Patents

Literature

142 results about "Copper-clad aluminium wire" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

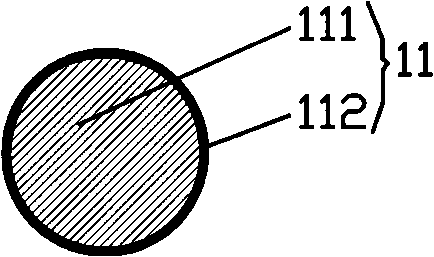

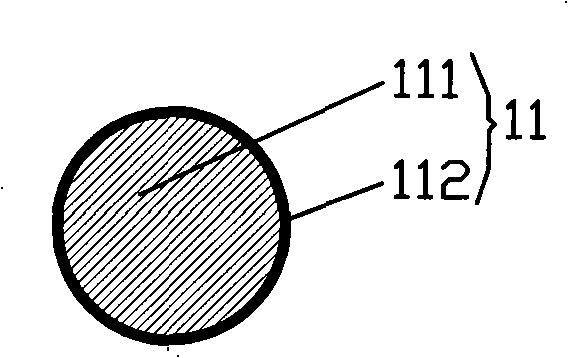

Copper-clad aluminium wire, commonly abbreviated as CCAW or CCA, is an electrical conductor composed of an inner aluminium core and outer copper cladding.

Copper covered aluminum wire forming technique

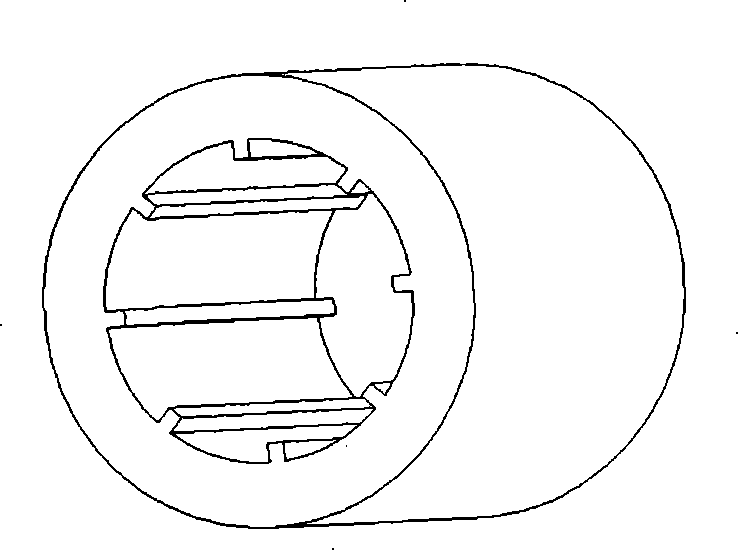

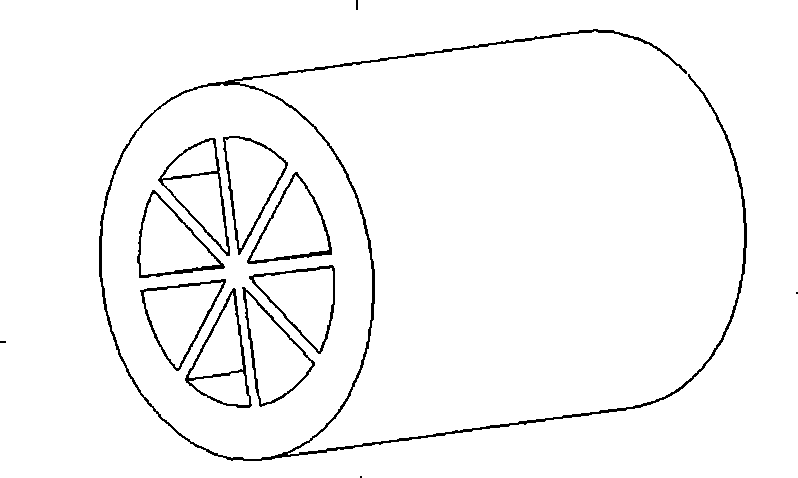

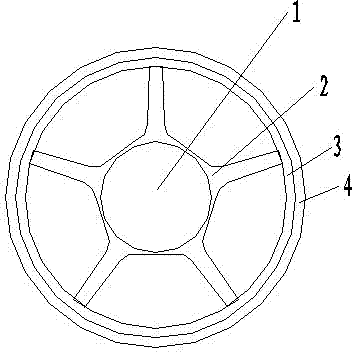

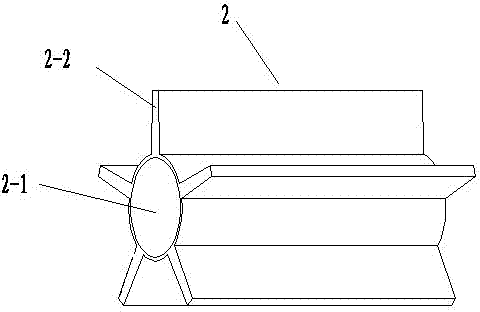

The invention discloses a copper-clad aluminum wire forming process, which is characterized in that the process comprises the following steps of: (1) pre-forming clad copper material into a copper pipe with uniform wall thickness according to the shape and size of an extrusion mold; (2) pre-heating the copper pipe to 200 to 350 DEG C, and die-casting aluminum solution in the copper pipe by low-pressure casting or pressure casting process at a die-casting temperature of 470 to 750 DEG C; and (3) directly carrying out extrusion by an extruder when the metal solution is solidified at an extrusion ratio of (5:1) to (20:1) to obtain the copper-clad aluminum wire meeting the size requirement. The copper pipe may be (a) a common copper pipe; (b) a copper pipe with rectangular ribs on the inner wall; (c) a reticular copper pipe having a cross section shape with fan-shaped holes; (d) a copper pipe with dovetail grooves on the inner wall; (e) a copper pipe with T-shaped groove on the inner wall; and (f) a copper pipe with helical ribs on the inner wall. The novel copper-clad aluminum wire forming process solves the problem that the copper-clad aluminum wire interface is unlikely to be firmly bonded, and the copper-clad aluminum wire achieves better interface metallurgic bonding and has better conductive performance.

Owner:YANSHAN UNIV

Copper-clad aluminium wire production method

InactiveCN101710503AImprove bindingThe overall thickness is thinCable/conductor manufactureMicrometerMetal

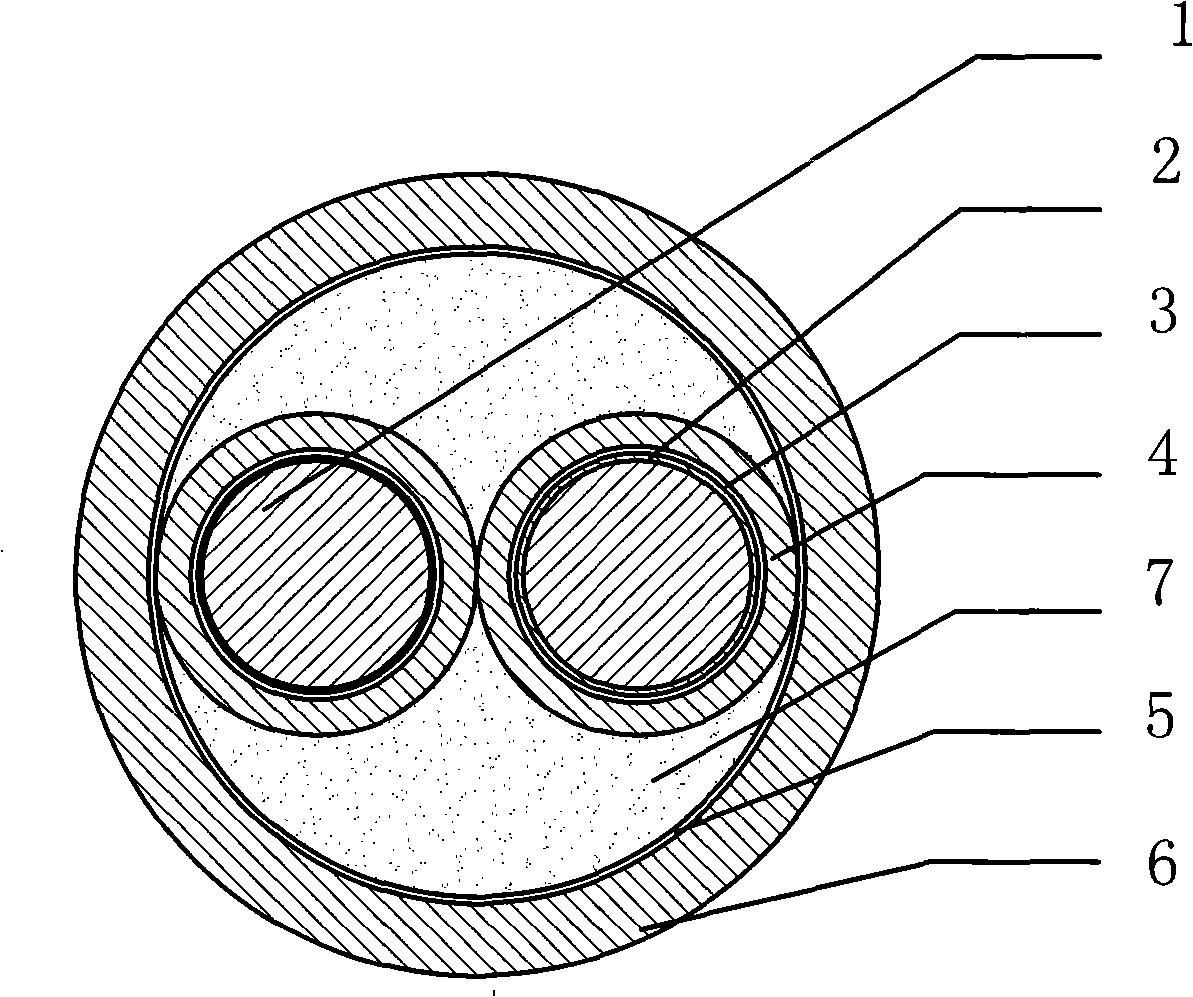

The invention relates to a copper-clad aluminium wire production method, comprising the following processes: a. surface treatment is carried out to aluminum core material and copper strips under protective atmosphere; b. the treated aluminum core material and the copper strips enter in a workbench immediately to lead the scrubbed copper strips to surround the outside of an aluminium rod to form a tubular shape, the inner diameter of the formed copper tube is larger than the outer diameter of the aluminium rod, a gap with 0.1-1.0mm is left between the aluminium and the copper, the gap formed by cladding is welded after the aluminum core material is arranged at the bottom part of the copper tube, and then the copper-clad aluminium wire which is cladded and welded is drawn out with 30-90 percent of section decreasing ratio; c. diffusing heat treatment is carried out to the drawn copper-clad aluminium wire, the temperature of heat treatment is 250-400 DEG C, so as to form a diffusing layer with 1-20 micrometers between the copper and aluminium interfaces; d. the diameter of soft wires is reduced through a series of diameter reducing treatment of multiple molds of a diameter reducing device which is provided with a single block machine and a continuous drawing machine, so as to obtain the wire diameter of the finished products. The method improves the combining property of the copper-clad aluminium wire and leads the section decreasing ratio of metal combination to be reduced to below 35 percent.

Owner:FUSHI INT DALIAN BIMETALLIC CABLE

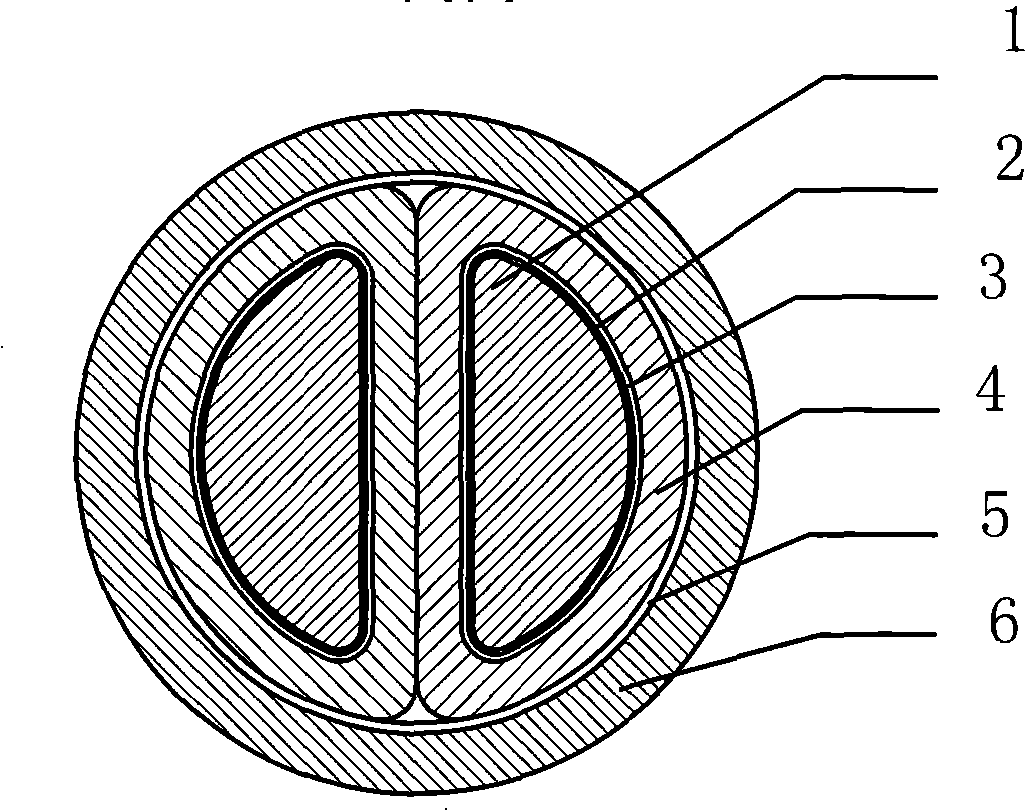

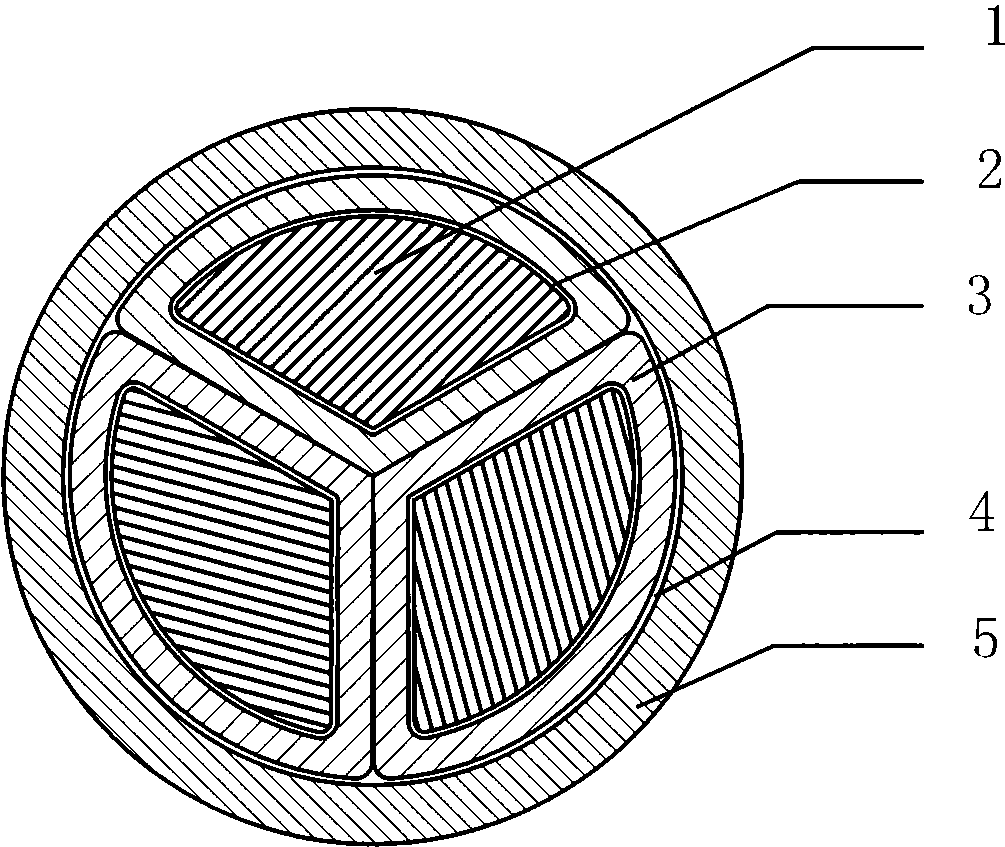

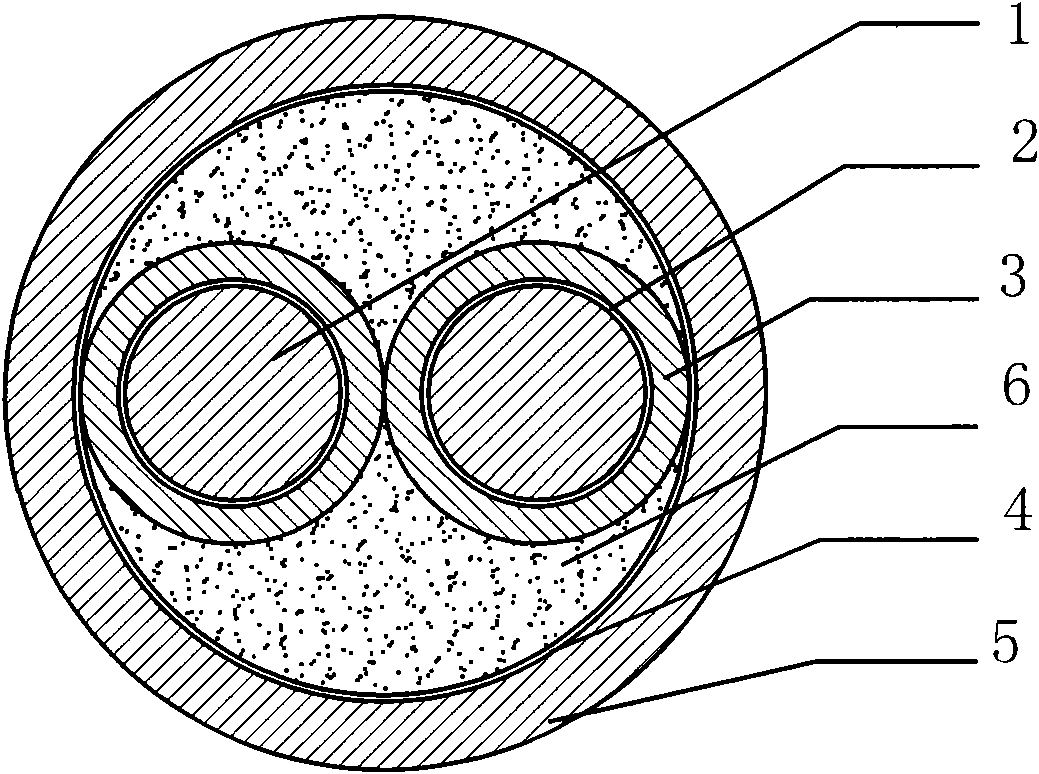

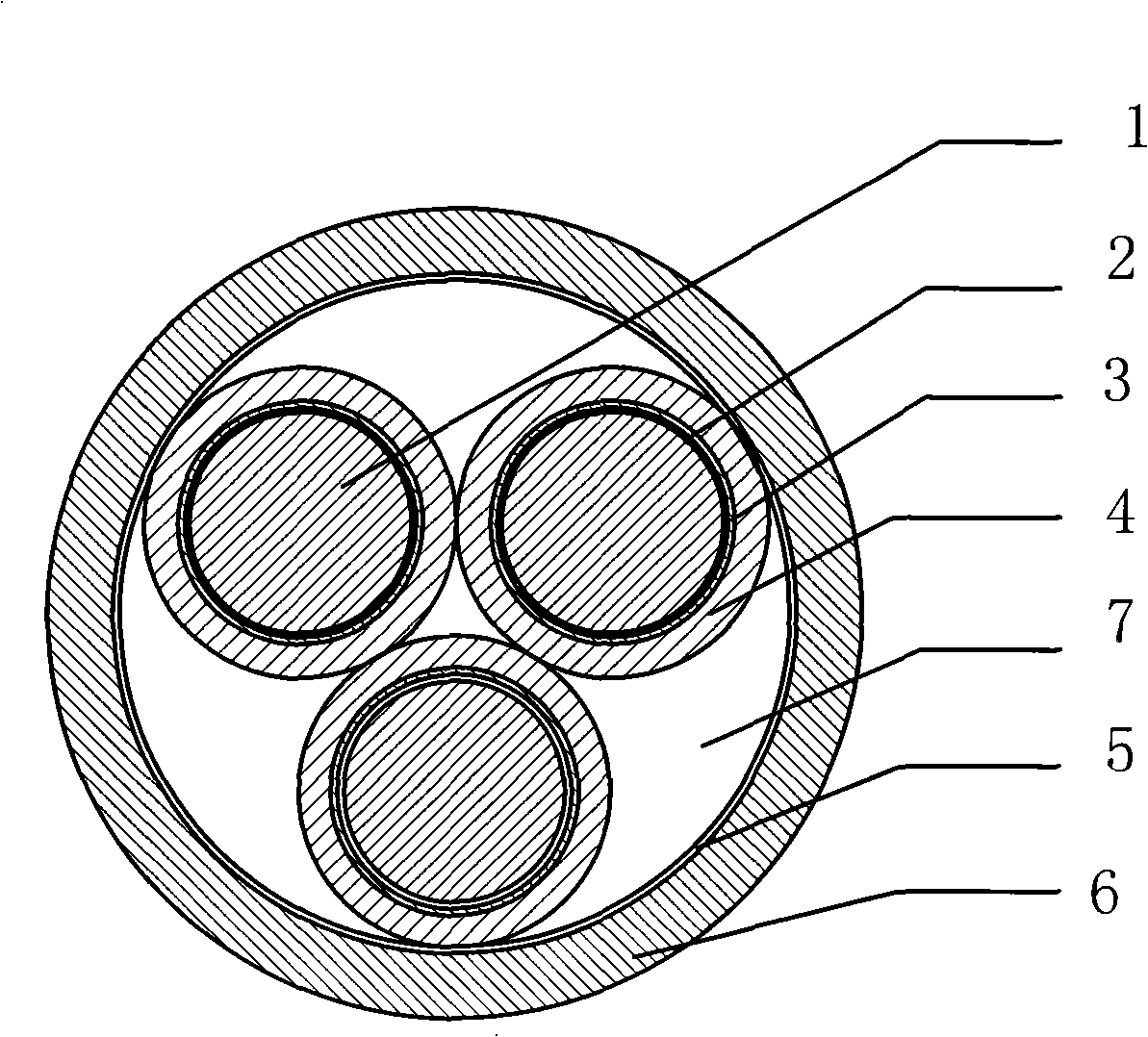

Copper coated aluminum dual-core flame-retardant refractory flexible electric cable and manufacturing method thereof

ActiveCN101335114AReduce copper usageReduce weightInsulated cablesMetal/alloy conductorsYarnInsulation layer

The invention discloses a copper-clad aluminum two-core flame retardant and fire resisting flexible cable and a manufacturing method thereof. The method comprises the steps that: a copper-clad aluminum conductor is made into a single conductive wire core; the single conductive wire core is processed into a conductive wire core provided with a semi-round section; a wire core fire resisting layer is formed on the outer surface of the conductive wire core provided with a semi-round section; an insulation material is extruded on the wire core fire resisting layer, and an insulation process for forming an insulation wire core provided with an insulation layer is carried out; a cable-froming process is carried out to two insulation wire cores provided with insulation layers, thereby forming a cable yarn; flame retardant plastic is extruded on the cable yarn so as to form a flame retardant restrictive coating. The cable of the invention has the advantages of low copper consumption, light weight and low cost.

Owner:JIANGSU ZHONGLI GRP CO LTD

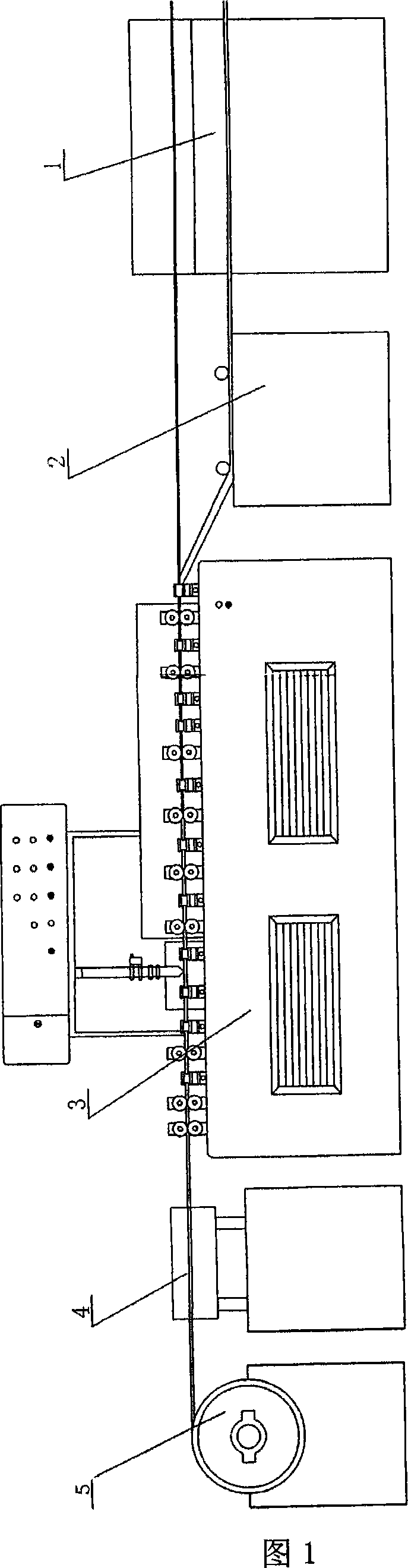

Copper cladding aluminium wire, copper cladding aluminium pipe production process and its equipment

InactiveCN101071662AIncrease profitImprove stabilityConductive materialCable/conductor manufactureManufacturing cost reductionState of art

This invention involves a copper coated aluminium wire, copper coated aluminum tubes production technology and equipment. It is the preferred production technology and equipment for Copper aluminium wire producing. This invention address the problems of existing technologies, provide a copper coated aluminium wire, copper coated aluminum tubes production technology and equipment, manufacturing process simple and reasonable, copper savings, reduce production processes significantly shorten product time to ensure that the copper coated aluminium wire the copper layer uniformity, and better meet both metallurgical combination of stable quality, high production efficiency, significantly reduce production costs of copper coated aluminium wire(tube) production technology. Drawing not only help reduce the number of metallurgical combine to achieve rapid product quality and help the stability at the same time in the past to resolve the metallurgical combine before tensile quality and difficult to control, simplify the process to improve the efficiency of production and the need to save burr edge copper, in particular when processing large diameter, the more obvious improve material utilization, significantly lower manufacturing costs, in addition to wide application of the different diameter sizes processing, but also processing copper coated aluminum tubes, and many other advantages and positive results, and it also has been proved by testing.

Owner:FUSHI INT DALIAN BIMETALLIC CABLE

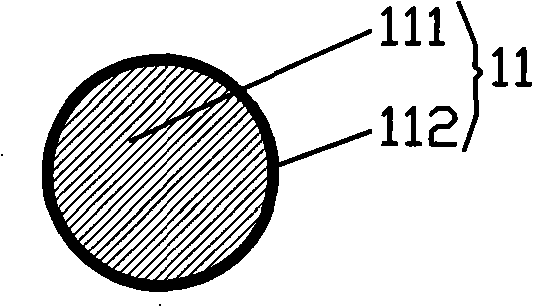

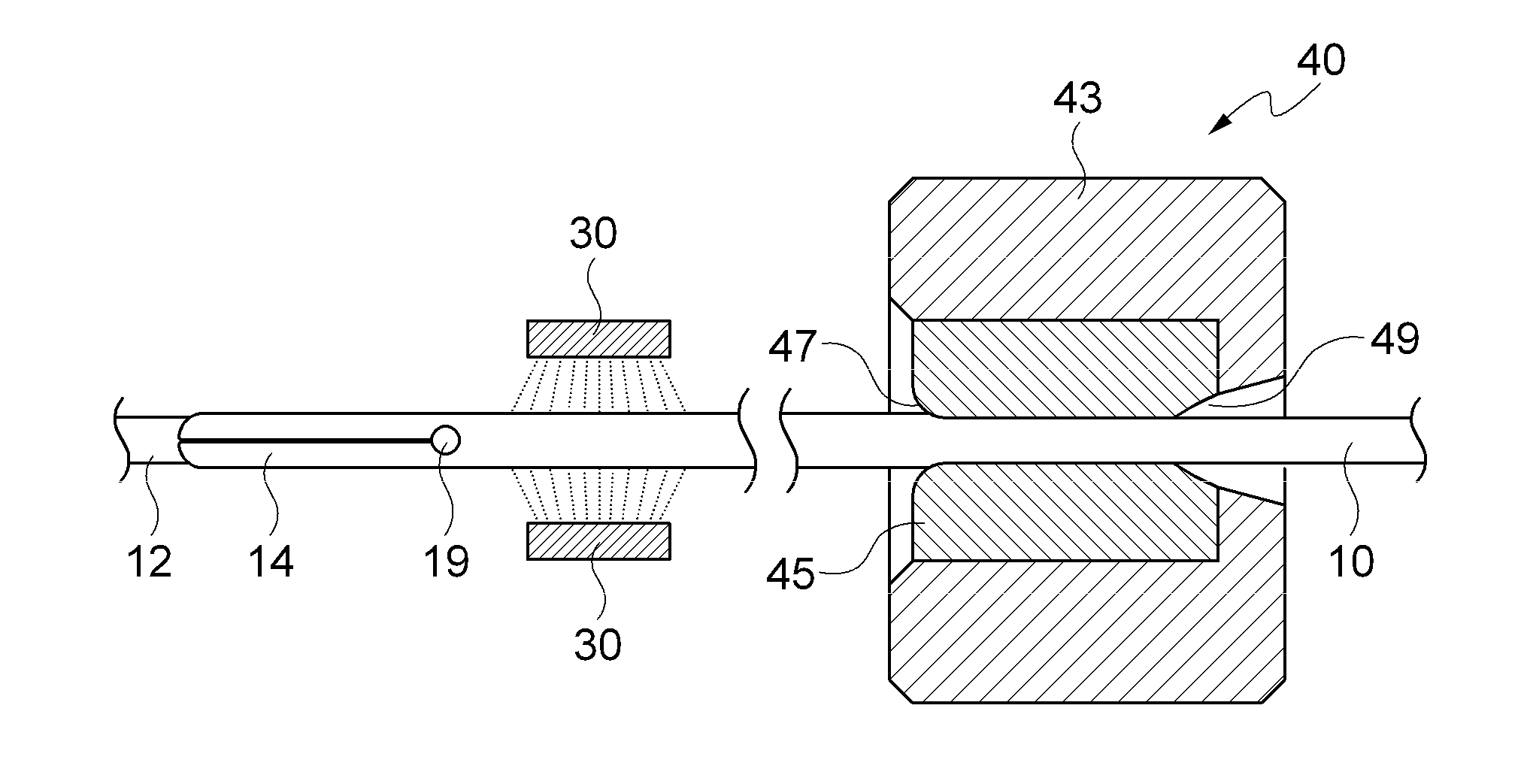

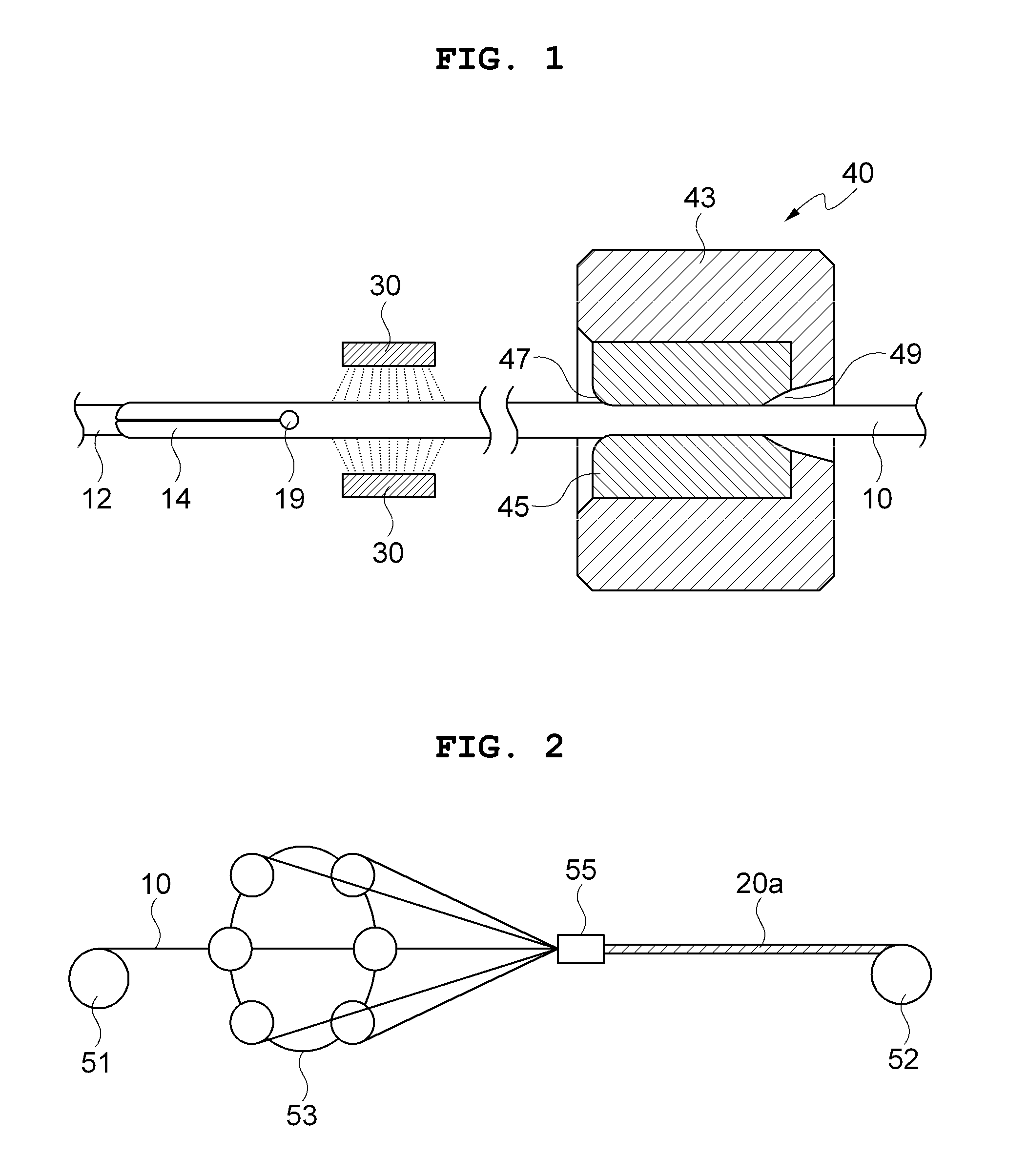

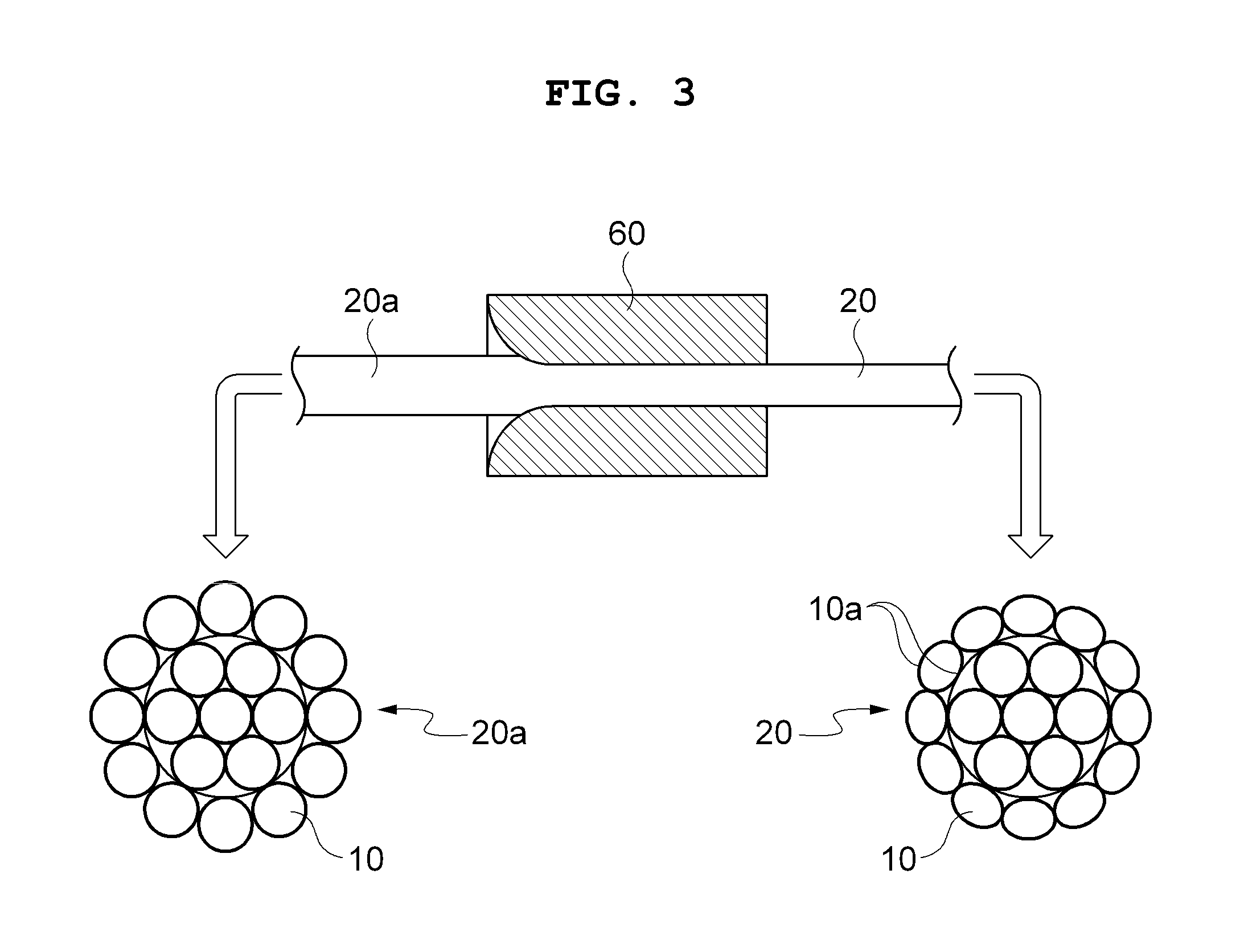

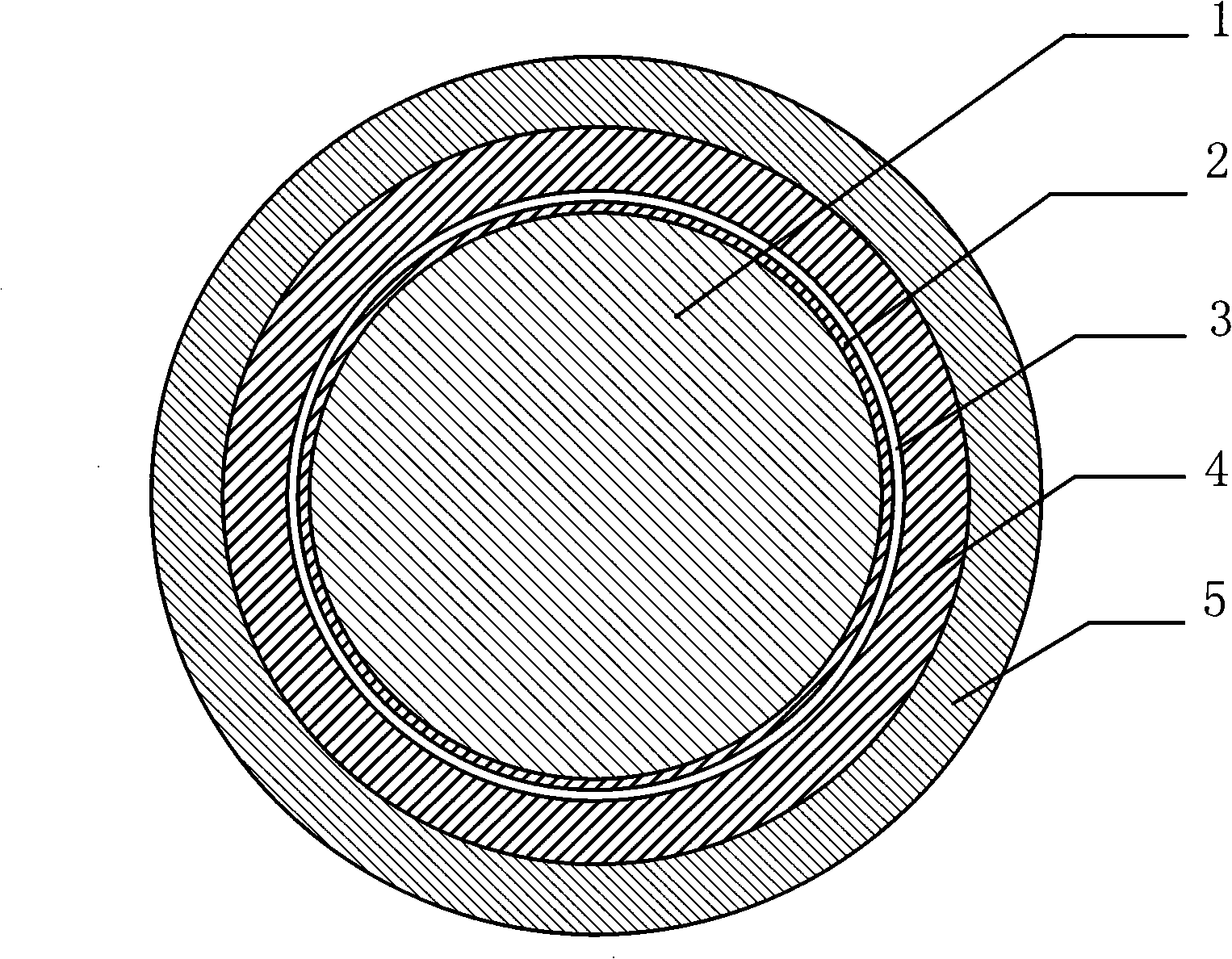

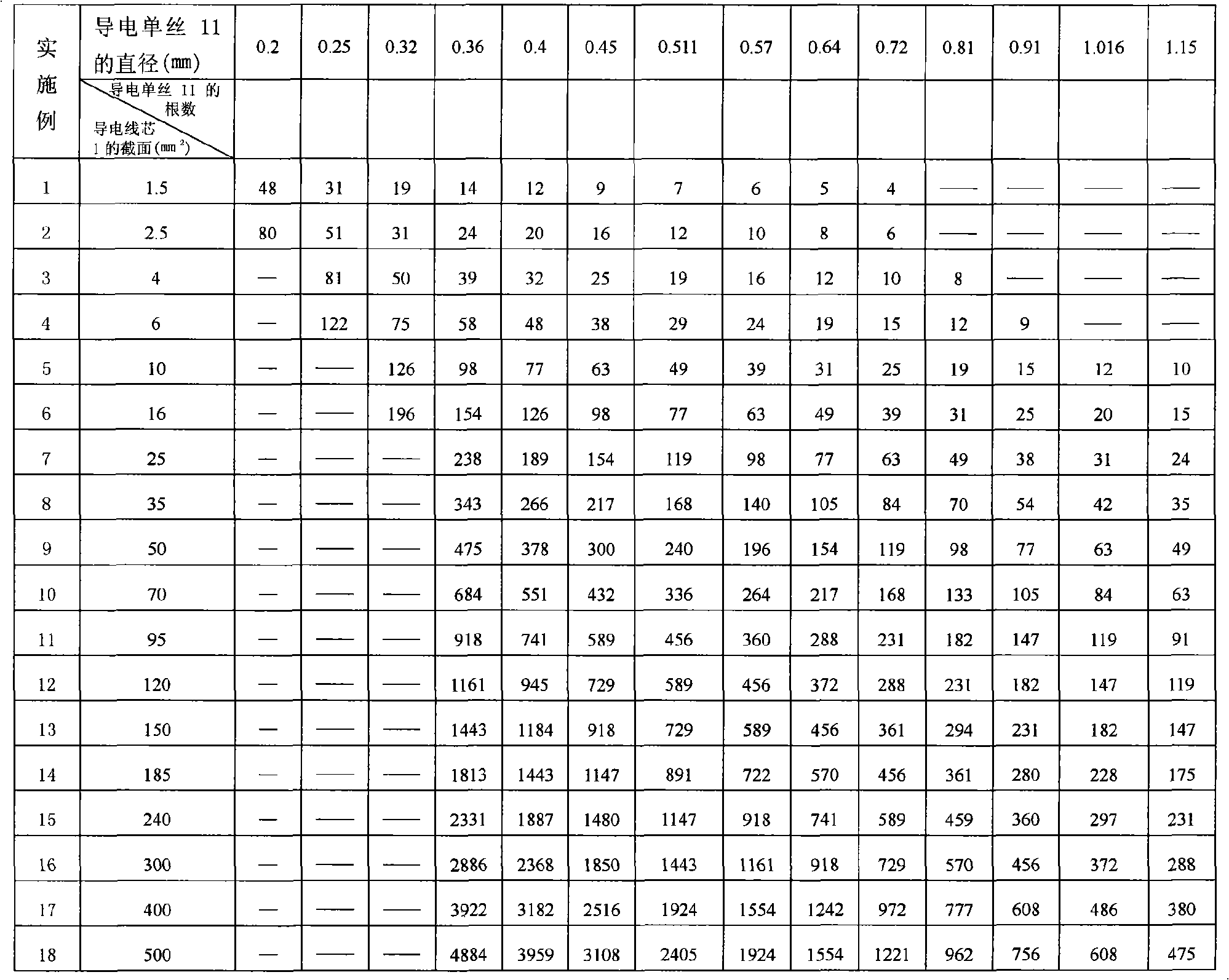

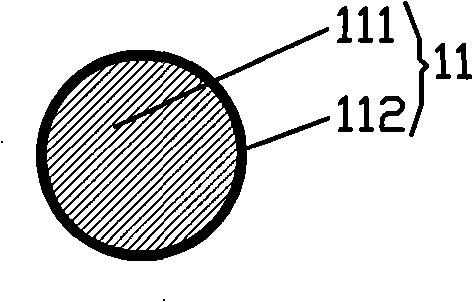

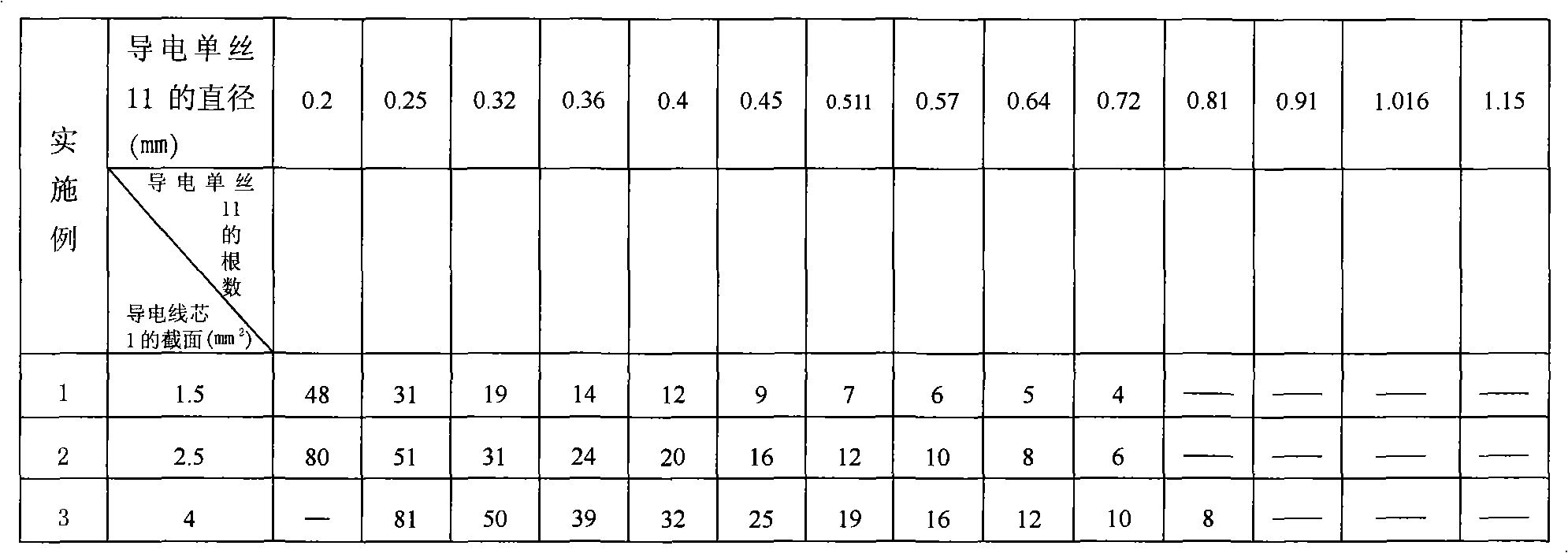

Copper clad aluminum wire, compressed conductor and cable including the same, and method of manufacturing compressed conductor

InactiveUS20130233586A1Increase the outer diameterEfficient use ofLine/current collector detailsPlastic/resin/waxes insulatorsCopper-clad aluminium wireCopper wire

Disclosed are a copper clad aluminum wire, a compressed conductor and a cable including the same and a method of manufacturing the compressed conductor. The copper clad aluminum wire, the compressed conductor and a cable including the copper clad aluminum wire and the method of manufacturing the compressed conductor according to embodiments of the present invention may exhibit electrical features similar to those of a conventional pure copper wire without greatly increasing outer diameters of the conductor and the cable, guarantee workability of a worker when the worker installs the cable even in a narrow work space, and efficiently utilize an installation space.

Owner:LS CABLE & SYST LTD

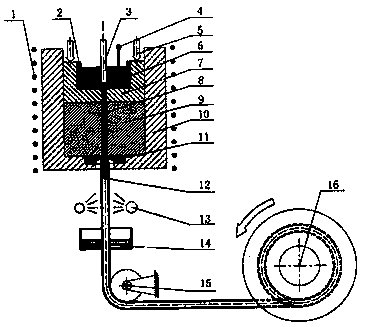

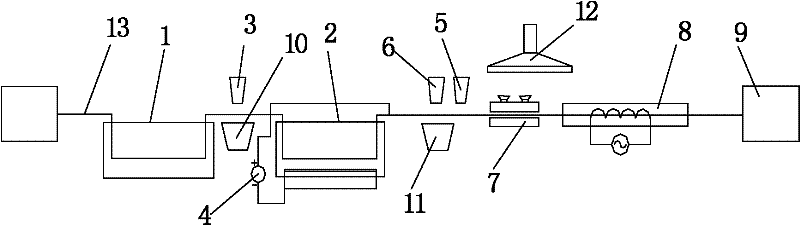

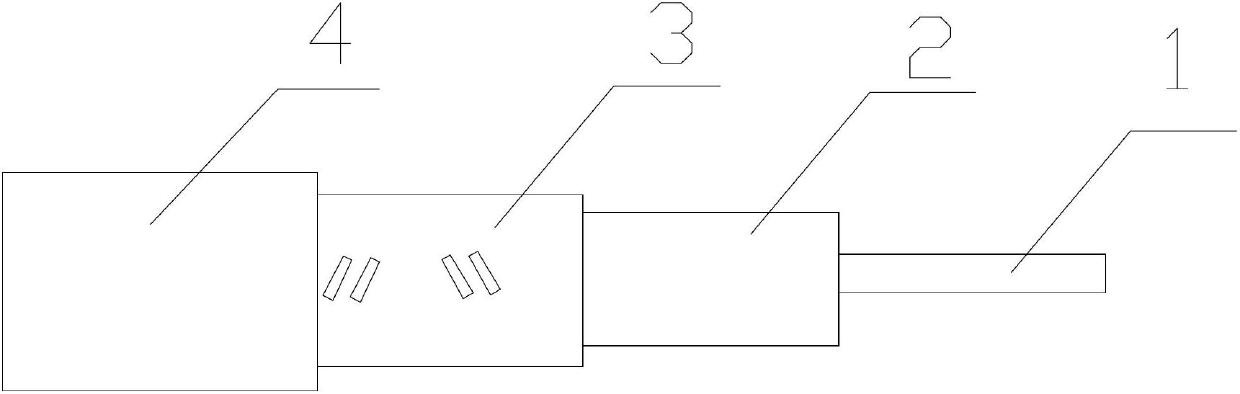

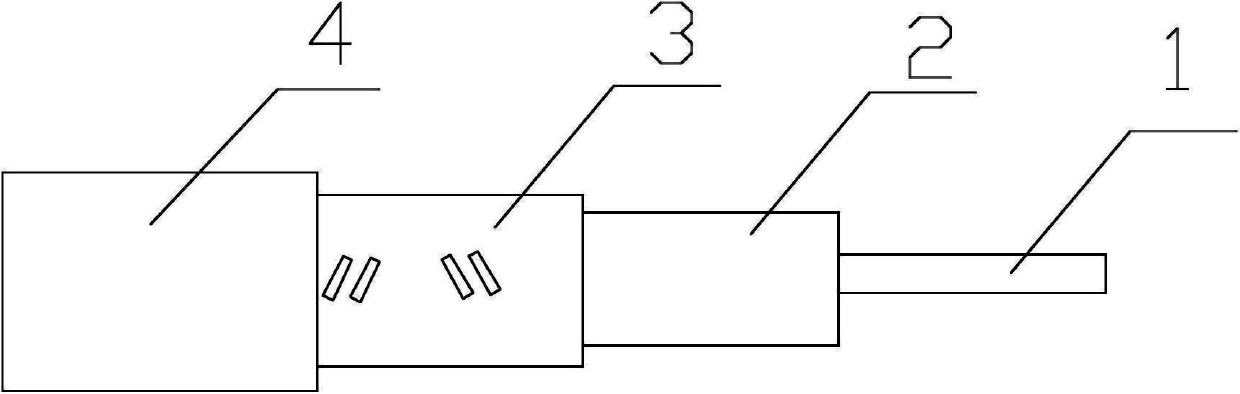

Production equipment and process of copper-clad aluminum bimetal composite wire rod

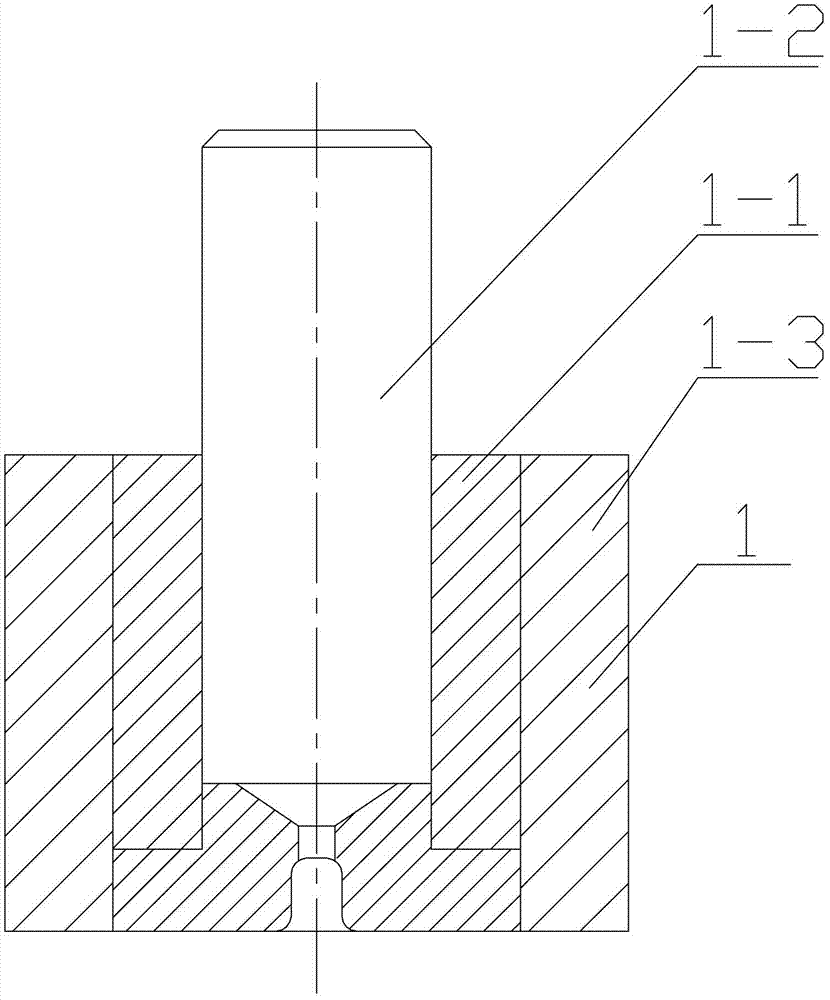

The invention relates to production equipment and process of a copper-clad aluminum bimetal composite wire rod, belonging to the technical field of metal material processing. The production equipment is composed of a heating element, a molten aluminum temperature control crucible, a core metal pouring stopper rod, a temperature measurement instrument, a pressure mechanism, an extrusion stem, a hollow hole forming pin, an extruding barrel, an extruding mold, a cooling device, a water tank, a tensioning mechanism and a winding machine. The production process comprises the following steps: a copper billet is placed in the extruding barrel and an aluminum ingot is placed in the temperature control crucible, heat is preserved after the heating element outside the extruding barrel is heated to be at the required temperature, the extrusion stem moves downwards under the action of the pressure mechanism to punch and extrude the copper billet in the extruding barrel to form a clad copper pipe; when the copper pipe is extruded out of a mold, the core metal molten aluminum pouring stopper rod is pulled, molten aluminum is sucked in the copper pipe under the action of the negative pressure in the pipe and solidified, is further cooled by the cooling device and the water tank, then passes through the tensioning mechanism, and finally is reeled and collected on the winding machine. The equipment is simple, the technological process is short, and both the equipment and the process are suitable for large-scale production; the prepared copper-clad aluminum wire rod has accurate boundary dimension, core metal has no casting defect, and the interface of outer layer metal copper and core metal aluminum is clean and free of pollution, and therefore, a good metallurgical bonding effect is achieved.

Owner:HUNAN UNIV

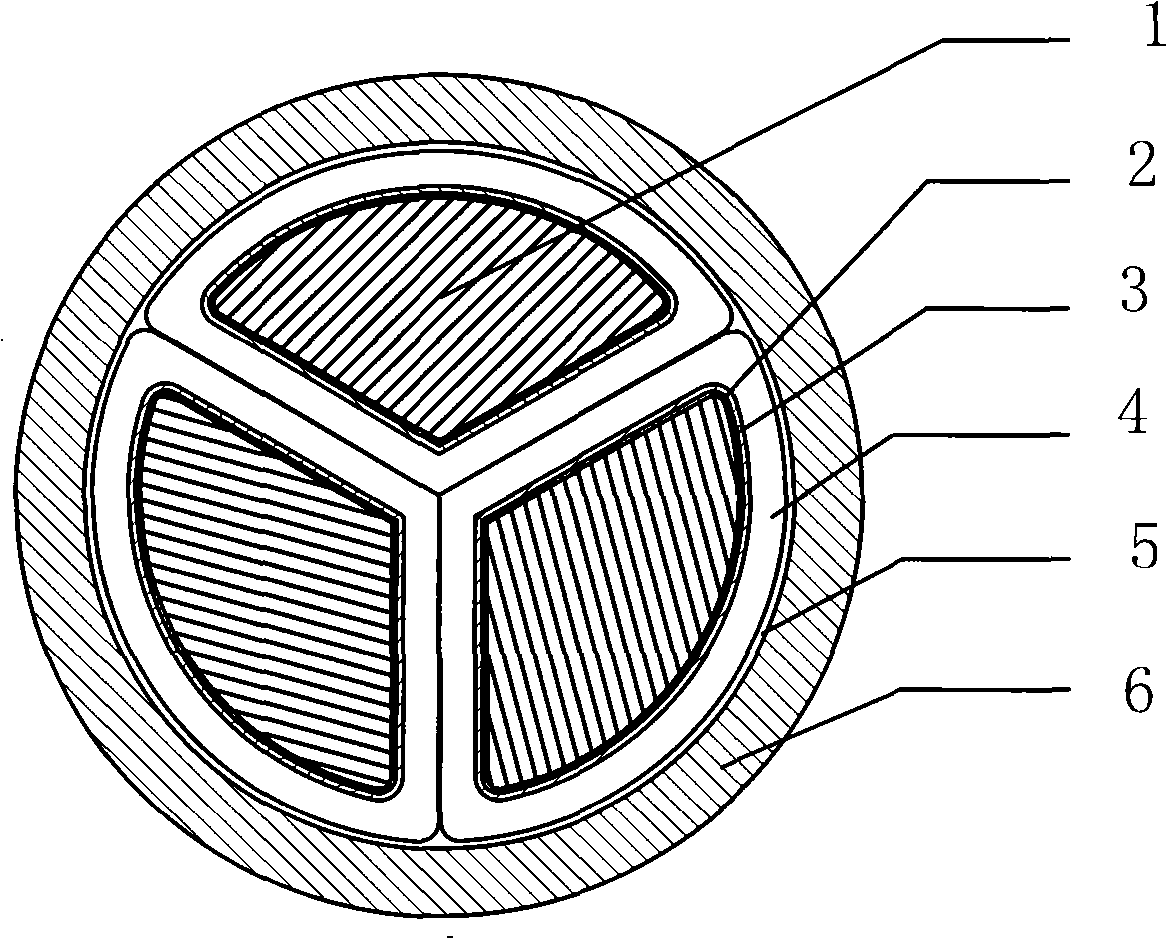

Special-shaped copper-clad aluminium wire and method of production

InactiveCN1655286AFulfil requirementsSolve technical problems such as high priceSingle bars/rods/wires/strips conductorsCable/conductor manufactureCopper coilMethods of production

This invention discloses an allotype copper and aluminum wire, which comprises aluminum core and copper cover layer with non-round section. The process method comprises the following steps: processing round copper coil and aluminum compound wire; using twenty to one hundred tons of pressure to roll the wires with speed as 100-800m / min; shaping by mode pulling; match fire processing with temperature of 260-350 Deg. C.

Owner:葛成林

Tinning copper clad aluminum wire production technology

ActiveCN102354575AHigh concentricityPrecise thickness controlCable/conductor manufactureTinningLayer thickness

The invention relates to tinning copper clad aluminum wire production technology. The tinning copper clad aluminum wire production technology comprises the following steps in order: employing cladding welding technology to making a copper clad aluminum rod, drawing, carrying out copper clad aluminum wire processing before electrodeposition, washing, carrying out electrodeposition tinning, second washing, carrying out alkaline neutralization, washing with hot water, drying and polishing. The tinning copper clad aluminum wire production technology has the following advantages that: accurate control of thickness of a tin coating, a uniform tin layer thickness, good concentricity, and good bonding force between the tin layer and a copper layer at a copper clad aluminum external surface.

Owner:浙江亿顺电导体有限公司

Copper cladded aluminum composite thin flat wire and its preparation method

ActiveCN101169987AReduce weightIncrease slot fill rateSingle bars/rods/wires/strips conductorsFlat/ribbon cablesFine lineAluminum composites

The invention relates to a copper-clad aluminum composite thin flat wire and a preparation method thereof. The copper-clad aluminum composite thin flat wire is composed of a core aluminum body and a pure copper cladding layer, and the pure copper cladding area ratio is 10% to 30%. , the thickness of the copper layer is evenly distributed, the minimum width of the cross-sectional dimension can reach 0.08mm, and the minimum thickness can reach 0.02mm. It is beneficial to reduce the volume and weight of the coil, and can meet the use requirements of micro-motor enameled wires for various precision micro-electrical appliances. The copper-clad aluminum composite thin flat wire is prepared by cold liquid extrusion to prepare copper-clad aluminum wire billet, combined with subsequent cold deformation strong processing (drawing, rolling) to prepare copper-clad aluminum composite thin flat wire, the prepared copper-clad aluminum composite thin The preparation process of the flat wire greatly reduces the number of annealing times, lowers the annealing temperature, and even does not need annealing according to needs, simplifies the production process, and reduces the production cost.

Owner:UNIV OF SCI & TECH BEIJING

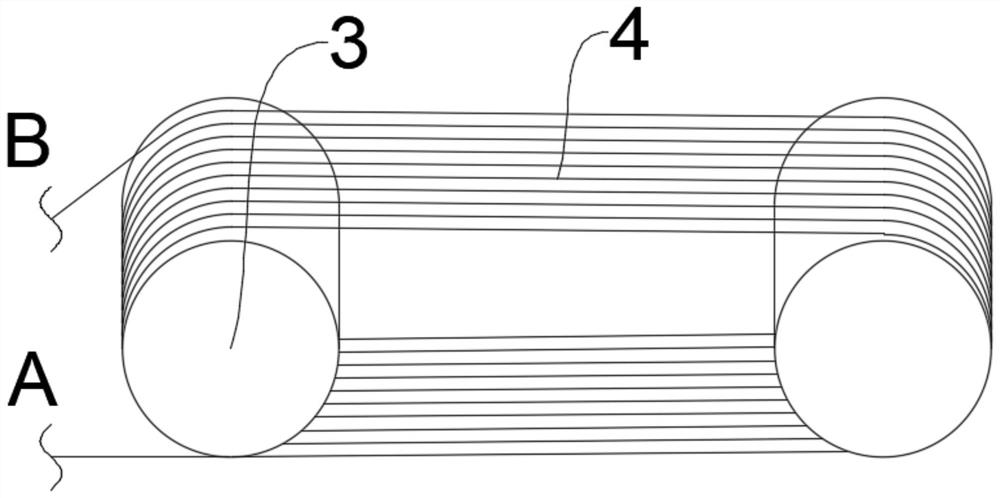

Manufacturing method for copper covered flat aluminum wire

InactiveCN101131892AMeet the use requirementsReasonable process arrangementNon-insulated conductorsTransformers/inductances coils/windings/connectionsCopper-clad aluminium wireInert gas

The present invention relates to a production method of copper clad aluminum wire, especially a production method of copper clad aluminum flat wire. Its process steps are shown as follow: (1) the copper clad aluminum welding is carried through under the protection of inert gas; (2) a series of drawing are carried through by the dies of drawing machine, and the wire temperature should be kept below 240deg.C when the drawing is going on, until the scheduled total deformation is achieved; (3) the anneal of diffusion restricted layer is carried through in annealing furnace which is filled with inert gas for protection, and when the scheduled temperature is reached, this temperature will be kept for 60-150 minutes; (4) at least one time of rolling should be taken on the high mill of which the roll diameter matches to wire diameter, and the scheduled size should be reached; (5) the finish drawing is carried on drawing machine with rectangle dies to reach the geometry size of a finished product; (6) softening, anneal and wire collection are carried through in inert gas environment. The present invention has advantages of saving 53-60% of copper material, stable and reliable performance, and absorbs the both advantages of copper and aluminum. The contact surface has reached metallurgical bonding, and the self weight has been reduced.

Owner:FUSHI INT DALIAN BIMETALLIC CABLE

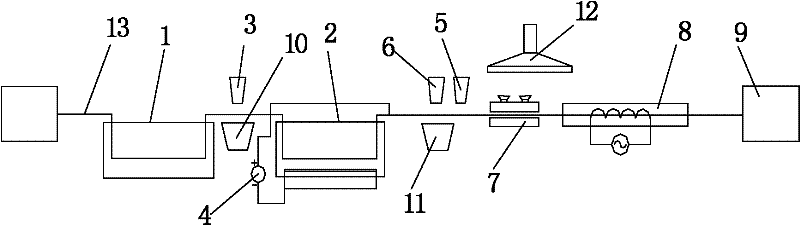

Production system for carrying out anodizing low-voltage insulation treatment on copper clad aluminum wires

InactiveCN102254638ALow costIncrease productivityInsulating conductors/cablesAnodizingProduction line

The invention relates to a production system for carrying out anodizing low-voltage insulation treatment on copper clad aluminum wires, and in particular relates to a production system for carrying out anodizing low-voltage insulation treatment on copper clad aluminum wires after the copper clad aluminum wires are annealed. The production system comprises a pretreatment tank which is arranged behind an original production line and used for pretreating the copper clad aluminum wires, a reinforced anodizing tank which is arranged behind the pretreatment tank and used for oxidizing the surfaces of the copper clad aluminum wires, a hot air device which is arranged behind the reinforced anodizing tank and used for drying the surfaces of the copper clad aluminum wires, a sealing device which is arranged behind the hot air device and used for coating insulating materials on the dried copper clad aluminum wires, a drying device which is connected with a rear end of the sealing device and a wire takeup device which is arranged behind the drying device and used for winding and packaging the copper clad aluminum wires. The production system is high in production efficiency, stable in quality of produced products, lower in cost and suitable for upgrading industries in plants.

Owner:徐志峰

Production method of copper clad aluminum superfine flat wire with high width-to-thickness ratio

InactiveCN102623107ASolve secondary pollutionGuaranteed deformation uniformityCable/conductor manufactureCopper conductorCarrying capacity

The invention discloses a production method of a copper clad aluminum superfine flat wire with a high width-to-thickness ratio. The method comprises the following producing steps that: (1) an aluminum rod or aluminum magnesium alloy rod is paid off and is peeled through a surface processing machine, and the surface processing machine adopts nitrogen gas for protection during skin removing; then the aluminum rod or aluminum magnesium alloy rod and copper strips pass through a cladding machine together, so that the copper strips clad the processed aluminum rod or aluminum magnesium alloy rod, and a primary copper clad aluminum wire is obtained; (2) the primary copper clad aluminum wire is immediately drawn through multiple drawing machines until the diameter of the wire achieves the necessary requirement; (3) the drawn primary copper clad aluminum wire is flattened for many times, and the copper clad aluminum superfine flat wire with the high width-to-thickness ratio is obtained. According to the method, the environment is protected, the width-to-thickness ratio of the flat wire is larger than 20:1, and aluminum cannot be exposed; the surface area of a conductor is increased, and the current-carrying capacity of the conductor is increased; and the copper clad aluminum superfine flat wire is used for replacing the application of a copper conductor with the same current-carrying capacity to some fields, therefore, the cost of raw materials is greatly reduced, and the resource is saved.

Owner:TONGLING GUOZHAN ELECTRONICS

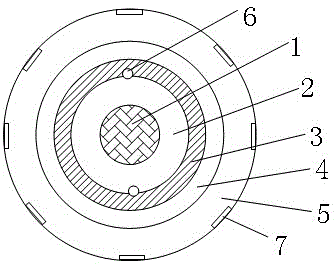

Low-loss radiation-type leakage coaxial cable

InactiveCN102683783AGood electrical performanceWide frequency bandWaveguidesCoupling lossUltrasound attenuation

The invention discloses a low-loss radiation-type leakage coaxial cable, comprising an inner conductor, wherein the inner conductor is sequentially coated by an insulating layer, an outer slotted conductor and a shell; and a copper wire, a copper-clad aluminum conductor or a hollow copper tube is used as the inner conductor, and the insulating layer and the shell are made from a poly-4-methyl-1-pentene foaming material. The low-loss radiation-type leakage coaxial cable disclosed by the invention has the advantages of small loss, wide use frequency range, low attenuation and low voltage standing wave ratio.

Owner:JIANGSU HENGXIN TECH CO LTD

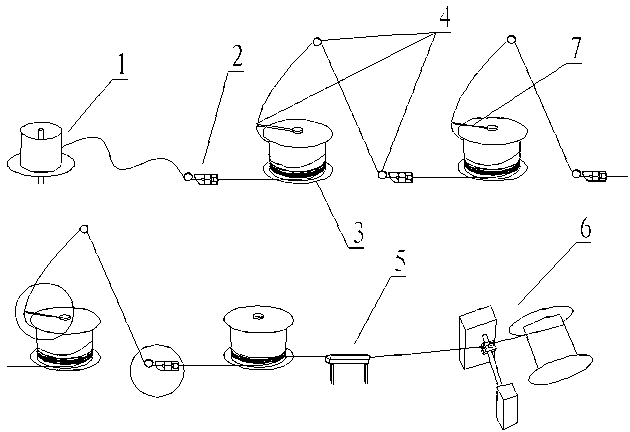

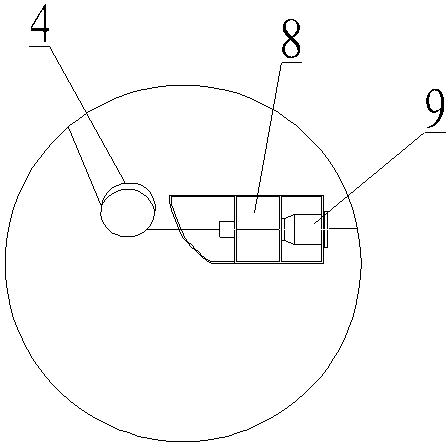

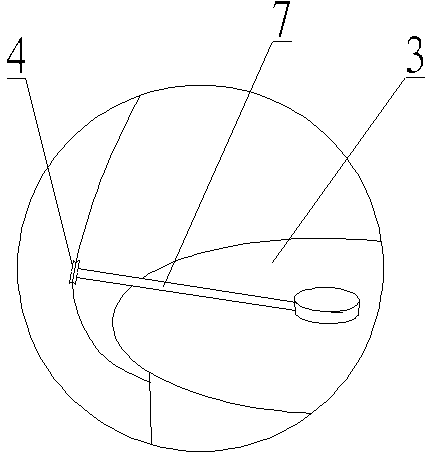

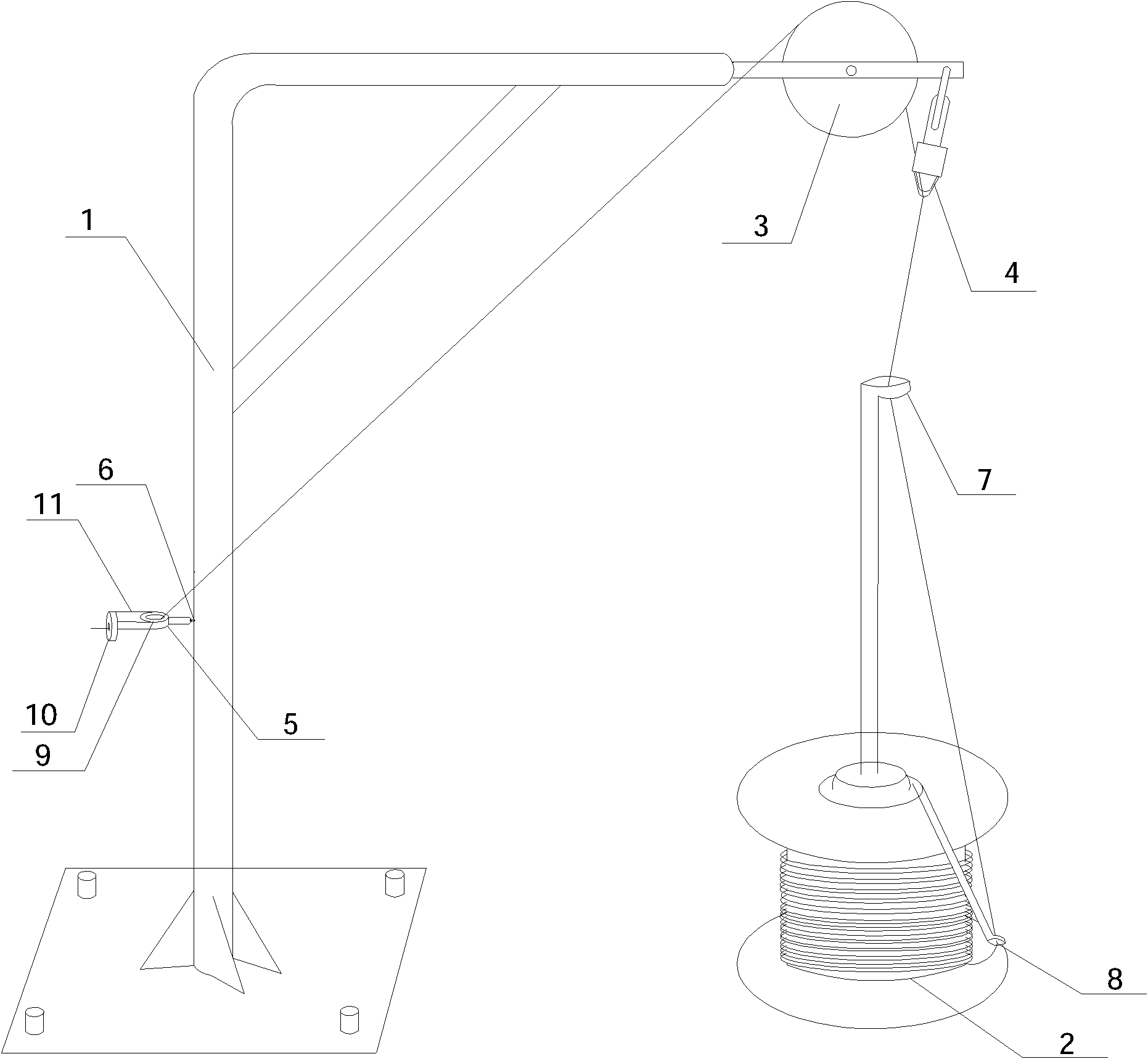

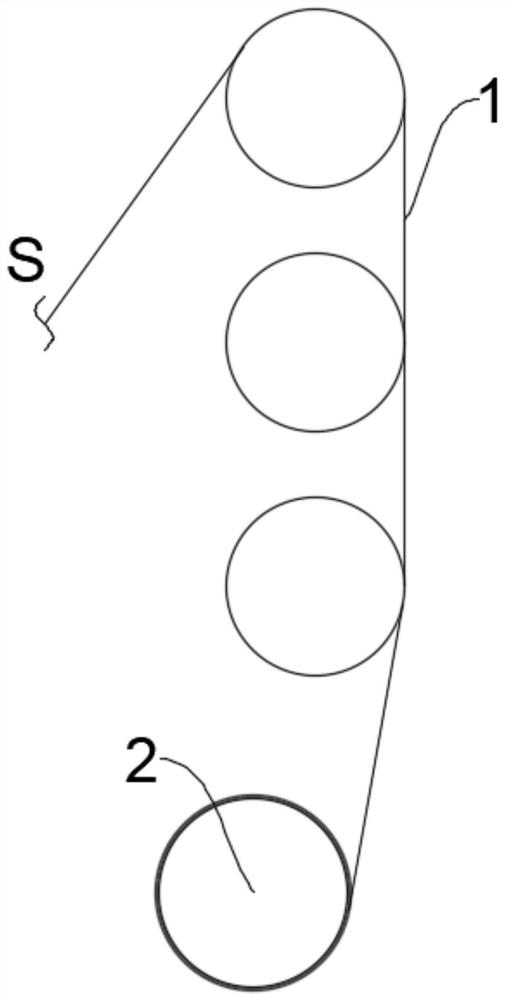

Combined stretcher

The invention relates to a combined stretcher which comprises a wire taking spool, a plurality of groups of stretching devices, a wire rubbing frame and a take-up spool, wherein the wire taking spool is used for winding a copper-clad aluminum wire which is not stretched; the wire rubbing frame is provided with cotton cloth; and each group of the stretching devices comprises a mould box, a wire spool and a plurality of guide pulleys, wherein the wire spool is arranged behind the mould box, the guide pulleys are used for guiding the copper-clad aluminum wire, a lubricating liquid and a stretching mould are arranged in the mould box, and the wire spool is provided with a cross rod which can be rotated around the axis of the wire spool. Because the combined stretcher is provided with the cross rod on the wire spool and the guide pulleys which are mutually matched, the copper-clad aluminum wire can be tensioned through the rotation of the cross rod, thereby achieving the purpose of combining a plurality of stretchers together, the workload of workers is reduced, the cost is saved, and the efficiency is increased.

Owner:苏州中信科技股份有限公司

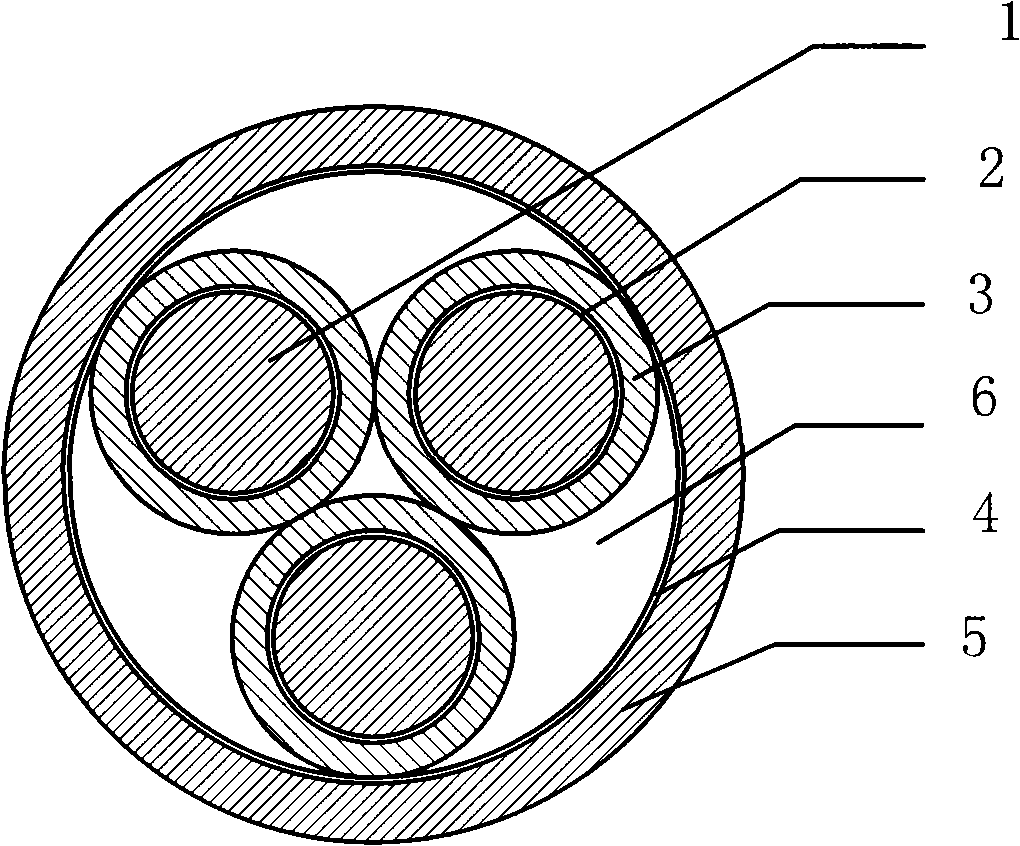

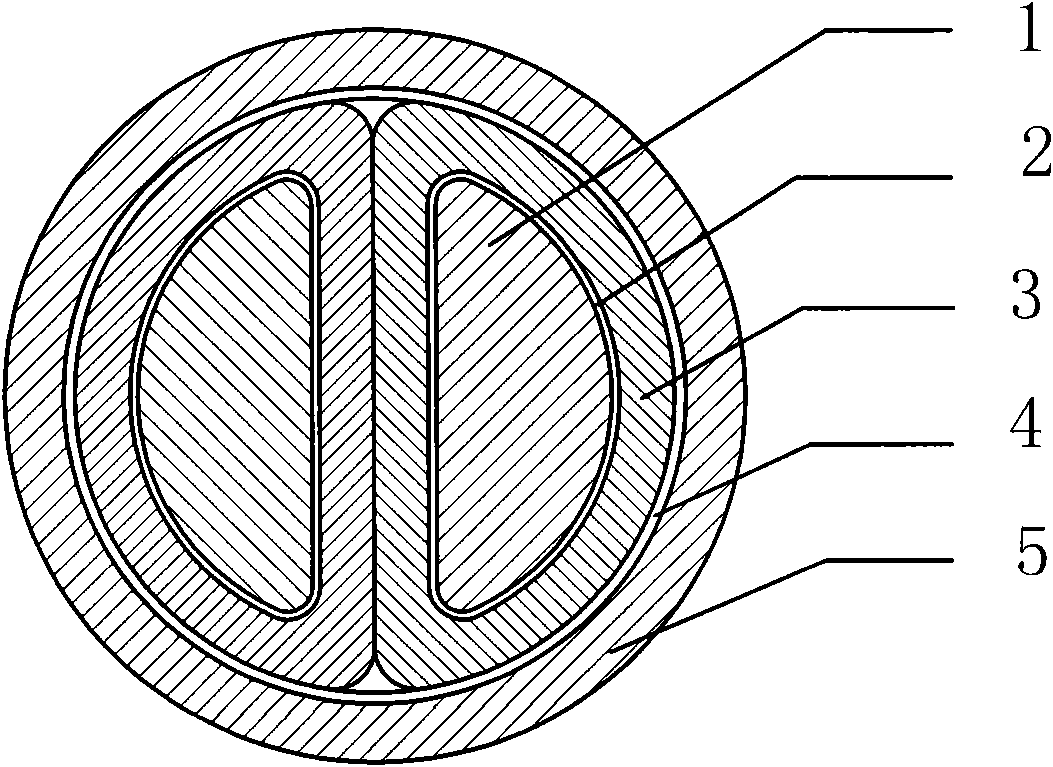

Copper coated aluminum three-core flame-retardant flexible electric cable and manufacturing method thereof

ActiveCN101335110AReduce copper usageReduce weightInsulated cablesMetal/alloy conductorsYarnInsulation layer

The invention discloses a copper-clad aluminum three-core flame retardant flexible cable and a manufacturing method thereof. The method comprises the steps that: a copper-clad aluminum conductor is made into a single conductive wire core; the single conductive wire core is processed into a conductive wire core provided with the section of a fan shape; an insulation process is carried out to the conductive wire core provided with the section of the fan shape, and an insulation process for forming an insulation wire core provided with an insulation layer is carried out; a cable-forming process is carried out to three insulation wire cores provided with insulation layers so as to form a cable yarn; plastic is extruded on the cable yarn so as to form a flame retardant restrictive coating, wherein, the step that the copper-clad aluminum conductor is made into the single conductive wire core comprises the steps that: a wire-drawing machine is utilized to draw the copper-clad aluminum conductor into a single conductive filament; an annealer is utilized to carry out an annealing process to the single conductive filament; a wire-bunching machine is utilized to bunch a plurality of annealed single conductive filaments into braided wires; a wire twisting machine is utilized to twist a plurality of braided wires into the conductive wire core. The cable of the invention has the advantages of low copper consumption, light weight and low cost.

Owner:JIANGSU ZHONGLI GRP CO LTD +1

Method for regenerating aluminium-copper intermediate alloy by extruding waste copper-clad aluminium conductor and waste copper conductor for three times

The invention relates to a method for regenerating aluminium-copper intermediate alloy by extruding the waste copper-clad aluminium conductor and the waste copper conductor for three times, belonging to the method for regenerating alloy, and aiming to solve the problems that the existing method for recovering the waste copper-clad aluminium conductor can not be used on a large scale, serious pollution is caused during recovering, more energy is consumed and the finished product from recovery can not be used directly. The method comprises the following steps: (1) mechanically processing the waste copper-clad aluminium conductor and the waste copper conductor; (2) assembling an extruding mold 1 and charging; (3) heating the extruding mold 1; (4) extruding for the first time; (5) mechanically processing the alloy rod obtained by extruding for the first time; (6) heating for the first time; (7) extruding for the second time; (8) mechanically processing the alloy rod obtained by extruding for the second time; (9) heating for the third time; and (10) extruding for the third time. The method is convenient to operate, is reasonable in design, discharges less carbon, is environmentally frienly and is used for regenerating the aluminium-copper intermediate alloy from the waste copper-clad aluminium conductor and the waste copper conductor.

Owner:哈尔滨吉星机械工程有限公司

Copper-clad aluminum varnished wire processing technique

ActiveCN102142304ALower trumpetImprove the level of research and developmentMetal/alloy conductorsCable/conductor manufactureCopper wireTransformer

The invention discloses a copper-clad aluminum varnished wire processing technique which comprises the following steps: (a), drawing a copper-clad aluminum varnished wire core for 4-6 times; (b), painting the drawn wire core for 10-13 times, wherein each painting comprises the following steps: (b1), lacquering the wire core, (b2), placing the lacquered wire core into an annealing furnace for annealing, and (b3), placing the annealed wire core into a drying oven for drying; (c), winding up, wherein the speed of winding up is 5 plus or minus 1 m / minute; and (d), unwinding and packaging. The copper-clad aluminum varnished wire processing technique is the combination of copper and aluminum metallurgy, obtains a certain diameter of copper clad aluminum varnished wire with the required electrical property and is endowed with the required mechanical property through a heat treatment method, thereby providing a material capable of replacing an enameled copper wire for a large-scale transformer; and through replacing the enameled copper wire with the copper-clad aluminum varnished wire, the consumption of copper resources is greatly reduced, the production cost is saved, and the performance is stable.

Owner:苏州市吴江神州双金属线缆有限公司

High-tension copper-clad aluminum varnished wire processing method

The invention relates to a copper-clad aluminum varnished wire processing method which comprises the following steps of 1, preparing a copper-clad aluminum wire core having copper content of 0.1-0.63wt%; 2, drawing the copper-clad aluminum wire core multiple times to obtain a wire having a predetermined diameter; 3, subjecting the copper-clad aluminum wire core to internal oxidation to obtain a copper-clad aluminum wire core having Al2O3 content of substantially 0.2 to 1.2 wt%; drawing the obtained Cu-Al2O3 copper-clad aluminum wire core having the predetermined size; 4, varnishing the copper-clad aluminum wire multiple times; 5, annealing the varnished copper-clad aluminum wire core in an annealing furnace, and placing the annealed copper-clad aluminum wire core in an oven for drying; and 6, collecting the copper-clad aluminum wire core. The produced copper-clad aluminum wire core has high tension.

Owner:深圳市广南电子有限公司

Paying-off device for copper-clad aluminum wires

InactiveCN102969078AControlControl speedCable/conductor manufactureEngineeringMechanical engineering

Owner:陈学明

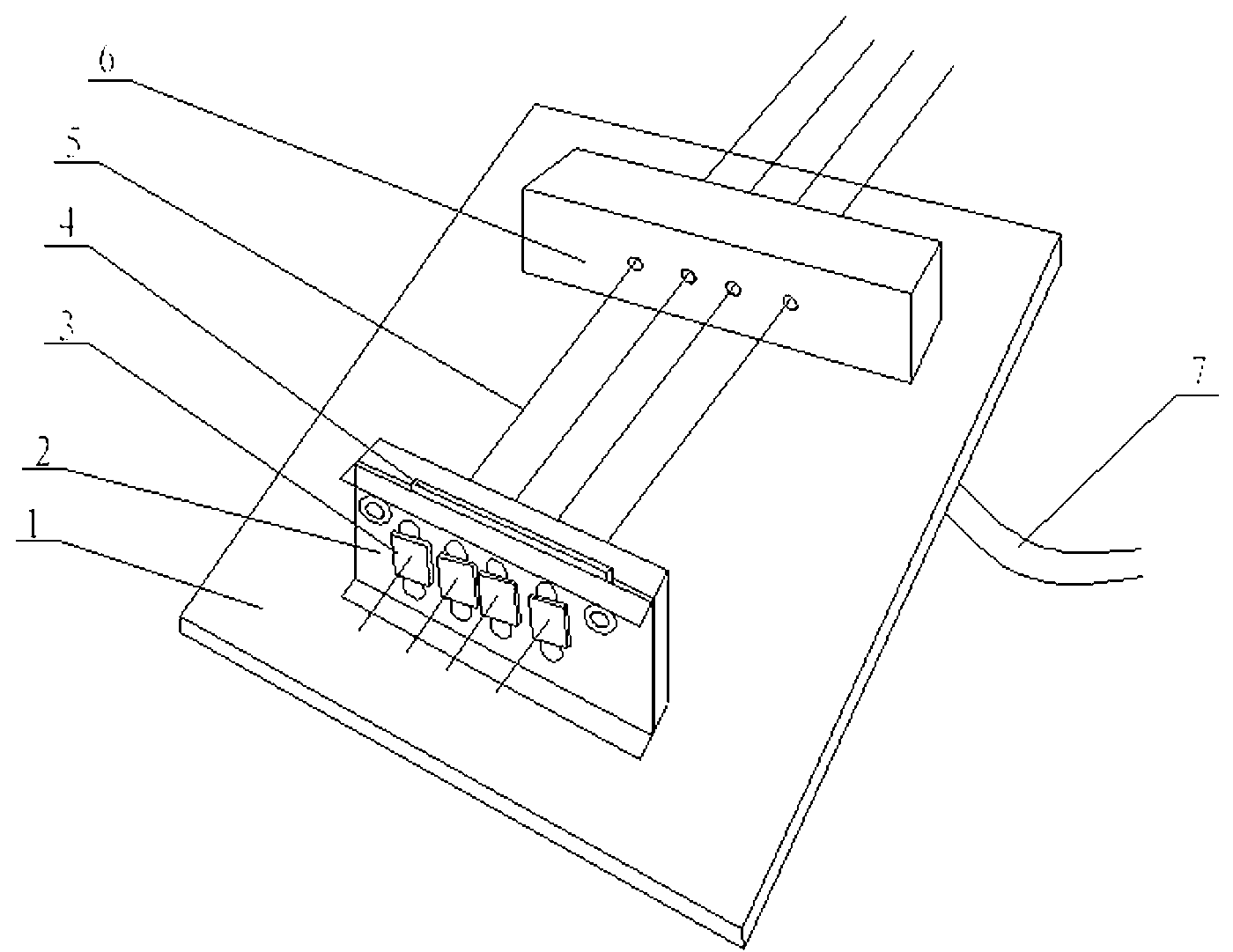

Draining and blow-drying equipment

ActiveCN103017495AQuick removalEasy to dryDrying gas arrangementsDrying machines with progressive movementsWater filterAir blower

The invention relates to draining and blow-drying equipment, which comprises a base, clamp plates arranged on the base and a blow-drying box arranged on the base, wherein a water filter sheet is sandwiched between the clamp plates, the inner cavity of the blow-drying box is communicated with an air tube of an air blower, the clamp plates are provided with through holes, through holes are formed at two sides of the blow-drying box, and silk threads penetrate through the through holes of the clamp plates and the water filter sheet firstly and then penetrate through the blow-drying box via the through holes of the blow-drying box. According to the invention, most water and impurities on the surface of a copper-clad aluminum conductor can be removed quickly through the water filter sheet, and the processed copper-clad aluminum conductor can be dried quickly, so that the production efficiency is improved.

Owner:苏州中信科技股份有限公司

High flame retarding radio frequency cable and manufacturing method

InactiveCN102931461AInsulation dielectric constant is smallHigh strengthWaveguidesElectrical conductorEngineering

The invention relates to a high flame retarding radio frequency cable and a manufacturing method. A center of a cross section of a polygonal polyethylene framework type half air insulating layer is a tubular body; a plurality of convex ribs are arranged on the outer wall of the tubular body; a conductor inside a copper-clad aluminum conductor is arranged inside a pipe core of the tubular body of the polygonal polyethylene framework type half air insulating layer; and a wrinkled copper pipe outer conductor and an extruded layer PVDF (Polyvinylidene Fluoride) jacket are sequentially arranged on the convex ribs of the polygonal polyethylene framework type half air insulating layer. The manufacturing method comprises the following steps of: 1, manufacturing an insulating manner, 2, machining an outer conductor, and 3, machining a jacket. The high flame retarding radio frequency cable and the manufacturing method provided by the invention have the characterized in that the entire weight of the cable is reduced; and the cost is reduced. Compared with strip type half air insulation, a machining process is reduced by using the polygonal polyethylene framework type half air insulating layer; and the insulating layer can be manufactured by forming a single polyethylene insulation material in one step. With the adoption of the PVDF jacket, the fire retardance level of the cable reaches the highest CMP (Corrugated Metal Pipe) fire retarding level of the UL (Underwriter Laboratories Inc).

Owner:TIANJIN ASCEND TECH

Copper-clad aluminum flexible cable and manufacture method thereof

The invention discloses a copper-clad aluminum two-core flame-retardant flexible cable and a manufacture method thereof. The method comprises a step of manufacturing copper-clad aluminum wires into single conductive wire cores, a step of processing the single conductive wire cores into conductive wire cores with semicircular cross sections, an insulation processing step of insulating the conductive wire cores with the semicircular cross sections to form insulated wire cores with insulation layers, a step of cabling two insulated wire cores with the insulation layers to form a cable and a stepof extruding plastics on the cable to form a flame-retardant sleeve layer, wherein the step of manufacturing copper-clad aluminum wires into single conductive wire cores is realized by utilizing a wire-drawing machine to draw copper-clad aluminum wires into single conductive monofilaments; utilizing an annealing machine to anneal the single conductive monofilaments; utilizing a wire-bundling machine to bundle a plurality of annealed conductive monofilaments into a braided wire; and utilizing a wire-twisting machine to twist a plurality of braided wires into a conductive wire core. The cable has the advantages of less copper consumption, light weight and low cost.

Owner:JIANGSU ZHONGLI GRP CO LTD +2

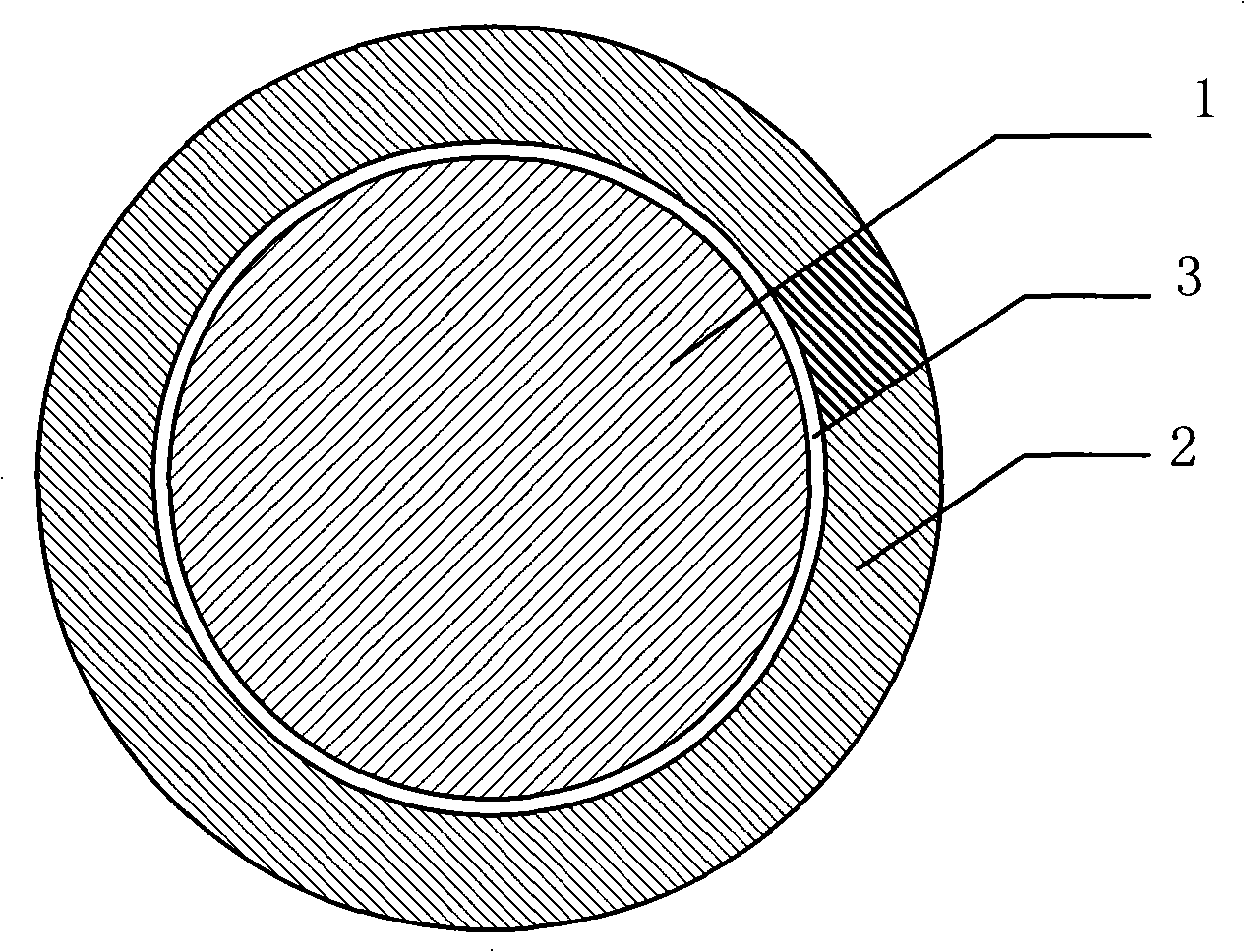

Copper coated aluminum uni-core flame-retardant refractory flexible electric cable with double sheath and manufacturing method thereof

InactiveCN101335116AReduce copper usageReduce weightInsulated cablesMetal/alloy conductorsInsulation layerSingle-core

The invention discloses a copper-clad aluminum single-core flame retardant and fire resisting flexible cable with double jackets and a manufacturing method thereof. The manufacturing method comprises the steps that: a copper-clad aluminum conductor is made into a single conductive wire core; a fire resisting layer is formed at the outer side of the single conductive wire core; plastic is extruded at the outer side of the of the fire resisting layer in an extrusion molding manner so as to form an insulation layer; plastic is extruded at the outer side of the insulation layer in the extrusion molding manner so as to form a restrictive coating, wherein, the step that the copper-clad aluminum conductor is made into the single conductive wire core comprises the steps that: a wire-drawing machine is utilized to draw the copper-clad aluminum conductor into a single conductive filament; an annealer is utilized to carry out an annealing process to the single conductive filament; a wire-bunching machine is utilized to bunch a plurality of annealed single conductive filaments into braided wires; a wire twisting machine is utilized to twist a plurality of braided wires into the conductive wire core. The cable of the invention has the advantages of low copper consumption, light weight and low cost. As a single filament structure with multiple filaments and small diameter, and a multi-strand twisting technology are adopted, the cable is particularly flexible and can be bended randomly.

Owner:GUANGDONG ZHONGDE CABLE

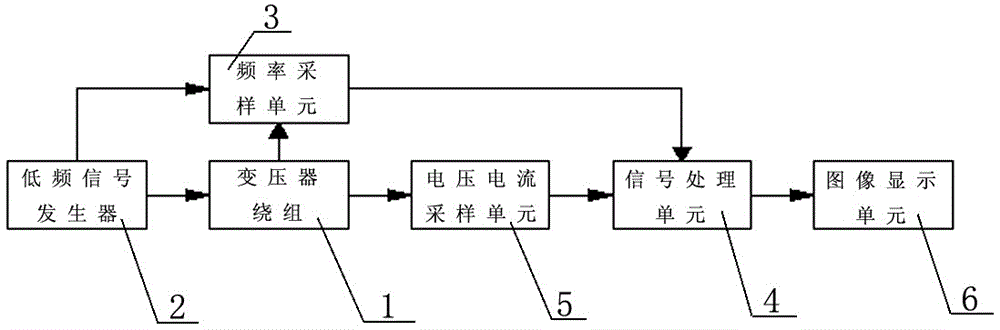

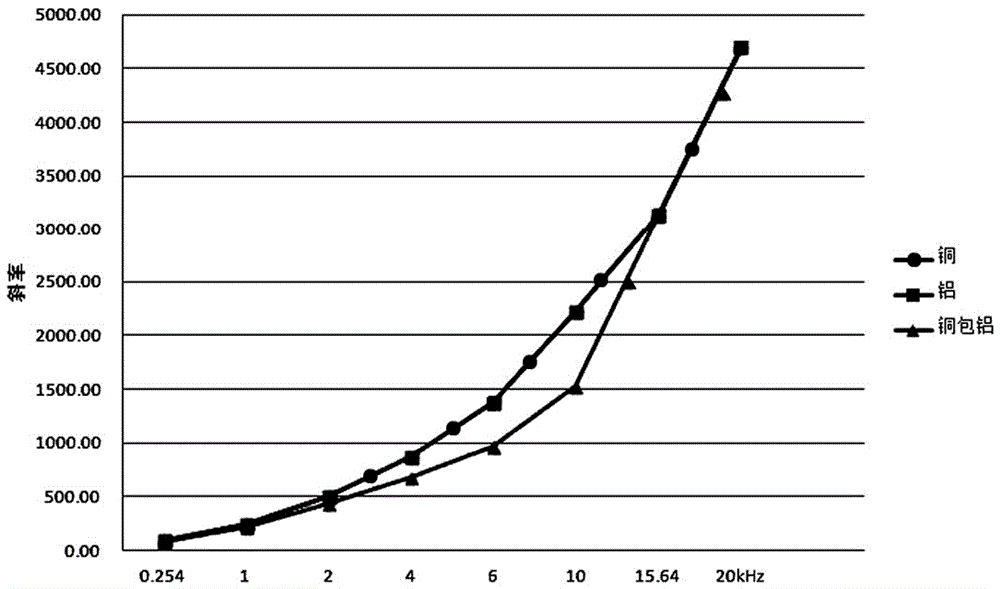

Transformer copper-clad aluminum winding detector and detection method

PendingCN106443317AReasonable structureEasy to operateElectric winding testingEngineeringAlternating current

The invention provides a transformer copper-clad aluminum winding detector and a detection method. The detector comprises a low-frequency signal generator, which is connected with a transformer winding and generates a sine wave signal for the transformer winding. The low-frequency signal generator and the lead end of the transformer winding are connected with a signal processing unit through one same frequency sampling unit; the lead end of the transformer winding is also connected with a voltage and current sampling unit capable of collecting voltage and current of a sampled signal; the signal processing unit carries out signal integration and calculation, and then, outputs AC resistance slope under each frequency to an image display unit connected therewith; and meanwhile, the signal processing unit calculates AC resistance slope of fine copper under each frequency according to the collected frequency and outputs the AC resistance slope to the image display unit connected therewith. The detection method is realized based on the alternating current skin effect principle, that is, the higher the alternating current frequency is, the larger the measured AC resistance is, so that whether a wire is a copper-clad aluminum coil can be effectively detected.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER CO LTD JIAXING POWER SUPPLY CO +1

Copper-clad aluminum conductor production process

The invention discloses a copper-clad aluminum conductor production process comprising the following processing steps of: 1, deoiling the aluminum conductor by soaking the aluminum conductor in a chemical solvent; 2, cleaning; 3, pickling the aluminum conductor in a pickling solution for activating; 4, pre-nickeling the aluminum conductor in a solution containing 5-30 g / L of nickel chlorite, 50-150 g / L of nickel aminosulfonate, 20-100 g / L of boric acid and additives; 5, cleaning; 6, coppering the pre-nickeled aluminum conductor in a solution containing 30-50 g / L of copper nitrate, hydroxy ethylidene diphosphate and additives at 25-40 DEG C and with current density of 2-5 A / dm<2>; 7, cleaning the aluminum conductor through clear water at 30-40 DEG C; and 8, winding and packaging the aluminum conductor. The copper-clad aluminum conductor production process disclosed by the invention is reasonable in process, the aluminum conductor is nickeled and coppered by the environmentally-friendly and non-pollution plating solutions, the plating combination strength of produced copper-clad aluminum conductors with various diameters is high, and the subsequent drawing quality of the conductors is good.

Owner:李振萍

Reciprocating production process of electroplated copper-clad aluminum

ActiveCN111778533AGood cleaning degreasingHigh bonding strengthProcess efficiency improvementWire rodOxidation resistant

The invention belongs to the field of metallurgy, and particularly relates to a reciprocating production process of electroplated copper-clad aluminum. The reciprocating production process comprises the following steps that multi-section alkali washing is carried out, specifically, alkali washing is carried out on an aluminum base material at least two times to obtain a cleaned aluminum material;zinc precipitation treatment is carried out, specifically, zinc precipitation is carried out on the cleaned aluminum material at least two times; layered copper plating is carried out, specifically, copper plating is carried out on the aluminum material subjected to zinc precipitation treatment a plurality of times, wherein the copper plating at least comprises three procedures of pre-plating, primary thick plating and main thick plating; and post-treatment is carried out, wherein the post-treatment comprises primary passivation, continuous drawing, flaw detection, annealing and post-passivation take-up. The reciprocating production process of electroplated copper-clad aluminum increases copper content in copper-clad aluminum wires, improves the signal transmission performance of the wholewires, improves the bonding strength between copper layers and base material aluminum cores, improves the oxidation resistance of the wires, and prolongs the service life.

Owner:ZHEJIANG PUJIANG BAICHUAN IND

Copper coated aluminum three-core flame-retardant refractory flexible electric cable

ActiveCN101335111AReduce copper usageReduce weightInsulated cablesMetal/alloy conductorsYarnInsulation layer

The invention discloses a copper-clad aluminum three-core flame retardant and fire resisting flexible cable and a manufacturing method thereof. The method comprises the steps that: a copper-clad aluminum conductor is made into a single conductive wire core; the single conductive wire core is processed into a conductive wire core provided with the section of a fan shape; a wire core fire resisting layer is formed on the outer surface of the conductive wire core provided with the section of the fan shape; an insulation material is extruded on the wire core fire resisting layer, and an insulation process for forming an insulation wire core provided with an insulation layer is carried out; a cable-froming process is carried out to three insulation wire cores provided with insulation layers, thereby forming a cable yarn; flame retardant plastic is extruded on the cable yarn so as to form a flame retardant restrictive coating. The cable of the invention has the advantages of low copper consumption, light weight and low cost.

Owner:JIANGSU ZHONGLI GRP CO LTD

Copper coated aluminum uni-core flame-retardant flexible electric cable and manufacturing method thereof

ActiveCN101335119AReduce copper usageReduce weightInsulated cablesMetal/alloy conductorsInsulation layerEngineering

The invention discloses a copper-clad aluminum single-core flame retardant flexible cable and a manufacturing method thereof. The manufacturing method comprises the steps that: a copper-clad aluminum conductor is made into a single conductive wire core; an isolation layer is formed on the single conductive wire core; flame retardant plastic is extruded on the isolation layer so as to from a flame retardant insulation layer, wherein, the step that the copper-clad aluminum conductor is made into the single conductive wire core comprises the steps that: a wire-drawing machine is utilized to draw the copper-clad aluminum conductor into a single conductive filament; an annealer is utilized to carry out an annealing process to the single conductive filament; a wire-bunching machine is utilized to bunch a plurality of annealed single conductive filaments into braided wires; a wire twisting machine is utilized to twist a plurality of braided wires into the conductive wire core. The cable of the invention has the advantages of low copper consumption, light weight and low cost. As a single filament structure with multiple filaments and small diameter and a multi-strand twisting technology are adopted, the cable is particularly flexible and can be bended randomly.

Owner:JIANGSU ZHONGLI GRP CO LTD +2

Processing technology of copper-clad aluminum varnished wires

InactiveCN103106981AReduced annealingReduce the process of annealingInsulating conductors/cablesMachining processMechanical engineering

The invention discloses a processing technology of copper-clad aluminum varnished wires. The processing technology of the copper-clad aluminum varnished wires comprises the following steps that (a) the copper-clad aluminium wire cores are drawn for a plurality of times; (b) a plurality of japannings are conducted to the drawn conductor wire cores. Each japanning comprises the following steps (b1) the wire cores are japanned, (b2) the japanned wire cores are placed into a baking oven and a plurality of dryings are conducted to the wire cores; (c) the wire cores are rewinded; (d) the wire cores are coiled and packaged. Four to six drawings are conducted to the copper-clad aluminum varnished wire cores. Ten to twelve japannings are conducted to the drawn the wire cores. In each japanning step, six to ten dryings are conducted to the japanned varnished wires. The speed of collected wire cores is (5 + / - 1) miles / minute. In the steps, due to the fact that a plurality of dryings are conducted to the wire cores so that the wire cores achieve the requirements of eliminating stress. Thus, the wire cores do not need to undergo an annealing process so that an annealing furnace is saved. Accordingly, production cost of a factory or an enterprise can be saved.

Owner:苏州市吴江神州双金属线缆有限公司

Leakage coaxial cable with strong radiation signals for coal mine

InactiveCN104157338AGood flexibilityStrong radiation signalFlexible cablesMetal/alloy conductorsElectrical conductorCoaxial cable

The invention discloses a leakage coaxial cable with strong radiation signals for a coal mine. A single conductor is arranged in the center of the cable; the conductor is a copper wire or copper-clad aluminium wire; a layer of foaming polyethylene tightly covers the conductor, and is used as an insulating layer; a layer of annealed copper wire is asymmetrically weaved outside the insulating layer, and is used as a leakage weaving layer; two dragging resistant steel wire ropes are arranged between the insulating layer and the leakage weaving layer; a layer of inflaming retarding polyethylene also tightly covers the leakage weaving layer, and is used as an inner sheath; a layer of inflaming retarding polyvinyl chloride further tightly covers the inner sheath, and is used as an outer sheath; a plurality of axial grooves are formed in the outer sheath, and are filled with fluorescent belts. The leakage coaxial cable meets the requirement of other indexes of electrical performance and mechanical performance, and meanwhile further has the ability of the strong radiation signals, and softer mechanical performance.

Owner:安徽宏源特种电缆集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com