting in an electric-arc furnace in an argon shield atmosphere of titanium absorbed oxygen to obtain an initial high-entropy alloy ingot, and conducting cold rolling, wherein rolling reduction is 20-50%; placing the ingot in a heat treatment furnace with a temperature ranging from 900 DEG C to 1000 DEG C for heat preservation for 0.5-2 hours, and conducting quenching; placing the ingot in a heat treatment furnace with a temperature ranging from 700 DEG C to 800 DEG C for heat preservation for 2-18 hours, and conducting quenching. By means of precipitation strength, on the premise that high plasticity is kept, yield strength and tensile strength are improved greatly. The room-temperature tensile strength of (FeCoNiCr)94Ti2Al4 in the final state reaches 1094 MPa, plastic elongation is 35%, work hardening effect is remarkable, comprehensive room-temperature mechanical property is prominent, high-temperature tensile strength can reach 400 MPa at the temperature of 800 DEG C and strain rate of 10<-3>, steady creep rate is smaller than or equal to 10<-8> under the stress of 100 MPa and at the temperature of 750 DEG C, and high-temperature tensile strength and creep mechanical property are excellent.

Owner:UNIV OF SCI & TECH BEIJING

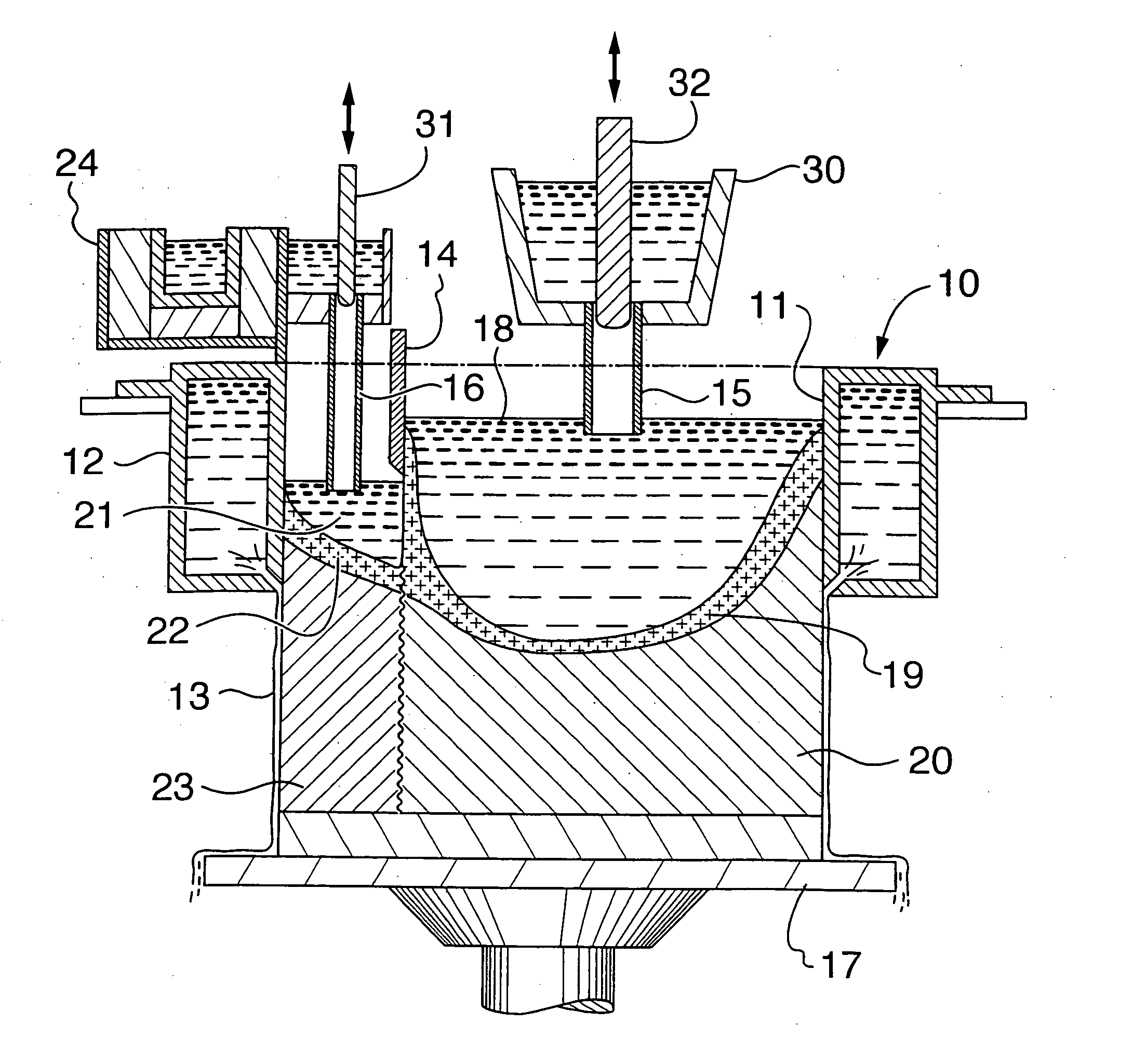

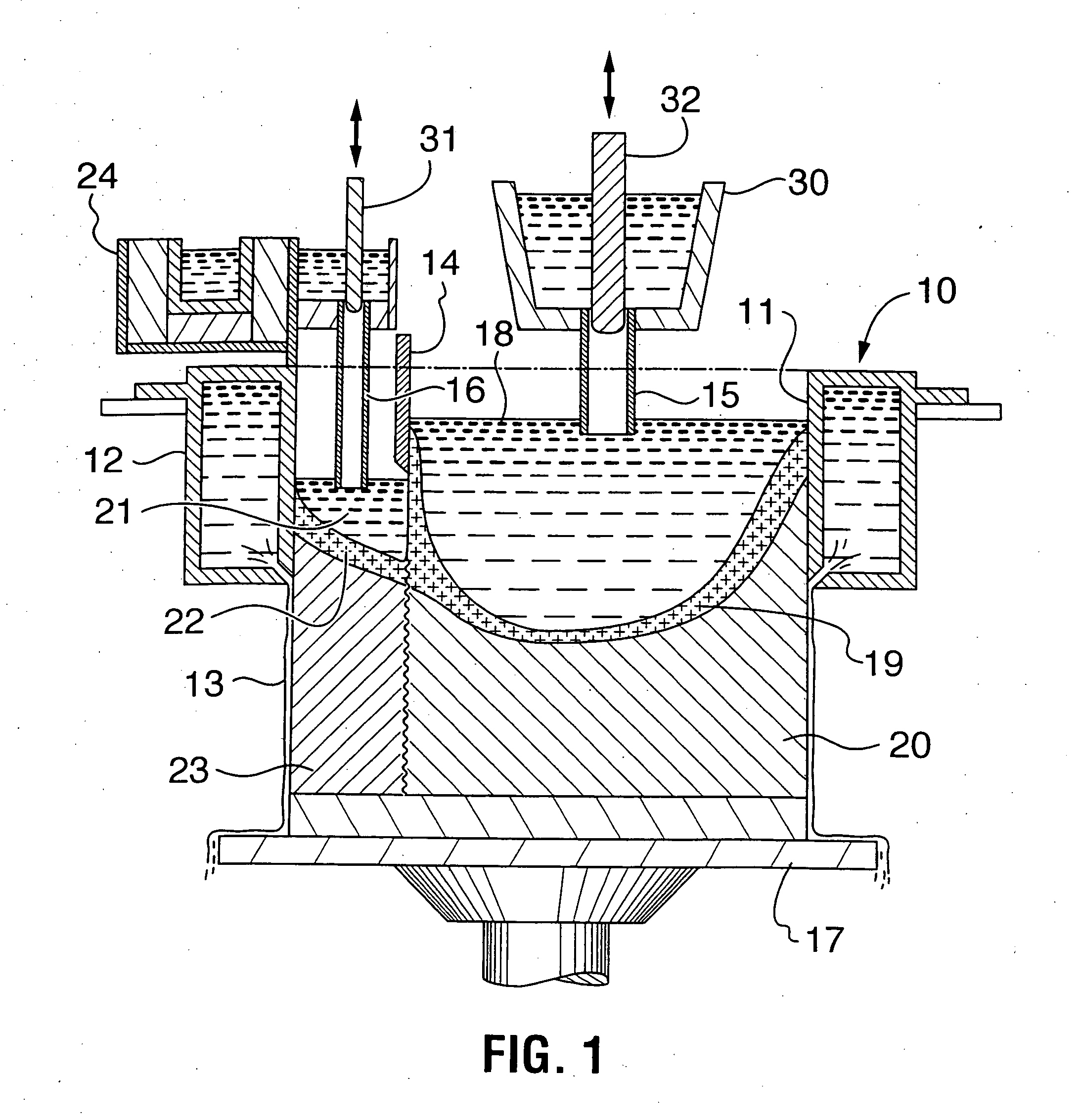

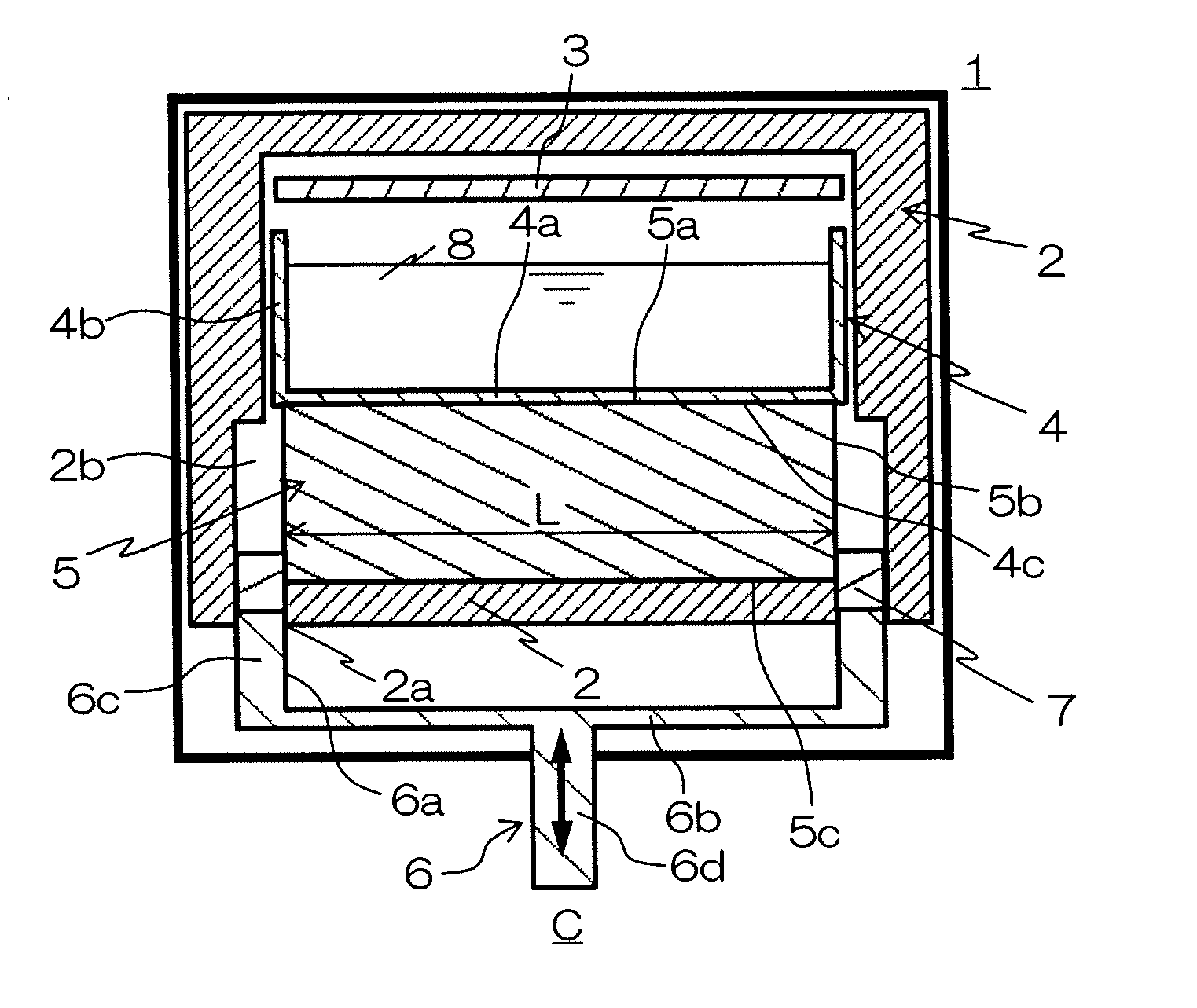

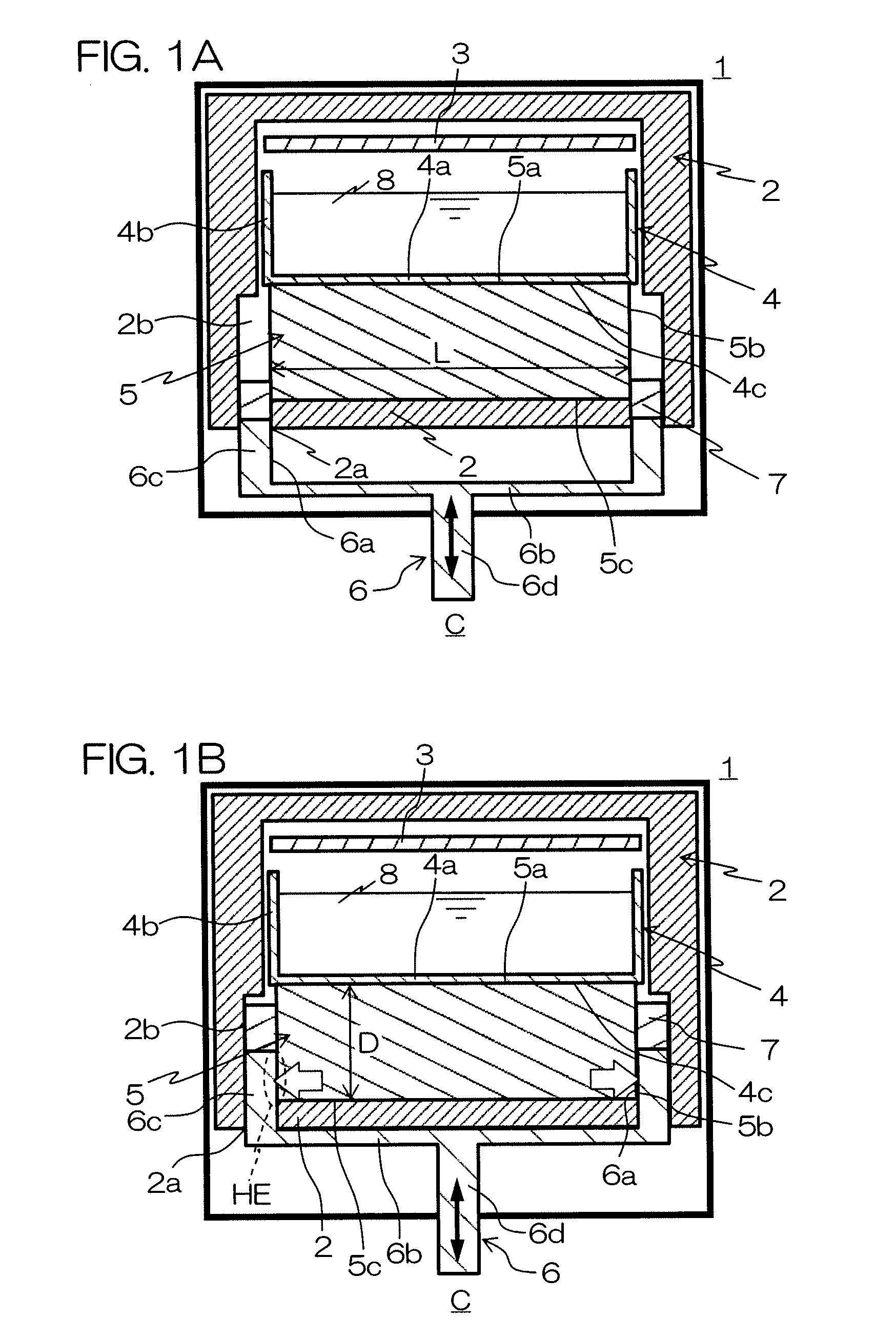

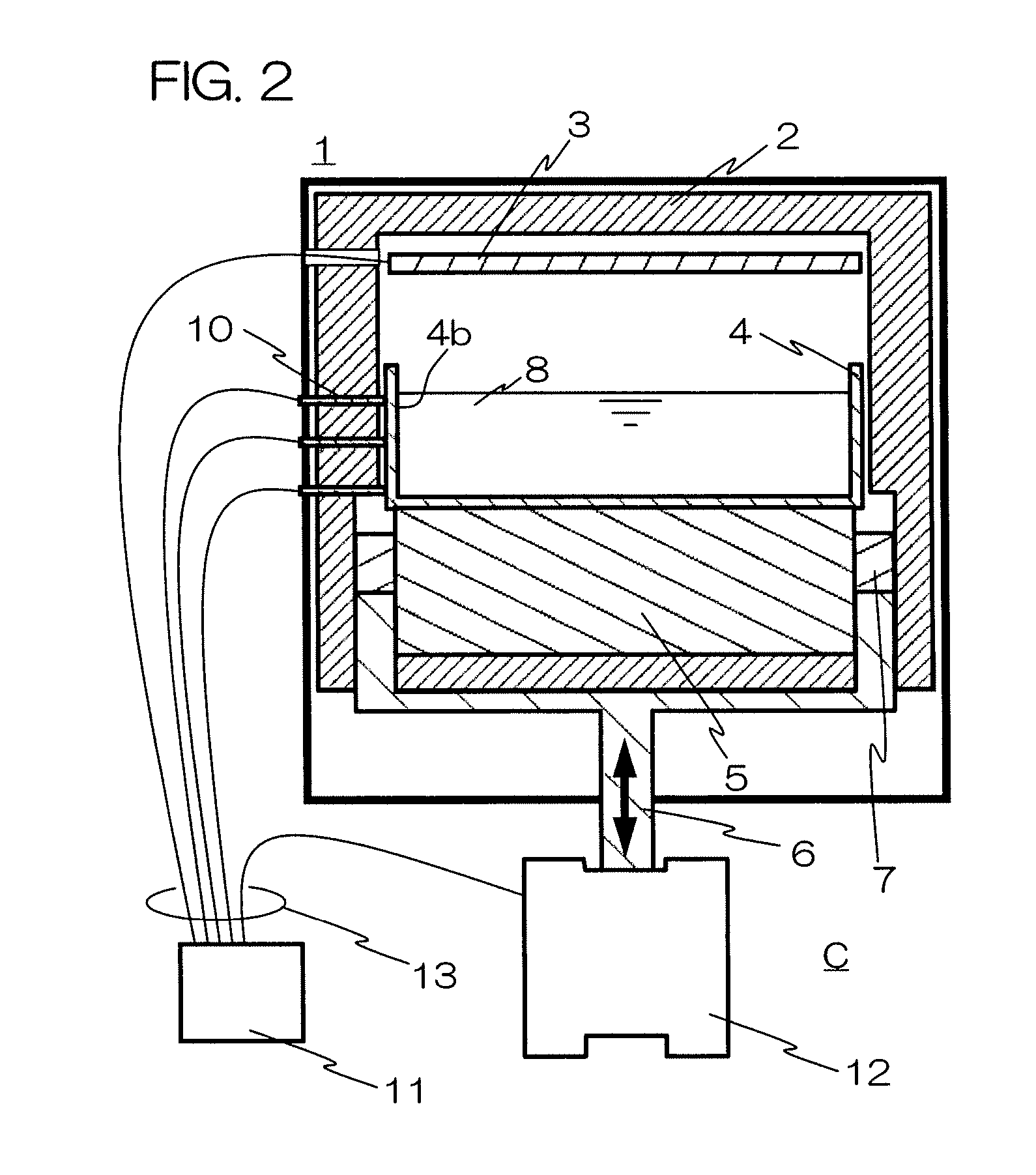

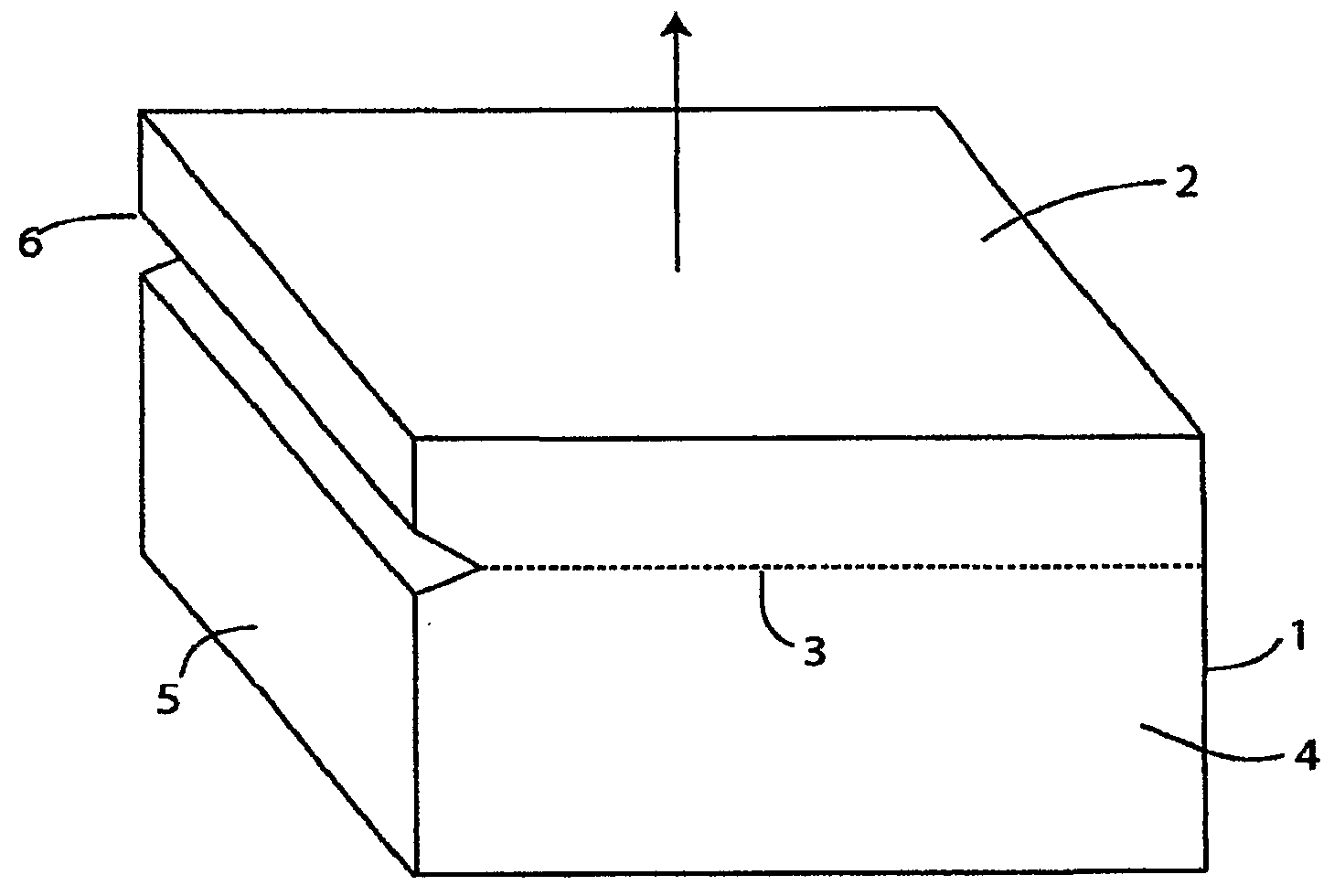

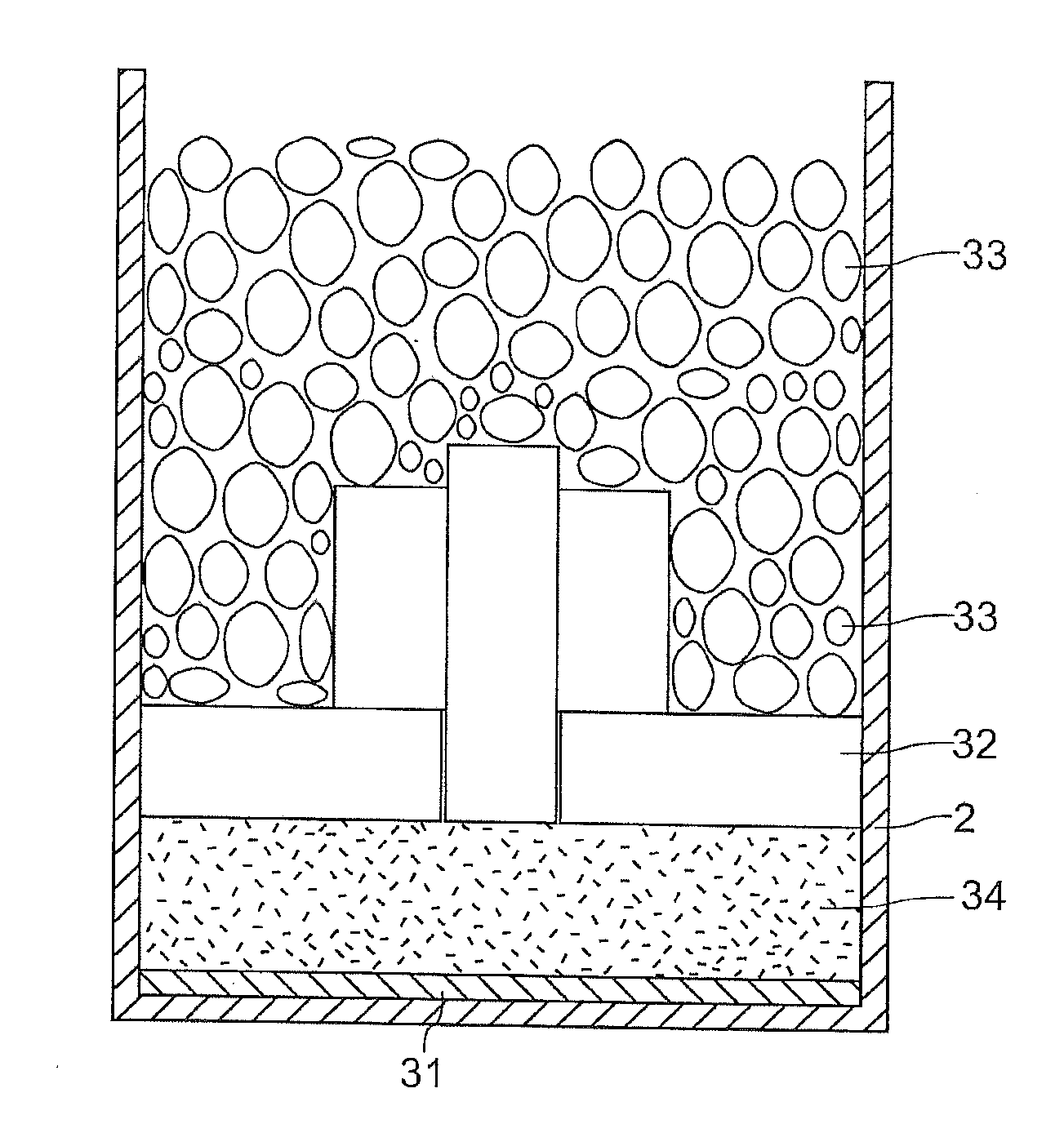

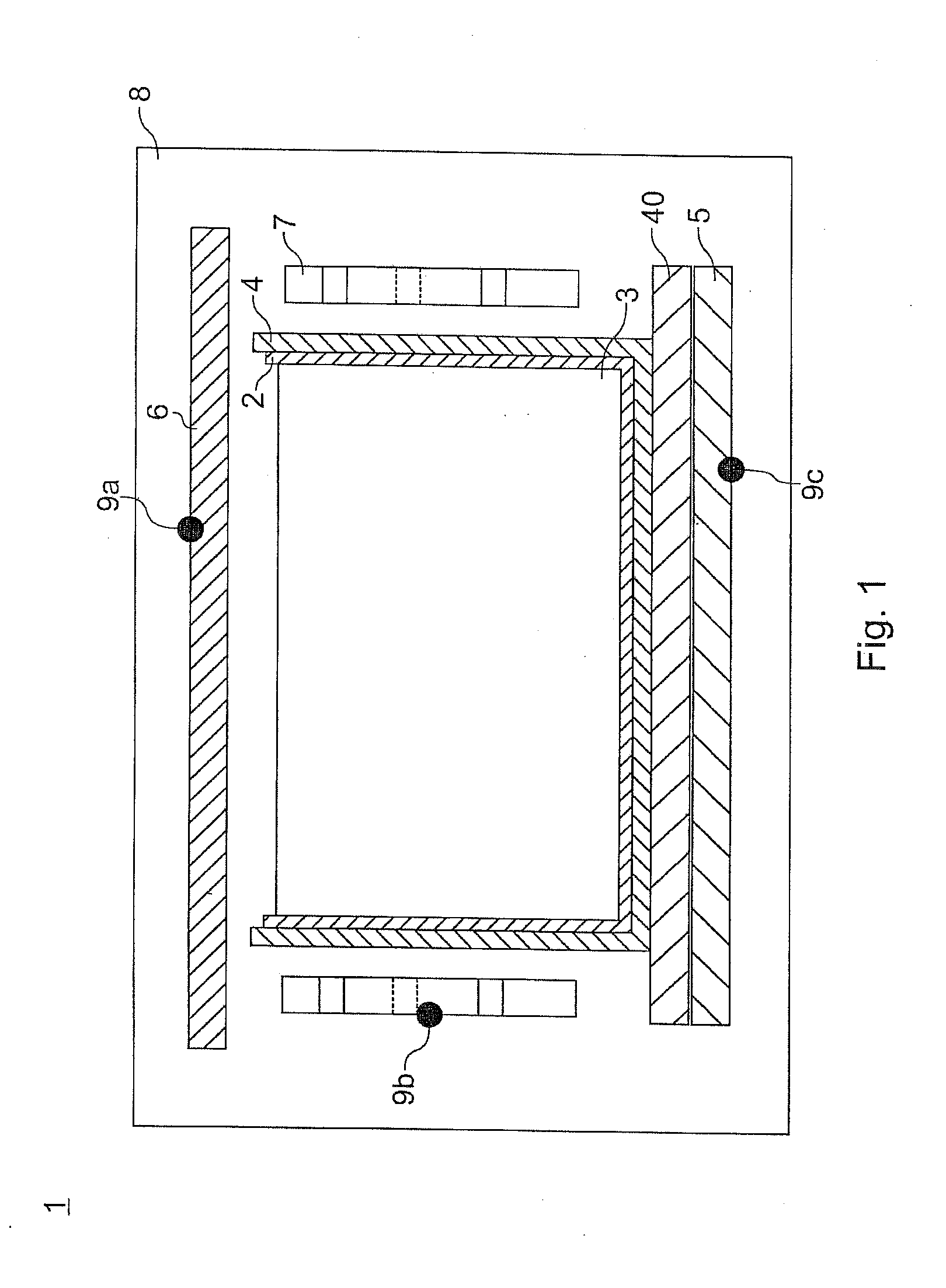

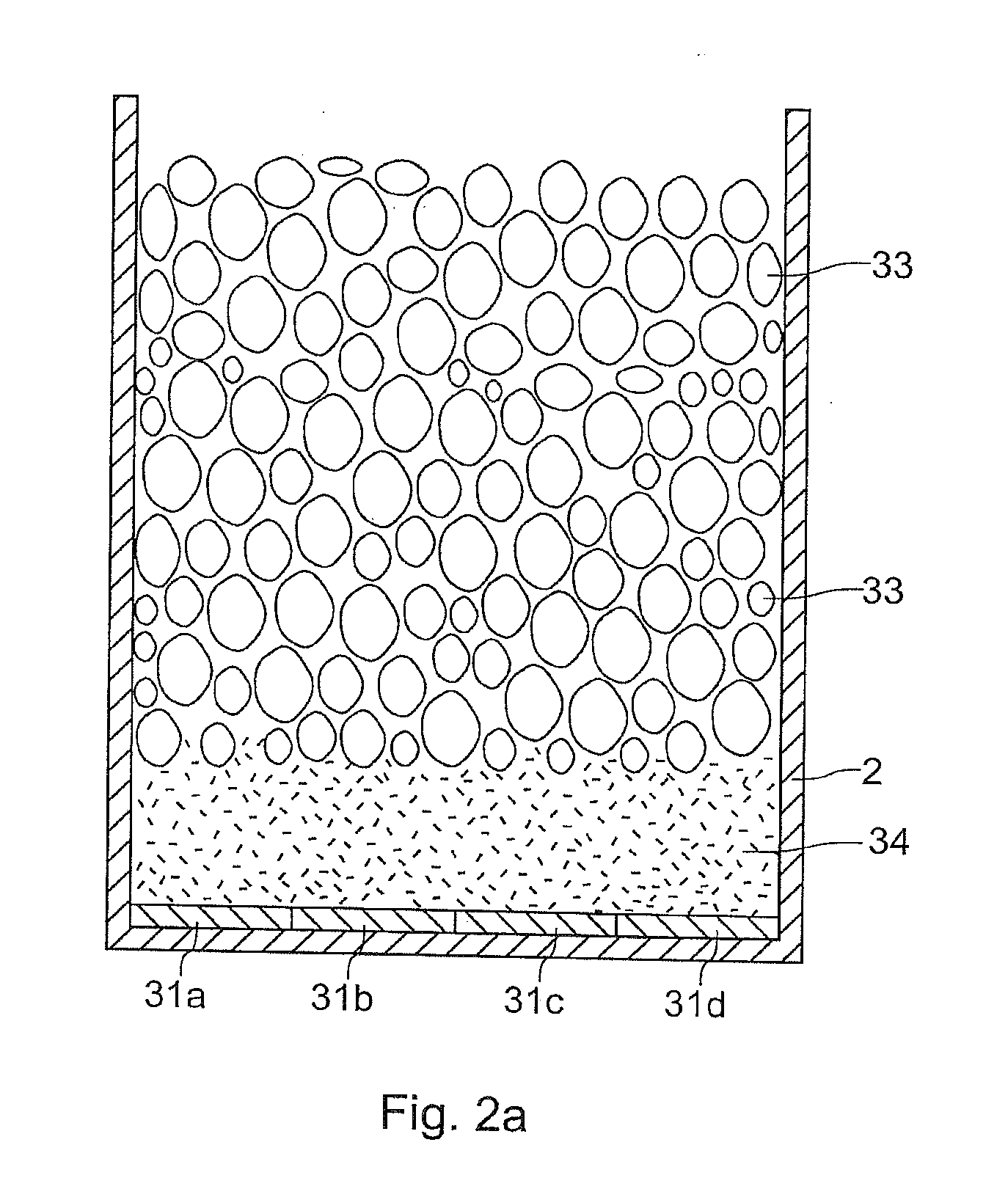

Silicon Casting Apparatus and Method of Producing Silicon Ingot

InactiveUS20070227189A1Good reproducibilityLow costFinal product manufactureGlass drawing apparatusIngotTemperature gradient

A silicon casting apparatus for producing polycrystal silicon ingot by heating a silicon melt (8) held in a mold (4) from above by a heater (3) and cooling it from below while changing the heat exchange area of a heat exchange region (HE), defined between a pedestal (5) having the mold (4) placed thereon and a bottom cooling member (6), in such a manner as to keep pace with the rise of the solid-liquid interface of the silicon melt (8), thereby causing unidirectional solidification upward along the mold (4); and a method of producing polycrystal silicon ingot using such apparatus. According to this production method, the temperature gradient given to the silicon melt (8) can be maintained at constant by adjusting the heat exchange area, so that polycrystal silicon ingot having good characteristics can be produced with good reproducibility.

Owner:KYOCERA CORP

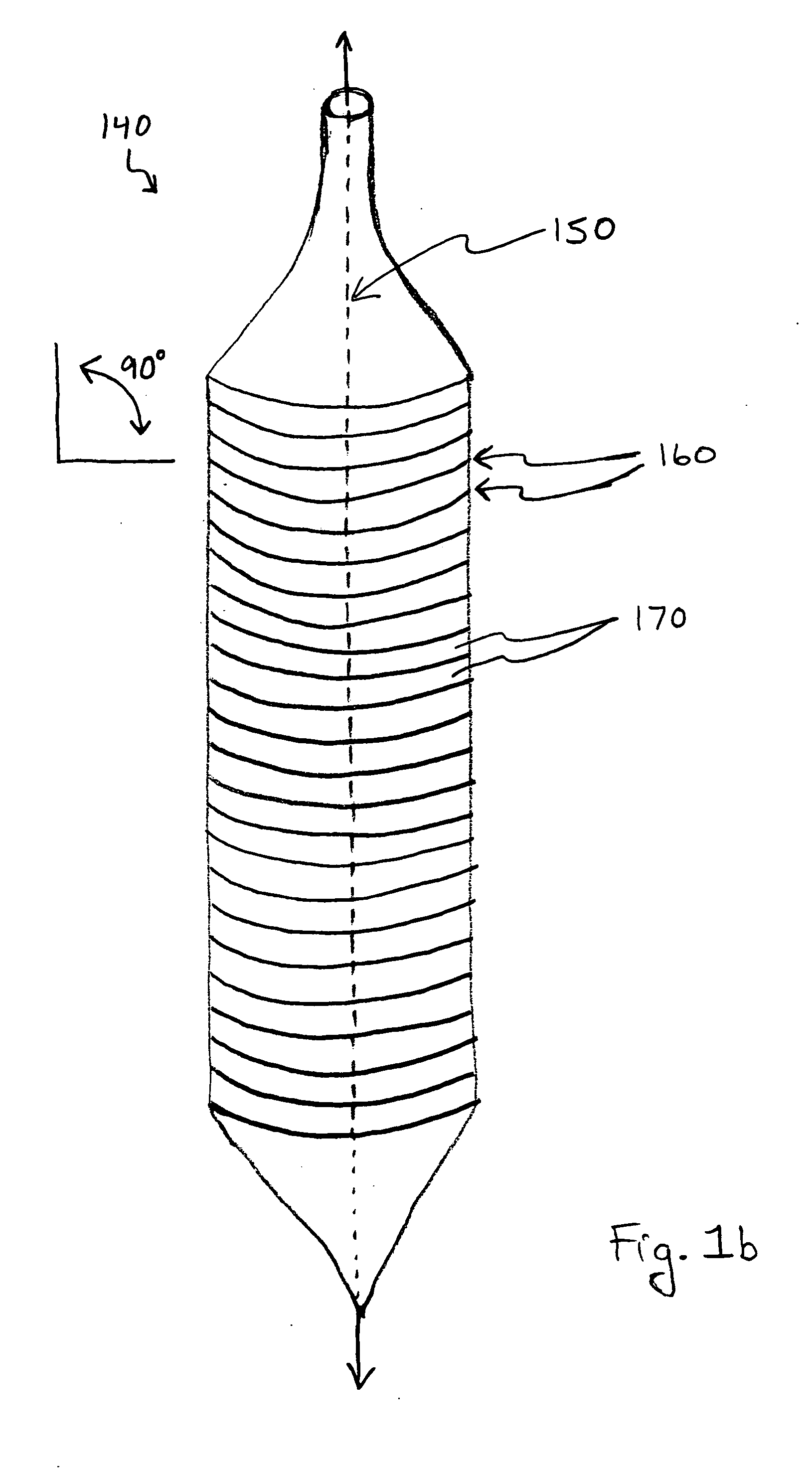

Cleaving Wafers from Silicon Crystals

ActiveUS20090056513A1Effective absorptionIncrease the areaAutomatic control devicesPolycrystalline material growthShortest distanceIngot

A method of creating thin wafers of single crystal silicon wherein an ingot of single-crystal silicon with a (111) axis is flattened and polished at one end normal to the axis, and a notch with a vertex in the (111) plane is produced on a side or edge of the ingot, such that the distance between this vertex and said end is the desired thickness of a wafer to be cleaved from the ingot and such this vertex is in the desired plane of cleavage. Light of a wavelength able to penetrate into the silicon crystal without significant absorption, when the intensity of the beam is low, but is efficiently absorbed and converted to heat when the intensity of the beam is high, is focused to an elongated volume with an axis of elongation in the desired cleavage plane, parallel to and a short distance from said notch edge. Heating and the resulting transient local expansion of the silicon in this illuminated volume causes tensile stress at the vertex of said notch, substantially normal to the desired cleavage plane, thereby causing fracture of the crystal in the chosen cleavage plane. Movement of the illuminated volume relative to the ingot allows the fracture to propagate across the desired cleavage plane, thereby completely severing the wafer from the rest of the ingot.

Owner:BAER

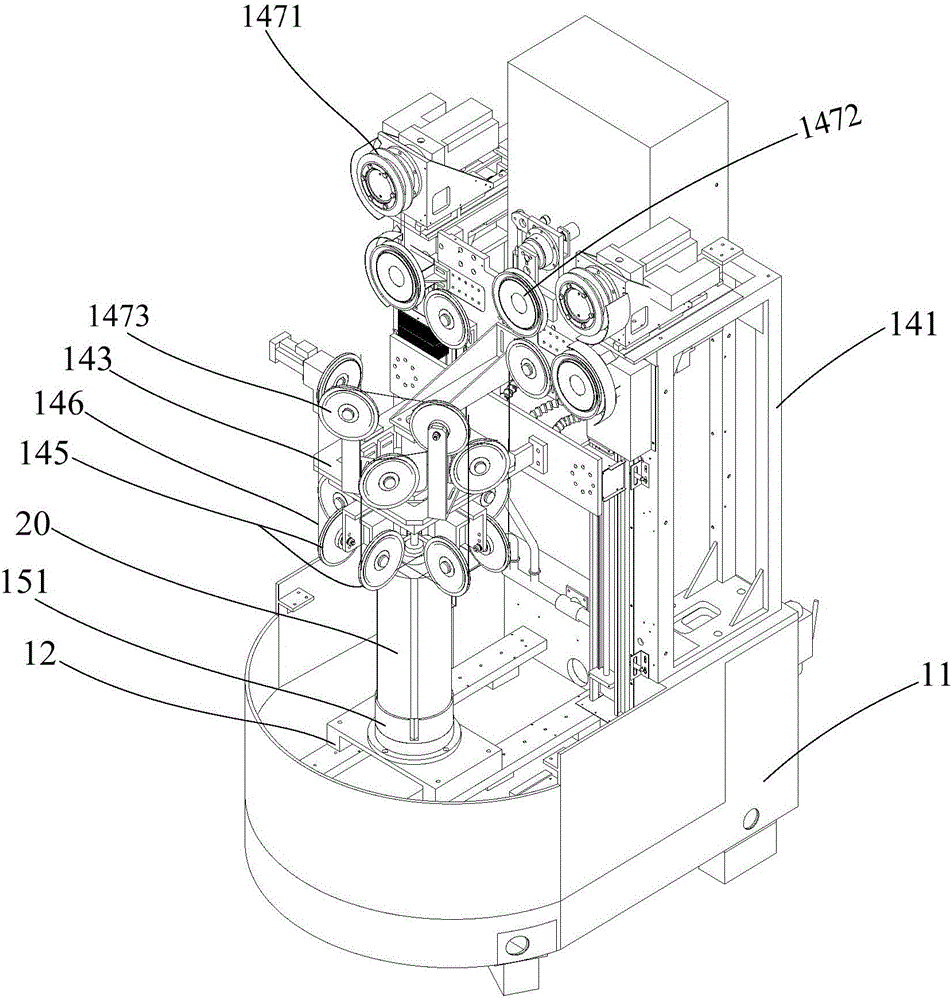

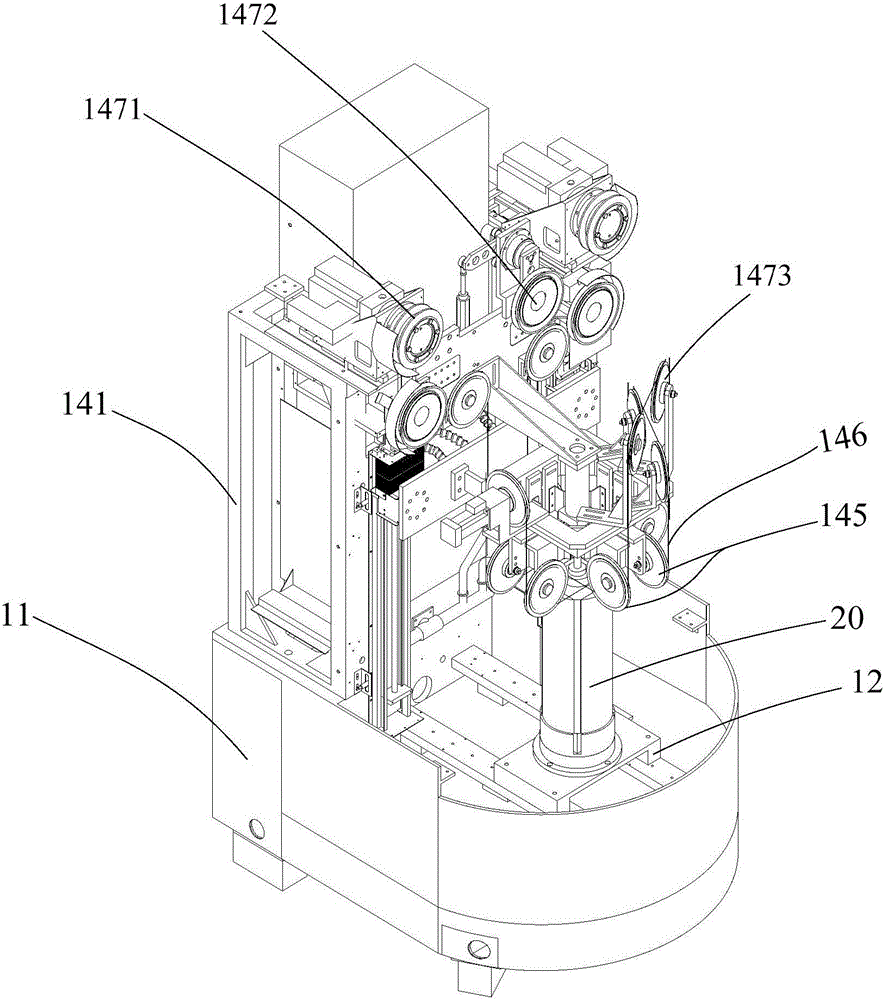

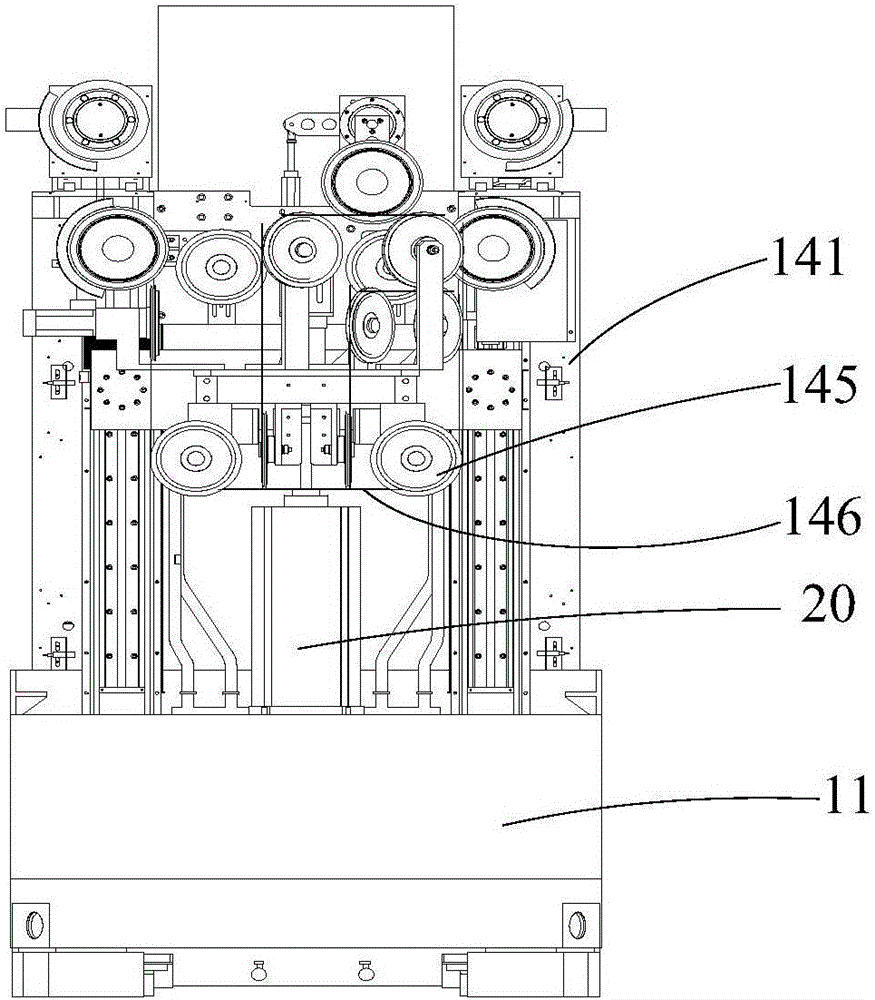

Silicon rod squarer

InactiveCN105818285AReduce labor costsIncrease productivityWorking accessoriesFine working devicesWire cuttingIngot

The invention provides a silicon rod squaring machine, comprising: a machine base with a square cutting area; a bearing platform arranged on the machine base and located in the square cutting area for carrying vertically placed silicon rods; The wire cutting equipment on the machine base includes: a cutting frame, which is arranged on the machine base and adjacent to the bearing table; The cut lines that form the cut line mesh. Compared with the prior art, the silicon ingot squaring machine of the present invention uses the supporting platform to carry the vertically placed silicon ingots, and cuts the silicon ingots below in a straight line through the wire cutting equipment, which can realize automatic cutting and complete the silicon ingot squaring operation. Save labor cost and improve production efficiency.

Owner:TDG NISSIN PRECISION MACHINERY CO LTD

Silver-free tin-bismuth-copper leadless solder and preparation method

ActiveCN1927525AGood solder wettabilityImprove antioxidant capacityWelding/cutting media/materialsSoldering mediaShielding gasIngot

The invention relates to a tin-base leadless solder without silver, and relative production. Wherein, it comprises Bi at 7.5-60% (without 7.5%), Cu at 0.1-3.0%, and the left is tin; and it also can contain Zn, Ni, P, Ge, Ga, In, Al, La, Ce, Sb, Cr, Fe, Mn, or Co while the total amount of micro alloy element is not higher than 1.0%. And the production comprises that in protective gas or vacuum, smelting middle alloy Sn-Cu10; then smelting into leadless solder alloy ingot which can be used as solder directly or be made into bar band, wire plate or powder. The inventive solder has low cost while its fusion point can be controlled between 140 and 230Deg. C. And it has strong anti-oxidization and anti-corrosion properties.

Owner:BEIJING COMPO ADVANCED TECH

Method for increasing sintering Nd-Fe-B coercive force by adding nano-oxide in crystal boundary phase

InactiveCN1688000ANot easily oxidizedIncrease the coercive force of the magnetInorganic material magnetismInductances/transformers/magnets manufactureIngotGrain boundary

This invention discloses a method for increasing sintered Nd FeB coercive force by adding nm oxide in grain-boundary phase including the following steps: 1,applying casting technology to produce NdFeB ingot alloy or applying rapid hardening film technology to produce NdFeB rapid hardening film of with host phase alloy, applying casting technology to produce ingot alloy or rapid hardening film technology to get rapid hardening film or rapid quench technology to manufacture a rapid quench strip with the grain boundary phase alloy, 2, processing powder with the two alloys, 3, adding a nm oxide to the grain boundary phase alloy powder, 4, pressing the mixed powder into formation, 5, producing sintered magnetic body in a vacuum sintering oven.

Owner:ZHEJIANG UNIV

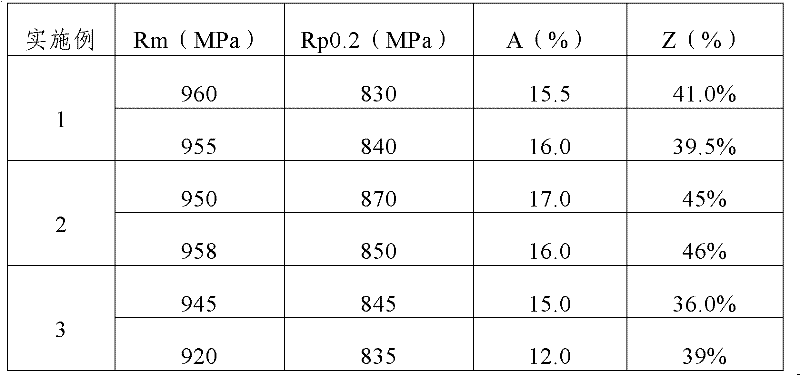

Processing method for TC4 titanium alloy large-sized bar

The invention discloses a processing method for a TC4 titanium alloy large-sized bar. The method comprises the following steps of: cogging and forging TC4 titanium alloy ingots for 2 to 3 heating times to obtain forging billets; 2, upsetting the forging billets repeatedly and performing drawing-out forging for 2 to 3 heating times; 3, upsetting the forging billets subjected to forging repeatedly and performing drawing-out forging for 3 to 5 heating times; and 4, performing chamfering round forging on the forging billets subjected to forging for 2 heating times to obtain the TC4 titanium alloy large-sized bar with the diameter of 200 to 400 mm and length of not less than 2,500 mm. The TC4 titanium alloy bar processed by the method has uniform and fine grains, few internal defects and high safety and accords with the domestic advanced level of the like products. In the processed TC4 titanium alloy bar, the room-temperature tensile strength is 920 to 960 MPa; the yield strength is 830 to 870 MPa; the elongation percentage is not less than 12 percent; the contraction ratio of the cross section is not less than 36 percent; flaw detection clutter reflects small signals; and the flaw detection level is high.

Owner:WESTERN TITANIUM TECH

Al-Fe-C-RE aluminium alloy, preparation method thereof and power cable

ActiveCN103103387AEvenly heatedEliminate damagePower cablesMetal/alloy conductorsPower cableMetallurgy

The invention provides an Al-Fe-C-RE aluminium alloy and a preparation method thereof. The preparation method comprises the following steps of: a) casting an aluminium alloy cast ingot; b) homogenizing the aluminium alloy cast ingot and rolling the homogenized aluminium alloy cast ingot to obtain an aluminium alloy rod material; c) intermittently annealing the aluminium alloy rod material obtained in the step b); and d) aging the aluminium alloy rod material obtained in the step c), thus obtaining the aluminium alloy. The invention also provides a power cable. The aluminium alloy has better overall performances by selecting and controlling the added elements and adopting a reasonable preparation process.

Owner:ANHUI JOY SENSE CABLE

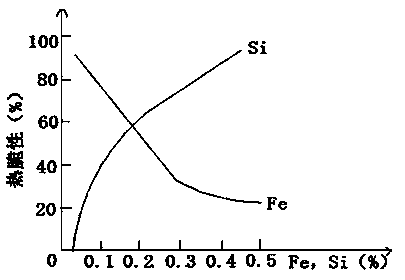

Ultrahigh-strength Al-Zn-Mg-Cu system aluminum alloy large-size flat cast ingot and making method thereof

The invention discloses an ultrahigh-strength Al-Zn-Mg-Cu system aluminum alloy large-size flat cast ingot and a making method thereof, and belongs to the aluminum alloy making field. The flat cast ingot comprises, by mass, 2.0-2.4% of Cu, 1.95-2.5% of Mg, 5.5-9.0% of Zn, 0.08-0.15% of Zr, 0.0003-0.0015% of Be, below 0.06% of Ti, below 0.04% of Cr, below 0.10% of Mn, 0.085% or less of Si, 0.14% or less of Fe, and the balance Al and inevitable elements, wherein the content of each of the inevitable elements is lower than 0.05%, the total amount of the inevitable elements is lower than 0.15%, and a content ratio of Fe to Si is not less than 1.6. The making method disclosed in the invention improves traditional making methods, and does not need pure aluminum bottoming, and the flat cast ingot made in the invention has the advantages of large size, high strength, no cracks, and high casting success rate.

Owner:广西南南铝加工有限公司

Method for producing monocrystalline metal or semi-metal bodies

InactiveUS20090047203A1Cheap methodCost effective productionPolycrystalline material growthSiliconVertical gradientCrucible

Owner:SCHOTT AG

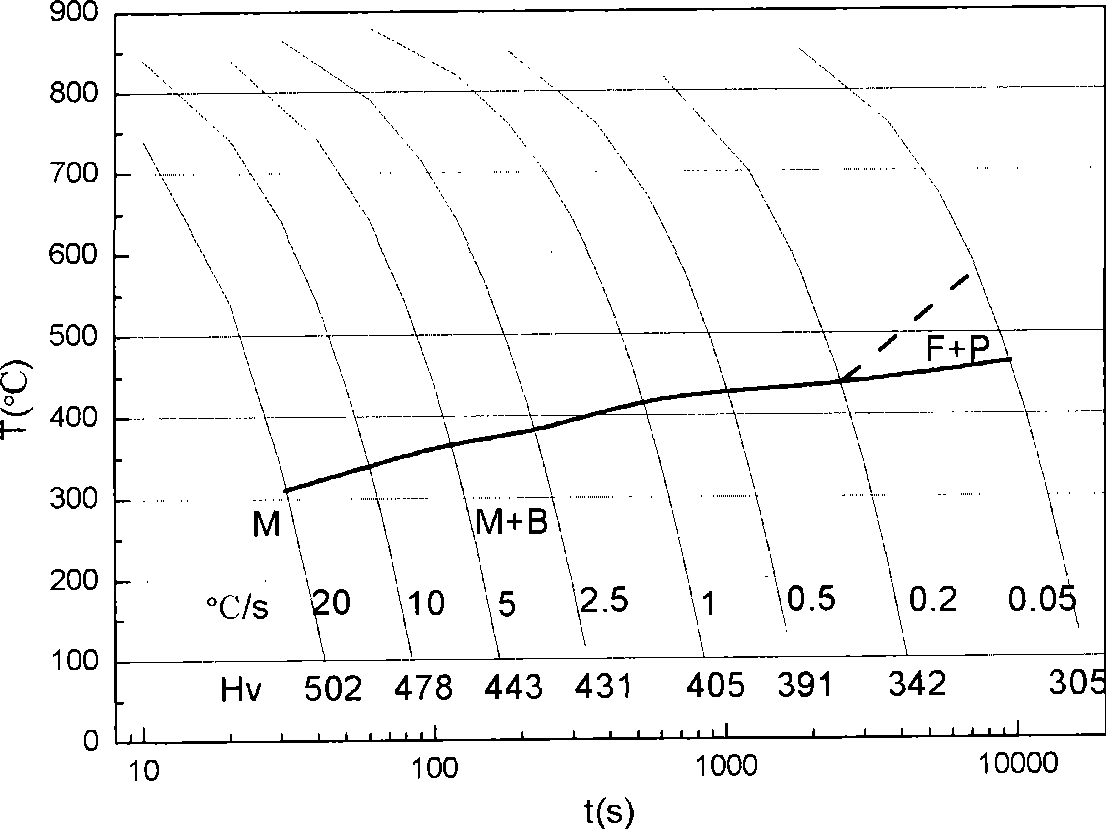

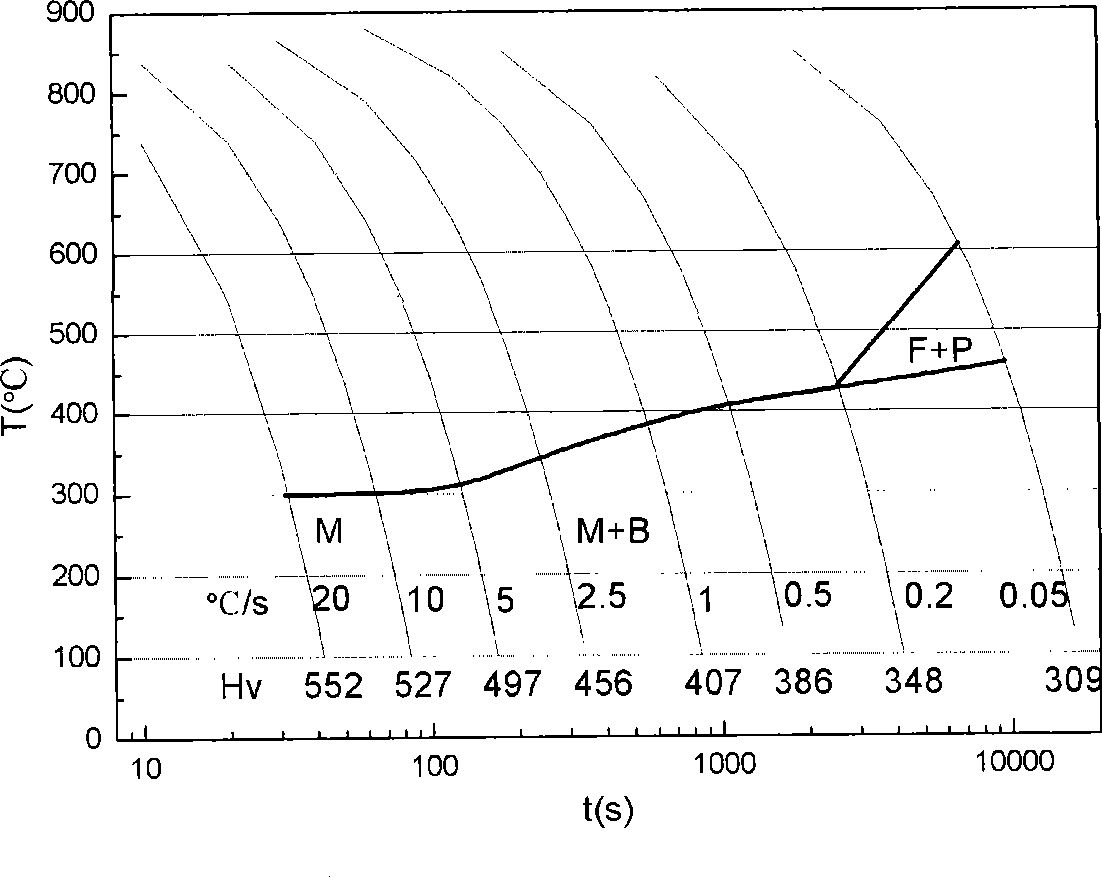

High-performance marine mooring chain steel and manufacturing method thereof

InactiveCN101519751AGood weather resistanceImprove corrosion resistanceMetal rolling arrangementsIngotHeating furnace

The invention relates to high-performance marine mooring chain steel and a manufacturing method thereof. The method comprises the following steps: a. tapping compositions comprise the following by weight percentage: C: 0.16 to 0.27, Mn: 0.40 to 1.45, Si: 0.15 to 0.50, Cr: 1.25 to 2.50, Ni: larger than 0 and less than 1.20, Mo: 0.20 to 0.60, Al: 0.01 to 0.06, N: 0.004 to 0.015, S: not larger than 0.005, P: not larger than 0.015, Cu: larger than 0 and less than 0.50, and the balance of Fe; b. a steel ingot or a continuous casting billet is casted after the steps of primary smelting in an electric stove or a converter, external refining and vacuum degassing; c. the charging temperature of a heating oven is not larger than 900 DEG C, the heating rate is not larger than 150 DEG C / h; when being raised to 1100 to 1300 DEG C, the temperature is kept for more than 40 minutes, cogging bloom or rolling by a finisher is carried out, and the finishing temperature is not larger than 1050 DEG C; and d. after heated at the temperature of 1000 to 1250 DEG C, the cogged ingot is hot-rolled or forged into round steel, the finishing temperature is not larger than 1050 DEG C, and after rolling, the steel is air-cooled, slow cooled or softening heat-treated at the temperature of not less than 600 DEG C. The performance of finished products achieves or exceeds the requirement of level 4.5 and level 5 of mooring chain steel.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

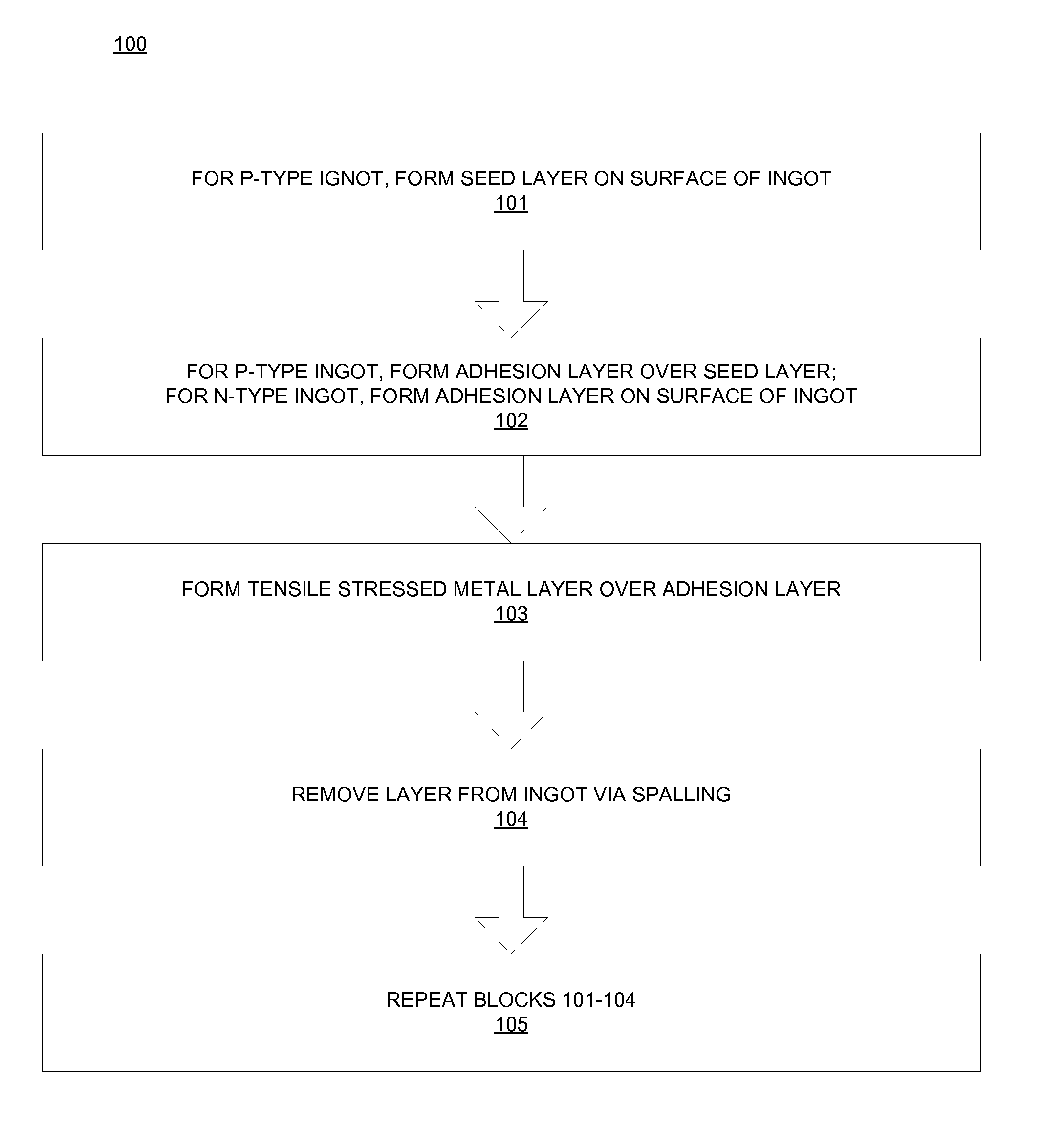

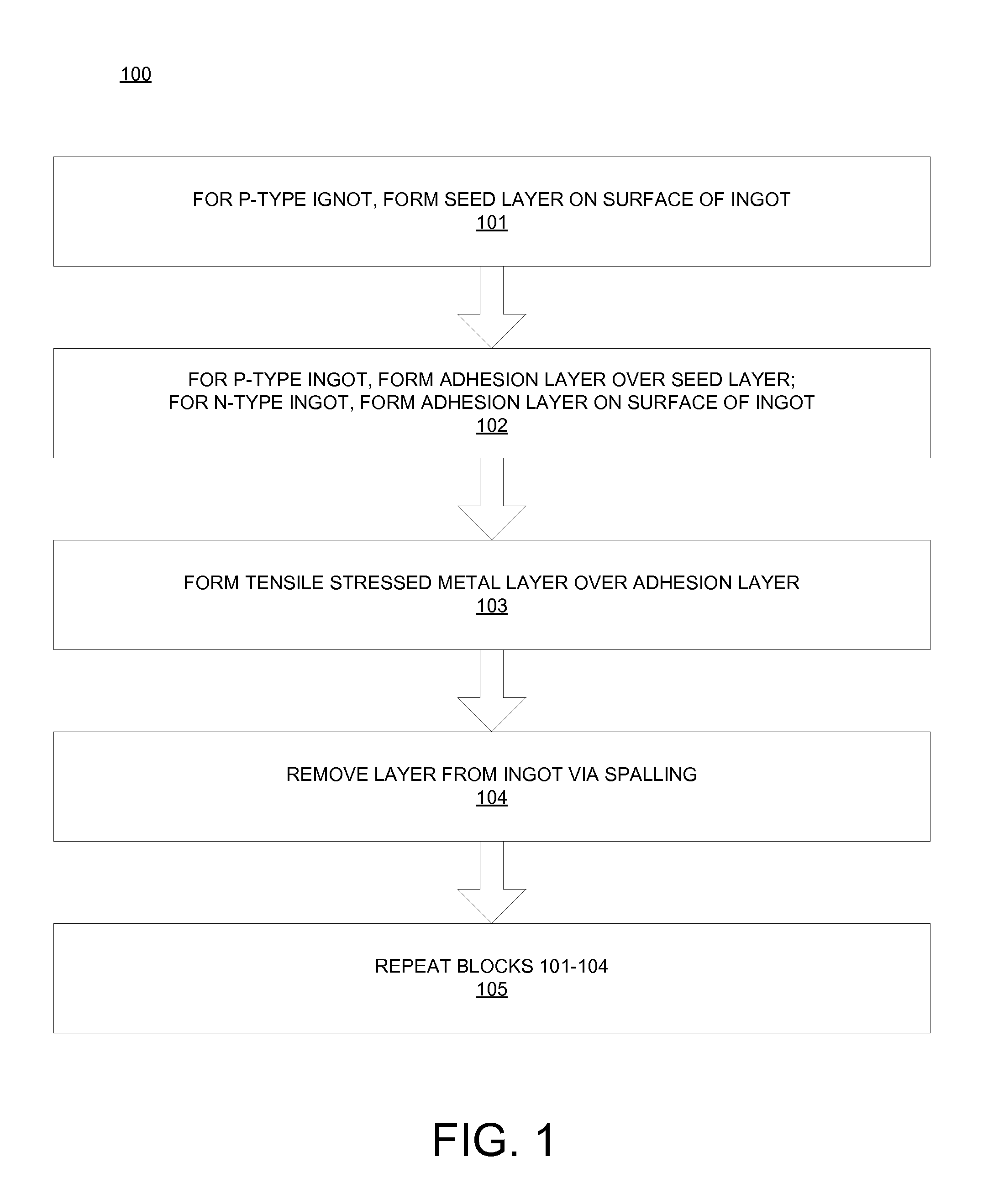

Spalling for a Semiconductor Substrate

InactiveUS20100310775A1Pretreated surfacesSemiconductor/solid-state device manufacturingIngotSemiconductor

A method for spalling a layer from an ingot of a semiconductor substrate includes forming a metal layer on the ingot of the semiconductor substrate, wherein a tensile stress in the metal layer is configured to cause a fracture in the ingot; and removing the layer from the ingot at the fracture. A system for spalling a layer from an ingot of a semiconductor substrate includes a metal layer formed on the ingot of the semiconductor substrate, wherein a tensile stress in the metal layer is configured to cause a fracture in the ingot, and wherein the layer is configured to be removed from the ingot at the fracture.

Owner:GLOBALFOUNDRIES INC

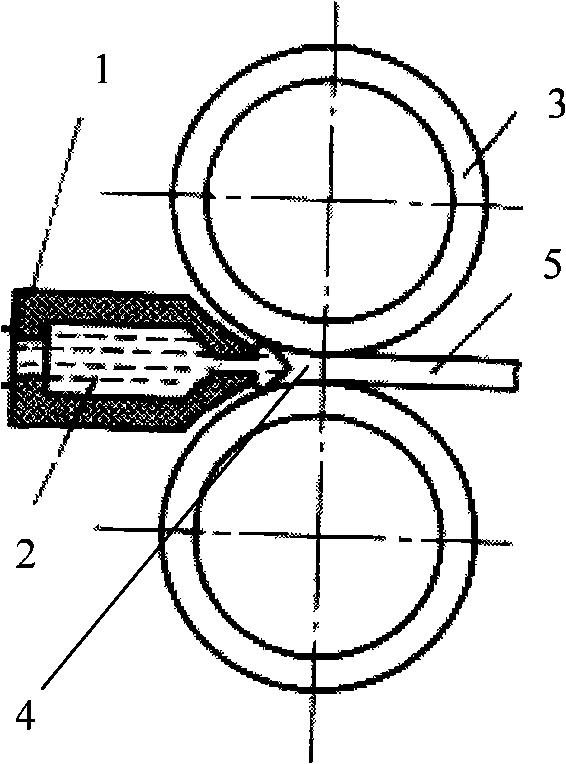

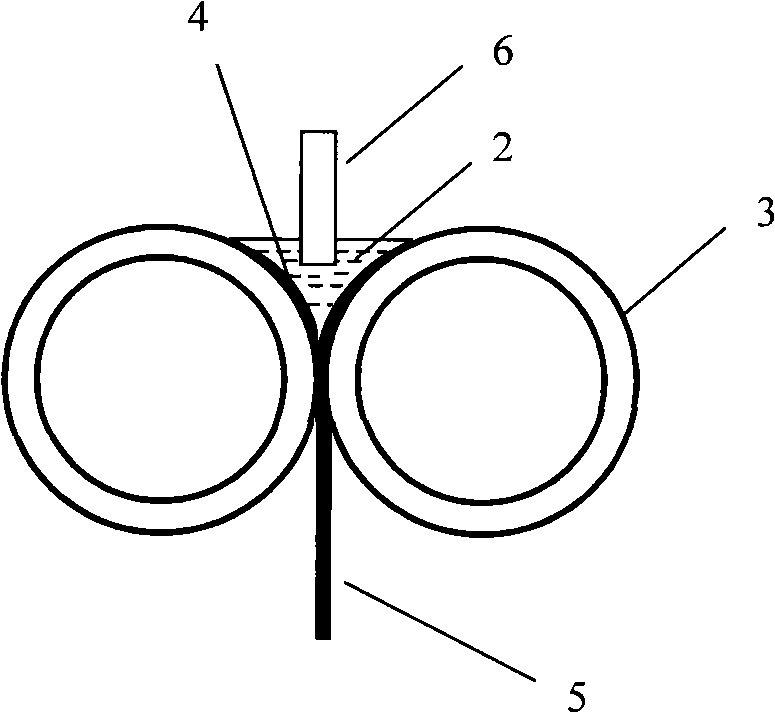

Continuous casting technique for aluminum alloy thin belt blank

InactiveCN101269406AImprove organizationComprehensive mechanical properties of high thin stripIngotMaterials science

The invention discloses a continuous casting process of an aluminum thin billet, which is characterized in that the following steps are included: aluminum alloy ingots are preheated and are melted in a melting furnace in the role of a flux; before casting, a side closure system is preheated to 400-450 DEG C, when the temperature of a melting body ranges from 650 DEG C to 680 DEG C, the aluminum alloy ingots are arranged into a tundish for 15 to 30 minutes in the role of the flux, then through a flux distributing device, the aluminum alloy ingots flow into an equant vertical twin-roll thin strip billet continuous caster, with a left forging seam gap being 0 mm and maintaining the height of a melting pool between 90 mm and 340 mm, the casting is carried out in a sinking way; when in casting, the casting speed of the casting machine ranges from 20 to 120m / min, the thin strip blank is sent into a pinch roll after leaving a casting roller, and the forged aluminum alloy thin strip has a thickness between 1.0 mm and 3.5 mm. The continuous casting process can directly make aluminum alloy thin strip blank from the liquid aluminum alloy, the forged thin strip blank has good quality on the surface, and the internal organizational structure is uniform, thereby being conducive to succeeding rolling processes. The continuous casting process for an aluminum thin blank has short process and low cost.

Owner:CHONGQING UNIV

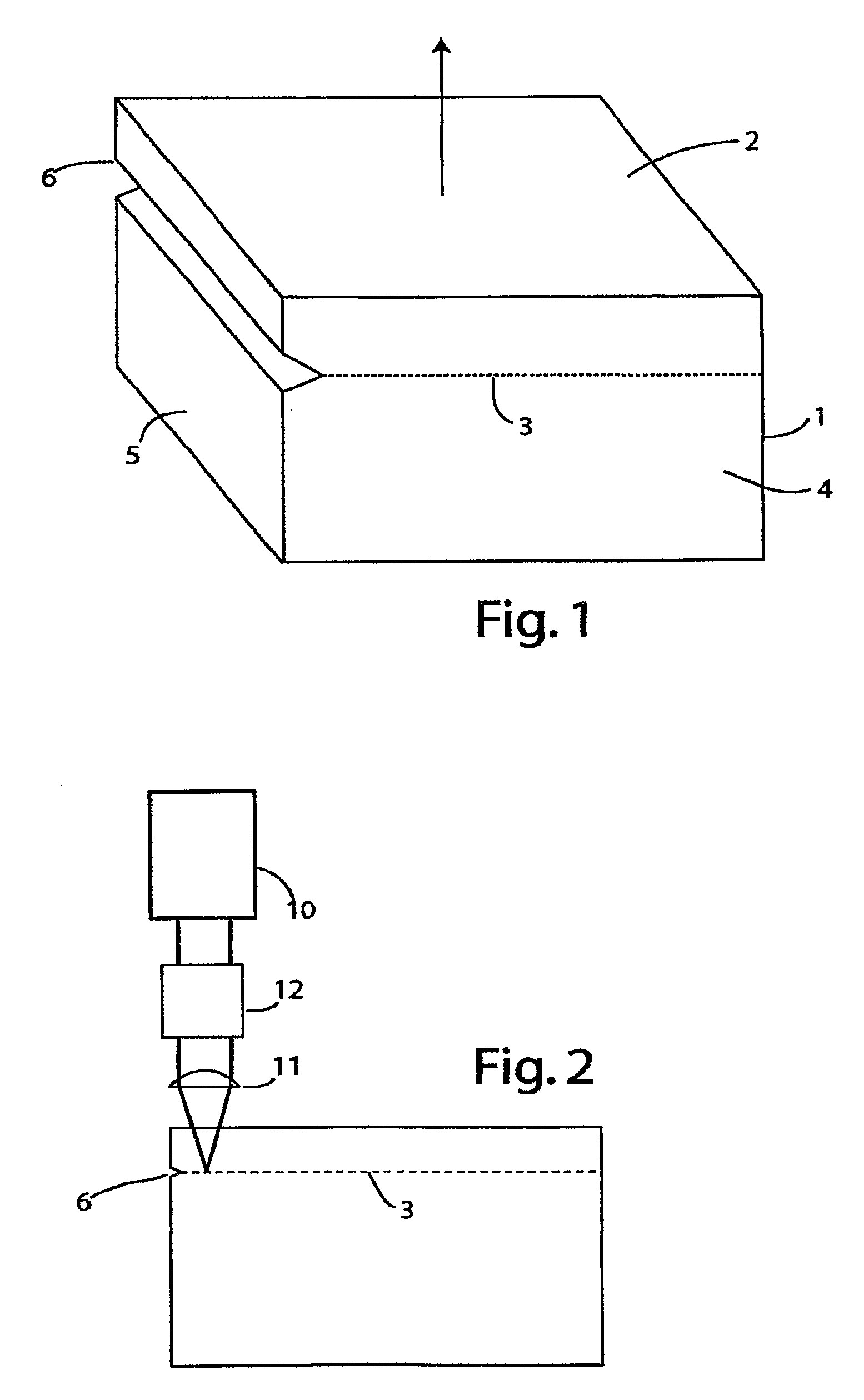

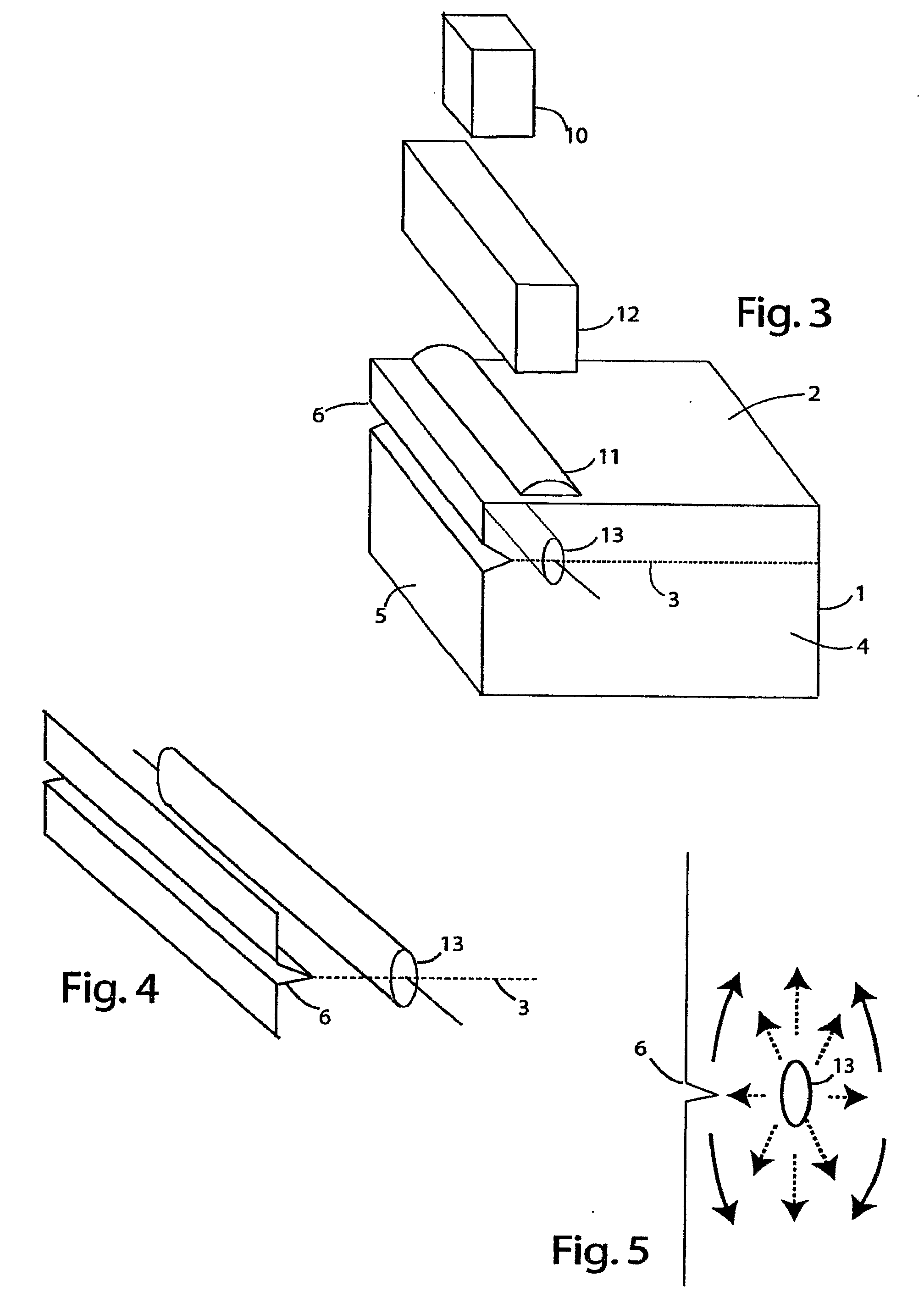

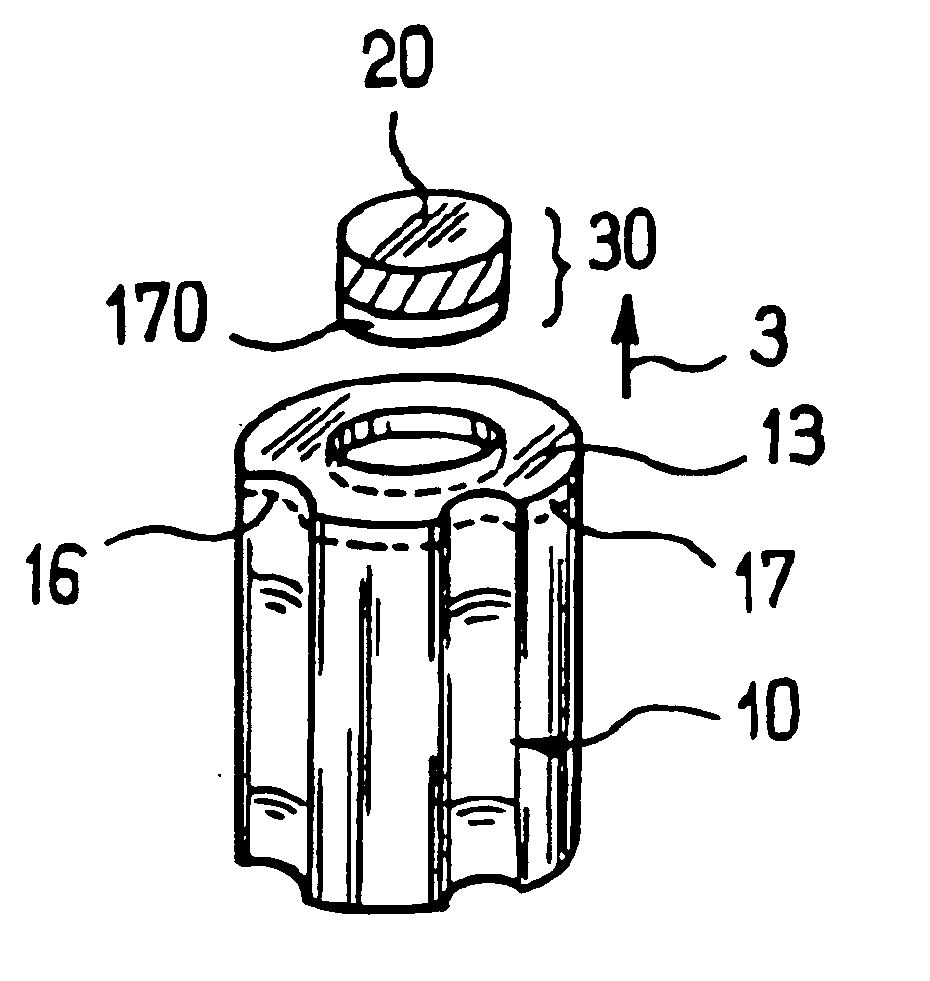

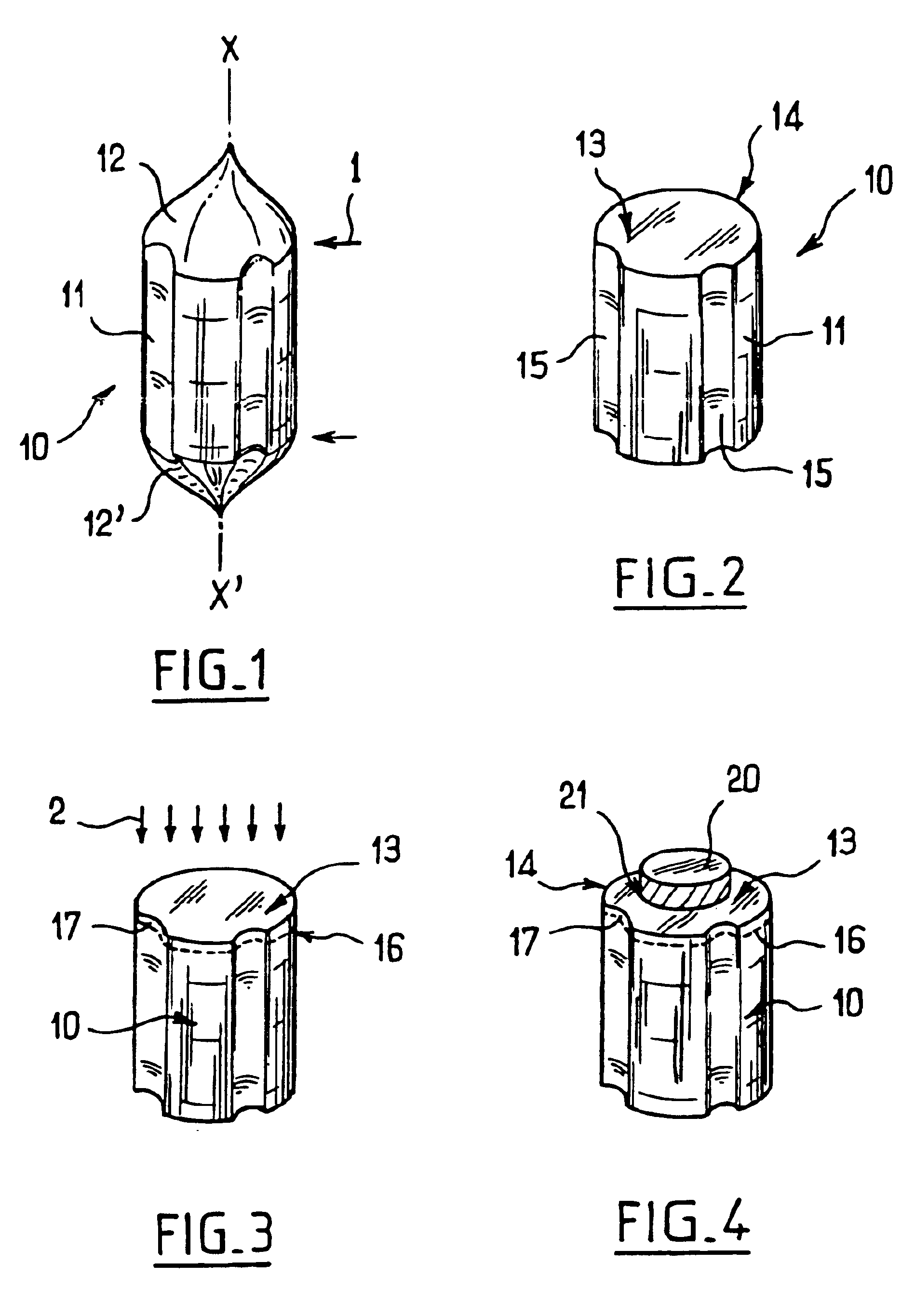

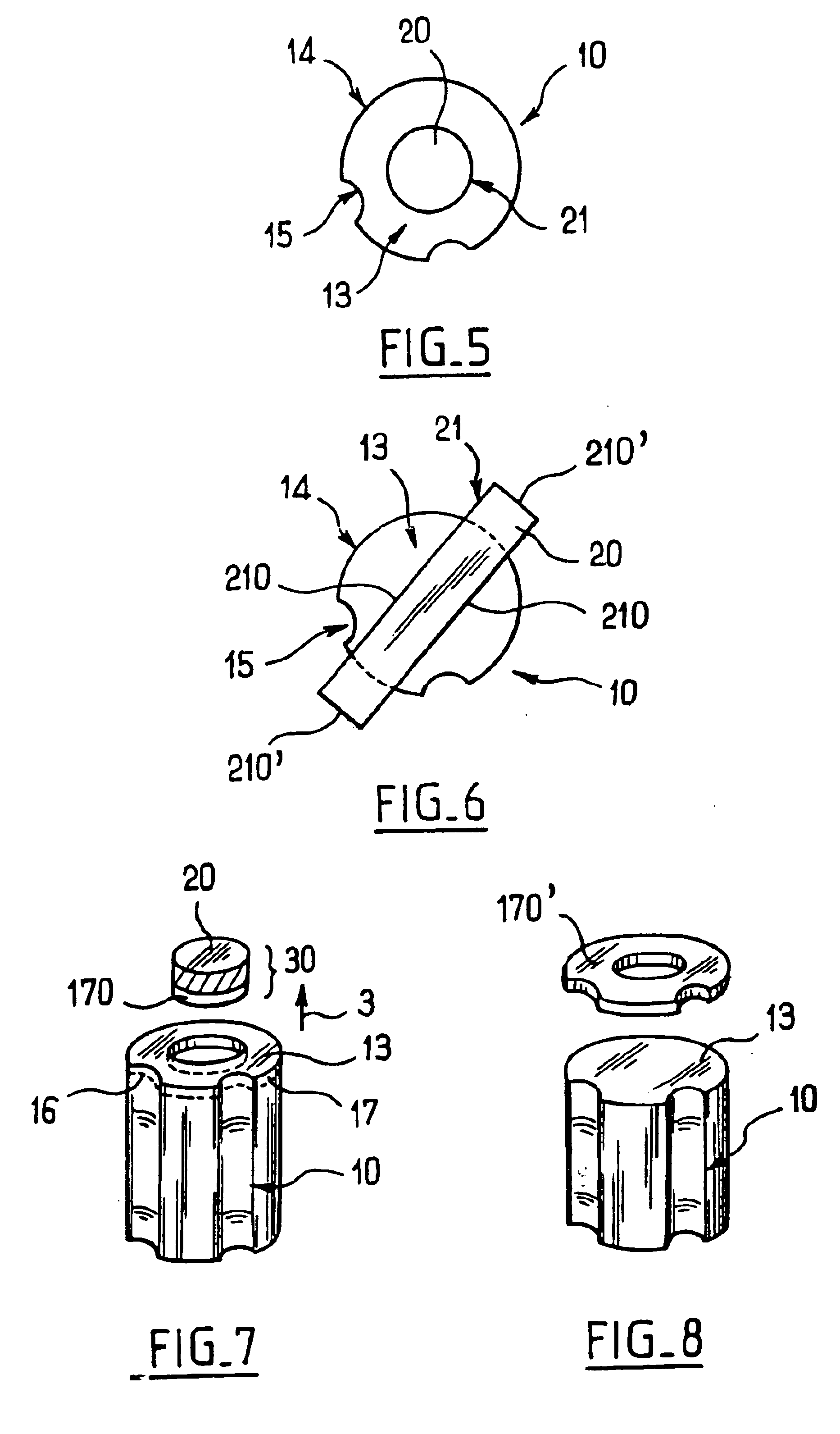

Method of fabricating substrates, in particular for optics, electronics or optoelectronics

ActiveUS6858107B2Reduce lossesDecorative surface effectsSemiconductor/solid-state device manufacturingOptoelectronicsIngot

A method of fabricating substrates while minimizing loss of starting material of an ingot, wherein a layer is transferred onto a support. The technique includes forming a flat front face on a raw ingot of material, implanting atomic species through the front face to a controlled mean implantation depth to create a zone of weakness that defines a top layer of the ingot, bonding a support to the front face of the ingot, wherein the support has a surface area that is smaller than a surface area of the front face of the ingot, and detaching from the ingot at the zone of weakness that portion of the top layer that is bonded to the support to form the substrate.

Owner:S O I TEC SILICON ON INSULATOR THECHNOLOGIES

Method for manufacturing polycrystalline silicon used for solar battery

InactiveCN101122047ASolve environmental problemsPolycrystalline material growthFinal product manufactureSilicon monoxideElectrical battery

A method of preparing a polycrystalline silicon for solar batteries adopts combined means of silicon monoxide disproportionation, acid dipping separation and vacuum melting and processes by the following procedures: (1) the silicon monoxide is made from chemical pure industrial silicon and high purity sand quartz. (2) the high purity silicon is obtained by disproportionation of the silicon monoxide. (3)impurities boron and phosphorus in the silicon are removed by soaking with aquafortis. (4) the high purity silicon is further purified by melting of a vacuum electro beam furnace, and parts with impurities heavily gathered in a cast ingot are cut. (5) nitrogen or nitrogen plus hydrogen is fed into a plasma furnace for melting, so as to further remove the rest boron, phosphorus and other impurities, and conduct directional solidification. (6)the outer skin and parts with impurities heavily gathered of the cast ingot are cut, and finally the high purity silicon which is above 6N pure and applicable to solar batteries is obtained. The invention rejects the technical route of the Siemens method, prevents environment pollution, improves safety of production, and is good for promotion and application in China.

Owner:李绍光

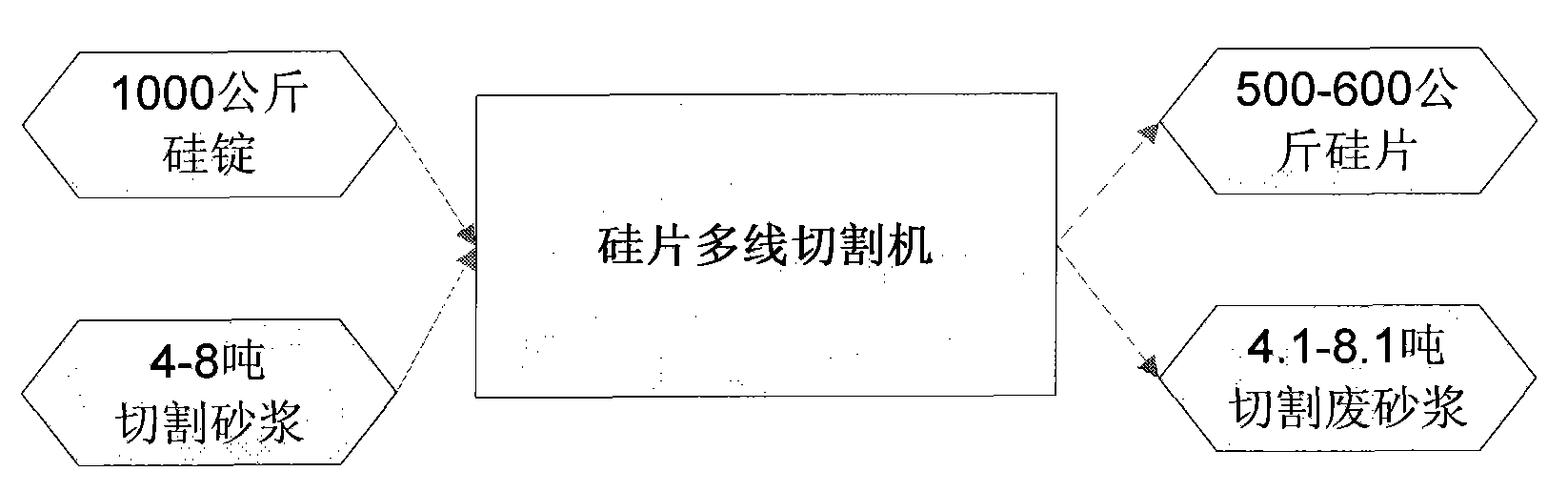

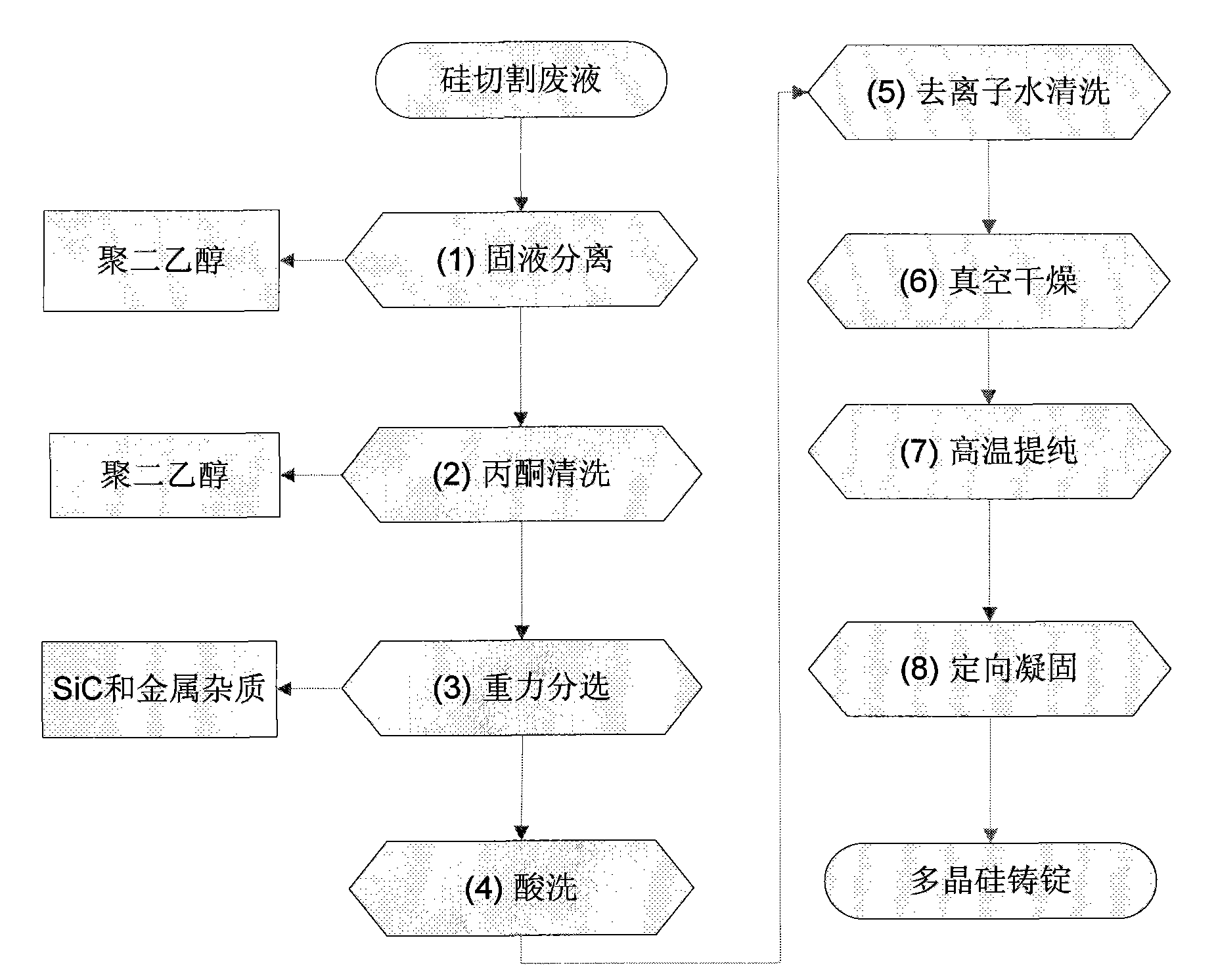

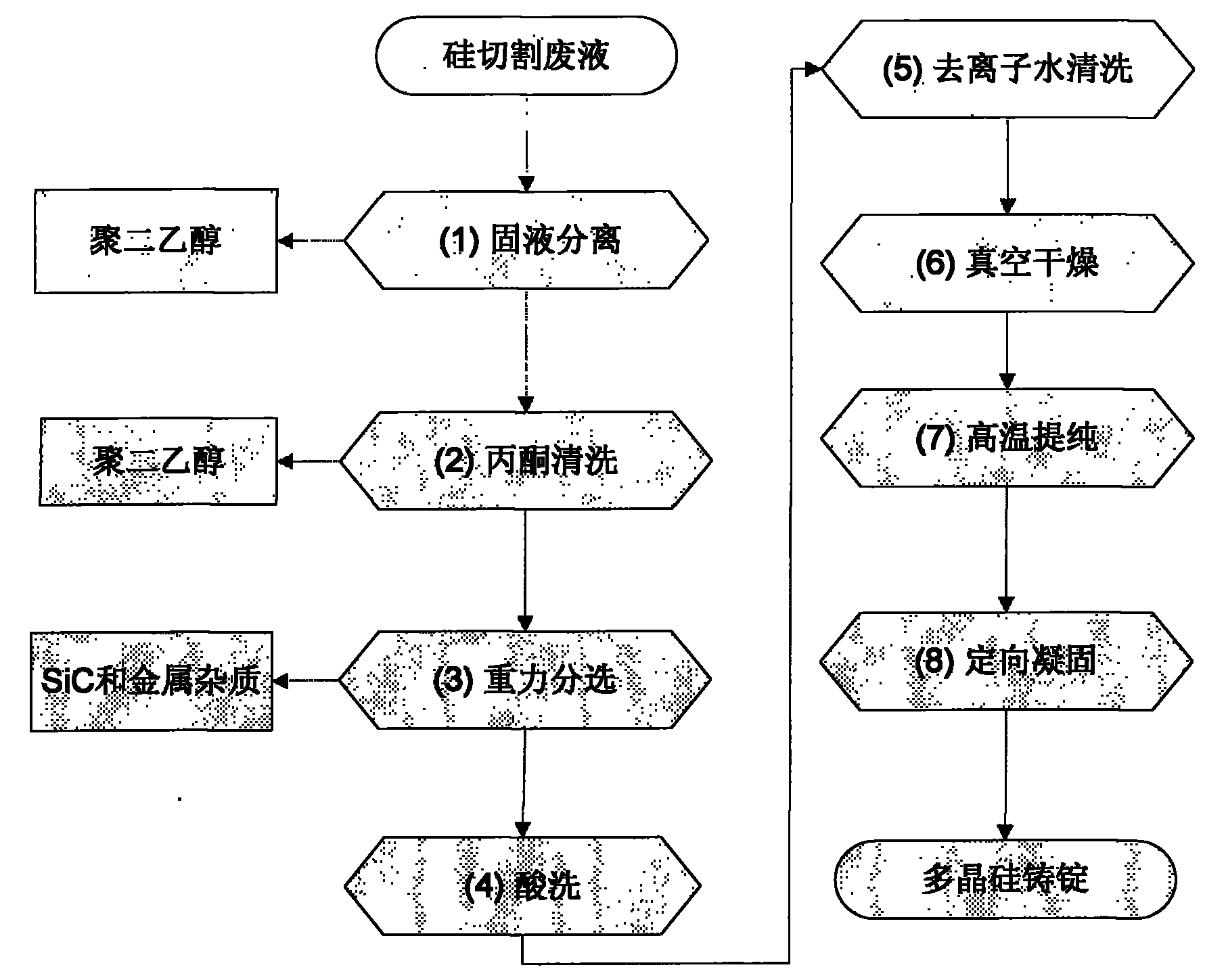

Method for recovering polysilicon ingots, carborundum powder and polyethylene glycol from cutting waste mortar

InactiveCN101792142AHigh yieldMultistage water/sewage treatmentSilicon compoundsPotassiumPolyethylene glycol

The invention discloses a method for recovering polysilicon ingots, carborundum powder and polyethylene glycol from cutting waste mortar. The recovering method comprises the following steps shown as an attached diagram, wherein the high temperature purification comprises the following steps of: mixing the prepared silicon micro powder with a fluxing agent according to the weight ratio of 1: 0.5-5 into lumps, carrying out high temperature treatment in a high temperature vacuum furnace with the treatment temperature range of 1450-1800 DEG C and the treatment time range of 1-10h; and then carrying out directional solidification on melting-state high purity silicon subjected to the high temperature treatment to obtain the polysilicon ingots; wherein the fluxing agent is selected from one or any mixture of silica, alumina, calcium oxide, magnesium oxide, potassium oxide, sodium oxide, calcium fluoride, magnesium fluoride, sodium fluoride, sodium chloride, potassium chloride and calcium chloride. The invention has the advantages that: the yields of carborundum and polyethylene glycol are high and can reach more than 70-80 percent; and the recovered polysilicon ingots reach the purity of 6-7N and completely satisfy of the requirement for preparing silicon slices of silicon solar cell.

Owner:唐康宁

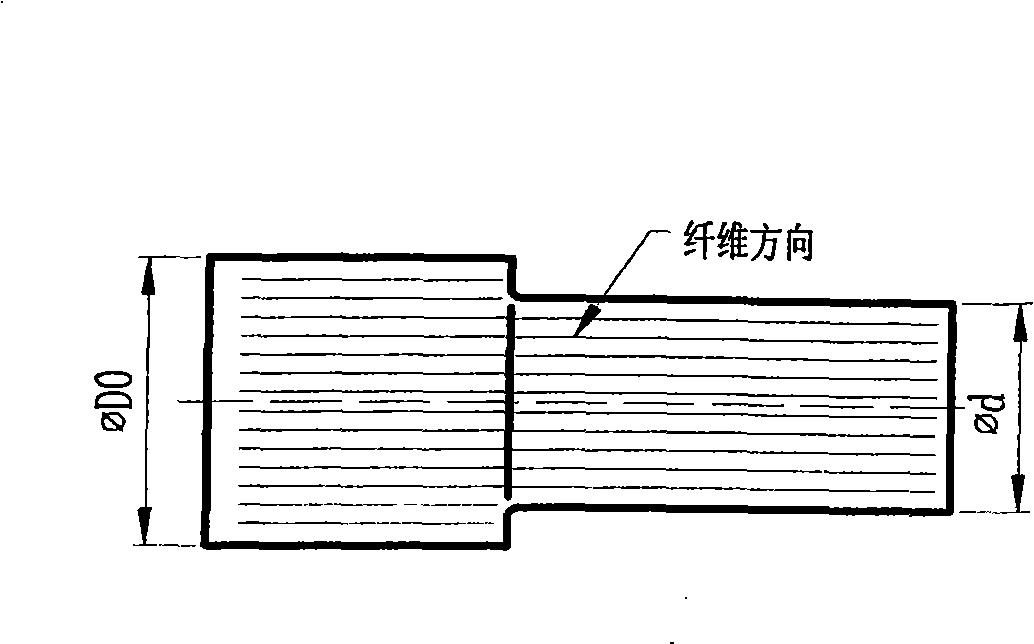

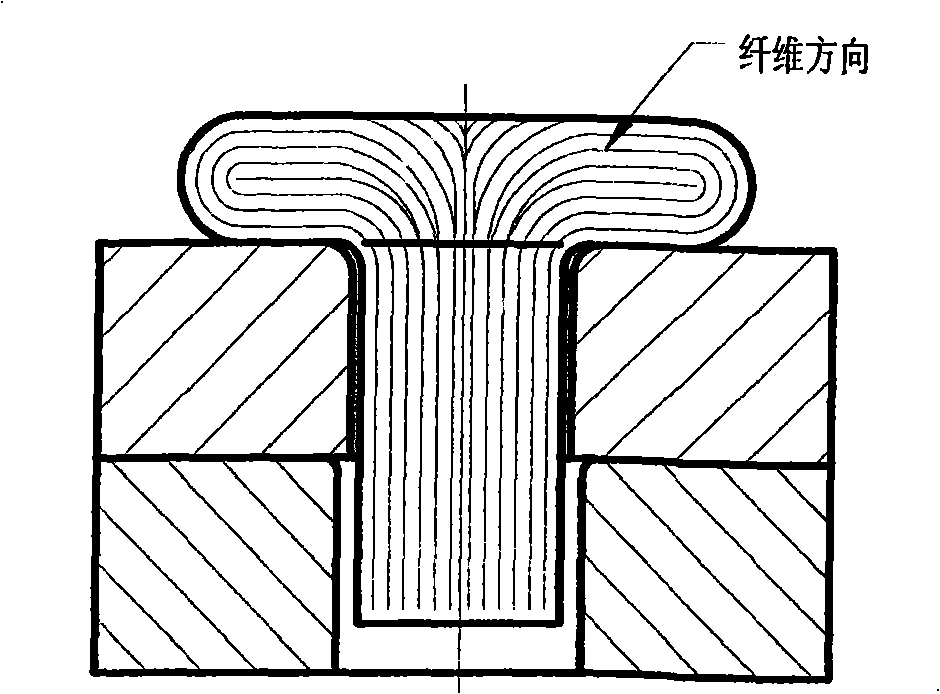

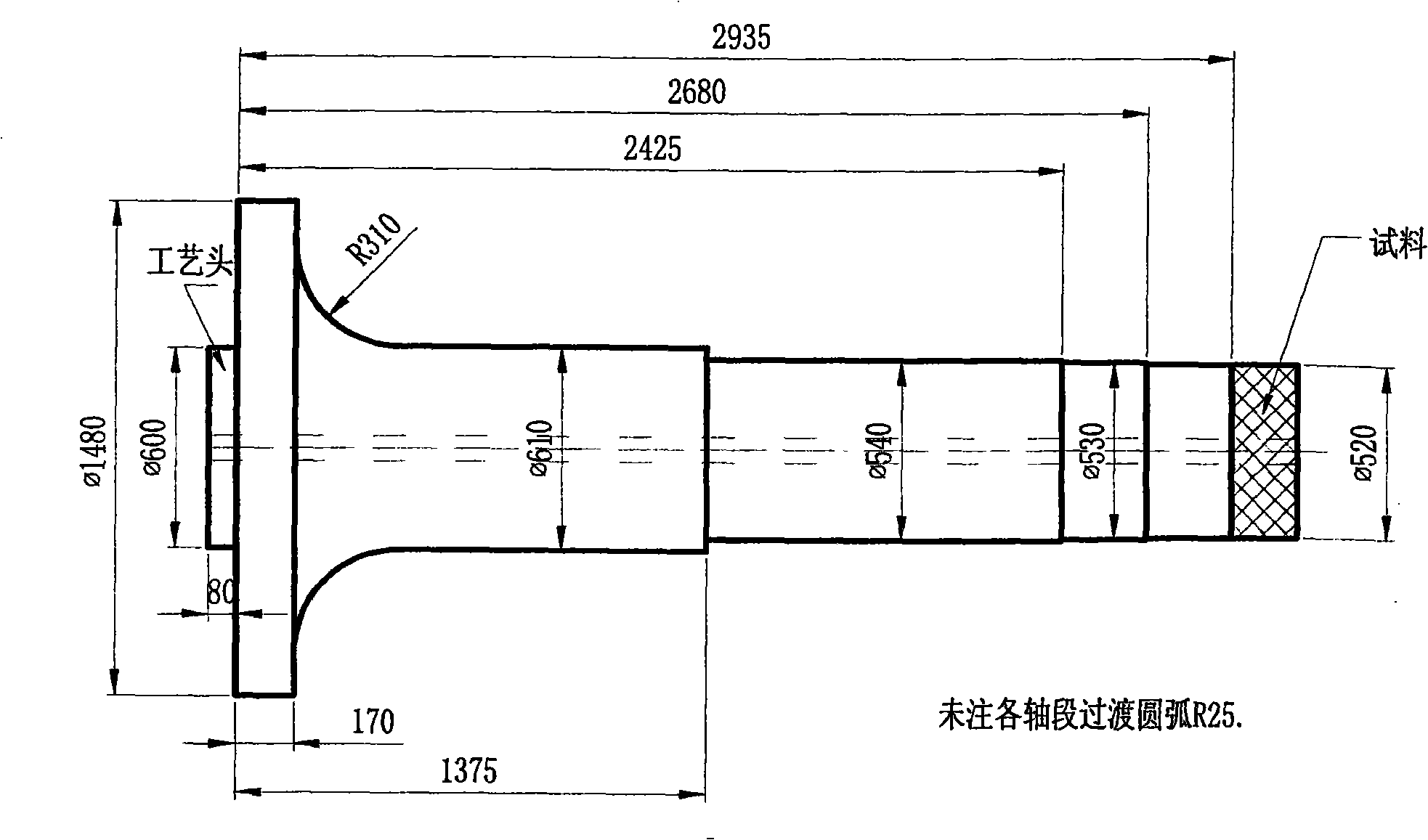

Method for producing wind-electricity principal axis with gathering stock full fibre upset forging

InactiveCN101314202ASolve the strength problemSolve process problemsShaftsFurnace typesElectricityIngot

The invention relates to a method for producing a wind-power mainshaft by local continuous upsetting and all-fibre upset forging. The method comprises the following: step one, the heating of steel ingot; step two, forging; step three, first heat processing; step four, rough machining and ultrasonic inspection; step five, quenching and tempering and heat processing; step six, fine machining, wherein, during the step two, the forging comprises that: (1) a first fire, during which, a steel ingot is subject to upset forging at a forging temperature of between 1250 and 900 DEG C; firstly, the bottom of the steel ingot is sawed off, and the steel ingot is subject to capping and upset forging; (2) a second fire, during which, the steel ingot is stretched towards various directions, marked and subject to intermediate billet cogging; after a pole part is molded, scrap on a T end is chopped and removed; after the forging is finished, the steel ingot returns to a heating furnace for being reheated; (3) a third fire, during which, the steel ingot is subject to local continuous upsetting and all-fibre upset forging; (4) a fourth fire, during which, the steel ingot is subject to rolling and leveling; the pole part is stretched; the disc edge of a hub end on the head part of an intermediate billet material after the local continuous upsetting and all-fibre upset forging is subject to rolling operation; after the rolling, the intermediate billet material is inserted into a leaking disc component again; the end face of the disc is pressed and leveled; after the shaping of the disc end is completed, a manipulator clamps the disc and stretches the pole part of the intermediate billet material to a dimension of a forgeable piece; thus, the mainshaft forging is completed. The method can improve the fatigue resisting strength of a wind-power mainshaft forging piece.

Owner:JIANGYIN ZENKUNG FORGING CO LTD

Aluminium-titanium-horon rare earth fining agent, and its preparing method

The invention relates to the thinning reagent having the aluminum, the boron and the lanthanide of the aluminum and the aluminum alloy, it belongs to the domain of the applied technique of the aluminum alloy. The said thinning reagent factors include the aluminum, the boron, the titanium and the lanthanide (mainly includes the lanthanum and the Ce), the said producing process is showed as follows: the pure aluminum ingot, the alloy ingot having the aluminum and the lanthanide, the potassium hexafluorotitanate and the potassium borofluoride are prepared according to the thinning reagent element confecting in advance; the aluminum ingot and the aluminum lanthanide ingot are heated and melted in the intermediate frequency inducing stove, then several material are added; the fusing body acts with the high temperature; the temperature keeps even and the dregs is removed after the action; then the fusing body is irrigated to the ingot or connecting cast and rolled to the line material. According to the said process condition, the high pure aluminum can be removed the pole crystal, the size of the crystal grain of the industry pure aluminum and all series of distortional aluminum alloy can be divided to under the 100um, the casting form crystal grain core can be reduced to under 2um firmly to all sorts of the aluminum used in the foil material; the size of the crystal grain of the alloy of the aluminum and the silicon can be reduced to under 150-200um. At the same time, the intension, the molding ability and the tenacity of the industry pure aluminum and all sorts of the aluminum alloy can be improved highly.

Owner:TSINGHUA UNIV

Preparation method of ultra-fine grain high-entropy alloy

The invention belongs to the technical field of metal materials and machining and relates to a preparation method of an ultra-fine grain high-entropy alloy. Firstly, smelting is conducted, an FeCoCrNiMn series high-entropy alloy is compounded to be an intermediate alloy composed of pure metal with the purity being higher than 99.5% or alloy elements, a vacuum furnace is adopted for smelting, and the furnace casting temperature is 1550-1600 DEG C; then after cast ingots are subjected to homogenization heat treatment at the temperature of 1000-1350 DEG C, strong deformation asynchronous and synchronous mixed cold rolling treatment is conducted, continuous rolling is conducted through single-pass large percent reduction, the total rolling quantity is no smaller than 85%, and alloy structure nanocrystallization is achieved; and the rolled alloy is subjected to annealing treatment under the temperature of 450-800 DEG C, and the high-entropy alloy of an ultra-fine grain structure is obtained. Compared with the prior art, the preparation method is simple in technique, easy to achieve on a plate rolling production line, high in production efficiency and low in cost; and the size of the prepared ultra-fine grain high-entropy alloy is large, the comprehensive mechanical performance is excellent, and the preparation method can be applied to the fields of engineering machinery, aeronauticsand astronautics, military industry, electronics, instruments and the like.

Owner:SHANGHAI JIAO TONG UNIV

Creep resistance magnesium alloy and preparation method thereof

A kind of alloy, which is anti-squirming, and the components of it and the weight percent of them is: 1.5-10%Y, 0.15-2.0%Zr, 0.3-2.0%Nd, 2.5-8%Gd, and one kind or several kinds of components among Sm, Dy, Tb, Ho, Er, Tm and Eu is also contained, the other is Mg. the following steps are contained in the method: (1) To prepare material (2) To improve the temperature of warm-up stove and melting stove (3) To warm up the material (4) To melt the purified magnesium ingots in batches (5) To melt the other materials, which has been warmed up, in the Mg solution. (6) To distribute equably the alloy components in the Mg solution. (7) To make into casting ingot, cast, billet, board material, pipe material, model material, stick material, line material and all kinds of forged piece. The Mg alloy can fulfill the need owing a higher mechanics performance and anti-squirming performance under high temperate, and the anti-causticity performance is higher than the Mg in existence.

Owner:GRIMAT ENG INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com