Patents

Literature

4872results about How to "Easy to stretch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

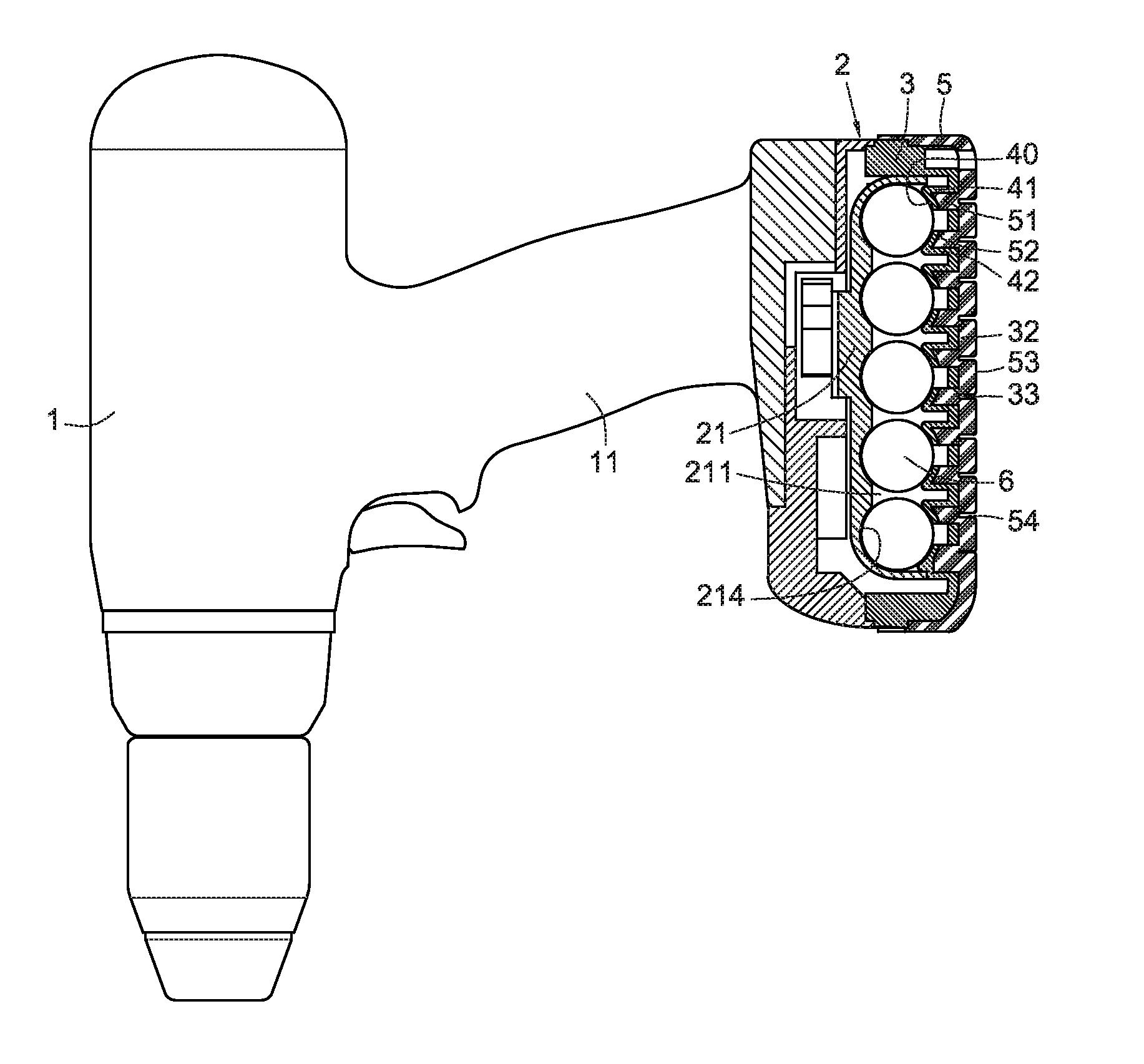

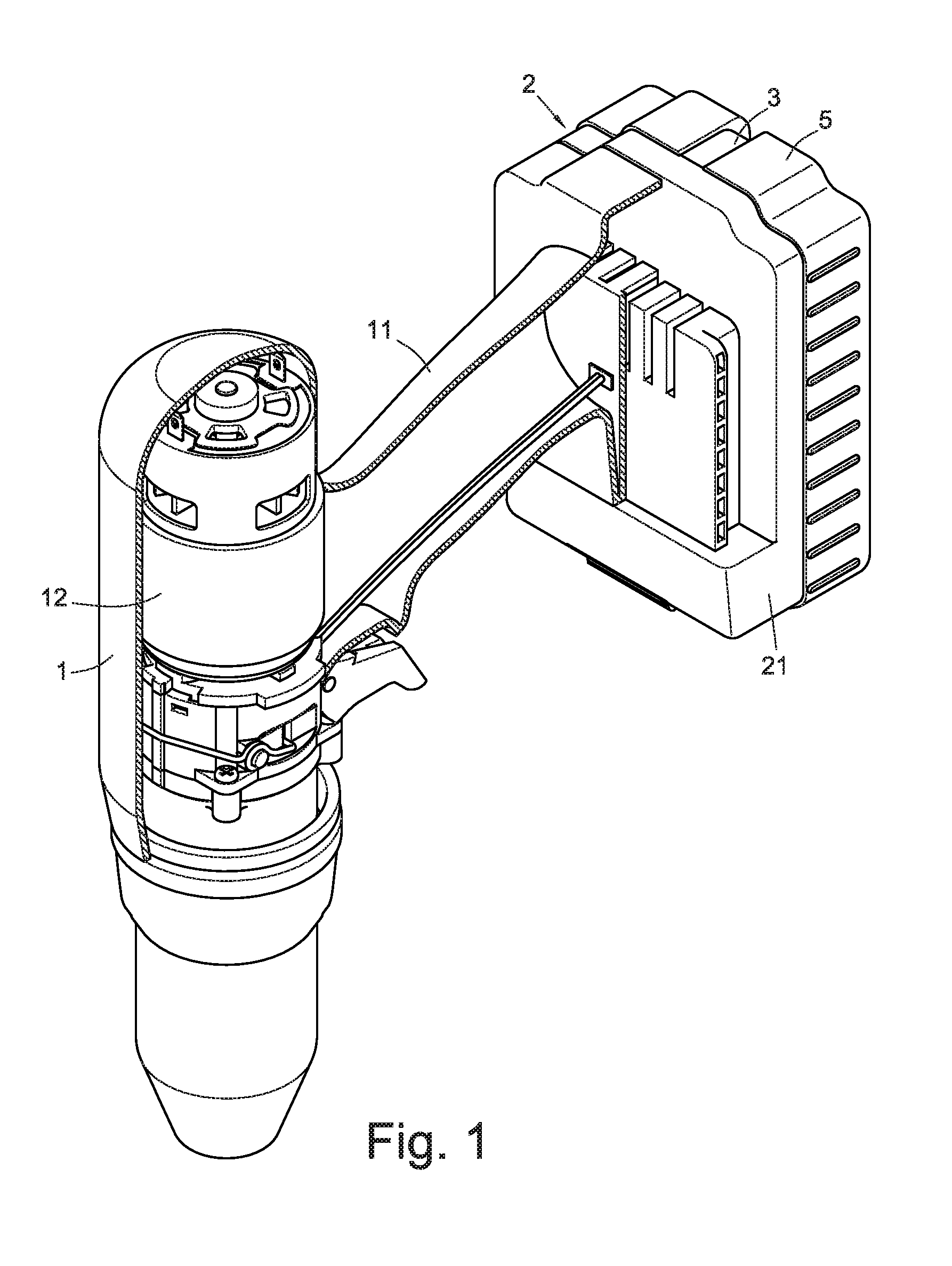

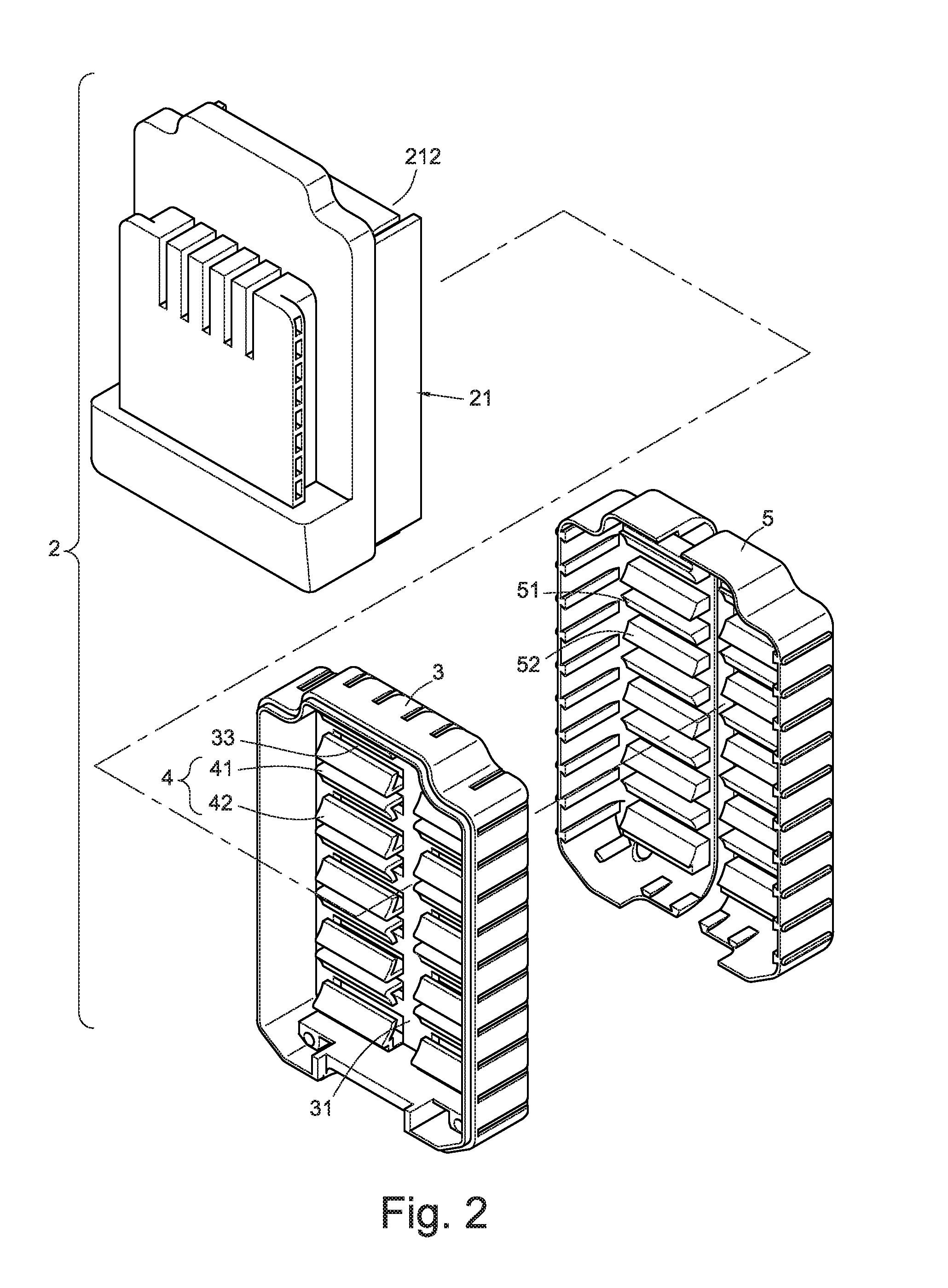

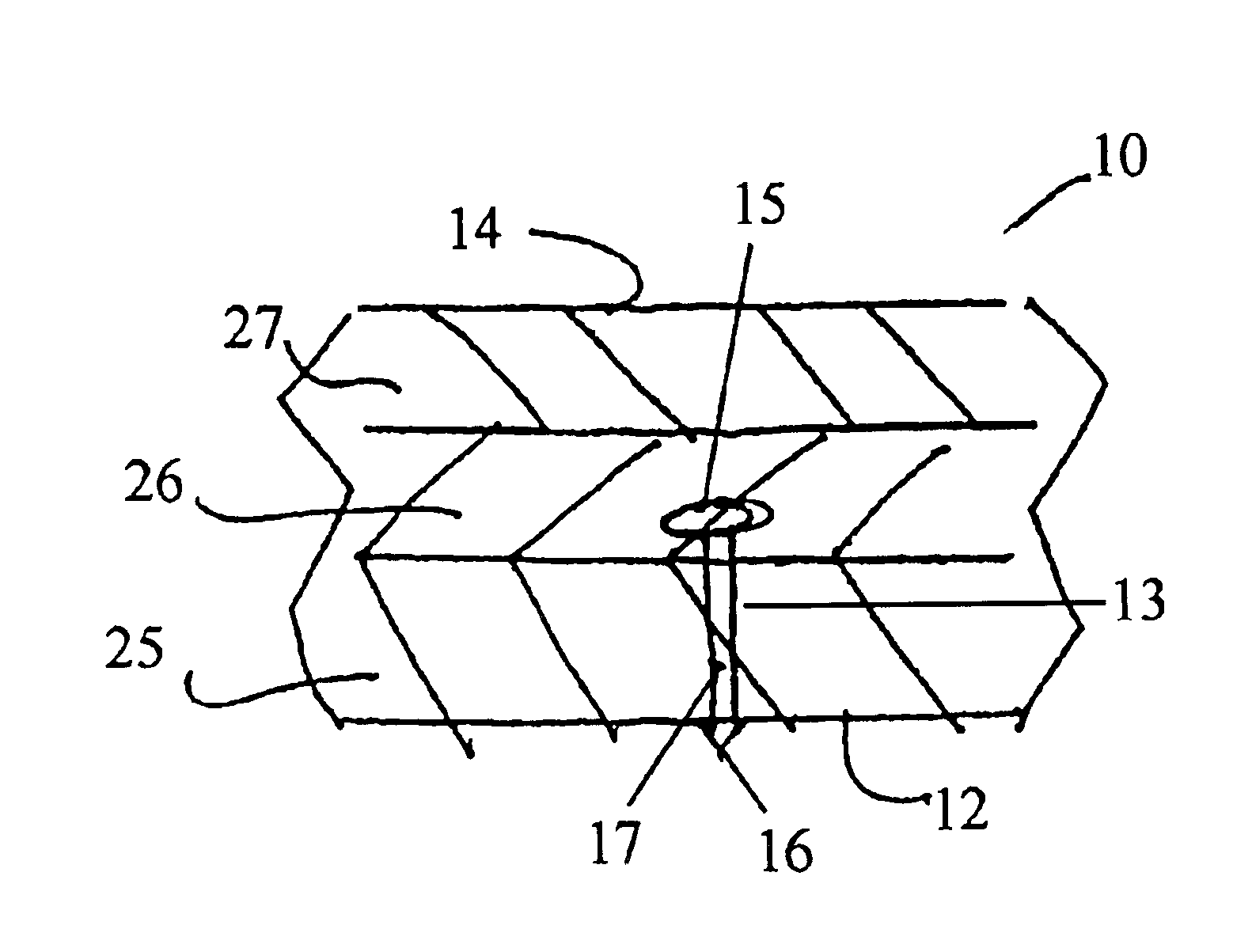

Shock proof structure of battery pack for receiving battery cell

InactiveUS20120251861A1Simple structureUpgrades stabilityBattery isolationPortable power-driven toolsEngineeringAbsorbance

A shock proof structure of a battery pack for receiving a battery cell is formed in an electrical tool. The battery pack includes a base having a space for receiving the battery cell and a lid for opening or closing the space. The space has a plurality of first buckling portions separated by a gap disposed at a bottom side thereof. A plurality of second buckling portions with shock absorbance is formed at an inner sidewall of the lid. The plate sets include two plates separated by a gap are symmetrically positioned. The plates of each plate set have a second buckling portion with a stretching gap formed in between. The second buckling portion is positioned at the opposite end of the first buckling portion to provide the battery cell to be steadily buckled between the first and the second buckling portions.

Owner:DE POAN PNEUMATIC

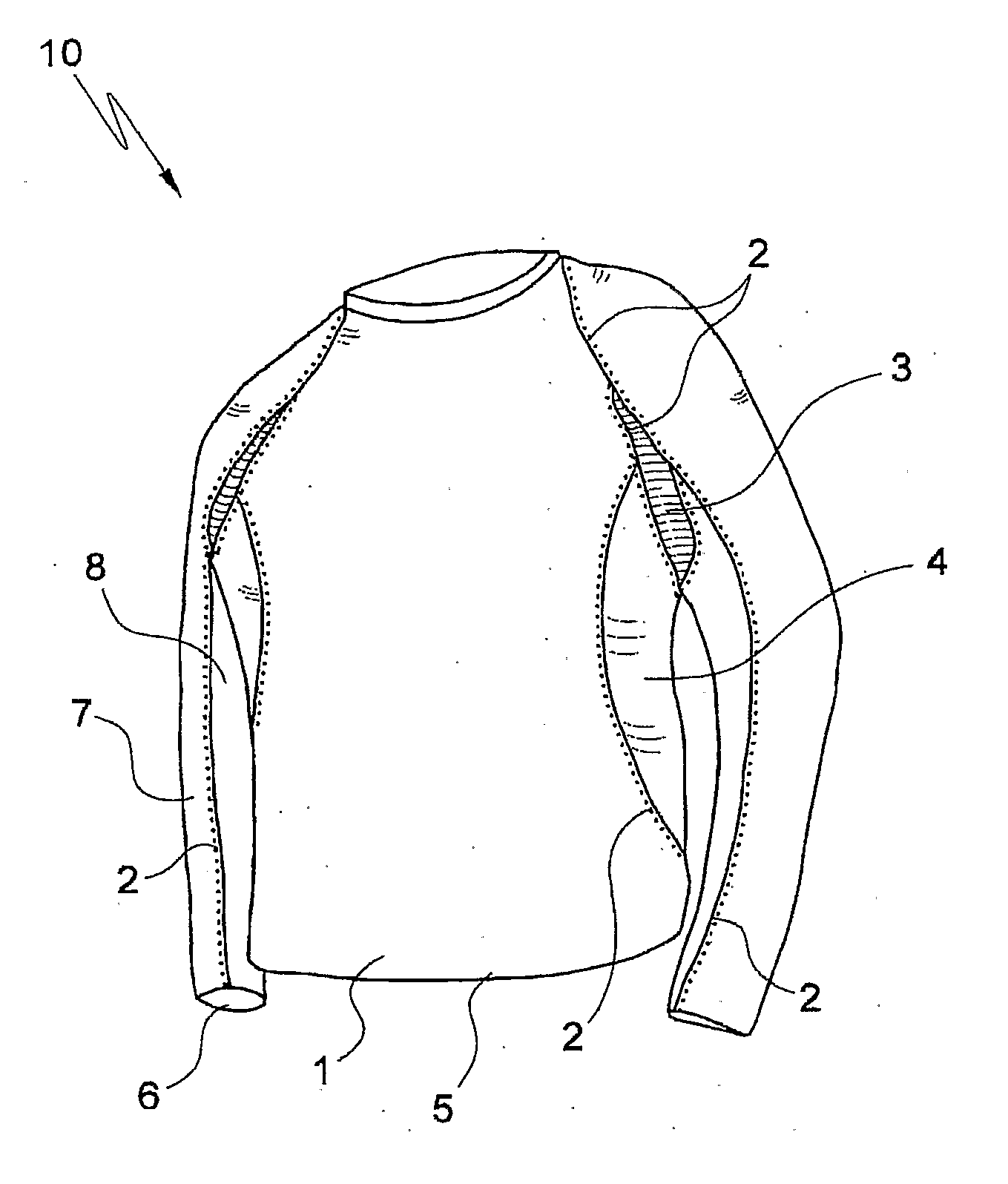

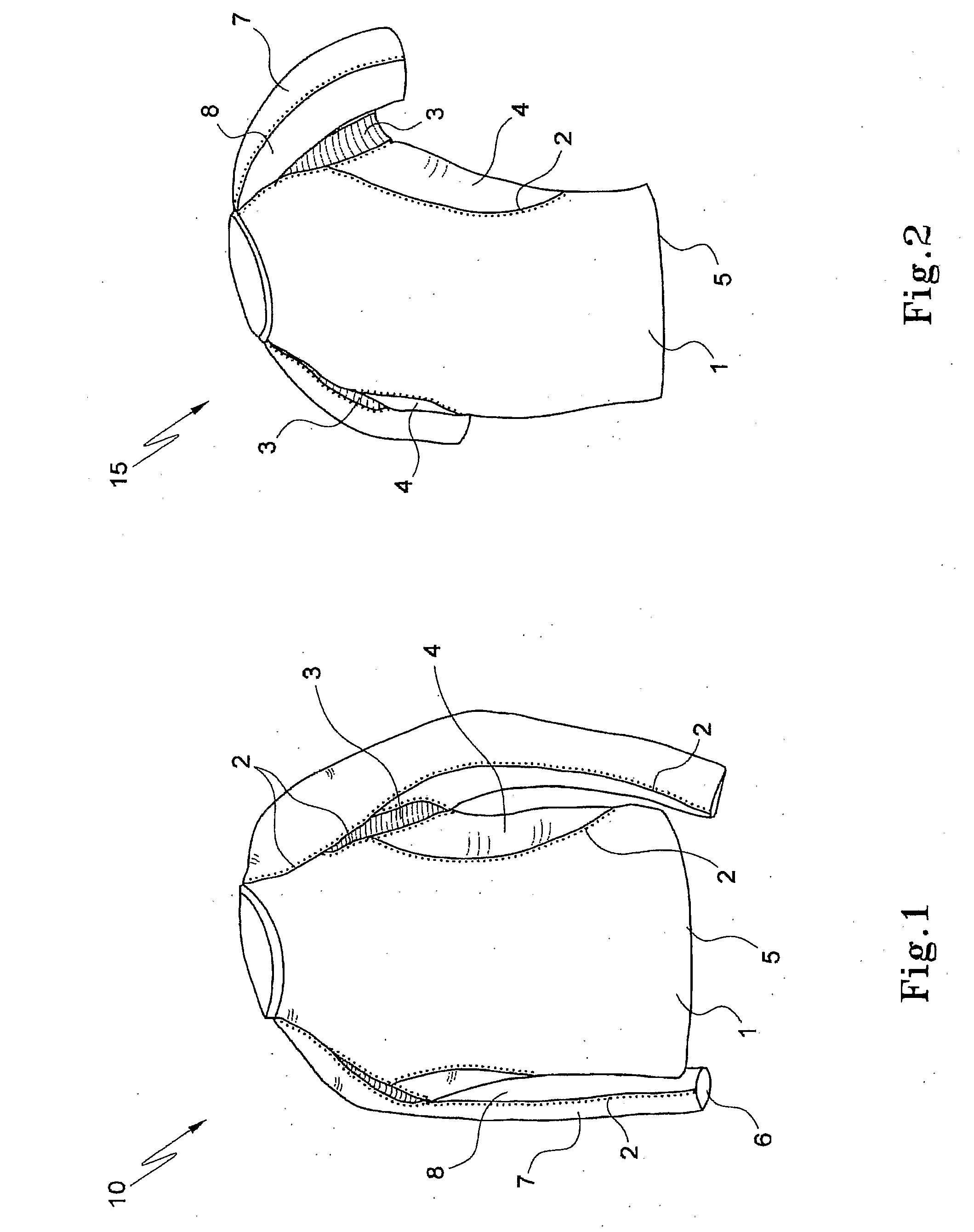

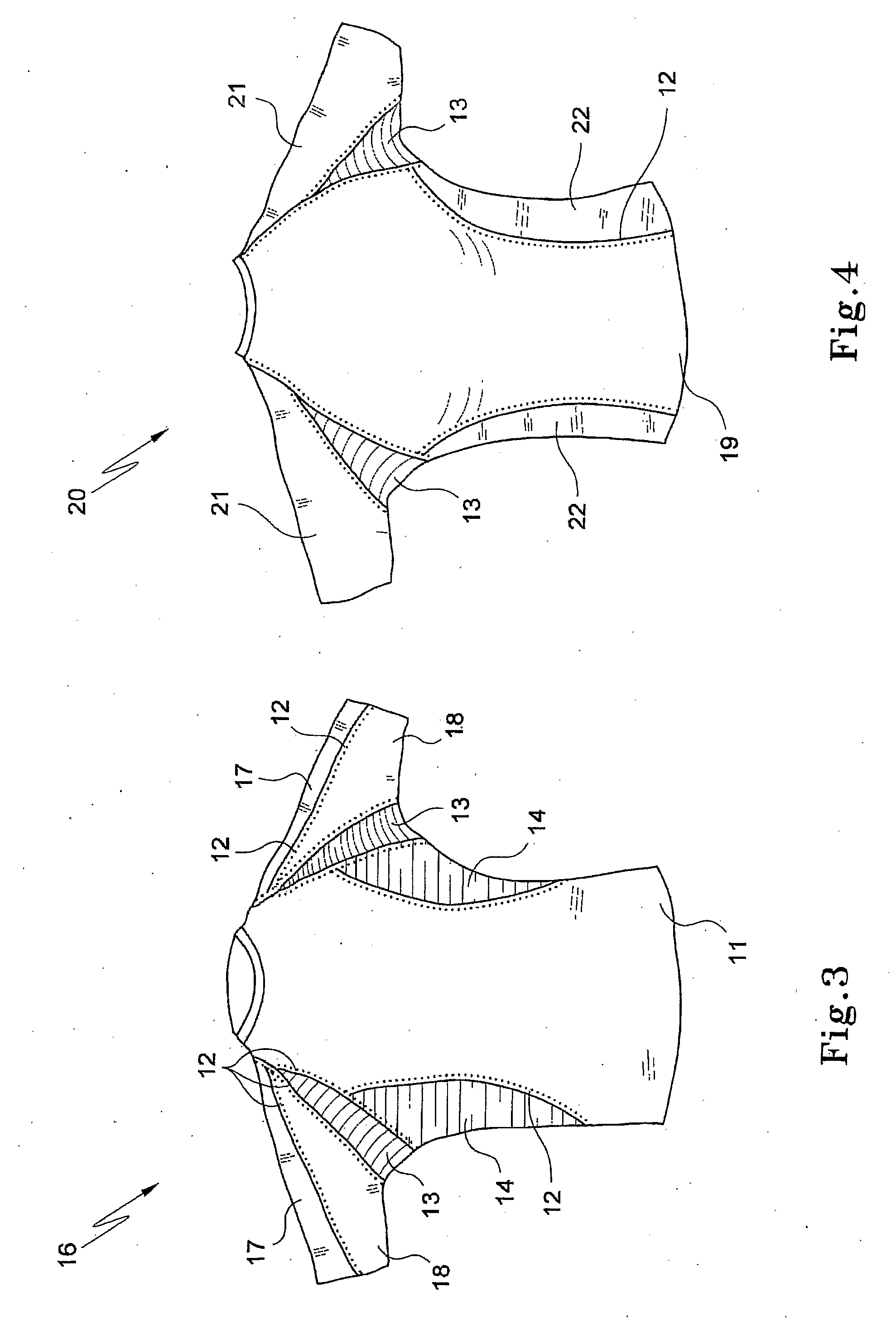

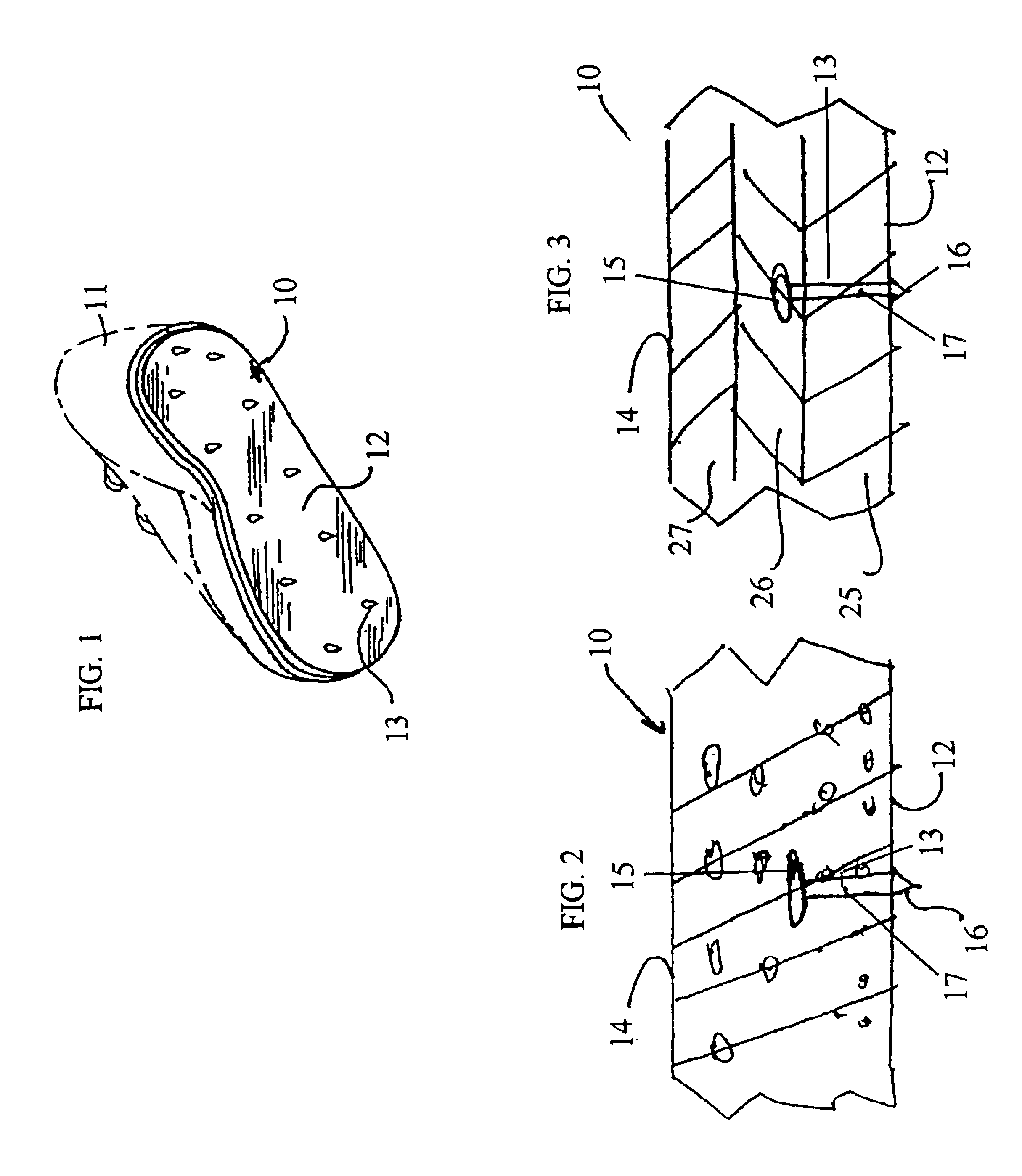

Compression Garments And A Method Of Manufacture

The invention provides a compression garment (50) for clothing a body part, such as a lower torso and the legs. The body part includes a muscle ridge, such as a lateral edge of the gluteus maximus (49). Compression garment (50) has first and second panels of stretchable material joined by a seam (32). At least part of the seam (32) is adapted to correspond to at least part of the muscle ridge, being at the edge of the gluteus maximus (49). The invention also provides a method of manufacturing a compression garment, using an algorithm to calculate size changes to produce desired compression.

Owner:SKINS INTEMATIONAL TRADING AG

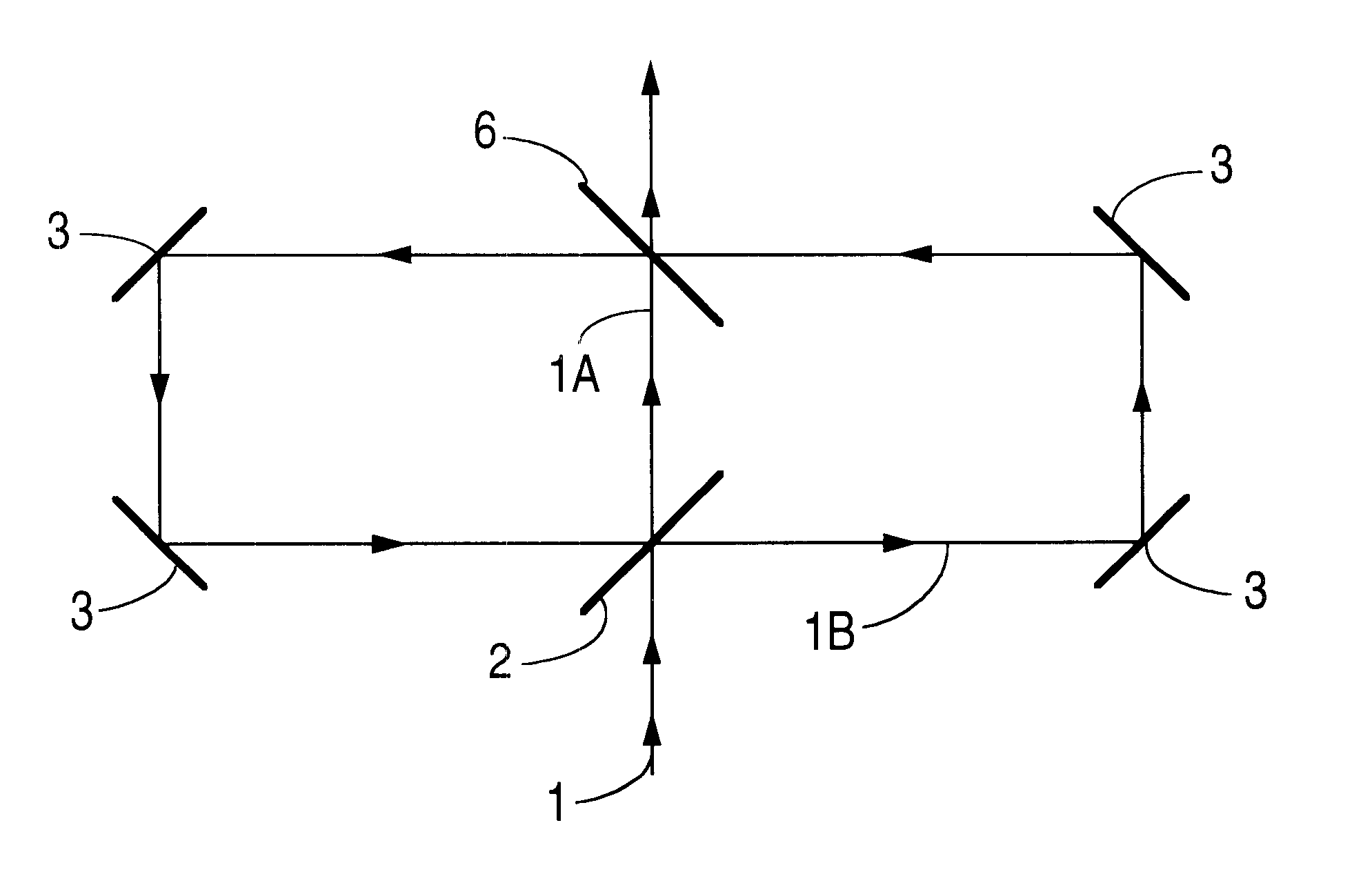

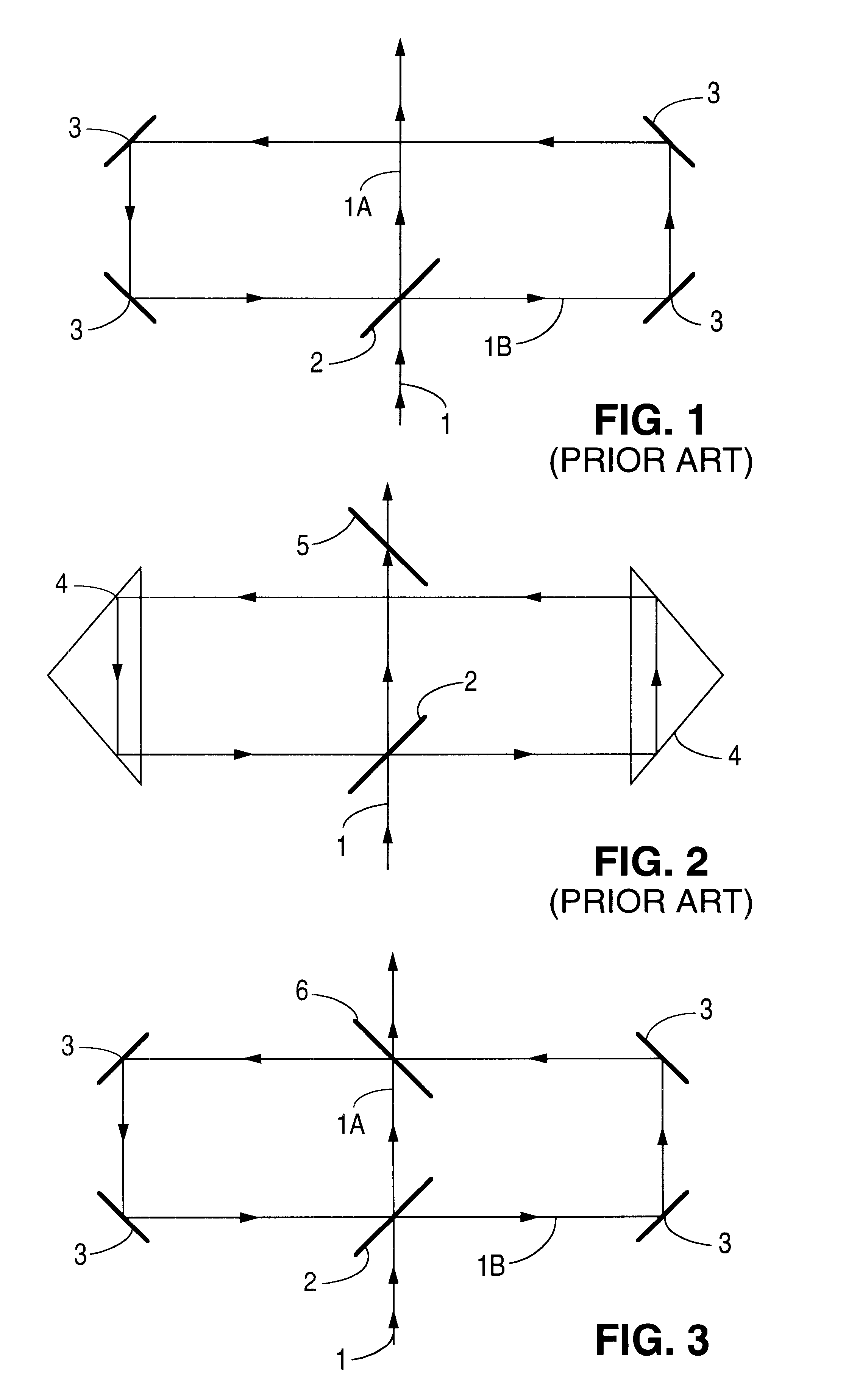

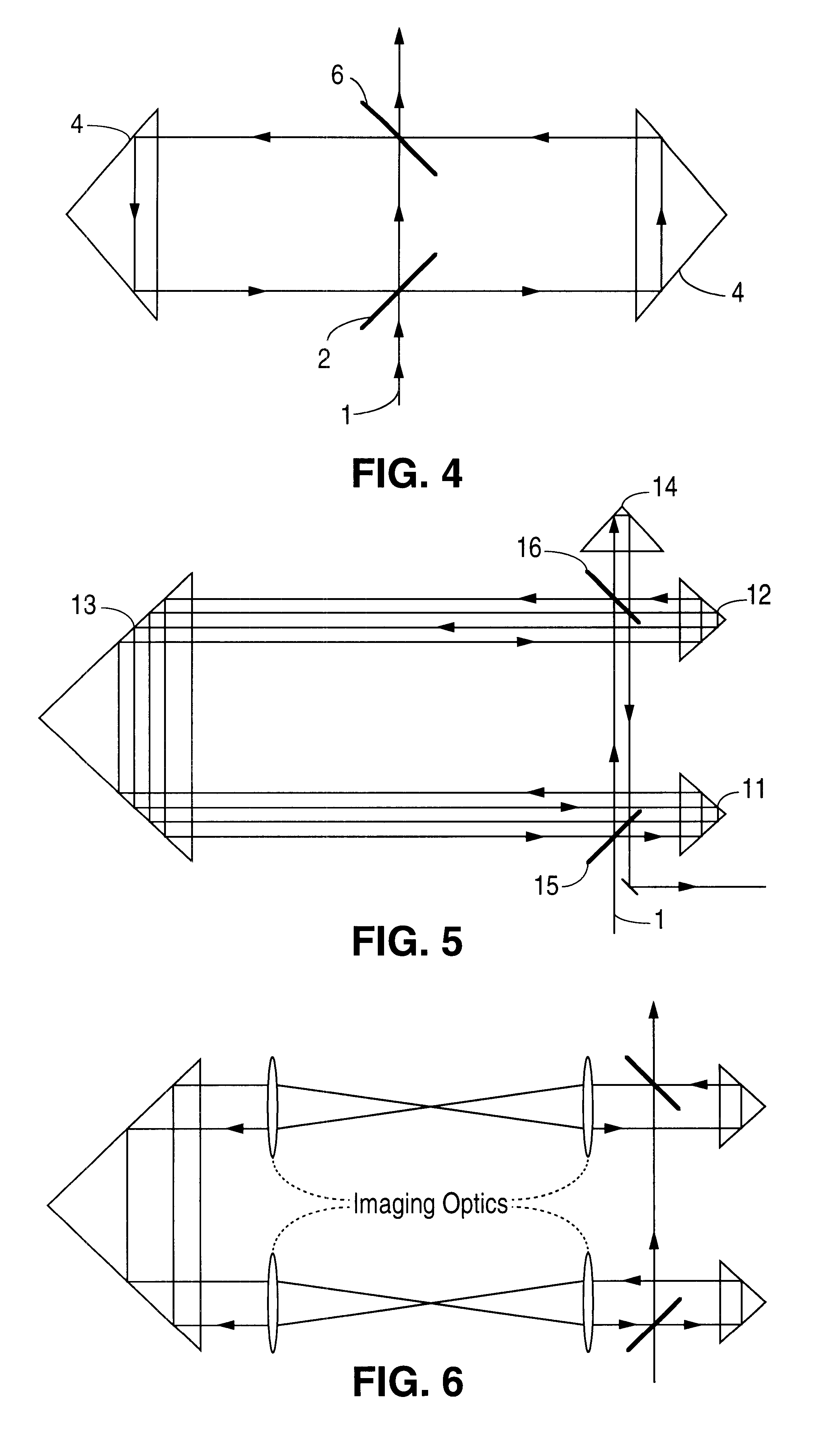

Optical pulse stretching and smoothing for ArF and F2 lithography excimer lasers

InactiveUS6389045B1Easy to stretchFlat shapeOptical resonator shape and constructionGenerators/motorsOptical reflectionLithographic artist

A method and apparatus are provided for temporally stretching and smoothing of the pulses of an output beam of excimer and lithography lasers. The method and apparatus are based upon providing an optical delay line or circuit having a plurality of optical reflectors and a plurality of beam recombiners or splitters so arranged as to divide the pulse into numerous portions which vary in their travel time through the circuit. As a result, the energy of the incident pulse is greatly stretched and smoothed.

Owner:COHERENT GMBH

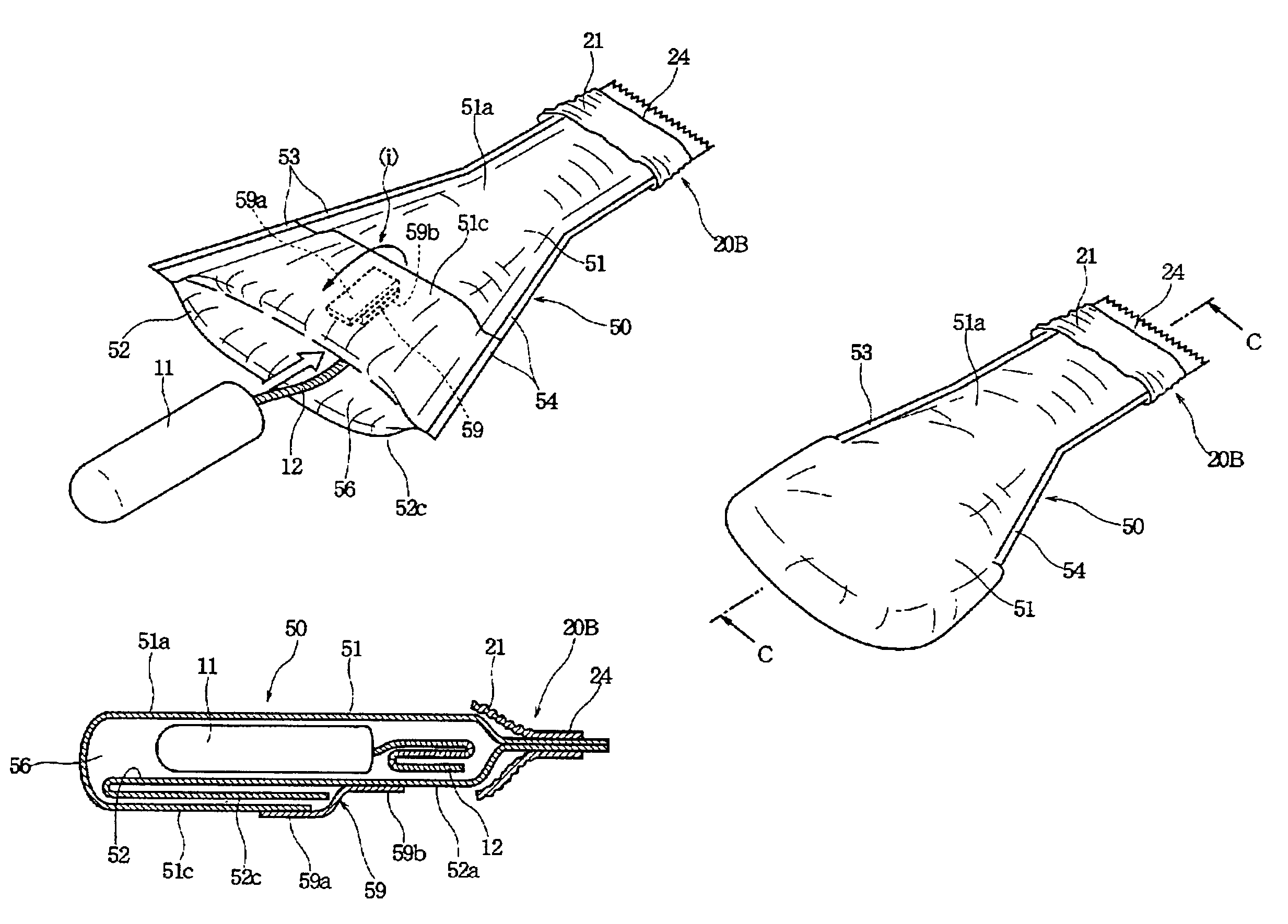

Individual package of body fluid absorbent article

An individual package of a body fluid absorbent article can instantly take care of used body fluid absorbent article without staining fingers with a used substance disposing sheet immediately after opening the package upon changing the body fluid absorbent article. In the individual package of a body fluid absorbent article, a used substance disposing sheet to be used for wrapping a used absorbent body taken out from a user's body for disposal, is packed within the individual package together with the body fluid absorbent article. The package sheet is provided with a cutting portion for separating the packaging bag into bag fractions. A part of the used substance disposing sheet is fixed to one of the bag fractions.

Owner:UNI CHARM CORP

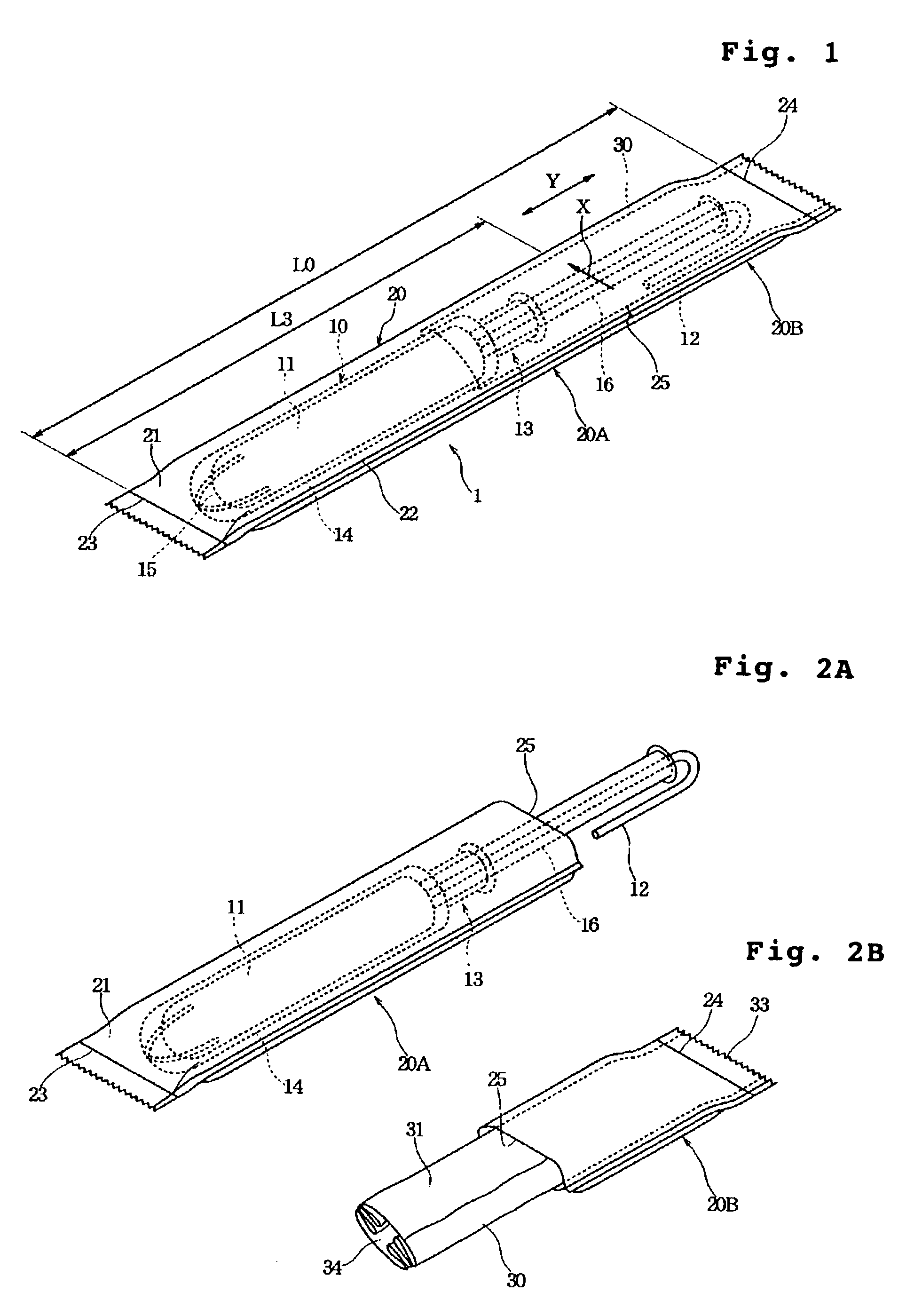

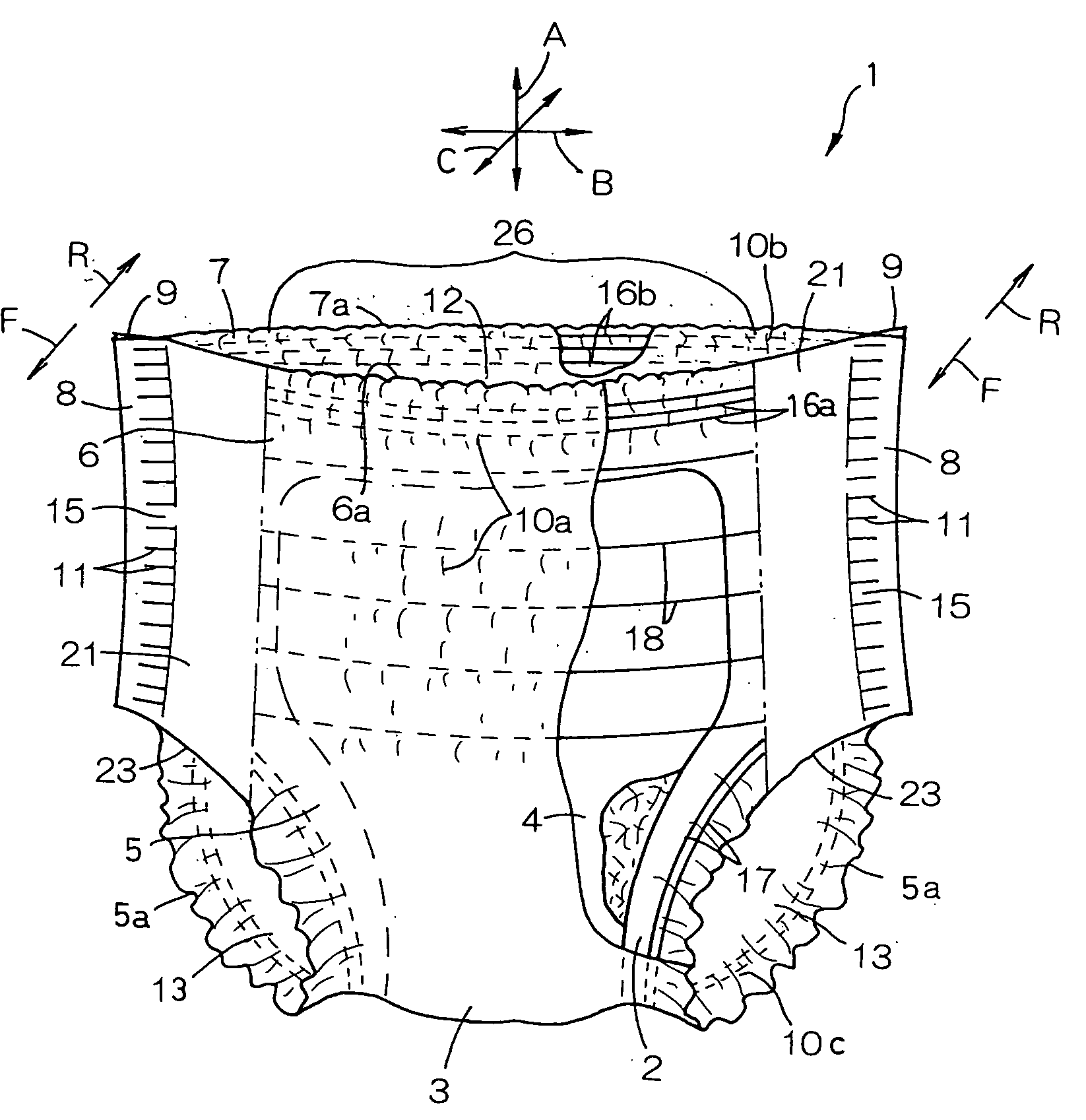

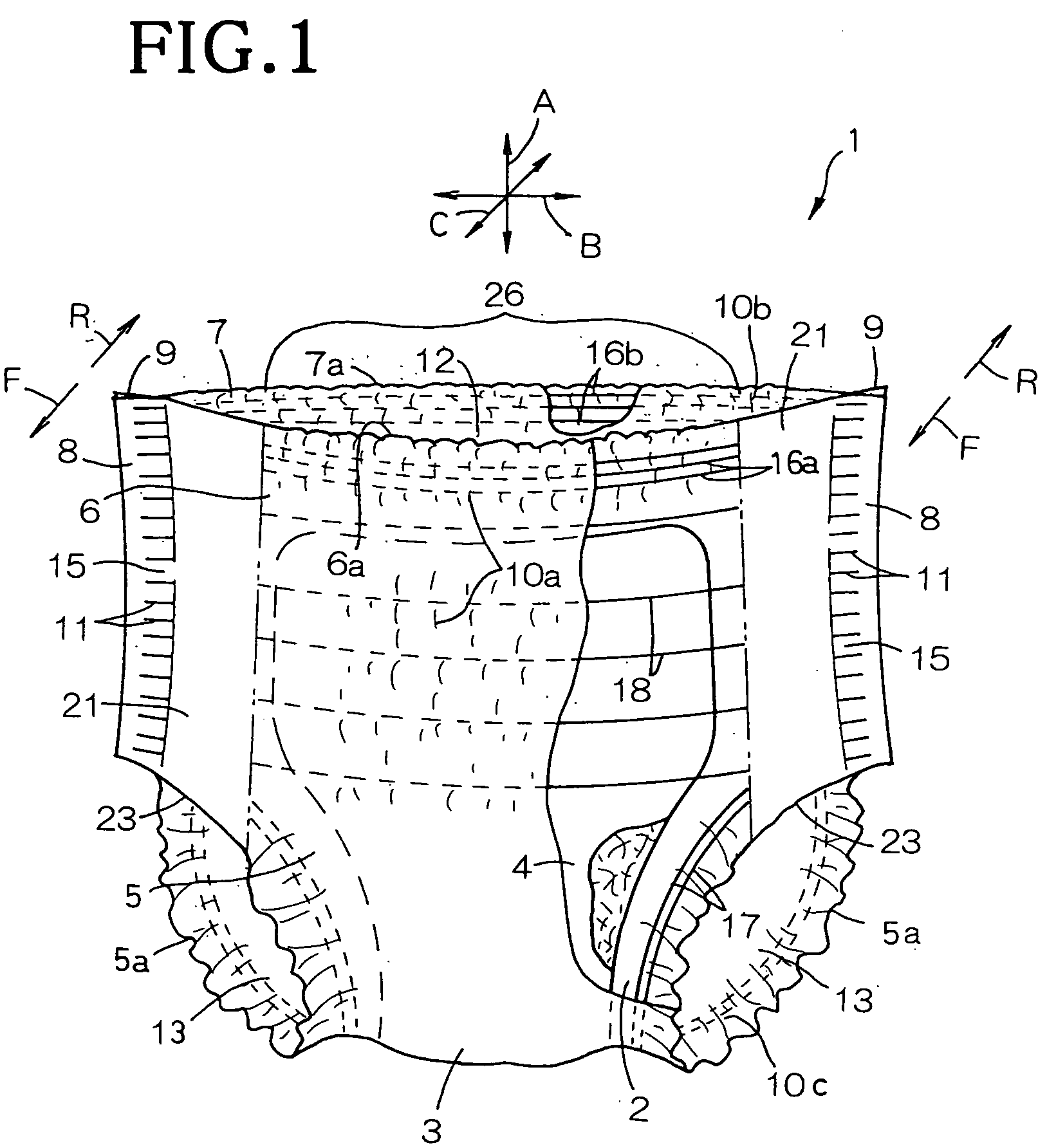

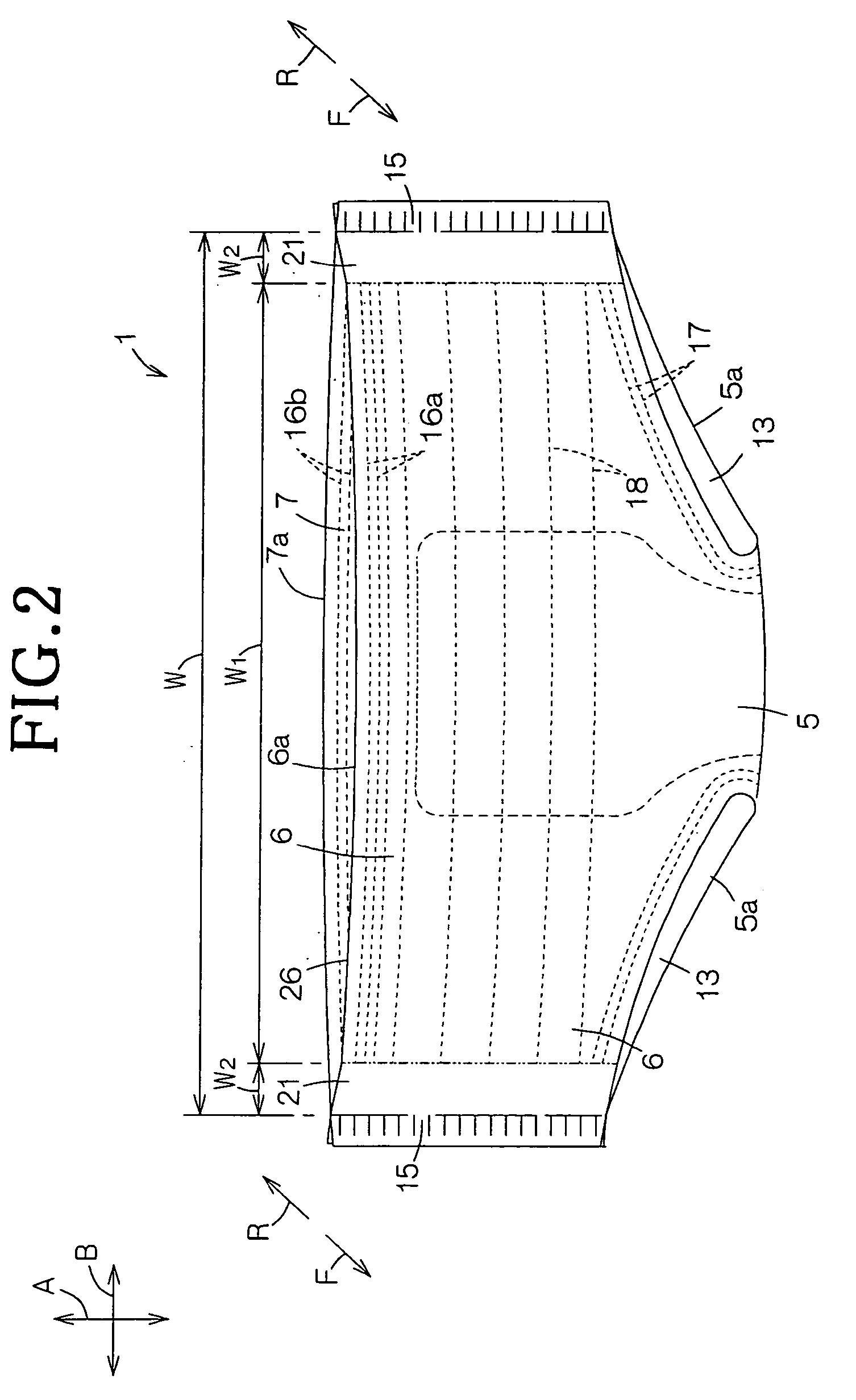

Pull-on disposable wearing article

A pull-on disposable wearing article has a first waist region and a second waist region. The first waist region has its full range in a transverse direction adapted to be elastically stretch- and contractible in the transverse direction. The second waist region is formed with a pair of finger-grip zones which are non-stretchable in the transverse direction and an elastically stretch- and contractible middle zone. The finger-grip zones respectively have a dimension in a range of 10 to 100 mm as measured in the transverse direction and extend from a peripheral edge of a waist-hole to one of peripheral edges of respective leg-holes and vicinities of these peripheral edges along a pair of bonded zones defined by transversely opposite side edges of the first and second waist regions bonded together. The middle zone extends between a pair of the finger-grip zones and has its full range in the transverse direction adapted to be elastically stretch- and contractible.

Owner:UNI CHARM CORP

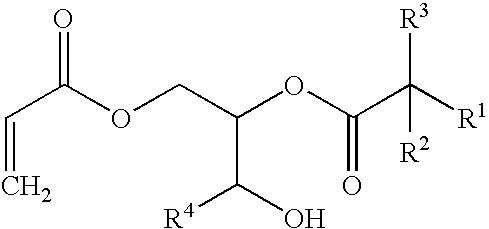

Radiation curable inks

Radiation curable ink compositions for impulse printheads are described. The compositions include a photoinitiator system, containing both a photocation polymerization initiator and a free-radical photoinitiator, an acrylate ester of a carboxylic acid ester, and at least one radiation curable material.

Owner:KAO CORP

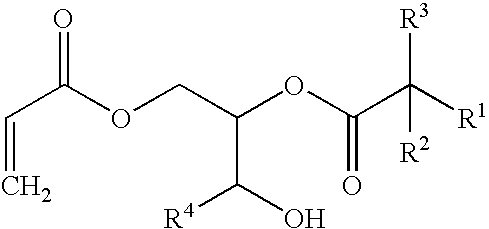

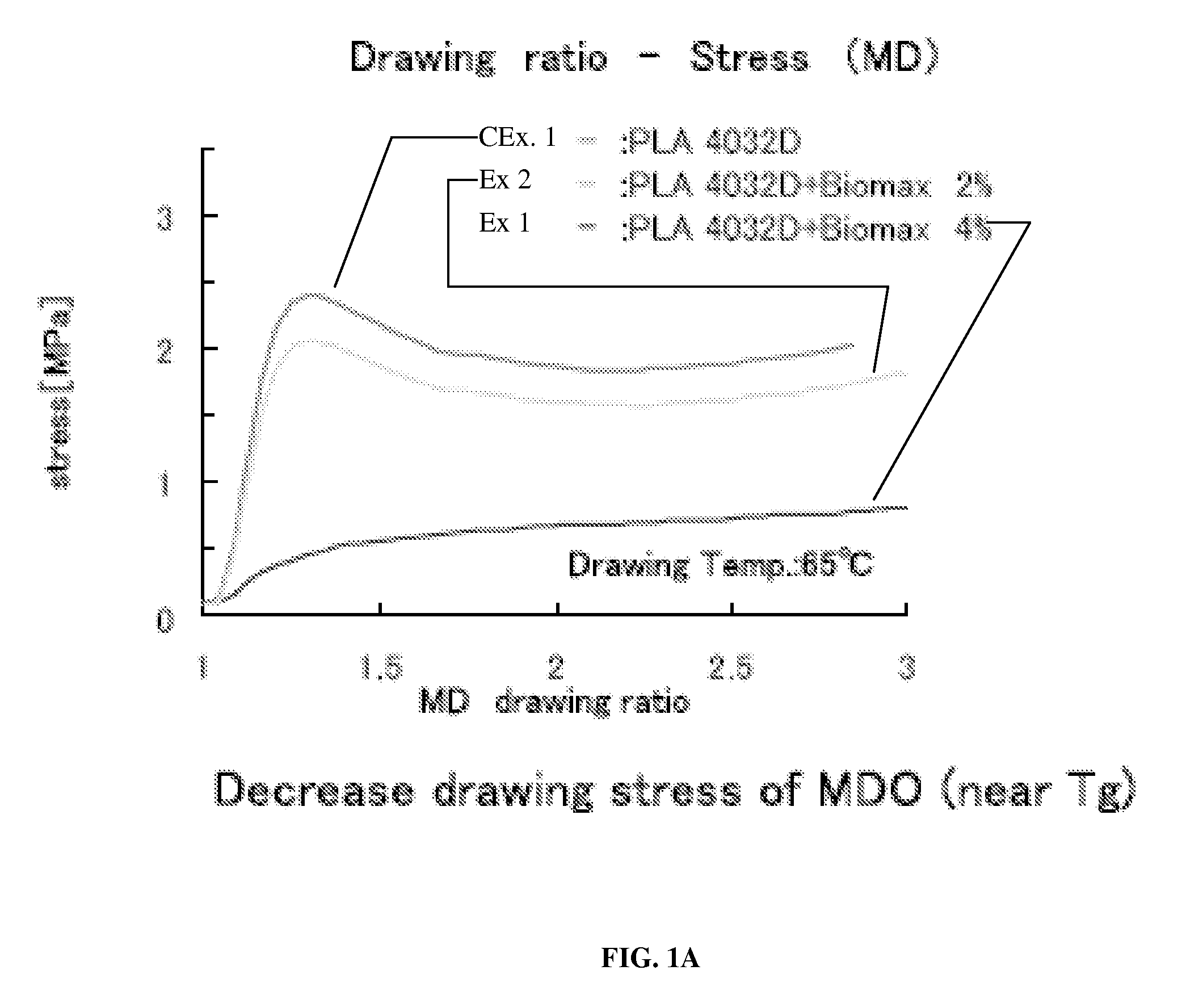

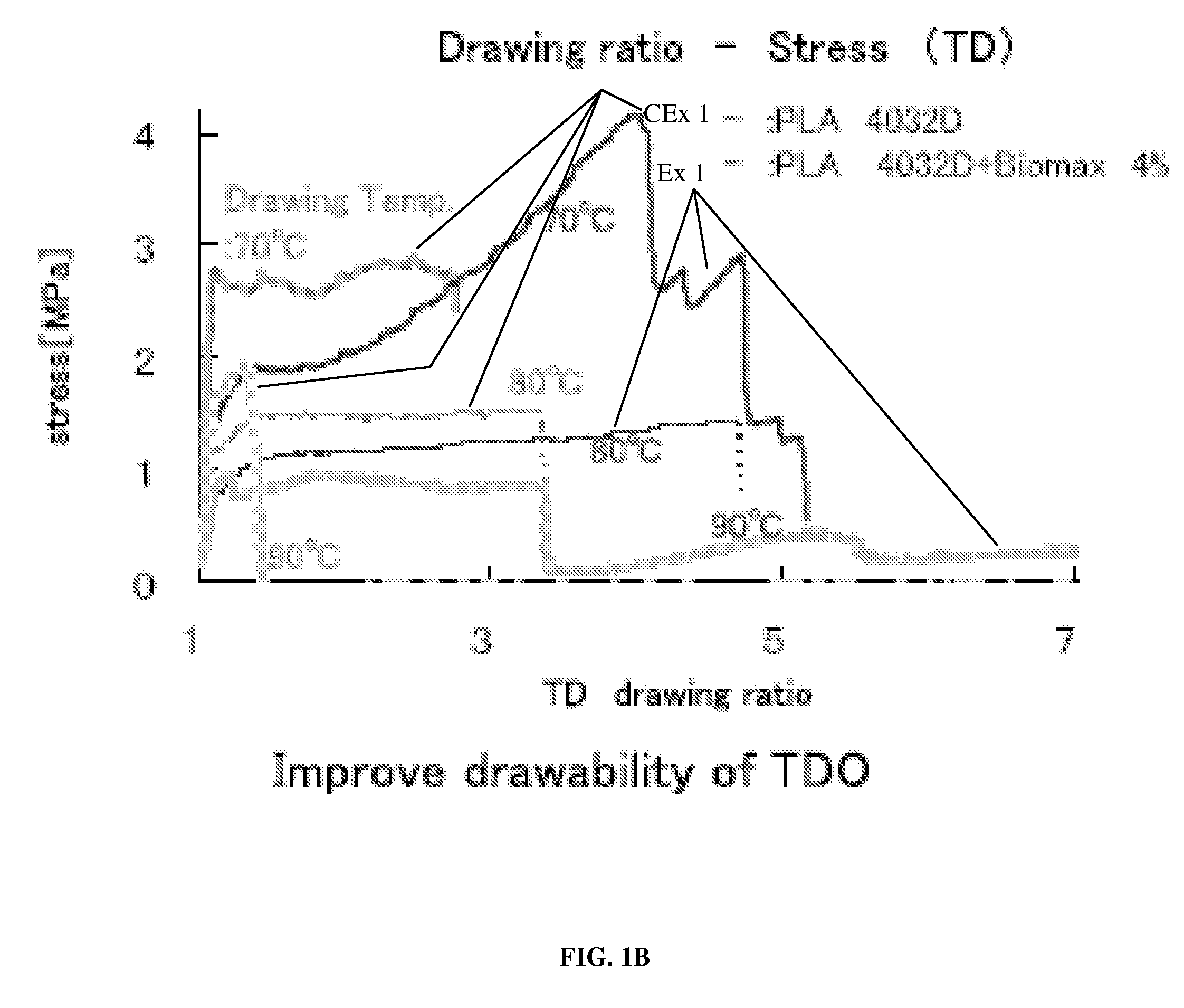

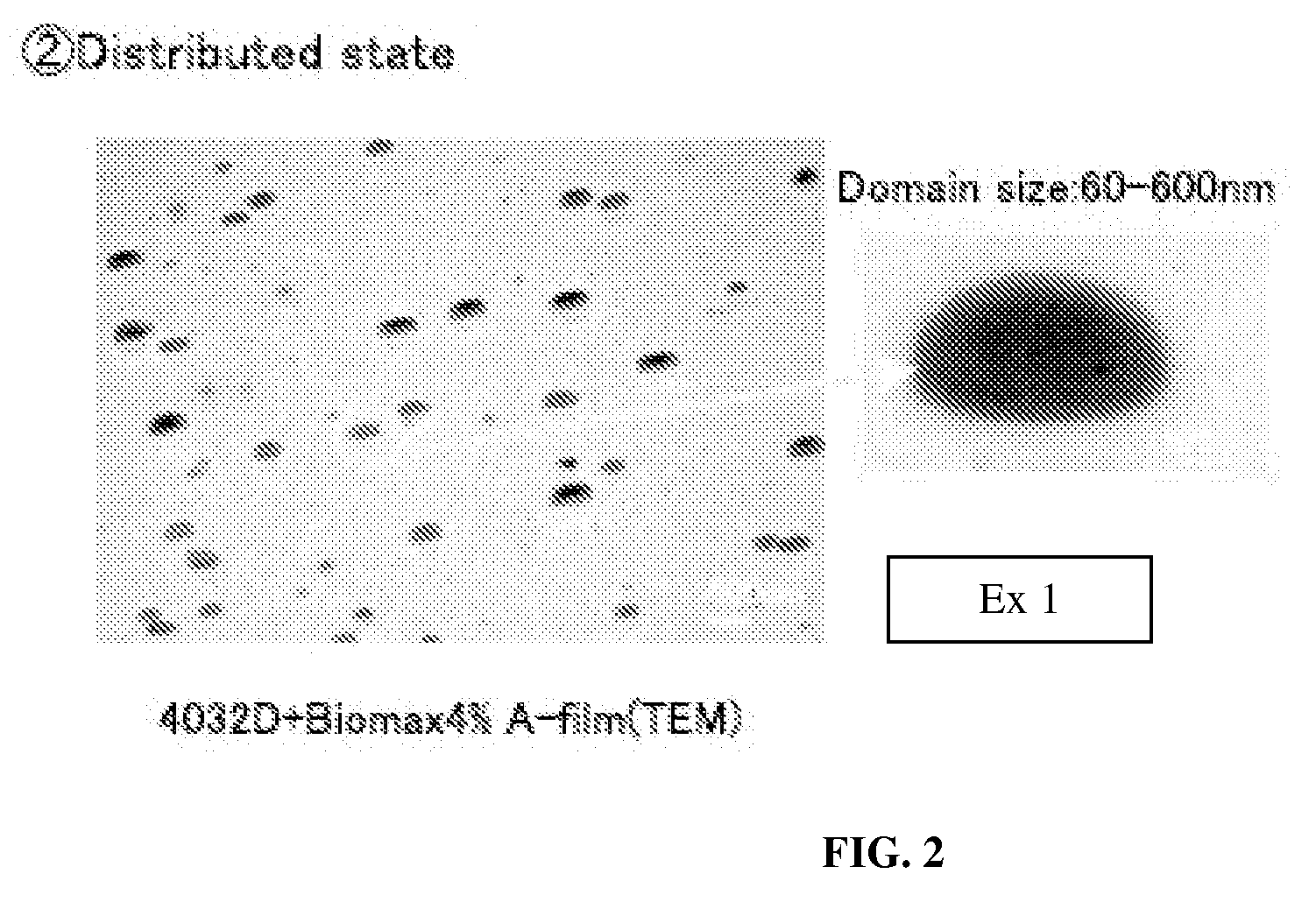

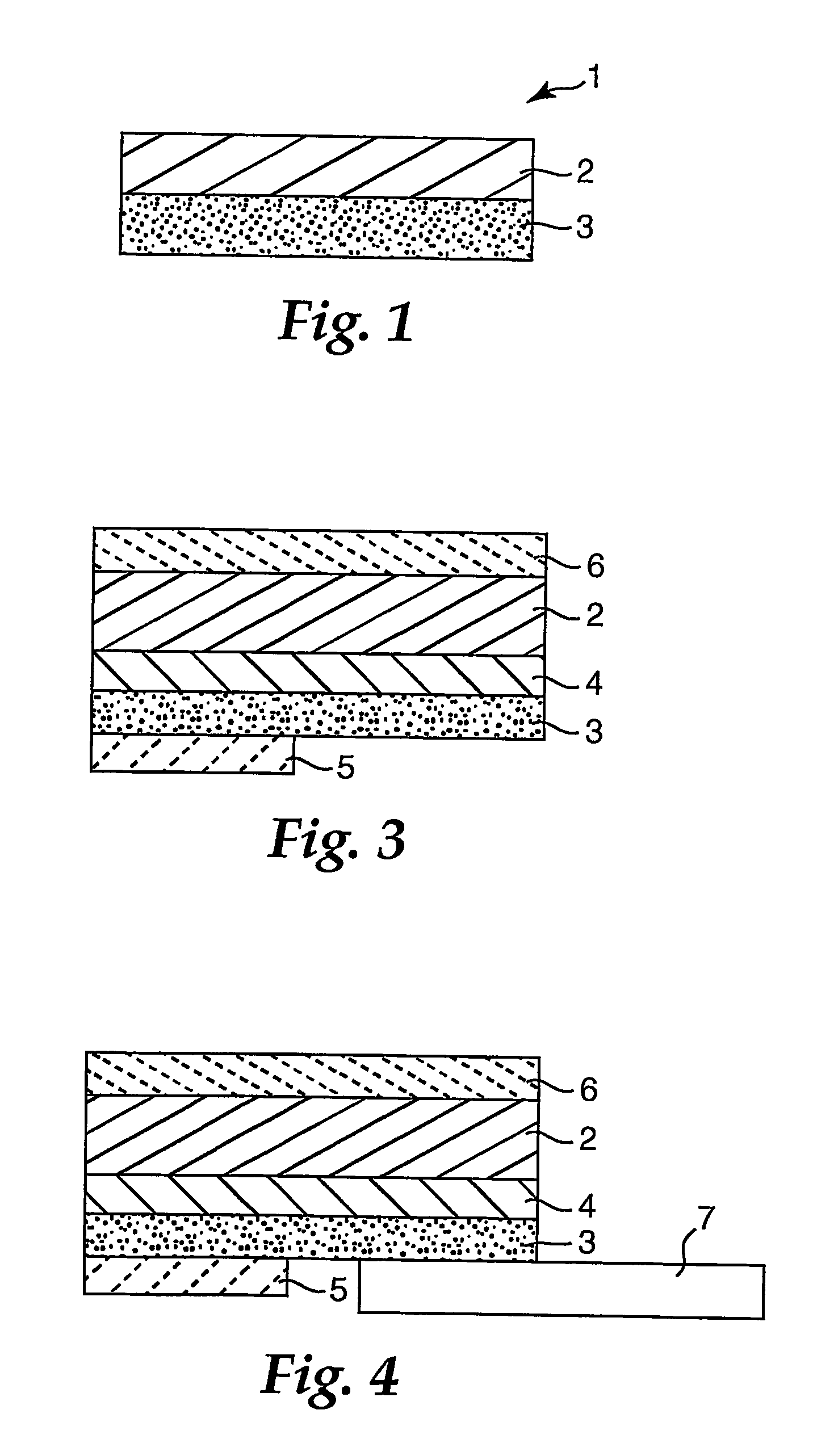

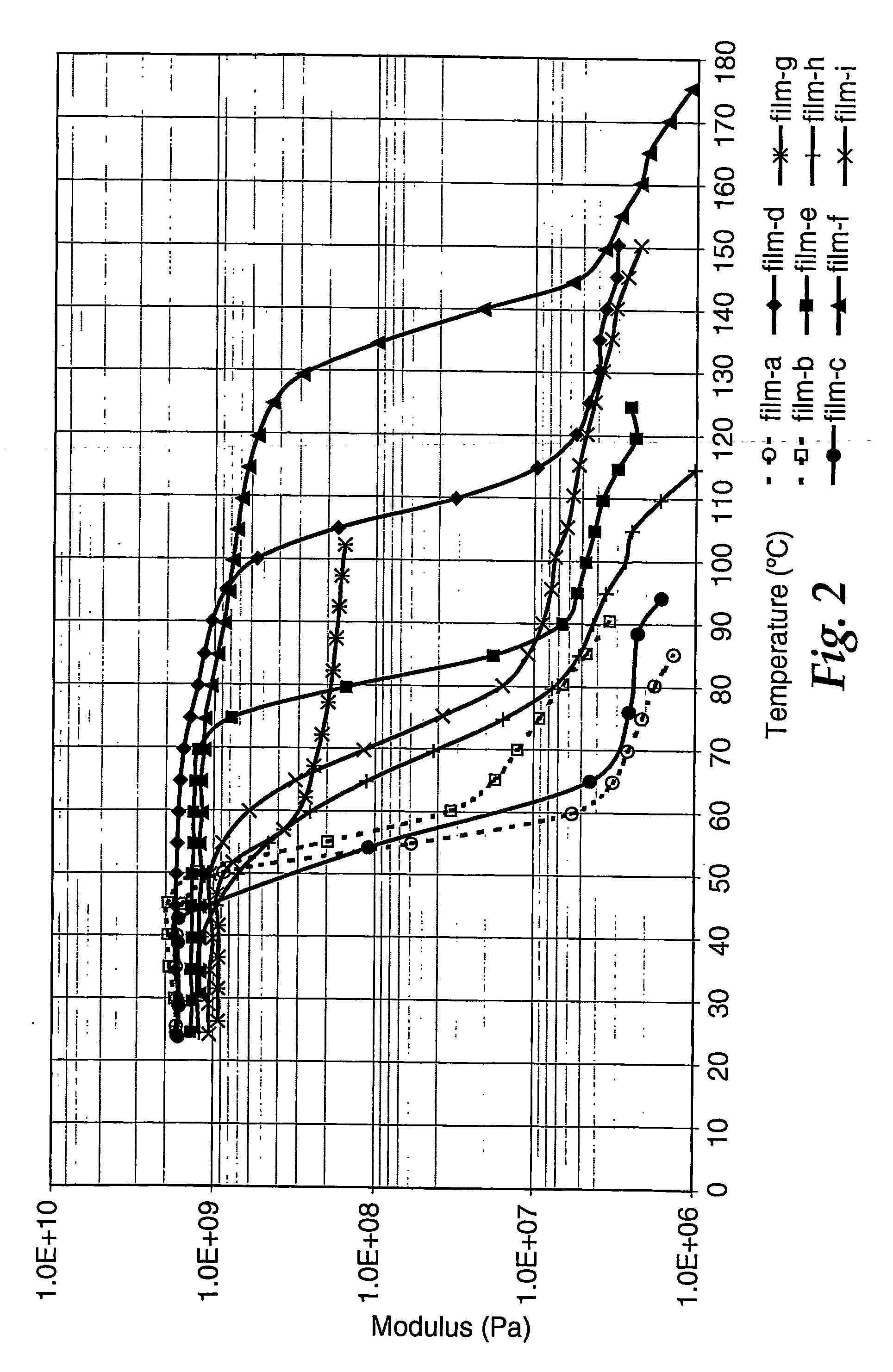

Process to produce biaxially oriented polylactic acid film at high transverse orientation rates

InactiveUS20090148715A1High rate of orientationEasy to stretchSynthetic resin layered productsDomestic articlesTransverse orientationEthylene

A biaxially oriented laminate film including a first amorphous polylactic acid polymer heat sealable resin layer and a second core layer including a blend of crystalline polylactic acid polymer and 2-10 wt % of the core layer of an ethylene-acrylate copolymer. The laminate film, exhibiting the property to be transverse oriented in excess of 6 times its original width, typically 8 to 10 times its original width with excellent operability and relatively low haze, is disclosed. The laminate film may further have additional layers such as a third polylactic acid resin-containing layer disposed on the side of the core layer opposite the heat sealable layer, a metal layer, or combinations thereof.

Owner:TORAY PLASTICS AMERICA

Resilient, all-surface soles for footwear

Owner:KASTNER

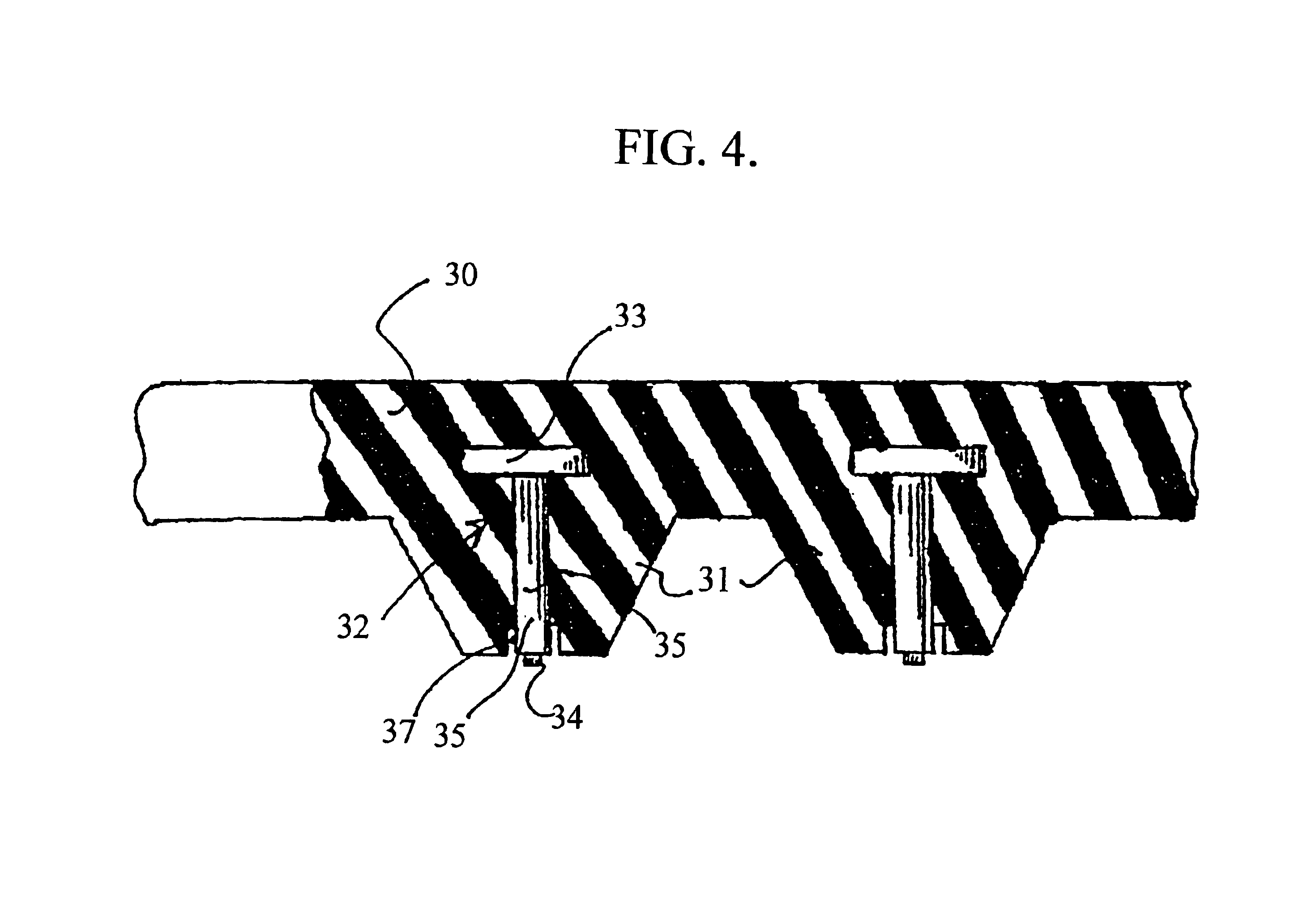

Thermoplastic light-duty composite plate and preparing method thereof

The invention discloses a thermoplastic light compound plate and the manufacturing method, characterized in that it comprises acupuncture fiber carpet dipped in double faced foam of thermoplastic glue liquid and thermoplastic glue liquid layer coated on the surface, the density of compound plate is 0.35-0.90g / cm3, the weight of fiber scattered in bunchiness is 15-45% of acupuncture fiber carpet. The merit of invention is very remarkable. Special super long fiber and bunchiness fiber with certain proportion are maintained in the material so that the mechanical performance of material can be improved. In addition, the material is provided with foam structure, very good effect of heat and sound insulation. The invention is also provided with environmental protection and recovery.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

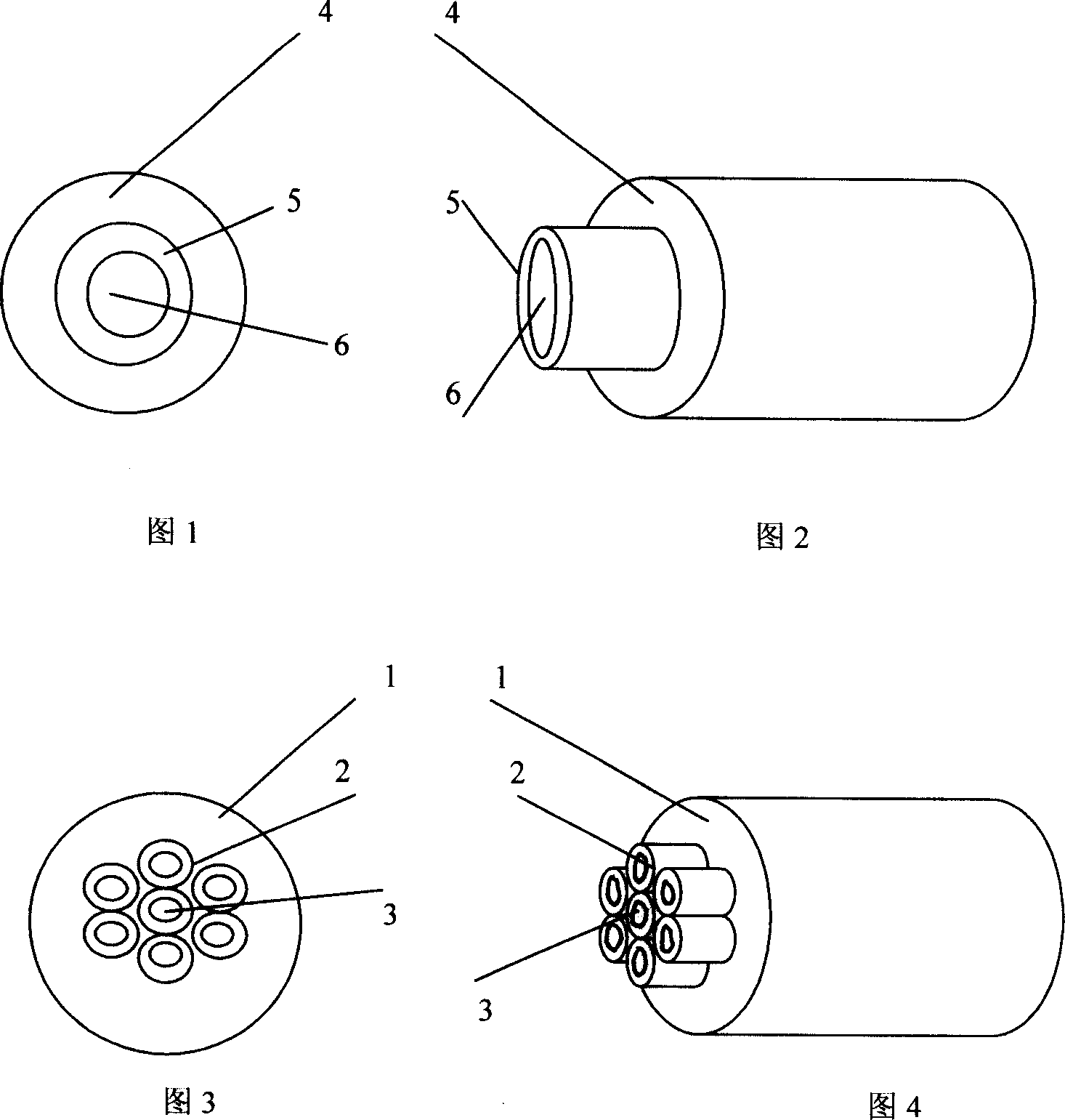

Aluminum core cable and line covered by copper

InactiveCN101086906AGood electrical conductivityHigh strengthRubber insulatorsPlastic/resin/waxes insulatorsCross-linked polyethyleneCopper-clad aluminium wire

The invention uses copper-clad aluminium conductor as conductive wire core whose inner core is aluminium wire and outer is cylinder copper roofing, the conductive wire also can be at least two conductive wire cores of copper-clad aluminium conductor which are parallel or winding with each other, the outer of conductive wire core is covered with insulated layer of PVC or polyethylene or cross-link polyethylene or rubber. The insulated material such as PVC, polyethylene, cross-link polyethylene or rubber is covered around the conductive wire core to produce copper-clad aluminium wire cable. The copper-clad aluminium wire cable possesses the same conductivity as copper core cable with the same specification, weight is light, easy to process, usage is convenient, and copper can be saved for 80% or above, cost of product can be decreased effectively, defects that the surface of aluminium cable is easy to be oxidized, resistance is big, corrosion resistance and machine performance are poor can be avoided.

Owner:大连极速金属复合材料有限公司

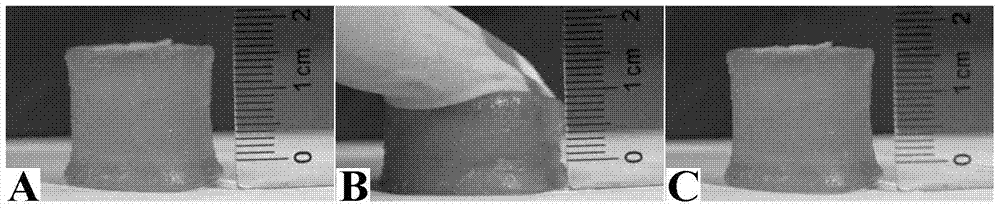

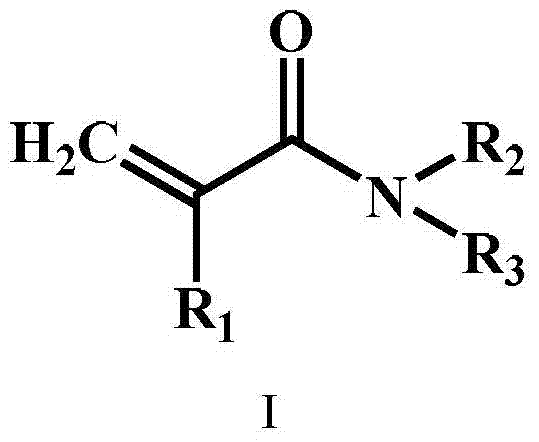

High-strength chemical-physical dual-network hydrogel with self-recovery capability, and preparation method and application of hydrogel

The invention discloses high-strength chemical-physical dual-network hydrogel with self-recovery capability, and a preparation method and application of the hydrogel. The high-strength chemical-physical dual-network hydrogel with the self-recovery capability is prepared from a first chemical network formed by the polymerization of hydrophilic monomers or by enabling hydrophilic macromolecules to be mixed and have a reaction, and a second physical network formed by carrying out physical crosslinking on polysaccharide and derivatives thereof, wherein the first chemical network and the second physical network are arranged in a way of being interspersed with each other. The dual-network hydrogel has high compressive strength and tensile strength, high toughness as well as good self-recovery property and fatigue resistance, and can maintain higher tensile strength and breakage elongation under the condition of having a notch. The prepared hydrogel has good mechanical property and biocompatibility, can be widely applied to the field of biological medicine, and can be used as a surface coating of a scaffold for tissue engineering, medical sponge or a medical implant.

Owner:INST OF CHEM CHINESE ACAD OF SCI

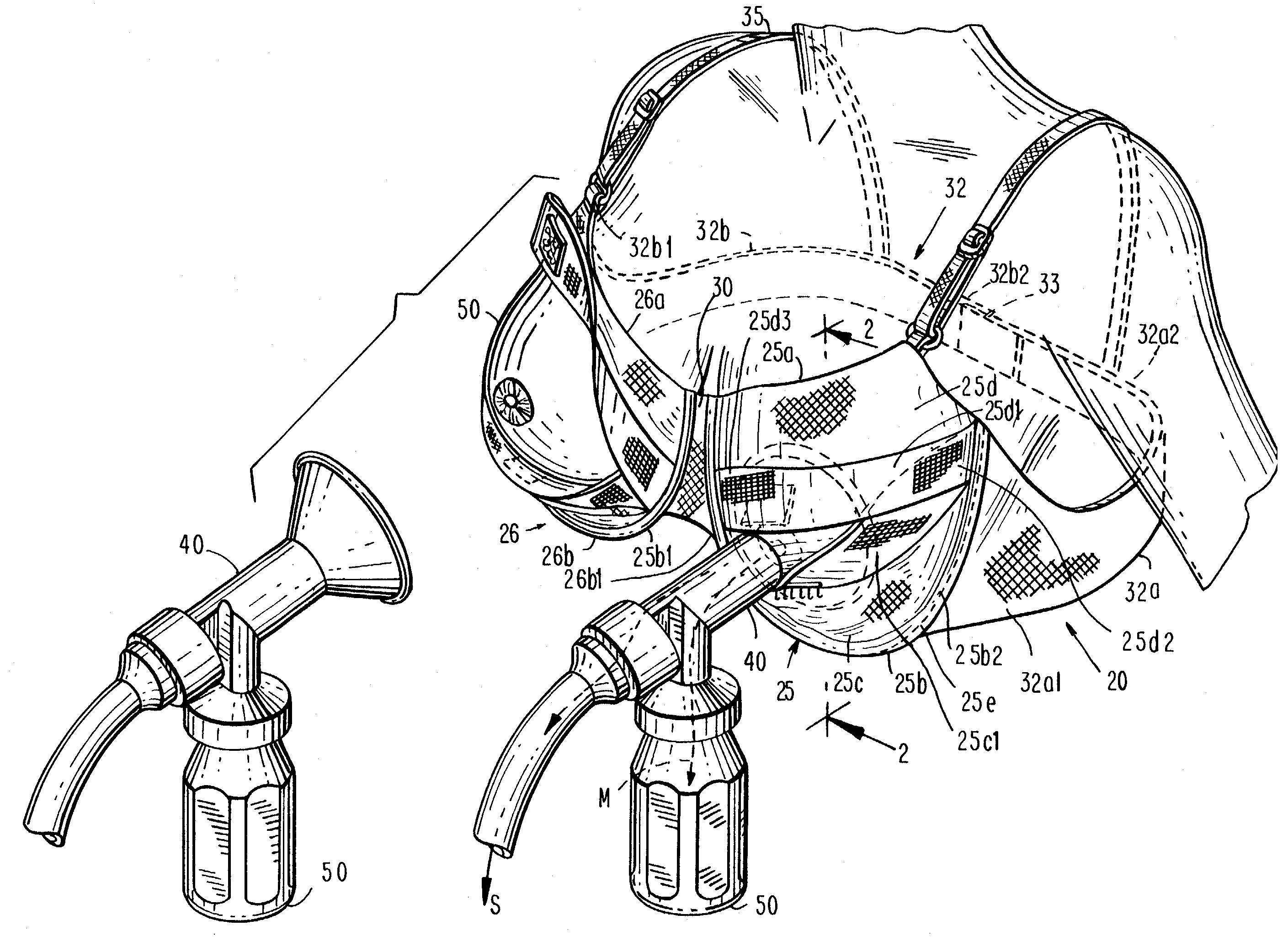

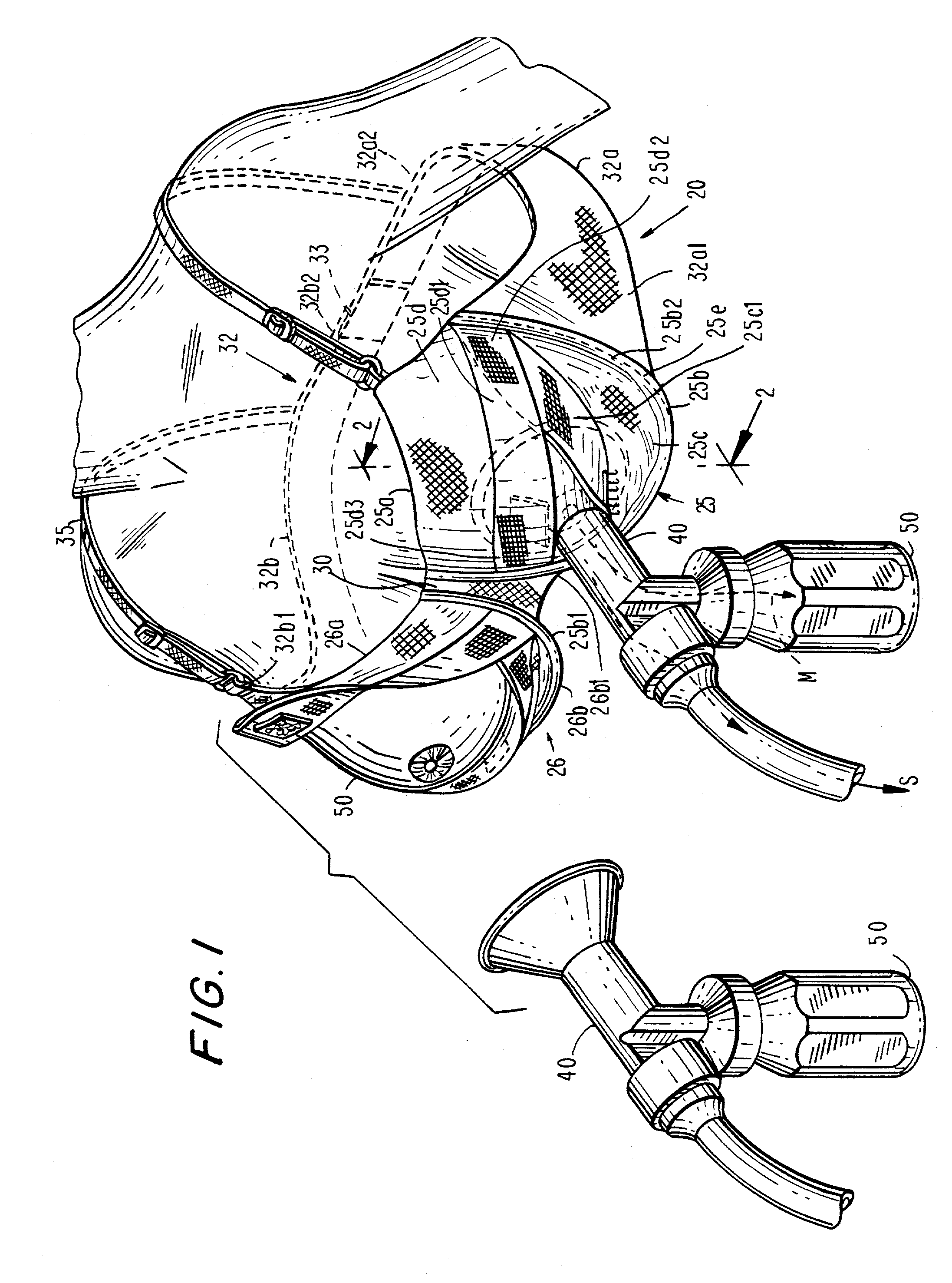

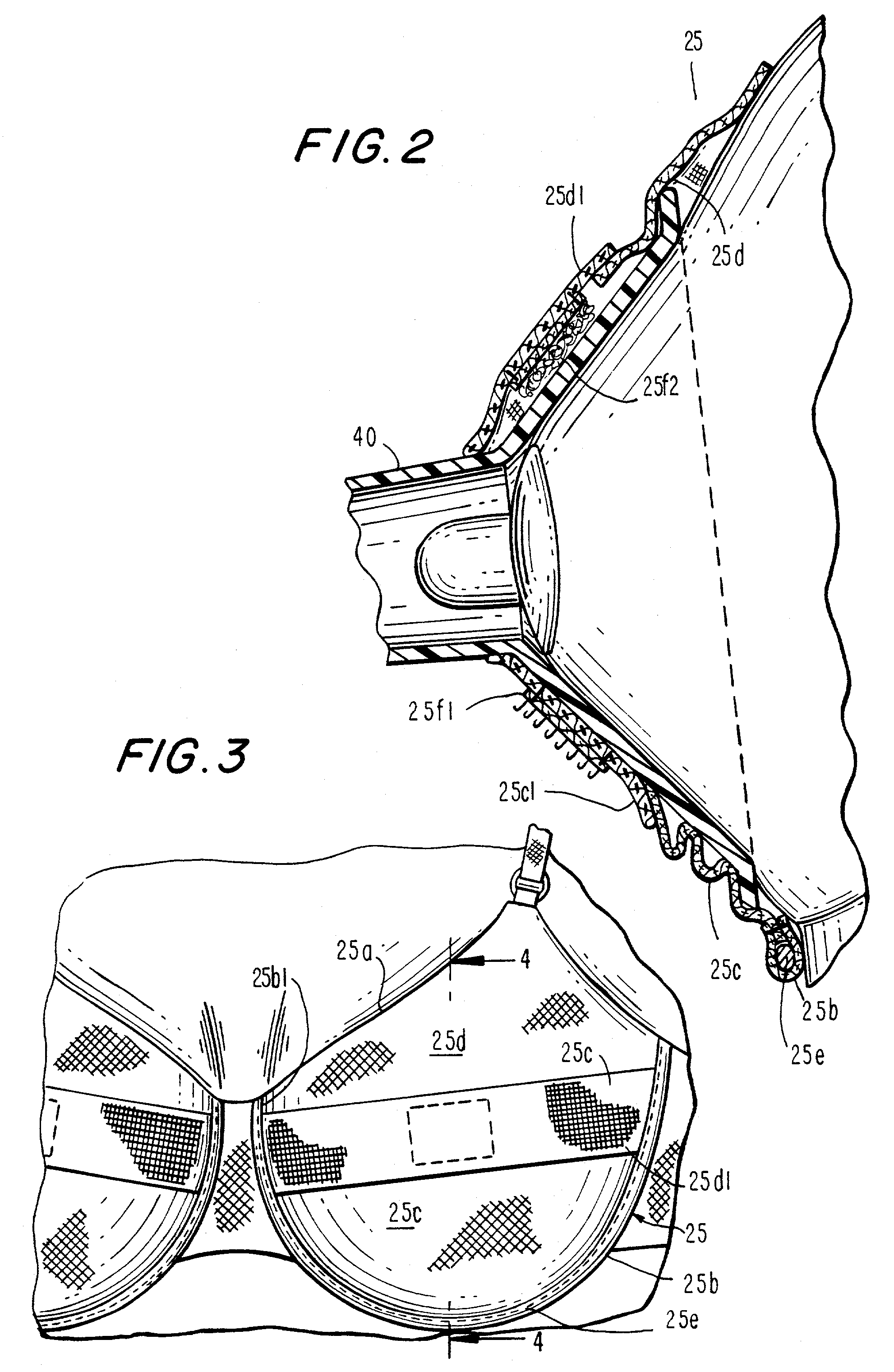

Brassiere for expressing breast milk

A brassiere for supporting the breasts of a wearer and for receiving and supporting a funnel for expressing breast milk, comprising a pair of cups, at least one of which includes a first portion and a second portion having at least one elastic band. The first and second portion, and of the cup are expandable to allow a funnel to be selectively inserted between said first portion and said second portion, and under said first portion, and under said second portion, so as to contact said breast for expressing milk.

Owner:MEDELA HLDG AG

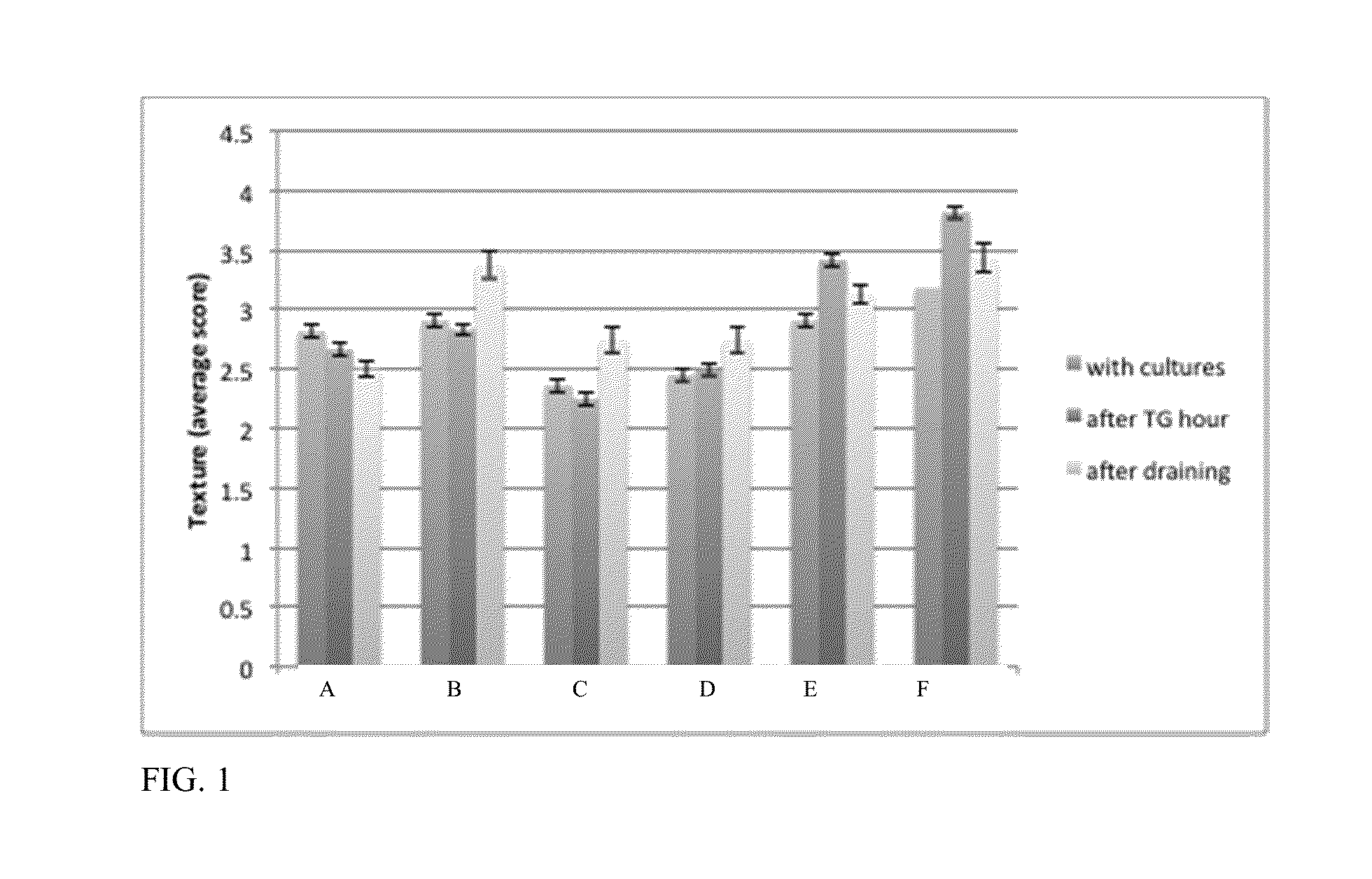

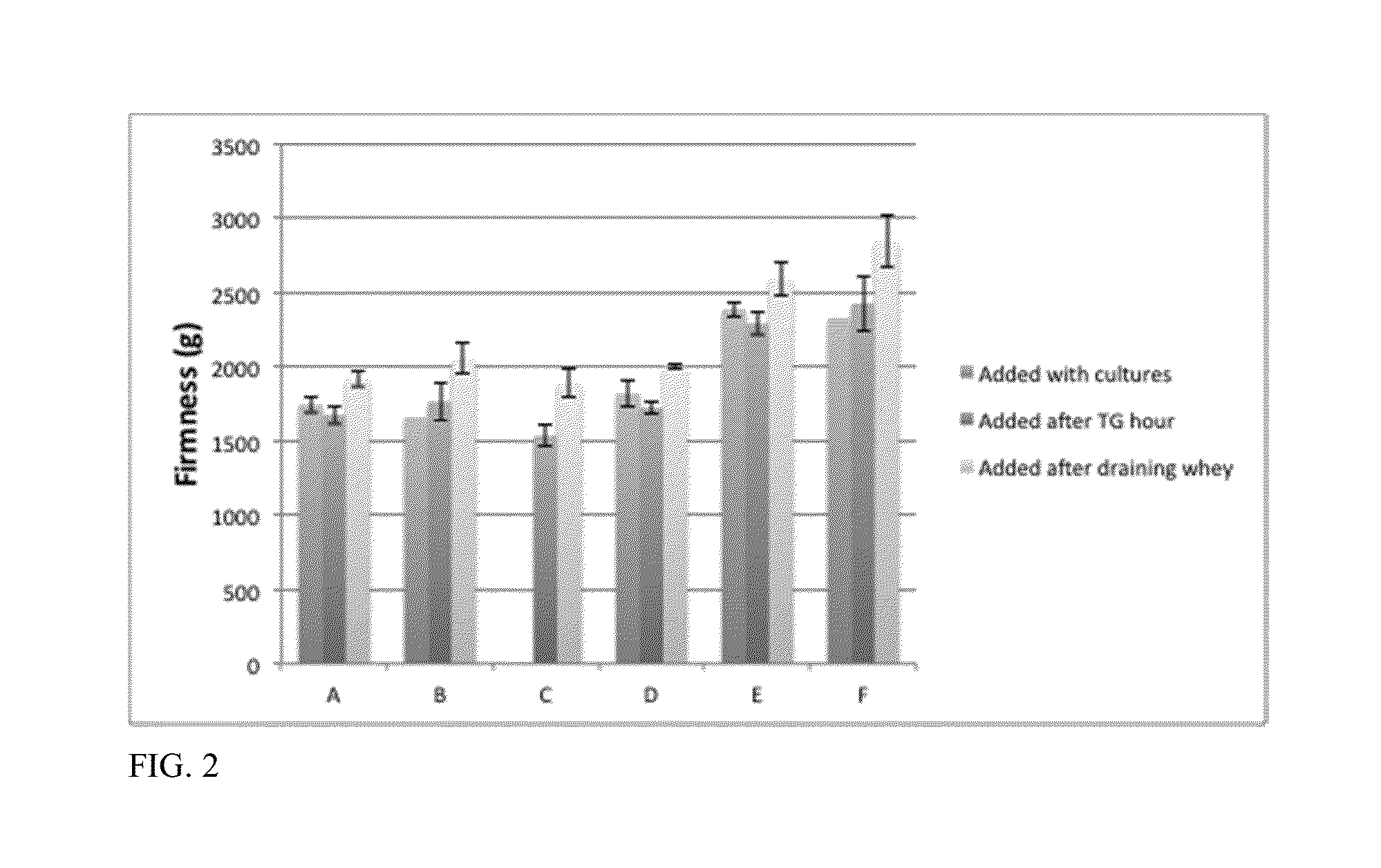

Methods and compositions for consumables

ActiveUS20150305361A1Increased creamy, milky, buttery, fruityReduced nutty, planty, beanyMilk preparationCheese manufactureBiotechnologyConsumables

Provided herein are methods and compositions for the production of cheese replicas. Generally the cheese replicas are produced by inducing the enzymatic curdling of non-dairy milks.

Owner:IMPOSSIBLE FOODS

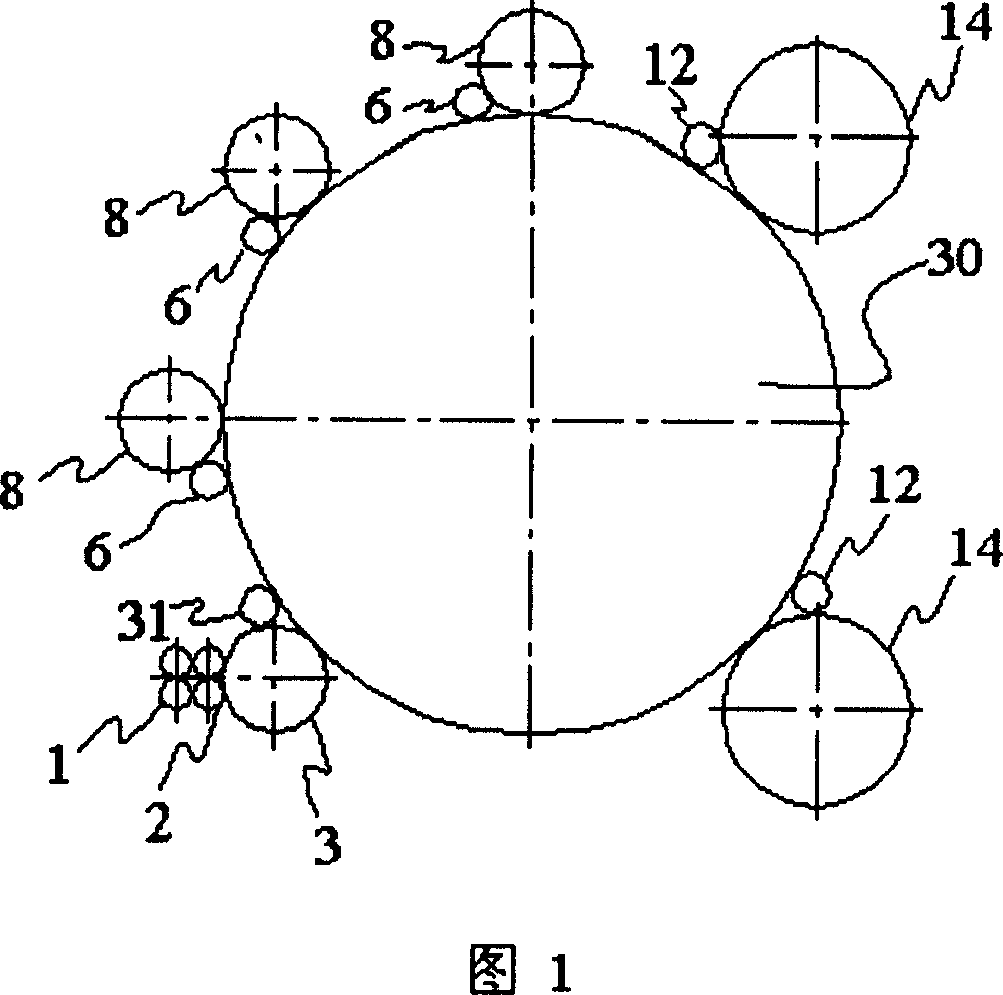

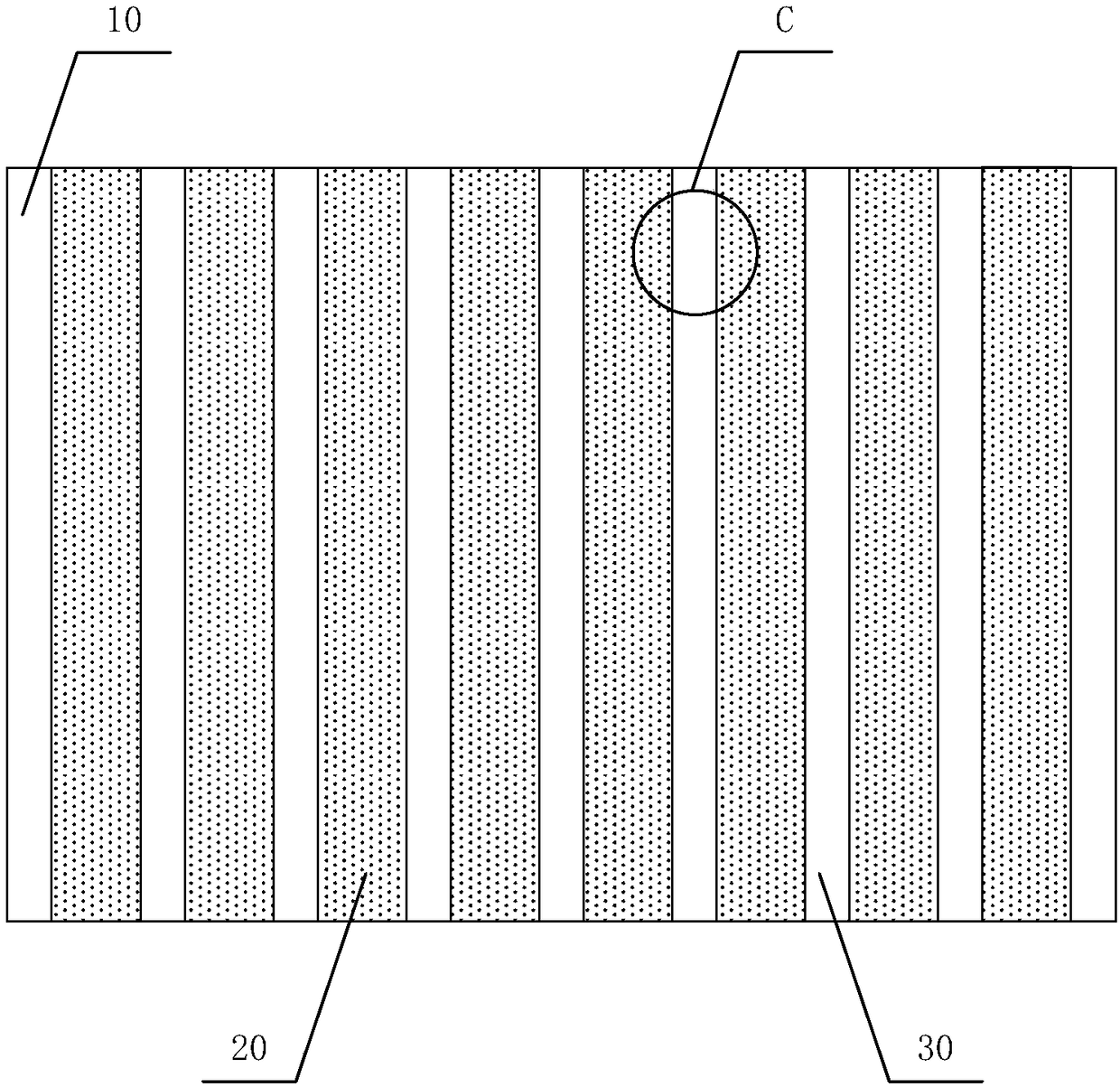

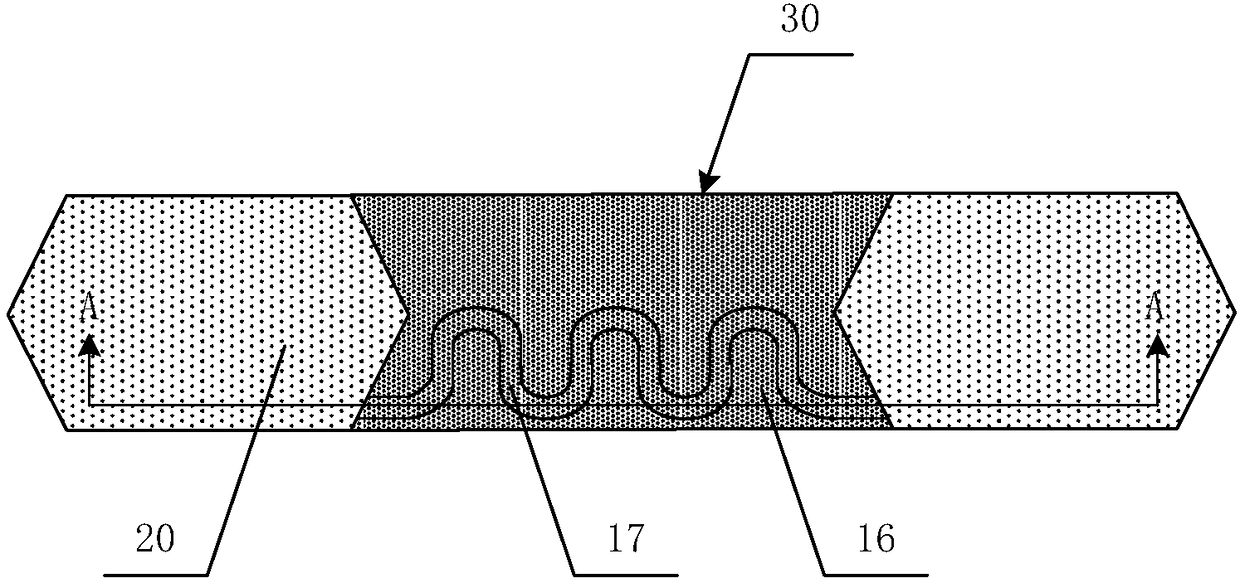

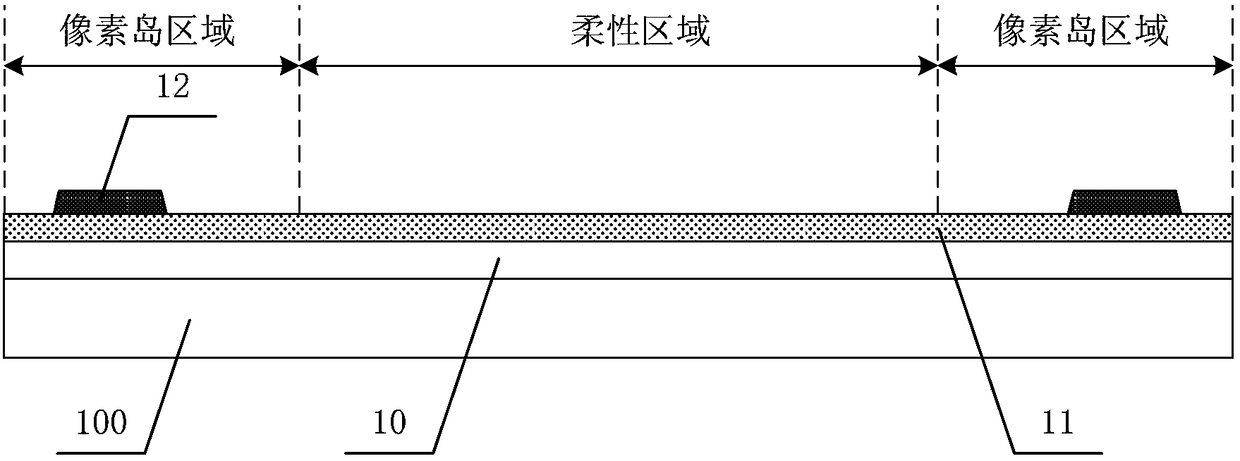

Flexible array substrate and preparation method thereof and flexible display panel

ActiveCN108461531AGood stretchImprove bendabilityFinal product manufactureSolid-state devicesFlexible displayComputer science

The invention relates to the technical field of display and discloses a flexible array substrate and a preparation method thereof and a flexible display panel. The flexible array substrate comprises aplurality of pixel island regions which are sequentially arranged; flexible areas are arranged between the adjacent pixel island regions; each pixel island region comprises a gate electrode; each flexible area comprises a first elastic layer; each first elastic layer is provided with a first connection line; each first connection line is provided with a second elastic layer; each second elastic layer is provided with a second connection line; a plurality of interlayer through holes are formed in each second elastic layer; an elastic conductive column is arranged in each interlayer through hole; the elastic conductive columns are electrically connected with the first connection lines and the second connection lines separately; and the first connection lines and / or the second connection lines are connected with the gate electrodes of the adjacent pixel island regions. Through the arrangement of the elastic conductive columns and a dual-layer connection electric structure, the flexible array substrate has relatively excellent tensile property in the direction vertical to the flexible array substrate, and good tensile property and bendability of the flexible array substrate are achieved.

Owner:BOE TECH GRP CO LTD

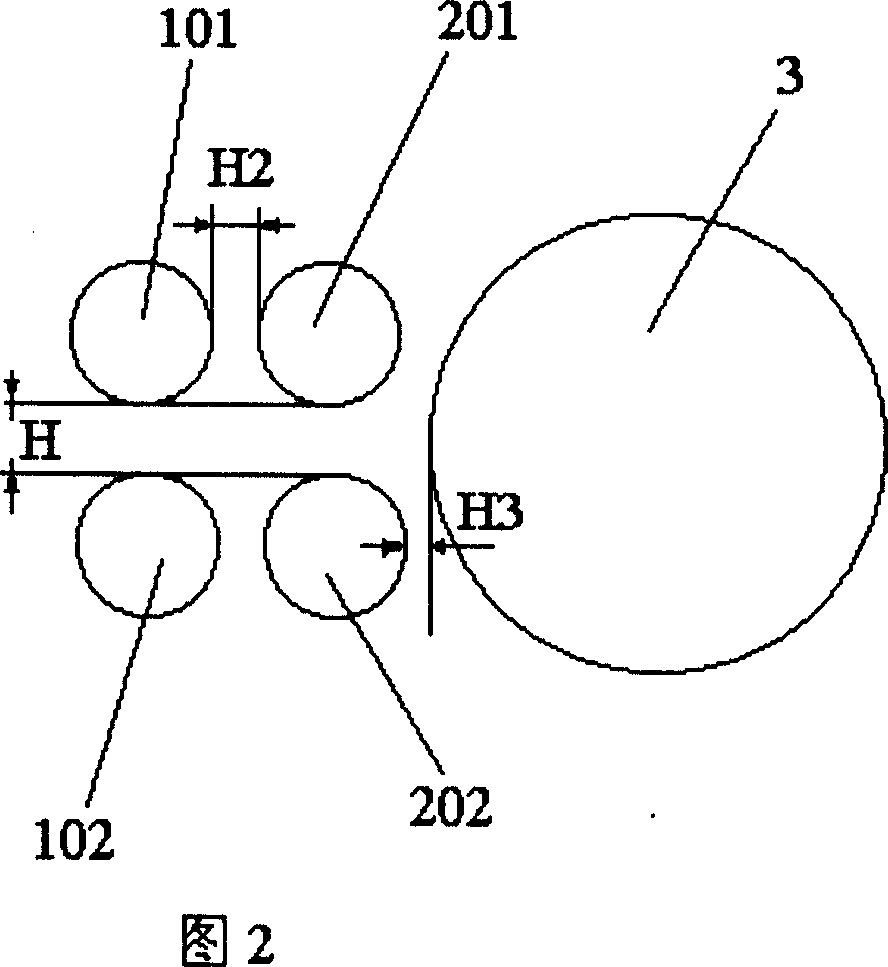

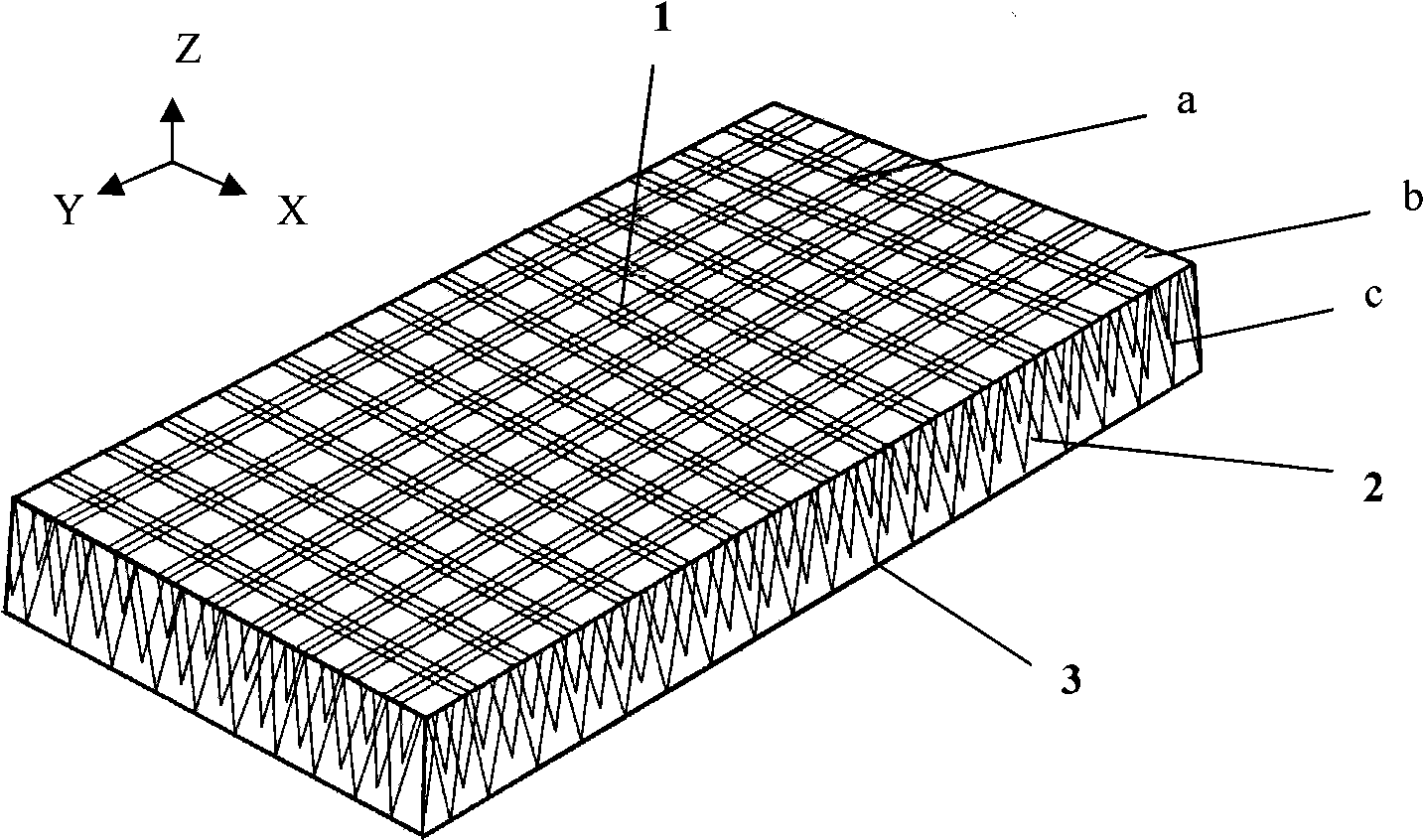

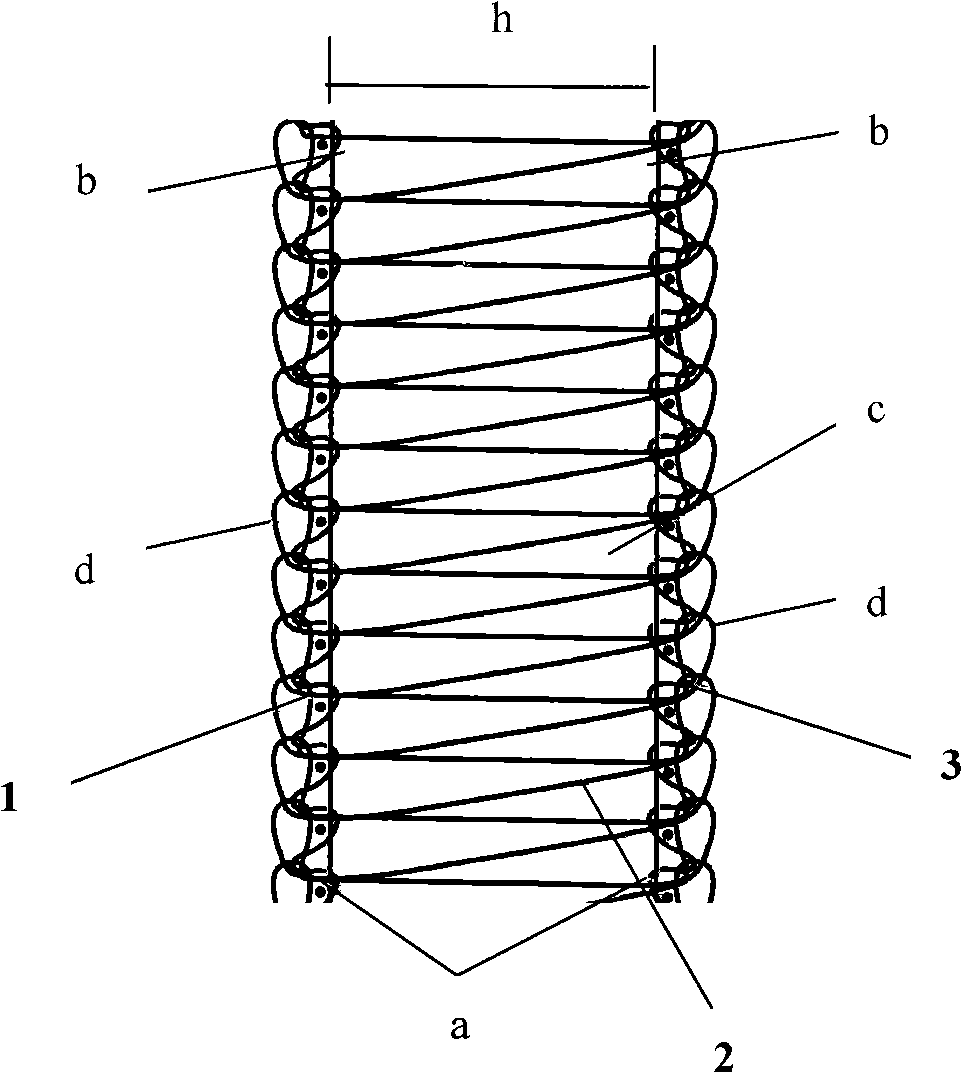

Production method for three-dimensional reinforced warp knitted spaced fabric

The invention relates to a manufacture method for three-dimensional reinforced warp knitted spaced fabric, and the warp knitted spaced fabric is produced on a modified double tricot raschel machine with full weft insertion devices. A main body of adopted raw materials is tows of high-performance fiber such as fiber glass, carbon fiber, aramid fiber, ultra high modulus polyethylene and the like. The manufacture method comprises the following steps: introducing high-performance fiber inserted weft yarns on the whole width of the machine in the X-axis direction through two weft insertion devices arranged on the front and the back of the machine; introducing high-performance fiber inserted warp yarns in the Y direction through guide bars; binding and fixing the inserted warp yarns and the inserted weft yarns through chain stitch or tricot stitch of common or high strength synthetic fiber filament yarns; adopting the high-performance fiber on upper and lower surface layer connecting yarns, ensuring the distance of 5 to 6 cm between the two surface layers, and providing reinforcing fiber in the Z-axis direction; and designing raw materials, densities, arrangement modes and interlayer thickness of the inserted warp and weft yarns of the surface layers and interlayer connecting yarns according to the requirements to form three-dimensional mesh structures with different mesh sizes and specifications. The manufacture method is characterized in that the high-performance fiber is extended and arranged in three-dimensional directions so as to overcome the defects and disadvantages of the prior spaced fabric taken as a reinforced material, and the manufacture method provides an ideal three-dimensional reinforced fabric for production of composite boards with good tensile, bending, shearing and compression properties and shock resistance.

Owner:JIANGNAN UNIV

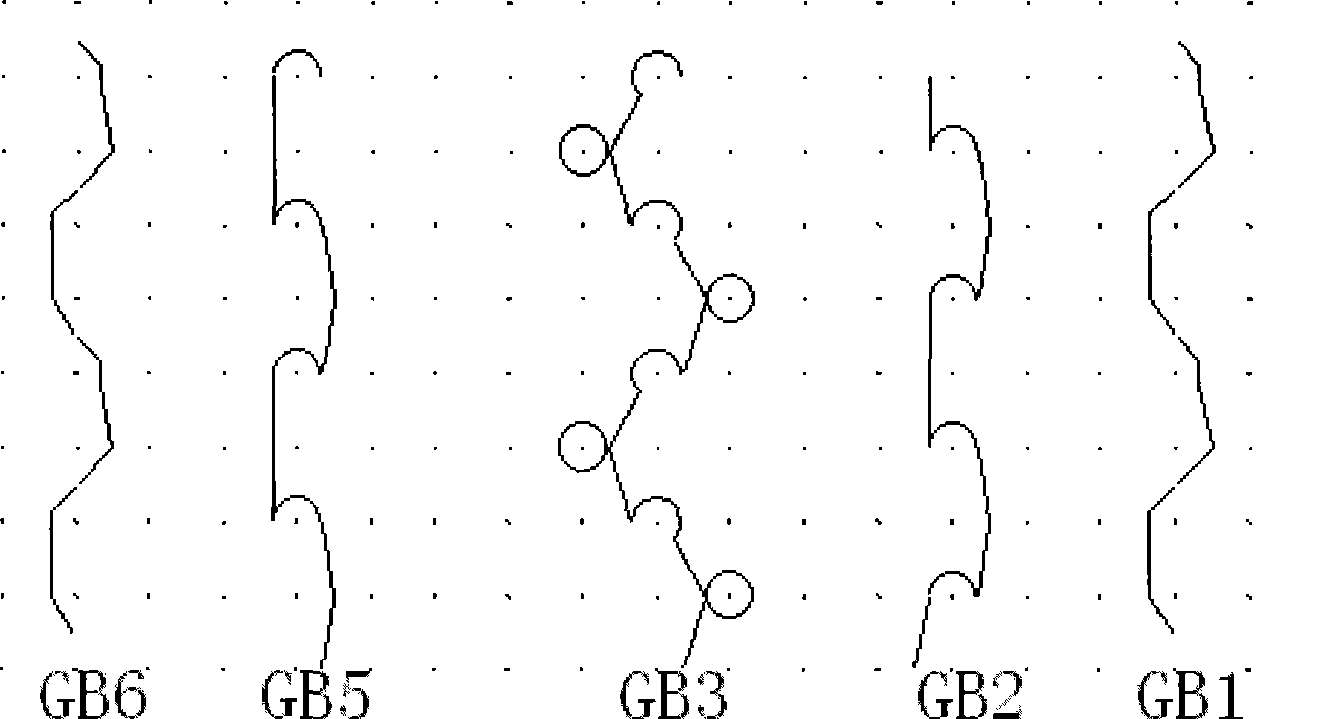

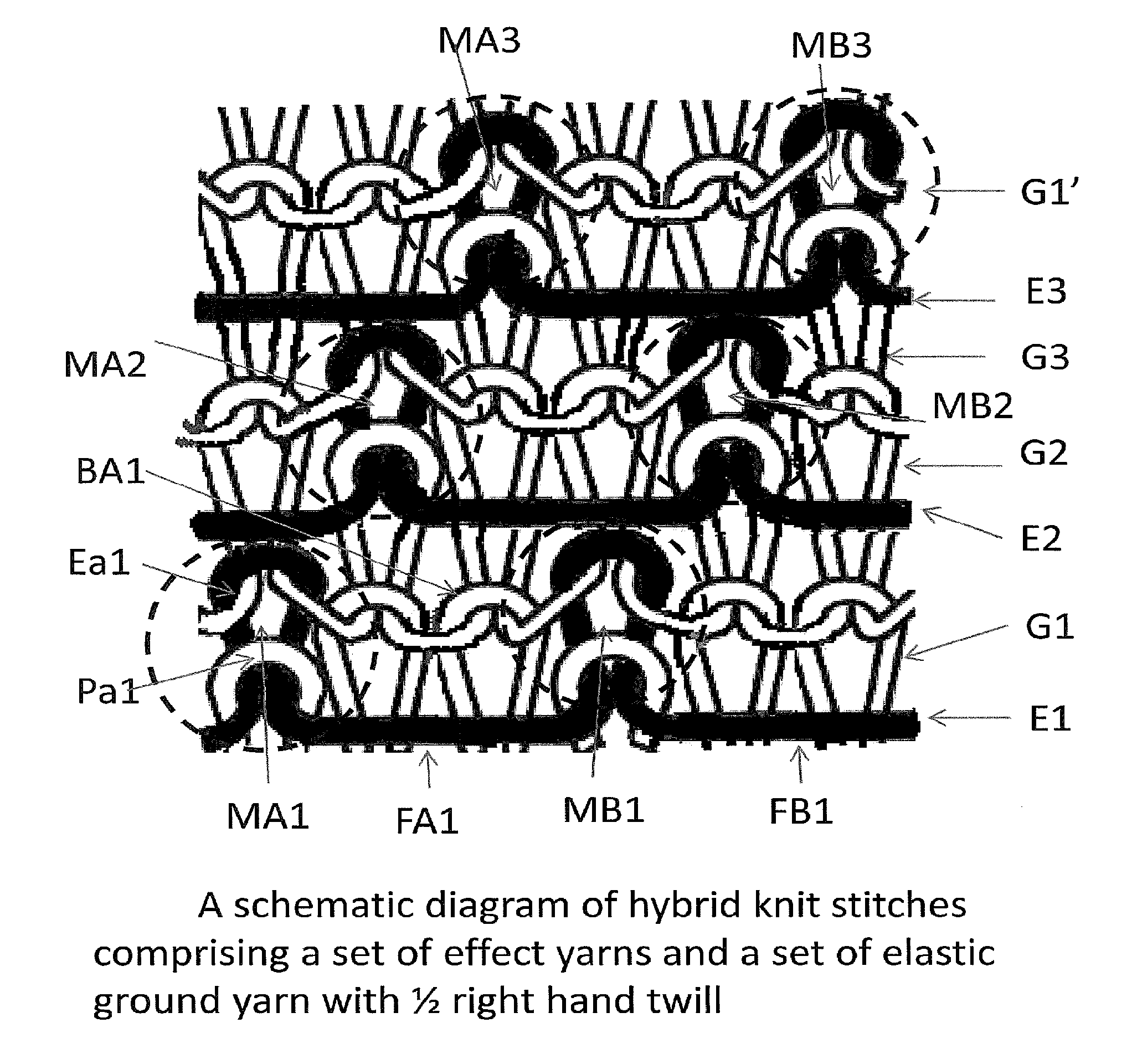

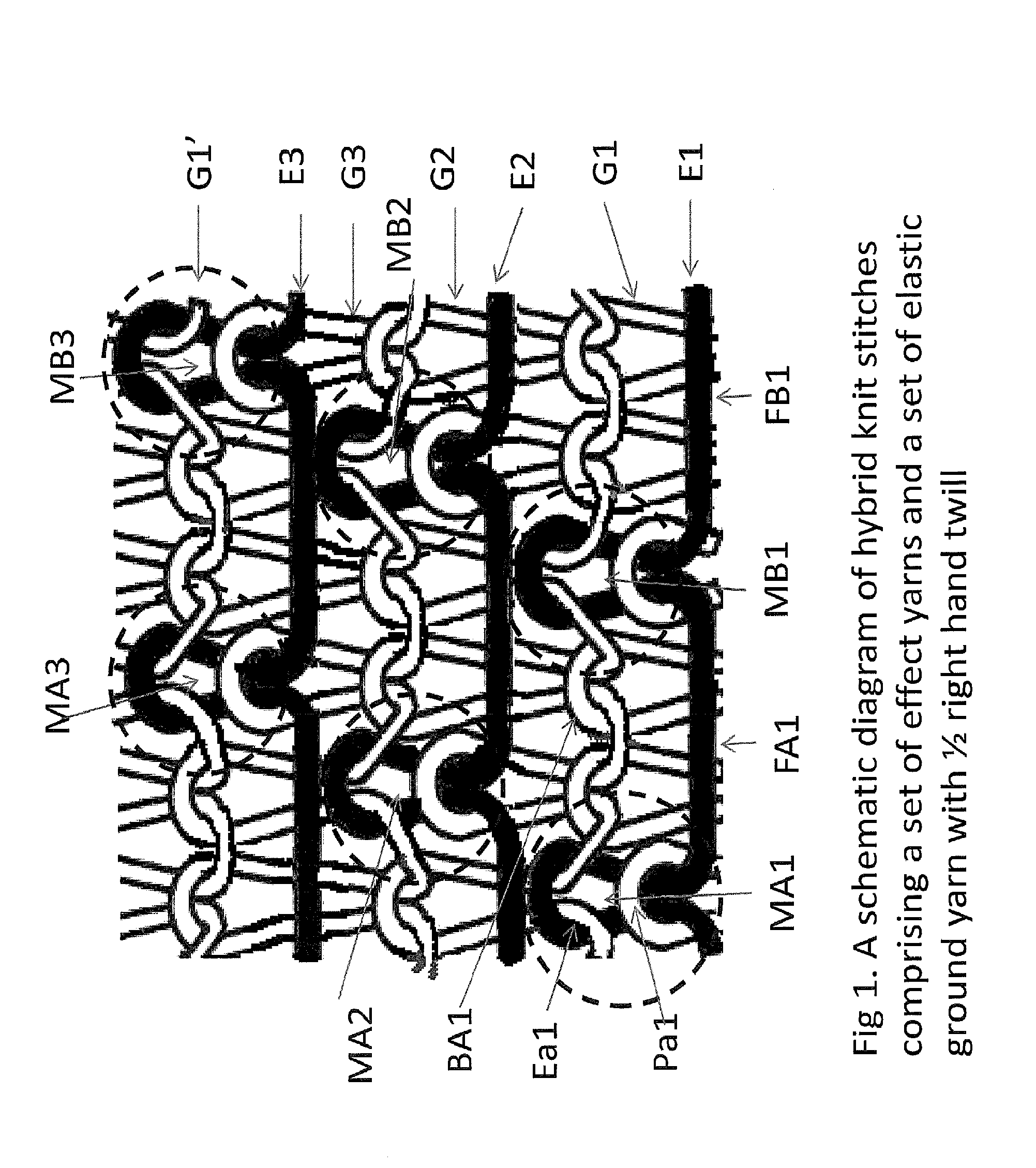

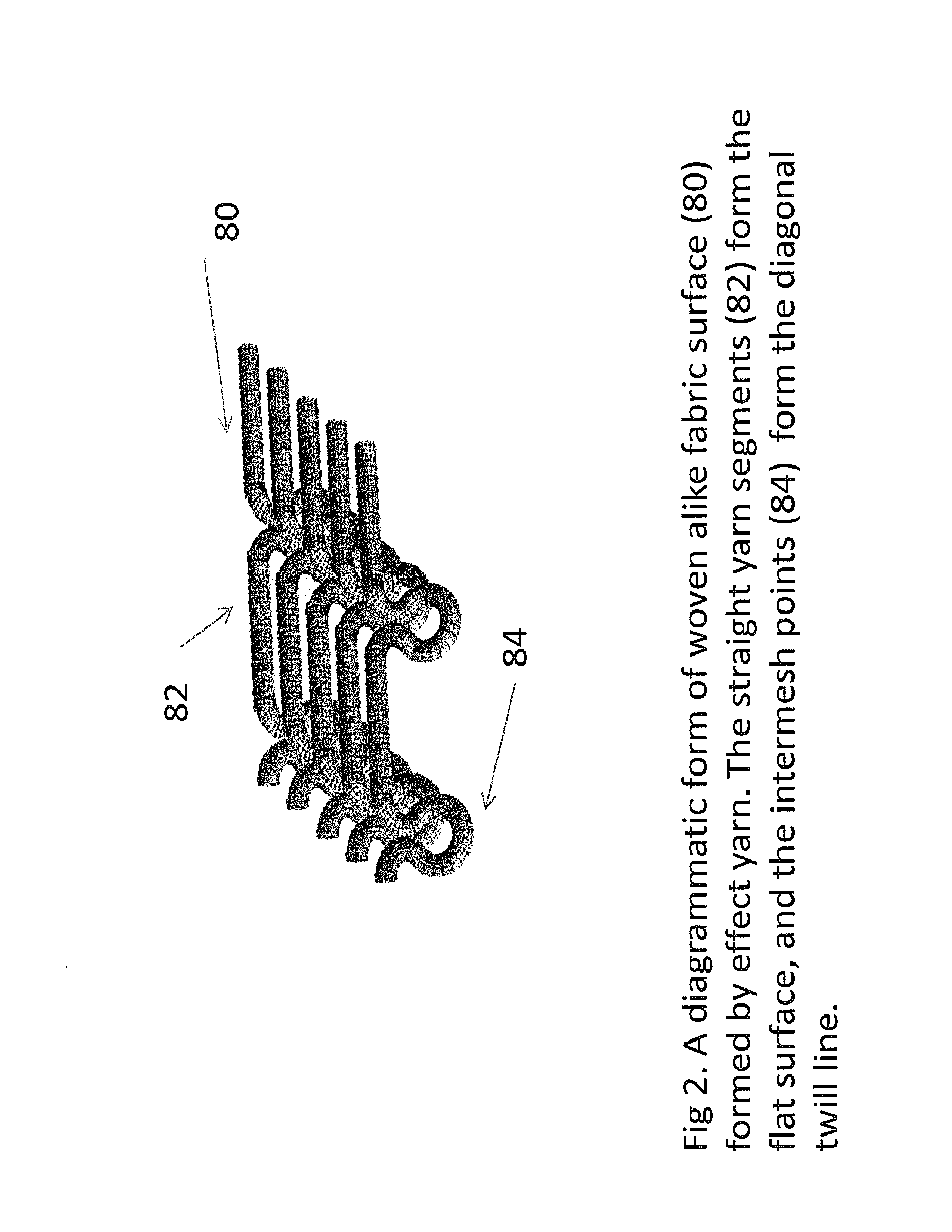

Stretch circular knit fabrics with multiple elastic yarns

ActiveUS20160251782A1Easy to stretchEasy to processWeft knittingOrnamental textile articlesYarnEngineering

An article comprising a knit fabric having a surface side and a base side, and including a set of ground yarns and a layer of effect yarns, wherein the ground yarns and effect yarns are knit through intermesh points in a predetermined arrangement wherein the effect yarns are alternately arranged with the ground yarns and wherein the ground yarns comprise at least one elastic fiber and optionally at least one hard fiber, and the effect yarns comprise at least one hard fiber and optionally an elastic fiber.

Owner:THE LYCRA CO LLC

Nickel-base high-temperature alloy with low density and high melting point and preparation process thereof

The invention relates to high-temperature alloy technology, and in particular provides an isometrical cast nickel-base high-temperature alloy with low density, high incipient melting temperature and good casting property and a preparation process thereof, which can be used for floating tile materials of a combustion chamber. The alloy comprises the following compositions by mass percentage: 0.03 to 0.06 percent of C, 5 to 12 percent of Cr, 5.5 to 6.5 percent of Al, 3 to 8 percent of Co, 3 to 7 percent of W, 2 to 4 percent of Mo, 1.6 to 3.2 percent of Nb, 0.01 to 0.03 percent of B, 0.008 to 0.025 percent of Y and the balance of Ni. A vacuum induction furnace is adopted to smelt a master alloy, and a smelting crucible is a CaO crucible or a MgO crucible; and the operation process comprises the following steps: putting alloying elements such as carbon, chromium, cobalt, tungsten, molybdenum and niobium in proportion and a nickel plate into the crucible; melting the alloy when the vacuum degree reaches between 50 and 0.1 Pa; and after completion of the melting, refining for 30 to 300 seconds at a temperature of between 1,550 and 1,600 DEG C, cutting off electricity, forming a film, breaking the film to add Al and Al-Y and Ni-B interalloy for uniform stirring, and casting a master alloy pig at a temperature of between 1,450 and 1,500 DEG C. The invention solves the problems of low incipient melting temperature, poor plasticity and inoxidability and the like of the nickel-base high-temperature alloy.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

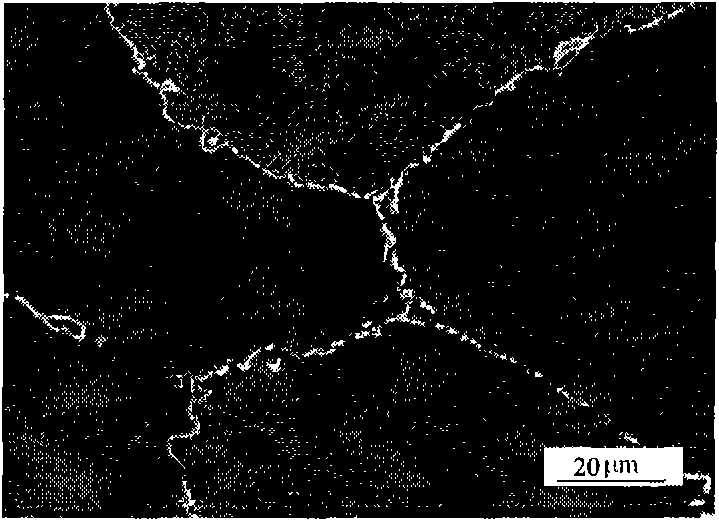

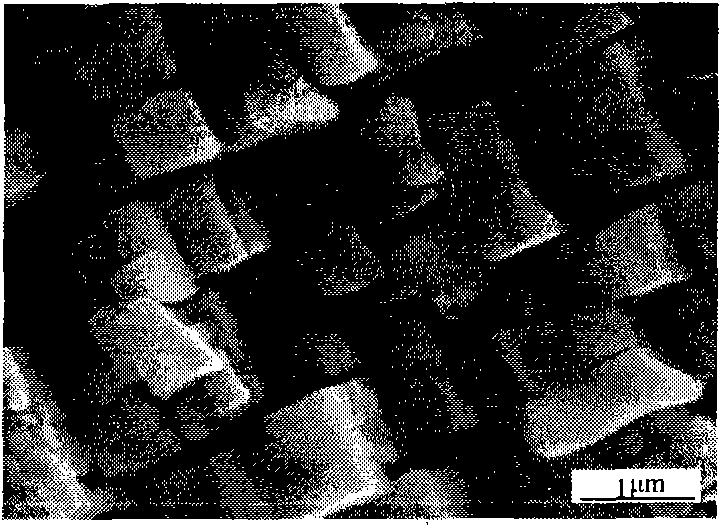

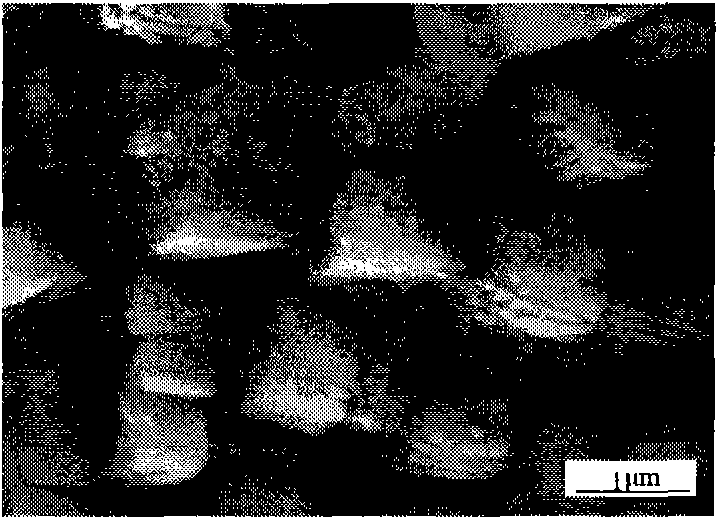

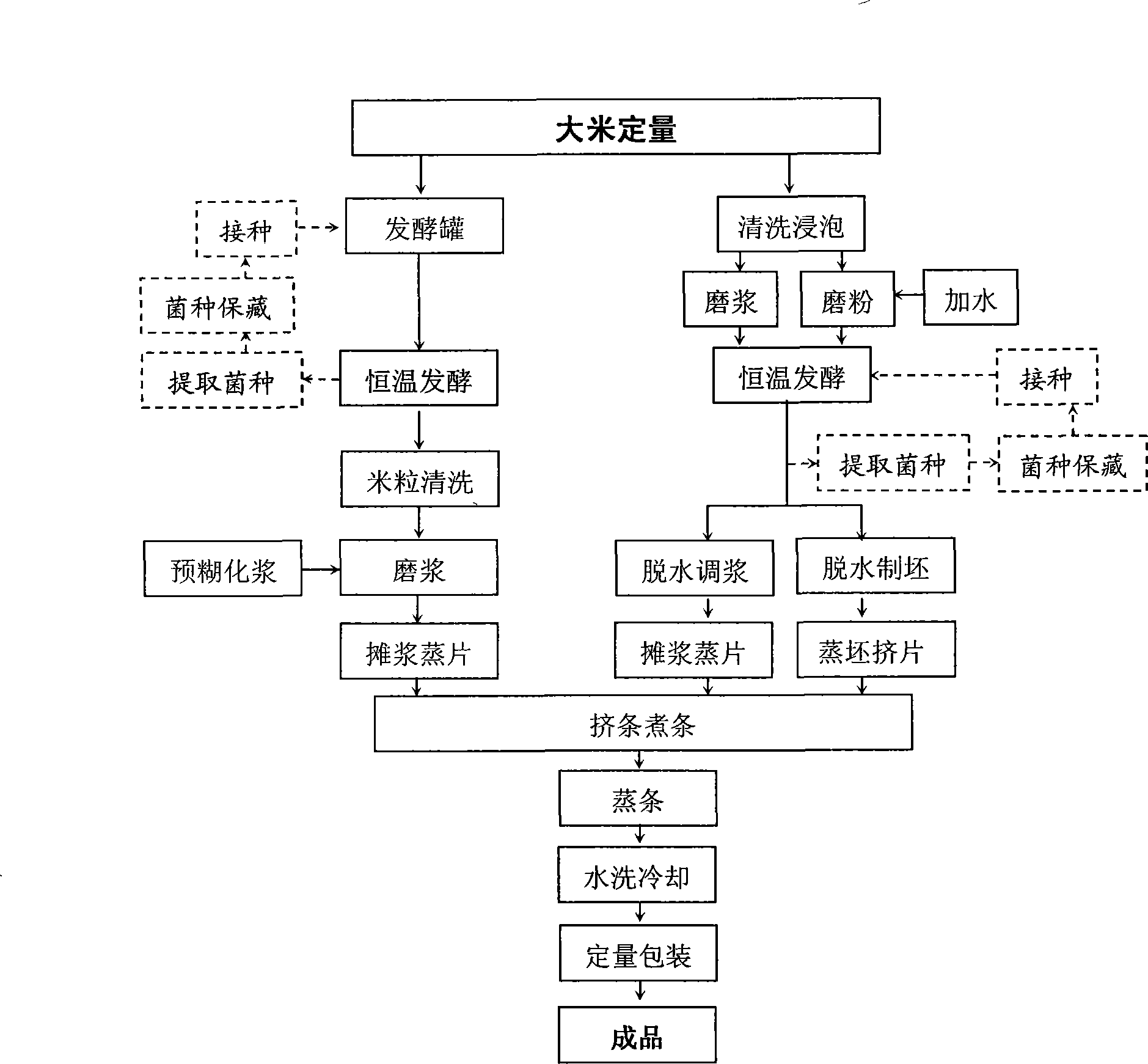

Method for processing lactic acid bacteria fermentation rice-flour noodles

InactiveCN101248852AShorten the production cycleReduce manufacturing costFood preparationBiotechnologyBroken rice

The invention discloses a processing method for fermenting rice flour by lactobacillus, namely using the lactobacillus to ferment and produce rice flour food with high quality, belonging to the technology field of food process. The technical proposal comprises the following steps of grinding the rice flour to thick liquid, spreading the thick liquid to steam a sheet, extruding and cooking rice bars, steaming the rice bars, and washing and cooling the rice bars. The processing method is characterized in that the selected material is rice or broken rice with amylose starch content more than 20%, the lactobacillus is added into the rice flour for fermentation at a constant temperature before or after grinding the rice flour to thick liquid, the number of the lactobacillus is 10<6> - 10<11>cfu / ml, the fermentation temperature is 30-50 DEG C, and the fermentation time is 8-18 hours. The processing method avoids the danger of latent miscellaneous bacteria by adopting pure strain enrichment fermentation, improves the flexibility and ensures the cleanness and the quality of the rice flour by utilizing pre-pasting rice milk instead of reserved rice sheet and fermented glutinous rice, and saves production cost due to the short production period.

Owner:CHINA AGRI UNIV

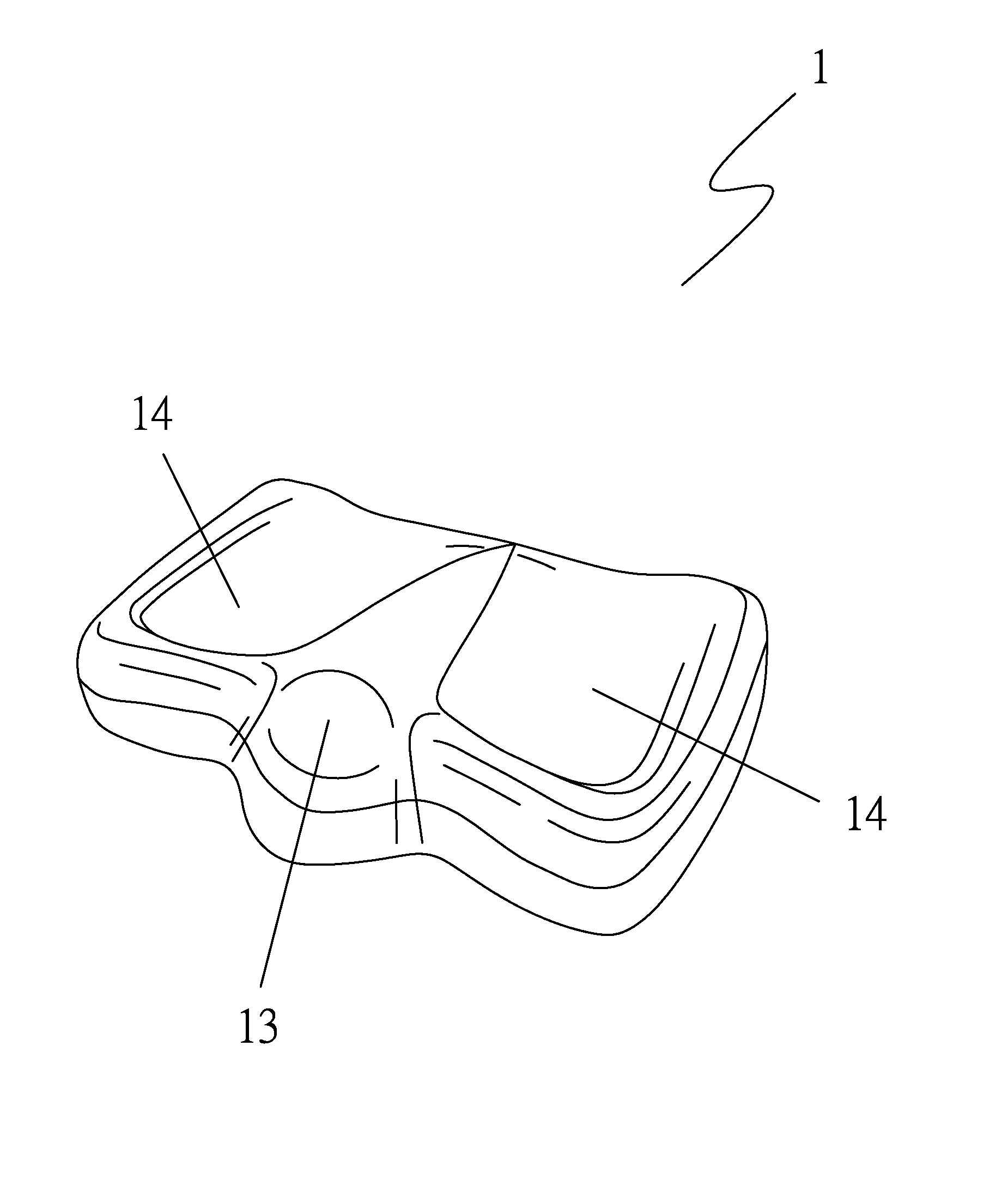

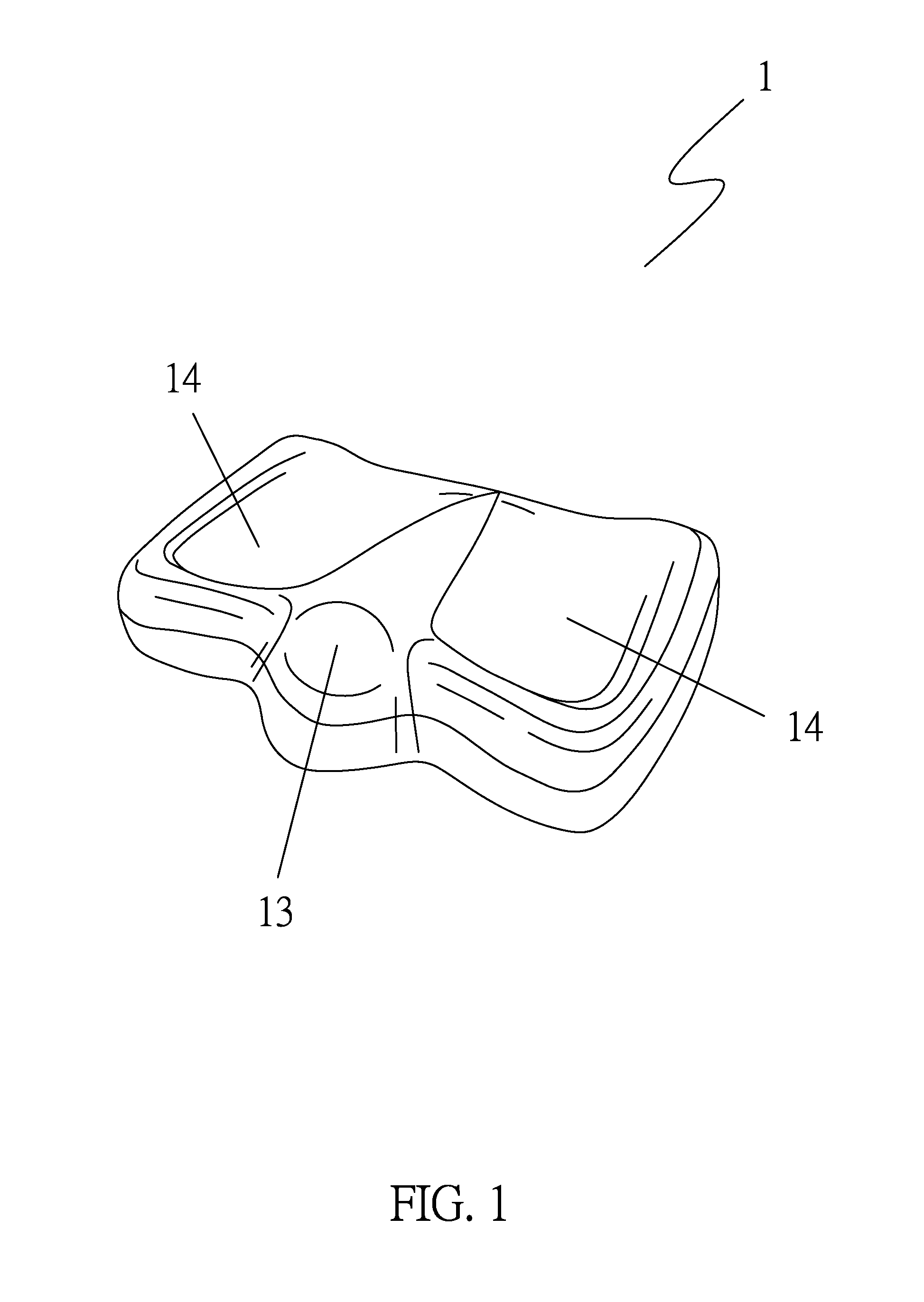

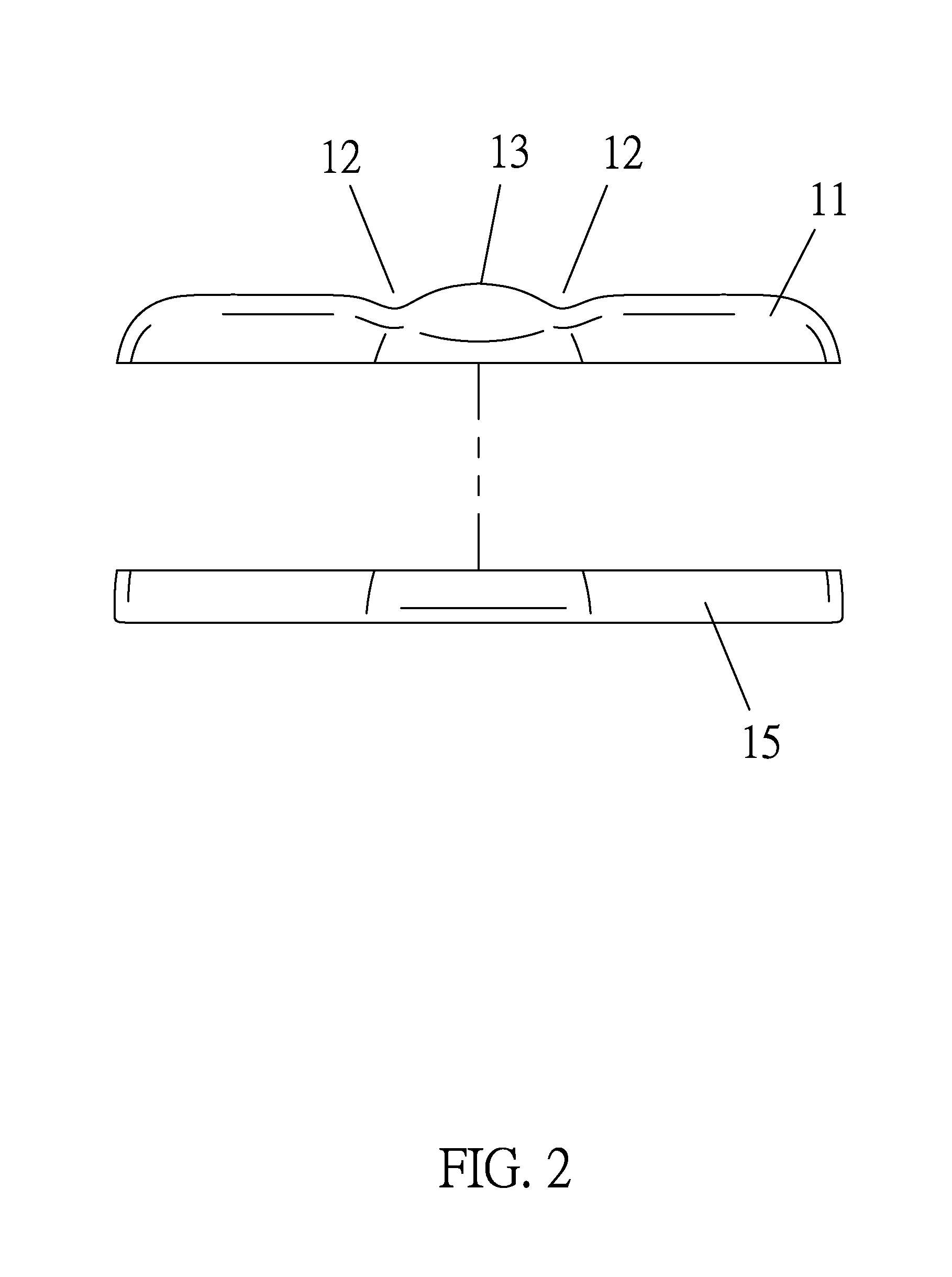

Snore suppression pillow

A snore suppression pillow includes a pillow body and at least one raising layer. The pillow body has a surface forming a high end and a low end. The high end includes a recessed portion formed in each of two sides of a middle portion thereof so that the middle portion is configured as a curved protrusion. The at least one raising layer is attachable to a bottom of the pillow body. As such, adjustment is achievable with the at least one raising layer to provide the pillow with a height suiting the need of a user and the protrusion of the pillow body allows the head of the user to turn aside to the left side or right side when the user is sleeping so as to stretch the respiratory tract to help prevent snoring caused by slackening of the respiratory tract.

Owner:GREEN SWEET MATTRESS CORP

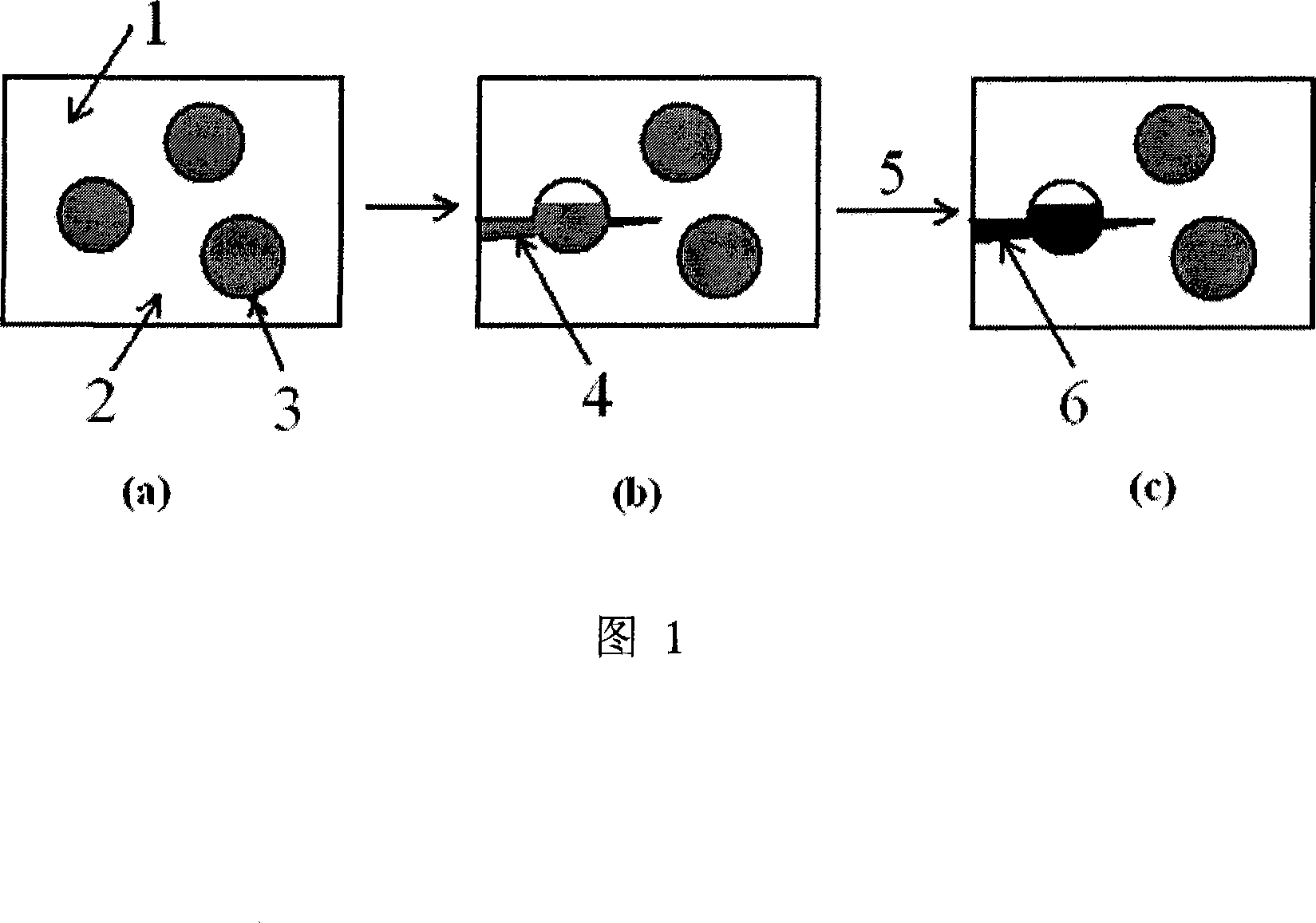

High temperature self-restoring epoxy resin material and preparation method thereof

The invention discloses a high-temperature self-repair-type epoxide resin material and a process for preparation, the process comprises adding microcapsule and accelerating agent which are evenly mixed into the basal body of epoxide resin, adding curing agent into the basal body of epoxide resin to evenly mix, finally, curing molding and getting high-temperature self-repair-type epoxide resin material. When cracks are produced on the high-temperature self-repair-type epoxide resin material of the invention because of forcing in the process of processing and employing, the cracks are extended to the built-in microcapsule, and the microcapsule wall is led to crack, liquid-state epoxide resin in the microcapsule is immediately released to fill into the cracks, the accelerating agent which is built in the basal body leads the liquid-state epoxide resin to be solidified under high temperature, thereby rebinding the cracks together, and the damage of the material is repaired, thereby keeping the mechanical properties of the epoxy composite material and prolonging the life span.

Owner:SUN YAT SEN UNIV

Oilfield ultrahigh-pressure acid-resistant rubber seal material and preparation method thereof

ActiveCN103396591AOvercome leaksOvercoming extrusion edge tearing phenomenonOther chemical processesPolymer scienceAntioxidant

An oilfield ultrahigh-pressure acid-resistant rubber seal material comprises, by weight, 85-65 parts of hydrogenated butadiene-acrylonitrile rubber, 15-35 parts of butadiene-acrylonitrile rubber, 5-7 parts of zinc oxide, 1-4 parts of stearic acid, 1-2 parts of an antioxidant, 50-65 parts of nanometer carbon black, 15-25 parts of white carbon black, 5-10 parts of a phenolic resin, 5-10 parts of a softener, 3-6 parts of a peroxide vulcanizing agent, 6-8 parts of a vulcanizing aid, 1-3 parts of sulfur, and 2-4 parts of a promoter, wherein the sum of the weight parts of the hydrogenated butadiene-acrylonitrile rubber and the butadiene-acrylonitrile rubber is 100. A seal ring made through adopting the rubber seal material can satisfy the seal of oilfield high-pressure acid-resistant liquid (hydrochloric acid or hydrofluoric acid) pipelines, and overcomes the leakage and torn edge extrusion phenomena of seal members under a high hydraulic pressure.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

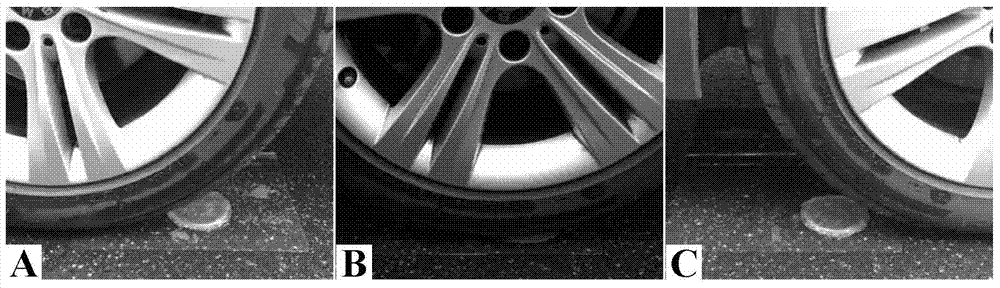

Wearable flexible stress sensor and preparation method and application thereof

The invention relates to a wearable flexible stress sensor and a preparation method and application thereof. Firstly, functional ink suitable for screen printing is prepared, and is printed on a wearable substrate through a screen printing method, and the stress sensor of a desired specification is produced. The stress sensor is used for monitoring physical deformation of stretching, bending, touching and the like from small ranges to large ranges, and has multiple application in the electronic skin fields and the biomedical application fields of human skins, expressions, pulses, heartbeats and the like, the human-computer interaction fields and the fields of virtual reality, entertainment technology and the like. The flexible stress sensor of the invention has the following advantages that the sensor has excellent stretching elasticity, and stretching strain can reach 100%; sensitivity is extremely high, and a sensitivity parameter (Gauge Factor) can be up to 8000 or more; linear relationships of working curves are excellent, stretching repeatability is good, and a stretching cycle lag is small; and a preparation process is simple, costs are low, massive integrated-device preparation is suitable, and application prospects are wide.

Owner:NANKAI UNIV

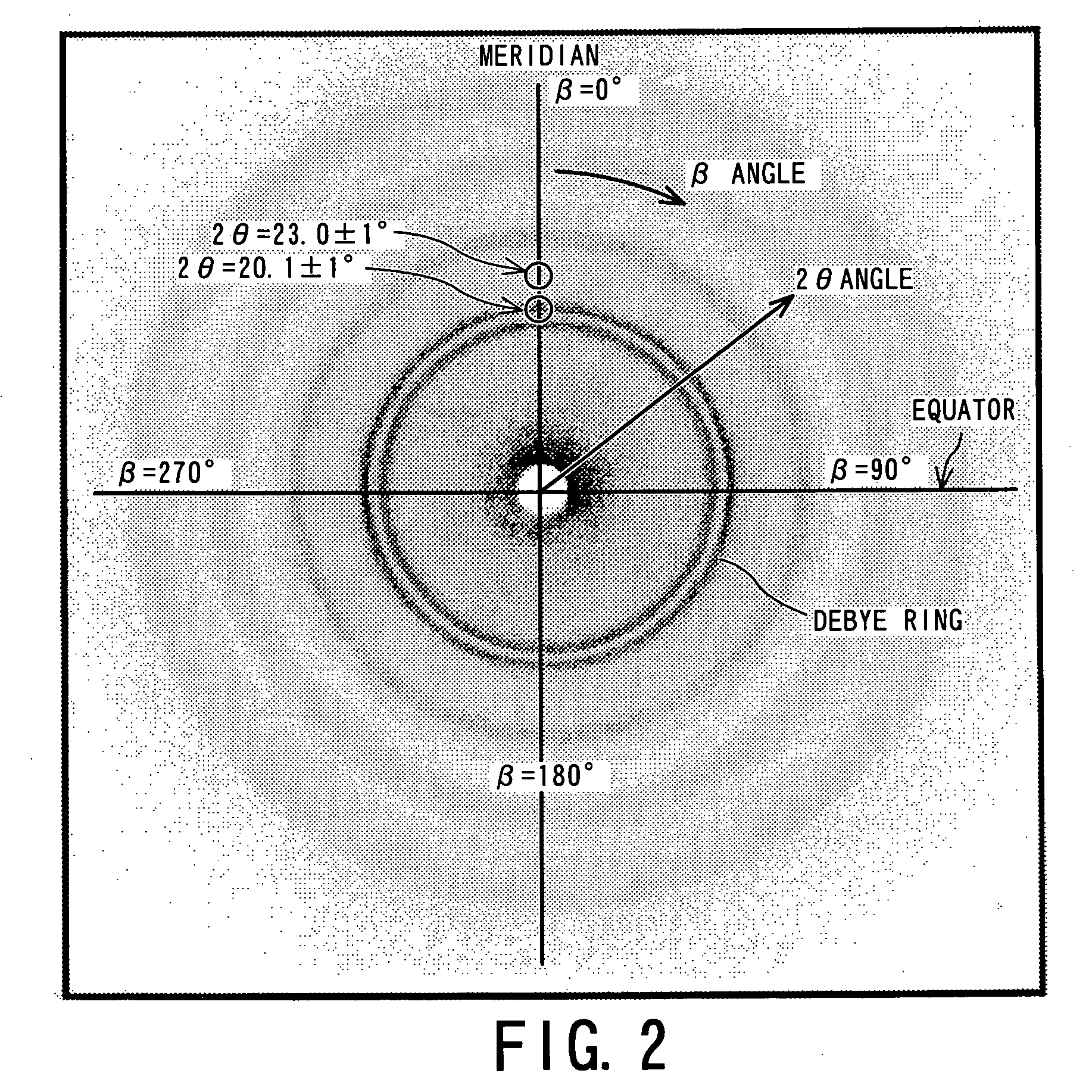

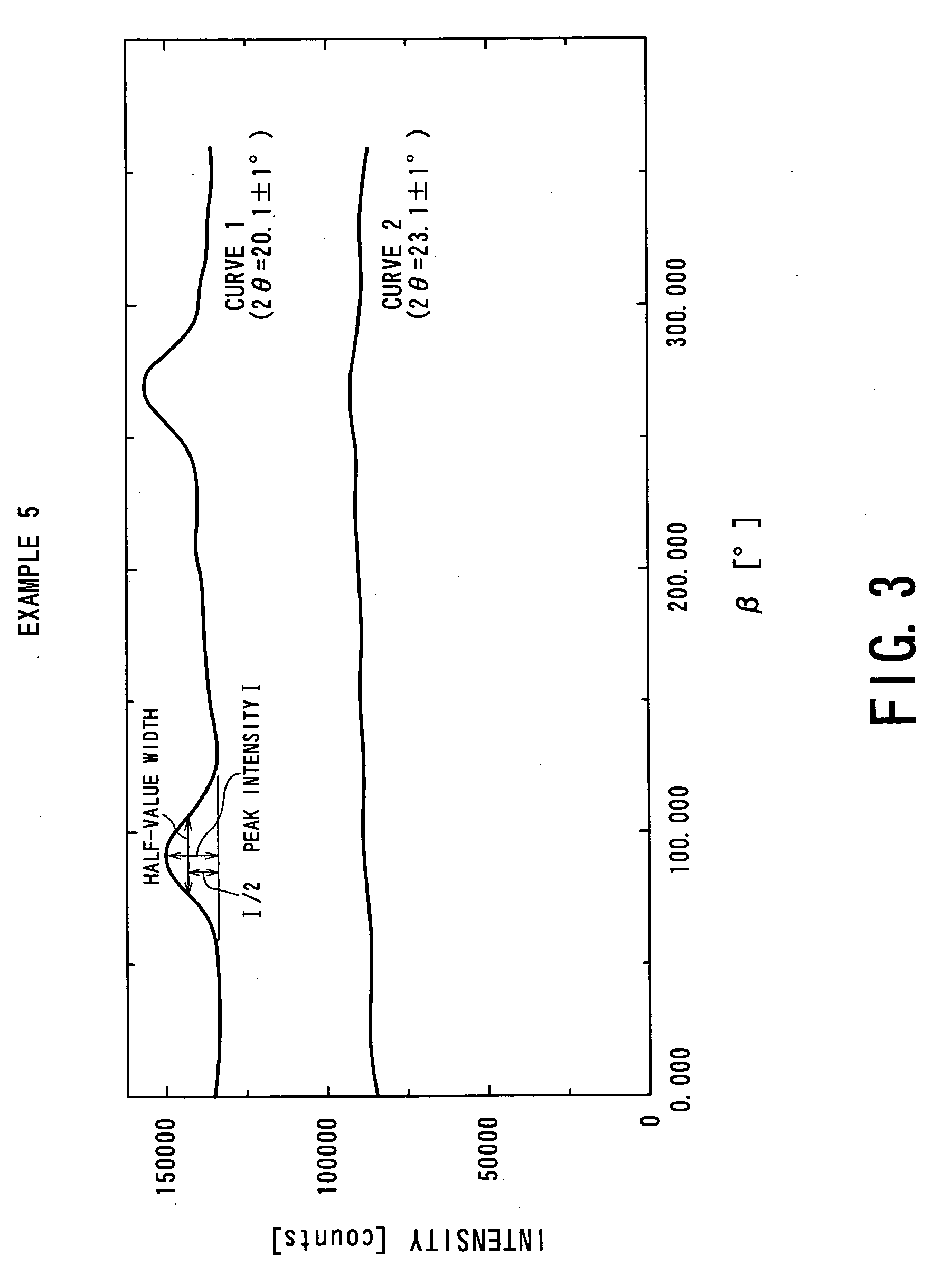

Porous membrane of vinylidene fluoride resin and process for producing the same

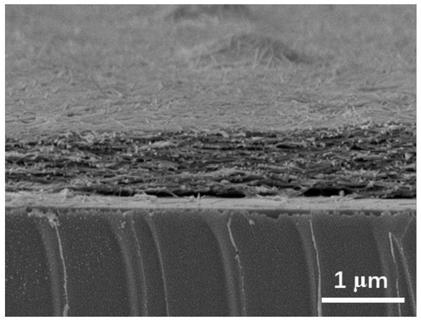

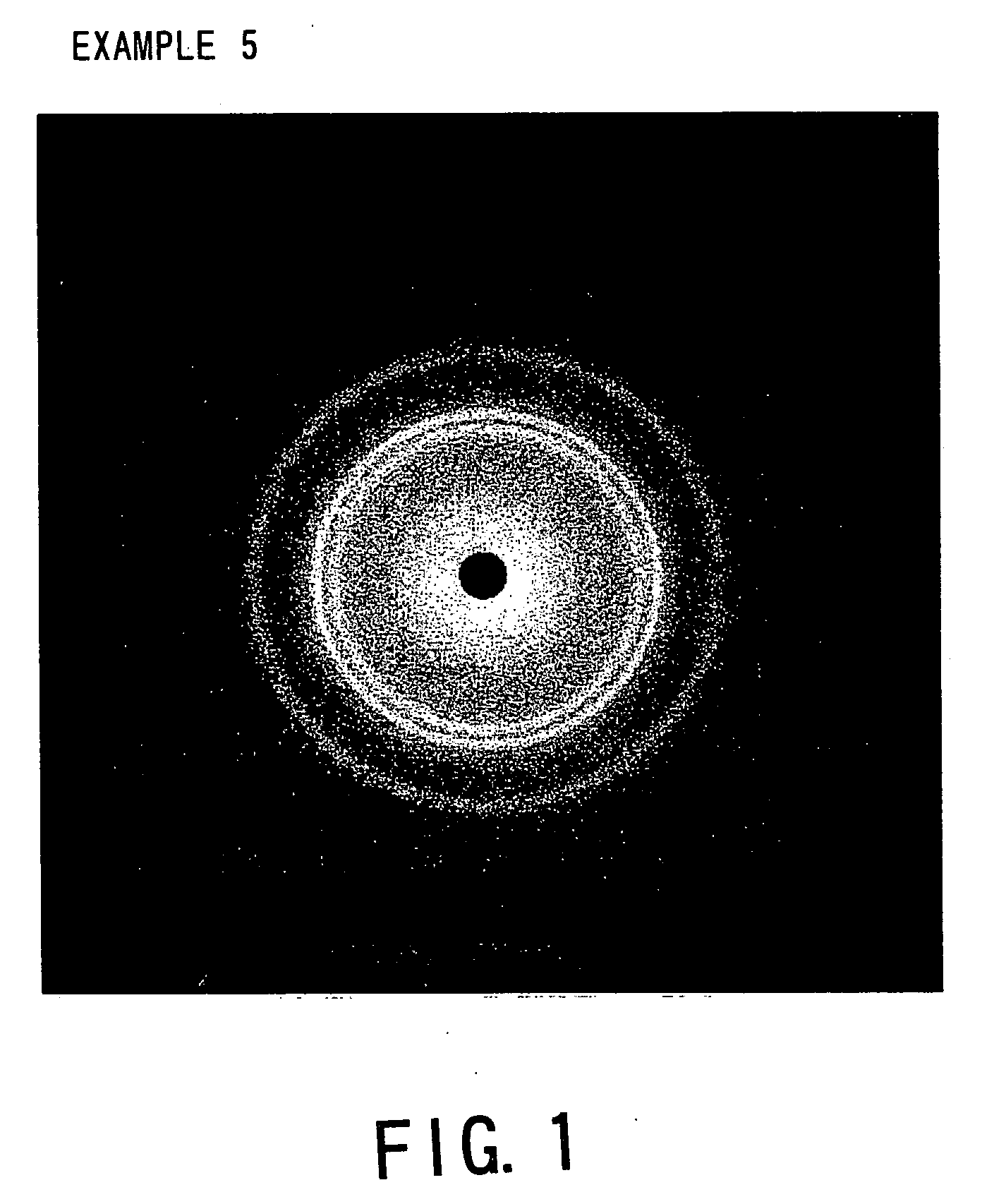

ActiveUS20060178480A1Improve heat distortion resistanceFacilitate stretchingSemi-permeable membranesMembranesSolventPorous membrane

There is provided a porous membrane of vinylidene fluoride resin which has pores of appropriate size and distribution and also excellent mechanical strength represented by tensile strength and elongation at break and is useful as a microfiltration membrane or a separator for batteries. The porous membrane of vinylidene fluoride resin is characterized by the presence in mixture of a crystalline oriented portion and a crystalline non-oriented portion as confirmed by X-ray diffraction, and is produced by subjecting a melt-extruded composition obtained by mixing a vinylidene fluoride resin having a molecular weight distribution which is appropriately broad and high as a whole with a plasticizer and a good solvent for vinylidene fluoride resin, to cooling for solidification from one surface, extraction of the plasticizer and stretching.

Owner:KUREHA KAGAKU KOGYO KK

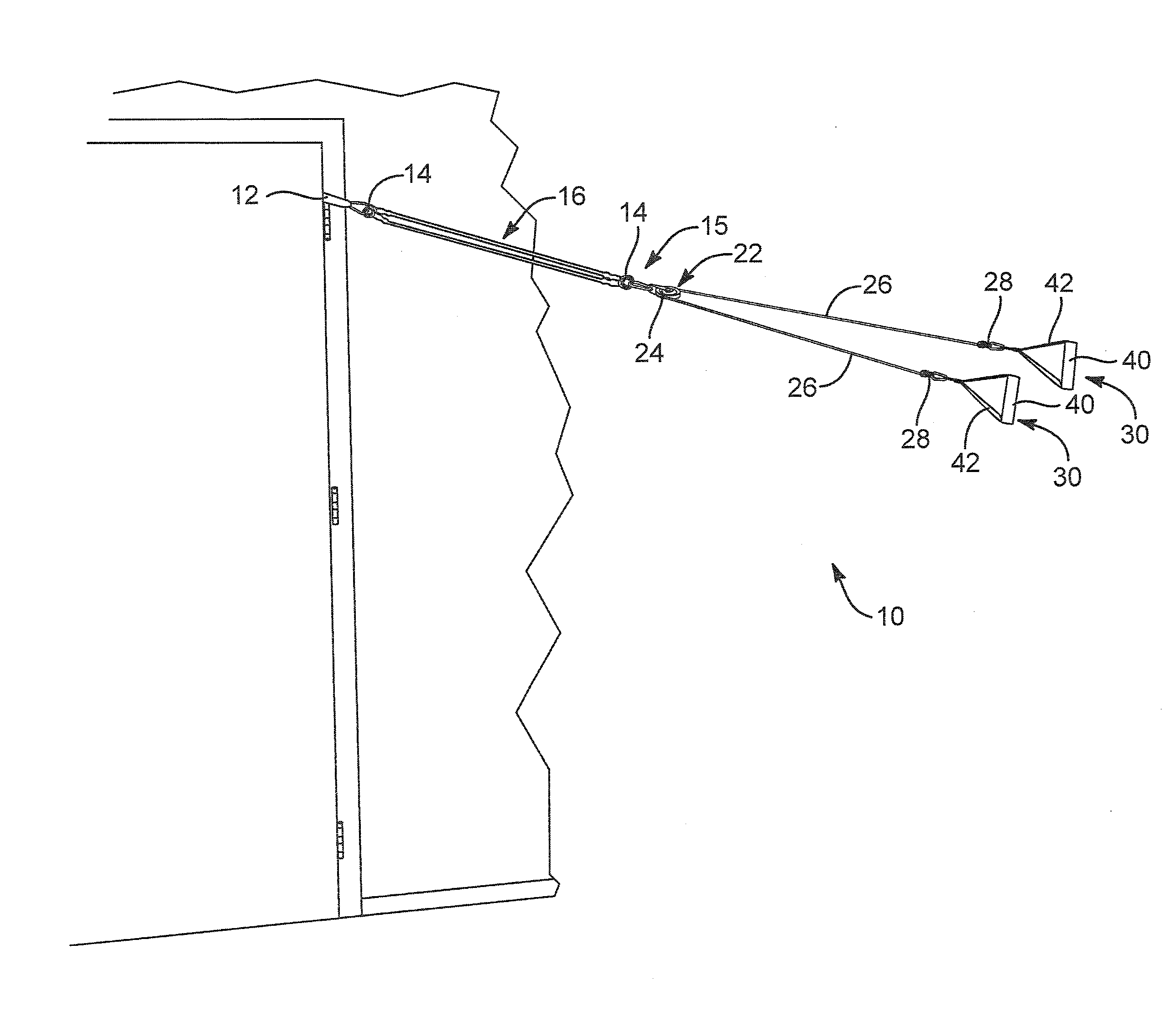

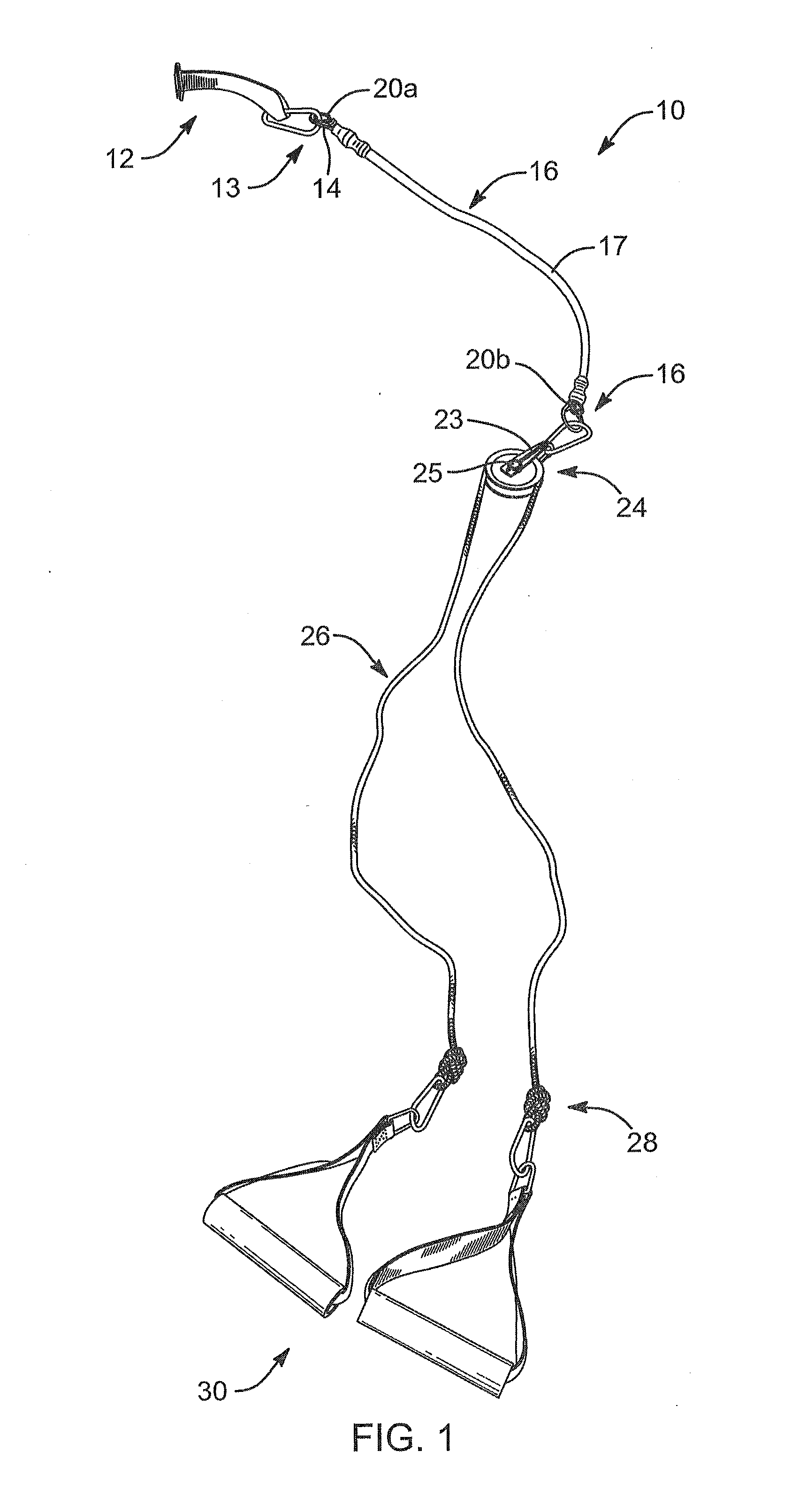

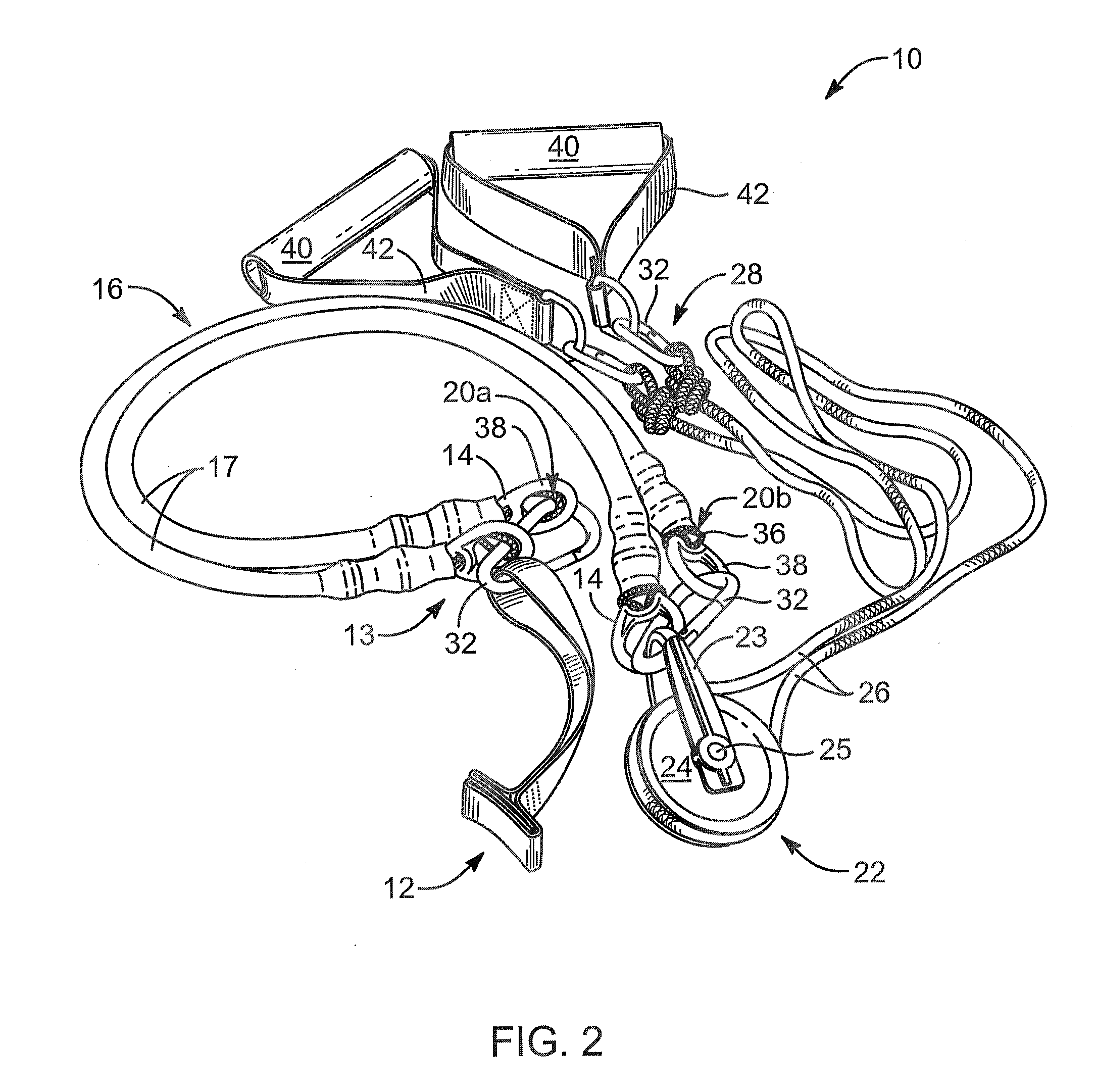

Assisted-resistance-control, free-form, exercise apparatus and method

ActiveUS20100292056A1Easy to stretchPrevent excess stretchingResilient force resistorsTherapy exerciseMovement activityRegimen

An apparatus and method provide an elastic resistance to a free-range of motion of a user. A cord running through a pulley and connected at either end to handles permits assisted resistance control (ARC) and a leverage advantage. In ARC, release by an anchor hand, still maintaining a load, may provide consistent or reduced force on the other, active, hand. One bodily member, such as a hand, may selectively halt and move as an “anchor” member, thereby simultaneously exercising itself and exerting control over another “active” bodily member operating in a “free range of motion.” Thereby, motion of the active hand may continue throughout a range desirable for a physical therapy regimen, a sporting activity, a work activity, or the like. A full range of motion of a bodily member and all supporting portions of the body is possible, without excessive stress or strain on joints due to a mismatch of position and load common to prior art systems.

Owner:BIRCH HEATHER L

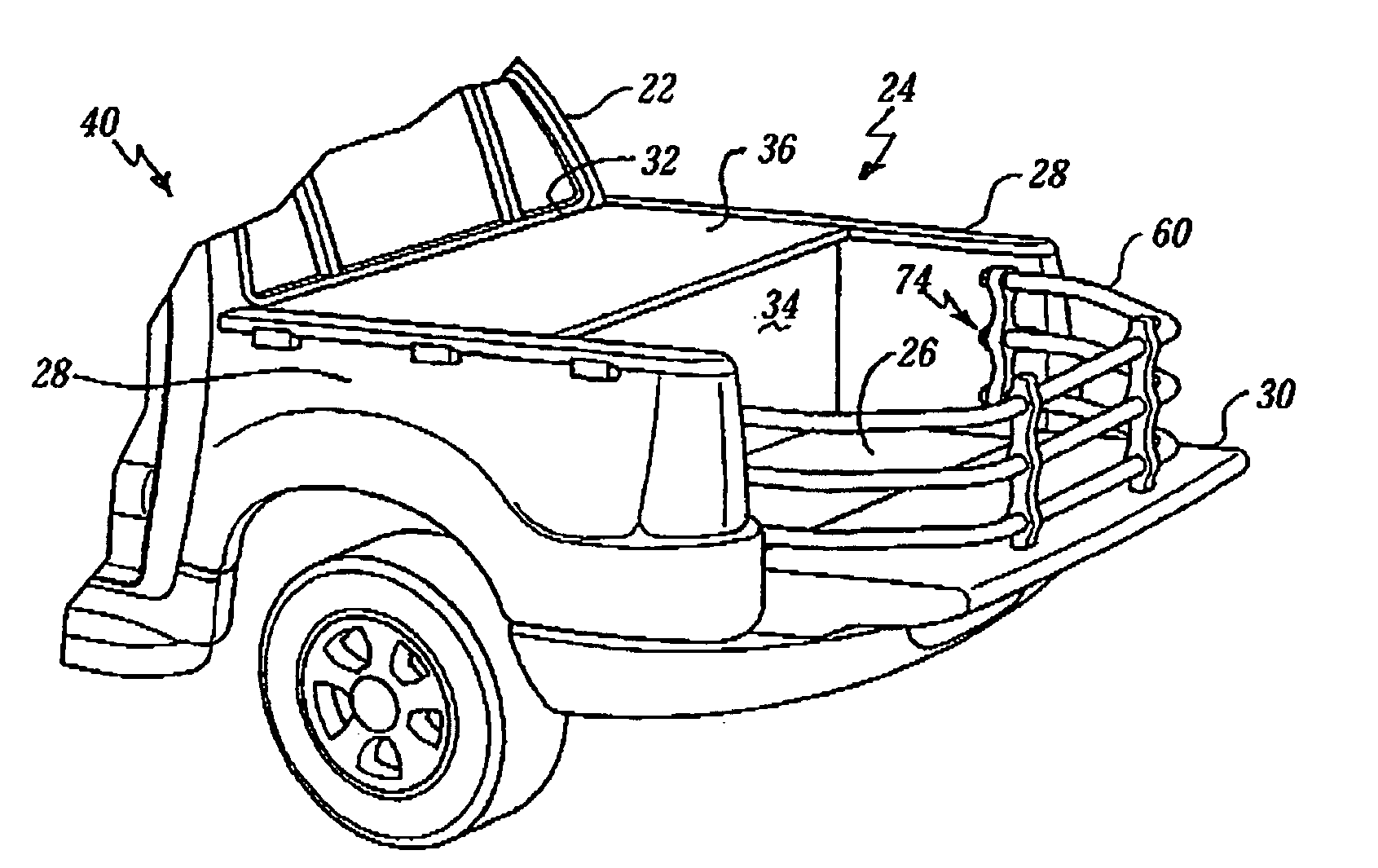

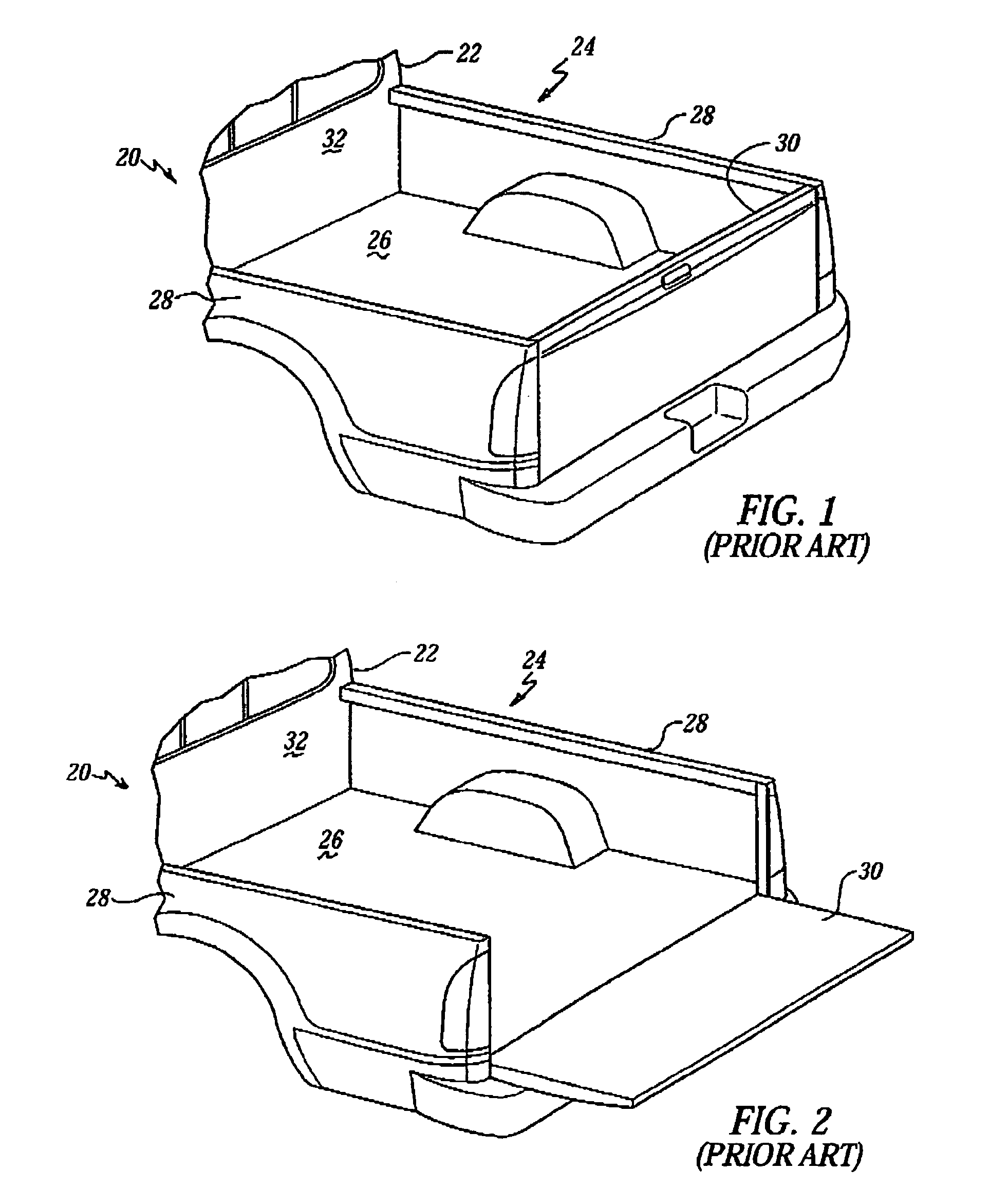

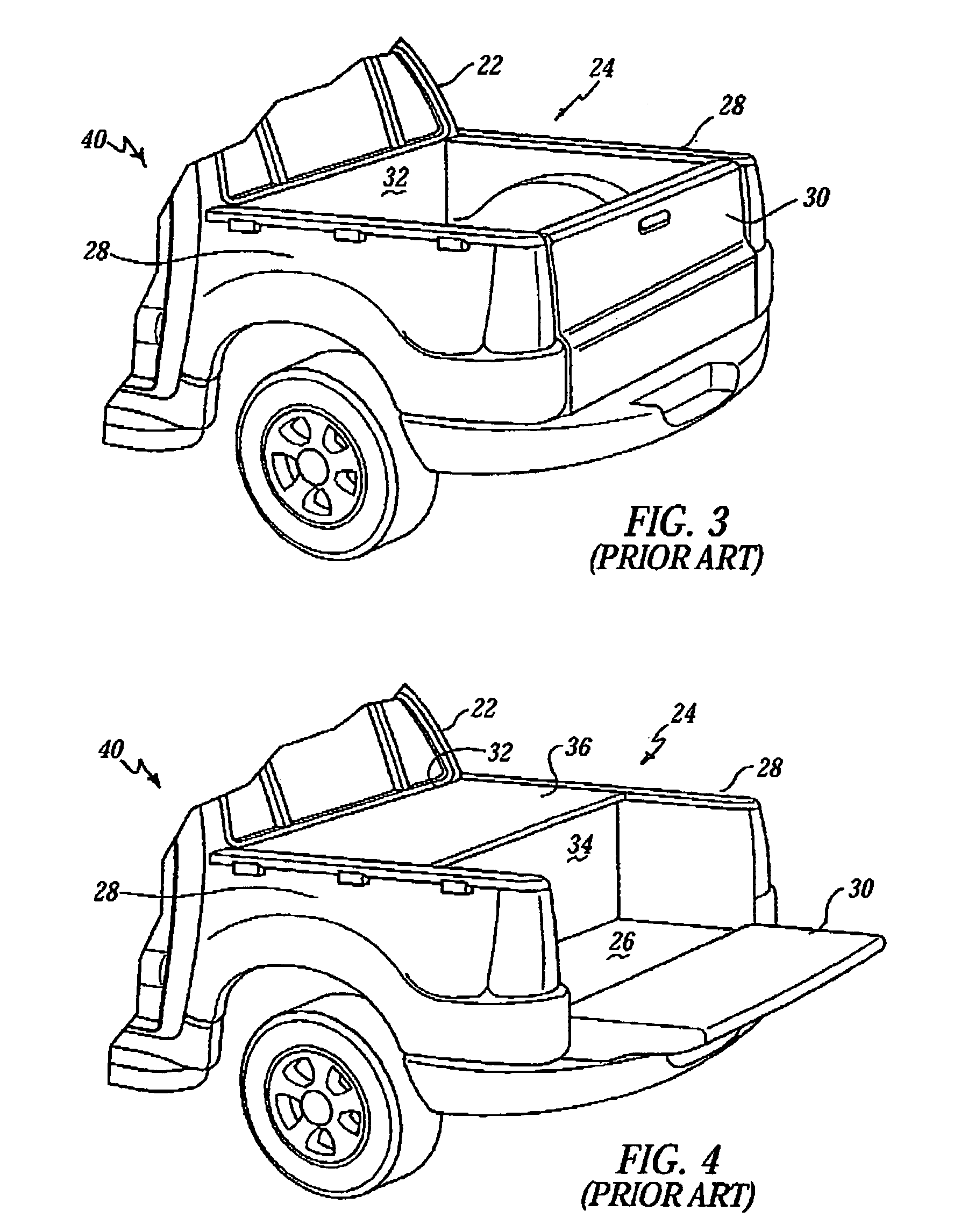

Vehicle cargo bed extender having a pin lock assembly

ActiveUS7121604B2Easy to stretchPrevent movementVehicle to carry long loadsVehicle with living accommodationEngineeringMechanical engineering

A vehicle cargo bed extender for a vehicle of the present invention includes a pair of sidewalls spaced from one another and a center wall extending therebetween. At least one lock assembly is disposed upon one of the sidewalls of the bed extender and includes a locking pin that operable to be selectively extended and retracted to engage with and disengage from the vehicle sidewall respectively. The lock assembly further includes a handle and a lever arm, which cooperate to facilitate the extension and retraction of the locking pin such that said extension of the locking pin locks the bed extender to the vehicle sidewall in the stowed and deployed positions to prevent any uncommanded movement of the extender. The locking assembly further operative to hold the locking pin in the extended and retracted positions respectively until selectively moved between positions.

Owner:GOLDMAN SACHS CREDIT PARTNERS L P +1

PVC (polyvinyl chloride) micro-foam floor and preparation method thereof

Owner:安徽济峰节能材料有限公司

Ostomy appliance

ActiveUS20140114265A1Improve fitEasy to separateNon-surgical orthopedic devicesColostomyEngineeringMechanical engineering

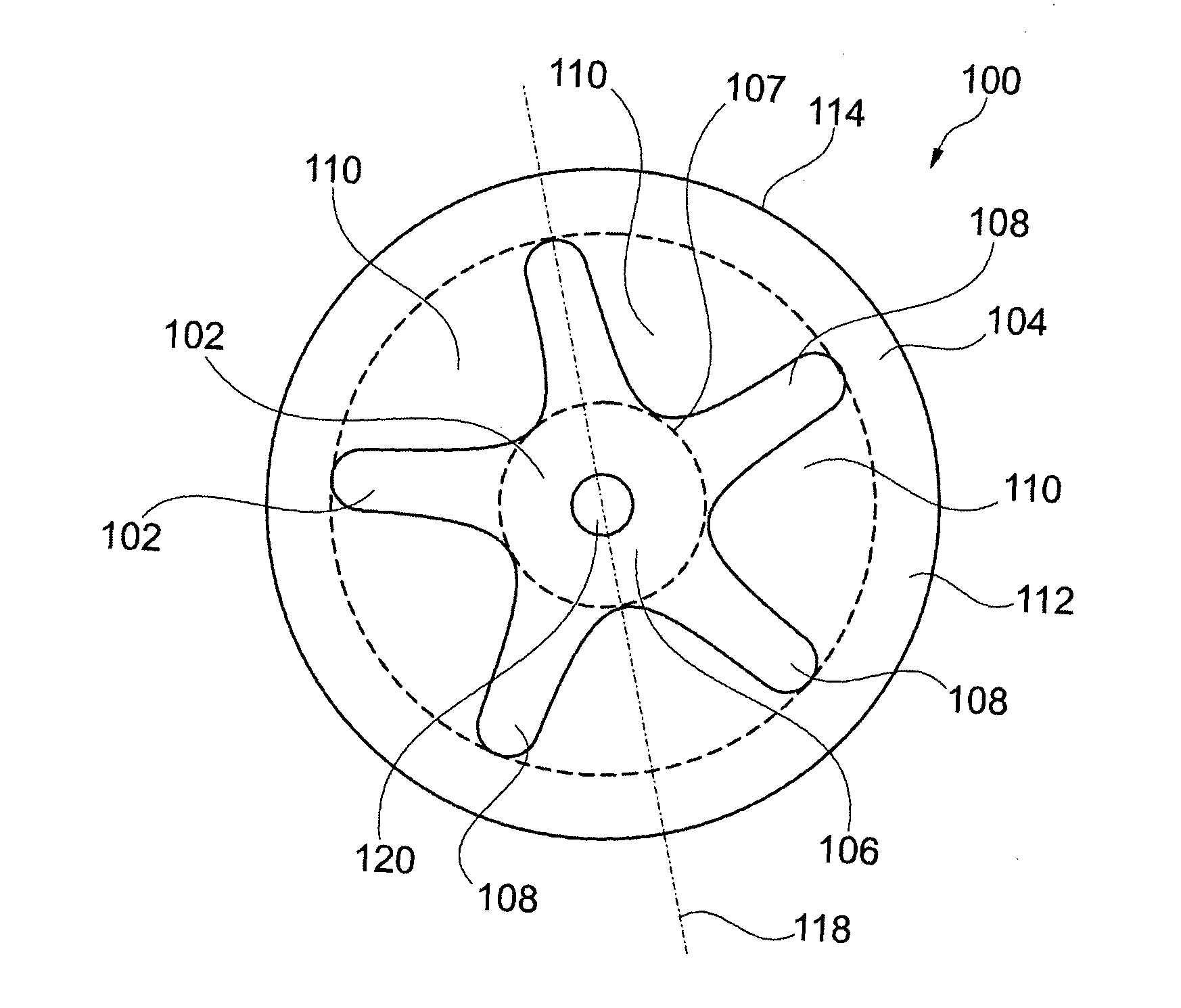

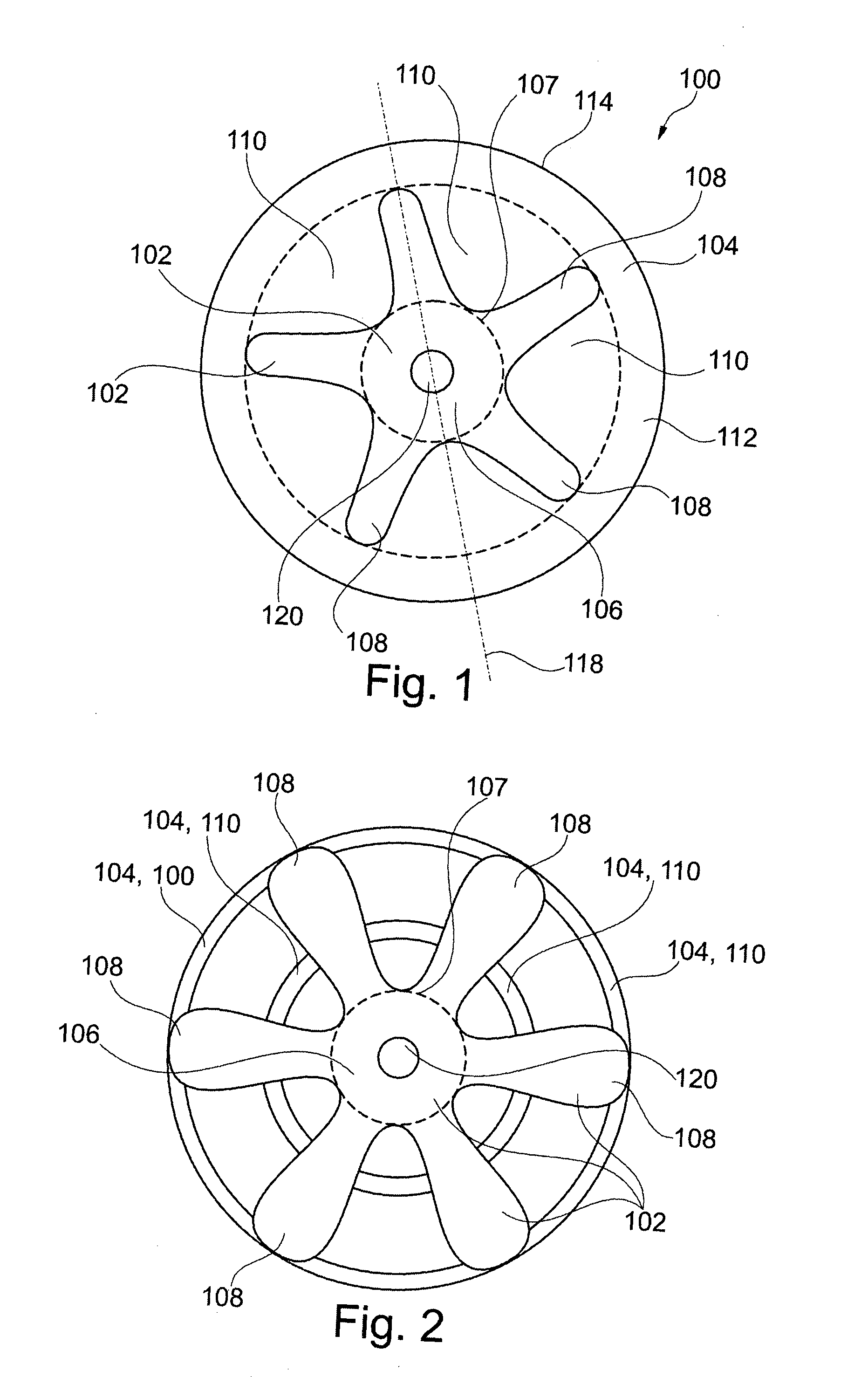

An ostomy appliance for attachment to a stoma, the ostomy appliance comprising: an adhesive wafer (100) defining a passage for receiving a stoma of a user, the adhesive wafer comprising a backing layer and a skin facing adhesive layer; and a collecting bag (116) which in use is secured to the adhesive wafer; wherein the adhesive wafer in a first adhesive zone has a first set of properties and in a second adhesive zone (104) has a second set of properties, the first zone defining three or more radially extending zones, wherein the second zone defines one or more interconnecting parts (110), each of which interconnects at least two of the radially extending zones (108).

Owner:COLOPLAST AS

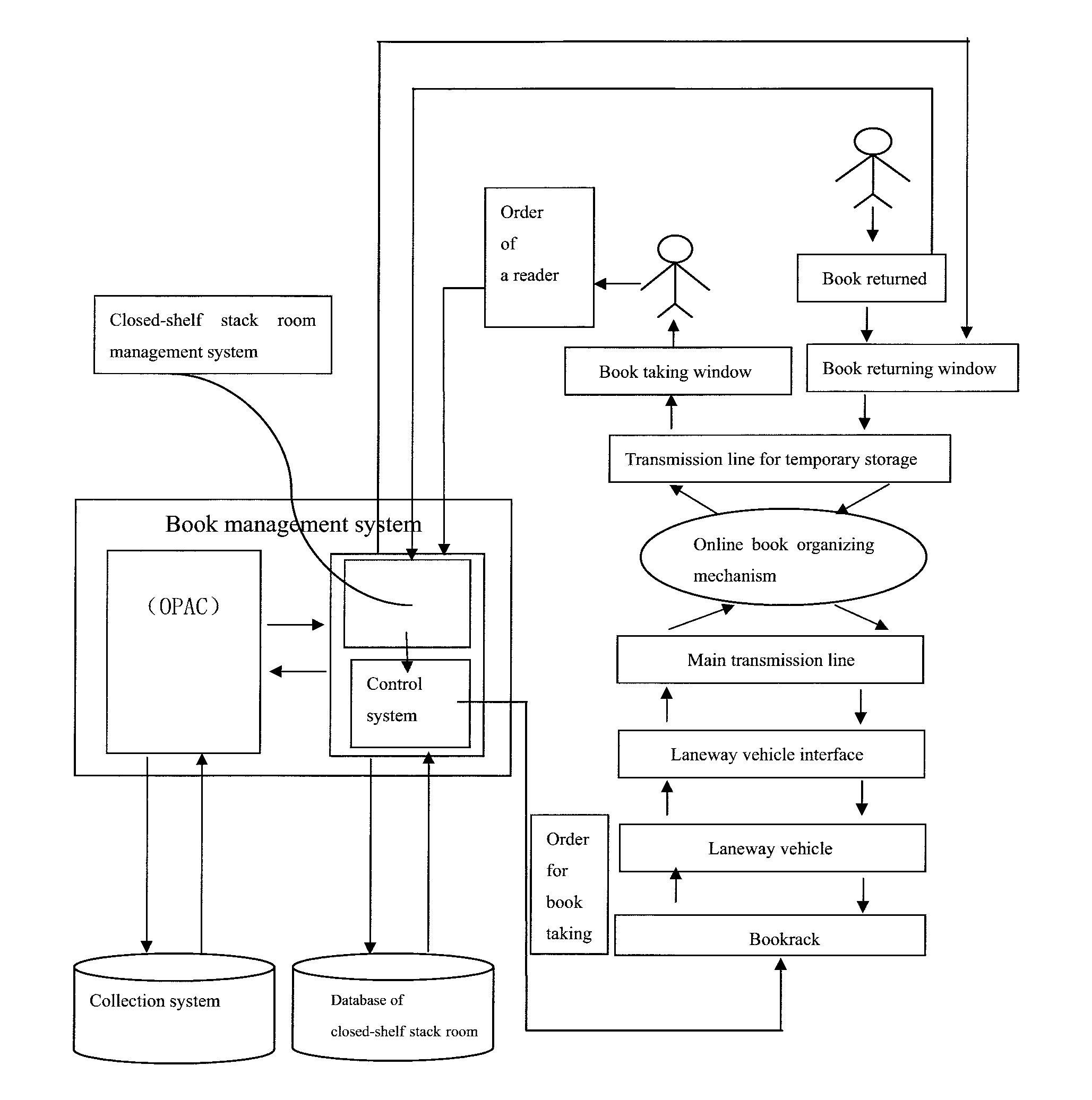

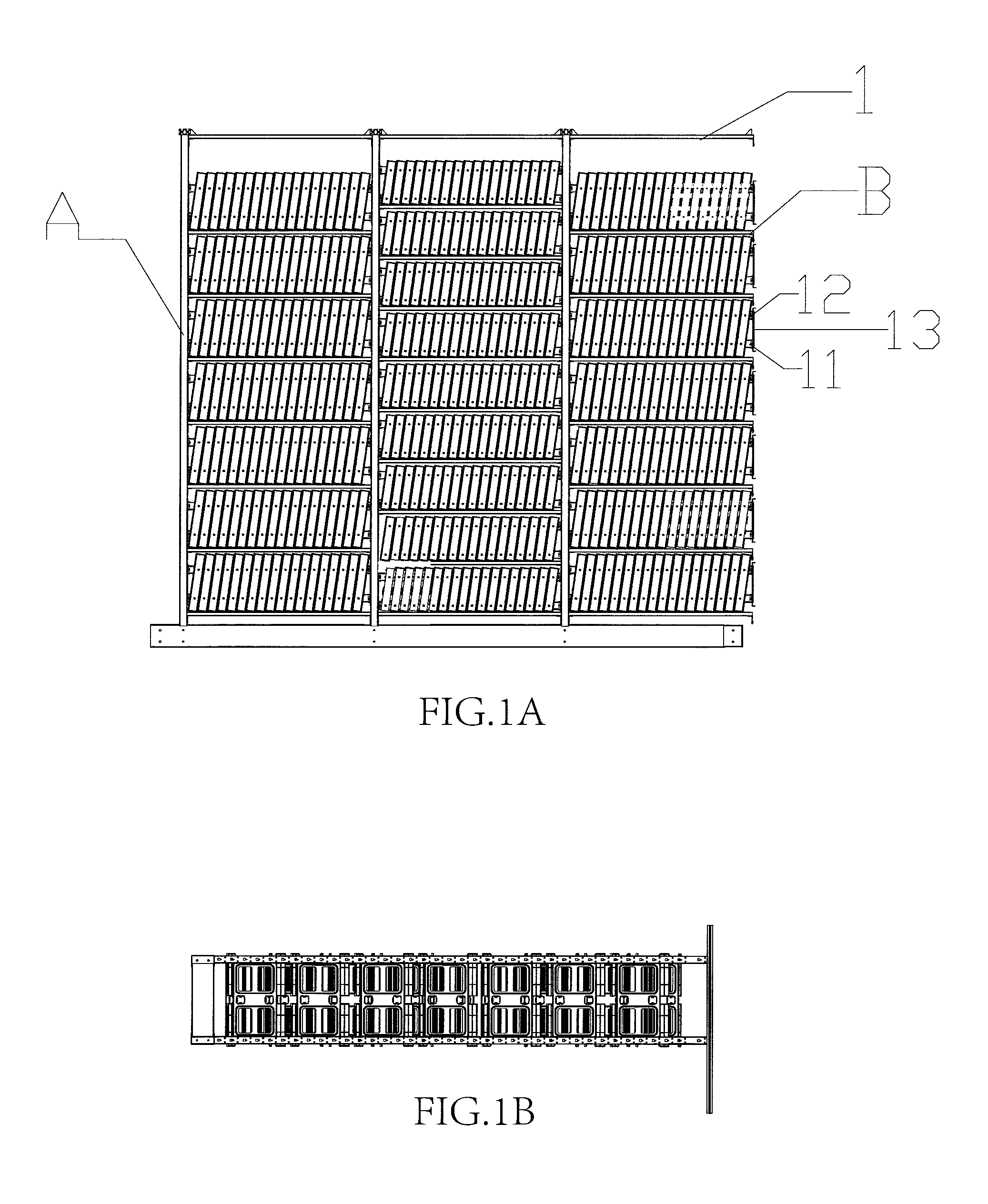

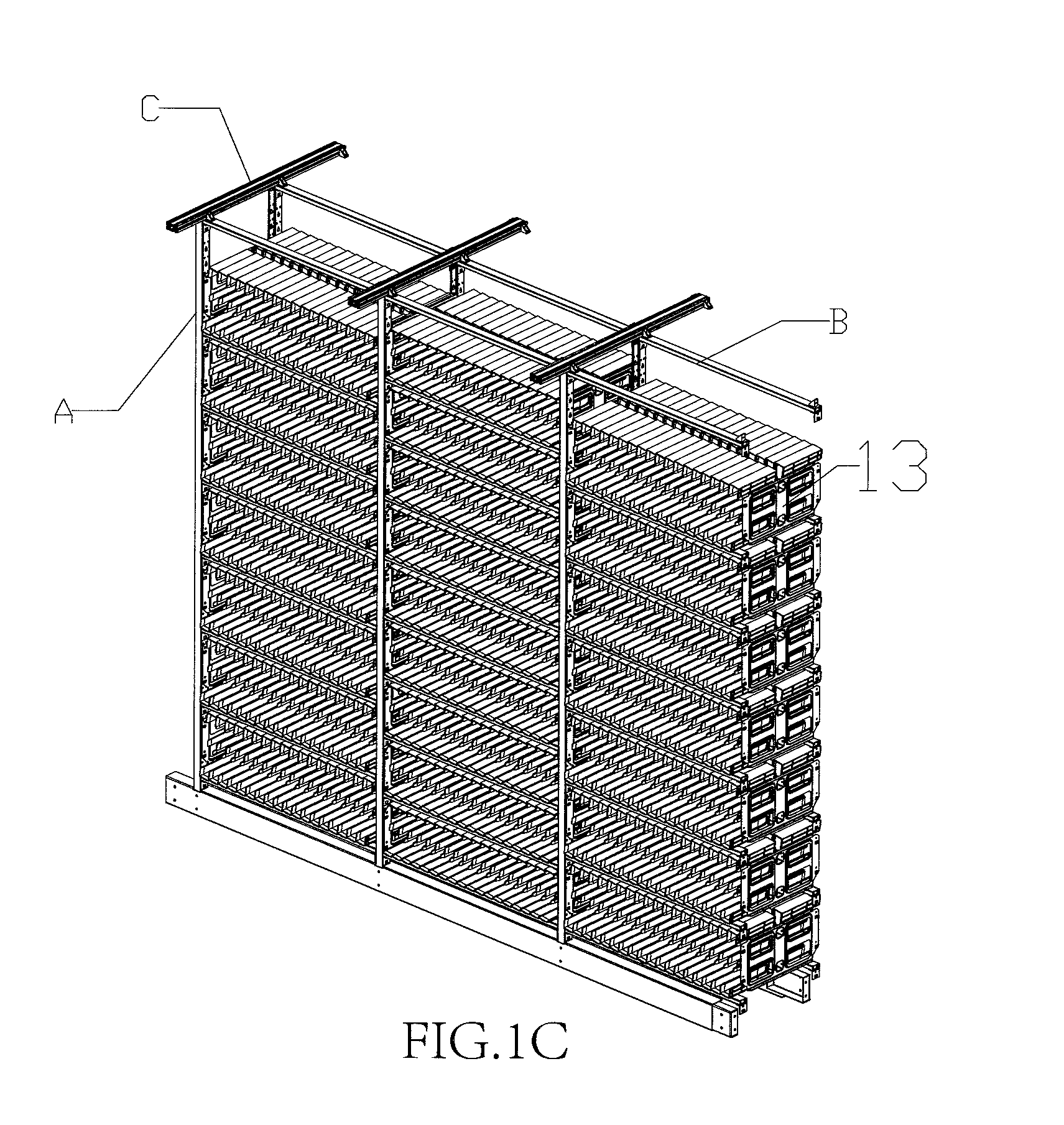

Unattended full-automatic book management system

InactiveUS20150057792A1Enhanced efficiencyOptimize functionBook cabinetsDigital data processing detailsCollection systemData information

Thorough optimization and improvement have been made on the basis of original closed-shelf stack room by the unattended full-automatic book management system of the invention. The concept of a book basket is brought in to process an order of each borrower in a batch. The device is simplified and the efficiency of single functional part is enhanced during the period of storing books, taking books, returning books, conveying a book basket and transmission, thereby the functions of the whole system being optimized. The system includes bookracks, a laneway vehicle, a laneway vehicle interface, a transmission device, a book taking window, and a book returning window, and further includes a book basket and a book box independent of the bookracks. The data information inside the database of the closed-shelf stack room system is administered and operated by the closed-shelf stack room management system to accomplish the interaction between the collection system and the control system of the full-automatic closed-shelf stack room. Ultimately books are administered through the full-automatic closed-shelf stack room.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Thermally activatable removable adhesive tapes

InactiveUS20060188706A1Easy to stretchEasy to fixFilm/foil adhesivesAdhesive articlesActivation temperatureChemistry

The present invention provides adhesive tapes that can be firmly bonded to a bonded article at a temperature below an activation temperature and cannot be easily peeled and removed, but can be easily peeled without substantially leaving adhesive residue on the bonded article and without damaging the bonded article at a temperature exceeding the activation temperature.

Owner:3M INNOVATIVE PROPERTIES CO

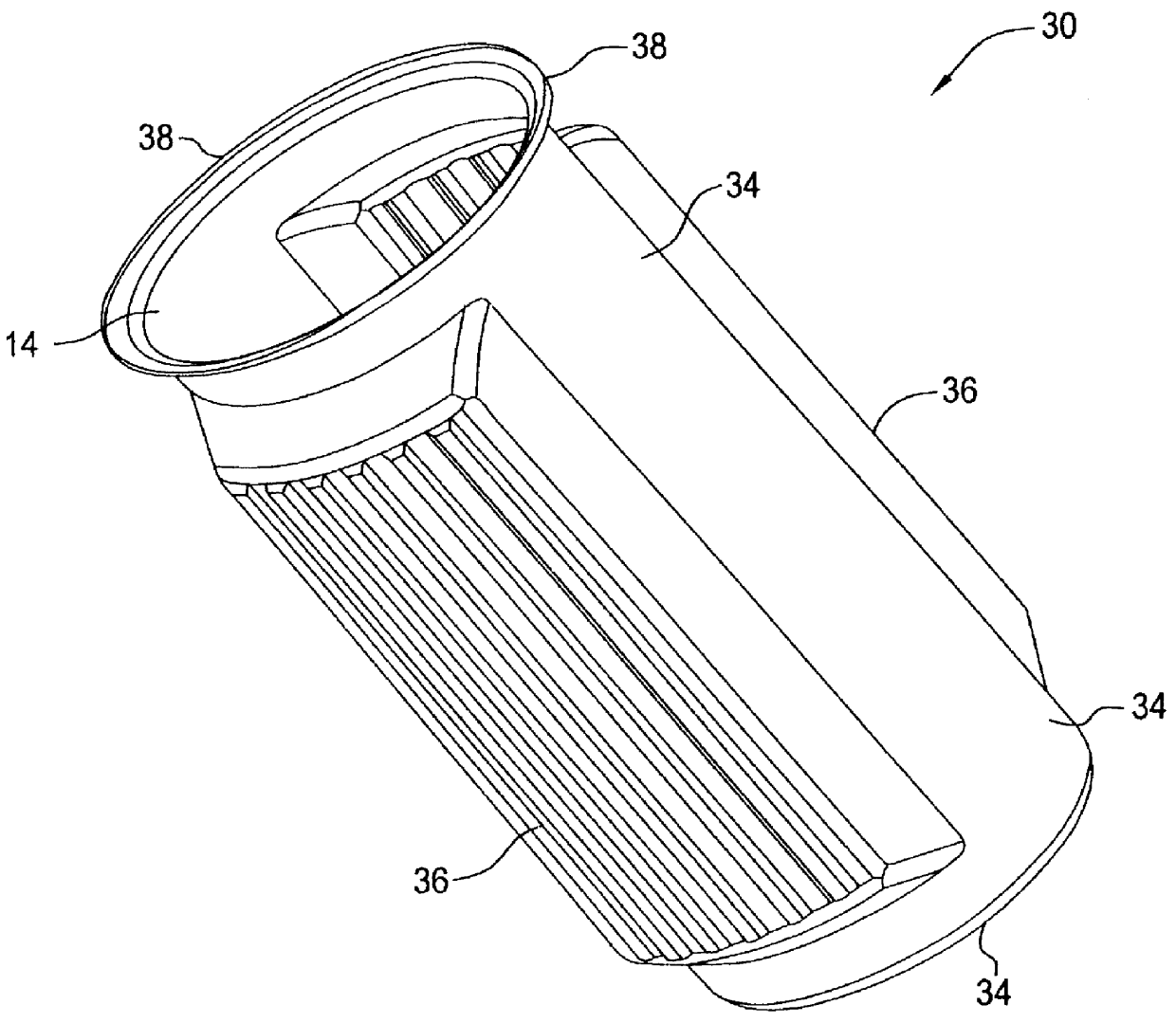

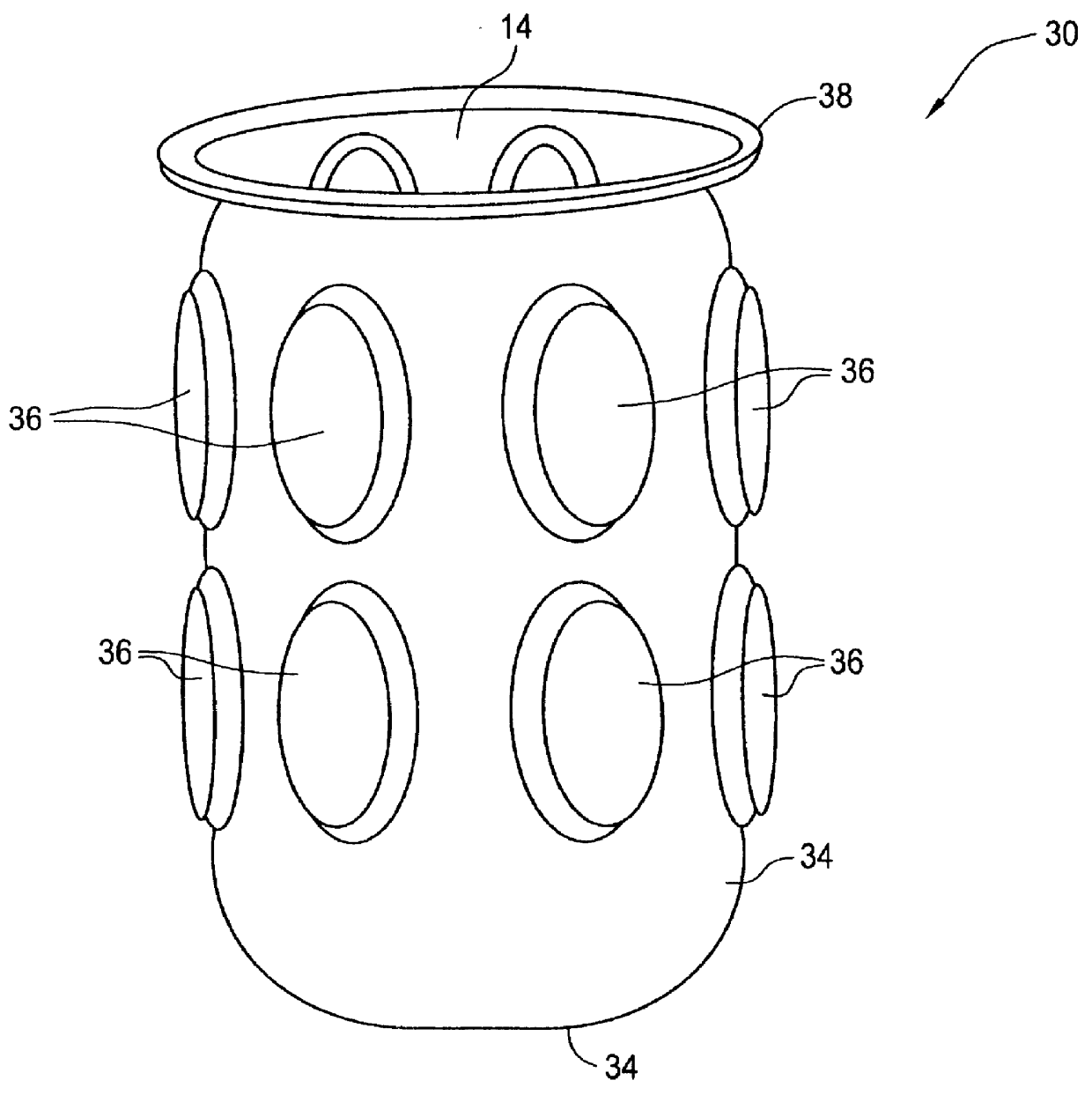

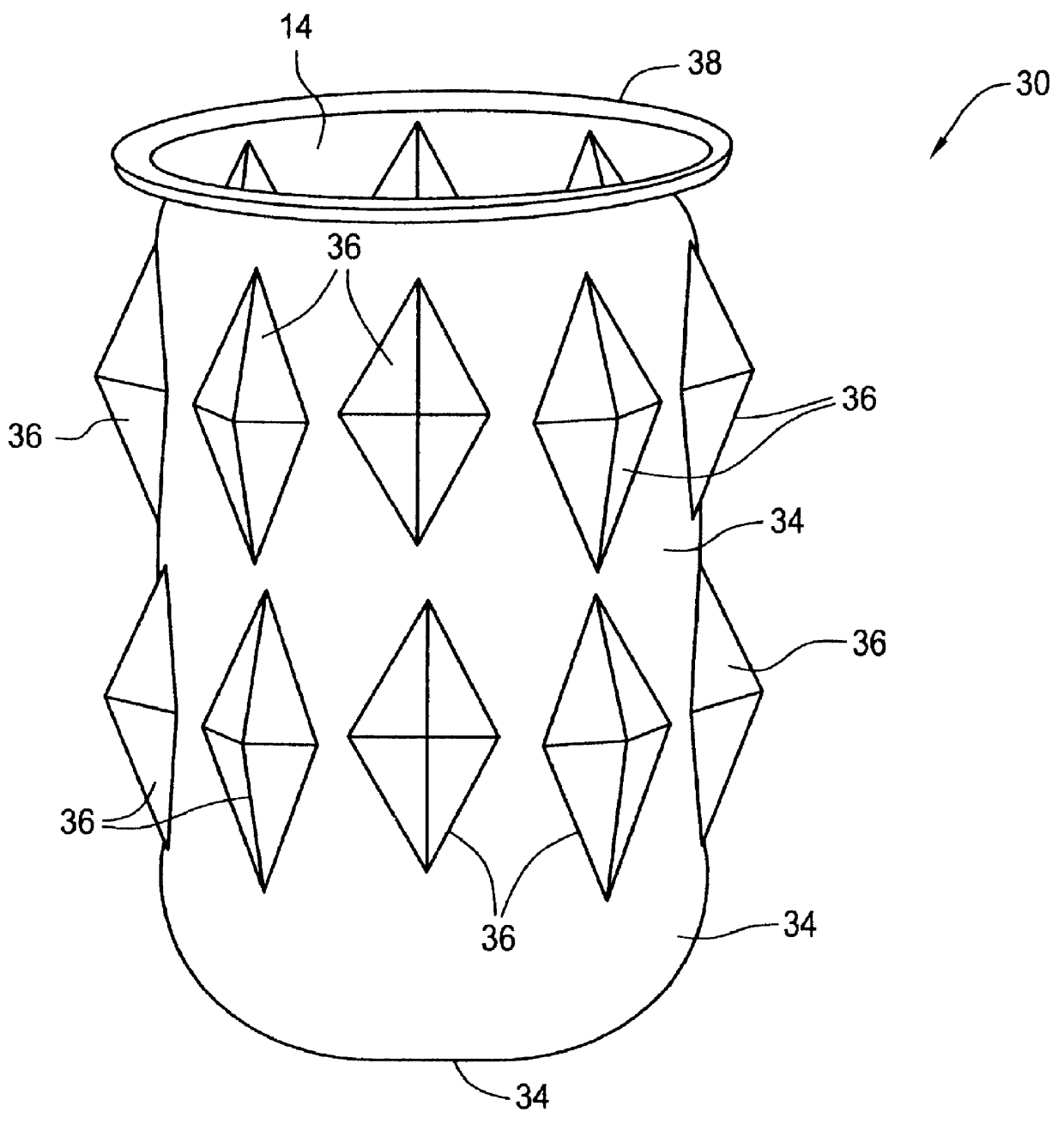

Self-cooling container with internal beverage vessel having a vessel wall with reversible wall bulges

InactiveUS6065300AMaximize capacityIncrease the heat transfer surface areaLighting and heating apparatusLarge containersAtmospheric airEngineering

A rapid refrigeration apparatus includes a container having a container upper end, a container wall with a container opening in the container upper end bordered by a container rim; a beverage retaining vessel extending within the container defining an annular refrigerant chamber between the container and the vessel containing a liquefied refrigerant and refrigerant vapor, and the vessel containing flowable vessel contents, the vessel being sized to fit at least partly through the container opening, the vessel including a vessel rim secured relative to the container rim, and a vessel wall including at least one reversible bulge; a lid sealingly secured to the container rim and including a lid opener mechanism for releasing the vessel contents from the vessel and container for consumption; the lid opener mechanism including a lid opener mechanism activation mechanism for voluntarily opening the lid opener mechanism at a selected moment in time; and a refrigerant release mechanism for releasing the refrigerant from the annular chamber into the atmosphere surrounding the apparatus; the refrigerant release mechanism including a refrigerant release mechanism activation mechanism for voluntarily opening the refrigerant release mechanism at a selected moment in time.

Owner:ANTHONY MICHAEL M

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com